Page 1

作成承認印 配布許可印

VBA12001-R.3668.A

Copyrighc2005 by Nikon Corporation.

All Rights Reserved.

無断転載を禁ず

!!

Printed in Japan June 2005

VBA12001

REPAIR MANUAL

M

サービス

計画課

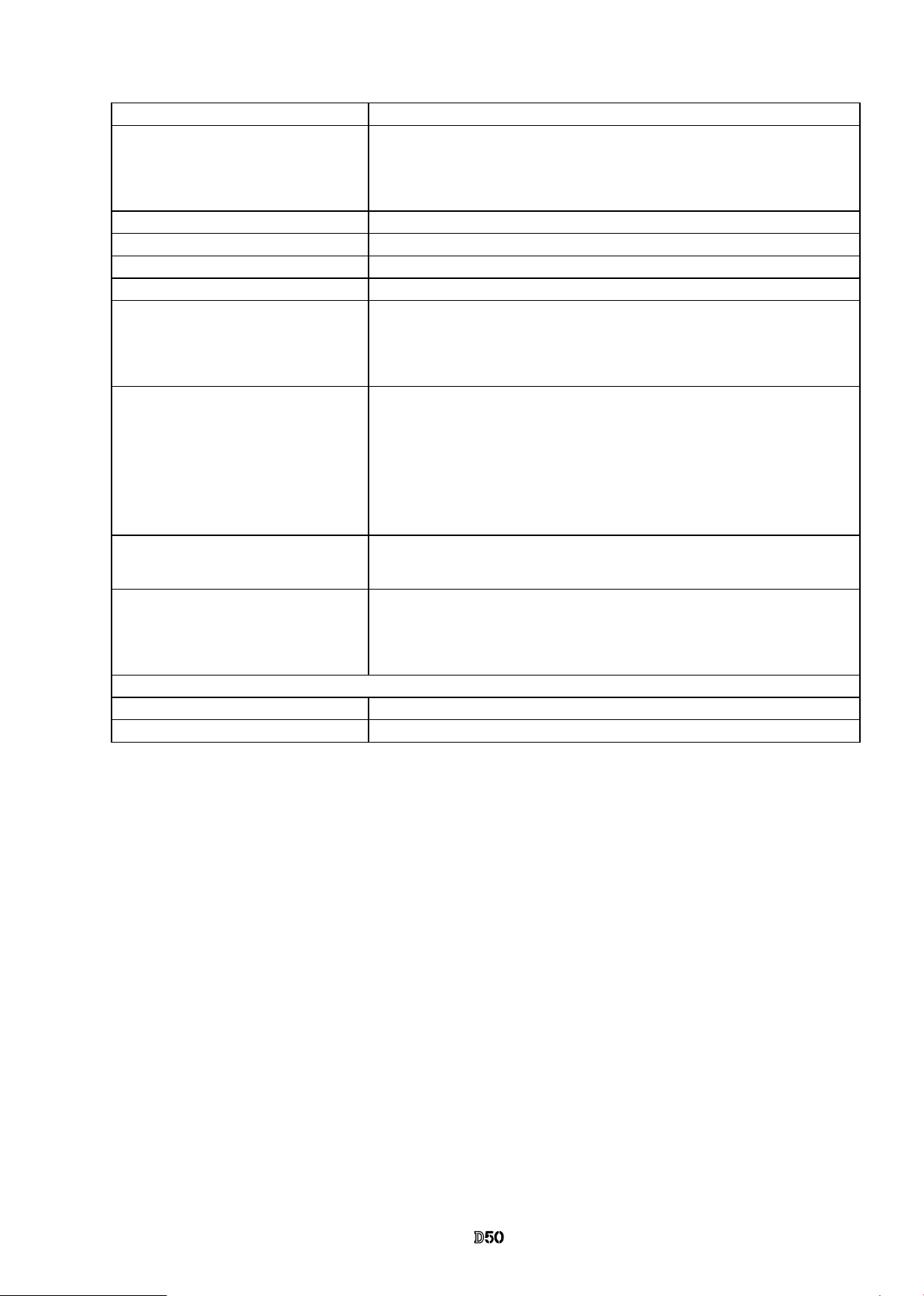

Page 2

- M1・ -

VBA12001-R.3668.A

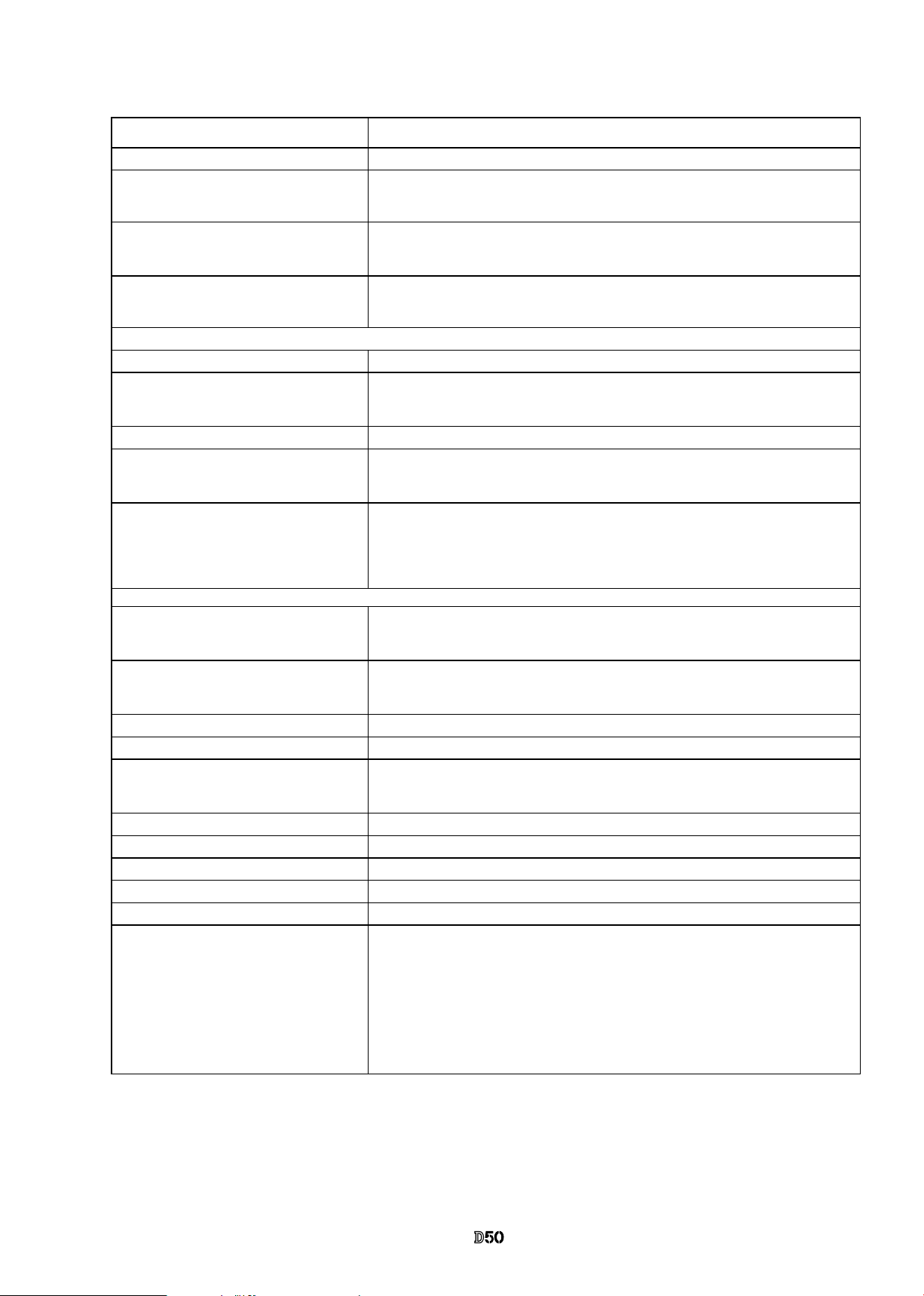

Type Single-lens reex digital camera with interchangeable lenses

Effective pixels 6.1 million

CCD 23.7 × 15.6 mm; total pixels: 6.24 million

Image size (pixels) • 3008 × 2000 (Large) • 2256 × 1496 (Medium)

• 1504 × 1000 (Small)

Lens mount Nikon F mount (with AF coupling and AF contacts)

Compatible lenses*

Type G or D AF Nikkor All functions supported

Micro Nikkor 85 mm

f/2.8D

All functions supported except autofocus and some exposure

modes

Other AF Nikkor† All functions supported except 3D color matrix metering II

AI-P Nikkor All functions supported except 3D color matrix metering II and

autofocus

Non-CPU Can be used in mode M, but exposure meter does not function;

electronic range nder can be used if maximum aperture is f/5.6

or faster

* IX Nikkor lenses can not be used † Excluding lenses for F3AF

Picture angle Equivalent in 35-mm format is approximately 1.5 times lens

focal length

Viewnder Fixed-eyelevel penta-Dach-mirror type

Diopter adjustment –1.6 – +0.5 m–1

Eyepoint 18 mm (–1.0 m–1)

Focusing screen Type B BriteView clear matte screen Mark V with superimposed

focus brackets

Frame coverage Approximately 95% of lens (vertical and horizontal)

Magnication Approximately 0.75× (50-mm lens at innity; –1.0 m–1

Reex mirror Quick return

Lens aperture Instant return with depth-of-eld preview

Focus-area selection Can be selected from 5 focus areas

Lens servo • Autofocus (AF): Instant single-servo AF(AF-S);continuous-

servo AF (AF-C); auto AF-S/AF-C selection(AF-A); predictive

focus tracking automatically activated according to subject status

• Manual focus (M)

Specications

Page 3

- M2・ -

VBA12001-R.3668.A

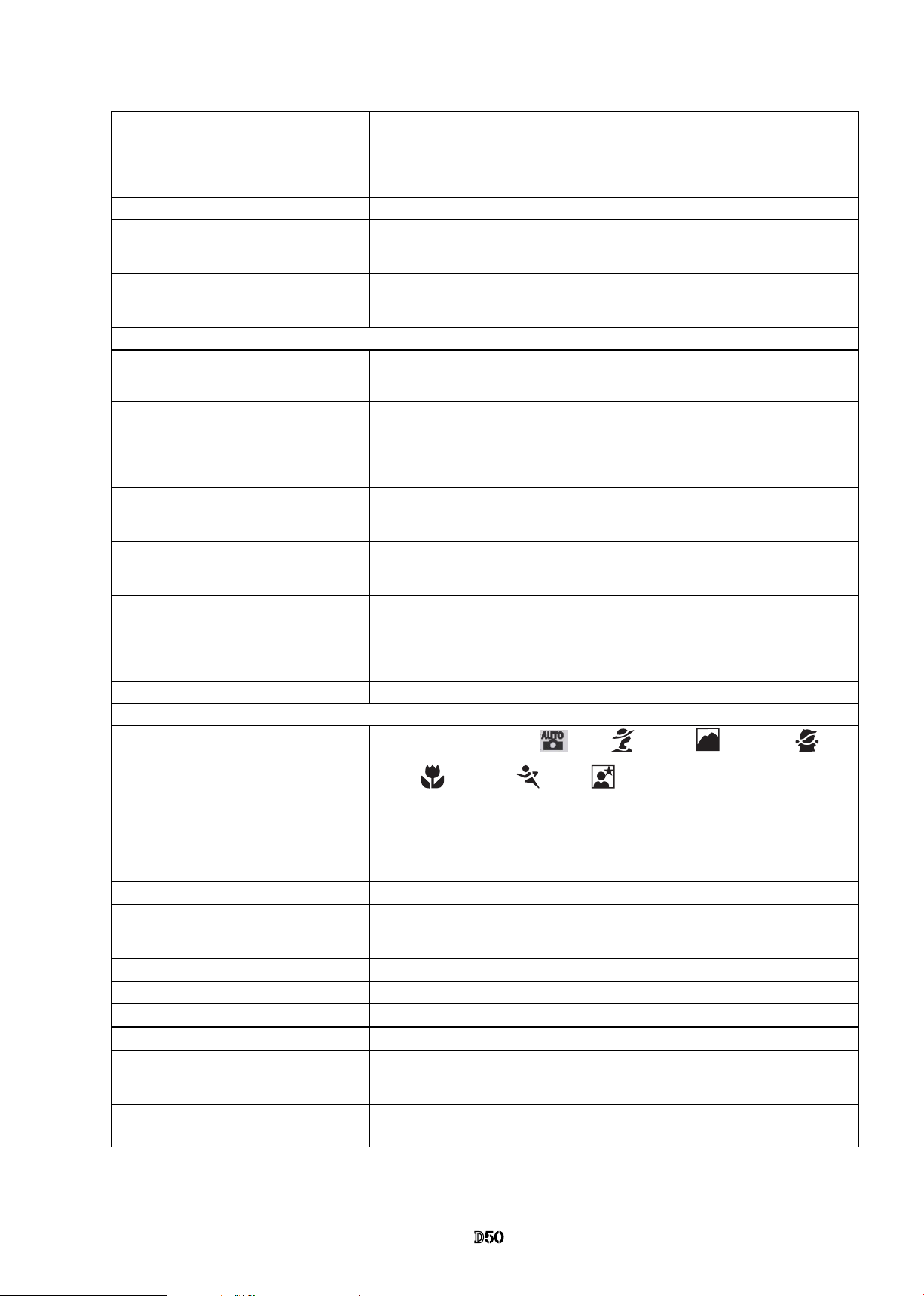

Autofocus TTL phase detection by Nikon Multi-CAM900 autofocus module

with AF-assist illuminator (range approximately 0.5–3.0 m / 1´8″–

9´10″)

Detection range –1 – +19 EV (ISO 100 at 20 °C/68 °F)

AF-area mode Single-area AF, dynamic-area AF, dynamic-area AF with closest

subject priority

Focus lock Focus can be locked by pressing shutter-release button halfway

(single-servo AF) or by pressing AE-L/AF-L button

Exposure

Metering Three-mode through-the-lens (TTL) exposure metering

Matrix 3D color matrix metering II (type G and D lenses); color matrix

metering II (other CPU lenses); metering performed by 420-

segment RGB sensor

Center-weighted Weight of 75% given to 6, 8, 10, or 12-mm circle in center of

frame

Spot Meters 3.5-mm circle (about 2.5% of frame) centered on active

focus area

Range

(ISO 100 equivalent, f/1.4 lens,

20 °C/68 °F)

0 – 20 EV (3D color matrix or center-weighted metering)

2 – 20 EV (spot metering)

Exposure meter coupling CPU coupling

Exposure control

Operating mode

Digital Vari-Program( auto, portrait,

landscape,

Child, close up, sports,

night portrait),

programmed auto (P) with exible program; shutter-priority

auto (S); aperture priority auto (A); manual (M)

Exposure compensation

–5 – +5 EV in increments of 1/3 or EV

Bracketing Exposure and / or ash bracketing (up to ± 2EV over 3

exposures)

Exposure lock Luminosity locked at detected value with AE-L/AF-L button

Shutter

Combined mechanical and CCD electronic shutter

Speed

30 – 1/4000 s in steps of 1/3 or EV, bulb, remote

Sensitivity

200 – 1600 (ISO equivalent) in steps of 1/3 EV

White balance Auto (TTL white-balance with 420 pixels RGB sensor), six

manual modes with preset white balance

Bracketing 3 exposures in increments of 1, 2, or 3

Page 4

- M3・ -

VBA12001-R.3668.A

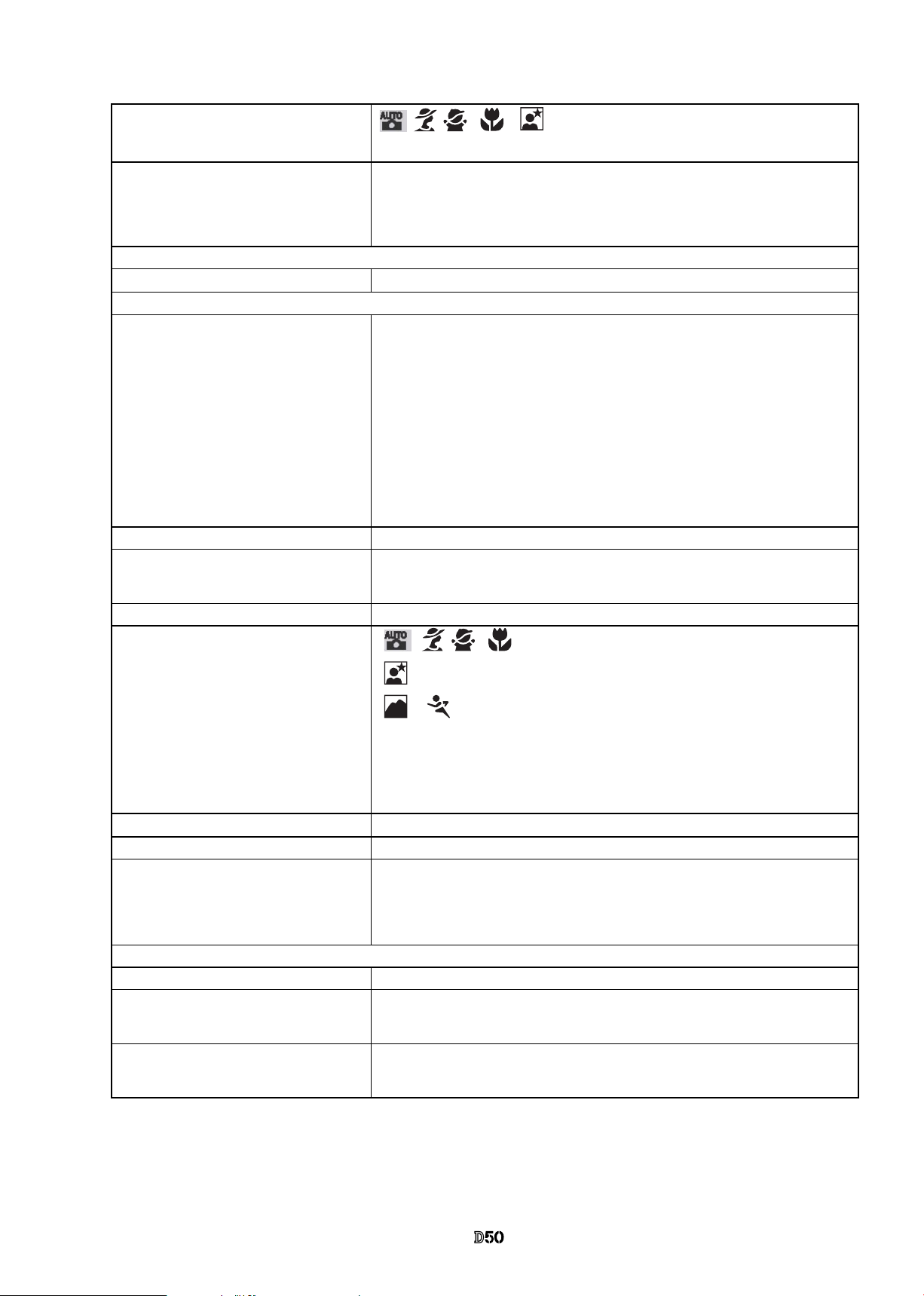

Built-in Speedlight

• , ,

, ,

auto flash with auto pop-up

• P, S, A,

M

: manual pop-up with button release

Guide number

(m / ft at 20 °C/68 °F)

