NOVATEK NT7502H-TABF1, NT7502H-BDT Datasheet

NT7502

65 X 132 RAM-Map LCD Controller / Driver

Features

! Direct RAM data display using the display RAM. When

RAM data bit is 0, it is not displayed. When RAM data bit

is 1, it is displayed. (At normal display)

! RAM capacity: 65 X 132 = 8580 bits

! Many command functions: Read/Write Display Data.

Display ON/OFF. Normal/Reverse Display. Page

Address Set. Set Display Start Line. Set LCD Bias,

Electronic contrast Controls, V0 voltage regulation

internal resistor ratio set, Read Modify Write, Select

Segment Driver Direction, Power Save

! High-speed 8-bit microprocessor interface allowing direct

connection to both the 8080 and 6800

! Serial interface

! Power supply voltage: 2.4 - 3.5V

! Maximum 12V LCD driving output voltage

! 2X / 3X / 4X on chip DC-DC converter

! Voltage regulator

! Voltage follower

! On-chip oscillator

General Description

The NT7502 is a single-chip LCD driver for dot-matrix liquid

crystal displays which is directly connectable to a

microcomputer bus. It accepts 8-bit serial or parallel display

data directly sent from a microcomputer and stores it in an

on-chip display RAM. It generates a LCD drive signal

independent of the microprocessor clock.

The set of the on-chip display RAM of 65 X 132 bits and a

one-to-one correspondence between LCD panel pixel dots

and on-chip RAM bits permit implementation of displays with

a high degree of freedom.

The NT7502 contains 65 common output circuits and 132

segment output circuits, so that a single chip of NT7502 can

make 65 X 132, 55 X 132, 49 X 132 and 33 X 132 dot

displays with pad option (DUTY1, DUTY0).

No external operation clock is required for RAM read/write

operations. Accordingly, this driver can be operated with a

minimum current consumption and its onboard

low-current-consumption liquid crystal power supply can

implement a high-performance handy display system with

minimum current consumption and the smallest LSI

configuration.

