Page 1

Customer Care Solutions

RH-18/36/38 Series Transceivers

Engine module

Issue 1 10/03 Nokia Corporation

Page 2

RH-18/36/38 Company confidential

Engine module CCS Technical Documentation

[This page left intentionally blank]

Page 2 Nokia Corporation. Issue 1 10/03

Page 3

Company confidential RH-18/36/38

CCS Technical Documentation Engine module

Table of Contents

Page No

Electronics of Nokia 1100.............................................................................................. 8

Environmental Specifications .....................................................................................8

Baseband HW Introduction ........................................................................................8

Technical Summary .....................................................................................................8

Modes of Operation ...................................................................................................10

No supply ................................................................................................................ 10

Power_off................................................................................................................ 10

Acting Dead............................................................................................................. 11

Active...................................................................................................................... 11

Sleep mode.............................................................................................................. 12

Charging.................................................................................................................. 12

DC Characteristics .....................................................................................................13

Supply Voltage Ranges........................................................................................... 13

Regulators’ Voltage Ranges.................................................................................... 14

Interconnection Diagram ...........................................................................................15

External Signals and Connections .............................................................................15

System connector (X102)........................................................................................ 15

Battery connector .................................................................................................... 16

Baseband – RF interface ......................................................................................... 17

Internal Signals and Connections ..............................................................................17

Audio....................................................................................................................... 17

Baseband board clocks............................................................................................ 18

Functional Description................................................................................................. 19

Audio External ...........................................................................................................19

Audio Internal ......................................................................................................... 19

Earpiece................................................................................................................... 19

Microphone ............................................................................................................. 20

Buzzer...................................................................................................................... 21

Flashlight................................................................................................................. 21

Batteries .....................................................................................................................22

Keyboard...................................................................................................................... 23

Display & Keyboard Backlight............................................................................... 24

Keyboard light......................................................................................................... 24

Display .......................................................................................................................24

Memory Module ........................................................................................................25

SIM Interface .............................................................................................................25

Vibra........................................................................................................................ 25

Test Interfaces ............................................................................................................26

Connections to Baseband ...........................................................................................26

FBUS Interface........................................................................................................ 26

MBUS Interface ...................................................................................................... 26

General description of the RF circuits ......................................................................... 27

Receiver signal path ...................................................................................................27

Transmitter signal path ..............................................................................................28

PLL ............................................................................................................................28

Power Supply .............................................................................................................30

Issue 1 10/03 Nokia Corporation. Page 3

Page 4

RH-18/36/38 Company confidential

Engine module CCS Technical Documentation

[This page left intentionally blank]

Page 4 Nokia Corporation. Issue 1 10/03

Page 5

Company confidential RH-18/36/38

CCS Technical Documentation Engine module

Abbreviations

Abbr. Description

ACI Accessory Control Interface

ADC Analog Digital Connector

ARM Advanced RISC Machines

ASIC Application Specific Integrated Circuit

ATR Answer To Reset

BB Baseband

BL-5C Battery type.

BSI Battery Size Indicator

Cbus Control bus (internal phone interface between UPP-UEM)

CCS Customer Care Service

CPH Copenhagen, Denmark

CTI Cover Type Indicator

CTSI Clock Timing Sleep and Interr up t

Dbus DSP controlled bus (Internal phone interface between UPP-UEM)

DC Direct Current

DCT4.0 Digital Core Technology, generation 4.0

DSP Digital Signal Processor

DUT Device under test

EAD External Accessory Detection

EMC Electro Magnetic Compatibility

ESD Electro Static Discharge

Fbus Fast Bus, asynchronous message bus connected to DSP (communications bus)

FCI Functional cover interface

FPC Flexible printed circuit

FR Full Rate

GENIO General Purpose Input/Output

GSM Global System Mobile

HW Hardware

IF Interface

Issue 1 10/03 Nokia Corporation. Page 5

Page 6

RH-18/36/38 Company confidential

Engine module CCS Technical Documentation

IHF Integrated Hands Free

IMEI International Mobile Equipment Identity

Jannette DCT3.x accessory program

LCD Liquid Crystal Display

LDO Low Drop Out

LED Light Emitting Diode

Li-Ion Lithium Ion battery

Lion Battery program

LN Lotus Notes

LPRF Low Power Radio Frequency

Lynx Battery type, Lion program, Salo – Finland

MALT Medium And Loud Transducer

Maxwell GSM phone program

Mbus Asynchronous message bus connected to MCU (phone control interface). Slow

message bus for control data.

MCU Micro Controller Unit

NO_SUPPLY UEM state where UEM has no supply what so ever

NRT Nokia Ringing Tones

NTC Negative temperature Coefficient, temperature sensitive resistor used as a tem-

perature sensor.

PA Power Amplifier (RF)

PDA Personal Digital Assistant

PDM Pulse Density Modulation

PDRAM Program/Data RAM

Phoenix SW tool of DCT4.x

Pippi Hdb12, Phone program (3510)

PLL Phase locked loop

PnPHF Plug and Play Handsfree

PUP General Purpose IO (PIO), USARTS and Pulse Width Modulators

PWB Printed Wired Board

PWR_OFF UEM state where phone is off

PWRONX Signal from power on key.

R&D Research and development

Page 6 Nokia Corporation. Issue 1 10/03

Page 7

Company confidential RH-18/36/38

CCS Technical Documentation Engine module

RESET UEM state where regulators are enabled

RTC UEM internal Real Time Clock

SARAM Single Access RAM

SIM Subscriber Identification Module

SLEEP UEM power saving state controlled by UPP

SPR Standard Product Requirements

SRAM Static RAM

STI Serial Trace Interface

SW Software

TBSF Through the Board Side Firing

TDB To Be Defined

TI Texas Instruments

UEM Universal Energy Management

UI User Interface

UPP Universal Phone Processor

VBAT Main battery voltage

VCHAR Charger input voltage

VCHARDET Charger detection threshold level

VMSTR+,

VMSTR

Master Reset threshold level

Issue 1 10/03 Nokia Corporation. Page 7

Page 8

RH-18/36/38 Company confidential

Engine module CCS Technical Documentation

Electronics of Nokia 1100

Environmental Specifications

Table 1: Environmental specifications

Parameter Ambient temperature Remarks

Normal operation -25 ° C … +55 °C Specifications fulfilled

Reduced performance -40 °C ..-25 °C

and +55 °C … +85 °C

No operation and/or storage

Humidity Relative humidity

< -40 °C or > +85 °C No storage or operation. An attempt to operate may

5...95%.

