Page 1

Customer Care Solutions

RH-18/36/38 Series Transceivers

T roubleshooting Instructions

Issue 1 10/03 Nokia Corporation

Page 2

RH-18/36/38 Company confidential

Troubleshooting Instructions CCS Technical Documentation

[This page left intentionally blank]

Page 2 Nokia Corporation. Issue 1 10/03

Page 3

Baseband troubleshooting.............................................................................................. 5

Baseband test points ....................................................................................................5

Troubleshooting diagrams ...........................................................................................5

Phone is dead ...............................................................................................................6

Flash programming do not work ..................................................................................7

Power does not stay on or phone is jammed ................................................................8

Display information : "Contact Service" .....................................................................9

The phone do not register to the network, or the phone cannot make a call .............10

SIM related faults ......................................................................................................11

Insert SIM card fault ............................................................................................... 11

SIM-Card rejected................................................................................................... 12

Audio related faults 1: Earpiece and microphone ......................................................13

Audio related faults 2: Headset ..................................................................................14

Charging failure troubleshooting ...............................................................................15

Charging troubleshooting 2 .......................................................................................16

General RF Troubleshooting........................................................................................ 17

RF Key component placement ...................................................................................18

RH-36 Receiver troubleshooting ................................................................................. 21

General Instructions for GSM850 RX Troubleshooting ...........................................21

Troubleshooting diagram for GSM850 Receiver................................................... 22

General Instructions for RH-36 GSM1900 RX Troubleshooting ..............................24

Phoenix commands ................................................................................................. 24

Troubleshooting diagram for GSM1900Receiver................................................... 25

Measurement points in the receiver ........................................................................ 27

RH-36 Transmitter troubleshooting ...........................................................................29

Measurement points for the transmitter .................................................................. 29

General instructions for RH-36 GSM TX troubleshooting .......................................30

GSM850 TX output power...................................................................................... 31

General instructions for RH-36 GSM1900 TX troubleshooting ...............................32

Phoenix commands ................................................................................................. 32

GSM1900 TX output power.................................................................................... 32

Troubleshooting diagram for GSM1900 TX .............................................................33

General Instructions for RH-18/38 GSM900 RX Troubleshooting............................. 35

Troubleshooting Chart for GSM900 Receiver........................................................ 36

General Instructions for GSM1800 RX Troubleshooting .........................................38

Troubleshooting Chart for GSM1800Receiver....................................................... 39

Measurement points in the receiver ........................................................................ 40

RH-18/38 Transmitter troubleshooting ......................................................................42

Measurement points for the transmitter .................................................................. 42

General instructions for RH-18/38 GSM TX troubleshooting ..................................43

PCN Transmitter General instructions for PCN TX troubleshooting ........................45

Synthesizer .................................................................................................................46

26 MHz Reference Oscillator ( VCXO )................................................................. 46

VCO ........................................................................................................................ 46

Troubleshooting diagram for PLL Synthesizer....................................................... 47

Phone fails after power on....................................................................................... 48

Measurement points at the VCXO.......................................................................... 48

Measurement points at the PLL/VCO..................................................................... 49

Issue 1 Page 3

Page 4

RH-18/38 Manual Alignment using Phoenix............................................................... 50

RX calibration ............................................................................................................50

GSM1800 RX calibration ..........................................................................................51

RX channel select filter .............................................................................................52

RX Band Filter Response ..........................................................................................53

Tx Power tuning ........................................................................................................54

TX power tuning GSM............................................................................................ 54

TX power tuning PCN............................................................................................. 57

I/Q tuning ...................................................................................................................59

RF control ..................................................................................................................61

Call testing .................................................................................................................62

Issue 1 Page 4

Page 5

Company confidential RH-18/36/38

CCS Technical Documentation

Baseband troubleshooting

Baseband test points

This document contains the Nokia 1100 troubleshooting diagrams.

Test points are described and listed in the A3 schematic diagrams.

Troubleshooting diagrams

In this section, Troubleshooting diagrams is provided for the most common problems of

the Nokia 1100

NOTE : Since both D200 (UEM) and D400(UPP) are underfilled, they can not be replaced.

If either D200 or D400 is defective, the whole PWB has be discarded.

Issue 1 10/03 Nokia Corporation. Page 5

Page 6

RH-18/36/38 Company confidential

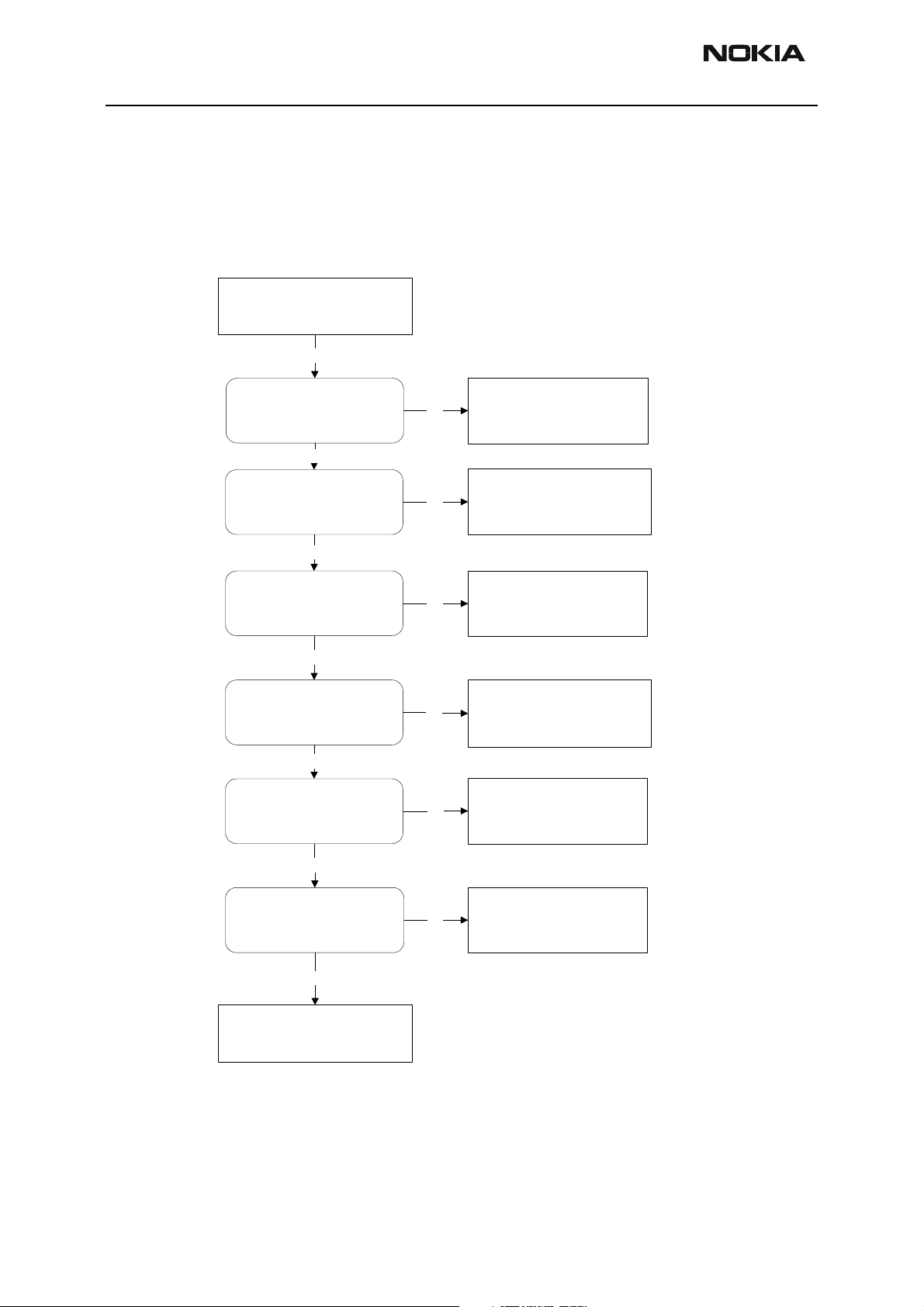

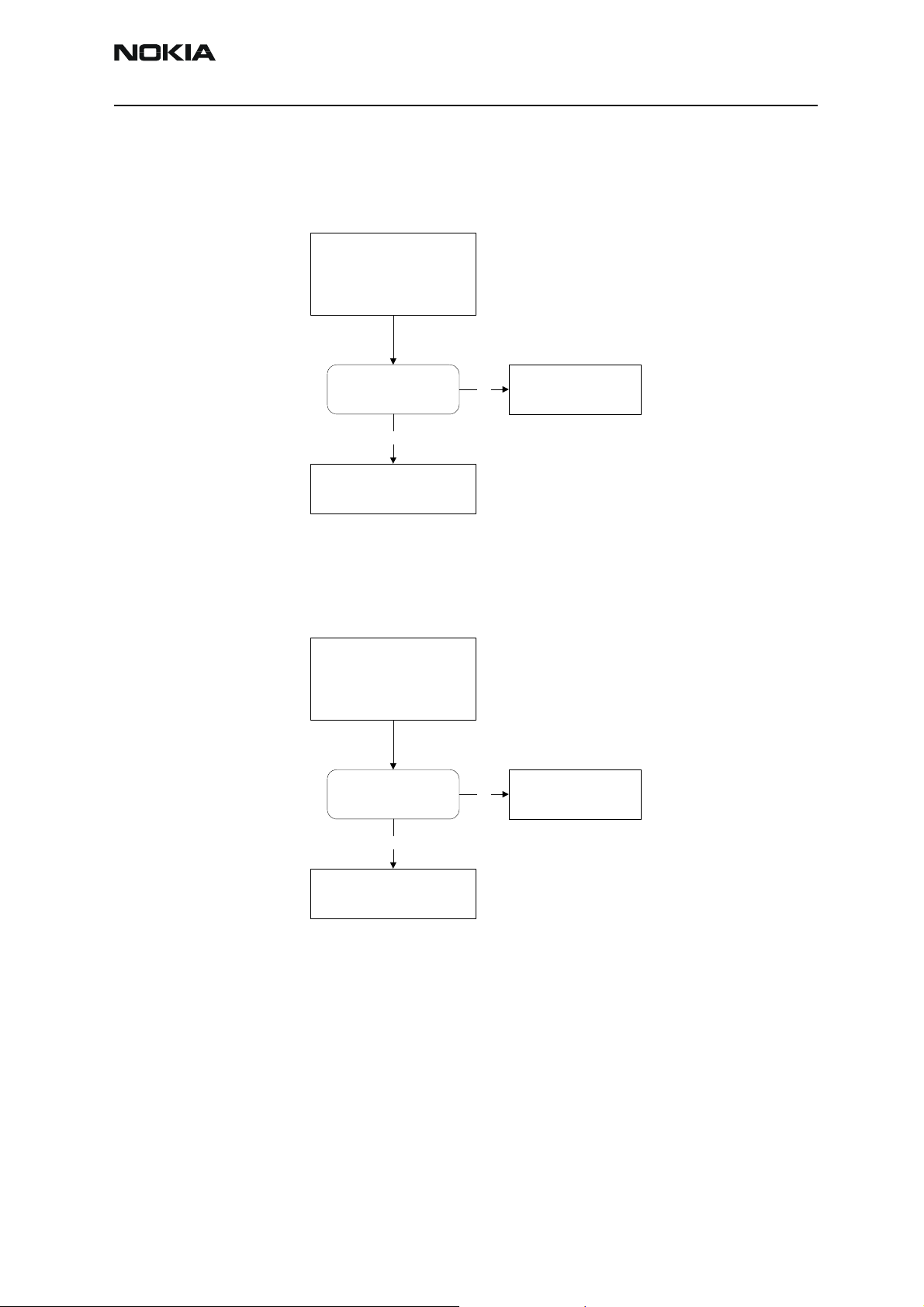

Phone is dead

This means that the phone do not draw any current at all when supply is connected and/

or powerkey is pressed.

