Novatek UBZ-302 User guide

NOVATEK-ELECTRO LTD

Research -and-Manufacture Company

ELECRTIC MOTORS

UNIVERSAL PROTECTION DEVICE

UBZ-302

SERVICE MANUAL

www.novatek-electro.com

- 2 -

1. GENERAL DESCRIPTION AND OPERATION

1.1 APPLICATION

UBZ-302 is the microprocessor based digital device, reliable and of highest degree of measurement accuracy. It

doesn’t require the operational external power supply since the controlled voltage at the same time is the power

supply for UBZ-302. It has 3 built-in current measurement transformers through which the motor power supply wires

are looped for continuous currents monitoring.

Universal electric motor protection device (hereinafter UBZ-302) is designed for the continuous control of the

power supply voltage, monitoring of acting values of phase/line currents in 3 phase electrical circuits and additionally performs the resistance test to check the level of motor coils insulation.

UBZ-302 performs protection of asynchronous electric motors with rated power from 2,5 to 30 kW using built in

current transformers. With the use of externally connected current transformers (not supplied together with

UBZ-302) is possible to protect motors with rated power up to 315 kW. Moreover UBZ-302 is capable to work in

electric circuits with isolated neutral (allows operation in both in 3 and 4 wire electric circuits).

UBZ-302 protects the electric motors in the following alarm situations:

Low quality power supply voltage:

o not allowable voltage surges and fluctuations, phase loss, wrong phase sequence, phase imbalance of

phase/line voltage, phase coincidences;

Mechanical overloads (symmetrical overload in phase/line currents);

Exceeding the threshold for reverse current sequence;

Non-symmetry of the phase currents in the absence of overload which may happen either due to fault of

insulation of the motor coils or the power supply cable. UBZ-302 performs comparison of non-symmetry coefficient

for reverse sequence current with the non-symmetry coefficient of the voltage on the reverse sequence.

Disappearing of the drive torque of the motor shaft (dry stroke for the pumps) – protection on the minimal

starting current and/or operation current;

Long lasting motor start or blocked rotor;

Checking the level of insulation between the stator and motor case before the motor start;

Earth leakage protection of stator coils during the motor operation;

Thermal overload protection for the motor;

Overheating protection for the motor coils. UBZ-302 performs temperature monitoring using built in to the

motor temperature sensors or the temperature of the motor case could be measured with the use of external

temperature sensors.

For every type of protection mentioned above it’s possible to set individually the autoreclosing parameters

(allowed or not allowed to start the motor automatically after certain type of fault or alarm situation).

UBZ-302 performs protection of a motor or equipment by operating with the magnetic coil of contactor which in

its turn commutates the required power load.

UBZ-302 has 2 output relays: power load relay and functional relay. Presence of 2 output relays gives the

possibility to arrange DELTA/STAR switching, turn ON with the delayed start (cascade turn ON of motors) and

remote signalization. UBZ-302 detects the presence of the currents when the power load relay contacts are open

and when the functional relay is in the DELTA/STAR mode. If these currents are detected then UBZ-302 indicates

the fault of the external contactor that turns motor ON. UBZ-302 will keep on indicating this fault until it will not be

deenergized (turned OFF).

DATA TRANSMISSION

- control operation and data transmission using RS-485 interface in accordance with MODBUS protocol,

- control operation and data transmission using RS-232 interface.

N o t i c e: Simultaneous use of RS-485 and RS-232 is impossible.

For work of the personal computer with UBZ-302 the program "Control panel UBZ-302", is placed on a

company site can be used (http://www.novatek-electro.com/production_ubz.htm).

The program "Control panel UBZ-302" is intended for the control of a condition and data gathering from devices

UBZ-302, to communication means (RS-232 or RS-485). The program allows to keep to (load) various options UBZ,

to conduct data gathering and to keep them for the further researches.

