ORIGINAL INSTRUCTIONS

OPERATOR’S MANUAL

T4.75F

T4.85F

T4.95F

T4.105F

Tractor

Part number 47593719

nd

edition English

2

October 2013

Replaces part number 47494640

Contents

1GENERALINFORMATION

NotetotheOwner..........................................................................1-1

Proposition65..............................................................................1-2

Internationalsymbols.......................................................................1-3

Introduction.................................................................................1-5

Tractorintendeduse........................................................................1-6

EcologyandtheEnvironment..............................................................1-8

Identicationplates.........................................................................1-9

ComponentIdentication..................................................................1-11

2SAFETYINFORMATION

Safetyrulesandsignalworddenitions...................................................2-1

Safetyinformation..........................................................................2-2

Airconditioningsafetyregulations..........................................................2-6

Cabguard..................................................................................2-7

Rolloverprotectivestructure(ROPS)......................................................2-9

Personalprotectiveequipment(PPE).....................................................2-10

Tractorjackingpoints......................................................................2-11

Hazardouschemicals......................................................................2-12

Burnprevention............................................................................2-13

Fireorexplosionprevention...............................................................2-14

Gettinginandoutofthemachine.........................................................2-15

Safetysigns...............................................................................2-16

3CONTROLS/INSTRUMENTS

ACCESSTOOPERATOR'SPLATFORM

Cab.....................................................................................3-1

Heatingsystem.........................................................................3-4

Heating,ventilationorair-conditioningcontrol.........................................3-5

Cabairlter.............................................................................3-7

OPERATOR'SSEAT

Operatorseat...........................................................................3-9

FORWARDCONTROLS

Analoguedashboard..................................................................3-11

Digitaldashboard......................................................................3-15

Frontcontrols..........................................................................3-21

LEFT-HANDSIDECONTROLS

ConsoleLeft-handconsole-Controlidentication....................................3-25

Parkingbrakeforhydraulictransmissions.............................................3-26

RIGHT-HANDSIDECONTROLS

ConsoleRight-handconsole-Controlidentication..................................3-27

REARWARDCONTROLS

Console-Controlidentication........................................................3-29

EXTERIORCONTROLS

Console-Controlidentication........................................................3-29

DISPLAYSETTINGS

Instrumentcluster-Program..........................................................3-30

TRANSMISSION

Transmission-Operating4WDmodels...............................................3-37

Transmissionwithgearreducerandmechanicalreversingmechanism..............3-38

Transmissionwithgearreducerandelectrohydraulicreversingmechanism.........3-41

Parkingbrakeforhydraulictransmissions.............................................3-44

Transmissionwithgearreducer,electrohydraulicreversingmechanismandHI-LOcon-

trol.....................................................................................3-45

Transmissionwithgearreducer,electrohydraulicreversingmechanism,HI-LOcontroland

electrohydraulicclutch.................................................................3-48

4OPERATINGINSTRUCTIONS

COMMISSIONINGTHEUNIT

Basicoperatingsafetyrules............................................................4-1

STARTINGTHEUNIT

Startingtheengine.....................................................................4-3

STOPPINGTHEUNIT

Stoppingtheengine....................................................................4-5

5TRANSPORTOPERATIONS

ROADTRANSPORT

Transportingthemachine..............................................................5-1

RECOVERYTRANSPORT

Towingthetractor.......................................................................5-2

6WORKINGOPERATIONS

FOURWHEELDRIVE(4WD)

Four-wheeldrivewithelectro-hydrauliccontrol.....................................6-1

DIFFERENTIALLOCK

Electrohydraulicdifferentiallock....................................................6-2

Mechanicaldifferentiallock.........................................................6-3

REMOTEVALVES

Generalsafetyrules................................................................6-4

Rearremotecontrolvalve(s).......................................................6-5

Electrohydraulicallycontrolledsidehydraulicvalves...............................6-9

Electrohydraulicallycontrolledrearremotecontrolvalves........................6-11

Sidehydraulicvalves..............................................................6-12

REARPOWERTAKE-OFF(PTO)

Powertakeoff(PTO)..............................................................6-13

FRONTPOWERTAKE-OFF(PTO)

FrontPowerT ake-Off(PTO)-Safetyrules........................................6-15

FrontPowerT ake-Off(PTO)-Operating..........................................6-16

REARHYDRAULICLIFT

Hydraulicliftwithmechanicalcontrol..............................................6-17

Lift-O-Matic®control-Operating..................................................6-18

Hydraulicliftwithelectroniccontrol................................................6-20

FRONTHYDRAULICLIFT

Hydraulicliftwithmechanicalcontrol..............................................6-25

Hydraulicliftwithelectroniccontrol................................................6-27

REAR3-POINTHITCH

OperatingInstructions.............................................................6-29

Attachtheimplement..............................................................6-33

Additionalequipmentattachmentpoints..........................................6-35

FRONT3-POINTHITCH

OperatingInstructions.............................................................6-37

SWINGINGDRAWBARS

Safetyrules........................................................................6-40

Swingingdrawbar.................................................................6-41

WHEELSANDTIRES

Wheelsandtires...................................................................6-42

Tyredimensions...................................................................6-46

WHEELTRACKADJUSTMENT

Wheeltreadsettings...............................................................6-48

TireCombinationsandTreadPositions...........................................6-51

BALLAST

Ballast.............................................................................6-54

7MAINTENANCE

GENERALINFORMATION

Generalsafetybeforeyouservice......................................................7-1

Introduction.............................................................................7-3

Variouscontrols........................................................................7-4

Bodymaintenance......................................................................7-5

Break-inperiod.........................................................................7-7

Fuelsupply.............................................................................7-8

Generalspecication-BiodieselFuels................................................7-9

Openingthehood.....................................................................7-10

Fluidsandlubricants..................................................................7-1 1

MAINTENANCECHART

MaintenanceChart....................................................................7-13

ASREQUIRED

Radiatorexpansiontank...............................................................7-15

Windscreenwashertank..............................................................7-15

Roadlight-Check.....................................................................7-15

Clutchpedaladjustment...............................................................7-16

Parkingbrakeorparkinglock-Adjust.................................................7-16

Radiator-Cleaning....................................................................7-16

Tyrepressure..........................................................................7-17

Wheelnutstorque.....................................................................7-18

Brakepedals..........................................................................7-18

ATWARNINGMESSAGEDISPLAY

Engineairlters.......................................................................7-19

Fuellterwaterdrain..................................................................7-20

Brakeuidlevel........................................................................7-21

EVERY10HOURSOREACHDAY

Engineoillevel........................................................................7-22

EVERY50HOURS

Rearwheelhub........................................................................7-23

Liftandlinkage........................................................................7-23

2WDsteeringcylinder.................................................................7-23

4WDsteeringcylinders................................................................7-24

2WDfrontaxlepivot...................................................................7-24

4WDfrontaxlepivot...................................................................7-24

4WDtransmissionshaft...............................................................7-25

2WDrightandleft-handstubaxle.....................................................7-25

Frontliftarmsshaft....................................................................7-25

FrontPTOcoupling....................................................................7-26

EVERY100HOURS

Transmissionoilcooler................................................................7-27

Airconditioningcondenser............................................................7-27

Intercooler.............................................................................7-27

Cabairlter............................................................................7-28

Cabrecirculatedairlter..............................................................7-28

EVERY300HOURS

Alternatorbelt..........................................................................7-29

Transmissionoillter..................................................................7-29

Oilltermodelswithpowershuttle/dualcommand....................................7-29

Engineairlters.......................................................................7-30

Transmissionoillevel..................................................................7-30

4WDfrontaxlehousing................................................................7-30

4WDfrontaxlenaldrives............................................................7-31

4WDfrontaxlesstub..................................................................7-31

2WDfrontwheels......................................................................7-31

EVERY500HOURS

Engineoilandlter....................................................................7-32

Fuellter...............................................................................7-33

Fuelpre-lter..........................................................................7-34

EVERY600HOURS

Engineoilandlter....................................................................7-35

Fuellter...............................................................................7-36

Fuelpre-lter..........................................................................7-37

EVERY1200HOURSORANNUALLY

Cabairlters..........................................................................7-38

Cabrecirculatedairlter..............................................................7-38

Engineairlters.......................................................................7-38

Fueltank...............................................................................7-39

EVERY1200HOURSOREVERY2YEARS

4WDfrontaxlehousing................................................................7-40

Enginevalves..........................................................................7-40

Changetransmissionoil...............................................................7-41

Washingcoolingsystem...............................................................7-42

EVERY1800HOURS

Fuelinjectors-Check.................................................................7-45

ELECTRICALSYSTEM

Battery.................................................................................7-46

Fusesandrelays......................................................................7-48

Fusesandrelayslocation.............................................................7-49

Fusesandrelayslocation.............................................................7-51

FusesandrelayslocationFusesandrelaysoncabrighthandupright..............7-53

Headlight-Adjust......................................................................7-53

Headlight-Replace...................................................................7-54

STORAGE

Tractorstorage....................................................................7-55

CALIBRATIONS

Dualcommandcalibration.............................................................7-56

8TROUBLESHOOTING

FAULTCODERESOLUTION

Displayfaultcodes.................................................................8-1

TROUBLESHOOTINGENGINE...................................................8-3

Electricalsystem-TroubleshootingELECTRICALSYSTEM......................8-5

Hydraulicsystems-TroubleshootingHYDRAULICSYSTEM.....................8-6

Rearthree-pointhitch-TroubleshootingHYDRAULICLIFTAND3−POINTLINKAGE

.....................................................................................8-7

Hydraulicservicebrakes-Troubleshooting........................................8-8

Cabclimatecontrol-Troubleshooting..............................................8-9

ALARM(S)

Alarms.........................................................................8-10

Alarms,cause,solutions......................................................8-12

9SPECIFICATIONS

Dimensionsandweights...................................................................9-1

Maximumpermittedloadsonfrontandrearaxle...........................................9-6

Maximumpermittedloadsondrawbar.....................................................9-7

Technicaldata..............................................................................9-8

10ACCESSORIES

Radio......................................................................................10-1

1-GENERALINFORMATION

1-GENERALINFORMATION###_1_###

NotetotheOwner

Thismanualcontainsinformationconcerningtheadjustmentandmaintenanceofyournewequipment.Y ouhave

purchasedadependablemachine,butonlybypropercareandoperationcanyouexpecttoreceivetheperformance

andlongservicebuiltintothisequipment.Pleasehavealloperatorsreadthismanualcarefullyandkeepitavailable

forreadyreference.

YourNEWHOLLANDdealerwillinstructyouinthegeneraloperationofyournewequipment.Yourdealer’sstaffof

factory-trainedservicetechnicianswillbegladtoansweranyquestionsthatmayariseregardingtheoperationofyour

machine.

NewHollandTopServiceisalsoavailable.Call1-866-NEWHLND(1-866-639-4563)

oremail:na.topservice@cnh.com.

YourNEWHOLLANDdealercarriesacompletelineofgenuineNEWHOLLANDserviceparts.Thesepartsare

manufacturedandcarefullyinspectedtoinsurehighqualityandaccuratettingofanynecessaryreplacementparts.

Bepreparedtogiveyourdealerthemodelandproductidenticationnumberofyournewequipmentwhenordering

parts.Locatethesenumbersnowandrecordthembelow.Refertothe’GeneralInformation’sectionofthismanual

forthelocationofthemodelandproductidenticationnumbersofyourmachine.

PLEASERECORDTHEFOLLOWINGINFORMA TION

Model:

ProductIdenticationNumber(PIN):

Thisisthesafetyalertsymbol.Itisusedwithandwithoutsignalwordstoalertyoutopotential

personalinjuryhazards.Obeyallsafetymessagesthatfollowthissymboltoavoidpossible

deathorinjury .

WARNING

Illustrationsinthismanualmayshowprotectiveshieldingopenorremovedtobetterillustrateaparticularfeatureoradjustment.

Replaceallshieldsbeforeoperatingthemachine.

Failuretocomplycouldresultindeathorseriousinjury .

W0012A

Enginetamperingstatement:

NOTICE:Thefuelsystemandengineonyourmachinearedesignedandbuilttogovernmentemissionsstandards.

Tamperingbydealers,customers,operatorsandusersisstrictlyprohibitedbylaw.Failuretocomplycouldresultin

governmentnes,reworkcharges,invalidwarranty,legalactionandpossibleconscationofthemachineuntilrework

tooriginalconditioniscompleted.Engineserviceand/orrepairsmustbedonebyacertiedtechnicianonly!

Improvements

CNHAmericaLLCiscontinuallystrivingtoimproveitsproducts.Wereservetherighttomakeimprovementsor

changeswhenitbecomespracticalandpossibletodoso,withoutincurringanyobligationtomakechangesoradditionstotheequipmentsoldpreviously.

1-1

1-GENERALINFORMATION

Proposition65

CALIFORNIA

Proposition65Warning

DieselengineexhaustandsomeofitsconstituentsareknowntotheStateofCaliforniatocausecancer,birth

defectsandotherreproductiveharm.

Batteryposts,terminalsandrelatedaccessoriescontainleadandleadcompounds.

Washhandsafterhandling.

1-2

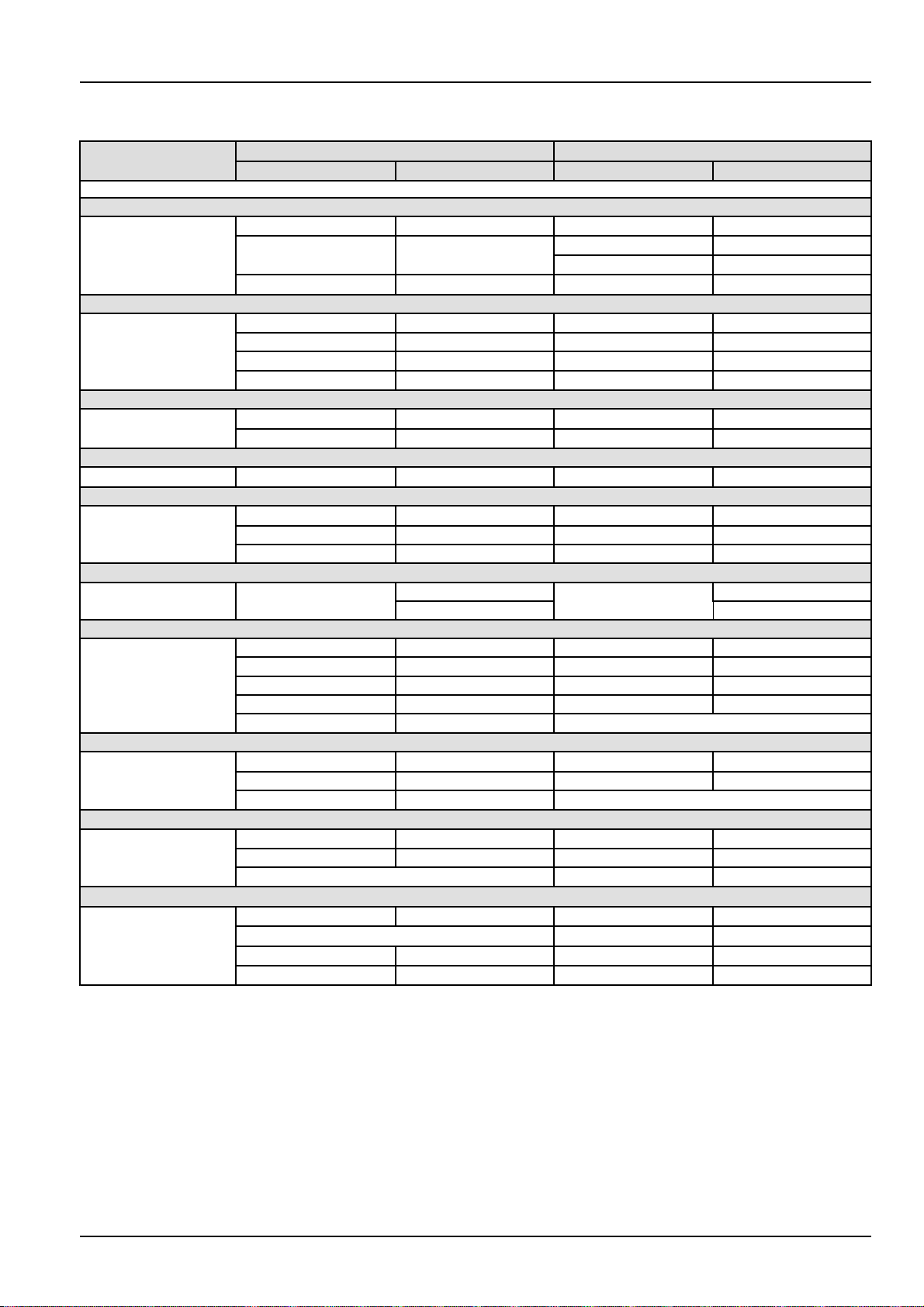

Internationalsymbols

1-GENERALINFORMATION

TYPICAL

APPLICATIONS

AREA

ELECTRICITY

FORCE

FORCEPERLENGTH

FREQUENCY

FREQUENCY-ROT A TIONAL

LENGTH

MASS

POWER

PRESSUREorSTRESS(FORCEPERAREA)

RECOMMENDEDSI(METRIC)UNITS

NAME

hectareha

squaremeter

squaremillimetre

ampere

voltVvoltV

microfarad

ohm

kilonewtonkNpoundlb

newton

NewtonmetresNmpoundinchlbin

megahertzMHzmegahertzMHz

kilohertzkHzkilohertzkHz

hertzHzhertzHz

revolutionperminute

kilometrekmmilemi

meter

centimetre

millimetre

micrometer

kilogramkgpoundlb

gramgounceoz

milligram

kilowattkWhorsepowerHp

watt

kilopascalkPapoundpersquareinchpsi

pascalPa

megapascalMPapoundpersquareinchpsi

IMPERIALUNIT

SYMBOL

acre

m²

mm²

A

µF

Ω

Npoundlb

r/minr/minª

rpm

m

cm

mm

µm

mg

W

squarefootft²

squareinch

squareinch

ampere

microfarad

ohm

revolutionperminute

footft

inchin

inchin

Btu/hourBtu/hr

Btu/minuteBtu/min

inchofmercury

inchofwaterinH2O

NAME

ha

in²

in²

A

µF

Ω

rpm

inHg

SYMBOL

1-3

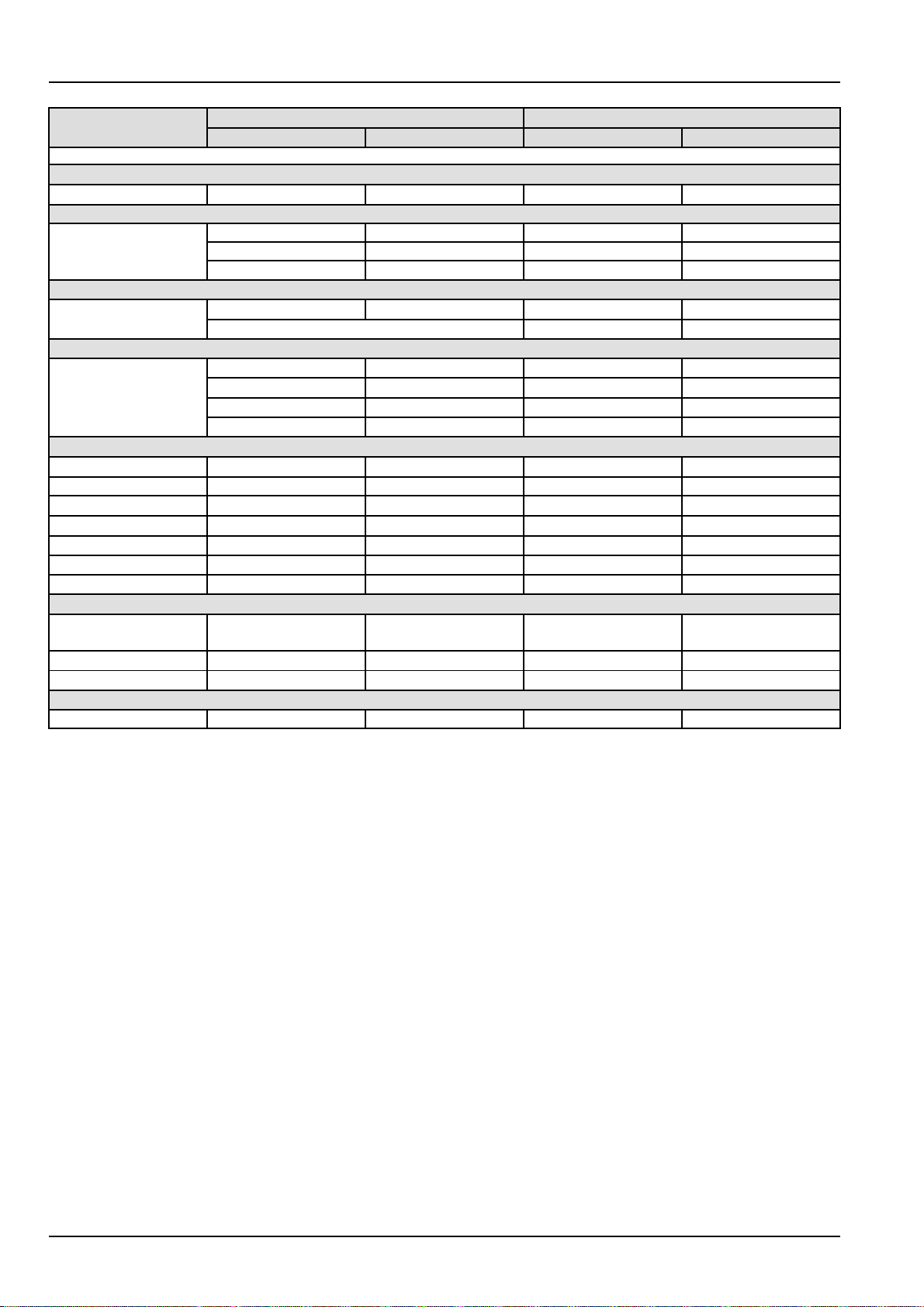

1-GENERALINFORMATION

TYPICAL

APPLICATIONS

RECOMMENDEDSI(METRIC)UNITS

NAME

SYMBOL

TEMPERATURE(otherthanTHERMODYNAMIC)

degreesCelsius°C

degreesFahrenheit

TIME

hourhhourh

minuteminminutemin

second

s

second

TORQUE(includesBENDINGMOMENT,MOMENTOFFORCE,andMOMENTOFACOUPLE)

newtonmeter

Nm

feet-poundsIbft

inch-poundIbin

VELOCITY

kilometreperhour

meterpersecond

millimetrepersecond

meterperminute

km/h

m/sfootpersecondft/s

mm/s

m/minfootperminuteft/min

mileperhourmph

inchpersecond

VOLUME(includesCAP ACITY)

cubicmeter

m³

cubicyard

litrelcubicinch

litrel

USgallonUSgal

U.K.gallonUKgal

USquartUSqt

U.K.quartUKqt

millilitreml

uidounceoz

VOLUMEPERTIME(includesDISCHARGEandFLOWRATE)

cubicmeterper

m³/mincubicfootperminuteft³/min

minute

litreperminute

millilitreperminute

l/minUSgallonperminuteUSgal/min

ml/min

UKgallonperminute

SOUNDPOWERLEVELandSOUNDPRESSURELEVEL

decibeldBdecibeldB

IMPERIALUNIT

NAME

SYMBOL

°F

s

in/s

yd³(cuyd)

in³

UKgal/min

1-4

1-GENERALINFORMATION

Introduction

Aboutthismanual

DANGER

Improperoperationorserviceofthismachinecanresultinanaccident.

Donotoperatethismachineorperformanylubrication,maintenance,orrepaironituntilyouhave

readandunderstoodtheoperation,lubrication,maintenance,andrepairinformation.

Failuretocomplywillresultindeathorseriousinjury.

D0010A

Thismanualgivesinformationforuseofyourmachine,as

intendedandundertheconditionsforeseenbythemanufacturerduringnormaloperationandroutineserviceand

maintenance.Readandunderstand;keepitingoodconditionsandalwayssafelystoreitintheprovidedpocket

inthebackofyourseatforlatereasyretrieval.Thismanualdoesnotcontainalltheinformationrelatedtoperiodicalservice,convertingandrepairstobecarriedoutby

professionalservicepersonnel.TheTableofContents

page(s)areprovicedtohaveanoverviewofmainmanual’stopics.Adetailedalphabeticindexisavailableatthe

endofthismanualforlocatingspecicitems.

Normaloperation

Normaloperationmeanstheuseofthetractorforthe

•

purposeintendedbythemanufacturerbyanopera-

torfamiliarwiththetractorandthemountedortowed

equipmentandcomplyingwiththeinformationforoperationandsafepractices,asspeciedbythemanufacturerinthismanualandbythedecalsonthetractor

andtheequipment.

Normaloperationincludesthepreparationandstorage

•

ofthetractor,swingingcomponentsintoworkposition

andviceversa,addingorremovingballastandpicking

upandsettingoffattachments.

Normaloperationincludestheadjustmentandsetting

•

ofthetractorandequipment,forthespeciccondition

oftheeldand/orthecrop.

Routineservice

Routineserviceandmaintenancemeansactivitiesthat

mustbedonedailybyanoperatorfamiliarwiththetractor

characteristicsandcomplyingwiththeinformationforroutineserviceandsafepractices,asspeciedbythemanufacturerinthismanualandbydecalsonthetractor,in

ordertomaintainitsproperfunction.Routineserviceincludesactivitiessuchasfueling,cleaning,washing,toppingupuidlevels,greasing,replacingofconsumable

articlessuchaslampbulbs.

Converting,periodicalserviceandrepair

Periodicalservicemeansactivitiesthatmustbedoneat

•

denedintervalsbytrainedpersonnelfamiliarwiththe

tractorcharacteristicsandwhicharecomplyingwiththe

informationforperiodicalserviceandsafepractices,as

partlyspeciedbythemanufacturerinthismanualand

inotherCompanyliterature,inordertomaintainthe

expectedlifetimeofthetractor.

Convertingmeansactivitiesthatmustbedoneby

•

professionalservicepersonnelfamiliarwiththetractor

characteristicsandcomplyingwiththeinformationfor

converting,aspartlyspeciedbythemanufacturerin

thismanual,inassemblyinstructionsorinotherCompanyliterature,inordertotthetractortoaspecic

conguration.

Repairmeansactivitiesthatmustbedonebyprofes-

•

sionalservicepersonnelonlyfamiliarwiththetractor

characteristicsandcomplyingwiththeinformationfor

repair,asspeciedbythemanufacturerinthedealer’s

workshopmanual,inordertorestoretheproperfunctionofthetractorafterafailureordegradationofperformance.

SpareParts

“Non-original”sparepartshavenotbeentestedorauthorisedbytheManufacturer.Installmentand/oruseofsuch

productsmayadverselyaffectthetractor'sdesignspecications,therebycompromisingoperationalsafety.The

manufacturercannotbeheldresponsibleforanydamage

resultingfromtheuseof“non-original”spareparts.No

modicationsmaybemadetothetractorwithoutwritten

authorisationfromtheManufacturer.

Warranty

Thetractorisguaranteedinaccordancewithcurrentlegislationinyourcountryandinlinewithcontractualagreementsreachedwiththedealeratthetimeofsale.However,thewarrantyisnolongervalidiftherulesandinstructionsfortheuseandmaintenanceofthetractor,describedinthisManual,arenotobserved.

Cleaningthetractor

Yourtractorisanadvancedmachine,ttedwithanelectrohydrauliccontrolsystem.Caremustbetakenwhen

cleaningthetractor,especiallyifapressurizedwater

cleanerisused.

Neverstandtooclosetothetractorordirectthewaterjet

onelectricalcomponents,sealsorintakeopenings,etc.

Neverdirectjetsofcoldwateratthehotengineorexhaust.

1-5

Tractorintendeduse

1-GENERALINFORMATION

NOTE:YourtractorisdesignedaccordingtoEuropean

directivesrelatedtohealthandsafetyrisks;thoughit

hasbeendesignedtominimizeallthepotentialrisksitis

mandatorytocarefullyread,understandandobserveall

thedecalsandlabelsandtoalwaysrefertoinformation

andprescriptionsoutlinedinthismanualtopreventall

residualpotentialrisks.Ifyouneedfurtherassistance

pleasedonothesitatetocontactyourdealer.

Yourtractorisdesignedandmadetopull,carryand

poweravarietyofmountedortowedequipment,althoughwithinsomephysicallimits.Theworkingspeed

andperformancemaydependonvariousfactors,such

asweatherandterrainconditions.Thoughthetractor

isdesignedtoperformincombinationwithavarietyof

equipment,theremaybeanumberofcombinationsofthe

aboveparametersforwhichthereisseveredegradation

ofperformanceofthetractorand/oritsmountedortrailed

equipment.Ifyounoticedegradationofperformance,

contactyourdealerforassistance,hemayhaveuseful

informationforimprovements,orakitmaybeavailable

toenhancetheperformance.

Pleasecarefullyreadandconsiderthefollowing

precautions:

Donotusethetractorforpurposesotherthanthose

•

intendedbythemanufacturerandoutlinedinthisman-

ual.

Donotusethetractorbeyonditslimitsofterraingradi-

•

entandstability.Usingthetractorbeyondtheselimits

mayresultinroll-overortip-over.Observetherecommendationsinthismanual.

Donotusethetractorathigherspeedsthanthoseal-

•

lowedbytheloadandtheenvironment.Awetsurface

orotherlowadherenceconditionsmayincreasethe

brakingdistanceorresultinvehicleinstability .Always

adaptyourtravellingspeedaccordingtotheloadofthe

vehicleandthecharacteristicsoftheroad.

Donotusethetractornearoronsoftvergesofcanals

•

andbrooksorbanksandvergesthatareundermined

byrodents.Thetractormaysinksidewaysandrollover.

Donotusethetractoronunstablecrossingsorbridges

•

and/oronsoftsurfacesoronesthatarenotstrong

enough.Theseconstructionsmaycollapseandcause

roll-overofthetractor.Alwaysinspectthecondition

andcarryingcapacityofbridgesandrampsbefore

crossing.

Donotuseequipmentmountedonthetractorwhichis

•

notcorrectlymatchingandrmlyxed.Theuseofim-

plementsoraccessoriesthathavenotbeenapproved

orarenotcorrectlyconnectedmayincreasetheriskof

roll-overofthetractoriftheycomeloose.Ensurethat

thedimensionsofthethree-pointlinkageinterfaceof

boththetractorandtheequipmentcomplywiththecategoriesdenedinISO730.Ensurethatthedimensions

andspeedofthePTOshaftonthetractorsmatchthose

oftheequipment.

Donotusethetractorincombinationwithequipment

•

withouthavingconsultedthespecicOperator’sMan-

ualprovidedwiththeequipment.Thetractorisauniversaltooltocarry,towanddriveavarietyofequipment.Thismanualalonecannotprovideyouwithall

theinformationrequiredforthesafeoperationofthe

combination.

Donotusethetractorforpullingwork,incaseswhere

•

youdonotknowwhethertheloadwillyield,forinstance

whenpullingstumps;thetractormayipoverwhenthe

stumpisnotyielding.

Becautiousthatthecentreofgravityofthetractormay

•

increasewhenloadsonthefront-endloaderorthe

three-pointlinkageareraised.Intheseconditions,the

tractormayrolloverearlierthanexpected.

Donotstepdownfromthetractorwithoutshuttingdown

•

thePTO,shiftingthetransmissiontoparkorneutraland

applyingtheparkbrake,unlesscontinuedPTOoperationisrequiredforsomeequipment,suchaspumps

orwoodchippers.Thelatterequipmentmayhavean

emergencystopdeviceontheequipmentitself,ashumaninterventionisneededduringoperation.Butother

equipment,engagedanddrivenbythetractorwillhave

nomeanstostopthepowertransmission,otherthan

thePTOclutchofthetractor.

Youmusttakethenecessaryprecautions(e.g.assis-

•

tance)toalwaysbeawareofthepossiblepresenceof

bystanders,especiallywhenmanoeuvringinconned

areas,suchasthefarmyardandsheds.Keeppeople

awayfromthetractorduringwork.Askbystandersto

leavetheeld.Thereisnotonlytheriskofbeingrun

overbythetractor,butobjectsejectedbysomeequipmentmountedonthetractor,suchasarotarymower,

maycauseharm.Stonesmaybethrownfurtherthan

themowedcrop.Paythenecessaryattentionwhileoperatingnexttopublicroadsorfootpaths.Thrownobjectscanbeprojectedoutsidetheeldandhitunprotectedpeoplesuchascyclistsorpedestrians.Waitto

cuttheedgeoftheeldtillitisclearofbystanders.

Donotallowridersonthetractor;donotallowpeople

•

tostandontheaccesssteptothecabwhenthetractor

ismoving.Yourviewtotheleftwillbeobstructedanda

riderrisksfallingfromthetractorduringunexpectedor

abruptmovements.

Alwaysstayclearfromtheimplementsoperatingarea

•

andespeciallydonotstandbetweenthetractorand

theimplementorthetrailedvehiclewhenoperatinglift

controls;ensurenobystandersareneartheseoperatingareas.

Certainfunctionsofyourtractorarecontrolledbysoft-

•

wareandsomeofthemaresafety-related.Donotat-

tempttomodifyordownloadsoftwarenotcertiedand

distributedbythemanufacturer.Electronicsettingsand

logicsmaybedestroyedandseriouslyaffectthefunctioningofthetractor.Thismayresultinunpredictable

andunsafebehaviourofthetractor .Alwaysreferto

yourdealer;hehastheappropriatetoolsanddatasets

1-6

1-GENERALINFORMATION

andownstheofciallyreleasedsoftwareversionsand

updatesforyourtractor.

Yourtractormaybeequippedwithanumberofsensors

•

tocontrolsafetyfunctions.Trippingthesesensorswill

resultinasafeoperationmode.Donotattempttobypassanyfunctiononthetractor.Y ouwillbeexposed

toserioushazards,andmoreover,thebehaviourofthe

tractormaybecomeunpredictable.

Thetractorhasonlyoneoperatorstationandthisisa

•

onemanoperatedvehicle.Thereisnoneedforother

peopleonoraroundthetractorduringnormaloperation.Donotallowridersonthetractor;donotallow

peopletostandneartheaccesstothecaboronthe

stepwhenthetractorismoving.Yourviewtotheleft

willbeobstructedandariderrisksfallingfromthetractorduringunexpectedorabruptmovements.

1-7

EcologyandtheEnvironment

1-GENERALINFORMATION

Soil,airandwaterareessentialelementsforagriculture

andforlifeingeneral.Iflocallegislationdoesnotcontrolthetreatmentofcertainsubstances,theproduction

ofwhichisnecessitatedbyadvancedtechnologies,productsderivedfromchemicalandpetrochemicalproducts

mustbeusedanddisposedofaccordingtotherulesof

commonsense.

Thefollowingrecommendationsmaybeofhelp:

Findoutwhattherelevantlegislationinyourcountry

•

stipulates.

Askyoursuppliersoflubricants,oils,fuels,antifreeze,

•

detergents,etc.forinformationontheeffectsofthese

productsonhumansandtheenvironmentandforinstructionsconcerningtheiruse,storageanddisposal.

Inmanycases,localagriculturalconsultantswillbe

abletoprovideassistance.

Suggestions

1.Avoidusingunsuitable,pressurisedllingsystems

orfuelcanswhenllingtanks,asthesemaycause

considerablespillageandleakageofliquids.

2.Asageneralrule,donotallowliquidfuels,lubricants,

acids,solvents,etc.,tocomeintocontactwiththe

skin.Themajorityoftheseproductscontainsubstancesthatarepotentialhealthhazards.

3.Modernlubricantscontainadditives.Donotburn

contaminatedfueloilsand/oroilsusedinconventionalheatingsystems.

4.Avoidspillagewhentransferringusedenginecooling

liquids,engineandtransmissionlubricants,hydraulic

oils,brakeuids,etc.Nevermixusedbrakeoilwith

fueloil,orfueloilwithlubricants.Storesafelyuntil

suitabledisposalcanbearrangedaccordingtonationallegislationorlocalregulations.

5.Modernanti-freezeliquidsandsolutions,e.g.antifreezeandotheradditives,mustbereplacedevery

twoyears.Theymustnotbelefttobeabsorbedinto

theground,butmustbecollectedanddisposedofin

asuitablemanner .

6.Donotopentheairconditioningsystemstocarryout

work.Thesesystemscontaingasthatmustnotbe

releasedintotheatmosphere.Contactyourdealer

orspecialisedpersonnel,whoareequippedwiththe

appropriateequipmentandareauthorisedtore-ll

thesystem.

7.Anyleakageordefectintheenginecoolingorhydraulicsystemsmustberepairedimmediately.

8.Donotincreasethepressureinpressurisedsystems,

asthismaycausecomponentpartstoburst.

9.Whenwelding,makesurethathosesareproperly

protectedassparksormoltenmaterialmaypuncture

orweakenthetubesandsleeves,resultinginleakageofoil,coolingliquid,etc.

10.Donotadjustthesettingofthefueldeliverysystem

asthiswillaltertheemissionofexhaustfumes.

NOTICE:Thefuelsystemandengineonyourmachine

aredesignedandbuilttogovernmentemissionsstandards.T amperingbydealers,customers,operatorsand

usersisstrictlyprohibitedbylaw.Failuretocomplycould

resultingovernmentnes,reworkcharges,invalidwarranty,legalactionandpossibleconscationofthemachineuntilreworktooriginalconditioniscompleted.Engineserviceand/orrepairsmustbedonebyacertied

technicianonly!

1-8

1-GENERALINFORMATION

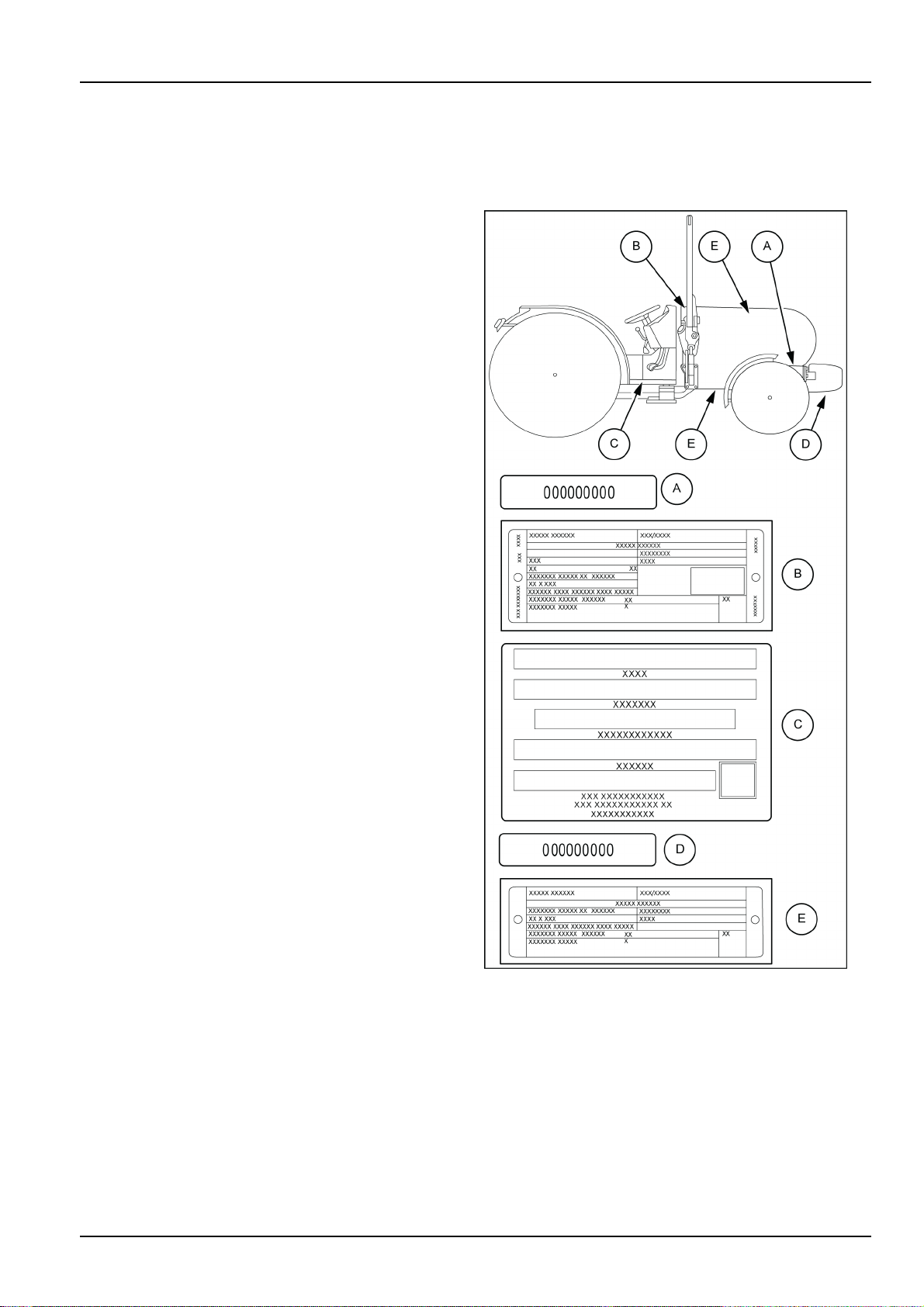

Identicationplates

Serialnumbersidentifythetractoranditsmaincomponents.Theidenticationdatamustbesuppliedbythedealer

forrequestsforsparepartsorserviceoperations.Identicationdataisoffundamentalimportanceintheeventoftheft

ofthetractor.Thelocationofthevariousidenticationdataisshownbelow.

(A)

FRAMEIDENTIFICA TIONDAT APLA TE

Thetractor’sframenumberisstampedoverthefrontsupport.Itgivesthesafetyframeidenticationdata.

(B)

ROPSFRAMEIDENTIFICATIONDATAPLATE

Theplategivestheidenticationdatafortheropsframe

ttedonthemachine.

(C)

FRAMEANDENGINETYPEIDENTIFICATIONSUMMARYDA T APLATE

Theplategroupstheidenticationdatawithyourmachine’sframenumberandenginenumber.

(D)

STANDARDFRONTAXLEIDENTIFICATIONPLATE

Theplateislocatedonthecomponentandgivestheidenticationdatafortheaxlettedonthemachine.

(E)

ENGINEIDENTIFICA TIONDATAPLA TE

Theplatewiththeenginedatainstalledonthetractoris

ttedontherightorlefthandsideoftheengine(dependingonthemodel).

MOIL13TR00766CA1

1-9

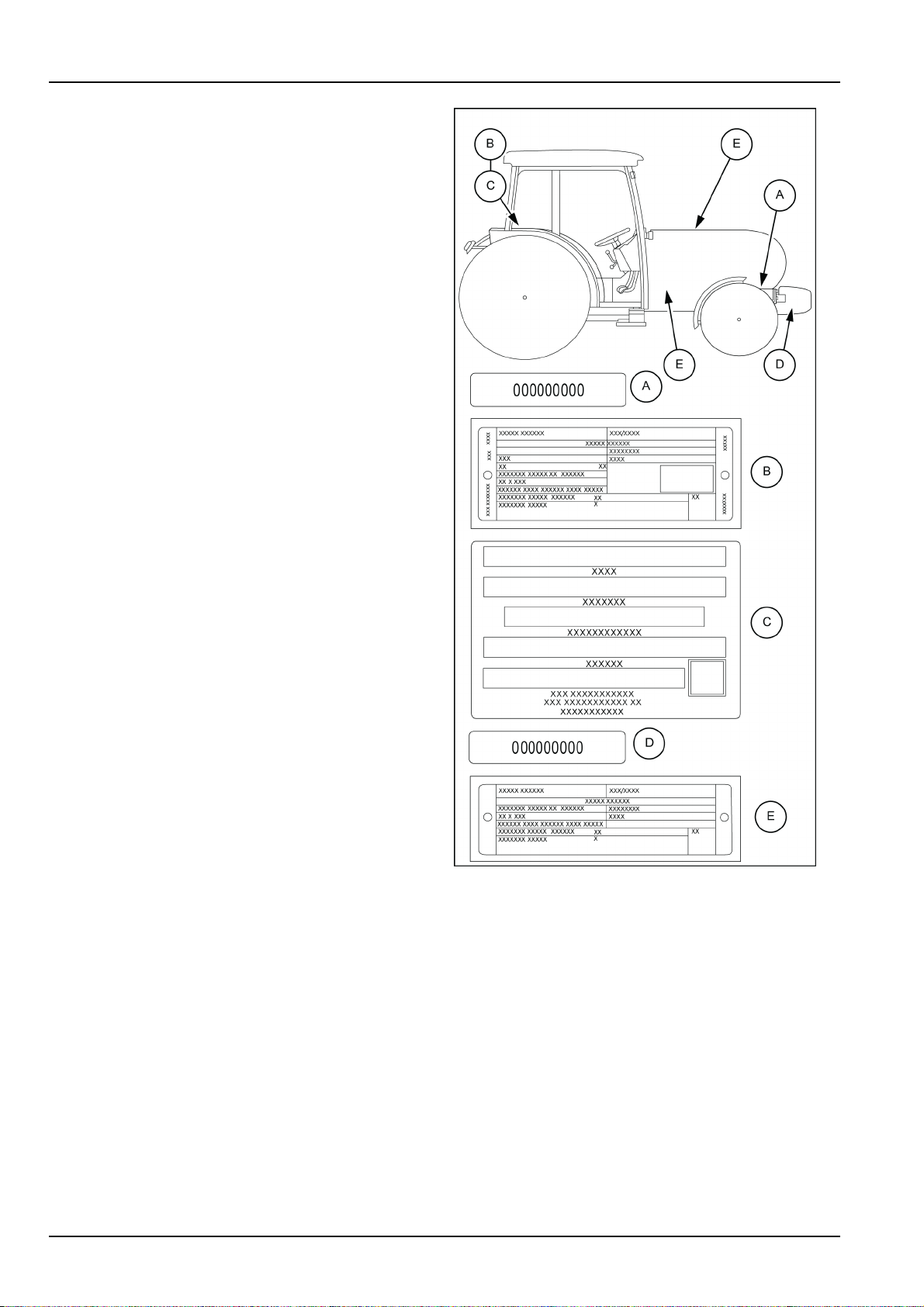

1-GENERALINFORMATION

(A)

FRAMEIDENTIFICA TIONDAT APLA TE

Thetractor’sframenumberisstampedoverthefrontsupport.Itgivesthesafetyframeidenticationdata.

(B)

CABIDENTIFICA TIONPLATE

Thecabidenticationplateislocatedattherearonthe

left−handsideasshowninthegure.

(C)

FRAMEANDENGINETYPEIDENTIFICATIONSUMMARYDA T APLATE

Theplategroupstheidenticationdatawithyourmachine’sframenumberandenginenumber.

(D)

STANDARDFRONTAXLEIDENTIFICATIONPLATE

Theplateislocatedonthecomponentandgivestheidenticationdatafortheaxlettedonthemachine.

(E)

ENGINEIDENTIFICA TIONDATAPLA TE

Theplatewiththeenginedatainstalledonthetractoris

ttedontherightorlefthandsideoftheengine(dependingonthemodel).

MOIL13TR00764CA2

1-10

1-GENERALINFORMATION

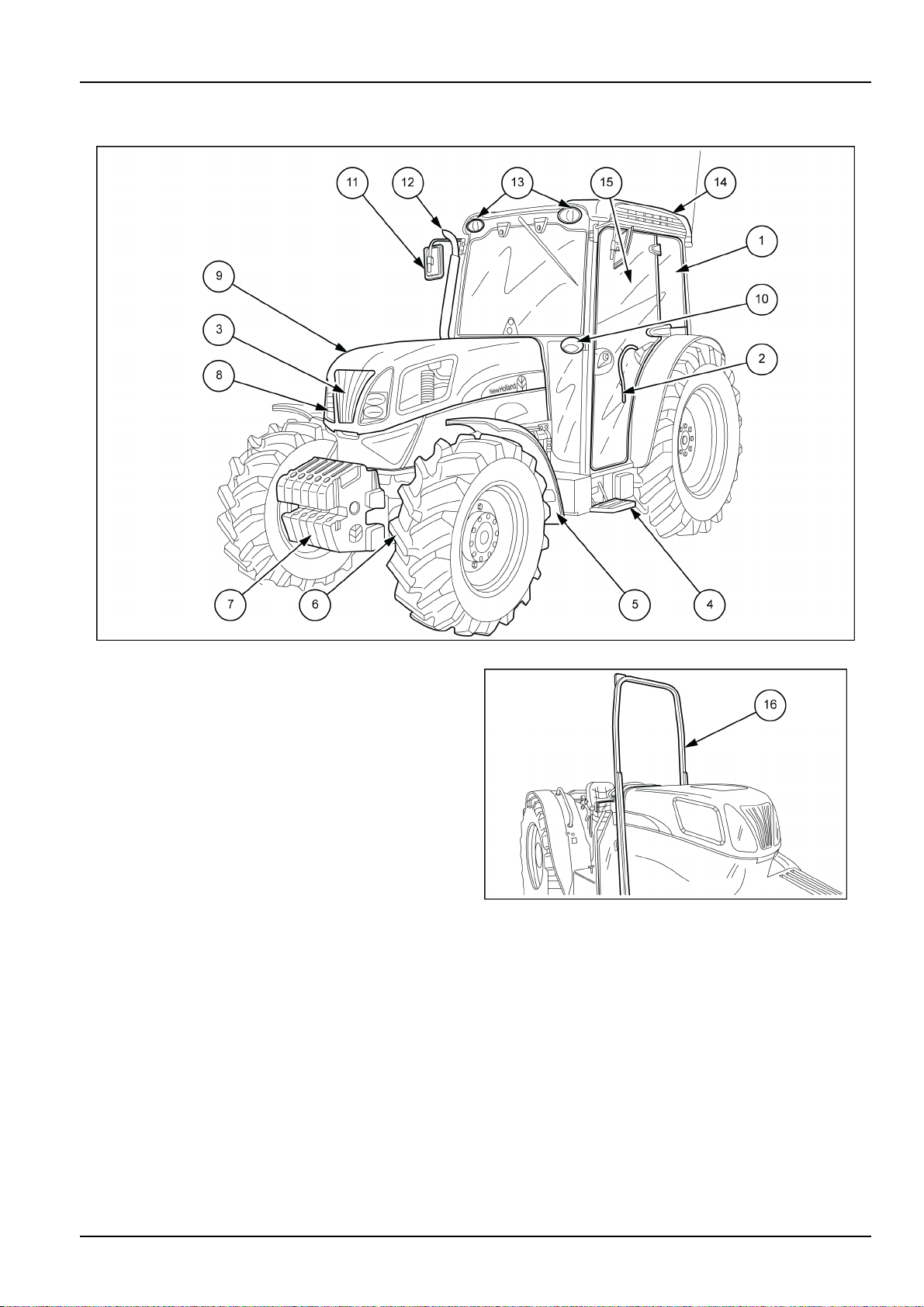

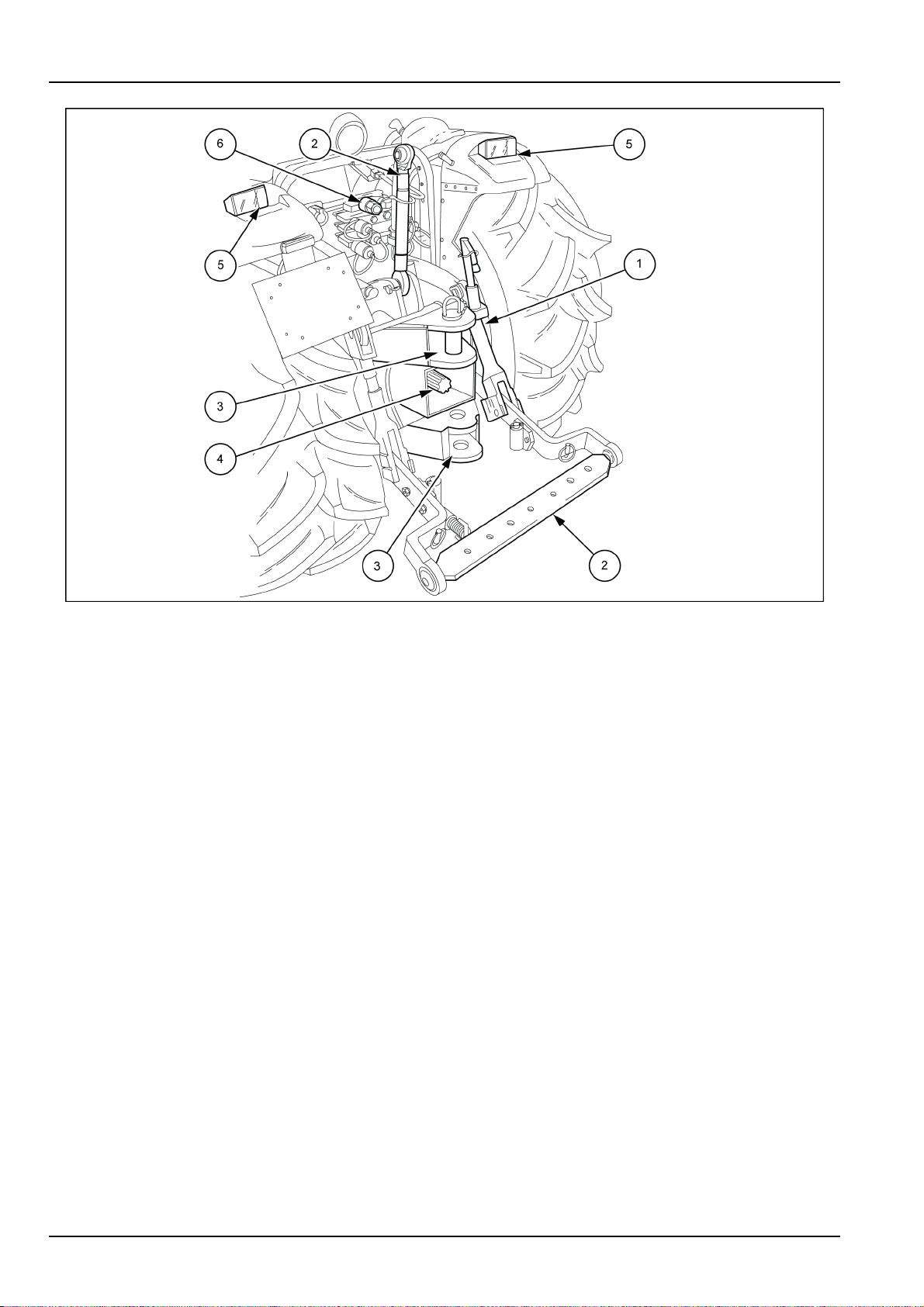

ComponentIdentication

1.Cab

2.Handrail

3.Fueltank

4.Steps

5.Transmission

6.Frontaxle

7.Ballast

8.Frontlight

9.Hood/Engine

10.Indicatorlight

11.Rearviewmirror

12.Exhauststack

13.Frontworklights

14.Rearworklights

15.Rearwidowemergencyexit

16.R.O.P .S.(RollOverProtectiveStructure)

MOIL13TR00772FA1

MOIL13TR00756AA2

1-11

1-GENERALINFORMATION

1.Rearaxle

2.Threepointlinkage

3.Hitch

4.Powertakeoff

5.Rearlights

6.Remotecontrolvalves

MOIL13TR00771FA3

1-12

2-SAFETYINFORMATION

2-SAFETYINFORMATION###_2_###

Safetyrulesandsignalworddenitions

Personalsafety

Thisisthesafetyalertsymbol.Itisusedtoalertyoutopotentialpersonalinjuryhazards.Obeyall

safetymessagesthatfollowthissymboltoavoidpossibledeathorinjury .

Throughoutthismanualandonmachinedecals,youwillndthesignalwordsDANGER,WARNING,andCAUTION

followedbyspecialinstructions.Theseprecautionsareintendedforthepersonalsafetyofyouandthoseworking

withyou.

Readandunderstandallthesafetymessagesinthismanualbeforeyouoperateorservicethemachine.

DANGERindicatesahazardoussituationwhich,ifnotavoided,willresultindeathorseriousinjury.The

colorassociatedwithDANGERisRED.

WARNINGindicatesahazardoussituationwhich,ifnotavoided,couldresultindeathorseriousinjury .

ThecolorassociatedwithWARNINGisORANGE.

CAUTION,usedwiththesafetyalertsymbol,indicatesahazardoussituationwhich,ifnotavoided,couldresult

inminorormoderateinjury.ThecolorassociatedwithCAUTIONisYELLOW.

FAILURETOFOLLOWDANGER,WARNING,ANDCAUTIONMESSAGESCOULDRESULT

INDEATHORSERIOUSINJURY .

Machinesafety

NOTICE:Noticeindicatesasituationwhich,ifnotavoided,couldresultinmachineorpropertydamage.Thecolor

associatedwithNoticeisBLUE.

ThroughoutthismanualyouwillndthesignalwordNoticefollowedbyspecialinstructionstopreventmachineor

propertydamage.ThewordNoticeisusedtoaddresspracticesnotrelatedtopersonalsafety.

Information

NOTE:Noteindicatesadditionalinformationwhichclariessteps,procedures,orotherinformationinthismanual.

ThroughoutthismanualyouwillndthewordNotefollowedbyadditionalinformationaboutastep,procedure,or

otherinformationinthemanual.ThewordNoteisnotintendedtoaddresspersonalsafetyorpropertydamage.

2-1

2-SAFETYINFORMATION

Safetyinformation

1.Duringthemanufacturingofthistractor,everystep

hasbeentakentoensuresafeoperation.However,

thebestwaytoavoidaccidentsistoexercisecaution

atalltimes.Oncetheaccidenthasalreadyhappened

itistoolatetorememberwhatstepsshouldhave

beentaken.

2.Readthismanualcarefullybeforestarting,using,

carryingoutmaintenance,refuellingorperforming

anyothertypeofoperationonthetractor.

3.Thetimespentreadingthismanualwillallowyouto

gettoknowyourtractor ,therebysavingtimeandeffort.Thiswillalsohelppreventaccidentsfromtaking

place.

4.Readallthesafetydecalsonthemachineandfollowtheinstructionsthereonbeforestarting,operating,refuellingorcarryingoutmaintenanceonthemachine.Promptlyreplaceanydecalsthataredamaged,lostorillegible.Cleanthedecalsiftheyare

coveredbymudordebris.

5.Rememberthatthetractorisexclusivelydesigned

foragriculturaluse.Anyotherusewillrequireprior

authorisationfromNEWHOLLAND.

6.Itisadvisabletokeeparstaidkitonhand.

7.Thetractormustonlybeusedbyresponsiblepersonnel,trainedintractoruseandauthorisedtooperate

themachine.

8.Donotaltertheinjectionsystemcalibrationinanattempttoincreasemaximumenginespeedsetbythe

Manufacturer.

13.Alwaysoperatewiththecaborrollbarcorrectlyand

securelyttedonthetractor:periodicallycheckthat

thettingsarenotlooseandthatallpartsofthestructurearefreefromanydamageanddeformation.Do

notmodifytherollbarbyweldingparts,drillingholes,

etc.,asthiscouldadverselyaffecttherigidityofthe

structure.

Startingthetractor

1.Beforestartingtheengine,checkthatthehandbrake

isonandthatthegearsandpowertake-offaredisengaged,evenifthetractoristtedwithastart-upsafety

device.Neverdisconnectthestart-upsafetyswitch.If

theswitchdoesnotworkcorrectly,contactyourlocal

dealerforeventualrepairoperations.

2.Beforestartingtheengine,makesurethatallattached

implementsareloweredtotheground.

3.Beforestartingtheengine,checkthatallcoversand

guardsarecorrectlyinposition(rollbar,bonnetside

panels,powertake-offguard,frontaxletransmission

shaftcover,etc.).

4.Neverstartormanoeuvrethetractorunlessseatedin

thedrivingposition.

DCSFTNEGB001S1A1

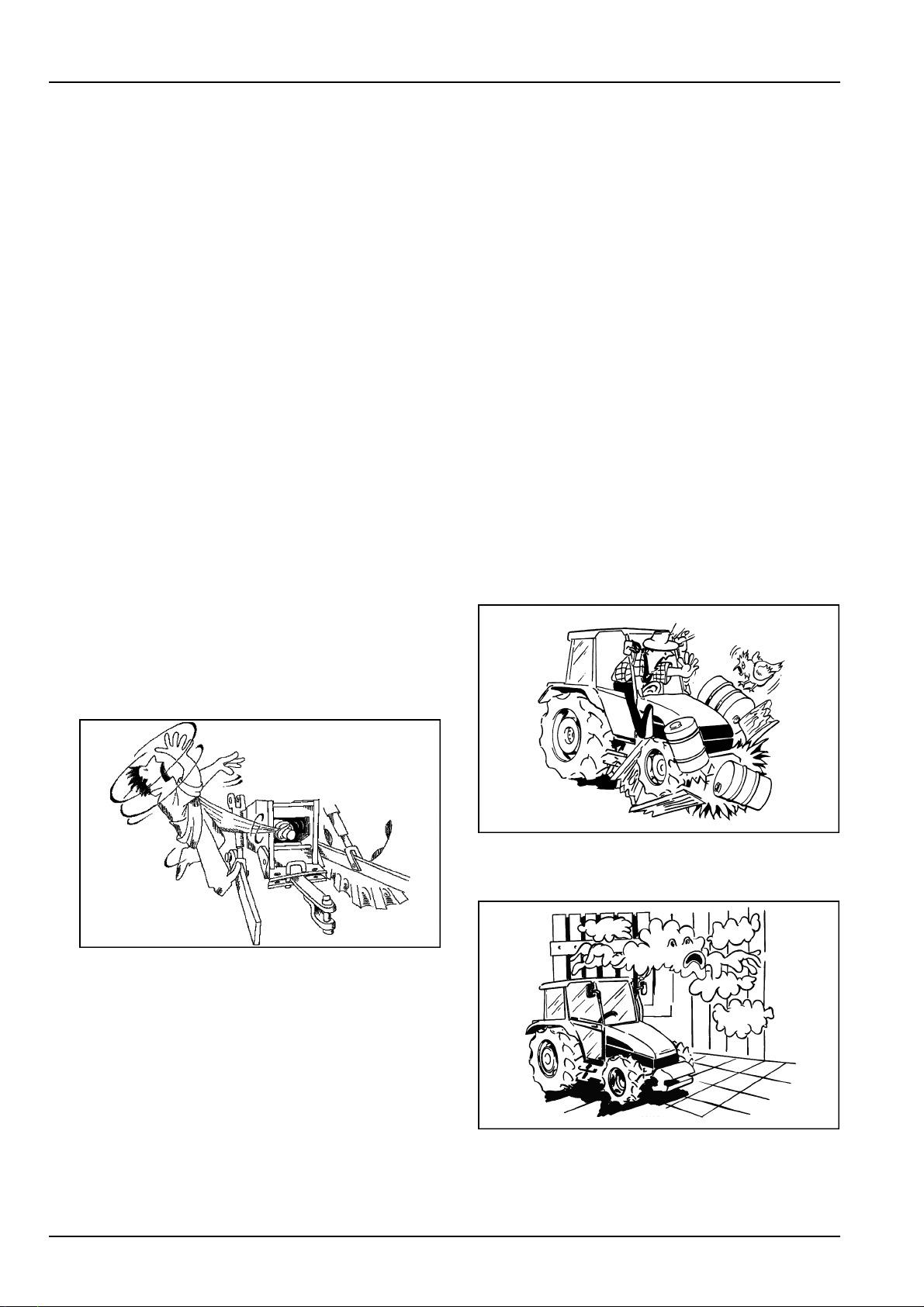

9.Donotwearlooseclothingthatmaybetrappedin

movingparts.Checkthatallrotatingpartsconnected

tothepowertake-offarecorrectlyprotected.

10.Donotalterthecalibrationofthepressurerelief

valvesinthevarioushydrauliccircuits(hydrostatic

steering,hydrauliclift,auxiliarydistributors,etc.).

11.Avoidusingthetractorinunsuitablephysicalconditions,stopworkinstead.

12.Enterandleavethetractorusingthestepsandhandlesprovided.Keepthesettingsfreeofmudand

debris.

DCSFTNEGB002S1A2

5.Beforemovingthetractor,alwayscheckthatthearea

isfreeofpersonsorobstacles.

DCSFTNEGB003S1A3

6.Neverruntheengineinaclosedspacewithoutensuringadequateventilation.Exhaustfumesaredamagingtothehealthandcanbelethal.

2-2

2-SAFETYINFORMATION

Useofthetractor

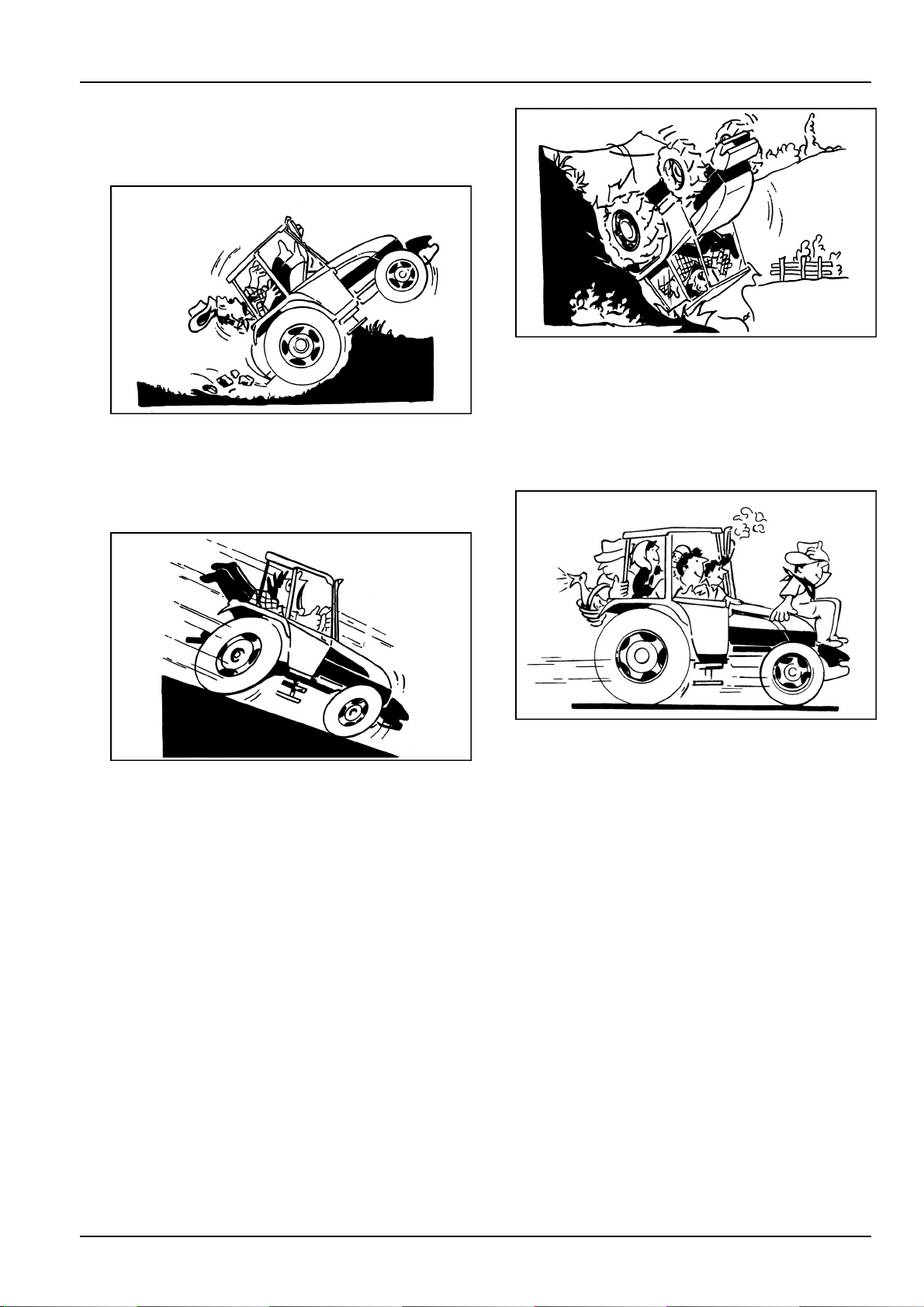

1.Selectthemostsuitablewheelsettingfortheworkin

hand,i.e.:thesettingthatprovidesthebeststability.

DCSFTNEGB004S1A4

2.Engagetheclutchslowly:ifengagedtooquickly,especiallywhenthetractorisgettingoutofahole,ditch

oroperatingonmuddygroundorsteepslopes,the

tractormayoverturn.Releasetheclutchimmediately

ifthefrontwheelsstarttolift.

DCSFTNEGB006S1A6

10.Proceedwithmaximumcautionwhenworkingwith

thewheelsneartheedgeofditchesorslopes.

11.Whendrivingonpublichighways,observetheHighwayCode.

12.Whendriving,donotrestyourfeetonthebrakeor

clutchpedals.

DCSFTNEGB005S1A5

3.Whentravellingdownhill,keepthetractoringear.

Neverreleasetheclutchandneverleavethegears

inneutral.

4.Whenthetractorismoving,theoperatormustremain

correctlyseatedinthedrivingposition.

5.Nevergetonoroffthetractorwhileinmovement.

6.Whenusingthebrakes,pressthepedaldownslowly .

7.Avoidtakingbendsathighspeeds.

8.Alwaysusethetractorataspeedthatwillguarantee

safeoperationonthetypeoflandbeingworked.

Whenworkingonunevenground,usemaximum

caretoensureproperstability.

9.Ifyouhavetoworkwiththetractoronagradient,

forexampleonhillsides,driveatmoderatespeed

especiallywhentakingbends.

DCSFTNEGB007S1A7

13.Nevercarrypassengers,noteveninsidethecab,unlessthemachineisttedwithanapprovedextraseat.

14.Whendrivingonroads,connectthebrakepedalsusingtheplateprovided.Brakingwhenthepedalsare

notconnectedcouldcausethetractortoskid.Avoid

excessivewearonthebrakesbyusingenginebraking.

Towingandtransport

1.T oguaranteetractorstabilitywhenmoving,adjustthe

hitchingdeviceaccordingtothetrailerorimplementto

beused.

2.Driveslowlywhentowingextremelyheavyloads.

3.Foryourownsafety,donottowtrailersthatarenot

ttedwithanindependentbrakingsystem.

4.Ifthetractorisusedtotowheavyloads,alwaysuse

thehitchingdeviceandneverhitchloadsontothe

lowerarmsorthetoplinkofthethree-pointlinkage,

sinceinthelattercasethereisadangerofrearingup

oroverturning.

2-3

2-SAFETYINFORMATION

DCSFTNEGB008S1A8

5.Whentowing,donotnegotiatebendswiththedifferentiallockengagedasthismaypreventyoufromsteeringthetractor.

Useofimplementsandagriculturalmachinery

1.Donotconnectimplementsormachinerythatrequire

morepowerthancanbegeneratedbyyourtractor

model.

2.Nevernegotiatesharpbendswiththepowertakeoffunderaheavyload;thismaydamagetheuniversaljointsonthetransmissionshaftconnectedtothe

powertake-off.

3.Neverstandbetweenthereversingtractorandtheimplementwhenhitching.

4.Whenusingimplementsthatrequirethetractortobe

stationarywiththeenginerunning,keepthegearand

rangeleversintheneutralposition,applythehandbrakeandusesuitablewheelchocks.

Stoppingthetractor

1.Whenthetractorisstationary,neverleaveconnected

implementsintheraisedposition.Allimplements

mustbeloweredbeforestoppingtheengine.

2.Beforeleavingthedrivingposition,movethegear

levertotheneutralposition,disengagethepower

take-off,applythehandbrakeandstoptheengine.

Alwaysremovetheignitionkeyfromthedashboard

whenleavingthetractorunattended.

3.Parkonatsurfaces,wherepossible,andapplythe

handbrakebeforeleavingthetractor.Onsloping

ground,besidesapplyingthehandbrake,asanadditionalsafetymeasure,usewheelchocks(available

asanoptional);thisprocedureiscompulsorywhen

parkingwithatrailerhitched.

DCSFTNEGB010S1A10

Servicingthetractor

1.WARNING

Illustrationsinthismanualmayshowprotectiveshieldingopenorremovedtobetterillustrateaparticularfeatureoradjustment.

Replaceallshieldsbeforeoperatingthe

machine.

Failuretocomplycouldresultindeathor

seriousinjury.

W0012A

DCSFTNEGB009S1A9

5.Donotoperatemachinesconnectedtothepower

take-offwithoutrstensuringthattheoperatingrange

ofthemachineisfreeofbystanders.Alsocheckthat

allrotatingpartsconnectedtothepowertake-offshaft

arecorrectlyprotected.

6.Addrearballastwhenusingliftingequipmentttedto

thefrontofthetractor.

Donotworkonthetyreswithunsuitableequipment

orwithoutthenecessaryexperience.Incorrecttyre

ttingmayputsafetyatrisk.Ifindoubt,contact

skilledpersonnel.

2.Whenchangingorstoringtyres,makesuretheyare

stackedcorrectlyandcannotrollortoppleovercausingpersonalinjury .

3.Beforeremovinganyhydraulictubing,checkthatthe

systemisnotpressurised.

2-4

2-SAFETYINFORMATION

DCSFTNEGB011S1A11

4.Oilunderpressuregettingoutcancauseserious

injuries.Whenlookingforleaksusetheappropriatesafetyequipment:screens,safetyglassesand

gloves.

5.Beforetouchinganyelectricalcomponents,disconnectthegroundleadfromthebattery.

DCSFTNEGB012S1A12

6.Onlyremovetheradiatorcapaftertheenginehas

beenallowedtocool.Withtheengineswitchedoff,

useaclothtoslowlyunscrewthecapandreleasethe

pressurebeforecompletelyremovingthecap.

DCSFTNEGB013S1A13

7.Beforeinspecting,cleaningorcarryingoutmaintenanceonthetractor(oranyimplementconnected

tothetractor),alwaysensurethattheengineis

switchedoff,thegearsareinneutral,thebrakes

areon,thepowertake-offisdisengagedandthatall

movingpartsarestationary.

8.Donotllupthefueltankcompletelyifthetractor

istoworkinextremelysunnyconditions,asthefuel

mayexpandandescape.Ifthisoccurs,dryupthe

spillageimmediately.

DCSFTNEGB014S1A14

9.Alwayskeepareextinguisherathand.

2-5

Airconditioningsafetyregulations

2-SAFETYINFORMATION

Theairconditioningsystemissafeandcanbeusedcontinuouslywithoutanyrisk.However,itisimportanttoobserveafewsimpleprecautions,listedbelow,toavoidany

riskofaccident.

1.Itisadvisednevertopersonallyattempttoadjustthe

system;anyrepairworkshouldbecarriedoutbythe

experiencedtechniciansoftheNEWHOLLANDServiceNetwork.

DCSFTNEGB015S1A1

2.Neverallowopenamesneartheairconditioningsystem,asifthereisaleakofcoolant,alethalgas:phosgene.

3.Theoilandcoolantmixtureispressurisedintheairconditioningcircuit.Thelooseningofanyconnections

orhandlingoftubingisthereforestrictlyforbidden.For

thesamereason,neverunscrewthecompressoroil

levelinspectioncapforanyreason.

4.Donotallowheatsourcesneartheair-conditioning

system,asthismaycauseexplosions.

DCSFTNEGB017S1A3

5.Coolantcanfreezetheskinand,aboveall,theeyes.

Ifanaccidentshouldoccur,proceedasfollows:

ifcoolantcomesintocontactwiththeeyes,washthem

•

immediatelywithafewdropsofmineraloil,thencontinuewashingthoroughlywithasolutionofboricacid

andwater(oneteaspoonofacidin1/4ofacupofwater)andconsultadoctoratonce;

freezingcausedbycoolantcanbetreatedbygradually

•

unfreezingtheinjuredzonewithcoldwaterandthen

applyingagreasebasedcream.Inanyevent,consult

adoctorasquicklyaspossible

DCSFTNEGB016S1A2

2-6

2-SAFETYINFORMATION

Cabguard

Comfortandsafetyinsidethecab

DenitionofCabCategory1

CabismeetingtherequirementsdenedinEN15695−1.

Thismeansthattheairdeliveryandltrationsystemdoes

notprovideaspeciedlevelofprotectionagainsthazardoussubstancesbutonlyfromexternalatmospheric

conditions(e.g.rain,wind,snow,etc).

DenitionofCabCategory2

CabismeetingtherequirementsdenedinEN15695−1.

Thismeansthattheairdeliveryandltrationsystemprovidesprotectionagainstdustandthattheminimumdifferentialpressureisensured.Necessarylteredfreshair

owratecanbeobtainedusingtheA/Csystemandsettingthefanonmaximumspeed,providedthatdoors,windowsandhatchesareclosed.

ATTENTION:Thecabcategory1doesnotguaranteea

fullprotectionagainstdust,aerosolsandvapours.The

cabcategory2providesprotectionagainstdust.For

applicationofplantprotectionproducts(e.g.pesticides,

fungicides,herbicides.....),pleaserefertotheinstructions

providedbythesupplierofthechemicalagentaswellas

instructionsprovidedbythesprayer'smanufacturer.Use

thespecialdevicesandPersonalProtectiveEquipment

(PPE)alsowheninsidethecaband,particularly,on

tractorswithoutacab.Althoughtheairdeliverysystem

cannotofferfullprotection,partialprotectioncanbe

achievedbyfollowingsomebasicrules:

PersonalProtectiveEquipment(PPE)andclothingre-

•

quired.

Keepdoors,windowsandhatchesclosedduringthe

•

sprayingoperation.

Keepthecabinteriorclean.

•

Donotenterthecabwithcontaminatedshoesand/or

•

clothing.

Keepallusedpersonalprotectiveequipmentoutside

•

thecab.

Bringthewireharnessoftheremotesprayercontrol

•

boxintothetractorcab.

Useonlygenuineltersandensurethatthelteriscor-

•

rectlyinstalled.

Checktheconditionofthesealingmaterialandlters,

•

replacingthemifdamaged.

OperatorProtection

RollOverProtectiveStructure(ROPS)

Donotusethetractorbeyonditslimitsofterraingradi-

•

entandstability.Usingthetractorbeyondtheselimits

mayresultinarolloveroratipover.Observetherecommendationsinthismanualandpayparticularattentionwhengoingdownsteephillsinaloadedcondition.

Donotusethetractornearoronsoftvergesofcanals

•

andbrooksorbanksandvergesthatareundermined

byrodents.Thetractormaysinksidewaysandroll−

over.

Donotusethetractoronunstablebridge–headsand

•

poorbridgeoors.Theseconstructionsmaycollapse

andcauseroll-overofthetractor .Alwaysinspectthe

conditionandcarryingcapacityofbridgesandramps

priortocrossing.

Alwaysfastentheseatbeltwhenusingthetractor.The

•

ROPScaborROPSstructurewillonlybefullyeffective

whenthedriverremainsattachedtohisseat.

Donotusethetractorbeyonditslimitsofdynamicsta-

•

bility.Highspeed,abruptmaneuversandfastandtight

corneringwillincreasetheriskofrollover.

Donotusethetractorforpullingwork,incaseswhere

•

youdonotknowwhethertheloadwillyield,forinstance

whenpullingstumps.Thetractormayipoverbackwardswhenthestumpisnotyielding.

Beextremelycautiouswhenworkingwiththetractoron

•

foragesiloswithoutsideconcretewalls.Toincrease

thetractor'ssidestability,itispossibletomounttwin

wheelsorincreaseitstracksetting.

Becautiousthatthecentreofgravityofthetractormay

•

increasewhenloadsonthefront–endloaderorthe

three-pointlinkageareraised.Intheseconditions,the

tractormayroll–overearlierthanexpected.

FallingObjectsProtectiveStructureFOPS

FOPScertiedcabisprovidingprotectionagainstfalling

objectsaccordingtoOECDcode10standard;itisrecommendedtouseacertiedFOPSstructurewhenworkingwithfront-endloadersorinforestryapplications;a

cabnotFOPScertiedisofferinginsufcientprotection

againstfallingrocks,bricksorpiecesofconcrete.

FOPSlevelonyourtractorcabiscertiedaccordingto

OECDCODE10.

Installationandworkingwithfrontloaderon

tractorsequippedwithcab

ATTENTION:Donotusethefront-endloaderwithout

takingprecautionsagainstfallingobjects.

Pleaseconsiderfollowingprecautionswhenworkingwith

afrontendloader:

ThistractorisprovidedwitheitheraROPSstructureor

aROPScab,offeringprotectionagainstrolloverrelated

hazards,allthesamepleaseconsiderthefollowingprecautions:

Donotliftthefront-endloadertoaheightfromwhich

•

objectsmayfallorrollonthedriver.

2-7

2-SAFETYINFORMATION

Alwaysusethecorrectimplement(grabforks,buckets,

•

etc)forthespecictasktoensurethattheloadisse-

curelykeptinplace.

Itisrecommendedtoinstallafrontloaderprovidedwith

•

aparallelguidesystemandtouseitalways;thissystem

keepstheloadinthebuckethorizontal,irrespectiveof

theliftheightofthearms.

Installationandworkingwithfrontloaderon

tractorswithoutcab

ATTENTION:Itisnotrecommendedtoinstallafrontendloaderonatractorwithoutcab,whichcannotoffera

minimumprotectionagainstfallingobjects.

Strictlyobservethefollowingprecautionarywarnings:

Donotliftthefront-endloadertoaheightfromwhich

•

objectsmayfallorrollonthedriver.

Alwaysusethecorrectimplement(grabforks,buckets,

•

etc)forthespecictasktoensurethattheloadisse-

curelykeptinplace.

Itisrecommendedtoinstallafrontloaderprovidedwith

•

aparallelguidesystemandtouseitalways;thissystem

keepstheloadinthebuckethorizontal,irrespectiveof

theliftheightofthearms.

IfavailableinstallaFOPSstructureoraskthesupplier

•

oftheloadertoinstalleitheraFOPScertiedstructure

onmainROPSstructureoratleastaminimalstructure

offeringpartialprotectionfromfallingobjects(e.g.a

“Suncanopy”).

bystanderstostandnearorundertheliftedbucketofa

front–endloader.

Donotusethefront–endloaderasaliftforpersons

•

foractivitiesthatmustbedoneatacertainheight(for

example,cleaningeaves).

Donotusethefront-endloaderinanareawithover-

•

headpowerlines.Incaseofcontactwithoverhead

powerlines,jumpfromthetractorwithoutmakinginstantcontactbetweentractorandground.Whenpossible,disconnectthepowerlinesfromthegrounds.

OperatorsProtectionStructureOPS.

ThistractorisnotprovidedwithanOPScertiedstructure;pleasecarefullyreadthefollowingimportantinformationespeciallywhenworkinginaforestryenvironment.

ForestryApplications

ATTENTION:Thistractorisnotdesignedforheavy

forestryapplications;usageisprohibitedunlessacertiedFORESTRYKITisinstalled;contactyourdealerto

verifywhetheraforestrykitexistsforthistractormodel.

Onlyaforestryspecickitwillprovidenecessaryprotectionagainstfallingtrees.

Protectionagainstpenetratingobjects(OPS)canbeobtainedonlyttingaspecicKIT,contactyourdealerto

verifywhetheranOPScertiedKITisavailableforyour

tractor.

Generalprecautionstobefollowedwhen

workingwithafront-end-loader

Donotallowbystandersinthemanoeuvringzoneofthe

•

tractorequippedwithafront−endloader.Donotallow

2-8

2-SAFETYINFORMATION

Rolloverprotectivestructure(ROPS)

OPERATORPROTECTIVESTRUCTURE

DANGER

Crushinghazard!

DONOToperatethemachinewiththeRoll-OverProtectiveStructure(ROPS)removed.Removethe

ROPSonlyforserviceorreplacement.

Failuretocomplywillresultindeathorseriousinjury.

DANGER

Crushinghazard!

DonotchangetheRollOverProtectiveStructure(ROPS)inanyway.Unauthorizedchangessuchas

welding,drilling,orcuttingwillweakentheROPSanddecreaseyourprotection.Haveanauthorized

dealerreplacetheROPSifdamageofanykindoccurs.DONOTTRYTOREPAIRTHEROPS.

Failuretocomplywillresultindeathorseriousinjury.

WARNING

Roll-overhazard!

Afteranaccident,re,tipover,orrollover,aqualiedtechnicianMUSTreplacetheRoll-OverProtectiveStructure(ROPS)beforereturningthemachinetotheeldorjobsiteoperation.

Failuretocomplycouldresultindeathorseriousinjury .

D0032A

D0037A

W0134A

YourmachineisequippedwithanoperatorProtective

Structure,suchas:aRolloverProtectiveStructure

(ROPS)orFallingObjectProtectiveStructure(FOPS)

orCabwithROPS.AROPSmaybeacabframeora

two-postedorfour-postedstructureusedfortheprotectionoftheoperatortominimizethepossibilityofserious

injury.Themountingstructureandfastenersformingthe

mountingconnectionwiththemachinearepartofthe

ROPS.

TheProtectiveStructureisaspecialsafetycomponent

ofyourmachine.TheProtectiveStructureandinterconnectingcomponentsareacertiedsystem.

ThemountingorsuspensionfortheProtectiveStructure,

operatorseatandsuspension,seatbeltsandmounting

componentsandwiringwithintheoperator'sprotective

systemMUSTbecarefullyinspectedfordamage.

AlldamagedpartsMUSTbereplaced.

NOTICE:TheROPScanbefoldeddownwhenworking

inareaswithlimitedheadroom.Unlessstrictlynecessary ,

alwaysworkwiththerollbarintheraisedposition,as

showninthegure.

Ifusedincorrectly,thetractormaytipover.Whenthe

tractorisusedwiththerollbarintheloweredposition,

thedriverisUNPROTECTED.Alwaysraisetherollbar

afterterminatingworkinareaswithlowheadroom.

2-9

2-SAFETYINFORMATION

Personalprotectiveequipment(PPE)

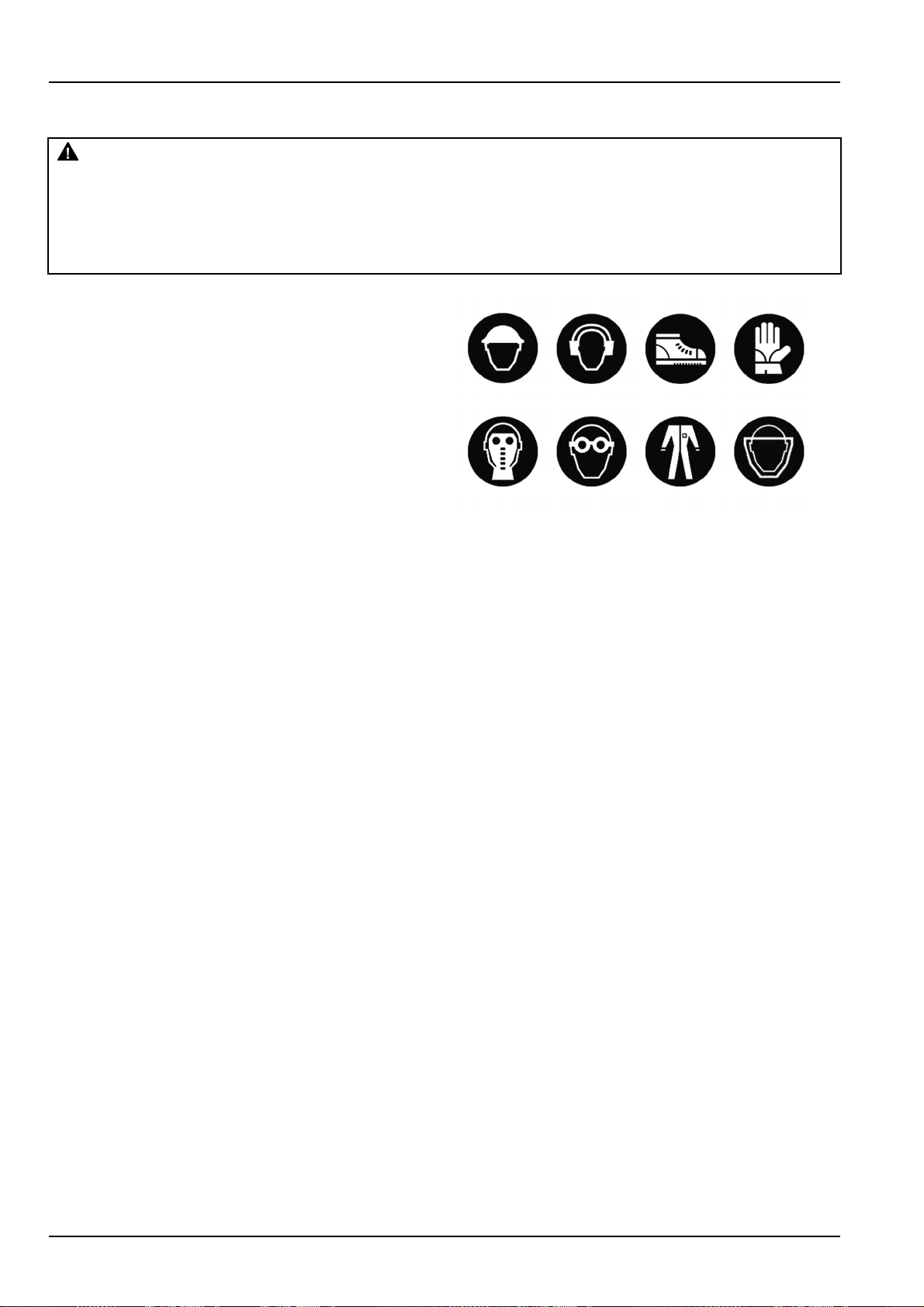

WARNING

PersonalProtectiveEquipment(PPE)required.

Whenassembling,operating,orservicingthemachine,wearprotectiveclothingandPPEnecessary

fortheparticularprocedure.SomePPEthatmaybenecessaryincludesprotectiveshoes,eyeand/or

faceprotection,hardhat,heavygloves,ltermask,andhearingprotection.

Failuretocomplycouldresultindeathorseriousinjury .

Personalprotectiveequipment(PPE)isanyequipment

intendedtobeputonandkeptbytheworkerforprotection

againstoneormorerisksatwork,liabletothreatensafety

orhealthduringwork,aswellasallthecomplementsor

accessoriesintendedforthispurpose.

PPEmustbeusedwhen,inspiteoftheriskbeingreduced

toaminimumatsource,therearehoweverrisksthatcannotbeeliminatedandthereforeitbecomesnecessaryand

obligatorywhenthereareso-called"residual"risks.

W0353A

DCAPLT5NE020S2A1

2-10

2-SAFETYINFORMATION

Tractorjackingpoints

WARNING

Equipmentfailurecouldcauseaccidentorinjury!

Onlyuseriggingequipmentthathasthecapacitytolifttheloadsthatyouaremoving.Alwayscheck

theriggingequipmenteachdayfordamagedormissingparts.Makesureotherworkersorbystanders

arenotundertheloadwhileitismoving.

Failuretocomplycouldresultindeathorseriousinjury .

WARNING

Jackstandscansliporfallover.Dropping,tipping,orslippingofmachineoritscomponentsispossible.

DONOTworkunderavehiclesupportedbyjackstandsonly .Parkmachineonalevelsurface.Block

wheels.Supportmachinewithsafetystands.

Failuretocomplycouldresultindeathorseriousinjury .

W0205A

W0069A

DCAPLT5NE019S2E1

Toliftthetractoruseonlythepointsshowninthegure.

ALWAYSraiseonlythebackorthefront,NEVERbothtogether.

ALWAYSputchocksinfrontoforbehindthewheelsoftheaxlethatisnottobelifted.

2-11

2-SAFETYINFORMATION

Hazardouschemicals

Exposuretoorcontactwithhazardouschemicalsubstancescancauseseriousinjuries.Theuids,lubricants,paints,

adhesives,coolants,etc.requiredforthemachine'soperationcanbeharmful.Inaddition,theycanattractdomestic

animalsandpeoplecreatingdangeroussituationsforhealth.

Thematerialssafetydatasheets(MSDS)provideinformationonthechemicalsubstancescontainedinaproduct,

onthemethodsofsafestorageandhandlingandontherstaidprocedurestofollowshouldsuchaproductget

accidentallyspilled.

Beforedoinganymaintenancework,readthematerialssafetydatasheets(MSDS)foreachsinglelubricant,liquid,

etc.usedonthemachine.Theinformationgivenonthesheetssignalstheassociatedrisksandenablescarryingout

themaintenanceworksafely.T operformmaintenancework,followtheinformationgivenontheMSDSsheets,the

informationprovidedbythemanufactureronthecontainersoftheproductsandtheinformationgiveninthismanual.

Disposeofalltheuids,ltersandcontainersinanenvironmentfriendlymanner,respectingthecurrentregulations

andlawsonthesubjectofenvironmentalprotection.Forcorrectinformationondisposal,contactyourlocaldifferentiatedwastecollectioncentreoryourdealer.

Storeuidsandltersaccordingtothelocalregulationsandlaws.T ostorechemicalorpetrochemicalsubstances,

useappropriatecontainersonly.

Keepthebatteriesoutofthereachofchildrenorofotherunauthorisedpeople.

Furtherprecautionsarenecessaryfortheappliedchemicalsubstances.Beforeusingchemicalsubstances,askthe

producerorretailerfordetailedinformation.

2-12

2-SAFETYINFORMATION

Burnprevention

WARNING

Hotsurfacepossible!

Waitforallcomponentstocoolbeforeperforminganyoperation.

Failuretocomplycouldresultindeathorseriousinjury .

CAUTION

Hotarea!

Usecarewhenworkingnearhotcomponents.Wearprotectivegloves.

Failuretocomplycouldresultinminorormoderateinjury .

WARNING

Burnhazard!

Beverycarefultoavoidcontactwithhotuids.Ifuidisextremelyhot,allowittocooltoamoderately

warmtemperaturebeforeproceeding.

Failuretocomplycouldresultindeathorseriousinjury .

W0251A

C0034A

W0362A

Therearepartsonthetractorwhoseoutsidesurfacesreachhightemperatureswiththe

consequentdangerofburnsbycontactwiththeskin.

Thehotpartsoffarmtractorsthatmayposeapotentialburnriskcomprise:

1.Theexhaustsystem(manifold,silencer,etc.).

2.Partsoftheengine.

3.Thegearboxandclutchhousing.

4.Thehydraulicdistributors.

5.Pipescarryinghotuids.

Whereverpossible,guardshavebeeninstalledtopreventdirectcontactbetweentheoperatorandthehotareas.For

otherpartsthatforreasonsofconstructionandoperationcannotbeprotected,itisnecessarytotaketheduesafety

precautionsandusetheappropriatepersonalprotectiveequipmentforthetypeofworktobecarriedout.

2-13

Fireorexplosionprevention

2-SAFETYINFORMATION

Removealllitterordebrisfromthemachineeachday;

especiallychecktheengineareaandexhaustsystem.

Asparkoranakedlightcancausethehydrogenina

batterytoexplode.T opreventanexplosioncarryout

thefollowing:•

Whendisconnectingthebatterycables,disconnectthe

•

negative(−)cablerst;whenconnectingthebattery

cables,connectthenegative(−)cablelast.

Whenconnectingjumpercablestostarttheengine,use

•

theprocedureshowninthismanual(seeAuxiliaryBat-

teryconnectionsinthismanual).

Donotweld,grindorsmokenearabattery.Sparks

•

fromtheelectricalsystemorengineexhuastcancause

anexplosionandre.Beforeyouoperatethemachine

inanareawithammabledustorvapors,usegood

ventilationtoremovetheammabledustorvapors.

Donotshortcircuitthebatterypostswithmetalitems.

•

Usenonammablecleaningsolventtocleanparts.

•

Keepthecoolingsystemcleanandmaintainthecorrect

•

coolantlevel.

MakesurethatyouDONOTstoreoilyragsorother

•

ammablematerialsonthemachine.

Enginefuelcancauseanexplosionorre.Donotll

•

thefueltankwiththeenginerunning,ifyouarenearan

openre,orifyouarewelding,smoking,etc.

Ifthemachinehasanoil,fuelorhydraulicleak,always

•

repairtheleakandcleantheareabeforeoperating.

Checktheelectricalsystemforlooseconnectionsor

•

frayedinsulation.

FireExtinguisher

Onlyoperateyourtractorwhenanapprovedreextinguisherisinstalled.Thereextinguisherdesignedlocationisidentiedonyourtractorwiththedecalshownin

theaccompanyingimage.

NOTICE:Pleaseensuretoinstallanappropriateandcertiedreextinguisher.

