Page 1

Nokia Customer Care

NPL-4/5 Series Transceivers

System Module and User

Interface

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved.

Page 2

NPL-4/5

System Module and User Interface Nokia Customer Care

[This page left intentionally blank]

Page 2 Copyright © 2004 Nokia Corporation. All rights reserved. Issue 1 05/04

Page 3

NPL-4/5

Nokia Customer Care System Module and User Interface

Table of Contents

Page No

Glossary of Terms..................................................................................................................................... 7

Introduction ........................................................................................................................................... 10

Electrical modules ..............................................................................................................................10

Interconnection diagram ..................................................................................................................10

Temperature conditions ....................................................................................................................11

Humidity ...............................................................................................................................................11

System Module...................................................................................................................................... 12

Baseband module ...............................................................................................................................12

Technical summary ............................................................................................................................13

PWB .................................................................................................................................................... 15

DC characteristics ..............................................................................................................................15

External and internal signals and connections ..........................................................................18

UI board interface signals ................................................................................................................24

Display interface signals............................................................................................................... 25

System connector interface signals ..............................................................................................26

SIM interface signals .........................................................................................................................27

FCI interface signals ..........................................................................................................................28

Camera interface signals ..................................................................................................................28

FM radio interface signals ...............................................................................................................29

Compass interface signals ...............................................................................................................30

Functional Description ........................................................................................................................ 31

Modes of operation ............................................................................................................................31

No supply ..............................................................................................................................................31

Backup ...................................................................................................................................................31

Acting dead ..........................................................................................................................................31

Active .....................................................................................................................................................31

Sleep mode ...........................................................................................................................................32

Charging ................................................................................................................................................33

Power up and reset ............................................................................................................................33

Power up with PWR key ...................................................................................................................34

Power up when charger is connected ..........................................................................................34

Battery ...................................................................................................................................................34

A/D channels ........................................................................................................................................36

Digital camera .....................................................................................................................................36

FM radio ................................................................................................................................................37

Electrical compass ..............................................................................................................................38

Thermometer ........................................................................................................................................38

Backup battery ....................................................................................................................................39

SIM interface .......................................................................................................................................39

FCI (Functional Cover Interface) ...................................................................................................40

Memory .................................................................................................................................................41

External memory .................................................................................................................................42

Compass .................................................................................................................................................. 43

Earth magnetic field ..........................................................................................................................43

Heading angle or azimuth (a) .................................................................................................... 44

Inclination (d) .................................................................................................................................. 44

Declination (l) .................................................................................................................................. 44

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved. Page 3

Page 4

NPL-4/5

System Module and User Interface Nokia Customer Care

Tilt (s).................................................................................................................................................. 45

HW Block Diagram ............................................................................................................................... 46

HW block functions ...........................................................................................................................46

Magnetometer Sensor......................................................................................................................... 48

Main features ......................................................................................................................................48

Block diagram ......................................................................................................................................49

Magnetometer control interface ...................................................................................................49

Pin Assignment................................................................................................................................ 49

Test Circuitry.......................................................................................................................................... 51

MagIC ASIC....................................................................................................................................... 51

Main features ......................................................................................................................................52

Block diagram and functional descriptions ................................................................................52

MagIC control interface ...................................................................................................................53

Pin assignment ................................................................................................................................ 53

MagIC ASIC interface - Magnetometer sensor...................................................................... 53

MagIC ASIC – UPP interface........................................................................................................ 54

MagIC ASIC – UEME interface.................................................................................................... 55

MagIC ASIC – UPP - External power supply interface......................................................... 55

MagIC - magnetometer sensor interface for constant current driver............................. 56

Power supplies .....................................................................................................................................56

Introduction...................................................................................................................................... 56

Using VIO for DVDD supply.......................................................................................................... 56

Using external regulator for AVDD............................................................................................ 56

Compass and phone basics ..............................................................................................................57

Phone directions .................................................................................................................................57

General description ............................................................................................................................58

Operation modes............................................................................................................................. 58

Compass function main features ...................................................................................................58

Compass display menu.................................................................................................................. 58

Compass display results................................................................................................................ 58

Compass calibration SW ........................................................................................................

User assisted calibration............................................................................................................... 59

Compass declination menu ..............................................................................................................59

Testpoints................................................................................................................................................ 60

Set/Reset ...............................................................................................................................................60

VBRIDGE ................................................................................................................................................60

Channel output A ...............................................................................................................................60

Channel output B ...............................................................................................................................60

Service Software Interface (Phoenix) ............................................................................................. 61

Performance........................................................................................................................................... 62

Calibration basics ...............................................................................................................................62

Calibration process flow ...................................................................................................................63

Compass digital values, limit values .............................................................................................63

Clock distribution ...............................................................................................................................65

User Interface ........................................................................................................................................ 66

Display .......................................................................................................................

UI Board ................................................................................................................................................67

Power supply for LEDs .......................................................................................................................68

............................66

...........59

Page 4 Copyright © 2004 Nokia Corporation. All rights reserved. Issue 1 05/04

Page 5

NPL-4/5

Nokia Customer Care System Module and User Interface

Keyboard LEDs driver .........................................................................................................................68

Display and air bubble LED driver ..................................................................................................69

Flashlight LEDs driver ........................................................................................................................69

Internal microphone ..........................................................................................................................70

Internal speaker ..................................................................................................................................71

IHF ...........................................................................................................................................................71

Headset connections .........................................................................................................................72

Vibra .......................................................................................................................................................73

RF Module............................................................................................................................................... 74

RF frequency plan........................................................................................................................... 75

DC characteristics ..............................................................................................................................76

Regulators......................................................................................................................................... 76

Power distribution.......................................................................................................................... 77

RF characteristics ...............................................................................................................................78

RF block diagram ............................................................................................................................ 79

RF block diagram NPL-4/5 ........................................................................................................... 79

Frequency synthesizers ................................................................................................................. 80

Receiver ............................................................................................................................................. 80

Transmitter ....................................................................................................................................... 81

Antenna switch module................................................................................................................ 82

Power Amplifier............................................................................................................................... 83

RF ASIC Helgo.................................................................................................................................. 84

AFC function .................................................................................................................................... 84

Antenna............................................................................................................................................ 84

List of Figures

Page No

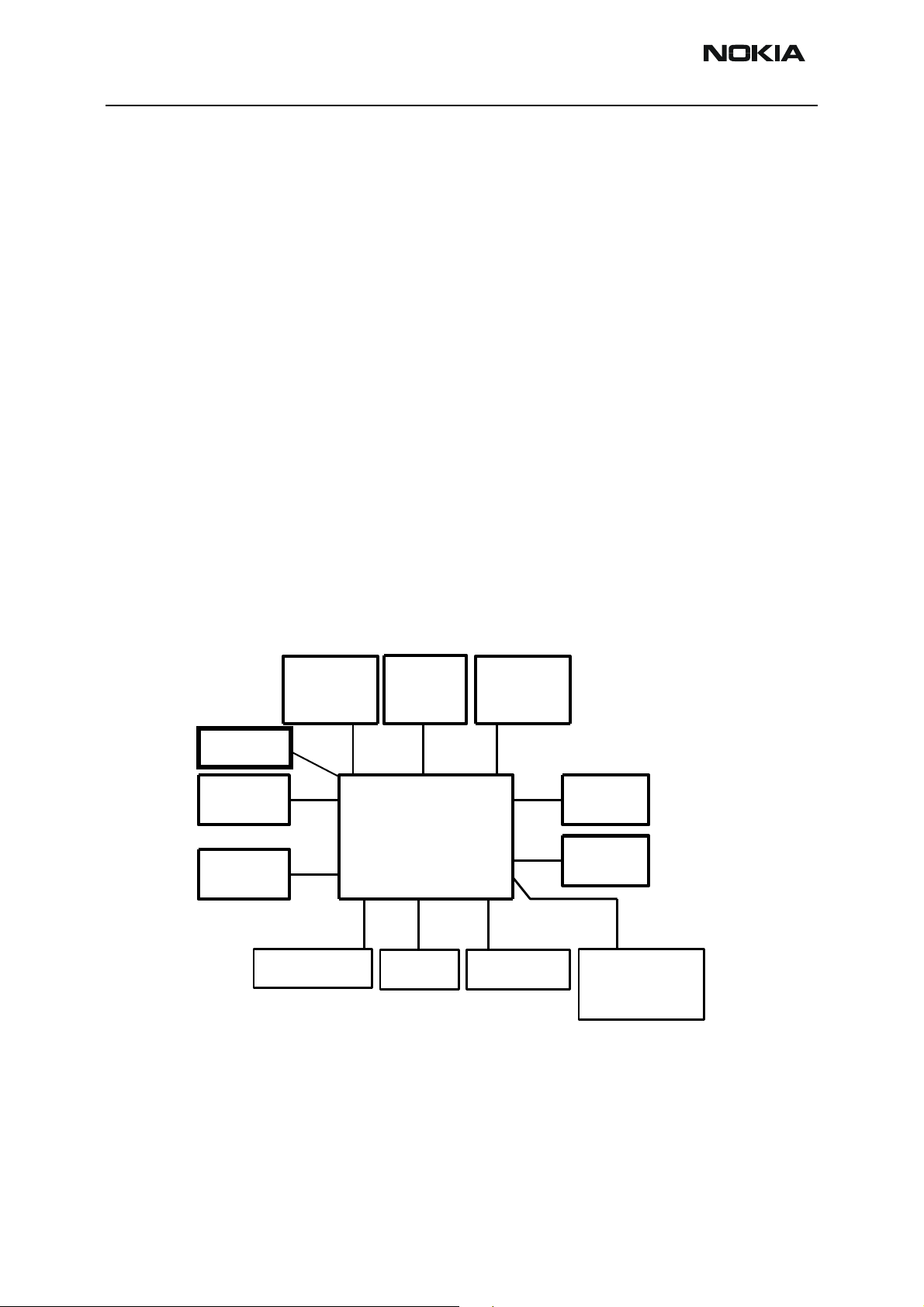

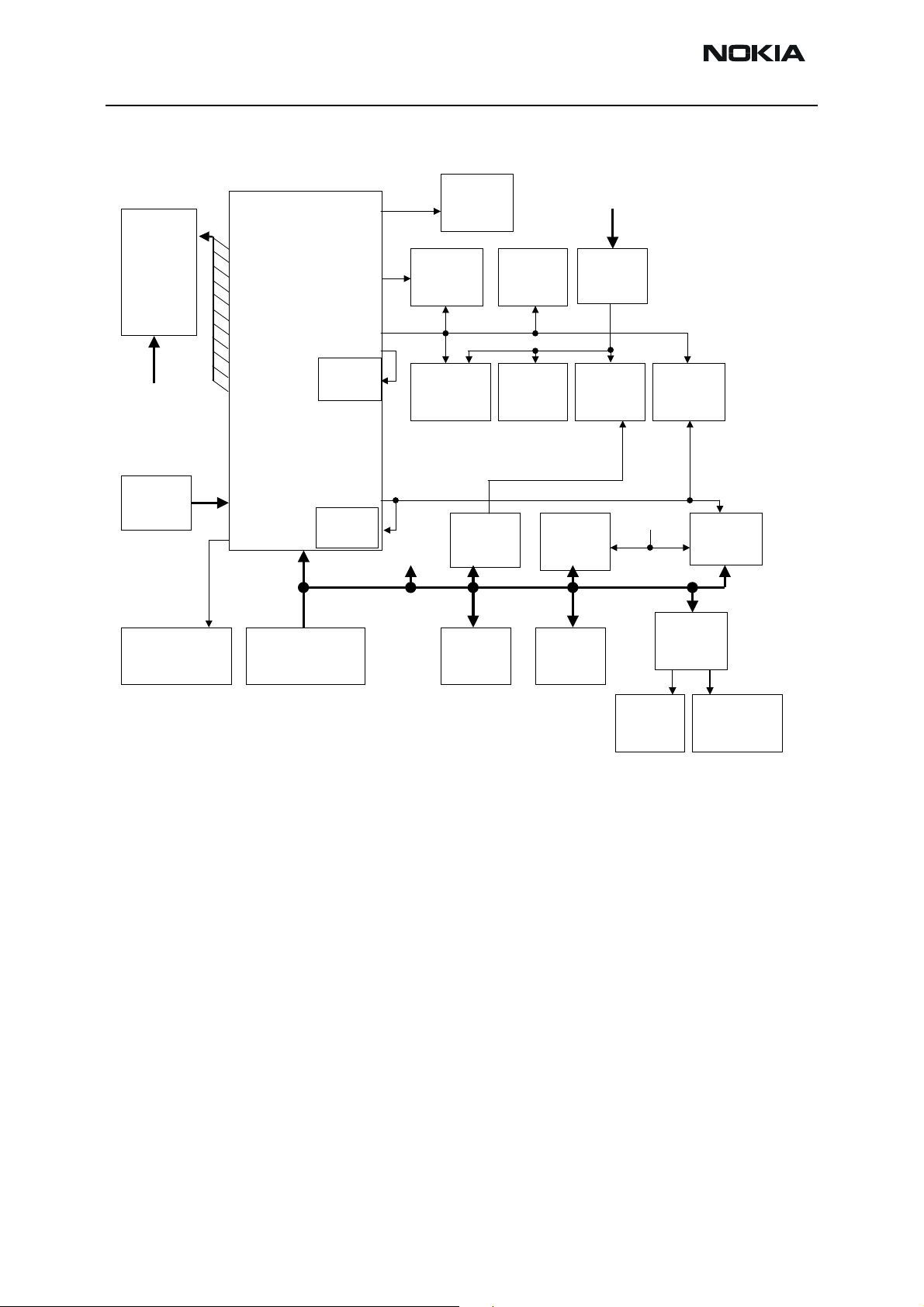

Fig 1 Interconnection diagram................................................................................................................... 10