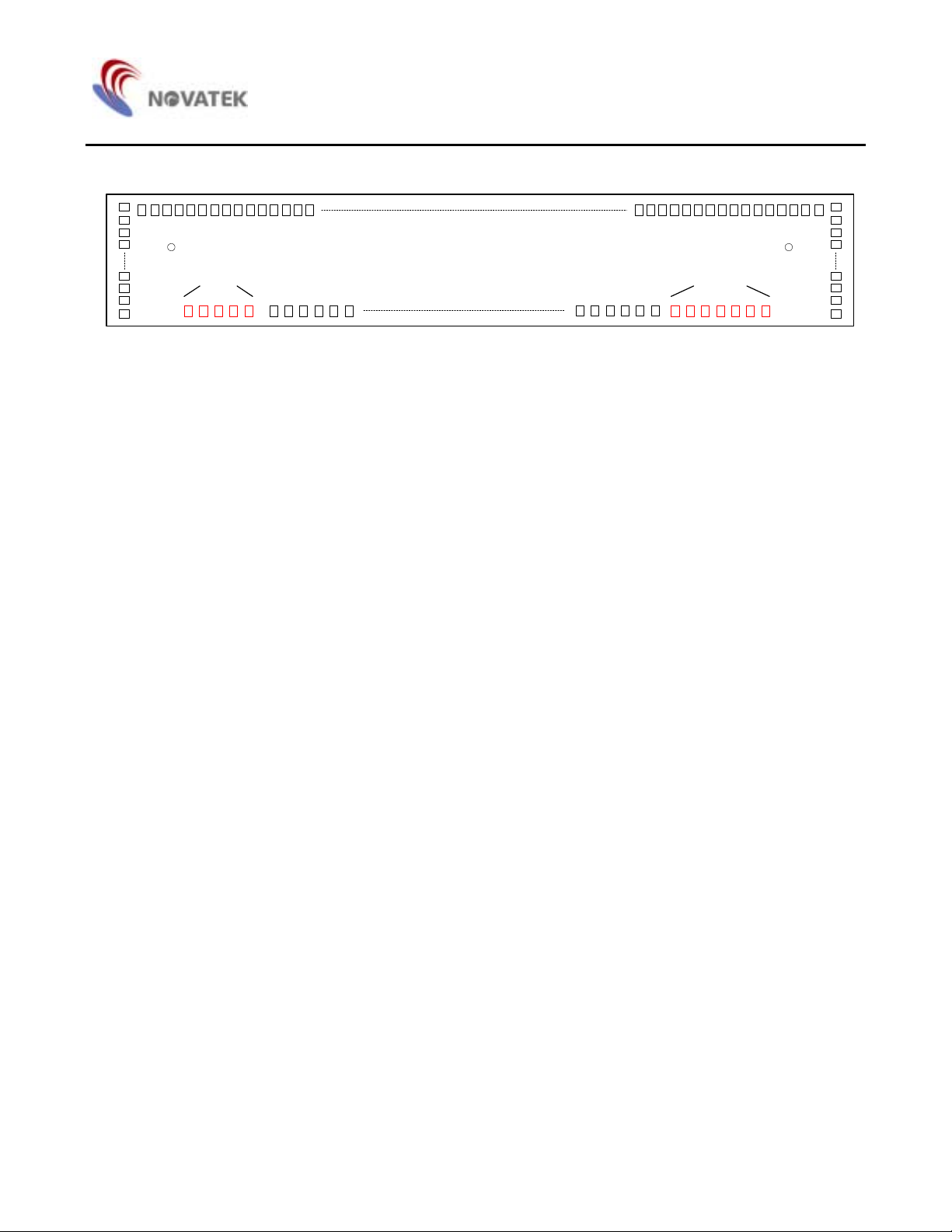

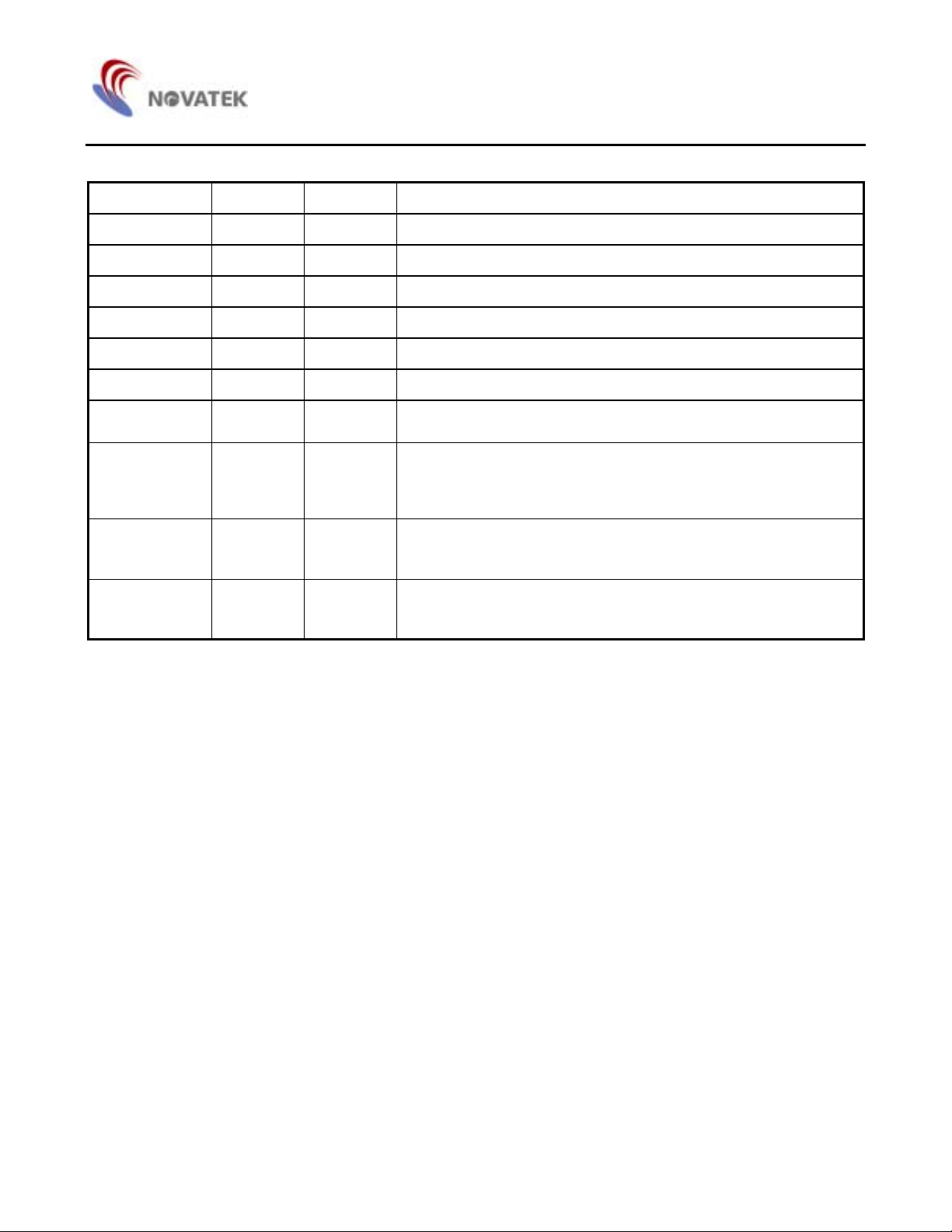

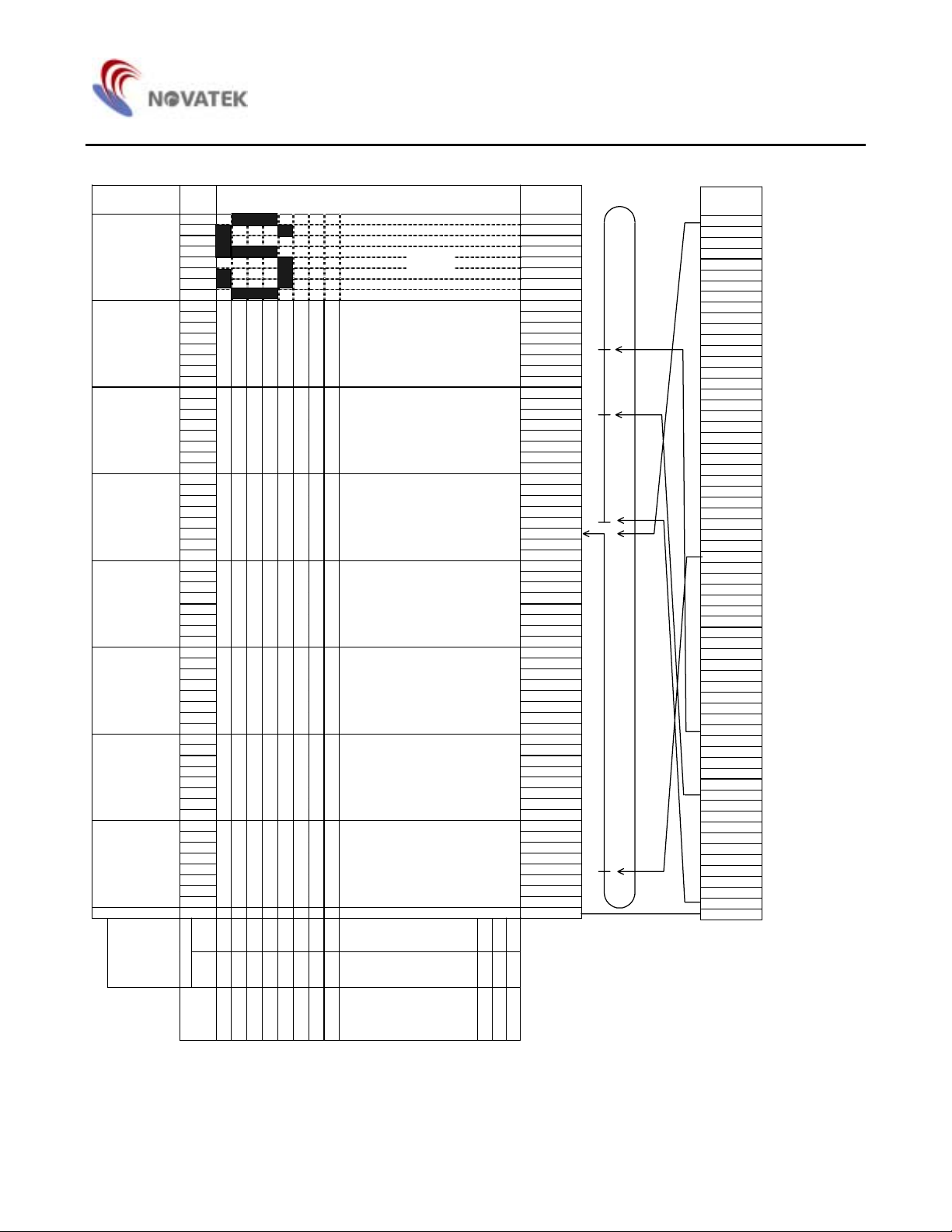

Pin Configuration

SEG130

48COM31

COM30

COM29

495051

COM28

COMS

COM1

COM0

SEG0

7879808182

SEG1

SEG2

83

SEG131

COM32

COM33

211

212

213

214

COM62

COM34

215

COM63

COMS

FRS

FR

243

244

245

246

247

NT7502H-TABF1

(Copper Side View)

40414243444546

47

P/S

HPM

IRS

39

V4

V3NCV0VRM/S

CLS

C86

+CAP2-VEXT

VRSV1V2

CAP1

+

VDD2

VSS

VOUTNCCAP3+CAP1-CAP2

1 V1.0

1011121314151617181920212223242526272829303132333435363738

CS1

CS2

RESA0WRRDD0D1D2D3D4D5D6D7DUTY0DUTY1VDD

NC

123456789

NCNCNCNCFRCLDOF

NT7502

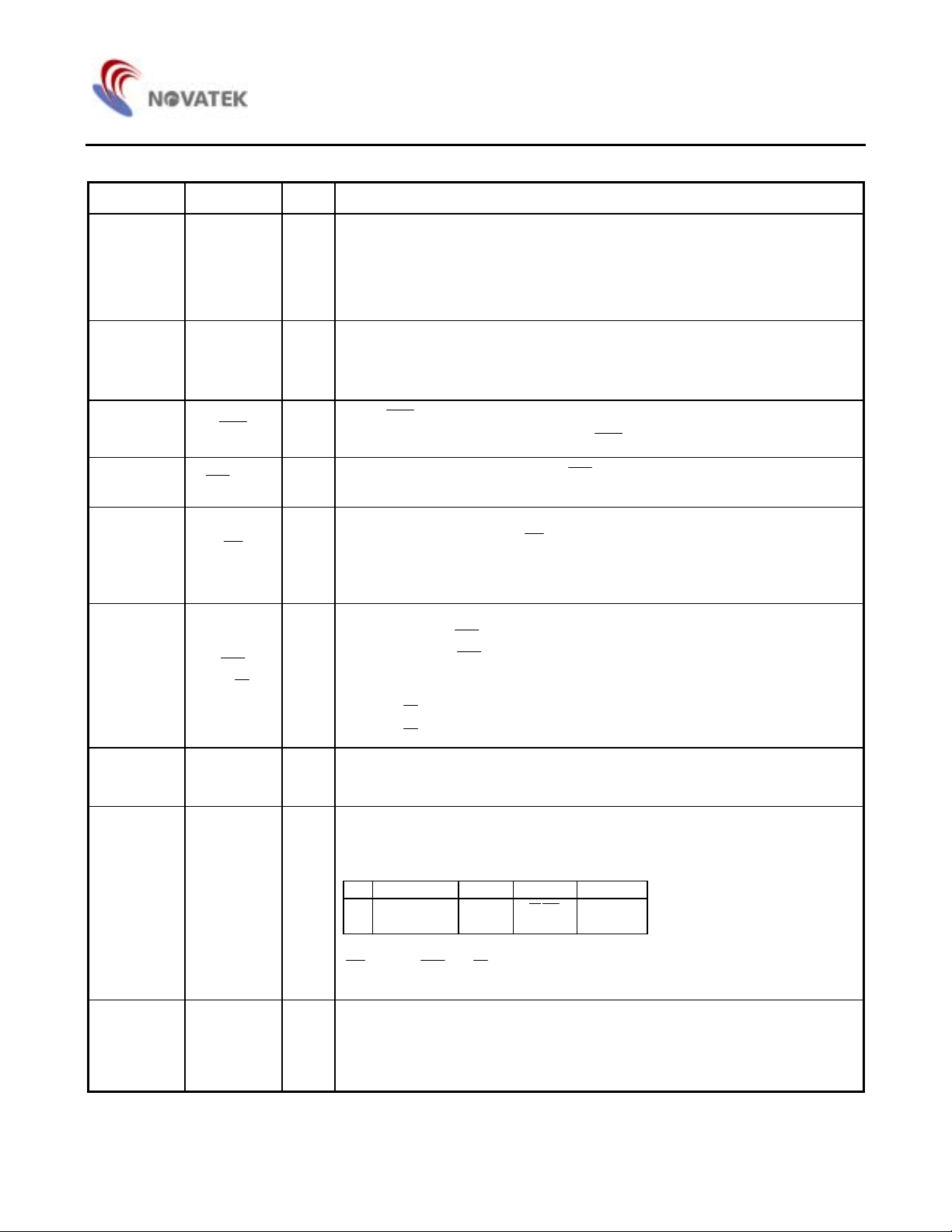

Pad Configuration

281

282

ALK_L ALK_R

118

NT7502

DUMMY DUMMY

298