It is assumed that the voltage supplied is 3.6 VDC. The UEM will prevent any functionality what so ever at battery/supply levels below 2.9 VDC.

Phone is dead

Yes

CCS Technical Documentation

X105

VBAT = 3,6VDC

Yes

L260,L261,L262,L263,L264,L265

C260,C261,C262,C263,C264,C265

Voltage = 3,6VDC

Yes

J404

Sleep-clock is

32.768 kHz, 1,8Vpp

Yes

J402

PURX = 1,8VDC,

1 sec. after power-key

is pressed

Yes

C227

VR3 = 2,78VDC

No

No

No

No

No

Check :

X105

Check :

L260,L261,L262,L263,L264,L265

C260,C261,C262,C263,C264,C265

Check :

B200, C209, C210, PW B. Else

defective D200*

Check :

PWB.

Else defective D200*

Check :

C227, PWB.

Else defective D200*

Yes

26 MHz clock min. 300mVACpp,

R426

probe Cin=10-13 pF/10M

Yes

No

Check :

C227, PWB.

Else defective D200*

Check :

D450 (Flash).

Else defective D200*

Figure 1: Phone is dead troubleshooting

Page 6 Nokia Corporation. Issue 1 10/03

Page 7

Company confidential RH-18/36/38

CCS Technical Documentation

Flash programming do not work

The flash programming can only be done via the pads on the PWB (J396).

In case of Flash failure in FLALI station, problem is most likely related to SMD problems.

Possible failures could be short-circuit of balls under µBGAs (UEM, UPP, FLASH). Missing

or misaligned components.

In flash programming error cases the flash prommer can give some information about a

fault.

The fault information messages could be:

- Phone doesn't set FBUS_TX line low

Because of the use of uBGA components it is not possible to verify if there is a short cir-

cuit in control- and address lines of MCU (UPP) and memory (flash).

Flash prgramming

do not work

Error fro m prom mer:

"Phone doesn't set

FBUS_T X line low"

Yes

J396, R108

Check connection between

pad 1,2 & 3 on J396

and R108

Yes

J409, J410, J411, J412

Voltage level at 1,8VDC

Yes

Try re a d in g MCU ID

with Phoenix.

Reading OK?

Yes

Try reading Flash ID

with Phoenix.

Reading OK?

No

No

No

No

Check :

R108, PW B

Check :

PWB.

Else defective D200*

Check :

PWB.

Else defictive D4 00*

Check :

Replace D450

Yes

Reflash phone

Figure 2: Flash programming fault

Issue 1 10/03 Nokia Corporation. Page 7

Page 8

RH-18/36/38 Company confidential

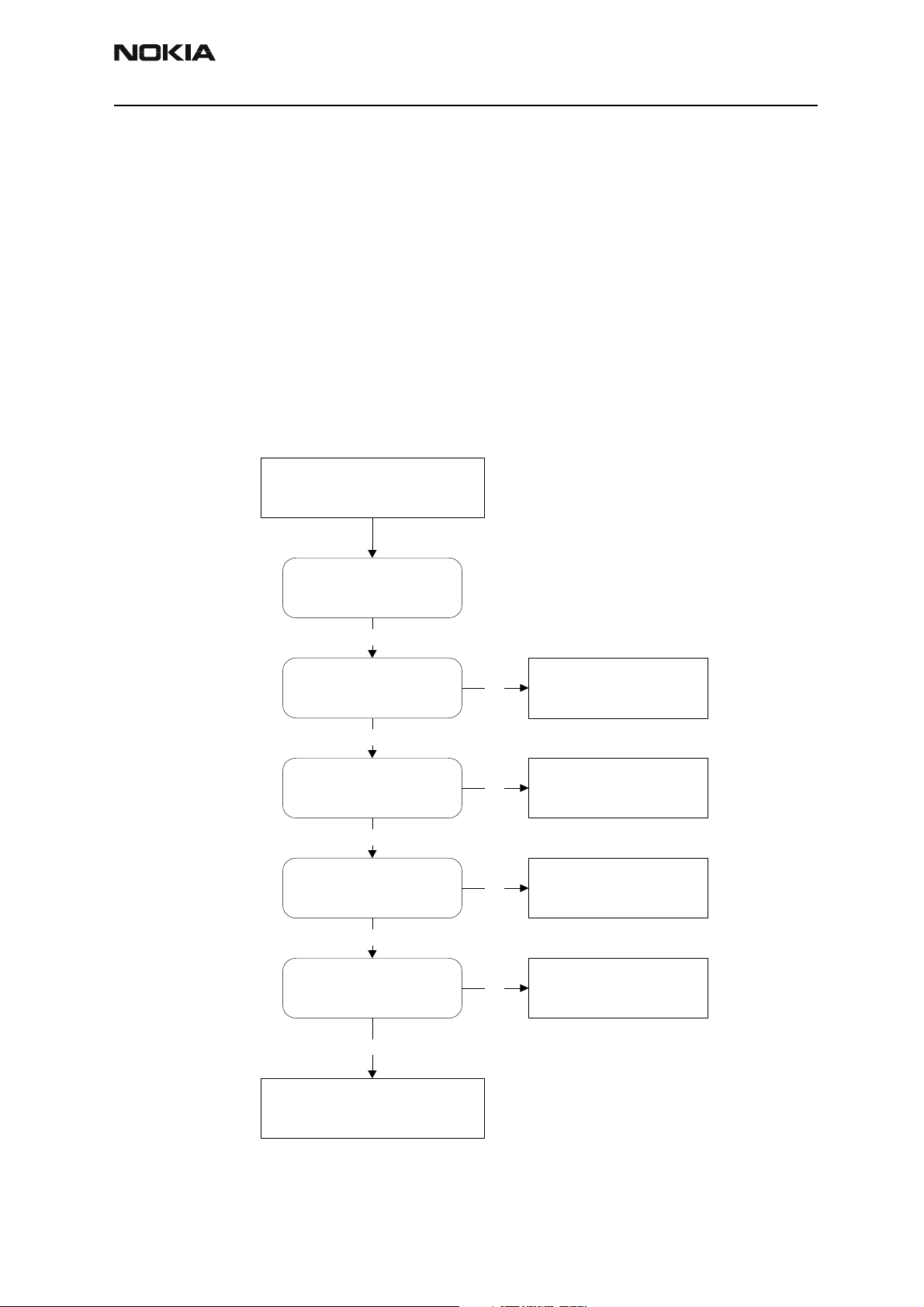

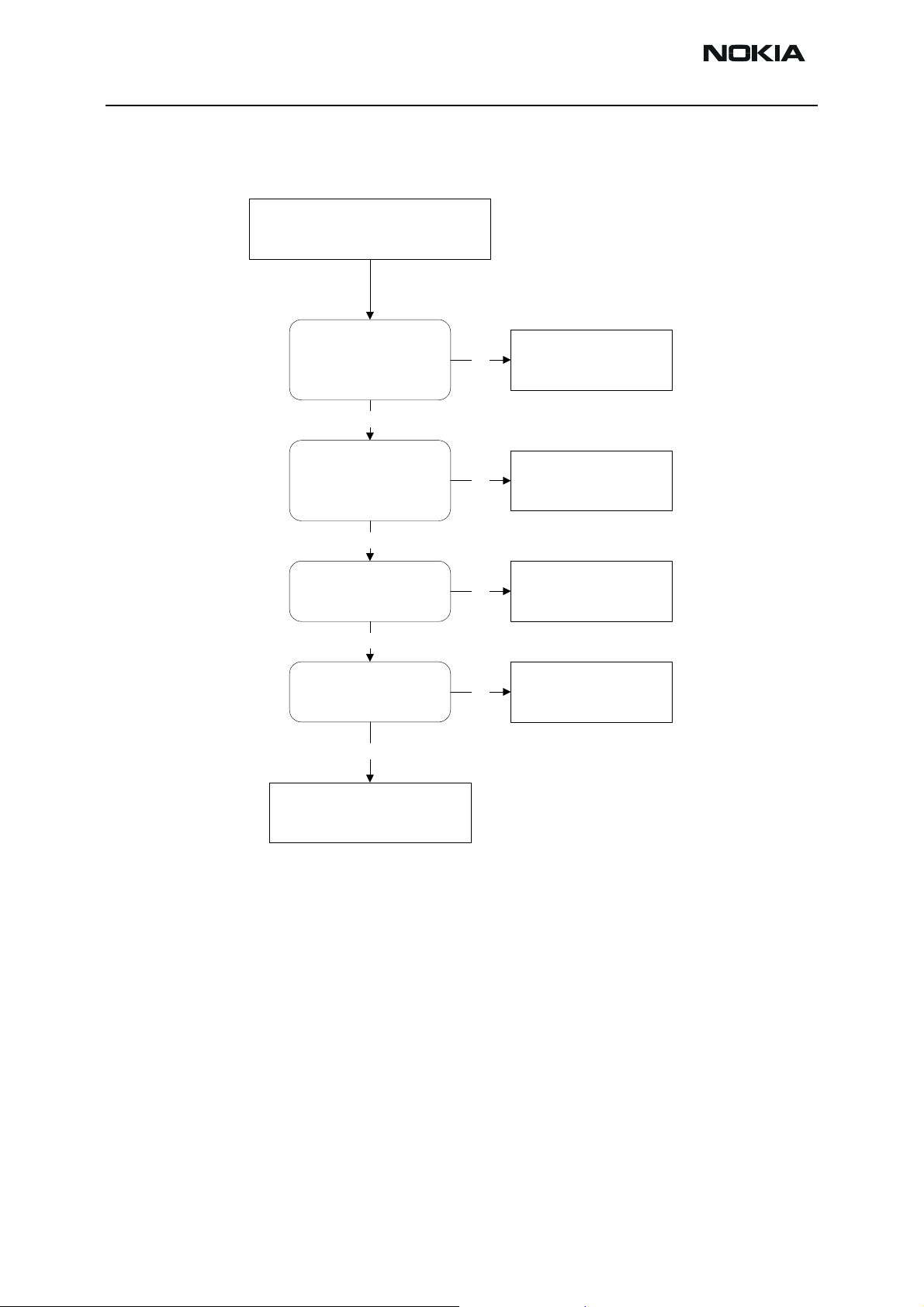

Power does not stay on or phone is jammed

If this kind of failure is presenting itself immediately after FLALI, it is most likely caused

by ASICs missing contact with PWB.

If for some reason the MCU does not service the watchdog register within the UEM, the

operations watchdog will run out after approximately 32 seconds. Unfortunately, the

service routine can not be measured.

Power doesn't stay on,

or phone is jammed

CCS Technical Documentation

J404

Sleep clock = 32.768 kHz,

1.8Vpp

Yes

J402

PURX = 1,8VDC,

1 sec. after power-key is

pressed

Yes

UI functionality,

and keys react

to pressure?

