AUTOMATIC TRANSAXLE

CONTENTS

EURO-OBD

TROUBLE DIAGNOSIS - INDEX ....................................5

Alphabetical & P No. Index for DTC ...........................5

PRECAUTIONS ...............................................................7

Supplemental Restraint System (SRS) ″AIR

BAG″ and ″SEAT BELT PRE-TENSIONER″...............7

Precautions for On Board Diagnostic (EURO-

OBD) System of A/T and Engine - Euro-OBD -..........7

Precautions..................................................................7

Service Notice or Precautions.....................................9

Wiring Diagrams and Trouble Diagnosis...................10

PREPARATION .............................................................11

Special Service Tools................................................11

Commercial Service Tools.........................................13

A/T FLUID......................................................................15

Checking A/T Fluid ....................................................15

Changing A/T Fluid....................................................15

OVERALL SYSTEM ......................................................16

A/T Electrical Parts Location .....................................16

Circuit Diagram..........................................................17

Cross-sectional View - 3AX00, 3AX01, 3AX19,

3AX63 and 3AX64 models ........................................19

Cross-sectional View - 3AX10 and 3AX18

models .......................................................................20

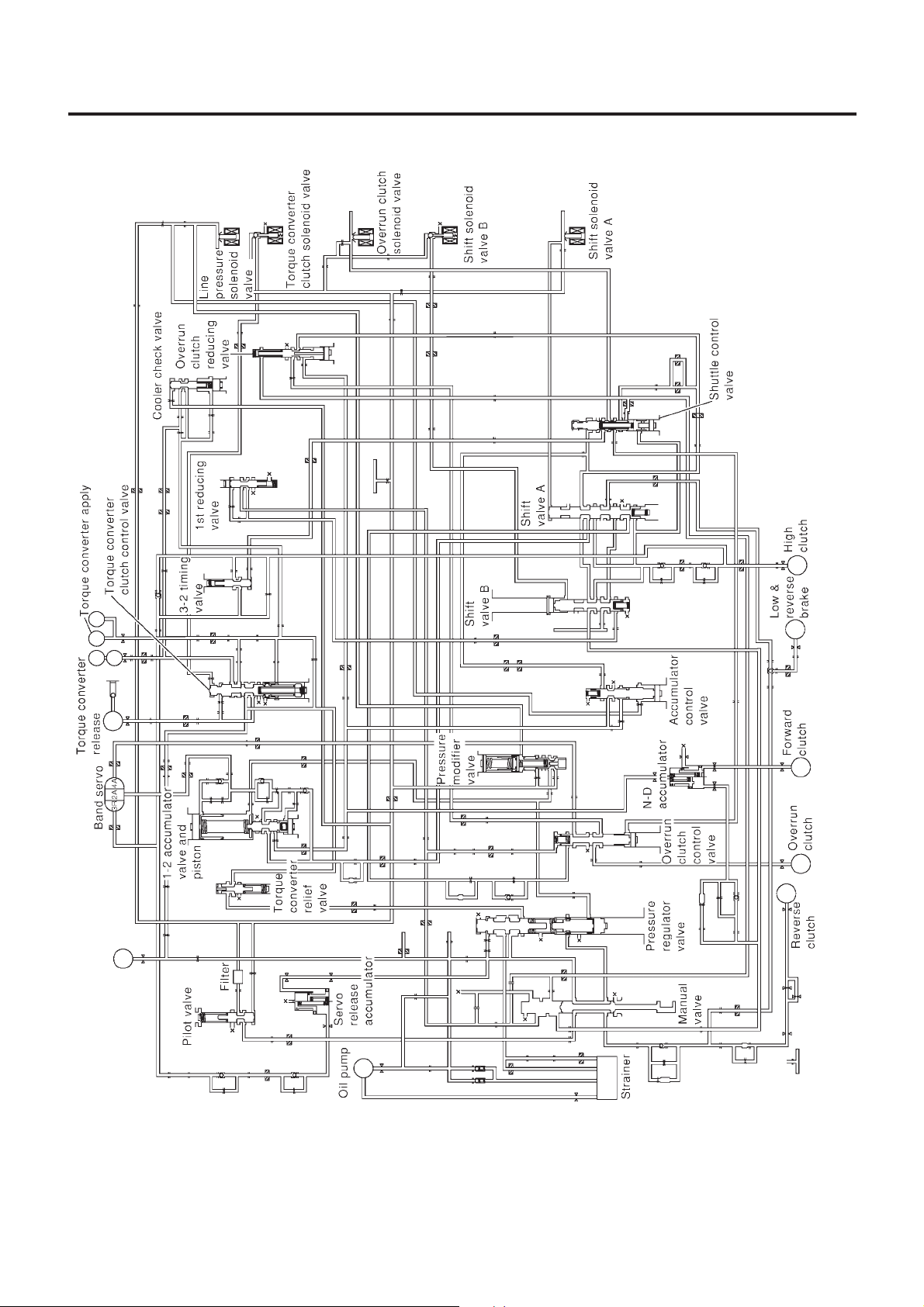

Hydraulic Control Circuit............................................21

Shift Mechanism ........................................................22

Control System ..........................................................31

Control Mechanism....................................................32

Control Valve .............................................................37

EXCEPT FOR EURO-OBD

ON BOARD DIAGNOSTIC............................................39

CONSULT-II...............................................................39

Diagnostic Procedure Without CONSULT-II..............44

SECTION

EURO-OBD

ON BOARD DIAGNOSTIC SYSTEM............................50

Introduction................................................................50

EURO-OBD Function for A/T System .......................50

One or Two Trip Detection Logic of EURO-OBD......50

EURO-OBD Diagnostic Trouble Code (DTC)............50

Malfunction Indicator (MI)..........................................54

CONSULT-II...............................................................54

Diagnostic Procedure Without CONSULT-II..............63

EXCEPT FOR EURO-OBD

TROUBLE DIAGNOSIS -...............................................69

Introduction................................................................69

Work Flow..................................................................73

EURO-OBD

TROUBLE DIAGNOSIS - INTRODUCTION..................74

Introduction................................................................74

Work Flow..................................................................78

TROUBLE DIAGNOSIS - BASIC INSPECTION...........80

A/T Fluid Check.........................................................80

Stall Test....................................................................80

Line Pressure Test.....................................................84

Road Test...................................................................85

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION.............................................................105

Symptom Chart........................................................105

TCM Terminals and Reference Value......................118

TROUBLE DIAGNOSIS FOR POWER SUPPLY........123

Wiring Diagram - AT - MAIN....................................123

Diagnostic Procedure ..............................................124

EXCEPT FOR EURO-OBD

VEHICLE SPEED SENSOR.A/T..................................126

AT

CONTENTS (Cont’d)

Description...............................................................126

Wiring Diagram - AT - VSSA/T................................128

Diagnostic Procedure ..............................................129

VHCL SPEED SEN.MTR VEHICLE ............................131

Description...............................................................131

Wiring Diagram - AT - VSSMTR..............................132

Diagnostic Procedure ..............................................133

THROTTLE POSITION................................................134

Description...............................................................134

Wiring Diagram - AT - TPS......................................136

Diagnostic Procedure ..............................................137

Component Inspection.............................................141

SHIFT SOLENOID VALVE A ......................................142

Description...............................................................142

Wiring Diagram - AT - SSV/A..................................144

Diagnostic Procedure ..............................................145

Component Inspection.............................................147

SHIFT SOLENOID VALVE B ......................................148

Description...............................................................148

Wiring Diagram - AT - SSV/B..................................150

Diagnostic Procedure ..............................................151

Component Inspection.............................................153

OVERRUN CLUTCH SOLENOID................................154

Description...............................................................154

Wiring Diagram - AT - OVRCSV..............................155

Diagnostic Procedure ..............................................156

Component Inspection.............................................158

TORQUE CONVERTER CLUTCH...............................159

Description...............................................................159

Wiring Diagram - AT - TCV......................................161

Diagnostic Procedure ..............................................162

Component Inspection.............................................164

BATT/FLUID TEMP SEN (A/T FLUID TEMP

SENSOR CIRCUIT AND TCM POWER SOURCE)....165

Description...............................................................165

Wiring Diagram - AT - BA/FTS................................167

Diagnostic Procedure ..............................................168

Component Inspection.............................................171

ENGINE SPEED SIGNAL............................................172

Description...............................................................172

Wiring Diagram - AT - ENGSS................................173

Diagnostic Procedure ..............................................174

LINE PRESSURE SOLENOID ....................................176

Description...............................................................176

Wiring Diagram - AT - LPSV....................................178

Diagnostic Procedure ..............................................179

Component Inspection.............................................182

EURO-OBD

DTC P0705 PARK/NEUTRAL POSITION (PNP)

SWITCH .......................................................................183

Description...............................................................183

Wiring Diagram - AT - PNP/SW...............................185

Diagnostic Procedure ..............................................186

Component Inspection.............................................188

DTC P0710 A/T FLUID TEMPERATURE SENSOR

CIRCUIT.......................................................................189

Description...............................................................189

Wiring Diagram - AT - FTS......................................191

Diagnostic Procedure ..............................................192

Component Inspection.............................................194

DTC P0720 VEHICLE SPEED SENSOR.A/T..............195

Description...............................................................195

Wiring Diagram - AT - VSSA/T................................197

Diagnostic Procedure ..............................................198

DTC P0725 ENGINE SPEED SIGNAL .......................200

Description...............................................................200

Wiring Diagram - AT - ENGSS................................201

Diagnostic Procedure ..............................................202

DTC P0731 A/T 1ST GEAR FUNCTION ....................204

Description...............................................................204

Wiring Diagram - AT - 1ST......................................207

Diagnostic Procedure ..............................................208

Component Inspection.............................................209

DTC P0732 A/T 2ND GEAR FUNCTION....................211

Description...............................................................211

Wiring Diagram - AT - 2ND......................................214

Diagnostic Procedure ..............................................215

Component Inspection.............................................216

DTC P0733 A/T 3RD GEAR FUNCTION....................217

Description...............................................................217

Wiring Diagram - AT - 3RD......................................220

Diagnostic Procedure ..............................................221

Component Inspection.............................................222

DTC P0734 A/T 4TH GEAR FUNCTION ....................223

Description...............................................................223

Wiring Diagram - AT - 4TH......................................227

Diagnostic Procedure ..............................................228

Component Inspection.............................................232

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE......................................................233

Description...............................................................233

Wiring Diagram - AT - TCV......................................235

Diagnostic Procedure ..............................................236

Component Inspection.............................................238

DTC P0745 LINE PRESSURE SOLENOID VALVE...239

Description...............................................................239

Wiring Diagram - AT - LPSV....................................241

Diagnostic Procedure ..............................................242

Component Inspection.............................................245

DTC P0750 SHIFT SOLENOID VALVE A ..................246

Description...............................................................246

Wiring Diagram - AT - SSV/A..................................248

Diagnostic Procedure ..............................................249

AT-2

CONTENTS (Cont’d)

Component Inspection.............................................251

DTC P0755 SHIFT SOLENOID VALVE B..................252

Description...............................................................252

Wiring Diagram - AT - SSV/B..................................254

Diagnostic Procedure ..............................................255

Component Inspection.............................................257

DTC P1705 THROTTLE POSITION SENSOR ...........258

Description...............................................................258

Wiring Diagram - AT - TPS......................................261

Diagnostic Procedure ..............................................263

Component Inspection.............................................267

DTC P1760 OVERRUN CLUTCH SOLENOID

VALVE..........................................................................268

Description...............................................................268

Wiring Diagram - AT - OVRCSV..............................270

Diagnostic Procedure ..............................................271

Component Inspection.............................................273

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP

SENSOR CIRCUIT AND TCM POWER SOURCE)....274

Description...............................................................274

Wiring Diagram - AT - BA/FTS................................276

Diagnostic Procedure ..............................................277

Component Inspection.............................................280

DTC VHCL SPEED SEN.MTR VEHICLE SPEED

SENSOR.MTR..............................................................281

Description...............................................................281

Wiring Diagram - AT - VSSMTR..............................283

Diagnostic Procedure ..............................................285

DTC CONTROL UNIT (RAM), CONTROL UNIT

(ROM)...........................................................................286

Description...............................................................286

Diagnostic Procedure ..............................................286

DTC CONTROL UNIT (EEP ROM).............................288

Description...............................................................288

Diagnostic Procedure ..............................................289

TROUBLE DIAGNOSES FOR SYMPTOMS...............290

Wiring Diagram - AT - NONDTC/General and

Except for Euro-OBD...............................................290

Wiring Diagram - AT - NONDTC/EURO-OBD.........292

1. O/D OFF Indicator Lamp Does Not Come On....296

2. Engine Cannot Be Started In ″P″ and ″N″

Position....................................................................299

3. In ″P″ Position, Vehicle Moves Forward Or

Backward When Pushed.........................................300

4. In ″N″ Position, Vehicle Moves ...........................301

5. Large Shock. ″N″ -> ″R″ Position .......................303

6. Vehicle Does Not Creep Backward In ″R″

Position....................................................................305

7. Vehicle Does Not Creep Forward In ″D″, ″2″

Or ″1″ Position.........................................................308

8. Vehicle Cannot Be Started From D

9. A/T Does Not Shift: D

Kickdown: D

-> D2..................................................314

4

10. A/T Does Not Shift: D

11. A/T Does Not Shift: D

-> D2Or Does Not

1

-> D3.............................317

2

-> D4.............................320

3

...................311

1

12. A/T Does Not Perform Lock-up.........................323

13. A/T Does Not Hold Lock-up Condition..............325

14. Lock-up Is Not Released...................................327

15. Engine Speed Does Not Return To Idle (Light

Braking D

16. Vehicle Does Not Start From D

17. A/T Does Not Shift: D

-> D3).....................................................328

4

.......................330

1

-> D3, When

4

Overdrive Control Switch ″ON″ -> ″OFF″ ...............331

18. A/T Does Not Shift: D

-> 22, When Selector

3

Lever ″D″ -> ″2″ Position.........................................332

19. A/T Does Not Shift: 2

-> 11, When Selector

2

Lever ″2″ -> ″1″ Position.........................................333

20. Vehicle Does Not Decelerate By Engine

Brake........................................................................334

21. TCM Self-diagnosis Does Not Activate (PNP,

Overdrive Control and Throttle Position Switches

Circuit Checks) ........................................................334

A/T SHIFT LOCK SYSTEM.........................................343

Description...............................................................343

Shift Lock System Electrical Parts Location............343

Wiring Diagram - SHIFT -........................................344

Diagnostic Procedure ..............................................345

KEY INTERLOCK CABLE ..........................................349

Components.............................................................349

Removal...................................................................349

Installation................................................................350

ON-VEHICLE SERVICE ..............................................351

Control Valve Assembly and Accumulators.............351

Control Cable Adjustment........................................352

Park/Neutral Position (PNP) Switch Adjustment .....352

Differential Side Oil Seal Replacement...................353

Revolution Sensor Replacement.............................353

REMOVAL AND INSTALLATION...............................354

Removal...................................................................354

Installation................................................................355

OVERHAUL .................................................................357

Components-1 3AX00, 3AX01, 3AX19, 3AX63

and 3AX64 models..................................................357

Components-1 3AX10 and 3AX18 models .............358

Components-2 3AX00, 3AX01, 3AX19, 3AX63

and 3AX64 models..................................................359

Components-2 3AX10 and 3AX18 models .............360

Components-3 3AX00, 3AX01, 3AX19, 3AX63

and 3AX64 models..................................................361

Components-3 3AX10 and 3AX18 models .............362

Oil Channel..............................................................363

AT-3

CONTENTS (Cont’d)