DUMMY0 DUMMY4 DUMMY5 DUMMY11

1001

117

101

2

NT7502

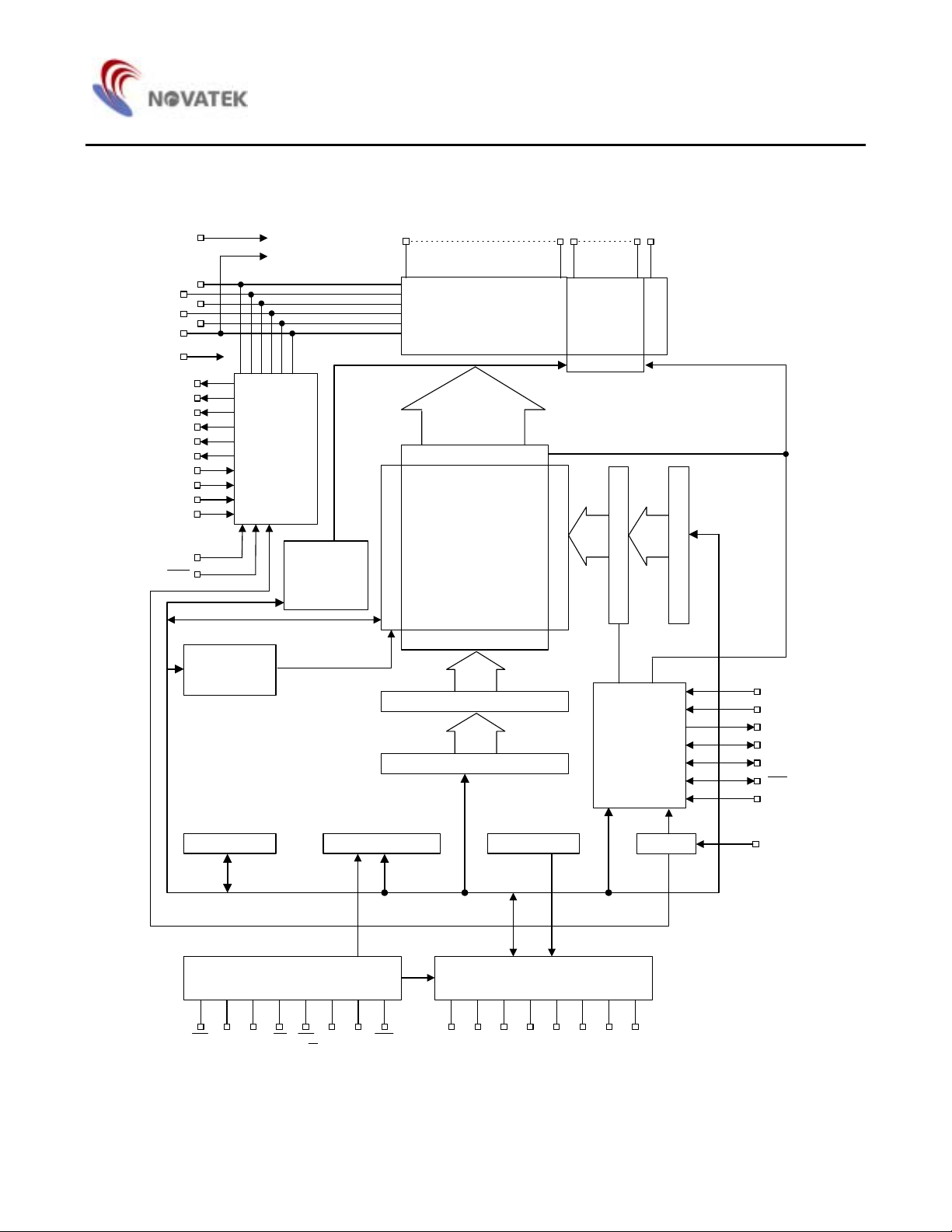

Block Diagram

V1

V3

Vss

TMPS

CAP1+

CAP1-

CAP2+

CAP2-

CAP3+

V

DD

V

0

V2

V4

V

EXT

OUT

V

V

DD2

V

R

V

RS

IRS

HPM

Page address

Power Supply

register

Circuit

Output

status

selector

circuit

SEG0

SEG131

Segment driver

Display data latch

132*65-dot

display data RAM

I/O buffer circuit

Column address decoder

8-bit column address counter

8-bit column address counter

COM0 COM63 COMS

Common

driver

Shift register

Line counter

line address decoder

Display timing

generator

circuit

COM S

Initial display line register

DUTY0

DUTY1

FRS

FR

CL

DOF

M/S

Bus holder Command decoder Bus holder

Oscillator

CLS

Microprocessor interface I/O buffer

CS2 A0

RD

(E)

