TRANSMISSION/TRANSAXLE

A

B

SECTION MT

CONTENTS

RS6F94R

SERVICE INFORMATION ............................

PRECAUTIONS ................................................... 3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .....................................

Precaution for Work ..................................................4

Precaution .................................................................4

PREPARATION ................................................... 5

Special Service Tool .................................................5

Commercial Service Tool ..........................................7

MANUAL TRANSAXLE

Removal and Installation .........................................19

Disassembly and Assembly .....................................20

3

INPUT SHAFT AND GEARS ............................37

Disassembly and Assembly .....................................37

MAINSHAFT AND GEARS ...............................41

3

3

Disassembly and Assembly .....................................41

REVERSE IDLER SHAFT AND GEARS ..........48

Disassembly and Assembly .....................................48

FINAL DRIVE ....................................................50

Disassembly and Assembly .....................................50

SHIFT CONTROL ..............................................52

Inspection ................................................................52

MT

D

E

F

G

H

I

J

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ............................

NVH Troubleshooting Chart ....................................10

10

DESCRIPTION ...................................................11

Cross-Sectional View ..............................................11

M/T OIL ...............................................................13

Changing M/T Oil ....................................................13

Checking M/T Oil .....................................................13

SIDE OIL SEAL ..................................................14

Removal and Installation .........................................14

POSITION SWITCH ............................................15

Checking .................................................................15

CONTROL LINKAGE .........................................16

Component of Shift Selector and Cable .................. 16

Removal and Installation .........................................16

AIR BREATHER HOSE ......................................18

Removal and Installation .........................................18

TRANSAXLE ASSEMBLY .................................19

Component ..............................................................19

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

General Specification ..............................................53

53

RS6F52A

SERVICE INFORMATION ...........................54

PRECAUTIONS .................................................54

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ...................................

Precaution for Work .................................................55

Service Notice or Precaution ...................................55

PREPARATION .................................................56

Special Service Tool ................................................56

Commercial Service Tool ........................................59

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ...........................

NVH Troubleshooting Chart ....................................61

DESCRIPTION ..................................................62

54

54

61

K

L

M

N

O

P

Revision: February 2013 2012 Sentra

MT-1

Cross-Sectional View ............................................. 62

Service Notice or Precaution ................................ 133

M/T OIL .............................................................. 64

Changing M/T Oil .................................................... 64

Checking M/T Oil .................................................... 64

SIDE OIL SEAL ................................................. 65

Removal and Installation ........................................ 65

POSITION SWITCH ........................................... 66

Checking ................................................................. 66

CONTROL LINKAGE ........................................ 67

Component of Shift Selector and Cable ................. 67

Removal and Installation ........................................ 67

AIR BREATHER HOSE ..................................... 69

Removal and Installation ........................................ 69

TRANSAXLE ASSEMBLY ................................ 70

Component ............................................................. 70

Removal and Installation ........................................ 70

Disassembly and Assembly .................................... 71

INPUT SHAFT AND GEARS ........................... 101

Disassembly and Assembly ...................................101

MAINSHAFT AND GEARS .............................. 108

Disassembly and Assembly ...................................108

PREPARATION ................................................134

Special Service Tool ............................................. 134

Commercial Service Tool ...................................... 137

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ...........................

NVH Troubleshooting Chart .................................. 139

139

DESCRIPTION ..................................................140

Cross-Sectional View ............................................ 140

M/T OIL .............................................................142

Changing M/T Oil .................................................. 142

Checking M/T Oil .................................................. 142

SIDE OIL SEAL ................................................143

Removal and Installation ....................................... 143

POSITION SWITCH ..........................................144

Checking ............................................................... 144

CONTROL LINKAGE .......................................145

Component of Shift Selector and Cable ................ 145

Removal and Installation ....................................... 145

AIR BREATHER HOSE ....................................147

Removal and Installation ....................................... 147

REVERSE IDLER SHAFT AND GEARS ......... 117

Disassembly and Assembly ...................................117

FINAL DRIVE ................................................... 119

Disassembly and Assembly ...................................119

SHIFT CONTROL ............................................ 123

Disassembly and Assembly ...................................123

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

General Specification ............................................126

Gear End Play .......................................................127

Baulk Ring Clearance ............................................127

Available Snap Rings ............................................127

Available C-Rings ..................................................128

Available Thrust Washer .......................................128

Available Adjusting Shims .....................................129

Available Shims .....................................................130

126

RS6F52H

SERVICE INFORMATION ..........................132

PRECAUTIONS ............................................... 132

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ................................................................

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect .................................

Precaution for Work ...............................................133

132

132

TRANSAXLE ASSEMBLY ...............................148

Component ........................................................... 148

Removal and Installation ....................................... 148

Disassembly and Assembly .................................. 149

INPUT SHAFT AND GEARS ............................179

Disassembly and Assembly .................................. 179

MAINSHAFT AND GEARS ..............................186

Disassembly and Assembly .................................. 186

REVERSE IDLER SHAFT AND GEARS ..........195

Disassembly and Assembly .................................. 195

FINAL DRIVE ....................................................197

Disassembly and Assembly .................................. 197

SHIFT CONTROL .............................................199

Disassembly and Assembly .................................. 199

SERVICE DATA AND SPECIFICATIONS

(SDS) ................................................................

General Specification ............................................ 202

Gear End Play ....................................................... 203

Baulk Ring Clearance ........................................... 203

Available Snap Rings ............................................ 203

Available C-Rings ................................................. 204

Available Thrust Washer ....................................... 204

Available Adjusting Shims ..................................... 205

Available Shims .................................................... 206

202

Revision: February 2013 2012 Sentra

MT-2

< SERVICE INFORMATION >

PRECAUTIONS

[RS6F94R]

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT PRE-TENSIONER"

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Ignition ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

INFOID:0000000007402949

A

B

MT

D

E

F

G

H

I

J

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000007402950

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYSTEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK″ position.

• Always use CONSULT to perform self-diagnosis as a part of each function inspection after finishing work. If

DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

K

L

M

N

O

P

Revision: February 2013 2012 Sentra

MT-3

PRECAUTIONS

< SERVICE INFORMATION >

5. When the repair work is completed, return the ignition switch to the ″LOCK″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of all control units using CONSULT.

[RS6F94R]

Precaution for Work INFOID:0000000007402951

• When removing or disassembling each component, be careful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component

with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty

area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Precaution INFOID:0000000007402952

• If transaxle assembly is removed from the vehicle, always replace CSC (Concentric Slave Cylinder).

Installed CSC returns to the original position when removing transaxle assembly. Dust on clutch disc sliding

parts may damage CSC seal, and may cause clutch fluid leakage.

• Do not reuse transaxle oil.

• Drain, fill and check transaxle oil with the vehicle on level surface.

• During removal or installation, keep inside of transaxle clear of dust or dirt.

• Check for the correct installation orientation prior to removal or disassembly. If matching marks are required,

be certain they do not interfere with the function of the parts they are applied to.

• In principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If tight-

ening sequence is specified, follow it.

• Be careful not to damage the sliding surfaces and mating surfaces of parts.

Revision: February 2013 2012 Sentra

MT-4

< SERVICE INFORMATION >

PREPARATION

[RS6F94R]

PREPARATION

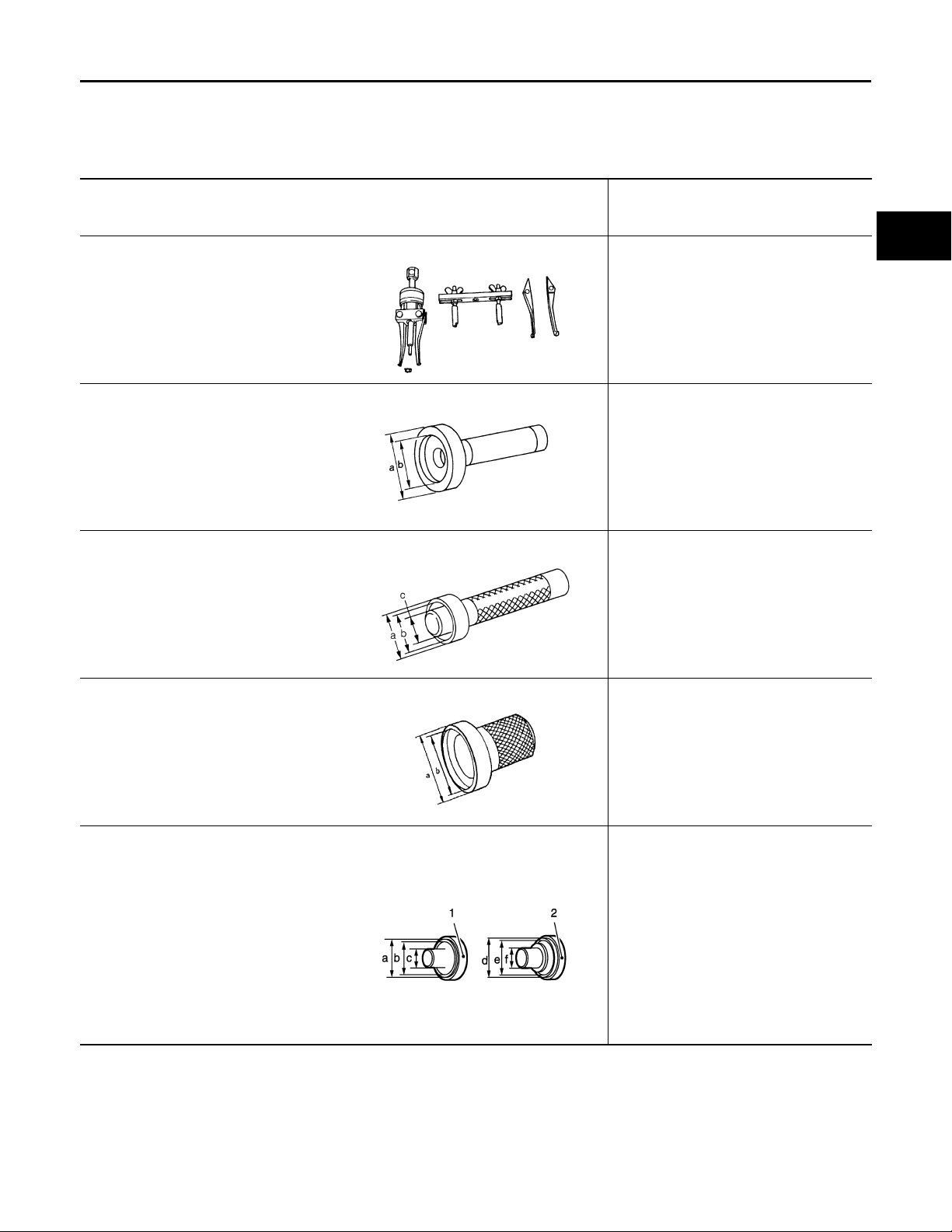

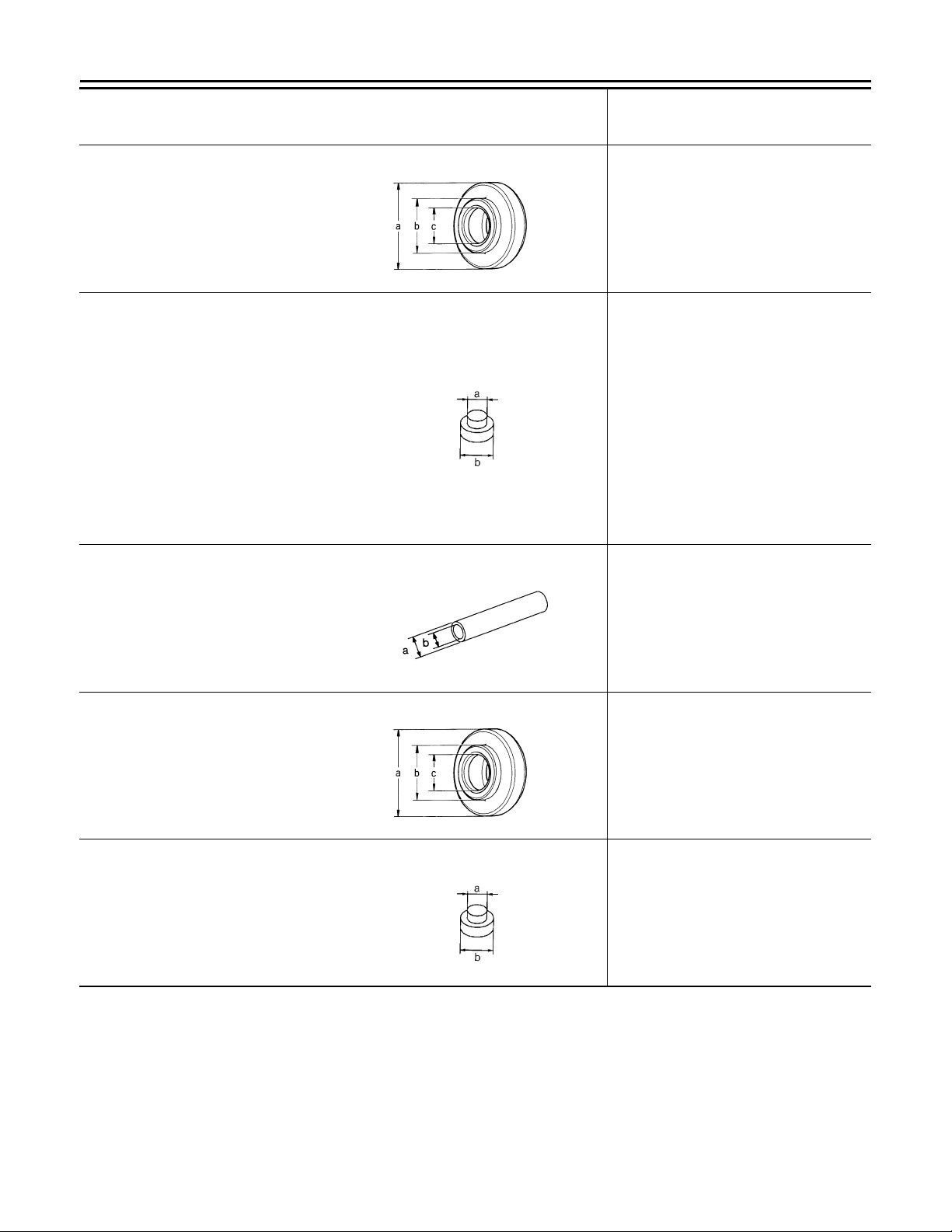

Special Service Tool INFOID:0000000007402953

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

KV381054S0

(J-34286)

Puller

ZZA0601D

KV38100200

(—)

Drift

ZZA1143D

ST33220000

(—)

Drift

Description

Removing mainshaft front bearing outer

race

• Installing mainshaft front bearing outer

race

• Installing mainshaft rear bearing outer

race

• Installing differential side bearing outer

race (clutch housing side)

a: 65 mm (2.56 in) dia.

b: 49 mm (1.93 in) dia.

Installing input shaft oil seal

a: 37 mm (1.46 in) dia.

b: 31 mm (1.22 in) dia.

c: 22 mm (0.87 in) dia.

A

B

MT

D

E

F

G

H

I

ST33400001

(J-26082)

Drift

KV32500QAA

(Renault SST: B.vi 1666))

Drift set

ZZA1046D

ZZA0814D

JPDIC0730ZZ

Installing differential side bearing outer

race (transaxle case side)

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

Installing differential side oil seal

1. —

(Stamping number: B.vi 1666-A)

Drift

a: 54.3 mm (2.138 in) dia.

b: 45 mm (1.77 in) dia.

c: 26.6 mm (1.047 in) dia.

2. —

(Stamping number: B.vi 1666-B)

Drift

a: 54.3 mm (2.138 in) dia.

b: 45 mm (1.77 in) dia.

c: 26.6 mm (1.047 in) dia.

