Page 1

SERVICE MANUAL

Nellcor Symphony

®

N-3000 Patient Monitor

SpO2, ECG, and Respiration Capabilities

To contact Nellcor Puritan Bennett’s representative: In the United States, call 1-800-NELLCOR or 510 463-4000;

outside the United States, call your local Nellcor Puritan Bennett representative.

Caution: Federal law (U.S.) restricts this device to sale by or on the order of a physician.

© 1996 Nellcor Puritan Bennett Incorporated. All rights reserved. 035071A-1096

Page 2

Corporate Headquarters

Regional/Local Offices

Nellcor Puritan Bennett Inc.

4280 Hacienda Drive

Pleasanton, California 94588 U.S.A.

Tel. 510 463-4000 or

1-800-NELLCOR

Fax 510 463-4420

U.S. Service Repair Center

Nellcor Puritan Bennett Inc.

2391 Fenton Street

Chula Vista, California 91914

U.S.A.

Tel. 619 482-5000

European Office

Nellcor Puritan Bennett Europe BV

Hambakenwetering 1

5231 DD ’s-Hertogenbosch

The Netherlands

Tel. +31.73.6485200

Asia/Pacific Office

Nellcor Puritan Bennett HK Ltd.

Room 1602 Evergo House

38 Gloucester Road

Wanchai

Hong Kong

Tel. +852.2529.0363

Nellcor Puritan Bennett UK Ltd.

10, Talisman Business Centre

London Road

Bicester

Oxfordshire OX6 0JX

United Kingdom

Tel. +44.1869.322700

Nellcor Puritan Bennett Belgium NV/SA

Interleuvenlaan 62/8, Zone 2

B-3001 Heverlee

Belgium

Tel. +32.16.400467

Nellcor Puritan Bennett France

21 rue Albert Calmette

78353 Jouy-en-Josas Cedex

France

Tel. +33.1.34.63.06.00

Nellcor Puritan Bennett Germany GmbH

Black-&-Decker-Strasse 28

65510 Idstein

Germany

Tel. +49.6126.5930

Nellcor Puritan Bennett Italia Srl

Via dei Tulipani, 3

20090 Pieve Emanuele (MI)

Italy

Tel. +39.2.90786404

To obtain information about a warranty, if any, for this product, contact Nellcor Puritan Bennett

Technical Services or your local Nellcor Puritan Bennett representative.

Purchase of this instrument confers no express or implied license under any Nellcor Puritan

Bennett patent to use the instrument with any sensor that is not manufactured or licensed by

Nellcor Puritan Bennett.

Nellcor Puritan Bennett, Durasensor, Nellcor Symphony, Oxisensor II, and the Nellcor Puritan

Bennett knob configuration are trademarks of Nellcor Puritan Bennett Incorporated.

Covered by one or more of the following U.S. Patents and foreign equivalents: 4,621,643;

4,653,498; 4,700,708; 4,770,179; 4,869,254; 5,078,136; 5,351,685; and 5,368,026.

Page 3

TABLE OF CONTENTS

List of Figures

List of Tables

Section 1: Introduction........................................................................... 1-1

1.1 Manual Overview ..................................................................... 1-1

1.2 N-3000 Patient Monitor Description .......................................... 1-1

1.3 Related Documents.................................................................. 1-2

Section 2: Routine Maintenance............................................................ 2-1

2.1 Cleaning................................................................................... 2-1

2.2 Periodic Safety and Functional Checks..................................... 2-1

2.3 Batteries................................................................................... 2-1

Section 3: Performance Verification...................................................... 3-1

3.1 Introduction .............................................................................. 3-1

3.2 Equipment Needed................................................................... 3-1

3.3 Performance Tests................................................................... 3-2

3.4 Safety Tests............................................................................. 3-19

Section 4: Configuration Mode, Service Mode, and Alarm

Active Function....................................................................................... 4-1

4.1 Introduction .............................................................................. 4-1

4.2 Configuration Mode.................................................................. 4-1

3.3.1 Battery Charge........................................................... 3-2

3.3.2 Battery Performance Test .......................................... 3-2

3.3.3 Power-up Performance............................................... 3-3

3.3.3.1 Power-On Self-Test.................................................... 3-3

3.3.3.2 Adult Power-On Defaults and Alarm Limit Ranges...... 3-4

3.3.3.3 Neonate Power-On Defaults and Alarm Limit Ranges 3-6

3.3.4 Hardware and Software Tests..................................... 3-7

3.3.4.1 Operation with a Pulse Oximeter Tester..................... 3-7

3.3.4.2 Operation with an ECG Simulator............................... 3-11

3.3.4.3 Operation with a Respiration Simulator ...................... 3-13

3.3.4.4 General Operation...................................................... 3-13

3.3.4.5 ECG Cable Test......................................................... 3-19

3.4.1 Ground Integrity ......................................................... 3-19

3.4.2 Electrical Leakage...................................................... 3-19

3.4.2.1 Chassis Source Current.............................................. 3-20

3.4.2.2 Patient Source Current............................................... 3-21

3.4.2.3 Patient Sink Current................................................... 3-22

4.2.1 Adult/Neonatal Mode Default...................................... 4-2

4.2.2 Default SpO2 Upper Alarm Limit ................................ 4-2

4.2.3 Default SpO2 Lower Alarm Limit................................. 4-3

4.2.4 Default Heart/Pulse Rate Upper Alarm Limit .............. 4-3

4.2.5 Default Heart/Pulse Rate Lower Alarm Limit............... 4-3

4.2.6 Default Respiration Rate Upper Alarm Limit............... 4-4

4.2.7 Default Respiration Rate Lower Alarm Limit............... 4-4

4.2.8 Default Alarm Volume................................................ 4-4

4.2.9 Default Alarm Silence Duration .................................. 4-4

4.2.10 Configuration Menu.................................................... 4-5

4.2.10.1 Pulse Tone Volume................................................... 4-6

4.2.10.2 UIF Software Version Report..................................... 4-6

4.2.10.3 SpO2 Software Version Report .................................. 4-6

4.2.10.4 Serial Port Baud Rate................................................ 4-6

4.2.10.5 Trend Type................................................................ 4-7

iii

Page 4

Table of Contents

4.2.10.6 Reset to Factory Defaults .......................................... 4-7

4.2.10.7 Primary Heart/Pulse Rate Source.............................. 4-7

4.2.10.8 Primary Pulse Tone Source....................................... 4-8

4.2.10.9 ECG Lead Selection.................................................. 4-8

4.2.10.10 ECG Pacer Filter Status .......................................... 4-8

4.2.10.11 ECG Low Frequency Filter Status............................ 4-9

4.2.10.12 ECG Software Version Report ................................. 4-9

4.2.10.13 Respiration Noise Timeout....................................... 4-9

4.2.10.14 Respiration Sensitivity Selection.............................. 4-10

4.3 Service Mode........................................................................... 4-10

4.3.1 Menu Item 1: Software Version Report....................... 4-13

4.3.2 Menu Item 2: Knob and Lamp Test............................. 4-14

4.3.3 Menu Item 3: Button Test........................................... 4-14

4.3.4 Menu Item 4: Speaker Test........................................ 4-15

4.3.5 Menu Item 5: Internal Configuration Code (ICC)

Report........................................................................ 4-15

4.3.6 Menu Item 6: Total Operating Hours Report............... 4-16

4.3.7 Menu Items 7-16: Error Log Record Report................ 4-16

4.3.8 Menu Item 17: Instrument Identification (IID) Report .. 4-16

4.3.9 Menu Item 18: Power Status ...................................... 4-17

4.3.10 Menu Item 19: Persistent Time Sense Report ............ 4-17

4.3.11 Menu Item 20: Reset to Factory Defaults.................... 4-18

4.3.12 Menu Item 21: Initial Cluster Instrument Number

Report........................................................................ 4-18

4.3.13 Menu Item 22: Latching Alarms.................................. 4-18

4.3.14 Menu Item 23: Enable/Disable Alarm Silence

Reminder................................................................... 4-19

4.3.15 Menu Item 25: Dump EEPROM Data ......................... 4-19

4.3.16 Menu Item 28: Enable/Disable Battery Charge

Circuit ........................................................................ 4-20

4.3.17 Menu Item 29: Instrument Compatibility Report.......... 4-20

4.3.18 Menu Item 30: SpO2 RCAL Report............................. 4-20

4.3.19 Menu Item 31: SpO2 IR and Red Offset Report.......... 4-21

4.3.20 Menu Item 32: SpO2 Corrected IR and Red Signals

Report........................................................................ 4-21

4.3.21 Menu Item 33: SpO2 IR LED Drive Test ..................... 4-21

4.3.22 Menu Item 34: SpO2 Red LED Drive Test .................. 4-22

4.3.23 Menu Item 35: SpO2 DM-Gain Test............................ 4-23

4.3.24 Menu Item 36: SpO2 P-Gain Test............................... 4-23

4.3.25 Menu Item 37: Set SpO2 Analog Test Mode............... 4-24

4.3.26 Menu Item 38: SpO2 A/D-Cal Line Test...................... 4-24

4.3.27 Menu Item 39: SpO2 Enable Automatic Operation...... 4-25

4.3.28 Menu Item 40: Set ECG Lead .................................... 4-25

4.3.29 Menu Item 41: Set ECG Pacer Filter .......................... 4-25

4.3.30 Menu Item 42: Set ECG Low Frequency Filter............ 4-26

4.3.31 Menu Item 43: Set ECG Baseline Reset..................... 4-26

4.3.32 Menu Item 44: ECG POST Test Signal ...................... 4-26

4.3.33 Menu Item 45: Check ECG Cable Off Detection......... 4-27

4.3.34 Menu Item 46: Check ECG Lead Off Detection .......... 4-27

4.3.35 Menu Item 47: Display ECG Output Value.................. 4-28

4.3.36 Menu Item 49: ECG Enable Automatic Operation....... 4-28

4.3.37 Menu Item 51: Set Respiration Baseline Reset........... 4-29

4.3.38 Menu Item 53: Display Respiration Output Value........ 4-29

4.3.39 Menu Item 54: Enable/Disable Respiration

Monitoring.................................................................. 4-30

iv

Page 5

Table of Contents

4.3.40 Menu Item 55: Enable/Disable Breath Pulses............. 4-30

4.3.41 Menu Item 56: Respiration Enable Automatic

Operation................................................................... 4-31

4.3.42 Menu Item 60: Set Serial Port Baud Rate................... 4-31

4.3.43 Menu Item 61: Serial Port Loop Back Test ................. 4-31

4.3.44 Menu Item 62: Serial Port Transmit Test .................... 4-32

4.4 Alarm Active Function.............................................................. 4-32

Section 5: Troubleshooting ................................................................... 5-1

5.1 Introduction .............................................................................. 5-1

5.2 How to Use this Section............................................................ 5-1

5.3 Who Should Perform Repairs................................................... 5-1

5.4 Replacement Level Supported.................................................. 5-1

5.5 Obtaining Replacement Parts................................................... 5-1

5.6 Troubleshooting guide.............................................................. 5-2

5.6.1 Power......................................................................... 5-3

5.6.2 Error Codes................................................................ 5-4

5.6.2.1 User-Correctable Error Codes .................................... 5-4

5.6.2.2 Failure Error Codes.................................................... 5-4

5.6.3 Buttons/Knob.............................................................. 5-7

5.6.4 Display/Alarms........................................................... 5-8

5.6.5 Operational Performance........................................... 5-9

5.6.6 Stacked Operation ..................................................... 5-10

5.6.7 Serial Port.................................................................. 5-12

Section 6: Disassembly Guide............................................................... 6-1