• ISO 200: approximately 15/49 (manual 17/56)

• ISO 100: approximately 11/36 (manual 12/39)

Flash

Sync contact

X-contact only; ash synchronization at up to 1/500 s

Flash control

TTL TTL ash control by 420-segment RGB sensor (CPU lenses only)

• Built-in Speedlight: i-TTL balanced ll-ash for digital SLR,

or standard i-TTL ash for digital SLR (spot metering or mode

dial set to M)

• SB-800 or 600: i-TTL balanced ll-ash for digital SLR, or

standard i-TTL ash for digital SLR (spot metering)

Auto aperture Available with SB-800 with CPU lens

Non-TTL auto Available with such Speedlights as SB-800, 80DX, 28DX, 28,

27, and 22s

Range-priority manual Available with SB-800

Sync modes

• 、 、

、 : front curtain sync, red-eye reduction

•

: slow sync, slow sync with red-eye reduction

•

、

: front curtain sync and red-eyereduction available

with optional Speedlights

•

P, S

, A,

M

: front curtain sync, slow sync, rear-curtain sync,

red-eye reduction, slow sync with red-eye reduction

Flash compensation

–3 – +1 EV in increments of 1/3 or EV

Accessory shoe Standard ISO hot-shoe contact with safety lock

Creative Lighting

System

Supports Flash Color Information Communication and FV lock

with built-in Speedlight, SB-800, and SB-600. SB-800 and 600

also support Advanced Wireless Lighting.

Storage

Media SD (Secure Digital) memory cards

File system Compliant with Design Rule for Camera File System (DCF)

2.0 and Digital Print Order Format (DPOF)

Compression • NEF (RAW): compressed 12-bit

• JPEG: JPEG baseline-compliant

Page 5

- M4・ -

VBA12001-R.3668.A

Self-timer Electronically controlled timer with 2 – 20 s duration

Monitor 2.0″, 130,000-dot, low-temperature polysilicon TFT LCD with

brightness adjustment

Video output Can be selected from NTSC and PAL

External interface USB 2.0 Hi-speed

Tripod socket ″ (ISO)

Firmware upgrades Firmware can be upgraded by user

Supported languages Chinese (Simplied and Traditional), Dutch, English, French,

German, Italian, Japanese, Korean, Portuguese, Russian,Spanish,

Swedish

Power source • One rechargeable Nikon EN-EL3 Li-ion battery;

charging voltage (MH-18a quick charger or optional MH-19

multi charger): 7.4 V DC

• EH-5 AC adapter (available separately)

Dimensions (W × H × D) Approximately 133 × 102 × 76 mm (5.2″ × 4.0″ ×3.0″)

Weight Approximately 540 g (1 lb 3 oz) without battery, memory card,

body cap, or monitor cover

Operating environment

Temperature 0 – 40 °C (+32 – 104 °F)

Humidity Less than 85% (no condensation)

• Unless otherwise stated, all gures are for a camera with a fully-charged battery operating at an

ambient temperature of 20 °C (68 °F).

• Nikon reserves the right to change the specications of the hardware and software described this

manual at any time and without prior notice. Nikon will not be held liable for damages that may

result from any mistakes that this manual may contain.

Page 6

- D1 ・ -

VBA12001-R.3668.A

Points to notice for Disassembly / Assembly

�

内部に高電圧部あり。カバーを外す 時は感電に注意すること。

カバーを外した後は、修理指針の指 示に従ってメインコンデン

サーの放電を必ず行うこと。

警告

Note:

①

When disassembling/(re)assembling, be sure to use the conductive mat (J5033) and wrist strap (J5033-5)

for static protection of electrical parts.

②

Before disassembling, be sure to remove batteries or AC power wires.

③

When disassembling, make sure to memorize the processing state of wires and FPC, screws to be xed

and their types, etc.

④ Because the low pass lter of the imaging CCD PCB is easily damaged, handle it with enough care.

Points to notice for Lead-free solder products

・ Lead-free solder is used for this product.

・ For soldering work, the special solder and soldering iron are required.

・ Do NOT mix up lead-free solder with traditional solder.

WARNING

Due to an internal high voltage area,

take extra care not to

get an electric shock when detaching covers.

.

After removing covers, be sure to discharge the main

condenser according to the instructions of repair manuals

.

Note:

When "Seprating Front and Rear bodies","Disassembling Image PCB",and"Disassembling Bayonet",

be sure to perform"Reset of AF defocus compensation amount"by D2X adjustment software after reassembly.

Page 7

- D2 ・ -

VBA12001-R.3668.A

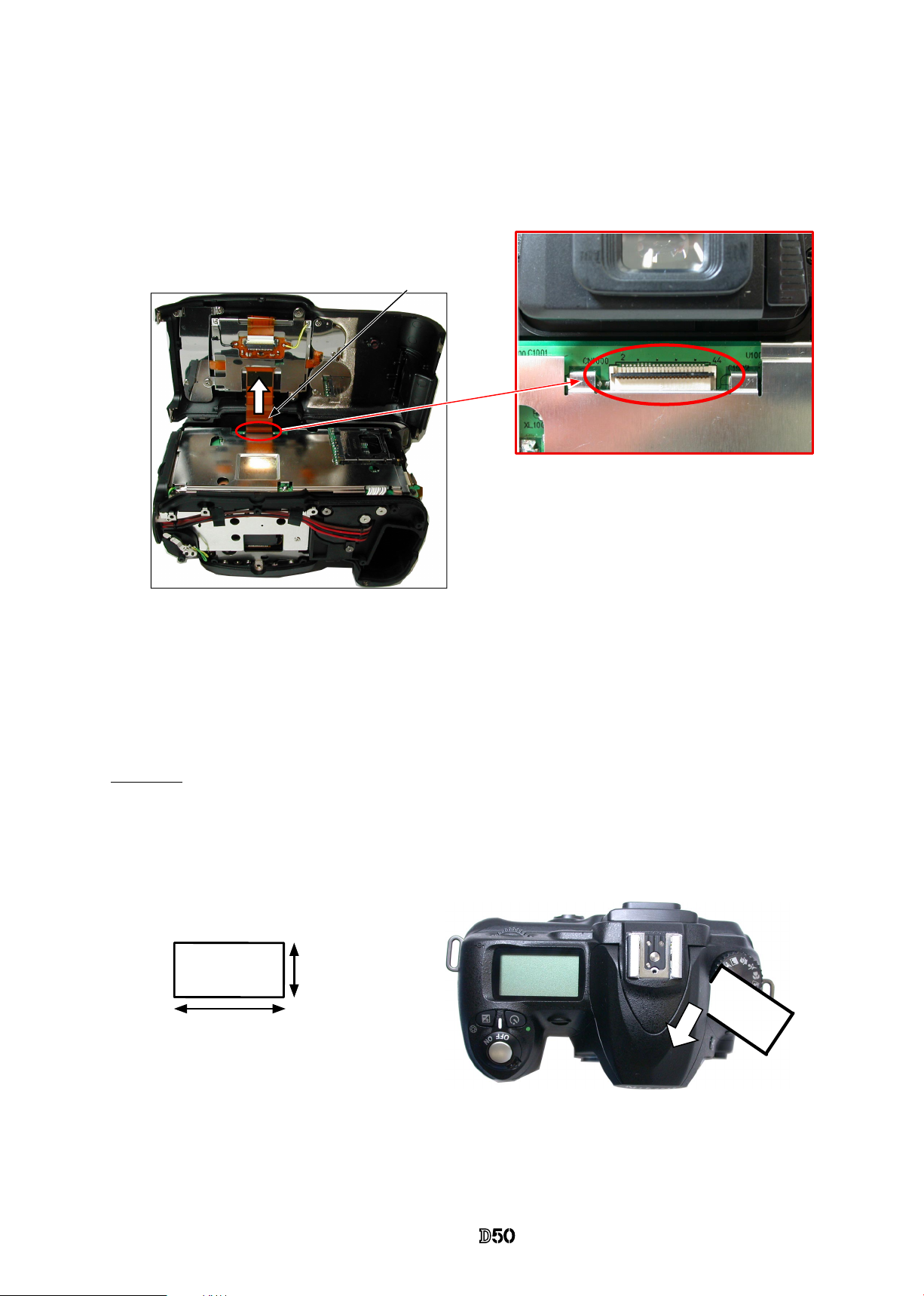

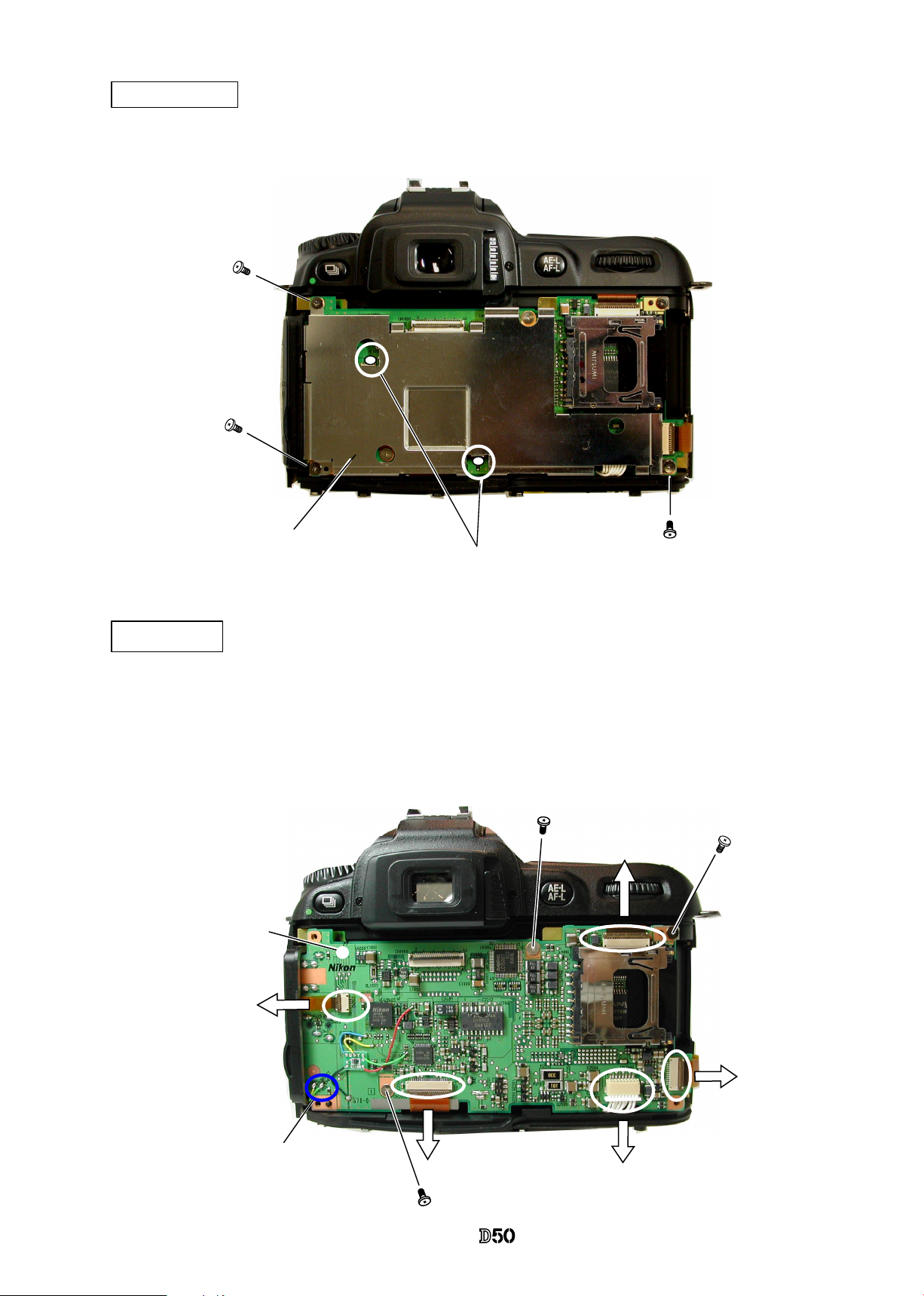

Disassembly

1. Separation of Front and Rear Bodies

Bottom Cover

#5692

#5697

#5677×7

Bottom cover

・

Take out the screws (#5692 and #5697) and 7 screws (#5677).

・

Remove the bottom cover.

Rear cover

・

Take out 4 screws (#623).

・

Cover to remove the rear cover.

Note: Remove the rear cover slowly so as not to cut TFT-PCB

connection FPC of the upper portion of the cover.