Locations of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings - 3AX00, 01,

19, 63 and 64 models..............................................364

Locations of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings - 3AX10 and

3AX18 models .........................................................365

DISASSEMBLY............................................................366

REPAIR FOR COMPONENT PARTS .........................381

Manual Shaft............................................................381

Oil Pump..................................................................384

Control Valve Assembly...........................................388

Control Valve Upper Body.......................................397

Control Valve Lower Body.......................................401

Reverse Clutch ........................................................403

High Clutch ..............................................................407

Forward Clutch and Overrun Clutch........................412

Low & Reverse Brake..............................................419

Rear Internal Gear, Forward Clutch Hub and

Overrun Clutch Hub.................................................423

O/Shaft, O/Gear, I/Gear, R/Pinion Gear and B/

Retainer - 3AX00, 01, 19, 63 and 64 models.........427

Output Shaft, Idler Gear, Reduction Pinion Gear

and Bearing Retainer - 3AX10 and 3AX18

models .....................................................................432

Band Servo Piston Assembly..................................437

Final Drive................................................................442

ASSEMBLY..................................................................446

Assembly (1)............................................................446

Adjustment (1) .........................................................447

Assembly (2)............................................................455

Adjustment (2) .........................................................459

Assembly (3)............................................................462

Assembly (4)............................................................465

SERVICE DATA AND SPECIFICATIONS (SDS).......470

General Specifications.............................................470

Shift Schedule..........................................................470

Stall Revolution........................................................473

Line Pressure...........................................................473

Control Valves..........................................................474

Clutch and Brakes...................................................474

Clutch and Brake Return Springs............................477

Oil Pump..................................................................477

Input Shaft ...............................................................478

Planetary Carrier......................................................478

Final Drive................................................................478

Reduction Pinion Gear ............................................480

Output Shaft - 3AX00, 3AX01, 3AX19, 3AX63

and 3AX64 models..................................................481

Output Shaft - 3AX10 and 3AX18 models..............483

Bearing Retainer......................................................484

Total End Play..........................................................484

Reverse Clutch End Play ........................................484

Accumulator.............................................................484

Band Servo..............................................................485

Removal and Installation.........................................485

Shift Solenoid Valves...............................................485

Resistance...............................................................485

ATF Temp. Sensor...................................................485

Revolution Sensor ...................................................485

Dropping Resistor....................................................485

AT-4

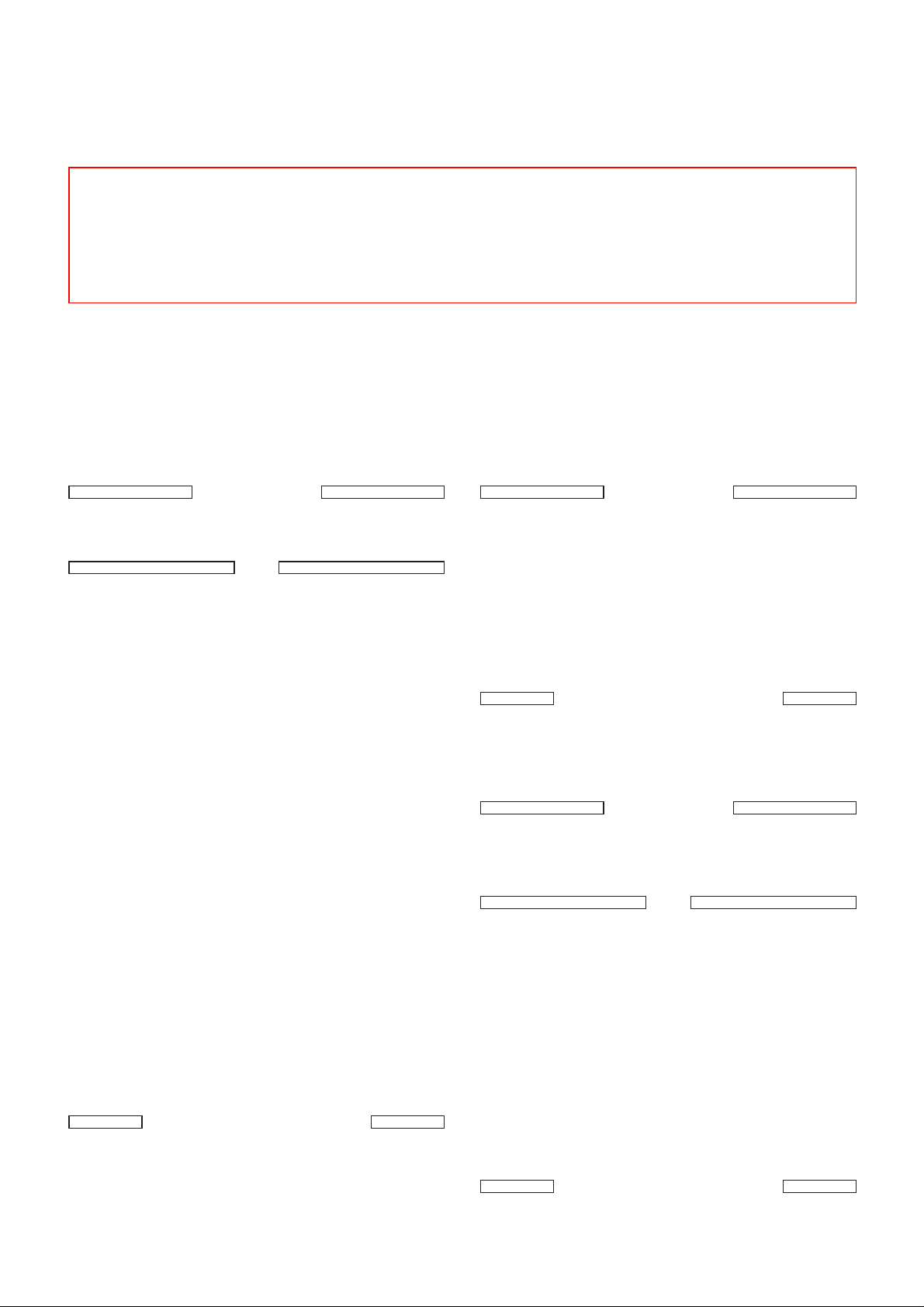

TROUBLE DIAGNOSIS — INDEX

EURO-OBD

Alphabetical & P No. Index for DTC

Alphabetical & P No. Index for DTC

ALPHABETICAL INDEX FOR DTC

Check if the vehicle is a model with Euro-OBD system or not by the

“Type approval number” on the identification plate. Refer to GI-40,

“IDENTIFICATION PLATE”.

Type approval number Model

Available With Euro-OBD system

Not available (blank) Without Euro-OBD system

Items

(CONSULT-II screen terms)

A/T 1ST GR FNCTN P0731 AT-204

A/T 2ND GR FNCTN P0732 AT-211

A/T 3RD GR FNCTN P0733 AT-217

A/T 4TH GR FNCTN P0734 AT-223

ATF TEMP SEN/CIRC P0710 AT-189

ENGINE SPEED SIG P0725 AT-200

DTC

CONSULT-II

GST*1

Reference page

NJAT0243

NJAT0243S01

L/PRESS SOL/CIRC P0745 AT-239

O/R CLTCH SOL/CIRC P1760 AT-268

PNP SW/CIRC P0705 AT-183

SFT SOL A/CIRC*2 P0750 AT-246

SFT SOL B/CIRC*2 P0755 AT-252

TCC SOLENOID/CIRC P0740 AT-233

TP SEN/CIRC A/T*2 P1705 AT-258

VEH SPD SEN/CIR AT*3 P0720 AT-195

*1: These numbers are prescribed by SAE J2012.

*2: When the fail-safe operation occurs, the MIL illuminates.

*3: The MIL illuminates when both the “Revolution sensor signal” and the “Vehicle speed sensor signal” meet the fail-safe condition at

the same time.

AT-5

TROUBLE DIAGNOSIS — INDEX

Alphabetical & P No. Index for DTC (Cont’d)

EURO-OBD

P NO. INDEX FOR DTC

Check if the vehicle is a model with Euro-OBD system or not by the

“Type approval number” on the identification plate. Refer to GI-40,

“IDENTIFICATION PLATE”.

Type approval number Model

Available With Euro-OBD system

Not available (blank) Without Euro-OBD system

DTC

CONSULT-II

GST*1

P0705 PNP SW/CIRC AT-183

P0710 ATF TEMP SEN/CIRC AT-189

P0720 VEH SPD SEN/CIR AT*3 AT-195

P0725 ENGINE SPEED SIG AT-200

P0731 A/T 1ST GR FNCTN AT-204

P0732 A/T 2ND GR FNCTN AT-211

P0733 A/T 3RD GR FNCTN AT-217

(CONSULT-II screen terms)

Items

Reference page

=NJAT0243S02

P0734 A/T 4TH GR FNCTN AT-223

P0740 TCC SOLENOID/CIRC AT-233

P0745 L/PRESS SOL/CIRC AT-239

P0750 SFT SOL A/CIRC*2 AT-246

P0755 SFT SOL B/CIRC*2 AT-252

P1705 TP SEN/CIRC A/T*2 AT-258

P1760 O/R CLTCH SOL/CIRC AT-268

*1: These numbers are prescribed by SAE J2012.

*2: When the fail-safe operation occurs, the MIL illuminates.

*3: The MIL illuminates when both the “Revolution sensor signal” and the “Vehicle speed sensor signal” meet the fail-safe condition at

the same time.

AT-6

PRECAUTIONS

Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER”

Supplemental Restraint System (SRS) “AIR

BAG” and “SEAT BELT PRE-TENSIONER”

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER” used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL N16 is as follows (The composition varies according to the destination and optional equipment.):

+ For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steering wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+ For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in the RS section of this Service Manual.

WARNING:

+ To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be performed by an authorized NISSAN dealer.

+ Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+ Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

NJAT0249

Precautions for On Board Diagnostic (EUROOBD) System of A/T and Engine — Euro-OBD

—

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

+ Be sure to turn the ignition switch “OFF” and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc.

will cause the MIL to light up.

+ Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

+ Be sure to route and secure the harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MIL to light up due to a short circuit.

+ Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to a malfunction of the EGR system or fuel injection system,

etc.

+ Be sure to erase the unnecessary malfunction information (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

Precautions

+ Before connecting or disconnecting the TCM harness

connector, turn ignition switch OFF and disconnect negative battery terminal. Failure to do so may damage the

TCM. Because battery voltage is applied to TCM even if

ignition switch is turned off.

NJAT0245

NJAT0246

SEF289H

AT-7

Precautions (Cont’d)

PRECAUTIONS

+ When connecting or disconnecting pin connectors into or

from TCM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on TCM

pin terminal, when connecting pin connectors.

AAT470A

+ Before replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions properly or not. (See page AT-118.)

MEF040DA

SAT964I

+ After performing each TROUBLE DIAGNOSIS, perform

“DTC (Diagnostic Trouble Code) CONFIRMATION PROCEDURE”.

The DTC should not be displayed in the “DTC CONFIRMATION PROCEDURE” if the repair is completed.

+ Before proceeding with disassembly, thoroughly clean the out-

side of the transaxle. It is important to prevent the internal parts

from becoming contaminated by dirt or other foreign matter.

+ Disassembly should be done in a clean work area.

+ Use lint-free cloth or towels for wiping parts clean. Common

shop rags can leave fibers that could interfere with the operation of the transaxle.

+ Place disassembled parts in order for easier and proper

assembly.

+ All parts should be carefully cleaned with a general purpose,

non-flammable solvent before inspection or reassembly.

+ Gaskets, seals and O-rings should be replaced any time the

transaxle is disassembled.

+ It is very important to perform functional tests whenever they

are indicated.

+ The valve body contains precision parts and requires extreme

care when parts are removed and serviced. Place disassembled valve body parts in order for easier and proper

assembly. Care will also prevent springs and small parts from

becoming scattered or lost.

+ Properly installed valves, sleeves, plugs, etc. will slide along

bores in valve body under their own weight.

+ Before assembly, apply a coat of recommended ATF to all

AT-8

PRECAUTIONS

Precautions (Cont’d)

parts. Apply petroleum jelly to protect O-rings and seals, or

hold bearings and washers in place during assembly. Do not

use grease.