WR

C86 P/S

)W/R(

RES1CS

D7

(SI)

D5 D4 D3 D2 D1 D0

D6

(SCL)

3

NT7502

V1V2V3V

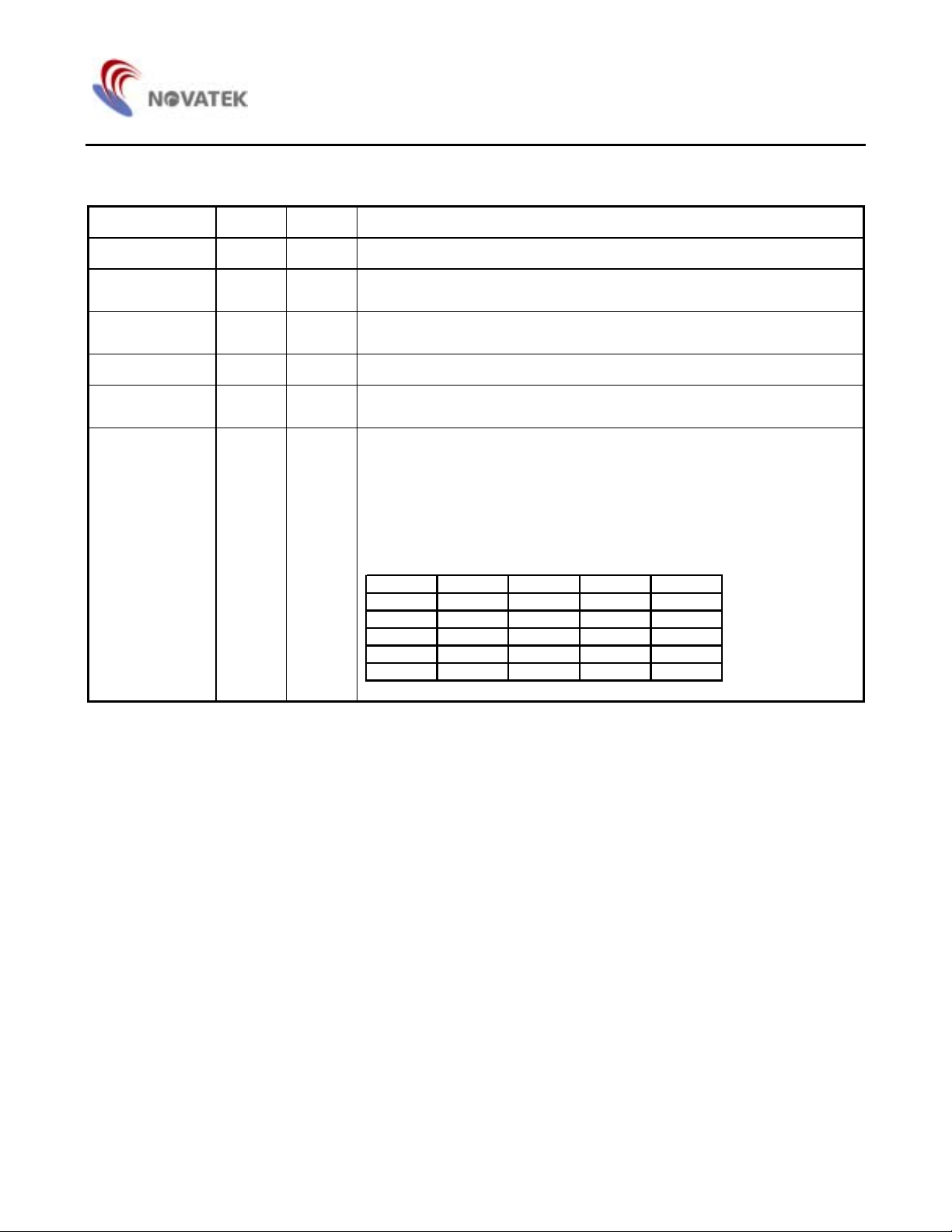

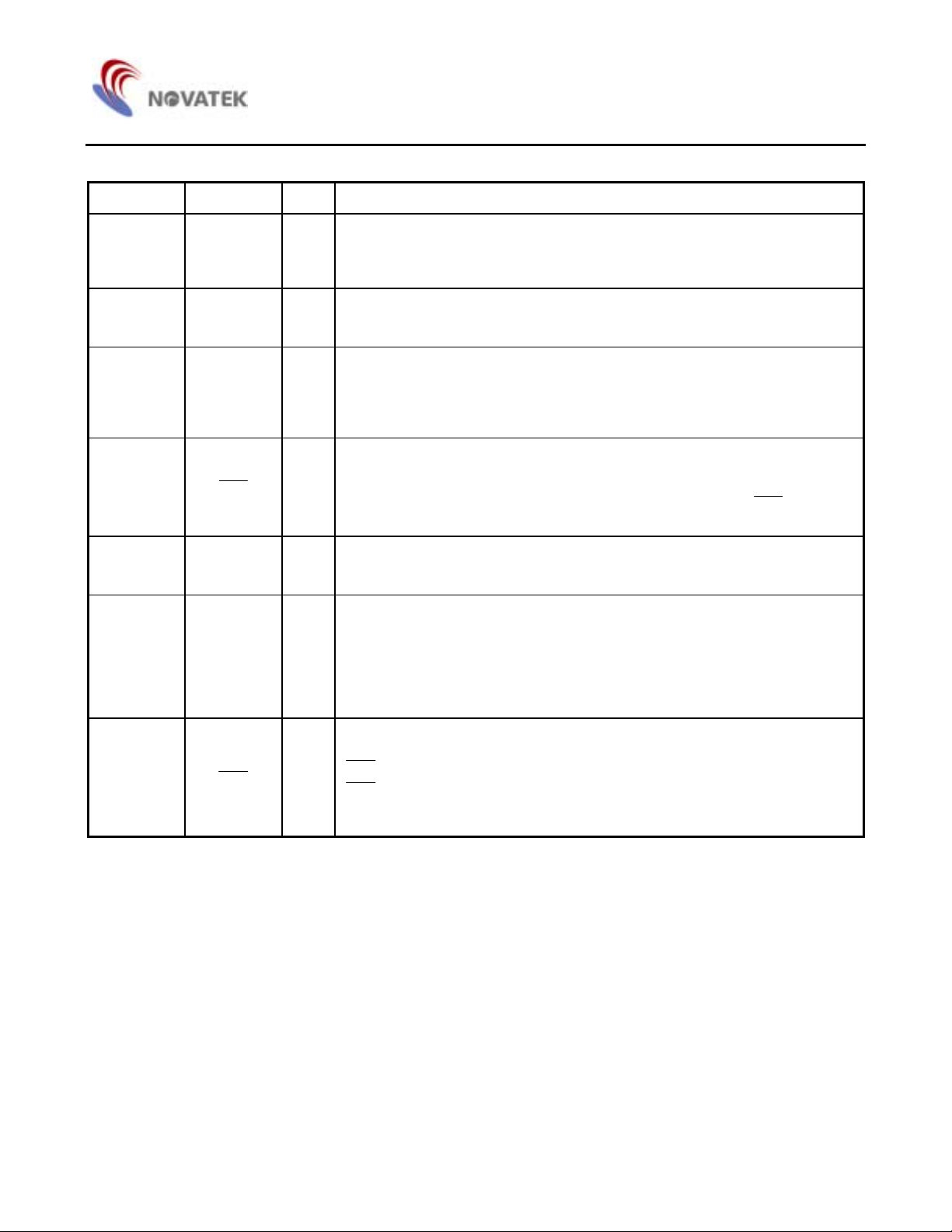

Pad Description

Power Supply

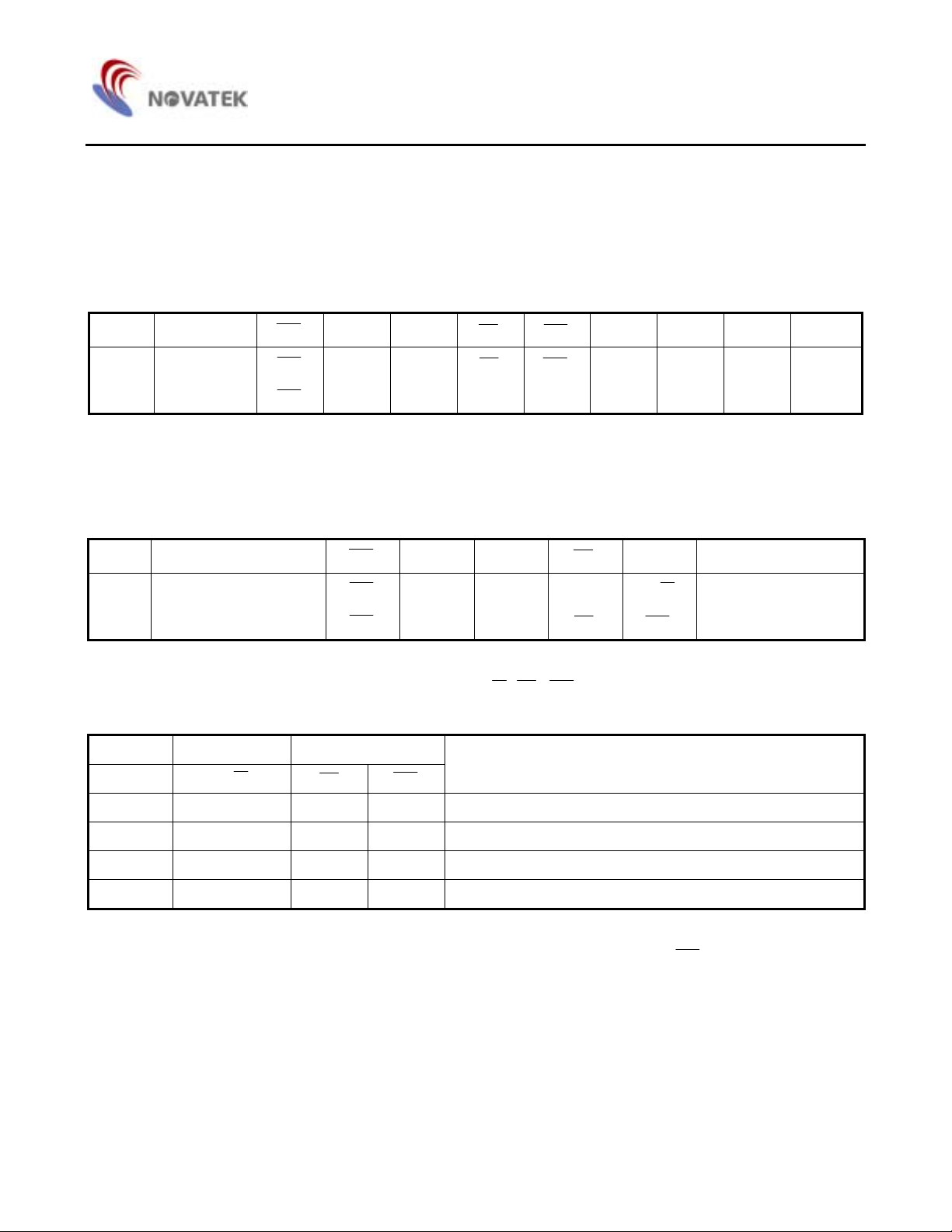

Pad No. Symbol I/O Descriptions

30 - 33 VDD Supply 2.4 - 3.5V power supply input. These pads must be connected each other

10, 16, 26, 53, 71,

77, 81, 91

34 - 36 VDD2 Supply

DD Supply 2.4 - 3.5V power supply output for pad option

V

This is the reference power supply for the step-up voltage circuit for the LCD.

These pads must be connected each other

37 - 40 VSS Supply Ground. These pads must be connected each other

7, 13, 25, 29 , 56,

69 - 70, 74, 79, 83

V

SS Supply Ground output for pad option

LCD driver supply voltages. The voltage determined by LCD cell is

impedance-converted by a resistive driver or an operation amplifier for

application. Voltages should be according to the following relationship:

0 ≥ V1 ≥ V2 ≥ V3 ≥ V4 ≥ VSS

65 - 66

57 - 58

59 - 60

61 - 62

63 - 64

V

V

V2

V3

V4

0

1

Supply

V

When the on-chip operating power circuit is on, the following voltages

are supplied to V

1 to V4 by the on-chip power circuit. Voltage selection is

performed by the Set LCD Bias command.

LCD bias

1/5 bias 4/5V0 3/5V0 2/5V0 1/5V0

1/6 bias 5/6V0 4/6V0 2/6V0 1/6V0

1/7 bias 6/7V0 5/7V0 2/7V0 1/7V0

1/8 bias 7/8V0 6/8V0 2/8V0 1/8V0

1/9 bias 8/9V0 7/9V0 2/9V0 1/9V0

4

4

NT7502

LCD Driver Supplies

Pad No. Symbol I/O Descriptions

45 - 46 CAP1- O Capacitor 1- pad for internal DC/DC voltage converter

47 - 48 CAP1+ O Capacitor 1+ pad for internal DC/DC voltage converter

51 - 52 CAP2- O Capacitor 2- pad for internal DC/DC voltage converter

49 - 50 CAP2+ O Capacitor 2+ pad for internal DC/DC voltage converter

43 - 44 CAP3+ O Capacitor 3+ pad for internal DC/DC voltage converter

41 - 42 VOUT O DC/DC voltage converter output

67 - 68 VR I

54 VEXT I

82 TMPS I

55 VRS I

Voltage adjustment pad. Applies voltage between V

0 and VSS using a

resistive divider

This is the external input reference voltage (VREF) for the internal

voltage regulator. It is valid only when external V

EXT must be ≥ 2.4V and ≤ VDD2

V

When using internal V

REF, this pad must be NC

REF is used.

Selects temperature coefficient of the reference voltage

TMPS = 0: -0.05% / °C

TMPS = 1: -0.2 % / °C

Select the internal voltage regulator or external voltage regulator,

VRS = 0: using the external VREF

VRS = 1: using the internal VREF

5

NT7502

System Bus Connection Pads

Pad No. Symbol I/O Descriptions

This is an 8-bit bi-directional data bus that connects to an 8-bit or 16-bit

standard MPU data bus.

When the serial interface is selected (P/S = “L”), then D7 serves as the serial

I/O

data input terminal (SI) and D6 serves as the serial clock input terminal (SCL)

At this time, D0 to D5 are set to high impedance.

17 - 24

D0 - D7

(SI)

(SCL)

When the chip select is inactive, D0 to D7 are set to high impedance.

This is connected to the least significant bit of the normal MPU address bus,

12 A0 I

and it determines whether the data bits are data or a command

A0 = “H” indicating that D0 to D7 are display data, and

A0 = “L” indicating that D0 to D7 are control data.

When

11

RES

I

RES is set to “L”, the settings are initialized.

The reset operation is performed by the

RES signal level.

This is the chip select signal. When

8, 9

1CS CS2

I

select becomes active, and data/command I/O is enabled.

When connected to an 8080 MPU, it is active LOW.

15

RD

(E)

This pad is connected to the

I

data bus is in an output status when this signal is “L”.

When connected to a 6800 Series MPU, this is active HIGH.

This is used as an enable clock input of the 6800 series MPU.

When connected to an 8080 MPU, this is active LOW. This terminal connects

to the 8080 MPU

14

(

WR

W/R )

rising edge of the

I

When connected to a 6800 Series MPU, this is the read/write control signal

input terminal.

When

When

This is the MPU interface switch terminal

75 C86 I

C86 = “H”: 6800 Series MPU interface

C86 = “L”: 8080 MPU interface

This is the parallel data input/serial data input switch terminal

P/S = “H”: Parallel data input

P/S = “L”: Serial data input

The following applies depending on the P/S status:

76 P/S I

P/S Data/Command Data Read/Write Serial Clock

"H" A0 D0 to D7

"L" A0 SI (D7) Write only SCL (D6)

When P/S = “L”, D0 to D5 are HZ. D0 to D5 may be “H”, “L” or Open.

RD(E) and WR ( WR/ ) are fixed to either “H” or “L”. With serial data input,

RAM display data reading is not supported.

1CS = “L” and CS2 = “H”, then the chip

RD signal of the 8080MPU, and the NT7502

WR signal. The signals on the data bus are latched at the

WR signal.

WR/ = “H”: Read

WR/ = “L”: Write

RDWR

Terminal is used to select whether enable or disable the display clock internal

oscillator circuit.

73 CLS I

CLS = “H”: Internal oscillator circuit is enabled

CLS = “L”: Internal oscillator circuit is disabled (requires external input).

When CLS = “L”, input the display clock through the CL pad.

6

DOF

This terminal selects the master/slave operation for the NT7502 chips.

Master operation outputs the timing signals that are required for the LCD display,

while slave operation inputs the timing signals required for the liquid crystal display,

synchronizing the liquid crystal display system.

This is the display clock input terminal.

When the NT7502 chips are used in master/slave mode, the various CL

terminals must be connected.

This is the liquid crystal alternating current signal I/O terminal

M/S = “H”: Output.

M/S = “L”: Input.

When the NT7502 chip is used in master/slave mode, the various FR terminals

must be connected.

This is the liquid crystal display blanking control terminal.

M/S = “H”: Output.

M/S = “L”: Input.

I/O

When the NT7502 chip is used in master/slave mode, the various

must be connected.

This is the output terminal for the static drive.

This terminal is only enabled when the static indicator display is ON in

master operation mode, and is used in conjunction with the FR terminal.

DOF terminals

NT7502

System Bus Connection Pads (continue)

Pad No. Symbol I/O Description

72 M/S I

4 CL I/O

3 FR I/O

5

2 FRS O

80 IRS I

78

HPM

This terminal selects the resistors for the V0 voltage level adjustment

IRS = “H”, Use the internal resistors.

IRS = “L”, Do not use the internal resistors.

The V0 voltage level is regulated by an external resistive voltage divider

attached to the VR terminal.

This pad is enabled only when the master operation mode is selected.

It is fixed to either “H” or “L” when the slave operation mode is selected.

This is the power control terminal for the power supply circuit for liquid

crystal drive.

HPM = “H”, Normal mode

I

HPM = “L”, High power mode

This pad is enabled only when the master operation mode is selected.

It is fixed to either “H” or “L” when the slave operation mode is selected.

