Page 1

Customer Care Solutions

Technical Documentation

SERVICE

MANUAL

[NMP Part No. 0275717]

Nokia 3560 (RH-14)

Cellular Phones

Issue 1 Copyright 2003 Nokia Corporation. Confidential. All Rights Reserved

Page 2

Customer Care Solutions

Technical Documentation

Amendment Record Sheet

Amendment No Date Inserted By Comments

05/2003 J Fraser Issue 1

Issue 1 Copyright 2003 Nokia Corporation. Confidential. All Rights Reserved

Page 3

Customer Care Solutions

Technical Documentation

Nokia 3560 (RH-14) Cellular Phones

Service Manual – Overall Manual Contents

Service Manual comprising

Nokia 3560 (RH-14) Transceiver booklet comprising

Foreword

General

Parts

Service Software Instructions

Service Tools

Disassembly/Assembly

Troubleshooting

System Module

Schematics

Issue 1 Copyright 2003 Nokia Corporation. Confidential. All Rights Reserved

Page 4

This document is intended for use by qualified service personnel only.

Company Policy

Our policy is of continuous development; details of all technical modifications will be

included with service bulletins.

While every endeavour has been made to ensure the accuracy of this document, some

errors may exist. If any errors are found by the reader, Nokia Corporation should be notified in writing.

Please state:

Customer Care Solutions

Technical Documentation

IMPORTANT

Title of the Document + Issue Number/Date of publication

Latest Amendment Number (if applicable)

Page(s) and/or Figure(s) in error

Please send to: Nokia Corporation

CCS Technical Documentation

PO Box 86

FIN-24101 SALO

Finland

Issue 1 Copyright 2003 Nokia Corporation. Confidential. All Rights Reserved

Page 5

Customer Care Solutions

Technical Documentation

Warnings and Cautions

Please refer to the phone's user guide for instructions relating to operation, care and

maintenance including important safety information. Note also the following:

Warnings:

1. CARE MUST BE TAKEN ON INSTALLATION IN VEHICLES FITTED WITH

ELECTRONIC ENGINE MANAGEMENT SYSTEMS AND ANTI-SKID BRAKING

SYSTEMS. UNDER CERTAIN FAULT CONDITIONS, EMITTED RF ENERGY CAN

AFFECT THEIR OPERATION. IF NECESSARY, CONSULT THE VEHICLE DEALER/

MANUFACTURER TO DETERMINE THE IMMUNITY OF VEHICLE ELECTRONIC

SYSTEMS TO RF ENERGY.

2. THE HANDPORTABLE TELEPHONE MUST NOT BE OPERATED IN AREAS LIKELY

TO CONTAIN POTENTIALLY EXPLOSIVE ATMOSPHERES EG PETROL STATIONS

(SERVICE STATIONS), BLASTING AREAS ETC.

3. OPERATION OF ANY RADIO TRANSMITTING EQUIPMENT, INCLUDING

Cautions:

1. Servicing and alignment must be undertaken by qualified personnel only.

2. Ensure all work is carried out at an anti-static workstation and that an

3. Ensure solder, wire, or foreign matter does not enter the telephone as

4. Use only approved components as specified in the parts list.

5. Ensure all components, modules screws and insulators are correctly

CELLULAR TELEPHONES, MAY INTERFERE WITH THE FUNCTIONALITY OF

INADEQUATELY PROTECTED MEDICAL DEVICES. CONSULT A PHYSICIAN OR

THE MANUFACTURER OF THE MEDICAL DEVICE IF YOU HAVE ANY

QUESTIONS. OTHER ELECTRONIC EQUIPMENT MAY ALSO BE SUBJECT TO

INTERFERENCE.

anti-static wrist strap is worn.

damage may result.

re-fitted after servicing and alignment. Ensure all cables and wires are

repositioned correctly.

Issue 1 Copyright 2003 Nokia Corporation. Confidential. All Rights Reserved

Page 6

Customer Care Solutions

Technical Documentation

Issue 1 Copyright 2003 Nokia Corporation. Confidential. All Rights Reserved

Page 7

CCS Technical Documentation

RH-14 Series Transceivers

General Information

Issue 1 05/2003 Confidential Nokia Corporation

Page 8

RH-14

General Information CCS Technical Documentation

Page 2 Nokia Corporation Confidential Issue 1 05/2003

Page 9

RH-14

CCS Technical Documentation General Information

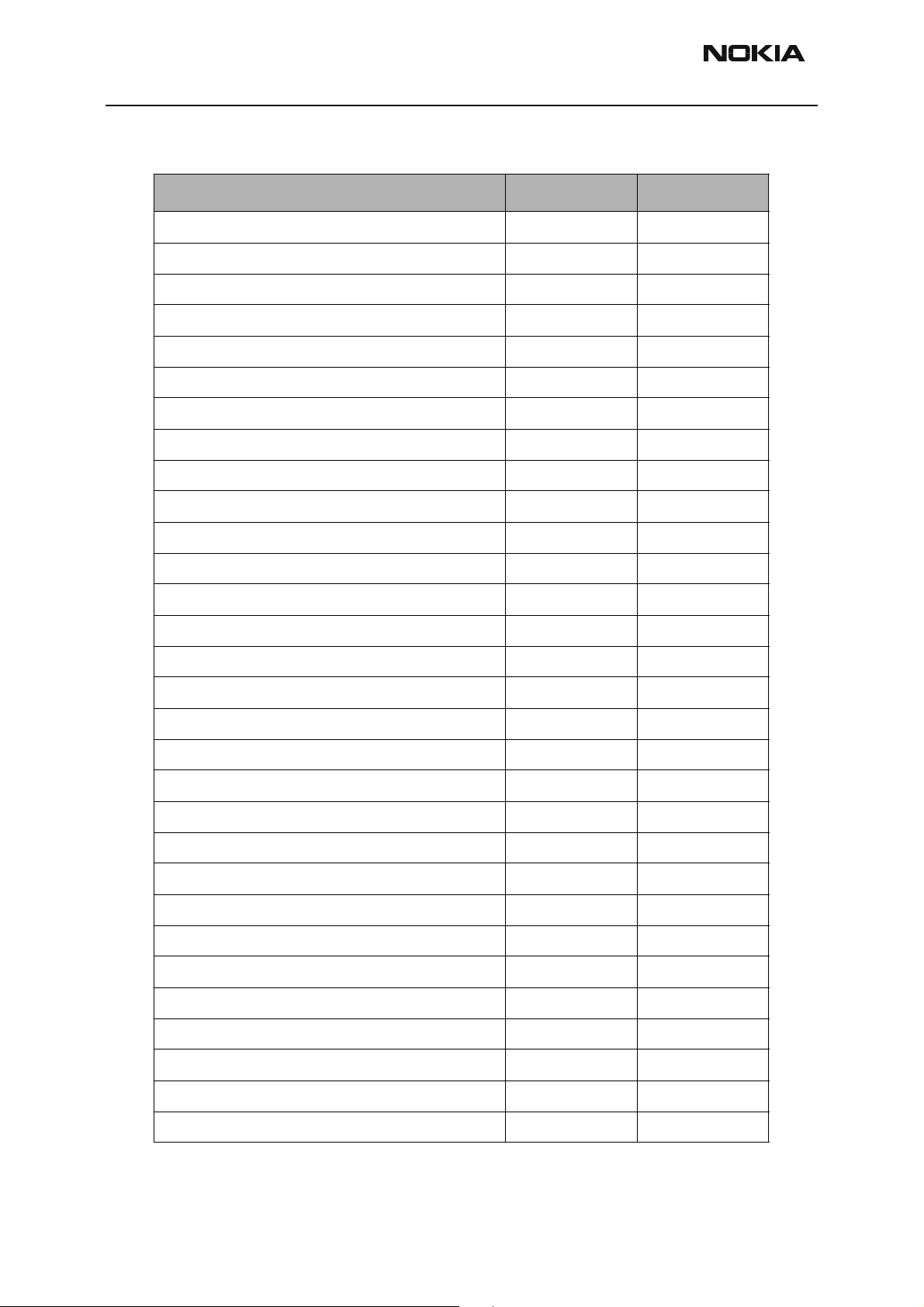

Contents

Page No

Product Selection ........................................................................................................... 5

Accessories ..................................................................................................................6

Module List ..................................................................................................................7

Technical Specifications ..............................................................................................7

General Specifications of Transceiver RH-14 .......................................................... 7

Issue 1 05/2003 Confidential Nokia Corporation Page 3

Page 10

RH-14

General Information CCS Technical Documentation

Page 4 Nokia Corporation Confidential Issue 1 05/2003

Page 11

RH-14

CCS Technical Documentation General Information

Product Selection

RH-14 (Model 3560) phone is a dual-band, dual-mode radio transceiver unit for 800/

1900 MHz Time Division Multiple Access (TDMA) networks. The transceiver consists of

system/RF module, keypad module, LCD module, and assembly parts. The user interface

(UI) consists of normal number, talk, end, scroll key, and two selection keys in the keymat.

The antenna is internal; antenna connection is provided by spring from PWB to antenna.

Issue 1 05/2003 Confidential Nokia Corporation Page 5

Page 12

RH-14

General Information CCS Technical Documentation

Accessories

Name Type Material Code

Standard Li-ion Battery 1000 mAh BLC-2 0670436

AC Travel Charger (Euro plug) 207-253 Vac ACP-7E 0675144

AC Travel Charger (US plug) 108-132 Vac ACP-7U 0675143

AC Travel Charger (US plug) 198-242 Vac ACP-7C 0675158

AC Travel Charger (UK plug) 207-253 Vac ACP-7X 0675145

AC Travel Charger (UK plug) 180-220 Vac ACP-7H 0675146

AC Travel Charger (Australia plug) 216-264 Vac ACP-7A 0675148

Performance Travel Charger Euro plug 90-264 Vac ACP-8E 0675195

Performance Travel Charger Korea plug 90-264 Vac ACP-8K 0675199

Performance Travel Charger UK plug 90-264 Vac ACP-8X 0675197

Performance Travel Charger US plug 90-264 Vac ACP-8U 0675196

Performance Travel Charger China plug 90-264 Vac ACP-8C 0675211

Performance Travel Charger Australia plug 90-264 Vac ACP-8A 0675214

Travel Charger: ACP-12E 0675294

Travel Charger ACP-12U 0675302

Extra Battery Charger DDC-1 0675243

Mounting Plate MKU-1 0620036

Swivel Mount HHS-9 0620037

Cigarette Lighter Charger LCH-9 0675120

Handsfree Microphone HFM-8 0690016

Headset HDE-2 0694075

Headset HDC-5 0271467

Headset HDC-10 0273651

Headset HDB-5 0694107

Phone Adapter (TTY/Headset) HDA-9 0694116

Loopset LPS-3 0272419

Passive Car Holder MCC-7 0650052

Cigarette Lighter Charger LCH-12 0675328

Express Car Kit CARK-125 0085193

Complete Car Kit CARK-134 0080641

Page 6 Nokia Corporation Confidential Issue 1 05/2003

Page 13

RH-14

CCS Technical Documentation General Information

Module List

TDMA800/1900 + AMPS TDMA800

Type designator RH-14 RH-21

Model number 3560 3520

Technical Specifications

General Specifications of Transceivers RH-14

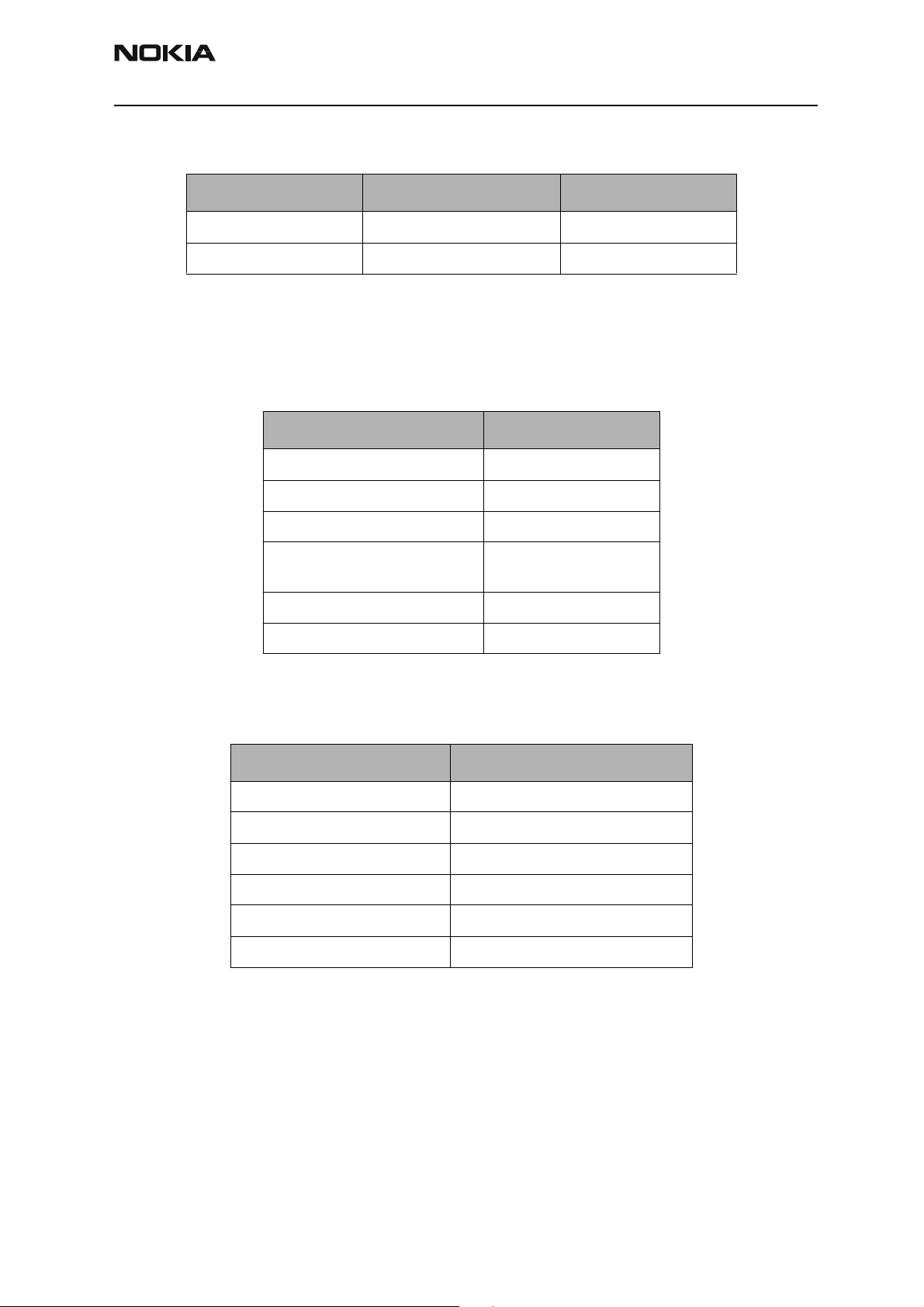

Table 1: Specifications for TDMA800+AMPS

Parameter Unit

Cellular system TDMA800 + AMPS

RX frequency band 869.01 - 893.97 MHz

TX frequency band 824.01 - 848.97 MHz

Output power AMPS: -5 to +24.7 dBm

TDMA800: -5 to +28 dBm

Number of RF channels 832

Channel spacing 30 kHz

Table 2: Specifications for TDMA 1900

Parameter Unit

Cellular system TDMA1900 + AMPS

RX frequency band 1930.05 - 1989.99 MHz

TX frequency band 1850.01 - 1909.95 MHz

Output power -5 to +28 dBm / 0.3 mW - 630 mW

Number of RF channels 1999

Channel spacing 30 kHz

Issue 1 05/2003 Confidential Nokia Corporation Page 7

Page 14

RH-14

General Information CCS Technical Documentation

Page 8 Nokia Corporation Confidential Issue 1 05/2003

Page 15

CCS Technical Documentation

RH-14 Series Transceivers

Parts Lists

Issue 1 05/2003 Confidential Nokia Corporation

Page 16

RH-14

Parts Lists CCS Technical Documentation

Page 2 Nokia Corporation Confidential Issue 1 05/2003

Page 17

RH-14

CCS Technical Documentation Parts Lists

Contents

Page No

Component Layout......................................................................................................... 5