+ Extreme care should be taken to avoid damage to O-rings,

seals and gaskets when assembling.

+ After overhaul, refill the transaxle with new ATF.

+ When the A/T drain plug is removed, only some of the fluid is

drained. Old A/T fluid will remain in torque converter and ATF

cooling system.

Always follow the procedures under “ChangingA/T Fluid” in the

AT section when changing A/T fluid. Refer to “Changing A/T

Fluid”, AT-15.

Service Notice or Precautions

FAIL-SAFE

NJAT0247

NJAT0247S01

The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major

electrical input/output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in third gear, even with a shift lever position of “1”, “2” or “D”. The

customer may complain of sluggish or poor acceleration.

When the ignition key is turned “ON” following Fail-Safe operation, O/D OFF indicator lamp blinks for about

8 seconds. (For GENERALAND EXCEPT FOR EURO-OBD; “SELF-DIAGNOSTIC PROCEDURE (WITHOUT

CONSULT-II)”, refer to AT-44 and for EURO-OBD; “TCM SELF-DIAGNOSTIC PROCEDURE (No Tools)”, refer

to AT-63.)

Fail-Safe may occur without electrical circuit damage if the vehicle is driven under extreme conditions (such

as excessive wheel spin followed by sudden braking). To recover normal shift pattern, turn the ignition key

“OFF” for 5 seconds, then “ON”.

The blinking of the O/D OFF indicator lamp for about 8 seconds will appear only once and be cleared. The

customer may resume normal driving conditions.

Always follow the “WORK FLOW” [Refer to AT-73 (General and except for Euro-OBD), AT-78 (EURO-OBD).]

The SELF-DIAGNOSIS results will be as follows:

The first SELF-DIAGNOSIS will indicate damage to the vehicle speed sensor or the revolution sensor.

During the next SELF-DIAGNOSIS, performed after checking the sensor, no damages will be indicated.

TORQUE CONVERTER SERVICE

NJAT0247S02

The torque converter should be replaced under any of the following conditions:

+ External leaks in the hub weld area.

+ Converter hub is scored or damaged.

+ Converter pilot is broken, damaged or fits poorly into crankshaft.

+ Steel particles are found after flushing the cooler and cooler lines.

+ Pump is damaged or steel particles are found in the converter.

+ Vehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

+ Converter is contaminated with engine coolant containing antifreeze.

+ Internal failure of stator roller clutch.

+ Heavy clutch debris due to overheating (blue converter).

+ Steel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are

worn or damaged — indicates that lining material came from converter.

AT-9

PRECAUTIONS

Service Notice or Precautions (Cont’d)

The torque converter should not be replaced if:

+ The fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

+ The threads in one or more of the converter bolt holes are damaged.

+ Transaxle failure did not display evidence of damaged or worn internal parts, steel particles or clutch plate

lining material in unit and inside the fluid filter.

+ Vehicle has been exposed to high mileage (only). The exception may be where the torque converter clutch

dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic, such

as taxi, delivery or police use.

EURO-OBD SELF-DIAGNOSIS — EURO-OBD —

NJAT0247S04

+ A/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the O/D OFF indicator or the malfunction indicator (MI). Refer to the table on AT-55

for the indicator used to display each self-diagnostic result.

+ The self-diagnostic results indicated by the MI are automatically stored in both the ECM and TCM memo-

ries.

Always perform the procedure “HOW TO ERASE DTC” on AT-52 to complete the repair and avoid

unnecessary blinking of the MI.

+ The following self-diagnostic items can be detected using ECM self-diagnostic results mode* only when

the O/D OFF indicator lamp does not indicate any malfunctions.

− PNP switch

− A/T 1st, 2nd, 3rd, or 4th gear function

*: For details of EURO-OBD, refer to EC-59, “ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION”.

+ Certain systems and components, especially those related to EURO-OBD, may use a new style

slide-locking type harness connector.

For description and how to disconnect, refer to EL-6, “HARNESS CONNECTOR”.

Wiring Diagrams and Trouble Diagnosis

NJAT0248

When you read wiring diagrams, refer to the following:

+ GI-11, “HOW TO READ WIRING DIAGRAMS”

+ EL-10, “POWER SUPPLY ROUTING”

When you perform trouble diagnosis, refer to the following:

+ GI-32, “HOW TO FOLLOW TEST GROUP IN TROUBLE DIAGNOSIS”

+ GI-21, “HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENT”

AT-10

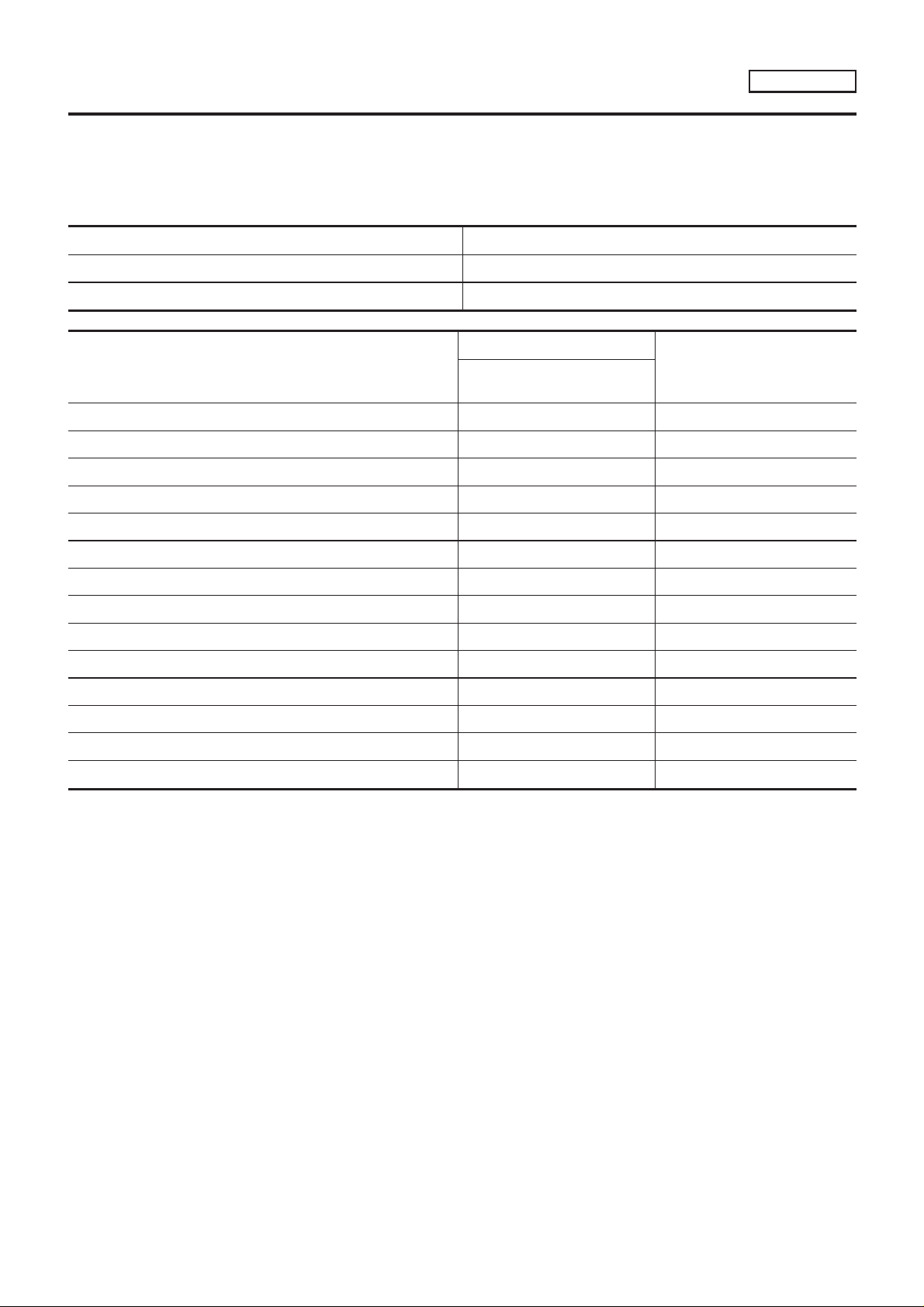

PREPARATION

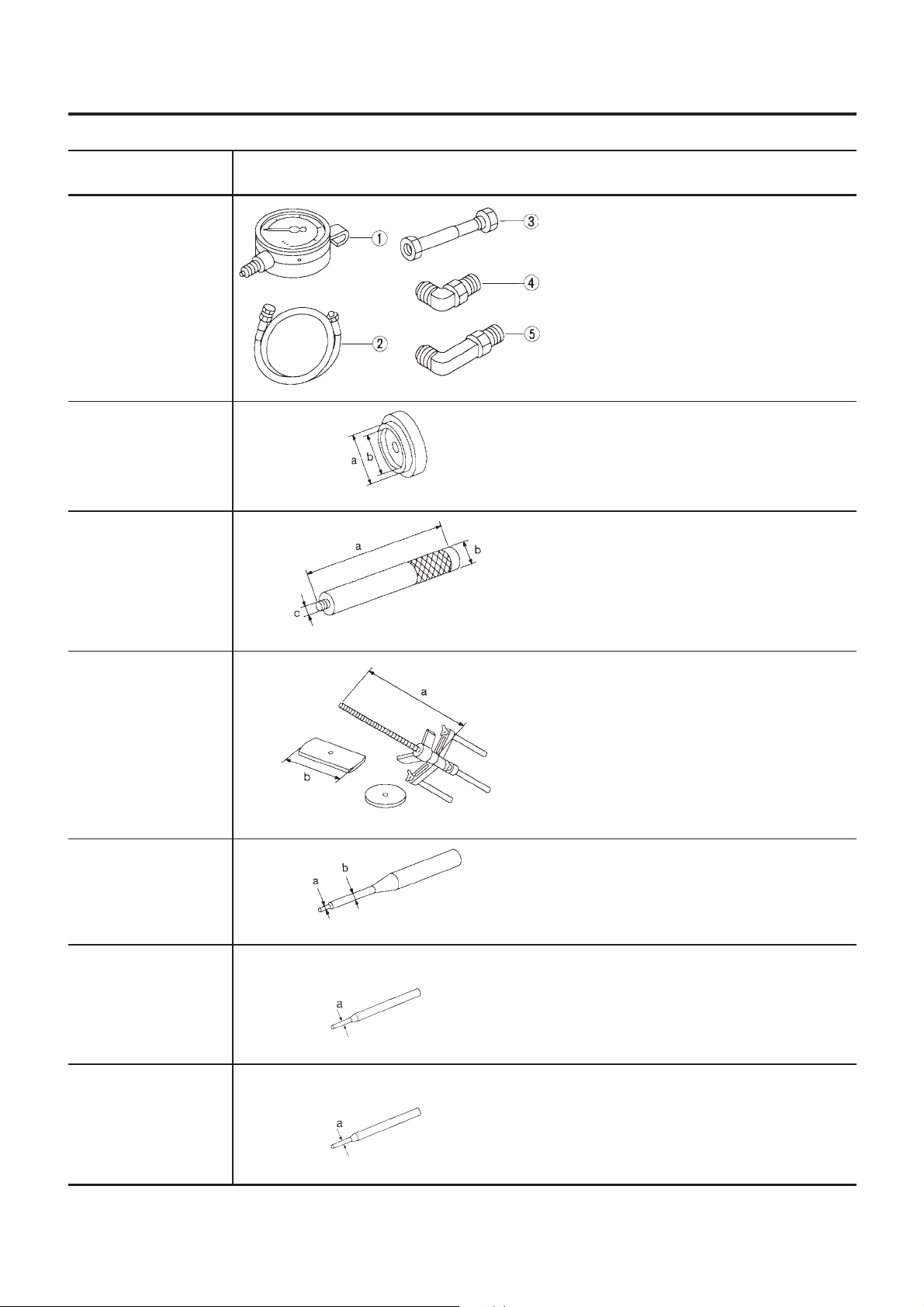

Special Service Tools

Tool number

Tool name

ST2505S001

Oil pressure gauge set

1 ST25051001

Oil pressure gauge

2 ST25052000

Hose

3 ST25053000

Joint pipe

4 ST25054000

Adapter

5 ST25055000

Adapter

KV31103000

Drift

ST35325000

Drift

Description

NT097

NT105

Special Service Tools

Measuring line pressure

Installing differential oil seal

(Use with ST35325000.)

a: 59 mm (2.32 in) dia.

b: 49 mm (1.93 in) dia.

Installing differential oil seal

(Use with KV31103000.)

a: 215 mm (8.46 in)

b: 25 mm (0.98 in) dia.

c: M12 x 1.5P

NJAT0006

KV31103200

Clutch spring compressor

ST23540000

Pin punch

KV32101000

Pin punch

ST25710000

Pin punch

NT417

Removing and installing clutch return spring

a: 320 mm (12.60 in)

b: 174 mm (6.85 in)

NT423

Removing and installing parking rod plate, manual

plate and differential pinion mate shaft retaining

pins

a: 2.3 mm (0.091 in) dia.

b: 4 mm (0.16 in) dia.

NT442

Installing throttle lever and manual shaft retaining

pins

a: 4 mm (0.16 in) dia.

NT410

Aligning groove of manual shaft and hole of transmission case

a: 2 mm (0.08 in) dia.

