Page 1

Ten

Garage door opener

Instructions and warnings for the fitter

Istruzioni ed avvertenze per l’installatore

Instructions et recommandations pour l’installateur

Anweisungen und Hinweise für den Installateur

Instrucciones y advertencias para el instalador

Instrukcje i uwagi dla instalatora

Aanwijzingen en aanbevelingen voor de installateur

TN2010

TN2020

Page 2

2

Ten

Index: page

1 Warnings 3

2 Product description and intended use 4

2.1 Limits of use 4

2.2 Product component check 5

2.3 Typical system 6

2.4 Wiring list 6

3 Installation 7

3.1 Preliminary checks and inspections 7

3.2 Gearmotor installation 7

3.3 Limit switch adjustment 10

3.4 Installation of various devices 10

3.5 Electrical connections 10

3.5.1 Description of electrical connections 11

3.5.2 Second motor electrical connection 12

4 Final checks and start-up 12

4.1 Power supply connection 12

4.2 Learning devices 12

4.3 Learning the door opening and closing

positions 13

4.4 Checking door movement 14

4.5 Pre-set functions 14

4.6 Radio receiver 14

5 Tests and commissioning 14

5.1 Testing 14

5.2 Commissioning 15

6 Maintenance and disposal 16

6.1 Maintenance 16

6.2 Disposal 16

7 Further information 16

7.1 Programming keys 16

7.2 Settings 16

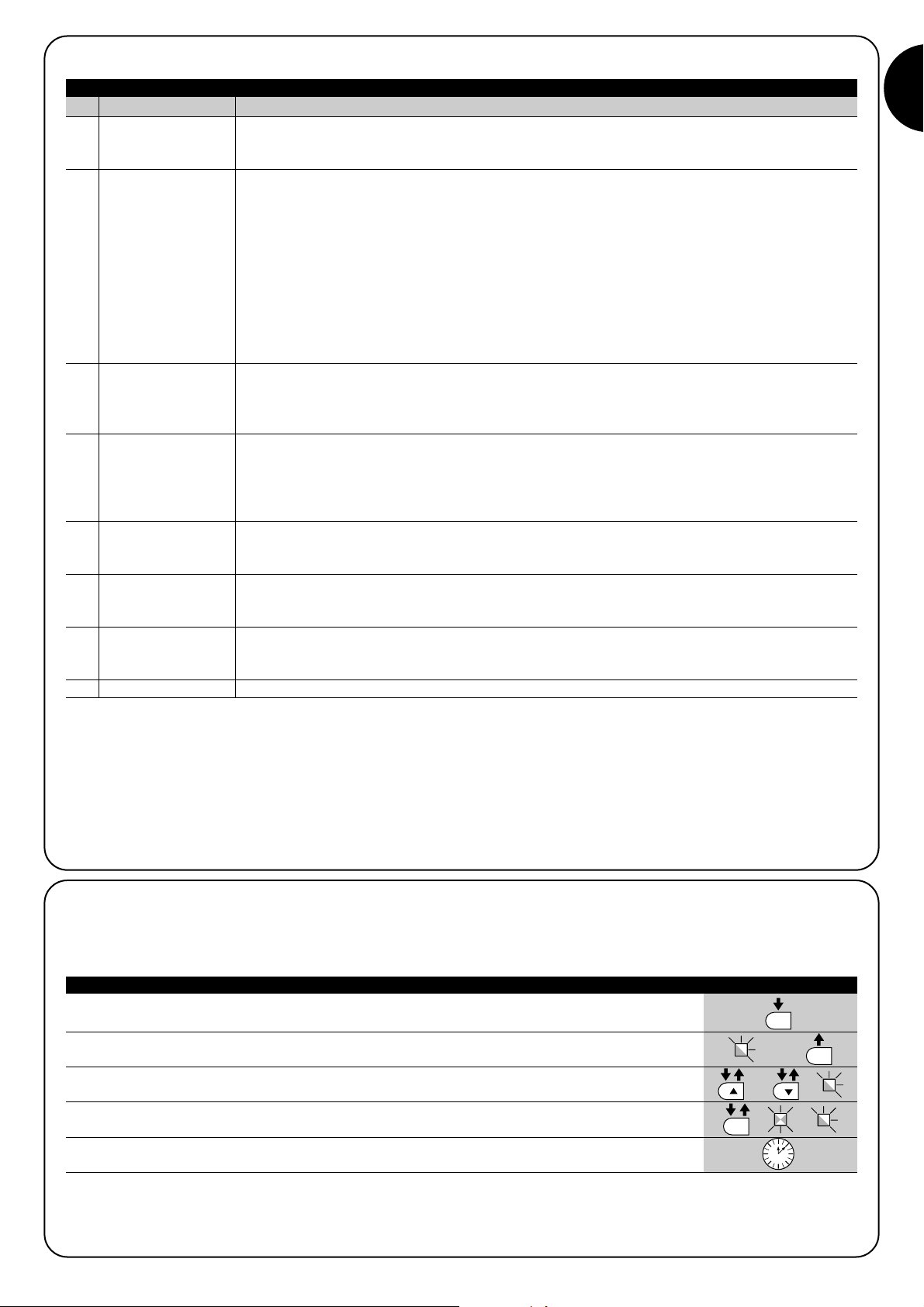

7.2.1 Level 1 functions (ON-OFF functions) 17

7.2.2 Level 1 programming (ON-OFF functions) 17

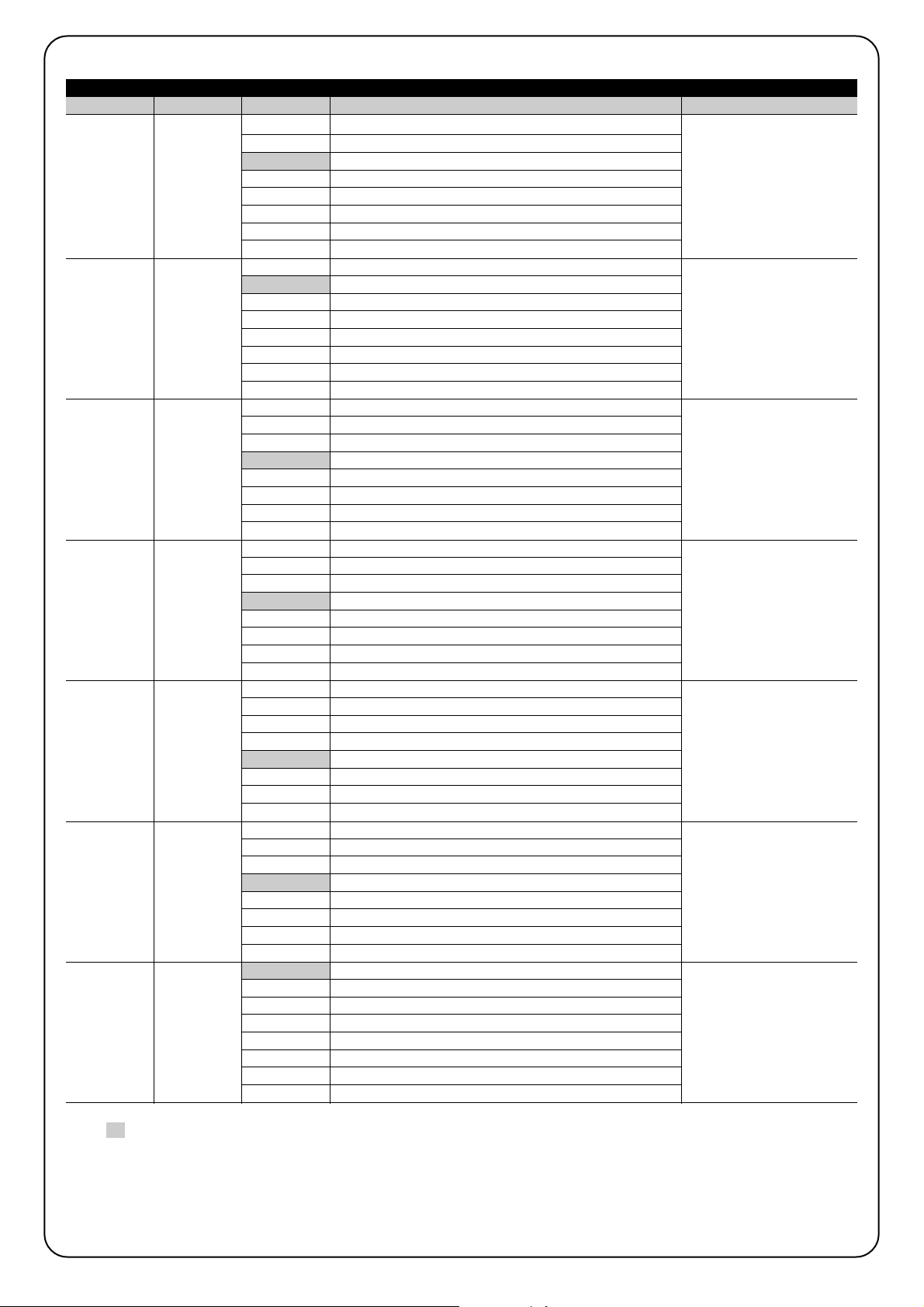

7.2.3 LEVEL 2 functions (adjustable parameters) 18

7.2.4 Level 2 programming (adjustable parameters) 19

7.2.5 Example of Level 1 programming

(adjustable parameters) 19

7.2.6 Example of Level 2 programming

(adjustable parameters) 20

7.3 Adding or removing devices 20

7.3.1 BLUEBUS 20

7.3.2 STOP input 20

7.3.3 Photocells 21

7.3.4 MOTB digital selector and proximity

reader for MOMB transponder badges 21

7.3.5 Learning other devices 22

7.3.6 Deleting the entire memory 22

7.3.7 Programming the direction of motor rotation 22

7.3.8 Resetting the encoder position 23

7.4 Special functions 23

7.4.1 “Always open” function 23

7.4.2 “Move anyway” function 23

7.4.3 Maintenance notification 23

7.4.4 Check of number of manoeuvres performed 24

7.4.5 Manoeuvre counter reset 24

7.5 Connecting other devices 24

7.6 Troubleshooting guide 25

7.6.1 Fault log list 25

7.7 Diagnostics and indicators 25

7.7.1 Signals with flashing light 26

7.7.2 Signals on control unit 27

7.8 Accessories 28

7.8.1 Remote programming unit 28

7.8.2 Buffer battery 29

7.8.3 Pre assembly for OTA11 29

8 Technical specifications 30

Instructions and warnings for TEN gearmotor users 31

Page 3

3

GB

1) Warnings

Important instructions for installation safety

Incorrect installation may cause serious injury.

Carefully follow all installation instructions.

This instruction manual contains important information regarding the

safety of installation; read all instructions before proceeding with installation. Keep this manual in a safe place for future consultation.

In consideration of the risks that may arise during installation and use of

TEN, ensure that the installation procedure is completed in full observance of application legislation, standards and regulations. This chapter

provides general warnings; other important warnings are given in chapters “3.1 Preliminary checks”; “5 Testing and commissioning”.

According to the most recent European legislation, the

automation of a door or gate is subject to the specifications

of the Machinery directive 98/37/CE and more specifically to

the standards: EN 13241-1 (harmonised standard); EN 12445;

EN 12453 and EN 12635, which enable declaration of conformity with the machinery directive.

Further information and guidelines on the risk assessment, useful when

drawing up the Technical Documentation are available on the site

”www.niceforyou.com”. This manual is aimed exclusively at technical

personnel qualified for installation. With the exception of the specifications attached, to be detached by the installer "Instructions and warnings for the TEN gearmotor user", no other information in this documentation is intended for the final user.

• Use of TEN other than that envisaged in these instructions is strictly

prohibited; improper use can lead to hazards, physical injury or damage.

• Before starting installation, an assessment of the associated risks must

be made, including a list of the essential safety requirements as envisaged in Appendix I of the Machinery Directive, specifying the relative

solutions adopted. Note that the risk assessment is one of the documents included in the automation Technical documentation.

• Check whether other devices or materials are required to complete

automation with TEN, evaluating the specific application and associated risks; for example considering the risks of impact, crushing, shearing, dragging and other hazards in general.

• Do not make any modifications to any part unless envisaged in these

instructions; this type of operation can only cause malfunctions. NICE

declines all liability for damage resulting from modified products.

• During installation and use, take care to prevent solid parts or liquids

from entering into the control unit and other open devices; if necessary

contact the NICE assistance service; use of TEN in these situations

can constitute a hazard.

• The automation cannot be used before commissioning the installation

as specified in the chapter: “5 Testing and Commissioning”.

• The TEN product packaging material must be disposed of in full obser-

vance of current local legislation governing waste disposal.

• In the case of faults not remediable using the information in this man-

ual, contact the NICE assistance service.

• If any circuit breakers trip or fuses blow, locate and eliminate the fault

before resetting.

• Before accessing the internal terminals under the TEN cover, discon-

nect all power circuits; if the disconnect device is not in a visible location, affix a notice: “WARNING: MAINTENANCE IN PROGRESS”.

Special warnings regarding the suitability of use of this product in relation to the "Machinery" Directive 98/37/EC (ex 89/392/EEC):

• This product is issued onto the market as a “machine component” and

is therefore constructed for incorporation in a machine or to be assembled with other machinery to constitute a “machine” in accordance

with the Directive 98/37 CE only in combination with the other components and according to the methods as described in this instruction

manual. As envisaged in the directive 98/37/EC, start-up of the product specified above is not admitted unless the manufacturer of the

machine, in which the product is incorporated, has identified and

declared the product as conforming to directive 98/37/EC.

Special warnings regarding the suitability of use of this product in relation to the “Low Voltage” Directive 73/23/EEC and subsequent amendment 93/68/EEC.

• This product complies with the requirements of the "Low Voltage"

Directive if used for the application and in the configurations envisaged

in this instruction manual and in combination with the articles present

in the catalogue produced by Nice S.p.a. Requirements may not be

guaranteed if the product is used in configurations or with other products not envisaged; use of the product in these conditions is strictly

prohibited unless the personnel assigned for installation have verified

compliance with the provisions of the directive.

Special warnings regarding the suitability of use of this product in relation to the “Electromagnetic Compatibility” Directive 89/336/EEC and

subsequent amendments 92/31/EEC and 93/68/EEC.

• This product has undergone testing for electromagnetic compatibility

in the most critical conditions of use, in the configurations envisaged

in this instruction manual and in combination with the articles present

in the product catalogue of Nice S.p.a. Electromagnetic compatibility

may not be guaranteed if the product is used in configurations or with

other products not envisaged; use of the product in these conditions

is strictly prohibited unless the personnel assigned for installation have

verified compliance with the provisions of the directive.

!

!

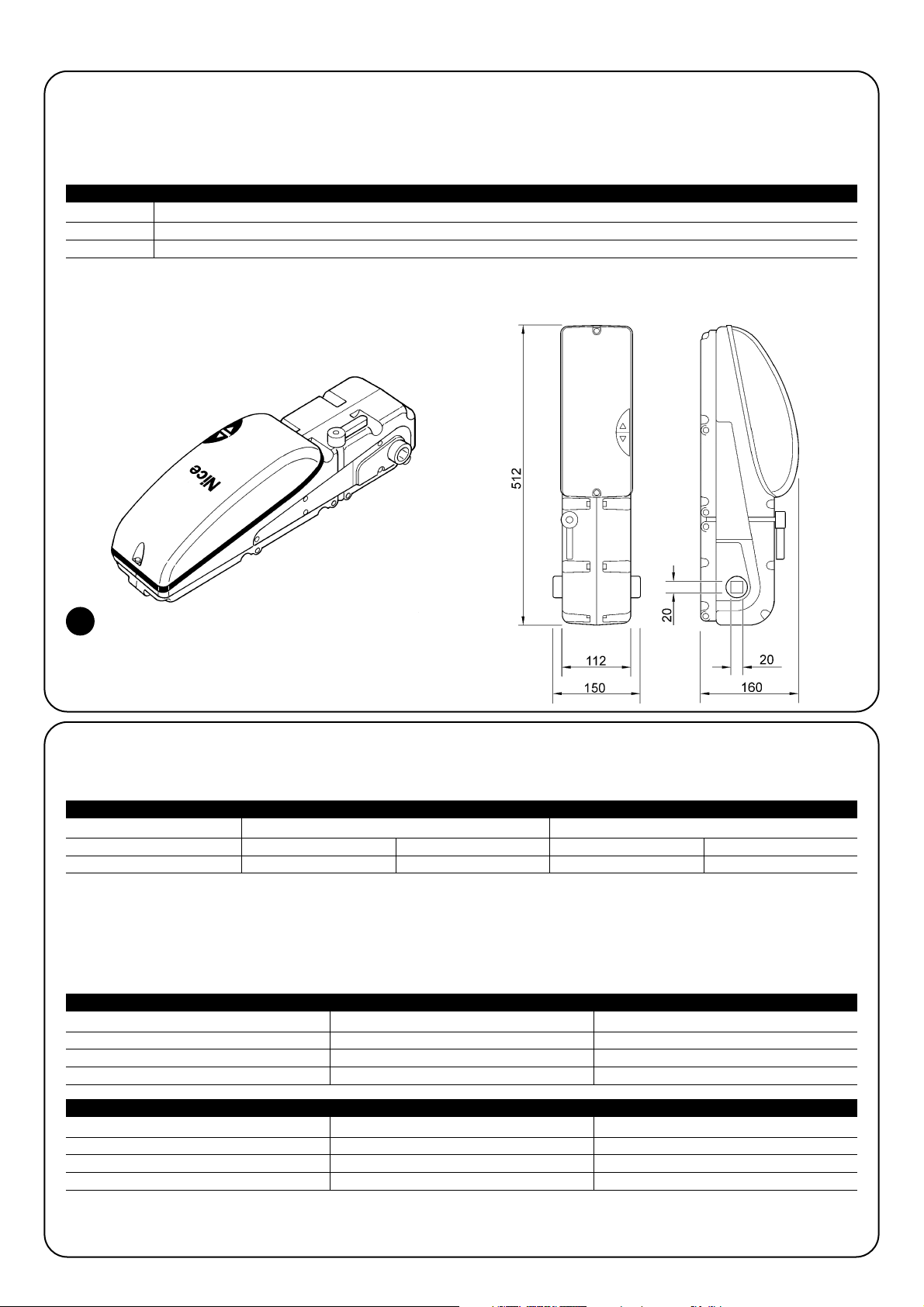

Page 4

4

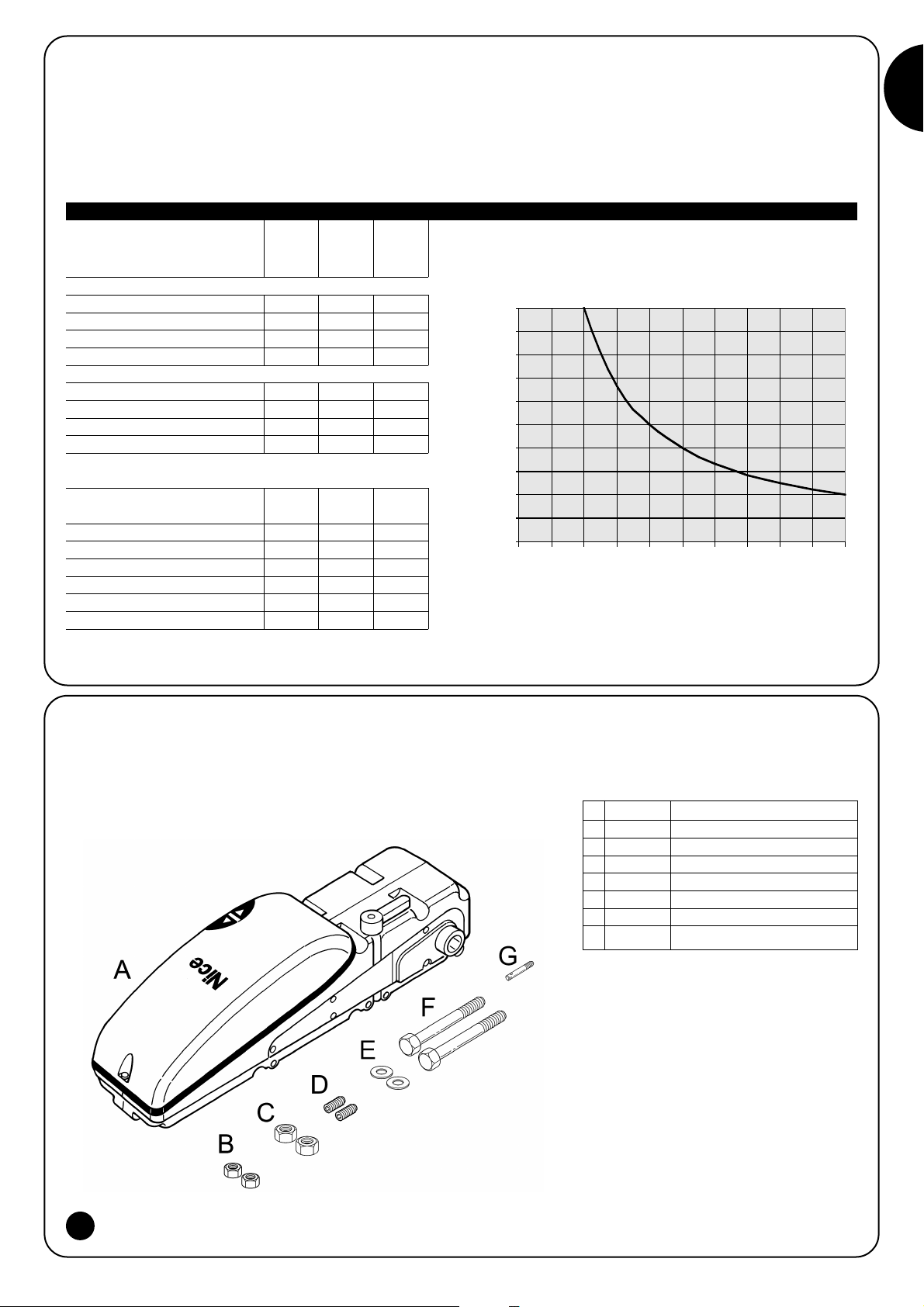

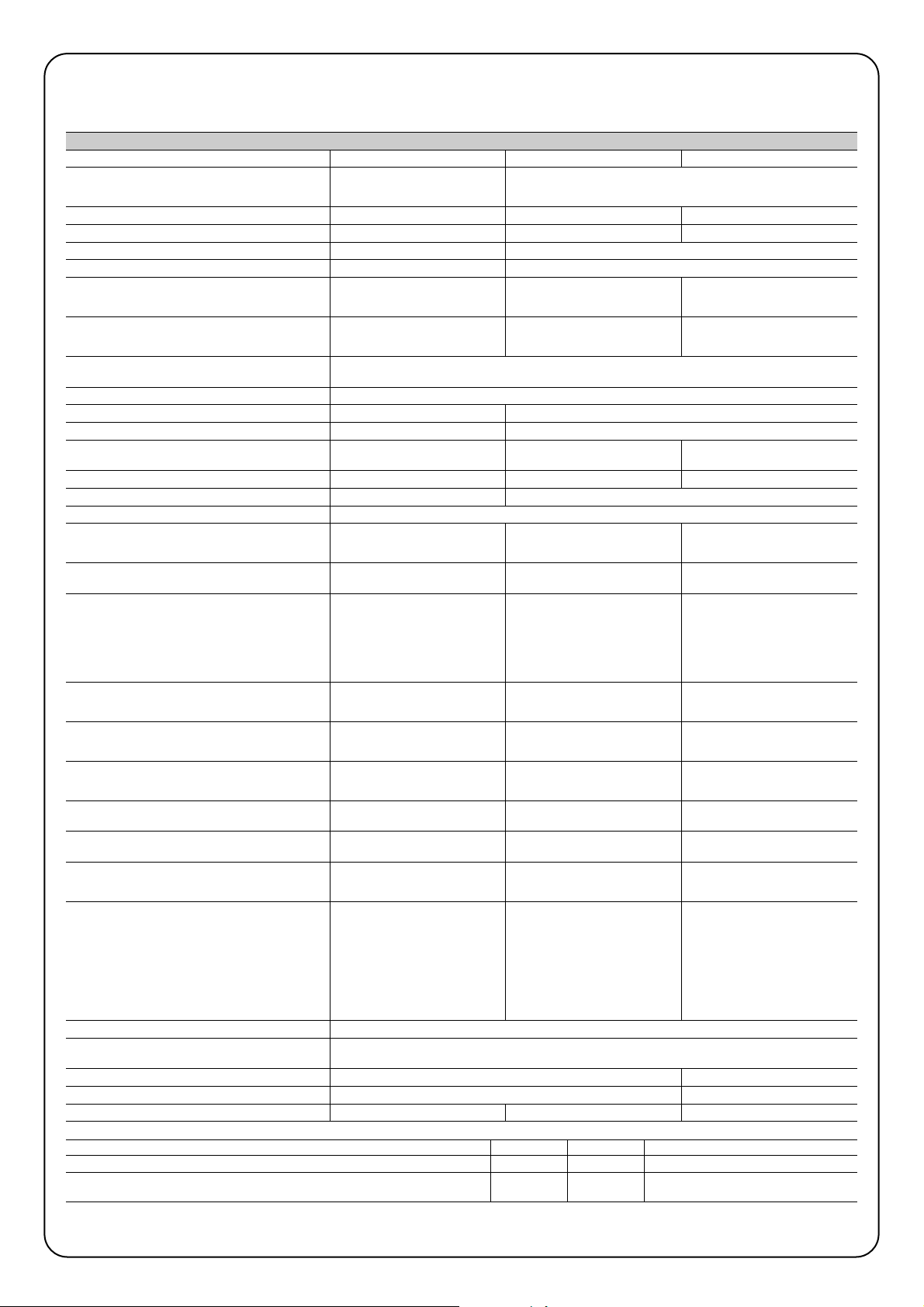

2.1) Limits of use

Data related to the performance of TEN are provided in chapter “8 Technical specifications” and are the only values that enable correct evaluation of the suitability of application. In general TEN can automate up-and-over doors within the limits stated in Table 2.

The measurements in table 2 are guideline only for general estimate purposes. The effective suitability of TEN for automation of a specific door

depends on the degree of leaf balancing, friction on tracks and other factors, also occasional, such as wind pressure or the presence of ice,

which may obstruct leaf movement. To ensure feasibility, it is absolutely indispensable to measure the force required to move the door throughout travel and to check that this never exceeds the “nominal torque” as specified in Chapter “8 Technical specifications”; it is also important to

establish the number of cycles per hour and consecutive cycles admissible, with reference to Table 3 and Table 4

Force required to move leaf (N) Maximum cycles per hour Maximum no. consecutive cycles

Up to 150 30 19

150÷250 28 16

250÷350 25 14

Table 4: Limits in relation to the force required to move the leaf with 1 TN2010 + 1 TN2020

Door type Power operated with 1 motor Power operated with 2 motors

Projecting up-and-over door Max. height 2.6 m Max. length 3m Max. height 2.6 m Max. length 5.4 m

Non-projecting up-and-over door Max. height 2.6 m Max. length 3m Max. height 2.6 m Max. length 5.4m

Table 2: Limits of use for TEN gearmotors

TEN (figure 1) is a gearmotor for the automation of counterweight up-and-over doors, spring up-and-over doors, projecting, non- projecting,

and articulated. TEN is fitted with an electronic limit switch system with absolute encoder to enable constant detection of the motor position,

even when the door is released for manual manoeuvres. It is able to reach the travel limit (opening and closing) through a deceleration phase.

It also ensures constant control of the force required during manoeuvres, detecting any anomalies, such as a sudden obstacle that blocks

leaf movement; in this case the automation executes a stop with brief inversion of movement.

Before proceeding with installation, check the condition of the product components, suitability of the selected model and conditions of the intended installation environment.

2) Product description and intended use

1

Model DESCRIPTION

TN2010 Irreversible gearmotor, control unit, electronic limit switch via absolute encoder and courtesy light.

TN2020 Irreversible gearmotor and courtesy light. To be used as “Slave” of TN2010 or TN2020

* If used in other configurations, ensure that the power supply is from a very low voltage safety system in which voltages never exceed the established

low voltage safety limits.

Table 1: Description of TEN composition

To avoid overheating, the control unit is equipped with a limiter based on the force and duration of the cycles, intervening when the maximum limit is exceeded.

Force required to move leaf (N) Maximum cycles per hour Maximum no. consecutive cycles

Up to 120 20 35

120÷180 18 33

180÷220 15 30

Table 3: Limits in relation to the force required to move the leaf with 1 TN2010

Page 5

5

GB

Chapter 8 “Technical specifications” also provides an estimate of “durability” i.e. average product lifetime. The value is strongly influenced by

the stress factors involved in the manoeuvre, i.e. all factors that contribute to wear. To make this estimate, the total of all the gravity ratings

in Table 5 must be calculated, for subsequent verification of the estimated feasibility in the graph. For example, TN2010 on a door of 130 Kg,

which requires a force of 180Nm to move the leaf, equipped with photocells and no other factors of fatigue, obtains a gravity rating of 60%

(30+20+10). The estimated durability on the graph is therefore 18,000 cycles.

Note that the estimate of durability is conducted on the basis of design calculations and results of tests performed on prototypes; as this is

an estimate it does not constitute any form of guarantee on the effective lifetime of the product.

Gravity rating % TN2010 TN2010

+

TN2020

Leaf weight Kg

Up to 100 20 10

100 ÷ 180 30 20

180 ÷ 230 40 30

Over 230 60 50

Force required to move leaf (N)

Up to 160 10 5

160 ÷ 240 20 15

240 ÷ 290 40 30

290 ÷ 350 - 50

Other factors of fatigue

(to be considered if the probability of occurrence exceeds 10%)

Ambient temperature over 40°C or

below 0°C or humidity over 80% 10 10

Presence of dust or sand 15 15

Presence of salt water 20 20

Interruption of manoeuvre by Photo 10 10

Interruption of manoeuvre by Stop 20 20

Speed over “L4 high” 15 15

Total gravity rating %

Table 5: Estimate of durability in relation to the manoeuvre gravity rating

Gravity rating %

Cycle durability

2.2) Product component check

• Check the condition of the packaging;

• unpack the product and ensure presence of (Figure 2):

N° PIECES TN2010

A 1 TEN Gearmotor

B 2 M6 nuts

C 2 M8 nuts

D 2 Threaded stud bolts M6x14

E 2 Ø8 washers

F 2 M8x110 screws

G 1 Release rod

2

50000

45000

40000

35000

30000

25000

20000

15000

10000

5000

0

0 102030405060708090100

Page 6

6

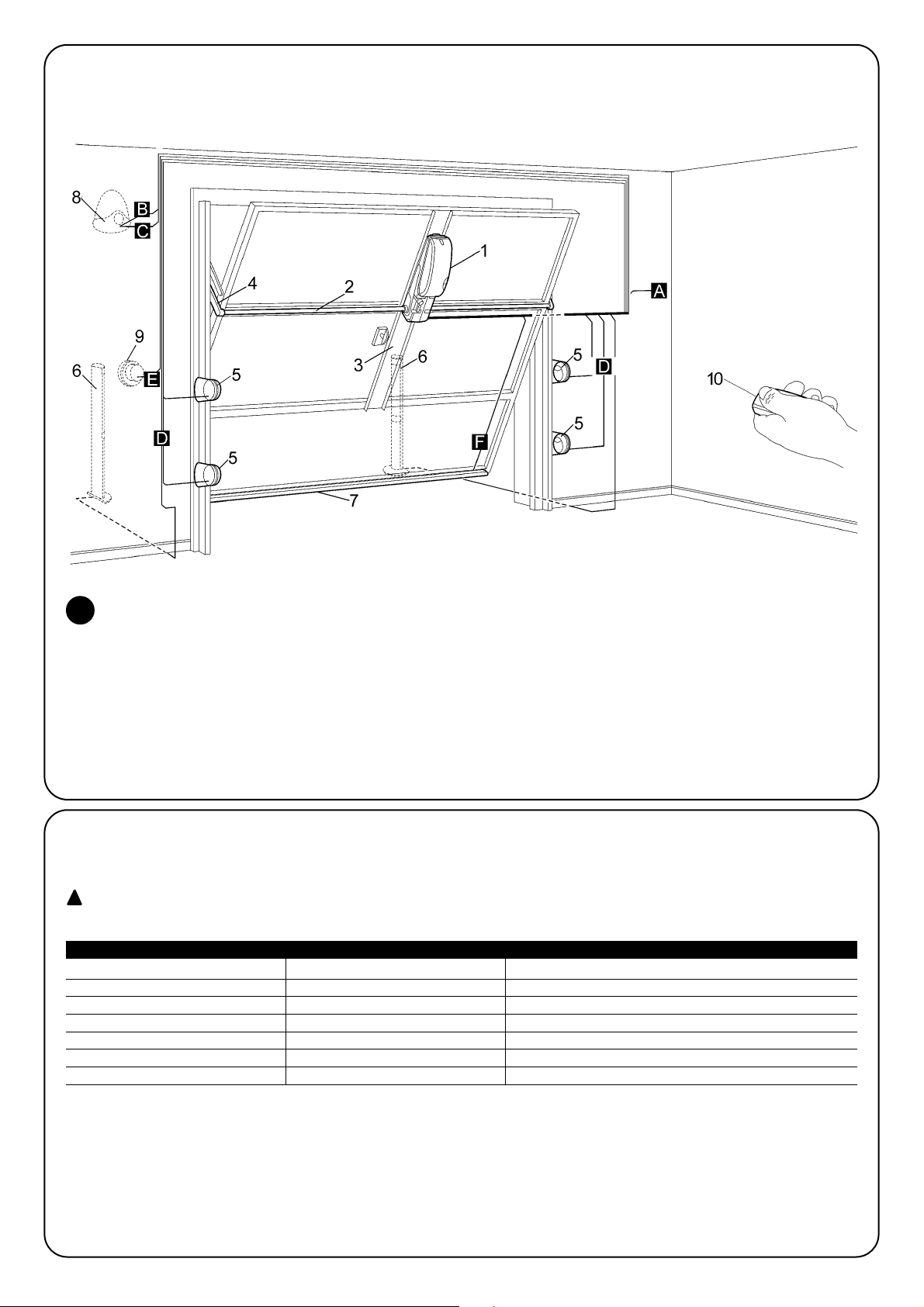

2.3) Typical system

Figure 3 shows a typical installation of an automation for up-and-over doors, using TEN.

1 TEN

2 Square tube 20x20

3 Support bracket

4 Telescopic arm

5 Photocells

6 Photocells on post

7 Sensitive edge

8 12 V Flashing light with incorporated aerial

9 Key-operated selector switch

10 Radio transmitter

2.4) Wiring list

On the typical system of figure 3 the cables are specified for connection of the various devices; table 6 specifies the relative characteristics

of the cables.

The cables used for connecting the various devices must be suitable for the type of installation: For example a cable

type H03VV-F is recommended if located indoors.

!

Note: (*) if the power cable is longer than 30 m, a cable with a larger section is required, (e.g. 3 x 2,5 mm2) and safety earthing is neces-

sary in the vicinity of the automation.

Connection Cable type Maximum admissible length

A: Electric power line 1 cable (3 x 1.5 mm²) 30 m (*)

B: 12V Flashing Light 1 cable (2 x 1 mm²) 20 m

C: Aerial 1 shielded cable (type RG58) 20 m (recommended: Less than 5 m)

D: Photocells 1 cable (2 x 0.5 mm²) 20 m

E: Key-operated selector switch 1 cable (4 x 0.25 mm²) 20 m

F: Sensitive edge 1 cable (2 x 0.25 mm²) 20 m

Table 6: Wiring list

3

Page 7

7

GB

Ten must be installed exclusively by qualified personnel in observance of current legislation, standards and regula-

tions, as well as all instructions in this manual.

!

3) Installation

3.1) Preliminary checks and inspections

Before installation of TEN, perform the following checks:

• Verify and ensure after installation that no door parts obstruct public roadways or pavements.

• Ensure that all material used is in perfect condition, suitable for use

and compliant with standards.

• Ensure that the weight and dimensions of the leaf are within the

limits of use specified in chapter “2.1 Limits of use”.

• With reference to the values specified in chapter “8 Technical

specifications”, ensure that the static friction (i.e. the force required

to move the leaf from stationary) is less than half the “Maximum

torque” and that the dynamic friction (i.e. the force required to keep

the leaf in movement) is less than half the “Nominal torque”; a margin of 50% is recommended of the force values as adverse climatic conditions can increase friction values.

• Ensure that there are no points of increased friction throughout the

travel of the up-and-over door.

• Check the strength of the mechanical stops and ensure there is no

risk of the door derailing from the tracks.

• Ensure that the door is well balanced, i.e. it must not move if left

stationary in any position.

• Ensure that the fixing points of the various devices (photocells,

pushbuttons etc.) are in area protected against impact and that fixing surfaces are sufficiently solid.

• Depending on the type of door, projecting, non-projecting or articulated, ensure that TEN can be fixed at the heights specified in figures 5, 6 or 7 respectively.

• Check and ensure that the manual release is fitted at a maximum

height of 1.8 m.

• If there is not sufficient space between the support arm and fixed

section of the door, the “curved arm” accessories should be used

to avoid crossover.

• Ensure that parts of the automation cannot come into contact with

water or other liquids.

• Never keep TEN components near heat sources or naked flames;

these actions can cause damage and malfunctions, fire or hazards.

• If the door is fitted with a pedestrian access door, ensure that this

does not obstruct normal travel and that a suitable interlock system is fitted.

• Connect the control unit to an electric power line equipped with an

earthing system.

• The electric power line must be protected by an adequate differential thermal magnetic cut-out device. The electrical mains power line must be equipped with a power disconnect device (with

overvoltage category III, i.e. minimum gap between contacts of 3.5

mm) or an equivalent system such as socket with removable plug.

If the power disconnect device is not in the vicinity of the automation, it must be fitted with a lockout facility to prevent inadvertent

or unauthorised connection.

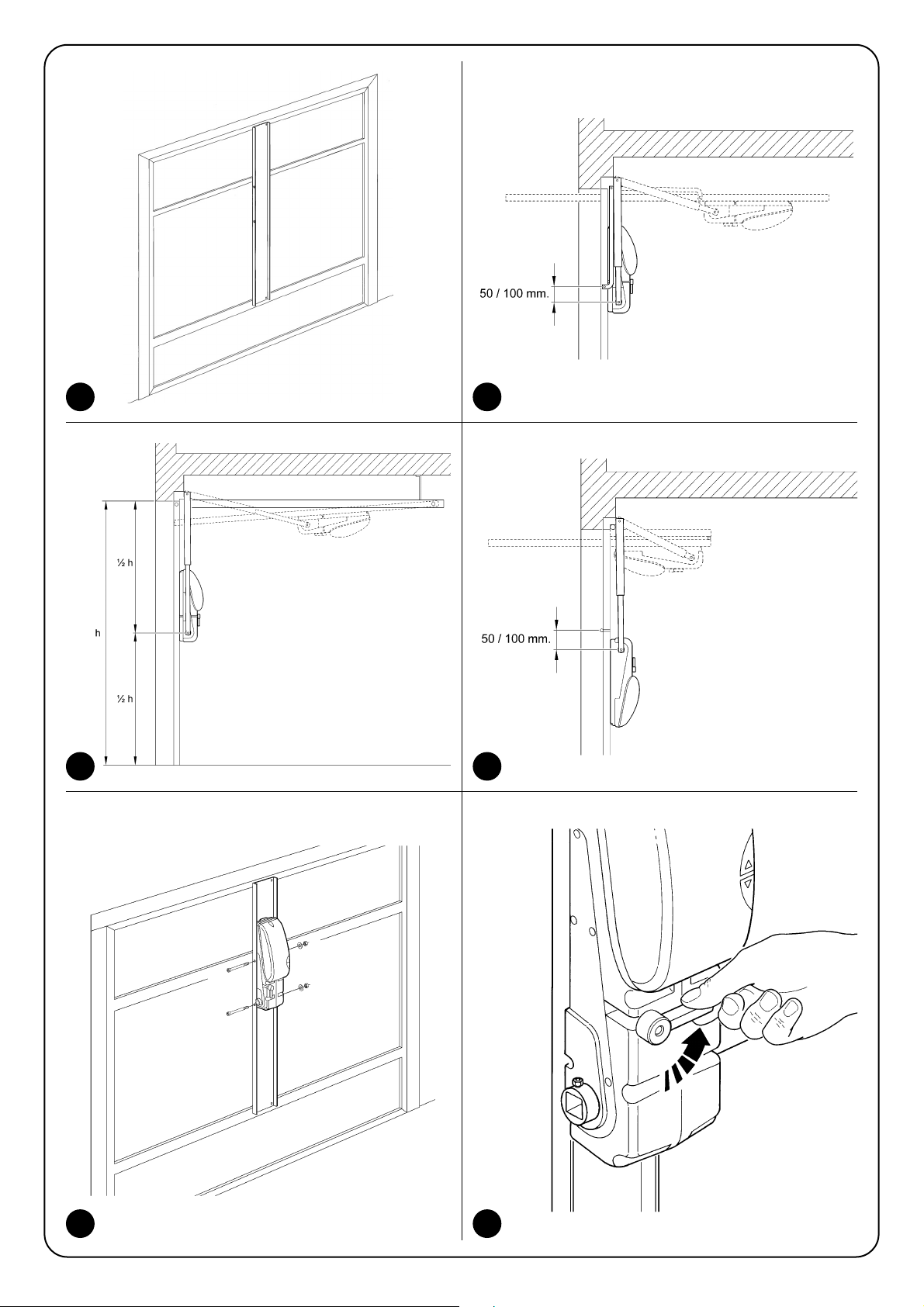

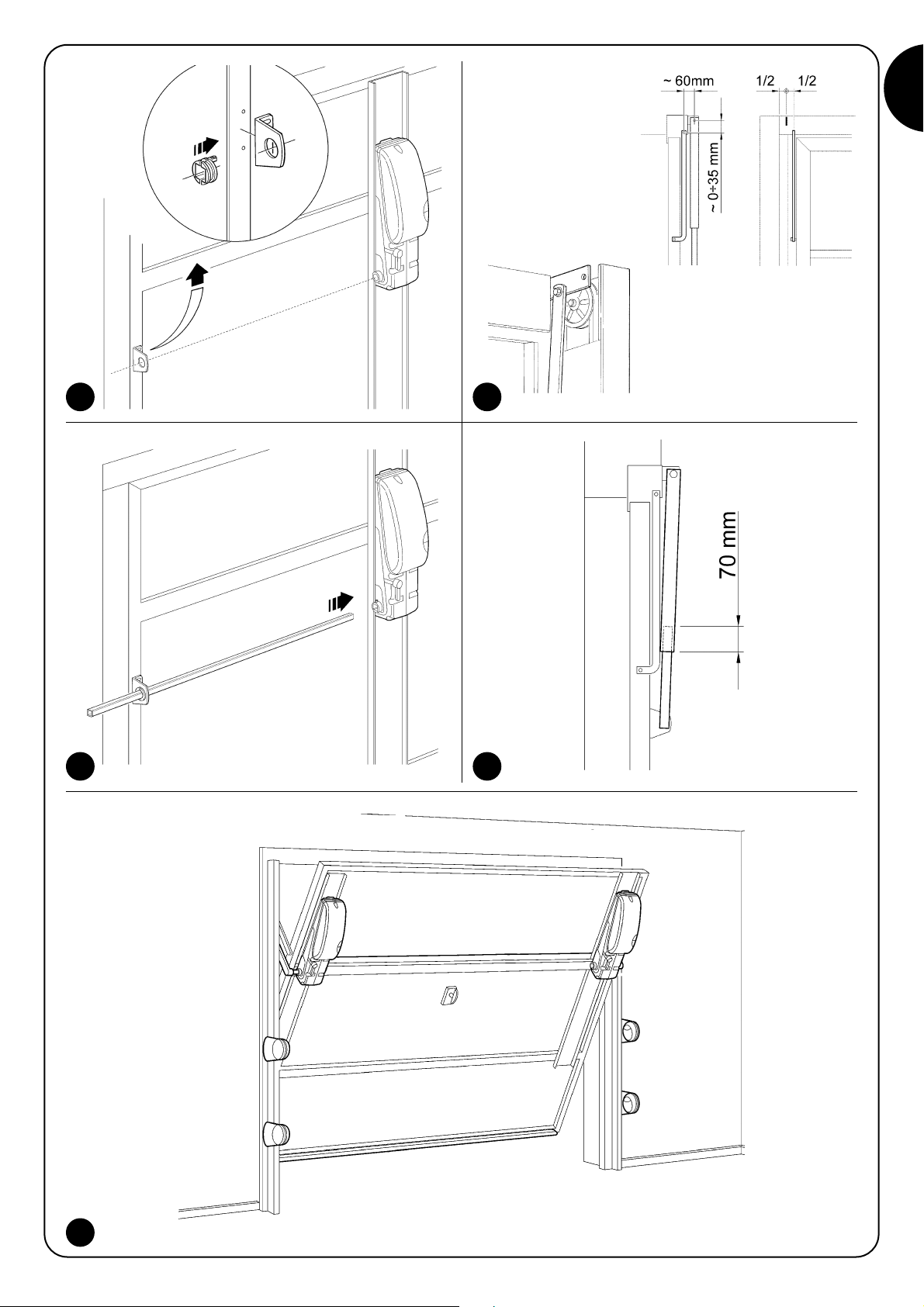

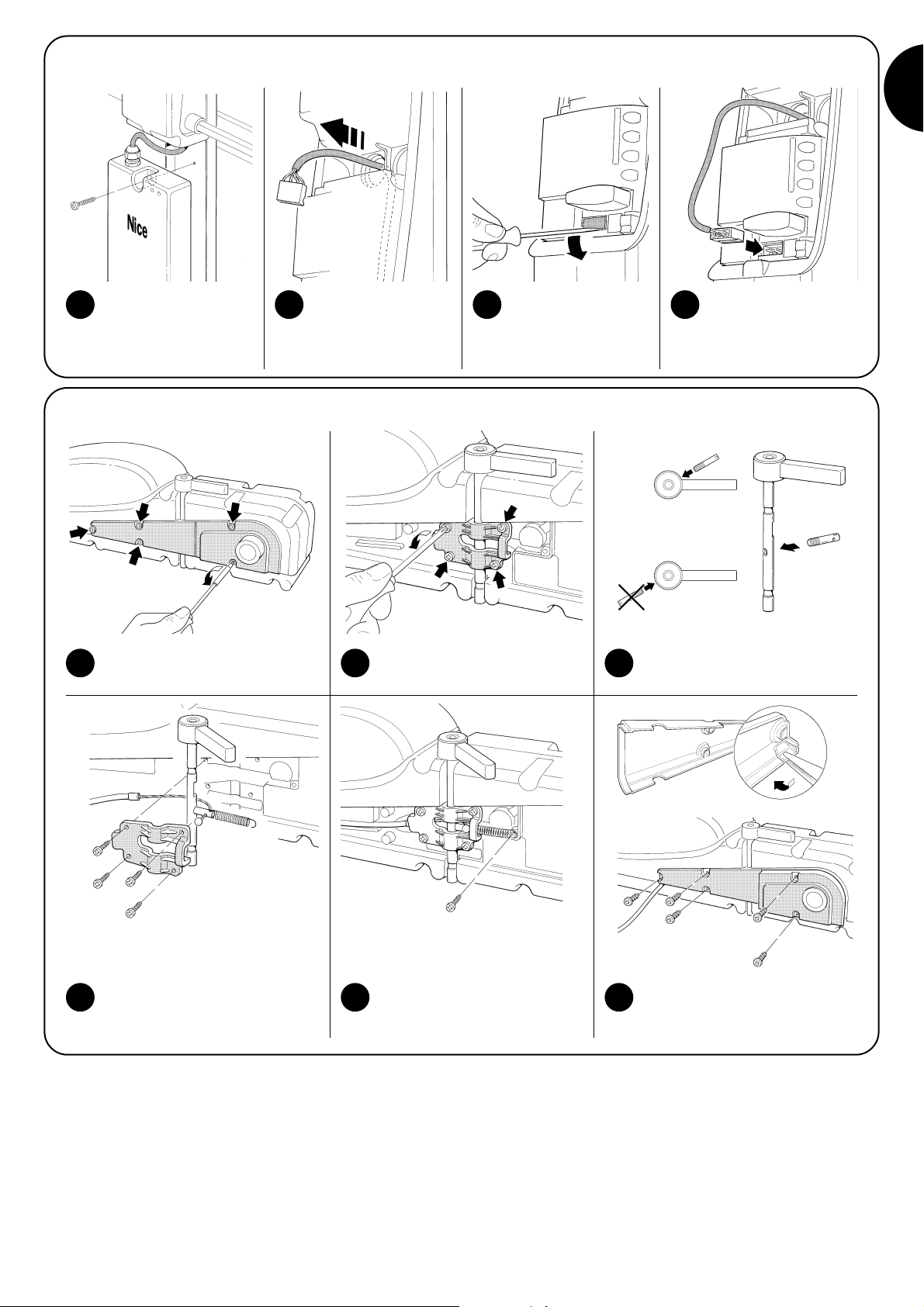

3.2) Gearmotor installation

Positioning of TEN varies according to the type of door to be automated and constrains specified in chapter “2.1 Limits of use”

TEN is equipped with an absolute encoder pre-set to

“nearly closed” operative also when the motor is released.

For this reason, step no.8 must be performed with the

DOOR CLOSED.

Note: For the installation of 2 motors follow the same procedure as

for one motor, with installation as shown in Figure 14.

1. Once the type is defined, fix the support bracket to the door, per-

fectly vertical (Figure 4), observing the specified distances.

1.1 For projecting up-and-over doors, the axis of arm rotation

must be 50÷100 mm below the door support arm.(Figure 5)

1.2 For non-projecting up-and-over doors, the axis of arm rotation must be in perfect alignment with the door support

arm.(Figure 6)

1.3 On articulated up-and-over doors, the axis of arm rotation

must be 50÷100 mm below the hinge of door rotation (Figure 7).

If using TEN upturned, the control unit must be

programmed using the remote programming unit

OView. For further information refer to paragraph

“7.8.1 Remote programming unit”.

2. Fix the gearmotor to the bracket by means of the relative screws

(Figure 8)

3. Release the gearmotor by rotating the handle anti-clockwise (Figure 9).

4. Securely fix the lateral support brackets, perfectly aligned with the

motor rotation shaft, and insert the adaptor bushings supplied.

(Figure 10).

Depending on the space between the support arm and

fixed frame of the door, straight or curved arms must be

used.

5. Fix the upper support to the door frame (Figure 11): If already pre-

sent, ensure that it is suitable for the arms to be used. The distances specified in figure 11 are guideline only: These may vary

according to the dimensions of the door.

6. Insert the transmission tube into the bushing of the arm and the

motor shaft, and cut to size. (Figure 12)

7. Open the door completely and cut the arms to size, considering

that with the door closed they need to slide by at least 70 mm

(Figure 13). If the length is not sufficient, reposition the upper support or use longer arms

8. Close the door, insert the arms in the respective guides and

ensure that the door slides freely without jams or obstructions.

Check balancing again: The door is well-balanced when it

does not move at all from stationary in any position

throughput its travel. If necessary, adjust the balancing

systems as required..

!

!

Page 8

8

4

5

6 7

8 9

Page 9

9

GB

10

11

12 13

14

Page 10

10

3.3) Limit switch adjustment

Ten 2010 is not fitted with mechanical limiters, but is equipped with an electronic system for absolute limitswitch. For settings, refer to paragraph “4.3 Learning the door opening and closing positions.”

3.4) Installation of various devices

Install the other devices envisaged as stated in the respective instructions. Refer to paragraph”3.5 Description of electrical connections “and

figure 17 for devices that can be connected to TEN

17

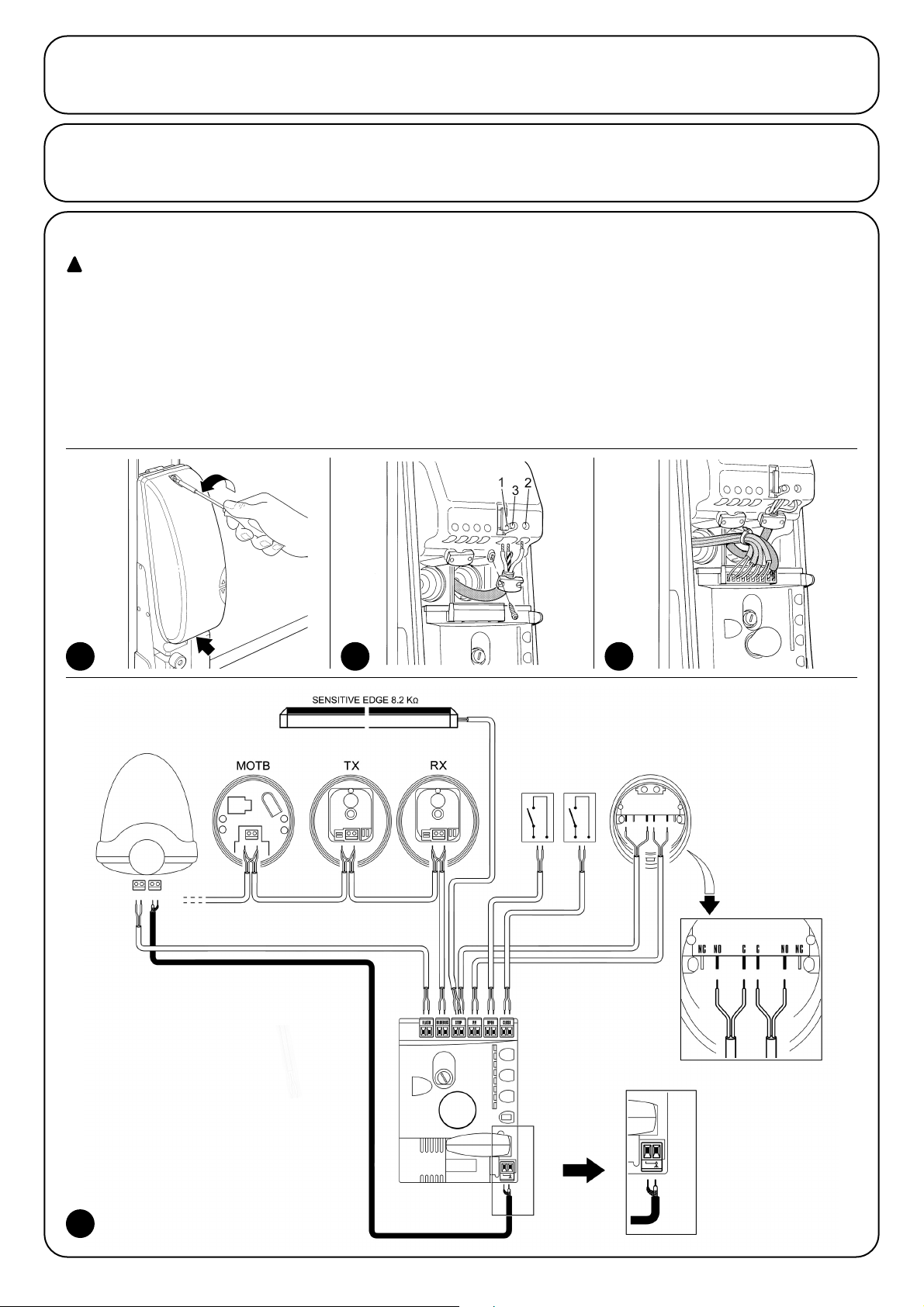

3.5) Electrical connections

All electrical connections must be made with the system disconnected from the power supply.

1. To proceed with electrical connections, loosen the screws of the cover (Figure 15)

2. Remove the two rubber membranes closing off the two cable routing holes. Cut a hole in the membrane and insert the power cable

through the membrane and right-hand hole. Cut a hole in the membrane and pass the other cables to the various devices through the

membrane and left-hand hole. Leave a cable length of 20÷30 cm longer than necessary. See table 6 for the cable types.

3. Connect the mains power cable directly to terminals 1(phase) and 2 (neutral), and 3 (earth); secure the cable with the collar as shown in

Figure 16

4. Make connections of the other cables as shown in the diagram of Figure 17. The terminals are removable to facilitate these operations.

5. On completion of connection, collect and secure the cables by means of clips (Figure 18).

!

18

15

16

Page 11

11

GB

3.5.1) Description of electrical connections

This paragraph provides a brief description of the electrical connections: for further information refer also to “7.3 Adding or removing devices”

FLASH this output is programmable (see L4 in table 10) to connect one of the following devices:

Flashing light

If programmed as “flashing light” the “FLASH” output can be connected to a NICE “LUCY B” MLB or MLBT flashing light

with a 12V 21W car type lamp.

During the manoeuvre the light flashes at an interval 0.5s on and 0.5s off

Function: “door open indicator”, “active if door closed” or “active if door open”

If programmed with one of these 3 functions, the “FLASH” output can be connected to a 24V max 5W indicator light to

signal the following:

“Door open indicator” function

Off: door closed

Slow flashing: Door opening

Quick flashing: Door closing

On: Door open (not closed)

“Active if door closed” function

On: door closed

Off: All other cases

“Active if door open” function

On: Door open

Off: All other cases

It may also be programmed for other functions; in the case refer to paragraph “7.2.3 Level 2 functions (adjustable parameters)”

Suction cup*

If programmed as “suction cup” the “FLASH” output can be connected to a 24V max 10W suction cup (versions with

electromagnet only, without electronic devices).

When the door is closed, the suction cup is activated to lock the door in place. During the opening and closing manoeuvre it is deactivated

Electric block*

If programmed as “electric block” the “FLASH” output can be connected to a max. 24V electric lock with latch (versions

with electromagnet only, without electronic devices).

During the opening manoeuvre, the electric lock is activated and remains active to free the door and perform the

manoeuvre. In the closing manoeuvre ensure that the electric block re-engages mechanically.

Electric lock*

If programmed as “electric lock” the “FLASH” output can be connected to a 24V max 10W electric lock with latch (versions with electromagnet only, without electronic devices).

During the opening manoeuvre, the electric lock is activated for a brief interval to free the door and perform the manoeuvre. In the closing manoeuvre ensure that the electric block re-engages mechanically.

BLUEBUS this terminal enables the connection of compatible devices; all are connected in parallel with just two wires conveying

the electric power and communication signals. More information on BlueBUS is available in paragraph “7.3.1 - BlueBUS”.

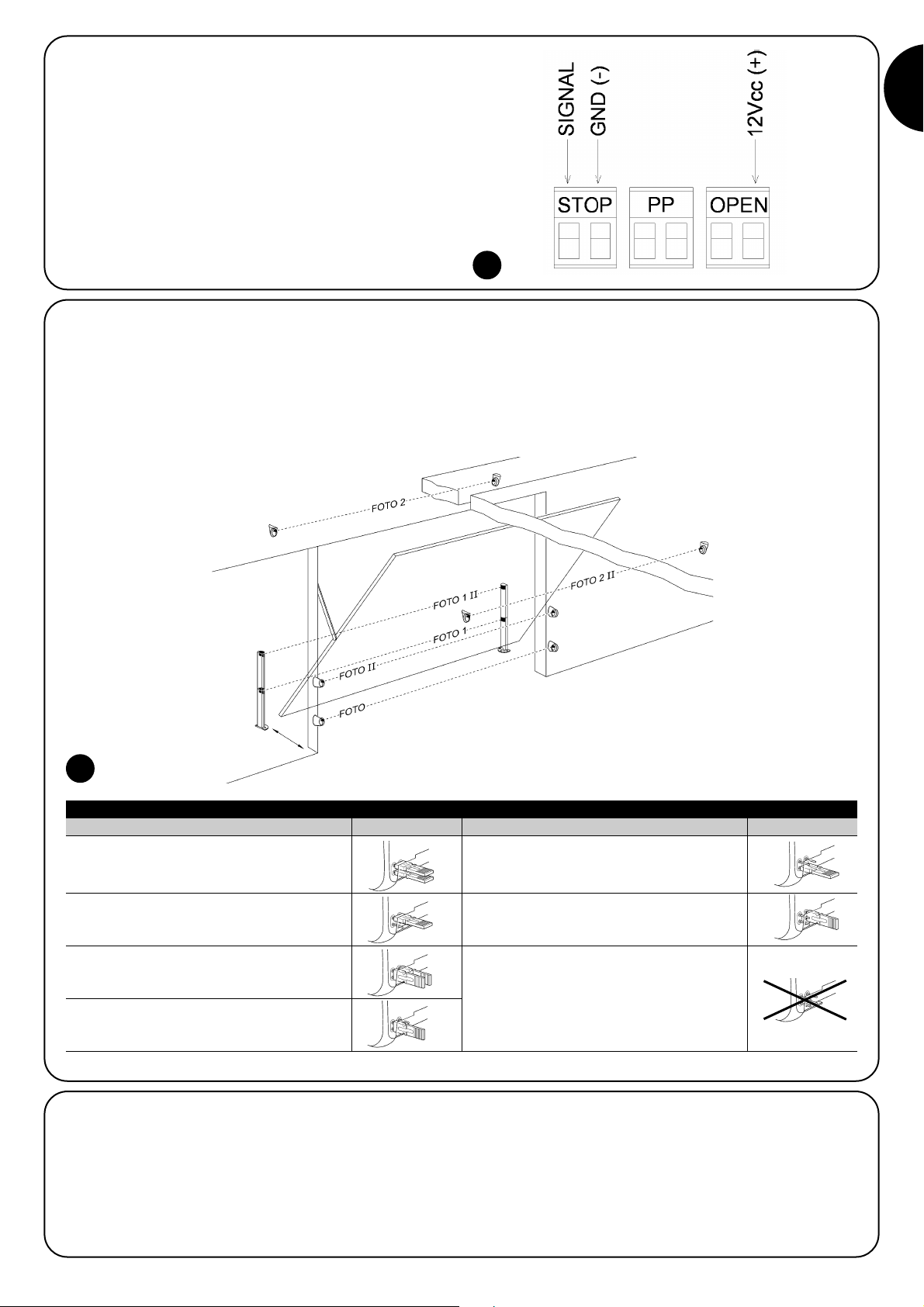

STOP Input for devices that block or shut down the manoeuvre in progress; by setting the input accordingly, it is possible to

connect Normally Closed type contacts, Normally Open contacts, constant resistance or optical devices. More information on STOP is available in paragraph “7.3.2 –STOP input”.

PP Input for devices that control movement in Step-Step mode, enabling the connection of Normally Open contacts.

OPEN Input for devices that control opening movement only, enabling the connection of Normally Open contacts.

CLOSE Input for devices that control closing movement only, enabling the connection of Normally Open contacts.

AERIAL Input for connection of the aerial for the radio receiver (the aerial is incorporated on LUCY B)

* Only devices containing exclusively the electromagnet can be connected

Never use devices other than those specified

!

Page 12

12

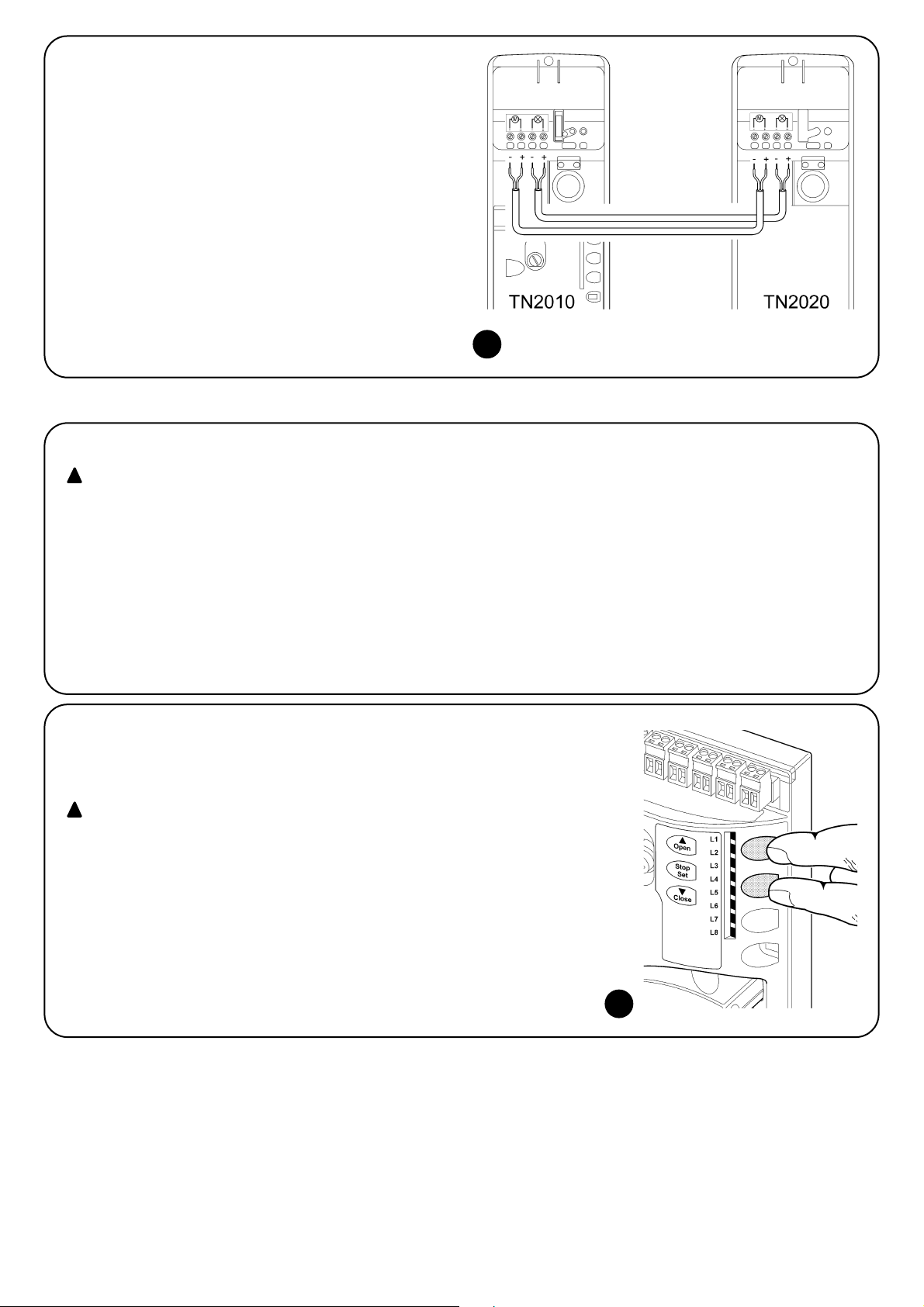

4.1) Power supply connection

TEN must be connected to the power supply by skilled and qualified personnel in possession of the requisites as spe-

cified and in full compliance with legislation, standards and regulations.

As soon as TEN is powered up, a number of checks are recommended:

1. Check that the BLUEBus led flashes quickly for a few seconds and then regularly with one flash per second (Figure 31).

2. If photocells are present, check that the leds on the latter also flash (both on TX and RX elements); the type of flash is not significant as

this depends on other factors.

3. Check that the device connected to the FLASH output is off

4. Ensure that the courtesy light is switched off.

If none of these conditions occur, disconnect the power supply immediately and check the electrical connections thoroughly.

Other information regarding fault-finding procedures are provided in the chapter “7.6 Troubleshooting”

!

4.2) Learning devices

After connecting to the power supply, the control unit must recognise the devices connected to the inputs BlueBUS and STOP. Before this phase, leds L1 and L2 flash to indicate that

the device self-learning process must be performed.

The device self-learning phase must be performed even if no device is con-

nected

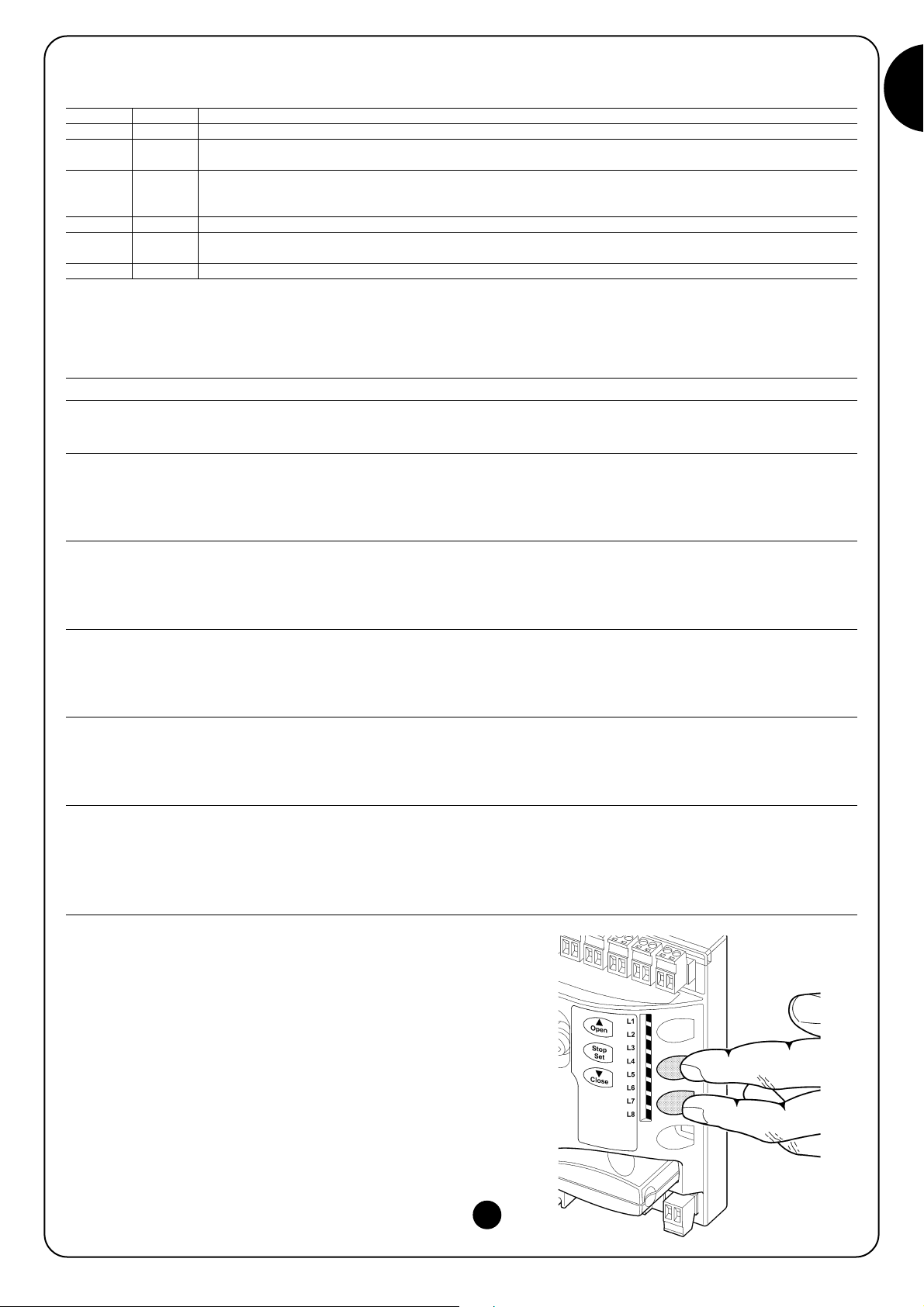

1. Press and hold keys [▲] and [Set](Figure 20)

2. Release the keys when leds L1 and L2 start to flash quickly (after around 3s)

3. Wait a few seconds for the control unit to finish device self-learning.

At the end of the self-learning process, the STOP led must remain lit, while leds L1 and L2

turn off (where relevant leds L3 and L4 start flashing).

The phase of self-learning the devices connected can be repeated at any time also after

installation, such as in the case that a device is added.

!

20

4) Final checks and start-up

3.5.2) Second motor electrical connection;

If the installation envisages the use of 2 motors, a TN2010 and a

TN2020, make the electrical connection of the second motor as

described below.

1. Make the same connections for gearmotor TN2010 as those for

a single motor installation.

2. Between the control unit of the TN2010 and terminal board of the

TN2020 make the cable connections “second motor” and “second motor courtesy light” as shown in (Figure 19), observing

polarity as specified.

19

Page 13

13

GB

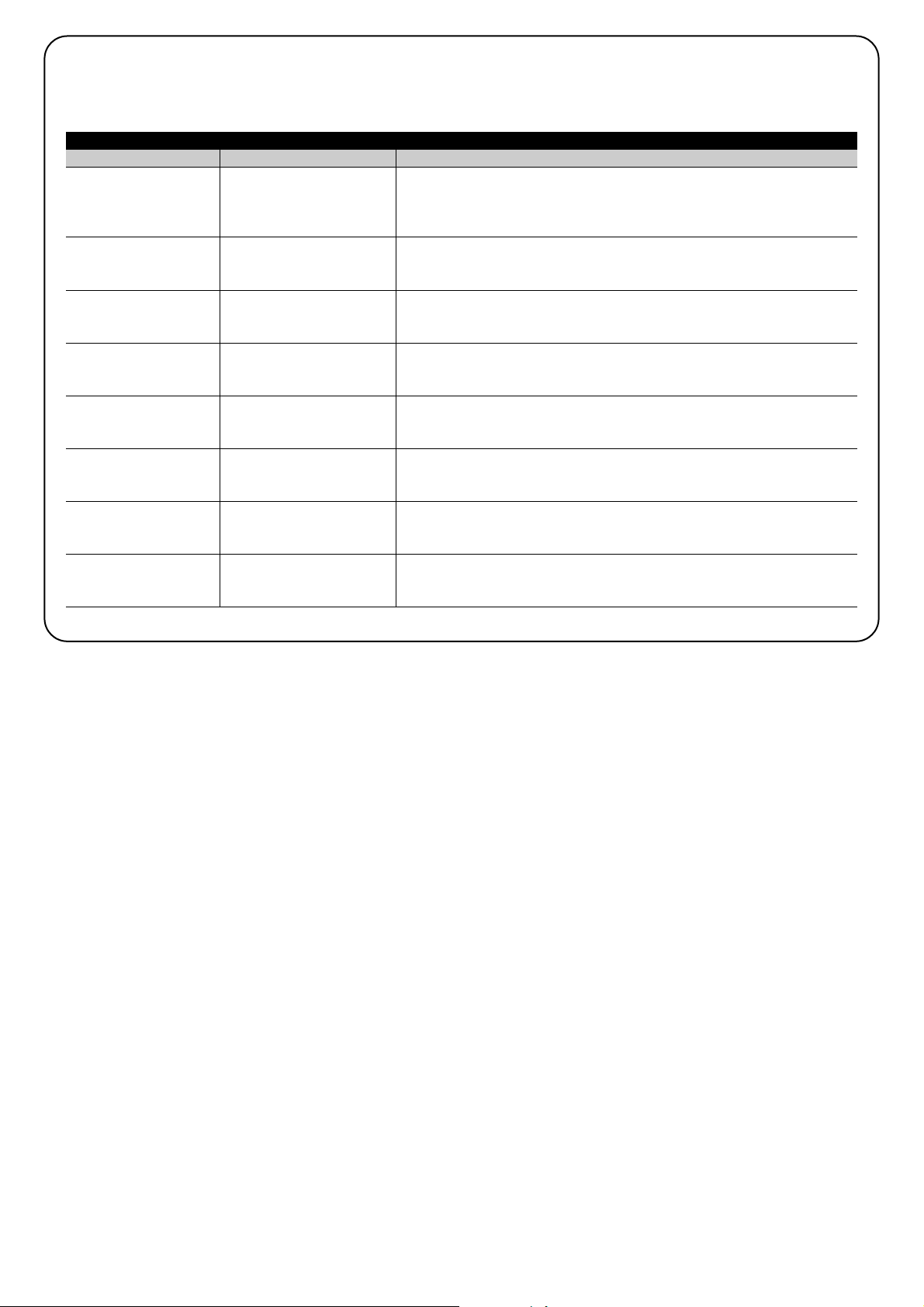

4.3) Learning the door opening and closing positions

After self-learning the devices, the control unit must recognise the door opening and closing positions, as well as a total of six other optional positions:

Position led Meaning

FCA L1 Maximum opening position. When the door reaches this position it stops

RA L2 Deceleration start position during the opening manoeuvre; when the door reaches this position the motor decelerates to

the minimum speed.

RI L4 Intermediate deceleration position in closing manoeuvre. When this point is programmed, the door starts to decelerate at

approx. 50 cm beforehand, to pass from the position RINT to minimum speed. On passing the RINT position the motor

returns to the set speed

AP L5 Partial opening position. This is the position at which the door stops after receiving a partial opening command.

RC L7 Deceleration start position during the closing manoeuvre; when the door reaches this position the motor decelerates to

the minimum speed.

FCC L8 Maximum closing position; when the door reaches this position it stops

During these manoeuvres, the control unit memorises the force

required for the opening and closing movements.

It is important that these preliminary manoeuvres are not

interrupted for example by a STOP command.

The position learning phase can be repeated at any time also after

installation, by simply repeating the procedure from point 1. However, if only one position needs to be modified, skip programming of

the positions not involved by pressing the key [Set] twice quickly for

each position to skip.

21

When the positions have not been acquired, leds L3 and L4 flash.

The position memorisation procedure is described below. Positions FCA and FCC require compulsory programming, while the others remain

optional; if not programmed the latter are calculated automatically by the control unit.

1. Press [Set] + [▼] for 3 seconds to enter position memorisation mode. (Figure 21)

Led L1 flashes: Position FCA programming

2. Use keys [▲] or [▼] to move the door to the opening position.

3. Press [Set] for 2 seconds to confirm position FCA. Led L1 remains lit

Led L2 flashes: Position RA programming

4. If the opening slowdown position programming is not required, press the key [Set] twice quickly to skip to the next programming;

led L2 remains off. Otherwise proceed with the sequence

5. Use keys [▲] or [▼] to move the door to the opening deceleration position.

6. Press [Set] for 2 seconds to confirm position RA. Led L2 remains lit

Led L4 flashes: Position RI programming

7. If the intermediate slowdown position programming is not required, press the key [Set] twice quickly to skip to the next

programming; led L4 remains off. Otherwise proceed with the sequence

8. Use keys [▲] or [▼] to move the door to the intermediate deceleration position.

9. Press [Set] for 2 seconds to confirm position RI. Led L4 remains lit

Led L5 flashes: Position AP programming

10. If the partial opening position programming is not required, press the key [Set] twice quickly to skip to the next programming; led

L5 remains off. Otherwise proceed with the sequence

11. Use keys [▲] or [▼] to move the door to the partial opening position.

12. Press [Set] for 2 seconds to confirm position AP. Led L5 remains lit

Led L7 flashes: Position RC programming

13. If the closing slowdown position programming is not required, press the key [Set] twice quickly to skip to the next programming;

led L7 remains off. Otherwise proceed with the sequence

14. Use keys [▲] or [▼] to move the door to the closing deceleration position.

15. Press [Set] for 2 seconds to confirm position RC. Led L7 remains lit

Led L8 flashes: Position FCC programming

16. Use keys [▲] or [▼] to move the door to the closing position.

17. Press [Set] for 2 seconds to confirm position FCC. Led L8 remains lit.

18. On release of [Set] all leds turn off.

19. Give an open command by pressing [Open] to execute a complete opening manoeuvre.

20. Give a close command by pressing [Close] to execute a complete closing manoeuvre.

Page 14

14

This is the most important phase of automation set-up to ensure

maximum safety. Testing can also be performed as a periodic check

of automation devices.

Testing of the entire system must be performed by

skilled and qualified personnel, who are responsible for

the tests required, according to the risk present, and for

ensuring observance of all legal provisions, standards and

regulations, and in particular all requirements of the standard EN 12445, which establishes the test methods for

checking automations for doors and gates.

!

5) Tests and commissioning

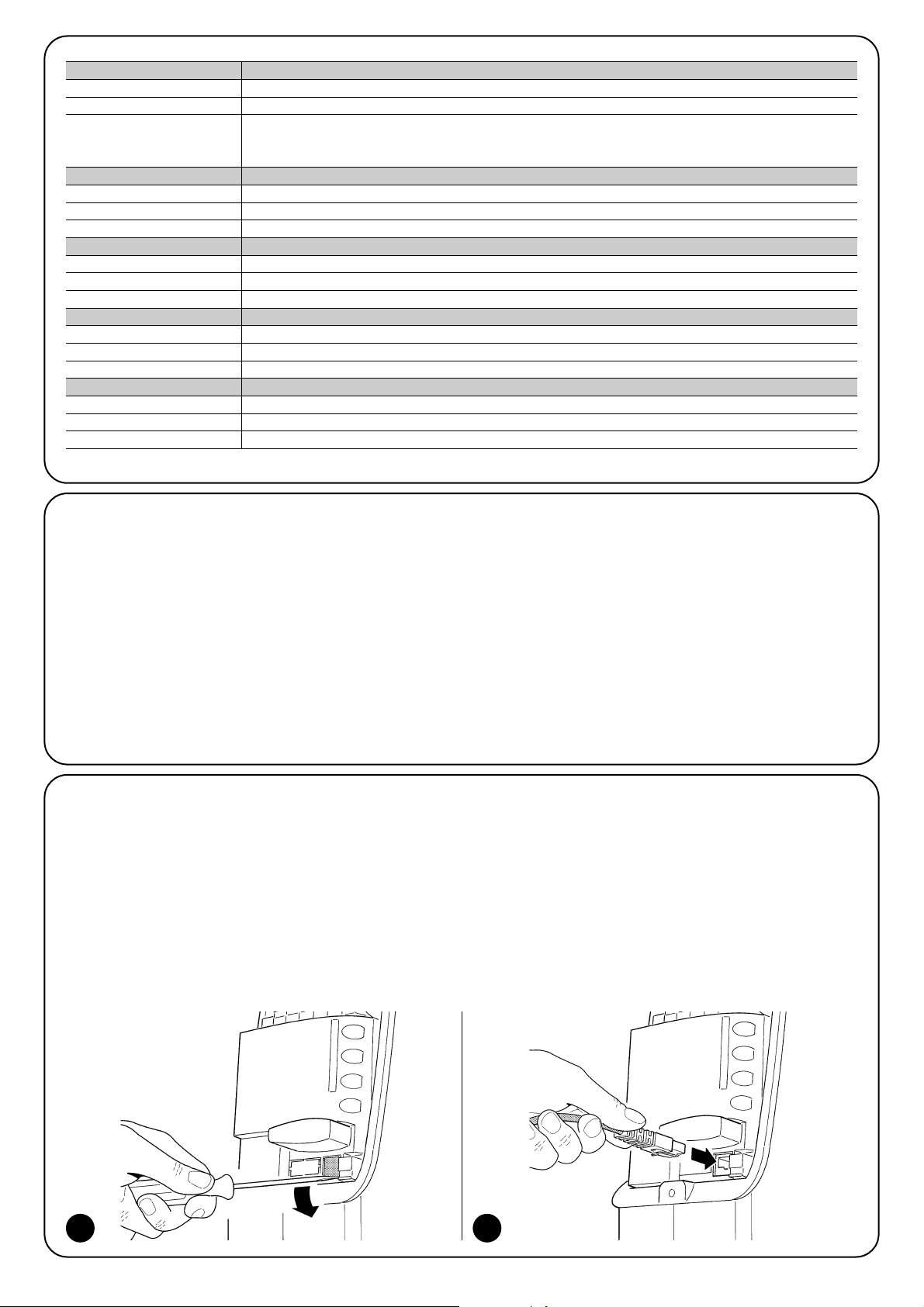

4.6) Radio receiver

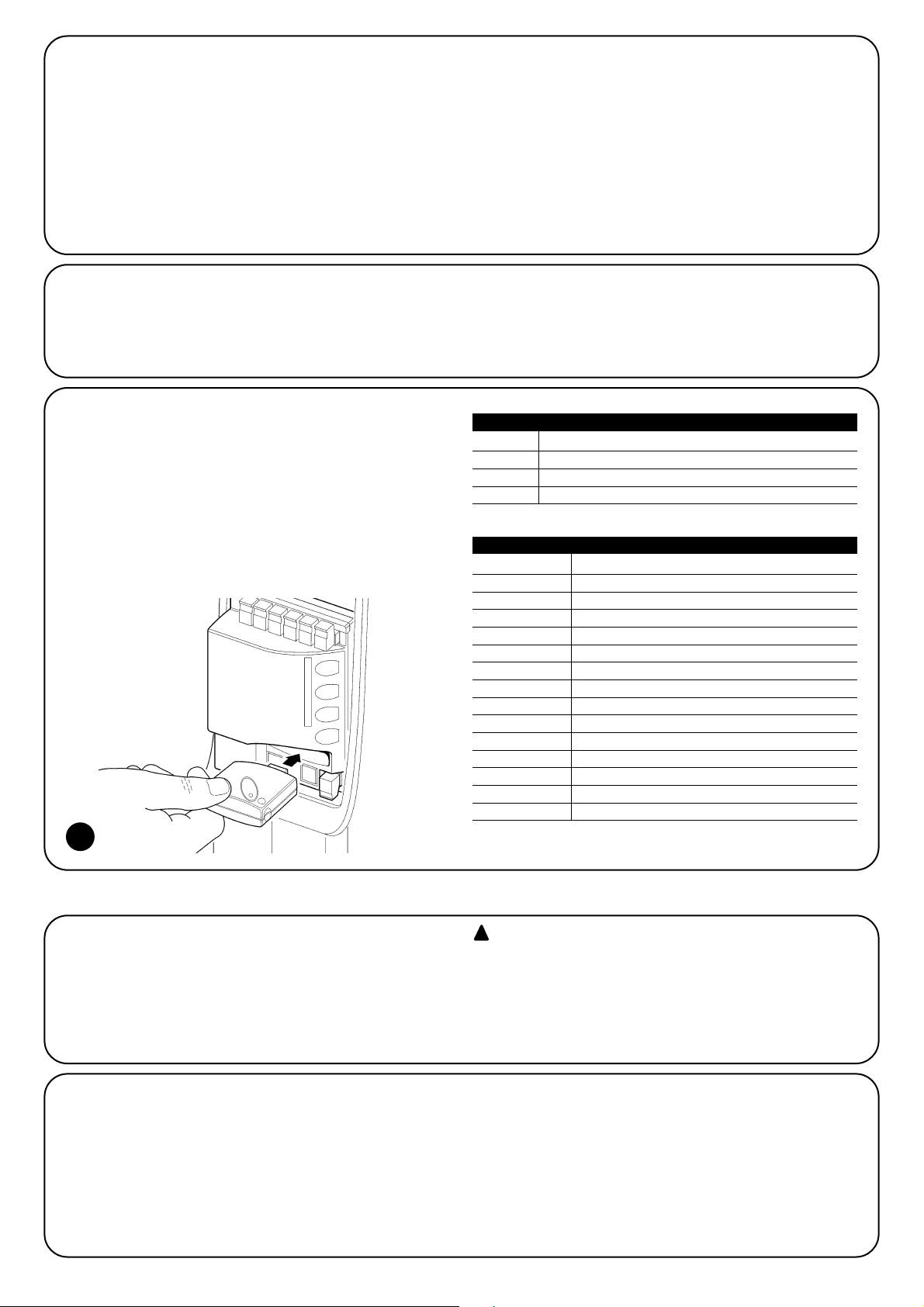

For remote control of TEN, the control unit is equipped with a connector SM for optional radio receiver types SMXI, SMXIS or OXI. To

insert the radio receiver, disconnect TEN from the power supply and

follow the procedure as indicated in figure 21. Table 7 shows the

association between the output of the radio receivers SMXI and

SMXIS and the command that TEN executes:

If the radio receiver OXI of the NiceOpera range is used, EXTENDED

MODE II enables the receiver to send the following commands:

Output N°1 “SS” command (Step-by-Step)

Output N°2 “Partial open” command

Output N°3 “Open” command

Output N°4 “Close” command

Table 7: commands with receiver SMXI, SMXIS

Command n°1 Step-Step

Command n°2 Partial opening 1

Command n°3 Open

Command n°4 Close

Command n°5 STOP

Command n°6 Apartment block step-by-step

Command n°7 Step-by-step high priority

Command n°8 Partial opening 2

Command n°9 Partial opening 3

Command n°10 Open and block automation

Command n°11 Close and block automation

Command n°12 Block automation

Command n°13 Release automation

Command n°14 Courtesy Light On Timer

Command n°15 Courtesy Light On-Off

Table 8: commands with receiver OXI

22

4.4) Checking door movement

After learning the positions, run a number of manoeuvres to ensure correct movement of the door.

1. Press [OPEN] to activate an “Open” manoeuvre; ensure that door opening is correct without variations in speed; also check that the

deceleration on opening is performed at the set position.

2. Press [CLOSE] to activate a “Close” manoeuvre; ensure that the door closes with a low speed start, followed by a change in speed and

then that the door decelerates on closing at the set position.

3. During the manoeuvre, ensure that the flashing light emits flashes at the frequency 0.5s on and 0.5s off.

4. Make a number of opening and closing manoeuvres to check for possible assembly defects or faulty adjustments and other malfunctions

such as points of increased friction.

5. resistant, also during sudden accelerations or decelerations in door movement

4.5) Pre-set functions

The TEN control unit has a number of programmable functions, which are factory set with values that should suit most types of automation;

however, these functions can be modified at any time by means of the specific programming procedure, as described in paragraph “7.2 Settings”.

5.1) Testing

Each component of the automation, such as the sensitive edges,

photocells, emergency stop, etc., requires a specific testing phase;

for these devices the specific procedures in the respective instruction manuals must be performed.

To test TEN, follow the procedure below:

1. Ensure that all specifications in this manual have been observed,

with special reference to the chapter “1 Warnings”;

2. Release the door by rotating each motor release handle anticlockwise (Figure 40); ensure that the door can be moved manually in the opening and closing directions with a force of maximum

225N at the point envisaged for manual movement.

3. Lock the motors to the door by rotating the release handle clockwise (Figure 41).

Page 15

15

GB

4. Using the envisaged control and stop devices (key-operated

selector switch, control pushbuttons or radio transmitters),

perform tests of opening, closing and stopping the door and

ensure that operations correspond to specifications.

5. Test several times to assess smooth operation of the door and

check for any defects in assembly or adjustment and any possible points of friction.

6. Check operation of all system safety devices one at a time (photocells, sensitive edges, emergency stop, etc.); in particular, each

time a device is activated the “OK” led on the control unit must

flash rapidly twice to confirm acknowledgement of the event.

7. To check the photocells, and to ensure there is no interference

with other devices, pass a cylinder with diameter of 5cm and

length 30cm on the optical axis, first close to the TX, then close

to the RX and lastly at the centre between the two and ensure

that in all cases the device engages, changing from the active

status to alarm status and vice versa. Lastly ensure that the envisaged action is generated on the control unit, for example: in the

closing manoeuvre it inverts movement.

8. If hazardous situations generated by the moving barrier are protected by means of impact force limitation, measure the force as

specified in the standard EN 12445. If speed and motor force

controls are used as auxiliary functions with the system for reduction of impact force, test and identify the setting that obtains the

best results.

5.2) Commissioning

Commissioning can only be performed after positive results of all test

phases on TEN and the other devices present. Partial or “makeshift”

commissioning is strictly prohibited.

1. The prepared automation technical documentation should be

conserved for at least ten years and must contain at least the following: overall drawing of the automation, electrical wiring diagram, risk assessment and relative solutions adopted, manufacturer’s declaration of conformity for all devices used (in the case

of TEN, use the EC declaration of conformity enclosed); copy of

the operation instruction manual and maintenance schedule for

the automation.

2. Affix a dataplate on the door, specifying at least the following

data: type of automation, name and address of manufacturer

(responsible for commissioning), serial number, year of construction and CE mark

3. Permanently affix a label or plate in the vicinity of the door, indicating the operations for door release and manual manoeuvres.

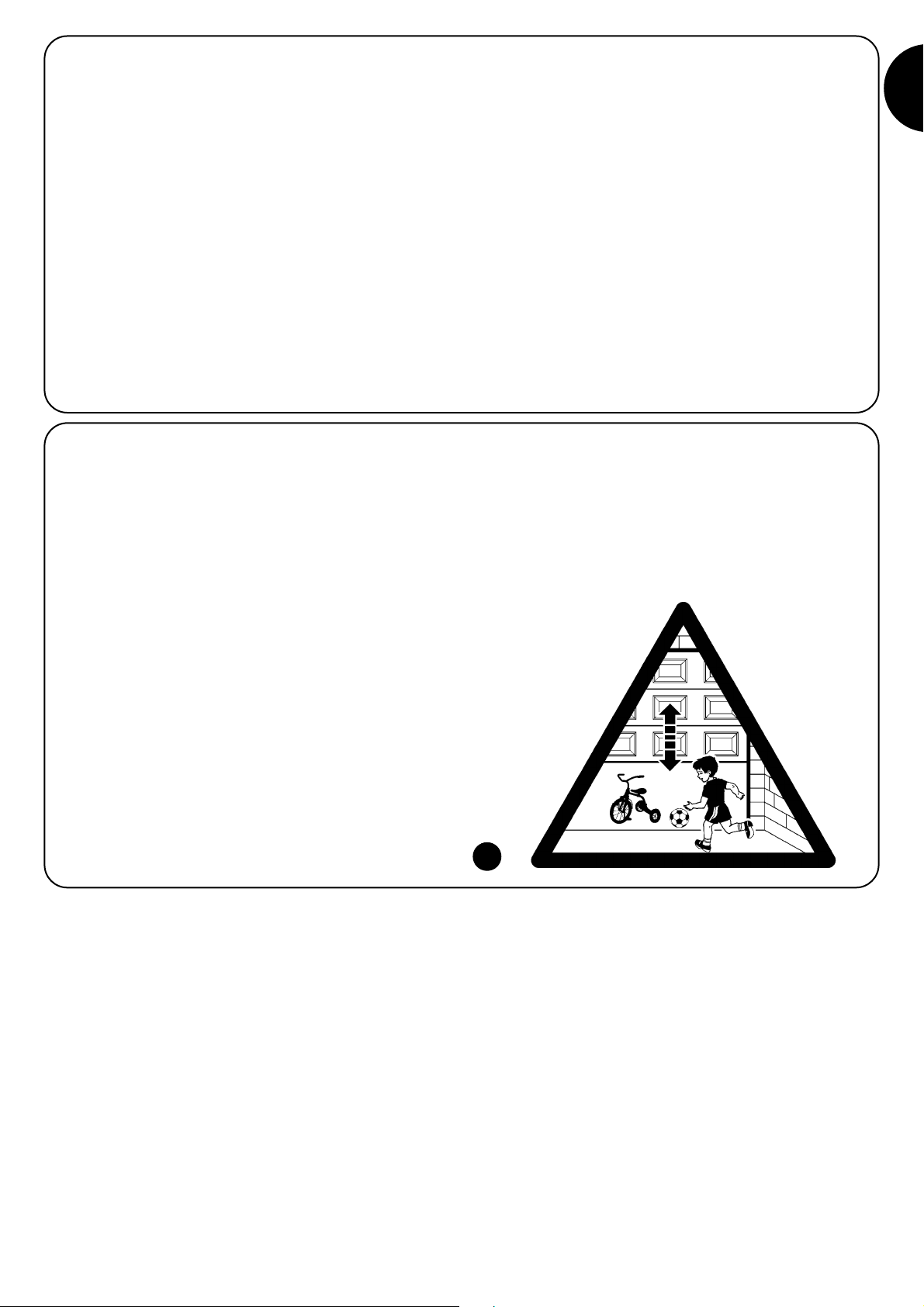

4. Permanently affix a label or plate on the door, bearing this image

(min. height 60 mm). (Figure 23)

5. Prepare and provide the owner with the declaration of conformity of the automation.

6. Prepare and provide the owner with the manual “Automation

operation instructions and warnings”.

7. Prepare and provide the owner with the automation maintenance

schedule (containing all prescriptions for maintenance of individual devices)

8. Before commissioning the automation, ensure that the owner is

adequately informed in writing (such as in the automation instruction and warning manual) of all associated risks and hazards.

23

Page 16

16

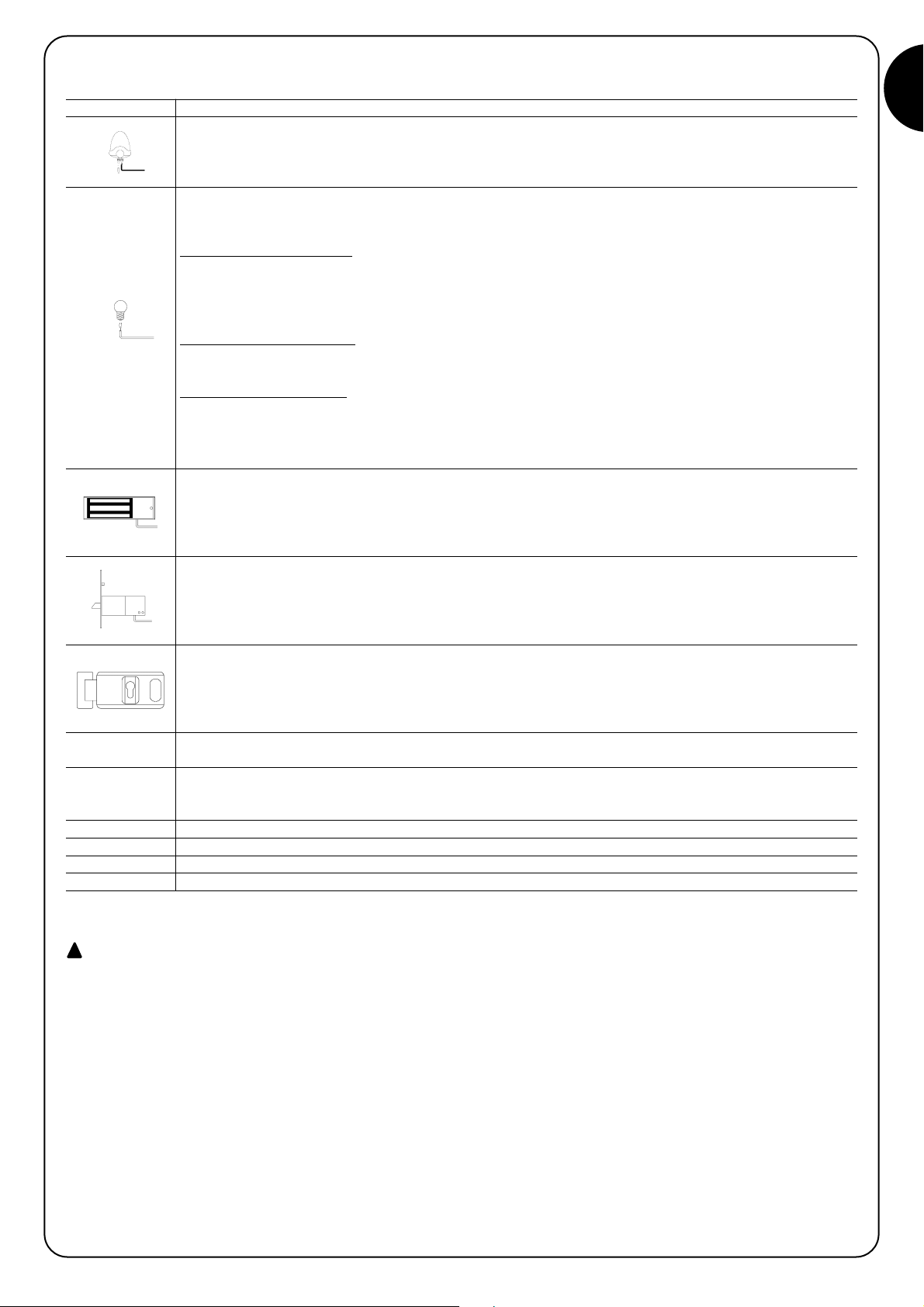

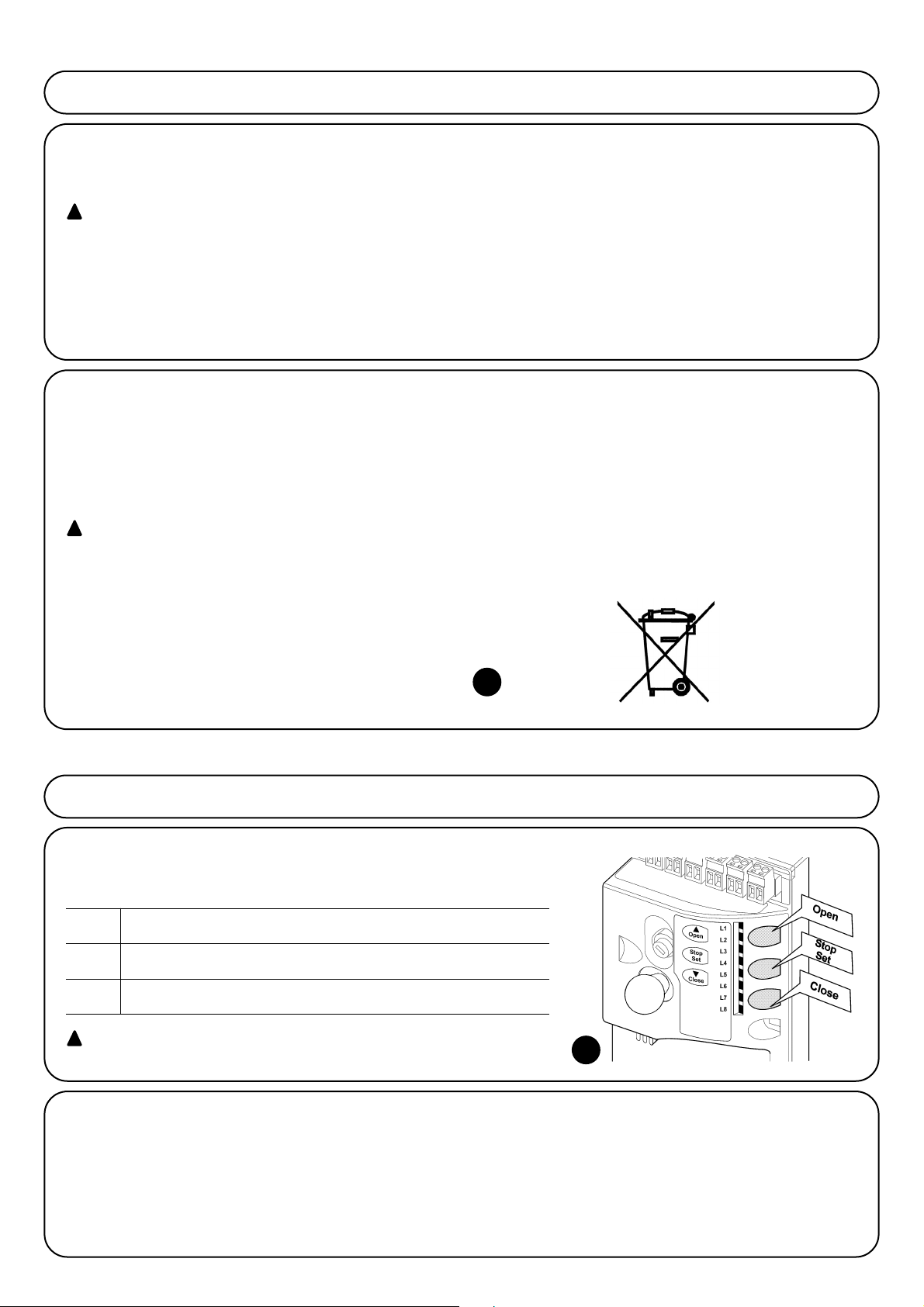

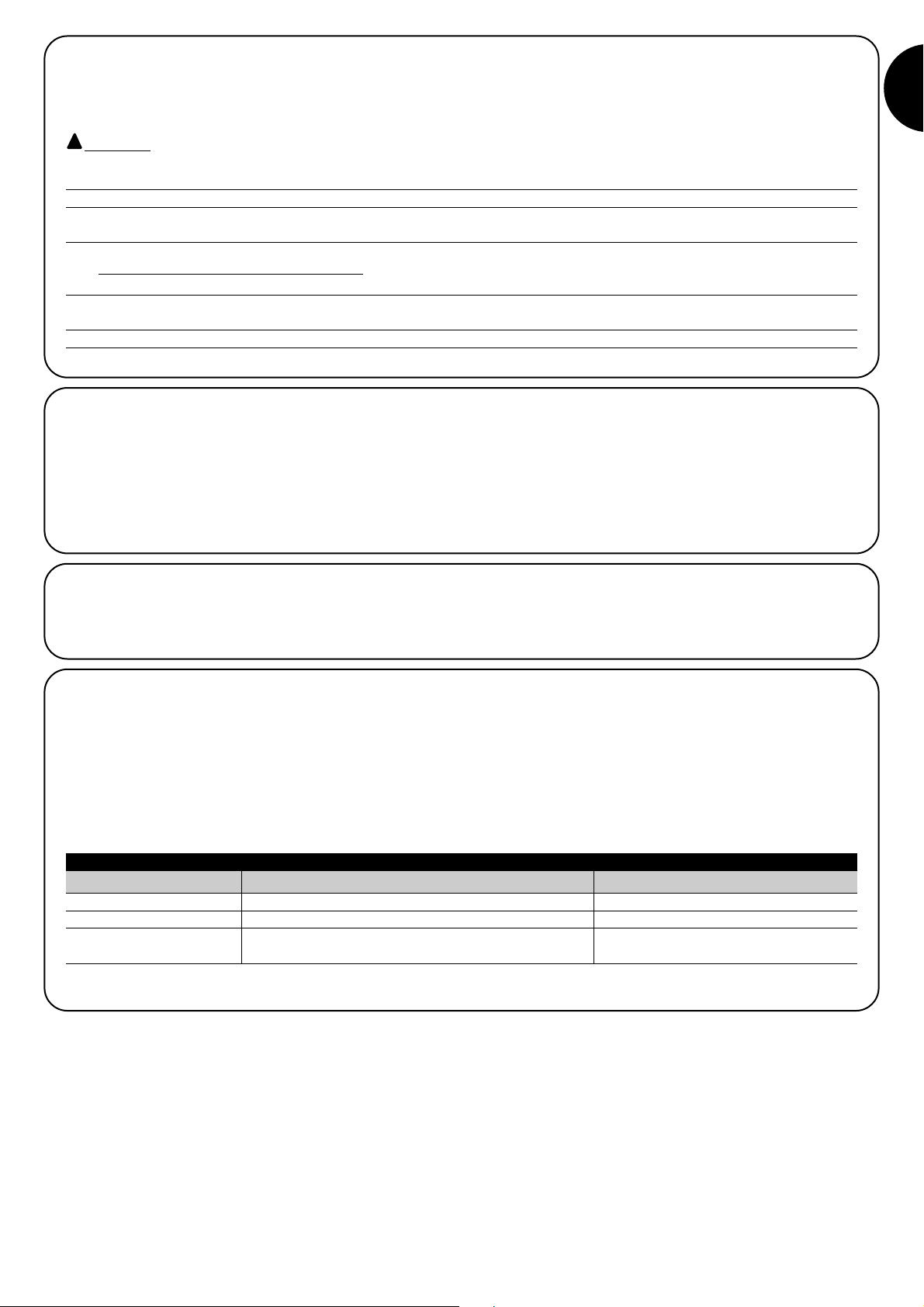

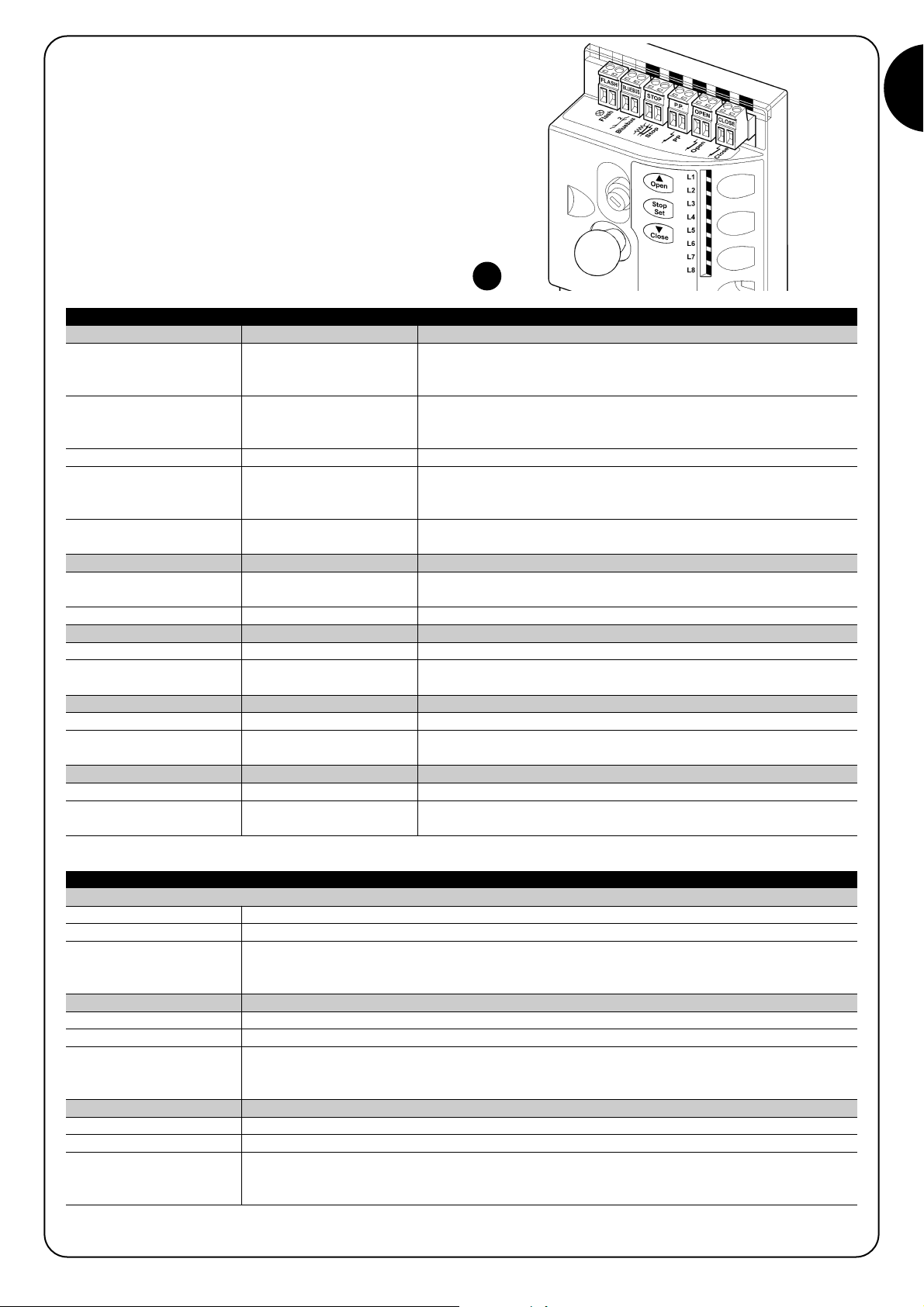

7.2) Settings

The TEN control unit is equipped with a number of programmable

functions; function settings are entered by means of the 3 keys on

the control unit: [▲][Set]and [▼] and are displayed by means of

8 leds: L1….L8.

The programmable functions available on TEN are divided into 2 levels:

Level 1: functions settable in ON-OFF mode (enabled or disabled);

in this case each led L1….L8 indicates a function, if lit the function

is enabled, if off the function is disabled; see Table 8.

Level 2: parameters settable on a scale of values (from 1 to 8); in

this case each led L1….L8 indicates a set value from the possible

8; see Table 10.

This chapter deals with the options for programming, personalisation, diagnostics and troubleshooting for the TEN gearmotor.

During the manoeuvre, whether opening or closing, all keys execute

the STOP function to shut down motor movement.

!

7) Further information

OPEN The “OPEN” key enables the user to open the door or scroll up

through the programming steps.

The STOP key stops the manoeuvre; If pressed for more than 5

seconds, it enables entry to programming mode.

The “CLOSE” key enables the user to close the door or scroll down

through the programming steps

7.1) Programming keys

The TEN control unit is fitted with 3 keys which can be used both for the control of the

unit during testing and the programming procedure (Figure 25).

25

▲

OPEN

STOP

SET

CLOSE

▼

This chapter provides the information required to draw up a maintenance schedule and for the disposal of TEN.

6) Maintenance and disposal

6.1) Maintenance

To maintain constant safety levels and guarantee maximum duration

of the entire automation, regular maintenance is required.

Maintenance must be performed in full observance of

the safety regulations specified in this manual and

according to current legislation and standards.

For other devices different from TEN follow the instructions in the

respective maintenance schedules.

1. In the case of TEN scheduled maintenance must be performed

within 6 months or 4.000 duty cycles since the previous maintenance operation.

2. Disconnect all electrical power supply sources.

3. Check the state of wear of all automation materials, with special

attention to possible erosion or oxidation of structural parts;

replace all parts that do not guarantee total efficiency.

4. Check the state of wear of all moving parts: Telescopic arms,

counterweight ropes and all parts of the leaf; replace all worn

parts.

5. Reconnect the electrical power sources and perform all tests and

inspections envisaged in the paragraph “5.1 Testing”:

!

6.2) Disposal

As in installation, also at the end of product lifetime, the disassembly

and scrapping operations must be performed by qualified personnel.

This product is made up of different types of material, some of which

can be recycled while others must be disposed of. Seek information

on the recycling and disposal systems envisaged by the local regulations in your area for this product category.

Some parts of the product may contain pollutant or

hazardous substances which, if disposed of into the environment, may cause serious damage to the environment

or physical health.

As indicated by the symbol in figure 24, disposal of this product in

domestic waste is strictly prohibited. Separate the waste into categories for disposal, according to the methods envisaged by current

legislation in your area, or return the product to the retailer when purchasing a new version. Local legislation may envisage serious fines

in the event of abusive disposal of this product.

1. Disconnect the automation from the electrical power supply,

including the buffer battery.

2. Disassemble all devices and accessories, following the procedure

described in chapter “3 Installation” in reverse order

3. Where possible, separate all parts that can be recycled or disposed of as classified waste, such as metal and plastic parts,

electronic boards, batteries etc.

4. Sort all groups and deliver separated waste to an authorised disposal firm in compliance with local regulations.

!

24

Page 17

17

GB

Led Function Description

L1 Automatic closure This function enables automatic closure of the door after a programmed pause; the default Pause Time is

set at 30 seconds but may be modified to 10, 20, 40, 60, 80, 120, 160 or 200 seconds.

If the function is not enabled, operation is set to “semi-automatic”

L2 Re-close After Photo This function enables the door to remain open only for the time required for transit; in fact activation of

“Photo” always activates automatic re-closure with a pause time of 5 seconds (regardless of the set value)

Operation depends on whether the “Automatic Closure" function is enabled or not.

With “Automatic closure” not active: The door always reaches the total opening position (even if

Photo is disengaged beforehand). On disengagement of Photo, automatic re-closure is activated with a

pause of 5 seconds.

With “Automatic closure” active: The opening manoeuvre is stopped immediately after the photocells

are disengaged and automatic re-closure is activated with a pause of 5 seconds.

The function "Re-close After Photo " is always disabled in manoeuvres interrupted by a Stop command.

If the function " Re-close After Photo " is not active, the pause time is as programmed and there is not

automatic re-closure if the function is not active.

L3 Always Close The function “Always Close” is activated, activating closure, when power is restored and the door is

detected as open.

For safety reasons, the manoeuvre is preceded by a 3-second pre-flashing interval.

If the function is not active, on power restoral the door remains stationary.

L4 Stand-By This function enables a reduction of consumption to a minimum. If this function is active, after 1 minute

from the end of the manoeuvre, the control unit turns off the BlueBUS output (and therefore all connected

devices) and all leds, except for the BlueBUS led, which flashes at a slower interval. When the control unit

receives a command it restores normal operating conditions. If the function is not active there is no

reduction in consumption.

L5 Long inversion This function enables the user to select the type of inversion that the door performs on receipt of command

from STOP or the force limiter. If the function is not active, inversion is short (approx. 15 cm). If the function

is active, inversion is activated through to the maximum opening or closing position.

L6 Pre-flash When the pre-flash function is active, a pause of 3 seconds is added between start-up of the flashing light

and the start of the manoeuvre, to give advance warning of a hazardous situation. If pre-flash is not active

the flashing light is started at the same time as the manoeuvre.

L7 Sensitivity This function enables a significant increase in motor sensitivity in obstacle detection. If used as an aid for

reading impact force, the parameters “Speed” and “Motor Force” in the level 2 menu should also be set

accordingly.

L8 2 motors This function must be enabled when the installation is with 2 motors.

During normal operation of TEN, i.e. when no manoeuvre is in progress, leds L1….L8 are lit or off depending on the status of the associated

function, for example L1 is lit if the function “Automatic closure” is enabled.

During the manoeuvre, leds L1…L8 flash, indicating the force required to move the door at that time. If L8 flashes, the force required is

minimal, and so on through to L1 which indicates the maximum force level.

Note that there is no relation between the force level indicated by the leds during movement (an absolute value) and the level indicated by

the leds during force programming (a relative value). See L5 and L6 in table 10.

Table 8: List of programmable functions: Level 1

7.2.1) Level 1 programming (ON-OFF functions)

7.2.2) Level 1 programming (ON-OFF functions)

By default level 1 function are all set to OFF, but can be modified at any time as described below. Take care during modification procedures,

as there is a maximum time interval of 10 seconds between pressing one key and another; otherwise the system exits the procedure automatically memorising the changes made up to that time.

1. Press and hold [Set] for approx. 3s

3s

2. Release the key [Set] when led L1 starts to flash

3. Press keys [▲] or [▼] to move the flashing led to the led associated with the function to be modified

4. Press [Set] to change the status of the function (short flash = OFF; long flash = ON)

5. Wait 10s to exit the programming mode automatically after the maximum time interval

10s

Note: points 3 and 4 can be repeated during the same programming phase to set other functions to ON or OFF

Table 9: To change the ON-OFF functions Example

L1

or

SET

SET

SET

Page 18

18

7.2.3) LEVEL 2 functions (adjustable parameters)

Table 10: List of programmable functions: Level 2

Pause Time

SS function

Motor speed

FLASH

Output

Motor force

on opening

Motor force

on closure

Maintenance

notification

L1

L2

L3

L4

L5

L6

L7

L8

L1

L2

L3

L4

L5

L6

L7

L8

L1

L2

L3

L4

L5

L6

L7

L8

L1

L2

L3

L4

L5

L6

L7

L8

L1

L2

L3

L4

L5

L6

L7

L8

L1

L2

L3

L4

L5

L6

L7

L8

L1

L2

L3

L4

L5

L6

L7

L8

10 seconds

20 seconds

40 seconds

60 seconds

80 seconds

120 seconds

160 seconds

200 seconds

Open - Stop - Close - Stop

Open - Stop - Close - Open

Open - Close - Open - Close

Apartment block

Apartment block 2 (more than 2” causes stop)

Step-by-Step 2 (less than 2” causes partial open)

Hold-to-run

Opening in “semiautomatic”, closure in “hold-to-run” mode

Speed 1 (30% - low)

Speed 2 (44%)

Speed 3 (58%)

Speed 4 (72%)

Speed 5 (86%)

Speed 6 (100% - high)

Open V4, close V2

Open V6, close V4

Door open indicator” function

Active if door closed

Active if door open

Flashing light

Electric block*

Electric lock

Suction cup

Maintenance indicator

Force 1 (low

Force 2

Force 3

Force 4

Force 5

Force 6

Force 7

Force 8 (high)

Force 1(low)

Force 2

Force 3

Force 4

Force 5

Force 6

Force 7

Force 8 (high)

Automatic (based on the gravity of the manoeuvres)

1.000

2.000

4.000

6.000

8.000

10.000

12.000

entryled Parameter Led (level) Value Description

Adjusts the pause time, i.e.

time before automatic closure.