Baseband HW Introduction

This document specifies the baseband module for the Nokia 1100. The baseband module

includes the baseband engine chipset, the UI components and the acoustical parts for

the transceiver.

Nokia 1100 is a hand-portable dualband 900/1800MHz or 850/1900MHz phone, featuring the DCT4 generation baseband (UEM/UPP) and RF (MJOELNER) circuitry.

Technical Summary

The baseband module contains 2 main ASICs named the UEM and UPP. The baseband

module furthermore contains a Flash IC of 16Mbit. The baseband is based on the DCT4

damage the phone permanently

The module is not protected against water. Con-

densed or splashed water might cause malfunction.

Any submerge of the phone will cause permanent

damage. Long-term high humidity, with condensation, will cause permanent damage because of corrosion.

Page 8 Nokia Corporation. Issue 1 10/03

Page 9

Company confidential RH-18/36/38

CCS Technical Documentation Engine module

engine program.

PA Supply

RF Supplies

RF RX/TX

SIM

Flashlight

EAR

MIC

speaker

Buzzer

UI

Battery

Baseband

UEM

External Audio

Charger connection

DLIGHT

SLEEPCLK

32kHz

CBUS/

DBUS

BB

Supplies

Mjoelner

26MHz

UPP

RFBUS

FLASH

MEMADDA

M

VIBRA

DCT4 Janette connector

MBus/FBus

Figure 1: Baseband block diagram

The UEM supplies both the baseband module as well as the RF module with a series of

voltage regulators. Both the RF and Baseband modules are supplied with regulated voltages of 2.78 V and 1.8V. UEM includes 6 linear LDO (low drop-out) regulators for baseband and 7 regulators for RF. The UEM is furthermore supplying the baseband SIM

interface with a programmable voltage of either 1.8 V or 3.0 V. The core of the UPP is

supplied with a programmable voltage of 1.0 V, 1.3 V, 1.5 V or 1.8 V.

UPP operates from a 26MHz clock, coming from the RF ASIC MJOELNER, the 26 MHz

clock is internally divided by two, to the nominal system clock of 13MHz. DSP and MCU

contain phase locked loop (PLL) clock multipliers, which can multiply the system.

The UEM contains a real-time clock, sliced down from the 32768 Hz crystal oscillator.

The 32768 Hz clock is fed to the UPP as a sleep clock.

The communication between the UEM and the UPP is done via the bi-directional serial

busses CBUS and DBUS. The CBUS is controlled by the MCU and operates at a speed of 1

MHz set by SW. The DBUS is controlled by the DSP and operates at a speed of 13 MHz.

Both processors are located in the UPP.

Issue 1 10/03 Nokia Corporation. Page 9

Page 10

RH-18/36/38 Company confidential

Engine module CCS Technical Documentation

The UEM ASIC mainly handles the interface between the baseband and the RF section.

UEM provides A/D and D/A conversion of the in-phase and quadrature receive and transmit signal paths and also A/D and D/A conversions of received and transmitted audio signals to and from the user interface. The UEM supplies the analog signals to RF section

according to the UPP DSP digital control.

RF ASIC MJOELNER is controlled through UPP RFBUS serial interface. There are also separate signals for PDM coded audio. Digital speech processing is handled by the DSP

inside UPP ASIC. UEM is a dual voltage circuit, the digital parts are running from the

baseband supply 1.8V and the analog parts are running from the analog supply 2.78V,

also VBAT is directly used by some blocks.

The baseband supports both internal and external microphone inputs and speaker outputs. Input and output signal source selection and gain control is done by the UEM

according to control messages from the UPP.

The transceiver module is implemented on 6 layer selective OSP/Gold coated PWB.

Modes of Operation

baseband has six different operating modes (in normal mode):

• No_Supply

• Power_off

• Acting_Dead

• Active

• Sleep

• Charging

Additionally two modes exist for product verification: 'testmode' and 'local mode'.

No supply

In No_Supply mode, the phone has no supply voltage. This mode is due to disconnection

of main battery or low battery voltage level.

Phone is exiting from No_Supply mode when sufficient battery voltage level is detected.

Battery voltage can rise either by connecting a new battery with VBAT > V

connecting charger and charging the battery above V

mstr+

.

mstr+

or by

Power_off

In this state the phone is powered off, but supplied. VRTC regulator is active (enabled)

having supply voltage from main battery. Note, the RTC status in PWR_OFF mode

depends on whether RTC was enabled or not when entering PWR_OFF. From Power_off

Page 10 Nokia Corporation. Issue 1 10/03

Page 11

Company confidential RH-18/36/38

CCS Technical Documentation Engine module

mode UEM enters RESET mode (after 20ms delay), if any of following statements is true

(logical OR –function):

– Power_on button detected (PWROFFX)

– charger connection detected (VCHARDET)

– RTC_ALARM detected

The Phone enters POWER_OFF mode from all the other modes except NO_SUPPLY if

internal watchdog elapses.

Acting Dead

If the phone is off when the charger is connected, the phone is powered on but enters a

state called”Acting Dead”, in this mode no RF parts are powered. To the user, the phone

acts as if it was switched off. A battery-charging alert is given and/or a battery charging

indication on the display is shown to acknowledge the user that the battery is being

charged.

Active

In the active mode the phone is in normal operation, scanning for channels, listening to

a base station, transmitting and processing information. There are several sub-states in

the active mode depending on if the phone is in burst reception, burst transmission, if

DSP is working etc.

In active mode the RF regulators are controlled by SW writing into UEM’s registers

wanted settings: VR1A/B must be kept disabled. VR2 can be enabled or forced into low

quiescent current mode. VR3 is always enabled in active mode. VR4 -VR7 can be enabled,

disabled or forced into low quiescent current mode.