NT410

AT-11

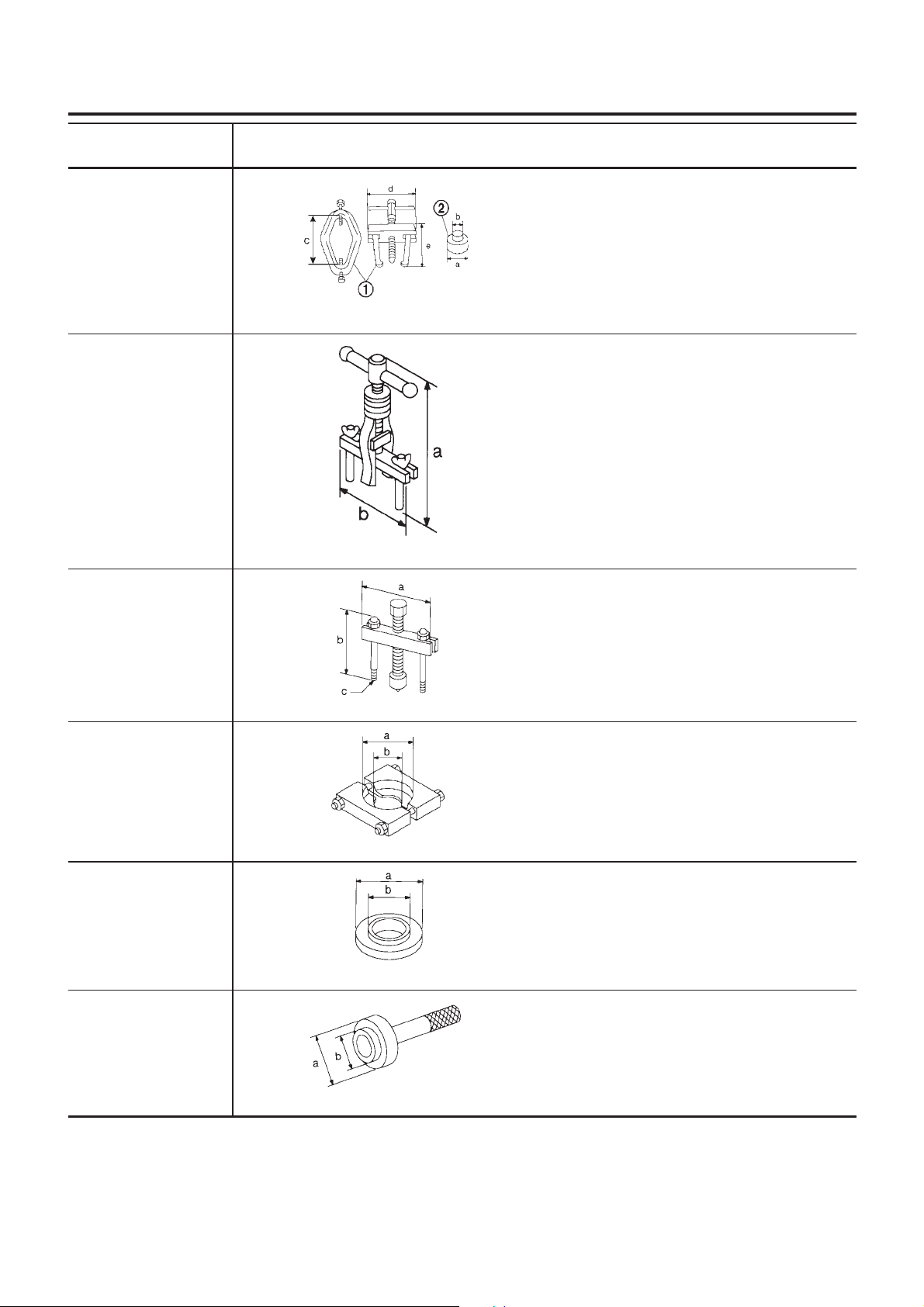

Special Service Tools (Cont’d)

PREPARATION

Tool number

Tool name

ST3306S001

Differential side bearing

puller set

1 ST33051001

Puller

2 ST33061000

Adapter

KV381054S0

Puller

ST27180001

Puller

Description

Removing differential side bearing inner race

a: 39 mm (1.54 in) dia.

b: 29.5 mm (1.161 in) dia.

c: 130 mm (5.12 in)

d: 135 mm (5.31 in)

e: 120 mm (4.72 in)

NT745

+ Removing idler gear bearing outer race

+ Removing differential side oil seals

+ Removing differential side bearing outer race

+ Removing needle bearing from bearing retainer

a: 250 mm (9.84 in)

b: 160 mm (6.30 in)

NT414

+ Removing idler gear

a: 100 mm (3.94 in)

b: 110 mm (4.33 in)

c: M8 x 1.25P

ST30031000

Puller

ST35272000

Drift

ST37830000

Drift

NT424

Removing reduction gear bearing inner race

a: 90 mm (3.54 in) dia.

b: 50 mm (1.97 in) dia.

NT411

+ Installing reduction gear bearing inner race

+ Installing idler gear bearing inner race

a: 72 mm (2.83 in) dia.

b: 35.5 mm (1.398 in) dia.

NT426

Installing idler gear bearing outer race

a: 62 mm (2.44 in) dia.

b: 39 mm (1.54 in) dia.

NT427

AT-12

PREPARATION

Special Service Tools (Cont’d)

Tool number

Tool name

ST35321000

Drift

ST30633000

Drift

ST35271000

Drift

ST33400001

Drift

Description

Installing output shaft bearing

a: 49 mm (1.93 in) dia.

b: 41 mm (1.61 in) dia.

NT073

Installing differential side bearing outer race

a: 67 mm (2.64 in) dia.

b: 49 mm (1.93 in) dia.

NT073

+ Installing idler gear

a: 72 mm (2.83 in) dia.

b: 63 mm (2.48 in) dia.

NT115

+ Installing oil pump housing oil seal

a: 60 mm (2.36 in) dia.

b: 47 mm (1.85 in) dia.

NT115

KV38105710

Preload adapter

NT087

KV40104840

Drift

NT108

Commercial Service Tools

Tool name Description

Puller

+ Measuring clearance between side gear and

differential case

+ Installing output shaft bearing outer race onto

bearing retainer

a: 49 mm (1.93 in) dia.

b: 42 mm (1.65 in) dia.

NJAT0007

+ Removing idler gear bearing inner race

+ Removing and installing band servo

piston snap ring

NT077

AT-13

Commercial Service Tools (Cont’d)

Tool name Description

PREPARATION

Drift

Drift

Drift

Removing idler gear bearing inner race

a: 34 mm (1.34 in) dia.

NT109

Installing differential left side bearing

a: 86 mm (3.39 in) dia.

b: 80 mm (3.15 in) dia.

NT115

Installing differential right side bearing

a: 46 mm (1.81 in) dia.

b: 40 mm (1.57 in) dia.

NT115

AT-14

A/T FLUID

Checking A/T Fluid

SMA827CA

Checking A/T Fluid

NJAT0228

1. Warm up engine.

2. Check for fluid leakage.

3. Before driving, fluid level can be checked at fluid temperatures

of 30 to 50°C (86 to 122°F) using “COLD” range on dipstick.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in “P” position.

c. Check fluid level with engine idling.

d. Remove dipstick and note reading. If level is at low side of

either range, and fluid to the charging pipe.

e. Re-insert dipstick into charging pipe as far as it will go.

f. Remove dipstick and note reading. If reading is at low side of

range, add fluid to the charging pipe.

Do not overfill.

4. Drive vehicle for approximately 5 minutes in urban areas.

5. Re-check fluid level at fluid temperatures of 50 to 80°C (122

to 176°F) using “HOT” range on dipstick.

6. Check fluid condition.

+ If fluid is very dark or smells burned, refer to AT section for

checking operation of A/T. Flush cooling system after repair of

A/T.

+ If A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair ofA/T. Refer to LC-16, “Radiator”.

SMA853B

SMA027D

Changing A/T Fluid

NJAT0229

1. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid from drain plug and refill with new A/T fluid.

Always refill same volume with drained fluid.

Fluid grade:

Nissan Matic “D” or Genuine Nissan Automatic

Transmission Fluid. Refer to “RECOMMENDED FLUIDS AND LUBRICANTS”, MA-16.

Fluid capacity (With torque converter):

7.0 ! (6-1/8 Imp qt)

Drain plug:

: 29 - 39 N·m (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

4. Run engine at idle speed for five minutes.

5. Check fluid level and condition. Refer to “Checking A/T Fluid”.

If fluid is still dirty, repeat steps 2 through 5.