J

K

L

M

N

O

P

Revision: February 2013 2012 Sentra

MT-5

< SERVICE INFORMATION >

PREPARATION

[RS6F94R]

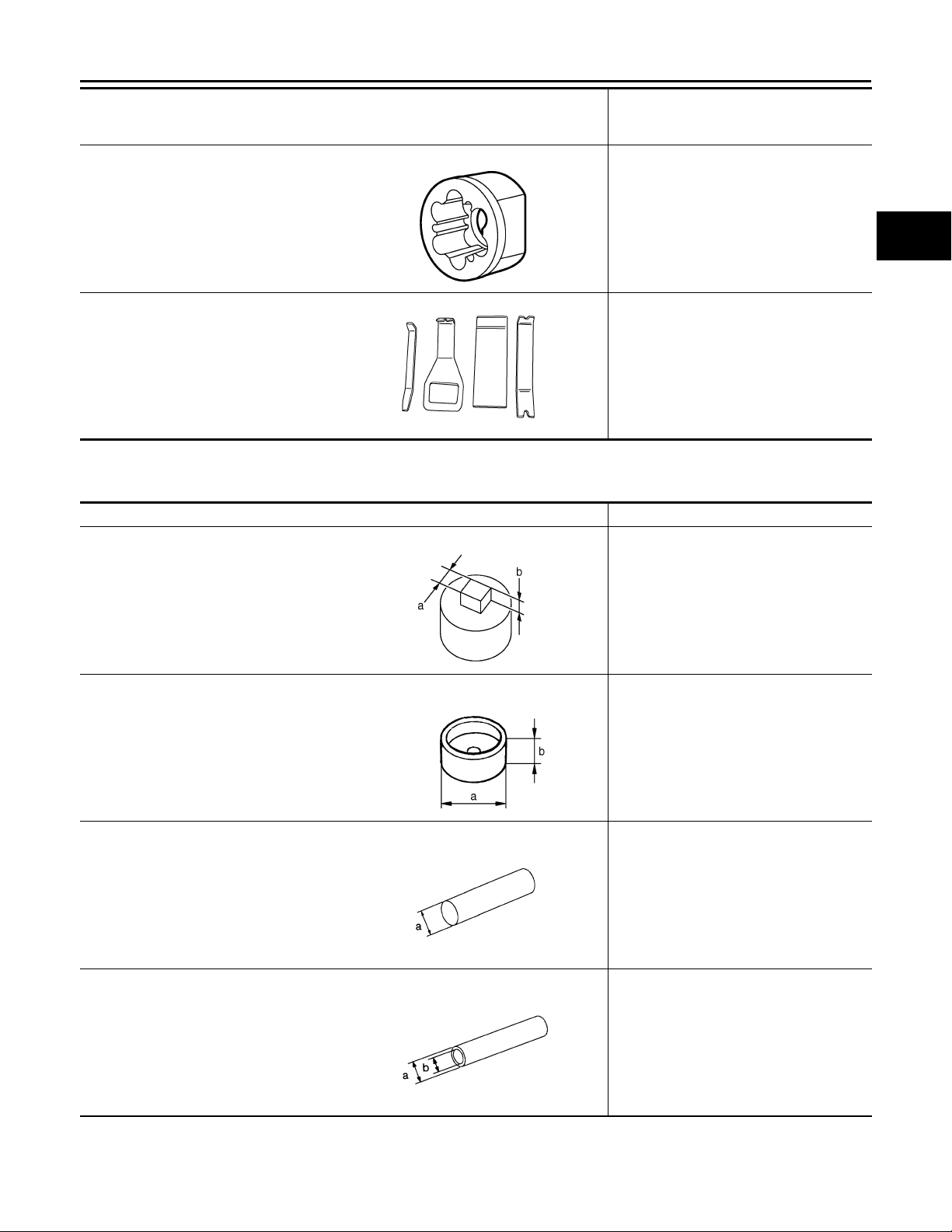

Tool number

(Kent-Moore No.)

Tool name

ST36720030

(—)

Drift

ST33052000

(—)

Drift

KV32102700

(—)

Drift

ST30901000

(J-26010-01)

Drift

ZZA0978D

ZZA0969D

S-NT065

Description

• Installing input shaft rear bearing

• Installing mainshaft front bearing inner

race

a: 70 mm (2.76 in) dia.

b: 40 mm (1.57 in) dia.

c: 29 mm (1.14 in) dia.

• Removing mainshaft rear bearing inner

race

• Removing 6th main gear

• Removing 5th main gear

• Removing 4th main gear

• Removing 1st main gear

• Removing 1st-2nd synchronizer assembly

• Removing 2nd main gear

• Removing bushing

• Removing 3rd main gear

• Removing mainshaft front bearing inner race

a: 22 mm (0.87 in) dia.

b: 28 mm (1.10 in) dia.

• Installing bushing

• Installing 2nd main gear

• Installing 3rd main gear

• Installing 4th main gear

• Installing 5th main gear

• Installing 6th main gear

a: 54 mm (2.13 in) dia.

b: 32 mm (1.26 in) dia.

Installing mainshaft rear bearing inner

race

a: 79 mm (3.11 in) dia.

b: 45 mm (1.77 in) dia.

c: 35.2 mm (1.386 in) dia.

ZZA0978D

ST33061000

(J-8107-2)

Drift

Removing differential side bearing inner

race (clutch housing side)

a: 28.5 mm (1.122 in) dia.

b: 38 mm (1.50 in) dia.

ZZA0969D

Revision: February 2013 2012 Sentra

MT-6

< SERVICE INFORMATION >

PREPARATION

[RS6F94R]

Tool number

(Kent-Moore No.)

Tool name

KV32300QAM

(Renault SST: B.vi 1823)

Drift

PCIB2078J

—

(J-46534)

Trim Tool Set

AWJIA0483ZZ

Description

Removing and installing input shaft rear

bearing bolt

Removing trim components

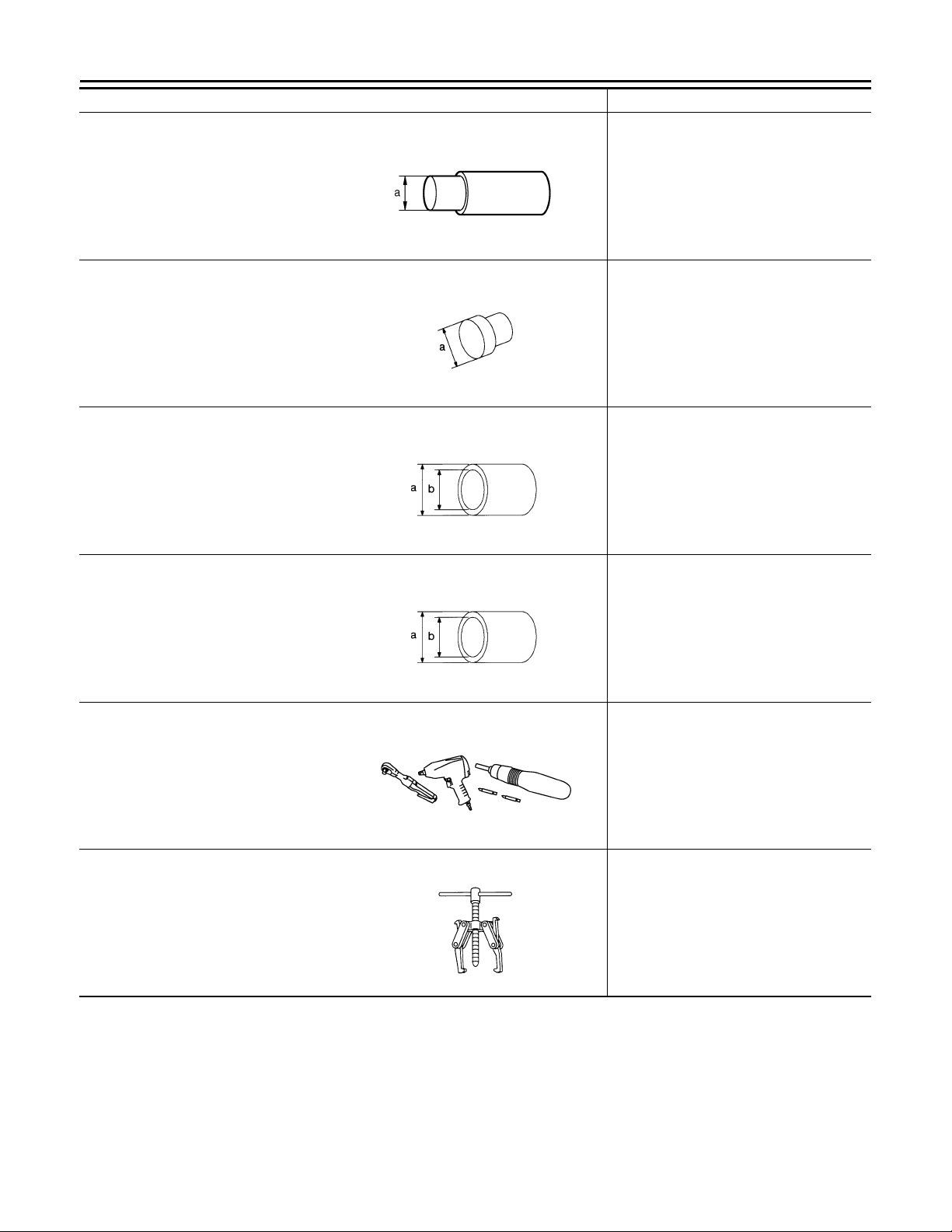

Commercial Service Tool INFOID:0000000007402954

Tool name Description

Socket Removing and installing drain plug

a: 8 mm (0.31 in)

b: 5 mm (0.20 in)

A

B

MT

D

E

F

G

H

PCIB1776E

Spacer Removing mainshaft front bearing outer

race

a: 25 mm (0.98 in) dia.

b: 25 mm (0.98 in)

PCIB1780E

Drift • Installing bushing

• Installing shift lever oil seal

• Installing select lever oil seal

a: 17 mm (0.67 in) dia.

S-NT063

Drift Installing input shaft front bearing

a: 35 mm (1.38 in) dia.

b: 25 mm (0.98 in) dia.

I

J

K

L

M

N

O

P

S-NT065

Revision: February 2013 2012 Sentra

MT-7

PREPARATION

< SERVICE INFORMATION >

Tool name Description

Drift Removing input shaft rear bearing

a: 24 mm (0.94 in) dia.

PCIB1779E

Drift • Removing differential side bearing in-

ner race (transaxle case side)

• Installing input shaft rear bearing

a: 43 mm (1.69 in) dia.

NT109

Drift Installing differential side bearing inner

race (clutch housing side)

a: 45 mm (1.77 in) dia.

b: 39 mm (1.54 in) dia.

[RS6F94R]

S-NT474

Drift Installing differential side bearing inner

race (transaxle case side)

a: 52 mm (2.05 in) dia.

b: 45 mm (1.77 in) dia.

S-NT474

Power tool Loosening nuts, screws and bolts

PIIB1407E

Puller Removing differential side bearing inner

race (clutch housing side)

Removing differential side bearing inner

race (transaxle case side)

NT077

Revision: February 2013 2012 Sentra

MT-8

< SERVICE INFORMATION >

PREPARATION

[RS6F94R]

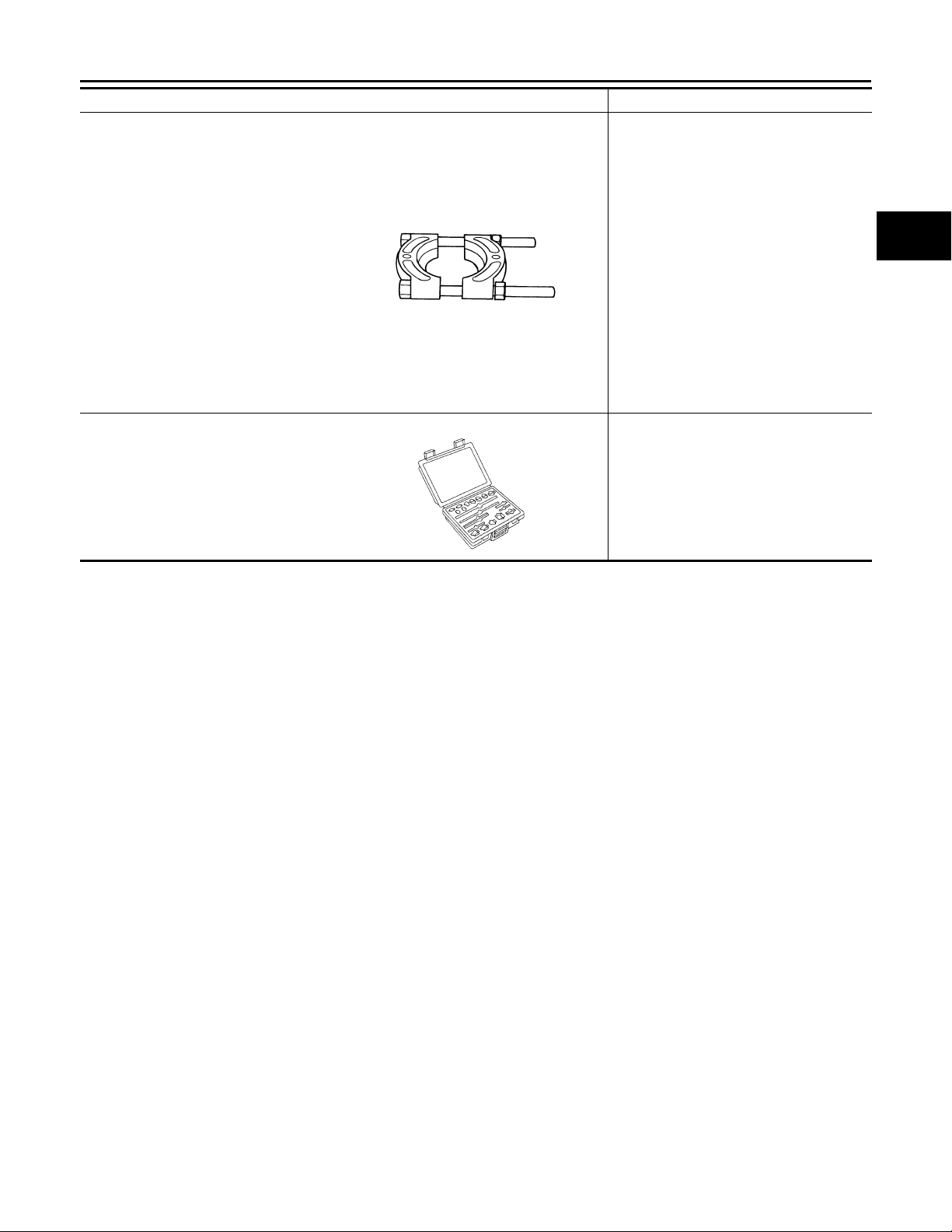

Tool name Description

Puller • Removing differential side bearing in-

ner race (clutch housing side)

• Removing differential side bearing inner race (transaxle case side)

• Removing input shaft rear bearing

• Removing input shaft front bearing

• Removing mainshaft rear bearing inner

race

• Removing 6th main gear

• Removing 4th main gear

• Removing 5th main gear

• Removing 1st main gear

ZZB0823D

Remover • Removing bushing

S-NT134

• Removing 1st - 2nd synchronizer hub

assembly

• Removing 2nd main gear

• Removing 3rd main gear

• Removing mainshaft front bearing outer race

• Removing mainshaft rear bearing outer race

A

B

MT

D

E

F

G

H

K

M

N

O

P

I

J

L

Revision: February 2013 2012 Sentra

MT-9

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

< SERVICE INFORMATION >

[RS6F94R]

