Page 1

nokia

RAE/K-1 Repairhints

Service & Competence Center Europe

Customer Care Training Group Date 05.04.2001

CONFIDENTIAL

Introduction Version 1.0 Approved

Repairhints

1 (29)

Communicator

9000/9000i

RAE/K-1/4

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 2

nokia

RAE/K-1 Repairhints

Service & Competence Center Europe

Customer Care Training Group Date 05.04.2001

CONFIDENTIAL

Introduction Version 1.0 Approved

GENERAL

-General handling

PDA-module GP-1, SIM-Flex GEM-1 and PDA-LCD are the same for all products.

CMT-module GE-8s ( MCM1 code 0200725 ) and User Interface-module GK-2 are meant for RAE-1/I,

while GE-9s ( MCM1 code 0200865 ) and UI-module GK-2-1 are meant for RAK-1/I.

To find out a failure easier, interchange separate modules with some which are working proper,

so that you can define the fault to a single module. Check general every connector for broken

solderings, if bent or soiled.

EMC grounding tape is recommended to replace always with new one after removal.

Take care not to destroy HF-Microphone and Coax-cable when assembling the communicator,

further more it is absolutely necessary to use the right screws at their intended places!

-Component characteristics:

Some components contain important data.

Several described steps are only practicable if you are able to reflash/ realign the phone and/or rewrite

IMEI/SIMlock in certain cases. Please pay attention to separate notes.

-Realign after repair

Characteristics of replacement parts are different.

To prevent additional faults after repair (eg. low standby time, loosing network etc…) it is necessary

to retune phone values after repair.

2 (29)

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 3

nokia

RAE/K-1 Repairhints

Service & Competence Center Europe

Customer Care Training Group Date 05.04.2001

CONFIDENTIAL

Introduction Version 1.0 Approved

INTRODUCTION

IMPORTANT:

This document is intended for use by authorized NOKIA service centers only.

The purpose of this document is to provide some further service information for NOKIA Communicator 9000/I.

It contains a lot of collected tips and hints to find failures and repair solutions easily.

It also will give support to the inexperienced technicians.

Saving process time and improving the repair quality is the aim of using this document.

We have built it up based on fault symptoms (listed in "Contents") followed by detailed description for further

analysis.

It is to be used additionally to the service manual and other service information like Service Bulletins, for that

reason it doesn't contain any circuit descriptions or schematics.

3 (29)

All measurements are made using following equipment:

Nokia repair SW : PCLocals V 1.9 for GSM / PC Locals V 0.7 for PCN

Nokia Module Jig : MJS-1

Digital multimeter : Fluke 73

Oscilloscope : Hitachi V-1565; Fluke PM 3380A/B

Spectrum Analyser : Advantest R3131 with an analogue probe

RF-Generator / : Rohde & Schwarz CMU 200

GSM Tester

Temperature chamber : Vötsch VT 4002

While every endeavour has been made to ensure the accuracy of this document, some errors may exist. If the

reader finds any errors, NOKIA should be notified in writing, using following procedure:

Please state:

Title of the Document + Issue Number/Date of publication.

Page(s) and/or Figure(s) in error.

Please send to: Nokia GmbH

Service & Competence Center Europe

Meesmannstr.103

D-44807 Bochum / Germany

Email: training.sace@nokia.com

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 4

nokia

RAE/K-1 Repairhints

Service & Competence Center Europe

Customer Care Training Group Date 05.04.2001

CONFIDENTIAL

Introduction Version 1.0 Approved

Contents

HW-CHANGES 5

UI-PROBLEMS 6

SIMCARD FAULTS 7

NOT CHARGING 10

SELFTEST FAILED 12

CMT DOES NOT SWITCH ON 13

SWITCHES OFF INTERMITTENT 15

PDA MODULE FAULTY 16

POOR OR NO SERVICE (RAE-1) 17

LOW OR NO TX POWER (RAE-1) 19

POOR OR NO SERVICE (RAK-1) 21

LOW OR NO TX POWER (RAK-1) 23

TX I/Q PROBLEMS 25

SIGNAL CHARTS 26

CHANGE HISTORY 29

4 (29)

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 5

nokia

RAE/K-1 Repairhints

Service & Competence Center Europe

Customer Care Training Group Date 05.04.2001

CONFIDENTIAL

Introduction Version 1.0 Approved

HARDWARE CHANGES RAE-1 / RAK-1

SB 010 / RAE-1

STRANGE CHARACTERS ON THE DISPLAY

In some communicators the phone display (LCD) becomes scrambled if the user has pressed e.g. 2-5-8-0 keys of

the phone’s keypad very quickly. Typically there will be additional, missing or odd pixels at the top of the field

strength or battery level bars. To prevent these strange characters to appear at the display, the value of C346 has

been changed from 100 pF to 47 pF (On GE8 module).

SB 015 / RAE-1 SB 004 / RAK-1

NEW REED RELAY S170

This new relay is more reliable and sensitive than the old one. Change if display message “PLEASE CLOSE COVER”

appears while cover is fully closed.

This modified relay was used in production from IMEI number 490169/10/041518/0.

SB 017

NEW HARDWARE VERSIONS 5.0 AND 5.1

To improve phone’s LCD functionality and for better PDA-performance, several changes have been done,

for details see Service Bulletin 017

5 (29)

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 6

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

USER INTERFACE PROBLEMS

Check all connectors and flexfoils for their condition –if bent, dirty or poor soldered.

Display failures

CMT: Too low or too strong Display contrast or missing segments:

Check for poor soldering and/or mechanical condition of flexfoil

Check if segments missing after fast pressing keypad (eg. keys 2-5-8-0)

If this is the case – change C346 from 100pf to 47 pf

see also Service Bulletin 010 for GE8 Modul

unstable LCD backlight – change PSL N230

PDA: Bad or flickering LCD – Display driver defect – change Display

LCD Contrast problems – check/change R93, R97

Audio failures

Always check GEM-1 SIMFLEX connections / - connectors X001 (UI) and X212 (CMT)

Bad Audio Quality incoming (Xmic) – check Earphone B001 if dirty / change if necessary.

Bad Audio Quality outgoing (MicX) – check Mic B002 for dirt / change if necessary.

Ringing tone problems – check Buzzer B003 if dirty or bend / change if necessary.

Keypad failures

If there are problems with any keypad and/or functionkeys –

Metal key domes are possibly mechanically defect –

disconnect CMT LCD and change GK2 / GK2-1 PCB.

SIM failures

Check mechanical condition of GEM-1 SIMFLEX.

Check connections / -connectors of SIMFLEX.

Check pads of SIMCARD reader X002 if bent.

Change GEM-1 SIMFLEX if necessary.

General start problems

Internal failure respectively Screensaver Error GEOS.ini.

Try to format and make SW – update after formatting.

This can be done with service-software

or by pressing Shift + Esc + F and installing the battery to boot the communicator.

Keep the keys pressed until you get a screen to confirm the formatting.

Note that formatting will remove all user-generated data. You should save user`s data before proceed !

6 (29)

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 7

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

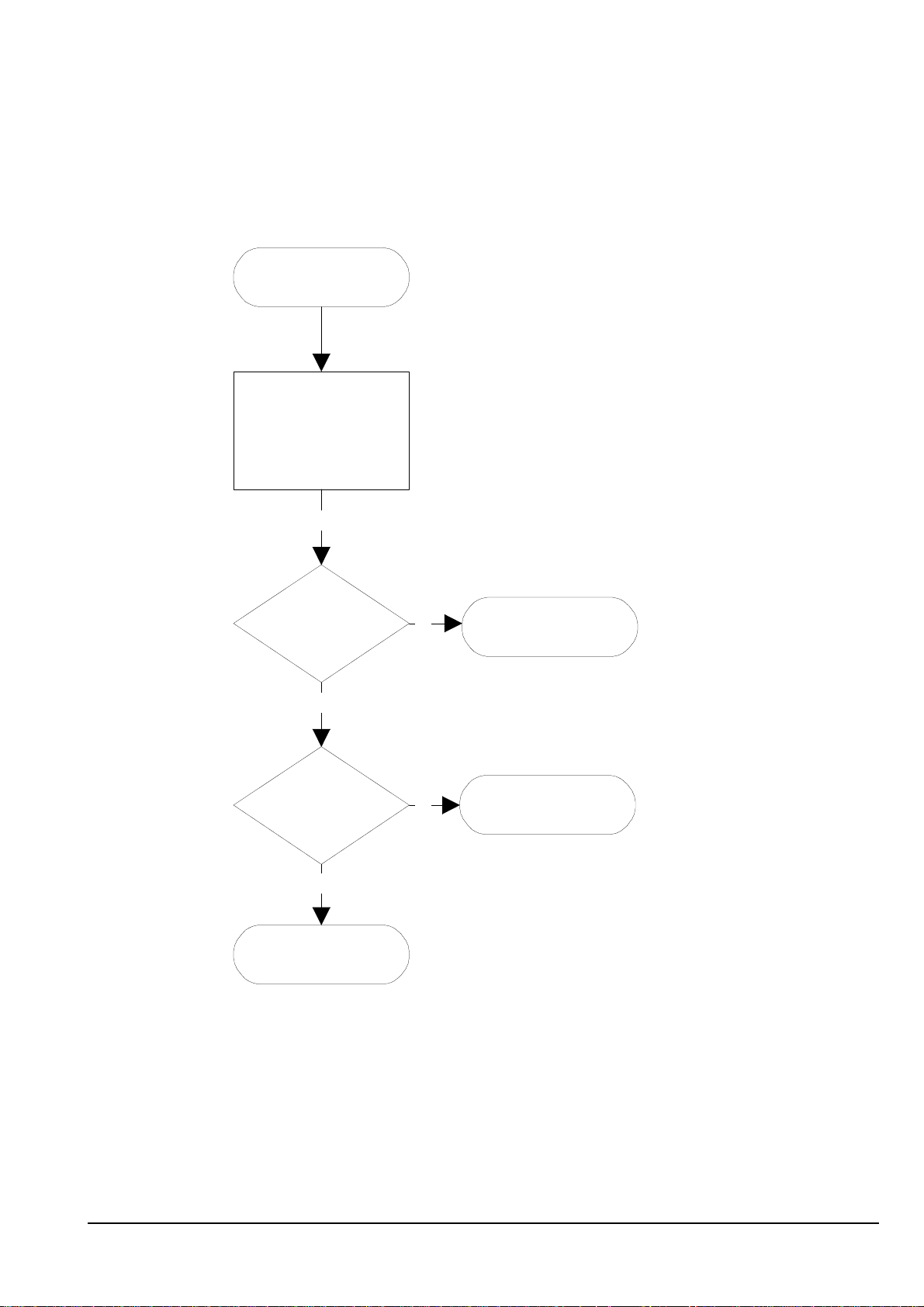

SIMCARD FAULTS

"Insert SIMcard"

Check mechanical

appearance of SIMflex

GEM-1, change if necessary

nOK

7 (29)

Check

signals at E400:

pin90 SIMreset

pin91 SIMdata

pin92 VSIM

pin94 SIMclk

nOK

Check voltage at

E400 pin 93, 4.8VDC

nOK

Check values around

V370

OK

OK

Check SIMlines for

disconnections or

shorts to GND

Change E400

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 8

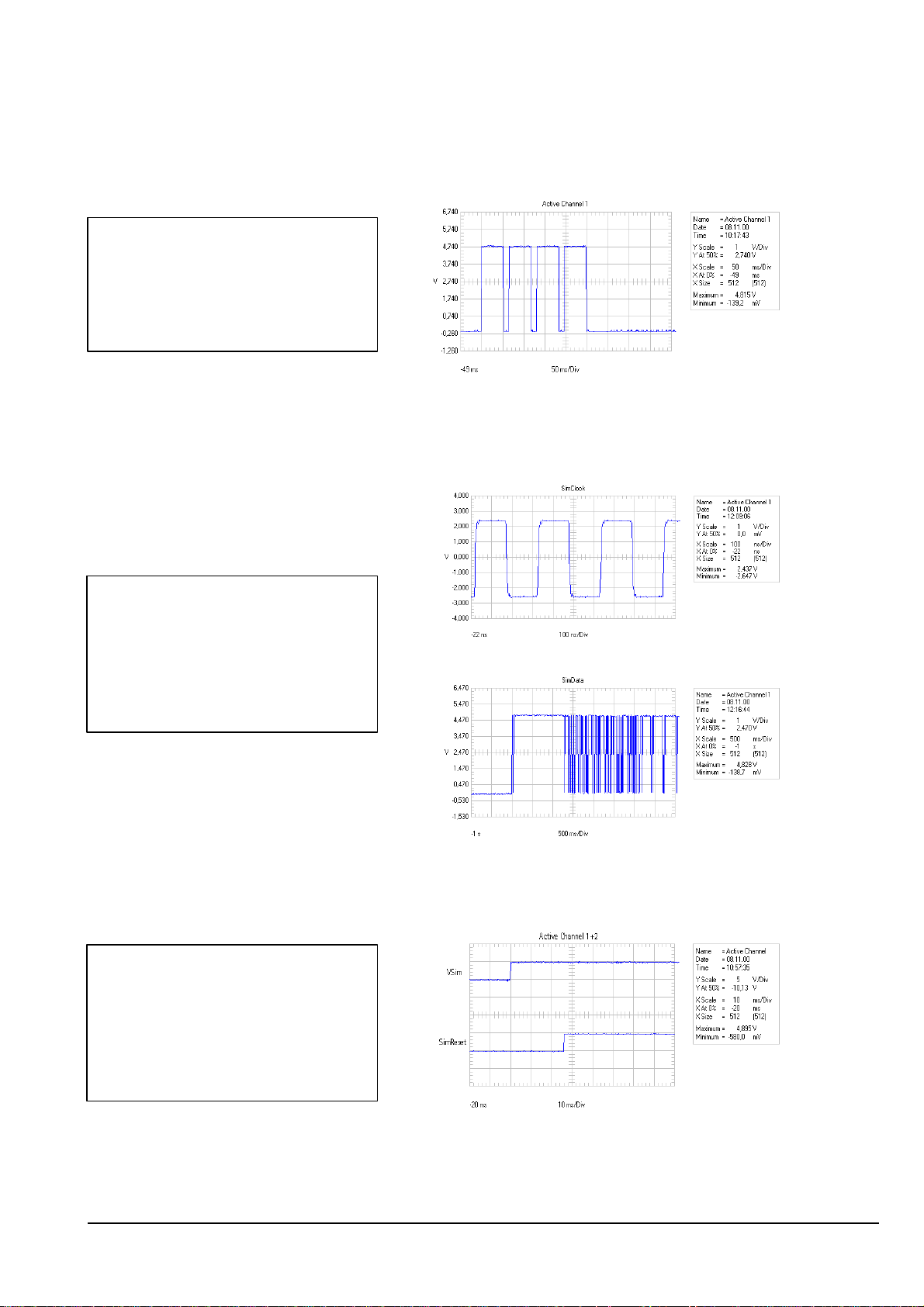

VSIM after switching on the phone without

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

SIMcard. E 400 pulses up VSIM four times

to an amplitude of 5 Volt.

8 (29)

If the phone is switched on with SIMcard Vsim keeps on 5 Volt expected that SIMcard is not dirty or damaged.

Note that SIMClock and SIMData are only

present when SIMcard is active, for

example when phone registers to network.

Some SIMcards do not allow to switch off

SIMClock but the clock-frequency can be

reduced from 3.25MHz to 1.625MHz

if SIMcard is not used.

SIMReset is low-active, that means that

the Simcard will be reseted when SIMReset

is 0 Volt.

This is the case after switching on the

phone. While VSIM is already high,

SIMReset keeps low for a few milliseconds

– in this time the card will be reseted.

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 9

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

SIMflex GEM-1

Check mechanical appearance of flexfoil, change if pads torn off or traces are damaged.

SIMlines faulty

Check connection between

E400 pin 90 and X212 pin 7 (100 Ohm, R331).

E400 pin 91 and X212 pin 9 (100 Ohm, R338).

E400 pin 94 and X212 pin 6 (68 Ohm, R330).

E400 pin 92 and X212 pin 8 (resistance is 1800 Ohm, to ensure functionality check also V330/331! ).

Check resistance of SIMlines to GND at X212, value shouldn’t decrease 100kOhm.

E 400 faulty

If SIMlines keep inactive even though SIMcard is inserted, Sim-Flex is ok, SIMlines

have no shorts to ground and voltage at E400 pin 93 is 4.8 Volt, it is necessary to change E400.

