Page 1

Service Manual

WarmTouch™

Convective Warming Unit

Page 2

COVIDIEN, COVIDIEN with logo, and Covidien logo are U.S. and internationally registered

trademarks of Covidien AG. Other brands are trademarks of a Covidien company.

©2013 Covidien.

Page 3

Table of Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2.1 Safety Symbol Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2.2 Warnings (Service) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.2.3 Cautions (Service) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.2.4 Warnings (Patient Treatment) . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.2.5 Cautions (Patient Treatment) . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1.3 ESD (Electrostatic Discharge) Precautions . . . . . . . . . . . . . . . . . . .1-7

1.4 Tools Required for Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

1.5 Serial Number, Software Version, and Error Codes . . . . . . . . . . . .1-9

1.6 Component Disposal - WEEE Directive . . . . . . . . . . . . . . . . . . . .1-11

1.7 Labeling Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

1.8 Obtaining Technical Assistance . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

1.9 Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

1.10 Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-17

2 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2.1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2.2 Indications for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.2.3 Contraindications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

2.2.4 Covidien WarmTouch™ Warming Blankets . . . . . . . . . . . . . .2-2

2.3 Product Views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.3.1 Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.3.2 Back View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.4 Operator’s Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 Safety Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.3 Attaching the Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3.4 Installing the Warming Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3.4.1 IV Pole Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

3.4.2 Bed Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

3.4.3 Cart Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Service Manual i

Page 4

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.2 Safety Reminder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

4.3 Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

4.4 Overview of Warming Unit Operating Modes . . . . . . . . . . . . . . . .4-3

4.5 Beginning Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

4.6 Controlling the Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-5

4.6.1 Using Boost Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-6

4.6.2 Using the Heat Off Setting . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4.6.3 Returning to Ready Mode . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

4.6.4 Returning to Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . .4-8

4.6.5 If Power is Interrupted... . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

4.7 Powering Off the Warming Unit . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.2 Safety Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

5.3 Cleaning the Warming Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

5.4 Safety Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

5.4.1 Physical Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

5.4.2 Temperature and Alarm Verification . . . . . . . . . . . . . . . . . . .5-3

5.4.3 Electrical Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

5.5 Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

5.6 Monitoring the Filter Status . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.2 Safety Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

6.3 Principles of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-2

6.3.2 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-3

6.3.3 Component Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-4

6.3.4 Component Cable Connections . . . . . . . . . . . . . . . . . . . . . .6-8

6.4 Basic Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-9

6.5 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-12

7 Performance Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.2 Safety Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7.3 Required Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

7.4 Service Screen Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

ii Service Manual

Page 5

7.5 Performance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.5.1 Power-On Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7.5.2 Keypad Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-5

7.5.3 Display Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-7

7.5.4 Temperature Accuracy Test . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

7.5.5 Flow Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-10

7.5.6 Thermostat Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-11

7.6 Electrical Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-14

7.6.1 Ground Bond Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-14

7.6.2 Earth Leakage Current Test (Line Leakage) . . . . . . . . . . . . .7-14

7.6.3 Enclosure Leakage Current Test (Line Leakage) . . . . . . . . . .7-14

8 External Component Replacement . . . . . . . . . . . . . . . . . . . . . . . . .8-1

8.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

8.2 Safety Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-1

8.3 Pole Clamp Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

8.4 USB Port Cover Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-4

8.5 Power Cord Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

8.6 Nozzle Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-8

8.7 Nozzle Strap with Clip Replacement . . . . . . . . . . . . . . . . . . . . . .8-10

8.8 No Free-Hosing Label Replacement . . . . . . . . . . . . . . . . . . . . . . .8-11

9 Accessing the Inside of the Warming Unit . . . . . . . . . . . . . . . . . .9-1

9.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

9.2 Safety Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

9.3 Separating the Front and Rear Enclosures . . . . . . . . . . . . . . . . . . .9-2

9.4 Rejoining the Front and Rear Enclosures . . . . . . . . . . . . . . . . . . . .9-5

10 Internal Component Replacement (Inside Front Enclosure) . . .10-1

10.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

10.2 Safety Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-2

10.3 Keypad Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-3

10.4 Display (LCD) Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-8

10.5 User Interface (UI) PCBA Replacement . . . . . . . . . . . . . . . . . .10-12

10.6 Ribbon Cable Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . .10-19

10.7 USB Cable Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-22

10.8 Clock Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . .10-29

10.9 Power PCBA Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . .10-31

10.10 Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-35

10.11 Speaker Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-37

10.12 Speaker Cable Replacement . . . . . . . . . . . . . . . . . . . . . . . . .10-40

Service Manual iii

Page 6

10.13 Power Supply Replacement . . . . . . . . . . . . . . . . . . . . . . . . .10-43

10.14 Power Supply Output Cable Replacement . . . . . . . . . . . . . . .10-46

10.15 Ground Cable Replacement . . . . . . . . . . . . . . . . . . . . . . . . .10-48

10.16 AC Power Inlet Replacement . . . . . . . . . . . . . . . . . . . . . . . .10-51

10.17 Equipotential Stud Replacement . . . . . . . . . . . . . . . . . . . . . .10-55

11 Internal Component Replacement (Inside Rear Enclosure) . . .11-1

11.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

11.2 Safety Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-2

11.3 Thermistor Sensor Assembly Replacement . . . . . . . . . . . . . . . .11-3

11.4 Thermostat Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-9

11.5 Thermostat Cable Replacement . . . . . . . . . . . . . . . . . . . . . . .11-14

11.6 Pole Clamp and Mounting Bolt Replacement . . . . . . . . . . . . .11-18

11.7 Hose Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-21

11.8 Hose Duct Adapter Replacement . . . . . . . . . . . . . . . . . . . . . .11-25

11.9 Fan Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . .11-33

11.10 Heater Assembly Replacement . . . . . . . . . . . . . . . . . . . . . . .11-43

12 Enclosure Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

12.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

12.2 Safety Reminders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

12.3 Front Enclosure Replacement . . . . . . . . . . . . . . . . . . . . . . . . . .12-2

12.4 Filter Enclosure Replacement . . . . . . . . . . . . . . . . . . . . . . . . .12-12

12.5 Rear Enclosure Replacement . . . . . . . . . . . . . . . . . . . . . . . . . .12-15

13 Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-1

13.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-1

13.2 Physical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-1

13.2.1 Warming Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-1

13.2.2 Transport Cart (Optional) . . . . . . . . . . . . . . . . . . . . . . . . .13-1

13.3 Electrical Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-2

13.4 Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . .13-2

13.4.1 Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-2

13.4.2 Shipping and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-2

13.5 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-3

13.6 Product Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-3

13.7 Electromagnetic Compatibility (EMC) . . . . . . . . . . . . . . . . . . . .13-4

13.7.1 Manufacturer’s Declaration . . . . . . . . . . . . . . . . . . . . . . . .13-4

13.7.2 Electromagnetic Emissions . . . . . . . . . . . . . . . . . . . . . . . . .13-4

13.7.3 Electromagnetic Immunity . . . . . . . . . . . . . . . . . . . . . . . . .13-5

iv Service Manual

Page 7

14 Packing for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-1

14.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-1

14.2 Returning the Warming Unit to Covidien . . . . . . . . . . . . . . . . .14-1

14.3 Packing in the Original Carton . . . . . . . . . . . . . . . . . . . . . . . . .14-2

14.4 Packing in a Different Carton . . . . . . . . . . . . . . . . . . . . . . . . . .14-4

A Parts and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.2 External Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

A.3 Internal Components (Inside Front Enclosure) . . . . . . . . . . . . . . . A-3

A.4 Internal Components (Inside Rear Enclosure) . . . . . . . . . . . . . . . A-5

A.5 Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

A.6 Miscellaneous Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

A.7 Parts Locator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-8

B Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

B.2 Error Codes and Suggested Resolutions . . . . . . . . . . . . . . . . . . . .B-2

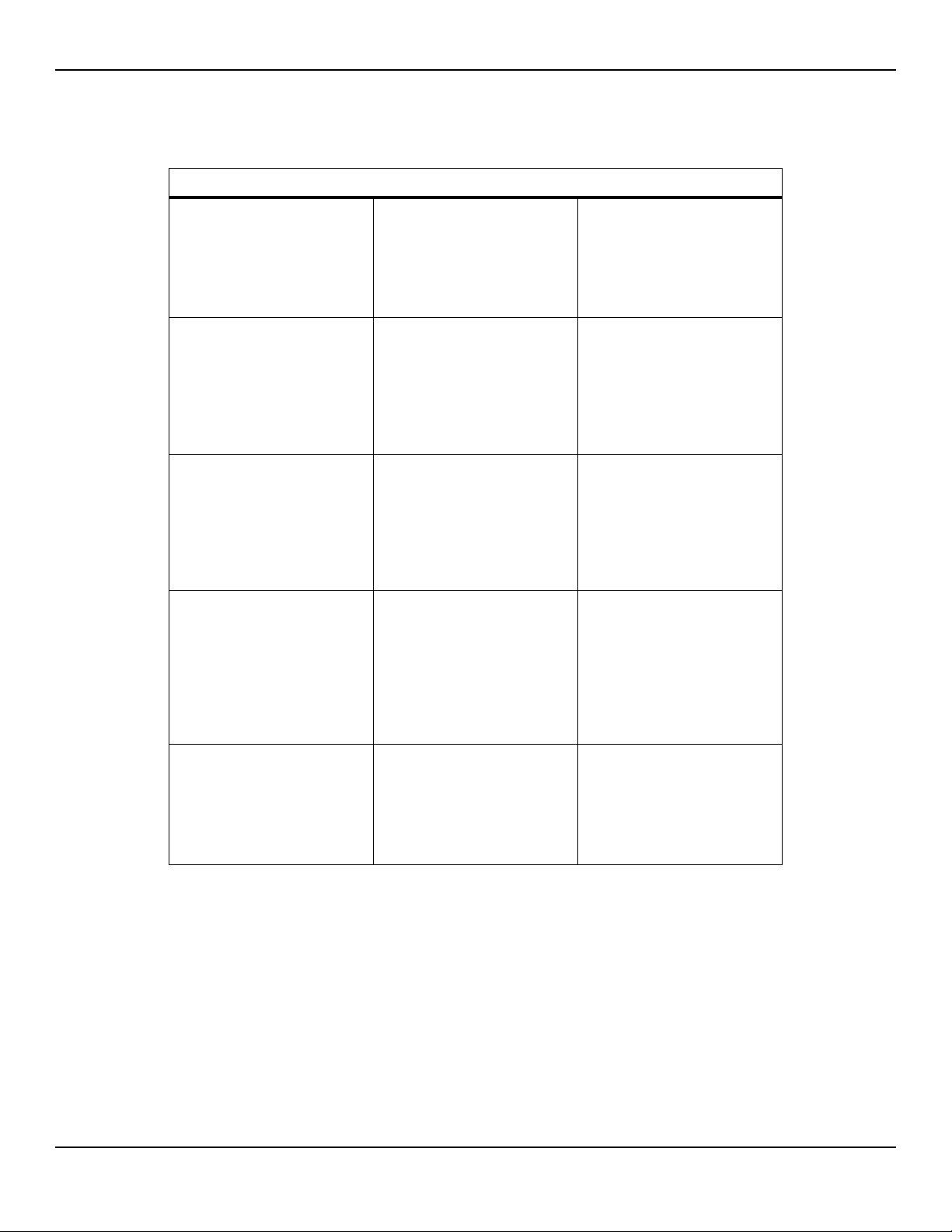

C Service Test Data Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

C.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-1

Service Manual v

Page 8

Page Left Intentionally Blank

vi Service Manual

Page 9

Figures

1 Introduction

Figure 1-1 Serial Number Label on Back of Warming Unit . . . . . . . . . . . .1-9

Figure 1-2 Menu Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Figure 1-3 System Information Screen . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

2 Product Overview

Figure 2-1 Front View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Figure 2-2 Back View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Figure 2-3 Operator’s Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

3 Installation

Figure 3-1 Positioning the Unit for Power Cord Installation . . . . . . . . . . .3-2

Figure 3-2 Power Cord Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Figure 3-3 Power Cord Wrapped and Secured . . . . . . . . . . . . . . . . . . . .3-4

Figure 3-4 Back View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Figure 3-5 Warming Unit Mounted on IV Pole . . . . . . . . . . . . . . . . . . . . .3-7

Figure 3-6 Bed Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-8

Figure 3-7 Back View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Figure 3-8 Cart Mounting Peg and Warming Unit Mounting Hole . . . . .3-10

Figure 3-9 Warming Unit Mounted on Cart . . . . . . . . . . . . . . . . . . . . . .3-11

4 Operation

Figure 4-1 Main Screen at Power-On . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Figure 4-2 Replace Filter Screen at Power-On . . . . . . . . . . . . . . . . . . . . . .4-4

Figure 4-3 Warming System Set to 40°C (Medium) . . . . . . . . . . . . . . . . .4-6

Figure 4-4 Warming System Set to Boost Mode . . . . . . . . . . . . . . . . . . . .4-6

Figure 4-5 Warming System Set to Heat Off . . . . . . . . . . . . . . . . . . . . . .4-7

Figure 4-6 Warming System Set to Ready Mode . . . . . . . . . . . . . . . . . . .4-7

5 Maintenance

Figure 5-1 Replace Filter Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-4

Figure 5-2 Filter Enclosure and Power Cord Connection . . . . . . . . . . . . . .5-5

Figure 5-3 HEPA Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Figure 5-4 Gasket inside Filter Enclosure . . . . . . . . . . . . . . . . . . . . . . . . .5-7

Figure 5-5 Replace Filter Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Figure 5-6 Filter Information Screen - Filter Expired . . . . . . . . . . . . . . . . .5-8

Figure 5-7 Main Screen at Power-On . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-9

Figure 5-8 Power Cord Wrapped and Secured . . . . . . . . . . . . . . . . . . . .5-9

Service Manual vii

Page 10

Figure 5-9 Menu Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Figure 5-10 Filter Information Screen . . . . . . . . . . . . . . . . . . . . . . . . . . .5-11

6 Troubleshooting

Figure 6-1 Warming Unit Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . .6-3

Figure 6-2 Cable Connections Between Major Components . . . . . . . . . .6-8

Figure 6-3 Low-Priority Alarm (Left) and Medium-Priority Alarm (Right) .6-12

7 Performance Verification

Figure 7-1 Key Code Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-2

Figure 7-2 Main Screen at Power-On . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

Figure 7-3 Replace Filter Screen at Power-On . . . . . . . . . . . . . . . . . . . . . .7-4

Figure 7-4 Position of Hose for Temperature Accuracy Test . . . . . . . . . . .7-8

Figure 7-5 Position of Hose for Flow Test . . . . . . . . . . . . . . . . . . . . . . . .7-10

Figure 7-6 Menu Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-11

Figure 7-7 Key Code Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-11

Figure 7-8 Select Test Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-12

Figure 7-9 Thermostat Test Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-12

8 External Component Replacement

Figure 8-1 Pole Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-2

Figure 8-2 Pole Clamp Foot and Knob . . . . . . . . . . . . . . . . . . . . . . . . . . .8-3

Figure 8-3 USB Port Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-4

Figure 8-4 Power Cord Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

Figure 8-5 Power Cord Wrapped and Secured . . . . . . . . . . . . . . . . . . . . .8-7

Figure 8-6 Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-8

Figure 8-7 Nozzle Clips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

Figure 8-8 Nozzle Strap with Clip . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-10

Figure 8-9 No Free-Hosing Labels on Front Enclosure (L) and Nozzle (R) .8-11

9 Accessing the Inside of the Warming Unit

Figure 9-1 Separated Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

Figure 9-2 Power Cord Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

Figure 9-3 Enclosure Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-4

Figure 9-4 Rejoining the Enclosures . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-5

Figure 9-5 Power Cord Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-6

Figure 9-6 Power Cord Wrapped and Secured . . . . . . . . . . . . . . . . . . . . .9-7

10 Internal Component Replacement (Inside Front Enclosure)

Figure 10-1 Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-3

Figure 10-2 Keypad Cable Connection on UI PCBA . . . . . . . . . . . . . . . .10-4

viii Service Manual

Page 11

Figure 10-3 Removing the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-5

Figure 10-4 Feeding the Keypad Cable Through the Access Slot . . . . . .10-6

Figure 10-5 Aligning the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

Figure 10-6 Keypad Cable Secured by Locking Bar . . . . . . . . . . . . . . . . .10-7

Figure 10-7 Display behind UI PCBA . . . . . . . . . . . . . . . . . . . . . . . . . . .10-8

Figure 10-8 Display Cable Connection on UI PCBA . . . . . . . . . . . . . . . .10-9

Figure 10-9 Positioning the Display . . . . . . . . . . . . . . . . . . . . . . . . . . .10-10

Figure 10-10 UI PCBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-12

Figure 10-11 UI PCBA Connections . . . . . . . . . . . . . . . . . . . . . . . . . . .10-14

Figure 10-12 USB Connection on UI PCBA . . . . . . . . . . . . . . . . . . . . . .10-15

Figure 10-13 Attaching Backing Plate and Cable Tie to UI PCBA . . . . .10-16

Figure 10-14 Keypad Cable Secured by Locking Bar . . . . . . . . . . . . . . .10-18

Figure 10-15 Ribbon Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-19

Figure 10-16 Ribbon Cable Connections . . . . . . . . . . . . . . . . . . . . . . .10-20

Figure 10-17 USB Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-22

Figure 10-18 USB Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-23

Figure 10-19 UI PCBA Connections . . . . . . . . . . . . . . . . . . . . . . . . . . .10-24

Figure 10-20 USB Connection on UI PCBA . . . . . . . . . . . . . . . . . . . . . .10-25

Figure 10-21 Attaching Backing Plate and Cable Tie to UI PCBA . . . . .10-26

Figure 10-22 Keypad Cable Secured by Locking Bar . . . . . . . . . . . . . . .10-28

Figure 10-23 Clock Battery on UI PCBA . . . . . . . . . . . . . . . . . . . . . . . .10-29

Figure 10-24 Power PCBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-31

Figure 10-25 Power PCBA Connections . . . . . . . . . . . . . . . . . . . . . . . .10-33

Figure 10-26 Fuses on Power PCBA . . . . . . . . . . . . . . . . . . . . . . . . . . .10-35

Figure 10-27 Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-37

Figure 10-28 Speaker Cable Connections . . . . . . . . . . . . . . . . . . . . . .10-38

Figure 10-29 Speaker Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-40

Figure 10-30 Speaker Cable Connections . . . . . . . . . . . . . . . . . . . . . .10-41

Figure 10-31 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-43

Figure 10-32 Power Supply Connections . . . . . . . . . . . . . . . . . . . . . . .10-44

Figure 10-33 Power Supply Output Cable . . . . . . . . . . . . . . . . . . . . . .10-46

Figure 10-34 Power Supply Output Cable Connections . . . . . . . . . . . .10-47

Figure 10-35 Ground Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-48

Figure 10-36 Ground Cable Terminal on Equipotential Stud . . . . . . . .10-49

Figure 10-37 AC Power Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-51

Figure 10-38 AC Power Inlet Connections . . . . . . . . . . . . . . . . . . . . . .10-52

Figure 10-39 Equipotential Stud Connections . . . . . . . . . . . . . . . . . . .10-53

Figure 10-40 Equipotential Stud . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-55

Figure 10-41 Equipotential Stud Connections . . . . . . . . . . . . . . . . . . .10-56

Figure 10-42 Equipotential Stud and Washer . . . . . . . . . . . . . . . . . . . .10-57

Service Manual ix

Page 12

11 Internal Component Replacement (Inside Rear Enclosure)

Figure 11-1 Thermistor Sensor Assembly . . . . . . . . . . . . . . . . . . . . . . . .11-3

Figure 11-2 Thermistor Wire and Rivet . . . . . . . . . . . . . . . . . . . . . . . . . .11-4

Figure 11-3 Thermistor Cable Connections . . . . . . . . . . . . . . . . . . . . . .11-5

Figure 11-4 Attaching Rivet to Thermistor Wire . . . . . . . . . . . . . . . . . . .11-6

Figure 11-5 Inserting Thermistor Wire and Rivet . . . . . . . . . . . . . . . . . .11-6

Figure 11-6 Thermistor Position Inside Hose Duct Adapter . . . . . . . . . . .11-7

Figure 11-7 Inserting the Hose Duct Adapter . . . . . . . . . . . . . . . . . . . . .11-7

Figure 11-8 Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-9

Figure 11-9 Thermostat Cable Connection to Thermostat . . . . . . . . . .11-10

Figure 11-10 Thermostat Rivets (Outside of Hose Duct Adapter) . . . . .11-11

Figure 11-11 Thermostat Rivets (Inside of Hose Duct Adapter) . . . . . . .11-12

Figure 11-12 Inserting the Hose Duct Adapter . . . . . . . . . . . . . . . . . . .11-12

Figure 11-13 Thermostat Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-14

Figure 11-14 Thermostat Cable Connection to Power PCBA . . . . . . . .11-15

Figure 11-15 Thermostat Cable Connection to Thermostat . . . . . . . . .11-16

Figure 11-16 Pole Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-18

Figure 11-17 Pole Clamp Foot and Knob . . . . . . . . . . . . . . . . . . . . . . .11-19

Figure 11-18 Pole Clamp Mounting Bolt . . . . . . . . . . . . . . . . . . . . . . .11-20

Figure 11-19 Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-21

Figure 11-20 Wire Attaching Hose to Hose Duct Adapter . . . . . . . . . .11-22

Figure 11-21 Inserting Hose Duct Adapter . . . . . . . . . . . . . . . . . . . . . .11-23

Figure 11-22 Hose Duct Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-25

Figure 11-23 Thermistor Wire and Rivet . . . . . . . . . . . . . . . . . . . . . . . .11-26

Figure 11-24 Thermostat Cable Connection to Thermostat . . . . . . . . .11-27

Figure 11-25 Wire Attaching Hose to Hose Duct Adapter . . . . . . . . . .11-28

Figure 11-26 Thermostat Rivets (Outside of Hose Duct Adapter) . . . . .11-29

Figure 11-27 Thermostat Rivets (Inside of Hose Duct Adapter) . . . . . . .11-30

Figure 11-28 Inserting the Hose Duct Adapter . . . . . . . . . . . . . . . . . . .11-31

Figure 11-29 Inserting Thermistor Wire and Rivet . . . . . . . . . . . . . . . .11-32

Figure 11-30 Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-33

Figure 11-31 USB Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-34

Figure 11-32 Filter Enclosure and Screws . . . . . . . . . . . . . . . . . . . . . . .11-35

Figure 11-33 Power PCBA Connections . . . . . . . . . . . . . . . . . . . . . . . .11-36

Figure 11-34 Fan Assembly Screws . . . . . . . . . . . . . . . . . . . . . . . . . . .11-37

Figure 11-35 Cable Tie Securing Fan Cable to Thermistor Cable . . . . .11-38

Figure 11-36 Position of Fan Assembly . . . . . . . . . . . . . . . . . . . . . . . .11-39

Figure 11-37 Inserting the Hose Duct Adapter . . . . . . . . . . . . . . . . . . .11-40

Figure 11-38 Securing the Hose Duct Adapter . . . . . . . . . . . . . . . . . . .11-40

Figure 11-39 USB Connector in Rear Enclosure . . . . . . . . . . . . . . . . . .11-41

Figure 11-40 Heater Assembly (below Fan Assembly) . . . . . . . . . . . . . .11-43

x Service Manual

Page 13

Figure 11-41 USB Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-44

Figure 11-42 Filter Enclosure and Screws . . . . . . . . . . . . . . . . . . . . . . .11-45

Figure 11-43 Power PCBA Connections . . . . . . . . . . . . . . . . . . . . . . . .11-46

Figure 11-44 Fan Assembly Screws . . . . . . . . . . . . . . . . . . . . . . . . . . .11-47

Figure 11-45 Fan Assembly and Hose Duct Adapter . . . . . . . . . . . . . . .11-48

Figure 11-46 Fan Assembly Pulled for Heater Replacement . . . . . . . . .11-49

Figure 11-47 Heater Assembly and Gasket . . . . . . . . . . . . . . . . . . . . .11-50

Figure 11-48 Routing of Heater Wires . . . . . . . . . . . . . . . . . . . . . . . . .11-51

Figure 11-49 Inserting the Hose Duct Adapter . . . . . . . . . . . . . . . . . . .11-52

Figure 11-50 Securing the Hose Duct Adapter . . . . . . . . . . . . . . . . . . .11-52

Figure 11-51 USB Connector in Rear Enclosure . . . . . . . . . . . . . . . . . .11-53

Figure 11-52 Routing of Cables around Fan Assembly . . . . . . . . . . . . .11-54

12 Enclosure Replacement

Figure 12-1 Front Enclosure – Components to be Removed/Reinstalled .12-2

Figure 12-2 Equipotential Stud Connections . . . . . . . . . . . . . . . . . . . . .12-3

Figure 12-3 AC Power Inlet Connections . . . . . . . . . . . . . . . . . . . . . . . .12-4

Figure 12-4 Power Supply Connections . . . . . . . . . . . . . . . . . . . . . . . . .12-5

Figure 12-5 Speaker Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-6

Figure 12-6 Power PCBA Connections . . . . . . . . . . . . . . . . . . . . . . . . . .12-7

Figure 12-7 UI PCBA Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-8

Figure 12-8 Keypad Cable Secured by Locking Bar . . . . . . . . . . . . . . . . .12-9

Figure 12-9 Filter Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-12

Figure 12-10 Power Cord Wrapped and Secured . . . . . . . . . . . . . . . . .12-14

Figure 12-11 Rear Enclosure (Outside) – Components to be

Removed/Reinstalled . . . . . . . . . . . . . . . . . . . . . . . . . . .12-15

Figure 12-12 Rear Enclosure (Inside) – Components to be

Removed/Reinstalled . . . . . . . . . . . . . . . . . . . . . . . . . . .12-16

Figure 12-13 USB Connector and Screws . . . . . . . . . . . . . . . . . . . . . . .12-18

Figure 12-14 Filter Enclosure and Power Cord Connection . . . . . . . . . .12-19

Figure 12-15 Power PCBA Connections . . . . . . . . . . . . . . . . . . . . . . . .12-20

Figure 12-16 Cable Ties to be Removed from Rear Enclosure . . . . . . . .12-21

Figure 12-17 Fan Assembly Screws . . . . . . . . . . . . . . . . . . . . . . . . . . .12-22

Figure 12-18 Heater Assembly and Gasket . . . . . . . . . . . . . . . . . . . . .12-23

Figure 12-19 Pole Clamps and Mounting Bolts . . . . . . . . . . . . . . . . . .12-24

Figure 12-20 Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-25

Figure 12-21 Cable Tie Mount for Thermistor Cable . . . . . . . . . . . . . .12-25

Figure 12-22 Position of Heater Cone and Screen . . . . . . . . . . . . . . . .12-26

Figure 12-23 Routing of Heater Wires . . . . . . . . . . . . . . . . . . . . . . . . .12-27

Figure 12-24 Position of Hose Duct Adapter . . . . . . . . . . . . . . . . . . . .12-28

Figure 12-25 Inserting the Hose Duct Adapter . . . . . . . . . . . . . . . . . . .12-29

Service Manual xi

Page 14

Figure 12-26 Securing the Hose Duct Adapter . . . . . . . . . . . . . . . . . . .12-29

Figure 12-27 USB Connector in Rear Enclosure . . . . . . . . . . . . . . . . . .12-30

Figure 12-28 Thermistor Cable Secured . . . . . . . . . . . . . . . . . . . . . . . .12-31

Figure 12-29 Cable Ties and Routing of Cables . . . . . . . . . . . . . . . . . .12-32

Figure 12-30 Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-33

14 Packing for Shipment

Figure 14-1 Packing in the Original Carton . . . . . . . . . . . . . . . . . . . . . .14-3

A Parts and Accessories

Figure A-1 External Components (Front) . . . . . . . . . . . . . . . . . . . . . . . . A-8

Figure A-2 External Components (Back) . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Figure A-3 External Components (Bottom) . . . . . . . . . . . . . . . . . . . . . . A-10

Figure A-4 HEPA Filter (Filter Enclosure Removed) . . . . . . . . . . . . . . . . A-10

Figure A-5 Internal Components (Inside Front Enclosure) . . . . . . . . . . . A-11

Figure A-6 Internal Components (Inside Rear Enclosure) . . . . . . . . . . . A-12

xii Service Manual

Page 15

1 Introduction

1.1 Overview

This manual, for use by qualified personnel only, contains instructions for

servicing, testing, and maintaining the Covidien WarmTouch™ Convective

Warming Unit. The manual includes all information necessary for

troubleshooting problems with the warming unit and replacing affected

components, including parts lists, replacement procedures, and system

diagrams.

Safety Information Page 1-2

ESD (Electrostatic Discharge) Precautions Page 1-7

Tools Required for Service Page 1-7

Serial Number, Software Version, and Error Codes Page 1-9

Component Disposal - WEEE Directive Page 1-11

Labeling Symbols Page 1-12

Obtaining Technical Assistance Page 1-14

Related Documents Page 1-17

Warranty Information Page 1-17

1-1

Page 16

Introduction

1.2 Safety Information

This section lists safety information associated with the warming unit. Where

appropriate in the manual, individual Warnings and Cautions are repeated as

reminders. Please familiarize yourself with this safety information before servicing the warming unit.

For reference, additional Warnings and Cautions that apply to operating the

warming system in the clinical environment are provided in Warnings (Patient

Treatment) on page 1-4 and Cautions (Patient Treatment) on page 1-6.

1.2.1 Safety Symbol Definitions

Table1-1.Safety Symbol Definitions

Symbol Definition

WARNING

Warnings alert users to potential serious outcomes (death, injury, or adverse

events) to the patient, user, or environment.

Caution

Cautions alert users to exercise appropriate care for safe and effective use of the

product.

Note

Notes provide additional guidelines or information.

1.2.2 Warnings (Service)

WARNING:

Possible electric shock hazard. Grounding reliability can be achieved only

when the warming unit is connected to a suitable mains outlet with

protective earth grounding.

WARNING:

The use of accessories or cables with the warming system other than those

indicated in this manual may result in non-compliance with the specifications

listed in Electromagnetic Compatibility (EMC) on page 13-4.

1-2 Service Manual

Page 17

WARNING:

No modification of this equipment is allowed. Modification can result in

death, injury, or property damage.

WARNING:

Before attempting to open or disassemble the warming unit, disconnect the

power cord from the AC power source.

WARNING:

Do not operate the warming unit with the filter enclosure removed.

1.2.3 Cautions (Service)

Safety Information

Caution:

Do not spray, pour, or spill any liquid on the warming unit, its accessories,

connectors, switches, or openings in the case.

Caution:

The HEPA filter must

whichever comes first.

Caution:

Operation of the warming system may affect or be affected by other devices

in the vicinity due to electromagnetic interference (EMI). If interference

occurs, try increasing the distance between devices, repositioning the cabling,

or plugging the devices into separate outlet circuit branches. Reference

Electromagnetic Compatibility (EMC) on page 13-4 for additional guidance.

Caution:

The institution should follow local governing ordinances and recycling

instructions regarding disposal or recycling of filter and device components or

end of life of the product.

be replaced every 2,000 hours of operation or 365 days,

Caution:

Observe ESD (electrostatic discharge) precautions when servicing the

warming unit.

Service Manual 1-3

Page 18

Introduction

WARNING:

WARNING:

WARNING:

1.2.4 Warnings (Patient Treatment)

The following additional Warnings apply to operating the warming system in

a clinical environment for patient treatment:

Possible explosion hazard. Do not use the device in the presence of flammable

anesthetics or in an oxygen-rich environment.

No free-hosing. Keep hose nozzle connected to a WarmTouch™ blanket at all

times or thermal injury may occur.

Possible burn or infection hazard. Do not allow warming blanket to come in

contact with open wounds. All patients’ wounds should be covered while

using the warming system.

WARNING:

Possible patient burns. Use caution and consider discontinuing use on

patients during vascular surgery when an artery to an extremity is clamped.

Do not apply the warming system to ischemic limbs.

WARNING:

Thermal injury may occur if the warming unit hose comes into contact with

the patient.

WARNING:

Possible fire hazard. Prevent the blanket material from coming into contact

with a laser or an electrosurgical active electrode.

WARNING:

Continuously monitor the patient's temperature during treatment with the

warming system. Use good clinical judgment in selecting and adjusting

temperature settings based on the patient's warming needs and response to

treatment.

1-4 Service Manual

Page 19

WARNING:

Using the warming system on patients with transdermal medication patches

may increase the rate of drug delivery, potentially causing harm to the

patient.

WARNING:

Thermally conductive materials, such as water, gel, and similar substances,

can decrease the patient's body temperature when the warming unit is

switched off.

WARNING:

Do not use the warming system during magnetic resonance imaging (MRI)

scanning.

Safety Information

WARNING:

Do not operate the warming system in a stacked configuration with other

equipment.

WARNING:

Do not operate the warming system adjacent to other equipment. If such a

configuration cannot be avoided, first test the warming system in the

intended configuration to verify normal operation.

WARNING:

Use WarmTouch™ blankets only as directed. Carefully follow the Instructions

for Use provided with the blankets regarding proper handling and

positioning.

WARNING:

WarmTouch™ blankets are for single patient use only.

WARNING:

Clean the warming unit after each use, as described in this manual.

WARNING:

If a fault or sudden change in performance occurs in the warming system,

discontinue use. Notify your sales/service center. The unit must be serviced by

qualified personnel using procedures provided in the Service Manual.

Service Manual 1-5

Page 20

Introduction

WARNING:

Caution:

Possible electrical shock hazard. To reduce the risk of electrical shock, do not

remove the back case. Servicing is only to be done by qualified personnel.

1.2.5 Cautions (Patient Treatment)

The following additional Cautions apply to operating the warming system in a

clinical environment for patient treatment:

Federal (U.S.A.) law restricts the use of the warming system to sale by or on

the order of a physician.

Caution:

Only use WarmTouch™ blankets with the WarmTouch warming unit. Do not

attempt to use other types of blankets with the warming unit. Similarly, do

not attempt to use WarmTouch blankets with other types of warming units.

Caution:

The USB port on the warming unit is for service use by qualified personnel

only. During patient treatment, a USB cable must not

warming unit.

be connected to the

1-6 Service Manual

Page 21

ESD (Electrostatic Discharge) Precautions

1.3 ESD (Electrostatic Discharge) Precautions

Caution:

Observe ESD (electrostatic discharge) precautions when servicing the

warming unit.

To avoid damaging ESD-sensitive components while service the warming unit,

follow all appropriate ESD guidelines. These guidelines include:

• Using an ESD wrist strap, properly connected to a reliable ground.

• Using an anti-static mat.

• Handling ESD-sensitive components properly. (Do not touch connection points,

connector pins, leads, or terminals.)

• Keeping non-conducting materials (plastic containers, foam cups, synthetic cloth-

ing, cellophane tape, etc.) away from the work area.

1.4 Tools Required for Service

• Electrical leakage tester

• Ground bond tester

• Ohmmeter or digital multi-meter with resistance function

• Temperature probe (see page 7-2 for requirements)

• Torque driver with:

#1 Phillips bit

#2 Phillips bit

11/32” hex socket

10mm hex socket

(See Table 1-2 on page 1-8 for torque requirements.)

• 10 mm open-end or box wrench

• 70% isopropyl alcohol solution and soft cloth for cleaning

• Small flat-blade screwdriver

• Pliers

Service Manual 1-7

Page 22

Introduction

• Medium flat-blade screwdriver with long handle

• Knife, box cutter, or similar tool with a thin, stiff blade

• Wire cutters

• Small knife or scissors

• Cable ties

• Strap or cable tie to wrap around handle of unit and hose duct adapter

• Non-metallic stylus or similar tool

• Ruler

• Small rubber mallet or similar tool

• Handheld blow-dryer

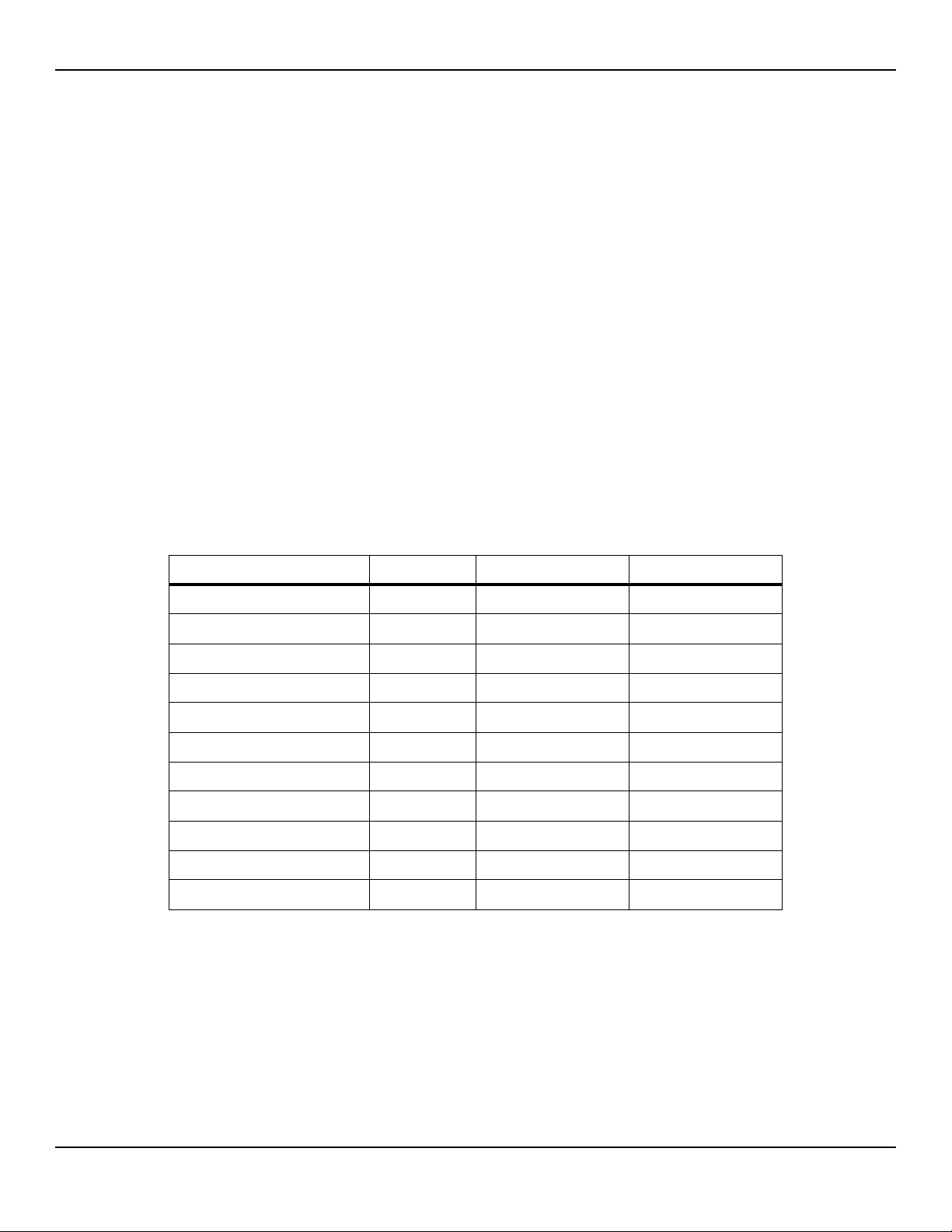

Table1-2.Torque Requirements

Item Bit Torque (Metric) Torque (English)

USB port cover screw Phillips #2 1.1 to 1.5 N-m 9.7 to 13.3 lb-in

USB cable connector screws Phillips #1 0.18 to 0.27 N-m 1.6 to 2.4 lb-in

Filter enclosure screws Phillips #2 1.2 to 1.6 N-m 10.6 to 14.2 lb-in

Front/rear enclosure screws Phillips #2 1.1 to 1.5 N-m 9.7 to 13.3 lb-in

UI PCBA screws 11/32" socket 0.4 to 0.6 N-m 3.5 to 5.3 lb-in

Power PCBA screws Phillips #2 1.1 to 1.5 N-m 9.7 to 13.3 lb-in

Speaker screws Phillips #2 1.1 to 1.5 N-m 9.7 to 13.3 lb-in

Power supply screws Phillips #1 0.4 to 0.6 N-m 3.5 to 5.3 lb-in

Equipotential stud screws 10mm socket 3.2 to 3.8 N-m 28.3 to 33.6 lb-in

AC power inlet screws Phillips #1 0.4 to 0.6 N-m 3.5 to 5.3 lb-in

Fan assembly screws Phillips #2 1.1 to 1.5 N-m 9.7 to 13.3 lb-in

1-8 Service Manual

Page 23

Serial Number, Software Version, and Error Codes

1.5 Serial Number, Software Version, and Error

Codes

Prior to servicing the warming unit, note the unit’s serial number, software

version, and any error codes.

The serial number is located on the back of the warming unit (Figure 1-1).

Figure1-1.Serial Number Label on Back of Warming Unit

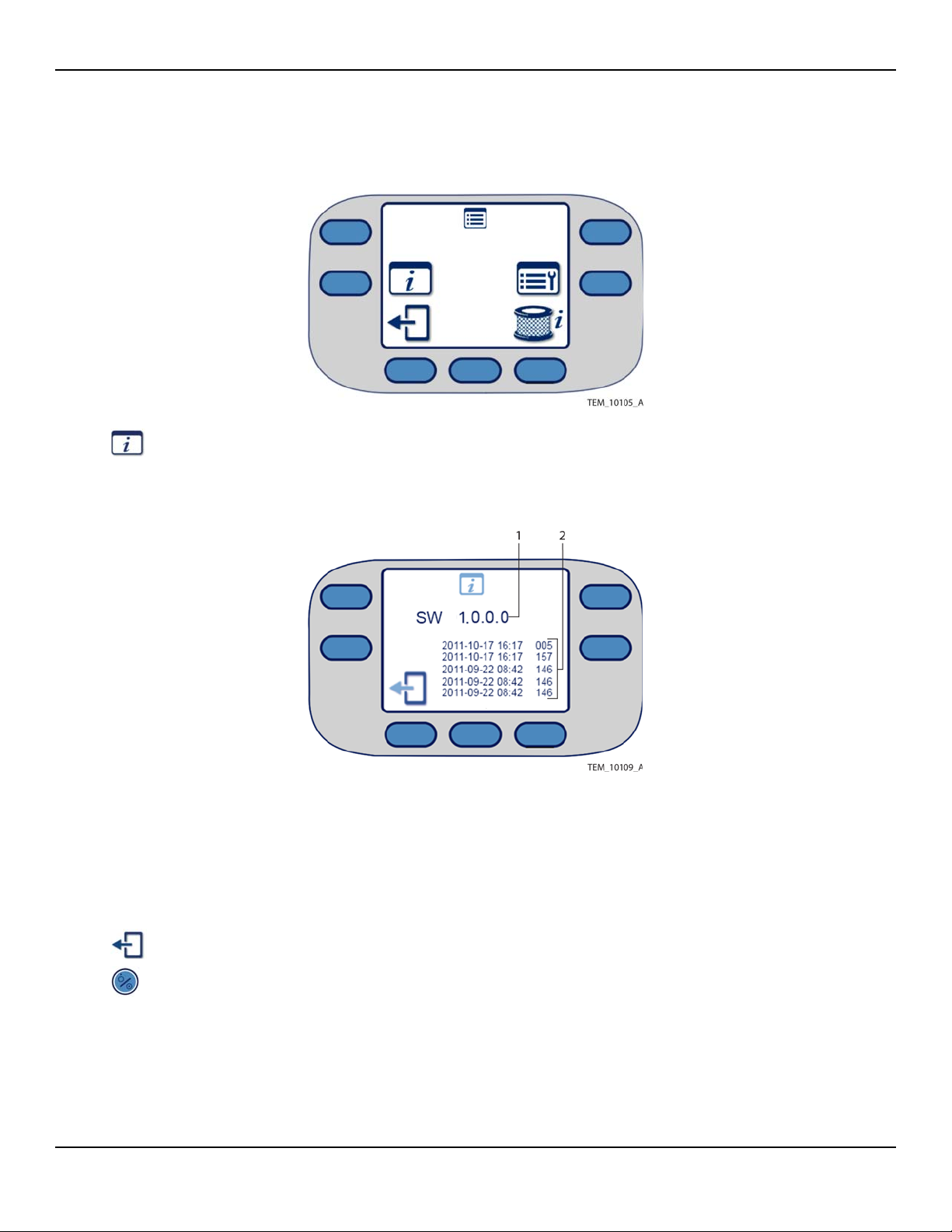

The software version number and error codes can be obtained from the

warming unit’s System Information screen as described below.

To access the System Information screen:

1. Plug the warming unit’s power cord into the outlet, and press the On/Standby

key.

2. Press the Menu key. The Menu screen appears (Figure 1-2).

Service Manual 1-9

Page 24

Introduction

Figure1-2.Menu Screen

3. Press the System Information key. The System Information screen shows the

software version and the most recent error messages, if any (Figure 1-3).

Figure1-3.System Information Screen

1 Software Version 2 Error Messages (Up to Six)

Note:

Time stamps associated with error messages do not necessarily reflect local time.

The warming unit is set to UTC (Coordinated Universal Time) at manufacture.

4. To return to the Main screen, press the Exit key twice.

5. Press the On/Standby key to power off the unit.

1-10 Service Manual

Page 25

Component Disposal - WEEE Directive

1.6 Component Disposal - WEEE Directive

The warming unit contains components that must be disposed of

in accordance with WEEE Directive. Do not dispose of the

warming unit as a whole or the following individual components

as unsorted municipal waste:

• Power cord – page 8-5

• Display (LCD) – page 10-8

• User Interface (UI) PCBA – page 10-12

• Clock battery – page 10-29

• Power PCBA – page 10-31

• Power supply – page 10-43

Service Manual 1-11

Page 26

Introduction

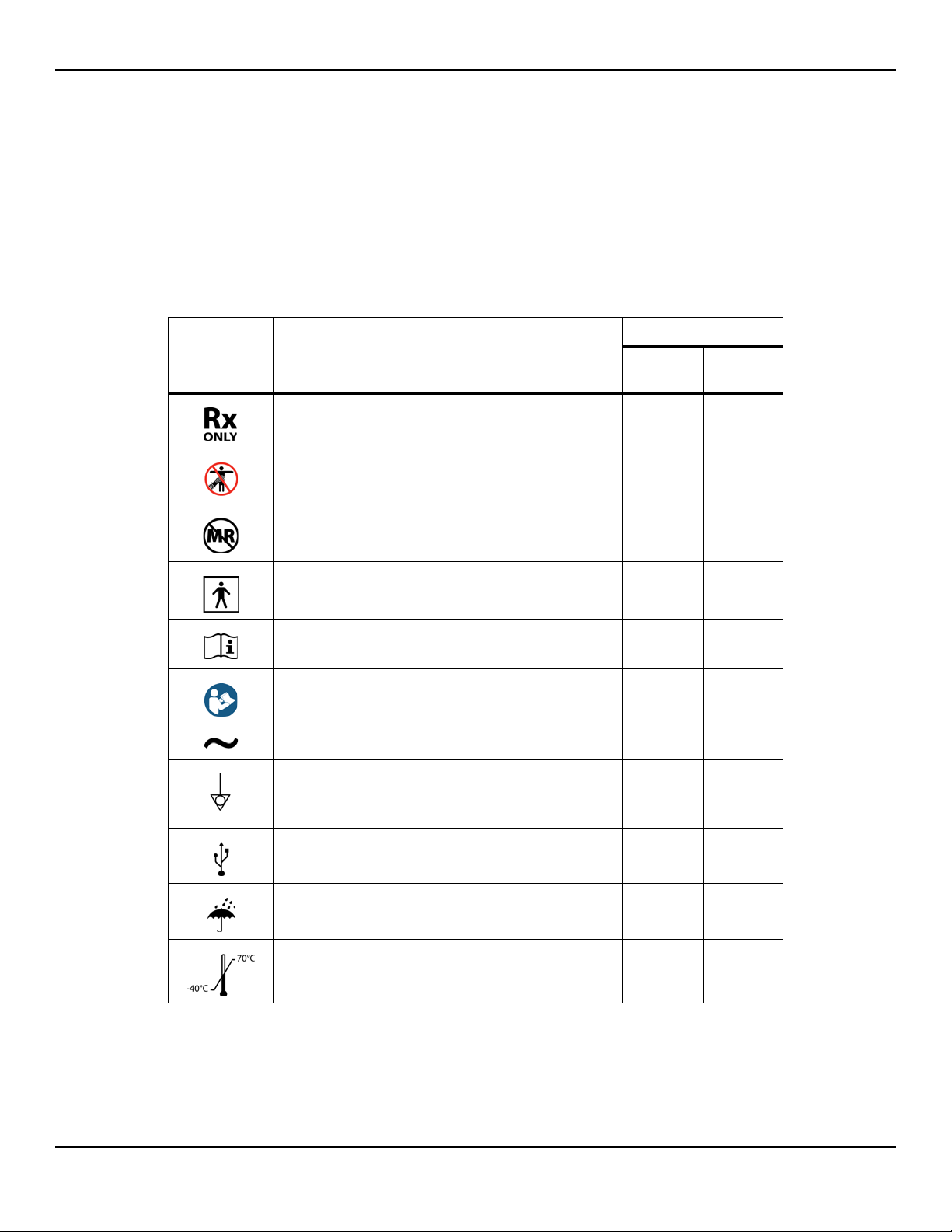

1.7 Labeling Symbols

Table 1-3 defines the symbols that appear on the warming unit or its shipping

label.

Table1-3.Symbols on the Warming Unit and Shipping Label

Symbol Description Appears On...

Warming

Unit

By prescription only X X

No Free Hosing: Hose nozzle must be connected to a

WarmTouch™ blanket or thermal injury may occur.

Do not use during magnetic resonance imaging (MRI). X X

Degree of protection from electric shock:

Protection Class I, Type BF applied part

Recommendation to consult accompanying documents X X

Requirement to consult accompanying documents X X

Nature of power supply: Alternating Current (AC) X

Potential equalization conductor terminal

Used to access the warming unit’s electrical ground for

electrical safety testing

X

X

X

Shipping

Label

Universal Serial Bus (USB) port

(For service use by qualified personnel only)

Keep dry X X

Temperature limitations (shipping/storage): -40°C to

+70°C

1-12 Service Manual

X

X

Page 27

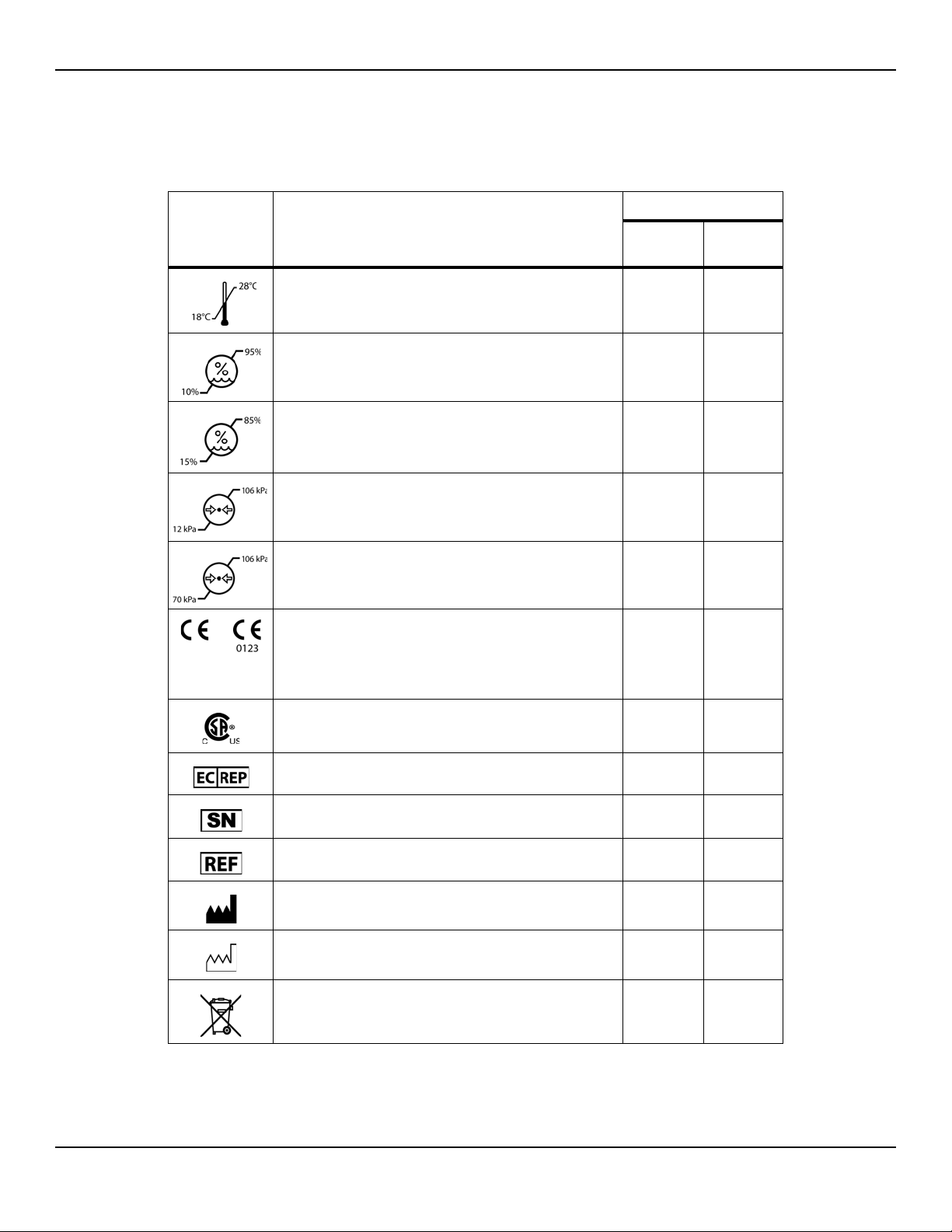

Table1-3.Symbols on the Warming Unit and Shipping Label (Continued)

Symbol Description Appears On...

Labeling Symbols

Warming

Unit

Temperature limitations (operating): +18°C to +28°C X

Relative humidity limitations (shipping/storage): 10% to

95% (non-condensing)

Relative humidity limitations (operating): 15% to 85%

(non-condensing)

Atmospheric pressure limitations (shipping/storage):

12 kPa to 106 kPa

Atmospheric pressure limitations (operating): 70 kPa to

106 kPa

CE – Conformité Européene authorization mark

0123 – TÜV SÜD Product Service GmbH (notified body)

Signifies compliance with Medical Device Directive

93/42/EEC

Shipping

Label

X

X

X

X

XX

CSA – Canadian Standards Association certification

mark

European Community (EC) authorized representative X X

Serial number X X

Catalog number X X

Manufacturer X X

Date of manufacture X X

Proper waste disposal for electrical and electronic equipment (WEEE)

X

X

Service Manual 1-13

Page 28

Introduction

1.8 Obtaining Technical Assistance

For technical assistance or to order parts and additional manuals, contact Covidien Technical Services or a local Covidien representative.

When contacting Covidien for troubleshooting or service issues, please provide

the information described in Serial Number, Software Version, and Error Codes

on page 1-9.

Covidien Technical Services

Covidien Argentina

Aguero 351

Capital Federal - 1171 ABC

Argentina

Tel: (5411) 4863-5300

Fax: (5411) 4863-4142

Covidien Austria GmbH

Campus21

Europaring F09402

Brunn am Gebrige

A-2345 Österreich

Tel: (+43) 2236 - 3788 39

Fax: (+43) 2236 - 3788 3940

Covidien Canada

19600 Clark Graham

Baie d'Urfe, QC, H9X 3R8

Canada

Tel:1-514-695-1220, Ext.4004

Fax: 1-514-695-4965

Covidien Colombia

Edificio Prados de la Morea

Carretera Central Del Norte

(Cra 7a) Kilometro 18,

Chia-Cundinamarca

Bogota, Colombia

Tel: (571) 619-5469

Fax: (571) 619-5425

Covidien Asia

Singapore Regional Service

Centre

15 Pioneer Hub, #06-04

Singapore 627753

Tel (65) 6578 5288

Fax (65) 6515 5260

Covidien Belgie S.A.-N.V.

Generaal De Wittelaan 9/5

Mechelen

2800

België

Tel +32 152 981 37

Fax +32 152 167 83

Covidien Chile

Camino lo Boza (Ex 8395)

Pudehuel

Santiago

Chile

Tel: (562) 739 - 3000

Fax: (562) 783 - 3149

Covidien Costa Rica

Global Park, Parkway 50

La Auroa de Heredia

Costa Rica

Tel: (506) 2239 - 5386

Fax: (506) 2239 - 5319

Covidien Australia

52A Huntingwood Drive

Huntingwood, NSW 2148

Australia

Tel: (+61) 1800 - 350702

Fax: (+61) 2967 - 18118

Covidien Brazil

Av. Das Nações Undias 12995

Andar 23 - Brooklin

São Paulo, SP

Brasil 04578-000

Tel: (5511) 2187-6200

Fax: (5511) 2187-6380

Covidien China

2F, Tyco Plaza

99 Tian Zhou Rd

Shang Hai 200233

P.R. China

Tel: (+86) 4008 1886 86

Fax: (+86) 2154 4511 18

Covidien ECE

Prosecká 851/64

190 00 Praha 9

Česká republika

Tel: +420 239 000 711

Fax: +420 239 000 437

1-14 Service Manual

Page 29

Covidien Technical Services (Continued)

Obtaining Technical Assistance

Covidien Danmark A/S

Langebrogade 6E, 4. sal

1411 København K

Danmark

Tel +45 702 753 50

Fax:+45 702 756 50

Covidien Finland Oy

Läkkisepäntie 23

00620 Helsinki

Finland

Te. +35 896 226 84 10

Fax +35 896 226 84 11

Covidien India

10th Floor Building No 9B

DLF Cyber City Phase III

Gurgaon

Haryana - 122002

India

Tel + 91 1244 709800

Fax + 91 1244 206850

Covidien Deutschland

GmbH

Technisches Service Center

Raffineriestr. 18

93333 Neustadt / Donau

Germany

Tel + 49 944 595 93 80

Fax + 49 944 595 93 65

Covidien France SA

Parc d'affaires Technopolis

Bat. Sigma, 3 Avenue du

Canada

LP 851 Les Ulis

91975 Courtaboeuf Cedex

France

Tel +33 169 821 416

Fax +33 169 821 532

Covidien Hungary

1095 Budapest

Mariassy u. 7

Magyarorszag

Hungary

Tel + 36 1880 7975

Fax + 36 1777 4932

Covidien ECE

Galvaniho 7/a

821 04 Bratislava

Slovakia

Tel.: +421 248 214 573

Fax: +421 248 214 501

Covidien Hong Kong

Unit 12 - 16, 18/F

BEA Tower

Millennium City 5

4187 Kwun Tong Road

Kwum Tong,

Kowloon, Hong Kong

Tel + 852 3157 7299

Fax + 852 2838 0749

Covidien Ireland

Block G, Ground Floor,

Cherrywood Technology Park,

Loughlinstown

County Dublin, Ireland

Tel +353 1 4381613

Fax 353 1 439 3039

Covidien Israel

5 Shacham St.

North Industrial Park

Caesarea

38900 Israel

Tel +97 246 277 388

Fax+97 266 277 688

Covidien Korea

5F, Hibrand Living Gwan,

#215,

Yangjae-Dong,

Seocho-Gu

Seoul, Korea

Tel: +822 570 5459

Fax: +822 570 5499

Covidien Italia S.p.A.

Via Rivoltana 2/D

20090 Segrate

Italy

Tel +39 027 030 81 31

Fax +39 027 031 72 84

Covidien Mexico

Insurgentes Sur # 863, Piso 16

Col. Nápoles

Del. Benito Juarez

Mexico, D.F. 03810 Mexico

Tel: (5255) 5804-1524

Fax: (5255) 5536-1326

Covidien Japan Inc.

Technical Support Center

83-1, Takashimadaira 1Chome

Itabashi-ku, Tokyo 175-0082

Japan

Tel: +81 (0) 3 6859 0120

Fax: +81 (0) 3 6859 0142

Covidien Nederland BV

Hogeweg 105

5301 LL Zaltbommel

Nederland

Tel +31 41 857 66 00

Service Manual 1-15

Page 30

Introduction

Covidien Technical Services (Continued)

Covidien Norge AS

Postboks 343

1372 Asker.

Norway

Tel +47 668 522 22

Fax +47 668 522 23

Covidien Portugal Lda.

Estrada do Outeiro de Polima,

Lote 10-1° Abóboda

2785-521 S.Domingos de Rana

Portugal

Tel +35 121 448 10 36 /30

Fax +35 121 445 1082

Covidien Saglik A.S.

Maslak Mahallesi Bilim Sokak

No: 5, Sun Plaza Kat: 2-3

Sisli, Istanbul 34398

Turkey

Tel +90 212 366 20 00

Fax +90 212 276 35 25

Covidien Sverige AB

Box 54

171 74 Solna

Sweden

Tel +46 858 56 05 00

Fax + 46 858 56 05 29

Covidien Panama

Parque Industrial Costa del Esta

Calle Primera, Edifio # 109

Panama City, Panama

Tel: (507) 264-7337

Fax: (507) 236-7408

Covidien Puerto Rico

Palmas Industrial Park

Road 869 Km 2.0 Bdlg. #1

Cataño, PR 00962

Tel. 787-993-7250

Ext. 7222 & 7221

Fax 787-993-7234

Covidien South Africa

Corporate Park North

379 Roan Crescent

Randjespark

Midrand, South Africa

Tel +27 115 429 500

Fax +27 115 429 624

Covidien Switzerland

Roosstrasse 53

8832 Wollerau

Schweiz

Tel +41 44786 5050

Fax +41 44786 5010

Covidien Polska

Al. Jerozolimskie 162

Warszawa. 02-342

Polska

Tel +48 223 122 130

Fax +48 223 122 020

Covidien Russia

53 bld. 5 Dubininskaya Street

Moscow

RUSSIA. 119054

Tel +70 495 933 64 69

Fax +70 495 933 64 68

Covidien Spain S.L.

Business Park World Trade

Center Almeda Park Edificio

7 - 3ª planta Plaça de la Pau s/n

Cornellà de Llobregat

Covidien Thailand

99 Soi Rubia,

Sukhumvit 42 Road

13 - 14 Fl., Berli Jucker Building

Prakanong, Klongtoey

Bangkok 10110, Thailand

Tel +662 2073 - 100

Fax +662 657 - 6325

Covidien UK

Unit 2, Talisman Business Park

London Road, Bicester

OX26 6HR, United Kingdom

Tel +44(0)1869 328092

Fax +44(0)1869 327585

1-16 Service Manual

Covidien US

15 Hampshire Street

Mansfield, MA 02048 USA

Tel 1.800.635.5267

Tel 1.925.463.4635 (toll)

Page 31

1.9 Related Documents

• Operator’s Manual - Covidien WarmTouch™ Convective Warming System — This

document provides instructions for operating the WarmTouch warming system in

a clinical environment.

• Instructions for Use - Covidien WarmTouch™ Warming Blanket — This document,

provided with WarmTouch warming blankets, contains important information

regarding intended use, handling, connection, and positioning of the blanket.

1.10 Warranty Information

To obtain warranty information, contact Covidien Technical Services or a local

Covidien representative. Reference Obtaining Technical Assistance on

page 1-14.

Related Documents

Service Manual 1-17

Page 32

Introduction

Page Left Intentionally Blank

1-18 Service Manual

Page 33

2 Product Overview

2.1 Overview

This chapter provides an introduction to the Covidien WarmTouch™ Convective Warming System, including information about its features and controls.

2.2 Product Description

The warming system provides a means for treating or preventing hypothermia

in adult and pediatric patients in clinical settings. The warming system consists

of an electronic blower (warming unit) that delivers heated air through a flexible hose to a lightweight blanket placed on the patient. The blanket distributes the heated air through numerous small perforations that allow the air to

reach the targeted areas of the patient’s body.

2.2.1 Features

• Multiple Temperature Settings — A range of temperature settings allows the

clinician to customize and adjust treatment based on the patient’s needs.

• Boost Mode — For rapid warming, air is generated at 47°C for 45 minutes, after

which the temperature automatically drops to the 45°C (High) temperature setting.

• HEPA Filter — A High Efficiency Particulate Air (HEPA) filter removes at least

99.97% of particles 0.3 micrometers or larger from the air delivered to the

warming blanket. The warming unit monitors the amount of time the filter is in

use and indicates when the filter needs to be replaced.

• Automatic Over- and Under-Temperature Protection — At any of the

heated air settings, if the temperature of the generated air is out of range for a

specific amount of time, the heater and fan automatically shut off and an alarm

is issued.

• Optional Cart with Wheel Locks — An optional transport cart, equipped with

wheel locks, is available for the warming unit. The wheel locks reduce cart movement while the system is in use.

2-1

Page 34

Product Overview

2.2.2 Indications for Use

2.2.3 Contraindications

2.2.4 Covidien WarmTouch™ Warming Blankets

The WarmTouch Convective Warming System (warming unit and blanket) is

intended for prevention and treatment of hypothermia, and for the management of appropriate normothermia.

None known.

The Covidien WarmTouch™ Convective Warming Unit is designed for use with

WarmTouch™ blankets only. WarmTouch blankets are designed to attach

securely to the warming unit’s hose nozzle. The nozzle features guides and a

clip to ensure correct orientation.

Do not attempt to use other types of blankets with the warming unit; the performance of the warming system has not been evaluated with other blankets

and cannot be predicted.

The warming unit is compatible with all WarmTouch blankets.

2-2 Service Manual

Page 35

2.3 Product Views

2.3.1 Front View

Product Views

Figure2-1.Front View

1 Operator’s Panel 4 Hose

2 Handle 5 Nozzle Strap with Clip

3 No Free-Hosing Label 6 Nozzle

Service Manual 2-3

Page 36

Product Overview

2.3.2 Back View

Figure2-2.Back View

1 No Free-Hosing Label 5 Mounting Channel (x2)

2 Serial Number Label 6 Pole Clamp (x3)

3 Symbols Label 7 Bed Hook

4 USB Port (Under Cover) 8 Power Cord

2-4 Service Manual

Page 37

2.4 Operator’s Panel

The operator’s panel includes an On/Standby key, a multi-functional keypad,

and a display that provides temperature and status information. The display

indicates the function of each adjacent key. Key functions change based on

operating context, as described in subsequent chapters.

Figure2-3.Operator’s Panel

Operator’s Panel

1

2

3

4 Temperature/Information Area – Displays the current air temperature being generated

(rounded to the closest 1°C). The following symbols can also appear in this area:

On/Standby Key – Press to place the warming unit in Ready mode or to return to

Standby mode. Reference Beginning Operation on page 4-4 and Returning to

Standby Mode on page 4-8.

Status LED – Indicates the warming unit’s operational status. Reference Overview

of Warming Unit Operating Modes on page 4-3.

Fan Off Key – During operation, press to turn off the fan. The heater, if running,

shuts off automatically. Reference Returning to Ready Mode on page 4-7.

Dashes instead of a temperature reading indicate that the warming

unit is in Ready mode (both heater and fan are off).

Animated symbol indicates that the fan is on.

Animated symbol indicates that the heater is on.

Service Manual 2-5

Page 38

Product Overview

Animated arrow indicates that the temperature is adjusting upward or

downward to a new setting. The symbol disappears when the temperature is within 1.5°C of the new setting.

5

6

7

8

9

10

Note:

When you press any of the temperature setting keys, the Heat Off key, or the Fan

Off key, the setting is highlighted on the display to indicate the current selection. For

example, in the previous figure, 34° is the current selection.

Menu Key – Press to access screens for viewing filter status and system information. Reference Monitoring the Filter Status on page 5-10 and Serial Number, Soft-

ware Version, and Error Codes on page 1-9.

Note: Symbol is shown for reference only. This menu is accessible only when the

heater and fan are off (Ready mode).

47°C (Boost Mode) Key – Press to generate air at 47°C (116.6°F) for 45 minutes.

Reference Using Boost Mode on page 4-6.

45°C (High) Key – Press to generate air at 45°C (113°F). Reference Controlling the

Temperature on page 4-5.

40°C (Medium) Key – Press to generate air at 40°C (104°F). Reference Controlling

the Temperature on page 4-5.

34°C (Low) Key – Press to generate air at 34°C (93.2°F). Reference Controlling the

Temperature on page 4-5.

Heat Off Key – Press to deliver air at room temperature (unheated). Reference

Controlling the Temperature on page 4-5.

Note:

A soft click tone indicates a successful key press.

2-6 Service Manual

Page 39

3 Installation

3.1 Overview

This chapter contains information for installing the Covidien WarmTouch™

Convective Warming Unit.

3.2 Safety Reminders

WARNING:

The use of accessories or cables with the warming system other than those

indicated in this manual may result in non-compliance with the specifications

listed in Electromagnetic Compatibility (EMC) on page 13-4.

WARNING:

No modification of this equipment is allowed. Modification can result in

death, injury, or property damage.

3-1

Page 40

Installation

3.3 Attaching the Power Cord

The warming unit is shipped with a power cord appropriate to the country

of use.

To attach the power cord:

1. Position the warming unit on its front so the bottom of the unit is accessible

(Figure 3-2).

Figure3-1.Positioning the Unit for Power Cord Installation

1 Power Cord Routing Bracket 2 Power Cord Socket

2. Insert the power cord into the socket on the warming unit, making sure that it is

fully seated.

Note: Do not route the power cord through the metal hook on the filter enclosure.

3. Press the power cord into the routing bracket until it is completely seated

(Figure 3-2). If necessary, use a screwdriver to carefully spread the sides of the

bracket while inserting the cord.

3-2 Service Manual

Page 41

Figure3-2.Power Cord Connection

Attaching the Power Cord

4. Set the warming unit upright. Wrap the power cord around the back of the unit,

and secure it with the attached strap (Figure 3-3).

Service Manual 3-3

Page 42

Installation

Figure3-3.Power Cord Wrapped and Secured

3-4 Service Manual

Page 43

3.4 Installing the Warming Unit

The warming unit can be used as a standalone device, or it can be mounted

on an IV pole, bed, or optional transport cart. The following sections provide

mounting instructions.

3.4.1 IV Pole Installation

The warming unit can be mounted on an IV pole with a maximum diameter of

3.2 cm (1.25 inches) and a minimum diameter of 1.9 cm (0.75 inches).

