Page 1

PAMS Technical Documentation

NHM-8NX Series Transceivers

Troubleshooting Instructions

Issue 1 05/02 ãNokia Corporation

Page 2

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

Table of Contents

Page No

Transceiver Troubleshooting ......................................................................................... 4

Troubleshooting steps ..................................................................................................4

General instructions................................................................................................... 4

Baseband Troubleshooting............................................................................................. 5

Baseband Testpoints ....................................................................................................5

Fault Finding Charts ....................................................................................................5

Phone is dead ...............................................................................................................7

Flash programming does not work ..............................................................................8

Power does not stay on or phone is jammed ................................................................9

Display information: "Contact Service" ....................................................................10

Phone does not register onto the network, or the phone cannot make a call .............11

SIM related faults ......................................................................................................12

Insert SIM card fault ............................................................................................... 12

SIM-Card rejected ................................................................................................... 13

Audio related faults ....................................................................................................14

Charging failure .........................................................................................................16

RF Troubleshooting ..................................................................................................... 18

General description of the RF circuits..................................................................... 18

Receiver................................................................................................................... 24

General Instructions for GSM900 RX Troubleshooting ......................................... 24

Fault Finding Chart for GSM900 Receiver............................................................. 26

General Instructions for GSM1800 RX Troubleshooting ....................................... 27

Fault Finding Chart for GSM1800 Receiver........................................................... 29

Measurement points in the receiver ........................................................................ 31

Transmitter .................................................................................................................32

Measurement points for the transmitter .................................................................. 32

General instructions for GSM TX troubleshooting................................................. 33

Fault finding chart for GSM900 transmitter ........................................................... 34

PCN TransmitterGeneral instructions for PCN TX troubleshooting ...................... 37

Synthesizer .................................................................................................................39

General instructions for Synthesizer troubleshooting ............................................. 39

26 MHz Reference Oscillator ( VCXO )................................................................. 39

VCO ........................................................................................................................ 41

Fault finding chart for PLL Synthesizer.................................................................. 41

Measurement points for the PLL............................................................................. 42

Frequency lists......................................................................................................... 45

Alignment ..................................................................................................................47

NHM-8NX manual align with Phoenix .................................................................. 47

RX calibration ............................................................................................................47

RX channel select filter .............................................................................................49

RX Band Filter Response ..........................................................................................50

Tx Power tuning ........................................................................................................51

TX power tuning GSM............................................................................................ 52

TX power tuning PCN............................................................................................. 55

I/Q tuning ...................................................................................................................57

RF control ..................................................................................................................59

Page 2 ãNokia Corporation Issue 1 05/02

Page 3

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

Call testing .................................................................................................................60

List of Figures

Page No

Fig 1 Receiver signal path ...................................................................................................19

Fig 2 Transmitter signal path ...............................................................................................20

Fig 3 Synthesiser..................................................................................................................21

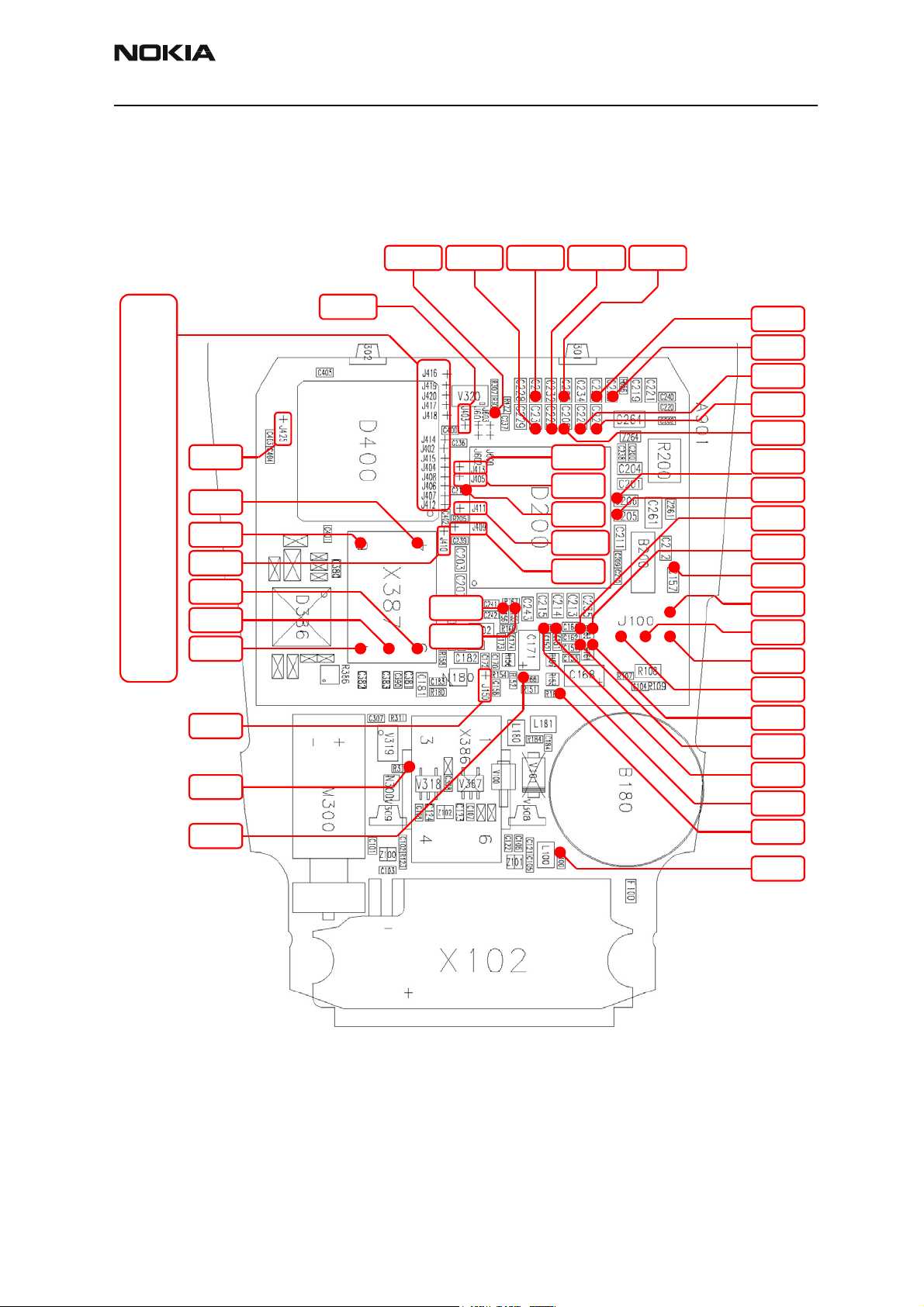

Fig 4 Key component location.............................................................................................22

Fig 5 Power supply configuration........................................................................................23

Fig 6 Supply points at UEM (D200)...................................................................................24

Fig 7 Supply point at Mjoelner (N600) ...............................................................................24

Fig 8 EGSM Receiver fault finding chart............................................................................26

Fig 9 RX900 I/Q signal waveform ......................................................................................27

Fig 10 GSM1800 receiver fault finding chart......................................................................29

Fig 11 RX1800 I/Q signal waveform ..................................................................................30

Fig 12 RX measurements point at the RX/TX Switch - Z700.............................................31

Fig 13 Measurements points at the RX-Filters – Z601/Z602 ..............................................31

Fig 14 RX I/Q Signals, Baseband shielding can UEM (D200) ...........................................32

Fig 15 TX measuremnet points in the PA ( N700 ) shielding can.......................................32

Fig 16 EGSM900 transmitter fault finding chart.................................................................35

Fig 17 VPCTRL_G & TXC.................................................................................................36

Fig 18 GSM1800 transmitter fault finding chart .................................................................38

Fig 19 VPCTRL_P & TXC ................................................................................................39

Fig 20 VCXO 26 MHz waveform .......................................................................................40

Fig 21 PLL fault finding chart .............................................................................................41

Fig 22 Measurement point for VCXO supply .....................................................................42

Fig 23 Measurement point for VCXO output......................................................................43

Fig 24 Measurement point for PLL .....................................................................................43

Issue 1 05/02 ãNokia Corporation Page 3

Page 4

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

Transceiver Troubleshooting

Troubleshooting steps

The following hints should help to find the cause of the problem when the circuitry

seems to be faulty. This trouble shooting instruction is divided into sections.

1 Phone is totally dead

2 Power does not stay on or the phone is jammed

3 Flash programming does not work

4 Display is not working

5 Plug in SIM card is out of order (insert SIM card).

6 Audio fault

7 Charging fault

The first thing to do is carry out a through visual check of the module. Ensure in particular that:

a) there are no mechanical damages

b) soldered joints are OK.

General instructions

Most semiconductors are static discharge sensitive! ESD protection must be taken care

of during repair (ground straps and ESD soldering irons). Mjoelner, PA, UEM, UPP, and

Flash are moisture sensitive and must be pre-baked prior to soldering, if they have been

out of their vacuum package longer than the specified time.

• Connect test jig (MJS-37) to computer with DAU-9S cable or to FPS-8 Flash

Prommer with AXS-4 serial cable.

• Make sure that you have PKD-1 dongle connected to computer’s parallel port.

• Connect DC power supply to module test jig (MJS-37) with FLC-2 cable.

• Set the MJS-37 supply voltage to 8-12VDC. If the input-voltage exceeds 12VDC,

the MJS-37 jig may be damaged.

Note: By default the MJS-37 supplies the phone with 4.1VDC. If other output voltages is

needed, it is possible to modify MJS-37 to support this by removing R110 and mount S104.

See MJS-37 schematic for more info.

• When doing BB energy management (EM) calibrations use JBV-1 jig and DC supply voltage 12 – 15 V.

• JBV-1’s current consumption is ~ 40 mA with 3.9 V supply voltage and ~ 80

• Set the phone module to test jig (MJS-37) and start Phoenix service software.

Initialize connection to phone (use FBUS driver when using DAU-9S and COMBOX driver when using FPS-8).

mA with 15 V supply voltage.

Page 4 ãNokia Corporation Issue 1 05/02

Page 5

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

Baseband Troubleshooting

Baseband Testpoints

Baseband testpoint PWB Placement

R306

DLIGHT

C230

VREFRF02

C231

VREFRF01

C222

VR4

C225

VR6

J416

EXTWRX

-

J419

FLSCLK

-

J420

FLSCSX

-

J417

EXTRDX

-

J418

FLS2CSX

-

J414

DBUSDA

-

J402

PURX

-

J413

DBUSEN1X

-

J404

SLEEPCLK

-

J408

CBUSENX

-

J406

CBUSCLK

-

J407

CBUSDA

-

J412

FBUSRX

J425

RFCLK

4

GND

6

SIM I/O

J410

MBUSRX

3

VSIM

2

RST

1

CLK

J150

HOOKINT

R310

KLIGHT

R166

MICB2

J403

SLEEPX

C156

MIC2P

C155

MIC2N

J413

DBUSCLK

J405

UEMINT

C218

VIO

J411

FBUSTX

J409

MBUSTX

C226

VR5

C223

VR2

C227

VR3

C224

VR7

C208

VCORE

C206

VANA

C205

VFLASH1

R183/1

HFCM

R183/2

HF

C157

HEADINT

PRODTP6

VPP

PRODTP7

MBUS

PRODTP2

FBUS TX

PRODTP3

FBUS RX

R161/1

EARP

R161/2

EARN

R164

MIC1N

R164

MIC1P

R165

MICB1

C100

VCHARIN

Fault Finding Charts

In this section, fault finding charts are provided for the most common NHM-8NX errors.

NOTE : Since both D200 (UEM) and D400(UPP) is underfilled, they can not be

replaced. If either D200 or D400 is defective, the whole PWB has to be dis-

Issue 1 05/02 ãNokia Corporation Page 5

Page 6

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

carded.

Page 6 ãNokia Corporation Issue 1 05/02

Page 7

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

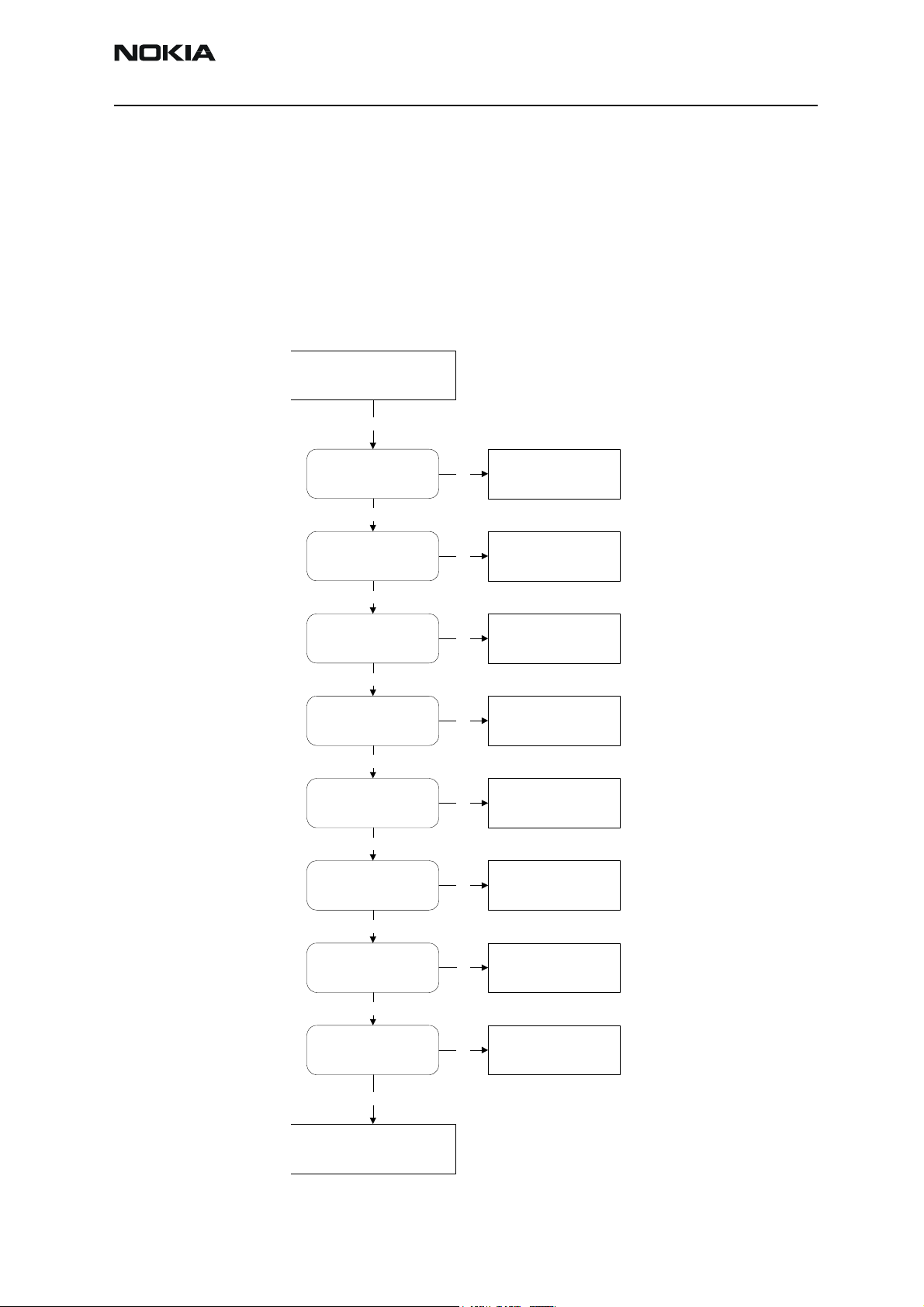

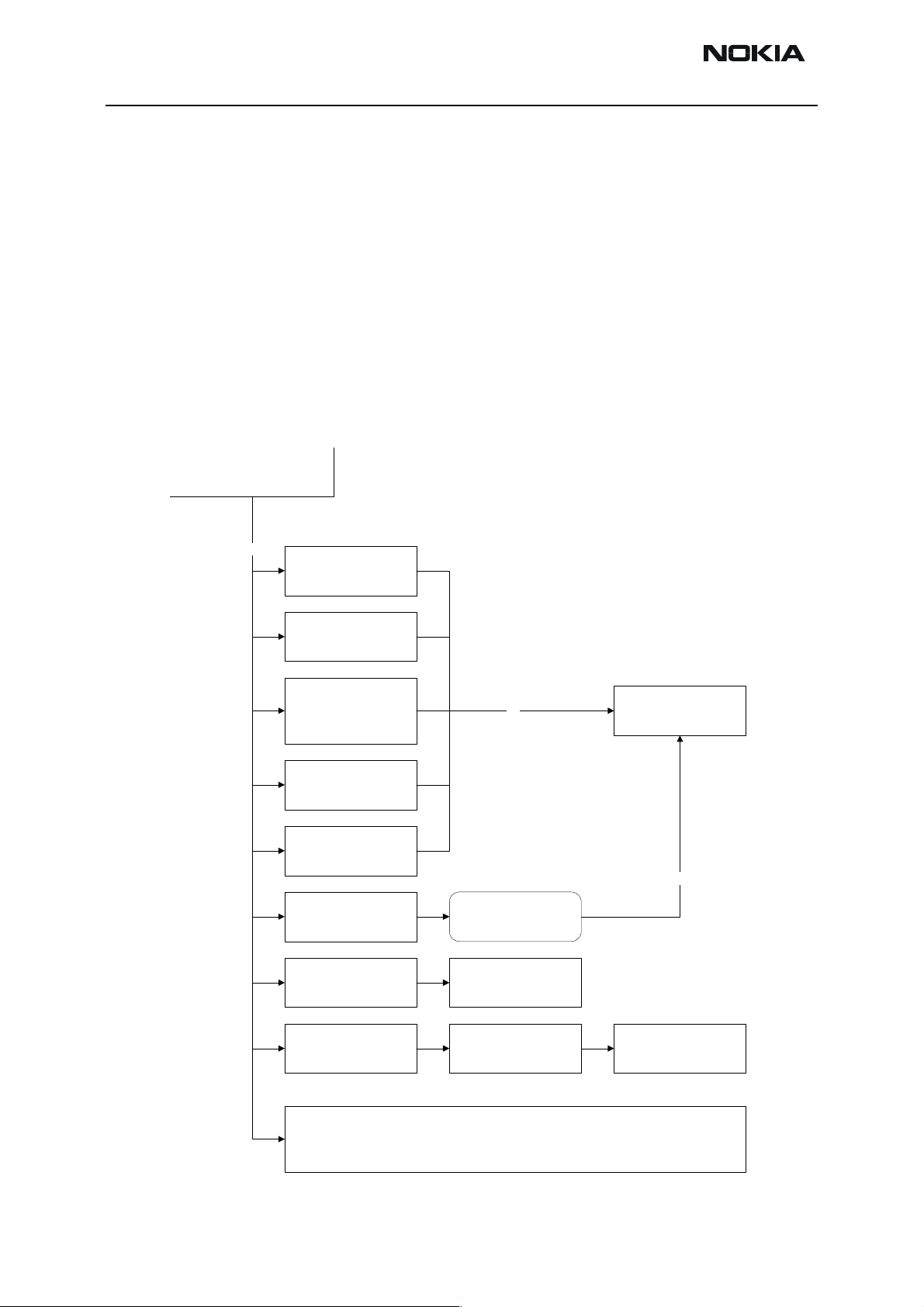

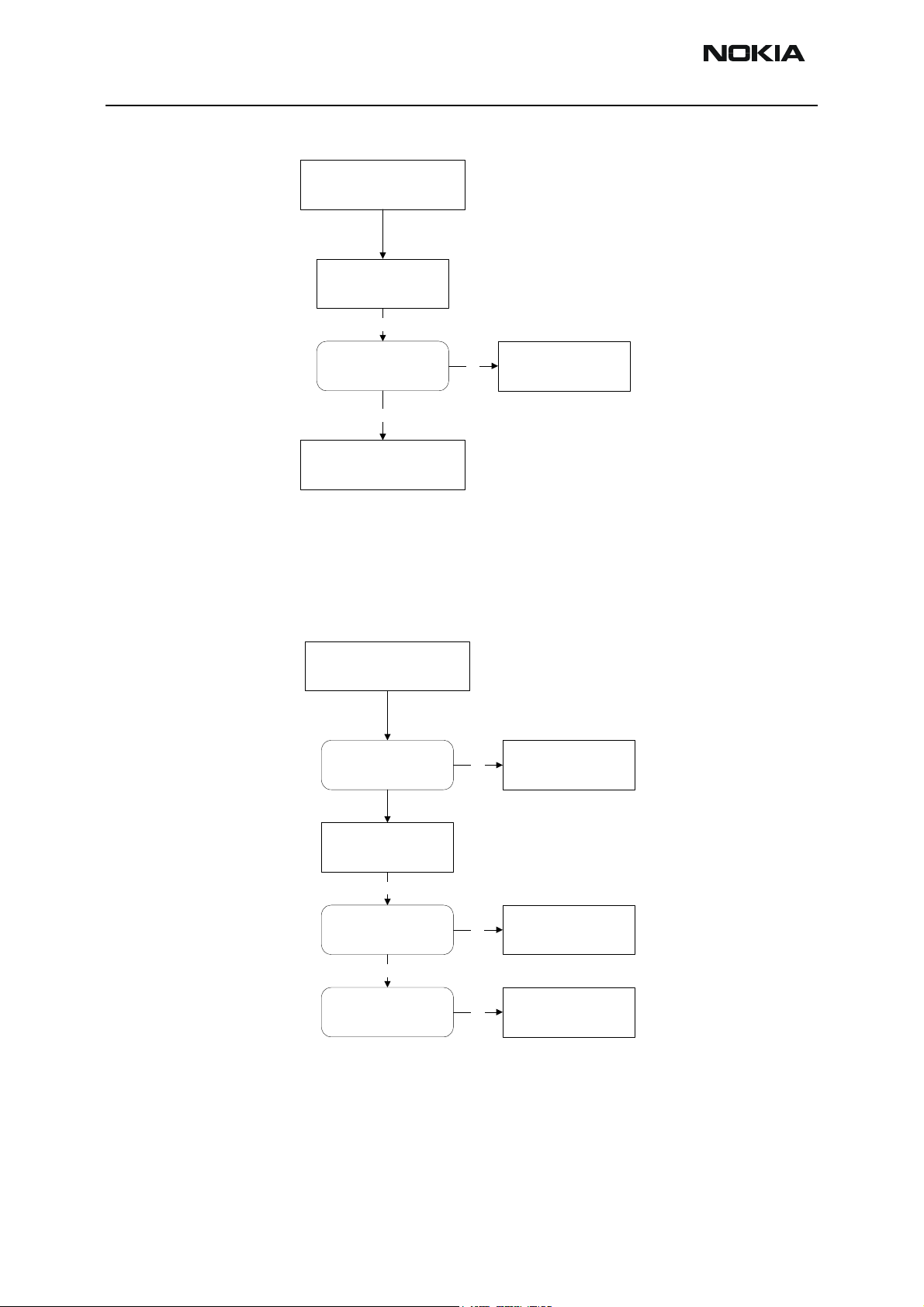

Phone is dead

This means that the phone do not draw any current at all when supply is connected and/

or powerkey is pressed.

It is assumed that the voltage supplied is 3.6 VDC. The UEM will prevent any functionality what so ever at battery/supply levels below 2.9 VDC

Phone is dead

Yes

X101

VBAT = 3,6VDC

Yes

Z261, C261, Z264,

C264

Voltage = 3,6VDC

Yes

S300

Pin 1 & 3 is HIGH when

power-key is untouched

Yes

S300

Pin 1 & 3 is 0VDC(LOW)

when power-key is pressed

Yes

J404

Sleep-clock is

32.768 kHz, 1,8Vpp

Yes

J402

PURX = 1,8VDC,

1 sec. after power-key

is pressed

Yes

No

No

Z261, C261, Z264, C264

No

No

No

B200, C209, C210, PWB.

No

Check :

X101

Check :

Check :

R317, C310

Check :

S300, PWB

Check :

Else defective D200*

Check :

PWB.

Else defective D200*

C227

VR3 = 2,78VDC

Yes

J425

26 MHz clock min.

300mVACpp,

probe Cin=10-13 pF/10M

Yes

Check :

D450 (Flash).

Else defective D200*

No

No

Check :

C227, PWB.

Else defective D200*

Check :

C227, PWB.

Else defective D200*

Issue 1 05/02 ãNokia Corporation Page 7

Page 8

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

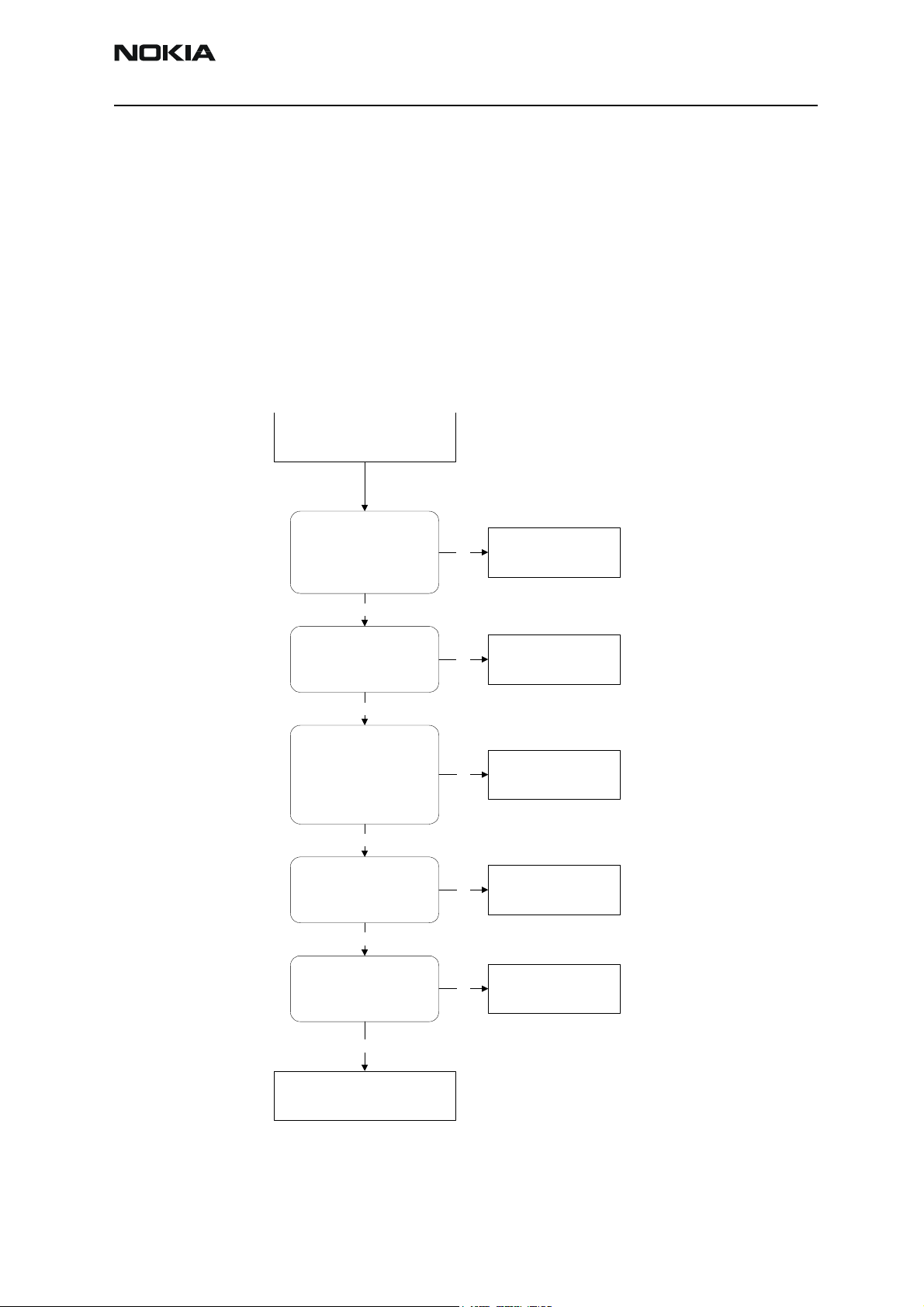

Flash programming does not work

The flash programming can only be done via the pads on the PWB (J100).

In case of Flash failure in FLALI station, problem is most likely related to SMD problems.

Possible failures could be short-circuit of balls under µBGAs (UEM, UPP, FLASH). Missing

or misaligned components.

In flash programming error cases the flash prommer can give some information about a

fault.

The fault information messages could be:

- Phone doesn't set FBUS_TX line low

Because of the use of uBGA components it is not possible to verify if there is a short circuit in control- and address lines of MCU (UPP) and memory (flash).

Flash prgramming

do not work

Error from prommer:

"Phone doesn't set

FBUS_TX line low"

Yes

J100, R108

Check connection between

pad 1,2 & 3 on J100

and R108

Yes

J409, J410, J411, J412

Voltage level at 1,8VDC

Yes

Try reading MCU ID

with Phoenix.

Reading OK?

Yes

Try reading Flash ID

with Phoenix.

Reading OK?

No

No

No

No

Check :

R108, PWB

Check :

PWB.

Else defective D200*

Check :

PWB.

Else defictive D400*

Check :

Replace D450

Yes

Reflash phone

Page 8 ãNokia Corporation Issue 1 05/02

Page 9

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

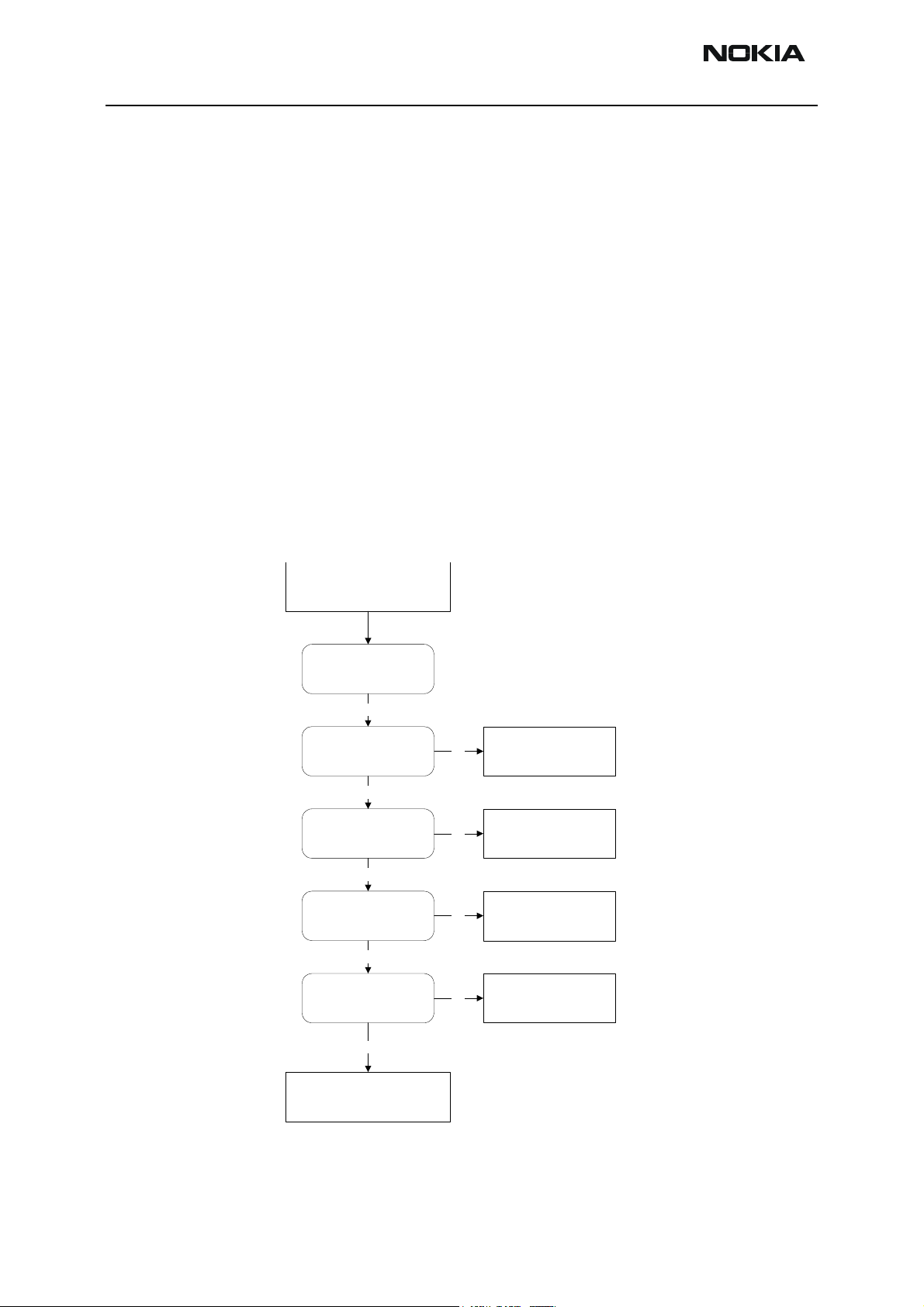

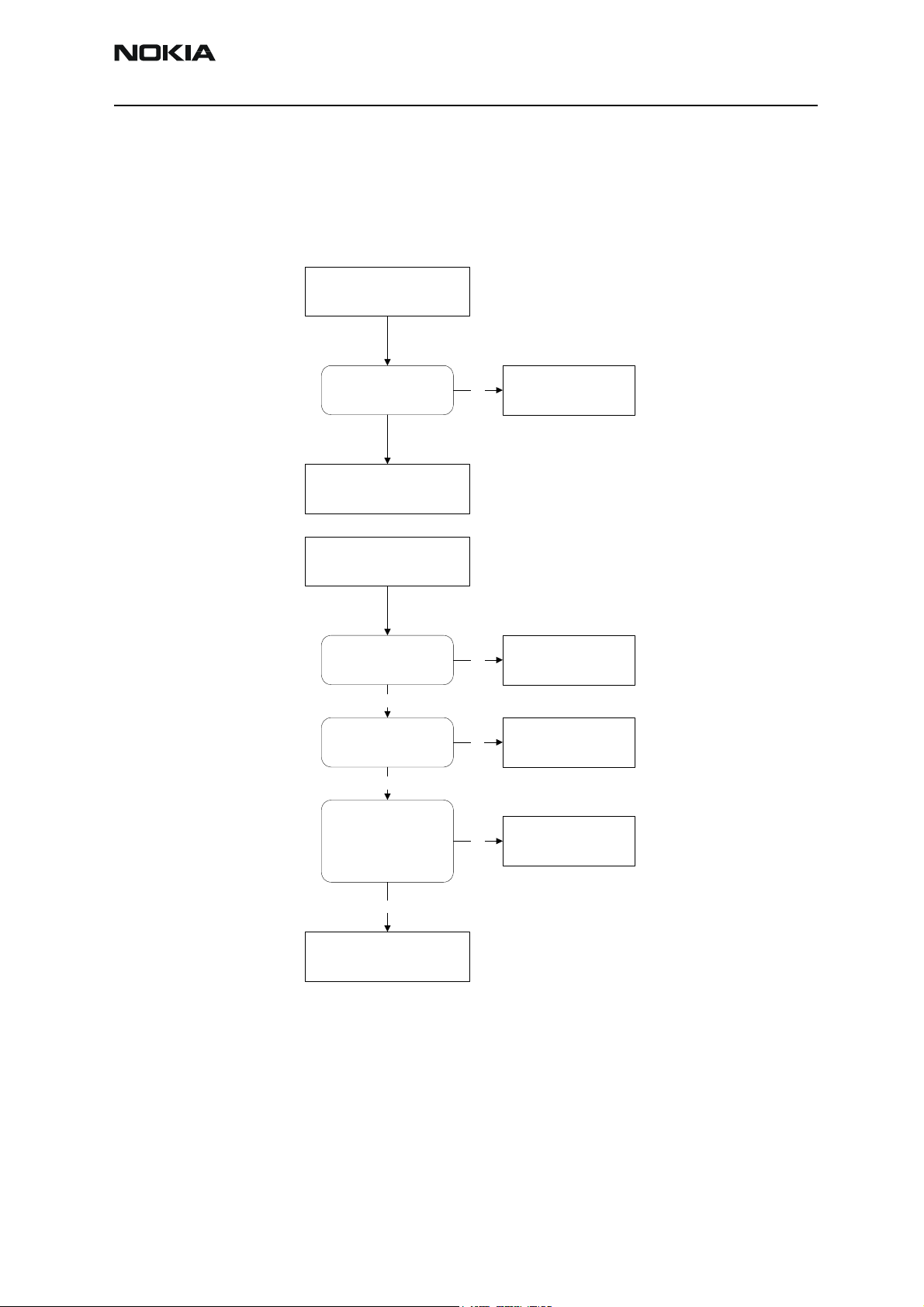

Power does not stay on or phone is jammed

If this kind of failure is presenting itself immediately after FLALI, it is most likely caused

by ASICs missing contact with PWB.

If for some reason the MCU does not service the watchdog register within the UEM, the

operations watchdog will run out after approximately 32 seconds. Unfortunately, the

service routine can not be measured.

Power doesn't stay on,

or phone is jammed

J404

Sleep clock = 32.768 kHz,

1.8Vpp

Yes

J402

PURX = 1,8VDC,

1 sec. after power-key is

pressed

Yes

UI functionality,

and keys react

to pressure?

Yes

J425

26 MHz clock min.

300mVACpp,

probe Cin=10-13 pF/10M

Yes

Reflash phone

No

B200, C209, C210, PWB.

No

No

No

Check :

Else defective D200*

Check :

PWB.

Else defictive D200*

Check :

D450, Keymat,

Lightguide, PWB.

Else defective D400*

Check :

C425, C426, R425,

R426, N600(Mjoelner)

Issue 1 05/02 ãNokia Corporation Page 9

Page 10

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

Display information: "Contact Service"

This error can only happen at power up where several self-tests is run. If any of these test

cases fails the display will show the message: "Contact Service".

It's individual test cases so the below lineup of error hunting's has no chronological

order. Use common sense and experience to decide which test case to start error hunting

at.

Display shows

"Contact Service"

Yes

AuxDa & UEMInt

SleepX & SleepClk

between UPP & UEM?

TXI/QD & RXI/QD?

SIM interface between

EarDa & MicDa

between

UPP and UEM?

MBUS interface

between

UPP and UEM?

between

UPP and UEM?

UPP & UEM

Key is stucked

No

R205

Check R205

(no short/open-circuit)

Check :

A-cover, Keymat, Lightguide,

PWB.

Check :

PWB.

Else defective D200*

or D400*

Error still present

Flash checksum

ASIC version vs. compilation flag, PMM checksum

PMM validity

Warrenty Information State

SIM-Lock

Reflash phone

Check :

Else defective D450 (FLASH)

PWB.

Page 10 ãNokia Corporation Issue 1 05/02

Page 11

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

Phone does not register onto the network, or the phone cannot make a call

If the phone doesn't register to the network, the fault can be in either BB or RF. Only few

signals can be tested since several signals is 'burried' in one or more of the inner layers of

the PWB.

First of all check that SIM LOCK is not causing the error by using a Test-SIM card and

connect the phone to a tester.

Phone do not register to

or phone cannot make a call

network

C222, C233, C224, C225,

C226, C227

Voltage = ~2,78VDC

All during GSM frame-

call mode.

Use TXP on C646 as trigger

Yes

C230, C231

Voltage = ~1,35VDC

All during GSM frame (call mode)

Use TXP on C646 as trigger

Yes

J608, J609, J610

Check RF serial bus during

GSM-frame :

Logic HIGH = 1,8VDC

Logic LOW = 0VDC

RFBUSCLK (J608),

RFBUSDA (J609),

RFBUSEN1X (J610)

Yes

R601, R603

Check analog signals during

GSM-frame (RX slot):

RXIP/N (R601) = 0-1,45VDC

RXQP/N (R603) = 0-1,45VDC

Yes

R610, R611

Check analog signals during

GSM-frame (TX slot):

TXIP/N (R610) = 1-1,75VDC

TXQP/N (R611) = 1-1,75VDC

C222,C223, C224, C225,

No

No

No

No

No

C226, C227, PWB.

Else defective D200 or D400*

C230, C231, PWB.

Else defective

D200* or D400*

Else defective D200*

Else defective D200*

R610, R611,PWB.

Else defective D200*

Check :

Check :

Check :

PWB.

or D400*

Check :

PWB.

or D400*

Check :

or D400*

Yes

Check RF

Issue 1 05/02 ãNokia Corporation Page 11

Page 12

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

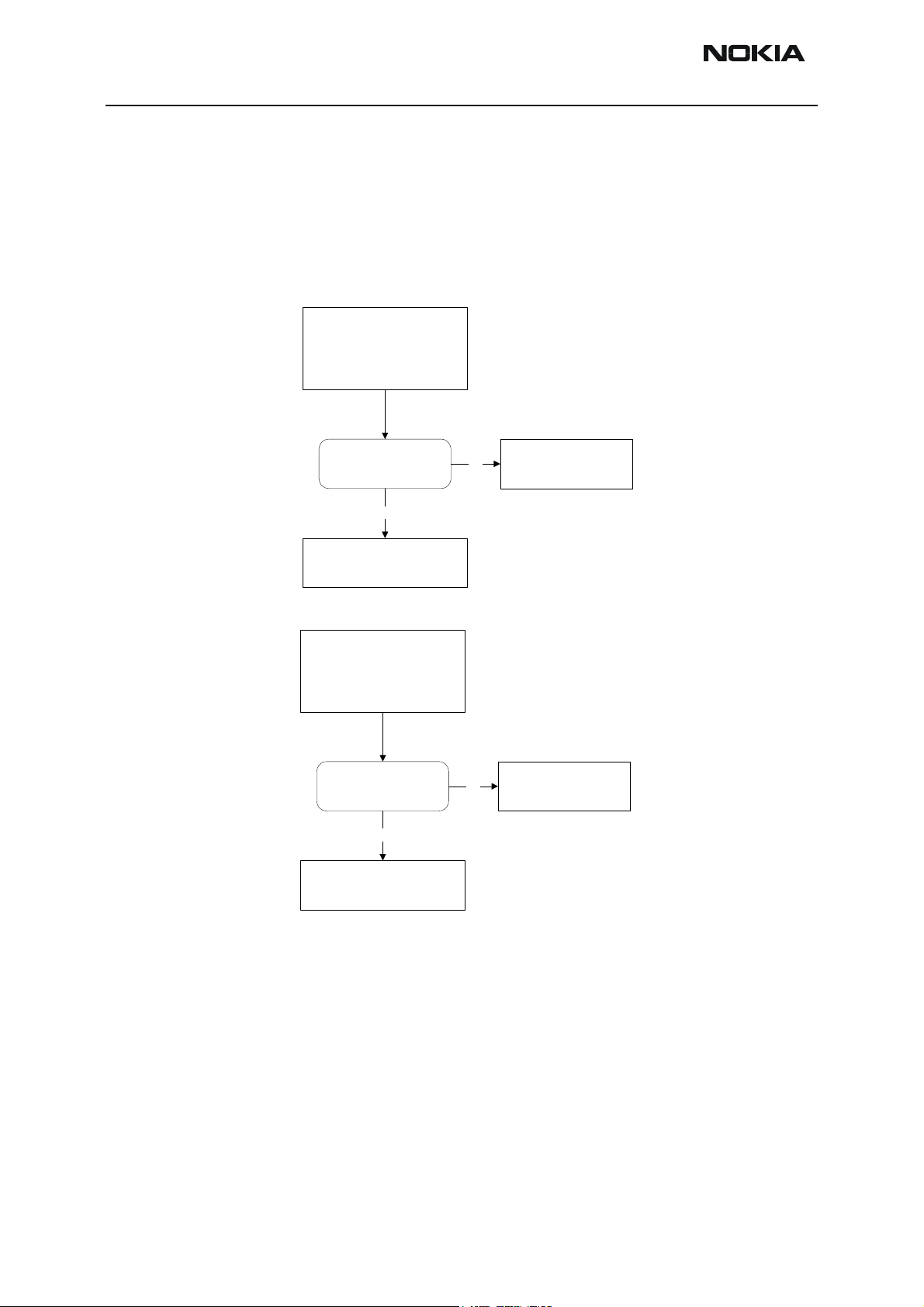

SIM related faults

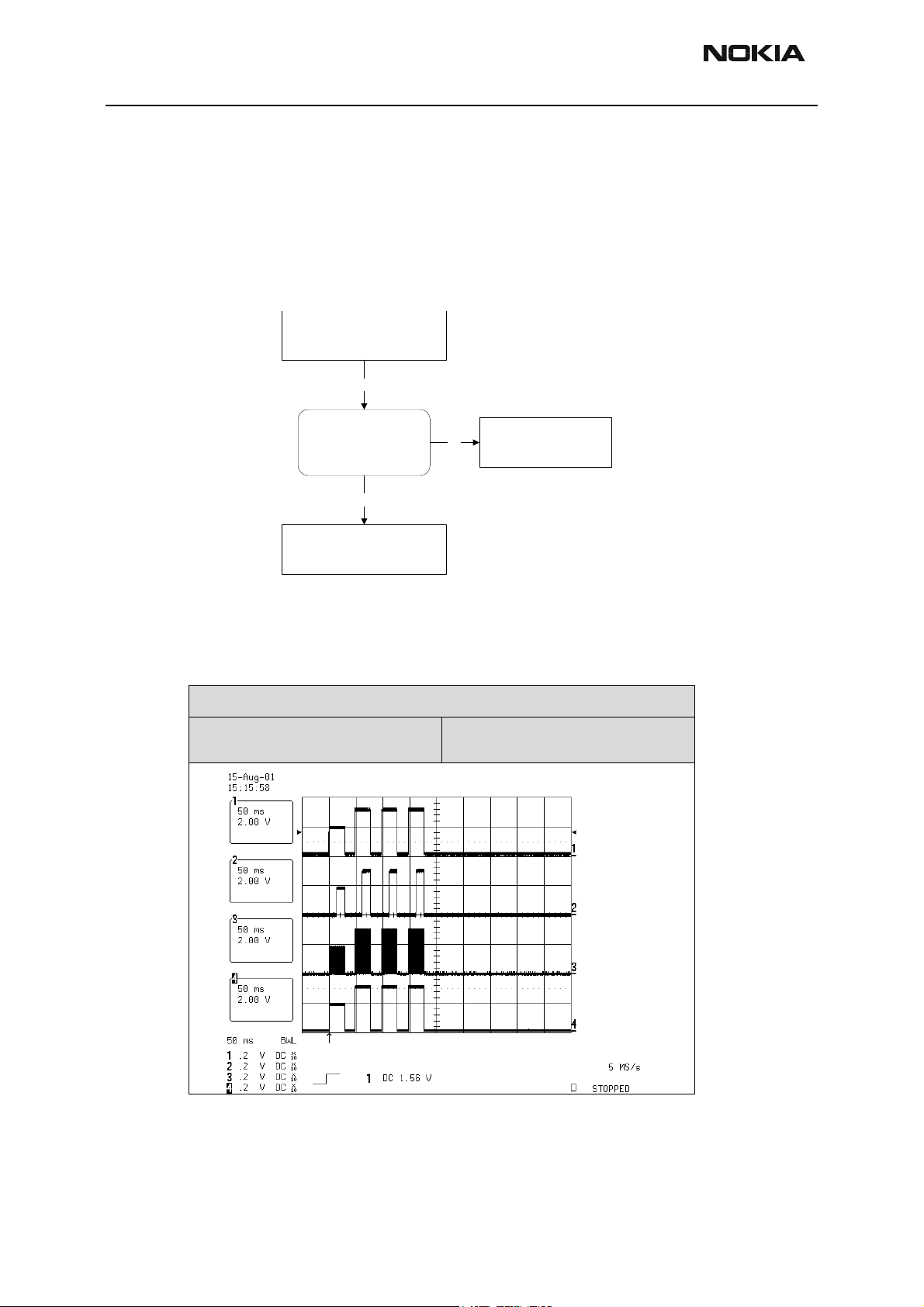

Insert SIM card fault

The hardware of the SIM interface from UEM (D200) to the SIM connector (X387) can be

tested without a SIM card. When the power is switched on the phone first check for a

1,8V SIM card and then a 3V SIM card. The phone will try this four times, whereafter it

will display ”Insert SIM card”.

Display shows :

"Insert SIM Card"

Yes

Check for SIM voltage during power-up

Ch1 : VSIM

Ch2 : RESET

X387

Verify that phone checks for

1,8V-SIM, and then 3V-SIM

during power-up.

(See illustration below)

Yes

SIM Interface OK

No

Check :

X387, R386, PWB.

Else defective D200*

Ch3 : CLOCK

Ch4 : DATA

Page 12 ãNokia Corporation Issue 1 05/02

Page 13

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

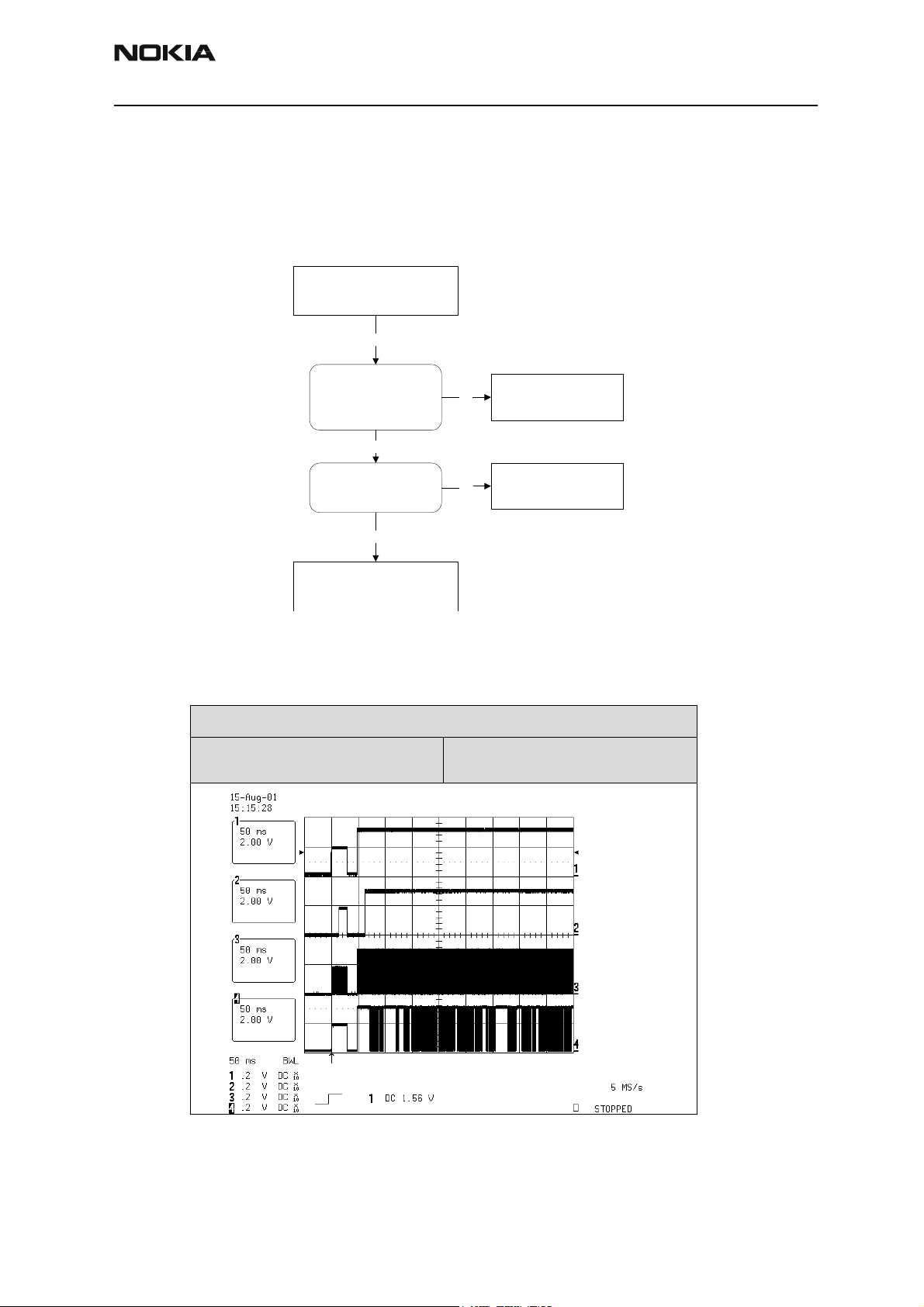

SIM-Card rejected

The error ”SIM card rejected” means that the ATR message received from SIM card is corrupted, e.g. data signal levels are wrong. The first data is always ATR and it is sent from

card to phone.

Display shows :

"SIM Card Rejected"

Yes

VSIM = min. 1,6V(1,8V Card)

X387

VSIM = min. 2,8V(3V Card)

(See illustration below)

Yes

X387

ATR data can be seen at

SIM data pin.

Yes

SIM Interface OK

No

No

Check :

R386, PWB.

Else defective D200*

Check :

X387, R386, PWB.

For reference a picture with normal SIM power-up is shown below.

Normal SIM power-up sequence

Ch1 : VSIM

Ch2 : RESET

Ch3 : CLOCK

Ch4 : DATA

Issue 1 05/02 ãNokia Corporation Page 13

Page 14

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

Audio related faults

Earpiece do not work

Replace :

Earpiece

Error still present

Z150, R161

Check Z150, R161 is

working correctly

(no short/open-circuit)

Yes

Defective D200*

No

Check :

R386, PWB.

Else defective D200*

Microphone do not work and

the isn't any mechanical

problem

C103, Z100

Check C103, Z100 is

working correctly

(no short/open-circuit)

Replace :

System Connoctor

Error still present

R165

Check voltage level on

R165 towards UEM (bias)

= 2,1V

Yes

R153

Check voltage level on

R153 towards mic-lines (bias)

= 1,0V - 1,4V

No

No

No

R153, R157,C151, C152,

Replace :

C103 and/or Z100

Check :

R165, C168, PWB.

Else defctive D200*

Check :

C153, C154, PWB.

Page 14 ãNokia Corporation Issue 1 05/02

Page 15

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

Headset earpiece do not

work and the isn't any

mechanical problem

R183, Z102

Check R183, Z102 is

working correctly

(no open-circuit)

Defective D200*

Headset microphone do not

work and the isn't any

mechanical problem

R166

Check voltage level on R166

towards UEM (bias) = 2,1V

Yes

R151

Check voltage level on R151

towards UEM (bias)

= 1,0V - 1,4V

Yes

R152, R165, R168,

C155, C156, C172,

C170, C173, C174,

Z101

Check XMIC line to UEM

(D200)

No

No

No

No

Replace :

C183 and/or Z102

Replace :

C183 and/or Z102

Check :

R166, R151, C171

Replace :

Defective component

Error still present

Defective D200*

Issue 1 05/02 ãNokia Corporation Page 15

Page 16

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

Charging failure

Phone is OFF - battery is

completely empty

(<=3,1VDC)

and no current from

charger when connected

L100

VCHAR > 2,1VDC

Yes

Defective D200*

Phone is ON or OFF - battery

nominal voltage (~3,6VDC)

and no current from

charger when connected

L100

VCHAR > 3,6VDC

Yes

Defective

D200 or D400*

No

F100, L100, V101, C100,

R200, System-connector.

No

F100, L100, V101, C100,

R200, System-connector.

Check :

Check :

Page 16 ãNokia Corporation Issue 1 05/02

Page 17

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

Display info when

charger is connected :

"Not charging"

R206

Voltage on R206 towards

D200 is ~0,8VDC

when power is connected.

(BSI must be 75K)

Yes

No

Check :

X101, R202, R206, C240.

Voltage (use scope) on R207

R207

towards D200 is ~0,9VDC at

peak.

(BTEMP must be 47K)

Yes

R200

Voltage on R200 towards

D200 same as VBAT voltage

Yes

R200

Voltage rises slowly on

R200 towards D200 when

charger is connected.

Yes

Check :

PWB

No

No

No

Check :

X101, R202, R207, C220.

Check :

R200, PWB.

Else defective D200*

Check :

PWB.

Else defective D200*

Issue 1 05/02 ãNokia Corporation Page 17

Page 18

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

RF Troubleshooting

Two types of measurements are used in the following. It will be specified if the measurement type is "RF" or "LF".

• RF measurements should be done with a Spectrum Analyser and a high-frequency 500 ohm passive probe, for example HP54006A. (Note that when measuring with the 500 ohm probe the signal will be around 20 dB attenuated. The

values in the following will have these 20 dB subtracted and represent the real

value seen on the spectrum analyser).

Note that the testjig have some losses which must be taken into consideration when

calibrating the test system.

• LF (Low frequency) and DC measurements should be done with a 10:1 probe and

an oscilloscope. The probe used in the following is 10MW/8pF passive probe. If

using another probe then bear in mind that the voltages displayed may be

slightly different.

Always make sure the measurement set-up is calibrated when measuring RF parameters

on the antenna pad. Remember to include the loss in the module repair jig when

realigning the phone.

Most RF semiconductors are static discharge sensitive. So ESD protection must be

taken during repair (ground straps and ESD soldering irons). Mjoelner and Bifrost is moisture sensitive so parts must be pre-baked prior to soldering.

Apart from key-components described in this document there are a lot of discrete components (resistors, inductors and capacitors) for which troubleshooting is done by checking if soldering of the component is done properly and checking if the component is

missing from PWB. Capacitors can be checked for short-circuiting and resistors for value

by means of an ohmmeter, but be aware in-circuit measurements should be evaluated

carefully.

In the following both the name EGSM and GSM900 will be used for the lower band and

both PCN and GSM1800 will be used for the upper band.

General description of the RF circuits

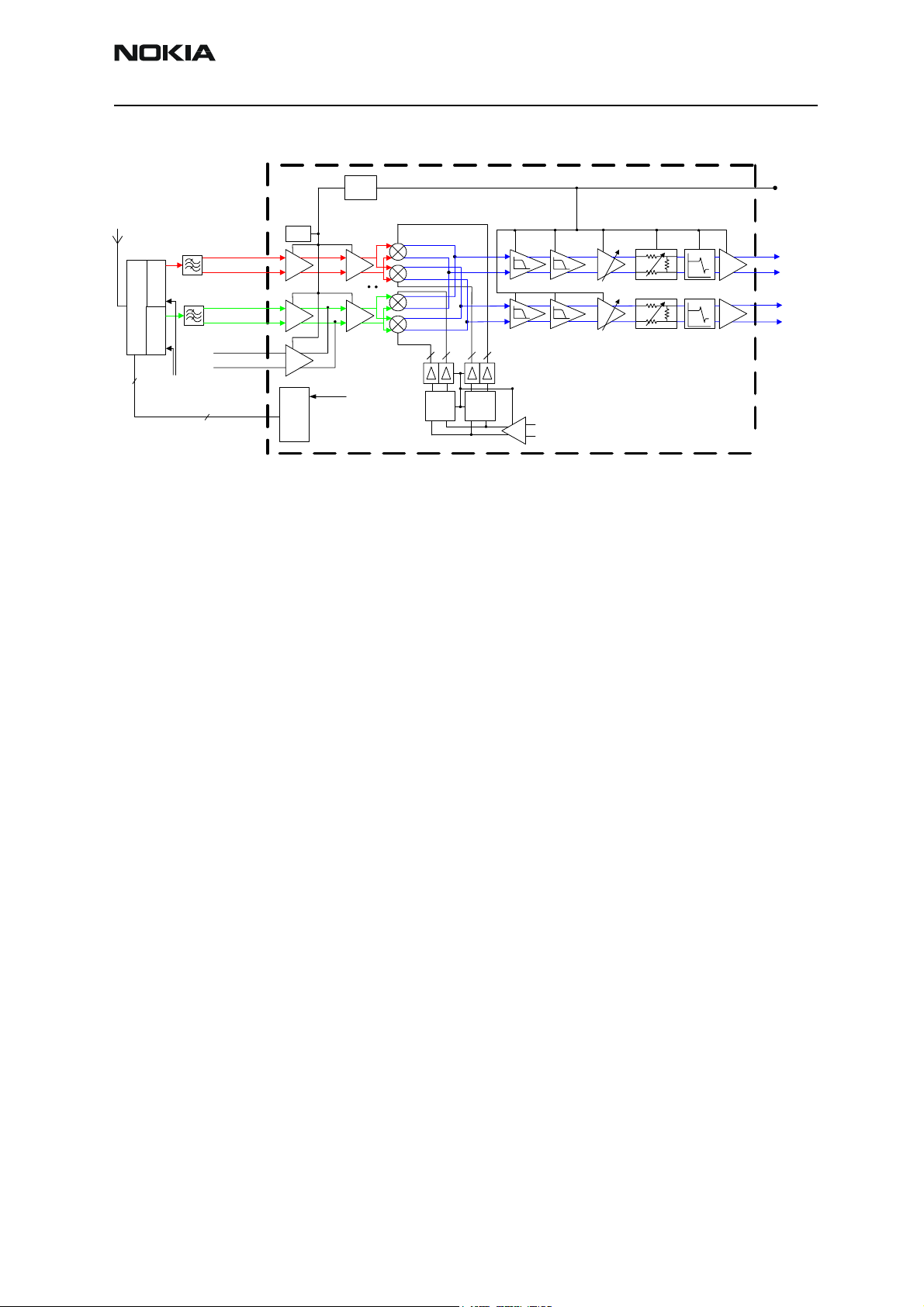

In the following general descriptions different colours are used in the block diagram. The

GSM 900 signal route is shown in red, the GSM1800 route in green and the common signal lines are shown in blue. Signal lines which is common for both

Receiver signal path

The signal from the antenna pad is routed to the RX/TX switch ( Z700). If no control voltage is present at VANT2 and VANT1 the switch works as a diplexer and the GSM900 signal is passed through the RX/TX switch to GSM-RX and the GSM1800 signal is passed to

DCS-RX.

Page 18 ãNokia Corporation Issue 1 05/02

Page 19

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

Figure 1: Receiver signal path

RX

Supply

filter

F

X

R

D

D

V

LNA

RX/TX

Z700

Ant

2

SAW

Z602

SAW

Z601

RX900

RX1800

RX1900

2

VANTL / VANTM

RX

GSM

TX

RX

Switch

PCN

TX

INPL

INML

INPM

INMM

INPH

INMH

Bias

LNA

LNA

LNA

RF

Controls

VDDDIG

Pregain

Pregain

22 22

1/2 1/4

BBAMP

BBAMP

LPF1

LPF1

B

B

X

R

D

D

V

DCN1

DCN1

Mjoelner

N600

BIQUAD

AGC

LPF2

BIQUAD

AGC

LPF2

From the RX/TX switch the GSM900 signal is routed to the SAW filter (Z602). The purpose of the SAW filter is to provide out-of band blocking immunity and to provide the

LNA in Mjoelner (N600) with a balanced signal. The front end of Mjoelner is divided into

a LNA and Pre-Gain amplifier before the mixers.

DCN2

DCN2

VRX

VR6

RXIP

RXIM

RXQP

RXQM

The output from the mixer is feed to Baseband part of Mjoelner where the signals amplified in the BBAMP and low pass filtered in LPF1 before the DC compensation circuits in

DCN1. The DCN1 output is followed by a controlled attenuator and a second lowpass filter LPF2. The output from LPF2 is DC centered in DCN2 before being feed to the BB for

demodulation.

The GSM1800 signal chain is similar to GSM900, the SAW filter numbered Z601.

Transmitter signal path

The I/Q signal from the BB is routed two the modulators for both 900 and 1800 MHz. The

output of the modulators is either terminated in a SAW filter ( Z603 ) for GSM 900 or a

balun for GSM1800. Both signals are amplified in buffers whereby a limiting effect takes

place to suppress some of the AM contents of the signal. The amplitude limited signal is

then amplified in the PA (N700) where the gain control takes place. In order to control

the TX level a sample of the signal is taken in a directional coupler ( L709 for GSM900

and L704 for GSM1800) and used in the power loop amplifier in Mjoelner to establish

the right output power. The TX signal from the couplers is feed to the RX/TX switch, used

to select which signal to route to the antenna.