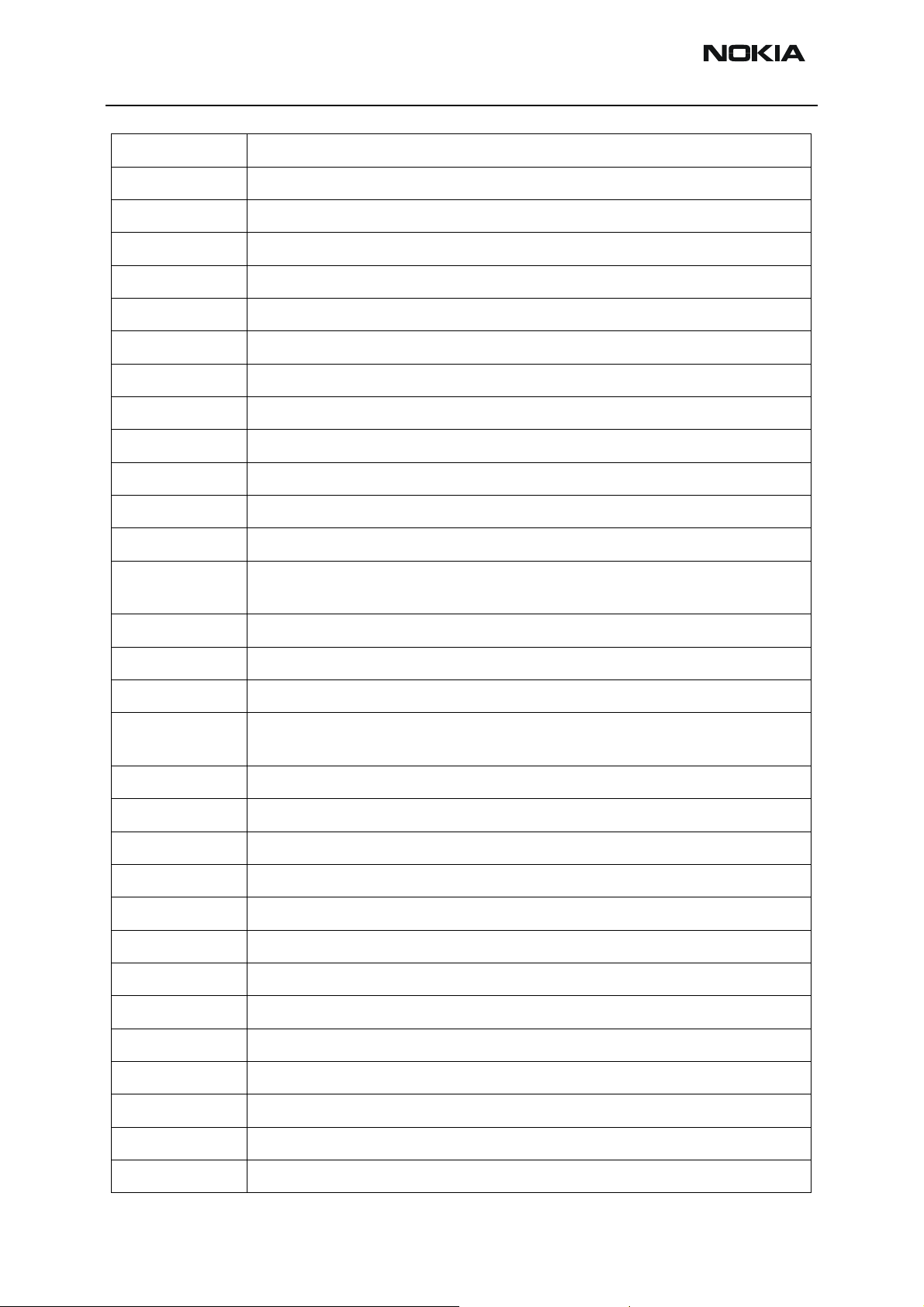

Table 2: Regulator controls

Regulator NOTE

VFLASH1 Enabled; Low Iq mode during sleep

VFLASH2 Disabled

VANA Enabled; Disabled in sleep mode

VIO Enabled; Low Iq mode during sleep

VCORE Enabled; Low Iq mode during sleep

VSIM Controlled by register writing.

VR1A Enabled; Disabled in sleep mode

VR1B Disabled

VR2 Controlled by register writing; Enabled in sleep mode

VR3 Enabled; Disabled in sleep mode

Issue 1 10/03 Nokia Corporation. Page 11

Page 12

RH-18/36/38 Company confidential

Engine module CCS Technical Documentation

Table 2: Regulator controls

VR4 Enabled; Disabled in sleep mode

VR5 Enabled; Disabled in sleep mode

VR6 Enabled; Disabled in sleep mode

VR7 Enabled; Disabled in sleep mode

IPA1-2 Disabled

Sleep mode

Sleep mode is entered when both MCU and DSP are in stand-by mode. Sleep is controlled

by both processors. When SLEEPX low signal is detected UEM enters SLEEP mode. VCORE,

VIO and VFLASH1 regulators are put into low quiescent current mode. All RF regulators,

except VR2, are disabled in SLEEP . When SLEEPX=1 is detected UEM enters ACTIVE mode

and all functions are activated.

The sleep mode is exited either by the expiration of a sleep clock counter in the UEM or

by some external interrupt, generated by a charger connection, key press, headset connection etc.

In sleep mode the main oscillator (26MHz) is shut down and the 32 kHz sleep clock oscillator is used as reference clock for the baseband.

Charging

Charging can be performed in parallel with any other operating mode. A BSI resistor

inside the battery pack indicates the battery type/size. The resistor value corresponds to

a specific battery capacity and technology.

The battery voltage, temperature, size and current are measured by the UEM controlled

by the charging software running in the UPP.

The charging control circuitry (CHACON) inside the UEM controls the charging current

delivered from the charger to the battery. The battery voltage rise is limited by turning

the UEM switch off when the battery voltage has reached VBATLim (programmable

charging cut-off limits 3.6V / 5.0V / 5.25V). Charging current is monitored by measuring

the voltage drop across a 220 mOhm resistor.

Page 12 Nokia Corporation. Issue 1 10/03

Page 13

Company confidential RH-18/36/38

CCS Technical Documentation Engine module

DC Characteristics

Supply Voltage Ranges

Table 3: Absolute Maximum Ratings

Signal Rating

Battery Voltage 0... 4.39V (VBAT)

Charger Input Voltage -0.3... 9.2VRMS (16,9 Vpeak)

Following voltages are the normal and extreme voltages for the battery:

Signal Min. Nom Max Note

VBAT 3.21V 3.80V 4.39V 1

Vcoff+ 3.0V 3.1 3.2 HW off to on

Vcoff- 2.7V 2.8V 2.9V HW on to off

Vmstr+ 2.0V 2.1V 2.2V UEM off to on

Vmstr- 1.8V 1.9V 2.0V UEM on to off

Sw shutdown - 3.1V - In Call

Sw shutdown - 3.2V - In Idle

Table 4: Battery voltage range

1

According to the GSM specifications, a GSM-device must work correctly if it is powered

by his nominal voltage +/-15%. The UEM hardware shut down is from 3.10V and below.

The Energy Managment of the phone is shutting down the phone at 3.20V in order to

perform a correct shutdown of the phone. Above 3.20V + tolerances, at 3.21V, the phone

is still fullfilling all the GSM requirements. The Nominal voltage is therefore set at 3.80V.

During fast charging of an empty battery voltages between 4.20 and 4.60 might appear

for a short while.

Issue 1 10/03 Nokia Corporation. Page 13

Page 14

RH-18/36/38 Company confidential

Engine module CCS Technical Documentation

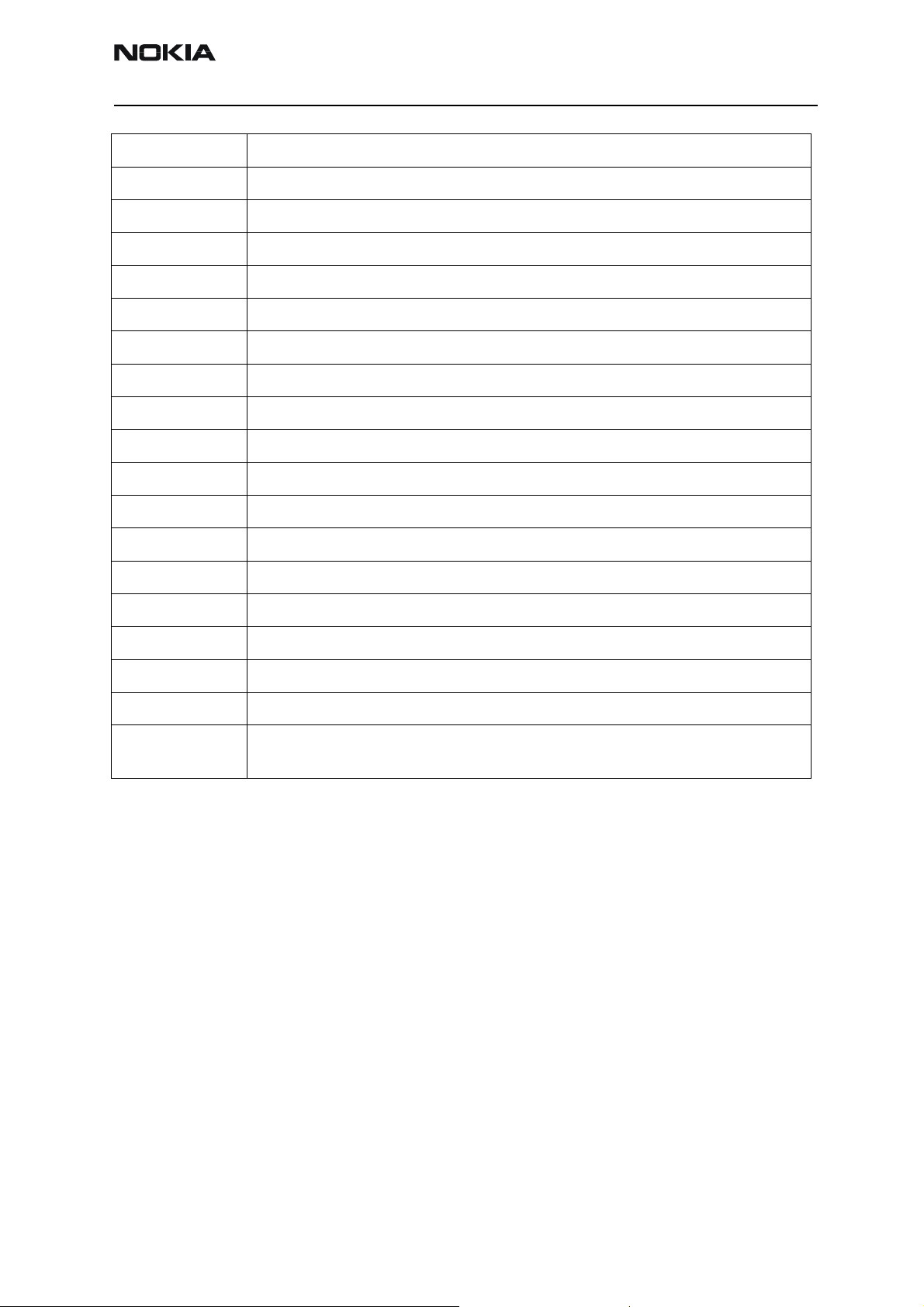

Regulators’ Voltage Ranges

Signal Min. Nom Max

VANA 2.70V 2.78V 2.86V

VFLASH1 2.70V 2.78V 2.86V

VFLASH2 2.70V 2.78V 2.86V

VSIM 1.745V

2.91V

VIO 1.72V 1.8V 1.88V

VCORE 1.000V

1.140V

1.235V

1.425V

1.710V

Signal Min. Nom Max

VR1A 4.6V 4.75V 4.9V

VR1B 4.6V 4.75V 4.9V

VR2 V

V

VR3 2.70V 2.78V 2.86V

VR4 2.70V 2.78V 2.86V

VR5 2.70V 2.78V 2.86V

out_on

out_sleep

2.70V

2.61V

1.8V

3.0V

1.053V

1.2V

1.3V

1.5V

1.8V

Table 5: BB regulators

2.78V 2.86V

1.855V

3.09V

1.106V

1.260V

1.365V

1.575V

1.890V

2.95V

VR6 2.70V 2.78V 2.86V

VR7 2.70V 2.78V 2.86V

Table 6: RF regulators

Page 14 Nokia Corporation. Issue 1 10/03

Page 15

Company confidential RH-18/36/38

CCS Technical Documentation Engine module

Interconnection Diagram

Battery

Baseband

VLED+

LED

Driver

VBAT

VBAT

UEM

RTC

Accessory

Regulator

Vout

RF Regulators

Baseband

Regulators

CHACON

VR1A

VR1B

VR2-7

VSIM

VCORE

VANA

VIO

VFLASH1

VR4

6

SIM

UPP

FLASH

SRAM

LCD

FM

Radio

PA Supply

System Connector

Figure 2: Power distribution diagram

External Signals and Connections

System connector (X102)

Pin Signal Min. Nom Max Condition Note

2VCHAR-11.1V

7.0

V

RMS

8.4 V

peak

RMS

1CHGND-0 - Charger ground

Table 7: DC connector

16.9 V

7.9 V

RMS

1.0 A

peak

9.2 V

RMS

850 mA

peak

Standard

charger

(ACP-7)

Fast

charger

Charger positive

input

Issue 1 10/03 Nokia Corporation. Page 15

Page 16

RH-18/36/38 Company confidential

Engine module CCS Technical Documentation

Signal Min. Nom Max Condition Note

MIC2P (Differential input P) - - 100mV

MIC2N (Differential input N) - - 100mV

MICB2 (Microphone Bias) 2.0 V 2.1 V 2.25 V DC Unloaded

External loading of MICB2 - - 600uA DC

Table 8: External microphone

Signal Min. Nom Max Units Note

Output voltage swing*

* seen from transducer side

Common voltage level for

HF output (HF & HFCM) VCMHF

Load Resistance (HF to HFCM) 154 194 234 W 2×22Ω (±5%) + 150Ω (±25%)

Load Capacitance (HF to HFCM) - - 10 NF Load to GND

Table 9: External speaker, differential output XEARP (HF) & XEARN (HFCM)

2.0 - - Vpp Differential output, with 60 dB sig-

0.75 0.8 0.85 V

G=20dB 1,22kΩ to MIC1B (AC con-

pp

G=20dB 1kΩ to GND

pp

dition)

nal to total distortion ratio

Signal Min. Nom Max Condition Note

HookInt 0V - 2.86V (Vflash1) Headset button call control, connected

to UEM AD-converter

HeadInt 0V - 2.86V (V flash1) Accessory detection, connected to

UEM AD-converter

Table 10: Headset detection

Battery connector

Battery temperature is estimated by measurement in Transceiver PWB with a separate

NTC resistor. Thus the Battery Interface has only 3 contacts.

Table 11: Battery connector

Name Description Test usage

VBAT Battery voltage terminal. Battery calibration.

GND Battery ground terminal.

BSI Battery size identification. Flash and local mode forcing.

Page 16 Nokia Corporation. Issue 1 10/03

Page 17

Company confidential RH-18/36/38

CCS Technical Documentation Engine module

Baseband – RF interface

The interface between the baseband and the RF can be divided into three categories:

- The digital interface from the UPP to the RF ASIC (Mjoelner). The serial digital interface

is used to control the operation of the different blocks in the RF ASICs.

- The analogue interface between UEM and the RF . The analogue interface consists of RX

and TX converter signals. The power amplifier control signal TXC and the AFC signal

comes as well from the UEM.

- Reference clock interface between Mjoelner and UPP which supplies the 26Mhz system

clock for the UPP .

Internal Signals and Connections

The tables below describe internal signals. The signal names can be found on the schematic for the PWB.

Audio

Signal Min. Nom Max Condition Note

MIC1P (Differential input P) - 5mV - G=0dB 1kΩ to MIC1B

(RC filtered by 220R/4.7uF)

MIC1N (Differential input N) - 5mV - G=0dB 1kΩ to GND

MICB1 (Microphone Bias) 2.0 V 2.1 V 2.25 V DC

External loading of MICB1 - - 600uA DC

Table 12: Internal microphone

Signal Min. Nom Max Units Note

Output voltage swing 4.0 - - Vpp Differential output

Load Resistance (EARP to EARN) 26 32 - W

Load Capacitance (EARP to EARN) - - 50 NF

Table 13:

Internal speaker (Differential output EARP & EARN)

Issue 1 10/03 Nokia Corporation. Page 17

Page 18

RH-18/36/38 Company confidential

Engine module CCS Technical Documentation

Baseband board clocks

Signal name From To Min. Typ. Max. Unit Notes

RFCLK MJOELNER U PP - 26 - MHz Active when

SLEEPX is high

SLEEPCLK UEM UPP - 32.768 - KHz Active when

VBAT is supplied

RFCONVCLK UPP UEM 13 - MHz Active when RF

converters are

active

RFBUSCLK UPP MJOELNER - 13 13 MHz Only active

when bus-enable is active

DBUSCLK UPP (DSP) UEM - 13 13 MHz Only active

when bus-enable is active

CBUSCLK UPP (MCU) UEM - 1 1.2 MHz Only active

when bus-enable is active

LCDCAMCLK UPP

(Write)

(Read)

LCD 0.3

Table 14: Board Clocks

3.25

0.650

4 MHz Only active

when bus-enable is active

Page 18 Nokia Corporation. Issue 1 10/03

Page 19

Company confidential RH-18/36/38

CCS Technical Documentation Engine module

Functional Description

Audio External

Nokia 1100 is designed to support fully differential external audio accessory connection.

A headset and PnPHF can be directly connected to system connector.

2.7V

Not all components are shown

Hookint

/MBUS

Headint

Headint

HFCM

EAD

Mic_bias

HF

UEM

MICB2

MIC2P

MIC2N

3...25k

Headset accessory uses 4-wire fully differential audio connection.

Audio Internal

Bottom

Connector

1k0

2.1V

33N

0.8V

0.8V

33N

1k0

Figure 3: Headset Interface

1.8V

0.3V

MicGnd

Earpiece

The earpiece selected is a 13-mm dynamic earpiece with a nominal impedance of 32 Ω (.

The earpiece is placed within the mechanic parts, e.g. C-cover and Light guide. The holes

of the A-cover and the choice of dust shield are made in a way to have the best transmission of the sound, without having much impact on the sound waves and sound qualities.

The acoustic design involves a sandwich of five parts: Earmat, A-cover, C-cover, lightguide- and D-cover.

On top of the lightguide there will be a metal frame (C-cover) that protects the earpiece.

The C-cover includes 5 acoustical holes and a double-sided gasket for sealing in the area

over the earpiece.

The front cover consists of two parts, an A-cover and an earmat with six acoustical holes,

2 direct front holes, and 4 leak holes.

Issue 1 10/03 Nokia Corporation. Page 19

Page 20

RH-18/36/38 Company confidential

Engine module CCS Technical Documentation

Two dust shields will be used: one in the gap between earmat and A-cover and one on

the C-cover.

The earpiece circuit includes only a few components:

two 10 ohm in order to have a stable output

an EMC filter

Placed in top of

PWB, near

earpiece

EARP

EARN

UEM

EARP

EARN

Placed near UEM

10

ohm

10

ohm

Microphone

An omni directional microphone is used. The microphone is placed in the system connector sealed in its rubber gasket. The sound port is provided in the system connector.

The microphone connection comprises a differential bias circuit, driven directly from the

MICB1 bias output with external RC-filters.

Figure 4: Earpiece interface

Figure 5: Bottom connector including the microphone

Page 20 Nokia Corporation. Issue 1 10/03

Page 21

Company confidential RH-18/36/38

CCS Technical Documentation Engine module

The RC filter (220 Ω, 4.7µF) is scaled to provide damping at 217 Hz.

Buzzer

UEM

MICB1

MIC1P

MIC1N

MICBCAP

Placed near

UEM

4.7uF

1k

1n 1n

2k2

2k2

1k

220

2k2

2k2

1u

22k

2*33n

Placed near

bottom

connector

MIC+

1n

MIC-

Figure 6: Internal electrical microphone interface

The ringing tones are generated by a buzzer , which gives monophonic ringing tones. Figure below shows the electrical interface of the buzzer..

UEMc

Vbat

Flashlight

The flashlight feature can be used to light up for example a keyhole.

Flashlight nominal

current

20mA 25°C See Figure 8

6mA 85°C See Figure 8

VBATDriv

Buzz0

VSADriv2

56pF

56pF

220nH

220nH

Figure 7: Electrical interface of buzzer

Temperature Note

Table 15: Flashlight LED currents

12pF

Buzzer

12pF

Issue 1 10/03 Nokia Corporation. Page 21

Page 22

RH-18/36/38 Company confidential

Engine module CCS Technical Documentation

Figure 8: Flashlight nominal currents

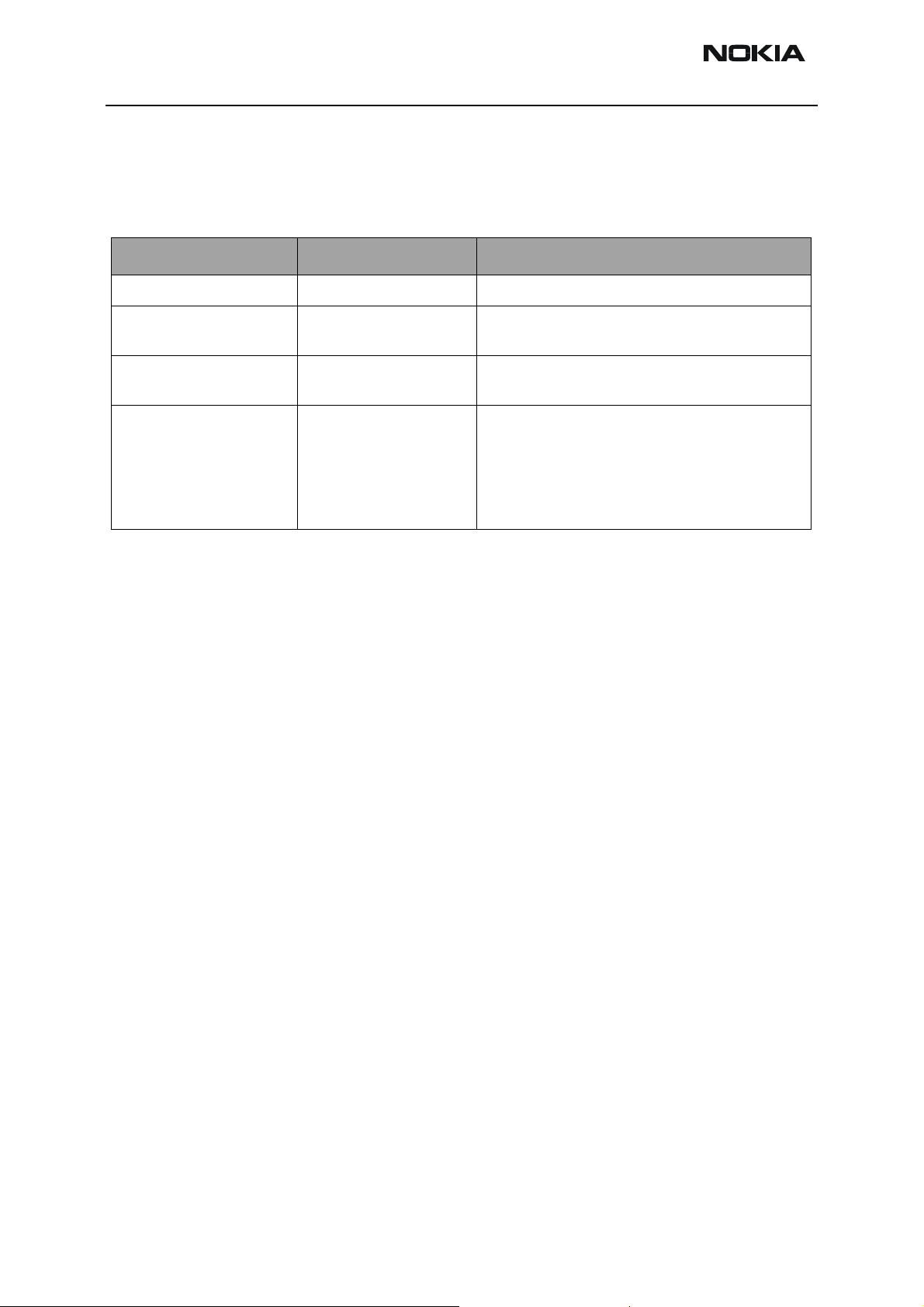

Batteries

Type: BL-5C battery

Technology:Li-Ion. 4.23V charging. 3.1V cut-off

Capacity:850 mA/h

Figure 9: BL-5C Battery

The BSI values:

Mode BSI (kOhm) Description

Min. Type Max

Normal 75 Used for calculating the Capacity (BL5-C = 850mA)

Service 3.2 3.3 3.4 Pull-down resistor in battery. Used for fast power-up in pro-

duction (LOCAL mode), R/D purposes or in after sales, 1% tolerance resistors shall be used.

Table 16: BSI levels BL-5C Battery

The battery includes an over-temperature and an over-voltage protection circuit.

Page 22 Nokia Corporation. Issue 1 10/03

Page 23

Company confidential RH-18/36/38

CCS Technical Documentation Engine module

Keyboard

The keyboard PWB layout consists of a grounded outer ring and an inner pad.

Power key is integrated in keypad. For the schematic diagram of the keyboard kindly refer

to the A3 schematic diagrams.

Table 17: Keyboard configuration

UPP Pin Pad symbol

GenIO1 0 In Up GenIOInt5 Falling edge interrupt

GenIO2/P05 7 In Up P0 int Falling edge interrupt

GenIO20 # In Up GenIOInt2 Falling edge interrupt

GenIO21 * In Up GenIOInt3 Falling edge interrupt

GenIO25 Up In Up GenIOInt4 Falling edge interrupt

GenIO27 1 In Up GenIOInt6 Falling edge interrupt

P00 Menu/(End) In Up P0 int Falling edge interrupt

P01 3 In Up P0 int Falling edge interrupt

P02 9 In Up P0 int Falling edge interrupt

P03 8 In Up P0 int Falling edge interrupt

P04 Down In Up P0 int Falling edge interrupt

P10 6 In Up P1 int Falling edge interrupt

In/

Out

Internal

Pull

Up/down

Interrupt

P11 4 In Up P1 int Falling edge interrupt

P13 5 In Up P1 int Falling edge interrupt

P14 C/(Send) In Up P1 int Falling edge interrupt

P15 2 In Up P1 int Falling edge interrupt

All lines are configured as input, when there is no key pressed.

When a key is pressed, the specific line where the key is placed is pulled low. This gener-

ates an interrupt to the MCU and the MCU now starts its scanning procedure.

When the key has been detected all the keypad-register inside the UPP is reset and it's

ready receiving new interrupt.

Issue 1 10/03 Nokia Corporation. Page 23

Page 24

RH-18/36/38 Company confidential

Engine module CCS Technical Documentation

Display & Keyboard Backlight

LCD Backlight (RH-18 only)

LCD Backlight consists of 2 sidefirering super yellow-green dual pack LED's which are

placed on the display FPC besides the LCD area. They lit into the light guide where the

light is distributed to generate sufficient backlight for the LCD & keyboard area.

Keyboard light

There is no dedicated keyboard light implemented. Keyboard light is provided by the LCD

backlight.

Display

The LCD is a black and white 96x65 full dot matrix display. The LCD has a standard DCT4

interface. The LCD cell is part of the complete LCD module, which includes C-cover, gasket, light guide, spring connector, transflector, LEDs and earpiece. The following figure

illustrates the complete overview of the LCD module.

Figure 10: LCD module exploded diagram

Figure 11: LCD module

Page 24 Nokia Corporation. Issue 1 10/03

Page 25

Company confidential RH-18/36/38

CCS Technical Documentation Engine module

Memory Module

The baseband memory module consists of external burst flash memory 2Mbyte (16Mbit)

(optional: 4Mbyte (32Mbit) or 8MByte (64Mbit)). The UPP contains internal SRAM with 2

Mbit (optional: 4Mbit or 8Mbit). The UPP will not be covered here.

SIM Interface

The whole SIM interface is located in the two ASICs, UPP and UEM.

The SIM interface in the UEM contains power up/down, port gating, card detect, data

receiving, ATR-counter, registers and level shifting buffers logic. The SIM interface is the

electrical interface between the Subscriber Identity Module Card (SIM Card) and mobile

phone (via UEM device). .

From Battery Type

contact

Vibra

SIM

C5 C6 C7

C1C2C3

C8

C4

BSI

SIMDATA

SIMCLK

SIMRST

VSIM

UEM

SIMIF

register

SIMClk

Data

UEM

digital

logic

Figure 12: SIM interface

The vibra is placed in the bottom of the phone.

UEM

GND

SIMIO

GND

SIMIO

SIMClk

Data

UPP

UIF Block

UEMInt

CBusDa

CBusEnX

CBusClk

Vbat

VBATDriv

VIBRA

Buzz0

VSADriv2

1u

M

10n

0

35%

5kohm

+/-

Vibraclk

Figure 13: Vibra driver circuit

Issue 1 10/03 Nokia Corporation. Page 25

Page 26

RH-18/36/38 Company confidential

Engine module CCS Technical Documentation

Test Interfaces

The test pattern is placed on engine PWB, for service and production purposes, same test

pattern is used for after sales purposes as well.

Through MBUS or FBUS connections, the phone HW can be tested by PC software (Phoenix) and production equipment (FLALI/FINUI/LABEL).

The test points are listed in the schematic diagrams

Connections to Baseband

The flash programming box, FPS8, is connected to the baseband using a galvanic connector or test pads for galvanic connection.