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

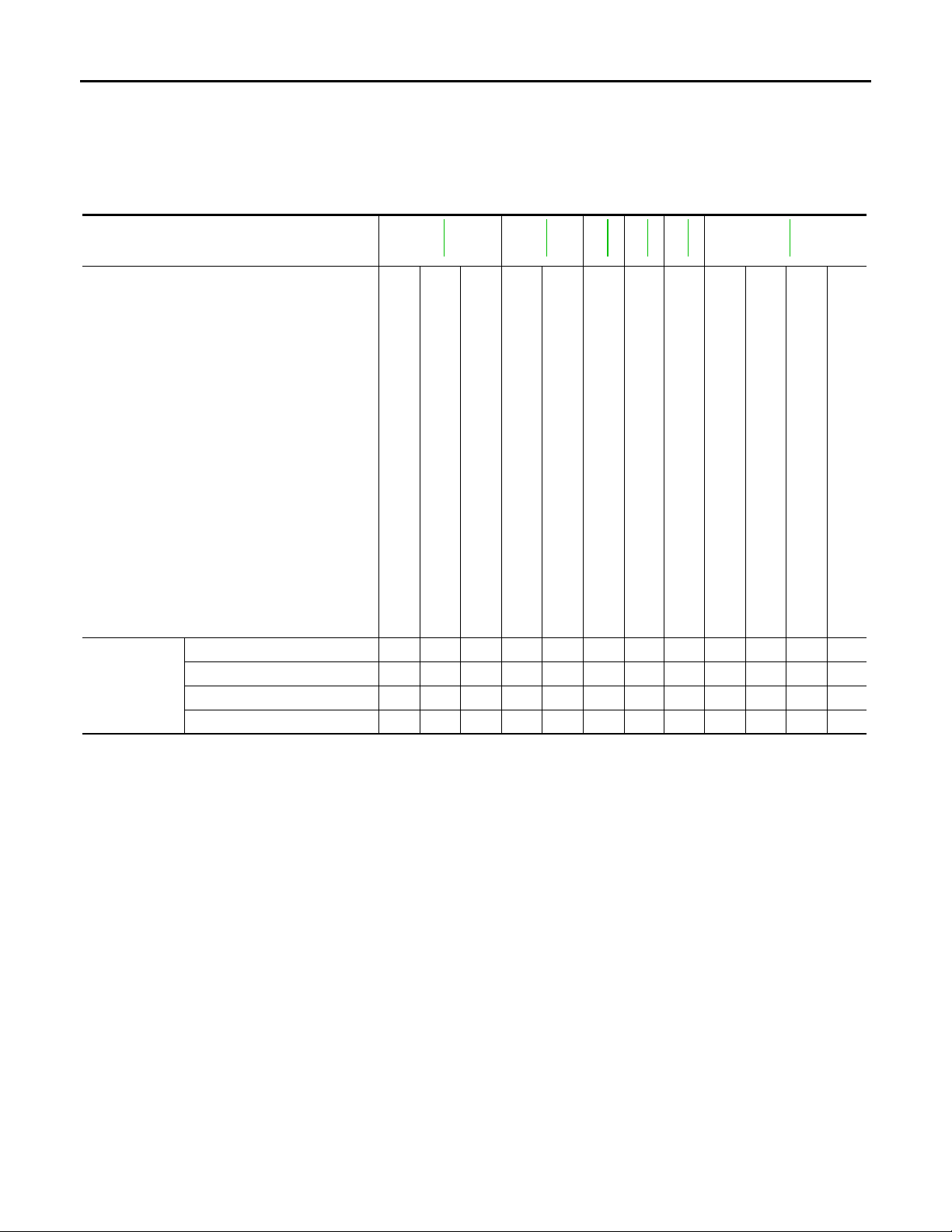

NVH Troubleshooting Chart INFOID:0000000007402955

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspection. If necessary, repair or replace these parts.

Reference page

SUSPECTED PARTS

(Possible cause)

Noise 1 2 3 3

Symptoms

Oil leakage 31222

Hard to shift or will not shift 1 1 2 3 3

Jumps out of gear 1 2 2

MT-13

OIL (Oil level is low.)

OIL (Wrong oil.)

OIL (Oil level is high.)

MT-20

GASKET (Damaged)

MT-20

MT-16

MT-20

OIL SEAL (Worn or damaged)

O-RING (Worn or damaged)

SHIFT CONTROL LINKAGE (Worn)

SHIFT FORK (Worn)

GEAR (Worn or damaged)

MT-20

BEARING (Worn or damaged)

BAULK RING (Worn or damaged)

INSERT SPRING (Damaged)

Revision: February 2013 2012 Sentra

MT-10

< SERVICE INFORMATION >

DESCRIPTION

[RS6F94R]

DESCRIPTION

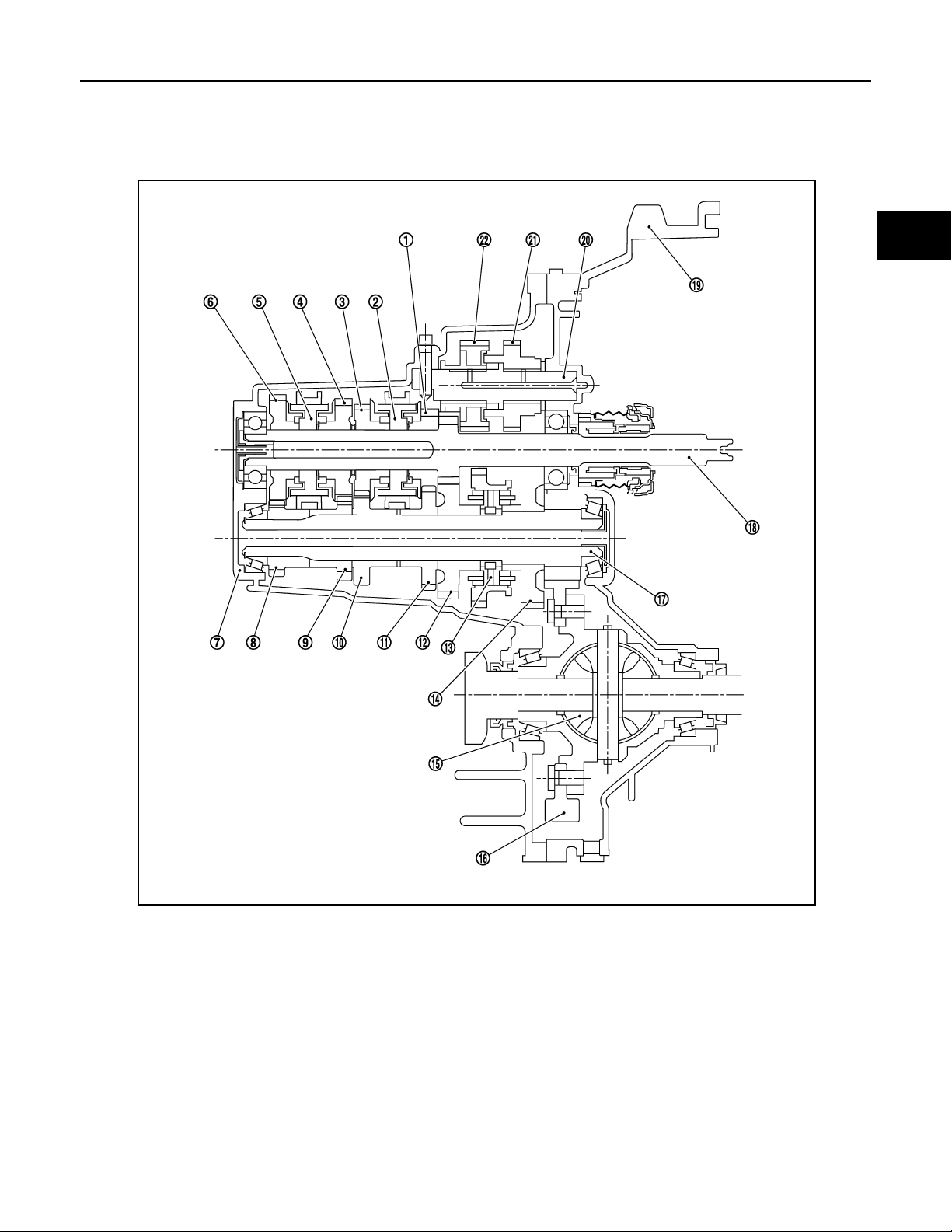

Cross-Sectional View INFOID:0000000007402956

A

B

MT

D

E

F

G

H

1. 3rd input gear 2. 3rd-4th synchronizer assembly 3. 4th input gear

4. 5th input gear 5. 5th-6th synchronizer assembly 6. 6th input gear

7. Transaxle case 8. 6th main gear 9. 5th main gear

10. 4th main gear 11. 3rd main gear 12. 2nd main gear

13. 1st-2nd synchronizer assembly 14. 1st main gear 15. Differential

16. Final gear 17. Mainshaft 18. Input shaft

19. Clutch housing 20. Reverse idler shaft 21. Reverse input gear

22. Reverse output gear

I

J

K

L

M

JPDIC0631ZZ

N

O

P

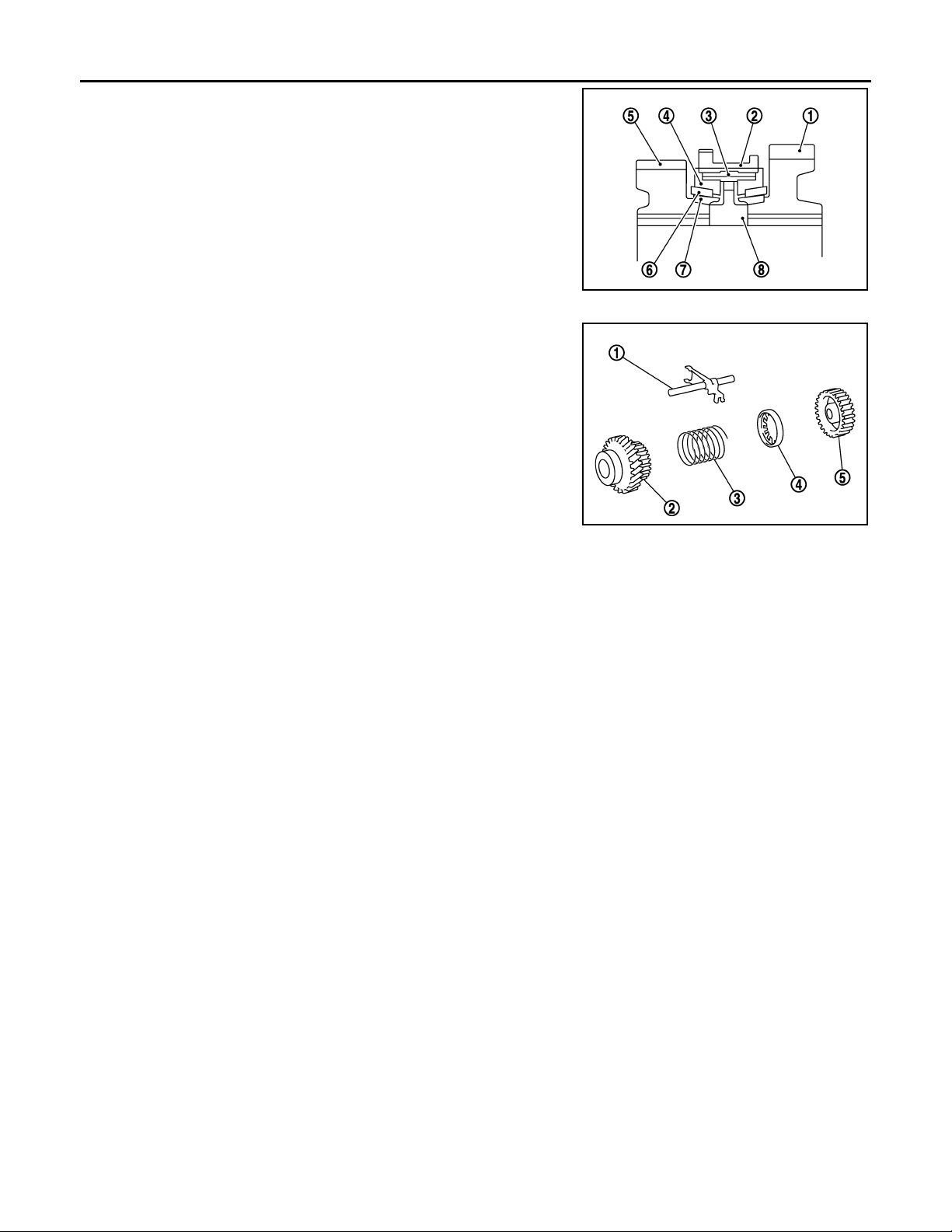

TRIPLE-CONE SYNCHRONIZER

Revision: February 2013 2012 Sentra

MT-11

DESCRIPTION

< SERVICE INFORMATION >

Triple-cone synchronizer is used for the 1st and the 2nd gears to

reduce operating force of the shift lever.

• 1st main gear (1)

• 1st-2nd coupling sleeve (2)

• Insert key (3)

• Outer baulk ring (4)

• 2nd main gear (5)

• Synchronizer cone (6)

• Inner baulk ring (7)

• 1st-2nd synchronizer hub (8)

REVERSE GEAR NOISE PREVENTION FUNCTION (SYNCHRONIZING METHOD)

Reverse gear assembly consists of reverse input gear, return spring,

reverse baulk ring and reverse output gear. When the shift lever is

shifted to the reverse position, the construction allows smooth shift

operation by stopping the reverse idler shaft rotation by frictional

force of synchronizer.

• Reverse fork rod (1)

• Reverse output gear (2)

• Return spring (3)

• Reverse baulk ring (4)

• Reverse input gear (5)

[RS6F94R]

SCIA7636E

SCIA7621E

Revision: February 2013 2012 Sentra

MT-12

< SERVICE INFORMATION >

M/T OIL

[RS6F94R]

M/T OIL

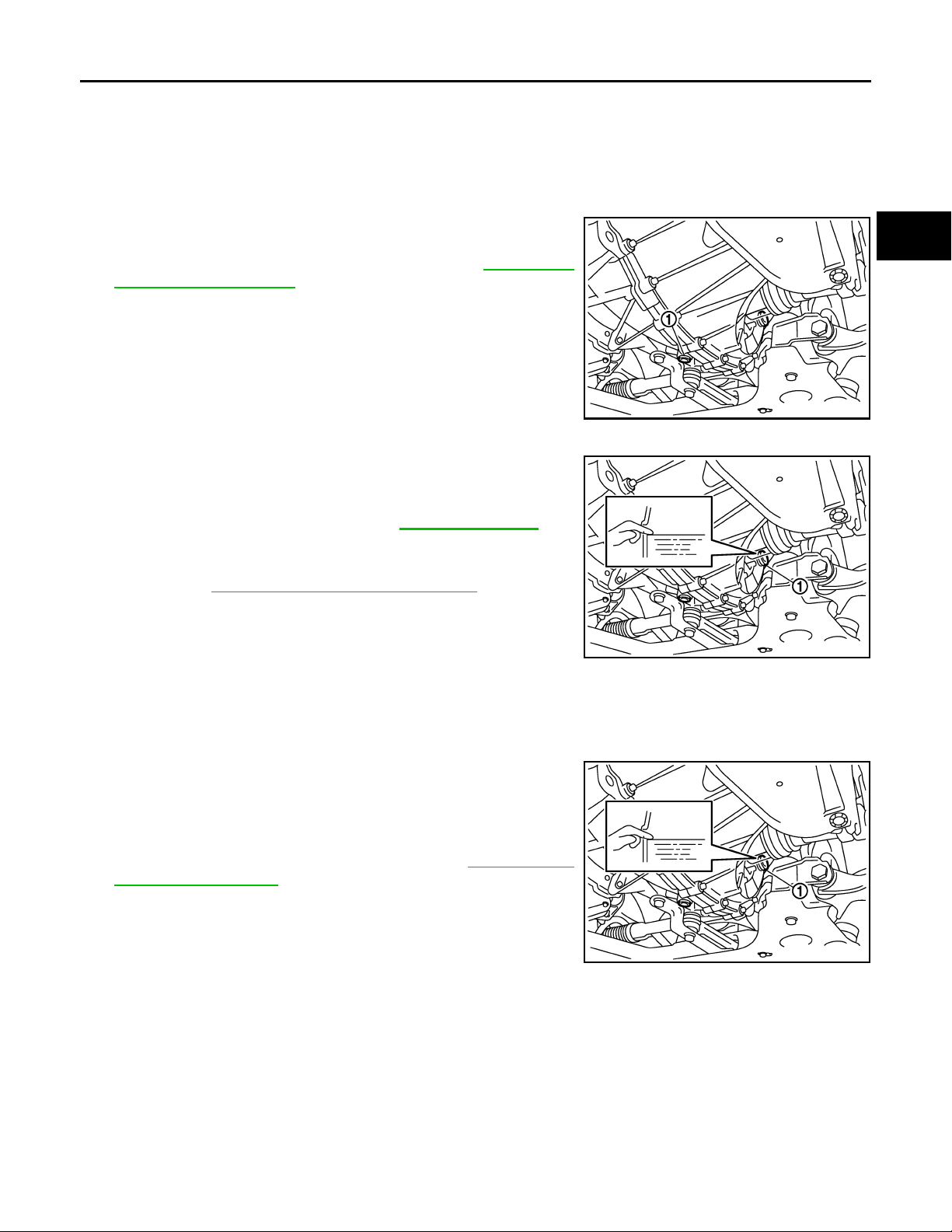

Changing M/T Oil INFOID:0000000007402957

DRAINING

1. Start engine and let it run to warm up transaxle.

2. Stop engine. Remove drain plug (1) and drain oil.

3. Install a new gasket onto drain plug (1) and install it into transaxle. Tighten drain plug to specification. Refer to MT-20, "Dis-

assembly and Assembly".

