Nellcor N-290 Service manual

SERVICE MANUAL

NPB-290 Pulse Oximeter

Caution: Federal law (U.S.A.) restricts this device to sale by or on the order of a physician.

To contact Mallinckrodt's representative: In the United States, call 1.800.635.5267 or 314.654.2000; outside of the United

States, call your local Mallinckrodt representative.

© 2002 Mallinckrodt Inc. All rights reserved. 061096D-1102

Nellcor Puritan Bennett Inc.

4280 Hacienda Drive

Pleasanton, CA 94588 USA

Telephone Toll Free 1.800.NELLCOR

Mallinckrodt Europe BV

Hambakenwetering 1

5231 DD”s-Hertogenbosch

The Netherlands

Telephone +31.73.648.5200

Nellcor Puritan Bennett is a wholly owned subsidiary of Mallinckrodt Inc. Nellcor, Nellcor Puritan Bennett, Oxinet II,

Oxisensor II, and Durasensor are trademarks of Mallinckrodt Inc.

To obtain information about a warranty, if any, for this product, contact Mallinckrodt Technical Services Department, or

your local Mallinckrodt representative.

Notice: Purchase of this instrument confers no express or implied license under any Mallinckrodt patent to use the

instrument with any sensor that is not manufactured or licensed by Mallinckrodt.

Covered by one or more of the following U.S. Patents and foreign equivalents: 4,621,643; 4,653,498; 4,700,708; 4,770,179;

4,869,254; 5,078,136; 5,351,685; 5,368,026; 5,533,507; and 5,662,106.

TABLE OF CONTENTS

List of Figures

List of Tables

Table of Contents......................................................................................... iii

List of Figures .......................................................................................... v

List of Tables ........................................................................................... vi

Section 1: Introduction............................................................................... 2-1

1.1 Manual Overview ........................................................................... 2-1

1.2 NPB-290 Pulse Oximeter Description ........................................... 2-1

1.3 Related Documents ....................................................................... 2-2

Section 2: Routine Maintenance ............................................................... 2-1

2.1 Cleaning......................................................................................... 2-1

2.2 Periodic Safety and Functional Checks......................................... 2-1

2.3 Battery............................................................................................ 2-1

Section 3: Performance Verification ......................................................... 3-1

3.1 Introduction .................................................................................... 3-1

3.2 Equipment Needed........................................................................ 3-1

3.3 Performance Tests ........................................................................ 3-1

3.4 Safety Tests................................................................................... 3-10

Section 4: Audible Alarm Settings and Service Menu ............................ 4-1

4.1 Introduction .................................................................................... 4-1

4.2 Audible Alarm Settings .................................................................. 4-1

4.3 Operator's Menu Options............................................................... 4-2

4.4 Service Menu Options ................................................................... 4-4

Section 5: Troubleshooting ....................................................................... 5-1

5.1 Introduction .................................................................................... 5-1

5.2 How to Use this Section ................................................................ 5-1

5.3 Who Should Perform Repairs........................................................ 5-1

5.4 Replacement Level Supported ...................................................... 5-1

5.5 Obtaining Replacement Parts........................................................ 5-1

5.6 Troubleshooting Guide .................................................................. 5-2

5.7 Error Codes ................................................................................... 5-8

Section 6: Disassembly Guide................................................................... 6-1

6.1 Introduction .................................................................................... 6-1

6.2 Prior to Disassembly...................................................................... 6-1

6.3 Fuse Replacement ........................................................................ 6-2

6.4 Monitor Disassembly ..................................................................... 6-3

6.5 Monitor Reassembly...................................................................... 6-4

6.6 Battery Replacement ..................................................................... 6-5

6.7 Power Entry Module (PEM) Removal/Replacement ..................... 6-6

6.8 Power Supply Removal/Replacement........................................... 6-7

6.9 Cooling Fan Removal/Replacement.............................................. 6-9

6.10 Display PCB Removal/Replacement............................................. 6-10

6.11 User Interface PCB Removal/Replacement .................................. 6-11

6.12 Alarm Speaker Removal/Replacement ......................................... 6-12

Section 7: Spare Parts................................................................................ 7-1

7.1 Introduction .................................................................................... 7-1

iii

Table of Contents

Section 8: Packing for Shipment............................................................... 8-1

8.1 General Instructions ...................................................................... 8-1

8.2 Repacking in Original Carton......................................................... 8-1

8.3 Repacking in a Different Carton .................................................... 8-3

Section 9: Specifications ........................................................................... 9-1

9.1 General .......................................................................................... 9-1

9.2 Electrical ........................................................................................ 9-1

9.3 Physical Characteristics ................................................................ 9-1

9.4 Environmental................................................................................ 9-1

9.5 Alarms............................................................................................ 9-2

9.6 Factory Default Settings ................................................................ 9-2

9.7 Performance .................................................................................. 9-2

Section 10: Data Port Interface Protocol .................................................. 10-1

10.1 Introduction .................................................................................... 10-1

10.2 Enabling the Data Port .................................................................. 10-1

10.3 Connecting to the Data Port .......................................................... 10-2

10.4 Real-Time Printout......................................................................... 10-3

10.5 Nurse Call ...................................................................................... 10-6

10.6 Analog Output................................................................................ 10-7

10.7 Interactive Mode ............................................................................ 10-7

Section 11: Technical Supplement ........................................................... 11-1

11.1 Introduction .................................................................................... 11-1

11.2 Oximetry Overview ........................................................................ 11-1

11.3 Circuit Analysis .............................................................................. 11-2

11.4 Functional Overview ...................................................................... 11-2

11.5 AC Input......................................................................................... 11-3

11.6 Power Supply PCB Theory Of Operation ...................................... 11-3

11.7 Battery............................................................................................ 11-4

11.8 User Interface PCB........................................................................ 11-5

11.9 Front Panel Display PCB and Controls ......................................... 11-8

11.10 Schematic Diagrams ..................................................................... 11-9

Section 12: Index ........................................................................................ 12-1

iv

LIST OF FIGURES

Table of Contents

Figure 1-1: NPB-290 Front Panel ................................................................. 2-1

Figure 1-2: NPB-290 Rear Panel.................................................................. 2-2

Figure 3-1: NPB-290 Controls ...................................................................... 3-2

Figure 3-2: Power-On Self-Test Display ....................................................... 3-3

Figure 3-3: Adjusting High %SpO2 Alarm Limit............................................ 3-4

Figure 3-4: Adjusting Low %SpO2 Alarm Limit ............................................ 3-4

Figure 3-5: Adjusting High Pulse Rate Alarm Limit ...................................... 3-4

Figure 3-6: Adjusting Low Pulse Rate Alarm Limit ....................................... 3-4

Figure 3-7: Alarm Silence Duration............................................................... 3-6

Figure 3-8: Alarm Volume Display ................................................................ 3-7

Figure 4-1: NPB-290 Controls ...................................................................... 4-1

Figure 6-1: Fuse Removal ............................................................................ 6-2

Figure 6-2: NPB-290 Corner Screws ............................................................ 6-3

Figure 6-3: Separating Case Halves............................................................. 6-4

Figure 6-4: Battery Removal......................................................................... 6-5

Figure 6-5: Power Entry Module ................................................................... 6-6

Figure 6-6: Power Supply ............................................................................. 6-7

Figure 6-7: Cooling Fan ................................................................................ 6-9

Figure 6-8: Display PCB ............................................................................... 6-10

Figure 6-9: User Interface PCB .................................................................... 6-11

Figure 6-10: Alarm Speaker.......................................................................... 6-13

Figure 7-1: NPB-290 Exploded View ............................................................ 7-2

Figure 8-1: Repacking the NPB-290............................................................. 8-2

Figure 10-1: Data Port Pin Layout ................................................................ 10-2

Figure 10-2: Real-Time Printout ................................................................... 10-3

Figure 10-3: Instrument Info Printout ............................................................ 10-9

Figure 10-4: Trend Printout........................................................................... 10-10

Figure 10-5: Error Log Printout ..................................................................... 10-10

Figure 11-1: Oxyhemoglobin Dissociation Curve ......................................... 11-2

Figure 11-2: NPB-290 Functional Block Diagram......................................... 11-3

Figure 11-3: User Interface PCB Front End Red/IR Schematic Diagram .... 11-9

Figure 11-4: Front End LED Drive Schematic Diagram................................ 11-9

Figure 11-5: Front End Power Supply Schematic Diagram.......................... 11-9

Figure 11-6: SIP/SOP Isolation Barrier Schematic Diagram ........................ 11-9

Figure 11-7: Data Port Drivers and Analog Output Schematic Diagram...... 11-9

Figure 11-8: User Interface PCB MC331 Core Schematic Diagram ............ 11-9

Figure 11-9: User Interface PCB MC331 Memory Schematic Diagram B ... 11-9

Figure 11-10: Speaker Driver Schematic Diagram A ................................... 11-9

Figure 11-11: User Interface PCB Power Supply Schematic Diagram B..... 11-9

Figure 11-12: Display Interface Schematic Diagram .................................... 11-9

Figure 11-13: Parts Locator Diagram for USER INTERFACE PCB ............. 11-9

Figure 11-14: Power Supply Schematic Diagram......................................... 11-9

Figure 11-15: Power Supply Parts Locator Diagram .................................... 11-9

Figure 11-16: Display PCB Schematic Diagram........................................... 11-9

Figure 11-17: Display PCB Parts Locator Diagram ...................................... 11-9

v

Table of Contents

LIST OF TABLES

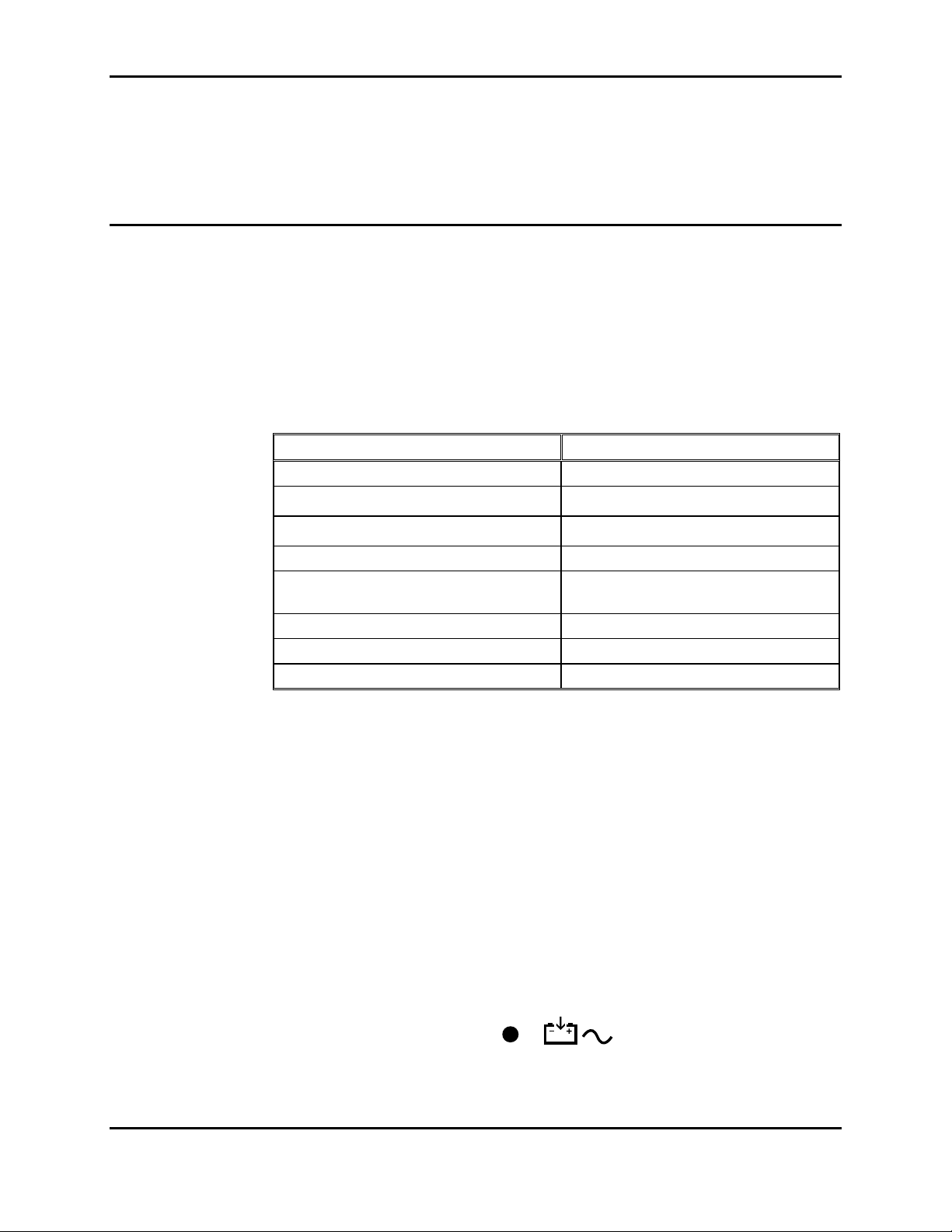

Table 3-1: Dynamic Operating Range .......................................................... 3-8