1.1.2 CHARACTERISTICS OF THE BUILT-IN OUTPUT TERMINALS

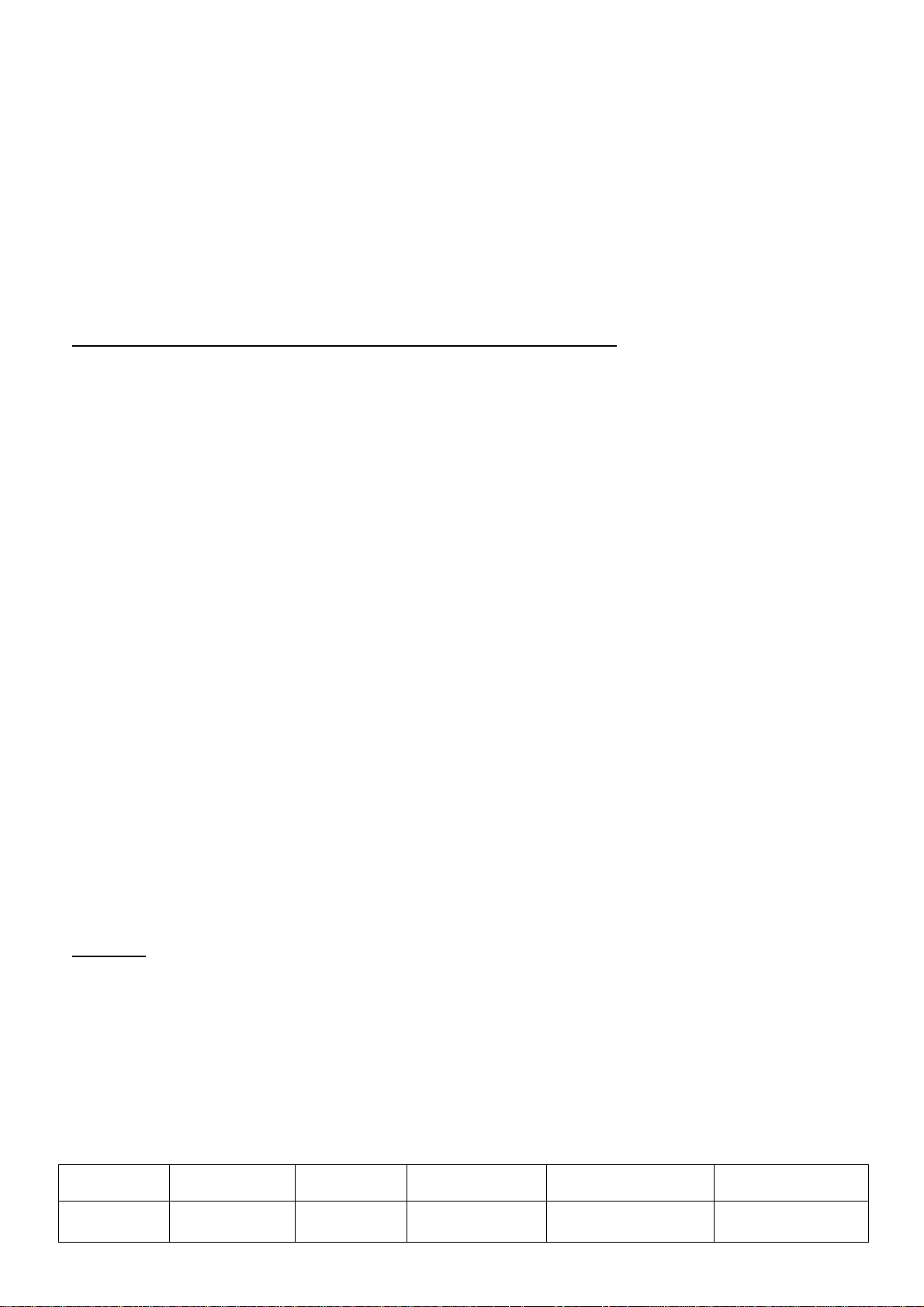

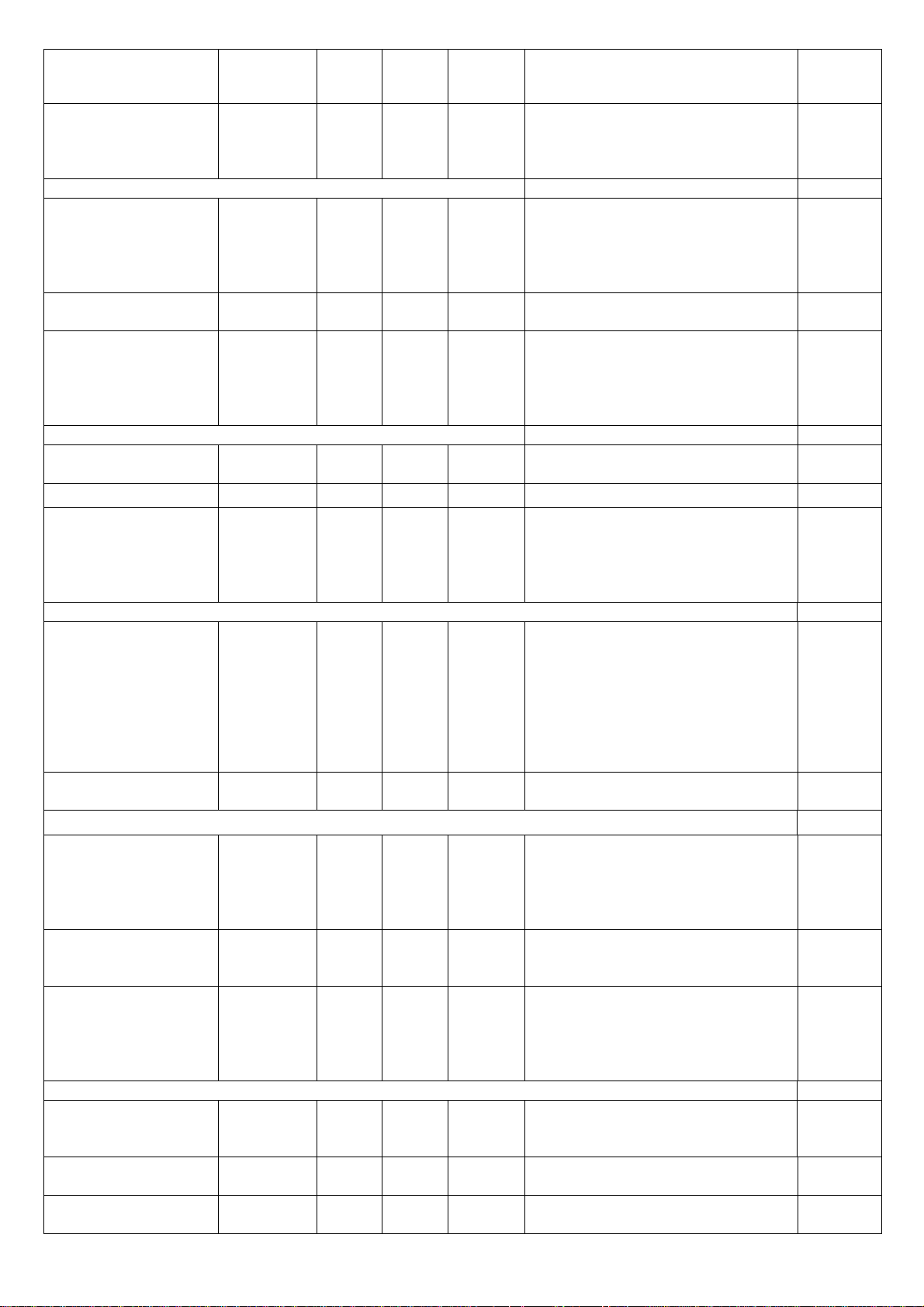

Basic characteristics of the UBZ-302 output relays are shown in Tables 1.1 and 1.2 shown below

Cos ϕ = 0,4

Cos ϕ = 1,0

UBZ-302

Table 1.1 - Power load relay

Maximal current

at U~250V

2 A

5 A

Commutation

lifetime х1000

100

100

Maximal power

for commutation

Maximal long lasting

withstand AC voltage

1000 VA 460 V 3 A (50000)

Maximal current at

=30V (commut.)