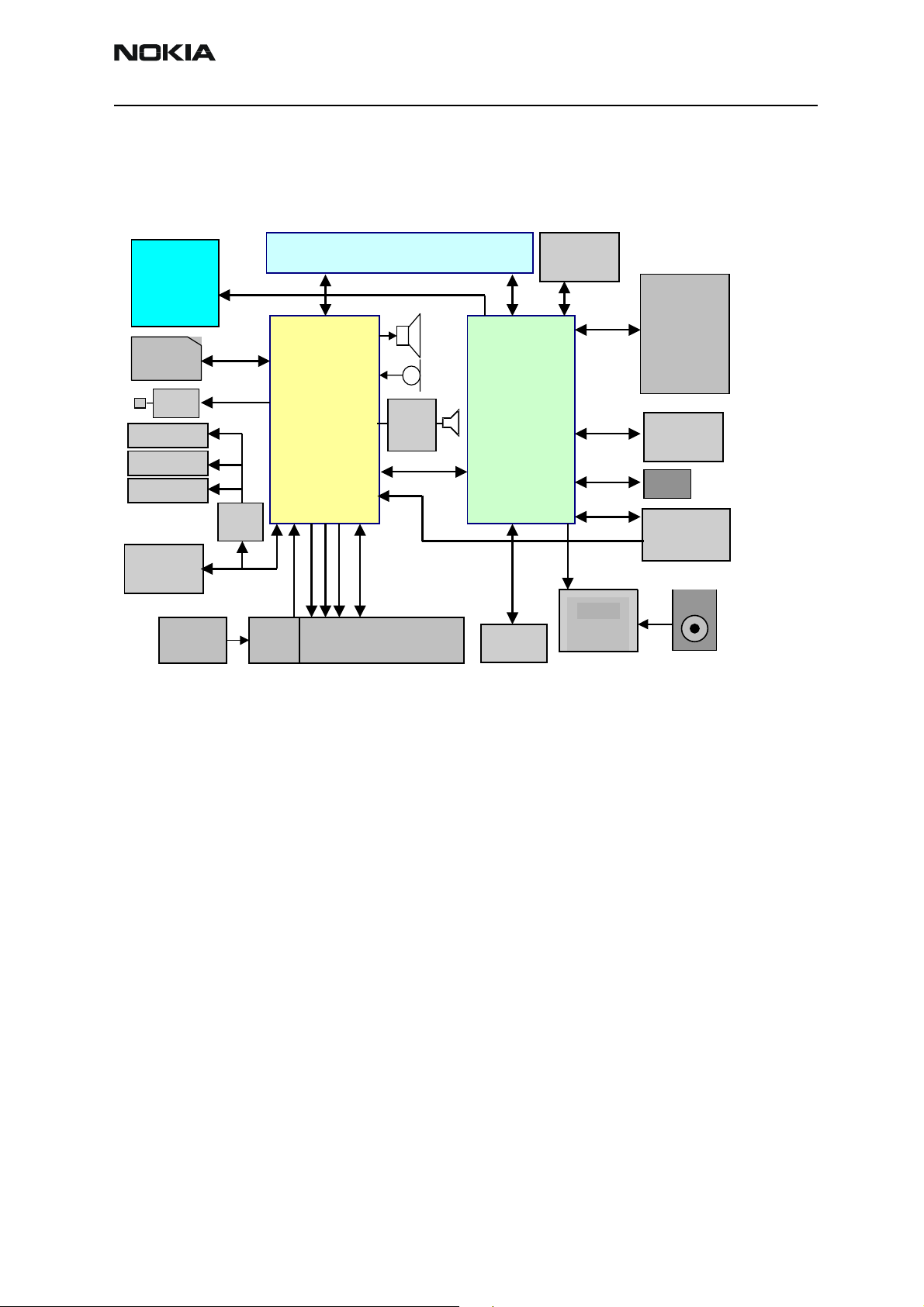

Fig 2 Baseband blocks. ................................................................................................................................ 13

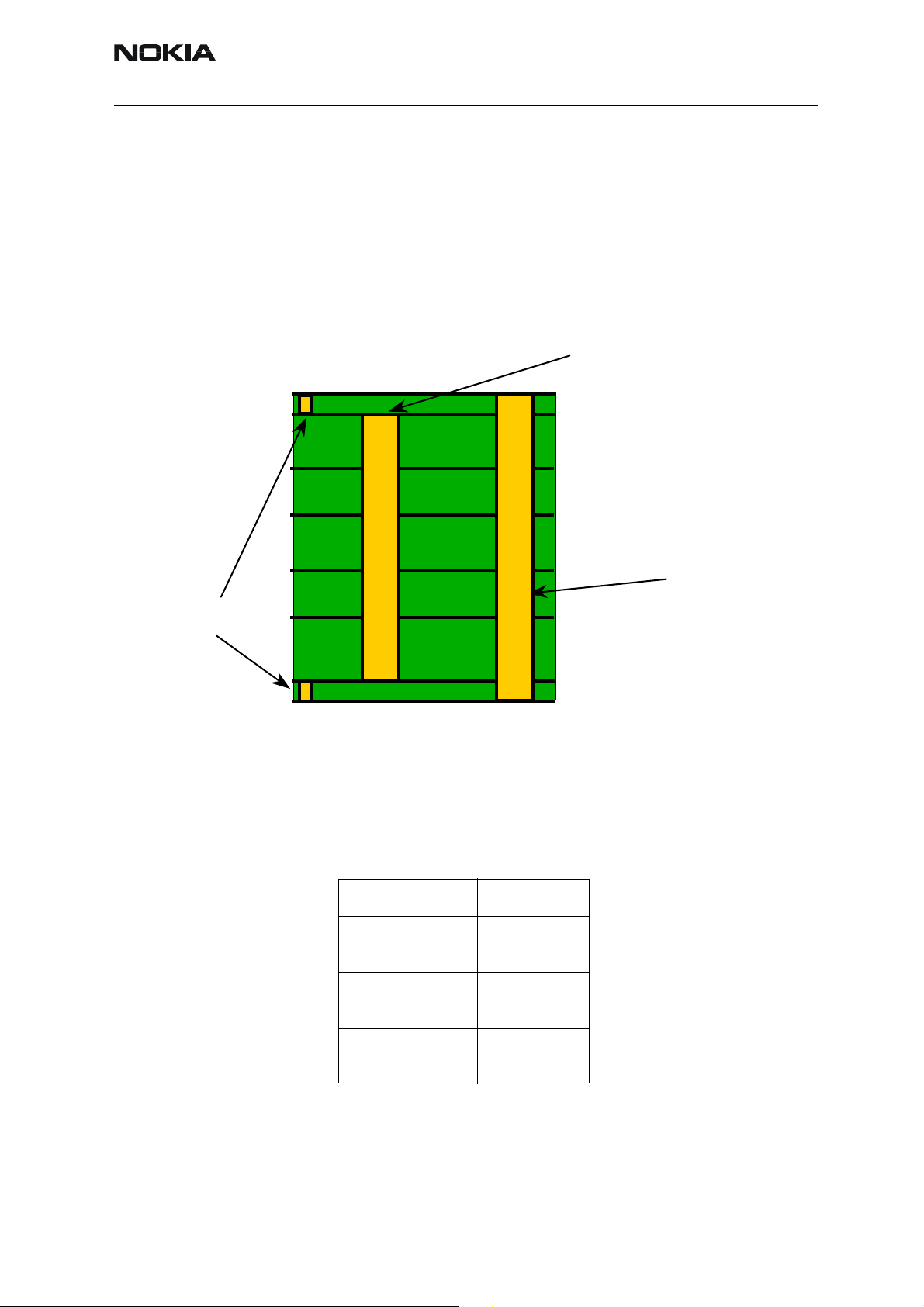

Fig 3 PWB vias ................................................................................................................................................ 15

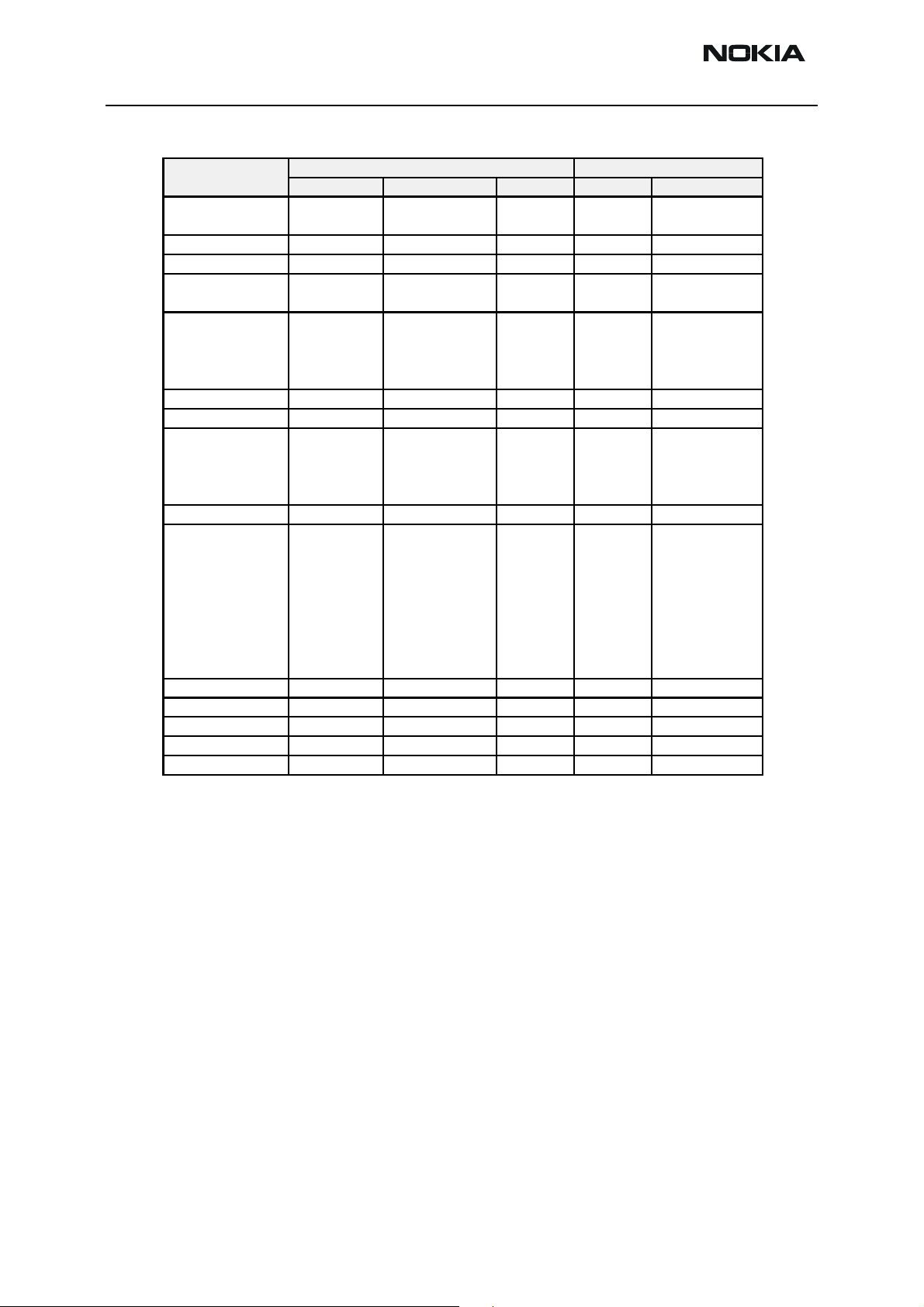

Fig 4 Power Distribution Diagram............................................................................................................. 18

Fig 5 Battery Pack Contacts........................................................................................................................ 35

Fig 6 Camera Connections to Baseband.................................................................................................. 37

Fig 7 FM Radio Audio-, Antenna- and Digital Interface Connections............................................ 37

Fig 8 Baseband and Compass Interface................................................................................................... 38

Fig 9 Ambient Temperature Sensor Interface to BB ............................................................................ 39

Fig 10 UPP/UEMEK SIM Interface Connections ....................................................................................40

Fig 11 FCI Interface....................................................................................................................................... 41

Fig 12 FCI Connector Pin Order on PWB................................................................................................. 41

Fig 13 Earth’s Magnetic Field..................................................................................................................... 44

Fig 14 Earths’s Magnetic Field Components.......................................................................................... 45

Fig 15 Block Diagram.................................................................................................................................... 46

Fig 16 Magnetometer Sensor Block Diagram ........................................................................................ 49

Fig 17 Pin Assignment In Package............................................................................................................ 50

Fig 18 Test Circuitry ...................................................................................................................................... 51

Fig 19 Offset strap coil current effect ......................................................................................

Fig 20 Block Diagram.................................................................................................................................... 52

Fig 21 Directions Through Phone .............................................................................................................. 57

............... 51

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved. Page 5

Page 6

NPL-4/5

System Module and User Interface Nokia Customer Care

Fig 22 Timing and Voltage Level l ............................................................................................................. 60

Fig 23 What Happened on Calibration (Track on x/y Plane while rotating) ................................. 63

Fig 24 Clock Distribution Diagram............................................................................................................ 65

Fig 25 User Interface Connections............................................................................................................ 66

Fig 26 Display Block ...................................................................................................................................... 66

Fig 27 UI Board............................................................................................................................................... 67

Fig 28 VLED Voltage Supply........................................................................................................................ 68

Fig 29 Keyboard Led Driver and Control Diagram ................................................................................69

Fig 30 Display and Air Bubble LEDs driver and Control Diagram..................................................... 69

Fig 31 Flashlight Driver and Control ........................................................................................................ 70

Fig 32 Microphone Connection.................................................................................................................. 70

Fig 33 IEarpiece Connection....................................................................................................................... 71

Fig 34 IHF Connection.................................................................................................................................. 71

Fig 35 NPL-4/5 Audio Connections .......................................................................................................... 73

Fig 36 RF Frequency plan............................................................................................................................. 75

Fig 37 Power distribution diagram ......................................................................................................... 77

Fig 38 RF Block Diagram.............................................................................................................................. 79

Fig 39 Antenna Switch Module ................................................................................................................ 83

Fig 40 Power Amplifier ................................................................................................................................ 84

Page 6 Copyright © 2004 Nokia Corporation. All rights reserved. Issue 1 05/04

Page 7

NPL-4/5

Nokia Customer Care System Module and User Interface

Glossary of Terms

ACI Accessory Control Interface

ADC Analog-Digital Converter

AEC Acoustic Echo Canceller

AFC Automatic Frequency Control

AGC Automatic Gain Control

AIF Application Interface

API Application Programming Interface

ARM Processor architecture

ASIC Application Specific Integrated Circuit

BB Baseband

CCI Camera Control Interface

CCP Compact Camera Port

CMT Cellular Mobile Telephone (MCU and DSP)

CPU Central Processing Unit

CTSI Clocking Timing Sleep Interrupt

CSP Chip Scale Package

DAC Digital-Analog Converter

DAI Digital Audio Interface

DB Dual band

DCT3 Digital Core Technology, 3rd generation

DCN Offset Cancellation control signal

DLL Dynamic Link Library

DRC Dynamic Range Controller

DSP Digital Signal Processor

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved. Page 7

Page 8

NPL-4/5

System Module and User Interface Nokia Customer Care

EGSM Extended – GSM

EFR Enhanced Full Rate

EGPRS Enhanced General Packet Radio Service

EMC Electromagnetic compatibility

EMI Electromagnetic Interference

EXT RF External RF

FBUS Asynchronous Full Duplex Serial Bus

GPRS General Packet Radio Service

GSM Global System for Mobile communications

HS Half Rate Speech

HSCSD High Speed Circuit Switched Data

IC Integrated Circuit

I/O Input/Output

IrDA Infrared Association

LCD Liquid Crystal Display

LNA Low Noise Amplifier

MBUS 1-wire half duplex serial bus

MCU Micro Controller Unit

MDI MCU-DSP Interface

MFI Modulator and Filter Interface

PA Transmit Power Amplifier

PC Personal Computer

PCM Pulse Code Modulation

PCM SIO Synchronous serial bus for PCM audio transferring

Page 8 Copyright © 2004 Nokia Corporation. All rights reserved. Issue 1 05/04

Page 9

NPL-4/5

Nokia Customer Care System Module and User Interface

PCMCIA PC Memory Card International Association

PIFA Planar Inverted F-antenna

PWB Printed Wiring Board

RF Radio Frequency

SIM Subscriber Identity Module

UEMEK Enhanced Universal Energy Management

UI User Interface

UPP Universal Phone Processor

VCXO Voltage Controlled Crystal Oscillator

VCTCXO Voltage Controlled Temperature Compensated Crystal Oscillator.

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved. Page 9

Page 10

NPL-4/5

T

System Module and User Interface Nokia Customer Care

Introduction

Electrical modules

The system module consists of Radio Frequency (RF) and baseband (BB). User Interface

(UI) contains display, keyboard, IR link, vibra, HF/HS connector and audio parts.

FM radio is located on the main PWB.

The electrical part of the keyboard is located in separate UI PWB. It is connected to radio

PWB through spring connectors.

The Baseband blocks provide the MCU, DSP, external memory interface and digital control functions in the UPP ASIC. Power supply circuitry, charging, audio processing and RF

control hard ware are in the UEMEK ASIC.

The purpose of the RF block is to receive and demodulate the radio frequency signal from

the base station and to transmit a modulated RF signal to the base station.

The UI module is described in a dedicated section of the manual.

Interconnection diagram

Keyboard

module

Flashlight

Antenna

Microphone

Figure 1: Interconnection diagram

Display

IHF

speaker

Radio

Module

NPL-4/5

NHL-4

IR Link

Earpiece

BatterySIM

Charger

omahawk

Accessories

Page 10 Copyright © 2004 Nokia Corporation. All rights reserved. Issue 1 05/04

Page 11

NPL-4/5

Nokia Customer Care System Module and User Interface

Temperature conditions

Specifications are met within range of -10...+55 deg. C ambient temperature

Storage temperature range -40...+70 deg. C

Humidity

Relative humidity range is 5... 95%.

This module is not protected against water. Condensated or splashed water might cause

malfunction momentary. Long term wetness will cause permanent damage.

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved. Page 11

Page 12

NPL-4/5

System Module and User Interface Nokia Customer Care

System Module

The System module (or Engine) consists of Baseband and RF sub-modules, each described

below.

Baseband module

Product NPL-4/5 is a DCT4 Active segment phone. There are two variants: An EGSM900 /

GSM1800 / GSM1900 phone and a US variant with GSM850/1800/1900.

The HW has the following features:

• HSCSD, GPRS (MSC10) and EGPRS (MSC6)

• DCT4 engine with UPP8M v3.5 and UEMEk v1.1

• AMR and 16 MIDI tones

• 128/16 Mbit Psram Combo memory

• Passive display with 4k colours

• Battery BL-5B

• Pop-Port interface

• 5-way navigation key with select

• Electrical compass

• FCI on bottom cover

• VGA Camera

•Vibra

•IHF

•FM Radio

•IrDA

•Torch

• PTT key

•Sidekeys

The NPL-4/5 BB is based on the DCT4 engine and is compatible to the Pop-Port accessories. The DCT4/4.5 engine consists basically of two ASICs. The UEMEK (Enhanced Universal Energy Management) IC including voltage regulators, charge control and audio

circuits, audio IFH amplifier from DCT4.5) and the UPP (Universal Phone Processor

including MCU, DSP and RAM from DCT4).

Page 12 Copyright © 2004 Nokia Corporation. All rights reserved. Issue 1 05/04

Page 13

NPL-4/5

j

A

Nokia Customer Care System Module and User Interface

Technical summary

The picture below shows the main Baseband function blocks

Figure 2: Baseband blocks.

LCD

Passive colour

STN

SIM

RF Interface

Compass

PSRAM

COMBO

128Mbit

Flash

16Mbit

PSRAM

Vibra

Keyboard

Illumination

Display

Illumination

Flashlight

UEMEk

D-class

mplifier

IHF

UPP8M

v3

Keyboard

1.8 V

IR

DC/

FM radio

TEA5767

VGA VV6450

BATTERY BL-5B

Charge

DC

DC

ack

System connector

Tomahaw

FCI

HWA

STV0900

Baseband is running from power rails 2.8V analog voltage and 1.8V I/O voltage. UPP core

voltages can be lowered down to 1.0V, 1.3V and 1.5V. UEMEK includes 7 linear LDO (Low

Drop-Out) regulator for baseband and 7 regulators for RF. It also includes 4 current

sources for biasing purposes and internal usage. UEMEK also includes SIM interface

which has supports both 1.8V and 3V SIM cards. Note: 5V SIM cards are no longer sup-

ported by DCT-4 generation baseband.

A real time clock function is integrated into the UEMEK, which utilizes the same 32kHz

clock supply as the sleep clock. A backup power supply is provided for the RTC-battery,

which keeps the real time clock running when the main battery is removed. The backup

power supply is a rechargeable surface mounted Li-Ion battery. The backup time with the

battery is 30 minutes minimum.

A UEMEK ASIC handles the analog interface between the baseband and the RF section.

UEMEK provides A/D and D/A conversion of the in-phase and quadrature receive and

transmit signal paths and also A/D and D/A conversions of received and transmitted

audio signals to and from the user interface.

The UEMEK supplies the analog TXC and AFC signals to RF section according to the UPP

DSP digital control. Data transmission between the UEMEK and the UPP is implemented

using two serial busses, DBUS for DSP and CBUS for MCU. There are also separate signals

for PDM coded audio. Digital speech processing is handled by the DSP inside UPP ASIC.

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved. Page 13

Page 14

NPL-4/5

System Module and User Interface Nokia Customer Care

UEMEK is a dual voltage circuit, the digital parts are running from the baseband supply

1.8V and the analog parts are running from the analog supply 2.78V.

VBAT is directly used for Vibra, LED-driver, Audio amplifier and FCI (Functional Cover

Interface).

The baseband architecture supports a power saving function called ”sleep mode”. This

sleep mode shuts off the VCTCXO, which is used as system clock source for both RF and

baseband. During the sleep mode the system runs from a 32 kHz crystal. The phone is

waken up by a timer running from this 32 kHz clock supply. The sleep time is determined

by network parameters. Sleep mode is entered when both the MCU and the DSP are in

standby mode and the normal VCTCXO clock is switched off.

The baseband supports both internal and external microphone inputs and speaker outputs. UEMEK also includes third microphone input. This input is used for FM-radio. Input

and output signal source selection and gain control is done by the UEMEK according to

control messages from the UPP. Keypad tones, DTMF, and other audio tones are generated and encoded by the UPP and transmitted to the UEMEK for decoding. An external

vibra alert control signals are generated by the UEMEK with separate PWM outputs.

The NPL-4/5 uses D-class amplifier to amplifying IHF speaker audios. It gives more sound

pressure from speaker and efficiency is in good level to improve thermal performance

compared to AB-class.

VGA Camera is connected to baseband (UPP) through HW accelerator IC. The camera

data bus is common with display bus. The HWA is taking care of camera control and it is

compressing the pictures.

NPL-4/5 has 2-axes electrical compass. It is implemented with magnetoresistive sensor

and MagIC ASIC.

NPL-4/5 has two serial control interfaces: FBUS and MBUS. FBUS and MBUS can be

accessed through production test pattern and FBUS can be also accessed thought Tomahawk System Connector.

The FCI interface is located to front bottom side area of the phone. This means that only

B-cover can be an active cover.

EMC shielding is implemented using a metal body profile, RF cans and PWB grounding.

Some components are outside of shielding. Heat generated by the circuitry is conducted

out via the PWB ground planes and by using buried vias between PWB layers.

Page 14 Copyright © 2004 Nokia Corporation. All rights reserved. Issue 1 05/04

Page 15

NPL-4/5

V

y

Nokia Customer Care System Module and User Interface

PWB

Characteristics of the PWB

8 layer board

Double side assembled

Figure 3: PWB vias

Buried via through

internal layers

TOP

RCC

Blind vias

BOTTOM

DC characteristics

RCC

Table 1: Battery voltage range

Signal

Battery Voltage

(Idle)

Note

-0.3…5.5V

ia through all

ers

la

Battery Voltage

(Call)

Charger Input

Voltage

Max 4.8V

-0.3V …16V

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved. Page 15

Page 16

NPL-4/5

System Module and User Interface Nokia Customer Care

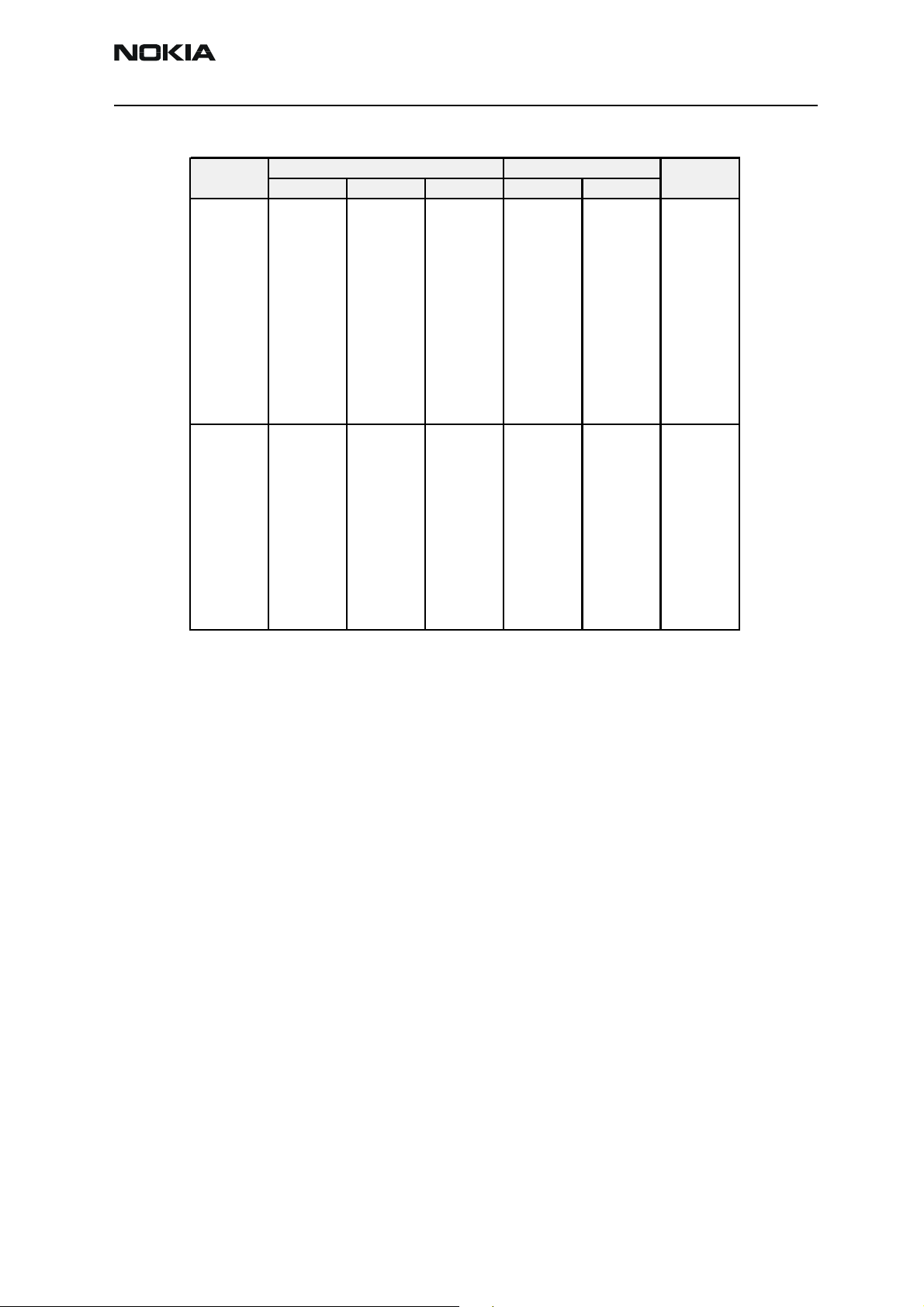

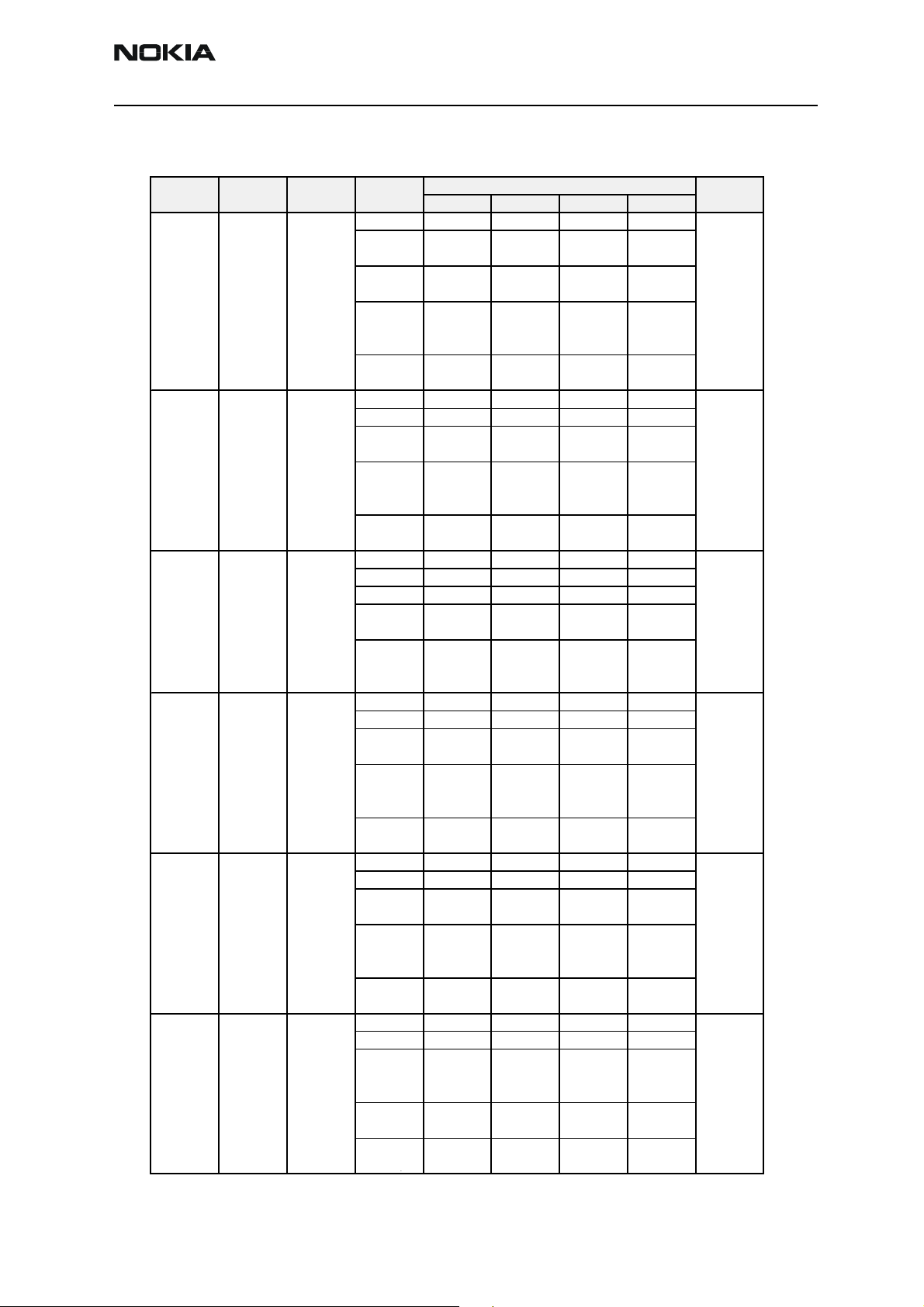

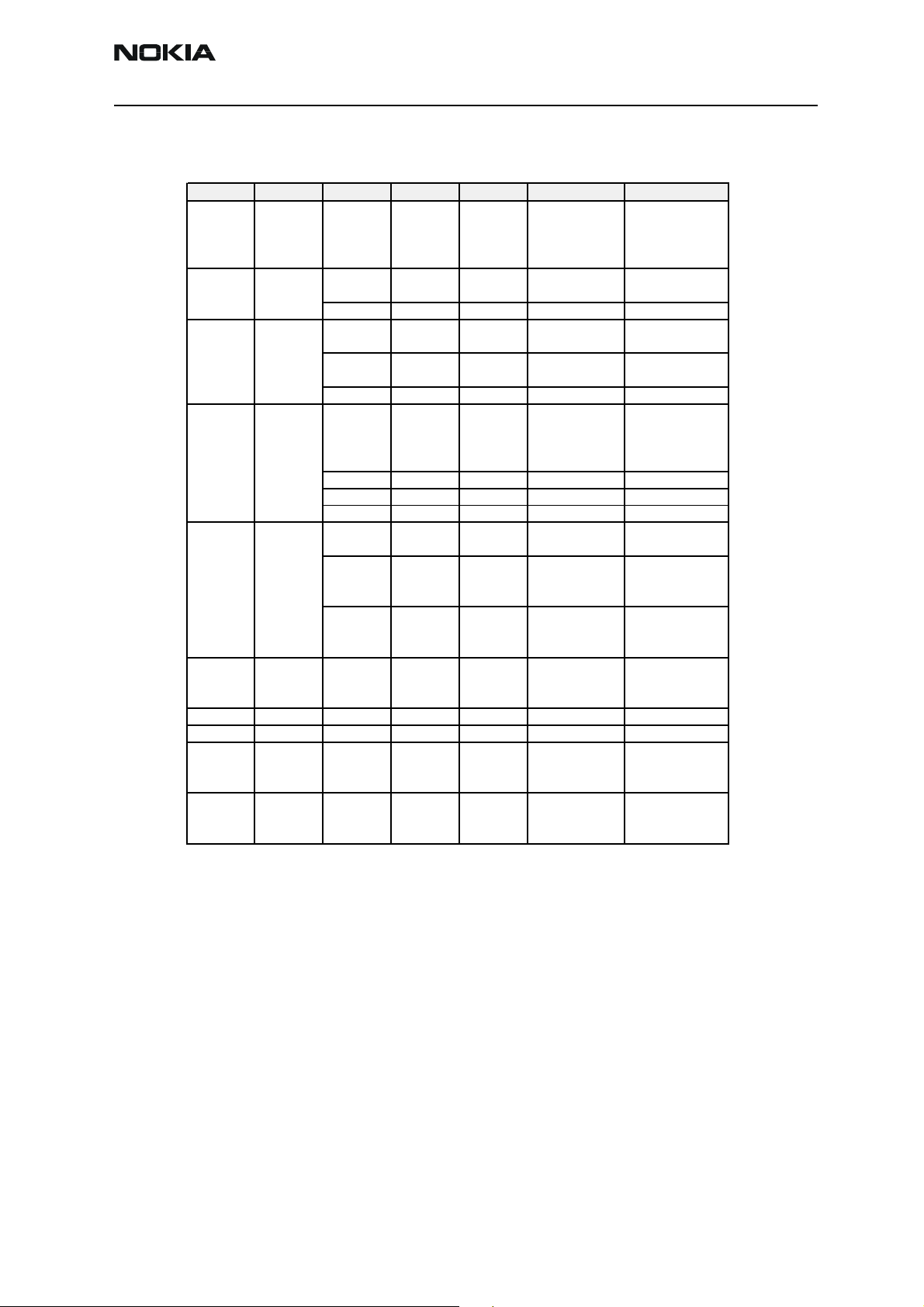

Table 2: UEMEK Regulators

Name Voltage (V) Current (mA)

Min Nom Max Max Sleep Max

VANA 2.7 2.78 2.86 80

VFLASH1 2.61 2.78 2.95 70 1.5

VIO 1.72 1.8 1.88 150 0.5

VCORE 1.48 1.57 1.66 200 0.2

VAUX1 50 0.5

VAUX2 2.7 2.78 2.86 70 0.5

VAUX3 2.7 2.78 2.86 10 0.5

VSIM 25 0.5

VR1A/B 4.6 4.75 4.9 10 VR2 100 -

VR3 2.7 2.78 2.86 20 VR4 2.7 2.78 2.86 50 0.1

VR5 2.7 2.78 2.86 50 0.1

VR6 2.7 2.78 2.86 50 0.1

VR7 2.7 2.78 2.86 45 -

1.745 1.8 1.855

2.91 3 3.09

1.745 1.8 1.855

2.91 3 3.09

2.7 2.78 2.86

-2.61 -2.78 -2.95

Page 16 Copyright © 2004 Nokia Corporation. All rights reserved. Issue 1 05/04

Page 17

NPL-4/5

Nokia Customer Care System Module and User Interface

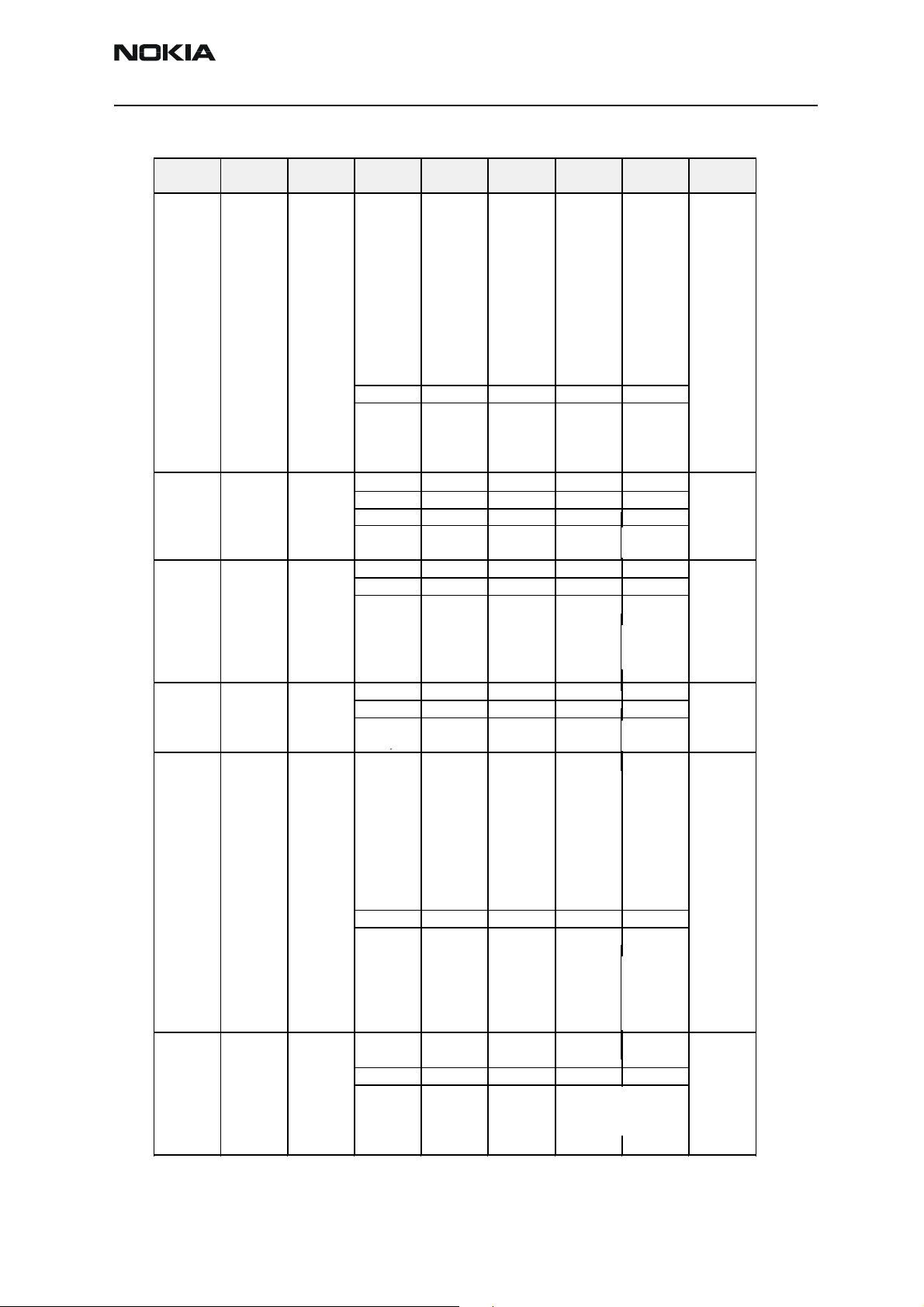

Table 3: 1-3 External Regulators

Signal

name

VCAMDIG 1.755 1.8 1.845 0.0015 150 Power

VANA_EXT 2.72 2.8 2.88 0.0015 150 Power

Min Nom Max Sleep Iq Max

Voltage (V) Current (mA) Note

supply for

camera

digital

parts. Imax

= 150mA.

Cam and

HWA max

current

60mA

supply for

camera,

compass

and FMradio

analog

parts. Imax

= 150mA.

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved. Page 17

Page 18

NPL-4/5

V

V

V

V

V

V

V

V

V

V

V

V

System Module and User Interface Nokia Customer Care

Figure 4: Power Distribution Diagram

RF

BATRF

Charger

POPPORT

Tomahawk /

Vout

VR1A

VR1B

VR2

VR3

VR4

VR5

VR6

VR7

IPA1

IPA2

IPA3

UEMEk

AUX2

BL-5B Battery

SIM

CORE

IO

ANA

UEME

analog

parts

AUX1

AUX3

FLASH1

UEME

digital parts

COMPASS

BATRF

UPP

v3.5

SIM

Ext. 1.8V

regulator

IHF PA

D-class

COMBO

128/16M

FMRadio

VIBRA

Ext. 2.8V

regulator

HWA and

Camera

FCI

Interfac

BAT

LCD

CSTN

IO

IR

module

DC/DC

External and internal signals and connections

This section describes the external and internal electrical connection and interface levels

on the baseband. The electrical interface specifications are collected into tables that

covers a connector or a defined interface.

Flashlight

Disp and

keypad

Illumination

Page 18 Copyright © 2004 Nokia Corporation. All rights reserved. Issue 1 05/04

Page 19

NPL-4/5

Nokia Customer Care System Module and User Interface

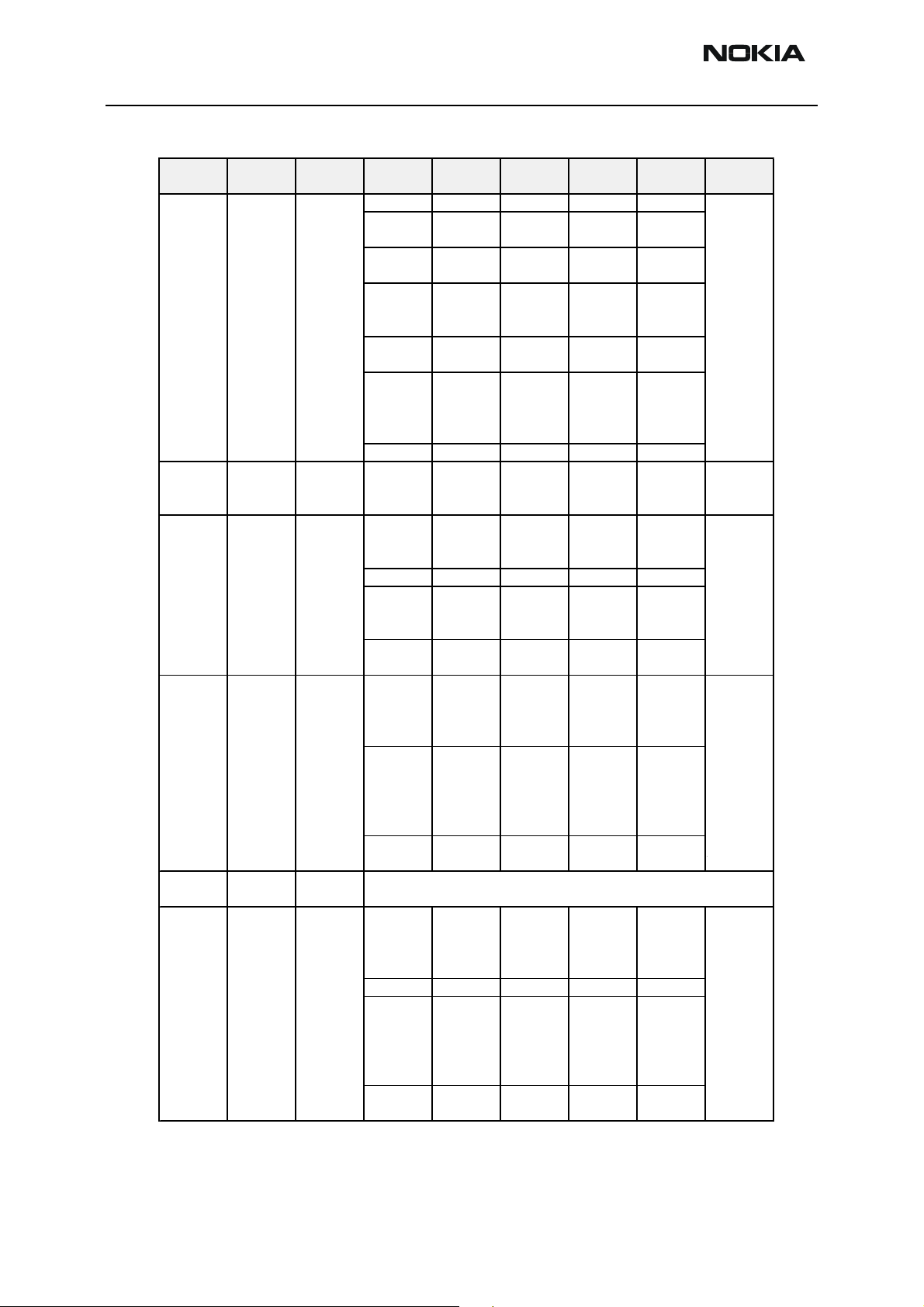

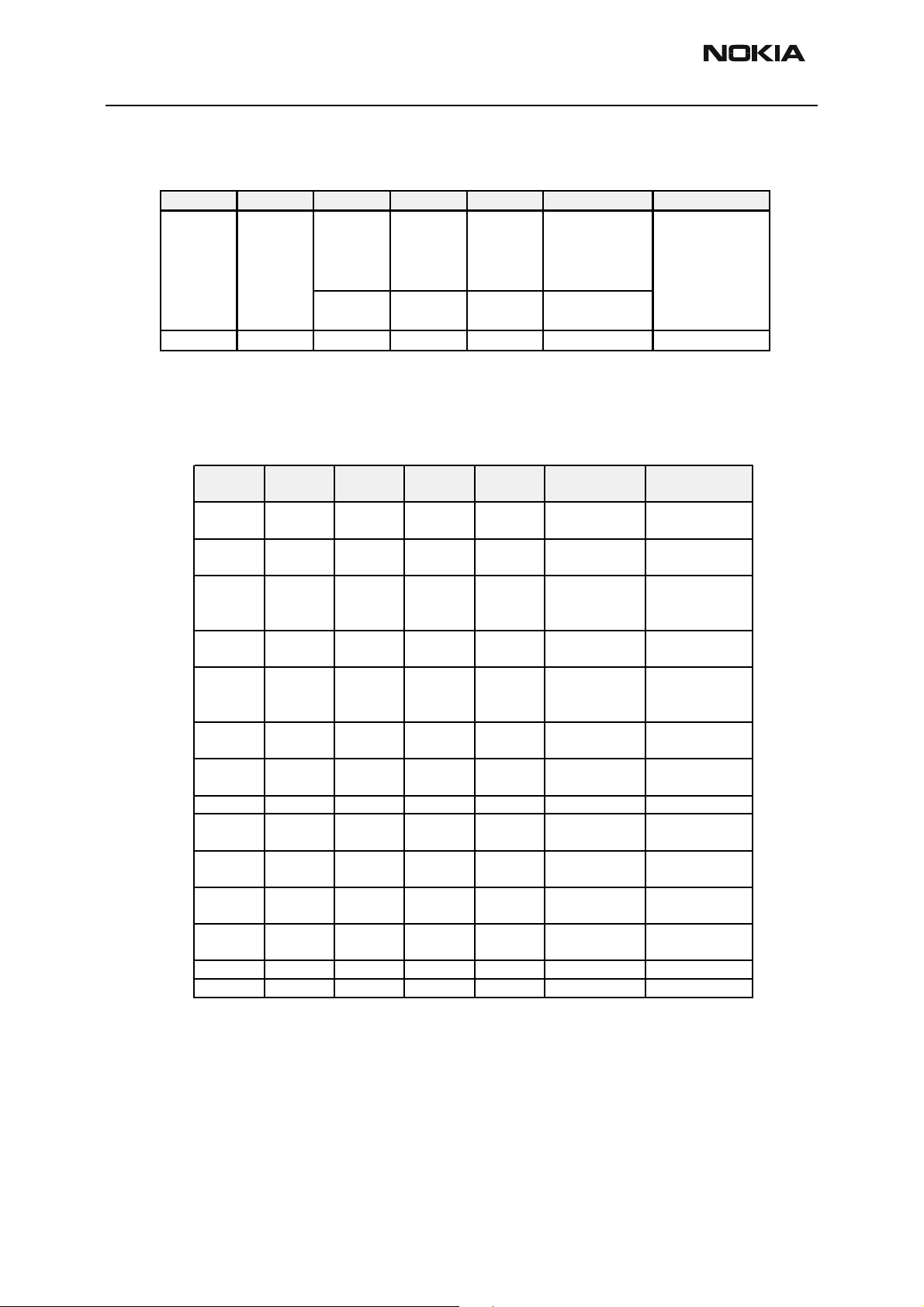

Table 4: AC and DC Characteristics of DCT4 RF-Baseband Voltage Supplies

Signal

name

VBAT Battery PA &

VR1A Voltage 4.6 4.75 4.9 V

VR1B Current 2 10 MA

VR2 UEMEK HELGO85 Supply for

VR3 UEMEK VCTCXO,

VR4 UEMEK HELGO85 Supply for

VR5 UEMEK HELGO85 Supply for

From To Parameter Min Typ Max Unit Function

Voltage 2.95 3.6 4.2 V

UEMEK

Current 2000 MA

Current

drawn by

PA when

”off”

UEMEK HELGO85 Supply for

Noise

density

Voltage 2.7 2.78 2.86 V

Current 65 100 MA

Noise

density

f=100Hz 120 nVrms/

f>300Hz

Voltage 2.7 2.78 2.86 V

HELGO85

Current 1 20 MA

Noise

density

Voltage 2.7 2.78 2.86 V

Current 50 MA

Noise

density

f=6Hz 5500 nVrms/

f=60Hz 550

f>600Hz 55

Voltage 2.7 2.78 2.86 V

Current 50 MA

Noise

density

BW=100Hz.

.. 100kHZ

0.8 2

240 nVrms/

240 nVrms/

240 nVrms/

µA

sqrt(Hz)

sqrt(Hz)

sqrt(Hz)

sqrt(Hz)

sqrt(Hz)

Battery

supply. Cutoff level of

DCT4

regulators

is 3.2V.

Losses in

PWB tracks

and ferrites

are taken

account to

minimum

battery

voltage

level.

charge

pump for

SHF VCO

tuning.

I/Qmodulators,

buffers, ALS

Supply for

VCTCXO,

PLL digital

parts

HELGO85R

X; PA bias

blocks.

Noise

density

decades

20dB/deg

from 6Hz to

600 Hz.

From

f>600Hz

max. noise

density

nVrms/

sqrt(Hz)

HELGO85PL

L; dividers,

LO- buffers,

prescaler,

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved. Page 19

Page 20

NPL-4/5

µ

V

System Module and User Interface Nokia Customer Care

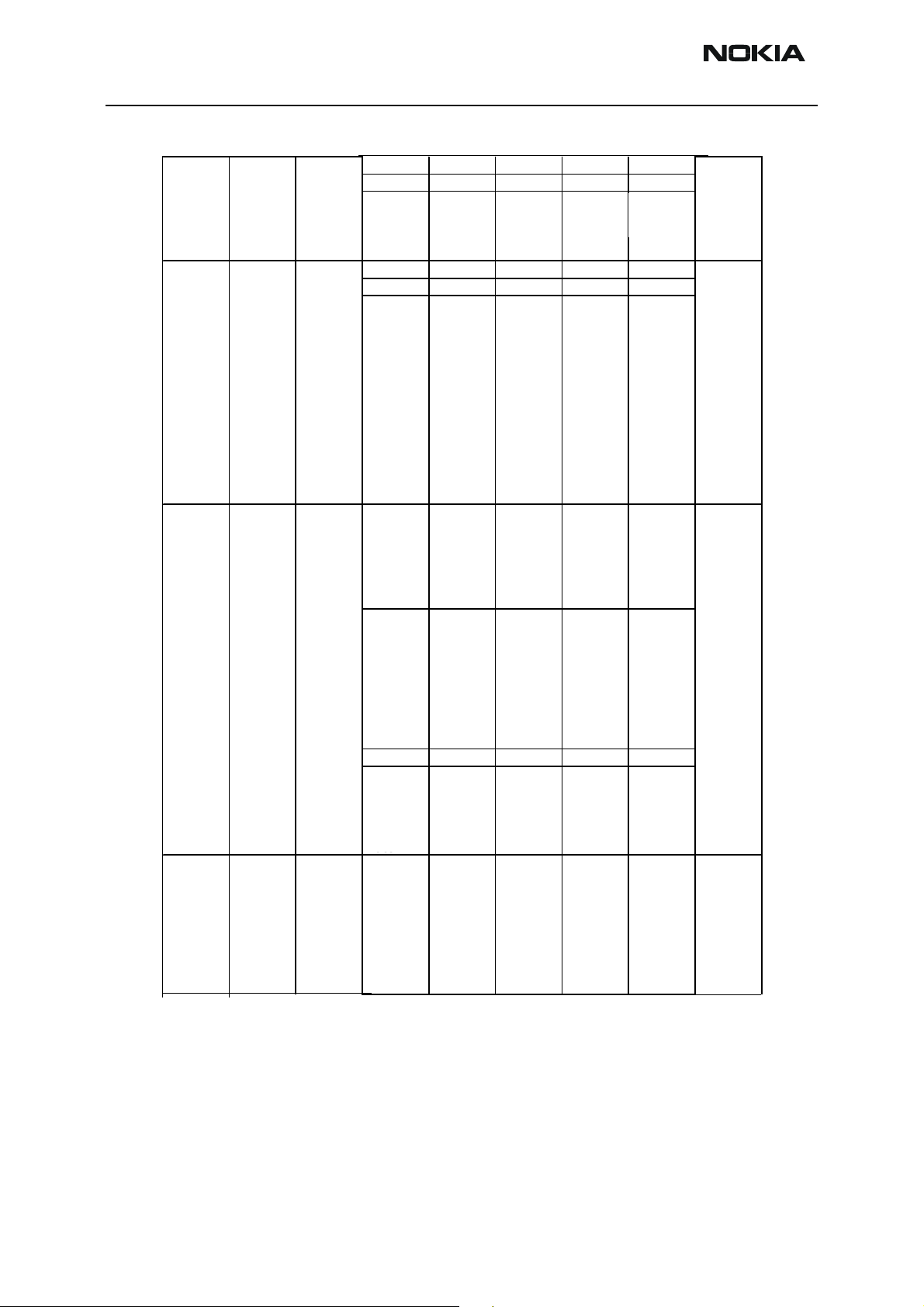

Table 5: AC and DC Characteristics of DCT4 RF-Baseband Voltage Supplies

VR6 UEMEK HELGO85 Supply for

VR7 UEMEK SHF VCO Supply for

VrefRF01 UEMEK HELGO85

VrefRF02 UEMEK VB_EXT Voltage 1.334 1.35 1.366

Voltage 2.7 2.78 2.86 V

Current 50 MA

Noise

density

BW=100Hz.

.. 100kHz

Voltage 2.7 2.78 2.86 V

Current 30 MA

Noise

density

100Hz<f<2

kHz

2kHz<f<10

kHz

10kHz<f<3

0kHz

30kHz<f<9

0kHz

90kHz<f<3

MHz

Voltage 1.334 1.35 1.366 V Voltage

Current 100

Temp Coef -65 65

Noise

density

BW=600Hz.

.. 100kHz

240 nVrms/

sqrt(Hz)

70 nVrms/

sqrt(Hz)

55

35

30

30

µA

/C

60 nVrms/

sqrt(Hz)

HELGO85

BB and

LNAs

SHF VCO

Reference

for

HELGO85

DCN2

op.amps.

Note

:

Below

600Hz

noise

density is

allowed to

increase 20

dB/oct

Note

V

Voltage

reference

for

HELGO85

bias block.

Not used

for

HELGO85

Page 20 Copyright © 2004 Nokia Corporation. All rights reserved. Issue 1 05/04

Page 21

NPL-4/5

T

µ

Nokia Customer Care System Module and User Interface

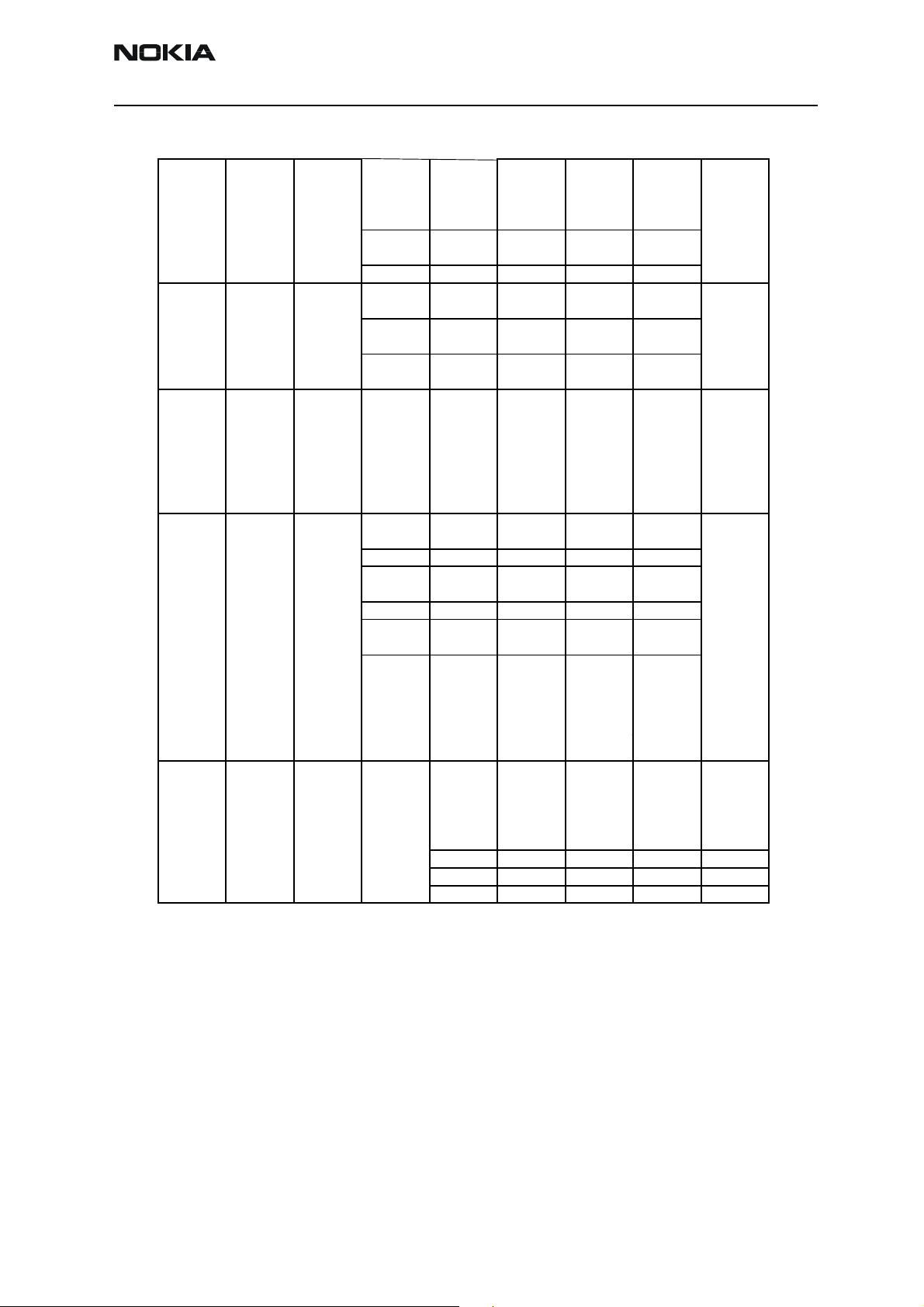

Table 6: AC and DC Characteristics of DCT4 RF-Baseband Digital Signals

Signal

name

TXP ”1” 1.38 1.88 V

(RFGenOut3

)

TXA UPP HELGO85 Power

RFBusEna1XUPP HELGO85 RFbus

From To Parameter Input Characteristics

Min

UPP HELGO85 Power

”0” 0 0.4 V

Load

Resistance

Load

Capacitanc

e

Timing

Accuracy

”1” 1.38 1.88 V

”0” 0 0.4 V

Load

Resistance

Load

Capacitanc

e

Timing

Accuracy

”1” 1.38 1.88 V

”0” 0 0.4 V

Current 50

Load

resistance

Load

capacitance

yp Max Unit

10 220

20 pF

¼ Symbol

10 220

20 pF

¼ symbol

10 220

20 pF

k

k

kΩ

Ω

Ω

A

Function

amplifier

enable

control loop

enable

enable

RFBusData UPP HELGO85 RFbus

RFBusClk UPP HELGO85 RFBus clock

RESET ”1” 1.38 1.85 V

(GENIO06) ”0” 0 0.4 V

UPP HELGO85 Reset to

”1” 1.38 1.88 V

”0” 0 0.4 V

Load

resistance

Load

capacitance

Data

frequency

”1” 1.38 1.88 V

”0” 0 0.4 V

Load

resistance

Load

capacitance

Data

frequency

Load

capacitance

Load

resistance

Timing

accuracy

10 220

20 pF

10 MHz

10 220

20 pF

10 MHz

20 pF

10 220

¼ symbol

data;

k

Ω

k

Ω

k

Ω

read/write

HELGO85

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved. Page 21

Page 22

NPL-4/5

System Module and User Interface Nokia Customer Care

Table 7: AC and DC Characteristics of DCT4 RF-Baseband Analogue Signals

Signal

name

VCTCXO VCTCXO UPP High

VCTCXOGnd VCTCXO UPP DC Level 0 V Ground for

RXI/RXQ HELGO85 UEMEK Received

TXIP / TXIN UEMEK HELGO88

TXQP /

TXQN

AFC UEMEK VCTCXO

From To Parameter Min Typ Max Unit Function

Frequency 13 26 MHz

stability

clock signal

for the

logic

circuits, AC

coupled.

Distorted

sinewave

e.g.

sawtooth.

reference

clock

demodulate

d IQ signals

ble voltage

swing.

ble

common

mode

voltage.

Between

TXIP-TXIN

frequency

control

signal for

VCTCXO

UEMEK HELGO85

Signal

amplitude

Input

Impedance

Input

Capacitanc

e

Harmonic

Content

Clear signal

window (no

glitch)

Duty Cycle 40 60 %

Voltage

swing

(static)

DC level 1.3 1.35 1.4 V

I/Q

amplitude

mismatch

I/Q phase

mismatch

Differential

voltage

swing

(static)

DC level 1.17 1.2 1.23 V Programma

Source

Impedance

Same spec as for TXIP / TXIN

Voltage

Min

Max

Resolution 11 Bits

Load

resistance

and

capacitance

0.2 0.8 2 Vpp

10

300 mVpp

1.35 1.4 1.45 Vpp

-5 5 Deg

2.15 2.2 2.25 Vpp Programma

00.1

2.4 2.6

1

K

Ω

10 pF

-8 dBc

0.2 DB

200

Ω

V Automatic

k

Ω

100 nF

Source

Impedance

200

Ω

Page 22 Copyright © 2004 Nokia Corporation. All rights reserved. Issue 1 05/04

Page 23

NPL-4/5

Nokia Customer Care System Module and User Interface

TxC UEMEK HELGO85

RFTemp HELGO85 UEMEK Temperatur

DC_sense PA UEMEK Voltage 0.6 V PA final

IPA1 / IPA2 UEMEK PA PA final

VCTCXOTEMPPA sheet UEMEK A/D Voltage

Voltage

Min

Max

Source

Impedance

Resolution 10 Bits

Voltage at 20oC

Voltage at

+25oC

Voltage at

+60oC

Output

Voltage

Current

range

Resolution 4 Bits

Current

tolerance

Noise

density

f=100 Hz-

800kHz

f=800kHz-

100MHz

2.4

1,57 V

1,7

1,79

02.7V

05MA

-6 6 %

0.1 V Transmitter

power level

and

ramping

200

88

110

Ω

nVrms/

sqrt(Hz)

control

e sensor of

RF in

HELGO

ASIC.

stage

quiescent

current

level

information

.

stage

quiescent

current

adjustment

PA

manufactur

er identifier

signal

1.2 1.6 V Agilent

0.7 1.1 V RFMD

00.1VHitachi

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved. Page 23

Page 24

NPL-4/5

x

System Module and User Interface Nokia Customer Care

UI board interface signals

Table 8: UI board interface signals

Pin Signal Min Nom Ma

1ROW(0)

2COL(0)

3 ROW(1) Keyboard matrix

4 COL(1) Keyboard matrix

5 ROW(2) Keyboard matrix

6 COL(2) Keyboard matrix

7 ROW(3) Keyboard matrix

8 COL(3) Keyboard matrix

9 COL(4) Keyboard matrix

10 ROW(4) Keyboard matrix

11 Temp Ambient

12 GND 0V

13 VLED- 0V Separate GND for

0.7xVIO VIO High Keyboard matrix

0 0.3xVIO Low row 0

0.7xVIO VIO High

00.3xVIO Low

0.7xVIO VIO High

00.3xVIO Low

0.7xVIO VIO High

00.3xVIO Low

0.7xVIO VIO High

00.3xVIO Low

0.7xVIO VIO High

00.3xVIO Low

0.7xVIO VIO High

00.3xVIO Low

0.7xVIO VIO High

00.3xVIO Low

0.7xVIO VIO High

00.3xVIO Low

0.7xVIO VIO High

00.3xVIO Low

Condition Note

Keyboard matrix

col 0

row 1

col 1

row 2

col 2

row 3

col 3

col 4

row 4

temperature

sensor

keypad LEDs

14 VLED+ 7.2V 8.2V

15 GND 0V

16 FCI Vout

17 FCI GND 0V

18 FCI Da

19 Fci Clk

20 FCIInt

2.8V 5.5V On

0V 0V Off

1.19V 1.9V high

0V 0.51V low

1.19V 1.9V high

0V 0.51V low

1.19V 1.9V high

0V 0.51V low

7.7V LED on

0V LED off

Supply Voltage for

Keyboard LED

[note1]

Page 24 Copyright © 2004 Nokia Corporation. All rights reserved. Issue 1 05/04

Page 25

NPL-4/5

Nokia Customer Care System Module and User Interface

Display interface signals

Table 9: LCD connector

Pin Signal Min Nom Max Condition Note

1 VDDI 1.72V 1.8V

2 RESX

3 SDA Serial data

4 SCLK Serial clock

5CSX

6 VDD 2.70V 2.78V

7 NC Not Connected

8 GND 0V Ground

VLED-

90V

0.7*VDDI VDDI Logic ’1’ Reset

0 0.3*VDDI Logic ’0’ Active low

1us trw Reset active

0.7*VDDI VDDI Logic ’1’

0 0.3*VDDI Logic ’0’

100ns tsds Data setup time

100ns tsdh Data hold time

0.7*VDDI VDDI Logic ’1’

0 0.3*VDDI Logic ’0’

250ns tscyc Clock cycle

100ns tshw Clock high

100ns tslw Clock low

0.7*VDDI VDDI Logic ’1’ Chip select

0 0.3*VDDI Logic ’0’ Active low

60ns tcss CXS low before

100ns tcsh CXS low after

1.88V

6.5MHz Max frequency

2.86V

Logic voltage

supply

Connected to

VIO

input

SCLK rising

edge

SCLK rising

edge

Supply Voltage.

Connected to

VFLASH1

Return current

(GND)

VLED 0V LED off

10 Supply Voltage

Display 7.7V LED on

7.2V 8.4V

for LEDs

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved. Page 25

Page 26

NPL-4/5

g

Ω

Ω

Ω

System Module and User Interface Nokia Customer Care

System connector interface signals

Table 10: DC Connector

Pin Signal Min Nom Max Condition Note

1 VCHAR 11.1Vpeak Standard charger Charger positive

7.0 VRMS

8.4 VRMS Fast charger

2 CHGND 0 Charger ground

Table 11: POPPORT System Connector/Bottom Connector

Pin Signal Description Spectral

Ran

1 CHARGE V Charge DC 0-9 V / 0.85

2GND Charge

GND

3 ACI ACI 1 kbit/s Dig 0 /

16.9 Vpeak

7.9 VRMS

1.0 Apeak

9.2 VRMS

850 mA

U/I levels Impedance Notes

e

A

47 Ω

2.78V

input

Insertion &

removal detection

4VOUT DC out DC 2.78V /

70mA

USB VBUS

5

(Not

connected)

6FBUS TX FBUS

115kbit

7FBUS RX FBUS

115kbit

8 SGND Data GND 0.85 A

9 XMIC N Audio in 300 - 8k 1Vpp &

10 XMIC P Audio in 300 - 8k 1Vpp &

11 HSEAR N Audio out 20 - 20k 1Vpp

12 HSEAR P Audio out 20 - 20k 1Vpp

13 HSEAR R P Audio out 20 - 20k 1Vpp

14 HSEAR R N Audio out 20 - 20k 1Vpp

0 / 2.78V

0 / 2.78V

2.78V

2.78V

100 mΩ

33 Ω

33 Ω

100 m

10 Ω

10 Ω

10

10

(PWB + conn.)

200mW

(PWB + conn.)

Ext. Mic Input

Ext. Mic Input

Ext. audio out

(left)

Ext. audio out

(left)

Page 26 Copyright © 2004 Nokia Corporation. All rights reserved. Issue 1 05/04

Page 27

NPL-4/5

T

Nokia Customer Care System Module and User Interface

SIM interface signals

Table 12: SIM Connector

Pin Name Parameter Min

1VSIM Supply

2SIMRST1.8V SIM

3 SIMCLK SIM clock

4DATA V

5NC Not

6GNDGND0 0 VGround

1.8V SIM

Card

3V SIM

Card

Card

3V SIM

Card

Frequency 3.25 MHz

Trise/Tfall 50 ns

1.8V Voh 0.9xVSIM

1.8V Vol 0

3V Voh 0.9xVSIM

3V Vol 0

1.8V Voh 0.9xVSIM VSIM

1.8V Vol 0 0.15xVSIM

3V Voh 0.9xVSIM VSIM

3V Vol 0 0.15xVSIM

1.8V Vih 0.7xVSIM VSIM SIM data

1.8V Vil 0 0.15xVSIM Trise/Tfall

3V Vil 0.7xVSIM VSIM

3V Vil 0 0.15xVSIM

1.6 1.8 1.9 V

2.8 3 3.2 V

0.9xVSIM VSIM

00.15xVSIM

0.9xVSIM VSIM

00.15xVSIM

yp Max Unit Notes

voltage

VSIM reset

(output)

V

VSIM V

VSIM V

SIM data

(output)

V

(input)

max 1us

connected

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved. Page 27

Page 28

NPL-4/5

Ω

Ω

g

System Module and User Interface Nokia Customer Care

FCI interface signals

Table 13: FCI Interface

BB Signal FCI Signal Min Nom Max Condition Note

VBATT VOUT

GND GND 0.5

GenIO(22) 1.19V 1.9V High

In/Out 0 0.51V Low

GenIO(2) 1.19V 1.9V High

Out 0 0.51V Low

GenIO(25) 1.19V 1.9V High

In 0 0.51V Low

GenIO(18) 1.19V 1.9V High

In 0 0.51V Low

VIO VCC 1.72V 1.80V 1.88V V Power supply for

FCI SDA

FCI SCL

FCI INT

CTRL FCI ASIP power

2.80V 5.5V V

0 110 mA

0.5

1uF

1.4 2 2.6

120 pF Capacitance

1.4 2 2.6

120 pF Capacitance

70 100 130

120 pF Capacitance

impedance

impedance

kΩ

kΩ

kΩ

.

Pull-up in

terminal

Pull-up in

terminal

Pull-up in

terminal

control

pull up resistors

Camera interface signals

BB Signal Camera

Si

nal

VANA_EXT AVDD 2.72V 2.80V 2.88V V I

VCAMDIG DVDD 1.72V 1.80V 1.88V V I

GenIO(3) 1.4V 1.88V High

Out 0 0.4V Low

GenIO(27) 1.4V 1.88V High

Out 0V 0.4V Low

GenIO(28) 1.4V 1.88V High

Out 0 0.6V Low

GenIO(26) 1.4V 1.88V High

Out 0 0.4V Low

GenIO(1) 1.4V 1.88V High

Out 0 0.4V Low

CLK 1.8V Clock signal for

TXDA 1.8V Control data for

CSX 1.8V CSX signal for

CE 1.8V CE signal for HWA

Reg_en 1.8V 1.8V and 2.8V

Table 14: Camera Interface

Min Nom Max Condition Note

= 16mA

max

= 100mA,

max

Common for

camera and HWA

Camera and HWA.

Common with

13 MHz

compass

HWA

HWA

and camera

regulators

enable/disable

Page 28 Copyright © 2004 Nokia Corporation. All rights reserved. Issue 1 05/04

Page 29

NPL-4/5

Nokia Customer Care System Module and User Interface

LCDUI(1) RXDA 1.4V 1.88V High

In/Out LCDCamTxD

a

LCDUI(0) DACLK 1.4V 1.88V High

Out LCDCamClk 0 0.4V Low

FM radio interface signals

BB Signal FM Radio

Signal

VANA_EXT

GenIO(24) FMClk 1.8V Reference clock

GenIO(8) FMWrEn 1.8V Write/Read

Vcca 2.7V 2.78V 2.86V I

Vcc(vco) 2.7V 2.78V 2.86V I

Vccd 2.7V 2.78V 2.86V I

1.8V Camera data

00.4VLow

1.8V Camera data clock

Table 15: FM-radio Interface

Min Nom Max Condition Note

10.5mA

Max

940uA

Max

3.9mA

Max

1.4V 1.88V High

for FM radio

00.4VLow

32768Hz Frequency

30ppm Stability

1.4V 1.88V High

0V 0.4V Low

module

enable

signal

GenIO(11) FMCtrlClk 1.8V

GenIO(12) FMCtrlDa 1.8V Bi-directional

FM Antenna RF1,RF2 76MHz 108MHz FM input

FM Radio L FM Audio L 100mV Audio level

FM Radio R FM Audio R 24dB 30dB Channel

1.4V 1.88V High

00.4VLow

1 MHz Frequency

1.4V 1.88V High

00.6VLow

separation

54dB 60dB S/N

2% Harmonic

distortion

data

frequency

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved. Page 29

Page 30

NPL-4/5

System Module and User Interface Nokia Customer Care

Compass interface signals

Table 16: Compass Interface

BB Signal MagIC Signal Min Nom Max Condition Note

VANA_EXT AVDD 2.72V 2.80V

VIO DVDD 1.72V 1.80V 1.88V V I

GenIO(3) 1.4V 1.88V High

Out 0 0.4V Low

CBUSCLK 1.4V 1.88V High

Out 0V 0.4V Low

CBUSDA 1.4V 1.88V High

In/Out 0 0.6V Low

CBUSENX 1.4V 1.88V High

Out 0 0.4V Low

PURX ClrX 1.8V

CLK 1.8V Clock signal for

13 MHz

CBUSCLK 1.8V Data clock for

CBUSDA 1.8V Data for MagIC

CBUSENX 1.8V CBUS enable

1.4V 1.88V High General reset from

2.88V V I

= 10mA and <

max

10uA in sleep.

= 2mA and

max

<10uA in sleep.

MagIC. Common

with camera

MagIC CBUS

and UPP

UEMEK. 0=Reset

0 0.4V Low and 1 = No Reset

Page 30 Copyright © 2004 Nokia Corporation. All rights reserved. Issue 1 05/04

Page 31

NPL-4/5

Nokia Customer Care System Module and User Interface

Functional Description

Modes of operation

Wv1 baseband engine has six different functional modes:

1. No supply

2. Backup

3. Acting Dead

4. Active

5. Sleep

6. Charging

No supply

In NO_SUPPLY mode, the phone has no supply voltage. This mode is due to disconnection

of main battery and backup battery or low battery voltage level in both of the batteries.

Phone is exiting from NO_SUPPLY mode when sufficient battery voltage level is

detected. Battery voltage can rise either by connecting a new battery with VBAT >

VMSTR+ or by connecting charger and charging the battery above VMSTR+.

Backup

In BACKUP mode the backup battery has sufficient charge but the main battery can be

disconnected or empty (VBAT < VMSTR and VBACK > VBUCOFF).

VRTC regulator is disabled in BACKUP mode. VRTC output is supplied without regulation from backup

Acting dead

If the phone is off when the charger is connected, the phone is powered on but enters a

state called ”Acting Dead”. To the user, the phone acts as if it was switched off. A battery-charging alert is given and/or a battery charging indication on the display is shown

to acknowledge the user that the battery is being charged.

Active

In the Active mode the phone is in normal operation, scanning for channels, listening to

a base station, transmitting and processing information. There are several sub-states in

the active mode depending on if the phone is in burst reception, burst transmission, if

DSP is working etc.

In Active mode the RF regulators are controlled by SW writing into UEMEK’s registers

wanted settings:

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved. Page 31

Page 32

NPL-4/5

System Module and User Interface Nokia Customer Care

VR1A can be enabled or disabled. VR2 can be enabled or disabled and its output voltage

can be programmed to be 2.78V or 3.3V. VR4 -VR7 can be enabled, disabled, or forced

into low quiescent current mode. VR3 is always enabled in Active mode.

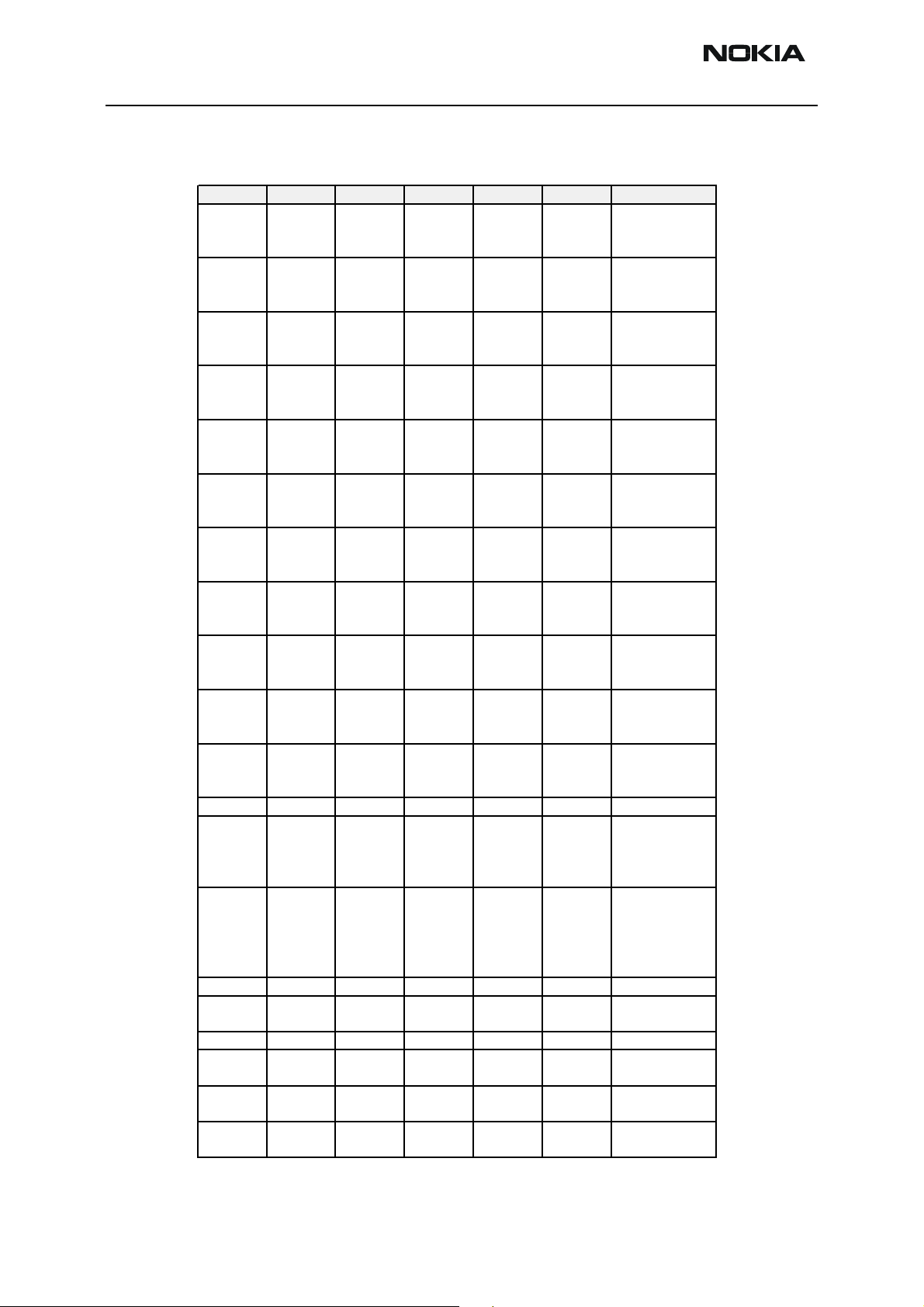

Table 17: Regulator Controls

Regulator NOTE

VFLASH1 Enabled

VAUX2

VAUX1

VAUX3 Controlled by register writing.

Controlled by register writing

Default state is off.

Controlled by register writing.

Defaul start up setting 1.8V

VANA

VIO Enabled

VCORE Enabled

VSIM Controlled by register writing.

VR1A/VR1B

VR2

VR3

VR4

VR5

VR6

VR7

IPA1 Controlled by register writing.

Enabled

Disabled in sleep mode

Controlled by register writing

Disabled in sleep mode

Controlled by register writing

Disabled in sleep mode

Enabled

Disabled in sleep mode

Enabled

Disabled in sleep mode

Enabled

Disabled in sleep mode

Enabled

Disabled in sleep mode

Enabled

Disabled in sleep mode

IPA2 Controlled by register writing.

IPA3 Controlled by register writing

VCAMDIG and

VANA_EXT

External regulators are controlled by

GenIO(01)

Sleep mode

Sleep mode is entered when both MCU and DSP are in stand–by mode. Both processors

control sleepmode.

Page 32 Copyright © 2004 Nokia Corporation. All rights reserved. Issue 1 05/04

Page 33

NPL-4/5

Nokia Customer Care System Module and User Interface

When SLEEPX signal (low) is detected UEMEK enters SLEEP mode. VCORE, VIO and

VFLASH1 regulators are put into low quiescent current mode. All the RF regulators are

disabled in SLEEP. When SLEEPX=1 detected UEMEK enters ACTIVE mode and all functions are activated.

The sleep mode is exited either by the expiration of a sleep clock counter in the UEMEK

or by some external interrupt, generated by a charger connection, key press, headset

connection etc.

In sleep mode VCTCXO is shut down and 32 kHz sleep clock oscillator is used as reference

clock for the baseband.

Charging

Charging can be performed in parallel with any operating mode. In NPL-4/5 the battery

type/size is indicated by a 75kOhm BSI-resistor, which is in battery back. The resistor

value corresponds to a specific battery capacity. NTC resistor, which is measuring battery

temperature is located on an engine board.

The battery voltage, temperature, size and current are measured by the UEMEK controlled by the charging software running in the UPP.