AT-15

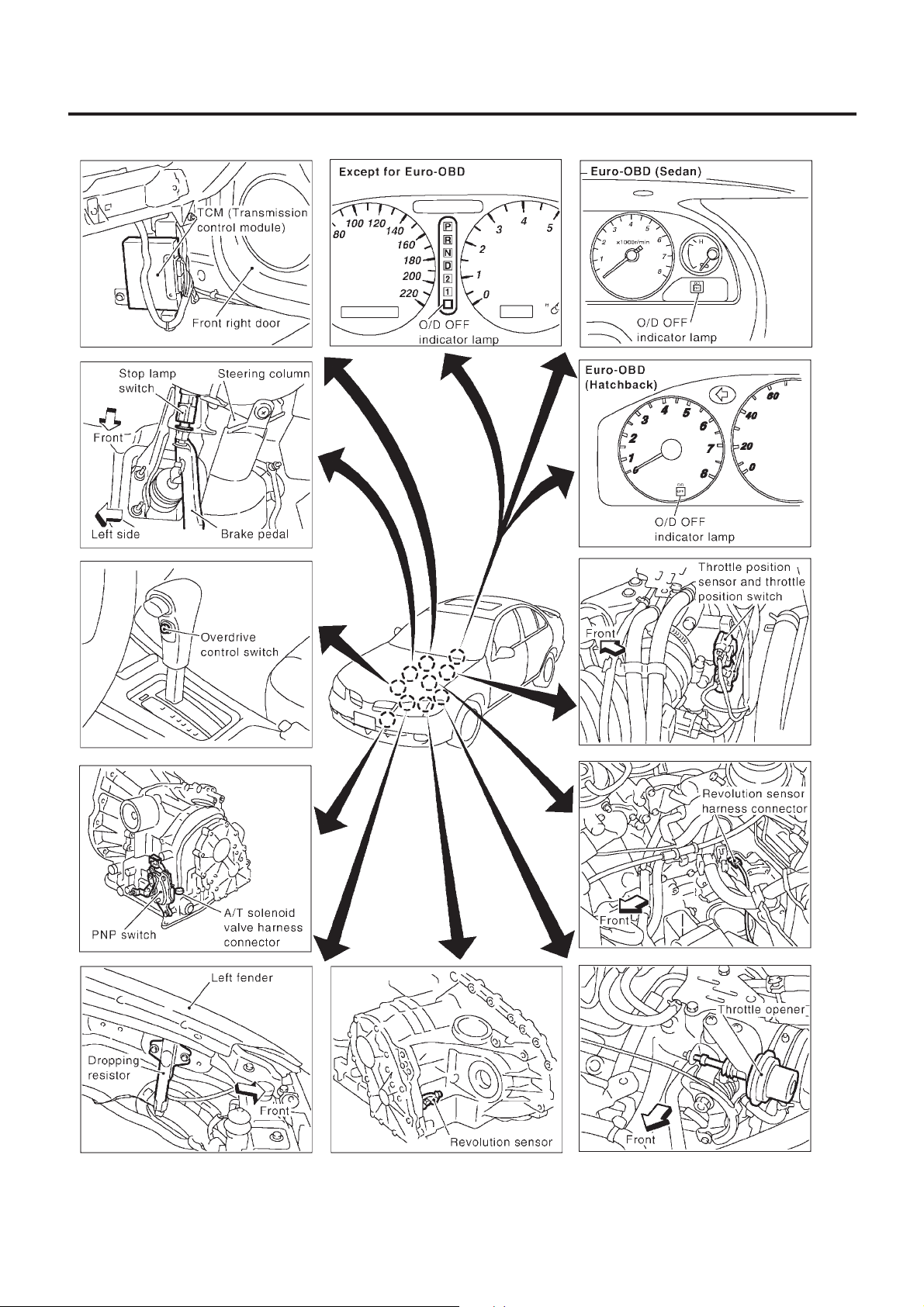

A/T Electrical Parts Location

OVERALL SYSTEM

A/T Electrical Parts Location

NJAT0008

AT-16

SAT069K

OVERALL SYSTEM

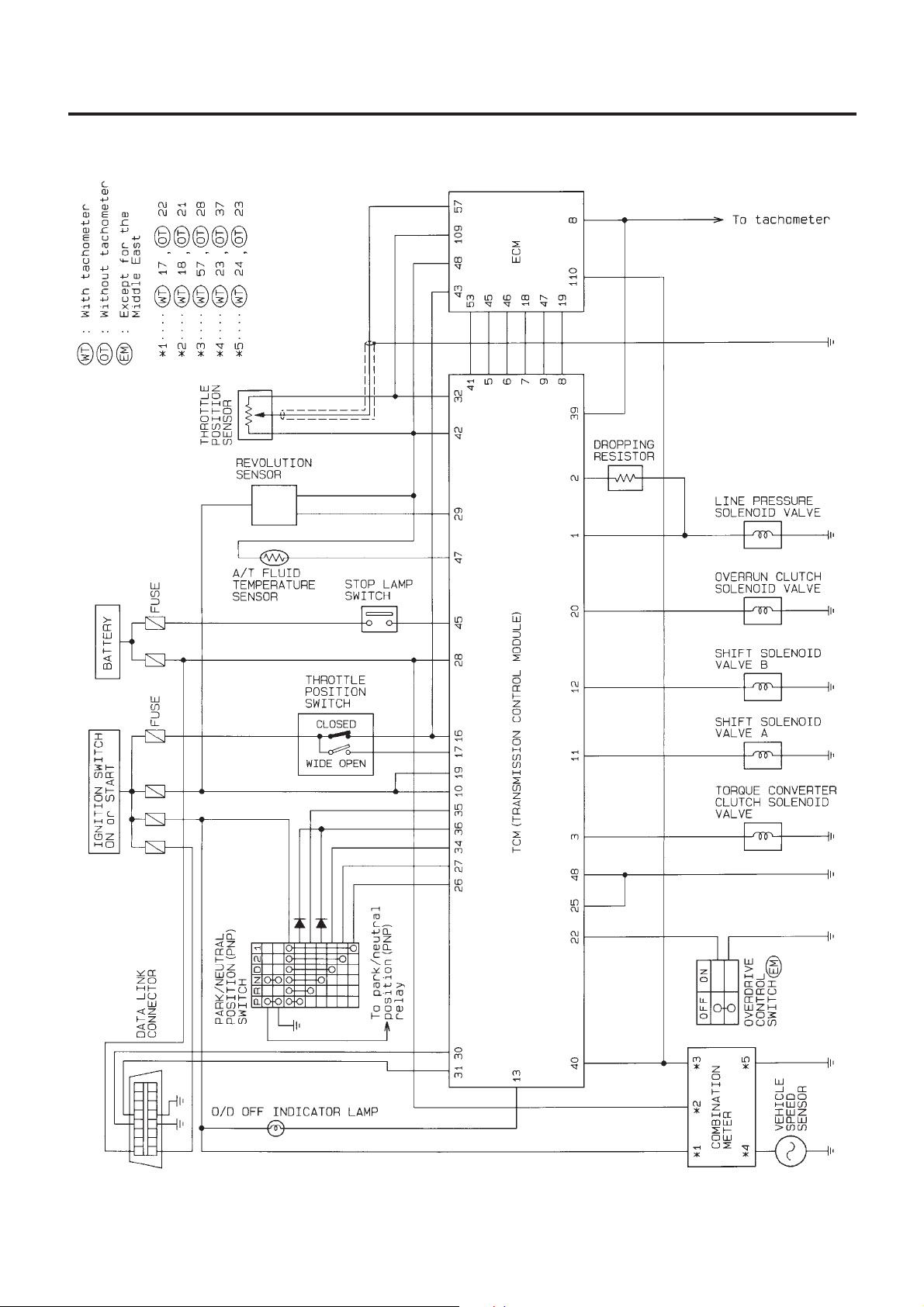

Circuit Diagram

Circuit Diagram

GENERAL AND EXCEPT FOR EURO-OBD

NJAT0009

NJAT0009S01

AT-17

HAT073

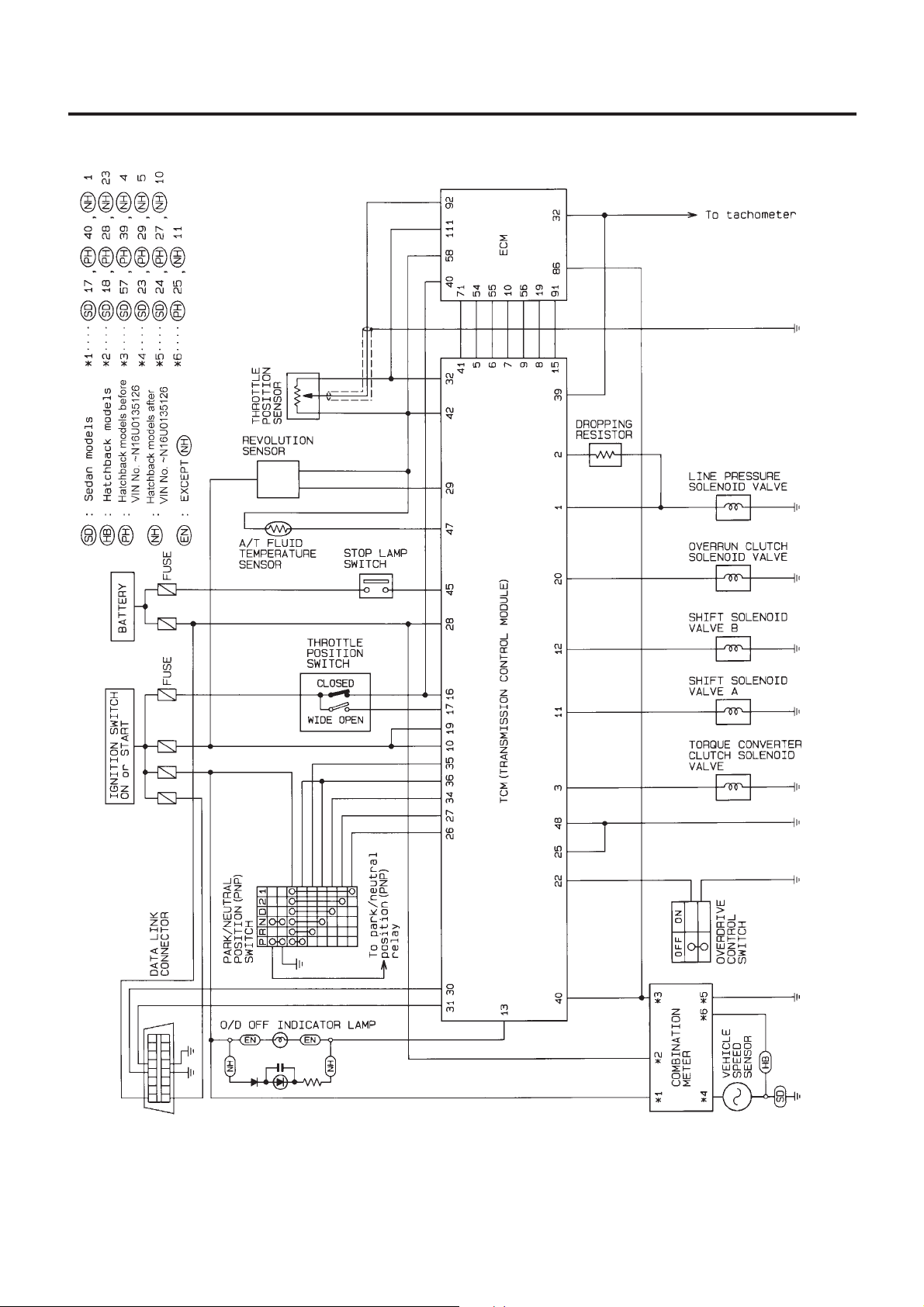

Circuit Diagram (Cont’d)