7

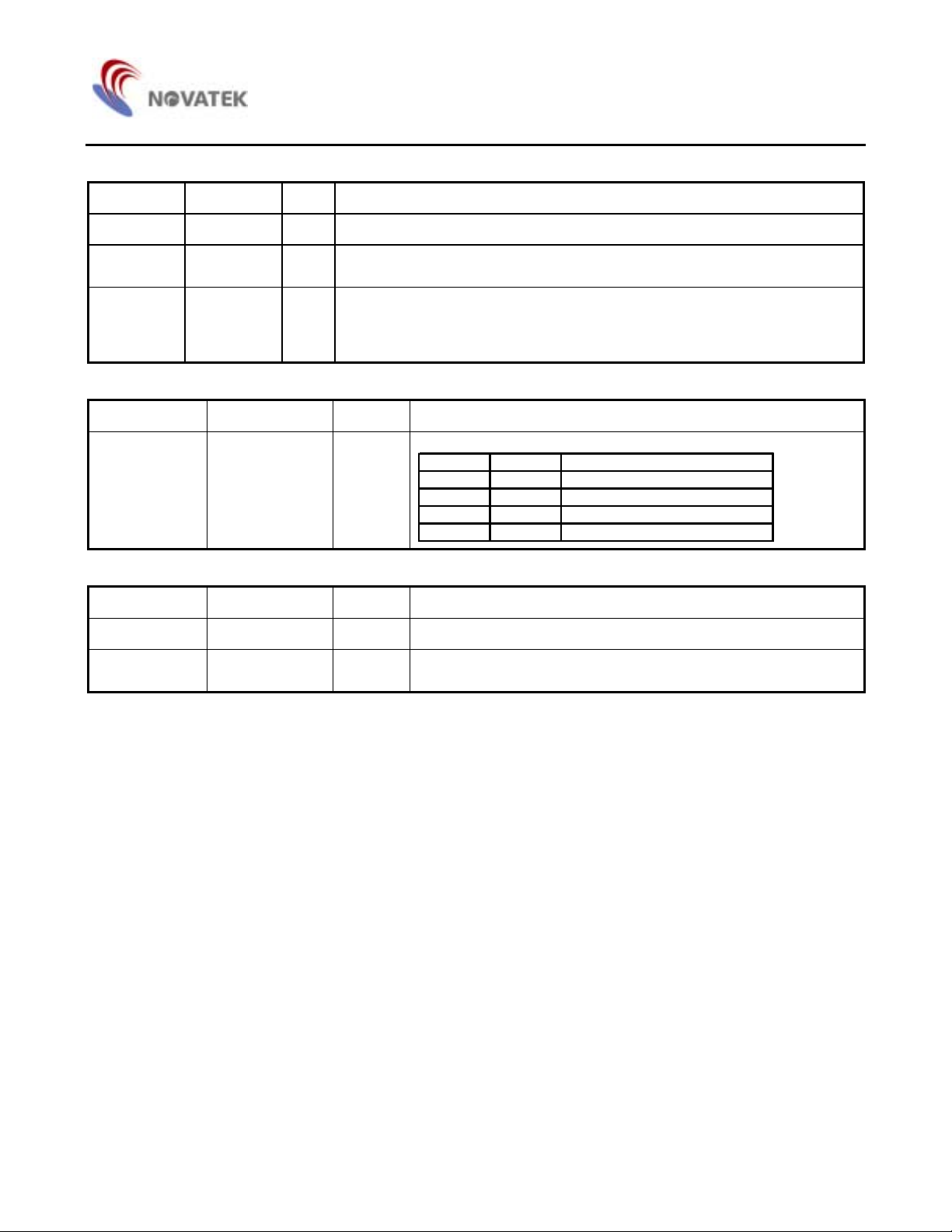

NT7502

y

Liquid Crystal Drive Pads

Pad No. Symbol I/O Description

134 - 265 SEG0 - 131 O Segment signal output for LCD display

101 - 132

266 - 297

133, 298 COMS O

Configuration Pads

Pad No. Symbol I/O Description

27, 28 DUTY0, DUTY1 I

Test Pads

Pad No. Symbol I/O Description

90 TEST3 I Test pads, and must be connected to VDD

1, 6, 84 - 89

92 - 100

COM31 - 0

COM32 - 63

NC NC pads, no connection for user

Common signal output for LCD display

O

When in master/slave mode, the same signal is output by both master and slave

These are the COM output terminals for the indicator. Both terminals output the

same signal

No connect these terminals if they are not used

When in master/slave mode, the same signal is output by both master and slave

Select the LCD driver duty

DUTY1 DUTY0 LCD driver dut

0 0 1/33

0 1 1/49

1 0 1/55

1 1 1/65

8

NT7502

Functional Description

Microprocessor Interface

Interface type selection

The NT7502 can transfer data via 8-bit bi-directional data bus (D7 to D0) or via serial data input (SI). When high or lo w is

selected for the parity of P/S pad, either 8-bit parallel data input or serial data input can be selected as shown in Table 1. When

serial data input is selected, the RAM data cannot be read out.

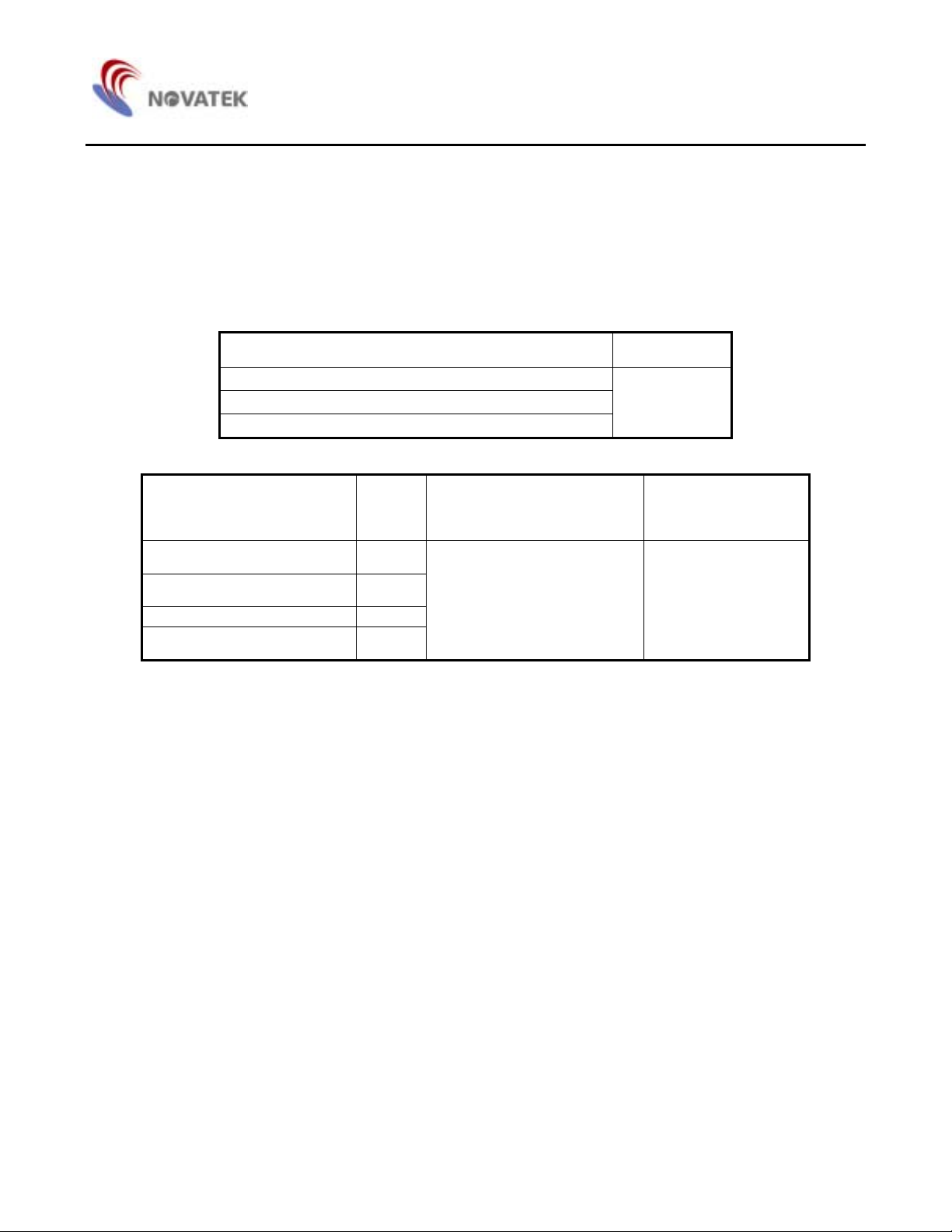

Table. 1

P/S Type

H Parallel Input

L Serial Input

Parallel Input

When the NT7502 selects parallel input (P/S = high), the 8080 series microprocess or or 6800 series microprocessor can be

selected by causing the c86 pad to go high or low as shown in Table 2.

C86 Type

H 6800 microprocessor bus

L 8080 microprocessor bus

Data Bus Signals

The NT7502 identifies the data bus signal according to A0, E,

Common 6800 processor 8080 processor

A0

1 1 0 1 Reads display data

W/R )

(

1CS

1CS

1CS

CS2 A0

CS2 A0

CS2 A0 - - - SI SCL (HZ)

1CS

1CS

1CS

RD WR

CS2 A0

CS2 A0 E

CS2 A0

RD WR

RD WR

Table. 2

WR/ (RD , WR ) signals.

Table. 3

C86 D7 D6 D0 to D5

C86 D7 D6 D0 to D5

“-” Must always be high or low

RD

RD WR

WR D0 to D7

WR/

Function

D0 to D7

D0 to D7

1 0 1 0 Writes display data

0 1 0 1 Reads status

0 0 1 0 Writes control data in internal register. (Command)

