Page 1

Model WT-5800 Patient Warming System

Service Manual

Page 2

© 2011 Nellcor Puritan Bennett LLC. All rights reserved.

To obtain warranty information contact your local Nellcor representative.

Page 3

Table of Contents

Safety Information.................................................................................................... 9

Overview ................................................................................................................ 9

Warnings ................................................................................................................ 9

Cautions................................................................................................................ 11

Introduction............................................................................................................. 13

Overview .............................................................................................................. 13

Intended Use ........................................................................................................ 13

Manual Availability.............................................................................................. 13

Background Information..................................................................................... 13

Safety Features..................................................................................................... 14

Customized Warming Therapy ..................................................................... 14

Automatic Temperature Stepdown.............................................................. 14

Automatic Over Temperature Shutdown .................................................... 14

Alarms ............................................................................................................ 15

HEPA Filter ..................................................................................................... 16

Wheel Locks ................................................................................................... 16

Symbols................................................................................................................. 17

Description of the Warming System................................................................... 17

Routine Maintenance ............................................................................................. 21

Overview .............................................................................................................. 21

HEPA Filter Replacement..................................................................................... 21

Power Cord Replacement.................................................................................... 24

Nozzle Replacement ............................................................................................ 25

Cleaning the Warming Unit ................................................................................ 26

Performance Verification........................................................................................ 27

Overview .............................................................................................................. 27

Power Fail / Start Alarm Check............................................................................ 27

Thermostat Protection Check.............................................................................. 28

Output Temperature Check ................................................................................ 31

Safety Tests........................................................................................................... 33

Repair....................................................................................................................... 35

Overview .............................................................................................................. 35

Filter Cover Assembly Replacement ................................................................... 36

Separating the Front and Rear Covers................................................................ 38

Rejoining the Front and Rear Covers.................................................................. 40

Front Cover Assembly Replacement ................................................................... 41

Control PCBA Replacement................................................................................. 49

Heater Assembly Replacement............................................................................ 53

Hose Replacement ............................................................................................... 64

Duct Adapter Assembly Replacement ................................................................ 66

Rear Cover Assembly Replacement..................................................................... 71

Service Manual iii

Page 4

Spare Parts & Accessories....................................................................................... 87

Overview .............................................................................................................. 87

Ordering Information.......................................................................................... 87

Replacement Parts and Accessories .................................................................... 90

Manual Availability.............................................................................................. 90

Packing for Shipment ............................................................................................. 91

Overview .............................................................................................................. 91

Returning the Warming Unit .............................................................................. 91

Repacking in Original Carton.............................................................................. 91

Repacking in a Different Carton......................................................................... 93

Specifications .......................................................................................................... 95

Overview .............................................................................................................. 95

Warming System Specifications .......................................................................... 95

Transport and Shipping in Shipping Container ................................................. 96

Compliance........................................................................................................... 96

Manufacturer’s Declaration ................................................................................ 96

Electromagnetic Compatibility (EMC)................................................................. 97

Electromagnetic Emissions ............................................................................ 97

Electromagnetic Immunity............................................................................ 97

Ground Integrity Test .......................................................................................... 99

Earth Leakage Current Test............................................................................... 100

Enclosure Leakage Current Test........................................................................ 100

Principles of Operation......................................................................................... 101

Overview ............................................................................................................ 101

Control Panel ..................................................................................................... 101

Main Circuit Board............................................................................................. 102

DC Power Supply Circuit.............................................................................. 102

Control Logic Circuit.................................................................................... 103

Automatic Temperature Stepdown............................................................ 103

Alarm Drive Circuits..................................................................................... 103

Temperature Control Circuit....................................................................... 104

LCD Hour Meter........................................................................................... 105

AC Power Section ........................................................................................ 105

Blower .......................................................................................................... 106

Heater........................................................................................................... 106

Thermostat Protection ................................................................................ 106

Over-Temperature Test Port ....................................................................... 106

iv Service Manual

Page 5

List of Figures

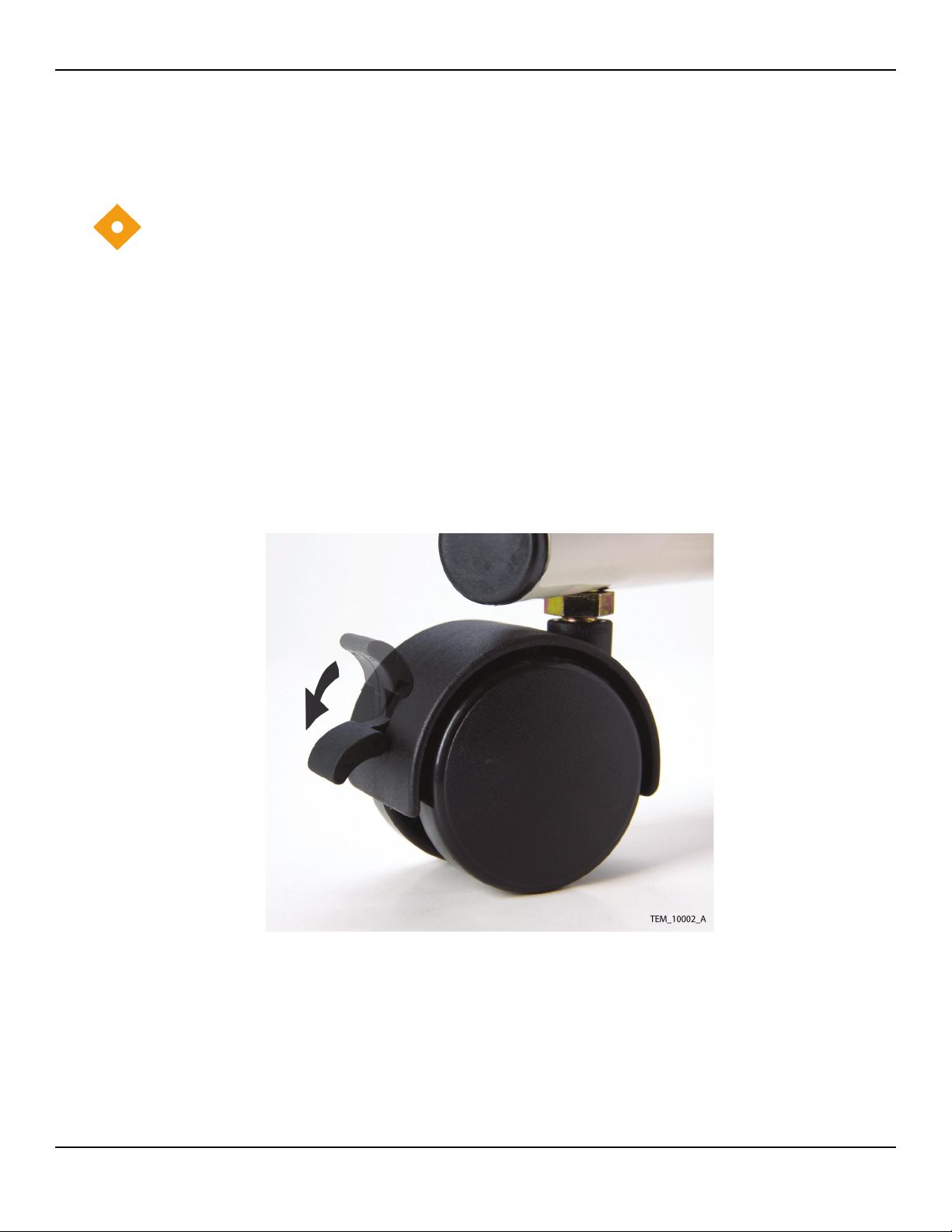

Figure 1: Cart Wheel Lock........................................................................................... 16

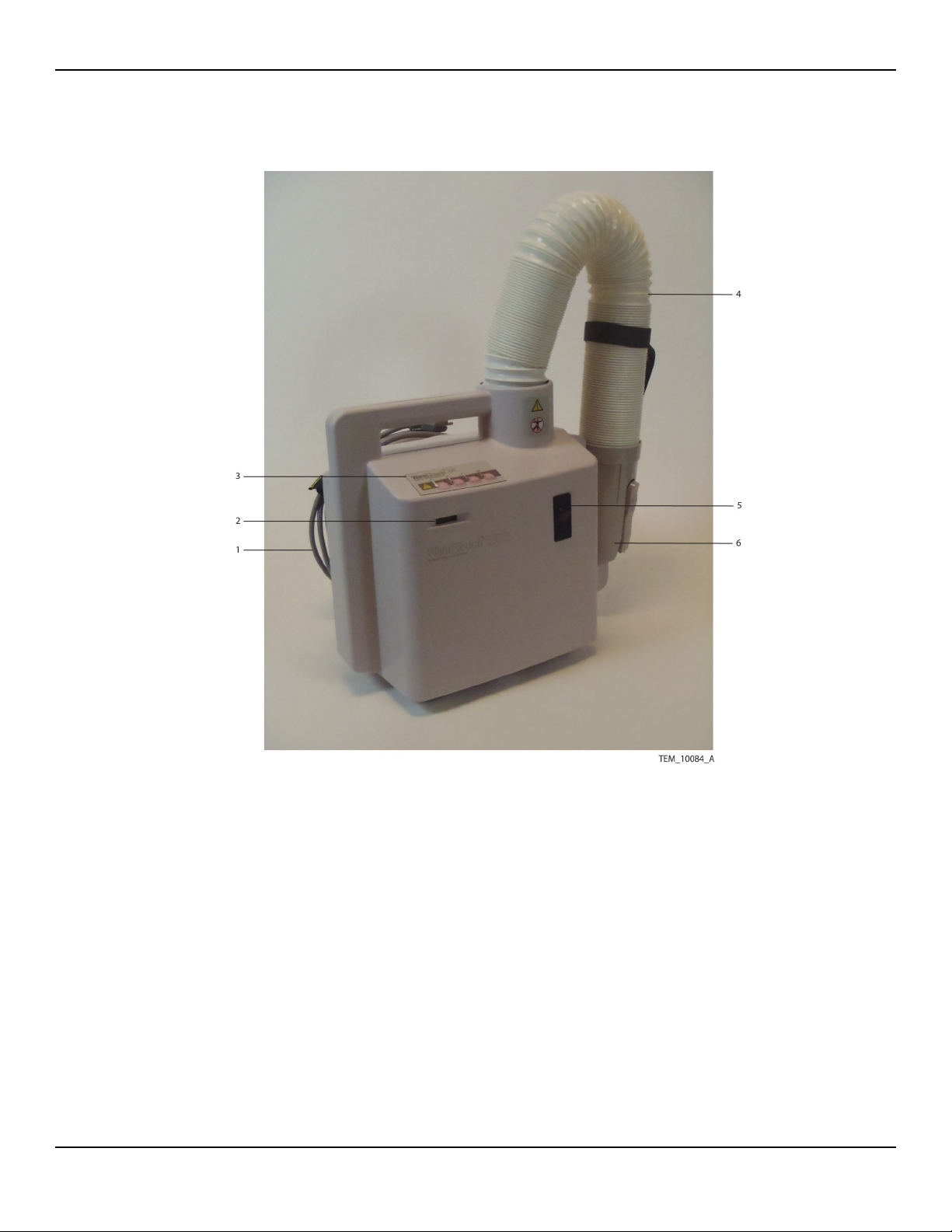

Figure 2: Front View.................................................................................................... 18

Figure 3: Back View.................................................................................................... 19

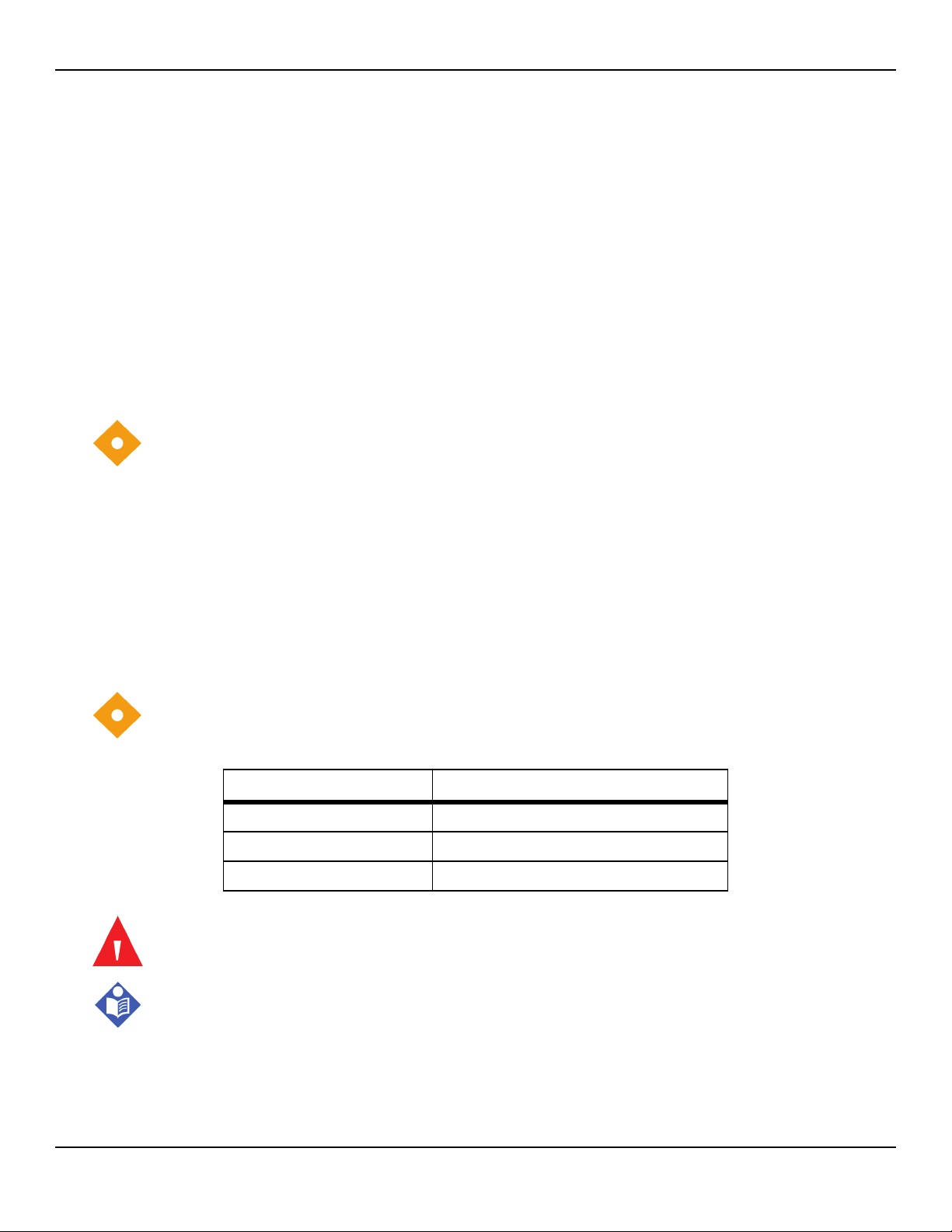

Figure 4: Operating Hours Meter............................................................................... 22

Figure 5: Filter Cover Screws....................................................................................... 22

Figure 6: HEPA Filter and Power Cord Strain Relief.................................................. 23

Figure 7: Power Cord Routing .................................................................................... 24

Figure 8: Over-Temperature Test Port ....................................................................... 29

Figure 9: WT-5800 High Temperature Setting .......................................................... 29

Figure 10: Warning Light............................................................................................ 30

Figure 11: Output Temperature Test Setup............................................................... 32

Figure 12: Temperature Selection .............................................................................. 32

Figure 13: Ground Stud............................................................................................... 33

Figure 14: Power Cord ................................................................................................ 37

Figure 15: Filter Cover Screws..................................................................................... 37

Figure 16: Power Cord ................................................................................................ 38

Figure 17: Cover Screw Locations............................................................................... 39

Figure 18: Separated Covers ....................................................................................... 39

Figure 19: Cover Screw Locations............................................................................... 40

Figure 20: Cable Harness Bundle Ties ........................................................................ 42

Figure 21: Front Cover Assembly................................................................................ 42

Figure 22: Power Switch Clips and Wires................................................................... 43

Figure 23: Cable Disconnect ....................................................................................... 43

Figure 24: Control PCB Screws.................................................................................... 44

Figure 25: Control PCB Lights ..................................................................................... 45

Figure 26: Control PCB Screws.................................................................................... 45

Figure 27: Cable Connections ..................................................................................... 46

Figure 28: Power Switch Clips and Wires................................................................... 46

Figure 29: Front Cover Assembly Component Locations .......................................... 47

Figure 30: Equipotential Ground Stud Wiring .......................................................... 47

Figure 31: Cable Harness Bundle Ties ........................................................................ 48

Figure 32: Control PCB Connections .......................................................................... 49

Figure 33: Control PCB Screws.................................................................................... 50

Figure 34: Control PCB Lights ..................................................................................... 50

Figure 35: Control PCB Screws.................................................................................... 51

Figure 36: Cable Connections ..................................................................................... 51

Figure 37: Cable Harness Bundle Ties ........................................................................ 52

Figure 38: Filter Removal ............................................................................................ 53

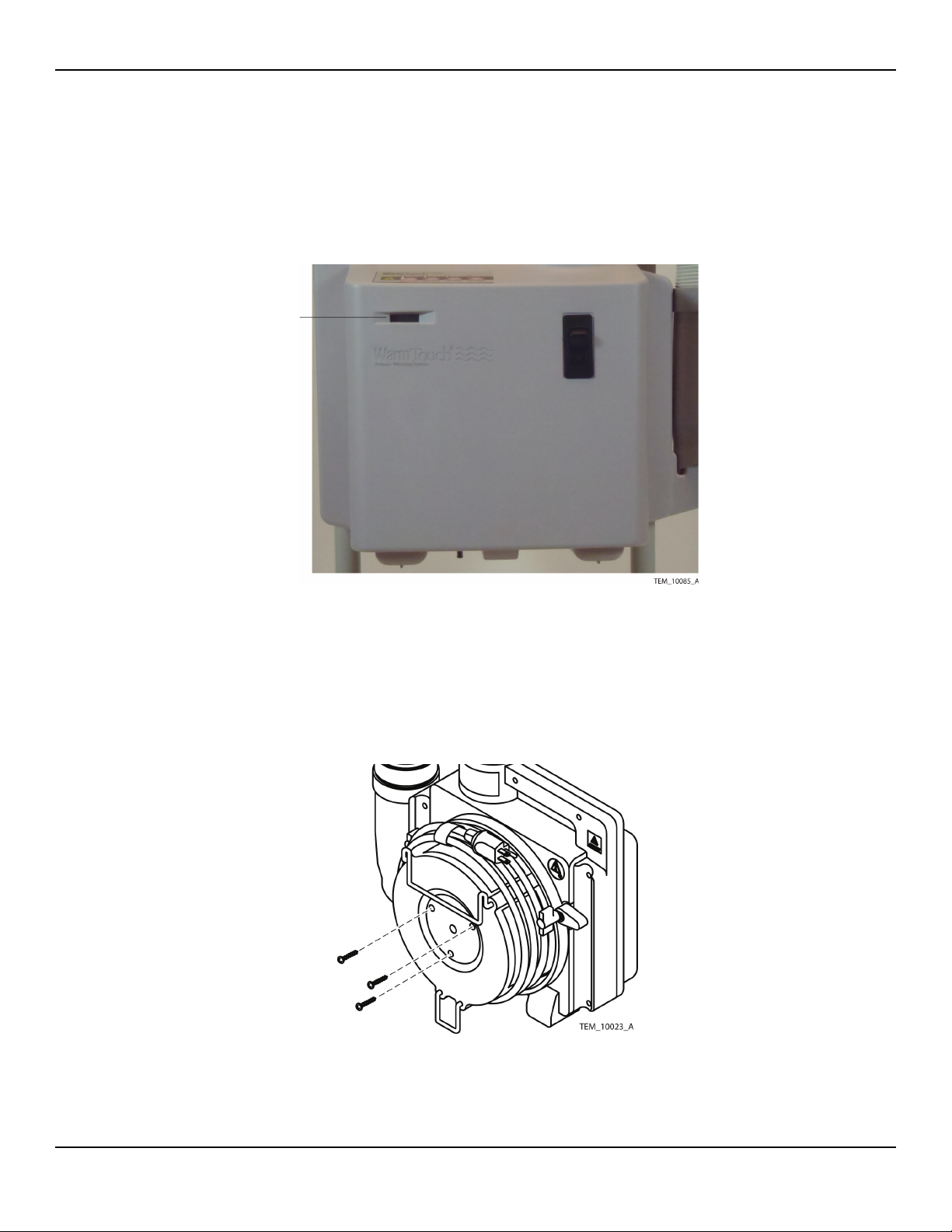

Figure 39: Blower Assembly Screws ........................................................................... 54

Figure 40: Cable Harness Bundle Ties ........................................................................ 54

Figure 41: Front Cover Assembly................................................................................ 55

Figure 42: Duct Adapter Placement ........................................................................... 56

Figure 43: Blower Motor Removal ............................................................................. 57

Figure 44: Blower Assembly Clips............................................................................... 57

Figure 45: Rubber Gasket ........................................................................................... 58

Service Manual v

Page 6

Figure 46: Heater Assembly ........................................................................................ 58

Figure 47: Heater Assembly Installation .................................................................... 59

Figure 48: Rubber Gasket ........................................................................................... 60

Figure 49: Blower Assembly Clips............................................................................... 60

Figure 50: Duct Adapter Placement ........................................................................... 61

Figure 51: Blower Assembly Screws ........................................................................... 62