CAUTION:

Do not reuse gasket.

SCIA7622E

FILLING

1. Remove filler plug (1). Fill with new oil until oil level reaches the

specified limit at filler plug hole as shown.

Oil grade and capacity : Refer to MA-15, "MR20DE".

2. After refilling oil, check oil level. Install a new gasket on filler plug

(1), then install it into transaxle. Tighten filler plug to specification. Refer to MT-20, "Disassembly and Assembly"

CAUTION:

Do not reuse gasket.

.

A

B

MT

D

E

F

G

H

I

SCIA7623E

Checking M/T Oil INFOID:0000000007402958

OIL LEAKAGE AND OIL LEVEL

1. Make sure that oil is not leaking from transaxle or around it.

2. Remove filler plug (1) and check oil level at filler plug hole as

shown.

CAUTION:

Do not start engine while checking oil level.

3. Install a new gasket onto filler plug (1) and install it into transaxle. Tighten filler plug to specification. Refer to MT-20, "Disas-

sembly and Assembly".

CAUTION:

Do not reuse gasket.

SCIA7623E

J

K

L

M

N

O

P

Revision: February 2013 2012 Sentra

MT-13

SIDE OIL SEAL

< SERVICE INFORMATION >

[RS6F94R]

SIDE OIL SEAL

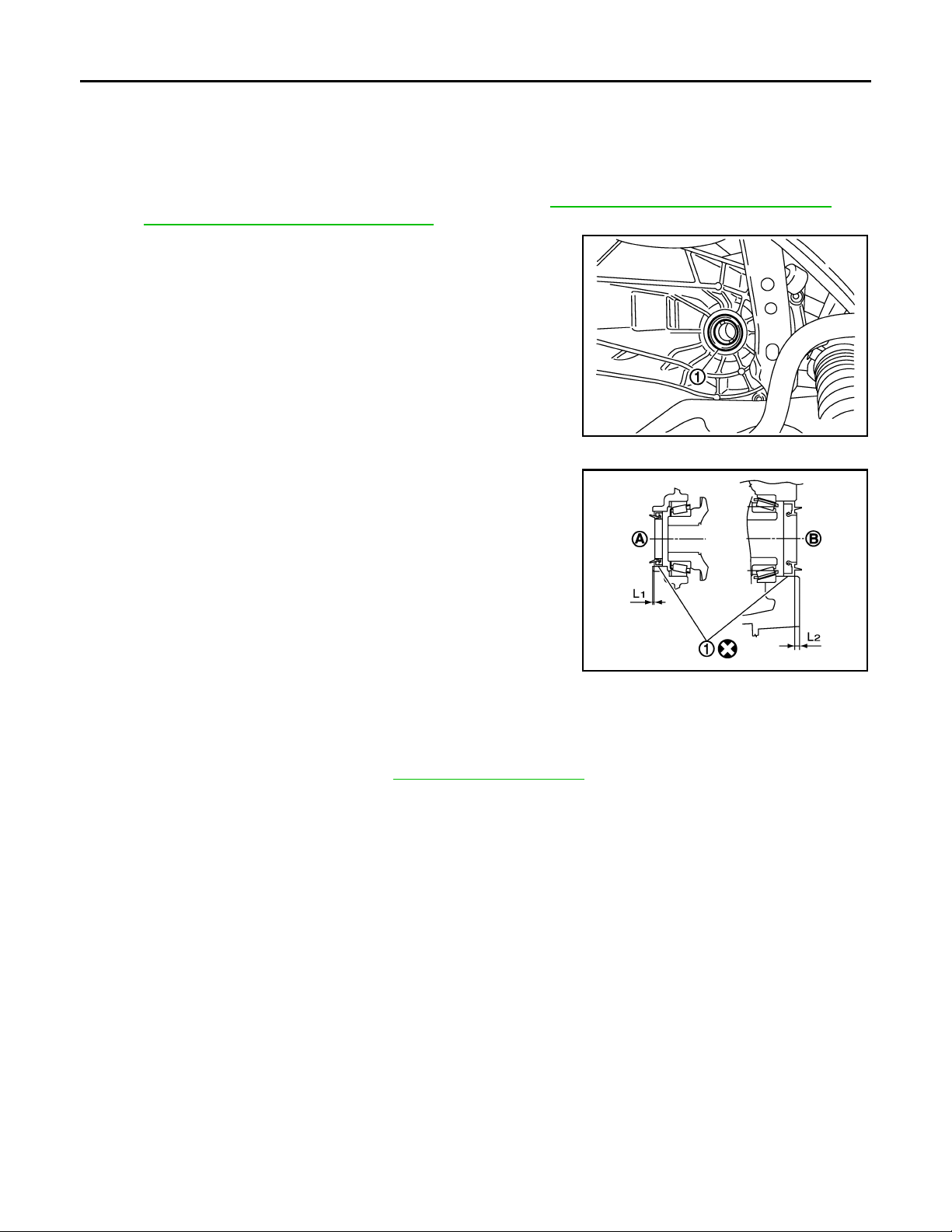

Removal and Installation INFOID:0000000007402959

REMOVAL

1. Remove front drive shafts from transaxle assembly. Refer to FAX-9, "Removal and Installation (LH)" (LH)

and FAX-11, "Removal and Installation (RH)"

2. Remove differential side oil seal (1) using a suitable tool.

CAUTION:

Be careful not to damage transaxle case and clutch housing.

INSTALLATION

Installation is in the reverse order of removal.

• Install differential side oil seal (1) to clutch housing and transaxle

case using Tool.

CAUTION:

Do not reuse oil seal.

(RH).

SCIA7625E

Tool number : KV32500QAA (B.vi 1666-B)

- A: Transaxle case side

- B: Clutch housing side

Dimension (L1) : 1.2 - 1.8 mm (0.047 - 0.071 in)

Dimension (L2) : 2.7 - 3.3 mm (0.106 - 0.130 in)

CAUTION:

• Never incline differential oil seal.

• Never damage clutch housing and transaxle case.

• Check oil level after installation. Refer to MT-13, "Checking M/T Oil"

JPDIC0454ZZ

.

Revision: February 2013 2012 Sentra

MT-14

< SERVICE INFORMATION >

POSITION SWITCH

[RS6F94R]

POSITION SWITCH

Checking INFOID:0000000007402960

NOTE:

For removal and installation of the switches, refer to MT-20, "Disassembly and Assembly"

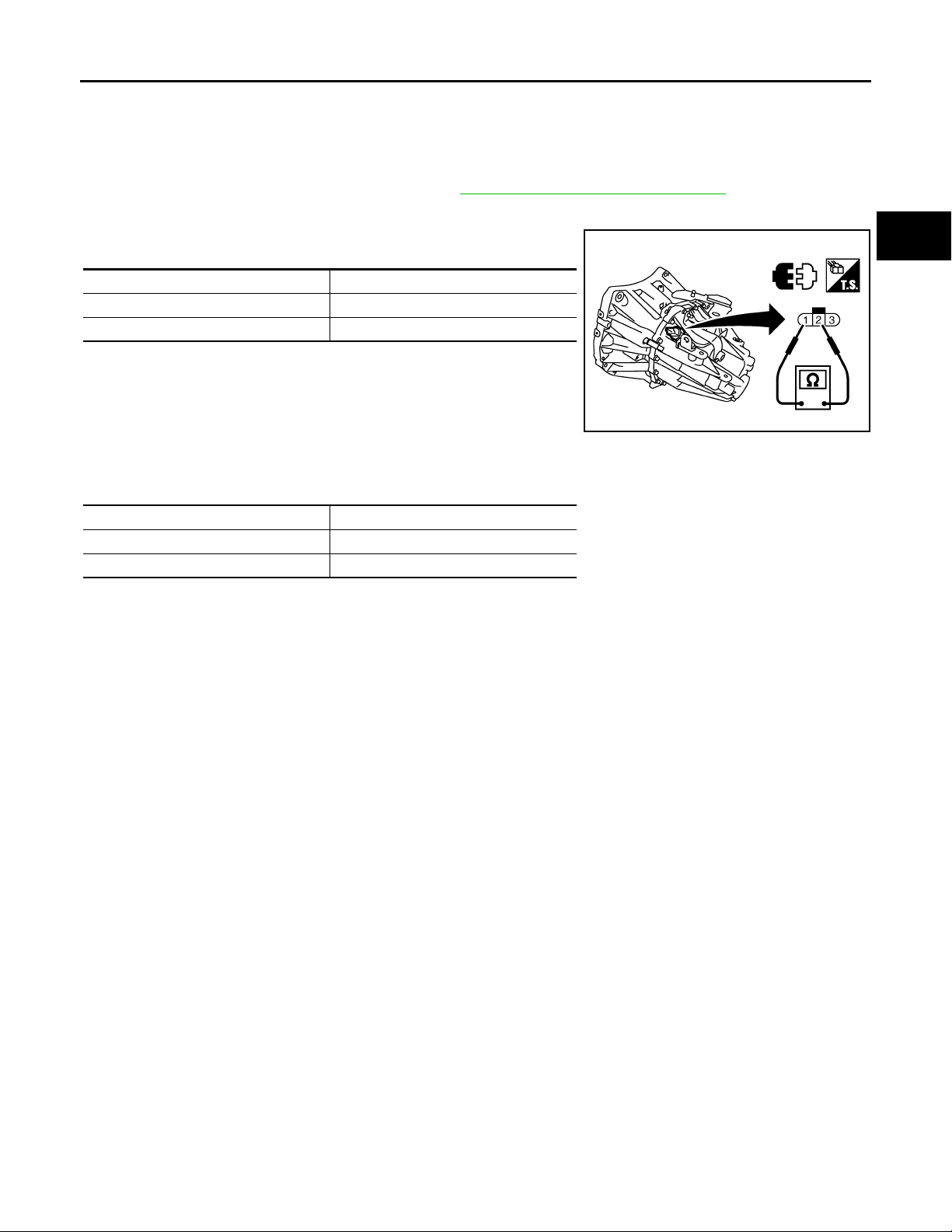

BACK-UP LAMP SWITCH

• Check continuity between terminals 1 and 2.

Gear position Continuity

Reverse Yes

Except reverse No

PARK/NEUTRAL POSITION (PNP) SWITCH

• Check continuity between terminals 2 and 3.

Gear position Continuity

Neutral Yes

Except neutral No

.

PCIB1781E

A

B

MT

D

E

F

G

H

K

M

N

O

P

I

J

L

Revision: February 2013 2012 Sentra

MT-15

CONTROL LINKAGE

< SERVICE INFORMATION >

[RS6F94R]

CONTROL LINKAGE

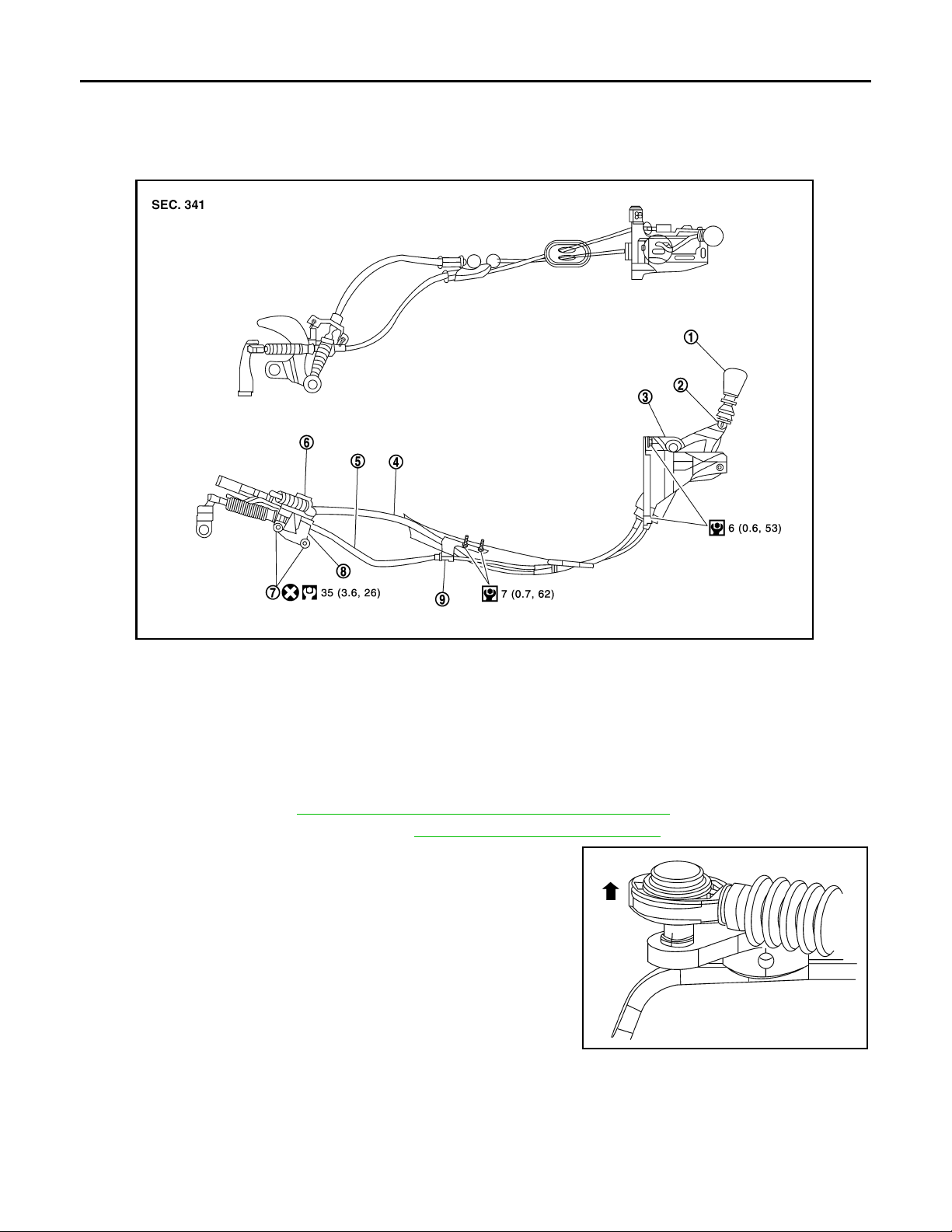

Component of Shift Selector and Cable INFOID:0000000007402961

AWCIA0011GB

1. Shift selector handle 2. Shift selector 3. Shift selector assembly

4. Select cable 5. Shift cable 6. Lock plate

7. Self-tapping bolt 8. Cable bracket 9. Cable support bracket

Removal and Installation INFOID:0000000007402962

REMOVAL

1. Remove battery. Refer to SC-7, "Removal and Installation (MR20DE Battery)".

2. Remove air cleaner and air duct. Refer to EM-16, "Removal and Installation"

3. Remove shift cable from shift lever as shown.

.

BCIA0052E

Revision: February 2013 2012 Sentra

MT-16

CONTROL LINKAGE

< SERVICE INFORMATION >

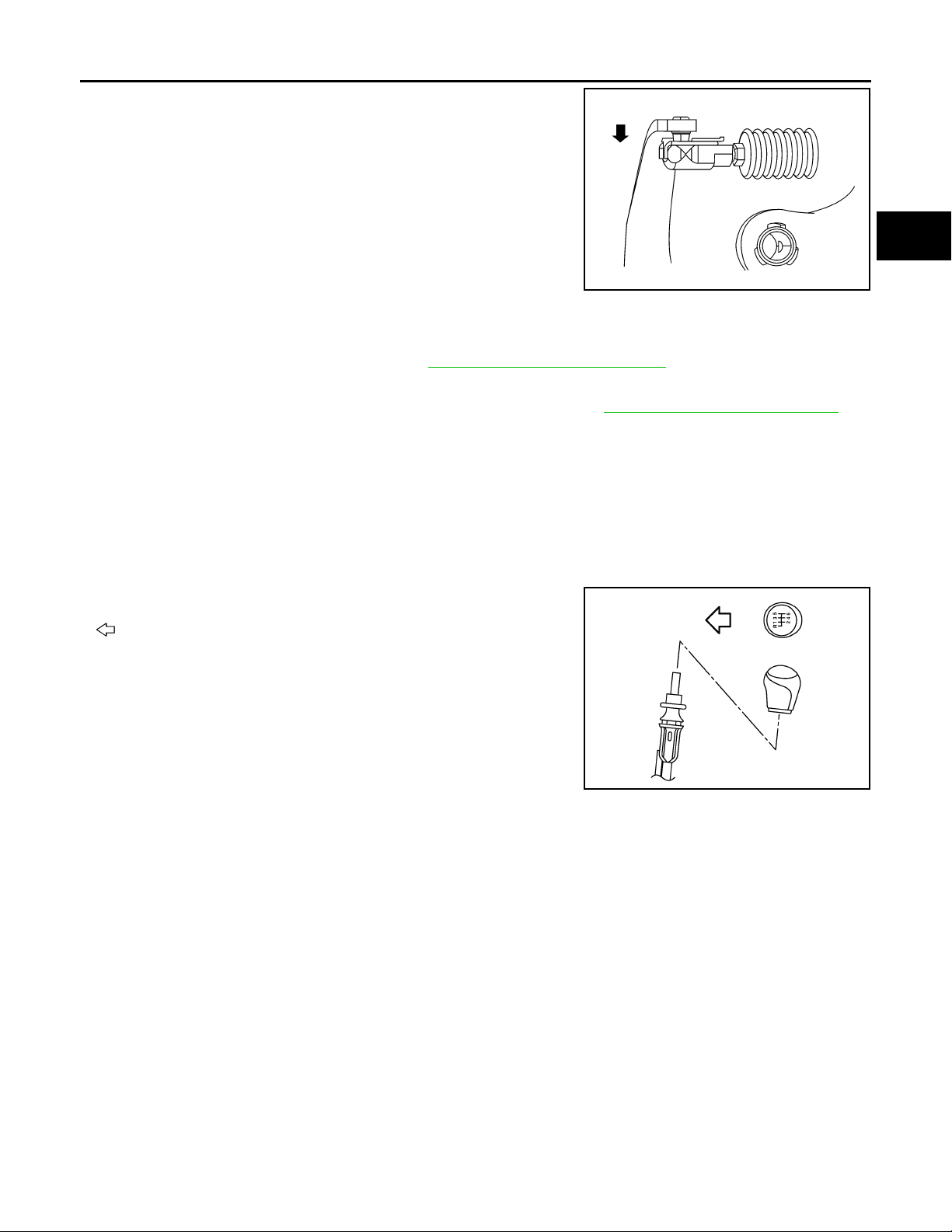

4. Remove select cable from select lever as shown.

5. Move shift selector to neutral position.

6. Remove shift selector handle.

7. Remove center console assembly. Refer to IP-12, "Removal and Installation"

.

8. Remove shift selector assembly nuts.

9. Remove exhaust front tube, center muffler and heat shield. Refer to EX-5, "Removal and Installation"

10. Remove cable support bracket.

11. Remove select cable and shift cable from cable bracket.

12. Remove shift selector assembly from the vehicle.

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

Bolt hole is not threaded on new clutch housing. Self-tapping bolt is used to attach lock plate to clutch housing.

• Securely install each cable to shift lever and select lever.

• Be careful about the installation direction, and screw shift selector

handle onto shift selector.

: Front

[RS6F94R]

BCIA0057E

.

A

B

MT

D

E

F

G

H

I

SCIA7630E

• When shift selector is moved to 1st-2nd side and 5th-6th side of neutral gate, confirm shift selector returns to

neutral position smoothly.

• When shift selector is moved to each position, make sure there is no binding or disconnection of each boot.

J

K

L

M

N

O

P

Revision: February 2013 2012 Sentra

MT-17

AIR BREATHER HOSE

< SERVICE INFORMATION >

[RS6F94R]

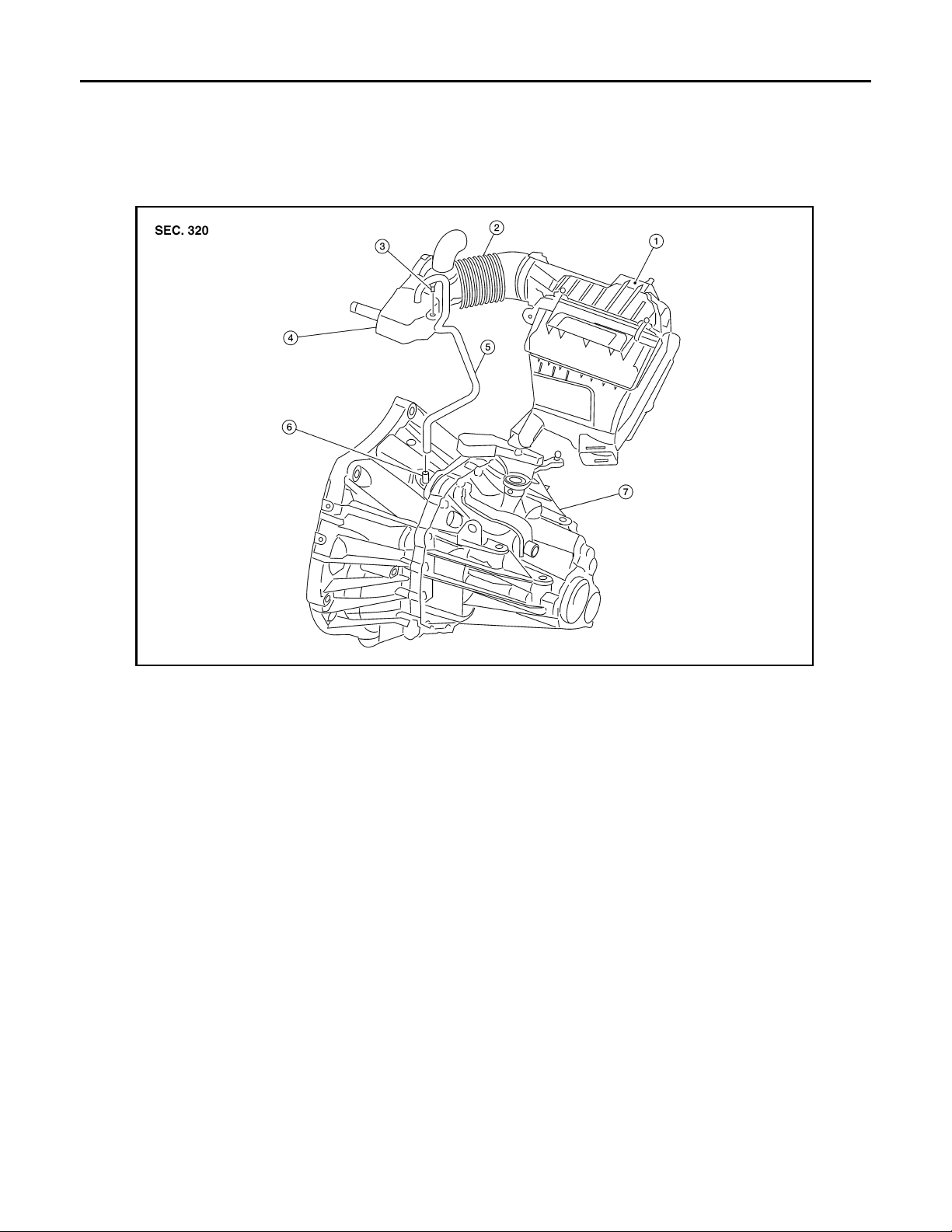

AIR BREATHER HOSE

Removal and Installation INFOID:0000000007402963

COMPONENTS

AWCIA0012ZZ

1. Air cleaner case 2. Air duct 3. Clip

4. Resonator 5. Air breather hose 6. Two way connector

7. Transaxle assembly

REMOVAL

1. Disconnect air breather hose clips and disconnect air breather hose from resonator.

2. Remove air breather hose.

CAUTION:

When removing air breather hose, be sure to hold two way connector securely.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Make sure air breather hose is not collapsed or blocked due to folding or bending when installed.

• When installing air breather hose on two way connector, push it until it hits transaxle case.

• When installing air breather hose on two way connector, aim paint mark toward the vehicle front.

• When installing air breather hose to resonator, make sure that clips are fully inserted.

Revision: February 2013 2012 Sentra

MT-18

< SERVICE INFORMATION >

TRANSAXLE ASSEMBLY

[RS6F94R]

TRANSAXLE ASSEMBLY

Component INFOID:0000000007402964

JPDIC0632ZZ

1. Transaxle assembly

: Refer to MT-19, "Removal and Installation"

.

A

B

MT

D

E

F

G

H

Removal and Installation INFOID:0000000007402965

CAUTION:

If transaxle assembly is removed from the vehicle, always replace CSC. Return CSC insert to original

position to remove transaxle assembly. Dust on clutch disc sliding parts may damage CSC seal and

may cause clutch fluid leakage.

NOTE:

When removing components such as hoses, tubes/lines, etc., cap or plug openings to prevent fluid from spilling.

REMOVAL

1. Remove clutch tube from CSC. Refer to CL-14, "Removal and Installation".

CAUTION:

Do not depress clutch pedal during removal procedure.

2. Remove engine and transaxle assembly. Refer to EM-76, "Removal and Installation"

3. Remove starter motor. Refer to SC-27, "Removal and Installation MR20DE"

.

4. Remove transaxle assembly to engine bolts.

5. Separate transaxle assembly from engine.

INSTALLATION

Installation is in the reverse order of removal.

• If transaxle assembly is removed from the vehicle, always replace CSC. Refer to CL-13, "Removal and

Installation".

.

