Page 1

en

enVersion 1.0

Service Manual Coffee Machine

Essenza

EF 347 / C99

Essenza

EF 348 / D99

Page 2

2

Service Manual EF 347 / EF 348 enVersion 1.0

Contents

Preface______________________________________________ 3

General _____________________________________________ 3

Nespresso technical website_____________________________ 3

Content updates ______________________________________ 3

General Safety Notes ________________________________ 4

Main Components ___________________________________ 5

Overview ____________________________________________ 5

Overview of rating plates________________________________ 6

Rating Plates - Essenza machine partners __________________ 7

Water circuit _________________________________________ 8

Tech nical D ata _______________________________________ 9

Operation __________________________________________ 10

Making coffee _______________________________________ 10

Programming the water system__________________________ 11

Emptying the water system _____________________________ 12

Energy saving mode __________________________________ 13

Reset to factory settings _______________________________ 14

Coffee machine status (1) ______________________________ 15

Coffee machine status (2) ______________________________ 16

Troubleshooting____________________________________ 17

Check Machine on receipt______________________________ 17

Repair______________________________________________ 20

Safety instructions ____________________________________ 20

General disassembly__________________________________ 21

Replacing NTC ______________________________________ 22

Replacing thermoblock ________________________________ 23

Replacing pump______________________________________ 24

Replacing electronic control board with button prints _________ 25

Replacing compact brewing unit _________________________ 26

Wiring diagram 220V - 240V IEC_________________________ 27

Wiring diagram 120V - 127V IEC_________________________ 28

Function Tests______________________________________ 29

Safety instructions ____________________________________ 29

Measuring flow rate (1) ________________________________ 30

Measuring flow rate (2) ________________________________ 31

Checking for leaks and pump pressure (1) _________________ 32

Checking for leaks and pump pressure (2) _________________ 33

Measuring coffee temperature___________________________ 34

Protective earth continuity test (1) ________________________ 35

Protective earth continuity test (2) ________________________ 36

Protective insulation test (1) ____________________________ 37

Protective insulation test (2) ____________________________ 38

Protective insulation test (3) ____________________________ 39

Maintenance________________________________________ 40

Descaling (1) ________________________________________ 40

Descaling (2) ________________________________________ 41

Spare Parts _________________________________________ 42

Repair accessories ___________________________________ 42

Spare parts EF 347 / C99 ______________________________ 43

Spare parts EF 348 / D99 ______________________________ 46

Page 3

3

Service Manual EF 347 / EF 348 enVersion 1.0

Preface

General

The purpose of this service manual is to

provide the service personnel with all necessary information with regards to correct

handling, maintenance and repair of the coffee

machines EF 347 and EF 348.

This manual should be used by the technicians as a valuable aid to guarantee the

permanent readiness for use of the machine.

In order to take full advantage of all the functions, it is absolutely necessary to follow the

instructions in this manual.

Nespresso technical website

Visit the Nespresso technical website periodically to check for upgrades, technical modifications, counter measures etc. for this coffee

machine: https://business.nespresso.com

Access is restricted and can be

obtained by asking your Nespresso

technical contact person.

Please keep this manual together with the

corresponding service documentation. This

way you are assured to have the necessary

information.

Content updates

The version number of this service

manual is printed on the lower right

corner of the page.

Version 1.0

First released service manual version.

Page 4

4

Service Manual EF 347 / EF 348 enVersion 1.0

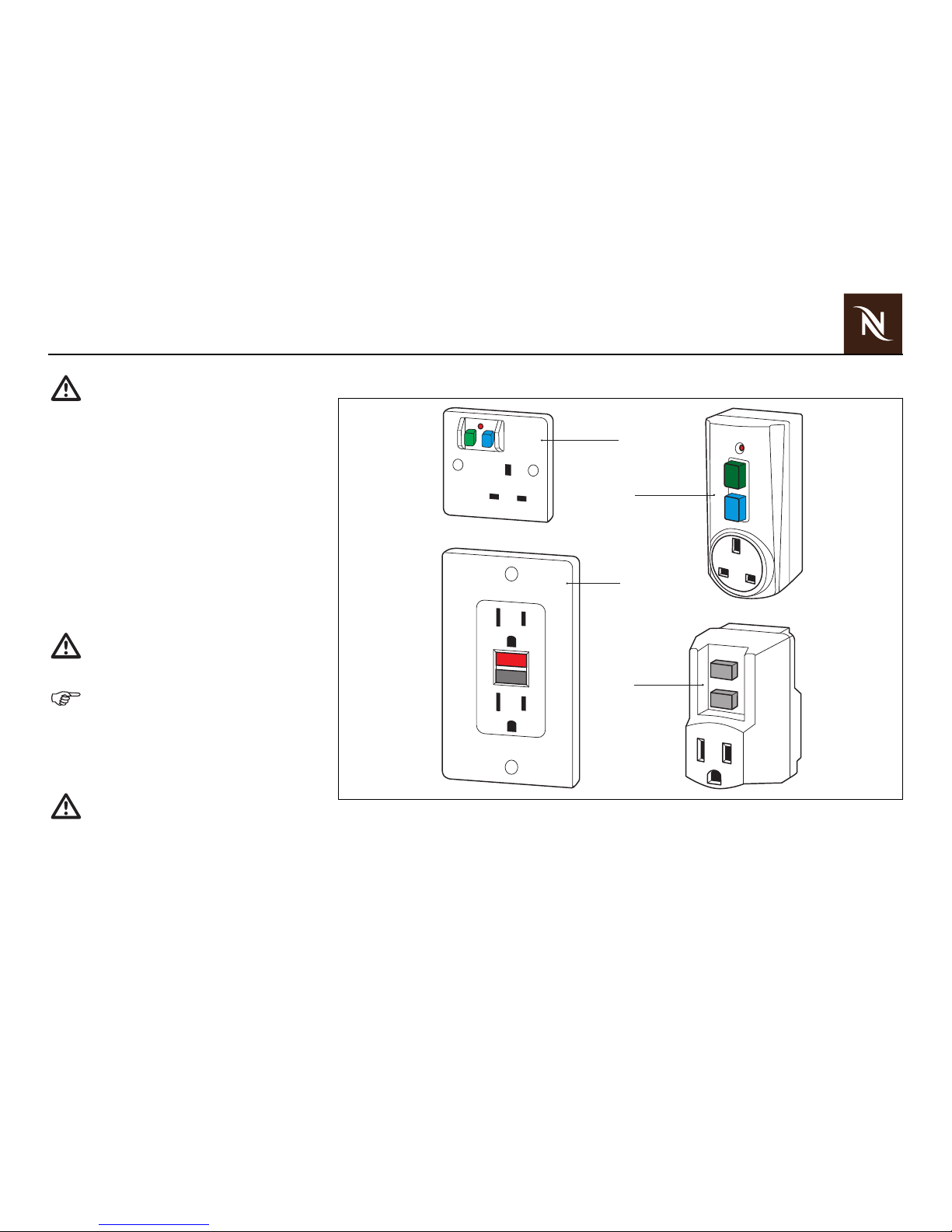

General Safety Notes

Risk of fatal electrical shock and fire!

Mains voltage inside the coffee

machine.

• Unplug appliance before cleaning.

• Never clean wet or immerse plug,

cord or appliance in any fluid.

• Disconnect the mains plug before

disassembly - the appliance must be

free of voltage.

As an additional safety measure, the use of a

residual current device (RCD), also called a

ground fault circuit interrupter (GFCI), in the

repair centre is highly recommended.

This device does not protect against

electrical shock due to contact with

both circuit conductors.

Use a GFCI with a trip level of 4 - 6 mA

(USA) resp. a RCD with a trip level of

15 - 30 mA (Europe). A trip level

above 30 mA provides only very

limited protection against harm from

an electric shock.

Danger of burns!

Hot parts and water under pressure

inside the coffee machine (particularly in the thermoblock).

• Let coffee machine cool down before

cleaning or disassembly.

Example illustrations of typical devices:

1) RCD protected socket-outlet

2) Plug-in RCD unit

3) GFCI socket

4) Plug-in GFCI

1

2

RESET

TEST

RESET

TEST

3

4

Page 5

5

Service Manual EF 347 / EF 348 enVersion 1.0

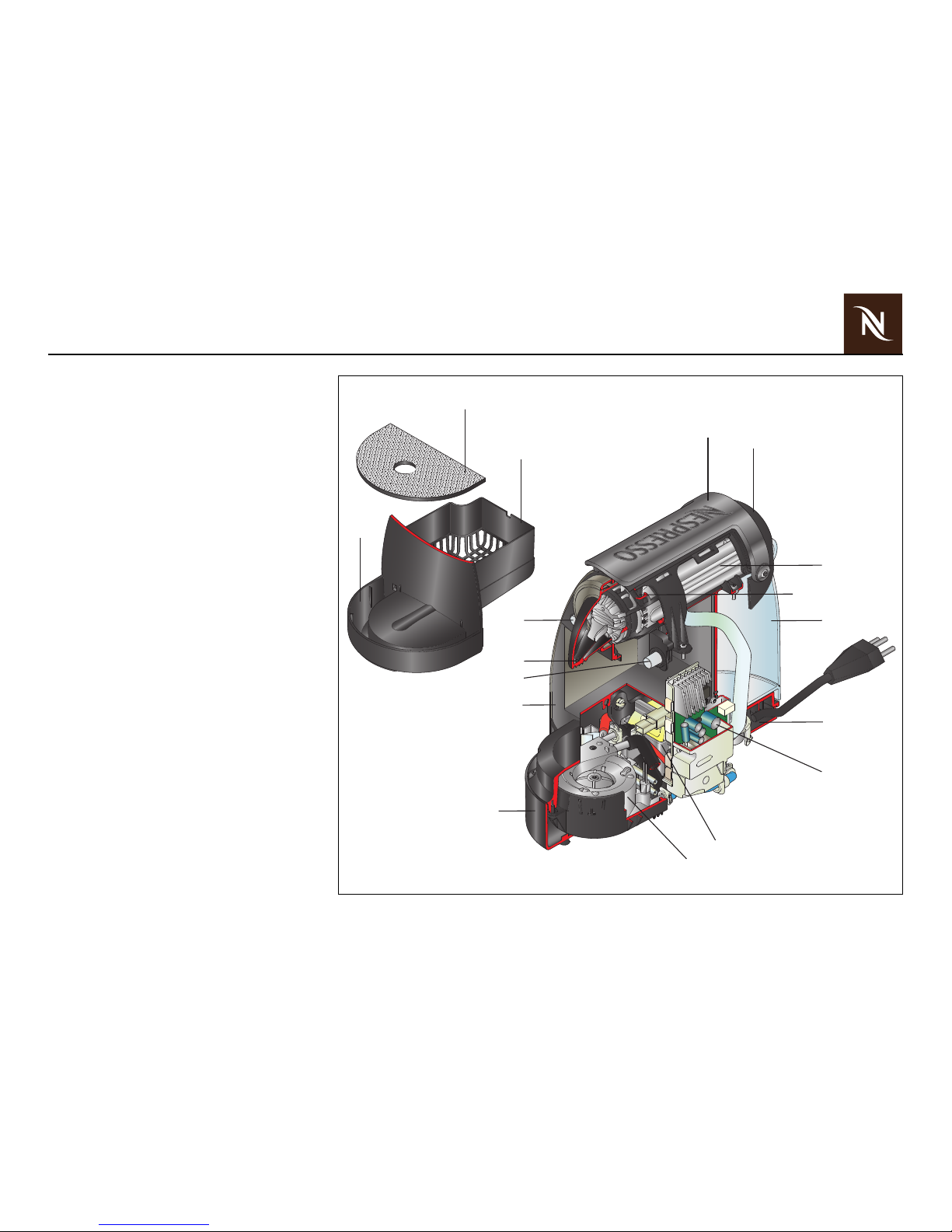

Main Components

Overview

1) Closing handle

2) Cover

3) Compact brewing unit (TCBU)

4) Capsule inlet

5) Side panel

6) Espresso button, back lighted

7) Coffee outlet

8) Lungo button, back lighted

9) Container for used capsules

10) Drip grid

11) Drip tray

12) Lower chassis

13) Thermoblock

14) Electronic control board

15) Pump

16) Upper chassis

17) Water tank

10

1

2

9

11

3

4

12

8

5

13

7

17

14

15

16

6

Page 6

6

Main Components

Service Manual EF 347 / EF 348 enVersion 1.0

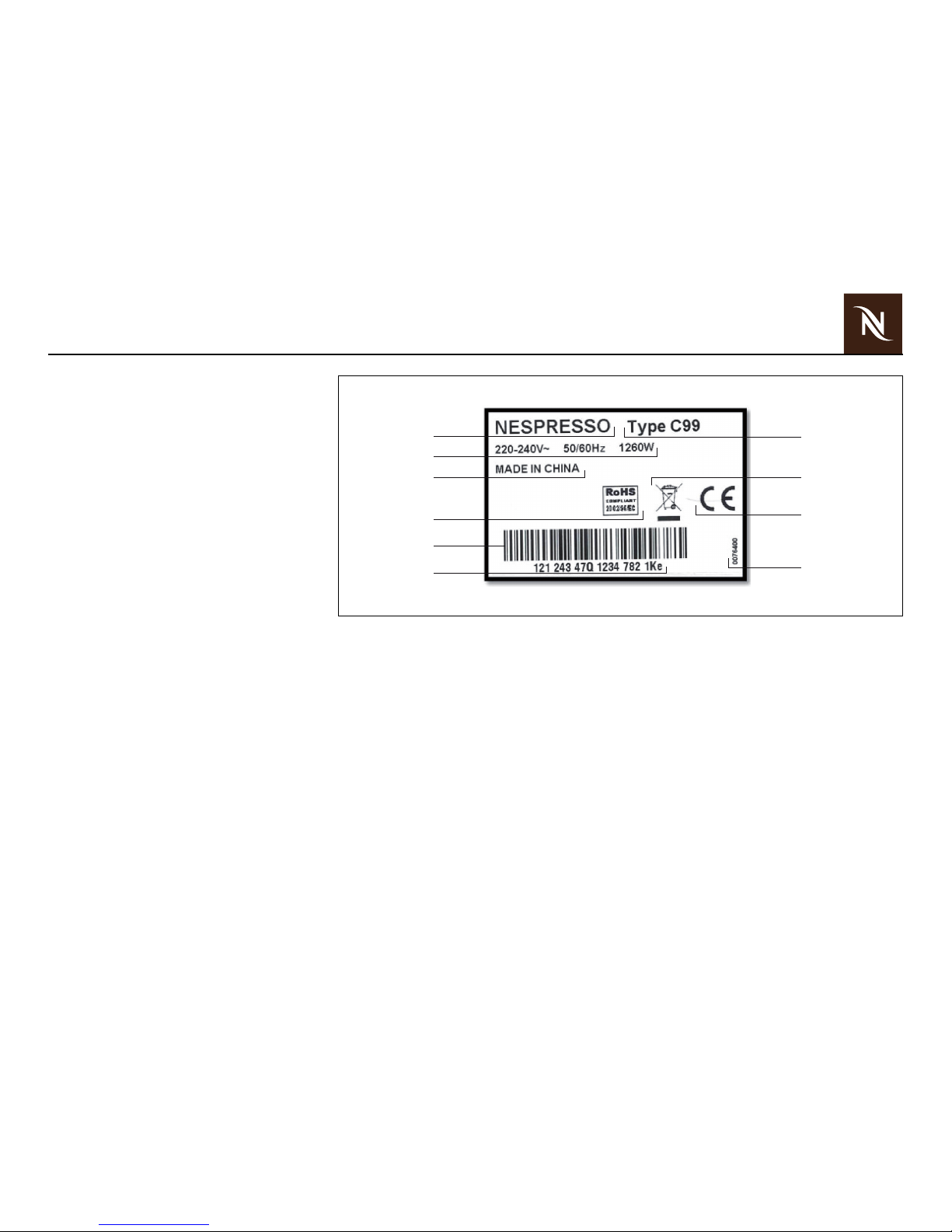

Overview of rating plates

The rating plate can be found at the underside

of the coffee machine. It is of varying design

depending on the brand and carries the

following information:

1. Brand name

2. Voltage and power rating

3. Manufacturing country

4. Conformity with RoHS guidelines

5. Bar code

6. Serial number

7. Machine type

8. Special disposal icon

9. Sign of conformity (CE)

10. Article number of the rating plate

Serial number codification

Example: 121 243 47Q 1234 782 1Ke

12124

production date: 124th day of year 2012

347 machine type (EF no.)

Q production site

1234 incremental number per production day

7 machine partner codification

8voltage

2 mains plug version

1K colour version

e checksum number

1

2

3

5

6

7

8

4

9

10

Page 7

7

Main Components

Service Manual EF 347 / EF 348 enVersion 1.0

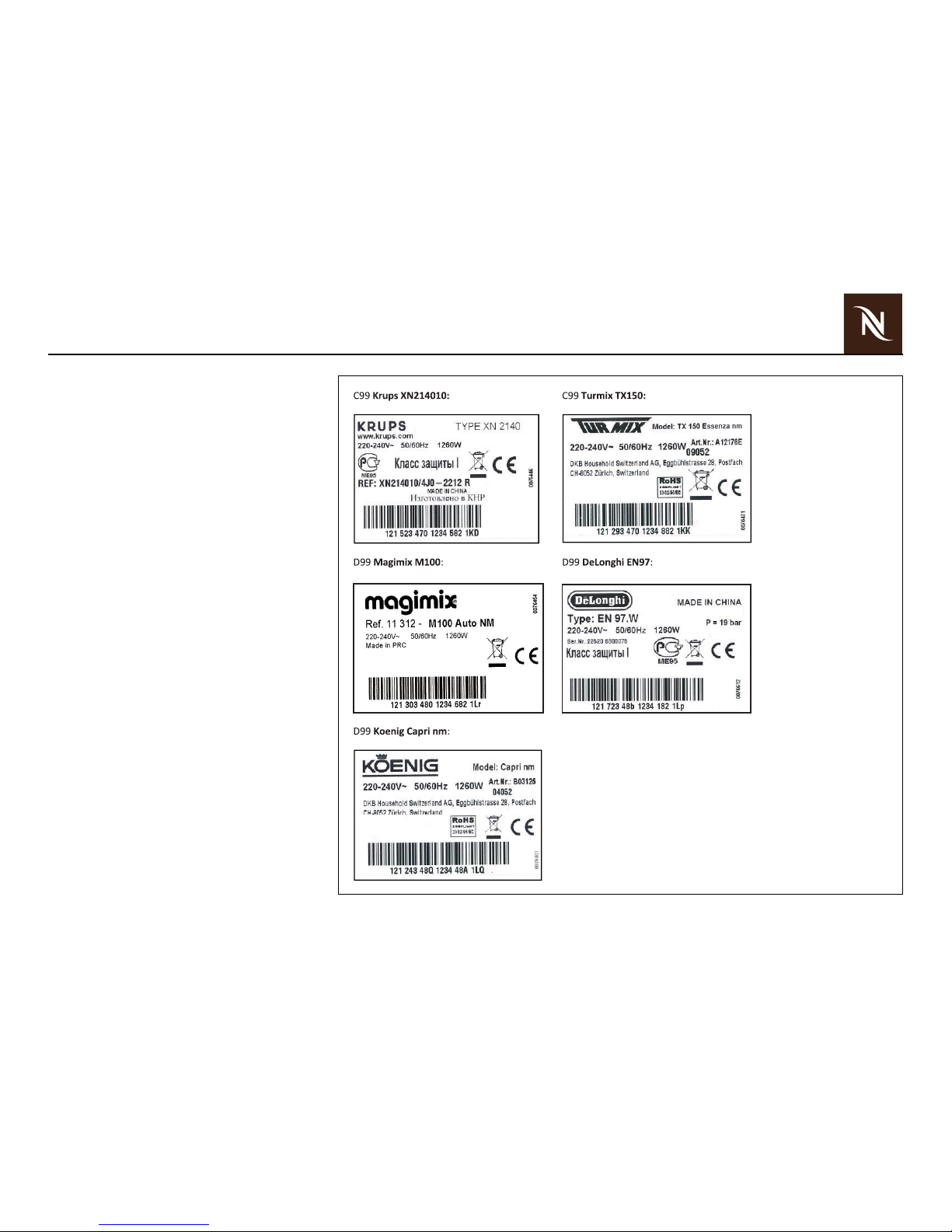

Rating Plates Essenza machine partners

Page 8

8

Main Components

Service Manual EF 347 / EF 348 enVersion 1.0

Water circuit

1) Water tank

2) Water tank valve and connector

3) Pump

4) Thermoblock

5) Flowmeter

6) Coffee outlet

7) Compact brewing unit (TCBU)

