Page 1

PAMS Technical Documentation

RAE–2 Series

Chapter 7

Troubleshooting

Original 02/99

Copyright 1999. Nokia Mobile Phones. All Rights Reserved.

Page 2

RAE–2

PAMS

Troubleshooting

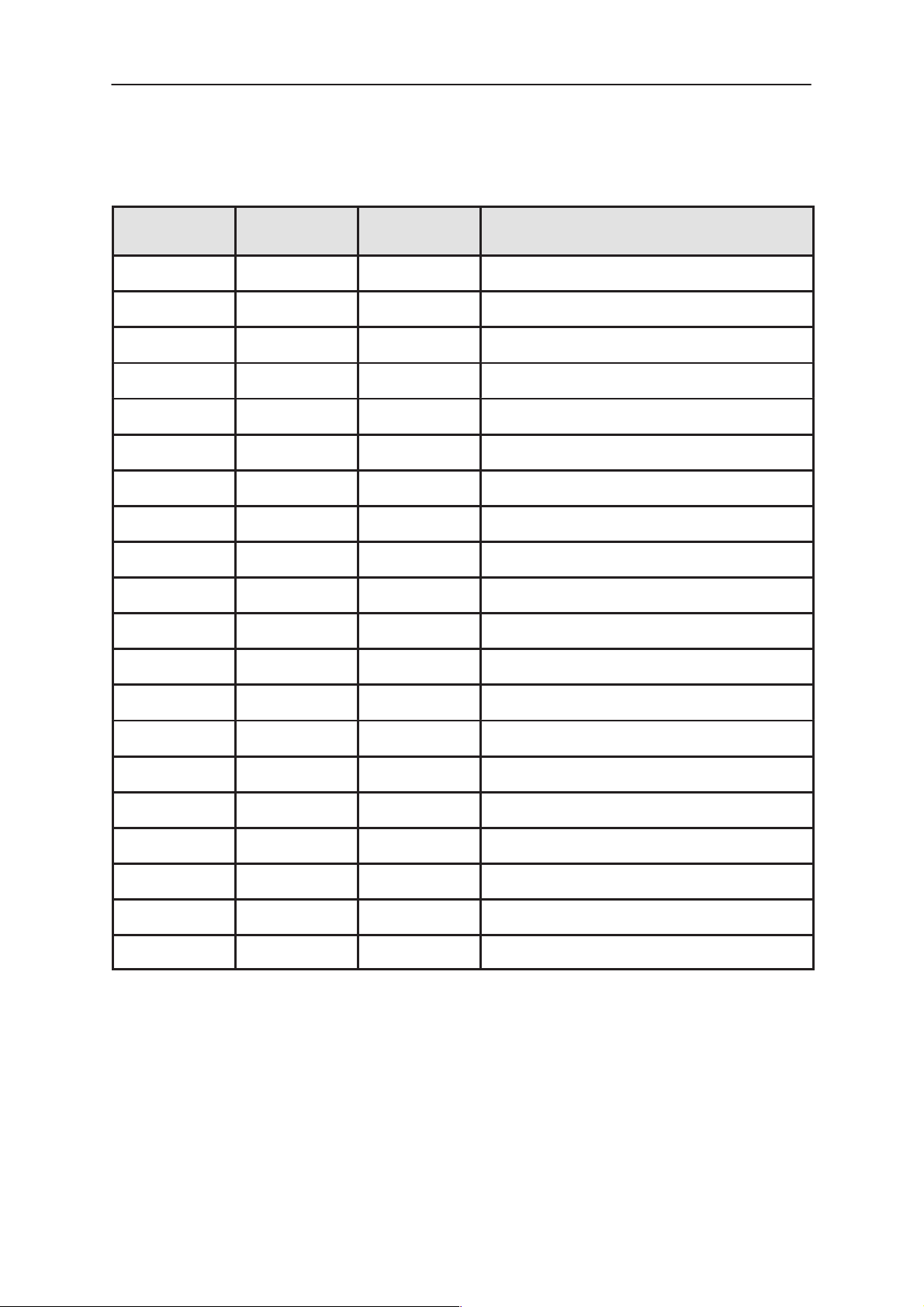

Amendment

Number

Date Inserted By Comments

02/99 Original

Technical Documentation

AMENDMENT RECORD SHEET

Page 7 – 2

Original 02/99

Page 3

PAMS

RAE–2

Technical Documentation

CONTENTS –Troubleshooting

Introduction 7 – 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 7 – 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current consumption 7 – 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Finding faulty module 7 – 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CMT Troubleshooting 7 – 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Baseband faults 7 – 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CMT is totally dead 7 – 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power doesn’t stay on or phone is jammed 7 – 9. . . . . . . . . . . .

Display Information: Contact Service 7 – 10. . . . . . . . . . . . . . . . . .

The phone doesn’t register to the network... 7 – 10. . . . . . . . . . .

SIM card is out of order 7 – 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Audio fault 7 – 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charging fault 7 – 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flash programming doesn’t work 7 – 17. . . . . . . . . . . . . . . . . . . . .

RF Fault 7 – 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Servicing Equipment: 7 – 21. . . . . . . . . . . . . . . . . . . . . .

Test Points on BS8 Module 7 – 21. . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter fault 7 – 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver fault 7 – 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AFC Fault 7 – 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1st IF 7 – 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2nd IF 7 – 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UHF LO 7 – 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VHF LO 7 – 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting

Page No

PDA Troubleshooting and Service 7 – 32. . . . . . . . . . . . . . . . . . . . . . . . .

Required Servicing Equipment: 7 – 32. . . . . . . . . . . . . . . . . . . . . . . . .

Block Diagram 7 – 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BS1 PDA Components 7 – 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BS1 Troubleshooting 7 – 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power–on malfunction 7 – 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Circuitry Check 7 – 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Diagram of the PLL clock 7 – 40. . . . . . . . . . . .

Troubleshooting Diagram of the LCD 7 – 44. . . . . . . . . . . . . . . . .

Troubleshooting Diagram of the PDA LCD Backlight 7 – 45. . . .

Troubleshooting Diagram of the PDA Keyboard 7 – 46. . . . . . . .

Troubleshooting Diagram of the serial connections 7 – 47. . . . .

Troubleshooting Diagram of the IR connection 7 – 49. . . . . . . . .

Troubleshooting Diagram of the lid switch 7 – 50. . . . . . . . . . . . .

Troubleshooting Diagram of the HF Speaker 7 – 51. . . . . . . . . . .

Troubleshooting Diagram of the Earphone 7 – 52. . . . . . . . . . . . .

Original 02/99

Page 7 – 3

Page 4

RAE–2

PAMS

Troubleshooting

Troubleshooting Diagram of the Memory Card interface 7 – 53.

POST BEEP Codes 7 – 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UI Troubleshooting 7 – 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Troubleshooting 7 – 55. . . . . . . . . . . . . . . . . . . . . . . . . . .

Keyboard Troubleshooting 7 – 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CMT LCD Module Troubleshooting 7 – 56. . . . . . . . . . . . . . . . . . . . .

PDA LCD Display Troubleshooting 7 – 59. . . . . . . . . . . . . . . . . . . . . .

CMT Backlighting Circuit Troubleshooting 7 – 63. . . . . . . . . . . . . . . .

PDA LCD Backlighting Circuit Troubleshooting 7 – 64. . . . . . . . . . .

Technical Documentation

Page 7 – 4

Original 02/99

Page 5

PAMS

RAE–2

Technical Documentation

Introduction

This document is intend to be a guide for localizing and repairing electrical faults in RAE–2 device. First there is short guide for fault localizing.

Then fault repairing is divided into three troubleshooting paths, each per

any module. Needed equipments are present before any actions.

Before any service operation you must be familiar with RAE–2 product

and module level architecture. You must also be familiar with RAE–2

specified service tools like the WinTesla service software, Flashing tools

and softwares. Basic skills of using RF measurement devices are required when you are starting to follow RF troubleshooting paths.

General

When you have a faulty RAE–2 device and you are starting troubleshooting it, check first the following basics.

Troubleshooting

–

Device hasn’t any mechanical damage.

– Device, especially connectors, are not dirty or moist.

– Screws are tightened as specificed.

– Battery voltage is high enough (nominal battery voltage is 3.6V).

– Current consumption is in normal area (this can be checked with Service Battery

BBS–5, if ReLink mode is disabled).

Current consumption

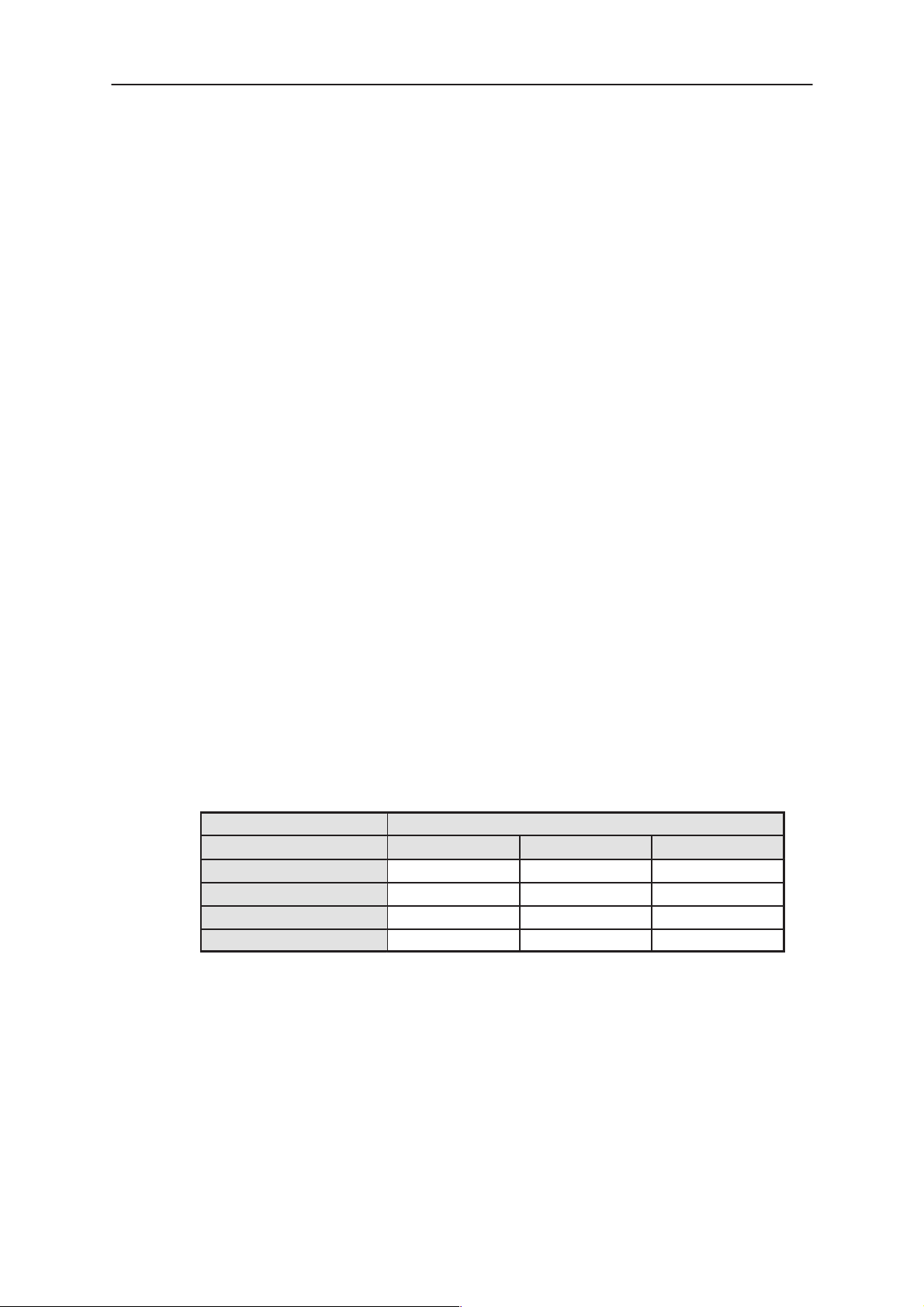

PDA mode (PDA current) Off (< 1.0mA) Idle (3–40mA) Call (140–320mA)

Active (200–380mA) 200–380mA 203–420mA 340mA–700mA

Standby (35–65mA) 35–45mA 38–85mA 175–365mA

Suspended (2–4mA) 2–3mA 5–43mA 142–323mA

Reset <1.0mA 3–40mA 140–320mA

Note1: CMT peak current consumption might be 5x more than is specified above.

Finding faulty module

CMT mode (CMT current)

Then you define the faulty module. Normally this isn’t difficult because

the RAE–2 device has three quite independent modules; CMT, PDA and

UI.

If you can’t conclude which is the faulty module, try to program new software to the RAE–2. Usually when a module has a real fault also its programming fails. If programming succeeds, it means that the CMT and

Original 02/99

Page 7 – 5

Page 6

RAE–2

PAMS

Troubleshooting

PDA modules basically work and the fault might be in UI module or flex

connectors between PDA and UI module. Before CMT programming

check that PDA goes to the ReLink mode (use BBS–5 service battery).

After that you can replace the faulty module with the reference (Golden

Sample) module and be sure that module is really faulty. Alternatively

you can change the suspected faulty module to the reference RAE–2 device. After this cross–checking you should have found certainty about the

faulty module(s) and you can start to study module level problems.

Technical Documentation

Page 7 – 6

Original 02/99

Page 7

PAMS

RAE–2

Technical Documentation

CMT Troubleshooting

The following hints should facility finding the cause of the problem when

the CMT circuitry seems to be faulty. This troubleshooting instruction is

divided in main level to BaseBand and RF faults.

The first thing to do is carry out a through visual check of the module. Ensure in particular that there are not any mechanical damages and soldered joints are OK. If the CMT module is able to communicate with WinTesla software, you can use it to find out faulty circuits from CMT module.