6.1 Introduction .............................................................................. 6-1

6.2 Removing the Battery............................................................... 6-2

6.3 Battery Replacement................................................................ 6-3

6.4 Fuse Replacement ................................................................... 6-4

6.5 Monitor Disassembly ................................................................ 6-4

6.5.1 Communications Board Switch Settings..................... 6-5

6.6 Removing the Alarm Speaker................................................... 6-6

6.7 Removing the SpO2 PCB and SpO2 Controller PCB................. 6-6

6.8 Removing the Communications PCB........................................ 6-7

6.9 Removing the ECG PCB and ECG Controller PCB .................. 6-8

6.10 Removing the UIF PCB and Display PCB................................. 6-8

6.10.1 Installing a Replacement UIF PCB ............................. 6-9

6.11 Control Knob Assembly Replacement....................................... 6-10

6.12 Lithium Battery Replacement.................................................... 6-11

6.13 Reassembly.............................................................................. 6-11

Section 7: Spare Parts............................................................................ 7-1

7.1 Introduction .............................................................................. 7-1

Section 8: Packing for Shipment........................................................... 8-1

8.1 General Instructions ................................................................. 8-1

8.2 Repacking in Original Carton.................................................... 8-1

8.3 Repacking in a Different Carton................................................ 8-2

Section 9: Specifications........................................................................ 9-1

9.1 General.................................................................................... 9-1

9.2 Electrical .................................................................................. 9-1

9.3 Physical Characteristics............................................................ 9-2

9.4 Environmental.......................................................................... 9-2

9.5 Alarms...................................................................................... 9-2

9.6 Factory Default Settings........................................................... 9-2

9.7 Performance............................................................................. 9-3

v

Page 6

Table of Contents

Appendix................................................................................................. A-1

A1 Error Types .............................................................................. A-1

A2 User-Correctable Error Codes................................................... A-2

A3 Failure Error Codes .................................................................. A-2

A4 Internally Corrected Error Codes .............................................. A-3

Technical Supplement............................................................................ S-1

S1 Introduction .............................................................................. S-1

S2 Oximetry Overview................................................................... S-1

S2.1 Automatic Calibration................................................. S-1

S2.2 Functional Versus Fractional Saturation..................... S-2

S2.3 Measured Versus Calculated Saturation..................... S-2

S3 Stackbus Interconnect .............................................................. S-2

S4 Circuit Analysis......................................................................... S-3

S4.1 Functional Overview .................................................. S-3

S4.2 Circuit Description...................................................... S-4

S4.2.1 SpO2 Module ............................................................. S-4

S4.2.2 ECG/Respiration Module............................................ S-6

S4.2.3 UIF Module ................................................................ S-9

S4.2.4 SpO2 Controller.......................................................... S-16

S4.2.5 ECG Controller........................................................... S-18

S4.2.6 Communications Submodule...................................... S-19

S4.2.7 Display Board............................................................. S-21

S.5 Schematic Diagrams ................................................................ S-22

vi

Page 7

LIST OF FIGURES

LIST OF TABLES

Table of Contents

1-1 N-3000 Front Panel ...................................................................... 1-2

3-1 Self-Test Display .......................................................................... 3-3

3-2 Serial Port Interface...................................................................... 3-15

3-3 Serial Port Connector - External Pin Locations ............................. 3-16

3-4 Battery Cover Removal ................................................................ 3-17

3-5 Speaker Test................................................................................ 3-18

3-6 ECG Cable Pin Locations............................................................. 3-19

4-1 Serial Port Pin Locations .............................................................. 4-33

6-1 Battery Replacement.................................................................... 6-2

6-2 Removing the Battery................................................................... 6-3

6-3 N-3000 Fuses............................................................................... 6-4

6-4 N-3000 Corner Screws.................................................................. 6-4

6-5 Opening the N-3000 Monitor......................................................... 6-5

6-6 Handle, Left Side Panel, and Speaker Disassembly...................... 6-6

6-7 Rear Panel and SpO2 Module Disassembly.................................. 6-7

6-8 Communications PCB Removal.................................................... 6-8

6-9 Display PCB and UIF PCB Disassembly....................................... 6-9

6-10 Knob Encoder Disassembly .......................................................... 6-10

6-11 Knob Disassembly........................................................................ 6-10

7-1 N-3000 Expanded View ................................................................ 7-2

8-1 Repacking the N-3000.................................................................. 8-1

S2-1 Oxyhemoglobin Dissociation Curve.............................................. S-2

S4-1 N-3000 Functional Block Diagram ................................................ S-4

S4-2 Timing Diagram............................................................................ S-5

S4-3 Internal/External Stackbus Connections........................................ S-13

S4-4 Communications Sub module Block Diagram............................... S-20

S4-5 Display Board Block Diagram ....................................................... S-21

3-1 Dynamic Operating Ranges........................................................... 3-9

3-2 Serial Port Voltages....................................................................... 3-16

3-3 ECG Cable Resistances................................................................ 3-20

4-1 Configuration Mode Menu ............................................................. 4-2

4-2 Configuration Menu....................................................................... 4-5

4-3 Service Mode Steady State - Main Menu....................................... 4-12

5-1 Problem Categories....................................................................... 5-2

5-2 Power Problems............................................................................ 5-3

5-3 N-3000 Failure Error Codes........................................................... 5-5

5-4 Buttons/Knob Problems................................................................. 5-7

5-5 Display/Alarms Problems .............................................................. 5-8

5-6 Operational Performance Problems............................................... 5-9

5-7 Stack Problems............................................................................. 5-10

5-8 Serial Port Problems ..................................................................... 5-12

A-1 Error Types ................................................................................... A-1

A-2 N-3000 User-Correctable Error Codes........................................... A-2

A-3 N-3000 Failure Error Codes........................................................... A-2

A-4 N-3000 Internally Corrected Error Codes....................................... A-3

S4-1 J13 Inter Stack Connector ............................................................. S-9

S4-2 J8 Connector................................................................................. S-14

S4-3 J12, J22 Inter Module Connector................................................... S-15

S4-4 J5 Display Connector .................................................................... S-16

S4-5 J2 Speaker Connector................................................................... S-16

S4-6 J3 Knob Connector........................................................................ S-16

vii

Page 8

Page 9

SECTION 1: INTRODUCTION

1.1 Manual Overview

1.2 N-3000 Patient Monitor Description

1.3 Related Documents

1.1 MANUAL OVERVIEW

This manual contains information for servicing the Nellcor Symphony

model N-3000 patient monitor. Only qualified service personnel should service

this product. Before servicing the N-3000, read the operator’s manual carefully

for a thorough understanding of operation.

1.2 N-3000 PATIENT MONITOR DESCRIPTION

The purpose and function of the Nellcor Symphony N-3000 patient monitor is to

noninvasively and continuously monitor functional arterial oxygen saturation,

ECG, pulse rate, heart rate, and respiration rate for adult, pediatric, and neonatal

patients in all hospital areas and hospital-type facilities. It may be used for

hospital transport when powered by its internal battery.

The N-3000 can operate as a standalone monitor or it can be connected to

(stacked with) other Nellcor Symphony instruments, such as the N-3100 blood

pressure monitor and N-3200 display/printer. When used with the N-3200

display/printer, the instruments can display and print out ECG, respiration, and

plethysmographic waveforms and SpO2, pulse rate, heart rate, and respiration

rate tabular data.

The physical and operational characteristics of the monitor are described in the

operator’s manual and Section 9, Specifications, of this manual.