7

6

4

3

1

5

2

Page 9

9

Service Manual EF 347 / EF 348 enVersion 1.0

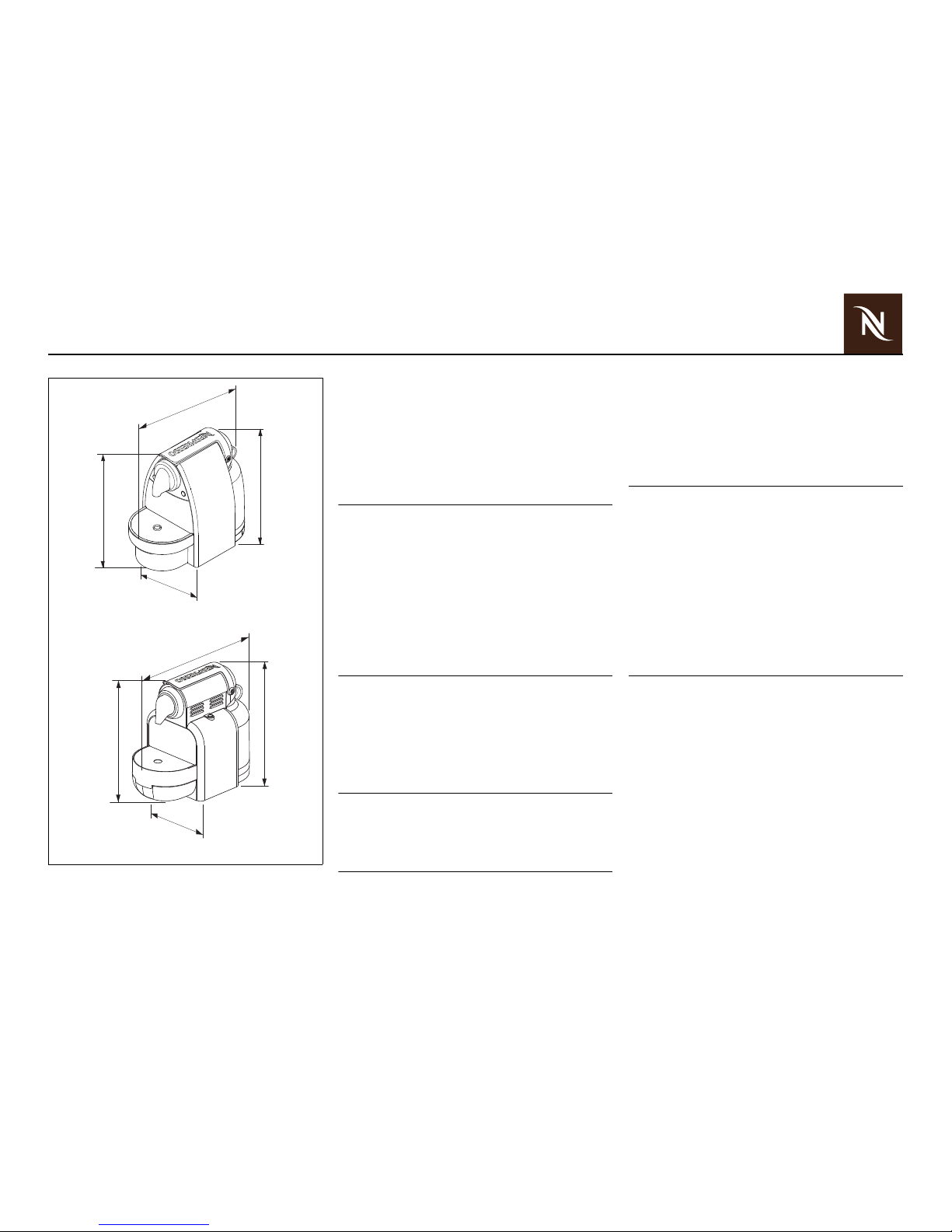

Technical Data

Mains

EUR 230V / 50 Hz

USA / CAN 120V / 60 Hz

Approvals SEV, CENELEC, CE-conform

UL, CUL, MITI

Cable length approx. 1.5 m

Pump data

Pump pressure

- max. permissible 17,5 bar ± 1,5 bar

- during coffee preparation 9 - 13 bar

(depending on brand of coffee)

Flow performance 120 - 240 ml/min. at 12 bar

Capacities

Water tank 0.9 l

Drip tray approx. 100 ml

Capsule container 10 - 14 pcs.

Power consumption

220 V / 240 V 1’260 W

Energy consumption

(CECED / FEA 2009 method)

Energy efficiency class level A - 40%

Daily energy consumption 63.8 Wh

Annual energy consumption 23.3 kWh

Various data

Pre-heating time approx. ~25 sec.

Storage temperature -25° C up to 60° C

Safety temperature (thermal cut-off) 167° C

Coffee temperature at outlet 86° C ± 3° C

Weight of machine approx. 3 kg

(without water)

166 mm

254 mm

291 mm

260mm

166 mm

254mm

291 mm

260mm

EF 347

EF 348

Page 10

10

Service Manual EF 347 / EF 348 enVersion 1.0

Operation

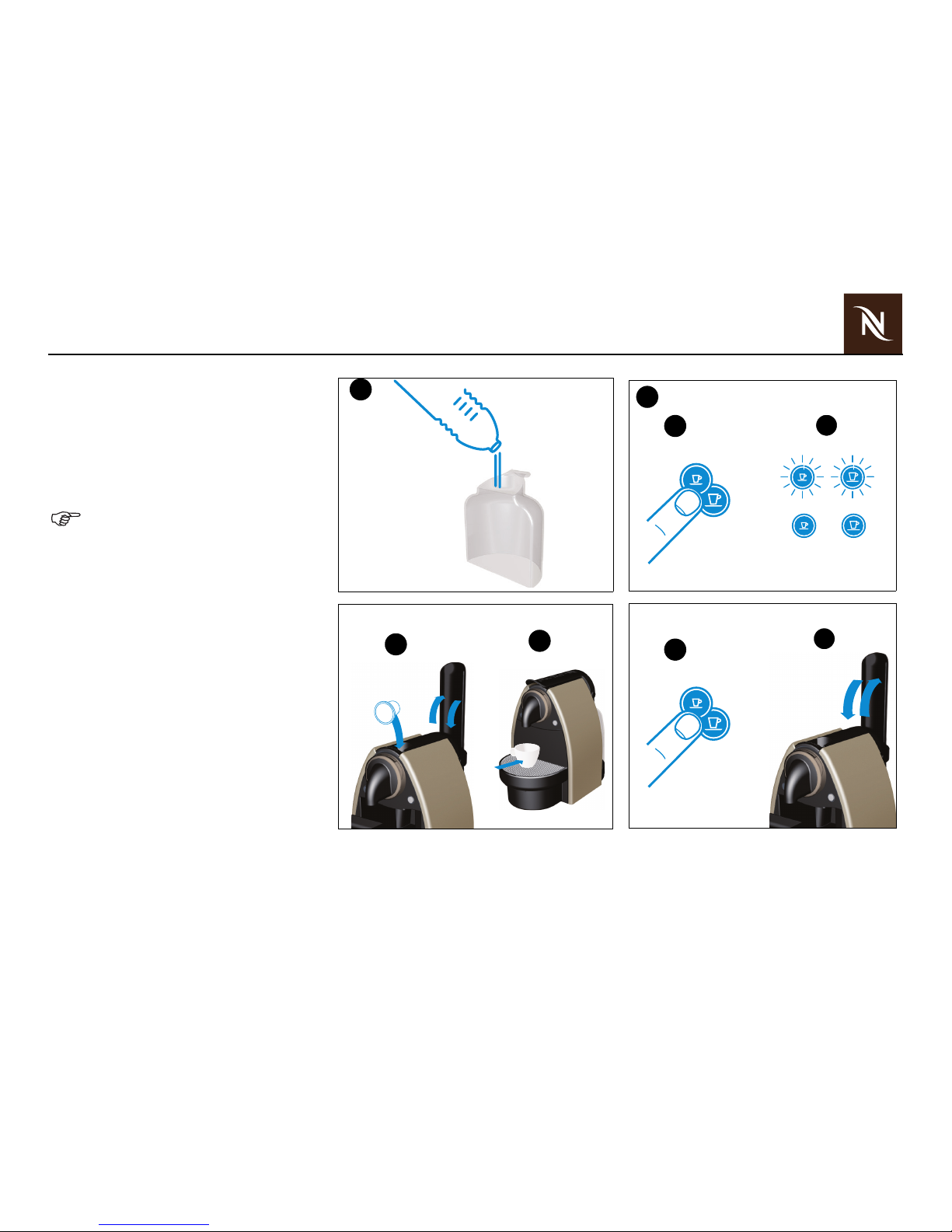

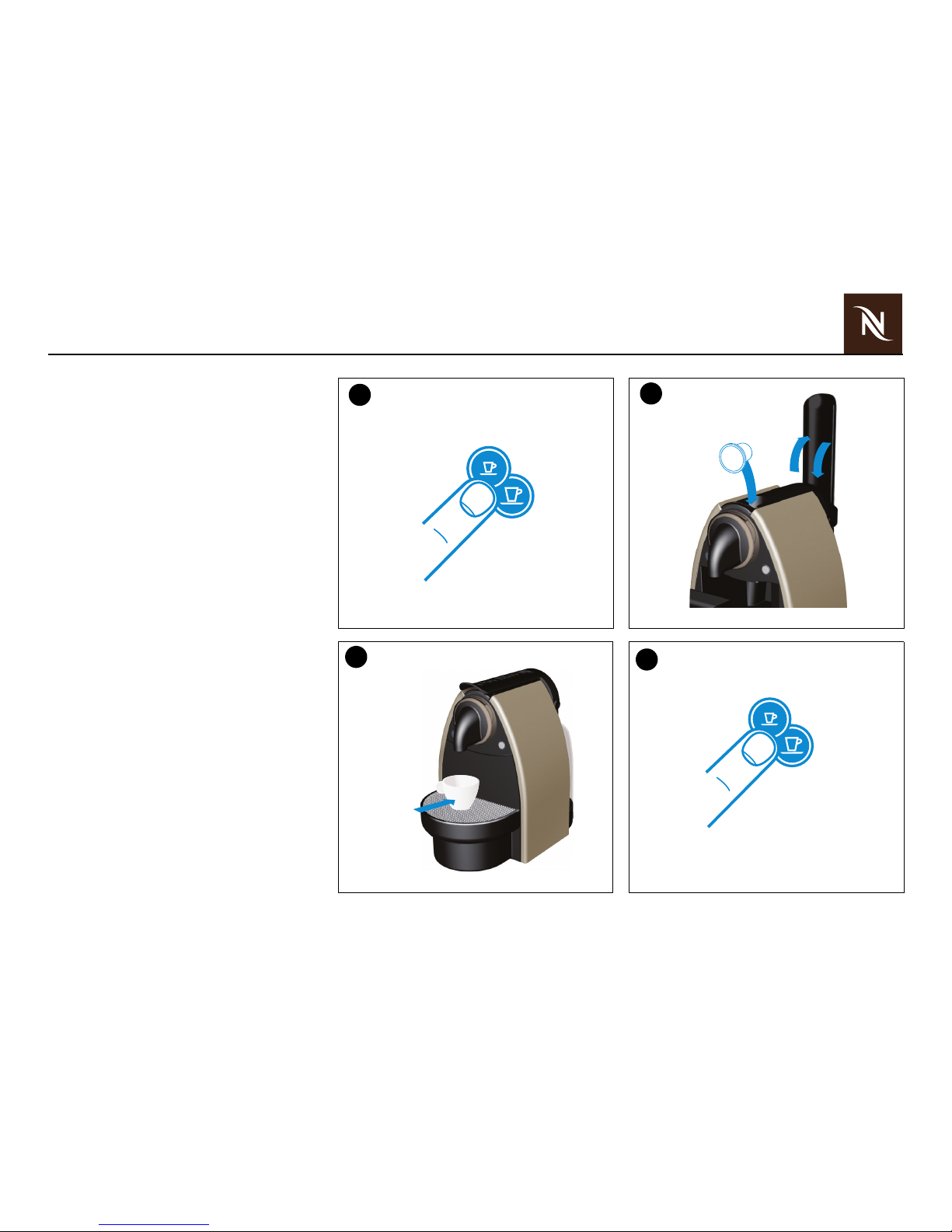

Making coffee

1. Rinse then fill the water tank with potable

water.

2. a) Press the Espresso or Lungo button to

activate the machine.

b) Blinking Lights: heating up (25 sec).

Steady Lights: ready.

Never lift lever during operation and

refer to the safety precautions to

avoid possible harm when operating

the appliance.

During heat up, you can press either

coffee button while blinking. The

coffee will then flow automatically

when the machine is ready.

3. Lift the lever completely and insert a

Nespresso capsule.

4. Close the lever and place a cup under the

coffee outlet.

5. Press the Espresso (40 ml) or the Lungo

(110 ml) button to start. Preparation will

stop automatically. To stop the coffee flow

or top up your coffee, press again.

6. Remove the cup. Lift and close the lever

to eject the capsule into the used capsule

container.

1

3

4

b

a

2

6

5

Page 11

11

Operation

Service Manual EF 347 / EF 348 enVersion 1.0

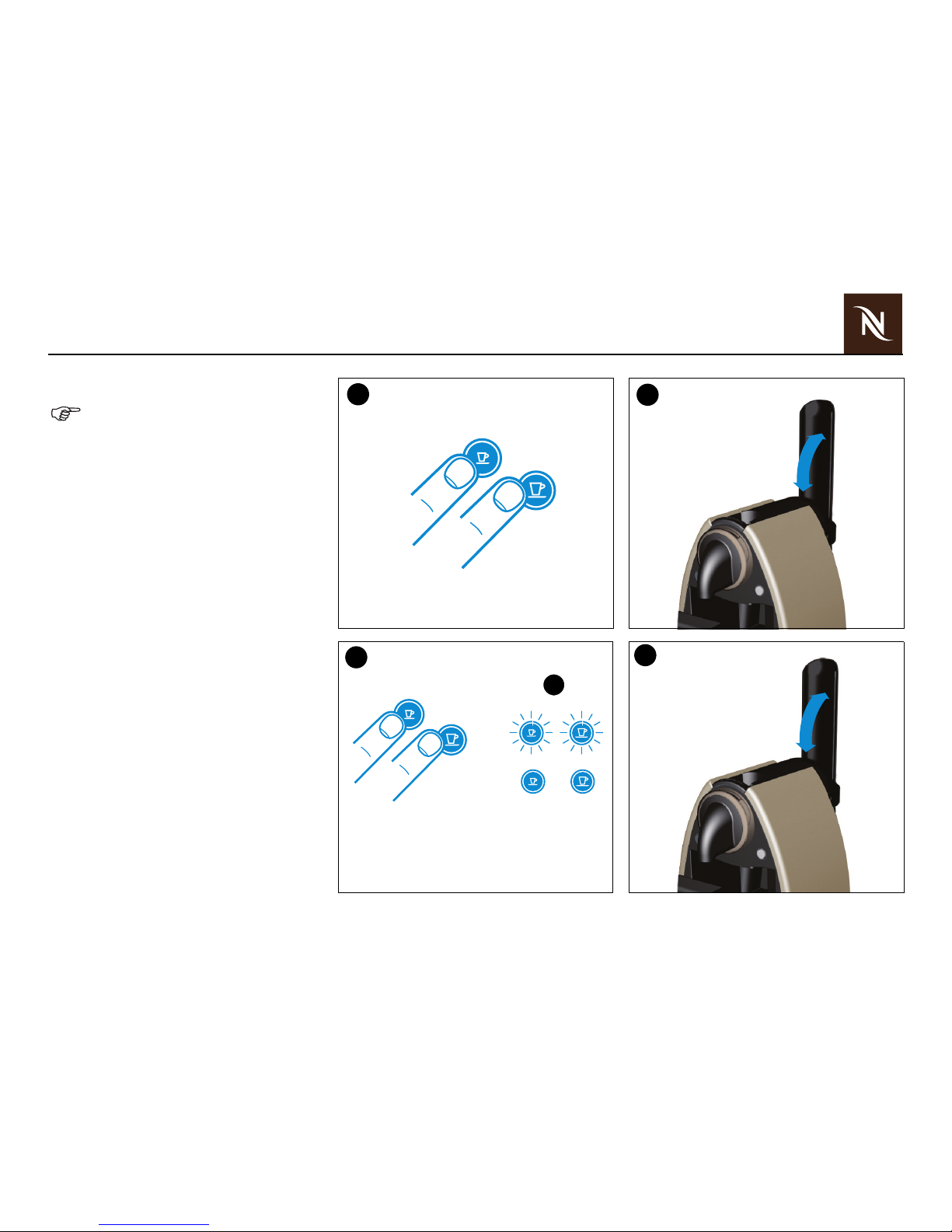

Programming the water system

1. Turn the machine on and wait for it to be

in ready mode (steady lights).

2. Fill the water tank with potable water and

insert a Nespresso capsule.

3. Place a cup under the coffee outlet.

4. Press and hold the Espresso or Lungo

button.

5. Release button once the desired volume

is served.

6. Water volume level is now stored.

1

3

2

4

Page 12

12

Operation

Service Manual EF 347 / EF 348 enVersion 1.0

Emptying the water system

The machine will be blocked for

10 minutes after emptying mode.

1. To enter the emptying mode, press both

the Espresso and Lungo button to turn the

machine off.

2. Remove the water tank and open the

lever.

3. Press both the Espresso and Lungo

button for 3 seconds.

a) Both LEDs blink alternatively.

4. Close the lever.

5. Machine switches off automatically.

6. Empty and clean the used capsule

container and drip tray.

1

a

3

2

4

Page 13

13

Operation

Service Manual EF 347 / EF 348 enVersion 1.0

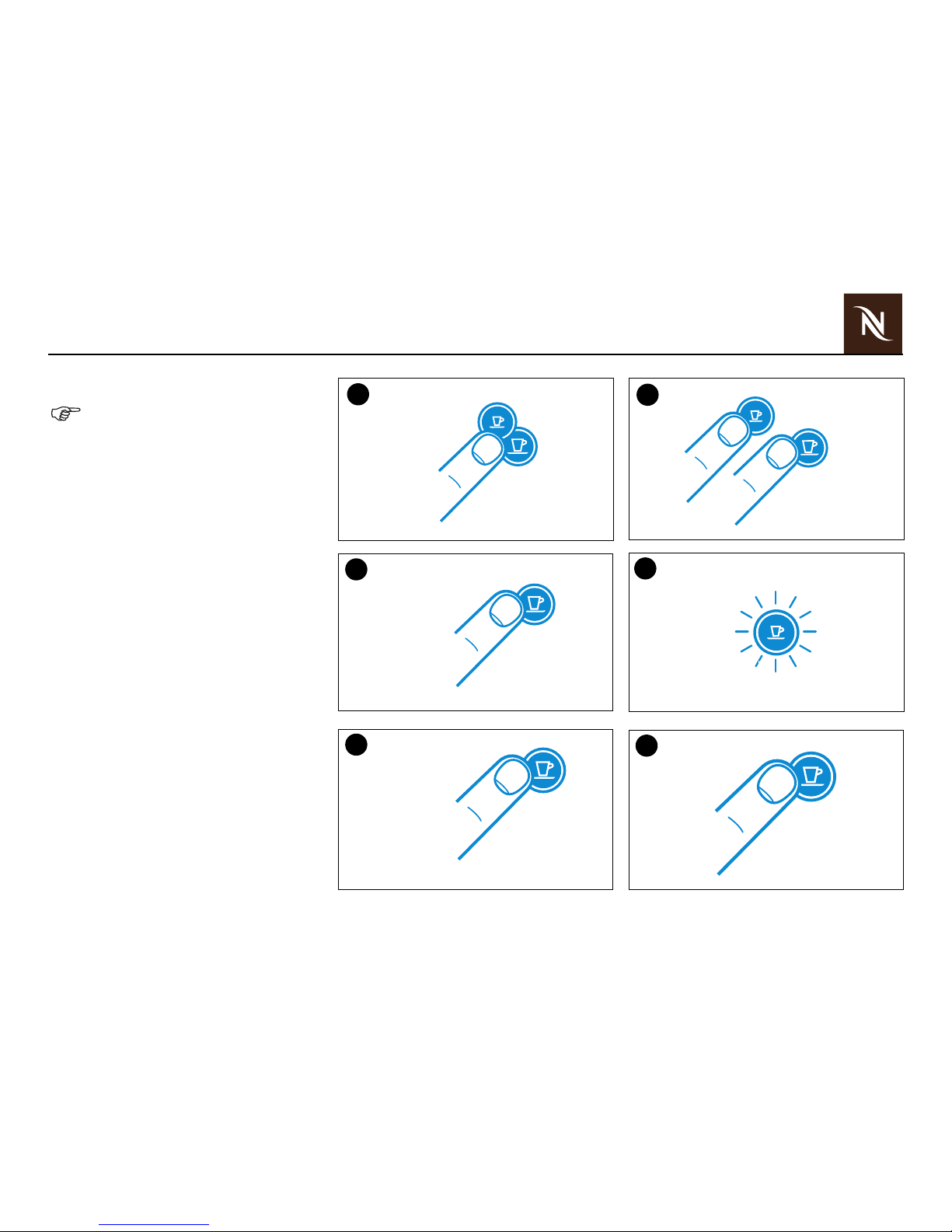

Energy saving mode

This machine is equipped with an

energy saving feature. The machine

will automatically enter power off

mode after 9 minutes.

