Page 1

E

Operator's

Manual

READ THIS BOOK

This book has important information for the use and safe operation of this machine. Failure to read this

book prior to operating or attempting any service or maintenance procedure to your ALTO machine could

result in injury to you or to other personnel; damage to the machine or to other property could occur as

well. You must have training in the operation of this machine before using it. If your operator(s) cannot

read this manual, have it explained fully before attempting to operate this machine.

Si Ud. o sus operadores no pueden leer el Inglés, se hagan explicar este manual completamente antes

de tratar el manejo o servicio de esta máquina.

All directions given in this book are as seen from the operator’s position at the rear of the machine.

Model

SPS-28

For new books write to: ALTO U.S. Inc., 2100 Highway 265, Springdale, Arkansas 72764.

Form No. 70100B 4/99 CLARKE TECHNOLOGY Printed in the U.S.A.

Page 2

Table of Contents

Operator Safety Instructions ................................................................................... 3

Operator Safety Instructions Battery Powered Machine .......................................... 4

Introduction & Machine Specifications .................................................................... 5

How to Prepare the Machine for Operation 28G ..................................................... 6

How to Check the Oil ................................................................................... 6

How to Fill the Gasoline Tank ...................................................................... 6

How to Prepare the Machine for Operation 28B ..................................................... 7

How to Charge the Batteries........................................................................ 7

How to Operate the Machine .................................................................................. 8

How to Operate the Sweeper........................................................................ 8

How to Operate the Side Broom ................................................................... 9

Sweeping ..................................................................................................... 9

How to Empty the Debris Hopper.................................................................. 10

How to Clean Filters ..................................................................................... 10

Parts and Service Manual - Section II

Maintenance Procedures ....................................................................................... 12

How to Check the Engine ............................................................................ 12

How to Clean the engine Air Filter................................................................ 12

How to Lubricate ......................................................................................... 12

How to Adjust the Main Broom..................................................................... 13

How to Adjust the Side Broom Belt.............................................................. 13

How to Adjust the Friction Drive Wheel ........................................................ 13

How to Adjust the Engine Speed (28G) ....................................................... 13

How to Stall a New Main Brush .................................................................... 13

Service Hints............................................................................................... 14

Capacitor Tests........................................................................................... 15

Diode Test .................................................................................................. 15

Assembly drawing for Main Frame, Brush and Drive system................................... 16

Parts List..................................................................................................... 17

Assembly drawing for Engine, Dust Control and Handle ......................................... 18

Parts List..................................................................................................... 19

Assembly drawing for Hopper and Optional Sidebroom Assembly ......................... 20

Parts List..................................................................................................... 21

Assembly drawing for Battery Powered Model SPS-28B........................................ 22

Parts List..................................................................................................... 22

Wiring Diagram...................................................................................................... 24

Parts List..................................................................................................... 25

Schematic Diagram ............................................................................................... 26

Page 2 CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual

Page 3

OPERATOR SAFETY INSTRUCTIONS

WARNING AVERTISSEMENT ADVERTENCIA

DANGER means: Severe bodily injury or death can occur to you or other personnel if the DAN-

GER statements found on your machine or in your Owner's Manual are ignored

or are not adhered to. Read and observe all DANGER statements found in

your Owner's Manual and on your machine.

WARNING means: Injury can occur to you and to other personnel if the WARNING statements

found on your machine or in your Owner's Manual are ignored or are not

adhered to. Read and observe all WARNING statements found in your

Owner's Manual and on your machine.

CAUTION means: Damage can occur to the machine or to other property if the CAUTION state-

ments found on your machine or in your Owner's Manual are ignored or are not

adhered to. Read and observe all CAUTION statements found in your Owner's

Manual and on your machine.

DANGER: Failure to read the Operator's Manual prior to using this machine could result in injury to

you or to other personnel; damage to the machine or to other property could occur as well.

You must have training in the operation of this machine before using it. If you or your

operator(s) cannot read English, have this manual explained fully before attempting to

operate this machine

DANGER: Machines can cause an explosion when operated near flammable materials and vapors. Do

not use this machine with or near fuels, grain dust, solvents, thinners, or other flammable

materials.

DANGER: Operating a machine that is not completely or fully assembled could result in injury or

property damage. Do not operate this machine until it is completely assembled.

DANGER: Filling a machine with fuel in an explosive or poorly-ventilated area can cause an explosion.

Only fill the fuel tank in an open area. Do not fill the tank near open flames or while the

machine is running. Do not smoke while filling the tank. Do not over-fill the tank. Wipe up

any spills. Tighten the cap on the tank when finished.

DANGER: Always leave the machine on a level surface. The machine could roll and cause injury to

the operator or property damage. When you stop the machine, always put the throttle

lever to stop position until the engine stops.

WARNING: Failure to read and observe all safety statements found on your machine or in this

Operator's Manual can result in serious injury or damage. Read and observe all safety

statements. Make sure that all labels, decals, warnings, cautions, and instructions are

fastened to the machine. Get new labels from your authorized Clarke distributor.

WARNING: To avoid inhaling exhaust fumes, operate machine in a well ventilated area only. Engine

exhaust fumes are dangerous to your health.

CAUTION: Maintenance and repairs performed by unauthorized personnel could result in damage or

injury. Maintenance and repairs performed by unauthorized personnel will void your warranty. Servicing of this unit must always be referred to an authorized Clarke distributor.

CAUTION: Use of this machine to move other objects or to climb on could result in injury or damage.

Do not use this machine as a step or furniture. Do not ride on this machine.

CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual Page 3

Page 4

Operator Safety Instructions for Battery Powered Machine

CAUTION: Connect or disconnect the battery plug only

when the charger supply cord is

or arcing and burning may result.

CAUTION: Do not expose to rain. Replace defective cords

immediately. If the charger is dropped or otherwise damaged, inspect it thoroughly.

CAUTION: Provide adequate ventilation while charging.

Improper ventilation could cause fumes or

gases to injure the operator or others.

CAUTION: Ne ver wor k on the charger with cords con-

nected to the AC supply or to the batteries.

WARNING: Leave the machine only on a level surface

to avoid injury. When you stop the machine, always put the switch in the "OFF"

position.

WARNING: Batteries must be installed and serviced by

authorized personnel only. Always wear eye

protection and protective clothing when working near batteries. NO SMOKING!

disconnected

WARNING: Lead acid batteries generate gases which can

cause an explosion! Keep sparks and flames

away from batteries. Do not put tools or other

metal objects across the battery terminals or

the top of the batteries.

NOTE: For best results, charge the batteries after each

use.

