Page 1

VBA15001-R.3701.A

M

サービス

計画課

INC

作成承認印 配布許可印

VBA15001

VBA15101

REPAIR MANUAL

Black

Silver

Copyright© 2006 by NIKON CORPORATION.

All Rights Reserved.

無断転載を禁ず!!

Printed in Japan Nov 2006

Page 2

VBA15001-R.3701.A

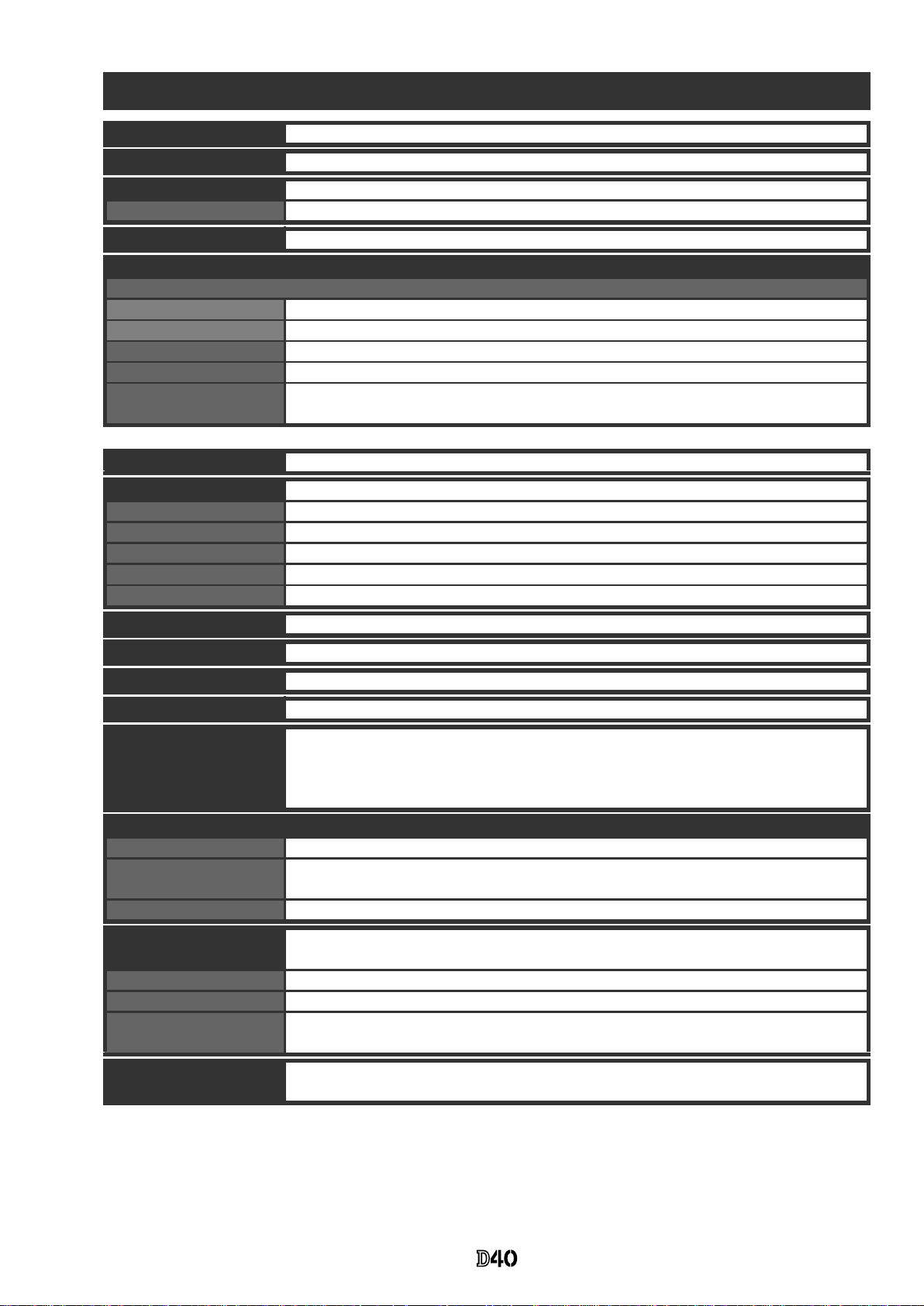

Specications

Type Single-lens reex digital camera with interchangeable lenses

Eective pixels 6.1 million

CCD 23.7×15.6mm; total pixels: 6.24 million

Image size (pixels) • 3,008 × 2,000 (Large) • 2,256 × 1,496 (Medium) • 1,504 × 1,000 (Small)

Lens mount Nikon F mount with AF coupling and AF contacts

Compatible lenses

*

Type G or D AF Nikkor

AF-S, AF-I All functions supported

Other Type G or D Nikkor All functions supported except autofocus

Micro Nikkor 85mm f/2.8D Can only be used in mode M; all other functions supported except autofocus

Other AF Nikkor†/AI-P Nikkor All functions supported except autofocus and 3D color matrix metering II

Non-CPU Can be used in mode M, but exposure meter does not function; electronic range nder

can be used if maximum aperture is f/5.6 or faster.

*IX Nikkor lenses can not be used †Excluding lenses for F3AF

Picture angle Equivalent in 35-mm format is approximately 1.5 times lens focal length.

Viewnder Fixed eye-level penta-Dach mirror type

Diopter –1.7–+0.5m

-1

Eyepoint 18mm (–1.0 m-1)

Focusing screen Type B BriteView clear matte screen Mark V with superimposed focus brackets

Frame coverage Approximately 95% of lens (vertical and horizontal)

Magnication Approximately 0.8× (50-mm lens at innity; –1.0 m-1)

Reex mirror Quick return

Lens aperture Electronically controlled with instant return

Self-timer Electronically controlled timer with 2, 5, 10 or 20s duration

Focus-area selection Focus area can be selected from 3 focus areas

Lens servo • Autofocus (AF): Instant single-servo AF (AF-S); continuous-servo AF (AF-C); auto AF-

S/AF-C selection (AF-A); predictive focus tracking activated automatically according

to subject status

• Manual focus (M)

Storage

Media SD (Secure Digital) memory cards; camera supports SDHC

File system Compliant with Design Rule for Camera File System (DCF) 2.0 and Digital Print Order

Format (DPOF)

Compression • NEF (RAW): compressed 12-bit • JPEG: JPEG baseline-complaint

Autofocus TTL phase detection by Nikon Multi-CAM 530 autofocus sensor module with AF-assist

illuminator (range approximately 0.5–3.0m/1ft. 8 in.–9 ft. 10in.)

Detection range –1.0–+19EV (ISO 100 at 20°C/68 °F)

AF-area mode Single-area AF, dynamic-area AF, dynamic-area AF with closest subject priority

Focus lock Focus can be locked by pressing the shutter-release button halfway (single-servo AF)

or by pressing the AE-L/AF-L button

ISO sensitivity (Recommended Exposure Index)

200–1600 in steps of 1EV with additional setting one step over 1600

INC

- M ・ -

Page 3

VBA15001-R.3701.A

Exposure

Metering Three-mode through-the-lens (TTL) exposure metering

Matrix 3D color matrix metering II (type G and D lenses); color matrix metering II (other CPU

lenses); metering performed by 420-segment RGB sensor

Center-weighted Weight of 75% given to 8-mm circle in center of frame

Spot Meters 3.5-mm circle (about 2.5% of frame) centered on active focus area

Range (ISO 100 equivalent,

f/1.4 lens, 20°C/68°F)

0–20EV (3D color matrix or center-weighted metering)

2–20EV (spot metering)

Exposure meter coupling CPU coupling

Digital Vari-Program/

exposure modes

Digital Vari-Program ( auto, auto/no ash, portrait, landscape, child,

sports, close-up, night portrait); programmed auto (P) with exible program;

shutter-priority auto (S); aperture-priority auto (A); manual (M)

Exposure compensation –5–+5EV in increments of1/3 EV

Exposure lock Exposure locked at detected value with AE-L/AF-L button

Shutter Combined mechanical and CCD electronic shutter

Speed 30– ¼,000 s in steps of1/3 EV, bulb

White balance Auto (TTL white balance with 420-segment RGB sensor); six manual modes with ne

tuning and preset white balance

Built-in ash • , , , , : Auto ash with auto pop-up

• P, S, A, M: Manual pop-up with button release

Guide number (m/ft) • Approximately 17/55 at ISO 200 and 20 °C/68°F (manual 18/59)

• Approximately 12/39 at ISO 100 and 20 °C/68°F (manual 13/42)

Flash

Sync contact X-contact only; ash synchronization at shutter speeds of up to1/500 s

Flash control

TTL TTL ash control by 420-segment RGB sensor. i-TTL balanced ll-ash for digital SLR

and standard i-TTL ll-ash for digital SLR available when CPU lens is used with built-in

ash, SB-400, SB-800, and SB-600

Auto aperture Available with SB-800 and CPU lens

Non-TTL auto Available with such Speedlights as SB-800, 80DX, 28DX, 28, 27, and 22s

Range-priority manual Available with SB-800

Flash mode • , , , : Auto, auto with red-eye reduction; ll-ash and red-eye reduction

available with optional Speedlight

• : Auto, auto slow sync, auto slow sync with red-eye reduction; slow sync and slow

sync with red-eye reduction available with optional Speedlight

• , : Fill-ash and red-eye reduction available with optional Speedlight

• P, A: Fill ash, rear-curtain with slow sync, slow sync, slow sync with red-eye reduction,

red-eye reduction

• S, M: Fill ash, rear-curtain sync, red-eye reduction

Flash-ready indicator Lights when built-in ash or SB-series Speedlight such as 400, 800, or 600 is fully

charged; blinks for about 3s after ash is red at full output

Accessory shoe Standard ISO hot-shoe contact with sync, signal, and ground contacts and safety lock

Nikon Creative Lighting

System

Supported with built-in ash, SB-400, SB-800, and SB-600; Advanced Wireless Lighting

supported with SB-800 or SU-800 as Commander.

Monitor 2.5in., 230,000-dot, low-temperature polysilicon TFT LCD with brightness adjustment

Video output Can be selected from NTSC and PAL

External interface USB 2.0 Hi-speed

Tripod socket ¼in. (ISO 1222)

Firmware upgrades Firmware can be upgraded by user

INC

- M ・ -

Page 4

VBA15001-R.3701.A

Unless otherwise stated, all gures are for a camera with a fully-charged battery operating at an ambient temperature of 20°C (68°F).

EN-EL9 Rechargeable Li-ion Battery

Supported languages Chinese (Simplied and Traditional), Dutch, English, Finnish, French, German, Italian,

Japanese, Korean, Polish, Portuguese, Russian, Spanish, Swedish

Power source • One rechargeable Nikon EN-EL9 Li-ion battery; charging voltage (MH-23 quick

charger): 7.4V DC

• EH-5 AC adapter (available separately; requires optional EP-5 AC adapter connector)

Dimensions (W ×D×H) Approximately 126×64× 94mm (5.0×2.5 × 3.7in.)

Approximate weight 475g (1lb. 1oz.) without battery, memory card, or body cap

Operating environment

Temperature 0 –+40°C (+32– 104°F)

Humidity Less than 85% (no condensation)

Type Rechargeable lithium-ion battery

Rated capacity 7.4V/1000 mAh

Dimensions (W ×D×H) Approximately 36×56× 14mm (1.4×2.2 ×0.6in.)

Approximate weight 51g (1.8oz.), excluding power cable

INC

- M ・ -

Page 5

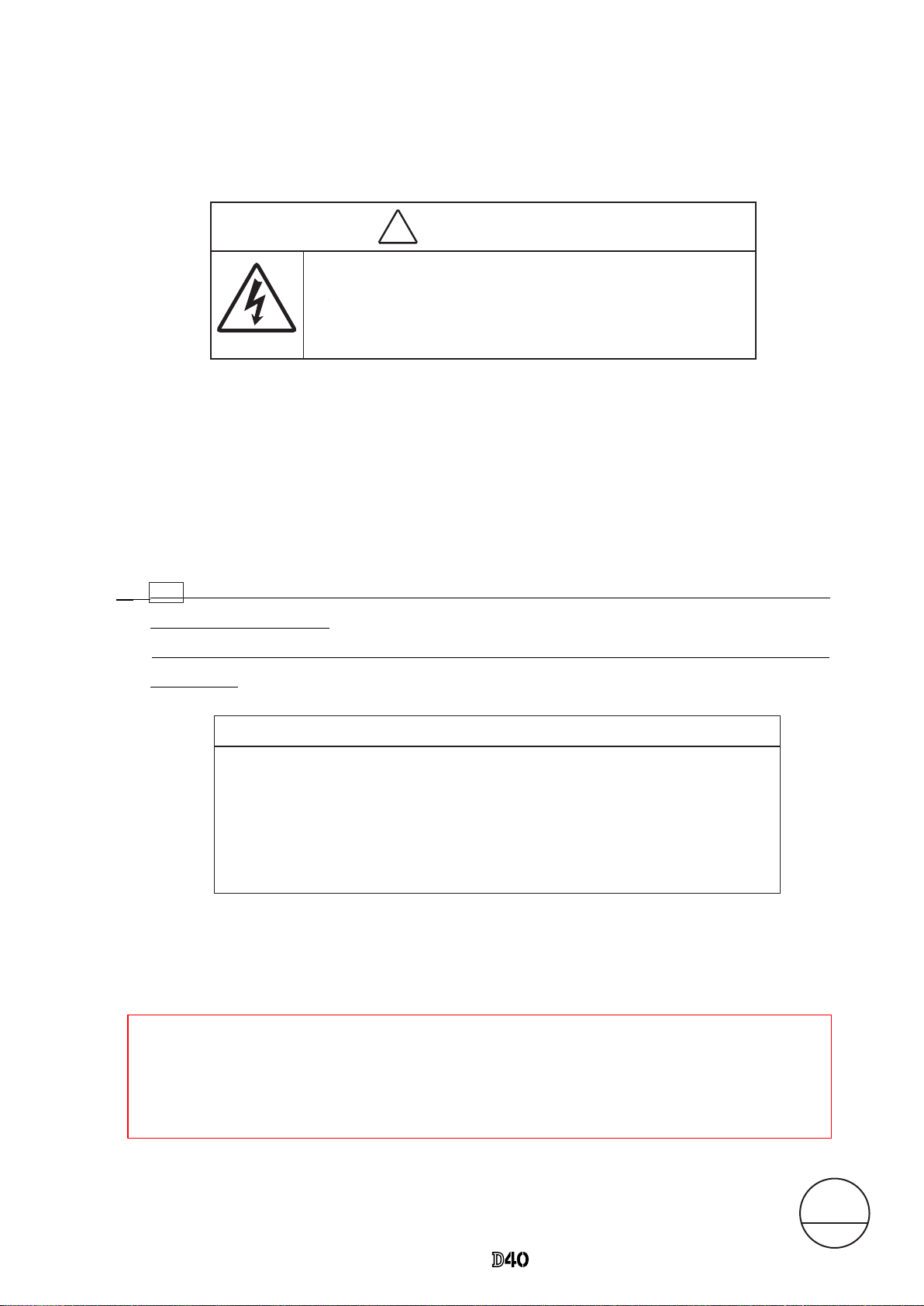

Points to notice for Disassembly / Assembly

㧍

内部に高電圧部あり。カバーを外す 時は感電に注意すること。

カバーを外した後は、修理指針の指 示に従ってメインコンデン

サーの放電を必ず行うこと。

警告

M

サービス

計画課

INC

WARNING

VBA15001-R.3701.A

(Addition)

△

Due to an internal high voltage area,

an electric shock when detaching covers.

After removing covers, be sure to discharge the main

condenser according to the instructions of repair manuals

Note:

When disassembling/(re)assembling, be sure to use the conductive mat (J5033) and wrist strap (J5033-5)

①

for static protection of electrical parts.

Before disassembling, be sure to remove batteries or AC power wires.

②

When disassembling, make sure to memorize the processing state of wires and FPC, screws to be xed

③

and their types, etc.

④ Because the low pass lter of the imaging CCD PCB is easily damaged, handle it with enough care.

is indicated in this manual when NK screw is used. Usually the same "NK" screw can be used

⑤

NK

approx. up to three times.

(NK screw = Loose-proong screw to which the adhesive is already applied and rmly xed when

screwed in.)

take extra care not to get

.

Points to notice for Lead-free solder products

・ Lead-free solder is used for this product.

・ For soldering work, the special solder and soldering iron are required.

・ Do NOT mix up lead-free solder with traditional solder.

・ Use the special soldering iron respectively for lead-free solder and lead solder.

They cannot be used in common.

Caution:

Whenever "Separation of Front and rear bodies", "Disassembly of CCD/FPC unit", or

"Disassembly of Bayonet" are performed, be sure to perform "RESET AF-DEFOCUS

COMPENSATION" of camera adjustment software after reassembling.

Changed page

△×

- D ・ -

Feb.05.2007

Page 6

Disassembly

M

サービス

計画課

INC

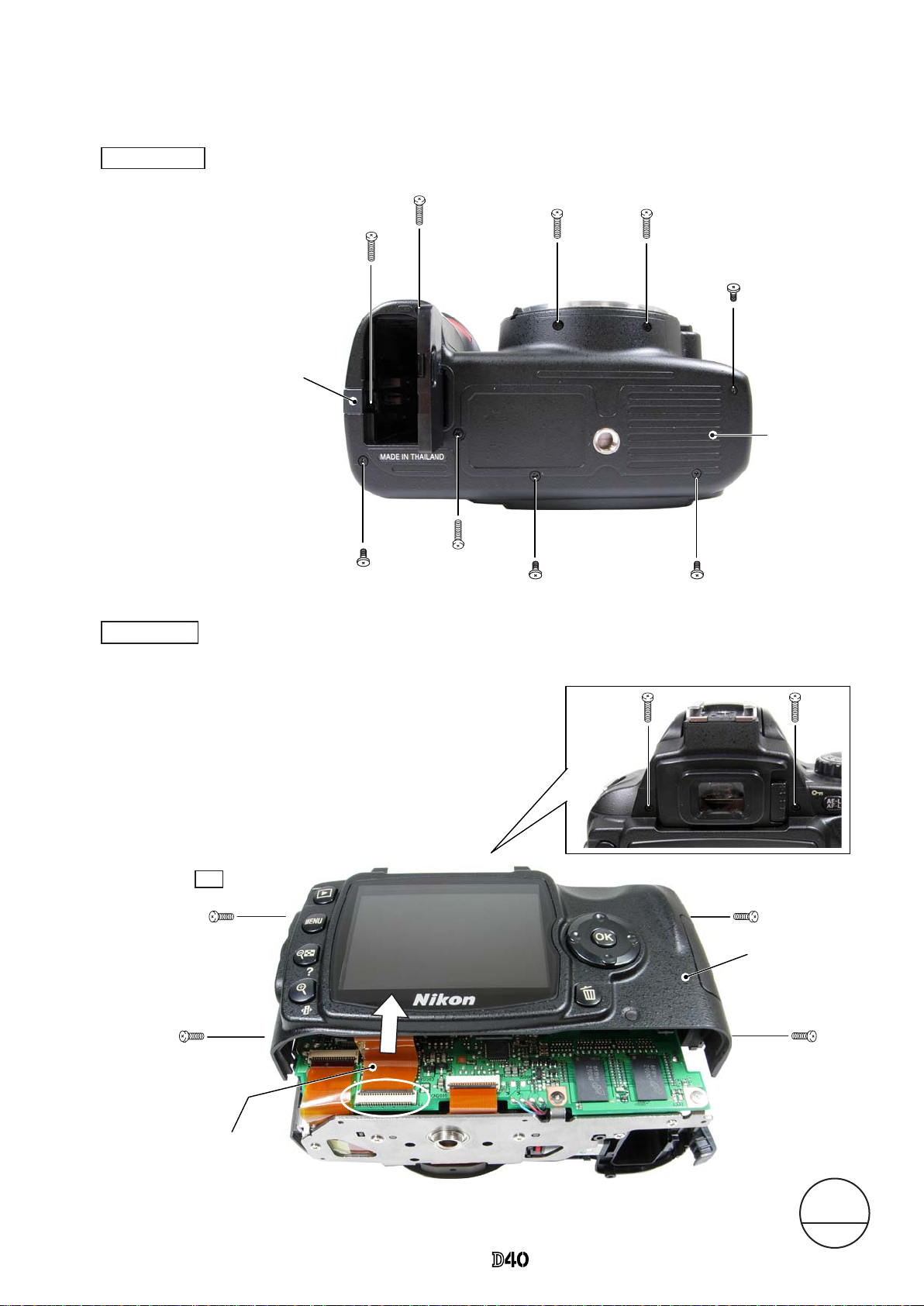

1. Separation of Front and Rear Bodies

Bottom Cover

VBA15001-R.3701.A

Take out the four screws (#5735)

・

and ve screws (#5674).

Open the power-wire lid.Open the power-wire lid.

・

Remove the bottom cover.

・

Power-wire lid

Rear cover

#5674

#5735

#5674

#5674

#5674×2

#5735

Bottom cover

#5735×2

Take out the four screws (#5690) and two screws (#5618).

・

Remove the rear cover.

・

Note: Remove the rear cover slowly so as not to cut rear FPC of

the upper portion of the cover.

Remove the rear FPC from the connector.

・

(Addition)

△

NK

#5690×4

#5618×2

Rear cover

Changed page

Rear FPC

△×

- D 2 ・ -

Feb.05.2007

Page 7

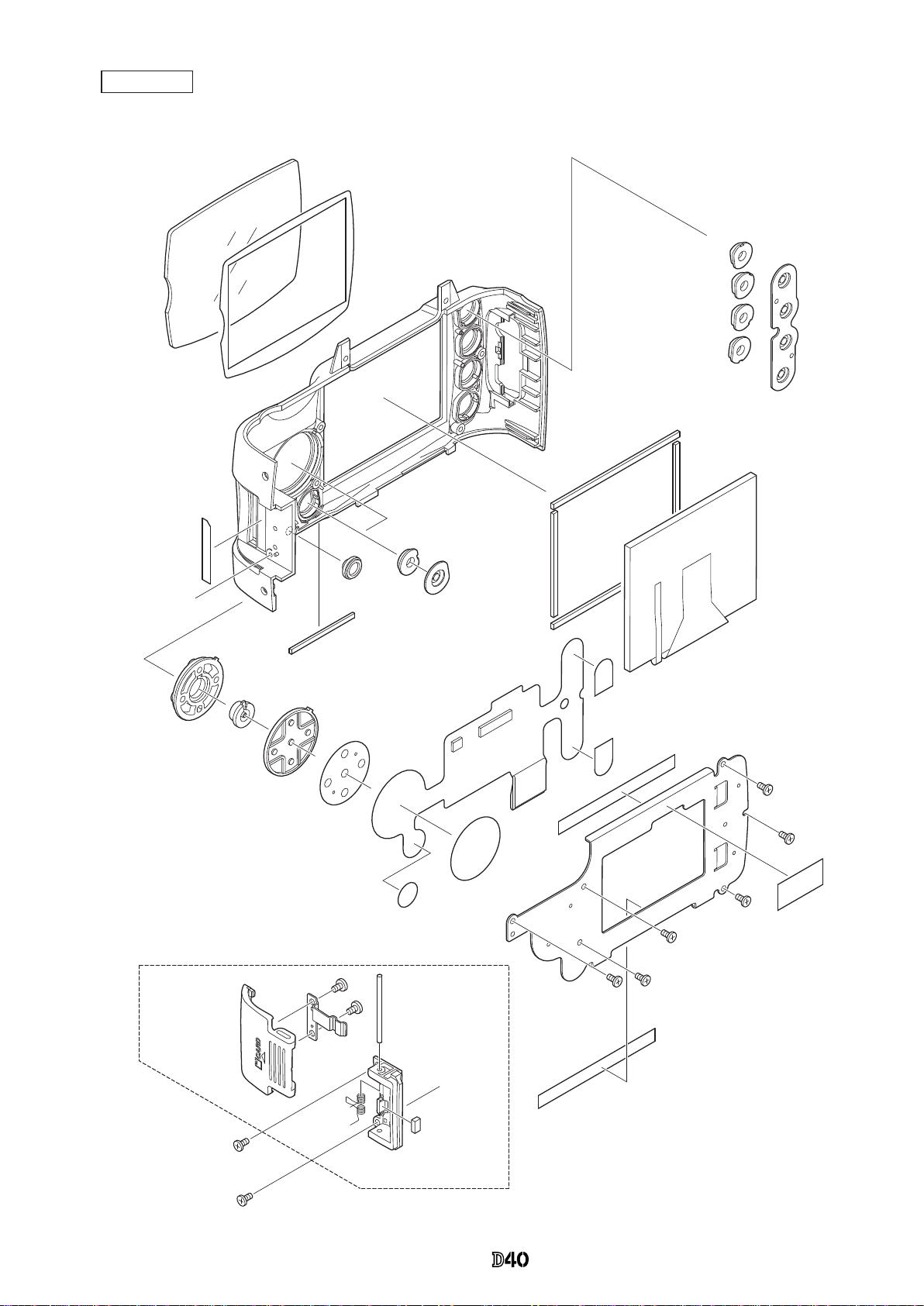

A

A

INC

Rear cover

VBA15001-R.3701.A

#402-3

#403

#5401-7

#405×2

#448

#408

#753

#5412-1

#5418-5

#5429-2

#1016-3

#423-2

#451×2

#5424-4

#5425-3

#5426-3

#5427-3

#421-2

#404×2

#1037

#5431-1

#5681×2

#413-1

#B5431

#414

#453

#406-3

#452

#750

#670×3

#630×3

#407-2×2

#433

#5432-1

- D ・ -

Page 8

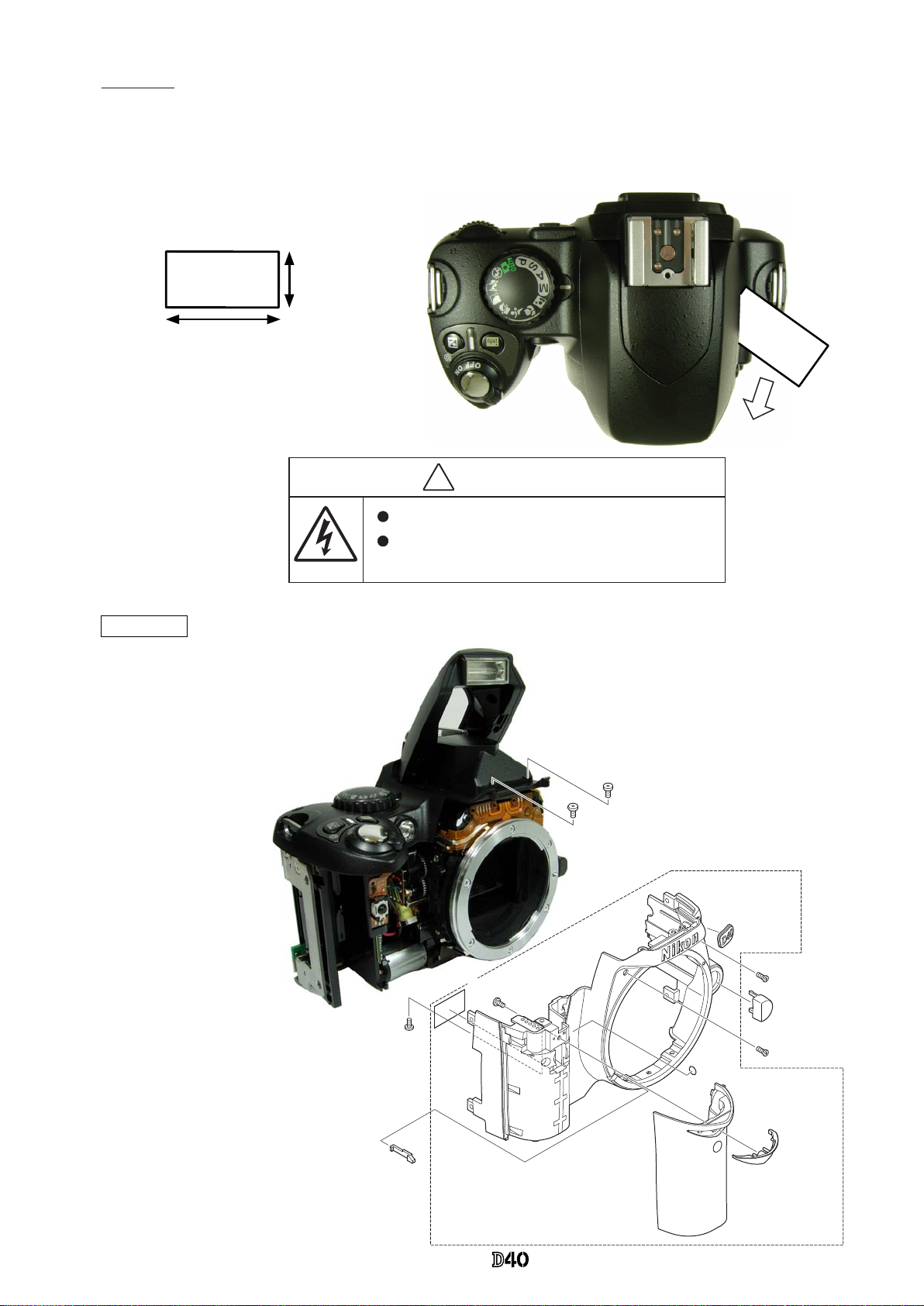

SB pop-up

㧍

内部に高電 圧部 あり 。カ バーを外す時は感電に注意す るこ と。

カバーを外 した 後は 、修 理指針の指示に従ってメイン コン デン

サーの放電 を必 ず行 うこ と。

警告

INC

Cut the tracing lm sheet, etc into the below size of piece.

・

Then insert it into the clearance of the top cover pop-up

part as shown right, and raise the SB by sliding the sheet in

the direction of the arrow.

Approx.2cm

Approx. 4cm

WARNING

Due to an internal high voltage area, take extra care not to get an

electric shock when detaching covers.

After removing the covers, be sure to discharge the main

condenser according to the instructions of repar manuals.

VBA15001-R.3701.A

Covers

Take out the four screws (#5610) and

・

the screw (#626).

Remove the front cover unit (#B5024)

・

and [#131].

#626

#750

#670

#5610×2

#5074

#792C

#B5024

#5120

#5610×2

#131

- D ・ -

#29-2

#26-2

Page 9

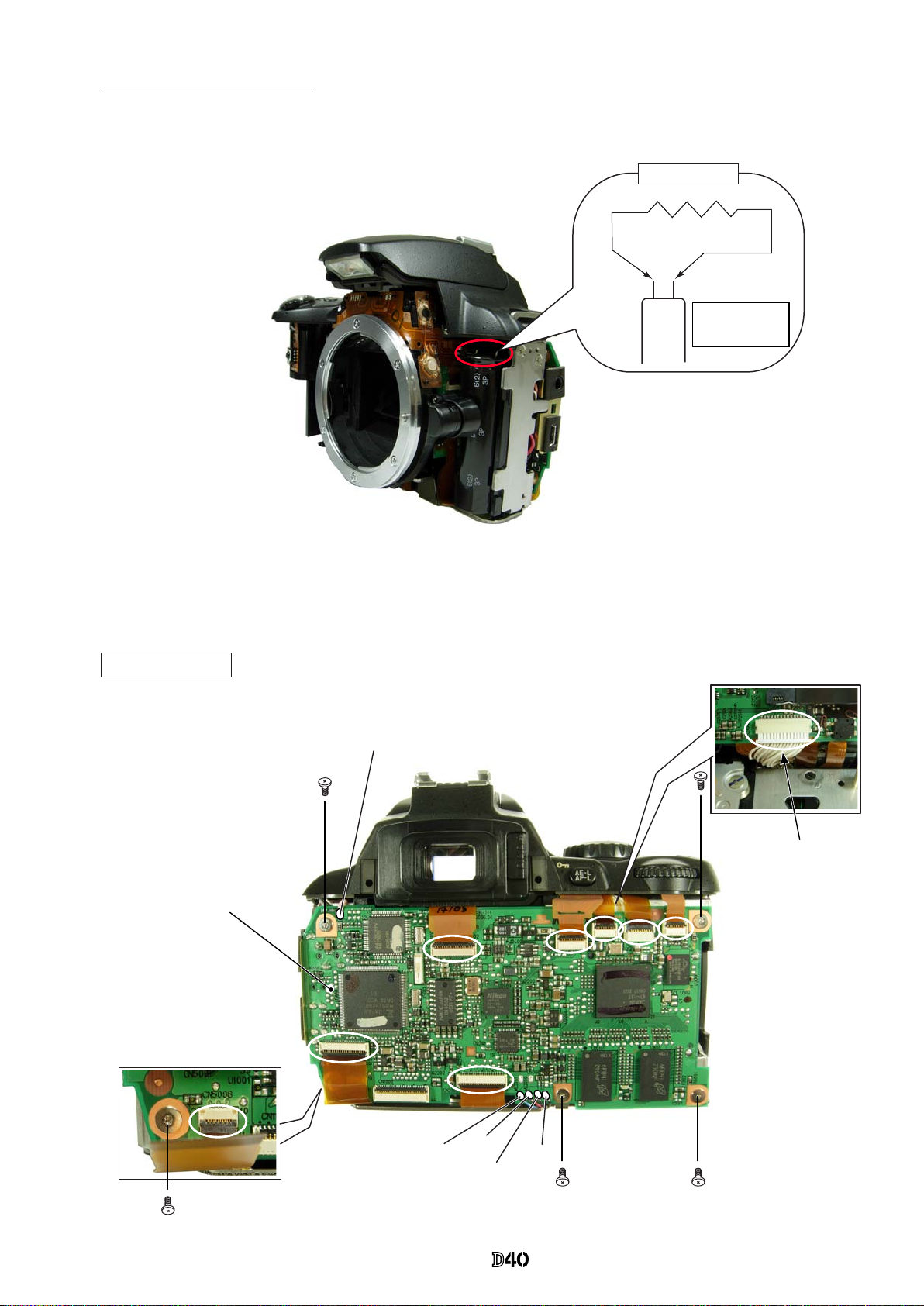

Discharge of Main condenser

INC

Discharge the main condenser from its both ends.

・

VBA15001-R.3701.A

Be careful so that the top cover does NOT touch the

discharge tool.

2KΩ/5W

Main

condenser

TOGO PCB unit

Disconnect the eight FPCs from the connector.

・

Unsolder the ve wires.

・

Take out the ve screws

・

Remove the harness.

・

Remove the TOGO PCB

・

#B2001-1).

(

TOGO PCB (#B2001-1)

#663).

(

Pink: Relay PCB

TOGO PCB unit: Back

Harness

Red

Blue

Gray

Gray

- D ・ -

#663×5

Page 10

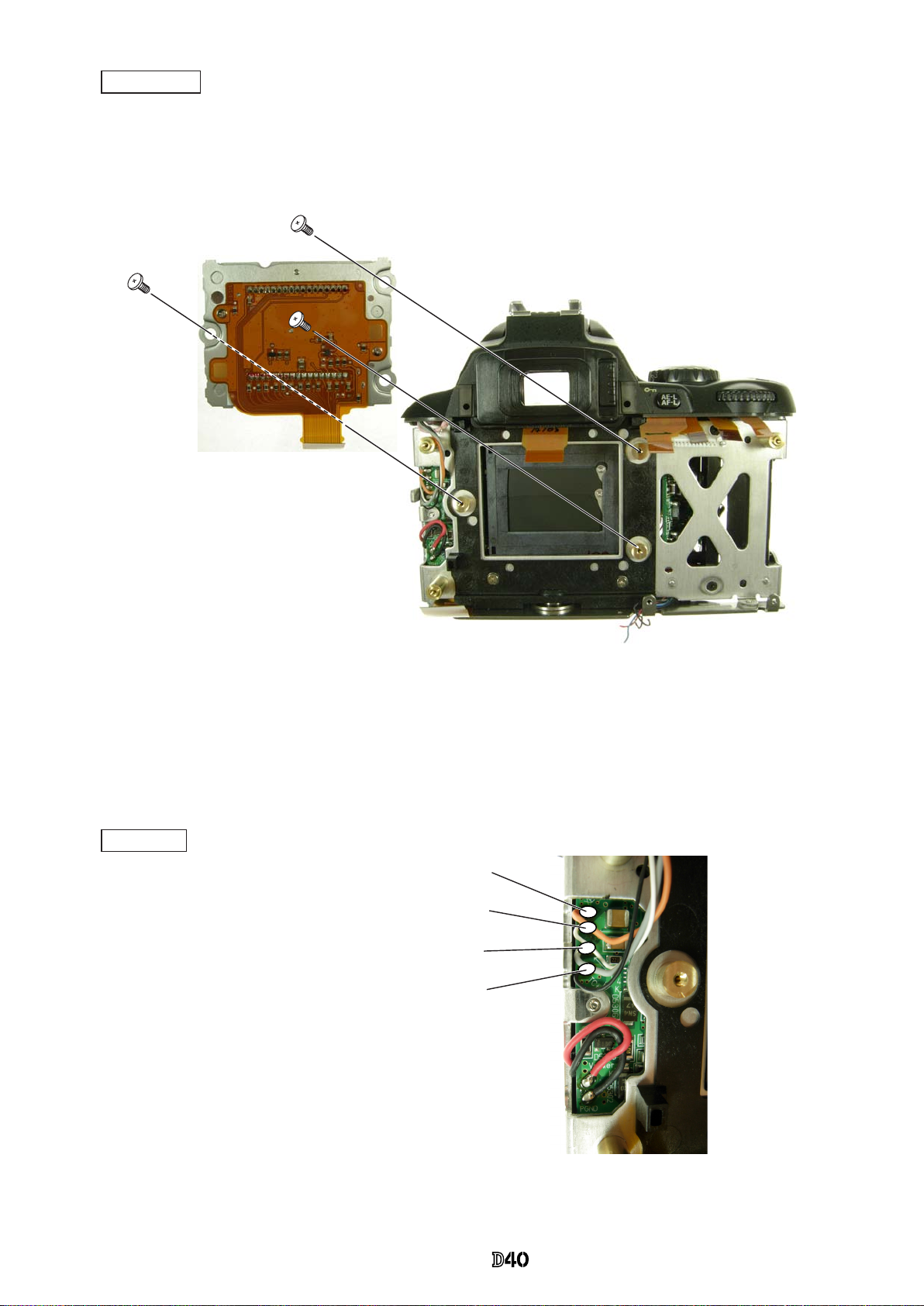

CCD unit

INC

Take out the three screws (#631), and remove the CCD unit (#B3051-1).

・

Caution:

VBA15001-R.3701.A

#B3051-1

#631×3

Some bodies have already washer(s) attached on

the mounting surface of CCD unit.

SB PCB

Unsolder the four wires (connected

・

from Top cover).

Orange: Top cover

White: Top cover

Gray: Top cover

Black: Top cover

- D ・ -

Page 11

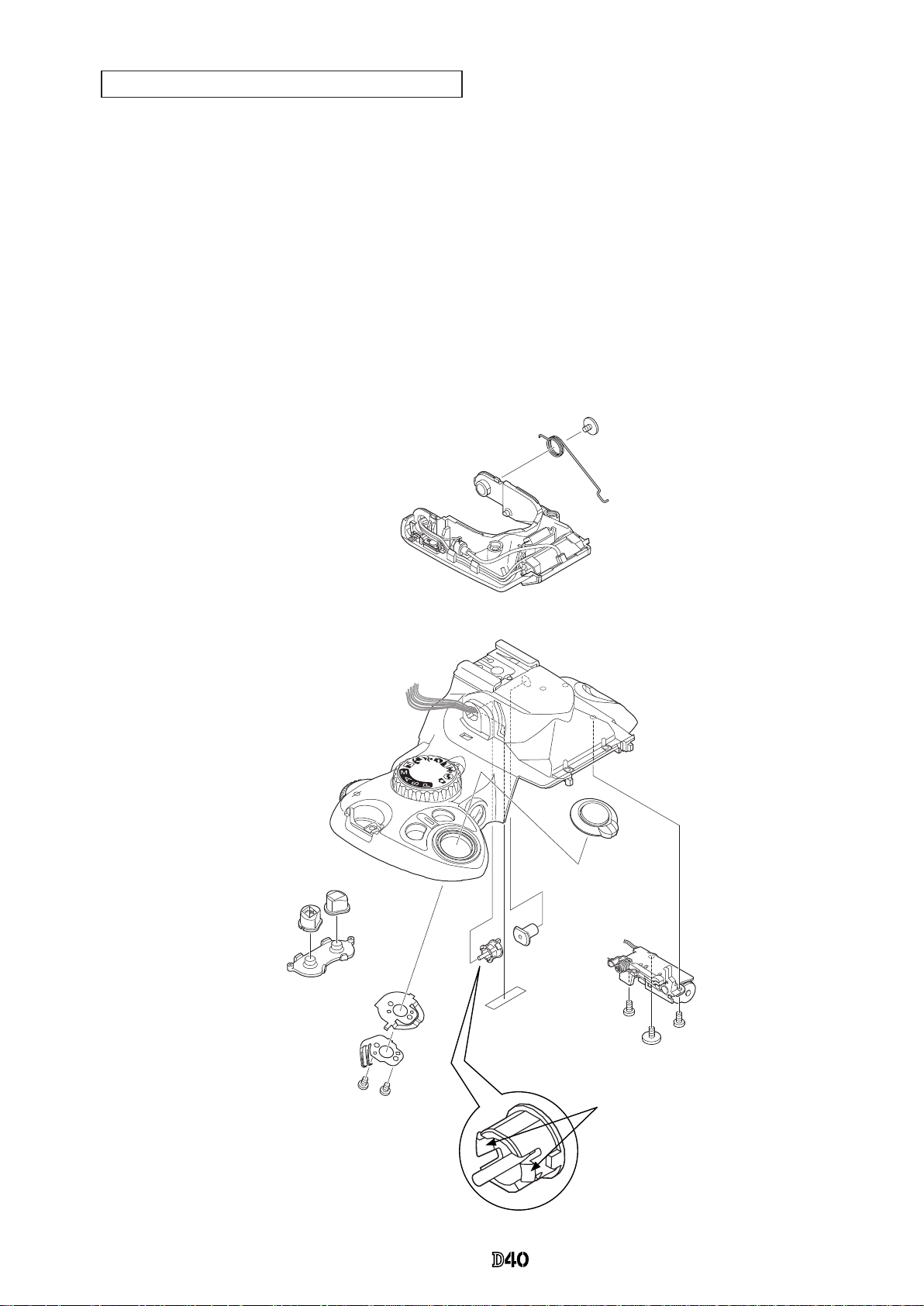

DC/DC PCB unit

info

AUT

O

M

サービス

計画課

INC

Unsolder the wire (connected from Top cover).

・

Top cover

Take out the two screws (#5737).

・

Take out the two screws (#635).

・

VBA15001-R.3701.A

Black: Top cover

The top cover and rubber eyecap (#B271)

・

come off.

(Revision)0~n

△

#797×2

#B271

#796A

#5737×2

D×n

~

Changed page

△×

#635×2

- D 7 ・ -

Feb.05.2007

Page 12

Disassembly of Top cover

INC

SB upper case

Press "Pop-up lever A part" of the top cover unit so that the built-in SB is raised.

・

Pop-up lever A part

Take out two screws (#632).

・

VBA15001-R.3701.A

#632×2

Release the two claws. House the built-in SB and remove the SB upper case (#5301).

・

SB upper case (#5301)

Claw

- D ・ -

Page 13

Top cover FPC / Wiring

M

サービス

計画課

INC

Unsolder the seven wires (connected from SB lower case unit and SB release base unit).

・

Remove the ve solder bridges.

・

Red: SB lower case unit

Blue: SB lower case unit

VBA15001-R.3701.A

Green: SB lower case unit

Black: SB lower case unit

Black: DC/DC PCB

AF-assist illuminator unit

Remove the two wires (black and uncoated) (connected from AF-assist illuminator unit).

・

Red: SB release base unit

Revision)

△ (

Blue: SB release base unit

Black: SB release base unit

Take out the screw (#608), and remove the AF-assist illuminator unit (#B325-1).

・

#608

AF-assist illuminator unit (#B325-1)

Black: AF-assist illuminator unit:

Uncoated wire: AF-assist illuminator unit

Changed page

△×

- D ・ -

Feb.05.2007

Page 14

VBA15001-R.3701.A

AUT

O

info

INC

SB lower case unit / SB release base unit / Buttons

Remove the rubber SW (#382-2), ± Aperture button (#5381), and INFO button (#5383-1).

・

Take out the two screws (#605), and remove [#348], [#347-1] and the release button unit (#B5350).

・

Take out the screw (#650), and release the wire from the boss.

・

Remove [#308-1], while releasing the two hooks.

・

While pressing the SB case rotating shaft (#306-1), take out the screw (#733) and remove the SB-up spring

・

(#305-1).

While watching the wires, remove the SB lower case unit (#B2302).

・

Take out the two screws (#607), and remove the SB release base unit (#B2455).

・

#733

#305-1

#B2302

#B5350

#5383-1

#5381

#306-1

#308-1

#382-2

#347-1

#956

#B2455

#607×2

#348

#605×2

#650

Hook × 2

- D 0 ・ -

Page 15

AUT

O

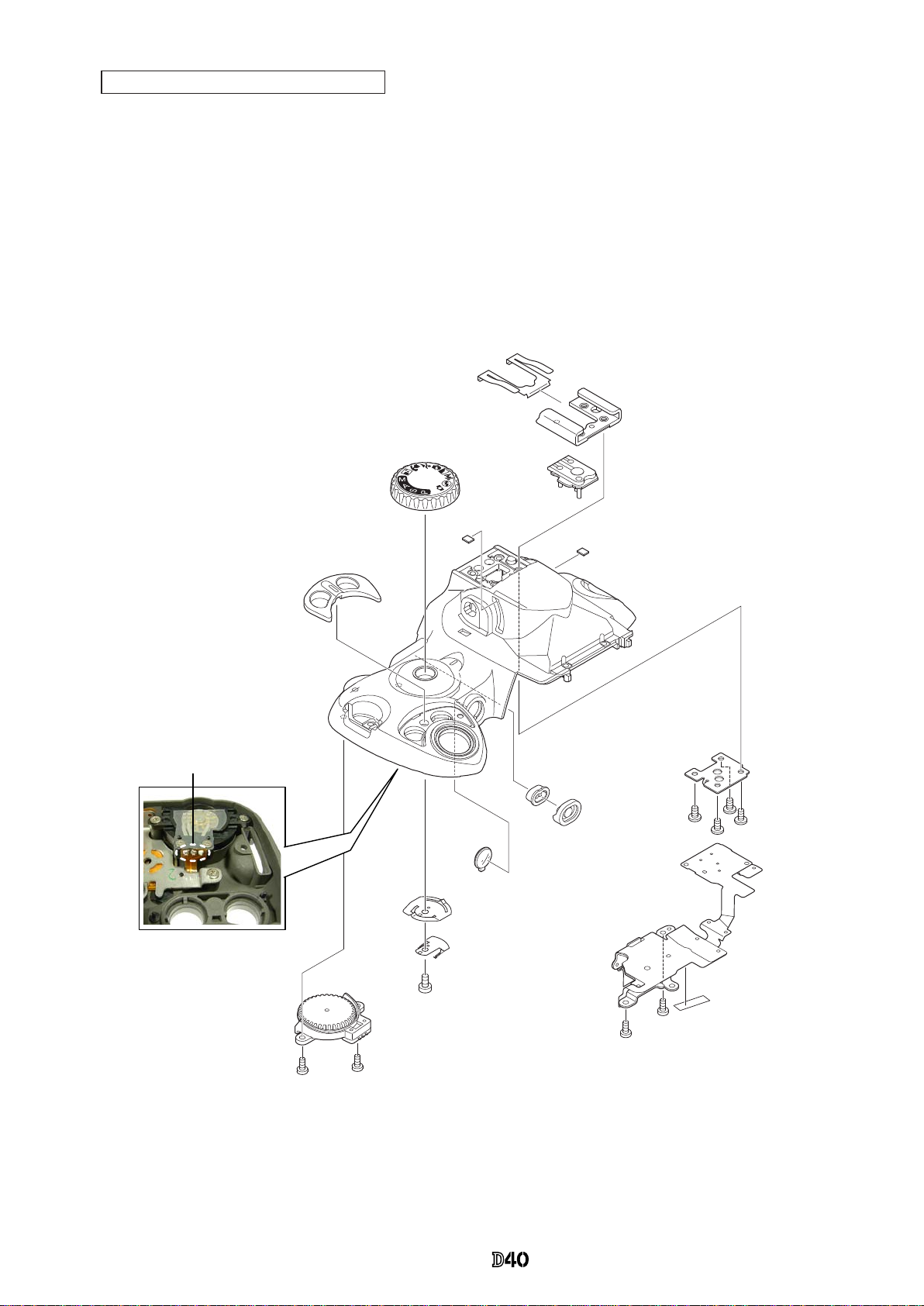

Top cover FPC unit / other small parts

INC

Remove the three solder bridges.

・

Take out the two screws (#635) and remove the top cover FPC unit (#B2007-1).

・

Remove the AF/AE lock button (#5386-1) and [#387-2].

・

Take out the two screws (#635), and remove the C/D unit (#B367).

・

Take out the screw (#640), and remove [#372], [#373], and mode dial unit (#B5375).

・

Take out the four screws (#654), remove [#322], [#318-1], shoe base (#316) and [#B317].

・

#318-1

#316

#B5375

#B317

VBA15001-R.3701.A

Solder bridge ×3

#B367

#27-2

#373

#372

#640

#326

#5386-1

#387-2

#311-1×2

#322

#654×4

#B2007-1

#956

#635×2

#635×2

- D ・ -

Page 16

SB PCB

INC

Unsolder the two wires (connected from Relay-PCB).

・

Red: Relay-PCB

Black: Relay-PCB

DC/DC PCB

Unsolder the two wires (connected from Mount GND plate and Frront body FPC).

・

Black: Mount GND plate

VBA15001-R.3701.A

Black: Front body FPC

Bottom base plate unit

Take out the ve screws (#616).

・

Take out the two screws (#691).

・

Remove the bottom base plate unit (#B66-2).

・

#616×5

#691

Bottom base

plate unit

(#B66-2)

#691

- D ・ -

Page 17

VBA15001-R.3701.A

INC

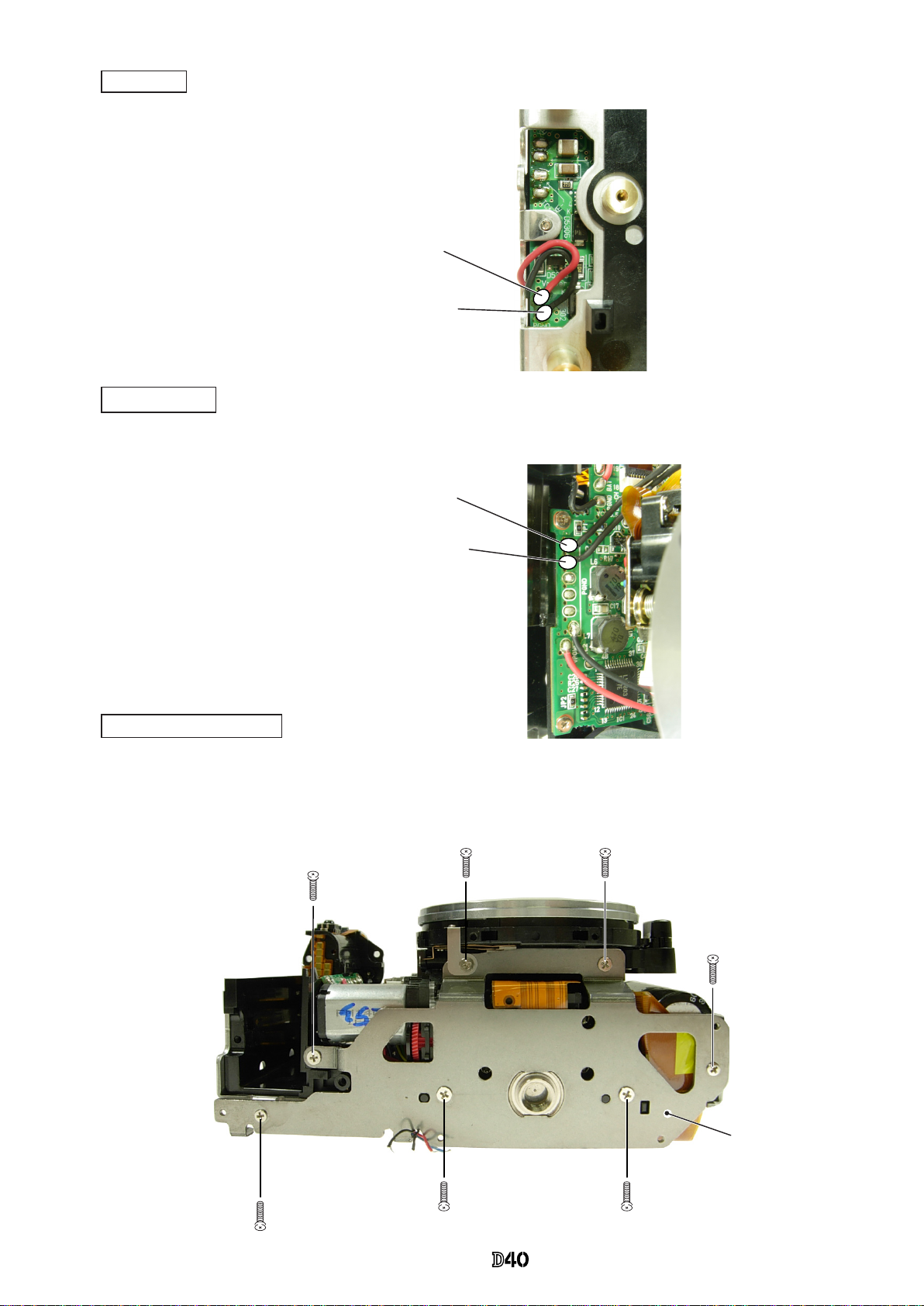

Separation of Front and Rear bodies

Take out the four screws (#624).

・

Separate the front body from the rear body.

・

Caution: Separate them slowly so as NOT to cut the two wires of the relay-PCB that pass through between the

SB PCB and main condenser.

#624×4

- D ・ -

Page 18

2. Rear body

INC

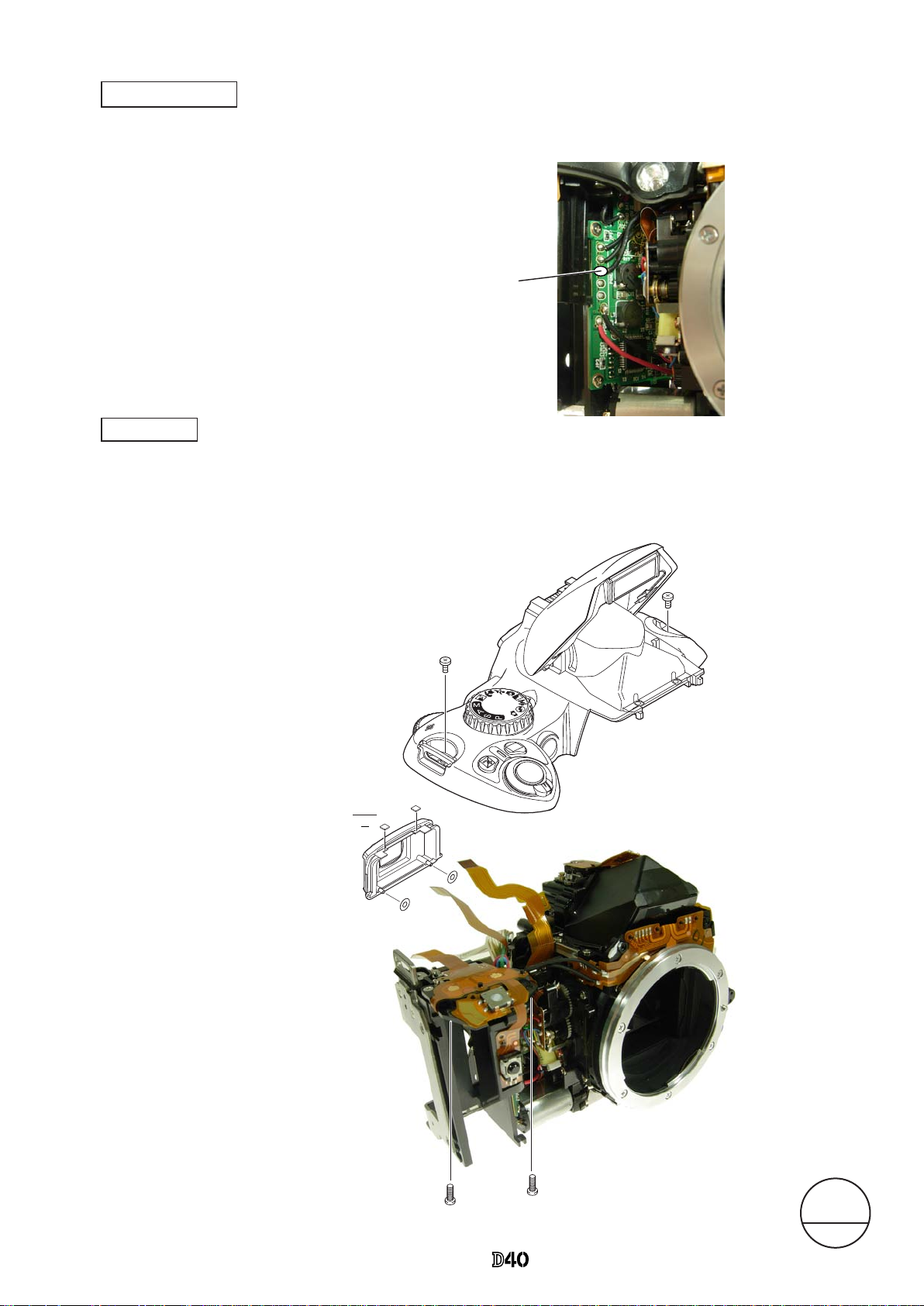

Remote block

Remove SW-FPC [#B2006].