1. To turn the machine on either press the

Espresso or Lungo button.

2. To turn the machine off before automatic

Power Off mode, press both the Espresso

and Lungo button simultaneously.

To change this setting

3. With machine being turned off, press and

hold the Espresso button for 3 seconds.

4. The Espresso button will blink to indicate

the current setting.

5. To change this setting press the Espresso

button:

One time for power off mode after

9 minutes

One more time for power off mode after

30 minutes

One more time to deactivate

6. To exit the energy saving mode press the

Lungo button for 3 seconds.

1

3

5

2

4

6

Page 14

14

Operation

Service Manual EF 347 / EF 348 enVersion 1.0

Reset to factory settings

1. With machine being turned off, press and

hold down the Lungo button for

5 seconds.

2. LEDS will blink fast 3 times to confirm

machine has been reset to factory

settings.

3. LEDs will then continue to blink normally,

as heating up, until ready. Steady lights:

machine ready

Factory settings:

Espresso Cup: 40 ml

Lungo cup: 110 ml

Power off mode: 9 min.

1

3

3x

2

Page 15

15

Operation

Service Manual EF 347 / EF 348 enVersion 1.0

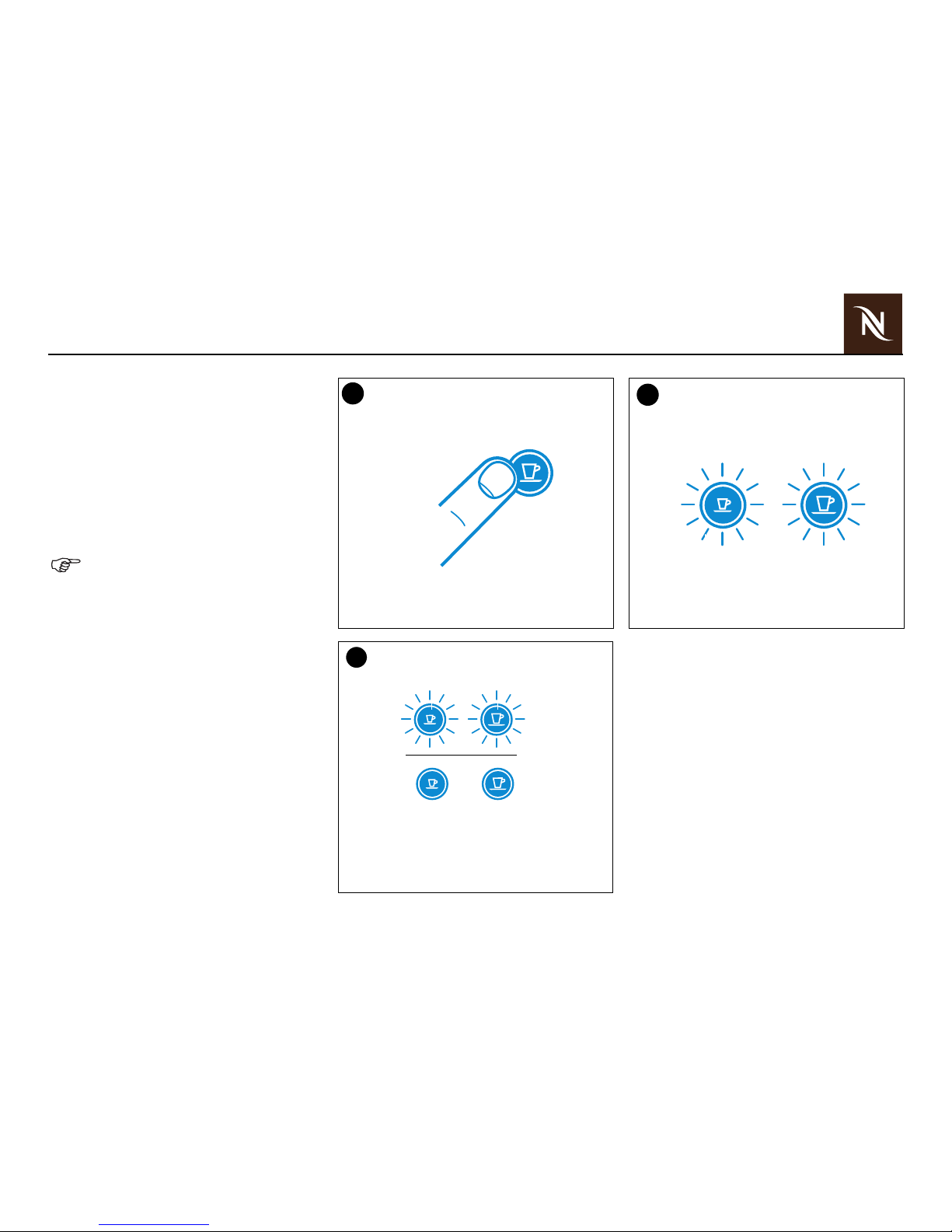

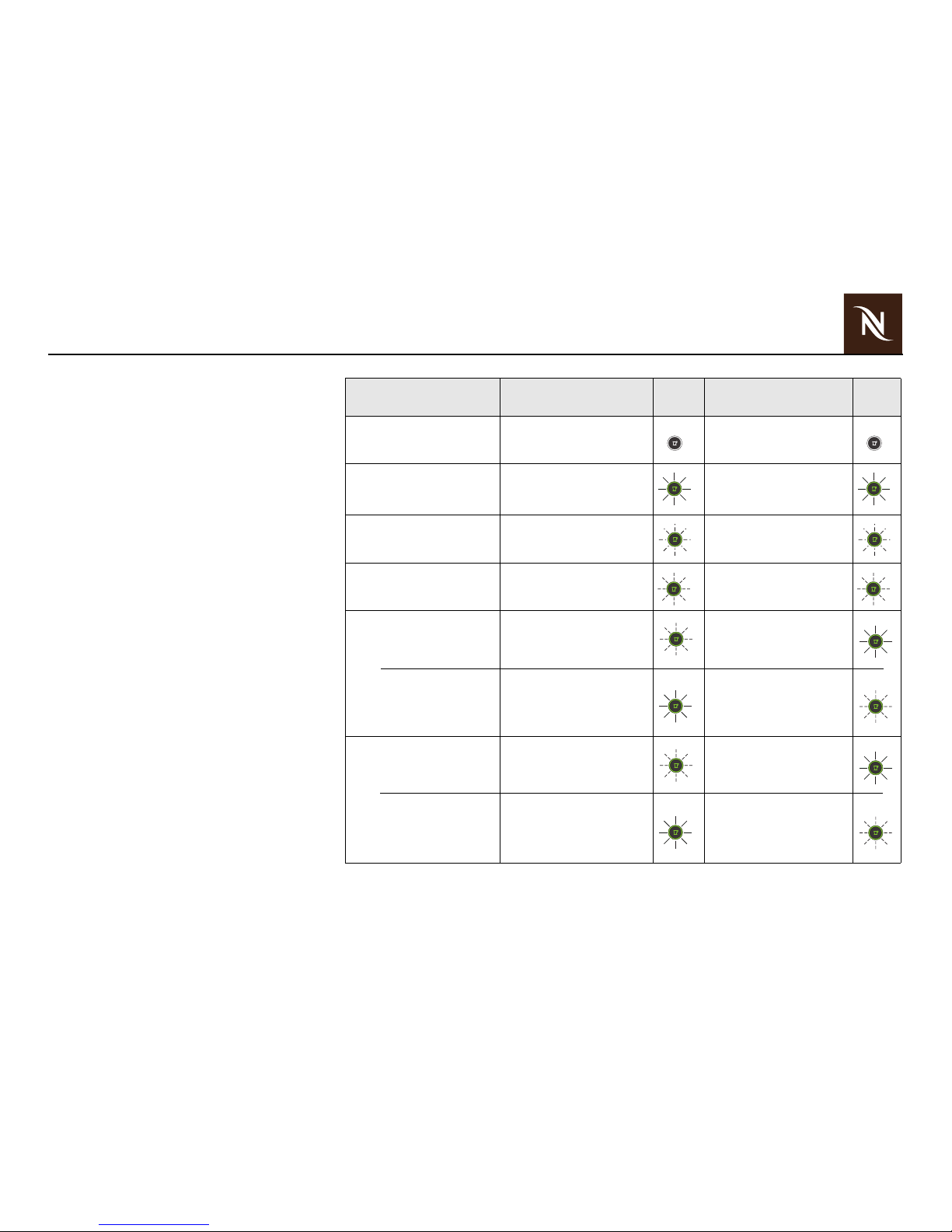

Coffee machine status (1)

After pressing the On/Off button, an automatic

self test is performed to check if

- the NTC is connected,

- the NTC is short circuited,

- the thermoblock reaches the standby

temperature within 2 minutes.

Operating modes and detected failures are

indicated by backlighted coffee buttons as

listed in the following table.

)

Operating mode Small cup

Led

signal

Big cup

LED

signal

Off off off

Ready on on

Error

blinking fast 3 times

every 2 sec.

blinking fast 3 times

every 2 sec

Heat up Blinking slow Blinking slow

Brewing small cup

Brewing big cup

Blinking slow

on

on

Blinking slow

Rinse small cup

Rinse big cup

Blinking slow

on

on

Blinking slow

Page 16

16

Operation

Service Manual EF 347 / EF 348 enVersion 1.0

Coffee machine status (2)

(

1

H

z

Operating mode Small cup

Led

signal

Big cup

LED

signal

Power off Program

Blinking small cup

- 1x for 9 min.

(factory setting)

- 2 x for 30 min.

- 3 x for deactivated

off

Emptying

Blinking fast

off

off

Blinking fast

Descaling ready

D. pump on descal)

D. pump off (descal)

Blinking fast Blinking fast

Overheat Blinking slow Blinking slow

Order small cup

(during heat)

Blinking slow off

Order big cup (during heat) off Blinking slow

No more stand by

No more power save

--

Resetting to factory Blinking 3 Hz Blinking 3 Hz

Page 17

17

Service Manual EF 347 / EF 348 enVersion 1.0

Troubleshooting

Check Machine on receipt

The receipt check enables you to rapidly

locate faults on the machine and to initiate

appropriate repair action.

Follow the check procedure.

Repair any faults found and check if the

machine is operating perfectly.

Check procedure Symptoms Action / repair work Further action / repair work

1 Check appliance for visible

damage

1.1 Parts of housing broken or damaged

YES - Replace parts if necessary

NO - Go to point 1.2

1.2 Mains cable damaged

YES - Replace mains cable

NO - Plug machine to the mains and go to point 2.1

2 Check mechanical elements

2.1 Closing handle works correctly

YES - Go to point 2.2

NO - It is hard or impossible to close the closing handle

YES - Screw on closing handle screws at defined

torque or replace CBU (see page 26)

NO - Replace the CBU

2.2 Is the capsule correctly ejected?

YES - Go to point 3

NO - Replace TCBU

3 Fill water tank 3.1 Water tank is leaking

YES - Replace water tank

NO - Go to point 4

Page 18

18

Troubleshooting

Service Manual EF 347 / EF 348 enVersion 1.0

4 Press any button to start coffee

machine to perform automatic self

test

4.1 Machine is not working (no function)

YES - a) Check if mains cable is functional

YES - Go to point b)

NO - Replace it

YES - c) Check if pump is working (press coffee

button)

YES - Go to point f)

NO - Go to point d)

YES - d) Check if coffee button is functional

YES - Go to point e)

NO - Replace it

YES - e) Check if pump's thermal fuse (128°C) is

defective

YES - Replace pump (see page 24)

NO - Go to point f)

YES - f) Check if thermoblock’s thermal fuse (167°C)

is defective

YES - Replace thermal fuse and if necessary

thermoblock too (see page 23)

NO - Go to point g)

YES - g) Check if electrical wires are functional

YES - Replace elect. mainboard and the NTC

(see page 25)

NO - Replace defective(s) wire(s)

NO - Go to point 4.2

4.2 Backlighted coffee button blinks at irregular

intervals

YES - Check if thermoblock heating element is functional

YES - Replace NTC (see page 22)

NO - Replace thermoblock (see page 23)

NO - Self test ok. Go to point 5

5 Check coffee temperature while

preparing a coffee (see page 34)

5.1 No coffee at outlet

YES - a) Water system is empty

YES - Fill water system (see page 11)

NO - Go to point b)

YES - b) Pyramid plate is clogged

YES - Replace TCBU (see page 26)

NO - Go to point c)

YES - c) Machine is blocked by scale YES - Descale machine (see page 40)

NO - Go to point 5.2

5.2 Temperature is too low (less than 83°C)

YES - Descale the machine (see page 40)

NO - Go to point 5.3

5.3 Temperature is too high (more than 89°C)

YES - Change NTC (see page 22)

NO - Go to point 6

Check procedure Symptoms Action / repair work Further action / repair work

Page 19

19

Troubleshooting

Service Manual EF 347 / EF 348 enVersion 1.0

6 Check for leaks and check flow

rate (see pages 28 and following)

6.1 Leakage at extraction system

YES - Replace TCBU (see page 26)

NO - Go to point 6.2

6.2 Leakage at tubes connection

YES - Replace defective tube and seal

NO - Go to point 6.3

6.3 Flow rate out of range YES - Machine is scaled

YES - Descale machine (see page 40)

NO - Replace pump

7 Descaling process (if needed) 7.1 Machine scaled

YES - Descale machine (see page 40)

NO - Go to point 8

8 Final cleaning

End of check procedure

Check procedure Symptoms Action / repair work Further action / repair work

Page 20

20

Service Manual EF 347 / EF 348 enVersion 1.0

Repair

Safety instructions

Risk of fatal electrical shock!

Mains voltage inside the coffee

machine.

Disconnect the mains plug before

disassembly - the coffee machine

must be free of voltage.

Danger of burns!

Hot parts and water under pressure

inside the coffee machine (thermoblock in particular).

Let coffee machine cool down before

disassembly.

Page 21

21

Repair

Service Manual EF 347 / EF 348 enVersion 1.0

General disassembly

Tool:

- Oval screwdriver

Procedure:

1. Remove water tank (33) and drip tray (8)

together with drip grid (7) and capsule

container (6).

2. Remove 2 screws (2) on the front side of

the machine.

3. Place machine on the repairing/service

holder device (see page 42).

4. Remove 6 screws (2) on the bottom of the

machine.

5. Swing out and remove both side panels (5).

6. Remove lower chassis (22).

5

5

33

6 + 7 + 8

2

2

22

Page 22

22

Repair

Service Manual EF 347 / EF 348 enVersion 1.0

Replacing NTC

Tools:

- Torx screwdriver Pin-TX10

- Open-ended spanner 9 mm AF

- Torque wrench

Procedure:

1. Follow general disassembly (see page

21).

2. Unplug NTC connector from electronic

control board (A).

3. Unscrew 3 screws (23) from thermobloc

cover.

4. Unscrew the screw fixing the cover to the

thermobloc and remove the cover.

5. Remove defective NTC temperature

sensor (43) from thermoblock (40) and

replace it with a new one.

6. Assemble in reverse sequence.

Re-use spring lock washer (42)

and tighten new NTC temperature

sensor (43) with torque wrench

(80 - 100 Ncm).

43

40

42

A

23

23

23

Page 23

23

Repair

Service Manual EF 347 / EF 348 enVersion 1.0

Replacing thermoblock

Tools:

- Torx screwdrivers Pin-TX10, TX20

- Open-ended spanner 9 mm AF

- Torque wrench

Procedure:

1. Follow general disassembly (see page 21).

2.

Remove 3 screws (23) and separate thermoblock assembly from upper chassis (1).

3. Unplug NTC connector from electronic

control board (28).

4. Remove clips (D) and 2 hose connectors

(B + C) from thermoblock.

5. Remove ground wire and electrical

connections from thermoblock.

6. Replace thermoblock (40)

7. Mount a new NTC temperature sensor

(43) on the thermoblock (40).

8. Assemble in reverse sequence.

Use a torque wrench (80 - 100 Ncm)

to tighten NTC temperature sensor

(43) with spring lock washer (42).

40*

23

40*

40*

A

43

28

D

B

40*

1

* (complete thermoblock group)

Page 24

24

Repair

Service Manual EF 347 / EF 348 enVersion 1.0

Replacing pump

Tools:

- Torx screwdriver Pin-TX10

- Long-nose pliers

- Blade screwdriver, no. 7

Procedure:

1. Follow general disassembly (see page

21).

2. Remove clip (14) and O-ring (15).

3. Remove pump (17).

4. Remove electrical connections from

pump.

5. Replace defective pump (17).

6. Plug in electrical connections on pump.

Check for correct wiring of pump.

7. Insert new O-ring (15).

8. Mount angled hose (26) with clip (14).

14

17

26

T 128°C

L

15

Page 25

25

Repair

Service Manual EF 347 / EF 348 enVersion 1.0

Replacing electronic control board

with button prints

Tools:

- Torx screwdriver Pin-TX10

The service engineer must be

earthed using an earthing strap!

Only touch button prints with dedicated gloves to avoid oxydation.

Procedure:

1. Follow general disassembly (see page

21).

2. Remove 2 screws (55) and remove

housing (A) from electronic control board.

3. Unplug NTC and flowmeter and all wires

from electronic control board (28).

4. Remove the 2 screws (23) from cover

(35), open the lever (37) and lift up lightly

the front part of the cover so the buttons

prints wires can pass.

5. Replace defect electronic control (B)

board with button prints (B).

6. Assemble in reverse sequence.

Check for correct wiring of electronic

control board (see page 27).

28

55

A

37

35

23

A

B

Page 26

26

Repair

Service Manual EF 347 / EF 348 enVersion 1.0

Replacing compact brewing unit

Tools:

- Torx screwdriver Pin-TX10

- Blade screwdriver no. 4

- Long-nose pliers

- Torque wrench

Procedure:

1. Remove water tank (33) and drip tray (8)

together with drip grid (7) and capsule

container (6).

2. Place machine on the repairing/service

holder device (see page 42).

3. Remove 4 screws (2) on the bottom of the

machine. Swing out and remove both side

panels (5).

4. Remove 2 screws (36) and pull off closing

handle (37).

5. Remove 2 screws (23) at the front and 1

screw (44) at the back to detach cover

(35).

C99 machine: All screws have the

same lenght.

D99 machine: The screw at the back

is longer than those at the front.

6. Remove clip (14) and hose (32) with Oring (15) from compact brewing unit.

7.

Unlatch coffee outlet (3) from compact

brewing unit (34) with a blade screwdriver.

Take care not to damaged the ring, otherwise replace it

8. Remove 4 screws (24) and detach

compact brewing unit (34).

Tighten closing handle screws (21)

with a torque of 230 - 270 Ncm.

34

36

36

3

32

24

35

37

23

15

14

44

2

5

Page 27

27

Repair

Service Manual EF 347 / EF 348 enVersion 1.0

Wiring diagram 220V - 240V IEC

Page 28

28

Repair

Service Manual EF 347 / EF 348 enVersion 1.0

Wiring diagram 120V - 127V IEC

Page 29

29

Service Manual EF 347 / EF 348 enVersion 1.0

Function Tests

Safety instructions

Some function tests are performed with an

energized, partly opened coffee machine.

Danger of electrocution!

Mains voltage inside the coffee

machine. Do not touch any live part

while performing tests.

Danger of burns!

Hot parts and water under pressure

inside the coffee machine. Do not

touch any hot parts while checking

for leakages! Always wear protective

goggles.

Required equipment

Pos. Component

1

Pressure gauge (EFR no. 16195)

2

Essenza pressure gauge adapter (for part

number refer to EF webshop)

3

Electronic thermometer (or digital multimeter

suitable for temperature measurement)

4

Time r

5

Measuring beaker

6

Test equipment for protective earth continuity

test and protective insulation test

T2

T1

RANGE

-200°C - 1370°C

-328°F - 2498°F

1

REL

HOLD

T1 T2

T1

←

T2

°C/°F

MAX MIN

1

5

4

6

3

MEASURE

LOCK/STOP

COMP

LIGHT

0Ω ADJ

2

Page 30

30

Function Tests

Service Manual EF 347 / EF 348 enVersion 1.0

Measuring flow rate (1)

Procedure:

1. Fill and insert water tank.

2. Open closing handle.

3. Insert connecting unit of pressure adapter

into capsule bay.

4. Push back sealing cone into capsule

cage.

5. Insert fixation unit of pressure adapter into

capsule bay.

6. Press down operating lever.

Continued on next page.

3

1

2

6

Page 31

31

Function Tests

Service Manual EF 347 / EF 348 enVersion 1.0

Measuring flow rate (2)

Procedure (continued):

7. Connect pressure hose to pressure tester.

8. Position measuring beaker underneath

exit tube of pressure tester.

9. Switch on machine.

10. Press coffee button after heating-up.

11. Open valve fully till water begins to flow.

12. Close valve slowly until 12 bar are indicated.

The manometer must be observed

continuously and the pressure regulated using the valve if necessary.

With increasing temperature the

pressure also increases, if necessary readjust the pressure to 12 bar.

13. Perform measurement for approx. 30 sec.

14. There must be at least 60 - 120 ml water

in the measuring beaker.

Notice:

- With a flow of < 60 ml the pump is defective

or there is a leak in the system.

- Large fluctuations in the pressure gauge

readings (± 4 bar) during measurement are

indicative of a defective pump.

8

7

1

0

9

30 sec

13

12

1

4

11

Page 32

32

Function Tests

Service Manual EF 347 / EF 348 enVersion 1.0

Checking for leaks and pump pressure (1)

The following components are checked for

leaks:

- Compact brewing unit (TCBU)

- Hose connections

- Thermoblock

-Pump

Preparation (unplug machine from mains):

1. Remove right side panel.

2. Open closing handle.

3. Insert connecting and fixation unit of pressure adapter into capsule bay (refer to

page 30).

4. Press down operating lever.

5. Position pot underneath exit tube of pressure plug.

6. Fill and insert water tank.

7. Connect mains cable.

Dangerous voltage inside coffee

machine! - Do not touch any live part

while performing checks.

Hot, pressurized parts inside coffee

machine! - Do not touch any hot part

while performing checks. Wear

safety glasses during inspection.

Continued on next page.

1

3

2

5

4

6

7

Page 33

33

Function Tests

Service Manual EF 347 / EF 348 enVersion 1.0

Checking for leaks and pump pressure (2)

Procedure (continued):

8. Press any button to start the coffee

machine. Press coffee button after

heating-up.

9. Open valve and leave water to run out for

approx. 10 sec.

10. Fully close valve. The pressure will rise

rapidly initially and stabilise between

16 - 19 bar (check of pump pressure).

The pressure will rise slowly due to

the temperature increase.

If the pressure exceeds 23 bar, the

machine has to be switched off and

pressure released through the pressure valve.

11. Perform visual and acoustic checks on all

pressurized connections.

The pump must not be in operation

for longer than 50 sec. without water

flow.

12. Open valve to empty pressure gauge.

8

8

11

10 sec

9

10

12

13

Page 34

34

Function Tests

Service Manual EF 347 / EF 348 enVersion 1.0

Measuring coffee temperature

Procedure:

1. Press any button for start the coffee

machine.

2. Position measuring beaker underneath

coffee outlet.

3. After warming up, press coffee button.

4. Preheat coffee outlet for 10 sec. with hot

water.

5. Empty measuring beaker.

6. Insert a capsule (Cosi is the most suitable).

7. Press coffee button.

8. Wait until 20 ml coffee has flown in the

measuring beaker.

9. Measure the coffee temperature approx.

5 - 10 mm below the outlet opening.

Coffee temperature should be

approx. 86 °C ± 3 °C (187 °F ± 5.4 °F).

1

2

6

5

10 sec

3

4

9

7

8

Page 35

35

Function Tests

Service Manual EF 347 / EF 348 enVersion 1.0

Protective earth continuity test (1)

What coffee machine model has to be tested and when?

This test is necessary

- for class 1 equipment (three-wire power

cord with protective earth)

- after a repair whenever the housing was

opened and for example a general disassembly was performed.

Therefore all coffee machine models have to

be tested after opening the housing, except

country-specific models without a protective

earth connection.

General

Legal regulation

In case of a repair/modification of the coffee

machine, the repair centre is bound by law to

protect the user/consumer by

- restoring the regular condition of the appliance and

- performing the respective tests according

to EN/IEC 60335-1 “Safety of household

and similar electrical appliances” and

national regulations (e.g. DIN VDE 0701).

Description

Protective earth continuity measurements are

made between the protective earth terminal of

the power plug and

- the thermoblock,

- all conductive, touchable parts of the coffee

machine where dangerous voltage could

occur if the basic insulation was to fail.

This test assures that

- the ground (earth) connection does not

have an interruption between the power

plug and the thermoblock

- the permissible ground resistance is less

than 0.3 Ohms (with a test current of

200 mA DC).

Test equipment

Special test equipment is needed that

complies with the regulations to perform

protective earth continuity measurements.

Detailed requirements and tolerances must be

verified by your local authorities or measurement supplier in any case.

Tes t repo rt

For legal reasons a repair or test report should

be prepared and filed with following information

- customer (name, address)

- type and serial number of coffee machine

- date of repair/test(s)

- performed test(s)/measuring value(s)

- used test equipment

- signature

Test sequence

Danger of electrocution!

Do not plug in the coffee machine

during the protective earth continuity test.

Read and observe safety instructions in user manual of test equipment.

This test sequence is not applicable

for coffee machines with two-wire

power cords (without ground pin).

Continued on next page.

Page 36

36

Function Tests

Service Manual EF 347 / EF 348 enVersion 1.0

Protective earth continuity test (2)

Test sequence (continued):

1. Connect black measuring cable to ground

pin of power plug with an alligator clip

(example shown: Swiss power plug).

2. Switch on test equipment and select

protective earth continuity test.

Symbolic illustration of test equipment.

3. Touch thermoblock tube with tip of red test

probe.

4. Press "measure" button and read off

displayed resistance.

The resistance must be lower than

0.3 Ohm.

5. Fill in measured value in a test report.

Proceed with protective insulation

test before reassembling the

housing of the coffee machine.

What to do if the protective earth continuity

test fails

Check ground wire connection on thermoblock

(refer to wiring diagrams on page 27).

1

MEASURE

LOCK/STOP

COMP

LIGHT

0Ω ADJ

0.215 Ohm

Test passed

3

4

MEASURE

LOCK/STOP

COMP

LIGHT

0Ω ADJ

2

Page 37

37

Function Tests

Service Manual EF 347 / EF 348 enVersion 1.0

Protective insulation test (1)

Perform the protective earth continuity test at first, if it is mandatory.

What is the protective insulation test

about?

This test is necessary

- for class 1 and 2 equipment (with/without

protective earth),

- after a repair whenever the housing was

opened and for example a general disassembly was performed.

General

Legal regulation

In case of a repair/modification of the coffee

machine, the repair centre is bound by law to

protect the user/consumer by

- restoring the regular condition of the appliance and

- performing the respective tests according

to EN/IEC 60335-1 “Safety of household

and similar electrical appliances” and

national regulations (e.g. DIN VDE 0701).

Description

The insulation test

- assures that wiring and insulation of the

coffee machine fullfill the normative

requirements after a repair,

- rates the insulation capability of the coffee

machine,

- is a very dangerous test because of a high

test voltage (500 V DC).

For the insulation test, phase and neutral wire

are shunted at the power plug. Then a test

voltage is applied between phase/neutral and

selected parts of the coffee machine.

Test equipment

Special test equipment is needed that complies

with the regulations to perform insulation and

withstanding voltage tests. Detailed requirements and tolerances must be verified with

your local authorities or measurement supplier

in any case.

Ideally the test equipment has a national

power socket for testing, so that the coffee

machine can plugged in directly. Otherwise a

special shunt is necessary to connect the

phase and neutral pin of the coffee machine’s

power plug.

Tes t repo rt

For legal reasons a repair or test report should

be prepared and filed with following information

- customer (name, address)

- type and serial number of coffee machine

- date of repair/test(s)

- performed test(s)/measuring value(s), test

points

- used test equipment

- signature

Test sequence

Danger of electrical shock/short

circuit!

• Do not plug in the coffee machine

during insulation test.

Danger of electrical shock!

• Do not touch tip of test probes.

• Do not touch metallic parts of coffee

machine during test.

•

Read and observe safety instructions

in user manual of test equipment.

Continued on next page.

Page 38

38

Function Tests

Service Manual EF 347 / EF 348 enVersion 1.0

Protective insulation test (2)

Test sequence (continued):

1. Connect the phase and neutral pin of the

power plug together with a test adapter

(procured by the repair centre).

A Swiss power plug is shown here as

an example.

2. Connect the black measuring cable to the

test adapter (see image).

Use a short circuit plug or special

alligator clips etc. as substitute for

this test adapter.

3. Switch on test equipment and select an

insulation test voltage of 500 V DC.

Symbolic illustration of test equipment.

Continued on next page.

1

2

MEASURE

LOCK/STOP

COMP

LIGHT

0Ω ADJ

3

Page 39

39

Function Tests

Service Manual EF 347 / EF 348 enVersion 1.0

Protective insulation test (3)

Test sequence (continued):

4. Touch closing handle screw with red test

probe.

Do not scratch surface of closing

handle with probe tip.

5. Press "measure" button.

6. Read off displayed insulation resistance

or test result.

The insulation resistance must be

higher than 300 kOhm (300,000 Ohm).

7. Fill in measured value in a test report.

8. Switch off test equipment.

9. Short red with black test probe to make

sure that test voltage is discharged.

What to do if the insulation test fails

Risk of damage!

A sparkover can damage the electronic control board and sensors etc.

Assume that the coffee machine is defect after

a failed insulation test.

Check wiring and locate fault.

After fault clearance proceed with trouble-

shooting check list (see page 16).

Test passed

7

8

Page 40

40

Service Manual EF 347 / EF 348 enVersion 1.0

Maintenance

Descaling (1)

Only use Nespresso decalcifier!

Decalcifier is aggressive to surfaces.

Immediately clean drops of

descaling solution.

This machine is equipped with a

descaling alarm (both LEDs blink

during ready mode).

Descaling duration:

approx. 15 minutes.

Carefully read safety instructions on

decalcifier package.

1. Remove the capsule and close the lever.

2. Empty the drip tray and used capsule

container.

3. Fill the water tank with 0.5 L of potable

water and add 1 Nespresso descaling

liquid.

2

3

1

Page 41

41

Maintenance

Service Manual EF 347 / EF 348 enVersion 1.0

Descaling (2)

Procedure (continued):

4. Place a container (min. volume 1 l) under

the coffee outlet.

5. To enter the descaling mode, while the

machine is turned on, press both the

Espresso and Lungo button for 3

seconds.

6. Both LEDs blink.

7. Press the Lungo button and wait until the

water tank is empty.

8. Refill the water tank with the used

descaling solution collected in the

container and repeat step 4 and 6.

9. Empty and rinse the water tank. Fill with

potable water.

When ready, repeat step 4 and 6 to now

rinse the machine.

10. To exit the descaling mode, press both the

Epresso and Lungo button for 3 seconds.

11. The machine is now ready for use.

4

5

6

7

8

9

10

Page 42

42

Service Manual EF 347 / EF 348 enVersion 1.0

Spare Parts

Repair accessories

* Repair accessories only available at

Nespresso. Please ask your Nespresso

technical contact person.

Manometer and pressure adapter are available at Eugster Frismag AG.

Pos. EFR No. Component

1*

Repairing/service holder device

(for C99 or D99)

2 42213 Manometer

3 60460 Pressure adapter G4

4 0004872 Screwdriver

5 0004878 Oval bit

- 64373 Spare part seal G4

2

3

4

5

1

Page 43

43

Spare Parts

Service Manual EF 347 / EF 348 enVersion 1.0

Spare parts EF 347 / C99

Page 44

44

Spare Parts

Service Manual EF 347 / EF 348 enVersion 1.0

Draw. No. Art. Nr. Part Description

001 0077828 Holder 473 black V3

002 0024863 Screw safety KST/PT 3.0x12 bl galvan oval head (SFS-Remform)

003 0079793 Outlet

005 0075782 Side wall 347 taupe earth high gl.

006 0059106 Capsule container

007 0077819 Drip grid 347 black V2

008 0075915 Drip tray

009 0005238 Hose silic 05.0x2.00mm meter ware, 70 Shore, transp (di/W)

010 0042592 Valve lifter 704 cpl mount.

011 0077824 Pump holder 470 black V3

012 0039196 Pump holder 470 black 60 sh D=00,0mm, 2 fix holes 0,0mm

013 0037384 Clip D=5mm browned inox

014 0005470 Clip D=4mm L=14mm Inox

015 0061701 O-Ring 03.40x1.90 EPDM V3 70 Shore black

016 0060761 Fluid connect elbow 90° black, 16.0x16.0mm crosspiece

017 0069200 Pump SAP.HP4.V04 230-240V/50Hz

018 0077573 Hose FEP D=4.0/2.50x115mm 2 clamp rings/2 tubul. rivets

021 0013299 Rubber feet 9.0x 0.8mm white SJ-5832

022 0077833 Base 470 black

023 0071635 Screw KST/PT 3.0x12 bl galvan rd head Torx-10

024 0045182 Strain relief clamp 966 transp,screwable

025 0075931 Line cord EU SF-71 H05VV-F3G0.75/L80/N180/PE40, assembled

026 0063089 Fluid connect elbow 90° V2 black, 1xF, 1xmale, crosspiece

027 0063049 Fluid connect V shape 55° V3 black, 2xF

028 0079586 Spare electronic 347 230V

029 0048034 Push-button 471 coffee V2 silic translucent

Page 45

45

Spare Parts

Service Manual EF 347 / EF 348 enVersion 1.0

030 0048033 Push-button 474 Espresso V2 silic translucent

032 0079584 Spare hose FEP D4/2.5x230 clamp ring/tubul. rivet/Serto mount.

033 0060988 Water tank

034 0065019 Spare extract unit 473 cpl. TCBU, packed

035 0077829 Hood 473 black V2 gravure: Nespresso capsules only

036 0076213 Screw KST/PT 4.0x16 blk galvan rd head Torx-20

037 0075784 Lock rod 347

040 0079581 Thermobl 2010/L 230V/1200W EF347 cpl V2

041 0043202 Insul. leeve Elbow connect black, FH6,3 US

042 0044585 Spring ring M 5 bl galvan

043 0064816 Temperature gauge 710 cpl NTC 104M5-S160A2

044 0071635 Screw KST/PT 3.0x12 bl galvan rd head Torx-10

046 0043073 Molded tube 473 silic neutral, flow meter pump

047 0067795 Flow meter FHKSC 12 0° 932-9521/A, double insulated

050 0077832 Cover 470 main switch V3 black

051 0075917 Thermost TB02-B-B8D-105 strd wires 95/150mm, 1xFHL6,3x0,8/1xFHL4,8x0,8

053 0079126 Damping element 347 thermobl black, 60 Shore

054 0079698 Pump holder 348 cpl

055 0071635 Screw KST/PT 3.0x12 bl galvan rd head Torx-10

056 0024374 O-Ring 003,40x1.90 silic/2-K 70 Shore red 2-comp silic

982 0078156 Polystyr. 347 2-part.

983 0050083 Covering box 475 slotted V2 449x339x321mm

992 0047595 Supplement ventilation 12-lang.

Draw. No. Art. Nr. Part Description

Page 46

46

Spare Parts

Service Manual EF 347 / EF 348 enVersion 1.0

Spare parts EF 348 / D99

Page 47

47

Spare Parts

Service Manual EF 347 / EF 348 enVersion 1.0

Draw. No. Art. Nr. Part Description

001 0077856 Holder 474 black V3

002 0024863 Screw safety KST/PT 3.0x12 bl galvan oval head (SFS-Remform)

003 0079587 Outlet 347 TCBU cpl black

005 0075783 Side wall 348 white sand high gl.

006 0059105 Caps contain 471 V2 black

007 0077854 Drip grid 348 black V2

008 0077855 Drip tray 471 black V3

009 0005238 Hose silic 05.0x2.00mm meter ware, 70 Shore, transp (di/W)

010 0042592 Valve lifter 704 cpl mount.

011 0077824 Pump holder 470 black V3

012 0039196 Pump holder 470 black 60 sh D=00.0mm, 2 fix holes 0.0mm

013 0037384 Clip D=5mm browned inox

014 0005470 Clip D=4mm L=14mm Inox

015 0061701 O-Ring 03.40x1.90 EPDM V3 70 Shore black

016 0060761 Fluid connect elbow 90° black, 16.0x16.0mm crosspiece

017 0069200 Pump SAP.HP4.V04 230-240V/50Hz

018 0077573 Hose FEP D=4.0/2,50x115mm 2 clamp rings/2 tubul. rivets

021 0013299 Rubber feet 9.0x0.8mm white SJ-5832

022 0077831 Base 471 black V4

023 0071635 Screw KST/PT 3.0x12 bl galvan rd head Torx-10

024 0045182 Strain relief clamp 966 transp, screwable

025 0075931 Line cord EU SF-71 H05VV-F3G0,75/L80/N180/PE40, assembled

026 0063089 Fluid connect elbow 90° V2 black, 1xF, 1xmale, crosspiece

027 0063049 Fluid connect V shape 55° V3 black, 2xF

028 0079586 Spare electronic 347 230V

029 0048034 Push-button 471 coffee V2 silic translucent

Page 48

48

Spare Parts

Service Manual EF 347 / EF 348 enVersion 1.0

030 0048033 Push-button 474 Espresso V2 silic translucent

032 0079584 Spare hose FEP D=4/2.5x230 clamp ring/tubul. rivet/ Serto mount.

033 0060991 Water tank 471 cpl transp V2

034 0079580 Spare extract unit 473 cpl TCBU

035 0077851 Hood 474 black V2 gravure: Nespresso capsules only

036 0076213 Screw KST/PT 4.0x16 blk galvan rd head Torx-20

037 0075784 Lock rod 347

040 0079581 Thermobl 2010/L 230V/1200W EF347 cpl V2

041 0043202 Insul. leeve Elbow connect black, FH6,3 US

042 0044585 Spring ring M 5 bl galvan

043 0064816 Temperature gauge 710 cpl NTC104M5-S160A2

044 0018904 Screw KST/PT 3.0x16 bl galvan rd head Torx-10 CA point

046 0043073 Molded tube 473 silic neutral, flow meter pump

047 0067795 Flow meter FHKSC 12 0° 932-9521/A, double insulated

050 0077832 Cover 470 main switch V3 black

051 0075917 Thermost TB02-B-B8D-105 strd wires 95/150mm, 1xFHL6,3x0,8/1xFHL4,8x0,8

053 0079126 Damping element 347 thermobl black, 60 Shore

054 0079698 Pump holder 348 cpl

055 0071635 Screw KST/PT 3.0x12 bl galvan rd head Torx-10

056 0024374 O-Ring 03.40x1.90 silic/2-K 70 Shore red 2-comp silic

981 0077354 Picture carton 348 Nespresso D 99.331x215x314mm

982 0078157 Polystyr. 348 2-part.

983 0050083 Covering box 475 slotted V2 449x339x321mm

990 0077040 Instr. man. 348 Nespresso

Essenza, 9-lang.NO/SW/DA/FI/GR/arabic/TR/FR/GB,

Zone 2

992 0047595 Supplement ventilation 12-lang.

Draw. No. Art. Nr. Part Description

Loading...

Loading...