Table 3-2: Earth Leakage Current Limits...................................................... 3-11

Table 3-3: Enclosure Leakage Current Limits .............................................. 3-11

Table 3-4: Patient Leakage Current Limits ................................................... 3-12

Table 3-5: Patient Leakage Current Test Configurations -

Mains Voltage on the Applied Part............................................. 3-13

Table 4-1: Language Selection..................................................................... 4-3

Table 4-2: Factory Default Settings .............................................................. 4-5

Table 5-1: Problem Categories..................................................................... 5-2

Table 5-2: Power Problems .......................................................................... 5-3

Table 5-3: Button Problems .......................................................................... 5-4

Table 5-4: Display/Alarms Problems ............................................................ 5-5

Table 5-5: Operational Performance Problems ............................................ 5-6

Table 5-6: Data Port Problems ..................................................................... 5-7

Table 5-7: Error Codes ................................................................................. 5-8

Table 6-1: Power Supply Leads Connections .............................................. 6-8

Table 7-1: Parts List...................................................................................... 7-1

Table 9-1: Default Settings ........................................................................... 9-2

Table 10-1 Data Port Pin Outs...................................................................... 10-2

Table 10-2: Status Codes ............................................................................. 10-6

Table 10-3: Nurse Call Relay Pin States ...................................................... 10-7

Table 10-4: Rating of Nurse Call Relay ........................................................ 10-7

vi

SECTION 1: INTRODUCTION

1.1 Manual Overview

1.2 NPB-290 Pulse Oximeter Description

1.3 Related Documents

1.1 MANUAL OVERVIEW

This manual contains information for servicing the NPB-290 pulse oximeter.

Only qualified service personnel should service this product. Before servicing

the NPB-290, read the operator's manual carefully for a thorough understanding

of how to operate the NPB-290.

Warning: Explosion hazard. Do not use the NPB-290 pulse oximeter in the

presence of flammable anesthetics.

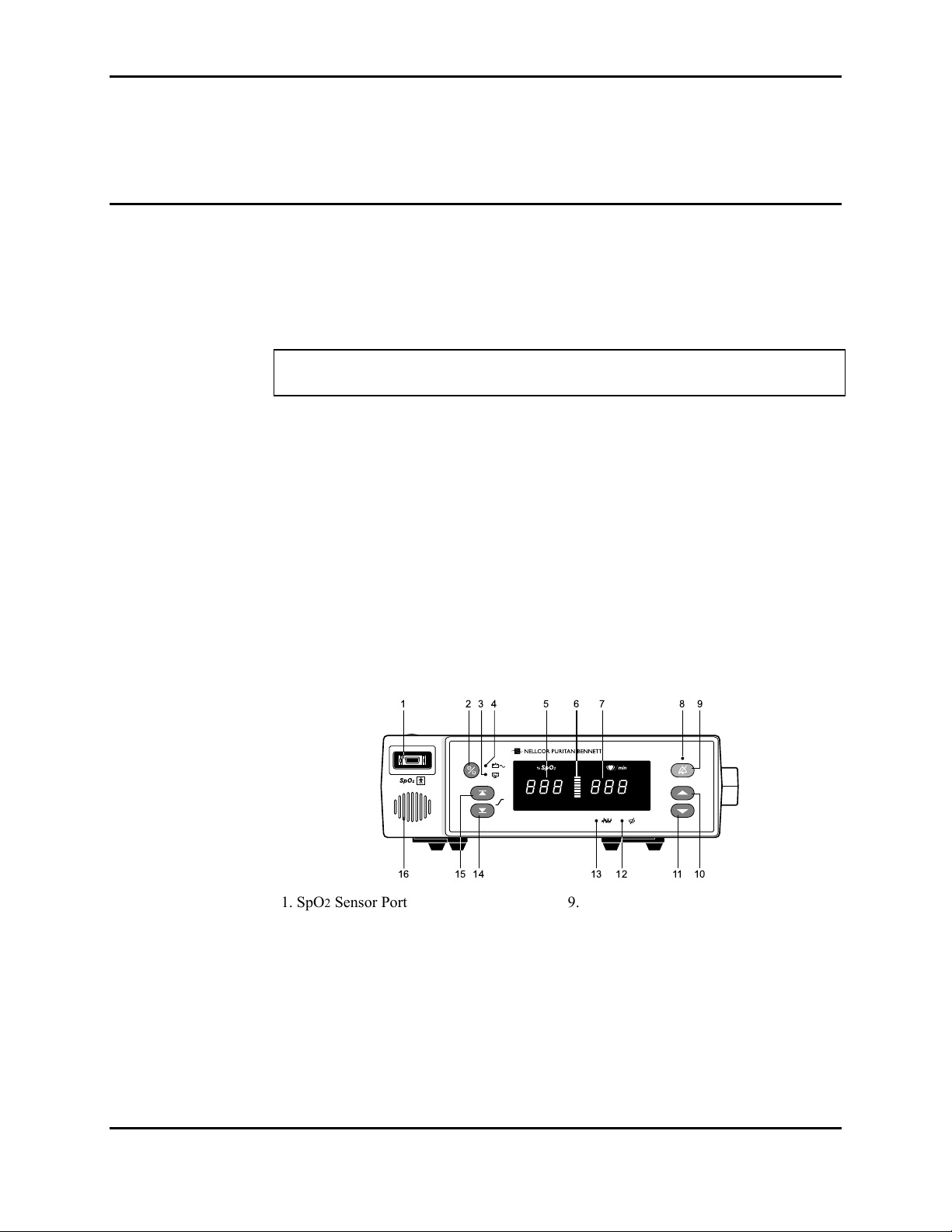

1.2 NPB-290 PULSE OXIMETER DESCRIPTION

The Nellcor NPB-290 pulse oximeter is intended for continuous, noninvasive

monitoring of functional oxygen saturation of arterial hemoglobin (SpO

pulse rate (measured by SpO

2 sensor).

2), and

The monitor is intended for use on adult, pediatric, and neonatal patients in all

hospital areas, hospital-type facilities, and in the home environment. It may be

used during intra-hospital transport when powered by its internal battery.

Digital displays are provided for oxygen saturation and pulse rate, and a 10segment light-emitting diode (LED) bar indicates pulse amplitude.

The NPB-290 can operate on AC or rechargeable internal battery power. The

controls and indicators for the NPB-290 are illustrated in Figure 1-1 and Figure

1-2.

"!#$ % & '

NPB-290

!"#$

1. SpO2 Sensor Port 9. Alarm Silence Button

2. Power On/Off Button 10. Adjust Up Button

3. Low Battery Indicator 11. Adjust Down Button

4. AC Power Indicator 12. Pulse Search Indicator

5. %SpO

6. Pulse Amplitude Indicator 14. Lower Alarm Limit Button

7. Pulse Rate Display 15. Upper Alarm Limit Button

8. Alarm Silence Indicator 16. Speaker

2 Display 13. Motion Indicator

Figure 1-1: NPB-290 Front Panel

1-1

Section 1: Introduction

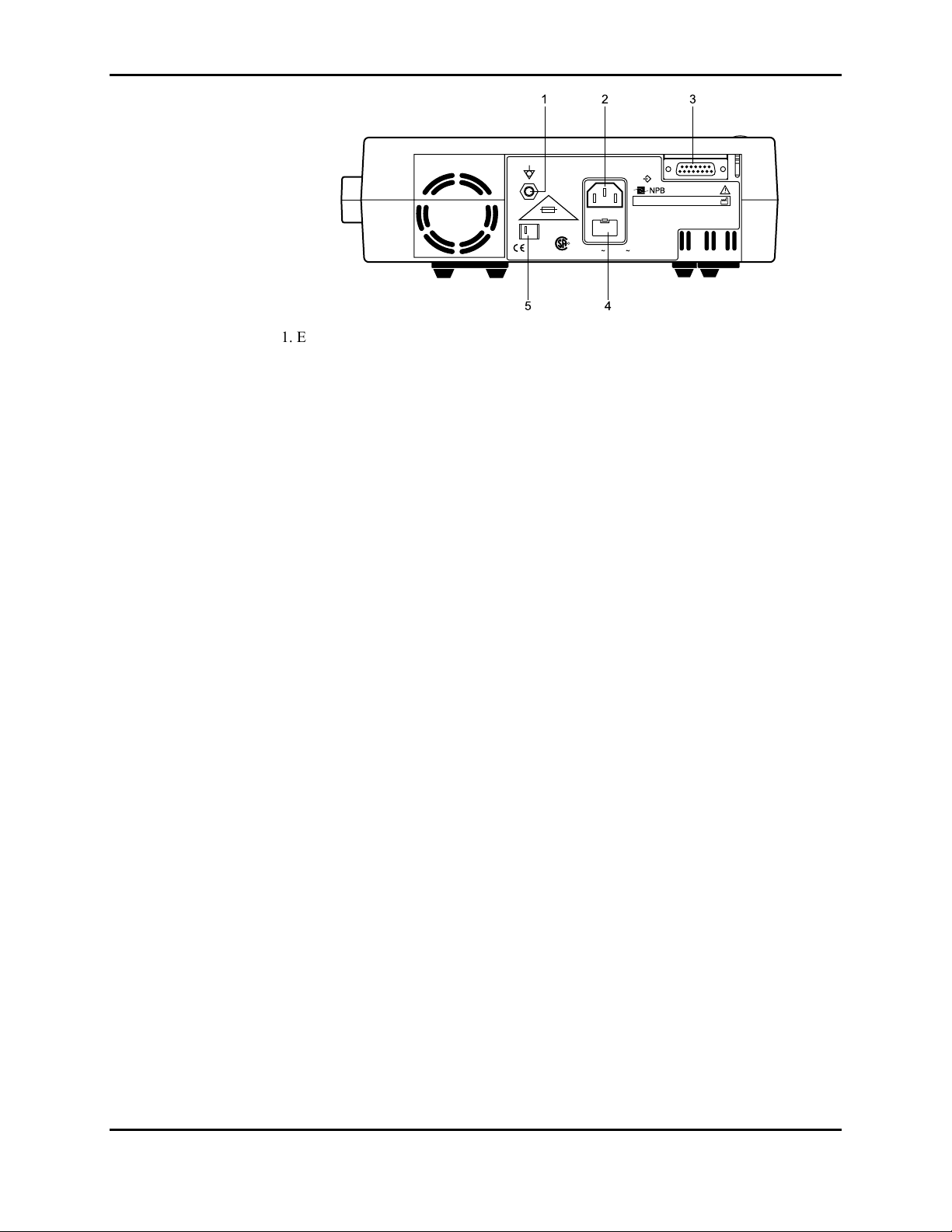

1. Equipotential Terminal 4. Fuse Drawer

2. AC Connector 5. Supply Voltage Selector Switch

3. Data Port

1.3 RELATED DOCUMENTS

To perform test and troubleshooting procedures and to understand the principles

of operation and circuit analysis sections of this manual, you must know how to

operate the monitor. Refer to the NPB-290 operator's manual. To understand the

various Nellcor sensors that work with the monitor, refer to directions for use for

individual sensors.

T 0.50A 250V

0123

#

2X

IPX1

NRTL/C

R

100-120 V 200-240 V

50/60 Hz 20VA

"

NPB-290

SN

NELLCOR PURITAN BENNETT, INC.

PLEASANTON, CA 94588, U.S.A.

NELLCOR PURITAN BENNETT EUROPE BV,

's-HERTOGENBOSCH, THE NETHERLANDS

U.S. PATENTS:

4,621,643; 4,653,498;

4,700,708; 4,770,179;

4,869,254; 4,911,167;

4,928,692; 4,934,372;

5,078,136

Figure 1-2: NPB-290 Rear Panel

!

MADE IN U.S.A.

035285X-1296

1-2

SECTION 2: ROUTINE MAINTENANCE

2.1 Cleaning

2.2 Periodic Safety and Functional Checks

2.3 Battery

2.1 CLEANING

Caution: Do not immerse the NPB-290 or its accessories in liquid or clean

with caustic or abrasive cleaners. Do not spray or pour any liquid on the

monitor or its accessories.

