WW

AtA

A

t

O3 O

O

O

O7

O

O OOPAA

to Com

ma

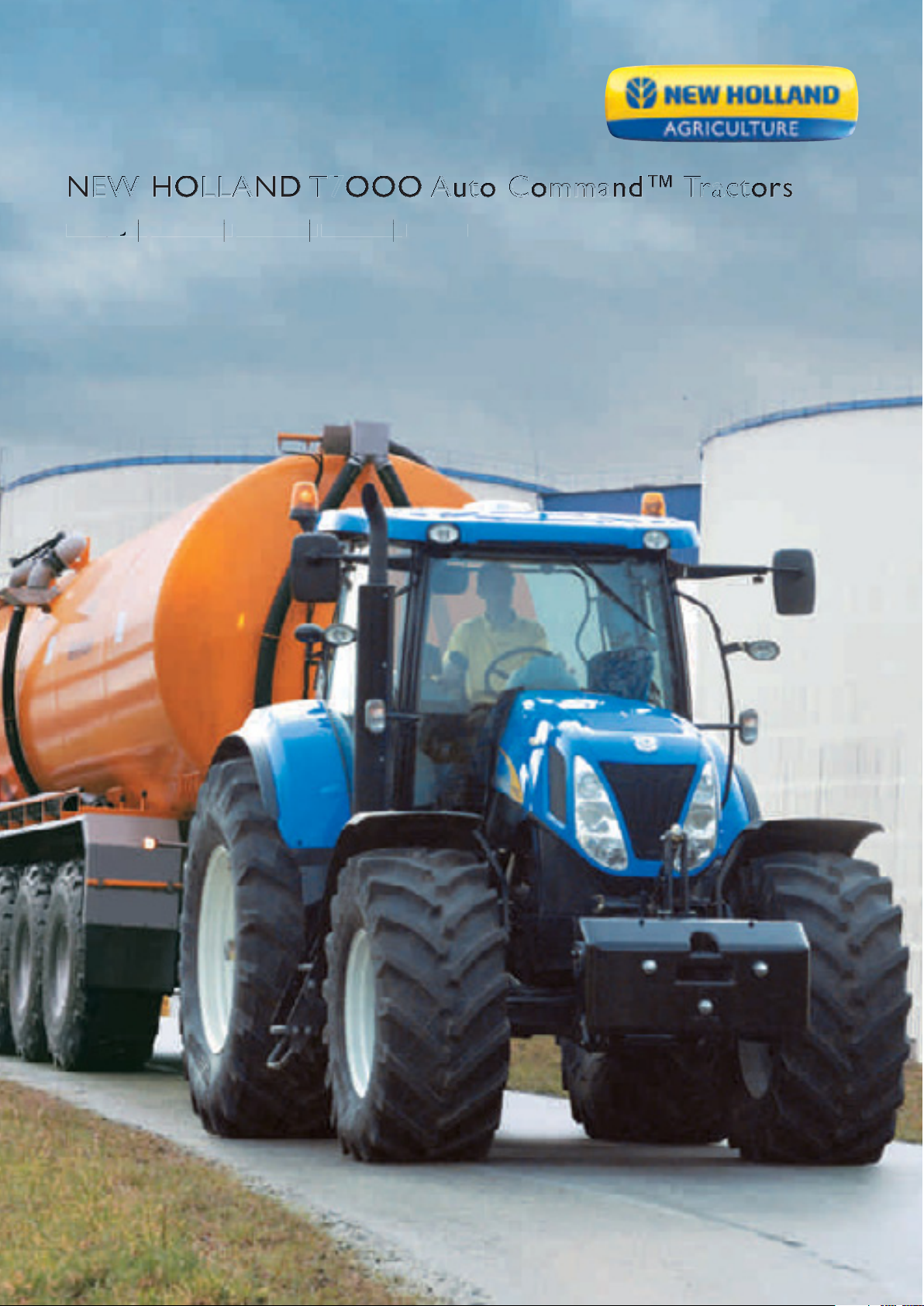

ot ease of

foperation. N Ncocx transmisonon men

.

tis. E

to va

e

a

y

y

undeto

to

d

eatr

.

Autoto

Comnd mmmch

ase o

pe

ti

ton w

excec

ptpp

io

io

y

O

WER AN

UCUTIVITY

(C

V)

T Ao mman

masasive

2

th

p

p

ower

b

g

hgt,

t,

vti a

p

p

ow T00 A Ammandd t

s

ve i t al

l.

