Page 1

PAMS Technical Documentation

NSE–6 Series Transceivers

Disassembly &

Troubleshooting

Instructions

Original 08/98

Page 2

NSE–6

PAMS

Disassembly & Troubleshooting Instructions

Technical Documentation

CONTENTS

Disassembly 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Baseband Testing 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alignments 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trouble Shooting 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone is totally dead 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flash programming doesn’t work 7. . . . . . . . . . . . . . . . . . . . . . .

Flash Programming failure (1) 9. . . . . . . . . . . . . . . . . . . . . . .

Flash Programming failure (2) 10. . . . . . . . . . . . . . . . . . . . . . .

Flash Programming failure (3) 11. . . . . . . . . . . . . . . . . . . . . . .

Flash Programming failure (4) 12. . . . . . . . . . . . . . . . . . . . . . .

Power doesn’t stay on, or phone is jammed 13. . . . . . . . . . . . . .

Display Information: Contact Service 14. . . . . . . . . . . . . . . . . . . .

The phone doesn’t register to the network or phone doesn’t make a call 15.

Phone register failure 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SIM card related failures 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SIM Card failure 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Audio failure 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charger failure 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Fault (1) 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Fault (2) 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Fault (3) 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Fault (4) 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Fault (5) 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Fault (6) 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter Fault (1) 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter Fault (2) 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter Fault (3) 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix D 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test points 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page No

Page 2

Original 08/98

Page 3

PAMS

NSE–6

Technical Documentation

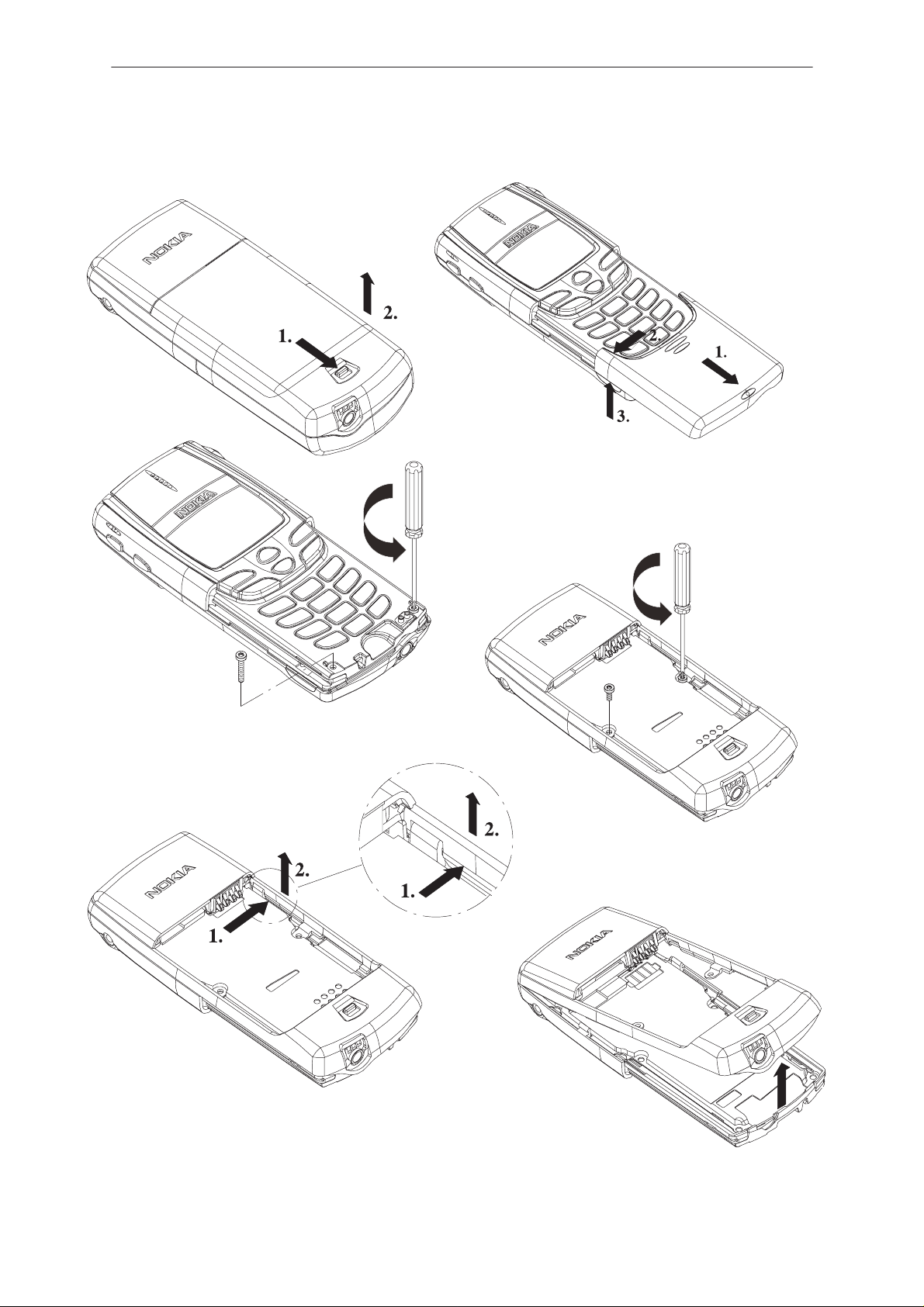

Disassembly

Remove battery

Disassembly & Troubleshooting Instructions

Step 1. Open slide cover.

Step 2. Push slide edge outwards.

Step 3. Lift slide up from the edge

and slide will be released.

Remove a–cover

screws (2 pcs)

NOTE: When assembling the

screws, use 17 Ncm torque.

Turn the phone around and remove C–cover screws (2 pcs)

Step 1. Push c–cover edge outwards to release it behind locking snap

Step 2. Lift up the edge to release c–cover.

Step 3. Repeat the operation on both sides.

Original 08/98

Remove c–cover by

lifting up rear and

pulling cover out.

Page 3

Page 4

NSE–6

PAMS

Disassembly & Troubleshooting Instructions

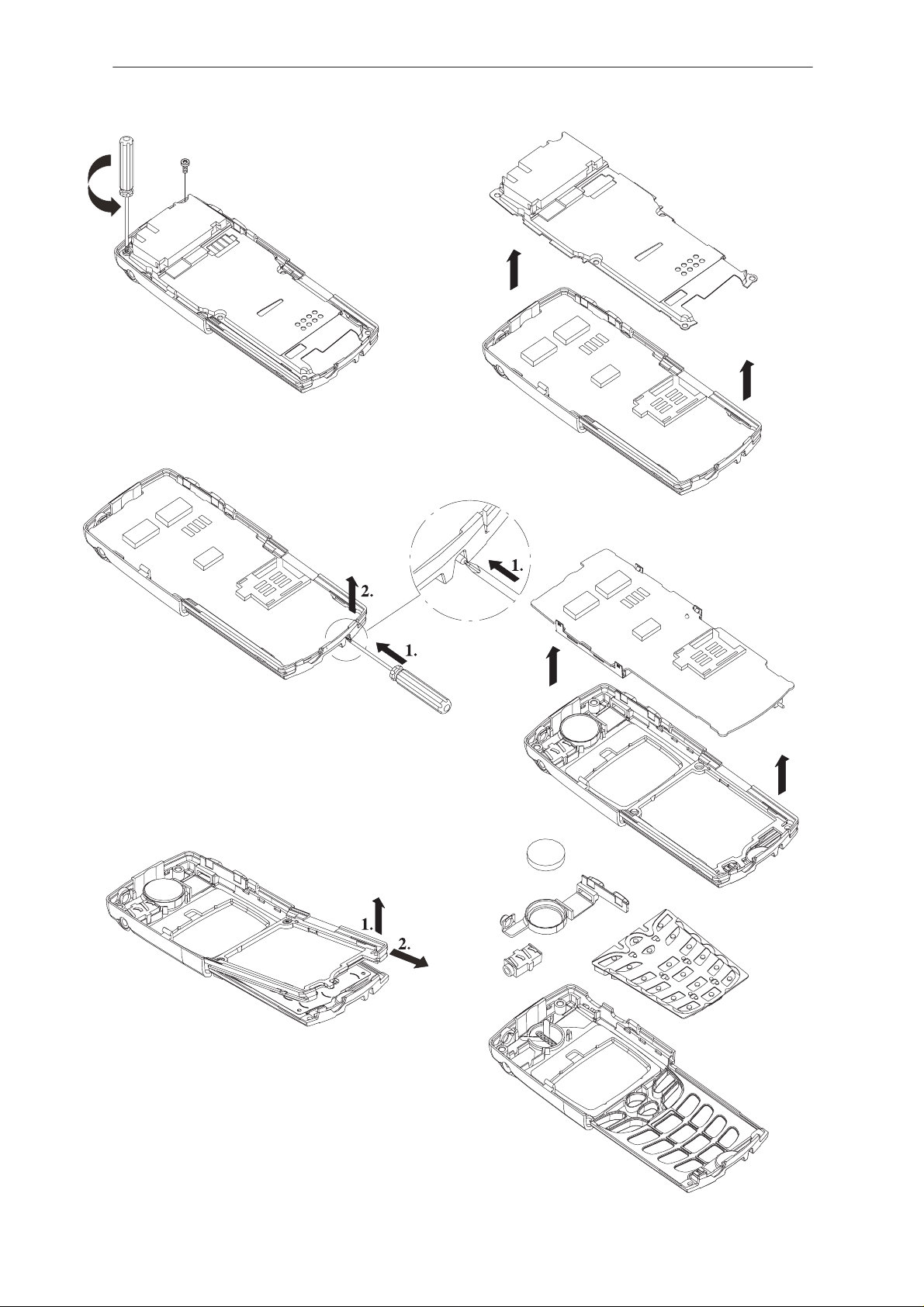

Remove shield

screws (2 pcs).

Step 1. Push slide detector

switch to the bottom and hold.

Step 2. Release main pcb by

lifting rear up and pulling.

Technical Documentation

Remove shield.

Step 1. Lift slide frame from botttom and loosen it from a–cover.

Step 2. Remove slide frame, UI–

board will follow.

Remove main pcb.

Page 4

Parts can be separated.

Original 08/98

Page 5

PAMS

NSE–6

Technical Documentation

Baseband Testing

The MCU software enters a local mode at start–up if suitable resistors are

connected to the BTEMP and BSI lines. NOTE! Baseband doesn’t wake up

automatically when the battery voltage is connected. Power must be

switched on via:

1. Pwr key or

2. BTEMP line or

3. Charger

In the local mode the baseband can be controlled through MBUS or FBUS

connections by a PC–locals software. Baseband internal connections are

tested with self tests if possible. By connecting MAD2 pin ROW5 to ground,

MAD2 pins are toggled as a daisy chain, which can be used for detecting

short circuits in MAD2 pins. Test pads are placed on engine pcb for service

and production troubleshooting purposes in some supply voltage and signal

lines.

Disassembly & Troubleshooting Instructions

Alignments

Within alignment those parameters are adjusted, that cannot be set accurate

enough by design because of component tolerances. Due to use of 5% resistor values, the channels of the CCONT A/D converters need to be aligned

in the production phase. Within battery voltage tuning the MCU software

reads the A/D reading from CCONT at 4.1V and stores this reading to EEPROM memory as a reference point. Another reference point is created by

assuming that while the input voltage is zero, A/D reading is also zero. Now

the slope is known and A/D readings can be calibrated. Calibration is included in VBAT A/D reading task.

Battery charging voltage VCHAR and current ICHAR are calibrated using

one test setting. T est jig in production/service must have a connection to battery terminals. ICHAR and VCHAR are supplied fron the jig and service software calculates values, which are then stored to EEPROM.

Original 08/98

Page 5

Page 6

NSE–6

PAMS

Disassembly & Troubleshooting Instructions

Trouble Shooting

The following hints should facility finding the cause of the problem when

the circuitry seems to be faulty. This trouble shooting instruction is divided following section.

1. Phone is totally dead

2. Flash programming doesn‘t work

3. Power doesn‘t stay on or the phone is jammed

4. Display information: Contact Service

5. Phone doesn‘t register to the network or phone doesn‘t make a call.

6. SIM card related failures ( insert SIM card or card rejected).

7. Audio fault.

8. Charging fault

The first thing to do is carry out a thorough visual check of the module.

Ensure in particular that:

a) there are not any mechanical damages

b) soldered joints are OK

Technical Documentation

Page 6

Original 08/98

Page 7

PAMS

NSE–6

Technical Documentation

Phone is totally dead

This means that the phone doesn’t take current at all when the power

switch is pressed or when the watchdog disable pin (X001 pin 11, J111) is

grounded. Used battery voltage must be higher than 3.1 V. Otherwise the

hardware of CCONT (N100) prevents totally power switch–on.

Phone is totally dead

Yes

J232 VBAT is 3.6 V

Yes

Voltage at J111 is 3.6V

Disassembly & Troubleshooting Instructions

No

Failure in VBA T line

Check L103

No

Faulty CCONT (N100)

Yes

VBB 2.8 V (R115, C107..)

VXO 2.8 V (C149..)

When PWR switch is pressed or

WDDIS is grounded (J111)

Yes

See section ”Power doesn’t stay on”

No

WDDIS (J111)) is

0V, when PWR switch

is pressed

Faulty CCONT (N100)

Flash programming doesn’t work

The flash programming can be done via panel connector X001 or via dedicated PCB pads. In production, the first programming is done via panel

connector. After this, the panel connector is cut away, thus the programming must be done via PCB pads visible through the shield under the battery. The main difference between these is that FLASH programming voltage is produced differently.

Yes

No

Check PWR switch

to CCONT line: R341,

R1 18

In flash programming error cases the flash prommer can give some information about a fault. The fault information messages could be:

– MCU doesn’t boot

– Serial clock line failure

– Serial data line failure

– External RAM fault

– Algorithm file or alias ID don’t find

– MCU flash Vpp error

Original 08/98

Page 7

Page 8

NSE–6

PAMS

Disassembly & Troubleshooting Instructions

In cases of unsuccesful flash programming there is a possibility to check

short circuits between the memories and the MCU (MAD2). It is useful to

do this test, when the fault information is: MCU doesn’t boot, Serial clock

line failure or Serial data line failure. The test procedure is following:

1. Connect testpoint J229 to ground.

2. Switch the power on.

3. If the voltage level in testpoint J225 is 2.8 V (”1”), the interface is OK. If

there is a short circuit, the voltage level in testpoint J225 stays low and 32kHz

square wave signal can be seen in the lines which are already tested.

It must be remembered that this test can only find short circuits, not open

pins. In addition upper data lines (15:8) of flash memory D220 are not included in this test.

CCONT pin 54

Technical Documentation

( PURX )

passed

MAD pin 38

MAD pin 134

J225

( MCUAD0)

( ExtSysResX))selftest

Page 8

Original 08/98

Page 9

PAMS

NSE–6

Technical Documentation

Flash Programming failure (1)

Flash programming doesn’t work

via panel connector

YES

If the fault information from prommer is:

a) MCU doesn’t boot

b) Serial data line failure

c) Serial clock line failure

connect watchdog disable (WDDIS, J111)

line to the ground

OK

VBB (R115, C107 upper side) 2.8 V

VXO (C149 upper side ) 2.8 V

YES

Check C213, R213

YES

NO

RFC (C664) 13 MHz

800 mV min

NO

J227 master reset (Purx) = ”1” (2.8 V)

YES

RfClk (R213 lower side) 13 MHz sine wave

clock signal: 500 mV

pp

YES

Disassembly & Troubleshooting Instructions

NO

See section ”Phone is totally dead”

NO

J228 sleep clock (SCLK)

square wave 32 kHz

YES

min

Faulty circuit N100

or overloaded PurX line

NO

Check sleep

clock circuitry

(B101, R154..)

Check buffer V660 and

VCTCXO G660

Check that following lines are correct:

FTX (fbus_tx) line: X001 pin 1 ––> R215

FRX (fbus_rx) line: X001 pin 2 ––> R201

FCLK (MBUS) line: X001 pin 3 ––> R115

Check also pullup and pulldown resistors R115, R201, R215

GND: X001 pin 7 ––> GND

OK

Enable the selftest function of D200 by connecting

J229 to ground

Connect oscilloscope to testpoint J225

(ExtSysResetX) and switch power on

Voltage level rises to ”1” after power on at testpoint J225

YES

There could be open pins in circuits D200 (D220, D240)

(open joints may be detectable with microscope)

If not, the PCB or D200 (D220, D240) is faulty.

There is a shortcircuit

NO

somewhere in memory control

lines or MCU address lines or

MCU lower (7:0) data lines

Original 08/98

Page 9

Page 10

NSE–6

PAMS

Disassembly & Troubleshooting Instructions

Flash Programming failure (2)

Flash programming doesn’t work

via panel connector

If the fault information is:

External RAM fault

Check control lines of SRAM (D230):

RamSelX (J235)..

There could be open joints in SRAM

Technical Documentation

Flash programming doesn’t work

via panel connector

If the fault information is:

Algorithm file or alias ID don’t find,

ID is unknown etc.

Check control lines of Flash (D220):

ROM1SelX (J234)..

Fault could be open joints in Flash or

In upper data lines (15:8)

Flash programming doesn’t work

via panel connector

If the fault information is:

MCU flash Vpp error

Check connections between X001;10

––> R21 1 upper side

Check components C212, R211

Faulty component D220

Page 10

Original 08/98

Page 11

PAMS

NSE–6

Technical Documentation

Flash Programming failure (3)

Flash programming doesn’t work

If the fault information from prommer is:

a) MCU doesn’t boot

b) Serial data line failure

c) Serial clock line failure

connect watchdog disable (WDDIS, J111)

line to the ground

VBB (R115, C107 upper side) 2.8 V

VXO (C149 upper side ) 2.8 V

Check C213, R213

YES

RFC (C664) 13 MHz

800 mV min

NO

NO

J227 master reset (Purx) = ”1” (2.8 V)

RfClk (R213 lower side) 13 MHz sine wave

clock signal: 500 mV

YES

OK

YES

YES

pp

YES

min

Disassembly & Troubleshooting Instructions

NO

VBAT is correct 3.6 V

NO

J228 sleep clock (SCLK)

square wave 32 kHz

YES

Faulty circuit N100

or overloaded PurX line

YES

Faulty circuit N100

NO

Check sleep

clock circuitry

(B101, R154..)

Check buffer V660 and

VCTCXO G660

Check that following lines are correct:

FTX (fbus_tx) line: X001 pin 1 ––> R215

FRX (fbus_rx) line: X001 pin 2 ––> R201

FCLK (MBUS) line: X001 pin 3 ––> R115

Check also pullup and pulldown resistors R115, R201, R215

GND: X001 pin 7 ––> GND

OK

Enable the selftest function of D200 by connecting

testpoint J229 to ground

Connect oscilloscope to testpoint J225

(ExtSysResetX) and switch power on

Voltage level rises to ”1” after power on at testpoint J225

YES

There could be open pins in circuits D200 (D220, D240)

(open joints may be detectable with microscope)

If not, the PCB or D200 (D220, D240) is faulty.

There is a shortcircuit

NO

somewhere in memory control

lines or MCU address lines or

MCU lower (7:0) data lines

Original 08/98

Page 11

Page 12

NSE–6

PAMS

Disassembly & Troubleshooting Instructions

Flash Programming failure (4)

Flash programming doesn’t work

If the fault information is:

External RAM fault

Check control lines of SRAM (D230):

RamSelX..

There could be open joints in SRAM

Technical Documentation

Flash programming doesn’t work

If the fault information is:

Algorithm file or alias ID not found,

ID is unknown etc.

Check control lines of Flash (D220):

ROM1SelX (J234)..

Fault could be open joints in Flash or

In upper data lines (15:8)

Flash programming doesn’t work

YES

If the fault information is:

MCU flash Vpp error

YES

Vpp > 2.8 V (C212)

YES

Check components C212, R211

OK

Faulty component D220

NO

Vpp > 2.8 V in J221

YES

Check UI connector X303

NO

Check regulator N202

Page 12

Original 08/98

Page 13

PAMS

NSE–6

Technical Documentation

Disassembly & Troubleshooting Instructions

Power doesn’t stay on, or phone is jammed

If this kind of fault has come after flash programming, there are most

probably open joints in ICs. The solder joints of ICs: MAD2 (D200), Flash

(D220) and SRAM (D230) are to be checked at the extent possible (by

microscope from the side of PCB and lightly pressing components while

switching power on).

Normally the power will be switched off by CCONT (N100) after 30 seconds if the watchdog of the CCONT can not be served by software. This

updating can be seen with an oscilloscope at CCONTCSX (J236). In normal case there is a short pulse from “1” to “0” every 8 seconds. The power off function can be prevented by connecting WDDIS (J111) to ground.

Check C213, R213

YES

RFC (C664) 13 MHz

800 mV min

NO

Check buffer V660

and VCTCXO G660

Power doesn’t stay on or phone is jammed

YES

CCONT watchdog is served?

(J236 pulses 1 ––> 0 every 8 sec)

NO

Connect J111 (WDDIS) to GND

OK

VBB (C107 upper side) 2.8 V

VXO (C149 upper side) 2.8 V

YES

Master reset PURX (J227) 2.8 V

NO

RfClk (R213 lower side) 13 MHz sine wave

clock signal: 500 mVpp min

Open pins or faulty circuit:

D200, D220, D230, N100, R215

Flashing can give information in deciding

which IC to change. Changed Flash ID

for example indicates Flash failure

YES

YES

YES

NO YES

Software is able to run

If power is switched off after

few seconds, check BSI and

BTEMP lines

VBAT is 3.6 V

NO NO

Sleep clock SCLK (J228)

square wave 32 kHz

YES

N100 faulty or

overloaded PurX line

N100 faulty

Check sleep clock

circuitry (B101, R154..)

Original 08/98

Page 13

Page 14

NSE–6

PAMS

Disassembly & Troubleshooting Instructions

Display Information: Contact Service

This fault means that software is able to run and thus the watchdog of

CCONT (N100) can be served. Selftest functions are run when power is

switched on and software is executed from flash. If any of the selftests

fails, a “contact service” text is shown on display.

MCU self tests are devided to those executed while power up (start up

tests) and ones that can be executed with connected PC. The tests and

included items are as follows:

1. MCU ROM checksum

Calculates 16 bit checksum out of Flash code and compares it to one

found in Flash. Items being checked are:

MAD2 <––> Flash data– and address lines, CE0,CE1, WE, BYTE, Vcc,

GND, Flash internal functionality

2. MCU RAM interface

3. MCU RAM component

4. MCU EEPROM interface

5. MCU EEPROM component

6. RTC battery

7. CCONT interface

8. A/D converter

9. SW reset

A Power off

B. Security data

C. EEPROM tune checksum

D. PPM checksum

E MCU download DSP

F. DSP alive

G. COBBA serial

H COBBA parallel

I. EEPROM sec checksum

K. PPM validity

Technical Documentation

Page 14

Original 08/98

Page 15

PAMS

NSE–6

Technical Documentation

Disassembly & Troubleshooting Instructions

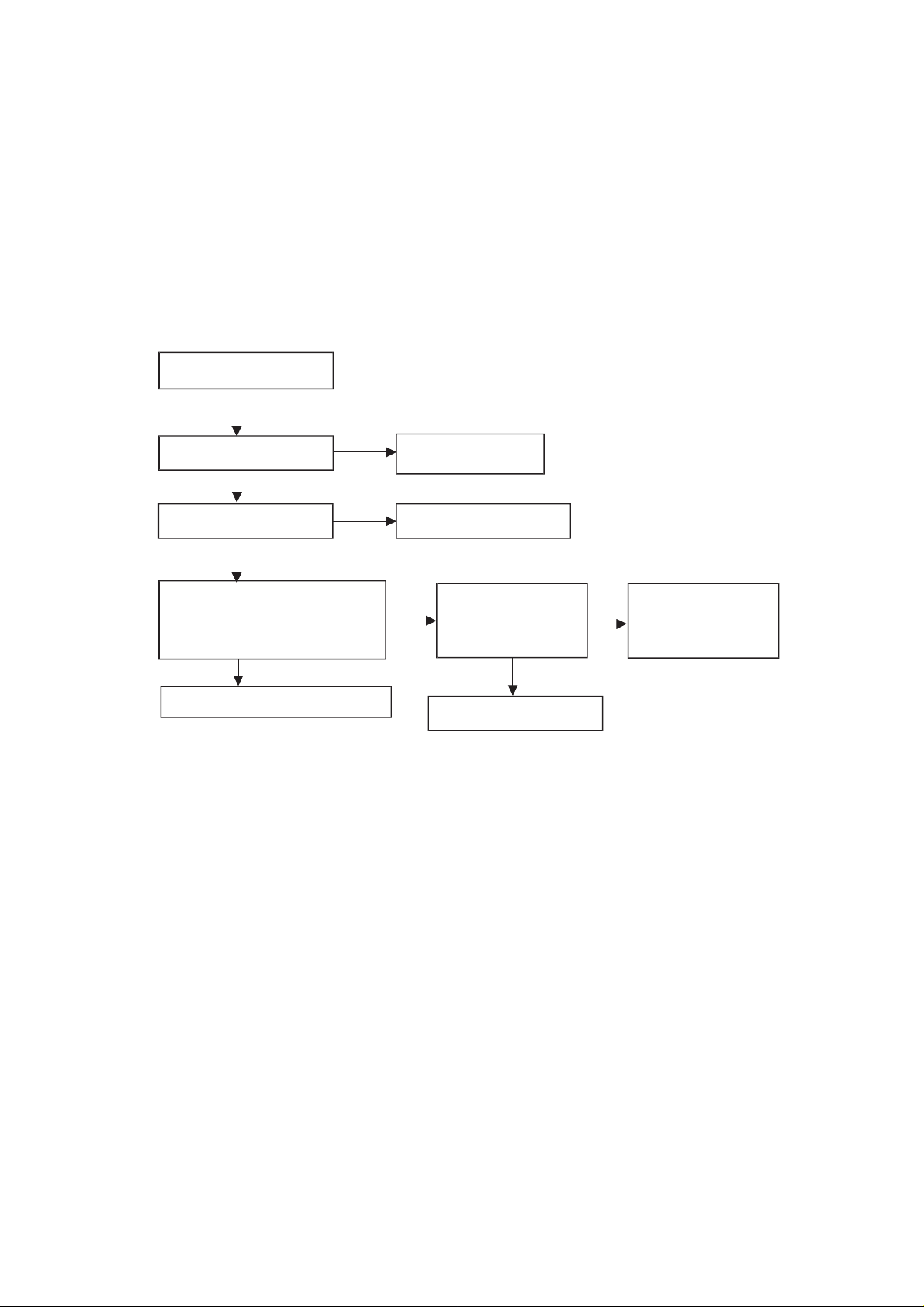

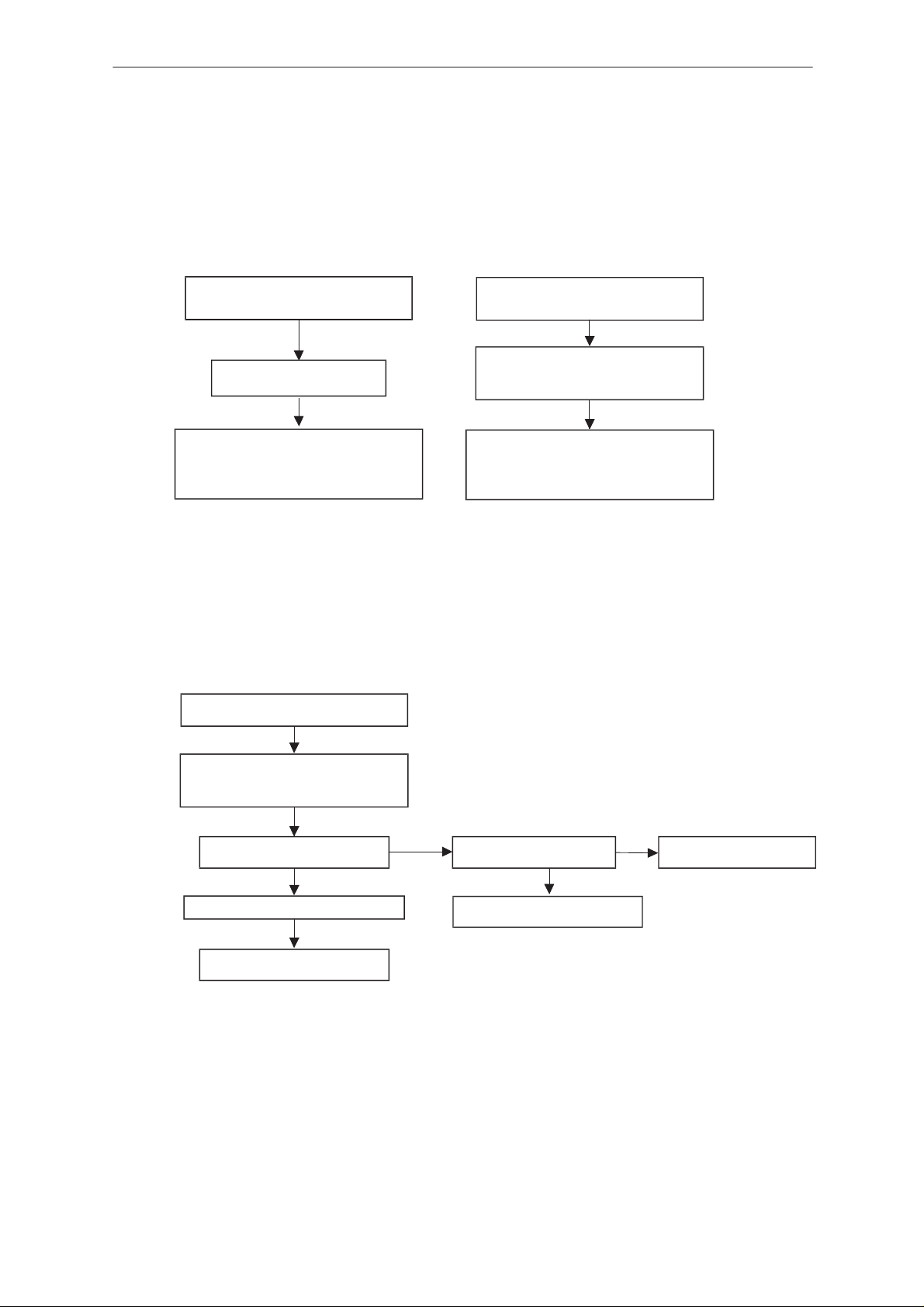

The phone doesn’t register to the network or phone

doesn’t make a call

If the phone doesn’t register to the network or the phone doesn’t make a

call, the reason could be either on baseband or RF. The phone can be set

to wanted mode with WinTesla service software in order to find out whether the fault is in RF or in baseband (RF interface measurements).

The control lines for RF are supplied both by the System Asic (inside of

MAD2;D200) and the RFI (inside of Cobba; N250). MAD2 handles digital

control lines (like SENA, TxP etc.) and Cobba handles analog control

lines (like AFC, TxC etc.). The DSP software is constructed so that operation states of DSP (MAD2) can be seen in external flag, DSPXF (J222).

After power up, DSP will signal all the completed functions by changing

the state of the XF pin.

1. DSP initialization done

2. Synchronization to network done

3. Registration to network done

321

DSPXF (J222)

Original 08/98

Page 15

Page 16

NSE–6

PAMS

Disassembly & Troubleshooting Instructions

init inialize

Patch code

download

Technical Documentation

1

DSP

constants

download

Iinitialization

done

2

channel

scan

starts

search

Send RACH

RACH OK

(transmitter on)

Last PSW OKPSW

Sycronization

OK

3

Go SDCCH immediate

assignment OK

(phone in serve state)

Page 16

Original 08/98

Page 17

PAMS

NSE–6

Technical Documentation

Phone register failure

Phone doesn’t register to network or

phone doesn’t make a call

Analog supply voltage VCOBBA is > 2.7

at C280 (C281, C282..)

Analog reference voltage Vref is 1.5

at C251 (R253 lower side)

– During the receiving slot:

Supply voltage VCP (J220) > 4.8

Supply voltage VRX (C148, C543..) > 2.7

Supply voltage VSYN_1 (C144, C505..) > 2.7

Supply voltage VSYN_2 (C143, C641..) > 2.7

– During the transmitting slot:

Supply voltage VTX (C145, C746..) > 2.7

YES

YES

YES

Disassembly & Troubleshooting Instructions

NO

V

NO

V

V

V

V

V

V

Check CCONT (N100)

Check R253, R251

NO

Check CCONT, MAD2

(N100, D200)

YES

Synthesizer lines:

SEna: Summa N540 pin 7

SClk: Summa N540 pin 5

SData: Summa N540 pin 6

pulses 0 ––> 1 during receiving slot

YES

RF control lines:

RxC (R263 upper side) 0 ––> 2.3 Vmax

AFC (R660 upper side) 0 –– 1.2

during receiving slot

YES

Analog data signals RxIP and RxIN (R544 upper sides)

0 ––> 1.5 V DC during receiving slot

Used benefit signal is biased to DC and its amplitude

is 50 mVpp nominal and frequency is 13 MHz

YES

RF control lines:

TxC (R740 upper side) 0 ––> 2.3 Vmax

TxP (Summa N540 pin 32) 0 –– 2.8 V

during transmitting slot

YES

Analog data signals TxIN, TxIP, TxQN, TxQP

(R749, R748, R746, R745 upper sides respectively)

0 ––> 0.8 V DC during transmitting slot

Used benefit signal is biased to DC and its amplitude

is 300 mVpp nominal and frequency is 64 kHz

Vtyp

NO

Check MAD2 (D200)

NO

Check COBBA (N250)

NO

Check COBBA (N250) if DC failed

Check RF if benefit signal failed

NO

Check COBBA (N250) if TxC failed

Check RF if benefit signal failed

NO

Check COBBA (N250)

YES

Check RF

Original 08/98

Page 17

Page 18

NSE–6

PAMS

Disassembly & Troubleshooting Instructions

SIM card related failures

The hardware of the SIM interface from MAD2 (D200) to the SIM connector (X451) can be tested without a SIM card. When the power is switched

on and the BSI line (J122) is grounded by a resistor, all the used lines

(VSIM, RST, CLK, DATA) rise up to 5 V four times. Thus “Insert SIM card”

faults can be found without SIM card.

The fault information “Card rejected” indicates that ATR message (the first

message is always sent from card to the phone) is sent from card but the

message is somehow corrupted, data signal levels are wrong etc. or factory set values (stored to the EEPROM) are not correct.

Insert SIM card failure

YES

Voltage < 1.5 V at C120 when

BSI resistor is connected

Technical Documentation

NO

Check R120. R122, C120,

Battery connector

YES

VSIM, DATA, RESET and CLOCK lines

(J252, J116, J118, J117) rise up to 5V

after power on

NO

VSIM, DATA_O,SIMRST_O and SIMCLK_O lines

rise up to 5V after power on at pins of SIM card

NO

SIMPWR, SIMRST_A, SIMCLK, SIMIO_C

lines (J1 12, J113, J114, J115) rise up to 2.8 V

after power on

NO

MAD2 (D200) or PCB is faulty

YES

Check SIM card and SIM

reader connectors

YES

Check

R124, R125, R128, X451

YES

Faulty circuit

N100 (CCONT)

Page 18

Original 08/98

Page 19

PAMS

NSE–6

Technical Documentation

SIM Card failure

Card rejected fault

VSIM (J252):

2.8 V min (with 3 V SIM card)

4.5 V min (with 5 V SIM card)

The ATR data can be seen at J116

SIMIOControl line (J1 15) is ”1”

during the ATR message

YES

YES

YES

YES

Disassembly & Troubleshooting Instructions

NO

CCONT (N100) faulty

NO

Check R124, X451

NO

Check MAD2 (D200)

Check MAD2 (D200)

Original 08/98

Page 19

Page 20

NSE–6

PAMS

Disassembly & Troubleshooting Instructions

Audio failure

Uplink (microphone) and downlink

(earphone) are disfunctional

YES

NO

Voltage at HOOKDET (C260)

2.8 V (without headset)

YES

NO

Voltage at HEADDET (C261)

2.8 V (without headset)

YES

NO

Frequency at J257 is square

wave 8 kHz 2.8 Vpp

Technical Documentation

Check R259, R260

Check R256, R257, R261

Check Cobba (N250)

Uplink (microphone) is

disfunctional

YES

Voltages at J261 and J262 are

1.8 V and 0.3 V during call

YES

DC voltage at C262 and C263

(on Cobba side) are 1.4 V

during a call

YES

Analog audio signal (few mV) at

C262 and C263 (on Cobba side)

during a call

YES

Check Cobba (N250)

NO

NO

NO

NOT OK

Change slide

Check Cobba (N250)

Check C262, C263 and PCB

routings

Downlink (earphone) is

disfunctional

YES

DC voltage at C291 and C292

are 1.4 V during a call

Check slide connector, V701, V250..

If OK, check that micbias line

(R267 upper side) is ”1” during call

NO

Check Cobba (N250)

Page 20

YES

Analog audio signal (some ten mV)

at C291 and C292 during a call

NO

Check Cobba (N250)

and MAD2 (D200)

Original 08/98

Page 21

PAMS

NSE–6

Technical Documentation

Charger failure

Nothing happens when charger is connected

Voltage at R103 is higher than 0.4 V

when the charger is connected

YES

YES

Check CCONT (N100)

Disassembly & Troubleshooting Instructions

NO

Check F101, L104

R104, R103

Display information: Not charging

YES

Voltage at C120 is about 0.8 V

when the power is connected

BSI resistor should be 39 K

YES

Voltage at C121 is about 0.5 V

when the power is connected

BTEMP resistor should be 47K

YES

32 Hz square wave at Chaps (N101) pin 7

YES

Voltage levels at Chaps (N101) pins

5 and 12 same as VB (J232)

YES

Voltage levels at Chaps (N101) pins

5 and 12 rise when charger is connected

NO

Check R120, R122,

battery connector

NO

Check R120, R122,

battery connector

NO

Check CCONT (N100)

NO

Check R131, N101

NO

Check Chaps (N101)

Original 08/98

Page 21

Page 22

NSE–6

PAMS

Disassembly & Troubleshooting Instructions

Receiver Fault (1)

if OK change Z501

Check soldered joints,

NO

Ω

Z501 input, loading > 1 M

if OK cange Z500

Check L500, C501, C502,

NO

Ω

YES

if OK change it

Check C503, L501 soldered joints,

YES

Z501 output,

loading > 1 M

Change Z501

Technical Documentation

YES

Change N500

change N500

Rise up N500

pin 7,8. If level

back to normal

NO

Ω

loading 50

N500 pin 7 and 8,

Receiver

Fault

YES

YES

N500 pin 25, SL: –61 dBm

Duplexer ant–pin, SL: –58 dBm

NO

Ω

N500 pin 25,

loading > 1 M

NO

YES

NO

Duplexer Rx–pin, SL: –61 dBm

NO

NO

YES

N500 pin 23, SL: –38 dBmN500 pin 26 is ”HIGH”

YES

NO

YES

Z501 input, SL: –44 dBm

NO

Z501 output, SL: –47 dBm

YES

N500 pin 17 and 19, 2.8V

NO

NO

YES

N500 pin 16, 1.5V

NO

YES

1st IF

N500 pin 7 and 8, SL: –57 dBm

Ω

YES

N500 pin 20, loading 8k2

NO

Ω

YES

N500 pin 23, loading 10 k

NO

71 MHz

Page 22

N500 pin 26,

change N500

Check C500, L505, if OK

Change duplexer

NO

YES

Ω

loading > 1 M

for short circuits

Check PDATA0–line

D200 pin 171

Check PDATA0–line

from CCONT

VSYN_1(J516) lines

Check VRX(J510) and

Check VREF_2(J518)

voltage line

Check soldered joints of N500

and R504, if OK change R504

of pin 23, if OK change N500

Check components in line out

Original 08/98

Page 23

PAMS

NSE–6

Technical Documentation

Receiver Fault (2)

UHFLO

NO

YES

SL: –28 dBm

G600 Out, 1018 MHz

Disassembly & Troubleshooting Instructions

OK change

short circiuts, if

Check input for

NO

Ω

loading > 1 M

to N500 pin 12

Check connections from G600

Z502 input 1 and 2,

Z502

Check output

YES

line to Z502

Check components in input

for short

change Z502

circiuts, if OK

NO

Ω

YES

loading > 1 M

Z502 output 1 and 2,

Check components in

output line. Check soldered

change Z502

joints at N540, if OK

1st IF

71 MHz

NO

YES

N500 pin 12,

1018 MHz SL: –28 dBm

YES

SL: –28

N500 pin 9 and 10,

NO

YES

N500 pin 15,

N500 pin 6, 2.8V

NO

NO

NO

YES

SL: –30

Z502 input 1 and 2,

Ω

YES

loading 10 k

N500 pin 9 and 10,

NO

Ω

YES

loading 10 k

NO

SL: –43

Z621 output,

Change N500

YES

NO

YES

SL: –43 dBm

N540 pin 37 and 38,

YES

N540 pin 35, 2.8V

NO

YES

DC–level ~1.7V

N540 pin 37 and 38

NO

Ω

YES

2nd IF

13 MHz

Change N540

Original 08/98

Check VRX

soldered joints

Check R500

OK at pads change N500

Rise up 9 and 10, if loading

of N540

Check soldered joints

loading 5 k

N540 pin 37 and 38,

NO

38 for short circuit

Check N540 pin 37 and

Page 23

Page 24

NSE–6

PAMS

Disassembly & Troubleshooting Instructions

Receiver Fault (3)

from COBBA pin 18

Check RXC control voltage

NO

YES

YES

~1.2V

N540 pin 36

Change N540

VHFLO

Check VRX supply voltage

NO

~2.8V

N540 pin 35

Technical Documentation

Change N540

NO

YES

DC–level ~1V

N540 pin 23 and 24

Change N250 (Cobba)

2nd IF

13 MHz

NO

N540 pin 8

SL: – 28 dBm

YES

NO

YES

N540 pin 30,

SL: – 19 dBm

YES

Z540 input

SL: –26 dBm

NO

joints

Check R540 and soldered

YES

Z540 output

SL: –28 dBm

NO

change Z540

Check soldered joints, if OK

NO

YES

and pin 25 , SL: –33 dBm

N540 pin 26, SL: –36 dBm

NO

YES

DC–level, ~1.4V

N540 pin 25 and 26,

YES

SL: – 29 dBm

N540 pin 23 and 24

Check R541 and R542

Change N250 (Cobba)

Page 24

NO

N540

Change

Original 08/98

Page 25

PAMS

NSE–6

Technical Documentation

Receiver Fault (4)

UHFLO

G600 VCC–pin voltage, 2.8V

YES

G600 VC voltage

~2.25V (Mid CH)

YES

Change G600

Disassembly & Troubleshooting Instructions

NO

Check VSYN_1–line and R603

NO

Check soldered joints

at G600, N540 components

in VC–line

Does G600 oscillate at

any frequency

N540 pin 15, 13 MHz clock

N540 pin 9, 16 and 19

N540 pin 13 and 22

2.8V

5V

YES

YES

YES

YES

YES

NO

NO

NO

NO

soldering joints at

Check VSYN_2 and

CNTVR3–control (J100)

from CCONT

Check VCP–voltage

from CCONT pin 32

Change G600

Check

N540, G600

N540 pin 41

1.5V

N540 pin 42

loading 15 k

SCLK, SDATA, SENA1

working OK

Change N540

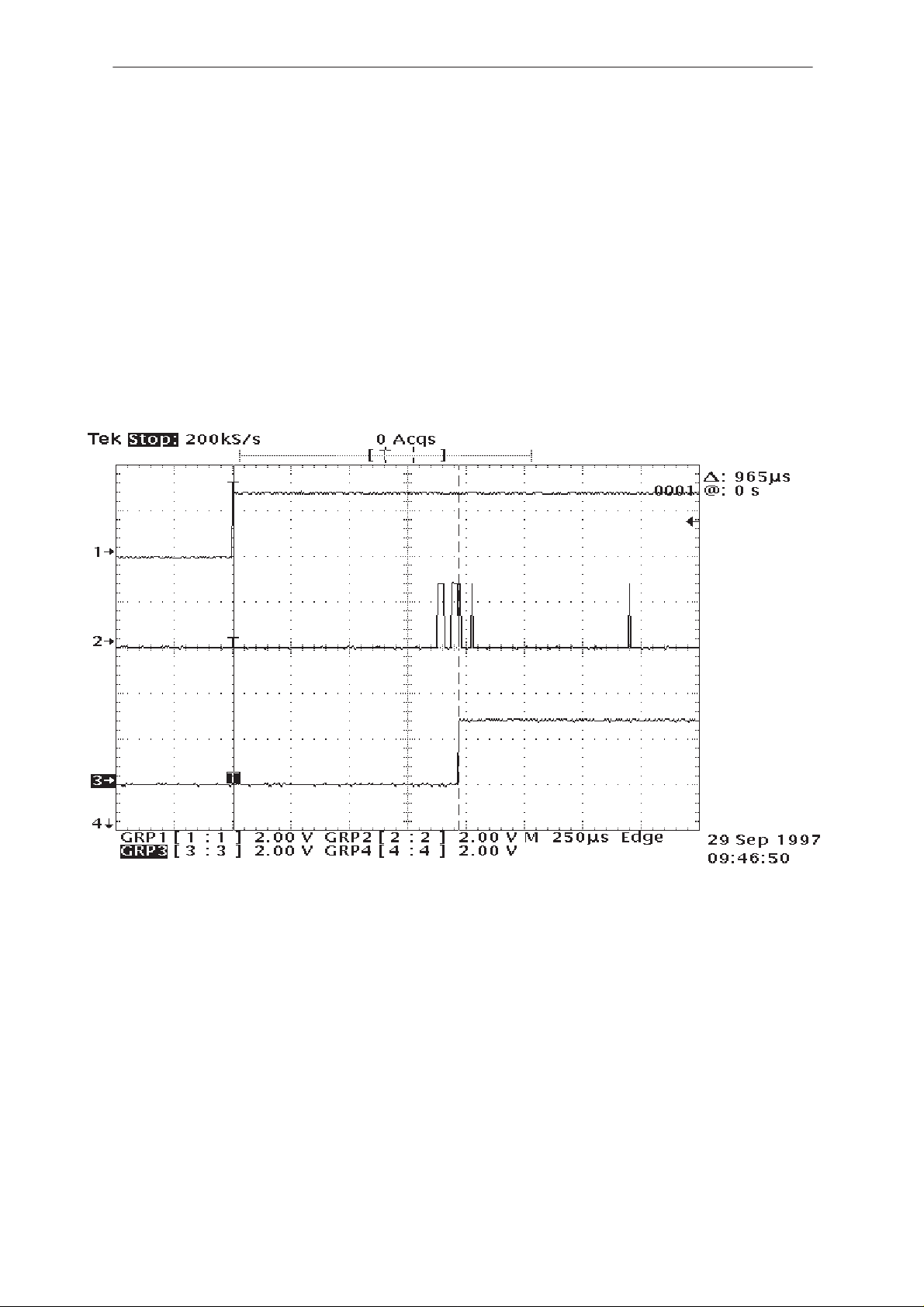

13 MHz clock oscilloscope picture in Appendix A

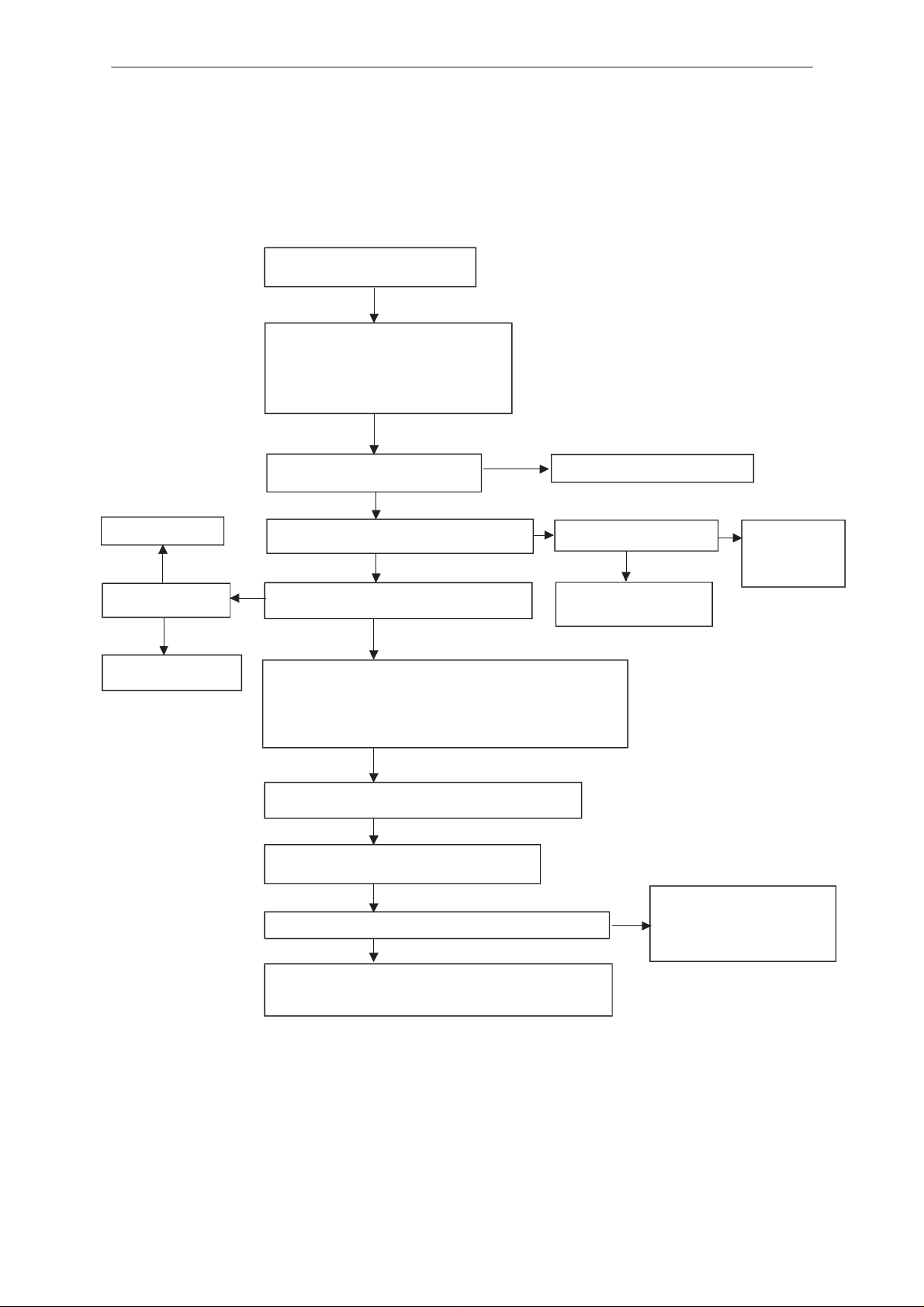

SCLK, SDATA, SENA1 oscilloscope pictures in Appendix B

YES

YES

YES

NO

NO

Ω

NO

Check VREF_1–line

Check soldering joints

at N540 and R543, if

OK change R543

Check SCLK, SDATA,

SENA1–lines from

MAD

Original 08/98

Page 25

Page 26

Page 26

VHFLO

Receiver Fault (5)

Disassembly & Troubleshooting Instructions

NSE–6

N540pins 9, 16 and 19 2.8V

N540 pin 13 and 22, 5V

Original 08/98

N540 pin 12, 2.3V

Change N540

~

YES

~

YES

NO

NO

~

NO

Does the VCO oscillate at any

frequency ?

YES

Check VSYN_2

supply voltage

Check VCP voltage line

NO

V621 collector,

~2.6V

YES

V621 base, 1.7V

V621 emitter, 1V

Check V620, L629, C622,

~

YES

~

YES

C623

NO

NO

NO

Check VSYN_1 supply

voltage line to V621

Check R623, R622 and

soldered joints

V621 emitter loading 330

if OK change V621

~

Technical Documentation

Ω

PAMS

Page 27

Original 08/98

AFC

Receiver Fault (6)

Technical Documentation

PAMS

RSSI tuning working OK ?

YES

N250 (R660)

voltage between 0.5 – 2.3V

YES

Set SpectrumAnalyzer

Frequency: 13 MHz

Span: 10 kHz

RESBW: 3 kHz

13 MHz in midst,

(L660)

NO

NO

short circuits, if OK change

Use sevice software to set AFC

NO

Receiver

Fault

Check AFC–line for

N250

to MAX

Disassembly & Troubleshooting Instructions

Page 27

NOTE !

properly, supply voltages stays

down.

If DSP in MAD does not work

AFC–voltage

~2.3V

YES

Main clock

> 13 MHz

NO

NO

Check R660 and C660, if

OK change N250

NSE–6

Change G660

Page 28

NSE–6

PAMS

Disassembly & Troubleshooting Instructions

Transmitter Fault (1)

from CCONT

R748, R749 and

if OK change N250

Check TXP–line from MAD

Check TXQP, TXIP, TXQN, TXIN

lines from COBBA, R746, R745,

soldered joints at N540 and and N250,

NO

YES

VHFLO

and TXIN, OK ?

N620: TXQP, TXQN, TXIP

NO

Check VTX supply voltage

NO

YES

N540 pin 32

TXP–pulse OK?

OK ?

N540 pin 47, VTX–pulse

Check VREF_1 – line

Check TXC–line from COBBA

NO

YES

N540 pin 34, TXC–pulse OK?

YES

NO

~1.5V

N540 pin 41,

Technical Documentation

joints

Change N540

Check R543 and soldered

NO

YES

NO

Ω

YES

N540 pin 42,

loading 15 k

~0.8V

N540 pin 44 and 45,

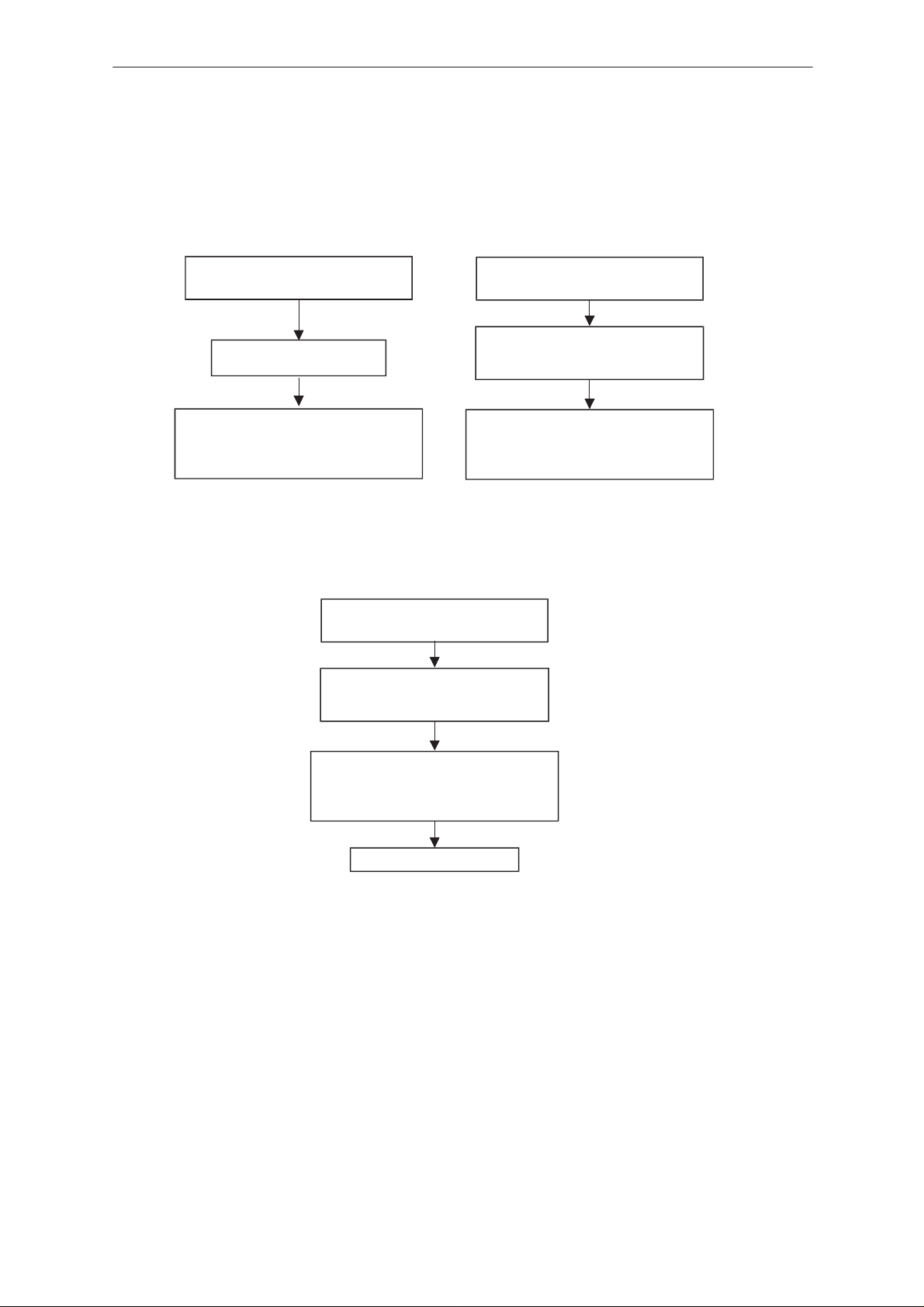

TXQP, TXIP, TXIN, TXQN, TXP and VTX:

Oscilloscope pictures in Appendix C

Fault

TXLEV 5

Transmitter

NO

N540 pin 8

NO

YES

N540 pin 44 and 45,

232 MHz SL: –28 dBm

116 MHz SL: –40 dBm

YES

N500 pin 2 and 3

NO

N500 pin 2 and 3,

NO

YES

116 MHz SL: –6 dBm

Ω

YES

loading > 1M

change N500

R760, R761, if OK

Check C760, C761, L760, L761,

YES

SL: –28 dBm

N500 pin 13 (RX–Continous),

NO

UHFLO

YES

SL: 2.5 dBm

N500 pin 30,

NO

YES

~2.8V

N500 pin 16,

N500 pin 1 and 29,

NO

NO

~1.5V

YES

N500 pin 20,

NO

1

Transmitter

Ω

YES

loading 8k2

Change N500

Page 28

OK change N500

3 for short circuits, if

Check N500 pin 2 and

from CCONT

Check VTX supply voltage

Check VREF_2 – line(J518)

joints

Check R507 and soldered

Original 08/98

Page 29

Original 08/98

Transmitter

1

TXLEV5

Transmitter Fault (2)

Technical Documentation

PAMS

Page 29

NO

Check Z700 output for short

circuits, if OK change Z700

Check VBATT–connections to

N550

Check soldered joints at N700

and N540, if OK change N540

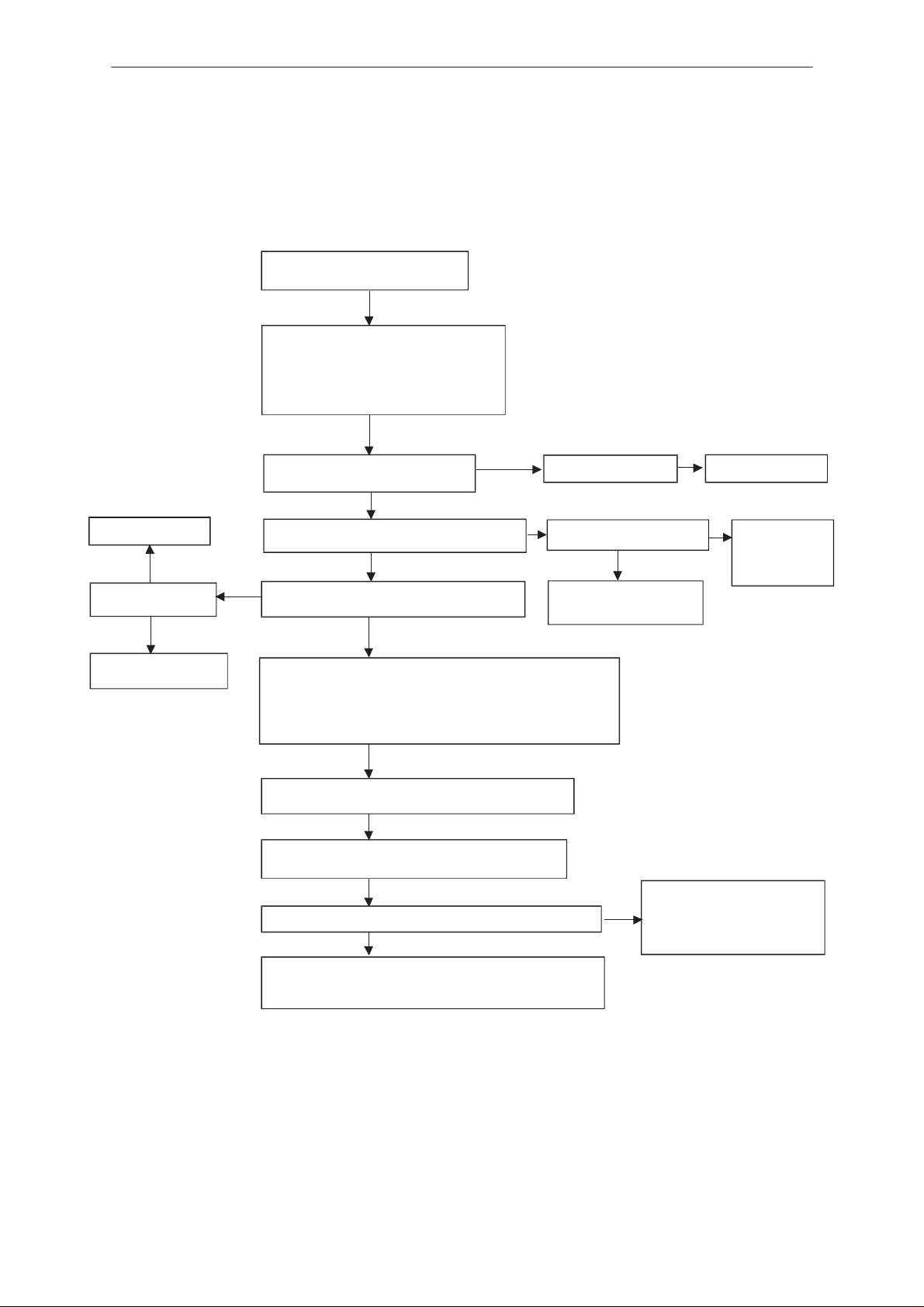

VTX and power contol pulse(TXC):

Oscilloscope pictures in Appendix D

NO

NO

Z700 output,

loading > 1 M

Change Z700

N700 pin 3

N700 pin 2,

power control pulse

Check soldered joints at N700,

if OK change N550

Ω

YES

~3.6V

YES

YES

Z700 input,

SL: +2.5 dBm – +5.0 dBm

NO

NO

Z700 output,

SL: 1.0 – 3.0 dBm

SL: 1.0 – 3.0 dBm

N700 pin 4,

Duplexer TX–pin,

RF–connector X700 pin 1,

YES

YES

N700 pin 1,

YES

SL: 35 dBm

YES

SL: 34.5 dBm

YES

SL: 32 dBm

NO

NO

NO

Z700 input,

loading > 1 M

Check C700

Check C711

Check N701.

check for short circuits, if OK

change Z500

NO

Check C784, if OK change

YES

Also

Z500

NO

Ω

Check Z700 input for short

circuits, if OK change Z700

Disassembly & Troubleshooting Instructions

NSE–6

Page 30

NSE–6

PAMS

Disassembly & Troubleshooting Instructions

Transmitter Fault (3)

Power

Control

TXLEV5

Transmitter working OK

YES

N250 H1, R740

TXC – pulse OK

NO

NO

Check TXC – line from N250

Transmitter

pin 17, if OK change N250

Technical Documentation

Fault

YES

N540 pin 33 and 34 pulses

are about the same

NO

R708, if OK change V700

V700 anode,

DC–voltage ~0.8V

YES

N540 pin 12,

loading ~4 k

YES

Check C709, R707 and

Ω

NO

NO

Check VSYN_1 voltage

through R704, R705 and R706

Check C743, if OK

change N540

TXC – pulse:

Oscilloscope picture in Appendix D

Page 30

Original 08/98

Page 31

PAMS

NSE–6

Technical Documentation

Appendix A

Disassembly & Troubleshooting Instructions

Picture 1. 13 MHz Main clock – signal

Original 08/98

Page 31

Page 32

NSE–6

PAMS

Disassembly & Troubleshooting Instructions

Appendix B

Picture 2. SCLK – signal

Technical Documentation

Picture 3. SDATA – signal

Picture 4. SENA1 – signal

Page 32

Original 08/98

Page 33

PAMS

NSE–6

Technical Documentation

Disassembly & Troubleshooting Instructions

Appendix C

Picture 5. TXQP, TXQN, TXIP and TXIN – signal

Picture 6. TXP – signal

Picture 7. VTX – signal

Original 08/98

Page 33

Page 34

NSE–6

PAMS

Disassembly & Troubleshooting Instructions

Appendix D

Technical Documentation

Picture 8. TXC – signal (TXLEV5)

Picture 9. DET – signal(N620 pin 12) TXLEV5

Page 34

Original 08/98

Page 35

PAMS

Á

Á

Á

ББББББ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

NSE–6

Technical Documentation

Test points

Test

ÁÁ

Point

ÁÁ

ÁÁ

J100

ÁÁ

ÁÁ

J101

ÁÁ

ÁÁ

J102

ÁÁ

ÁÁ

J103

ÁÁ

ÁÁ

Name

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

SYNTHP

ÁÁÁÁ

ÁÁÁÁ

SLEEPX

ÁÁÁÁ

ÁÁÁÁ

TXPWR

ÁÁÁÁ

ÁÁÁÁ

RXPWR

ÁÁÁÁ

ÁÁÁÁ

Logic

Level

Á

Á

Á

0

Á

1

Á

0

Á

1

Á

0

Á

1

Á

0

Á

1

Á

Min

ÁÁ

ÁÁ

ÁÁ

0

ÁÁ

2.0

ÁÁ

0

ÁÁ

2.0

ÁÁ

0

ÁÁ

2.0

ÁÁ

0

ÁÁ

2.0

ÁÁ

Disassembly & Troubleshooting Instructions

Max

0.8

2.85

0.5

2.85

0.5

2.85

0.5

2.85

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Unit

Á

Á

Á

V

Á

Á

V

Á

Á

V

Á

Á

V

Á

Á

Description

ББББББББББББББ

ББББББББББББББ

ББББББББББББББ

Control line for VSYN_1 and VSYN_2.

ББББББББББББББ

ББББББББББББББ

Control line for VCXO module supply.

ББББББББББББББ

If low, 13 MHz clock is disabled.

ББББББББББББББ

Control line for VTX voltage

ББББББББББББББ

ББББББББББББББ

Control line for VRX voltage

ББББББББББББББ

ББББББББББББББ

J107

J108

ÁÁ

ÁÁ

ÁÁ

J109

ÁÁ

J110

ÁÁ

ÁÁ

J111

ÁÁ

J112

ÁÁ

ÁÁ

J113

ÁÁ

ÁÁ

J114

ÁÁ

L_GND

CHRG_CTRL

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

VIN

ÁÁÁÁ

VPP

ÁÁÁÁ

ÁÁÁÁ

WDDIS

ÁÁÁÁ

SIM_PWR

ÁÁÁÁ

ÁÁÁÁ

SIMRST_A

ÁÁÁÁ

ÁÁÁÁ

SIMCLK

ÁÁÁÁ

0

0

Á

1

Á

Á

0

ÁÁ

2.0

ÁÁ

ÁÁ

0

ÁÁÁÁ

2.8

Á

Á

ÁÁ

ÁÁ

0

0.8

Á

2.85

Á

Á

15

Á

3.2

Á

Á

5.3

ÁÁÁÁÁÁ

0

Á

1

Á

0

Á

1

Á

0

Á

1

0

ÁÁ

2.0

ÁÁ

0

ÁÁ

2.0

ÁÁ

0

ÁÁ

2.0

0.8

Á

2.85

Á

0.8

Á

2.85

Á

0.8

Á

2.85

V

V

Á

Á

Á

Vpe

Á

ak

V

Á

Á

V

Á

V

Á

Á

V

Á

Á

V

Á

Charger ground

Charger control for external charger. 1

ББББББББББББББ

Hz for stand– by charging, 32 Hz for

ББББББББББББББ

continuous charging.

ББББББББББББББ

Charging voltage

ББББББББББББББ

Supply voltage for flash programming

ББББББББББББББ

(Vpp). Vpp will be switched on only dur-

ББББББББББББББ

ing flash programming.

Power is forced to stay on when WDDIS

ББББББББББББББ

is grounded (watchdog disable)

Control line for SIM voltage supply.

ББББББББББББББ

ББББББББББББББ

Control line for SIM reset

ББББББББББББББ

ББББББББББББББ

Clock to SIM interface (3.25MHz, MAD2

ББББББББББББББ

side of CCONT)

J115

ÁÁ

ÁÁ

J116

ÁÁ

ÁÁ

ÁÁ

Original 08/98

SIM I/O_C

ÁÁÁÁ

ÁÁÁÁ

DATA_O

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

0

Á

1

Á

0

Á

1

Á

Á

ÁÁ

2.0

ÁÁ

ÁÁ

2.8/4

ÁÁ

ÁÁ

.0

0

0

0.8

Á

2.85

Á

0.5

Á

3.2/5

Á

.2

Á

V

SIM data on MAD2 side of CCONT

Á

Á

Á

Á

Á

ББББББББББББББ

ББББББББББББББ

V

SIM data in SIM contacts

ББББББББББББББ

ББББББББББББББ

ББББББББББББББ

Page 35

Page 36

NSE–6

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

PAMS

Disassembly & Troubleshooting Instructions

J117

ÁÁ

ÁÁ

J118

ÁÁ

ÁÁ

J119

J153

ÁÁ

J154

ÁÁ

ÁÁ

ÁÁ

J220

J221

ÁÁ

ÁÁ

J222

ÁÁ

ÁÁ

SIMCLK_O

ÁÁÁÁ

ÁÁÁÁ

SIMRST_O

ÁÁÁÁ

ÁÁÁÁ

VCOBBA

GND

ÁÁÁÁ

MBUS

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

V5V

5V

ÁÁÁÁ

ÁÁÁÁ

DSPXF

ÁÁÁÁ

ÁÁÁÁ

0

Á

1

Á

0

Á

1

Á

0

ÁÁ

2.0

ÁÁ

0

ÁÁ

2.8/4

ÁÁ

.0

2.7

ÁÁÁÁ

0

Á

Á

1

Á

0

0

ÁÁ

ÁÁ

2.0

ÁÁ

4.8

2.8

Á

Á

Á

Á

ÁÁ

ÁÁ

0

1

0

ÁÁ

2.0

ÁÁ

0.8

Á

2.85

Á

0.5

Á

3.2/5

Á

.2

2.85

0

Á

0.8

Á

Á

2.85

Á

5.2

3.2

Á

Á

0.8

Á

2.85

Á

Technical Documentation

V

Clock line to Sim (3.25MHz)

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ББББББББББББББ

ББББББББББББББ

V

Sim reset line

ББББББББББББББ

ББББББББББББББ

V

Supply voltage for analog part of COBBA

V

ББББББББББББББ

V

Data I/O for external device and clock

ББББББББББББББ

signal from flash prommer to MAD2

ББББББББББББББ

ББББББББББББББ

V

Supply voltage for RF circuits. (VCP)

V

Supply voltage for flash programming

ББББББББББББББ

(Vpp). Vpp will be switched on only dur-

ББББББББББББББ

ing flash programming.

V

Test point for fault diagnostic.

ББББББББББББББ

ББББББББББББББ

J223

ÁÁ

ÁÁ

ÁÁ

ÁÁ

J224

ÁÁ

J225

ÁÁ

ÁÁ

J226

ÁÁ

ÁÁ

ÁÁ

J227

ÁÁ

ÁÁ

ÁÁ

J228

ÁÁ

ÁÁ

CCONTINT

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

VSRM

ÁÁÁÁ

EXTSYSRE-

ÁÁÁÁ

SETX

ÁÁÁÁ

EXTSYSRE-

ÁÁÁÁ

SETX

ÁÁÁÁ

ÁÁÁÁ

PurX

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

SLEEPCLK

ÁÁÁÁ

ÁÁÁÁ

0

Á

1

Á

Á

Á

0

ÁÁ

2.0

ÁÁ

ÁÁ

ÁÁ

5.2

ÁÁÁÁ

0

Á

1

Á

0

Á

1

Á

Á

0

Á

1

Á

Á

0

Á

1

Á

0

ÁÁ

2.0

ÁÁ

0

ÁÁ

2.0

ÁÁ

ÁÁ

0

ÁÁ

2.0

ÁÁ

ÁÁ

0

ÁÁ

2.0

ÁÁ

0.8

Á

2.85

Á

Á

Á

5.5

Á

0.8

Á

2.85

Á

0.8

Á

2.85

Á

Á

0.8

Á

2.85

Á

Á

0.8

Á

2.85

Á

V

Interrupt line from CCONT to MAD2.

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ББББББББББББББ

Used for charger indication and RTC

ББББББББББББББ

alarm indication. If high, an interrupt is

ББББББББББББББ

generated.

ББББББББББББББ

V

Supply voltage for flash programming

ББББББББББББББ

regulator N201 from CCONT (N100)

V

Testpoint for fault diagnostic. If missing,

ББББББББББББББ

check power supply, PurX line and 13

V

ББББББББББББББ

MHz clock signal.

V

Testpoint for fault diagnostic. If missing,

ББББББББББББББ

check power supply, PurX line and 13

ББББББББББББББ

MHz clock signal.

ББББББББББББББ

V

Power up reset line from CCONT to

ББББББББББББББ

MAD.

ББББББББББББББ

If low, the bb circuits are in reset state.

ББББББББББББББ

V

32 kHz square wave clock from CCONT

to MAD.

ББББББББББББББ

ББББББББББББББ

J229

ÁÁ

ÁÁ

J230

ÁÁ

Page 36

SELF TEST

ÁÁÁÁ

ÁÁÁÁ

GND

ÁÁÁÁ

0

Á

1

Á

ÁÁÁÁ

ÁÁ

2.0

ÁÁ

0

0

0.8

Á

2.85

Á

0

Á

V

Self test pin. If short–circuit is made be-

Á

Á

Á

ББББББББББББББ

tween testpoint J229 and J230, the self

test will be executed.

ББББББББББББББ

V

ББББББББББББББ

Original 08/98

Page 37

PAMS

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

NSE–6

Technical Documentation

J231

ÁÁ

J232

ÁÁ

J233

ÁÁ

ÁÁ

J234

ÁÁ

J235

ÁÁ

J236

ÁÁ

ÁÁ

ÁÁ

J250

J251

MCURDX

ÁÁÁÁ

VB

ÁÁÁÁ

MCUWRX

ÁÁÁÁ

ÁÁÁÁ

ROM1SELX

ÁÁÁÁ

RAMSELX

ÁÁÁÁ

CCONCSX

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

GND

AGND

0

Á

1

ÁÁÁÁ

0

Á

1

Á

0

Á

1

0

Á

1

0

Á

1

Á

Á

0

ÁÁ

2.0

3.0

0

ÁÁ

2.0

ÁÁ

0

ÁÁ

2.0

0

ÁÁ

2.0

0

ÁÁ

2.0

ÁÁ

ÁÁ

0

0

Disassembly & Troubleshooting Instructions

0.5

Á

V

MCU read strobe

Á

ББББББББББББББ

2.85

5.3

Á

0.5

Á

2.85

Á

0.5

Á

2.85

0.5

Á

V

Battery voltage

Á

Á

Á

Á

Á

ББББББББББББББ

V

MCU write strobe

ББББББББББББББ

ББББББББББББББ

V

Flash memory select

ББББББББББББББ

V

Sram memory select

ББББББББББББББ

2.85

0.8

Á

2.85

Á

Á

0

0

V

Chip select for CCONT from MAD2. Ac-

Á

Á

Á

ББББББББББББББ

tive low. Pulses 1––>0 every 8 sec, if

ББББББББББББББ

software is running

ББББББББББББББ

V

V

J252

ÁÁ

ÁÁ

J253

ÁÁ

J254

J254

J255

ÁÁ

ÁÁ

ÁÁ

J256

ÁÁ

ÁÁ

ÁÁ

J257

ÁÁ

J261

J262

J780

VSIM

ÁÁÁÁ

ÁÁÁÁ

VSRM

ÁÁÁÁ

SGND

–

FBUS_RX

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

FBUS_TX

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

8KHZ

ÁÁÁÁ

MICP

MICN

(VDDTXMIX)

(5V)

Á

(3V)

Á

4.8

ÁÁ

2.8

ÁÁ

5.2

ÁÁÁÁ

0

0

Á

1

Á

Á

0

Á

1

Á

Á

0

Á

1

0

ÁÁ

2.0

ÁÁ

ÁÁ

0

ÁÁ

2.0

ÁÁ

ÁÁ

0

ÁÁ

2.15

5.2

Á

3.2

Á

5.5

Á

0

0.8

Á

2.85

Á

Á

0.5

Á

2.85

Á

Á

0.5

Á

2.85

4.1

4.1

V

SIM supply voltage

Á

Á

Á

ББББББББББББББ

ББББББББББББББ

V

Supply voltage for flash programming

ББББББББББББББ

regulator N201 from CCONT (N100)

V

V

Data input from external device, data

Á

Á

Á

Á

Á

Á

Á

mV

mV

ББББББББББББББ

from IR to MCU module, and data from

ББББББББББББББ

flash prommer to MCU.

ББББББББББББББ

V

Data output for external device, data

ББББББББББББББ

from MCU to IR module, and data to

ББББББББББББББ

flash prommer.

ББББББББББББББ

V

8 KHz frame sync

ББББББББББББББ

Internal microphone positive pole

Internal microphone negative pole

ÁÁÁÁÁÁÁ

VBB

VXO

RFCLK

Original 08/98

ÁÁÁÁ

2.7

2.7

0.5

2.85

Á

2.85

V

Á

V

Vpp

Baseband main voiltage

ББББББББББББББ

VCTCXO voltage (13 MHz clock)

13 Mhz clock for baseband and RF

Page 37

Page 38

NSE–6

PAMS

Disassembly & Troubleshooting Instructions

Technical Documentation

This page intentionally left blank.

Page 38

Original 08/98

Loading...

Loading...