The flash programming interface connects the flash prommer to the UPP via the UEM

and the connections correspond to a logic level of 2.7 V. The flash prommer is connected

to the UEM via the MBUS (bi-directional line), FBUS_TX, and FBUS_RX. The programming

interface connections between the UEM and the UPP constitute the MBUS_TX,

MBUS_RX, FBUS_TX, and FBUS_RX lines. The interface also uses the BSI

(Battery_Size_Indicator).

FBUS Interface

FBUS is an asynchronous data bus having separate TX and RX signals. Default bit rate of

the bus is 115.2 kbit/s. FBUS is mainly used for controlling phone when flashing.

MBUS Interface

MBUS interface is used for controlling the phone in service. It is bi-directional serial bus

between the phone and PC. The default transmission speed is 9.6 kbit/s.

Page 26 Nokia Corporation. Issue 1 10/03

Page 27

Company confidential RH-18/36/38

CCS Technical Documentation Engine module

General description of the RF circuits

In the following general descriptions different colours are used in the block diagram. The

GSM 850 signal route is shown in red, the GSM1900 route in green and the common signal lines are shown in blue. Signal lines which is common for both

Receiver signal path

The signal from the antenna pad is routed to the RX/TX switch (Z700). If no control voltage is present at VANT2 and VANT1 the switch works as a diplexer and the GSM850 signal is passed through the RX/TX switch to GSM-RX and the GSM1900 signal is passed to

DCS-RX.

Figure 14: Receiver signal path

From the RX/TX switch the GSM850 signal is routed to the SAW filter (Z602). The purpose of the SAW filter is to provide out-of band blocking immunity and to provide the

LNA in Mjoelner (N600) with a balanced signal. The front end of Mjoelner is divided into

a LNA and Pre-Gain amplifier before the mixers.

The output from the mixer is feed to Baseband part of Mjoelner where the signals amplified in the BBAMP and low pass filtered in LPF1 before the DC compensation circuits in

DCN1. The DCN1 output is followed by a controlled attenuator and a second lowpass filter LPF2. The output from LPF2 is DC centered in DCN2 before being feed to the BB for

demodulation.

The GSM1900 signal chain is similar to GSM850, the SAW filter numbered Z601.

Issue 1 10/03 Nokia Corporation. Page 27

Page 28

RH-18/36/38 Company confidential

Engine module CCS Technical Documentation

Transmitter signal path

The I/Q signal from the BB is routed to the modulators for both 850 and 1900 MHz. The

output of the modulators is either terminated in a SAW filter (Z603) for GSM 850 or a

balun for GSM1900. Both signals are amplified in buffers.

The amplitude limited signal is then amplified in the PA (N700) where the gain control

takes place. The TX signal from the couplers is fed to the RX/TX switch, used to select

which signal to route to the antenna.

Figure 15: Transmitter signal path

PLL

The PLL supplies Local Oscillator (LO) signals for the RX and TX-mixers. In order to be able

to generate LO-frequencies for the required EGSM and PCN channels a regular synthesizer-circuit is used. All blocks for the PLL except for the VCO, reference X-tal and loop

filter is located in the Mjoelner IC.

The reference frequency is generated by a 26MHz Voltage Controlled X-tal Oscillator

(VCXO) which is located in the Mjoelner IC. Only the X-tal is external. 26MHz is supplied

to BB where a divide-by-2 circuit (located in the UPP IC) generates the BB-clock at

13MHz. The reference frequency is supplied to the reference divider (RDIV) where the

frequency is divided by 65. The output of RDIV (400kHz) is used as reference clock for the

Phase Detector (ϕ).

The PLL is a feedback control system controlling the phase and frequency of the LO-sig-

Page 28 Nokia Corporation. Issue 1 10/03

Page 29

Company confidential RH-18/36/38

CCS Technical Documentation Engine module

nal. Building blocks for the PLL include: Phase detector, Charge Pump, Voltage Controlled

Oscillator (VCO), N-Divider and loop filter. As mentioned earlier only the VCO and loop

filter is external to the Mjoelner IC.

The VCO (G600) is the component that actually generates the LO-frequency. Based on

the control voltage input the VCO generates a single-ended RF output. The signal is then

differentiated through a balun. This signal is fed to the Prescaler and N-divider in Mjoelner, these 2 blocks will together divide the frequency by a ratio based on the selected

channel.

The divider output is supplied to the phase detector which compares the frequency and

phase to the 400kHz reference clock. Based on this comparison the phase detector controls the charge pump to either charge or discharge the capacitors in the loop filter. By

charging/discharging the loop filter the control voltage to the VCO changes and the LOfrequency will change. Therefore the PLL keeps the LO-frequency locked to the 26MHz

VCXO frequency.

The loop filter consists of the following components: C639-C641 and R618-R619.

The PLL is operating at twice the channel center frequency when transmitting or receiv-

ing in the PCN band. For the EGSM band the PLL is operating at 4-times the channel frequency . Therefore divide-by-2 and divide-by-4 circuits are inserted between the PLL

output and LO-inputs to the PCN and EGSM mixers.

Table 18: Frequency plan

Issue 1 10/03 Nokia Corporation. Page 29

Page 30

RH-18/36/38 Company confidential

Engine module CCS Technical Documentation

Power Supply

All power supplies for the RF Unit are generated in the UEM IC (D200). All power outputs

from this IC has a decoupling capacitor at which the supply voltage can be checked.

The power supply configuration is described in the block diagram below:

Figure 16: Power supply configuration

The names in bold are signal names used on the RF schematic pages. Names in the boxes within the Mjoelner and the VCO refers to pin names on the respective ICs (N600, G600).

Table 19: Power supply signals

Supply name RF Supply name UEM Min Typ Max Unit

VTX VR2 2.64 2.78 2.86 V

VXO VR3 2.64 2.78 2.86 V

VCP VR1A 4.75 V

VPLL VR5 2.64 2.78 2.86 V

VRX VR6 2.64 2.78 2.86 V

VVCO VR7 2.64 2.78 2.86 V

VBB VIO 1.72 1.8 1.88 V

VREF2 VrefRF01 1.334 1.35 1.366 V

VBATT BATTERY 3.1 3.6 5.2 V

Page 30 Nokia Corporation. Issue 1 10/03

Loading...

Loading...