Nissan Quest Maintenance MA 2000 Owner's Manual

MAINTENANCE

GI

CONTENTS

PRECAUTIONS ...............................................................2

Precautions for Supplemental Restraint System

(SRS) ″AIR BAG″........................................................2

PREPARATION ...............................................................3

Special Service Tool....................................................3

Commercial Service Tool.............................................3

Preparation for Changing Engine Coolant ..................3

GENERAL MAINTENANCE............................................4

PERIODIC MAINTENANCE ............................................6

Schedule 1...................................................................7

EMISSION CONTROL SYSTEM MAINTENANCE

CHASSIS AND BODY MAINTENANCE

Schedule 2...................................................................9

EMISSION CONTROL SYSTEM MAINTENANCE

CHASSIS AND BODY MAINTENANCE

RECOMMENDED FLUIDS AND LUBRICANTS...........11

Fluids and Lubricants ................................................11

SAE Viscosity Number ..............................................12

GASOLINE ENGINE OIL

Anti-freeze Coolant Mixture Ratio .............................12

ENGINE MAINTENANCE..............................................13

Checking Drive Belts.................................................13

Changing Engine Coolant..........................................14

Flushing Cooling System...........................................18

Checking Fuel Lines..................................................18

Changing Fuel Filter..................................................18

WITH CONSULT–II

WITHOUT CONSULT–II

Changing Air Cleaner Filter .......................................19

VISCOUS PAPER TYPE

Changing Engine Oil..................................................19

Changing Oil Filter.....................................................20

Changing Spark Plugs...............................................21

Checking EVAP Vapor Lines.....................................22

..........................................12

.............................................18

......................................19

...........................................19

........................8

......................10

.........7

.........9

SECTION

CHASSIS AND BODY MAINTENANCE.......................24

Checking Exhaust System.........................................24

Checking A/T Fluid ....................................................24

Changing A/T Fluid....................................................25

Balancing Wheels......................................................25

Tire Rotation..............................................................25

Checking Brake Fluid Level and Leaks.....................25

Checking Brake Lines and Cables............................26

Checking Disc Brake.................................................26

ROTOR

CALIPER

PAD

Checking Drum Brake ...............................................26

WHEEL CYLINDER

DRUM

LINING

TEMPORARY METHOD FOR CHECKING LINING

WEAR

Checking Steering Gear, Linkage..............................27

STEERING GEAR

STEERING LINKAGE

Checking Power Steering Fluid and Lines................27

CHECKING FLUID LEVEL

CHECKING LINES

Lubricating Locks, Hinges and Hood Latches...........28

Checking Seat Belts, Buckles, Retractors,

Anchors and Adjusters...............................................28

SERVICE DATA AND SPECIFICATIONS (SDS).........29

Engine Maintenance..................................................29

DRIVE BELT DEFLECTION

DRIVE BELT TENSION

SPARK PLUG TYPE

Chassis and Body Maintenance................................29

WHEEL BALANCE

...................................................................26

.................................................................26

........................................................................26

.....................................................................26

....................................................................27

.....................................................................27

MA

..................................................26

....................................................27

...............................................27

........................................27

...................................................27

......................................29

............................................29

................................................29

...................................................29

EM

LC

EC

FE

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PRECAUTIONS

Precautions for Supplemental Restraint System (SRS) “AIR BAG”

Precautions for Supplemental Restraint System

(SRS) “AIR BAG”

The Supplemental Restraint System “AIR BAG”, used alongwith a seat belt, helps to reduce therisk or severity

of injury to the driver and front passenger in a frontal collision. The Supplemental Restraint System consists

of air bag modules (located in the center of the steering wheel and on the instrument panel on the passenger side), a diagnosis sensor unit, warning lamp, wiring harness and spiral cable. Information necessary to

service the system safely is included in the RS section of this Service Manual.

WARNING:

쐌 To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be performed by an authorized NISSAN dealer.

쐌 Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

쐌 Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses are covered with yellow insulation either just before the

harness connectors or for the complete harness, for easy identification.

NDMA0001

MA-2

PREPARATION

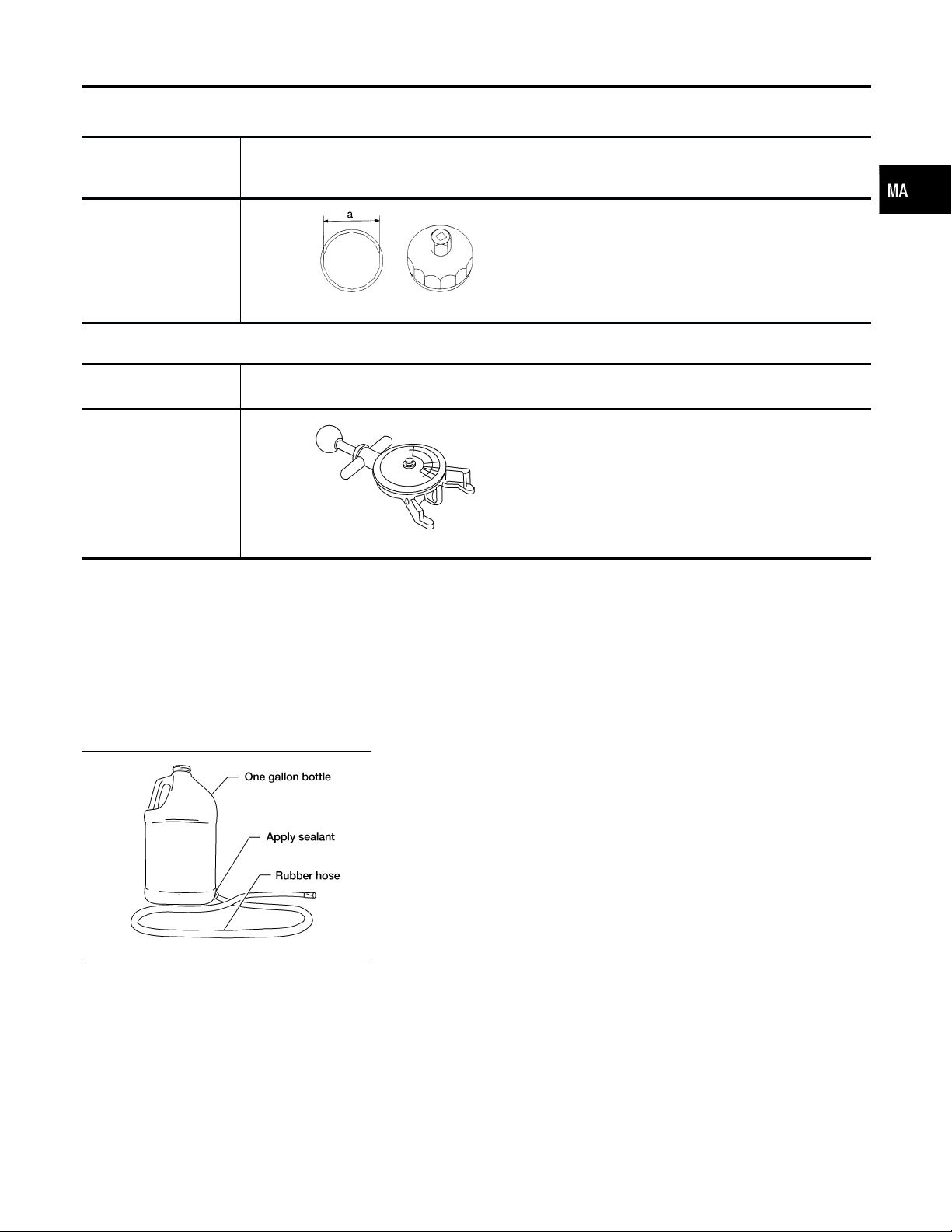

Special Service Tool

Special Service Tool

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

KV10115801

(J38956)

Oil filter cap wrench

Description

Removing oil filter

a: 64.3 mm (2.531 in)

NT375

Commercial Service Tool

Tool name

(Kent-Moore No.)

Belt tension gauge

(BT3373-F)

Description

Measuring drive belt tension

AMA126

NDMA0002

NDMA0011

GI

EM

LC

EC

FE

AT

AX

SU

AMA139

Preparation for Changing Engine Coolant

NDMA0012

Prepare an empty one gallon bottle, such as used for windshield

washer fluid. Obtain a 1371mm (54in) length of hose with the same

inner diameter as the coolant reservoir hose. Modify a one gallon

bottle by making a hole at the bottom of the bottle slightly smaller

than the hose outer diameter that will be covered by fluid when

filled.

쐌 Insert the hose in the bottom of the bottle.

쐌 Seal the hose to the bottle so it will not leak.

BR

ST

RS

BT

HA

SC

EL

IDX

MA-3

NDMA0003

GENERAL MAINTENANCE

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or they can have their NISSAN dealers do them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

Item Reference page

Tires Check the pressure with a gauge periodically when at a service station,

including the spare, and adjust to the specified pressure if necessary. Check

carefully for damage, cuts or excessive wear.

—

Wheel nuts When checking the tires, make sure no nuts are missing, and check for any

loose nuts. Tighten if necessary.

Tire rotation Tires should be rotated every 12,000 km (7,500 miles). MA-25

Wheel alignment and

balance

Windshield wiper

blades

Doors and engine

hood

If the vehicle pulls to either side while driving on a straight and level road, or

if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed.

Check for cracks or wear if they do not wipe properly. —

Check that all doors and the engine hood operate smoothly as well as the

trunk lid and back hatch. Also make sure that all latches lock securely. Lubricate if necessary. Make sure that the secondary latch keeps the hood from

opening when the primary latch is released.

When driving in areas using road salt or other corrosive materials, check

lubrication frequently.

MA-25, “Front Wheel

—

Alignment”,SU-5

MA-28

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

Item Reference page

Lamps Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check

headlamp aim.

—

Warning lamps and

buzzers/chimes

Windshield wiper and

washer

Windshield defroster Check that the air comes out of the defroster outlets properly and in suffi-

Steering wheel Check that it has the specified play. Be sure to check for changes in the

Seats Check seat position controls such as seat adjusters, seat back recliner, etc.

Seat belts Check that all parts of the seat belt system (e.g. buckles, anchors, adjusters

Brakes Check that the brakes do not pull the vehicle to one side when applied. —

Accelerator pedal Check the pedal for smooth operation and make sure the pedal does not

Make sure that all warning lamps and buzzers/chimes are operating properly. —

Check that the wipers and washer operate properly and that the wipers do

not streak.

cient quantity when operating the heater or air conditioning.

steering condition, such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)

to make sure they operate smoothly and that all latches lock securely in

every position. Check that the head restraints move up and down smoothly

and that the locks (if equipped) hold securely in all latched positions. Check

that the latches lock securely for folding-down rear seat backs.

and retractors) operate properly and smoothly and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage.

catch or require uneven effort. Keep the floor mats away from the pedal.

“Seat Belt Inspection”,

″Accelerator control

—

—

—

—

MA-28

RS-7

system″, FE-3

MA-4

GENERAL MAINTENANCE

Item Reference page

Brake pedal and

booster

Parking brake Check that the lever has the proper travel and make sure that the vehicle is

Automatic transaxle

“Park” mechanism

Check the pedal for smooth operation and make sure it has the proper distance under it when depressed fully. Check the brake booster function. Be

sure to keep floor mats away from the pedal.

held securely on a fairly steep hill when only the parking brake is applied.

Check that the brake pedal must be depressed for the selector lever to be

moved from the “P” position. On a fairly steep hill, check that the vehicle is

held securely with the selector lever in the “P” position without applying any

brakes.

“Brake Pedal and

Bracket”, BR-13 and

“Brake Booster”, BR-18

“Parking Brake Control”,

BR-29

—

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

Item Reference page

Windshield washer

fluid

Engine coolant level Check the coolant level when the engine is cold. MA-14

Radiator and hoses Check the front of the radiator and clean off any dirt, insects, leaves, etc.,

Brake fluid level Make sure that the brake fluid level is between the “MAX” and “MIN” lines on

Check that there is adequate fluid in the tank. —

that may have accumulated. Make sure the hoses have no cracks,

deformation, deterioration or loose connections.

the reservoir.

—

MA-25,

GI

EM

LC

EC

FE

AT

AX

SU

Battery Check the fluid level in each cell. It should be between the “MAX” and “MIN”

lines.

Engine drive belts Make sure that no belt is frayed, worn, cracked or oily. MA-13

Engine oil level Check the level on the dipstick after parking the vehicle on a level spot with

the engine off for at least 30 seconds.

Power steering fluid

level and lines

Automatic transaxle

fluid level

Exhaust system Make sure there are no loose supports, cracks or holes. If the sound of the

Underbody The underbody is frequently exposed to corrosive substances such as those

Fluid leaks Check under the vehicle for fuel, oil, water or other fluid leaks after the

Check the level on the dipstick with the engine off. Check the lines for

improper attachment, leaks, cracks, etc.

Check the level on the dipstick after putting the selector lever in “P” with the

engine idling.

exhaust seems unusual or there is a smell of exhaust fumes, immediately

locate the trouble and correct it.

used on icy roads or to control dust. It is very important to remove these

substances, otherwise rust will form on the floor pan, frame, fuel lines and

around the exhaust system. At the end of winter, the underbody should be

thoroughly flushed with plain water, being careful to clean those areas where

mud and dirt can easily accumulate.

vehicle has been parked for a while. Water dripping from the air conditioner

after use is normal. If you should notice any leaks or gasoline fumes are

evident, check for the cause and correct it immediately.

—

MA-19

MA-27

MA-24

MA-24

—

—

BR

ST

RS

BT

HA

SC

EL

IDX

MA-5

NDMA0004

PERIODIC MAINTENANCE

Two different maintenance schedules are provided, and should be used, depending upon the conditions in

which the vehicle is usually operated. After 60,000 miles (96,000 km) or 48 months, continue the periodic

maintenance at the same mileage/time intervals.

Schedule 1

Schedule 2

Follow Periodic Maintenance Schedule 1 if owner’s driving habits frequently

includes one or more of the following driving conditions:

쐌 Repeated short trips of less than 5 miles (8 km).

쐌 Repeated short trips of less than 10 miles (16 km) with outside temperatures

remaining below freezing.

쐌 Operating in hot weather in stop-and-go “rush hour” traffic.

쐌 Extensive idling and/or low speed driving for long distances, such as police,

taxi or door-to-door delivery use.

쐌 Driving in dusty conditions.

쐌 Driving on rough, muddy, or salted roads.

쐌 Towing a trailer, using a camper or a car-top carrier.

Follow Periodic Maintenance Schedule 2 if none of the driving conditions

shown in Schedule 1 apply to owner’s driving habits.

Emission Control System Maintenance

Chassis and Body

Maintenance

Emission Control System Maintenance

Chassis and Body

Maintenance

MA-7

MA-8

MA-9

MA-10

MA-6

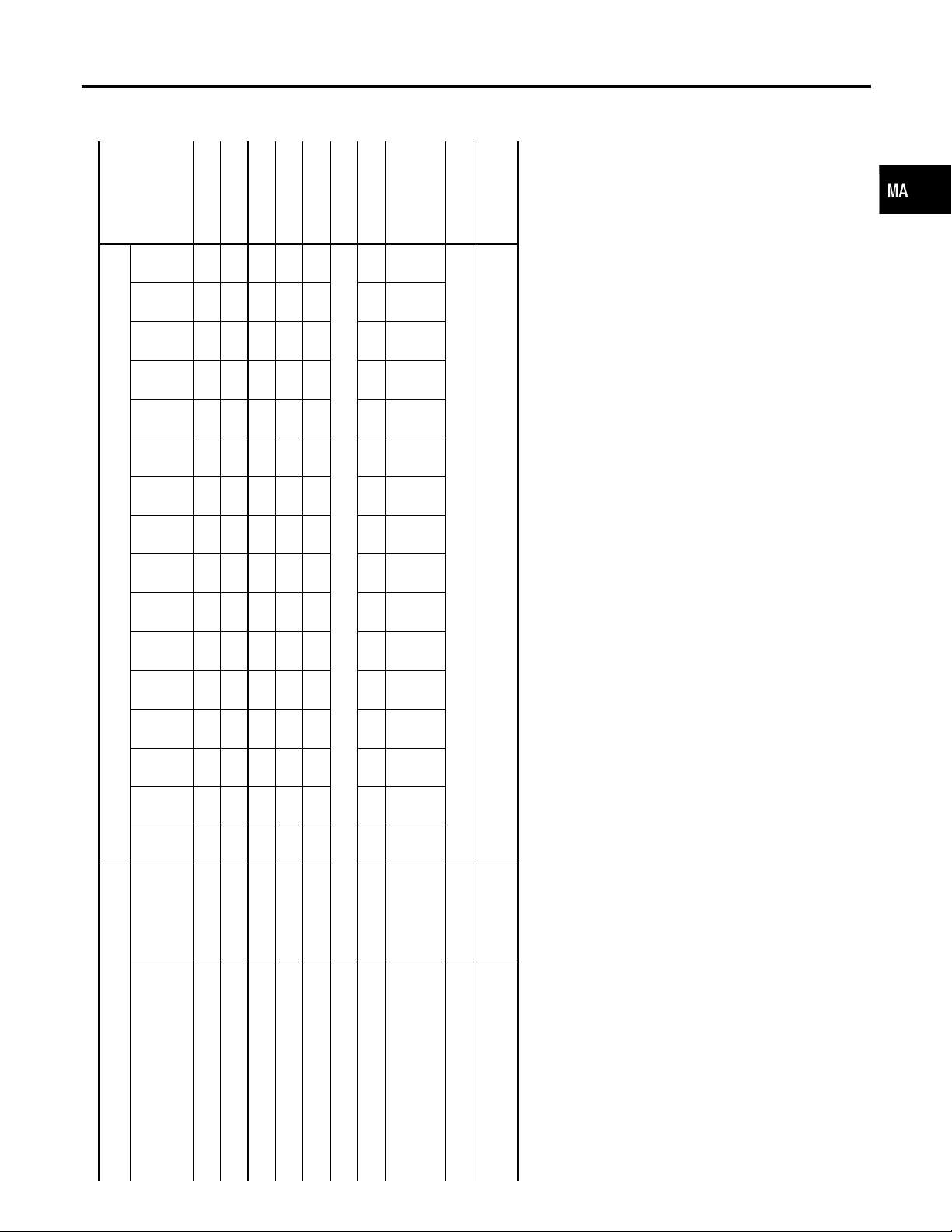

PERIODIC MAINTENANCE

Schedule 1

Schedule 1

EMISSION CONTROL SYSTEM MAINTENANCE

or

- Page

Section

Reference

60

(96)

(90)

56.25

(84)

52.5

(78)

48.75

45

(72)

(66)

41.25

(60)

37.5

(54)

33.75

30

(48)

- Content Title

48

45

42

39

36

33

30

27

24

EM-17

Timing Belt

NDMA0004S01

NDMA0004S0101

GI

EM

LC

EC

FE

AT

AX

SU

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

(42)

26.25

(36)

22.5

(30)

18.75

15

(24)

(18)

11.25

7.5

(12)

(6)

3.75

(km x 1,000)

Miles x 1,000

21

18

15

12

9

6

3

Months

BR

ST

RS

BT

HA

RRRRRRRRRRRRRRRR MA-20

SC

EL

IDX

Drive belts NOTE (1) I* MA-13

Air cleaner filter NOTE (2) [R] [R] MA-19

EVAP vapor lines I* I* MA-22

Fuel lines I* I* MA-18

Fuel filter* NOTE (3) MA-18

Engine coolant Replace every 30,000 miles (48,000 km) or 36 months.* MA-14

Engine oil RRRRRRRRRRRRRRRR MA-19

Engine oil filter (Use part No.

15208-7B000 or 15208–9E000 or

equivalent.)

Spark plugs (platinum-tipped type) Replace every 105,000 miles (168,000km) MA-21

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform at number of miles, kilo-

meters or months, whichever

comes first.

Timing belt Replace every 105,000 miles (168,000 km)

NOTE:

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months.

(2) If operating mainly in dust conditions, more frequent maintenance may be required.

(3) When the filter becomes clogged, the vehicle speed cannot be increased as the driver wishes. In such an event, replace the filter.

★ Maintenance items and intervals with “*” are recommended by NISSAN for reliable vehicle operation. The owner need not perform such maintenance in order to maintain the

emission warranty or manufacturer recall liability. Other maintenance items and intervals are required.

MA-7

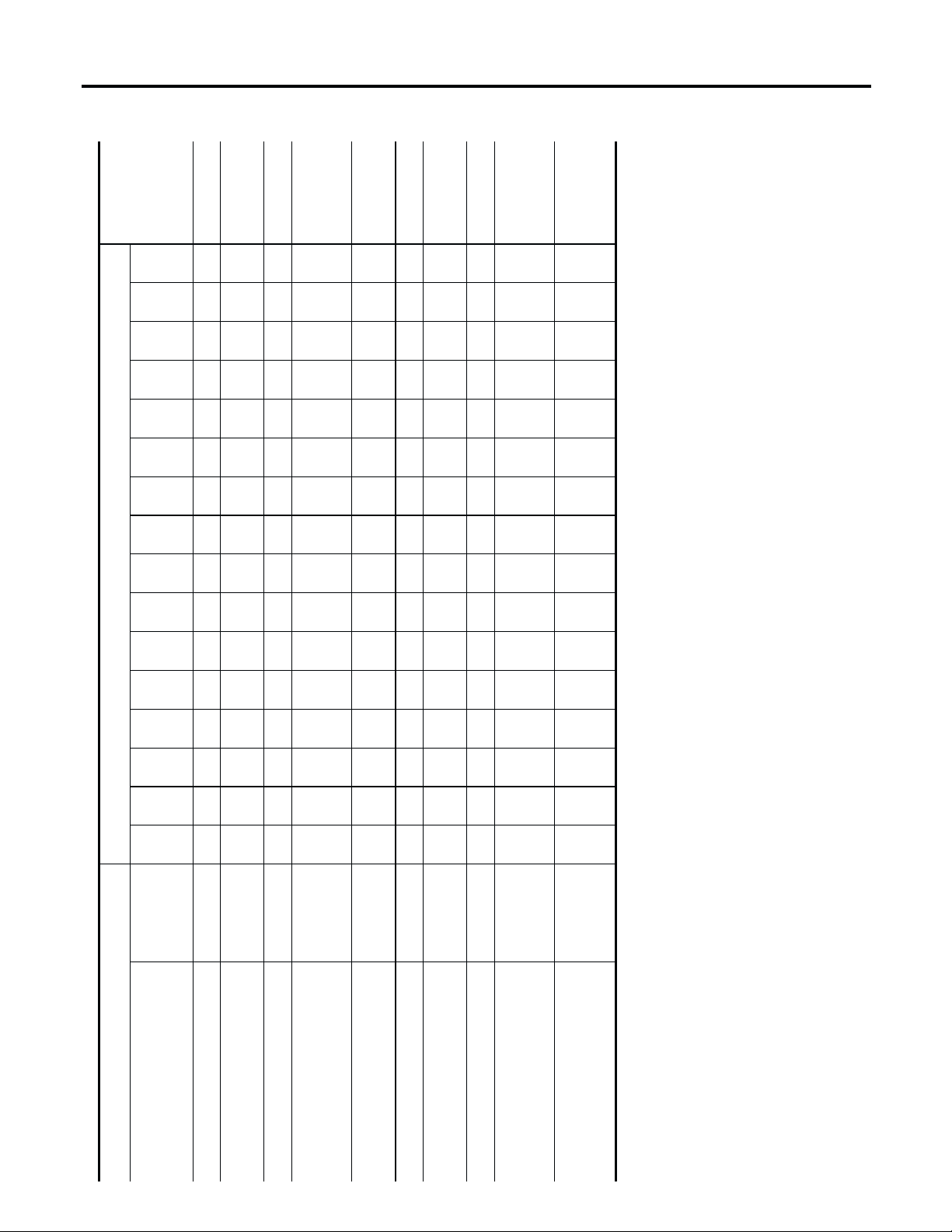

Schedule 1 (Cont’d)

PERIODIC MAINTENANCE

CHASSIS AND BODY MAINTENANCE

or

- Page

Section

Reference

60

(96)

(90)

56.25

(84)

52.5

(78)

48.75

45

(72)

(66)

41.25

(60)

37.5

(54)

33.75

- Content Title

48

45

42

39

36

33

30

27

HA-140

Cabin

air filter

MA-27

NOTE (4)

AX-13

Drive Shaft

RS-2

Items

Maintenance

Actuator

EL-205 ASCD

NDMA0004S0102

Check

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. L = Lubricate.

30

(48)

(42)

26.25

(36)

22.5

(30)

18.75

15

(24)

(18)

11.25

7.5

(12)

(6)

3.75

(km x 1,000)

Miles x 1,000

24

21

18

15

12

9

6

3

Months

IIIIIIIIMA-26, 26

NOTE (4) IIIIIIII

Brake lines & cables IIIIMA-26

Brake pads, rotors, drums & lin-

ings

Automatic transaxle fluid NOTE (1) IIIIMA-24

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform at number of miles, kilo-

meters or months, whichever

comes first.

Cabin air filter NOTE (5) R R R R

Steering gear, linkage, axle & sus-

pension parts

Tire rotation NOTE (2) MA-4

Drive shaft boots IIIIIIII

Exhaust system IIIIIIIIMA-24

Supplemental air bag system NOTE (3)

ASCD vacuum hoses 1111

NOTE:

(1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, change (not just inspect) oil at every 30,000 miles (48,000 km) or 24 months.

(2) Refer to “Tire Rotation” under the “General Maintenance” heading earlier in this section.

(3) Inspect the air bag system 10 years after the date of manufacture noted on the FMVSS certification label.

(4) Refer to “Front Suspension Parts”, SU-5, “Rear Suspension Parts”, SU-16, “Front Axle Parts”, AX-3 and “Rear Axle Parts”, AX-18.

(5) If operating mainly in dusty conditions more frequent maintenance may be required.