Figure 52: Cable Harness Bundle Ties ........................................................................ 62

Figure 53: Filter Installation........................................................................................ 63

Figure 54: Filter Cover Installation ............................................................................. 63

Figure 55: Hose Attachment....................................................................................... 65

Figure 56: Thermistor Silicone .................................................................................... 67

Figure 57: Thermistor Removal .................................................................................. 67

Figure 58: Duct Adapter Removal .............................................................................. 68

Figure 59: Duct Adapter Placement ........................................................................... 69

Figure 60: Thermistor Position Within Duct Adapter ............................................... 69

Figure 61: Filter Cover Screws..................................................................................... 72

Figure 62: Filter Removal ............................................................................................ 72

Figure 63: Separated Covers ....................................................................................... 73

Figure 64: Front Cover Assembly................................................................................ 74

Figure 65: Cable Disconnect ....................................................................................... 75

Figure 66: Thermistor Cable Removal ........................................................................ 75

Figure 67: Blower Assembly Screws ........................................................................... 76

Figure 68: Blower Capacitor ....................................................................................... 76

Figure 69: Blower Motor Removal ............................................................................. 77

Figure 70: Blower Assembly Clips............................................................................... 77

Figure 71: Rubber Gasket ........................................................................................... 78

Figure 72: Heater Assembly ........................................................................................ 78

Figure 73: Heater Assembly Installation .................................................................... 79

Figure 74: Rubber Gasket ........................................................................................... 80

Figure 75: Blower Installation .................................................................................... 80

Figure 76: Blower Screws ............................................................................................ 81

Figure 77: Thermistor Cable Installation.................................................................... 81

Figure 78: Capacitor Installation ................................................................................ 82

Figure 79: Cable Connections ..................................................................................... 82

Figure 80: Front Cover Assembly................................................................................ 83

Figure 81: Equipotential Ground Stud Wiring .......................................................... 84

Figure 82: Cable Harness Bundle Ties ........................................................................ 84

Figure 83: Filter Installation........................................................................................ 85

Figure 84: Filter Cover Installation ............................................................................. 85

Figure 85: Spare Parts (Sheet 1).................................................................................. 89

Figure 86: Spare Parts (Sheet 2).................................................................................. 90

Figure 87: Packing the Warming Unit in Original Carton ........................................ 92

Figure 88: Control Panel ........................................................................................... 101

Figure 89: Hour Meter .............................................................................................. 105

Figure 90: Warming Unit Schematic (Sheet 1)......................................................... 107

Figure 91: Warming Unit Schematic (Sheet 2)......................................................... 108

vi Service Manual

Page 7

List of Tables

Table 1: Symbols on the Warming System................................................................. 17

Table 2: Equipment Required for HEPA Filter Replacement .................................... 21

Table 3: Equipment Required for Thermostat Protection Check ............................. 28

Table 4: Equipment Required for Output Temperature Check................................ 31

Table 5: Filter Cover Assembly Components ............................................................. 36

Table 6: Tools Required for Replacing FIlter Cover Assembly .................................. 36

Table 7: Tools Required for Separating Front and Rear Covers ............................... 38

Table 8: Filter Cover Assembly Components ............................................................. 41

Table 9: Tools Required for Replacing Front Cover Assembly.................................. 41

Table 10: Tools Required for Replacing Control PCB ................................................ 49

Table 11: Heater Assembly Components ................................................................... 53

Table 12: Tools Required for Replacing Heater Assembly ........................................ 53

Table 13: Hose Assembly Components ...................................................................... 64

Table 14: Tools Required for Replacing Hose Assembly ........................................... 64

Table 15: Duct Adapter Assembly Components ........................................................ 66

Table 16: Tools Required for Replacing Duct Adapter Assembly............................. 66

Table 17: Rear Cover Assembly Components ............................................................ 71

Table 18: Tools Required for Replacing Rear Cover Assembly ................................. 71

Table 19: Spare Parts and Accessories........................................................................ 88

Table 20: System Specifications .................................................................................. 95

Table 21: Shipping Container Specifications ............................................................. 96

Table 22: Compliance Standards ................................................................................ 96

Table 23: Electromagnetic Emissions Guidelines....................................................... 97

Table 24: Electromagnetic Immunity Guidelines....................................................... 97

Table 25: Recommended Separation Distances......................................................... 99

Table 26: Earth Leakage Current Test...................................................................... 100

Table 27: Enclosure Leakage Current Test............................................................... 100

Service Manual vii

Page 8

Page Left Intentionally Blank

viii Service Manual

Page 9

1 Safety Information

Overview

This chapter contains safety information requiring users to exercise

appropriate caution when servicing the WarmTouch™ Model WT-5800

patient warming system.

The WARNING symbol identifies warnings.

Overview

Warnings alert the user to potential serious outcomes, such as death, injury,

or adverse events to the patient or user.

The CAUTION symbol identifies cautions.

Cautions alert the user to exercise care necessary for the safe and effective

use of the warming system.

The NOTE symbol identifies notes.

Notes contain important information that may otherwise be overlooked or

missed.

Warnings

WARNING

Possible explosion hazard. Do not use the device in the presence of

flammable anesthetics.

Service Manual 9

Page 10

Safety Information

WARNING

Possible electrical shock hazard. To reduce the risk of electrical shock do not

remove the back case. Servicing is only to be done by qualified personnel.

WARNING

Possible electric shock hazard. Grounding reliability can be achieved only

when the warming system is connected to a suitable mains outlet.

WARNING

Possible fire hazard. Prevent the blanket material from coming into contact

with a laser or an electrosurgical active electrode; rapid combustion could

result.

WARNING

Possible burn hazard. Do not apply heat directly to open wounds. All

patient’s wounds should be covered while using the warming system.

WARNING

Possible patient burns. Use caution and consider discontinuing use on

patients during vascular surgery when an artery to an extremity is clamped.

Do not apply the warming system to ischemic limbs.

WARNING

Possible patient burns. Use caution and monitor closely if used on patients

with severe peripheral vascular disease.

WARNING

If a malfunction occurs in the warming system, discontinue use. Notify your

sales/service center of the malfunction. The unit must be serviced by an

authorized service technician.

WARNING

TM

No free-hosing. Keep hose nozzle connected to a WarmTouch

blanket at

all times or thermal injury may occur.

WARNING

TM

WarmTouch CareDrape

and CareQuiltTM blankets are for single patient use

only.

10 Service Manual

Page 11

WARNING

The warming system should not be operated in the presence of

electromagnetic fields that are greater than 3 volts/meter. This could cause

shutdown of the warming system by the fail-safe function within the

equipment.

WARNING

The warming system is not suitable for use during magnetic resonance

imaging (MRI) scanning. The warming system may affect the MRI image.

WARNING

Continuously monitor the patient's temperature. Reduce the air temperature

or discontinue therapy when normothermia is reached.

WARNING

The patient must be closely monitored for rewarming. Vasodilation and

potential hypotension can occur. Use good judgment when selecting a

temperature. If unsure of proper setting, consult with the attending

physician.

Cautions

WARNING

The use of accessories and power cables other than those specified may

result in increased emission and/or decreased immunity of the warming

system.

WARNING

Thermal injury may result if the warming system hose comes into contact

with the patient.

WARNING

Using the warming system on transdermal medication patches may increase

the rate of drug delivery, potentially causing harm to the patient.

WARNING

Before attempting to open or disassemble the warming system, disconnect

the power cord from the AC power source.

Cautions

Caution

Federal (U.S.A.) law restricts the use of the warming system to sale by or on the order

of a physician.

Service Manual 11

Page 12

Safety Information

Caution

The warming system is fitted with an air filter; however, airborne contamination

should be considered when using the warming system.

Caution

If the warming system is mounted on the intravenous (IV) pole, it should be installed

with the top of the unit’s handle less than 76 cm (30 inches) above the floor to

prevent the IV pole from tipping over.

Caution

The institution should follow local governing ordinances and recycling instructions

regarding disposal or recycling of filter and device components or end of life of the

product.

Caution

The HEPA filter must be changed every 2,000 hours of operation. Refer to the

Routine Maintenance section for replacement procedures requiring a qualified

technician.

Caution

Do not spray, pour, or spill any liquid on the warming unit, its accessories,

connectors, switches or openings in the case.

Caution

Observe ESD (electrostatic discharge) precautions when working within the warming

system.

Caution

Repairs to the warming system should only be accomplished by trained service

technicians.

Caution

Ensure that the patient is dry or the warming system may be ineffective.

12 Service Manual

Page 13

1 Introduction

Overview

This chapter provides an introduction to the WarmTouch™ Model WT-5800

patient warming system.

Intended Use

The WarmTouch™ Model WT-5800 patient warming system (warming unit

and blanket) is intended for prevention and treatment of hypothermia, for

example, with the surgical patient, the patient in the pre-operative holding

area, the pregnant woman who shivers during epidural anesthesia due to

hypothermia, or any patient who is uncomfortable anywhere in the cold

critical care environment.

Overview

Manual Availability

The most recent revision of this manual is available on the Internet at:

http://www.nellcor.com/serv/manuals.aspx

Background Information

There are numerous ways of warming your patient, from cotton blankets to

water mattresses. Research has shown that low temperatures surrounding the

patient are a major factor contributing to hypothermia.

system covers the patient with warm air and actively transfers heat across the

skin. The result is to achieve normothermia.

1

Morris RH, Wilkey BR. “The Effects of the Ambient Temperature on Patient Temperature

During Surgery Not Involving Body Cavities.” Anesthesiology 32:102

2

Morris RH. “Influence of Ambient Temperature on Patient Temperature During

Intra

-abdominal Surgery.” Annals of Surgery 173:230-233, 1971.

1,2

The warming

-107, 1970.

Service Manual 13

Page 14

Introduction

In creating this warm customized pocket of air around the hypothermic

patient, it is important to note that stagnant air, even if it is warm, does not

work as an effective heat transfer medium. Stagnant air acts as an insulator,

preventing the boundary layer of molecules next to the skin surface from

transferring heat.

Forced air warming causes warmed air molecules to flow over cooler skin

surface. It is this active flow of warmed molecules that acts as a heat transfer

medium. With the warming system, air is warmed and delivered into a

lightweight blanket (CareQuilt or CareDrape blanket) that rests over or under

the patient. The CareQuilt and CareDrape blankets have many small

perforations on the underside that allow air to exit the blanket and surround

the patient.

Safety Features

The warming system is designed to give healthcare professionals more control

over the patient’s core body temperature. There are several safety features of

the warming system which make it safe and appropriate for such use.

Customized Warming Therapy

Clinicians select temperature range setting at the onset of warming therapy

to help ensure the appropriate setting is selected for every patient.

Automatic Temperature Stepdown

The warming system provides a 45-minute temperature stepdown feature.

When in High temperature mode, blower temperature will automatically drop

to the Medium temperature setting after each 45 minutes of use. The

temperature may be reset to High at any time by selecting the High

temperature setting on the control panel to start another 45-minute cycle.

Automatic Over Temperature Shutdown

The automatic temperature controller and two back-up systems help to

ensure temperature will not reach excessive levels. If necessary, the control

system automatically turns off the heater element when the blower outlet

temperature rises to between 47º C and 50º C, illuminates the warning light,

14 Service Manual

Page 15

and sounds an audible alarm. The warming system heater will start producing

heat when the warming system temperature drops to between approximately

34º C and 37º C. A yellow warning light illuminates whenever the control

system identifies an over-temperature condition.

Alarms

The WarmTouch control circuit manages and monitors operation of the

patient warming system. Should the control circuit encounter a failure

condition, it reports failures using both visual and audible alarms. The visual

alarm is a yellow warning indicator on the control panel that lights at power

on, upon power restoration following power failure, and whenever the

control system identifies an alarm condition. The audible alarm sounds

intermittently or continuously, depending on the alarm condition. Investigate

immediately.

Safety Features

The WarmTouch control circuit recognizes two failure conditions.

1. Power On/Power Fail Alarm — This condition causes an intermittent

audible alarm and continuous visual alarm. It appears at power on and

after power failure, indicating the operator must select the desired

temperature. Upon selection of a temperature key, the system cancels the

alarm and the blower operates at the desired temperature.

2. Over-temperature Alarm — This condition causes a continuous audible

alarm and a flashing visual alarm. It appears when reaching the

temperature safety limit, and the control system turns off the heater. Once

the system air temperature returns to a safe operating temperature of

between 34ºC and 37ºC, the heater will turn back on.

If the control system determines the heater again exceeds the safety limit,

the warming system alarms once more. Take the warming system out of

service for repair by a qualified service technician.

If a power failure occurs while the warming system is in the overtemperature fault condition, and the warming system is still in the overtemperature fault condition when power is restored, both continuous

audible and visual alarms will activate. In this instance, the overtemperature fault cannot be cleared. Take the warming system out of

service for repair by a qualified service technician.

Note:

The Power Fail/Start Alarm is only found on WT-5800 warming units containing a

Control PCBA with part number GR100305.

Service Manual 15

Page 16

Introduction

HEPA Filter

Caution

The HEPA filter must be changed every 2,000 hours of operation. Refer to the

Routine Maintenance section for replacement procedures requiring a qualified

technician.

The system's High Efficiency Particulate Air Filter is 99.97% efficient at

0.3-micron particle size.

Wheel Locks

The cart is equipped with two wheel locks. The wheel locks prevent the cart

from moving while in use. The wheel locks must be released when moving

the cart. Press the wheel lock arm down to lock the wheel. Lift the wheel lock

arm to release the wheel lock. See Figure 1.

Figure 1. Cart Wheel Lock

16 Service Manual

Page 17

Symbols

The symbols identified in Table 1 are the symbols used on the warming unit.

Table 1. Symbols on the Warming System

Symbols

Attention symbol, consult accompanying documentation

Do not direct air from the hose to the patient (free-hosing); use hose only

with warming blankets.

Dangerous voltage

Protection Class I

Protection Type BF

Date of manufacture

Visual and audible alert

.

Description of the Warming System

The warming unit (Figure 2 and Figure 3) and CareQuiltTMand CareDrape

blankets are intended for prevention and treatment of hypothermia. For

example, use the warming system with the surgical patient, the patient in the

preoperative holding area, the pregnant woman who shivers during epidural

anesthesia due to hypothermia, or any patient who is uncomfortable

anywhere in the cold critical care environment.

Service Manual 17

TM

Page 18

Introduction

1 Power Cord 4 Hose

2 Hours Meter 5 Power Switch

3 Control Panel 6 Nozzle

Figure 2. Front View

18 Service Manual

Page 19

Description of the Warming System

1 Over-Temperature Test Port 5 Filter Cover

2 Instruction Label 6 Bed Hook Bracket

3 Blower Cart Clamp 7 Nozzle Strap with Clip

4 Warning Label

Figure 3. Back View

Service Manual 19

Page 20

Introduction

Page Left Intentionally Blank

20 Service Manual

Page 21

1 Routine Maintenance

Overview

This chapter provides routine maintenance procedures for the WarmTouch™

Model WT-5800 patient warming system.

Caution

The institution should follow local governing ordinances and recycling instructions

regarding disposal or recycling of filter and device components or end of life of the

product.

Overview

HEPA Filter Replacement

The warming system filter must be replaced after every 2,000 hours of use.

Contact Nellcor’s Customer Service Department (1.800.635.5267, press 3 in

the U.S.A.) or your local Nellcor representative to purchase new filters. The

correct filter will be sent to your hospital for installation.

Caution

Only qualified hospital personnel should replace the air filter.

Table 2. Equipment Required for HEPA Filter Replacement

Equipment Description / Use

Phillips screwdriver #2 / Removing screws

Replacement filter P/N 505-2200

Flat blade screwdriver Detaching power cord from filter cover

WARNING

Do not operate the warming system with the back cover removed.

Note:

To read the operating hours meter, the warming system must be running.

Service Manual 21

Page 22

Routine Maintenance

To replace the HEPA filter:

1. Write the date and total hours of operation of the warming system on the

new filter label and warming system label. The operating hours meter is on

the front of the warming system (see Figure 4).

Figure 4. Operating Hours Meter

2. Unplug the warming system.

3. Lay the warming unit on its front side so that the bottom of the warming

unit is visible.

4. Unwrap the power cord from the filter cover.

5. Remove the filter cover screws. See Figure 5.

Figure 5. Filter Cover Screws

22 Service Manual

Page 23

HEPA Filter Replacement

6. Unseat the power cord from the power cord routing bracket on the filter

cover. If necessary, use the head of the flat blade screwdriver to separate

the halves of the bracket sufficiently to allow unseating of the cord.

7. Remove the filter cover.

8. Remove the filter. See Figure 6.

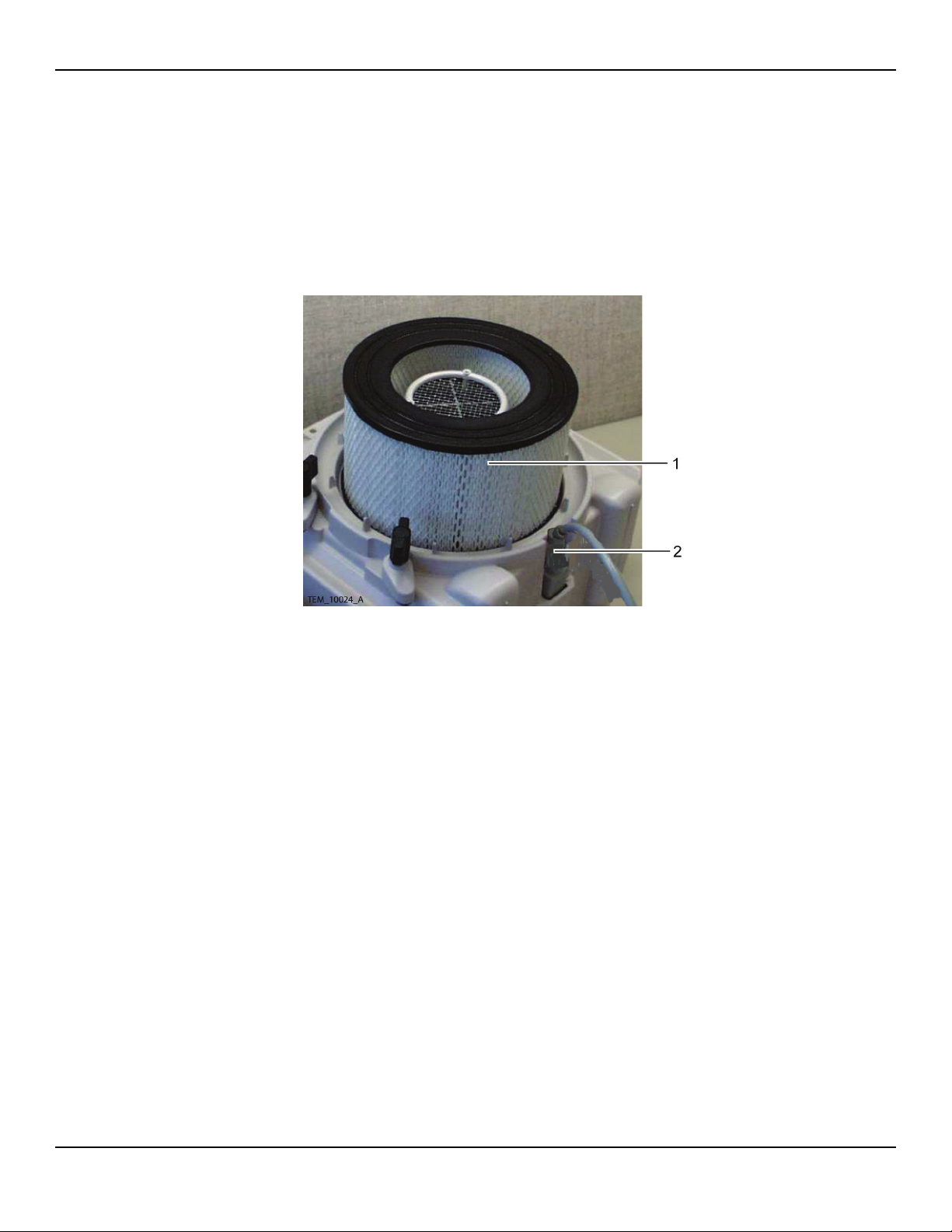

1 HEPA Filter 2 Power Cord Strain Relief

Figure 6. HEPA Filter and Power Cord Strain Relief

9. Place the new filter into the warming unit.

10. Ensure that the power cord’s female connector is still fully inserted into the

socket in the warming unit housing.

11. Place the filter cover on the case and reseat the power cable into the

power cable routing bracket on the bottom of the cover.

12. Align the filter cover with the three screw holes in the filter and install the

three screws holding the filter cover to the warming unit.

13. Attach the completed replacement filter label to the rear surface of the

filter cover. If a replacement filter label is already present, cover it with the

new label.

Service Manual 23

Page 24

Routine Maintenance

Power Cord Replacement

The warming system is equipped with a detachable power cord. If the power

cord is damaged, contact your local Nellcor representative.

Caution

Only qualified hospital personnel should replace the power cord.

The only equipment required for this procedure is a flat blade screwdriver.

To replace the power cord:

1. Unplug the warming system power cord from the AC outlet.

2. Lay the warming unit on its rear side so that the bottom of the warming

unit is visible.

3. Unwind the power cord from the filter cover.

4.

Unseat the power cord from the power cord routing bracket (Figure 7, item 4)

on the filter cover. If necessary, use the head of the flat blade screwdriver to

separate the halves of the bracket sufficiently to allow unseating of the cord

5. Disconnect the power cord connector (Figure 7, item 2) from its socket in

the blower housing.

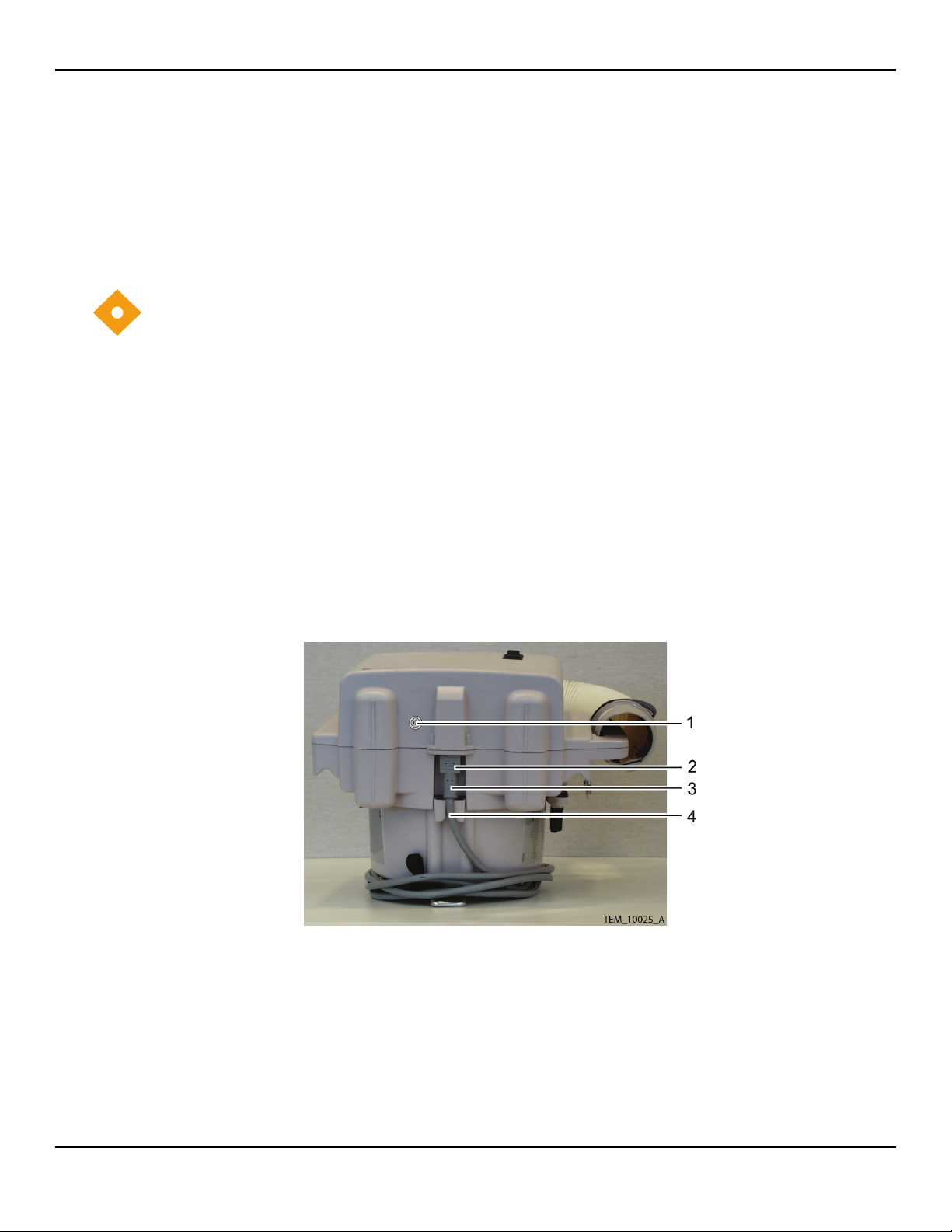

1 Equipotential Ground 3 Strain Relief

2 Power Cord Female Connector 4 Power Cord Routing Bracket

.

Figure 7. Power Cord Routing

24 Service Manual

Page 25

Nozzle Replacement

6. Connect the replacement power cord connector to the warming unit,

making sure the connector is fully inserted into the socket in the warming

unit housing.

7. Reseat the power cord into the power cord routing bracket. If necessary,

use the head of the flat blade screwdriver to separate the halves of the

bracket sufficiently to allow reseating of the cord.

Nozzle Replacement

If the nozzle is damaged, contact your Nellcor representative.

The only equipment required for this procedure is a flat blade screwdriver. The

nozzle is held in place at its base by four clips on the hose assembly; make

sure the screwdriver is long enough to reach inside the nozzle to the clips.

To replace the nozzle:

1. Insert the screwdriver blade into the nozzle, positioning it between one of

the clips and the inner surface of the nozzle.

2. Use the screwdriver blade to push the clip in toward the center of the

nozzle, while simultaneously pulling the nozzle away from the hose until

the clip is disengaged from the base of the nozzle.

3. Repeat steps 1 and 2 to disengage the other three clips.

4. Remove the nozzle from the hose.

5.

Put the replacement nozzle over the end of the hose

6. Push the replacement nozzle down onto the hose until all four clips

engage with the nozzle.

.

Service Manual 25

Page 26

Routine Maintenance

Cleaning the Warming Unit

Caution

Do not spray, pour, or spill any liquid on the warming unit, its accessories,

connectors, switches, or openings in the case.

For surface-cleaning and disinfecting, follow your institution's procedures or

the recommended actions below.

Surface cleaning — Use a soft cloth dampened with either a commercial,

•

nonabrasive cleaner or a solution of 70% alcohol in water, lightly wiping

the surfaces of the warming unit.

• Disinfection — Use a soft cloth saturated with a solution of 10% chlorine

bleach in tap water, lightly wiping the surfaces of the warming unit.

26 Service Manual

Page 27

1 Performance Verification

Overview

This chapter provides performance verification procedures to be used when

servicing the WarmTouch™ Model WT-5800 patient warming system.

Power Fail / Start Alarm Check

This procedure ensures the Power Fail / Start Alarm functions correctly and

can be canceled properly. Perform this procedure before returning the

warming system into service.

Overview

Note:

The Power Fail/Start Alarm is only found on WT-5800 warming units containing a

PCBA with part number GR100305. WT-5800 warming units with earlier versions of

the Control PCBA (referred to as the Universal PCBA in earlier versions of this

manual) do not have this alarm, and do not need this test.

At power up, both audible and visual alarms activate, regardless of the reason for

power loss. Selecting any blower temperature cancels both types of alarms.

No equipment is required for this check.

To check the Power Fail / Start Alarm:

1. Plug in the warming system.

2. Turn on the warming system using the power switch. The audible alarm should

sound intermittently, and the warning light should be on steady. The Low

temperature indicator light on the control panel should also be on steady.

3. Select any temperature setting. The audible alarm should stop, and the

warning light should turn off. The indicator light for the selected

temperature should be on steady.

4. Turn off the warming system and unplug it.

Service Manual 27

Page 28

Performance Verification

Thermostat Protection Check

This procedure checks to ensure that the thermostat protection controls are

working properly. This procedure should be performed before returning the

warming system into service.

Calibration of the thermostat protection is neither required nor possible. If the

test time or temperatures are outside the allowable range, factory service is

required. Contact your local Nellcor representative.

Table3.Equipment Required for Thermostat Protection Check

Equipment Description / Use

Temperature probe Mon-a-Therm subcutaneous temperature probe, or

equivalent, and monitor with an accuracy of ±0.2ºC.

Tape To hold the temperature probe in place.

Stopwatch Manual or electronic

Jumper wire with alligator clips 3 to 12 in (8 to 30 cm) long, alligator clip at each

end, 12 gauge minimum.

Phillips screwdriver #2 / Loosening and tightening test port screw.

WarmTouch CareDrape Lower

Body blanket

To complete patient warming system.

To check thermostat protection:

1. Lay the temperature probe beside the warming unit nozzle at the end of

the hose and bend approximately 1.5 inches (4 cm) of the temperature

probe into the nozzle opening.

2. Position the tip of the temperature probe approximately 1 to 2 in (2.5 to 5

cm)) inside the nozzle, centered in the nozzle opening.

3. Tape the probe in place.

4. Connect the probe to the temperature monitor.

5. Connect the nozzle to the blanket.

6. Unplug the warming system.

7. Loosen the over-temperature test port screw. See Figure 8.

8. Slide the over-temperature test port cover to the side.

28 Service Manual

Page 29

Thermostat Protection Check

Figure 8. Over-Temperature Test Port

WARNING

Possible patient injury. Connecting the jumper wire disables (shorts out) the

thermistor that is part of the temperature control system.

9. Connect the jumper wire across the two terminals in the over-temperature

test port.

10. Plug in the warming system and turn it on.

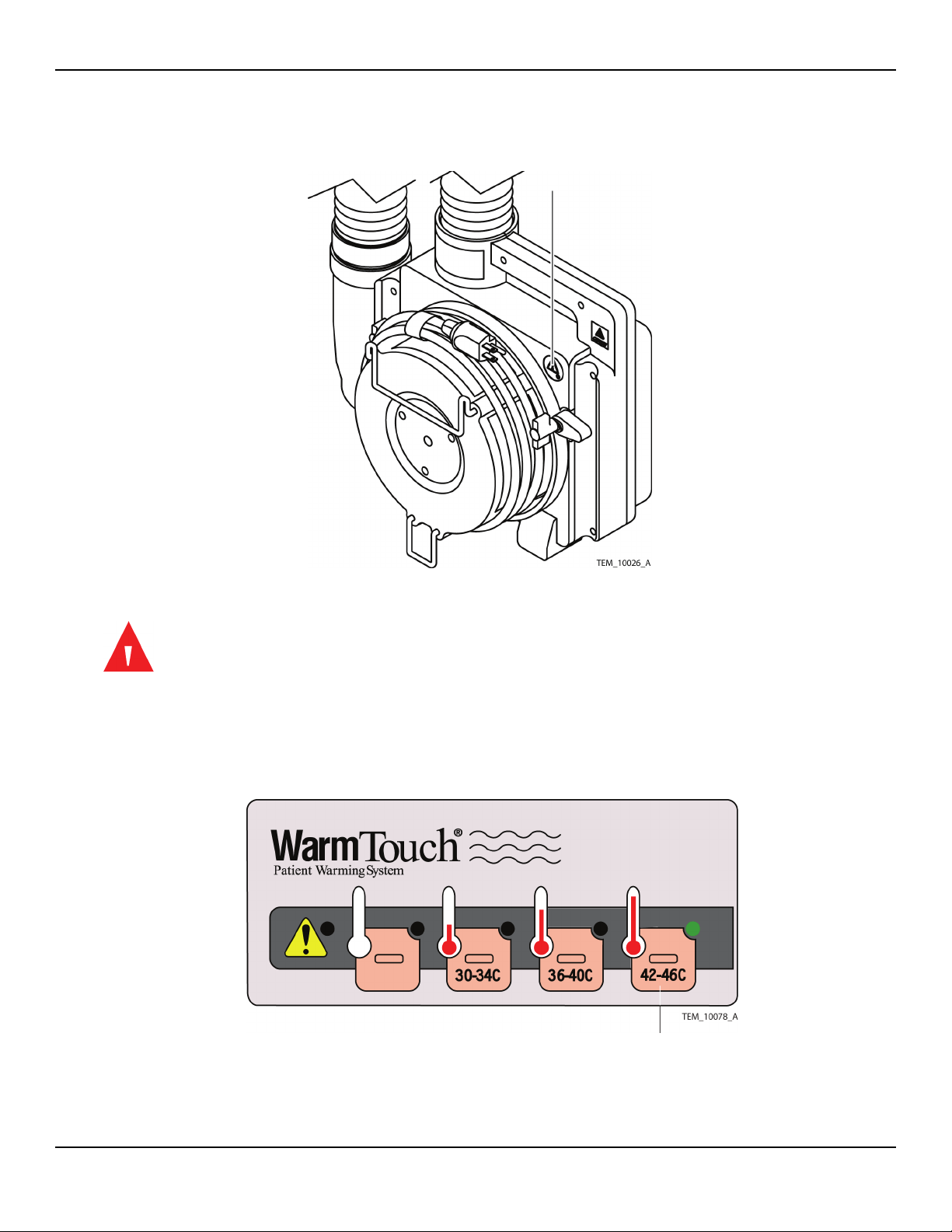

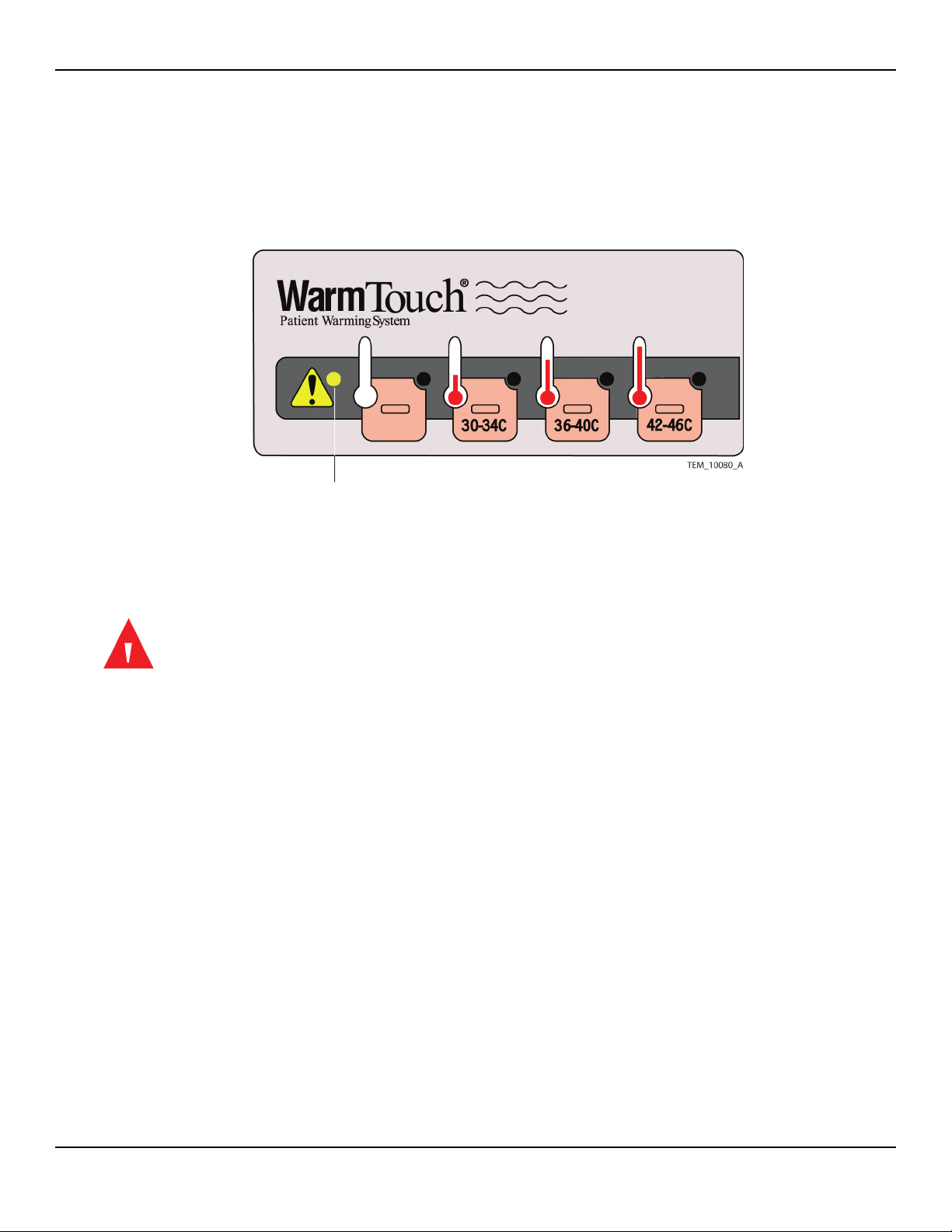

11. Select the High (42-46C) temperature setting. See Figure 9.

Figure 9. WT-5800 High Temperature Setting

Service Manual 29

Page 30

Performance Verification

12. When the monitored temperature exceeds 46ºC, start the stopwatch.

13. When the alarm starts to sound and the warning light indicator lights, stop

the stopwatch. See Figure 10.

Figure 10. Warning Light

14. Time elapsed on the stopwatch should be 5 minutes or less, and the

temperature monitor should not exceed 58ºC.

15. Turn off the warming system and unplug it.

WARNING

Possible patient injury. Connection of the jumper wire disables (shorts out)

the thermistor that is part of the temperature control system. The jumper

wire must be removed.

16. Remove the jumper wire from the over-temperature test port. See Figure 8.

17. Close the over-temperature test port and tighten the screw.

18. Disconnect the warming unit from the blanket.

19. Allow the warming unit to cool for 30 minutes before using it on a patient.

30 Service Manual

Page 31

Output Temperature Check

Output Temperature Check

This procedure measures the warming system output air temperature at the

input to the blanket. This procedure should be performed before returning

the warming system into service.

Calibration of the temperature control circuit is neither required nor possible.

If the test temperatures are outside the allowable range, factory service is

required. Contact your local Nellcor representative.

Table4.Equipment Required for Output Temperature Check

Equipment Description/Use

Temperature Probe Mon-a-Therm subcutaneous temperature probe, or

equivalent, and monitor with an accuracy of ±0.2ºC.

Tape To hold the temperature probe in place.

WarmTouch CareDrape™

Lower Body blanket

To complete patient warming system.

To check output temperature:

1. Lay the temperature probe alongside the warming unit nozzle at the end

of the hose and bend approximately 1.5 in (4 cm) of the temperature

probe into the nozzle opening.

2. Position the tip of the temperature probe so that it is approximately 1 to 2

in (2.5 to 5cm) inside the nozzle, centered in the nozzle opening.

3. Tape the probe in place.

4. Connect the probe to the temperature monitor.

5. Connect the nozzle to the blanket.

6. Extend the hose to match the configuration shown in Figure 11.

Service Manual 31

Page 32

Performance Verification

1 14 to 16 in (35.6 to 40.6 cm) 2 28 to 30 in (71.1 to 76.2 cm)

Figure 11. Output Temperature Test Setup

7. Turn on the warming system.

8. Select the Ambient temperature setting (Figure 12, item 1).

1 Ambient Temperature Select 3 Medium Temperature Select

2 Low Temperature Select 4 High Temperature Select

Figure 12. Temperature Selection

9. Allow the warming system to run for a few minutes at the Ambient

setting. The temperature monitor should indicate little to no change from

the ambient room air temperature.

10. Select the Low (30-34C) temperature setting (Figure 12, item 2).

11. Allow 8 to 10 minutes for the temperature to stabilize at the Low setting.

The temperature monitor should indicate 30ºC to 34ºC.

32 Service Manual

Page 33

12. Select the Medium (36-40C) temperature setting (Figure 12, item 3).

13. Allow 8 to 10 minutes for the temperature to stabilize at the Medium

setting. The temperature monitor should indicate 36ºC to 40ºC.

14. Select the High (42-46C) temperature setting (Figure 12, item 4).

15. Allow 8 to 10 minutes for the temperature to stabilize at the High setting.

The temperature monitor should indicate 42ºC to 46ºC.

16. Turn off the warming system and unplug it.

17. Disconnect the warming unit from the blanket.

18. Remove the temperature probe from the nozzle.

19. Allow the warming system to cool for 30 minutes before using it on a

patient.

Safety Tests

Safety Tests

The warming system is provided with a ground stud to allow safety testing

without opening the case. See Figure 13.

Figure 13. Ground Stud

Note:

Use applicable standards for institution and country. Test equipment and its

application must comply with the applicable standard.

To perform safety tests:

• Test ground integrity. See page 99 for test values.

• Test earth leakage current. See page 100 for test values.

• Test enclosure leakage current. See page 100 for test values.

Service Manual 33

Page 34

Performance Verification

Page Left Intentionally Blank

34 Service Manual

Page 35

1 Repair

Overview

This chapter provides procedures for servicing the WarmTouch™ Model WT5800 patient warming system.

WARNING

Before attempting to open or disassemble the warming system, disconnect

the power cord from the AC power source.

Caution

Observe ESD (electrostatic discharge) precautions when working within the warming

system.

Caution

Repairs to the warming system should only be accomplished by trained service

technicians.

Follow local government ordinances and recycling instructions regarding the disposal

of the warming system and/or parts.

Overview

Service Manual 35

Page 36

Repair

Filter Cover Assembly Replacement

Table5.Filter Cover Assembly Components

Qty Component

1 Filter cover

1 Bed hook

1 Foot, filter cover, short

4 Truss HD screws (8-32)

1 Gasket, WarmTouch

1 Operating instructions label

1 Grounding reliability label

Table6.Tools Required for Replacing FIlter Cover Assembly

Tool Parameter / Use

Phillips screwdriver #2 / Removing screws.

Torque driver 8 to 12 in/lbs (20 to 30 cm/kg)

Flat blade screwdriver Detaching filter cover from power cord.

To replace the filter cover assembly:

1. Unplug the warming system power cord from the AC outlet.

2. Lay the warming unit on its front side, so that the bottom of the unit is

visible.

36 Service Manual

Page 37

Filter Cover Assembly Replacement

3. Unwind the power cord from the filter cover. See Figure 14.

Figure 14. Power Cord

4. Unseat the power cord from the power cord routing bracket on the filter

cover. If necessary, use the head of the flat blade screwdriver to separate

the halves of the bracket sufficiently to allow unseating of the cord.

5. Disconnect the power cord connector from the warming unit.

6. Remove the filter cover screws. See Figure 15.

Figure 15. Filter Cover Screws

7. Remove the filter cover assembly from the warming unit.

Service Manual 37

Page 38

Repair

8. Place the replacement filter cover assembly on the warming unit and install

the screws. Tighten the screws to 8 to 12 in/lbs (20 to 30 cm/kg). See

Figure 15.

9. Reconnect the power cord to the warming unit. Ensure the connector is

fully inserted into the socket on the blower housing.

10. Reseat the power cord into the power cord routing bracket. If necessary,

use the head of the flat blade screwdriver to separate the halves of the

bracket sufficiently to allow reseating of the cord.

Separating the Front and Rear Covers

Table7.Tools Required for Separating Front and Rear Covers

Tool Parameter / Use

Phillips screwdriver #2 / Removing screws.

Flat blade screwdriver Detaching power cord from filter cover.

To separate the warming unit covers:

1. Unplug the warming system power cord from the AC outlet.

2. Lay the warming unit on its front side, so that the bottom of the unit is

visible.

3. Unwind the power cord from the filter cover. See Figure 16.

4. Unseat the power cord from the power cord routing bracket on the filter

cover. If necessary, use the head of the flat blade screwdriver to separate

the halves of the bracket sufficiently to allow unseating of the cord.

Figure 16. Power Cord

38 Service Manual

Page 39

Separating the Front and Rear Covers

5. Disconnect the power cord connector from the warming unit.

6. Remove the screws holding the front and rear covers together. See

Figure 17.

Figure 17. Cover Screw Locations

Caution

Separate the front and rear covers very carefully. Do not apply too much pressure

to the wires connecting the covers. They are short and easily damaged.

7. Carefully separate the front and rear covers. See Figure 18.

Figure 18. Separated Covers

Service Manual 39

Page 40

Repair

Rejoining the Front and Rear Covers

Caution

Ensure that the cable harness between the two covers is not pinched by the covers

when joining them back together.

To rejoin the warming unit covers:

1. Carefully align the covers and put them back together, placing the rear

cover atop the front cover so that the covers nest.

2. Install the screws through the holes in the rear cover to attach it to the

front cover. Tighten screws to 7 to 10 in/lbs (18 to 25 cm/kg). See

Figure 19.

Figure 19. Cover Screw Locations

3. Connect the power cord connector to the warming unit, making sure the

connector is fully inserted into the socket in the warming unit housing.

4. Reseat the power cord into the power cord routing bracket. If necessary,

use the head of the flat blade screwdriver to separate the halves of the

bracket sufficiently to allow reseating of the cord.

40 Service Manual

Page 41

Front Cover Assembly Replacement

Table8.Filter Cover Assembly Components

Qty Component

1 Front enclosure

1 Key pad

1 Lens

1 Ground symbol label

1 Cable tie mount

1 Cable clamp

1 Ground equipotential label

1 0.25 in (6.5 mm) hole for equipotential ground pin

Front Cover Assembly Replacement

Table9.Tools Required for Replacing Front Cover Assembly

Tool Parameters / Uses

Phillips screwdriver #2

Torque driver/wrench 4 to 12 in/lbs (10 to 30 cm/kg)

36 to 40 in/lbs (91 to 112 cm/kg)

Wire cutter Cutting cable ties.

Socket wrench 10 mm

Flat blade screwdriver Detaching power cord from filter cover.

Contact removal tool Souriau RX2025GE1 or equivalent

To replace the front cover assembly:

1. Separate the front and rear covers. See page 38, Separating the Front and

Rear Covers.

Service Manual 41

Page 42

Repair

2. Cut the cable harness bundle ties. See Figure 20.

Figure 20. Cable Harness Bundle Ties

3. Disconnect the 9-pin connector from the Control PCB (Figure 21, item 1).

1 9-Pin Connector 4 Cable Clamp

2 Equipotential Ground Terminal 5 Power Switch

3 AC Power Connector

Figure 21. Front Cover Assembly

42 Service Manual

Page 43

Front Cover Assembly Replacement

4. Disconnect the equipotential ground stud and remove it from the front

cover assembly (Figure 21, item 2).

5. Remove the AC power connector from the front cover assembly (Figure 21,

item 3).

6. Remove the cable clamp from the front cover assembly (Figure 21, item 4).

Caution

Write down the color code of each wire connected to the power switch. This will

ensure that the wires will be reconnected properly.

7. Disconnect the four wires from the power switch. See Figure 22.

8. Depress the four clips on the power switch and push the power switch

through its hole in the front cover assembly. See Figure 22.

Figure 22. Power Switch Clips and Wires

9. Cut the cable tie securing the thermistor cable to the front cover assembly

(Figure 23, item 1).

Figure 23. Cable Disconnect

Service Manual 43

Page 44

Repair

10. Remove the ground screw (Figure 23, item 2).

11. Cut the cable tie securing the thermistor cable connector (Figure 23, item

3) to the Control PCBA.

12. Disconnect the thermistor cable (Figure 23, item 3).

13. Disconnect the ribbon cable (Figure 23, item 4).

14. Remove the screws holding the Control PCB onto the front cover assembly.

Figure 24. Control PCB Screws

15. Carefully lift the Control PCB out of the front cover assembly.

16. Discard the old front cover assembly.

44 Service Manual

Page 45

Front Cover Assembly Replacement

Caution

Carefully align the lights on the Control PCB with the control panel key pad push

buttons. Failure to do so could damage the key pad or the Control PCB lights. See

Figure 25, items 1-5.

Figure 25. Control PCB Lights

17. Carefully place the Control PCB into the replacement front cover assembly

and install the mounting screws. Tighten the screws to 4 to 6 in/lbs (10 to

15 cm/kg). See Figure 26.

Figure 26. Control PCB Screws

Service Manual 45

Page 46

Repair

18. Connect the ribbon cable (Figure 27, item 4) to the Control PCBA.

Figure 27. Cable Connections

19. Connect the thermistor cable (Figure 27, item 3).

20. Install a cable tie around the thermistor cable connector (Figure 27, item 3)

and Control PCB connector to secure the thermistor cable to the PCBA.

21. Connect the keypad grounding strap and blower ground wire. See

Figure 27, item 2. Tighten the screw to 4 to 6 in/lbs (10 to 15 cm/kg).

22. Install a cable tie around the thermistor cable and the cable tie mount

(Figure 27, item 1) to secure the thermistor cable to the front cover.

23. Slide the power switch through its hole in the front of the front cover

assembly until the four clips on the power switch click into place. Ensure

that the “0”, marked on the front of the power switch, is towards the

bottom of the front cover assembly. See Figure 28.

Figure 28. Power Switch Clips and Wires

46 Service Manual

Page 47

Front Cover Assembly Replacement

24. Connect the four wires to the power switch. Make sure to reconnect the

wires in the same way they were connected before; refer to the list of wire

colors and where they were connected to the switch, as recorded in Step

7. See Figure 29, item 5.

Figure 29. Front Cover Assembly Component Locations

25. Install the cable clamp around the power switch cables. Tighten the screw

to 4 to 6 in/lbs (10 to 15 cm/kg. See Figure 29, item 4.

26. Install the AC power connector into the front cover assembly. Tighten

screws to 4 to 6 in/lbs (10 to 15 cm/kg). See Figure 29, item 3.

27. Install the equipotential ground (Figure 29, item 2) and attach ground wires

as shown in Figure 30. Tighten nuts to 36 to 44 in/lbs (91 to 112 cm/kg).

1 Blower Housing Ground 3 AC Power Connector Ground

2 Blower Motor Ground

Figure 30. Equipotential Ground Stud Wiring

Service Manual 47

Page 48

Repair

28. Connect the 9-pin connector to the Control PCB. See Figure 29, item 1.

29. Install the cable harness bundle ties. See Figure 31.

Figure 31. Cable Harness Bundle Ties

30. Rejoin the front and rear covers. See page 40, Rejoining the Front and Rear

Covers.

31. Perform the following checks/tests to verify proper operation of the

warming unit prior to returning it into service:

a. Power Fail / Start Alarm Check on page 27

b. Thermostat Protection Check on page 28

c. Output Temperature Check on page 31

d. Safety Tests on page 33

48 Service Manual

Page 49

Control PCBA Replacement

The replacement Control PCB (P/N GR100305) comes fully assembled.

Table10.Tools Required for Replacing Control PCB

Tool Parameter / Use

Phillips screwdriver #2 / Removing screws.

Torque driver 4 to 20 in/lbs (10 to 51 cm/kg)

Wire cutter Cutting cable ties and jumpers.

Flat blade screwdriver Detaching power cord from filter cover.

To replace the Control PCB assembly:

1. Separate the front and rear covers. See page 38, Separating the Front and

Rear Covers.

Control PCBA Replacement

2. Disconnect the 9-pin connector from the Control PCB (Figure 32, item 1).

1 9-pin Connector 3 Keypad Ribbon Cable Connector

2 Keypad and Blower Ground 4 Thermistor Cable Connector

Figure 32. Control PCB Connections

3. Cut the cable tie securing the thermistor cable connector (Figure 32, item

4) to the Control PCBA.

Service Manual 49

Page 50

Repair

4. Disconnect the thermistor cable.

5. Disconnect the ribbon cable (Figure 32, item 3).

6. Remove the screws holding the Control PCB onto the front cover assembly.

Figure 33. Control PCB Screws

7. Carefully lift the Control PCB out of the front cover assembly.

Caution

Carefully align the lights on the Control PCB with the control panel key pad push

buttons. Failure to do so could damage the key pad or the Control PCB lights. See

Figure 34, items 1-5.

Figure 34. Control PCB Lights

50 Service Manual

Page 51

Control PCBA Replacement

8. Carefully place the replacement Control PCB into the front cover assembly

and install the mounting screws. Tighten the screws to 4 to 6 in/lbs (10 to

15 cm/kg. See Figure 35.

Figure 35. Control PCB Screws

9. Connect the ribbon cable (Figure 36, item 3).

Figure 36. Cable Connections

10. Connect the thermistor cable.

Service Manual 51

Page 52

Repair

11. Install a cable tie around the thermistor cable connector (Figure 36, item 4)

and Control PCB connector to secure the thermistor cable to the PCBA.

12. Connect the 9-pin connector to the Control PCB (Figure 36, item 1).

13. Install the cable harness bundle ties. See Figure 37, item 1.

Figure 37. Cable Harness Bundle Ties

14. Rejoin the front and rear covers. See page 40, Rejoining the Front and Rear

Covers.

15. Perform the following checks/tests to verify proper operation of the

warming unit prior to returning it into service:

a. Power Fail / Start Alarm Check on page 27

b. Thermostat Protection Check on page 28

c. Output Temperature Check on page 31

d. Safety Tests on page 33

52 Service Manual

Page 53

Heater Assembly Replacement

Table11.Heater Assembly Components

Qty Component

1 Heater, 230V

2 Pins, 16-18 GA, 13 A

Table12.Tools Required for Replacing Heater Assembly

Tool Parameter / Use

Phillips screwdriver #2 / Removing screws

Wire cutter Cutting cable ties

Socket 10 mm

Contact removal tool Souriau RX2025GE1 or equivalent

Heater Assembly Replacement

Torque driver/wrench 4 to 12 in/lbs (10 to 30 cm/kg)

36 to 44 in/lbs (91 to 112 cm/kg)

Flat blade screwdriver Detaching power cord from filter cover

To replace the heater assembly:

1. Remove the filter cover assembly from the rear cover assembly. See page

36, Filter Cover Assembly Replacement.

2. Remove the filter from the rear cover assembly. See Figure 38, item 1.

Figure 38. Filter Removal

Service Manual 53

Page 54

Repair

Note:

The blower assembly is attached to the rear cover assembly by four screws and four

clips. It is easier for two people to release the clips and lift the blower assembly from

the rear cover assembly.

3. Remove the screws holding the blower assembly to the rear cover

assembly. See Figure 39.

Figure 39. Blower Assembly Screws

4. Separate the front and rear covers. See page 38, Separating the Front and

Rear Covers.

5. Cut the cable harness bundle ties. See Figure 40, items 1 and 2.

Figure 40. Cable Harness Bundle Ties

6. Disconnect the 9-pin connector from the Control PCB. See Figure 41, item 1.

54 Service Manual

Page 55

Heater Assembly Replacement

Note:

During the remainder of this procedure, make sure not to apply excessive pressure to

the wires still connected between the separated halves of the warming unit.

1 9-Pin Connector 4 Cable Clamp

2 Equipotential Ground Terminal 5 Power Switch

3 AC Power Connector

Figure 41. Front Cover Assembly

Caution

Care must be taken when moving the duct adapter. The thermistor connection to the

duct adaptor is fragile and will become disconnected if too much pressure is applied

to it.

Service Manual 55

Page 56

Repair

7. Carefully lift the duct adapter and lay the duct adapter on the rear cover

handle. See Figure 42.

1 Duct Adapter 2 Thermistor Connection

Figure 42. Duct Adapter Placement

56 Service Manual

Page 57

Heater Assembly Replacement

8. Rotate the blower motor assembly clockwise to disengage two of the four

clips. See Figure 43 and Figure 44.

Figure 43. Blower Motor Removal

Figure 44. Blower Assembly Clips

9. Slide the blower motor assembly away from the engaged clips to

disengage them.

Service Manual 57

Page 58

Repair

10. Lay the blower motor assembly beside the rear cover assembly. Do not

overstress the connecting wires.

11. Remove the rubber gasket from the rear cover assembly.

Figure 45. Rubber Gasket

Caution

Do not touch the heater coil. Body oil can damage the heater coil when it is in use.

12. Lift the heater assembly (Figure 46, item 1) out of the rear cover assembly.

Figure 46. Heater Assembly

58 Service Manual

Page 59

Heater Assembly Replacement

Note:

For the next four steps, use a Souriau RX2025GE1 contact removal tool or equivalent.

13. Remove the black wire and pin (Figure 46, item 3) from pin 2 of the 9-pin

connector (Figure 46, item 5).

14. Remove the red wire (may be white in some assemblies) and pin (Figure 46,

item 2) from pin 8 of the 9-pin connector (Figure 46, item 4).

15. Install the red (or white) wire and pin from the new heater into pin 8 of the

9-pin connector.

16. Install the black wire and pin from the new heater into pin 2 of the 9-pin

connector.

Note:

Ensure that the heater thermostat (Figure 47, item 3) is oriented upward when

reinstalling the heater in the rear cover assembly.

17. Slide the new heater into the rear cover assembly. See Figure 47.

1 Heater Assembly (removed) 3 Heater Assembly (in place)

2 Rear Panel Assembly 4 Heater Wire Cutouts

Figure 47. Heater Assembly Installation

18. Orient the heater so that the heater thermostat (Figure 47, item 3) is

nearest the rear cover assembly handle (Figure 47, item 2).

19. Route the wires from the heater through the cut-outs in the rear cover

assembly (Figure 47, item 4).

Service Manual 59

Page 60

Repair

20. Place the rubber gasket into the rear cover assembly, with the wire

indentations over the heater wires. See Figure 48, item 1.

Figure 48. Rubber Gasket

21. Place the blower assembly into the rear cover assembly and ensure that the

blower assembly clips (shown in Figure 49) attach over the edges of the

blower assembly.

Figure 49. Blower Assembly Clips

60 Service Manual

Page 61

Heater Assembly Replacement

Caution

Exercise caution when moving the duct adapter. Do not apply excessive pressure, as

the thermistor connection to the duct adaptor is fragile and can easily become

disconnected.

22. Carefully reinsert the duct adapter into the blower assembly. See Figure 50.

1 Duct Adapter 2 Thermistor Connection

Figure 50. Duct Adapter Placement

Note:

If the rivet holding the thermistor in place in the duct is loose or pulled out entirely,

follow the instructions in the Duct Adapter Assembly Replacement section (page 66)

to reseat the thermistor.

Service Manual 61

Page 62

Repair

23. Install the blower assembly mounting screws into the rear cover assembly.

Tighten the screws to 4 to 6 in/lbs (10 to 15 cm/kg).

Figure 51. Blower Assembly Screws

24. Connect the 9-pin connector to the Control PCB. See Figure 41, item 1.

25. Install the cable harness bundle ties. See Figure 52, items 1 and 2.

Figure 52. Cable Harness Bundle Ties

26. Rejoin the front and rear covers. See page 40, Rejoining the Front and Rear

Covers, steps 1 and 2.

62 Service Manual

Page 63

27. Place the filter into the rear cover assembly.

Figure 53. Filter Installation

Heater Assembly Replacement

28. Install the filter cover assembly on the rear cover assembly. Tighten the

screws to 8 to 12 in/lbs (20 to 30 cm/kg). See Figure 54.

Figure 54. Filter Cover Installation

29. Install the power cord on the warming system, inserting the female

connector into its socket on the warming system housing, and seating the

cord in the routing bracket on the filter cover. If necessary, use the head of

a flat blade screwdriver to separate the halves of the routing bracket

sufficiently to allow seating of the cord.

Service Manual 63

Page 64

Repair

30. Perform the following checks/tests to verify proper operation of the

warming unit prior to returning it into service:

a. Power Fail / Start Alarm Check on page 27

b.

Thermostat Protection Check on page 28

c. Output Temperature Check on page 31

Safety Tests on page 33

d.

Hose Replacement

Table13.Hose Assembly Components

Qty Component

1 Hose

1 Nozzle Strap with Clip

Table14.Tools Required for Replacing Hose Assembly

Tool Parameter / Use

Wire cutter Cutting reinforcing wire

Pliers Bending reinforcing wire

Note:

If the warming system hose is damaged, contact your local Nellcor representative to

obtain a replacement hose. The hose for the warming system is made of plastic

reinforced with wire.

Caution

Only qualified service technicians should replace the hose.

To replace the hose:

1. Separate the front and rear covers. See page 38, Separating the Front and

Rear Covers.

2. Locate the end of the hose on the duct adapter.

64 Service Manual

Page 65

3. Find the end of the hose’s reinforcing wire that is inserted into the locking

hole in the duct adapter (Figure 55, item 1). Straighten the end of the wire

and pull it out of the locking hole.

Hose Replacement

Figure 55. Hose Attachment

4. Turn the hose counterclockwise to unscrew it from the duct adapter.

5. On the replacement hose, trim the end of the reinforcing wire that is free

of the hose material so that approximately 5/8” remains.

6. At a point 1/2” from its free end, bend the wire 90 degrees, so it is

perpendicular to the edge of the hose.

7. Put the end of the replacement hose onto the duct adapter.

8. Turn the hose clockwise to screw it onto the duct adapter, until the bent

end of the reinforcing wire is aligned with and can easily be placed into the

locking hole.

9. Hook the end of the wire through the locking hole, then bend it to secure

the hose in place. (See Figure 55.)

10. Remove the nozzle from the end of the old hose and install it onto the free

end of the replacement hose. Refer to page 25, Nozzle Replacement.

11. Remove the blanket clip from the old hose and slide it over the nozzle onto

the replacement hose.

12. Rejoin the front and rear covers. See page 40, Rejoining the Front and Rear

Covers.

Service Manual 65

Page 66

Repair

13. Perform the following checks/tests to verify proper operation of the

warming unit prior to returning it into service:

• Power Fail / Start Alarm Check on page 27

• Thermostat Protection Check on page 28

• Output Temperature Check on page 31

• Safety Tests on page 33

Duct Adapter Assembly Replacement

Table15.Duct Adapter Assembly Components

Qty Component

1 Duct Adapter

2 Screen

Table16.Tools Required for Replacing Duct Adapter Assembly

Tool Parameter / Use

Phillips screwdriver #2 / Removing screws

Wire cutter Cutting cable ties

Knife Removal of silicone RTV

Silicone RTV Thermistor connection

Torque driver/wrench 7 to 12 in/lbs (18 to 30 cm/kg)

Flat blade screwdriver Detaching power cord from filter cover

Removing thermostat rivets

Needlenose pliers Removing thermostat rivets

To replace the duct adapter assembly:

1. Separate the front and rear covers. See page 38, Separating the Front and

Rear Covers.

Caution

The thermistor is very delicate and easily damaged. Use extreme care when handling,

removing, or replacing the thermistor.

66 Service Manual

Page 67

Duct Adapter Assembly Replacement

2. Remove the silicone RTV from the thermistor connection on the duct

adapter assembly. See Figure 56.

Figure 56. Thermistor Silicone

3. Carefully detach the thermistor rivet (Figure 57, item 3) and slide the

thermistor (Figure 57, item 2) out of the duct adapter assembly.

Figure 57. Thermistor Removal

4. Detach the wires from the two thermostats on the side of the duct

transition. Leave the jumper wire connecting the two thermostats

(Figure 57, item 1) in place.

Service Manual 67

Page 68

Repair

5. Lift the duct adapter assembly out of the rear cover assembly. See

Figure 58, item 1.

Figure 58. Duct Adapter Removal

6. Using the flat blade screwdriver, reach inside the duct and push the locking

pin on each of the plastic rivets holding the thermostats in place

downward, so that the pins are flush with the surface of the rivet.

7. Outside the duct, use the needlenose pliers to pull each locking pin

upward (out from the duct) until the rivet is loose and pulls free from the

duct. Save the rivets and their locking pins.

8. Line up the holes in the thermostat mounting flanges with the holes in the

replacement duct.

9. Reinstall the plastic rivets, pushing them through the holes in the

thermostat mounting flanges into the holes in the replacement duct.

Outside the duct, use the flat blade screwdriver to push the locking pins on

the rivets inward so that they are flush with the tops of the rivets.

10. Connect the two wires previously attached to the old duct adapter onto

the replacement duct adapter, connecting them to the same connection

points.