Page 1

+

Jomesh

TECHNOLOGIES

PTY

LTD

INSTRUCTION

Postal

Telephone

Facsimile:

Address:

PATIENT

MODEL

P.O.

Box

National

National

WARMING

PWS

AND

879,

(03)

5228 0200 | International:

(03)

5229

SERVICE

Belmont,

3551 | International:

SYSTEM

2000

Victoria

3216,

MANUAL

Australia

+613 5229

+613 5229

0200

3551

|

|

Prepared:

Revised:

Revision:

Applies

to:

10

May,

2000

6

February,

c

Board

Copyright © 2000

2001

Revision

c

Jomesh

Technologies

Pty

Ltd

Page 2

Jomesh

Technologies

CONTENTS

PWS

2000 Patient

Warming

System

SPECIFICATIONS..

INTRODUCTION

OPERATION.

WARNINGS

SERVICE

SCHEMATIC

μοι

8.1,

6.2.

63.

6.4,

7.

TA.

73.

7.4.

Microcontroller

Digital

Reset

System

PREVENTATIVE

Electrical

2.

|

Over-Temperature

Filter

Performance

DIAGRAM

Temperature

Circuit

Block

Replacement

DESCRIPTION

Sensor

Diagram...

MAINTENANCE

Safety

Inspection

In

Cutout

...........

ça

Testing

e

seno

.

eri

sa

3

4

4

5

6

*

8

8

9

9

9

0

11

11

CONTROL

8.

SCHEMATIC

8.

9.1.

9.2.

10

10.1.

10.2.

44,

Control

System

PARTS

General

Control

CERTIFICATIONS

BOARD

DIAGRAMS

Board

Block

LIST

Assembly.

Board...

COMPONENT

Schematic

Diagram

AND

COMPLIANCES

LEGEND.

Diagram

ore

ο

πο

.....

ο

μμ

rr

o

τος

13

14

15

16

16

sost

Page 3

—

Jomesh

Technologies

PWS

2000

Patient

Warming

System

1.