The charging control circuitry (CHACON) inside the UEMEK controls the charging current

delivered from the charger to the battery. The battery voltage rise is limited by turning

the UEMEK switch off when the battery voltage has reached 4.2 V. Charging current is

monitored by measuring the voltage drop across a 220 mOhm. resistor.

Power up and reset

Power up and reset is controlled by the UEMEK ASIC. NPL-4/5 baseband can be powered

up in following ways:

1 Press power button which means grounding the PWRONX pin on UEMEK

2 Connect the charger to the charger input

3 Supply battery voltage to the battery pin.

4 RTC Alarm, the RTC has been programmed to give an alarm

After receiving one of the above signals, the UEMEK counts a 20ms delay and then enters

its reset mode. The watchdog starts up, and if the battery voltage is greater than Vcoff+

a 200ms delay is started tp allow references etc. to settle. After this delay elapses the

VFLASH1 regulator is enabled. 500us later VR3, VANA, VIO and VCORE are enabled.

Finally the PURX line is held low for 20 ms. This reset, PURX, is fed to the baseband ASIC

UPP, resets are generated for the DSP and the MCU. During this reset phase the UEMEK

forces the VCXO regulator on regardless of the status of the sleep control input signal to

the UEMEK. The sleep signal from the ASIC is used to reset the flash during power up and

to put the flash in power down during sleep. All baseband regulators are switched on at

the UEMEK power on except for the SIM regulator that is controlled by the MCU. The

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved. Page 33

Page 34

NPL-4/5

System Module and User Interface Nokia Customer Care

UEMEK internal watchdog is running during the UEMEK reset state, with the longest

watchdog time selected. If the watchdog expires, the UEMEK returns to power off state.

The UEMEK watchdog is internally acknowledged at the rising edge of the PURX signal in

order to always give the same watchdog response time to the MCU.

Power up with PWR key

When the Power on key is pressed the UEMEK enters the power up sequence. Pressing

the power keycauses the PWRONX pin on the UEMEK to be grounded. The UEMEK

PWRONX signal is not part of the keypad matrix. The power key is only connected to the

UEMEK. This means that when pressing the power key an interrupt is generated to the

UPP that starts the MCU. The MCU then reads the UEMEK interrupt register and notice

that it is a PWRONX interrupt. The MCU now reads the status of the PWRONX signal

using the UEMEK control bus, CBUS. If the PWRONX signal stays low for a certain time

the MCU accepts this as a valid power on state and continues with the SW initialization

of the baseband. If the power on key does not indicate a valid power on situation, the

MCU powers off the baseband.

Power up when charger is connected

In order to be able to detect and start charging in a case where the main battery is fully

discharged (empty) and hence UEMEK has no supply (NO_SUPPLY or BACKUP mode of

UEMEK) charging is controlled by START-UP CHARGING circuitry.

Whenever VBAT level is detected to be below master reset threshold (VMSTR-) charging

is controlled by START_UP charge circuitry. Connecting a charger forces VCHAR input to

rise above charger detection threshold, VCHDET+. By detection start-up charging is

started. UEMEK generates 100mA constant output current from the connected charger’s

output voltage. As battery charges its voltage rises, and when VBAT voltage level higher

than master reset threshold limit (VMSTR+) is detected START_UP charge is terminated.

Monitoring the VBAT voltage level is done by charge control block (CHACON). MSTRX=‘1’

output reset signal (internal to UEMEK) is given to UEMEK’s RESET block when

VBAT>VMSTR+ and UEMEK enters into reset sequence.

If VBAT is detected to fall below VMSTR- during start-up charging, charging is cancelled.

It will restart if new rising edge on VCHAR input is detected (VCHAR rising above VCHDET+).

Battery

NPL-4/5 uses BL-5B 760 mAh Lithium Polymer battery pack. The battery size is

5.7x34x46mm. Other battery packs aren’t supported.

Page 34 Copyright © 2004 Nokia Corporation. All rights reserved. Issue 1 05/04

Page 35

NPL-4/5

V

Nokia Customer Care System Module and User Interface

Table 18: BL-5B Characteristics

Description

Nominal discharge cut-off voltage 3.1V

Nominal battery voltage 3.7V

Nominal charging voltage 4.2V

Maximum charger output current 850 mA

Minimum charger output current 200 mA

Table 19: Pin Numbering of Battery Pack

Signal

Pin number Function

alue

name

VBAT 1 Positive battery terminal

BSI 2 Battery capacity

measurement (fixed

resistor inside the

battery pack)

GND 3 Ground/negative/comm

on battery terminal

Figure 5: Battery Pack Contacts

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved. Page 35

Page 36

NPL-4/5

System Module and User Interface Nokia Customer Care

A/D channels

The UEMEK contains the following A/D converter channels that are used for several measurement purposes. The general slow A/D converter is a 10-bit converter using the

UEMEK interface clock for the conversion. An interrupt will be given at the end of the

measurement.

The UEMEK’s 11-channel analog to digital converter is used to monitor charging functions, battery functions, user interface and RF functions.

The monitored battery functions are battery voltage (VBATADC), battery type (BSI) and

battery temperature (BTEMP) indication.

The battery type is recognized through a resistive voltage divider. In phone there is a

100k. pull up resistor and a 75kohm BSI pull down resistor in the same line. Regardless of

the battery type the pull down resistor is always same. The battery temperature is measured equivalently from engine board by NTC pull down resistor in the BTEMP line.

The monitored RF functions are PATEMP and VCXOTEMP measurements. PATEMP input is

used to measure temperature of the RF-IC HELGO. VCXOTEMP input is used for RF PA

manufacturer identification in NPL-4/5.

AUXDET and HEADINT2 inputs can be used for keyboard scanning purposes. These inputs

are routed internally from the miscellaneous block. These lines are used for thermometer

in NPL-4/5.

The output of the backup battery, VBACK, is connected to the converter using a NMOS

switch. There is also a pulldown switch in the VBACK input, which can be used to discharge the back up battery line. The pulldown switch should be disabled during the measurement of the voltage level of the VBACK.

Digital camera

VGA camera module is used in NPL-4/5. Camera is connected to baseband (UPP) through

HW Accelerator IC. The camera data bus is common with display bus. External 1.8V and

2.8V regulators are used as a power supply (VDIG and VANA) for camera module and HW

accelerator. The 2.8V regulator is common for camera, compass and FM-radio.

Page 36 Copyright © 2004 Nokia Corporation. All rights reserved. Issue 1 05/04

Page 37

NPL-4/5

A

r

Nokia Customer Care System Module and User Interface

Figure 6: Camera Connections to Baseband

GenIO(01)

REG

2.8V

REG

1.8V

VANA_EXT

VDIG

VGA camera has a resolution of 640 x 480. Pixel size is 5.6um x 5.6um. Both camera and

HW accelerator support sleep functionality in order to minimize the current consumption.

FM radio

FM radio circuitry is implemented using highly integrated radio IC, TEA5767. The MCU

SW controls FM radio circuitry through serial bus interface. The FM radio power supply is

VANA_EXT, which is common with camera and compass.

UPP

LCDUI(1)

LCDUI(0)

GenIO(27)

GenIO(28)

GenIO(26)

GenIO(3)

LCDCamTxDa

LCDCamClk

CamRxDa

CamCSX

CamSDX

CamClk

HW

ccelerato

CCISCL

CCIDA

CCPCLKN

CCPCLKP

CCPDATAN

CCPDATAP

Camera

Figure 7: FM Radio Audio-, Antenna- and Digital Interface Connections

GENIO11

GENIO12

GENIO8

GENI24

VIO

GND

TEA5767

SDA

SCL

W/R

Clk

VAFL

VAFR

VDIG/

VANA

Ant

FMCtrlDa

FMCtrlClk

FMWrEn

FMClk

UEMEUPP

Filter

VANA_EXT

1U

GND

MIC3NR

MIC3PR

MIC3N

MIC3P

C1

L1

C2

C3

C4

1

14

Tomahawk

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved. Page 37

Page 38

NPL-4/5

System Module and User Interface Nokia Customer Care

Electrical compass

The compass will have two magnetometer channels and it uses anisotropic magnetoresistive (AMR) magnetometer component (containing both X- and Y-axes). Each measurement axis is configured as a 4-element Whetstone bridge converting the magnetic field

into differential output voltage. This sensor element is capable of sensing fields in milligauss range. In order to achieve the measurement resolution, the sensor must be frequently reset by a current pulse run through the set/reset coil of the sensor element. The

MagIC ASIC will interface the phone engine through the CBUS interface. The calculation

of the compass heading and the calibration of the magnetometer are carried out in the

phone engine.

NPL-4/5 will have an air-bubble for the user to level the device.

The heading is shown by compass rose in phone display.

Figure 8: Baseband and Compass Interface

Vbridge

x-axes

y-axes

Magneto

meter

UEMEK

UEME

VIO

PURX

CBUS

MagIC

DVdd

Clr

UPP

Thermometer

The 1% accuracy NTC-resistor is used for ambient temperature measurement. NTC resistor sensor is located on UI-board under the keypad shield. It is connected with two A/D –

lines (AuxDet and Headint2) to UEMEK.

Voltages are measured over 1% accuracy resistor that is connected series with temperature sensor. This gives sufficient accuracy for temperature measurement without calibration.

GenIO3

GenIO1

S/R

Clk

AVdd

2.8V

Regulator

Page 38 Copyright © 2004 Nokia Corporation. All rights reserved. Issue 1 05/04

Page 39

NPL-4/5

A

A

A

Nokia Customer Care System Module and User Interface

Figure 9: Ambient Temperature Sensor Interface to BB

VANA

Backup battery

Backup battery is used in case when main battery is either removed or dis-charged.

Backup battery is used for keeping realtime clock running for minimum of 30 minutes.

Rechargeable backup battery is connected between UEMEK VBACK and GND. In UEMEK

backup battery charging high limit is set to 3.2V. The cut–off limit voltage (V BUCoff– )

for backup battery is 2.0V.

R211, 12k

5%

R212, 68k

1%

R101,10k

NTC 1%

uxDet

Headint2

UI board

/D

MUX

UEMEk

Slow

DC

Backup battery charging is controlled by MCU by writing into UEM register. Li-Ion SMD

battery type is used. The nominal capacity of the battery is 0.01 mAh.

Parameter

Test conditions

Back-up battery

voltage

Back-up battery

cut-off limit

Charging voltage

(VBAT 3.4V)

Charging current I

SIM interface

The UEMEK contains the SIM interface logic level shifting. The SIM interface can be programmed to support 3V and 1.8V SIM. A register in the UEMEK selects SIM supply volt-

Table 20: Backup Battery Circuitry

Symbol Min

Typ Max Units

VBACK 2.43 3.3 V

V_BU

V_BU

COFF+

COFF-

2.04 2.1 2.16 V

1.94 2 2.06 V

VBU 3.1 3.2 3.3 V

LIMVBU

150 500 uA

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved. Page 39

Page 40

NPL-4/5

V

T

yp

V

g

System Module and User Interface Nokia Customer Care

age. It is only allowed to change the SIM supply voltage when the SIM IF is powered

down.

The whole SIM interface locates in two chips UPP and UEMEK.

The SIM interface in the UEMEK contains power up/down, port gating, card detect, data

receiving, ATRcounter, registers and level shifting buffers logic. The SIM interface is the

electrical interface between the Subscriber Identity Module Card (SIM Card) and mobile

phone (via UEMEK device).

Table 21: SIMCARDet Detection

Parameter

SIMCARDet, BSI

ariable Min

yp Max Unit

Vkey 1.94 2.1 2.26 V

comparator

Threshold

SIMCARDet, BSI

Vsimhyst 50 75 100 mV

comparator

Hysteresis (1)

The data communication between the card and the phone is asynchronous half duplex.

The clock supplied to the card is in GSM system 1.083 MHz or 3.25 MHz.

Figure 10: UPP/UEMEK SIM Interface Connections

SIM

C5 C6 C7

C1

C3

C2

C8

C4

SIM

ASIP

SIMIO

SIMClk

SIMRst

SIM

UEME

SIMIO

SIMClk

SIMRst

SIMIF

register

UPP

SIMIO

SIMClk

SIMR

UIF Block

From Battery

ype contact

t

BSI

UEME

K

digital

lo

ic

UEMEKI

CBusDa

CBusEnX

CBusClk

FCI (Functional Cover Interface)

NPL-4/5 has functional cover interface for changeable functional B-cover. The functional

cover interface consists of FCI ASIP chip and five contact pads on UI PWB. HW does not

support the I2C in BB4.0 engine whereupon interface uses SW emulated I2C protocol.

The FCI ASIP chip includes switch for power supply control and EMC filters for data lines.

Page 40 Copyright © 2004 Nokia Corporation. All rights reserved. Issue 1 05/04

Page 41

NPL-4/5

Nokia Customer Care System Module and User Interface

Figure 11: FCI Interface

GenIO_18

EN

VBAT

VIO

FCI ASIP

Switch

+

Short Circuit

protection

Terminal Functional Cover

ferrite

FC_Vout

Cout

ferrite

Reg.

Cin

GenIO_22

UPP

GenIO_2

GenIO_25

Bottom View

Keypad-side FC conn.

Pad layout

ferrite

ferrite

ferrite

FC_SDA

FC_SCL

FC_INT

ferrite

ferrite

ferrite

MCU

Figure 12: FCI Connector Pin Order on PWB

1. Vout

2. GND

3. SDA

4. SCL

5. FCIInt

15

Memory

For the MCU UPP includes ROM, 2 Kbytes, that is used mainly for boot code of MCU. To

speed up the

MCU operation small 64-byte cache is also integrated as a part of the MCU memory

interface. For program memory 8Mbit (512 x 16bit) PDRAM is integrated. RAM block can

Issue 1 05/04 Copyright © 2004 Nokia Corporation. All rights reserved. Page 41

Page 42

NPL-4/5

System Module and User Interface Nokia Customer Care

also be used as data memory and it is byte addressable. RAM is mainly for MCU purposes

but also DSP has also access to it if needed.

MCU code is stored into external flash memory. Size of the flash is 128Mbit (8M x 16bit).

The NPL-4/5 baseband supports a burst mode flash with multiplexed address/data bus.