Note that you have to realign phone values after changing E400.

9 (29)

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 10

Check voltage divider R232/233

Check voltage divider R263/264

Check R202, R206/207

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

NOT CHARGING

If it is necessary to take measurements in the charging-circuit you have the possibility to activate

charging-mode in the service-jig by closing SW 1!

Nothing happens if charger is connected

First check X121 and PAR-1 if soiled or oxidized.

Check Vcharge-line for disconnections. Charger-voltage is supplied via connector X121,

over L970 / V970 (overvoltage-protection, located on PDA-board) to board-to-board connector X102/201 and

from there to V250/251, which are responsible for the fault in most cases.

If charger-voltage is ok at V250 or fault persists after changing V250/251, check CHRDET at E400

Pin 97 (~ 4V DC when charging active).

“Not charging“ appears on LCD

Calibrate battery/charger voltage with PCLocals under CMT Testing and Adjustments/Adjustments/

Battery & Charge Voltage Adjustment, values should be ~ 300 for charge voltage and ~ 600 for

battery voltage. If any AD-value is out of reference, check corresponding voltage-divider (see table below). If

calibration is ok but charging still not possible, check AD converters for Battery temp/type with PCLocals under

CMT Testings and Adjustments/Logic Controls/Read AD-Converters.

Battery voltage ~ 720*

Charger voltage ~ 360*

Battery temperature ~ 430

Battery type ~ 600 Check R208/209

* The AD-values of battery/charger voltage in the table differ from the values in calibration because

calibration is done with 6 Volt while AD-converters are read with a battery voltage of 7.2 Volt.

If charging is possible when communicator is switched on but charger is not recognized in off-state mode,

check voltage at N230 pin 11, which is normally 1.7V DC. The only function of CHRDETI line is to get phone from

off-state mode into acting-dead mode (phone is powered up but to the user it seems that phone is still switched

off, only the battery indicator is scrolling). If there is a disconnection in CHRDETI-line, above mentioned fault will

appear.

AD-value reference Possible reason if AD-value is not ok

change N230 or E200

change E200

change N230 or E200

check BATDET line for overload or disconnection

10 (29)

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 11

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

NOT CHARGING

"Not charging"

appears if charger is

connected

11 (29)

Calibrate

Charger/batt.voltage

with PCLocals

nOK

OK

Check AD_converters with

PCLocals

Try to charge after

calibration

nOK

Battery voltage out of limits

OK ~ 720

Charge voltage out of limits

OK ~ 360

nOK

nOK

Check Vcharge line

for disconnections

Check voltage divider

R232/233 or change

N230, E200

Check voltage at

V250

nOK

OK

Check voltage divider

R263/264, change

E200

© NMP 2001

Battery temperature out of

limits

OK ~ 430

Battery type out of limits

OK ~ 600

Checked by:

nOK

nOK

Check R202/206/207,

change N230/ E200

Check R208/209

check BATDET-line

for overloading

Customer Care Training Group

Approved by:

SCCE

Page 12

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

SELFTEST FAILED

If “Selftest failed“ appears on LCD, MCU (located on MCM1) is able to work and the watchdog of

PSL (N230) can be served.

To get more information about the fault use PCLocals: initialise CMT to local mode and choose

CMT Power up Selftests.

Try to flash CMT-module in case of failed selftests like MCU DSP code download or similar.

In most cases of Selftest failures one of the two multichip-modules E200 / E400 is defect. It is also

possible that one defect MCM damages the other, so that you have to change both MCMs in case

of doubt.

After changing E200 it is necessary to flash CMT-part. Then you have to write back product-code and

HW version, only after this procedure it is possible to write back the IMEI.

Don`t forget to realign RX/TX-values, because tuning values will be lost after changing E200

Note: Changing of E200 requires IMEI reconstruction process for DCT 1 phones

In case of Selftest failures which appears from time to time check DSP-oscillator. It is enabled by ASIC

(Check E400 pin 88, 4.8V DC).

Critical parts are the crystal G300, coil L300 and transformer T300. If it is necessary to change the crystal,

take care not to destroy L300, which is thermical sensitive!

12 (29)

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 13

nokia

RAE/K-1 Repairhints

Service & Competence Center Europe

Customer Care Training Group Date 05.04.2001

CONFIDENTIAL

Introduction Version 1.0 Approved

CMT MODULE DOES NOT SWITCH ON

In this case check first of all the fault with the normal battery, do NOT connect a service-battery

to the phone. If the CMT-module does not switch on disassemble it and check resistance of capacitors

C763 and C790-793. If resistance of every capacitor is ok, you can connect phone to a service-battery

to check current consumption – the use of other tools may result in burnt traces !

Off state current should be ≤ 2mA, sleep mode current ≤ 20mA, call mode current varies

between 200mA and 600mA (depends on TX powerlevel and lights).

Note: If module is placed in service-jig, deactivate the PDA-module by closing S170, before powering on CMT with

the powerswitch!

It is also not possible to switch on CMT of an assembled communicator with an open lid; you can check

state of lid with PCLocals under CMT Testings and Adjustments/Logic Controls/Read AD Converters in

local mode: Cover information with open lid ~ 870, closed ~ 100.

13 (29)

If CMT does not switch on, it can also be necessary to update the CMT software.

Because of two different CMT-modules GE-8/GE-9 you have to check out the MCU internal software version.

This is necessary to update the different versions with the matching version of CMT-software,

for example MCU int. SW 2.16 with ext. SW GE8_216.502 and MCU int. SW 2.17 with ext. SW GE8_217.502

If there is no possibility to read out MCU int. SW, try to flash several times with the different versions.

How to carry out the upgrade procedure of the CMT side SW see also SB-005.

Note that it is necessary to retune RSSI if CMT-SW has been upgraded to version GE8_216.502 / GE8_217.502.

Due to GEOS Operating System licence agreement it is NOT ALLOWED to upgrade Nokia 9000 to

Nokia 9000i by using Nokia 9000i Flash (CMT or PDA) SW!

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 14

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

CMT DOES NOT SWITCH ON

Does not

switch on

14 (29)

Check if PWR

consumption is fixed

or about 500mA

No

Check Vbatt at

N230, pin 5,20

OK

Check DETin 1.8VDC

at N230, pin 12

OK

Check that

XPWRon at N230 pin 10

decreases to 0 if

PWRswitch is pressed

OK

Check VL1 4.8V DC

at C241

Yes

nOK

nOK

nOK

nOK

Check Vbatt line for

shorts to GND or try

to flash CMT-module

Check

X202,L200/202

Check Voltage divider

R230/231

Check S36, X001,

R984/985, V130,

X102/201

Check/change L230,

V230, N230

OK

Check Vref 4.65VDC

+/-2% at C247

OK

Check MCUCLK at

E200 pin 85, 26MHz,

5Vpp squarewave

nOK

nOK OK

Check Vref-line for

overloading, change

N230

Check 26MHz Clk at

E400 pin 13, 5.5V

squarewave

nOK

OK

Check XRES 4.8VDC

at E400 pin 96

OK OK OK

nOK

Change N230 Check/change E400 Check/change E200

Check RESETX 4.8V

at E400 pin 112

nOK

Check values around

B800, also check

D300/301

Check/change E400

Check XPWROFF at

E200 pin 22, 5Vpp

squarewave

nOK

Powerunit is ok

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 15

nokia

RAE/K-1 Repairhints

Service & Competence Center Europe

Customer Care Training Group Date 05.04.2001

CONFIDENTIAL

Introduction Version 1.0 Approved

SWITCHES OFF INTERMITTENT

12

If the communicator switches off itself after turning power on while message „recharge battery“ appears

on CMT-display, check voltage at E200 pin 53, should be 3.6V DC. If voltage is not ok, check VBATDETline between N230 pin 23 and E200 pin 53 for shorts to ground or disconnection. Check also voltage divider

R232/233, change N230 or E200 if necessary.

Note that you have to flash CMT-part, write back phone data and realign phone values when changing

E200 because it contains both Flash and EEPROM!

12.87

If the communicator intermittent switches off itself

and the symptom can be reproduced by moving the

battery sideways, check that the space between the

right edge of connector X202 and the chassis is

0.5mm. If distance is not ok, try to correct it by

opening screws of shield and chassis and push CMTmodule to the left, check gap after tightening the

screws. If this does not work, replace connector

X202.

15 (29)

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 16

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

PDA – MODULE FAULTY

Because of very detailed troubleshooting diagrams in the service manual we will describe in the

following only the most common faults of the PDA-module.

For more information refer to Servicemanual chapter 8 (Faultfinding & Disassembly).

If you suppose a faulty FLASH, never change D163. This part contains the boot-code, which PDA needs to

start. Without boot-code PDA won`t work, it is even impossible to ping PDA or make SW-update.

As you won`t be able to rewrite boot-code, you have to swap module.

PDA-module not initialising

Check Communicator in temperature chamber at +5°C for 10min. if fault occurs only from time to time.

If PDA module does not initialize after temperature check or hangs up, make HW-update as described in SB017.

Other possibilities if HW-update does not solve the problem :

Check connector X121 for cold solderings, if bent or soiled. Check also V970, L970 and C970

PDA does not start

Check state of lid with PCLocals: CMT Testings and Adjustments/Logic Controls/Read AD Converters

in local mode: Cover information with open lid ~ 870, closed ~ 100. If value is fixed on ~ 100, check

mechanical/electrical appearance of S170,also check R150/151. Probably force of magnet is too low.

Check Vb 7.2V DC at both sides of L80, change coil if necessary.

Check voltage at C89, 22V DC. If not ok, check R77 for defect or cold soldering, change N83 if necessary

Check R184 (33 Ohm) for defect or broken solderings

Check voltage at connector X010 pin1 on UI-module, which is 3.3V DC when PDA is active.

If not ok, check R926/927, also check flex foil of PDA-LCD, which can be easily damaged while disassembling.

16 (29)

Check 32.768kHz sinewave at D130

pin 86. In most cases the crystal

B130 is defect if signal is not ok.

In some cases it can be necessary to format file system. This can be done with service-software

or by pressing Shift + Esc + F and installing the battery to boot the communicator.

Keep the keys pressed until you get a screen to confirm the formatting.

Note that formatting will remove all user-generated data. You should save user`s data before proceed !

PDA does not start after screensaver was active/standby-problems

This fault occurs often, if Communicator is checked in temperature chamber at +5°C for 10min.

In this case HW-update as described in SB17 is necessary

Change R120- R129 from 22kOhm to 4.7kOhm and replace D130 with new part (code 4370339)

Screensaver Error GEOS.ini / internal error

It is necessary to format file system and make SW-update.

(press Shift + Esc + F and install battery to boot the communicator; all user-generated data will be lost!).

Date & time lost after battery removal

Check that voltage of G87 is ≥ 2.8 VDC. Change if voltage is lower than 2.8V – G87 is NOT chargeable!

PDA Display failures

Bad or flickering LCD – Display driver defect – change Display

LCD Contrast problems – check/change R93, R97

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 17

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

POOR OR NO SERVICE (RAE–1)

First of all: Check the appearance of all mechanical components, connectors and connections like coax cable and

connectors X503 / X501 / X035.

If the mechanical condition is OK, calibrate RX/TX values to find out the trouble.

RX failed

Check the TX-spectrum at standard frequency (902MHz /CH 60). If spectrum is ok, check the following points.

Measurements taken by input signal 947 MHz / CH 60 and level –40dBm

Check Data signals coming from MCM2

SCLK : 3Vpp squarewave at R823

SDATA : 4.5Vpp squarewave at R824

SENA1 : 3Vpp squarewave at R825

PDATA0 : 5Vpp squarewave at R507

Change MCM2 / E400 if one or more of these signals failed

If these signals are ok, check the reference frequency of 26 MHz at N820, pin 8, frequency deviation ≤ 50Hz.,

change B800 if necessary.

Check also VREF 4.65VDC ± 2% (from PSL)

Check also VPLL, VHLO, VRX, RXPWR and SYNTHPWR: 4.7V, see diagrams at page #26 and / or change N601 if

necessary.

Check UHF oscillator frequency 1018 MHz at N820, pin 6, change G001 if necessary

Check VHF oscillator frequency 232 MHz at N820, pin 15

Check 947 MHz at Z500, RX pin ~ -50dBm

Check 947 MHz at V501, Base pin ~ -70dBm and output at collector pin ~ -52dBm

Check 947 MHz in and out at Z505, attenuation ≤ 5dBm

Change corresponding components

Check UHF 1018 MHz at V511

Check IF 71 MHz at V511 / L511 ~ -65dB / change V511 if necessary

Check IF 71 MHz at L542 (input of Z541) approximately –37dBm and

output of Z541 with ≤20dBm attenuation at C545 / C546

Check IF 71 MHz at N551, pin 1,2 ~ -56dBm

Check IF 13 MHz at N551 out, pin 7 and in at pin 9,10

Check 13 MHz RXI / RXQ ~ -21dBm at N551, pin 13,12

Change Z551 / N551 if necessary

Note that the measured RF values depend on used measurement equipment.

17 (29)

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 18

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

RAE-1

18 (29)

Change PSL N230

Change N601

nOK

nOK

RX FAIL

Check

SCLK at R823

SDATA at R824

SENA1 at R825

PDATA0 at R507

Check VREF: 4.65V (+-2%)

Check VBATT at N601: 7.2V

Check VPLL, VHLO, VTX,

TXPWR, all ~ 4.7V

Check:

TXIN at R551

TXIP at R553

TXQP at R554

TXQN at R556

OK

Check AFC at R800: ~2.7V

OK

OK

Check 26MHz at C803

OK

OK

Check SYNTHPWR at R601

OK

OK

Check UHF 1018 MHz at

OK

N820, pin6

nOK

nOK

nOK

nOK

Change E400

Change B800

Check/change E400

Change G001

Check values at V840

and 841, change N820 if

Check/change

components in line to

Change Z541 if

necessary

necessary

V511

Check VHF 232MHz at N820,

pin15

Check UHF 1018MHz at

V511

Check IF71 MHz at L542 and

Values at C545/546

Check IF 13MHz at N551/

pin 7 output and pin 9,10

input

OK

Check 947 MHz at V501,

check 947 MHz at Z505

OK

OK

OK

OK

OK

OK

OK

in&out (att~5dB)

Check IF 71MHz at V511 and

L511

Check 71MHz at input N551

pin1,2

Check RX I/Q values at

N551, pin 12/13

nOK

nOK

nOK

Check C506, change

corresponding

components

Change V511

Check/change

components in lines

to N551

Change Z551/N551

corresponding on

failed signal

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 19

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

LOW OR NO TX POWER (RAE–1)

First of all check always the appearance of all mechanical components, connections or connectors like coax cable,

and connectors X503 / X501 / X035.

TX failed

Measurements taken by active unit TX channel 60, 902MHz

Check TX I/Q and Data signals coming from MCM2

TXIN : 400mVpp squarewave at R551

TXIP : 400mVpp squarewave at R553

TXQP : 400mVpp squarewave at R554

TXQN : 400mVpp squarewave at R556

SCLK : 3Vpp squarewave at R823

SDATA : 4.5Vpp squarewave at R824

SENA1 : 3Vpp squarewave at R825 and/or see diagrams at page 26

Change MCM2 / E400 if one or more of these signals failed

If these signals are ok check the reference frequency of 26 MHz at N820, pin 8, frequency deviation ≤ 50Hz.

change B800 if necessary

Check also VREF 4.65VDC ± 2% (from PSL).

Check also VPLL, VHLO, VTX, TXPWR and SYNTHPWR 4.7V

see diagrams at page #26 and / or change N601 if necessary

Check UHF oscillator frequency 1018 MHz at N820, pin 6, change G001 if necessary

Check VHF oscillator frequency 232 MHz at N820, pin 15

Check VHF 232 MHz at N551, pin 16,19 ~ -26dBm

Check ½ VHF 116 MHz output at N551, pin 28 ~-30dBm, change N551 if necessary

Check ½ VHF 116 MHz at C710 (~ -12dBm) and at V702 (~ -25dBm)

Check UHF 1018 MHz at V702 ~ -10dBm

Check 902 MHz at V710, Basis pin ~ -39dBm and collector pin ~ -20dBm

Check 902 MHz at Z713 input (~ -23dBm) and output (~ -26dBm)

Check VBATT 6.5V before and after R743 and R756, change corresponding component

Check 902 MHz at V725 / V738 / V756 and V768 in- & output

If V756/V768 defect for itself, change the second one as well in every case

Check 902 MHz at Z500 (~ -12dBm), change corresponding component(s)

19 (29)

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 20

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

RAE-1

20 (29)

Change PSL N230

Change N601

nOK

nOK

TX FAIL

Check

SCLK at R823

SDATA at R824

SENA1 at R825

Check VREF: 4.65V (+-2%)

Check VBATT at N601:

7.2VDC

Check VPLL, VHLO, VTX,

TXPWR, all 4.7V

Check:

OK

OK

OK

OK

OK

OK

OK

OK

OK

TXIN at R551

TXIP at R553

TXQP at R554

TXQN at R556

Check AFC at R800:

0.2-4.6VDC

Check 26MHz at C803

freq.-devitation <=50Hz

Check SYNTHPWR at R601

Check UHF 1018 MHz at

N820, pin6

nOK

nOK

nOK

nOK

Change E400

Change B800

Check/change E400

Change G001

Change cor. comp.If

V756/768 def.,change

2nd one too

Check VHF 232MHz at N820,

pin15 and values at N551,

Check 1/2 VHF 116MHz at

C710 (~-12dBm) and V702

Check 902 MHz at Z713

nOK

pin 16/19

(~-25dBm)

input ~-23dBm, output

~-26dBm

Check 902 MHz at

V725/738/756/768

OK

Check 1/2 VHF 116MHz at

OK

OK

OK

OK

OK

OK

OK

N551, pin28

Check UHF 1018MHz at

V702 ~-10dBm, check 902

MHz at V710 basis

~-39dBm/ collector ~-20dB

Check VBATT 6.5V before and

after R743/756

Check 902 MHz at Z500

~-12dB

nOK

nOK

nOK

Change N551

Change def.

component

Change

corresponding

components in line

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 21

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

POOR OR NO SERVICE (RAK–1)

First of all check always the appearance of all mechanical components, connections or connectors like coax cable,

and connectors X503 / X501 / X035.

If the mechanical condition is OK, calibrate RX/TX values to find out the trouble.

RX failed

At first check if there is a TX-spectrum is standard frequency of 1747,4MHz /CH 698

If TX spectrum and an RSSI calibration not possible – probably MCM2 / E400 faulty

If spectrum ok, check the following points…

Measurements taken by input signal 1842,4MHz / CH 698 and level –40dBm

Check Data signals coming from MCM2

SCLK : 3Vpp squarewave at R823

SDATA : 4.5Vpp squarewave at R824

SENA1 : 3Vpp squarewave at R825

PDATA0 : 5Vpp squarewave at R507

and/or see diagrams at page #26, check also AFC at R800, 0.2-4.6VDC.

Change MCM2 / E400 if one or more of these signals failed

If these signals are ok, check the reference frequency of 26 MHz at N820, pin 8 frequency deviation ≤ 50Hz,

change B800 if necessary.

Check also VREF 4.65VDC ± 2% (from PSL),

Check also VPLL, VHLO, VRX, RXPWR and SYNTHPWR 4.7V.

See diagrams at page #26 and / or change N601 if necessary

Check UHF oscillator frequency 1529.4 MHz at N820, pin 5, change G001 if necessary

Check VHF oscillator frequency 400MHz at N820, pin 16.

Check 1842.4MHz at Z500, RX pin ~ -50dBm.

Check 1842.4MHz at V501, Basis pin ~ -70dBm and output at collector pin ~ -52dBm.

Check 1842.4MHz in and out at Z505, attenuation ≤ 5dBm.

Change corresponding components, check UHF 1529.4MHz at V511.

Check 1st IF 313MHz at V511 / L511 ~ -65dBm / change V511 if necessary, check 313MHz at V531 / L530.

Check 87MHz at L531 – if not ok – check / change V531.

nd

Check 2

IF 87MHz at L542 (input of Z541) approximately –37dBm and output of Z541 with ≤ 20dBm

attenuation at C545 / C546.

Check 2nd IF 87MHz at N551, pin 1,2 ~ -56dBm – not ok check lines back to Z541

Check 3rd IF 13 MHz at N551 out, pin 7 and in at pin 9,10

Check 13 MHz RXI / RXQ ~ -21dBm at N551, pin 13,12, change Z551 / N551 if necessary

21 (29)

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 22

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

RAK-1

RX FAIL

Check

SCLK at R823

SDATA at R824

SENA1 at R825

PDATA0 at R507

OK

Check AFC at R800

0.2-4.6VDC

nOK

Change E400

22 (29)

Change PSL N230

Change N601

Check values at V840

and 841, change N820 if

necessary

Check/change

components in line to

V511

nOK

Check VREF: 4.65V (+-2%)

Check VBATT at N601: 7.2V

nOK

nOK

Check VPLL, VHLO, VTX,

Check VHF 400MHz at N820,

nOK

Check 313MHz at V511 and

TXPWR, all 4.7V

pin15

L511

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

Check 26MHz at C803

frequency deviation

+- 50Hz

Check SYNTHPWR at R601

Check UHF 1529.4 MHz at

N820, pin6

Check 1842.4 MHz at V501

and Z505 in&out (att<5dB)

Check IF 87MHz at V531 and

values at C545/546

nOK

nOK

nOK

nOK

nOK

Change B800

Check/change E400

Change G001

Check C506, change

corresponding

components

Change V511

Change Z541 if

necessary

© NMP 2001

nOK

Check IF 87MHz at input

N551, pin 1,2

OK

Check IF 13MHz at N551

pin7 output and pin 9,10

OK

Check RXI/Q signals at

N551/pin 12,13

OK

Check RX I/Q signals at

N551, pin 12/13

OK

Checked by:

Customer Care Training Group

input

nOK

nOK

Check/change

components in lines

to N551

Change Z551/N551

corresponding on

failed signal

Approved by:

SCCE

Page 23

nokia

RAE/K-1 Repairhints

Service & Competence Center Europe

Customer Care Training Group Date 05.04.2001

CONFIDENTIAL

Introduction Version 1.0 Approved

LOW OR NO TX POWER (RAK–1)

First of all check always the appearance of all mechanical components, connections or connectors like coax cable,

and connectors X503 / X501 / X035.

Measurements taken by active unit TX channel 698, 1747.4MHz

Check TX I/Q and Data signals coming from MCM2

TXIN : 400mVpp squarewave at R551

TXIP : 400mVpp squarewave at R553

TXQP : 400mVpp squarewave at R554

TXQN : 400mVpp squarewave at R556

SCLK : 3Vpp squarewave at R823

SDATA : 4.5Vpp squarewave at R824

SENA1 : 3Vpp squarewave at R825 and/or see diagrams at page 26

Change MCM2/E400 if one or more of these signals failed.

If these signals are ok check the reference frequency of 26 MHz at N820, pin 8 frequency deviation ≤ 50Hz

Change B800 if necessary.

Check also VREF 4.65V ± 2% (from PSL),

Check also VPLL, VHLO, VTX, TXPWR and SYNTHPWR: 4.7V

See diagrams at page #26 and / or change N601 if necessary.

Check UHF oscillator frequency 1529.4MHz at N820, pin 5, change G001 if necessary.

Check VHF oscillator frequency 400MHz at N820, pin 16.

Check VHF 400MHz at N551, pin 16,19: (~ -26dBm)

Check ½ VHF 200MHz output at N551, pin 28: (~-30dBm), change N551 if necessary

Check ½ VHF 200MHz at C710 (~ -12dBm) and at V702 (~ -25dBm)

Check UHF 1547.4MHz at V702 ~ -10dBm.

Check 1747.4MHz at V710, Base pin ~ -39dBm and collector pin ~ -20dBm.

Check 1747.4MHz at Z713 in & out (attenuation ≤10dBm).

Check VBATT 7.2V at V738 and V755, R768, change corresponding component.

Check 1747.4MHz at V725 / V738 / V756 and V768 in- & output.

If V756/V768 defect for itself, change the second one as well in every case.

Check C772, C775, C776, and C774 – change if necessary.

Check 1747.4MHz at Z500 (~ -12dBm), change corresponding component(s).

23 (29)

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 24

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

RAK-1

24 (29)

Change E400

Change PSL N230

Change N601

nOK

nOK

nOK

TX FAIL

Check

SCLK at R823

SDATA at R824

SENA1 at R825

Check VREF: 4.65V (+-2%)

Check VBATT at N601:

7.2VDC

Check VPLL, VHLO, VTX,

TXPWR, all 4.7VDC

Check:

OK

OK

OK

OK

OK

OK

OK

OK

OK

TXIN at R551

TXIP at R553

TXQP at R554

TXQN at R556

Check AFC at R800:

0.2-4.6VDC

Check 26MHz at C803

frequenz-devitation

+-50Hz

Check SYNTHPWR at R601

Check UHF 1529.4 MHz at

N820, pin5

nOK

nOK

nOK

nOK

Change E400

Change B800

Check/change E400

Change G001

Change corresponding

components in line

Change cor. comp.If

V756/768 def.,change

back

2nd one too

Check VHF 400MHz at N820,

pin16 and values at N551,

Check 1/2 VHF 200MHz at

nOK

Check 1747.4 MHz at Z713

nOK

V725/738/756/768, check

pin 16/19

V702

V710 (att. <=10dBm)

Check 1747.4 MHz at

C772/775/776/774

OK

Check 1/2 VHF 200MHz at

OK

OK

OK

OK

OK

OK

OK

N551, pin28

Check UHF 1547.4 MHz at

V702

Check VBATT 7.2V at

V738/755

Check 1747.4 MHz at Z500

~-12dBm

nOK

nOK

nOK

Change N551

Change def.

component

Change

corresponding

components in line

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 25

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

Spectrum out of range / no spectrum (noise only)

First of all check always the appearance of all mechanical components, connections or connectors like coax cable,

and connectors X503 / X501 / X035.

Check 26 MHz reference frequency at N820, pin 8

Change B800 if frequency deviation higher than +/-50Hz

Check VREF 4.65VDC ± 2% at C806

Change N230 if VREF fails

Check TX I/Q signals coming from MCM2 / E400

TXIN : 400mVpp squarewave at R551

TXIP : 400mVpp squarewave at R553

TXQP : 400mVpp squarewave at R554

TXQN : 400mVpp squarewave at R556

25 (29)

Check TXC (at R574) and TXP (at R571) signals to N551

See diagrams at pages #26+27

Check soldering / change N551 if necessary

Check soldering / change E400 if necessary

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 26

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

SIGNAL CHARTS

26 (29)

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 27

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

27 (29)

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 28

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

28 (29)

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Page 29

nokia

CONFIDENTIAL

RAE/K-1 Repairhints

Service & Competence Center Europe

Introduction Version 1.0 Approved

Customer Care Training Group Date 05.04.2001

CHANGE HISTORY

Originator State Version Date Comment

CC-TrainingGroup

CC-TrainingGroup

Draft 0.1

Approved 1.0 05.04.2001 First approved version. Comments of repairgroup added.

16.03.2001

First draft version for the repair group

29 (29)

© NMP 2001

Checked by:

Customer Care Training Group

Approved by:

SCCE

Loading...

Loading...