I

J

K

L

M

N

O

P

Revision: February 2013 2012 Sentra

MT-19

TRANSAXLE ASSEMBLY

< SERVICE INFORMATION >

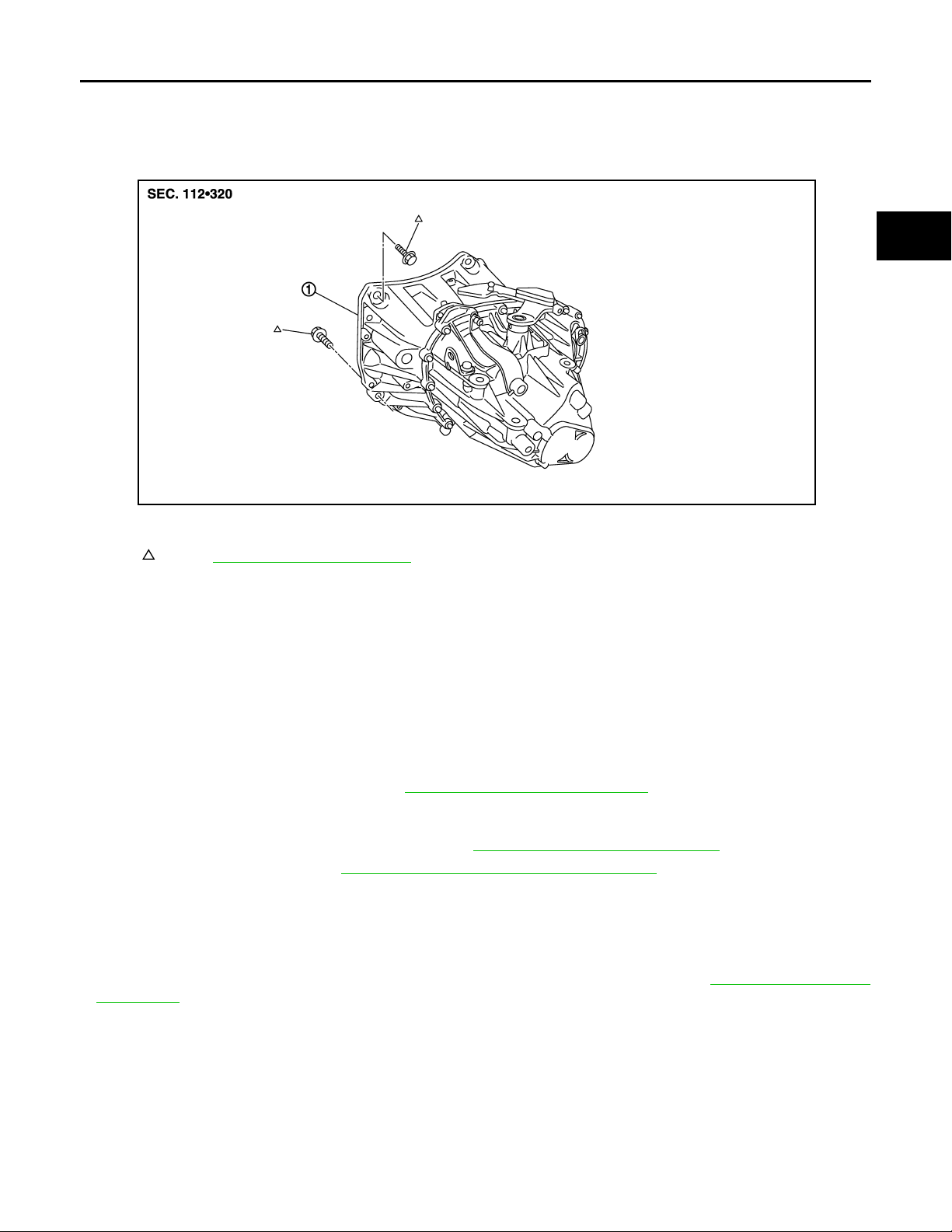

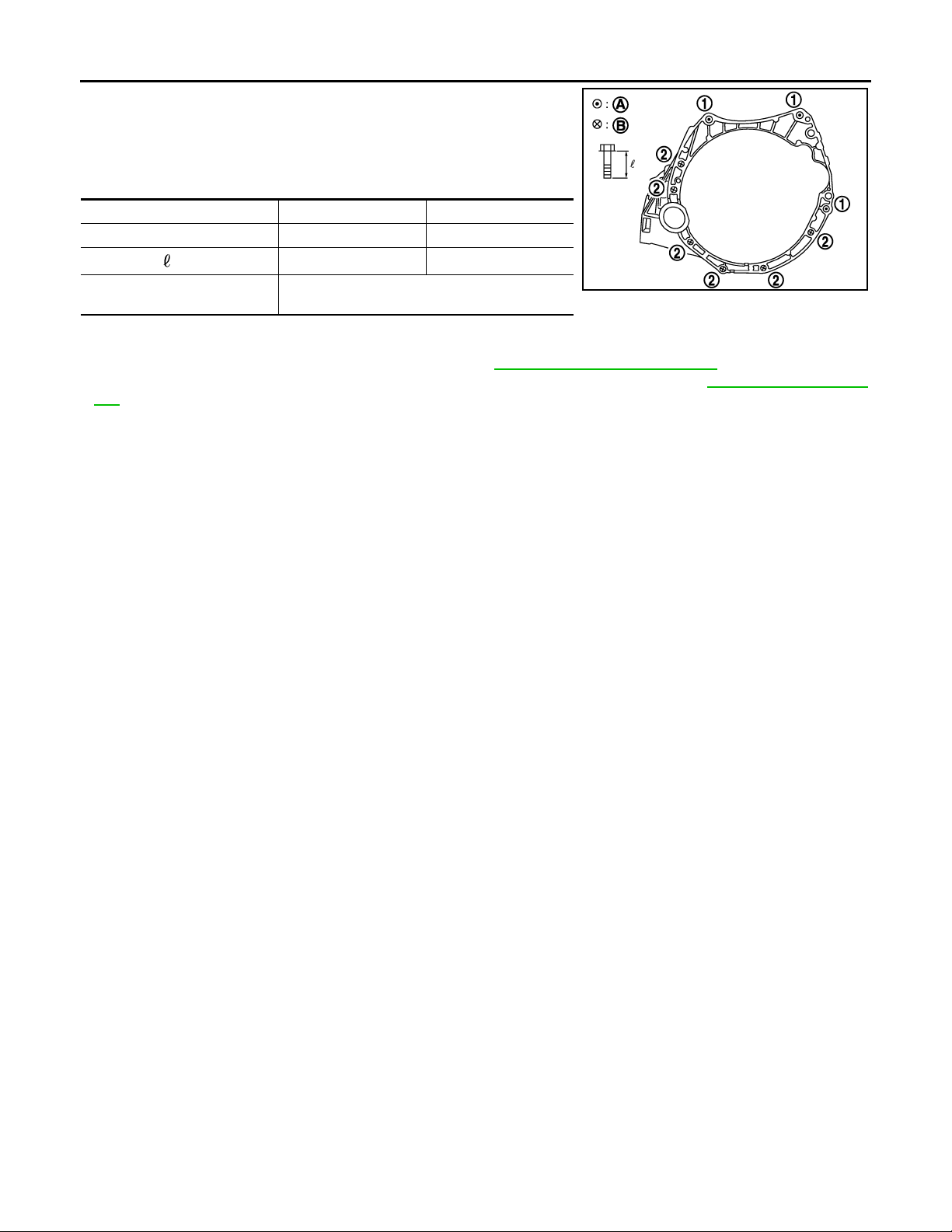

• When installing the transaxle assembly to the engine, install the

bolts as shown.

CAUTION:

When installing transaxle assembly, be careful not to bring

transaxle input shaft into contact with clutch cover.

Bolt No. 1 2

Quantity 3 6

Bolt length “ ” mm (in)

Tightening torque

N·m (kg-m, ft-lb)

60 (2.36) 50 (1.97)

62.0 (6.3, 46)

A: M/T to engine

B: Engine to M/T

• Bleed the air from the clutch hydraulic system. Refer to CL-9, "Air Bleeding Procedure"

.

• After installation, check oil level, and check for leaks and loose mechanisms. Refer to MT-13, "Checking M/T

Oil".

[RS6F94R]

PCIB1786E

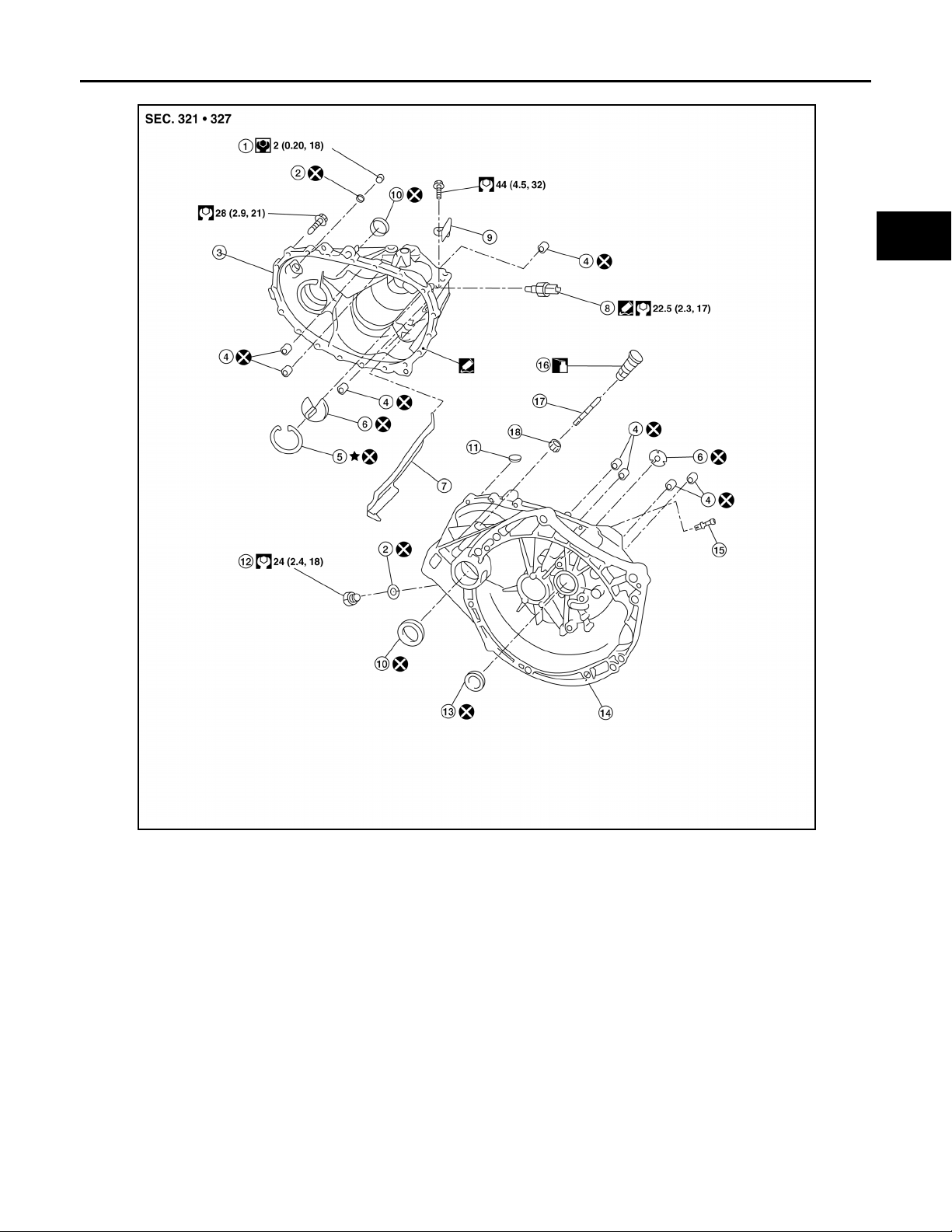

Disassembly and Assembly INFOID:0000000007402966

COMPONENTS

Case and Housing Components

Revision: February 2013 2012 Sentra

MT-20

< SERVICE INFORMATION >

TRANSAXLE ASSEMBLY

[RS6F94R]

A

B

MT

D

E

F

G

1. Filler plug 2. Gasket 3. Transaxle case

4. Bushing 5. Snap ring 6. Oil channel

7. Oil gutter 8. Back-up lamp switch 9. Bracket

10. Differential side oil seal 11. Magnet 12. Drain plug

13. Input shaft oil seal 14. Clutch housing 15. Two way connector

16. Plug 17. Pinion shaft 18. Pinion gear

Gear Components

H

I

J

K

L

AWDIA0884GB

M

N

O

Revision: February 2013 2012 Sentra

MT-21

P

< SERVICE INFORMATION >

TRANSAXLE ASSEMBLY

[RS6F94R]

JPDIC0407GB

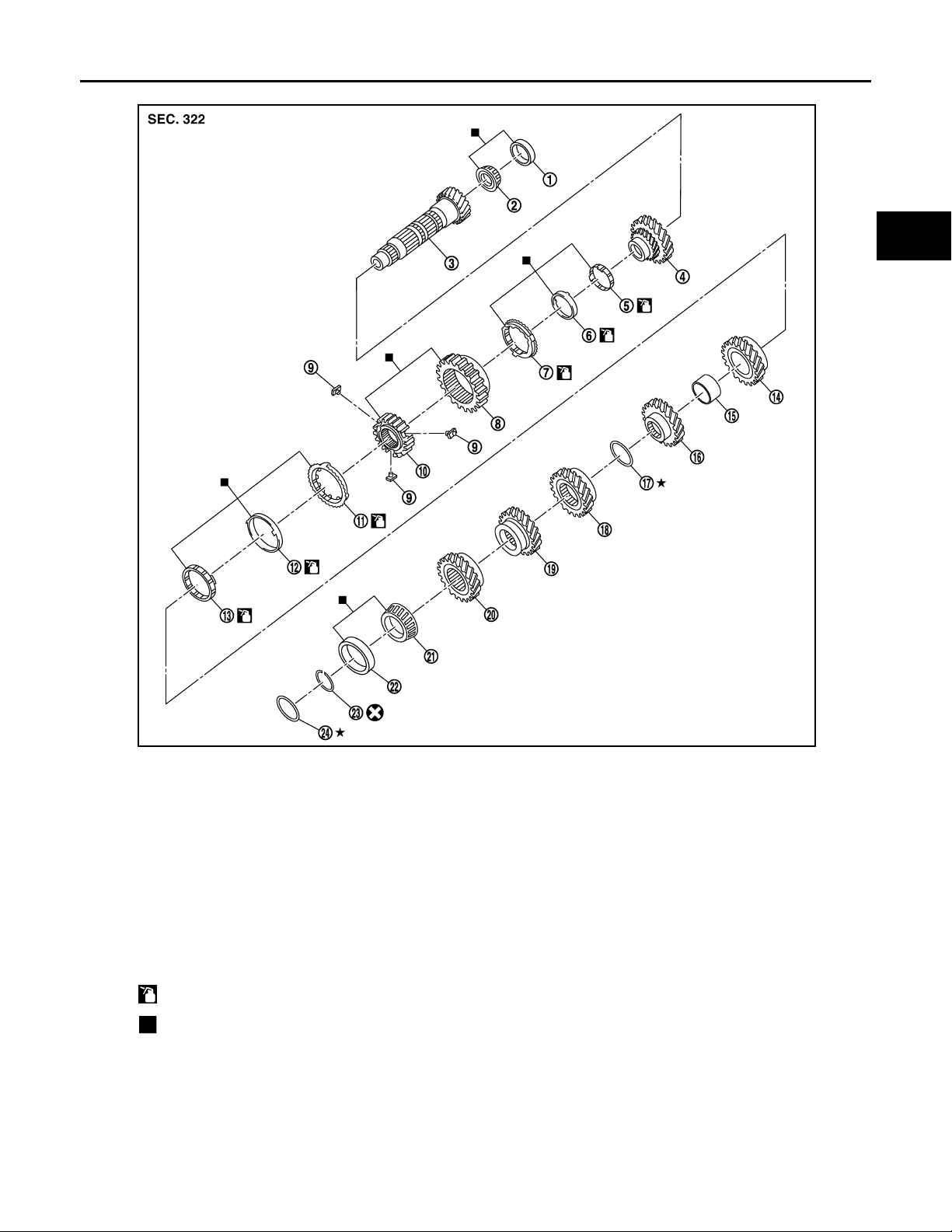

1. Input shaft front bearing 2. Input shaft 3. 3rd input gear

4. Spacer 5. Snap ring 6. 3rd baulk ring

7. 3rd-4th coupling sleeve 8. 3rd-4th synchronizer hub 9. Insert key

10. 4th baulk ring 11. 4th input gear 12. 5th input gear

13. 5th baulk ring 14. 5th-6th coupling sleeve 15. 5th-6th synchronizer hub

16. 6th baulk ring 17. Needle bearing 18. 6th input gear

19. Input shaft rear bearing

A: First step B: Final step

: Apply gear oil.

: Replace the parts as a set.

Revision: February 2013 2012 Sentra

MT-22

< SERVICE INFORMATION >

TRANSAXLE ASSEMBLY

[RS6F94R]

A

B

MT

D

E

F

G

SFIA3293E

1. Mainshaft front bearing outer

race

4. 1st main gear 5. 1st inner baulk ring 6. 1st synchronizer cone

7. 1st outer baulk ring 8. 1st-2nd coupling sleeve 9. Insert key

10. 1st-2nd synchronizer hub 11. 2nd outer baulk ring 12. 2nd synchronizer cone

13. 2nd inner baulk ring 14. 2nd main gear 15. Bushing

16. 3rd main gear 17. Mainshaft adjusting shim 18. 4th main gear

19. 5th main gear 20. 6th main gear 21. Mainshaft rear bearing inner

22. Mainshaft rear bearing outer

race

: Apply gear oil.

: Replace the parts as a set.

2. Mainshaft front bearing inner race 3. Mainshaft

race

23. Snap ring 24. Mainshaft rear bearing adjusting shim

H

I

J

K

L

M

N

O

P

Revision: February 2013 2012 Sentra

MT-23

< SERVICE INFORMATION >

TRANSAXLE ASSEMBLY

[RS6F94R]

