Nissan Sentra 2005 Owner's Manual

C TRANSMISSION/TRANSAXLE

A

B

SECTION

CONTENTS

RS5F70A

PRECAUTIONS .......................................................... 3

Precautions .............................................................. 3

PREPARATION ..................................... ...................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 6

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING .......................... ...................... 8

NVH Troubleshooting Chart ..................................... 8

DESCRIPTION ......................... ................................... 9

Cross-sectional View ................................................ 9

DOUBLE-CONE SYNCHRONIZER ...................... 9

M/T OIL ..................................................................... 10

Replacement .......................................................... 10

DRAINING ................................ ............. .............. 10

FILLING .............................. ...... ........................... 10

Checking ................................................................ 10

OIL LEAKAGE AND OIL LEVEL ......................... 10

SIDE OIL SEAL .........................................................11

Removal and Installation .........................................11

POSITION SWITCH .................................................. 12

Position Switch Check ............................................ 12

BACK-UP LAMP SWITCH .................................. 12

PNP SWITCH ...................................................... 12

CONTROL LINKAGE ............................................... 13

Removal and Installation ........................................ 13

TRANSAXLE GEAR CONTROL ......................... 13

STRIKING ROD OIL SEAL ................................. 14

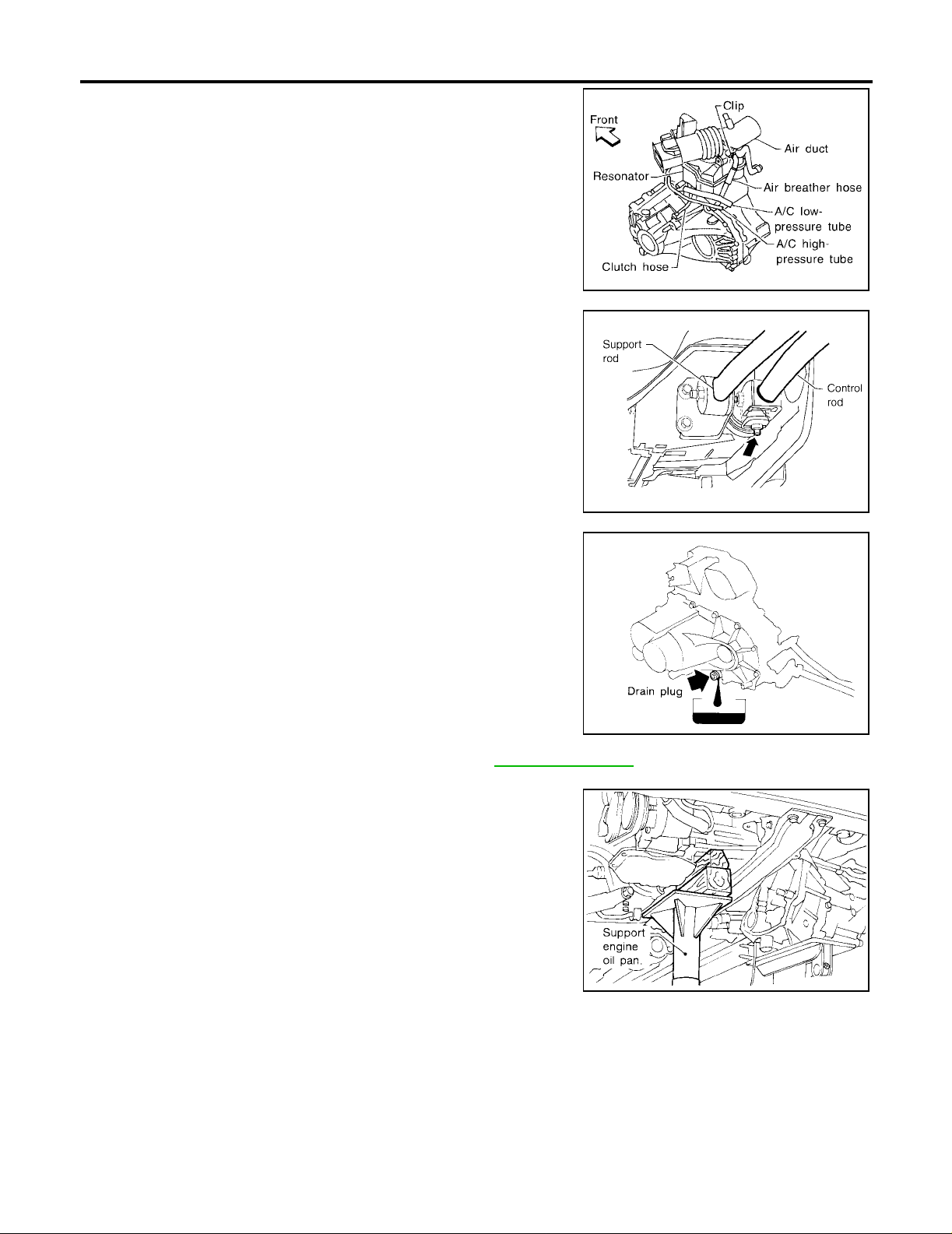

TRANSAXLE ASSEMBLY ........................................ 15

Removal and Installation ........................................ 15

REMOVAL ........................................................... 15

INSTALLATION ................................................... 17

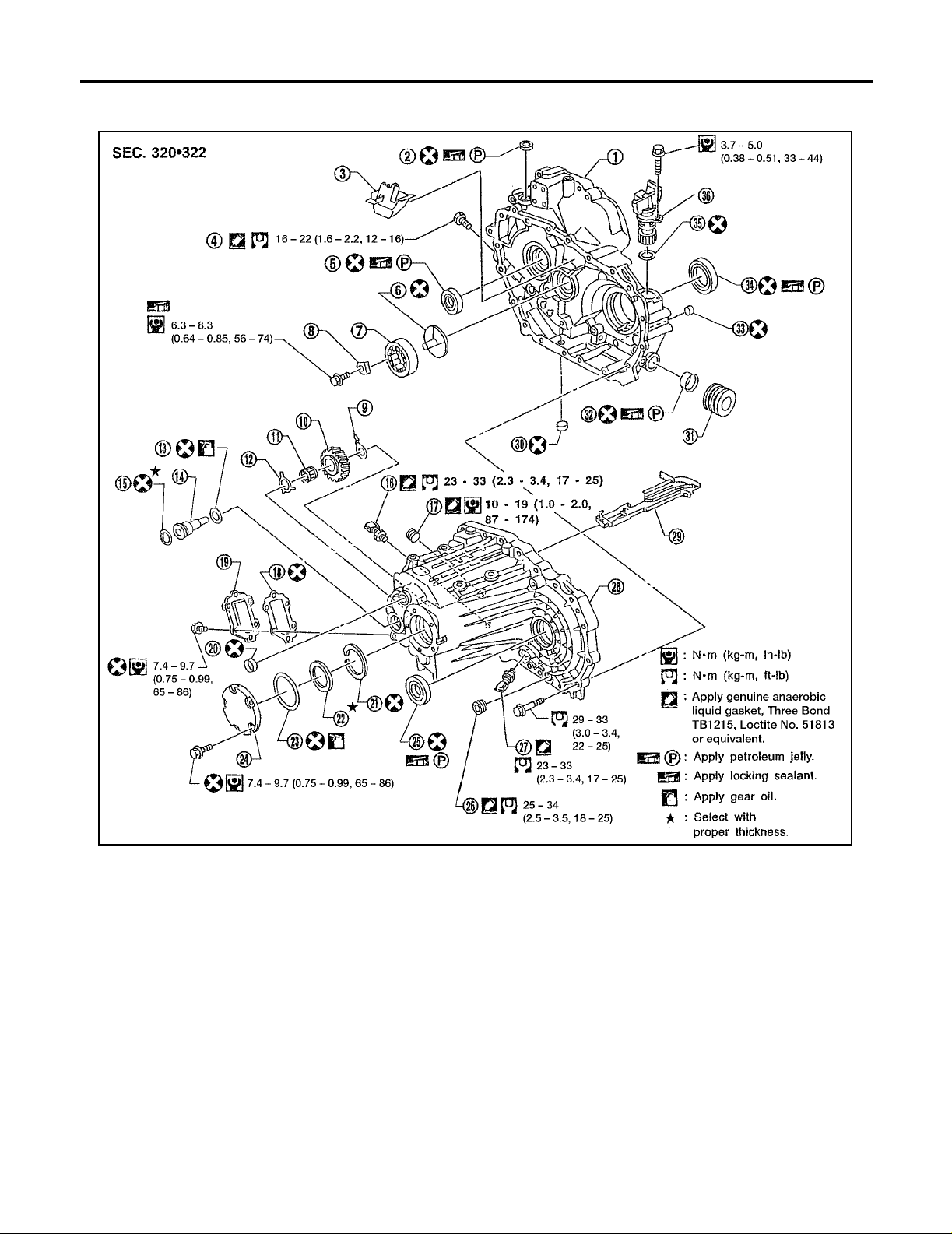

Component Parts ................................................... 18

CASE COMPONENTS ........................................ 18

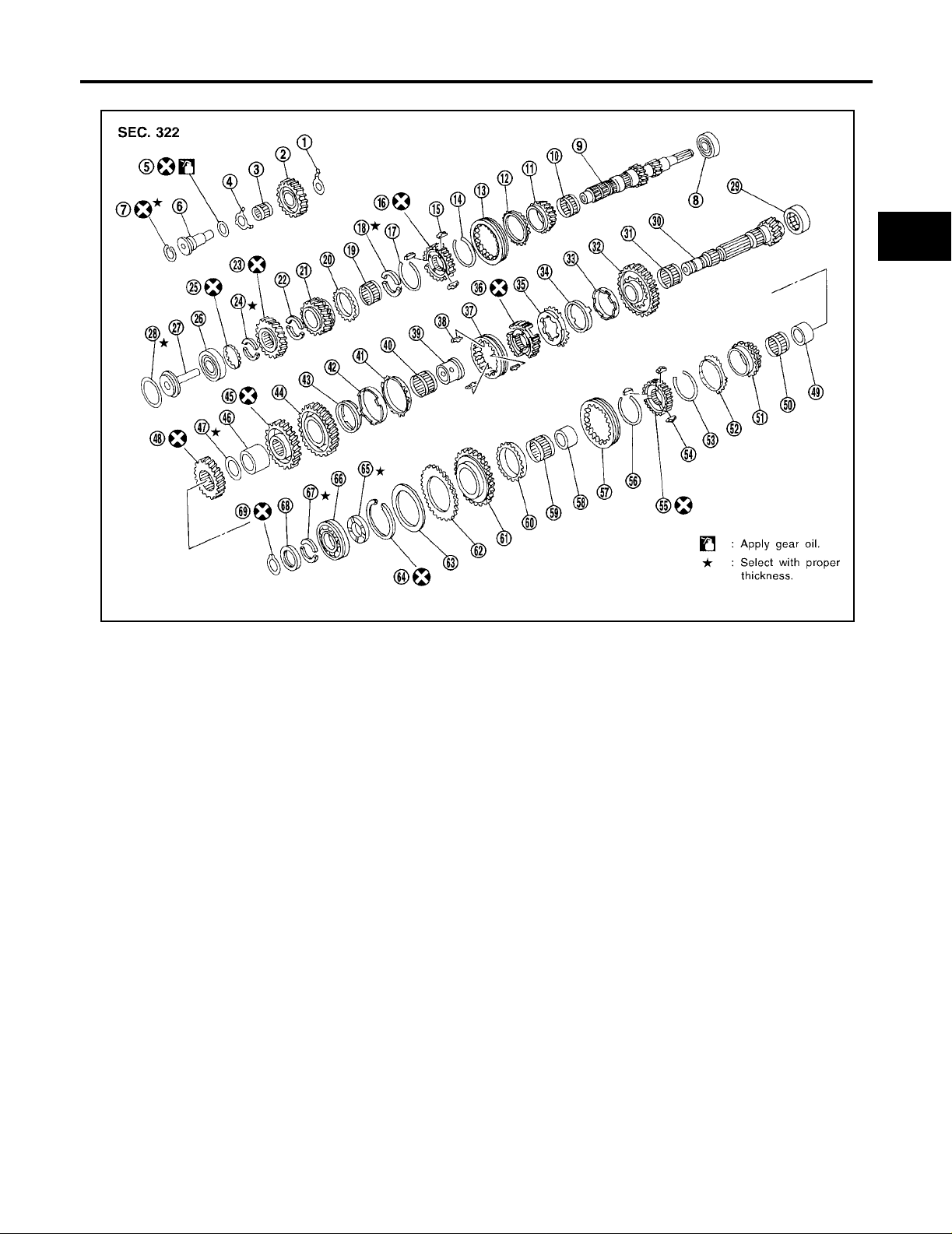

GEAR COMPONENTS ....................................... 19

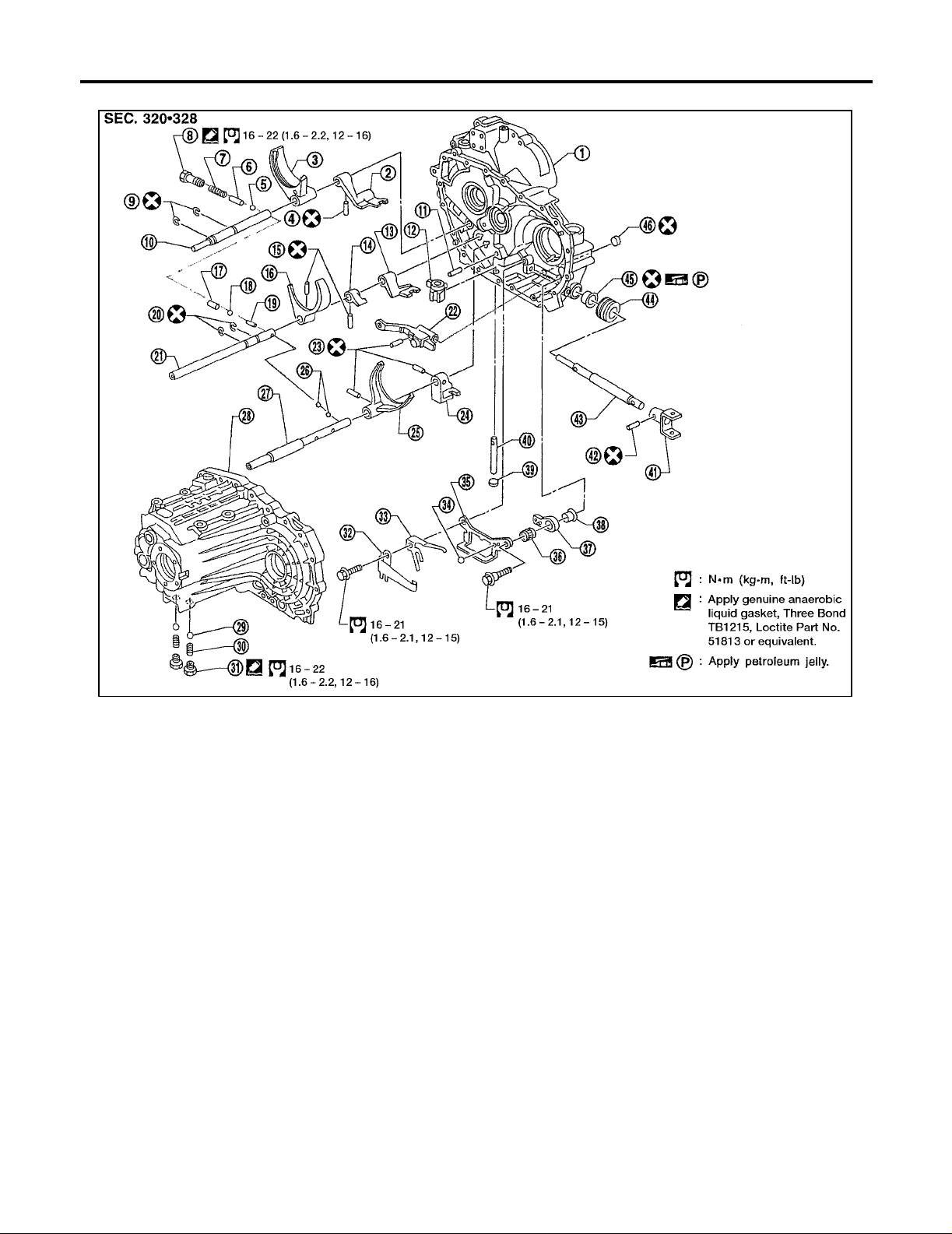

SHIFT CONTROL COMPONENTS ...... ....... ....... 20

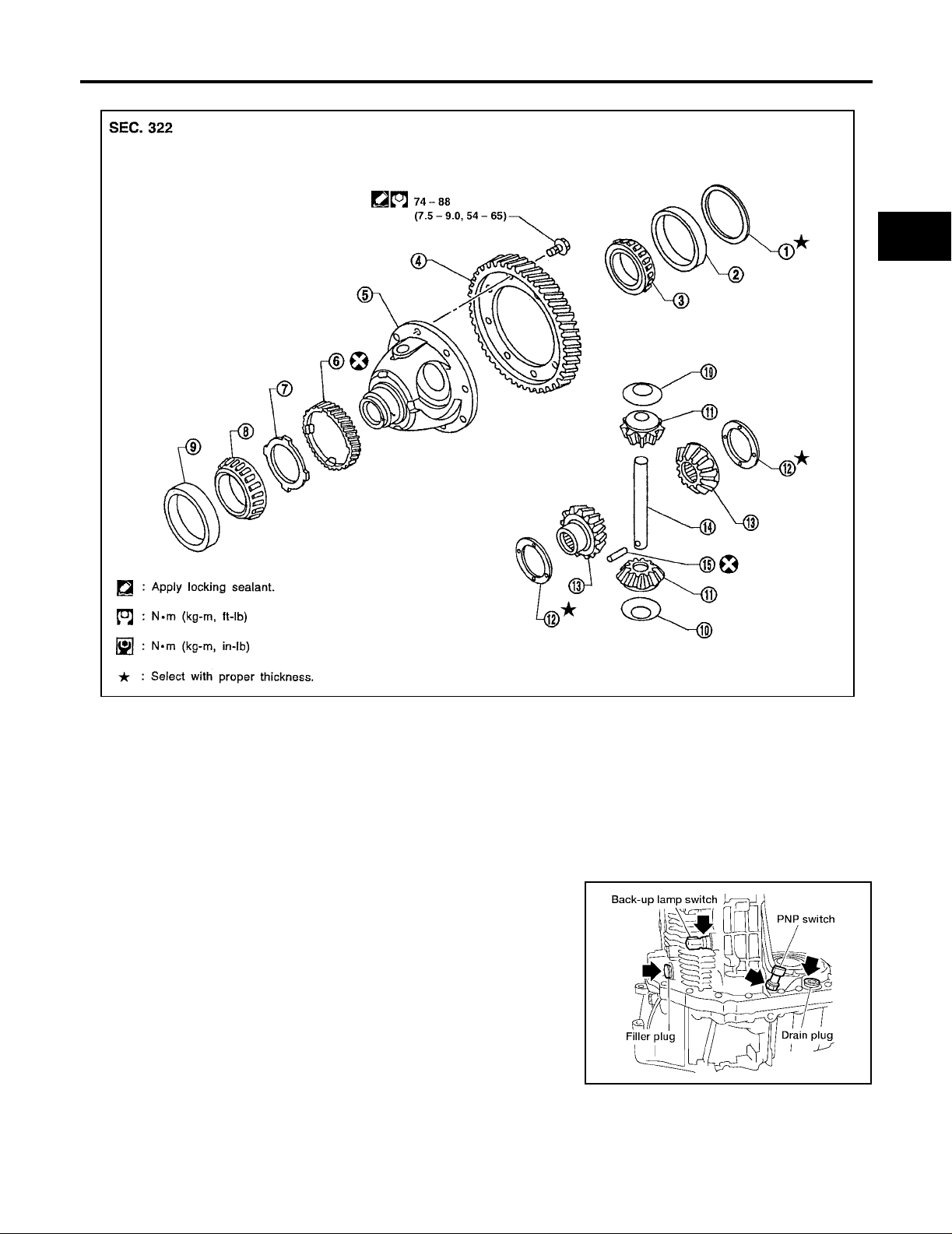

FINAL DRIVE COMPONENTS ........................... 21

Disassembly and Assembly ................................... 21

DISASSEMBLY ................................................... 21

ASSEMBLY ......................................................... 28

MANUAL TRANSAXLE

INPUT SHAFT AND GEARS .................................... 38

Disassembly ...........................................................38

Inspection ...............................................................39

GEAR AND SHAFT .............................................39

SYNCHRONIZERS ............................................. 40

BEARING ............................................................41

Assembly ..................... ........................................... 41

MAINSHAFT AND GEARS ....................................... 45

Disassembly ...........................................................45

Inspection ...............................................................47

GEAR AND SHAFT .............................................47

SYNCHRONIZERS ............................................. 47

BEARING ............................................................48

Assembly ..................... ........................................... 49

FINAL DRIVE .................................... ....... ...... ....... ....55

Pre-inspection ....... ....... ...... ....... ...... ....... ...... ....... .... 55

DIFFERENTIAL CASE SIDE . ...... ....... ...... ....... .... 55

Disassembly ...........................................................55

Inspection ...............................................................56

GEAR, WASHER, SHAFT AND CASE ...............56

BEARING ............................................................56

Assembly ..................... ........................................... 56

SHIFT CONTROL .....................................................59

Inspection ...............................................................59

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 60

General Specifications . ...... ....... ...... ........................60

TRANSAXLE .......................................................60

FINAL GEAR .......................................................60

Gear End Play ........................................................ 61

Clearance Between Baulk Ring and Gear ..............61

3RD, 4TH, 5TH, REVERSE BAULK RING ..........61

1ST AND 2ND BAULK RING .............................. 61

Available Snap Rings ............................................. 61

SNAP RING ......................................................... 61

Available C-rings ....................................................61

4TH INPUT GEAR C-RING .................................61

5TH INPUT GEAR REAR C-RING ......................62

MAINSHAFT C-RING ..........................................62

Available Adjusting Shims ......................................62

INPUT SHAFT REAR BEARING ADJUSTING

MT

D

E

F

G

H

I

J

K

L

M

Revision: July 2004 2005 Sentra

MT-1

SHIM ...................... ............. ............. ............. ....... 62

MAINSHAFT ADJUSTING SHIM ........................ 63

MAINSHAFT REAR BEARING ADJUSTING

SHIM ...................... ............. ............. ............. ....... 63

Available Thrust Washer .........................................64

MAINSHAFT THRUST WASHER ........................ 64

Available Washers ..................................................64

DIFFERENTIAL SIDE GEAR THRUST WASHER

...64

Available Shims — Differential Side Bearing Pre-

load and Adjusting Shim .........................................65

BEARING PRELOAD ..........................................65

DIFFERENTIAL SIDE BEARING ADJUSTING

SHIMS ................................................................. 65

RS6F51H

PRECAUTIONS ........................ ...... ....... ...... ....... .......66

Caution ...................................................................66

PREPARATION .........................................................67

Special Service Tools .................. ....... ...... ..............67

Commercial Service Tools .................. ...... ..............69

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ..............................................70

NVH Troubleshooting Chart ....................................70

DESCRIPTION .......................................................... 71

Cross-sectional View ..............................................71

DOUBLE-CONE SYNCHRONIZER ....................72

TRIPLE-CONE SYNCHRONIZER .......................72

REVERSE GEAR ................................................ 72

M/T OIL ......................................................................73

Replacement ..........................................................73

DRAINING ........................................................... 73

FILLING ............................................................... 73

Checking ................... .......................... ....................73

OIL LEAKAGE AND OIL LEVEL .........................73

SIDE OIL SEAL ......................................................... 74

Removal and Installation ........................................74

REMOVAL ...........................................................74

INSTALLATION ...................................... ..............74

POSITION SWITCH ................. ...... ....... ...... ....... ....... 75

Checking ................... .......................... ....................75

BACK-UP LAMP SWITCH .. ...... ....... ...... ....... ....... 75

PA RK/NEUTRAL POSITION SWITCH ................75

CONTROL LINKAGE ................................................76

Removal and Installation of Control Device and

Cable ......................................................................76

Cable Adjustment ...................................................77

AIR BREATHER HOSE .............................................78

Removal and Installation ........................................78

TRANSAXLE ASSEMBLY .................... ...... ....... .......79

Removal and Installation ........................................79

REMOVAL ...........................................................79

INSTALLATION ...................................... ..............80

Component Parts ....................................................81

CASE AND HOUSING COMPONENTS .............. 81

GEAR COMPONENTS ........................................82

SHIFT CONTROL COMPONENTS .....................84

FINAL DRIVE COMPONENTS ............................85

Disassembly and Assembly ............ ....... ...... ....... ....85

DISASSEMBLY ................................................ ....85

ASSEMBLY ...................................................... ....89

Adjustment ..............................................................96

INPUTSHAFT END PLAY ....................................96

DIFFERENTIAL SIDE BEARING PRELOAD .......97

MAINSHAFT END PLAY ......................................98

REVERSE IDLER GEAR END PLAY ..................99

INPUT SHAFT AND GEARS ...................................101

Disassembly and Assembly ............ ....... ...... ....... ..101

DISASSEMBLY ................................................ ..101

INSPECTION AFTER DISASSEMBLY ..... ....... ..102

ASSEMBLY ...................................................... ..103

MAINSHAFT AND GEARS .....................................108

Disassembly and Assembly ............ ....... ...... ....... ..108

DISASSEMBLY ................................................ ..108

INSPECTION AFTER DISASSEMBLY ..... ....... ..109

ASSEMBLY ...................................................... ..112

REVERSE IDLER SHAFT AND GEARS ................117

Disassembly and Assembly ............ ....... ...... ....... ..117

DISASSEMBLY ................................................ ..117

INSPECTION AFTER DISASSEMBLY ..... ....... ..117

ASSEMBLY ...................................................... ..118

FINAL DRIVE ..........................................................119

Disassembly and Assembly ............ ....... ...... ....... ..119

DISASSEMBLY ................................................ ..119

INSPECTION AFTER DISASSEMBLY ..... ....... ..119

ASSEMBLY ...................................................... ..119

SHIFT CONTROL ....................................................121

Inspection ..................... ............. ............. ............. ..121

SHIFT FORK ......................................................121

SERVICE DATA AND SPECIFICATIONS (SDS) ....122

General Specifications ..........................................122

TRANSAXLE ................... ....... ...... ....... ...... ....... ..122

FINAL GEAR ......................................................123

Gear End Play .......................................................123

Clearance Between Baulk Ring and Gear ............123

3RD, 4TH, 5TH, 6TH & REVERSE BAULK RING .123

1ST AND 2ND BAULK RING .............................124

Available Snap Rings ............................................124

6TH BUSHING ...................................................124

Available C-rings ...................................................124

MAINSHAFT C-RING ........................................124

Available Thrust Washers .....................................125

INPUT SHAFT THRUST WASHER ...................125

Available Adjusting Shims .....................................125

MAINSHAFT ADJUSTING SHIM .......................125

INPUT SHAFT REAR BEARING ADJUSTING

SHIM ......................... .........................................125

MAINSHAFT REAR BEARING ADJUSTING

SHIM ......................... .........................................126

REVERSE IDLER GEAR ADJUSTING SHIM ....126

6TH MAIN GEAR ADJUSTING SHIM ................126

Available Shims – Differential Side Bearing Preload

and Adjusting Shim(s) ............... ...... ....... ...... .........126

BEARING PRELOAD .........................................126

DIFFERENTIAL SIDE BEARING ADJUSTING

SHIM(S) .............................................................126

Revision: July 2004 2005 Sentra

MT-2

PRECAUTIONS

[RS5F70A]

PRECAUTIONS PFP:00001

Precautions ECS005TD

● Do not reuse transaxle oil, once it has been drained.

● Check oil level or replace oil with vehicle on level ground.

● During removal or installation, keep inside of transaxle clear of dust or dirt.

● Check for the correct installatio n status prior to rem oval or d isassembly. If mating marks are requ ired, be

certain they do not interfere with the function of the parts they are applied to.

● In principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If

tightening sequence is specified, use it.

● Be careful no t to damage sliding surfaces and mating surfaces.

A

B

MT

D

E

F

G

H

K

M

I

J

L

Revision: July 2004 2005 Sentra

MT-3

PREPARATION

[RS5F70A]

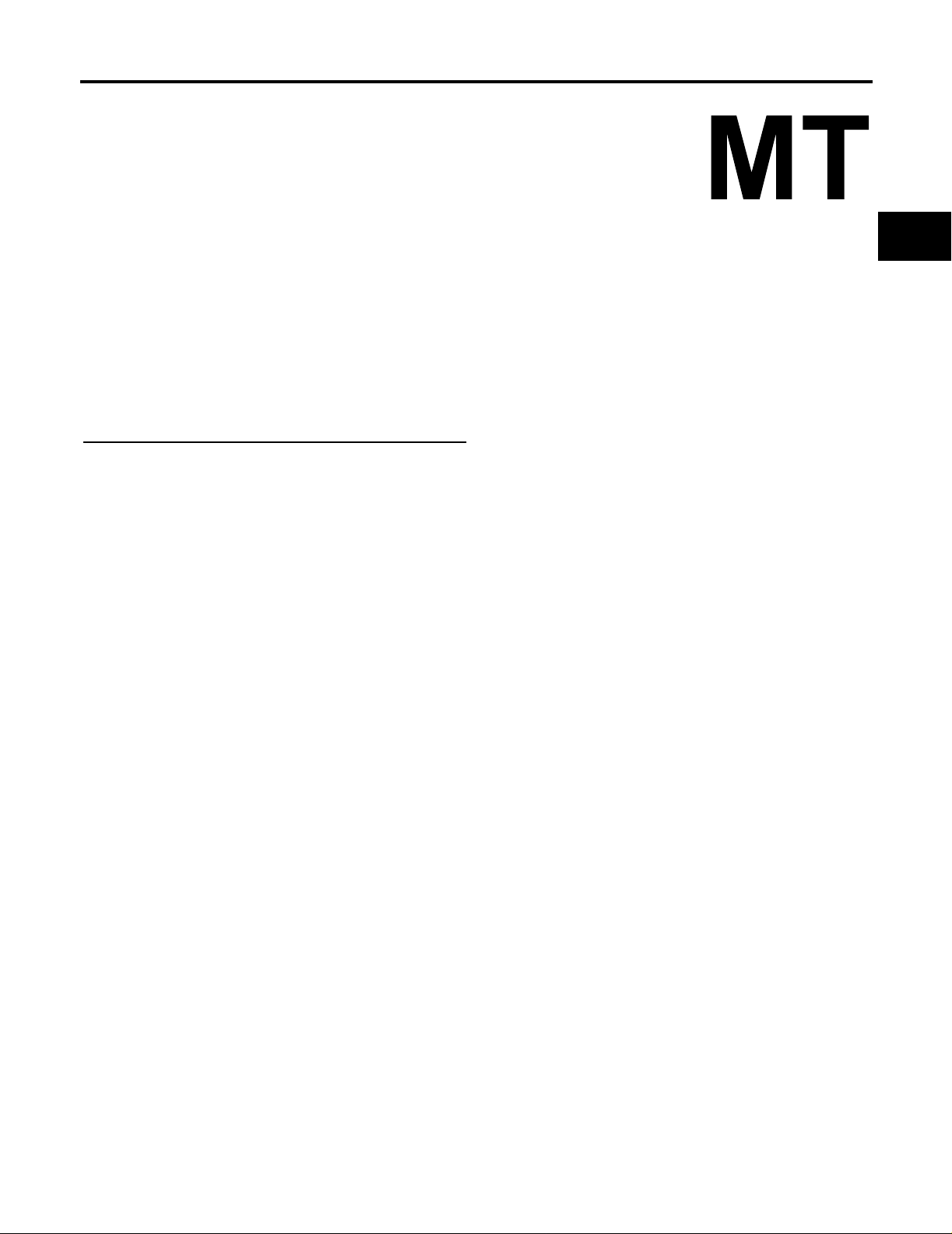

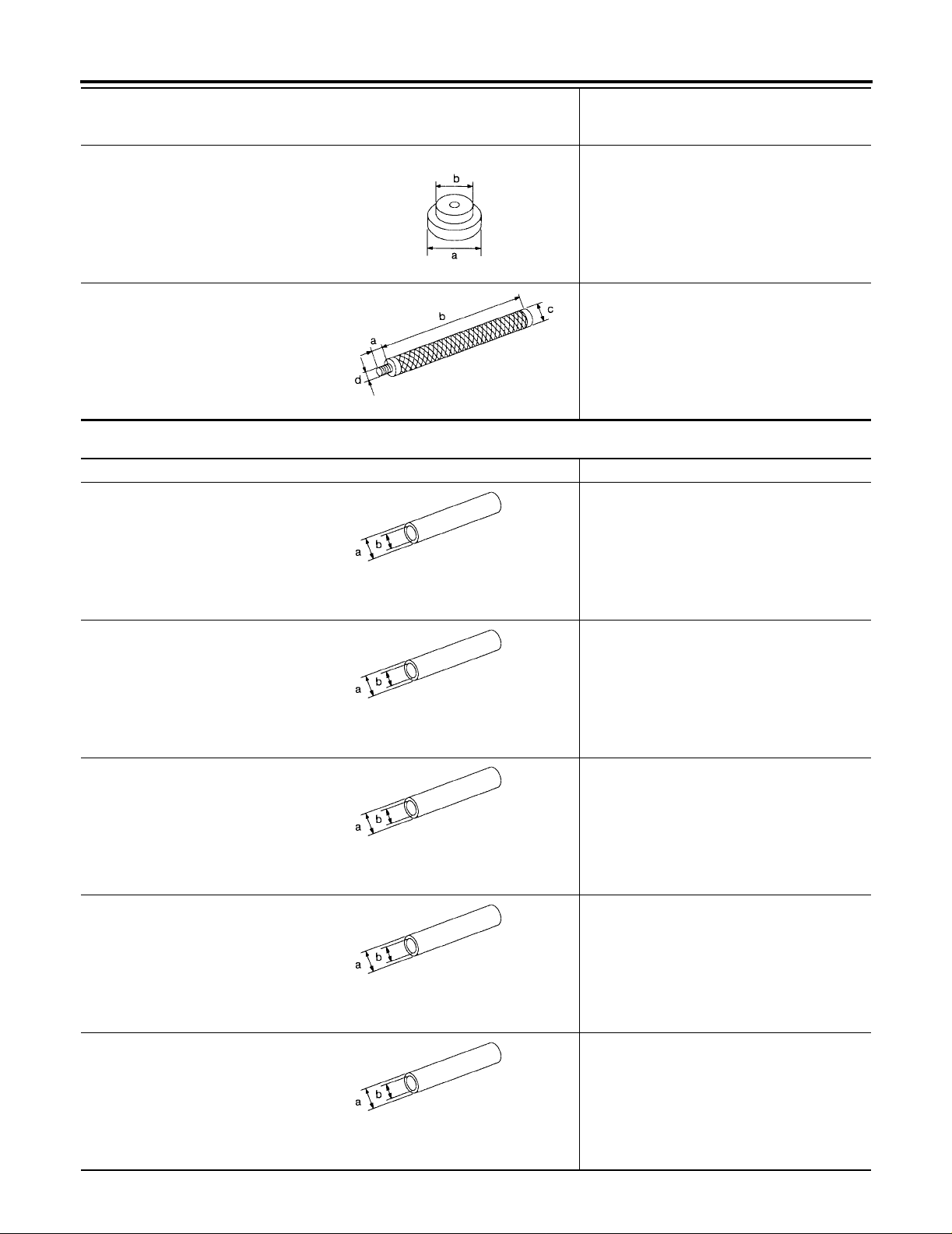

PREPARATION PFP:00002 Special Service Tools ECS005TE

The actual shapes of the Kent-Moore tools m ay di ffer from those of the speci al service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

KV38107700

(J39027)

Preload adapter

NT087

KV38106000

(J34291-B)

Height gauge adapter

(differential side bearing)

NT418

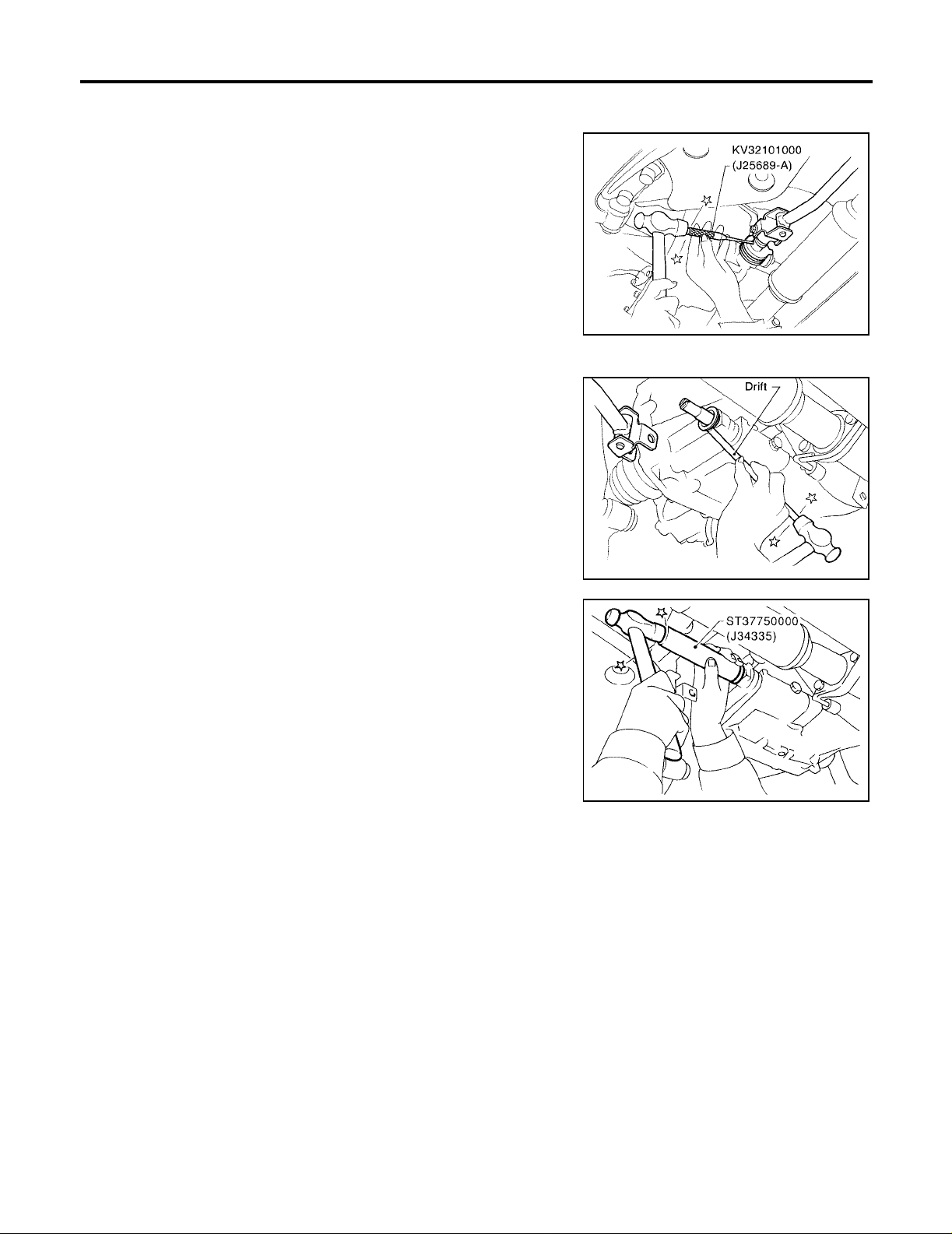

KV32101000

(J25689-A)

Pin punch

Description

Measuring turning torque of final drive assembly

Measuring total turning torque

Measuring clearance between side gear and

differential case with washer

Selecting differential side bearing adjusting

shim [Use with KV38106000 (J34291-B).]

Selecting differential side bearing adjusting

shim [Use with KV38107700 (J39027).]

a: 140 mm (5.51 in)

b: 40 mm (1.57 in)

c: 16 mm (0.63 in) dia.

d: M8 × 1.25P

Removing and installing retaining pin

Removing and installing lock pin

Removing selector shaft

Removing welch plug

a: 4 mm (0.16 in) dia.

KV31100300

(J25689-A)

Pin punch

ST30031000

(J22912-01)

Puller

ST30021000

(J22912-01)

Puller

NT410

NT410

NT411

NT411

Removing and installing retaining pin

a: 4.5 mm (0.177 in) dia.

Removing 3rd, 5th input gear

Removing 3rd & 4th and 5th & Rev synchronizer hub

Removing mainshaft rear bearing

Removing 2nd gear, 5th gear bush

Removing 1st & 2nd synchronizer hub, 1st

and 4th main gear

Removing and installing differential side bearing

a: 90 mm (3.54 in) dia.

b: 50 mm (1.97 in) dia.

Removing input shaft front and rear bearing

Installing input shaft front and rear bearing

Installing 5th input gear, 3rd main gear and

4th main gear

Installing 1st & 2nd, 3rd & 4th and 5th & Rev

synchronizer hub

Installing 2nd gear bush, 5th gear bush, Rev

gear bush

Installing mainshaft rear bearing

a: 110 mm (4.33 in) dia.

b: 68 mm (2.68 in) dia.

Revision: July 2004 2005 Sentra

MT-4

PREPARATION

[RS5F70A]

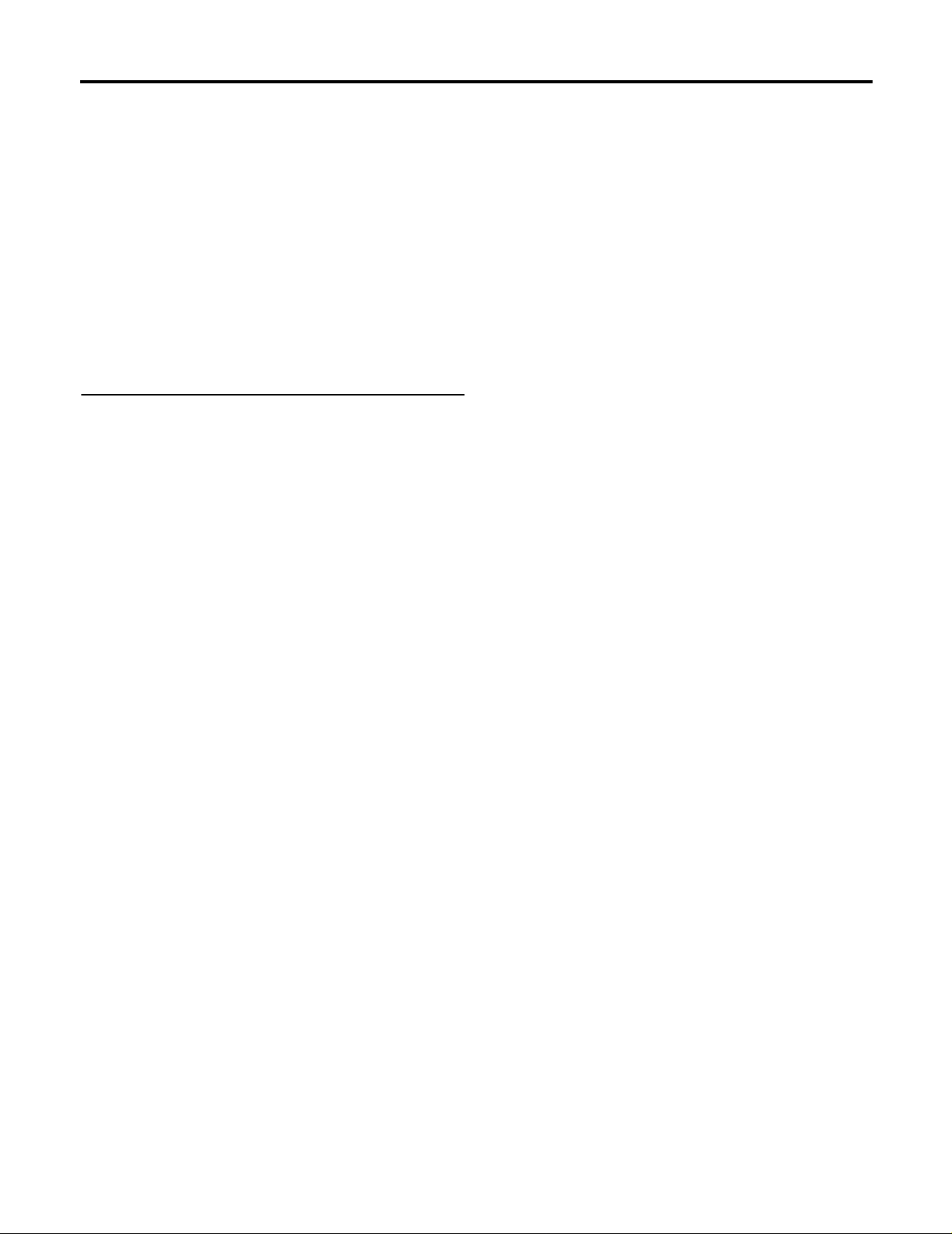

Tool number

(Kent-Moore No.)

Tool name

ST33061000

(J8107-2)

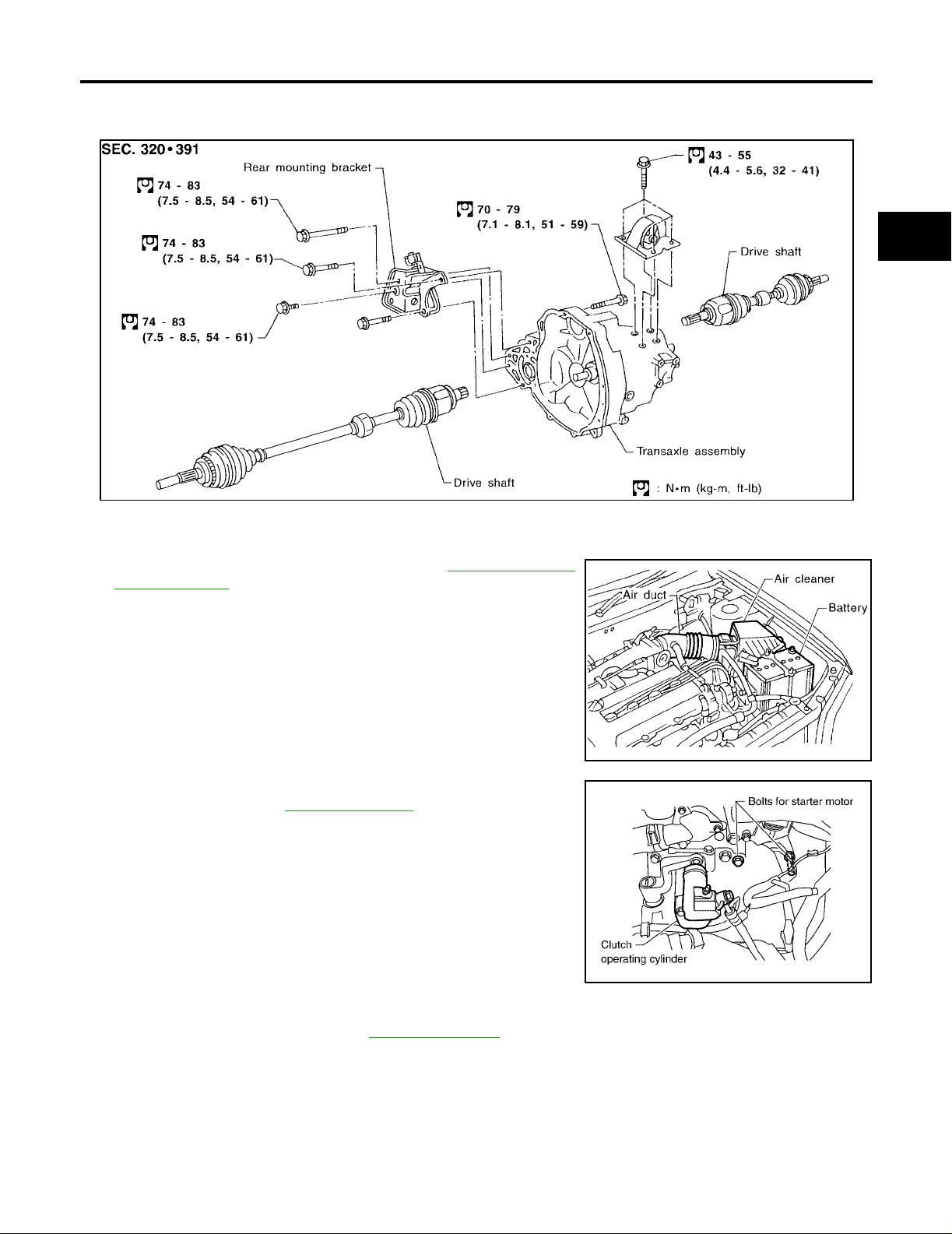

Drift

ST33290001

(J34286)

Puller

ST33230000

(J25805-01)

Drift

ST30720000

(J25405)

Drift

NT073

NT414

NT084

Description

Removing differential side bearing

a: 39 mm (1.54 in) dia.

b: 29.5 mm (1.16 in) dia.

● Removing idler gear bearing outer race

a: 250 mm (9.84 in)

b: 160 mm (6.30 in)

Removing differential oil seal

Installing differential side bearing

a: 51 mm (2.01 in) dia.

b: 28.5 mm (1.122 in) dia.

Installing differential side bearing outer race

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

A

B

MT

D

E

F

G

H

I

ST22350000

(J25678-01)

Drift

ST22452000

(J34335)

Drift

ST37750000

(J34335)

Drift

NT115

NT065

NT065

NT065

Installing input shaft front and rear bearing

a: 34 mm (1.34 in) dia.

b: 28 mm (1.10 in) dia.

Installing 3rd and 4th main gear

Installing 5th gear bush

Installing 5th & Rev synchronizer hub

Installing Rev gear bush

Installing mainshaft rear bearing

a: 45 mm (1.77 in) dia.

b: 36 mm (1.42 in) dia.

Installing input shaft oil seal

Installing 5th synchronizer

Installing mainshaft rear bearing

Installing 5th main gear

Installing 3rd & 4th synchronizer hub

Installing striking rod oil seal

Installing clutch housing dust seal

a: 40 mm (1.57 in) dia.

b: 31 mm (1.22 in) dia.

J

K

L

M

Revision: July 2004 2005 Sentra

MT-5

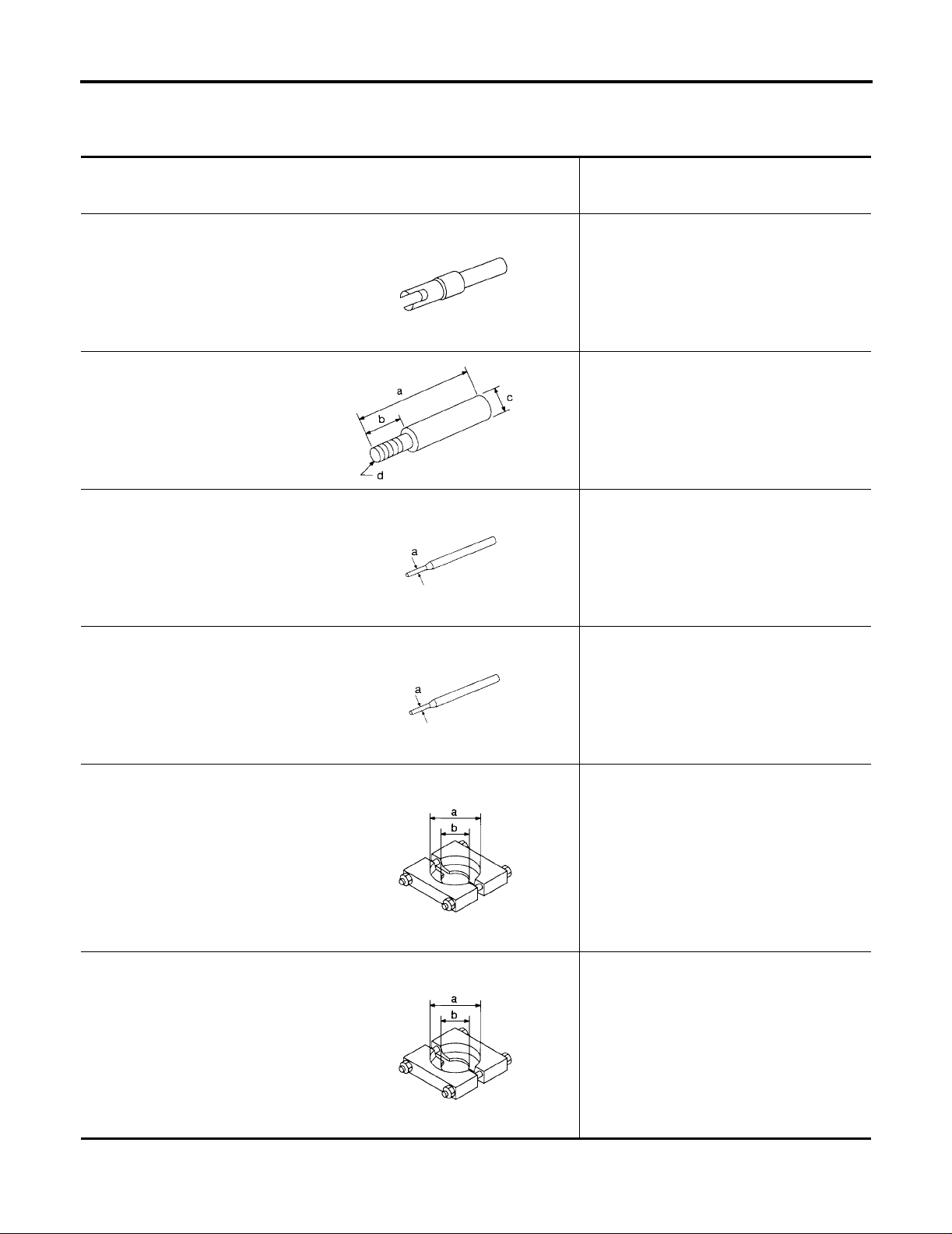

PREPARATION

[RS5F70A]

Tool number

(Kent-Moore No.)

Tool name

ST30621000

(J35869)

Drift

NT073

ST30611000

(J25742-1)

Drift handle

NT419

Description

Installing differential side bearing outer race

[Use with ST30611000 (J25742-1).]

a: 79 mm (3.11 in) dia.

b: 59 mm (2.32 in) dia.

Installing differential side bearing outer race

[Use with ST30621000 (J35869).]

a: 15 mm (0.59 in)

b: 335 mm (13.19 in)

c: 25 mm (0.98 in) dia.

d: M12 × 1.5P

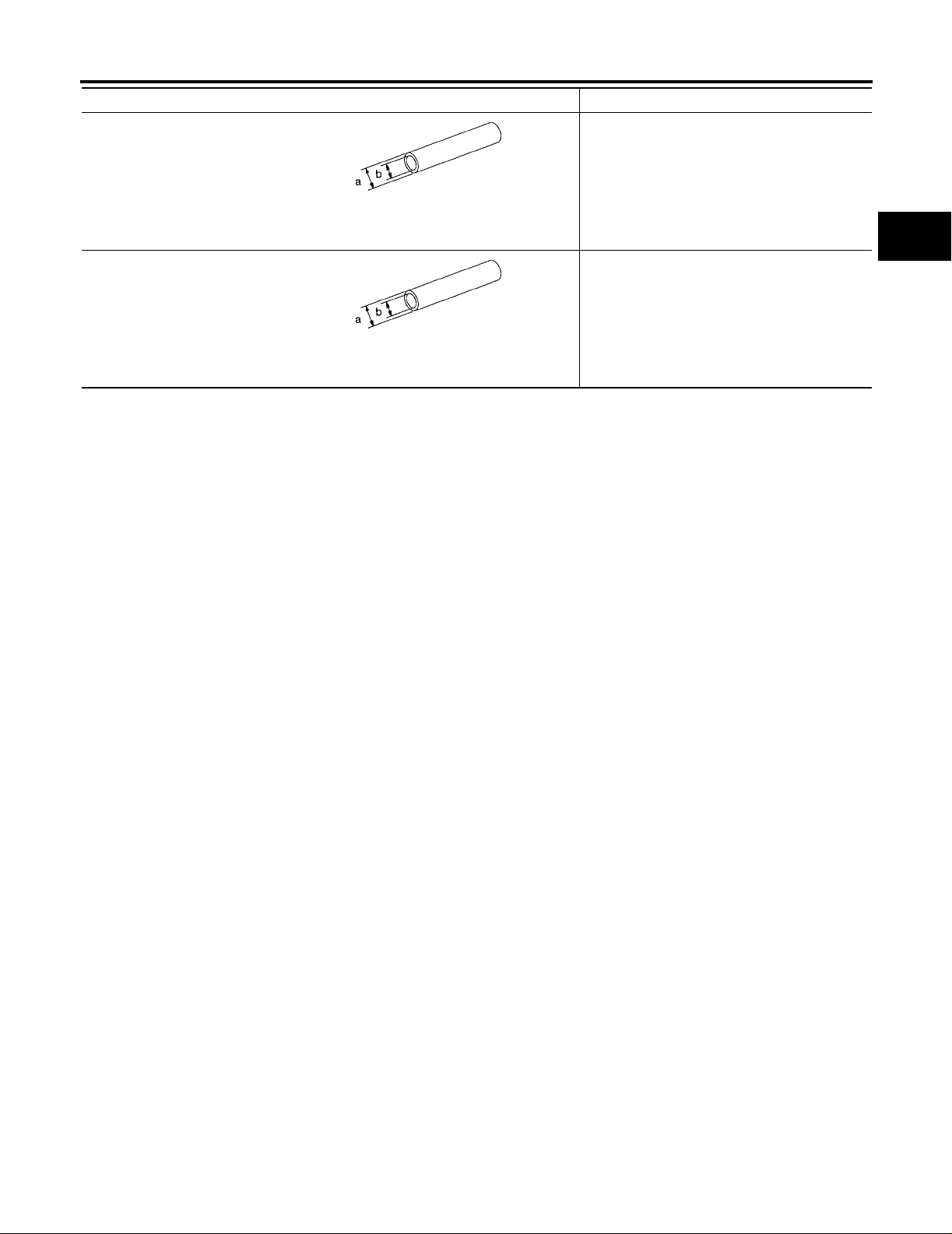

Commercial Service Tools ECS005TF

Tool name Description

Drift Installing differential side bearing inner race

a: 56 mm (2.20 in) dia.

b: 50.5 mm (1.988 in) dia.

NT065

Drift Removing input shaft rear bearing

Removing mainshaft rear bearing

a: 22 mm (0.87 in) dia.

b: 16 mm (0.63 in) dia.

NT065

Drift Installing differential oil seal

(Transaxle case side)

a: 58 mm (2.28 in) dia.

b: 50 mm (1.97 in) dia.

NT065

Drift Installing differential oil seal

(Clutch housing side)

a: 54 mm (2.13 in) dia.

b: 50 mm (1.97 in) dia.

NT065

Drift Installing 2nd gear bush

a: 38 mm (1.50 in) dia.

b: 33 mm (1.30 in) dia.

NT065

Revision: July 2004 2005 Sentra

MT-6

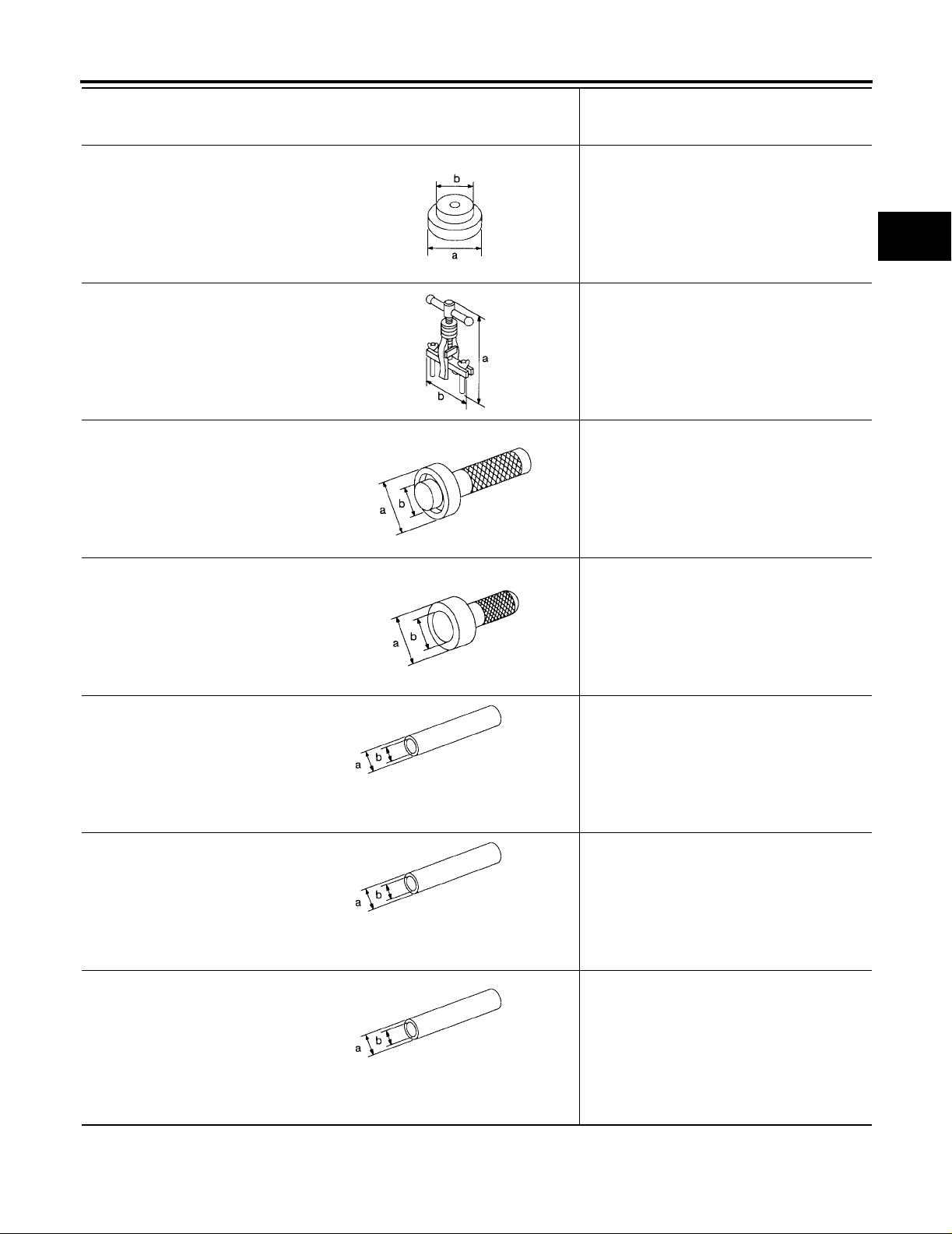

PREPARATION

[RS5F70A]

Tool name Description

Drift Installing 3rd & 4th and 1st & 2nd synchroniz-

er hub

Installing mainshaft front bearing

a: 50 mm (1.97 in) dia.

b: 41 mm (1.61 in) dia.

NT065

Drift Installing input shaft oil seal

Installing 5th input gear

a: 39 mm (1.54 in) dia.

b: 30 mm (1.18 in) dia.

NT065

A

B

MT

D

E

F

G

H

K

M

I

J

L

Revision: July 2004 2005 Sentra

MT-7

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

[RS5F70A]

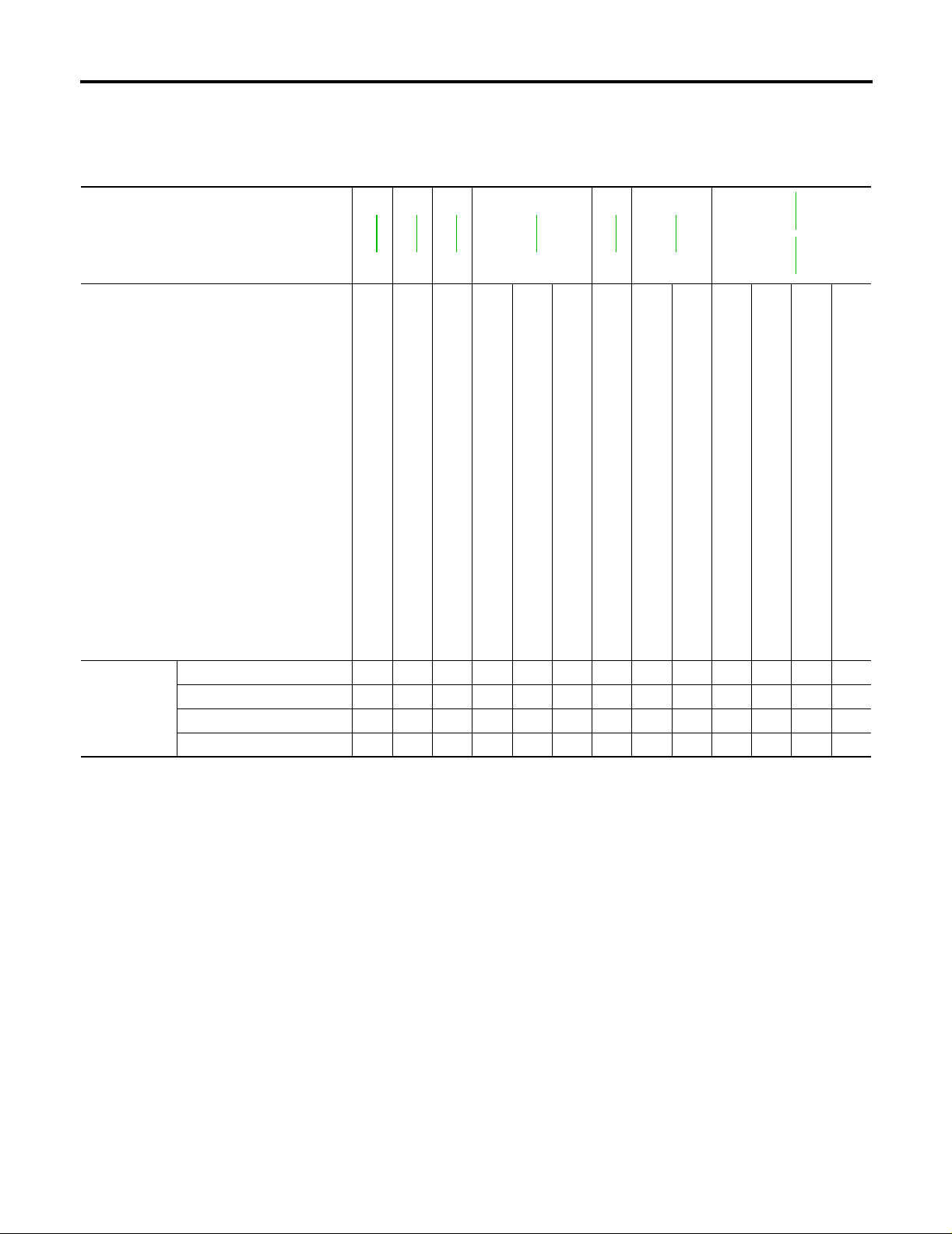

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING PFP:00003 NVH Troubleshooting Chart ECS005TG

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspection. If necessary, repair or replace these parts.

Reference page

Suspected Parts (Possible cause)

Noise 1 2 3 3

Symptom

Oil leakage 3 1 2 2 2

Hard to shift or will not shift 1 1 2 3 3

Jumps out of gear 1 2 3 3

MT-10

(Oil level is low)

MT-10

MT-10

(Wrong oil)

(Oil level is high)

Gasket (Damaged)

MT-18

Oil Seal (Worn or damaged)

MT-13

O-Ring (Worn or damaged)

Control Rod (Worn)

Check Plug Return Spring and Check Ball (Worn or damaged)

MT-20

MT-19, MT-21

Shift Fork (Worn)

Gear (Worn or damaged)

Bearing (Worn or damaged)

Baulk Ring (Worn or damaged)

Insert Spring, Shifting Insert (Damaged)

Revision: July 2004 2005 Sentra

MT-8

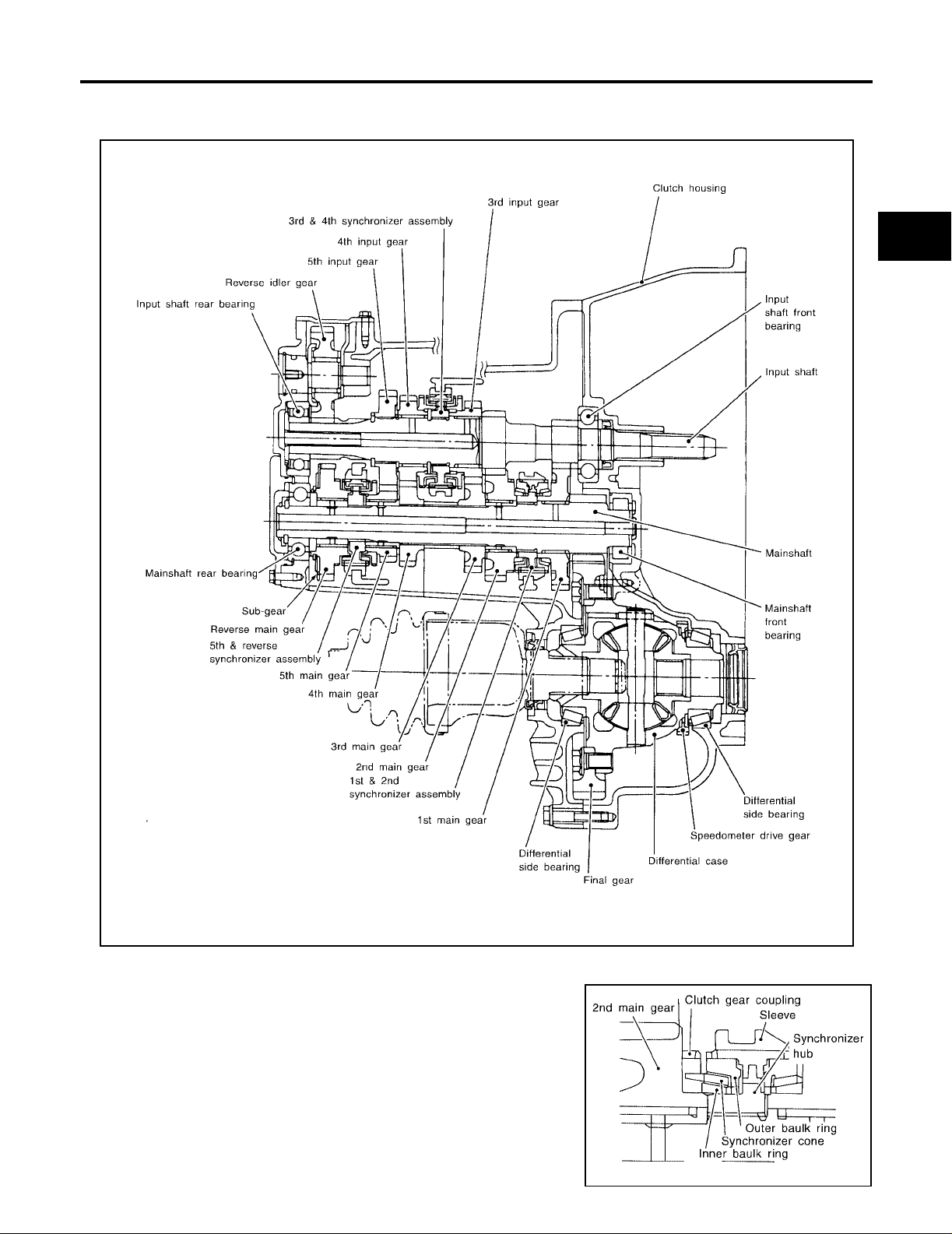

DESCRIPTION

[RS5F70A]

DESCRIPTION PFP:00000

Cross-sectional View ECS005TH

A

B

MT

D

E

F

G

DOUBLE-CONE SYNCHRONIZER

Double-cone synchronizer is used for 1st and 2nd gears to reduce

operating force of the shift lever.

H

I

J

K

L

M

WCIA0017E

SMT837DA

Revision: July 2004 2005 Sentra

MT-9

M/T OIL

[RS5F70A]

M/T OIL PFP:KLD20 Replacement ECS005TI

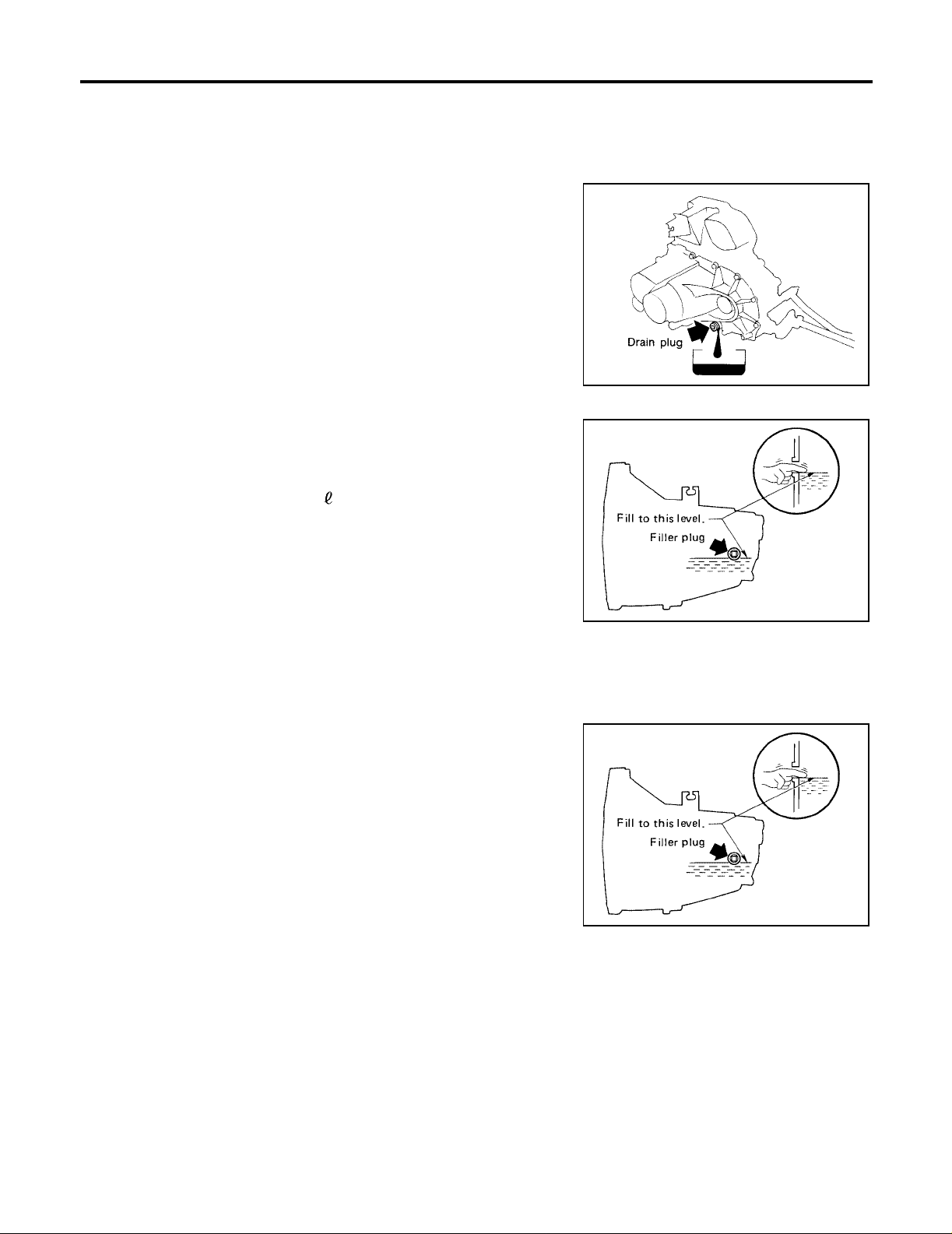

DRAINING

1. Start the engine and let it run to warm up the transaxle.

2. Stop the engine. Remove drain plug and drain oil.

3. Set a gasket on the drain plug and install it on the transaxle.

Drain plug : 10 - 19 N·m (1.0 - 2.0 kg-m, 87 - 173 in-lb)

CAUTION:

Do not reuse gasket.

SMA145AA

FILLING

1. Remove filler plug. Fill with new oil until oil level reaches the

specified limit ne ar fill er plu g mo un ting hole as shown.

Oil grade : API GL-4, Viscosity SAE 75W-85

Capacity

(approximately)

: 3.0 (3 1/8 US qt, 2 5 /8 Imp qt)

2. After refilling oil, check oil level as shown.

3. Install the filler plug in the transaxle case using a new gasket .

Filler plug : 10 - 19 N·m (1.0 - 2.0 kg-m, 87 - 173 in-lb)

CAUTION:

Do not reuse gasket.

SMA066C

Checking ECS005TJ

OIL LEAKAGE AND OIL LEVEL

1. Check that oil is not leaking from transaxle.

2. Check oil leve l from filler plug moun ting hole as shown.

CAUTION:

Never start the engine while checking the oil level.

3.

Install the filler plug in the transaxle case using a new gasket .

Filler plug : 10 - 19 N·m (1.0 - 2.0 kg-m, 87 - 173 in-lb)

CAUTION:

Do not reuse gasket.

SMA066C

Revision: July 2004 2005 Sentra

MT-10

SIDE OIL SEAL

[RS5F70A]

SIDE OIL SEAL PFP:32113

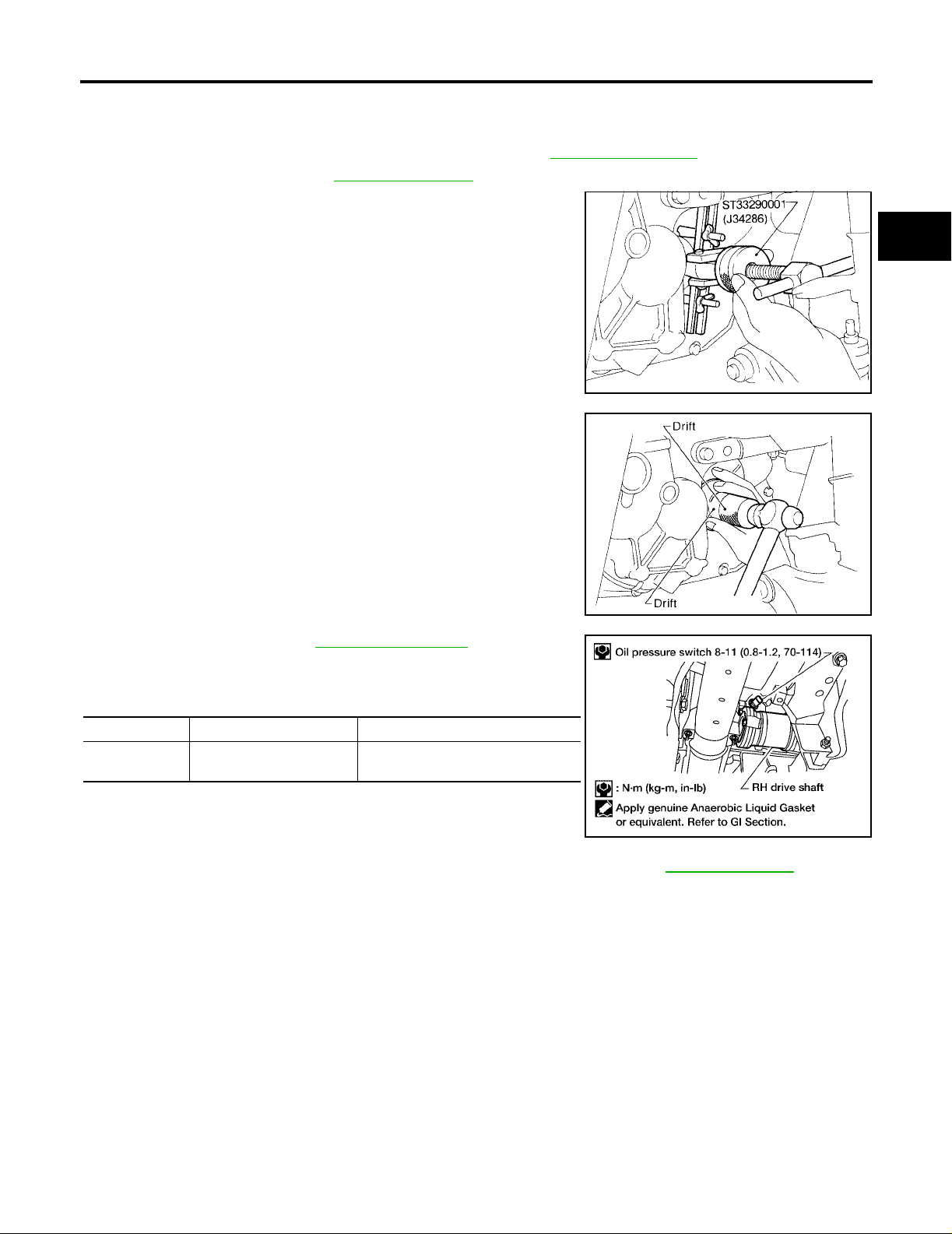

Removal and Installation ECS005TK

1. Remove drain plug and drain the oil from transaxle. Refer to MT-10, " DRAINING" .

2. Remove drive sha fts. Refer to FAX-14, "

3. Remove differential oil seal using Tool.

Removal" .

SMT563A

A

B

MT

D

E

4. Install differential oil seal with a suitable tool (drift).

● Apply multi-p urp ose gre ase to seal lip of oi l seal befo re inst a ll-

ing.

5. Install driv e sh af ts. Refer to FAX-16, "

● Install differential oil se al so that dimensions “A” and “B” are

Installation" .

within specifications.

Unit: mm (in)

Model Dimension “A” Dimension “B”

QG18DE

(RS5F70A)

0.5 (0.020) or less 5.5 - 6.5 (0.217 - 0.256)

6. Refill the transaxle oil and install the drain plug using a new gasket. Refer to MT-10, "FILLING" .

SMT126DB

WCIA0001E

F

G

H

I

J

K

L

M

Revision: July 2004 2005 Sentra

MT-11

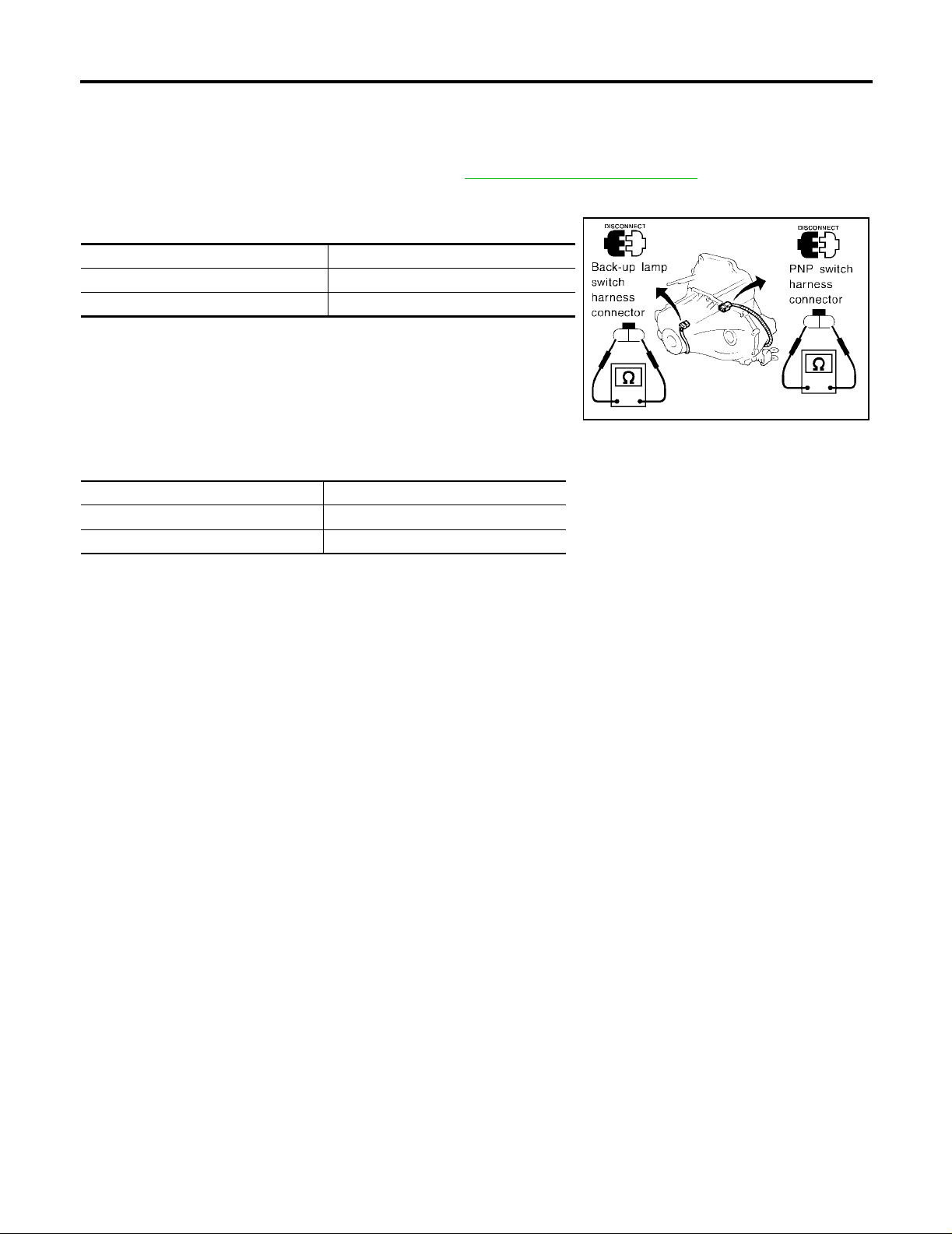

POSITION SWITCH

[RS5F70A]

POSITION SWITCH PFP:32005 Position Switch Check ECS005TL

NOTE:

For removal and installation of the switches. Refer to MT-18, "

BACK-UP LAMP SWITCH

● Check continuity.

Gear position Continuity

Reverse Yes

Except reverse No

PNP SWITCH

● Check continuity.

Gear position Continuity

Neutral Yes

Except neutral No

CASE COMPONENTS" .

SMT715BD

Revision: July 2004 2005 Sentra

MT-12

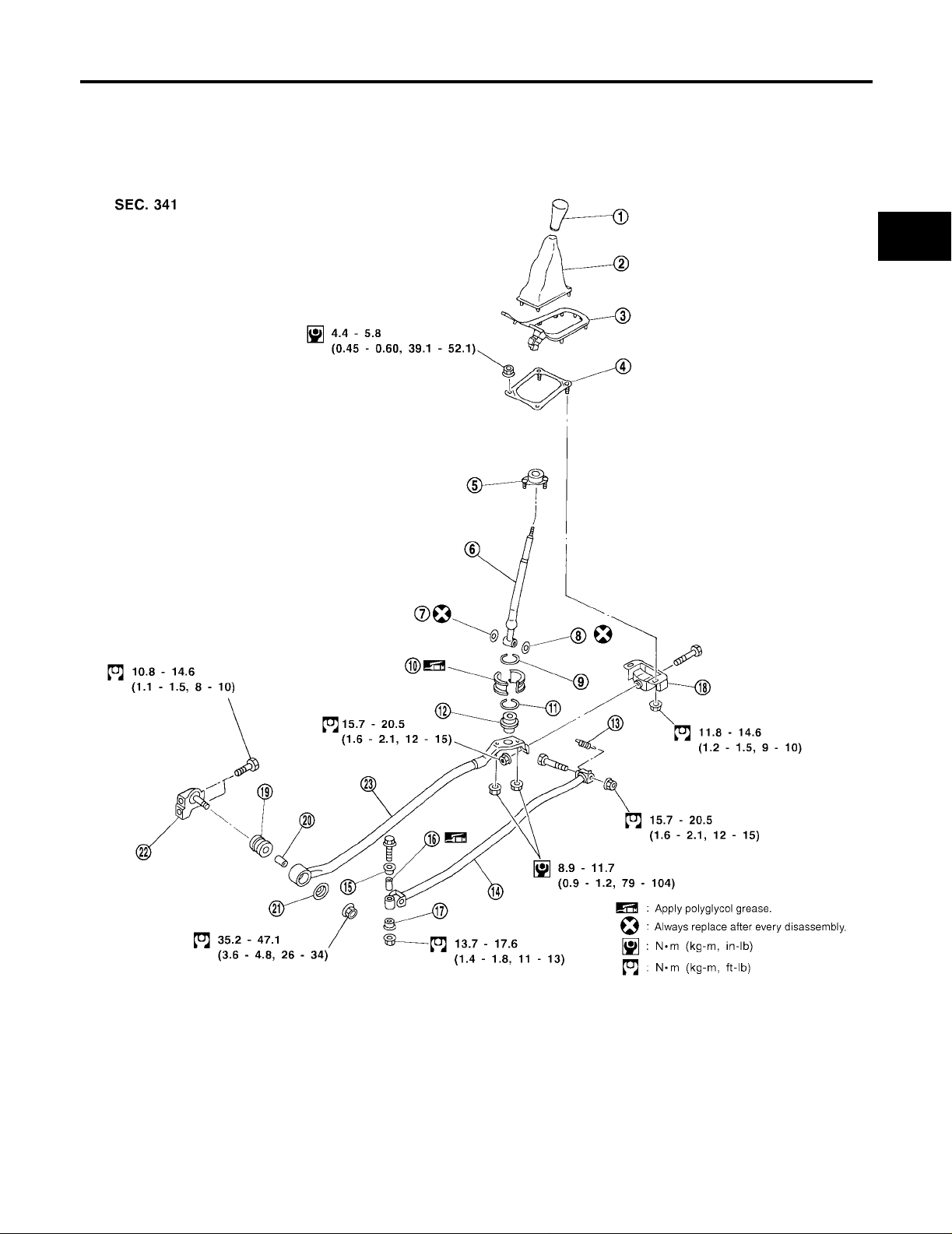

CONTROL LINKAGE

[RS5F70A]

CONTROL LINKAGE PFP:34103

Removal and Installation ECS005TM

TRANSAXLE GEAR CONTROL

Refer to the illustration for the removal and installation procedure.

A

B

MT

D

E

F

G

1. Control lever knob 2. Boot 3. Finisher

4. Control lev e r br acket 5. Socket 6. Control lever

7. O-ring 8. O-ring 9. Ring spring

10. Bearing seat 11. Ring spring 12. Seat

13. Return sprin g 14. Control rod 15. Bushing

16. Collar 17. Bushing 18. Bracket

19. Bushing 20. Collar 21. Washer

22. Support rod bra cket 23. Support rod

H

I

J

K

L

M

WCIA0135E

Revision: July 2004 2005 Sentra

MT-13

CONTROL LINKAGE

STRIKING ROD OIL SEAL

1. Remove the transaxle control rod from yoke.

2. Remove the retaining pin from the yoke using Tool as shown.

CAUTION:

Be careful not to damage the boot.

3. Remove the boot .

4. Remove the striking rod oil seal with a suitable tool (drift) .

[RS5F70A]

SMT143DB

5. Install the striking rod oil seal using T ool as shown.

● Apply multi-purpose grease to the seal lip of the oil seal

before installing.

6. Install the boot.

7. Install the yoke and retaining pin.

8. Connect the transaxle control rod to the yoke.

SMT566A

SMT570AA

Revision: July 2004 2005 Sentra

MT-14

TRANSAXLE ASSEMBLY

[RS5F70A]

TRANSAXLE ASSEMBLY PFP:32010

Removal and Installation ECS005TN

A

B

MT

D

E

F

REMOVAL

1. Disconn ec t the ne ga tiv e ba tte ry term in al .

2. Remove the air cleaner and air duct. Refer to EM-15, "

and Instal lation" .

3. Disconnect the clutch operating cylinder from the transaxle and

position aside. Refer to CL-11, "

Removal" .

Removal

WMT009

WMT010

G

H

I

J

K

L

M

WCIA0006E

4. Disconnect back-up lamp switch, VSS sensor, PNP switch, and ground harness connectors.

5. Remove the starter motor . Refer to SC-20, "

Revision: July 2004 2005 Sentra

Removal" .

MT-15

TRANSAXLE ASSEMBLY

6. Remove the air breather hose.

7. Remove the shift control rod and support rod from transaxle.

[RS5F70A]

SMT132D

8. Remove the drain plug and drain the gear oil from the transaxle.

9. Remove the drive shafts from the transaxle. Refer to FAX-14, "

10. Support the engine by placing a jack under the oil pan as shown.

CAUTION:

Do not plac e the jack under the oil pan drain plug.

WMT005

SMA145AA

Removal" .

SMT659B

Revision: July 2004 2005 Sentra

MT-16

TRANSAXLE ASSEMBLY

11. Remove LH side and rear side mounting bolts.

[RS5F70A]

A

B

MT

D

E

F

12. Remove the lower housing bolts.

13. Remove the bolts securing the transaxle to the engine.

14. Lower the transaxle while supporting it with the jack.

INSTALLATION

Installation is in the reverse order of removal.

● Tighten the starter motor bolts to specification.

Starter motor bolts : 31 - 42 N·m (3.2 - 4.3 kg-m, 23 - 31 ft-lb)

● Tighten the LH and rear mounts to specification. Refer to MT-15, "Removal and Installation" .

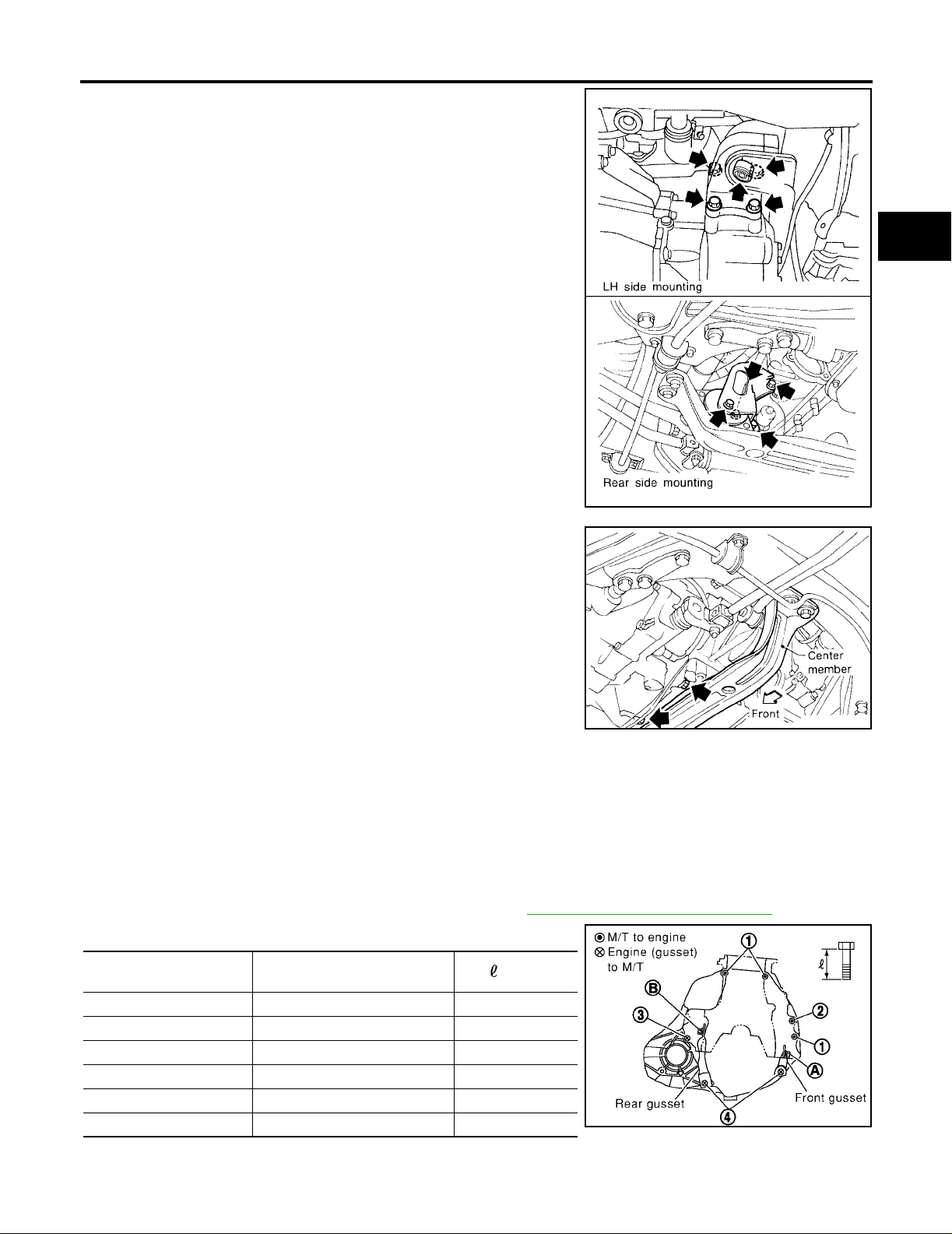

● Tight en the transaxle to engine bolts to specification.

WMT007

SMT658B

G

H

I

J

K

L

M

Bolt No.

1 30 - 40 (3.1 - 4.1, 22 - 30) 70 (2.76)

2 30 - 40 (3.1 - 4.1, 22 - 30) 80 (3.15)

3 30 - 40 (3.1 - 4.1, 22 - 30) 30 (1.18)

4* 16 - 21 (1.6 - 2.1, 12 - 15) 25 (0.98)

Front gusset A to engine 30 - 40 (3.1 - 4.1, 22 - 30) 20 (0.79)

Rear gusset B to engine 16 - 21 (1.6 - 2.1, 12 - 15) 16 (0.63)

*: With gussets

Revision: July 2004 2005 Sentra

Tightening torque

N·m (kg-m, ft-lb)

" " mm (in )

SMT930D

MT-17

TRANSAXLE ASSEMBLY

[RS5F70A]

Component Parts E C S005TO

CASE COMPONENTS

WMT014

1. Clutch housing 2. Dust seal 3. Oil pocket

4. Check plug 5. Input shaft oil seal 6. Oil channel

7. Mainshaft front bearing 8. Bearing retainer 9. Re ver se i dle r gea r front thr ust washer

10. Reverse idler gear 11. Reverse idler gear bear in g 12. R e verse idler gear rear thrust washer

13. O-ring 14. Reverse idler gear shaft 15. Snap ring

16. Back-up lamp switch 17. Filler plug 18. Side cover gasket

19. Side cover 20. Welch plug 21. M ainshaft bearing snap ring

22. Mainshaft rear bearing adjusting shim 23. O-ring 24. Rear cover

25. Differential oil seal 26. Drain plug 27. PNP switch

28. Transmission case 29. Oil gutter 30. Welch plug

31. Boot 32. Striking rod oil seal 33. Welch pl ug

34. Differential oil seal 35. O-ring 36. Speedometer pinion

Revision: July 2004 2005 Sentra

MT-18

GEAR COMPONENTS

TRANSAXLE ASSEMBLY

[RS5F70A]

A

B

MT

D

E

F

G

SMT641DA

1. Reverse idler gear front thrust washer 2. Reverse idler gear 3. Reverse idl er gea r bea ring

4. Reverse idler gear rear thrust washer 5. O-ring 6. Reverse idler gear shaft

7. Snap ring 8. Input shaft front be aring 9. Input shaft

10. 3rd gear needle bearing 11. 3rd input gear 12. 3rd gear baulk ring

13. Coupling sleeve 14 . Spread spring 15. Shifting insert

16. 3rd & 4th synchronizer hub 17. Spread spring 18. 4th gear C-ring

19. 4th gear needle bear in g 20. 4th gear baul k ring 21. 4th input gear

22. 5th gear front C-ring 23. 5th input gear 24. 5th gear rear C-ring

25. C-ring holder 26. Input shaft rear bearing 27. Oil channel

28. Input shaft rear bear i ng adjust i ng shi m 29. Mainshaft front bearing 30. Mainshaft

31. 1st gear needle bearing 32. 1st main gear 33. 1st inner baulk ring

34. 1st synchronizer cone 35. 1st outer baulk ring 36. 1st & 2nd synchronizer hub

37. Coupling sle eve 38. Insert spring 39. 2nd gear bushing

40. 2nd gear needle be aring 41. 2nd gear oute r baulk ring 42. 2nd gear synchronizer cone

43. 2nd inner baulk ring 44. 2nd main gear 45. 3rd main gea r

46. Spacer 47. Mainshaft adjusting shim 48. 4th main gear

49. 5th gear bushing 50. 5th gear need le be aring 51. 5th main gear

52. 5th gear baulk ring 53. Spread spring 54. Shifting insert

55. 5th & reverse synchronizer hub 56. Spread spring 57. Coupling sleeve

58. Reverse gear bushing 59. Reverse gear needl e bear i ng 60. Reverse gear baulk ring

61. Reverse main gear 62. Sub-gear 63. Sub-gear w asher

64. Snap ring 65. Mainshaft thrust w asher 66. Mainshaft rear bearing

67. Mainshaft C-ri ng 68. C-ring holder 69. Snap ring

H

I

J

K

L

M

Revision: July 2004 2005 Sentra

MT-19

SHIFT CONTROL COMPONENTS

TRANSAXLE ASSEMBLY

[RS5F70A]

1. Clutch housing 2. 3rd & 4th bracket 3. 3rd & 4th shift fork

4. Retaining pin 5. Check ball 6. Check pin

7. Check spring 8. Check pl ug 9. Stopper ring

10. 3rd & 4th fork rod 11. Selector shaft pin 12. Selector

13. 5th & reverse bracket 14. Reverse switch bracket 15. Retaining pin

16. 5th & reverse shift fork 17. Interlock plunger 18. Check ball

19. Interlock pin 20. Stopper ring 21. 5th & reverse fork rod

22. Striking lever 2 3. Retaining pin 24. 1st & 2nd bracket

25. 1st & 2nd shift fork 26. Check ball 27. 1st & 2nd fork rod

28. Transaxle case 29. Check ball 30. Check spring

31. Check plug 32. S elect check leaf spring 33. Return spring

34. Steel ball 35. Reverse gate 36. Return bearing

37. Selector arm 38. Bushing 39. Welch plug

40. Selector shaft 41. Striking yoke 42. Retaining pin

43. Striking rod 4 4. Dust boot 45. Striking rod oil seal

46. Welch plug

WMT015

Revision: July 2004 2005 Sentra

MT-20

FINAL DRIVE COMPONENTS

TRANSAXLE ASSEMBLY

[RS5F70A]

A

B

MT

D

E

F

G

WCIA0003E

1. Differential side bearing adjusting shim 2. Differential side bearing outer race 3. Differential side bearing

4. Final gear 5. Differential case 6. Speedometer drive gear

7. Speedomete r stopper 8. Differential side bearing 9. Differential side bearing outer race

10. Pinion mate thrust washer 11. Pinion mat e gear 12. Side gear thrust washer

13. Side gear 14. Pinion mate shaf t 15. Lock pin

Disassembly and Assembly ECS005TP

DISASSEMBLY

Transaxle Case

1. Remov e the back-up la mp switch, PNP sw itch, drain plug , and

filler plug from the transaxle case.

H

I

J

K

L

M

WMT023

Revision: July 2004 2005 Sentra

MT-21

TRANSAXLE ASSEMBLY

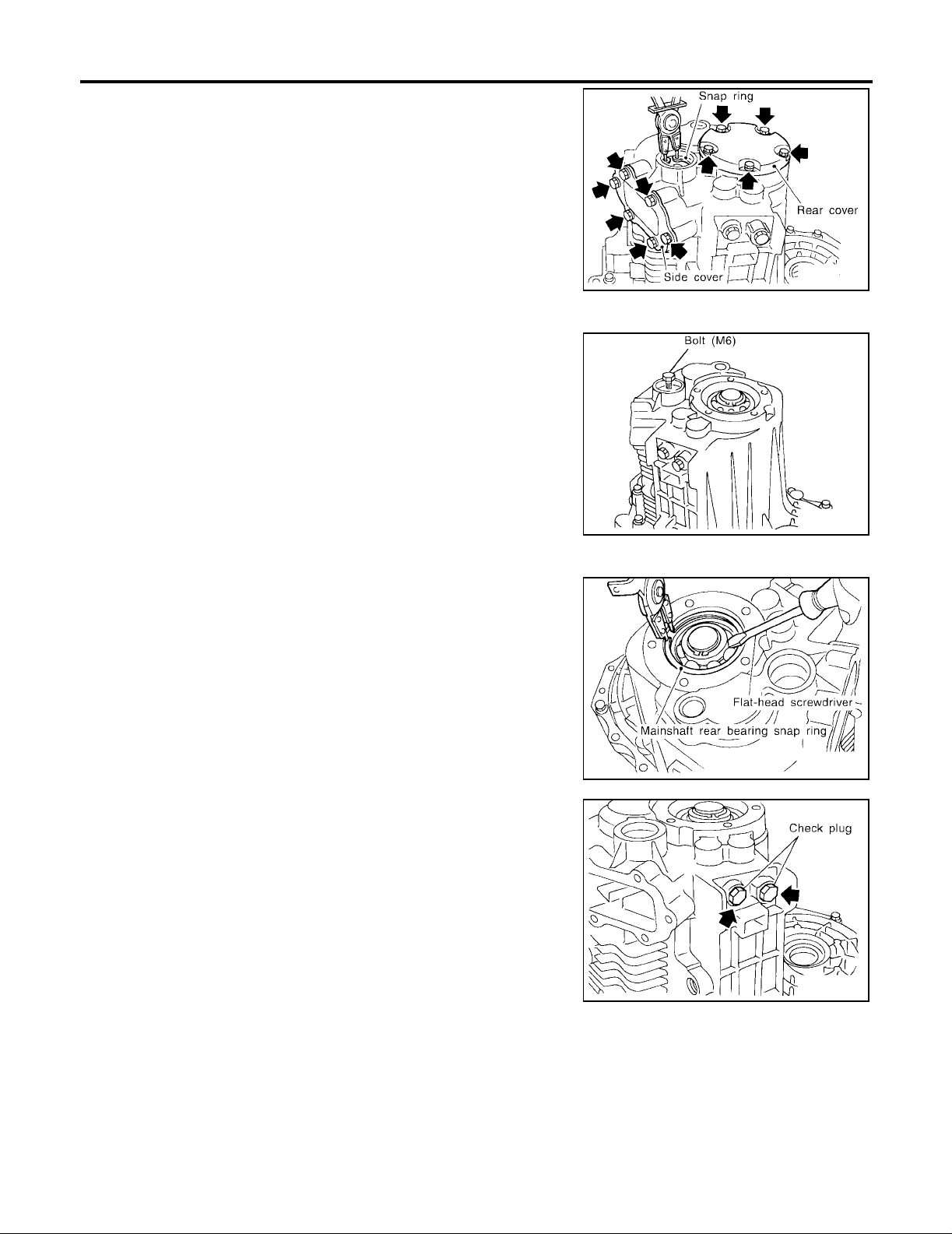

2. Remove snap ring from reverse idler shaft as shown.

3. Remove side cover and rear cover from case.

4. Remove O-ring and mainshaft bearing adjusting shim.

5. Remove reverse idler gear shaft.

a. Attach bolt (M6) to thread of reverse idler gear shaft end as

shown.

b. Pull out the at tached bolt (M6), and remove reverse idle r gear

shaft from case.

[RS5F70A]

SMT644D

6. Remove reverse idler gear, thrust washer (front and rear), and bearing from ca se.

7. Remove mainshaft rear bearing snap ring from case.

8. Remove check plugs, springs, and check balls f rom case.

SMT645D

SMT646D

SMT647D

Revision: July 2004 2005 Sentra

MT-22

TRANSAXLE ASSEMBLY

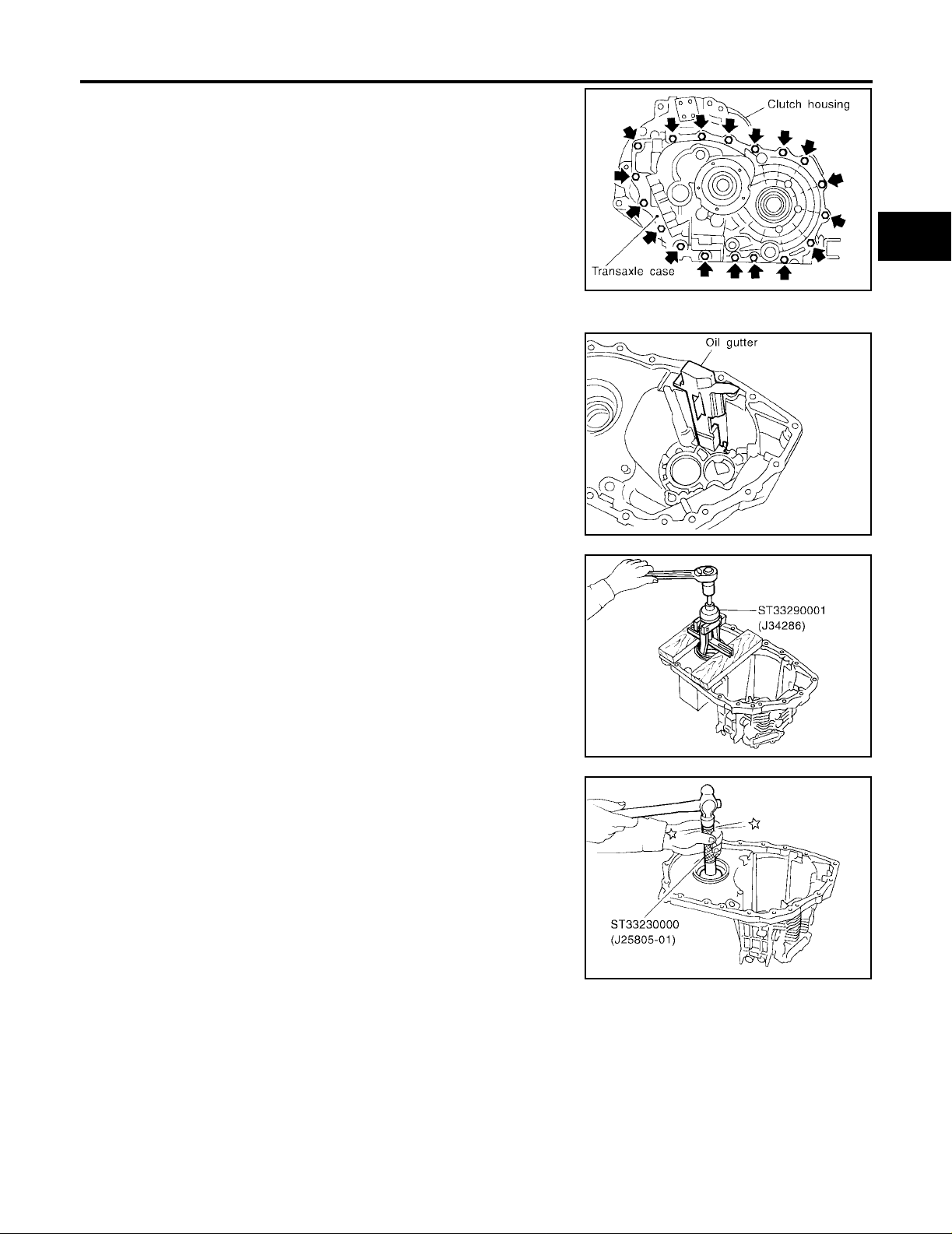

9. Remove transaxle case mounting bolts.

10. Remove input shaft rear bearing adjusting shim from transaxle case.

11. Remove oil gutter from transaxle case.

[RS5F70A]

A

B

MT

SMT649D

D

E

F

G

12. Remove differential side b earing outer race and ad justing shim

from transaxle case using Tool.

13. Remove differential oil seal from transaxle case using Tool.

SMT650D

H

I

J

K

SMT651DA

L

M

SMT653DA

Revision: July 2004 2005 Sentra

MT-23

TRANSAXLE ASSEMBLY

14. Remove welch plugs from transaxle case using Tool.

Clutch Housing

1. Remove transaxl e case from the clutch housing.

2. Remove check plugs, check springs, check pins, and check

balls from the clutch housing.

[RS5F70A]

SMT839DA

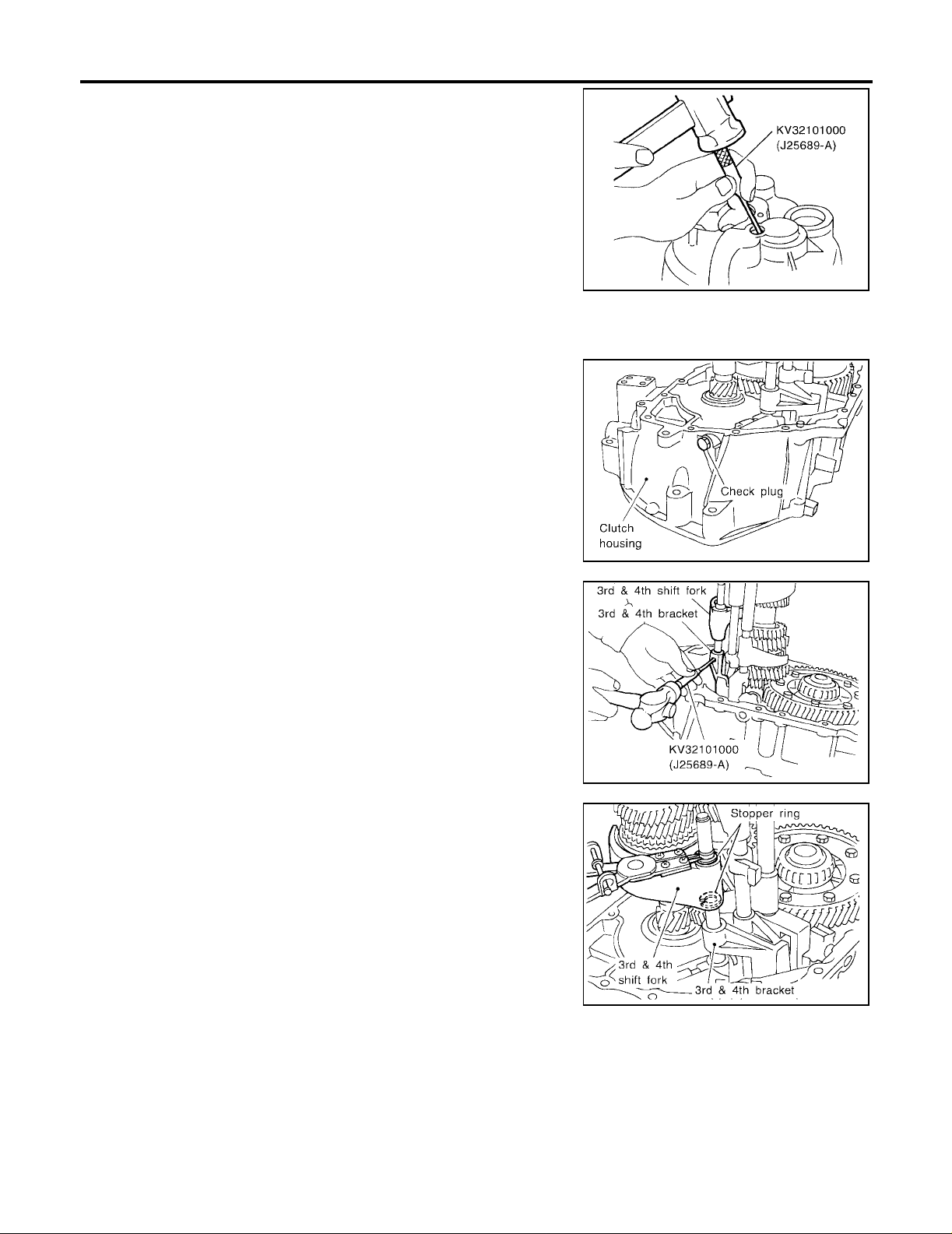

3. Remove 3rd & 4th bracket retaining pin using Tool.

4. Remove 3rd & 4th shift fork stopper ring.

5. Remove 3rd & 4th fork rod.

6. Remove 3rd & 4th shift fork and bracket.

SMT654D

SMT656DA

SMT655D

Revision: July 2004 2005 Sentra

MT-24

TRANSAXLE ASSEMBLY

7. Remov e int erl oc k plu nger and check ball.

8. Remove 5th & reverse bracket stopper ring .

9. Remove retaining pins from 5th & reverse shift fork and 5th &

reverse bracket usin g Tool.

10. Remove 5th & reverse fork rod.

11. Remove interlock pin from 5th & reverse fork rod using Tool.

12. Remove reverse switch bracket and 5th & reverse bracket.

[RS5F70A]

A

B

MT

SMT658D

D

E

F

G

SMT657DA

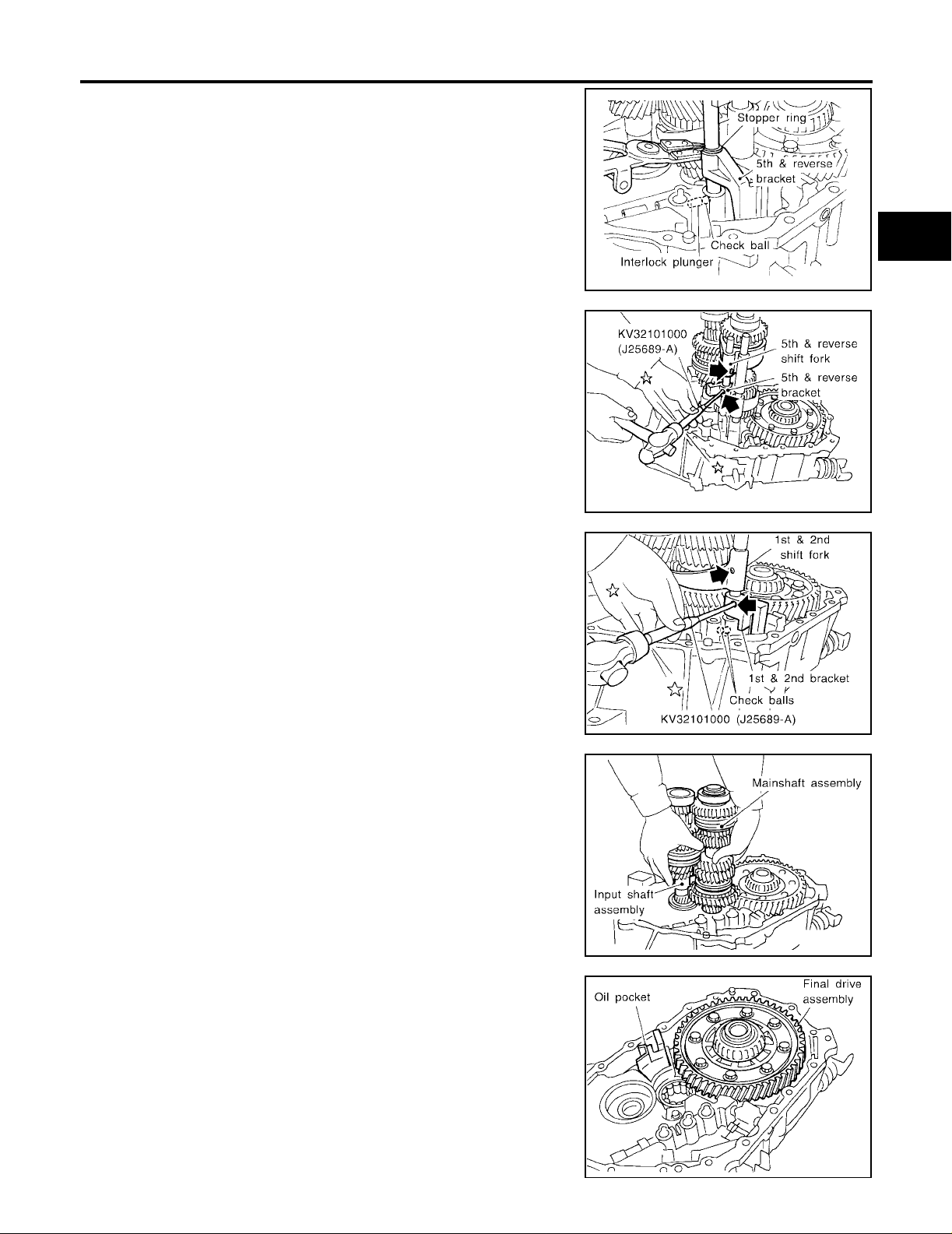

13. Rem ov e ch ec k ba ll from housing.

14. Remove retaining pin for 1st & 2nd shift fork and 1st & 2nd

bracket using Tool.

15. Remove 1st & 2nd fork rod.

16. Rem ove 5th & reve rse and 1 st & 2nd shift fork s, and 1st & 2nd

bracket.

17. Rem ove both input shaft and mainshaft assemblie s from housing.

18. Remove final drive assembly from housin g.

19. Remove oil pocket from housing.

SMT659DA

SMT660D

H

I

J

K

L

M

SMT661D

Revision: July 2004 2005 Sentra

MT-25

TRANSAXLE ASSEMBLY

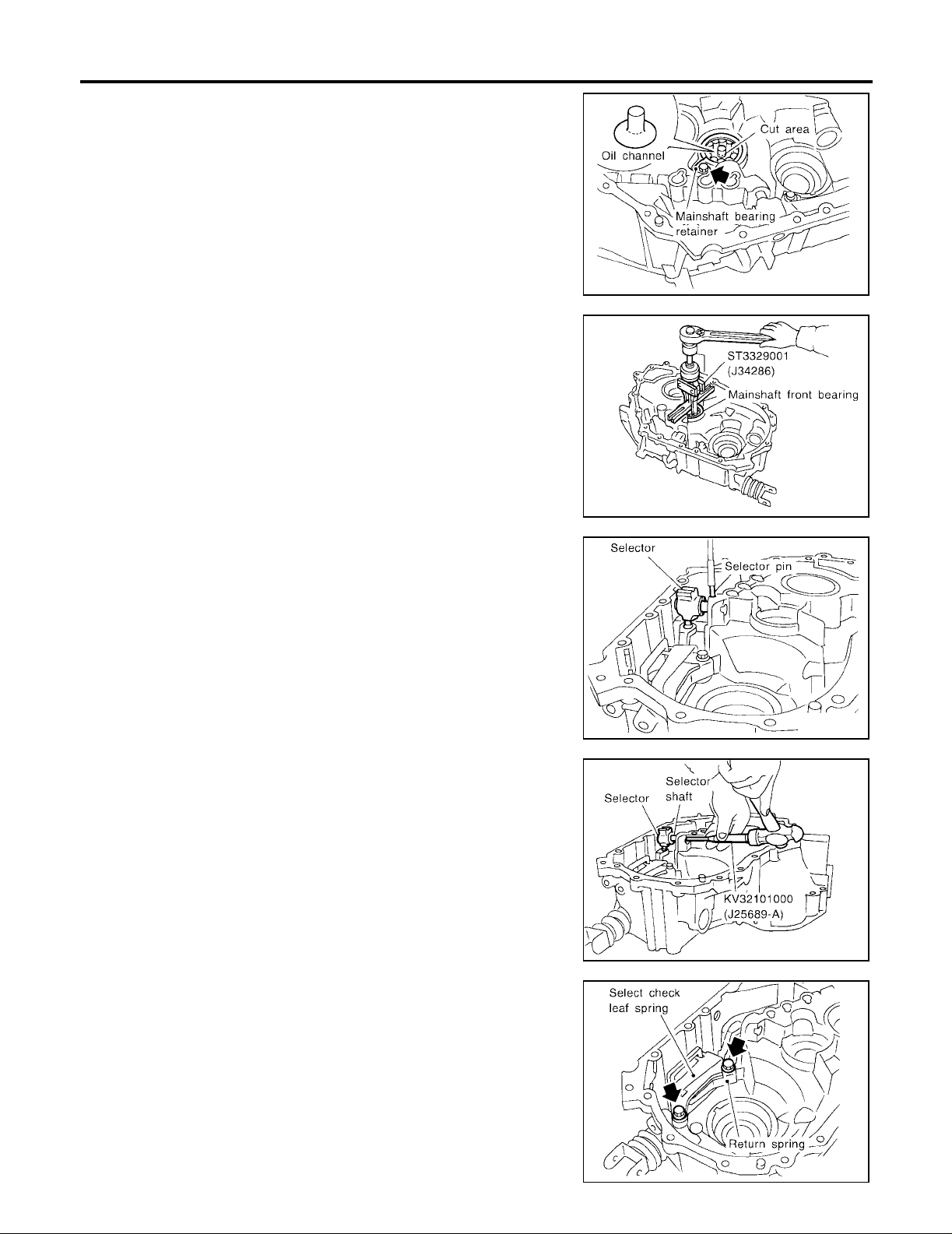

20. Remove mainshaft bearing retainer from housing.

21. Cut off oil channel using a cutter as shown.

22. Remove mains haft front bearing from housing using Tool.

[RS5F70A]

SMT662D

23. Using a magnet or other suitable tool, remove selector pin from

selector shaft.

24. Remove selector shaft and plug, then remove selector using

Tool.

SMT663DA

SMT664D

SMT665DA

25. Remove reamer bolts, then remove select check leaf spring,

return sprin g, st e el bal l , rev er s e gat e, sel ec tor arm, be ari ng , and

bushing.

CAUTION:

Be careful not to lose the steel ball.

SMT666DA

Revision: July 2004 2005 Sentra

MT-26

TRANSAXLE ASSEMBLY

[RS5F70A]

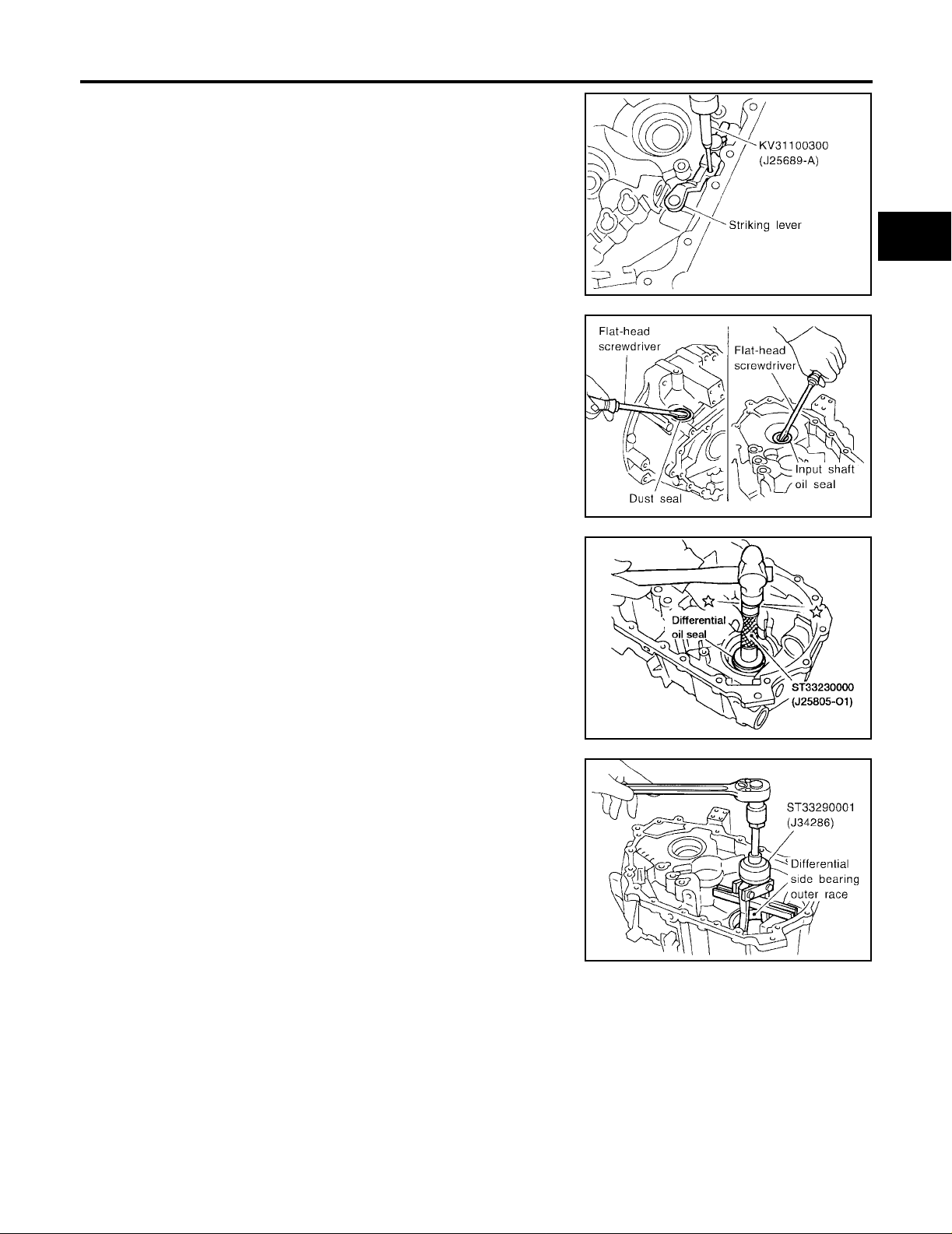

26. Remove retai ning pin and plug from striking lever using Tool.

27. Remove striking rod, then striking lever from housing.

28. Using a flat-head screwdriver or other suitable tool, remove dust

seal, input shaft oil seal, and striking rod oil seal from housing.

CAUTION:

When removing dust and oil seals, be careful not to damage

mounting surfaces of dust seal and oil seal.

29. Remove differential oil seal from ho using using Tool.

A

B

MT

SMT667DA

D

E

F

G

SMT668D

H

30. Remove differential side outer race from housing using Tool.

WMT021

SMT670DA

I

J

K

L

M

Revision: July 2004 2005 Sentra

MT-27

TRANSAXLE ASSEMBLY

ASSEMBLY

Clutch Housing

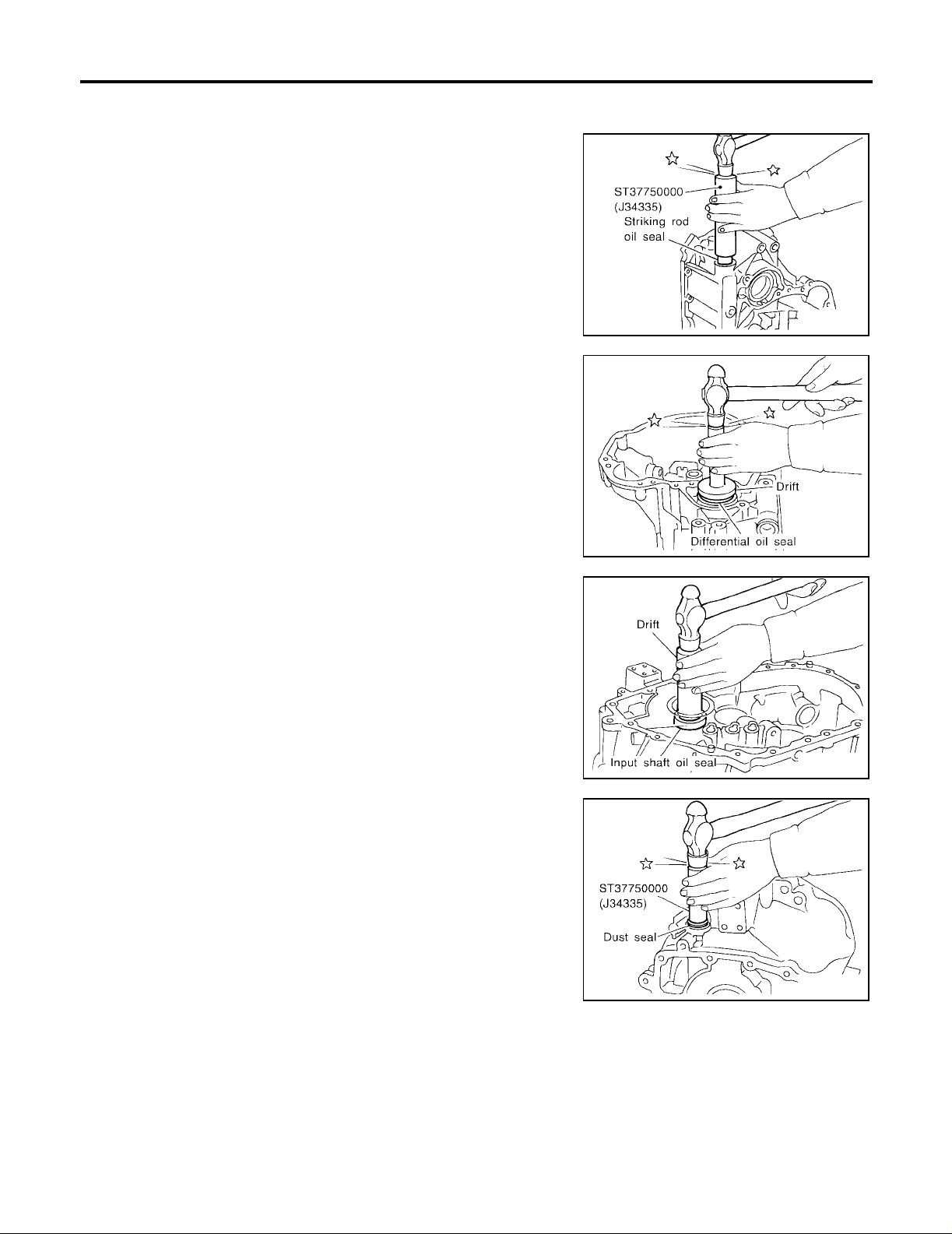

1. Hammer the ne w striking rod oil seal into clu tch housing as far

as it will go using Tool.

CAUTION:

Do not reuse striking rod oil seal.

2. Hammer the differential oil seal into clutch housing with a suitable tool until it becomes flush with clutch housing end face.

CAUTION:

Do not reuse differential oil seal.

[RS5F70A]

SMT722DA

3. Hammer input shaf t oil se al in to cl utch ho usin g as f ar a s it wi ll go

with a suitable tool.

CAUTION:

Do not reuse input shaft oil seal.

4. Hammer the dust seal into clutch housing as far as it will go

using Tool.

CAUTION:

Do not reuse dust seal.

SMT723DA

SMT724DA

SMT725DA

Revision: July 2004 2005 Sentra

MT-28

TRANSAXLE ASSEMBLY

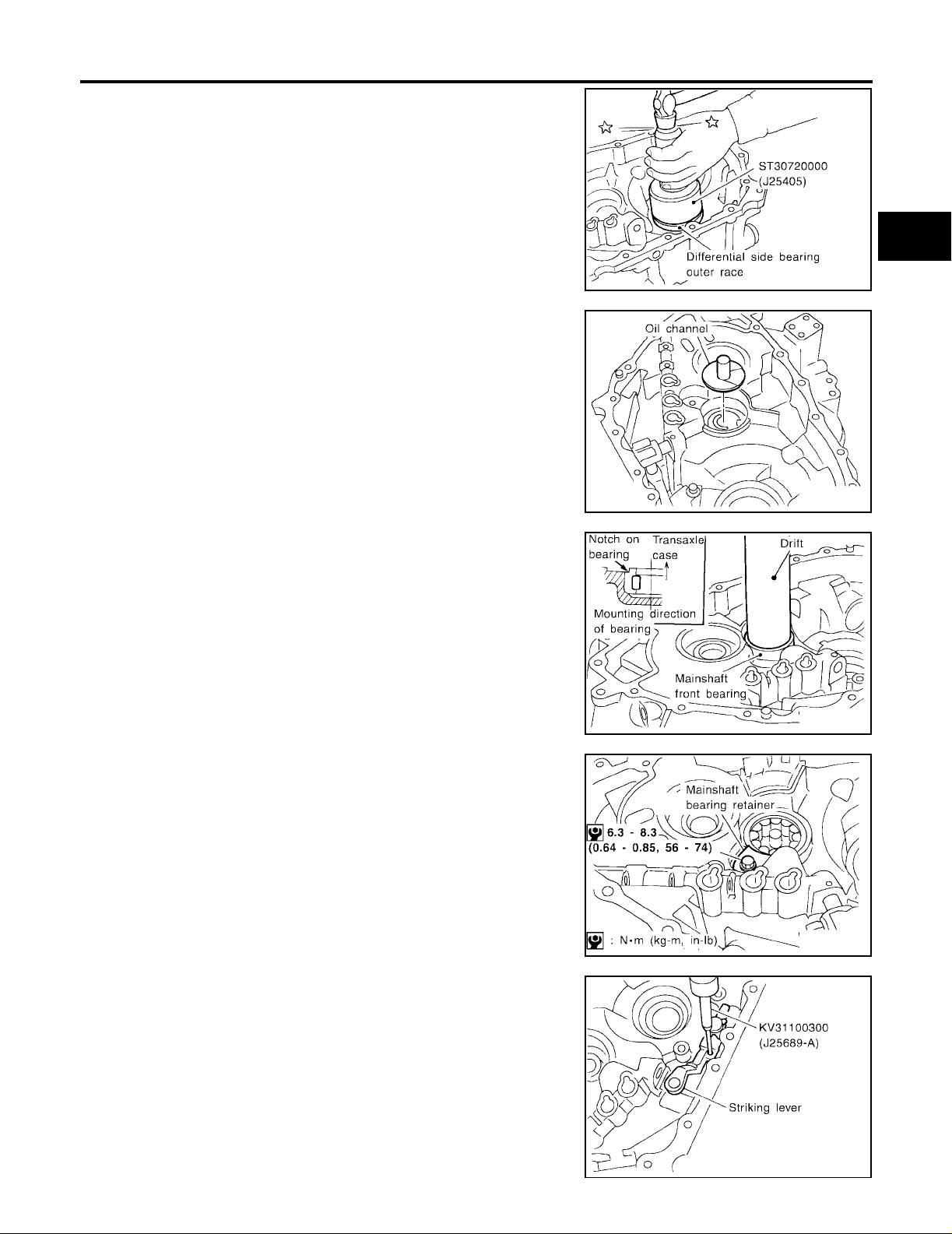

5. Install oute r race of differential side bearing using Tool.

6. Install new oil channel (mainshaft).

CAUTION:

Pay attention to installation direction of oil channel.

[RS5F70A]

A

B

MT

SMT726DA

D

E

F

G

SMT727D

7. Align the notches o n main shaf t fro nt be aring and t ransax le ca se.

Then, install mainshaft front bearing with a suitable tool.

8. Install mainshaft bearing retainer, tighten bolt to specification.

9. Attach boot, striking rod, and striking lever to clutch housing.

Install ne w retaining pin for striking lever using Tool.

CAUTION:

● Before installing striking rod, wrap the end with a vinyl

tape or similar product to prevent oil seal from being

damaged.

● Do not reuse retaining pin.

SMT728DA

SMT729D

H

I

J

K

L

M

SMT667DA

Revision: July 2004 2005 Sentra

MT-29

TRANSAXLE ASSEMBLY

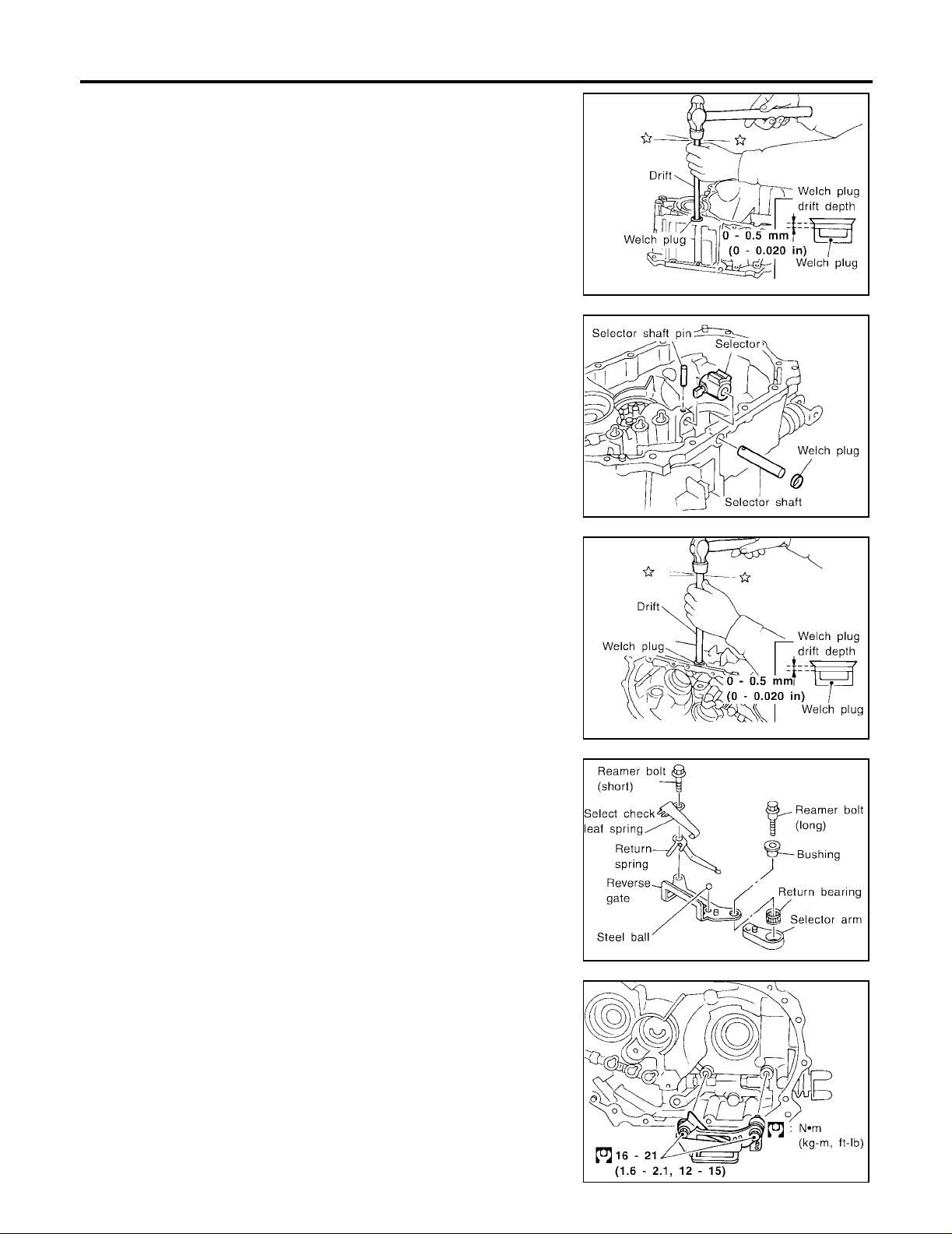

10. Hammer th e new we lch pl ug (st rik ing le ver si de) with a gen eralpurpose dri ft [OD: 12 mm (0.47 in)].

CAUTION:

Do not reuse welch plug.

11. Install selector, selector s haft, and select or shaft pin into clutch

housing.

[RS5F70A]

SMT730D

12. Hammer the new welch plug (selector shaft side) with a generalpurpose dri ft [OD: 12 mm (0.47 in)].

CAUTION:

Do not reuse welch plug.

13. Install select check leaf spring, return spring, steel ball, reverse

gate, selector arm, bushing, and return bearing.

SMT731D

SMT732D

SMT733DA

14. Tigh ten the two reamer bolt s to specification.

CAUTION:

Use correct reamer bolts for each installation point,

because each bolt has a different length.

SMT734D

Revision: July 2004 2005 Sentra

MT-30

Loading...

Loading...