Issue 1 05/02 ãNokia Corporation Page 19

Page 20

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

Figure 2: Transmitter signal path

2

Ant

Switch

RX/TX

Z700

RX

GSM

TX

RX

PCN

TX

L704

Dir.

Coupler

L709

DET

VBATTRF

PA

N700

PCN

V701

Buffer

Buffer

EGSM

V702

VANTL / VANTM

2

Balun

VTX

SAW

Z603

PWloop

filter

VPCH/VPCL

VANTH

VB_DET

VTXLOL

VTXLOH

VTXBH

VTXBL

DET

PLFB1

PLFB2

2

Controls

Controls

OUTHP

OUTHM

OUTLP

OUTLM

VDDDIG

RF

VDDRXBB

RF

PWC

TXC

TXP

TX

P

VDDTX

Supply

filter

VTX

TX

VR2

C

Mjoelner

N600

1/2

2

2

2

TXQM

TXQP/

1/4

2

2

2

TXIM

TXIP/

PLL

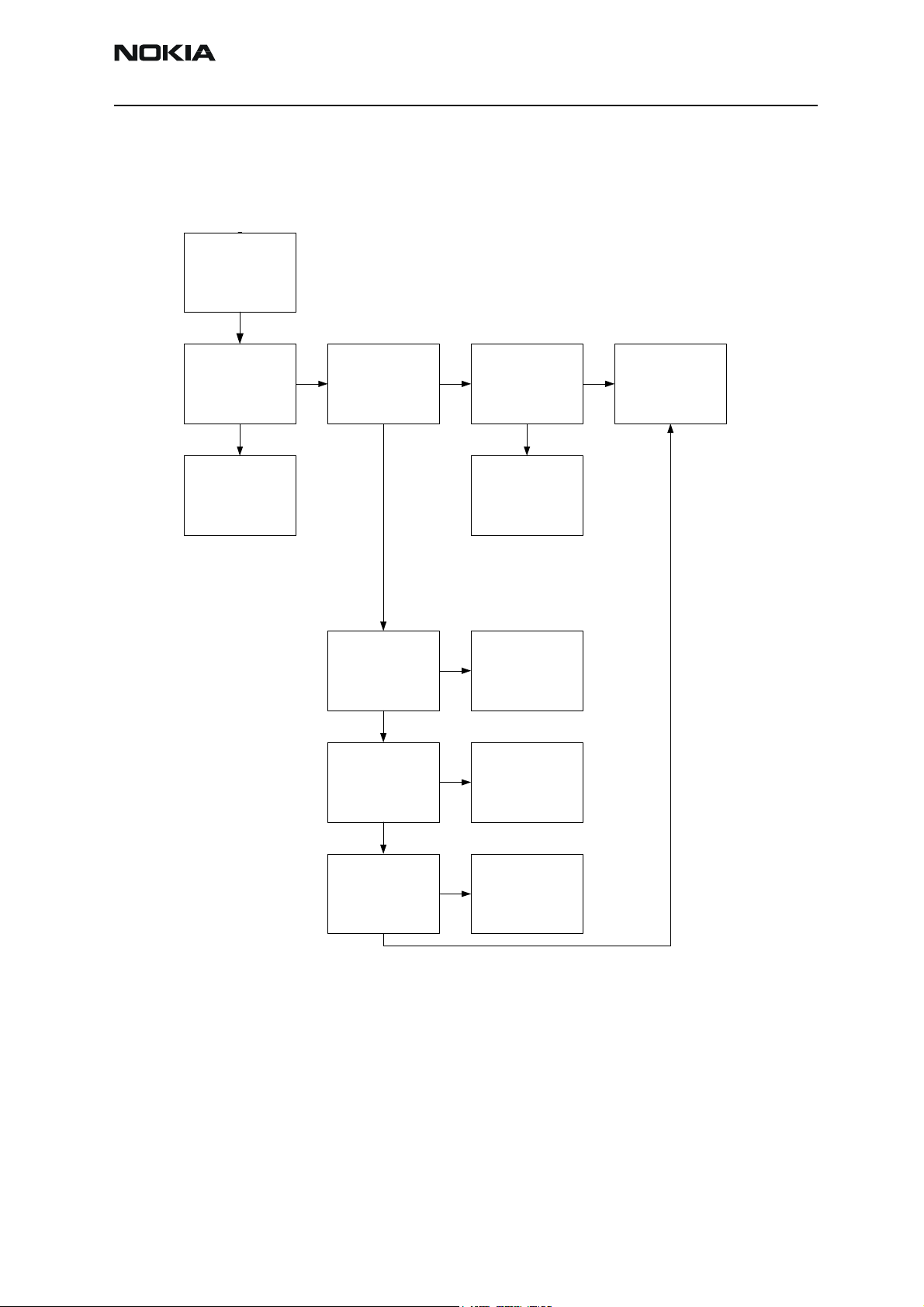

The PLL supplies Local Oscillator (LO) signals for the RX and TX-mixers. In order to be able

to generate LO-frequencies for the required EGSM and PCN channels a regular synthesiser-circuit is used. All blocks for the PLL except for the VCO, reference X-tal and loopfilter is located in the Mjoelner IC.

The reference frequency is generated by a 26MHz Voltage Controlled X-tal Oscillator

(VCXO) which is located in the Mjoelner IC. Only the X-tal is external. 26MHz is supplied

to BB where a divide-by-2 circuit (located in the UPP IC) generates the BB-clock at

13MHz. The reference frequency is supplied to the reference divider (RDIV) where the

frequency is divided by 65. The output of RDIV (400kHz) is used as reference clock for the

Phase Detector (ϕ).

The PLL is a feedback control system controlling the phase and frequency of the LO-signal. Building blocks for the PLL are: Phase detector, Charge Pump, Voltage Controlled

Oscillator (VCO), N-Divider and loopfilter. As mentioned earlier only the VCO and loopfilter is external to the Mjoelner IC.

The VCO (G600) is the component that actually generates the LO-frequency. Based on

the control voltage input the VCO generates a single-ended RF output. The signal is then

differentiated through a balun. This signal is fed to the Prescaler and N-divider in Mjoelner, these 2 block will together divide the frequency by a ratio based on the selected

channel. The divider output is supplied to the phase detector which compares the frequency and phase to the 400kHz reference clock. Based on this comparison the phase

Page 20 ãNokia Corporation Issue 1 05/02

Page 21

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

detector controls the charge pump to either charge or discharge the capacitors in the

loopfilter. By charging/discharging the loopfilter the control voltage to the VCO changes

and the LO-frequency will change. Therefore the PLL will make the LO-frequency stay

locked to the 26MHz VCXO frequency.

The loopfilter consists of the following components: C639-C641 and R618-R619.

The PLL is operating at twice the channel center frequency when transmitting or receiving in the PCN band. For the EGSM band the PLL is operating at 4-times the channel frequency. Therefore divide-by-2 and divide-by-4 circuits are inserted between the PLL

output and LO-inputs to the PCN and EGSM mixers.

Table 1: Frequency plan

Frequency band Channel System Frequency Band (MHz) PLL Frequency band (MHz)

EGSM RX 975-1023

TX 880.2 – 914.8 3520.8 – 3659.2

1 - 12

925.2 - 959.8 3700.8 - 3839.2

PCN RX 512 – 885 1805.2 – 1879.8 3610.4 – 3759.6

TX 1710.2 – 1784.8 3420.4 – 3569.6

According to the table above the PLL must be able to cover the frequency range

3420.4MHz to 3839.2MHz.

Figure 3: Synthesiser

To PC N RX

mixer

2 22

2

1/2 1/4

1/2 1/4

2

222

To PCN

Modulator

Mjoelner

N600

To GSM RX

mixer

To GSM

Modulator

VDDRXBB

Resistor Ext/R2H/R2

VBEXT

Ref.

filter

VREF1

RFCONV_0(9)

Main B ias

Circ uit

VDDLO

VDDPLL

VDDPRE

Buffer

VDDCP

CPOU T

VDDXO

VDDBBB

REFOUT

XTA LM

XTALP

INPLO

INMLO

VDDDIG

VDDDL

SELADDR

RESETX

RF_E N

RF_CLK

RF_DA TA

RESETX

VCOSENSE

Cha rge

Pump

Lock

Det ect

1/2

I/O

level

shift

3

64/

65

RBEXT

LOCNT

REFCN T

2,7k

NDIV

ADIV

VCXO Bias

VDDRXBB

SENSE

Rpa

PA vend or

indication

18k : Hitachi

82k : RFMD

RDI V

R2H/R2

VDDTX

Sensor

BIST / Temp.

ϕ

AGC

AFC/ CAL

Cont rol

Buf/

Digital

Control

3

26MHz

Synth

supply

filter

Vcp

supply

filter

PLL

loop

filter

VCXO

supply

filte r

VCTRL

REFO UT (26M Hz)

VCO (G600)

RESETX_Mjoel

RF Key component placement

VPLL

VXO

VVCO

VBB (1.8V)

Ref clk set

RFBUSX

RFBUSDA

RFBUSCLK

VR1A

VR5

VR3

VR7

VR2

VIO

VIO

GENIO6

Issue 1 05/02 ãNokia Corporation Page 21

Page 22

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

Figure 4: Key component location

Table 2:

N600 Mjoelner RF IC

Z601 PCN RX SAW

Z602 EGSM RX SAW

Z603 EGSM TX SAW

B600 26 MHz crystal

G600 VCO ( 3.6 GHz UHF VCO )

N700 Power Amplifier (PA)

Z700 RX/TX switch

Power Supply Configuration

All power supplies for the RF Unit are generated in the UEM IC (D200). All power outputs

from this IC has a decoupling capacitor at which the supply voltage can be checked.

The power supply configuration used in the HDb12 phone is shown in the blockdiagram

below:

Page 22 ãNokia Corporation Issue 1 05/02

Page 23

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

Figure 5: Power supply configuration

PA

UEM

Battery

VR2

VR3

VR5

VR1A

VR6

MJOELNER

Vtx

VXO

VPLL

VCP

Vrx

Vbb

VddXO

Vddbbb

VddRXF

VddRXBB

VddTX

Vdddig

VddPLL

VddLO

VddPre

VddCP

VIO

Vref01

VR7

Vvco

Vref1

Vbext

module

Sel_addr

VddDL

VCO

The names in bold are signal names used on the RF schematic pages. Names in the boxes

within the Mjoelner and the VCO refers to pin names on the respective ICs (N600, G600).

Table 3:

Supply name RF Supply name UEM Min Typ Max Unit

VTX VR2 2.64 2.78 2.86 V

VXO VR3 2.64 2.78 2.86 V

VCP VR1A 4.75 V

VPLL VR5 2.64 2.78 2.86 V

VRX VR6 2.64 2.78 2.86 V

VVCO VR7 2.64 2.78 2.86 V

VBB VIO 1.72 1.8 1.88 V

VREF2 VrefRF01 1.334 1.35 1.366 V

VBATT BATTERY 3.1 3.6 5.2 V

Please see the picture below for measuring points at the UEM (D200).

Issue 1 05/02 ãNokia Corporation Page 23

Page 24

NHM-8NX

1

Troubleshooting Instructions PAMS Technical Documentation

Figure 6: Supply points at UEM (D200)

VR2=Vtx (C643)

VR5=Vpll (C226)

VR7=Vvco (C224)

VR3=Vvcxo (C227)

VR6=Vrx (C225)

Vref01=Vref2 (C23

Receiver

Figure 7: Supply point at Mjoelner (N600)

Vio = Vbb

(C621)

General Instructions for GSM900 RX Troubleshooting

Connect the phone to a PC with the module repair jig.

Start Phoenix and establish connection to the phone

Select File. Select Scan for Product Ctrl-R

Select Maintenance, Testing and then RF Controls

Page 24 ãNokia Corporation Issue 1 05/02

Page 25

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

Select:

Band: GSM900

Active Unit: RX

Operation Mode: Continuous

Rx/Tx Channel: 37

AGC: 9

The setup should now look like this:

Issue 1 05/02 ãNokia Corporation Page 25

Page 26

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

Fault Finding Chart for GSM900 Receiver

Figure 8: EGSM Receiver fault finding chart

1

2

3

4

1

Apply -55 dBm

942.4 MHz, offset

67.71 kHz

from generator to

antenna connector

YES

Oscilloscope at RX

I/Q

signal 588 mVpp

DC offset 1.35 V

freq. 67.71 kHz

YES

EGSM chain

functional

NO

switch at RX 900

Spectrum analyzer

EGSM SAW filter

output -65 dBm

2

Check RX/TX

Z700

-56 dBm

YES

Z602

NO

check Vc1 and Vc2

at Z700 signal 0V

NO

Check SAW filter

3

Oscilloscop

YES

Check RX/TX

switch

Z602

4

NO

Check Mjoelner

YES

YES

Spectrum analyzer

Check signal after

5

inductors L603 and

L602

-65 dBm

NO

Check inductors

L603, L602

YES

Oscilloscope

6

VRX 2.7 V

check Mjoelner

serial interface

NO

Check Base band

By measuring with an oscilloscope at RXIP or RXQP on a working GSM 900 receiver this

picture should be seen.

Signal amplitude peak-peak 588 mV

DC offset 1.33 V

Page 26 ãNokia Corporation Issue 1 05/02

Page 27

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

Figure 9: RX900 I/Q signal waveform

General Instructions for GSM1800 RX Troubleshooting

Connect the phone to a PC with the module repair jig.

Start Phoenix and establish connection to the phone

Select File. Select Scan for Product Ctrl-R

Select Maintenance, Testing and RF Controls

Select:

Band: GSM1800

Active Unit: RX

Operation Mode: Continuous

Rx/Tx Channel: 700

AGC: 9

Issue 1 05/02 ãNokia Corporation Page 27

Page 28

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

The setup should now look like this:

Page 28 ãNokia Corporation Issue 1 05/02

Page 29

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

Fault Finding Chart for GSM1800 Receiver

Figure 10: GSM1800 receiver fault finding chart

1

2

3

4

1

Apply -55 dBm

1842.8 MHz, offset

67.71 kHz

from generator to

antenna connector

YES

Oscilloscope at RX

I/Q

signal 408 mVpp

DC offset 1.33 V

freq. 67.71 kHz

YES

PCN chain

functional

NO

switch at RX 1800

Spectrum analyzer

PCN SAW filter

output -65 dBm

2

Check RX/TX

Z700

-57 dBm

YES

Z601

NO

check Vc1 and Vc2

at Z700 signal 0V

NO

Check SAW filter

3

Oscilloscop

YES

Check RX/TX

switch

Z601

4

NO

Check Mjoelner

YES

YES

Spectrum analyzer

Check signal after

5

inductors L611 and

L601

-65 dBm

NO

Check inductors

L611, L601

YES

Oscilloscope

6

VRX 2.7 V

check Mjoelner

serial interface

NO

Check Base band

By measuring with an oscilloscope at RXIP or RXQP on a working GSM 900 receiver this

picture should be seen.

Signal amplitude peak-peak 588 mV

DC offset 1.33 V

Issue 1 05/02 ãNokia Corporation Page 29

Page 30

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

Figure 11: RX1800 I/Q signal waveform

Page 30 ãNokia Corporation Issue 1 05/02

Page 31

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

Measurement points in the receiver

Figure 12: RX measurements point at the RX/TX Switch - Z700

Vc1

Z700

Vc2

Z700

RX900 output

Z700

Mjoelner input INML

RX900

SAW filter

Z602

SAW filter

RX1800 output

Z700

Figure 13: Measurements points at the RX-Filters – Z601/Z602

RX900

L602

bal output

RX900

unbal input

Z602

RX900

Mjoelner input INPL

L603

RX1800

Mjoelner input INMM

L611

RX900

Mjoelner input INPM

L601

SAW filter

RX1800

SAW filter

unbal input

Z601

RX1800

bal output

Z601

Issue 1 05/02 ãNokia Corporation Page 31

Page 32

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

Figure 14: RX I/Q Signals, Baseband shielding can UEM (D200)

RXQM

D200

RXIM

D200

RXIP

D200

RXQP

D200

Transmitter

Measurement points for the transmitter

Figure 15: TX measuremnet points in the PA ( N700 ) shielding can

Vcon1_GSM

ANT

DCS-Tx

DET_Out

GSM-Tx

(C717)

Vcon2_DCS

Pout_DCS

Pin_DCS

VPCTRL_P

VTX_B_P

VPCTRL_G

Pout_GSM

(C717)

Pin_GSM

VTX_B_G

'

Page 32 ãNokia Corporation Issue 1 05/02

Page 33

NHM-8NX

'

X

VTX

PAMS Technical Documentation Troubleshooting Instructions

Figure 16 : TX measurement point in Mjolner (N600) shielding can

TXQI

Bal_Input1

Bal_Input1

Bal_Input2

GSM

Bal_Input2

GSM

OUT_D_T

OUT_G_TX

TXIP

TXIM

General instructions for GSM TX troubleshooting

Apply a RF-cable to the RF-connector to allow the transmitted signal act as normal. RFcable should be connected to measurement equipment or to at least a 10-dB attenuator,

otherwise the PA may be damaged.

Start Phoenix-Service-Software and establish a connection to the phone e.g. FBUS.

Select File and Product: Gemini

Select: Maintenance, Testing and RF Controls

Band: GSM 900

Active Unit: TX

Tx Power Level: 5

Tx Data Type: Random

Issue 1 05/02 ãNokia Corporation Page 33

Page 34

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

Your screen should look like:

Measure the output power of the phone; it should be around 32.5 dBm. Remember the

loss in the jig; around 0.3 dB.

Fault finding chart for GSM900 transmitter

Fault finding in output power

For the spectrum analyser measurements in the following chart use the 500 ohm passive

probe. Since the signal measured is bursted it is advised to set the analyser to maxhold.

Page 34 ãNokia Corporation Issue 1 05/02

Page 35

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

Figure 16: EGSM900 transmitter fault finding chart

NO

NO

VTX= 2.7 V +

Yes

discretes around

With Scope check :

TXQP

( See figure 19 )

Check TXIP and

Yes

Check Baseband

seriel bus

Checl Mjolner + the

NO

to Z603

-20 dBm

Measure BAL input

input

Measure

OUT_G_TX Buffer

-12 dBm

Measure Pin_GSM

13 dBm

Measure

Pout_GSM

Yes

Yes

-25 dBm

Yes

Yes

Check Z603

( TX SAW filter)

Yes

VTX_B_G = 2.7 V

With Scope check :

VPCTRL_G

( See figure 18 )

With Scope check :

( Coupler )

Check L709

Yes

Check V702

Check N700

+

NO

( PA )

discretes around

NO

NO

TXC

( See figure 18 )

With Scope check :

Yes

Check V700

+

( detector )

discretes around

on GSM-TX.

Power ~ 8 dBm

Measure TX Power

Yes

TX/RX Swith:

Vcon2_DCS = 0V

With Scope check on

Yes

Vcon1_GSM = 2.7 V

Check Z700

( RX/TX Switch )

No No No No No No

> 30.5 dBm

Meter or RCT

ANT with Power

Measure Power on

Yes

Check C739, L702

Issue 1 05/02 ãNokia Corporation Page 35

Page 36

NHM-8NX

o

Troubleshooting Instructions PAMS Technical Documentation

Figure 17: VPCTRL_G & TXC

Yellow trace: Vpctrl_G @ power level 5, ch37

Pink trace: TXC GSM900 band

Fault finding in modulation

The following plots show different situations of TX IQ measurements. Depending on the

time the modulation may cause the signal to look differently.

TX I/Q waveforms

Pink trace: TXQP Blue trace: TXIP - All 1 Pink trace: TXQP Blu etrace: TXIP - Random

Pink trace: TXQP Blue trace: TXIP - All 1 (Zoom In)

Pink trace: TXQP Blu etrace: TXIP - Random ( Zo

Page 36 ãNokia Corporation Issue 1 05/02

Page 37

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

I/Q signals look almost the same regardless if modulation is by "1" or by "0". There is no

significante difference between TXIP and TXIM. The same is valid for TXQP and TXQM.

PCN TransmitterGeneral instructions for PCN TX troubleshooting

Apply a RF-cable to the RF-connector to allow the transmitted signal act as normal. RFcable should be connected to measurement equipment or to at least a 10-dB attenuator,

otherwise the PA may be damaged.

Start Phoenix-Service-Software and establish a connection to the phone e.g. FBUS.

Select File. Choose Product: Gemini

Select: Maintenance, Testing and then RF Controls.

Band: GSM 1800

Active Unit: TX

Tx Power Level: 0

Tx Data Type: Random

Your screen should look like:

Measure the output power of the phone; it should be around 28.5 dBm. Remember the

loss in the jig; around 0.7 dB.

Path of the transmitted PCN signal

Fault finding chart for PCN transmitter

Issue 1 05/02 ãNokia Corporation Page 37

Page 38

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

Figure 18: GSM1800 transmitter fault finding chart

NO

NO

VTX= 2.7 V +

Yes

discretes around

With Scope check :

to T600

Measure BAL input

Buffer input

Measure OUT_D_TX

-14 dBm

Measure Pin_DCS

Measure

Pout_DCS

Yes

-16 dBm

Yes

-19 dBm

Yes

Yes

11 dBm

Check TXIP an d

With Scope check :

TXQP

Check T600

With Scope check :

VPCTRL_P

Check L709

( See figure 19 )

( PCN Balun)

VTX_B_P = 2.7 V

( See figure 21 )

( Coupler )

Yes

Check Baseband

NO

Yes

Yes

Check V701

+

discretes around

NO

( PA )

Check N700

NO

NO

TXC

( See figure 21 )

With Scope check :

Yes

seriel bus

Checl Mjolner + the

+

( detector )

Check V700

discretes ar ound

Measure TX Power

Measure Power on

on DCS-TX.

Yes

Power ~ 9 dBm

TX/RX Swith:

Vcon2_DCS = 2.7 V

With Scope check on

Yes

Vcon1_GSM = 2.7 V

Check Z700

( RX/TX Switch )

No No No No No No

Yes

> 27.5 dBm

Meter or RCT

ANT with Power

Check C739, L702

Page 38 ãNokia Corporation Issue 1 05/02

Page 39

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

Figure 19: VPCTRL_P & TXC

Yellow trace : Vpctrl_P @ power level 0, ch700

Pink trace : TXC PCN1800 band

** TXIQ signals look the same in PCN and GSM

Synthesizer

There is only one PLL synthesizer generating Local Oscillator frequencies for both RX and

TX in both bands ( PCN and EGSM). The VCO frequency is divided by 2 for PCN operation

or by 4 for EGSM operation inside the Mjoelner IC.

General instructions for Synthesizer troubleshooting

Start the Phoenix-Service-Software and

Select: Product: NHM-8NX

Select: Maintenance, Testing and then RF Controls.

Band GSM1800

Active Unit RX

Operation Mode Continuous

RX/TX Channel 700

It is not possible to measure the output of the VCO (G600) directly as this component is

placed underneath a shielding can without detachable lid. However with spectrum analyzer and 500 ohm passive probe it is possible to get an indication if the VCO outputs the

correct frequency. To do this probe R656 – the frequency should be 3685.6MHz and the

power should be around –50 dBm.

26 MHz Reference Oscillator ( VCXO )

The 26 MHz oscillator is located in the Mjoelner IC (N600). The coarse frequency for this

oscillator is set by an external crystal (B600). The reference oscillator is used as a reference frequency for the PLL synthesizer and as the system clock for BaseBand. The

Issue 1 05/02 ãNokia Corporation Page 39

Page 40

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

26MHz signal is divided by 2 to achieve 13MHz inside the UPP IC (D400). The 26 MHz

signal from the VCXO can be measured by probing R425 (must be measured on the UPP

side of R425 i.e. the end not connected to C425). The level at this point is approx.

700mVpp. Frequency of this oscillator is adjusted by changing the AFC-register inside the

Mjoelner IC. This is done via the Mjoelner serial interface.

Example Signal Measured at VCXO output (R425)

Figure 20: VCXO 26 MHz waveform

Page 40 ãNokia Corporation Issue 1 05/02

Page 41

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

VCO

The VCO is generating frequencies in the range of 3420.2MHz – 3839.2 MHz when the

PLL is running. The output frequency from the VCO is led to the Local oscillator input of

the Mjoelner IC (N600), where the frequency is divided by 2 or 4 so that they can generate all channels in EGSM and PCN respectively. Frequency of the VCO is controlled by a

DC-voltage ( Vctrl ) coming from the loopfilter. The loopfilter consists of the components

R618, R619 and C639-C641. Range of the Vctrl when the PLL is running (locked) is 0.7V

– 3.8V. Even if the PLL is not in locked state (Vctrl out of range) there is some frequency

at the output of the VCO (G600) which is between 3 and 4 GHz. This is of course only

true if the VCO is working and if the VCO power supply is present (2.7V).

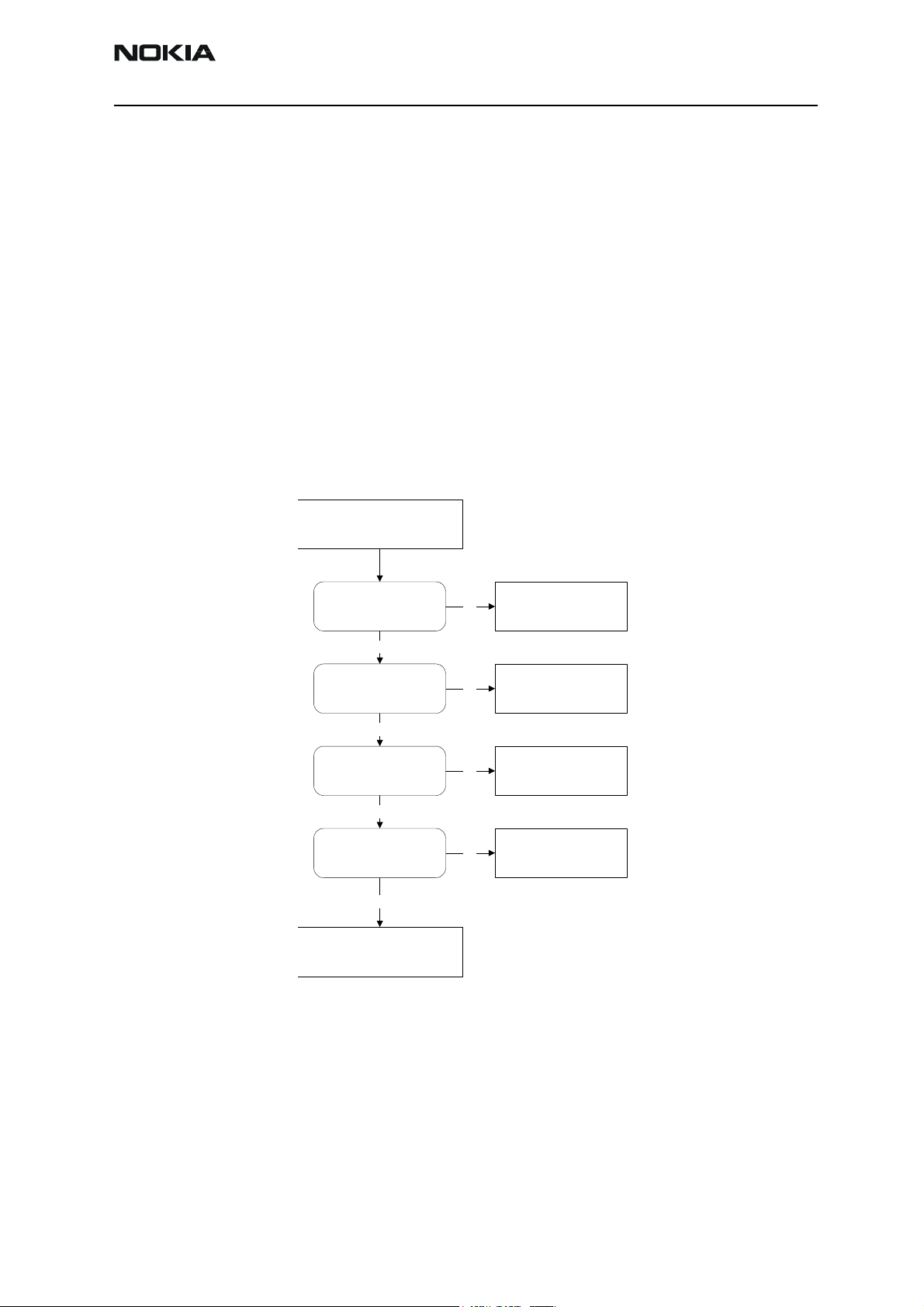

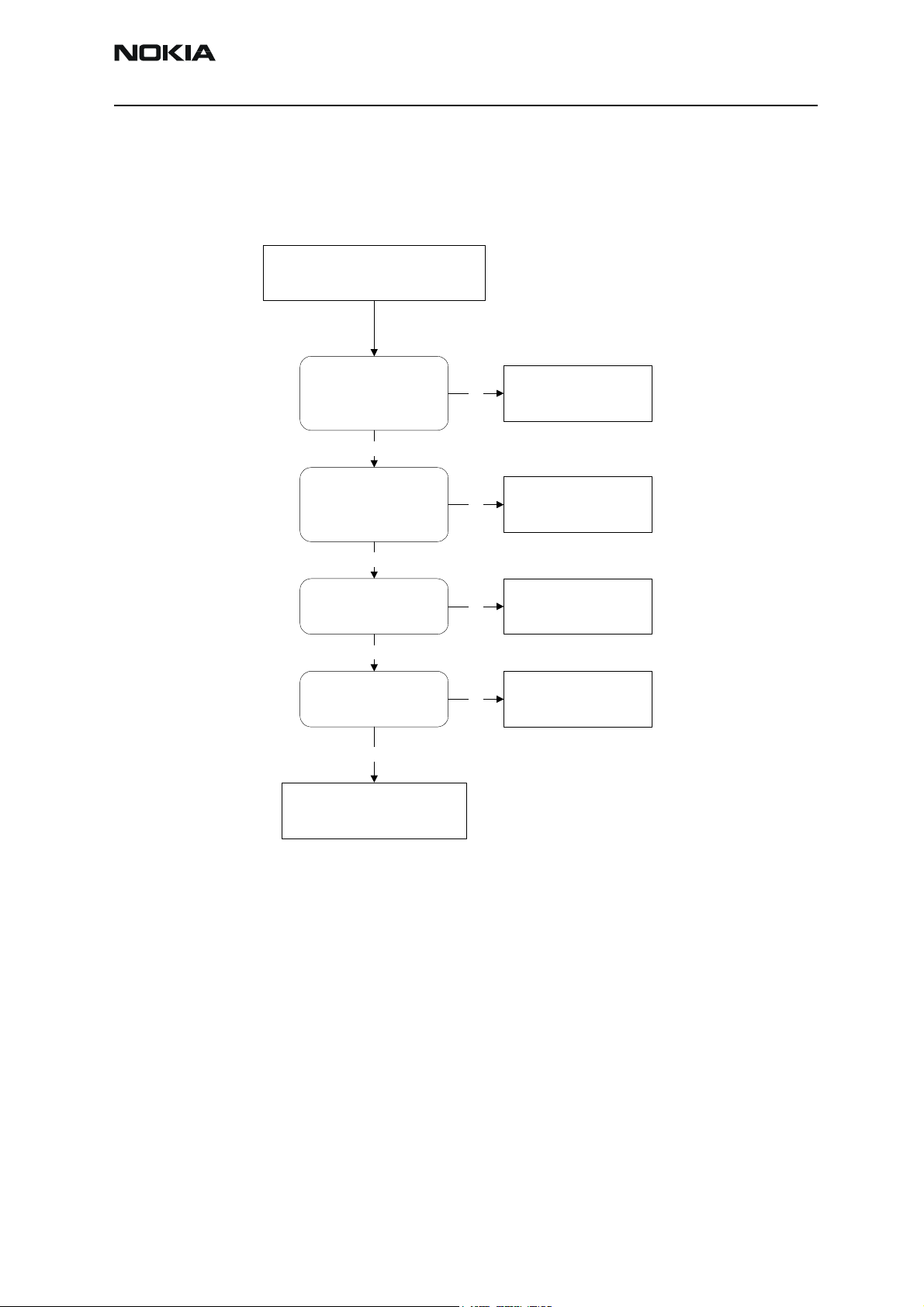

Fault finding chart for PLL Synthesizer

Figure 21: PLL fault finding chart

From Phoenix chose:

File

> Choose Product > NHM-8NX

Mainenance

GSM1800 > RX > Continuous > Ch 700

> Testing > RF Controls >

Spectrum Analyzer:

Measure

VCO frequency at R656

3685.6MHz

Yes

PLL block functional

Oscilloscope:

Measure

VCXO Power Supply at C620

2.7 V

Yes

Oscilloscope:

Measure

VCXO output

On (R425) 26 MHz,

Approx. 700mVpp

Yes

Oscilloscope:

Measure

VCO Power Supply

(R656)

2,7 V

Yes

Oscilloscope:

Measure

PLL Power Supply

C614 & C634

Both 2,7 V

Yes

Oscilloscope:

Measure

CP

Supply C616

V

4,7 V

Yes

Spectr um Analyzer:

Measure

VCO output (R656)

Some signal between

3 and 4 GHz

Yes

Oscilloscope:

Measure

Control Voltage C641

between 0.5 and 4.0 V

Yes

Check

Mjoeln er N600,

UPP D400,

RFBusClk J608,

RFBusDA J610,

RFBusX j609

& Reset_Mjoel

No

No

No

No

No

No

No

UEM, Software??