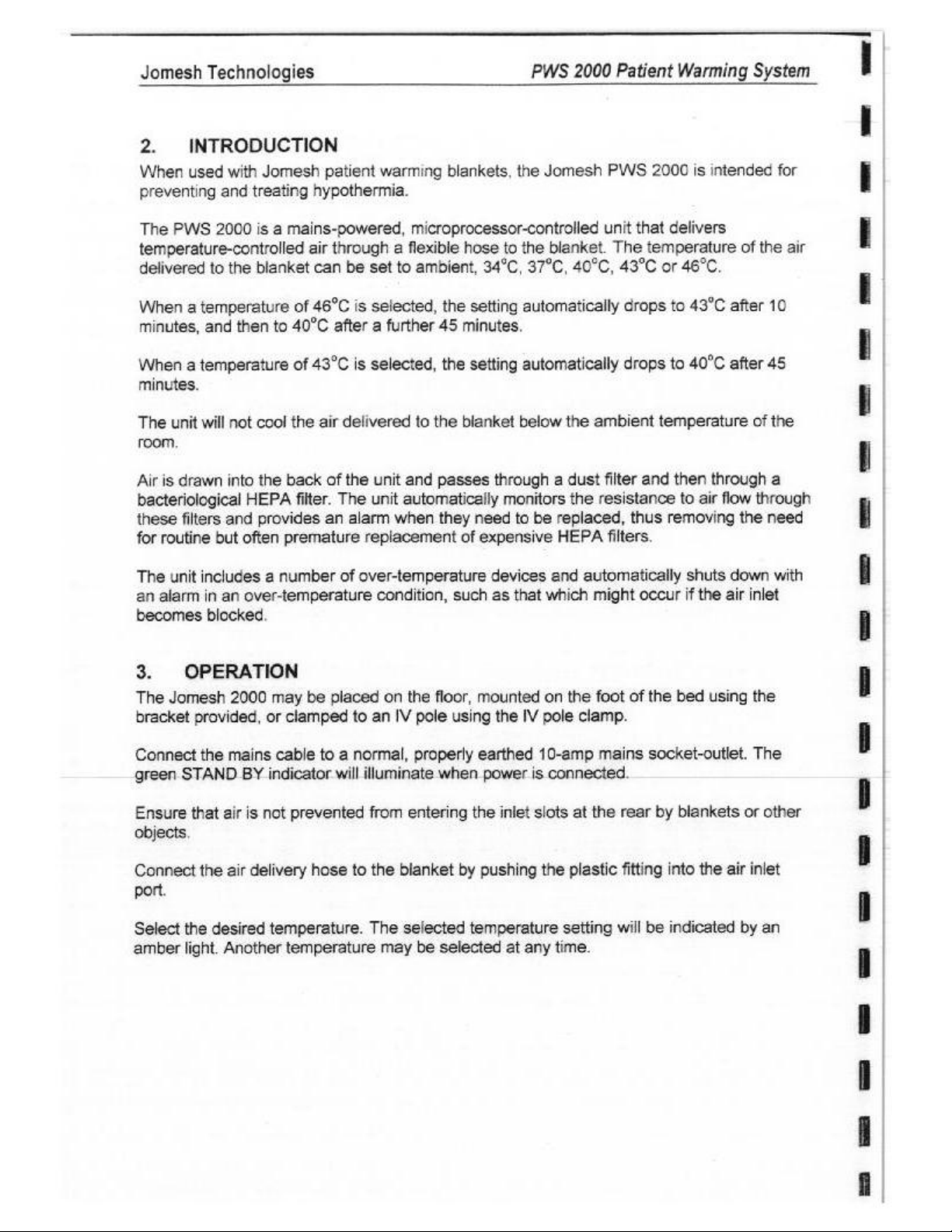

(GENERAL

[Model

(Supply

Supply

Supply

External

¡Type

[Degree

(Applied

¡Degree

Method

mmm

mmm

mmm

[Degree

[ammable

lairioxygen/nitrous

Mode

Environmental

transport.

PERFORMANCE

‘Temperature

[Temperature

[except

Environmental

ithe

‘Time

¡temperature

following

DIMENSIONS

[Width

Depth

[Height

WEIGHT

SPECIFICATIONS

Number

Voltage

Frequency

Power

Fuses

of

protection

of

protection

Part

of

protection

of

disinfection

of

safety

in

anaesthetic

of

operation [Continuous

conditions

storage

settings

accuracy

for

the

ambient temperature

conditions

specified

required

temperature

to

accuracy

a

change

——

_

against

the

oxide

and

attain

in

electric

against

against

presence of

for

of

temperature

electric

ingress

mixtures

required

operation

delivered

of

delivered

required

accuracy

the

specified

delivered

shock

shock

of

water

with

for

air

air.

setting

to

achieve

air

setting

PWS

2000

[240

Vac + 6%

50

Hz

1300

Watts

2 x 8 Amp

[Class

1

[Type

ВЕ

[Warming

[Not

specified

[Surface

‘moistened

[Not

specified

10°C

to

humidity,

Ambient,

は

2°C

with

[Not

specified

|20°C

to

Inon-condensing

(5

minutes

360

milimetres

210

millimetres

370

milimetres

10

kilograms

Maximum

DA205

Blanket & Delivery

disinfection

with a mild

40°C,

non-condensing

34°C,

delivery

22°C,

5x20mm

is

possible

disinfectant

Less

than

37°C,

40°C,

hose

without

30%

delivery

to

70%

Hose

90%

relative

43°C

cover

hose

relative

m

=

using a cloth

]

|

solution.

or

46°C

cover

humidity,

=

e

Itis a pre-requisite

understand

e

mmm

for

all

the

operating

staff

skilled

procedures

in

using

contained

convective

herein.

patient

warming

devices

to

Page 4

Jomesh

2.

When

preventing

The

temperature-controlled

delivered

When a temperature

minutes,

When a temperature

minutes.

The

room.

Airis

bacteriological

these

for

Technologies

INTRODUCTION

used

with

and

treating

PWS

2000

is a mains-powered,

to

the

blanket

and

then

unit

will

not

cool

drawn

routine

into

the

HEPA

filters

and

provides

but

often

Jomesh

to

patient

hypothermia.

air

through a flexible

can

of

46°C

40°C

after a further

of

43°C

the

air

delivered

back

of

filter.

The

an

premature

be

set

is

is

the

alarm

replacement

PWS

2000

warming

to

selected,

selected,

unit

unit

when

blankets,

microprocessor-controlled

hose

ambient,

the

45

minutes.

the

to

the

blanket

and

passes

automatically

they

of

the

Jomesh

to

the

blanket.

34°C,

37°C,

setting

setting

need

automatically

automatically

below

through a dust

monitors

to

be

replaced,

expensive

HEPA

40°C,

the

ambient

the

resistance

Patient

PWS

unit

The

43°C

drops

drops

filter

thus

filters,

Warming

2000

is

that

delivers

temperature

or

46°C.

to

43°C

to

40°C

temperature

and

then

to air

removing

System

intended

after

after

through

flow

for

of

the

air

10

45

of

the

a

through

the

need

The

unit

includes a number

an

alarm

in

an

becomes

3.

The

bracket

Connect

green

Ensure

blocked

OPERATION

Jomesh

provided,

the

STAND

that

air

objects

Connect

the

port.

Select

amber

the

desired

light.

Another

of

over-temperature

over-temperature

2000

may

be

or

clamped

mains

air

cable

to a

BY

indicator

is

not

prevented

delivery

hose

temperature.

temperature

condition,

placed

will

on

to

an

normal,

illuminate

from

to

the

The

may

such

the

floor,

mounted

IV

pole

using

properly

entering

blanket

selected

be

earthed

when

power

the

by

pushing

temperature

selected

devices

as

and

that

which

on the foot

the

IV

pole

10-amp

is

connected.

inlet

slots

the

plastic

setting

at

any

time.

automatically

might occur

of

shuts

if

the

bed

the

using

clamp.

mains

at

the

socket-outlet.

rear

by

blankets

fitting

into

the

will

be

indicated

down

air

inlet

the

The

or

other

air

inlet

by

an

with

Page 5

Jomesh

The

to

43°C

selecting

THE

CIRCULATION.

The

to

40°C

selecting

Technologies

internal

46°C

intemal

10

minute

after

10

46°C.

SETTING

45

minute

after

45

43°C.

timer

that

minutes

minutes

can

IS

NOT

timer

that

can

automatically

be reset

RECOMMENDED

be

by

automatically

reset

by

decreases

momentarily

ON

decreases

momentarily

PWS

2000

Patient

the

temperature

selecting

PATIENTS

selecting

another

WITH

the

temperature

another

Warming

setting

setting

IMPAIRED

setting

setting

from

and

then

from

and

then

System

46°C.

re-

43°C

re-

‘Switch

unit

The

indicator

+

supply

*

Inthe

4.

+

Use

+

Monitor

+

Do

+

+

the

unit

is

off,

unit

will

will

In

the

event

restricted

blocked

the

electricity

Do

Consider

filter.

problem

and

event

WARNINGS

only

in

patient

not

use

not

apply

discontinuing

off

by

pressing

automatically

illuminate

of a FILTER

by

an

persists,

have

of a FAULT

supply

accordance

on

patients

warm

together

object

Remove

disconnect

the

fiter(s)

and

have

temperature

air

OFF.

switch

such

any

alarm,

with

with

directly

use

off

with

alarm,

as a blanket,

such

replaced

the

these

during

impaired

to

during

The

green

STAND

in an

alarm

condition

the red

check

restriction

the

disconnect

unit

serviced

instructions.

use

an

vascular

FILTER

that

air

as

and

PWS

2000

by a trained

the

with

circulation

open

wound

surgery

indicator

flow

this

will

select

from

technician.

PWS

by a trained

unconscious

BY

indicator

and

the

or the

into

the

be

automatically

the

desired

the

patient

2000

from

technician.

patients.

when

an

will

green

red

back

of

the

temperature

and

from

the

patient

artery

is

illuminate

STAND

FAULT

unit

detected

clamped

when

BY

indicator.

is

not

being

as

a

setting.

the

electricity

and

from

the

the

If

+

Do

not

apply

warm

+

Discontinue

+

Unit

must

+

Ensure

specified

only

the

unit

in

this

use

be

air

directly

in

alarm

condition.

opened

is

subjected

manual

or

serviced

to

to

the

patient

by a trained

the

electrical

safety

from

the

hose.

technician.

and

performance

inspections

as

Page 6

Jomesh

Technologies

PWS

2000

Patient

Warming

System

5.

This

Patient

paramedical,

purposes

Confidence

available

Jomesh

SERVICE

Manual

presents

Warming

of

to

System.

engineering

maintenance

material

any

to

other

Technologies

information,

This

Manual

+

Descriptions

+

Discussion

+

Descriptions

+

All

printed

While

every

responsibilty

product

change

If

you,

as a user

PWS

2000

contact

presents

of

the

of

Electrical

of

the

circuit

board

attempt

is

taken

improvement

without

details

notice.

of

this

or

this

Manual,

are

located

all

the

relevant

This

and

technical

and

repair

the

Jomesh

organisation

Ply.

Ltd.

the

following:

schematic

Safety

necessary

component

has

been

made

for

any

errors

and product

manual,

have

your

on

the

technical

information

personnel.

of

the

Distributor

or

person

Refer

to

the

diagrams.

inspection

preventative

legend,

to

ensure

or

omissions.

specifications

any

relevant

communication

first

page

information

is

provided

This

PWS

2000.

or

PWS

without

previous

for

as a service

information

It

is

2000

the

specific

sections

procedures.

maintenance.

schematic

this

Jomesh

and

comments

with

of

this

Manual.

diagram,

Manual

is

has a policy

component

Jomesh

the

Jomesh

to

medical,

is

intended

provided

Owner

of

accurate

or

would

es

Commercial-in-

and

shall

written

this

permission

Manual

and

parts

and

of

continuous

types

are

questions

be

about

welcomed.

PWS

2000

nursing,

for

the

fair

not

be

made

of

for

operator

list

information.

complete,

subject

no

to

the

Our

The

PWS

2000

has

been

product.

provide a user-friendly

approximately

unit

HEPA

through

‘The

switches

functions.

grouped

(FILTER / FAULT)

after

minutes.

Air

controlled

temperature

The

PWS

2000

operator

0.85

m°/min

through a two-stage

filter.

The

filtered

the

PVC

delivery

PWS

2000

operator

grouped

The

into

10

minutes. A set

temperature

by

into

OFF

PWS

2000

OFF (STAND

functions.

temperature of

is

measured

the

microcontroller.

cutout

switches

filter

replaced.

designed

utilises

(30

air

passes

hose.

controls

(STAND

operator

BY),

A

as

to

provide a sophisticated

microcontroller

interface.

f/m)

system

consist

ON

set

it

exits

The

Airfiow through the

by a mains-powered fan

comprising a replaceable

over a 1250

of

BY)

and

indicators

(34°C / 37°C / 40°C / 43°C / 46°C)

temperature

43°C

the

PWS

and a pressure

Patient

technology

Watt

seven

automatically

unit

2000

switch

front

ON

(34°C / 37°C / 40°C / 43°C / 46°C)

consist

of

46°C

by a digital

includes

that

to

control

PWS

blower.

dust

heating

of

automatically

element

panel

push-button

nine

front

decreases

temperature

two

independent

detects

when

Warming

all

functions

2000

is

maintained

Room

air

filter

and a replaceable

and

exits the

membrane

panel

visual

and

ALARM

decreases

to

44°C

after

sensor

over-

the

filter(s)

System

and

at

enters

the

unit

indicators

to

43°C

45

and

need

to

be

Page 7

Jomesh

Technologies

PWS

2000

Patient

Warming

System

6.

This

the

‘Schematic

The

+

+

«

‘The

SCHEMATIC

section

Printed

describes

Circuit

Board (PCB)

Diagrams

following

The

Schematic

Electrical

a

schematic

Net

labels

logic

PWS

should

Diagrams

connectivity

sheet

(signal

*0”

(eg:

SIGNAL).

2000

Board

assist

or

names)

Microcontroller.

Digital

Reset

Push-button

Fan

LED

Buzzer

Power

Power

temperature

circuit.

and

pressure

and

heater

displays

and

relays.

and

their

its

driver.

supplies.

supply

decoupling

Connectors.

DIAGRAM

the

PWS

DESCRIPTION

2000 schematic

Component

contained

is

net

implements

sensor.

drivers.

in

Section

with

the

interpretation

are

organised

shown

labels

by

on

are

prefixed

the

continuous

partial

following

switches.

capacitors.

diagrams.

Legend

contained

9.

of

the

Schematic

in a fiat

wires

with a forward

structure.

wires

and

between

slash

functions:

Reference

in

net

labels

schematic

when

should

Section 8 and

Diagrams:

on

partial

sheets.

they

are

be

made

to

the

wires

within

asserted

with

a

The more

The Atmel

*

CPU

+

Program

+

RAM

+

Interrupt

External

Counter/Timers

‘Watchdog

Digital

‘The

+

Monitors

*

Monitors

*

Controls

Controls

important

6.1.

Microcontroller

of

AT8958252

ROM

controller

interrupts

timer

Input/Output

microcontroller

the

the

the

the fan

performs

air

temperature

push-button

display

and

these

functions

microcontroller

are

elaborated

(U1)

integrates

ports

the

through

and

pressure

and

buzzer

heater

relays.

following

drivers.

functions:

the

digital

switches.

below.

a

number

temperature

of

functions:

sensor.

Page 8

Jomesh

The

software

of a microcontroller

The

8

technique

controlled

When

+

Digital

+

Signal

The

+

Signal

The

‘Thus

off

with

Technol

microcontroller

program

6.2.

Dallas

6.3.

the

Digital

DS1820

that

by

and

Reset

microcontroller

Input/Output

/FAN_RELAY

fan

blower

/HEAT_RELAY

heater

the

reset

the

heater

ROM

contained

fault,

Jomesh

Temperature

direct-to-digital

utilises

communicates

low

Circuit

is

ports

goes

is

switched

goes

is

switched

process

being

off.

implements a safety

tumed

is

0 - 3 go

factory

in

programmed

the

microcontrolier

must

temperature

and

high

temperature

with

the

reset

either

high.

low

switching

on.

high

switching

on.

PWS

with

ROM

ft a replacement

Sensor

sensor

coefficient

microcontroller

by

power-on

on the

fan

off

the

strategy

2000

the

application

is

subject

part

(U4)

measures

oscillators.

(U1)

over a single

or

by

the

watchdog

relay.

heater

to

relay.

prevent

Patient

to

Warming

software

copyright.

temperature

The

sensor

“wire”.

timer

the fan

blower

System

program.

In

the

event

through

is

being

turned

7

The

Power-On

Following

connected

asserted

Watchdog

The

hardware.

To

prevent

overflows

software

watchdog

microcontroller

from

Reset

power-on

to

ground.

high.

Reset

microcontroller

When a watchdog

such a system

by

the

application

malfunction,

timer.

This

from

occurring.

capacitor

watchdog

running

(C3)

This

causes

timer

timer

reset

the

software

the

application

failure

will

produce a system

out

of

charges

the

is

overflow

microcontroller

software

control.

from

zero

Reset

input

incremented

occurs

program.

If

the

program

This

prevents a potentially

to

of

the

regularly

the

microcontroller

watchdog

microcontroller

will

reset

on

+5V

(VCC)

microcontroller

by the

timer

fail

overflow

through

microcontroller

is

is

reloaded

suffers a hardware

to

load

the

thus

hazardous

resistor

to

be

momentarily

reset.

microcontroller

preventing

before

situation

(R1)

it

or

the

Page 9

Jomesh

Technologies

PWS

2000

Patient

Warming

System

6.4.

The

System

PWS

2000

+

Mains

Over-temperature

Mains

Heater.

Fan

biower.

Control

Solid-state

Before

removing

subassemblies,

connections

The

System

does

warrant

7.

PREVENTATIVE

7.4.

It

is

recommended

PWS

2000.

published

System

Block

electrical

Diagram

and

fuses.

cutout

power

filter

Board.

relay

any

of

make a careful

could

compromise

Block

Diagram

extensive

Electrical

that a program

Information

technical

standards.

Block

Diagram

shows

electronic

the

general

subassemblies:

switches.

the

connections

note

so

that

patient

is

presented

discussion.

MAINTENANCE

Safety

on

the

type

safety

as

Inspection

of

regular

and

frequency

electrical

between

the electrical

these

may

and/or

an

aid

electrical

damage

to

of

testing

connectivity

and

be

correctly

the

understanding

safety

inspections

may

between

electronic

reinstated.

PWS

2000.

the

PWS

be

be

obtained

the

various

Incorrect

2000

and

instituted

from

for

the

locally

In

Australia,

+

AS3511

This

programs

management

safety,

・

AS2500

This

equipment

patient

installations

A

Hospital

by

Jomesh

electrical

Programmed

patient

the

relevant

Technical

standard

for

medical

and

essential

Guide

standard

provides

used

and

operator

to

Biomedical

or

the

Jomesh

safety

inspections

electrical

safety.

Mandatory,

apply.

technical

management

specifies

safety

to

in

be

procedures

devices.

routine

health

used

testing

and

performance

the

safe

use

a

comprehensive

care

facilities.

safety,

including

for

particular

Some

Engineering

distributor

and

providing

safety

inspections

statutory

standards

programs

required

of

medical

of

these

are:

for

medical

to

develop

include

devices.

testing.

of

electricity

details

medical

Department

would

suitable

are

requirements

in

patient care.

guide

to

the

Measures

of

are

the

classes

procedures.

or

third

party

be

capable

of

test

documentation

essential

for

electrical

devices.

equipment

procedures

This

standard

safe

use

detailed

of

service

performing

to

confirm

safety

management

for

specifies

of

electrically

to

provide

equipment

organisation

the

continued

inspections

acceptance,

fault

electrical

operated

and

maintain

and

electrical

nominated

necessary

operator

and

may

also

Page 10

Jomesh

Technologies

PWS

2000

Patient

Warming

System

7.2.

The

PWS

adequately

Required:

+

PWS

+

Digital

‧

Light-weight

STEP

1

if

Place

(Do

‘Connect

|Familiarise

|with

[The

+

|*

+

+

|*

・

[The

'*

。

|

Performance

2000

verify

2000

Instruction

Thermometer.

you

have

the

not

connect

reference

temperature

Ensure

Ensure

humidity,

Place

Check

following

Check

to

within

Note

that

delivered

hose.

the

degree

filter

Select

Progressively

light-weight

With

new

before

Inspection

does

not

require

the

PWS

2000

&

Service

plastic

the

the

The

occlusion

the

the

bag.

not

already

PWS

2000

the

PWS

yourself

to

the

delivery

that

the

non-condensing,

digital

that

the

a

change

that

the

42°C

some

air

is

magnitude

to

which

Ambient

occlude

plastic

filters,

“Filter”

done

on a firm, level

PVC

delivery

2000

to

with

the

the

PWS

2000

control system

hose

environmental

thermometer

temperature

in

set

temperature

variation

possible

of

the

the

monitoring

temperature

the air

bag

until

it

should

alarm

occurs.

adjustment

functions.

Manual.

so,

the

240V

operation of

is verified

cover

of

temperature.

of

between

because

heat

hose

system

the

be

possible

or

calibration.

PROCEDURE

read the

hose

Instruction

is

conditions

sensor

delivered

delivered

of

is

longitudinally

setting.

inlet

“Filter”

PWS

surface.

to a warming

supply

loss

louvres

mains.

the

PWS

and

as

follows:

undamaged

are

in

the

centre

air

stabilises

air

corresponds

the

set

temperature

the

heat

will

depend

is

verified as

on

alarm

to

occlude

A

performance

2000

the

Instruction

blanket.

2000

by

operating

Service

and

20°C

loss

compressed

ocours.

almost

Manual.

that

it

covers

to

22°C,

30%

of

the

PVC

within

that

on

the

follows:

rear

of

five

with the

and

temperature

occurs

ambient

or

the

PWS

all

of

the

inspection

and

Service

the

the

entire

to

70%

delivery

(5)

minutes

set

temperature

in

the

PVC

temperature

extended.

2000

air

inlet

will

Manual.

PWS 2000

hose.

relative

hose

outlet.

of

delivery

using

louvres

|

and

Ee

a

Page 11

Jomesh

Technologies

PWS

2000

Patient

Warming

System

7.3.

‘The

PWS

performance

of

those

Items

+

+

‘Shorting

Required:

PWS

Digital

STEP)

1

_|if

2

|e

+

‘+

3

|»

・

+

>

'»_

5

[Replace

|At

8

[Place

7

[Important

the

(components

8

[Check

jattains

9

|*

+

+

|e

10

|Replace

11

[Confirm

inspection

Over-Temperature

2000

inspection.

responsible

2000

Disconnect

Remove

Ensure

Instruction

Thermometer.

link

comprising

you

have

Place

the

Do

not

Disconnect

Locate

Locate

Securely

Repeat

the

Remove

front

panel.

Remove

the

the

this

stage,

the

Ambient

tnat the

70+10°С.

that

the

thet

Cutout

over-temperature

This

for

the

8:

Service

two

not

already

PWS

2000

connect

the

the

connect

digital

Connect

may

step 3 above.

the

front

as

the

the

PWS

front

panel

eight

solid-state

front

fit

temperature

PWS

the PWS

shorting

all

the

detailed

(8)

front

panel.

the

panel

screws

thermometer

the

be

demaged

2000

internal

panel

PWS

cutout

test

is

technical

4mm

done

on a firm,

PVC

delivery

2000

with

Philips

relay

shorting

by

reversing

sufficient

PWS

setting.

ceases

2000

from

link

from

wiring

by

reversing

2000

functions

in

Section

function

entirely

management

Manual.

ring

terminais

PROCEDURE

so,

read

level

hose

from

the

the

warning

head

which

is

link

only

sensor

2000

to

The

by

excessive

operation

the

the

solid-state

is

correctly

7.2

Testing

does

not

require

optional

the

240V

screws

mounted

across the

step 3 above,

to

in

the

fan

240V

step 3 above.

correctly

and

may

of

the

PWS

joined

PWS

surface.

to a warming

label.

located

hold

the

centre

240V

must

heat.

when

supply

reinstated.

by

2000

Instruction

supply mains.

around

on

the

solid-state

the

front

of

the

supply

operate

the

temperature

mains.

relay

output

by

undertaking

adjustment,

be

performed

2000.

10cm

of

10Amp

and

blanket.

the

perimeter

_

inside

panel

of

the

left

relay

output

in

place.

PVC

delivery

mains

and

immediately

during

this

test

of

terminais.

a

performance

calibration

at

the

discretion

rated

wire.

Service

of

the

panel.

terminais.

hose

outlet.

otherwise

delivered

or

Manual.

select

air

=

|

7.4.

‘The

PWS

replaceable

replacement

Filter

2000

has a two-stage

HEPA

filter.

when a “Filter”

Replacement

filter

The

dust

filter

alarm

occurs.

system

comprising a replaceable

or

both

the

dust

filter

and

HEPA

dust

filter

filter

may require

and

a

Page 12

SY

Jomesh

Items

+

Replaceable

Replaceable

STEP,

1

2

10

n

12

13

14

Technologies

Required:

PWS

2000

Instruction

Philips

ola

Number 1 Screwdriver.

dust

HEPA

İf

you

have

not

¡+

Place

the

PWS

|»

Do

not

connect

le

Connect

[Determine the

la.

Select

le

Confirm

[Disconnect

le

Locate

|

Remove

panel.

|+

Remove

le

Remove

»

Replace

Replace

At

this

Again,

«

Select

‘=

Confirm

・

Ifthe

next

+

Ifthe

replaced.

Ifyou

Repeat

Remove

Remove

securing

+

Remove

je

Remove

le.

Replace

Ensure

Replace

Replace

[Confirm

inspection

the

occluded

the

Ambient

that

the

the

rear

the

the

the

the

the

rear

stage,

fit

determine

the

Ambient

that

“Filter”

step.

“Filter

Proceed

wish

to

step 5 above.

the

the

the

the

frame.

the

the

the

HEPA

the

frame

the

rear

that

the

as

detailed

filter.

filter.

already

PWS

the

PWS

eight

rear

dust

dust

screws

the

alarm

alarm

replace

dust

four

HEPA

HEPA

HEPA

PWS

&

Service

2000

the

PVC

2000

temperature

“Filter”

2000

panel

(8)

panel.

filter

filter

panei

by

the

occluded

temperature

‘Filter’

occurs,

does

to

filter.

(4)

Philips

fitter.

filter

filter

filter gasket

securing

panel

2000

in

Manual.

done

so,

on a firm,

delivery

to

the

state

of

the

alarm

from the

with

the

Philips

with a new item.

sufficient

step

the

by

head

and

discard.

reversing

state

alarm

then

not occur,

13.

HEPA

head

and

discard

with a new

the

HEPA

reversing

functions

Section

PROCEDURE

read

the

PWS

level

240V

occurs.

air

only

does

filter

is

surface.

hose

to @ warming

supply

filter(s)

setting.

240V

inlet

screws

step 5 above.

to

of

the

setting

or

the

HEPA

then

screws

item.

located on the

filter

step 5 above.

correctly

mains.

as

follows:

supply

louvres.

located

hold

the

filter(s)

does

filter

the

anyway,

located

by

reversing

7.2.

PWS

2000

Patient

2000

Instruction

blanket.

mains.

around

rear

as

not occur.

must

HEPA

filter

proceed

near

air-off

by

undertaking

the

panel

follows:

in

be

replaced.

does

to

the

the

comers

face

of

step

Warming

and

Service

perimeter

place.

not have

next

the

filter.

10

above.

a

performance

of

Proceed

tobe

step.

of

the

frame

System

Manual.

the

rear

|

|

|

to

the

|

Page 13

Jomesh

Technologies

PWS

2000

Patient

Warming

System

CONTROL

BOARD

COMPONENT

LEGEND

Page 14

Jomesh

Technologies

PWS

2000

Patient

Warming

System

Page 15

Jomesh

Technologies

PWS

2000

Patient

Warming

System

9.2.

System

Block

Diagram

|

|

em

Mom

1omrNoo

Page 16

Jomesh

Technologies

PWS

2000

Patient

Warming

System

10.

PARTS

10.1.

PART

LIST

General

KUNDER

ddddda

1

TEE

Por

IO7.3

19 5 SU-12

04300.

有朋

μπας

РСТ

еда

106

sz

Ро

Temos

|

ES

TES

Assembly

DESCRIPTION

(Board

‘Cone

Raney,

ne

Karam,

[Саба

давать,

Ea

Asem

fes

Asse.

[cade

Asse,

[Cable

Assembly,

Cale

Assembly,

(Cab

Asma

Ea

Assenti

ae

Kam

[Се

Зо

Eco

IV

Poke

EA

06 で で 3 Per

[bel

HEPA

(Fer,

Pret

(Fano.

Hose.

[Foot

Rubber.

ie,

Am,

1000.

10004,

[Label

Swen

Wang

Tao,

Assembly,

Seka

[Erich

Mio,

İSA

Thermal NE

Comat

read Chas

Gru

Power,

Por

oie

Power,

Power,

Power,

For

Power,

Gay

Вы

Camp

ae

Бо

12122,

os,

Slant

Bower

Grey,

Dolny

Some,

1400.

sing

Test Pack

Sate,

OC

NO

Fer

Grass

Fei

Fe

lia

Hester

Maine

Pug

Treml

TRE

Can

Тот

Gant

em

End,

Sack

End,

Black

SeAdhesive

Panel

19000

CH,

Zero Y Sah

SOR

Opening

lr

Sue

Fier

Term

Sr

Fier

Gara

Fier,

8

Ray,

Far

Sold

Ste

Corin à Chamas

Sela

mul

Sh

Thema

Bar

Gn

Cable

TOR

on

AN

ON

Face

Mou

Br

Taba

DNS

amparo

Ral

ard

Fan

Chasis

Relay

F:

Siti

Sae

Fay

BA

Load

EEE

Page 17

Jomesh

Technologies

PWS

2000

Patient

Warming

System

(ERC

=

Em

oz

En

区

ERİ

Em

DIZ

1081

回

a

12

Pes

a

回

[Rê

a

RT

ru

回

Gu

回

στ

τος

στ

品

E

10.2.