To clean the NPB-290, dampen a cloth with a commercial, nonabrasive cleaner

and wipe the exterior surfaces lightly. Do not allow any liquids to come in

contact with the power connector, fuse holder, or switches. Do not allow any

liquids to penetrate connectors or openings in the instrument cover. Wipe sensor

cables with a damp cloth. For sensors, follow the individual directions for use.

2.2 PERIODIC SAFETY AND FUNCTIONAL CHECKS

The NBP-290 requires no calibration.

The battery should be replaced at least every 24 months (paragraph 6.6).

The following checks should be performed at least every 24 months by a qualified

service technician.

2.2.1 Periodic Safety Checks

1. Inspect the equipment for mechanical and functional damage.

2. Inspect safety labels for legibility. If the labels are not legible, contact

Mallinckrodt Technical Services Department or your local Mallinckrodt

representative.

2.2.2 Functional Checks

If the monitor has been visibly damaged or subjected to mechanical shock (for

example, if dropped), perform the performance tests, refer to paragraph 3.3.

The following checks should be performed at least every 2 years by a qualified

service technician.

1. Perform the electrical safety tests detailed in paragraph 3.4. If the unit fails

these electrical safety tests, refer to Section 6, Troubleshooting.

2. Inspect the fuses for proper value and rating (F1 & F2 = 0.5 amp, 250 volts).

2.3 BATTERY

Mallinckrodt recommends replacing the instrument battery every 2 years. When

the NPB-290 is going to be stored for 2 months or more, remove the battery. To

replace or remove the battery, refer to Section 6, Disassembly Guide.

2-1

Section 2: Routine Maintenance

If the NPB-290 has been stored for more than 30 days, charge the battery as

described in paragraph 3.3.1. A fully discharged battery requires 14 hours to

receive a full charge when the NPB-290 is in the standby mode and 18 hours if

the NPB-290 is in use. The battery is being charged anytime that the instrument

is plugged into AC power.

2-2

SECTION 3: PERFORMANCE VERIFICATION

3.1 Introduction

3.2 Equipment Needed

3.3 Performance Tests

3.4 Safety Tests

3.1 INTRODUCTION

This section discusses the tests used to verify NPB-290 performance following

repairs or during routine maintenance. All tests can be performed without

removing the NPB-290 cover.

If the NPB-290 fails to perform as specified in any test, repairs must be made to

correct the problem before the monitor is returned to the user.

3.2 EQUIPMENT NEEDED

Equipment Description

Digital multimeter (DMM) Fluke Model 87 or equivalent

Durasensor® oxygen transducer

Oxisensor® II oxygen transducer

Pulse oximeter tester SRC-2

Safety analyzer Must meet current AAMI ES1/1993 &

Sensor extension cable SCP-10 or MC-10

Serial interface cable Refer to paragraph 10.3

Stopwatch Manual or electronic

DS-100A

D-25

IEC 601-1/1998 specifications

3.3 PERFORMANCE TESTS

The battery should be charged before the monitor is repaired whenever possible.

Note: This section is written using Mallinckrodt factory-set defaults. If your

institution has pre-configured custom defaults, those values will be

displayed. Factory defaults can be reset using the configuration

procedure described in paragraph 4.4.5.

3.3.1 Battery Charge

Perform the following procedure to fully charge the battery.

1. Connect the monitor to an AC power source.

2. Verify that the monitor is off and that the AC Power/Battery Charging

indicator is lit.

3. Charge the battery for at least 14 hours.

3-1

Section 3: Performance Verification

3.3.2 Performance Tests

The power-up performance tests (3.3.2.1 and 3.3.2.2) verify the following

monitor functions:

• 3.3.2.1 Power-On Self-Test

• 3.3.2.2 Factory Power-On Defaults and Alarm Limit Ranges

NPB-290

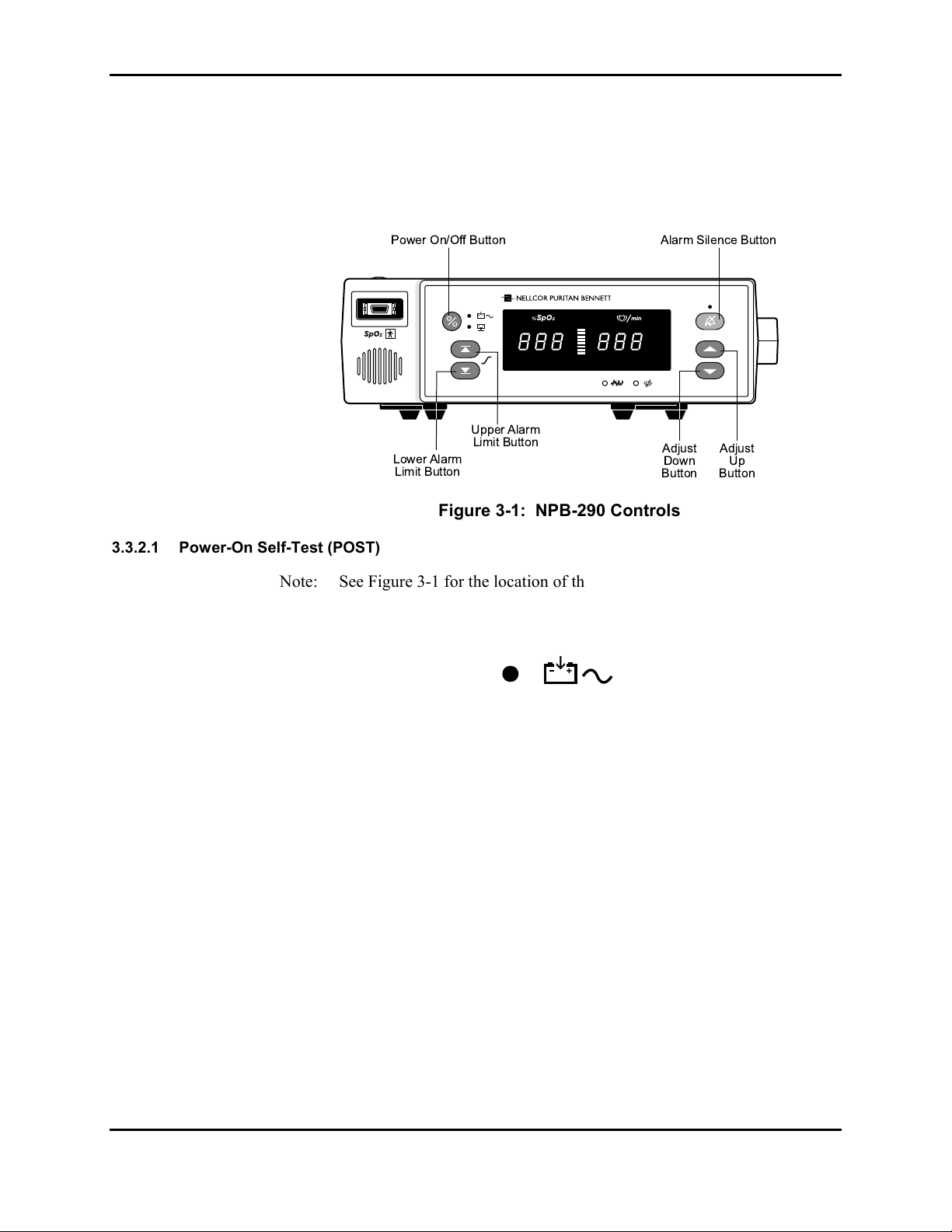

Figure 3-1: NPB-290 Controls

3.3.2.1 Power-On Self-Test (POST)

Note: See Figure 3-1 for the location of the NPB-290 controls.

1. Connect the monitor to an AC power source. Verify the AC Power/Battery

Charging indicator is lit.

2. Do not connect any input cables to the monitor.

3. Observe the front panel of the monitor. With the monitor off, press the

Power On/Off button. Verify that the monitor performs the following

sequence:

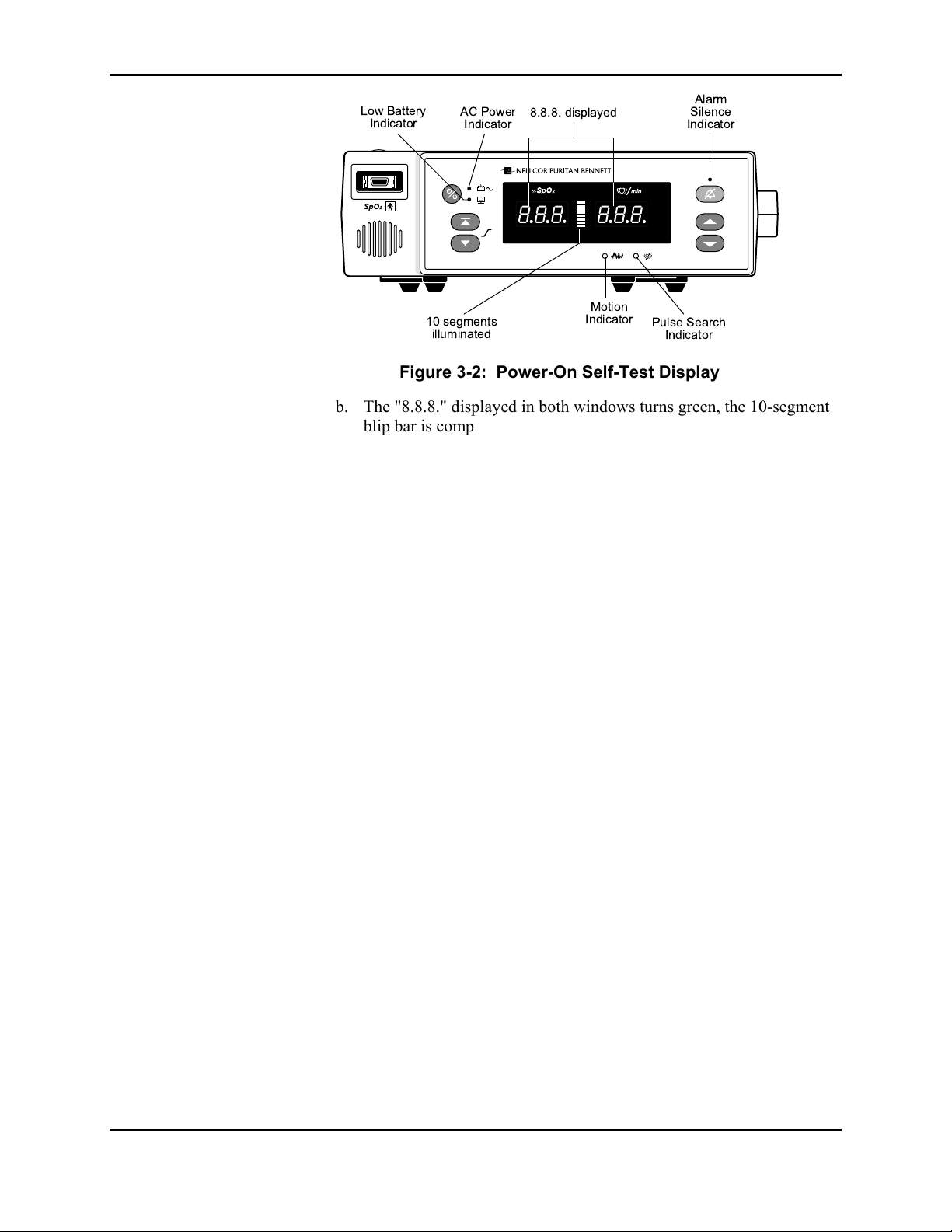

a. Red "8.8.8." is displayed in both windows for a few seconds and the 10-

segment blip bar is completely illuminated in green. Only the AC Power

Indicator is illuminated.

3-2

Section 3: Performance Verification

Low Battery

Indicator

AC Power

Indicator

10 segments

illuminated

8.8.8. displayed

Motion

Indicator

NPB-290

Alarm

Silence

Indicator

Pulse Search

Indicator

Figure 3-2: Power-On Self-Test Display

b. The "8.8.8." displayed in both windows turns green, the 10-segment

blip bar is completely illuminated in green, and all LEDs are

illuminated as shown in Figure 3-2.

c. The software version is displayed and all LEDs are illuminated.

d. A 1-second POST beep sounds, 3 dashes are displayed in each

window, and all LEDs are off except the AC Power LED.

