New Holland BB9OOO, BB9O8O, BB9O6O User Manual

NEW HOLLAND BB9OOO

BB9O6O BB9O8O

WORLD-WIDE LEADERSHIP IS NOT A COINCIDENCE

New Holland has played a dominant role in the big square

bale revolution from the start. Together with industry partners

New Holland was responsible for some of the major product

and feature introductions. This shared expertise is the basis for

the world-wide success of the uncontested leader on the big

baler market. Large farmers and contractors have given their

confidence to the brand and that confidence was awarded,

model after model.

PROVEN HERITAGE

4

8

10

14

16

BALING EXCELLENCE

SUPERIOR CHOPPING

COMFORT AND CONVENIENCE

RELIABILITY AND QUALITY

SPECIFICATIONS

BB9060

BB9080

THE HIGH PERFORMANCE FARMING

AND CONTRACTOR BUSINESS

Two models of big balers combining bale widths of

80 or 120 cm and bale height of 90 cm, represent the

largest portion of the big baler market. These different

bale sections not only result in different package volumes,

but also allow perfect adapting to any handling system

and storage situation. The two new models described

in this leaflet are a development of an extremely

successful and proven range of big balers.

Bale dimension (cm) BB9060 BB9080

Width 80 120

Height 90 90

Length 250 250

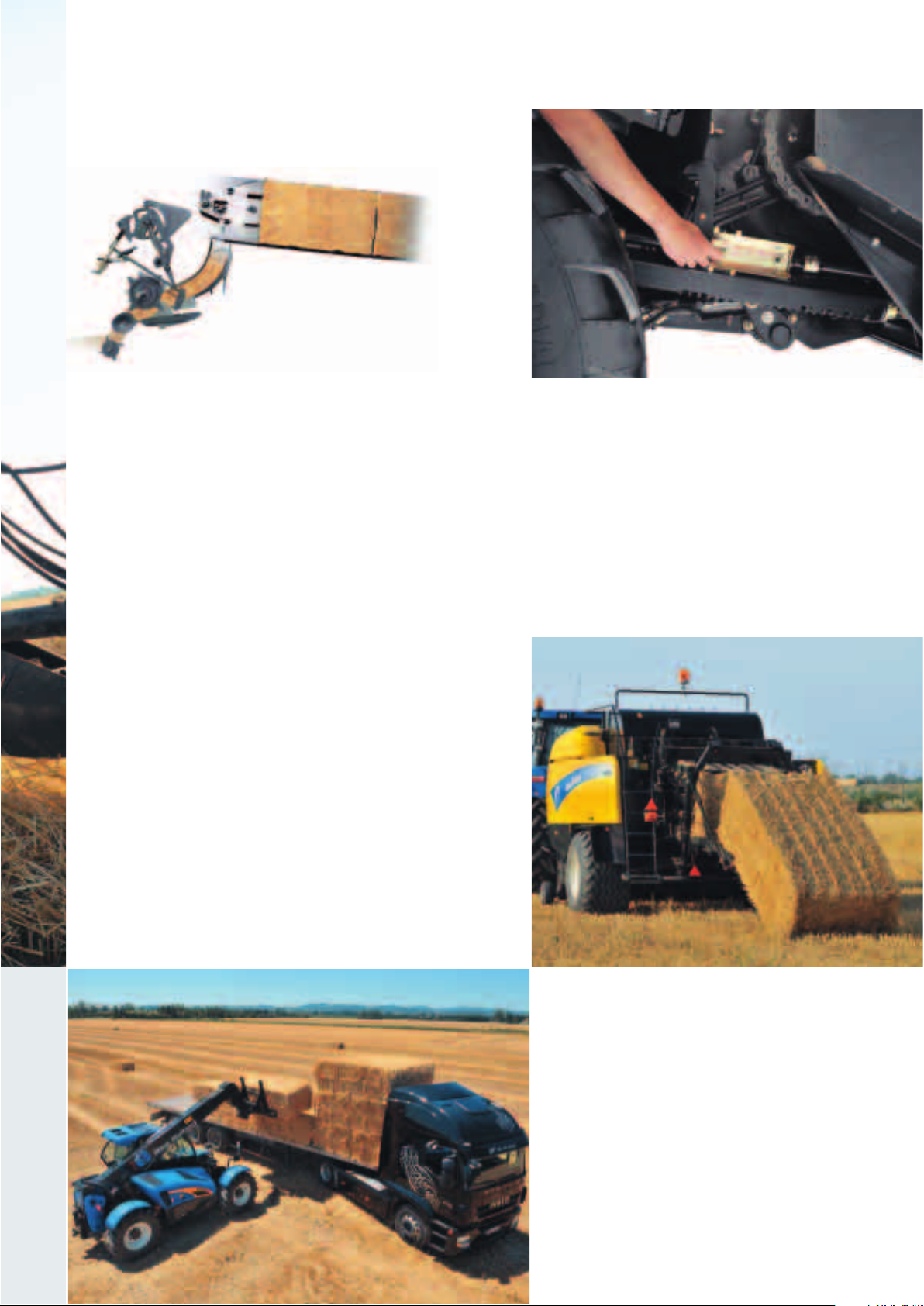

Even the shortest piece of straw or the smallest dry leaf

of valuable hay is taken up by the Super Sweep™ pick-up.

Proven characteristics like curved tines and close tine spacing

combined with an efficient wind-guard and pneumatic gauge

wheels help to sweep fields clean at a high speed.

TAKE ALL THE CROP

BALING EXCELLENCE45

BALES FORMED THE RIGHT WAY

The stuffer forks that lift the crop from the

pre-compression chamber to the bale chamber

only operate when the trip sensor fingers indicate

that the required density has been reached.

This assures a consistent bale density wad

after wad. This quality of a big bale is highly

appreciated when it is opened for bedding

or feeding.

EXCELLENT FIELD BEHAVIOUR

For a smooth field operation, the

Super Sweep™ pick-up mounting

includes an adjustable flotation spring.

Adjusting the flotation range is quick

and simple and doesn’t require the

use of any tools.

CONSISTENTLY FIRM PACKAGES

MAKE A PERFECT STACK

An extremely consistent density management

system that is monitored by IntelliView III™

monitoring systems, constantly measures the

load on the plunger sensors.

Any change in that load or any change of

the density requirement results in an automatic

adjustment of the hydraulic pressure on the side

doors and top chamber rail. Each and every

bale will be exactly made the way you want it!

SQUARE CORNERS, EQUALLY FILLED

As the stuffer fork moves the pre-compressed

crop into the bale chamber, its speed is increasing.

This “fine tuning” of the bale formation process,

introduced on the new BB9000 models, further

assures a perfect filling of the top corners of the

bale, whether it be working in straw, hay or silage.

Loading...

Loading...