Neveralteritspositionorremoveit.

Ensuretoreplaceitorhaveitcheckedorrelledafter

everyusageand/ordateofexpiryaccordingtomanufacturer’smaintenanceprescriptions.

Itisnotintendedforuseonanout−of−controlre,such

asonewhichhasreachedtheceiling,ortheoperator;it

ismeantonlytohelpyou

Tocheckiftheextinguisherisstillunderpressure,proceed

asfollows:

1.Unscrewthepressuregaugefromthevalve.

2.Theneedlewillgofromthegreenareato”0”inthered

area.

3.Rescrewthepressuregaugeonthevalve.Theneedle

willgofrom”0”intheredareatothegreenarea.

Operatetheextinguisherfromasafedistance.

•

PullthePinatthetopoftheextinguisher.

•

Aimatthebaseofthere,nottheames.

•

Squeezetheleverslowly.Thiswillreleasetheextin-

•

guishingagent;Ifthehandleisreleased,thedischarge

willstop.

Sweepfromsidetoside.Usingasweepingmotion,

•

movethereextinguisherbackandforthuntilthere

iscompletelyout.

Checkforre-ignitionofre.

•

DCAPLNEGB125S2A1

2-14

2-SAFETYINFORMATION

Gettinginandoutofthemachine

WARNING

Fallhazard!

Jumpingonoroffthemachinecouldcauseaninjury .Alwaysfacethemachine,usethehandrails

andsteps,andgetonoroffslowly.Maintainathree-pointcontacttoavoidfalling:bothhandsonthe

handrailsandonefootonthestep,oronehandonthehandrailandbothfeetonthesteps.

Failuretocomplycouldresultindeathorseriousinjury .

Getonandoffthemachineonlybyusingthespecicaccessesequippedwithahandrail,stepsorladder.

Donotjumpoffthemachine.

Checkthatthesteps,laddersandplatformsremainclean

andclearofdebrisandforeignmatter.Slipperyareascan

beacauseofaccidents.

Nevergetonoroffthemachinewhileinmovement.

Donotusethesteeringwheeloranyothercontrolsor

accessoriesasahandrailwhengettingintooroutofthe

cab.

MOIL13TR00855AA1

W0141A

2-15

2-SAFETYINFORMATION

Safetysigns

Thesafetydecalsonthefollowingpagesarepositionedonyourtractorinthelocationsshowninthedrawingsbelow.

Thesesafetydecalsareimportantbothforyoursafetyandthatofpersonnelworkingwithyou.

Werecommendthatyoustudythesepagesandndthepositionsofthesafetydecalsonthetractor,checkingthat

theirmeaningsareclear.Readtheinstructionsbelowwiththetractordriversthatwilloperatethemachine.

WARNING

Avoidinjury!

Makesuredecalsareperfectlylegible.Cleandecalsregularly.Replacealldamaged,missing,painted

over,orillegibledecals.Seeyourdealerforreplacementdecals.Whenreplacingpartsbearingdecals,

besuretoputnewdecalsoneachnewpart.

Failuretocomplycouldresultindeathorseriousinjury .

W0229A

DCSPFNAGB001S2D1

2-16

2-SAFETYINFORMATION

(A)

Positionedinseveralplacesonthetractor

GeneralWarning:Readandunderstandallthewarning

notesprintedinthisOperator'sManualwithregardstothe

relevantpartwherethedecalisapplied.

(B)

Positionedinseveralplacesonthetractor

GeneralWarning:dangerduetomechanicalmoving

parts.

(1)

Location:internalportionoftheconveyor:

Air−conditioningsystemwarning.

(2)

Location:lefthandsideonthefanshield.

Toavoidseriousinjury,keephandsandclothingaway

fromtherotatingfan,beltsandanyotherrotatingparts.

(3)

Location:lefthandsideonthecabwindow.

Donotclimbontothetankoruseitasastep,itisnot

designedtosustainweight.

(4)

Location:right-handsideofbrakesystemuidcontainer.

Tokeepthebrakingsystemingoodworkingorder,refer

totheUseandMaintenanceManual.Iftheredwarning

lightontheinstrumentpanelilluminates,thereisafaultin

thebrakingsystem.

(5)

Location:Frontontheradiator.

Pressurisedcoolingsystem.Leavetocoolandthencarefullytakeoffthecap.Useaclothtoslowlyunscrewthe

capandreleasethepressurebeforecompletelyremoving

thecap..

(6)

Location:Insidecabonright-handsidewindow.

DCSPVNAGB006S2D2

2-17

2-SAFETYINFORMATION

(7)

Location:Ontheintakemanifold.

Donotuseetheronthecoolingsystem.

(8)

Location:Right-handsideonthestartermotor.

(9)

Location:right-handsideontheradiator.

Toavoidseriousinjury,keephandsandclothingaway

fromtherotatingfan,beltsandanyotherrotatingparts.

(10)

Location:Ontheinternalpartoftheleft−handrearfender:

donotoperateonthepowertake-offwiththeenginerunning.

(11)

Location:Ontheinsideoftheright−handfender.

(12)(13)

Location:Appliedatthefrontonthebattery .

(14)

Location:rearpartonthemudapsoftherightandlefthandmudguardwithelectronicliftandonfrontpart.

Topreventinjury,donotstandontheimplementorbetweentheimplementandthetractorwhiletheexternallift

controlsareinuse.

(15)

Location:undertheupperuprightoftherollbar.

(16)

Location:frontpart.Danger!Topreventinjury,donot

standclosetorotatingmechanicalparts.

DCSPFNAGB002S2D3

2-18

3-CONTROLS/INSTRUMENTS

3-CONTROLS/INSTRUMENTS###_3_###

ACCESSTOOPERATOR'SPLA TFORM

Cab

WARNING

Misusehazard!

Thecabisanintegralpartofthemachine'sstructure.DONOTrepair,weld,orstraightenthecab.

ContactyourDealerandfollowtheirinstructionstoavoidreducingthestructuralintegrityofthemachine.

Failuretocomplycouldresultindeathorseriousinjury .

Thecabhasbeendesignedforoperatorcomfortandconvenience.Inside,thesidetrimpanels,roofandoorare

insulatedtoreducenoisetoaminimum.Thecabisavailableintwoversions:

-Withheatingandventilation.

-Withairconditioning.

Thecabmustbereplacedintheeventofoverturning.

Alltheinternalparts,suchasthedriverseat,includinganyseatbeltssuppliedonrequest,mustbecarefullychecked

andmustshownosignofanydamagewhatsoever.

Alldamagedpartsmustbereplaced.

W0045B

Openingdoorsfromoutside

Withthedoorunlocked,pressbutton(1)andpullthedoor

towardsyou.

Bothopeningbuttons(1)areequippedwithalockforlock-

ingbothcabdoors.

Openingdoorsfrominside

Pullthelever(1)towardsyourself.

Whenpresseddownwards,theleverisheldbyamechanicalcatchthatpreventsopeningthedoorfromtheoutside.

MOIL13TR00490AA1

MOIL13TR00491AA2

3-1

3-CONTROLS/INSTRUMENTS

OpeningFrontWindscreen

Toopen,pullhandle(1)upwardsandpushforward.The

windowwillbeheldinpositionbyspecialstruts.

RearWindow

Toopen,pullhandle(1)upwardsandpushforward.The

windowwillbeheldinpositionbyspecialstruts.

MOIL13TR00492AA3

Windscreenwasherspraynozzle

Forbetterwindscreencleaning,adjusttheangleofthe

spraynozzle(1)usingascrewdriver.Iftheoriceofthe

spraynozzleisobstructed,clearitwithapin.

Sunshade

Pullthetabofthesunblinddowntoopenit,asindicated

bythearrowinthegure.Torewindthesunblind,press

button(1).

MOIL13TR00493AA4

MOIL13TR00495AA5

MOIL13TR00547AA6

3-2

3-CONTROLS/INSTRUMENTS

Rearviewmirrorexternal

Themirrorcanbeadjustedintwoways,asdescribed

below:

turnthesupportbracket(1)onitsaxistoadjustthean-

•

gleofthemirror;

turnthemirror(2)intothepositionthatprovidesthebest

•

rearview.

Interiorcablight

Theceilinglightsunitcomprisesacourtesylight(1)anda

readinglight(2),botharepoweredwiththekeyon.

Theinternallightsarecontrolledbyathree-position

switch:

A=courtesylight(1)on

•

centralposition=lightsOFF

•

B=courtesylight(1)offandreadinglight(2)on.

•

MOIL13TR00494AA7

MOIL13TR00496AA8

3-3

3-CONTROLS/INSTRUMENTS

Heatingsystem

Adjustablevents

Ontheroofinsidethecabtherearefouradjustablevents

(1).Theventscanbeadjustedindependentlytodirecthot

orcoldaironthewindscreenandsidewindowsinsidethe

cab.T oopen,pressononesideandturntheventtodirect

theairowwhererequired.

Airre-circulationvents

Airmaybeselectedfrominsideoroutsidethecabby

adjustingthesiderecirculationvents(1)whichcanbe

placedintwopositions:

Ventsclosed:airisdrawnfromoutsidethecabthrough

•

thelaterallters.Freshairdrawnintothecabfrom

outsideisalwaysltered.

Ventsopen:thegreaterpartoftheairisdrawnfrom

•

insidetheairthroughthevents.

MOIL13TR00497AA1

NOTE:Withthefaninoperationanddoors,windows,and

recirculationventsclosed,thepressureinsidethecabis

greaterthantheexternalpressure.Consequently ,aircan

onlyenterthecabthroughthelaterallters,aftersuitable

ltering.

Ventilationandheating

Byturningthetemperatureadjustmentknob(1)counter

clock-wise(fullytotheleft),thecirculationofhotairinthe

cabisinterrupted;byturningtheknobclockwise(fullyto

theright),maximumcabairtemperatureisselected.With

theelectricfan(2)ispossiblechangethequantityofair

leavingbytheadjustablevents.

Theelectricfanswitchispoweredupwhenthestarterkey

isONposition.

AElectricfanOFF.

BLowspeed.

CMediumspeed.

DHighspeed.

MOIL13TR00498AA2

MOIL13TR00499AA3

3-4

3-CONTROLS/INSTRUMENTS

Heating,ventilationorair-conditioningcontrol

Theair-conditioningsystemcansupplyeithercoolor

warmdehumidiedair.

Tousethesystem,proceedasfollows.

NOTICE:Whentheengineisnotrunning,theairconditionerwillnotworkbecausethecompressorisdrivenby

theengine.

Starting

WiththeenginerunningandtheelectricfanON,turnthe

knob(2)clockwisetostarttheairconditioner.

NOTE:Alwaysswitchtheelectricfanonbeforetheair

conditioning.Theairconditioningcannotworkwhenthe

electricfanisoff.

Afterrunningforafewminutes,theinspectionglasson

thetopofthedehydratingltershouldbeclearandnot

containanybubbles.

Ifthisdoesnotoccur,switchofftheair-conditioningand

seekspecialisthelpatyourdealer.

Adjustment

Foracorrectlyairconditionedcab,openthere-circulation

ventswhentheairconditioningisrunning,andkeepthe

doors,roofandrearwindowclosed.Tolowerthetemperatureinthecaband,atthesametime,reducetheair

humidity,turntheknob(3)counter-clockwiseuntilthede-

siredtemperatureisobtained.

fromenteringthecab;itisalsoadvisedtoclosethere-circulationvents.

Ifonlythedehumidicationfunctionontheairconditioning

systemisrequired,withoutloweringtheairtemperature,

turntheknob(3)clockwiseuntilthedesiredtemperature

isobtained.

Torestorethetemperatureinthecabafteraprolonged

haltinthesun,startthetractor,switchontheairconditioningandafteraboutaminuteopentherearfanlightor

therooftoletthehotairescape.

Stopping

Beforestoppingtheengine,alwaysturntheelectricfan

knob(1)andtheair-conditionerknob(2)anticlockwise

intotheOFFposition.

NOTICE:Beforestartingtheengine,checkthattheair

conditioningisOFF .

NOTE:Whenworkinginverydustyenvironments,the

cabpressuremayhavetobeincreasedtopreventdust

MOIL13TR00469AA1

3-5

3-CONTROLS/INSTRUMENTS

Cabairconditioningcontrols

MOIL13TR00469AA2

3-speedelectricfancontrolknob(1)

Thefanoperateswiththeignitionkeyinthestartingposition.

ALowspeed.

BMediumspeed.

CHighspeed.

Airconditioningandtemperaturecontrol

knob(2)

Annualmaintenance

Atthestartoftheseason,havethespecialistpersonnel

fromtheNEWHOLLANDservicenetworkcarryoutthe

followingoperations:

Checktheoillevelinthecompressor

•

Checksystempressureand,ifnecessary,llthesys-

•

temwithHFCR134A

Draintheairconditioningsystemandreplacethede-

•

hydrationlter,onlyifstrictlynecessary.

FillthesystemwithHFCR134A

•

Checkoperationofsystem.

•

SPECIFICATIONS

CoolantHFCR134A

Quantity1.2 kg(2.6 lb)

CompressorSANDENSD-5H11-

6332

Numberofcylinders

Capacity155 cm³(9.5 in³)

OiltypeSANDENSP20

Quantityofoil180 g(6.3 oz)

5

Thesystemoperateswiththeignitionkeyswitchedon.

Withtheelectricfanknob(1)inpositionsA-BorC,turn

theknob(2)clockwiseandpasstherstclicktoturnon

theair-conditioner.Tolowerthetemperatureoftheair

comingintothecab,turntheknob(2)clockwise.

Heatercontrolknob(3)

Turnknob(3)fullyclockwise(totheright)formaximum

heat.Toshutoffthewatersupplytotheheaterandswitch

offtheheater,turntheknob(3)fullycounter-clockwise.

Periodicalinspections

Atleastonceeverythreemonths:

Removeanyforeignmatterfromthecondenserand

•

evaporatorns.

Checkthetensionofthecompressorbelt.

•

Checktheconditionofthetubing,connectionsand

•

mountingbrackets.