Note: When a sensor is connected, a zero is displayed in each window, a 1-

second Power-On Self-Test (POST) beep sounds and the Pulse Search

LED is illuminated along with the AC Power/Battery Charging LED.

e. The NPB-290 begins normal operation if a sensor is connected.

Without a sensor, the monitor will display 3 dashes in each window.

3.3.2.2 Factory Power-On Defaults and Alarm Limit Ranges

Note: See Figure 3-1 for the location of the NPB-290 controls.

Note: When observing or changing default limits, a 3-second timeout is in

effect, that is, if no action is taken within 3 seconds, the monitor

automatically returns to the normal mode.

1. Turn the monitor on by pressing the Power On/Off button.

a. Wait for POST to be completed.

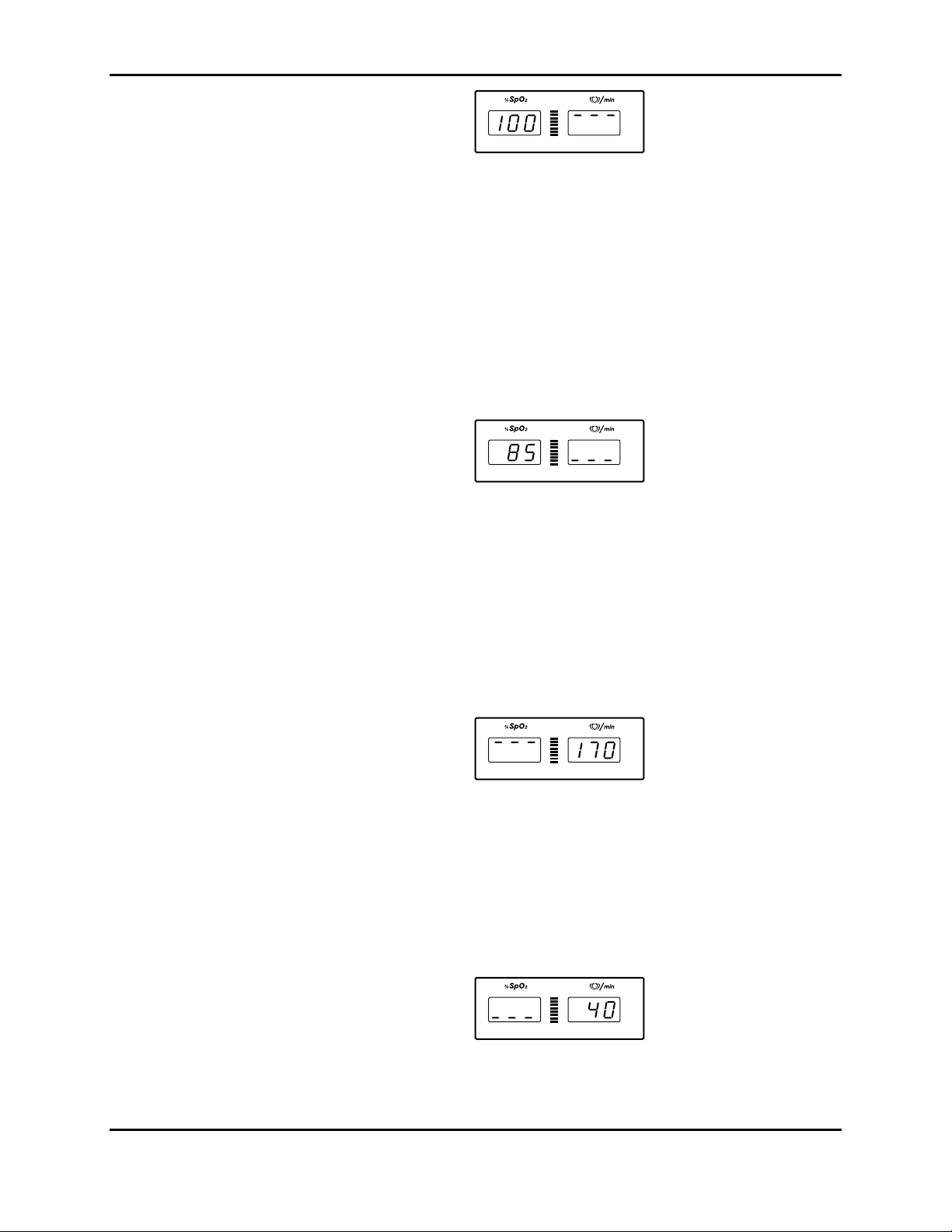

b. Press and release the Upper Alarm Limit button.

c. Verify that the monitor emits a single beep and the %SpO

indicates a high alarm limit of "100" for about 3 seconds.

d. Verify that three dashes are displayed at the top of the pulse rate display.

See Figure 3-3.

2 display

Note: The location of the three dashes indicates the type of alarm limit that is

being adjusted. Three dashes in the top of the display window indicate a

high alarm limit and three dashes in the bottom of the display window

indicate a low alarm limit.

3-3

Section 3: Performance Verification

Figure 3-3: Adjusting High %SpO

2 Alarm Limit

2. Press the Upper Alarm Limit button. Within 3 seconds press and hold the

Adjust Down button. Verify the %SpO

2 display reduces to a minimum of

"85."

Note: A decimal point to the right of the value in either display indicates that

the alarm limits are not power-on default values.

3. Press the Lower Alarm Limit button. Verify that the monitor emits a single

beep and that the %SpO

2 display indicates an alarm limit of "85" for 3

seconds. Verify that three dashes are displayed at the bottom of the pulse

rate display. See Figure 3-4.

Figure 3-4: Adjusting Low %SpO

2 Alarm Limit

4. Press the Lower Alarm Limit button. Within 3 seconds press and hold the

Adjust Down button and verify that the %SpO

2 display reduces to a

minimum of "20." Press and hold the Adjust Up button and verify that the

2 display cannot be raised past the upper alarm limit setting of "85."

%SpO

5. Press the Upper Alarm Limit button two times rapidly (twice within 3

seconds). Verify that the monitor emits two beeps, the pulse rate display

indicates an alarm limit of "170," and that the %SpO

2 display window shows

three dashes at the top for about 3 seconds. See Figure 3-5.

Figure 3-5: Adjusting High Pulse Rate Alarm Limit

6. Press the Upper Alarm Limit button two times rapidly. Within 3 seconds

press and hold the Adjust Down button. Verify that the pulse rate display

reduces to a minimum of "40." See Figure 3-6.

7. Press the Lower Alarm Limit button two times rapidly. Verify that the pulse

rate display indicates an alarm limit of "40" and that the %SpO

2 display

shows three dashes at the bottom for 3 seconds.

Figure 3-6: Adjusting Low Pulse Rate Alarm Limit

3-4

Section 3: Performance Verification

8. Press the Lower Alarm Limit button two times rapidly. Within 3 seconds

press and hold the Adjust Down button. Verify that the pulse rate display

reduces to a minimum of "30."

9. Press the Lower Alarm Limit button two times rapidly. Within 3 seconds

press and hold the Adjust Up button. Verify that the pulse rate display

cannot be adjusted above "40."

10. Press the Power On/Off button to turn the unit off. Turn the unit back on.

11. Press and release the Upper Alarm Limit button. Verify that the %SpO

display indicates an alarm limit of "100."

12. Press and release the Lower Alarm Limit button. Verify that the %SpO

display indicates an alarm limit of "85."

13. Press the Upper Alarm Limit button two times rapidly. Verify that the pulse

rate display indicates an alarm limit of "170."

14. Press the Lower Alarm Limit button two times rapidly. Verify that the pulse

rate display indicates an alarm limit of "40."

15. Press the Power On/Off button to turn the monitor off.

3.3.3 Hardware and Software Tests

Hardware and software testing includes the following tests:

• 3.3.3.1 Operation with a Pulse Oximeter Tester

• 3.3.3.2 General Operation

3.3.3.1 Operation with a Pulse Oximeter Tester

Operation with an SRC-2 pulse oximeter tester includes the following tests:

• 3.3.3.1.1 Alarms and Alarm Silence

• 3.3.3.1.2 Alarm Volume Control

2

2

• 3.3.3.1.3 Pulse Tone Volume Control

• 3.3.3.1.4 Dynamic Operating Range

• 3.3.3.1.5 Nurse Call

• 3.3.3.1.6 Analog Output

• 3.3.3.1.7 Operation on Battery Power

3.3.3.1.1 Alarms and Alarm Silence

1. Connect the SRC-2 pulse oximeter tester to the sensor-input cable and

connect the cable to the monitor. Refer to SRC-2 Operator's manual. Set the

SRC-2 switches as follows:

SWITCH POSITION

RATE 38

LIGHT HIGH 1

MODULATION OFF

RCAL/MODE RCAL 63/LOCAL

3-5

Section 3: Performance Verification

2. Press the Power On/Off button to turn the monitor on. After the normal

power-up sequence, verify that the pulse rate initially indicates zeroes.

Note: The pulse amplitude indicator may occasionally indicate a step change

as the monitor is in the pulse search mode.

3. Set the modulation switch on the SRC-2 to HIGH.

4. Verify that the following monitor reactions:

a. The pulse amplitude indicator begins to track the artificial pulse signal

from the SRC-2.

b. The pulse tone is heard.

c. Zeroes are displayed in the %SpO

2 and pulse rate displays.

d. After about 10 to 20 seconds, the monitor displays oxygen saturation and

pulse rate as specified by the tester. Verify that the values are within the

following tolerances:

• Oxygen saturation range 79% to 83%

• Pulse rate range 37 to 39 bpm

e. The audible alarm sounds and both the %SpO

2 and pulse rate displays

flash the values in red. This is an indication that both parameters have

violated the default alarm limits.

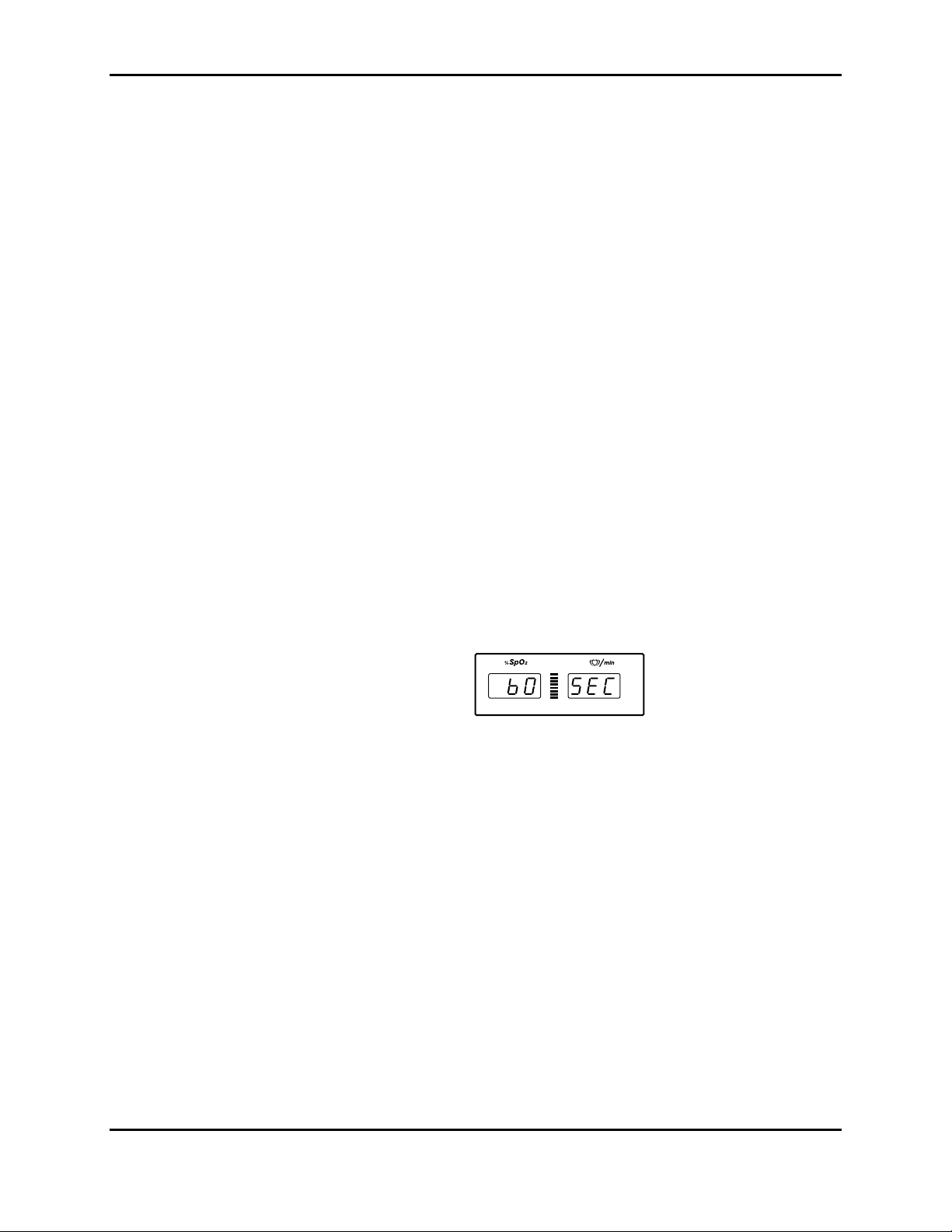

5. Press and hold the Alarm Silence button located on the front of the monitor

for less than 3 seconds. Verify that the pulse rate display indicates "SEC"

and the %SpO

2 display indicates "60" while the Alarm Silence button is

pressed. The alarm is silenced when the button is released. See Figure 3-7.

Figure 3-7: Alarm Silence Duration

6. Release the Alarm Silence button. Verify the following:

3-6

a. The alarm remains silenced.

b. The Alarm Silence indicator lights.

c. The %SpO

2 and pulse rate displays resume flashing.

d. The pulse tone is still audible.

e. The audible alarm returns after approximately 60 seconds.

7. While pressing the Alarm Silence button, press the Adjust Down button until

the %SpO

2 display indicates "30."

8. Press the Adjust Up button and verify that the displays indicate 60 SEC, 90

SEC, 120 SEC, and OFF. Release the button when the display indicates

"OFF."

9. Press the Alarm Silence button again and verify that the Alarm Silence

indicator flashes.

10. Wait approximately 3 minutes. Verify that the alarm does not return.

11. After 3 minutes ± 10 seconds, the alarm silence reminder beeps three times,

and continues to do so at 3-minute intervals.

3.3.3.1.2 Alarm Volume Control

After completing the procedure in paragraph 3.3.3.1.1:

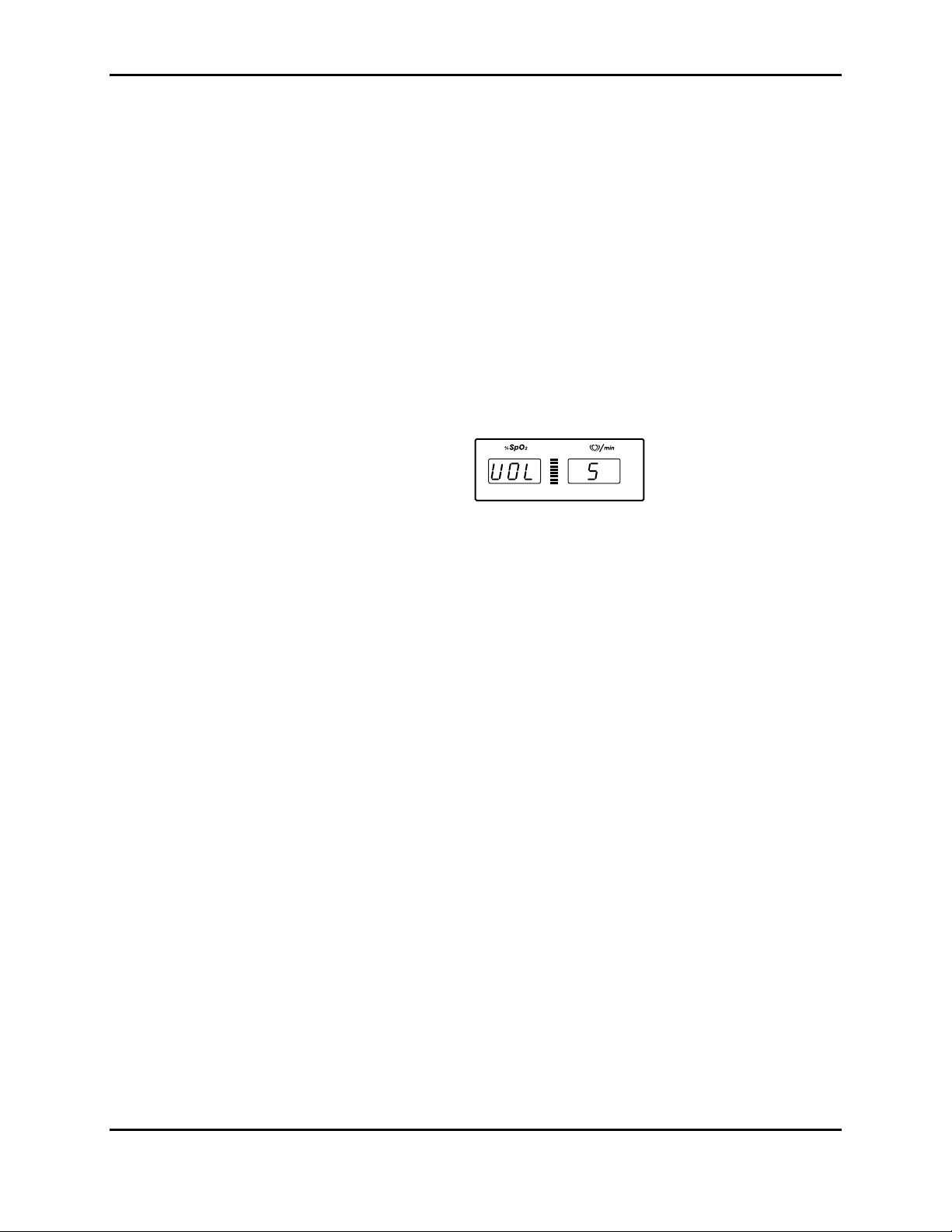

1. Press and hold the Alarm Silence button for more than 3 seconds. Verify the

following:

a. "OFF" is displayed for approximately 3 seconds.

b. After 3 seconds:

• a steady tone is heard at the default alarm volume setting

Section 3: Performance Verification

• the %SpO

• the pulse rate display indicates the default setting of 5.

2. Press the Adjust Down button until an alarm volume setting of 1 is displayed.

Verify that the volume of the alarm has decreased but is still audible.

3. Press the Adjust Up button to increase the alarm volume setting to a

maximum value of 10. Verify that the volume increases.

4. Press the Adjust Down button until a comfortable audio level is attained.

5. Release the Alarm Silence button. The tone stops.

3.3.3.1.3 Pulse Tone Volume Control

1. When a valid pulse has been acquired, press the Adjust Up button and verify

that the sound level of the beeping pulse tone increases.

2. Press the Adjust Down button and verify that the beeping pulse tone

decreases until it is no longer audible.

2 display indicates "VOL." See Figure 3-8.

Figure 3-8: Alarm Volume Display

3. Press the Adjust Up button to return the beep volume to a comfortable level.

3.3.3.1.4 Dynamic Operating Range

The following test sequence verifies proper monitor operation over a range of

input signals:

1. Turn the instrument off and connect the SRC-2 to the NPB-290. Turn the

NPB-290 on.

2. Place the SRC-2 in the RCAL 63/LOCAL mode.

3. Set the SRC-2 as indicated in Table 3-1. Verify that the NPB-290 readings

are within the indicated tolerances. Allow the monitor several seconds to

stabilize the readings.

3-7

Section 3: Performance Verification

Note: An asterisk (*) indicates values that produce an alarm. Press the Alarm

Silence button to silence the alarm.

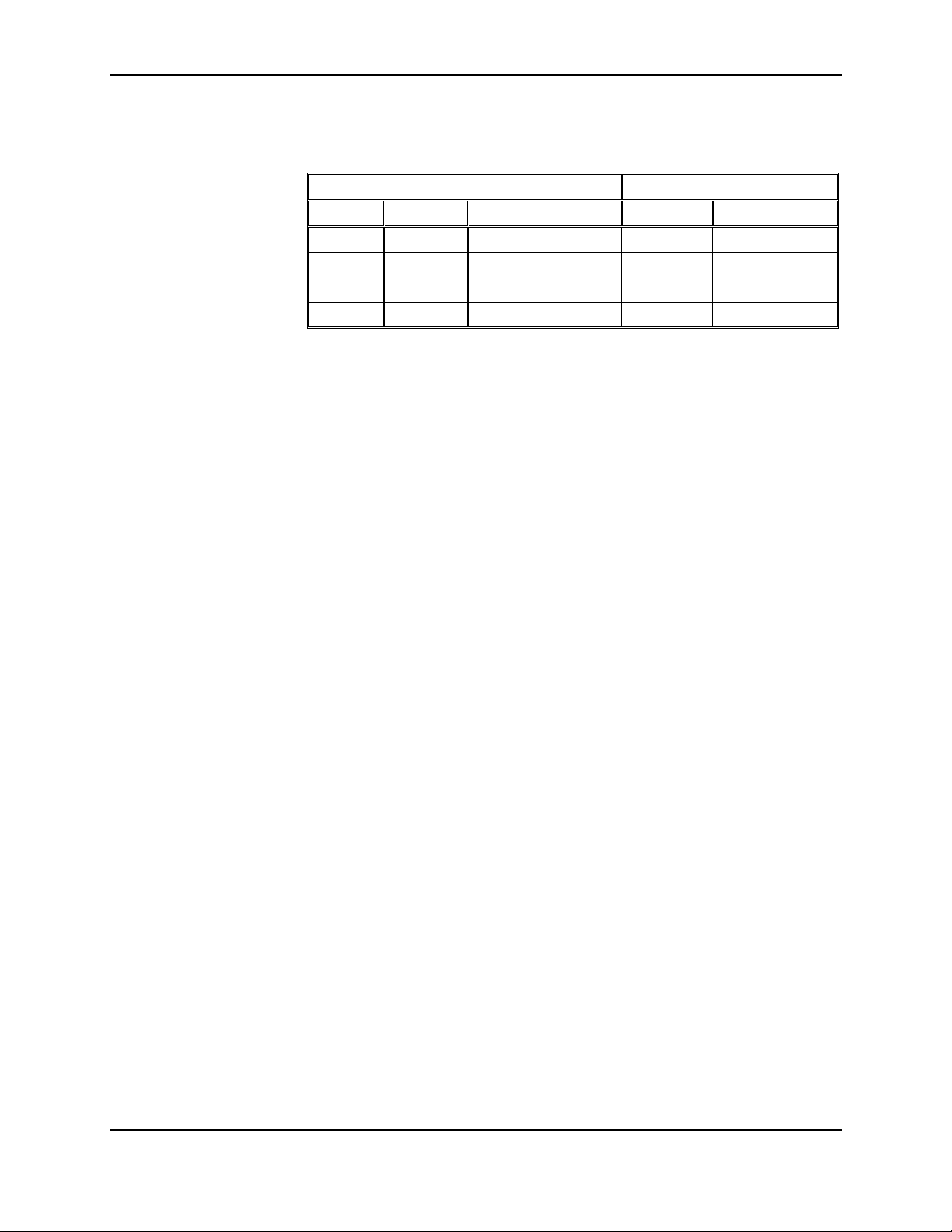

Rate Light Modulation SpO2 Pulse Rate

38 HIGH2 LOW 79 - 83* 37 - 39*

112 HIGH1 HIGH 79 - 83* 110 - 114

201 LOW LOW 79 - 83* 195 - 207*

201 LOW HIGH 79 - 83* 195 - 207*

3.3.3.1.5 Nurse Call

Note: The Nurse Call tests must be performed with the instrument operating on

AC power.

1. Connect the negative lead of a voltmeter to pin 10 and the positive lead to

pin 11 of the data port on the back of the instrument (Figure 10-1). Ensure

that the audible alarm is not silenced or turned off.

2. Set the pulse rate switch of the SRC-2 to create an alarm condition. Refer to

the SRC-2 Operator's manual. Verify that an output voltage at pins 10 and

11 between +5 and +12 volts DC.

Table 3-1: Dynamic Operating Range

SRC-2 Settings NPB-290 Indications

3. Press the Alarm Silence button. With no active audible alarm, the output

4. With the instrument in an alarm condition, use an ohmmeter to verify that

5. Adjust the alarm limits so that there is no alarm condition. Use an ohmmeter

3.3.3.1.6 Analog Output

Note: The Analog Output tests must be performed with the instrument

1. Connect the negative lead of a voltmeter to pin 10 and the positive lead to

2. Turn the instrument off, then turn it back on.

3. Verify that the output voltage is 0.000 ± 0.025 volts DC, then after about a

4. Move the positive lead to pin 13 and repeat steps 2 and 3.

5. Move the positive lead to pin 14 and repeat steps 2 and 3.

voltage at pins 10 and 11 must be between -5 and -12 volts DC.

there is no continuity between pins 8 and 15 and that there is continuity

between pins 7 and 15.

to verify that there is continuity between pins 8 and 15 and that there is no

continuity between pins 7 and 15.

operating on AC power.

pin 6 of the data port located on the back of the instrument (Figure 1-2).

minute verify that the voltage has increased to +1.000 ± 0.025 volts DC.