Selftest checks all CMT baseband Asics and memory components and

reports the result as passed or failed. If every test is passed, you can

perform different kind of calibration and tuning operations and deduce

which is the faulty circuit.

Baseband faults

At least the following measurement devices are needed for fault debugging in BaseBand section:

Troubleshooting

– PC for the Wintesla with software protection key (dongle)

– RS–232 cable (DAU –9C)

– Repairing jig MJS–4

– Flashing Tools FLA–7, FPS–4 and TDF–4

– Service Battery BBS–5

– Calibration Unit JBE–1

– power supply, digital multimeter and oscilloscope

Original 02/99

Page 7 – 7

Page 8

RAE–2

PAMS

Troubleshooting

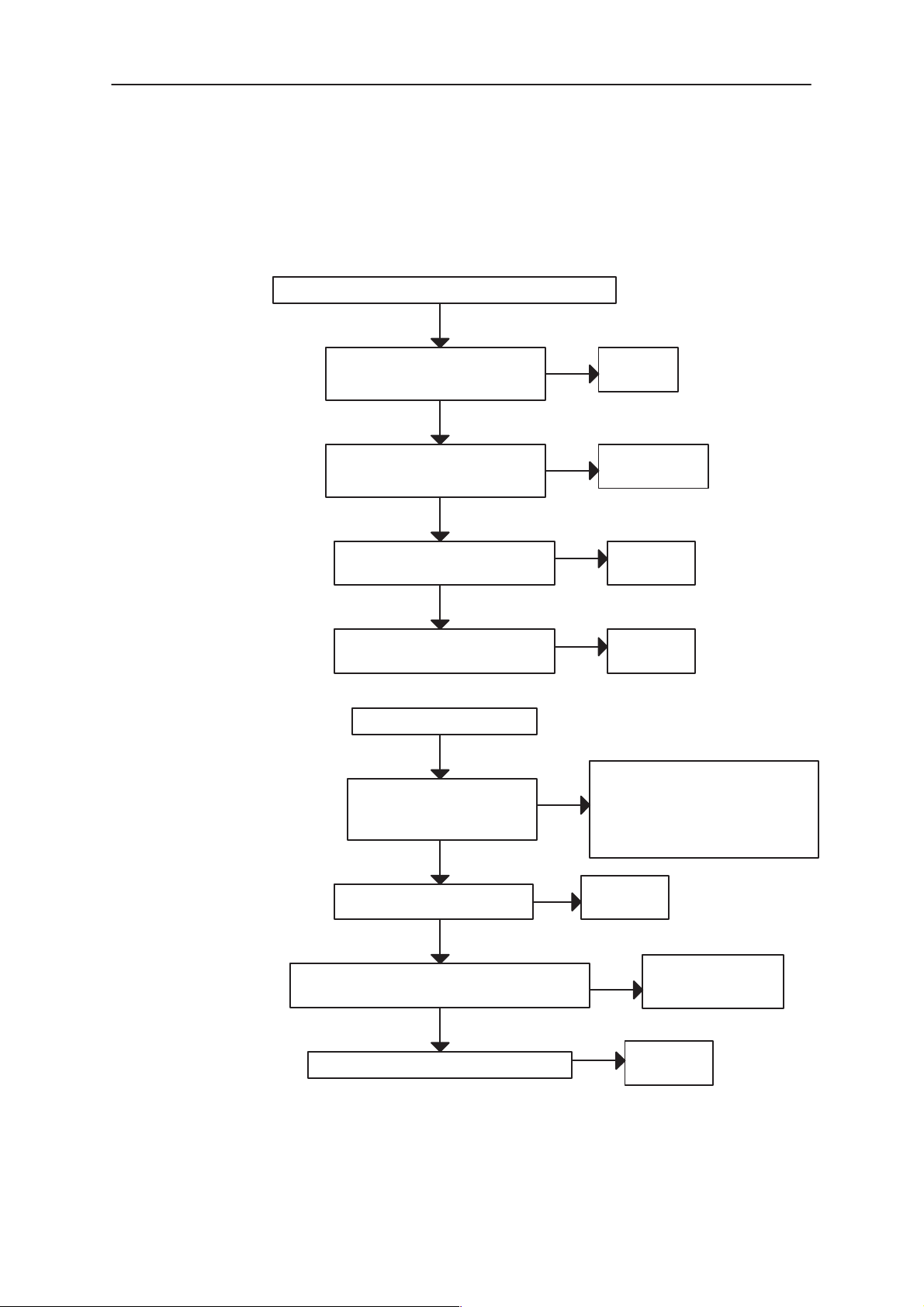

CMT is totally dead

Phone is totally dead

YES

J111

VBAT is 3.6 V

YES

J113 (PWRONx) 3.6 V

NO

Failure in VBAT line

Check X160,L103

Check shortcircuits

NO

Technical Documentation

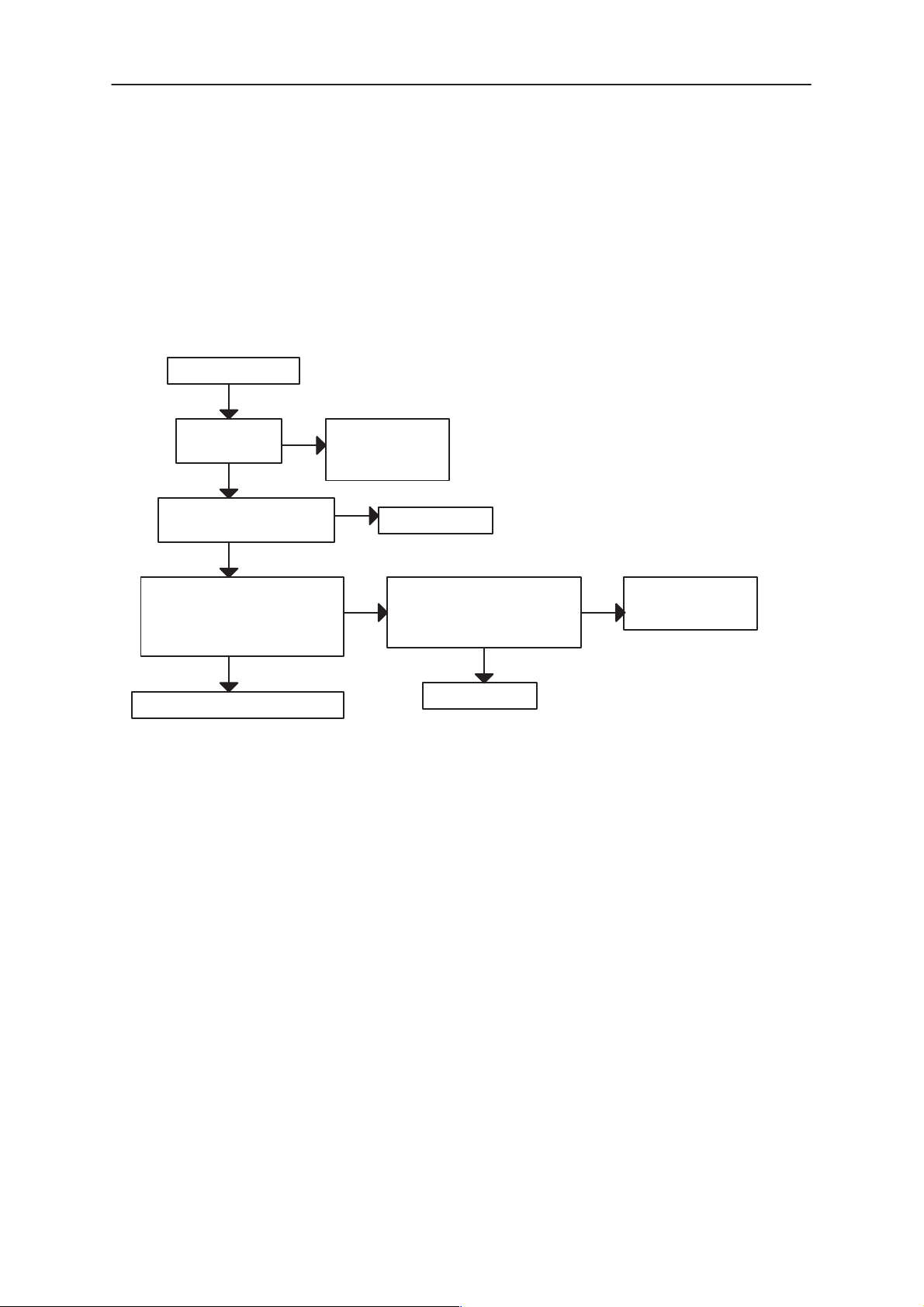

This means that CMT doesn’t take current at all when

the power switch is pressed or when the Watchdog

Disable signal (J113) is rounded. Used battery voltage must be at least the nominal, 3.6 V.

Faulty circuit N110

YES

J109 (VBB) 2.8 V

N110 pin 25 (VXO) 2.8 V

when PWR switch is pressed

or watchdog disable pin is grounded

YES

See section: Power Doesn’t Stay On

Figure 1. Trouble Shooting Diagram for Phone is totally dead failure

PWRONX level (J113) low when

NO

PWR switch is pressed or

watchdog disable pin is (J100)

grounded

Faulty circuit N110

YES

Check V195, R195

NO

Check UI module

Page 7 – 8

Original 02/99

Page 9

PAMS

RAE–2

Technical Documentation

Power doesn’t stay on or phone is jammed

Normally the power will be switched off by CCONT (N110) after 30 seconds, if the watchdog of the CCONT can not be served by software. The

watchdog updating can be seen by oscilloscope at pin 50 (DataselX) of

CCONT. In normal case there is a short pulse from ”1” –> 0 every 8 seconds.

The power off function of CCONT can be prevented by connecting a short

circuit wire from CCONT pin 29 (or J113) to ground.

Power doesn’t stay on or phone is jammed

YES

CCONT watchdog is served?

(pin 50 pulses 1 –> 0)

NO

YES

Troubleshooting

software is able to run

check UI module

If power is switched off

after few seconds, check

BSI and BTEM lines

connect the shortcircuit wire from J113 to ground (watchdog)

OK

check C213, R213

YES

J706 (RFC) 13 MHz

800 mV min

NO

check buffer V702 and

VCXO G690

J109 (VBB) 2.8V

J704 (VXO) 2.8V

YES

J240 master reset (Purx) =”1” (2.8V)

YES

NO

J219: 13MHz sine wave

clock signal: 500 mVpp min.

YES

Open pins or faulty circuit:

D200, D210, D221, N110

NO

VBAT is correct

3.6 V

NO J241 sleep clock (SLCK)

square wave 32 kHz

Faulty circuit N110

or over loaded PURX line

YES

YES

N110 is faulty

N110 is faulty

YES

NO

32 kHz in J100?

check PDA 32kHz

circuit and its

connections to

Figure 2. Trouble Shooting Diagram for Power Doesn’t Stay On or phone is jammed failures

NO

CMT

Original 02/99

Page 7 – 9

Page 10

RAE–2

PAMS

Troubleshooting

Technical Documentation

Display Information: Contact Service

This fault means that software is able to run and thus the watchdog of

CCONT (N110) can be served. Selftest functions are run when power is

switched on and the software is started to execute from flash. If any of the

self–tests fails, Contact Service text will be shown on the display. Find

out which circuit is faulty using the WinTesla software (select from Testing

menu item Self Tests... and WinTesla shows which circuit are not passed

selftests).

The phone doesn’t register to the network or phone doesn’t make a call

If the phone does not register to the network or the phone does not make

a call, the reason could be either the baseband or the RF part. The phone

can be set to wanted mode by WinTesla service software and determinate

if the fault is in RF or in baseband part (RF interface measurements).

The control lines for RF part are supplied both the System Asic (MAD2;

D200) and the RFI (Cobba; N250). MAD2 handles the digital control lines

(like synthe, TxP etc.) and Cobba handles the analog control lines (like

AFC, TxC etc.).

The DSP software is constructed so that the operation states of DSP

(MAD2) can be seen in external flag (DSPXF) output pin (J222). After

power up, the DSP signals all completed functions by changing the state

of the XF pin.

1. DSP initialization done

2.Synchronization to network

done

3. Registrarition to network

done.