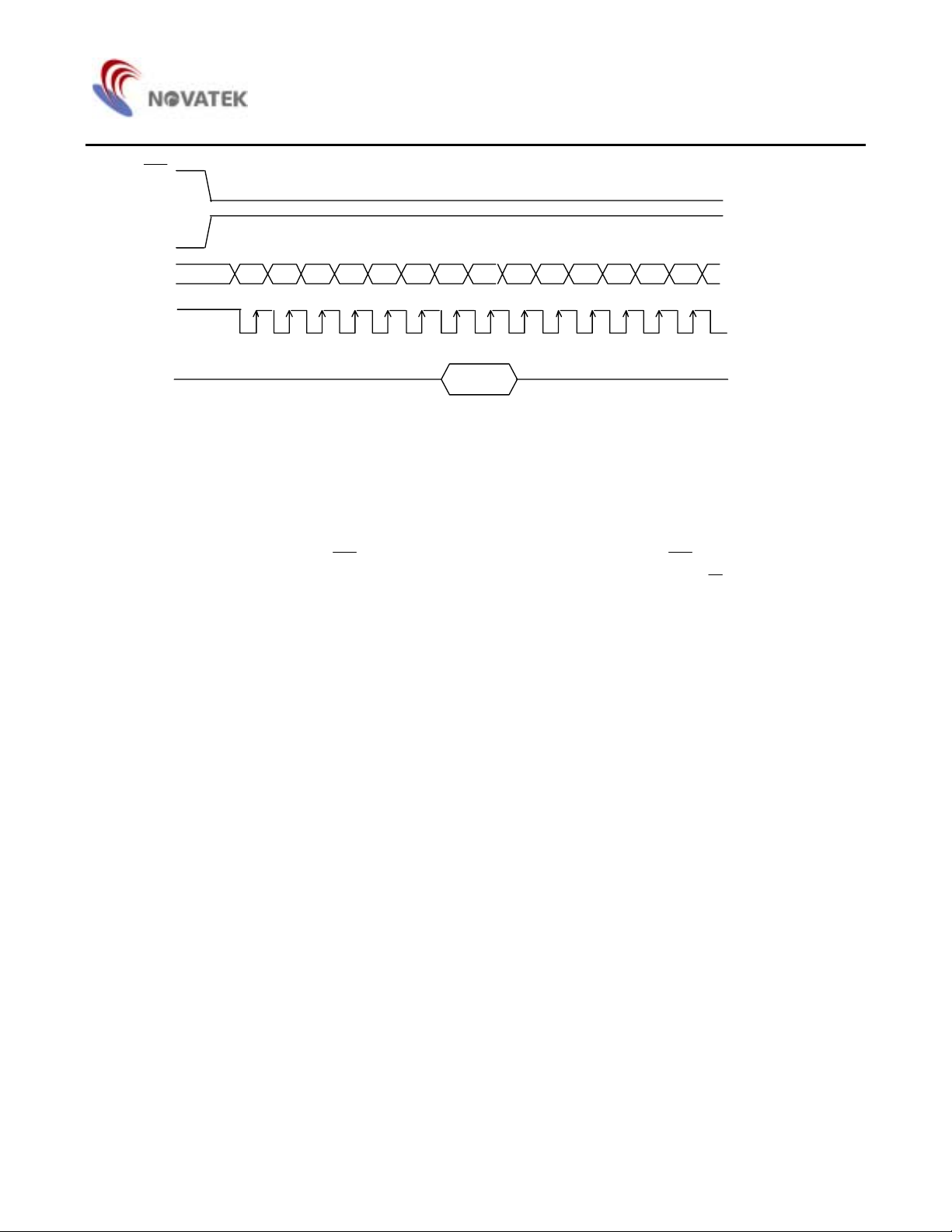

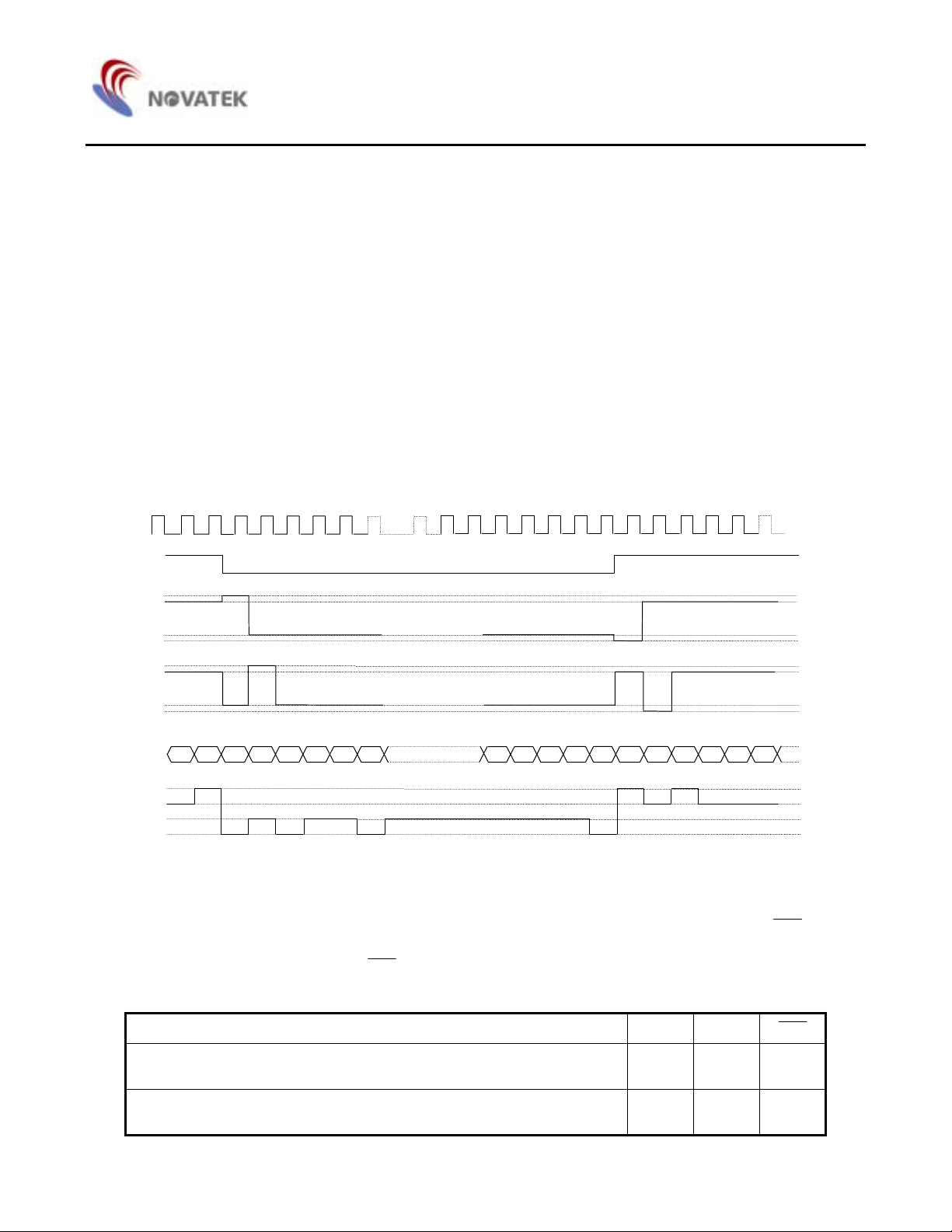

Serial Interface (P/S is low)

When the serial interface has been selected (P/S = “L”), then when the chip is in active state (

serial data input (SI) and the serial clock input (SCL) can be received. The serial data is read from the serial data input pin in the

rising edge of the serial clocks D7, D6 through D0, in this order. This data is converted to 8 bits of parallel data in the rising edge

of eighth serial clock for processing.

The A0 input is used to determine whether or the serial data input is display data, and when A0 = “L” then the data is command

data. The A0 input is read and used for detection every 8th rising edge of the serial clock after the chip becomes active.

Figure 1 is the serial interface signal chart.

9

1CS = “L” and CS2 = “H”), the

NT7502

1CS

CS2

SI

SCL

A0

D7 D6 D5 D4 D3 D2 D1 D0 D7 D6 D5 D4 D3 D2

123456 789101112 13 14

Figure. 1

# When the chip is not active, the shift registers and the counter are reset to their initial states.

# Reading is not possible while in serial interface mode.

# Caution is required on the SCL signal when it comes to line-end reflections and external noise. We recommend the

operation be rechecked on the actual equipment.

Chip Select Inputs

The NT7502 has two chip select pads.

When these pads are set to any other combination, D0 to D7 are high impedance and A0, E and

1CS and CS2 can interface to a microprocessor when 1CS is low and CS2 is high.

WR/ inputs are disabled.

When serial input interface is selected. the shift register and counter are reset.

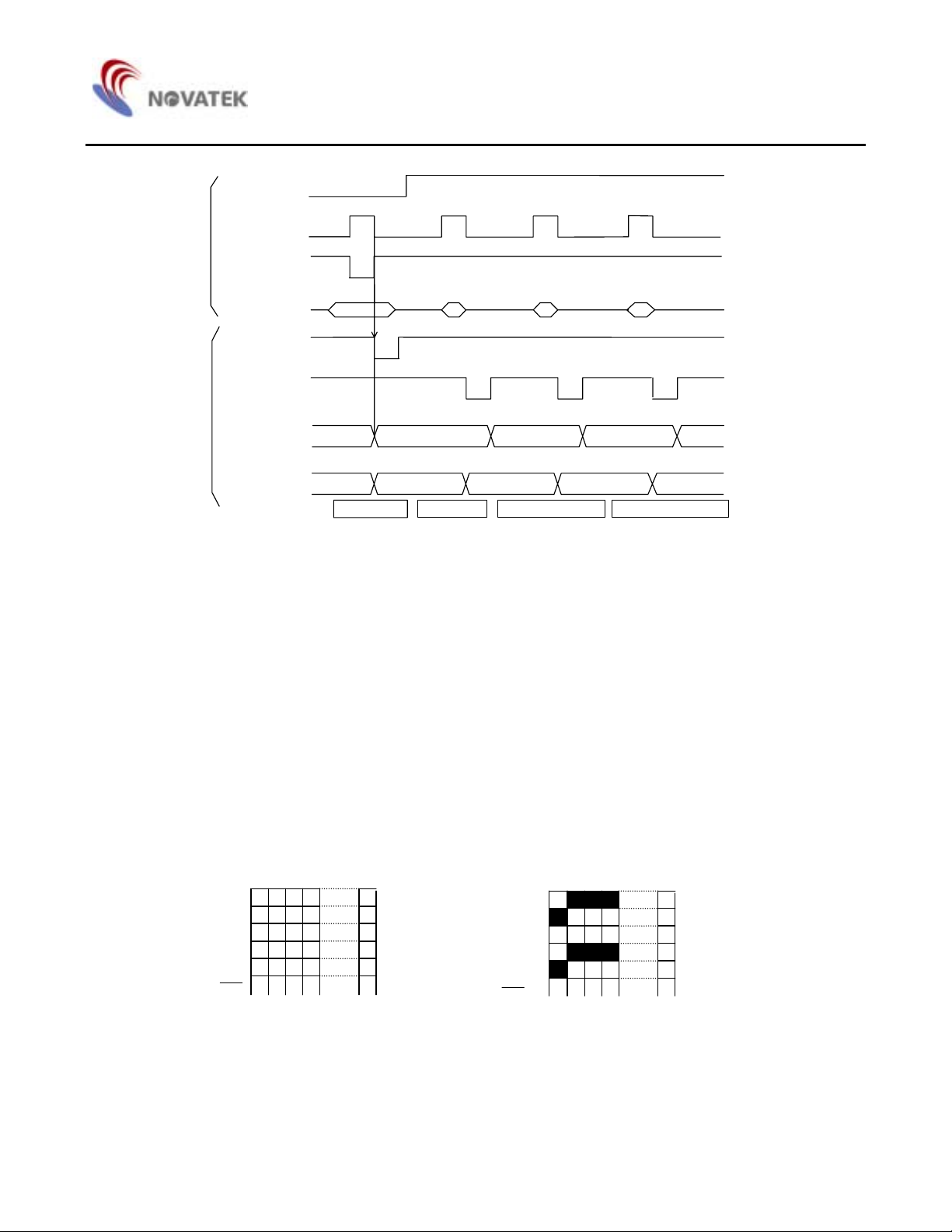

Access to Display Data RAM and Internal Registers

The NT7502 can perform a series of pipeline processing between LSI’s using the bus holder of the internal data bus in order to

match the operating frequency of display RAM and internal registers with the microprocessor. For example, the microprocessor

reads data from display RAM in the first read (dummy) cycle, stores it in the bus holder, and outputs it onto system bus in the

next data read cycle.

Also, the microprocessor temporarily stores display data in the bus holder, and stores it in display RAM until the next data write

cycle starts.

When viewed from the microprocessor, the NT7502 access speed greatly depends on the cycle time rather than access time to

the display RAM (t

ACC). This view shows the data transfer speed to / from the microprocessor can increase. If the cycle time is

inappropriate, the microprocessor can insert the NOP instruction that is equivalent to the wait cycle setup. However, there is a

restriction in the display RAM read sequence. When an address is set, the specified address data is NOT output at the

immediately following read instruction. The address data is output during the second data read. A single dummy read must be

inserted after address setup and after the write cycle (refer to Figure2).

10

NT7502

A0

MPU

Internal

timing

E

R/W

DATA

Address preset

Read signal

Column address

BUS holder

N

Preset

Set address n Dummy read Data Read address n Data Read address n+1

N

N N+1 N+2

N n n+1

n n+1

Incremented

n+2

Figure. 2

Busy Flag

When the busy flag is “1”, it indicates that the NT7502 chip is running internal processes, and at this tim e no command asi de

from a status read will be received. The busy flag is outputted to D7 pad with the read instruction. If the cycle time (t

maintained,

it is not necessary to check for this flag before each command. This makes vast improvements in MPU processing

CYC) is

capabilities possible.

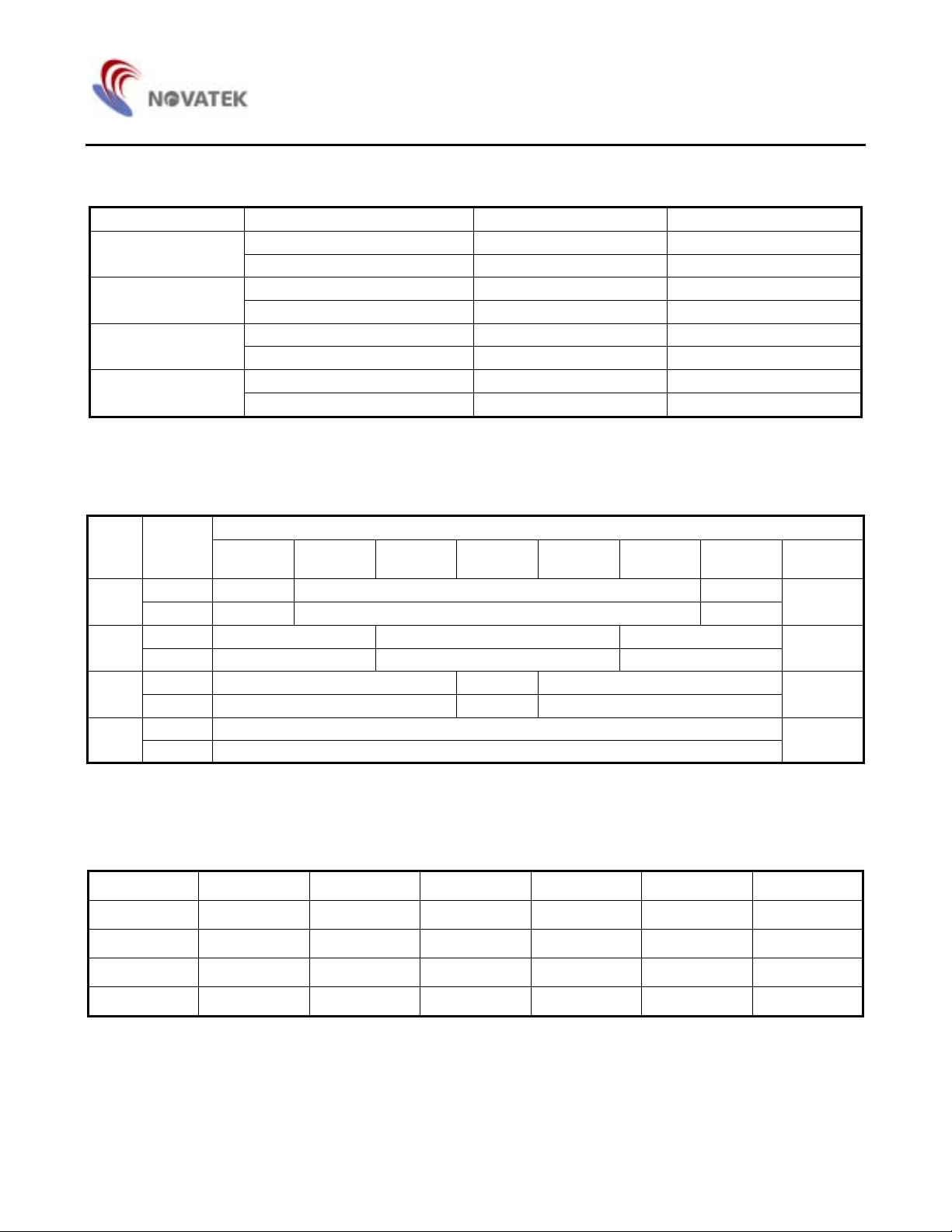

Display Data RAM

Display Data RAM

The display data RAM is RAM that stores the dot data for the display. It has a 65 (8 page * 8 bit+1)*132 bit structure. It is

possible to access the desired bit by specifying the page address and the column ad dress. Because, as is sho wn in Figure3,

the D7 to D0 display data from the MPU corresponds to the liquid crystal display common direction, there are few constraints at

the time of display common direction, and there are few constraints at the time of displa y data transfer when multiple NT7502

chips are used, thus display structures with a high degree of freedom can be created easily .

Moreover, reading from and writing to the display RAM from the MPU side is performed through the I/O buffer, which is an

independent operation from signal reading for the liquid crystal driver. Consequently, even if the display data RAM is accessed

asynchronously during liquid crystal display, it will not cause adverse effects on the displ ay (such as flickering).

D0

D1

D2

D3

D4

111

0

000

1

0000

111

0

000

1

0

0

0

0

0

COM0

COM1

COM2

COM3

COM4

Display data RAM Display on LCD

Figure. 3

11

NT7502

The Page Address Circuit

As shown in Figure 4, page address of the display data RAM is specified through the Page Address Set Command. The page

address must be specified again when changing pages to perform access.

Page address8 (D3, D2, D1, D0 = 1, 0, 0, 0,) is the page for the RAM region used; only display data D0 is used.

The Column Address

As shown in Figure 4, the display data RAM column address is specified by the Column Address Set command. The specified

column address is incremented (+1) with each display data read / write command. This allows the MPU display data to be

accessed continuously. Moreover, the incrimination of column addresses stops with 83H, because the column address is

independent of the page address. Thus, when moving, for exam ple, from page0 column 83H to page 1 column 00H, it is

necessary to respecify both the page address and the column address.

Furthermore, as is shown in Table 4, the ADC command (segment driver direction select command) can be used to reverse the

relationship between the display data RAM column address and the segment output. Because of this, the constraints on the IC

layout can be minimized when the LCD module is assembled.

Table. 4

SEG Output SEG0 SEG131

ADC “0” 0 (H)$ Column Address $83 (H)

(ADC) “1” 83 (H)% Column Address %0 (H)

The Line Address Circuit

The line address circuit, as shown in Table 4, specifies the line address relating to the COM output when the conten ts of the

display data RAM are displayed. Using the display start line address set command, what is normally the top line of the display

can be specified. This is the COM0 output when the common output mode is normal, and the COM63 output for NT7502, when

the common output mode is reversed. The display area is a 65-line area for the NT7502 from the display start line address.

If the line addresses are changed dynamically using the display start line address set command, screen scrolling, page

swapping, etc. can be performed.

12

NT7502

Relationship between display data RAM and address. (if initial display line is 1DH)

Page Address Data

D0 00

D1 01

D3, D2,

D1, D0

0, 0, 0, 0

0, 0, 0, 1

0, 0, 1, 0

0, 0, 1, 1

0, 1, 0, 0

0, 1, 0, 1

0, 1, 1, 0

0, 1, 1, 1

1, 0, 0, 0 D0 Page8

Column

D2 02

D3 03

D4 04

D5 05

D6 06

D7 07

D0 08

D1 09

D2 0A

D3 0B

D4 0C

D5 0D

D6 0E

D7

D0 10

D1 11

D2 12

D3 13

D4 14

D5 15

D6 16

D7

D0 18

D1 19

D2 1A

D3 1B

D4 1C

D5 1D

D6 1E

D7

D0 20

D1 21

D2 22

D3 23

D4 24

D5 25

D6 26

D7

D0 28

D1 29

D2 2A

D3 2B

D4 2C

D5 2D

D6 2E

D7

D0 30

D1 31

D2 32

D3 33

D4 34

D5 35

D6 36

D7

D0 38

D1 39

D2 3A

D3 3B

D4 3C

D5 3D

D6 3E

D7

000102

“0”

D0=

ADC

address

D0=

”1”

838281

Page0

Page1

Page2

Page3

Page4

Page5

Page6

Page7

818283

020100

Line

Address

0F

17

1F

27

2F

37

3F

Start

COM

output

COM0

COM1

COM2

COM3

COM4

COM5

COM6

COM7

COM8

COM9

COM10

COM11

COM12

COM13

COM14

COM15

COM16

COM17

COM18

COM19

COM20

COM21

COM22

COM23

COM24

COM25

COM26

COM27

COM28

COM29

COM30

COM31

COM32

COM33

COM34

COM35

COM36

COM37

COM38

COM39

COM40

COM41

COM42

COM43

COM44

COM45

COM46

COM47

COM48

COM49

COM50

COM51

COM52

COM53

COM54

COM55

COM56

COM57

COM58

COM59

COM60

COM61

COM62

COM63

COMS

LCD

OUT

SEG0

SEG1

SEG2

SEG129

SEG130

SEG131

Figure. 4

13

NT7502

The Display Data Latch Circuit

The display data latch circuit is a latch that temporarily stores the display data output to the liquid crystal driver circuit from the

display data RAM.

Because the display normal/reverse status, display ON/OFF status, and display all points ON/OFF commands control only the

data within the latch, they do not change the data within the display data RAM itself.

The Oscillator Circuit

This is a CR-type oscillator that produces the display clock. The oscillator circuit is only enabled when M/S = “H” and CLS = “H”.

When CLS = “L” the oscillation stops, and the display clock is input through the CL terminal.

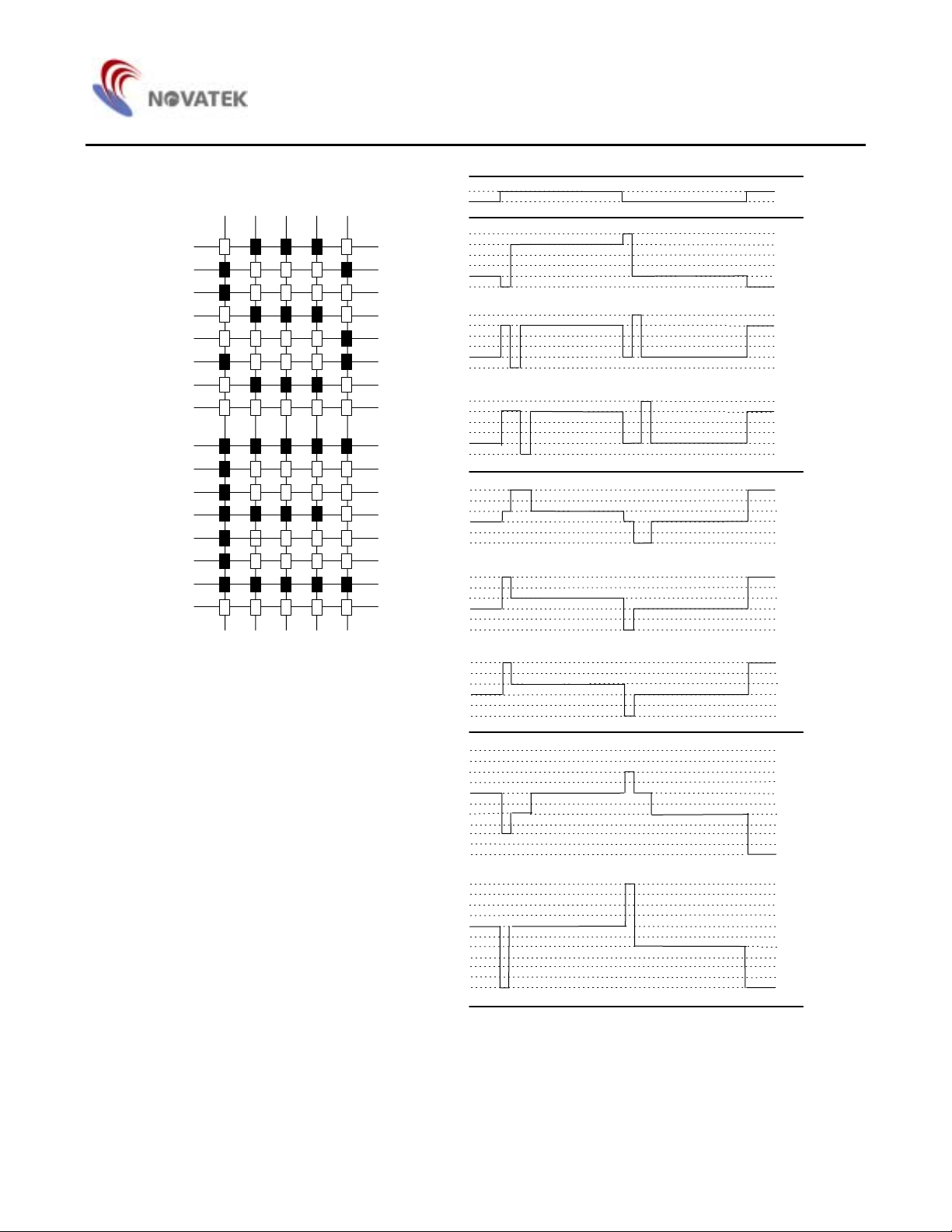

Display Timing Generator Circuit

The display timing generator circuit generates the timing signal to the line address circuit and the display data latch circuit using

the display clock. The display data is latched into the display data latch circuit synchronized with the display clock, and is output

to the data driver output terminal. Reading to the display data liquid crystal driver circuits is completely independent of access to

the display data RAM by the MPU. Consequently, even if the display data RAM is accessed as ynchronously during liquid

crystal display, there is absolutely no adverse effect (such as flickering) on the display.

Moreover, the display timing generator circuit generates the common timing and the liquid crystal alternating current signal (FR)

from the display clock. It generates a drive waveform using a 2 frame alternating current drive method, as is shown in Figure 5,

for the liquid crystal drive circuit.

23451 6

CL

FR

61 62 63 64 65

23451

66564

60

V

0

V

V4

V

V

V

V4

V

V

V

V3

V

1

SS

0

1

SS

0

2

SS

COM0

COM1

RAM

data

SEGn

Figure. 5

When multiple NT7502 chips are used, the slave chips must be supplied with the display timing signals (FR, CL, DOF ) from the

master chip[s].

Table 5 shows the status of the FR, CL, and

DOF signals.

Table. 5

Operating Mode FR CL

Master (M/S = “H”) The internal oscillator circuit is enabled (CLS = “H”)

The internal oscillator circuit is disabled (CLS = “L”)

Slave (M/S = “L”) The internal oscillator circuit is disabled (CLS = “H”)

The internal oscillator circuit is disabled (CLS = “L”)

Output

Output

Input

Input

Output

Input

Input

Input

DOF

Output

Output

Input

Input

14

NT7502

Table 6 shows the relationship between oscillation frequency and frame frequency

Table. 6

Duty Item f

1/65

1/55

1/49

1/33

On-chip oscillator is used fOSC/6 fCL/(2 X 65)

On-chip oscillator is not used External input f

On-chip oscillator is used fOSC/8 fCL/(2 X 55)

On-chip oscillator is not used External input f

On-chip oscillator is used fOSC/8 fCL/(2 X 49)

On-chip oscillator is not used External input f

On-chip oscillator is used fOSC/12 fCL/(2 X 33)

On-chip oscillator is not used External input f

CL fFR

CL fCL/(2 X 65)

CL fCL/(2 X 55)

CL fCL/(2 X 49)

CL fCL/(2 X 33)

Common Output Control Circuit

This circuit controls the relationship between the number of common output and specified duty ratio. Common output mode

select instruction specifies the scanning direction of the common output pads.

Table. 7

Common output pads

Duty Status

1/33

1/49

1/55

1/65

Normal COM[0-15] NC COM[16-31]

Reverse COM[31-16] NC COM[15-0]

Normal COM[0-23] NC COM[24-47]

Reverse COM[47-24] NC COM[23-0]

Normal COM[0-26] NC COM[27-53]

Reverse COM[53-27] NC COM[26-0]

Normal COM[0-63]

Reverse

COM

[0-15]

COM

[16-23]

COM

[24-26]

COM

[27-36]

COM[63-0]

COM

[37-39]

COM

[40-47]

COM

[48-63]

COMS

COMS

COMS

COMS

COMS

This is a 197-channel multiplexes that generate voltage levels for driving the liquid crystal. The combination of the display data,

the COM scan signal, and the FR signal produces the liquid crystal drive voltage output.

Figure 6 shows example of the SEG and COM output wave form.

Configuration Setting

The NT7502 has two optional configurations, configured b y DUTY0, DUTY1

DUTY1, DUTY0 Common Segment V1 V2 V3 V4

1, 1 65 132 8/9V0, 6/7V0 7/9V0, 5/7V0 2/9V0, 2/7 V0 1/9V0, 1/7V0

1, 0 55 132 7/8V0, 5/6V0 6/8V0, 4/6V0 2/8V0, 2/6 V0 1/8V0, 1/6V0

0, 1 49 132 7/8V0, 5/6V0 6/8V0, 4/6V0 2/8V0, 2/6 V0 1/8V0, 1/6V0

0, 0 33 132 5/6V0, 4/5V0 4/6V0, 3/5V0 2/6 V0, 2/5V0 1/6V0, 1/5V0

15

NT7502

COM0

COM1

COM2

COM3

COM4

COM5

V

FR

COM0

COM1

DD

V

SS

V

0

V

1

V

2

V

3

V

4

V

SS

V

0

V

1

V

2

V

3

V

4

V

SS

COM6

V

COM7

COM8

COM2

0

V

1

V

2

V

3

V

4

V

SS

COM9

V

COM10

COM11

COM12

SEG0

0

V

1

V

2

V

3

V

4

V

SS

COM13

V

COM14

COM15

SEG1

0

V

1

V

2

V

3

V

4

V

SS

SEG2

COM0 - SEG0

COM0 - SEG1

Figure. 6

V

0

V

1

V

2

V

3

V

4

V

SS

V

0

V

1

V

2

V

3

V

4

V

SS

-V

4

-V

3

-V

2

-V

1

-V

0

V

0

V

1

V

2

V

3

V

4

V

SS

-V

4

-V

3

-V

2

-V

1

-V

0

16

NT7502

The Power Supply Circuit

The power supply circuits are low-power consumption power supply circuits that generate the voltage le vels required for the

liquid crystal drivers. They comprise Booster circuits, voltage regulator circuits, and voltage follower circuits. They are only

enabled in master operation.

The power supply circuits can turn the Booster circuits, the voltage regulator circuits, and the vo ltage follower circuits ON or

OFF independently through the use of the Power Control Set command. Consequently, it is possible to make an external power

supply and the internal power supply function somewhat in parallel. Table 7 shows the Power Control Set Command 3-bit data

control function, and Table 8 shows reference combinations.

Table. 8 The Control Details of Each Bit of the Power Control Set Command

Item

Status

“1” “0”

D2 Booster circuit control bit ON OFF

D1 Voltage regulator circuit (V regulator circuit) control bit ON OFF

D0 Voltage follower circuit (V/F circuit) control bit ON OFF

Table. 9

Step-up

voltage

system

terminal

Use Settings D2 D1 D0

1. Only the internal power supply

is used

2. Only the V regulator circuit and

the V/F circuit are used

Step-up

circuit

Voltage

regulator

circuit

V/F circuit

External

voltage input

1 1 1 O O O V

0 1 1 X O O V

OUT, VDD2 Open

DD2 Used

3. Only the V/F circuit is used 0 0 1 X X O V0, VDD2 Open

4. Only the external power supply

is used

0 0 0 X X X V

0 to V4 Open

*The “step-up system terminals” refer CAP1+, CAP1-, CAP2+, CAP2-and CAP3+.

*While other combinations, not shown above, are also possible, these combinations are not recommended because they have

no practical use.

The Step-up Voltage Circuits

Using the step-up voltage circuits within the NT7502 chips it is possible to product 4X, 3X, 2X step-ups of the V

DD2-VSS voltage

levels

17

Loading...

Loading...