3-8

6. Disconnect the voltmeter from the instrument.

3.3.3.1.7 Operation on Battery Power

1. Turn the instrument on using AC power.

2. Disconnect the instrument from AC and verify the AC Power Indicator turns

off.

3. Verify the instrument continues monitoring normally and that the Low

Battery Indicator is not lit.

Note: If the Low Battery Indicator is lit, perform the procedure in paragraph

3.3.1.

4. Connect the instrument to AC and verify that the AC Power Indicator lights

and that the instrument is monitoring normally.

3.3.3.2 General Operation

The following tests are an overall performance check of the system:

• LED Excitation Test

• Monitor Operation with a Live Subject

3.3.3.2.1 LED Excitation Test

Section 3: Performance Verification

This procedure uses normal system components to test circuit operation. A

®

Nellcor Oxisensor

II oxygen transducer, model D-25, is used to examine LED

intensity control. The red LED is used to verify intensity modulation caused by

the LED intensity control circuit.

1. Connect the monitor to an AC power source.

2. Connect an SCP-10 or MC-10 sensor input cable to the monitor.

3. Connect a D-25 sensor to the sensor-input cable.

4. Press the Power On/Off button to turn the monitor on.

5. Leave the sensor open with the LEDs and photodetector visible.

6. After the monitor completes its normal power-up sequence, verify that the

sensor LED is brightly lit.

7. Slowly move the sensor LED in close to the photodetector element of the

sensor. As the LED approaches the photodetector, verify that the LED

intensity decreases.

8. Open the sensor and notice that the LED intensity increases.

9. Repeat step 7 and the intensity will again decrease. This variation is an

indication that the microprocessor is in proper control of LED intensity.

10. Turn the NPB-290 off.

3.3.3.2.2 Monitor Operation with a Live Subject

Pulse oximetry involves connecting the monitor to a live subject for a qualitative

test.

1. Ensure that the monitor is connected to an AC power source.

3-9

Section 3: Performance Verification

2. Connect an SCP-10 or MC-10 sensor input cable to the monitor.

3. Connect a Nellcor Durasensor

sensor input cable.

4. Clip the DS-100A to an adult subject as recommended in the sensor

directions for use.

5. Press the Power On/Off button to turn the monitor on and verify that the

monitor is operating.

6. The monitor should stabilize on the subject's physiological signal in about 15

to 30 seconds. Verify that the saturation and heart rates are reasonable for

the subject.

3.4 SAFETY TESTS

NPB-290 safety tests meet the standards of, and are performed in accordance

with, IEC 601-1 (EN 60601-1, Second Edition, 1988; Amendment 1, 1991-11,

Amendment 2, 1995-03) and UL 2601-1 (August 18, 1994), for instruments

classified as Class 1 and TYPE BF, and AAMI Standard ES1 (ANSI/AAMI ES1

1993).

3.4.1 Ground Integrity

®

oxygen transducer, model DS-100A, to the

This test checks the integrity of the power cord ground wire from the AC plug to

the instrument chassis ground. The current used for this test is <

50 or 60 Hz, and 25 A.

1. Connect the monitor AC power cord to the analyzer as recommended by the

analyzer operating instructions.

2. Connect the analyzer resistance input lead to the equipotential terminal

(grounding lug) on the rear panel of the instrument. See Figure 1-2. Verify

that the analyzer indicates 100 milliohms or less.

3.4.2 Electrical Leakage

The following tests verify the electrical leakage of the monitor:

• Earth Leakage Current

• Enclosure Leakage Current

• Patient Applied Risk Current

• Patient Isolation Risk Current (Mains Voltage on the Applied Part)

Note: For the following tests, ensure the AC switch on the rear of the

6 volts RMS,

instrument is configured for the AC voltage being supplied.

3-10

3.4.2.1 Earth Leakage Current

This test is in compliance with IEC 601-1 (earth leakage current) and AAMI

Standard ES1 (earth risk current). The applied voltage for AAMI ES1 is 120

volts AC, 60 Hz; for IEC 601-1 the voltage is 264 volts AC, 50 to 60 Hz. All

measurements shall be made with the power switch in both the "On" and "Off"

positions. Refer to Table 3-2.

1. Connect the monitor AC plug to the electrical safety analyzer as

recommended by the analyzer operating instructions.

2. The equipotential terminal is not connected to ground.

Section 3: Performance Verification

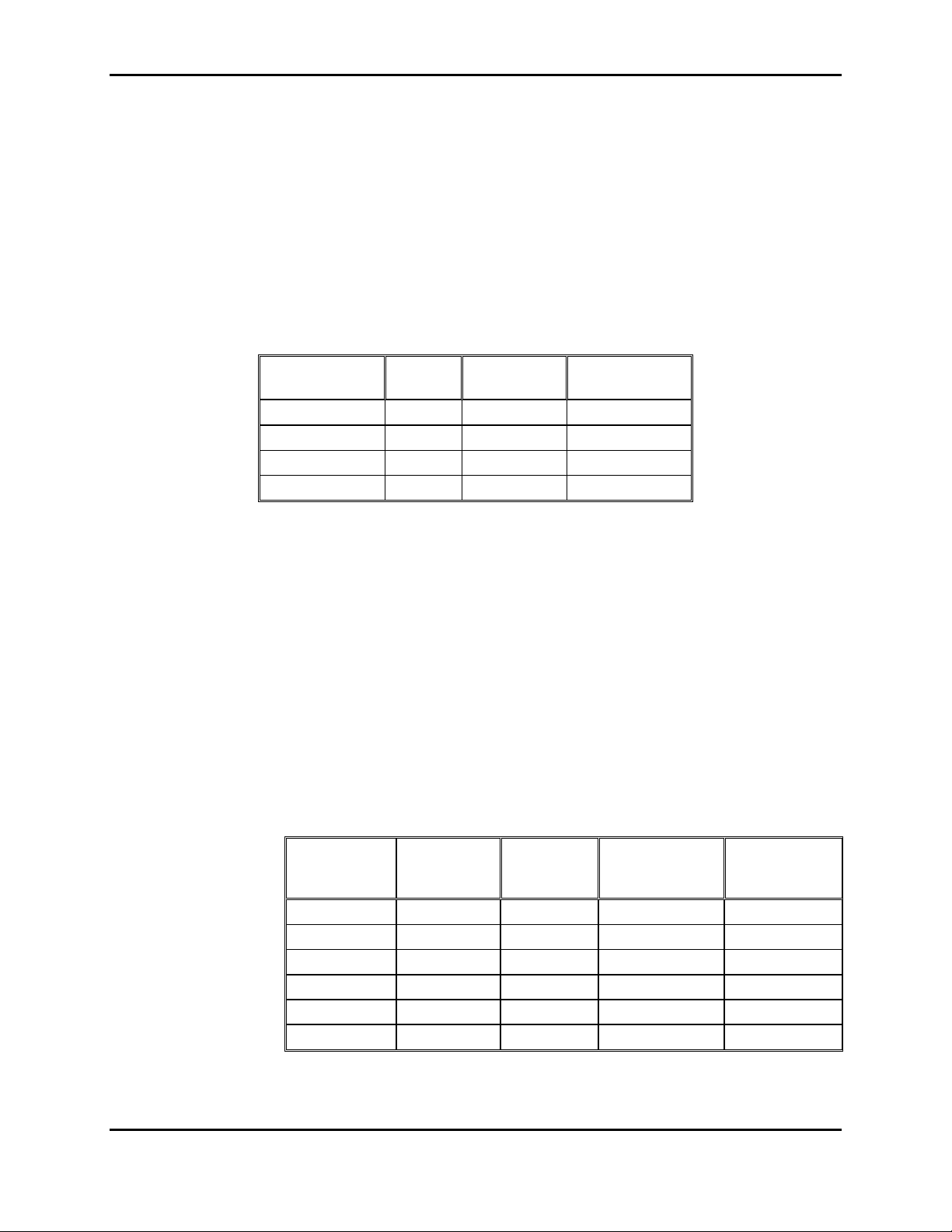

Table 3-2: Earth Leakage Current Limits

AC Polarity Line

Normal Closed Closed 500 µA

Reversed Closed Closed 500 µA

Normal Open Closed 1000 µA

Normal Closed Open 1000 µA

3.4.2.2 Enclosure Leakage Current

This test is in compliance with IEC 601-1 (enclosure leakage current) and AAMI

Standard ES1 (enclosure risk current). This test is for ungrounded enclosure

current, measured between enclosure parts and earth. The applied voltage for

AAMI/ANSI is 120 volts AC, 60 Hz, and for IEC 601-1 the applied voltage is

264 volts AC, 50 to 60 Hz. Refer to Table 3-3.

1. Connect the monitor AC plug to the electrical safety analyzer as

recommended by the analyzer operating instructions.

2. Place a 200-cm

is not in contact with any metal parts of the enclosure that may be grounded.

Measure the leakage current between the foil and earth.

Note: The analyzer leakage indication must not exceed values listed Table 3-3.

Neutral

Cord

2

foil in contact with the instrument case, making sure the foil

Cord

Leakage

Current

Table 3-3: Enclosure Leakage Current Limits

AC Line

Cord

Closed Closed Closed 100 µA 100 µA

Closed Closed Open 500 µA 300 µA

Closed Open Closed 500 µA 300 µA

Open Closed Closed 500 µA 100 µA

Open Open Closed 500 µA 300 µA

Open Closed Open 500 µA 300 µA

Neutral Line

Cord

Power Line

Ground

Cable

IEC 601-1 AAMI/ANSI

ES1 Standard

3-11

Section 3: Performance Verification

3.4.2.3 Patient Applied Risk Current

This test is in compliance with AAMI Standard ES1 (patient applied risk

current), and IEC 601-1 (patient auxiliary current). The leakage current is

measured between any individual patient connection and power (earth) ground.

The applied voltage for AAMI/ANSI is 120 volts AC, 60 Hz, and for IEC 601-1

the applied voltage is 264 volts AC, 50 to 60 Hz. Refer to Table 3-4.

1. Configure the electrical safety analyzer as follows:

Function: Patient Leakage

Range: µA

2. Connect the monitor AC plug to the electrical safety analyzer as

recommended by the analyzer operating instructions for Patient Leakage

Current.

3. Connect the patient leakage input lead of the electrical safety analyzer to all

pins of the monitor's patient cable at the end of the cable.

4. The equipotential terminal is not connected to ground.

5. All functional earth terminals are not connected to ground.

6. Measure the leakage current between the patient connector and earth.

Table 3-4: Patient Leakage Current Limits

AC Line

Polarity

Normal Closed Closed 100 µA 10 µA

Normal Open Closed 500 µA 50 µA

Normal Closed Open 500 µA 50 µA

Reverse Closed Closed 100 µA 10 µA

Reverse Open Closed 500 µA 50 µA

Reverse Closed Open 500 µA 50 µA

3.4.2.4 Patient Isolation Risk Current - (Mains Voltage on the Applied Part)

Neutral Line Power Line

Ground

Cable

IEC 601-1 AAMI/ANSI

This test is in compliance with AAMI Standard ES1 (patient isolation risk current

[sink current]), and IEC 601-1 (patient leakage current). Patient Leakage Current

is the measured value in a patient connection if mains voltage is connected to that

patient connection. The applied voltage for AAMI/ANSI is 120 volts AC, 60 Hz,

and for IEC 601-1 the applied voltage is 264 volts AC,

50 to 60 Hz.

ES1 Standard

3-12

Warning: AC mains voltage will be present on the patient cable terminals

during this test. Exercise caution to avoid electrical shock hazard.

1. Configure the electrical safety analyzer as follows:

Function: Patient Leakage (Mains On Applied Part)

Range: µA

Section 3: Performance Verification

2. Connect the monitor AC plug to the electrical safety analyzer as

recommended by the operating instructions for patient sink (leakage) current.

3. Connect the patient leakage input lead of the electrical safety analyzer to all

connectors in the patient cable at the patient end of the cable.

4. The equipotential terminal is not connected to ground.

5. All functional earth terminals are not connected to ground.

6. The analyzer leakage current must not exceed the values shown in Table 3-5.

Table 3-5: Patient Leakage Current Test Configurations -

Mains Voltage on the Applied Part

AC Line

Polarity

Normal Closed Closed 5 mA 50 µA

Reverse Closed Closed 5 mA 50 µA

Neutral Line Power Line

Ground

Cable

IEC 601-1 AAMI/ANSI

ES1 Standard

3-13

(Blank Page)

SECTION 4: AUDIBLE ALARM SETTINGS AND SERVICE MENU

4.1 Introduction

4.2 Audible Alarm Settings

4.3 Operator's Menu Options

4.4 Service Menu Options

4.1 INTRODUCTION

This section discusses use of the service menu to reconfigure power-on default

values, and how to control the behavior of the audible alarm.

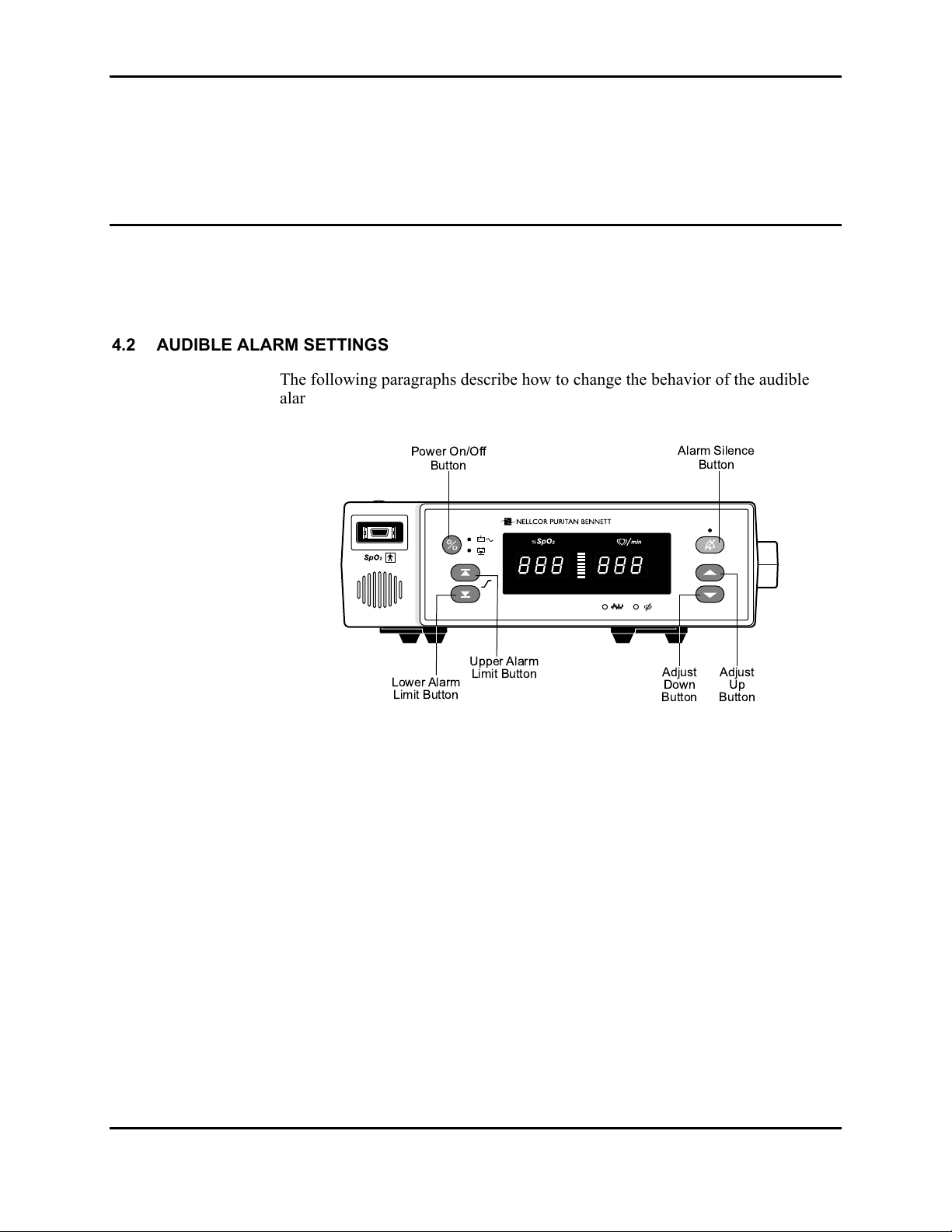

4.2 AUDIBLE ALARM SETTINGS

The following paragraphs describe how to change the behavior of the audible

alarm. Operators can select the volume of the alarm and the duration of alarm

silence. Controls for the NPB-290 are shown in Figure 4-1.

4.2.1 Alarm Silence State

Press the Alarm Silence button to silence the alarm. Press the button a second

time to turn the alarm back on.

4.2.2 Alarm Silence Duration

1. Press and hold the Alarm Silence button for less than 3 seconds.

Figure 4-1: NPB-290 Controls

NPB-290

2. Before 3 seconds have passed, the Adjust Up or Adjust Down button can be

4.2.3 Alarm Volume

1. Press and hold the Alarm Silence button for more than 3 seconds.

2. After 3 seconds, while still pressing the Alarm Silence button, the Adjust Up

used to change the duration of the alarm silence. The alarm duration can be

set to 30, 60, 90, or 120 seconds, or the alarm can be turned to Off.

or Adjust Down button can be used to select alarm volumes from 1 to 10.

Select a level that is suitable for the monitor's location.

4-1

Section 4: Audible Alarm Settings and Service Menu

4.3 OPERATOR'S MENU OPTIONS

The menu items listed below are options that are available to the operator. These

options can be used to print or clear trend data, and to change the configuration

of data from the data port. Changes can be made in menu options 1 through 5

while monitoring a patient. Menu items beyond 5 cannot be accessed when a

sensor is connected to the instrument. Unless changes are saved as power-on

default values, they will be lost when the NPB-290 is turned off. When the

instrument is turned on again, it will begin to use the power-on default values

that have been stored. Factory-set power-on default values are listed in Table

4-2.

4.3.1 Accessing Menu Items

1. Menu items can be accessed at any time by pressing the Upper and Lower

Alarm Limit buttons simultaneously for at least 3 seconds. Menu options

have been accessed when a "1" appears in the pulse rate display.

2. Pressing the Adjust Up or Adjust Down button selects the menu item

number. Menu items 3, 5, 8, and 11 have options within them that can be

selected by first pressing the Upper Alarm Limit button, and then pressing

the Adjust Up or Adjust Down key. The option being selected is displayed

in the %SpO

2 display window.

Note: Service menu items numbered above 5 cannot be accessed if a sensor is

connected to the monitor.

3. Once adjustments have been made within a menu item, the Upper Alarm

Limit button can be used to initiate the current selection. To save the current

settings as power-on default values, refer to the procedure outlined in

paragraph 4.4.4.

4. Menu options can be exited without making changes by pressing the Lower

Alarm Limit button. If a period of 10 seconds passes with no button presses,

the instrument will exit the service menu, go to normal monitoring, and no

changes will have been made.

4.3.2 Menu Item 1 (Trend Print)

Trend data can be viewed (if connected to a PC), or a trend printout can be made,

if the Upper Alarm Limit button is pressed when menu item 1 is displayed. For

more information about trend printouts, refer to paragraph 10.4.

4.3.3 Menu Item 2 (Trend Clear)

When menu item 2 is selected, trend data that is available through the use of

menu item 1 will be deleted when the Upper Alarm Limit button is pressed and

held until three beeps are heard.

4.3.4 Menu Item 3 (Language Selection)

4-2

1. Seven languages are available for data output to the data port. Once menu

item 3 has been accessed, press the Upper Alarm Limit button. Then press

the Adjust Up or Adjust Down button until the desired number is displayed

in the %SpO

2 window. Table 4-1 lists the languages and their numbers.

2. When the desired option is indicated in the %SpO2 display, press the Upper

Alarm Limit button to initiate the current selection.

4.3.5 Menu Item 4 (Baud Rate)

1. Baud rates of 2400, 9600, and 19200 can be selected by first pressing the

Upper Alarm Limit button, then using the Adjust Up or Adjust Down button

to select the desired baud rate. The baud rates will be displayed in the

%SpO

Section 4: Audible Alarm Settings and Service Menu

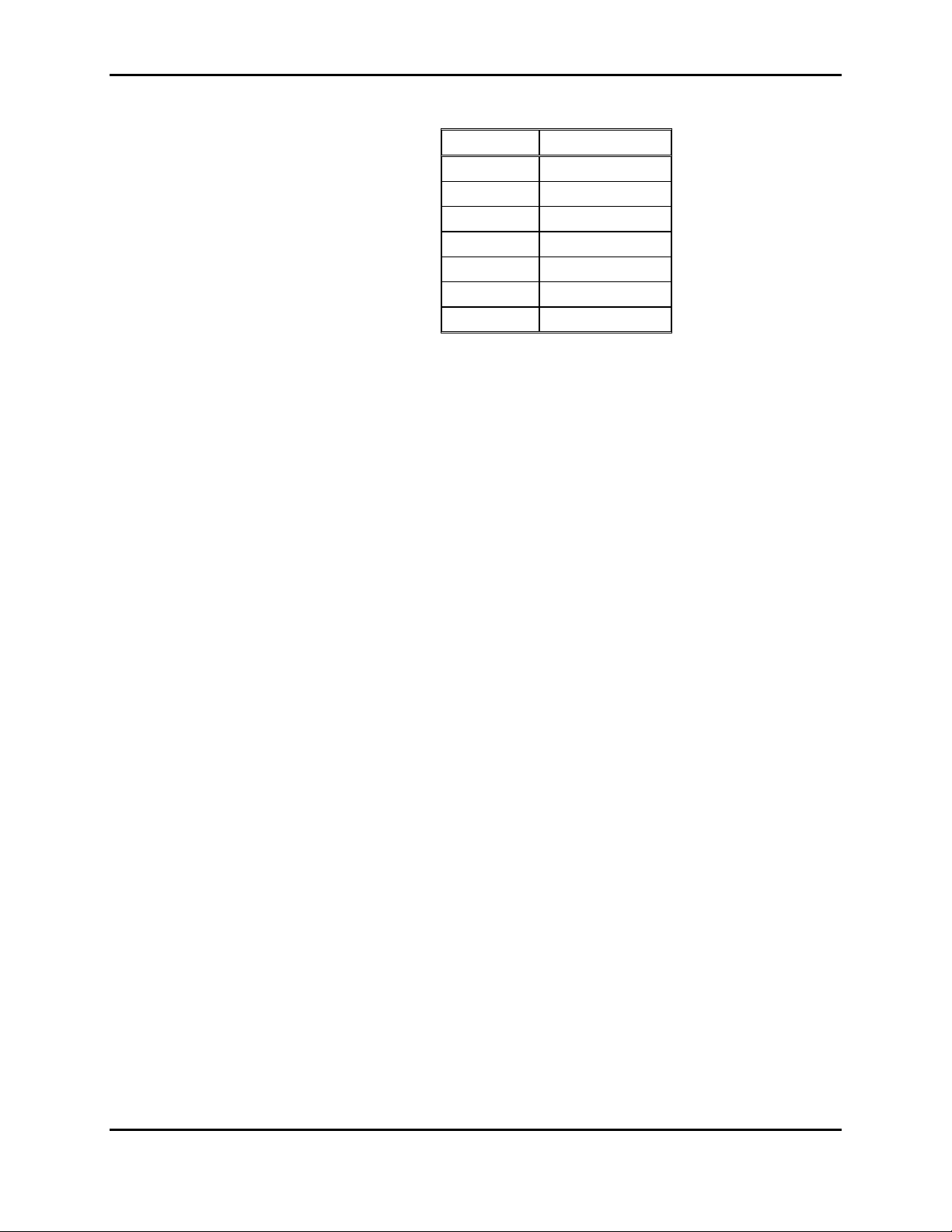

Table 4-1: Language Selection

Number Language

0 English

1 French

2 German

3 Italian

4 Spanish

5 Dutch

6 Portuguese

2 window as 24, 96, or 192.

2. When the desired option is indicated in the %SpO

Alarm Limit button to initiate the current selection.

4.3.6 Menu Item 5 (EPP mode)

1. This menu item is used to change the method of sending data to the data port.

Three options -- 0, 1, or 2 -- can be accessed by first pressing the Upper

Alarm Limit button, then using the Adjust Up or Down button to scroll to the

desired number.

• Option "0" enables ASCII. This option would be used to send data to a

printer or to receive instructions from a computer.