・

Take the two screws (#683).

・

Remove the remote block (#158-1).

・

#683×2

VBA15001-R.3701.A

#B2006

#354

#158-1

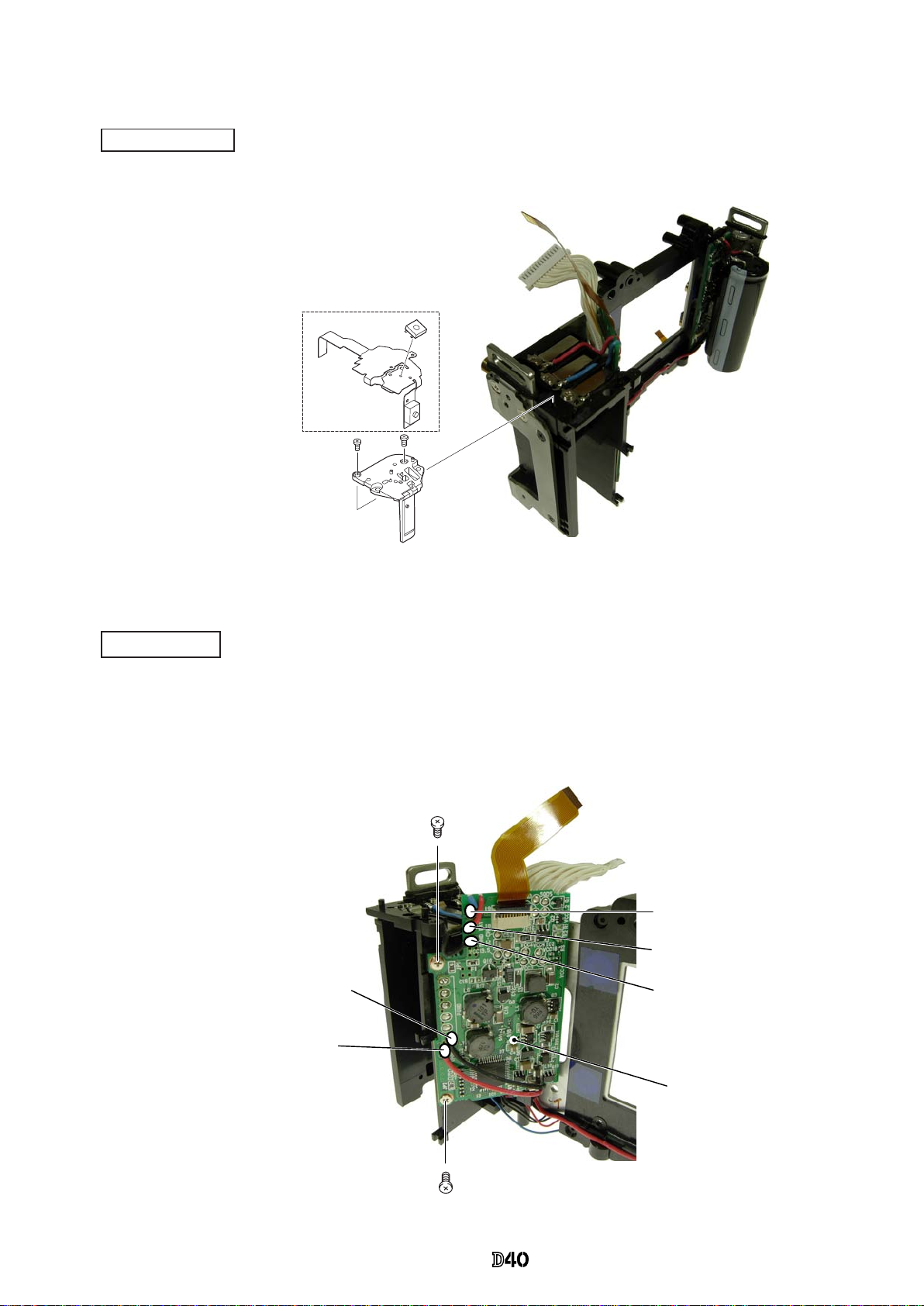

DC/DC PCB

Remove the ve wires (connected from SB-PCB and Battery box) .

・

Take out the two screws (#670).

・

Remove the DC/DC PCB.

・

#670×2

Black:SB PCB

Red:SB PCB

Blue: Battery box

Red: Battery box

Black: Battery box

DC/DC PCB

- D ・ -

Page 19

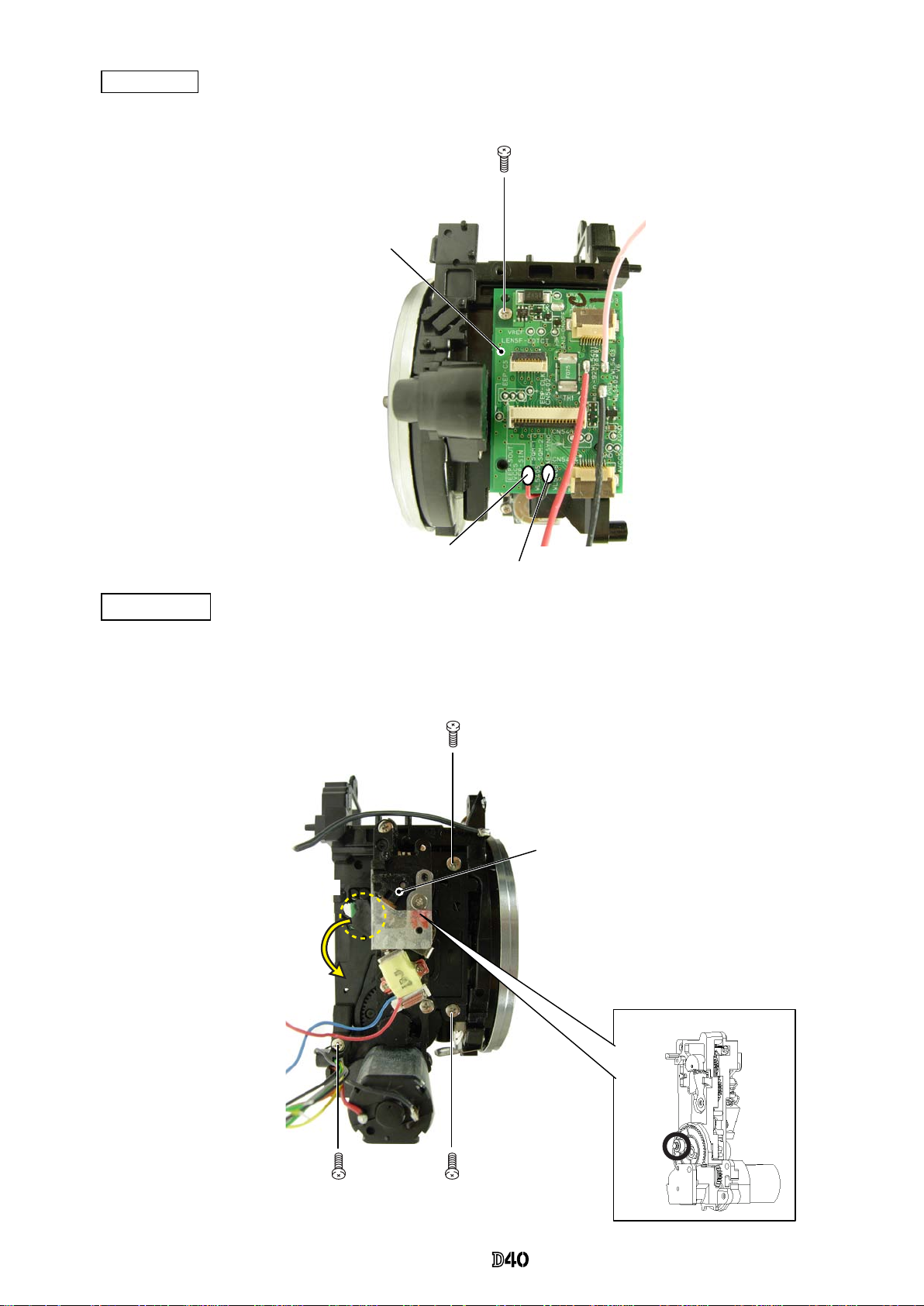

SB PCB

INC

Remove the two wires (yellow-circled) of the main condenser.

・

Remove the main condenser that is attached on with the adhesive double-

・

coated tape.

Take out the screw (#687).

・

Remove the SB PCB.

・

SB PCB

#687

VBA15001-R.3701.A

Main condenser

#142

#1076

#1077

#141×2

#1043-3

Main condenser

#1043-3

DC/DC lug plate

Eyelet ring unit

Other small parts

Battery box

Buzzer unit

#607×3

#157×3

#B145×2

#694×2

#694×2

#143×3

#615×4

TA-0005

(7×15)

#159-1

DC/DC

lug plate

Backup battery

Battery box

#607

- D ・ -

Page 20

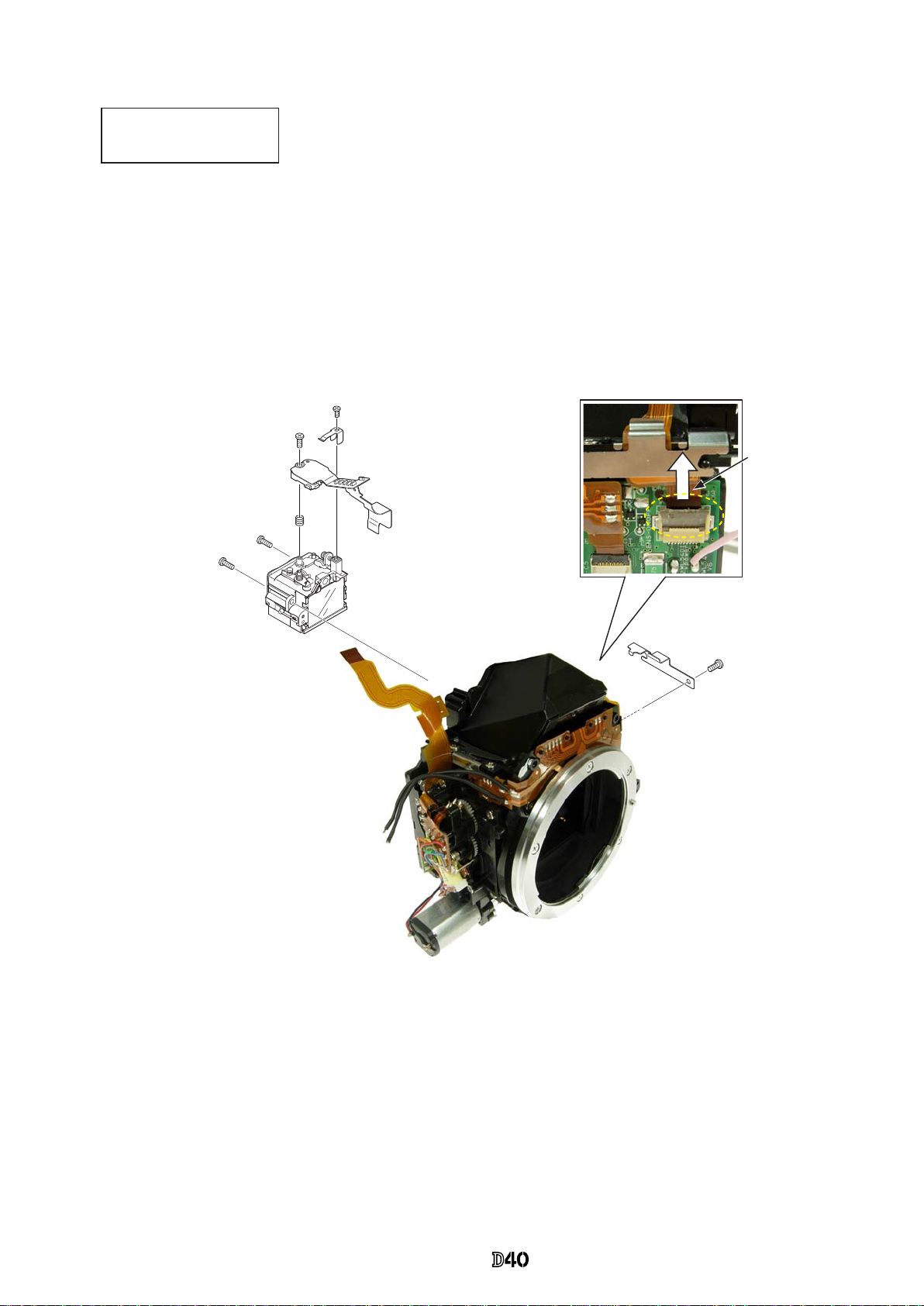

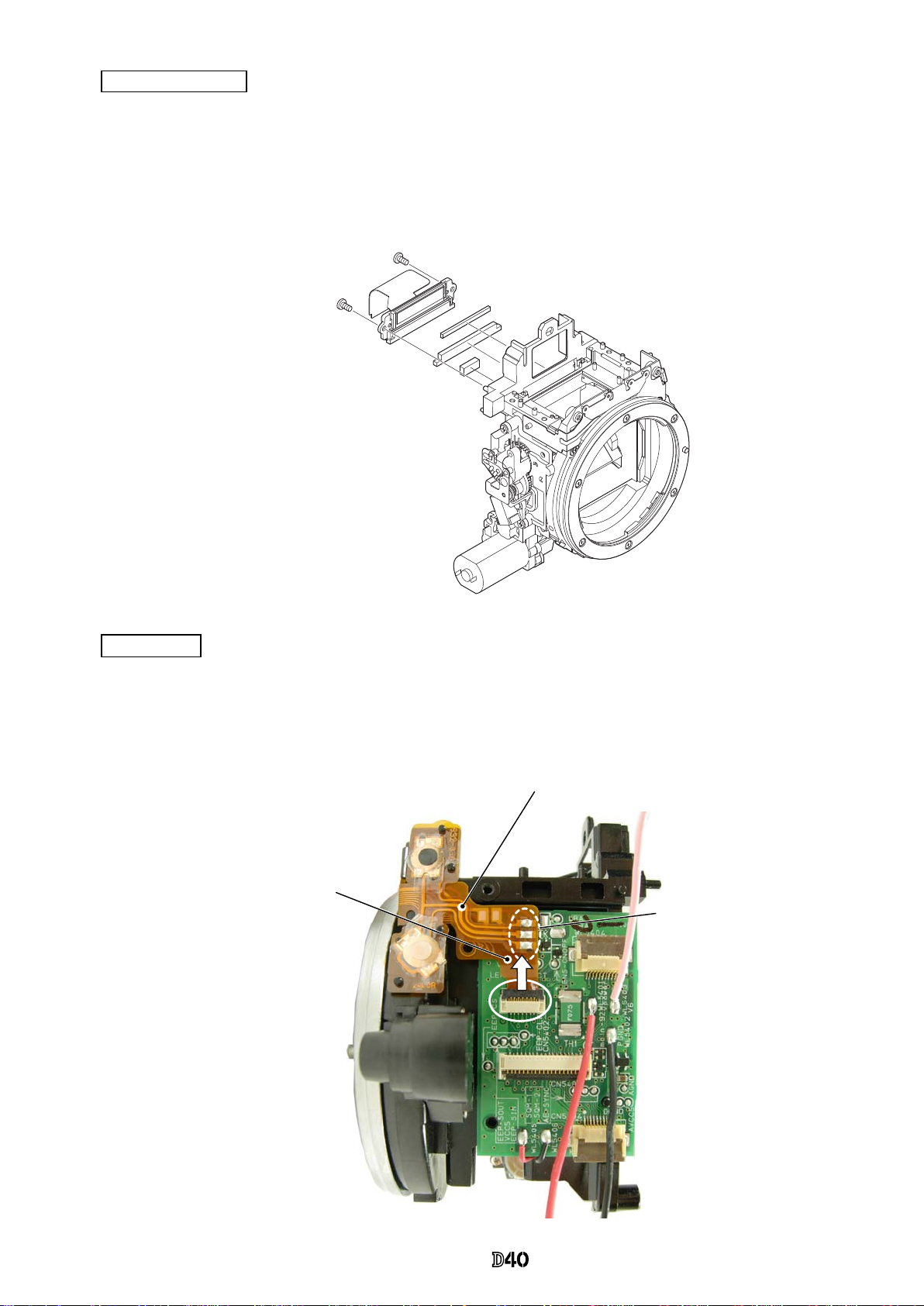

3. Front Body

INC

Eyepiece barrel unit

AE FPC unit

Take out the screw (#607), and remove the AE FPC retainer plate (#293).

・

Remove the FPC of the AE FPC unit (#B2008) from the connector.

・

Take out the screw (#604), and remove the AE sensor plate spring (#285-3).

・

Take out the screw (#291-1), and remove [#B2008] and [#290].

・

Take out the two screws (#638), and remove the eyepiece barrel unit (#B261).