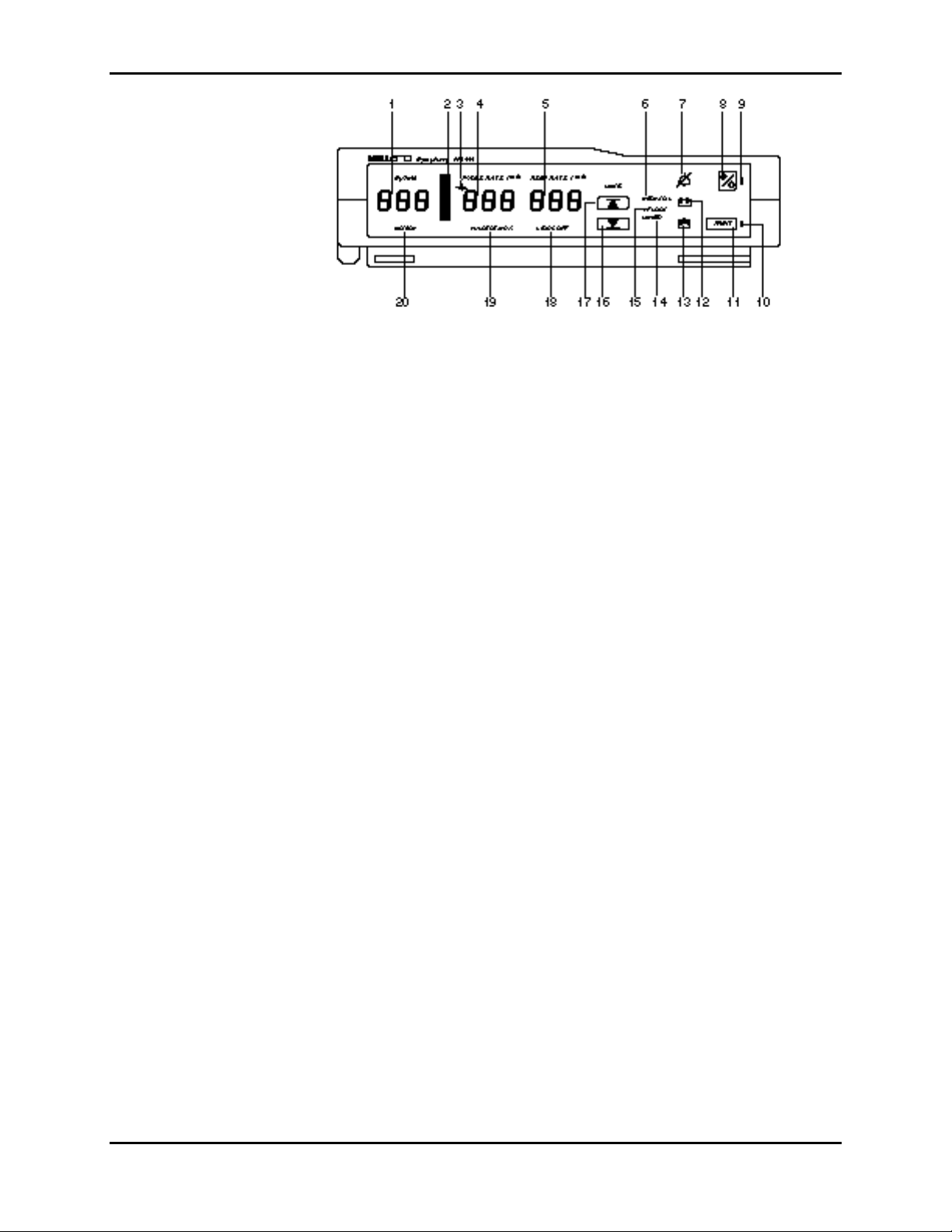

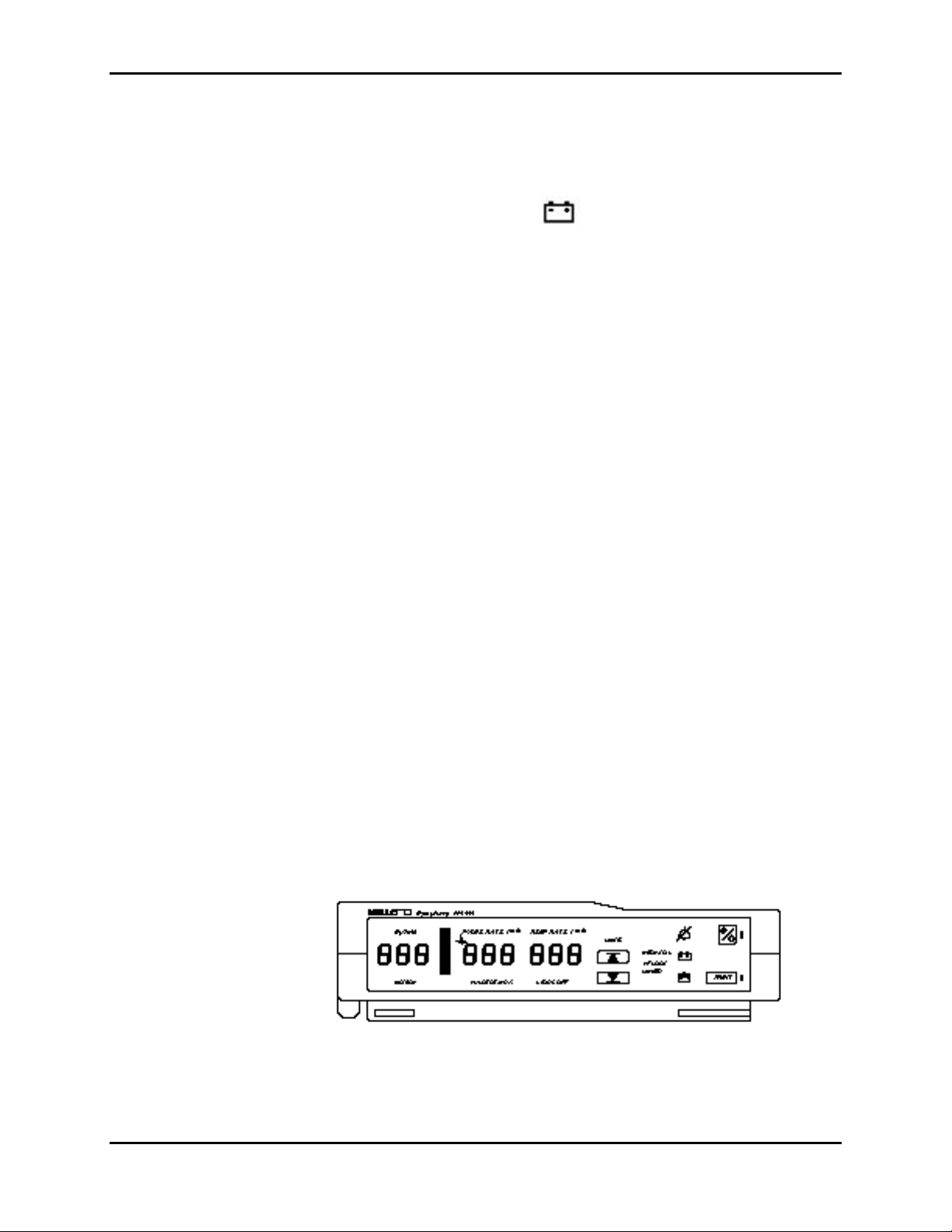

Figure 1-1 depicts the front panel of the N-3000 and the names of its displays

and controls.

1-1

Page 10

Section 1: Introduction

Figure 1-1: N-3000 Front Panel

1. SpO2% display 11. PRINT button

2. PULSE AMPLITUDE indicator 12. BATTERY IN USE/BATTERY LOW

indicator

3. ECG HEART RATE indicator 13. BATTERY CHARGING indicator

4. HEART/PULSE RATE display 14. LINKED indicator*

5. RESPIRATION RATE display 15. RF LOCKED indicator*

6. NEONATAL MODE indicator 16. LOWER ALARM LIMIT button

7. AUDIBLE ALARM OFF indicator 17. UPPER ALARM LIMIT button

8. ON/STANDBY button 18. LEADS OFF indicator

9. POWER ON indicator 19. PULSE SEARCH indicator

10. STACKED indicator 20. PATIENT MOTION indicator

* Not used on this model

1.3 RELATED DOCUMENTS

To perform test and troubleshooting procedures and to understand the principles

of operation and circuit analysis sections of this manual, you must know how to

operate the monitor. Refer to the N-3000 operator’s manual. To understand the

various Nellcor Puritan Bennett sensors and ECG leads that work with the

monitor, refer to the individual sensor or leads directions for use.

1-2

Page 11

SECTION 2: ROUTINE MAINTENANCE

2.1 Cleaning

2.2 Periodic Safety and Functional Checks

2.3 Batteries

2.1 CLEANING

Caution: Do not immerse the N-3000 or its accessories in liquid or clean

with caustic or abrasive cleaners. Do not spray or pour any liquid on the

monitor or its accessories.

To clean the N-3000, dampen a cloth with a commercial, nonabrasive cleaner

and wipe the exterior surfaces lightly. Do not allow any liquids to come in contact

with the power connector, fuse holder, or switches. Do not allow any liquids to

penetrate connectors or openings in the instrument cover. Wipe sensor and ECG

lead extension cables with a damp cloth. For sensors and ECG leads, follow the

individual directions for use.

2.2 PERIODIC SAFETY AND FUNCTIONAL CHECKS

The following checks should be performed at least every 2 years by a qualified

service technician.

1. Inspect the exterior of the N-3000 for damage.

2.3 BATTERIES

2. Inspect safety labels for legibility. If the labels are not legible, contact

Nellcor Puritan Bennett’s Technical Services Department or your local

Nellcor Puritan Bennett representative.

3. Verify that the unit performs properly as described in paragraph 3.3.

4. Perform the electrical safety tests detailed in paragraph 3.4. If the unit fails

these electrical safety tests, do not attempt to repair. Contact Nellcor

Puritan Bennett’s Technical Services Department or your local Nellcor

Puritan Bennett representative.

5. Inspect the fuses for proper value and rating (F1: 1.0 Amp, 250 Volt, Slo-

Blow and F2: 2.5 Amp, 250 Volt, Slo-Blow) as discussed in paragraph 6.4.

Nellcor Puritan Bennett recommends replacing instrument batteries at least

every 2 years. To replace the batteries, refer to Section 6, Disassembly Guide.

If the N-3000 has been stored for more than 30 days, charge the battery as

described in paragraph 3.3.1. A fully discharged battery requires 14 hours of

charging time for a full charge. A 6-hour charge is required for 1 hour of

operating time.

2-1

Page 12

Page 13

SECTION 3: PERFORMANCE VERIFICATION

3.1 Introduction

3.2 Equipment Needed

3.3 Performance Tests

3.4 Safety Tests

3.1 INTRODUCTION

This section discusses the tests used to verify performance following repairs or

during routine maintenance. All tests can be performed without removing the N3000 cover. All tests except the battery charge and battery performance tests

must be performed as the last operation before the monitor is returned to the

user.

If the N-3000 fails to perform as specified in any test, repairs must correct the

problem before the monitor is returned to the user.

3.2 EQUIPMENT NEEDED

Equipment Description

AC power adapter Use an appropriate Nellcor Symphony

SPS-N1 or PSS-1 power supply.

Connector adapter 6-pin, “D”

Digital multimeter (DMM) Fluke Model 87 or equivalent

Durasensor

®

oxygen transducer DS-100A

ECG cable SCE-10

ECG electrodes standard

ECG leads SLE series

ECG simulator Dynatech Nevada, medSim 300 or

equivalent

Oxisensor® II oxygen transducer D-25

Pulse oximeter tester SRC-2

Respiration simulator Dynatech Nevada, medSim 300 or

equivalent

Safety analyzer Must meet current AAMI

specifications

Sensor cable SCP-10

Serial interface cable EIA-232 cable (optional)

Stopwatch Manual or electronic

3.3 PERFORMANCE TESTS

The battery charge procedure should be performed before monitor repairs

whenever possible. It should also be performed before and after performing the

battery performance test (paragraph 3.3.2).

3-1

Page 14

Section 3: Performance Verification

This section is written using Nellcor Puritan Bennett factory-set defaults. If your

institution has preconfigured custom defaults, those values will be displayed.

Factory defaults can be reset using the configuration mode procedure described

in paragraph 4.2.10.6.

3.3.1 Battery Charge

Perform the following procedure to fully charge the battery.

1. Connect the monitor to an AC power source using an external power supply.

2. Verify that the monitor is off and that the BATTERY CHARGING indicator is

lit.

3. Charge the battery for at least 14 hours.

Note: The BATTERY CHARGING indicator is programmed to go out

when the N-3000 has been connected to AC power for

approximately 14 hours with no power interruptions. If there are

any power interruptions, the 14-hour charging period begins again

when power is restored.

4. The only way to check for a full charge is to perform the procedure in

paragraph 3.3.2 “Battery Performance Test.”

3.3.2 Battery Performance Test

The monitor is specified to operate on battery power a minimum of 4 hours.

(This time may decrease if the N-3000 is operating in the stacked configuration

with an N-3100 or N-3200.) Before performing this test, ensure that the battery is

fully charged (paragraph 3.3.1).

1. Connect the Nellcor Puritan Bennett SRC-2 pulse oximeter tester to the

monitor via the SCP-10 sensor cable.

2. Set the SRC-2 switches as follows:

SWITCH POSITION

RATE 38

LIGHT LOW

MODULATION LOW

RCAL/MODE RCAL 63/LOC

An illuminated BATTERY CHARGING indicator is not necessarily

an indication that the battery contains less than a full charge. It is

merely used as a timer to indicate that the battery has been

continuously charging for less than 14 hours.

3-2

3. Ensure that the monitor is not connected to AC power.

Page 15

4. With the N-3000 turned off, press the ON/STANDBY button and verify that

the BATTERY IN USE/BATTERY LOW indicator lights after the power-on

self-test is completed. Verify that the monitor is responding to the simulator

signal and the audible alarm is sounding. Do not silence the alarm during

this test.

5. The monitor must operate for at least 4 hours.

6. Verify that the BATTERY IN USE/BATTERY LOW indicator will start to

flash after about 3.5 to 3.75 hours (15-30 minutes before the battery fully

discharges).

7. Allow the monitor to operate until it automatically powers down due to the

low battery.

8. If the monitor passes this test, immediately recharge the battery (paragraph

3.3.1, steps 1 - 3).

3.3.3 Power-up Performance

The power-up performance tests (3.3.3.1 through 3.3.3.3) verify the following

monitor functions:

Section 3: Performance Verification

• 3.3.3.1 Power-On Self-Test

• 3.3.3.2 Adult Defaults and Alarm Limit Ranges

• 3.3.3.3 Neonate Defaults and Alarm Limit Ranges

3.3.3.1 Power-On Self-Test

1. Connect the monitor to an AC power source and verify that the BATTERY

2. Do not connect any input cables to the monitor.

3. Observe the monitor front panel. With the monitor off, press the

CHARGING indicator is lit.

ON/STANDBY button. The monitor must perform the following sequence.

a. The monitor emits three consecutively higher pitched beeps.

b. All indicators light for a few seconds as illustrated in Figure 3-1. Verify

that the SpO2% (left-most display), HEART/PULSE RATE (middle),

and RESPIRATION RATE (right) displays all indicate “8.8.8.”.

Figure 3-1: Self-Test Display

c. All displays turn off momentarily.

3-3

Page 16

Section 3: Performance Verification

d. Digital displays individually light in a scanning test pattern.

e. A 1-second beep sounds and all displays again illuminate momentarily.

f. All displays turn off except the POWER ON and BATTERY

CHARGING indicators. The SpO2% and HEART/PULSE RATE

displays are blank. The RESPIRATION RATE display indicates “0” for

about 15 seconds, then is blank. The monitor is in the “normal mode

steady state.”

g. Press and hold the NEW PATIENT/NEONATAL button (located on the

rear panel) for 3 seconds until you hear three beeps, indicating that

stored patient data is cleared.