Phone not in function

VCXO is not functional

Phone not in function

UEM, Software??

Phone not in function

UEM, Software??

Phone not in function

R603, UEM, Software??

VCO G600 is not functional

Loopfilter R618,R619,

Check

Check

Crystal B600

Check

Check

Check

Check

C639-C641

Issue 1 05/02 ãNokia Corporation Page 41

Page 42

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

If the phone stops working a short time after the power is turned ON, a possible reason

forthis might be that the 26MHz system clock signal is not getting to the UPP clockinput in BaseBand. In this case check the following:

1 Turn on the phone and check

2 VCXO Power supply (C620) = 2.7V

3 VCXO output (R425 – end not connected to C425) is 26MHz and approx.

700mVpp

If this is not the case check the reference crystal (B600) and Mjolner (N600) as well as

R425, R426, C425, C426.

Measurement points for the PLL

Measurement points at the VCXO

Figure 22: Measurement point for VCXO supply

VCXO Vcc (C620)

Page 42 ãNokia Corporation Issue 1 05/02

Page 43

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

Figure 23: Measurement point for VCXO output

VCXO Output (R425)

Measure at this end!

Measurement points at the PLL/VCO

Figure 24: Measurement point for PLL

VCO Vcc (R656)

VCO Output is also

detected here!

Issue 1 05/02 ãNokia Corporation Page 43

Page 44

NHM-8NX

A

Troubleshooting Instructions PAMS Technical Documentation

CP Vcp (C616)

Vcp=VR1

PLL Vcc

(C614, C634)

Page 44 ãNokia Corporation Issue 1 05/02

Page 45

NHM-8NX

q

PAMS Technical Documentation Troubleshooting Instructions

Frequency lists

GSM900

uency list NHM-5 GSM900

CH TX RX VCO TX VCO RX CH TX RX VCO TX VCO RX CH TX RX VCO TX VCO RX

975 880.2 925.2 3520.8 3700.8 1 890.2 935.2 3560.8 3740.8 63 902.6 947.6 3610.4 3790.4

976 880.4 925.4 3521.6 3701.6 2 890.4 935.4 3561.6 3741.6 64 902.8 947.8 3611.2 3791.2

977 880.6 925.6 3522.4 3702.4 3 890.6 935.6 3562.4 3742.4 65 903 948 3612 3792

978 880.8 925.8 3523.2 3703.2 4 890.8 935.8 3563.2 3743.2 66 903.2 948.2 3612.8 3792.8

979 881 926 3524 3704 5 891 936 3564 3744 67 903.4 948.4 3613.6 3793.6

980 881.2 926.2 3524.8 3704.8 6 891.2 936.2 3564.8 3744.8 68 903.6 948.6 3614.4 3794.4

981 881.4 926.4 3525.6 3705.6 7 891.4 936.4 3565.6 3745.6 69 903.8 948.8 3615.2 3795.2

982 881.6 926.6 3526.4 3706.4 8 891.6 936.6 3566.4 3746.4 70 904 949 3616 3796

983 881.8 926.8 3527.2 3707.2 9 891.8 936.8 3567.2 3747.2 71 904.2 949.2 3616.8 3796.8

984 882 927 3528 3708 10 892 937 3568 3748 72 904.4 949.4 3617.6 3797.6

985 882.2 927.2 3528.8 3708.8 11 892.2 937.2 3568.8 3748.8 73 904.6 949.6 3618.4 3798.4

986 882.4 927.4 3529.6 3709.6 12 892.4 937.4 3569.6 3749.6 74 904.8 949.8 3619.2 3799.2

987 882.6 927.6 3530.4 3710.4 13 892.6 937.6 3570.4 3750.4 75 905 950 3620 3800

988 882.8 927.8 3531.2 3711.2 14 892.8 937.8 3571.2 3751.2 76 905.2 950.2 3620.8 3800.8

989 883 928 3532 3712 15 893 938 3572 3752 77 905.4 950.4 3621.6 3801.6

990 883.2 928.2 3532.8 3712.8 16 893.2 938.2 3572.8 3752.8 78 905.6 950.6 3622.4 3802.4

991 883.4 928.4 3533.6 3713.6 17 893.4 938.4 3573.6 3753.6 79 905.8 950.8 3623.2 3803.2

992 883.6 928.6 3534.4 3714.4 18 893.6 938.6 3574.4 3754.4 80 906 951 3624 3804

993 883.8 928.8 3535.2 3715.2 19 893.8 938.8 3575.2 3755.2 81 906.2 951.2 3624.8 3804.8

994 884 929 3536 3716 20 894 939 3576 3756 82 906.4 951.4 3625.6 3805.6

995 884.2 929.2 3536.8 3716.8 21 894.2 939.2 3576.8 3756.8 83 906.6 951.6 3626.4 3806.4

996 884.4 929.4 3537.6 3717.6 22 894.4 939.4 3577.6 3757.6 84 906.8 951.8 3627.2 3807.2

997 884.6 929.6 3538.4 3718.4 23 894.6 939.6 3578.4 3758.4 85 907 952 3628 3808

998 884.8 929.8 3539.2 3719.2 24 894.8 939.8 3579.2 3759.2 86 907.2 952.2 3628.8 3808.8

999 885 930 3540 3720 25 895 940 3580 3760 87 907.4 952.4 3629.6 3809.6

1000 885.2 930.2 3540.8 3720.8 26 895.2 940.2 3580.8 3760.8 88 907.6 952.6 3630.4 3810.4

1001 885.4 930.4 3541.6 3721.6 27 895.4 940.4 3581.6 3761.6 89 907.8 952.8 3631.2 3811.2

1002 885.6 930.6 3542.4 3722.4 28 895.6 940.6 3582.4 3762.4 90 908 953 3632 3812

1003 885.8 930.8 3543.2 3723.2 29 895.8 940.8 3583.2 3763.2 91 908.2 953.2 3632.8 3812.8

1004 886 931 3544 3724 30 896 941 3584 3764 92 908.4 953.4 3633.6 3813.6

1005 886.2 931.2 3544.8 3724.8 31 896.2 941.2 3584.8 3764.8 93 908.6 953.6 3634.4 3814.4

1006 886.4 931.4 3545.6 3725.6 32 896.4 941.4 3585.6 3765.6 94 908.8 953.8 3635.2 3815.2

1007 886.6 931.6 3546.4 3726.4 33 896.6 941.6 3586.4 3766.4 95 909 954 3636 3816

1008 886.8 931.8 3547.2 3727.2 34 896.8 941.8 3587.2 3767.2 96 909.2 954.2 3636.8 3816.8

1009 887 932 3548 3728 35 897 942 3588 3768 97 909.4 954.4 3637.6 3817.6

1010 887.2 932.2 3548.8 3728.8 36 897.2 942.2 3588.8 3768.8 98 909.6 954.6 3638.4 3818.4

1011 887.4 932.4 3549.6 3729.6 37 897.4 942.4 3589.6 3769.6 99 909.8 954.8 3639.2 3819.2

1012 887.6 932.6 3550.4 3730.4 38 897.6 942.6 3590.4 3770.4 100 910 955 3640 3820

1013 887.8 932.8 3551.2 3731.2 39 897.8 942.8 3591.2 3771.2 101 910.2 955.2 3640.8 3820.8

1014 888 933 3552 3732 40 898 943 3592 3772 102 910.4 955.4 3641.6 3821.6

1015 888.2 933.2 3552.8 3732.8 41 898.2 943.2 3592.8 3772.8 103 910.6 955.6 3642.4 3822.4

1016 888.4 933.4 3553.6 3733.6 42 898.4 943.4 3593.6 3773.6 104 910.8 955.8 3643.2 3823.2

1017 888.6 933.6 3554.4 3734.4 43 898.6 943.6 3594.4 3774.4 105 911 956 3644 3824

1018 888.8 933.8 3555.2 3735.2 44 898.8 943.8 3595.2 3775.2 106 911.2 956.2 3644.8 3824.8

1019 889 934 3556 3736 45 899 944 3596 3776 107 911.4 956.4 3645.6 3825.6

1020 889.2 934.2 3556.8 3736.8 46 899.2 944.2 3596.8 3776.8 108 911.6 956.6 3646.4 3826.4

1021 889.4 934.4 3557.6 3737.6 47 899.4 944.4 3597.6 3777.6 109 911.8 956.8 3647.2 3827.2

1022 889.6 934.6 3558.4 3738.4 48 899.6 944.6 3598.4 3778.4 110 912 957 3648 3828

1023 889.8 934.8 3559.2 3739.2 49 899.8 944.8 3599.2 3779.2 111 912.2 957.2 3648.8 3828.8

0 890 935 3560 3740 50 900 945 3600 3780 112 912.4 957.4 3649.6 3829.6

Fre

51 900.2 945.2 3600.8 3780.8 113 912.6 957.6 3650.4 3830.4

52 900.4 945.4 3601.6 3781.6 114 912.8 957.8 3651.2 3831.2

53 900.6 945.6 3602.4 3782.4 115 913 958 3652 3832

54 900.8 945.8 3603.2 3783.2 116 913.2 958.2 3652.8 3832.8

55 901 946 3604 3784 117 913.4 958.4 3653.6 3833.6

56 901.2 946.2 3604.8 3784.8 118 913.6 958.6 3654.4 3834.4

57 901.4 946.4 3605.6 3785.6 119 913.8 958.8 3655.2 3835.2

58 901.6 946.6 3606.4 3786.4 120 914 959 3656 3836

59 901.8 946.8 3607.2 3787.2 121 914.2 959.2 3656.8 3836.8

60 902 947 3608 3788 122 914.4 959.4 3657.6 3837.6

61 902.2 947.2 3608.8 3788.8 123 914.6 959.6 3658.4 3838.4

62 902.4 947.4 3609.6 3789.6 124 914.8 959.8 3659.2 3839.2

Issue 1 05/02 ãNokia Corporation Page 45

Page 46

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

PCN

CH TX RX VCO TX VCO RX CH TX RX VCO TX VCO RX CH TX RX VCO TX VCO RX CH TX RX VCO TX VCO RX

512 1710.2 1805.2 3420.4 3610.4 606 1729 1824 3458 3648 700 1747.8 1842.8 3495.6 3685.6 794 1766.6 1861.6 3533.2 3723.2

513 1710.4 1805.4 3420.8 3610.8 607 1729.2 1824.2 3458.4 3648.4 701 1748 1843 3496 3686 795 1766.8 1861.8 3533.6 3723.6

514 1710.6 1805.6 3421.2 3611.2 608 1729.4 1824.4 3458.8 3648.8 702 1748.2 1843.2 3496.4 3686.4 796 1767 1862 3534 3724

515 1710.8 1805.8 3421.6 3611.6 609 1729.6 1824.6 3459.2 3649.2 703 1748.4 1843.4 3496.8 3686.8 797 1767.2 1862.2 3534.4 3724.4

516 1711 1806 3422 3612 610 1729.8 1824.8 3459.6 3649.6 704 1748.6 1843.6 3497.2 3687.2 798 1767.4 1862.4 3534.8 3724.8

517 1711.2 1806.2 3422.4 3612.4 611 1730 1825 3460 3650 705 1748.8 1843.8 3497.6 3687.6 799 1767.6 1862.6 3535.2 3725.2

518 1711.4 1806.4 3422.8 3612.8 612 1730.2 1825.2 3460.4 3650.4 706 1749 1844 3498 3688 800 1767.8 1862.8 3535.6 3725.6

519 1711.6 1806.6 3423.2 3613.2 613 1730.4 1825.4 3460.8 3650.8 707 1749.2 1844.2 3498.4 3688.4 801 1768 1863 3536 3726

520 1711.8 1806.8 3423.6 3613.6 614 1730.6 1825.6 3461.2 3651.2 708 1749.4 1844.4 3498.8 3688.8 802 1768.2 1863.2 3536.4 3726.4

521 1712 1807 3424 3614 615 1730.8 1825.8 3461.6 3651.6 709 1749.6 1844.6 3499.2 3689.2 803 1768.4 1863.4 3536.8 3726.8

522 1712.2 1807.2 3424.4 3614.4 616 1731 1826 3462 3652 710 1749.8 1844.8 3499.6 3689. 6 804 1768.6 1863.6 3537.2 3727.2

523 1712.4 1807.4 3424.8 3614.8 617 1731.2 1826.2 3462.4 3652.4 711 1750 1845 3500 3690 805 1768.8 1863.8 3537.6 3727.6

524 1712.6 1807.6 3425.2 3615.2 618 1731.4 1826.4 3462.8 3652.8 712 1750.2 1845.2 3500.4 3690.4 806 1769 1864 3538 3728

525 1712.8 1807.8 3425.6 3615.6 619 1731.6 1826.6 3463.2 3653.2 713 1750.4 1845.4 3500.8 3690.8 807 1769.2 1864.2 3538.4 3728.4

526 1713 1808 3426 3616 620 1731.8 1826.8 3463.6 3653.6 714 1750.6 1845.6 3501.2 3691.2 808 1769.4 1864.4 3538.8 3728.8

527 1713.2 1808.2 3426.4 3616.4 621 1732 1827 3464 3654 715 1750.8 1845.8 3501.6 3691.6 809 1769.6 1864.6 3539.2 3729.2

528 1713.4 1808.4 3426.8 3616.8 622 1732.2 1827.2 3464.4 3654.4 716 1751 1846 3502 3692 810 1769.8 1864.8 3539.6 3729.6

529 1713.6 1808.6 3427.2 3617.2 623 1732.4 1827.4 3464.8 3654.8 717 1751.2 1846.2 3502.4 3692.4 811 1770 1865 3540 3730

530 1713.8 1808.8 3427.6 3617.6 624 1732.6 1827.6 3465.2 3655.2 718 1751.4 1846.4 3502.8 3692.8 812 1770.2 1865.2 3540.4 3730.4

531 1714 1809 3428 3618 625 1732.8 1827.8 3465.6 3655.6 719 1751.6 1846.6 3503.2 3693.2 813 1770.4 1865.4 3540.8 3730.8

532 1714.2 1809.2 3428.4 3618.4 626 1733 1828 3466 3656 720 1751.8 1846.8 3503.6 3693.6 814 1770.6 1865.6 3541.2 3731.2

533 1714.4 1809.4 3428.8 3618.8 627 1733.2 1828.2 3466.4 3656.4 721 1752 1847 3504 3694 815 1770.8 1865.8 3541.6 3731.6

534 1714.6 1809.6 3429.2 3619.2 628 1733.4 1828.4 3466.8 3656.8 722 1752.2 1847.2 3504.4 3694.4 816 1771 1866 3542 3732

535 1714.8 1809.8 3429.6 3619.6 629 1733.6 1828.6 3467.2 3657.2 723 1752.4 1847.4 3504.8 3694.8 817 1771.2 1866.2 3542.4 3732.4