・

#604

#291-1

#285-3

#B2008

VBA15001-R.3701.A

#B2008

#638×2

#290

#B261

#293

#607

- D ・ -

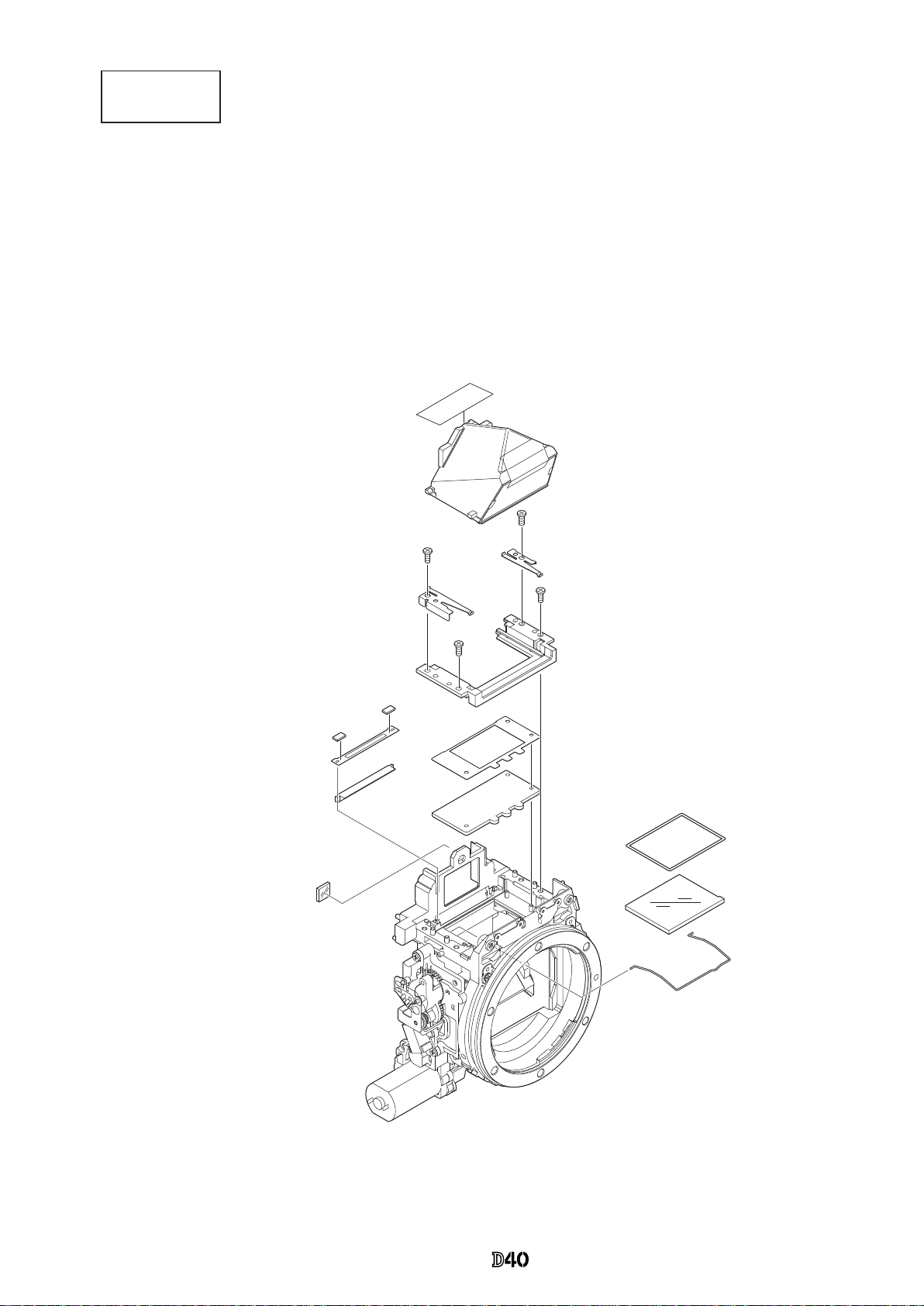

Page 21

INC

Penta unit

Screen areas

Take out the two screws (#635), and remove [#201] and [#202-1].

・

Remove the hollow penta prism unit (#B4) ,which is adheved by Super X.

・

Remove the nder eld frame 2 (#283).

・

Take out the two screws (#635), and remove the SI retaining unit (#B277).

・

Remove the nder eld frame 1 (#282-1).

・

Remove the in-nder display prism (#9).

・

Remove the SI display plate (#13-1).

・

Remove [#284], [#3], and [#297A].

・

#759

#B4

VBA15001-R.3701.A

#793×2

#9

#11

#635×2

#201

#202-1

#635×2

#B277

#282-1

#283

#13-1

#297A

#3

#284

- D ・ -

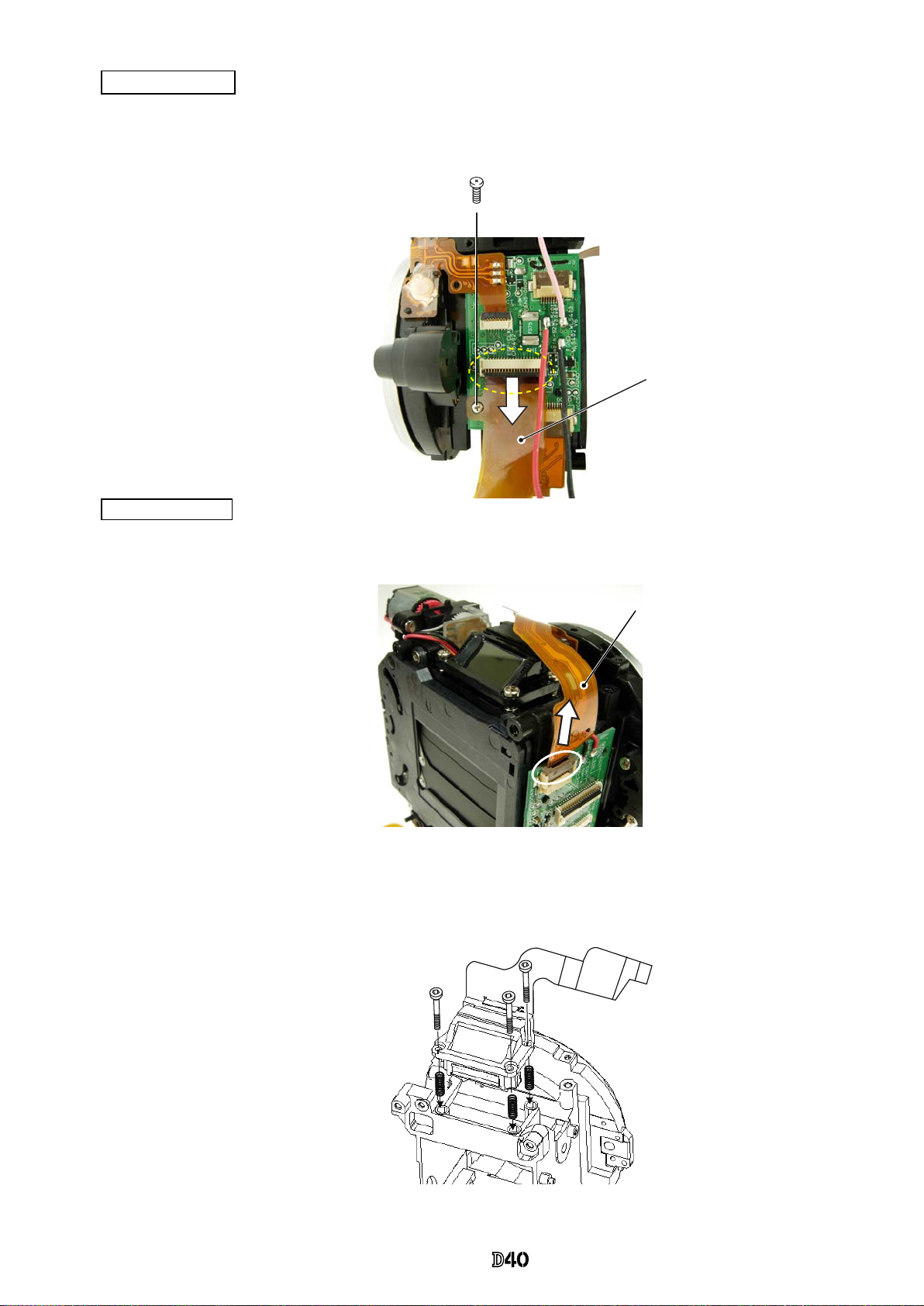

Page 22

B2

2

INC

Connection-FPC

Take out the screw (#670).

・

Remove the connection-FPC (#1020) from the connector.

・

AF sensor unit

VBA15001-R.3701.A

#670

Connection-FPC (#1020)

Disconnect the AF sensor unit FPC from the connector.

・

Take out the three screws (#162) with hexagonal wrench (φ1.5mm).

・

The AF sensor unit (#B2163) and the three springs (#161) come off.

AF sensor unit FPC

AF sensor unit (#B2163)

#162×3

#161×3

- D ・ -

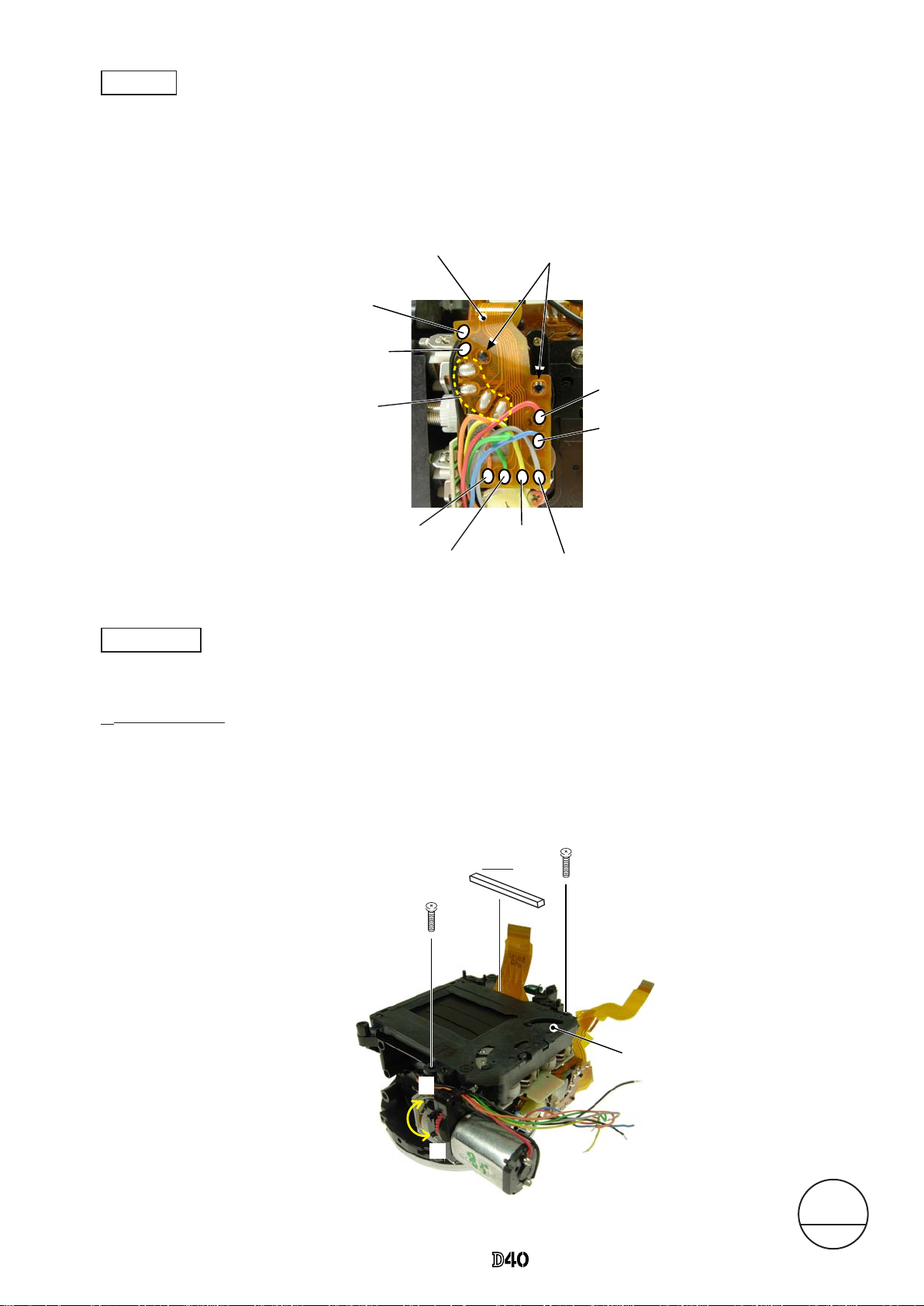

Page 23

SQ FPC

M

サービス

計画課

INC

Unsolder eight wires (connected from SQ, Fmin, and Mg).

・

Remove the four solder bridges.

・

Remove the SQ FPC by releasing from the bosses.

・

VBA15001-R.3701.A

SQ FPC

Black:SQ

Black:Fmin

Solder bridge ×4

Orange:Fmin

Green:SQ Gray:SQ

Yellow:SQ

Shutter unit

Turn the white gear in the direction of "A", and raise the mirror.

・

Boss×2

Red:Mg

Blue:Mg

(Addition)

Remove [#757].

・

Take out the two screws (#635).

・

Remove the shutter unit (#31).

・

Turn the white gear in the direction of "B", and get the mirror down.

・

△

△

#635×2

(Addition)

A

B

#757

Shutter (#31)

Changed page

△× 2

- D ・ -

Feb.05.2007

Page 24

In-nder LCD unit

INC

Take out the two screws (#683).

・

Remove the in-nder LCD unit (#B2010).

・

VBA15001-R.3701.A

#683×2

#B2010

#276

#295

#758

SB SW unit

Remove the three solder bridges.

・

Remove the SB SW unit.

・

Remove the front body FPC from the connector.

・

Front body FPC

SB SW unit (#B1012)

Solder bridge ×3

- D 0 ・ -

Page 25

Front body FPC

INC

SI LED-FPC

Remove the seven solder bridges and the other four solder bridges.

・

Solder bridge×4

VBA15001-R.3701.A

Solder bridge×7

Remove the SI LED-FPC (#1011) and [#279].

・

Remove the front body FPC (#1009).

・

#278×2

#1011

#279

#1009

- D ・ -

Page 26

Relay PCB

INC

Unsolder the two wires (connected from SQ PCB unit).

・

Take out the screw (#607).

・

Remove the relay PCB.

・

Relay PCB

VBA15001-R.3701.A

#607

Red:SQ PCB unit

Black:SQ PCB unit

SQ PCB unit

Take out the three screws (#638).

・

Turn "① " part in the direction of the arrow, and remove the SQ PCB unit, while releasing from the roller

・

section.

#638×3

SQ PCB unit

①

SQ PCB unit

Roller

section

- D ・ -

Page 27

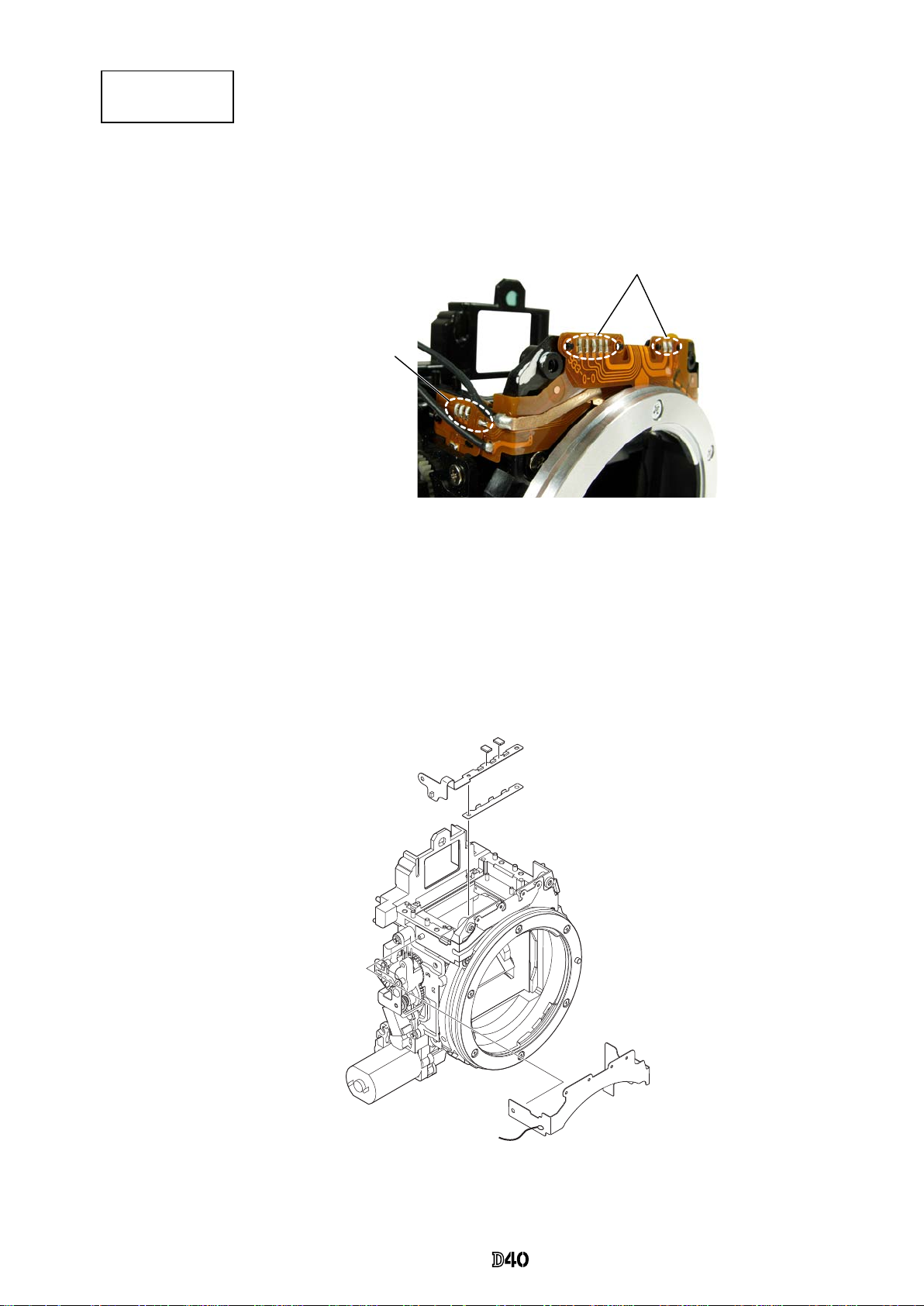

Bayonet /

INC

A/M-change SW /

Lens-contact areas

VBA15001-R.3701.A

#621×2

#115-1

#119

#B116

#137-1

#135-1

#B2113

#198

#638×2

#189

#112×3

#607

#111

- D ・ -

#660

#648×5

Page 28

Aperture lever /

INC

F-min SW areas

VBA15001-R.3701.A

#190

#205

#206

Mirror unit

#639

#210

#208-1

#213

#207-1

#B2231

#209

#204

#1105

#203-2

#1106

#133-1

#136

#134-1

#645

#240-4

#238-3

#239-2

#199×2

#236-1

- D ・ -

Page 29

Assembly/ Adjustment

INC

1. Front body

VBA15001-R.3701.A

NOTE: For undescribed tapes and sponges here

・

in"Assembly", refer to PARTS LIST.

Mirror unit

#238-3

#B2231

#239-2

#240-4

Be careful NOT to bend here.

#199×2

#236-1

With the mirror being raised, assemble the

・

pins and apply the adhesive (Super X) on

each pin.

#236

Adhesive Super X

Apply the adhesive only

on 1/4 periphery of the

pin on mount side.

Adhesive

Super X

- A ・ -

Page 30

Aperture lever

INC

F-min SW areas

VBA15001-R.3701.A

Grease: LEN317A

Grease: LEN317A

#639

#208-1

#213

#206

#210

#205

#190

#209

#207-1

#204

#1105

#203-2

#133-1

#136

#134-1

#645

#1106

Black:SQ FPC

Orange:SQ FPC

Position for hooking spring

Hook [#205] and then [#204].

・

Hook [#213].

・

Grease: LEN317A

Mirror-down spring (#206)

hooking position

#205 (white/short)

#204 (black)

#213 (white/long)

- A ・ -

Page 31

VBA15001-R.3701.A

約

6

0

°

INC

SQ PCB unit

Move the roller section to the position as shown in Fig.①.

・

Turn "1" all the way to the end in the direction of the arrow. Then, Press "2" in the direction of "Lock".

・

Turn "3", and insert the roller section between [#207-1] and [#203-2].

・

Tighten the three screws (#638).

・

Press "2" in the direction of "Unlock".

・

Note: Be careful not to bend contact blade of F-min SW.

Fig.

①

Approx.60°

angle

#208-1

Roller section

3

Aperture control unit

1

2

Lock

Unlock

#207-1 #203-2

#638×3

SQ PCB unit

#253-1

- A ・ -

Page 32

Lens contacts unit

INC

VBA15001-R.3701.A

#B2113

#198

#638×2

#189

Release button unit

#621×2

#115-1

#119

#B116

- A ・ -

Page 33

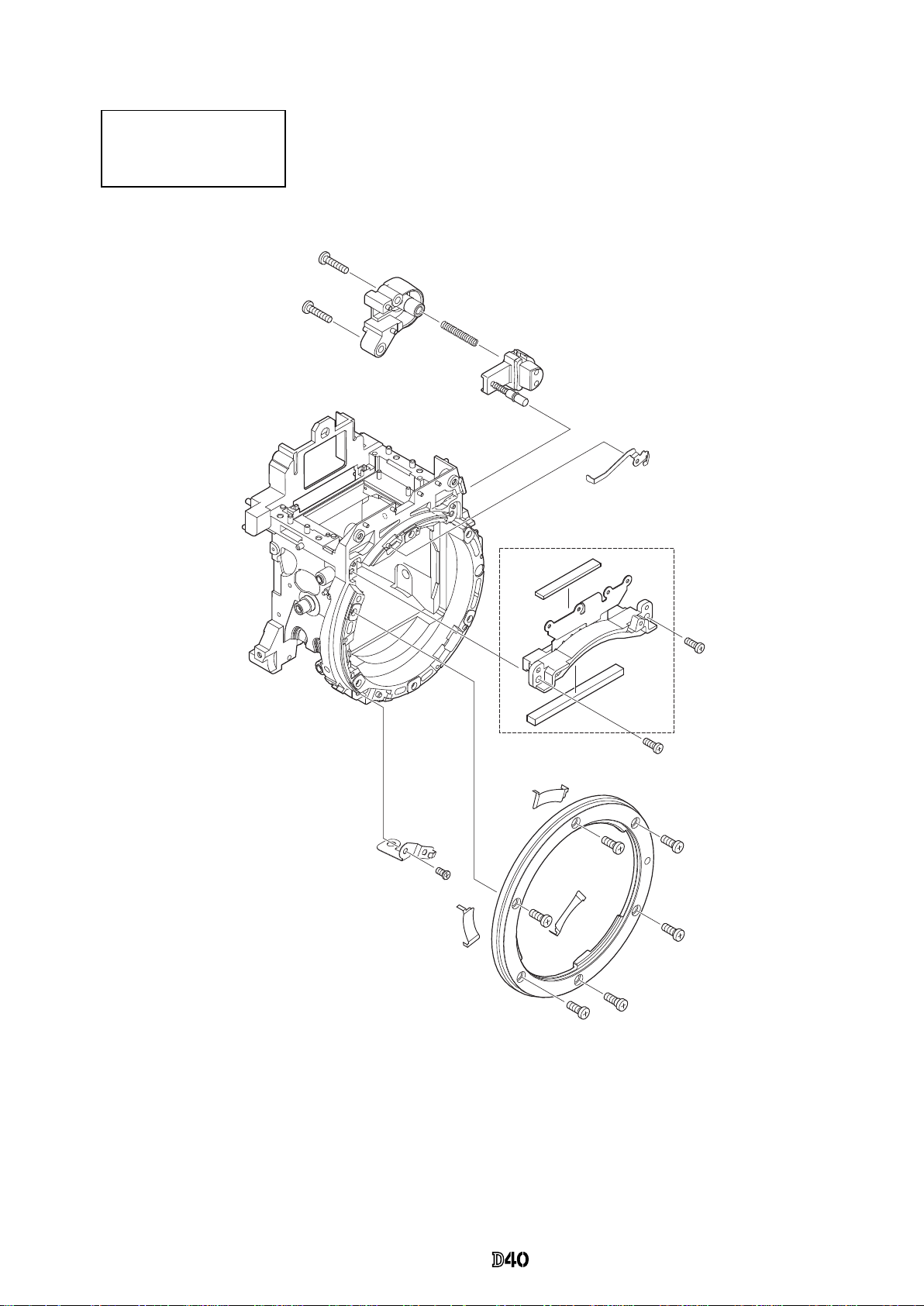

Bayonet

INC

Mount GND plate

Put [#135-1] and x it with the screw (#607).

・

Attach [#137-1].

・

Attach three pieces [#112].

・

Mount the bayonet (#111).

・

Tighten the screw (#660) and ve screws (#648)

・

in the order from ① to ⑥.

#135-1

#607

#112×3

②

④

#648×5

⑤

VBA15001-R.3701.A

#137-1

#112

Grease: LEN317A

#111

③

⑥

#660

①

Height adjustment of Aperture lever

Measure the height of the aperture lever by using the tool (J18004).

・

Standard: 3.4±0.1mm

In case the value is out of standard, make an adjustment by bending the aperture lever.

Be careful NOT to bend the inner part of the lever when adjusting.

Height of Aperture lever

3.4±0.1 mm

Aperture lever

- A ・ -

Page 34

VBA15001-R.3701.A

M

サービス

計画課

INC

Relay-PCB unit

Mount the relay-PCB unit (#1004-1) in the direction for positioning, and x it with the screw (#607).

・

Arrange the wires as shown in "Fig. ①".

・

Solder the ve wires (connected from

・

#607

SB-PCB, TOGO PCB, and SQ PCB unit).

Relay-PCB

Red:SB PCB

Pink:TOGO PCB

Through the hole

(Deletion)

Direction for positioning

Black:SB PCB

△

Super X

Solder here.

Red:SQ PCB unit

Black:SQ PCB unit

Arrange around bosses.

Front body FPC unit

Attach the front body-FPC (#1009), and connect it to the connector of the relay-PCB unit.

・

Attach the SI diffusing plate (#279) and SI-LCD FPC (#1011) and two pieces (#278).

・

Mount the SB SW unit (#B1012).

・

Make the three solder bridges.

・

#278×2

#1011

#279

SB SW unit (#B1012)

Fig.

①

Solder bridge ×3

Changed page

△× 1

Relay-PCB

#1009

Feb.05.2007

- A ・ -

Page 35

Fold the contact-FPC down, and attach it by tting the four bosses in the holes.

INC

・

Make seven solder bridges and four solder bridges.

・

Solder bridge×7

Solder bridge×4

VBA15001-R.3701.A

Contact-FPC

In-nder LCD unit

Fix the in-nder LCD unit (#B2010) with the two screws (#683).

・

#683×2

#B2010

#276

#295

#758

- A ・ -

Page 36

Shutter unit

M

サービス

計画課

INC

Turn the white gear in the direction of "A", and raise the mirror.

・

Mount the shutter unit (#31), and x it with two screws (#635).

・

Turn the white gear in the direction of "B", and let the mirror down.

・

(Addition)

Attach [#757].

・

△

△

#635×2

(Addition)

A

#757

VBA15001-R.3701.A

Shutter (#31)

B

SQ FPC

Attach the SQ FPC (#1014) by tting the bosses of the SQ-PCB unit in the holes.

・

Make ve solder bridges.

・

Solder the eight wires (connected from SQ, Fmin, and Mg).

・

SQ FPC (#1014)

Black:SQ

Black:Fmin

Boss×2

Changed page

△× 2

Solder bridge×4

Wire arrangement:

Do NOT let all the wires

positioned across this line.

Orange:Fmin

- A ・ -

Red:Mg

Blue:Mg

Yellow:SQ

Green:SQ Gray:SQ

Feb.05.2007

Page 37

VBA15001-R.3701.A

B2

2

INC

AF sensor unit

Put three springs (#161) and mount the AF sensor unit [#B2163].

・

Turn three screws (#162) with

・

Hexagonal wrench (φ1.5mm) in

the order from ① to ③ all the

way lightly to the end, then give

each two-turns counterclockwise.

Attach the AF sensor unit FPC by conforming to the external shape, and connect it to the connector.

・

#162×3

#161×3

②

③

①

#B2163

AF sensor unit FPC

Connection-FPC

Connect the connection-FPC (#1020) to the connector, and x it with the screw (#670).

・

#670

Connection-FPC (#1020)

- A ・ -

Page 38

VBA15001-R.3701.A

INC

Penta unit

Screen areas

Mount SI (#13-1).

・

Mount the nder eld frame 1 (#282-1).

・

Attach the in-nder display prism (#9).

・

Mount the SI-retaining unit (#B277) and x it with two screws (#635).

・

Mount the nder eld frame 2 (#283).

・

Mount the hollow penta (#B4).

・

Attach the penta-retaining springs (#201 and #202-1) and x them each with the two screws (#635).

・

Mount [#284], then [#3] and [#297A].

・

#759

Adhesive: Super X

#B4

#793×2

#9

#11

#635×2

#201

#202-1

#635×2

#B277

#282-1

#283

#13-1

#297A

#3

#284

- A 0 ・ -

Page 39

VBA15001-R.3701.A

INC

Eyepiece barrel unit

AE FPC unit

Mount the eyepiece barrel unit (#B261), and x it with two screws (#638).

・

Put the AE sensor adjusting-spring [#290] and AE FPC unit [#B2008], then x them with the screw (#291-1).

・

Put the AE sensor plate-spring (#285-3), and x it with the screw (#604).

・

Connect the FPC of the AE FPC unit (#B2008) to the connector.

・

Put the AE FPC retainer plate (#293), and x it with the screw (#607).

・

#604

#638×2

#291-1

#290

#285-3

#B261

#B2008

#293

#B2008

#607

- A ・ -

Page 40

Angle inspection and adjustment of Main mirror and sub-mirror

INC

Device:

*

VBA15001-R.3701.A

1.Main mirror 45° inspection and adjustment

Collimator (J19110)

①

Reection mirror (J18362)

②

Optical parallel (J18037-2)

③

Hexagonal wrench

④

Collimator

(J18037-2)

Bayonet

Eccentric pin for

the main mirror

2.Sub-mirror 47.75° inspection and adjustment

Collimator (J19110)

①

47.75° mirror tool (J61218)

②

Hexagonal wrench

③

Collimator

(J61218)

Bayonet

(J18362)

Standard

*

Left-right

deviation

Up-down

deviation

Distortion

Caution:

*

Before and after the adjustment, check the accuracy by moving the main mirror up- and downwards a few

・

Main mirror

Main mirror Sub-mirror

±25′

±5′

6′ or less

__

0′±3′

6′ or less

Up-down

Reference line

Eccentric pin for

the sub-mirror

Width of line indicates deviation

Left-right

Sub-mirror

times.

Check for the up-down deviation. In case the result is out of standard, make an adjustment by turning theCheck for the up-down deviation. In case the result is out of standard, make an adjustment by turning the

・

eccentric pin with Hexagonal wrench..

In case the the result of checking up-downward and right-leftward deviation is out of standard, the front plate

・

area or mirror unit should be defective.

In case inspection and adjustment are made for the mirror only in the front body, check again after assembling

・

the front body into the rear body.

- A ・ -

Page 41

2. Rear body

INC

Battery box

VBA15001-R.3701.A

#607×3

#157×3

DC/DC lug plate

Buzzer unit

Backup battery

Battery box

DC/DC lug plate

Eyelet ring unit

Other small parts

Put the DC/DC lug plate (#159-1) at the nal stage, then x the battery box with the four screws (#615).

・

#B145×2

#694×2

#615×4

#607

#694×2

#143×3

TA-0005

(7×15)

#159-1

- A ・ -

Page 42

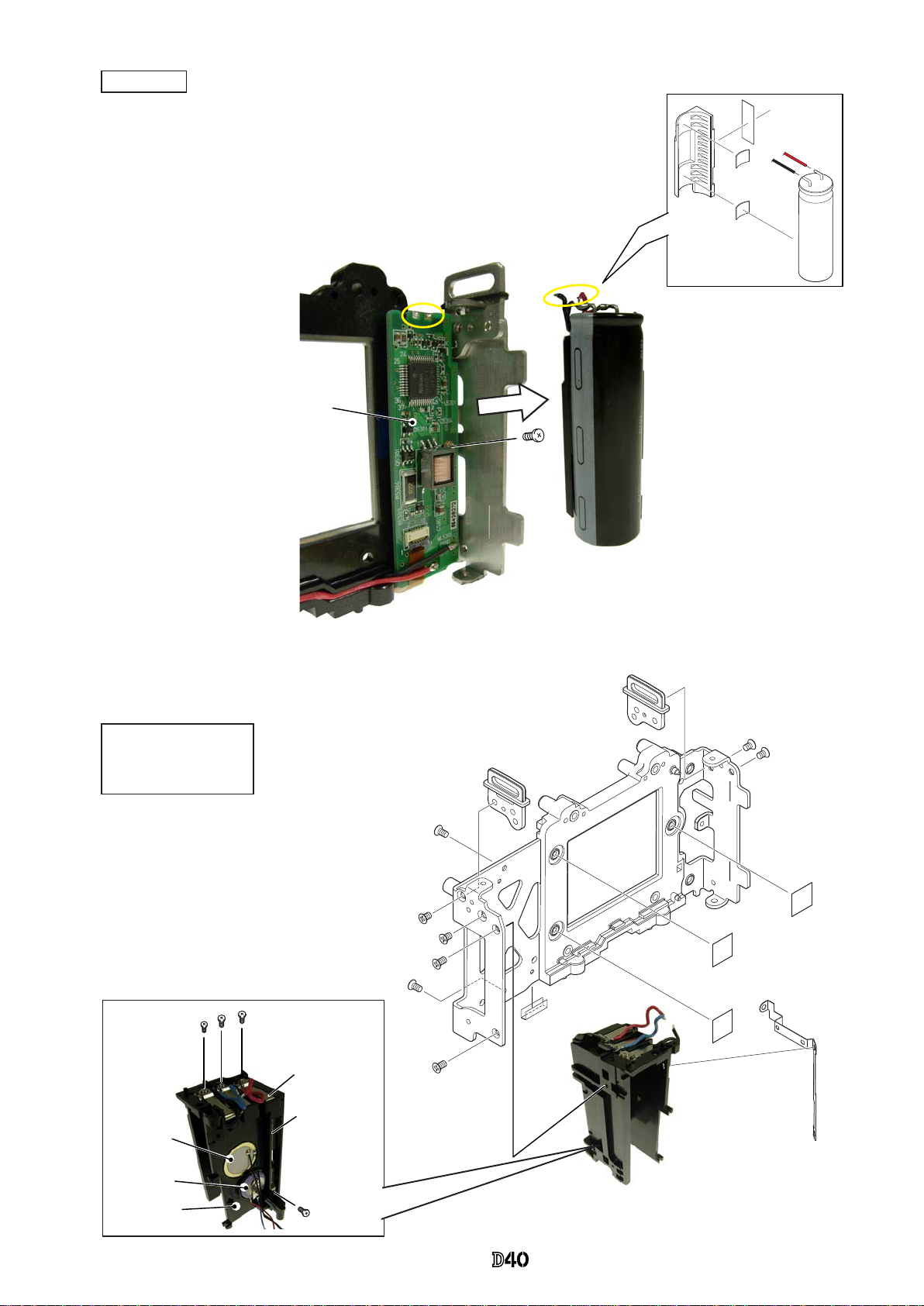

SB PCB

INC

Mount the SB-PCB, and x it with the screw (#687).

・

Solder the two wires (connected from DC/DC-PCB) and put them in the

・

groove for arrangement.

Adhere the main condenser with the adhesive double-coated tape by putting

・

in the direction for positioning.

Solder the two wires (yellow-circled) of the main condenser.

・

VBA15001-R.3701.A

Main condenser

#142

#1076

#1077

SB-PCB

Red

Black

FPC:TOGO-PCB

Solder

#141×2

#1043-3

Main condenser

#1043-3

#687

Black:DC/DC-PCB

Red:DC/DC-PCB

Groove

Direction for

positioning

- A ・ -

Page 43

VBA15001-R.3701.A

INC

DC/DC PCB

Mount the DC/DC-PCB, and x it with two screws (#670).

・

Put the wires in the groove for arrangement, and solder ve wires (connected from SB-PCB and Battery box).

・

#670×2

Groove

Blue: Battery box (ID)

Red: Battery box (+)

Black:SB-PCB

Red:SB-PCB

Remote block

Mount the remote block (#158-1), and x it with two screws (#683).

・

Attach SW-FPC [#B2006].

・

Black: Battery box (-)

DC/DC-PCB

Groove

#B2006

#354

#683×2

#158-1

- A ・ -

Page 44

VBA15001-R.3701.A

M

サービス

計画課

INC

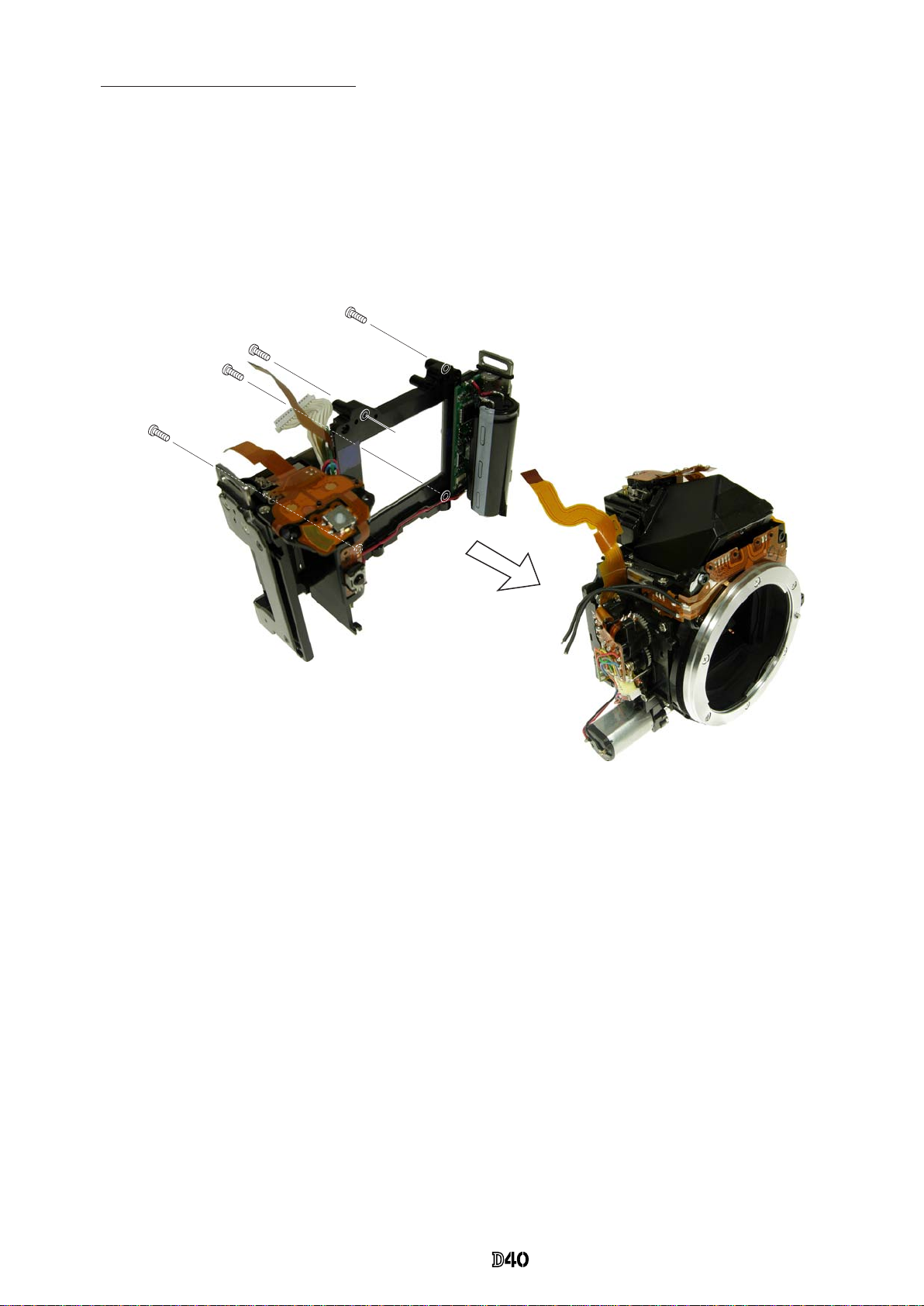

3. Mounting of Front body on Rear body

Mount the front body on the rear body

Pass the wires of the relay-PCB through behind the main condenser, and assemble the front body into the rear

・

body.