Yes

R426

26 MHz clock min.

300mVACpp,

probe Cin=10-13 pF/10M

No

No

No

No

Check :

B200, C209, C210, PW B.

Else defective D200*

Check :

PWB.

Else defictive D200*

Check :

D450, Keymat,

Lightguide, PWB .

Else defective D400*

Check :

C420, C426, R420,

R426, N600(Mjoelner)

Yes

Reflash phone

Figure 3: Phone jammed troubleshooting

Page 8 Nokia Corporation. Issue 1 10/03

Page 9

Company confidential RH-18/36/38

CCS Technical Documentation

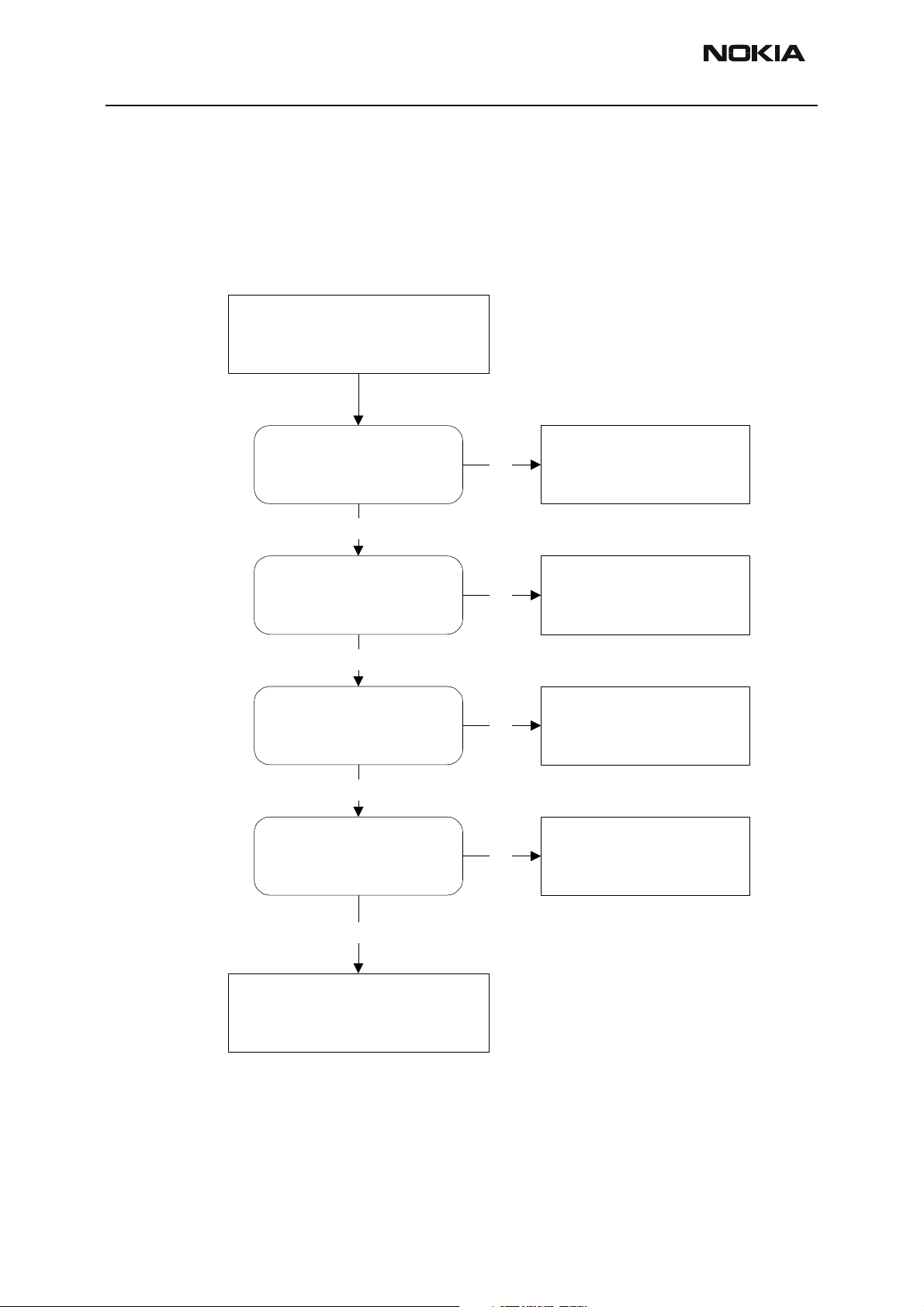

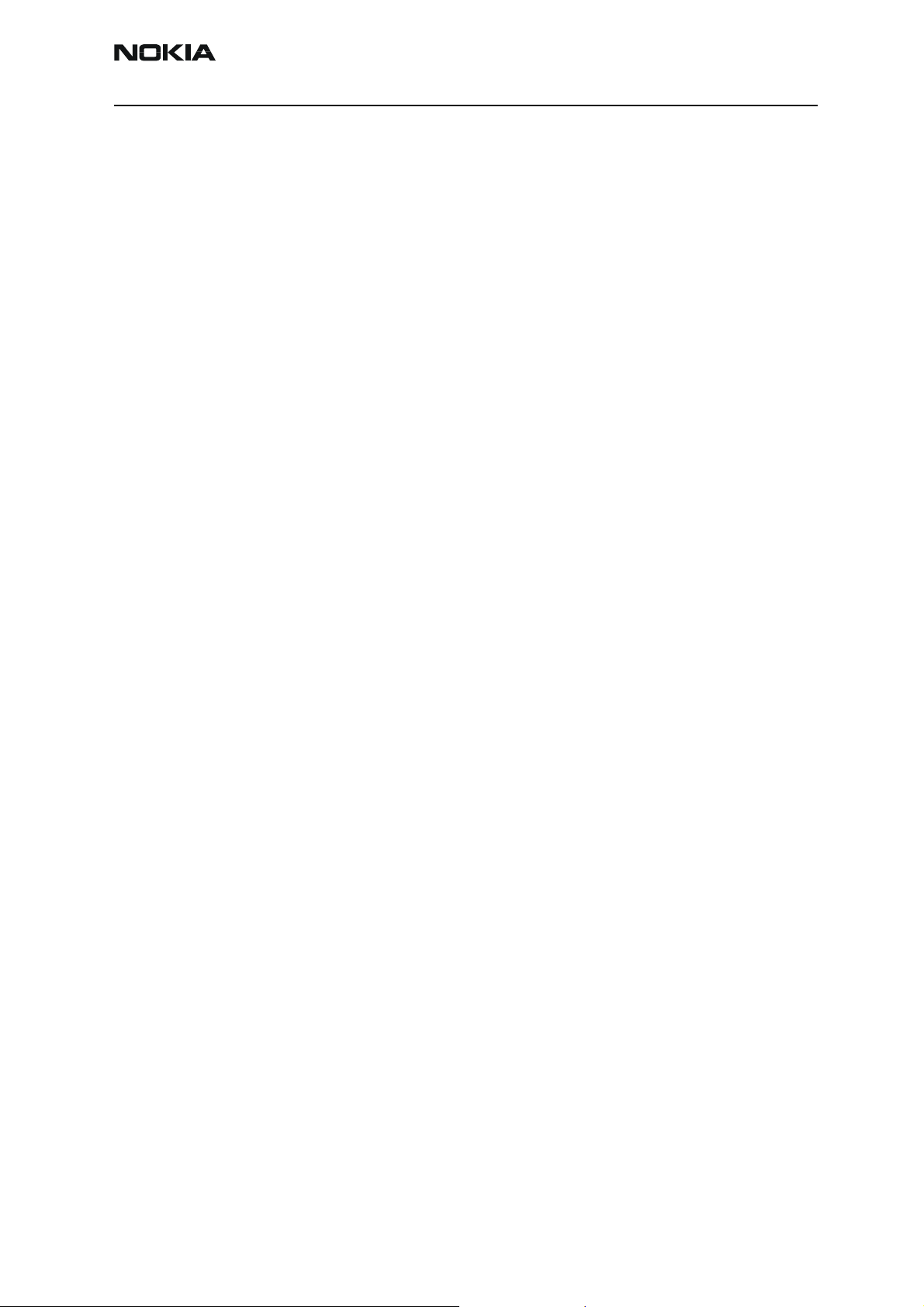

Display information : "Contact Service"

This error can only happen at power up where several self-tests is run. If any of these test

cases fails the display will show the message: "Contact Service".

It's individual test cases so the below lineup of error hunting's has no chronological

order. Use common sense and experience to decide which test case to start error hunting

at.

Display shows

"Contact Service"

Yes

EarDa & MicDa

between

UPP and UEM?

MBUS interface

between

UPP and UEM?

AuxDa & UEMInt

between

UPP and UEM?

SleepX & SleepClk

between UPP & UEM?

TXI/QD & RXI/QD?

SIM interface between

UPP & UEM

No

Check :

PWB.

Else defecti v e D20 0*

or D400*

Key is stucked

Flash checksum

! ASIC version vs. compilation flag, PMM checksum

! PMM validity

! Warrenty Information State

! SIM-Lock

Check :

A-cover, Keymat, Lightguide,

PWB.

Reflash phone

Check :

PWB.

Else defective D450 (FLASH)

Figure 4: Troubleshooting when Contact Service message seen

Issue 1 10/03 Nokia Corporation. Page 9

Page 10

RH-18/36/38 Company confidential

CCS Technical Documentation

The phone do not register to the network, or the phone cannot make a call

If the phone doesn't register to the network, the fault can be in either BB or RF. Only few

signals can be tested since several signals is 'burried' in one or more of the inner layers of

the PWB.

First of all check that SIM LOCK is not causing the error by using a Test-SIM card and

connect the phone to a tester.

Phone do not register to

network

or phone cannot make a ca ll

C222, C223, C224, C225,

C226, C227

Voltage = ~2,78VDC

All during GSM frame-

call mode.

Use TXP on C646 as trigger

Yes

C230, C231

Voltage = ~1,35VDC

All during GSM frame (call mode)

Use TXP on C646 as trigger

Yes

J421, J422, J423

Check RF serial bus during

GSM-frame :

Logic HIGH = 1,8VDC

Logic LOW = 0V DC

RFBUSC LK (J421),

RFBUSD A (J422),

RFBUSEN1X (J423)

Yes

R601, R603

Check analog signals during

GSM-frame (RX slot):

RXIP/N (R601) = 0-1,45VDC

RXQP/N (R603) = 0-1,45VDC

Check :

No

C222,C223, C224, C225,

C226, C 227 , P WB .

Else defective D200 or D400*

Check :

No

C230, C 231 , P WB .

Else defective

D200* or D400*

Check :

No

Else defective D200*

Check :

No

Else defective D200*

PWB.

or D400*

PWB.

or D400*

Yes

R610, R611

Check analog signals during

GSM-frame (TX slot):

TXIP/N (R610) = 1-1,75VDC

TXQP/N (R611) = 1-1,75VDC

Yes

No

Check :

R610, R 611 ,P WB .

Else defective D200*

or D400*

Check RF

Figure 5: No call troubleshooting

Page 10 Nokia Corporation. Issue 1 10/03

Page 11

Company confidential RH-18/36/38

CCS Technical Documentation

SIM related faults

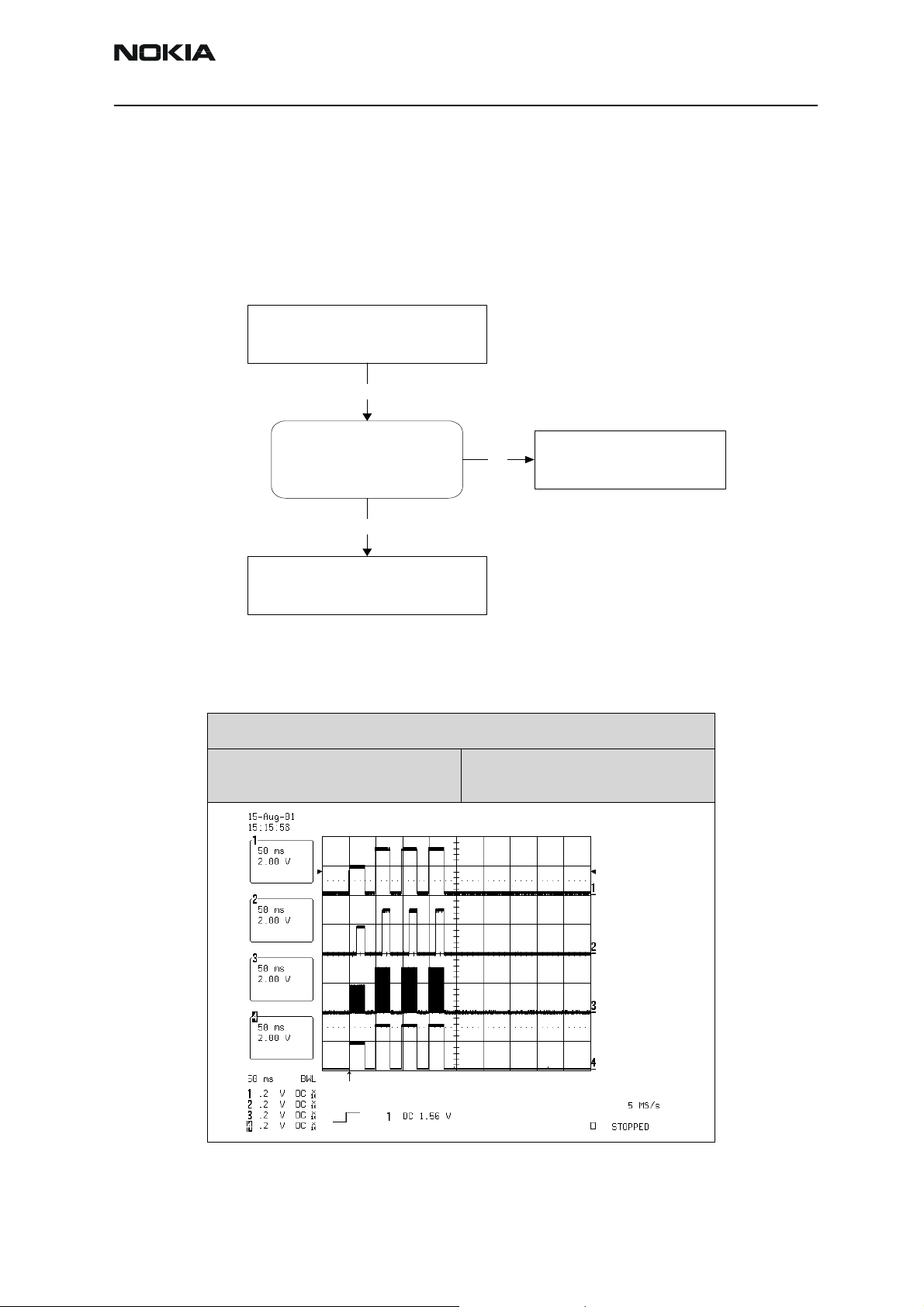

Insert SIM card fault

The hardware of the SIM interface from UEM (D200) to the SIM connector (X387) can be

tested without a SIM card. When the power is switched on the phone first check for a

1,8V SIM card and then a 3V SIM card. The phone will try this four times, whereafter it

will display ”Insert SIM card”.

Display shows :

"Insert SIM Card"

Yes

Verify that phone checks for

1,8V-SIM, and then 3V-SIM

Check for SIM voltage during power-up

Ch1 : VSIM

Ch2 : RESET

X387

during power-up.

(See illustration below)

Yes

SIM Interface OK

Figure 6: SIM troubleshooting

No

Ch3 : CLOCK

Ch4 : DATA

Check :

X387, R386, PWB.

Else defective D200*

Figure 7: Signal diagram

Issue 1 10/03 Nokia Corporation. Page 11

Page 12

RH-18/36/38 Company confidential

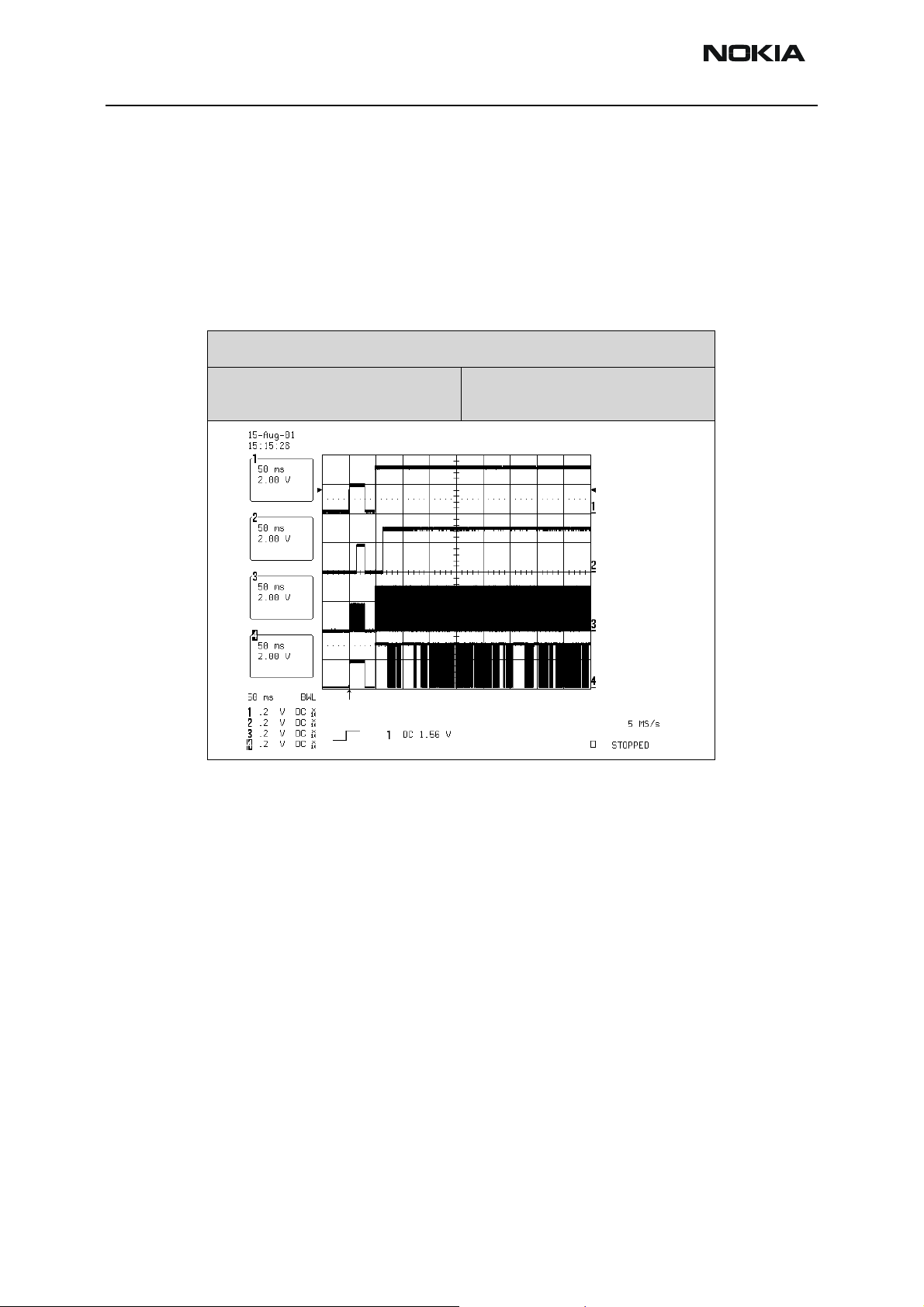

SIM-Card rejected

The error ”SIM card rejected” means that the ATR message received from SIM card is corrupted, e.g. data signal levels are wrong. The first data is always ATR and it is sent from

card to phone.

For reference a picture with normal SIM power-up is shown below.

Normal SIM power-up sequence

CCS Technical Documentation

Ch1 : VSIM

Ch2 : RESET

Ch3 : CLOCK

Ch4 : DATA

Figure 8: Signal diagram

Page 12 Nokia Corporation. Issue 1 10/03

Page 13

Company confidential RH-18/36/38

CCS Technical Documentation

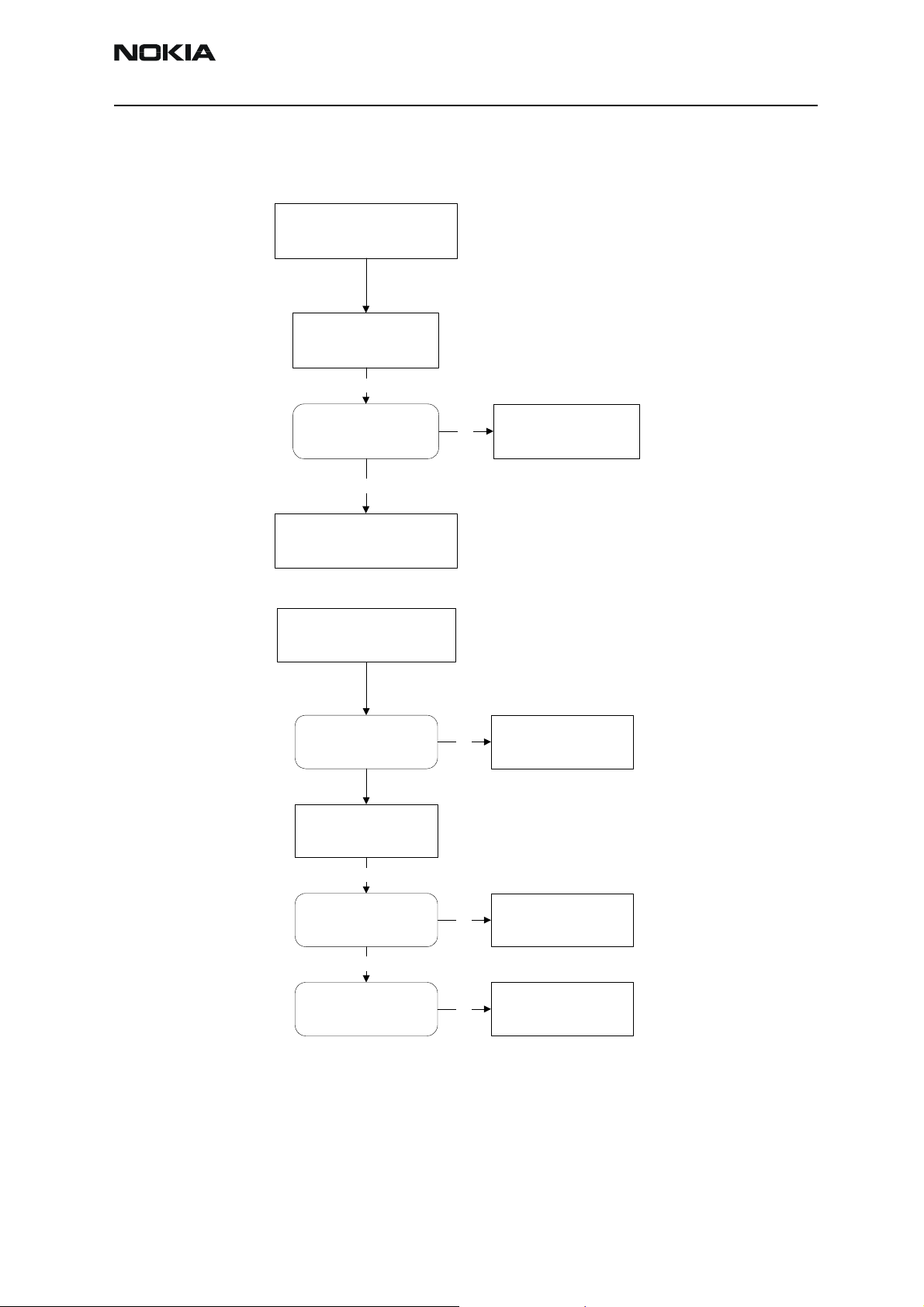

Audio related faults 1: Earpiece and microphone

Earpiece do not work

Replace :

Earpiece

Error still present

Z150, R161

Check Z150, R161 is

working correctly

(no short/open-circuit)

Yes

Defective D200*

Microphone do not work and

the isn't any mechanical

problem

Z100

Check Z100 is

working correctly

(no short/open-circuit)

Replace :

System Connoctor

No

No

Check :

R386, PWB.