#623×4

Rear cover

Page 8

- D3 ・ -

VBA12001-R.3668.A

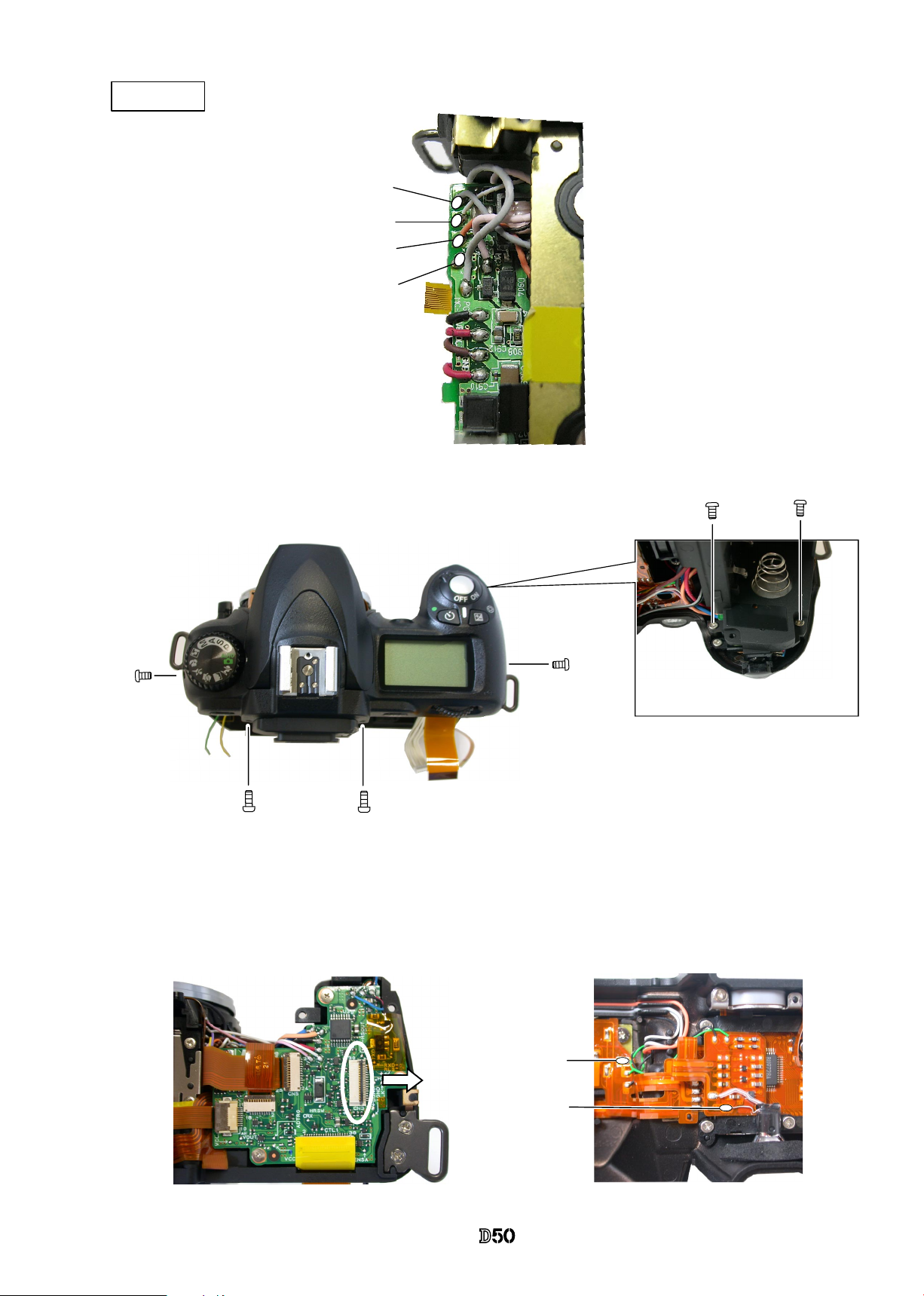

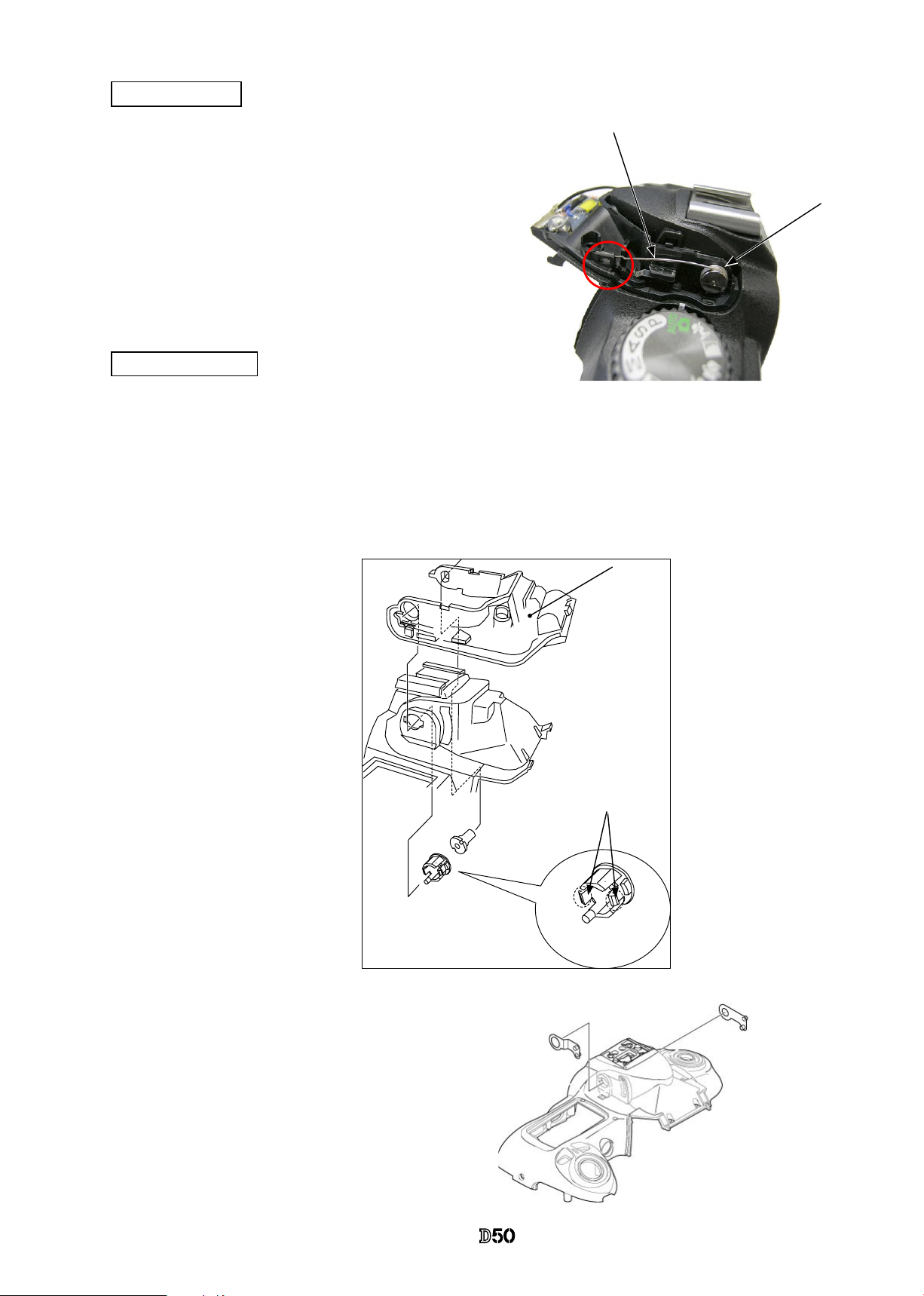

SB pop-up

Approx.2cm

Approx. 4cm

・

Remove TFT-PCB connection FPC from the connector.

・

Cut the tracing lm sheet, etc into the below size of piece. Then insert it into

the clearance of the top cover pop-up part as shown right, and pop it up by

sliding the sheet in the direction of the arrow.

TFT-PCB connection FPC

Page 9

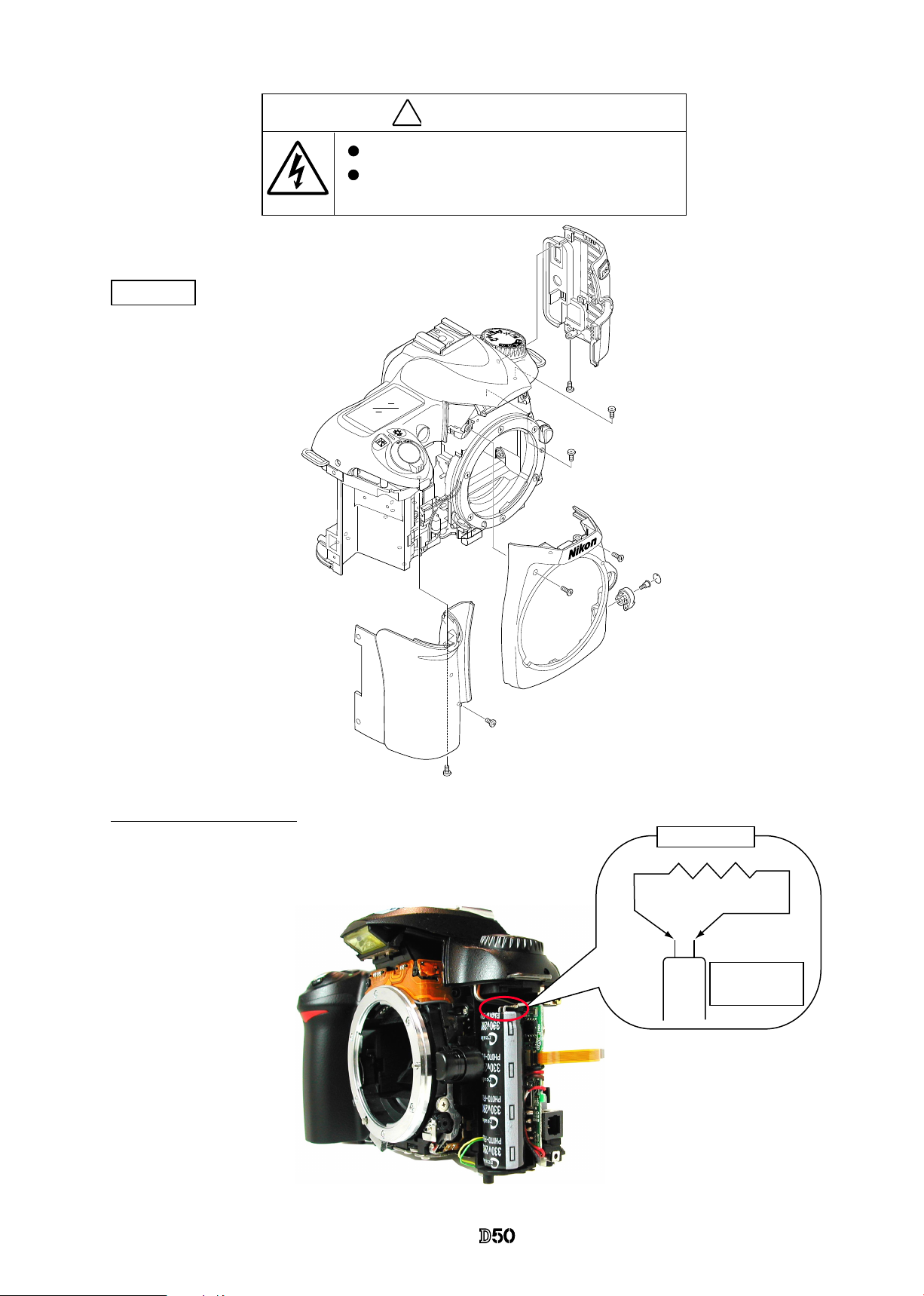

- D4 ・ -

VBA12001-R.3668.A

Discharge Main condenser

・

Discharge the main condenser from its both terminal.

#627 × 3

Main

condenser

2KΩ/5W

�

内部に高電 圧部 あり 。カ バーを外す時は感電に注意す るこ と。

カバーを外 した 後は 、修 理指針の指示に従ってメイン コン デン

サーの放電 を必 ず行 うこ と。

警告

Covers

・

First, remove the front cover (#B5024).

#B5028

WARNING

Due to an internal high voltage area, take extra care not to get an

electric shock when detaching covers.

After removing the covers, be sure to discharge the main

condenser according to the instructions of repar manuals.

#635

#659

#5124

#5121

#611×2

#635

#635

#26

#B5024

A

U

T

O

#611 × 2

Page 10

- D5 ・ -

VBA12001-R.3668.A

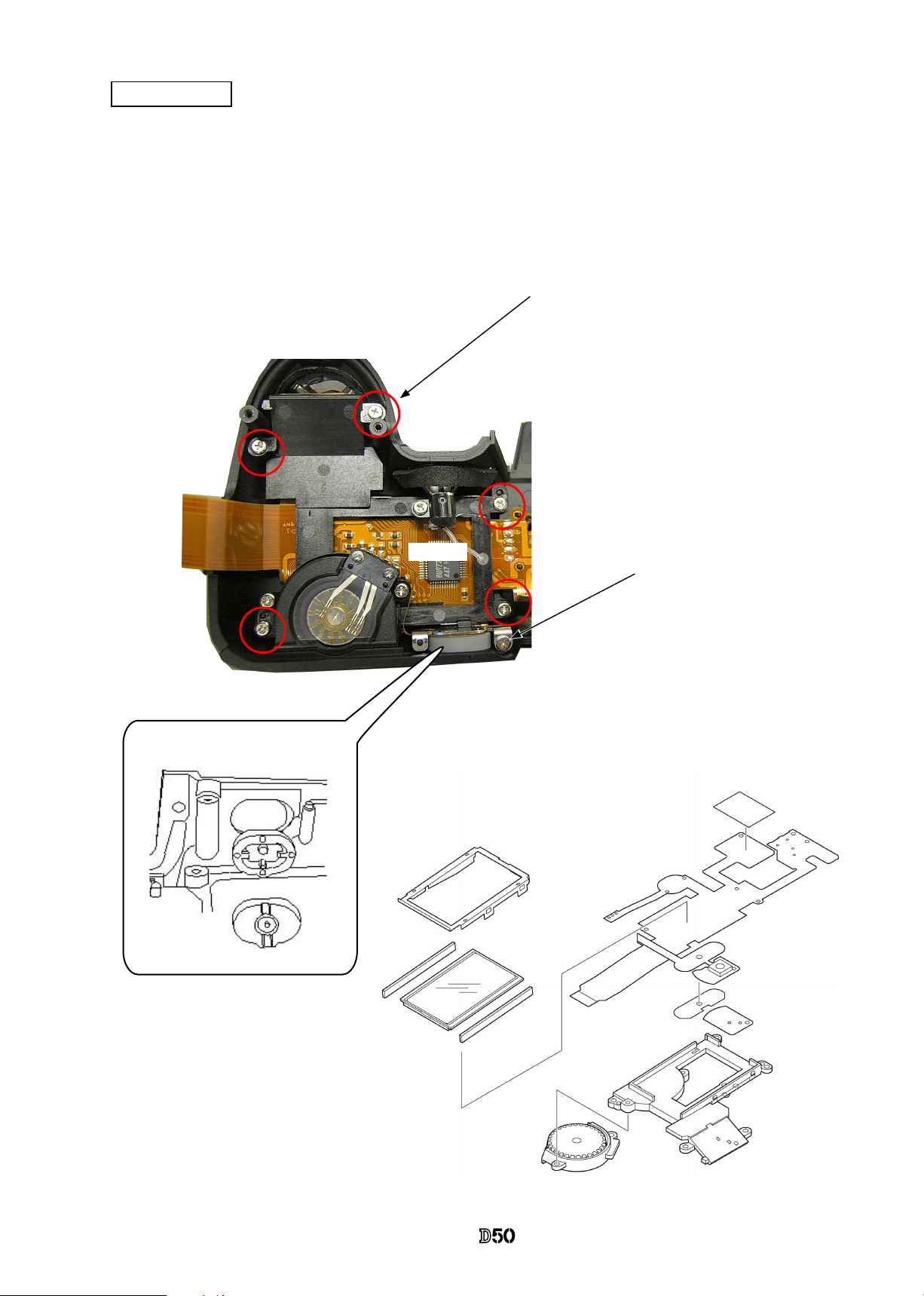

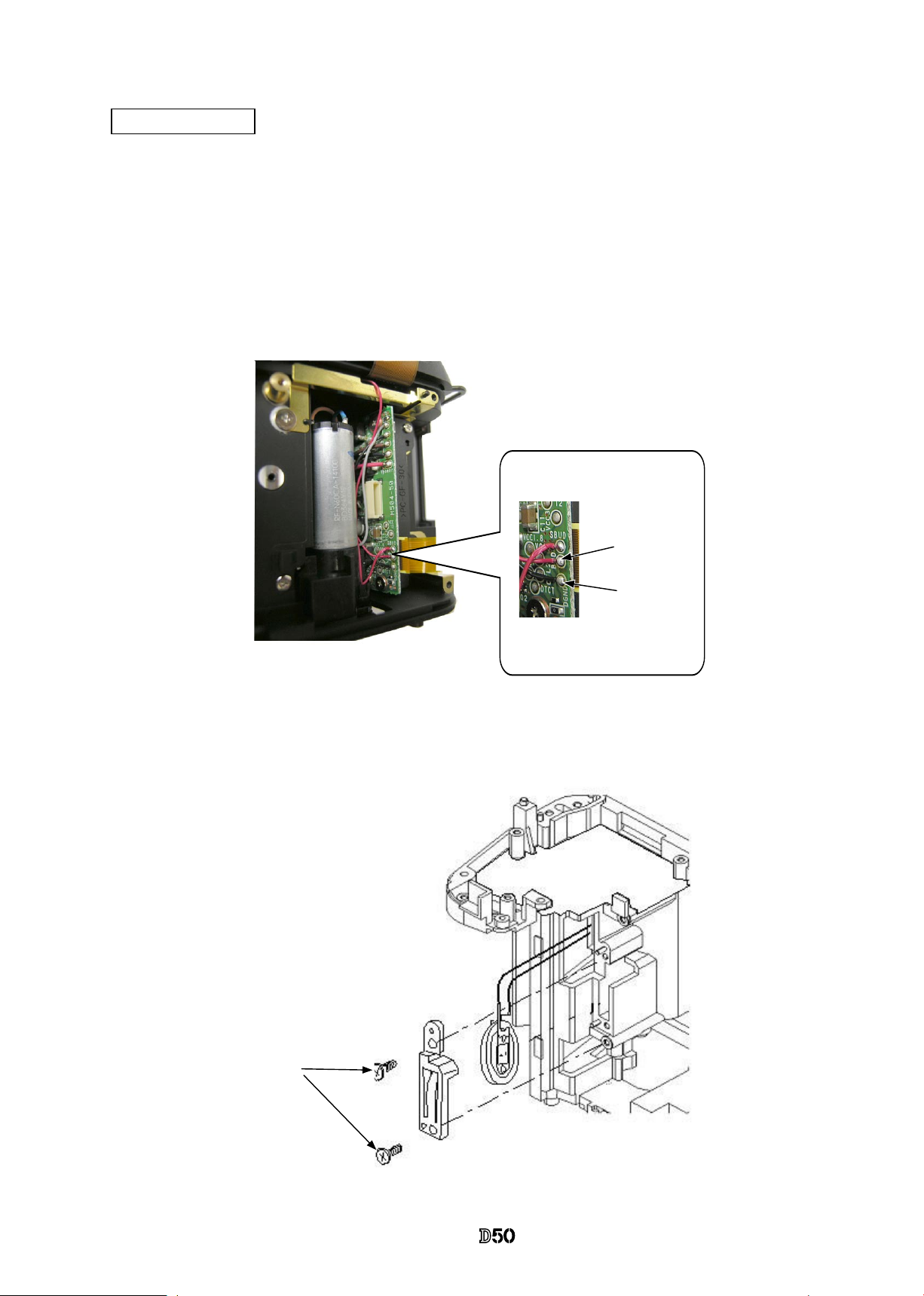

DG shield plate

#78

#627×3

DG-PCB unit

・

Remove 5 connectors.

・

Unsolder 2 reset SW wires.

・

Take out 2 screws (#663) and the screw (#627) to remove the DG-PCB unit (#B2031).

・

Remove 2 soldering bridges.

・

Take out 3 screws (#627).

・

Remove the DG shield plate (#78).

Soldering bridges

Green

Yellow

: Reset SW wire

#663×2

#627

#B2031

Page 11

- D6 ・ -

VBA12001-R.3668.A

・

Take out 3 screws (#669) to remove the CCD/FPC unit (#B2032).

CCD/FPC unit

#669×3

#B2032

Page 12

- D7 ・ -

VBA12001-R.3668.A

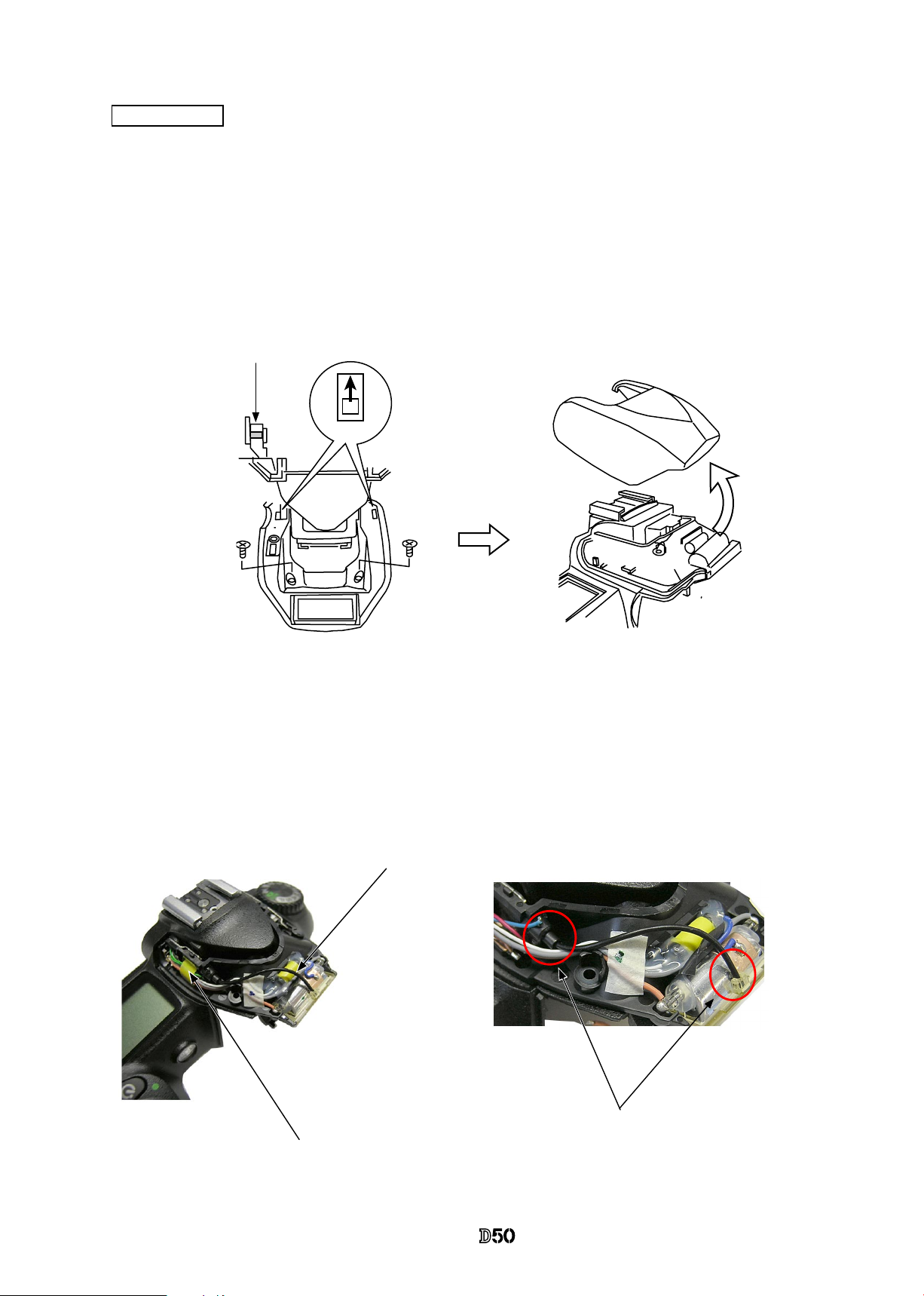

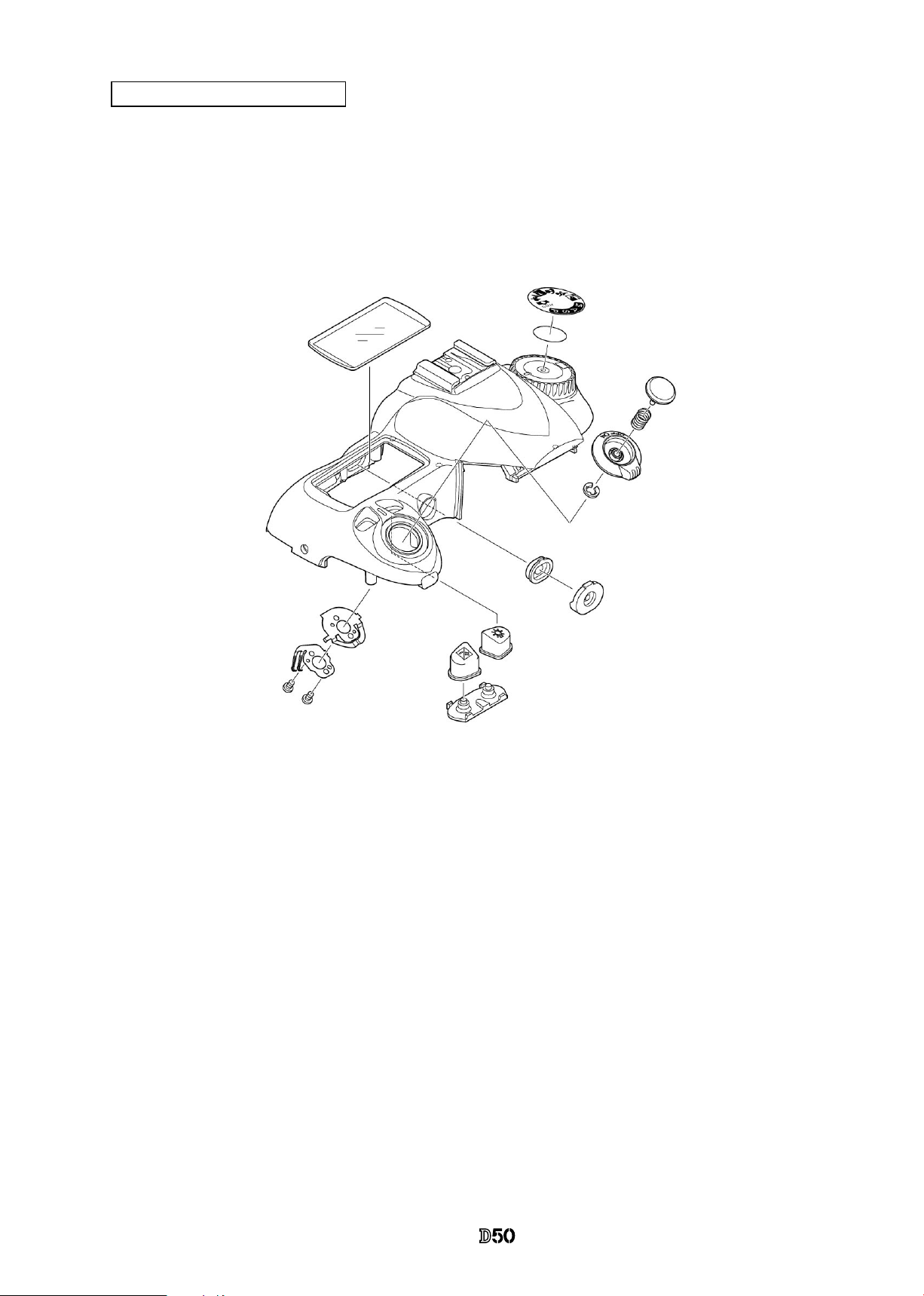

Top Cover

・

Unsolder 4 wires.

・

Take out 2 screws each of (#635, #656, and #5618).

The eyepiece frame (#B271) comes off, too.

Black

Orange

White

Gray

・

Remove the top cover FPC (#1007) from the connector.

・

Unsolder 2 wires of the top cover FPC.

* The solder land of gray wire is same as AF assist lanp unit.

Black

*Gray

#

656

#5618×2

#B271

#B0023

#656

#635×2

Top cover FPC

Page 13

- D8 ・ -

VBA12001-R.3668.A

Fig.1

・

Remove the tape (#709).

・

Remove the optical ber (#470) from the sensor.

#629×2

Note) Both ends of the optical ber are just

inserted in each part without any adhesive.

Optical ber

#470

#709

SB upper case

・

Press the pop-up lever A part of the top cover unit so that the built-in SB pops up.

・

Take out 2 screws (#629).

・

Push from beneath the hooking lever of the SB upper case as shown in Fig.1 . Then slide 2 hooks in the

direction of the arrow to remove the lever.

・

Deactivate pop-up of the SB lower case unit, and remove the SB upper case. (Fig.2)

Pop-up lever A part

SB upper case

Fig.2

Hooking lever

SB lower case unit

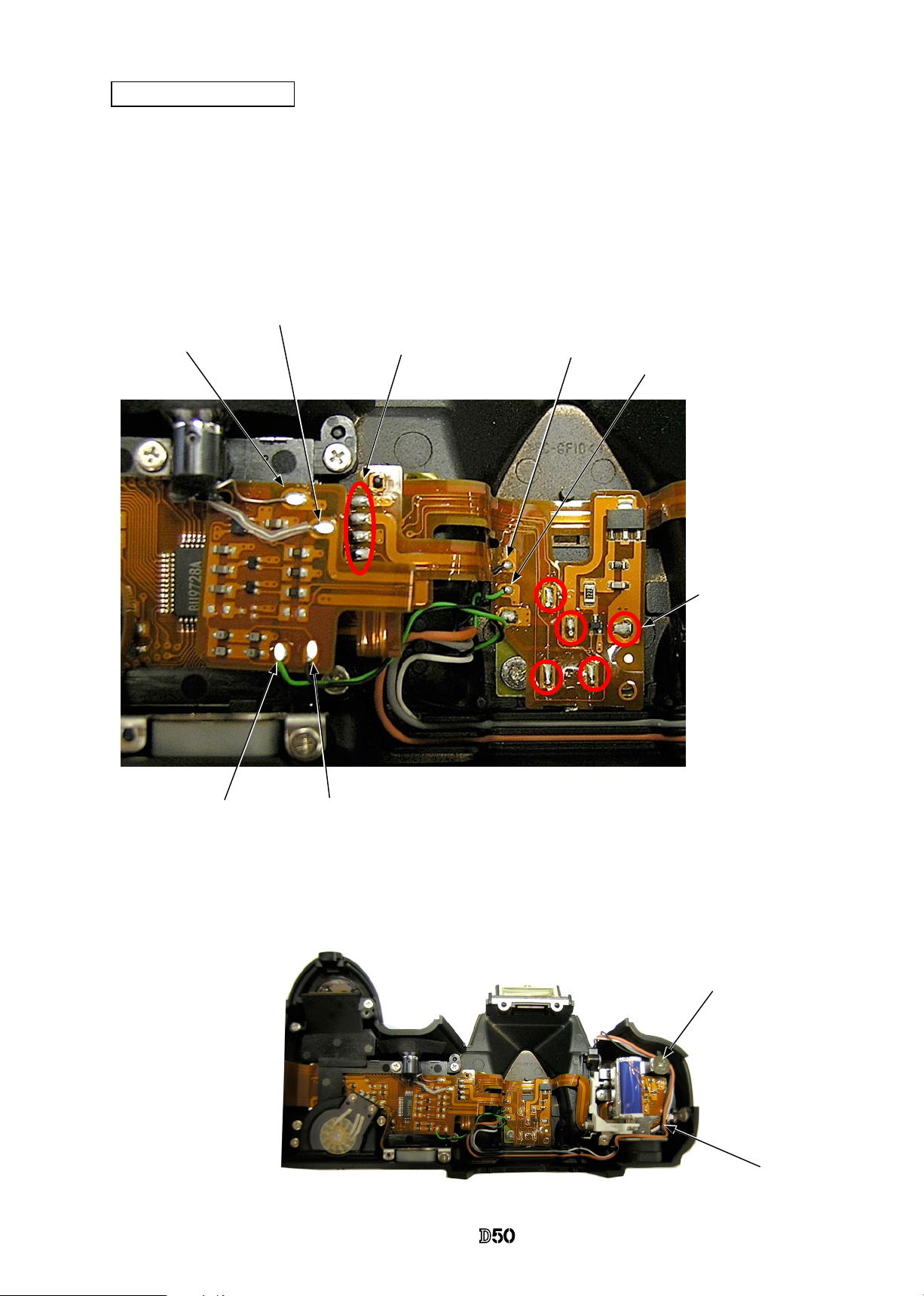

Page 14

- D9 ・ -

VBA12001-R.3668.A

・

Remove the wire-retaining screw (#650).

・

Remove wires.

Top cover FPC / Wiring

・

Remove the soldering bridges.

・

Remove the 2 solders of AF-assist illuminating lamps.

・

Remove the solders of 2 SPD sensor wires.

・

Remove the solders of 2 pop-up change SW wires.

・

Remove the solders of 5 accesory shoe contacts.

#

650

SPD sensor wire (Green)

SPD sensor wire (Black)

AF-assist illuminating

lamp

AF-assist illuminating lamp

(

covered for insulation

)

Soldering bridges

Pop-up change switch (Black)

Pop-up change switch (Green)

Accessory shoe contact ×5

Wires

Page 15

- D10 ・ -

VBA12001-R.3668.A

・

Remove #B341 and #B342.

Flash-up spring

#650

#305

#306

#308

2 hooks

#B2302

SB lower case unit

・Unhook the Flash-up spring

(#305).

・Take out the screw (#650) and

remove the Flash-up spring

(#305).

・Pull each wire out of hole.

・Loosen 2 hooks of the collar (#308) to remove it.

・Remove the SB case axle (#306).

・Detach the SB lower case unit (#B2302) from the top cover.

#B341

#B342

Page 16

- D11 ・ -

VBA12001-R.3668.A

M/DFPC unit

AF-assist illuminating lamp / Command dial

・

Take out 2 screws (#640) to remove the M/DFPC unit (#B2455).

・

Remove the rubber SW (#389) and shooting operation-mode button (#388).

・

Remove the light-leak proof sponge (#766).

・

Take out the screw (#635).

・

Remove the AF-assist illuminating lamp (#B325).

・

Remove 2 screws (#635).

・

Lift to slack the command dial (#B367).

#640 × 2

#388

#389

#B2455

#766

#635

#B325

#B367

#635 × 2

Page 17

- D12 ・ -

VBA12001-R.3668.A

Top cover FPC

・

Take out the screw (#644).

・

Take out 5 screws (#635).

・

Remove the top cover FPC (#B2007).

・

Remove the AE-L rubber SW (#387) and AE-L button (#386).