Tighten four screws (#624).

・

SB-PCB

Main condenser

#624×4

(Addition)

△

Bottom base plate unit

Do NOT let wires

mount on the coil.

Mount the bottom base plate unit (#B66-2) so that [#135-1] comes in front, and x it

・

with two screws (#691) and ve screws (#616).

#616×5

#135-1

Direction for

positioning

Pull the wires from

#691

Changed page

△× 1

here.

- A 1 ・ -

#691

FPC must NOT

mount on this.

Bottom base plate unit

(#B66-2)

Feb.05.2007

Page 45

Inspection and Adjustment of Body back

M

サービス

計画課

INC

* "0" positioning of the dial gauge

Surface plate

VBA15001-R.3701.A

0

50

40

30

70

0

20

90

10

0

0" position of D40

10

0

Put the tool (J18001-1) on the surface plate, and set the dial gauge to "0".

①

Turn the index ring in the direction of the arrow, and set to the scale "8" from "0" that was set in ①. (This is

②

"0"-position of D40.)

Measure the body back based on "0" reference position of the index ring.

③

(Revision)

△

Measure three parts from the bayonet face to the CCD-

・

PCB attaching face.

Standard:48.59±0.015mm/ Parallelism: within 0.015mm

・In case it is out of standard, make an adjustment

by loosening screws that attach the front and rear bodies,

or by putting the washer(s) on the contact surface

between the front body and rear body.

Measuring point

Note: For some bodies, washer(s) are already put on the attaching face of the CCD-bracket.

There are two cases as follows.

1. Purpose:To adjust the height of the camera body

There are indications by color marker on the CCD-PCB attaching face of the camera body side .

{Blue =0.02mm (#87), Red

By adding the measured value to the thickness of washers, check if it is within the standard (48.59±0.015mm).

*

0.01mm (#88), Green =0.06mm (#89)}

=

2. Purpose:To adjust the height of the CCD bracket

There are indications by marker on the CCD-bracket attaching face

One marking=Put three washers [#88(0.02mm)] at three places

Fig.

①

Two markings=Put three washers [#87(0.1mm)] at three places

When the CCD PCB is replaced, remove the washers.

*

(Addition)

△

Any marking(s) of the three in the right "Fig.①"

3.

=

Put the tracing-lm sheet (#84) in the marked place(s).

Changed page

△× 2

- A 17 ・ -

Marking

Feb.05.2007

Page 46

DC/DC PCB

M

サービス

計画課

INC

Solder the two wires (connected from Mount GND plate and Front body FPC).

・

Black: Mount GND plate

Black: Front body FPC

VBA15001-R.3701.A

SB PCB

Solder the two wires (connected from Relay-PCB).

・

Red: Relay-PCB

Black: Relay-PCB

Changed page (Overall revision)

- A 1 ・ -

Feb.05.2007

Page 47

Assembly of Top cover

AUT

O

M

サービス

計画課

INC

Top cover FPC unit / other small parts

Fix [#322], [#B317], shoe base (#316), and [#318-1] with four screws (#654).

・

Fix the mode dial unit (#B5375), [#373], and [#372] with the screw (#640).

・

Fix the C/D unit (#B367) with two screws (#635).

・

Attach [#387-2] and AF/AE lock button (#5386-1).

・

#318-1

#B5375

#B317

Grease:

LEN317A

Oil barrier: OS-30MF

#27-2

Grease:

LEN317A

Grease:

LEN317A

(Revision)

△

VBA15001-R.3701.A

#316

#311-1×2

#322

#5386-1

#387-2

Adhesive Super X

#654×4

#326

#373

Adhesive Super X

#372

#640

#B367

Direction for positioning

#635×2

Changed page

△× 1

Feb.05.2007

- A 19 ・ -

Page 48

SB lower case unit / SB release base unit / Buttons

AUT

O

INC

Mount the SB lower case unit (#B2302).

・

Arrange the wire (#1070-1) as shown below.

・

Mount the top cover FPC unit (#B2007-1), and x it with two screws (#635).

・

Make three solder bridges.

・

Mount the SB release base unit (#B2455), and x it with two screws (#607).

・

VBA15001-R.3701.A

While releasing the two hooks, attach [#308-1].

・

Arrange the wires, and x them with the screw (#650).

・

Grease: LEN317A

#B2302

Grease: LEN317A

Hook ×2

#308-1

Solder bridge ×3

#635×2

Grease: LEN317A

#B2007-1

#1071-1

Grease: LEN317A

#607×2

#B2455

#650

Black : DC/DC PCB PCB

Arrange wires.

- A 0 ・ -

Page 49

VBA15001-R.3701.A

AUT

O

info

INC

While pressing the SB case rotating shaft (#306-1), attach the SB-up spring (#305-1) by pushing it in the attach the SB-up spring (#305-1) by pushing it in the

・

direction of the arrow, then x it with the screw (#733).

#305-1

#733

#306-1

Mount the release button unit (#B5350), [#347-1], and [#348], and x them with two screws (#605).

・

Attach the INFO button (#5383-1), ±aperture button (#5381), and rubber SW (#382-2).

・

Grease: LEN317A

Put the

button with

ON-directed.

#B5350

#5383-1

#5381

#382-2

#956

#347-1

#348

#605×2

- A ・ -

Page 50

AF-assist illuminator unit

M

サービス

計画課

INC

Mount the AF-assist illuminator unit (#B325-1), and x it with the screw (#608).

・

Solder the two wires (connected from AF-assist illuminator unit).

・

#608

AF-assist illuminator unit (#B325-1)

Black : AF-assist illuminator unit

Uncoated wire: AF-assist illuminator unit

VBA15001-R.3701.A

Top cover FPC / Wiring

Make ve solder bridges.

・

Solder the seven wires (connected from SB lower case unit, DC/DC PCB and SB release base unit).

・

Red: SB lower case unit

Blue: SB lower case unit

Green: SB lower case unit

Black: SB lower case unit

Black: DC/DC PCB

Solder bridge

×5

Red: SB release base unit

Revision)

△ (

Blue: SB release base unit

Black: SB release base unit

Changed page

△× 1

Feb.05.2007

- A 22 ・ -

Page 51

SB upper case

INC

Mount the SB upper case (#5301) on the SB lower case unit.

・

VBA15001-R.3701.A

SB upper case

Claw

Press the pop-up lever A part of the top cover unit, and raise the built-in SB.

・

#5301

SB lower case unit

Tighten two screws (#632).

・

Pop-up lever A part

#632×2

- A ・ -

Page 52

info

AUT

O

When the AE-CCD positioning is adjusted, solder the only four wires that connected from the

M

サービス

計画課

INC

top cover to SB-PCB. Then, make a temporary assembly without mounting the rubber eye-

Top cover

Mount the rubber eyecap (#B271).

・

Watching the wires and FPCs, mount the top cover.

・

Tighten two screws (#5737) and two screws (#635).

・

cap (#B271), and assemble up to Page A25.

(Revision) 0~n

△

#797×2

#B271

#796A~D×n

VBA15001-R.3701.A

#5737×2

DC/DC PCB unit

Solder the wire (connected from Top cover).

・

SB PCB

Solder the four wires

・

Orange: Top cover

White: Top cover

(connected from Top

cover).

Gray: Top cover

Black: Top cover

#635×2

Black: Top cover

Changed page

△×1

- A 24 ・ -

Feb.05.2007

Page 53

VBA15001-R.3701.A

INC

CCD unit

Mount the CCD unit (#B3051-1) by following the direction for positioning, and x it with three screws (#631).

・

#B3051-1

TOGO PCB unit

#631×3

Direction for positioning

Caution:

Some bodies have already washer(s) attached on

the mounting surface of CCD unit.

Connect the harness.

・

Watching the wires and FPCs, mount the TOGO-PCB (#B2001-1).

・

Tighten ve screws (#663).

・

Solder ve wires (connected from Relay-PCB, Backup battery and Buzzer unit).

・

Connect the FPC to the connector at eight places.

・

Pink: Relay-PCB

TOGO-PCB (#B2001-1)

TOGO-PCB unit: Back

Harness

Blue:

Backup battery

Red:

Backup battery

Gray:

Buzzer unit

Gray:

Buzzer unit

- A ・ -

Pull the wires from here.

#663×5

Page 54

VBA15001-R.3701.A

㧍

内部に高電圧部あり。カバーを外す 時は感電に注意すること。

カバーを外した後は、修理指針の指 示に従ってメインコンデン

サーの放電を必ず行うこと。

警告

INC

Adjustment of AE CCD positioning

WARNING

Take extra care not to get an electric shock when detaching

covers.

After removing covers, be sure to discharge the main

condenser according to the instructions of repair manuals

Under the environment where the AE-CCD positioning is adjusted, use the reference body (and change the

*

environment depending on measured results).

In case the measured value is out of standard, check if there is no misalignment of the focus areas.

・

In case the measured value is out of standard, change the environment of measurements. (e.g. setting place/

・

direction, room brightness, etc)

Procedure

Only solder the four wires (connected from the top cover) on the SB-PCB. Assemble temporarily withoutolder the four wires (connected from the top cover) on the SB-PCB. Assemble temporarily without

①

attaching the screws (for xing the top cover) and mounting the rubber eyecap (#B271), then make a

temporary assembly of the front cover unit (#B5024) and rear cover with four screws (#5690).

Mount "AF50/1.4D" on the camera, and x them on the tripod horizontally.

②

Connect the camera and PC via USB cable (UC-E4).

③

Provide power by the battery tool (J61219).

④

**

⑦

Looking through the viewnder, move the camera so that the focus areas of the camera coincide with the

*

⑧

*

⑨

⑩

⑪

Be careful NOT to cause a short-circuit at uncovered portions.

Attach the AE-CCD positioning tool (J15428) in the color viewer (J63070), and turn power ON.

Keep the 0.7-m distance between the front face of the AE-CCD positioning tool and the reference surface

of the camera. Set the camera AF to manual, and the focus ring to "0.7 m" by rotating it.

Start up the inspection and adjustment software for D40 (J18416), and select "Inspection and Adjustment

for AE CCD POSITION" then "Set Camera for AE CCD POSITION".

circular holes of the AE-CCD positioning tool.

Set the camera and AE-CCD positioning tool horizontally.

Select "Inspection and Adjustment for AE CCD POSITION".

Cover the camera with a black cloth, etc, when measured.

Attach the metering FPC unit without tightening three screws (#291). Then give each screw two and half

turns counterclockwise. By following instructions on PC, make the position adjustment of AE-CCD by the

screws (a:#741, b:#291).

Fix the two screws with screwlock.

Fix the four locations of the AE CCD sensor-base with screwlock. (ref. Page A27 for the adhering posi-

.

tions.)

AE-CCD positioning

tool (J15428)

AF50/1.4

Approx. 0.7

Color viewer (J63070)

m

- A ・ -

D

Attaching surface of

the imaging-PCB

Page 55

VBA15001-R.3701.A

INC

-direction (a)

X

tightening

Standard →

X-direction

Y-direction

Y-direction (b)

tightening

Y-direction (b) loosening

Reference screw

→

→

a: Screw

b: Screw

-direction (a)

X

loosening

a:

#741

#B2008Metering FPC unit

Adhesive: Screwlock

b:

#291

Discharge of Main condenser

Discharge currents from both terminals of the main condenser.

・

2KQ/5W

Main

condenser

After completing the adjustment, remove the temporarily-assembled rear cover and front cover. Then mount

⑫

the rubber eyepiece (#B271) and x the top cover with two screws (#5737) and two screws (#635).

- A ・ -

Page 56

Covers

INC

Assemble the front cover unit

・

(#B5024) together with the

Fmin coupling block (#131).

VBA15001-R.3701.A

#5610×2

Adhesive: Super X

#B5024

#5074

#670

#626

#131

Gap adjustment of SB lighting unit

In case the result is out of standard, pop the SB unit up

・

and make an adjustment by turning the adjusting dial

with Hexagonal wrench.

#5120

#5610×2

#29-2

#26-2

Standard: 0.14~0.5mm

Adjusting dial

- A ・ -

Page 57

A

A

INC

Rear cover

VBA15001-R.3701.A

#402-3

Direction for positioning

#448

#408

#403

#5401-7

#5429-2

#423-2

#5424-4

#5425-3

#5426-3

#5427-3

#421-2

#405×2

#404×2

Direction for positioning

#1037

#5412-1

#5431-1

#5418-5

#413-1

#B5431

#414

#453

#1016-3

#433

#451×2

#406-3

#452

#750

#670×3

#630×3

#407-2×2

#5681×2

#5432-1

- A ・ -

Page 58

M

サービス

計画課

INC

Rear cover (continued)

Connect the TFT-PCB connection-FPC to the connector.

・

Mount the rear cover.

・

Tighten four screws (#5690) and two screws (#5618).

・

(Addition)

△

NK

#5690×4

VBA15001-R.3701.A

#5618×2

TFT-PCB connection-FPC

Rear cover

Changed page

△×1

- A 30 ・ -

Feb.05.2007

Page 59

Accuracy inspection and adjustment (Camera body)

INC

(except Image unit)

USB cable: UC-E4

VBA15001-R.3701.A

: New tool

★

To USB terminal

★

D40 adjustment FD: IBM 3.5

Shutter tester (EF-1) (J19123)

J18416

Stabilized power source(Set value = 7.4V

0.3Ω 5.0A)

+ D40 battery tool (J61219) or

AC adapter (EH-5)

Power connector (EP-5)

+

★

D40 battery

tool (J61219)

Caution: When performing “Adjustment for BATTERY

CHECK LEVEL” use the D40 battery tool (J61219).

Flash meter

AE-CCD positioning tool (J15428)

Set up in front of color viewer (J63070)

J18267

Caution:

When the inspection and adjustment are made with the shutter tester, turn the tester ON to light a lamp, and carry out the

aging for 3-5 minutes.

AF28/2.8D

- A ・ -

Page 60

VBA15001-R.3701.A

INC

D40 Inspection and Adjustment Software (J18416)

This inspection and adjustment software runs on Windows.

Install the software by following the below procedure.

<Operating environment>

Check the following operating environment which is required for installing this program on PC.

PC IBM PC/AT compatible

OS Windows XP Professional Edition, Windows XP Home Edition,

Windows2000,

CPU Pentium II 300MHz ~

RAM (memory) 256 MB or more

HD 6MB-or-more free disk space is required when installing

Monitor resolution 1024 × 768 pixels or more

Interface

As long as the above hardware requirements are met, any PC such as desktop or laptop, etc is available.

※ USB interface (V1.1, 2.0)

< Cautions in starting program >

When starting this program, close all the other applications.

If some other applications are running, this program may not be activated.

< File >

D40.exe Application execution le

NkdPTP.dll Library le: USB communication application extension le for Windows XP

NkdPTPDi.dll Library le: USB communication application extension le for Windows 2000

PTPC Driver le storing folder for PTP: for Windows 2000

- A ・ -

Page 61

VBA15001-R.3701.A

INC

<Procedure for installation>

The le (PD40.EXE) of this program is provided via FD or e-mail.

Because this is the self-extracting le, decompress the le before installing, and follow the next procedure.

1. Create a folder for install under any name in any drive.

(e.g.)C: ¥D40

2. Paste the le (PD40.EXE) in the created folder.

- A ・ -

Page 62

3. Double-click on the pasted le to display the following screen.

INC

Press the OK button, then decompression starts.

VBA15001-R.3701.A

4. When the decompression of le is nished, the le (D40.exe) is created.

5. The install is completed.

- A ・ -

Page 63

VBA15001-R.3701.A

INC

< Procedure for installing USB driver >

If this program is used by the USB interface, installing the USB driver is necessary.

But if the OS is "Windows XP", the driver is already preloaded so it is not necessary to install it.

1. Set the USB of camera to "PTP".

(SETUP menu → USB setting → PTP)

2. Connect the camera and PC by USB cable.

Turn camera ON.

3. When "Add New Hardware Wizard" is displayed, click "Next".

4.Click "Yes".

5. Click "Reference". Select “C:\D40\PTPC" of C drive, and click "OK".

6. Reboot the PC and the install is completed.

- A ・ -

Page 64

VBA15001-R.3701.A

INC

<Start-up of Program>

1. Double-click the le (D40.exe), then Inspection and adjustment program for D40 starts.

2. To display in Japanese, select the radio button "JAPANESE" in "LANGUAGE" in the lower right-hand corner

of the screen.

However, this is not properly viewed in the English OS.

. When the "Version" button at the lower-left is pressed, the program version will be displayed.

. Select each item button according to operation.

Follow the instructions on the next screen that will be shown after pressing the item button.

. To nish the program, press the "Close (×)" button in the right-hand corner of the screen or "QUIT.".

- A ・ -

Page 65

VBA15001-R.3701.A

INC

AE inspection and adjustment

USB connection communication

《

AE CCD alignment inspection and adjustment (ref. Page A26, A27 for details

①

AE accuracy inspection and adjustment

②

Aperture accuracy inspection

③

Adjustment for battery check level [Use the D40 battery tool (J61219) and stabilized power supply.]

④

Built-in SB ash inspection and adjustment

〔Tools required〕ref. Page A31.

AE accuracy inspection and adjustment

・

When AE accuracy inspection and adjustment is made,

Two types of lenses (AF50/1.4D and AF28/2.8D) are used.

Caution:

AE accuracy is not inspected in the traditional manner that uses the exposure value of the shutter tester. The

metering value is displayed on PC screen.

Battery check voltage level adjustment

・

Connect the D40 battery tool (J61219) to the camera, and turn the communication change-SW to ON. Then

make adjustment.