Is effective only if automatic

closure is enabled

Adjusts the sequence of commands associated with the SS

input or the radio command.

Sets the motor speed during

normal travel.

Selects the device connected

to the FLASH output. Before

changing settings, take care

to ensure that the device connected to the FLASH terminal

is as described in paragraph

3..4.1 “Description of electrical

connections”.

Sets the motor force control

system to adapt it to the

weight of the door during the

opening manoeuvre and consequently the obstacle detection sensitivity.

Sets the motor force control

system to adapt it to the

weight of the door during the

closing manoeuvre and consequently the obstacle detection sensitivity.

Sets the number of manoeuvres after which the maintenance request signal can be

enabled (see paragraph “7.4.3

Maintenance notification”.

L1

L2

L3

L4

L5

L6

L7

Note: “ ” represents factory settings SEGUE

Page 19

19

GB

Fault log list

L1

L2

L3

L4

L5

L6

L7

L8

Result of 1stmanoeuvre (the most recent)

Result of 2ndmanoeuvre

Result of 3rdmanoeuvre

Result of 4thmanoeuvre

Result of 5thmanoeuvre

Result of 6thmanoeuvre

Result of 7thmanoeuvre

Result of 8

th

manoeuvre

entryled Parameter Led (level) Value Description

Enables the user to check the

type of fault occurring in the

last 8 manoeuvres (see paragraph “7.6.1 Fault log list”).

L8

Note: “ ” represents factory settings

All parameters can be adjusted as required without any contraindications, only the “Motor force on opening” and “Motor force in closing”

may require special attention:

• Use of high force values are not recommended to compensate for the fact that the leaf has anomalous points of friction; excessive force

may impair the safety system and damage the leaf.

• If the “Motor force control” is used in support of the system for impact force reduction, after each adjustment the force measurement pro-

cedure must be performed, as envisaged by standard EN 12445.

• Wear and atmospheric conditions influence movement of the gate; force settings should be checked periodically

7.2.4) Level 2 programming (adjustable parameters)

By default the settable parameters are set as shown in Table 10 with: “ “ but can be modified at any time as described below. Take care

during modification procedures, as there is a maximum time interval of 10 seconds between pressing one key and another; otherwise the

system exits the procedure automatically memorising the changes made up to that time.

1. Press and hold [Set] for approx. 3s

3s

2. Release the key [Set] when led L1 starts to flash

3. Press keys [▲] or [▼] to move the flashing led to the “input led” associated with the parameter to

be modified

4. Press and hold [Set] during steps 5 and 6

5. Wait approx. 3s after which the led associated with the current level of the parameter to be modified

will light up.

6. Press keys [▲] or [▼] to move the led associated with the parameter value

7. Release [Set]

8. Wait 10s to exit the programming mode automatically after the maximum time interval

10s

Note: Points 3 to 7 can be repeated during the same programming phase to modify other parameters

Table 11: To change adjustable parameters Example

L1

or

or

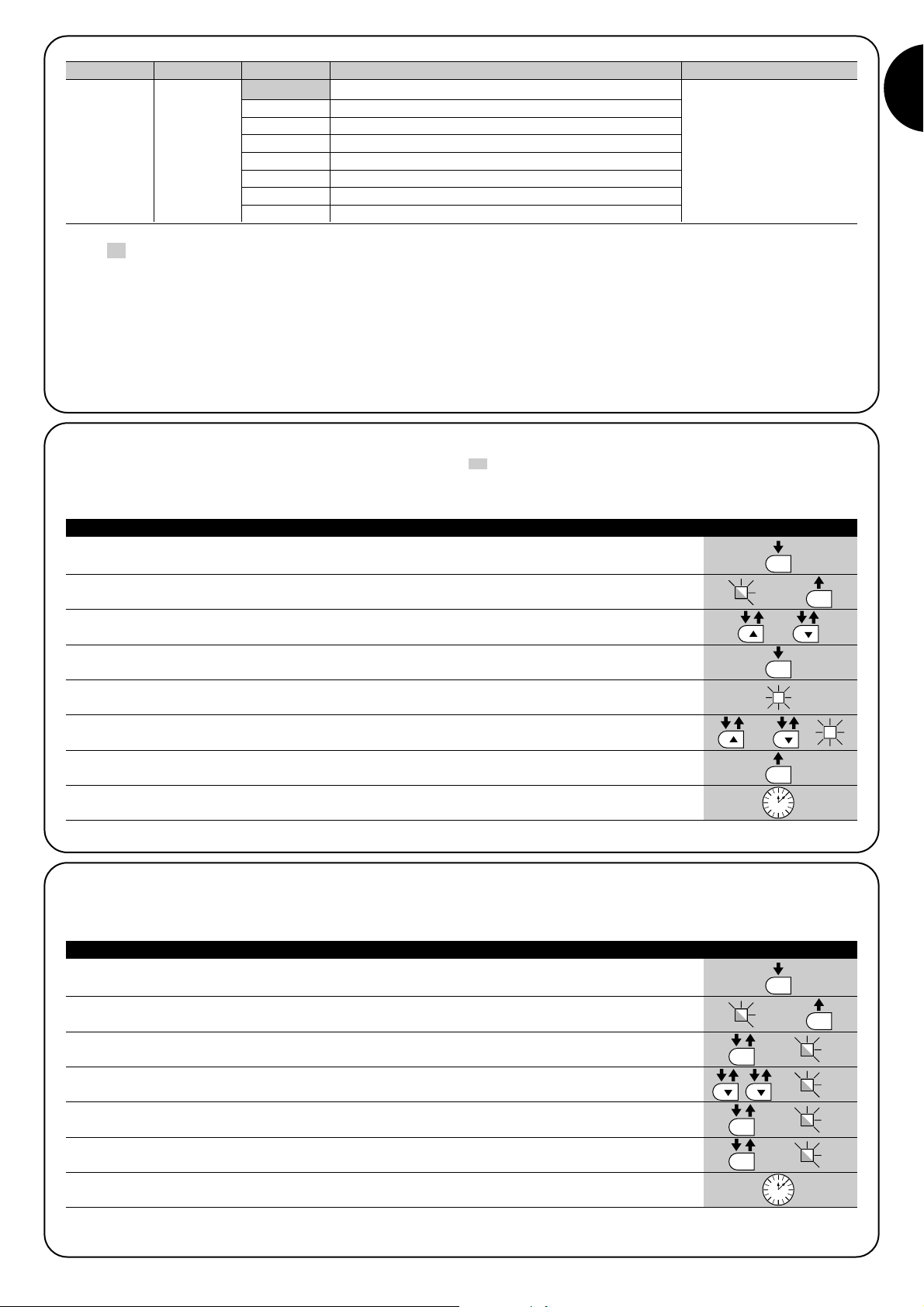

7.2.5) Level 1 programming examples (ON-OFF functions)

This example shows the sequence of operations required to change the factory setting of the functions “Automatic Closure” (L1) and “Always

Close” (L3).

1. Press and hold [Set] for approx. 3s

3s

2. Release the key [Set] when led L1 starts to flash

3. Press [Set] once to change the status of the function associated with L1

(Automatic closure) led L1 now emits long flashes

4. Press [▼] twice to move the flashing led onto led L3

5. Press [Set] once to change the status of the function associated with L3 (Always close) led L3 now

emits long flashes

6. Press [Set] once to change the status of the function associated with L3 (Automatic closure) led L3 now

emits long flashes

7. Wait 10s to exit the programming mode automatically after the maximum time interval

10s

At the end of these operations leds L1 and L3 must remain lit to indicate that the functions “Automatic closure” and “Always Close” are enabled.

Table 12: Example of Level 1 programming Example

L1

L1

L3

L3

L3

SET

SET

SET

SET

SET

SET

SET

SET

SET

Page 20

20

7.2.6) Example of Level 2 programming (adjustable parameters)

This example shows the sequence of operations required to change the factory setting of the parameters and set the functions of the “Pause

Time” to 60s (input on L1 and level on L4) and “Speed” to L6 (input on L4 and level on L6).

1. Press and hold [Set] for approx. 3s

3s

2. Release the key [Set] when led L1 starts to flash

3. Press and hold [Set] during steps 4 and 5.

4. Wait approx. 3s until led L3 lights up, indicating the current level of “Pause Time”

3s

5. Press the key [▼] once to move the illuminated led onto L3, indicating the new value of “Pause Time”

6. Release [Set]

7. Press [▼] twice to move the flashing led onto led L3

L3

8. Press and hold [Set] during steps 9 and 10.

9. Wait approx. 3s until led L4 lights up, indicating the current level of “Motor speed”

3s

10. Press the key [▼] twice to move the illuminated led onto L6, indicating the new value of “Motor speed”

L3

11. Release [Set]

12. Wait 10s to exit the programming mode automatically after the maximum time interval

10s

Table 13: Example of LEVEL 2 programming Example

7.3) Adding or removing devices

Devices can be added or removed at any time on an automation using TEN. In particular the inputs “BlueBUS” and “STOP” can be connected to various types of device as indicated in the paragraphs below.

After adding or removing devices, the device learning procedure must be repeated, as described in the paragraph “7.3.5 Learning other

devices”.

7.3.1) BLUEBUS

BlueBUS is a technology that enables the connection of compatible devices with just two wires conveying the electric power and communication signals. All devices are connected in parallel on the same 2 BlueBUS wires, without the need to observe polarity; each devices is recognised individually as it is assigned with an exclusive address during installation. BlueBUS can be used, for example, to connect the following:

photocells, safety devices, control pushbuttons, indicator lamps, etc. The TEN control unit recognises each one of the devices connected by

means of a specific self-learning phase and is able to detect all possible faults in maximum safety. For this reason each time a device is connected to or removed from BlueBUS the self-learning phase must be repeated, as described in paragraph “7.3.5 Learning other devices”.

L1

L3

L3

L4

7.3.2) STOP input

STOP is the input that causes immediate shutdown of movement

followed by a brief inversion of the manoeuvre This input can be connected to devices with an output with NO normally open contacts,

NC normally closed contacts, OPTO SENSOR contacts or devices

with constant resistance 8.2KΩ output, such as sensitive edges. As

in the case of BlueBUS, the control unit recognises the type of

device connected to the STOP input during the self-learning phase

(see paragraph “7.3.5 Learning other devices”); after which a STOP

command is activated whenever a variation with respect to the

learned status is detected.

When set accordingly, more than one device can be connected to

the STOP input, also different from one another:

• Several NO devices can be connected in parallel with no limit to

number.

• Several NC devices can be connected in parallel with no limit to

number.

• Two devices with constant resistance 8.2KΩ can be connected in

parallel; if there are more than 2 devices then all must be connected in cascade, with a single terminating resistance of 8.2KΩ.

• NO and NC combinations are possible by placing the 2 contacts

in parallel, taking care to place a 8,2KΩ resistance in parallel to the

NC contact (thus enabling the combination of 3 devices: NO, NC

and 8,2KΩ).

If the STOP input is used to connect devices with safety functions, only the devices with a constant resistance

of 8,2KΩ or OPTO SENSOR optical devices guarantee

safety category 3 against faults in accordance with the

standard EN 954-1.

!

SET

SET

SET

SET

SET

SET

Page 21

21

GB

For connection of an optical device type OPTO SENSOR make the

connections as shown in Figure 26. The maximum current supplied

on the 12Vdc line is 40mA.

26

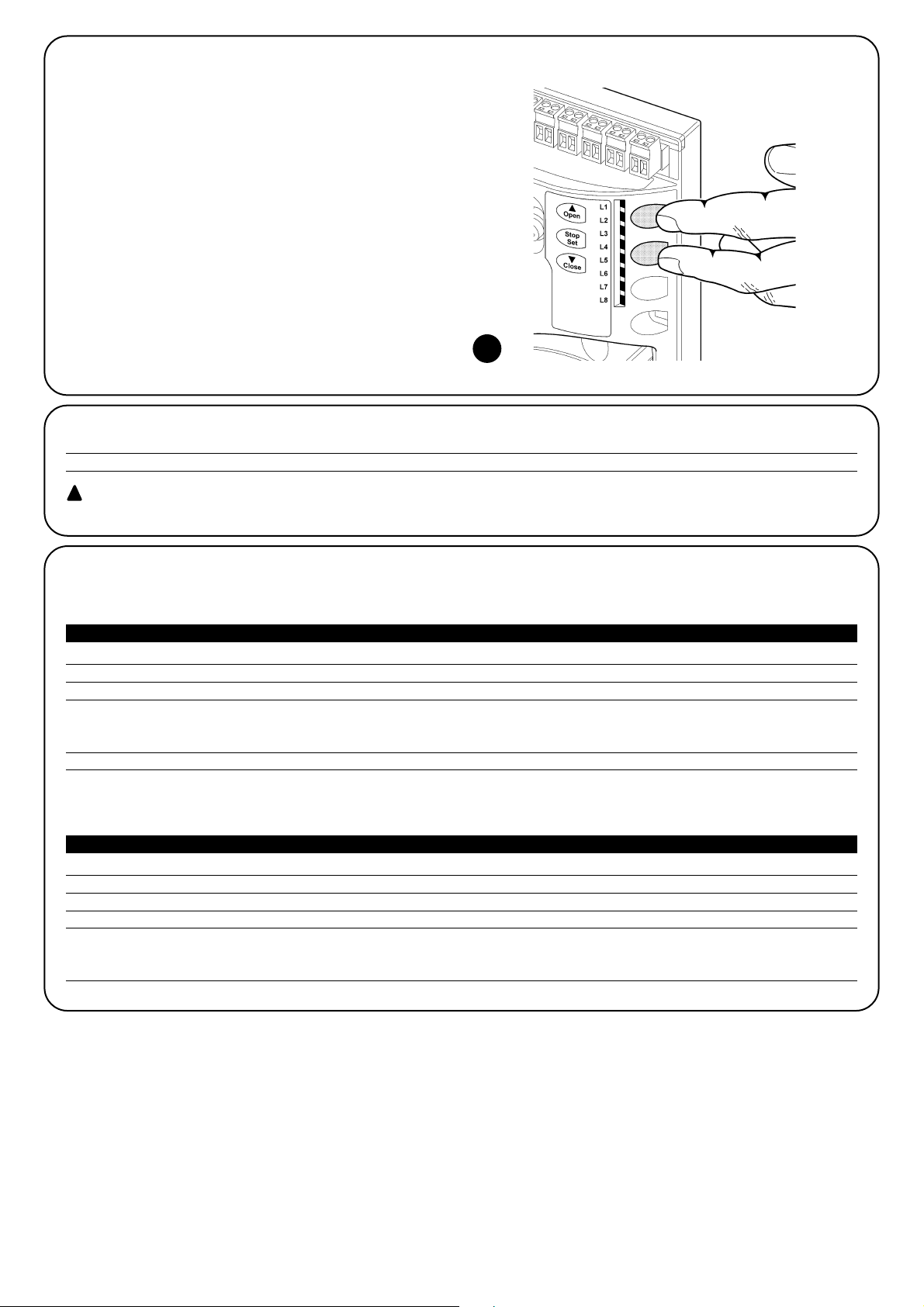

7.3.3) Photocells

The “BlueBUS” system enables, by means of address assignment using the specific jumpers, recognition of the photocells by the control unit

and assignment of the correct detection function. The address assignment procedure is performed both on the TX and RX (setting the

jumpers in the same way) and ensuring that there are no other pairs of photocells with the same address.

In an automation for up-and-over doors with TEN photocells can be installed as shown in Figure 27. After installing or removing photocells

the learning phase must be repeated on the control unit as described in the paragraph “4.2 Learning devices”.

27

PHOTO

Photocell h = 50

With activation on closure

PHOTO II

Photocell h = 100

With activation on closure

PHOTO 1

Photocell h = 50

With activation on closure and opening

PHOTO 1 II

Photocell h = 100

With activation on closure and opening

PHOTO 2

Photocell

With activation on opening

PHOTO 2 II

Photocell

With activation on opening

PHOTO 3

CONFIGURATION NOT ADMITTED

Table 14: Photocell addresses

Photocell Jumpers Photocell Jumpers

7.3.4) MOTB digital selector and proximity reader for MOMB transponder badges

BlueBUS can be connected to up to 4 digital MOTB selectors or MOMB type transponder badge readers.

MOTB enables control of the automation after entering a valid numerical code that has been previously memorised.

MOMB enables control of the automation by moving a valid transponder badge that has been previously memorised.

These devices are equipped with an individual ID code and are recognised by the control unit only after being memorised, which is performed

during the device acquisition phase. This prevents any unauthorised attempt to replace the device and inhibits control of the automation. For

further information see the specific instruction manuals for MOTB and MOMB.

Page 22

22

7.3.5) Learning other devices

Normally the operation for learning devices connected to BlueBUS

and the STOP input is performed during the installation phase; however if other devices are added or removed, the learning procedure

can be repeated as described below.

1. Press and hold keys [▲] and [Set] (Figure 28)

2. Release the keys when leds L1 and L2 start to flash quickly (after

around 3s)

3. Wait a few seconds for the control unit to finish device self-learning.

4. At the end of the self-learning process, the STOP led must

remain lit, while leds L1 and L2 turn off (where relevant leds L3

and L4 start flashing).

After adding or removing devices, the automation test

cycle must be repeated as described in paragraph “5.1

Testing”.

28

7.3.6) Deleting the entire memory

7.3.7) Programming the direction of motor rotation

When total deletion is required, to restore factory settings, proceed as follows with the motor stationary.

1. Press [▲]+[▼] for 3 seconds; release the keys when all leds illuminate simultaneously.

Leds L1 and L2 start flashing at the end of the procedure.

This procedure does not modify the parameter for the direction of Ten rotation or the encoder position.

!

Ten is factory set to execute the opening manoeuvre as shown in figure 5. The direction of rotation can be inverted by programming the opening manoeuvre as shown in figure 7.

Procedure for programming the direction of motor rotation

1. Press and hold [Set] for approx. 3s

2 Release [Set] when led L1 starts flashing

3. Press keys [▲]and[▼] at the same time to modify the motor direction

4. Release keys [▲]and[▼]

• If the courtesy light is lit, the inverted direction of motor rotation has been programmed

• If the courtesy light is off, the standard direction of motor rotation has been programmed

5. Wait 10s to exit programming mode in timeout.

Note: Points 3 and 4 can be repeated during the same programming phase to change the direction of motor rotation.

When the direction of motor rotation is changed, the “Position memorisation” procedure must be repeated.

Checking the programmed direction of motor rotation

To check the set direction of motor rotation, proceed as follows:

1. Disconnect Ten from the power supply (removing the plug or fuse)

2. Power up Ten

3. After the initial flash of leds L1 to L8 a single led illuminates to indicate the encoder position.

4. On the signal indicating the encoder position, check the courtesy light:

• If the courtesy light is lit, the inverted direction of motor rotation has been programmed

• If the courtesy light is off, the standard direction of motor rotation has been programmed

Page 23

23

GB

7.4) Special functions

7.4.1) “Always open” function

The “always open” function is a feature of the control unit that enables continuous activation of an opening manoeuvre when the “Step-bystep” command lasts more than 3 seconds; this can be useful for example to connect the SS terminal with the contact of a programme clock

to keep the gate open during a specific time band. This feature is valid regardless of the setting of the input SS (see “Function SS” in Table

10).

7.4.2) “Move anyway” function

In the event that a safety device malfunctions or is out of service, the door may still be moved in “hold-to-run” mode. For details, refer to the

paragraph “Control with safety devices out of service” in the enclosure “Instructions and warnings for the TEN gearmotor user”.

7.4.3) Maintenance notification

TEN enables the user to be notified when a maintenance

check needs to be performed on the automation. The

number of manoeuvres after which the signal can be

enabled is selectable from 8 levels, by means of the modifiable parameter “Maintenance notification” (see Table

10).

Adjustment level 1 is “automatic” and takes into account manoeuvre

stress, i.e. force and duration of the manoeuvre, while the other adjustments are set on the basis on the number of manoeuvres. The maintenance requirement notification is via the flashing light or the maintenance

indicator, depending on the relative settings (see Table 10). On the basis

of the number of manoeuvres performed with respect to the programmed limit, the Flash flashing light and maintenance indicator activate

the signals as described in Table 15.

Number of manoeuvre Signalling on Flash Signalling on maintenance indicator

Below 80% of limit Normal (0.5s on, 0.5s off) On for 2s at start of opening

Between 81 and 100% of limit Remains lit for 2s at start of manoeuvre then proceeds normally Flashes throughout manoeuvre

Over 100% of limit Remains lit for 2s at start and end of manoeuvre then proceeds Always flashes.

normally

Table 15: Maintenance notification with Flash and maintenance indicator

7.3.8) Resetting the encoder position

This procedure enables return of the encoder to the factory-set position to enable the assembly of Ten with the door closed.

If the direction of motor rotation needs to be changed, first complete the “Programming the direction of motor rotation” procedure and then

“Resetting the encoder position”.

CAUTION! THE PROCEDURE DESCRIBED BELOW MUST BE PERFORMED EXCLUSIVELY ON A WORKBENCH.

NEVER PERFORM THIS PROCEDURE WITH THE MOTOR INSTALLED ON THE DOOR.

1. Press and hold keys [▲]and[▼] until all leds from L1 to L8 illuminate.

2. Release the keys when the leds turn off.

After all leds turn off, a single led from L1 to L8 lights up again to indicate the encoder position.

3. At this time, press and hold [Set] until the motor starts up.

Release the key as ten as the motor starts up.

The control unit activates motor movement to bring the encoder position to led L6.

4. After the motor has stopped, all leds turn on and then off, after which check that the led that lights up again is L6. If this does not

occur, repeat the procedure from point 1.

5. At the end of the sequence leds L1 and L2 continue to flash.

!

Page 24

24

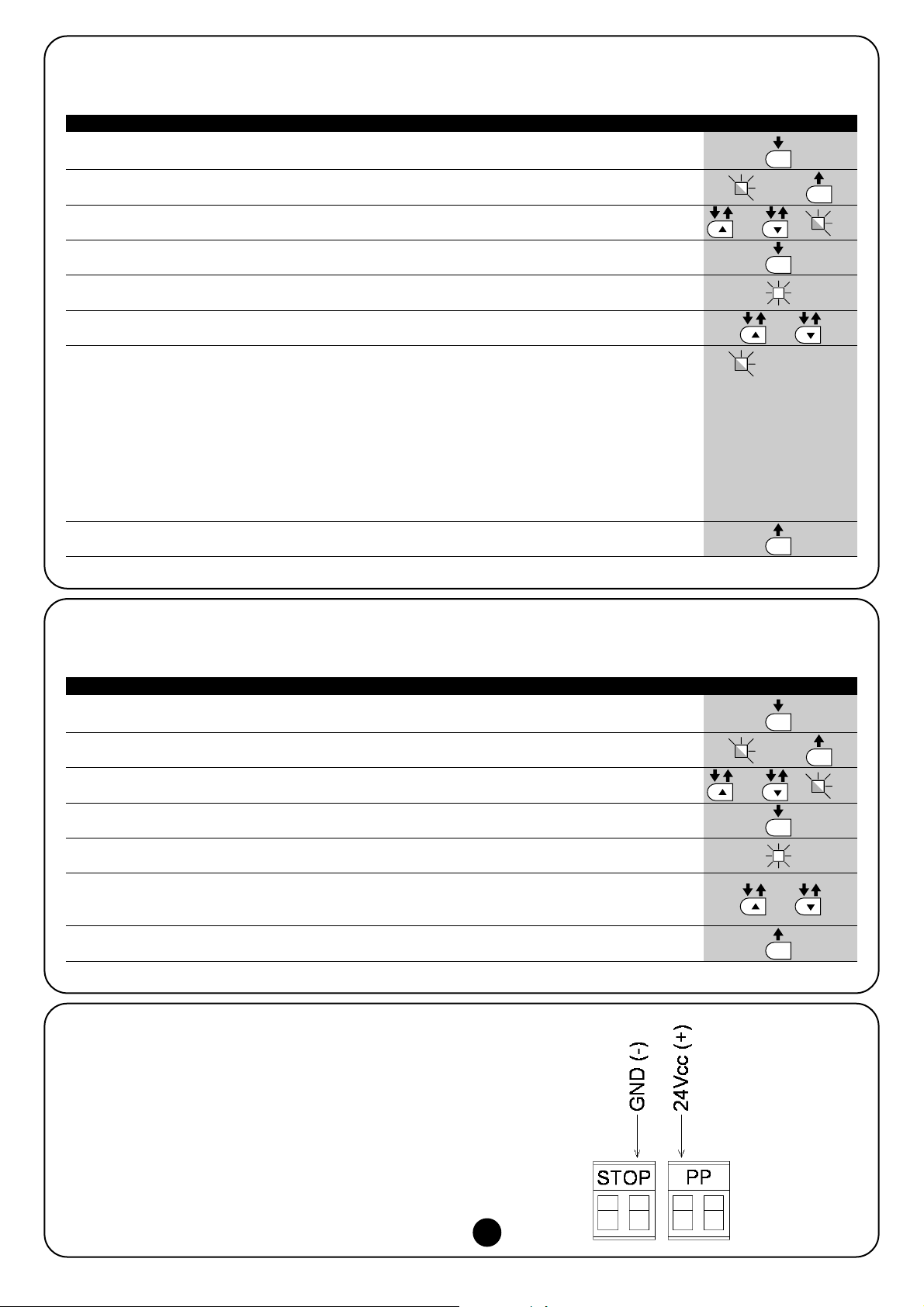

7.5) Connecting other devices

If external devices need to be powered, such as a proximity reader

for transponder badges or the lighting of a key-operated selector

switch, power can be supplied as shown in figure 29. The supply

voltage is 24Vcc -30% ÷ +50% with maximum available current of

100mA.

29

7.4.4) Check of number of manoeuvres performed

The function “Maintenance notification” enables the user to check the number of manoeuvres performed as a percentage of the set limit. To

check, proceed as follows:

1. Press and hold [Set] for approx. 3s

3s

2. Release the key [Set] when led L1 starts to flash

3. Press keys [▲] or [▼] to move the flashing led to L7, i.e. the “input led” associated with the

parameter “Maintenance notification”

4. Press and hold [Set] during steps 5, 6 and 7

5. Wait approx. 3s after which the led associated with the current level of the parameter

“Maintenance notification” will light up. 3s

6. Briefly press keys [▲] and [▼]

7. The led corresponding to the selected level flashes a few times. The number of flashes indicates the

percentage of manoeuvres performed (in multiples of 10%) with respect to the set limit.

For example: when the maintenance notification is set on L7 i.e. 10000, 10% corresponds to 1000

manoeuvres; if the indicator led flashes 4 times, this means that 40% of the maximum number of

manoeuvres has been reached (i.e. between 4000 and 4999 manoeuvres).

If 10% has not yet been reached, the led does not flash at all.

8. Release [Set]

Table 16: Check of number of manoeuvres performed

Example

L1

X1 = 10%

X2 = 20%

X3 = 30%

X4 = 40%

X5 = 50%

X6 = 60%

X7 = 70%

X8 = 80%

X9 = 90%

X10 = 100%

L7

or

and

7.4.5) Manoeuvre counter reset

After performing system maintenance the manoeuvre counter must be reset.

Proceed as described in table 17

1. Press and hold [Set] for approx. 3s

3s

2. Release the key [Set] when led L1 starts to flash

3. Press keys [▲] o [▼]to move the flashing led to L7, i.e. the “input led” associated with the parameter

“Maintenance notification”

4. Press and hold [Set] during steps 5 and 6

5. Wait approx. 3s after which the led associated with the current level of the parameter

“Maintenance notification” will light up. 3s

6. Press and hold keys [▲] and [▼] for at least 5 seconds, then release. The led corresponding to the

selected level shows a series of quick flashes to indicate that the manoeuvre counter has been reset.

7. Release [Set]

Table 17: Manoeuvre counter reset

Example

L1

L7

or

and

SET

SET

SET

SET

SET

SET

SET

SET

Page 25

25

GB

7.7) Diagnostics and indicators

Some devices offer special direct indicators to display the relative operating status or malfunctions..

7.6) Troubleshooting guide

Table 18 provides some useful information to deal with any malfunctions that may occur during installation, or in the event of faults.

30

Table 18: troubleshooting

Symptom Probable cause and possible remedy

The radio transmitter does not control the door

and the transmitter led does not illuminate

The radio transmitter does not control the door

but transmitter led illuminates

…no manoeuvre is activated and the OK led

does not flash

…no manoeuvre is activated and the flashing

light is off

…the manoeuvre does not start and the courtesy

light flashes a few times

The manoeuvre starts but immediately afterwards

a brief inversion is activated

Check that the transmitter batteries are not discharged; replace if necessary.

Check that the transmitter is correctly memorised on the radio receiver.

Ensure correct emission of the radio signal of the transmitter with the following empirical

test: Press a key and place the led against the aerial of a standard radio (the cheaper the

better) switched on and tuned to FM at the frequency of 108.5Mhz or as close to this

value as possible; a slight noise with a scratching pulse noise should be heard.

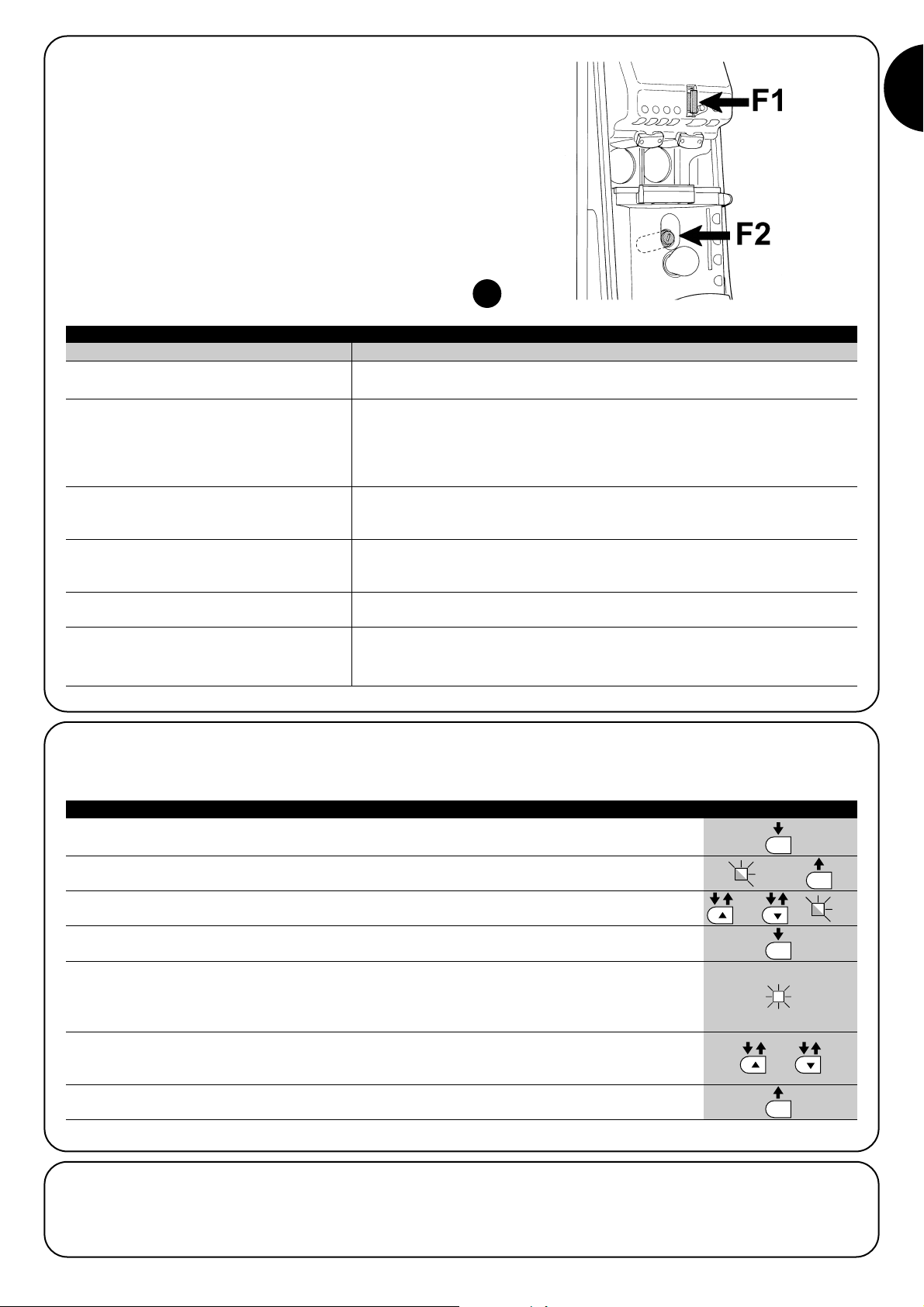

Ensure that TEN is powered from a 230V mains. Check that fuses F1 and F2 are not

blown; in this case, identify the cause of the fault and then replace with versions of the

same current value and specifications (Figure 30).

Check that the command is effectively received. If the command reaches the SS input

and the led OK emits a double flash to indicate that the command has been received.

Count the number of flashes and check with reference to the data in Table 20.

The selected force may be too low to move the door. Check whether there are any

obstacles, and if necessary select a higher force

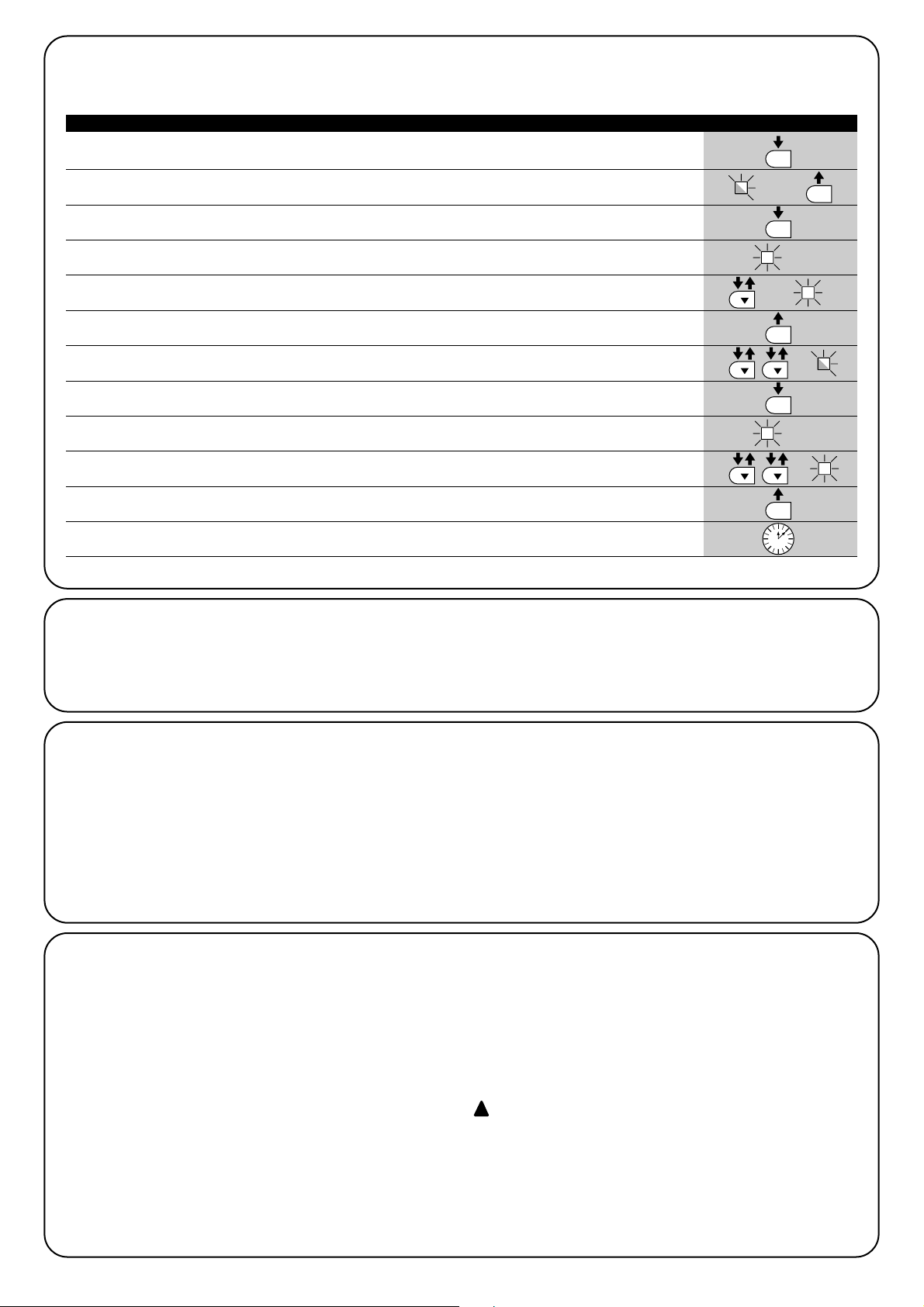

7.6.1) Fault log list

TEN enables the display of any faults that have occurred in the last 8 manoeuvres, for example interruption of a manoeuvre due to activation

of a photocell or sensitive edge. To check the fault list, proceed as shown in table 19.

1. Press and hold [Set] for approx. 3s

3s

2. Release the key [Set] when led L1 starts to flash

3. Press keys [▲] or [▼] to move the flashing led to L8, i.e. the “input led” associated with the

parameter “Fault log”

4. Press and hold [Set] during steps 5 and 6

5. Wait approx. 3s after which the leds corresponding to the manoeuvres subject to faults will light up.

Led L1 indicates the result of the most recent manoeuvre, while led L8 indicates the result of the

eighth manoeuvre. If the led is lit this means that faults have occurred during the manoeuvre; if off this

means that the manoeuvre was completed without faults. 3s

6. Press the keys [▲] and [▼] to select the required manoeuvre:

The corresponding led emits a number of flashes equal to those normally emitted by the flashing light

after a fault (see table 20).

7. Release [Set]

Table 19: Fault log list Example

L1

L8

or

and

SET

SET

SET

SET

Page 26

26

At the start of the manoeuvre, the check on devices connected to BlueBUS does

not correspond to those memorised during the learning phase. There may be

faulty devices; check and replace as necessary. If modifications are made, repeat

the learning procedure (7.3.4 Learning other devices).

7.7.1) Signals with flashing light

If a flashing light is connected it emits one flash per second during the manoeuvre; in the event of faults, the flashing frequency increases

with flashes repeated twice, separated by a pause of a second. The same conditions apply to the courtesy light.

Table 20: Signals on FLASH flashing light

Quick flashes Cause ACTION

1 flash

Pause of 1 second

1 flash

Error on BlueBUS

3 flashes

Pause of 1 second

3 flashes

4 flashes

Pause of 1 second

4 flashes

5 flashes

Pause of 1 second

2 flashes

6 flashes

Pause of 1 second

6 flashes

7 flashes

Pause of 1 second

7 flashes

Activation of Motor Force limiter

During movement, the door is subject to points of increased friction; check cause

2 flashes

Pause of 1 second

2 flashes

Activation of a Photocell

At the start of the manoeuvre one or more photocells do not enable the movement; check for the presence of obstacles

During movement this is normal if an obstacle is effectively present

Stop input activation

At the start of or during movement, the STOP input is activated; check cause

Error in internal parameters of

the electronic control unit

Wait at least 30 seconds and retry a command; if the condition persists, this may