3560 Component Layout - Top ....................................................................................5

Exploded Views............................................................................................................. 7

Main Assembly ............................................................................................................7

Assembly Parts List .....................................................................................................7

Internal Module Assembly Structure ...........................................................................8

Assembly Parts List .....................................................................................................8

Parts List ........................................................................................................................ 9

RH-14 (3560) — EDMS Issue 2.11 Code: 0202068 ...................................................9

Issue 1 05/2003 Nokia Corporation Confidential Page 3

Page 18

RH-14

Parts Lists CCS Technical Documentation

Page 4 Nokia Corporation Confidential Issue 1 05/2003

Page 19

RH-14

CCS Technical Documentation Parts Lists

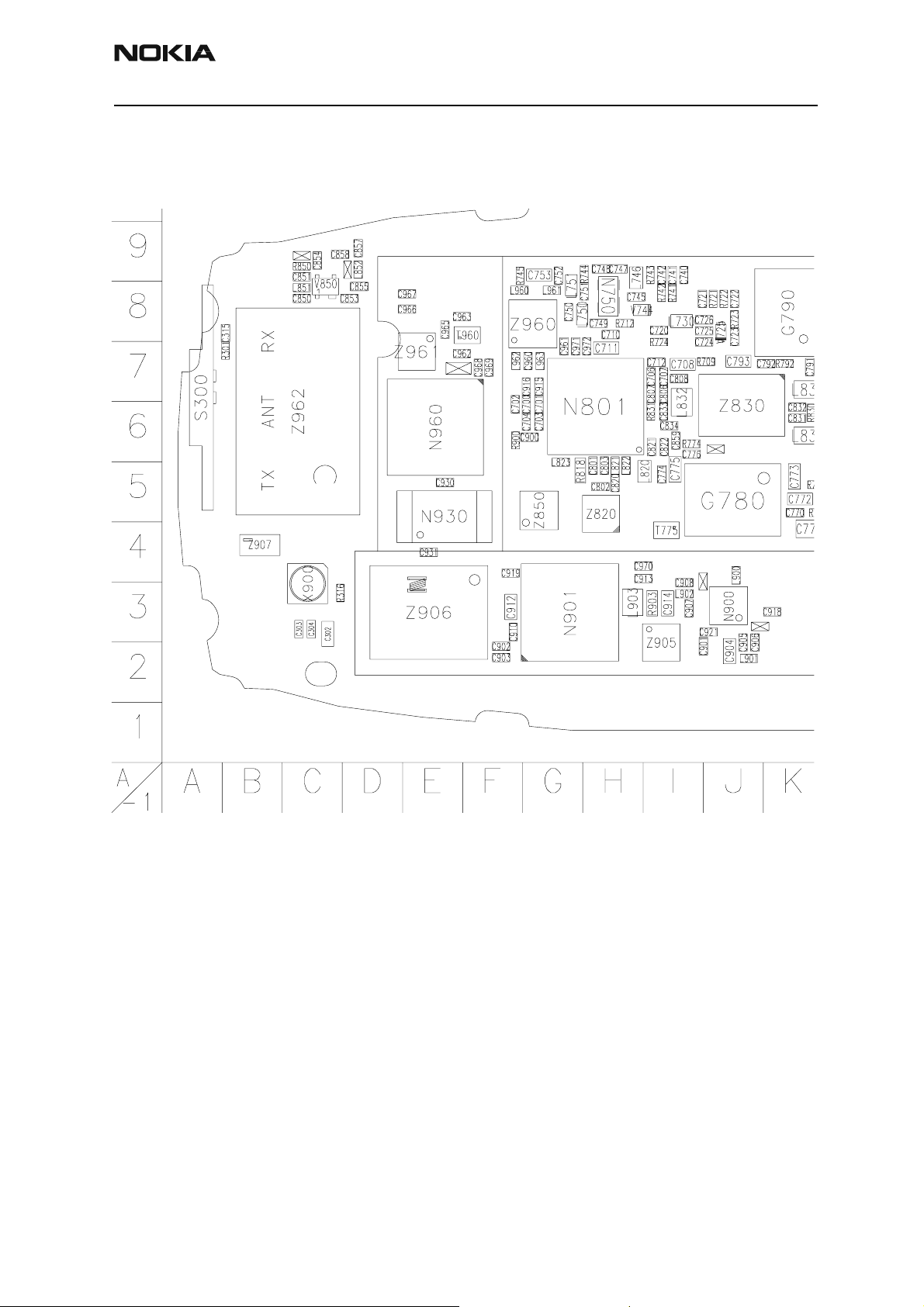

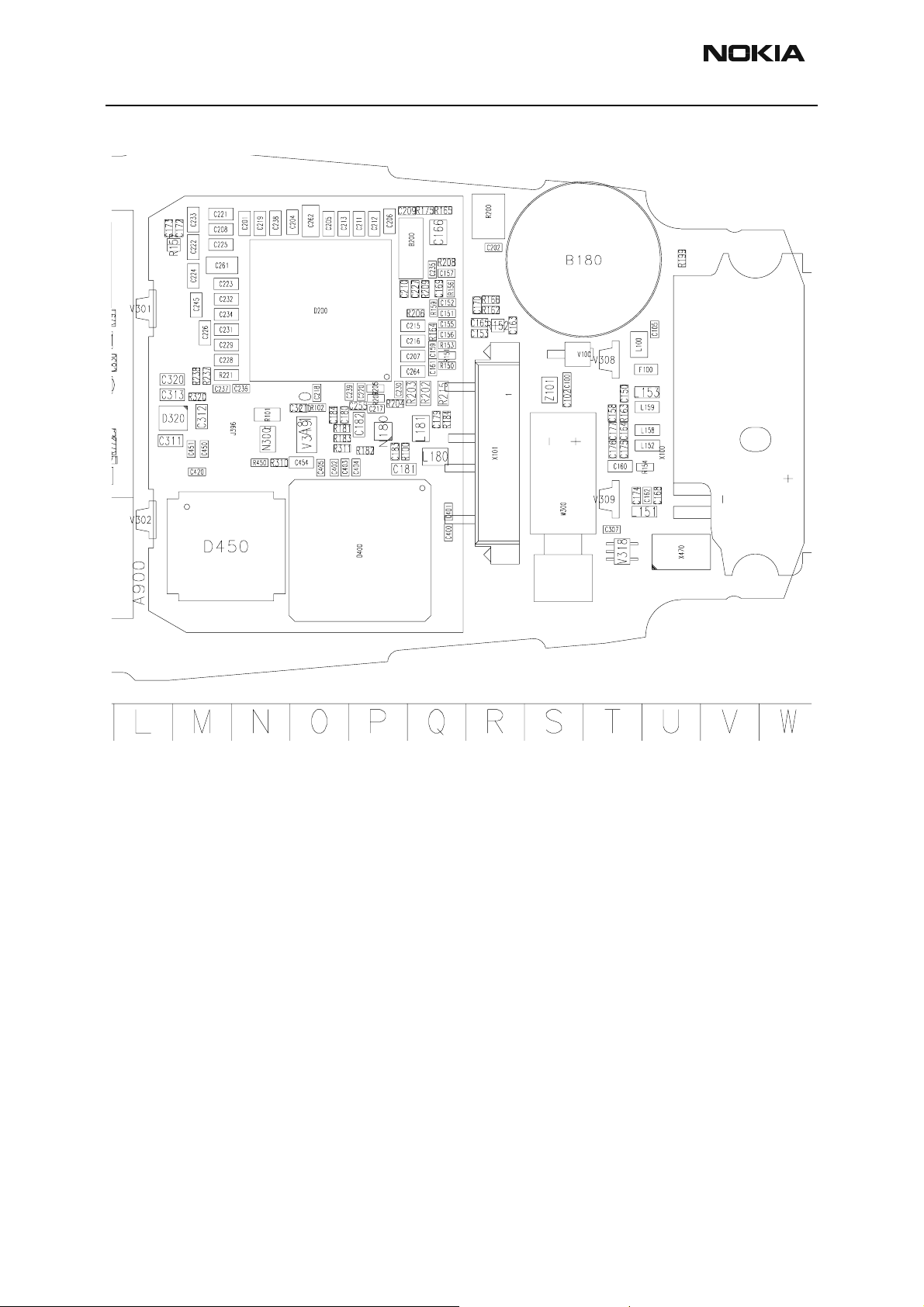

Component Layout

3560 Component Layout - Top

Issue 1 05/2003 Nokia Corporation Confidential Page 5

Page 20

RH-14

Parts Lists CCS Technical Documentation

Page 6 Nokia Corporation Confidential Issue 1 05/2003

Page 21

RH-14

CCS Technical Documentation Parts Lists

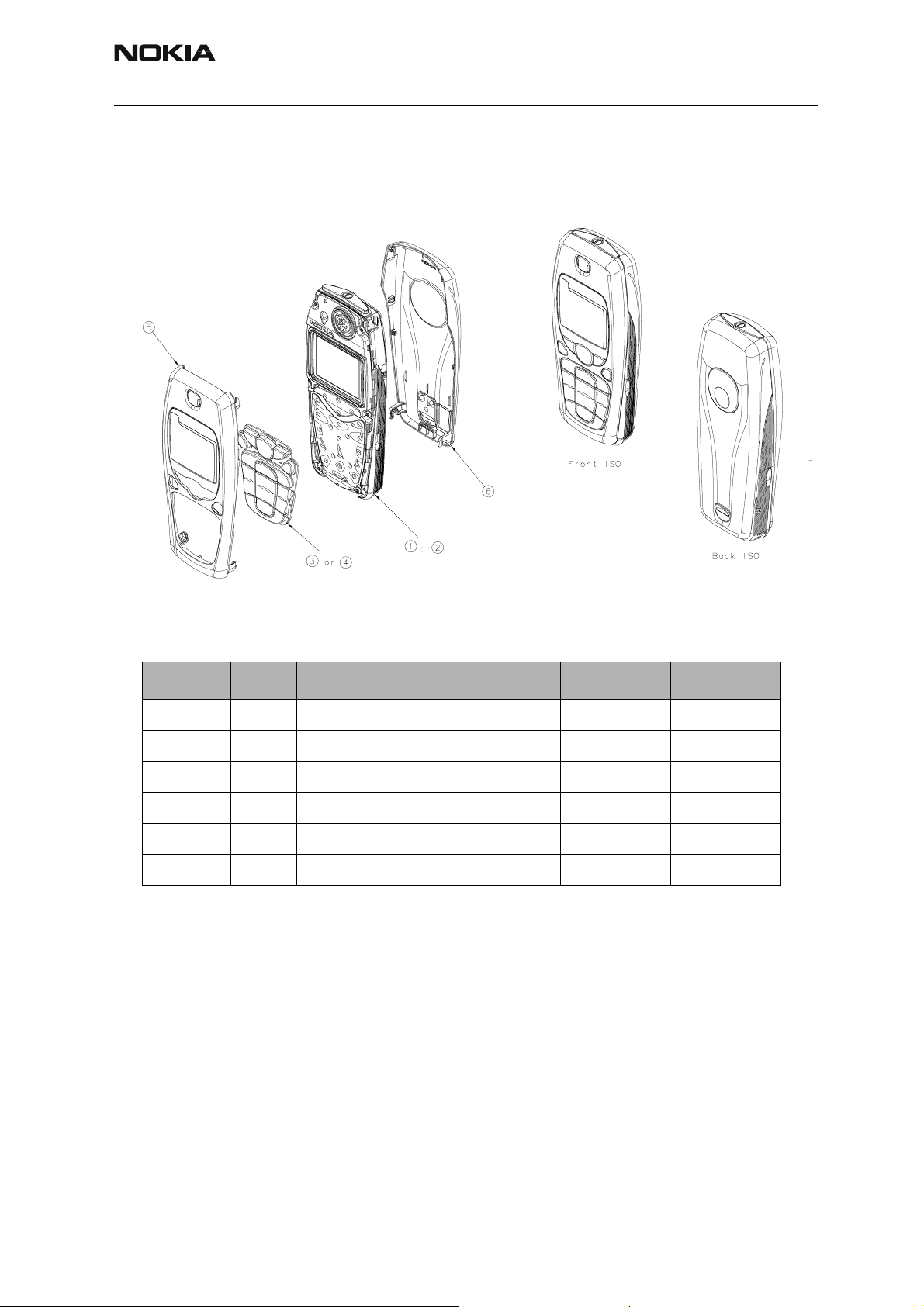

Exploded Views

Main Assembly

Assembly Parts List

Item No. Qty. Part Code Value

1 1 (INTERNAL) MODULE DUAL BAND 0510315 DMC06652

2 1 (Internal) Module Single Band 0510318 DMC06652

3 1 Keymat Assembly - Latin 9790837 DMC06537

4 1 Keymat Assembly - Hebrew 9790846 DMC05982

5 1 A-cover Assembly - Pearl White 9491237 DMC06073

6 1 B-cover Assembly - Pearl White 9491242 DMC06032

Issue 1 05/2003 Nokia Corporation Confidential Page 7

Page 22

RH-14

Parts Lists CCS Technical Documentation

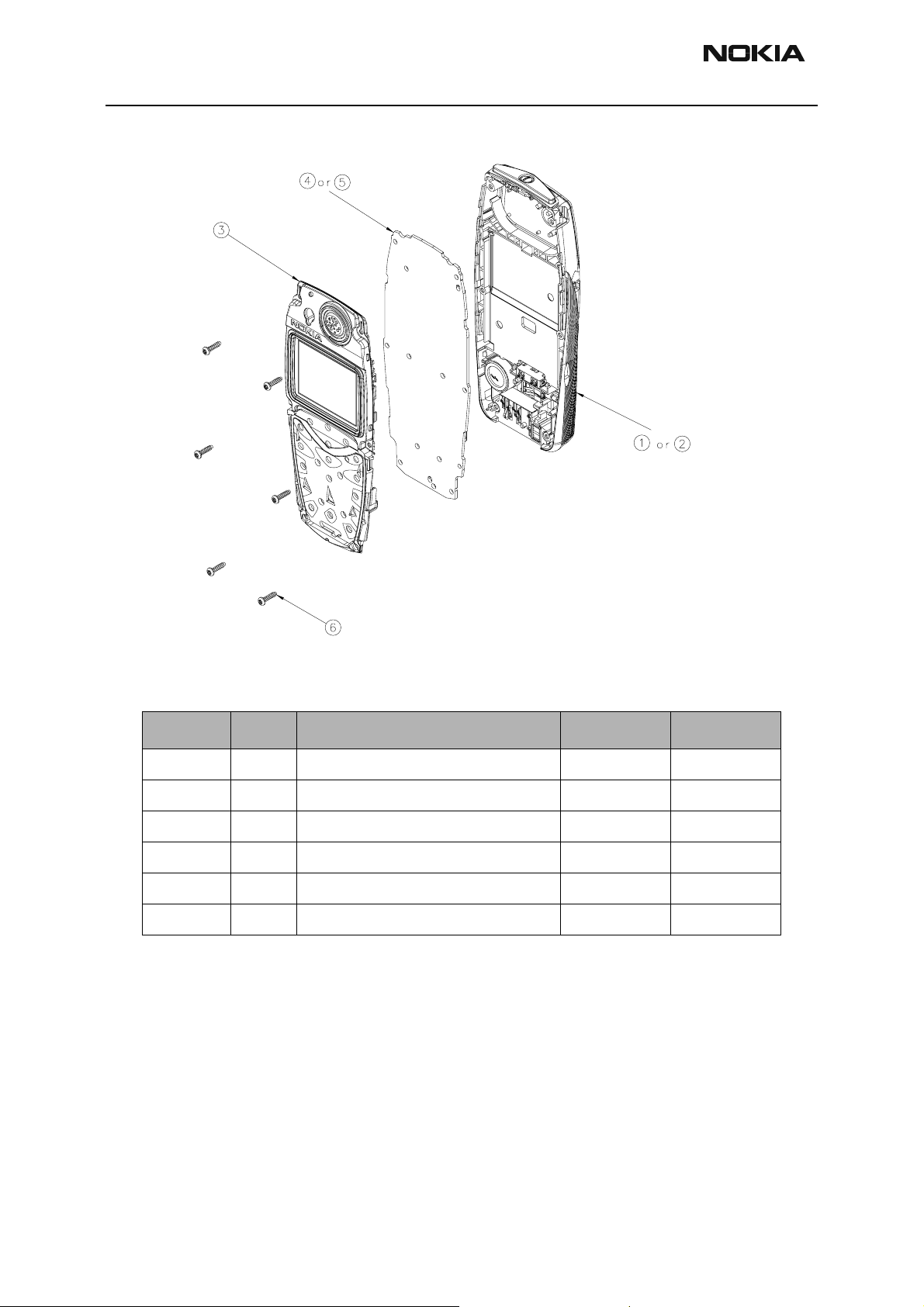

Internal Module Assembly Structure

Assembly Parts List

Item No. Qty. Part Code Value

1 1 D-COVER ASSEMBLY - DUAL BAND 9491055 DMC05767

2 1 D-cover Assembly - single band 9491109 DMC05767

3 1 Color Display/UI Assembly 4850277 DMC05329

4 1 PWB - DUAL BAND 0202068

5 1 PWB - single band 0202092

6 6 Screws 1.8 x 7 mm 6290107 DMD05791

Page 8 Nokia Corporation Confidential Issue 1 05/2003

Page 23

RH-14

CCS Technical Documentation Parts Lists

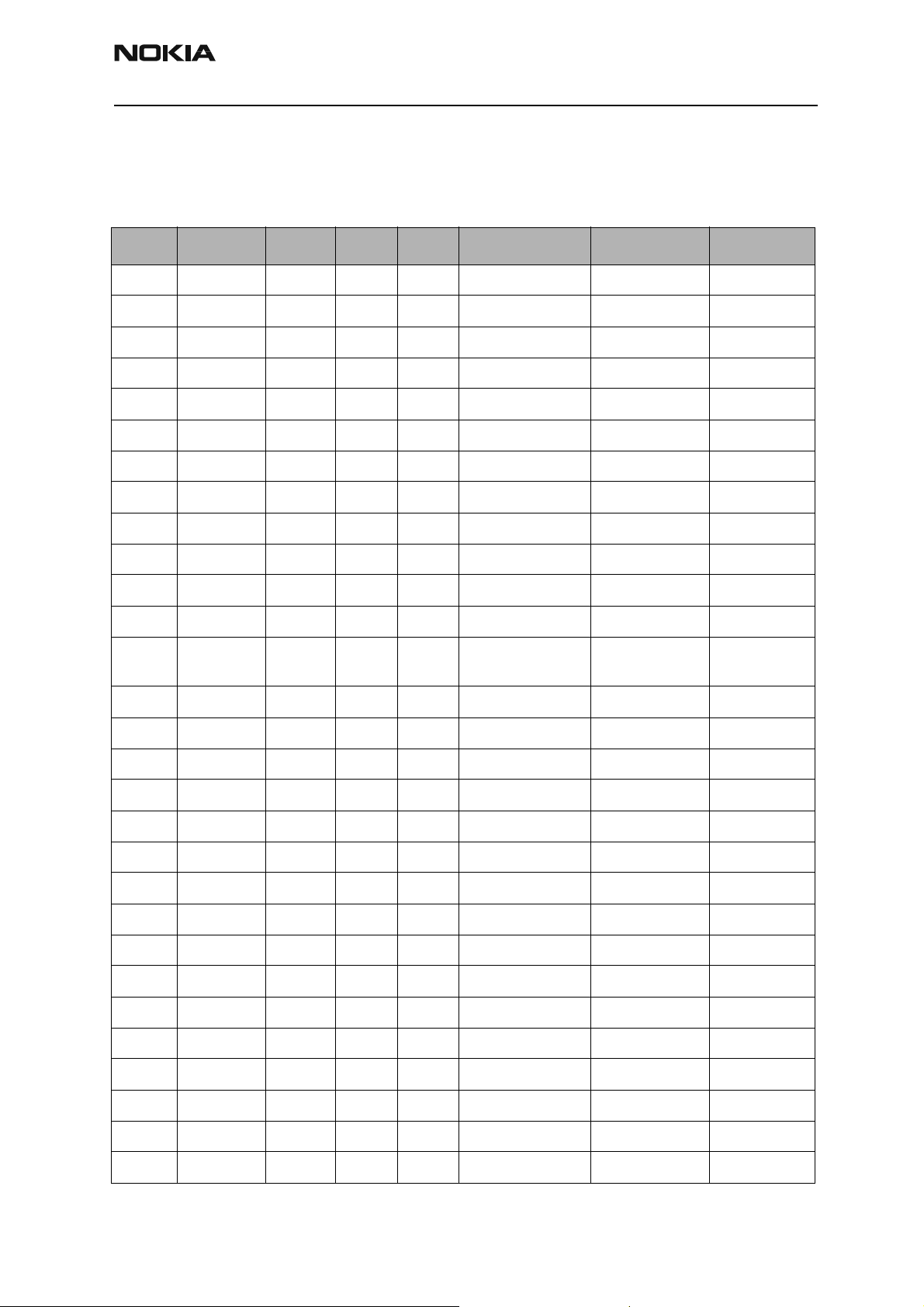

Parts List

RH-14 (3560) — EDMS Issue 2.11 Code: 0202068

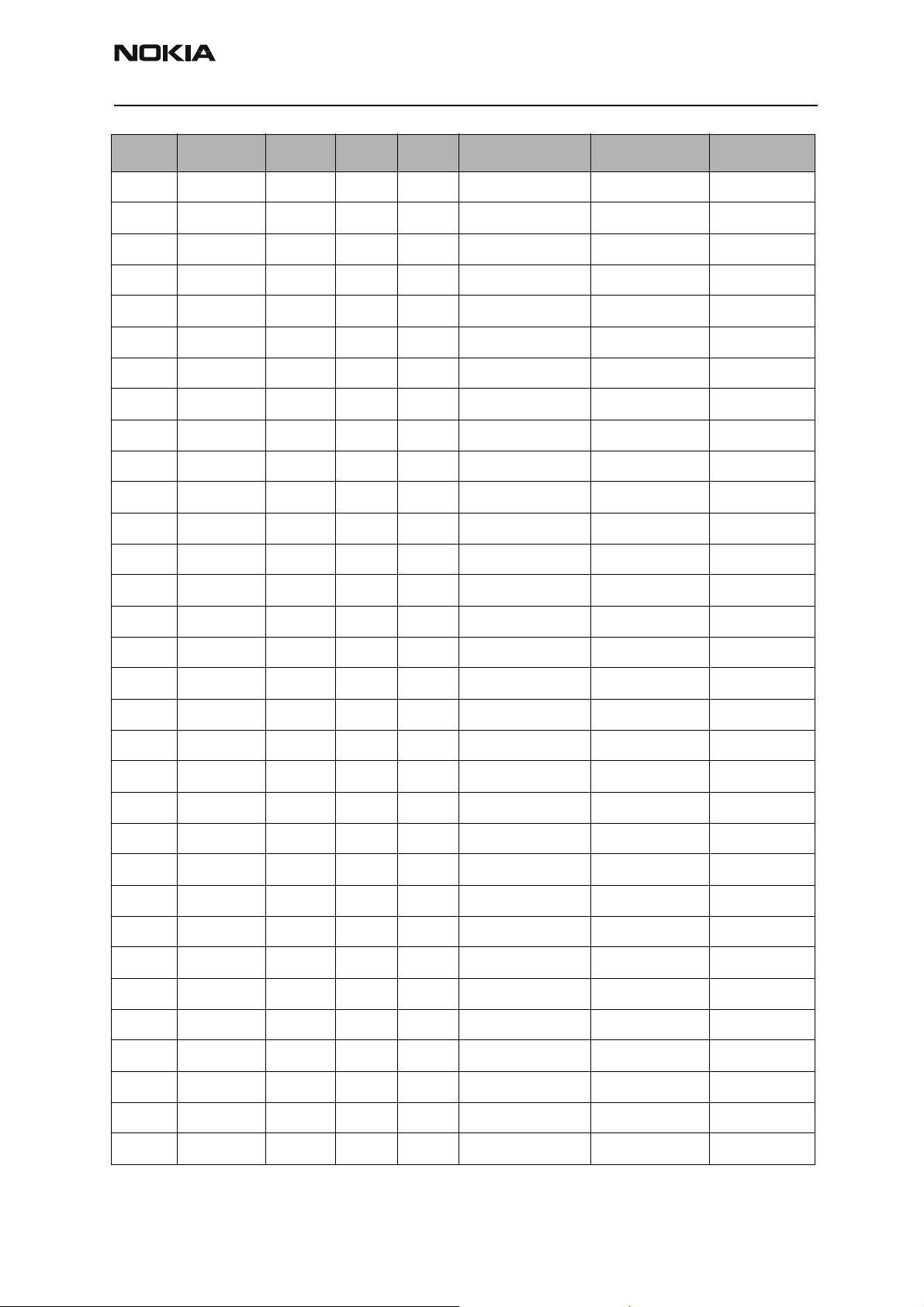

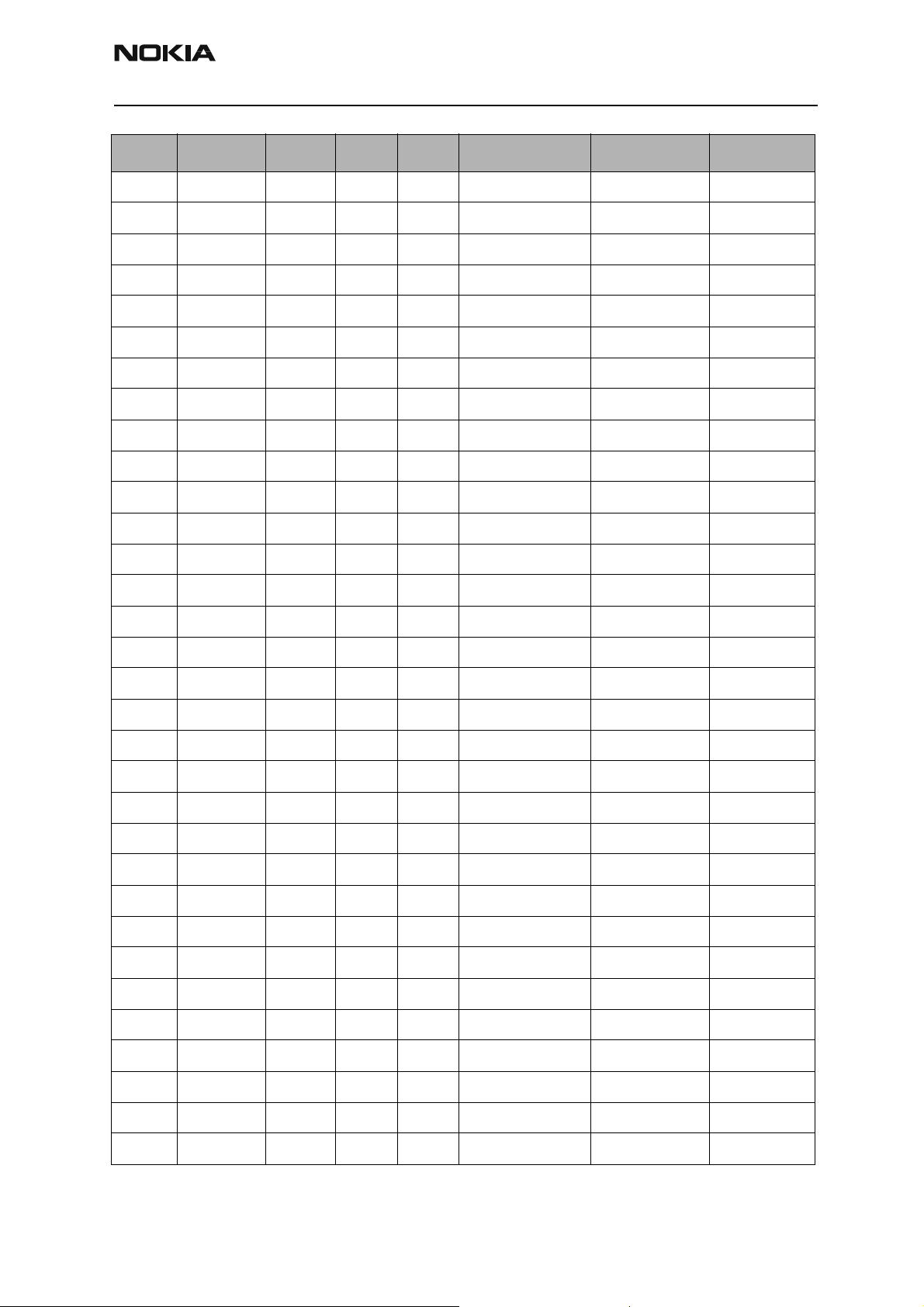

Item Code Side X Y Description Value Type

R100 1430788 Top P 5 chip res 0W06 22K J 0402

R101 1620063 Top N 5 res network 0W06 4X100R J 0804

R102 1430812 Top O 6 chip res 0W06 220K J 0402

R150 1430754 Top Q 6 chip res 0W06 1K0 J 0402

R151 1430754 Top Q 6 chip res 0W06 1K0 J 0402

R152 1620031 Top R 7 res network 0W06 2X1K0 J 0404

R153 1430754 Top Q 7 chip res 0W06 1K0 J 0402

R154 1430778 Top U 5 chip res 0W06 10K J 0402

R156 1430762 Top Q 8 chip res 0W06 2K2 J 0402

R157 1620035 Top M 8 res network 0W06 2X10R J 0404

R159 1430788 Top Q 7 chip res 0W06 22K J 0402

R162 1430762 Top R 7 chip res 0W06 2K2 J 0402

R163 1825033 Top T 5 chip varistor VWM14V

VC46V

R164 1430796 Top Q 7 chip res 0W06 47K J 0402

R165 1430710 Top Q 9 chip res 0W06 22R J 0402

R166 1430762 Top R 7 chip res 0W06 2K2 J 0402

R175 1430710 Top Q 9 chip res 0W06 22R J 0402

R181 1430770 Top O 5 chip res 0W06 4K7 J 0402

R182 1430788 Top P 5 chip res 0W06 22K J 0402

R183 1430770 Top O 5 chip res 0W06 4K7 J 0402

R184 1430778 Top Q 5 chip res 0W06 10K J 0402

R200 1419003 Top R 9 chip res 0W5 0R22 J 200 PPM 1210

0402

R202 1430087 Top Q 6 chip res 0W06 100K J 0603

R203 1430087 Top Q 6 chip res 0W06 100K J 0603

R204 1430804 Top P 6 chip res 0W06 100K J 0402

R205 1430770 Top P 6 chip res 0W06 4K7 J 0402

R206 1430804 Top Q 7 chip res 0W06 100K J 0402

R207 1430770 Top P 6 chip res 0W06 4K7 J 0402

R208 1430778 Top Q 8 chip res 0W06 10K J 0402

Issue 1 05/2003 Nokia Corporation Confidential Page 9

Page 24

RH-14

Parts Lists CCS Technical Documentation

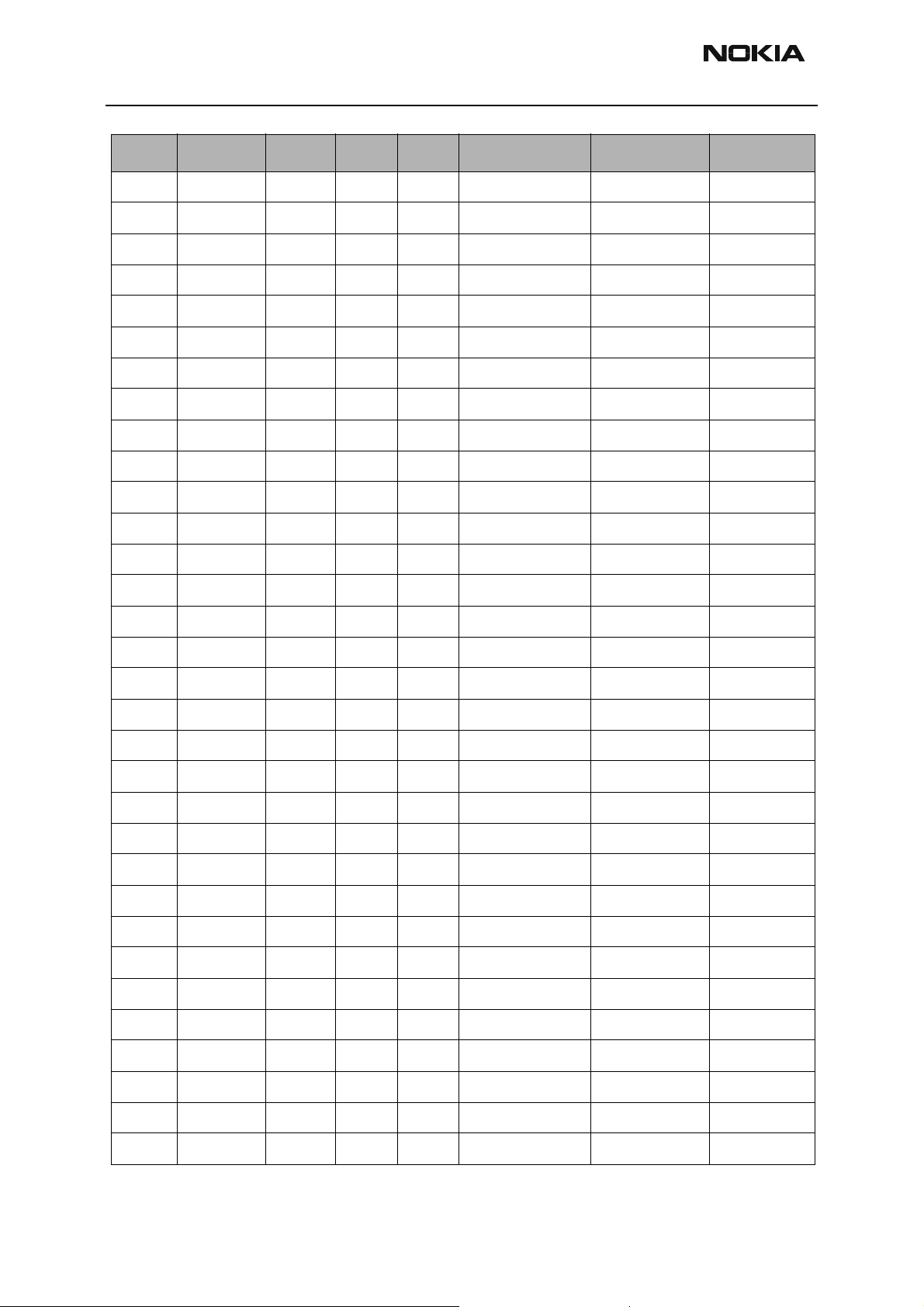

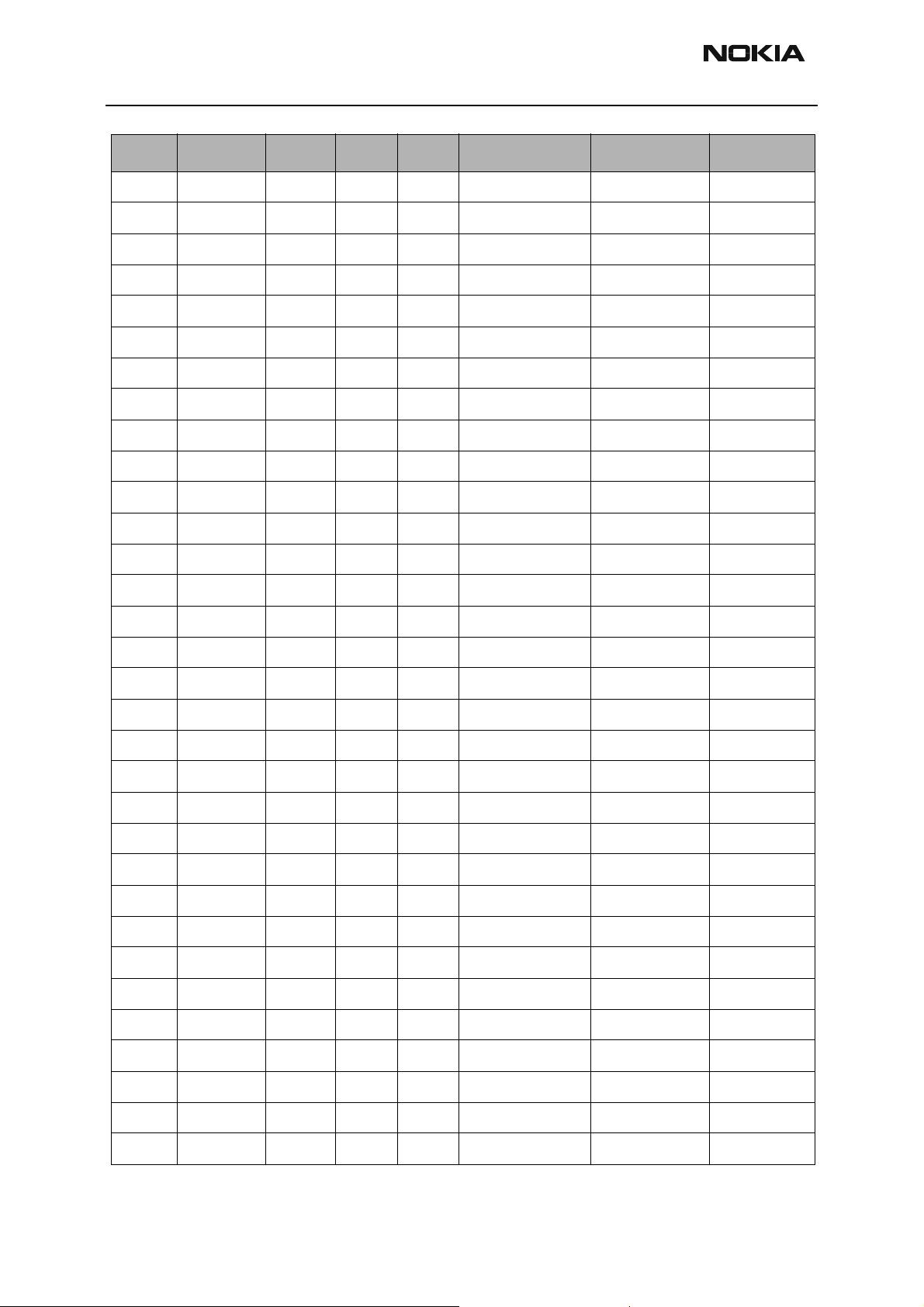

Item Code Side X Y Description Value Type

R209 1430804 Top Q 8 chip res 0W06 100K J 0402

R215 1430087 Top Q 6 chip res 0W06 100K J 0603

R221 1430268 Top M 6 chip res 0W06 27K F 100 PPM 0603

R237 1430690 Top M 6 chip res jumper 0R0 0402

R301 1430770 Top B 7 chip res 0W06 4K7 J 0402

R310 1430754 Top N 5 chip res 0W06 1K0 J 0402

R311 1430700 Top O 5 chip res 0W06 10R J 0402

R316 1430778 Top C 3 chip res 0W06 10K J 0402

R320 1430117 Top M 6 chip res 0W06 100R F 200 PPM 0402

R450 1430803 Top N 5 chip res 0W06 47K7 F 200 PPM 0402

R709 1430700 Top J 7 chip res 0W06 10R J 0402

R712 1430700 Top H 8 chip res 0W06 10R J 0402

R721 1430774 Top J 8 chip res 0W06 6K8 J 0402

R722 1430772 Top J 8 chip res 0W06 5K6 J 0402

R723 1430764 Top J 8 chip res 0W06 3K3 J 0402

R724 1430691 Top I 7 chip res 0W06 2R2 J 0402

R741 1430770 Top I 8 chip res 0W06 4K7 J 0402

R742 1430772 Top I 8 chip res 0W06 5K6 J 0402

R743 1430764 Top I 9 chip res 0W06 3K3 J 0402

R744 1430744 Top H 9 chip res 0W06 470R J 0402

R745 1430700 Top F 9 chip res 0W06 10R J 0402

R771 1430786 Top K 5 chip res 0W06 18K J 0402

R772 1430726 Top K 5 chip res 0W06 100R J 0402

R773 1430700 Top K 5 chip res 0W06 10R J 0402

R774 1430700 Top I 6 chip res 0W06 10R J 0402

R791 1430778 Top K 7 chip res 0W06 10K J 0402

R792 1430700 Top K 7 chip res 0W06 10R J 0402

R818 1430268 Top G 5 chip res 0W06 27K F 100 PPM 0603

R830 1430832 Top K 6 chip res 0W06 2K7 J 0402

R831 1430734 Top I 6 chip res 0W06 220R J 0402

R850 1430788 Top C 9 chip res 0W06 22K J 0402

R900 1430718 Top F 6 chip res 0W06 47R J 0402

Page 10 Nokia Corporation Confidential Issue 1 05/2003

Page 25

RH-14

CCS Technical Documentation Parts Lists

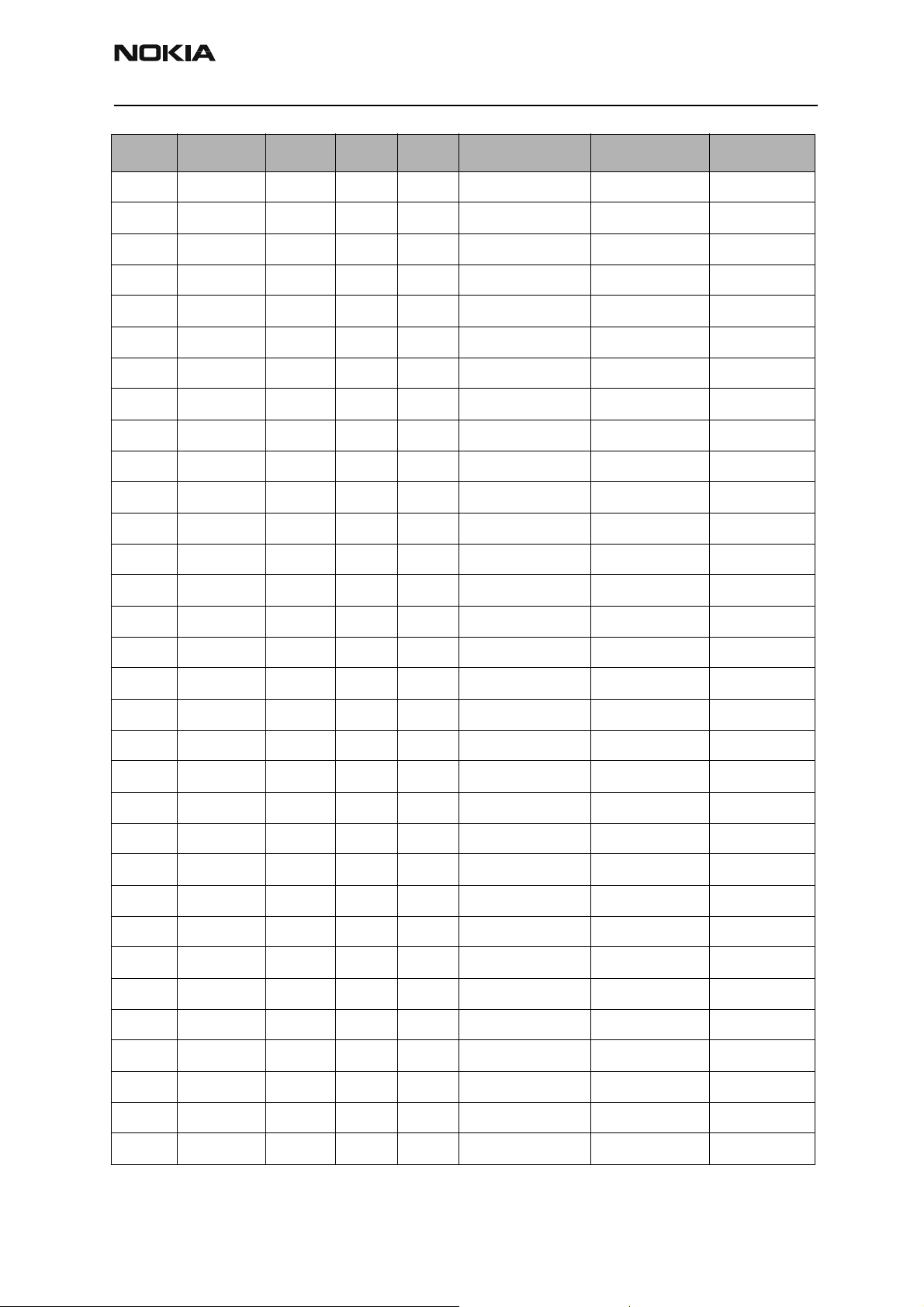

Item Code Side X Y Description Value Type

R903 1430169 Top I 3 chip res 0W06 56R J 0603

C100 2320536 Top S 6 chip cap NP0 10P J 50V 0402

C102 2320536 Top S 6 chip cap NP0 10P J 50V 0402

C105 2320744 Top U 7 chip cap X7R 1N0 K 50V 0402

C150 2320544 Top T 6 chip cap NP0 22P J 50V 0402

C151 2320783 Top Q 7 chip cap X7R 33N K 10V 0402

C152 2320783 Top Q 7 chip cap X7R 33N K 10V 0402

C153 2320546 Top R 7 chip cap NP0 27P J 50V 0402

C155 2320805 Top Q 7 chip cap X5R 100N K 10V 0402

C156 2320805 Top Q 7 chip cap X5R 100N K 10V 0402

C157 2320560 Top Q 8 chip cap X7R 680P J 50V 0402

C158 2320544 Top T 5 chip cap NP0 22P J 50V 0402

C159 2320560 Top Q 7 chip cap X7R 680P J 50V 0402

C160 2320481 Top T 5 chip cap X5R 1U K 6V3 0603

C161 2320744 Top Q 6 chip cap X7R 1N0 K 50V 0402

C162 2320744 Top U 4 chip cap X7R 1N0 K 50V 0402

C163 2320744 Top R 7 chip cap X7R 1N0 K 50V 0402

C164 2320744 Top T 5 chip cap X7R 1N0 K 50V 0402

C165 2320546 Top R 7 chip cap NP0 27P J 50V 0402

C166 2312201 Top Q 9 chip cap

C168 2320544 Top U 4 chip cap NP0 22P J 50V 0402

C169 2320805 Top Q 8 chip cap X5R 100N K 10V 0402

C170 2320546 Top R 7 chip cap NP0 27P J 50V 0402

C172 2320546 Top M 9 chip cap NP0 27P J 50V 0402

C173 2320546 Top L 9 chip cap NP0 27P J 50V 0402

C174 2320544 Top T 4 chip cap NP0 22P J 50V 0402

C175 2320744 Top T 5 chip cap X7R 1N0 K 50V 0402

C176 2320544 Top T 5 chip cap NP0 22P J 50V 0402

C177 2320544 Top T 5 chip cap NP0 22P J 50V 0402

C179 2320805 Top Q 5 chip cap X5R 100N K 10V 0402

C180 2320805 Top O 5 chip cap X5R 100N K 10V 0402

C181 2320481 Top P 5 chip cap X5R 1U K 6V3 0603

Issue 1 05/2003 Nokia Corporation Confidential Page 11

Page 26

RH-14

Parts Lists CCS Technical Documentation

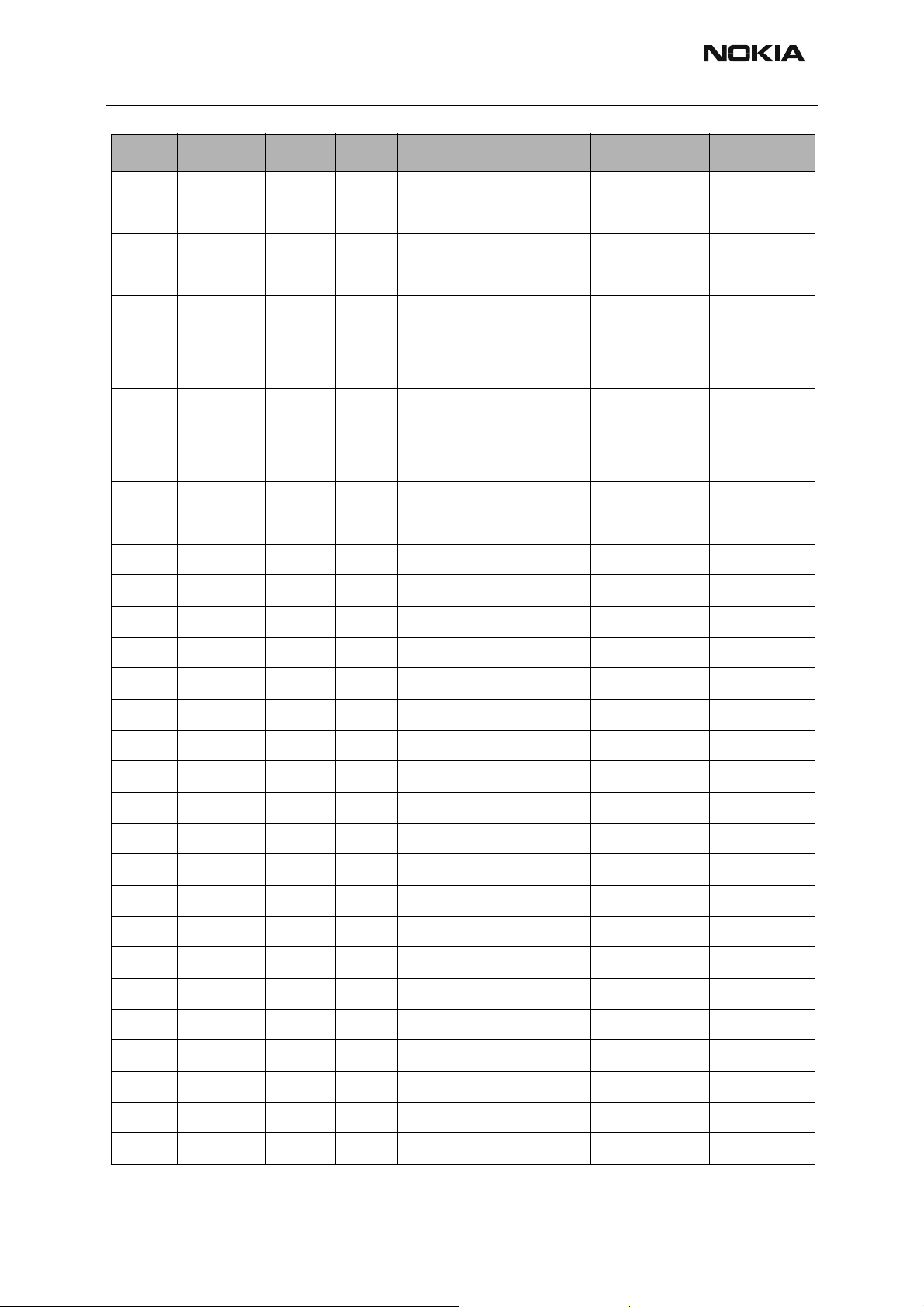

Item Code Side X Y Description Value Type

C182 2320481 Top P 5 chip cap X5R 1U K 6V3 0603

C183 2320582 Top P 5 chip cap X7R 820P J 50V 0402

C184 2320805 Top O 5 chip cap X5R 100N K 10V 0402

C201 2320481 Top N 9 chip cap X5R 1U K 6V3 0603

C202 2320778 Top R 8 chip cap X7R 10N K 16V 0402

C204 2320481 Top O 9 chip cap X5R 1U K 6V3 0603

C205 2320481 Top O 9 chip cap X5R 1U K 6V3 0603

C206 2320481 Top P 9 chip cap X5R 1U K 6V3 0603

C207 2320481 Top Q 6 chip cap X5R 1U K 6V3 0603

C208 2320481 Top M 9 chip cap X5R 1U K 6V3 0603

C209 2320536 Top P 9 chip cap NP0 10P J 50V 0402

C210 2320536 Top P 8 chip cap NP0 10P J 50V 0402

C211 2320481 Top P 9 chip cap X5R 1U K 6V3 0603

C212 2320481 Top P 9 chip cap X5R 1U K 6V3 0603

C213 2320481 Top O 9 chip cap X5R 1U K 6V3 0603

C215 2320481 Top Q 7 chip cap X5R 1U K 6V3 0603

C216 2320481 Top Q 7 chip cap X5R 1U K 6V3 0603

C217 2320778 Top P 6 chip cap X7R 10N K 16V 0402

C218 2320805 Top O 6 chip cap X5R 100N K 10V 0402

C219 2320481 Top N 9 chip cap X5R 1U K 6V3 0603

C220 2320744 Top P 6 chip cap X7R 1N0 K 50V 0402

C221 2320481 Top M 9 chip cap X5R 1U K 6V3 0603

C222 2320481 Top M 8 chip cap X5R 1U K 6V3 0603

C223 2320481 Top M 8 chip cap X5R 1U K 6V3 0603

C224 2320481 Top M 8 chip cap X5R 1U K 6V3 0603

C225 2320481 Top M 8 chip cap X5R 1U K 6V3 0603

C226 2320481 Top M 7 chip cap X5R 1U K 6V3 0603

C227 2320544 Top Q 8 chip cap NP0 22P J 50V 0402

C228 2320481 Top M 6 chip cap X5R 1U K 6V3 0603

C229 2320481 Top M 7 chip cap X5R 1U K 6V3 0603

C230 2320778 Top P 6 chip cap X7R 10N K 16V 0402

C231 2320481 Top M 7 chip cap X5R 1U K 6V3 0603

Page 12 Nokia Corporation Confidential Issue 1 05/2003

Page 27

RH-14

CCS Technical Documentation Parts Lists

Item Code Side X Y Description Value Type

C232 2320481 Top M 7 chip cap X5R 1U K 6V3 0603

C233 2320481 Top M 9 chip cap X5R 1U K 6V3 0603

C234 2320481 Top M 7 chip cap X5R 1U K 6V3 0603

C235 2320805 Top Q 8 chip cap X5R 100N K 10V 0402

C236 2320805 Top N 6 chip cap X5R 100N K 10V 0402

C237 2320805 Top M 6 chip cap X5R 100N K 10V 0402

C238 2320491 Top N 9 chip cap X7R 220N K 10V 0603

C239 2320805 Top P 6 chip cap X5R 100N K 10V 0402

C245 2320481 Top M 7 chip cap X5R 1U K 6V3 0603

C255 2320778 Top P 6 chip cap X7R 10N K 16V 0402

C261 2312243 Top M 8 chip cap X5R 4U7 K 6V3 0805

C262 2312243 Top O 9 chip cap X5R 4U7 K 6V3 0805

C264 2320481 Top Q 6 chip cap X5R 1U K 6V3 0603

C302 2320125 Top C 3 chip cap X5R 1UK 16V 0603

C303 2320805 Top C 3 chip cap X5R 100N K 10V 0402

C304 2320805 Top C 3 chip cap X5R 100N K 10V 0402

C307 2320778 Top T 3 chip cap X7R 10N K 16V 0402

C311 2320125 Top L 5 chip cap X5R 1UK 16V 0603

C312 2320125 Top M 5 chip cap X5R 1UK 16V 0603

C313 2320125 Top L 6 chip cap X5R 1UK 16V 0603

C315 2320544 Top B 8 chip cap NP0 22P J 50V 0402

C320 2320125 Top L 6 chip cap X5R 1UK 16V 0603

C321 2320546 Top O 6 chip cap NP0 27P J 50V 0402

C400 2320778 Top Q 3 chip cap X7R 10N K 16V 0402

C401 2320805 Top Q 4 chip cap X5R 100N K 10V 0402

C402 2320778 Top O 5 chip cap X7R 10N K 16V 0402

C403 2320778 Top O 5 chip cap X7R 10N K 16V 0402

C404 2320778 Top P 5 chip cap X7R 10N K 16V 0402

C405 2320778 Top O 5 chip cap X7R 10N K 16V 0402

C420 2320744 Top M 4 chip cap X7R 1N0 K 50V 0402

C450 2320778 Top M 5 chip cap X7R 10N K 16V 0402

C451 2320805 Top M 5 chip cap X5R 100N K 10V 0402

Issue 1 05/2003 Nokia Corporation Confidential Page 13

Page 28

RH-14

Parts Lists CCS Technical Documentation

Item Code Side X Y Description Value Type

C454 2320779 Top O 5 chip cap X7R 100N K 16V 0603

C700 2320552 Top G 6 chip cap NP0 47P J 50V 0402

C701 2320536 Top G 6 chip cap NP0 10P J 50V 0402

C702 2320805 Top F 6 chip cap X5R 100N K 10V 0402

C703 2320536 Top G 6 chip cap NP0 10P J 50V 0402

C704 2320805 Top G 6 chip cap X5R 100N K 10V 0402

C706 2320552 Top I 7 chip cap NP0 47P J 50V 0402

C707 2320744 Top I 7 chip cap X7R 1N0 K 50V 0402

C708 2320481 Top I 7 chip cap X5R 1U K 6V3 0603

C710 2320740 Top H 8 chip cap X7R 680P K 50V 0402

C711 2320481 Top H 7 chip cap X5R 1U K 6V3 0603

C712 2320552 Top I 7 chip cap NP0 47P J 50V 0402

C720 2320588 Top I 8 chip cap X7R 1N5 J 50V 0402

C721 2320783 Top I 8 chip cap X7R 33N K 10V 0402

C722 2320588 Top J 8 chip cap X7R 1N5 J 50V 0402

C723 2320522 Top J 8 chip cap NP0 2P7 C 50V 0402

C724 2320548 Top J 7 chip cap NP0 33P J 50V 0402

C725 2320520 Top J 8 chip cap NP0 2P2 C 50V 0402

C726 2320744 Top J 8 chip cap X7R 1N0 K 50V 0402

C740 2320590 Top I 9 chip cap X7R 1N8 J 50V 0402

C741 2320783 Top I 9 chip cap X7R 33N K 10V 0402

C742 2320588 Top I 9 chip cap X7R 1N5 J 50V 0402

C745 2320548 Top H 8 chip cap NP0 33P J 50V 0402

C747 2320536 Top H 9 chip cap NP0 10P J 50V 0402

C748 2320538 Top H 9 chip cap NP0 12P J 50V 0402

C749 2320744 Top H 8 chip cap X7R 1N0 K 50V 0402

C750 2320514 Top G 8 chip cap NP0 1P2 C 50V 0402

C751 2320520 Top H 8 chip cap NP0 2P2 C 50V 0402

C752 2320740 Top G 9 chip cap X7R 680P K 50V 0402

C753 2320481 Top G 9 chip cap X5R 1U K 6V3 0603

C770 2320580 Top K 5 chip cap X7R 680P J 50V 0402

C771 2480003 Top K 4 chip cap PPS 8N2 J 16V 0805

Page 14 Nokia Corporation Confidential Issue 1 05/2003

Page 29

RH-14

CCS Technical Documentation Parts Lists

Item Code Side X Y Description Value Type

C772 2320495 Top K 5 chip cap NP0 1N0 J 50V 0603

C773 2320466 Top K 5 chip cap NP0 220P J 50V 0603

C774 2320536 Top I 5 chip cap NP0 10P J 50V 0402

C775 2320481 Top I 5 chip cap X5R 1U K 6V3 0603

C776 2320778 Top I 6 chip cap X7R 10N K 16V 0402

C791 2320805 Top K 7 chip cap X5R 100N K 10V 0402

C792 2320778 Top K 7 chip cap X7R 10N K 16V 0402

C793 2320481 Top J 7 chip cap X5R 1U K 6V3 0603

C801 2320552 Top H 5 chip cap NP0 47P J 50V 0402

C802 2320778 Top H 5 chip cap X7R 10N K 16V 0402

C803 2320536 Top H 5 chip cap NP0 10P J 50V 0402

C806 2320552 Top I 7 chip cap NP0 47P J 50V 0402

C807 2320536 Top I 7 chip cap NP0 10P J 50V 0402

C808 2320805 Top I 7 chip cap X5R 100N K 10V 0402

C820 2320552 Top H 5 chip cap NP0 47P J 50V 0402

C821 2320552 Top I 6 chip cap NP0 47P J 50V 0402

C822 2320805 Top I 6 chip cap X5R 100N K 10V 0402

C830 2320778 Top K 6 chip cap X7R 10N K 16V 0402

C831 2320602 Top K 6 chip cap NP0 4P7 C 50V 0402

C832 2320602 Top K 6 chip cap NP0 4P7 C 50V 0402

C833 2320536 Top I 6 chip cap NP0 10P J 50V 0402

C834 2320536 Top I 6 chip cap NP0 10P J 50V 0402

C850 2320536 Top C 8 chip cap NP0 10P J 50V 0402

C851 2320536 Top C 9 chip cap NP0 10P J 50V 0402

C853 2320546 Top D 8 chip cap NP0 27P J 50V 0402

C854 2320546 Top C 9 chip cap NP0 27P J 50V 0402

C855 2320508 Top D 8 chip cap NP0 1P0 C 50V 0402

C857 2320536 Top D 9 chip cap NP0 10P J 50V 0402

C858 2320584 Top C 9 chip cap X7R 1N0 J 50V 0402

C859 2320536 Top I 6 chip cap NP0 10P J 50V 0402

C900 2320744 Top G 6 chip cap X7R 1N0 K 50V 0402

C901 2320631 Top J 2 chip cap NP0 180P J 25V 0402

Issue 1 05/2003 Nokia Corporation Confidential Page 15

Page 30

RH-14

Parts Lists CCS Technical Documentation

Item Code Side X Y Description Value Type

C902 2320744 Top F 2 chip cap X7R 1N0 K 50V 0402

C903 2320631 Top F 2 chip cap NP0 180P J 25V 0402

C904 2320005 Top J 2 chip cap NP0 HQ 82P J 25V 0603

C905 2320546 Top J 2 chip cap NP0 27P J 50V 0402

C906 2320546 Top J 2 chip cap NP0 27P J 50V 0402

C907 2320536 Top I 3 chip cap NP0 10P J 50V 0402

C908 2320744 Top I 3 chip cap X7R 1N0 K 50V 0402

C910 2320744 Top F 3 chip cap X7R 1N0 K 50V 0402

C912 2320481 Top F 3 chip cap X5R 1U K 6V3 0603

C913 2320560 Top H 4 chip cap X7R 680P J 50V 0402

C914 2320481 Top I 3 chip cap X5R 1U K 6V3 0603

C915 2320536 Top G 7 chip cap NP0 10P J 50V 0402

C916 2320805 Top G 7 chip cap X5R 100N K 10V 0402

C918 2320744 Top K 3 chip cap X7R 1N0 K 50V 0402

C919 2320635 Top F 4 chip cap NP0 0P5 C 50V 0402

C921 2320744 Top J 3 chip cap X7R 1N0 K 50V 0402

C930 2320536 Top E 5 chip cap NP0 10P J 50V 0402

C931 2320744 Top E 4 chip cap X7R 1N0 K 50V 0402

C960 2320508 Top G 7 chip cap NP0 1P0 C 50V 0402

C961 2320522 Top G 7 chip cap NP0 2P7 C 50V 0402

C962 2320536 Top E 7 chip cap NP0 10P J 50V 0402

C963 2320536 Top E 8 chip cap NP0 10P J 50V 0402

C965 2320508 Top E 8 chip cap NP0 1P0 C 50V 0402

C966 2320536 Top E 8 chip cap NP0 10P J 50V 0402

C967 2320536 Top E 7 chip cap NP0 10P J 50V 0402

C968 2320778 Top E 7 chip cap X7R 10N K 16V 0402

C969 2320536 Top E 7 chip cap NP0 10P J 50V 0402

C970 2320540 Top H 4 chip cap NP0 15P J 50V 0402

C971 2320536 Top G 7 chip cap NP0 10P J 50V 0402

C972 2320805 Top H 7 chip cap X5R 100N K 10V 0402

L100 3203743 Top T 7 ferrite bead 0R03 42R/100MHz 3A 0805

L151 3203741 Top U 4 ferrite bead 0R5 600R/100MHz 0603

Page 16 Nokia Corporation Confidential Issue 1 05/2003

Page 31

RH-14

CCS Technical Documentation Parts Lists

Item Code Side X Y Description Value Type

L152 3203741 Top U 5 ferrite bead 0R5 600R/100MHz 0603

L153 3203741 Top U 6 ferrite bead 0R5 600R/100MHz 0603

L158 3203741 Top U 5 ferrite bead 0R5 600R/100MHz 0603

L159 3203741 Top U 6 ferrite bead 0R5 600R/100MHz 0603

L180 3203743 Top Q 5 ferrite bead 0R03 42R/100MHz 3A 0805

L181 3203743 Top Q 5 ferrite bead 0R03 42R/100MHz 3A 0805

L730 3645333 Top I 8 chip coil 27N G Q40/250MHz 0603

L746 3645331 Top H 9 chip coil 47N G Q38/200MHz 0603

L750 3645145 Top G 8 chip coil 39N J Q12/100MHz 0603

L751 3645145 Top G 8 chip coil 39N J Q12/100MHz 0603

L820 3645211 Top I 5 chip coil 6N8 K Q27/250MHz 0603

L821 3646069 Top H 5 chip coil 33N J Q23/800MHz 0402

L822 3646063 Top H 5 chip coil 22N J Q28/800MHz 0402

L823 3646007 Top G 5 chip coil 27N J Q27/800MHz 0402

L830 3643087 Top K 6 chip coil 180N J Q13/50MHz 0805

L831 3643087 Top K 7 chip coil 180N J Q13/50MHz 0805

L832 3645067 Top I 6 chip coil 330N J Q48/250MHz 0805

L851 3646059 Top C 8 chip coil 5N6

+-0N3

L852 3646051 Top D 9 chip coil 3N9

+-0N3

L900 3646065 Top J 4 chip coil 12N J Q31/800MHz 0402

L901 3646083 Top J 2 chip coil 100N J Q16/300MHz 0402

L902 3646061 Top I 3 chip coil 15N J Q30/800MHz 0402

L903 3643085 Top H 3 chip coil 5N6

+-0N5

L960 3646075 Top F 8 chip coil 56N J Q21/800MHz 0402

Q28/800MHz 0402

Q28/800MHz 0402

Q35 1.5A 0805

L961 3646075 Top G 8 chip coil 56N J Q21/800MHz 0402

L962 3646083 Top F 7 chip coil 100N J Q16/300MHz 0402

L963 3646083 Top G 7 chip coil 100N J Q16/300MHz 0402

Z101 3640085 Top S 6 filt 470NF 16V 0R03 2A 0805

Z820 4511217 Top H 5 Saw Filt 881.5+-

12.5MHz/3.5DB

3X3

Issue 1 05/2003 Nokia Corporation Confidential Page 17

Page 32

RH-14

Parts Lists CCS Technical Documentation

Item Code Side X Y Description Value Type

Z830 4511209 Top J 7 Saw Filt 135.54+-

0.013MHz/

5.3DB

Z850 4511267 Top G 5 Saw Filt 1960+-30MHz/

4.5DB

Z905 4511151 Top I 2 Saw Filt 824-849MHz/

3.8DB

Z906 4512143 Top E 3 Dupl 824-849/

869-894MHz

Z907 4550141 Top B 4 Dipl 824-894/

1850-1990MHz

Z960 4511259 Top G 8 Saw Filt 181.8+-

0.015MHz

Z961 4511203 Top E 7 Saw Filt 1880+-30MHz/

5.0DB

Z962 4512147 Top C 6 Dupl 1850-1910/

1930-1990MHz

V100 4113721 Top S 6 TVS DI

1PMT16AT3

V301 4860417 Top L 7 LED CL400S-WDH >371MCD INGAN TBSF

V302 4860417 Top L 4 LED CL400S-WDH >371MCD INGAN TBSF

16V 175W PWRMITE

3X3X1

3X3

9.5X7.5

3.2X1.6

3.8X3.8

3X3X1

17X10

V308 4860425 Top T 6 LED CL400S-WAL >265MCD INGAN TBSF

V309 4860425 Top T 4 LED CL400S-WAL >265MCD INGAN TBSF

V318 4113669 Top T 3 ZDIX4 TVS/ESD RSA6.1EN 6V1 SOT353

V319 4210221 Top O 5 TR MMBT6589 P 30V 1A LOWSAT TSOP6

V725 4110953 Top J 8 cap di 1SV280 C2V/C10V=2.4 SOD523

V744 4110911 Top H 8 cap di MA2SV01 15/7PF 1/3V SOD523

V850 4210287 Top C 8 TR NE661M05 N LNA 2GHz 3V3 SOT343

N180 4341221 Top P 5 AF AMP 0.4W/

2.6V

N300 4210371 Top N 5 TRX2 UMF28N N&P 50V 0.1A SOT363

N750 4210247 Top H 8 RF CASCODE AMP BGA416 LNA SOT143

N801 4370777 Top H 6 Safari_T2

A807HEGT

N900 4341179 Top J 3 UPCONV 900MHz (OM5968) TSSOP10

N901 4350311 Top G 3 PW AMP RF9200 TDMA 800MHz

N930 4350267 Top E 5 PWR Detector

Module

(LM4890) USMD9

BICMOS6M LFBGA

800/1900MHz

Page 18 Nokia Corporation Confidential Issue 1 05/2003

Page 33

RH-14

CCS Technical Documentation Parts Lists

Item Code Side X Y Description Value Type

N960 4350309 Top E 6 PW AMP RF9201 TDMA 1900MHz

D200 4370825 Top O 7 UEMK W-DOG ENA TO21 TFBGA168

D320 4341425 Top M 5 White LED Driver (LM2795BLX) USMD14

D400 4370873 Top P 3 UPP8M V2.2 F751986B C035 UBGA144

D450 4341529 Top M 3 Flash 4MX16 1.8/1.8V TBGA48

G780 4350279 Top J 5 VCO 2GHz 2.78V 10.5MA TDMA

G790 4510307 Top K 8 VCTCXO

19.44MHz

B200 4510219 Top Q 8 Crystal 32.768KHz +-30PPM 9PF

T775 4550153 Top I 4 Transf Balun 2060+-70MHz 2.0X1.25

T960 4550173 Top E 8 Transf Balun 1920+-70MHz 2X1.25

F100 5119019 Top U 6 Sm Fuse F 1.5A 32V 0603

X900 5429021 Top C 3 Sm Conn RF+SW 100V 1W 50R 2.2GHz

A100 9517229 Top O 5 BB Shield Assy DMC05660 HDDC2

A900 9517245 Top H 6 RF Shield Assy DMC05865 Cobra

+-2.5PPM 2.78V

Issue 1 05/2003 Nokia Corporation Confidential Page 19

Page 34

RH-14

Parts Lists CCS Technical Documentation

Page 20 Nokia Corporation Confidential Issue 1 05/2003

Page 35

CCS Technical Documentation

RH-14 Series Transceivers

Service Software Instructions

Issue 1 05/2003 Confidential Nokia Corporation

Page 36

RH-14

Service Software Instructions CCS Technical Documentation

Page 2 Nokia Corporation Confidential Issue 1 05/2003

Page 37

RH-14

CCS Technical Documentation Service Software Instructions

Contents

Page No

Phoenix User’s Guide .................................................................................................... 5

Introduction ..................................................................................................................5

Setting up Phoenix .......................................................................................................5

HW requirements for using Phoenix ...........................................................................6

Installing Phoenix ........................................................................................................6

Uninstalling Phoenix ...................................................................................................6

Data Packages ..............................................................................................................7

Starting a session .........................................................................................................7

Concepts.................................................................................................................... 7

Selecting a connection............................................................................................... 7

Selecting a product.................................................................................................... 7

Phoenix environment................................................................................................. 8

Using components..................................................................................................... 8

Issue 1 05/2003 Confidential Nokia Corporation Page 3

Page 38

RH-14

Service Software Instructions CCS Technical Documentation

Page 4 Nokia Corporation Confidential Issue 1 05/2003

Page 39

RH-14

CCS Technical Documentation Service Software Instructions

Phoenix User’s Guide

Introduction

This section briefly describes how to install the Phoenix software and includes some

basic information on how to use the program. For more detailed information, please refer

to the Phoenix Help files. Each feature in Phoenix has its own Help function, which can

be activated while running the program.

Setting up Phoenix

1 Download the latest release. Please contact your regional Customer Care Solu-

tions contact for information on where to download the latest release.

2 Install Phoenix by executing the Phoenix installation package and follow the

instructions on the screen.

Note: In some products, the setup may require you to reboot the computer. In either case, the

setup will register Phoenix components. This process can take several minutes.

3 Download the latest data packages for the products you will be using.

By default, the program files are stored under C:\Program Files\Nokia\Phoenix

The Phoenix program has been built using component architecture. This means

that the actual program is very small and most of the program’s functionality is

divided into dynamically loaded modules (DLLs).

The data packages will create product-specific directories under the installation

directory.

Issue 1 05/2003 Confidential Nokia Corporation Page 5

Page 40

RH-14

Service Software Instructions CCS Technical Documentation

HW requirements for using Phoenix

Table 1: HW requirements for AMS

Minimum HW requirements for AMS

Processor 233 Mhz

RAM 64 MB

Needed disk space 50 - 100 MB

Table 2: Recommended HW for Windows 2000

Minimum HW requirements for Field Test

Processor 700 Mhz

RAM 512 MB

Needed disk space 50 - 100 MB

Installing Phoenix

1 Before you start installing the program, check that:

• the dongle is attached to parallel port. Contact your supervisor in

order to obtain a suitable dongle.

• you have administrator rights (Windo w s NT or Windows 2000). This

is required in order to be able to install P hoenix.

2 The installation checks that the latest supported dongle driver version is installed.

The dongle driver is installed if there is no previous installation of the dongle

driver or if the installed dongle driver is older than the latest supported version.

Table 3: Supported Operating Systems

Supported Operating Systems

Windows 95

Windows 98

Windows NT 4.0

Windows 2000

3 Reboot your PC before using Phoenix, if you are requested to do so.

Uninstalling Phoenix

Uninstalling another Phoenix version:

1 Make sure that the dongle is attached.

Page 6 Nokia Corporation Confidential Issue 1 05/2003

Page 41

RH-14

CCS Technical Documentation Service Software Instructions

2 Go to Control Panel and select Add/Remove Programs.

3Select TSS4 Phoenix Release xx.yy.zzz for uninstallation and click Add/Remove.

4Click OK to remove the application.

You may be required to reboot your PC after uninstallation.

Note: If you have different product packages installed, the components are uninstalled only if they are

not included in other product packages.

Data Packages

Data Packages (DP) is a name for a helpful feature in the Phoenix software. This feature

provides a flexible way of distributing and installing Phoenix and its data files.

All product-specific data is separated from the program code and installed separately.

This means that the installation is performed in at least two steps.

Each product has its own DP. The FPS-8 flashing equipment also has its own package.

Starting a session

Concepts

In the Phoenix context, Product means the cellular phone attached to a PC. More specifically, it is a particular type of phone.

Connection means the type of cable used to attach the phone to the port to which the

other end of the cable is attached.

Selecting a connection

The connection defines the cable and the communications port that will be used when

connecting to the phone.

1 Active connections are listed in the toolbar’s Connection drop-down menu. You

should make sure that the connection is correct before using the software.

Change it, if necessary.

In case the connection is the wrong one, you need to create a new one.

2Select Settings from the drop-down menu.

3Select Add in the Connection List Dialog and fill in the relevant fields in the Con-

nection setup dialog.

Selecting a product

Many of Phoenix’s features are product-specific. It is, therefore, mandatory to choose the

product you will be working on at the beginning of the session.

Issue 1 05/2003 Confidential Nokia Corporation Page 7

Page 42

RH-14

Service Software Instructions CCS Technical Documentation

1Select File - Scan Product (or hold the Ctrl key down and press R). Phoenix will

scan the connected product and load additional menus which are designed for

the product. If the product is not supported, then an error message will be displayed and a different Phoenix data package may be required.

2 If you want to manually choose the product or if the phone is dead, select File -

Choose Product. You will be presented with a list of available products.

After the product selection, you will see an additional menu item on the main

menu. If you take a look at the available menu items, you will see that their

number has increased.

Phoenix environment

You can configure the program’s main toolbar and the product or tool-specific options to

your liking.

You can control which toolbars are visible by selecting View and Toolbars from the dropdown menu. The visible toolbars are marked with a check.

The rest of the options are product- or tool-specific. The tool-specific options are set

using the associated toolbar.

Using components

When working with Phoenix, each task generally has its own component that will perform the task. The first thing, therefore, is to open the desired component.

Opening a component means that you open a tool window within Phoenix.

Page 8 Nokia Corporation Confidential Issue 1 05/2003

Page 43

CCS Technical Documentation

RH-14 Series Transceivers

Service Tools

Issue 1 05/2003 Confidential Nokia Corporation

Page 44

RH-14

Service Tools CCS Technical Documentation

Page 2 Nokia Corporation Confidential Issue 1 05/2003

Page 45

RH-14

CCS Technical Documentation Service Tools

Contents

Page No

Service Tools.................................................................................................................. 5

3560 .............................................................................................................................5

Flashing and Testing Setups ........................................................................................ 11

FPS-8 Flash Prommer for Heavy Flash .....................................................................11

FPS-8C Flash Prommer for Heavy Parallel Flash .....................................................11

User Instructions .......................................................................................................... 12

FLA-39 ......................................................................................................................12

MJF-23 .......................................................................................................................14

Issue 1 05/2003 Confidential Nokia Corporation Page 3

Page 46

RH-14

Service Tools CCS Technical Documentation

Page 4 Nokia Corporation Confidential Issue 1 05/2003

Page 47

RH-14

CCS Technical Documentation Service Tools

Service Tools

3560

Photo Code Service Tool Code Description

MJ-8 Module Jig 0770522 This jig allows phone

PWB-level service and

troubleshooting. Electric currents should be

protected against

over-voltage and

over-current.

FLS-4S POS Flash Adapter 0080543 The Point of Sale

(POS) flash is a lowcost software upgrade

tool. This requires the

XCS-1 cable and

ACP-8U for operation.

FPS-8 Flash Prommer 0080321 The Flash Prommer

FPS-8 is used for

flash.

FPS-8C Heavy Flash Prommer 0080396 The Heavy Flash

Prommer FPS-8C is

used for heavy parallel flashing.

Issue 1 05/2003 Confidential Nokia Corporation Page 5

Page 48

RH-14

Service Tools CCS Technical Documentation

Photo Code Service Tool Code Description

JBV-1 Docking Station 0770298 The Docking Station

and the Docking Station Adapter (MJF-23)

are needed for Mbus,

Fbus, RF, and audio

connections.

This setup allows connection between flash

prommers. When the

audio box is connected, it has to be

connected to the

phone’s audio connector.

MJF-23 Docking Station

Adapter

CPL-1 Coupler 0770287 The coupler has been

JBA-8 Audio Box 0770320 The Audio Box is

0770489 The Docking Station

can be powered by

FPS-8 or external

power supply.

NOTE: SEE USER

INSTRUCTIONS FOR

MJF-23 ON PAGE 13.

developed for antenna

go/no go testing.

needed for audio connections. The box

must support DCT4

Janette audios. JBA-8

provides an interconnection between the

phone’s system connector (XEAR, XMIC)

through a fixed audio

cable and audio tester

with a BNC-BNC

coax. Connection to a

PC can be made with

the service battery,

through a DAU-9

cable.

Page 6 Nokia Corporation Confidential Issue 1 05/2003

Page 49

RH-14

CCS Technical Documentation Service Tools

Photo Code Service Tool Code Description

FLA-39 Flash Adapter 0770490 FLA-39 allows a con-

tinuous maximum

power supply for the

phone from an external power supply, the

ACP-8.

NOTE: SEE USER

INSTRUCTIONS FOR

FLA-39 ON PAGE 12.

Note: FLA-39 is not to

be used for handset

testing; it is only

designed for flashing.

RJ-15 Soldering Jig 0770611 RJ-15 is used to hold

the PWB during repair

and troubleshooting.

AXP-8 Printer Cable 073F000 The Parallel Printer

Cable connects the

parallel connector of

the PC and the parallel input of the FPS-8.

AXS-4 D9-D9 Cable 0730090 The AXS-4 D9-D9

service cable is used

to connect two 9-pin

connectors (e.g.,

between PC and

FPS-8). AXS-4 length

is 2 meters

ADS-3 Audio Cable 0730197 The audio cable con-

nects to the audio box

JBA-6.

Issue 1 05/2003 Confidential Nokia Corporation Page 7

Page 50

RH-14

Service Tools CCS Technical Documentation

Photo Code Service Tool Code Description

ADS-4 Audio Cable 0730222 ADS-4 is the service

cable between the

phone and the service

audio box.

SCB-3 DC Cable 0730114 The DC Cable SCB-3 is

used to connect the

docking station to the

charger connection

(Vin) of the phone to

conduct the charger

calibration service

procedure.

DAU-9S Mbus Cable 0730108 The Mbus Cable has a

modular connector

and is used with the

service audio box

JBA-4 or a modular

T-adapter.

PCS-1 Power Cable 0730012 The Power Cable

PCS-1 is used to connect the service tools

(JBV-1, MJF-23) to

an external power

supply.

XRF-1 RF Cable 0730085 The XRF-1 cable con-

nects a service tool

and RF measurement

equipment.

Page 8 Nokia Corporation Confidential Issue 1 05/2003

Page 51

RH-14

CCS Technical Documentation Service Tools

Photo Code Service Tool Code Description

XCS-4 Mbus/Fbus Cable 0730178 The XCS-4 Service

Cable is a modular

cable for flashing

DCT4 products.

PKD-1 SW Security Device 0750018 SW security device

PKD-1 is hardware

device that, when

connected to the parallel (LPT) port of the

PC, enables the use of

the service software.

Without the dongle

present, it is not possible to use the service software. Printers

or other peripheral

devices can be connected to the PC

through the dongle, if

needed.

Caution: Make sure

that you have

switched off the PC

and the printer before

making connections!

Caution: Do not connect the PKD-1 to the

serial port. You may

damage your PKD-1!

SA-12

XRS-11

RF Probe Support

RF Probe

0770623

0770562

The RF Cable is used

for connection to the

RF output of the PWB.

The XRS-11 Cable is

used together with

the SA-12 to ensure a

good connection.

Issue 1 05/2003 Confidential Nokia Corporation Page 9

Page 52

RH-14

Service Tools CCS Technical Documentation

Photo Code Service Tool Code Description

GAC-8/

GAC-9K

Adapter 0080834 The GAC-8/GAC-9K

adapter is needed for

proper RF connection.

The adapter allows

galvanic connections

to assembled handset

RF switches. The

adapter permits the

handset to be connected to RF measuring and test

equipment during test

and repair and can be

used with covers on or

off.

NOTE: GAC-8 must be

used with GAC-9k.

Page 10 Nokia Corporation Confidential Issue 1 05/2003

Page 53

RH-14

CCS Technical Documentation Service Tools

Flashing and Testing Setups

FPS-8 Flash Prommer for Heavy Flash

The FPS-8 flash prommer is used for heavy flashing. The sales pack product code is

0080321.

FPS-8C Flash Prommer for Heavy Parallel Flash

The FPS-8C flash prommer is used for heavy parallel flashing. The sales pack product

code is 0080396.

Issue 1 05/2003 Confidential Nokia Corporation Page 11

Page 54

RH-14

Service Tools CCS Technical Documentation

User Instructions

FLA-39

Follow these instructions to avoid damage to the adapter or the phone.

Note: Using the adapter in any way other than described here may harm the important

pins and connectors of the adapter. It cannot be used like the FLA-13 for 3520/3560 products.

1 Place the adapter in your left hand and the phone in your right hand.

2 Align the battery connecter with the battery contacts of the adapter. Gently

press the phone onto the adapter (see following picture).

Page 12 Nokia Corporation Confidential Issue 1 05/2003

Page 55

RH-14

CCS Technical Documentation Service Tools

3 Press the upper end of the handset down onto the adapter until the battery tabs

of the D-cover catch the adapter.

To remove adapter, follow the inverse order of the installation in Steps 1 through 3.

Issue 1 05/2003 Confidential Nokia Corporation Page 13

Page 56

RH-14

Service Tools CCS Technical Documentation

MJF-23

Follow these instructions to avoid causing any damage to the adapter or the phone.

Note: Using the adapter in any other way may harm the important pins and connectors of

the adapter. It cannot be used like the MJF-2 for 3520/3560 products.

1 Place the adapter in your left hand and the phone in your right hand.

Page 14 Nokia Corporation Confidential Issue 1 05/2003

Page 57

RH-14

CCS Technical Documentation Service Tools

2 Let the other edge of the phone down in place.

3 Press down the upper end of the phone with your finger until the battery latch

locks the phone in place.

4 To remove the phone from the adapter, push the bottom connector end of the

phone down to the hollow in the adapter. At the same time, push the upper end

of the phone until it detaches from its place. Detach the phone in inverse order

from installation.

Issue 1 05/2003 Confidential Nokia Corporation Page 15

Page 58

RH-14

Service Tools CCS Technical Documentation

Page 16 Nokia Corporation Confidential Issue 1 05/2003

Page 59

CCS Technical Documentation

RH-14 Series Transceivers

Disassembly/Assembly

Issue 1 05/2003 Confidential Nokia Corporation

Page 60

RH-14

Disassembly/Assembly CCS Technical Documentation

Page 2 Nokia Corporation Confidential Issue 1 05/2003

Page 61

RH-14

CCS Technical Documentation Disassembly/Assembly

Contents

Page No

ESD Protection ............................................................................................................5

Step-by-Step Disassembly Guide................................................................................ 5

Remove B-cover ..........................................................................................................5

Remove RF Plug ..........................................................................................................6

Remove A-cover ..........................................................................................................6

Remove screws ............................................................................................................6

Remove lightguide assembly .......................................................................................7

Remove metal frame and earpiece ...............................................................................7

Remove PWB assembly ..............................................................................................8

Remove shielding lids ..................................................................................................9

Remove components from D-cover assembly .............................................................9

SALT speaker.......................................................................................................... 10

Step-by-Step Assembly Guide................................................................................... 11

Mount components in D-cover ..................................................................................11

Mount shielding lids on PWB ...................................................................................12

Mount PWB on D-cover ............................................................................................12

Mount earpiece and metal frame ...............................................................................12

Mount domesheet .......................................................................................................13

Mount display assembly on D-cover .........................................................................13

Mount screws .............................................................................................................14

Mount keymat and A-cover assembly .......................................................................14

Insert RF Plug ............................................................................................................15

Place battery ...............................................................................................................16

Mount B-cover assembly ...........................................................................................16

Issue 1 05/2003 Confidential Nokia Corporation Page 3

Page 62

RH-14

Disassembly/Assembly CCS Technical Documentation

Page 4 Nokia Corporation Confidential Issue 1 05/2003

Page 63

RH-14

CCS Technical Documentation Disassembly/Assembly

ESD Protection

Step-by-Step Disassembly Guide

The following diagrams may be helpful in explaining the correct sequence and technique

for disassembly of the RH-14 handsets.

Remove B-cover

1 Turn phone off

2 Remove the B-cover by pushing the button (indicated by arrow)

3 Lift the B-cover up as shown by the arrows.

Issue 1 05/2003 Confidential Nokia Corporation Page 5

Page 64

RH-14

5

4

Disassembly/Assembly CCS Technical Documentation

Remove RF Plug

Remove the RF Plug from RF connector opening in the antenna.

Remove A-cover

Place thumb under the edge of the A-cover and fingers on top of the A-cover, then pull

gently until it snaps. Once lifted, ensure that the keymat does not fall out of the A-cover.

Remove screws

Unscrew the six screws as indicated.

3

1

2

6

Page 6 Nokia Corporation Confidential Issue 1 05/2003

Page 65

RH-14

CCS Technical Documentation Disassembly/Assembly

Remove lightguide assembly

Follow the steps indicated in the following diagram:

Remove metal frame and earpiece

Follow the numbered steps in the following diagram.

Note: Use screwdriver size 2.50 – 3.50 mm.

1 Turn screwdriver at snaps only on one side

2 When removing the metal frame, be careful not to damage the four springs in

the corners

3 Remove earpiece

Issue 1 05/2003 Confidential Nokia Corporation Page 7

Page 66

RH-14

1

LED

Disassembly/Assembly CCS Technical Documentation

b

1a

2

3

Remove PWB assembly

Lift the PWB as indicated in the following drawing. Then, place the PWB on ESD table

with LEDs on top.

Page 8 Nokia Corporation Confidential Issue 1 05/2003

Page 67

RH-14

CCS Technical Documentation Disassembly/Assembly

Remove shielding lids

Caution: Do not re-use shielding lid once it is removed.

When working with the PWB, always use a repair jig.

Remove components from D-cover assembly

The following components are removable:

1Power key

2 Battery connector

3 SALT speaker (see diagram)

4Vibra

5 Bottom connector

Issue 1 05/2003 Confidential Nokia Corporation Page 9

Page 68

RH-14

Disassembly/Assembly CCS Technical Documentation

SALT speaker

Page 10 Nokia Corporation Confidential Issue 1 05/2003

Page 69

RH-14

CCS Technical Documentation Disassembly/Assembly

Step-by-Step Assembly Guide

Mount components in D-cover

1Power key

2 Battery connector

3SALT speaker

4Vibra

5 Bottom connector

Note: Ensure that all components are placed correctly.

Issue 1 05/2003 Confidential Nokia Corporation Page 11

Page 70

RH-14

Disassembly/Assembly CCS Technical Documentation

Mount shielding lids on PWB

Mount PWB on D-cover

Mount earpiece and metal frame

1 Mount the earpiece in the lightguide

2 Place metal frame on lightguide — be careful about the springs in each of the

four corners

3 Push the metal frame down (indicated with arrows in drawing below) until it

snaps on

Page 12 Nokia Corporation Confidential Issue 1 05/2003

Page 71

RH-14

CCS Technical Documentation Disassembly/Assembly

Mount domesheet

When mounting the domesheet, use the two holes indicated as guide.

Mount display assembly on D-cover

1 Place the display assembly in the D-cover

2 Push the display assembly down (indicated by arrows in the drawing below) until

it snaps on

Issue 1 05/2003 Confidential Nokia Corporation Page 13

Page 72

RH-14

5

4

Disassembly/Assembly CCS Technical Documentation

Mount screws

Fasten the screws in the sequence indicated in the following diagram. Be sure to use a

torx #6 screwdriver.

Note: Max torque 28Ncm at 500-600RPM.

3

Mount keymat and A-cover assembly

1

2

6

1 Place keymat

2 Push down the A-cover until it snaps on

Page 14 Nokia Corporation Confidential Issue 1 05/2003

Page 73

RH-14

CCS Technical Documentation Disassembly/Assembly

Insert RF Plug

Insert RF Plug into RF connector opening in the antenna.

Issue 1 05/2003 Confidential Nokia Corporation Page 15

Page 74

RH-14

Disassembly/Assembly CCS Technical Documentation

Place battery

Slide battery under the hooks in the D-cover.

Mount B-cover assembly

1 Place B-cover assembly on D-cover

2 Push the B-cover in the direction indicated by the arrow in drawing below until

the B-cover snaps on

Page 16 Nokia Corporation Confidential Issue 1 05/2003

Page 75

CCS Technical Documentation

RH-14 Series Transceivers

Troubleshooting

Issue 1 05/2003 Confidential Nokia Corporation

Page 76

RH-14

Troubleshooting CCS Technical Documentation

Page 2 Nokia Corporation Confidential Issue 1 05/2003

Page 77

RH-14

CCS Technical Documentation Troubleshooting

Contents

Page No

Troubleshooting............................................................................................................. 5

Baseband Troubleshooting ..........................................................................................5

General testing information....................................................................................... 5

Troubleshooting ........................................................................................................ 5

Phone does not start up normally or does not stay on............................................... 8

Flash Programming does not work.......................................................................... 10

Charging.................................................................................................................. 12

Audio failures.......................................................................................................... 13

Accessory detection................................................................................................. 15

Sleep Clock ............................................................................................................. 16

User Interface.......................................................................................................... 18

Receiver Troubleshooting ..........................................................................................20

General Instructions for RX troubleshooting.......................................................... 20

Path of the received signal ...................................................................................... 20

Fault-finding charts for receiver chain.................................................................... 21

Transmitter fault-finding ...........................................................................................28

General instructions for TX troubleshooting .......................................................... 28

Path of the transmitted signal.................................................................................. 28

Fault-finding charts for transmitter......................................................................... 28

Power control loop.................................................................................................. 31

Synthesizer fault-finding ...........................................................................................34

19.44 MHz reference oscillator............................................................................... 34

RX VHF VCO......................................................................................................... 36

TX VHF VCO......................................................................................................... 37

UHF Synthesizer..................................................................................................... 37

Issue 1 05/2003 Confidential Nokia Corporation Page 3

Page 78

RH-14

Troubleshooting CCS Technical Documentation

Page 4 Nokia Corporation Confidential Issue 1 05/2003

Page 79

RH-14

CCS Technical Documentation Troubleshooting

Troubleshooting

The first thing to do when a problem is encountered is to carry out a thorough visual

check of the module. Make sure that:

• there are no mechanical damages

• the solder joints are OK

Note: Before changing anything, ALL SUPPLY VOLTAGES AND THE SYSTEM CLOCK / SLEEP

CLOCK should be checked.

Baseband Troubleshooting

General testing information

There are three different modes for testing and/or repairing the phone. The mode can be

selected with suitable resistors connected to BSI- and BTEMP- lines as illustrated in the

following table:

Table 1: Phone operating mode

Mode BSI- resistor

Normal 68k 75k

Local 560_(<1k_) Whatever

Test > 1k 560_(<1k_) Recommended for baseband testing. Same as local

BTEMP

resistor

Remarks

mode, but making a phone call is possible.

If the corresponding resistors are connected, the MCU software automatically enters into

the local or test mode when the supply voltage is connected to the phone.

The power can be switched on by:

1 Pressing the power key.

2 Connecting the local/test mode resistors to the BSI/BTEMP lines and connecting

the battery voltage to the phone.

3 Connecting a charger.

4 Using the phone’s internal functions (real-time clock alarm).

In the local and test mode, the baseband can be controlled through MBUS or FBUS (FBUS

is recommended) connections using Phoenix service software.

Troubleshooting

Note: Most of the baseband repair actions require removing the baseband shield. The shield must not

be removed unless separately authorized by the program.

Issue 1 05/2003 Confidential Nokia Corporation Page 5

Page 80

RH-14

Troubleshooting CCS Technical Documentation

Note: The phone’s ESN has to re-written to the UEM, if the UEM is replaced. This can be done only in

Central Service.

The baseband troubleshooting instructions include the following topics:

1Power up

2 Flash programming

3Audio

• Earpiece

• Microphone

4 Charging

5 Accessory detection

6Sleep clock

7 User interface

Power-up faults

Power-up sequence

1 The UEM acts as a HW master during start up

• Vbatt limits: 2.1V for internal state machine, 3V triggering whole startup

•Display

•Lights

•MIDI

•Vibra

• Keyboard

• Regulator sequencing

• HW "core" regulators "on": Vio, Vcore, VR3, Vflash1

• These regulators supply the processors, memory chip interfaces

and clock source in RF

• Reset releasin g del ay

Page 6 Nokia Corporation Confidential Issue 1 05/2003

Page 81

RH-14

CCS Technical Documentation Troubleshooting

• Supply voltages stabilize to their UEM HW default values

• RFCLK grows to full swing

• The core is ready to run but waiting for the PURX release

• Reset releasing

• The UPP releases the SLEEPX up to the "non sleep" state to prevent the UEM switching the regulators "OFF"

2 MCU starts running the Bootstrap Code

• written in stone/ UPP internal ROM

• the program checks if there is any reason for the FDL mode (Flash

Down Load)

• If there is an executable code in FLASH and there is no reason for

FDL, the MCU starts running the MCU program from FLASH

3 MCU runs the FLASH MCU code

• the phone initialization, user interfaces, internal blocks, etc.

• Core regulator voltage setting for required DSP speed

• Initializes the DSP and concerning HW

• Releases DSP reset -> DSP starts running

Note: In the following figure, the RF_Clk frequency appears to be lower than 19.44MHz because of a

too low oscilloscope sampling frequency (2kS/s).

Issue 1 05/2003 Confidential Nokia Corporation Page 7

Page 82

RH-14

Troubleshooting CCS Technical Documentation

Figure 1: Power-up sequence

1 Power key pressed

• After 20ms, UEM enters RESE T MODE if VBAT>Vmstr+

• VFLASH1, Vana, Vcore, Vio, and VR3 goes high

• VCTCXO enabled by VR3 -> RFClk 19.44 MHz running

2 Purx released

• Purx released by UEM, UEMINT goes high for 100 ms, SleepX

goes high, and SleepClk (32 KHz) starts running.

3 Software running

• Default value for Vcore is 1.5 volts and, if software is running, Vcore

will rise to 1.8 volts

• Cbus (1.08MHz) and Dbus clocks start running

Phone does not start up normally or does not stay on

Note: In the case of power-up faults, it is not possible to force the phone on by disabling the watchdog.

Instead, measurements should be taken immediately when the power key is pressed or when the battery voltage is connected to the phone (local / test mode).

The easiest way to check if the software is running when the phone takes an abnormal

amount of current is to measure the cbusclk and Vcore.

The Dbus clock (programmable 9.72MHz) is not automatically visible in the test and local

modes.

Page 8 Nokia Corporation Confidential Issue 1 05/2003

Page 83

RH-14

CCS Technical Documentation Troubleshooting

Figure 2: Fault tree, phone does not power up

Issue 1 05/2003 Confidential Nokia Corporation Page 9

Page 84

RH-14

Troubleshooting CCS Technical Documentation

Flash Programming does not work

Flash programming procedure

1 The phone communicates with the prommer via the production test pattern,

using the following signals:

• FBUSTX (serial data to phone)

• FBUSRX (serial da t a from phon e)

• MBUS (serial clock for FBUSRX)

• VPP (External flashing voltage for speed up flashing)

• The BSI line is also used when initializing flashing (battery connector)

2 When the phone is powered (VBAT>3V), the MBUS and FBUSTX lines are pulled

up internally by the phone.

3 The prommer sends a command to the UEM, using FBUSRX, to enter the Flash-

mode. During the sending of this command, the prommer keeps the BSI line high

and MBUS is used as a serial clock.

4 When the Flash-mode command is acknowledged, UEM enters the Flash-mode

and releases reset (PURX) to MCU.

5 After reset is released, UPP checks if there is a request for the Bootstrap code

(that resides in the UPP ROM).

6 The request for Bootstrap is the MBUS pulled down by the prommer (if the boot-

strap is not requested, the bootstrap code jumps to FLASH SW).

7 If the Bootstrap code is requested, UPP enters the Flash-mode and sets FbusTX to

'0' as an acknowledgement to the prommer. This is an indication that UPP can

run, at least, the fixed Bootstrap code – although it is not able to run the FLASH

code. UPP then sends an UPP-ID to the prommer via the FBUSTX line.

8 After the prommer has received the UPP-ID, it sends a corresponding Secondary

Boot Code to the phone via FBUSRX. The Secondary Boot Code, when run in UPP,

requests UPP to send information to the prommer about the flash type and other

HW-related parameters about the device to be flashed.

9 The prommer then sends the Algorithm Code corresponding to the HW parame-

ters, and this algorithm, when run in UPP, takes over handling the MCUSW transfer to Flash.

10 12 volts can be supplied to Vpp (by the prommer) to speed up flashing.

Page 10 Nokia Corporation Confidential Issue 1 05/2003

Page 85

RH-14

CCS Technical Documentation Troubleshooting

11 The FLASH Program includes a package of MCU and DSP software and all default

parameters for the phone. The tuning values will be added/rewritten during the

Flash/Alignment phase.

Flash programming error codes

The various error codes can be seen from the "FPS-8 Flash" in Phoenix.

The underlined text in the following table means that the item under consideration is

being used for the first time in the flashing sequence.

Error Description Not working properly

C101 "The Phone does not set FbusTx line high after the star-

tup."

C102 "The Phone does not set FbusTx line low after the line

has been high. The Prommer generates this error also

when the Phone is not connected to the Prommer."

C103 "Boot serial line fail." Mbus from Prommer->UEM-

C104 "MCU ID message sending failed in the Phone." FbusTx from UPP->UEM->Prommer

C105 "The Phone has not received Secondary boot codes

length bytes correctly."

Vflash1

VBatt

BSI and FbusRX from prommer to UEM.

FbusTx from UPP->UEM->Prommer(SA0)

PURX(also to Safari)

VR3

Rfclock(VCTCXO->Safari->UPP)

Mbus from Prommer->UEM>UPP(MbusRx)(SA0)

FbusTx from UPP->UEM->Prommer(SA1)

BSI and FbusRX from prommer to UEM.

>UPP(MbusRx)(SA1)

FbusRx from Prommer->UEM->UPP

FbusTx from UPP->UEM->Prommer

Mbus from Prommer->UEM>UPP(MbusRx)

FbusRx from Prommer->UEM->UPP

FbusTx from UPP->UEM->Prommer

C106 "The Phone has not received Secondary code bytes cor-

rectly."

C107 "The Phone MCU can not start Secondary code cor-

rectly."

C586 "The erasing status response from the Phone informs

about fail."

C686 "The programming status response from the Phone

informs about fail."

Cx81 "The Prommer has detected a checksum error in the mes-

sage, which it has received from the Phone."

Mbus from Prommer->UEM>UPP(MbusRx)

FbusRx from Prommer->UEM->UPP

FbusTx from UPP->UEM->Prommer

UPP

Flash

Flash

FbusTx from UPP->UEM->Prommer

Issue 1 05/2003 Confidential Nokia Corporation Page 11

Page 86

RH-14

Troubleshooting CCS Technical Documentation

Cx82 "The Prommer has detected a wrong ID byte in the mes-

sage, which it has received from the Phone."

A204

Cx83

Cx84

Cx85

Cx87 "Wrong MCU ID." RFClock

Startup

for

flashing

"The flash manufacturer and device IDs in the existing

Algorithm files do not match with the IDs received from

the target phone."

"The Prommer has not received Phone acknowledge to

the message."

"The Phone has generated NAK signal during data block

transfer."

"Data block handling timeout"

Required startup for flashing Vflash1

FbusTx from UPP->UEM->Prommer

Flash

UPP

VIO/VANA?

Signals between UPP-Flash

Mbus from Prommer->UEM>UPP(MbusRx)

FbusRx from Prommer->UEM->UPP

FbusTx from UPP->UEM->Prommer

UPP(Vcore)

VBatt

Charging

Note: The charging voltage and current can be checked by connecting the phone to the service software and reading the ad- converter values of the vchar and ichar.

If charging fails when the ACP-9 or the LCH-9 is used, but works with ACP-7, ACP-8, and

LCH-8, check that the charge control pin of the system connector is connected to the

ground.

Page 12 Nokia Corporation Confidential Issue 1 05/2003

Page 87

RH-14

CCS Technical Documentation Troubleshooting

Figure 3: Fault tree, charging

Audio failures

In case of audio failures, there are three possibilities to check the audio lines.

1 Make a phone call against tester and check audios.

2 If the earpiece/XMIC fails: Feed a 1Khz signal to the XMIC line and measure the

signal from the earpiece line. The Audio test box JBA-8 is needed. The Audio loop

(Audio test/Ext In Hp Out) must be switched on by the Phoenix service software.

This loop will connect audios only through the UEM. In this case, the UPP is not

used.

If the internal microphone/XEAR fails: Feed the tone to the microphone and measure the signal from the XEAR line. The Audio test box JBA-8 is needed. The

Audio loop (Audio test/Hp In Ext Out) must be switched on by the Phoenix service

software. This loop will connect audios only through the UEM. In this case, the

Issue 1 05/2003 Confidential Nokia Corporation Page 13

Page 88

RH-14

Troubleshooting CCS Technical Documentation

UPP is not used.

3 Run the audio-loop self-test with Phoenix (BB Self Tests/

ST_EAR_DATA_LOOP_TEST). This loop will test the ear-data/mic-data lines

between the UPP and the UEM.

Earpiece or external microphone line does not work

Figure 4: Fault tree, earpiece failure

Page 14 Nokia Corporation Confidential Issue 1 05/2003

Page 89

RH-14

CCS Technical Documentation Troubleshooting

Microphone or XEAR line does not work

Figure 5: Fault tree, microphone failure

Accessory detection

1 Start the phone in the normal mode when checking for accessory detection.

2 The Ad-converter value of the hookint-line can be checked with the Xmic switch

on an MJ-8 test jig. Changes normally from high to low when no accessory is

connected.

3 When the headset HDC-5 is connected, the hookint-value should be between

600 and 800.

Issue 1 05/2003 Confidential Nokia Corporation Page 15

Page 90

RH-14

Troubleshooting CCS Technical Documentation

Figure 6: Fault tree, accessory detection

Sleep Clock

Missing/nonfunctional sleep clock causes

• Entering sleep mode fails (higher current consumption -> shorter

standby time)

• Baseband self-tests cannot be run

• Phone clock (on display) does not function properly

Page 16 Nokia Corporation Confidential Issue 1 05/2003

Page 91

RH-14

CCS Technical Documentation Troubleshooting

Figure 7: Fault tree, sleep clock

Issue 1 05/2003 Confidential Nokia Corporation Page 17

Page 92

RH-14

Troubleshooting CCS Technical Documentation

User Interface

Display/Keyboard lights do not work

Figure 8: Fault tree, Display/Keyboard lights

Page 18 Nokia Corporation Confidential Issue 1 05/2003

Page 93

RH-14

CCS Technical Documentation Troubleshooting

Display does not work

Figure 9: Fault tree, Display does not work

Issue 1 05/2003 Confidential Nokia Corporation Page 19

Page 94

RH-14

Troubleshooting CCS Technical Documentation

MIDI does not work

Check speaker B180 and the following components: N180, R100, R181, R182, R183,

R184, C183, C180, C184, C181, C182, C179, L180, and L181

• No sound: Try using a known good SAL T speaker instead. If there is still

no sound, change the UEM (D200)

• Weak sound: Use the Audio test in Phoenix to set the SALT speaker

parameters (frequency, strength). If it does not affect the sound level,

change the SALT speaker.

Vibra does not work

Check spring connectors and C307 and C308.

• No vibration: Try using a known good vibra instead. If there is still no

vibration, change the UEM (D 200)

• Weak vibration: Use the Vibra test in Phoenix to set the vibra’s parameters (frequency, duty cycle). If it does not affect the magnitude of the

vibration, change the vibra.

Keyboard does not work

Check that there is no dirt between the dome sheet and the PWB. If the keyboard still

does not operate normally, try to use the Keyboard test in Phoenix to see if the pressed

key is identified. If it is not identified, change the UPP (D400).

Receiver Troubleshooting

General Instructions for RX troubleshooting

Start the Phoenix software and use it to start the required RX mode of the mobile phone.