#B2007

#331

#1044

#B367

#733

#1007

#735

#734

#332 × 2

#330

#386

#387

#644

#635 × 5

Page 18

- D13 ・ -

VBA12001-R.3668.A

Release button / other small parts

#5460

#461

#350

#351

#5345

#

352

#387

#5386

#5381

#382

#347

#348

#604 × 2

#335

#5383

Page 19

- D14 ・ -

VBA12001-R.3668.A

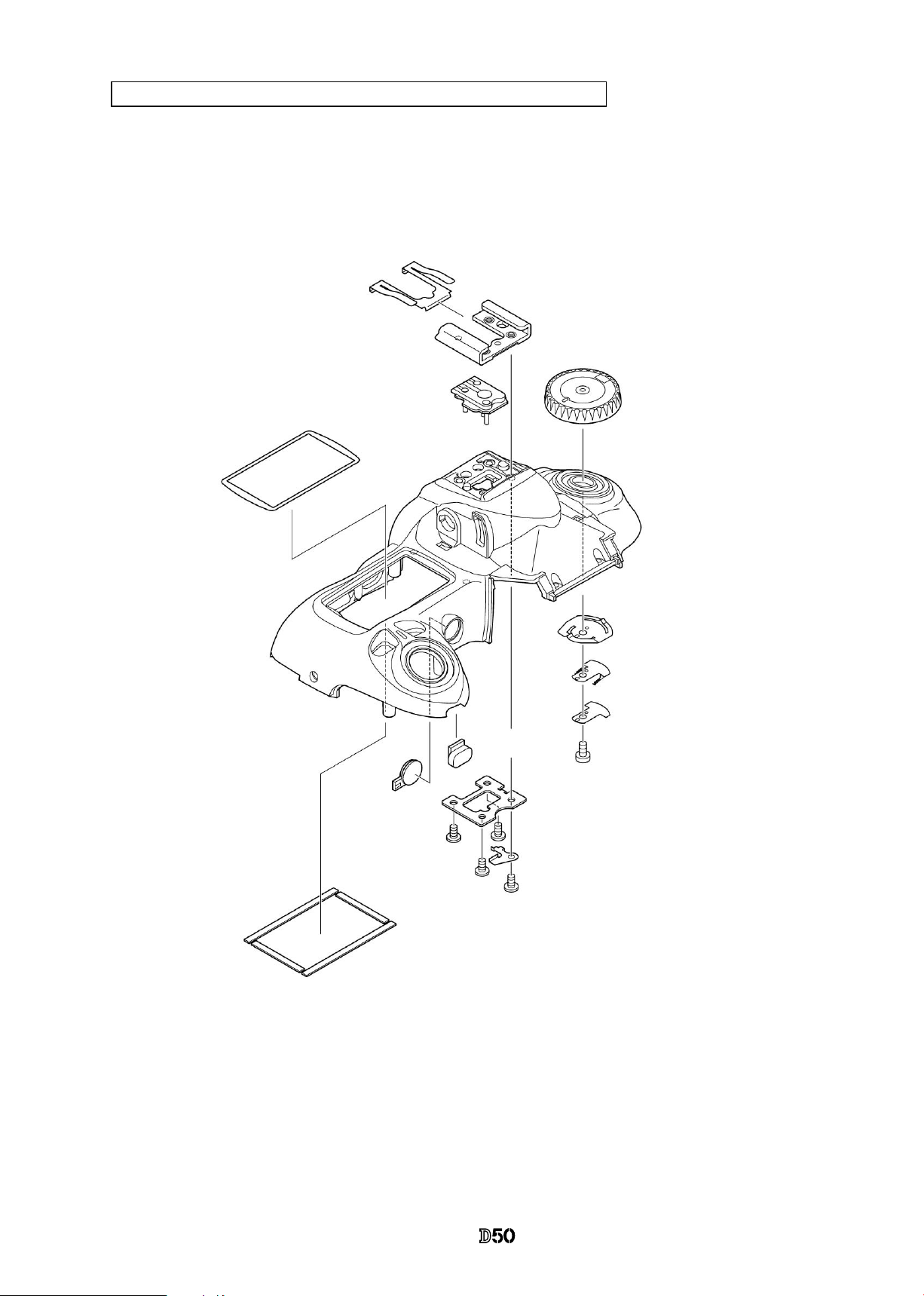

Outer LCD window / shoe mold unit / accessory shoe / other small parts

#452

#454

#654 × 4

#322

#640

#336 × 2

#337 × 2

#453

#338

#5451

B317

#316

#318

#321

#326

#463

Page 20

- D15 ・ -

VBA12001-R.3668.A

Main PCB unit

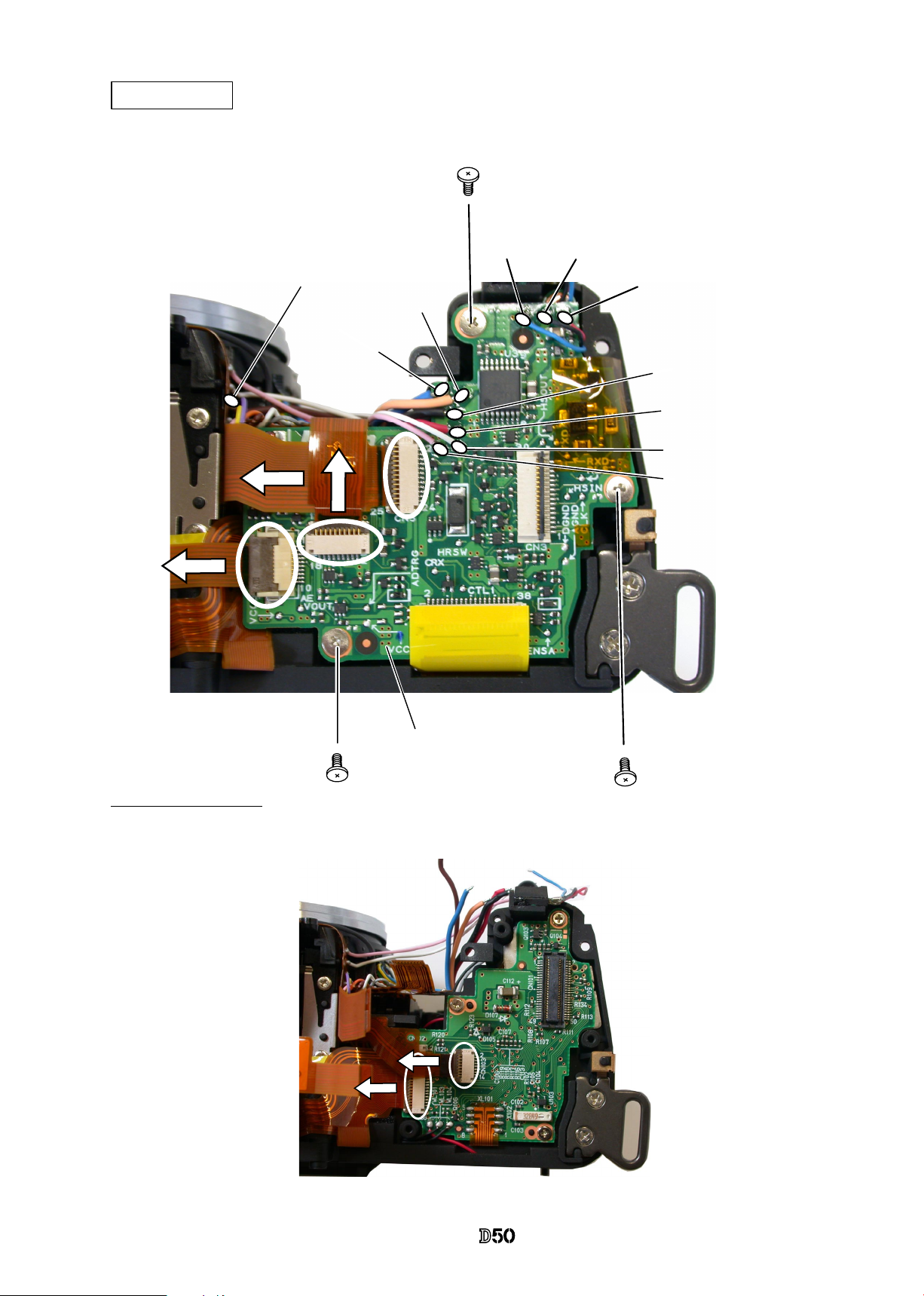

Removal of Connector

・

Remove 2 FPCs from the connector

・

Remove 3 FPCs from the connector.

・

Unsolder 10 wires.

・

Take out 3 screws (#640) to remove the

main-PCB unit from the sub-PCB.

Blue

Black

#640×3

Red

Orange

Blue

Black

Red

White

Pink

Main PCB unit #1001

Brown

Page 21

- D16 ・ -

VBA12001-R.3668.A

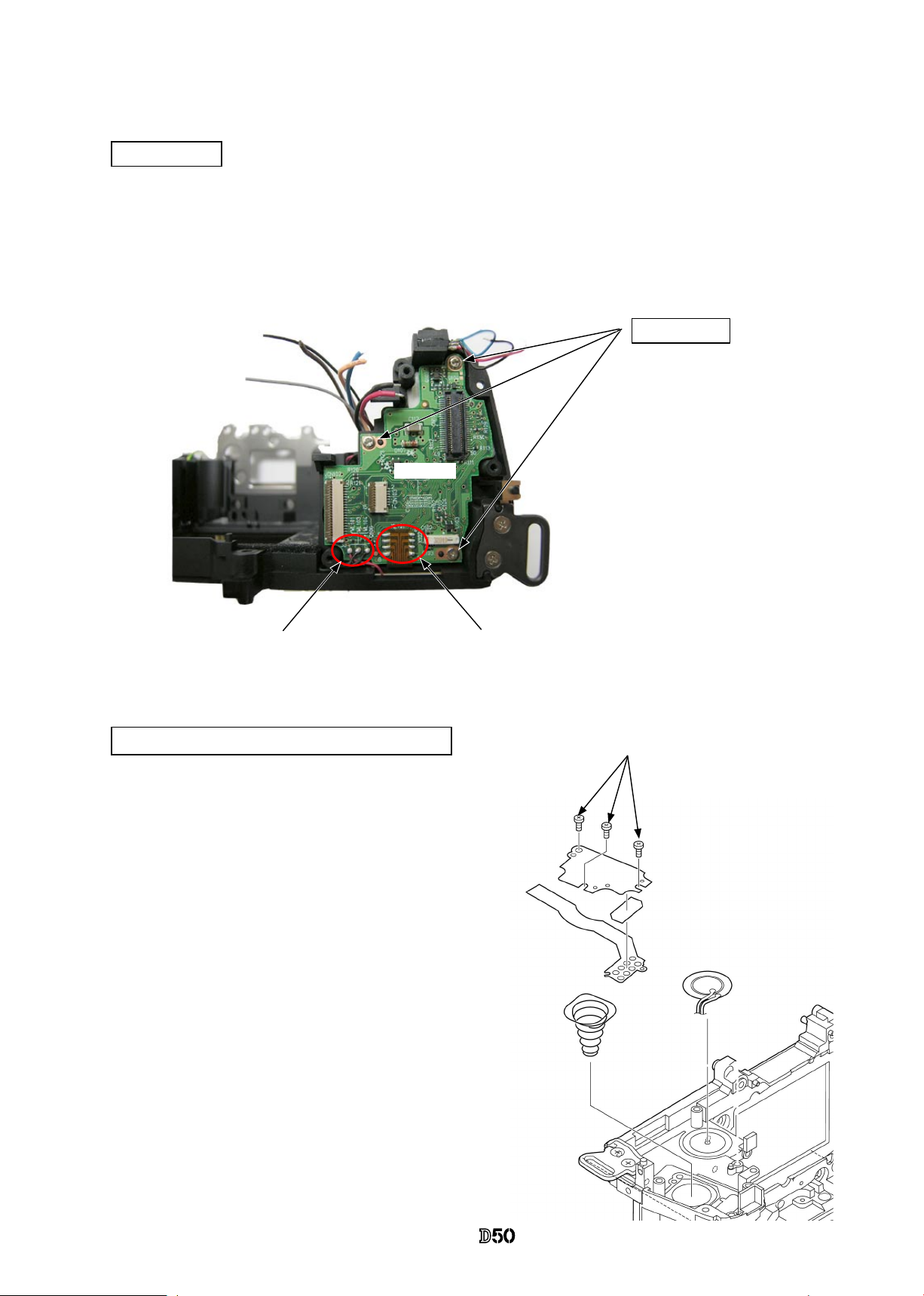

Separation of Front and Rear bodies

#642×3

Front body

Rear body

#699×3

#634×4

・

Take out 3 screws (#699), 4 screws (#634), and 3 screws (#642) to remove the front body.

Page 22

- D17 ・ -

VBA12001-R.3668.A

2. Rear body

・

Unsolder 3 wires of electronic buzzer .

・

Remove the soldering bridges.

・

Take out 3 screws (#644).

・

Remove Sub-PCB.(#B2002)

・

Take out 3 screws (#673).

・

Remove the retaining plate (#159).

・

Remove the battery-extrusion spring (#158).

・

Remove the electronic buzzer unit (#1055).

Sub-PCB unit

Electronic buzzer unit / Battery-extrusion spring

#

644×3

#673×3

#158

#

159

#1055

3 wires of electronic buzzer .

Soldering bridges

#B2002

Page 23

- D18 ・ -

VBA12001-R.3668.A

・

Unsolder 2 wires of the clock battery unit.

・

Remove 2 screws (#642).

・

Remove the clock battery holder (#73).

・

Remove the clock battery unit (B1059).

#

642×2

Clock battery unit

Black

Red

#73

(

B1059

)

Page 24

- D19 ・ -

VBA12001-R.3668.A

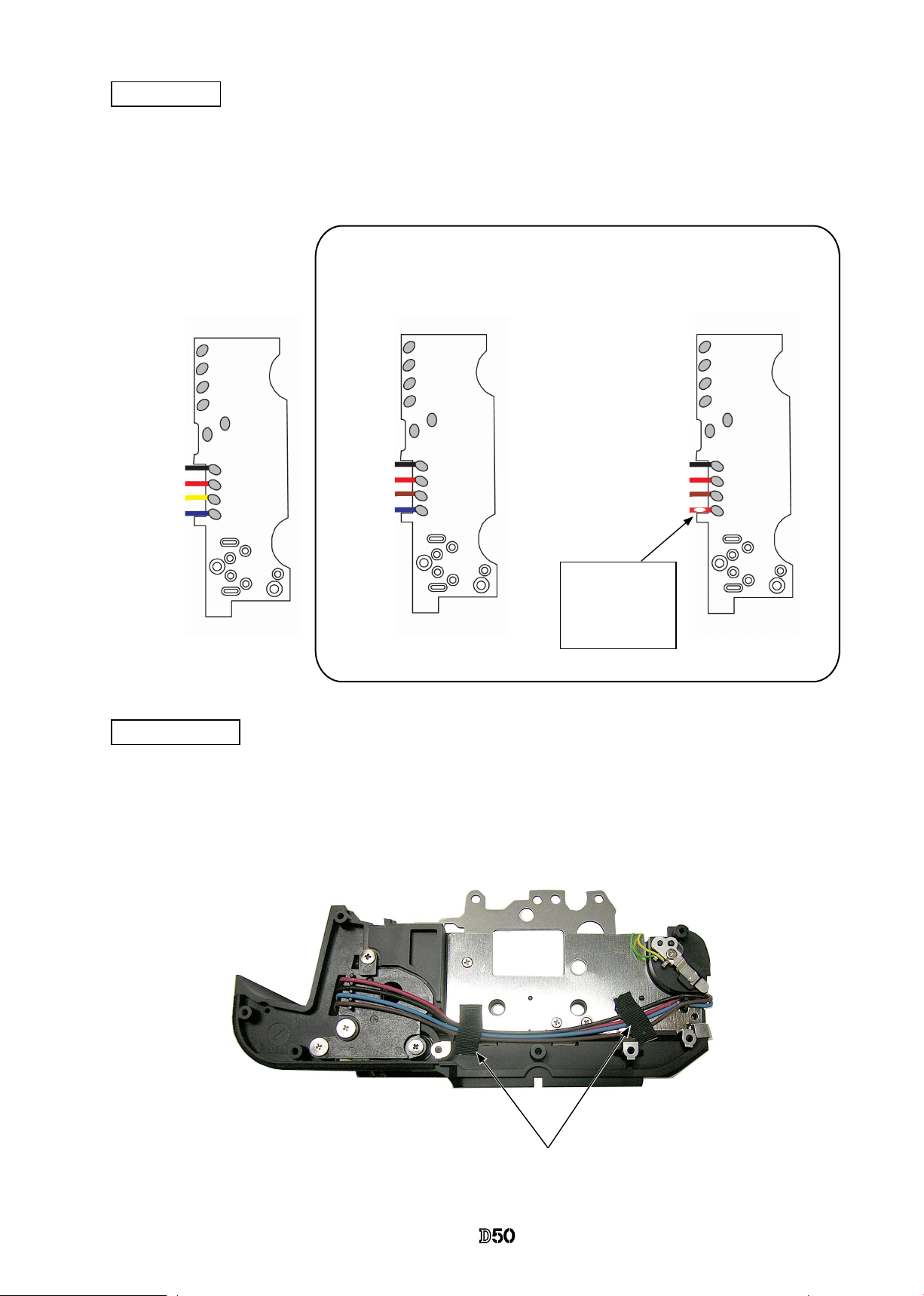

Bottom wires

Black

Red

Yellow

Blue

Wire arrangement tape

#715×2

・

Remove 2 pieces of tape that arrange wires (#715).

・

Remove wires.

・

Unsolder 4 wires of DC/DC PCB unit.

SB-PCBwires

Be careful that some PCBs at the inital stage of mass-production have

different colored wire.

Black

Red

Blown

Blue

Black

Red

Blown

Red

White marking is

painted for

identication.

Page 25

- D20 ・ -

VBA12001-R.3668.A

・

Take out 2 screws (#693).

・

Remove the DC/DC PCB unit (B2030).

#627×2

#633

#693×2

・

Take out 2 screws (#627).

・

Take out the screw (#633).

・

Remove the SQ-PCB (B91).

DC/DC PCB unit

SQ PCB

(B91

)

(

B2030

)

Page 26

- D21 ・ -

VBA12001-R.3668.A

・

Take out 4 screws (#635).

・

Remove the bottom base unit (#66) and bottom conduction plate (#106).

・

Take out the screw (#647).

・

Remove #80.

・

Take out the screw (#633).

・

Remove #81.

・

Remove #2030.

・

Take out 2 screws (#633).

#633×2

Lug plate / Bottom base unit

#80

#647

#633

#81

#2030

#635×4

#106

#66

Page 27

- D22 ・ -

VBA12001-R.3668.A

・

Remove the condenser (B1043).

・

Take out 2 screws (#635).

・

Remove the SB unit (B2041).

SB unit

(

B1043

)

#635×2

(

B2041

)

The condensor (#B1043) is xed

with 2 pieces of the both-sided

adhesive tape (#754).

Page 28

- D23 ・ -

VBA12001-R.3668.A

#680×2

#746

#777

#150

#146

#617×2

#145

#149

#617×2

#76×2

#714

#790

#761

#765

#790×2

#764×2

#747

Rear body small parts

Page 29

- D24 ・ -

VBA12001-R.3668.A

3. Front Body

・

Take out 3 screws (#291) to remove the metering FPC unit (#B2008).

・

3 springs (#290) come off.

・

Take out 2 screws (#635) to remove the metering FPC-base unit (#B286).

・

Remove the tape (#796).

・

Take out the screw (#635) to remove the eyepiece-lens unit (#B261).

Note:

The screws (#291) are attached with the

adhesive.

In case they (#291) are moved, AE CCD

position adjustment (ref. Assembly) becomes

necessary.

#796

Eyepiece unit

Metering FPC unit

#291×3

#290×3

#635×2

#B286

#B2008

#635×2

#B261

Page 30

- D25 ・ -

VBA12001-R.3668.A

Penta unit

#284

#283

#9

#1046

#B279×2

#282

#B1021

#278

#B277

#642×2

#B4-2

#255

#256

#642×2

#297

#3

#739×2

Adhesive

#709×2

#792A×2

#280×2

Page 31

- D26 ・ -

VBA12001-R.3668.A

AF PCB unit

Shutter unit

・

Unsolder 7 wires.

・

Take out the screw (#607 and #627) to detach the shutter unit

(#B31).

#B31

#607

#627

#170×3

#636×3

AF PCB unit #B2163

#709×2

AF PCB FPC

・

Remove the tape (#709).

・

Remove AF-PCB connectoin FPC from connector.

・

Take out 3 screws (#636) with Hexagonal wrench

to remove AF PCB unit (#B2163).

・

3 springs (#170) come off, too.

Pink

White

Yellow

Brown

Orange

Gray

Purple

#728

Page 32

- D27 ・ -

VBA12001-R.3668.A

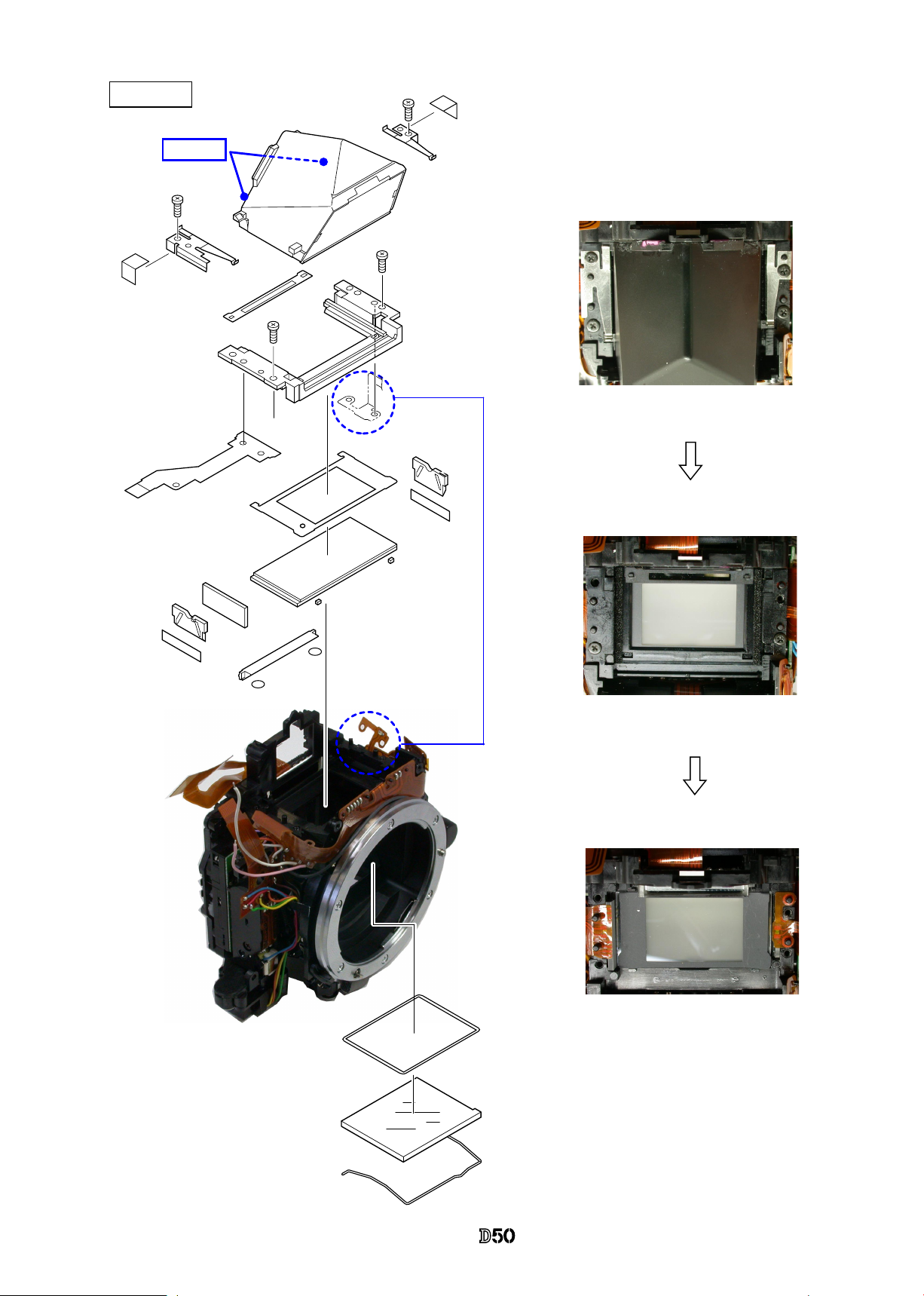

Inner LCD unit

・

Take out 2 screws (#626) to remove the inner LCD

unit (#B2010).

Front body FPC unit

#B2010

#626 × 2

・

Remove the sponge (#797 and #748).

#797

#748

Soldering bridges

Soldering bridges

Black:AF motor

Red:AF motor

Pink:V6

White:LBAT

Yellow:A/M SW

Black:A/M SW

AF PI

FPC

Front body FPC unit: #B1009

#619

Page 33

- D28 ・ -

VBA12001-R.3668.A

Aperture control unit

Procedure

①

Unsolder 2 wires .

②

Remove the screw (#661), spring (#214) and the lever (#254).

③

Take out 3 screws (#642).

④

Press down the aperture lever with Finger to move the aperture coupling lever (#207) in the direction

of arrow(

① )

.

⑤

In state of ④, remove the aperture control unit (#B241) by pulling it in the direction indicated by

arrow (②) while letting the arm (#B241) escape.

Front body viewed from the bottom

#642×3

#254

#214

#661

#B241

Aperture lever

#207

#203

Arrow

②

Arrow

①

#B241

Arm of #B241

Brown:Fmin SW

Black:Fmin SW

Page 34

- D29 ・ -

VBA12001-R.3668.A

#B172

#637×2

#185

#122

#191

#630

#B116

#195

#193

#630

#115

#119

#642

#621

・

First, remove the

horizontal lever

(#193).

AF driving unit

Lens release button

Vertical lever

Horizontal lever

Bayonet unit

A/M-change SW unit

(5)

#660

#111

#131

Soldering bridge of

#126 and #114

#642

#B125

#126

#642×2

#112×3

#132

#135

#114

#648×5

#189

#607

#123

#B2113

#607

Page 35

- D30 ・ -

VBA12001-R.3668.A

Aperture lever unit

F-min Switch unit

#639

#208

#213

#375

#375

#203

#206

#209

#207

#210

#212

#205

#642

#134

#B133

#190

#239

#238

#234

#199

#199

#B2231

#236

Mirror unit

・

Note that 2 pins (#199) and the

pin (#236) are attached with

the Super X.

Page 36

- A1 ・ -

VBA12001-R.3668.A

Assembly/

Adjustment

#239

#238

#234

#199

#199

#B2231

#236

#119

#236

Adhesive:C-8008B

Adhesive:C-8008B

Grease:LEN317A

#236

Apply to the inner diameter

surface where to put #199 in.

・

NOTE: For undescribed tapes and sponges here in"Assembly",

refer to"other tapes/sponges" on PARTS LIST.

1. Front body

Mirror unit

・

With being mirror-up as shown right,

assemble the pins and apply C-8008B

(Adhesive: Super X) on each pin.

Do NOT allow the adhesive

to be forced out on the head

of #199.

Apply the adhesive only on

1/4 periphery of the pin on

mount side.

Page 37

- A2 ・ -

VBA12001-R.3668.A

Aperture lever unit

F-min SW

中

#639

#208

#213

#375

#375

#203

#206

#209

#207

#210

#212

#205

#642

#134

#B133

#190

#1086

#1087

Brown

Black

Grease:

LEN317A

Grease: MZ-800S

#375×2

#205

#212

#213

(short)

(long)

#212

#205

Spring hooking shaft

Grease: LEN317A

Apply to overall of #209 and #210.

Apply inner diameter surface of

#203, #207, and #208.

Apply to periphery of shaft

Position for hooking spring

White

(middle)

Page 38

- A3 ・ -

VBA12001-R.3668.A

1. Turn the sequence white gear of the aperture control unit in the direction of the arrow, and position the arm as

shown in Fig.①.

2. Place #248 in center of movement of range, and lock it with #249. (ref. Fig.①)

3. Insert the arm between #207 and #203. (ref. Fig.②)

4. Attach 3 screws (#642). (ref. Fig.③ and

④)

Fig.

①

Fig.

②

#248

#249

Arm

#

207

#

203

Fig.

③

Fig.

④

#

642

#

642×2

Direction for

positioning

Aperture control unit

*

Note: Be careful not to bend contact blade of F-min SW.

Aperture control unit

Page 39

- A4 ・ -

VBA12001-R.3668.A

#

637×2

#B172

#254

#

214

#

661

#661

・

After screwing the

spring (#214), hook

it to #254.

AF driving unit

#214

・

Position #B172 by fol-

lowing the direction

and screw it.

#637×2

#642

#B125

#126

#B116

Grease: LEN317A

Apply a little on sliding surface

A/M change SW

Lens release button

Page 40

- A5 ・ -

VBA12001-R.3668.A

Position

for hooking

spring#195

#185

#630

#193

Grease: LEN317A

#191

#630

#122

Grease:LEN317A

Apply to inner diameter of

#122 and #191

・

Assemble by the following order.

#

122→

#

191→

#

630

*

Note: Be careful NOT to bend contact

blade of the lens release SW.

Vertical lever

Lens release SW

comes on the lever.

Horizontal lever

・

Insert t he U-shap ed part of

#193 into the groove of the

AF driving shaft (#185).

#195

Page 41

- A6 ・ -

VBA12001-R.3668.A

(5)

Soldering bridge of #126 and #114

Yellow

Black

#126

#119

#115

#642

#621

#135

#112×3

#607

#131

#132

#111

#114

#660

#648×5

#189

#642×2

#607

Grease: LEN317A

#112×3

Bayonet unit

AF lens contacts

A/M change SW cover unit

#123

#B2113

Page 42

- A7 ・ -

VBA12001-R.3668.A

#185

Bayonet mount

1.7±0.15mm

#625

Adhesive: Screw lock

3.4±0.1mm

絞りレバー

Height adjustment of AF coupling shaft

①

Set the A/M change cam (#122) to

AF side. (i.e. The AF coupling

shaft

(#

185) sticks out of the

bayonet.

)

②

Adjust the height of the AF coupling

shaft (#185) with the screw (#625)

so that it becomes 1.7±0.15mm.

③

After the adjustment, x the screw

(#625) with screwlock.

#

122

A/M change cam

Height adjustment of Aperture lever

・

Measure the height of the aperture lever by using the tool (J18004).

Standard: 3.4±0.1mm

In case the value is out of standard, make an adjustment by bending the circled part.

Be careful NOT to bend the inner part of the lever when adjusting!

Aperture lever

Page 43

- A8 ・ -

VBA12001-R.3668.A

#295

#B22

Cross-section view

#B2010

#626×2

#797

#748

Attachment of #797 and #748

#1009

Soldering bridges

Pink:V6

White:LBAT

Soldering bridges

Yellow:A/M SW

Black:A/M SW

・

Insert the tip of AF PI FPC and make a

soldering bridge.

Black:AF motor

Red:AF motor

Front body FPC

Inner LCD unit

・

Attach the sponge (#295) on the front plate (#22).

・

Attach the inner LCD unit (#B2010)

with 2 screws (#626).

・

Attach the

sponge

(#797) and (#748)

#619

Page 44

- A9 ・ -

VBA12001-R.3668.A

・

Solder 9 wires.

#B31

#607

#627

Pink:Shtter

White:Shtter

Yellow:Shtter

Brown:Shutter

Orange:Shutter

Gray:Shutter

Purple:Shtter

・

Make an arrangement of wires

and attach the tape (#713).

Wires arrangement

#713

Shutter unit

・

Attach the shutter unit (#B31) with the screws

(#607 and #627).

Black:F min SW

Brown:F min SW

Page 45

- A10 ・ -

VBA12001-R.3668.A

#728

Horizontal lever (#193)

Position for attaching #728

FPC of AF CCD unit

AF CCD FPC unit

#B2163

#170×3

#636×3

AF CCD FPC unit

#B2163

AF sensor FPC unit

・

Attach 3 screws (#636) with Hexagonal

wrench to screw up but not too tight, then

give it about 1 turn counterclockwise.

・

Attach 2 tapes (#709).

・

Attach #728 so that the FPC of

AF CCD FPC unit can be protected.

#709 × 2

Page 46

- A11 ・ -

VBA12001-R.3668.A

Adhesive: C-8008B

Direction for positioning

of SI glass (#1046)

#284

#297

#3

#283

#9

#1046

#B279×2

#280×2

#282

#B1021

#278

#B277

#642×2

#B4-2

#255

#739×2

Adhere

Penta unit

#709 × 2

#256

#642 × 2

#792A×2

Page 47

- A12 ・ -

VBA12001-R.3668.A

Angle adjustment of Main mirror and sub-mirror

*Tools required:

1.Main mirror 45°Inspection and Adjustment

2. Sub-mirror 47.75° Inspection and Adjustment

J18037

J18362

①

Collimator (J19002)

②

Reection mirror (J18362

)

③

Optical parallel (J18037

)

④

Hexagonal wrench

Main mirror

Eccentric pin for

the main mirror

Collimator

Bayonet

J18324

①

Collimator (J19002)

②

Sub-Mirror 45 deg. inspection tool

(J18324

)

③

Hexagonal wrench

Sub-mirror

Eccentric pin

for the submirror

Collimator

Bayonet

* Standard:

Main mirror Sub-mirror

Left-right

deviation

±30’ or less

__

Up-down

deviation

±10’

+15’~-50'

Distortion

8’or less

8’or less

Up-down

Left-right

Reference

line

Width of line indicates

deviation.

・

Before and after the adjustment, check the accuracy by moving the main mirror up- and downwards a few

times.

・

Check for the up-down deviation. In case the deviation is out of standard, make an adjustment by turning the

eccentric pin with Hexagonal wrench.

・

In case the deviations of up-down and left-right are out of standard, the front plate unit or mirror unit is

regarded as malfunctioning.

・

In case of checking or adjusting only the front body, check again after assembling the front body into the rear

body.

* Note:

Page 48

- A13 ・ -

VBA12001-R.3668.A

#291×3

#290×3

#635×2

#635×2

#B286

#B261

・

Attach 3 screws (#291) until the

metering FPC unit is lightly

xed.

Give the reference screw 1 turn

counterclockwise.

#B2008

#796

Reference screw

Eyepiece unit

Metering FPC unit

・

Position the eyepiece unit (#B261)

downward and x it with 2 screws

(#635).

・

Attach the tape (#796).

・

Fix the metering FPC-base unit

(#B286) with 2 screws (#635).

・

Attach the metering FPC unit (#B2008)

and 3 springs (#290) temporarily with

3 screws (#291)

.

Note: Be careful that slack here

catches the rear body when it

is assembled.

No slack

2 pieces of tape (#709)

2 pieces of tape (#709)

Page 49

- A14 ・ -

VBA12001-R.3668.A

2. Rear body

#680×2

#746

#777

#150

#146

#617×2

#145

#149

#617×2

#76×2

#714

#790

#761

#765

#790×2

#764×2

#747

Rear body small parts

Page 50

- A15 ・ -

VBA12001-R.3668.A

・

Install the SB unit (B2041).

・

Fix 2 screws (#635).

・

Attach 2 pieces of tape (#754).

・

Mount the condenser (#B1043) by positioning it in the direction of the arrow.

#635×2

SB unit

#754×2

(B1043)

(B2041)

Position downwards.

(B2041)

Page 51

- A16 ・ -

VBA12001-R.3668.A

・

Mount the bottom base unit (#66) and bottom conducting plate (#106).

・

Fix 4 screws (#635).

・

Fix 2 screws (#633).

・

Attach #80.

・

Fix the screw (#647).

・

Attach the short-circuit proof tape (#787) on #80.

・

Attach #81.

・

Fix the screw (#633).

・

Attach #2030.

#80 must NOT seat below #150.

Bottom base unit / Lug plate

#80

#150

#635×4

#106

#66

#633×2

#80

#647

#633

#81

#2030

#787

Page 52

- A17 ・ -

VBA12001-R.3668.A

・

Mount the DC/DC PCB unit (B2030).

・

Pass the wires through the holes.

・

Fix 2 screws (#693).

Pass the wires

through the holes.

Pass the wire of the electronic

buzzer (red) through the hole.

#693×2

(

B2030

)

・

Mount the SQ PCB (B91).

・

Arrange wires by pulling them in the direction of the arrow.

・

Fix the screw (#633).

・

Fix 2 screws (#627).

#627×2

#633

Direction for pulling wires

(

B91

)

DC/DC PCB unit

SQ unit

Page 53

- A18 ・ -

VBA12001-R.3668.A

・

Arrange wires.

・

Attach 2 pieces of tape (#715).

Arrange 4 wires of the DC/DC PCB properly

by put each into between bosses as shown

above.

Put 2 of 4 wires each into

between bosses.

To keep wires from covering the AF adjustment

holes, attach 2 pieces of tape (#715).

Bottom wires

・

Solder 4 wires of DC/DC PCB unit.

Black

Red

Yellow

Blue

SB-PCBwires

Be careful that some PCBs at the inital stage of mass-production have

different colored wire.

Black

Red

Blown

Blue

Black

Red

Blown

Red

White marking is

painted for

identication.

AF adjustment holes.

Page 54

- A19 ・ -

VBA12001-R.3668.A

・

Set the clock battery unit (B1059).

・

Pass the wires through the hole.

・

Attach the clock battery holder (#73).

・

Fix 2 screws (#642).

・

Solder 2 wires of the clock battery unit.

#

642×2

#73

#B1059

Pass the wires through the hole.

Clock battery unit

Red

Black

Page 55

- A20 ・ -

VBA12001-R.3668.A

・

Mount the electronic buzzer unit (#1055).

・

Set the battery-extrusion spring (#158).

・

Attach the retaining plate (#159).

・

Fix 3 screws (#673).

・

Mount the sub-PCB.(B2002)

・

Fix 3 screws (#644).

・

Solder 3 wires of the electronic buzzer .

・

Make the soldering bridges.

#673×3

Assemble so that the

soldering portion of

#1055 comes within the

range of the arrow.

Do NOT push central part.

Electronic buzzer unit / Battery-extrusion spring

Sub-PCB unit

#1055

#644×3

Red Black Black

#159

#158

#1055

Soldering bridges

#B2002

Page 56

- A21 ・ -

VBA12001-R.3668.A

①

Do NOT pinch wires and FPCs. Assemble by positioning them.

②

Fix 3 screws (#642) by the following order: ①, ②, and ③.

③

Fix 4 screws (#634) by the following order: ①, ②, ③, and ④.

④

Fix 3 screws (#699) by the following order: ①, ②, and ③.

①

②

③

#642 × 3

Front body

Rear body

#699 × 3

#634 × 4

Arrange FPCs of the inner LCD by putting

them into the clearance between rear body

and eyepiece.

①

①

②

②

③

③

④

3. Mount Front body on Rear body

Mount the front body on the rear body

Direction for

positioning to

attach the front

plate.

Page 57

- A22 ・ -

VBA12001-R.3668.A

・

Measure 4 parts from the bayonet face to the CCD-PCB

attaching face.

Standard:48.25±0.015mm/ Parallelism: within 0.015mm

・

In case it is out of standard, make an adjustment

by loosening screws that attach the front and rear bodies,

or

by putting the washer(s) on the contact surface be-

tween the front body and rear body.

Measuring points

* "0" positioning of the dial gauge

Inspection and Adjustment of Body back

0" position of D50

①

Put the tool (J18001-1) on the surface plate, and set the dial gauge to "0".

②

Turn the index ring to shift the position by "0.42 mm" from "0" that was set in ①.

(This position is "0" of D50.)

③

Measure the body back based on "0" reference position of the index ring.

Surface plate

Note: For some bodies, washer(s) are already put on the attaching face of the CCD-bracket.

There are 2 cases as follows.

1. Purpose:To adjust the height of the camera body

There are indications(color mark) on the camera body side of the CCD-PCB attaching face.

{Blue =0.02mm (#87), Red=0.1mm (#88), Green=0.06mm (#89)}

*

By adding the measured value to the thickness of washers, check if it is within the standard

(48.25±0.015mm).

2. Purpose:To adjust the height of the CCD bracket

There are indications(color mark) of the CCD-bracket attaching face

{

Red 2 lines=0.02mm (#87), Red 1 line=0.1mm (#88)}

*

When the CCD PCB is replaced, remove the washers.

Page 58

- A23 ・ -

VBA12001-R.3668.A

#1023

#1002

#640×3

#1001

#786

#783

①

②

Main PCB unit

・

Solder 1 wire

・

Connect each

FPC to the connectors

in the order of

①

and then

②

.

・

Pass the D/G main FPC (#1023) through the hole

of the rear body.

・

Connect the connectors of the backside of the

main FPC (#1001) and the sub-PCB (#1002).

・

Fix 3 screws (#640).

・

Attach the twe tapes (#783 and #786)

SUB PCB unit

Brown:DC/DC PCB

connectors

Brown:DC/DC PCB

Page 59

- A24 ・ -

VBA12001-R.3668.A

・

Solder 9 wires.

Blue: Remote

Red: Remote

Black: Remote

Orange: Sequence motor

Blue: Sequence motor

Black: DC/DC PCB

Red: DC/DC PCB

Pink: Front body FPC

White: Front body FPC

・

Connect each

FPC to the connectors

in the order of

①

and

②

the

③

.

①

②

③

Page 60

- A25 ・ -

VBA12001-R.3668.A

#669×3

#B2032

CCD/FPC unit

DG PCB unit

*

Note

1. In case a washer is put between the rear body and the

CCD bracket, follow the instructions of Page A22.

2. In case a spacer is attached on "a" part of the body,

do NOT remove and leave it as it is. (There is No

indication of marking.)

・

Attach the CCD/FPC unit (#B2032) with 3 screws (#669).

・

Attach the DG-PCB (#B2031) with 2 screws (#663) and

the screw (#627).

・

Solder 2 wires of the reset SW.

・

Connect 5 connectors.

#663×2

#627

#B2031

: Reset SW wires

Yellow

Green

Directin for positioning

CCD bracket

Page 61

- A26 ・ -

VBA12001-R.3668.A

・

Attach the DG shield plate (#78) with 3 screws (#627).

・

Make 2 soldering bridges.

・

Attach the tape (#799)

#78

Soldering bridge

#627×3

Tape (#799)

Remove backlash of the rear cover.

DG shield plate

Page 62

- A27 ・ -

VBA12001-R.3668.A

・

Procedure

①

To prevent short circuit, attach the grip (#26) with the screw (#635), and

also I/F cover (#B5028) with the screws (#635). Insert

AECCD alignment tool (J15417)

between the FD screen and the SI plate.

*

Position AE-CCD positioning tool in the direction of the arrow to

insert.

②

Connect camera and PC via USB cable UC-E4.

③

Provide power to camera via AC adapter EH-5.

*Note: Be careful of short circuit where there is no cover.

④

Start up the inspection and adjustment software for D50 (J18385),

and select "INSPECTION AND ADJUSTMENT FOR AECCD

POSITION" then "CCD ALIGNMENT INSPECTION AND

ADJUSTMENT".

*

Cover the camera with black cloth, when measured.

⑤

By following instructions on PC, make the position adjustment of

AECCD by the screws (#291 a,b).

⑥

Select “CCD SLANT INSPECTION” of the adjustment software and

make an inspection.

⑦

After the adjustment, x the AECCD by applying Crazy glue slightly..

⑧

Remove EH-5, UC-E4, and AECCD positioning tool(J15417).

⑨

Take out the grip (#26), and I/F cover unit (#B5028).

Adhesive: Super glue

Reference screw

b:#291

AE-CCD positioning

tool (J15417)

・

Atach the metering FPC unit

slightly with 3 screws (#291).

Give the reference screw 1

turn counterclockwise, then

make an adjustment by the

screws (a and b).

Note:

With the metering FPC unit being

attached slightly, if more than 3

turns are given to loose, the head

of the screws touch the top cover.

Inspection and adjustment of AE CCD Alignment

Meterring FPC unit

a:#291

Page 63

- A28 ・ -

VBA12001-R.3668.A

#454

#452

#453

#338

#5451

B317

#316

#318

#336×2

#322

#321

#337×2

#654×4

#463

#326

#640

Outer LCD window / shoe mold unit / accessory shoe / other small parts

A part

Attach #336 and #337 so that they

they are NOT separated by a gap at

"A" part.

Adhesive: Super X

Grease: LEN317A

Grease: LEN317A

Grease: OS-30MF

Top cover grease-applied location

Power dial greaseapplied location

Grease: LEN317A

Mode dial grease-applied location

Page 64

- A29 ・ -

VBA12001-R.3668.A

Release button / other small parts

#5460

#461

#350

#351

#5345

#352

#387

#5386

#5381

#382

#347

#348

#604 × 2

#335

#5383

Page 65

- A30 ・ -

VBA12001-R.3668.A

Top cover FPC

・

Attach the top cover FPC (#B2007).

・

Assemble AE-L button (#386) and AE-L rubber SW (#387).

・

Fix the screw (#644).

・

Fix 5 screws (#635).

#387

#331

#1044

B367

#733

#1007

#735

#734

#332 × 2

#330

#644

#635 × 5

#386

#387

#B2007

Page 66

- A31 ・ -

VBA12001-R.3668.A

Positioning pin

#

635

#B367

AF-assist illuminating lamp / command dial

・

Position the command dial (#B367).

・

Fix 2 screws (#635).

・

Attach the AF assist illuminating lamp (#B325).

・

Fix the screw (#635).

・

Attach the light-leak proof sponge (#766).

#B325

M/DFPC unit

・

Attach the shooting operation-mode button (#388) and

the rubber SW (#389).

・

Mount M/DFPC unit (#B2455).

・

Fix 2 screws (#640).

Position in the direction of

the arrow.

#

766

#

635

#

388

#

389

#640×2

#B2455

Page 67

- A32 ・ -

VBA12001-R.3668.A

SB lower case unit

・

Mount the SB lower case unit (#B2302) on

the top cover.

・

Insert the collar (#308) in the direction

shown in Fig.1 into the top cover, and set it

in place by hooking 2 parts.

・

Put the turning-shaft (#306) in the top cover.

・

Pass each wire through the hole of the collar

(#308).

Grease: MZ-800S

Grease: MZ-800S

Grease:MZ-800S

Inserting d i r e c t i o n o f t h e c ol l ar

(#308)

Fig.1

・

Attach #B341 and #B342.

B341

B342

・

Arrange the wires that were passed through the hold of

the collar as shown below.

・

Fix them with the tape (#709).

#709

#306

#308

#306

#B2302

2 hooks

Page 68

- A33 ・ -

VBA12001-R.3668.A

・ Attach the ash-up spring (#305) and x it with the

screw (#650).

・ Hook the ash-up spring (#305) in the direction of

the arrow.

・

Arrange the wires as shown below.

・

Fix the wire-retaining screw (#650).

#

305

#

650

From the top

Orange

Gray

White

Black

Orange

Gray

White

From the top

Orange

Gray

White

Black

Arrange the wires by putting them into the groove.

#

650

Flash-up spring

Black

Wiring / Top cover FPC

Page 69

- A34 ・ -

VBA12001-R.3668.A

・

Assemble the FPC as shown below.

・

Solder 5 accessory shoe contacts.

・

Solder 2 pop-up change switches.

・

Solder 2 SPD sensor wires.

・

Solder AF-assist illuminating lamp.

・

Make soldering bridges.

AF-assist illuminating

lamp

AF-assist illuminating lamp

(

covered for insulation

)

Soldering bridges

Pop-up change switch (Black)

Pop-up change switch (Green)

A c c e s so r y s h o e

contact ×5

SPD sensor wire (Green)

SPD sensor wire (Black)

Page 70

- A35 ・ -

VBA12001-R.3668.A

・

Attach the optical ber (#470).

SB upper case

・

Mount the SB upper case on the SB lower case. (Fig.1)

・

Press the pop-up lever A part of the top cover unit, and pop up the built-in SB.

・

Conrm that the hooking levers of the SB upper case are surely hooked in the 2 holes. (Fig.2)

・

Fix 2 screws (#629).

Hooking lever

Fig.1

#629×2

Pop-up lever A part

SB lower case unit

SB upper case

Fig.2

#738×2

#738×2

Optical ber

#470

Note) Both ends of the optical ber are just

inserted in each part without any adhesive.

Page 71

- A36 ・ -

VBA12001-R.3668.A

Mount Top cover

・

Solder 2 wires on the top cover FPC unit (#1007).

*

The solder land of gray wire is same as AF assist lanp unit.

・

Connect the top cover FPC to the connector of the main PCB unit (#1001).

*

Insert FPC all the way seated without any slant.

Top cover

Black:DC/DC P

CB

Main PCB unit (#1001)

Top cover FPC

Gray:DC/DC PCB

Page 72

- A37 ・ -

VBA12001-R.3668.A

・

Assemble the eyepiece frame (#B271) by putting the diopter adjusting lever at the lowermost position.

・

Fix 2 screws (#635), 2 screws (#656), and 2 screws (#5618).

*

After pushing outside the AE/AF lock button from the inside of the top cover, assemble the top cover.

#

656

#5618×2

#B271

#635 × 2

#B0023

#656

Diopter adjusting lever

・

Solder 4 wires on the SB PCB unit (#1041).

Gray: Top cover SB

Orange:

Top cover SB

White: Top cover SB

Black: Top cover SB

SB PCB unit (#1041)

Page 73

- A38 ・ -

VBA12001-R.3668.A

・

Assemble the front cover (#5024) at the last stage.

・

Pop up the SB lighting unit by pressing the lock

lver in the direction of the arrow, then x 2

screws (#611).

Adjusting dial

A

U

T

O

#B5028

#659

#5124

#5121

#611×2

#635

#635

#635

#26

#5024

#611×2

Covers

Gap adjustment of SB lighting unit

Standard:0~0.5mm

・

In case it is out of standard, pop the SB unit up and

make an adjustment by turning the adjusting dial with

Hexagonal wrench.

Page 74

- A39 ・ -

VBA12001-R.3668.A

�

�

�

�

�

�

�

�

�

#402

#403

#407

#5424

#5425

#5426

#5427

#5428

#422

#670x3

#405x2

#410

#421

#5401

#404x2

#409

#1037

#1099

#1100

#406

#666x3

#670x3

#415

#414

#413

#681x2

#448

#423

#5429

#408

#1036

#5412

Adhesive:Crazy glue

B5431

#1100

#1099

Yellow

Black

Yellow

Black

Rear cover

Direction

for positoninng

Direction

for positoninng

Direction

for positoninng

Page 75

- A40 ・ -

VBA12001-R.3668.A

Rear cover

・

Connect TFT-PCB connection FPC to the connector of the DG-PCB.

TFT-PCB connection FPC

・

Fix the rear cover with 4 screws (#623).

#623 × 4

Rear cover

Page 76

- A41 ・ -

VBA12001-R.3668.A

・ To connect to PC, as shown below, connect USB cable UC-E4 to the USB terminals of PC and camera.

To USB terminal

J18385

D50 inspection and adjustment

software

AECCD

alignment tool

(J15417)

AF50/1.4D

Flash meter

Not prepared as RJ

Battery tool

J15418

*

Note

:

When checking “battery check”,

be sure to use the battery tool

(J15418).

USB cable UC-E4

Accuracy inspection and adjustment (Camera body)

Stabilized power supply

Set value = 7.8V 0.3Ω 5.0A

or AC adapter EH-5

Shutter tester (EF-8000, etc)

Page 77

- A42 ・ -

VBA12001-R.3668.A

【In case of using USB interface】

PC IBM PC/AT compatible

OS

Windows XP Professional Edition, Windows XP Home Edition,

Windows 2000, Windows 98 Second Edition (SE)

CPU

Pentium Ⅱ 266MHz ~ Pentium 4 2.2GHz

RAM (memory) 64MB or more

HD 6MB-or-more free disk space is required when installing

Monitor resolution 800×600 pixels or more

Interface USB Interface : USB1.1

As long as the above hardware requirements are met, any PC such as desktop or laptop, etc is available.

D50 Inspection and Adjustment Software (J18385)

This inspection and adjustment software runs on Windows.

Install the software by following the below procedure.

<Operating environment>

The following operating environment is required for installing this program on PC.

Page 78

- A43 ・ -

VBA12001-R.3668.A

<Procedure for installation>

The le (D50SOFT.EXE) of this program is provided via FD or e-mail.

Because this is the self-extracting le, decompress the le before installing, following the next procedure.

The operating system used here is "Windows 98 SE".

1. Create a folder for installation under a name you like and PC drive.

(e.g.) C:\D50

Paste the le (D50SOFT.EXE) in the created folder.

2. Double-click on the pasted le to display the following screen.

3. Open the folder D50SOFT , the following 5 les and PTPControl folder are appeared.

Page 79

- A44 ・ -

VBA12001-R.3668.A

< How to install USB driver >

If this program is used by the USB interface, installing the USB driver is necessary.

But if the OS is "Windows XP", the driver is already preloaded so it is not necessary to install it.

1. Set the USB of camera to "PTP".

(SETUP menu → USB setting → PTP)

2. Connect the camera and PC by USB cable.

Turn camera ON.

4. Select "Search for a better drive than the one your device is using now. (Recommended)", and click "Next".

5. Check the box of "Specify a location" and select "¥D50¥D50SOFT¥PTPControl " of C drive. Then click “Next”.

3. When "Add New Hardware Wizard" is displayed, click "Next".

Page 80

- A45 ・ -

VBA12001-R.3668.A

6. Conrm that the driver is located at the right place, and click "Next".

7. Click "Finish" to complete the installation.

Page 81

- A46 ・ -

VBA12001-R.3668.A

< File >

D50.exe Application executable le

Nk_PTP.INF INF le: PTP control driver installation le

NKCamUSD.dll Library le: PTP control driver registration le

NkdPTP.dll Library le: USB communication application extension le

for Windows XP

NkdPTPDi.dll Library le: USB communication application extension le

for Windows 98 SE, Windows 2000

PTPControl PTP driver le storing folder: for Windows 98 SE, Windows 2000

< Point to notice for starting up program >

Before starting up this program, close all the other applications softwares.

If other application softwares are running, this program may not work.

Page 82

- A47 ・ -

VBA12001-R.3668.A

<Start-up of Program>

1. Double-click the le (D50.EXE), then Inspection and adjustment program for D50 starts.

2. To display in Japanese, select the radio button "JAPANESE" in "LANGUAGE" in the lower right-hand

corner of the screen.

3. When the "HISTORY" button at the lower-left is pressed, the program version will be displayed.

4. Select each item button according to operation.

Follow the instructions on the next screen that will be shown after pressing the item button.

5. To nish the program, press the "Close (×)" button in the right-hand corner of the screen or "QUIT.".

Page 83

- A48 ・ -

VBA12001-R.3668.A

Outer LCD indication

Set voltage of Stabilized power supply

①

7.80V

⑦

7.715±0.1V

②

7.415±0.1V

⑥

7.620±0.1V

③

7.320±0.1V

⑤

7.470±0.1V

④

7.170±0.1V

Blink

①

AE CCD alignment inspection and adjustment (ref. Page A27 for details

)

②

AE accuracy inspection and adjustment

③

Aperture accuracy inspection

④

Adjustment for battery check level (Use the battery tool (J15418) and stabilized power supply.

)

⑤

Built-in SB ash inspection and adjustment

〔Tools required〕ref. Page A41.

AE inspection and adjustment

・

Inspection on Battery check indications

After the battery check adjustment, input each voltage of the below into camera, and check the indications of the

outer LCD.

Note: Make an inspection by switching the voltage in the order of ①-⑦.

・

Built-in SB ash inspection and adjustment

Set the distance between camera and ash meter to 1 m, and inspect and adjust the light volume of the built-

in SB. (ref. adjustment software for details)

①

AF accuracy inspection and adjustment (Make all the

following adjustments.)

②

YAW, PITCH inspection and adjustment

③

LARK adjustment (inc.

CCD output adjustment)

〔Tools required〕

1. When adjusting for all adjustment items

ref. Page A41.

2. When inspecting AF accuracy

① AF

adjustment lens (J18266)

②

AF adjusting tool (J15259

)

③

Lens holder for F4 (J15280)

④

AF chart

(J18344)

⑤

Chart illuminator for AF

(J15264)

3. When adjusting YAW, PITCH

YAW, PITCH tool(J18230

)

4. When adjusting LARK

The above tool when inspecting AF accuracy

Note:

When using the adjustment software for the rst time, prepare 5 cameras of D70s (or D70) and input the

average value of the 5 cameras, which was measured when checking the AF accuracy, in "WRITING OF AF

ADJ. LENS OFFSET VALUE" on the main menu.

AF inspection and adjustment

Page 84

- A49 ・ -

VBA12001-R.3668.A

#5692

#5697

#5677×7

Bottom cover

・

Attach the bottom cover with the screw (#5692), the screw (#5697), and 7 screws (#5677).

Bottom cover

・

Replace the nder screen with the innity focus check screen (J15410), and use the reference lens (J18010)

and read the value. In case it is out of standard, increase or decrease washers (#297A or#297B) for

adjustments. * Supply the power (Battery or EH-5) for checking.

∞ Innity alignment & adjustment

Reference

line

"0" position

J18010

Standard:

±0.07mm

(

1 scale

=

0.01mm

)

Value of J18010 Adjustment

+0.07~-0.07 Adjustment unnecessary if within standard

+0.08~+0.15 Decrease washers (#297) (for thinning)

-0.08~-0.15 Increase washers (#297) (for thickening)

+0.15 or more; -0.15 or less Check if Front body or Penta box is not

deformed.

Page 85

- A50 ・ -

VBA12001-R.3668.A

1. D50 adjustment software and updates

Adjustments

Parts to be

replaced

EEPROM

xed

values

AE CCD

positioning

adjustment

AE

accuracy

inspection

& adjust-

ment

Aperture

accuracy

inspection

battery

check level

adjustment

built-in SB

light volume

inspection

& adjust-

ment

AF

accuracy

inspection

& adjust-

ment

VrUP

Shutter unit

Main FPC

○ △ ○ ○ ○ ○ ○ ○

Sub PCB unit

AF sensor unit

○

Top cover or

SB lower case unit

○

DC/DC PCB unit

○ ○

Metering FPC unit

○ ○

Aperture control

PCB unit

○

*

1 Before the adjustment, update the rmware.

*

2 Make an inspection.

* 1

* 2

Necessary adjustments when parts are replaced

Page 86

- A51 ・ -

VBA12001-R.3668.A

2. Shooting image adjustment software and updates

Adjustments

Parts to be

replaced

Sensitivity

Gr/Gb

com-

pensation

ADJ

(R/B lter)

Sensitivity ratio

Gr/Gb com-

pensation

inspection

(No lter)

CCD black

point defect

compensation

CCD white

point defect

compensation

TFT

angle of

view

VrUP

Shutter unit

Main PCB unit

○

AF sensor unit

DC/DC PCB unit

Metering FPC unit

DG PCB unit

○ ○ ○ △ ○ ○ ○

CCD/FPC PCB unit

○ ○ ○ △ ○ ○

TFT monitor

○

*

1 Before the adjustment, update the rmware.

*

2 Make an inspection.

* 1

* 2

* 2

Page 87

- A52 ・ -

VBA12001-R.3668.A

Shooting Image Adjustment

1. Summary

When D50 shooting image-related and listed parts on Page A51 are replaced, be sure to make an adjustment

by the shooting image adjustment software for D70s (J65076). The details of its function and how to use this

software are as follows:

2. Adjustment software function

(1) "Sensitivity" adjustment

(2) Gr/Gb compensation adjustment (R/B lter)

(3) "Sensitivity ratio" adjustment

(4) Gr/Gb compensation inspection (No lter)

(5) CCD black point defect compensation

(6) CCD white point defect compensation

(7) "Sensitivity" and "Sensitivity ratio" reference values calculation

(8) "TFT angle of view" adjustment

(9) Reading of RISC version

※ When the adjustments from (1) to (3) are made, calculate the sensitivity and sensitivity ratio reference

values of (7) by using the reference body in advance, then perform the adjustments.

3. Hardware requirements

OS: Widows98SE,Windows2000,WindowsXP

Japanese or English OS

PC: CPU Pentium Ⅱ or more

Memory 128MB or more

USB1.1

Screen size: 1024×768 pixels or more

4. How to set up

Create any directory in the harddisc of PC, and copy the following les.

・D50IMG.exe・・・・・・・・ Application le

・STD.DAT・・・・・・・・・ Standard le

・NkdPTP.dll・・・・・・・・・USB-communication application extension le for WinXP

・NkdPTPDi.dll・・・・・・・・USB-communication application extension le for Win98SE,Win2000

※ Be sure to copy the above les in the same directory.

5. Install USB driver

When this software is used, USB driver becomes necessary. However, USB-driver installation is not needed

if USB driver has already been installed at the time of installing "D50 inspection and adjustment program".

As for WindowsXP, the installation is neither needed, because it is already included in OS.

Page 88

- A53 ・ -

VBA12001-R.3668.A

Fig.2

Fig.1

6. How to use

(1) Perform the D50IMG.exe to start up the main screen. (ref. Fig.1)

(2) Select ENGLISH / JAPANESE in Language to display the expected menu.(ref. Fig.2)

(3) Click the desired button to start adjustments.

※ When the adjustments from 1. to 3. are made, calculate to get the “Sensitivity” and “Sensitivity ratio”

reference values of (7) by using the reference body beforehand, then perform the adjustments.

(4) Follow the instructions to be displayed on screen.

(5) To complete the procedure, click "QUIT" button or "Close" button at the upper-right corner of the menu.

Page 89

- A54 ・ -

VBA12001-R.3668.A

7. Required equipment and conditions

※ AC adapter EH-5 and USB cable (mini B type) UC-E4 are used for all adjustments so they are not

specied in the list.

Item Required device Setting/Remarks

1

Sensitivity adjustment

・5100K color viewer J63070

(ex-model viewer J63049 is also

available.)

・Luminance meter BM-3000

J63068

・Tool lens(to x aperture) J61185

・ND lter

(ND8×1+ND4×2)

Equivalent to luminance LV13

Aperture F8

52 mm,5-step light reduction; Use

the packaged product

2

Gr/Gb compensation

adjustment (R/B lter)

・5100K color viewer J63070

(ex-model viewer J63049 is also

available.)

・Luminance meter BM-3000

J63068

・Tool lens(Fixed aperture) J61185

・SP3 (R lter) J63087

・SP1 (B lter) J63085

Equivalent to luminance LV13

Aperture F5.6

3

Sensitivity ratio adjustment

・5100K color viewer J63070

(ex-model viewer J63049 is also

available.)

・Luminance meter BM-3000

J63068

・Tool lens(to x aperture) J61185

Equivalent to luminance LV13

Aperture F8; No lter

4

Gr/Gb compensation

inspection (No lter)

・5100K color viewer J63070

(ex-model viewer J63049 is also

available.)

・Luminance meter BM-3000

J63068

・Tool lens(to x aperture) J61185

Equivalent to luminance LV13

Aperture F5.6; No lter

5

CCD black point defect

compensation

・5100K color viewer J63070

(ex-model viewer J63049 is also

available.)

・Luminance meter BM-3000

J63068

・Tool lens(to x aperture) J61185

Equivalent to luminance LV13

Aperture F5.6

6

CCD white point defect

compensation

Body cap or lens cap Environmental temperature

approx. 20 - 25℃

7

Sensitivity, sensitivity ratio

reference value calculation

Same as "Sensitivity adjustment" No lter when sensitivity ratio

reference value is calculated.

8

TFT angle of view adjustment None Only for NTSC (unnecessary for

PAL)

9

Reading of RISC version None

★ New established tool

Page 90

- A55 ・ -

VBA12001-R.3668.A

8. Summary

The summary on each adjustment is as follows:

(1) Sensitivity adjustment

Face the camera to the color viewer of LV13 equiv. putting the ND lter (-5 step) between them, and make

an adjustment by changing the ampgain so that G output can fall in the standard range. Adjust the gain

value so that the G output average value (Average of Gr/Gb) in the center (300×300 pixels) can reach the

target output level (approx. 600LSB). The actual adjustment of the gain value is made only under the

condition of ISO200 and ISO1600, and the medium sensitivity is calculated by the adjustment values of

these 2 conditions.

For target output level, use the G output average of sensitivity reference value (ISO200) that was calculated

by the reference body.

(2) Gr/Gb compensation adjustment (R/B lter)

Face the camera to the light-emitting box (color viewer) of LV13 equiv. putting the SP3 (R lter)/SP1 (B

lter) between them, and make an adjustment so that the output difference in G output average between

G-B line and G-R line when the whole screen is divided into areas can fall in the standard range.

(3) Sensitivity ratio adjustment

Face the camera to the color viewer of LV13 equiv., and make an adjustment so that the R/G, B/G output

becomes the same as the output ratio of the sensitivity ratio reference value that was calculated by the

reference body. Adjust only under the condition of ISO200, and use the average value of the center (300

pixels × 300 pixels).

(4) Gr/Gb compensation inspection (No lter)

None

(5) CCD black point defect compensation

When pixels of which the output level is under specied value with LV13 equiv., are detected, rewrite the

coordinates of the detected pixels as pixel defect compensation data.

(6) CCD white point defect compensation

Take a shot on the dark surface. In case the pixel output is found to be beyond the standard value, store the

detected pixel coordinate as the pixel defect compensation data.

(7) "Sensitivity" and "Sensitivity ratio" reference values calculation

・Sensitivity reference value calculation

By using the reference body, face the camera to the color viewer of LV13 equiv. putting the ND lter (-5

step) between them. Then, store the G output average value of the center (300 pixels × 300 pixels) in

the STD.DAT le as the sensitivity reference value.

・Sensitivity ratio reference value calculation

By using the reference body, face the camera to the color viewer of LV 13 equiv. (without lter). Then,

calculate the sensitivity ratio reference value GR and GB based on the G/R/B output average of the

center (300 pixels × 300 pixels), and store them in the STD.DAT le.

It is necessary to calculate the reference values of "Sensitivity" and "Sensitivity ratio" in order to prevent

the color temperature uctuation caused by color viewer's changes over time from affecting the results of

the shooting image adjustment. By using the reference body, calculate the reference values once in about

every 3 months, when the uorescent of the color viewer is replaced.

Page 91

- A56 ・ -

VBA12001-R.3668.A

(8) TFT view angle adjustment

This is for adjusting the display position of TFT. Make an adjustment only for NTSC. (Unnecessary for

PAL)

(9) Reading of RISC version

Display the RISC rmware version.

Page 92

- A57 ・ -

VBA12001-R.3668.A

9. Procedure

9-1. Shooting image adjustment

● Calculate the "Sensitivity" and "Sensitivity ratio" reference values by using D50 reference body

beforehand, then perform the adjustments. (ref. 9-5.)

● For the shooting image adjustment from (1) to (3), perform all of them in this order. The adjustments from

(1) through (3) are all programmed to be executed in serial order. When (1) is completed, the software

automatically goes on to the next adjustment.

● In case adjustments are interrupted by NG, it is possible to continue the adjustments again after NG. As for

adjustments that were ended with OK, the storage of adjustment values into EEPROM and the ashram-up

are completed.

Start adjustments

・Provide the power for the camera via AC adapter.

・Reset "Custom setting".

・Set "PTP" mode by Setup menu.

・Set the focus mode to M, exposure mode to M, and the exposure compensation to "0" of the camera.

・Connect the camera and PC via USB cable.

・Set the color viewer luminance to LV13 equiv.

(1) Sensitivity adjustment

・Click "SENSITIVITY ADJUSTMENT" of the main menu on screen.

・Attach the tool lens (Aperture F8) and ND lter (ND 8× 1+ ND 4 ×1)to the camera.

・Get the camera closest to the center of the illuminated surface of the color viewer.

・The adjustment starts. When it is completed, "OK" is displayed.

・The software automatically goes on to the next adjustment item.

(2) CCD Gr/Gb compensation adjustment (R/B lter)

・Click "Gr/Gb COMPENSATION ADJ (G FILTER)" on the menu.

・Attach the tool lens (Aperture F5.6) and SP3 (R lter) to the camera.

・Get the camera closest to the center of the illuminated surface of the color viewer.

・The adjustment starts. When it is completed, the next instructions are displayed.

・Attach the tool lens (Aperture F5.6) and SP1 (B lter) to the camera.

・Get the camera closest to the center of the illuminated surface of the color viewer.

・The adjustment starts. When it is completed, "OK" is displayed.

・The software automatically goes on to the next adjustment.

(3) Sensitivity ratio adjustment

・Click "SENSITIVITY ADJUSTMENT" of the main menu on screen.

・Attach the tool lens (Aperture F8) to the camera (without lter).

・Get the camera closest to the center of the illuminated surface of the color viewer.

・The adjustment starts. When it is completed, "OK" is displayed.

*

Note: Adjustments are not possible without resetting "Custom setting" of this camera.

Before the adjustments, record the details of "Custom setting" set by customers if necessary.

Page 93

- A58 ・ -

VBA12001-R.3668.A

9-2. Gr/Gb compensation inspection (No lter)

・Click "SENSITIVITY ADJUSTMENT" of the main menu on screen.

・Attach the tool lens (Aperture F5.6) to the camera (without lter).

・Get the camera closest to the center of the illuminated surface of the color viewer.

・When the inspection is completed, the data is indicated twice and "Gr/Gb COMPENSATION INSP IS

GOOD." is displayed.

9-3. Pixel defect (black spots) compensation

・Set the color viewer luminance to LV13 equiv.

・Provide the power for the camera via AC adapter.

・Reset "Custom setting".

・Set "PTP" mode by Setup menu.

・Set the focus mode to M, exposure mode to M, and the exposure compensation to "0" of the camera.

・Connect the camera and PC via USB cable.

・Click "CCD BLACK POINT DEFECT COMPENSATION" of the menu on screen.

・Attach the tool lens (Aperture F5.6) to the camera (without lter).

・Get the camera closest to the center of the illuminated surface of the color viewer.

・When the adjustment starts, pixel defects are detected, displaying the number of pixels and addresses.

・After conrming the above, click "X" button.

・When it is completed, "OK" is displayed.

9-4. Pixel defect (white spots) compensation

・Check the environmental temperature (approx. 20-25°C.).

・Provide the power for the camera via AC adapter.

・Reset "Custom setting".

・Set "PTP" mode by Setup menu.

・Set the focus mode to M, exposure mode to M, and the exposure compensation to "0" of the camera.

・Connect the camera and PC via USB cable.

・Click "CCD WHITE POINT DEFECT COMPENSATION" of the menu on screen.

・Cap the camera with the body cap or lens cap to shield light from the mount.

・When the adjustment starts, pixel defects are detected, displaying the number of pixels and addresses.

・After conrming the above, click "X" button.

・When it is completed, "OK" is displayed.

*

Note: In some cases, NG occurs due to dusts on the CCD.

Be sure to clean the CCD surface before adjustments.

Page 94

- A59 ・ -

VBA12001-R.3668.A

9-5. Sensitivity ratio reference value calculation

・Set the color viewer luminance to LV13 equiv.

・Provide the power for the camera via AC adapter.

・Reset "Custom setting".

・Set "PTP" mode by Setup menu.

・Set the focus mode to M, exposure mode to M, and the exposure compensation to "0" of the camera.

・Connect the camera and PC via USB cable.

・Select "SENSITIVITY, RATIO REFERENCE VALUE CALC" of the menu on screen.

・The current reference value is displayed on screen.

・Click "SENSITIVITY, RATIO REFERENCE VALUE CALC".

・The calculation of the sensitivity reference value starts. The message to set conditions is displayed.

・Attach the tool lens (Aperture F8) and ND lter (ND 8× 1 + ND 4 ×1)to the camera.

・Get the camera closest to the center of the illuminated surface of the color viewer.

・The adjustment starts. When it is completed, the software goes on to the sensitivity ratio reference value.

・Attach the tool lens (Aperture F8)(Remove ND lter).

・The adjustment starts. When it is completed, the sensitivity and sensitivity reference values are stored in

the standard setting le (STD, DAT).

・After this procedure, when the shooting image adjustment is made, the sensitivity and sensitivity ratio that

were calculated this time are used.

※ Calculate the sensitivity and sensitivity ratio reference values once in about every 3 months, and when the

uorescent of the color viewer is replaced.

9-6. "TFT angle of view" adjustment (only for NTSC; unnecessary for PAL)

・Provide the power for the camera via AC adapter.

・Set "PTP" mode by Setup menu.

・Connect the camera and PC via USB cable.

・Click "TFT VIEW ANGLE ADJUSTMENT" of the menu on screen.

・When the adjustment starts, a frame appears in the LCD area of camera.

・By clicking the "Left", or "Right", or "Up" or "Down" buttons on the window, move the frame from right

to left or up and down to prevent the frame from running off the edge of the TFT monitor of the camera.

9-7. Reading of RISC version

・Provide the power for the camera via AC adapter.

・Set "PTP" mode by Setup menu.

・Connect the camera and PC via USB cable.

・Click "READING OF RISC VERSION" of the menu on screen.

・RISC version is displayed.

9-8. Procedure for upgrading RISC rmware:

・ After preparing the CF card, copy the latest version ( XXXX. BIN) into the root directory.

・ Insert the CF card, and select "FIRMWARE VERSION" from the SETUP menu.

・ Follow the instructions on screen for version upgrading. It takes approx. 3-4 minutes.

・ Check the version of rmware by "RISC VERSION" of the image adjustment software.

Note: