Explorer AP380

Autopilot

Installation and Operation Manual

www.northstarnav.com

DANGER

!

WARNING

!

CAUTION

IMPORTANT SAFETY INFORMATION

Please read carefully before installation and use.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards, Obey all safety messages that follow this symbol to

avoid possible injury or death.

WARNING indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury

CAUTION indicates a potentially hazardous situation which, if not avoided,

could result in minor or moderate injury.

CAUTION

DISCLAIMER: It is the owner’s sole

responsibility to install and use the instrument

and transducers in a manner that will not cause

accidents, personal injury or property damage.

The user of this product is solely responsible for

observing safe boating practices.

BRUNSWICK NEW TECHNOLOGIES INC. AND ITS

SUBSIDIARIES AND AFFILIATES DISCLAIM ALL

LIABILIT Y FOR ANY USE OF THIS PRODUCT IN A

WAY THAT MAY CAUSE ACCIDENTS, DAMAGE OR

THAT MAY VIOLATE THE LAW.

Governing Language: This statement,

any instruction manuals, user guides and

other information relating to the product

(Documentation) may be translated to, or

CAUTION used without the safety alert symbol indicates a potentially

hazardous situation which, if not avoided, may result in property damage.

has been translated from, another language

(Translation). In the event of any conf lict

between any Translation of the Documentation,

the English language version of the

Documentation will be the official version of the

Documentation.

This manual represents the Explorer AP380

as at the time of printing. Brunswick New

Technologies Inc. and its subsidiaries and

affiliates reserve the right to make changes to

specifications without notice.

Copyright © 2006 Brunswick New Technologies

Inc. Northstar™ is a registered trademark of

Brunswick New Technologies Inc.

FCC Statement

Note: This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference in a normal installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in

a particular installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an output on a circuit different from that to which the receiver is

connected.

Consult the dealer or an experienced technician for help.

A shielded cable must be used when connecting a peripheral to the serial ports.

Northstar Explorer AP380 System Installation and Operation Manual

3

Installation Contents

Important ................................................................................................................................................ 5

1 Introdu ction .......................................................................................................................................... 6

1-1 A typical Explorer AP380 system installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-2 Using the Explorer AP380 system with other instruments . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Explor er AP380 system hardware ........................................................................................................... 8

2-1 What comes with your Explorer AP380 system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-2 Other parts required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Instal lation ............................................................................................................................................ 9

3-1 Installation sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3-2 Installation guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3-3 Installing the MCU600 (Main Control Unit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3-4 Installing the power supplies and steering drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3-5 Installing the RFU (rudder feedback unit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3-6 Installing the Compass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

3-7 Installing the Gyro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

3-8 Installing the Explorer AP380 display unit and other instruments . . . . . . . . . . . . . . . . 23

4 Docks ide setup ..................................................................................................................................... 27

4-1 Start dockside setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4-2 Calibrating the rudder feedback unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

5 Sea tria ls .............................................................................................................................................. 28

5-1 Calibrating the compass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

5-2 Aligning the compass and the rudder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Append ix A - Specifica tions - MCU600 ......................................................................................................29

Append ix B - Specifica tions - AP380 Display .............................................................................................30

Append ix C - User data ............................................................................................................................ 31

Operati on Section .................................................................................................................................. 34

4

Northstar Explorer AP380 System Installation and Operation Manual

Important

It is the owner’s sole responsibility to install and use the instrument and transducer/s in a manner

that will not cause accidents, personal injur y or property damage. The user of this product is solely

responsible for observing safe boating practices.

The choice, location, and installation of all components in any AP380 system is critical. If installation is

not correct, the unit can not perform at its designed potential. If in doubt, consult your Northstar dealer.

Ensure that any holes that cut are in a safe position and will not weaken the boat’s structure. If in doubt,

consult a qualified boat builder.

Using the Exp lorer AP380 system :

The Explorer AP380 system is intended as an aid to save a helmsman from having to steer for long

periods of time, not as the main means of steering the boat.

The Explorer AP380 system is not intended for use in extreme weather, in adverse conditions or in

water near other boats, dangerous waters or land.

The Explorer AP380 system can not control the boat better than a helmsman. In adverse conditions

steer the boat manually.

Never leave the helm unattended. Keep a watch at all times. The helmsman should always monitor

the course of the boat and the E xplorer AP380 system and be ready to resume steering the boat

manually.

The performance of the Explorer AP380 system can be affected by the failure of a part,

environmental conditions, improper installation and use.

Northstar Explorer AP380 System Installation and Operation Manual

5

1 Introduction

Using this man ual

This manual describes how to install and set up

the Explorer AP380 system. Refer to the Explorer

AP380 Operation Section for information on how

to operate the Explorer AP380 display unit.

To install a Explorer AP380 system, you must

perform installation, dockside setup and sea trials

(see sections 3, 4 and 5).

To fully set up a Explorer AP380 system after

a part has been changed or if a problem is

suspected, perform dockside setup and sea trials

again (see sections 4 and 5).

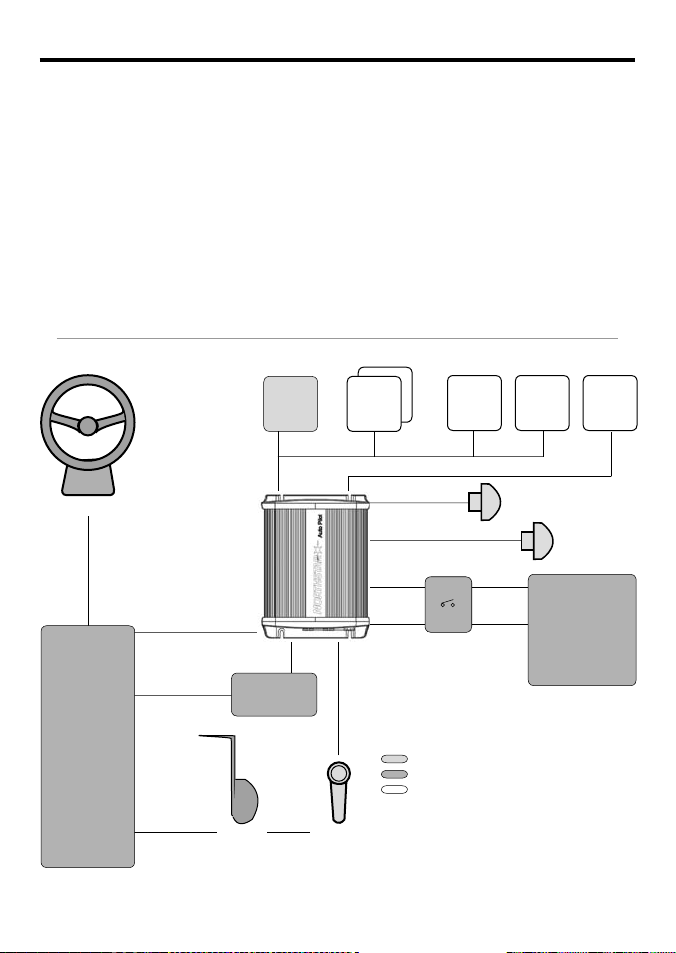

1-1 A typical E xplorer AP380 system installat ion

Display

unit

NavBus

Manual helm

MCU60

To verify that the Explorer AP380 system is

operating correctly, perform sea trials (see

section 5).

Cleaning a nd maintenance

Clean the parts of the Explorer AP380 system with

a damp cloth or mild detergent. Avoid abrasive

cleaners, petrol or other solvents.

Do not paint any part of the Explorer AP380

system except for the cables.

Optional instruments

More

display

units

WIND

0

SPEED

Compass

Gyro

GPS

NMEA

Clutch drive

(optional)

Steering

Power switch or

switches and

power protection

Light duty

Heavy duty

12 V DC

Power supply

drive

unit

Key

Parts supplied with Explorer AP380 system

Other parts required

Optional parts

Note: Above shows typical installation

only. Please refer to the information

supplied with your drive for further

information.

Rudder

control

Rudder

6

Northstar Explorer AP380 System Installation and Operation Manual

Rudder

feedback

1-2 Using the Explorer AP380 system with ot her instruments

1-2-1 Using othe r instruments

The Explorer AP380 system can use data from

these instruments:

GPS: A GPS or chart plotter, such as a Northstar

Explorer 500 series chartplotter must be

connecte d to the Explorer AP380 system for the

AP380 to operate in GPS mode (see the Explorer

AP380 Operation Section ).

Note: GPS must be via NMEA input.

WIND: A wind instrument, such as a

Northstar WIND series, must be connected

to the Explorer AP380 system for the AP380

to operate in WIND mode (see the Explorer

AP380 Operation Section ).

SPEED: A speed instrument, such as:

Northstar’s SPEED with a paddlewheel

speed sensor

or a GPS or char tplotter, such as

Northstar’s Explorer 500 or Explorer 660

series can be connected to the Explorer

AP380 system to increase steering

accuracy.

Note: The speed from a p addlewheel sensor is

the speed that the boat is mov ing through the

water. The speed from a GPS is the spee d over

the ground. If there is a water current then these

two speeds will be dif ferent. If the Explorer AP380

system is connected to an instrume nt with a

paddlewheel se nsor and to a GPS, then the

Explorer AP380 system will a utomatically use the

speed from the pad dlewheel sensor instrument.

1-2-2 Na vBus

NavBus is a Northstar proprietary system that

allows systems of multiple instruments to be

built using a single set of transducers. When

instruments are connected by NavBus:

If you change the units, alarms or calibration

in one instrument, then the values will

automatically change in all other instruments

of the same t ype.

Each instrument can be assigned to a group

of instruments, called a NavBus group (see

NavBus group in the S etup > Comms menu, in

the Explorer AP380 Op eration Section).

If you change the backlight in an instrument

in group 1, 2, 3 or 4 then the backlight

will automatically change in the other

instruments in the same group. If you change

the backlight in an instrument in group 0

then no other instruments are affected.

If an alarm sounds, mute it on any instrument

which can display that alarm.

For more information, refer to the NavBus

Installation and Operation Manual.

Note: GPS must b e via NMEA in put.

NavBus and the E xplorer AP380 system

The Explorer AP380 system will automatically

work with additional Explorer AP380 displays.

The Explorer AP380 system can receive wind

data from Northstar’s WIND over NavBus.

The Explorer AP380 system can receive speed

data from Nor thstar’s SPEED over NavBus.

1-2-3 NM EA

NMEA is an industry standard, but is not as

flexible as NavBus as it requires dedicated

connections between instruments. The Explorer

AP380 system has one NMEA input port and one

port that can be configured to be an input or an

output (See Explorer AP380 Operation S ection).

Explore r AP380 system NMEA inputs

GPS: The Explorer AP380 system can receive

NMEA GPS data from a compatible GPS or

chartplotter, such as Northstar’s Explorer 500

series chartplotter:

XTE (from APA, APB or XTE sentences) is

required for the Explorer AP380 system to use

GPS mode

BRG (from APA sentences) and BOD (from APA

or APB sentences) are optional and improve

performance

COG (from VTG sentences) is optional and can

be displayed.

Northstar Explorer AP380 System Installation and Operation Manual

7

WIND: The Explorer AP380 system can receive

NMEA wind data from a compatible wind

instrument:

True or apparent wind direction (from MWV

sentences) is required for the Explorer AP380

system to use Wind mode.

SPEED: The Explorer AP380 system can

receive NMEA speed data from a compatible

paddlewheel or GPS instrument:

SOG (from V TG sentences) is optional and

Explore r AP380 system NMEA outputs

The NMEA 2 port can be configured to be an

input or to be output:

(see NMEA mode in the S etup > Comms menu, See

Explorer AP380 Op eration Section).

improves performance.

Note: If the Explorer AP380 system is connected

to a Northstar series wind o r speed instrument

using NavBus, then the Expl orer AP380 system will

automatically receive an d use the wind or speed

data, and the NMEA connec tion need not be wired.

2 Explorer AP380 system hardware

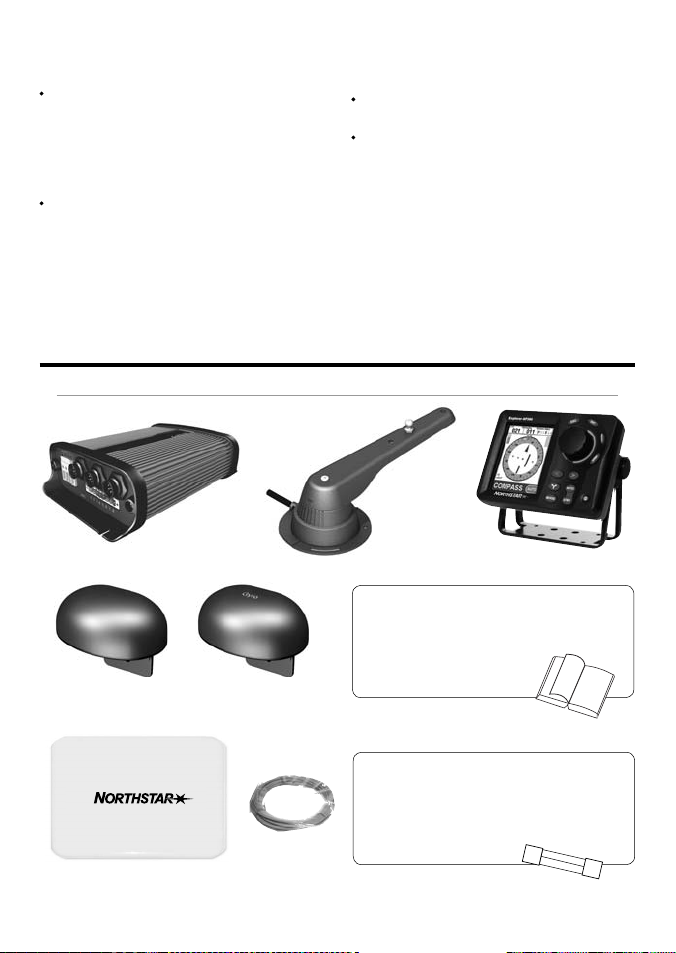

2-1 What comes with your Ex plo re r AP3 80 s yst em

either heading (HDG & HDT) and rudder

angle (RSA) at once per second

or heading (HDG) at ten times per second

MCU600 (Main Control Unit)

Compass, with 10 m

(33 ft) attached cable

Protective cover for

display unit

8

RFU - Rudder feedback unit

Documentation

• Warranty

• Display unit mounting template

• This Installation/Operation

manual

Gyro, with 10 m

(33 ft) attached cable

Additional hardware

• Mounting hardware

• Cable cover

• Strain relief

• Spare fuses

2 mm (#14) twin

stranded cable for high

current wiring

Northstar Explorer AP380 System Installation and Operation Manual

Explorer AP380 Display unit

2-2 Other parts req uired

Power supply: The Explorer AP380 system

requires two power supplies, both nominally 12

V DC:

A heavy dut y supply for the steering drive

A light duty supply for the Explorer AP380

system electronics and display unit; this

supply also powers any additional display

units and other instruments.