.

V

Y

W

AAY

O

23

is all

implified function

N

asy acce

es e

and

nal effi

o

enc

P

e new

wi

D

d™ tractor of a

. Li

51 hp(CV)

ractor

BEST RETN

ON

Y

I

S

EN

T

makak

eaie

an e evebebebefofo

r

op

p

timise per

a

d

y

w

T7T000 Auto Comma t ract r r

ysys y

y

vevstme ffte

out th

twoworkfe of thtr

fi

t frfr you

fo

gh

gh

t

to

nvevst in the bstt

V

V

A

uto

CCom

ma

ractcarar

ed, ved anmanufafa

New H

Ad

vaed hvester contr tec

ol

en

pe

pe

a

i

b

ne to

od

thihi

ing it

Holl

DN

ty com

nd t

r th

.

e desi

.

give you the verbest in m

E

to

actoyou bene

nce

our

ogy and pr

nkin

ur

v

tivit

45

N

IT

III

ibl

ude wo

rk

III

d

attachme

ts

as

deWier

I

a

usted to

p

ytcyo

ur

nee

.

TR

hyd

t

p

ly

C

TR

tr

s

O

RCE LO

GI

V

Y

s

in

g the same operati

inciples as used on New Holland

f

orage harvesters, the CommandGri

p™

ndle is eased forw

ar

ar

operator having

pr

is

r

speed of the tractor

c

on

tr

to slow down. Sim

pl

TAKE CONTROL. ALL NEW SIDEWINDER™ II ARMREST

isel

HSCREE

TELLIVIEW™ III MON

tellw

operator with easily access

fomation to incl

statistics, service data a

lly ISO BUS compatible,

tellw

to operate a wide range

ovides t

nce monitori.

can be use

n

SIMPLICIT

to move forw

e contr

. Pull the

RE

e

nly be easily operated fr SideWinder™ I

est, but set up to match your applicatio

ickly Sim

ove

CON

raulic rotes and the PTO can

E

ideWinder II el

rapidly match your driving style.

NIC ADJUSTMENT

nically adjust

PUTS YOU IN CHARGE

AILOR TH

AS YWI

S

k

facto

Y

choose the

.

TE

GA C CONTRTL P

Cotr Pan

el

g

es

e

a cc

es

f

thaht nce

al

alaoc

ocok™

nagent

ag

™ II

s

Autoto

.

t t t t

has

n

a

RS AR

WHERE

Y

YWA

k

ey

h

s

ur

tr

.

OOO

A

CO

eally is easy to use: you get in, key on,

UK

E CONT

TD

est your arm on the SideWinder™ II, and not

w your hand is positioned to rch all

nctions. Over 300 customers worked wit

to make

at is easy and comfole to use

we came up with a con

NT

H

C mouse and hydraulic joystic

the

yout to suit your needs

r

E POSITION

EW HOLLAND

rian Neal - Contractor - Newmarket,

7

MMAND

e Inteated

s to

tracn

drivg mo

ttg

e

peionan

s andstyle

ctor

ev

AUTO COMMAND™ TRANSMISSION67

A SPEED FOR EVER

NEED

t

s

S

FIT Y

.

r

ission to maintain it

y

d

four dir

.

AILABLE

y

,

.

n

.

0016001500

00

ph

UP TO 10% ENGINE

SPEED REDUCTION

FOR GREA

TER FUEL

ECONOMY

m

INNOVATIVE AUTO COMMAND OFFERS

ADVANCED NEW HOLLAND FEATURES

Designed and built by New Holland, T7000 Auto Comman

benefits frm a new generation of CVT transmission.

With

eficiency, plus advanced double clutch contr, you

get the smoothest and most productive CVT available

ect drive points, ofering 100% mechanical

Speed diara

MAKING THE MOST

RQUE

ew Holland has developed its

Auto Command transmissions so the

can exploit the low running speed

e New Holland engines

With 50 kph ECO, the engine can ru

at a fuel eficient 1550 rpm

rwar

Auto Command allows the operator to set a targe

speed of between 30 m/hr right thrugh to 50 km/hr

o steps. No range changes. Just a seamles

choice to match your ever need.

17

1650

1550

14

NH T7000

Auto Command

Engine speed at 50 k

1700

COMPETITOR B

COMPETITOR A

DRIVING MODE

Auto Command can be operated in one of four modes

• Manual Mode. Allows the operator to set the engine

nd forwar

sing the For

• Auto Mode. Select the desi

nd Auto Command will match the engine and

ransm

• Cruise Mode. Once a desir operating speed has been

chieved, Cruise Mode allows the operator to set the

ransmission to maintain the speed for economy and productivit

• PTO mode. As soon as the PTO is engaged, Auto Command

ill operate to pr

speed r

e Based CommandGrip™ handle.

uired. Speed can be adjusted

serve a constant engine speed.

R DRIVING STYLE

rget Speed

.

Activate IntelliSteer system push button to

R

hyd

.

S

d

red

r

s

e

n

r

.

drg

e

le

n

e

d

f

Thi

d,

AUTO COMMAND™ TRANSMISSION89

O

W

Y ALLY

GS

of

All r

t

for

.

CONTINUOUSLY VARIABLE TRANSMISSION

FOR BEST PRODUCTIVITY AND FUEL SAVINGS

The CommandGrip™ handle prvides access to all major contr

same ergonomic design as the proven CommandGrip™ handle used in New Hollan

FR forage harvesters. A key advantage of the design is that it enables a range o

tasks to be completed together.

raising the linkage, operating the rote valves or activating automated functions.

s can include adjusting the tractor’ spee

ls. It shar th

ngage automatic guidance system. A choice

correctional signals is available. With an

ignal, the tractor will steer itself with a pass to

ass accuracy of between 1 cm to 2 cm.

raulic r

ingertip contr

anagement contr. Activates the pr

perator to switch between two set engine speed

works automatically to optimise pe

l of two r

equence and engine spee

Sequence or alte

ol – Auto Command™ transmiss

ote controls –

mote valves

p dir

-

thenatively allows

.

ection chang

io

rget speed selection – allows you

o change between three target speeds

it is useful when moving betwee

INTELLIVIEW III SH

R SPEED SETTIN

Intelliview III will show the dirion

travel, thre set target speeds and

selected driving mode.

in

ation is easy to see at a glance

van

et speed adjustment – set a target sp

ifntfields or wher crop

ields have altered.

e

,to match your exact needs. As an examp

A

S

n

h

r

ACTIVE STARTSTOP

A key safety feature of Auto Command™ is Active StartStop. When the

tractor is brought to a standstill, the transmission prevents the tractor

moving back or forwards. Even with a heavy load. When the transmission

takes up drive, there is no risk of roll back on steep inclines. For safe

parking, an electronic brake is easily engaged via the shuttle lever.

T DIRECTION CHANGE

Changing direction is simple with Auto Command. The operator ca

ither move the CommandGrip™ handle, use the Powershuttle switc

on the handle or use the steering column mounted shuttle leve

QUIET, COMFORTABLE AND OFFERING A GREAT VIEW

A

A

AAA

A

V

V

VVV

V

Y WHERE

Y

A

so

.

HELP

Y

D

A

Y LONG PR

ibili

DESIGNED

New Holland has always put maximum design effor

This is fur

R

e rsed, premium quality Horizon™ cab is quiet, spacious and ofers class leading all-rund vis

er enhanced by the low prile of the controls on the SideWinder™ II arst.

DUCTIVITY

into its operating envirnment.

ITION

he SideWinder™ II ar

ouch of a button. It can be quickly moved by the

erator to suit individual pr

e easily moved to suit difent applications

HE SIDEWINDER II

ty

st adjusts via the

fernce. It can al

COMF

OR

shock loads r

he

y

t

f

or

standar

R

Y

des

f

e

l,

y

D

A

S

tted to

g

g

e

kligh

ily

fr

HID high

.

V

lliview™ III

d

stood

lik

m

Low frquency suspension technology

operator. Over a long working da

this helps rduce fatigue. The sea

can be set-up to suit all sizes o

operator. With New Holland comf

mes as

eaching t

.

NT

The Integrated Control Panel pr

quick and simple access to a range

operating functions. These includ

o

traction management, suspension contro

auto PTO and transmission sensitivit

BRIGHT LIGHTS FOR

A full range of worklights ar fi

all models as standar. These can be

led to suit the application. Ofering

an

ht and brad spread of light, th

a bri

wor

ntensity lights ar ofer

ts are eas

edicated switch panel.

K NIGHT

contrlled

as an option.

vi

IBLE INTELLIVIEW III

IDES MORE

nte

R9000 combines, has a touchscreen interace. This

nables the operator to quickly navigate between easily

nder

ser navigate through various settings - just

n CR9000 combines.

monitor, as used on the flagship New Hollan

information menus. Pop-up screns help the

e the syste

ENGINE12 13

illi

e

O

WER.ANC

M

Co

(

2

oost

e

0

x

2

S

n

)

)

00

55075200500700

00

00700

)

0

r

r

CLEAN, SIX-CYLINDER INTERCOOLED EFFICIENCY

RE P

RE PERFOR

he T7070 Auto

s rated at 225 hp

eveloping up to

wer B

eight of the tracto the T707

enefits fr

o weight ratio of

. Link

E

mmand tractor

V), the engine

51 hp(CV) with

to the low overall

r

cellent power om an e

9 kg/hp(CV).

UEL EFFICIENT PERFORMANCE

he combination of Auto Command™ transmissions

nd extremely eficient New Holland NEF engines

elivers br

odel T7000 Auto Command™ tractor range spans

ated power outputs from 167 hp(CV) to 225 hp(CV).

m

er Cu

ant per

mance and economyThe fiv

DERN FUEL

ll New Holland e

ontact your dealer for mor

5

12

kW

1

ue Cu

ines have been

infor

ation.

2

Nm

COSTS

.

e

e

y

d,

n

ced

ter

s

g

.

O

WER,

BUT ONL

D

blished N

EPM,

en

l

o

.

p)

NGINE OUTPUT (h

p)

TO OUTPUT (h

RWARD SPEED (kph)

ING

combination of factors r

uto Command tractor operating costs

These include 600 hour engine servic

ntervals, class leading maintenanc

access and operating eficienc

combination of intercoole

turbocharged, common rail fuel injectio

nd advan

r

ulation all help control operatin

in

nal exhaust ga

costs

uce T7000

PM BRINGS MORE P

e esta

system is standar

ew Holland Engine Power Management,

on all T7000 Auto Command tractors. W

WHEN ITS NEEDE

pr

and needing no operator intervention to activate, EPM will deliver

ess extra power in demanding conditions, r

seam

ndar

output as conditions ease. The r

ower of a high power

tractor, but only when you need it

r

ng back t

v

AXLES AND TRACTION14 15

igh

.

,

e

d,

g r

p

.

Y

A

n

Ride™

The

d

.

h

.

vib

e

MAXIMUM POWER TO THE GROUND

All T7000 Auto Command tractors are fitted with extremely robust Class IV front axles.

This enables the gross vehicle weight to be increased to 13000 kg at a full 50km/hr for Auto Command models.

A range of features are fitted as standard to help boost in-field productivity. These include easy to use

Headland Turn Sequencing for fast headland turns and advanced Terralock™ automatic traction management.

10% more productivity

ONE ELSE OFFERS

VT WITH

perators demanding a really t

ur

radius can specify the unique

ew Holland SuperSteer™ front axle

f

ering a tight 65 degr

uperSteer™ can dramatically cut th

me it takes to tur

th the potential to boost work rates

in applications includin

ies.

PERSTEER™

tur

on the headlan

wcro

angle

ration at seat bas

LIDE™ FR

t

rraglide™ II fr

pgraded to match the T7000 Auto Command™

ransmission. Standar

rraglide II is designed to compliment the

omfor

ult is a smoother ride over difcult terrain an

nhanced per

rraglide II will work safely wit

eavy r

ar mounted implements

NT AXLE

nt axle suspension has bee

on all 50 km/hr models,

cab suspension system.

mance at high transporspeeds

G

ly

lly

lly

r

r

e

e

.

ADVANCED TRACTION MANAGEMENT

c

New Holland Terralock is well established. The operator simply selects the traction package needed

for a specific application. Terralock will then manage drive to the front axle and engage and release

the differential locks automatically. During a headland turn or moving from work to transport,

Terralock will ensure the differentials and four wheel drive are unlocked without operator intervention.

HEADLAND TURN

EQUENCIN

Sequencing, HTS, system makes it extreme

simple to set up and use. During a headland tur the operator initia

engaging the HTS

to r

eat them by prssing a single button on the CommandGrip™ handle. A new HTS featur is that th

programme. Once the sequence of actions has been

carries out the tur

sequence can be edited to fine-tune settings to suit changing conditions

sec

sec

sequences manua

ded by HTS, it can then b

se

sec

HYDRAULICS AND REAR LINKAGE16 17

ADVANCED HYDRAULICS

AND MASSIVE LIFT CAPACITY

The Closed Centre, load sensing CCLS hydraulic system has been

engineered by New Holland so it operates at peak efficiency at all times.

When the demand upon the system is low, the main hydraulic pump

consumes minimal power. When instant hydraulic flow is required,

the MegaFlow™ pump option can deliver its maximum capacity

of 150 litres per minute in an instant.

V

S

ect

O

W ON U

S

ote valves eac

dual

in

lliV

III

S

ted contr

O

d. The l

g an

r

EFFICIENT

AND PO

WERFUL

d

.

pr

h

.

ated up to a massive 10463 kg, the rar linkage is designe

to work with heavy mounted equipment over extended periods

The system incorporates integral dynamic ride contrl shock

load

eavy mounted implement at transpor speeds

a

ion. This will r

uce bounce when travelling with

ADJUST THE FL

The hydraulic rm

flow contr. Flow and timing to each valve can be

ndividually adjusted using simple ‘pop-up’ menus

the Inte

nd four frnt valves ar available.

ew™

touch-screen. Up to five r

P

NINE REMOE

h have indivi

FENDER-MOUNTED CONTRL

Fender moun

nkage to be raised and lowerd, the PT

to be engaged and for a rote valve to be

operate

an hydraulic top link when attachin

mplement to the tracto

atter makes it easy to adjust

ls allow the r

r

LECTR

he el

r via the paddles on the SideWinder™ II arrst. A joystick is also fitted. This will

perate up to four valves, and is ideal for working a fr

r

nic r

mote valves can be operated from the CommandGrip™ handle

NTR

L

nt linkage or loader

PTO AND FRONT LINKAGE18 19

r

f

o

pr

THE FULLY INTEGRATED PACKAGE

is the di

drive PTO. This ensures minimal power is lost between the engine and PTO

output sha

urer incr

t. A high capacity frnt linkage and PTO can be specified t

uctivity

d

ic

O

r

o

O

e

Thi

he

m

also

PURPOSE DESIGNED FOR A PERFECT FI

T

t

.

ge

New Holland ofers a purpose designed fron

linkage to fit all T7000 Auto Command™ tractors

Developed to offer a high lift capacity with

xcellent contr

package can also be specified with a PTO.

l frm the cab, the fr

nt linka

LECTR

TO speed selection is made easily

an

speeds ar

ngine speed.

NIC PT

quickly by using the electron

r

switch. For economy PT

achieved at a

SELECTION

ION

uto PTO can be selected t

automatically disengage the PT

as the rear linkage is raised abov

pre-set point.

TO shaft and tractor. The syste

r

-engage drive as the

nkage is lower

s protects t

.

IS

TE

A

C STEERING SY

EM

riies T7000 can be specifwith a f i

nt

eg

eg

ratew lland de

de

gn

nd delop IelliSteer™ Auta

at

ee

Syste Usi DGPor R

T

T

ol

o

ogy and

fuinteat c

tr

ms the IelliSteer™

systetem

s

p

p

ee

s

ys

ys

te

tem i

de

eedi a

p

p

in

g

mag situations and dramticall

d

co

o

ad

ti

o

b

u uu u

ng

g

co

rr

h

the telliS

i

th

te

ed

y

y

to

y

y

ear r

bili

i

g

r

i

ort with t

ay

’

momo f

g

techchnii

ququ

AlAlth

th

ththt a

of aa b b b ttoto

n

sin

s

g R

g Rg g g g

g

ion

ion

i

TETLWW™ IIIMM MONONOOOITIT

EEN

D

OEOS

A

th

ex

Intelli II ccc

,

ell

iSt

eer

eer

iss ea esil

s

y i

y i

te

gra

g

ted

ed

in

in

n

to

to

the

the

00

00

Automand

op

op

a

tin

yst

yst

em.

Sys

tem

ca

er

a

ese a

A

VIGA

I

,

ya

y

d

te

gr

A

S

NeN NNeN

es

builtlt

ste

sen

sen

sor

sor

s t

th th th

e N

e N

e N

avi

avi

avi

gat

gat

ionion

tr

tr

tr

er or of

of

wh wh whwheel

eeleel

di di di

.

te

ted

ted

in

in

to

to

to

to

hyhyhy

hy hy

dra

dradra

yst

yst

stysyst

em

em

tr

trtrtr

val

ve whwh

whiwwhi

ch

ver

ver

ve

v

the

the

the

si

si

si

si

s

s

gnagna

ls

ls

fr

Na

Na

vigvigvig

vig

ati

ati

ati

ati

on ontrtrtr

er

er

er

o h

o hho h

ydr

ydr

yd

aul

aul

nts

nts

ts

ofof o

o

thth th

th

e s

e s

tee

tee

rin

rin

n

g sg s

g s

g s

ystysyst

yst

2262 RCEIVE

NH

26 22 r

ivess

abl

f w

f w

f w

ork

ork

ork

wi

withth

Om

niS

T

orK corrio

R

eradio mounts under

B

A

base station can be

20 21

NEW HOLLAND OFFERS SO MUCH MORE

NTE

™

e

nsur rallel

ass to pass accuracy of up to 1 –

the most de

si

R

ction w

corr

he IntelliStee

number of difent patter. Th

s

een

rm

T

a

ol syste

cm*. T IntelliSt

y

teer™ system

es operator per

e gu

an

rmance an

ear

nd morat the touch

r

applications a slim prfil

he river

n. For

al f

s

r

. An

ata

ty which is becom

K

to br

ignal to achieve a pass to

ass accuracy of 1-2 cm.

n

a corr

lant

ion

N

The Navigation Contrller II is the main contr

system which continually corr for rll, pitch

w by using state of the ar 6-axis soli

r

ial sensors to give you a true

on-

d position.

ED CONTR

w Holland IntelliSteer™ System us

ering

LLER I

L SYTEM

BEYOND THE PRODUCT

g

h

tensive class

based courses

r

sur

real

ill al

he

pr

AILORED

Y

SS

l

blished

ce

s

y

ONG

CE

des owners of

r

dditi

f

actur

actual

r

details. T

ditions

ly

IVE

technicians rceive r

updates. These ar carried out bot

hr

ugh on-line courses as well as

r

in

s advanced app

er w

skills needed to look after the latest and

most advanced New Holland

m

ways have access to t

ular trainin

en

.

you

BUSINE

NH Capitial, the financial services

ompany of New Holland, is wel

sta

ricultural sector

ackages tailored to your specific

ou have the peace of mind that come

r

m dealing with a financing compan

.

that specialises in agricultur

and r

are available. With CNH Capital,

pected within the

Advice and finan

.

E PLAN

L

LASTING CONFIDEN

ESP coverage prvi

ew Holland agricultural machine

with a

he manuf

warrantyPlease ask your dealer fo

app

onal cover on the expir o

r’ contr

and con

SPECIFICATIONS22 23

S

7O3O

7O7O

l

III

III

III

III

III

l

A

d**

y

28728728728728

e

132x132x132x132x132

0

)]

167 / 1825 / 197

2137 / 22

204 / 21872 / 234

238 / 247

0

)]

1807 / 20056 / 212 / 223 / 230

234

24178 / 2425 / 251

d

)

4@1400

0@1400

4@1600

@16005@1500

t

357 / 307 / 30 / 30

n

n

ke

y

)

l

)

(40 kph)

m

40

40

40

40

40

m

0.03 / 50.03 / 50.03 / 50.03 / 50

n

lide™ F

e

65

65

65

65

65

m

s

s

le

0 / 150 / 150 / 150 / 150

y

lic

lic

lic

lic

lic

s

l

)

s

)

8578

85785

40E / 1000

1893

1893

1893

1893

00

/ 1893

t

n

ke

s

s

MODEL

No of Cylinders / Aspiration / V

Fuel System - High Pressure Common Rai

pproved Biodiesel Blen

apacit

Bore and Strok

Rated Power - ISO TR14396- ECE R12

Rated Power - ISO TR14396- ECE R120 Engine Power Management / hp(cv)]50 /

Max. Power - ISO TR14396- ECE R12

Max. Power - ISO TR14396- ECE R120 Engine Power Management / hp(cv)]58 / 215

ated engine spee

que ISO TR14396

que ISO TR14396 Engine Power Management

rque rise standard / with Power Managemen

Viscous Coupled Cooling Fa

Reversible fa

xhaust Bra

nk capacit

erce intera

Auto Command™ Constantly Variable Tnsmission

nimum speed / Max speed @ 1450 rp

Auto Command™ Constantly Variable Tnsmission (50 kph ECO)

nimum speed / Max speed @ 1550 rp

Active StopStart functio

ves / Emission leve

/ hp(cv

/ hp(cv

T

T / 4v / Ter

cm7

mm)x

/

/

rpm

m)7

m)7

5 / 35

tres

ours

ph).03 /

ph).03 / 5

T / 4v / Ter

72 /

5 /

.03 /

T / 4v / Ter

77 /

5

.03 /

T / 4v / Ter

57 /

75 /

.03 /

T

WT / 4v / Ter

5

5

.03 /

WD front axle

rrag

upersteer™ Front axl

Fast Steer™ syste

rralock™ function

Dynamic front Fender

ar rear ax

Main Pump flow Standard / MegaFlow™ option

Electronic Draft Control (EDC)

emote Vves

ax no. rear valve

oystick contro

ax no. mid mount valves

Max lift Capacity at ball ends - 110 mm rams

Max lift Capacity through the range (610 mm behind ball ends) - 110 mm ram

Front linkage lift capacity at ball ends (through the range

Auto Soft Start

ngine speed at: 540 / 5

Auto PTO managemen

Electronic PTO selectio

Front PTO (1000 rpm)

ront axle suspension

LS Closed Centre Load sensing

rpm

pm) / 15

rpm)569 / 1700 /

g

g)7

55 / 55 /

ectro hydrau

55 / 55 /

ectro hydrau

5

569 / 1700 /

55 / 55 /

ectro hydrau

785

569 / 1700 /

55 / 55 /

ectro hydrau

7

569 / 1700 /

55 / 55 /

ectro hydrau

569 / 17

ectronic Park Bra

ydraulic Trailer Brake

ptional Pneumatic tractor Brake

b

k

t

t

Ai

g

A

l

Air Recirati

Fil

n

e

d

r

y

1

6,6,6,6,6

y

Fit R

05

)

3357345735736736ni

h

)

)

le

)

le

)

)

x

8

8

8

8

8

x

2698

2698

2698

2698

2698

23 / 523 / 523 / 523 / 523

050505050

)

2007200

e

00070007000

)

t

MODEL

S

7O5O

7O7O

360° Horizon Ca

High visibility roof hatch

pening RHS door

lighting pac

Auto Comfort™ sea

Auto Comfort™ leather sea

ideWinder™ II Armrest

ommandGrip™ Handle

Electronic Adjustment of SideWinder II armrest

r conditionin

utomatic climate contro

on

ters

omfort Ride™ cab suspensio

eadland Trn Sequenc

ender mounted external controls

erormance Monitor with enhanced key pa

IntelliView™ III colour monitor with ISO 11783 connecto

IntelliSteer™ Guidance Read

ptimum Cab Noise level EC 77/31

actor

otating Beacon

T

,

T

ning radius with SuperSteer™ front axle

ning radius with standard/suspension front axle

verall length (front link. to rear link.)

mum widt

Height at centre of rear axle to top of cab

eelbase:

tandard ax

uspended ax

uperSteer™

ack width: Front Min / Ma

ear min / ma

round clearance (min/max)

nimum Unballasted / shipping weights

tandard Front axle

raglide™ suspended front axle

uperSteer™ front axl

Max permissible weight at 50kph

xle

mm)5705 5705 5705 5705 57

mm

mm)7

mm

mm

mm

mm

mm

mm)560 / 225

mm)528 /

mm) / 5

g)5

g

g)7

kg

560 / 225

528 /

560 / 225

528 /

560 / 225

528 /

7

560 / 225

528 /

YOUR OWN DEALE

R

at:

www

wholland.com

9673 7777

K

St Ma

0

9

e

s

e

r

y

d

Y

A AAAA

A

URAL B

afety begins with a thorough understanding of th

quipment. Always make sure you and your operator

ead the Operator’s Manual before using th

equipment. Pay close attention to all safety and

Visit our w site

1-53

he data indicated in this folder is approximate. The models described here can be subjected to modifications without any notic by the manufacturer

he drawings and photos may refer to equipment that is either optional or intended for other countries. Please apply to our Sals Network for any further

information. Published by New Holland Brand Communications. Bts Adv - Printed in Australia - T7000 07/0

rys NSW 276

- tel:+61 2

operating decals and never operate machine

without all shields, protective devices an

structures in place.

Loading...

Loading...