》

)

Built-in SB ash inspection and adjustment

・

Set the distance between camera and ash meter to 1 m, and inspect and adjust the light volume of the built-in

SB. (ref. adjustment software for details)

AF inspection and adjustment

Note: When using the adjustment software for the rst time, prepare three cameras of D40 and measure by

"WRITING of AF ADJ. LENS OFFSET VALUE" on the main menu.

<< USB connected communication >>

AF accuracy adjustment (Make the overall following adjustment.)

①

YAW, PITCH inspection and adjustment

②

LARK adjustment (inc.

③

④ AF shift adjustment

〔Tools required〕

1. When adjusting for all adjustment items

ref. Page A31.

2. When inspecting AF accuracy

① AF

②

③

④

3. When adjusting YAW, PITCH

4. When adjusting LARK

The above tool when inspecting AF accuracy

In "AF shift adjustment", the distance from the bayonet reference plane to the imaging area (CCD) is calculated

by the actual shot photo, and its error is recorded in EEPROM as compensation amount, and adjusted.

adjustment Z lens (J18266)

AF adjusting tool (J15259

Lens holder (J15280)

AF accuracy measuring chart D40 (

Chart illuminator for AF

YAW, PITCH tool(J18230

CCD output adjustment)

)

J18415)

(J15264)

)

- A ・ -

Page 66

Bottom cover

M

サービス

計画課

INC

Mount the bottom cover.

・

Fix it with four screws (#5735) and ve screws (#5674).

・

VBA15001-R.3701.A

(Addition)

△

#5674

Grease:MZ-00S

#5735

#5674

#5674

#5674×2

#5735

Bottom cover

#5735×2

∞ Innity focus inspection & adjustment

Replace the nder screen with the innity focus adjustment screen (J15410), and use the reference lens (J18010)

・

and read the value. In case it is out of standard, increase or decrease washers (#297A, #297B) for adjustments.

Caution: When (J15410) is put in to replace the nder screen, put it with the silver spacers upward, which are

attached on both sides.

"0" position

J18010

Reference line

Standard:

#297A 1K602-153 Innity-focus adjusting washer

#297B 1K602-154 Innity-focus adjusting washer

±0.06mm

(T=0.1) 0.10mm

(T=0.2) 0.20mm

1 scale

0.01mm

=

)

Changed page

△× 1

Feb.05.2007

- A 3 ・ -

Page 67

Necessary adjustments when parts are replaced

INC

1. D40 adjustment software and updates

Replacement parts

Shutter unit

TOGO PCB unit

Firmware

(

MAIN,RISC)

Adjustments

*

Writing of

EEPROM

xed

values

2

○ △ ○ ○ ○ ○ ○

AE CCD

positioning

adjustment

*

accuracy

inspection &

adjustment

AE

Aperture

accuracy

inspection

Battery

check volt-

age level

adjustment

Built-in SB

light volume

inspection &

adjustment

VBA15001-R.3701.A

AF

accuracy

inspection &

adjustment

Relay-PCB

EEPROM

(

AF sensor unit

Top cover or

SB lower case unit

DC/DC PCB unit

Metering FPC unit

)

*

2

*

○ △ ○ ○ ○ ○ ○

○

○

○ ○

○ ○

Aperture control PCB

unit

1. Make an inspection.

*

2.When only TOGO PCB unit is replaced without replacing the relay-PCB, be sure to update the MAIN and RISC

*

rmware before writing the xed values.

Caution: If the rmware cannot be recognized by MAIN rmware name (AD40XXXXXX.bin), change the rmware name

to (A330XXXXXX.bin), and update again. If the RISC rmware name (R330XXXX.BIN) is used, update by

following the procedure for forcible updating on Page A49.

When both TOGO PCB and relay-PCB are replaced at the same time, write the xed values and update the MAIN

and RISC rmware. Then, write the xed values again and make an adjustment.

○

- A ・ -

Page 68

2. Shooting image adjustment software and Software updates

INC

Writing

Adjustments

Replacement

parts

Shutter unit

Writing

of xed

values

2

*

Sensi-

tivity

Gr/Gb com-

pensation

adj. (R/B

lter)

Sensitiv-

ity ratio

Pixel

defect

com-

pensa-

tion -

Black

point

Pixel

defect

compen-

sation -

White

point

of TFT

xed

values

VBA15001-R.3701.A

Factory

default

setting

Relay PCB

AF sensor unit

DC/DC PCB unit

Metering FPC unit

TOGO PCB unit

Firmware MAIN,RISC)

(

CCD/FPC PCB unit

TFT monitor

*1.

EEPROM

(

*

)

1

○ ○ ○ ○ ○ ○ ○ ○

○ ○ ○ ○ ○

○

When TOGO-PCB unit is replaced, be sure to update the rmware before writing the xed values.

When both TOGO-PCB unit and relay-PCB are replaced at the same time, write the xed values before updating,

and after updating the MAIN and RISC rmware, write the xed values again.

When TOGO PCB is adjusted, the xed values are written automatically.

*2.

- A 0 ・ -

Page 69

VBA15001-R.3701.A

INC

Shooting Image Adjustment

1. Summary

When D40 shooting image-related and listed parts on Page A40 are replaced, be sure to make an adjustment

by the shooting image adjustment software for D40 (J65094). The details of its function and how to use this

software are as follows:

2. Adjustment software function

① "Sensitivity" adjustment

② Gr/Gb compensation adjustment (R/B lter) / Line crawl adjustment

③ "Sensitivity ratio" adjustment

④ Pixel defect compensation - black point

Pixel defect compensation - white point

Getting reference values

⑦ Factory default setting

⑧ Checking of the adjustment value

⑨ Reading of RISC version

⑩ TFT adjustment

※ When the adjustments from ① to ③ are made, get in advance the reference values of by using the

reference body, then perform the adjustments.

3. Hardware requirements

OS: Windows2000, WindowsXP

Japanese or English OS

PC: CPU Pentium Ⅱ or more

Memory 256MB or more

USB1.1 or 2.0

Screen size: 1024×768 pixels or more

4. How to set up

Create any directory in the hard disc (except desk top) of PC, and copy the following les.

・D40IMG.exe・・・・・・・Application le

・D40STD.DAT ・・・・・・ Standard le

・NkdPTP.dll・・・・・・・・USB-communication application extension le for WinXP

・NkdPTPDi.dll・・・・・・・USB-communication application extension le for Win98SE and Win2000

・CCDFLG.DAT・・・・・・・ Fixed value data for TOGO-PCB adjustment

・CCDINIT.DAT ・・・・・・・Fixed value data for TOGO-PCB adjustment

・TFTFLG.DAT ・・・・・・TFT xed value data

・TFTINIT.DAT ・・・・・・・TFT xed value data

※ Be sure to copy the above le in the same directory.

5. Install of USB driver

When this software is used, the USB driver is necessary. However, this install becomes unnecessary if the D40

camera inspection and adjustment program was installed including the USB driver.

Also, WindowsXP OS has already the USB driver, so this install anew is not necessary, either.

- A ・ -

Page 70

VBA15001-R.3701.A

INC

6. Basic usage

(1) Execute "D40IMG.exe" to start up the main screen. (ref. Fig.1)

(2) Select ENGLISH / JAPANESE in Language to display any menu. (ref. Fig.2)

(3) Click the button to start adjustments.

※ When the adjustments from ① to are made, calculate to get the reference values ( ) by using the

reference body beforehand, then perform the adjustments.

(4) Follow the instructions on screen.

(5) To complete the procedure, click "QUIT" button or "X" button at the upper-right corner of the menu.

Fig.1

Fig.2

- A ・ -

Page 71

VBA15001-R.3701.A

INC

7. Required equipment and conditions

※ AC adapter EH-5, Power connector (EP-5) and USB cable (mini B type) UC-E4 are used for all

adjustments so they are not specied in the list.

Item Required device Setting/Remarks

1 Sensitivity adjustment

2 Gr/Gb compensation adjustment

(R/B lter)

/ Line crawl adjustment

3 Sensitivity ratio adjustment

4 Pixel defect compensation -

black point

・5100K color viewer J63070J63070

(ex-model viewer J63049 is also available.)

・Luminance meter BM-3000 J63068

・Tool lens (to x aperture) J61185

・ND lter (ND8×2)ND8×2)

・5100K color viewer J63070J63070

(ex-model viewer J63049 is also available.)

・Luminance meter BM-3000 J63068

・Tool lens (Fixed aperture) J61185

・SP3 (R lter) J63087

・SP1 (B lter) J63085

・ Shutter tester

・Tool lens (to x aperture) J61185

・5100K color viewer J63070

(ex-model viewer J63049 is also available.)

Luminance LV13 equivalent

Aperture F8

52 mm,

Use the packaged product; 6-step light

reduction

Luminance LV13 equivalent

Aperture F5.6

Luminance LV12

Aperture F5.6; No lter

Luminance LV13 equivalent

★ New tool

・Luminance meter BM-3000 J63068

・Tool lens (to x aperture) J61185

5 Pixel defect compensation -

white point

6 Getting of reference values Same as "Sensitivity adjustment" and "sen-

7 Factory default setting None

8 Checking of adjustment value None

9 Reading of RISC version None

10 TFT adjustment None

Body cap or lens capdy cap or lens cap Environmental temperature approx. 20

sitivity ratio adjustment".

Aperture F5.6; No lter

- 25℃

- A ・ -

Page 72

VBA15001-R.3701.A

INC

8. Summary

The summary on each adjustment is as follows:

① Sensitivity adjustment

Camera is faced to the color viewer of LV13 equiv. with ND lter (-6 steps) being put between them, and

the adjustment is made by changing the ampgain so that G output can fall in the standard range. The gain

value is adjusted so that the G output average value (Average of Gr/Gb) in the center (300×300 pixels) can

reach the target output level (approx. 960LSB). The actual adjustment of the gain value is made only under

the condition of ISO200 and ISO1600, and the medium sensitivity is calculated by the adjustment values

of these 2 conditions.

For target output level, G output average of sensitivity reference value (ISO200) is used, which was

calculated by the reference body.

② Gr/Gb compensation adjustment (R/B lter) / Line crawl adjustment

Camera is faced to the light-emitting box (color viewer) of LV13 equiv. with SP3 (R lter) or SP1 (B lter)

being put between them, and the adjustment is made so that the difference in G output average between

B-G line and G-R line, when the whole screen is divided in areas, can fall in the standard range.

③ Sensitivity ratio adjustment

With the shutter tester of LV13, the adjustment is made so that the R/G, B/G output becomes the same

as the output ratio of the sensitivity ratio reference value that was calculated by the reference body. The

adjustment is made only under the condition of ISO200, and the average value of the center (300 pixels ×

300 pixels) is used.

④ Pixel defect compensation - black point

When pixels of which the output level is under specied value with LV13 equiv., are detected, the

coordinates of the detected pixels are rewritten as pixel defect compensation data.

Pixel defect compensation - white point

Shots are taken on the dark surface. In case the pixel output is found to be beyond the standard value, the

detected pixel coordinate is additionally written as the pixel defect compensation data.

Getting of reference values

・Sensitivity reference value calculation

The reference body is faced to the color viewer of LV13 equiv. with the ND lter (-6 step) being put

between them. Then, store the G output average value of the center (300 pixels × 300 pixels) is stored in

the D40BSD.DAT le as the sensitivity reference value.

・Sensitivity ratio reference value calculation

The reference body is faced to the shutter tester of LV 12 equiv. (without lter). Then, the sensitivity

ratio reference value GR and GB is calculated, based on the G/R/B output average of the center (300

pixels × 300 pixels), and they are stored in the D40BSD.DAT le.

It is necessary to calculate the reference values of "Sensitivity" and "Sensitivity ratio" in order to prevent

the color temperature uctuation caused by color viewer's changes over time from affecting the results of

the shooting image adjustment. By using the reference body, calculate the reference values once in about

every 3 months, when the uorescent of the color viewer is replaced.

- A ・ -

Page 73

⑦ Factory default setting

INC

This selects and sets the language and video mode at the time of shipping products.

⑧ Checking of adjustment value

The adjustment value is conrmed, functioning as substitute for the traditional "READING AND

REWRITING OF EEPROM DATA.".

⑨ Reading of RISC version

The RISC rmware version is displayed.

⑩ TFT adjustment

None

VBA15001-R.3701.A

- A ・ -

Page 74

VBA15001-R.3701.A

INC

9. Procedure

9-1. TOGO PCB adjustment

● Calculate the "Sensitivity" and "Sensitivity ratio" reference values by using D40 reference body beforehand,

then perform the adjustments. (ref. 9-4.)

● For shooting image adjustment, make all items from ① to ③ . The adjustments from ① through ③ are all

programmed to be executed in serial order. When 1 item is completed, the software automatically goes on

to the next adjustment.

● In case adjustments are interrupted by NG, the adjustments can be continued again after NG. As for

adjustments that were ended with OK, saving the adjustment values in EEPROM and updating the ash

memory are completed.

Note: Adjustments are not possible without resetting "Custom setting" of this camera.

*

Start adjustments

・Provide the power for the camera via AC adapter.

・Reset "Custom setting".

・Set "PTP" mode by Setup menu.

・Set the focus mode to M, exposure mode to M, and the exposure compensation to "0" of the camera.

・Connect the camera and PC via USB cable.

・Set the luminance of the color viewer to LV13 equivalent.

・Set the shutter tester to LV12. (for sensitivity ratio)

① Sensitivity adjustment

・Click "SENSITIVITY ADJUSTMENT" of the main menu on screen.

・Click "Start".

・Setting conditions are indicated.

・Attach the tool lens (Aperture F8) and ND lter (ND 8× 2)to the camera.

・Get the camera closest to the center of the illuminated surface of the color viewer.

・Click "OK".

Before the adjustments, record the details of "Custom setting" set by customers if necessary.

・The adjustment starts. When it is completed, "OK" is displayed.

・Click "OK".

・Click "Next".

② Gr/Gb compensation adjustment (R/B lter)

・Click "Gr/Gb COMPENSATION ADJ (R/B FILTER)" on the menu.

・Setting conditions are displayed soon.

・Attach the tool lens (Aperture F5.6) and SP3 (R lter) to the camera.

・Get the camera closest to the center of the illuminated surface of the color viewer.。

・Click "OK".

・The adjustment starts. When it is completed, the next conditions are displayed.

・Attach the tool lens (Aperture F5.6) and SP3 (B lter) to the camera.

・Get the camera closest to the center of the illuminated surface of the color viewer.。

・Click "OK".

・The adjustment starts. When it is completed, the next conditions are displayed.

- A ・ -

Page 75

VBA15001-R.3701.A

INC

[・Attach the tool lens (Aperture F5.6) and SP1 (B lter) to the camera.]

・Get the camera closest to the center of the illuminated surface of the color viewer.

・Click "OK".

・The adjustment starts. When it is completed, the next conditions are displayed.

・Attach the tool lens (Aperture F5.6) and SP3 (R lter) to the camera.

・Click "OK".

・The adjustment starts. When it is completed, "OK" is displayed.

・Click "OK".

・Click "Next".

③ Sensitivity ratio adjustment

・Click "Start".

・Setting conditions are indicated.

・Attach the tool lens (Aperture F5.6) to the camera (without lter).

・Get the camera closest to the center of the illuminated surface of the shutter tester (LV12).

・Click "OK".

・The adjustment starts. When it is completed, "OK" is displayed.

・Click "OK".

・Click "Next".

9-2. Pixel defect compensation

④ Compensation - black point

・Set the color viewer luminance to LV13 equiv.

・Provide the power for the camera via AC adapter.

・Reset "Custom setting".

・Set "PTP" mode by Setup menu.

・Set the focus mode to M, exposure mode to M, and the exposure compensation to "0" of the camera.

・Connect the camera and PC via USB cable.

・Click "Start".

・Setting conditions are indicated.

・Attach the tool lens (Aperture F5.6) to the camera (without lter).

・Get the camera closest to the center of the illuminated surface of the color viewer.

・Click "OK".

・When the adjustment starts, pixel defects are detected, displaying the number of pixels and addresses.

・When it is completed, "OK" is displayed.

・Click "OK".

*

Note: In some cases, NG occurs due to dusts on the CCD.

Be sure to clean the CCD surface before adjustments.

- A ・ -

Page 76

VBA15001-R.3701.A

INC

9-3.

Compensation - white point

・Check the environmental temperature (approx. 20-25°C).

・Click "Start".

・Setting conditions are indicated.

・Cap the camera with the body cap or lens cap to shield light from the mount.

・Click "OK".

・When the adjustment starts, pixel defects are detected, displaying the number of pixels and addresses.

・When it is completed, "OK" is displayed.

・Click "OK".

・Click "End".

9-4.

Getting of reference values

・Select "OBTAIN REFERENCE VALUE." of the menu on screen.

・Click "Start".

・Click "Start" again.

・The message of setting conditions is displayed.

・Click "OK".

・Attach the tool lens (Aperture F8) and ND lter (ND 8× 2) to the camera.

・Get the camera closest to the center of the illuminated surface of the color viewer.

・The adjustment starts, and getting "Sensitivity" reference value is completed.

・Click "OK".

・Click "Next".

・Click "Start" of "OBTAIN RATIO REFERENCE VALUES".

・Attach the tool lens (Aperture F5.6). (Remove the lter).

・Get the camera closest to the center of the illuminated surface of the shutter tester (LV12).

・The adjustment starts. When it is completed, the sensitivity and sensitivity ratio reference values are stored

in the standard setting le (D40BSD.DAT).

・After this procedure, when the shooting image adjustment is made, the sensitivity and sensitivity ratio that

were calculated this time are used.

※ Calculate the sensitivity and sensitivity ratio reference values once in about every 3 months, and when the

uorescent of the color viewer is replaced.

9-5. TFT adjustment

Writing of TFT xed values

・Click "REWRITING THE TFT FIXED VALUE".

・The message "Will you rewrite the CAMERA?" appears.

・Click "Yes".

・Writing is completed.

・Click "OK".

- A ・ -

Page 77

VBA15001-R.3701.A

INC

Flicker adjustment

・Usually default value is set and adjustment is not necessary.

・If icker is recognized by visual check, adjust by the slider so that no icker is visible.

・Remove the USB cable from the camera, then remove the AC adapter without turning the camera OFF.

Hue adjustment

・Usually default value is set and adjustment is not necessary.

・If some problem is found with hue by visual check, adjust and correct it by the slider.

・Remove the USB cable from the camera, then remove the AC adapter without turning the camera OFF.

Brightness adjustment

・Usually default value is set and adjustment is not necessary.

・If some problem is found with brightness by visual check, adjust and correct it by the slider.

・Remove the USB cable from the camera, then remove the AC adapter without turning the camera OFF.

9-6. Reading of RISC version

・Click "RISC VERSION" of the menu on screen.

・RISC version is displayed.

9-7. Procedure for upgrading RISC rmware: for upgrading RISC rmware:

・ After preparing the SD card, copy the latest version ( BD40XXXX. BIN) into the root directory.

・ Insert the SD card, and select "FIRMWARE VERSION" from the SETUP menu.

・ Follow the instructions on screen for version upgrading. It takes approx. 3-4 minutes.

・ Check the version of rmware by "RISC VERSION" of the image adjustment software.

Caution: