Page 1

Service Manual

N-20/N-20P Portable Pulse Oximeter

Caution: Federal law (U.S.A.) restricts this device to sale by or on the order of a physician.

To contact Mallinckrodt’s representative: In the United States, call 1.800.635.5267 or 314.654.2000; outside the United States, call

your local Mallinckrodt representative.

2000 Mallinckrodt Inc. All rights reserved. 062397B-0600

0123

Page 2

Mallinckrodt Inc.

675 McDonnell Boulevard

P.O. Box 5840

St. Louis, MO 63134 USA

Tel 314.654.2000

Toll Free 1.800.635.5267

Mallinckrodt Europe BV

Hambakenwetering 1

5231 DD's-Hertogenbosch

The Netherlands

Tel +31.73.6485200

Nellcor Puritan Bennett Inc.

4280 Hacienda Drive

Pleasanton, CA 94588 USA

Nellcor Puritan Bennett Inc. is a wholly owned subsidiary of Mallinckrodt Inc. Nellcor, Nellcor Puritan Bennett, Durasensor,

Oxisensor II, Oxinet, Dura-Y, Oxiband, and Oxicliq are trademarks of Mallinckrodt, Inc.

To obtain information about a warranty, if any, for this product, contact Mallinckrodt's Technical Services Department, or

your local Mallinckrodt representative.

Purchase of this instrument confers no expressed or implied license under any Mallinckrodt patent to use the instrument with

any sensor that is not manufactured or licensed by Mallinckrodt.

Covered by one or more of the following U.S. Patents and foreign equivalents: 4,621,643; 4,700,708; and 4,770,179.

Page 3

CONTENTS

1 Introduction.................................................................................................................................................... 1-1

1.1 Manual Overview ........................................................................................................................................ 1-1

1.2 Warnings and Cautions............................................................................................................................... 1-1

1.3 Description of N-20 Portable Pulse Oximeter ............................................................................................ 1-1

2 Routine Maintenance ..................................................................................................................................... 2-1

2.1 Overview...................................................................................................................................................... 2-1

2.2 Cleaning ...................................................................................................................................................... 2-1

2.3 Periodic Safety and Functional Checks ...................................................................................................... 2-1

2.4 Battery......................................................................................................................................................... 2-1

3 Performance Verification .............................................................................................................................. 3-1

3.1 Introduction................................................................................................................................................. 3-1

3.2 Required Materials...................................................................................................................................... 3-1

3.3 Performance Tests....................................................................................................................................... 3-1

4 Troubleshooting ............................................................................................................................................. 4-1

4.1 How to Use this Section............................................................................................................................... 4-1

4.2 Who Should Perform Repairs...................................................................................................................... 4-1

4.3 Replacement Level Supported ..................................................................................................................... 4-1

4.4 Obtaining Replacement Parts ..................................................................................................................... 4-1

4.5 Troubleshooting Guide................................................................................................................................ 4-1

4.6 Service Procedures...................................................................................................................................... 4-5

4.7 Error Codes................................................................................................................................................. 4-7

5 Disassembly Guide ......................................................................................................................................... 5-1

5.1 Introduction................................................................................................................................................. 5-1

5.2 Required Equipment/Tools.......................................................................................................................... 5-1

6 Spare Parts ..................................................................................................................................................... 6-1

6.1 N-20/N-20P Spare Parts ............................................................................................................................. 6-1

7 Packing for Shipment..................................................................................................................................... 7-1

7.1 General Instructions.................................................................................................................................... 7-1

7.2 Repacking in Original Carton..................................................................................................................... 7-1

iii

Page 4

CONTENTS

8 Specifications .................................................................................................................................................. 8-1

8.1 Readout ....................................................................................................................................................... 8-1

8.2 Controls....................................................................................................................................................... 8-1

8.3 Operating Modes......................................................................................................................................... 8-1

8.4 Printer Output ............................................................................................................................................. 8-2

8.5 N-20/N-20P Performance............................................................................................................................ 8-2

8.6 Sensor Types................................................................................................................................................ 8-3

8.7 Electrical Specifications.............................................................................................................................. 8-3

8.8 Environmental Specifications...................................................................................................................... 8-4

8.9 Physical Specifications................................................................................................................................ 8-4

9 Technical Supplement.................................................................................................................................... 9-1

9.1 Overview...................................................................................................................................................... 9-1

9.2 Functional versus Fractional Saturation .................................................................................................... 9-1

9.3 Measured versus Calculated Saturation ..................................................................................................... 9-1

9.4 Circuit Analysis........................................................................................................................................... 9-2

9.5 Functional Overview................................................................................................................................... 9-2

9.6 SpO2 Analog Circuitry Block Diagram (Figure 9-3).................................................................................. 9-3

9.7 Definition of Terms...................................................................................................................................... 9-5

9.8 Overall Block Diagram ............................................................................................................................... 9-6

9.9 SpO2 Analog Circuitry................................................................................................................................ 9-7

9.10 Digital Circuitry ................................................................................................................................... 9-12

9.11 Support Illustrations............................................................................................................................. 9-30

FIGURES

Page Number

Figure 5-1: Sensor Lock, and Printer, Paper, and Battery Access Doors...........................................................5-2

Figure 5-2: N-20 Covers with the PCB and Display Assembly............................................................................ 5-3

Figure 5-3: Main, Auxiliary, and Display PCB Assembly.................................................................................... 5-4

Figure 5-4: Printer and Flex Circuit Installation.................................................................................................. 5-5

Figure 9-1: Oxyhemoglobin Dissociation Curve .................................................................................................. 9-2

Figure 9-2: Overall Block Diagram........................................................................................................................ 9-3

Figure 9-3: SpO2 Analog Circuitry Block Diagram............................................................................................. 9-3

Figure 9-4: Digital Circuitry Block Diagram........................................................................................................ 9-4

Figure 9-5: Power Supply Block Diagram............................................................................................................ 9-4

Figure 9-6: Display Control Block Diagram ........................................................................................................ 9-5

Figure 9-7: Printer Control Block Diagram......................................................................................................... 9-5

Figure 9-11: Variable Gain Circuit.................................................................................................................... 9-10

Figure 9-12: Filtering Circuit .............................................................................................................................. 9-11

Figure 9-4: Digital Circuitry Block Diagram...................................................................................................... 9-12

Figure 9-14: N-20 Hardware Block Diagram..................................................................................................... 9-14

iv

Page 5

CONTENTS

Figure 9-15: Address Demultiplexing Circuit .................................................................................................... 9-15

Figure 9-16: Address Decoding Circuit .............................................................................................................. 9-16

Figure 9-17: CPU Memory Circuit ..................................................................................................................... 9-17

Figure 9-18: Input Port Circuit ........................................................................................................................... 9-18

Figure 9-20: Real-Time Clock Circuit ................................................................................................................ 9-19

Figure 9-21: Audio Output Circuit ..................................................................................................................... 9-20

Figure 9-6: Display Control Block Diagram ...................................................................................................... 9-20

Figure 9-23: User Controls Circuit ..................................................................................................................... 9-22

Figure 9-26: Analog Reference Voltage Circuit................................................................................................. 9-25

Figure 9-27: Ambient Light Circuit.................................................................................................................... 9-25

Figure 9-28: Ambient Temperature Circuit ....................................................................................................... 9-26

Figure 9-29: Battery Voltage Circuit .................................................................................................................. 9-26

Figure 9-30: Battery Type Circuit....................................................................................................................... 9-26

Figure 9-32: Printer Flex Circuit ........................................................................................................................ 9-28

Figure 9-8: LED Drive Circuit ........................................................................................................................... 9-30

Figure 9-9: Differential Synchronous Demodulation Circuit .......................................................................... 9-30

Figure 9-10 N-20 HSO Timing Diagram............................................................................................................ 9-30

Figure 9-13: AC Variable Gain Control Circuits .............................................................................................. 9-30

Figure 9-19: Output Port Circuit ........................................................................................................................ 9-30

Figure 9-22: Display Control Circuit.................................................................................................................. 9-30

Figure 9-24: Power Supply Circuit ..................................................................................................................... 9-30

Figure 9-25: Power Control Circuit.................................................................................................................... 9-30

Figure 9-31: Printer Interface Circuit ................................................................................................................ 9-30

Figure 9-33: N-20 SpO2 Analog Block Diagram................................................................................................ 9-30

Figure 9-34: CPU Circuit..................................................................................................................................... 9-30

Figure 9-35: N-20 Main PCB Schematic Diagram............................................................................................. 9-30

Figure 9-36: N-20 Auxiliary PCB Schematic Diagram...................................................................................... 9-30

Figure 9-37: N-20 Flex Circuit Schematic Diagram .......................................................................................... 9-30

TABLES

Table 4-1: Microprocessor Error Codes............................................................................................................... 4-7

Table 8-1: Sensors................................................................................................................................................... 8-3

v

Page 6

Page 7

1 INTRODUCTION

1.1 Manual Overview

1.2 Warnings and Cautions

1.3 Description of the N-20 Portable Pulse Oximeter

1.1 Manual Overview

This manual contains service information for the Nellcor

N-20/N-20P, that is necessary to maintain and repair the N-20/N-20P by qualified service personnel.

Note that models designated for sale in Europe differ from models designated for sale in the USA only

in that the user control buttons and display use icons rather than alphabetical characters, and that the

product labels reflect the appropriate European certifications and company addresses.

1.2 Warnings and Cautions

"WARNING" is used to call attention to procedures that could result in an error in calibration or

performance, and/or precautions that are important to ensure the safety of both service personnel and

patients.

"CAUTION" is used to call attention to procedures that should be carefully followed to prevent

damage to the instrument.

1.3 Description of N-20 Portable Pulse Oximeter

®

portable pulse oximeter, models

The Nellcor portable pulse oximeters model N-20 (without printer) and N-20P (with printer) provide

noninvasive and continuous information about the percent of oxygen that is combined with

hemoglobin (SpO

) and pulse rate. A pulse amplitude indicator provides a qualitative indication of

2

pulse activity and patient perfusion. These instruments can be operated in either spot-check mode

(single-measurement), or extended-measurement mode (30 minutes of data). Patients are connected to

the instrument by a Nellcor oximeter sensor. The sensor LEDs are driven by the SpO

analog section,

2

which also conditions the incoming signals, and provides CPU adjustable gains stages. The CPU

measures the sensor's analog outputs, continually controls the gain stages, and calculates SpO

.

2

The N-20/N-20P is automatically calibrated each time it is switched on, and whenever a new sensor is

connected; it sets sensor-specific calibration coefficients by reading a calibration resistor in the sensor.

Also, the intensity of the sensor's light sources is adjusted automatically to compensate for differences

in tissue thickness and skin color.

Standard user controls consist of a Measure button and a Check-Battery button. The Measure button

signals the power control circuit to switch on the power supply. The power supply then provides

regulated power to the unit. Once power is on, the CPU reads both the Measure and Check-Battery

buttons for user commands.

The N-20P printer provides a hard copy of acquired patient measurements. The printer circuit

includes three user control buttons: ON (on/off), ADV (advance), and D/D (day/date). In addition, an

ambient temperature sensor is used with the battery voltage input to control printout quality.

1-1

Page 8

Page 9

2 ROUTINE MAINTENANCE

2.1 Overview

2.2 Cleaning

2.3 Periodic Safety and Functional Checks

2.4 Battery

2.1 Overview

The N-20/N-20P requires no routine maintenance, routine service, or calibration. If service is

necessary, contact qualified service personnel or Mallinckrodt’s representative. Use only

Mallinckrodt-approved test equipment when running a performance test on the N-20/N-20P. The

user's institution and/or local or national agencies may require testing.

2.2 Cleaning

Dampen a cloth with a commercial, nonabrasive cleaner, and lightly wipe the surfaces of the

N-20/N-20P. Do not spray or pour liquid on the instrument or accessories. Do not allow liquid to

contact connectors, switches, or openings in the chassis.

2.3 Periodic Safety and Functional Checks

The following checks should be performed at least every 2 years by a qualified service technician.

Inspect the exterior of the N-20/N-20P for damage.

Inspect safety labels for legibility. If the labels are not legible, contact Mallinckrodt Technical

Services Department or your local Mallinckrodt representative.

2.4 Battery

When the N-20/N-20P is going to be stored for 3 months or more, remove the battery prior to storage.

To replace or remove the battery, refer to Section 5, Disassembly Guide.

2-1

Page 10

Page 11

3 PERFORMANCE VERIFICATION

3.1 Introduction

3.2 Required Materials

3.3 Performance Tests

Caution: Adhere to all testing instructions; failure to do so may damage the N-20/N-20P.

3.1 Introduction

This section describes performance verification for the N-20 and N-20P pulse oximeters (hereafter

called the “monitor”), following repairs. The N-20/N-20P are powered by alkaline batteries. The

N-20/N-20P design includes built-in electrical insulation; no ground resistance or electromagnetic

leakage testing is required.

The tests can be performed without removing the monitor cover. If the monitor fails to perform as

specified in any test, repairs must correct the discrepancy before the monitor is returned to the user.

3.2 Required Materials

Durasensor Nellcor DS-100A

Tester, Pulse Oximeter Nellcor SRC-2

3.3 Performance Tests

The N-20/N-20P will operate in conjunction with the Nellcor® pulse oximetry tester, model SRC-2,

to test instrument performance. The SRC-2 plugs into the DB-9 sensor connector and uses the

instrument's power supply and diagnostic software to test the display and the operation of the

instrument. Refer to the operator's manuals for the SRC-2 for details on performance testing with the

SRC-2.

Other tests, which are outlined below, include the display backlight test, the low battery indicator test,

the power-up self-test, and the thermal printer test (printer test applies only to N-20P).

3.3.1 Backlight Test

The electroluminescent backlight illuminates the display in three sections: (1) the main section, i.e.,

the Oxygen Saturation and Pulse Rate display fields, and the 14-segment pulse rate amplitude

indicator; (2) the Low Battery indicator, and (3) Pulse Search indicators each have their own

backlight. All backlights flash once during Power-On Self-Test.

The ambient light detector is located underneath a small circular window in the top right corner of the

N-20/N-20P display. Under low light conditions, the main section backlight is switched on. If a Low

Battery and Pulse Search indicator are lit, the monitor’s backlight is also lit.

To test for proper operation of the display backlight, observe the N-20/N-20P in a darkened room. If

any backlight section is not working correctly, contact Mallinckrodt's Technical Services Department

or Mallinckrodt's local representative for assistance.

3.3.2 Battery Performance

This test is provided to verify that the monitor will operate for the period specified.

The monitor is specified to operate on battery power as follows:

3-1

Page 12

Performance Verification

N-20 (no printer) 37 hours with Alkaline batteries.

N-20/P (with printer) 32 hours with Alkaline batteries.

This test requires a new set of batteries. The new batteries must be installed after the test.

Connect the Nellcor SRC-2 pulse oximeter tester to the monitor.

Set the switches on the SRC-2 as follows:

Switch Setting

RATE 38

LIGHT LOW

MODULATION LOW

RCAL/MODE RCAL 63/LOCAL

Momentarily press the MEASURE button, and verify the following power-up sequence:

All indicators—OXYGEN SATURATION, PULSE RATE, PULSE SEARCH, LOW BATTERY,

and the PULSE BARS—light for a few seconds. Verify the OXYGEN SATURATION, and PULSE

RATE displays indicate "888.”

The OXYGEN SATURATION display momentarily indicates the monitor 3-digit software version.

The other displays are not lit.

Software versions may vary depending on the type of monitor and the date of manufacture.

The N-20P will display printer status immediately after displaying the software version. The

OXYGEN SATURATION display will indicate “Pr”and the PULSE RATE display will indicate

either “On” or “OFF.”

The OXYGEN SATURATION display momentarily indicates the letters ”tSt” and the monitor sounds

a single tone. The other displays are not lit. “tSt” verifies that the monitor recognizes that a tester is

connected.

The OXYGEN SATURATION and PULSE RATE displays indicate “0,” the PULSE SEARCH

indicator is flashing, and the PULSE BAR will start to register the simulated pulse.

After a few beats a pulse tone will be heard, and the PULSE SEARCH indicator will turn off. The

OXYGEN SATURATION display indicates between 79 and 83, and the PULSE RATE display

indicates between 37 and 39.

The monitor must operate for at least 37 hours if the printer is not turned on.

Verify that the LOW BATTERY indicator lights steadily sometime after 30 hours of operation.

Verify that the monitor turns off approximately 1 hour after the LOW BATTERY indicator starts

flashing.

Allow the monitor to continue operation until power-down due to low battery.

3.3.3 Power-Up Performance

Monitors with the same software must demonstrate identical startup routines. The power-up tests

verify the self-test function.

When an N-20/N-20P is switched on, a sequence of diagnostic tests is run that examines the

instrument electronics and display functions. This power-on self-test consists of the following events:

3-2

Immediately after power is switched on, the instrument simultaneously:

Displays the number "8" in all six Oxygen Saturation and Pulse Rate display field segments;

•

Illuminates all 14 pulse rate amplitude indicator segments;

•

• Illuminates the Pulse Search and Low Battery indicators; and

Page 13

Illuminates the display backlight.

•

During the next few seconds, the instrument:

Switches off the display backlight;

•

• Displays three digits in the Oxygen Saturation display field representing the software version (for

example, 123 is software version 1.2.3).

• Only the N-20P displays the printer status in the display fields; that is, either "Pr On" or "Pr OFF."

If a sensor is attached to the instrument, a zero ("0") appears in first position of the display fields. The

Pulse Search indicator flashes; if no sensor is attached to the instrument, horizontal dashes appear in

all six Oxygen Saturation and Pulse Rate display fields, and the Pulse Search indicator flashes.

After approximately 1 minute, a short beep occurs and the instrument automatically switches off.

If at any time during the test sequence "Err" followed by a code number is displayed, make a note of

the error code and refer to Section 4.7, Error Codes, for a description.

3.3.3.1 How To Run the Self-Test

Place a new set of batteries in the monitor.

Do not connect a sensor or SRC-2 to the monitor.

Momentarily press the MEASURE button, verify the following power-up sequence:

Performance Verification

All indicators—OXYGEN SATURATION, PULSE RATE, PULSE SEARCH, LOW BATTERY,

and the PULSE BARS—light for a few seconds. Verify that the OXYGEN SATURATION and

PULSE RATE displays indicate "888."

The OXYGEN SATURATION display momentarily indicates the monitor 3-digit software version.

The other displays are not lit.

Software versions may vary depending on the type of monitor and the date of manufacture.

The N-20P will display printer status immediately after it displays software version. The OXYGEN

SATURATION display will indicate “Pr” and the PULSE RATE display will indicate either “On”or

“OFF.”

OXYGEN SATURATION and PULSE RATE display dashes (– – –) in each window, the monitor

sounds a single tone, and the PULSE SEARCH indicator is flashing. The other displays are not lit.

Verify that the monitor automatically turns off after 60 seconds.

If the Measure button was held down for more than 3 seconds (extended mode), the monitor will not

turn off after 60 seconds but will operate for approximately 3 minutes before automatically turning

off.

3.3.4 Printer Test

The following procedure applies to the N-20P only.

The SRC-2 must be used to test the operation of the N-20P printer and the printer's user-control

buttons. When an SRC-2 is plugged into the DB-9 connector, the N-20P does not respond to button

presses during Power-On Self-Test; however, it does acknowledge any button press after the self-test

with an immediate beep and the following display codes:

Button Press Display

Measure 9O

battery check bAt

3-3

Page 14

Performance Verification

ON On

ADV Ad

D/D dd

combinations Err

1. Press the Measure button: "9O" appears in the Oxygen Saturation display.

2. Press the Battery-Check button: "bAt" appears in the Oxygen Saturation display.

3. Press the printer ON button: "On" appears in the Oxygen Saturation display. A

printer test pattern prints out; the following is an approximate example of the test

pattern:

Examine the test pattern to verify that all dots print with a uniform darkness. Overall printout

darkness can be adjusted; to adjust printer darkness, see paragraph 4.6.7. If printout darkness is

either irregular or dots are missing, contact Mallinckrodt's Technical Services Department or

Mallinckrodt's local representative for assistance.

1. Press the printer ADV button. “Ad” appears in the Oxygen Saturation display. Paper advances

one line for each button press.

2. Press the printer D/D button: "dd" appears in the Oxygen Saturation display.

3. End SRC-2 printer test.

3.3.5 Hardware and Software Tests

Hardware and software tests include the following:

Operation with a Pulse Oximeter Tester

Normal Operation

3.3.5.1 Pulse Oximeter Tester

1. Connect the Nellcor SRC-2 pulse oximeter tester to the monitor.

2. Set the switches on the SRC-2 as follows:

Switch Setting

RATE 38

LIGHT LOW

MODULATION LOW

RCAL/MODE RCAL 63/LOCAL

3-4

3. Momentarily press the MEASURE button, and verify the following power-up sequence:

Page 15

Performance Verification

4. All indicators—OXYGEN SATURATION, PULSE RATE, PULSE SEARCH, LOW

BATTERY, and the PULSE BARS—light for a few seconds. Verify that the OXYGEN

SATURATION and PULSE RATE displays indicate "888.”

5. The OXYGEN SATURATION display momentarily indicates the monitor 3 digit software

version. The other displays are not lit.

6. Software versions may vary depending on the type of monitor and the date of manufacture.

The N-20P will display printer status immediately after software version display. The OXYGEN

SATURATION display will indicate “Pr,” and the PULSE RATE display will indicate either “On” or

“OFF.”

The OXYGEN SATURATION display momentarily indicates the letters ”tSt” and the monitor sounds

a single tone. The other displays are not lit. “tSt” verifies that the monitor recognizes that a tester is

connected.

The OXYGEN SATURATION and PULSE RATE displays indicate “0,” the PULSE SEARCH

indicator is flashing, and the PULSE BAR will start to register the simulated pulse.