1 2 3

Page 7 – 10

MAD2 (DSPXF)

J222

Original 02/99

Page 11

PAMS

RAE–2

Technical Documentation

init

initialize

1

patch code

download

2

dsp

constants

download

initialization

done

Troubleshooting

MAD2 (DSPXF)

J222

channel

scan starts

PSW

search last PSW

OK

3

send RACH

RACH OK

go SDCCH

imediate assigment

OK

synchronization

OK

MAD2 (DSPXF)

J222

MAD2 (DSPXF)

J222

Original 02/99

Figure 3. The states of DSP after power on

Page 7 – 11

Page 12

RAE–2

PAMS

Troubleshooting

Phone doesn’t register to the network

or

phone doesn’t make a call

YES

Analog supply voltage VCOBBA is >2.7 V)

at testpad J110

YES

Analog reference voltage Vref is 1.5 V

at J107

YES

Supply voltage VCP (N110 pin 32) > 4.8 V

Supply voltage VRX (N110 pin 9) > 2.7 V

Supply voltage VSYN_1 (N1 10 pin 15) > 2.7 V

Supply voltage VSYN_2 (N1 10 pin 4) > 2.7 V

during the receiving slot

Supply voltage VTX (N110 pins 11, 20) > 2.7 V

during the transmitting slot

NO

Check VCOBBA line

and N110 (CCONT)

NO

Check

R251

NO

Technical Documentation

Fault in N110 (CCONT)

or D200 (MAD2)

YES

Synthesizer lines: SEna (N690 pin 7),

SClk (N690 pin 5)

SData (N690 pin 6)

pulses 0 –> 1 during receiving slot

YES

NO

Fault in

D200 (MAD2)

RF control lines: RxC (N690 pin 36) 0 –> 2.3 Vmax during receiving slot

AFC (R547) 0 – 1.2 V typ. during receiving slot

YES

Analog data signal RxIP (N690 pin 24) 0–> 1.5 V DC during receiving slot

Analog data signal RxIN (N690 pin 23) 0–> 1.5 V DC during receiving slot

Used benefit signal is biased to DC and its amplitude is 50 mVpp

nominal and frequency is 13 MHz

YES

NO

DAX signal (J254) pulses 1 –> 0 during receiving slot

YES

RF control lines: TxC (N690 pin 34) 0 –> 2.3 Vmax during transmit slot

TxP (N690 pin 32) 0–>1 (2.8 V) during transmit slot

YES

NO

Fault in

N250 (COBBA)

NO

Fault in

N250 if DC is failed

Check

RF part if benefit signal is failed

Fault in

N250 (COBBA)

Fault in

NO

N250 if TxC is failed

Check

D200 if TxP is failed

Page 7 – 12

Analog data signals: TxIN (N690 pin 3) 0–> 0.8 V DC during transmit slot

TxIP (N690 pin 4) 0 –>0.8 V DC during transmit slot

TxQN (N690 pin 1) 0 –>0.8 V DC during transmit slot

TxQP (N690 pin 2) 0 –>0.8 V DC during transmit slot

Used benefit signal is biased to DC and its amplitude is 300 mVpp

nominal and frequency is 64 kHz

Figure 4. The phone doesn’t register or doesn’t make a call

NO

N250 (COBBA)

YES

Check

RF part

Original 02/99

Fault in

Page 13

PAMS

RAE–2

Technical Documentation

SIM card is out of order

The hardware of the SIM interface from the MAD2 (D200) to the SIM connector (X150) can be tested without SIM card. When the power is

switched on and if the BSI line (X160;2) is grounded by resistor, all the

used lines (VSIM, RST, CLK, DATA) rise up to 5 V four times. Thus ”In-

sert SIM card” faults can be found without SIM card. The fault information ”Card rejected” means that the ATR message (the first message is

always sent from card to phone) is sent from card to phone but the message is somehow corrupted, data signal levels are wrong etc. or factory

set values (stored to the EEPROM) are not correct.

Card Rejected fault

YES

VSIM is according the specification

VSIM = 2.8 V min (with 3 V SIM card)

VSIM = 4.5 V min (with 5 V SIM card)

NO

N110 (CCONT)

Troubleshooting

faulty circuit

YES

The ATR data can be seen at pin 43

(CCONT, N110)

YES

The ATR data can be seen

at pin 44 (CCONT, N110)

YES

SIMIOControl line (N110 pin 39)

is ”1”during the ATR message

YES

Check D200

NO

Fault in

NO

N110 (CCONT)

NO

Fault in

D200 (MAD2)

Check X302, R124,

X150 and shorcircuit

in V140, R141

Insert SIM card fault

YES

Voltage level < 1.5 V

at pin 2 of D100 when

BSI resistor is connected

YES

VSIM, DATA, RESET and CLOCK lines

rises up to 5 V after power on at pins

of SIM card

NO

VSIM(36), DATAO(43),SIMRSTO(42) and SIMCLKO(38) lines

rises up to 5 V after power on at pins of N110 (CCONT)

NO

SIMPWR(30), DATAA(44), SIMRSTA(40), SIMCLK(41) and

SIMIOC(39) lines rises up to 2.8V after power on pins of N110

NO

NO

Check

R120, R122, X160

YES

Check

SIM card and SIM

reader connectors

YES

Check X105,

R124, R125,

R128, V140,

R141

YES

faulty circuit

N110 (CCONT)

Original 02/99

Check again that voltage level at pin 2 (SIMCardDetX) of D110 is lower than 1.5V

If it is, change D200

Figure 5. Troubleshooting for SIM card faults

Page 7 – 13

Page 14

RAE–2

PAMS

Troubleshooting

Audio fault

Troubleshooting tree for Audio fault:

Uplink (microphone) and downlink (earphone) are broken

Voltage at resistor R260 is 2.8 V

(without external audio devices)

HOOKDET

Voltage at resistor R261 is 2.8 V

(without external audio devices)

HEADDET

Frequency at J256 is 1 MHz, square

wave 2.8 Vpp

YES

YES

YES

Technical Documentation

NO

Check

R259, R260

NO

NO

Check

R257, R256, R261

Fault in

N250 (Cobba)

YES

Frequency at J257 is 8 kHz, square

wave 2.8 Vpp

Uplink (microphone) is broken

YES

Voltage at pin 1 of V271 is 1.8 V

Voltage at pin 3 of V271 is 0.3 V

during a call

YES

DC voltage at capacitors C273 and

C274 is 1.4 V during a call

YES

Analog audio signal (few millivolts) at capacitors C273

and C274 during a call

YES

Digital PCM data at J255 during a call

NO

NO

NO Fault in

Fault in

N250 (Cobba)

Check microphone, mic connections to

PCB and micbias components V250...

If OK, check that micbias control line

is (V270 base) 2.8 V during a call.

If no there is fault in D200 (MAD)

N250 (Cobba)

NO

NO

Check

C273, C274 and PCB

routings

Fault in

N250 (Cobba)

Page 7 – 14

Figure 6. Trouble Shooting Diagram for Audio Failure

Original 02/99

Page 15

PAMS

RAE–2

Technical Documentation

Digital PCM data at J258 during a call

DC voltage at capacitors C252

and C256 is 1.4 V during a call

Analog audio signal (some ten millivolts) at C252 and

C256 during a call

Check earpeace connections to PDA module and

earpiece signal routing from CMT to PDA.

Downlink (earphone) is broken

YES

YES

YES

YES

NO

NO

N250 (Cobba)

Fault in

D200 (MAD2)

Fault in

NO

Troubleshooting

Fault in

N250 (Cobba)

Figure 7. Trouble Shooting Diagram for Audio Failure

Original 02/99

Page 7 – 15

Page 16

RAE–2

PAMS

Troubleshooting

Charging fault

When you are charging totally empty battery, remember that start–up

charging might take 2 minutes with ACP–9 charger and several minutes

with ACP–7 charger. During this time display is blank.

If charger is not

NMP approved type

then the software

doesn’t start charging.

Remove and reconnect battery and

charger few times

before you start to

measure module.

This check ensure if

module fault really

exist.

Display Information: Not charging

YES

Technical Documentation

Nothing happens when charger is connected

YES

Voltage level at pin 60 of CCONT (N110)

is higher than 0.4 V when charger is connected

YES

Check with WinTesla software if SW has

detected charger and measured charger

current and voltage properly.

YES

Perform Energy Management

Calibration with WinTesla software and JBE–1 set and recheck

charger detection. If still fails

(CHAPS or CCONT) is broken.

NO

NO

Check

X170, F170

L170 and R170

Fault in N110

(CCONT)

Voltage level at pin 62 of CCONT (N110)

is about 0.45 V when power is connected.

BSI resistor value should be 33 k

YES

Voltage level at pin 63 of CCONT (N110)

is about 0.5 V when power is connected

BTEMP resistor value should be 47 k

YES

Check with WinTesla software if SW is

detected approved charger and measured

charger current and voltage properly.

YES

32 Hz square wave frequency at pin 7 of CHAPS (N120)

YES

Voltage levels at pins 5 and 12 of CHAPS (N120)

are same as VB

YES

Voltage levels at pins 5 and 12 of CHAPS (N120)

rises when charger is connected

NO

NO Check

NO

Check

X160, R121, R122,

D100, R123 and

VSYS = 2.8V

X160, R121, R122

Perform Energy Management

Calibration with WinTesla software and JBE–1 set and recheck charger detection, charger voltage and current. OK?

YES

NO

NO

NO

Charging?

Check

R131, N120

(CHAPS)

Fault in

N120 (CHAPS)

NO

Fault in N110

(CCONT) or

SW corrupted

Fault in

N110 (CCONT)

Page 7 – 16

Figure 8. Trouble Shooting Diagram for Charging Failure

Original 02/99

Page 17

PAMS

RAE–2

Technical Documentation

Flash programming doesn’t work

The flash programming is done over the system connector X170.

In flash programming error cases the flash prommer can give some in-

formation about a fault. The fault information messages could be:

– MCU doesn’t boot

– Serial clock line failure

– Serial data line failure

– External RAM fault

– Algorithm file or alias ID don’t find

– MCU flash Vpp error

In cases that the flash programming doesn’t succeed there is a possibility

to check short circuits between the memories and the MCU (MAD2).This

test is useful to do, when the fault information is:

MCU doesn’t boot,

Serial clock line failure or

Serial data line failure.

Troubleshooting

The test procedure is following:

1. Connect the short circuit wire between the test points J229 and ground.

2. Switch power on

3. If the voltage level in testpoint J203 is 2.8 V (”1”), the interface is OK. If

there is a short circuit, the voltage level in testpoint J203 stays low and

32kHz square wave signal can be seen in the lines which are already tested.

One must be noticed that this test can be found only short circuits, not

open pins. Also upper data lines (15:8) of flash circuit D210 are not included to this test.

Original 02/99

Page 7 – 17

Page 18

RAE–2

PAMS

Troubleshooting

passed

Technical Documentation

CCONT pin 54

J240

MAD pin N3

SRAM pin 20

MAD pin B15

J203

(PURX)

(MCUAD0)

(FlashRP)selftest

Figure 9. MAD selftest indication after power on (passed)

Page 7 – 18

Original 02/99

Page 19

PAMS

RAE–2

Technical Documentation

Flash programming doesn’t work

If the fault information from the prommer is:

Note:

When

Relink

OK,

PDA display

shows text

”Relink enabled”.

connect the short circuit wire J113 (WDOG) to ground

EEPROM (D240) pin 8 (VBB) 2.8 V

YES

a) MCU doesn’t boot

b) serial data line failure

c) serial clock line failure

Check ReLink

OK

OK

J704 (VXO) 2.8 V

YES

NOT OK

NO

PDA fault

VBAT is correct

3.6 V

Troubleshooting

YES

N110 is faulty

check C213, R213, V702 ...

YES

J706 (RFC) 13 MHz

800 mV min

NO

check

VCXO G690

NO J100 sleep clock (clk32k)

J240 master reset (PURX) = ’1’ (2.8 V)

YES

NO

check also pullup and pulldown resistors: R216, R215, R201

Enable the selftest function of D200 by connecting

shortcircuit between testpoints J229 and ground

Connect an oscilloscope to testpoint J203 and switch

Voltage level rises to ”1” after power on at testpoint J203

J219: 13 MHz sine wave

clock signal: 500 mVpp min.

YES

Check that following lines are correct:

FCLK (MBUS) line: X170 pin 7 –> J208

FTX (fbus_tx) line: X190 pin 38 –> J207

FRX (fbus_rx) line: X190 pin 37 –> J206

and series resistors R240

GND : X170 pin 1 –> GND

OK

power on

YES

or overloaded PurX line

square wave 32 kHz

YES

Faulty circuit N110

NO

There is a shortcircuit

somewhere in memory control

lines or MCU address lines or

MCU lower (7:0) data lines

NO

pin 14 –> J100

Check 32kHz

clock line

X173 pin 9

or

C190 pin 14

There could be open pins in circuits D200 (D210, D230)

If not, the PCB or D200 (D210, D230) is faulty

Figure 10. Trouble Shooting Diagram for flash programming doesn’t work (via system connector X170)

Original 02/99

Page 7 – 19

Page 20

RAE–2

PAMS

Troubleshooting

Flash programming doesn’t work

YES

If the fault information from the prommer is:

External RAM fault

YES

Check pins of SRAM (D220)

Check control lines of SRAM:

RAMSelX ...

Flash programming doesn’t work

YES

Technical Documentation

If the fault information from the prommer is:

Algorithm file or alias ID don’t find, ID is unknown etc.

Faulty component D210 or faulty lines

Flash programming doesn’t work

YES

If the fault information from the prommer is:

MCU flash Vpp error

YES

Vpp > 4.5 V in C212

YES

Check components C212, R211

OK

NO

YES

Vpp > 4.5 V in C131

NO

Check C131, C132, V116, N110...

YES

Check regulator N201

Faulty component D210

Figure 11. Trouble shooting Diagram for Flash programming doesn’t work (via system connector X170)

Page 7 – 20

Original 02/99

Page 21

PAMS

RAE–2

Technical Documentation

RF Fault

Here is a block diagram for repairing the RF section. First select the fault

and follow the diagram.

Required Servicing Equipment:

– PC for the Wintesla

– Power supply

– Digital multimeter

– Oscilloscope

– Spectrum analyzer

– GSM MS test set

– Signal generator

– RF probe

– Phone test jig

Test Points on BS8 Module

Troubleshooting

Test points are placed on baseband for service and production trouble

shooting purposes in some supply voltage and signal lines.

Because some of baseband signal are routed totally inner layers (due to

uBGA packages) some testpoints are added for these signals.

Original 02/99

Page 7 – 21

Page 22

RAE–2

PAMS

Troubleshooting

MCUGenIO15

McuGenIO1

DSPXF

RFClk

D220

MCUGenIO12

MCUGenIO13

MCUGenIO14

MCUGenIO11

MCUGenIO10

MCUGenIO09

MCUGenIO8

D210

ExtSysRSTX

MCUAD19

Technical Documentation

Flash Chip Select

MCUAD18

Flash Write Protection

N120

AccTXData

D200

AccRxData

McuGenIO4

PCMRxData

TestMode

PCMTxData

PCMDCLK

PCMSLCK

COBBADAX

COBBACKL

RFIWrX

COBBAAd0

RFIRdX

ROW5LCDCD

COBBADa0

ResetX

MBUS

DSPGenOut1

VCORE

CCONTINT

PURX

GENSCLK

VBB

SLCLK

32kHz

V5V

GENSIO

N110

VCXOPwr

D250

VREF

The figure above describes and the next table lists the test points.

VB

PWRONx

VCOBBA

Page 7 – 22

Original 02/99

Page 23

PAMS

RAE–2

Technical Documentation

Test Point Name Description

J100 32kHz 32kHz clock from BS1 module

J103 CCONTINT CCONT interrupt output

J105 GENSCLK Serial data clock

J106 GENSIO Serial data

J107 VREF Reference voltage

J108 V5V Supply voltage for flash programming (Vpp) and RF circuits.

J109 VBB Supply voltage for digital circuits

J110 VCOBBA Supply voltage for analog circuits

J111 VB Battery voltage

J112 VCORE Supply voltage for MAD c07 core

J113 PWRONx CCONT’s PWRONx / Watchdog disable signal

J203 ExtSysRSTX Testpoint for fault diagnostic. If missing, check power supply , PurX line and 13 MHz clock

signal.

J204 VCXOPwr Control line for VCXO module. If low, 13 MHz clock signal for baseband is disable.

J206 AccRxData FBUS RX

J207 AccTxData FBUS TX

J208 MBUS Serial data bus max 9600b/s. Flash programming clock

J209 McuGenio4 General purpose out in MAD

J211–J218 MCUGenIO(8:15) Test point for fault diagnostic. MCUDA(15:8)

J219 RFClk 13 Mhz System clock

J220 TestMode MAD test mode select input

J221 DSPGenOut1 General purpose DSP out

J222 DSPXF Test point for fault diagnostic.

J223–J224 MCUAD(18:19) Memory address signals

J225 Flash Chip Sel Flash chip select pin

J226 Flash Write Prot Flash write protection pin

J229 ROW5LCDCD Selftest pin. If shortcircuit is made between testpoint J229 and J230, the selftest will be

executed.

J232 COBBAAd0

J233 COBBADa0

J240 PurX Reset line from CCONT to MAD. If low, the BB circuits are in reset state.

J241 SLCLK 32 kHz clock from CCONT to MAD

J243 McuGenio1 General purpose input in MAD

J250 RFIRdX COBBA paraller interface read strobe

J251 RFIWrX COBBA paraller interface write strobe

J252 ResetX COBBA master reset

J253 COBBACLK COBBA 13Mhz clock

J254 COBBADAX COBBA paraller interface data available strobe

J255 PCMTxData COBBA PCM bus transmit data

J256 PCMDCLK COBBA bus data transfer clock

J257 PCMSCLK COBBA bus 8kHz frame sync

J258 PCMRxData COBBA PCM bus receive data

Troubleshooting

Original 02/99

Page 7 – 23

Page 24

RAE–2

PAMS

Troubleshooting

Transmitter fault

Troubleshooting tree for Transmitter fault:

Technical Documentation

Ref1

ref4

ref5

ref2

ref3

Page 7 – 24

Figure 12. Transmitter fault TX level 5

Original 02/99

Page 25

PAMS

RAE–2

Technical Documentation

Troubleshooting

ref6

ref7

ref8

ref9

ref10

ref11

ref12

Figure 13. Transmitter 1 TX level 5

Original 02/99

Page 7 – 25

Page 26

RAE–2

PAMS

Troubleshooting

Receiver fault

Troubleshooting tree for Receiver fault:

Technical Documentation

Page 7 – 26

Original 02/99

Page 27

PAMS

RAE–2

Technical Documentation

AFC Fault

Troubleshooting tree for AFC fault:

Troubleshooting

Original 02/99

Figure 14. AFC

Page 7 – 27

Page 28

RAE–2

PAMS

Troubleshooting

1st IF

Troubleshooting tree for First IF fault:

ref19

ref21

Technical Documentation

ref20

N690

ref22

ref23

ref24

Page 7 – 28

Figure 15. 1st IF 71MHz

Original 02/99

Page 29

PAMS

RAE–2

Technical Documentation

2nd IF

Troubleshooting tree for Second IF fault:

ref25

ref26

Troubleshooting

ref27

ref28

ref31

ref29

ref30

900X910

Original 02/99

Figure 16. 2nd IF 13MHz

Page 7 – 29

Page 30

RAE–2

PAMS

Troubleshooting

UHF LO

Troubleshooting tree for UHF LO fault:

Technical Documentation

Page 7 – 30

Figure 17. UHF LO

Original 02/99

Page 31

PAMS

RAE–2

Technical Documentation

VHF LO

Troubleshooting tree for VHF LO fault:

Troubleshooting

2.5V

1.2V

Figure 18. VHF LO

1.8V

Original 02/99

Page 7 – 31

Page 32

RAE–2

PAMS

Troubleshooting

PDA Troubleshooting and Service

The purpose of this sectionis to provide methods to find the component

that is malfunctioning in the PDA module of the RAE–2. Due to the large

integration scale of used components, it is always not possible to point

the faulty component for sure. However the flow diagram introduced here

is made to fulfill the aim as well as it is possible.

Required Servicing Equipment:

– PC for the Wintesla

– Service battery BBS–5

– Service cable DAU–9C

– Combox TDC–4

– IR transceiver module JLP–1

– digital multimeter

– oscilloscope

– frequency counter (optional)

Technical Documentation

Block Diagram

The block diagram of the BS1 PDA is described in the next figure:

Page 7 – 32

Original 02/99

Page 33

PAMS

RAE–2

Technical Documentation

PDALCD

GND

LCD PWR IF(6:0)

PWRU

V28_3

VPDA

D6:0

SA1:0

Charging

io(3:0)

Backupbattery

control (6:0)

VBACK

X32kHz out

X32kHz in

sio(1:0)

VSYS

VBATT

FLASH

1Mx16

LCD(10:0)

MMC(3:0)

BS2

Flex connector

FLASH

1Mx16

MA(11:0)

D(15:0)

Am486 CPU

SA(21:0)

SD(15:0)

JTAG(4:0)

io(5:0)

Softkeys

FLASH

1Mx16

FBUS_RXD

FBUS_TXD

MBUS

C(3:0), R(1:0)

C(7:0), R(9:0)

io(1:0)

RS_IF(2:0)

io(3:0)

x32

CMT

Keypad

Troubleshooting

CMT LCD

CMTLCD(5:0)

X800

BS1

QWERTY

Keyboard

Audio

Earpiece

HF

HF_IF(1:0), EAR(1:0)

VBATT

IR transceiver

GND

FBUS_RXD

DRAM

1Mx16

Test–

pads

FBUS_TXD

FBUS_TXD2

MBUS

BoBo

Connector

Memory Card

Figure 19. BS 1 PDA block in RAE–2 product

CMT

PWRKEY

C4:0,R3:0

System connector X810

GND

X830

BS8

Original 02/99

Page 7 – 33

Page 34

RAE–2

PAMS

Troubleshooting

BS1 PDA Components

The following components of the BS1 have an dramatic effect to the

functionality of the module, a fault in any of these may cause the module

to appear totally ‘dead’:

– PDA power unit

– CPU

– PLL clock generation circuit

– UCS Flash chip

If the device has some functionality, then the following components, along

with the ones above, can be tested:

– DRAM chip

– CS1 and CS0 Flash chips

– Handsfree speaker circuitry

Technical Documentation

– Earpice circuitry

– IR transceiver

– keyboard

– LCD module

– Memory Card interface

– Serial connections (FBUS and system bus)

Page 7 – 34

Original 02/99

Page 35

PAMS

RAE–2

Technical Documentation

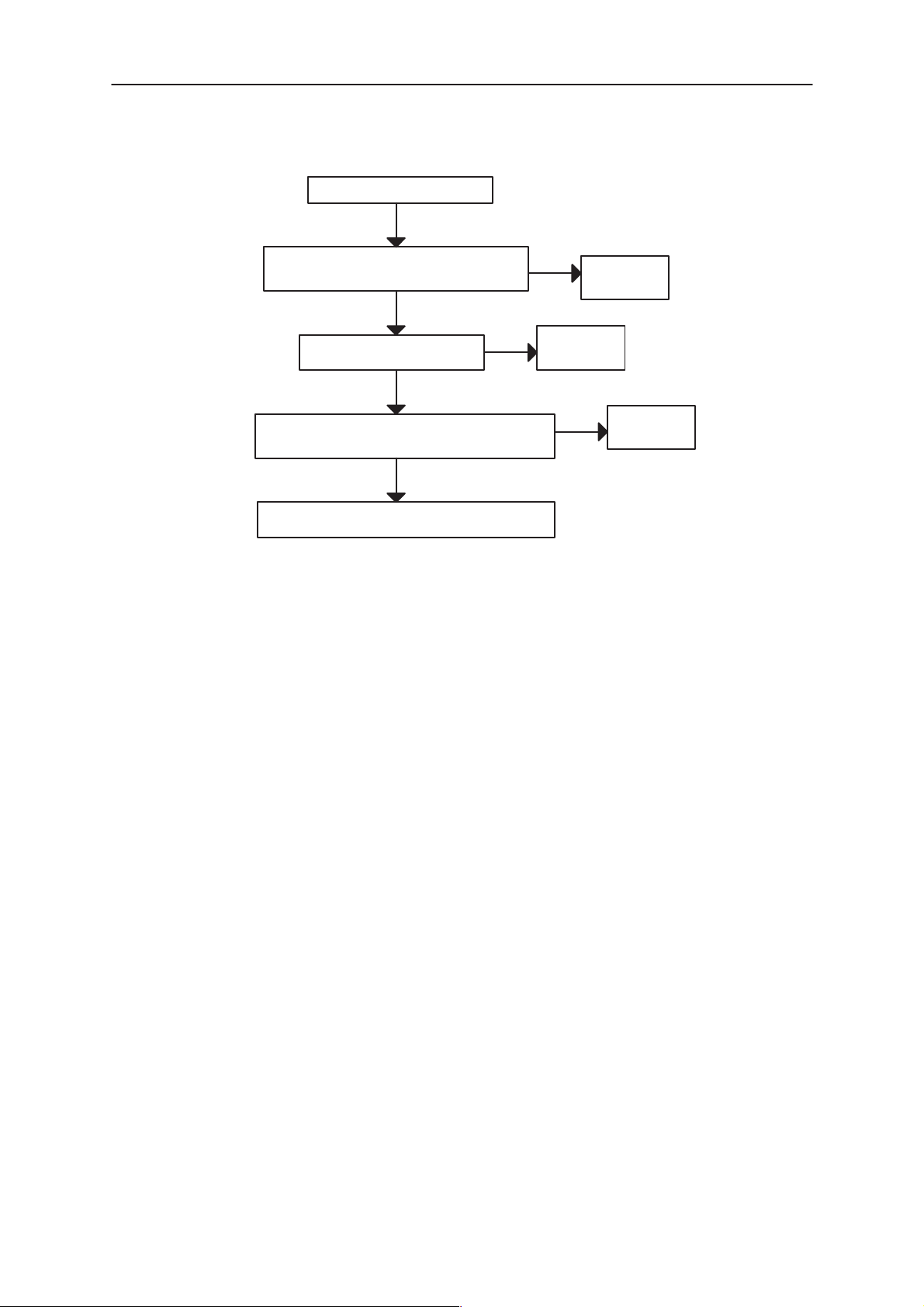

BS1 Troubleshooting

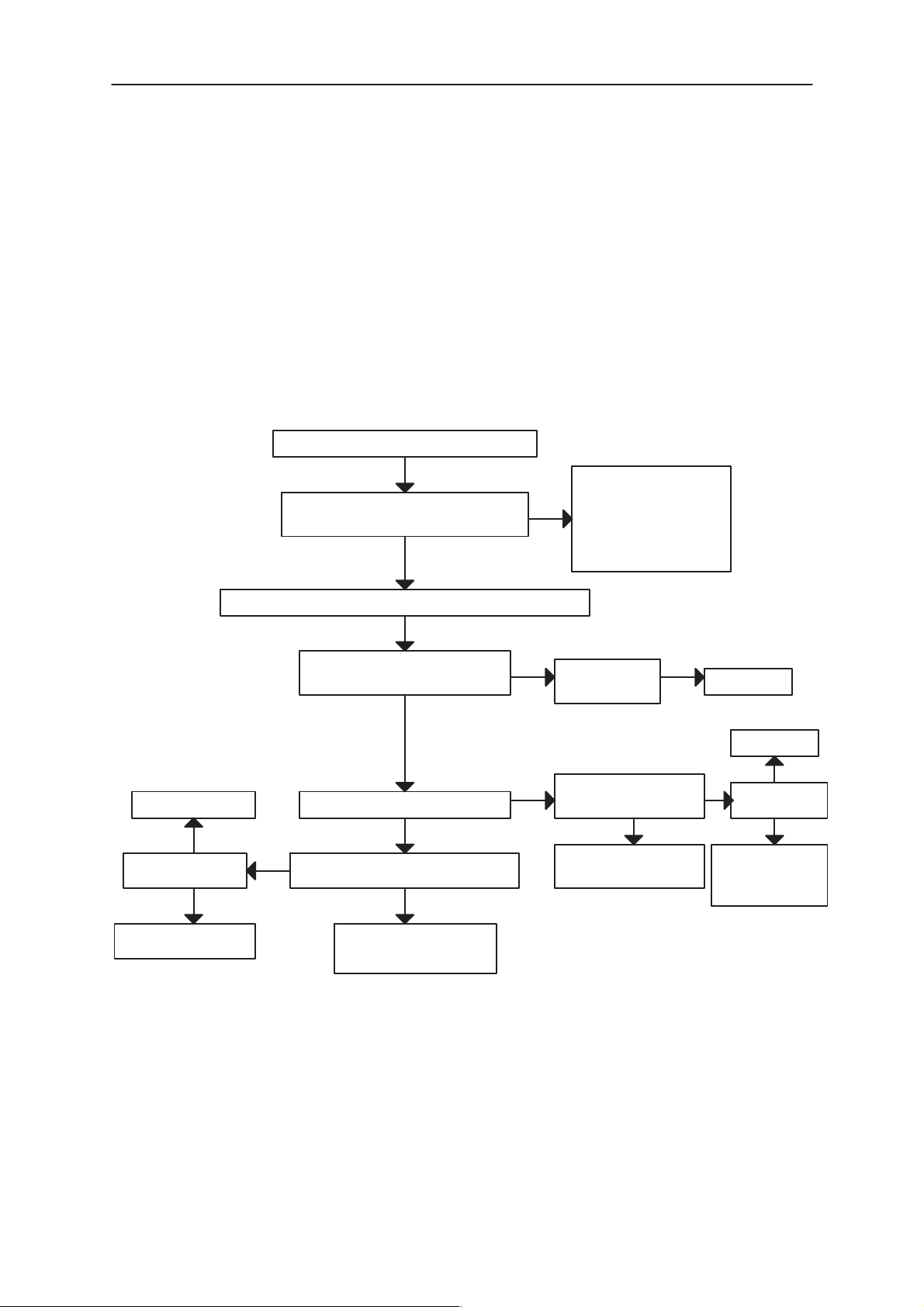

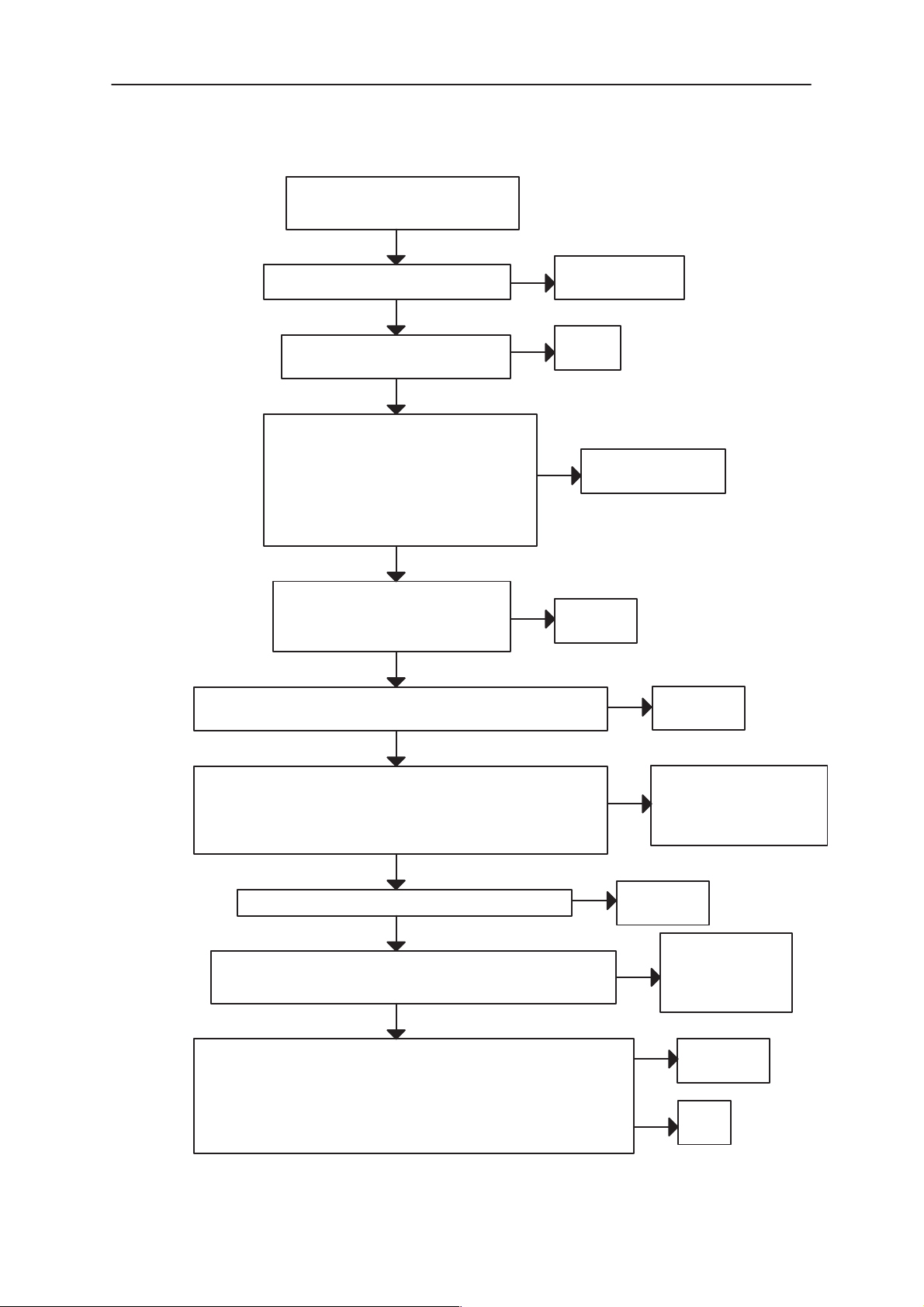

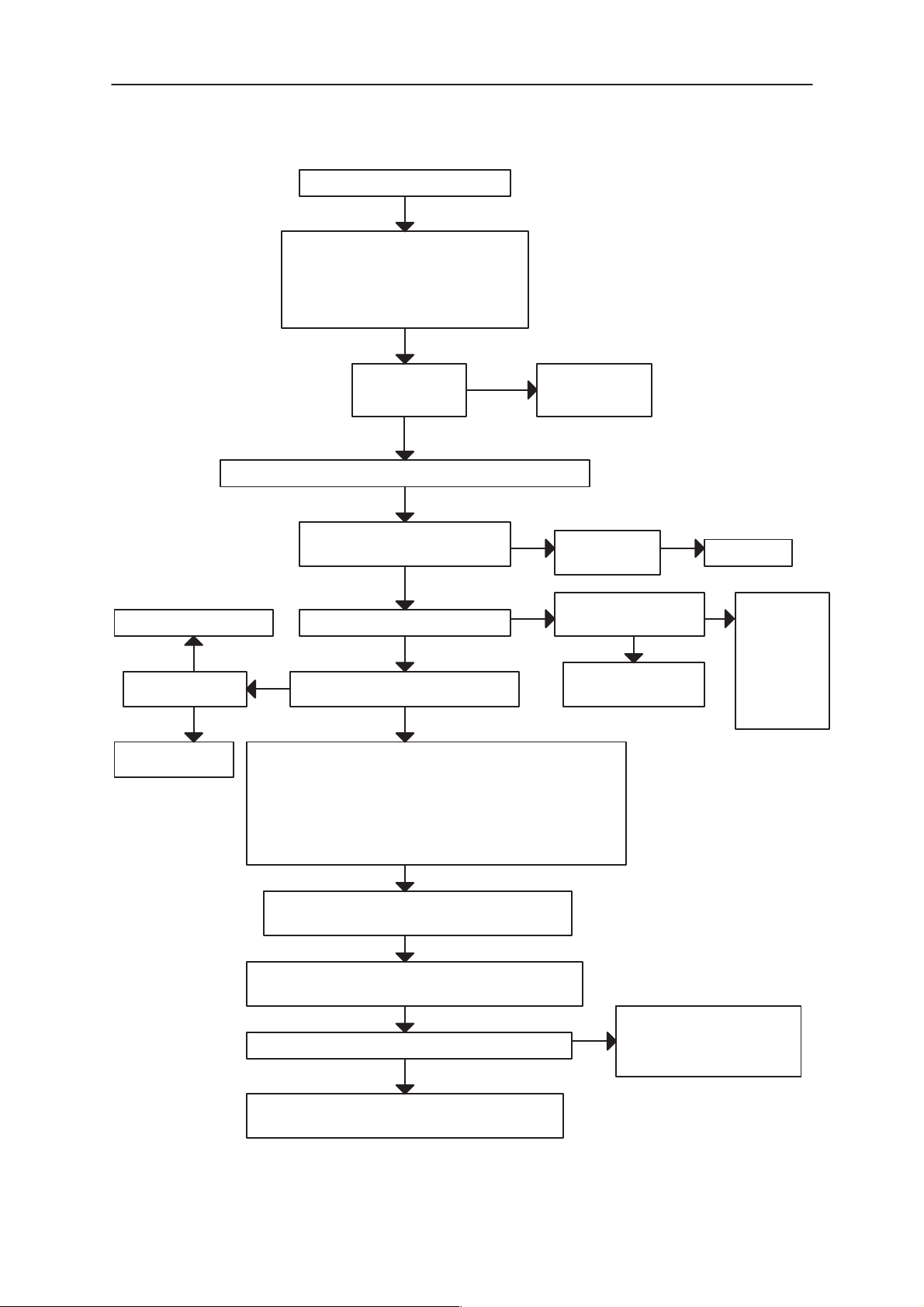

The highest level of the RAE–2 PDA troubleshooting diagram is shown in

the following figure. All the diagrams are made assuming that there is no

visible faults, such as short–circuits or loose pins, on the PDA.

The module check begins with connecting the supply voltage to the PDA.

If the current consumption differs a great deal from the normal limits, it is

good to proceed to the Power–On check.

During BIOS detects some error during POST it tries to beep the buzzer

for further fault analysis for the user. The POST beep codes, number of

beeps are in the Appendix A on p.54.

If the current consumption is OK, it can be tried if the wintesla service

software is able to get connection to the PDA. If the target PDA does not

respond to the pings from the host, it is good to check the Power–On procedure.

Troubleshooting

When the PDA responds to the wintesla, further peripheral tests may be

carried out. The execution order is not significant and it may be freely

changed. Along with the actual tests, wintesla offers advanced methods

for isolating the possible cause of the fault.

After all the functional tests are working, the device under test should be

re–booted, and the normal usability of the GEOS, along with the CMT

module should be checked before the PDA can be considered to be fully

functional.

Original 02/99

Page 7 – 35

Page 36

RAE–2

PAMS

Troubleshooting

PDA MODULE CHECK

Connect VBatt

Current

consumption

OK?

YES

Respond

to wintesla?

YES

POST–code

check

PLL clock circuits

check

NO

NO

Technical Documentation

See Power On

malfunctions

See Power On

malfunctions

DRAM

check

Flash memories

check

LCD

check

Backlight

check

keyboard

check

Serial connections

check

IR

check

Lid Switch

check

Handsfree speaker

check

Earphone

check

Page 7 – 36

Memory card interface

check

OS BOOT

GEOS

Usage Test

OK

Figure 20. The highest level of the PDA troubleshooting diagrams

Original 02/99

Page 37

PAMS

RAE–2

Technical Documentation

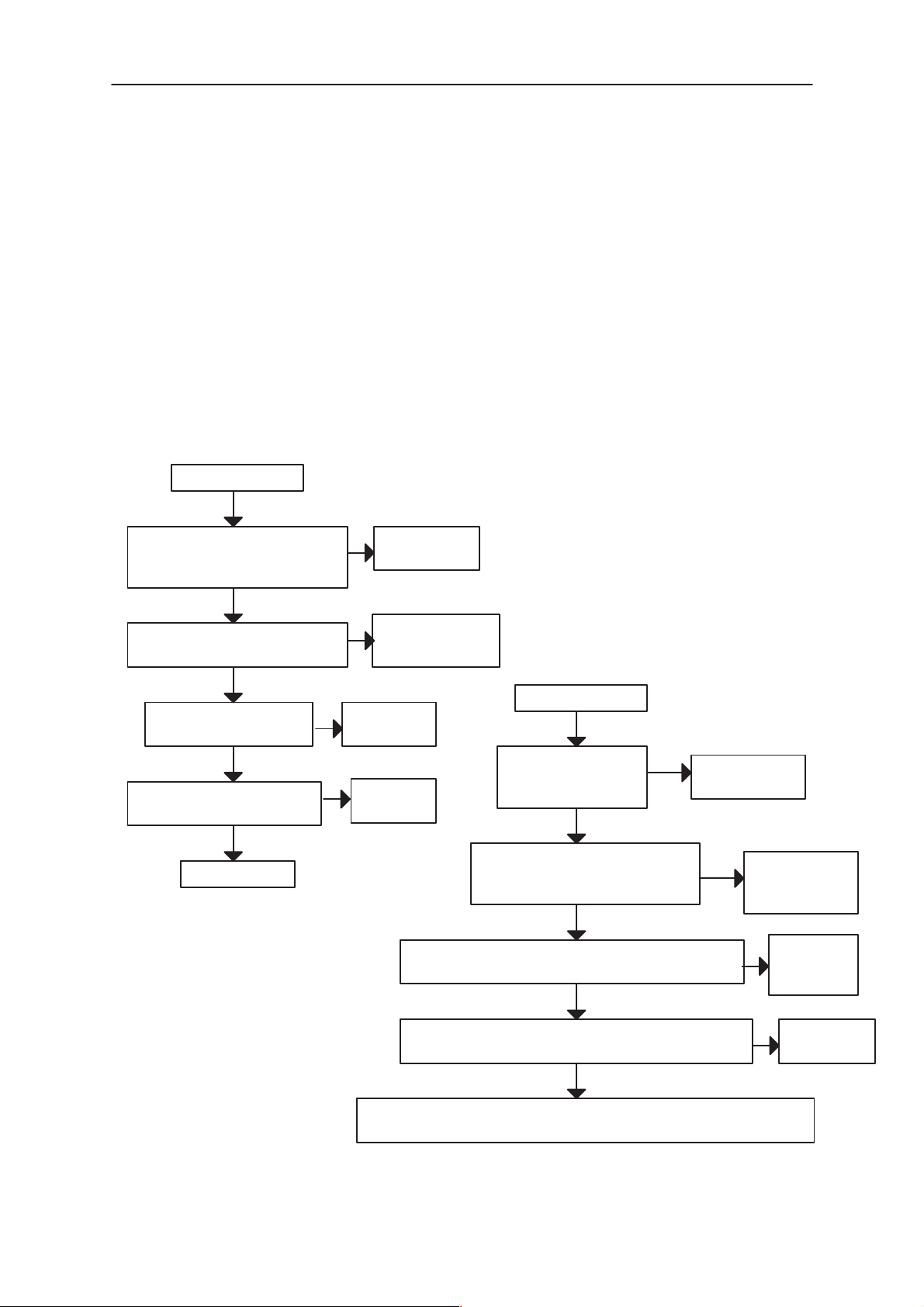

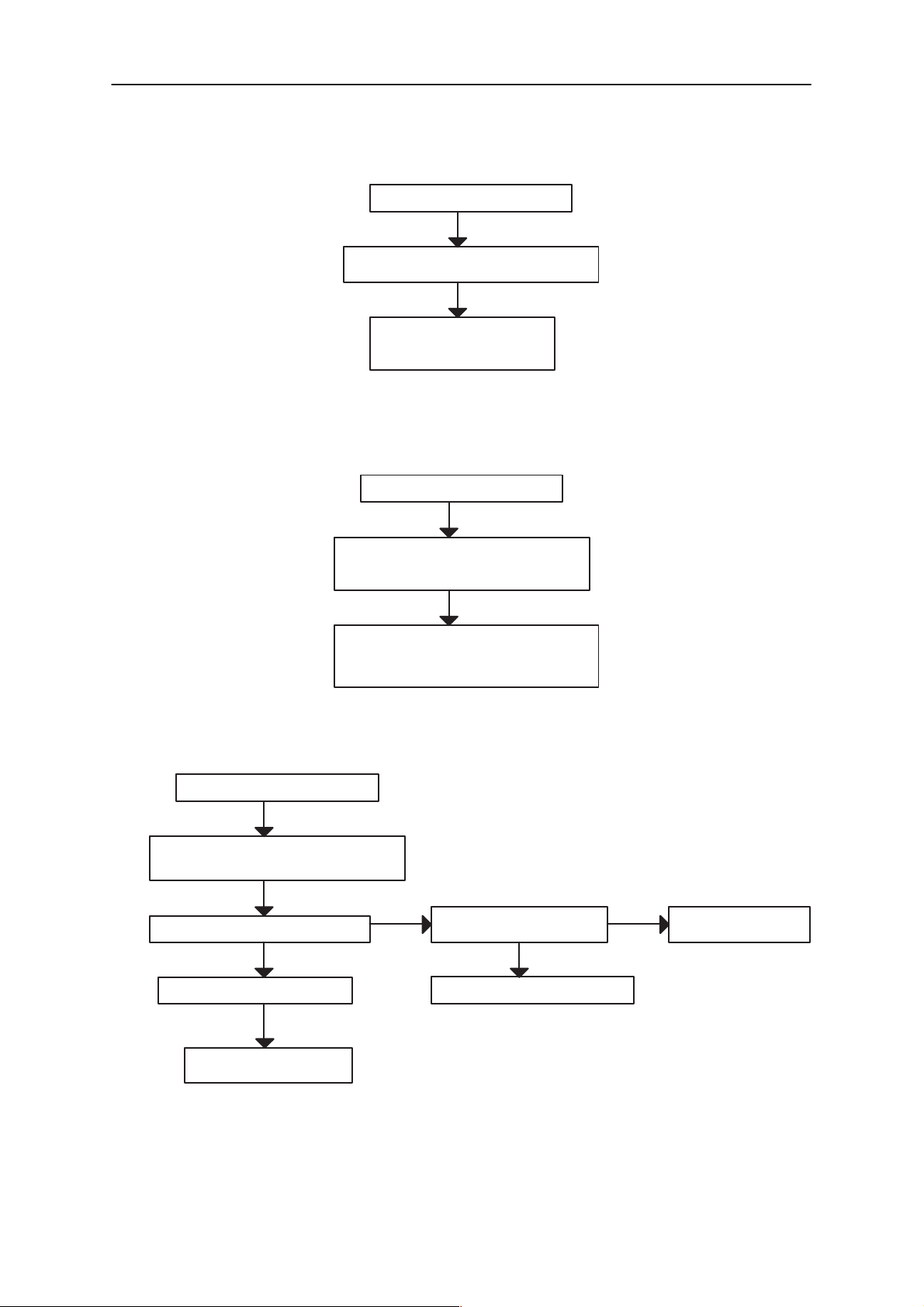

Power–on malfunction

The following picture illustrates the troubleshooting diagram for Power–

On malfunctions.

Start

POST

BEEP Code

error?

YES

NO

Vsys

OK? E312

YES

Troubleshooting

NO

CPU

related error?

YES

Memory

fault

in Flash

NO

Program

V alid boot code

Check

External RS

Memory

flash

NO

YES

fault

NO

INT_PLL

OK? J400

(1.4MHZ)

YES

Bus activity?

D/A, R/W, CS

J440–J449

YES

Reboot and ping

from the wintesla

while in TestMode

Respond to

Power On

OK!

5.

PING from host?

YES

NO

NO

Check

PLL–circuit

Reset OK ?

J449

Check PDA

power unit

Original 02/99

Figure 21. Troubleshooting of the power–on malfunction

Page 7 – 37

Page 38

RAE–2

PAMS

Troubleshooting

Power Circuitry Check

The following figure illustrates how to check power circuits. The upper

part of the flowchart must be passed before the swicthable voltages (lower part of the flowchart) can be considered to be alright.

The LCD temperature compensation affects the LCD bias voltage values.

Because of this temperature compensation, the LCD bias voltages are

different in different temperatures, but anyway bias voltage maximum and

minimum values should differ 4 Volts from the typical value (DAC 63) in

every temperature.

Figure on the next page.

Technical Documentation

Page 7 – 38

Original 02/99

Page 39

PAMS

RAE–2

Technical Documentation

Power

check

NO

NO

NO

Check

Input filter

Power ASIC

fault

VBATT

OK?

YES

VPDA

OK?

YES

VBACK

OK?

Check

CMT

YES

Board to board

connector

OK?

NO

Troubleshooting

Change

connector

YES

VSYS

OK?

YES

RESET

OK?

YES

(If you can not enable some voltage, try enable some other to be sure that CPU and bus from/to it is OK)

Select

I/O functions/

Phaser calibration

in WinTesla

LCDTEMP

OK?

NO

Hinge flex

OK?

YES

NO

NO

NO

DAC value 63

BATTDET

OK?

SELECT TROUBLE RELATED BRANCH

Select

I/O functions/

Phaser calibration

in WinTesla

Select max.

V17OUT

V17OUT

MAX voltage?

YES

Select

YES

NO

Power ASIC

fault

Power ASIC

fault

YES

VCOMP1

OK?

Select

I/O functions/

Signal control

in WinTesla

Enable LCD

V28_1

OK?

NO

Signal control Signal control

PDA LCD

locig

voltage OK

Check

R461 – R463

R469

R493 – R495

YES

N496

OK?

Select

I/O functions/

in WinTesla

Enable IR

V28_2

OK?

NO

NO

I/O functions/

YES

IR–

transceiver

logic

voltage OK

Change

N496

Select

in WinTesla

Enable

MMC power

V28_3

OK?

NO

YES

Memory

card

power OK

NTC OK

on UI?

YES

Power ASIC

fault

Original 02/99

V17OUT

typical vol–

tage?

YES

PDA LCD

bias voltage OK

Figure 22. Power unit troubleshooting diagram

NO

Power ASIC

fault

Page 7 – 39

Page 40

RAE–2

PAMS

Troubleshooting

Technical Documentation

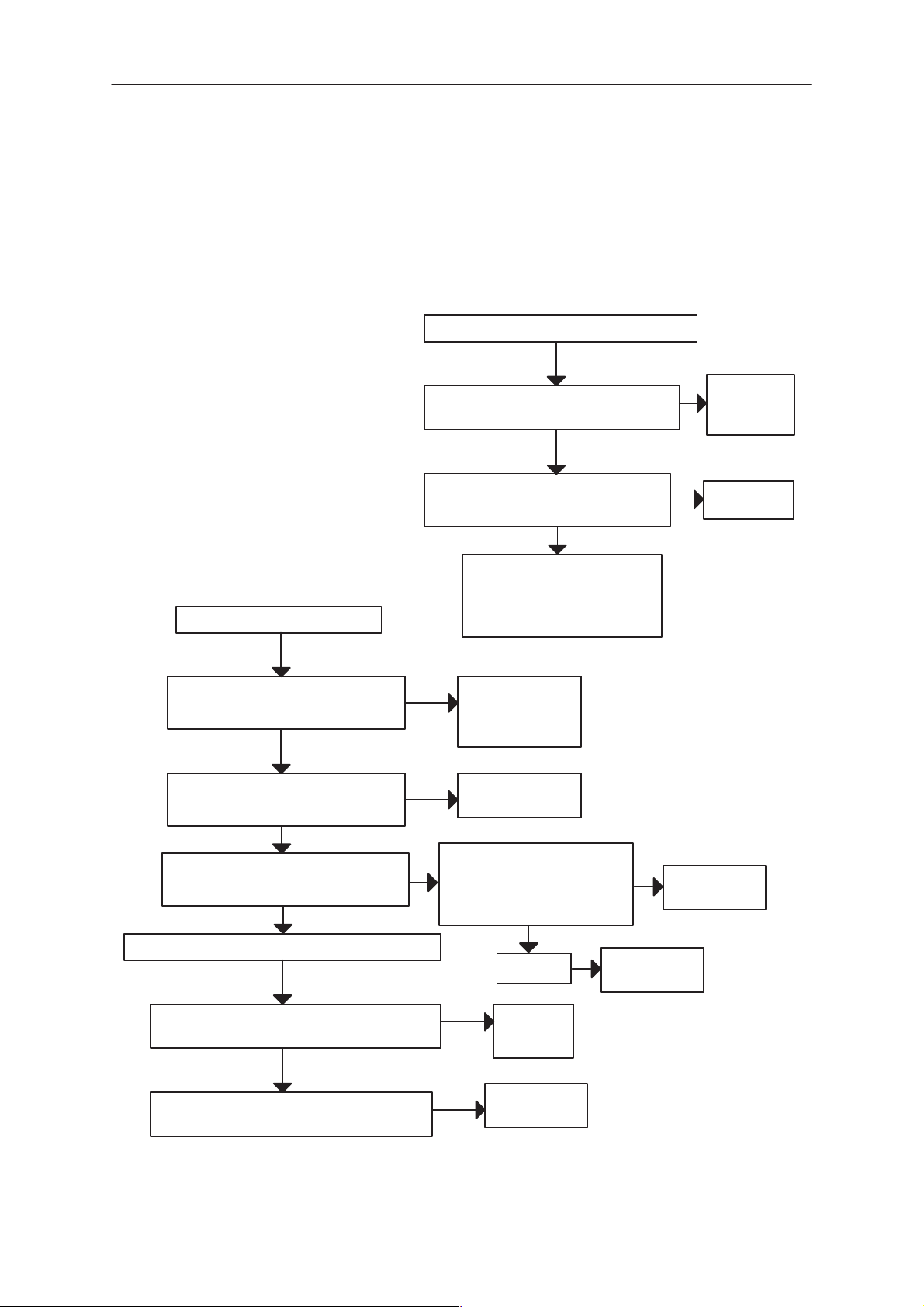

Troubleshooting Diagram of the PLL clock generation circuit

The following diagram illustrates how to check PLL clock generation circuits.

PLL Circuit

check

X32_CLK

OK?

J401

YES

NO

Vback OK?

E307

YES

NO

Check power

ASIC N450

PLL intermediate

voltage 1.2V?

J430

YES

check

XIP

flashes

XIPs

OK?

NO

YES

NO

1.4MHZ

OK?

J400

YES

PLLs

OK

components on

Discrete

PLL OK?

YES

CPU

fault

XTAL OK?

32kHz

J434, J435

NO

NO

Change faulty

discrete

component

Check

XTAL

Page 7 – 40

Figure 23. PLL clock generation circuit check

Original 02/99

Page 41

PAMS

RAE–2

Technical Documentation

Troubleshooting Diagram of the DRAM

The following figure illustrates how to check DRAM. Open DRAM test in

WInTesla and select RandomTest. If test passed DRAM should be alright.

If the test is not passed, run test again and measure the data and control

lines activity.

DRAM

check

Start the DRAM

Random test

Troubleshooting

DRAM test

succesful?

YES

DRAM

OK

NO

Figure 24. DRAM troubleshooting diagram

Bus activity?

(R/W, CAS, RAS, ADD)

J446–J449

J4555,J456

YES

DRAM or

CPU fault

NO

CPU

fault

Original 02/99

Page 7 – 41

Page 42

RAE–2

PAMS

Troubleshooting

Troubleshooting Diagram of the Flash memories

The PDA comprises two kind of flash memories, two XIP (eXecute In

Place) flashes and one RFD flash.

The XIP flash can be checked by comparing image checksum and calculated checksum.

If you can read and write from/to RFD flash, it is likely to be OK.

Technical Documentation

Page 7 – 42

Original 02/99

Page 43

PAMS

RAE–2

Technical Documentation

XIP

Flashes

check

Read

image checksum

Compare

calculated checksum

and

image checksum

Are

Checksums

equal?

YES

XIP flashes

OK

NO

Bus activity ?

(AD, D, CE, WE)

J441, J442

J453, J454

NO

CPU

fault

YES

Troubleshooting

Flash fault

NO

Flash

status output

STSx(J451 or J452)

OK?

YES

CPU fault

RFD

flash

check

Write to

RFD flash

Read from

RFD flash

write and read

OK?

YES

RFD flash

OK

Flash fault

NO

NO

Figure 25. Flash memories troubleshooting diagrams

Bus activity ?

(AD, D, CE, OE, WE, WP)

J440, J442–J444

J453, J454

NO

CPU

fault

YES

status output

STSx (J450)

YES

Flash

OK?

CPU fault

Original 02/99

Page 7 – 43

Page 44

RAE–2

PAMS

Troubleshooting

Troubleshooting Diagram of the LCD

The idea of the following diagram of the LCD Check is to make the difference whether the LCD BS2 module or the PDA BS1 is broken. The case

where the fault is in the BS2 module is beyond the scope of this document. The fix in that case is likely the change of the whole module.

0.

Start

1.

NO

LCD ON?

1.1

Disconnect UI

flex

Technical Documentation

YES

5.

Test–patterns

OK?

YES

LCD OK!

NO

1.2 1.2.1

V28_1

OK? N450/22

YES

V17

OK?

E300

YES

1.4 1.5

UI flex OK?

NO YES

NO V28_OUT

1.2.2

CPU fault

1.3

NO V17_OUT

NO

active?

N450/61

NO

NO

1.3.1

active?

N450/60

1.3.2 Check

PDA PWRU

CPU fault

LCD control

signals OK?

J805–J808

YES

1.5.2

Page 7 – 44

1.4.1 UI flex

fault

Figure 26. Troubleshooting of LCD signals

1.5.1 LCD

module fault

Original 02/99

Page 45

PAMS

RAE–2

Technical Documentation

Troubleshooting Diagram of the PDA LCD Backlight

This troubleshooting diagram describe troubleshooting procedure on the

PDA LCD backlight. If PDA is OK, look then backlight troubleshooting procedure from next chapter UI TROUBLESHOOTING.

PDA LCD

Backlight

check

Enable

backlight

Troubleshooting

Check

hinge flex

connector

NO

Backlight

OK?

YES

Backlihgt

OK

NO

Disconnect

hinge

flex

Figure 27. PDA LCD backlight troubleshooting

Backlight

enable signal

(X800/24)

OK?

NO

CPU fault

YES

VPDA

OK?

(X800/51)

YES

Check

backlight

connections

on UI module

Original 02/99

Page 7 – 45

Page 46

RAE–2

PAMS

Troubleshooting

Troubleshooting Diagram of the PDA Keyboard

This section describe PDA keyboard troubleshooting procedure. Possible

cause to keyboard faults are keyboard interface in CPU, broken keymat

or keydomes (UI) . Also, dirty keymat or keypad area can cause the fault.

Keyboard

check

Start the

keyboard test

Technical Documentation

Press a QWERTY/

softkey

Keypress

regognized?

YES

NO

pressed

keyboard

All

keys

YES

OK

NO

Figure 28. Keypad troubleshooting diagram

Other

same row or

column keys

regognized?

NO

CPU fault

YES

pressed key

YES

hinge flex and

softkey domes on UI

Was

a lidkey

Check

NO

Keypad

or keymat

fault

Page 7 – 46

Original 02/99

Page 47

PAMS

RAE–2

Technical Documentation

Troubleshooting Diagram of the serial connections

External bus connection is alright if the device is PINGing, if not is good to

check system connector and discrete components on RX and TX lines.

External bus use RS232 data protocol, but signal voltage levels on PDA

and system connector are only 2.8V digital voltage levels. External buffer

cable needed (DLR–2) for connecting to PC.

Serial connection between CMT and PDA (FBUS) can be checked as following flow chart described.

FBUS

check

Troubleshooting

Open RS test

and run COM2

local loop test

COM2

local loop test

OK?

NO

CPU

fault

Remove CMT

YES

Figure 29. FBUS troubleshooting diagram

and connect

RX and TX

together on

board to board

connector

Run COM2

external loop

test

Check

CMT side

YES

COM2

external loop

OK?

NO

Check

board to board

connector

Original 02/99

Page 7 – 47

Page 48

RAE–2

PAMS

Troubleshooting

External

RS

check

PiNG

target?

NO

Test

connections

OK?

NO

Repair

test

connections

YES

YES

External

RS

OK

RX

signal OK?

(X810/8)

X810

V870, V871,

R806

OK?

YES

NO

YES

CPU

fault

Technical Documentation

TX

signal OK?

(X810/9)

NO

X810 and

V870

OK?

YES

Figure 30. External serial connection troubleshooting diagram

Page 7 – 48

Original 02/99

Page 49

PAMS

RAE–2

Technical Documentation

Troubleshooting Diagram of the IR connection

This section describe infrared connection troubleshooting procedure.

IR test need Combox TDC–4 with IR transceiver JLP–1.

Place PDA so that IR transceiver have clear light route to JLP–1 and run

the IR test. If test not passed follow flowchart to find out the fault.

IR shutdown is not in use.

Check

power ASIC

N450

YES

R301, C301

OK?

NO

V28_2

OK?

(N300/6)

YES

IR

check

IR

test

OK?

NO

test connections

Repair

test

connections

NO

External

Ok?

YES

Troubleshooting

Check

R300,

R302–R304

C300

NO

VPDA

OK?

(N300/1)

YES

IrDA

OK

YES

CPU fault

CPU fault

Figure 31. IR connections troubleshooting diagram

NO

COM1

local loop

test OK?

YES

IR–

transceiver

fault

NO

YES

NO

YES

TXD

OK?

(N300/3)

RXD

OK?

(N300/4)

Original 02/99

Page 7 – 49

Page 50

RAE–2

PAMS

Troubleshooting

Troubleshooting Diagram of the lid switch

The idea of this diagram is to find out whether the CPU or the reed relay

circuit is not working.

If CPU and reed relay circuit on PDA is alright, then possible cause of

fault is magnet in lid.

Lid

switch

check

Open

WinTesla

Signal control

Technical Documentation

Lid switch

OK

LID OPEN?

NO

LID_SWITCH_IF

high?

J310

NO

R310

OK?

NO

Change

R310

YES

YES

Place magnet

near the reed

relay

CPU

fault

Figure 32. Lid switch troubleshooting diagram

Select

Refresh

in WinTesla

YES

LID CLOSED?

NO

LID_SWITCH_IF

low?

J310

NO

Reed relay

fault

Page 7 – 50

Original 02/99

Page 51

PAMS

RAE–2

Technical Documentation

Troubleshooting Diagram of the HF Speaker

The idea of this diagram is to find out whether the CPU, loudspeaker, or

power amplifier or it circuitry is not working.

Start

VAMP OK?

R855/R856

YES

NO

Check

R891, R892 and

C880 – C882, C892

Troubleshooting

Signal from

COBBA OK?

J881

YES

PA–Enabled?

N880/1

NO

V880 NO

OK?

Check

CMT CPU

NO

YES

Check COBBA

on CMT

Signal amplified?

Change V880

Speaker fault

N880/5,8

YES

NO

HFPA–Fault

Original 02/99

Figure 33. HF–Speaker troubleshooting diagram

Page 7 – 51

Page 52

RAE–2

PAMS

Troubleshooting

Troubleshooting Diagram of the Earpiece

The following diagram illustrates how to check earpiece connections on

the PDA side.

Run the wintesla buzzer test. If the sound is not good then check earpiece connections as following flowchart illustrates.

Earpiece

connection

check

Start

buzzer

test

Technical Documentation

Buzzer

sound Ok?

NO

BZR_IF

signal OK?

J854

YES

VAMP OK?

(R855/R856)

NO

Check

R891, R892 and

C880 – C882,

C892

YES

NO

YES

Buzzer OK

Check PDA CPU

V872

and

V873

OK?

NO

Change faulty

component

YES

Check

Earphone

Page 7 – 52

Figure 34. Earphone troubleshooting diagram

Original 02/99

Page 53

PAMS

RAE–2

Technical Documentation

Troubleshooting

Troubleshooting Diagram of the Memory Card interface

To check the memory card interface:

Take a good memory card and place it in the memory card

connector.

Run Wintesla MMC test. If test failed then take memory

card out and run test again.

Measure memory card system voltage and bus signals

when test running.

If the signal and the card voltage are OK, then the interface is likely to be

OK. If everything is not alright check interface connections as the flowchart illustrate.

Memory Card

interface

check

Run

MMC

test

Test

OK?

NO

MMC_DAT,

MMC_CMD and

MMC_CLK

OK?

YES

MMC_SYS

OK?

NO

Enable

MMC power

in WinTesla

NO

YES

Board to

board and memory

card connectors

OK?

YES

CPU

fault

NO

Change

faulty

connector

V28_3

OK?

(X830/46)

YES

Check

CMT side

Original 02/99

NO

Check

Power ASIC

N450

Figure 35. Memory card interface troubleshooting diagram

Page 7 – 53

Page 54

RAE–2

PAMS

Troubleshooting

POST BEEP Codes

1 Memory refresh is not working.

3 Memory failure in 1st 64kB of memory.

4 Timer T1 not operational.

5 CPU test failed.

6 Gate A20 failure.

10 CMOS shutdown register failed.

13 Exhaustive low memory test failed.

14 Exhaustive extended memory test failed.

15 CMOS restart byte can’t hold data.

16 Address line test failed.

18 Interrupt controller failure.

Technical Documentation

Page 7 – 54

Original 02/99

Page 55

PAMS

RAE–2

Technical Documentation

UI Troubleshooting

Mechanical Troubleshooting

In mechanical failures it is better to replace a whole unit or module than try

to fix it in service. The replaceable units or modules on BS2 UI module are:

– BC2 CMT LCD module

– PDA LCD display

– UI PCB

– EL backlight panels

– Keydome sheets

Keyboard Troubleshooting

Troubleshooting

– Equipment: Resistance meter (multimeter)

– If CMT keyboard does not function when the lid is closed, it is possible

that reed relay (in the BS1 module) is damaged. If text ”Please close

cover” comes to CMT LCD when a CMT key is pressed when lid is

closed, the reed relay is probably damaged.

– Check that the dome sheets are properly placed. Improperly placed

dome sheet may cause malfunction of some key(s) or power down of

the CMT when a key is pressed.

Table 1. CMT keyboard checklist.

Non–functioning CMT keys Check components

6, 9, # R704, C707

1, 2, 3, Soft_left R705, C706

4, 5, Send, Up R705, C714

7, 8, End, Down R705, C713

0, *, Mode, Soft_right R706, C712

3, 6, Send, End, Mode R706, C708

9, Soft_left, Soft_right, Up, Down R707, C709

1, 4, 7, #, * R707, C710

2, 5, 8, 0 R708, C711

Original 02/99

Page 7 – 55

Page 56

RAE–2

PAMS

Troubleshooting

CMT LCD Module Troubleshooting

Start

No

Is display properly

on its place?

Remove and put the display back to its place and

test again.

Display shows unexpected

characters

LCD glass is probably

mechanically damaged. Inspect and re-

Yes

place.

What is the

problem?

Pixel line(s) missing.

Display does not work

Yes No

Is display properly

Yes

on its place?

Can Vout voltage be

measured from

J715 when display

is on its place.It

must be 6...9 volts.

Technical Documentation

No

Remove and put the display back to its place and

test again.

Yes

Problem might be some

randomize behavior or

unclean contact pads of

CMT LCD. Clean contacts and try again.

Problem might be elastomer or misaligned hinge

flex. Remove and connect hinge flex again.

Check elastomer.

Press some phone

key. Are GENSCLK

(J706), GENSDIO

(J707) OK and is

LCDRSTx (J708)

’high’?

No

Does display work OK?

Check C705 and in

BS2_10 R709.

Is VBB (J713) OK?

Yes

Remove LCD and check

the elastomer. Clean

contact pads on PCB and

try again.

No

No

– Testing equipment: Multimeter and oscilloscope.

Page 7 – 56

Yes

End

Figure 36. Flow chart for the troubleshooting of CMT LCD module.

