Page 1

C 100.7

C 105.7

C 110.7

C 120.7 - C 120.7 X-TRA

C 125.7 - C 125.7 X-TRA

Repair Manual ver. 1.1

Page 2

Index

A. Saftey precautions 3

B. Technical data 4-5

C. Construction 6-8

D. Service / Repair 9-18

E. Torque 18-20

F. Operating supplies 21

G. Operation 22-24

H. Diagram 25

2

Page 3

Safety precautions.

A

WARNING!

High pressure jets can be dangerous. Never direct the water jet at persons

pets, live electrical equipment or the machine self.

The operator and anyone in the immediate vicinity of the site of cleaning

should take action to protect themselves from being struck by debris dislodged during operation. Wear goggles during operation.

Never try to clean clothes or footwear on yourself or other persons.

Do not let children or people who have not read the instruction manual

operate the machine.

Never use the machine in an environment where there could be a danger of

explosion. If any doubt arises, please contact the local authorities.

It is not allowed to clean asbestos- containing surfaces with high pressure.

This high pressure washer must not be used at temperatures below 0°C.

Never let any persons stay under the product when stored on the wall.

3

Page 4

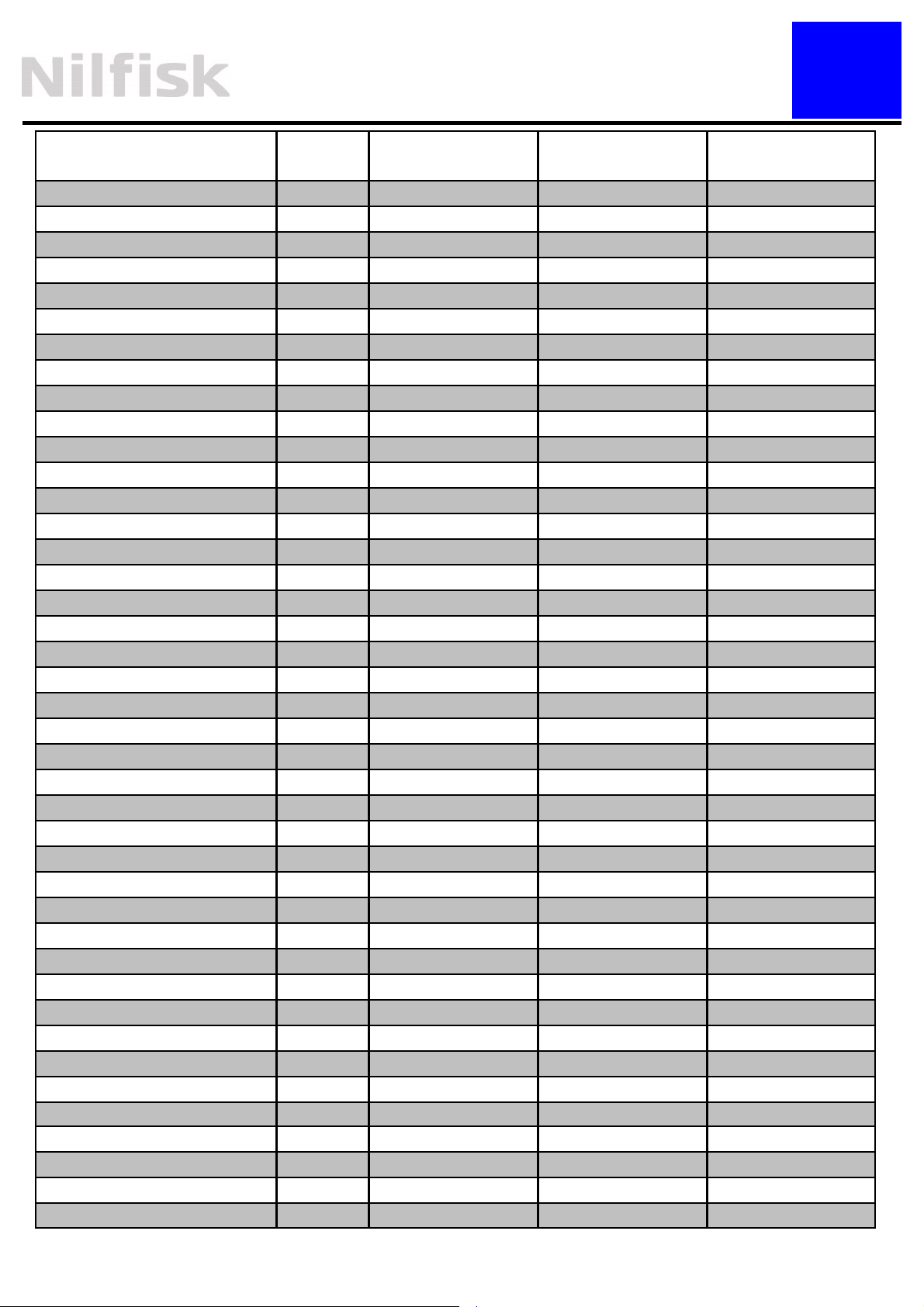

Technical Data.

Product segment: Consumer C100.7 C105.7

Specification

Voltage

Frequency

Power consumption A

Power absorbed KW

Numbers of revolutions

Water volume, HP l / min.

Pump pressure bar

Nozzle pressure bar

Opening pressure bar

Retaining time min.

Oil contents

Oil type

Max water inlet temperature

Max water inlet pressure bar

High pressure hose length m

Suction height m

Electric cable m

Insulation class

Tightness

bar

V

Hz

rpm./ min.

ml

ARTL 32 ARTL 32 ARTL 32

C 40 40 40

B B B

IPX5 IPX5 IPX5

Max 100 Max 105 Max 110

220-240 220-240 220-240

50-60 50-60 50-60

6 6 6

1,3 1,4 1,4

17.500-18.500 17.500-18.500 17.500-18.500

5,3 5,2 5,2

70 75 80

53-63 57-67 62-72

90-110 90-110 90-110

5 5 5

55 55

10 10 10

3m/5m Textile 5m Textile 5m Textile

0,5 0,5 0,5

5m 5m 5m

B

C110.7 /

C110.7 X-tra

55

4

Page 5

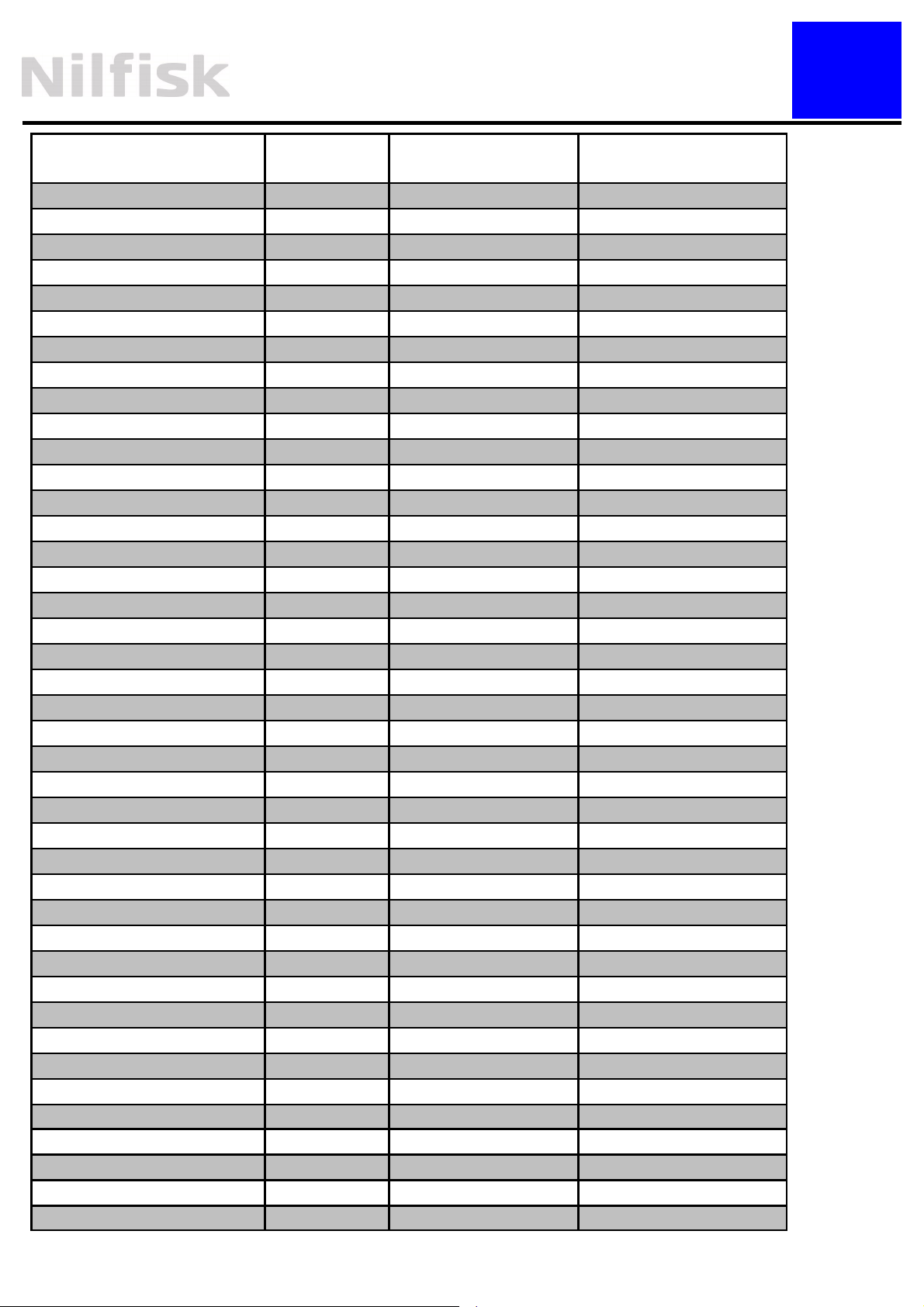

Technical Data.

Product segment: Consumer C120.7 / C120.7 X-tra C125.7 / C125.7 X-tra

Specification

Voltage

Frequency

Power consumption A

Power absorbed KW

Numbers of revolutions

Water volume, HP l / min.

Pump pressure bar

Nozzle pressure bar

Opening pressure bar

Retaining time min.

Oil contents

Oil type

Max water inlet temperature

Max water inlet pressure bar

High pressure hose length m

Suction height m

Electric cable m

Insulation class

Tightness

bar

V

Hz

rpm./ min.