3.3.3.2 Adult Power-On Defaults and Alarm Limit Ranges

Note: When observing or changing default limits, a 3-second timeout is in

effect, that is, if no action is taken within 3 seconds, the monitor

automatically returns to the normal mode steady state.

1. Ensure that the monitor is on. Press and release the UPPER ALARM LIMIT

button. Verify that the monitor emits a single beep and the SpO2% display

indicates an alarm limit of “100” for about 3 seconds. Verify that the other

displays indicate a single bar at the top of each window while the “100” is

displayed.

At the end of the 3 seconds, the displays are blank (normal mode steady

state).

2. Press and release the UPPER ALARM LIMIT button. Begin rotating the

control knob counterclockwise (CCW) within 3 seconds. Verify that the

SpO2% display reduces to a minimum of “85.”.

Note: A decimal point in the display indicates that the alarm limits have

changed.

3. Press and release the LOWER ALARM LIMIT button. Verify that the

monitor emits a single beep and the SpO2% display indicates an alarm limit

of “85” for 3 seconds. Verify that the other displays indicate a single bar at

the bottom of each window.

4. Press and hold the LOWER ALARM LIMIT button. Rotate the control knob

CCW and verify that the SpO2% display reduces to a minimum of “20”.

Rotate the control knob clockwise (CW) and verify that the SpO2% display

cannot be raised past the upper alarm limit setting of “85”.

5. Press the UPPER ALARM LIMIT button two times rapidly (twice within 3

seconds). Verify that the monitor emits two beeps and the HEART/PULSE

RATE display indicates an alarm limit of “170” for about 3 seconds.

3-4

Page 17

Section 3: Performance Verification

6. From the normal mode steady state, press the UPPER ALARM LIMIT

button two times rapidly. Begin rotating the control knob CCW within

3 seconds. Verify that the HEART/PULSE RATE display reduces to a

minimum of “40”.

7. Press the LOWER ALARM LIMIT button two times rapidly. Verify that the

HEART/PULSE RATE display indicates an alarm limit of “40” for 3 seconds.

8. From the normal mode steady state, press the LOWER ALARM LIMIT

button two times rapidly. Rotate the control knob CCW. Verify that the

HEART/PULSE RATE display reduces to a minimum of “30”.

9. Press the LOWER ALARM LIMIT button three times rapidly. Verify that the

RESPIRATION RATE display indicates an alarm limit of “4” for 3 seconds.

10. From the normal mode steady state, press the LOWER ALARM LIMIT

button three times rapidly. Begin rotating the control knob CW within

3 seconds. Verify the RESPIRATION RATE display increases to a

maximum of “40”.

11. Press the UPPER ALARM LIMIT button three times rapidly. Verify the

RESPIRATION RATE display indicates an alarm limit of “40” for 3 seconds.

12. Press the UPPER ALARM LIMIT button three times rapidly. Begin rotating

the control knob CW within 3 seconds. Verify that the RESPIRATION RATE

display increases to a maximum of “150”.

13. Press the ON/STANDBY button to turn the monitor off. Verify that the

monitor emits three decreasing pitch beeps.

14. Press the ON/STANDBY button to turn the N-3000 back on.

15. Press and release the UPPER ALARM LIMIT button. Verify that the SpO2%

display indicates an alarm limit of “100”.

16. Press and release the LOWER ALARM LIMIT button. Verify that the

SpO2% display indicates an alarm limit of “85”.

17. Press the UPPER ALARM LIMIT button two times rapidly. Verify that the

HEART/PULSE RATE display indicates an alarm limit of “170”.

18. Press the LOWER ALARM LIMIT button two times rapidly. Verify that the

HEART/PULSE RATE display indicates an alarm limit of “40”.

19. Press the UPPER ALARM LIMIT button three times rapidly. Verify that the

RESPIRATION RATE display indicates an alarm limit of “40”.

20. Press the LOWER ALARM LIMIT button three times rapidly. Verify that the

RESPIRATION RATE display indicates an alarm limit of “4”.

21. Press the ON/STANDBY button to turn the monitor off.

3-5

Page 18

Section 3: Performance Verification

3.3.3.3 Neonate Power-On Defaults and Alarm Limit Ranges

Note: When observing or changing default limits, a 3-second timeout is in

effect, that is, if no action is taken within 3 seconds, the monitor

automatically returns to the normal mode steady state.

1. Turn the monitor on.

2. Press the NEW PATIENT/NEONATAL button on the rear panel twice within

2 seconds. Verify that there is an audible beep each time the button is

pressed.

3. Verify that the NEONATAL MODE indicator on the front panel is lit.

4. Press and release the UPPER ALARM LIMIT button. Verify that the SpO2%

display indicates an alarm limit of “95” for 3 seconds. Verify that the other

displays indicate a single bar at the top of each window while the “95” is

displayed.

5. Press and release the UPPER ALARM LIMIT button. Begin rotating the

control knob CCW within 3 seconds. Verify that the SpO2% display reduces

to a minimum of “80”.

6. Press and release the LOWER ALARM LIMIT button. Verify that the SpO2%

display indicates an alarm limit of “80”. Verify that the other displays

indicate a single bar at the bottom of each window.

7. From the normal mode steady state, press and release the LOWER ALARM

LIMIT button. Rotate the control knob CCW. Verify that the SpO2% display

reduces to a minimum of “20”.

8. Press the UPPER ALARM LIMIT button two times rapidly (twice within 3

seconds). Verify that the HEART/PULSE RATE display indicates an alarm

limit of “190”.

9. Press the LOWER ALARM LIMIT button twice rapidly. Verify that the

HEART/PULSE RATE display indicates an alarm limit of “90”.

10. Press the UPPER ALARM LIMIT button three times rapidly. Verify that the

RESPIRATION RATE display indicates an alarm limit of “80”.

11. Press the LOWER ALARM LIMIT button three times rapidly. Verify that the

RESPIRATION RATE display indicates an alarm limit of “20”.

12. Press the ON/STANDBY button to turn the monitor off.

13. Press the ON/STANDBY button to turn the monitor on. The monitor

performs the sequence described in 3.3.3.1. Verify that the “NEO” indicator

is not lit.

14. Press and release the UPPER ALARM LIMIT button. Verify that the SpO2%

display indicates an alarm limit of “100”.

3-6

15. Press and release the LOWER ALARM LIMIT button. Verify that the SpO2%

display indicates an alarm limit of “85”.

16. Press the ON/STANDBY button to turn the monitor off.

Page 19

This completes the power-up performance tests.

3.3.4 Hardware and Software Tests

Hardware and software testing include the following tests.

• 3.3.4.1 Operation with a Pulse Oximeter Tester

• 3.3.4.2 Operation with an ECG Simulator

• 3.3.4.3 Operation with a Respiration Simulator

• 3.3.4.4 General Operation

3.3.4.1 Operation with a Pulse Oximeter Tester

Operation with an SRC-2 pulse oximeter tester includes the following tests.

• 3.3.4.1.1 Alarms and Alarm Silence

• 3.3.4.1.2 Alarm Volume Control

• 3.3.4.1.3 Pulse Tone Volume Control

• 3.3.4.1.4 Dynamic Operating Range

• 3.3.4.1.5 RCAL Determination

• 3.3.4.1.6 LED Drive Test

3.3.4.1.1 Alarms and Alarm Silence

Section 3: Performance Verification

1. Connect the SRC-2 pulse oximeter tester to the sensor input cable and

connect the cable to the monitor. Set the SRC-2 as follows:

SWITCH POSITION

RATE 38

LIGHT LOW

MODULATION OFF

RCAL/MODE RCAL 63/LOCAL

2. Press the ON/STANDBY button to turn the monitor on. After the normal

power-up sequence, verify that the SpO2%, HEART/PULSE RATE and

RESPIRATION RATE displays initially indicate zeroes.

Note: The pulse bar may occasionally indicate a step change as the

monitor is in the pulse search mode.

3. Move the modulation switch on the SRC-2 to LOW.

4. Verify that the following monitor reaction:

a. The pulse bar begins to track the artificial pulse signal from the SRC-2.

b. The pulse tone is heard.

c. Zeroes are displayed in the SpO2%, HEART/PULSE RATE, and

RESPIRATION RATE displays.

d. After about 10 to 20 seconds, the monitor displays a saturation and

pulse rate as specified by the tester. Verify that the values are within

the following tolerances:

Oxygen Saturation Range 79% to 83%

Pulse Rate Range 37 to 39 bpm

3-7

Page 20

Section 3: Performance Verification

e. The audible alarm sounds and both the SpO2% and HEART/PULSE

5. Press and momentarily hold the AUDIBLE ALARM OFF button on the top of

the monitor. Verify that the HEART/PULSE RATE display indicates “60” and

the RESPIRATION RATE display indicates “SEC” while the AUDIBLE

ALARM OFF button is pressed. The alarm is silenced.

6. Release the AUDIBLE ALARM OFF button. Verify the following:

a. The alarm remains silenced.

b. The AUDIBLE ALARM OFF indicator lights.

c. The SpO2% and HEART/PULSE RATE displays resume flashing.

d. The pulse tone is still audible.

e. The audible alarm returns in approximately 60 seconds.

7. Press and hold the AUDIBLE ALARM OFF button. Rotate the control knob

CCW until the HEART/PULSE RATE display indicates “30”. Rotate the

control knob CW and verify that the displays indicate 60 SEC, 90 SEC, 120

SEC, and OFF. Release the button when the display indicates “OFF”. Verify

that the AUDIBLE ALARM OFF indicator flashes.

RATE displays will flash, indicating both parameters have violated the

default alarm limits.

8. Wait approximately 3 minutes. Verify that the alarm does not return. After 3

minutes, the alarm silence reminder beeps three times, and will continue to

do so at 3-minute intervals.

3.3.4.1.2 Alarm Volume Control

After completing the procedure in paragraph 3.3.4.1.1:

1. Press and hold the AUDIBLE ALARM OFF button on the top of the monitor.

Verify the following:

a. “OFF” is displayed for approximately 3 seconds.

b. After 3 seconds, a steady tone is heard at the default alarm volume

setting, the HEART/PULSE RATE display indicates “VOL”, and the

RESPIRATION RATE display indicates the default setting of 5.

2. While continuing to hold the AUDIBLE ALARM OFF button, rotate the

control knob CCW to decrease the alarm volume setting to a minimum

value of 1. The alarm tone should decrease but still be audible.

3. Rotate the control knob CW to increase the alarm volume setting to a

maximum value of 10. Verify the volume increases. Rotate the knob CCW

until a comfortable audio level is attained.

4. Release the AUDIBLE ALARM OFF button. The tone will stop.

3-8

3.3.4.1.3 Pulse Tone Volume Control

1. Rotate the control knob CW and verify that the beeping pulse tone sound

level increases.

Page 21

Section 3: Performance Verification

2. Rotate the control knob CCW and verify that the beeping pulse tone

decreases until it is no longer audible. Rotate the knob CW to return the

beep volume to a comfortable level.

3.3.4.1.4 Dynamic Operating Range

The following test sequence verifies proper monitor operation over a range of

input signals.

1. Connect the SRC-2 to the N-3000 and turn the N-3000 on.

2. Place the SRC-2 in the RCAL 63/LOCAL mode.

3. Set the SRC-2 as indicated in Table 3-1. Verify that the N-3000 readings

are within the indicated tolerances. Allow the monitor several seconds to

stabilize the readings.

Note: A “*” indicates values that produce an alarm. Press the AUDIBLE

ALARM OFF button to silence the alarm.

Table 3-1: Dynamic Operating Range

SRC-2 Settings N-3000 Indications

RATE LIGHT MODULATION SpO2 Pulse Rate

38 HIGH2 LOW 79 - 83* 37 - 39*

112 HIGH1 HIGH 79 - 83* 110 - 114

201 LOW LOW 79 - 83* 195 - 207*

201 LOW HIGH 79 - 83* 195 - 207*

4. Turn the monitor off.

3.3.4.1.5 RCAL Determination

1. Ensure that the N-3000 is turned off and connected to AC power via an

external power supply.

2. Connect the SRC-2 pulse oximeter tester to the sensor input cable and

connect the cable to the monitor. Set the SRC-2 as follows:

SWITCH POSITION

RATE 38

LIGHT LOW

MODULATION OFF

RCAL/MODE RCAL 63/LOCAL

3. Enter the service mode as follows:

a. While simultaneously holding down the UPPER and LOWER ALARM

LIMIT buttons and the PRINT button, press and release the

ON/STANDBY button. Continue to press and hold the UPPER and

LOWER ALARM LIMIT and PRINT buttons while the monitor performs

the power-on test.

b. When “SEr” begins flashing in the AUXILIARY display, release the

UPPER and LOWER ALARM LIMIT and PRINT buttons.

3-9

Page 22

Section 3: Performance Verification

c. Press the PRINT button within 15 seconds or the monitor will turn off

4. Select menu item 30 by rotating the knob until “30” appears in the SpO2%

display.

5. Press the UPPER ALARM LIMIT button.

6. Verify the RCAL index number “63” is displayed in the HEART/PULSE

RATE display.

7. Set the SRC-2 RCAL/Mode switch to 64/LOCAL and verify that “64” is

displayed in the HEART/PULSE RATE display.

8. Press the ON/STANDBY button to turn the monitor off.

3.3.4.1.6 LED Drive Test

1. Ensure that the N-3000 is turned off and connected to AC power via an

external power supply.

2. Connect the SRC-2 pulse oximeter tester to the sensor input cable and

connect the cable to the monitor. Set the SRC-2 as follows:

automatically. The number “1” appears in the SpO2% display. You are

now in the service mode steady state.

SWITCH POSITION

RATE 38

LIGHT LOW

MODULATION OFF

RCAL/MODE RCAL 63/LOCAL

3. Enter the service mode as follows:

a. While simultaneously holding down the UPPER and LOWER ALARM

LIMIT buttons and the PRINT button, press and release the

ON/STANDBY button. Continue to press and hold the UPPER and

LOWER ALARM LIMIT and PRINT buttons while the monitor performs

the power-on test.

b. When “SEr” begins flashing in the AUXILIARY display, release the

UPPER and LOWER ALARM LIMIT and PRINT buttons.

c. Press the PRINT button within 15 seconds or the monitor will turn off

automatically. The number “1” appears in the SpO2% display. You are

now in the service mode.

4. Select menu item 33 by rotating the knob until “33” appears in the SpO2%

display.

5. Press the UPPER ALARM LIMIT button.

3-10

6. Verify that the SpO2 IR LED drive value “170” is displayed in the

HEART/PULSE RATE display and the IR indicator on the SRC-2 is

illuminated.

7. Rotate the control knob to adjust the IR LED drive level indicated in the

HEART/PULSE RATE display to “255”.

Page 23

Section 3: Performance Verification

8. While watching the IR indicator on the SRC-2, press the UPPER ALARM

LIMIT button and verify that the LED intensity increases.

9. Rotate the knob to adjust the IR LED drive level to “0”.

10. Press the UPPER ALARM LIMIT button. Verify that the IR LED turns off.

11. Rotate the knob to adjust the IR LED drive level to “170”.

12. Press the UPPER ALARM LIMIT button and verify that the LED intensity

increases.

13. Press the LOWER ALARM LIMIT button to return to the service mode

steady state.

14. Select menu item 34 by rotating the knob until “34” appears in the SpO2%

display.

15. Press the UPPER ALARM LIMIT button.

16. Verify that the SpO2 red LED drive value “170” is displayed in the

HEART/PULSE RATE display and that the IR indicator on the SRC-2 is

illuminated.

17. Rotate the control knob to adjust the red LED drive level to “255”.

18. Press the UPPER ALARM LIMIT button and verify that the LED intensity

increases.

19. Rotate the knob to adjust the red LED drive level to “0”.

20. Press the UPPER ALARM LIMIT button and verify that the RED indicator turns

off.

21. Rotate the knob to adjust the red LED drive level back to “170”.

22. Press the UPPER ALARM LIMIT button and verify that the RED indicator

intensity increases.

23. Press the LOWER ALARM LIMIT button to return to the service mode

steady state.

24. Press the ON/STANDBY button to turn the N-3000 off.

3.3.4.2 Operation with an ECG Simulator

1. With the monitor off, connect the ECG leads RA, LA, and LL to the

appropriate jacks on the ECG tester.

Nellcor Puritan Bennett ECG leads are color-coded as follows:

Right arm (RA) - white

Left arm (LA) - Black

Left leg (LL) - Red

3-11

Page 24

Section 3: Performance Verification

2. Connect the leads to the SCE-10 ECG cable. Connect the SCE-10 to the

ECG input port on the N-3000. Set the ECG tester as follows:

PARAMETER SETTING

HEART RATE 30 bpm

AMPLITUDE 1 millivolt

LEAD SELECT I

SINUS RHYTHM Normal

RCAL/MODE Adult

Note: The accuracy of N-3000 ECG measurements is + 5 bpm. In the

3. Ensure that the monitor is connected to an AC power source. Press the

ON/STANDBY button to turn the monitor on. After the normal power-up

sequence, verify the following monitor reactions:

a. The heart rate “beep” will be heard.

b. After at least five heartbeats, the monitor displays a heart rate of 30 ± 5

c. The audible alarm will sound and the HEART/PULSE RATE display will

procedure below, add the tolerance of the simulator to the acceptable

range of readings.

bpm.

flash, indicating the heart rate is below the default lower alarm limit.

The heart rate “beep” can still be heard.

4. Press the AUDIBLE ALARM OFF BUTTON. Verify that the alarm is

silenced.

5. Increase the heart rate setting on the ECG simulator to 240 bpm. Verify that

the rate of beeps increases and the HEART/PULSE RATE display value

increases.

6. After at least five heartbeats, verify that the monitor displays a heart rate of

240 ± 5 bpm.

7. Verify that the audible alarm sounds and the HEART/PULSE RATE display

flashes, indicating that the heart rate is above the default upper alarm limit.

8. Press AUDIBLE ALARM OFF button to silence the alarm.

9. Decrease the heart rate setting on the ECG simulator to 120 bpm.

10. After at least five heartbeats, verify that the monitor displays a heart rate of

120 ± 5 bpm.

11. Disconnect the LL lead from the ECG simulator. Verify that the LEADS OFF

indicator lights, three dashes are displayed in the HEART/PULSE RATE

display, and a low priority audible alarm sounds.

3-12

Page 25

12. Reconnect the LL lead to the ECG simulator. Verify that the LEADS OFF

indicator is no longer lit and that the alarm is silenced.

Note: Depending on the lead used and pleth configuration, the

HEART/PULSE RATE display may revert to a pulse rate as leads

are removed in step 11. If a medium priority alarm results and is

silenced, the low priority alarm from leads off will not break

through.

13. Repeat steps 11 and 12 for the LA and RA leads.

14. Turn the monitor off.

3.3.4.3 Operation with a Respiration Simulator

1. With the monitor off, connect the Nellcor Puritan Bennett ECG leads to the

appropriate jacks on the respiration simulator.

2. Connect the leads to the SCE-10 ECG cable. Connect the SCE-10 to the

ECG input port on the N-3000.

Note: The accuracy of N-3000 ECG measurements is + 3 breaths per

minute. In the procedure below, add the tolerance of the simulator

to the acceptable range of readings.

Section 3: Performance Verification

3. Set the simulator for a respiration rate of 100 breaths per minute.

4. Ensure that the monitor is connected to an AC power source. Press the

5. Press the AUDIBLE ALARM OFF BUTTON. Verify that the alarm is

6. Decrease the respiration rate setting on the respiration simulator to 20

7. After at least 5 breaths, verify that the monitor displays a respiration rate of

8. Power down the monitor and disconnect it from the simulator.

3.3.4.4 General Operation

ON/STANDBY button to turn the monitor on. After the normal power-up

sequence, verify the following monitor reactions:

a. After about 20-25 seconds, the monitor displays a respiration rate of

100 ± 3 breaths per minute.

b. The audible alarm will sound and the RESPIRATION RATE display will

flash, indicating the respiration rate is above the default upper alarm

limit.

silenced.

breaths per minute.

20 ± 3 breaths per minute.

The following tests are an overall performance check of the system:

• 3.3.4.4.1 LED Excitation Test

• 3.3.4.4.2 Operation with a Live Subject

• 3.3.4.4.3 Serial Interface Test

• 3.3.4.4.4 Piezo Speaker Test

• 3.3.4.4.5 Persistent Time Clock Test

3-13

Page 26

Section 3: Performance Verification

• 3.3.4.4.6 ECG Cable Test

3.3.4.4.1 LED Excitation Test

This procedure uses normal system components to test circuit operation. A

Nellcor Puritan Bennett™ Oxisensor II® oxygen transducer, model D-25, is used

to examine LED intensity control. The red LED is used to verify intensity

modulation caused by the LED intensity control circuit.

1. Connect the monitor to an AC power source through the SPS-N1 or PSS-1

power supply.

2. Connect an SCP-10 sensor input cable to the monitor.

3. Connect a D-25 sensor to the sensor input cable.

4. Press the ON/STANDBY button to turn the monitor on.

5. Leave the sensor open with the LEDs and photodetector visible.

6. After the monitor completes its normal power-up sequence, verify that the

sensor LED is brightly lit.

7. Slowly move the sensor LED in proximity to the photodetector element of

the sensor. Verify, as the LED approaches the optical sensor, that the LED

intensity decreases.

8. Open the sensor and notice that the LED intensity increases.

9. Repeat step 7 and the intensity will again decrease. This variation is an

indication that the microprocessor is in proper control of LED intensity.

10. Turn the N-3000 off.

3.3.4.4.2 Operation with a Live Subject

Patient monitoring involves connecting the monitor to a live subject for a

qualitative test.

1. Ensure that the monitor is connected to an AC power source through the

SPS-N1 or PSS-1 power supply.

2. Connect an SCP-10 sensor input cable to the monitor.

3. Connect a Nellcor Puritan Bennett™ Durasensor® oxygen transducer,

model DS-100A, to the sensor input cable.

4. Clip the DS-100A to the subject as recommended in the sensor directions

for use.

5. Connect ECG electrodes to the patient.

6. Connect an SCE-10 ECG cable to the N-3000. Connect ECG leads to the

cable.

3-14

7. Connect the ECG leads to the electrodes on the patient according to the

leads directions for use.

Page 27

Section 3: Performance Verification

8. Press the ON/STANDBY button to turn the monitor on and verify that the

monitor is operating.

9. The monitor should stabilize on the subject’s physiological signal in about

15 to 30 seconds. Verify that the saturation and heart and respiration rates

are reasonable for the subject.