Else defective D200*

Replace :

Z100

Error still present

R165

Check voltage level on

R165 towards UEM (bias)

= 2,1V

Yes

R153

Check voltage level on

R153 towards mic-lines (bias)

= 1,0V - 1,4V

No

No

Check :

R165, C168, PWB.

Else defctive D200*

Check :

R153, R157,C151, C152,

C153, C154, PWB.

Figure 9: Top: Earpiece troubleshooting, bottom: Microphone troubleshooting

Issue 1 10/03 Nokia Corporation. Page 13

Page 14

RH-18/36/38 Company confidential

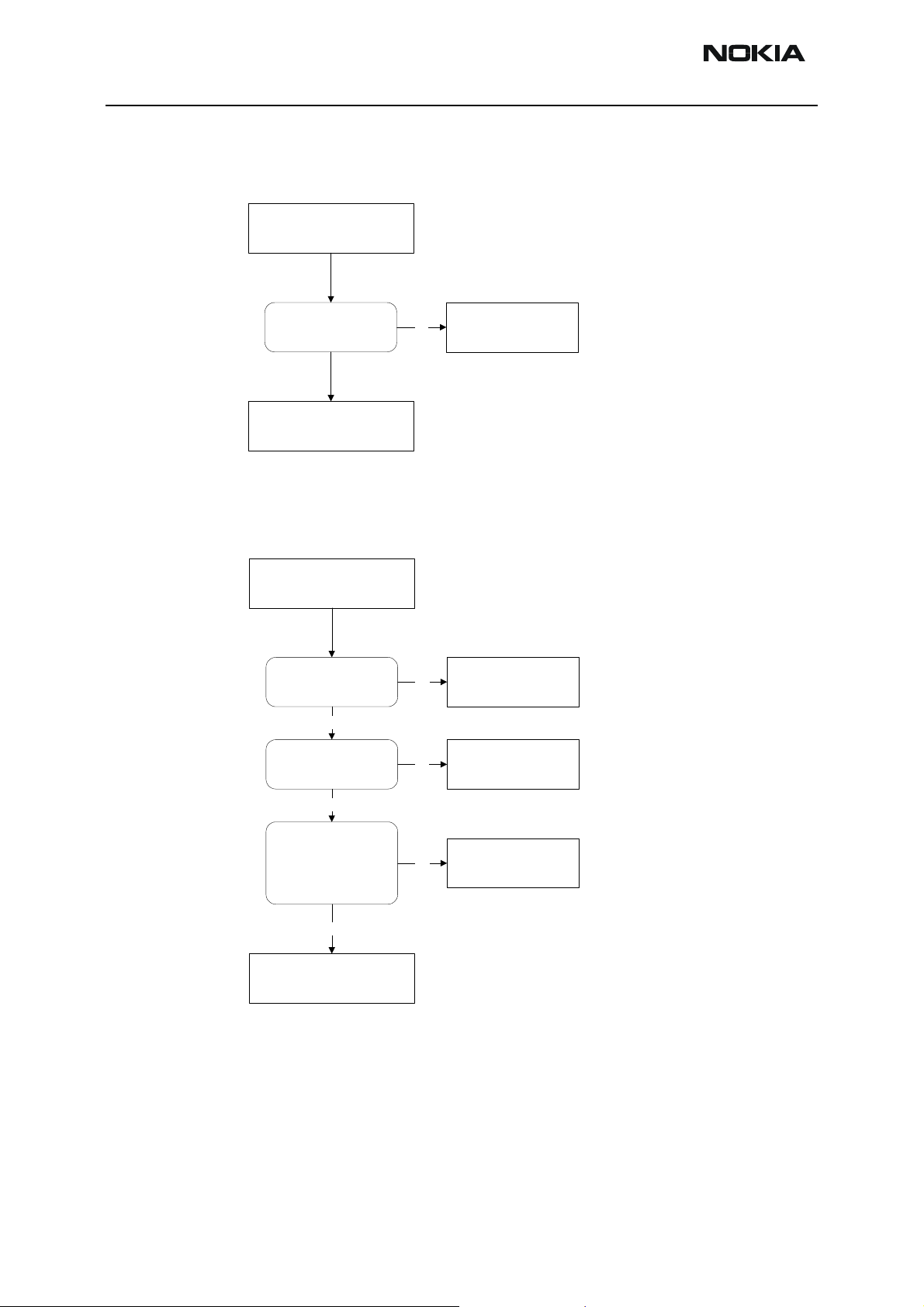

Audio related faults 2: Headset

Headset earpiece do not

work and the isn't any

mechanical problem

CCS Technical Documentation

R183, Z102

Check R183, Z102 is

working correctly

(no open-circuit)

Defective D200*

Headset microphone do not

work and the isn't any

mechanical problem

R166

Check voltage level on R166

towards UEM (bias) = 2,1V

Yes

R151

Check voltage level on R151

towards UEM (bias)

= 1,0V - 1,4V

Yes

No

No

No

Replace :

C183 and/or Z102

Replace :

C183 and/or Z102

Check :

R166, R151, C171

R152, R165, R168,

C172, C170, C173,

C174, Z101

Check XMIC line to UEM

(D200)

Error still present

No

Replace :

Defective component

Defective D200*

Figure 10: Headset troubleshooting

Page 14 Nokia Corporation. Issue 1 10/03

Page 15

Company confidential RH-18/36/38

CCS Technical Documentation

Charging failure troubleshooting

Phone is OFF - battery is

completely empty

(<=3,1VDC)

and no current from

charger when connected

L100

VCHAR > 2,1VDC

Yes

Defective D200*

No

Check :

F100, L100, V100, C100,

R200, System-c onnector.

Phone is ON or OFF - battery

nominal voltage (~3,6VDC)

and no current from

charger when connected

L100

VCHAR > 3,6VDC

No

Check :

F100, L100, V100, C100,

R200, System-c onnector.

Yes

Defective

D200 or D400*

Figure 11: Charging troubleshooting 1

Issue 1 10/03 Nokia Corporation. Page 15

Page 16

RH-18/36/38 Company confidential

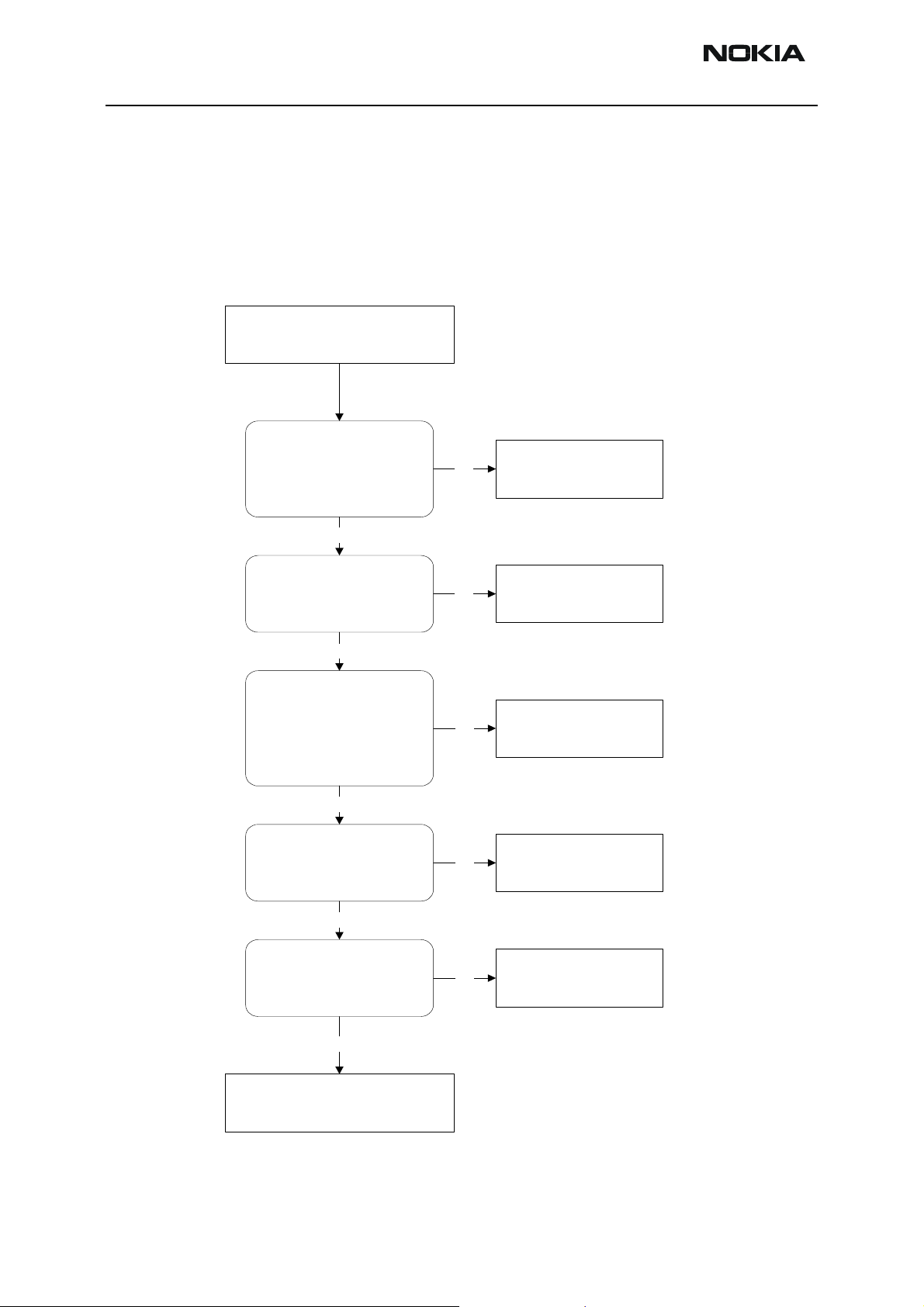

Charging troubleshooting 2

Display info when

charger is connected :

"Not charging"

CCS Technical Documentation

Voltage on R206 towards

R206

D200 is ~0,8VDC

when power is connected.