536 1715 1810 3430 3620 630 1733.8 1828.8 3467.6 3657.6 724 1752.6 1847.6 3505.2 3695.2 818 1771.4 1866.4 3542.8 3732.8

537 1715.2 1810.2 3430.4 3620.4 631 1734 1829 3468 3658 725 1752.8 1847.8 3505.6 3695.6 819 1771.6 1866.6 3543.2 3733.2

538 1715.4 1810.4 3430.8 3620.8 632 1734.2 1829.2 3468.4 3658.4 726 1753 1848 3506 3696 820 1771.8 1866.8 3543.6 3733.6

539 1715.6 1810.6 3431.2 3621.2 633 1734.4 1829.4 3468.8 3658.8 727 1753.2 1848.2 3506.4 3696.4 821 1772 1867 3544 3734

540 1715.8 1810.8 3431.6 3621.6 634 1734.6 1829.6 3469.2 3659.2 728 1753.4 1848.4 3506.8 3696.8 822 1772.2 1867.2 3544.4 3734.4

541 1716 1811 3432 3622 635 1734.8 1829.8 3469.6 3659.6 729 1753.6 1848.6 3507.2 3697. 2 823 1772.4 1867.4 3544.8 3734.8

542 1716.2 1811.2 3432.4 3622.4 636 1735 1830 3470 3660 730 1753.8 1848.8 3507.6 3697.6 824 1772.6 1867.6 3545.2 3735.2

543 1716.4 1811.4 3432.8 3622.8 637 1735.2 1830.2 3470.4 3660.4 731 1754 1849 3508 3698 825 1772.8 1867.8 3545.6 3735.6

544 1716.6 1811.6 3433.2 3623.2 638 1735.4 1830.4 3470.8 3660.8 732 1754.2 1849.2 3508.4 3698.4 826 1773 1868 3546 3736

545 1716.8 1811.8 3433.6 3623.6 639 1735.6 1830.6 3471.2 3661.2 733 1754.4 1849.4 3508.8 3698.8 827 1773.2 1868.2 3546.4 3736.4

546 1717 1812 3434 3624 640 1735.8 1830.8 3471.6 3661.6 734 1754.6 1849.6 3509.2 3699.2 828 1773.4 1868.4 3546.8 3736.8

547 1717.2 1812.2 3434.4 3624.4 641 1736 1831 3472 3662 735 1754.8 1849.8 3509.6 3699.6 829 1773.6 1868.6 3547.2 3737.2

548 1717.4 1812.4 3434.8 3624.8 642 1736.2 1831.2 3472.4 3662.4 736 1755 1850 3510 3700 830 1773.8 1868.8 3547.6 3737.6

549 1717.6 1812.6 3435.2 3625.2 643 1736.4 1831.4 3472.8 3662.8 737 1755.2 1850.2 3510.4 3700.4 831 1774 1869 3548 3738

550 1717.8 1812.8 3435.6 3625.6 644 1736.6 1831.6 3473.2 3663.2 738 1755.4 1850.4 3510.8 3700.8 832 1774.2 1869.2 3548.4 3738.4

551 1718 1813 3436 3626 645 1736.8 1831.8 3473.6 3663.6 739 1755.6 1850.6 3511.2 3701.2 833 1774.4 1869.4 3548.8 3738.8

552 1718.2 1813.2 3436.4 3626.4 646 1737 1832 3474 3664 740 1755.8 1850.8 3511.6 3701.6 834 1774.6 1869.6 3549.2 3739.2

553 1718.4 1813.4 3436.8 3626.8 647 1737.2 1832.2 3474.4 3664.4 741 1756 1851 3512 3702 835 1774.8 1869.8 3549.6 3739.6

554 1718.6 1813.6 3437.2 3627.2 648 1737.4 1832.4 3474.8 3664.8 742 1756.2 1851.2 3512.4 3702.4 836 1775 1870 3550 3740

555 1718.8 1813.8 3437.6 3627.6 649 1737.6 1832.6 3475.2 3665.2 743 1756.4 1851.4 3512.8 3702.8 837 1775.2 1870.2 3550.4 3740.4

556 1719 1814 3438 3628 650 1737.8 1832.8 3475.6 3665.6 744 1756.6 1851.6 3513.2 3703.2 838 1775.4 1870.4 3550.8 3740.8

557 1719.2 1814.2 3438.4 3628.4 651 1738 1833 3476 3666 745 1756.8 1851.8 3513.6 3703.6 839 1775.6 1870.6 3551.2 3741.2

558 1719.4 1814.4 3438.8 3628.8 652 1738.2 1833.2 3476.4 3666.4 746 1757 1852 3514 3704 840 1775.8 1870.8 3551.6 3741.6

559 1719.6 1814.6 3439.2 3629.2 653 1738.4 1833.4 3476.8 3666.8 747 1757.2 1852.2 3514.4 3704. 4 841 1776 1871 3552 3742

560 1719.8 1814.8 3439.6 3629.6 654 1738.6 1833.6 3477.2 3667.2 748 1757.4 1852.4 3514.8 3704. 8 842 1776.2 1871.2 3552.4 3742.4

561 1720 1815 3440 3630 655 1738.8 1833.8 3477.6 3667.6 749 1757.6 1852.6 3515.2 3705.2 843 1776.4 1871.4 3552.8 3742.8

562 1720.2 1815.2 3440.4 3630.4 656 1739 1834 3478 3668 750 1757.8 1852.8 3515.6 3705.6 844 1776.6 1871.6 3553.2 3743.2

563 1720.4 1815.4 3440.8 3630.8 657 1739.2 1834.2 3478.4 3668.4 751 1758 1853 3516 3706 845 1776.8 1871.8 3553.6 3743.6

564 1720.6 1815.6 3441.2 3631.2 658 1739.4 1834.4 3478.8 3668.8 752 1758.2 1853.2 3516.4 3706.4 846 1777 1872 3554 3744

565 1720.8 1815.8 3441.6 3631.6 659 1739.6 1834.6 3479.2 3669.2 753 1758.4 1853.4 3516.8 3706.8 847 1777.2 1872.2 3554.4 3744.4

566 1721 1816 3442 3632 660 1739.8 1834.8 3479.6 3669.6 754 1758.6 1853.6 3517.2 3707.2 848 1777.4 1872.4 3554.8 3744.8

567 1721.2 1816.2 3442.4 3632.4 661 1740 1835 3480 3670 755 1758.8 1853.8 3517.6 3707.6 849 1777.6 1872.6 3555.2 3745.2

568 1721.4 1816.4 3442.8 3632.8 662 1740.2 1835.2 3480.4 3670.4 756 1759 1854 3518 3708 850 1777.8 1872.8 3555.6 3745.6

569 1721.6 1816.6 3443.2 3633.2 663 1740.4 1835.4 3480.8 3670.8 757 1759.2 1854.2 3518.4 3708. 4 851 1778 1873 3556 3746

570 1721.8 1816.8 3443.6 3633.6 664 1740.6 1835.6 3481.2 3671.2 758 1759.4 1854.4 3518.8 3708.8 852 1778.2 1873.2 3556.4 3746.4

571 1722 1817 3444 3634 665 1740.8 1835.8 3481.6 3671.6 759 1759.6 1854.6 3519.2 3709.2 853 1778.4 1873.4 3556.8 3746.8

572 1722.2 1817.2 3444.4 3634.4 666 1741 1836 3482 3672 760 1759.8 1854.8 3519.6 3709.6 854 1778.6 1873.6 3557.2 3747.2

573 1722.4 1817.4 3444.8 3634.8 667 1741.2 1836.2 3482.4 3672.4 761 1760 1855 3520 3710 855 1778.8 1873.8 3557.6 3747.6

574 1722.6 1817.6 3445.2 3635.2 668 1741.4 1836.4 3482.8 3672.8 762 1760.2 1855.2 3520.4 3710.4 856 1779 1874 3558 3748

575 1722.8 1817.8 3445.6 3635.6 669 1741.6 1836.6 3483.2 3673.2 763 1760.4 1855.4 3520.8 3710.8 857 1779.2 1874.2 3558.4 3748.4

576 1723 1818 3446 3636 670 1741.8 1836.8 3483.6 3673.6 764 1760.6 1855.6 3521.2 3711.2 858 1779.4 1874.4 3558.8 3748.8

577 1723.2 1818.2 3446.4 3636.4 671 1742 1837 3484 3674 765 1760.8 1855.8 3521.6 3711.6 859 1779.6 1874.6 3559.2 3749.2

578 1723.4 1818.4 3446.8 3636.8 672 1742.2 1837.2 3484.4 3674.4 766 1761 1856 3522 3712 860 1779.8 1874.8 3559.6 3749.6

579 1723.6 1818.6 3447.2 3637.2 673 1742.4 1837.4 3484.8 3674.8 767 1761.2 1856.2 3522.4 3712.4 861 1780 1875 3560 3750

580 1723.8 1818.8 3447.6 3637.6 674 1742.6 1837.6 3485.2 3675.2 768 1761.4 1856.4 3522.8 3712.8 862 1780.2 1875.2 3560.4 3750.4

581 1724 1819 3448 3638 675 1742.8 1837.8 3485.6 3675.6 769 1761.6 1856.6 3523.2 3713.2 863 1780.4 1875.4 3560.8 3750.8

582 1724.2 1819.2 3448.4 3638.4 676 1743 1838 3486 3676 770 1761.8 1856.8 3523.6 3713.6 864 1780.6 1875.6 3561.2 3751.2

583 1724.4 1819.4 3448.8 3638.8 677 1743.2 1838.2 3486.4 3676.4 771 1762 1857 3524 3714 865 1780.8 1875.8 3561.6 3751.6

584 1724.6 1819.6 3449.2 3639.2 678 1743.4 1838.4 3486.8 3676.8 772 1762.2 1857.2 3524.4 3714.4 866 1781 1876 3562 3752

585 1724.8 1819.8 3449.6 3639.6 679 1743.6 1838.6 3487.2 3677.2 773 1762.4 1857.4 3524.8 3714.8 867 1781.2 1876.2 3562.4 3752.4

586 1725 1820 3450 3640 680 1743.8 1838.8 3487.6 3677.6 774 1762.6 1857.6 3525.2 3715.2 868 1781.4 1876.4 3562.8 3752.8

587 1725.2 1820.2 3450.4 3640.4 681 1744 1839 3488 3678 775 1762.8 1857.8 3525.6 3715.6 869 1781.6 1876.6 3563.2 3753.2

588 1725.4 1820.4 3450.8 3640.8 682 1744.2 1839.2 3488.4 3678.4 776 1763 1858 3526 3716 870 1781.8 1876.8 3563.6 3753.6

589 1725.6 1820.6 3451.2 3641.2 683 1744.4 1839.4 3488.8 3678.8 777 1763.2 1858.2 3526.4 3716.4 871 1782 1877 3564 3754

590 1725.8 1820.8 3451.6 3641.6 684 1744.6 1839.6 3489.2 3679.2 778 1763.4 1858.4 3526.8 3716.8 872 1782.2 1877.2 3564.4 3754.4

591 1726 1821 3452 3642 685 1744.8 1839.8 3489.6 3679.6 779 1763.6 1858.6 3527.2 3717.2 873 1782.4 1877.4 3564.8 3754.8

592 1726.2 1821.2 3452.4 3642.4 686 1745 1840 3490 3680 780 1763.8 1858.8 3527.6 3717.6 874 1782.6 1877.6 3565.2 3755.2

593 1726.4 1821.4 3452.8 3642.8 687 1745.2 1840.2 3490.4 3680.4 781 1764 1859 3528 3718 875 1782.8 1877.8 3565.6 3755.6

594 1726.6 1821.6 3453.2 3643.2 688 1745.4 1840.4 3490.8 3680.8 782 1764.2 1859.2 3528.4 3718.4 876 1783 1878 3566 3756

595 1726.8 1821.8 3453.6 3643.6 689 1745.6 1840.6 3491.2 3681.2 783 1764.4 1859.4 3528.8 3718.8 877 1783.2 1878.2 3566.4 3756.4

596 1727 1822 3454 3644 690 1745.8 1840.8 3491.6 3681.6 784 1764.6 1859.6 3529.2 3719.2 878 1783.4 1878.4 3566.8 3756.8

597 1727.2 1822.2 3454.4 3644.4 691 1746 1841 3492 3682 785 1764.8 1859.8 3529.6 3719.6 879 1783.6 1878.6 3567.2 3757.2

598 1727.4 1822.4 3454.8 3644.8 692 1746.2 1841.2 3492.4 3682.4 786 1765 1860 3530 3720 880 1783.8 1878.8 3567.6 3757.6

599 1727.6 1822.6 3455.2 3645.2 693 1746.4 1841.4 3492.8 3682.8 787 1765.2 1860.2 3530.4 3720.4 881 1784 1879 3568 3758

600 1727.8 1822.8 3455.6 3645.6 694 1746.6 1841.6 3493.2 3683.2 788 1765.4 1860.4 3530.8 3720.8 882 1784.2 1879.2 3568.4 3758.4

601 1728 1823 3456 3646 695 1746.8 1841.8 3493.6 3683.6 789 1765.6 1860.6 3531.2 3721.2 883 1784.4 1879.4 3568.8 3758.8

602 1728.2 1823.2 3456.4 3646.4 696 1747 1842 3494 3684 790 1765.8 1860.8 3531.6 3721.6 884 1784.6 1879.6 3569.2 3759.2

603 1728.4 1823.4 3456.8 3646.8 697 1747.2 1842.2 3494.4 3684.4 791 1766 1861 3532 3722 885 1784.8 1879.8 3569.6 3759.6

604 1728.6 1823.6 3457.2 3647.2 698 1747.4 1842.4 3494.8 3684.8 792 1766.2 1861.2 3532.4 3722.4

605 1728.8 1823.8 3457.6 3647.6 699 1747.6 1842.6 3495.2 3685.2 793 1766.4 1861.4 3532.8 3722.8

Page 46 ãNokia Corporation Issue 1 05/02

Page 47

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

Alignment

NHM-8NX manual align with Phoenix

In Phoenix select connection Fbus and Product Gemini. If you power up the board before

selecting Fbus, it works without any error messages. Use Jig or other device for RF and

bus connection. Attenuation in the probe alone is 0.5dB for 900 and 1dB for 1800. Use

CMD55 or other suitable device. Default channels are 37 for GSM900 and 700 for

GSM1800. The alignments and calibrations must be performed in the order shown to

give reliable results.

The way to save data to the phone and to load data from the phone is made different in

the various tunings. Always look what is shown in the windows regarding these issues

and act accordingly.

To vary a selected parameter you can use + and – key or in some cases directly type the

new value. + and – steps the value for every press. Repeat function seems not to work. In

I/Q you can use the side arrows.

RX calibration

Select Maintenance, Tuning, RX Calibration

Select Band: GSM 900

The result should be like the shown:

Issue 1 05/02 ãNokia Corporation Page 47

Page 48

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

1 Select Automatic, set to 60dBm in small window in top bar

2 Start and select PM settings in the start parameters that pops up

3OK

Page 48 ãNokia Corporation Issue 1 05/02

Page 49

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions

1 The existing data in the phone is shown

2 Calibrate, and the new data is shown

3 Stop, and the little window pops up where you can select to save or not

4 Select GSM1800 in the top bar and repeat at channel 700

1 The existing data in the phone is shown

2 Calibrate, and the new data is shown

3 Stop, and the little window pops up where you can select to save or not

RX channel select filter

1 Select Maintenance, Tuning, Rx Channel Select Filter Calibration

2 Press Start and you can select to load values from the phone or not

3 Press AutoTune

Issue 1 05/02 ãNokia Corporation Page 49

Page 50

NHM-8NX

Troubleshooting Instructions PAMS Technical Documentation

4 Press Stop and you can select to save values to the phone or not

Note: This calibration requires no input signal

RX Band Filter Response

1 Select Maintenance, Tuning, Rx Band Filter Response Compensation

2 Press Start, Read from PM area and you can select to load values from the phone

or not

3 Press Manual Tuning

4 Set the Signal generator according to the pop-up windows

5 When finished press Stop, Write to PM area and you can select to save values to

the phone or not

Page 50 ãNokia Corporation Issue 1 05/02

Page 51

NHM-8NX

PAMS Technical Documentation Troubleshooting Instructions