MA-8

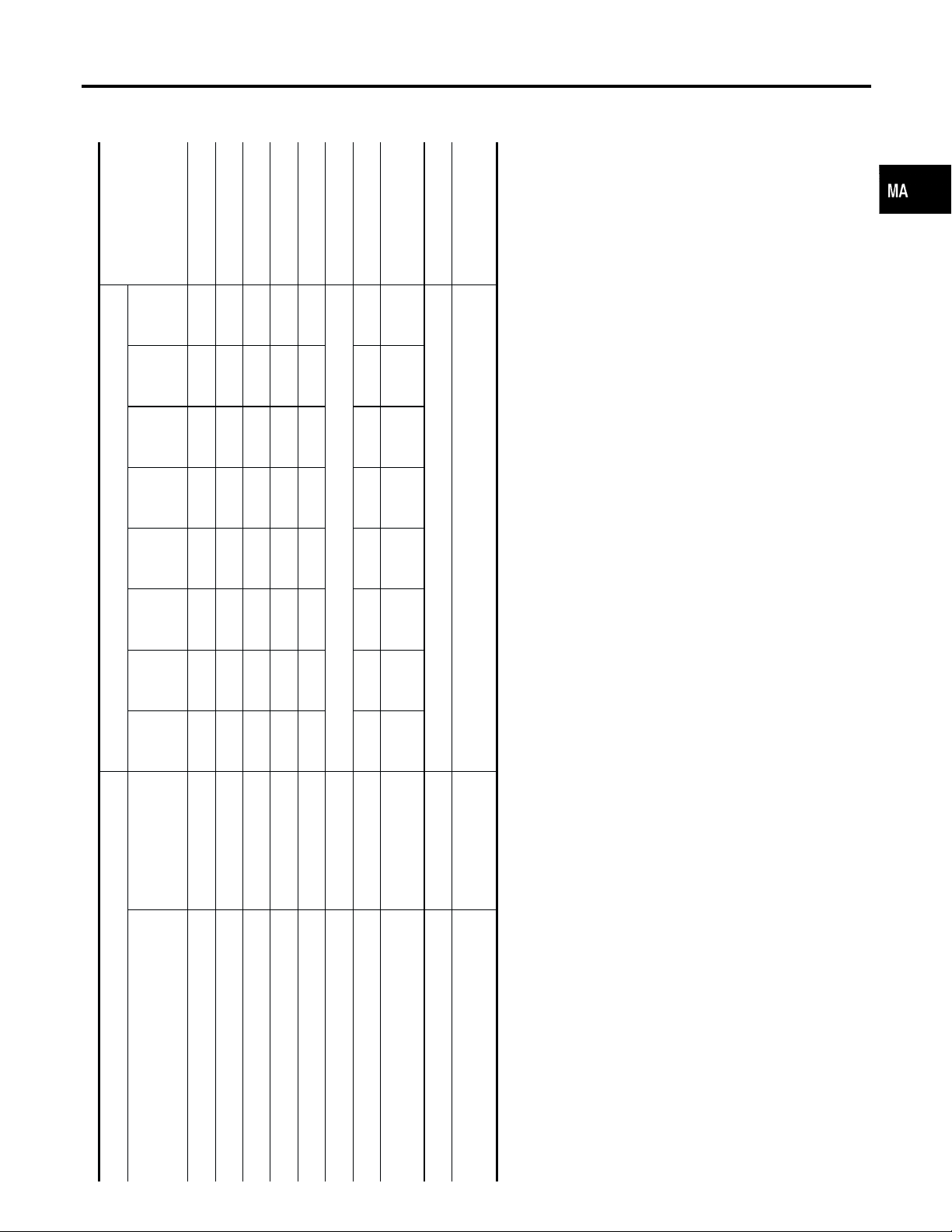

PERIODIC MAINTENANCE

Schedule 2

Schedule 2

EMISSION CONTROL SYSTEM MAINTENANCE

or

- Page

60

52.5

45

37.5

- Content Title

(96)

(84)

(72)

(60)

48

42

36

30

Reference Section

EM-17

Timing Belt

NDMA0004S02

NDMA0004S0201

GI

EM

LC

EC

FE

AT

AX

Abbreviations: R = Replace. I = Inspect. Correct or replace if necessary. [ ]: At the mileage intervals only

30

(48)

(36)

22.5

15

(24)

7.5

(12)

(km x 1,000)

Miles x 1,000

24

18

12

6

Months

SU

BR

ST

RS

RRRRRRRR MA-20

BT

HA

SC

EL

IDX

MAINTENANCE OPERATION MAINTENANCE INTERVAL

Perform at number of miles, kilometers or

months, whichever comes first.

Drive belts NOTE (1) I* MA-13

Air cleaner filter [R] [R] MA-19

EVAP vapor lines I* I* MA-22

Fuel lines I* I* MA-18

Fuel filter* NOTE (2) MA-18

Engine coolant Replace every 30,000 miles (48,000 km) or 36 months.* MA-14

Engine oil RRRRRRRR MA-19

Engine oil filter (Use part No. 15208-7B000

or 15208–9E000 or equivalent.)

Spark plugs (platinum-tipped type) Replace every 105,000 miles (168,000 km) MA-21

Timing belt Replace every 105,000 miles (168,000 km)

NOTE:

(1) After 60,000 miles (96,000 km) or 48 months, inspect every 15,000 miles (24,000 km) or 12 months.

(2) When the filter becomes clogged, the vehicle speed cannot be increased as the driver wishes. In such an event, replace the filter.

★ Maintenance items and intervals with “*” are recommended by NISSAN for reliable vehicle operation. The owner need not perform such maintenance in order to maintain the

emission warranty or manufacturer recall liability. Other maintenance items and intervals are required.

MA-9

Loading...

Loading...