(BSI must be 75K)

Yes

R207

Voltage (use scope) on R207

towards D200 is ~0,9VDC at

peak.

(BSI must be 47K)

Yes

R200

Voltage on R200 towards

D200 same as VBAT voltage

Yes

R200

Voltage rises slowly on

R200 towards D200 when

charger is connected.

Yes

No

No

No

No

Check :

X105, R202, R206, C240.

Check :

X105, R202, R207, C220.

Check :

R200, PWB.

Else defective D200*v

Check :

PWB.

Else defective D200*

Check :

PWB

Figure 12: Charging troubleshooting 2

Page 16 Nokia Corporation. Issue 1 10/03

Page 17

Company confidential RH-18/36/38

CCS Technical Documentation

General RF Troubleshooting

Two types of measurements are used in the following. It will be specified if the measurement type is "RF" or "LF".

• RF measurements are done with a Spectrum Analyser and a high-frequency 500

ohm passive probe, for example HP54006A. (Note that when measuring with the

500 ohm probe the signal will be around 20 dB attenuated. The values in the following will have these 20 dB subtracted and represent the real value seen on the

spectrum analyser).

Note that the testjig have some losses which must be taken into consideration when calibrating the

test system.

• LF (Low frequency) and DC measurements should be done with a 10:1 probe and

an oscilloscope. The probe used in the following is 10MW/8pF passive probe. If

using another probe then bear in mind that the voltages displayed may be

slightly different.

Always make sure the measurement set-up is calibrated when measuring RF parameters

on the antenna pad. Remember to include the loss in the module repair jig when

realigning the phone.

Most RF semiconductors are static discharge sensitive. So ESD protection must be applied during repair (ground straps and ESD soldering irons). Mjoelner and Bifrost is moisture sensitive so parts must be pre-baked prior to soldering.

Apart from key-components described in this document there are a lot of discrete components (resistors, inductors and capacitors) for which troubleshooting is done by checking if soldering of the component is done properly and checking if the component is

missing from PWB. Capacitors can be checked for short-circuiting and resistors for value

by means of an ohmmeter, but be aware in-circuit measurements should be evaluated

carefully.

In the following both the name EGSM and GSM850 will be used for the lower band and

both PCN and GSM1900 will be used for the upper band.

Issue 1 10/03 Nokia Corporation. Page 17

Page 18

RH-18/36/38 Company confidential

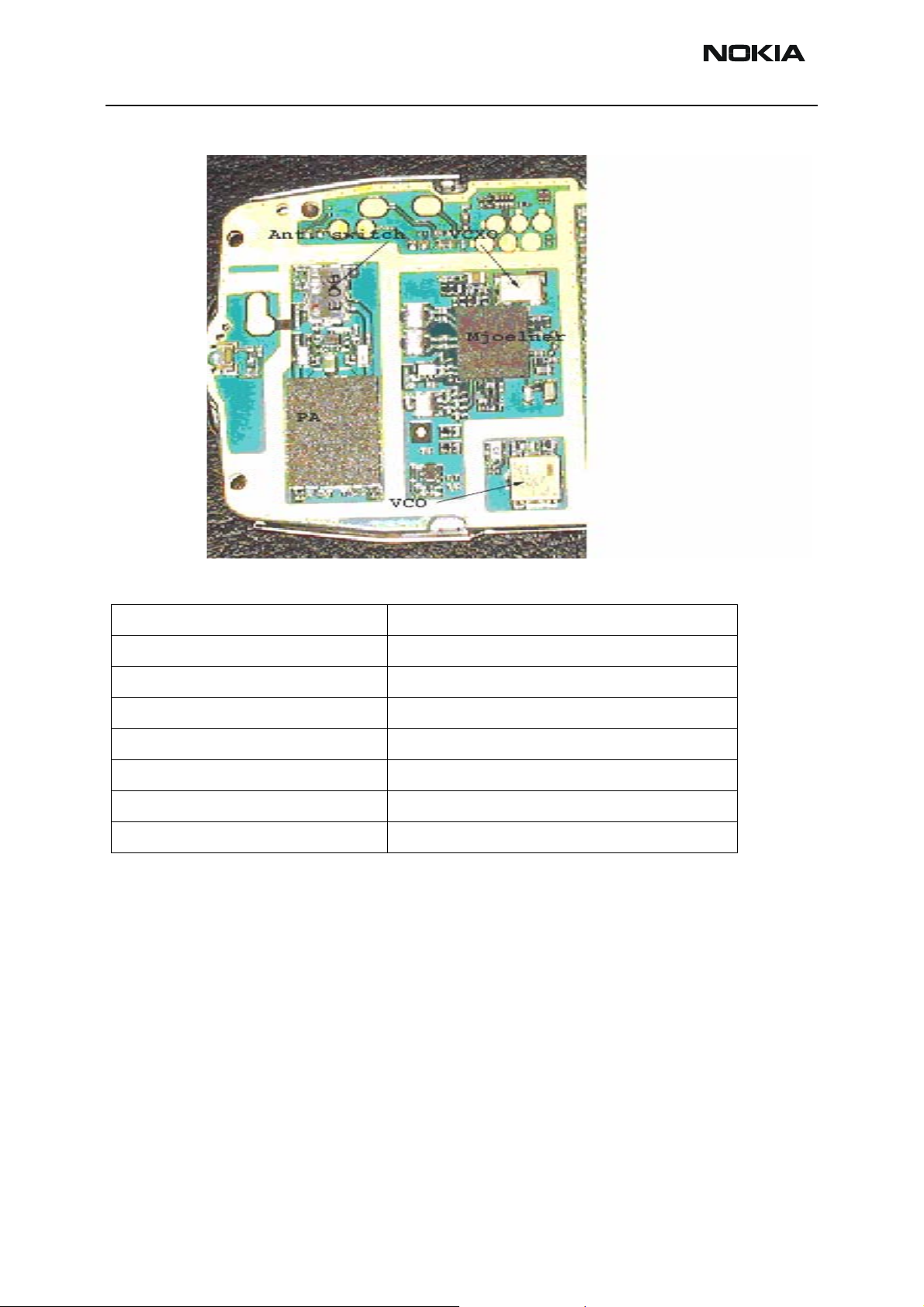

RF Key component placement

CCS Technical Documentation

Figure 13: RF key components

Table 1: RF component placement

N600 Mjoelner RF IC

Z601 PCN RX SAW

Z602 EGSM RX SAW

Z603 EGSM TX SAW

B600 26 MHz crystal

G600 VCO ( 4.0 GHz UHF VCO )

N700 Power Amplifier (PA)

Z700 RX/TX switch

Page 18 Nokia Corporation. Issue 1 10/03

Page 19

Company confidential RH-18/36/38

CCS Technical Documentation

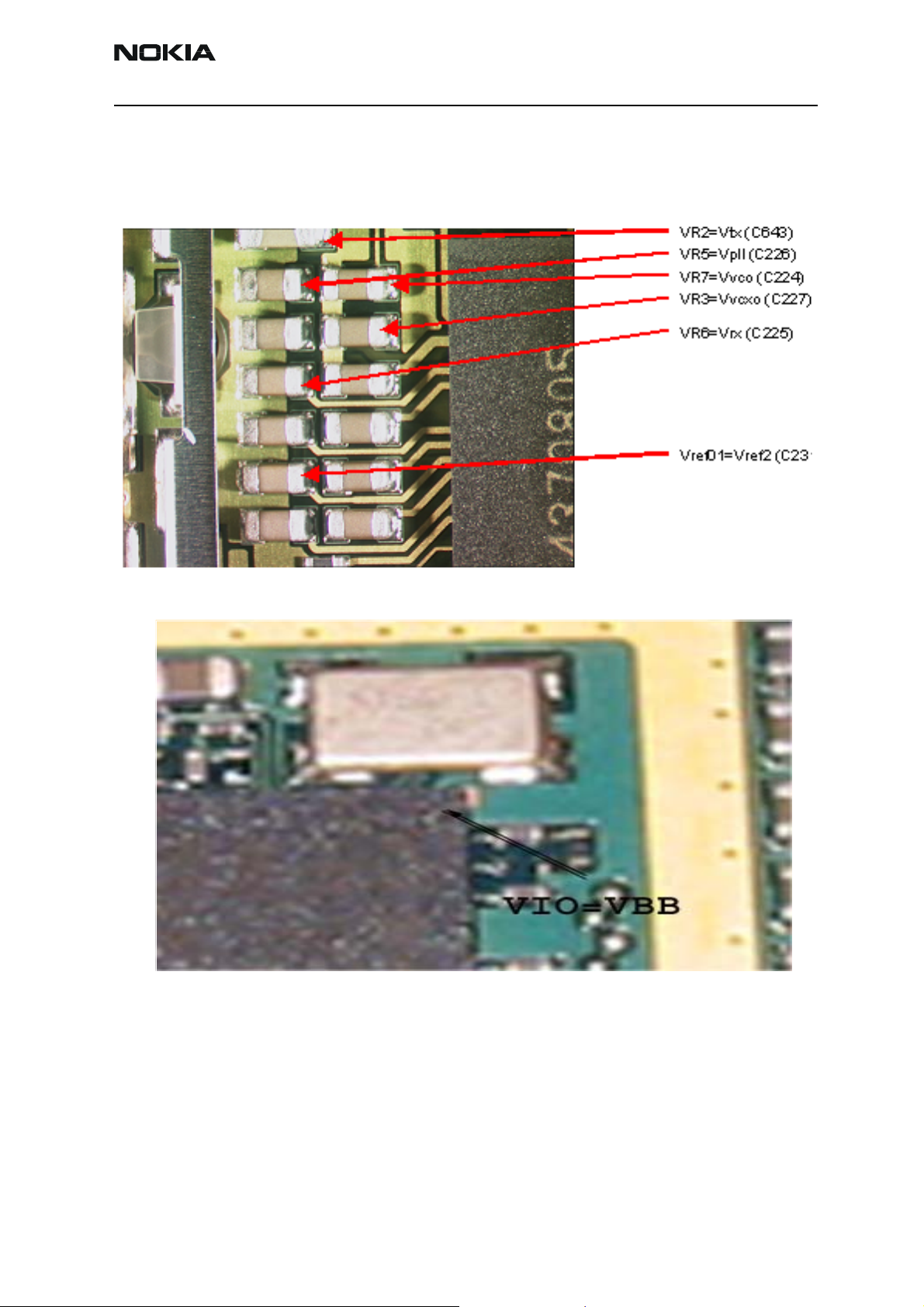

Refer to the picture below for measuring points at the UEM (D200).

Figure 14: Supply points at UEM (D200)

Figure 15: Supply point at Mjoelner (N600)

Issue 1 10/03 Nokia Corporation. Page 19

Page 20

RH-18/36/38 Company confidential

CCS Technical Documentation

[This page left intentionally blank]

Page 20 Nokia Corporation. Issue 1 10/03

Page 21

Company confidential RH-36

CCS Technical Documentation

RH-36 Receiver troubleshooting

General Instructions for GSM850 RX Troubleshooting

Connect the phone to a PC with the module repair jig.