DESIGNATION

而

而

Control

[MANUF.

A

TE

Ser

Piles

Raye

Tico

д

R

Laine

Tanem

а

Tae

Woes

74800.

Wacomp

cies

A

A

Rat

at [5

Word

Waa

e

Te

ar

ai

me

Board

[PARTAUMBER

A

İz

ПОЗ

22000

бт

A

A

La

—[OWE218082

İTE

ОГ

ei

TIZI

ETO

ok

|

RESEN

O

A

[314001

140.023

PFT

БИ

rss

[ет

E

İsme

[DESCRIPTION

Cover

em

Sd

re

Erp,

aşar

[Capra

(Diode,

(Diode,

m)

AAA

eser

A

[Resistor,

iia

Teror

ie

(or 1 ANRT,

Corni

Capac,

Sec,

Crane

ci,

Smal

Signal

Bridge,

[Fuse

ender.

NES,

Rand

Sar

Ba PR

0.250

Ne

i

Prose

Mane

none

Dari

OI

ee

equi

Crt

Bow

Rin

EVE

507

ka

504,

29V

75V

400V

TA

Pr

PCB

Pr,

Fen

POE

1%

Va

Cd,

TOR

NO,

DIRO

Sap

OK

Sör

TO

ear

Doe

nm

POE

Tör

OF

PR

Низы

ОЕ

0203

0

Ph

Ra

07

PM

150mA_

(4

Pin

Plasto

DIP)

TEN

Sama

Wr. 4 Way,

ek

Moe © Way,

Va

Rear

cda

Deer

AVAYA

Fan

ZA

Precio

Pra

AS

ACTA)

Sed

OF

FCB

Wat 7 War

OT

BA

Canes

Common

OPA

Pin

Pini

DE

PRIS

EVO

Coni

PTH

Pa

PR

Pack

PER

PH

Gee

ES

PSE

ZE)

af

TO) | 1.

OT

Tİ

T

τ

PRA,

Ta

a

2

|

τ

7

T

|

τ

Ξ

i

т

E

7

7

т

7

т

Page 18

Report

No:

M000546

Page

2of

16

Test

Sample:

Model

Number:

‘Serial

Number:

Manufacturer:

Tested

For:

Address:

rest

Standards

Certificate

EMC

Technologies

Issue

Patent

Warming

Jomesh

2078

PWS

Biomedical

Biomedica!

РО

Box

Elhem,

+613

Vl

9458

of

Date:

2600

Engineering

Engineering

856,

3095

1963

+813 9456 2088

Peter

Ampi

IEC

601-4-2:

‘Medical

safety

Requirements

EN85011:

IEC

801-2:

IEG

801-3:

1EC

801-4:

IEC

801-5:

1999 / ASINZS

electrical

2.

Collateral

and

1998 / ASINZS2064:

1991

1992

(Draft)

1988

(Draft)

Compliance

Report

4%

No:

M000546

July,

2000

System

Company

Company

of

of

Australia

Australia

2200.1.2:

equipment

Standard:

tests

immunity

Immunity

immunity

Part

1:

Electromagnetic

1907

to

Electrostatic

Immunity

to

to

Electrical

to

High

Voltage

Australia

Ply

Lic

Ply

Ltd

1995

General

Radiated

requirements

compatibility

Emission

Discharges

Fields

fast

Transients

Surges

for

-

Result

of

Test:

‘Tost

Dates:

Test

Officers:

‘Authorised

5292

Signature:

Issued

by

EMC

Phone:

Tie

Australia.

of

accreditation.

Laboralory

The

test

sample

Refer

to

Report

23“

May

to 2 June

Philips

Technologies

Technologies

+61

Tho

loss

Pty.

Ltd.,

393353333

Ts

accredied

reported

by

herein

complied

M000546

2000

Pty

57

Assembly

Fax:

+61

39338

the

National

have

been

with

the

above

standards.

for

full

details

Lid

Dve.,

Tullamarine,

9260 | www.emctech.com.au

Assocation

performed

of

in

accordance

Vic.,

3043,

Testing

Author

with

its

terms

Australia.

Loading...

Loading...