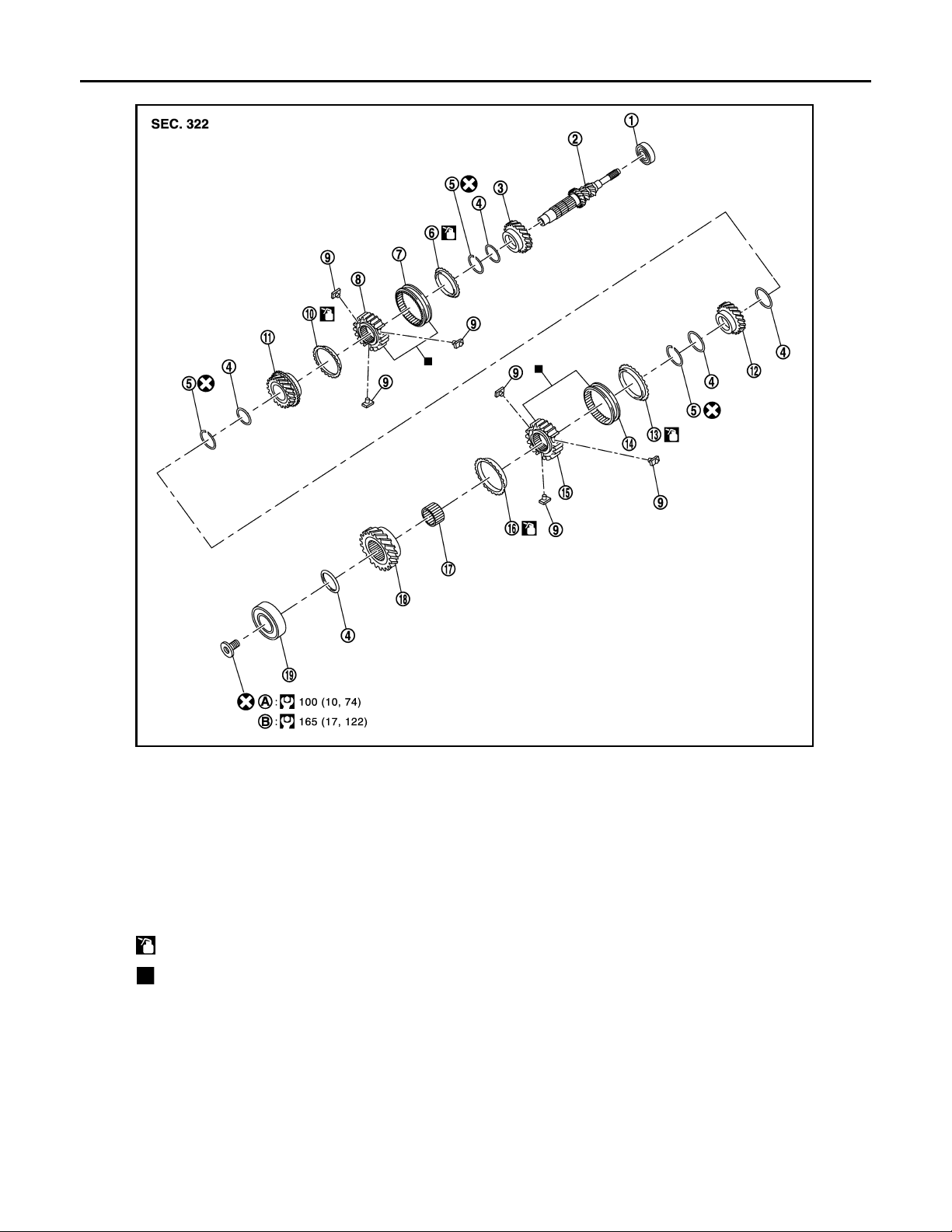

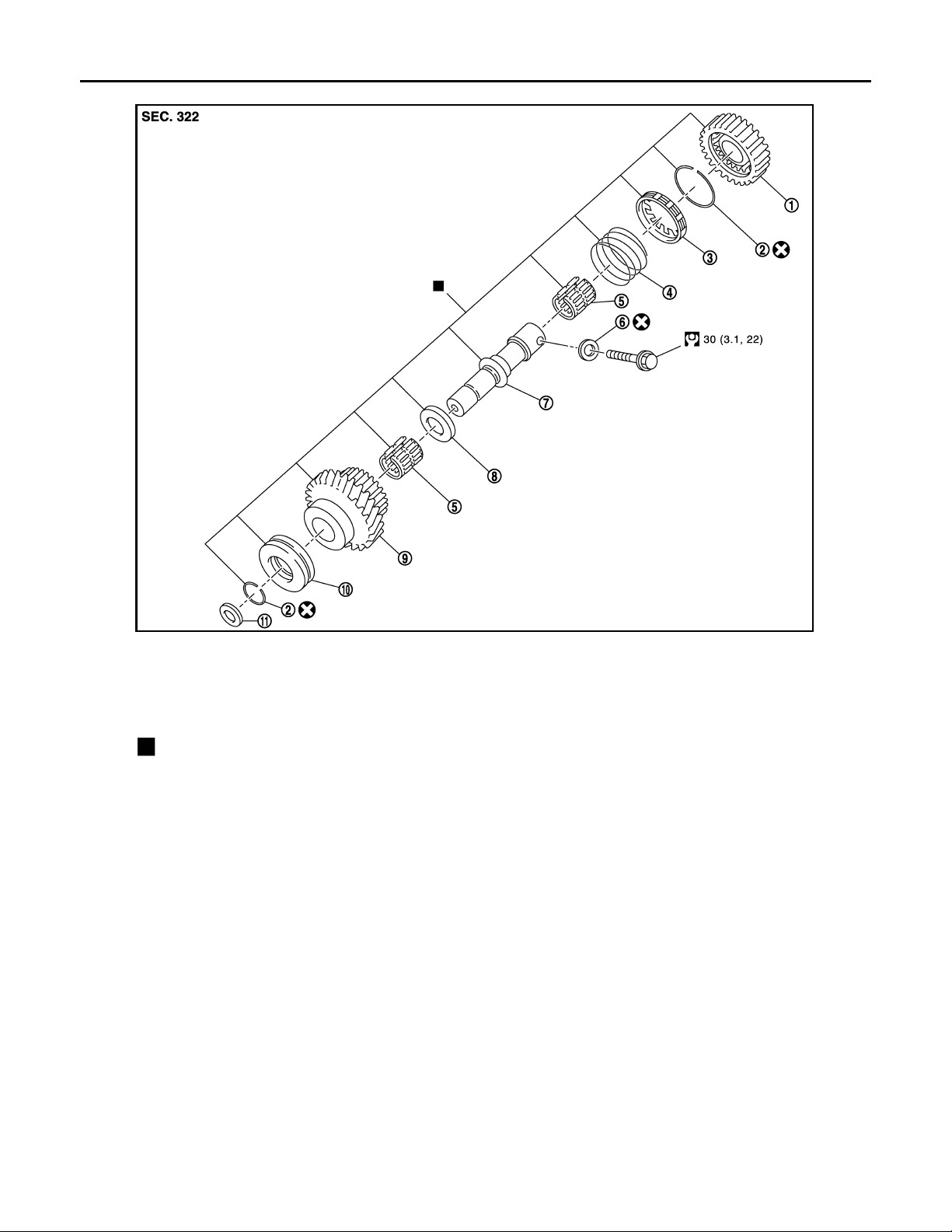

1. Reverse output gear 2. Snap ring 3. Reverse baulk ring

4. Return spring 5. Needle bearing 6. Seal washer

7. Reverse idler shaft 8. Spacer 9. Reverse input gear

10. Lock washer 11. Spring washer

: Replace the parts as a set.

Shift Control Components

JPDIC0425GB

Revision: February 2013 2012 Sentra

MT-24

< SERVICE INFORMATION >

TRANSAXLE ASSEMBLY

[RS6F94R]

A

B

MT

D

E

F

G

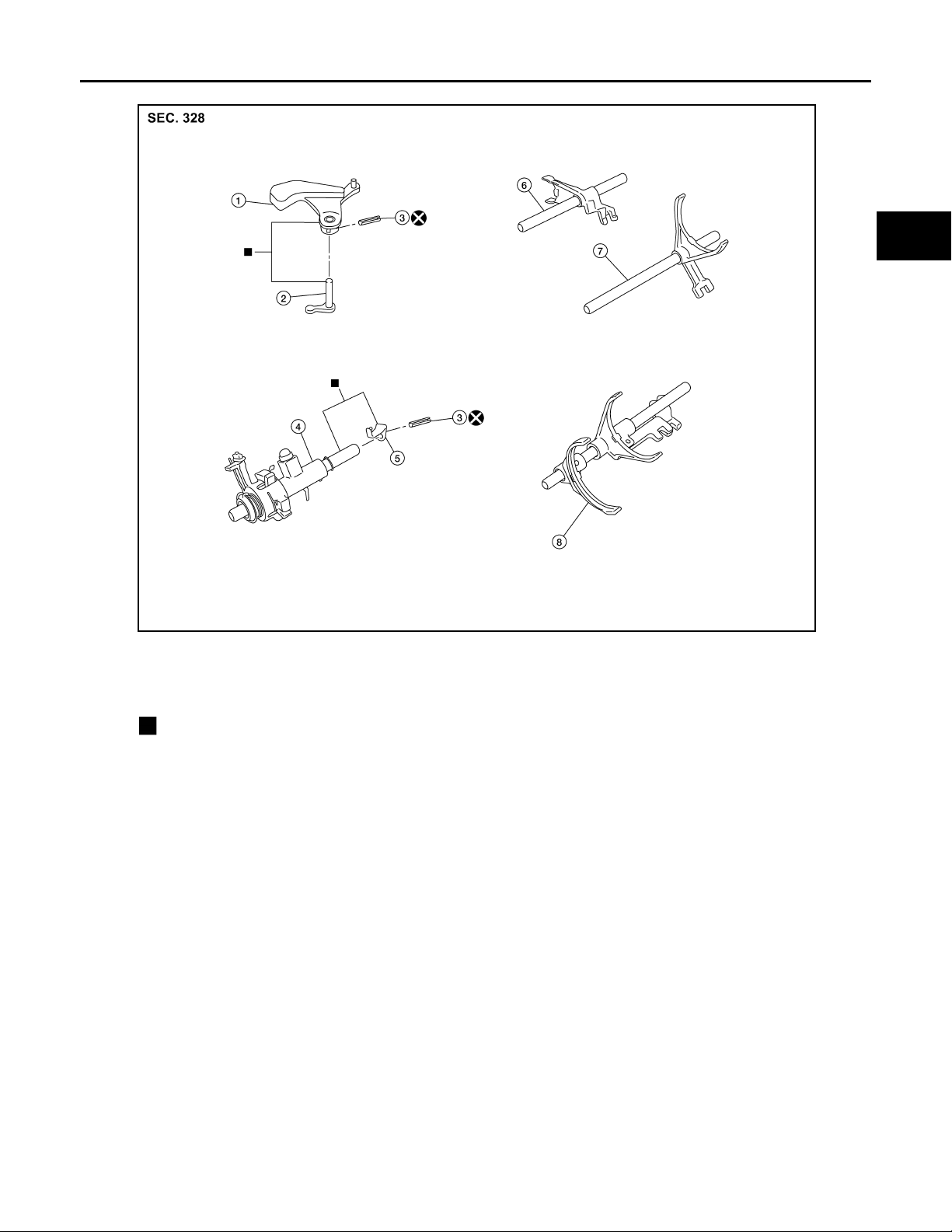

1. Shifter lever A 2. Shifter lever B 3. Retaining pin

4. Selector 5. Selector lever 6. Reverse fork rod

7. 1st-2nd fork rod 8. Fork rod

: Replace the parts as a set.

Final Drive Components

H

I

AWDIA0716ZZ

J

K

L

M

N

O

Revision: February 2013 2012 Sentra

MT-25

P

< SERVICE INFORMATION >

TRANSAXLE ASSEMBLY

[RS6F94R]

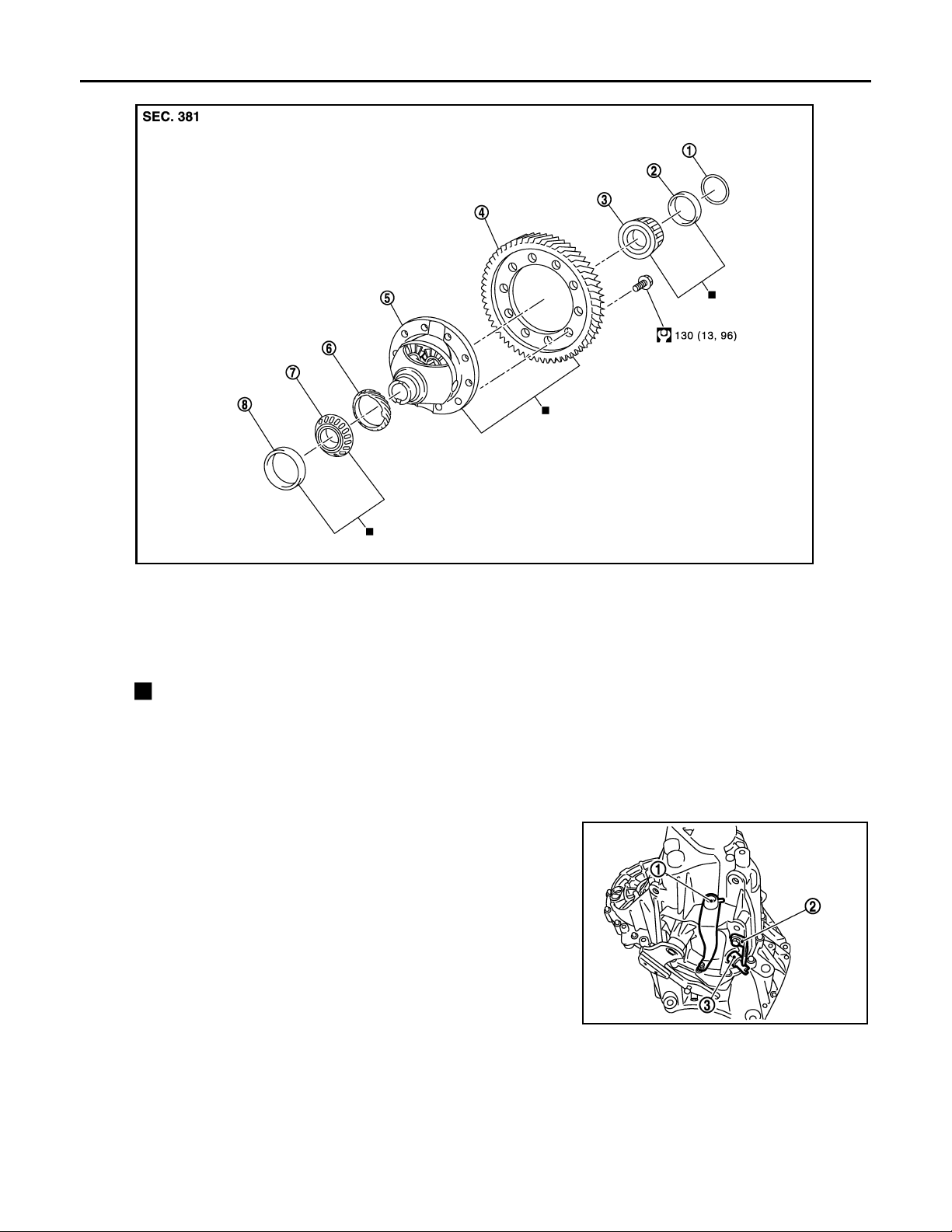

JPDIC0604GB

1. Shim 2. Differential side bearing outer

race (transaxle case side)

4. Final gear 5. Differential case 6. Speedometer drive gear

7. Differential side bearing inner

race (clutch housing side)

: Replace the parts as a set.

8. Differential side bearing outer

race (clutch housing side)

3. Differential side bearing inner race

(transaxle case side)