Start Phoenix and establish connection to the phone

Phoenix commands

RF Controls .Band GSM 850 RX .Continuous mode

Channel 190 .AGC 8 FEG ON + 46 dB

The setup should now look like this:

Figure 16: GSM850 RF controls window

Issue 1 10/03 Nokia Corporation. Page 21

Page 22

RH-36 Company confidential

Troubleshooting diagram for GSM850 Receiver

Figure 17: GSM850 Receiver troubleshootingt

Apply -55dBm

942.4 MHz

offset 67.71kHz

from generator

to

antenna conn

YES

CCS Technical Documentation

Oscilloscope

at RX i/Q

signal 588mVpp

DC offset 1.35V

Freq.67.71kHz

YES

EGSM

chain

OK

Check RX/TX

switch at

RX900

Z700

-56dBm

YES

Spectrum analyzer

EGSM SAW filter

Z602

output

-65dBm

YES

Spectrum analyzer

check signal after

inductors

L602 and L603

-65DbM

NO NO

NO

Oscilloscope

check

VC1 and VC2

at Z700

Signal = 0V

NO

YES

Check

RX/TX

switch

Check

SAW filter

Z602

Check

Inductor

L603, L602

Check Mjoelner

YES

YES

Oscilloscope

VRX 2.7V

Check Mjoelner

serial

interface

NO

Check

Baseband

Page 22 Nokia Corporation. Issue 1 10/03

Page 23

Company confidential RH-36

CCS Technical Documentation

By measuring with an oscilloscope at RXIP or RXQP on a working GSM 850 receiver this

picture should be seen.

Signal amplitude peak-peak 789 mV

DC offset 1.2 V

Figure 18: RX850 I/Q signal waveform

Issue 1 10/03 Nokia Corporation. Page 23

Page 24

RH-36 Company confidential

CCS Technical Documentation

General Instructions for RH-36 GSM1900 RX Troubleshooting

Connect the phone to a PC with the module repair jig.

Start Phoenix and establish connection to the phone

Phoenix commands

RF Controls .Band GSM 1900 RX .Continuous mode

Channel 661 .AGC 8 FEG ON + 46 dB

The setup should now look like this:

Figure 19: GSM1900 RF controls

Page 24 Nokia Corporation. Issue 1 10/03

Page 25

Company confidential RH-36

CCS Technical Documentation

Troubleshooting diagram for GSM1900Receiver

Figure 20: GSM1900 receiver troubleshooting diagram

Apply -55dBm

1842.8 MHz

offset 67.71kHz

from generator

to

antenna conn

YES

Oscilloscope

at RX i/Q

signal 588mVpp

DC offset 1.35V

Freq.67.71kHz

YES

EGSM

chain

OK

Check RX/TX

switch at

RX1800

Z700

-56dBm

YES

Spectrum analyzer

PCN SAW filter

Z602

output

-65dBm

YES

Spectrum analyzer

check signal after

inductors

L601 and L611

-65DbM

NO NO

NO

Oscilloscope

check

VC1 and VC2

at Z700

Signal = 0V

NO

YES

Check

RX/TX

switch

Check

SAW filter

Z601

Check

Inductor

L601, L611

Check Mjoelner

YES

YES

Oscilloscope

VRX 2.7V

Check Mjoelner

serial

interface

NO

Check

Baseband

Issue 1 10/03 Nokia Corporation. Page 25

Page 26

RH-36 Company confidential

By measuring with an oscilloscope at RXIP or RXQP on a working GSM 1900 receiver this

picture should be seen.

Signal amplitude peak-peak 460 mV

DC offset 1.2 V

Figure 21: RX1900 I/Q signal waveform

CCS Technical Documentation

Page 26 Nokia Corporation. Issue 1 10/03

Page 27

Company confidential RH-36

CCS Technical Documentation

Measurement points in the receiver

Figure 22: RX measurements point at the RX/TX Switch - Z700

Figure 23: Measurements points at the RX-Filters – Z601/Z602

Issue 1 10/03 Nokia Corporation. Page 27

Page 28

RH-36 Company confidential

Figure 24: RX I/Q Signals, Baseband shielding can UEM (D200)

CCS Technical Documentation

Page 28 Nokia Corporation. Issue 1 10/03

Page 29

Company confidential RH-36

CCS Technical Documentation

RH-36 Transmitter troubleshooting

Measurement points for the transmitter

Figure 25: Figure 15: TX measuremnet points in the PA ( N700 ) shielding can

Figure 26: TX measurement point in Mjolner (N600) shielding can

Issue 1 10/03 Nokia Corporation. Page 29

Page 30

RH-36 Company confidential

CCS Technical Documentation

General instructions for RH-36 GSM TX troubleshooting

Apply a RF-cable to the RF-connector to allow the transmitted signal act as normal. RFcable should be connected to measurement equipment or to at least a 10-dB attenuator,

otherwise the PA may be damaged.

Start Phoenix-Service-Software and establish a connection to the phone e.g. FBUS.

Select File and Product: Gemini

Select: Maintenance, Testing and RF Controls

Band: GSM 850

Active Unit: TX

Tx Power Level: 5

Tx Data Type: Random

Your screen should look like:

Figure 27: GSM850 RF controls window

Page 30 Nokia Corporation. Issue 1 10/03

Page 31

Company confidential RH-36

CCS Technical Documentation

GSM850 TX output power

Measure the output power of the phone; it should be around 32.5 dBm.

Remember the loss in the jig; around 0.3 dB.

Figure 28: VPCTRL_G & TXC

Issue 1 10/03 Nokia Corporation. Page 31

Page 32

RH-36 Company confidential

CCS Technical Documentation

General instructions for RH-36 GSM1900 TX troubleshooting

Apply a RF-cable to the RF-connector to allow the transmitted signal act as normal. RFcable should be connected to measurement equipment or to at least a 10-dB attenuator,

otherwise the PA may be damaged.

Start Phoenix-Service-Software and establish a connection to the phone e.g. FBUS.

Phoenix commands

RF Controls .Band GSM 1900 RX .Continuous mode

Channel 661

Your screen should look like:

Figure 29: GSM1900 RF controls screen shot

GSM1900 TX output power

Measure the output power of the phone.

It should be around 28.5 dBm.

Remember the loss in the jig; around 0.7 dB.

Page 32 Nokia Corporation. Issue 1 10/03

Page 33

Company confidential RH-36

CCS Technical Documentation

Troubleshooting diagram for GSM1900 TX

Figure 30: GSM1900 TX troubleshooting

Issue 1 10/03 Nokia Corporation. Page 33

Page 34

RH-36 Company confidential

CCS Technical Documentation

[This page left intentionally blank]

Page 34 Nokia Corporation. Issue 1 10/03

Page 35

Company confidential RH-18/38

CCS Technical Documentation

General Instructions for RH-18/38 GSM900 RX Troubleshooting

Connect the phone to a PC with the module repair jig.

Start Phoenix and establish connection to the phone

Phoenix commands

RF Controls .Band GSM 900 RX .Continuous mode

Channel 190 .AGC 8 FEG ON + 46 dB

The setup should now look like this:

Figure 31: GSM900 RF Controls window

Issue 1 10/03 Nokia Corporation. Page 35

Page 36

RH-18/38 Company confidential

Troubleshooting Chart for GSM900 Receiver

Figure 32: EGSM Receiver Troubleshooting chart

Apply -55dBm

942.4 MHz

offset 67.71kHz

from generator

to

antenna conn

YES

CCS Technical Documentation

Oscilloscope

at RX i/Q

signal 588mVpp

DC offset 1.35V

Freq.67.71kHz

YES

EGSM

chain

OK

Check RX/TX

switch at

RX900

Z700

-56dBm

YES

Spectrum analyzer

EGSM SAW filter

Z602

output

-65dBm

YES

Spectrum analyzer

check signal after

inductors

L602 and L603

-65DbM

NO NO

NO

Oscilloscope

check

VC1 and VC2

at Z700

Signal = 0V

NO

YES

Check

RX/TX

switch

Check

SAW filter

Z602

Check

Inductor

L603, L602

Check Mjoelner

YES

YES

Oscilloscope

VRX 2.7V

Check Mjoelner

serial

interface

NO

Check

Baseband

Page 36 Nokia Corporation. Issue 1 10/03

Page 37

Company confidential RH-18/38

CCS Technical Documentation

By measuring with an oscilloscope at RXIP or RXQP on a working GSM 900 receiver this

picture should be seen.

Signal amplitude peak-peak 789 mV

DC offset 1.2 V

Figure 33: RX900 I/Q signal waveform

Issue 1 10/03 Nokia Corporation. Page 37

Page 38

RH-18/38 Company confidential

CCS Technical Documentation

General Instructions for GSM1800 RX Troubleshooting

Connect the phone to a PC with the module repair jig.

Start Phoenix and establish connection to the phone

Phoenix commands

RF Controls .Band GSM 1800 RX .Continuous mode

Channel 661 .AGC 8 FEG ON + 46 dB

The setup should now look like this:

Figure 34: GSM1800 RF control window

Page 38 Nokia Corporation. Issue 1 10/03

Page 39

Company confidential RH-18/38

CCS Technical Documentation

Troubleshooting Chart for GSM1800Receiver

Figure 35: GSM1800 receiver Troubleshooting chart

Apply -55dBm

1842.8 MHz

offset 67.71kHz

from generator

to

antenna conn

YES

Oscilloscope

at RX i/Q

signal 588mVpp

DC offset 1.35V

Freq.67.71kHz

YES

EGSM

chain

OK

Check RX/TX

switch at

RX1800

Z700

-56dBm

YES

Spectrum analyzer

EGSM SAW filter

Z601

output

-65dBm

YES

Spectrum analyzer

check signal after

inductors

L601 and L611

-65DbM

NO NO

NO

Oscilloscope

check

VC1 and VC2

at Z700

Signal = 0V

NO

YES

Check

RX/TX

switch

Check

SAW filter

Z602

Check

Inductor

L603, L602

Check Mjoelner

YES

YES

Oscilloscope

VRX 2.7V

Check Mjoelner

serial

interface

NO

Check

Baseband

Issue 1 10/03 Nokia Corporation. Page 39

Page 40

RH-18/38 Company confidential

XIP or RXQP on a working GSM 1800 receiver this picture should be seen.

Signal amplitude peak-peak 460 mV

DC offset 1.2 V

Figure 36: RX1800 I/Q signal waveform

CCS Technical Documentation

Measurement points in the receiver

Figure 37: RX measurements point at the RX/TX Switch - Z700

Page 40 Nokia Corporation. Issue 1 10/03

Page 41

Company confidential RH-18/38

CCS Technical Documentation

Figure 38: Measurements points at the RX-Filters – Z601/Z602

Figure 39: RX I/Q Signals, Baseband shielding can UEM (D200)

Issue 1 10/03 Nokia Corporation. Page 41

Page 42

RH-18/38 Company confidential

RH-18/38 Transmitter troubleshooting

Measurement points for the transmitter

Figure 40: TX measuremnet points in the PA ( N700 ) shielding can

CCS Technical Documentation

Figure 41: TX measurement point in Mjolner (N600) shielding can

Page 42 Nokia Corporation. Issue 1 10/03

Page 43

Company confidential RH-18/38

CCS Technical Documentation

General instructions for RH-18/38 GSM TX troubleshooting

Apply a RF-cable to the RF-connector to allow the transmitted signal act as normal. RFcable should be connected to measurement equipment or to at least a 10-dB attenuator,

otherwise the PA may be damaged.