To avoid tipping, the warming unit must be mounted on the pole with the

handle no higher than 76 cm (30 inches) above the floor.

Requirements:

• Measuring tape

Installing the Warming Unit

To install the warming unit on an IV pole:

1. On the IV pole, mark the maximum mounting height. The warming unit’s handle

must be no higher than 76 cm (30 inches) above the floor.

2. Ensure that the power cord is secured at the back of the warming unit. Reference

Figure 3-4 on page 3-6.

3. Locate the mounting channel with two clamps at the back of the warming unit.

Do not use the mounting channel with one clamp. Reference Figure 3-4 on

page 3-6.

4. Loosen the knobs on the two clamps and rotate the clamp feet away from the

mounting channel.

Service Manual 3-5

Page 44

Installation

Figure3-4.Back View

1 Mounting Channel 3 Clamp Knob (x2)

2 Clamp Foot (x2)

5. Bracing the IV pole, position the warming unit against the pole so that the pole is

fully seated in the mounting channel. Verify that the handle is not

above the

maximum height.Reference Figure 3-5 on page 3-7.

6. Rotate the two clamp feet across the IV pole, and tighten the clamp knobs to

secure the warming unit. Do not overtighten.

3-6 Service Manual

Page 45

Figure3-5.Warming Unit Mounted on IV Pole

Installing the Warming Unit

Service Manual 3-7

Page 46

Installation

3.4.2 Bed Installation

The warming unit can be attached to a bed that has a mounting surface up to

3.6 cm (1.4 inches) wide. Typically, the unit is attached to the bed’s head board

or foot board.

To attach the warming unit to a bed:

1. Locate the bed hook on the back of the warming unit. Reference Figure 2-2 on

page 2-4. The hook slides in and out to accommodate different mounting surface

widths.

2. Hang the bed hook over the mounting surface to attach the warming unit to the

bed.

Figure3-6.Bed Installation

3-8 Service Manual

Page 47

3.4.3 Cart Installation

An optional transport cart is available for the warming unit. Contact Covidien

Technical Services or a local Covidien representative to purchase the transport

cart. Reference Obtaining Technical Assistance on page 1-14.

To install the warming unit on the cart:

1. Ensure that the power cord is secured at the back of the warming unit. Reference

Figure 3-7.

2. Loosen the knobs on the three clamps at the back of the warming unit, and rotate

the clamp feet away from the mounting channels.

Figure3-7.Back View

Installing the Warming Unit

1 Mounting Channel (x2) 3 Clamp Foot (x3)

2 Clamp Knob (x3)

Service Manual 3-9

Page 48

Installation

3. Locate the mounting pegs on the cart’s vertical poles, and locate the holes at the

bottom of the warming unit’s mounting channels.

Figure3-8.Cart Mounting Peg and Warming Unit Mounting Hole

1 Mounting Channel (x2) 3 Mounting Peg (x2)

2 Mounting Hole (x2)

4. Holding the warming unit by the handle and bracing the cart, position the

warming unit against the cart so that the mounting holes engage the mounting

pegs. The cart poles must be fully seated in the mounting channels.

5. Rotate each of the three clamp feet across the cart poles, and tighten the clamp

knobs to secure the warming unit. Do not overtighten.

3-10 Service Manual

Page 49

Figure3-9.Warming Unit Mounted on Cart

Installing the Warming Unit

Service Manual 3-11

Page 50

Installation

Page Left Intentionally Blank

3-12 Service Manual

Page 51

4 Operation

4.1 Overview

This chapter provides basic operating instructions for the Covidien WarmTouch™ Convective Warming Unit. Full instructions for operating the unit in a

clinical setting are provided in the Covidien WarmTouch™ Convective

Warming System Operator’s Manual. Clinicians intending to use the warming

system for treatment of patients must consult the Operator’s Manual.

Applying Power Page 4-2

Overview of Warming Unit Operating Modes Page 4-3

Beginning Operation Page 4-4

Controlling the Temperature Page 4-5

Powering Off the Warming Unit Page 4-8

4.2 Safety Reminder

WARNING:

The use of accessories or cables with the warming system other than those

indicated in this manual may result in non-compliance with the specifications

listed in Electromagnetic Compatibility (EMC) on page 13-4.

4-1

Page 52

Operation

4.3 Applying Power

WARNING:

Possible electric shock hazard. Grounding reliability can be achieved only

when the warming unit is connected to a suitable mains outlet with

protective earth grounding.

To apply power to the warming unit:

1. Locate a hospital-grade or suitable mains outlet with protective earth grounding.

Ensure that the power outlet is easily accessible; disconnection from the outlet is

the only way to completely remove power from the warming unit.

2. Plug the warming unit’s power cord into the outlet. The status LED illuminates

amber to indicate that the warming unit is in Standby mode. The fan and heater

are off, and the display is blank.

4-2 Service Manual

Page 53

Overview of Warming Unit Operating Modes

4.4 Overview of Warming Unit Operating Modes

Standby Mode

• Status LED: AMBER

• Heater: OFF

• Fan: OFF

• Display: OFF

Ready Mode

• Status LED: GREEN

• Heater: OFF

• Fan: OFF

• Display: ON

Treatment Mode

• Status LED: GREEN

• Heater: ON or OFF

• Fan: ON

• Display: ON

See Operator’s Panel on

page 2-5 for descriptions of

the display symbols.

1 On/Standby Key — Press to place the unit in Ready mode and prepare for

operation, or press to return to Standby mode when treatment is complete.

See Beginning Operation on page 4-4 and Returning to Standby Mode on

page 4-8.

2 Temperature Keys — Press to place the unit in Treatment mode, delivering

air to the blanket. See Controlling the Temperature on page 4-5.

3 Fan Off Key — Press to return to Ready mode, pausing air delivery. See

Returning to Ready Mode on page 4-7.

Service Manual 4-3

Page 54

Operation

4.5 Beginning Operation

To begin operation:

1. Press the On/Standby key. The unit enters Ready mode:

• The status LED turns green, and the display turns on.

• A short tone indicates a successful power-on self-test (POST). If POST is unsuc-

cessful, an alarm screen appears. See Alarms on page 6-12.

• The Main screen appears (Figure 4-1). Note that if the filter needs to be

replaced, the Replace Filter screen appears instead of the Main screen

(Figure 4-2).

Figure4-1.Main Screen at Power-On

Figure4-2.Replace Filter Screen at Power-On

2. If you see the Replace Filter screen, follow the procedure Filter Replacement on

page 5-4. It is possible to continue operation; however, failure to replace the filter

4-4 Service Manual

Page 55

as recommended can adversely affect device performance. If you choose to continue operation, press the OK key. The Main screen appears (Figure 4-1). Until the

filter is replaced, the Replace Filter screen reappears at each subsequent poweron.

4.6 Controlling the Temperature

Note:

During patient treatment, a WarmTouch™ warming blanket must be attached to the

warming unit at all times.

Select a setting by pressing one of the temperature keys. Change the setting

as desired.

Note that the temperature settings and readings on the display correspond to

internal measurements of the air entering the hose. The air temperature entering the blanket is lower and can vary depending on environmental conditions.

Use Table 4-1 as a guideline for selecting temperature settings.

Controlling the Temperature

Setting Avg. Temperature

Entering Hose

Room temperature Room temperature To aid in cooling the patient, if

(Heat Off)

34°C (93°F) 32°C (90°F) To help prevent or treat hypo-

(Low)

40°C (104°F) 38°C (100°F)

(Medium)

45°C (113°F) 42°C (108°F)

(High)

47°C (117°F) for 45

(Boost)

minutes

Table4-1.Temperature Settings

Avg. Temperature

Entering Blanket

44°C (111°F) To rapidly warm patients.

Typical Use

necessary.

thermia, or to maintain appropriate normothermia.

Service Manual 4-5

Page 56

Operation

Figure4-3.Warming System Set to 40°C (Medium)

Note that when you change the temperature setting, an amber arrow appears

next to the current temperature while it adjusts. When the temperature is

within approximately 1.5°C of the new setting, the arrow disappears.

4.6.1 Using Boost Mode

Boost mode allows rapid warming of patients. Air is generated at 47°C

(116.6°F) for 45 minutes. After 45 minutes, the setting automatically changes

to 45°C (High).

To use Boost mode, press the 47°C (Boost Mode) key. A countdown timer

shows the time remaining before the temperature switches to the 45°C (High)

setting. Boost mode sessions can be repeated as necessary.

Figure4-4.Warming System Set to Boost Mode

4-6 Service Manual

Page 57

4.6.2 Using the Heat Off Setting

The heat off setting provides a means to cool a patient. To use the heat off

setting, press the Heat Off key. Air is delivered to the warming blanket at

room temperature (heater off).

Figure4-5.Warming System Set to Heat Off

Controlling the Temperature

4.6.3 Returning to Ready Mode

During operation, you can switch back to Ready mode (fan and heat off) any

time you do not need to apply air to the warming blanket. The display stays

on, and the unit remains ready to operate.

To return to Ready mode, press the Fan Off key. Note that in Ready mode, the

temperature reading shows dashes.

Figure4-6.Warming System Set to Ready Mode

Service Manual 4-7

Page 58

Operation

4.6.4 Returning to Standby Mode

Use Standby mode when you are finished using the warming system but do

not wish to unplug it.

To return to Standby mode during operation, press the On/Standby key. The

heater and fan shut off, the display goes blank, and the status LED turns

amber.

4.6.5 If Power is Interrupted...

If power is interrupted during operation, the warming unit responds as follows, based on the duration of the power loss:

• Power restored within approximately 15 seconds — The warming unit

powers up, performs a power-on self-test (POST), and resumes operation in the

same mode as before the power loss.

• Power restored after approximately 15 seconds — The warming unit

powers up in Standby mode.

If the warming unit powers back up in Standby mode, press the On/Standby

key to enter Ready mode, then select a temperature setting to resume operation.

4.7 Powering Off the Warming Unit

To power off the warming unit:

1. Press the On/Standby key. The fan and heater (if running at the time) turn off.

The display goes blank, and the status LED turns amber.

2. To completely remove power from the warming unit, unplug the unit’s power

cord from the outlet.

4-8 Service Manual

Page 59

5 Maintenance

5.1 Overview