Page 4 CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual

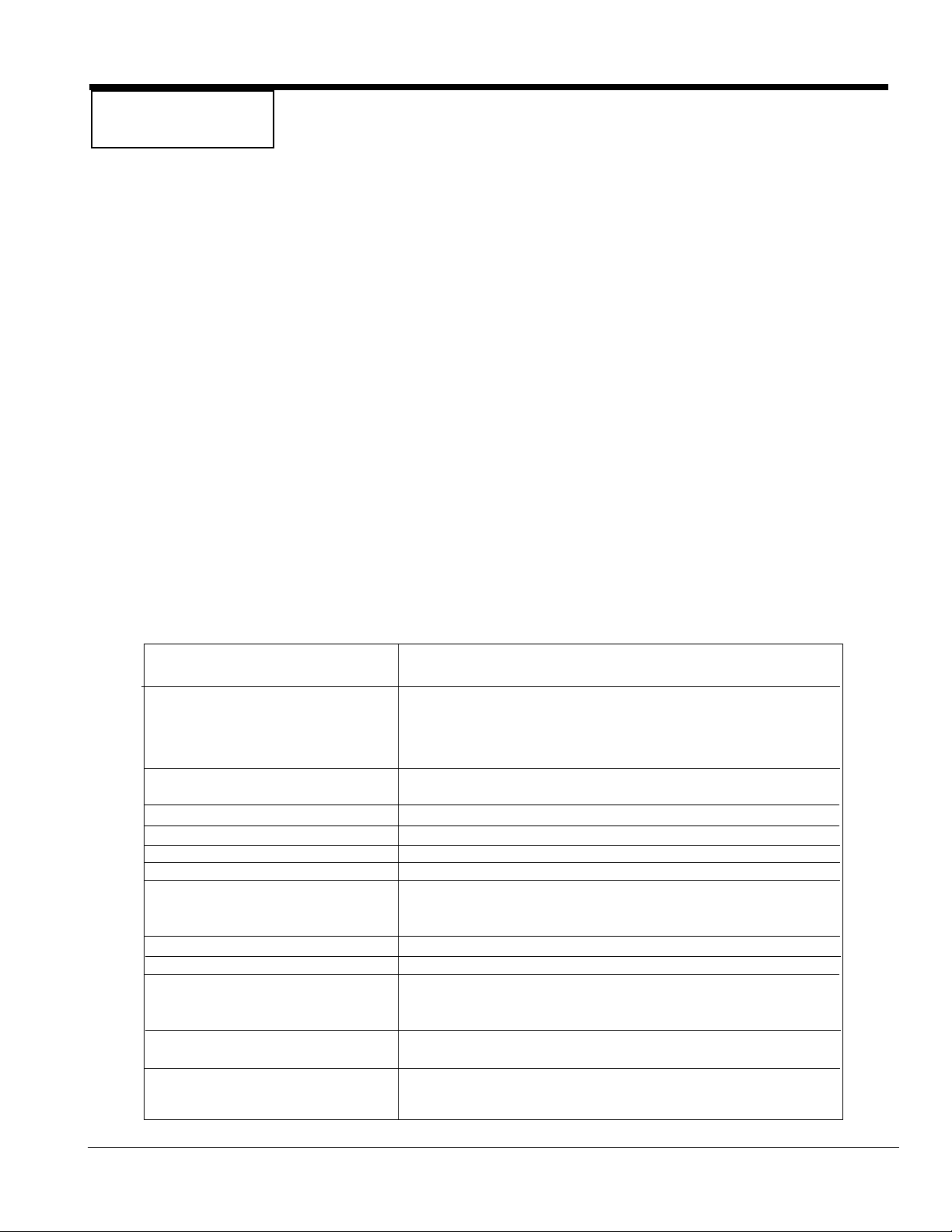

Page 5

INTRODUCTION

The Model SPS-28 will effectively and efficiently sweep your floors at minimum cost, provided you operate this

machine with reasonable care and maintain it in accordance with the intructions contained in this operator's

manual.

SPECIFICA TIONS

Gasoline Engine (Model 28G): 5 HP (2.98 kw) Briggs and Stratton (2,150 R.P.M. factory set)

Electric Motor: (Model 28B): ¾ HP (56 kw) D.C. permanent magnet

Batteries: Two 12-volt in 24 volt system (95 amp hours -SAE 6 hr . rate

Charger: 24-volt

Forward Speed: V ariable up to 250 ft./min. (76.2 m/min.)

(35,000 sq. ft. (3252 m

2

)m per hour

Front Hopper: 1.5 cu. ft. (.4m3) capacity

Rear Hopper: 1.8 cu. ft. (.5m3) capacity

Wheel: One 8 inch (20.3 cm) diameter swivel, sealed bearings

Casters: Two 4 inch (10.2 cm) diameter swivel, sealed bearings

Main Broom: 10 inch (25.4 cm) diameter x 28 inch (71.1 cm) long

Polypropyene bristles. Brush height adjustable.

Optional brush for sweeping carpets - Union mix bristles

Broom Speed: 300 RPM

Sweeping Swath: 28 inch (71.1 cm.), 36 inch (91.4 cm.) with optional side broom

Filter: Standard (dry paper) panel type with 34.34 sq. ft. (5.98 cm2)

filtering area. Optional accordian type filter with 55.23 sq. ft.

(5.13 cm2) filter area

Dimensions: 56 L x 33 H x 37½ W over handle

142.2 cm x 83.8 cm x 95.3 cm

Weight - Gasoline 209 lbs. (94.8 kg)

Battery 339 lbs. (153.8 kg)

CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual Page 5

Page 6

How to Prepare The Machine for Operation

Model 28G (Gasoline Powered)

NOTE: Do not attempt to operate the CLARKE Model

SPS-28 before reading the instructions in this manual.

WARNING: To prevent injury , always wear protec-

tive clothing. Do not wear loose clothing.

Before starting the MODEL SPS -28G follow these instructions:

HOW TO CHECK THE OIL

WARNING: Do not check the engine oil level when

the engine is running. Failure to check

the oil level before you use the machine

can destroy the engine. Always make

sure the machine has the correct amount

of oil.

Follow this procedure to check the oil:

1. Make sure the machine is on level ground.

2. Turn the cap marked "Engine Oil" counterclockwise.

3. Lift the dipstick out of the tube.

4. If the mark is below "OK", add oil.

5. When adding oil, make sure the oil does not pass the mark

"FULL" on the dipstick.

See the engine manual for the correct type of oil.

HOW TO FILL THE GASOLINE TANK

WARNING: Fill the gasoline tank in an open area.

Do not fill the tank near open flames.

Do not fill the gasoline tank while the

engine is running. Gasoline is very flammable and creates vapors. Serious injury

to the operator or others could occur.

WARNING: Gasoline is very flammable. When filling

the gasoline tank, make sure the gasoline only reaches the bottom of the filter

neck of the fuel tank.. Make sure you do

not spill any gasoline. Use a cloth to

remove spilled gas.

WARNING: Do not mix oil with the gasoline. Damage

to the engine could occur.

Fill the gasoline tank only with regular unleaded gasoline. Use

a clean container. Prevent dirt and debris from falling into the

tank. Always tighten the cap on the tank.

Page 6 CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual

Page 7

How to Prepare The Machine for Operation

Model SPS-28B - Battery Powered

1. Before starting the SPS-28B lift the battery box cover and

make sure the battery cables are connected.

2. Place all controls in "NEUTRAL".

3. Turn OFF/ON switch to "ON" position. (Switch is located on

left side, below hourmeter .

NOTE: The OFF/ON switch is also a circuit breaker which

senses overload on the drive motor and breaks the circuit.

Should this occur, determine the cause of the overload

(e.g., remove the debris jamming the main broom) and

turn the circuit breaker back to the "ON" position.

HOW TO CHARGE THE BATTERIES

Put the charger on a flat surface. Make sure the vents on

the sides of the charger are at least two inches away from

the walls and other objects. Make sure there are no

objects near the bottom vents of the charger.

To charge the batteries, follow this procedure:

1. Turn the machine OFF.

2. Connect the DC connector on the charger to the

connecting plug on the batteries. See Fig. 1

3. Connect the AC plug on the charger to a receptacle

that has the correct voltage and frequency for your

charger. Make sure the receptacle is connected to

the electrical ground.

4. The electronic timer stops the charger when the

batteries are fully charged.

See the instruction book for the charger, and for more

instructions on how to use the charger and charge the

batteries.

Fig. 1

CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual Page 7

Page 8

HOW TO OPERATE THE MACHINE

NOTE: Do not attempt to operate the CLARKE Model

SPS-28 before reading the instructions in this manual.

WARNING: To prevent injury , always wear protec-

tive clothing. Do not wear loose clothing.

WARNING: Do not check the engine oil level when

the engine is running. Failure to check

the oil level before you use the machine

can destroy the engine. Always make

sure the machine has the correct amount

of oil.

Follow the procedures below when operating the machine:

1. Turn the timer-switch to the "OFF" position.

2. Insert the DC charger plug into the unkeyed battery bank

plug.

3. Plug the AC cord into a single phase grounded outlet with

voltage and frequency corresponding to the charger nameplate. Assure that the circuit has adequate capacity to

handle the nameplate current.

4. Turn the timer-switch clockwise directly to the "ON" position. The AC pilot light and the DC ammeter show that the

charger is on and charging.ammeter show that the charger

is on and charging. The charger will run for a total period of

sixteen (16) hours; the timer-switch knob will rotate

clockwise and automatically turn the charger off when the

pointer reaches the "OFF" position.