OVERALL SYSTEM

EURO-OBD

NJAT0009S02

AT-18

NAT353

OVERALL SYSTEM

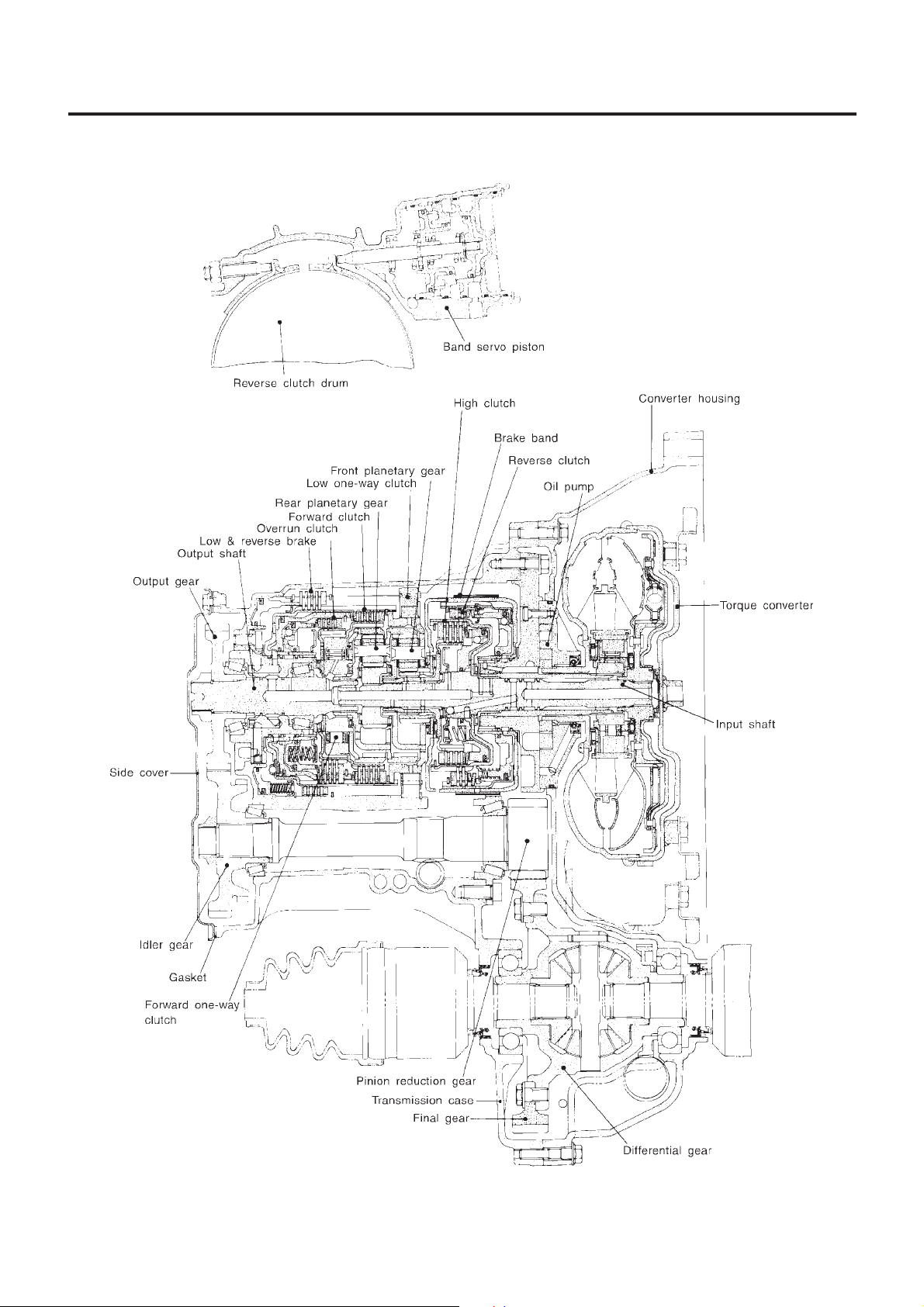

Cross-sectional View — 3AX00, 3AX01, 3AX19, 3AX63 and 3AX64 models

Cross-sectional View — 3AX00, 3AX01, 3AX19,

3AX63 and 3AX64 models

NJAT0011

AT-19

SAT042K

OVERALL SYSTEM

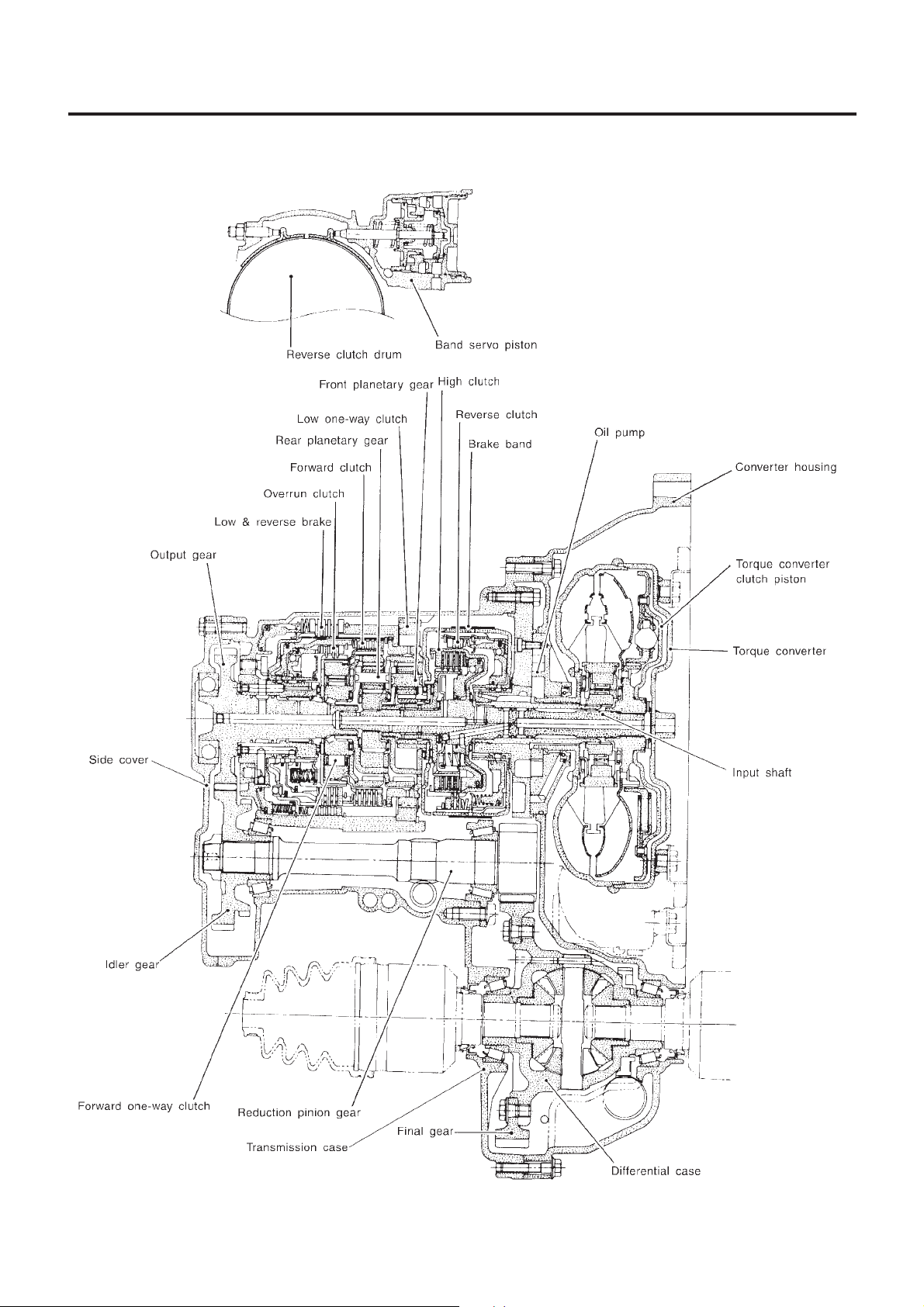

Cross-sectional View — 3AX10 and 3AX18 models

Cross-sectional View — 3AX10 and 3AX18

models

NJAT0217

AT-20

SAT842J

OVERALL SYSTEM

Hydraulic Control Circuit

Hydraulic Control Circuit

NJAT0012

AT-21

SAT844J

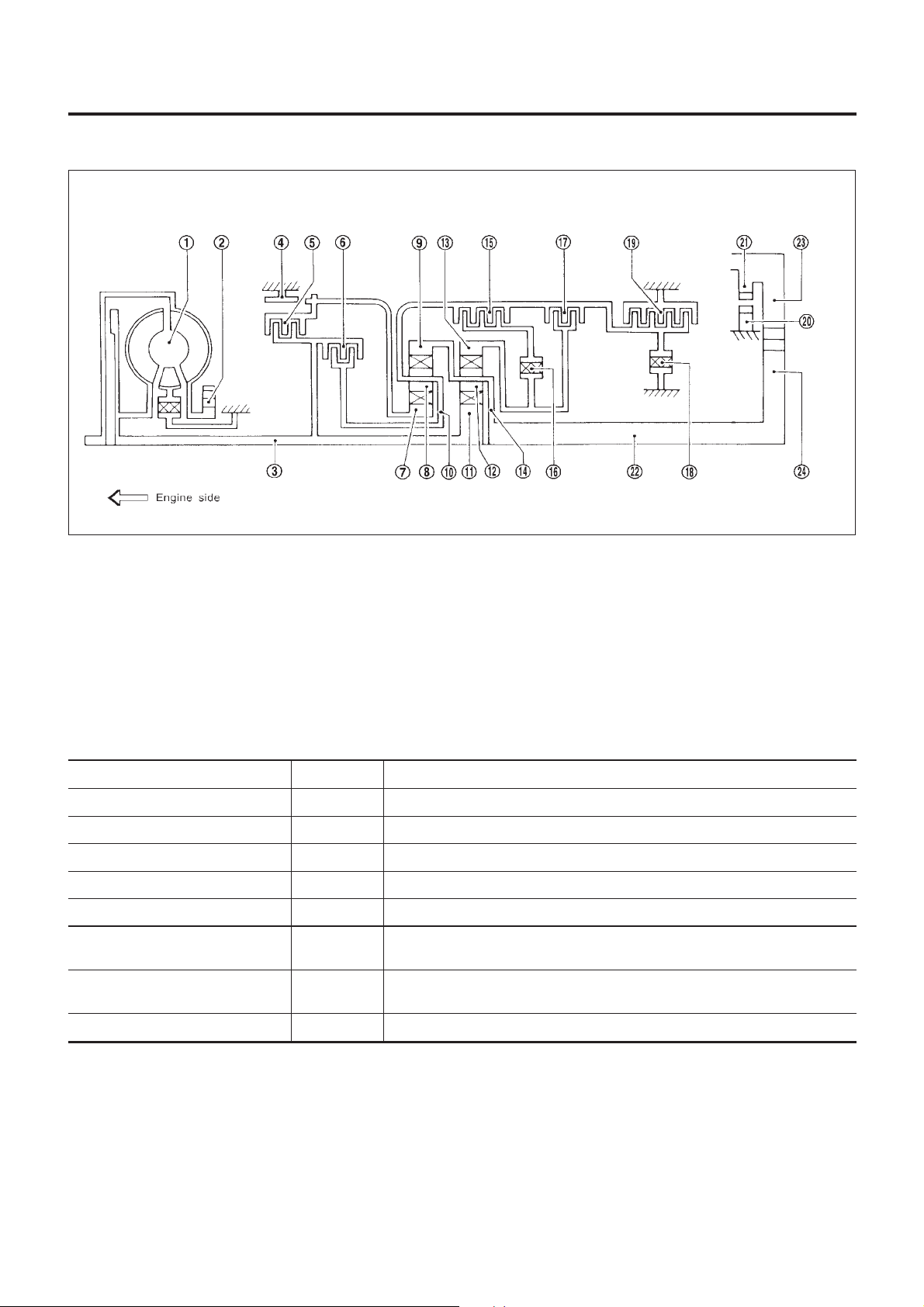

Shift Mechanism

OVERALL SYSTEM

CONSTRUCTION

1. Torque converter

2. Oil pump

3. Input shaft

4. Brake band

5. Reverse clutch

6. High clutch

7. Front sun gear

8. Front pinion gear

Shift Mechanism

9. Front internal gear

10. Front planetary carrier

11. Rear sun gear

12. Rear pinion gear

13. Rear internal gear

14. Rear planetary carrier

15. Forward clutch

16. Forward one-way clutch

NJAT0013

NJAT0013S01

SAT998I

17. Overrun clutch

18. Low one-way clutch

19. Low & reverse brake

20. Parking pawl

21. Parking gear

22. Output shaft

23. Idle gear

24. Output gear

FUNCTION OF CLUTCH AND BRAKE

Clutch and brake components Abbr. Function

5 Reverse clutch R/C To transmit input power to front sun gear 7.

6 High clutch H/C To transmit input power to front planetary carrier 10.

15 Forward clutch F/C To connect front planetary carrier 10 with forward one-way clutch 16.

17 Overrun clutch O/C To connect front planetary carrier 10 with rear internal gear 13.

4 Brake band B/B To lock front sun gear 7.

16 Forward one-way clutch F/O.C When forward clutch 15 is engaged, to stop rear internal gear 13 from rotat-

ing in opposite direction against engine revolution.

18 Low one-way clutch L/O.C To stop front planetary carrier 10 from rotating in opposite direction against

engine revolution.

19 Low & reverse brake L & R/B To lock front planetary carrier 10.

NJAT0013S03

AT-22

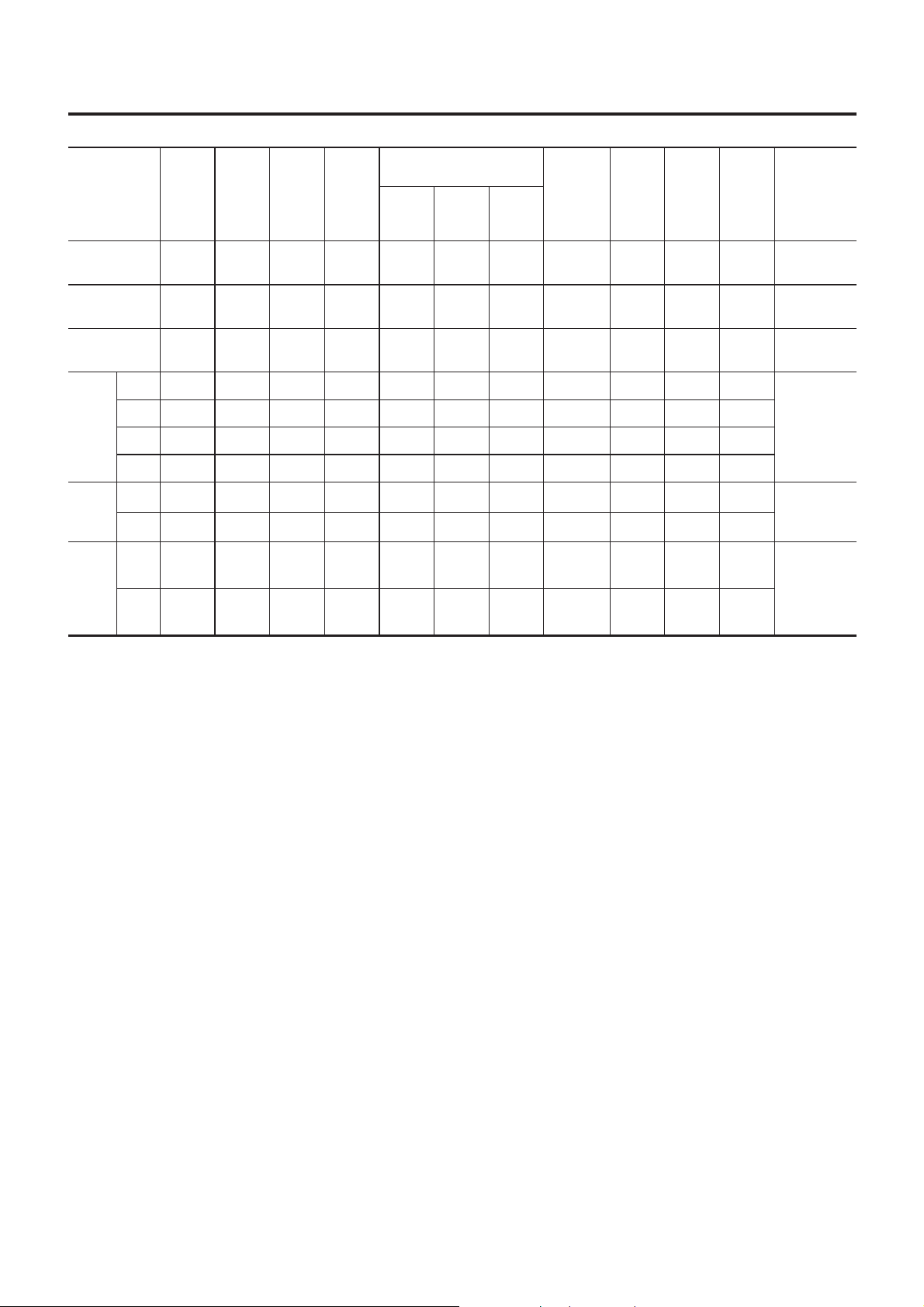

OVERALL SYSTEM

Shift Mechanism (Cont’d)

CLUTCH AND BAND CHART

2nd

apply

Band servo

3rd

release

4th

apply

Forward

one-way

clutch

16

Reverse

Shift position

P

R j j

N

D*4

2

1

clutch

1st j *1D B B

2nd j *1A j B

3rd jj*1A *2C C B *5j

4th j C *3C C jj

1st j DBB

2nd j A j B

1st jj B j

2nd jjj B

High

clutch

5

For-

ward

clutch

6

15

Over-

run

clutch

17

Low

one-

way

clutch

18

Low &

reverse

brake

19

NJAT0013S04

Lock-up Remarks

PARK

POSITION

REVERSE

POSITION

NEUTRAL

POSITION

Automatic

shift

1 ⇔ 2 ⇔ 3

⇔ 4

Automatic

shift

1 ⇔ 2

Locks (held

stationary)

in 1st

speed

1 ⇐ 2

*1: Operates when overdrive control switch is set in “OFF” position.

*2: Oil pressure is applied to both 2nd “apply” side and 3rd “release” side of band servo piston. However, brake band does not contract

because oil pressure area on the “release” side is greater than that on the “apply” side.

*3: Oil pressure is applied to 4th “apply” side in condition *2 above, and brake band contracts.

*4: A/T will not shift to 4th when overdrive control switch is set in “OFF” position.

*5: Operates when overdrive control switch is “OFF”.

j : Operates.

A: Operates when throttle opening is less than 3/16, activating engine brake.

B: Operates during “progressive” acceleration.

C: Operates but does not affect power transmission.

D: Operates when throttle opening is less than 3/16, but does not affect engine brake.

AT-23

Shift Mechanism (Cont’d)

