Nissan Sentra 2007 Owner's Manual

J AIR CONDITIONER

A

B

SECTION MTC

MANUA L AIR COND ITIO NER

CONTENTS

PRECAUTIONS .......................................................... 4

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ..................................................................4

Precautions for Working with HFC-134a (R-134a) ..... 4

Contamin at e d Refrigerant ........................................ 4

General Refrigerant Precautions .............................. 5

Precautions for Leak Detection Dye ......................... 5

A/C Identification Label ............................................ 5

Precautions for Refrigerant Connection ................... 5

FEATURE S OF NEW TYPE REFRIGER ANT

CONNECTION ......................................................6

O-RING AND REFRIGERANT CONNECTION ..... 7

Precaution s fo r Se r vicing Compressor ....................11

Precautions for Service Equipment .........................11

RECOVERY/RECYCLING EQUIPME NT ....... ......11

ELECTRONIC LEAK DETEC TOR . ......................11

V ACUUM PUMP ...... ...................................... ..... 12

MANIFOLD GAUGE SET .................................... 12

SERVICE HOSES ............................................... 12

SERVICE COUPLERS ........................................ 13

REFRIGERANT WEIGHT SCALE . ..................... 13

CHARGING CYLINDER ................. ..................... 13

PREPARATION ......................................................... 14

Special Service Tools ............................................. 14

HFC-134a (R-134a) Service Tools and Equipment ... 14

Commercial Service Tools ...................................... 17

REFRIGERATION SYSTEM ..................................... 18

Refrigeran t Cycle ................................................... 18

REFRIGERANT FLOW .......... ............................. 18

Refrigeran t System Protectio n .. ............................. 18

REFRIGERANT PRESSURE SENSOR ............. 18

PRESSURE RELIEF VALVE ............................... 18

Component Layout ................................................. 19

OIL ............................................................................ 21

Maintenance of Oil Quantity in Compressor .......... 21

OIL ...................................................................... 21

CHECKING AND ADJUSTING ........................... 21

AIR CONDITIONER CONTROL ............................... 24

Overview Air Conditioner LAN Control System ...... 24

System Construction ..............................................24

OPERATION .......................................................24

TRANSMISSION DATA AND TRANSMISSION

ORDER ...............................................................25

AIR MIX DOOR CONTROL .................................25

BLOWER SPEED CONTROL .............................26

INTAKE DOOR CONTROL ....... ..........................2 6

MODE DOOR CONTROL ......... ..........................26

MAGNET CLUTCH CONTROL ...........................26

Overview of Control system ....................................26

Control Operati o n ......... ..........................................27

AIR CONDITIONER (A/C) SWITCH ....................2 8

TEMPERATURE DIAL (POTENTIO TEMPERA-

TURE CONTROL) ...............................................28

BLOWER CONTROL DIAL/OFF SWITCH .......... 28

RECIRCULATION () SWITCH .............................28

DEFROSTER SWITCH ...... ........................ .........28

MODE DIAL .........................................................28

REAR WINDOW DEFOGGER SWITCH .............28

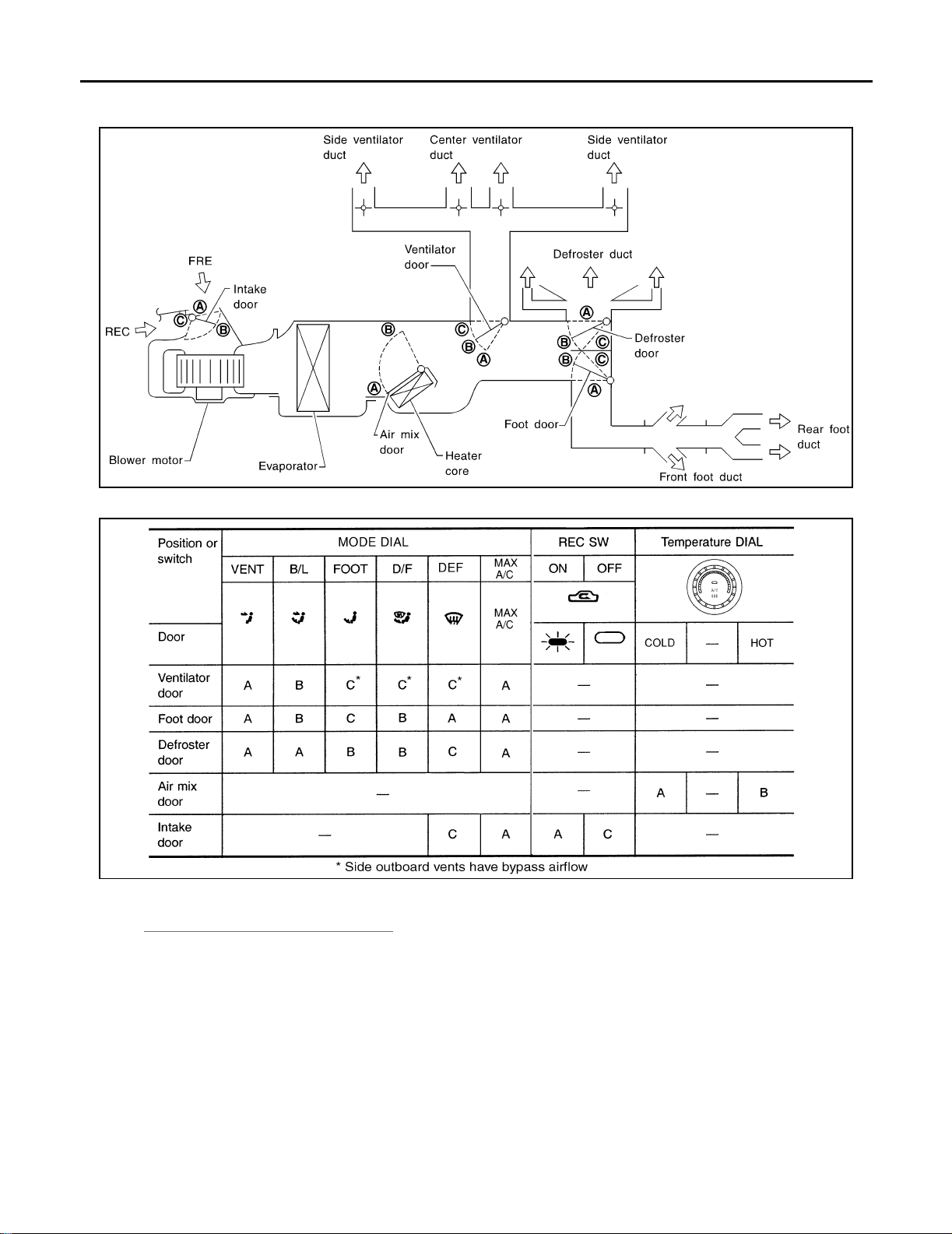

Discharge Air Flow .................................................29

System Description .................................................30

SWITCHES AND THEIR CONTROL FUNCTION ...30

CAN Communication System Description ..............30

TROUBLE DIAGNOSIS ............................................31

How to Perform Trouble Diagnoses for Quick and

Accurate Repair ........................ ..............................31

WORK FLOW ......................................................3 1

SYMPTOM TABLE ..............................................31

Component Parts and Harness Connector Location ...32

ENGINE COMPARTMENT - QR25DE ................32

ENGINE COMPARTMENT - MR20DE ................3 3

PASSENGER COMPARTMENT .........................34

Circuit Diagram ....................................................... 35

Wiring Diagram — HEATER — ..............................36

Wiring Diagram — A/C,M — ...................................38

Front Air Control T erminals and Reference Values ...41

INSPECTION OF FRONT AIR CONTROL ..........41

FRONT AIR CONTROL HARNESS CONNEC-

TOR TERMINAL LAYOUT ...................................41

TERMINAL AND REFERENCE VALUES FOR

C

D

E

F

G

H

I

MTC

K

L

M

Revision: December 2006 2007 Sentra

MTC-1

FRONT AIR CONTROL ....................................... 41

Operatio n al Check .................................... ..............43

CHECKING BLOWER ..... ............................... .....43

CHECKING DISCHARGE AIR ........... .................43

CHECKING RECIRCULA TION ....................... .....43

CHECKING TEMPERATURE DECREASE .........43

CHECKING TEMPERATURE INCREASE ..........43

CHECKING A/C SWITCH (IF EQUIPPED) ......... 43

Power Supply and Ground Circuit for Front Air Con-

trol ...........................................................................44

INSPECTION FLOW ...........................................44

COMPONENT DESCRIPTION ................ ............45

DIAGNOSTIC PROCEDURE ..............................45

LAN System Circuit ................................................ 47

DIAGNOSTIC PROCEDURE ..............................47

Mode Door Motor Circu it .. ......................................50

INSPECTION FLOW ...........................................50

SYSTEM DESCRIPTION ....................................51

COMPONENT DESCRIPTION ................ ............51

DIAGNOSTIC PROCEDURE ..............................51

Air Mix Door Motor Cir cu it ......................................52

INSPECTION FLOW ...........................................52

SYSTEM DESCRIPTION ....................................53

COMPONENT DESCRIPTION ................ ............53

DIAGNOSTIC PROCEDURE ..............................53

Intake Door Motor Circuit ........................................54

INSPECTION FLOW ...........................................54

SYSTEM DESCRIPTION ....................................55

COMPONENT DESCRIPTION ................ ............55

DIAGNOSTIC PROCEDURE ..............................55

Blower Motor Circuit ............................................... 56

INSPECTION FLOW ...........................................56

SYSTEM DESCRIPTION ....................................57

COMPONENT DESCRIPTION ................ ............57

DIAGNOSTIC PROCEDURE ..............................58

COMPONENT INSPECTION .............................. 61

Magnet Clutch Circuit .............................................62

INSPECTION FLOW ...........................................62

SYSTEM DESCRIPTION ....................................63

DIAGNOSTIC PROCEDURE ..............................63

Insufficient Cooli n g ........... ......................................66

INSPECTION FLOW ...........................................66

PERFORMANCE TEST ANALYSIS ............. ....... 68

PERFORMANCE CHART ........... ........................70

TROUBLE DIAGNOSIS FOR ABNORMAL

PRESSURE .........................................................70

Insufficient Heating .................................................74

INSPECTION FLOW ...........................................74

Noise ......................................................................76

INSPECTION FLOW ...........................................76

CONTROL UNIT ........................................................ 77

Removal and Installation ................................. ....... 77

FRONT AIR CONTROL ....................................... 77

FRONT BLOWER MOTOR .......................................78

Removal and Installation ................................. ....... 78

REMOVAL ...........................................................78

INSTALLATION ....................................................78

IN-CABIN MICROFILTER ..........................................79

Removal and Installation .........................................79

FUNCTION ..........................................................79

REPLACEMENT TIMING ....................................79

REPLACEMENT PROCEDURES ............. ...........79

HEATER & COOLING UNIT ASSEMBLY .................81

Removal and Installation .........................................81

REMOVAL ............................................................81

INSTALLATION ....................................................82

HEATER CORE .......... ...............................................83

Removal and Installation .........................................83

REMOVAL ............................................................83

INSTALLATION ....................................................83

INTAKE DOOR MOTOR ....... .....................................84

Removal and Installation .........................................84

REMOVAL ............................................................84

INSTALLATION ....................................................84

MODE DOOR MOTOR ..............................................85

Removal and Installation .........................................85

REMOVAL ............................................................85

INSTALLATION ....................................................85

AIR MIX DOOR MOTOR ...........................................86

Removal and Installation .........................................86

REMOVAL ............................................................86

INSTALLATION ....................................................86

FAN CONTROL AMPLIFIER .....................................87

Removal and Installation .........................................87

REMOVAL ............................................................87

INSTALLATION ....................................................87

DUCTS AND GRILLES .............................................88

Removal and Installation .........................................88

CENTER VENTILATOR GRILLE RH, LH ............89

UPPER DEFROSTER GRILLE ............................89

SIDE VENTILATOR GRILLE RH, LH ...................90

SIDE DEFROSTER GRILLE RH, LH ...................90

SIDE VENTILATOR DUCT RH, LH .....................90

DEFROSTER NOZZLE ........................................90

SIDE DEFROSTER DUCT RH, LH ......................90

FRONT FOOT DUCT RH ....................................90

FRONT FOOT DUCT LH .....................................90

REAR FLOOR CONNECTOR DUCT ..................90

REAR FLOOR DUCT RH ....................................91

REAR FLOOR DUCT LH .....................................91

REFRIGERANT LINES .............................................92

HFC-134a (R-134a) Service Procedure ..................92

SETTING OF SERVICE TOOLS AND EQUIP-

MENT ...................................................................92

Components ............................................................94

Removal and Installation for Compressor -

MR20DE .................................................................97

REMOVAL ............................................................97

INSTALLATION ....................................................97

Removal and Installation for Compressor —

QR25DE ..................................................................98

REMOVAL ............................................................98

INSTALLATION ....................................................98

Removal and Installation for Compressor Clutch -

MR20DE .................................................................99

REMOVAL ............................................................99

Revision: December 2006 2007 Sentra

MTC-2

INSPECTION AFTER REMOVAL ..................... 100

INSTALLATION ................................................. 100

INSPECTION AFTER INSTALLA TION ........ ..... 101

BREAK-IN OPERATION ................................... 101

Removal and Installation for Compressor Clutch -

QR25DE ............................................................... 101

REMOVAL ......................................................... 101

INSPECTION AFTER REMOVAL ..................... 102

INSTALLATION ................................................. 103

INSPECTION AFTER INSTALLA TION ........ ..... 104

BREAK-IN OPERATION ................................... 104

Removal and Installation for Low-pressure Flexible

Hose and Muffler Pipe .......................................... 104

REMOVAL ......................................................... 104

INSTALLATION ................................................. 104

Removal and Installation for High-pressure Flexible

Hose ..................................................................... 104

REMOVAL ......................................................... 104

INSTALLATION ................................................. 105

Removal and Installation for High-pressure Pipe . 105

REMOVAL ......................................................... 105

INSTALLATION ................................................. 105

Removal and Installation for Refrigerant Pressure

Sensor .................................................................. 105

REMOVAL ......................................................... 105

INSTALLATION .................................................105

Removal and Installation for Condenser ..............105

REMOVAL .........................................................105

INSTALLATION .................................................106

Removal and Insta l lation for Evaporator ....... .......106

REMOVAL .........................................................106

INSTALLATION .................................................107

Removal and Installation for Expansion Valve ......107

REMOVAL .........................................................107

INSTALLATION .................................................107

Checking for Refrigerant Leaks ............................107

Checking System for Leaks Using the Fluorescent

Leak Detector .......................................................108

Dye Injection .........................................................108

Electronic Refri g e r an t Lea k De te cto r ....................108

PRECAUTIONS FOR HANDLING THE LEAK

DETECTOR .......................................................108

CHECKING PROCEDURE ...................... .........109

SERVICE DATA AND SPECIFICATIONS (SDS) .....111

Service Data and Specifications (SDS) .................111

COMPRESSOR .................................................111

OIL ......................................................................111

REFRIGERANT ..................................................111

ENGINE IDLING SPEED ...................................111

BELT TENSION ..................................................111

A

B

C

D

E

F

G

H

I

MTC

K

L

M

Revision: December 2006 2007 Sentra

MTC-3

PRECAUTIONS

PRECAUTIONS PFP:00001

Precautions fo r Su ppl em ental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSION ER”, used along

with a front sea t belt, h el ps to red uce the ris k or sever ity of injur y to the driv er and f ron t passe nger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Manual.

WARNING:

● To avoid rend ering the SRS in operative , w hich cou ld increas e t he risk o f pers onal inj ury or deat h

in the event of a collision which w ould result in air bag inflation, all maintena nce must be performed by an authorized NISSAN/INFINITI dealer.

● Improper main tenance, including in correct removal and installation of the SRS, can lead to per-

sonal injury caused by un intenti onal act iva tion of t he syste m. Fo r removal o f Spiral Ca ble and Air

Bag Modu le, see the SRS section.

● Do not use electrical t est equipme nt on any circu it related to the SR S unless ins tructed to in this

Service Manual. SR S wiring harnesses can be identified by yellow and /or orange harnesses or

harness connectors.

EJS005O4

Precautions fo r Working w ith HFC - 134a ( R- 134a) EJS005O5

WARNING:

● CFC-12 (R-12 ) refrig eran t and HFC- 134 a (R- 134a ) refrig erant a re not co mpatible. If the ref riger ants

are mixed compresso r failure is likely to occur. Refer to MTC-4, "

determine the purity of HFC-134a (R-134a) in the vehicle and recovery tank, use Refrigerant

Recovery/Recycling Recharging equipment and Refrigerant Identifier.

● Use only s pec ified oi l for the HF C-134a ( R-134a ) A/C sy stem an d HF C -134a ( R-13 4a) co mpo nents.

If oil other than that specified is used, co mpressor failure is likely to occur.

● The specified HFC-134a (R-134a) oil rapidly absorbs moisture from the atmosphere. The following

handling precautions must be observed:

– When removing refrigeran t components from a vehicle, imme diately cap (seal) the componen t to

minimize the entry of moisture from the atmosphere.

– When installing refr igerant components to a vehi cle, do not remove the caps ( unseal) until just

before connect ing t he co m pone nts. Connect all refri gerant lo o p com ponen ts as qu ickly as poss ible to minim ize the entry of moisture into system.

– Only use the s pecified oil from a seal ed container. Immediately reseal containers o f oil. Without

proper sealing, oil will become moisture saturated and should not be used.

– Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Remove HFC-134a (R-134a) from the A/C system using certified service equipment meeting

requirements of SAE J2210 [HFC-134a (R-134a) recycling equipment], or J2209 [HFC-134a (R-134a)

recycling equipmen t ], If acciden tal system discha rge occu rs, ve ntilat e work area befo re resum ing

service. Addi tional healt h and safety inf ormation may be o btained fro m refrigera nt and o il manu facturers.

– Do not allow A/C oil to come in contact with styrofoam parts. Damage may result.

Contaminated Refrig erant" . To

Contaminated Refrigerant EJS005O6

If a refrigerant other than pure HFC-134a (R-134a) is identified in a vehicle, your options are:

● Explain to the cus tomer that environmental r egulations prohibit the releas e of contaminated refriger ant

into the atmosphere.

● Explain that r ecov ery of the co ntaminated r efrige rant c ou ld dam age y our ser vice e qui pme nt a nd refr iger -

ant supply.

● Suggest the c ustome r retur n t he veh icle to the loca tio n of previou s se rvice wh ere the co ntamination may

have occurred.

● If you choose to perform the repair, recover the refrigerant using only dedicated equipment and contain-

ers. Do not reco ver contaminated re frigerant into yo ur existing servi ce equipme nt. If your facility

Revision: December 2006 2007 Sentra

MTC-4

PRECAUTIONS

does not have dedicated recovery equipment, you may contact a local refrigerant product retailer for available service. This refrigerant m ust be dispos ed of in acco rdance with al l federal and loc al regulations . In

addition, replacement of all refrigerant system components on the vehicle is recom mended.

● If the vehicle is within the warranty period, the air conditi oner warranty is void. Please con tact NISSAN

Customer Affairs for further assistance.

General Refrig er ant Pr ecaut i ons EJS005O7

A

B

WARNING:

● Do not release refrigerant into the air. Use approved recovery/ recycling eq uipment to cap ture the

refrigerant every time an air co nditioning system is discharged.

● Always wear eye and hand prot ection (gog gles and glo ves) wh en working w ith any refrige rant or

air conditioning system .

● Do not store or heat refrigerant containers above 52°C (125°F).

● Do not heat a refrigerant container with an op en flame; if container warm ing is required , place t he

bottom of the container in a warm pail of water.

● Do not intentio nally drop, puncture, or incinerate refrigerant containers.

● Keep refrigerant away from open flames: poisonous gas will be produced if refrigerant burns.

● Refrigerant will disp lace oxygen, therefore b e certain to work in well ventila ted areas to prevent

suffocation.

● Do not pressure test or leak test HFC-13 4a (R-134a) service equ ipment and/or veh icle air condi-

tioning sys tems with com pressed air durin g repair. Some mixtures of air an d HFC-13 4a (R-134a)

have been shown to be comb ustible at eleva ted pressu res. These m ixtures, if igni ted, may cause

injury or p rop ert y da mage . Addi ti on al h ea lt h a nd s afe t y informat ion m ay be o btained from r efr i ger ant manufacturers.

Precautions f or Leak Detection Dye EJS005O8

● The A/C system co nta ins a fl uor escent lea k detect ion dye used f or loca tin g ref rigeran t le aks. An ult r aviole t

(UV) lamp is required to illuminate the dye when inspecting for leaks.

● Always wear fluorescence enhancing UV safety goggles to protect your eyes and enhance the visibility of

the fluorescent dye.

● A compressor shaft seal should not be repaired because of dye seepage . The compressor shaft seal

should only be repaired after confirming the leak with an electronic refrigerant leak detector (J-41995).

● Always remove any dye fro m the leak area after repairs are complete to av oid a misdiagnosis during a

future service.

● Do not allow dye to come into contact wit h painted body panels or interior com ponents. If dye is spilled,

clean immediately with the approved dye cleaner. Fluorescent dye left on a surface for an extended period

of time cannot be removed .

● Do not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

● Do not use more than one refrigerant dye bottle (1/4 ounce / 7.4 cc) per A/C system.

● Leak detection dyes for HFC-134a (R-134a) and CFC-12 (R-12) A /C systems are different. Do not use

HFC-134a (R- 134a) leak dete ction dye in C FC-12 (R-12) A/C systems or CFC-12 (R-12) leak detec tion

dye in HFC-134a (R-134a) A/C systems or A/C system damage may result.

● The fluorescent properties of the dye will remain for over three (3) years unless a compressor failure

occurs.

C

D

E

F

G

H

I

MTC

K

L

M

A/C Identification Label EJS005O9

Vehicles with factory installed fluorescent dye have this green identification label on the underside of hood.

Precautions f or Ref riger ant Connection EJS005OA

A new type refrigerant connection has been introduced to all refrigerant lines except the following locations.

● Expansion valve to cooling unit

● Evaporator pipes to evaporator (inside cooling unit)

● Refrigerant pressure sensor

Revision: December 2006 2007 Sentra

MTC-5

PRECAUTIONS

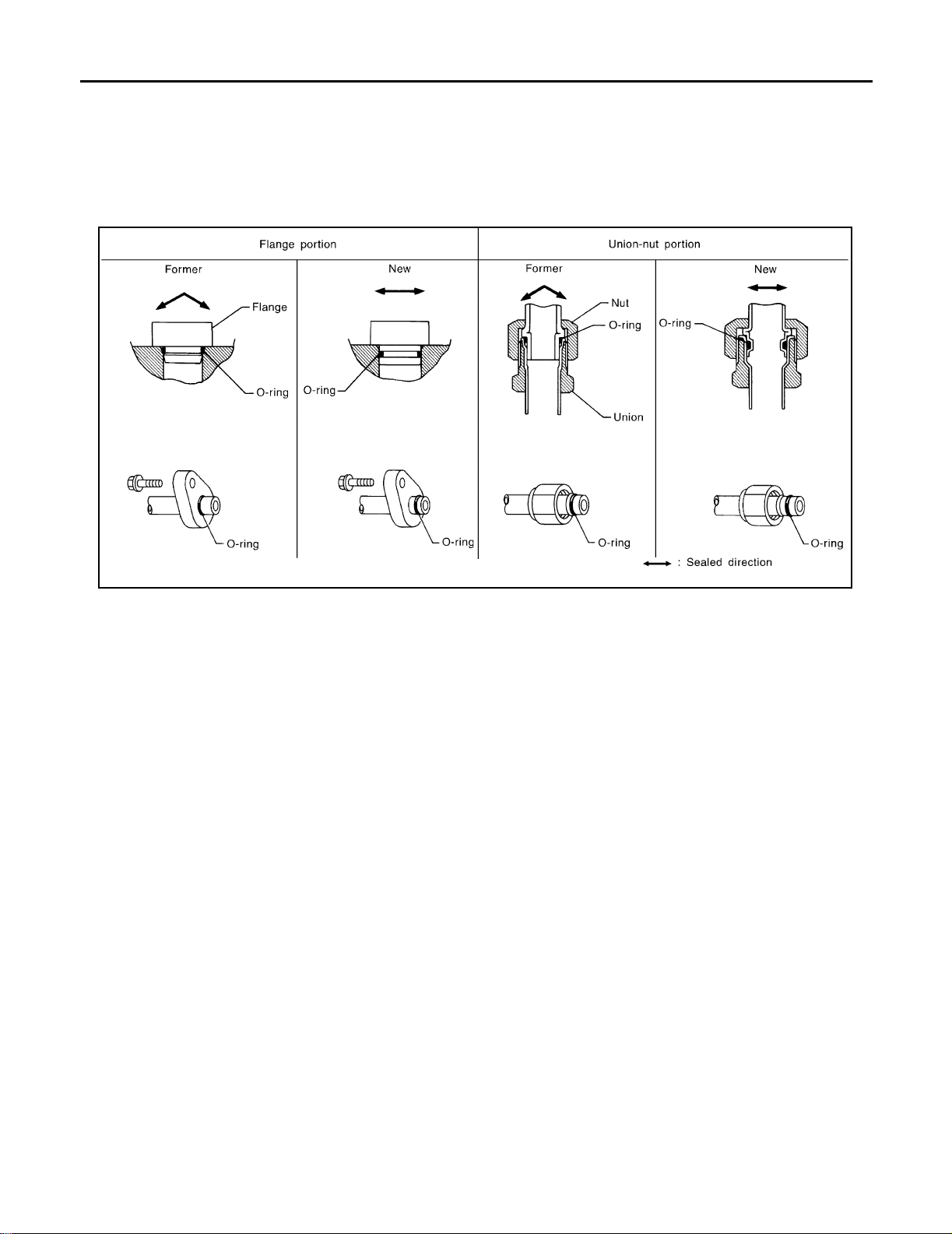

FEATURES OF NEW TYPE REFRIGERANT CONNECTION

● The O-ring has been relocate d. It has also been pro vided with a gr oove for proper installatio n. This el imi-

nates the chance o f the O-ring being caught in, or damaged by, the mating part. The sealing directio n of

the O-ring is now set vertically in relation to the contacting surface of the mating part to improve sealing

characteristics.

● The reaction force of the O-ring will not occur in the direction that causes the joint to pull out, thereby facil-

itating piping connections.

SHA815E

Revision: December 2006 2007 Sentra

MTC-6

PRECAUTIONS

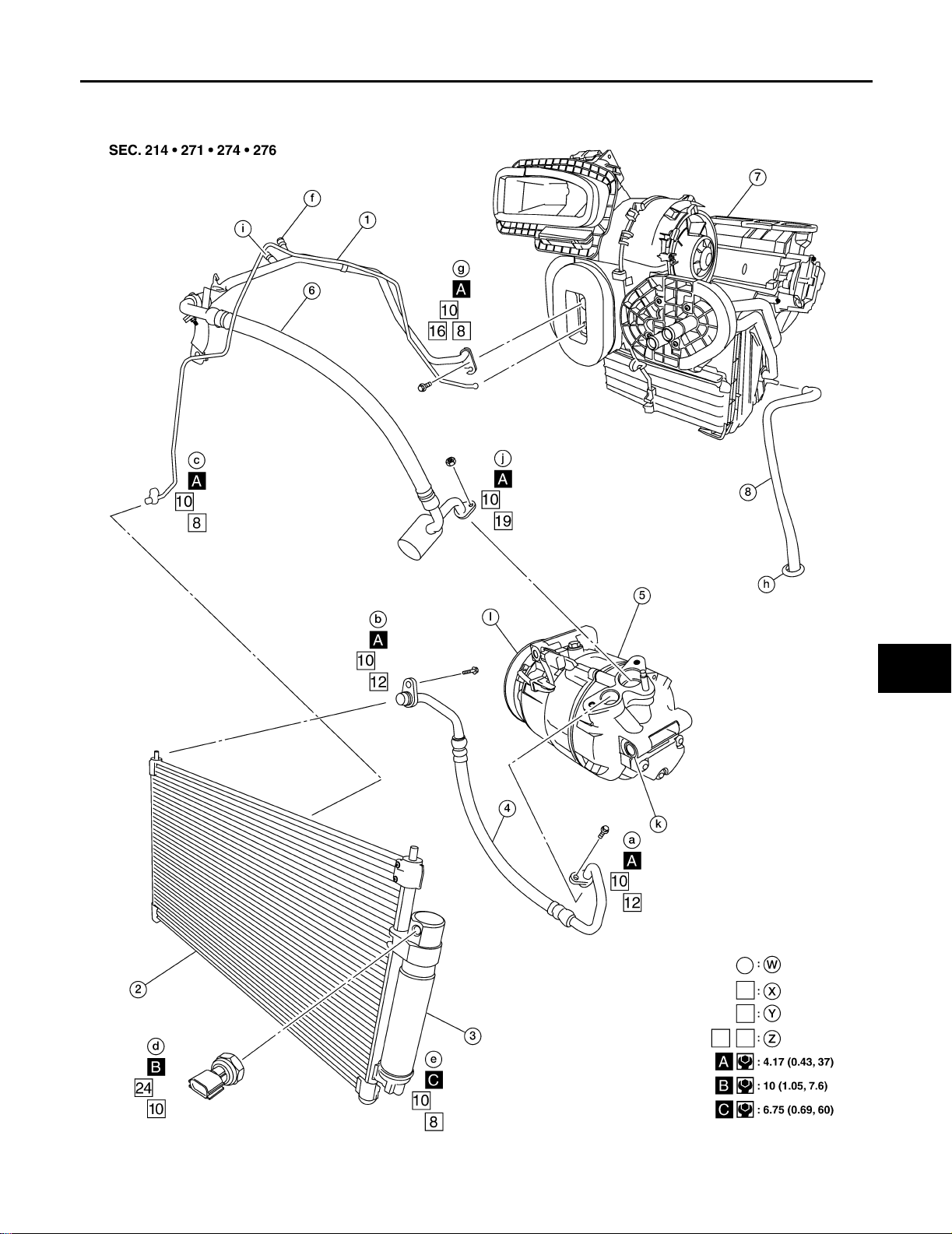

O-RING AND REFRIGERANT CONNECTION

MR20DE

A

B

C

D

E

F

G

H

I

MTC

K

L

M

BJIA0022E

Revision: December 2006 2007 Sentra

MTC-7

PRECAUTIONS

1. High-pressure pipe 2. Condenser 3. Liquid tank

4. High-pressure flexible hose 5. Compressor 6. Low-pressure flexible hose

7. Heater and cooling unit assembly 8. Drain hose W. Refrigerant leak checking order

X. Tightening torque (A-C) Y. Wrench size Z. O-ring size

Revision: December 2006 2007 Sentra

MTC-8

PRECAUTIONS

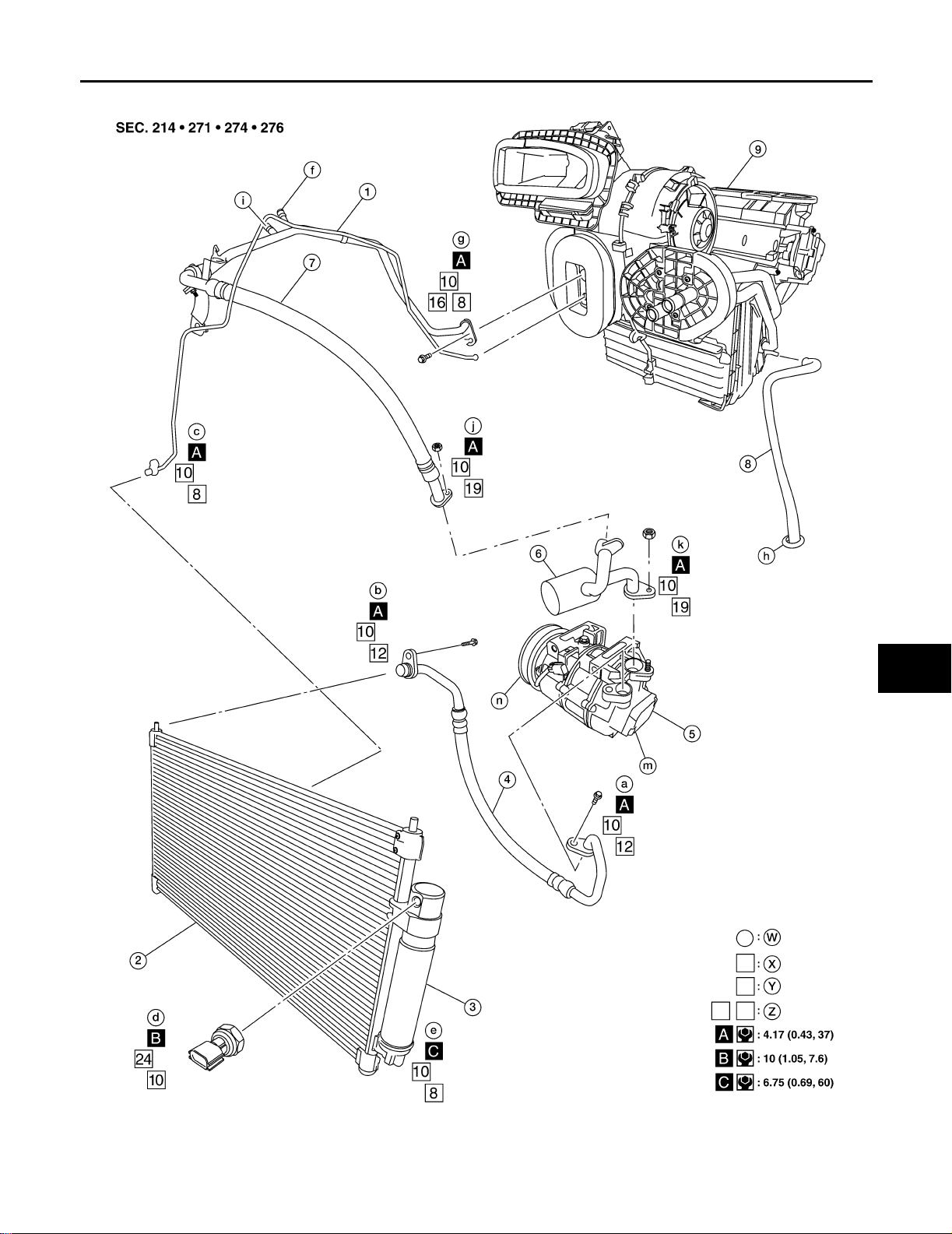

QR25DE

A

B

C

D

E

F

G

H

I

MTC

K

L

M

WJIA2304E

1. High-pressure pipe 2. Condenser 3. Liquid tank

4. High-pressure flexible hose 5. Compressor 6. Muffler pipe

Revision: December 2006 2007 Sentra

MTC-9

PRECAUTIONS

7. Low-pressure flexible hose 8. Drain hose 9. Heater and cooling unit assembly

W. Refrigerant leak checking order X. Tightening torque (A-C) Y. Wrench size

Z. O-ring size

CAUTION:

The new and form er refrigerant connections us e different O-ring configuration s. Do not confuse Orings since they are not interchangeable. If a wrong O-ring is installed, refrigerant will leak at, or

around, the connection.

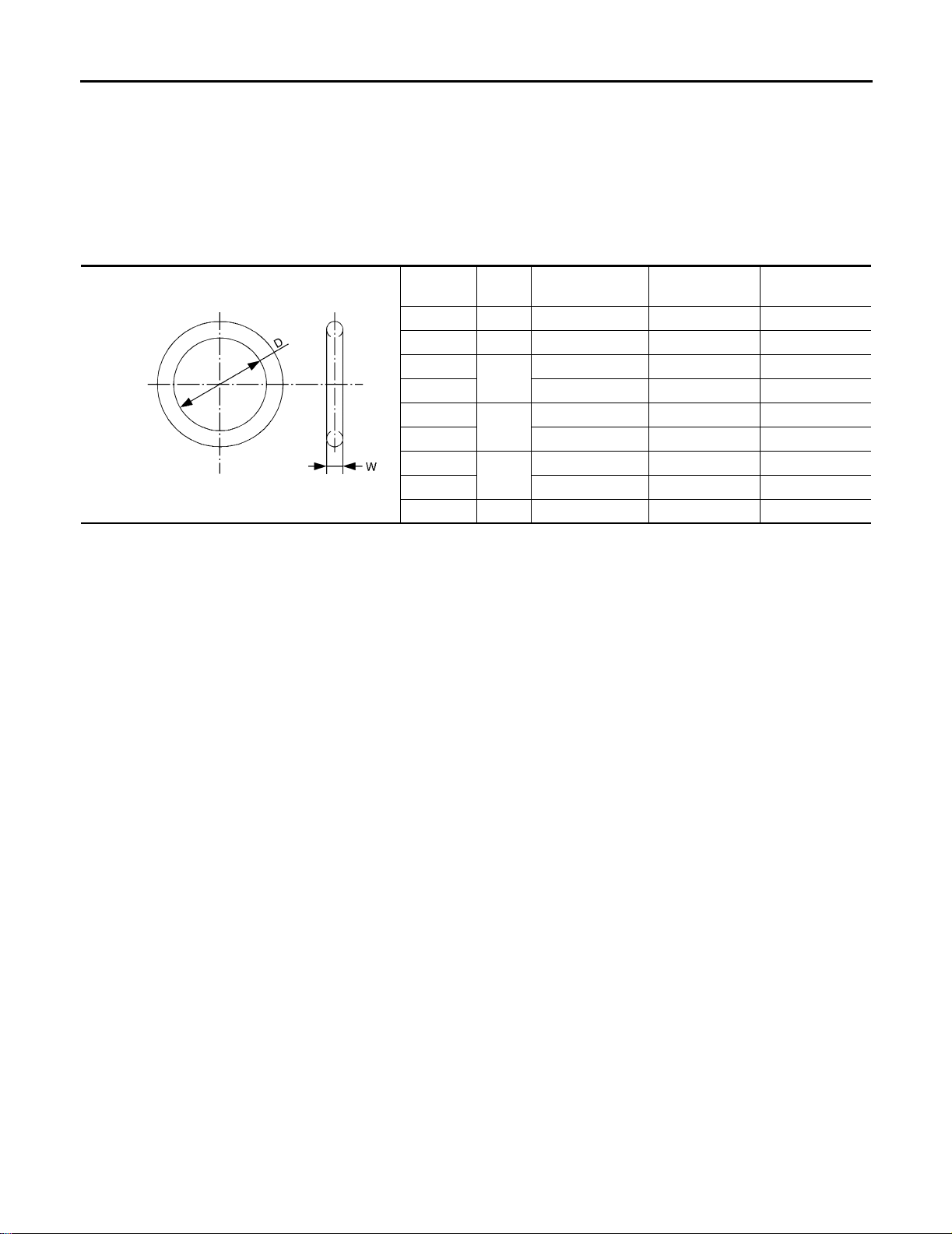

O-Ring Part Numbers and Specifications

Connection type

New 8 92471 N8210 6.8 (0.268) 1.85 (0.0728)

Former 10 J2476 89956 9.25 (0.3642) 1.78 (0.0701)

New

Former 92475 71L00 11.0 (0.433) 2.4 (0.094)

New

Former 92475 72L00 14.3 (0.563) 2.3 (0.091)

New

SHA814E

*: Always check with the Parts Department for the latest parts information.

Former 92477 N8200 17.12 (0.6740) 1.78 (0.0701)

New 24 92195 AH300 21.8 ( 0.858) 2.4 (0.0 94)

WARNING:

Make sure all refrigerant is discharged into the recycling equ ipment and the pressure in the syste m is

less than atmospheric pressure. Then gradually loosen the discharge side hose fitting and remove it.

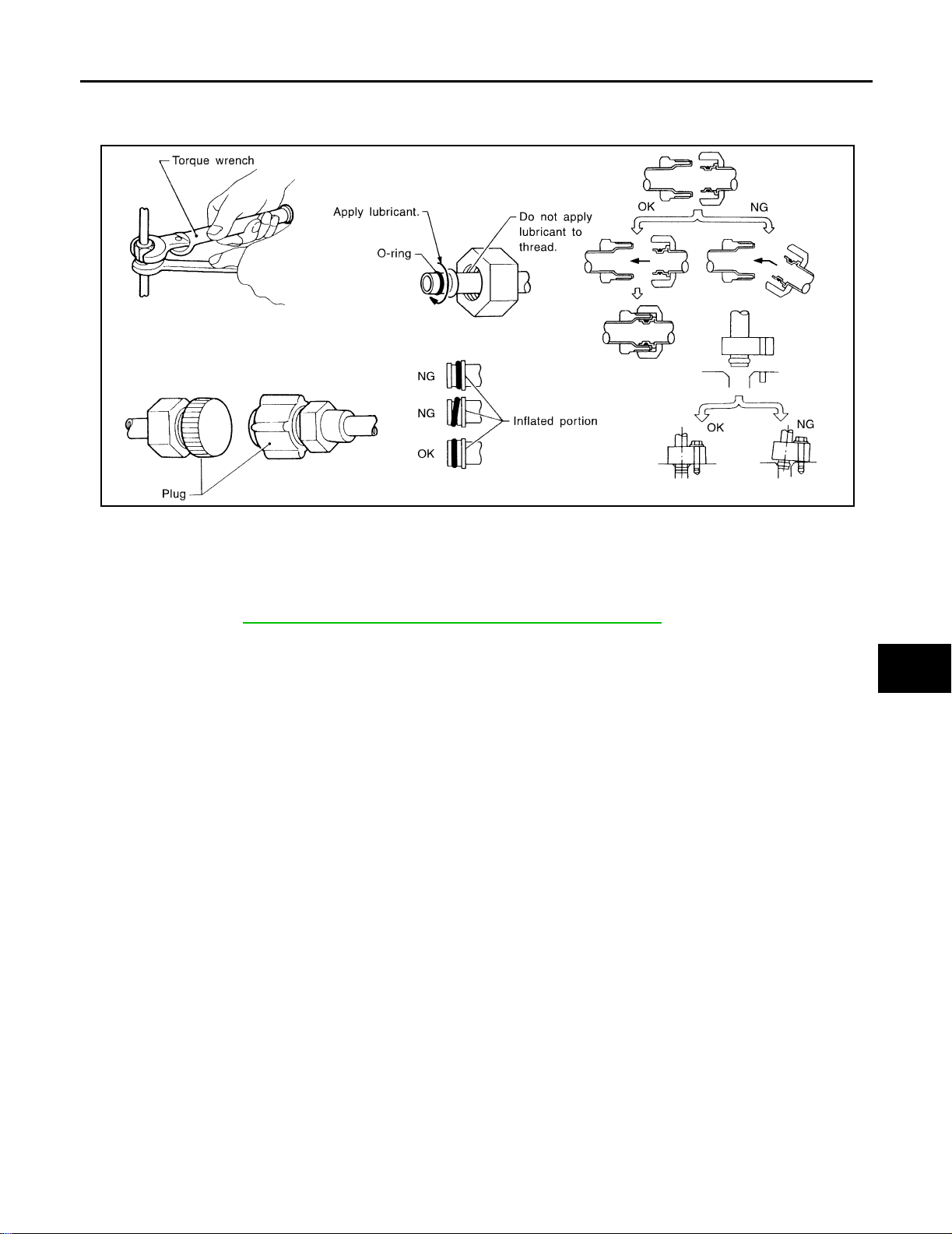

CAUTION:

When replacing or cleaning refrigerant cycle components, observe the following.

● When the com presso r is rem oved , store it in t he sa me p ositi on a s i t is w hen mou nted on the car.

Failure to do so will cause oil to enter the low pressure chamber.

● When connecting tubes, always use a torque wrench and a back-up wrench.

● After disconnecting tubes, immediately plug all openings to prevent entry of dirt and moisture.

● When installing an air conditioner in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and other com ponents until just before required f or

connection.

● Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming in side A/C components.

● Thoroughly remove moisture from the refrigeration system before charging the refrigerant.

● Always replace used O-rings.

● When connect ing tube, apply oil to circle of the O-rings shown in illu stration. Be careful not t o

apply oil to threaded portion.

Oil name: NISSAN A/C System Oil Type S or equivalent

● O-ring must be closely attached to grooved portion of tube.

● When replacing the O-ring, be careful not to damage O-ring and tube.

● Connect tube until you hear it click, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to tube correct ly.

O-ring

size

12

16

19

Part number* D mm (in) W mm (in)

92472 N8210 10.9 (0.429) 2.43 (0.0957)

92473 N8210 13.6 (0.535) 2.43 (0.0957)

92474 N8210 16.5 (0.650) 2.43 (0.0957)

Revision: December 2006 2007 Sentra

MTC-10

PRECAUTIONS

● After connecting line, co ndu ct leak tes t and make sure that there is no leakag e from conn ections.

When the gas leaking point is found, disconnect that line and replace the O-ring. Then tighten connections of seal seat to the specified t orque.

A

B

C

D

E

F

RHA861F

Precautions for Servicing Compressor EJS005OB

● Plug all openings to prevent moisture and foreign matter from entering.

● When the compressor is removed, store it in the same position as it is when mounted on the car.

● When replacing or repairing compressor, follow “Maintenance of Oil Quantity in Compressor”

exactly. Refer to MTC-21, "

● Keep friction surfaces between clutch and pulley cle an. If the surface is contaminated, with oil,

Maintenance of Oil Quantity in Compressor" .

wipe it off by using a clean waste cloth moistened with thinner.

● After compressor service opera tion , turn the compre sso r shaft by hand m ore than 5 turn s in both

directions. Th is will equally distribute oil inside the compressor. After the compressor is installed,

let the engine idle and operate the compressor for 1 hour.

● After replacing the compressor magnet clutch, apply voltage to the new one and check for normal

operation. [Gap between clutch disc an d pulley is 0.3 - 0.6 mm (0.012 - 0.024 in)]

Precautions for Service Equipment EJS005OC

RECOVERY/REC YCLING EQUIPMENT

Follow the manu fac turer's instruc tions for machi ne ope ration and mach ine mainten ance. N ev er introduc e an y

refrigerant other than that specified into the machine.

ELECTRONIC LEAK DETECTOR

Follow the manufacturer's instructions for tester operati on and tester maintenance.

G

H

I

MTC

K

L

M

Revision: December 2006 2007 Sentra

MTC-11

PRECAUTIONS

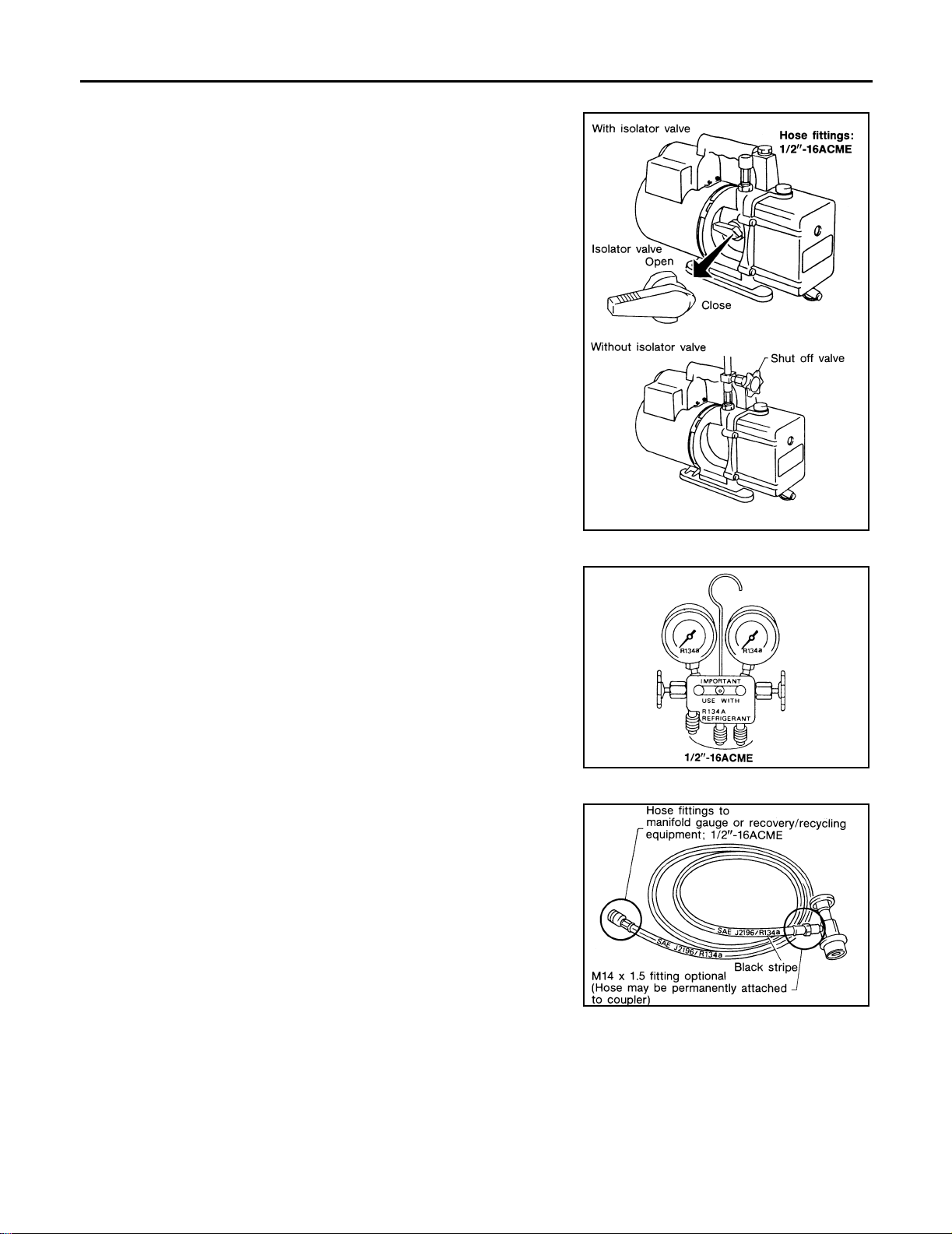

VACUUM PUMP

The oil contained inside the vacuum pump is not compatible with the

specified oil for HFC -134a (R-134a) A/C s ystems. The vent side of

the vacuum pump is exposed to atmos pheric pressure so the vacuum pump oil may migrate out of the pump into the service hose.

This is possible when the pump is switched off after evacuation (vacuuming) and hose is connected to it.

To prevent this migration, use a manual valve situated near the

hose-to-pump connection, as follows.

● Usually vacuum pum ps have a manual isola tor valve as part of

the pump. C lose this valv e to isolate th e service hose fr om the

pump.

● For pumps without an isolator, use a hose equipped with a man-

ual shut-off valve near the pump end. Clos e the valve to isolate

the hose from the pump.

● If the hose has an automatic shut o ff valve, disconnect the hose

from the pump : as long as the hose is conne cted, the valve is

open and lubricating oil may migrate.

Some one-way valves open when vacuum is applied and close

under a no vacuum cond ition. Such valves may restric t the pump's

ability to pull a deep vacuum and are not rec ommended.

MANIFOLD GAUGE SET

Be certain that the gau ge fac e indic ate s R-1 34a o r 134a. Ma ke sure

the gauge set has 1/2″-16 ACM E threaded connecti ons for service

hoses. Confirm the set has been used only with refrigerant HFC134a (R-134a) along with specified oil.

SERVICE HOSES

Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must include positive shutoff devices (either manual or autom atic) near the end of the hoses

opposite the manifold gauge.

RHA270D

SHA533D

RHA272D

Revision: December 2006 2007 Sentra

MTC-12

PRECAUTIONS

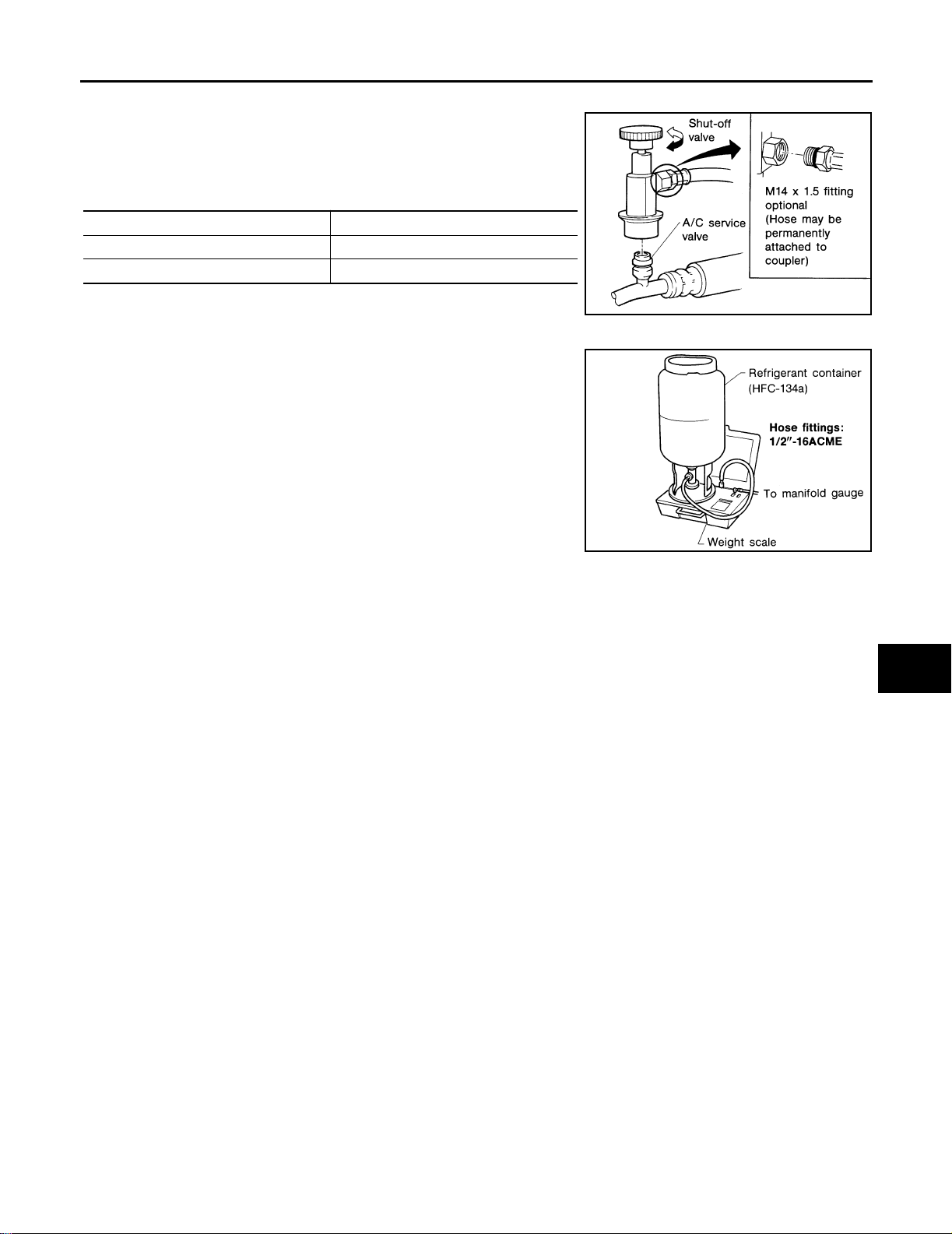

SERVICE COU PLE RS

Never attempt to connect HFC-134a (R-13 4a) service couplers to a

CFC-12 (R-12) A/C system . The HFC-134a (R-134a) cou plers will

not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

Shut-off valve rotation A/C service valve

Clockwise Open

Counterclockwise Close

A

B

C

RHA273D

REFRIGERANT W EIGHT SCALE

Verify that no refrigerant other than HFC134a (R-134a) and specified

oils have been u sed with the scale . If the scale controls refrige rant

flow electronically, the hose fitting must be 1/2”-16 ACME.

RHA274D

CHARGING CYLINDER

Using a charging cylinde r is not recommended. Refrige rant may be vented into air from cylinder's top valve

when filling the cylinder w ith refrigerant. Also, the acc uracy of the cy linder is gener ally less than that of an

electronic scale or of quality recycle/recharge equipment.

D

E

F

G

H

I

MTC

K

Revision: December 2006 2007 Sentra

MTC-13

L

M

PREPARATION

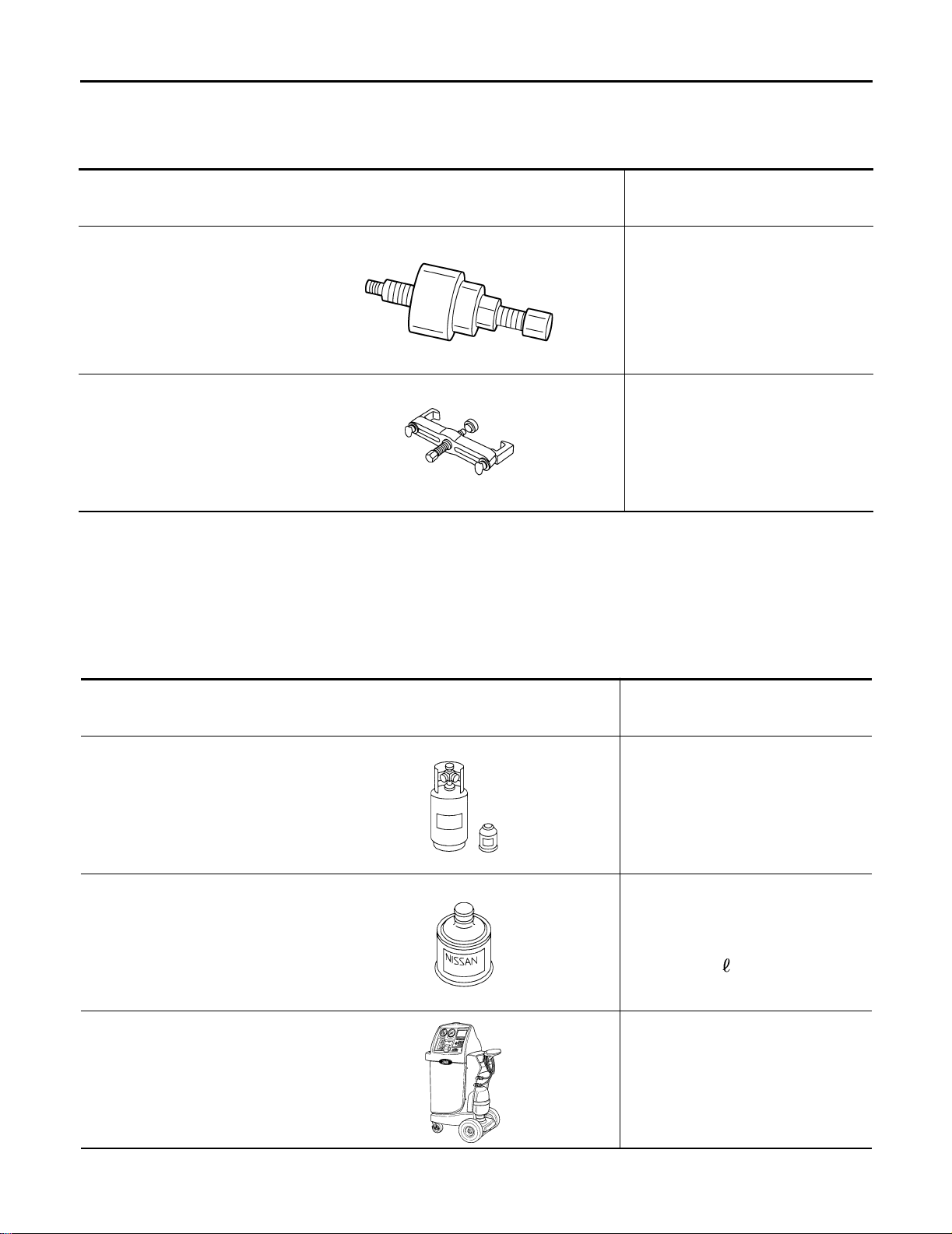

PREPARATION PFP:00002 Special Serv ice Tools EJS005OD

The actual shapes of Kent-Moore tools may differ from those of special servi ce tools illustrated here.

Tool numbe r

(Kent-Moore No.)

Tool name

—

(J-38873-A)

Drive plate installer

WJIA0367E

KV99233130

(J-29884)

Pulley puller

LHA172

Description

Installing pulley and drive plate

Removing pulley

HFC-134a (R-134a) Service Tools and Equipment EJS005OE

Never mix HFC-134a refrigerant and/or its specified oil with CFC-12 (R-12) refrigerant and/or its oil.

Separate and non-interchangeable service equipment must be used for ha ndling each type of refrigerant/oil.

Refrigerant c ontainer fittings, servi ce hose fittings a nd service equipment fittings (equipment which handles

refrigerant and /or oil) are different between C FC-12 (R-12) and H FC-134a (R-134a). Thi s is to avoid mixed

use of the refrigerants/oil.

Adapters tha t convert one s ize fitting to a nother must n ever be us ed: refrigerant/ oil contamination will occur

and compressor failure will result.

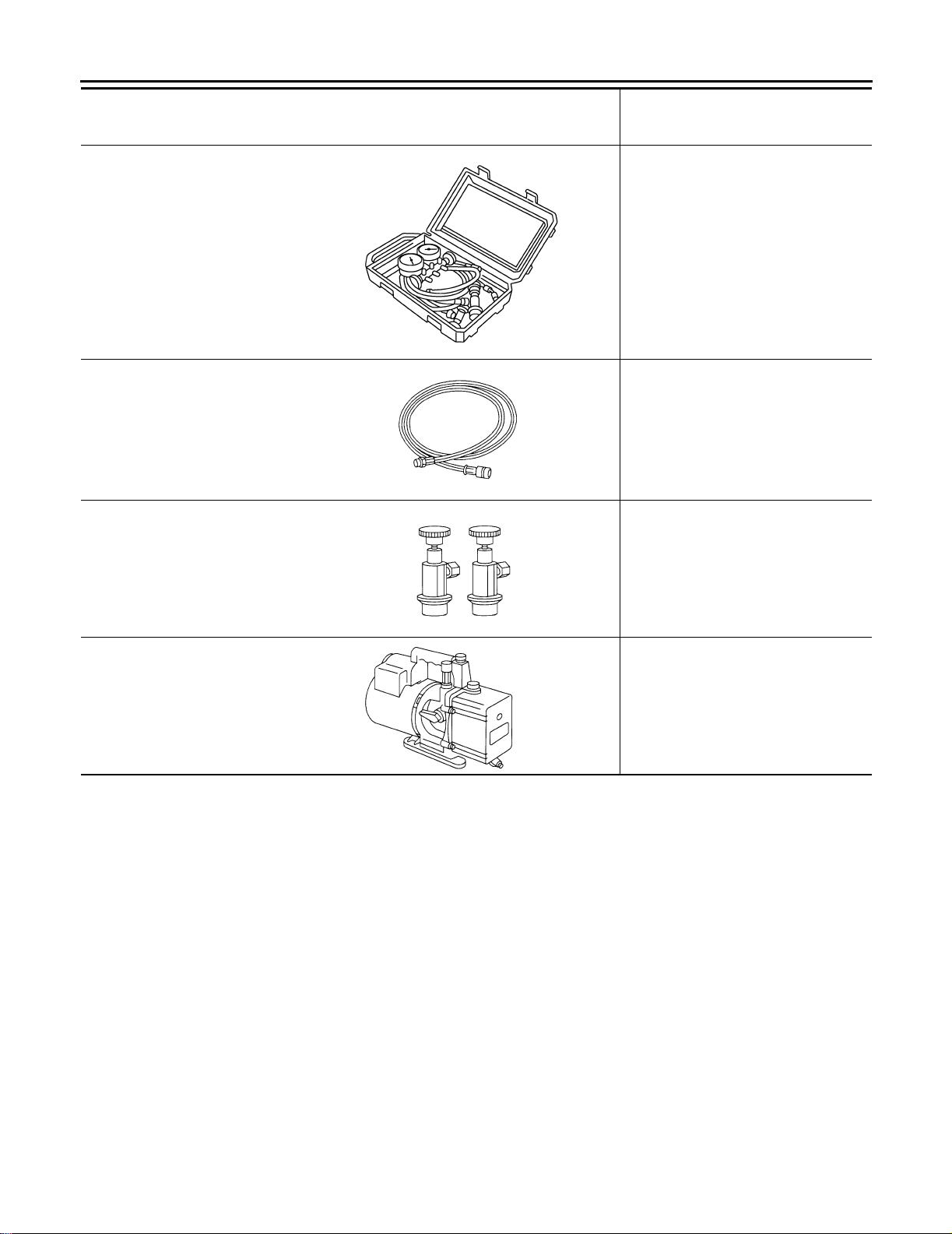

Tool number

(Kent-Moore No.)

Tool name

—

(—)

Refrigerant HFC-134a (R-134a)

S-NT196

—

(—)

Genuine NISS AN A/C System Oil

Type S

S-NT197

K991J0130

(ACR2005-NI)

ACR A/C Service Center

Description

Container color: Light blue

Container marking: HFC-134a (R134a)

Fitting size: Thread size

● large container 1/2 in -16 ACME

Type: Poly alkaline glycol oil (PAG),

type S

Application: HFC-134a (R-134a)

swash plate compressors (NISSAN

only)

Lubricity: 40 m (1.4 US fl oz, 1.4 Imp

fl oz)

Refrigerant recovery, recycling and recharging

WJIA0293E

Revision: December 2006 2007 Sentra

MTC-14

PREPARATION

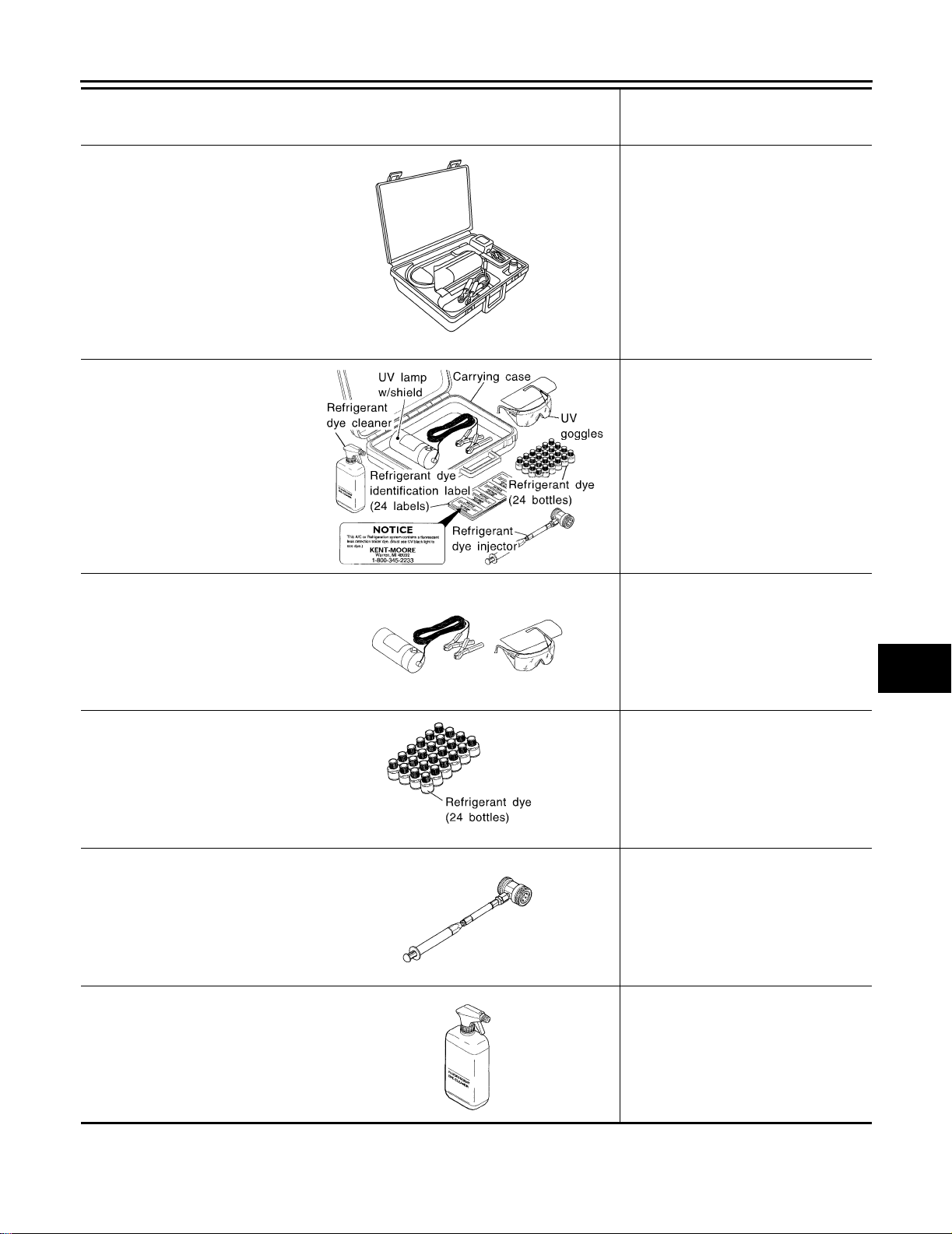

Tool number

(Ken t-Moore No.)

Tool name

—

(J-41995)

Electronic refrigerant leak detector

—

(J-43926)

Refrigerant dye leak de tecti on kit

Kit includes:

(J-42220) UV lamp and UV safety

goggles

(J-41459) Refrigerant dye injector

(J-41447) qty. 24

HFC-134a (R-134a) refrigerant

dye

(J-43872) Refrigerant dye cleaner

—

(J-42220)

Fluorescent dye leak detector

AHA281A

ZHA200H

Description

Power supply: DC 12V (Battery terminal)

Power supply: DC 12V (Battery terminal)

Power supply: DC 12V (Battery terminal)

For checking refrigerant leak when fluorescent dy e is inst alled i n A/C syst em.

Includes: UV lamp and UV safety goggles

A

B

C

D

E

F

G

H

I

MTC

—

(J-41447)

HFC-134a (R-134a) Fluorescent

leak detection dye

(Box of 24, 1/ 4 ounce bottl es)

—

(J-41459)

HFC-134a (R-134a) Dye injector

Use with J-4 1447, 1/4 ou nce bottle

—

(J-43872)

Refrigerant dye cleaner

SHA438F

SHA439F

SHA440F

SHA441F

Applicati on: For HFC-134a (R-134a)

PAG oil

Container: 1/4 ounce (7.4cc) bottle

(Includes self-adhesive dye identification labels for affixing to vehicle after

char ging system with dye.)

For injecti ng 1/ 4 oun ce of fluo r es cent

leak detection dye into A/C system.

For cleaning dye spills.

K

L

M

Revision: December 2006 2007 Sentra

MTC-15

PREPARATION

Tool number

(Kent-Moore No.)

Tool name

—

(J-39183-C)

Manifold gauge set (with hoses

and couplers)

Service hoses

● (J-39500-72B)

High side hose

● (J-39500-72R)

Low si de hose

● (J-39500-72Y)

Utility hose

Service couplers

● (J-39500-20A)

High side coupler

● (J-39500-24A)

Low si de coupler

S-NT201

Description

Identification:

● The gauge face indicates R-134a.

Fitting size: Thread size

● 1/2 in -16 ACME

RJIA0196E

Hose color:

● Low side hose: Blue w it h black st ripe

● High side hose: Red with black s trip e

● Utility hose: Yellow with black stripe

or green with black stripe

Hose fitting to gauge:

● 1/2 in -16 ACME

Hose fitting to service hose:

● M14 x 1.5 fitti ng is op tion al o r perma -

nently attached.

—

(J-39649)

Vacuum pump

(Including the isolator valve)

S-NT202

Capacity:

● Air displacement: 4 CFM

● Micron rating: 20 micron s

● Oil capacity: 482 g (17 oz)

Fitting size: Thread size

● 1/2 in -16 ACME

S-NT203

Revision: December 2006 2007 Sentra

MTC-16

PREPARATION

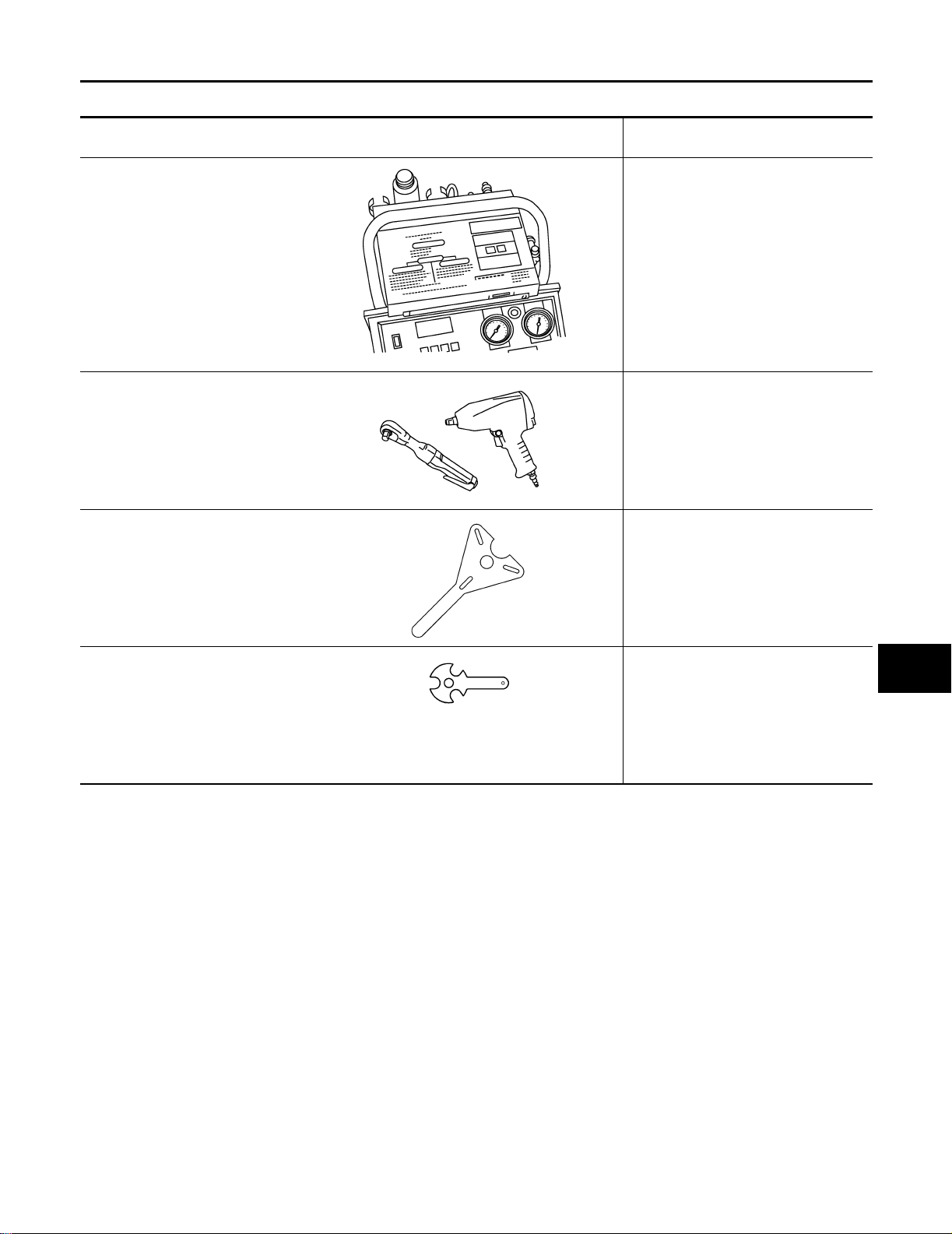

Commercial Service Tools EJS005OF

Tool number

Tool name

J-41810-NI

Refrigerant identifier equipment

HFC 134a (R-134a)

Description

Checkin g refrigeran t purity and sys tem

contamination

A

B

C

D

RJIA0197E

Power tool Removi ng bol t s and nuts

PBIC0190E

Universal spanner wrench Holding compressor clutch for removal

and installation

LJIA0202E

J-44614

Clutch disc holding tool

WHA230

Holding clutch disc for removal and installation

E

F

G

H

I

MTC

K

L

Revision: December 2006 2007 Sentra

MTC-17

M

REFRIG ERATION SYSTEM

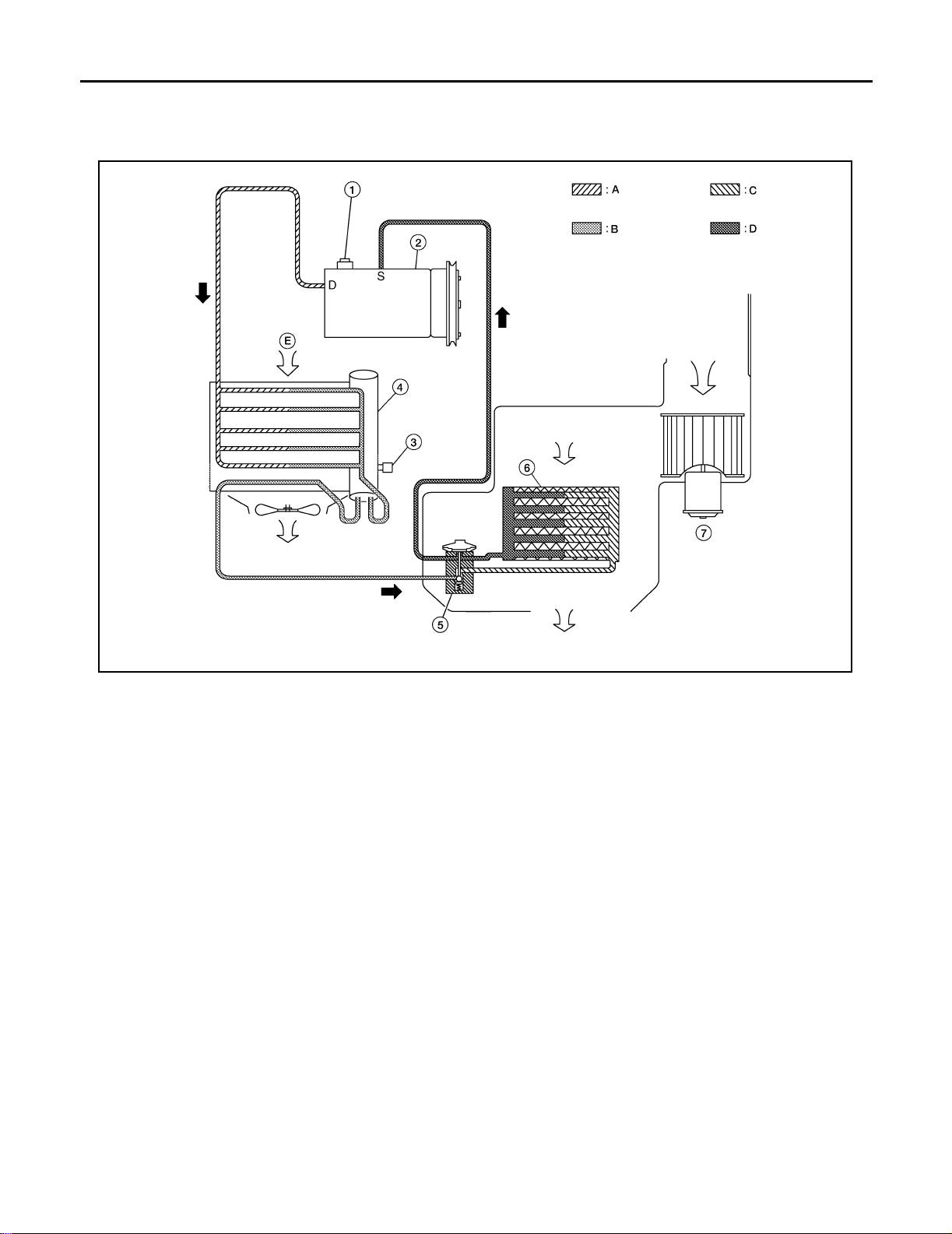

REFRIGERATION SYSTEM PFP:KA990 Refrigerant Cycle EJS005OG

REFRIGERANT FLOW

WJIA2295E

1. Pressure relief valve 2. Compressor 3. Refrigerant pressure sensor

4. Condenser (with liquid tank) 5. Expansion valve 6. Evaporator

7. Front blower motor A. High-pressure gas B. High-pressure liquid

C. Low-press ure liquid D. Low-press ure gas E. Outsid e air

The refrigera nt flows in the standard pattern, that i s, through the compr essor, the condenser wi th liquid tank,

through the evaporator, and back to the compressor. The refrigerant evaporation through the evaporator coil is

controlled b y an externally equalized expansion valve, located inside the evaporator case.

Refrigerant System Protection EJS005OH

REFRIGERANT PRESSURE SENSOR

The refrigerant system is protected against excessively high or low pressures by the refrigerant pressure sensor, located on the liquid tank. If the system pressure rises above or falls below the specifications, the refrigerant pressur e sens o r detec ts the pres sure ins ide th e re frigera nt li ne and sends the vo ltage s ignal to the EC M.

The ECM then signa ls the BCM (via CAN communication lines) to cease suppling power to the A/C relay

which disengages and stops the compressor. This occurs when pressure on the high pressure side (as

2

detected by refrigerant pressure sensor) is over approximately 2,746 kPa (28 kg/cm

2

approximately 120 kPa (1.22 kg/cm

, 17.4 psi).

PRESSURE RELIEF VALVE

The refrigerant system is also protected by a pressure reli ef valve, located in the re ar head of the compressor.

When the refri gerant pressure in the system increases to an abnormal level [more than 3,600 kP a (36.7 kg/

2

, 522 psi)], the release port on th e pr essu re relie f valve autom atical ly ope ns and r eleases refr igera nt into

cm

the atmosphere.

, 398 psi), or below

Revision: December 2006 2007 Sentra

MTC-18

REFR IGERATION SYSTE M

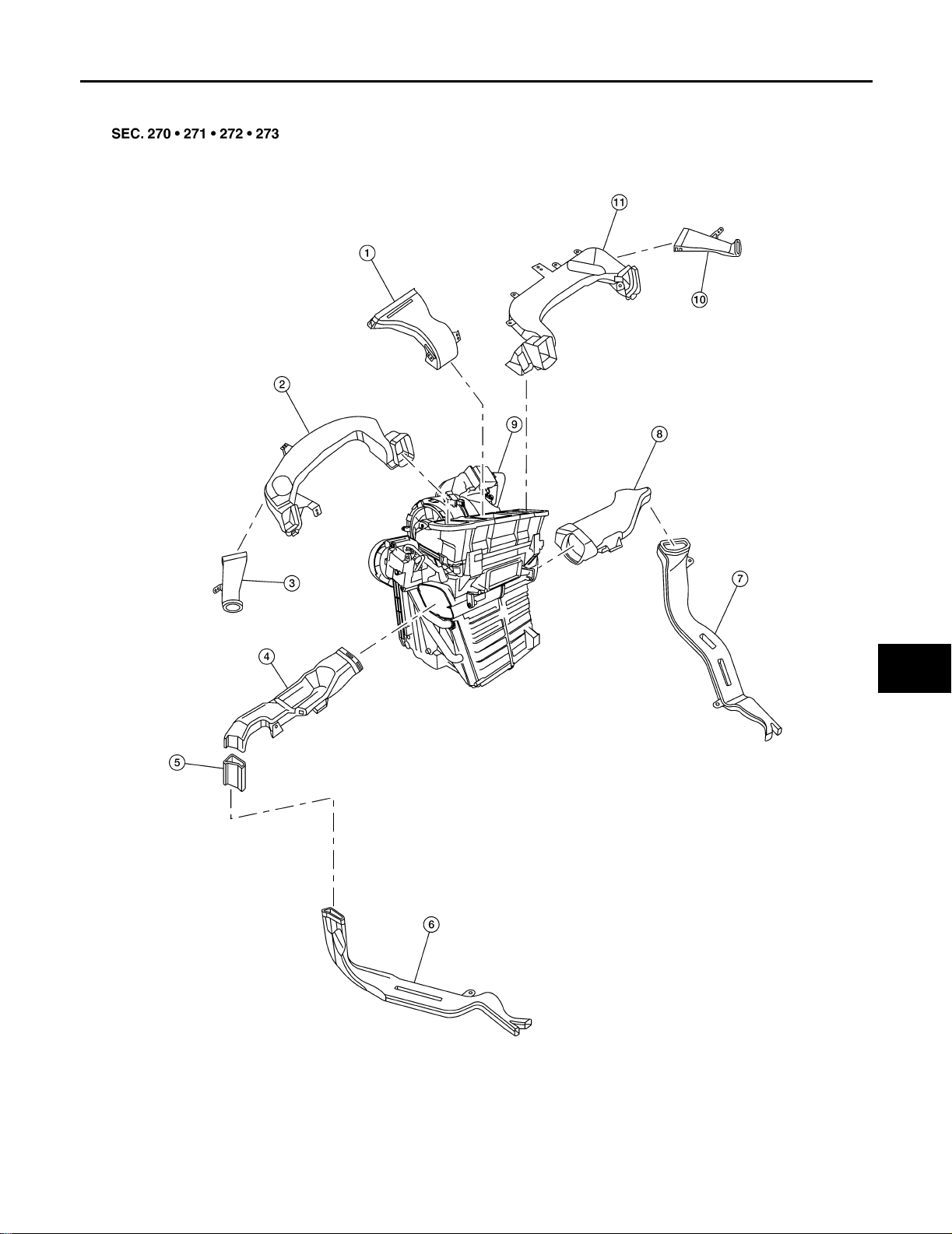

Component Layout EJS005OI

A

B

C

D

E

F

G

H

I

MTC

K

L

M

BJIA0023E

Revision: December 2006 2007 Sentra

MTC-19

REFRIG ERATION SYSTEM

1. Defroster nozzle 2. Side ve ntilator duct (LH) 3. Side de frost er duct (LH)

4. Front foot duct (LH) 5. Rear floor connector duct (Canada

only)

7. Rear floor duct (RH) (Canada only) 8. Front foot duct (RH) 9. Heater and cooling unit assembly

10. Side defroster duct (RH) 11. Side ventilator duct (RH)

6. Rear floor duct (LH) (Canada only)

Revision: December 2006 2007 Sentra

MTC-20

OIL

OIL PFP:KLG00

Maintenance of Oil Qua ntit y in Co m pr essor EJS005OJ

The oil in the compressor circulates through the system with the refrigerant. Add oil to compressor when

replacing any component or after a large refrigerant leakage has occurred. It is important to maintain the specified amount.

If oil quantity is not maintained properly, the following malfunctions may result:

● Lack of oil: May lead to a seized compressor

● Excessive oil: Inadequate cooling (thermal exchange interference)

OIL

● Oil type: NISSAN A/C System Oil Type S or equivalent

CHECKI NG AN D ADJ U ST ING

CAUTION:

If excessive oil leakage is noted, do no t perform the oil return operation.

Start the engine and set the following conditions:

Test Condition

● Engine speed: Idling to 1,200 rpm

● A/C switch: On

● Blower fan speed: Max. position

● Temp. control: Optional [Set so that intake air temperature is 25° to 30° C (77° to 86°F).]

● Intake position: Recirculation ( )

● Perform oil return operation for about ten minutes

Adjust the oil quantity according to the following table.

A

B

C

D

E

F

G

H

Oil Adjusting Procedure for Components Replacement Except Compressor

After replacing any of the following major components, add the correct amount of oil to the system.

Amount of Oil to be Added

Oil to be added to system

Part replaced

Evaporator 75 (2.5, 2.6) —

Condenser 75 (2.5, 2.6) —

Liquid tank 5 (0.2, 0.2) Add if compressor is not replaced.

In case of refrigerant leak

*1: If refrigerant leak is small, no addition of oil is needed.

Amount of oil

m (US fl oz, Imp fl oz)

30 (1.0, 1.1) Large leak

— Small leak *1

Remarks

I

MTC

K

L

M

Revision: December 2006 2007 Sentra

MTC-21

OIL

Oil Adjustment Procedure for Compressor Replacement

WJIA1716E

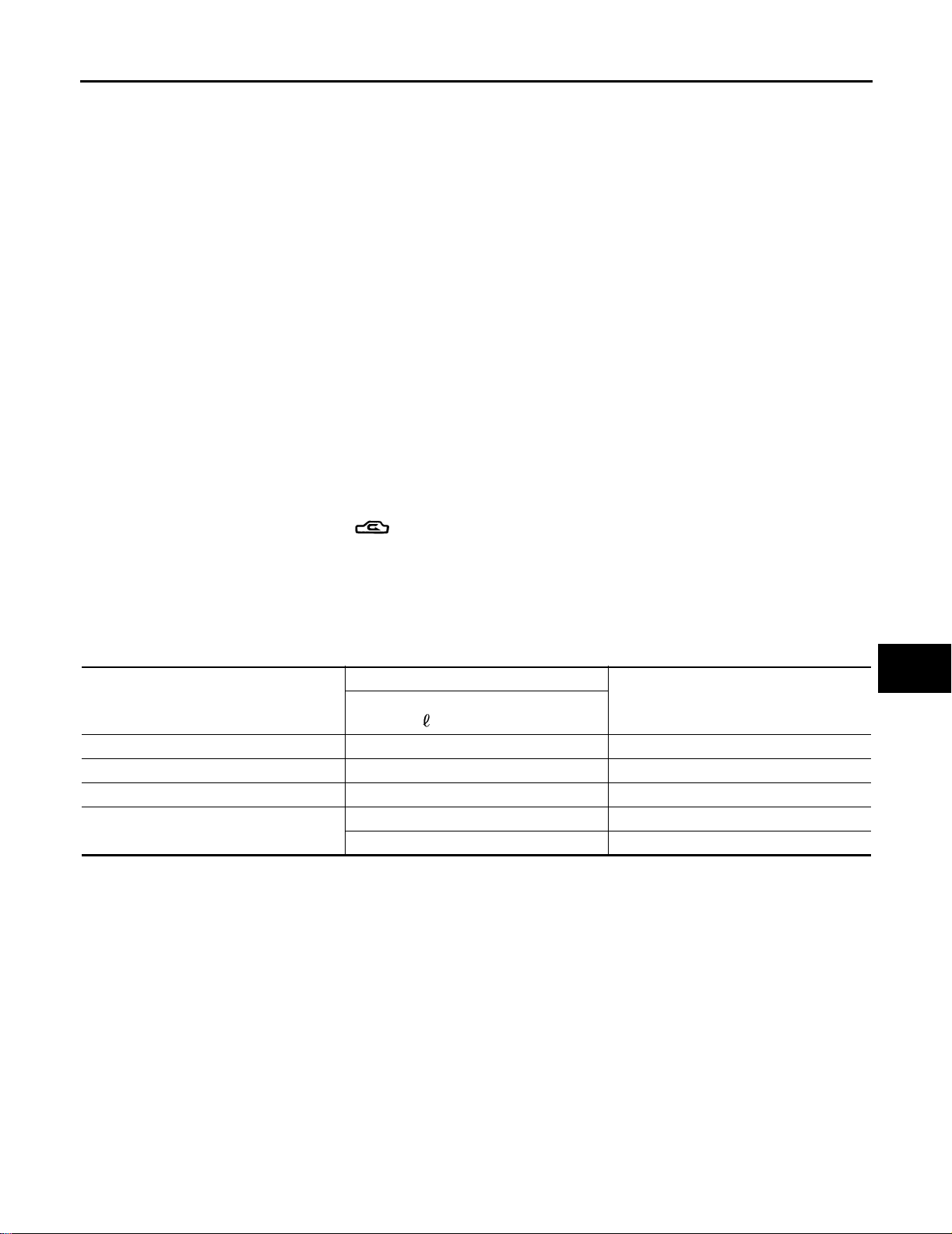

1. New compressor 2. Old compressor 3. Recovery/recycling equipment

4. Measuring cup X 5. Measuring cup Y 6. New oil

A. Drain oil from the new compressor

into clean container

D. Install new oil equal to recorded

amounts in mea su ring cu ps X plus Y

B. Record amount of oil recovered C.

Add an additional 5 m (0.2 US fl oz,

0.2 Imp fl oz) of new oil when replacing liquid tank

1. Before connecting re covery/recycling equipment to vehicle, check recovery/recycling equipment gauges.

No refrigerant pressure should be displayed. If NG, recover refrigerant from equipment lines.

2. Connect recovery/recycling equipment to vehicle. Confirm refrigerant purity in supply tank using recovery/

recycling equ ipment and refrigerant identifier. If NG, refer to MTC-4, "

Contaminated Refrigerant" .

3. Confirm refrigerant purity in vehicle A/C system using recovery/recycling equipment and refrigerant identifier. If NG, refer to MTC-4, "

Contaminated Refrigerant" .

4. Dis charge refrigerant into the refrigerant recov ery/recycling equ ipment. Measure oil discharged into the

recovery/recycling equipment.

5. Drai n the oil from the “ old” (remov ed) com pressor into a grad uated container and re cover the am ount of

oil drained.

6. Drain the oil from the “new” compressor into a separate, clean container.

7. Mea sure an amount of new oil installed equal to amoun t drained from “old ” compressor. Add this oil to

“new” compressor through the suction port opening.

8. Mea sure an amount of new oil equal to the amount recover ed during discharging. Ad d this oil to “new”

compressor through the suction port opening.

9. If the liquid tank also needs to be replaced, add an additional 5 m (0.2 US fl oz, 0.2 Imp fl oz) of oil at this

time.

Revision: December 2006 2007 Sentra

MTC-22

OIL

CAUTION:

Do not add this 5 m (0.2 US fl oz, 0.2 Imp fl oz) of oil if only replacing the compressor and not the

liquid tank.

A

B

C

D

E

F

G

H

I

MTC

K

L

M

Revision: December 2006 2007 Sentra

MTC-23

AIR CONDITIONER CONTROL

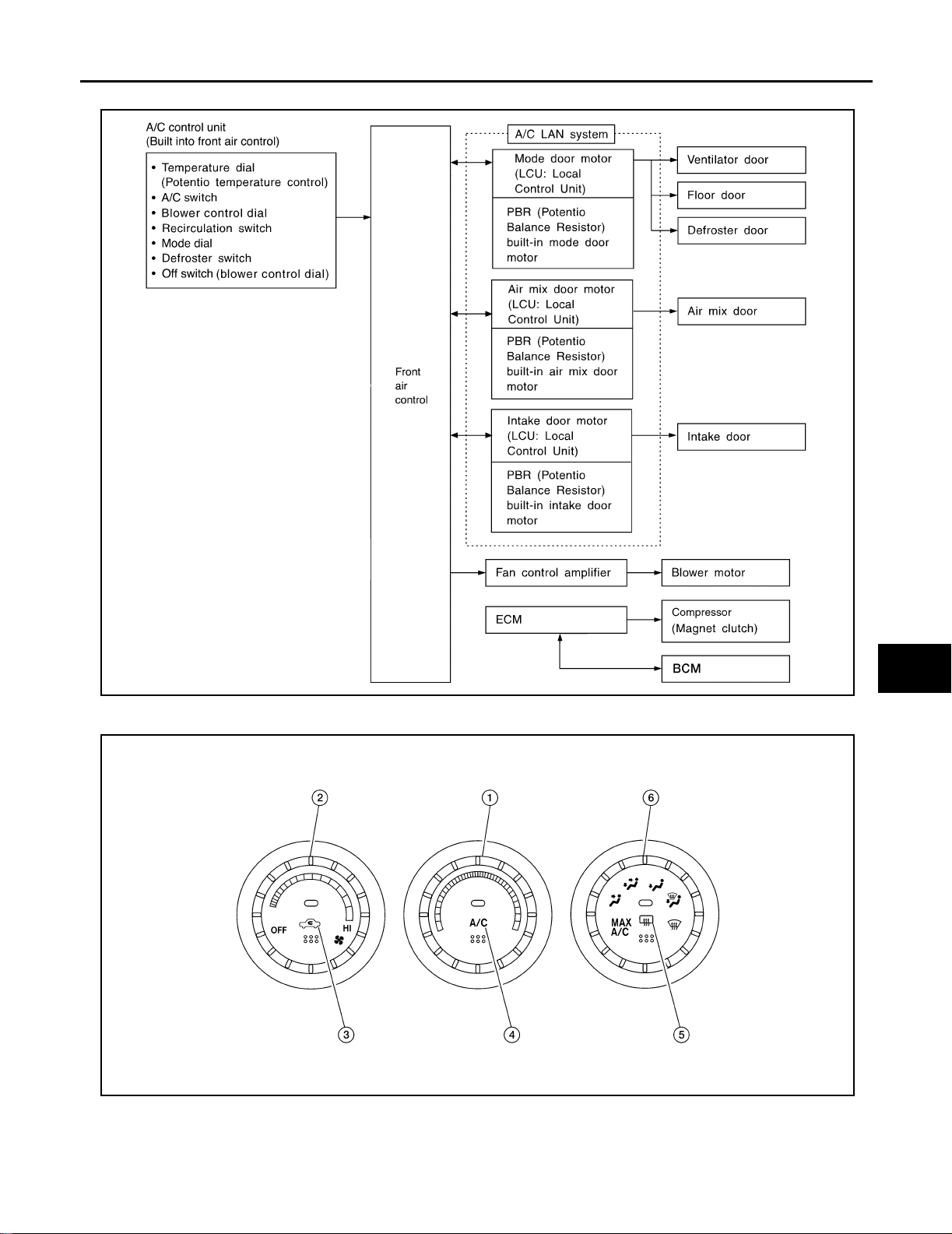

AIR COND ITIONER CONTROL PFP:27500 Overview Air Conditioner LAN Control Syst em EJS005OK

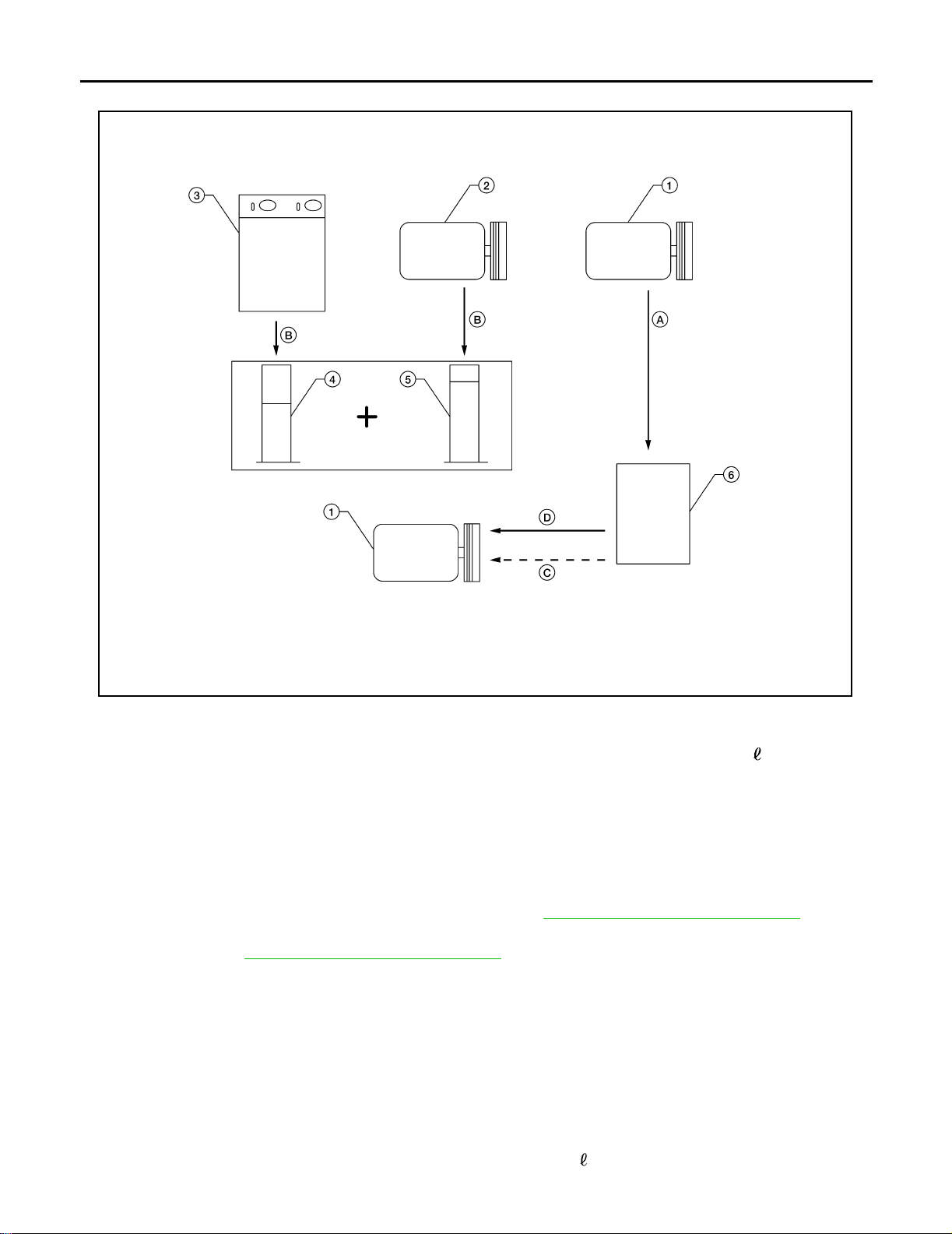

The LAN (local area netwo rk) system consists of front air control, air mix door motor, intake door motor, and

mode door motor.

A configuration of these co mponents is shown in the diagram below.

WJIA0876E

System Construction EJS005OL

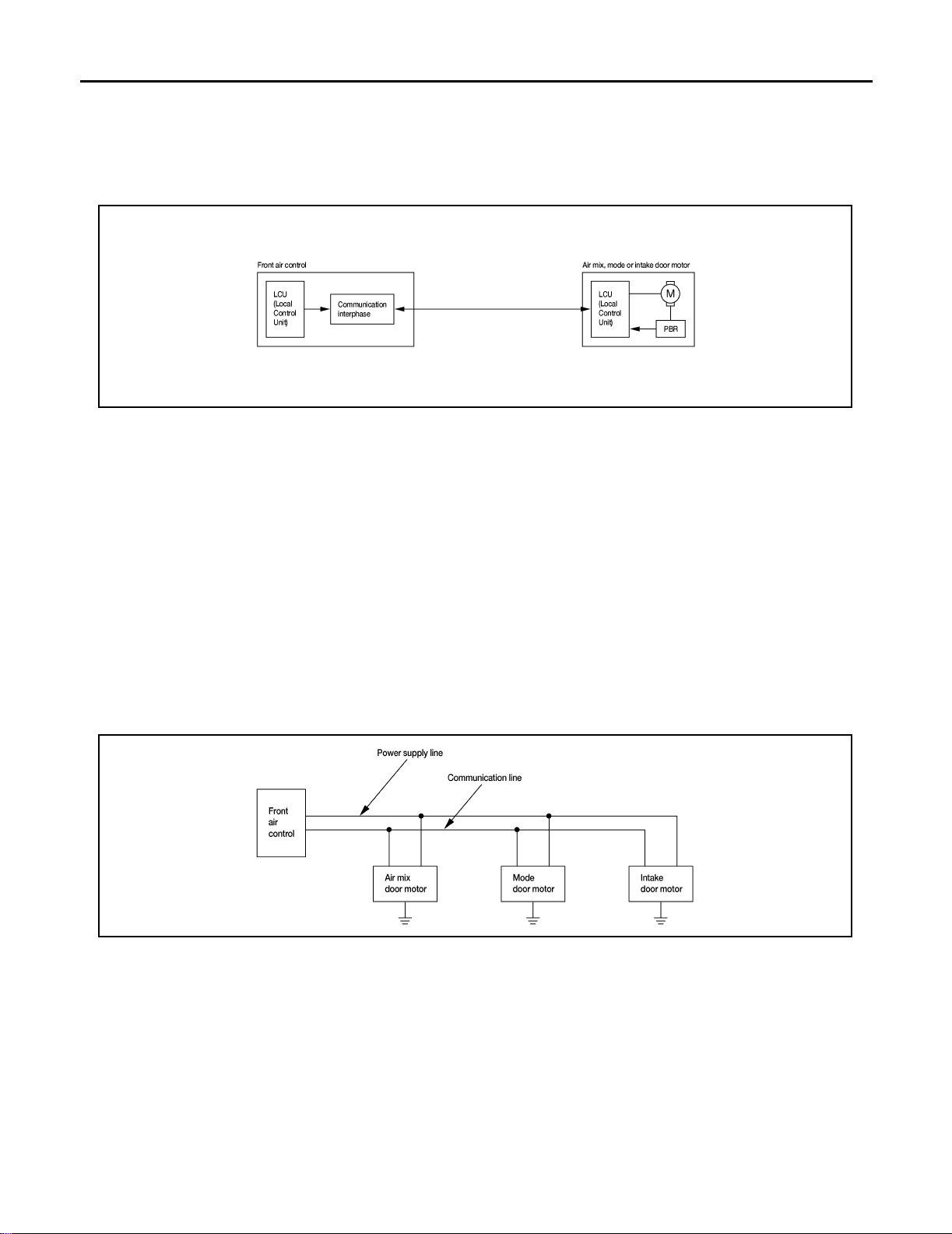

A small networ k is con struc ted between the fr ont air contr ol, air mix d oor moto r, intake door motor, and mode

door motor. The front air control and motors are connected by data transmission lines and motor power supply

lines. The LAN network is built through the ground circuits of the two motors.

Addresses, m otor ope ni ng an gle sig nals, mot or sto p s ignals and error ch eckin g mess ag es are al l tran smitted

through the data transmission lines connecting the front air control and each motor.

The following func tions are contained in LCUs built in to the air mix door motor, intake door motor, and the

mode door motor.

● Address

● Motor opening angle signals

● Data transmission

● Motor stop and drive decision

● Opening angle sensor (PBR function )

● Comparison

● Decision (front air control indicated value and motor opening angle comparison)

WJIA0877E

OPERATION

The front air contro l receives signals fro m its various dials and switc hes. The front air con trol then sends air

mix door, mode door and intake door opening angle data to the air mix door motor LCU, mode door motor LCU

and intake door motor LCU.

The air mix door motor, mode door motor and intake door motor read their respective signals according to the

address signal. Opening angle indication signals received from the front air control and each of the motor position sensors ar e com pared by the LCU s in each m otor with the exi sti ng de cision an d op ening a ngl es. Sub se -

Revision: December 2006 2007 Sentra

MTC-24

AIR COND ITIONER CONTROL

quently, HOT/COLD, DEFROST/VENT or FRESH/RECIRCULATION operation is selected. The new selection

data is returned to the front air control.

WJIA0878E

A

B

C

D

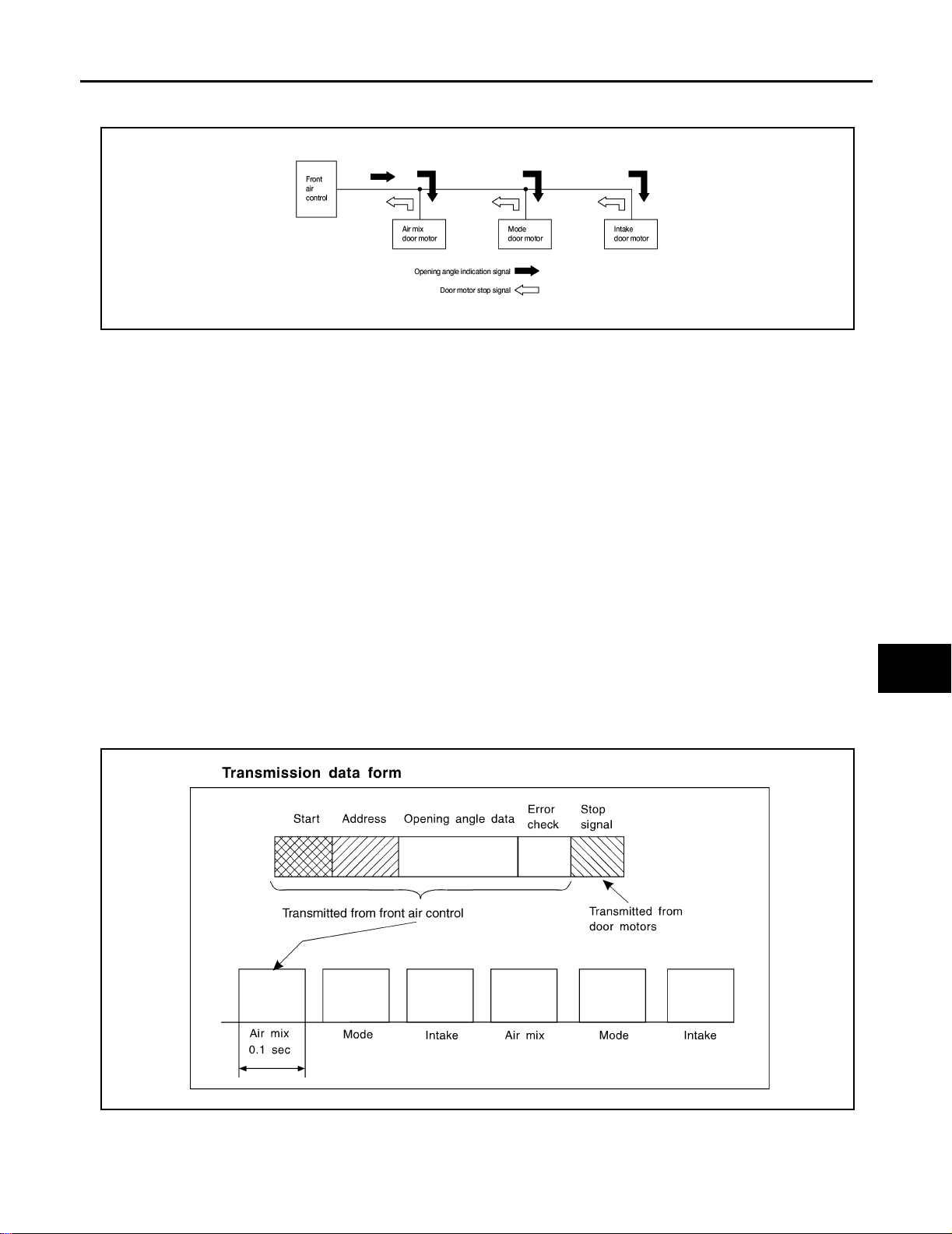

TRANSMISSION DATA AND TRANSMISSION ORDER

Front air control data is transmitted consecutively to each of the door motors following the form shown in figure

below.

Start: Initial compulsory signal sent to ea ch of the door motors.

Address: Data sent from the front air control is selected according to data-based decisions made by the air mix

door motor, mode door motor and intake door motor.

If the addres ses are identi cal, the o peni ng angle d ata and e rror che ck si gna ls are rec eive d by the door motor

LCUs. Th e LCUs t hen make t he appr opriate erro r decision. If the ope ning angl e data is nor mal, door control

begins.

If an error exists, the received data is rejected and corrected data received. Finally, door control is based upon

the corrected opening angle data.

Opening angle: Data that shows the indicated door opening angle of each door motor.

Error check: Pr ocedure by which sent and r eceived data is checked for erro rs. Error data is then compiled.

The error c heck prevents corrupted data from being us ed by the air mix door motor, mode door motor and

intake door motor. Error data can be related to the followin g problems.

● Abnormal electrical frequency

● Poor electrical connections

● Interference from other signal transmission lines

● Signal level fluctuation

Stop signal: At the end of each trans mission, a sto p operation, in-ope ration, or inter nal problem mes sage is

delivered to the front air control. This completes one data transmission and control cycle.

E

F

G

H

I

MTC

K

L

WJIA0882E

AIR MIX DOOR CONTROL

The air mix door is controll ed by the front air control based on input fro m the temperature dial setting.

Revision: December 2006 2007 Sentra

MTC-25

M

AIR CONDITIONER CONTROL

BLOWER SPEED CONTROL

Blower speed is controlled by the front air control based on the position of the blower control dial.

With the blower control dial set to any position except OFF, the blower will begin to operate.

INTAKE DOOR CONTROL

The intake door is con trolled by the front air co ntrol based on input from t he recircul ation swi tch settin g, and

the MAX A/C switch setting.

MODE DOOR CONTROL

The mode door is controlled by the front air control based on input from the mode dial setting.

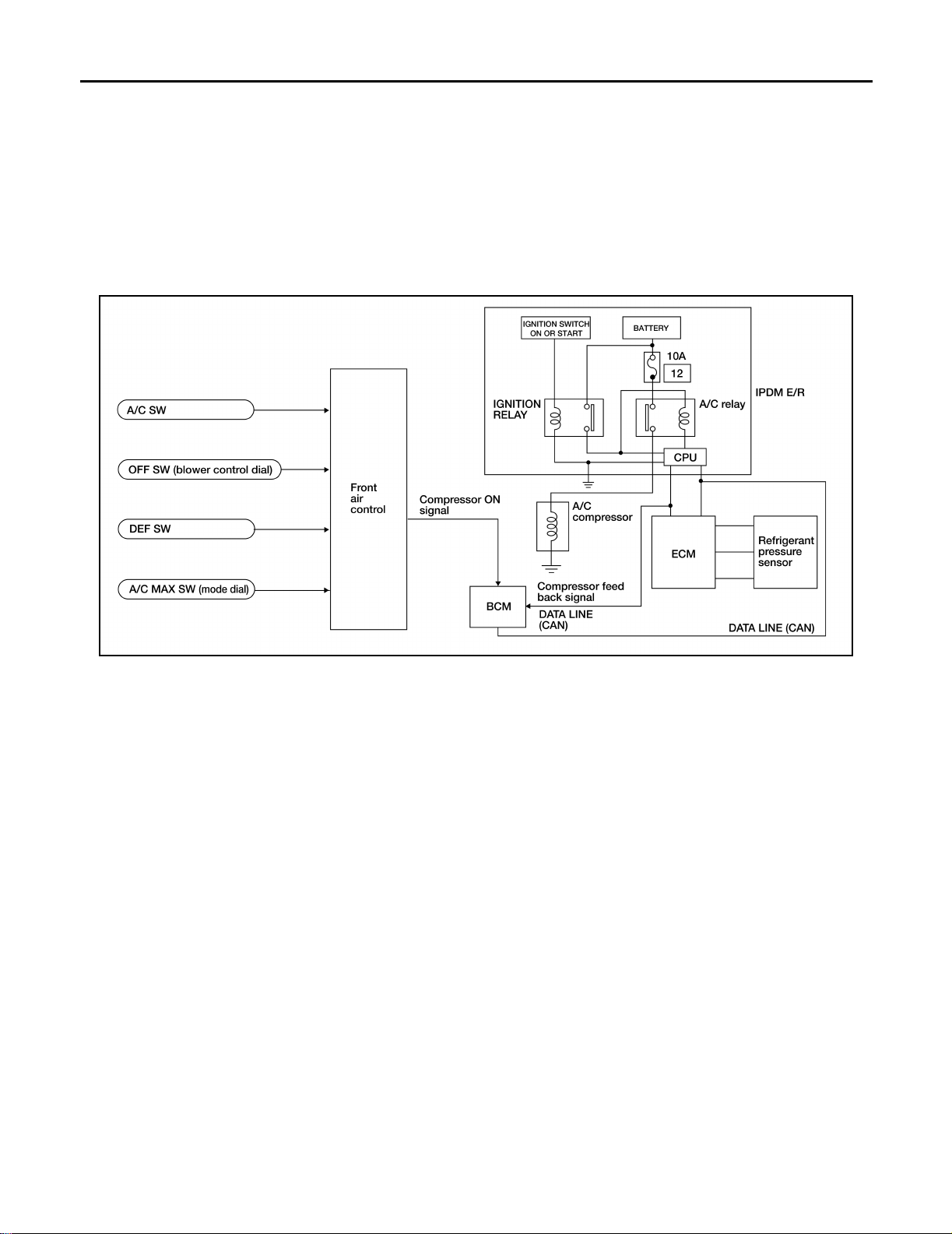

MAGNET CLUTCH CONTROL

WJIA2307E

The ECM controls compressor operation using input signals from the throttle position sensor and front air control.

Overview of Control syst em EJS005OM

The control system consists of an input sensor, switches, the front air control and outputs.

Revision: December 2006 2007 Sentra

MTC-26

AIR COND ITIONER CONTROL

The relationship of these components is shown in the diagram below:

A

B

C

D

E

F

G

BJIA0003E

Control Ope ra tio n EJS005ON

H

I

MTC

K

L

M

BJIA0004E

1. Temperat u re di a l 2. Blower contro l dia l 3. Recircu l ation switch

4. A/C switch 5. Rear window defogger switch 6. Mode dial

Revision: December 2006 2007 Sentra

MTC-27

AIR CONDITIONER CONTROL

AIR CONDI T ION E R (A/C ) SWIT CH

The air conditioner switch controls the A/C system. When the switch is pressed with the blower ON , the compressor will turn ON. The indicator lamp will also illuminate.

The air conditioner cooling function operates only when the engine is running.

TEMPERATURE DIAL (POTE NTIO TEMPERATURE CONTR OL)

Increases or decreases the s et temperature.

BLOWER CONTROL DIAL/OFF SWITCH

Manually controls the blower speed.

In the off po sition, the comp re ssor a nd blower a re O F F, the intake do or i s s et t o th e cho sen p os ition, a nd the

air mode doors are set to the chosen posi tion.

RECIRCULATION () SWITCH

OFF position: Outside air is drawn into the passenger compartment.

ON position: Interior air is recirculated inside the vehicle.

DEFROSTER SWITCH

Positions t he air mode doors to the defrost position. Also positions the intake doors to the outside air position.

The compressor remains ON until the ignition is turned OFF or if the customer turns the mode to a non-defrost

mode and turns the A/C button to OFF.

MODE DIAL

Controls the air discharge through control of mode door, also controls MAX A/C function.

REAR WINDOW DEFOGGER SWITCH

This switch turns the rear w indow defogger ON and OFF.

Revision: December 2006 2007 Sentra

MTC-28

AIR COND ITIONER CONTROL

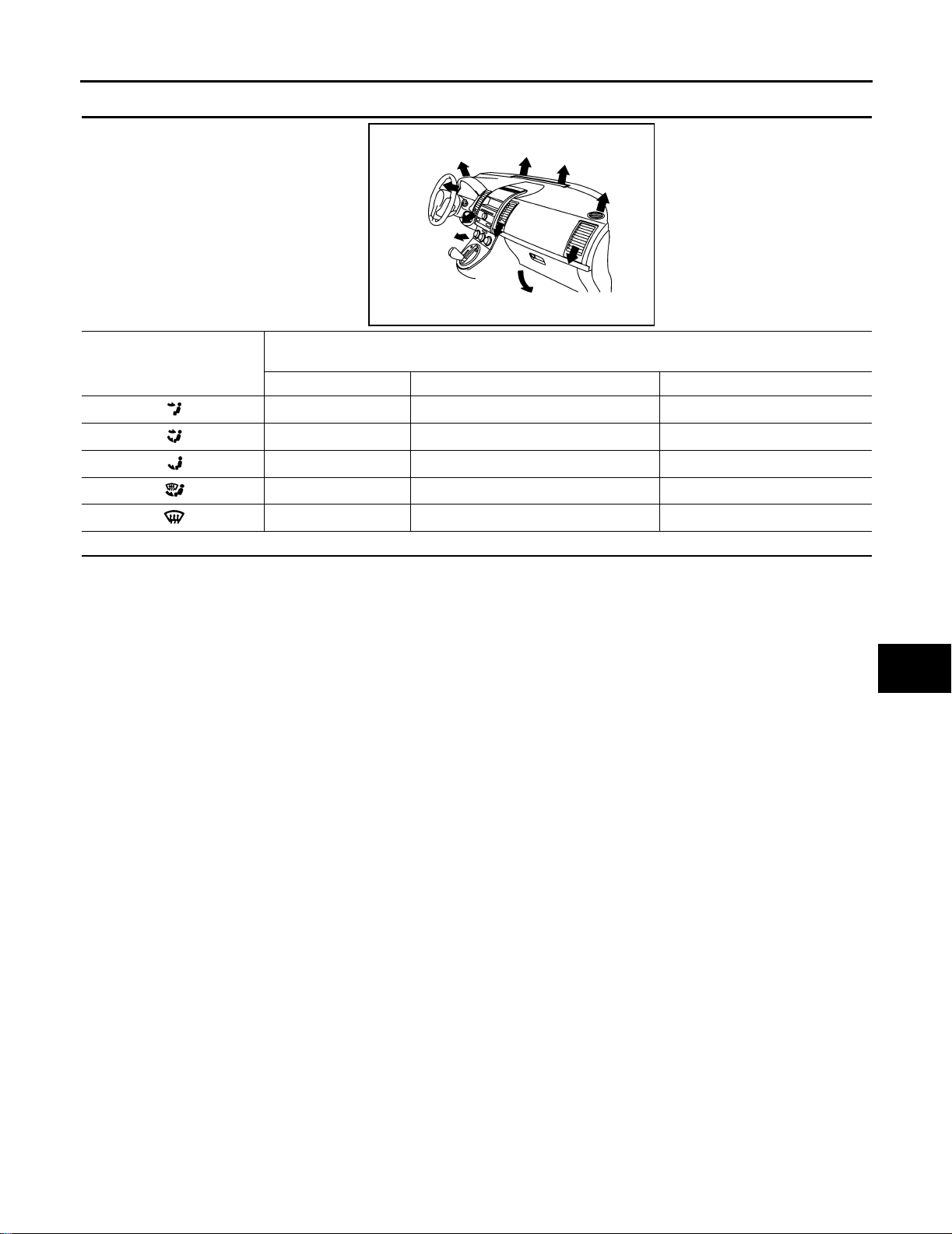

Discharge Air Flow EJS005OO

BJIA0006E

A

B

C

D

Mode door position

Air outlet/distribution

Vent Foot Defroster

100% — —

60% 40% —

10% 60% 30%

11% 50% 39%

15% — 85%

Airflow always present at driver and passenger side demisters

E

F

G

H

I

MTC

K

L

Revision: December 2006 2007 Sentra

MTC-29

M

AIR CONDITIONER CONTROL

System Description EJS005OP

SWITCH E S AND THE I R CON TRO L FUNC TION

RHA044GA

WJIA2294E

CAN Communication System Description EJS005OQ

Refer to LAN-4, "SYSTEM DESCRIPTION" .

Revision: December 2006 2007 Sentra

MTC-30

Loading...

Loading...