Page 1

VBA24001-R.3783.A

M

サービス

計画課

INC

作成承認印 配布許可印

VBA24001

REPAIR MANUAL

Printed in Japan APRIL.2009

Copyrightc2009 by Nikon Corporation.

All Rights Reserved.

無断転載を禁ず

!!

Page 2

VBA24001-R.3783 .A

INC

CONTENTS

Points to notice for Disassembly and Assembly ......................................................................................................................D1

Disassembly ................................................................................................................................................................................D2

1. External section ...............................................................................................................................................................D2

Bottom cover ..................................................................................................................................................................D2

Removal of back cover ..................................................................................................................................................D4

2. Back cover ........................................................................................................................................................................D6

Sponge/Button/FPC/Speaker ....................................................................................................................................... D8

SD cover unit ............................................................................................................................................................... D10

SD cover ........................................................................................................................................................................ D11

TFT monitor unit .......................................................................................................................................................D12

3. Front cover .....................................................................................................................................................................D18

Pop-up of Flash unit (SB) ...........................................................................................................................................D18

Front cover ................................................................................................................................................................... D18

4. Top cover ........................................................................................................................................................................ D19

TOGO PCB unit ..........................................................................................................................................................D19

Removal of top cover ................................................................................................................................................... D20

SB upper cover ............................................................................................................................................................D21

lower control unit..................................................................................................................................................D22

SB

SB release base unit .................................................................................................................................................... D24

AF-assist lamp unit ...................................................................................................................................................... D24

Power SW FPC unit .................................................................................................................................................... D25

Release button unit

C/D unit ....................................................................................................................................................................... D26

Top cover FPC unit .....................................................................................................................................................D26

Mode dial unit / AF/AE-L button / Delete button / AF-assist lamp window .........................................................D27

Hot shoe ........................................................................................................................................................................D27

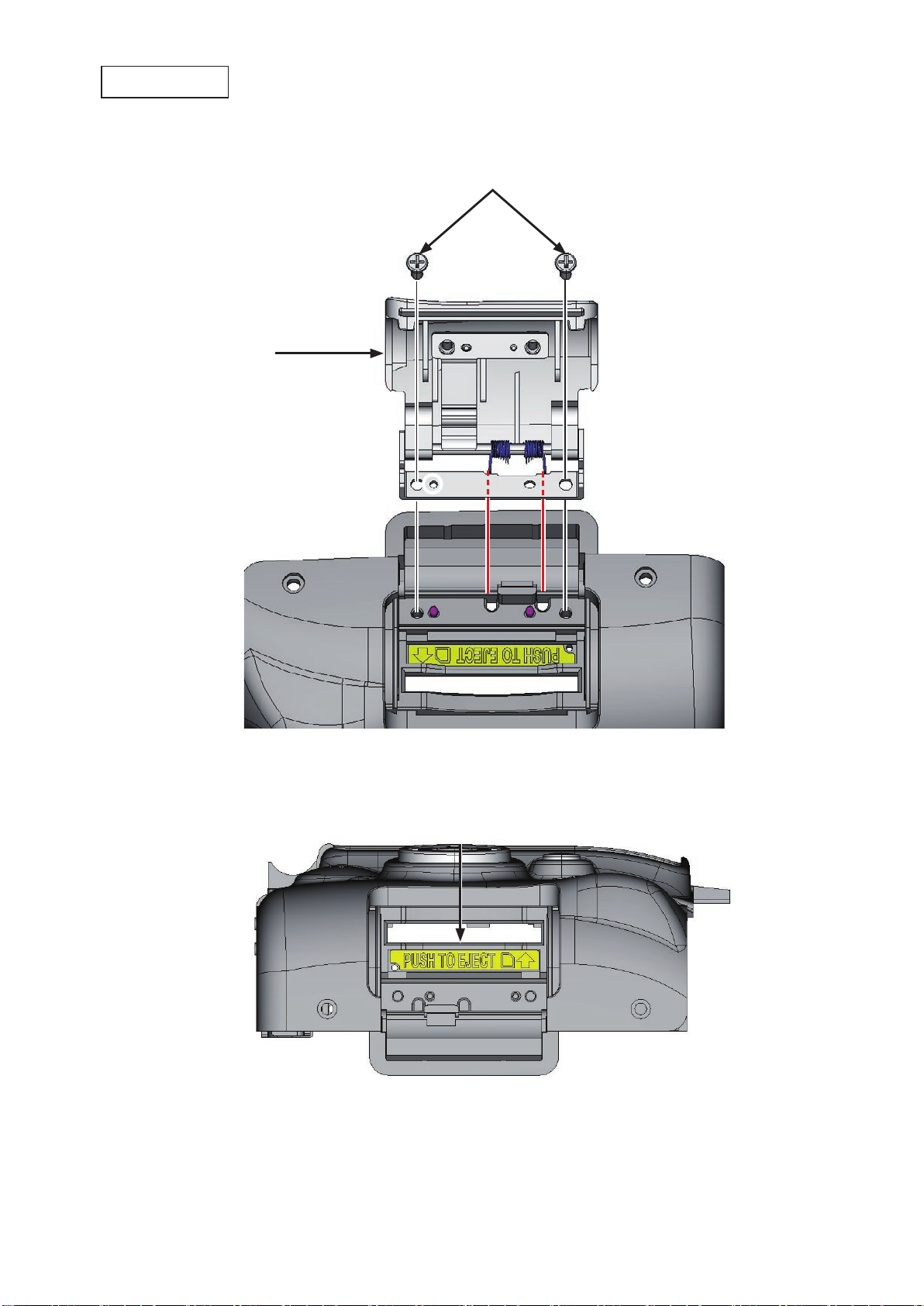

5. Image sensor ...................................................................................................................................................................D28

SZ-DC/DC PCB unit .................................................................................................................................................. D28

Image sensor unit .........................................................................................................................................................D28

6. Separation of Front body from Rear Body .................................................................................................................D29

Bottom base unit .......................................................................................................................................................... D29

/ each button, etc ....................................................................................................................... D25

7. Rear body ....................................................................................................................................................................... D32

Microphone .................................................................................................................................................................D32

Main condenser ...........................................................................................................................................................D32

SB PCB unit ................................................................................................................................................................. D33

DC/DC PCB unit ........................................................................................................................................................D34

Battery box .................................................................................................................................................................. D35

Eyelet unit, etc ............................................................................................................................................................D36

8. Front body ...................................................................................................................................................................... D37

Shutter ........................................................................................................................................................................D37

- D5000 -

Page 3

Meterring FPC unit .................................................................................................................................................... D38

INC

VBA24001-R.3783 .A

Eyepiece barrel unit ...................................................................................................................................................D38

Penta unit ....................................................................................................................................................................D39

SI unit ..........................................................................................................................................................................D40

Relay PCB unit ...........................................................................................................................................................D42

Removal of bayonet .....................................................................................................................................................D43

Lens contact unit .........................................................................................................................................................D43

SQ base unit ................................................................................................................................................................. D45

AF sensor unit ............................................................................................................................................................. D46

Inside finder LCD unit ............................................................................................................................................... D46

plate ..............................................................................................................................................................................D47

Release button unit ..................................................................................................................................................... D47

F-min SW section .........................................................................................................................................................D48

Mirror unit/Aperture lever section ............................................................................................................................D48

Assembly/Adjustment ...............................................................................................................................................................A1

1. Front body ....................................................................................................................................................................... A1

Mirror unit .................................................................................................................................................................... A1

Aperture lever section ...................................................................................................................................................A2

Spring hooking position ................................................................................................................................................A2

F-min SW section ...........................................................................................................................................................A3

Release button unit ....................................................................................................................................................... A3

plate ...............................................................................................................................................................................A4

Inside finder LCD unit ................................................................................................................................................. A4

AF sensor unit ............................................................................................................................................................... A5

SQ PCB unit .................................................................................................................................................................. A5

Lens contact unit ..........................................................................................................................................................A7

Mounting of bayonet .................................................................................................................................................... A8

Height adjustment of Aperture lever

Relay-PCB unit .........................................................................................................................................................A10

SI unit ..........................................................................................................................................................................A11

Attachment position for Finder field frame ............................................................................................................A12

Penta unit ....................................................................................................................................................................A14

.......................................................................................................................... A9

Eyepiece barrel unit ...................................................................................................................................................A15

AE FPC unit ................................................................................................................................................................ A15

adjustment of Main mirror and Sub-mirror ........................................................................................................... A16

Shutter .........................................................................................................................................................................A25

2. Rear body ....................................................................................................................................................................... A26

Eyelet unit, etc ............................................................................................................................................................A26

Battery box .................................................................................................................................................................. A27

DC/DC PCB unit ........................................................................................................................................................A29

SB PCB unit ................................................................................................................................................................. A30

Main condenser ...........................................................................................................................................................A31

- D5000 -

Page 4

Microphone .................................................................................................................................................................A31

INC

VBA24001-R.3783 .A

3. Assembly of front body into rear body ........................................................................................................................A32

Bottom base unit .......................................................................................................................................................... A33

Inspection and Adjustment of Body back ................................................................................................................A34

4. Image sensor ...................................................................................................................................................................A38

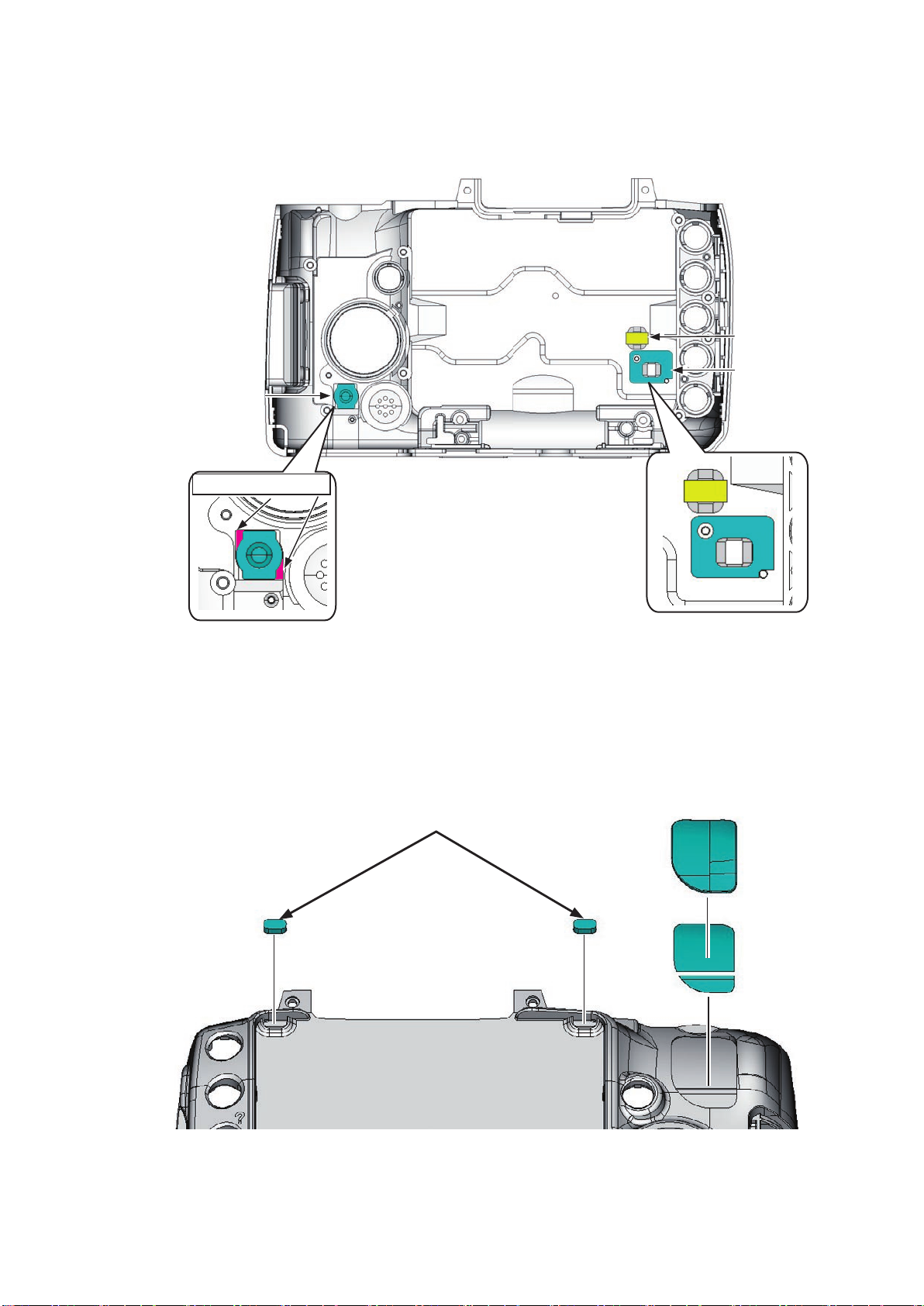

Sponge ..........................................................................................................................................................................A38

Image sensor unit ........................................................................................................................................................A38

SZ-DC/DC PCB unit .................................................................................................................................................. A39

5. Top cover ........................................................................................................................................................................ A40

Hot shoe ........................................................................................................................................................................A40

AF-assist lamp unit & AF/AE lock button ................................................................................................................ A40

Mode dial unit & Delete-button-rubber SW ............................................................................................................. A41

Top cover FPC unit .....................................................................................................................................................A41

C/D unit ....................................................................................................................................................................... A42

Release button unit

Power SW FPC unit .................................................................................................................................................... A43

AF-assist lamp unit ...................................................................................................................................................... A44

SB release base unit .................................................................................................................................................... A44

lower control unit..................................................................................................................................................A45

SB

SB upper cover ............................................................................................................................................................A48

Top cover .....................................................................................................................................................................A49

TOGO PCB unit ..........................................................................................................................................................A50

Inspection and adjustment of AE CCD positioning ................................................................................................A51

Discharge of main condenser .....................................................................................................................................A52

6. Front cover .....................................................................................................................................................................A53

Gap adjustment of SB (ash unit) section ..................................................................................................................A53

7. Back cover .....................................................................................................................................................................A54

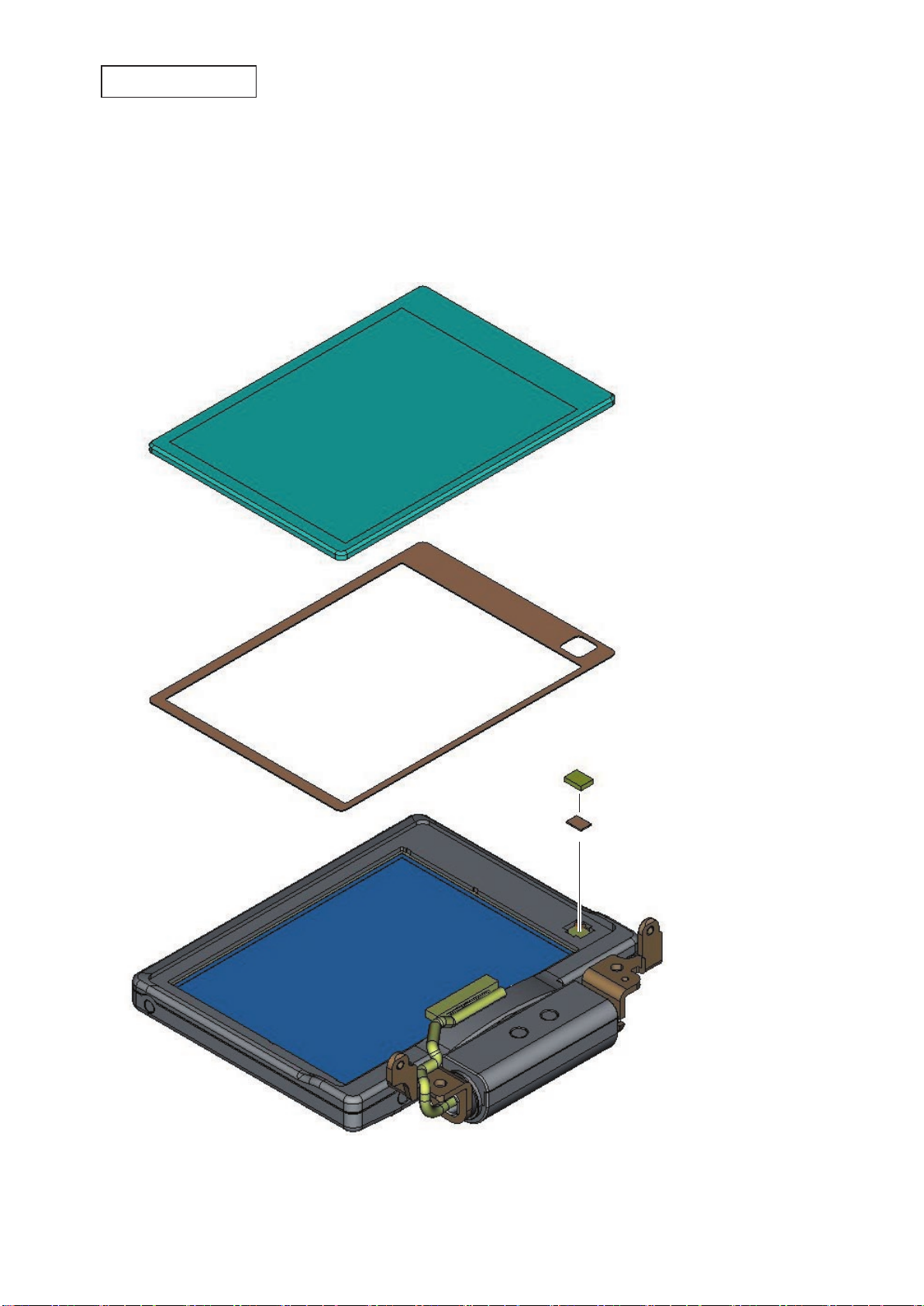

TFT monitor unit .......................................................................................................................................................A54

Back cover ...................................................................................................................................................................A61

Sponge/button/FPC/Speaker ......................................................................................................................................A62

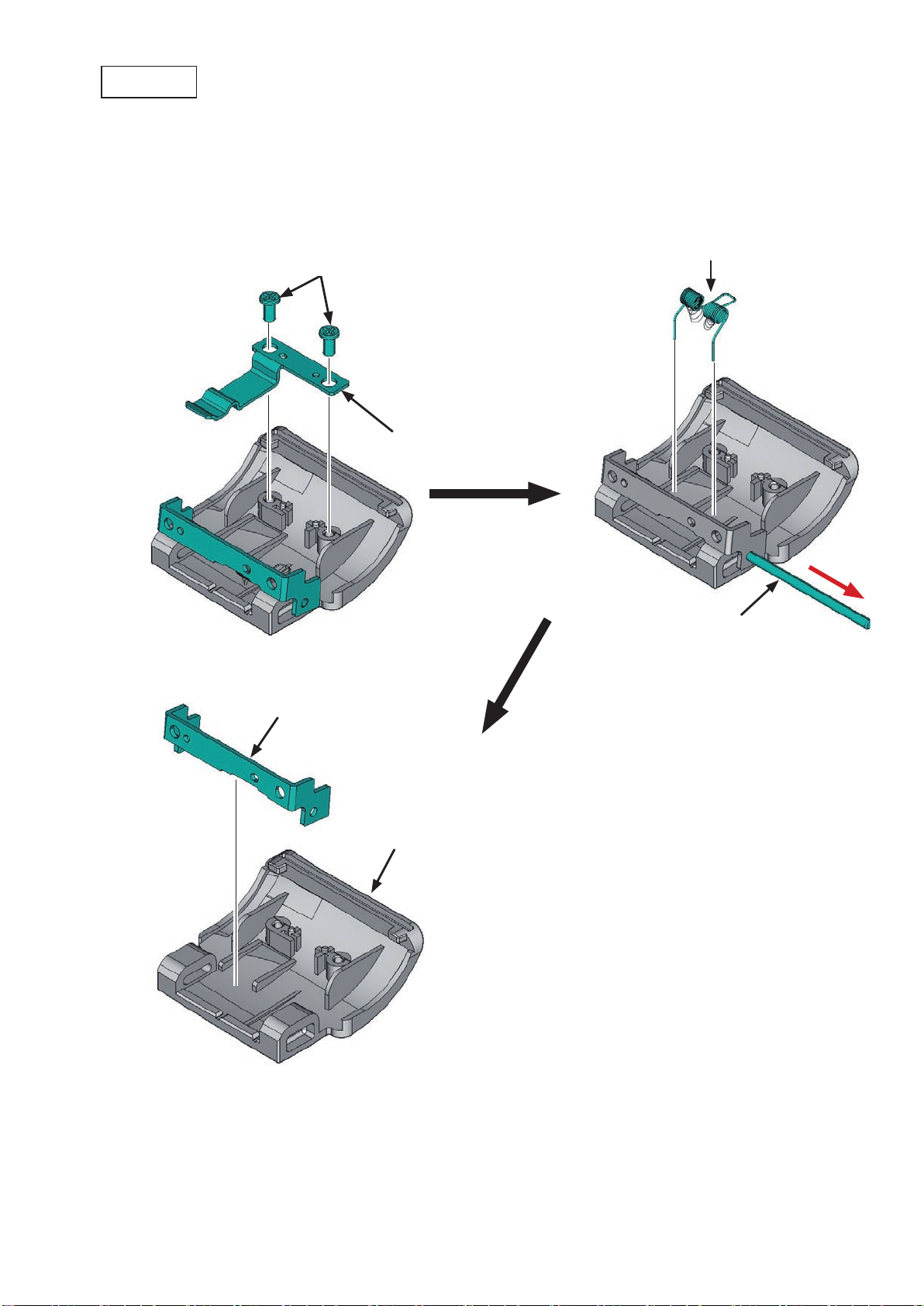

SD cover .......................................................................................................................................................................A65

/ each button, etc ....................................................................................................................... A43

SD cover unit ............................................................................................................................................................... A66

8. External appearance .....................................................................................................................................................A68

Accuracy inspection and adjustment (Camera body excl. imaging) ....................................................................A69

D5000 Inspection and Adjustment Software (J65135) ............................................................................................. A70

Procedure for installation ...........................................................................................................................................A71

Procedure for installing USB driver .......................................................................................................................... A74

Necessary adjustments when parts are replaced ...................................................................................................... A76

Firmware update .........................................................................................................................................................A77

AE inspection and adjustment ...................................................................................................................................A84

AF inspection and adjustment ....................................................................................................................................A86

Bottom cover ................................................................................................................................................................A90

Shooting-image Adjustment .......................................................................................................................................A91

- D5000 -

Page 5

Shooting image adjustment software and Software updates ...................................................................................A92

INC

VBA24001-R.3783 .A

Image adjustment ........................................................................................................................................................A93

∞ Infinity focus inspection & adjustment ............................................................................................................... A97

Measurement of Consumption current value ...........................................................................................................A98

Cleaning between Penta unit and SI-LCD ................................................................................................................A99

Operation check of cleaning image sensor ..............................................................................................................A100

Hinge SW inspection ................................................................................................................................................. A103

Main/sub mirror angle inspection tool - use chart .................................................................................................A104

Wiring ......................................................................................................................................................................................... E1

Mounting Drawing .................................................................................................................................................................... E2

Inspection standards .................................................................................................................................................................. R1

Tools ............................................................................................................................................................................................T1

Screw sheet ..................................................................................................................................................................................S1

- D5000 -

Page 6

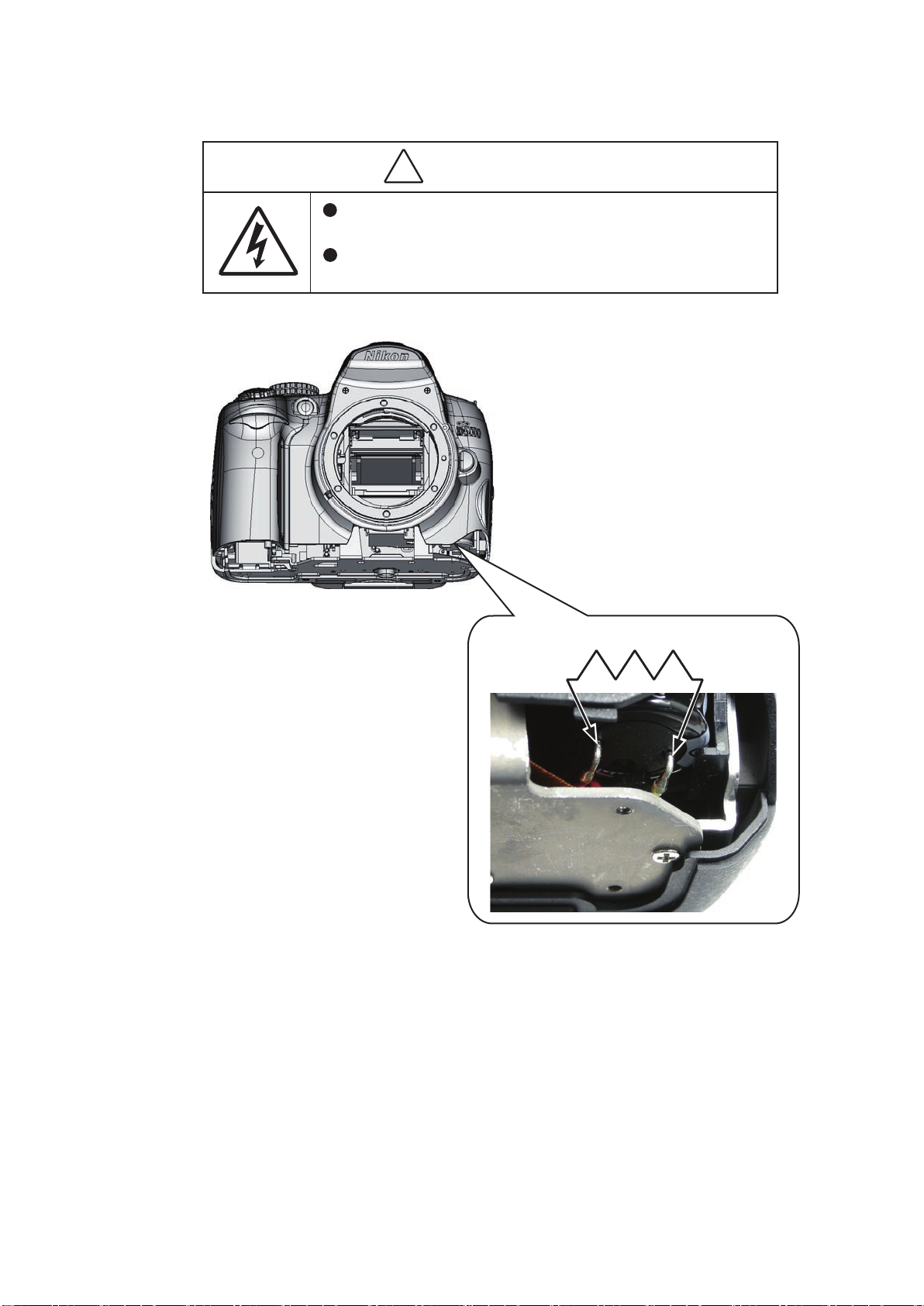

Points to notice for Disassembly and Assembly

WARNING

There are high voltege parts inside. Be careful of this electric shock,

when you remove the cover.

You must discharge the main condenser according to the instruction

of this repair manual after you remove the cover.

!

INC

Caution:

① In disassembly/(re)assembly, be sure to use conductive mat (J5033) and wrist strap (J5033-5), in

order to protect electric parts from static electricity.

VBA24001-R.3783.A

② Before disassembling, be sure to remove batteries or AC power cord.

③ In disassembling, be sure to memorize the processing state of wires and FPC, screws to be fixed and

their types, etc.

④ The low-pass filter of the image PCB/base plate is easily damaged. Handle it very carefully.

Points to notice for Lead-free solder products

・ Lead-free solder is used for this product.

・ For soldering work, the special solder and soldering iron are required.

・ Do NOT mix up lead-free solder with traditional solder.

Caution:

When "Separation of Front body from Rear body", "Disassembly of Image sensor unit"

and "Disassembly of Bayonet" are performed, be sure to carry out "RESET AF-DEFOCUS

COMPENSATION" of the D5000 adjustment software after assembly.

- D1 ・ D5000 -

Page 7

Disassembly

INC

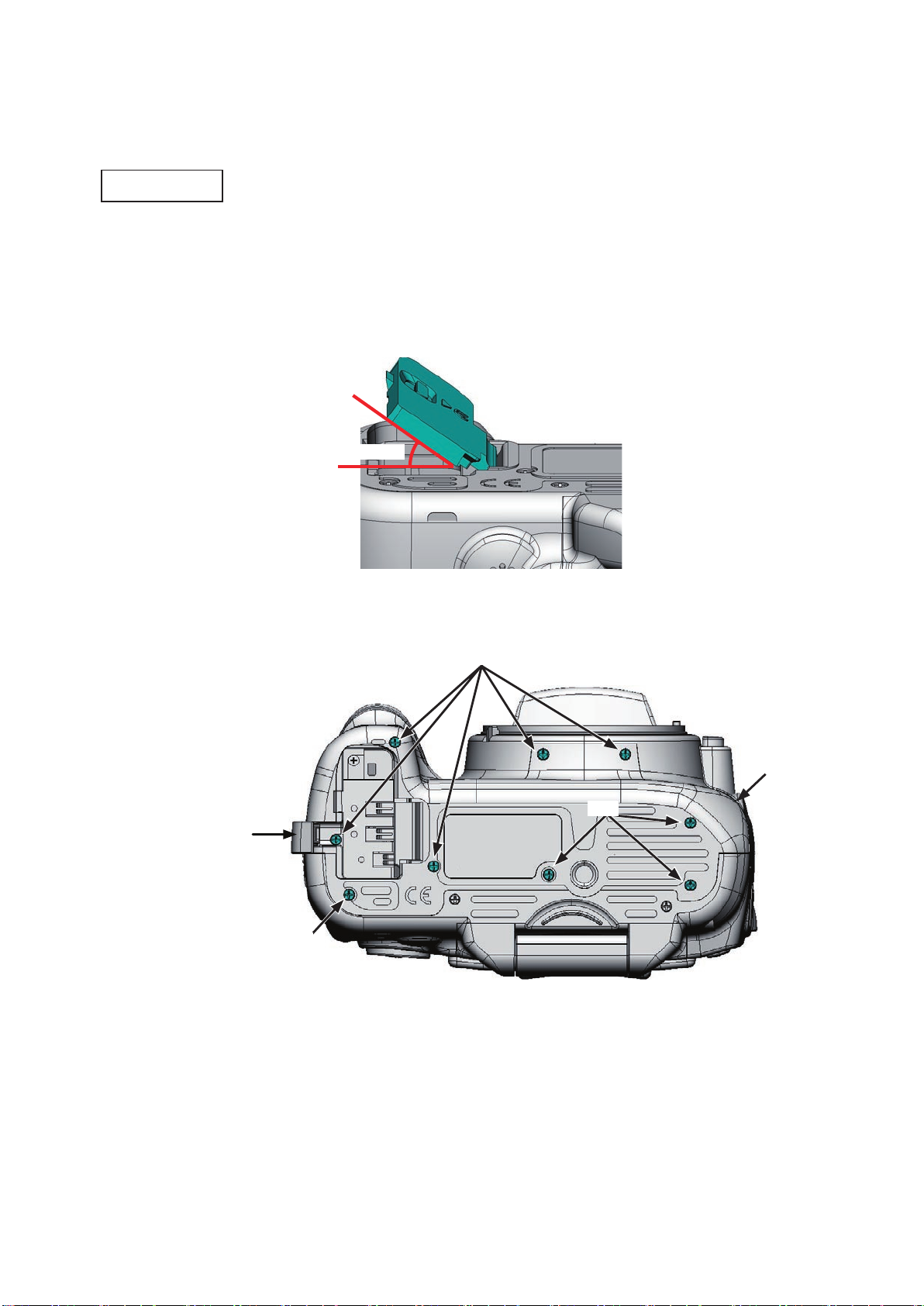

1. External section

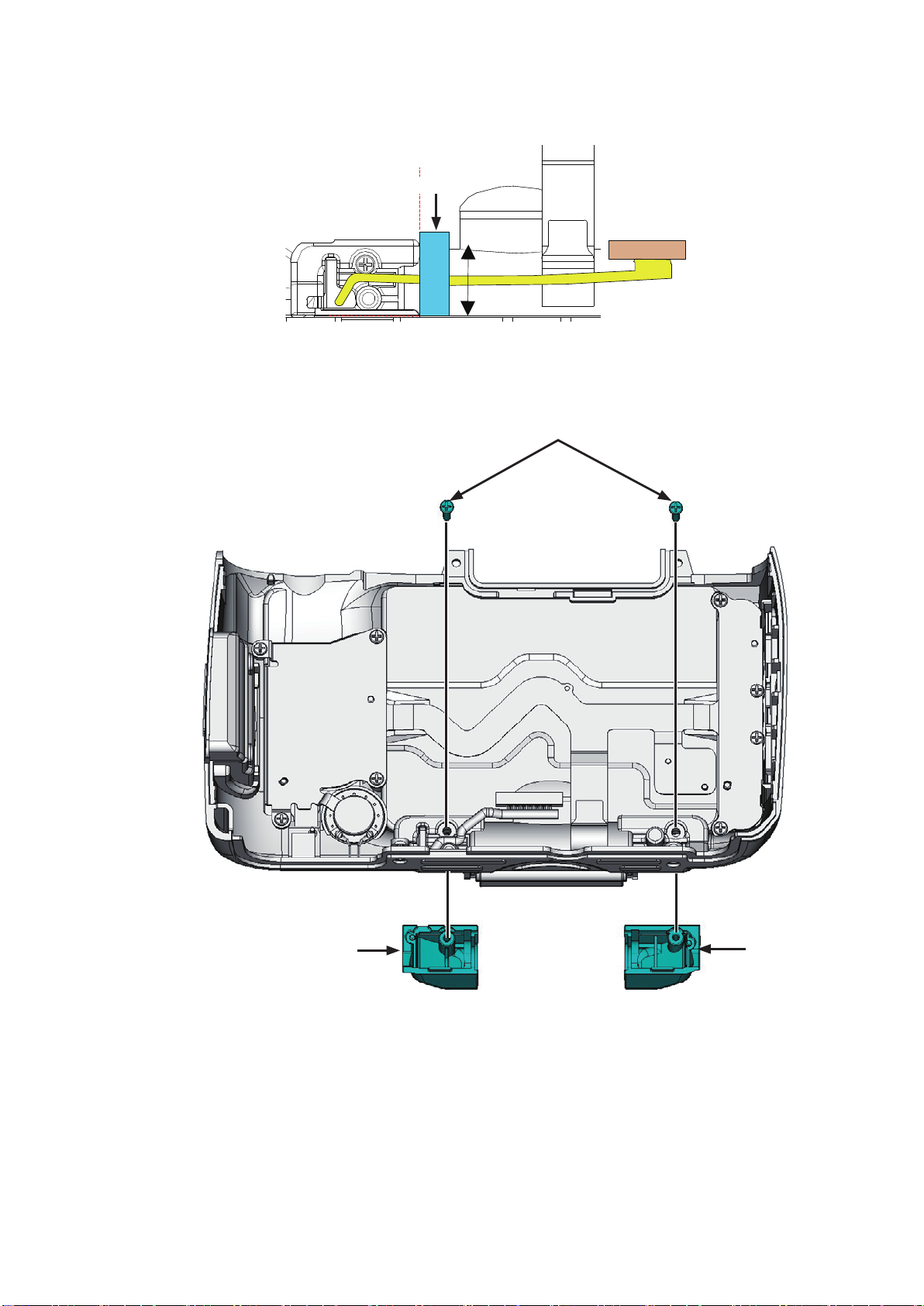

Bottom cover

・ Open and tilt the battery cover unit (#B151) at approx. 35° angle, then pull it out at the angle.

・ Open the power cable cover.

・ Take out the four screws (#735) and five screws (#671).

・ Remove the bottom cover (#25).

Approx. 35°

VBA24001-R.3783.A

Power cable cover

#671

#25

#735

#735

- D2 ・ D5000 -

Page 8

VBA24001-R.3783.A

WARNING

There are high voltege parts inside. Be careful of this electric shock,

when you remove the cover.

You must discharge the main condenser according to the instruction

of this repair manual after you remove the cover.

!

INC

2K Ω /5W

- D3 ・ D5000 -

Page 9

VBA24001-R.3783.A

INC

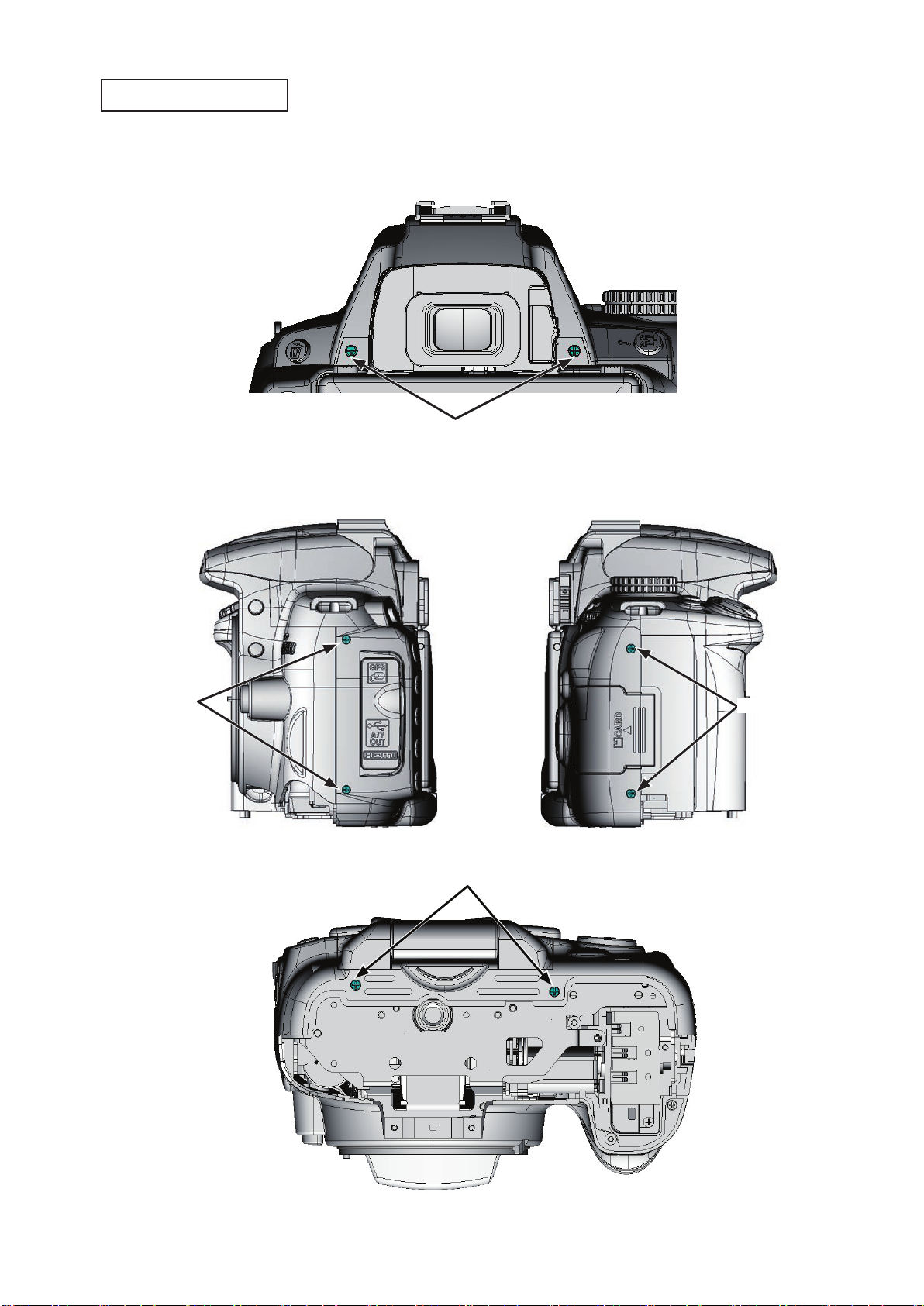

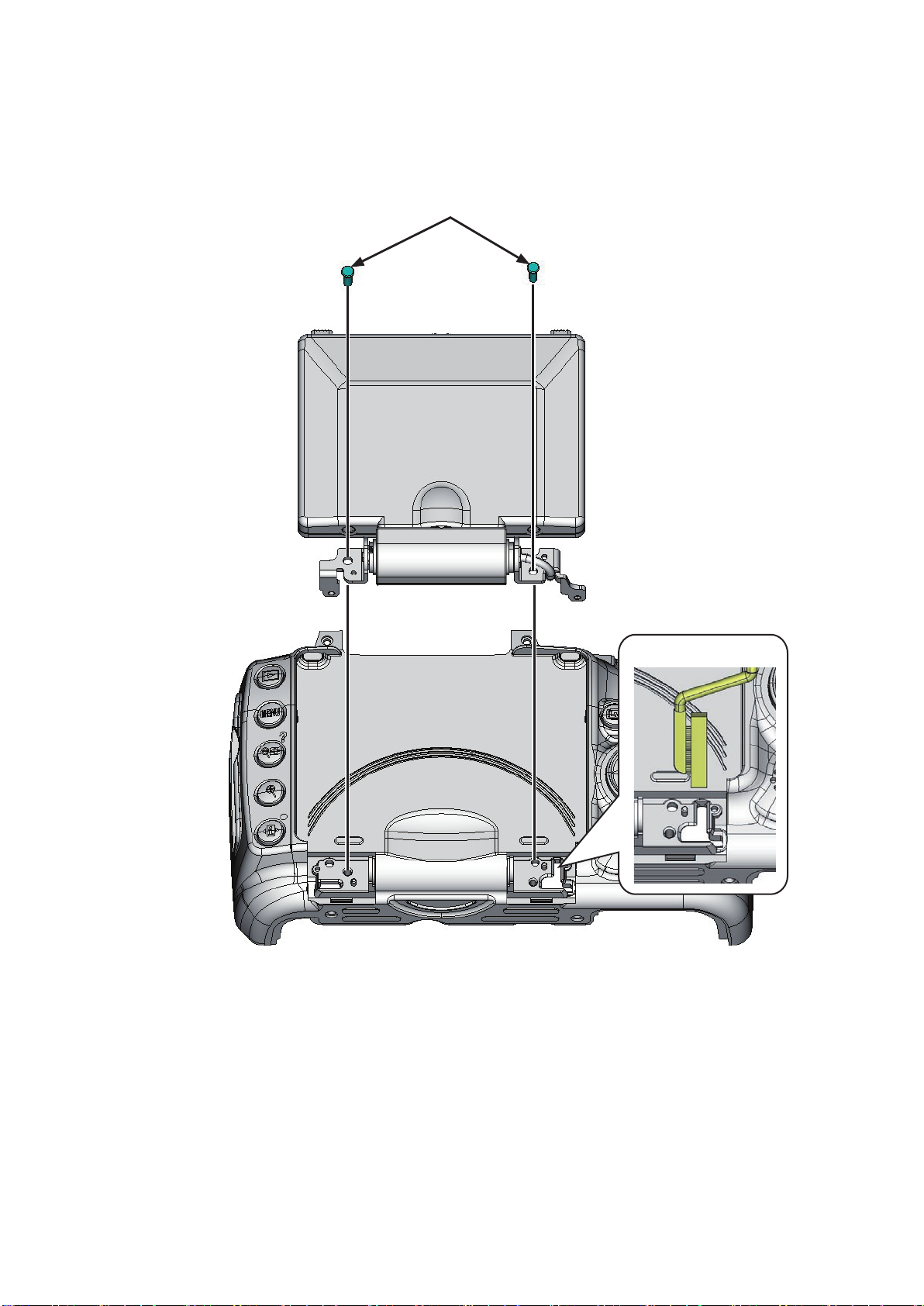

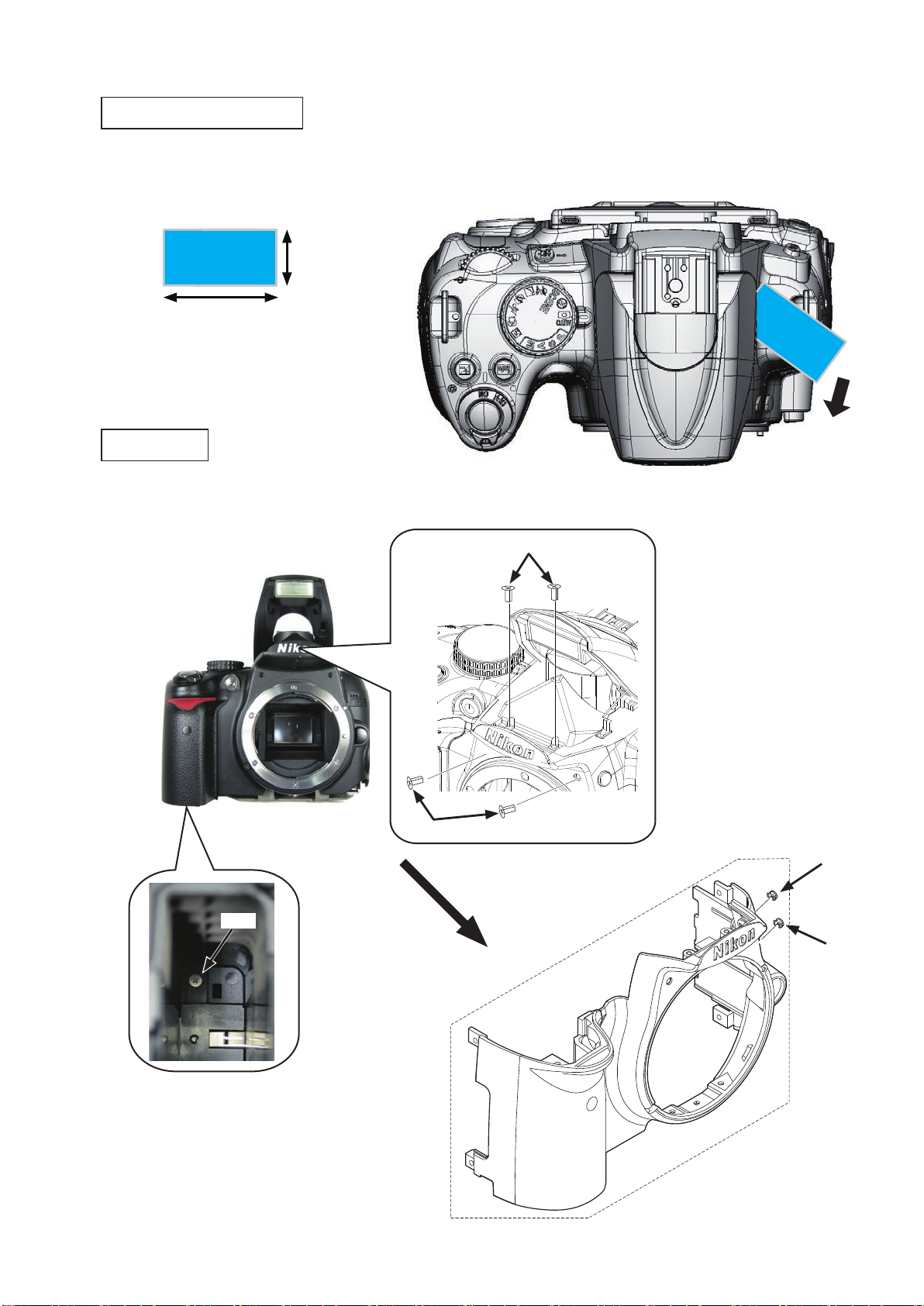

Removal of back cover

・ Take out the two screws (#618), the two screws (#690), the two screws (#697) and two screws (#740).

#618

#697

#690

#740

- D4 ・ D5000 -

Page 10

VBA24001-R.3783.A

INC

・ Remove the cover by lifting it at the grip side first, and then the whole.

・ Disconnect the FPC and harness (of the rear cover) from the connectors of the TOGO PCB UNIT(#B2001).

Remove the IF cover (#71).

・

#71

- D5 ・ D5000 -

Page 11

2. Back cover

INC

・ Peel off the tape (#705).

#705

・ Take out the two screws (#741).

・ Remove the hinge rear cover A (#445) and hinge rear cover B (#446).

#741

VBA24001-R.3783.A

#446

#445

- D6 ・ D5000 -

Page 12

・ Take out the two screws (#682).

INC

・ Remove the TFT monitor unit from the back cover.

(When removing this, be careful not to catch the harness.)

#682

VBA24001-R.3783.A

Be careful NOT to catch.

- D7 ・ D5000 -

Page 13

Sponge/Button/FPC/Speaker

INC

・ Peel off the tape (#707).

・ Unsolder the speaker (#1047).

#707

VBA24001-R.3783.A

#478

#412

#418

#413

#475

#474

#471

#472

#1047

#B1019

#424

#425

#426

#427

#422

#419

#421

#683

#683

#707

#415

#729

- D8 ・ D5000 -

Page 14

・ Peel off the tape (#477).

INC

・ Peel off the tape (#706).

・ Remove the superglue from the SD access lamp window (#408), and remove [#408].

#408

Adhesive: Superglue

VBA24001-R.3783.A

#706

#477

・ Remove the two rubbers (#473).

・ Remove the rubber (#469).

・ Peel off the double-stick tapes (#470 and #476).

#473

#469

#470

#476

- D9 ・ D5000 -

Page 15

SD cover unit

INC

・ Take out the two screws (#684).

・ Remove the SD cover unit (#B443).

#B443

VBA24001-R.3783.A

#684

・ Peel off the label (#448).

#448

- D10 ・ D5000 -

Page 16

VBA24001-R.3783.A

INC

SD cover

・ Take out the two screws, and remove the SD-cover click spring.

・ Pull out the shaft, and remove the SD-cover torsion spring. (Be careful NOT to lose the spring.)

・ Remove the plate from the SD cover (#443).

SD-cover torsion spring

Screw

SD-cover click spring

Plate

Shaft

#443

- D11 ・ D5000 -

Page 17

VBA24001-R.3783.A

INC

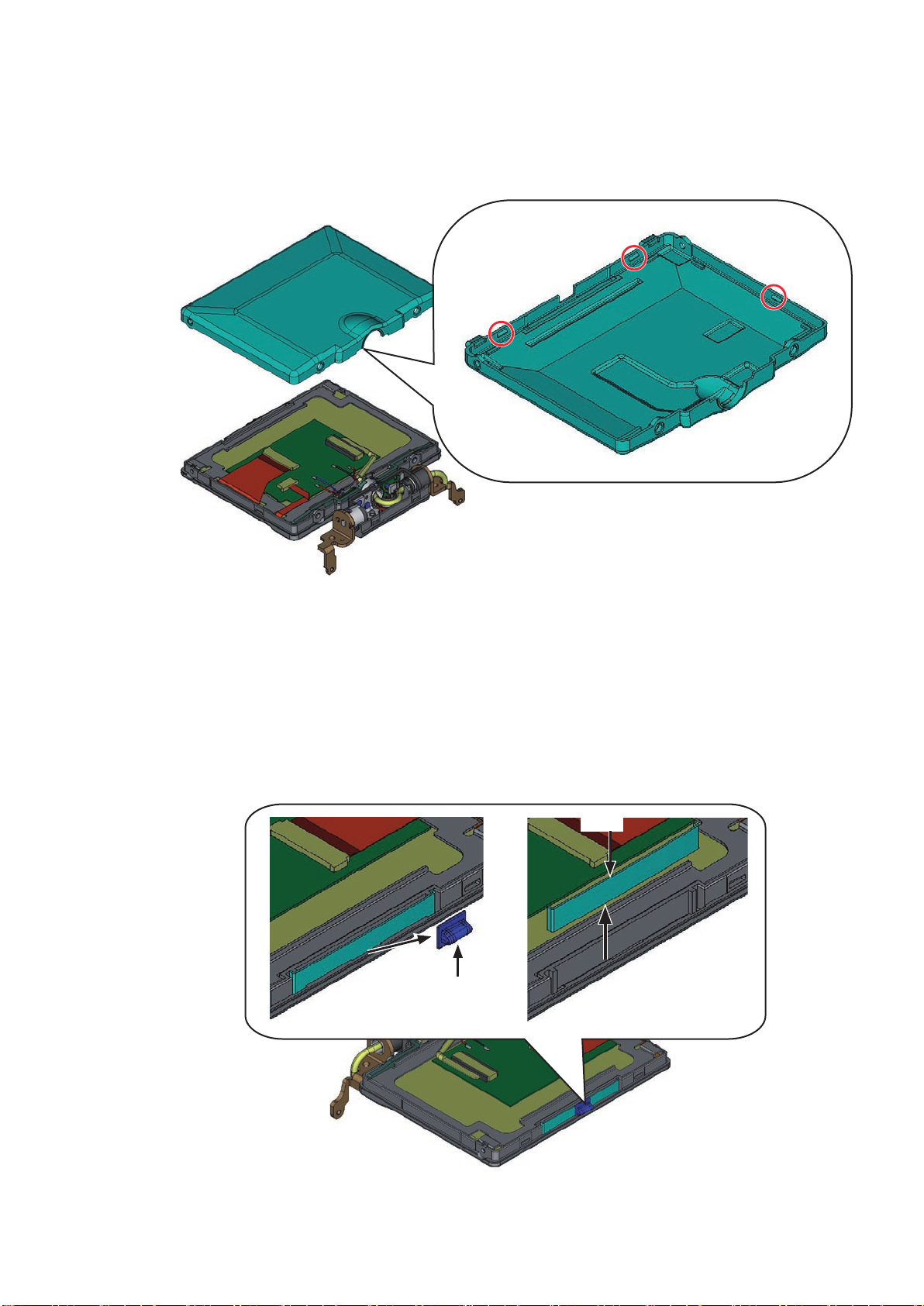

TFT monitor unit

・ Remove the TFT window (#402), and peel off the TFT window double-sticking tape (#403).

・ Remove the sensor magnet (#490) from the TFT monitor unit (#B2049).

・ Remove the magnet spacer (#494) from the sensor magnet (#490).

#402

#403

#B2049

#490

#494

- D12 ・ D5000 -

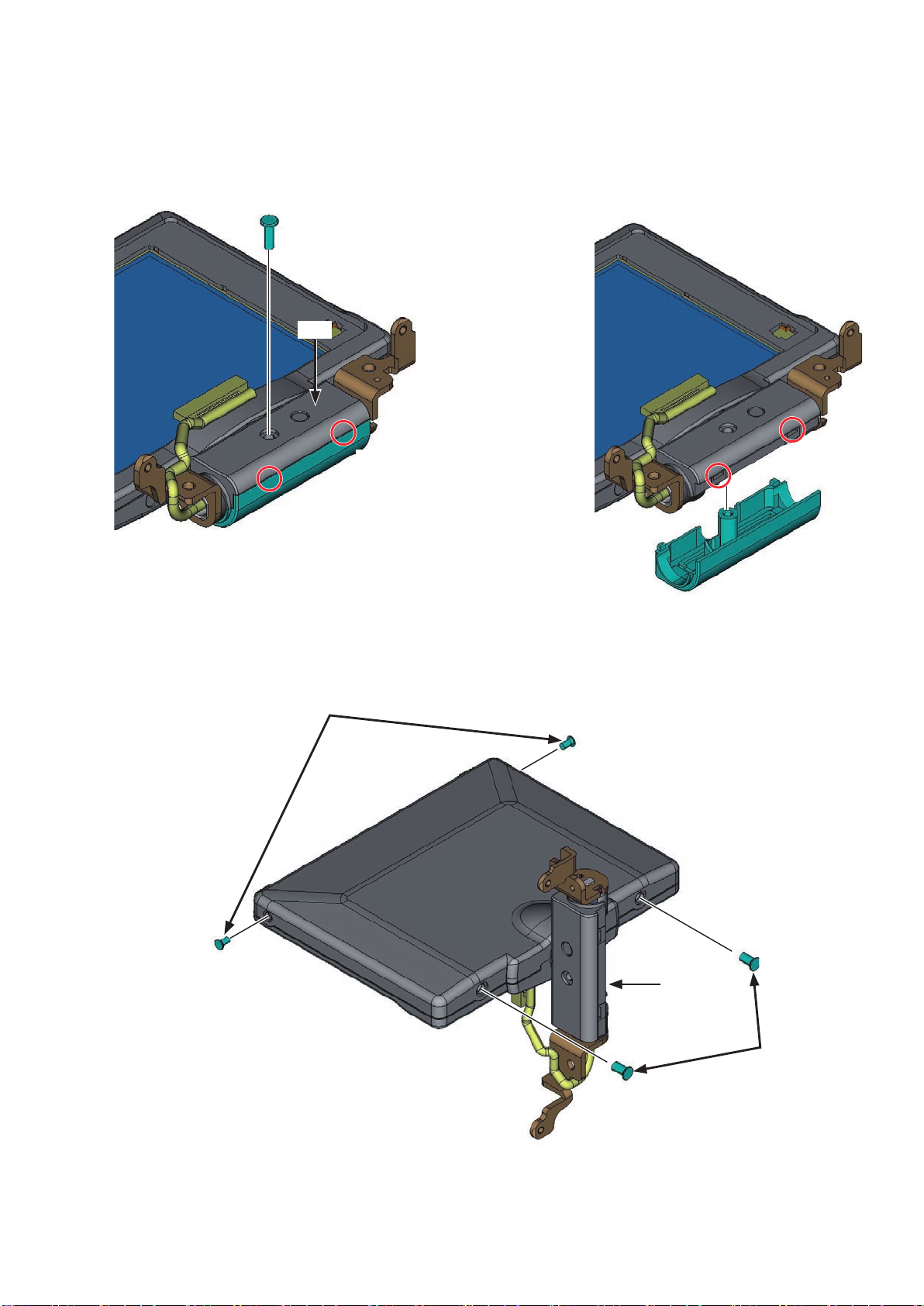

Page 18

VBA24001-R.3783.A

INC

・ Take out the screw (#671).

・ Release the two inside hooks of the hinge bottom cover (#438), and remove the hinge top cover (#437).

(Caution : must be exercised that each part do not get scratched or dented. If it does, use a new one.)

#671

#438

Unhook here

#437

・ Position [#B454] as below, and take out the two screws (#673) and two screws (#674).

#673

Unhook here

#B454

#674

- D13 ・ D5000 -

Page 19

VBA24001-R.3783.A

INC

・ Release the three hooks, and remove the TFT top cover (#434).

[When removing this, be careful NOT to lose the lock-plate spring (#432) and lock knob (#431).]

(Caution : must be exercised that each part does not get scratched or dented. If it does, use a new one.)

Back

#434

・ Remove the lock knob (#431).

・ Remove the lock-plate spring (#432).

#432

#431

- D14 ・ D5000 -

Page 20

VBA24001-R.3783.A

INC

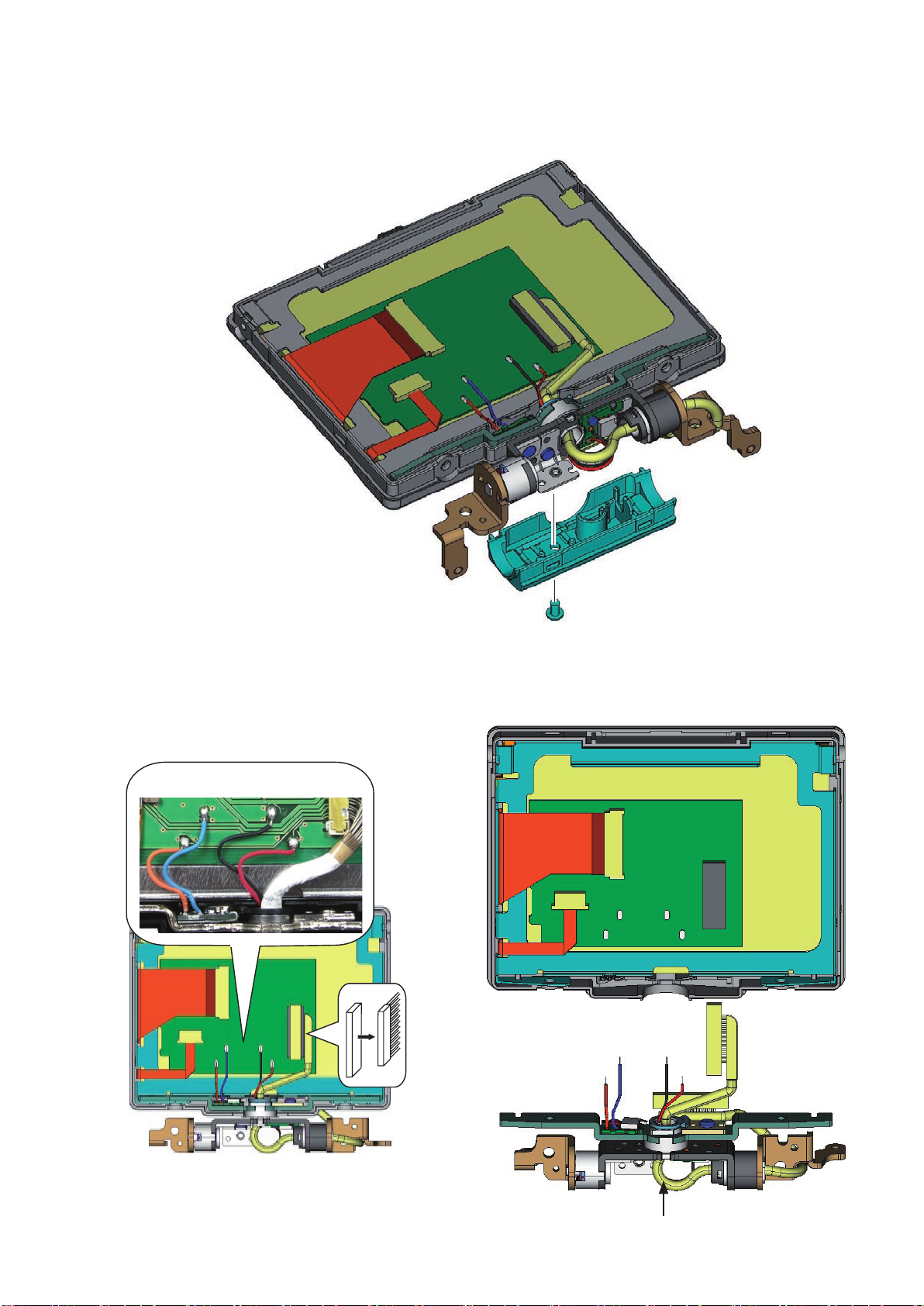

・ Take out the screw (#677).

・ Remove the hinge bottom cover (#438).

(Caution must be exercised that the part does not get scratched or dented. If it does, use a new one.)

・ Unsolder the wires [Orange/Blue/Black/Red].

・ Disconnect the harness from the connector.

・ Remove the hinge unit (#B454).

[Orange/Blue/Black/Red]

#438

#677

#B454

- D15 ・ D5000 -

Page 21

・ Remove the harness (#1058) from the hinge unit (#B454)

INC

#B454

VBA24001-R.3783.A

#1058

・ Disconnect the FPC.

・ While passing the FPC through, remove the retaining plate (#406).

#406

- D16 ・ D5000 -

Page 22

・ Remove the TFT monitor unit (#B1049).

INC

VBA24001-R.3783.A

#B1049

・ Remove the two sponges (#404) and two sponges (#405).

#404

#405#405

- D17 ・ D5000 -

Page 23

VBA24001-R.3783.A

INC

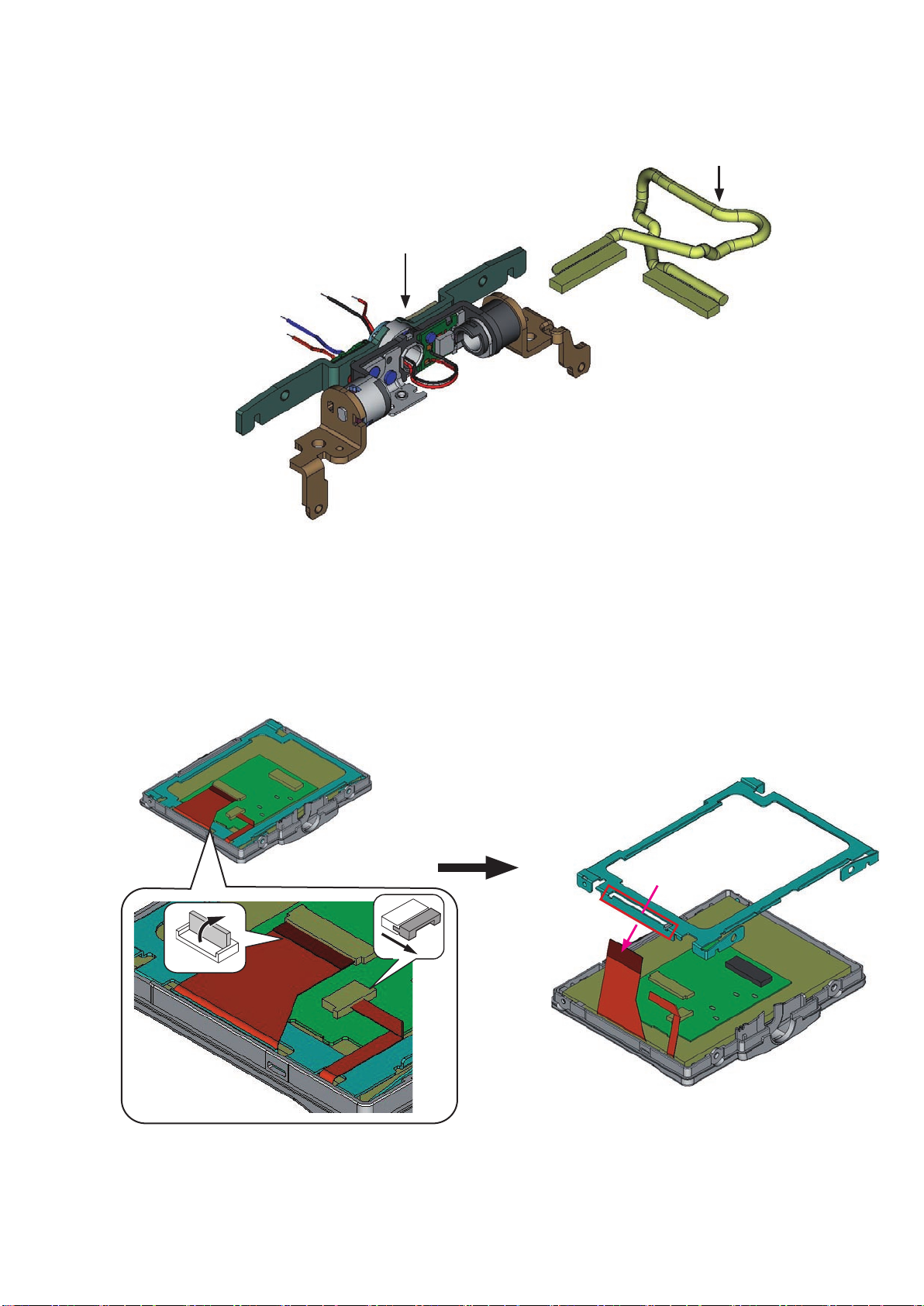

3. Front cover

Pop-up of Flash unit (SB)

・ Cut the lumirror sheet, etc, into the below size, and inset it in the clearance of the top cover pop-up

section. Then, slide it in the direction of the arrow and raise (pop-up) the flash unit.

Approx. 2cm

Approx. 4cm

Front cover

・ Take out the four screws (#610) and the one screw (#626).

・ Remove the front cover unit (#B24).

#626

#610

#610

#B24

#466

#465

- D18 ・ D5000 -

Page 24

VBA24001-R.3783.A

INC

4. Top cover

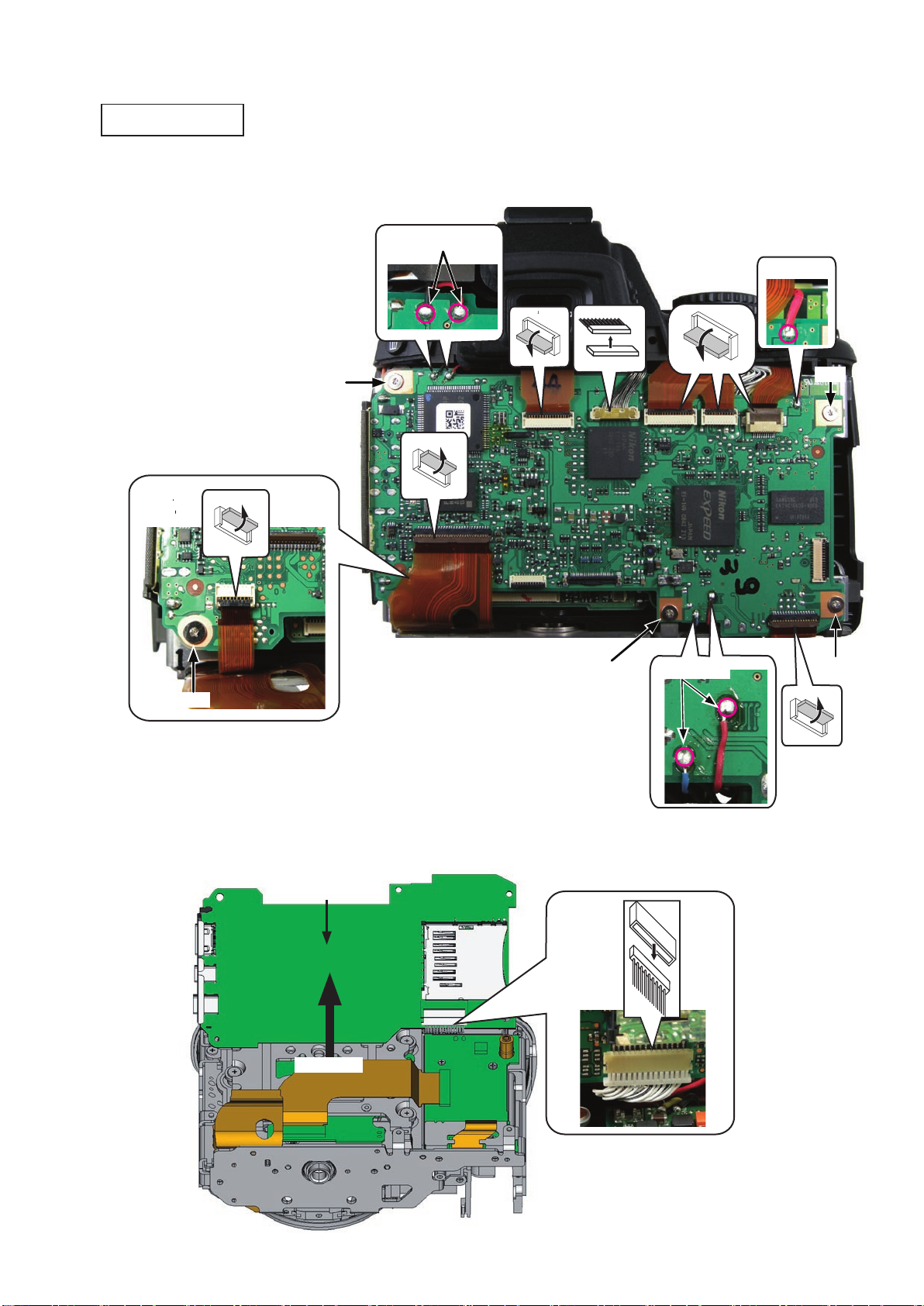

TOGO PCB unit

・ Disconnect the seven FPCs, and remove the harness from the connector.

・ Unsolder the wires in the upper right [Red], upper left [Black/Red] and lower right [Blue/Red] corner of

the PCB.

・ Take out the five screws (#663).

#663

[Black/Red]

#663

[Blue/Red]

[Red]

#663

#663

#663

・ Lift the one side of the PCB as below, and disconnect the connector of the back.

・ Remove the TOGO PCB unit (#B2001).

#B2001

Turn up

- D19 ・ D5000 -

Page 25

VBA24001-R.3783.A

INC

Removal of top cover

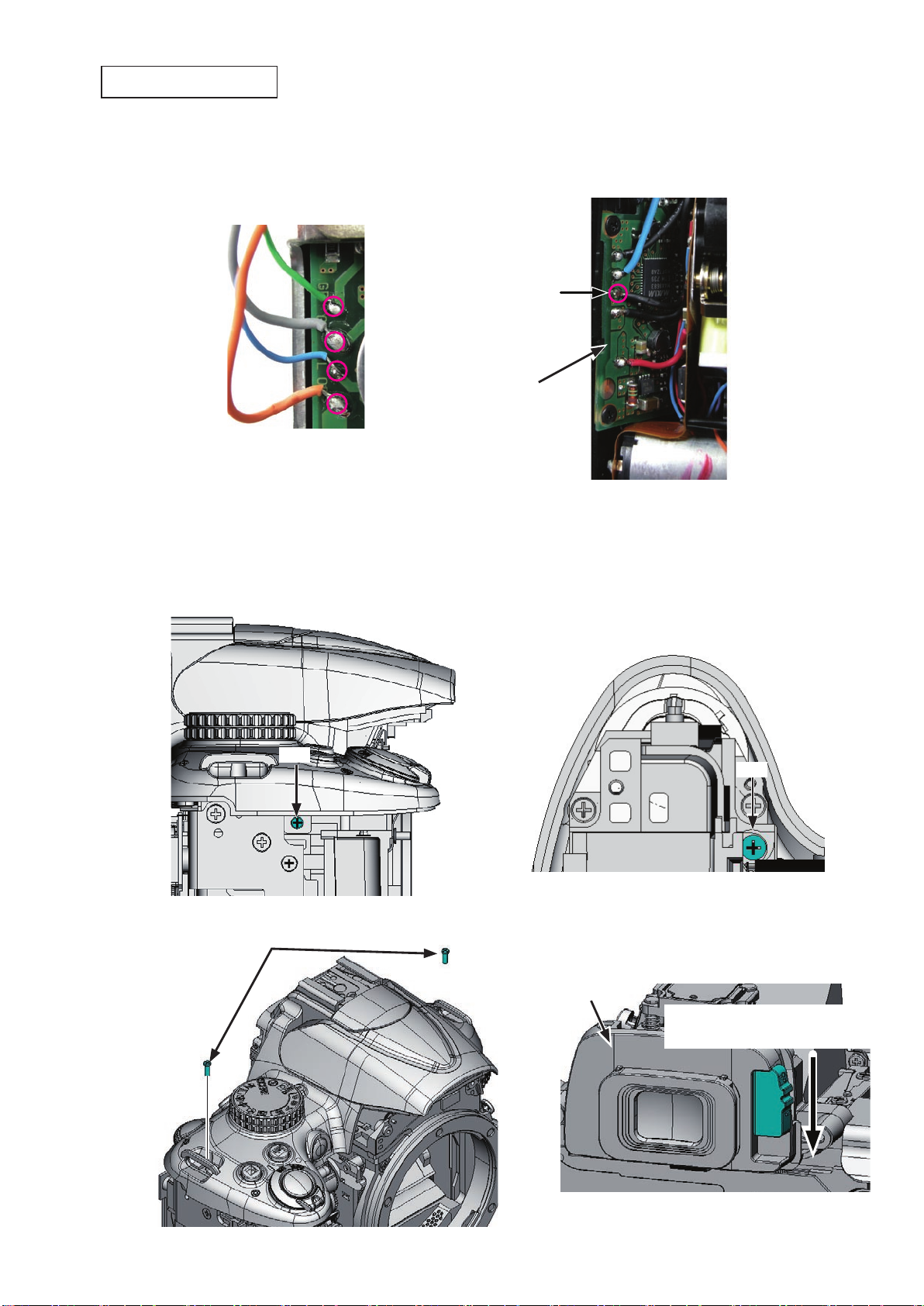

・ Remove the solders of the wires [Green/Gray/Blue/Orange] from the SB PCB unit (#B2006).

・ Remove the solder of the wire [Black] from the DC/DC PCB (#B2002).

[Green/Gray/Blue/Orange]

[Black]

#B2002

・ Take out the screw (#638).

・ Take out the screw (#607).

・ Take out the two screws (#737).

・ Remove the top cover and the eyepiece mold unit (#B271).

#607

#737 × 2

#638

#B271

Lowering this lever will facilitate

the removal of [#B271].

- D20 ・ D5000 -

Page 26

VBA24001-R.3783.A

INC

SB upper cover

・ Push the SB lock lever in the direction of the arrow, and raise (pop-up) the built-in SB (flash unit).

SB lock lever

・ Take out the two screws (#632).

#632

・ House the SB lower control unit (#B302), and remove the SB upper cover (#301).

#301

- D21 ・ D5000 -

Page 27

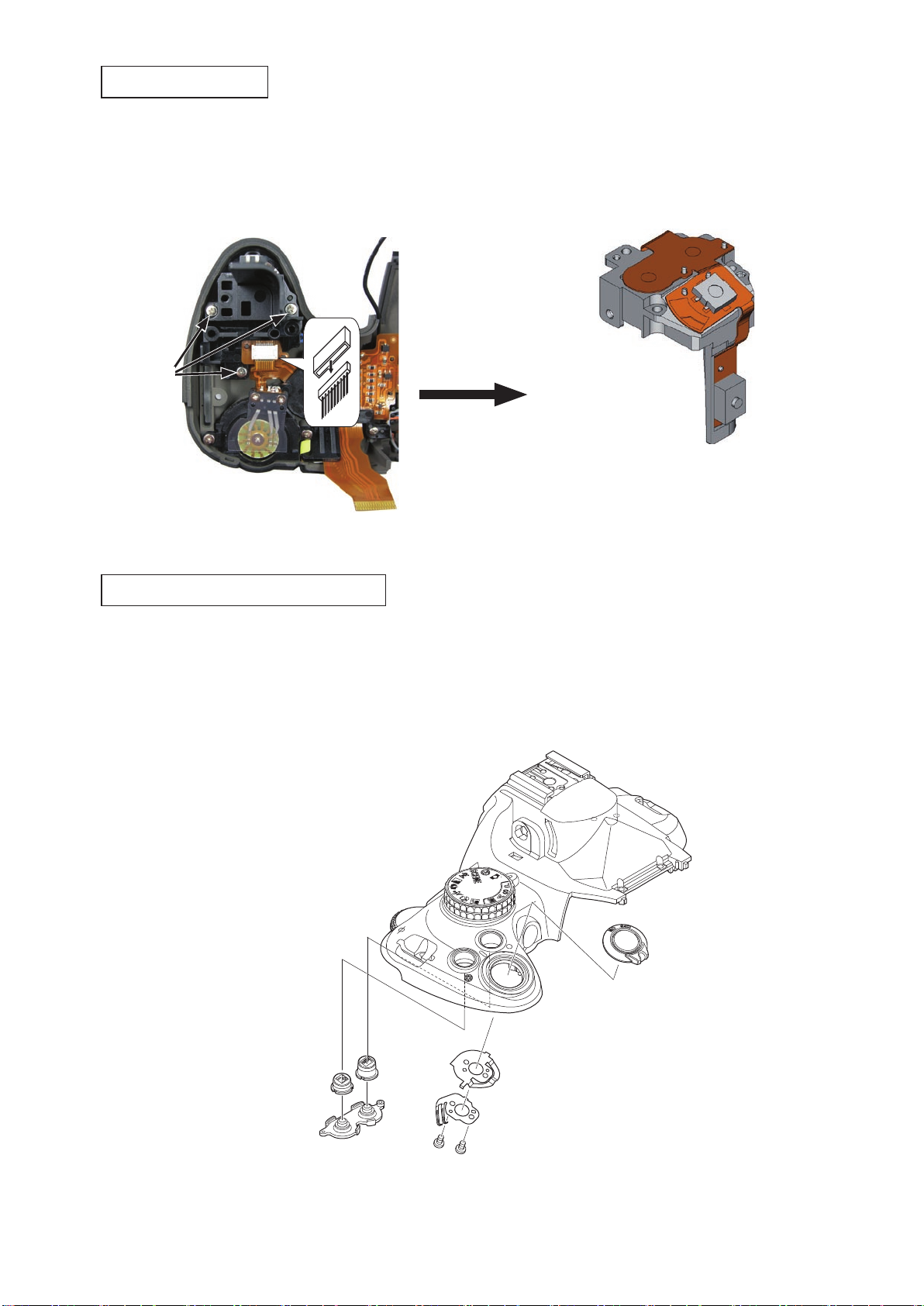

lower control unit

INC

SB

・ Take out the screw (#650), and release the wires from the bosses.

・ Unsolder the wires [Red/Blue/Green/Black] of the top cover FPC unit (#B1012).

[Red/Blue/Green/Black]

#B1012

VBA24001-R.3783.A

#650

・ Pull out the eight wires.

Boss

Boss

- D22 ・ D5000 -

Page 28

VBA24001-R.3783.A

AU

T

O

AU

T

O

INC

・ While pushing the rotate shaft (#306), take out the screw (#733) and remove the spring (#305).

・ Remove [#306].

・ Remove the SB rotating collar (#308), while releasing its two hooks.

・ Remove the SB lower control unit (#B302).

#733

#305

#B302

Remove this while

Unhook here.

pushing.

・ Remove the two rubbers (#311).

#306

#308

#311

- D23 ・ D5000 -

Page 29

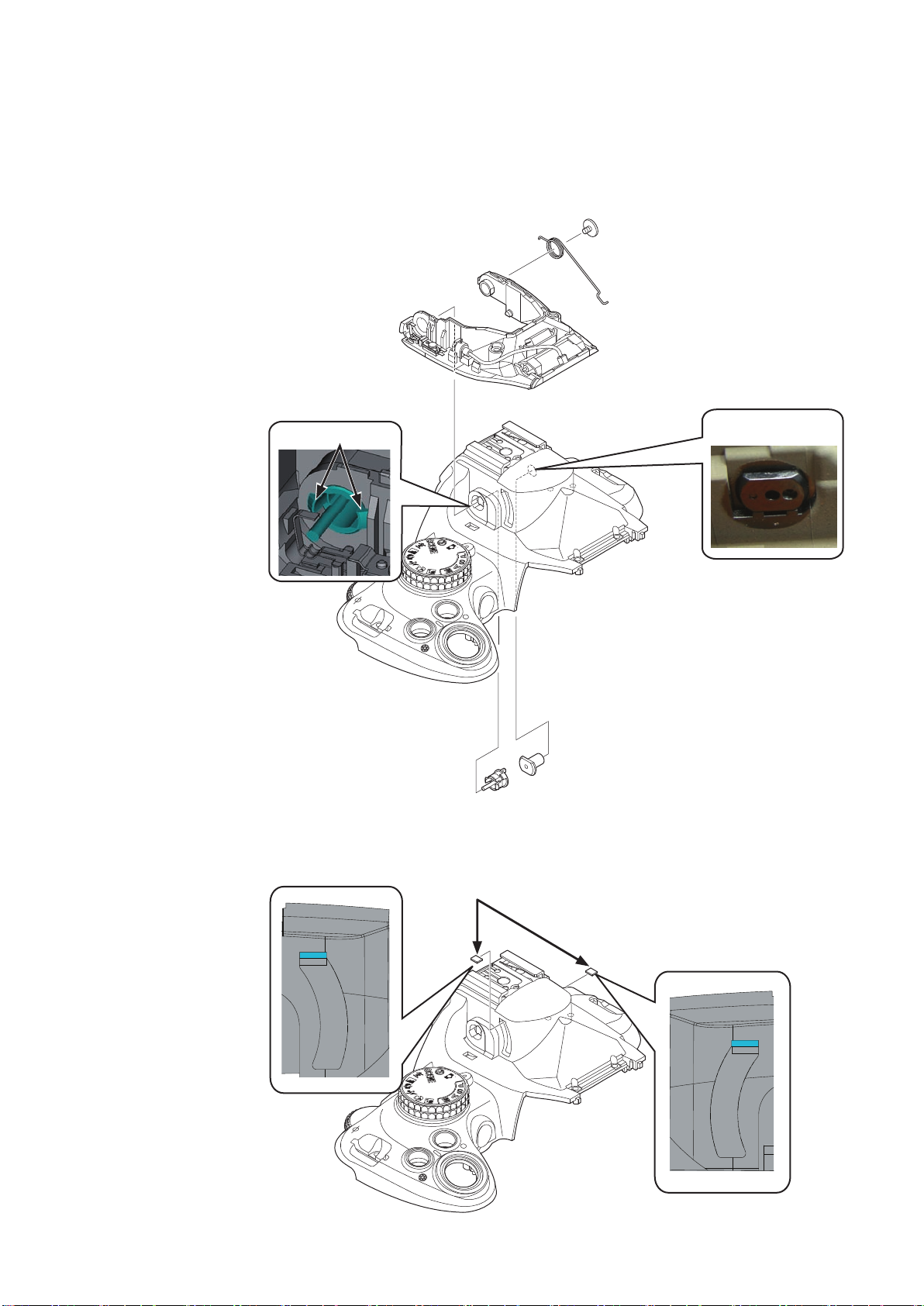

SB release base unit

INC

・ Remove the solders of the wires [Red/Black] from the top cover FPC unit (#B1012).

・ Release the wires [Red/Black] from the guides.

・ Take out the two screws (#609), and remove the SB release base unit (#B2455).

Guide

#B2455

[Red/Black]

VBA24001-R.3783.A

#609

AF-assist lamp unit

・ Unsolder the wire [uncoated/Black].

・ Peel off the flocked sheet (#327).

・ Take out the screw (#608), and remove the AF-assist lamp unit (#B325).

#327

#608

[uncoated/Black]

#B325

#B1012

- D24 ・ D5000 -

Page 30

AU

T

O

Power SW FPC unit

INC

・ Remove the FPC.

・ Take out the three screws (#635).

・ Remove the power SW FPC unit (#B1011).

#635

VBA24001-R.3783.A

#B1011

Release button unit

/ each button, etc

・ Remove the rubber SW (#382), the + - /aperture button (#381) and the info button (#384).

・ Take out the two screws (#605).

・ Remove the on-off SW brush (#348), on-off click spring (#347), and on-off dial (#B345).

#B345

#381

#382

#384

- D25 ・ D5000 -

#347

#348

#605 × 2

Page 31

C/D unit

INC

・ Remove the three solder bridges.

・ Take out the two screws (#635), and remove the C/D unit (#B367).

#B367

#635

Top cover FPC unit

・ Remove the five solder bridges.

VBA24001-R.3783.A

・ Unsolder the wire [Black] that is connected to the DC/DC PCB.

・ Take out the two screws (#635), and remove the top cover FPC unit (#B1012).

[Black]

#635

#B1012

- D26 ・ D5000 -

Page 32

AU

T

O

Mode dial unit / AF/AE-L button / Delete button / AF-assist lamp window

INC

・ Take out the screw (#640).

・ Remove the contact brush (#372), click spring (#373), and mode dial unit (#B371).

・ Remove the retainer ring (#387), and remove the AF/AE-L button (#386).

・ Remove the delete button rubber SW (#423), and delete button (#428).

・ Remove the super X, and detach the AF-assist lamp window (#326).

#B371

#386

#428

#423

VBA24001-R.3783.A

#387

#373

#326

Adhesive: Super X

Hot shoe

#372

#640

・ Take out the four screws (#654).

・ Remove the backing plate (#322), shoe spring (#318), hot shoe (#316), and hot shoe mold unit (#B317).

#318

#316

#B317

#322

#654 × 4

- D27 ・ D5000 -

Page 33

5. Image sensor

INC

SZ-DC/DC PCB unit

VBA24001-R.3783.A

・ Disconnect the connection-FPC (#1026) from the

connector.

・ Unsolder the wires [Yellow/Black].

・ Take out the two screws (#670) and the one ne

screw (#687).

・ Remove the SZ-DC/DC PCB unit (#B2003).

#1026

[Yellow/Black]

#B2003

#687

#670

Image sensor unit

・ Unsolder the wires [Green/Purple].

・ Take out the three screws (#631), and remove the image sensor unit (#B2051).

Caution: Some bodies have already the washer put on the surface where the image sensor unit is mounted

or already the lumirror sheet attached on the side.

In the latter case (lumirror sheet attached), remove the super X, which is applied to the side (see below

" ■ " area), and then remove the image sensor unit.

#631

#B2051

[Green/Purple]

- D28 ・ D5000 -

Page 34

6. Separation of Front body from Rear Body

INC

Bottom base unit

・ Take out the five screws (#616).

・ Take out the three screws (#691).

#616

VBA24001-R.3783.A

#691

#691

・ Remove the bottom base unit (#B66) by kind of scooping up as below.

#B66

- D29 ・ D5000 -

Page 35

・ Unsolder the wires [Black/Blue], which are connected from the penta unit.

INC

・ Unsolder the wires [Black/Red], which are connected from the SQ PCB unit.

[Black/Blue]

[Black/Red]

VBA24001-R.3783.A

・ Take out the four screws (#624).

#624

- D30 ・ D5000 -

Page 36

・ Separate the front body from the rear body.

INC

(Be careful of wires and FPCs.)

VBA24001-R.3783.A

- D31 ・ D5000 -

Page 37

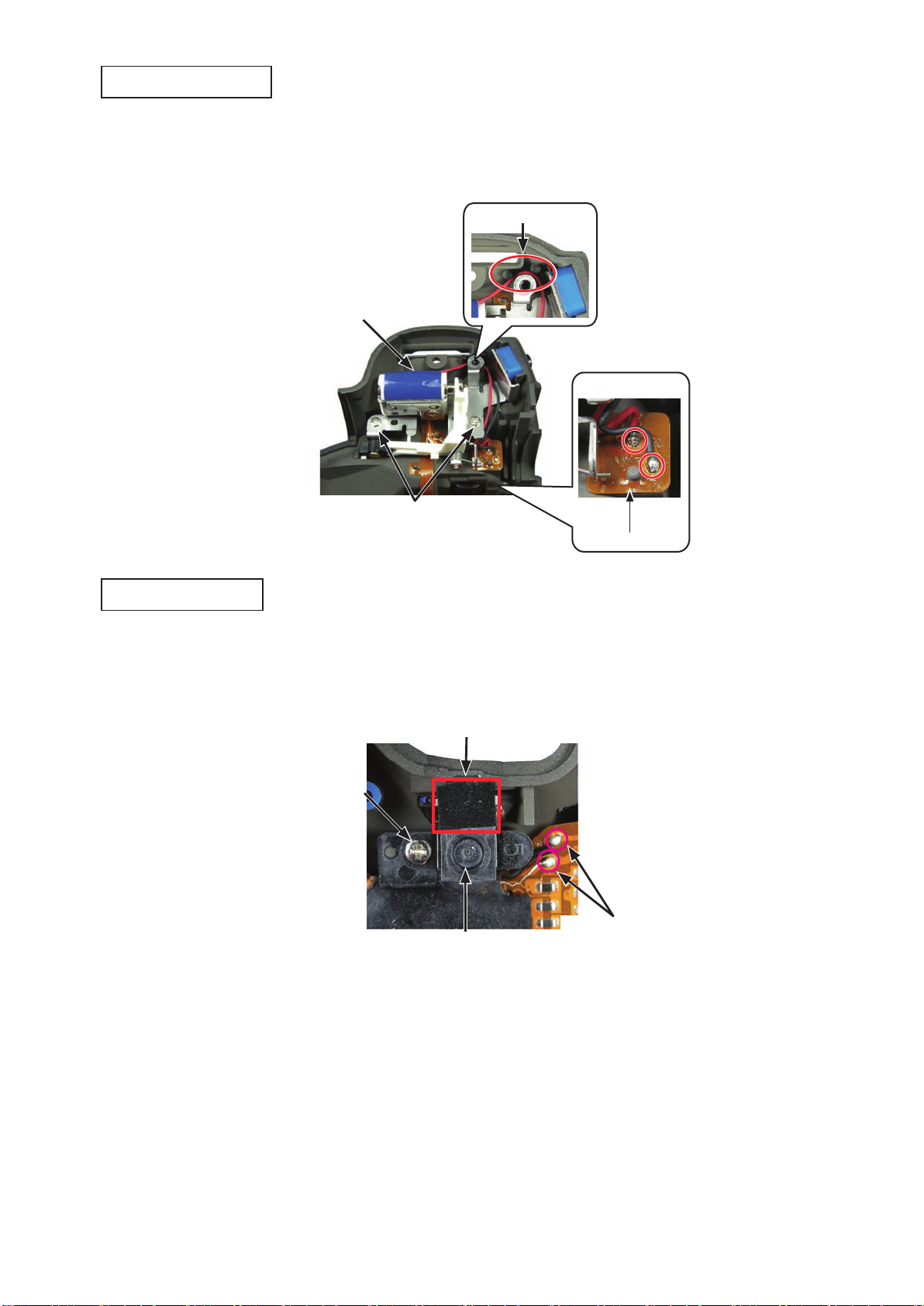

7. Rear body

INC

Microphone

・ Remove the microphone (#1046).

Main condenser

VBA24001-R.3783.A

#1046

・ Unsolder the wires [Red/Black].

・ Take out the two screws (#615).

・ Remove the SB condenser unit (#B1048).

・ Remove the condenser (#1048) and two pieces of the double-stick tape (#141) from the condenser holder.

[Red/Black]

Condensor holder

#1048

#B1048

#615

#141

- D32 ・ D5000 -

Page 38

VBA24001-R.3783.A

INC

SB PCB unit

・ Unsolder the wires [Red/Black].

・ Remove the FPC (#1029) (being careful of the boss).

・ Take out the screw (#687).

・ Remove the SB PCB unit (#B2006) from between the SB PCB plate unit (#B82) and rear body unit.

・ Remove [#B82].

#B2006

Boss

#B82

#687

[Red/Black]

#B82

Rear body unit

- D33 ・ D5000 -

Page 39

DC/DC PCB unit

INC

・ Unsolder the battery-contact wires [Black/Red/Blue].

・ Take out the two screws (#665).

・ Disconnect the FPC.

・ Remove the DC/DC PCB unit (#B2002).

[Black/Red/Blue]

VBA24001-R.3783.A

#665

- D34 ・ D5000 -

Page 40

Battery box

INC

・ Take out the four screws (#615).

・ The battery BOX unit (#B156) will come off.

・ The lug plate (#159) will come off.

#615

VBA24001-R.3783.A

#B156

#159

・ Take out the screw (#607).

・ Remove the spring (#160).

・ Take out the three screws (#607).

・ Remove the three springs (#157).

・ Remove the backup battery (#B1044).

・ Peel off the double-stick tape (#141).

#607

#160

#607

#157

- D35 ・ D5000 -

#141

#B1044

Page 41

Eyelet unit, etc

INC

VBA24001-R.3783.A

#694

#957

#147

#735

#145

#147

#65

#143

#145

#694

#143

TA-0026(6x11)

TA-0026(6x11)

#143

#139

#904

#906

- D36 ・ D5000 -

Page 42

8. Front body

INC

Shutter

・ Remove the sponge (#757).

VBA24001-R.3783.A

#757

・ Remove the sponge (#149).

・ Turn the red gear in the direction of the arrow, and raise the mirror.

・ Remove the solder bridge.

・ Take out the two screws (#635).

・ Remove the shutter (#31).

#635

#149

- D37 ・ D5000 -

Page 43

VBA24001-R.3783.A

INC

Meterring FPC unit

・ Take out the screw (#607), and remove the retainer plate (#293).

・ Disconnect the FPC from the connector.

・ Take out the three screws (#607), and remove the metering FPC unit 1 (#B11013).

(Caution: Do NOT touch the red-marked screws during disassembly, because they are for adjustments.)

#293

#607

Do NOT touch here.

#607

#B11013

Eyepiece barrel unit

・ Take out the two screws (#638), and remove the eyepiece barrel unit (#B261).

#638

#B261

- D38 ・ D5000 -

Page 44

Penta unit

INC

・ Remove the super X (at red-marked " " two areas)

・ Take out the two screws (#635), and remove the springs (#201 and #202).

・ Remove the pent unit (#B4).

#635

#201

#202

VBA24001-R.3783.A

- D39 ・ D5000 -

Page 45

SI unit

INC

・ Turn the gear in the direction of the arrow, and lower the mirror.

・ Take out the two screws (#610), and remove the mirror setting unit (#B120).

#610

VBA24001-R.3783.A

#B120

・ Peel off the tape (#709), and remove the FPC.

#709

・ Release the hook as below.

・ Remove the SI unit (#B2050).

#B2050

- D40 ・ D5000 -

Page 46

・ Take out the two screws (#635).

INC

・ Remove SI retainer unit (#B277).

#635

・ Remove the two SI light guides (#335).

・ Disconnect the FPC from the connector.

・ Take out the two screws (#606).

・ Peel off the tape (#709).

・ Remove the SI LED FPC unit (#1017).

VBA24001-R.3783.A

#B277

#709

#335

#606

#1017

- D41 ・ D5000 -

Page 47

Relay PCB unit

INC

・ Take out the screw (#670).

・ Disconnect the three FPCs from the connectors.

・ Unsolder the wires [Yellow/Black].

VBA24001-R.3783.A

#670

[Yellow/Black]

・ With the FPC of the lens contact unit (#B2113) being turned up, take out the screw (#670).

・ Remove the Relay PCB unit (#1007).

Turn up the FPC of [#B2113]

#670

#1007

Boss

- D42 ・ D5000 -

Page 48

Removal of bayonet

INC

・ Take out the five screws (#648) and the one screw (#660).

・ Remove the bayonet (#111).

・ Remove the lug plate (#137).

・ Remove the three bayonet springs (#112).

VBA24001-R.3783.A

#137

#648

#660

Lens contact unit

・ Take out the two screws (#607).

・ Remove the plate (#339).

#607

・ Take out the two screws (#642).

#112

#339

#642

- D43 ・ D5000 -

Page 49

・ Peel off the synchro-mode/SB pop-up SW area, and turn up the FPC.

INC

・ Remove the lens contact unit (#B2113).

VBA24001-R.3783.A

- D44 ・ D5000 -

Page 50

SQ base unit

INC

・ Unsolder the wires [Orange/Black].

VBA24001-R.3783.A

[Orange/Black]

・ Take out the three screws (#638).

・ Pull the head of the aperture lever of the SQ PCB unit (#B242) from the gap of the front body unit

(#B22RP), and remove [#B242].

#638

#B242

- D45 ・ D5000 -

Page 51

B2

2

INC

AF sensor unit

・ Take out the three screws (#162) with hex key ( φ 1.5mm).

・ The AF sensor unit (#B2163) and three springs (#161) will come off.

#162 × 3

#161 × 3

VBA24001-R.3783.A

#B2163

Inside finder LCD unit

・ Take out the two screws (#683).

・ Remove the inside finder LCD unit (#B1021).

#683 × 2

#B1021

#332

#758

#276

#37

#38

- D46 ・ D5000 -

Page 52

plate

INC

Release button unit

VBA24001-R.3783.A

#299

#621 × 3

#B115

#119

#B116

- D47 ・ D5000 -

Page 53

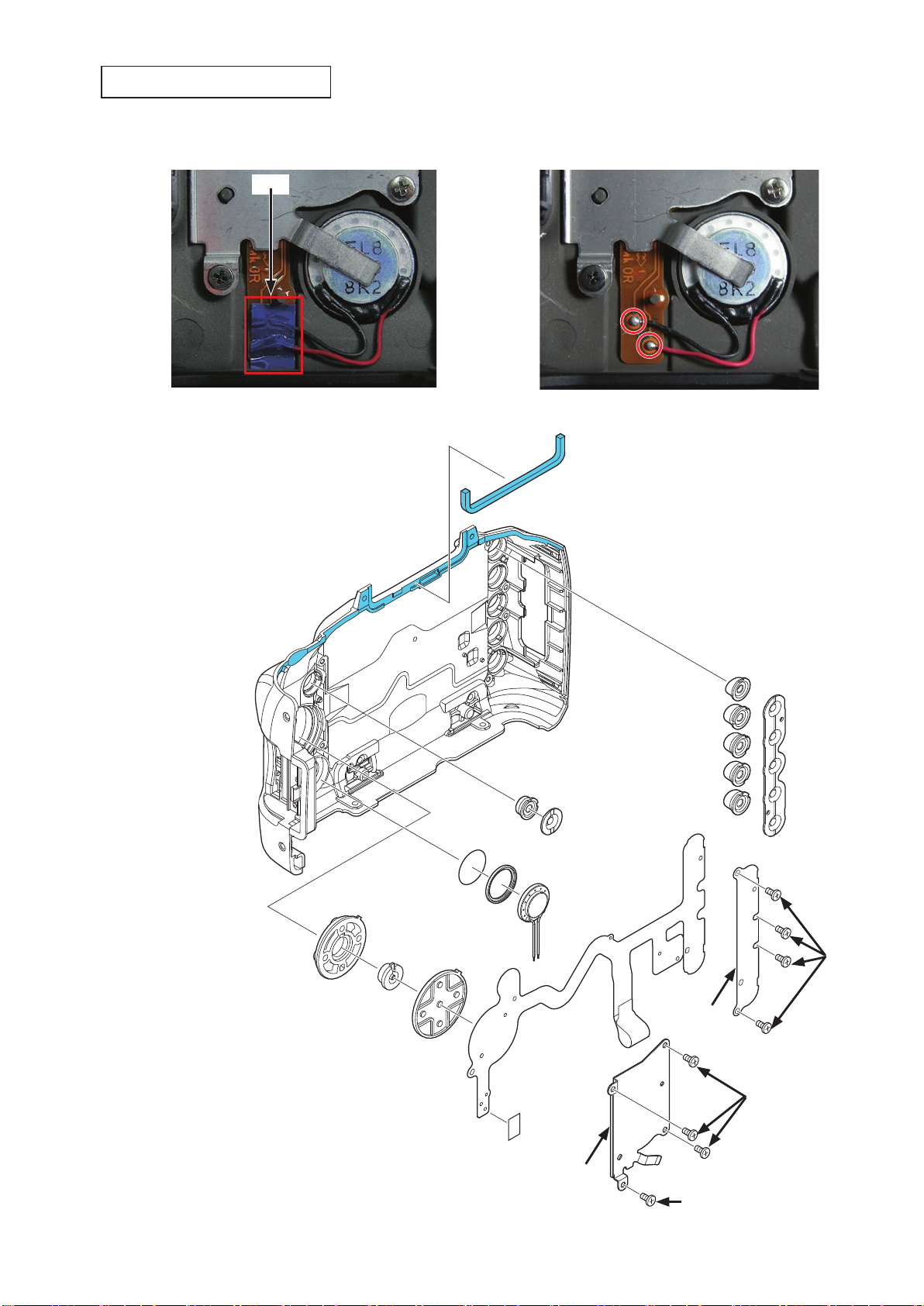

F-min SW section

INC

VBA24001-R.3783.A

#607

#131

Mirror unit/Aperture lever section

・ Remove the super X.

#135

Orange:SQ FPC

Black:SQ FPC

#645

#134

#136

#133

#236

Adhesive: Super X

Adhesive: Super X

- D48 ・ D5000 -

Page 54

・ Remove each part/component.

INC

#238

VBA24001-R.3783.A

#B2231

#240

#239

#205

#206

#643

#199 × 2

#236

#190

#191

#203

- D49 ・ D5000 -

Page 55

VBA24001-R.3783.A

INC

Assembly/Adjustment

1. Front body

Mirror unit

#B2231

#238

Caution: For the tapes or sponges which are not described in

"Assembly" section, refer to the repair parts list.

#240

#239

Be careful NOT to bend this.

#199 × 2

#236

・ With the mirror being raised, insert the pins and apply the adhesive (Super X) to each pin.

#236

Adhesive: Super X

Apply to only one-fourth of the mount-side surrounding area.

Adhesive: Super X

- A1 ・ D5000 -

Page 56

Aperture lever section

INC

VBA24001-R.3783.A

#190

#205

Spring hooking position

・ Hook the spring (#206).

#206

#643

#191

#203

Grease:LEN317A

・ Hook the spring (#205).

Grease:LEN317A

#206

#205

- A2 ・ D5000 -

Page 57

F-min SW section

INC

#645

#134

VBA24001-R.3783.A

#607

#135

Orange:SQ FPC

Black:SQ FPC

Release button unit

#136

#133

#131

#621 × 3

Grease:LEN317A

#B115

#119

#B116

Boss hole

- A3 ・ D5000 -

Page 58

plate

INC

・ Mount the screen-case retaining plate (#299).

#299

Inside finder LCD unit

・ Attach the tape (#38) to the air plate (#37), ant mount it on the front body unit (#B22RP).

・ Attach the dust-proof sponge (#276) and the sponge (#332).

・ Mount the inside finder LCD unit (#B1021).

VBA24001-R.3783.A

・ Tighten the two screws (#683).

・ Attach the sponge (#758).

[#B1021] positioning direction

[#276/#332] attaching position

[#276 and #332] attaching position

#683 × 2

#B1021

#332

[#758] attaching position

#758

#276

#B22RP

[#332] must be attached to the mold.

#758

- A4 ・ D5000 -

#38

Attaching position

#37

Page 59

VBA24001-R.3783.A

B2

2

INC

AF sensor unit

・ Attach the three springs (#161).

・ Place the AF sensor unit (#B2163)

・ Turn the three screws (#162) lightly all the way with hex key ( φ 1.5mm), and then give each 1.5-turn

counterclockwise.

#B2163

#162 × 3

#161 × 3

SQ PCB unit

・ Move the aperture lever of the SQ PCB unit (#B242) in the direction of the arrow, and check that it is

movable freely.

(If not, turn the red-indicated gear in "Fig. 1" in the direction of the arrow, and make it movable.)

・ Move the (red-circled) roller section all the way to the end.

Aperture drive lever

#B242

Roller section

Fig. 1

- A5 ・ D5000 -

Page 60

VBA24001-R.3783.A

INC

・ Operate the mirror-up lever (#203), which is assembled in [#B22RP] in the direction of the arrow, and set

to be "mirror-down" as below.

・ While inserting the head of the aperture lever of the SQ PCB unit (#B242) into the gap of [#B22RP], mount

by fitting with the boss.

#B22RP

#203

#B242

・ Tighten the three screws (#638).

・ After mounting the SQ PCB unit (#B242), check whether the aperture lever can operate smoothly.

Pass the wires [Orange/Black] through inside the lug plate (#135) and behind the FPC of the SQ PCB unit

・

#B242), and then solder them.

(

[Orange/Black]

#638

Pass through inside #135

Pass through

behind FPC

- A6 ・ D5000 -

Page 61

INC

Lens contact unit

・ While turning up the FPC, mount the lens contact unit (#B2113).

#B2113

VBA24001-R.3783.A

・ Attach the FPC by fitting with the bosses.

・ Tighten the two screws (#642).

= Boss

#642

- A7 ・ D5000 -

Page 62

VBA24001-R.3783.A

INC

・ Mount the plate (#339).

・ Tighten the two screws (#607).

#339

#607

Mounting of bayonet

・ Mount the lug plate (#137).

・ Attach the three bayonet springs (#112).

・ Mount the bayonet mount (#111).

・ Tighten the five screws (#648) and the one screw (#660) in the below numeric order from ① to ⑥ .

#137

#112

②

④

⑤

③

#648

#660

⑥

①

Grease:LEN317A

Grease:LEN317A

- A8 ・ D5000 -

Page 63

VBA24001-R.3783.A

INC

Height adjustment of Aperture lever

Measure the height of the aperture lever with the tool (J18004).

・

Standard: 3.3 - 3.6mm

In case the result does not meet the standard, bend the aperture

lever section for adjustment.

Be careful NOT to bend the inside of the lever.

Height of aperture lever

3.3 - 3.6 mm

Aperture lever

- A9 ・ D5000 -

Page 64

VBA24001-R.3783.A

INC

Relay-PCB unit

・ With the FPC of the lens contact unit (#B2113) being turned up, mount the relay-PCB (#1007) by fitting

with the bosses.

・ Tighten the screw (#670).

Turn up the FPC of [#B2113].

Boss

#670

#1007

Boss

・ Solder the wires [Yellow/Black].

・ Connect the three FPCs to the connectors.

・ Tighten the screw (#670).

#670

[Yellow/Black]

(#1030 back)

[#905/#750] attaching position

#905

#750

Attach to the back.

- A10 ・ D5000 -

Page 65

SI unit

INC

・ Mount the SI LED FPC unit (#1017).

・ Attach the tape (#709).

・ Tighten the two screws (#606).

・ Connect the FPC to the connector.

VBA24001-R.3783.A

・ Mount the two SI light guides (#335).

#335

#1017

#709

#606

- A11 ・ D5000 -

Page 66

VBA24001-R.3783.A

INC

Attachment position for Finder field frame

・ Attach the tape (#295) to the SI retainer unit (#B277).

・ Attach the two sponges (#793) to the finder field frame 2 (#283), and then mount on the SI retainer unit

(#B277).

#295

#B277

NOT squeeze into the inside.

= Boss

#283

#793

Boss hole

Align the lateral locations with the boss holes.

NOT to be squeezed from [#283] lengthwise.

・ Mount the SI retainer unit (#B277).

・ Tighten the two screws (#635).

Boss hole

Direction for positioning

#B277

#635

- A12 ・ D5000 -

Page 67

VBA24001-R.3783.A

INC

・ Pass the FPC of the SI unit (#B2050) through □ -framed area of the retainer plate (#339), and mount it.

・ Engage the hook.

#B2050

#339

□ -framed area

・ Connect the FPC to the connector, and attach the tape (#709).

・ Mount the mirror setting unit (#B120), and tighten the two screws (#610).

#B120

#709

#610

- A13 ・ D5000 -

Page 68

Penta unit

INC

・ Mount the penta unit (#B4).

・ Attach the springs (#201 and #202), and tighten the two screws (#635).

・ Apply "Super X" to the below " " red-colored two places.

#B4

VBA24001-R.3783.A

#201

Direction for positioning

#635

#202

- A14 ・ D5000 -

Page 69

VBA24001-R.3783.A

INC

Eyepiece barrel unit

・ Mount the eyepiece barrel unit (#B261) by fitting with the boss, and tighten the two screws (#638).

#638

AE FPC unit

・ Mount the AE FPC unit (#B11013) by fitting with the boss, and tighten the three screws (#607).

・ Connect the FPC to the connector.

・ Mount the plate (#293) by fitting with the boss, and tighten the screw (#607).

(Caution: Do NOT touch the red-marked screws during assembly, because they are for adjustments.)

#B261

Do NOT touch here.

#607

#B11013

#293

#607

- A15 ・ D5000 -

Page 70

adjustment of Main mirror and Sub-mirror

WARNING

NEVER look directly at the laser beam which is reflected

by the mirror of cameras/inspection tools.

!

INC

VBA24001-R.3783.A

・

Position of operator and where the laser beam must not be looked directly.

Operator

Chart area

Chart

Laser beam path Laser beam path

Laser beam path

- A16 ・ D5000 -

Page 71

1. Positioning of Main mirror (reference 45° angle)

J19132H

MAIN/SUB MIRROR ANGLE INSPECTION TOOL-USE CHART

45°

47.75°

49°

47.75°

54°

51°

59°

Flat mirror

Tilted mirror

Tilted mirror

Tilted mirror

Tilted mirror

Tilted mirror

Flat mirror

Reference Line

INC

Positioning to become 45° angle

①

・Push the laser-beam axis-check mirror toward the

mount-face by hand.

・Radiate the laser beam, and check the position of

the reected image of the laser beam (without

looking directly at the laser beam.)

・Conrm that the position of the reected image

VBA24001-R.3783.A

Laser-beam axis-check mirror

coincides with that of the projecting point of the

laser. (i.e. The incident angle coincides with the

●

reection angle.)

・The positioning of reference 45° angle is

completed.

Remove the nder screen. Replace it with the D5000.45 deg. angle main-mirror tool (J15436).

②

Measurement of 45° degree angle of Main mirror

③

・Attach the camera body to the mount-face, and operate

the mirror a few times.

Position the camera in the direction of the arrow.

・

・Radiate the laser beam, and check the position of the

reected image of the laser beam.

- A17 ・ D5000 -

Camera: D300

Page 72

Check whether the results meet the standard. If not, make the adjustment.

INC

・

Standard value

<

>

Left-right deviation

Up-down deviation

Main mirror

0 ±2’

±4’

Device

HEX. KEY WRENCH (φ1.5mm)

VBA24001-R.3783.A

Press the lock/release button to detach the body from the mount-face.

・

Eccentric pin for

the main mirror

- A18 ・ D5000 -

Page 73

2. Positioning of Sub-mirror

MAIN/SUB MIRROR ANGLE

INSPECTION TOOL-USE CHART

45°

47.75°

49°

47.75°

54°

51°

59°

Flat mirror

Tilted mirror

Tilted mirror

Tilted mirror

Tilted mirror

Tilted mirror

Flat mirror

Reference Line

INC

The sub-mirror angle of this model is 51 degree angle. However, because the mirror tool for this angle is

not set as RP, regard the position which is 105.2 mm lower than the 54 degree-angle index position as the

51 degree-angle one, and make a necessary check.

VBA24001-R.3783.A

70mm

3mm

3mm

Regard this index position as a reference,

and make a measurement.

230mm

105.2 mm

Print out and use the chart of

Page A104.

- A19 ・ D5000 -

June. 22. 2009Changed page (Overall revision)

Page 74

VBA24001-R.3783.A

INC

・Set the 54°-angle measurement-use mirror, which is prepared as single part (J19132D), by placing it

horizontally, as if sandwiched in between the two adjustment boards.

・Slide the height display (of the measurement-use mirror) forward, and turn the screw to secure it.

Screw

Slide forward.

Sandwich in

Measurement-use mirror

Position slid forward.

Height display (of measurement-use mirror)

・Turn the mirror height adjusting micrometer, and set the measurement-use mirror visually to 54°-angle

position of the height display as below.

・After completing the positioning, be sure to return the height display to the standard position and x it with

the screw.

Mirror height adjusting micrometer

Standard position

Rough indication: Height of

※

measurement-use mirror of D5000

・Attach the mirror-angle reference tool to the mount.

・Loosen the below screw, and adjust the tool to the measurement position (54°).

・Tighten the screw and position it in the direction of the arrow.

Changed page △×1

Screw

Positioning

- A20 ・ D5000 - △ (Addition)

June. 22. 2009

Page 75

VBA24001-R.3783.A

J19132H

49°

47.75°

54°

59°

Tilted mirror

Tilted mirror

Tilted mirror

Flat mirror

INC

・Move the (measurement-use) mirror stage to the stop position.

・Conrm that the camera-release guard is kept raised horizontally at the stop position.

Move to stop position.

Camera release guard

・Radiate the laser beam. Conrm that the laser reected image is positioned at the scale of the set angle.

If the reected image is out of alignment, adjust it by turning the adjustable screw X (

・

(vertically) with the laser beam being radiated.

horizontally) or Y

Adjustable screw: X

Adjustable screw: Y

●

・Return the mirror stage to the standard position.

・Conrm that the camera-release guard is kept lowered, and detach the mirror angle reference tool from the

mount-face.

Standard position

Camera-release guard

- A21 ・ D5000 -

Page 76

VBA24001-R.3783.A

J19132H

45°

47.75°

49°

47.75°

54°

51°

59°

Flat mirror

Tilted mirror

Tilted mirror

Tilted mirror

Tilted mirror

Tilted mirror

Flat mirror

INC

Angle measurement of Sub-mirror

Attach the camera body to the mount-face, and operate the mirror a few times.

・

Position the camera in the direction of the arrow.

・

Camera: D300

・With the mirror being raised, move the (measurement-use) mirror stage to the stop position.

・Conrm that the camera-release guard is kept raised horizontally at the stop position, then lower the mirror.

Turn the (mirror height) adjusting micrometer and get the position where the laser reected image does not

・

move. At this position, check the angle of the sub-mirror.(The 51 degree-angle index position is 105.2 mm

Camera-release guard

lower than the 54 degree-angle index position.)

Mirror height adjust-

ing micrometer

Camera: D300

- A22 ・ D5000 -

●

Measure at the position where the

laser reected image does not move.

Page 77

VBA24001-R.3783.A

ミラーボックス底面

ミラーボックス底面

ミラーボックス底面

INC

Caution for measuring the angle of sub-mirror:

Make measurements by keeping the measurement-use mirror from coming in contact with the camera's

main mirror and the bottom section of the mirror box.

Main mirror

Sub-mirror

Measurement-use mirror

Avoid contact

Bottom section of mirror box

Position of laser reected image Cause Measure

Reference position

Laser reected image here

Laser reected image here

Measurement-use mirror contacts

the main mirror.

Bottom section of mirror box

Measurement-use mirror contacts the

Turn the (mirror height)

adjusting micrometer counter-

clockwise.

Turn the (mirror height) ad-

justing micrometer clockwise.

bottom section of the mirror box.

Reference position

Bottom section of mirror box

- A23 ・ D5000 -

Page 78

Check whether the results meet the standard. If not, make the adjustment.

INC

・

Standard value

<

>

Left-right deviation

Sub mirror

-

VBA24001-R.3783.A

Up-down deviation

Device

0 ± 7’

Eccentric pin for

the sub-mirror

HEX. KEY WRENCH (φ1.5mm)

・After completing the inspection and adjustment, with the mirror being raised, return the mirror stage to the

standard position.

・Conrm that the camera-release guard is kept lowered, and lower the mirror.

・Detach the camera body from the mount-face.

Standard position Camera-release guard

- A24 ・ D5000 -

Camera: D300

Page 79

Shutter

INC

・ Turn the red gear in the direction of the arrow, and raise the mirror.

・ Mount the shutter (#31).

・ Tighten the two screws (#635).

・ Make the solder bridges.

・ Attach the sponge (#149).

#31

#635

VBA24001-R.3783.A

#149

・ Attach the sponge (#757) to the gap between the shutter (#31) and the front body unit (#B22RP).

No gap from the sponge (#758)

#757

#758

The edge of the sponge must protrude

from edge face of the shutter.

- A25 ・ D5000 -

Page 80

2. Rear body

INC

VBA24001-R.3783.A

Eyelet unit, etc

[#147] attaching position

Joint line

Oil barrier:OS-30MEL

#147

#957

#694

#735

#145

#65

#143

#147

#143

#145

TA-0026 (6x11)

[#147] attaching position

Joint line

Oil barrier:OS-30MEL

#694

#143

TA-0026 (6x11)

#139

The holes must

be hidden.

#904

Attaching position

The holes must be

unseen.

Align with the

mold edge.

The hole must be unseen.

#906

Position in

center.

Back

- A26 ・ D5000 -

Page 81

Battery box

INC

・ Attach the double-stick tape (#141) to the battery box (#156).

・ Insert the backup battery (#B1044).

・ Attach the three springs (#157).

・ Tighten the three screws (#607).

・ Attach the spring (#160) by inserting its head into the hole.

・ Tighten the screw (#607).

#607

VBA24001-R.3783.A

#156

#157

#141

#B1044

#607

#160

Dipping

Grease: CFD-409Z

Insert the

head into the

hole.

- A27 ・ D5000 -

Page 82

・ Mount the lug plate (#159) by fitting with the bosses.

INC

・ Mount the battery box (#156) on the rear body.

・ Tighten the four screws (#615).

VBA24001-R.3783.A

#159

#615

- A28 ・ D5000 -

Page 83

DC/DC PCB unit

INC

・ Mount the DC/DC PCB unit (#B2002) and tighten the two screws (#665).

・ Connect the FPC.

・ Solder the battery-contact wires [Black/Red/Blue].

[Black/Red/Blue]

VBA24001-R.3783.A

#665

#B2002

- A29 ・ D5000 -

Page 84

VBA24001-R.3783.A

INC

SB PCB unit

・ Mount the SB PCB shield plate unit (#B82).

・ Put the SB PCB unit (#B2006) in between [#B82] and the rear body unit. (Put the wires inside the shield.)

・ Tighten the screw (#687).

・ Attach the connection-FPC (#1029) by fitting with the boss.

・ Arrange the wires [Red/Black], which are connected from the DC/DC PCB unit (#B2002), as below, and

solder them.

#B82

#B2006

#B2002

#B82

Rear body unit

Place inside the shield.

#687

- A30 ・ D5000 -

Boss

[Red/Black]

#1029

Page 85

VBA24001-R.3783.A

INC

Main condenser

・ Attach the two pieces of the double-stick tape (#141) to the condenser holder, and adhere the condenser.

・ Mount the SB condenser unit (#B1048) by fitting with the boss.

・ Tighten the two screws (#615).

・ Solder the wires [Red/Black], which are connected from the SB PCB unit (#B2006).

Condenser holder

#1048

[#1048] attaching area

#141

Direction for positioning

Attaching position:

The corner must come to the center of the rib.

#B1048

Microphone

・ Attach the microphone (#1046).

[Red/Black]

#615

#1046

- A31 ・ D5000 -

Page 86

VBA24001-R.3783.A

INC

3. Assembly of front body into rear body

・ Put mirror down, and assemble the front body into the rear body (being careful of wires and FPCs).

・ Tighten the four screws (#624) in the numeric order from ① to ④ .

①

#624

③

②

④

- A32 ・ D5000 -

Page 87

VBA24001-R.3783.A

INC

Bottom base unit

・ Mount the bottom base unit (#B66) (being careful NEITHER to be caught by the PCB NOR to pinch the

wires as below).

・ Tighten the five screws (#616) and three screws (#691) in the numeric order from ① to ⑧ .

#B66

③

⑥

⑤

#691

Do NOT pinch the wires.

#616

⑧

① ②

⑦

④

#691

- A33 ・ D5000 -

Page 88

ZERO/ABS

PRESET

TOL.

ON/OFF

0.00

mm

定盤

ZERO/ABS

PRESET

TOL.

ON/OFF

mm

定盤

2.12

10

20

30

40

50

40

30

20

10

0

10

20

30

40

50

40

30

20

10

0

定盤

定盤 定盤

20

10

0

10

20

30

40

50

40

30

20

10

0

Inspection and Adjustment of Body back

INC

・

"0" positioning of the dial gauge

(1)

J18001-1

(2)

Turn clockwise to 12 (0.12mm) position

Index circle

(3)

VBA24001-R.3783.A

△ (Revision)

0 ± 0.015 mm

Standard: 0±0.05 mm

Parallelism: 0.015mm or less

Surface plate

Surface plate

Surface plate

(1) Mount the tool (J18001-1) on the surface plate as above, then set the dial gauge to "0".

(2) From "0" position of (1), turn the index circle in the direction of the arrow so that the needle is on 12 (0.12mm)

position.

(3) Measure the body back based on "0" position of the index circle.

0 ± 0.015 mm

△ (Revision)

If the value is "0±0.05 mm / Parallelism: 0.015mm or less", it is within standard.

・

"0" positioning of the digital gauge

e.g.

2.12-2.12=0

So this is within

standard.

J18001-1

Surface plate

ABS] button so that the value becomes "0".

(2) Measure the body back based on "0" position

(3) Subtract "2.12mm" from the measured value. If the value is "Subtract "2.12mm" from the measured value. If the value is "2.12mm" from the measured value. If the value is "" from the measured value. If the value is "0±0.05 mm / Parallelism: 0.015mm or less",

(1) Mount the tool (J18001-1) on the surface plate as above, then turn the digital gauge ON and press [ZERO/

0 ± 0.015 mm

it is within standard.

Surface plate

△ (Revision)

※ "2.12mm" is a difference, resulting from subtracting [the height (46.67mm) of the body back tool

(J18001-1)] from [D5000 standard value (48.79mm)].

Changed page △× 3

- A34 ・ D5000 -

June. 22. 2009

Page 89

VBA24001-R.3783.A

INC

Measure six places from the bayonet face to the image PCB attaching face.

・

Measure the six places from the bayonet face to the image

・

PCB attaching face.

○ mark: to be measured

Standard: 48.79±0.05mm / Parallelism: 0.015mm or less

48.79 ± 0.015mm

・ In case the result is out of standard, loosen the screws

that attach the front and rear bodies, and make necessary

adjustments by changing the status of the attachments or

by using washers which are put on the mounting face of

the front and rear bodies.

・ Note: For some bodies, the washer(s) is/are already put on the attaching face of the image sensor, or

already the lumirror sheet attached on the side. The details are as follows:

Location ① Purpose: To adjust the height of the camera body

△ (Revision)

There are mark indications on the image-sensor-unit attaching face of the camera body where the washers

are necessary.

Blue = 0.02mm (#85); red = 0.1mm (#86); green = 0.06mm (#87)

* By adding the thickness of the washer to the measured value, check whether the result is within standard By adding the thickness of the washer to the measured value, check whether the result is within standard

48.79 ± 0.015mm

(48.79 ± 0.05mm) or not.

Location ② Purpose: To adjust the height of the image-sensor

There are mark indications on the image-sensor attaching face.

One marking = Three washers (#86: 0.1mm) are put on the face

Two markings = Three washers (#85: 0.02mm) are put on the face

No marking = The three lumirror sheets (#84) are attached on the side

* When the image sensor unit is replaced, remove the washers and lumirror sheet.When the image sensor unit is replaced, remove the washers and lumirror sheet.

Mark indication

Location

①

△ (Revision)

Marking where the washer is necessary.

Changed page △× 2

- A35 ・ D5000 -

June. 22. 2009

Page 90

VBA24001-R.3783.A

INC

Location

②

Marking

When the lumirror sheet is attached to

the side face, apply the suepr X after

tightening the screw.

Marking

Marking

Attaching position

- A36 ・ D5000 -

Page 91

・ Solder the wire [Black] which is connected from the ground.

INC

・ Solder the wire [Blue] which is connected from the lens contact.

・ Solder the wires [Black/Red] which are connected from the SQ PCB unit.

[Black]

[Blue]

[Black/Red]

VBA24001-R.3783.A

- A37 ・ D5000 -

Page 92

4. Image sensor

INC

Sponge

・ Attach the sponge (#144).

VBA24001-R.3783.A

Align with the

mold edge.

Image sensor unit

・ Mount the image sensor unit (#B2051), and tighten the three screws (#631).

・ Solder the wires [Green/Purple].

Caution: Some bodies have already the washer put on the surface where the image sensor unit is mounted

or already the lumirror sheet attached on the side.

In the latter case (lumirror sheet attached), remove the super X, which is applied to the side (see below

#144

Attachment area

" ■ " area), and then remove the image sensor unit.

#631

Direction for positioning

②

[Green/Purple]

#B2051

③

①

- A38 ・ D5000 -

Page 93

SZ-DC/DC PCB unit

INC

VBA24001-R.3783.A

・ Mount the SZ-DC/DC PCB unit (#B2003), and tighten

the two screws (#670) and the one screw (#687).

・ Connect the connection-FPC (#1026) to the connector.

・ Solder the wires [Yellow/Black].

#1026

[Yellow/Black]

#B2003

#687

#670

- A39 ・ D5000 -

Page 94

VBA24001-R.3783.A

INC

5. Top cover

Hot shoe

・ Attach the backing plate (#322), shoe spring (#318), hot shoe (#316), and hot shoe mold unit (#B317).

・ Tighten the four screws (#654) in the numeric order from ① to ④ .

#318

#316

Oil barrier: OS-30MEL

#B317

AF-assist lamp unit & AF/AE lock button

・ Mount the AF-assist lamp window (#326), and apply the super X.

・ Attach the AF/AE-L button (#386) and secure it with the retainer ring (#387).

④

② ③

#322

#654 × 4

①

Oil barrier: OS-30MEL

#386

#326

#387

Adhesive: Super X

- A40 ・ D5000 -

Page 95

AU

T

O

Mode dial unit & Delete-button-rubber SW

INC

・ Attach the mode dial unit (#B371), click spring (#373), and contact brush (#372).

・ Tighten the screw (#640).

・ Attach the delete button (#428) and delete-button-rubber SW (#423).

VBA24001-R.3783.A

Grease: LEN317A

Top cover FPC unit

#373

#372

#640

#B371

#428

#423

Back of top cover

Grease: LEN317A

・ Mount the top cover FPC unit (#B1012) by fitting with the bosses.

#B1012

= Boss

- A41 ・ D5000 -

Page 96

VBA24001-R.3783.A

INC

・ Solder the wire [Black], which is connected to DC/DC PCB, and arrange the wire in the groove.

・ Tighten the two screws (#635) in the numeric order from ① to ② . (When mounting [#B1012], fit in the

AF/AE-L button firmly.)

・ Make the five solder bridges.

[Black]

Grease: PL-22SEL

②

①

#635

AF/AE-L button fitting-in area

OK

C/D unit

NG: Not Good

・ Mount the C/D unit (#B367) in the direction for positioning.

・ Tighten the two screws (#635) in the numeric order from ① to ② .

・ Make the three solder bridges.

#B367

Direction for positioning

①

②

#635

- A42 ・ D5000 -

Page 97

VBA24001-R.3783.A

AU

T

O

AU

T

O

INC

Release button unit

/ each button, etc

・ Mount the on-off dial (#B345) set to ON position, and attach the on-off click spring (#347), and on-off

SW brush (#348).

・ Tighten the two screws (#605).

・ Mount the info button (#384), the + -/aperture button (#381), and the ribber SW (#382).

Grease: LEN317A

Front

#B345

#384

#381

#347

#348

#382

#605 × 2

Power SW FPC unit

・ Mount the power SW FPC unit (#B1011) by fitting with the bosses.

・ Tighten the three screws (#635) in the numeric order from ① to ③ .

・ Connect the FPC.

#B1011

Grease: PL-22SEL

Grease: LEN317A

Back

③

②

#635

①

- A43 ・ D5000 -

Page 98

VBA24001-R.3783.A

- A44 ・ D5000 -

・ Mount the AF -assist lamp unit (#B325) by fitting with the boss, and tighten the screw (#608).

・ Solder the wire [Black/uncoated].

・ Attach the flocked sheet (#327), which is for dust-proof.

#608

#B325

[Black/uncoated]

・ Mount the SB release base unit (#B2455) by fitting with the boss.

・ Tighten the two screws (#609) in the numeric order from ① to ② .

・ Arrange the wires [Red/Black] along the guide, and solder them on the top cover FPC unit (#B1012).

#609

#B2455

[Red/Black]

Guide

#327

Boss position

Attaching position

①

②

AF-assist lamp unit

SB release base unit

INC

Page 99

AU

T

O

lower control unit

INC

SB

・ Attach the two rubbers (#311) by aligning each position.

#311

VBA24001-R.3783.A

・ Mount the SB lower case unit (#B302), while holding and the both sides and pulling outward as below.

Grease: CFD-409Z

Grease: CFD-409Z

Grease: CFD-409Z

#B302

Grease: CFD-409Z

- A45 ・ D5000 -

Page 100

AU

T

O

・ Attach the SB rotating collar (#308), and engage the hooks.

INC

・ Attach the SB case rotate shaft (#306). While holding it, tighten the screw (#733).

Attach [#306] by

holding it.

VBA24001-R.3783.A

Hook here

Dipping

Grease: CFD-409Z

#306

#308

・ Attach the spring (#305) by aligning with the groove, and engage the hook.

#733

#305

Align with the

groove.

- A46 ・ D5000 -

Loading...

Loading...