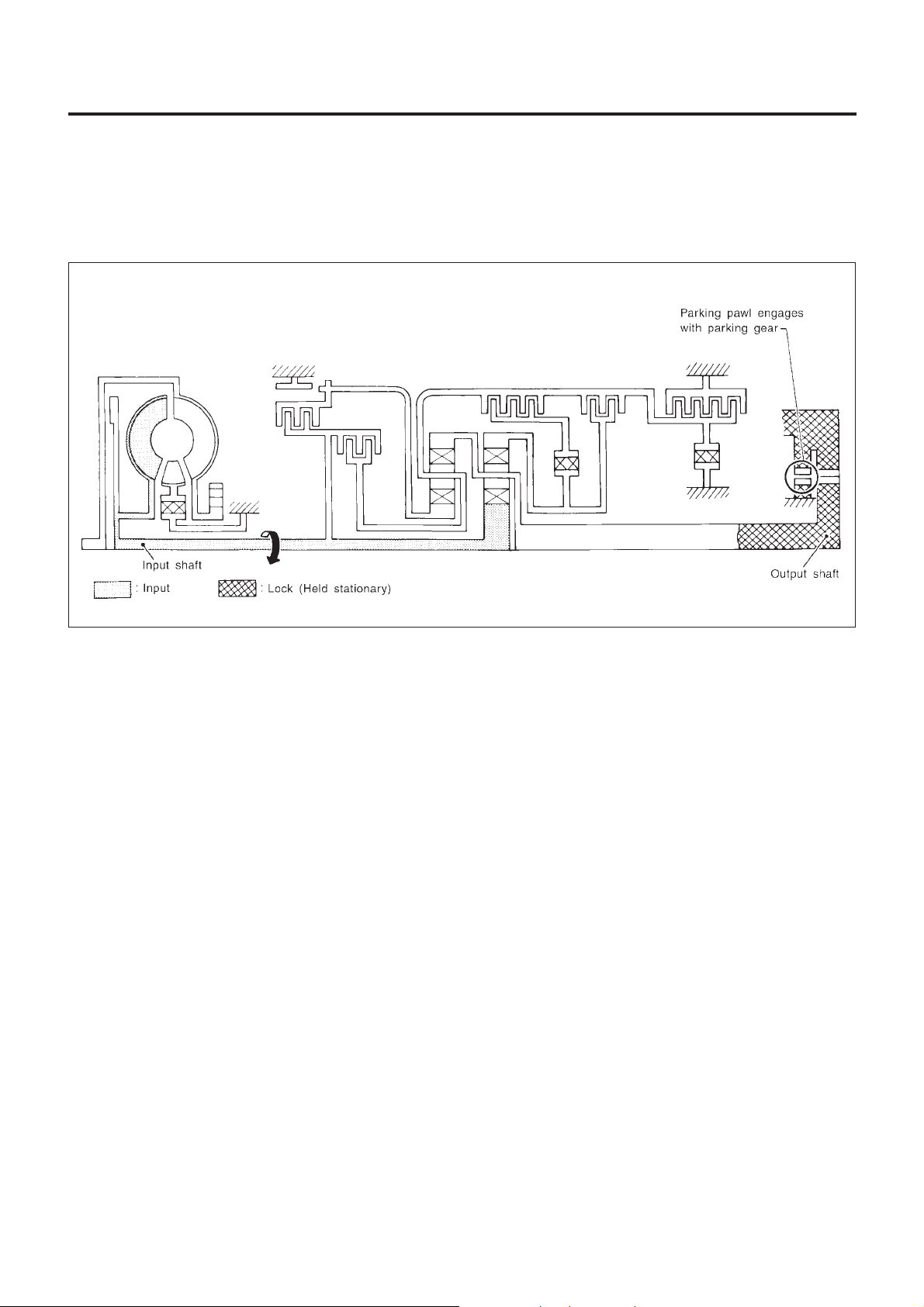

OVERALL SYSTEM

POWER TRANSMISSION

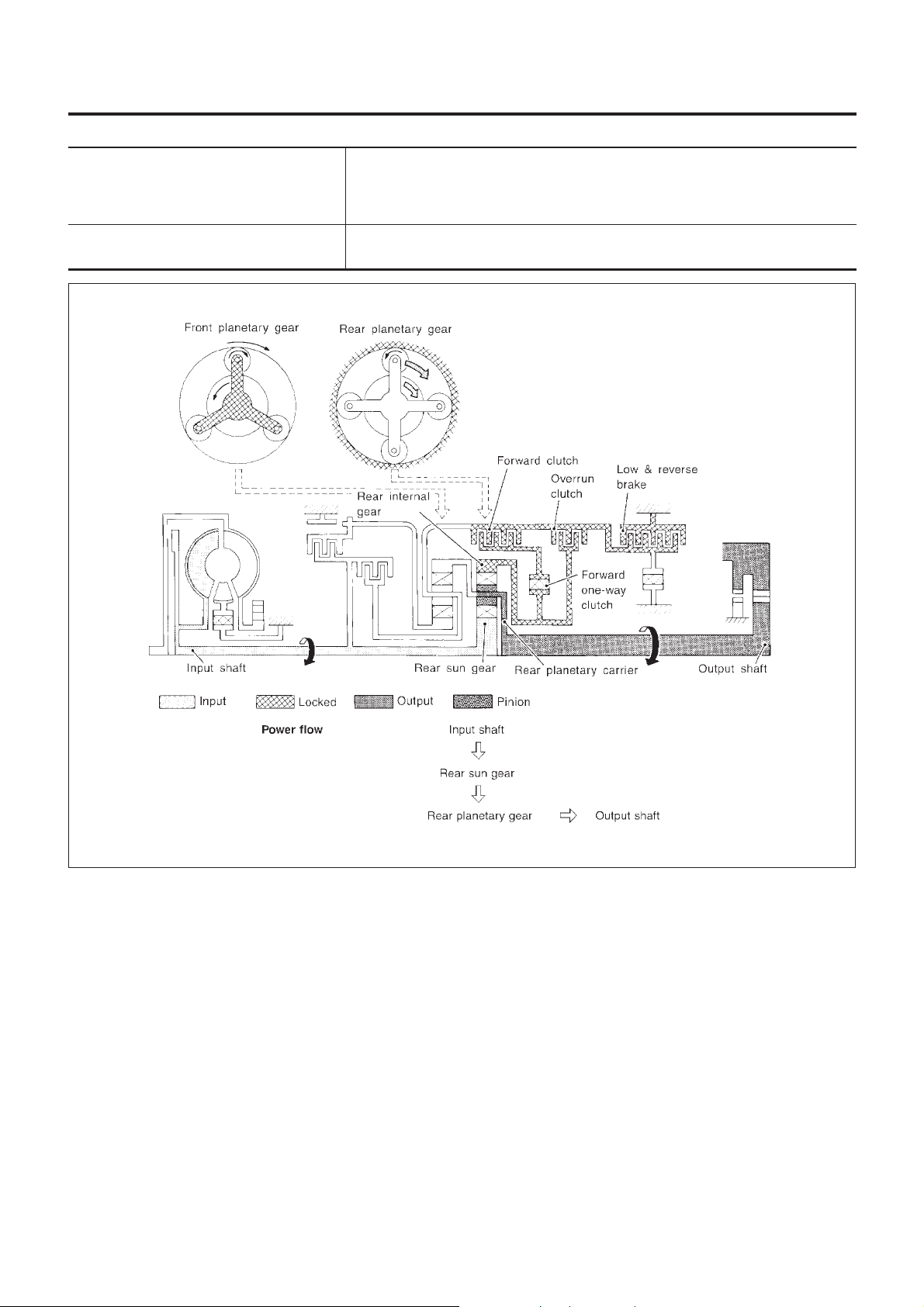

“N” and “P” Positions

+ “N” position

Power from the input shaft is not transmitted to the output shaft because the clutches do not operate.

+ “P” position

Similar to the “N” position, the clutches do not operate. The parking pawl engages with the parking gear

to mechanically hold the output shaft so that the power train is locked.

=NJAT0013S02

NJAT0013S0201

SAT991I

AT-24

OVERALL SYSTEM

Shift Mechanism (Cont’d)

“11” Position

+ Forward clutch

+ Forward one-way clutch

+ Overrun clutch

+ Low and reverse brake

Engine brake Overrun clutch always engages, therefore engine brake can be obtained when

As overrun clutch engages, rear internal gear is locked by the operation of low and

reverse brake.

This is different from that of D

decelerating.

and 21.

1

=NJAT0013S0202

AT-25

SAT374J

Shift Mechanism (Cont’d)

OVERALL SYSTEM

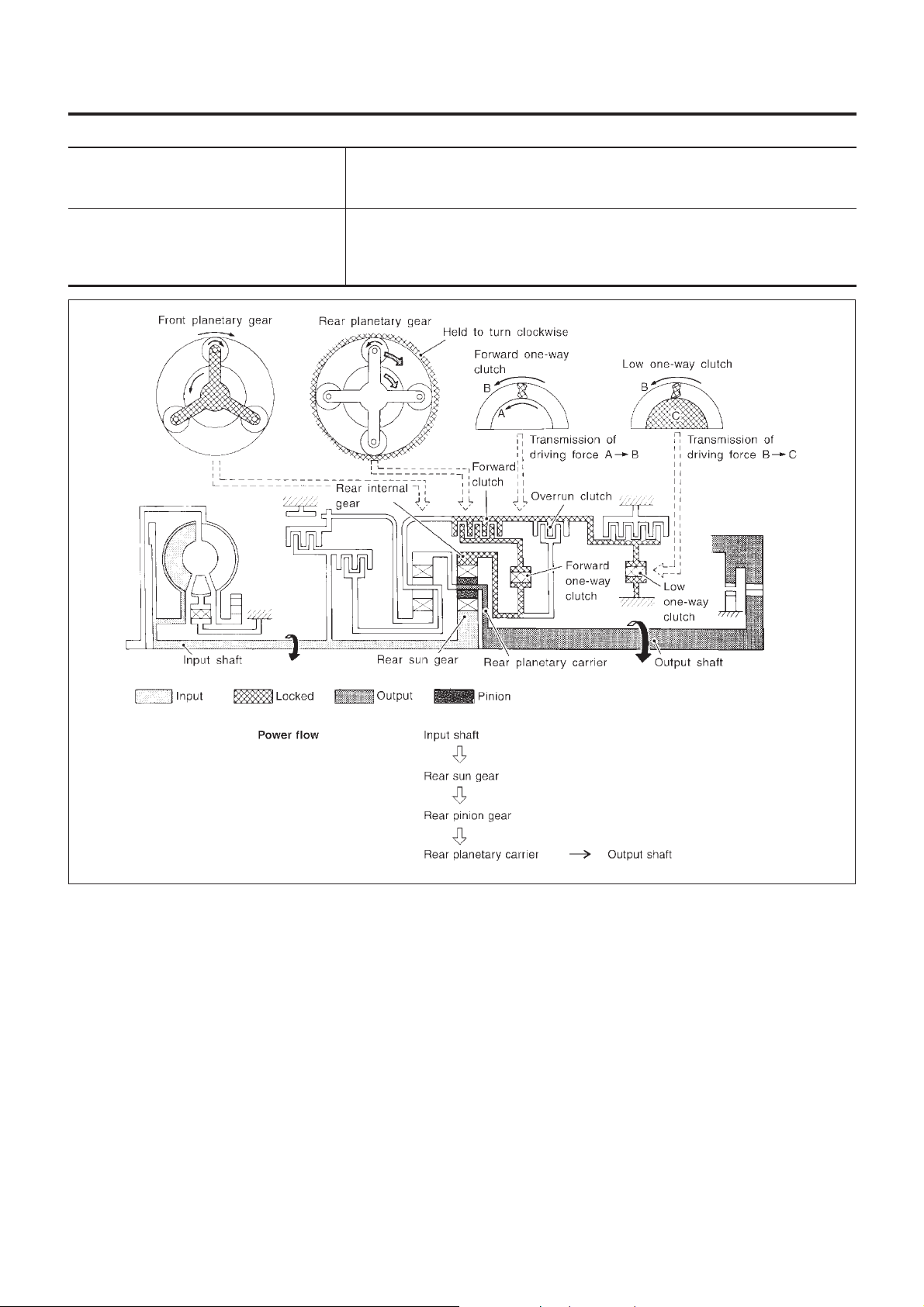

“D1” and “21” Positions

+ Forward one-way clutch

+ Forward clutch

+ Low one-way clutch

Overrun clutch

engagement conditions

(Engine brake)

=NJAT0013S0203

Rear internal gear is locked to rotate counterclockwise because of the functioning of

these three clutches.

: Overdrive control switch “OFF” and throttle opening is less than 3/16

D

1

2

: Always engaged

1

At D

and 21positions, engine brake is not activated due to free turning of low one-

1

way clutch.

AT-26

SAT377J

OVERALL SYSTEM

Shift Mechanism (Cont’d)

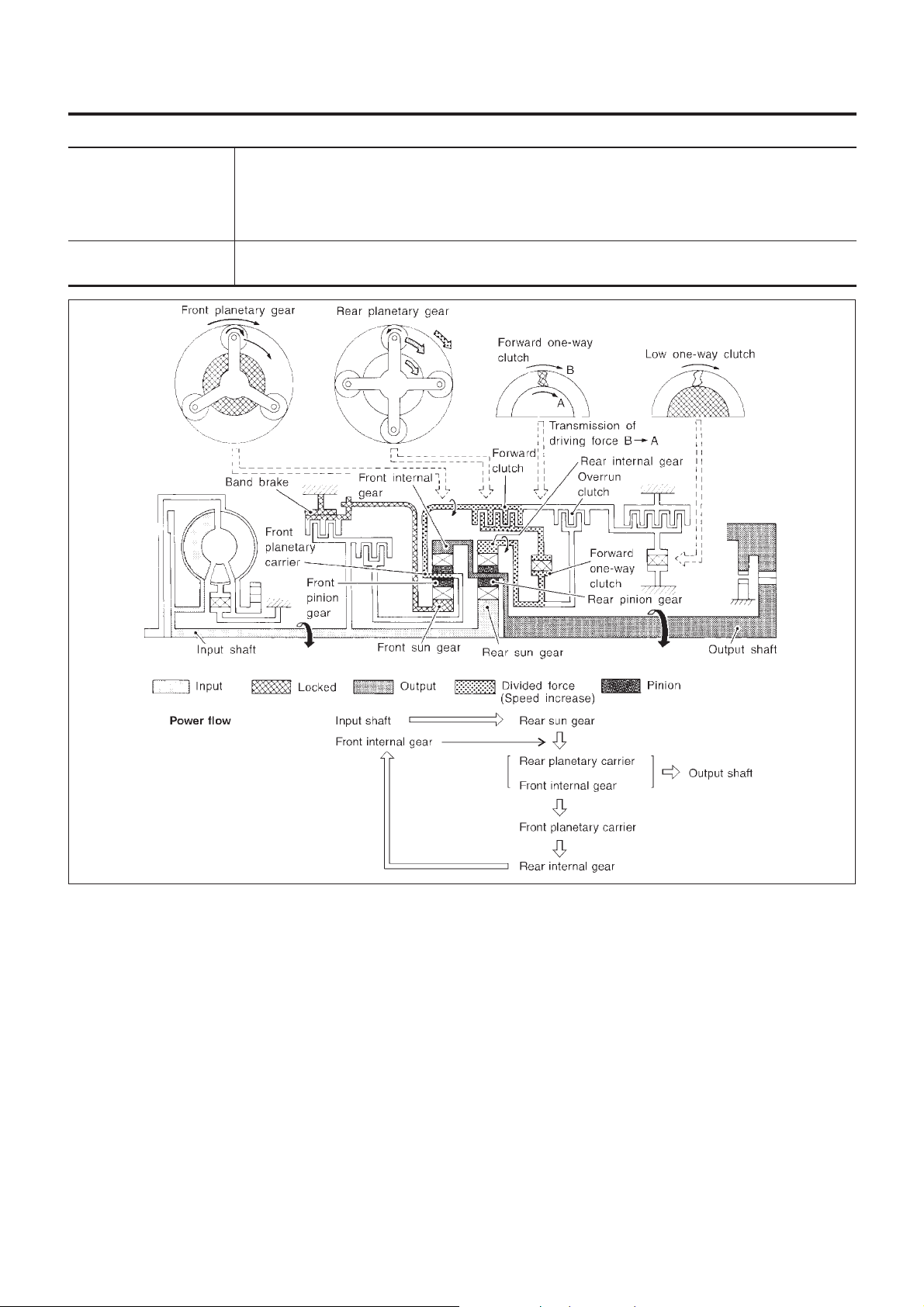

“D2”, “22” and “12” Positions

+ Forward clutch

+ Forward one-way

clutch

+ Brake band

Overrun clutch

engagement conditions

Rear sun gear drives rear planetary carrier and combined front internal gear. Front internal gear now

rotates around front sun gear accompanying front planetary carrier.