Original 02/99

Page 57

PAMS

RAE–2

Technical Documentation

Troubleshooting

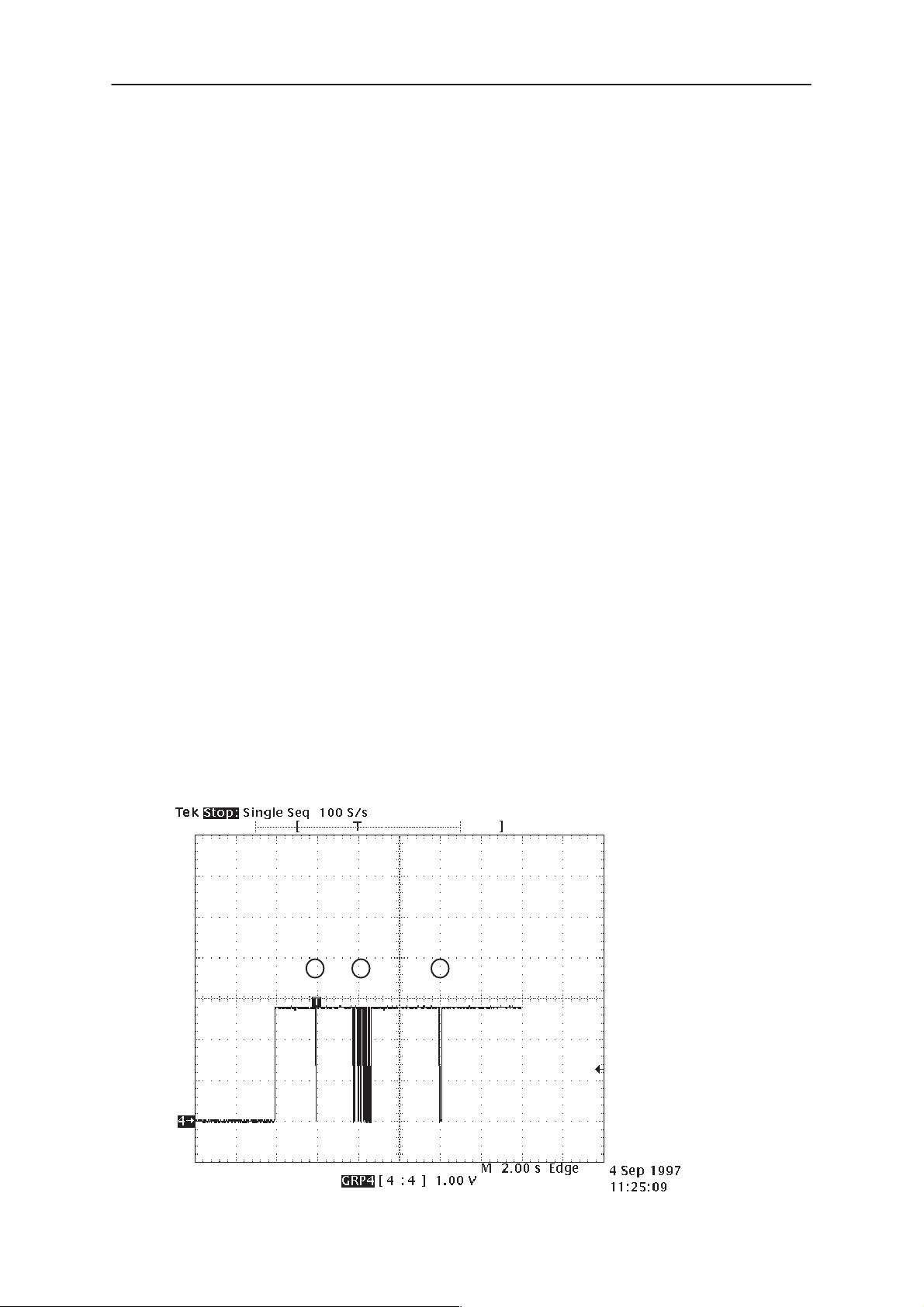

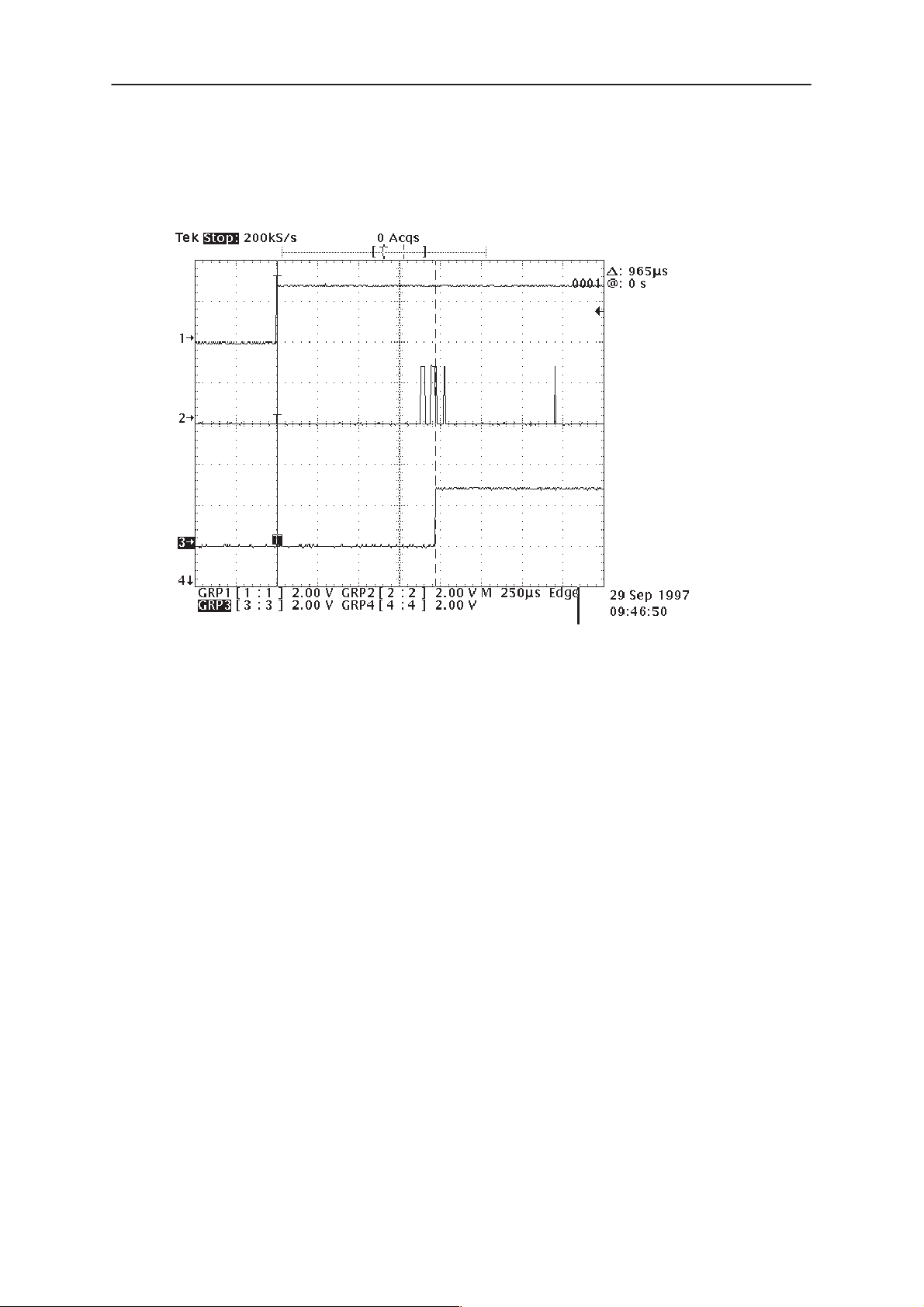

Figure 37. GENSCLK (J706) and LCDCSx (pin 5/H700) , LCD active after

pressing a key.

Original 02/99

Figure 38. GENSCLK (J706) and LCDCSx (pin 5/H700), LCD inactive, serial

bus used for communication between MAD and CCONT.

Page 7 – 57

Page 58

RAE–2

PAMS

Troubleshooting

Technical Documentation

Figure 39. GENSDIO (J707)

Page 7 – 58

Original 02/99

Page 59

PAMS

RAE–2

Technical Documentation

PDA LCD Display Troubleshooting

START

What is wrong?

Large part of the

Make sure that the

flex of the display is

Yes

properly connected

to X730. Does the

display work now?

Check C740–C744

and in BS2_10

Yes

R736–R739. Does

the display work

now?

Are V28_1

(J700) and

LCD_ON (J701)

about 2.8V?

No

No

No

Yes

display is black

or dark blue or

pixel line(s) is

missing

LCD is mechanically

damaged. Replace

the display.

No

Bad picture qualityDisplay does not work

Check C740–C744

and in BS2_10

R736–R739. Does

the display work

now?

Yes

Make sure that the

flex of the display is

properly connected

to X730. Does the

display work now?

YesNo

Troubleshooting

Is V17_OUT (J709)

as specified?

No

Yes

Are FRM (J702), M

(J703), LC (J704)

and SCK (J705) as

specified?

Yes

Display is probably

damaged. Replace

it with a new

display.

No

Reason may be

misaligned hinge

flex. Remove and

connect flex

again and test

display again.

Does the display

work OK now?

Yes

END

No

Figure 40. Flowchart for troubleshooting of the PDA LCD.

– Testing equipment: Multimeter and oscilloscope.

Original 02/99

Page 7 – 59

Page 60

RAE–2

PAMS

Troubleshooting

Technical Documentation

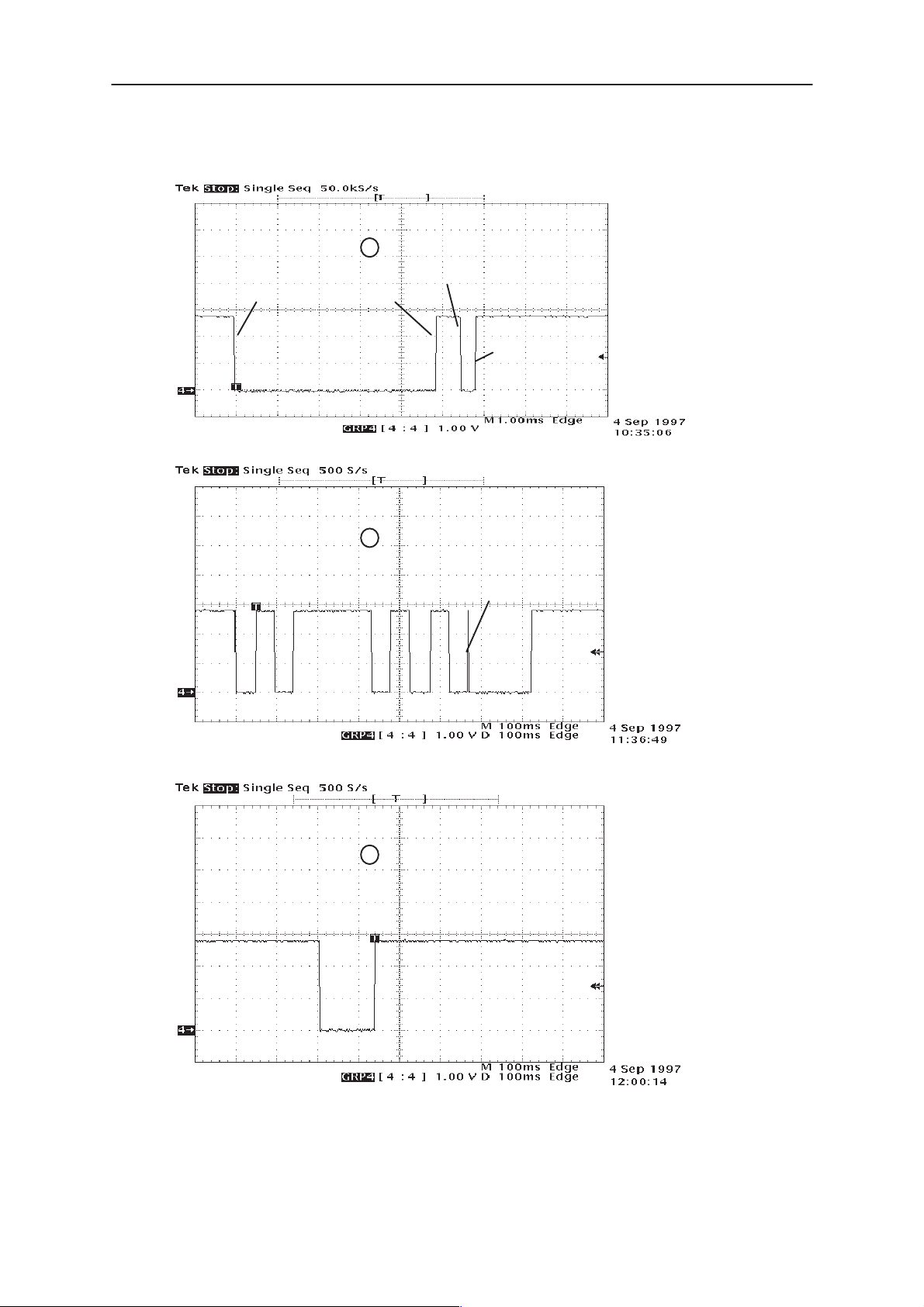

Figure 41. LCDD0 (J712)

Page 7 – 60

Figure 42. LC (J704)

Original 02/99

Page 61

PAMS

RAE–2

Technical Documentation

Troubleshooting

Figure 43. M (J703)

Original 02/99

Figure 44. SCK (J705)

Page 7 – 61

Page 62

RAE–2

PAMS

Troubleshooting

Technical Documentation

Figure 45. FRM (J702)

Page 7 – 62

Original 02/99

Page 63

PAMS

RAE–2

Technical Documentation

CMT Backlighting Circuit Troubleshooting

When troubleshooting the CMT backlighting circuit, remember that backlighting goes off after a certain period from the last key pressing.

START

Check that EL panel

Yes

contacts are OK.

Does the backlight

work now?

Is VPDA voltage OK

on UI board (J714)?

No

NoYes

Troubleshooting

Is the voltage of pin

1/N700 higher than

3.0 V?

Yes

Is driver circuit’s out–

put as specified

(6,7/N700)?

No

Are coil L700, diode V701,

capacitors C701–C703 and

resistors R700–R702

(R703 in BS2_10) OK?

Yes

Replace with new

circuit.

No

Yes

No Replace faulty com–

ponents. Does the

backlight work now?

Is CMT_BL_ON

signal voltage at

J710 about 2.8V?

Try with a new EL

panel. Does the

backlight work

now?

Yes

No YesInverter is damaged.

No

Yes

No

V702 or V703 is

damaged.

Replace them.

END

Reason may be

misaligned hinge

flex. Remove and

connect flex

again and test

display again.

Does the

backlight work

OK now?

Yes

No

Figure 46. Flowchart for troubleshooting of the CMT backlighting circuit.

Original 02/99

Page 7 – 63

Page 64

RAE–2

PAMS

Troubleshooting

PDA LCD Backlighting Circuit Troubleshooting

For PDA backlighting troubleshooting you can use test mode and WinTesla SW to set the backlighting on all the time.

START

Check that EL panel

Yes

contacts are OK.

Does the backlight

work now?

No

Technical Documentation

Is the voltage of pin

1/N730 higher than

3.0 V?

Yes

Is driver circuit’s out–

put as specified

(6,7/N730)?

No

Are coil L730, diode V730,

capacitors C736–C738 and

resistors R730–R732

(R733 in BS2_10) OK?

Yes

Replace with new

circuit.

No Replace faulty com–

No

Try with a new EL

Yes

panel. Does the

backlight work

now?

ponents. Does the

backlight work now?

No YesInverter is damaged.

Is VPDA voltage OK

on UI board (J714)?

Is PDA_BL_ON

signal voltage at

J711 about 2.8V?

Yes

Yes

No

NoYes

No

V731 or V732 is

damaged.

Replace them.

Reason may be

misaligned hinge

flex. Remove and

connect flex

again and test

display again.

Does the

backlight work

OK now?

Yes

No

Figure 47. Flowchart for troubleshooting of the PDA backlighting circuit.

– Testing equipment: Multimeter and oscilloscope. Note that voltage rating of the oscilloscope and probe must be over 250 V peak–to–peak.

Page 7 – 64

END

Original 02/99

Page 65

PAMS

RAE–2

Technical Documentation

Troubleshooting

Figure 48. Example of a typical EL driver output waveform,

measured between pins 6 and 7 of the driver.

Original 02/99

Page 7 – 65

Page 66

RAE–2

PAMS

Troubleshooting

Technical Documentation

Page 7 – 66

Original 02/99

Loading...

Loading...