Start Phoenix-Service-Software and establish a connection to the phone e.g. FBUS.

Select File and Product: RH-18

Select: Maintenance, Testing and RF Controls

Band: GSM 900

Active Unit: TX

Tx Power Level: 19

Tx Data Type: All 1

Your screen should look like:

Figure 42: GSM900 RF controls window

Measure the output power of the phone; it should be around 32.5 dBm.

Remember the loss in the jig; around 0.3 dB.

Issue 1 10/03 Nokia Corporation. Page 43

Page 44

RH-18/38 Company confidential

Figure 43: VPCTRL_G and TXC signal

CCS Technical Documentation

Page 44 Nokia Corporation. Issue 1 10/03

Page 45

Company confidential RH-18/38

CCS Technical Documentation

PCN Transmitter General instructions for PCN TX troubleshooting

Apply a RF-cable to the RF-connector to allow the transmitted signal act as normal. RFcable should be connected to measurement equipment or to at least a 10-dB attenuator,

otherwise the PA may be damaged.

Start Phoenix-Service-Software and establish a connection to the phone e.g. FBUS.

Phoenix commands

RF Controls .Band GSM 1800 RX .Continuous mode

Channel 37 .AGC 14 FEG ON + 24 dB

Your screen should look like:

Figure 44: RF controls window

Measure the output power of the phone; it should be around 28.5 dBm. Remember the

loss in the jig; around 0.7 dB.

Troubleshooting chart for PCN transmitter: refer to Figure 17, “GSM1900 receiver troubleshooting diagram,” on page 24

Issue 1 10/03 Nokia Corporation. Page 45

Page 46

RH-18/38 Company confidential

Synthesizer

There is only one PLL synthesizer generating Local Oscillator frequencies for both RX and

TX in both bands ( PCN and EGSM). The VCO frequency is divided by 2 for PCN operation

or by 4 for EGSM operation inside the Mjoelner IC.

26 MHz Reference Oscillator ( VCXO )

The 26 MHz oscillator is located in the Mjoelner IC (N600). The coarse frequency for this

oscillator is set by an external crystal (B600). The reference oscillator is used as a reference frequency for the PLL synthesizer and as the system clock for BaseBand. The

26MHz signal is divided by 2 to achieve 13MHz inside the UPP IC (D400).

The 26 MHz signal from the VCXO can be measured by probing R425 (must be measured

on the UPP side of R425 i.e. the end not connected to C425). The level at this point is

approx. 700mVpp. Frequency of this oscillator is adjusted by changing the AFC-register

inside the Mjoelner IC. This is done via the Mjoelner serial interface.

Example Signal Measured at VCXO output (R425)

CCS Technical Documentation

Figure 45: VCXO 26 MHz waveform

VCO

The VCO is an ASIC with all the frequency determining parts inside.

In order to reduce the requirements of the tuning voltage and coverage of the VCO, the

VCO core is composed of four VCOs in parallel. This VCO circuit enables a very wide tuning range of 3.4 - 4.0 GHz .

Page 46 Nokia Corporation. Issue 1 10/03

Page 47

Company confidential RH-18/38

CCS Technical Documentation

Troubleshooting diagram for PLL Synthesizer

Figure 46: PLL Troubleshooting diagram

Issue 1 10/03 Nokia Corporation. Page 47

Page 48

RH-18/38 Company confidential

Phone fails after power on

If the phone stops working a short time after the power is turned ON, a possible reason

for this could be that the 26MHz system clock signal is not getting to the UPP clockinput in BaseBand. In this case check the following:

1 Turn on the phone and check

2 VCXO Power supply (C620) = 2.7V

3 VCXO output (R425 – end not connected to C425) is 26MHz and approx. 700mVpp

If this is not the case check the reference crystal (B600) and Mjolner (N600) as well as

R425, R426, C425, C426.

Measurement points at the VCXO

Figure 22: Measurement point for VCXO supply

CCS Technical Documentation

Figure 23: Measurement point for VCXO output

Page 48 Nokia Corporation. Issue 1 10/03

Page 49

Company confidential RH-18/38

CCS Technical Documentation

Measurement points at the PLL/VCO

Figure 47: Measurement point for PLL

Issue 1 10/03 Nokia Corporation. Page 49

Page 50

RH-18/38 Company confidential

CCS Technical Documentation

RH-18/38 Manual Alignment using Phoenix

In Phoenix select connection Fbus and Product Gemini. If you power up the board before

selecting Fbus, it works without any error messages.

Use Jig or other device for RF and bus connection. Attenuation in the probe alone is

0.5dB for 900 and 1dB for 1800. Use CMD55 or other suitable device. Default channels

are 37 for GSM900 and 700 for GSM1800. The alignments and calibrations must be performed in the order shown to give reliable results.

The way to save data to the phone and to load data from the phone is made different in

the various tunings. Always look what is shown in the windows regarding these issues

and act accordingly .

To vary a selected parameter you can use + and – key or in some cases directly type the

new value. + and – steps the value for every press. Repeat function seems not to work. In

I/Q you can use the side arrows.

RX calibration

Select Maintenance, Tuning, RX Calibration

Select Band: GSM 900

Select Automatic and follow the promts

The result should be like the shown:

Figure 48: RX calibration window

Page 50 Nokia Corporation. Issue 1 10/03

Page 51

Company confidential RH-18/38

CCS Technical Documentation

GSM1800 RX calibration

1 The existing data in the phone is shown

2 Calibrate, and the new data is shown

3 Stop, and the little window pops up where you can select to save or not

4 Select GSM1800 in the top bar and repeat at channel 700

Figure 49: GSM1800 RX calibration window

1 The existing data in the phone is shown

2 Calibrate, and the new data is shown

3 Stop, and the little window pops up where you can select to save or not

Issue 1 10/03 Nokia Corporation. Page 51

Page 52

RH-18/38 Company confidential

RX channel select filter

1 Select Maintenance, Tuning, Rx Channel Select Filter Calibration

2 Press Start and you can select to load values from the phone or not

3 Press AutoTune

4 Press Stop and you can select to save values to the phone or not to..

Figure 50: RX channel selection window

CCS Technical Documentation

Note: This calibration requires no input signal

Page 52 Nokia Corporation. Issue 1 10/03

Page 53

Company confidential RH-18/38

CCS Technical Documentation

RX Band Filter Response

1 Select Maintenance, Tuning, Rx Band Filter Response Compensation

2 Press Start, Read from PM area and you can select to load values from the phone

or not

3 Press Manual Tuning

4 Set the Signal generator according to the pop-up windows

5 When finished press Stop, Write to PM area and you can select to save values to

the phone or not

6 Repeat for GSM1800

Figure 51: RX Band filter response window

Note: This calibration requires a lot of different frequencies from the generator. If you have a signal

generator with a frequency list option you can with advantage use Auto Tuning (Dwell should be

around 10ms).

Issue 1 10/03 Nokia Corporation. Page 53

Page 54

RH-18/38 Company confidential

Tx Power tuning

Select Maintenance, Tuning, Tx Power Level Tuning

TX power tuning GSM

1 Select edge off, GSM 900

Figure 52: TX power tuning window1

CCS Technical Documentation

2 Press Start and select from where to load values. It is best to have PC saved data

from a good phone. The data from a "good" phone can be saved to PC for use

later.

Page 54 Nokia Corporation. Issue 1 10/03

Page 55

Company confidential RH-18/38

CCS Technical Documentation

Figure 53: TX power levwel tuning window 2

1 Select the modulation 1, 0 or random in Tx Data Type. Select random if a GSM

tester is used. Then it can synchronise to the burst.

2 Select Tx PA Mode High

3 Tune the highlighted values to the wanted power (Use average burst power)

4 Tune base level to –28dBm (Close to lowest level CMD55 can keep synchronisa-

tion)

5 Calculate coefficients

Issue 1 10/03 Nokia Corporation. Page 55

Page 56

RH-18/38 Company confidential

Figure 54: TX power level tuning 3

CCS Technical Documentation

1 Select Tx PA Mode low and tune the high lighted values.

2 The base level coefficient is taken from the high mode. Do not change it.

3 Calculate and select Stop

Figure 55: Stop TX power level tuning dialogue

If you are satisfied with the coefficients and the power, then save to the Permanent

memory.

You can also save the table to the PC, so that you can load it to an other phone. Or you

can select not to do anything by removing both ticks.

Only way to end the tuning session is with Yes

Page 56 Nokia Corporation. Issue 1 10/03

Page 57

Company confidential RH-18/38

CCS Technical Documentation

TX power tuning PCN

Figure 56: PCN (GSM1800) TX power tuning window

1 Select GSM 1800 band (PCN)

2Start

3 Select where to get values from. Normally Permanent Memory

4OK

Figure 57: Start TX power level tuning dialogue

Issue 1 10/03 Nokia Corporation. Page 57

Page 58

RH-18/38 Company confidential

Figure 58: GSM1800 TX power level tuning window

CCS Technical Documentation

1 Select the wanted modulation. Random if a GSM tester is used, so that you can

synchronise the burst.

2 Only high mode is possible

3 Tune the highlighted values to the wanted power

4 Tune base level to –27dBm

5Stop

Figure 59: Stop TX power level tuning dialogue

6 Select where to save the values, one, both or no one can be selected.

7 Yes. That’s the only way to end tuning.

Page 58 Nokia Corporation. Issue 1 10/03

Page 59

Company confidential RH-18/38

CCS Technical Documentation

I/Q tuning

Select Maintenance, Tuning, Tx IQ tuning

Set CMD55 to Narrow Spectrum on the same band as the phone. Selected in the top

menu.

Figure 60: I/Q tuning window

1 Select where to get values. Normally select Load From Product

2Start

3 Tune offset values to lowest carrier. Use Side arrows or +, - .

4 Tune Amplitude and phase to lowest sideband.

5 Check eventually with other modulation (0).

Issue 1 10/03 Nokia Corporation. Page 59

Page 60

RH-18/38 Company confidential

Figure 61: TX I/O tuning window

CCS Technical Documentation

Note: Remember to tick Save to Product if you want to save the values in the phone.

1. Stop to end the tuning with the selected save option

2. Same procedure for PCN as for GSM.

3. Remember to tick Save To Product.

4. Stop. Ends tuning and does what you have ticked.

Page 60 Nokia Corporation. Issue 1 10/03

Page 61

Company confidential RH-18/38

CCS Technical Documentation

RF control

This menu can be placed in maintenance or in tuning depending on the Phoenix.

It is meant to check the receiver or transmitter without going in call. It works very much

like a call, but you have control via the PC, and not via the tester.

The TX mode GSM900 can select between Free, High and low mode. It changes the PA

mode, but changes also the power level if a level is selected that is not supported in that

mode.

If you want to tune at other channels than the default, then you must select it first in RF

control and then start the tuning.

Figure 62: RF control window

Issue 1 10/03 Nokia Corporation. Page 61

Page 62

RH-18/38 Company confidential

Call testing

If all tunings are done, and the phone TX and RX is working a call is the ultimate test of

the phone.

Set CMD55, or similar tester, to manual test and switch the phone to normal if it was in

local. Remember to have a test simcard in the phone.

When the phone has made a registration a call can be made, and it is possible to let the

phone answer via Phoenix. In the Autocaller (Maintenance Testing) you can answer by

ticking Answer when button pushed and then posh the button.

CCS Technical Documentation

Page 62 Nokia Corporation. Issue 1 10/03

Loading...

Loading...