• Option "1" sends data from the data port that can be used by the Nellcor

Oxinet II system and with Score Software.

Note: When using Score software use the latest version. Contact

• Option "2" is intended for Mallinckrodt use only.

2. When the desired option is indicated in the %SpO

Alarm Limit button to initiate the current selection.

Note: Menu items greater than 5 cannot be accessed when a valid sensor is

connected to the unit.

2 display, press the Upper

Mallinckrodt's Technical Services Department or your local

Mallinckrodt representative to determine the latest version of

Score software.

2 display, press the Upper

4-3

Section 4: Audible Alarm Settings and Service Menu

4.4 SERVICE MENU OPTIONS

Service menu options can be accessed only when the sensor is disconnected from

the instrument. Only qualified service personnel should access these options.

Refer to paragraph 4.3.1 for instructions on how to access the menu options and

make selections within them.

Note: To reach menu item 8, two invalid tones will be heard when passing

through menu items 6 and 7. An invalid tone is a single low-pitched

tone.

4.4.1 Menu Item 6 (Not Displayed)

4.4.2 Menu Item 7 (Not Displayed)

4.4.3 Menu Item 8 (Nurse Call Polarity)

A negative voltage is provided on pin 10 and a positive voltage on pin 11 that

can be used to drive a Nurse Call alarm. This voltage will be either -5 volts DC

to -12 volts DC or +5 volts DC to +12 volts DC, depending on the state of the

audible alarm. An audible alarm causes the voltage to change polarity. Using

menu item 8, a choice can be made to make the voltage go either positive or

negative during an audible alarm.

1. Two options, 0 or 1, can be accessed by first pressing the Upper Alarm Limit

button, then using the Adjust Up or Down button to scroll to the desired

number.

• Selecting option "0" makes the voltage negative during an audible alarm

and positive when there is no audible alarm.

• Selecting option "1" makes the voltage positive during an audible alarm

and negative when there is no audible alarm.

2. When the desired option is indicated in the %SpO

Alarm Limit button to save the current selection.

4.4.4 Menu Item 9 (Save Current Values as Power-On Default)

If menu item 9 is selected, the current values for alarm limits, alarm volume,

pulse beep volume, audible alarm silence duration, alarm silence behavior,

communications protocol, and baud rate will be saved as the power-on default

settings. To save new values as the current power-on default values, press the

Upper Alarm Limit button. Three tones will sound to indicate that the changes

have been accepted.

The following values are not allowed to be saved as power-on default values.

• Alarm Silence Duration of Off

• Low %SpO

2 alarm limits less than 80%.

2 display, press the Upper

4-4

If an invalid tone is heard instead of the triple beep, the current settings were not

changed. An invalid tone is a single low-pitched tone.

Note: Current values will not be stored in memory as defaults if power is

interrupted before exiting this menu option.

Section 4: Audible Alarm Settings and Service Menu

Note: When the operator changes an alarm limit to a value other than a

power-on default value, a decimal point is displayed to the right of the

parameter whose alarm limit was changed.

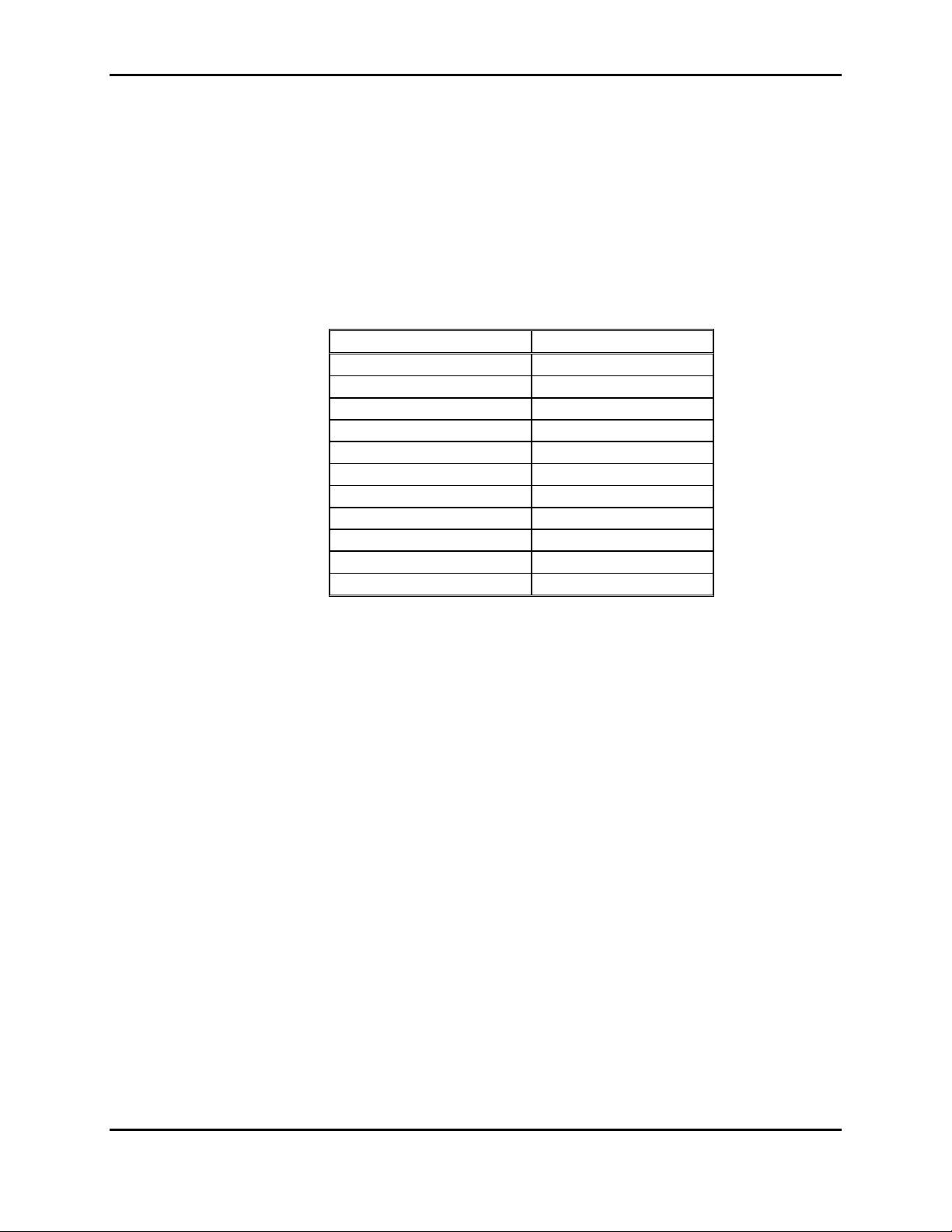

4.4.5 Menu Item 10 (Return to Default Settings)

Menu item 10 resets the monitor to factory default settings as shown in Table

4-2, three confirmation tones will be heard.

After menu item 10 has been selected, cycle power to the NPB-290 and verify

that the factory default values have been reinstated.

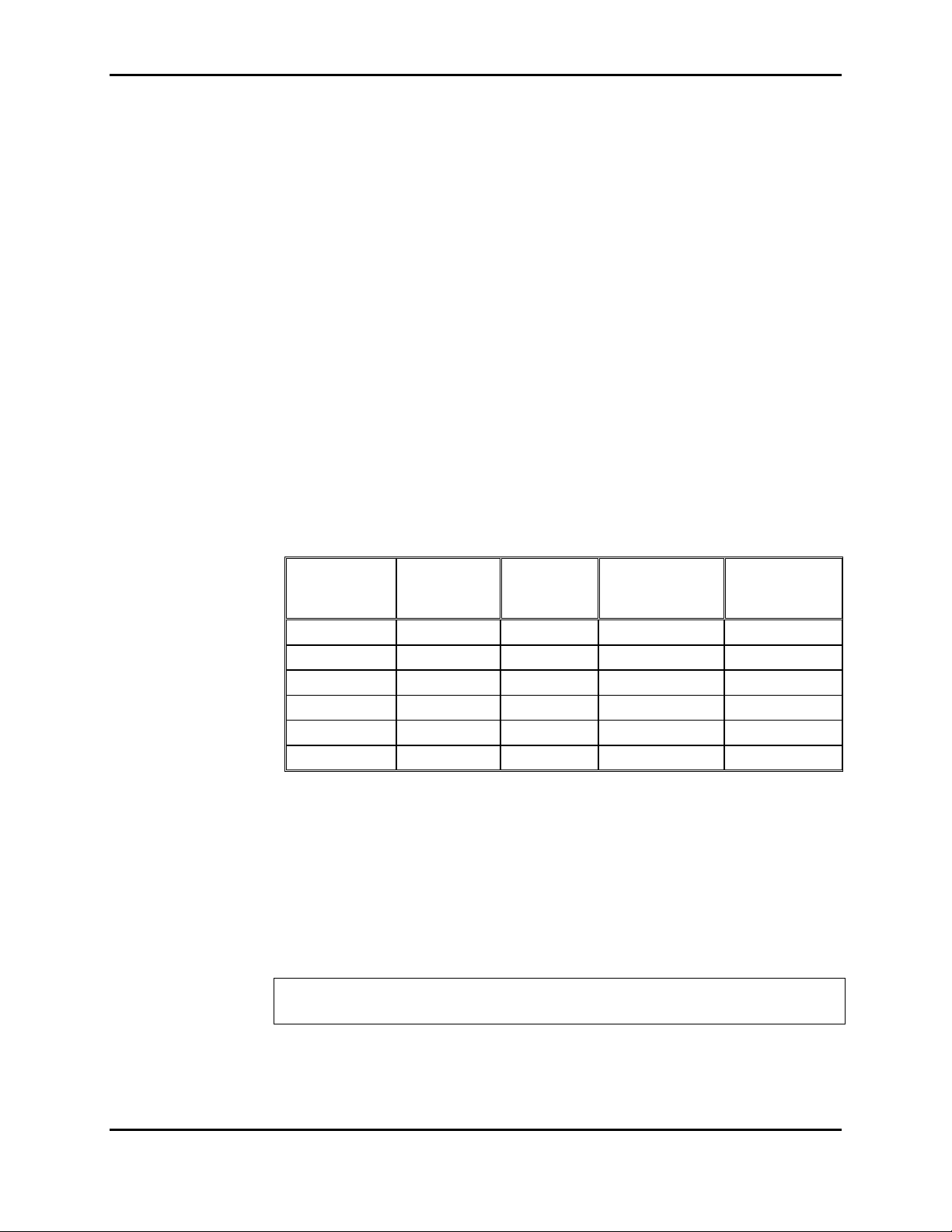

Table 4-2: Factory Default Settings

Parameter Default Value

Alarm Silence Behavior 0 (Off with reminder)

Alarm Silence Duration 60 seconds

Alarm Volume Level 5

Baud Rate 9600

Data Port Format Real-time ASCII

Nurse Call Polarity Normally Low

Pulse beep volume Level 4

Pulse rate High 170 bpm

Pulse rate Low 40 bpm

SpO2 High 100%

SpO2 Low 85%

4.4.6 Menu Item 11 (Alarm Silence Behavior)

1. This menu item is used to change alarm silence behavior. Three options (0,

1, or 2) can be accessed by first pressing the Upper Alarm Limit button, then

using the Adjust Up or Down button to scroll to the desired number.

• Option "0" allows the operator to select Alarm Silence Off. There will

be a reminder tone every 3 minutes.

• Option "1" allows the operator to select Alarm Silence Off. There will

be no reminder tone.

• Option "2" does not allow the operator to select Alarm Silence Off.

2. When the desired option is indicated in the %SpO

Alarm Limit button to save the current selection.

Note: The low battery audible alarm cannot be disabled.

4.4.7 Menu Item 12

Do not use. For use by Mallinckrodt Customer Service Engineer.

4.4.8 Menu Item 13

Do not use. For use by Mallinckrodt Customer Service Engineer.

2 display, press the Upper

4-5

Section 4: Audible Alarm Settings and Service Menu

4.4.9 Menu Item 14 (Calibration Signal)

Menu item 14 will initiate the calibration signal. The calibration signal will

begin at 0.0 volts DC and hold that point for 60 seconds. It will then jump up to

its maximum of +1.0 volt DC and hold that value for 60 seconds. The third part

of the calibration signal is a stair-step signal. The stair-step signal starts at 0.0

volts DC and increases up to +1.0 volt DC in 0.1-volt increments. Each

increment will be held for 1 second. Refer to Table 10-1 for Data port pin outs.

4-6

Loading...

Loading...