U

const

NOVATEK-ELECTRO

- 3 -

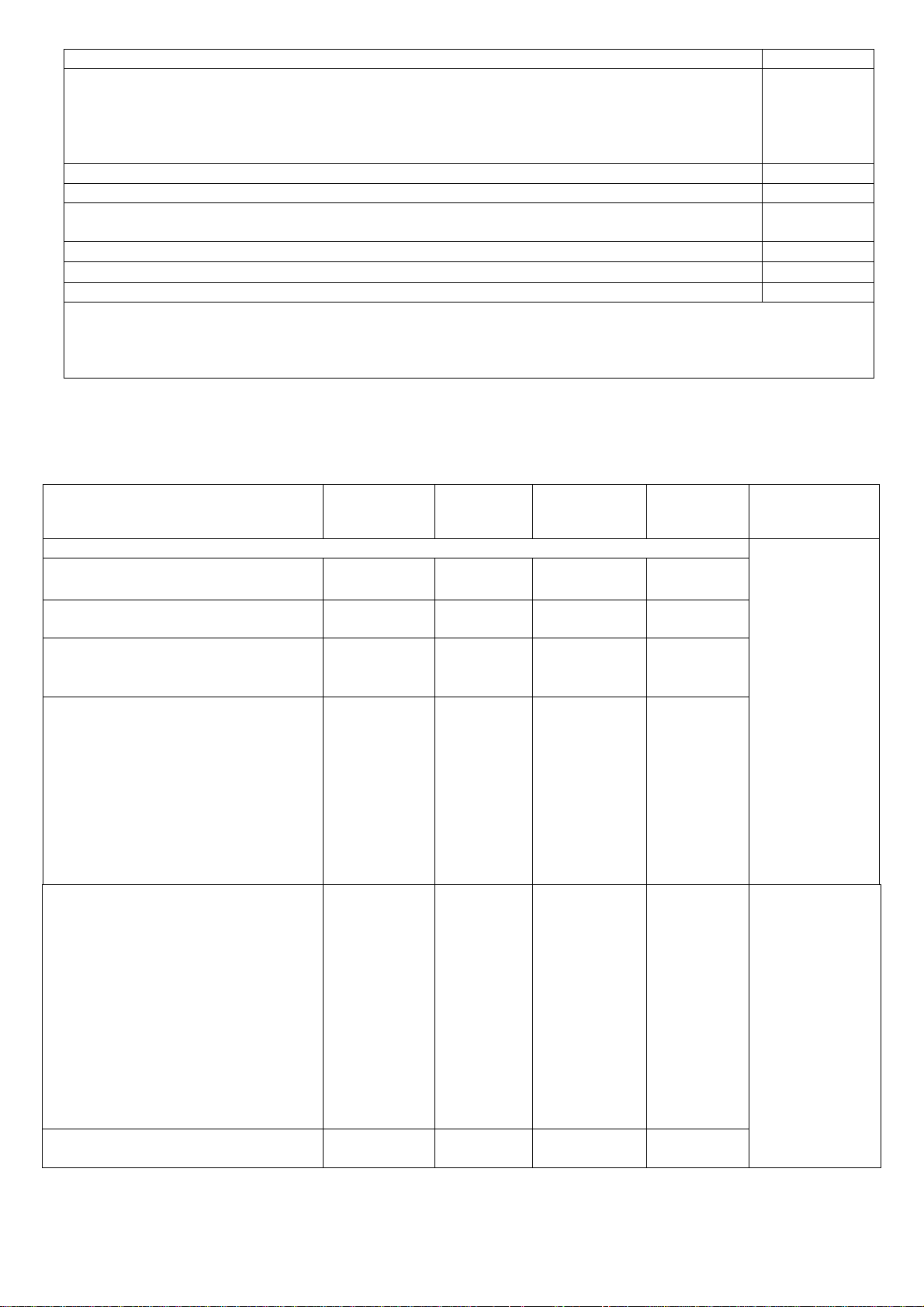

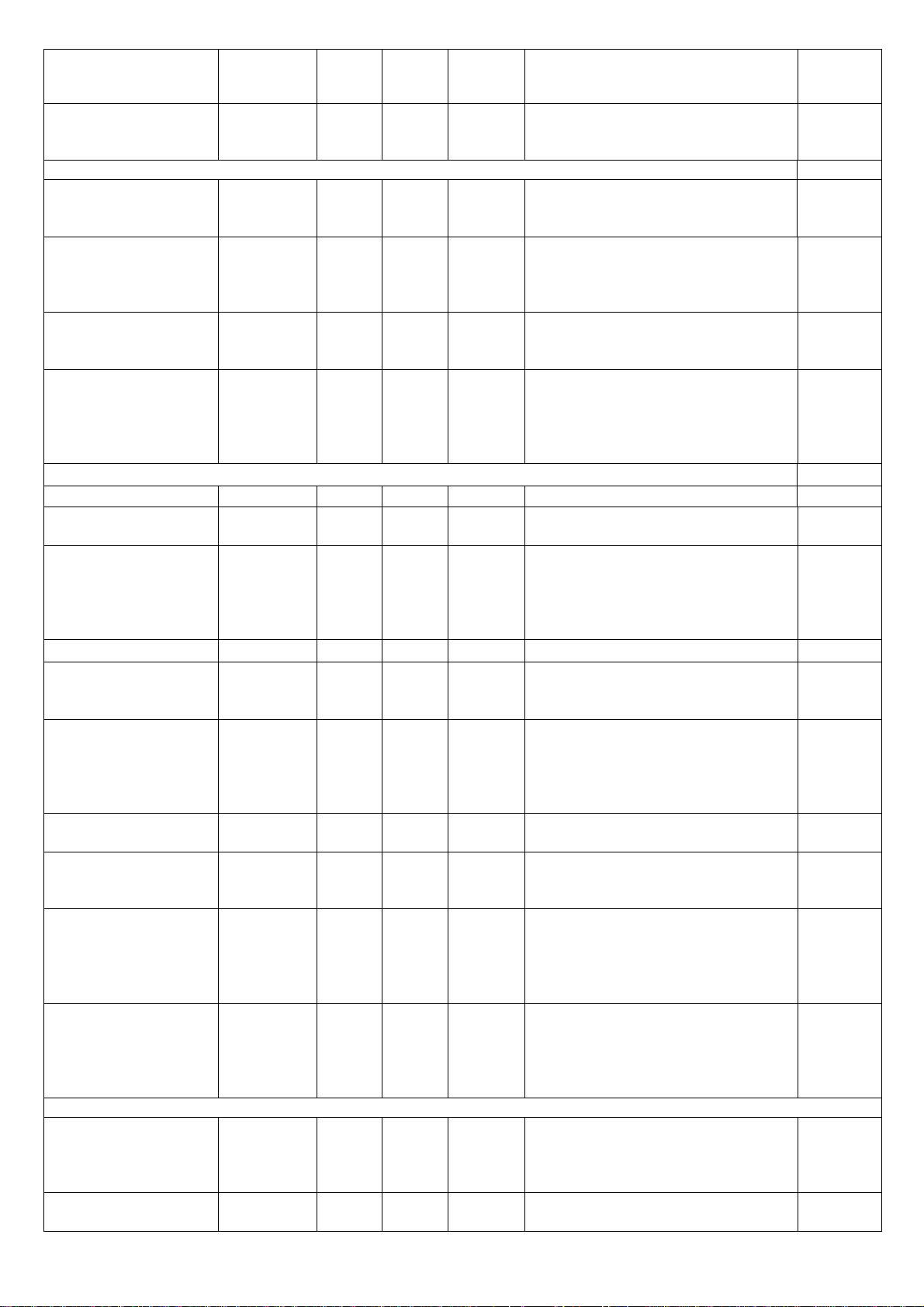

Cos ϕ = 0,4

Cos ϕ = 1,0

Maximal current

at U~250V

5 A

16 A

Table 1.2 -Functional relay

Commutation

lifetime х1000

100

100

Maximal power

for commutation

Maximal long lasting

withstand AC voltage

Maximal current at

U

const

4000 VA 440/300 V 3 A

=30V(commut.)

1.1.3 Restrictions for the UBZ-302 application and the selection of the parameters

1.1.3.1 The use of built-in current transformers.

It’s prohibited to use the UBZ-302 for the protection of the motors with rated power more than 20 kW.

When measuring the currents in the range from 63 A to 300A the measurement error does not exceed 5% value

but if the currents are more than 320 A, then the current transformer core saturation happens and this lead to

significant decrease of measurement accuracy.

Disregarding the real value of the current the UBZ-302 will not be able to measure the currents more than 400A.

The setting of several programmable parameters (maximal current protection, overcrank start and locked rotor or

thermal overload) without taking into consideration the saturation of current transformers will lead to disabling of the

effective protection.

For example when setting

delay), i

=

S =9 (multiplication factor for tripping to maximal current faults) maximal current protection must trip

ind=50 (rated motor current), i = P =0 (current protection with independent time

when current is 450A. But due to the saturation of current transformer core measured value of current will never

exceed 380-400A even there will be a short circuit in the coils of motor and currents more than 1000A – and thus

the UBZ-302 will not turn the motor OFF. In this case (

ind=50) the user must set the value for multiplication factor

for the maximal current protection and set the value not more than 6.

1.1.3.2 The use of external current transformers.

All the tested samples of standard current transformers the saturation of the core takes place when the

measured current value exceed 4-5 fold of rated. Taking this fact into consideration it’s necessary to select the

external current transformers with such a rated value that it will be at least 2-fold more than the rated motor current

or to select the transformer taking into consideration possible saturation of the current transformer core.

1.1.3 LIST OF ABBREVIATIONS USED IN THIS PRESENT MANUAL

AR – automatic reclosing of the output contacts (autoreclosing)

MC – magnetic contactor

PC – personal computer

CT – current transformer

MMSP – mode with minimal number of setting parameters

Itt – rated current for the current transformers. It should be set up in case of using external current transformers

( For example CT Т-0.66 300/5, then Itt is 300А)

In – rated current of motor. As a rule it’s the value that is shown on the motor shield but depending on the usage

conditions it’s possible to set some other required value.

1.2 TECHNICAL PARAMETERS

1.2.1 Basic technical parameters are shown below in Table 1.3.

Table 1.3

Rated power supply voltage: three phase 415V 50 Hz

Operational voltage frequency, Hz 48-62

Range of the rated currents when UBZ-302 use built in current transformers, А 5-63

Voltage hysteresis (phase/line), V 10/17

Thermal hysteresis, % of accumulated heat at turn OFF 33

Current tripping threshold detection accuracy, not more then, in % of rated 2

Voltage tripping threshold detection accuracy, not more then, V 3

Accuracy for the detection of phase imbalance basing voltage measurements, V, not more then 3

Operational input voltage:

-phase voltage, when power supply from one phase and neutral wire connected,

-line voltage, in case of 3 phase power supply, not more then, В

Analog inputs:

not less then, V

180

450

- 2 analog inputs for the temperature sensors connection (type Pt100, Ni100, Ni120)

- analog input for the connection of the sensor with the output 0 – 10V

- analog input for the connection of the sensor with the output 4mA (0mA) – 20mA

- 3 analog inputs for the connection of current transformers with the output of 5 A (type Т-0.66 or

similar)

NOVATEK-ELECTRO

UBZ-302

- 4 -

- input for the connection of the differential current transformer

Basic outputs:

Power load relay – 2 groups of changeover contacts to operate with the motor starting contactor - 5A 250V at cosφ=1;

Functional relay – one group of changeover contacts 16A 250V at cosφ=1 (the application of

this relay contact is user defined);

Temperature sensors measurement accuracy, °С.

1

Consumed power (under the load), not more then, VA 5,0

Protection degree: - case enclosure

- contact terminals

Operational temperature range, °С

Storage temperature, °С

IP40

IP20

from-35 to +55

from-45 to +70

Weight, not more then, kg 0,5

Outer dimensions ( kindly see Fig.1.1)

Nine standard S-modules width

Mounting on standard DIN rail 35 mm

Mounting position - arbitrary

1.2.2. The measured and calculated parameters, which values are deduced on the display device*, limits of

their measurement and an error are resulted in the Table 1.4.

Table 1.4 - Measured and Indicated parameters

Measurements Range Accuracy Indication on

display

(mnemonics)

Currents

Acting value of phase currents, A 0,5-630 2%

iF1, iF2,

iF3

Acting value of zero-sequence

0,3-5,0 2%

iF0

Address Measurement

units at data

transmission

Tenths of

100, 101,

ampere

102

103

current, A

Average current value on each of the

phase within the time preset by the

iS1, iS2,

iS3

104, 105,

106

parameter tSi

Maximal value of average current on

each phase, obtained from the

moment of the last load. To reset all

average values press button

RES/MEM/SEL – then UBZ-302 will

<3 Itt

> 3 Itt

2%

10%

in1,

in2,

in3

107, 108,

109

display maximal average current

value on corresponding phase and

start further measurements (it doesn’t

reset the initial value to zero after

pressing RES/MEM/SEL).

Starting current of motor (averaged

by phases)

Overload current (averaged by

phases)

Starting time, seconds

Starting time – is a period of time

from the moment when 3 phase

currents exceed 1,2×In and up to the

moment when all those 3 currents will

decrease lower then 1,2×In. Maximal

phase current that was achieved

<3 Itt

> 3 Itt

0,1-600

2%

10%

iPU

iPE

tPU

110

112

111

Tenths of

ampere

during the startup is considered to be

maximal starting current.

Reverse sequence current

0,2-200 5%

ioP

113

(imbalance), A

__________

* The display device correspond:

- Two three-digit seven-segment indicators on the UBZ face panel;

UBZ-302

NOVATEK-ELECTRO

- 5 -

- PC connected to one of UBZ interfaces (MODBUS, RS-232)

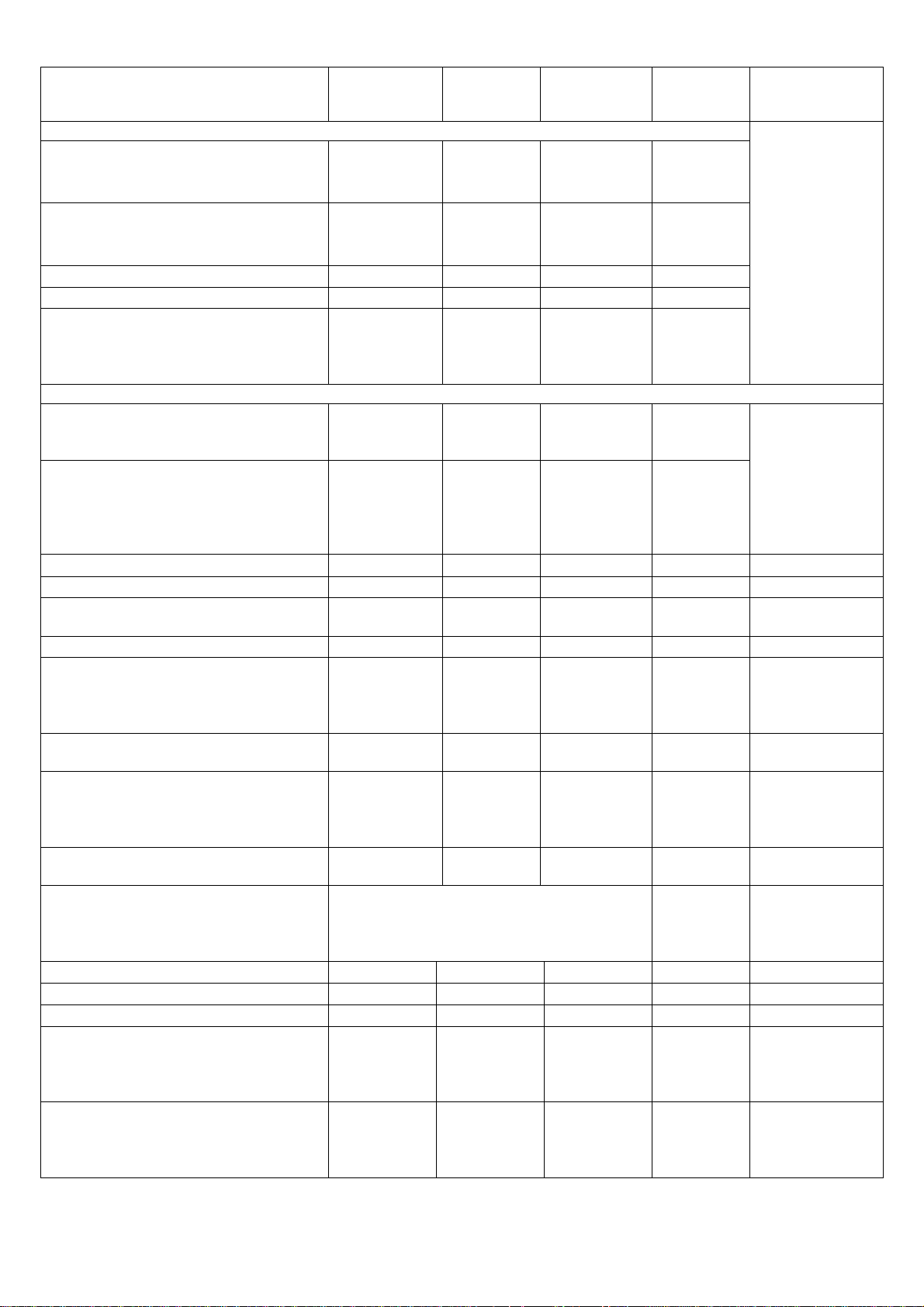

Measurements Range Accuracy Indication on

display

(mnemonics)

Voltage

Acting value of phase voltage

(measured when the neutral wire is

connected to the UBZ-302), V

Acting value of line voltage, V 100-475 5 V

100-300 3 V

UF1,

UF2,

UF3

UL1,

UL2,

Address Measurement

units at data

transmission

Volts

114,115

116

117,118

119

UL3

Positive sequence voltage, V 100-300 3 V

Reverse sequence voltage, V 3 -300 3 V

Zero sequence voltage (vector sum of

3-100 3 V

UPP

UÓP

UnP

120

121

122

3 phase voltages divided by 3), (calculated when neutral wire connected to

the UBZ-302), V

Others

Temperature of the Sensor 1 (type of

the sensor is defined according the

table 1.6.),

0

C *

Temperature of the Sensor 2 (type of

the sensor is defined according the

table 1.6.),

0

C *

from -40

to +220

from -40

to +220

o

C

o

C

o

C

o

C

0

1

C

td1

123

5000 – sensor is

disabled

0

C

1

td2

124

1000±10 –short

circuit of the

sensor

2000±10 –sensor

is not connected

or cut

Value of current input (4-20) mA, mA 0-25 2%

Voltage value on analog input 0-10 V 0-10 V 2%

Running time counter for the

0-999

ini

inU

Str

125 Hundreds of µA

126 Tenths of Volt

127

machinery, days

Power supply frequency, Hz 45-65 1%

Remaining time before tripping to

0-600 1 sec

FFF

tOP

128 Tenths of Hz

129 Seconds

overload (shows the remaining time

that is left before Turning OFF basing

the thermal overload para-meter), sec

Remaining time to the end of

0-900 1 sec

tAP

130 Seconds

autoreclosing interval, sec**

Latency time after overload caused

0-900 1 sec

ttP

131 Seconds

turn OFF (shows the latency time

which remains to turn ON the motor

after the thermal overload fault), sec***

Resistance of the motor insulation,

MOhms ****

Termal balans of the motor Parameters only for reading the information

using MODBUS or RS-232 protocols

0-19,9 10%

rid

Number 1100 thousand corresponds 100

% of saved up heat at which occurs the

engine is “off” position at the included

132 Hundreds of

kOhms

133, 134

protection on a thermal overload (1.2.5.7)

Full Capacity, kVA***** 0-5000 5%

Active power capacity, kW***** 0-5000 5%

Reactive power capacity, kVAR***** 0-5000 5%

Cos of the angle between voltage

0-1000 5% 141, 142

Pot

PoA

PoJ

135, 136 Tens of W

137, 138

139, 140 Tens of W

and current on Phase A*1000

This parameter is read-only for the

interface RS-232, RS-485

Cos of the angle between voltage

0-1000 5% 143,144

and current on Phase B*1000

This parameter is read-only for the

interface RS-232, RS-485

NOVATEK-ELECTRO

UBZ-302

- 6 -

p

Cos of the angle between voltage

0-1000 5% 145,146

and current on Phase C*1000

This parameter is read-only for the

interface RS-232, RS-485

* NOTICE. If the temperature value exceed the mentioned limits – then on the indicator will be displayed the

alarm code according to the Table 2.6;

** NOTICE. If the autoreclosing is prohibited by the user – then on display will be glowing sing “not”;

*** NOTICE. If the time interval before switching to thermal overload fault or the autoreclosing time interval

(ttP) is not defined (more then 900 sec), then on the indicator will be displayed code “---“. If the protection

function is cancelled then the indicator should show sign “not”.

**** NOTICE. If the value of the motor insulation is more then 20 MOhms – then indicator shows code “1. “

(one with the decimal point in the lower order).

When the motor is turned ON (power supply is applied to the motor) the insulation resistance is not defined and

on the indicator is being displayed the code “---“ (if the insulation test measurement circuit is connected).

***** If the power capacity consumed by the load is more than 990 kW (kVA, kVAR) then MW (MVA) will be

displayed with dots looking like “n” in the middle decade. For example if the indicator shows “3n4”, then it means

that 3,4 МW (МVА).

****** NOTES. In the program version 15 when working with external transformers with rated current more than

100A, measured currents and calculated values except the zero-sequence current (earthing current) on the

RS-232/RS485 interface are being transmitted the values in Amperes.

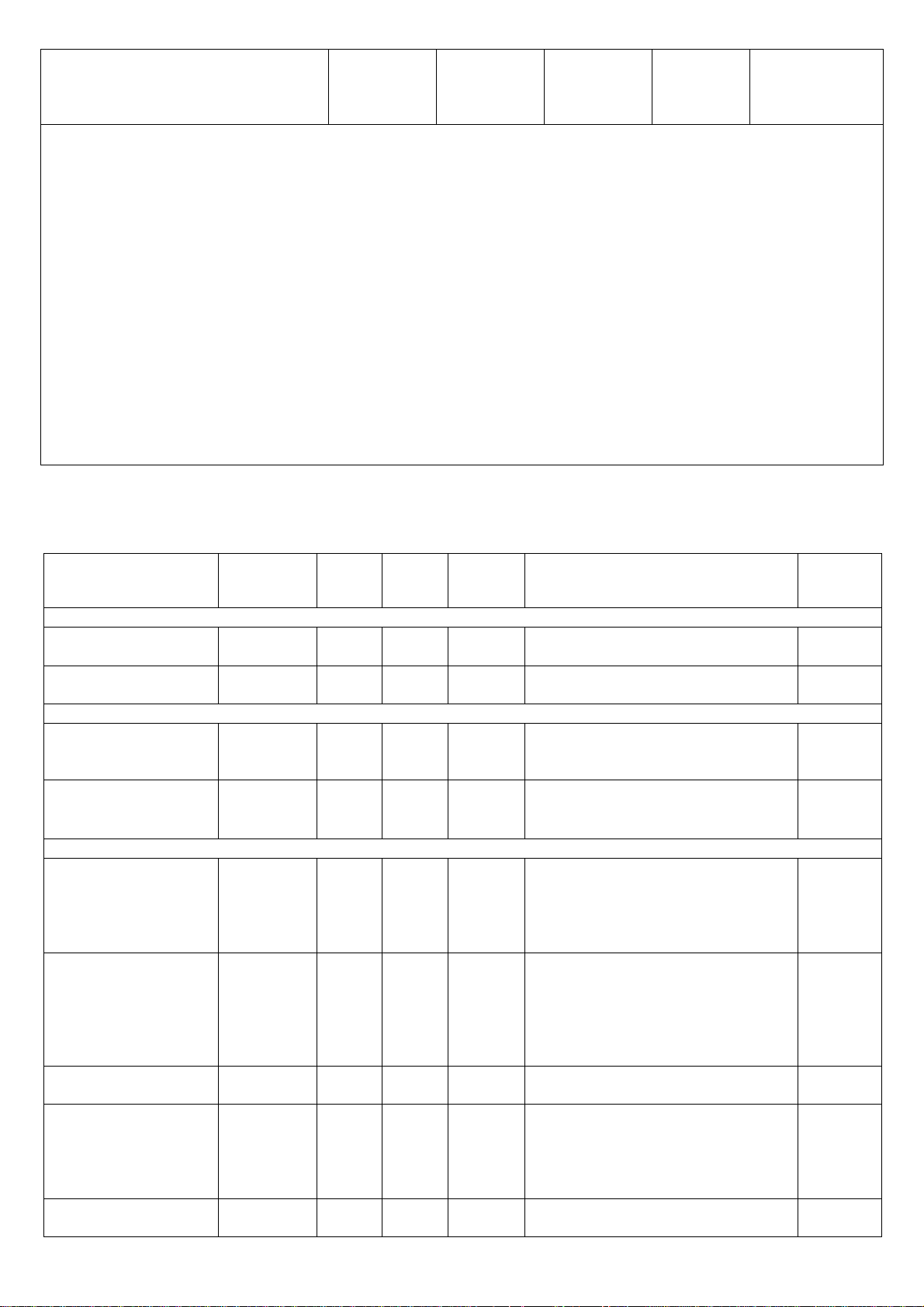

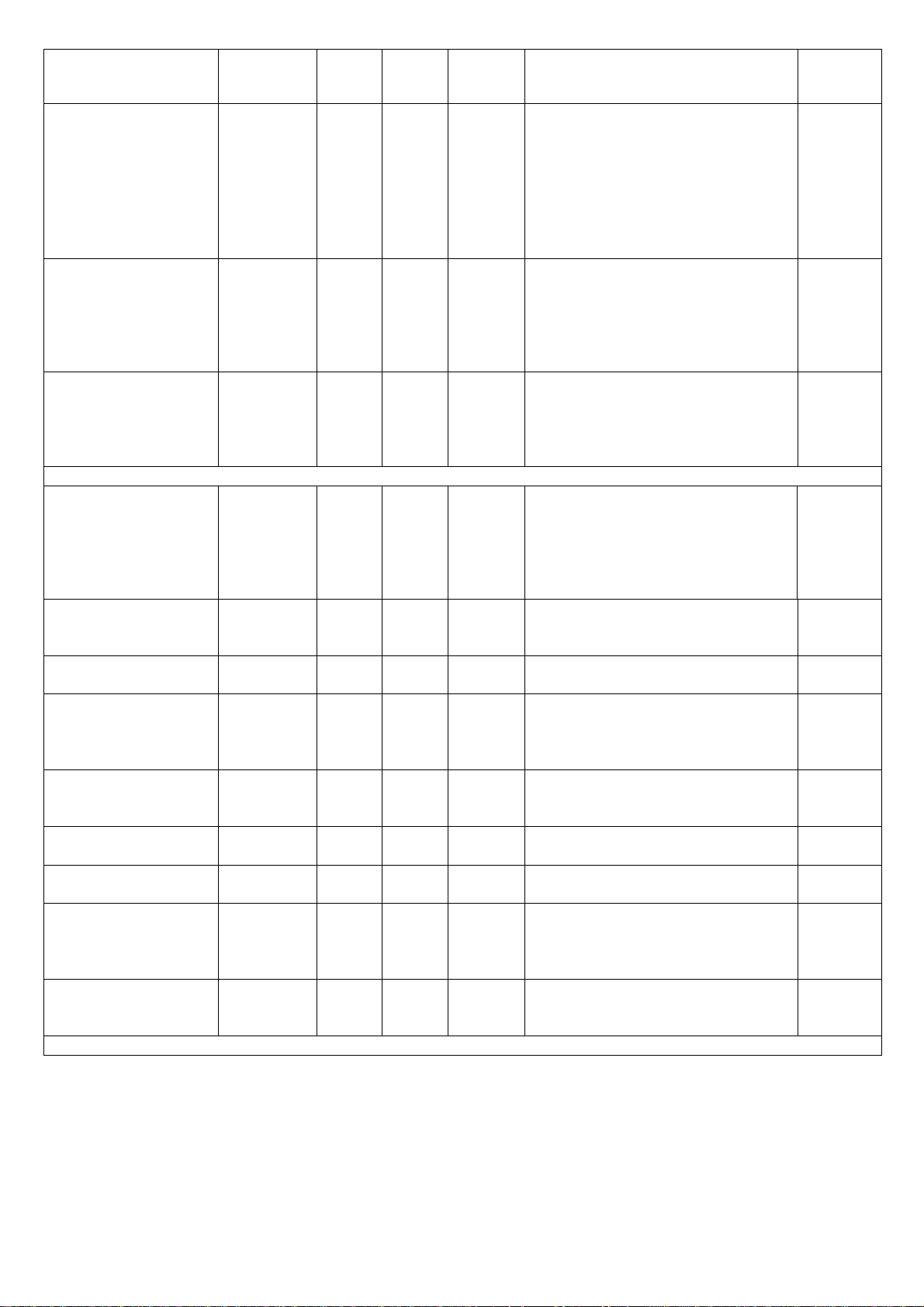

1.2.3. Programmed parameters and their respective values are shown in the Table 1.5 below:

Default and readable

parameters

Codes of

parameters

Table 1.5 - Programmable parameters

Min

value

Max

Value

Default

factory

setting

Action Address

Current transformers

Use of current

transformer

Rated current for the

current transformer, А

tPt

tnt

0 1 0 0 - Use of built-in transformers

1-Use of external transformers

20 800 100 For the external current

transformer

150

151

Others

Rated current of

motor, А

ind

0 630 0 0 - current value is not set: UBZ-302

will not allow to close the output

152

power relay (see section 2.3.7.)

Time frame for the

measurement of average current value, sec

tSi

10 600 60 Time frame during which the avera-

ge current value is measured (para-

meters iS1, iS2, iS3 from Table1.4)

153

Protection from maximal currents

Type of maximal

current protection

i = P

0 5 0 0- protection with the independent

time delay;

154

Type of protections with time depen-

dent delays: 1-SIT; 2-VIT (LTI);

3-EIT; 4-UIT; 5-RI

Tripping threshold to

cut the load basing the

i = S

0,8 9,0 4,0 Multiplication factor value is set up

basing the rated current of motor.

155

detected maximal, current values. User defined multiplication

factor

Tripping time delay for

i = t

0,1 600 10,0 156

current faults, sec

ON/OFF mode for

this type of protection

i = r

0 2 2 0- protection disabled

1- protection enabled, but auto-

reclosing after the fault is prohibited

157

2- protection enabled and auto-

reclosing is allowed afterwards

Tripping sequence of

rotection depen-

the

i = n

0 1 1 0- protection trips the current inde-

pendently from thermal protection

158

UBZ-302

NOVATEK-ELECTRO

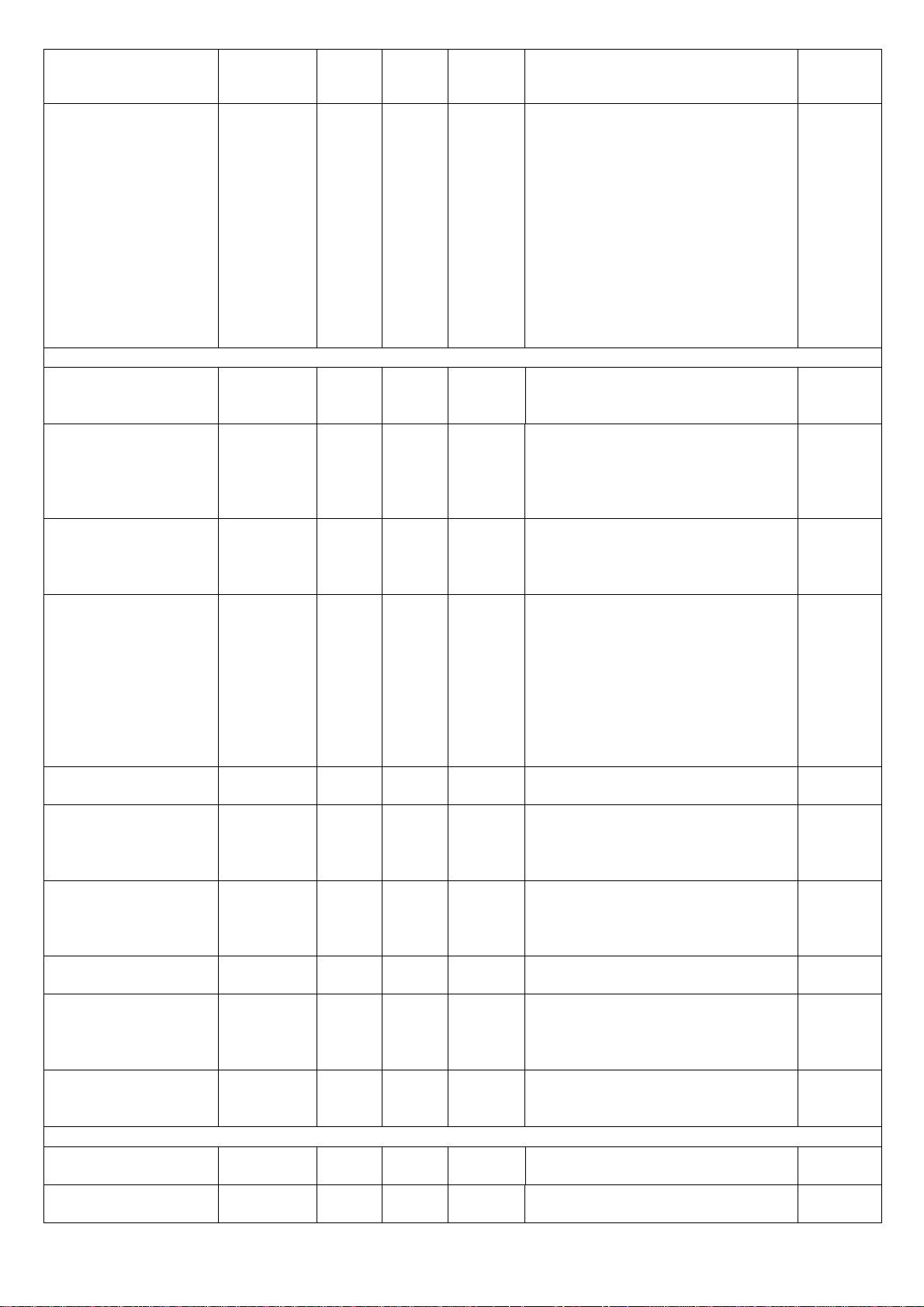

- 7 -

p

Default and readable

parameters

ding on thermal overload protection

Earth leakage protection Current tripping setting, А

Tripping time delay

for the protection, sec

ON/OFF mode for

this type of protection

Reverse current sequence protection

Tripping threshold, %

Tripping time delay,sec

ON/OFF mode for

this type of protection

Analysis of the tripping basing the reverse current sequence

Multiplication factor for

the exceeding of 2

coefficients dependency: when the reverse

sequence current coefficient is devided by

reverse sequence

voltage coefficient

Permission of the

analysis

Thermal overload (thermal model of AC motor)

ON/OFF mode for

this type of protection

Tripping time in case of

2-times current overload, sec

Coefficient of the cooling time augmentation

when the motor was

switched of due to

thermal overload

Minimal phase current

Tripping threshold

setting, %

Tripping time delay

for the protection, sec

ON/OFF mode for

this type of protection

Codes of

parameters

i_S

i_t ñ

i_r

ioS

iot

Ior ñ

iOS

iOr

dtr

dtt

dtP

i

S

=

i

t

=

i

r

=

Min

value

0,3 5,0 0,5 If this parameter is not included into

0,1 2,0 1,0 160

0 2 2 0- protection is disabled

5 20 10 Is being set in the % of rated motor

0,2 10,0 5,0 163

0 2 2 0- protection is disabled

2 4 2 165

0 1 1 0- OFF

0 2 2 0- protection is disabled

10 120 60 168

1,0 4,0 1,0 Compensation of the time required

11 90 20 Tripping threshold for the protection

1 100 5 171

0 2 2 0- protection is disabled

Max

Value

Default

factory

setting

Action Address

1- if there is no thermal overload

then it’s indicated on the display but

the power relay doesn’t turn the

motor OFF

the list of MMSP then the default

values are the following:

0,5 at In<=50A;

1,0 at In>50A

1- protection enabled but autoreclosing after the fault is prohibited

2- protection enabled and autoreclosing is allowed

current value

1- protection enabled but autoreclosing after the fault is prohibited

2- protection enabled and

autoreclosing is allowed

1- ON

1- protection enabled but autoreclosing after the fault is prohibited

2- protection enabled and

autoreclosing is allowed

for motor cooling after motor turn

OFF due to the thermal overload

to minimal operating current in % of

adjusted rated current

rotection enabled but autoreclo-

1-

159

161

162

164

166

167

169

170

172

NOVATEK-ELECTRO

UBZ-302

- 8 -

Default and readable

parameters

Codes of

parameters

Min

value

Max

Value

Default

factory

setting

Action Address

sing after the fault is prohibited

2- protection enabled and

autoreclosing is allowed

Long lasting (Overcrank) motor start, blocked rotor fault Tripping threshold to current, multiplicity

PPS

1,5 7,0 5,0 User defined multiplicity coefficient

to rated current value

173

coefficient

Tripping time delay for

PPt

1 600 10 Time for starting up the motor 174

the protection from long

lasting start of the

motor, sec

Tripping time delay in

Pbt

0,1 300 1.0 175

case the blocked rotor

detected, sec

ON/OFF mode for

this type of protection

PPr

0 2 1 0- protection is disabled

1- protection enabled but auto-

176

reclosing after the fault is prohibited

2- protection enabled and

autoreclosing is allowed

Voltage monitoring and protection

Minimal line voltage, V

Tripping time delay to

U

U

=

=

S

t

270 415 320 177

5 30 10 178

minimal voltage fault, s

ON/OFF mode for

minimal line voltage

level protection

U

r

=

0 2 2 0- protection is disabled

1- protection enabled but auto-

179

reclosing after the fault is prohibited

2- protection enabled and

autoreclosing is allowed

Maximal line voltage, V

Tripping time delay to

U = S

=

t

U

330 475 415 180

1 10 2 181

maximal voltage fault,

sec

ON/OFF mode for

maximal line voltage

level protection

U = r

0 1 2 0- protection is disabled

1- protection enabled but autoreclosing after the fault is prohibited

182

2- protection enabled and

autoreclosing is allowed

Line voltage

U

n

S

15 120 35 Reverse voltage sequence 183

imbalance, V

Tripping time delay to

U n t ñ

1 30 5 184

line voltage imbalance

fault, sec

ON/OFF mode for

the protection from

line voltage

imbalance control

U n r

0 2 2 0- protection is disabled

1- protection enabled but autoreclosing after the fault is prohibited

2- protection enabled and

185

autoreclosing is allowed

ON/OFF mode for

the correct phase

sequence control

U Y r

0 2 1 0- protection is disabled

1- protection enabled but autoreclo-

sing after the fault is prohibited

186

2- protection enabled and

autoreclosing is allowed

AC motor operation and autoreclosing parameters

Autoreclosing time

Atn

0 900 600 187

after the tripping for

minimal current fault,

sec

Autoreclosing time

Att

0 900 5 188

setting, sec

UBZ-302

NOVATEK-ELECTRO

Default and readable

parameters

ON/OFF mode for all

Codes of

parameters

Arr

Min

value

0 1 1 0-autoreclosing disabled

type of faults

Permission of motor

APd

0 2 1 0 – motor is started manually

start after the power

supply is given to the

input terminals of

UBZ-302

Motor operation

ACd

0 3 0 0-disabled

using the UBZ-302

Temperature control and monitoring

ON/OFF mode for the

—1r

0 2 0

temperature control

function and setting the

type of the Sensor 1

Threshold temperature

to turn OFF the motor

(sensor 1),

o

C

Correction coefficient

C1S

C1c

0 100 80 193

-9 9 0 194

for the Sensor 1

ON/OFF mode for the

C2r

0 3 0 0 – disabled

temperature control

function and setting the

type of the Sensor 2

Threshold temperature to turn OFF the

motor (sensor 2),

o

Alarm indication

C2S

C

C2A

0 220 180 196

0 220 170 197

temperature value

Correction coefficient

C2c

-9 9 0 198

for the Sensor 2

Autoreclosing after the

CPA

1 2 1 1- autoreclosing after the fault

thermal overload fault

detected and motor is

OFF

Action in case the

——r

0 1 0 0- alarm indication and continuous

temperature sensor

fault detected

Control of the motor coil insulation level

Max

Value

- 9 -

Default

factory

setting

Action Address

1-autoreclosing enabled

The action of the

Arr parameter is

valid for all faults and alarms except

the voltage faults. To disable autoreclosing on the detect of voltage

faults it’s necessary to use the

=

parameters U

r , U = r, U n

1– motor starts with the user preset

autoreclosing time

2 – Motor starts with 2 seconds delay after power supply is given to

UBZ-302

1-motor start allowed

2-alarm motor stop allowed

3-motor start and stop allowed

For details kindly see section 2.4.7.

– disabled

1- built-in sensor (protection trips the

motor if the sensor resistance

exceed 1.7 kOhm)

– external PTC sensor (1kOhm at

0

С)

25

1 –type Pt100

2- type Ni100

3- type Ni120

prohibited

2- autoreclosing after the fault

allowed

operation of the motor running;

1- alarm indication and motor stop

189

190

191

192

195

199

200

NOVATEK-ELECTRO

UBZ-302

Default and readable

parameters

Control of the

Codes of

parameters

rid

Min

value

0 10 5 0-disabled

minimal insulation

level of the AC motor

Other parameters and controls

Mode with minimal set

Sin

0 1 1 0-disabled

of user defined parameters

Indication on the

SiP

0 2 1 0- line voltage in between lines AB

UBZ-302 front panel

before the permission

to start the motor

Parameter indication

SiC

0 1 1 0 – parameter value is being

mode

Operation mode for

rrS

0 2 0 0 – relay is used as a signalization

the functional relay

output

Timer setting for the

rrt

0 300 30 Kindly see line above and

functional relay, sec

Total running time for

UBZ-302, days

Total motor running

time, days

Users access code

Advanced user

tbU

tCO

LOC

PAS

0

0

0 9 0 0 – keys are unblocked

000 999 123 000 – access to the advanced user

access code

Reset default factory

PPP

0 1 0 After the entry “1” and exit from the

settings

Serial interface parameters (RS-485/ RS-232)

Communication

rSA

1 247 1 212

address of UBZ-302

Data transmission

rSS

0 1 0 0: 9600 symbols per second;

speed

Max

Value

999

999

- 10 -

Default

factory

setting

0

0

Action Address

5-if the insulation resistance is less

then 500 kOhms then motor start is

not allowed.

Autoreclosing allowed

10- motor is not allowed to start if the

resistance of the coils is less then

1000 kOhms.

Autoreclosing allowed

15- motor is not allowed to start if the

resistance of the coils is less then

500 kOhms. A

utoreclosing prohibited

20- motor is not allowed to start if the

resistance of the coils is less then

1000 kOhms.

Autoreclosing prohibited

1-enabled

(Uab)

1-Resistance of the insulation rid

2- Countdown of the remaining

autoreclosing time

shown continuously

1 – parameter value is shown on

display within 15 seconds

output

1- relay is used like a time delay

relay (closes its contacts with the

user defined parameter

rrt. After

the power supply is given to the

input of UBZ-302

2- relay is used for the delta-star

switching

parameters of rrS

* when information is transmitted

using MODBUS/RS-232 interface –

then the total running time is

transmitted in hours

* when information is transmitted

using MODBUS/RS-232 interface –

then the total running time is

transmitted in hours

1-9 – user defined password

settings allowed

000-999 – password of the advanced

user

settings mode – UBZ-302 returns

to factory default settings

1: 19200 symbols per second;

201

202

203

204

205

206

207

208

209

210

211

213

UBZ-302

NOVATEK-ELECTRO

Loading...

Loading...