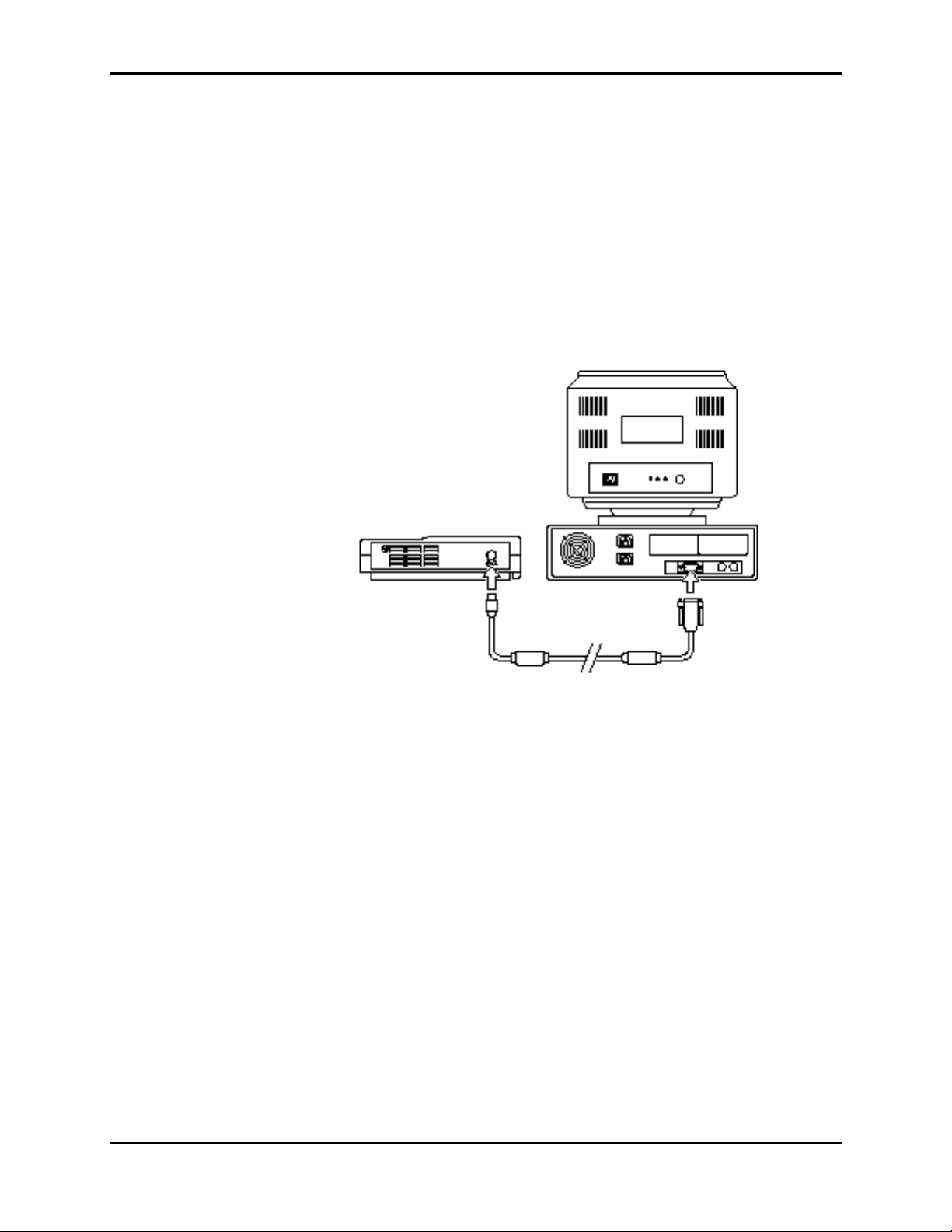

3.3.4.4.3 Serial Interface Test

The communications submodule of the N-3000, using an asynchronous EIA-232

communications format, allows communications between the N-3000 and a PC

via the 6-pin connector on the rear panel of the N-3000, as illustrated in Figure

3-2. An SAK-232 cable and detailed directions for use are available by

contacting your local Nellcor Puritan Bennett representative.

Figure 3-2: Serial Port Interface

The two configurable options of serial data interface are RS-232 and EIA-422.

The N-3000 is shipped with the RS-232 setting. To change the settings, refer to

paragraph 6.5.1.

Perform the following procedure to test the serial port voltages. The test is

qualitative and will only verify that the serial interface port is powered correctly.

1. Connect the monitor to an AC power source through the SPS-N1 or PSS-1

power supply and turn the monitor on.

2. Connect a 6-pin miniature connector adapter to the serial interface port.

3. Set up the DMM with the function set to “VDC” at a range of 10 volts.

4. Connect the DMM negative lead to connector pin 4 (GND).

3-15

Page 28

Section 3: Performance Verification

5. Connect the DMM positive lead to the following pins and verify the voltage

values listed in Table 3-2. If the voltages are not as indicated, follow the

procedures in paragraph 5.6.7.

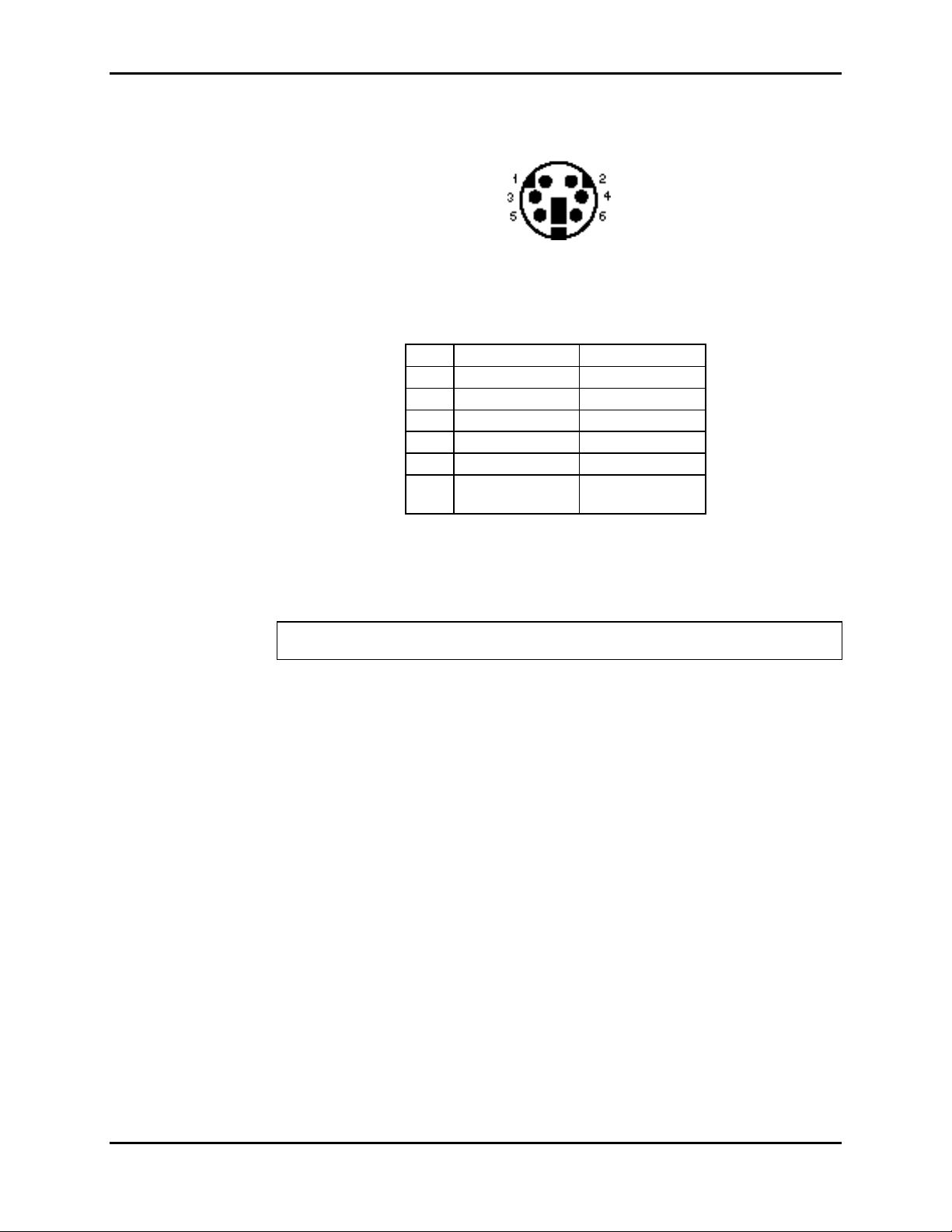

Figure 3-3: Serial Port Connector - External Pin Locations

Table 3-2: Serial Port Voltages

Pin Line Voltage

1 DTR 7.5 ± 2.5

2 DSR 0.0 ± 0.4

3 TXD -7.5 ± 2.5

4 GND 0.0 ± 0.4

5 RXD 0.0 ± 0.4

6 Alarm Active 0.0 ± 0.4 or

3.3 ± 0.4

3.3.4.4.4 Piezo Speaker Test

The following test verifies that the Piezo power-loss alarm speaker sounds when

the N-3000 loses power.

WARNING: Before attempting to open or disassemble the N-3000,

disconnect the power cord from the N-3000.

Caution: Observe ESD (electrostatic discharge) precautions when working

within the monitor.

3-16

Page 29

Section 3: Performance Verification

1. Ensure that the N-3000 is turned off.

2. Disconnect the monitor from the external power supply.

3. Set the N-3000 upside down facing you, as shown in Figure 3-4.

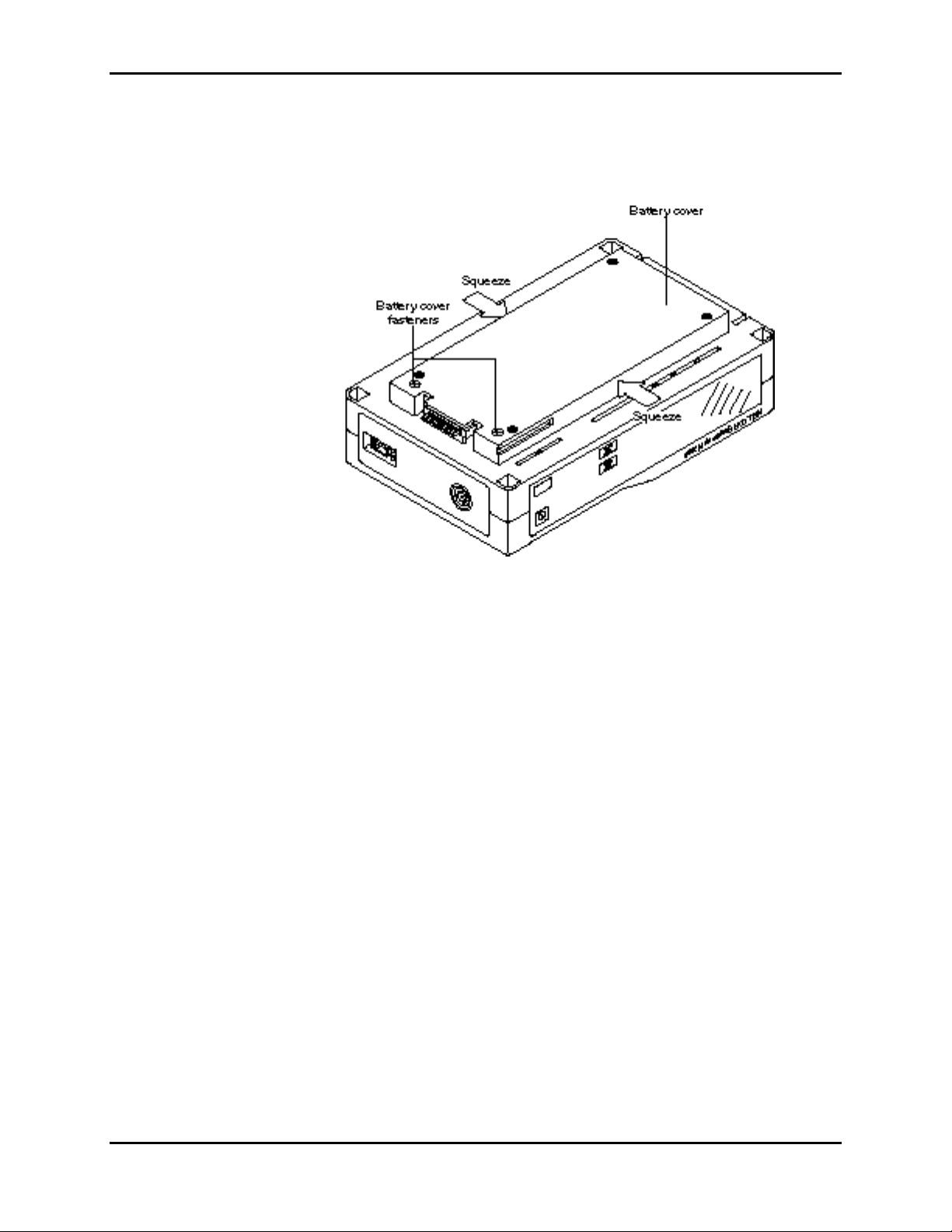

Figure 3-4: Battery Cover Removal

4. Using a small, Phillips-head screwdriver, loosen the two battery cover

retaining fasteners securing the battery compartment cover.

5. Gently squeeze the battery cover sides in the middle as you swing the

cover open (it is hinged on the right with three tabs that extend into slots on

the chassis).

3-17

Page 30

Section 3: Performance Verification

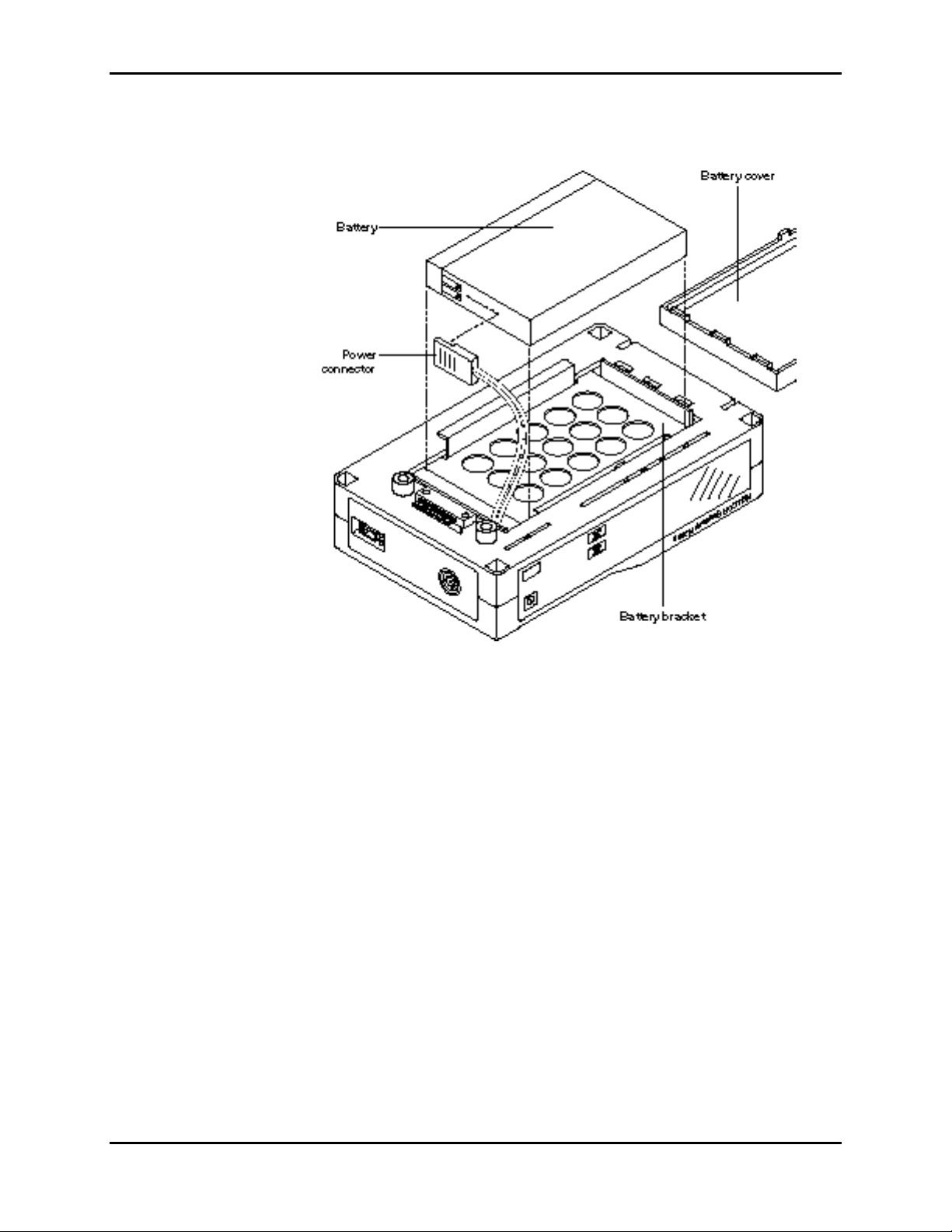

6. Lift the battery out of the compartment, as shown in Figure 3-5. It may be

necessary to use the edge of a flat tip screwdriver to gently pry the battery

loose.

Figure 3-5: Speaker Test

7. Turn the monitor on by pressing the ON/STANDBY button.

8. When the power-on self-test is complete, disconnect the power connector

from the battery. Verify that a shrill, beeping alarm is emitted from the

speaker.

9. Reconnect the power connector to the battery. Verify that the alarm is

silenced and the monitor powers back on.

10. Disconnect the power connector from the battery a second time. Verify that

the Piezo alarm sounds.

11. Press the AUDIBLE ALARM OFF button and verify that the alarm is

silenced.

12. Reconnect the power connector to the battery. Verify that the alarm remains

silent and the monitor powers back on.

13. Turn the monitor off by pressing the ON/STANDBY button.

14. Replace the battery in the battery bracket and reconnect the battery cover.

3-18

Page 31

Section 3: Performance Verification

3.3.4.4.5 Persistent Time Clock Test

This procedure allows you to check the operation of the persistent time clock.

1. Enter the service mode as follows:

a. While holding down the UPPER and LOWER ALARM LIMIT buttons

and the PRINT button, press and release the ON/STANDBY button.

Continue to hold the UPPER and LOWER ALARM LIMIT and PRINT

buttons while the monitor performs the power-on test.

b. When “SEr” begins flashing in the AUXILIARY display, release the

UPPER and LOWER ALARM LIMIT and PRINT buttons.

c. Press the PRINT button within 15 seconds or the monitor will turn off

automatically. The number “1” appears in the SpO2% display. You are

now in the service mode steady state.

2. Select menu item 19 by rotating the control knob.

3. Press the UPPER ALARM LIMIT button. The persistent time in seconds is

displayed in the SpO2% and HEART/PULSE RATE displays. For example,

“001 688” indicates that the monitor has been powered on for 1,688

seconds = 28 minutes, 8 seconds. Verify that the right-most digit is counting

seconds.

3.3.4.5 ECG Cable Test

If the display reads “999 999”, this indicates that persistent time is greater

than or equal to 999,999 seconds. If dashes are displayed, the contents of

the memory of the persistent time circuit are lost. This can occur when the

backup lithium battery has been replaced.

4. Using a timepiece, track the clock to verify proper operation.

5. Press the LOWER ALARM LIMIT button to return to the service mode

steady state.

6. Turn the monitor off by pressing the ON/STANDBY button.

The following test should be completed after defibrillation has been performed

on a patient attached to ECG leads and a Nellcor Puritan Bennett SCE-10 ECG

cable. It does not need to be performed as a component of an N-3000

performance verification test.

Perform the following procedure to test the ECG cable.

1. Disconnect the SCE-10 ECG cable from the N-3000 and the ECG leads.

Pin locations for both ends of the ECG cable are identified in Figure 3-6.

3-19

Page 32

Section 3: Performance Verification

2. Measure the resistances between the pins as indicated in Table 3-3.

3. If the resistances are not as indicated, replace the cable.

Figure 3-6: ECG Cable Pin Locations

Table 3-3: ECG Cable Resistances

Pin To Pin Resistance

2 A 900 - 1100 ohms

3 B 900 - 1100 ohms

8 C 900 - 1100 ohms

5 D, E, F 0 - 5 ohms

8 5 open

2 5 open

3 5 open

A D open

B E open

C F open

3.4 SAFETY TESTS

N-3000 safety tests consist of:

• Ground Integrity

• Electrical Leakage

3.4.1 Ground Integrity

This test verifies the integrity of the power cord ground wire from the AC plug

and connection with the external power supply chassis ground.

1. Configure the electrical safety analyzer as follows:

2. Connect the monitor’s AC plug to the analyzer as recommended by the

3. Connect the analyzer “resistance” input lead to the grounding lug on the

3.4.2 Electrical Leakage

Function: Ground resistance test

Range: Milliohms

analyzer operating instructions.

rear panel of the external power supply. Verify that the analyzer indicates

150 milliohms or less.

The following tests verify the electrical leakage of the monitor.

• Chassis Source Current

• Patient Source Current

• Patient Sink Current

3.4.2.1 Chassis Source Current

3-20

Page 33

Section 3: Performance Verification

This test is in compliance with IEC 601.1 and AAMI Standard ES1, paragraph

3.3.1, Chassis Source Current, between the power ground and (part b), exposed

conductive hardware.

1. Configure the electrical safety analyzer as follows:

Function: Leakage

Range: Microamps

2. Connect the monitor AC plug to the electrical safety analyzer as

recommended by the analyzer operating instructions.

3. Connect the electrical safety analyzer “leakage” input lead to the monitor’s

external power supply grounding lug.

The analyzer leakage indication must not exceed 100 microamps at

100–120 VAC or 500 microamps at 220–240 VAC for the following AC

power configurations while the monitor is turned on and while turned off.

3.4.2.2 Patient Source Current

This test is in compliance with AAMI Standard ES1, paragraph 3.3.2. Patient

Source Current is measured between any individual patient connection and

power (earth) ground.

1. Configure the electrical safety analyzer as follows:

Function: Leakage

Range: Microamps

2. Connect the monitor AC plug to the electrical safety analyzer as

recommended by the analyzer operating instructions for patient source

current.

3. Connect the electrical safety analyzer leakage input lead to the monitor’s

sensor input connector.

AC LINE

POLARITY

POWER LINE

GROUND CABLE

Normal Normal

Reverse Normal

Reverse Open

Normal Open

The analyzer leakage indication must not exceed 10 microamps for all of

the following AC power configurations with the monitor on.

AC LINE

POLARITY

POWER LINE

GROUND CABLE

Normal Normal

Reverse Normal

Reverse Open

3-21

Page 34

Section 3: Performance Verification

3.4.2.3 Patient Sink Current

This test is in compliance with AAMI Standard ES1, paragraph 4.4. Patient sink

current is measured in a patient connection if a source of 240 volts, 50 Hz (or

120 volts, 60 Hz) with respect to power (earth) ground, is connected to that

patient connection.

1. Configure the electrical safety analyzer as follows:

Function: Leakage

Range: µA

2. Connect the monitor AC plug to the electrical safety analyzer as

recommended by the operating instructions for patient sink current.

3. Connect the electrical safety analyzer leakage input lead to the monitor’s

sensor input.

The analyzer leakage indication must not exceed 50 microamps for

240 volts (10 microamps for 120 volts) for the following AC power

configurations with the monitor on.

Normal Open

AC LINE

POLARITY

POWER LINE

GROUND CABLE

Normal Normal

Normal Open

3-22

Page 35

SECTION 4: CONFIGURATION MODE, SERVICE MODE, AND ALARM

ACTIVE FUNCTION

4.1 Introduction

4.2 Configuration Mode

4.3 Service Mode

4.4 Alarm Active Function

4.1 INTRODUCTION

This section discusses use of the configuration mode to reconfigure power-on

default values, the service mode to identify and correct monitor difficulties, and

the alarm active function.

4.2 CONFIGURATION MODE

The following paragraphs describe how to enter the N-3000 configuration mode

and change factory power-on default settings.

The N-3000 cannot enter the configuration mode while it is stacked unless the

other instruments are in the configuration mode or are turned off. If the other

instruments are in the configuration mode, the N-3000 knob may be used to

scroll to the desired menu item and adjust the settings of the other instruments.

Likewise, if the N-3000 is stacked with an N-3200, and both are in the

configuration mode, the N-3200 knob may be used to scroll to the desired menu

item and adjust the settings of the N-3000.

Use the following procedure to enter configuration mode:

1. If the monitor is on, turn it off.

2. While simultaneously pressing both UPPER and LOWER ALARM LIMIT

buttons, turn the monitor on. Continue to press both buttons until “CFG”

begins flashing in the RESPIRATION RATE display.

3. Release the UPPER and LOWER ALARM LIMIT buttons.

4. Press the PRINT button. “CFG” stops flashing and remains displayed in the

RESPIRATION RATE display. (If the PRINT button is not pressed within

15 seconds after “CFG” begins flashing, the monitor will turn off

automatically.)

You are now in configuration mode steady state. The N-3000 automatically

powers down if no action is taken for approximately 2 minutes.

After changing or viewing a default setting, you can return to the configuration

mode steady state by allowing the display to timeout (3 seconds).

To exit the configuration mode, turn the monitor off by pressing the

ON/STANDBY button. Default settings take place when the monitor is turned off.

Default settings also take place if the N-3000 powers down due to the 2-minute

timeout.

Note: While changing default limits, there must be some user interaction with

the monitor within a 3-second period or the monitor will return to

configuration mode steady state operation.

4-1

Page 36

Section 4: Configuration Mode, Service Mode, and Alarm Active Function

Table 4-1 lists the default settings that can be configured and the respective

entry procedures to access the settings. Methods used to change the default

settings are detailed in paragraphs 4.2.1 through 4.2.10.

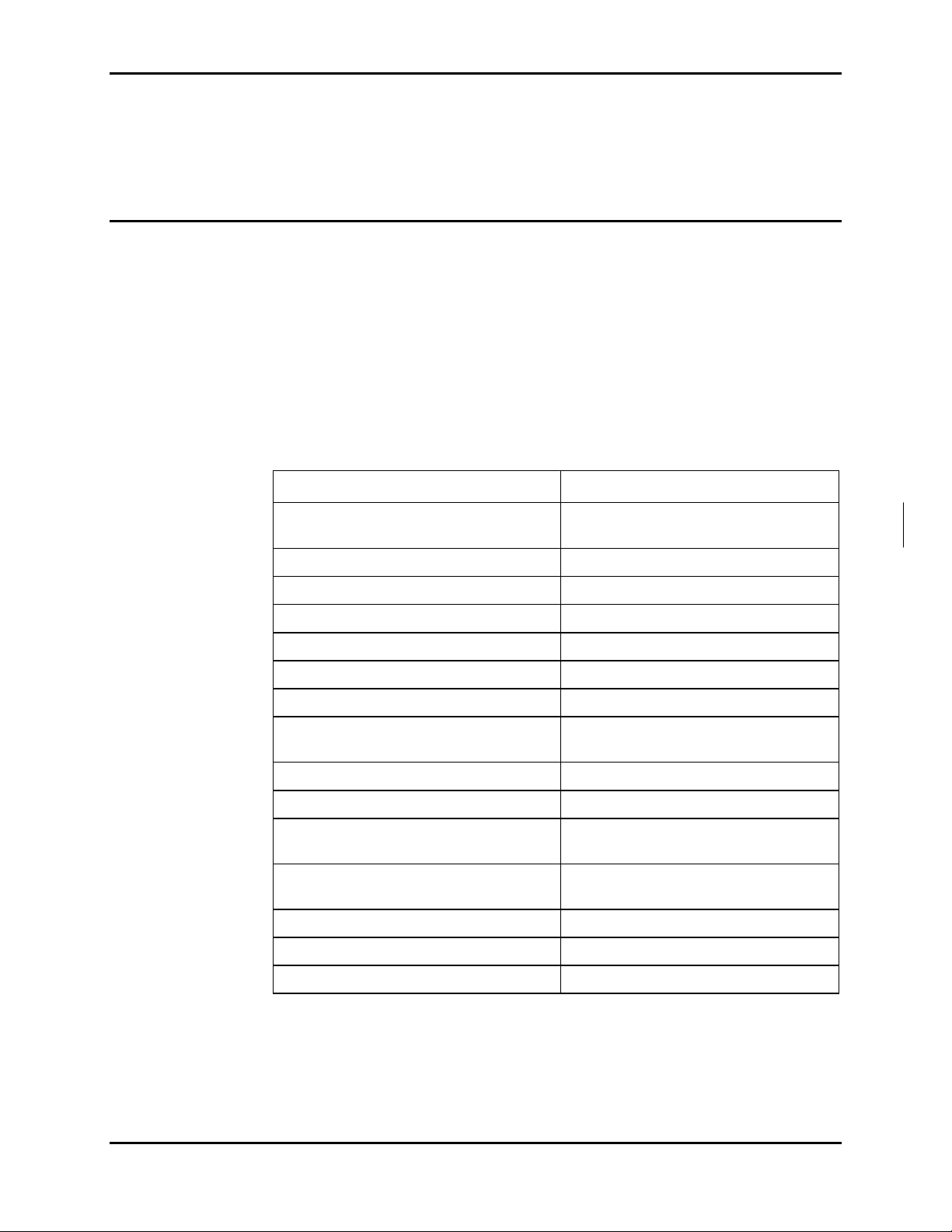

Table 4-1: Configuration Mode Menu

Power on Default

Setting

Button Press Procedure from

Configuration Mode Steady State

Paragrap

h

Described

Adult/Neonatal Mode NEW PATIENT/NEONATAL button

4.2.1

twice

SpO2 Upper Alarm Limit UPPER ALARM LIMIT button 4.2.2

SpO2 Lower Alarm Limit LOWER ALARM LIMIT button 4.2.3

Heart/Pulse Rate Upper

UPPER ALARM LIMIT button twice 4.2.4

Alarm Limit

Heart/Pulse Rate Lower

LOWER ALARM LIMIT button twice 4.2.5

Alarm Limit

Respiration Rate Upper

Alarm Limit

Respiration Rate Lower

Alarm Limit

Alarm Volume ALARM SILENCE button (press and

UPPER ALARM LIMIT button three

times

LOWER ALARM LIMIT button three

times

4.2.6

4.2.7

4.2.8

hold for 3 seconds before turning

knob)

Alarm Silence Duration ALARM SILENCE button (press and

4.2.9

hold; turn knob within 3 seconds)

Configuration Menu UPPER/LOWER ALARM LIMIT

Note: To change neonate default limits, enter the neonatal mode from

configuration mode steady state by pressing the NEW

PATIENT/NEONATAL button twice within 2 seconds. Change the

desired limit using the same method as adult default limits.

When an SpO2 or heart/pulse rate default limit has been changed, a decimal

point will appear after the displayed limit until the configuration mode is exited.

4.2.1 Adult/Neonatal Mode Default

The mode (adult or neonatal) that the monitor is in when exiting the

configuration mode, becomes the power-on default.

To change from a power-on default of adult mode to a power-on default of

neonatal mode, enter the configuration mode steady state. Press the NEW

PATIENT/NEONATAL button twice within 2 seconds and then power-down by

pressing the ON/STANDBY button.

4.2.2 Default SpO2 Upper Alarm Limit

4.2.10

buttons simultaneously

4-2

Page 37

Section 4: Configuration Mode, Service Mode, and Alarm Active Function

1. From the configuration mode steady state, press and release the UPPER

ALARM LIMIT button. The current default value is displayed in the SpO2%

display. Dashes appear in the HEART/PULSE RATE display (the upper

horizontal segments of the display), indicating that the monitor is in the “set

SpO2 upper alarm limit” mode.

2. To change the upper alarm limit default value, rotate the knob on top of the

monitor (or, if stacked with an N-3200 in the configuration mode, the knob

on the N-3200). You cannot decrease the value lower than the current SpO2

lower alarm limit default setting. The SpO2 upper alarm limit cannot be set

higher than 100.

3. Return to configuration mode steady state.

Note: If you press the LOWER ALARM LIMIT button before the 3-second

timeout, you can then change the SpO2 lower alarm limit default. If

you press the UPPER ALARM LIMIT button, you can then change

the pulse rate upper alarm limit default. This method can also be

used while setting the other default alarm limits.

4.2.3 Default SpO2 Lower Alarm Limit

1. From the configuration mode steady state, press and release the LOWER

ALARM LIMIT button. The current default value is displayed in the SpO2%

display.

2. To change the lower alarm limit default value, rotate the knob on top of the

monitor. You cannot increase the value higher than the current SpO2 upper

alarm limit setting. The SpO2 default lower alarm limit cannot be set lower

than 80.

3. Return to the configuration mode steady state.

4.2.4 Default Heart/Pulse Rate Upper Alarm Limit

1. From the configuration mode steady state, press the UPPER ALARM LIMIT

button twice within 3 seconds. The current default value is displayed in the

HEART/PULSE RATE display. Dashes appear in the SpO2% display (the

upper horizontal segments of the display), indicating that the monitor is in

the “set pulse rate upper alarm limit” mode.

2. To change the upper alarm limit default value, rotate the control knob on

top of the monitor. You cannot decrease the value lower than the current

pulse rate lower alarm limit default setting. The pulse rate default upper

alarm limit cannot be set higher than 250.

3. Return to configuration mode steady state.

4.2.5 Default Heart/Pulse Rate Lower Alarm Limit

1. From the configuration mode steady state, press the LOWER ALARM

LIMIT button twice within 3 seconds. The current default value is displayed

in the HEART/PULSE RATE display.

2. To change the default lower alarm limit value, rotate the knob CW to

increase, or CCW to decrease. You cannot increase the value higher than

the current pulse rate upper limit setting. The pulse rate lower alarm limit

cannot be set lower than 30.

4-3

Page 38

Section 4: Configuration Mode, Service Mode, and Alarm Active Function

3. Return to the configuration mode steady state.

4-4

Page 39

Section 4: Configuration Mode, Service Mode, and Alarm Active Function

4.2.6 Default Respiration Rate Upper Alarm Limit

1. From the configuration mode steady state, press the UPPER ALARM LIMIT

button three times within 3 seconds. The current default value is displayed

in the RESPIRATION RATE display.

2. To change the default upper alarm limit value, rotate the control knob on

top of the monitor CW to increase or CCW to decrease. You cannot

decrease the value lower than the current respiration rate lower limit setting.

The respiration rate upper alarm limit cannot be set higher than 150.

3. Return to the configuration mode steady state.

4.2.7 Default Respiration Rate Lower Alarm Limit

1. From the configuration mode steady state, press the LOWER ALARM

LIMIT button three times within three seconds. The current default value is

displayed in the RESPIRATION RATE display.

2. To change the default lower alarm limit value, rotate the knob CW to

increase, or CCW to decrease. You cannot increase the value higher than

the current respiration rate upper limit setting. The respiration rate lower

alarm limit cannot be set lower than 3.