ml 55 55

ARTL 32 ARTL 32

C 40 40

B B

IPX5 IPX5

Max 120 Max 125

220-240 220-240

50-60 50-60

6 6,5

1,4 1,5

16.500-17.500 16.000-17.000

5,2 5,4

85 95

66-76 75-85

110-130 110-130

5 5

10 10

6m Textile 6m Textile

0,5 0,5

5m 5m

B

5

Page 6

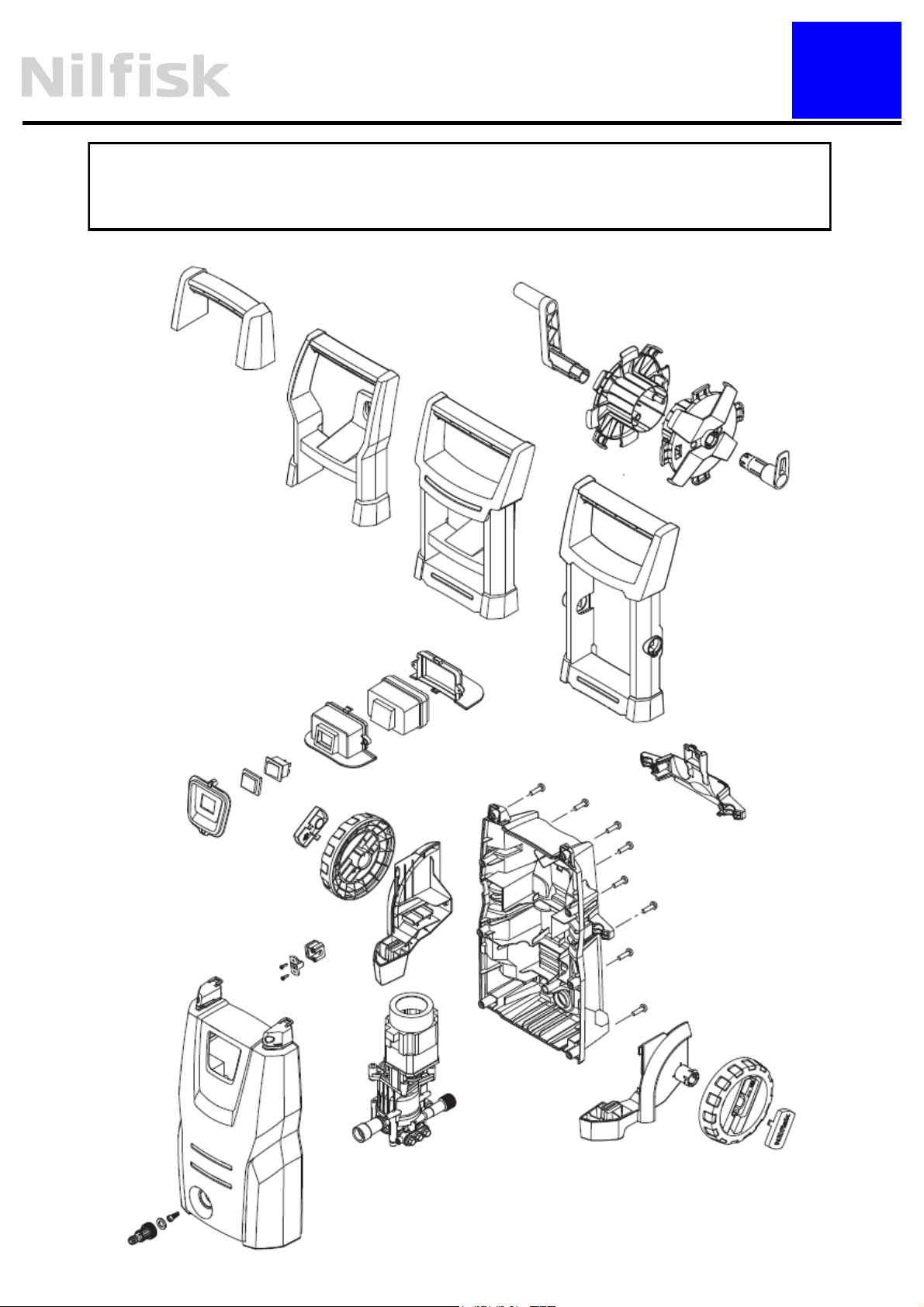

Construction.

C 100.7 - C 105.7 - C 110.7 C 120.7 - C 120.7 X-TRA

Construction of cabinet parts.

C

(!)

(!) Part 24, 25, 26 are on only used on PG versions

6

Page 7

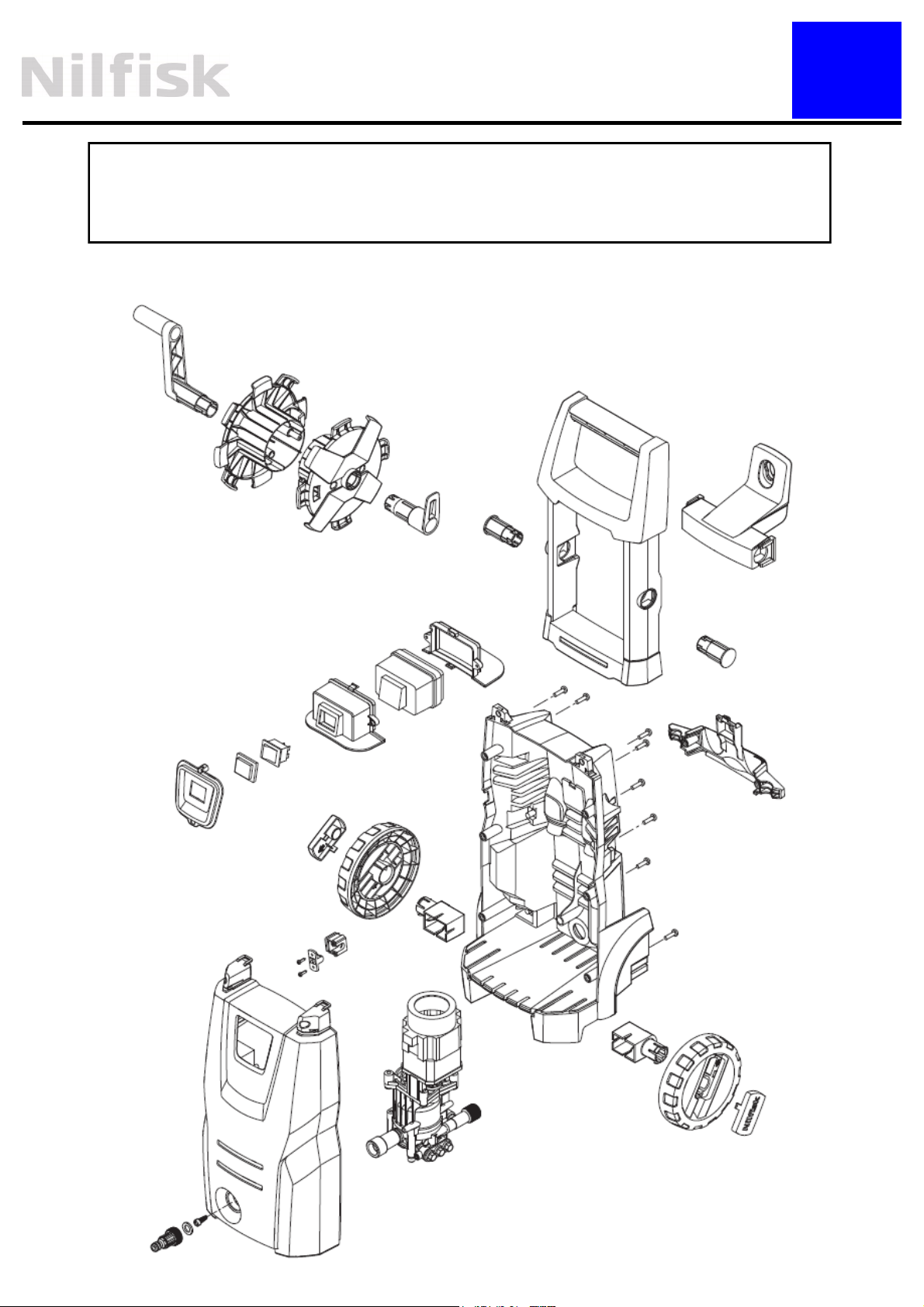

Construction.

C 125.7 - C 125.7 X-TRA

Construction of cabinet parts.

C

(!)

7

Page 8

Construction.

C 100.7 - C 105.7 - C 110.7

C 120.7 - C 120.7 X-TRA - C 125.7 - C 125.7 X-TRA

Construction of pump unit.

C

8

Page 9

Service / Repair.

D

Dismounting of cabinet rear part on following variants:

C 100.7 - C 105.7 - C 110.7 - C 120.7 - C 120.7 X-TRA

1. Tools: Screwdriver PH2

2. Remove the 2 screws (Long) fixing the handle

3. Remove the 6 screws (Short) from the rear side (fig. 3)

4. Don’t remove the accessory bracket and the wheels

5. The cabinet rear part can be removed and there is now access to the motor pump unit

Fig. 1

Fig. 2

Long screws

Short screws

9

Page 10

Service / Repair.

D

Dismounting of cabinet rear part on following variants:

C 125.7 - C 125.7 X-TRA

1. Tools: Screwdriver PH2

2. Remove the 2 screws (Long) fixing the handle (fig. 3)

3. Remove the 6 screws (Short) from the rear side (fig. 4)

4. Don’t remove the accessory bracket

5. Remove the wheels and remove the 2 screws behind the wheel parts (fig. 5)

6. The cabinet rear part can be removed and there is now access to the motor pump unit

Fig. 3

Fig. 4

Long screws

Short screws

Fig. 5

10

Page 11

Service / Repair.

D

Dismount / mounting of switch box cover and switch box.

1. Remove the 2 screws . Fig 1

2. Release the snap on switch box form the hook on the switch box cover. Fig 2

3. Release the hook on the switch box from the snap on the switch box cover by using a

small ordinary screw driver and remove the switch box cover Fig 3

4. Assembly: Ensure that the cover/gasket on the on/off switch is correctly mounted in the

hole in the front part and the taps on the switchbox is fixed the slots in the ribs Fig. 4

5. Click on the switch box cover on the switch box and mount the 2 screws

Fig. 1

Fig. 2

Fig. 3

Fig. 4

11

Page 12

Service / Repair.

Dismounting / mounting of the start / stop valve.

Fig 1 is showing how the start / stop valve must be assembled.

A special tool is needed in order to take out the seat of the start / stop valve (fig 2)

Please use “Puller for valve seat M4” item number 31000189.

NOTE: the valve seat is no longer usable after using the puller.

Fig. 1

D

Fig. 2

12

Page 13

Service / Repair.

Dismounting / mounting of water / oil seal and valves.

To change the oil seals, water seals and pressure valve, use a screw driver to dismount the

parts (fig 3 & 4).

Alternatively there is a puller number 1220103 to pull out the valves seats (pressure and

suction valves.

Note: the seat is no longer usable after using the puller

Cleanup and lubricate before mounting!

Fig 1 is showing the pump after opening the cylinder head from the cylinder block.

Fig 2 is showing how all the parts must be assembled into the cylinder head.

Fig. 1

Fig. 2

D

13

Fig. 4 Fig. 3

Page 14

Service / Repair.

IMPORTANT mounting information:

In order to optimize the self suction mode the valve bodies must be positioned correct according to the water canals inside the cylinder head. The “leg” of the valve body must not be

placed in front of a canal. Fig 1 is showing the WRONG positioning and fig 2 is showing the

CORRECT positioning.

Fig. 2 Fig. 1

D

14

Page 15

Service / Repair.

D

Precaution when assembling the switch box.

1. Ensure that the cable and the 2 wires are mounted in the groves Fig. 1

Precautions when assembling the machine.

1. Ensure that the gasket for the water inlet is mounted correctly inside the front part before

mounting the motor pump unit in the front part Fig. 2

2. Ensure the power cable is not placed on the internal ribs before assembly Fig. 3

3. Ensure the cable relief is mounted correctly Fig. 3

Fig. 1

Fig. 2

!

Fig. 3

OK

OK

15

Page 16

Service / Repair.

D

Assembly of cabinet rear part on following variants:

C 125.7 - C 125.7 X-TRA

1. Tools: Screwdriver PH2 Fig. 3

2. Note that screws has different lengths:

Short type:8 pcs

Long type 2 pcs ( for handle):

3. Mount 2 short screws behind the wheel parts (fig. 5)

4. Ensure that the wheels are mounted correctly by sliding the parts together, before

mounting the screws Fig. 6

5. Mount the wheels and mount 6 short screws on rear side (fig. 4)

6. Mount the handle and the 2 long screws to fix the handle (fig. 4)

Fig. 3

Fig. 4

Fig. 6

Long screws

Short screws

16

Fig. 5

Page 17

Service / Repair.

Assembly of cabinet rear part on following variants:

C 100.7 / C 105.7 / C 110.7 / C 120.7 / C 120.7 X-TRA

1. Tools: Screwdriver PH2

2. Mount the 6 short screws from the rear side (fig. 3)

3. Mount the handle and the 2 long screws to fix the handle

Fig. 1

D

Fig. 2

Xx/yy mm

Xx/yy mm

17

Page 18

Pump torque.

Torque.

8 Nm

E

18 Nm

10 Nm

16 Nm

18

8 Nm

Page 19

Torque.

Cabinet torque. C 100.7 - C 105.7 - C 110.7 - C 120.7 - C 120.7 X-TRA

E

19

2 Nm

Page 20

Torque.

Cabinet torque. C 125.7 - C 125.7 X-TRA

E

2 Nm

20

Page 21

Operating supplies

Recommended oil types:

The pump is filled with 55 ml ARTL 32 from the production.

In case of service where the oil must be changed NilfiskAdvance recommends to use 80 ml Bartran HV 46.

Alternative oil types that are allowed:

BP, Bartram HV 46

Shell, Tellus T 46

F

Exxon, Statoil Univis N 46

Mobil Oil Mobil DTE 25

Recommended lubrication:

White grease for o-rings, sealings etc.:

Silicone grease, DOW CORNING(R) 55 O-RING LUBRICANT

Special tools:

Puller for valve seat M4—item number 31000189 (Page 12).

Puller for valve seat (pressure and suction valve) - item number

1220103 (Page 13)

21

Page 22

Operation.

3.0 Start stop System guide

3.1 No pressure in system

No pressure in system - except inlet pressure 3 bar. Machine switch off.

Pump

3 BAR

Non return valve

Inlet

3 BAR

G

Outlet

3 BAR

3.2 Start up-pressure build up

Machine switch on / Start up – Pressure build up

Pump

>5 BAR

Non return valve

Outlet

>5 BAR

Inlet

3 BAR

22

Page 23

Operation.

3.3 Pressure build up-opening pressure / close gun

Gun close. Pressure build up. Opening pressure. Micro switch is activated

Pump

100-125 BAR

Non return valve

Inlet

Outlet

100-125 BAR

3 BAR

G

3.4 Motor stop – Standby pressure

Gun close. Motor stops. Pressure in hose decreases to standby pressure.

Pump pressure is also standby pressure.

Pump

15 BAR

Non return valve

Outlet

Inlet

15 BAR

3 BAR

23

Page 24

Operation.

3.5 Gun is activated

Gun is open - Control piston is closed. Micro switch is deactivated. Motor

starts.

Pump

3 BAR

Non return valve

3 BAR

Outlet

Inlet

3 BAR

G

3.6 Machine run

Machine runs (normal working pressure). Gun is open.

Pump

70-95 BAR

Non return valve

Outlet

65-90BAR

Inlet

24

3 BAR

Page 25

Wiring Diagram

Wiring and Circuit Diagram

S1

H

M

S2

25

Loading...

Loading...