5. The charger may remain connected to the batteries for

extended periods without harming the charger or discharging the batteries.

How to Operate the Sweeper

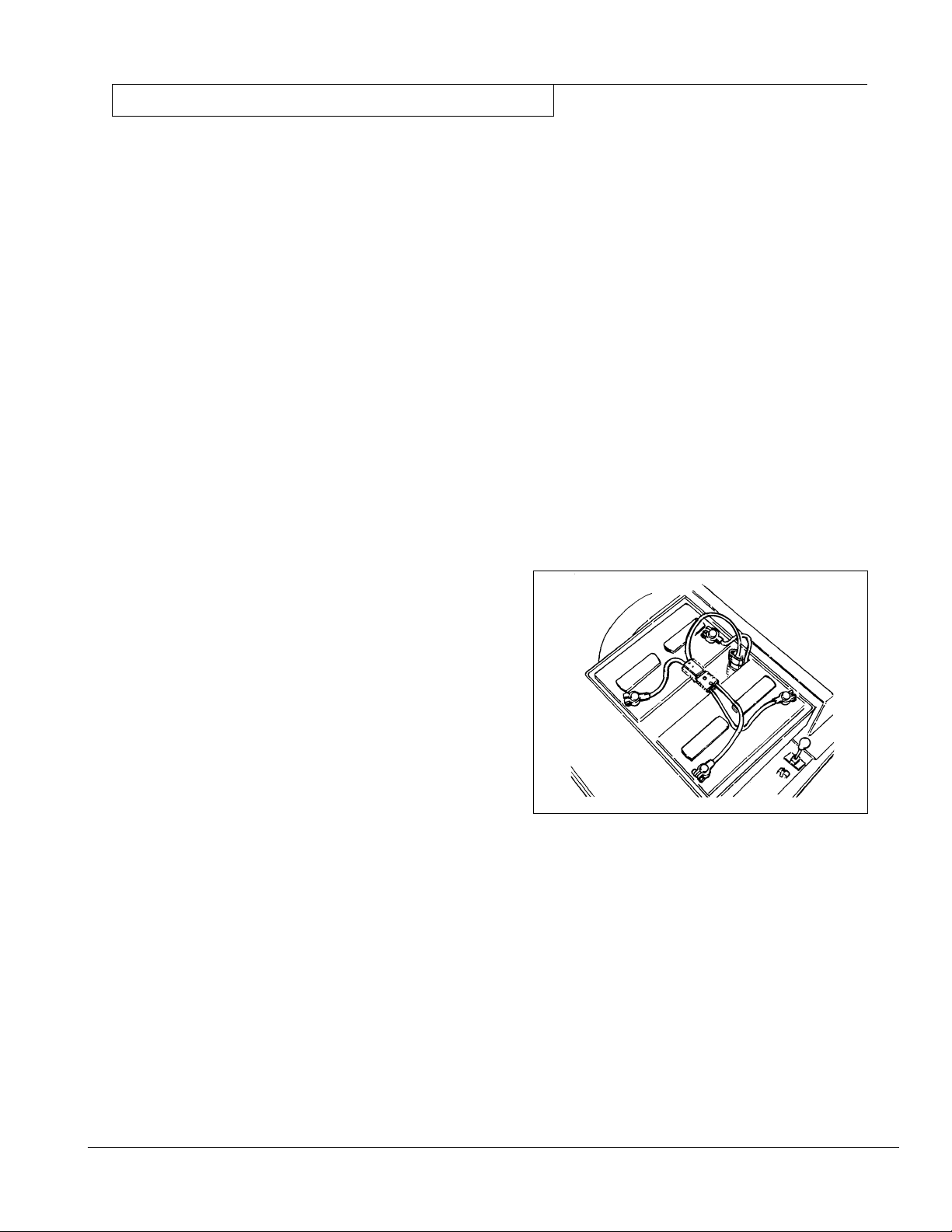

1. Adjust the main broom to correct sweeping* by rotating

broom adjusting lever - clockwise to raise, counterclockwise to lower. (See Fig. 2)

2. Lower the main broom to "SWEEP" setting by placing the

adjusting lever in the horizontal latched position.

Fig. 2

Page 8 CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual

Page 9

HOW TO OPERATE THE MACHINE (cont)

How to Operate the Side Broom (Optional):

1. Engage the side broom in "SWEEP" position by grasping

the head assembly, pulling forward and rotating downward

until the pin in the arm assembly is against the stop on the

locating collar. Turn off engine or motor when adjusting

sode broom.

2. When adjusting the side broom, the most effective setting

for the side broom is generally having about one-third of the

bristles engaged with the floor in "SWEEP" positon.

3. To change the angle of the broom, to the floor, loosen the

knob and rotate the head assembly until the desired anfle

is obtained.

To change the height of the side broom, i.e., (1) lower or more

bristle contact; (2) higher or less bristle contact, follow these

instructions:

1. Lower the broom assembly to its engaged position and

be certain the locking pin is in its slot on the collar.

2. Loosen the two socket head screws which lock the split

collar to the tubular bumper.

3. Swivel the collar until the correct height is obtained. Hold

in this position, maintaining tension on the side broom belt,

and tighten the two screws to lock the collar.

Sweeping

Stand behind the machine and push the control handle down

toactivate the clutch, which supplies forward motion.

Turning the sweeper will be easier if down pressure is released

on the control handle just before starting to make a turn.

To stop the machine, release the down pressure on the control

handle.

To stop the engine (Model 28G) turn stop switch OFF.

To stop motor (Model 28B), turn OFF/ON switch to "OFF"

position.

CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual Page 9

Page 10

HOW TO OPERATE THE MACHINE (cont)

How to Empty Debris Hopper:

WARNING: To prevent injury , always stop the en-

gine or motor before you empty the

hoppers or clean the filter.

1. Grasp the hopper by the handle provided and lift out until

clear of frame.

2. Dump debris in appropriate location and replace hopper in

machine. (See Fig. #3)

3. Release the two (2) retaining latches on either side of the

hopper.

4. Slide the hopper out (toward the rear) from under the filter

compartment.

5. Dump dust and debris in appropriate location and replace

hopper in machine.

6. Snap retaining latches to hold hopper. (See Fig. 4)

Fig. 3

Cartridge (Panel) Filter

To insure continued maximum efficiency of the dust control

system on your sweeper, the cartridge filter should be removed

and cleaned often. The frequency of this cleaning is related to

the sweeping appliaction; i.e., the dustier the area is, the more

frequently the filter should be cleaned.

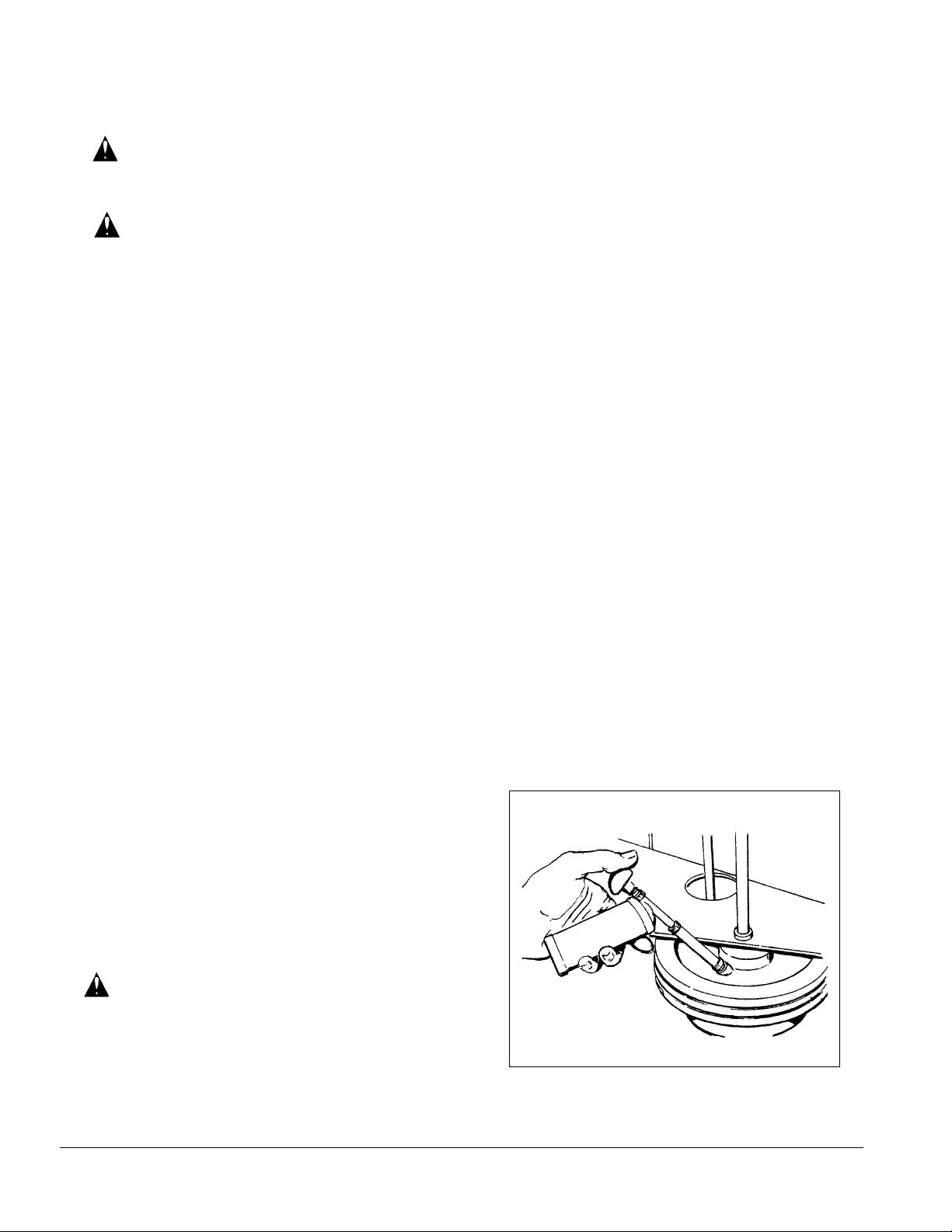

Cleaning Panel Filter

Remove from machine and tap gently on flat surface, dirty side

down. (See Fig. 5)

OR

Use compressed air (100 psi maximum), directing it through

the panel opposite the direction of the arrows.

OR

Soak for fifteen minutes in water and a low-foaming, mild

detergent. Rinse with water until clean (maximum 40 psi).

Air Dry - Do not use compressed air.

Accordion Type Cloth Filter (Optional)

To insure continued maximum efficiency of the dust control

system on your sweeper, the cloth type filter should be

frequently shaken (See Fig. 6) using the handles provided.

The dustier an area is, the more often the shakedown should

be done. The dust hopper should then be emptied.

How to Clean the Cloth Filter

Remove filter assembly from the machine. Direct compressed air through material opposite the normal air flow

direction. (See Fig. 7)

OR

Wash with a mild low-foaming detergent and water. Let dry

thoroughly before putting back into service.

Fig. 4

Fig. 5

Fig. 6

NOTE: This filter is treated wuth a flame retardant chemical.

The washing method of cleaning neutralizes and/or

eliminates this resistance to burning.

Page 10 CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual

Fig. 7

Page 11

SPS-28

Space Sweeper

(INCLUDES 28G & 28B)

Section II

Parts and Service Manual

(70100B)

CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual Page 11

Page 12

SERVICE AND MAINTENANCE

WARNING: Maintenance and repairs must be done

by authorized personnel only. Keep

Adjustments according to specifications.

WARNING: To prevent injury always stop the en-

gine or motor before doing any maintenance or repairs to this machine. Separate the connectors between the machine and batteries. Disconnect the

wire from the spark plug.

How To Check the Engine

1. Check oil level regularly. Change oil after using first two

tanks of gasoline. change oil regularly after each twentyfive (25) operating hours, or more often in extremely dirty

conditions.

2. Keep the engine clean and remove dirt and oil from coiling

fins, screen and flywheel for best engine performance and

to prevent damage from overheating.

Do not allow dirt to enter the engine when checking oil or

adding fuel.

Wire brush carbon deposits from spark plug electrodes

and regap at .030 in.

How to Clean the Engine Air Filter

Clean and re-oil every ten (10) hours - more often under

extremely dusty conditions.

1. Remove filter element. Separate pre-filter from pleated

filter.

2. Clean pre-filter only in detergent and warm water.

3. Squeeze dry.

4. Apply liberal amount of clean engine oil and distribute

evenly. Squeeze out excess oil.

5. Install element.

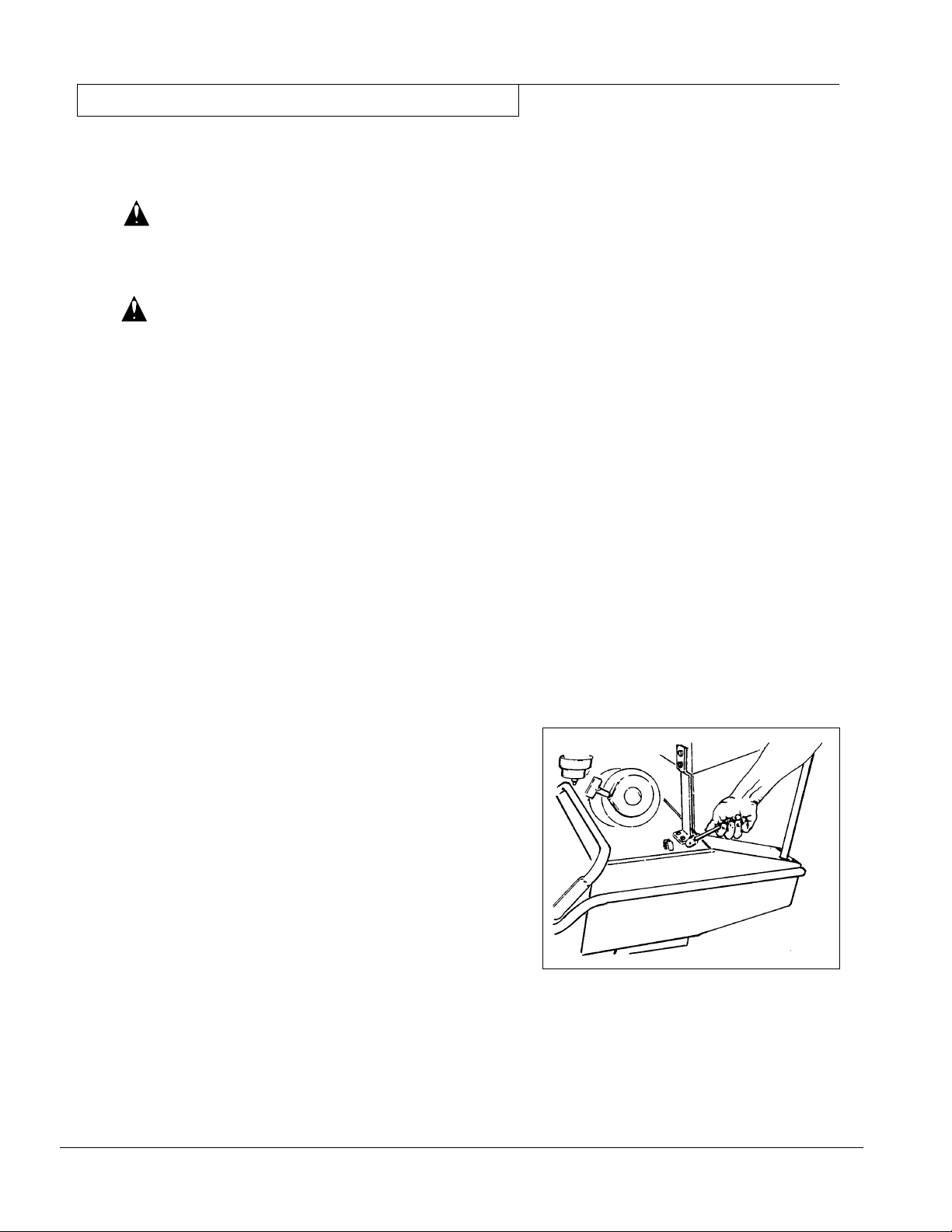

Lubrication

The Model SPS-28 has one grease fitting on the main drive

wheel. Apply two strokes of lubricant (PN 883853) from a

grease gun each month. (See Fig. 8)

WARNING: To prevent injury and damage, remove

the batteries or gasoline before tipping

the machine.

To get access to the grease fitting, remove the batteries and

hoppers and tip the machine on its side.

Fig. 8

Page 12 CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual

Page 13

Drive Belts

WARNING: To prevent injury always stop the

engine or motor before doing any

maintenance or repairs to this machine.

The drive belts are automatically tensioned by a springloaded idler wheel. (See Fig. 9)

1. Remove the idler pulley tension spring.

2. Slip the belt off the pulley.

3. Install a new belt.

4. Assemble idler tension spring.

5. Align pulleys and belts if necessary.

Main Broom Adjustment

The main broom should be periodically readjusted as

needed to compensate for wear. Use the broom-adjusting

lever to accomplish this. rotate counterclockwise to lower

and clockwise to raise. (See Fig. 2, page 6)

Side Broom Belt Adjustment

To increase tension on the side broom belt, loosen the two

(2) socket set screws. Push the split clamp forward on the

tubular frame until belt is sufficiently tight to drive broom

without slipping. Tighten clamp screws.

Fig. 9

Friction Drive Wheel

The friction drive wheel should be adjusted so it touches the

mating drive wheel. The machine should NOT creep or

move when the operator handle is in neutral "UP" position.

(See Fig. 10)

ENGINE SPEED ADJUSTMENT (Model 28G)

The engine speed (rpm) is governor-controlled and preset

at the factory at 2150 rpm (no load). Should it be necessary

to check or readjust this setting, use a good strobe

tachometer and adjust the governor rod threaded end to

maintain 2150 rpm (no load). Be certain all brooms are

raised for this adjustment.

Installation of new Main Brush

The main brush is made up of five (5) bristle strips, installed

and retained on the core by three (3) screws and washers

for each strip. Do not change (1) new bristle strip with (4)

worn strips.

Remove the three screws and washers and the bristle strip

retained by them. Install the new strip and assemble the

retaining screws and washers. Be sure to install the "V" of

each strip in the same relation to the core as its companion

strips. (See Fig. 11)

Fig. 10

Fig. 1 1

CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual Page 13

Page 14

Installation of New Main Brush (cont)

Remove the three screws and washers and the bristle

strip retained by them. Install the new strip and assemble

the retaining screws and washers. Be sure to install the

"V" of each strip in the same relation to the core as its

companion strips. (See Fig. 11, page 11)

CAUTION: The strips must be carefully centered

on the core before they are firmly

locked into position. Rotate the broom

by hand through a full revolution to

check for possible interference with

the shaft carriers at each end. Failure

to check this area could result in

damage to the drive mechanism.

Continue to replace one strip at a time, checking end

clearance on each end, until all strips have been replaced with new fillers.

Readjust the broom to allow for the new bristle strips.

The main brush is preadjusted at the factory to insure

even engagement with the floor across its full width.

However, should the brush show signs of uneven wear,

end to end, compensating adjustments may be made.

Raise or lower either end as required by changing the

length of the adjusting rod. (See fig. 12)

Fig. 12

SHOP EVALUATION OF CHARGERS

(Qualified Service Personnel Only)

Service Hints

1. Check the AC power supply (plug, cords, building

fuses and switched, etc.)

2. Check for physical damage.

3. If there is no DC output, check for blown internal

fuse(s); blown fuses may be caused by reversed DC

connections or by a defective diode.

4. Check parts - ammeter, timer-switch, diodes, trans-

former and fuses for tight connections and for

discoloration due to electrical failure.

WARNING: Always wear eye and face shield,

and protective clothing when

working with batteries to avoid

injury.

5. Check the condition of the batteries.

a. Specific gravity (1.280 is ideal for fully charged

batteries.

b. The battery bank voltage should come up to

about 30.7 volts at the end of the cycle.

c. The DC charging current should start in the

"normal" range and end in the "finish" range.

If the charger is still inoperative after the above checks

have been made, call your nearest authorized service

center.

Page 14 CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual

Page 15

Capacitor T est

If a commercial capacitor checker is not available, the

following test may be made:

1. Briefly short the capacitor terminals together with a

screwdriver.

2. Disconnect a wire from either capacitor terminal.

3. Adjust an ohmmeter to a high value such as RX10K or

RX1 Meg.

4. Connect the ohmmeter leads to the capacitor terminals.

5. A good capacitor will cause the indicator to move quickly

to zero ohms, then slowly return to infinite ohms. An

open capacitor will not cause any indicator movement; a

shorted capacitor will give a continuous zero ohms

reading.

6. If the test is to be repeated, the capacitor terminals must

again be shorted together briefly .

Diode T est

1. Y ou must have a #308 ct. Everready continuity tester or

equivalent/

2. Desolder both wires from the diode lead connections.

(Clamp heatsink pliers on the diode leads to avoid

damaging the diodes.)

3. Attach one of the test unit leads to either diode lead.

4. Attach the other test unit lead to the diode heatsink.

5. Turn the test unit on and note if the test unit bulb lights.

DANGER: Reversing charge or polarity of wiring

could cause batteries to EXPLODE causing serious bodily harm to yourself or

others.

6.. Reverse the test unit leads in Steps 3 and 4.

7. Turn the test unit on and note if the test unit bulb lights.

8. Good diode - test light bulb should light up in one of

Step s 5 and 7 and not in the other .

Defective diode - test bulb will light up in both

Steps 5 and 7.

Defective Diode - Test bulb will not light up in either

Steps 5 or 7.

CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual Page 15

Page 16

92

93

CLARKE TECHNOLOGY Model SPS-28

Main Frame, Brush Assembly and Drive System Drawing 1/99

4

2

5

49

21

6

4

1

14

3

81

80

78

89

49

66

94

28

42

69

95

49

62

42

3

42

68

87

74

59

69

24

22

20

31

23

83

82

19

33

70

84

32

22

10

7

8

11

12

14

13

72

42

24

25

26

27

30

29

31

35

33

27

32

47

34

38

28

27

39

40

28

41

36

29

46

22

43

13

12

11

10

22

37

20

2

15

17

16

18

10

18

49

85

58

49

50

49

48

44

45

51

26

25

73

25

60

4

6

5

4

82

49

65

82

42

49

28

77

75

74

32

4

76

5

86

96

95

49

69

62

33

71

90

24

25

26

6

70

96

3

4

88

52

34

53

54

52

55

56

57

22

78

37

22

67

36

Page 16 CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual

Page 17

CLARKE TECHNOLOGY Model SPS-28

Main Frame, Brush Assembly and Drive System Parts Lists 1/99

Ref # Part No. Description Qty

1 790322 Arm, Lower Clutch, R.H. 1

1

2 925543 Pin,

/8 x 1¼ Roll 3

3 920349 Nut, ¼-20 3

4 920160 Nut

5

/16 - 18 Hx Jam 6

5 980652 Washer 5/16 Lock 3

6 791323 Block, Pedal Pivot 3

5

7 85813A Screw

8 980652 Washer

/16 -18 x 1" Hx 4

5

/16 Lock 8

9 799728 Wheel 1

10 902710 Bearing, Wheel Shaft 3

11 980023 Washer, Thrust 2

12 877661 Seal, Oil 2

13 902682 Bearing, Wheel 2

14 799729 Wheel 1

15 790326 Arm, Lower clutch, L.H. 1

16 797721 Shaft, Wheel 1

17 798530 Support, Wheel Bearing 1

18 962385 Screw, 10-24 x ½ 2

19 915044 Key, 3/16 x 3/16 x 1 1

20 797727 Shaft, Brush Drive 1

21 903540 Belt, Drive 1

22 962103 Screw, 5/16 -18 x 3/8 6

23 796920 Pulley, Driven 1

24 962686 Screw, 5/16 -18 x 1½ Hx 2

25 980638 Washer, 3/8 "Lock 4

26 808256 Spacer, Parallel Arm Rear 3

27 962219 Screw, ¼-20 x 7/8 Hex 2

28 980657 Washer, ¼ Lock 2

29 902713 Bearing 2

30 790324 Arm, Clutch 1

31 797422 Rod, Brush Lift 3

32 980651 Washer, 5/16 Plain 3

33 925036 Pin, 3/32 x ¾ Cotter 3

34 925550 Pin, 1/8 x x 1" Roll 1

35 799727 Wheel, Friction Drive 1

36 796921 Pulley, Brush Drive 2

37 915076 Key, 3/16 x 3/16 x 9/16 Ling Sq. 2

38 167308 Retaining Ring 1

39 857301 Retaining Ring 1

40 902659 Bearing 1

41 796926 Pulley, Brush Drive Idler 1

42 962455 Screw, ¼-20 x 1" Hex 6

43 790320 Arm Assembly, Idler Pulley 1

44 798220 Spacer, clutch Arm 1

45 858345 Spring, Bracket Adjusting Screw 1

46 903539 Belt, Brush Drive 1

47 815051 Knob, Handle 1

48 793923 Handle Assembly, Brush Lift 1

49 962546 Screw, 10 x ½ Rd. Hd. Type 23 26

Ref # Part No. Description Qty

50 302101 Clamp 1

51 796623 Plate, Brush Lift 1

52 791121 Bushing, Spring 2

53 797423 Rod, Brush Lift 1

54 858302 Spring 1

55 920329 Nut,

5

/16 -24 Hex 1

56 809904 Yoke 1

57 806705 Pin 1

58 795121 Label, Instruction 1

59 60072A Frame Assembly, Main 1

60 962302 Screw, 3/8 x 16 x 5/8 Hex 1

61

62 798526 Skirt, Brush Rear 1

63 798528 Skirt, Brush L.H. 1

64 797225 Retainer, L.H. Skirt 1

65 797224 Retainer, L.H. Skirt 1

66 798527 Skirt, Brush R.H. 1

67 797722 Shaft, Brush 1

68 798525 Skirt, Hopper Top 1

69 797221 Retainer 2

70 790337 Arm, Brush 2

71 797620 Seal, Brush Arm 2

72 883351 Grease Fitting 1

73 920260 Nut, 3/8 -16 x 5/16 Hex 2

74 53038A Spring 2

75 962139 Screw, ¼-20 x 5/8 Hex 2

76 920208 Nut, ¼-20 2

77 962709 Screw, ¼-20 x ½ Hex 4

78 902746 Bearing, Brush Shaft 2

79

80 797829 Shield Assembly, Broom Dust 1

81 796922 Pulley, Side Broom Drive 1

82 792703 Driver, Brush 3

83 962893 Screw ¼-20 x 7/8 Hex 15

84 797205 Retainer 15

85 920364 Nut, ¼-20 speed 15

86 925070 Pin, ¼ x 1½ Roll 3

87 790923 Brush Segment Carpet 10

790920 Brush Segment 28" 5

88 797828 Shield Assembly, Broom Dust L.H. 1

89 797223 Retainer, R.H. Skirt 1

90 856702 Pin, Hair, cotter 1

91 797235 Retainer, Brush Strp. (Std Mach. Only) 15

92 980675 Washer, #10 Shakeproof 1

93 798541 Strap, Static Discharge 1

94 798232 Spacer 2

95 797236 Retainer 2

96 858207 Spacer 2

CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual Page 17

Page 18

CLARKE TECHNOLOGY Model SPS-28

Engine, Dust Control & Handle Assembly Drawing 4/99

34

62

46

66

26

25

22

26

94

93

23

11

11

92

47

48

83

63

71

64

65

15

11

67

70

26

59

50

49

69

52

8

53

72

24

60

26

49

49

61

51

58

12

3

10

4

5

96

6

1791

34

9

8

13

95

14

16

26

90

18

19

20

83

21

56

57

55

75

11

78

8

78

40

8

76

79

34

7

82

80

81

68

73

11

74

53

54

28

29

43

31

30

32

44

33

45

1

43

34

84

77

85

26

83

88

87

86

89

35

36

37

38

27

11

42

26

37

39

11

41

31

34

34

Page 18 CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual

Page 19

CLARKE TECHNOLOGY Model SPS-28

Engine, Dust Control & Handle Assembly 4/99

Ref # Part No. Description Qty

1 60072A Frame, Main 1

2u 792920 Engine, 5 H.P. Briggs and Stratton 1

3 285161 Label, Gasoline 1

4 722824 Elbow, ¼ x 45° Street Brass 1

5 755721 Nipple, ¼ x 2½" Brass 1

6 822806 Elbow, ¼ x 90° Brass 1

7 Drain Plug - Part of Engine

5

8 822806 Washer

/16 Lock 8

9 196157 Screw, 5/16 -18 x 1¼ Hex 4

10 796924 Pulley, Engine 1

11 962103 Screw,

5

/16 -18 x 3/8 Set 8

12 915044 Key 3/16 x 3/16 x 1" Square 1

Ref # Part No. Description Qty

51 793820 Guide, Dust Hopper 2

52 682006 Clamp Assembly, Lid 2

53 930086 Rivet, 3/16 x .450 Long 10

54 285102 Latch, Inspection Door 3

55 60070A Hopper, Dust 1

56 797226 Retainer, Dust Hopper 2

57 962385 Screw 10- 24 x ½ Bdg. Hd. 4

58 920200 Nut, 10 - 24 Hex 4

59 790832 Bracket, Dust Housing Support 1

60 53038A Spring 1

61 793425 Gasket, Dust chamber Bottom 2

62 Serial No. Plate - Gasoline (Blank) 1

13 790335 Arm, Assembly 1

14 798231 Spacer, Parallel Arm Rear 1

15 987013 Wrench, Allen 5/32"1

16 962216 Screw, 3/8 x 16 x 1" Hex 1

17 793624 Guard, Gas Tank 1

18 796925 Pulley, Idler 1

19 902659 Bearing 1

20 857301 Retaining Ring 1

21 962454 Screw, ¼-20 x 1" 1

22 60073A Housing Assembly, Blower 1

23 793424 Gasket, Duct to Filter 1

24 791221 Bumper, Dust Hopper 1

25 793423 Gasket, Duct to Frame 1

26 962709 Screw ½ Sems 20

27 980657 Washer ¼ Lock 4

28 920110 Nut, 5/16 -18 Elastic Stop 1

29 980210 Washer, Impeller 1

30 614820 Impeller 1

31 915044 Key, 3/16 x 3/16 x 1" Square 1

32 793420 Gasket, Blower Mounting Adapter 1

33 790221 Adapter Assembly, Blower Mounting 1

34 962835 Screw, 10 x 24 x ½ Hx St. T yp F 6

35 618220 Spacer, Impeller 1

36 067304 Snap Ring 1

37 902550 Bearing 2

38 617704 Shaft, Impeller 1

39 794224 Housing, Bearing 1

40 856702 Pin, Hair Cotter 2

41 796923 Pulley, Blower 1

42 793620 Guard, Belt 1

43 790830 Bracket, Lift Shaft 2

44 797726 Shaft Assembly 1

45 920993 Nut, 3/16 -18 Panel 6

46 60074A Cover, Filter 1

47 793320 Filter, Dust 1

48 15724A Housing Asm., Dust Chamber 1

63 215104 Label, Warning 1

64 755129 Label, Patent Pending 1

65 795120 Label, Instruction 1

66 793920 Handle, Upper 1

67 790825 Bracket, Handle Pivot 2

68 806705 Pin 1

69 790824 Bracket, Handle 2

70 796721 Pin, Handle Pivot 2

71 925004 Pin, 1/16 x ½ Cotter 2

72 85818A Screw, 5/16 - 18 x 2½ Hex 4

73 796720 Pin Assembly, Handle Release 2

74 85392A Screw 6-32 x 3/8 Pan Hd 2

75 793922 Handle, Lower 2

76 798524 Support, Handle 2

77 962894 Screw, 5/16 - 18 x 2½ 4

78 920160 Nut, 5/16 - 18 Jam 4

79 797420 Rod, Traverse 1

80 920329 Nut, 5/16 -24 Hex 1

81 809904 Yoke 1

82 62665A Cover, Frame 2

83 980646 Washer, ¼ Plain 7

84 796631 Plate, Stabilizer Whl. Stiffner 2

85 798537 Support, Rear Wheel 2

86 419702 Wheel 2

87 796722 Pin, Wheel Support 2

88 925036 Pin, 3/32 x ¾ Cotter 4

89 799724 Wheel Assembly, Stabilizer 2

90 798230 Spacer, Idler Pulley 1

91 962086 Screw, ¼-20 x ¾ Hx Hd. 2

92 962799 Screw, ¼-20 x 3/8 Soc. Cap 1

93 920148 Nut, 3/8 -16 Hex Jam 1

94 790846 Bracket, Idler Arm 1

95 980202 Washer Wave 1

96

97 170266 Coupling 1

49 793422 Gasket, Dust Chamber 4

50 793421 Gasket, Dust Chamber Top 2

NOTE: uindicates a change has taken place since

last publication of this manual.

Serial No. Plate - Battery (Blank) 1

CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual Page 19

Page 20

Page 20 CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual

27

28

52

51

50

53

55

54

52

62

OPTIONAL

SIDE BROOM

ASSEMBLY

43

57

58

61

39

40

41

37

38

26

32

33

33

32

35

36

29

30

31

BOTTOM

20

42

64 65

TOP

14

7

47

49

34

Hopper and Optional Sidebroom Assembly Drawing 1/99

17

16

19

CLARKE TECHNOLOGY Model SPS-28

5

6

24

2

20

6

7

22

15

4

25

23

21

3

11 OR 63

43

48

44

45

46

13

14

64

12

65

8

3

10

66

13

Page 21

CLARKE TECHNOLOGY Model SPS-28

Hopper and Optional Sidebroom Assembly Parts List 1/99

Ref # Part No. Description Qty

1 60075A Hopper 1

2 798529 Support, Hopper Top 1

3 930090 Rivet,

5

/32 Dia. 8

4 725197 Label, Clarke 1

5 793921 Handle, Hopper 1

6 798203 Spacer, Carrying Handle 2

7 962568 Screw, 5/16 -18 x ½ Bdg. Hd. 2

8 797820 Shield, Hopper 1

9 962385 Screw, 10-24 x ½ Bdg. Hd. 3

10 962677 Screw, 10-24 x ¾ Pan Hd. 8

11 791220 Bumper, Front 1

12 962803 Screw 5/16 -18 x 1½ 1

13 889706 Wheel, Swivel 2

14 920196 Nut ½-13 ESNA 2

15 790823 Bracket, Skirt to Hopper 1

16 798523 Skirt, Hopper 1

17 797220 Retainer, Lower Skirt 1

18 793426 Gasket, Hopper 1

19 797222 Retainer, Hopper Skirt 1

20 962073 Screw, 10 - ½ Rd. Hd. T ype Z 11

21 797421 Rod, Roller 1

22 797501 Roller 26

23 920160 Nut, 5/16 -18 Hex Jam 2

5

24 920110 Nut,

/16 -18 Elastic Stop 2

25 920200 Nut, 10-24 Hex

Optional Sidebroom Assembly

26 794201 Housing, side Brush 1

27 419702 Wheel 1

28 960953 Screw, Wheel 1

29 796902 Pulley 1

30 796903 Pulley 1

31 960970 Shoulder Bolt, Pulley 1

32 902659 Bearing 1

33 167308 Ring, Retaining 2

Ref # Part No. Description Qty

34 796922 Pulley, Side Broom Drive 1

35 857301 Ring, Retaining 1

36 798205 Spacer 1

37 796901 Pulley, Side Brush Drive 1

38 792401 Clutch 1

39 794320 Hub, Side Brush 1

40 925062 Roll Pin 1

41 794001 Holder, Side Brush 1

42 797701 Shaft 1

43 790901 Brush, Side 2

44 796420 Plate, Brush Retaining 1

45 980657 Washer, ¼ Lock 5

46 962481 Screw, ¼-20 x 1¼ Hx Cap 4

47 793621 Guard, Side Broom Belt 1

48 798228 Spacer 1

49 903538 Belt, Side Brush Round 1

50 793622 Guard, side Brush 1

51 725020 Knob 1

52 962716 Screw, ¼-20 x 1½ 2

53 790331 Arm, Side Brush, Top 1

54 790331 Arm, Side Brush, Bottom 1

55 790331 Arm Assembly, side brush 1

56 925132 Pin, ¼ x ¾ 1

57 792023 Clamp, Top 1

58 792023 Clamp, Bottom 1

59 962454 Screw, ¼-20 x 1" 2

60 980657 Washer, ¼ Lock 2

61 792023 Clamp Asm., Side Brush 1

62 987516 Wrench, 3/16 1

63 61300A Bumper (Carpet Only) 1

64 980626 Washer, ½ Lock 2

65 980662 Washer (Carpet Only) 2

66 63900A Guard, Caster (Carpet Only) 2

CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual Page 21

Page 22

CLARKE TECHNOLOGY Model SPS-28

Battery Powered Model Drawing 1/99

1

23

53

2

25

51

4

6

19

21

54

22

24

50

27

26

30

28

29

36

5

7

20

43

11

12

19

49

31

34

32

33

35

40

38

42

36

39

41

47

3

48

36

37

14

36

37

14

13

11

12

16

17 46

18

11

12

16

24

44

45

26

55

52

41

23

30

30

Page 22 CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual

Page 23

CLARKE TECHNOLOGY Model SPS-28

Battery Powered Model Drawing 1/99

Ref # Part No. Description Qty

1 60071A Cover Assembly, Batter y Access 1

2 962003 Screw,

3 930093 Rivet,

4 871376 Battery, 95 Amp Hr. (Wet) 2

871377 Battery, 95 Amp Hr. (Dry) 2

5 15726A Housing Assembly, Battery 1

6 799224 Tray, Battery 2

7 15725A Housing Assembly, Motor 1

8 962709 Screw, ¼-20 x ½ Hx St. Sems 3

9 980657 Washer, ¼ Lock 6

10 790826 Bracket, Battery Support 1

11 85811A Screw, 5/16 -18 x ¾ Hex Hd. 8

12 980652 Washer 5/16 Lock 12

13 796927 Pulley, Motor 1

14 962103 Screw, 5/16 x 18 x 3/8 2

15 915044 Key, 3/16 x 3/16 x 1" Long Square 1

16 980651 Washer, 5/16 -Plain 4

17 790827 Bracket Asm., Motor Mounting 1

18 60072A Main Frame Assembly 1

19 962800 Screw, ¼-20 x ½ Flat Hd. 4

20 962212 Screw 6-32 x 7/8 Rd. Hd. 2

21 911470 Wire Assembly, Battery Plug 1

22 797827 Shield, Battery 2

23 795136 Label, Warning 2

24 791120 Bushing, Conduit Insulating 2

25 895196 Label, Warning 1

26 792437 Connector 90° Conduit 2

27 799024 Tubing, Battery Enclosure to Circuit Breaker 1

28 792322 Cover Assembly, Enclosure 1

29 980603 Washer, #1110 Shakeproof 6

30 962546 Screw, 10 x ½ Rd. Hd. Type 23 10

31 962399 Screw, 8-32 x 1¼ 2

32 980612 Washer #8 Lock 1

33 911438 Block, Ter minal 1

34 911440 Switch, Toggle 1

35 792921 Enclosure, Circuit Breaker 1

36 980607 Washer, #1106 Shakeproof 5

37 962045 Screw, 6-32 x ¼ Rd. Hd. 2

38 792325 Cover, enclosure 1

39 962330 Screw, 6-32 x 3/8 Rd. Hd. 3

40 792438 Connector, Straight Conduit 1

41 799021 Tubing, Circuit Breaker to Motor 1

42 792436 Connector, 45° Conduit 1

43 795145 Label, Wiring Diagram 1

44 795220 Motor, Drive 24 Volt DC 1

45 794720 Insulation, Paper (Motor) 1

46 980614 Washer, #1114 Shakeproof 2

47 793623 Guard, Switch 1

48 792337 Cover, Switch Guard 1

49 796327 Plate, Safety Label (Eng. Sp.) 1

50 980303 Washer 1

51 895178 Label, Battery Care Instruction 1

52 62665A Cover, Frame 2

53 795151 Label, Battery Size 1

54 795143 Label, UL Decal 1

55 790926 Brush, Motor 1

6

/32 x 3/8 Rd. Hd. 4

1

/8 x 1/4 - 5/16 Pop 4

CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual Page 23

Page 24

CLARKE TECHNOLOGY Model SPS-28

Wiring Diagram & Electrical Schematic 1/99

Page 24 CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual

Page 25

CLARKE TECHNOLOGY Model SPS-28

Wiring Diagram 1/99

Ref # Part No. Description Qty

1 871376 Battery, 95 amp Hr. (Wet) 2

871377 Battery, 95 amp Hr. (Dry) 2

2 41207A Cable, Battery 1

3 911470 Connector 1

4 951006 Wire Assembly 1

5 855607 Hour Meter (Optional) 1

6 911440 Circuit Breaker 1

7 980614 Washer, ¼ External Tooth 4

8 950807 Wire Assembly, #10 White 1

9 950806 Wire Assembly, #10 White 1

10 950805 Wire Assembly, Teminal Board - Mtr. 1

11 951004 Wire Assembly, #10 Black 1

12 794720 Insulator Motor 1

13 795220 Motor, Drive 1

14 911438 Block, Terminal 1

15 950813 Wire Assembly 1

16 842406 Cable 1

CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual Page 25

Page 26

NOTES

Page 26 CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual

Page 27

ALTO® PRODUCT SUPPORT BRANCHES

U. S. A. Locations European Locations

HEAD OFFICE

AL T O U.S . Inc., St. Louis, Missouri

16253 Swingley Ridge Road, Suite 200

Chesterfield, Missouri 63017-1725

PRODUCTION FACILITIES

AL T O U.S. Inc., Springdale, Arkansas

2100 Highway 265

Springdale, Arkansas 72764

(501) 750-1000

Customer Service - 1-800-253-0367

Tec hnical Service - 1-800-356-7274

AL T O U.S . Inc., Bo wling Green, Ohio 43402

1100 Haskins

AL T O U.S. Inc., Clearwater , Florida 33765

1500 N. Belcher Road

SERVICE FACILITIES

AL T O U .S . Inc., Carlstadt, New Jersey 07072

150 Commerce Road

(201) 460-4774

PRODUCTION FACILITIES

AL T O Danmark A/S, Aalborg

Blytaekkervej 2

DK-9000 Aalborg

+45 72 18 21 00

AL T O Danmark A/S, Hadsund

Industrikvarteret

DK-9560 Hadsund

+45 72 18 21 00

SALES SUBSIDIARIES

AL TO Canada Ltd., Re xdale Ontario

24 Constellation Ct.

(416) 675-5830

ALTO Ov erseas Inc., Sydney (Australia)

1B/8 Resolution Drive

Caringbah NSW 2229

+61 2 9524 6122

AL T O Cleaning Systems Asia Pte Ltd., Singapore

No. 17 Link Road

Singapore 619034

+65 268 1006

AL T O U .S. Inc., Elk Grov e, Illinois 60007

2280 Elmhurst Road

(847) 956-7900

AL T O U.S. Inc., Den ver , Colorado 80204

1955 West 13th A ve .

(303) 623-4367

AL T O U.S . Inc., Houston, Texas 77040

7215 North Gessner Road

SALES AND SERVICE FACILITIES

AL TO U.S. Inc., Madison Heights, Michigan 48071-0158

29815 John R.

(810) 544-6300

AL T O U.S. Inc., Marietta, Georgia 30062

1355 West Oak Common Lane

(770) 973-5225

CLARKE TECHNOLOGY

AMERICAN SANDERS TECHNOLOGY

A.L. COOK TECHNOLOGY

Customer Service Headquarters and Factory

2100 Highway 265

Springdale, Arkansas 72764

(501) 750-1000

Technical Service

CLARKE TECHNOLOGY Model SPS-28 Space Sweeper Operator's Manual Page 27

1-800-356-7274

AL TO Deutschland GmbH, F rondenberg (Germany)

Ardeyer Str . 15

D-58730 Frondenberg

+49 2373 754 200

AL T O Cleaning Systems (UK) Ltd., Penrith

Gilwilly Industrial Estate

Penrith

Cumbria CA11 9BN

+44 1768 868 995

AL T O France S .A. Strasbourg

B.P. 44, 4 Place d’Ostwald

F-67036 Strasbourg

Cedex 2

+33 3 8828 8400

AL TO Nederland B .V . Vianen

Stuartweg 4C

NL-4131 NJ Vianen

+31 347 324000

AL TO Sv erige AB, Molndal (Sweden)

Aminogatan 18

Box 4029

S-431 04 Molndal

+46 31 706 73 00

ALTO Norge A/S , Oslo (Norwa y)

Bjornerudveien 24

N-1266

+47 2275 1770

Page 28

CLARKE TECHNOLOGY LIMITED U.S. WARRANTY

This Clarke Industrial/Commercial Product is warranted to be free from defects in materials and workmanship under

normal use and service for a period of one year from the date of purchase, when operated and maintained in accordance

with Clarke's Maintenance and Operations instructions.

This warranty is extended only to the original purchaser for use of the product. It does not cover normal wear parts such

as electrical cable, rubber parts, hoses and motor brushes.

If a difficulty develops with the product, you should:

a) Contact the nearest authorized Clarke repair location or contact the ALTO U.S. Service Operations Department, 2100

Highway 265, Springdale Arkansas 72764, for the nearest authorized Clarke repair location. Only these locations are

authorized to make repairs to the product under this warranty.

b) Return the product to the nearest Clarke repair location. Transportation charges to and from the repair location must be

prepaid by the purchaser.

c) Clarke will repair the product and/or replace any defective parts without charge within a reasonable time after receipt of

the product.

Clarke's liability under this warranty is limited to repair of the product and/or replacement of parts and is given to

purchaser in lieu of all other remedies, including INCIDENTAL AND CONSEQUENTIAL DAMAGES.

THERE ARE NO EXPRESS WARRANTIES OTHER THAN THOSE SPECIFIED HEREIN. THERE ARE NO WARRANTIES WHICH

EXTEND BEYOND THE DESCRIPTION OF THE F ACE HEREOF . NO WARRANTIES, INCLUDING BUT NOT LIMITED TO WARRANTY OF MERCHANTABILITY, SHALL BE IMPLIED. A warranty registration card is provided with your Clarke product.

Return the card to assist Clarke in providing the performance you expect from your new floor machine.

ALTO U.S. Inc., 2100 Highway 265, Springdale, Arkansas 72764.

CLARKE TECHNOLOGY reserves the right to make changes or improvements to its machine without notice.

Always use genuine Clarke Parts for repair.

CLARKE TECHNOLOGY

2100 Highway 265

Springdale, Arkansas, 72764

Loading...

Loading...