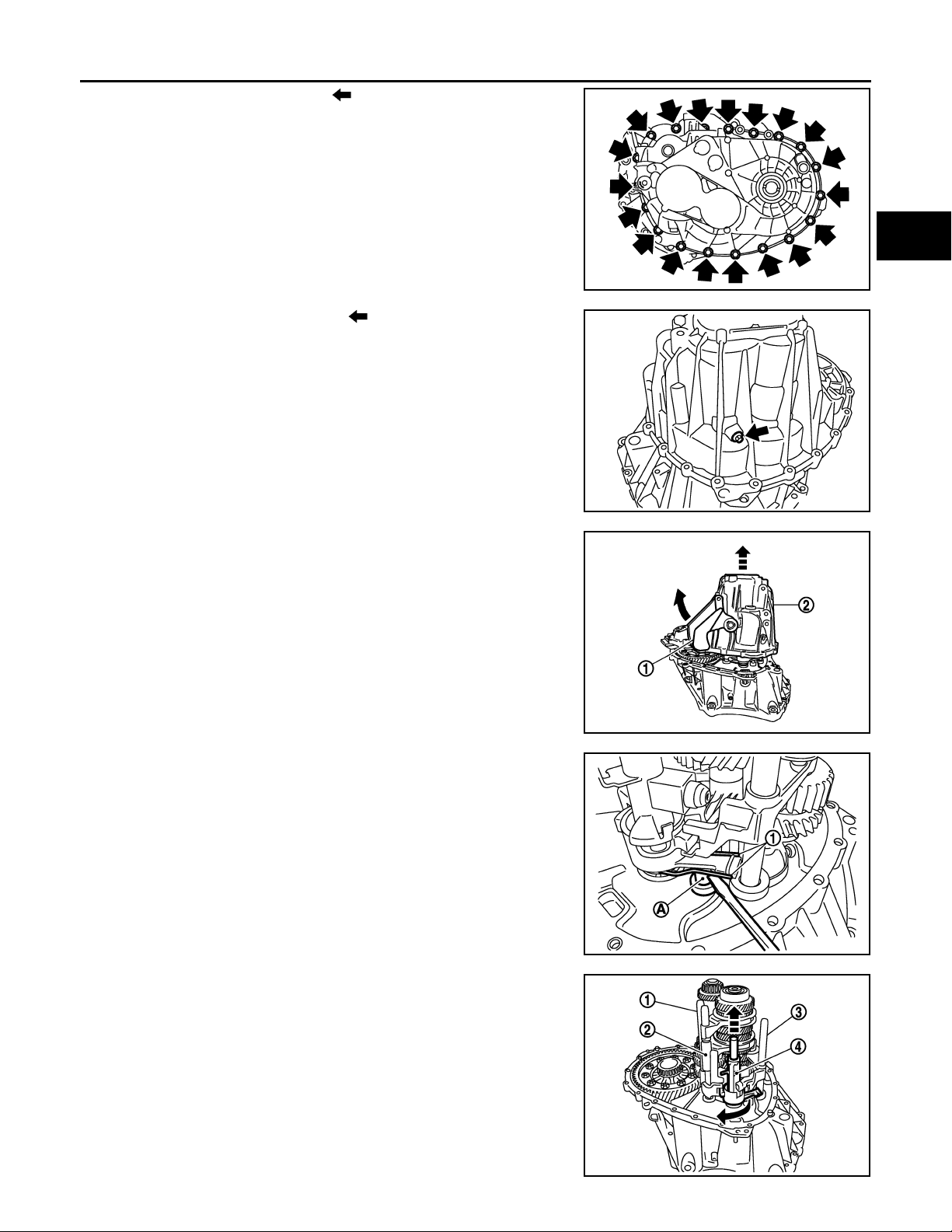

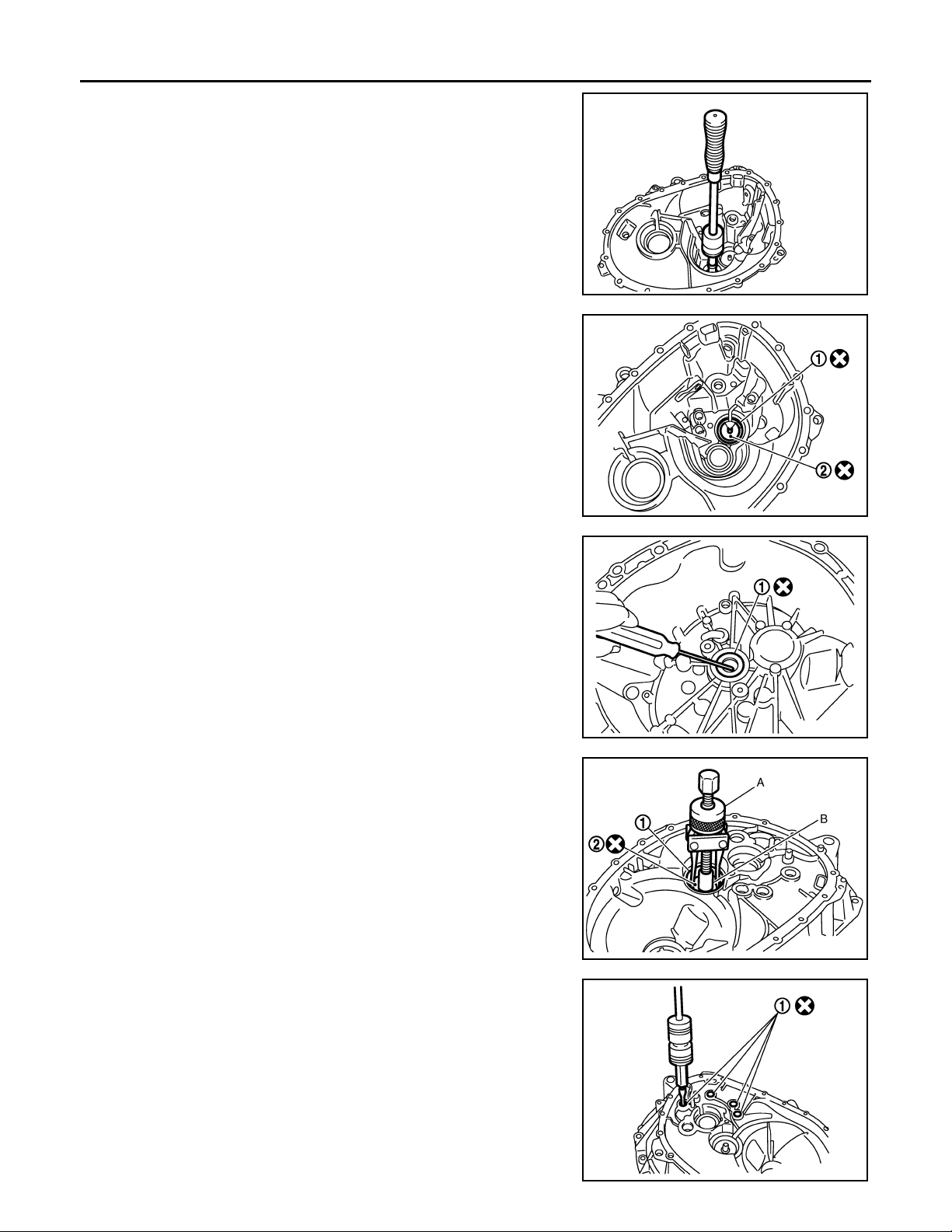

DISASSEMBLY

1. Remove drain plug and gasket from clutch housing, using a suitable tool and then drain gear oil.

2. Remove filler plug and gasket from transaxle case.

CAUTION:

Do not reuse gasket.

3. Remove selector lever (1) retaining pin with a pin punch to

remove selector lever.

4. Remove bracket (2) and position switch (3) from transaxle case.

PCIB1693E

Revision: February 2013 2012 Sentra

MT-26

TRANSAXLE ASSEMBLY

< SERVICE INFORMATION >

5. Remove transaxle case bolts ( ).

6. Remove reverse idler shaft bolt ( ) and seal washer.

[RS6F94R]

A

B

MT

PCIB1694E

D

E

F

G

PCIB1695E

7. Remove transaxle case (2) while rotating shifter lever A (1) in

the direction as shown.

8. Remove selector spring (1) from return bushing (A).

9. Shift 1st-2nd fork rod (1), fork rod (2), and reverse fork rod (3) to

the neutral position.

10. Remove selector (4) from clutch housing.

JPDIC0444ZZ

JPDIC0445ZZ

H

I

J

K

L

M

N

O

P

PCIB1698E

Revision: February 2013 2012 Sentra

MT-27

TRANSAXLE ASSEMBLY

< SERVICE INFORMATION >

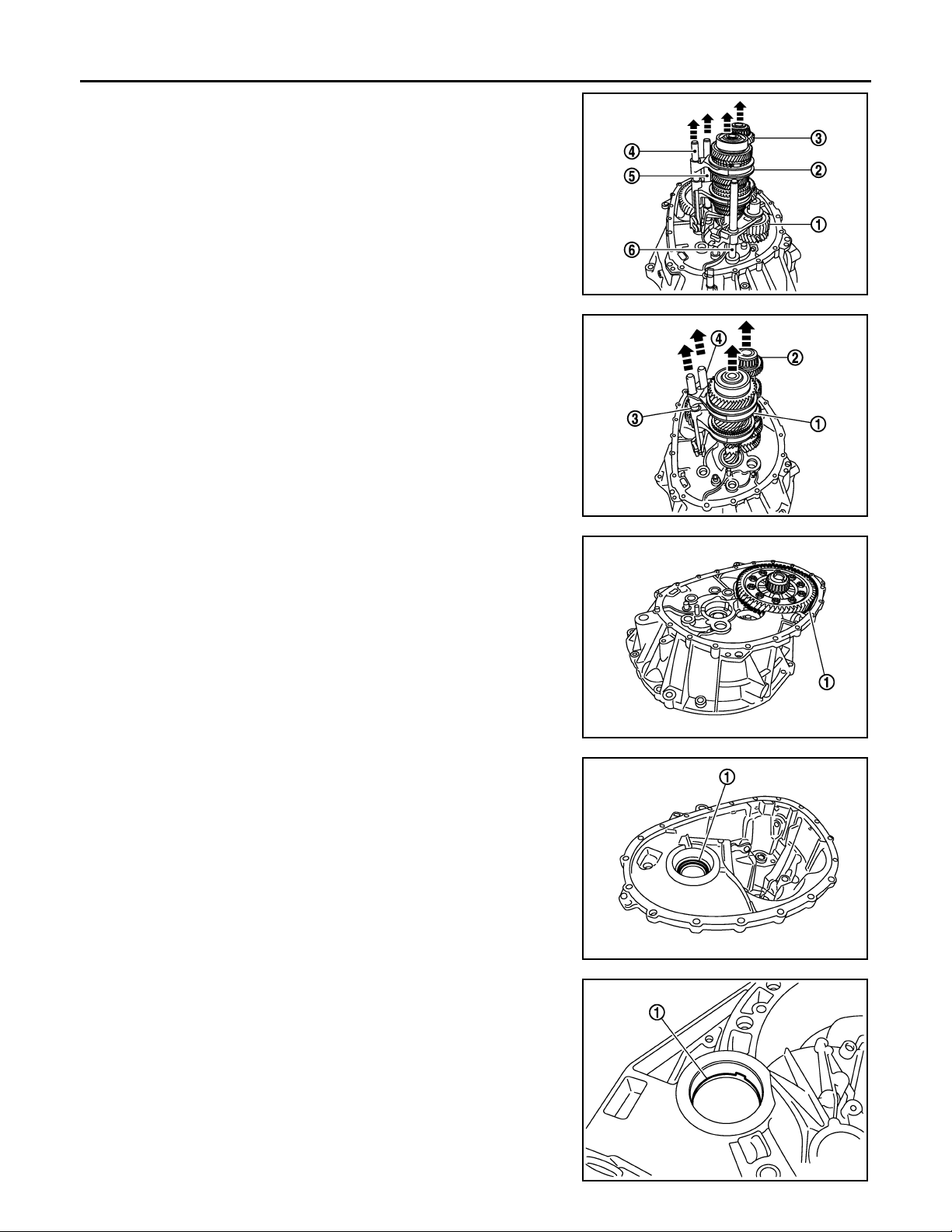

11. Remove reverse idler shaft assembly (1) according to the following procedures.

a. Pull up input shaft assembly (2), mainshaft assembly (3), fork

rod (4), and 1st-2nd fork rod (5).

NOTE:

It is easier to pull up when shifting each fork rod to each shaft

side.

b. Remove reverse idler shaft assembly and reverse fork rod (6)

from clutch housing.

12. Remove spring washer from clutch housing.

13. Pull up and remove input shaft assembly (1), mainshaft assembly (2), fork rod (3), and 1st-2nd fork rod (4) from clutch housing.

NOTE:

It is easier to pull up when shifting each fork rod to each shaft

side.

[RS6F94R]

JPDIC0606ZZ

14. Remove final drive assembly (1) from clutch housing.

15. Remove magnet from clutch housing.

16. Remove differential side oil seals (1) from clutch housing and

transaxle case.

CAUTION:

• Never damage clutch housing and transaxle case.

• Do not reuse oil seals.

JPDIC0607ZZ

PCIB1703E

PCIB1704E

17. Remove differential side bearing outer race (1) from clutch housing, using a brass rod.

CAUTION:

Never damage clutch housing.

PCIB1716E

Revision: February 2013 2012 Sentra

MT-28

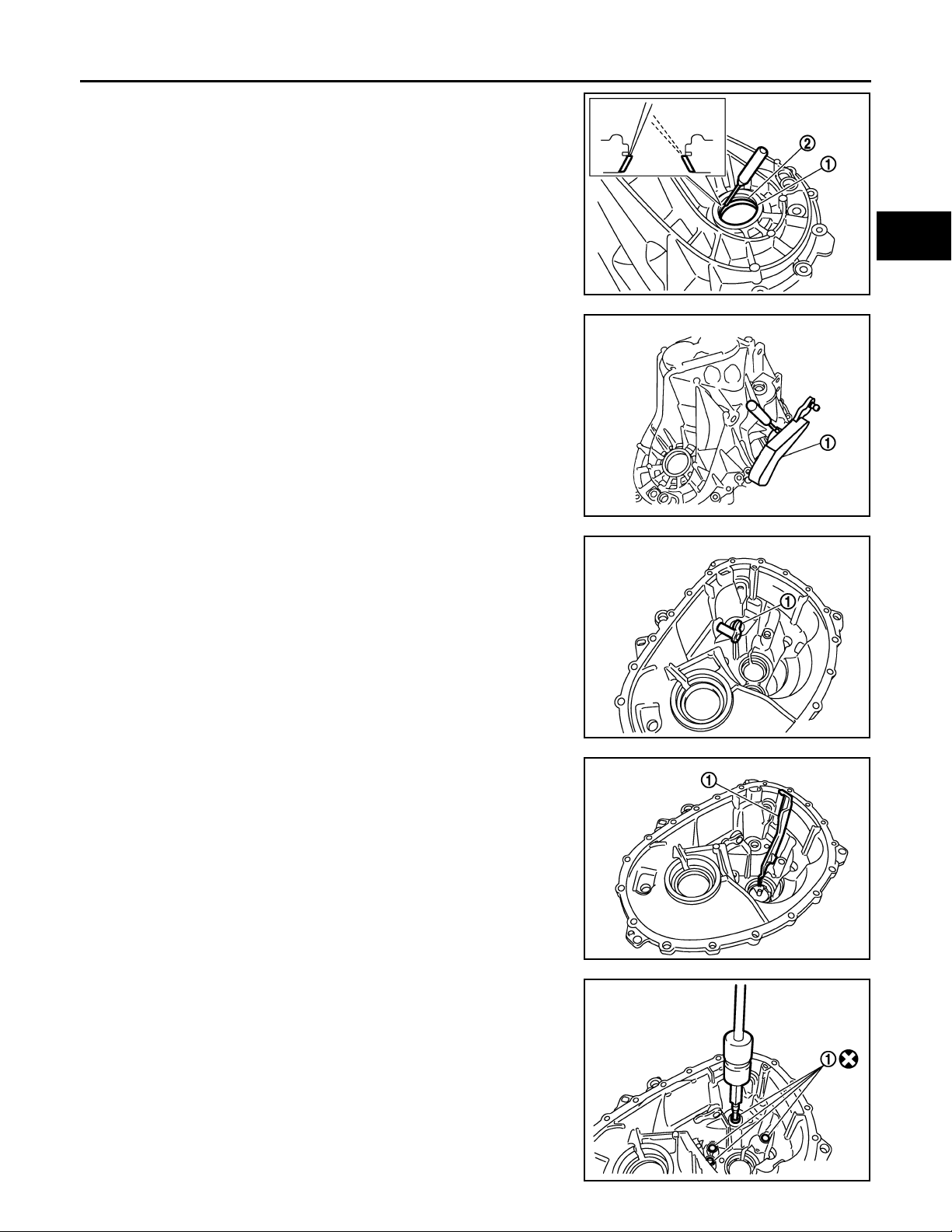

< SERVICE INFORMATION >

TRANSAXLE ASSEMBLY

[RS6F94R]

18. Remove differential side bearing outer race (1) from transaxle

case, using a brass rod.

CAUTION:

Never damage transaxle case.

19. Remove shim (2) from transaxle case.

20. Remove shifter lever A (1) retaining pin, using a suitable tool.

21. Remove shifter lever A from transaxle case.

22. Remove shifter lever B (1) from transaxle case.

A

B

MT

PCIB1705E

D

E

F

G

JPDIC0106ZZ

H

23. Remove oil gutter (1) from transaxle case.

24. Remove bushings (1) from transaxle case, using a suitable tool.

PCIB1712E

PCIB1707E

I

J

K

L

M

N

O

P

PCIB1710E

Revision: February 2013 2012 Sentra

MT-29

TRANSAXLE ASSEMBLY

< SERVICE INFORMATION >

25. Remove mainshaft rear bearing outer race from transaxle case,

using a suitable tool.

26. Remove mainshaft rear bearing adjusting shim from transaxle

case.

27. Remove snap ring (1) and oil channel (2) from transaxle case.

[RS6F94R]

PCIB1706E

28. Remove input shaft oil seal (1) from clutch housing, using a suitable tool.

CAUTION:

• Never damage clutch housing.

• Do not reuse oil seal.

29. Remove mainshaft front bearing outer race (1) from clutch housing, using Tool (A) and a suitable tool (B).

Tool number : KV381054S0 (J-34286)

30. Remove oil channel (2) from clutch housing.

PCIB1708E

PCIB1714E

JPDIC0107ZZ

31. Remove bushing (1) from clutch housing, using suitable tool.

PCIB1717E

Revision: February 2013 2012 Sentra

MT-30

Loading...

Loading...