The power supplies require one or two switches

and fuses or circuit breakers (see section 3-4).

Steering drive: The Explorer AP380 system can

power a hydraulic pump, constantly running

pump set, hydraulic linear drive or mechanical

drive rated at 12 V DC and up to 20 A.

Rudder linkage: To link rudder to rudder

feedback unit (see section 3-5).

For wiring, see Select Wire Table in section 3-4-2.

3 Installation

Exte rnal beepers o r lights (optio nal ):

The external output is switched to ground,

30 V DC and 250 mA maximum. If the beepers

and lights require more than 250 mA total, fit a

relay.

Other marine instruments (optional): Wind,

speed or GPS instruments can be connected (see

section 1-2).

Other parts: For systems of several instruments,

wiring and connectors are required. Northstar

junction boxes can simplif y wiring several

Northstar instruments together (see section 1-2

or the NavBus Installation and Operation Manual).

Coupling connectors and 10 m (33 ft) extension

cables are available to extend the rudder

feedback unit, compass or gyro cables. Do not fit

more than one extension cable to each unit.

For more information, consult your

Northstar dealer.

Correct installation is critical to the performance

of the unit. It is vital to read this manual and the

documentation that comes with the other par ts

before starting installation.

The MCU600 is not waterproof. Mount the

unit in a dry place.

3-1 Installation sequence

The recommended installation sequence is:

1 Read this manual and the documentation

that comes with the other parts.

2 Plan the installation: select where the

equipment and wiring will be installed (see

section 3-2).

3 Install the MCU600 (see section 3-3).

4 Install the steering drive and wire the heavy

duty and light duty power supplies

(see section 3-4).

5 Install the rudder feedback unit

(see section 3-5).

6 Install the compass (see section 3-6).

Northstar Explorer AP380 System Installation and Operation Manual

The Explorer AP380 system display unit is

waterproof.

The compass, gyro and rudder feedback

unit are completely waterproof.

Ensure that any holes that you cut will not

weaken the boat’s structure. If in doubt, consult

a qualified boat builder.

7 Install the gyro (see section 3-7).

8 Install the display unit and any other marine

instruments that will be used with the

Explorer AP380 system (see section 3-8).

9 Carry out the dock side setup

(see section 4).

10 Carry out the sea trials (see section 5).

If you are unsure where a part should be

installed, mount and wire the part temporarily,

without cutting holes in the boat. After the sea

trials have been completed, install and wire the

part permanently.

9

3-2 Installation guide

This is a general guide for locating and wiring the parts of the Explorer AP380 system. The instructions

for a particular part may have additional requirements.

3-2-1 Locat ion guide

Do not mount any part where it can be used

as a handhold, where it will inter fere with the

operation of the boat or where it might be

submerged.

Do not mount any part where it will interfere

with launching or retrieving

the boat.

Do not mount any part within 0.5 m (20”) of

the plane of a radar antenna.

Mount the compass and gyro:

At least 1 m (3 ft) away from sources of

electrical signals or noise, such as the

batteries, high-current cables, other boat

cables, engines, fluorescent lights, power

inverters, radio or radar transmitters and

antennas.

At least 1 m (3 ft) away from equipment

containing a magnet, such as a compass

or speaker.

3-2-2 Wiri ng guide

The Explorer AP380 system has two kinds of

cables:

The heavy-duty power supply and steering drive

usually require high-current cables:

Select the wire gauge from the wire size table

(see section 3-4-2).

Fit high-current cables at least 1 m (3 ft) away

from other electronic devices in

the boat.

Keep the cables as short as possible.

Twin 2 mm (#14) cable is supplied with the

Explorer AP380 system and can be used for

the high current cable if its gauge is suitable.

All the other cables are low-current:

Fit low-current cables at least 1 m (3 ft) away

from sources of electrical signals or noise,

such as the high- current cables, other boat

cables, engines, fluorescent lights, power

inverters and radio or radar transmitters and

antennas.

If the cable for the rudder feedback unit,

compass or gyro is too long, do not shorten

the cable; instead coil the cable up near the

main control unit.

The cable for the rudder feedback unit,

compass or gyro can be ex tended by

adding a 10 m (33 ft) extension cable and

coupling connector. Do not fit more than one

extension cable to each unit.

When fitting any type of cable:

Do not crush, pinch or strain the cable.

Secure the cable at regular intervals.

Ensure no connectors or exposed terminals

are in the bilge.

10

Northstar Explorer AP380 System Installation and Operation Manual

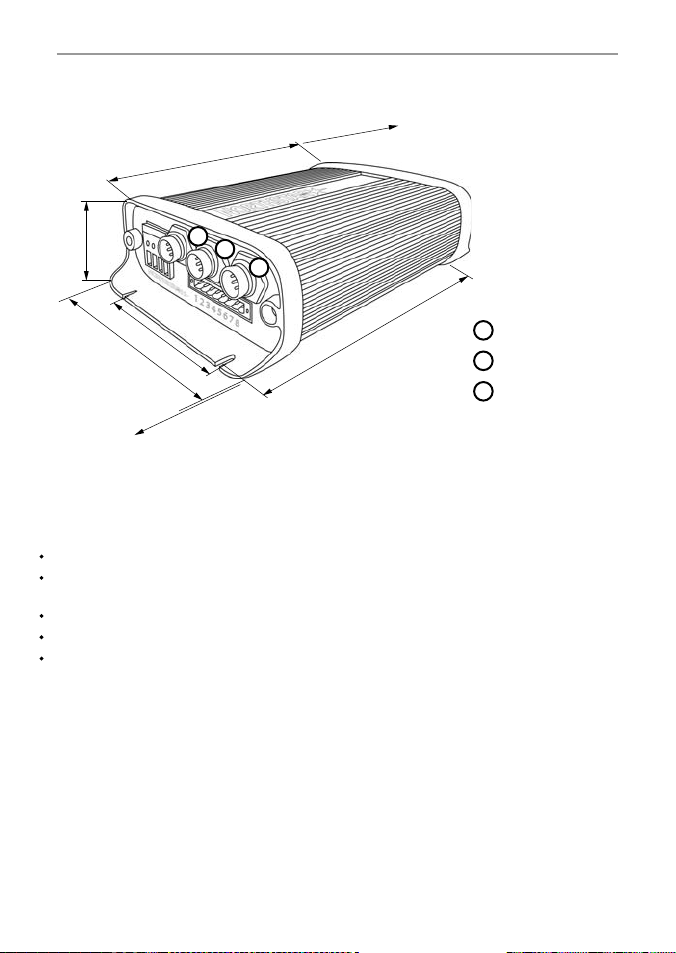

3-3 Installing the MCU600 ( Main Control Unit)

Physical

IMPORTANT: 200 mm

(7.87”) clearance required

for cover removal

(7.24”) apart

RFU

1

Gyro

2

Compass /

3

Heading Sensor

(2.16”)

55 mm

Screws 90 mm (3.54” ) apart

140 mm (5.10”)

200 mm (7.87”)

1

2

200 mm (7.87”)

3

mm

Screw holes 184

60 mm (2.36”)

IMPORTANT: 60 mm (2.36”)

clearance required for cable s

Installation

Find a suitable location for the unit:

In a dry, cool place; if possible not the engine room.

Close to the high-current power supply and the steering drive, to reduce the length of the high

current wiring.

Accessible for installation and service.

If possible on a vertical panel which does not vibrate.

Follow the location guide (see section 3-2-1).

Mount the unit with the cable connectors at the bottom or to one side, using the screws provided.

Do not mount the unit with the connectors at the top, because dust or moisture might enter the unit.

Northstar Explorer AP380 System Installation and Operation Manual

11

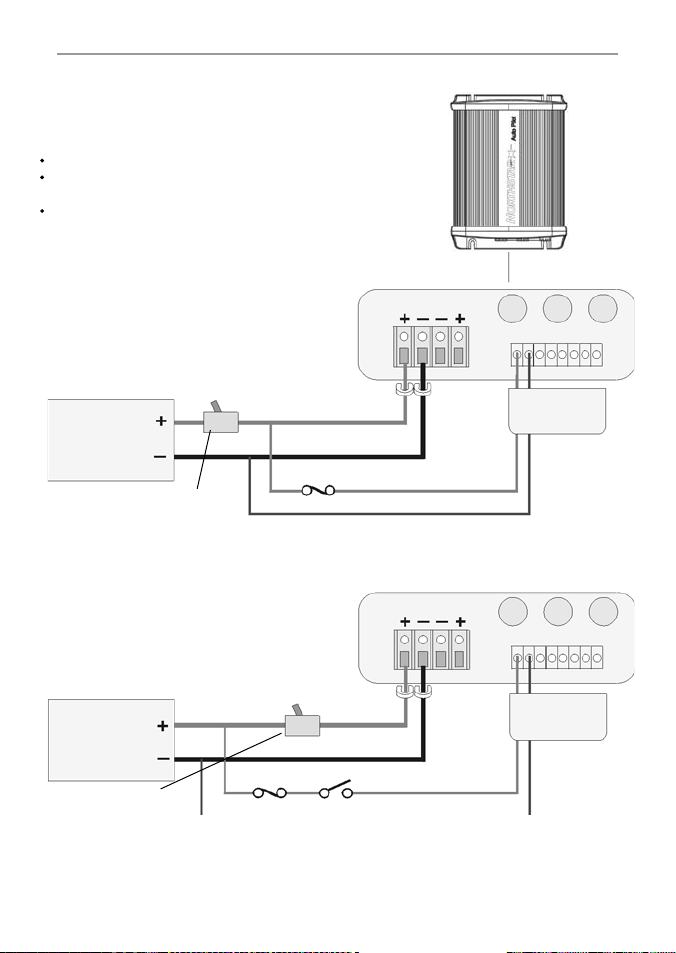

3-4 Installi ng the power supplies a nd steering drive

3-4-1 Installing t he power supplies

The MCU 600 system requires a light duty and a heavy duty power

supply, both 12 V DC.

Note:

Keep all wiring as short as possible.

For the heavy duty supply, use the wire size given in the table

(see section 3-4-2).

Follow the wiring guide (see section 3-2-2).

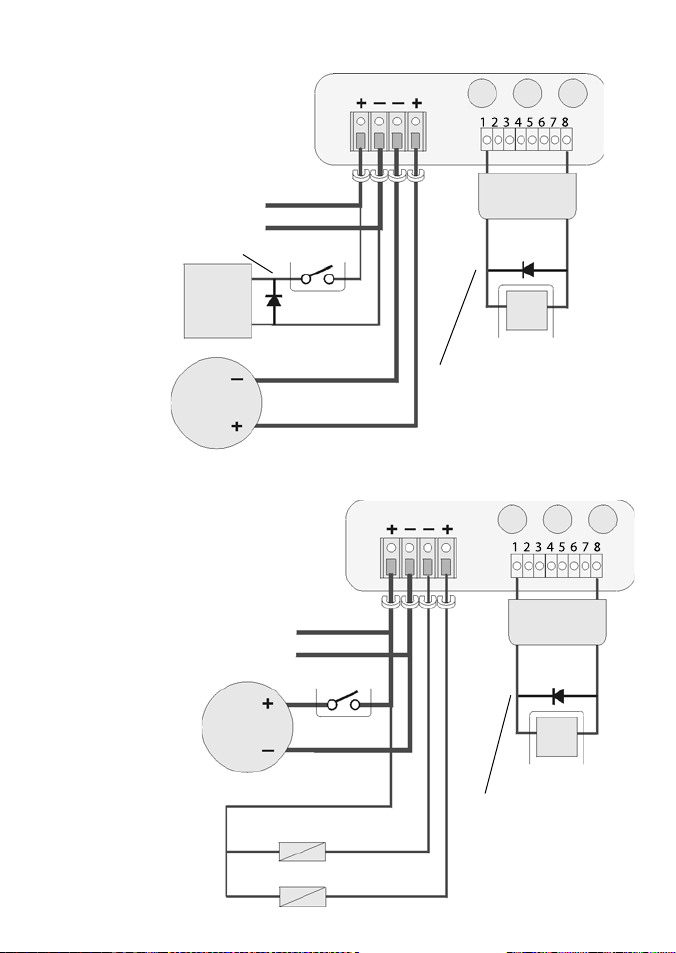

Power supp ly: one switch configuration

Choose this configuration to have one switch to

turn the Explorer AP380 system and any other

instruments on and off.

Fit strain relief

12 V DC power

supply, current to

suit drive

Fuse 1 A

Circuit breaker or fuse and

switch, current rating to suit

Power supp ly: two switch co nfiguration

Choose this configuration to be able to turn the

drive power off and leave other instruments

powered.

steering drive

Heavy duty

power

MCU600

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

Connector

cover

Light duty

power

12 V DC power

supply, current to

suit drive

Circuit breaker or fuse

and switch, current

rating to suit steering

drive

Fuse 1 A

Fit strain relief

Switch

Heavy duty

power

Connector

cover

Light duty

power

Note: If powering more than three ex tra display units or other series instruments, fit another switch

and fuse for the light duty power supply for these extra instruments

12

Northstar Explorer AP380 System Installation and Operation Manual

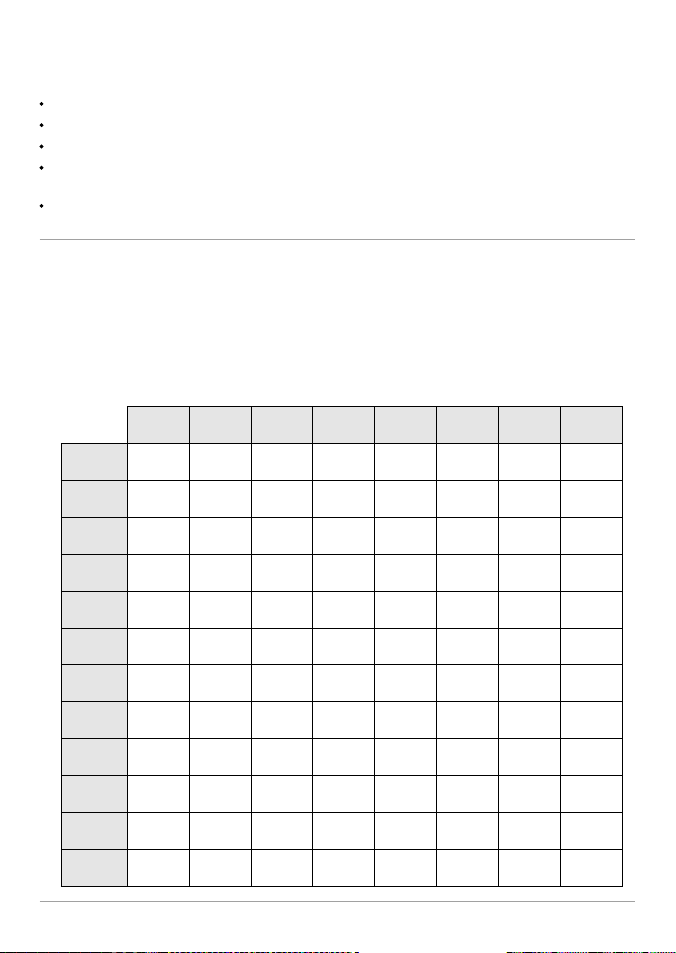

3-4-2 Installing th e steering drive

Install the steering drive according to one of the diagrams on the following pages.

Note

Keep all wiring as short as possible.

Use the wire size given in the table below.

Follow the wiring guide (see section 3-2-2).

Wire less than #10 gauge will not fit directly into the four way terminal block. Fit ferrules or

reterminate the wire with #10 gauge wire.

If more than one wire is to be fit ted to a terminal of the four way terminal block, join the wires

together in a suitable way.

Wire size table

To choose a wire gauge for an installation:

1 Measure the length of twin cable required, i.e. the distance from the main control unit to the heavy

duty power supply or to the drive.

2 Choose the column with the cable length and the row with the circuit current. The intersection of

the row and column gives the preferred (minimum) cable wire gauge for less than 3% voltage drop

in a 12 V system.

1 amp

2 amp

3 amp

4 amp

5 amp

6 amp

7 amp

Current

8 amp

9 amp

10 amp

15 amp

20 amp

Cable le ngth (from main control unit to power supply or to drive)

2.5 ft

0.7 m

#18

0.75 mm

#18

0.75 mm

#18

0.75 mm

#18

0.75 mm

#18

0.75 mm

#18

0.75 mm

#18

0.75 mm

#18

0.75 mm

#18

0.75 mm

#18

0.75 mm

#16

1.5 mm

#14

2.5 mm

5 ft

1.5 m

#18

0.75 mm

#18

0.75 mm

#18

0.75 mm

#18

0.75 mm

#16

1.5 mm

#16

1.5 mm

#16

1.5 mm

#16

1.5 mm

#16

1.5 mm

#14

2.5 mm

#12

4 mm

#12

4 mm

7.5 ft

2.2 m

0.75 mm

0.75 mm

0.75 mm

1.5 mm

1.5 mm

1.5 mm

2.5 mm

2.5 mm

2.5 mm

4 mm

4 mm

6 mm#810 mm#810 mm#616 mm#616 mm

#18

#18

#18

#16

#16

#16

#14

#14

#14

#12

#12

#10

10 ft

3 m

#18

0.75 mm

#18

0.75 mm

#16

1.5 mm

#16

1.5 mm

#14

2.5 mm

#14

2.5 mm

#14

2.5 mm

#12

4 mm

#12

4 mm

#12

4 mm

#10

6 mm

12.5 ft

3.7 m

0.75 mm

0.75 mm

1.5 mm

2.5 mm

2.5 mm

4 mm

4 mm

4 mm

4 mm

6 mm

6 mm#810 mm#810 mm#616 mm

#18

#18

#16

#14

#14

#12

#12

#12

#12

#10

#10

15 ft

4.5 m

#18

0.75 mm

#16

1.5 mm

#16

1.5 mm

#14

2.5 mm

#12

4 mm

#12

4 mm

#12

4 mm

#10

6 mm

#10

6 mm

#10

6 mm

17.5 ft

5.2 m

#18

0.75 mm

0.75 mm

#16

1.5 mm

2.5 mm

2.5 mm

1.5 mm

#14

2.5 mm

#14

4 mm

#12

4 mm

4 mm

6 mm

6 mm

6 mm

6 mm#810 mm

#12

#10

#10

#10

#10

4 mm

6 mm

6 mm

6 mm

6 mm

16 mm

20 ft

6 m

#18

#16

#14

#12

#12

#10

#10

#10

#10

#6

Northstar Explorer AP380 System Installation and Operation Manual

13

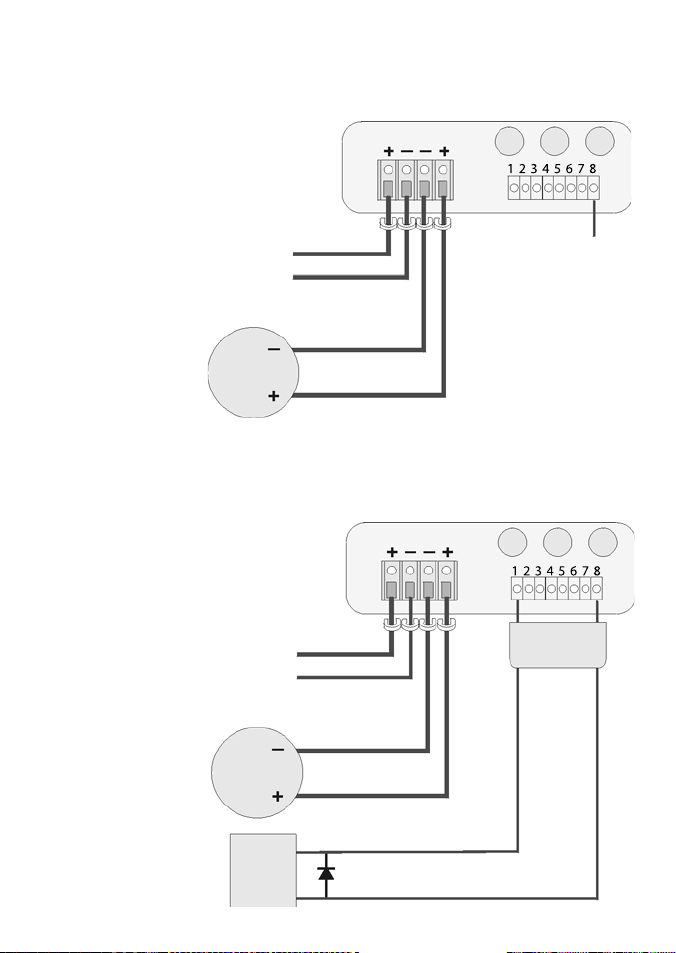

Example of hydraulic steering with hydraulic help pump.

In the Setup > Vessel menu (See Explorer AP380 Op eration Section), set Drive Type to Motor.

MCU600

Fit strain relief

Heavy duty power (see

section 3-4-1)

Motor

Wiring polarity does

not matter.

No connection

Example of mechanical steered power vessels with hydraulic linear drive for sailing boat

In the Setup > Vessel menu (See Explorer AP380 Op eration Section), set Drive Type to Motor.

MCU600

Note: Clutch relay coil must draw

less than 300mA

Fit strain relief

Heavy duty power (see

section 3-4-1)

Wiring polarity does

not matter.

Motor

Clutch

relay

coil

14

Northstar Explorer AP380 System Installation and Operation Manual

1N4002 diode or equivalent

Fit close to relay coil

Connector cover

Installing a electric drive motor with clutch relay

In the Setup > Vessel menu (See Explorer AP380 system Operation Section), set Drive Type to Motor.

MCU600

Heavy duty power (see section 3-4-1)

1N4002 diode or equivalent

Fit close to relay coil

Clutch

coil

Motor

Fit strain relief

Relay contacts

Wiring polarity does

not matter.

Connector cover

Relay coil

1N4002 diode or equivalent. Fit

close to relay coil

Note: Relay is required if the clutch circuit

is greater than 300 mA.

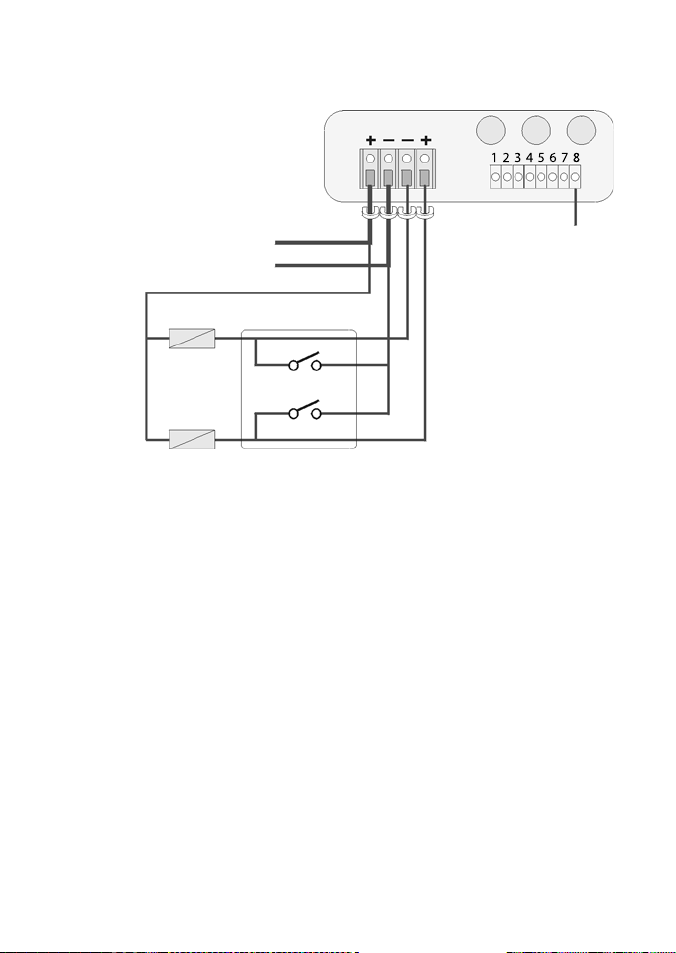

Installing a continuous running pump and solenoid valves.

In the Setup > Vessel menu (See Explorer AP380 system Operation Section), set Drive Type to Spool grou nd.

MCU600

Heavy duty power (see section 3-4-1)

Note: Motor is not

required for engine

PTO systems.

Motor

Fit strain relief

Relay contacts

Wiring polarity does

not matter.

Starboard

Port

Connector cover

Relay coil

1N4002 diode or equivalent

Fit close to relay coil

Note: Relay is required if the

clutch circuit is greater than

300 mA.

Northstar Explorer AP380 System Installation and Operation Manual

15

Installing solenoid valves or relays with jog or electric steering

In the Setup > Vessel menu (See Explorer AP380 Op eration Section), set Drive Type to Spool groun d.

MCU600

Fit strain relief

Heavy duty power (see

section 3-4-1)

No connection

Starboard

Port

Jog/steer controls

16

Northstar Explorer AP380 System Installation and Operation Manual

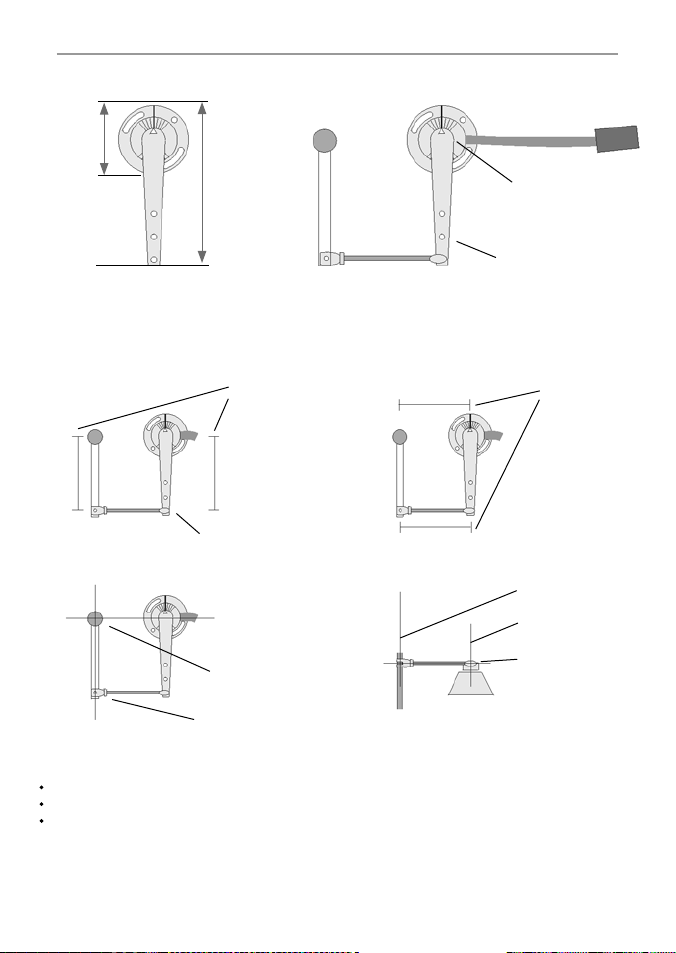

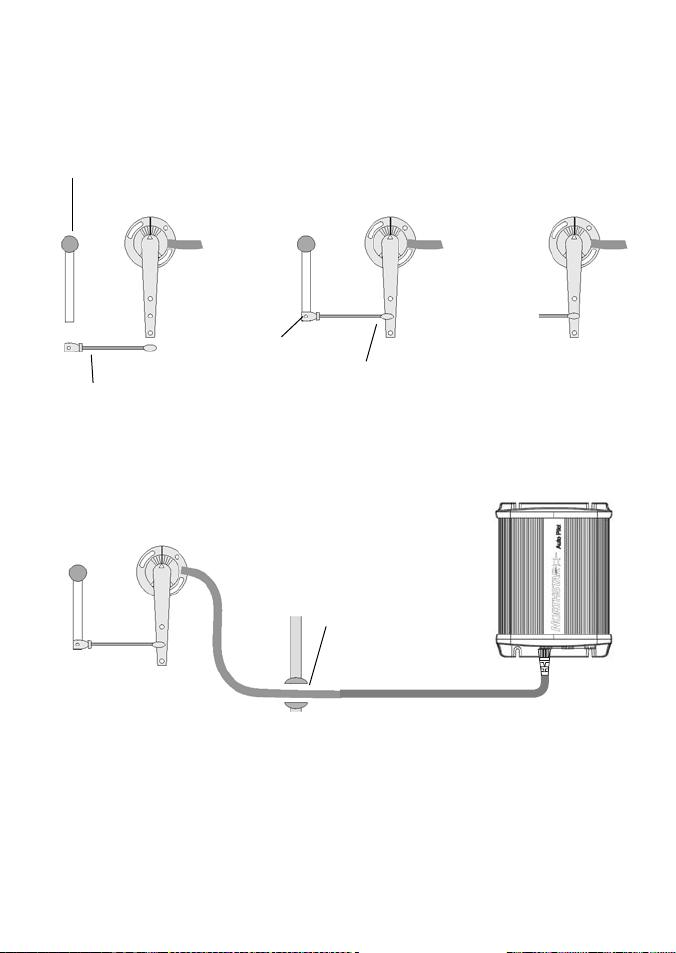

3-5 Installing the RFU (ru dder feedback unit)

Physical

90 mm

(3.5”)

220 mm

(8.7”)

Linkage to

rudder

Rudder

shaft

Connecting rod, with quick

release fittings and lock nuts

each end

Base

Arm rotates freely

Arm

around base.

End of connecting rod

snaps into one of the

holes on the arm.

LT8 connector

10 m (33 ft) cable

Mounting requirements

These two

distances to

be equal.

Adjust position of rod on

arm if required.

Base to be adjacent to

rudder shaft so that this

angle is 90°

Cut connecting rod

if required.

Note

The unit is completely waterproof but should not be immersed.

Mount the unit on a panel which does not vibrate.

Follow the location guide (see section 3-2-1).

Northstar Explorer AP380 System Installation and Operation Manual

Thread = M5

These two

distances to

be equal.

Rudder shaft to be

parallel to shaft in

base.

Rudder linkage and

arm to move in the

same plane

17

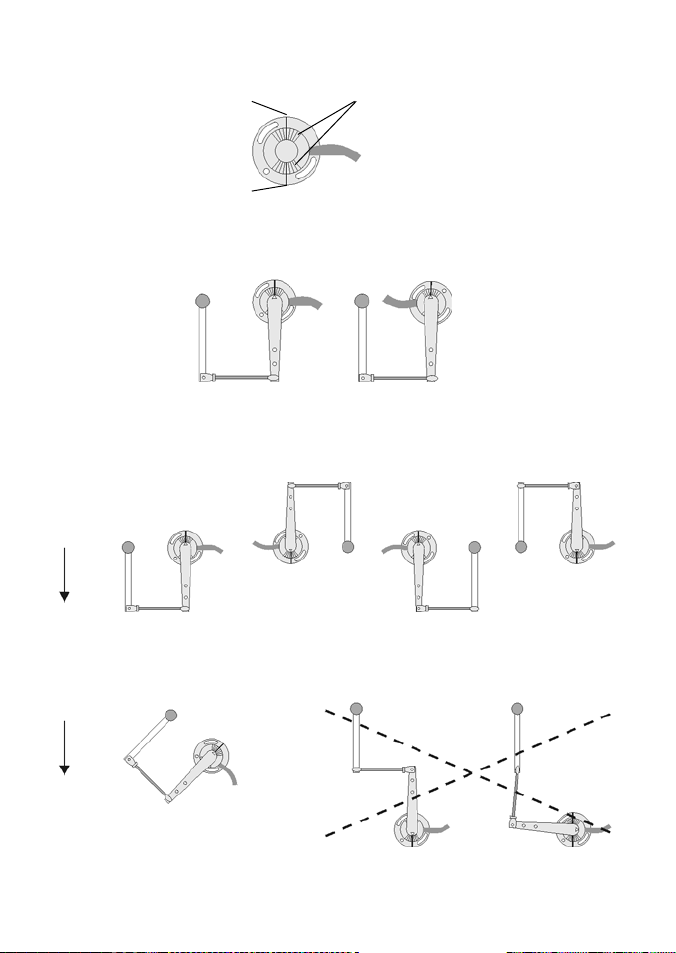

Alignment

The arm can rotate freely around the base. When the rudder is amidships, the arrow on the arm must

point to one of the centre lines on the base.

Centre line

Base

Centre line

Sets of lines

show the two linear

ranges of the unit.

Therefore in an installation, the base can be rotated to two positions. We recommend the position that

has the cable on the opposite side to the connecting rod.

Recommended

(rudder amidships).

Not recommended, cable can

foul rudder linkage.

Arrangements

Recommended: U-shaped arrangement with the arm parallel to the length of boat:

Bow of

boat

Satisfactory: U-shaped arrangement

with arm not parallel to length of boat, for

example:

Bow of

boat

18

Northstar Explorer AP380 System Installation and Operation Manual

Not recommended: Z-shaped arrangement,

for example:

If rudder turns too far, the unit might not return to the Z

shape.

Installation

1 Find a suitable location and arrangement for the unit as described above.

2 Choose, assemble and fit a suitable rudder linkage.

3 Fit the unit as shown below:

Set rudder

amidships.

If necessary, mount

base on block to set

height.

Rotate base so arrow on arm

points near centre line on base.

Fit two screws provided loosely

in middle of slots.

Rotate base so arrow on arm

points to centre line on base.

Fit third screw provided,

tighten all screws.

Ensure rudder is

amidships.

Join coupling to

rudder linkage.

If necessary, cut connecting

Snap end into

correct hole in arm.

rod at this end, then replace

coupling and lock nut.

4 Wire the cable back to the MCU600, following the wiring guide (see section 3-2-2).

Holes in the bulkheads must

be at least 18.5 mm (0.73” )

diameter.

Plug connector into the RFU socket

MCU600

Northstar Explorer AP380 System Installation and Operation Manual

19

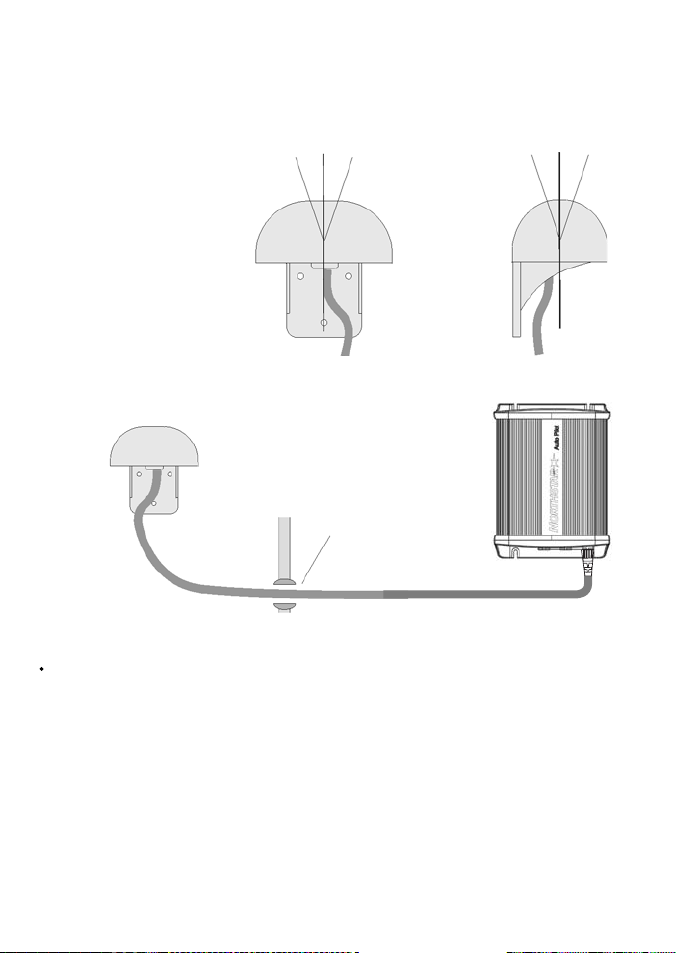

3-6 Install ing the Compass

Physical

Mounting holes for

screws

101 mm, (4”)

71 mm, (2.8”)

97 mm, (3.8”)

LT8 connector

10 m (32.8 ft)

Location

Mount the compass:

At least 1 m (3 ft) away from any steel or

iron boat par t, such as:

a steel hull, deck, cabin or steel

reinforcing in ferro-cement hulls

steel equipment such as motors and

cooking equipment

places where steel objects are stored,

such as the anchor locker and storage

lockers

At least 2 m (6 f t) away from equipment with

a magnet and equipment which generates

electromagnetic fields, such as a compass, a

battery, high current wiring, an electric motor

and a radio or radar transmitter or antenna.

Fibreglass or wood hull and cabin: mount compass at the centre of movement (for planing hulls, the

centre of movement is usually close to the stern):

Steel hu ll, non-stee l cabin: mount compass

1 m, (3 ft) above hull:

1 m (3 ft)

As close as possible to the centre of

movement of the boat, to minimise how

much the compass moves when the boat

rocks and pitches. If the compass can not

be mounted at the centre of movement, it is

usually best to mount the compass as low as

possible.

On a vertical panel which does not vibrate.

The unit is completely waterproof but should

not be immersed. The compass is not affected

by other metals, such as stainless steel, copper

or brass. Follow the location guide (see section

3-2-1).

Steel hu ll and steel cabin: mount compass on

a pole 1 m (3 ft) above the hull and at least 1 m

(3 ft) from the cabin:

At least 1 m (3 ft)

1 m (3 ft)

20

Northstar Explorer AP380 System Installation and Operation Manual

Installation

1 Find a suitable location for the unit as described above.

2 Mount the unit with the three screws provided. Use a level to ensure the unit is vertical to within 10°.

Less than

10° 10°

3 Wire the cable back to the MCU600, following the wiring guide (see section 3-2-2).

Holes in the bulkheads must

be at least 18.5 mm (0.73 in)

diameter.

Plug connector into the Compass/HS socket

Note

If you move the compass with respect to

the gyro while the power is on, wait for the

heading to stabilize.

Less than 10° 10°

MCU600

Northstar Explorer AP380 System Installation and Operation Manual

21

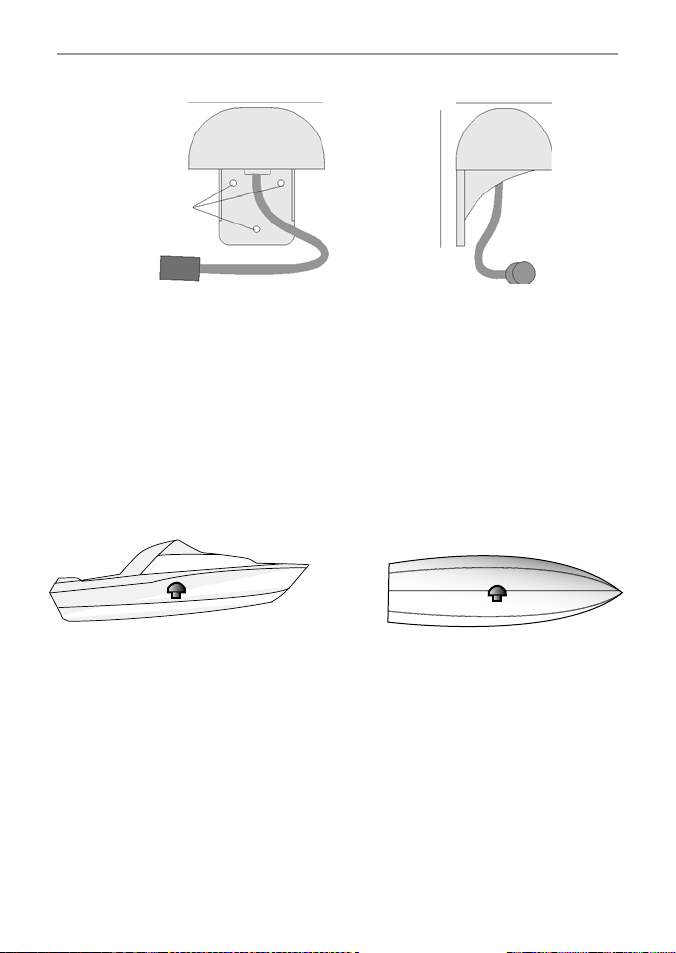

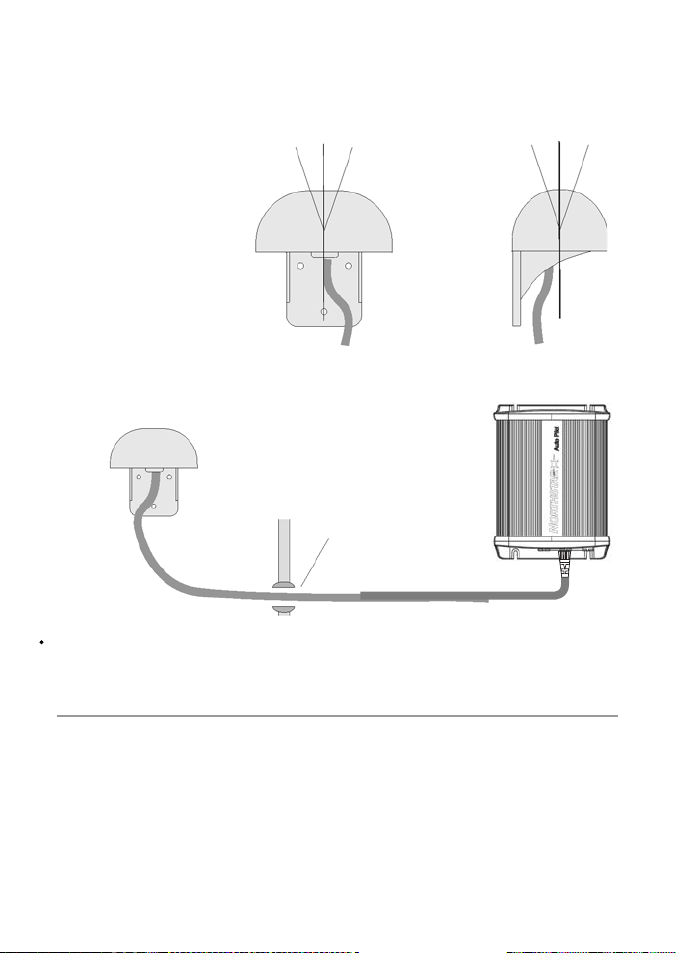

3-7 Installing the Gyro

Physical

101 mm, (4”)

71 mm, (2.8”)

Mounting holes for

screws

LT8 connector

10 m (32.8 ft)

97 mm, (3.8”)

Location

Mount the gyro as close as possible to the centre of movement of the boat, to minimize how much the

gyro moves when the boat rocks and pitches.

Mount the gyro on a panel which does not vibrate.

The unit is completely waterproof but should not be immersed. Follow the location guide (see section

3-2-1).

The Ideal location is at the centre of movement (for planing hulls, the centre of movement is usually

close to the stern).

22

Northstar Explorer AP380 System Installation and Operation Manual

Installation

1 Find a suitable location for the unit as described above.

2 Mount the unit with the three screws provided. Use a level to ensure the unit is vertical to within 10°.

Less than

10° 10°

Less than

10° 10°

3 Wire the cable back to the MCU600, following the wiring guide (see section 3-2-2).

MCU600

Note

Holes in the bulkheads must

be at least 18.5 mm (0.73”)

diameter.

Plug connector into the Gyro socket

If you move the gyro with respect to the compass while the power is on, wait for the heading to

stabilise.

3-8 Installi ng the Explorer AP380 display u nit and other instru ments

There are two mounting arrangements:

Flush mounting requires a solid panel with

access behind for wiring and mounting screws.

After flush mounting, the display cannot be

tilted or moved after installation to reduce any

unwanted glare or reflections. Carefully select

the best viewing position before installation. This

would generally be in a shaded area.

Northstar Explorer AP380 System Installation and Operation Manual

Flush mou nting direct ions

1 Cut a hole in the bulkhead for the display unit

using the flush mount template as a guide.

2 Drill four holes for the mounting studs using

the flush mount template as a guide.

3 Screw the four studs into the brass inserts in

the back of the display unit.

4 Sit the display unit in place and fit the

washers and nuts to the studs.

23

Loading...

Loading...