As front planetary carrier transfers the power to rear internal gear through forward clutch and forward

one-way clutch, this rotation of rear internal gear increases the speed of rear planetary carrier compared with that of the 1st speed.

D

: Overdrive control switch “OFF” and throttle opening is less than 3/16

2

2

and 12: Always engaged

2

=NJAT0013S0204

AT-27

SAT378J

Shift Mechanism (Cont’d)

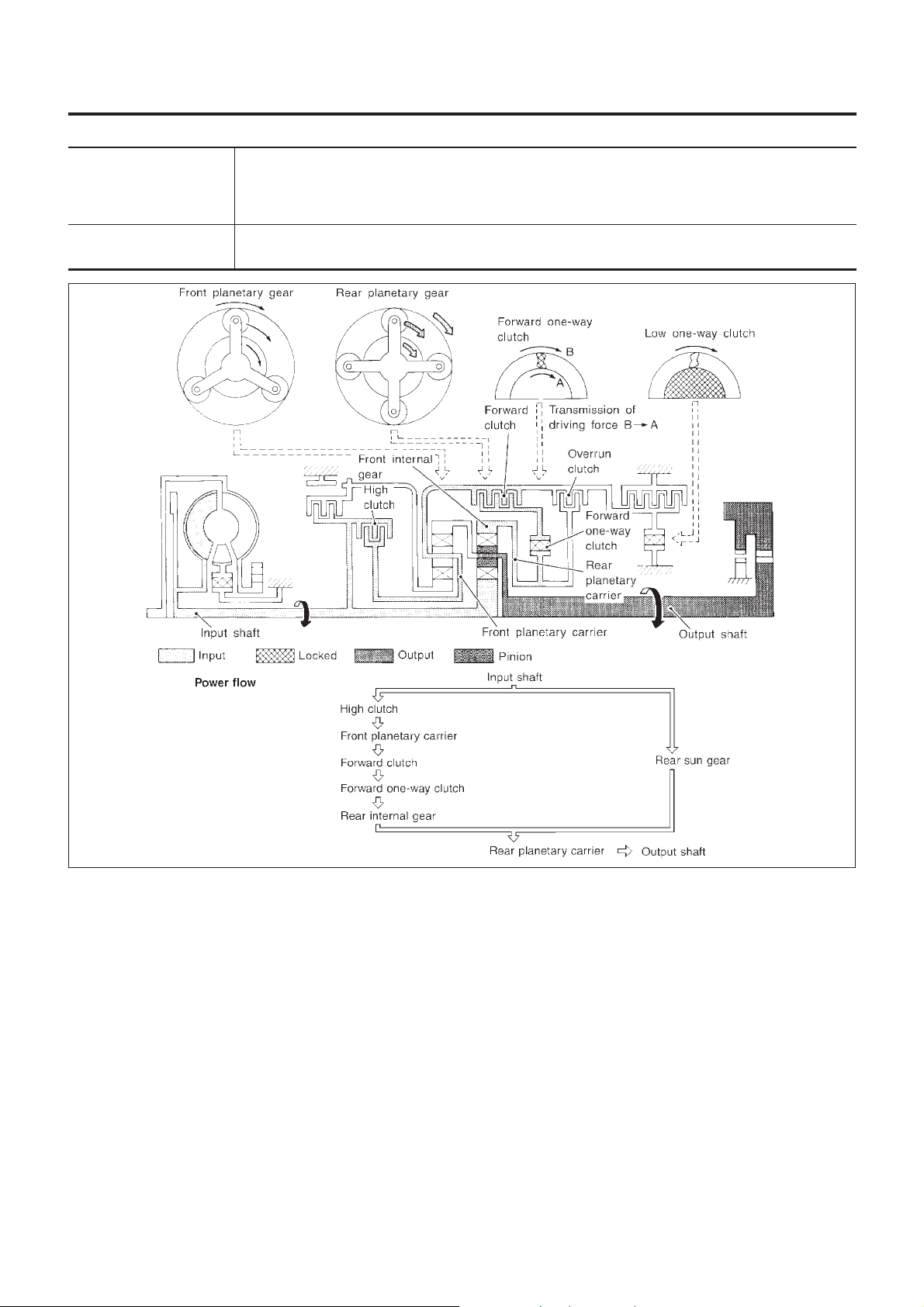

OVERALL SYSTEM

“D3” Position

+ High clutch

+ Forward clutch

+ Forward one-way

clutch

Overrun clutch

engagement conditions

=NJAT0013S0205

Input power is transmitted to front planetary carrier through high clutch. And front planetary carrier is

connected to rear internal gear by operation of forward clutch and forward one-way clutch.

This rear internal gear rotation and another input (the rear sun gear) accompany rear planetary carrier

to turn at the same speed.

D

: Overdrive control switch “OFF” and throttle opening is less than 3/16

3

AT-28

SAT379J

OVERALL SYSTEM

Shift Mechanism (Cont’d)

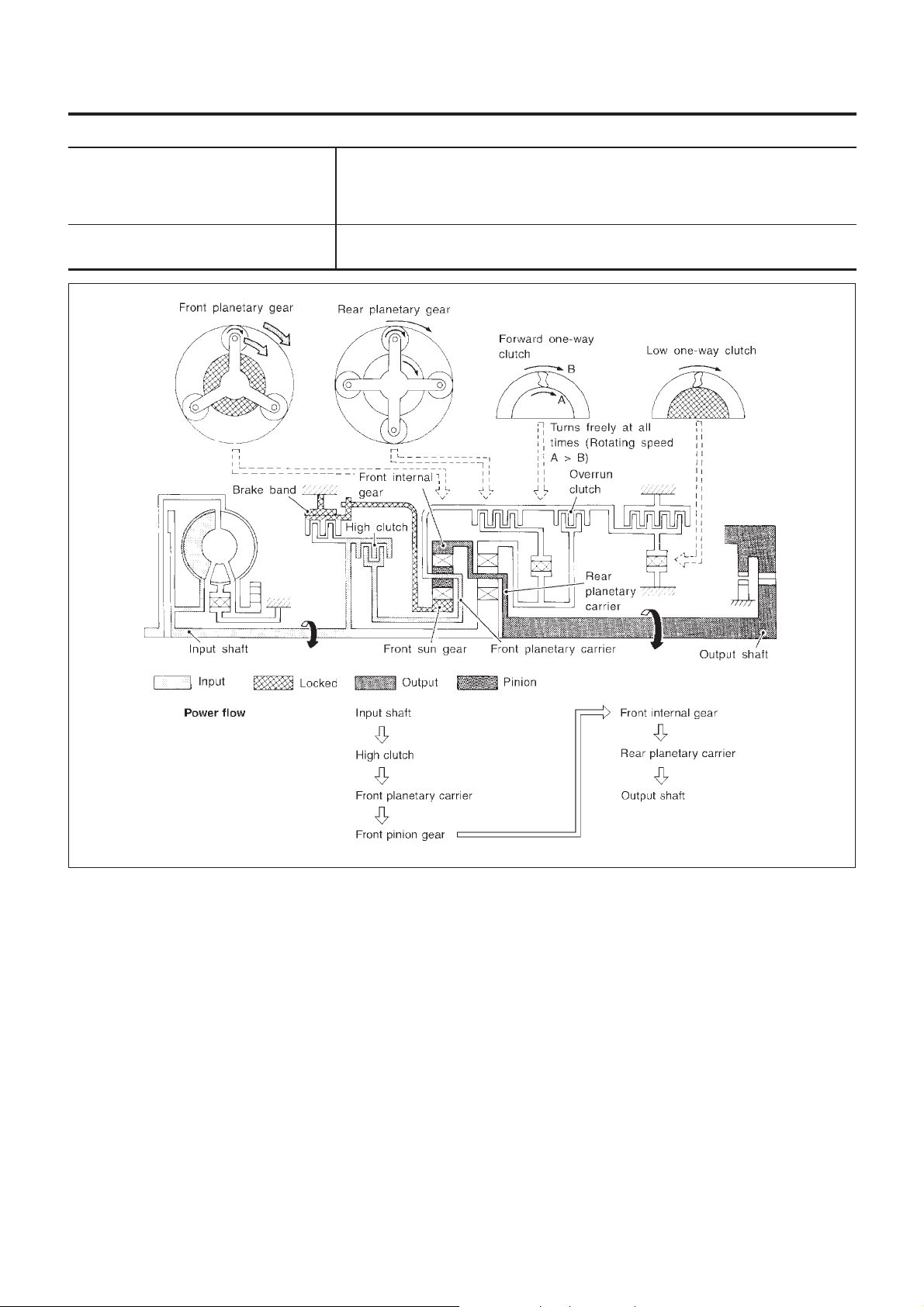

“D4” (OD) Position

+ High clutch

+ Brake band

+ Forward clutch (Does not affect power

transmission)

Engine brake

=NJAT0013S0206

Input power is transmitted to front carrier through high clutch.

This front carrier turns around the sun gear which is fixed by brake band and makes

front internal gear (output) turn faster.

At D

position, there is no one-way clutch in the power transmission line and engine

4

brake can be obtained when decelerating.

AT-29

SAT380J

Shift Mechanism (Cont’d)

OVERALL SYSTEM

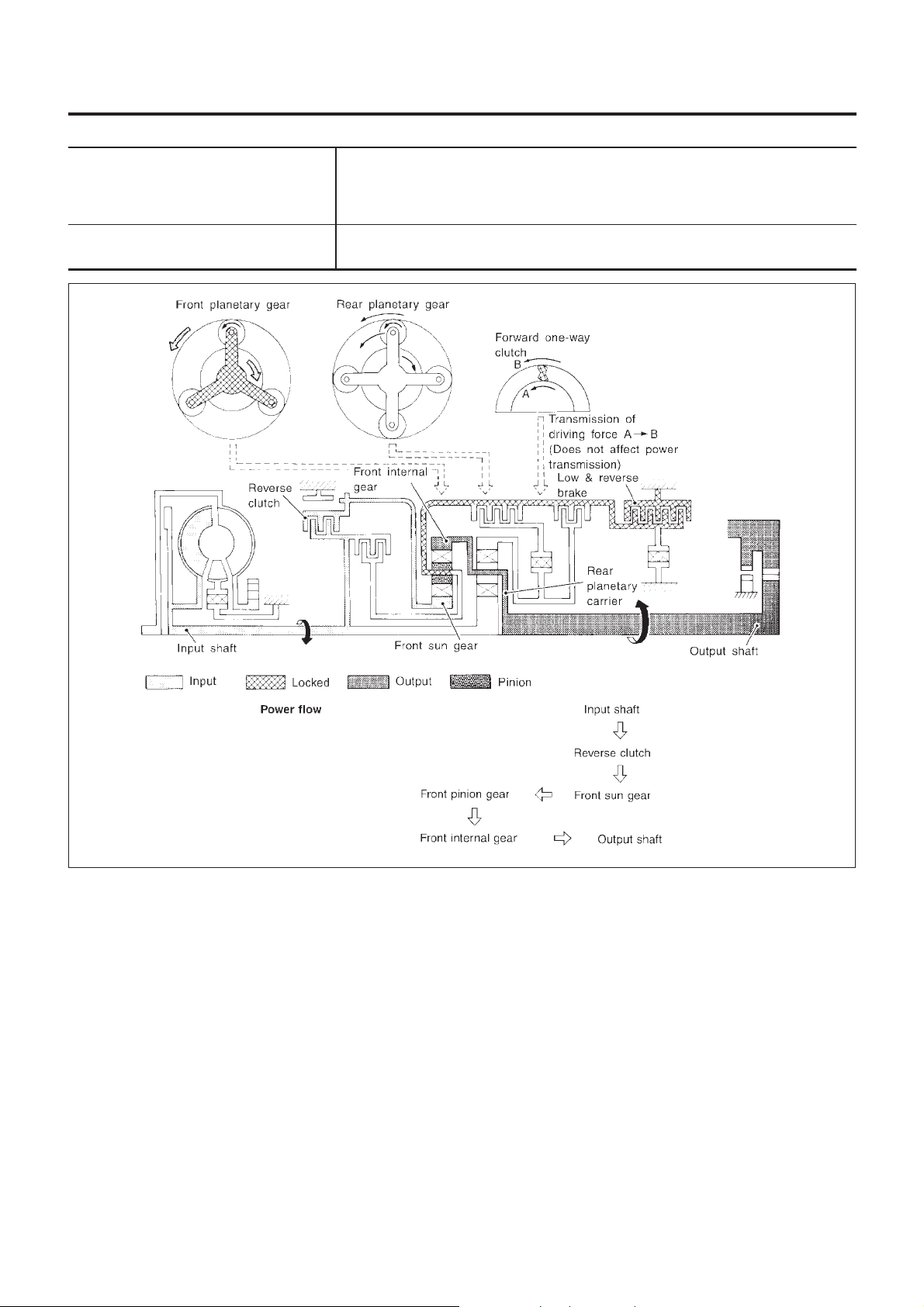

“R” Position

+ Reverse clutch

+ Low and reverse brake

Engine brake

=NJAT0013S0207

Front planetary carrier is stationary because of the operation of low and reverse

brake.

Input power is transmitted to front sun gear through reverse clutch, which drives front

internal gear in the opposite direction.

As there is no one-way clutch in the power transmission line, engine brake can be

obtained when decelerating.

AT-30

SAT381J

Loading...

Loading...