Page 1

PAMS Technical Documentation

RAE–2 Series PDA Phone

Chapter 2

–Transceiver BS8–

Baseband Block

Original 02/99

Copyright 1999 Nokia Mobile Phones. All rights reserved.

Page 2

RAE–2

PAMS

Baseband

Amendment

Number

Technical Documentation

AMENDMENT RECORD SHEET

Date Inserted By Comments

11/98 Original

Page 2– 2

Original 02/99

Page 3

PAMS

RAE–2

Technical Documentation

CONTENTS –Baseband

Introduction 2– 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Summary 2– 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Specifications 2– 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Ratings 2– 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Characteristics 2– 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Characteristics 2– 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connectors 2– 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External Connections from Baseband section of BS8 module 2– 9

Connectors to other modules of the product 2– 9. . . . . . . . . . . . . .

Bottom Connector 2– 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Connector 2– 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SIM card Connector 2– 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Card Connector 2– 13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Board to Board Connector 2– 14. . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Coax cable connector 2– 17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Internal Signals and Connections 2– 17. . . . . . . . . . . . . . . . . . . . . . .

Microphone 2– 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF– Baseband interface 2– 18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Baseband

Page No

Functional Descriptions 2– 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Management 2– 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery identification 2– 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery charging 2– 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Startup charging 2– 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery overvoltage protection 2– 24. . . . . . . . . . . . . . . . . . . . . . .

Battery removal during charging 2– 25. . . . . . . . . . . . . . . . . . . . . .

PWM control 2– 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery temperature 2– 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supply voltage regulators 2– 26. . . . . . . . . . . . . . . . . . . . . . . . . . .

MAD core regulator 2– 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switched mode supply VSIM 2– 28. . . . . . . . . . . . . . . . . . . . . . . .

Power up 2– 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power up with power switch (PWRKEYx) 2– 28. . . . . . . . . . .

Power up with a charger 2– 29. . . . . . . . . . . . . . . . . . . . . . . . . .

Service Request State (SRS) 2– 30. . . . . . . . . . . . . . . . . . . . . .

Active Mode 2– 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sleep Mode 2– 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charging 2– 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Off 2– 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Watchdog 2– 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Original 02/99

Page 2– 3

Page 4

RAE–2

PAMS

Baseband

Audio control 2– 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PDA Tones 2– 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CMT Alert Signal Generation 2– 34. . . . . . . . . . . . . . . . . . . . . . . .

External audio connections 2– 34. . . . . . . . . . . . . . . . . . . . . . . . . .

Analog audio accessory detection 2– 36. . . . . . . . . . . . . . . . . . . .

Headset detection 2– 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Headset switch detection 2– 36. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Internal audio connections 2– 37. . . . . . . . . . . . . . . . . . . . . . . . . . .

4–wire PCM serial interface 2– 37. . . . . . . . . . . . . . . . . . . . . . . . .

Digital control 2– 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAD2 2– 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAD2 memory configuration 2– 40. . . . . . . . . . . . . . . . . . . . . .

MCU Memory Map 2– 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memories 2– 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Memory 2– 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SRAM Memory 2– 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EEPROM Memory 2– 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flash Programming 2– 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RAE–2 Flashing connections 2– 43. . . . . . . . . . . . . . . . . . . . . .

Flashing methods 2– 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flashing procedure 2– 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Security 2– 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COBBA–GJ ASIC 2– 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Documentation

Page 2– 4

Original 02/99

Page 5

PAMS

RAE–2

Technical Documentation

Introduction

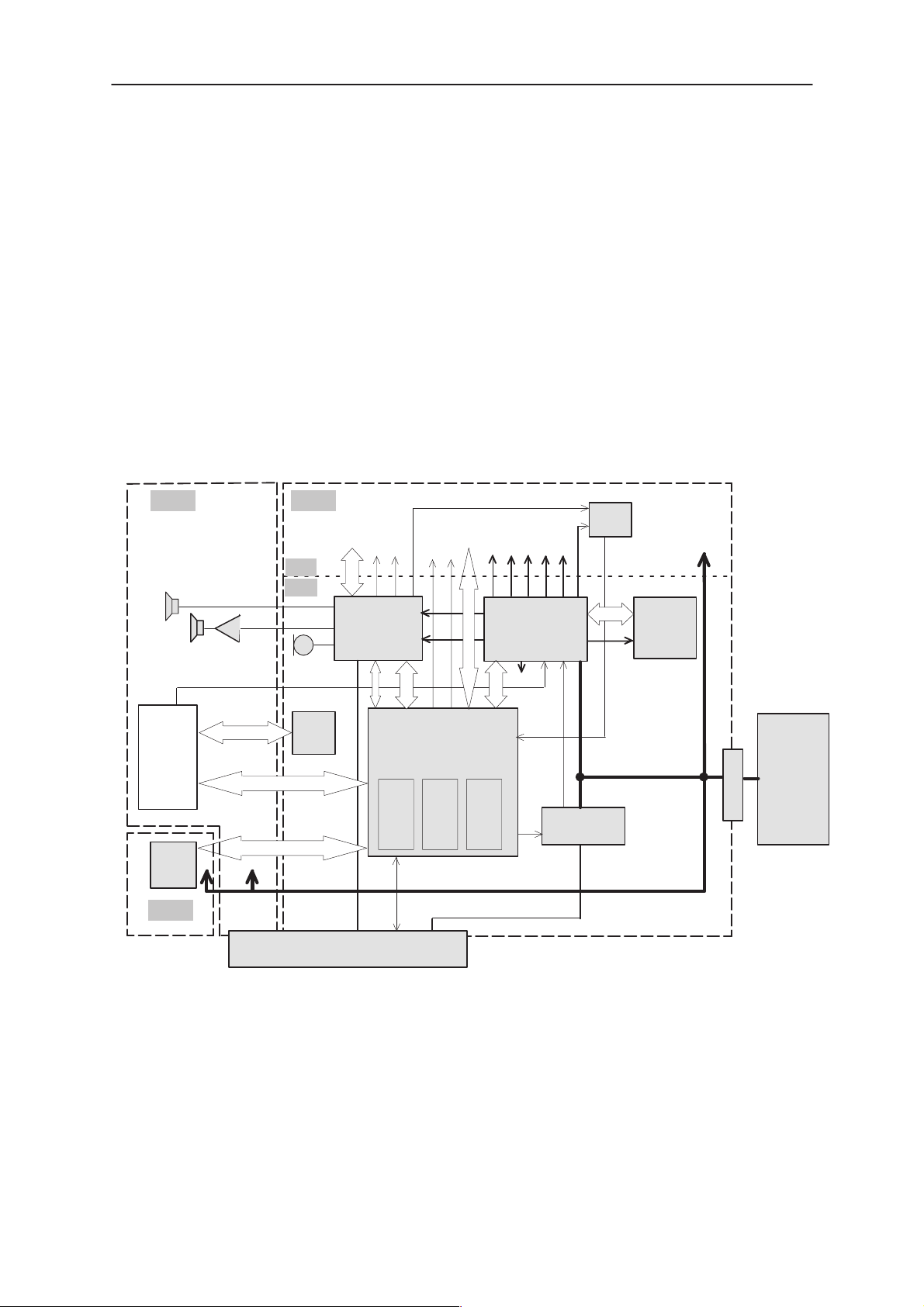

This document contains the specification to the Baseband section of the

BS8 module. The BS8 module carries out almost all CMT functions of

RAE–2. BS8 can be divided into two functional sections; BaseBand (BB)

and RF. Some of CMT baseband circuits are implemented to both BS1

and BS2 modules.

The Baseband module BS8 comprises four ASICs (CHAPS, CCONT,

COBBA–GJ and MAD2) that perform the baseband functions of the mod-

ule.

BS1

earphone

HF

BS8

RF

BB

MIC

TX/RX

TXC RXC

COBBA

TXPa

Synthesizer

control

LNA

RF SUPPLIES

VREF

CCONT

VCOBBA

VBB

AFC

VCOPWR

32kHz

Baseband

VCTCXO

13MHz

PA SUPPLY

SIMCONN

VSIM

MMC IF

SCOTTY

CMT

UI

BS2

MMC

CONN

CMT–PDA IF

CMTUI IF

Ext. audio

IF

BOTTOM CONNECTOR

Figure 1. BS8 BaseBand block in RAE–2 product

Technical Summary

The BS8 module is implemented on a single double side 8–layer printed

circuit board. The main part of the baseband area is located on the bot-

tom side of the PCB and only some components (bottom connector, bat-

tery connector and some filter components) are placed on the upper side

(RF side). Component height space on the baseband is 2.0mm.

Flash

512k

MAD

+

Memories

MAD

Sram

256k

MBUS

Eeprom

8k

VCHARG

CHAPS

LIM

Charger IF

VBATT

BATTERY

BATT.CONN

Original 02/99

Page 2– 5

Page 6

RAE–2

PAMS

Baseband

Technical Documentation

The baseband is running from a 2.8V power rail, which is supplied by the

power controlling ASIC. In the CCONT ASIC there are 6 individually con-

trolled regulator outputs for RF–section and two outputs for the base-

band. In addition there is one +5V power supply output (V5V) for flash

programming voltage and for other purposes where a higher voltage is

needed. The CCONT contains also a SIM interface, which supports both

3V and 5V SIM–cards.

BaseBand Side RF Side

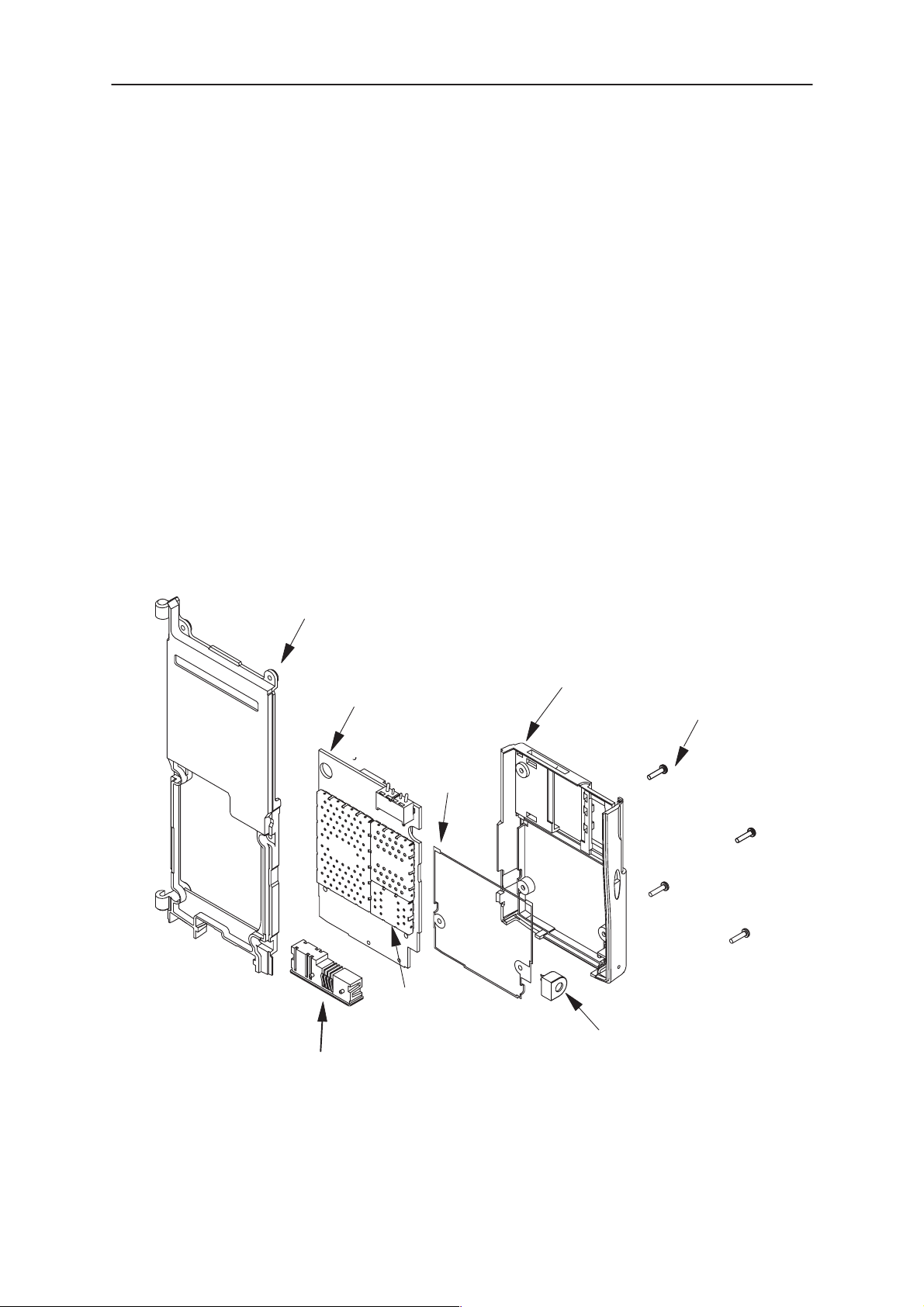

Figure 2. BS8 Module

The interface between the baseband and the RF section is handled by

the specific ASIC COBBA. The COBBA provides:

– A/D and D/A conversion of the in–phase and quadrature receive and

transmit signal paths

– A/D and D/A conversions of received and transmitted audio signals to

and from the UI section.

The COBBA supplies the analog TXC and AFC signals to the RF section

according to the MAD DSP digital control and converts the analog AGC

into digital signal for the DSP. The data transmission between the COB-

BA and the MAD is implemented using a parallel connection for high

speed signalling and a serial connection for PCM coded audio signals.

Digital speech processing is handled by the MAD asic.

The COBBA is a dual voltage circuit, the digital parts are running from the

baseband supply VBB and the analog parts are running from the analog

supply VCOBBA.

Page 2– 6

Original 02/99

Page 7

PAMS

RAE–2

Technical Documentation

The COBBA supports three microphone inputs and two earphone out-

puts. The inputs can be taken from an internal microphone, a headset mi-

crophone or from an external microphone signal source.

The output for the internal earphone is a dual ended type output capable

of driving a dynamic type speaker. Input and output signal source selec-

tion and gain control are performed inside the COBBA according to con-

trol messages from the MAD. Call alerts, keypad tones, DTMF, and other

audio tones are generated and encoded by the MAD and transmitted to

the COBBA for decoding.

EMC shielding (figure below) is implemented on the BB side using a me-

tallized plastic B–cover and conductive gasket between the B–cover and

the PCB. On the RF side the engine is shielded with a conductive frame

which makes a contact to a ground ring of the CMT board and a ground

plane of the PDA board. There is a conductive gasket between the frame

and the PCB for ensuring proper shielding. In addition he RF area has

three metal cans for RF shielding. Heat generated by the circuitry is con-

ducted out mainly via the PCB ground planes.

Baseband

Conductive frame +gasket

BS8 module

Metal

gasket

Metal cans

Bottom connector

Metallized B–cover

4 srews for fastening

B–cover to frame

Microphone

Original 02/99

Page 2– 7

Page 8

RAE–2

PAMS

Baseband

Technical Documentation

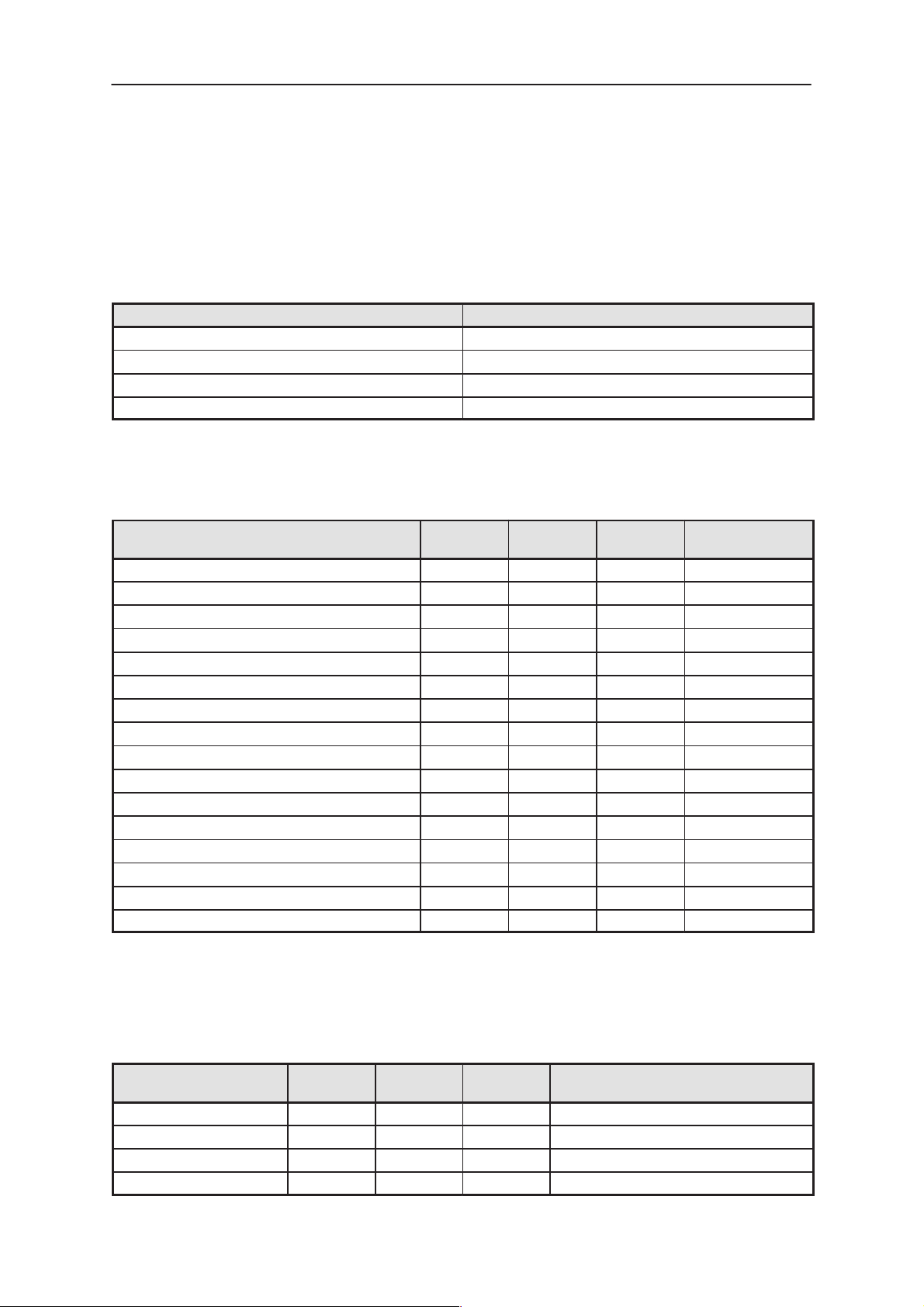

Technical Specifications

Maximum Ratings

Parameter Rating

Battery voltage, idle mode –0.3 ... 4.1V without charger

Charger input voltage –5.0 ... 16V

Operating temperature range –25C to +70 C

Storage temperature range –40C to +85 C

DC Characteristics

Supply voltages

Line Symbol Minimum Typical /

Nominal

Supply battery voltage 3.0 3.6 4.1 V

Battery powerup voltage (HW) 2.9 3.0 3.1 V

Battery cut off voltage (HW) 2.7 2.8 2.9 V

Regulated baseband supply voltage 2.7 2.8 2.85 V

Regulated baseband supply current 3 50 125 mA

Regulated VCORE supply voltage 1.3 – 2.65 V (changeable)

Regulated VCORE supply current 50 mA

COBBA analog supply voltage 2.7 2.8 2.85 V

COBBA analog supply current 5 20 100 mA

Regulated 5V supply voltage 4.8 5.0 5.2 V

Regulated 5V supply current 0 1 30 mA

Regulated 5V SIM supply voltage 4.8 5.0 5.2 V

Regulated 5V SIM supply current 3 10 30 mA

Regulated 3V SIM supply voltage 2.8 3.0 3.2 V

Regulated 3V SIM supply current 1 6 30 mA

Voltage reference 1.4775 1.5 1.5225 V

Maximum Unit / Notes

Note: The RF voltages are described later

AC Characteristics

Line symbol Minimum Typical /

32kHz 32768 Hz, Sleep clock

RFIClk 13 MHz, System clock

PCMClk 8 kHz, PCM clock

SIMClk 3.25 MHz, SIM Clock

Page 2– 8

Table 1. AC Specifications

Maximum Unit / Notes

Nominal

Original 02/99

Page 9

PAMS

RAE–2

Technical Documentation

Baseband

Connectors

External Connections from Baseband section of BS8 module

This section describes the external electrical connections and interface

levels on the baseband section of the BS8 module. The electrical inter-

face specifications are collected into tables that cover a connector or a

defined interface each.

Connectors to other modules of the product

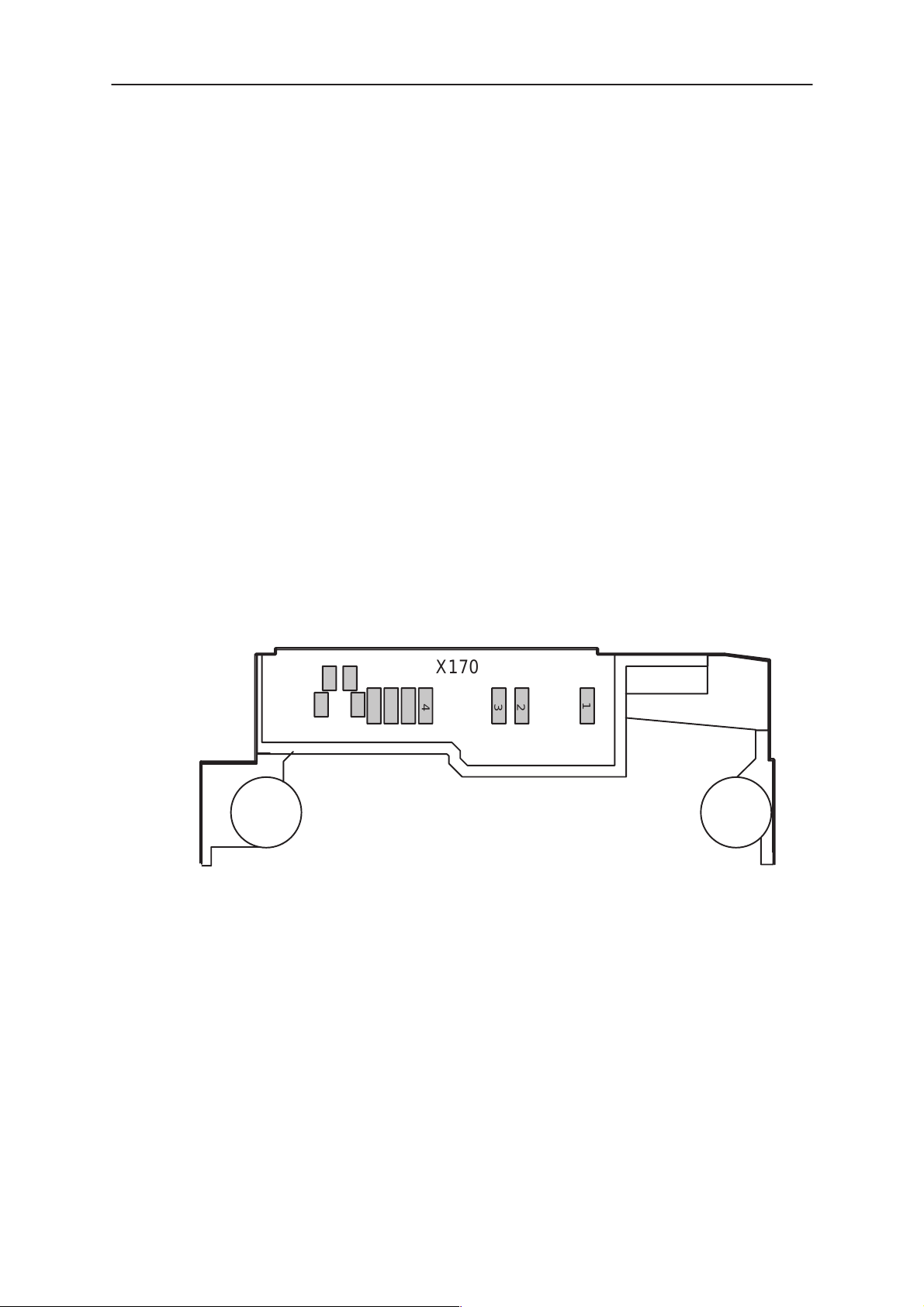

Bottom Connector

The bottom connector has spring type of connections. In BS8 module

there are contact pads for the spring connections.

10

9

11

Figure 3. Bottom connector pads in BS8 module

6

7

8

X170

5

4

2

3

1

The electrical specifications in the next table show the bottom connector

signals and levels on the baseband. The system connector is used to

connect the transceiver to accessories. The table gives the idle voltage

produced by the acceptable chargers at the DC connector input. The ab-

solute maximum input voltage is 30 V due to the transient suppressor that

is protecting the charger input.

Original 02/99

Page 2– 9

Page 10

RAE–2

CTRL

Baud rate 9600 Bit/s

PAMS

Baseband

Technical Documentation

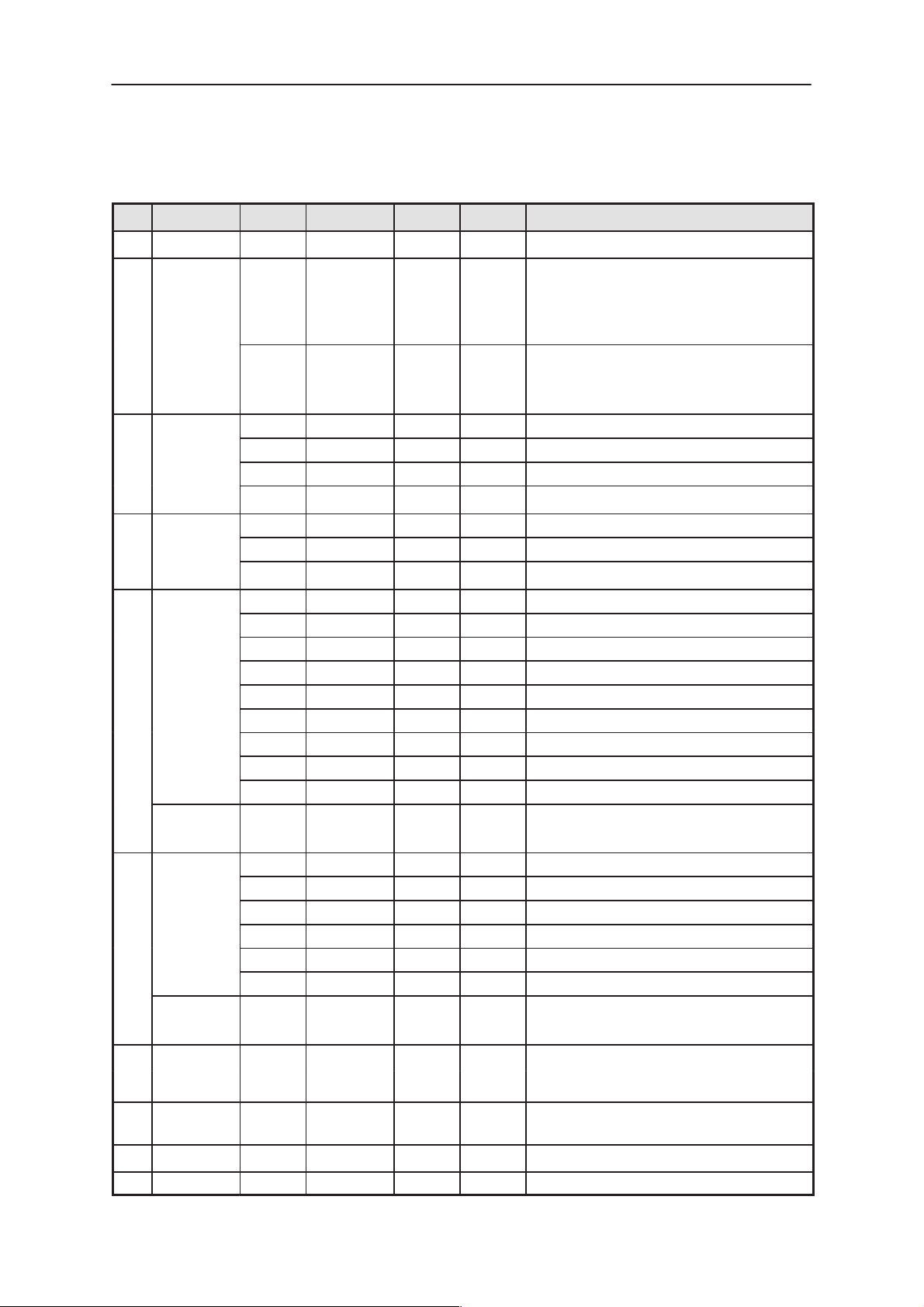

Table 2. Baseband signals of the bottom connector (X170)

Pin Name Min Typ Max Unit Notes

1 L_GND 0 0 V Supply ground

2 VIN

3 CHRG_

4 SGND

7.25

3.25

320

7.1

3.25

720

0 0.5 V Charger control PWM low

2.0 2.85 V Charger control PWM high

1 99 % PWM duty cycle

7.6

3.6

370

8.4

3.6

800

32 Hz PWM frequency for a ACP–9

47 Ω Output AC impedance (ref. GND)

10 µF Series output capacitance

380 Ω Resistance to phone ground

7.95

16.9

3.95

420

9.3

3.95

850

V

V

V

mA

V

V

mA

Unloaded ACP–7 Charger (5kohms load)

Peak charger output voltage (5kohms load)

Loaded charger output voltage (10ohms load)

Supply current

Unloaded ACP–9 Charger

Loaded charger output voltage (10ohms load)

Supply current

5 XEAR

HEAR 28 626 mV Earphone signal (HF– HFCM)

6 XMIC

HMIC 0 3.2 29.3 mV Microphone signal

47 Ω Output AC impedance (ref. GND)

10 µF Series output capacitance

16 300 Ω Load AC impedance to SGND (Headset)

4.7 10 kΩ Load AC impedance to SGND (Accessory)

1.0 Vpp Maximum output level (no load)

22 626 mV Output signal level

10 kΩ Load DC resistance to SGND (Accessory)

16 1500 Ω Load DC resistance to SGND (Headset)

2.8 V DC voltage (47k pull–up to VBB)

Connected to COBBA HF output

2.0 2.2 kΩ Input AC impedance

1 Vpp Maximum signal level

1.47 1.55 V Mute (output DC level)

2.5 2.85 V Unmute (output DC level)

100 600 µA Bias current

58 490 mV Maximum signal level

Connected to COBBA MIC3P input

7 MBUS 0 logic low 0.5 V Serial bidirectional control bus.

2.1 logic high 2.85

12,1

5

13 RF_OUT 5 (TX levels) 33 dBm RF signal from RF switch to internal antenna

14 RF_IN 5 (TX levels) 33 dBm RF signal from PA to RF switch.

GND 0 0 V RF ground

Page 2– 10

Phone has a 4k7 pullup resistor

Original 02/99

Page 11

PAMS

RAE–2

Technical Documentation

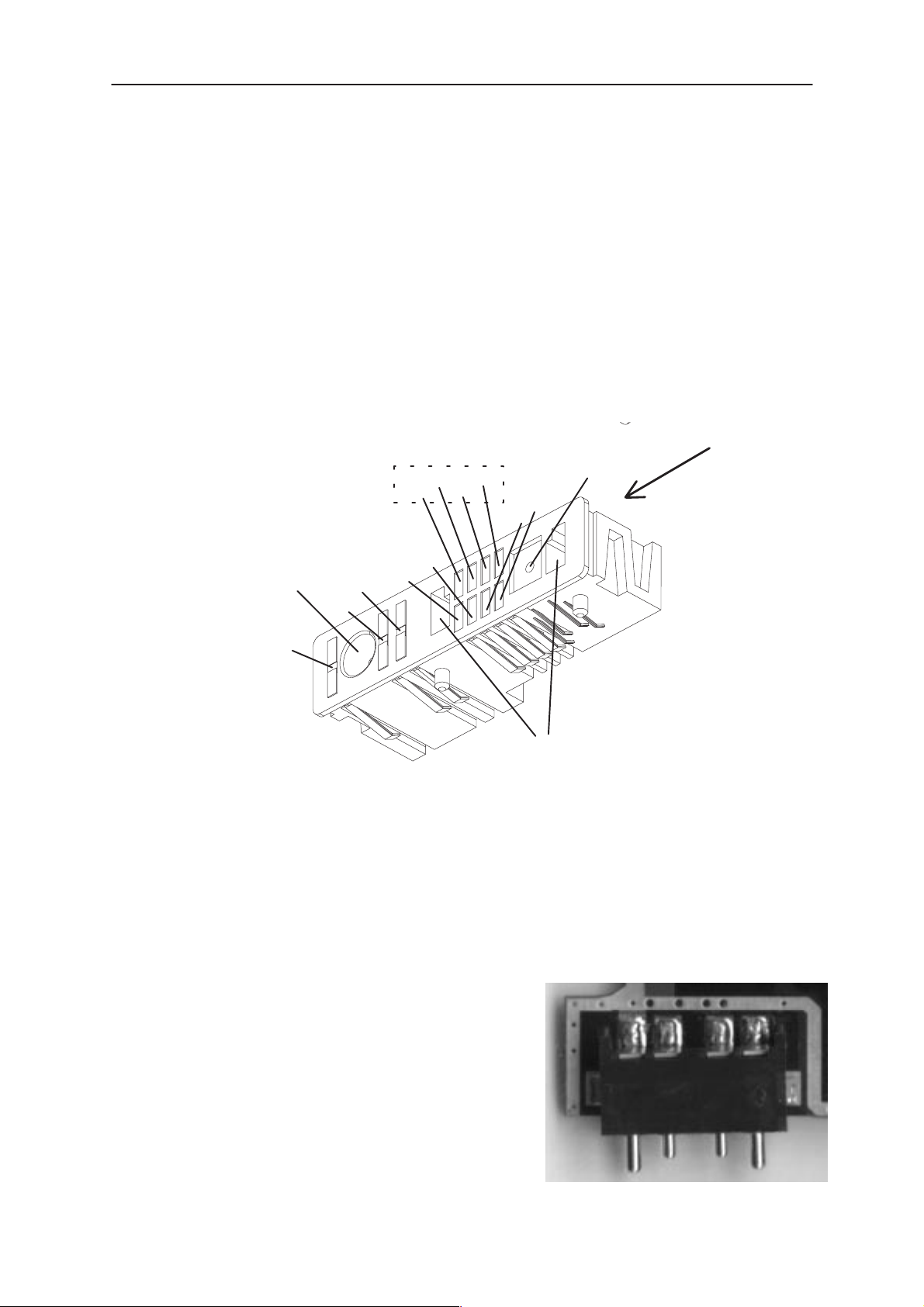

The bottom connector has mounting holes for a fastening to a shielding

frame located between the PDA and CMT modules. The bottom connector has spring type connections to the CMT and the PDA module.

The bottom connector includes the following parts:

– DC connector for external plug–in charger and a desktop charger

– System connector for accessories.

– Connector for external RF signal. This connector is equipped with

throw–over–switch. This is needed to change the RF signal path between external and internal antenna depending whether the ext antenna cable is connected or not.

PDA connections

RXTXDTR

GND

Baseband

PDA SIDE

External RF with switch

MBUS

XMIC

DC–jack

GND

Battery Connector

The electrical specifications for the battery connector are listed in the

next table. The BSI contact of the battery connector is also used to detect

when the battery is removed suddenly.

This information is needed for driving the SIM card safely down before

supply voltage is lost. The BSI contact in the battery connector has

0.5mm shorter working length than

the supply power contacts to give

enough time for the SIM shut down.

CHRG_CTRL

VIN

Figure 4. Bottom Connector

XEAR

SGND

Guiding and locking holes

GND

CMT SIDE

X160

BSI BTEMP

VBATT

Original 02/99

Figure 5. Battery Connector

Page 2– 11

Page 12

RAE–2

PAMS

Baseband

Technical Documentation

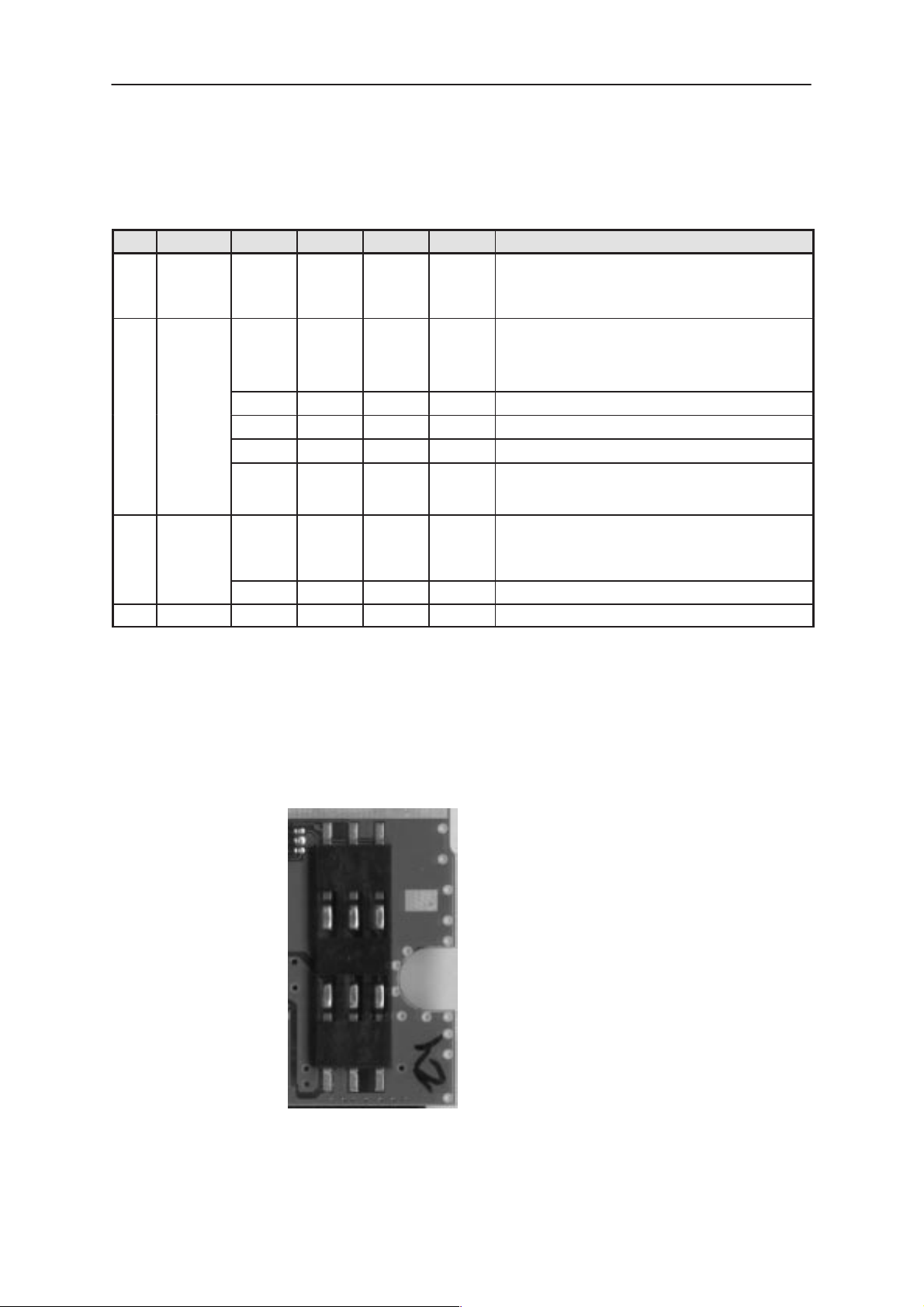

Table 3. Battery Connector Electrical Specifications (X160)

Pin Name Min Typ Max Unit Notes

1 VBATT 3.0 3.6 4.1 V Battery voltage

2 BSI

3 BTEMP

4 GND 0 0 V Battery ground

0 2.85 V Battery size indication

CMT has 180kohm pull up resistor.

SIM Card removal detection

(Threshold is 2.4V@VBB=2.8V)

17.1 18 18.9 kohm Field Test Battery (4.1V)

21.8 22 22.2 kohm BBS–5 Service battery (No cells)

31.35 33 34.65 kohm BLN–3 Li–ion battery (4.1V)

5 ms The minimum time from BSI contact disengaged its bat-

tery contact to VBATT/GND disengaged its battery con-

tacts when battery is removed.

0 1.4 V Battery temperature indication

CMT has a 100k (+–5%) pullup resistor,

Battery package has a NTC pulldown resistor:

47k+–5%@+25C , B=4050+–3%

0 1 kohm Local mode initialization (in production)

SIM card Connector

The SIM card connector is located on the baseband side of the BS8 module. The contacts of the SIM card connector are protected against electric discharge with ESD protection components.

VSIM

X150

GND

SIMRST

VSIM

SIMDATA SIMCLK

Page 2– 12

Figure 6. SIM Card Connector

Original 02/99

Page 13

PAMS

RAE–2

Technical Documentation

Table 4. SIM Connector Electrical Specifications (X150)

Pin Name Parameter Min Typ Max Unit Notes

4 GND GND 0 0 V Ground

3, 5 VSIM 5V SIM Card

3V SIM Card

6 DATA 5V Vin/Vout

3V Vin/V out

2 SIMRST 5V SIM Card

3V SIM Card

1 SIMCLK Frequency

Trise/Tfall

4.8

2.8

4.0

2.8

4.0

2.8

5.0

3.0

”1”

0

0

”0”

”1”

”0”

”1”

”1”

3.25

5.2

3.2

VSIM

0.5

VSIM

0.5

VSIM

VSIM

25

V Supply voltage

V SIM data

Trise/Tfall max 1us

V SIM reset

MHz

ns

SIM clock

VSIM supply voltages are specified to meet type approval requirements

regardless the tolerances in components.

Baseband

Memory Card Connector

The Memory card connector locates on BS8 module. Memory card is a

changeable Flash or ROM memory with variable memory size. The PDA

CPU can access with Memory card via synchronous serial interface.

Memory card signals are routed from BS1 module to BS8 module through

board to board connector.

MMC_DATA

MMC_GND

MMC_CLK

MMC_VSYS

MMC_GND

MMC_CMD

Figure 7. Memory Card Connector

X191

NC

The signals of the MMC connector are specified in the board to board

connector table.

Original 02/99

Page 2– 13

Page 14

RAE–2

3,4

PAMS

Baseband

Board to Board Connector

All interfaces (except RF antenna

signal) from the BS8 module to the

other RAE–2 modules are routed

over a 50–pins board to board connector. The interfaces can be divided into several groups; CMT–UI,

CMT–HF audio, CMT–PDA, MMC–

PDA and supply lines for the BS1

and the BS2 modules.

The CMT keyboard with keyboard illumination parts and the CMT display

module with display illumination parts are implemented on a separate UI

module (BS2), which contains also the PDA user interface and an antenna matching circuit. The baseband signals to the UI are routed over an

board to board connector to the BS1 module and from the BS1 module

through the hinge flex to the BS2 module.

Technical Documentation

pin 25pin 1

X190

pin 26pin 50

Figure 8. BoBo Connector

The Handsfree speaker and earpiece are included in the audio holder.

Because the audio holder and the HF amplifier are located on the PDA

module, several signals through the board to board connector are needed for carrying audios from the CMT to the PDA.

There are data signals for data transmission between the CMT and the

PDA modules. Some I/O signals are needed for carrying logic state information between modules.

Signal definition and the most important specifications of signals are listed

in the next table.

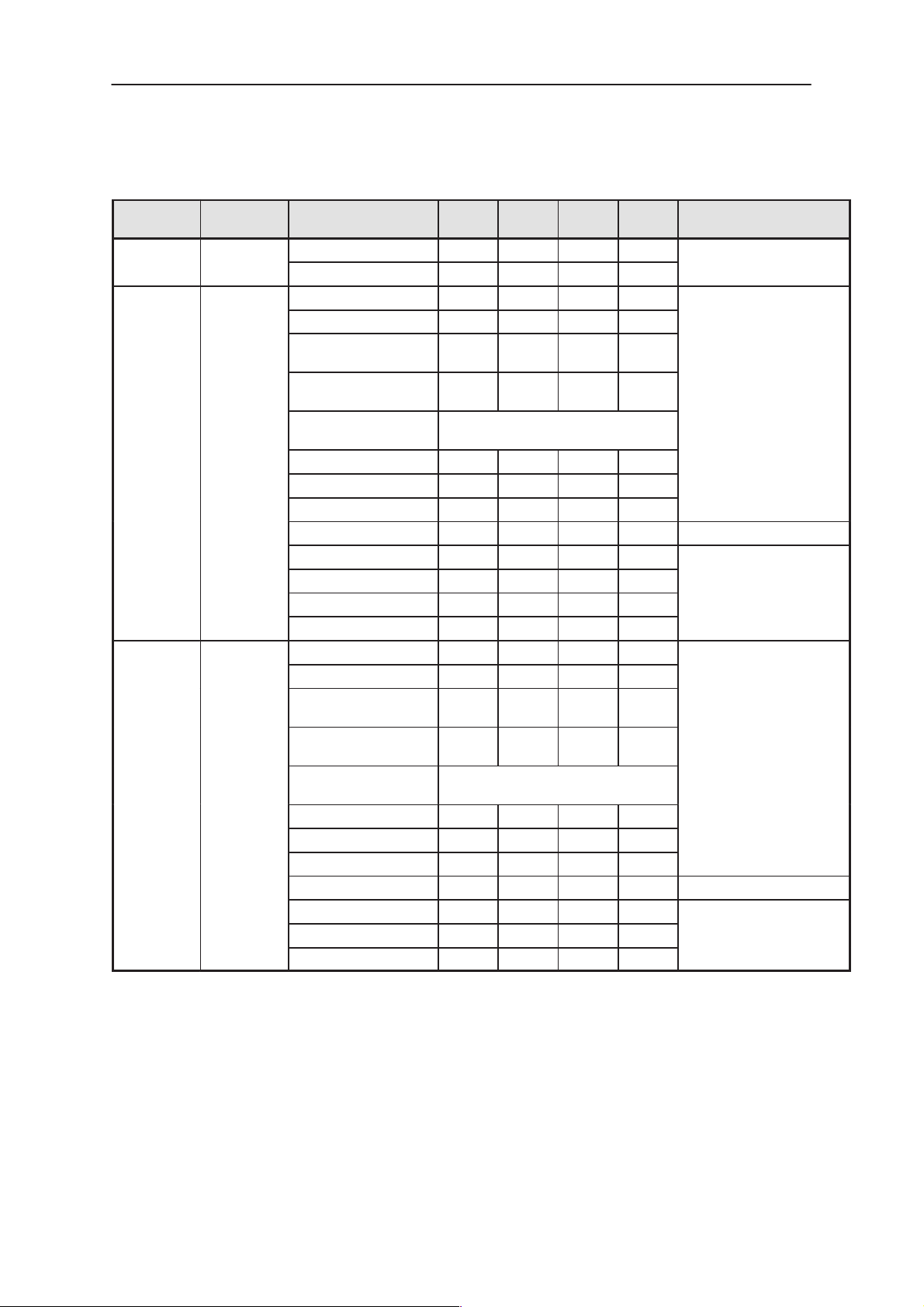

Table 5. Board to Board Connector (X190)

Pin I/O Name Function Min Typ Max Unit Description /

1,2,

,

5

6 O XEAR Audio Output for Handsfree 500 mVpp

7 GND Global Ground Reference for oth-

8 O BATTDET Battery Position Information

9 O HFENA Internal Handsfree Amplifier

VBATT Battery Positive

Control

3.0 3.6 4.1 VDC Unregulated Bat-

1.5 1000 mA Current to BS1

0.23 0.26 0.28 VDC Field T est battery

0.28 0.30 0.33 VDC Service battery

0.39 0.43 0.48 VDC BLN–3 battery

0 0.5 VDC Low, HF amplifier

2.1 2.85 VDC High, HF amplifier

Note

tery Voltage

and BS2 module

(max=peak current)

er signals

(only R&D use)

(BBS–5)

disabled

enabled

Page 2– 14

Original 02/99

Page 15

PAMS

between EARP

RAE–2

Technical Documentation

Table 5. Board to Board Connector (X190) (continued)

10 O EARP Earpiece Positive

11 O EARN Earpiece Negative

12 GND Global Ground

13 I PWRONx PDA start CMT to Service Re-

quest State (SRS)

14 I 32kHz Sleep clock to CMT

15 GND Global Ground

16 O VBB CMT regulated system volt-

age

17 I PWRKEYx CMT Power On/Off Switch

18 O CMT_BL_ON CMT UI Backlight On

19 I ROW3 CMT Keys Row 3

20 I ROW2 CMT Keys Row 2

21 I ROW1 CMT Keys Row 1

22 I ROW0 CMT Keys Row 0

23 GND Global Ground

24 O COL4 CMT Keys Column 4

25 O COL3 CMT Keys Column 3

26 O COL2 CMT Keys Column 2

27 O COL1 CMT Keys Column 1

28 O COL0 CMT Keys Column 0

29 GND Global Ground

Baseband

Description /

UnitMaxTypMinFunctionNameI/OPin

Note

50 223 mVpp Differential voltage

and EARN nodes

0 0.45 VDC Active state, min.

2.3 2.8 2.85 VDC Inactive state

0 0.45 VDC Pulse low level

2.3 2.8 2.85 VDC Pulse high level

12 mA Maximum current

32768 Hz Pulse frequency

20 50 80 % Duty cycle (CMT

1 % Jitter (CMT re-

2.7 2.8 2.85 VDC Regulated CMT

1 mA Maximum current

0 0.5 Low, active state

2.7 2.85 VDC High, inactive state

0 0.5 VDC Low, backlight off

2.1 2.8 2.85 VDC High, backlight on

0 0.2 VDC Low

2.5 2.8 2.85 VDC High

0 0.2 VDC Low

2.5 2.8 2.85 VDC High

0 0.2 VDC Low

2.5 2.8 2.85 VDC High

0 0.2 VDC Low

2.5 2.8 2.85 VDC High

0 0.5 VDC Low

2.1 2.85 VDC High

0 0.5 VDC Low

2.1 2.85 VDC High

0 0.5 VDC Low

2.1 2.85 VDC High

0 0.5 VDC Low

2.1 2.85 VDC High

0 0.5 VDC Low

2.1 2.85 VDC High

64ms

from PDA

requirements)

quirements)

baseband voltage

Original 02/99

Page 2– 15

Page 16

RAE–2

Sel

Clock

D

USE!

PAMS

Baseband

Technical Documentation

Table 5. Board to Board Connector (X190) (continued)

Description /

UnitMaxTypMinFunctionNameI/OPin

Note

30 O LCDCD CMT LCD Command / Data

ect

31 O LCDRSTx CMT LCD Reset

32 O LCDCSx CMT LCD Chip Select

33 GND Global Ground

34 O GENSCLK CMT LCD and CCONT Serial

35 O GENSDIO CMT LCD and CCONT Serial

ata

36 GND Global Ground

37 I FBUS_RXD Fast Serial Data to CMT

38 0 FBUS_TXD Fast Serial Data to PDA

39 GND Global Ground

40 I/O MBUS Bidirectional Serial Bus

41 I VSYS PDA regulated system voltage 2.75 2.8 2.85 VDC Max current 1mA

42 I LIDSWITCH Lid State Information

43 THIS SIGNAL IS NOT IN

0 0.5 VDC Low, Command

2.1 2.85 VDC High, Data

0 0.5 VDC Low, Reset active

2.1 2.85 VDC High, Reset inac-

tive

0 0.5 VDC Low, active

2.1 2.85 VDC High, inactive

0 0.5 VDC Low

2.1 2.85 VDC HIgh

3.250 MHz Pulse frequency in

active state (LCD

communication)

0 0.5 VDC Low

2.1 2.85 VDC High

1.625 MHz Maximum pulse

frequency

0 0.45 VDC Low

2.3 2.85 VDC High

220 k Pulldown resistor

in CMT

0 0.5 VDC Low

2.1 2.85 VDC High

47 k Pullup resistor in

CMT

0 0.5 VDC Low, to the PDA

2.1 2.85 VDC Low, to the PDA

0 0.45 VDC Low, from the PDA

2.3 2.8 2.85 VDC High, from the

PDA

47 k Pullup resistor in

CMT

0 VDC Low, Lid closed

2.75 2.8 2.85 VDC High, Lid open

10 kohm Pull–up resistor in

PDA

44 GND Global Ground

Page 2– 16

Original 02/99

Page 17

PAMS

l

RAE–2

Technical Documentation

Table 5. Board to Board Connector (X190) (continued)

45 I/O MMC_CMD Memory Card Command / Ad-

dress / Response, Bidirectiona

46 I MMC_VSYS Memory Card Power Supply 2.75 2.85 VDC

47 I/O MMC_DATA Memory Card Bidirectional

Data

48 GND Global Ground

49 I MMC_CLK Memory Card Clock

50 GND Global Ground

0 0 0.45 VDC Low, Data to the

2.3 2.8 2.85 VDC High, Data to the

0.34 VDC Low, Data from the

2.1 VDC High, Data from

259.3 kHz Frequency

0 0 0.45 VDC Low , Data to the

2.3 2.8 2.85 VDC High, Data to the

0 0 0.34 VDC Low , Data from the

2.1 VDC High, Data from

8.294 MHz Frequency

0 0 0.45 VDC Low

2.3 2.8 2.85 VDC High

0.2592 8.294 MHz Frequency

Description /

UnitMaxTypMinFunctionNameI/OPin

Note

card

card, pulled up

with 10kohm resistor to MMC_VSYS

in CMT module

card

the card, pulled up

with 10kohm resistor to MMC_VSYS

in CMT module

card

card, pulled up

with 10kohm resistor to MMC_VSYS

in CMT module

card

the card, pulled up

with 10kohm resistor to MMC_VSYS

in CMT module

Baseband

RF Coax cable connector

A small SMD coax cable connector is situated on the baseband side of

the BS8 module. It comprises the RF output for the internal antenna.

Internal Signals and Connections

This section describes the internal electrical connections and interface

levels on the baseband part of the BS8 module. The electrical interface

specifications are collected into tables that cover a connector or a defined

interface each.

Microphone

The internal microphone is connected to the PCB with spring contacts.

The microphone input level is specified in the table below. The micro-

Original 02/99

Page 2– 17

Page 18

RAE–2

RF

(PA

/PA off)

CCONT

CCONT

CCONT

CCONT

CRFU1A

SUMMA

SUMMA

SUMMA

PAMS

Baseband

Technical Documentation

phone requires a bias voltage to operate. The bias voltage is generated

from the VCOBBA supply with a transistor which is driven by the MAD

general I/O signal (MCUGenOut5).

Table 6. Microphone signals (B250)

Pin Name Min Typ Max Unit Notes

6 MICP 3.2 20 mVpp Differential voltage between MICP and MICN

RF– Baseband interface

The interface signals between the BB and the RF section are shown in

next the table as a logical interface. On PCB level the baseband supplies voltages from the CCONT to the separate rf–sub–blocks. The maximum values specified for the digital signals in the table are the absolute

maximum values from the RF interface point of view.

Signal name From

To

VBATT Battery

VXOENA MAD

SYNPWR MAD

RXPWR MAD

TXPWR MAD

VREF CCONT

SUMMA

PDATA0 MAD

SENA MAD

SDATA MAD

SCLK MAD

Table 7. AC and DC Characteristics of RF/BB signals

Parameter Mini-

mum

Voltage 3.0 3.6 5.0/6.0 V

Current 3500 mA

Logic high ”1” 2.1 2.85 V VR1, VR6 in CCONT ON

Logic low ”0” 0 0.5 V VR1, VR6 in CCONT

Logic high ”1” 2.1 2.85 V VR3, VR4 in CCONT ON

Logic low ”0” 0 0.5 V VR3,VR4 in CCONT OFF

Logic high ”1” 2.1 2.85 V VR2, VR5 in CCONT ON

Logic low ”0” 0 0.5 V VR2, VR5 in CCONT OFF

Logic high ”1” 2.1 2.85 V VR7 in CCONT ON

Logic low ”0” 0 0.5 V VR7 in CCONT OFF

Voltage 1.478 1.5 1.523 V

Current 100 uA

Source resistance 10 ohm

Logic high ”1” 2.1 2.85 V Nominal gain in LNA

Logic low ”0” 0 0.5 V Reduced gain in LNA

Logic high ”1” 2.1 2.85 V

Logic low ”0” 0 0.5 V

Logic high ”1” 2.1 2.85 V

Logic low ”0” 0 0.5 V

Data rate frequency 3.25 MHz

Logic high ”1” 2.1 2.85 V

Logic low ”0” 0 0.8 V

Data rate frequency 3.25 MHz

Typical Maxi-

mum

Unit Function

Supply voltage for RF

on

OFF

Reference voltage for

SUMMA and CRFU1a

PLL enable

Synthesizer data

Synthesizer clock

Page 2– 18

Original 02/99

Page 19

PAMS

VCTCXO

VC(TC)XO

MAD

COBBA

d

RF

RAE–2

Technical Documentation

Table 7. AC and DC Characteristics of RF/BB signals (continued)

Signal name

AFC COBBA

RFC VCTCXO

RXIP/RXIN SUMMA

To

Voltage 0.046 2.254 V

Resolution 11 bits

Load resistance (dynam-

ic)

Load resistance (static) 1 Mohm

Noise voltage 500 uVrms

Settling time 0.5 ms

Frequency 13 MHz

Signal amplitude 0.5 1.0 2.0 Vpp

Load resistance 10 kohm

Load capacitance 5 7 10 pF

Output level 50 1344 mVpp

Source impedance 600 ohm

Load resistance 1 Mohm

Load capacitance 4 pF

Baseband

ParameterFrom

mum

10 kohm

TypicalMini-

mum

Automatic frequency control

signal for

10...10000Hz

High stability clock signal for

the logic circuits

Differential RX 13 MHz signal to baseban

FunctionUnitMaxi-

TXIP/TXIN COBBA

SUMMA

TXQP/TXQN COBBA

SUMMA

Differential voltage swing 0.75 x

1.022

DC level 0.784 0.8 0.816 V

Differential offset voltage

(corrected)

Diff. offset voltage temp.

dependence

Source impedance 200 ohm

Load resistance 40 kohm

Load capacitance 10 pF

DNL +/– 0.9 LSB

INL +/–1 LSB

Group delay missmatch 100 ns

Differential voltage swing 0.75 x

1.022

DC level 0.784 0.8 0.816 V

Differential offset voltage

(corrected)

Diff. offset voltage temp.

dependence

Source impedance 200 ohm

Load resistance 40 kohm

Load capacitance 10 pF

Resolution 8 bits

DNL +/– 0.9 LSB

INL +/–1 LSB

Group delay mismatch 100 ns

0.75 x

1.1

0.75 x

1.1

0.75 x

1.18

+/– 2.0 mV

+/– 1.0 mV

0.75 x

1.18

+/– 2.0 mV

+/– 1.0 mV

Vpp

Vpp

Differential in–phase TX

baseband signal for the RF

modulator

Differential quadrature phase

TX baseband signal for the

modulator

Original 02/99

Page 2– 19

Page 20

RAE–2

SUMMA

SUMMA

SUMMA

PAMS

Baseband

Table 7. AC and DC Characteristics of RF/BB signals (continued)

Signal name

TXP MAD

TXC COBBA

RXC COBBA

To

Technical Documentation

ParameterFrom

mum

Logic high ”1” 2.1 2.85 V

Logic low ”0” 0 0.5 V

Voltage Min 0.12 0.18 V

Voltage Max 2.27 2.33 V

Vout temperature depen-

dence

Source impedance

active state

Source impedance

power down state

Input resistance 10 kohm

Input capacitance 10 pF

Settling time 10 us

Noise level 500 uV rms 0...200 kHz

Resolution 10 bits

DNL +/–0.9 LSB

INL +/– 4 LSB

Timing inaccuracy 1 us

Voltage Min 0.12 0.18 V

Voltage Max 2.27 2.33 V

Vout temperature depen-

dence

Source impedance

active state

Source impedance

power down state

Input resistance 1 Mohm

Input capacitance 10 pF

Settling time 10 us

Noise level 500 uV rms 0...200 kHz

Resolution 10 bits

DNL +/–0.9 LSB

INL +/– 4 LSB

TypicalMini-

mum

Transmitter power control

enable

Transmitter power control

10 LSB

200 ohm

high Z

Receiver gain control

10 LSB

200 ohm

grounded

FunctionUnitMaxi-

Page 2– 20

NOTE: Logic controls in low state when RF in power off.

Original 02/99

Page 21

PAMS

RAE–2

Technical Documentation

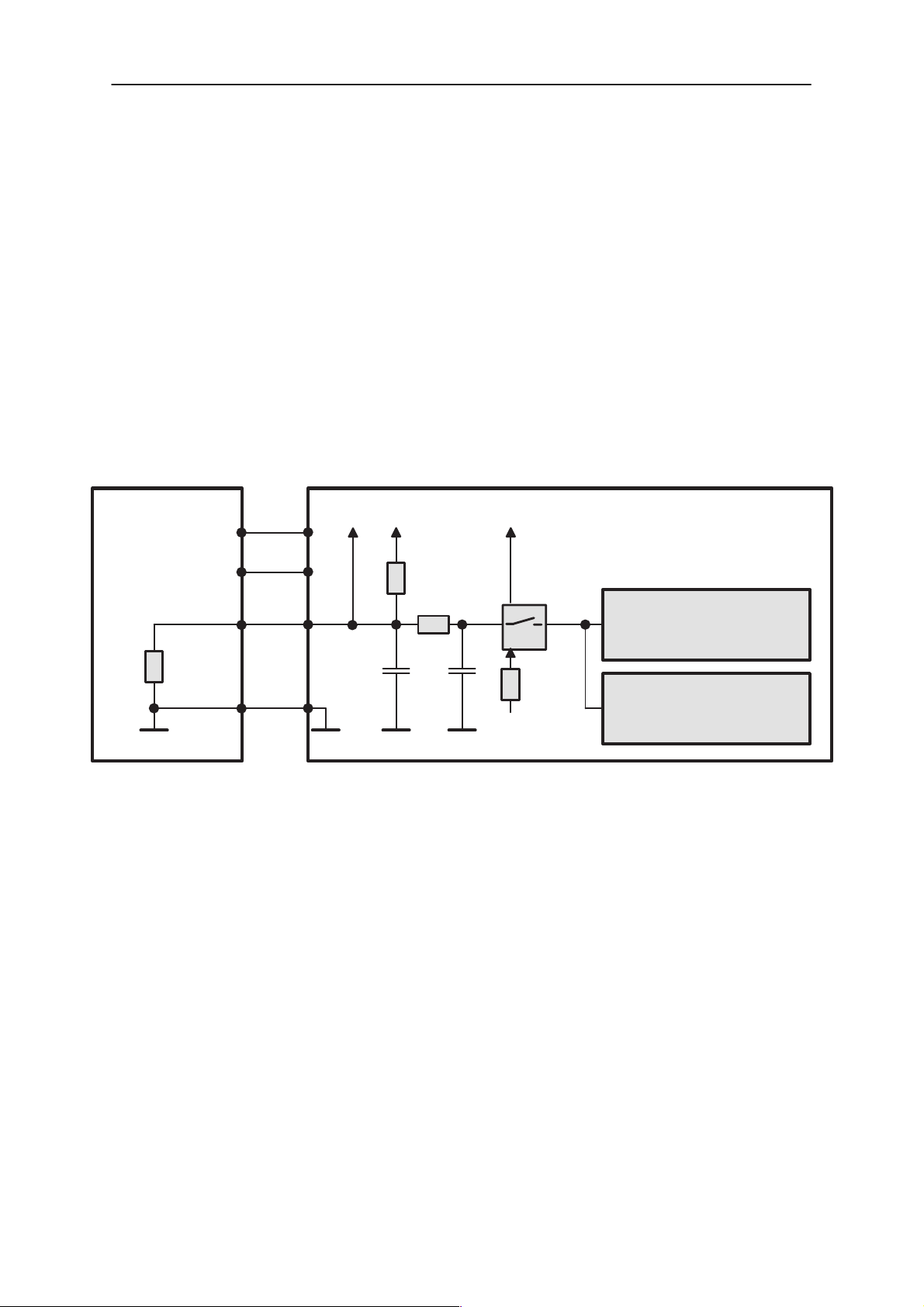

Functional Descriptions

Power Management

RF

BASEBAND

HF–amp

HF

SCOTTY

COBBA

VCOBBA

VBB

MAD

MAD

+

MEMORIES

VREF

RF SUPPLIES

VRX

VREF

SYNPWR

VCORE

VTX

VSYN

CCONT

PWRKEYx

PURX

VCP

VCO

VSIM

PA SUPPLY

SIMCONN

13MHz

CLK

Baseband

CMT

UI

BS2

PHASER

BS8BS1

BOTTOM CONNECTOR

CHARGER IF

LIM

VBATT

BATT.CONN

CHAPS

GNDAGND

VIN

Figure 9. CMT power distribution

In normal operation the baseband is powered from the phone Li–ion battery. The battery consists of two Lithium–Ion cell connected in parallel.

An external charger is used for recharging the battery and supplying power to the phone. The charger is a ”performance travel charger” (Nokia

ACP–9) that can deliver supply current up to 850 mA . It is also possible

to use a standard travel charger (Nokia ACP–7). The ACP–7 delivers

only 400 mA which is too little for charging the battery during a call.

The baseband contains components that control power distribution to the

CMT parts excluding those that use continuous battery supply. The battery feeds power directly to three CMT parts of the system: CCONT, power amplifier, and CMT UI. The figure above is the block diagram of the

power distribution.

Li–ion

Battery

3.6V

Original 02/99

Page 2– 21

Page 22

RAE–2

PAMS

Baseband

The charging control ASIC called CHAPS provides protection against

overvoltages, charger failures and pirate chargers etc. that would otherwise cause damage to the phone.

Battery identification

Battery types are identified by a pulldown resistor inside the battery pack.

The MCU can identify the battery by reading the BSI line DC–voltage level with a CCONT A/D converter.

Also the PDA needs to know whether the battery is connected or not. The

BSI line inside transceiver has a 180k pullup to PDA system voltage,

VSYS. CMOS switch (D100) is added between VSYS powered and VBB

powered circuits for preventing leakage current.

BATTERY

BLN–3

33k

VBATT

BTEMP

BSI

GND

To PDA

VSYS

27p

180k

10k

2n2

VSYS

VCC

EN

VBB

D100

100k

Technical Documentation

BS8

BSI

SIMCardDetX

CCONT

MAD

Figure 10. BSI connections

The battery identification line is used also for battery removal detection on

the CMT side. The BSI line is connected to a SIMCardDetX line of MAD2

(D200). SIMCardDetX is a threshold detector with a nominal input switching level 0.85xVcc for a rising edge and 0.55xVcc for a falling edge. The

battery removal detection is used as a trigger to power down the SIM card

before the power is lost. The working length of the BSI contact in the battery connector is made 0.5 mm shorter than the supply voltage contacts

so that there is a delay between battery removal detection and supply

power off.

Page 2– 22

Original 02/99

Page 23

PAMS

RAE–2

Technical Documentation

Vcc

0.850.05 Vcc

0.550.05 Vcc

SIMCARDDETX

GND

Battery charging

The electrical specifications define the idle voltages generated by the acceptable chargers at the DC connector input. The absolute maximum input voltage is 30V due to the transient suppressor that is protecting the

charger input. At the phone end there is no difference between a plug–in

charger or a desktop charger. The DC–jack pins and bottom connector

charging pads are connected together inside the phone. Charging block

diagram is below.

Figure 11. SIMCardDetX detection levels

S

IGOUT

Baseband

BLN–3

Li–ion

1030mAh

To PA

33R/

100MHz

VBAT

MAD

LIM

VOUT

0R22

ICHAR

PWM_OUT

VCHAR

CCONT

CCONTINT

GND

CHAPS

RSENSE

PWM

MAD

22k

1n

VCH

GND

5.5V

Figure 12. Charging block diagram

47k

4k7

33R/100MHz

1u

BS8

27p

1.5A

30V

33R/

100MHz

CHARGER

VIN

CHRG_

CTRL

(ACP–7)

ACP–9

LCH–9

NOT IN

ACP–7

L_GND

Startup charging

When a charger is connected, the CHAPS is supplying a startup current

minimum of 130mA to the phone. The startup current provides initial

Original 02/99

Page 2– 23

Page 24

RAE–2

PAMS

Baseband

Technical Documentation

charging to a phone with an empty battery. The startup circuit charges

the battery until the battery voltage level 3.0V (+/– 0.1V) is reached. Then

the CCONT releases the PURX reset signal and the program execution

starts. The charging mode is changed from startup charging to PWM

charging that is controlled by the MCU software. If the battery voltage

reaches 3.55V (3.75V maximum) before the program has taken control

over the charging, the startup current is switched off. The startup current

is switched on again when the battery voltage has sunk to 100mV (nominal).

Table 8. Startup characteristics

Parameter Symbol Min Typ Max Unit

VOUT Start– up mode cutoff limit Vstart 3.45 3.55 3.75 V

VOUT Start– up mode hysteresis

NOTE: Cout = 4.7 uF

Start–up regulator output current VOUT = 0V

... Vstart

Vstarthys 80 100 200 mV

Istart 130 165 200 mA

Battery overvoltage protection

Output overvoltage protection is used to protect the phone from damage.

The power switch is immediately turned OFF if the voltage in VOUT rises

above VLIM1.

Table 9. VLIM characteristics

Parameter Symbol LIM input Min Typ Max Unit

Output voltage cutoff limit VLIM1 LOW 4.4 4.6 4.8 V

When the switch in output overvoltage situation has once turned OFF, it

stays OFF until the the battery voltage falls below VLIM1 and PWM =

LOW is detected. The switch can be turned on again by setting PWM =

HIGH.

Page 2– 24

Original 02/99

Page 25

PAMS

RAE–2

Technical Documentation

VCH

VCH<VOUT

VOUT

VLIM1

SWITCH

PWM (32Hz)

ON OFF

Baseband

t

t

ON

Figure 13. Output overvoltage protection( in principle; not in timescale)

Battery removal during charging

Output overvoltage protection is also needed in case the main battery is

removed when charger connected or charger is connected before the battery is connected to the phone.

If the battery is removed during charging, the SIMCardDetX signal goes

active and the SIMCard is driven down.

PWM control

The ACP–9 is controlled with PWM at a frequency of 32Hz. When the

PWM rate is 32Hz CHAPS keeps the power switch continuously in the ON

state.

SWITCH

PWM (32Hz)

ON

Figure 14. Switch control with 32 Hz frequency (in this case 50% duty cycle)

Battery temperature

The battery temperature is measured with a NTC inside the battery pack

(see table 12). The BTEMP line in the transceiver has a 100k pull–up to

Original 02/99

Page 2– 25

Page 26

RAE–2

PAMS

Baseband

Technical Documentation

the VREF. The MCU calculates the battery temperature by reading the

BTEMP line DC–voltage level with a CCONT A/D–converter.

BATTERY

R

T

NTC

BVOLT

BSI

BTEMP

BGND

VREF

100k

10k

27p 10n

BTEMP

CMT

CCONT

MAD

Figure 15. Standard battery BTEMP connection

Based on 47k ± 5 % NTC with B = 4090 ±1.5 %. Without any alignment,

with that and 1 % pull–up resistor, ± 2.5 _C accuracy is achieved between

– 20 and +60 _C (± 3.5 _C @ –40 ... +85 _C).

Table 10. Battery temperature vs. AD readings and NTC resistance

T [_C] AD R [k] T [_C] AD R [k] T [_C] AD R [k]

–40 963 1589 5 560 120.9 50 145 16.53

–35 942 1151 10 497 94.53 55 122 13.63

–30 915 842.8 15 436 74.40 60 103 11.30

–25 882 622.6 20 379 58.95 65 88 9.404

–20 842 464.1 25 327 47.00 70 74 7.865

–15 795 349.0 30 280 37.71 75 63 6.607

–10 743 264.6 35 238 30.43 80 54 5.573

–5 685 202.3 40 202 24.70 85 46 4.721

0 623 155.8 45 171 20.15 90 39 4.015

NOTE: NTC R values and corresponding AD values are calculated values. Because of tolerances real values may differ from the calculated values.

Supply voltage regulators

The heart of the CMT power distribution is the CCONT. It includes all the

voltage regulators and feeds power to the whole system. The baseband

digital parts are powered from the VBB regulator which provides 2.8V

baseband supply. The baseband regulator is active always when the

phone is powered on. The VBB baseband regulator feeds the MAD and

memories, the COBBA digital parts and the LCD driver in the UI section.

There is a separate regulator for the SIM card. The regulator is selectable

Page 2– 26

Original 02/99

Page 27

PAMS

RAE–2

Technical Documentation

Baseband

between 3V and 5V and controlled by the SIMPwr line from MAD to

CCONT. The COBBA analog parts are powered from a dedicated 2.8V

supply VCOBBA. The CCONT supplies also 5V for RF and for flash VPP.

Table 11. Regulator activity in different operating modes

Operating mode Vref RF REG VCOBBA VBB VSIM SIMIF

Power off Off Off Off Off Off Pull down

Power on On On/Off On On On On/Off

Reset On Off

VR1 On

Sleep On Off Off On On On/Off

On On Off Pull down

NOTE: The COBBA regulator is off in SLEEP mode. Its output pin

may be fed from VBB in SLEEP mode by setting bit RFReg(5) to ’1’

(default).

CCONT includes also five additional 2.8V regulators providing power to

the RF section. These regulators are controlled either by the direct control

signals from the MAD or by the RF regulator control register in the

CCONT which the MAD updates. Below are the listed the MAD control

lines and the regulators they are controlling.

– TxPwr controls VTX regulator (VR5)

– RxPwr controls VRX regulator (VR2)

– SynthPwr controls VSYN_1 and VSYN_2 regulators (VR4 and VR3)

– VCXOPwr controls VXO regulator (VR1)

The CCONT generates also a 1.5 V reference voltage VREF to the COB-

BA, SUMMA and CRFU. The VREF voltage is also used as a reference

to some of the CCONT A/D converters.

In addition to the above mentioned signals, the MAD includes also a TXP

control signal to the SUMMA power control block and to the power amplifier. The transmitter power control TXC is led from the COBBA to theSUMMA.

NOTE 1: Characteristics above are NOT valid if Vbat < 3.0V.

NOTE 2: Line regulation is 20dB for f<100kHz when battery voltage is lower than 3.1V.

MAD core regulator

This block includes a linear voltage regulator with programmable output

voltage, which supplies the MAD core. The output voltage can be

changed from typical 1.30 V to 2.65 V in 225mV steps. The default output

voltage is 1.975V. Control is possible via control register CVReg; the details are available in the digital specification of CCONT ASIC. If the regulator is not used, the control must be set to ’0’, and the output left floating.

Original 02/99

Page 2– 27

Page 28

RAE–2

PAMS

Baseband

The lower core voltage is used only with MAD c07 technology in near future. There are two jumper resistors (R151 and R152, see the BS8 schematics) in baseband for selecting between normal or lower MAD core

voltage.

Switched mode supply VSIM

There is a switched mode supply for SIM–interface. SIM voltage is selected via serial IO. The 5V SMR can be switched on independently of the

SIM voltage selection, but can’t be switched off when the VSIM voltage

value is set to 5V.

In the next figure the principle of the SMR / VSIM–functions is shown.

CCONT External

V5V_4

VBAT

Technical Documentation

Power up

V5V_3

V5V_2

VSIM

Figure 16. Principle of the SMR power functions

The baseband is powered up by:

1. Pressing the power key

2. Connecting a charger to the phone.

5V5

V5V

5V

5/3V

3. PDA can power BB to SRS by pulling PWRONx line to low

state.

Power up with power switch (PWRKEYx)

When the power on switch is pressed, the PWRKEYx signal goes low and

pulls the CCONT PWRONx pin to low. The CCONT then switches on the

CCONT digital section and the VCXO as was the case with the charger

Page 2– 28

Original 02/99

Page 29

PAMS

RAE–2

Technical Documentation

driven power up. If the PWRONX is low when the 62 ms delay expires,

the PURX is released and the SLEEPX control goes to MAD. If the

PWRONX is not low when 62 ms expires, the PURX will not be released,

and CCONT will go to power off ( digital section will send power off signal

to analog parts).

Baseband

SLEEPX

PURX

PWRONX

VR1,VR6

VBB (2.8V)

Vchar

12 3

1:Power switch pressed ==> Digital voltages on in CCONT (VBB)

2: CCONT digital reset released. VCXO turned on

3: 62 ms delay to see if power switch is still pressed.

Figure 17. Power up with switch

Power up with a charger

When the charger is connected, the CCONT switches on the CCONT digital voltage as soon as the battery voltage exceeds 3.0V. The reset for the

CCONT’s digital parts is released when the operating voltage is stabilized

(50 us from switching on the voltages). The operating voltage for the

VCXO is also switched on. The counter in the CCONT digital section

keeps the MAD in reset for 62 ms (PURX) to make sure that the clock

provided by VCXO is stable. After this delay the MAD reset is released,

and the VCXO –control (SLEEPX) is given to the MAD. The CMT start to

so called acting dead–state which means that only the charging software

is running and e.g. the RF is powered off.

The next diagram describes the power on procedure with charger (the

picture assumes empty battery, but the situation would be the same with

full battery):

Original 02/99

Page 2– 29

Page 30

RAE–2

PAMS

Baseband

Technical Documentation

SLEEPX

PURX

VXO

Vbat

VR6

VR1

VBB (2.8V)

Vchar

Vref

12 3

1: Battery voltage over 3.0==>Digital voltages to CCONT (VBB)

2: CCONT digital reset released. VCXO turned on

3: 62ms delay before PURX released

Figure 18. Power up with charger

Service Request State (SRS)

If CMT is powered off, the PDA has a possibility to startup the CMT to

SERVICE REQUEST (SRS) state by using PWRONx line. The PDA can

do it by pulling the PWRONx line to the low (”0”) state. The difference between the SRS and acting dead is that the SRS is invisible to the user.

Also during the SRS the RF parts are always powered off.

The SRS is needed when the PDA is going to communicate with the CMT

(e.g. asking some SIM information or battery voltage information) when

the CMT is powered off.

Page 2– 30

Original 02/99

Page 31

PAMS

RAE–2

Technical Documentation

PDA

SCOTTY

inactive: ”HighZ”

active: ”0”

CMT is powered

by PWRKEYx:

PWRONx

CMT

PWRKEYx

01

Baseband

1k

ROW0

MAD

VBAT

200k / 2k

10k

PWRONX

2

pwroff / pwron

CCONT

3

ROW0

PWRONx

(CCONT pin 29)

VBB

CMT is powered

by PWRONx:

0: –CCONT PWRONx input goes to ”0”. CCONT start power on se

quency and releases BB regulator (VBB → 2.8V).

1: –When PWRONx has been ”0” at least 62ms, CCONT gives system

control to MAD. MAD start execute MCU SW.

2: –MCU SW read the state of the ROW0 signal.

3: –Power on/off key or PWRONx are released.

0s 62ms

01

2

3

0s 62ms

– If it is ”1” MCU SW go to SRS

– If it is ”0” MCU SW continues to active state.

Figure 19. SRS versus normal powerup.

t

ROW0

PWRONx

(CCONT pin 29)

VBB

t

Active Mode

In the active mode the phone is in normal operation, scanning for channels, listening to a base station, transmitting and processing information.

All the CCONT regulators are operating. There are several sub–states in

the active mode depending on if the phone is in burst reception, burst

transmission, if DSP is working etc..

Original 02/99

Page 2– 31

Page 32

RAE–2

PAMS

Baseband

Sleep Mode

In the sleep mode all the regulators except the baseband VBB and the

SIM card VSIM regulators are off. Sleep mode is activated by the MAD

after MCU and DSP clocks have been switched off. The voltage regulators for the RF section are switched off and the VCXO power control,

VCXOPwr is set low. In this state only the 32 kHz sleep clock oscillator in

CCONT is running. The flash memory power down input is connected to

the ExtSysResetX signal, and the flash is deep powered down during the

sleep mode.

The sleep mode is exited either by the expiration of a sleep clock counter

in the MAD or by some external interrupt, generated by a charger connection, key press, headset connection etc. The MAD starts the wake up

sequence and sets the VCXOPwr and ExtSysResetX control high. After

VCXO settling time other regulators and clocks are enabled for active

mode.

If the battery pack is disconnected during the sleep mode, the CCONT

pulls the SIM interface lines low as there is no time to wake up the MCU.

Technical Documentation

Charging

Charging can be performed in any operating mode. The battery type is

indicated by a resistor inside the battery pack. The resistor value corresponds to a specific battery capacity which is defined in the RAE–2 to

1030mAh.

The battery voltage, temperature, size and current are measured by the

CCONT controlled by the charging software running in the MAD.

The power management circuitry controls the charging current delivered

from the charger to the battery. Charging is controlled with a PWM input

signal, generated by the CCONT. The PWM pulse width is controlled by

the MAD and sent to the CCONT through a serial data bus. The battery

voltage rise is limited by turning the CHAPS switch off when the battery

voltage has reached 4.1V (Li–Ion). Charging current is monitored by measuring the voltage drop across a 220mohm resistor.

Power Off

The baseband is powered down by:

1. Pressing the power key, that is monitored by the MAD, which

starts the power down procedure.

Page 2– 32

2. If the battery voltage is dropped below the operation limit, either by not charging it or by removing the battery.

3. Letting the CCONT watchdog expire, which switches off all

CCONT regulators and the phone is powered down.

The power down is controlled by the MAD. When the power key has

been pressed long enough or the battery voltage is dropped below the

Original 02/99

Page 33

PAMS

RAE–2

Technical Documentation

limit, the MCU initiates a power down procedure and disconnects the SIM

power. Then the MCU outputs a system reset signal and resets the DSP.

If there is no charger connected, the MCU writes a short delay to CCONT

watchdog and resets itself. After the set delay the CCONT watchdog expires, which activates the PURX and all regulators are switched off and

the phone is powered down by the CCONT.

If a charger is connected when the power key is pressed the phone enters into the acting dead mode.

Watchdog

The Watchdog block inside the CCONT contains a watchdog counter and

some additional logic which are used for controlling the power on and

power off procedures of CCONT. Watchdog output is disabled when

WDDisX pin is tied low. The WD-counter runs during that time, though.

Watchdog counter is reset internally to 32s at power up. Normally it is reset by the MAD writing a control word to the WDReg.

Baseband

Audio control

The audio control and processing is controlled by the COBBA–GJ ASIC,

which contains the audio and rf codecs, and the MAD2, which contains

the MCU, ASIC and DSP blocks handling and processing the audio signals. The RAE–2 audio block diagram is presented in the figure next

page.

SCOTTY

PWM

Earphone

FET

Switch

HF–speaker

amp

MIC

VCOBBA

Bias+

EMC

XEAR

HFCM

AuxOut

Emc + Acc.

Interface

MIC2

MIC1

MIC3

HF

Ear

Premult.

Preamp Multipl.

Amp

Multipl.

Micbias

HFena

HookDet

HeadDet

COBBA

MAD

MCU

LP

Pre

LP

DSP

encoding

decoding

VAD

echo cancel

equalization

A

Serial

IF

A

D

D

PCM BUS

The baseband supports three microphone inputs and two earphone outputs. The inputs can be taken from an internal microphone, a headset mi-

Original 02/99

XMIC

BS8BS1

BOTTOM CONNECTOR

SGND

CCONTEAD

Figure 20. RAE–2 audio block diagram

Page 2– 33

Page 34

RAE–2

PAMS

Baseband

Technical Documentation

crophone or from an external microphone signal source. The microphone

signals from different sources are connected to separate inputs at the

COBBA–GJ. Inputs for the microphone signals are differential type.

The MIC3 input is used for a headset microphone that can be connected

directly to the system connector. The internal microphone is connected to

the MIC2 input and an external pre–amplified microphone (handset/

handsfree) signal is connected to the MIC1 input. In the COBBA there

are also three audio signal outputs of which dual ended EAR lines are

used for internal earpiece and HF line for accessory audio output. The

third audio output AUXOUT is used only for bias supply to the headset

microphone.

When the lid is open the downlink audios can be routed to the internal HF

amplifier. This amplifier and the HF speaker are located on the PDA module. The MAD is able to enable the HF amplifier with an HFena–signal.

The internal microphone acts as a handsfree microphone during a HF

call. The microphone signal level is amplified more during an HF call than

a normal call.

PDA Tones

The PDA keyclicks and warning tones are played via the earphone.

There is an external paraller FET switch circuit with earphone located on

the PDA module. The PWM output of the PDA processor is connected to

this circuit and thus the PDA is able to play tones via the earphone.

CMT Alert Signal Generation

A HF speaker is used for giving alert tones and/or melodies as a signal of

an incoming call. The alert signals are routed to the XEAR line by the

DSP. Keypress and user function response beeps are generated with the

earphone.

External audio connections

The external audio connections are presented in the next figure. A headset can be connected directly to the system connector. The headset microphone bias is supplied from the COBBA AUXOUT output and fed to

the microphone through the XMIC line. The 330ohm resistor from the

SGND line to the AGND provides a return path for the bias current.

Page 2– 34

Original 02/99

Page 35

PAMS

RAE–2

Technical Documentation

Baseband

HookDet

MAD

HeadDet

CCONT

EAD

AUXOUT

Baseband

22k

22k

1u

100n

2.8 V

47k

2k2

2.8 V

47k

COBBA

HF

HFCM

MIC1N

MIC1P

MIC3N

MIC3P

10m

10m

33n

33n

33n

33n

47R

47R

1m

450ohm/

100M

XEAR

22p

450ohm/

100M

SGND

22p

330R

450ohm/

100M

XMIC

22p

Figure 21. Combined headset and system connector audio signals

Original 02/99

(Headset can be connected to system connector)

Page 2– 35

Page 36

RAE–2

PAMS

Baseband

Technical Documentation

Analog audio accessory detection

The XEAR signal line comprises a 47 kW pullup in the transceiver and 10

kW pulldown to SGND in the accessory. The XEAR is pulled down when

an accessory is connected, and pulled up when disconnected. The XEAR

is connected to the HookDet line (in MAD), an interrupt is given due to

both connection and disconnection. There is filtering between XEAR and

HookDet to prevent audio signal giving unwanted interrupts.

External accessory notices tha powered–up phone by detecting voltage in

XMIC line. The table below is a truth table for detection signals.

Table 12. Truth table for HookDet and HeadDet

Accessory connected HookDet HeadDet Notes

No accessory connected High High Pullups in the transceiver

Headset HDC–8 with a button switch pressed Low Low XEAR and XMIC loaded (dc)

Headset HDC–8 with a button switch released High Low *) XEAR unloaded (dc)

Handsfree (HFU–2) High High Detected via MBUS

*) HeadDet (MAD) cannot be used during a call, because of the 1.5V bias from

AUX OUT (COBBA)

Headset detection

The external headset device is connected to the system connector, from

which the signals are routed to the COBBA headset microphone inputs

and earphone outputs. In the XMIC line there is a (47 + 2.2) kW pull–up in

the transceiver. The microphone is a low resistancepull–down compared

to the transceiver pull–up.

When there is no call going, the AUXOUT is in high impedance state and

the XMIC is pulled up. When the headset is connected, the XMIC is

pulled down. The XMIC is connected to the HeadDet line (in MAD), an

interrupt is given due to both connection and disconnection. There is

filtering between the XMIC and the HeadDet to prevent audio signal giving unwanted interrupts (when an accessory is connected).

Headset switch detection

The XEAR line comprises a 47 kW pull–up in the transceiver. The earphone is a low resistance pull–down compared with the transceiver pull–

up. When a remote control switch is open, there is a capacitor in series

with the earphone, so the XEAR (and HookDet) is pulled up by the phone.

When the switch is closed, the XEAR (and HookDet) is pulled down via

the earphone. So both press and release of the button gives an interrupt.

Page 2– 36

During a call there is a bias voltage (1.5 V) in the AUXOUT, and the

HeadDet cannot be used. The headset interrupts should to be disabled

during a call and the EAD line (AD converter in CCONT) should be polled

to see if the headset is disconnected.

Original 02/99

Page 37

PAMS

RAE–2

Technical Documentation

Internal audio connections

The speech coding functions are performed by the DSP in the MAD2 and

the coded speech blocks are transferred to the COBBA–GJ for digital to

analog conversion, down link direction. In the up link direction the PCM

coded speech blocks are read from the COBBA–GJ by the DSP.

There are two separate interfaces between the MAD2 and COBBA–GJ: a

parallel bus and a serial bus.

The parallel bus features 12 data bits, 4 address bits, read and write

strobes and a data available strobe. The parallel interface is used to

transfer all the COBBA–GJ control information (both the RFI part and the

audio part) and the transmit and receive samples.

The serial interface between MAD2 and COBBA–GJ includes transmit

and receive data, clock and frame synchronization signals. It is used to

transfer the PCM samples. The frame synchronization frequency is 8 kHz

which indicates the rate of the PCM samples and the clock frequency is 1

MHz. The COBBA generates both clocks.

Baseband

4–wire PCM serial interface

The interface consists of the following signals:

a PCM codec master clock (PCMDClk),

a frame synchronization signal to DSP (PCMSClk),

a codec transmit data line (PCMTX) and

a codec receive data line (PCMRX).

The COBBA–GJ generates the PCMDClk clock, which is supplied to DSP

SIO. The COBBA–GJ also generates the PCMSClk signal to DSP by dividing the PCMDClk. The PCMDClk frequency is 1.000 MHz and is generated by dividing the RFIClk 13 MHz by 13. The COBBA–GJ further divides the PCMDClk by 125 to get a PCMSClk signal, 8.0 kHz.

PCMDClk

PCMSClk

PCMTxData

PCMRxData

Original 02/99

sign extended

15 14 13 12 011 10

sign extended

MSB

MSB

LSB

LSB

Page 2– 37

Page 38

RAE–2

PAMS

Baseband

Digital control

All the baseband functions are controlled by the MAD2 ASIC, which consists of a MCU, a system ASIC and a DSP. In addition to the internal

RAM/ROM memory, the MAD2 has an external RAM memory and external FLASH and EEPROM type of memories.

MAD2

MAD2 comprises the following building blocks:

– ARM RISC processor with both 16–bit instruction set (THUMB mode)

and 32–bit instruction set (ARM mode)

– TI Lead DSP core with peripherals:

Technical Documentation

– API (Arm Port Interface memory) for MCU–DSP commu-

nication, DSP code download, MCU interrupt handling vec-

tors (in DSP RAM) and DSP booting

– Serial port (connection to PCM)

– Timer

– DSP memory (80 kW RAM in PD version of MAD2)

– BUSC (BusController for controlling accesses from ARM to API, Sys-

tem Logic and MCU external memories, both 8– and 16–bit memories)

– System Logic

– CTSI (Clock, Timing, Sleep and Interrupt control)

– MCUIF (Interface to ARM via B

tROM

– DSPIF (Interface to DSP)

– MFI (Interface to COBBA AD/DA Converters)

– CODER (Block encoding/decoding and A51&A52 ciphering)

– AccIF(Accessory Interface)

– SCU (Synthesizer Control Unit for controlling 2 separate

synthesizer)

– UIF (Keyboard interface, serial control interface for COBBA

PCM Codec, LCD Driver and CCONT)

USC). Contains MCU Boo-

Page 2– 38

– SIMI (SimCard interface with enhanced features)

– PUP (Parallel IO, USART and PWM control unit for vibra

and buzzer)

The MAD2 operates from a 13 MHz system clock, which is generated

from the 13MHz VCXO frequency. The MAD2 supplies a 6,5MHz or a

Original 02/99

Page 39

PAMS

RAE–2

Technical Documentation

13MHz internal clock for the MCU and system logic blocks and a 13MHz

clock for the DSP, where it is multiplied to 45.5MHz DSP clock. The system clock can be stopped for a system sleep mode by disabling the

VCXO supply power from the CCONT regulator output. The CCONT provides a 32kHz sleep clock for internal use and to the MAD2, which is used

for the sleep mode timing. The sleep clock is active when there is a battery voltage available i.e. always when the battery is connected.

MAD2

MCU

ARM CORE

BUSC

M

YSTEMLOGIC

S

UIF

PUP

Baseband

ICE

JTAG

CRUSHER

TESTIF

JTAG

DSP RAM

DSP

DSP

PERIPHERALS

LEAD C

API

ORE

C

U

I

F

D

S

P

SIMIF

CTSI

MFI

CODER

I

Original 02/99

F

Figure 22. MAD2 ARCHITECTURE

ACCIF

SCU

Page 2– 39

Page 40

RAE–2

PAMS

Baseband

MAD2 memory configuration

MAD2 contains 12 kb RAM memory, 68 kb ROM memory. Memory is divided as follows

– Data: 10 kb DARAM 2 kb API RAM

– Program: 48 kb PROM

– Program/Data: 4 kb PDROM

PROGRAM

0000h

RESERVED (OVLY=1)

NOT USED (OVLY=0)

0080h

0800h

ON–CHIP RAM (OVLY=1)

NOT USED (OVLY=0)

NOT USED (OVLY=0)

API RAM (OVLY=1)

16 kb DROM

0000h

0060h

0080h

0800h

Technical Documentation

DATA

MEMORY MAPPED REGISTERS

SCRATCH–PAD RAM

N–CHIP RAM

O

O

N–CHIP API RAM

12 kW RAM

1000h

3000h

5000h

5800h

F000h

FFFFh

ON–CHIP RAM (OVLY=1)

NOT USED (OVLY=0)

B

ON–CHIP PROGRAM ROM

(MPNMC=0)

OUNDARIES

B

AINTERNAL DARAM TO EXTERNAL BOUNDARY

BEXTERNAL BOUNDARY TO INTERNAL PROM

CE

XTERNAL BOUNDARY TO INTERNAL PDROM

48 kW PROM 4 kW PDROM

B000h

FFFFh

1000h

3000h

F000h

N–CHIP RAM

O

N

OT USED

ON–CHIP DATA ROM

(DROM=1)

NOT USED (DROM=0)

NOTE! MPNMC IS TIED TO 0

A

C

16 kW DROM

Page 2– 40

Figure 23. MAD2 12/68 DSP MEMORY MAP

Original 02/99

Page 41

PAMS

RAE–2

Technical Documentation

Baseband

MCU Memory Map

The MAD2 supports a maximum of 4GB internal and 4MB external address space. The external memories use address lines MCUAd0 to

MCUAd21 and 8–bit/16–bit databus. The BUSC bus controller supports

8– and 16–bit access for byte, double byte, word and double word data.

Access wait states (0, 1 or 2) and used databus width can be selected

separately for each memory block.

Table 13. MCU Memory map

Memory block Chip select Start address Stop address Size Size

boot ROM (*) internal 0000 0000 0000 FFFF 64k 64k

API RAM internal 0001 0000 0001 FFFF 64k 64k

System logic internal 0002 0000 0002 FFFF 64k 64k

API ctl reg. internal 0003 0000 0003 FFFF 64k 64k

Bus Controller Internal 0004 0000 0007 FFFF 256k 256k

The same as

0–7FFFF

ext. RAM (*) RAMSelX 0010 0000 001F FFFF 1M 1M

ext. ROM1 ROM1SelX 0020 0000 005F FFFF 4M 4M

ext. ROM2 (*) ROM2SelX 0060 0000 009F FFFF 4M 4M

ext. EEPROM EEPROMSelX 00A0 0000 00DF FFFF 4M 4M

reserved 00E0 0000 00FF FFFF 4M 4M

The same as 0–FF

FFFF

0008 0000 000F FFFF 512 k 512 k

0100 0000 FFFF FFFF 4G – 16 M 4G – 16 M

(*) After reset and when BootROMDis and ROM2Boot are low.

MCU can boot from different memory locations, depending on hardware

(GenSDIO0) and software settings.

Table 14. MCU boot memory selection

Start

address

0000 0000 0000 FFFF boot ROM External RAM ext. ROM2 External RAM

Stop

address

BootROMDis=0

ROM2Boot=0

BootROMDis=1

ROM2Boot=0

BootROMDis=0

ROM2Boot=1

BootROMDis=1

ROM2Boot=1

Memories

The BusController (BUSC) section in the MAD decodes the chip select

signals for the external memory devices and the system logic. The BUSC

controls the internal and external bus drivers and multiplexers connected

to the MCU data bus. The MCU address space is divided into access

areas with separate chip select signals. The BUSC supports a programmable number of wait states for each memory range.

The minimum access time for all external memories is specified to 120ns.

Program Memory

The MCU program code resides in the program memory. The program

memory size is 8Mbits (512kx16bit) and package is uBGA48.

Original 02/99

Page 2– 41

Page 42

RAE–2

PAMS

Baseband

The flash memory has a power down pin that is kept low during the power

up phase of the flash to ensure that the device is powered up in the correct state, read only. The power down pin is utilized in the system sleep

mode by connecting the ExtSysResetX to the flash power down pin to

minimize the flash power consumption during the sleep.

SRAM Memory

The work memory is a static ram of size 2Mbits (256kx8bit) in a shrink

TSOP32 package. The work memory is supplied from the common baseband VBB voltage and the memory contents are lost when the baseband

voltage is switched off. All retainable data is stored into the EEPROM (or

flash) when the phone is powered down.

EEPROM Memory

An EEPROM is used for a nonvolatile data memory to store the tuning

parameters and phone setup information. The short code memory for

storing user defined information is also implemented in the EEPROM.

The EEPROM size is 8kbytes and the default package is SO8. The

memory is accessed through a serial bus including also write protection

signal for protecting EEPROM content against any malfunctions.

Technical Documentation

Page 2– 42

Original 02/99

Page 43

PAMS

RAE–2

Technical Documentation

Flash Programming

RAE–2 Flashing connections

the RAE–2 has two entities which can be programmed: PDA and CMT.

There are four different interfaces from outside to the RAE–2 which can

be used to transmit software code to the RAE–2. These interfaces are the

following:

– JTAG (PDA flashing only)

– MMC (PDA flashing only)

– FBUS/MBUS (PDA and/or CMT flashing)

Baseband

PDA_MBUS

IR

MMC

Flashing methods

During external CMT programming only the FBUS and MBUS is used for

transmitting software data. The data transmission is done in DCT3 way.

This means that the data is transmitted through the FBUS synchronously.

The clock signal is transmitted on the MBUS line. Since the FBUS does

not go directly to the CMT (as in DCT3 phone) the PDA has to be driven

to ReLink mode before the external CMT programming. In order to boot

the PDA to Relink mode Testmode connection has to established. This is

done inside the Service battery.

FBUS_RX

ReLink

FBUS_RX

Bottom connector

Figure 24. SPOCK’s flashing connections

FBUS_TX

Service battery

FBUS_TX

5

JTAG

DB_MBUS

BC_MBUS

CMTPDA

MBUS

The relink causes changes to the DCT3 type power–up procedure during

programming. This is because if the RAE–2’s VBAT is turned off and on,

the PDA will lose the Relink mode. In order to prevent this the CMT is

started by using IBI pulse.

Original 02/99

Page 2– 43

Page 44

RAE–2

PAMS

Baseband

In the DCT3 type the CMT programming bootstrap code is used for starting SW downloading. The bootstrap code resides in the small internal

ROM of the MAD. The bootstrap code is a small part of the download

code and is used only for downloading more code into the RAM.

Data on CMT Flash is divided on two parts:

The idea is that first the CMT SW code is programmed and after that the

PPM is programmed in same method. This allows the change of language without changing the software code.

Flashing procedure

The phone is connected to the flash loading adapter FLA–7 so that supply

voltage for the phone and data transmission lines can be supplied from/to

the FLA–7. When the FLA–7 triggers an IBI pulse to the phone, the program execution starts from the BOOT ROM and the MCU investigates in

the early start–up sequence if the flash prommer is connected. This is

done by checking the status of the MBUS–line. Normally this line is high

but when the flash prommer is connected the line is forced low by the

prommer.

Technical Documentation

– CMT SW code

– PPM

The flash prommer serial data receive line is in receive mode waiting for

an acknowledgement from the phone. The data transmit line from the

baseband to the prommer is initially high. When the baseband has recognized the flash prommer, the TX–line is pulled low. This acknowledgement is used to start to toggle MBUS (FCLK) line three times in order that

MAD2 gets initialized. This must be happened within 15 ms after TX line

is pulled low. After that the data transfer of the first two bytes from the

flash prommer to the baseband on the RX–line must be done within 1 ms.

When the MAD2 has received the secondary boot byte count information,

it forces TX line high. Now, the secondary boot code must be sent to the

phone within 10 ms per 16 bit word (If these timeout values are exceeded, the MCU (MAD2) starts normal code execution from flash). After this,

the timing between the phone and the flash prommer is handled with

dummy bytes.

A 5V programming voltage is supplied inside the transceiver from the battery voltage with a switch mode regulator (5V/30mA) of the CCONT.

Table 15. Flash programming timing characteristic

Characteristics Min Typ Max Unit

Time from boot indication to MAD2 initialization sequence 15 ms

Time from MAD2 initialization sequence to byte lenght information 1 ms

Time from byte length information to end of secondary boot code load-

ing.

10 per16 bit

word

ms

Page 2– 44

Original 02/99

Page 45

PAMS

RAE–2

Technical Documentation

Security

The phone flash program and IMEI code are software protected using an

external security device that is connected between the phone and a PC.

The security device uses the phone given IMEI number, the software version number and a 24bit hardware random serial number that is read

from the COBBA and calculates a flash authority identification number

that is stored into the phone EEPROM.

COBBA–GJ ASIC

The COBBA–GJ ASIC provides an interface between the baseband and

the RF–circuitry. The COBBA–GJ performs analogue to digital conversion of the received signal. For transmit path the COBBA_GJ performs

digital to analogue conversion of the transmit amplifier power control

ramp and the in–phase and quadrature signals. A slow speed digital to