After a few beats a pulse tone will be heard, and the PULSE SEARCH indicator will turn off. The

OXYGEN SATURATION display indicates between 79 and 83 and the PULSE RATE display

indicates between 37 and 39.

3.3.6.2 Normal Operation

These tests are an overall qualitative check of the system and require connecting a live subject to the

monitor:

Connect a DS-100A Sensor to monitor.

Place the DS-100A Sensor on the subject as recommended in the monitor Operator's Manual.

Press the Measure button for at least 5 seconds to turn on the monitor.

The monitor should stabilize on the subject's physiological signal in about 10 to 15 seconds. Verify

that the saturation value and pulse rate are acceptable.

3-5

Page 16

Performance Verification

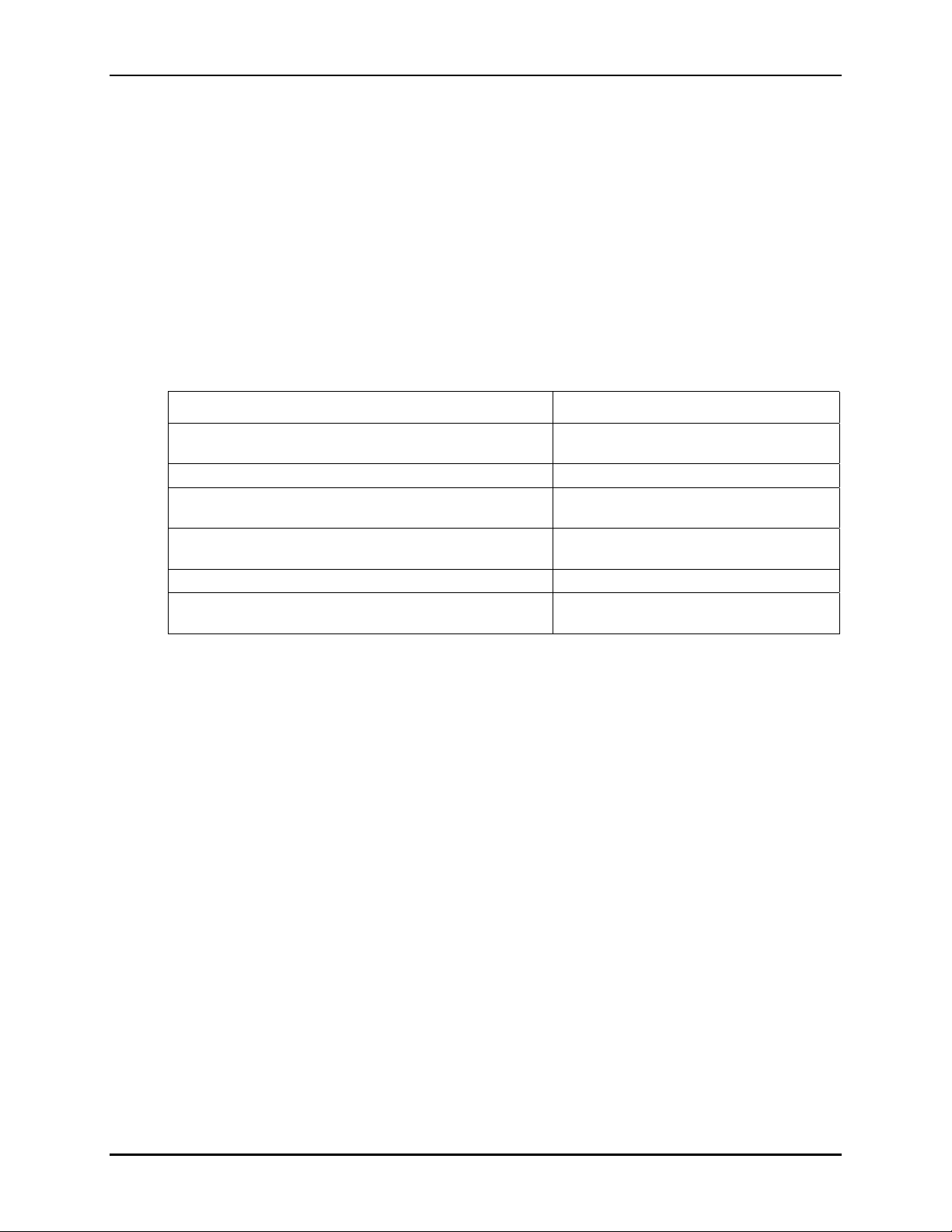

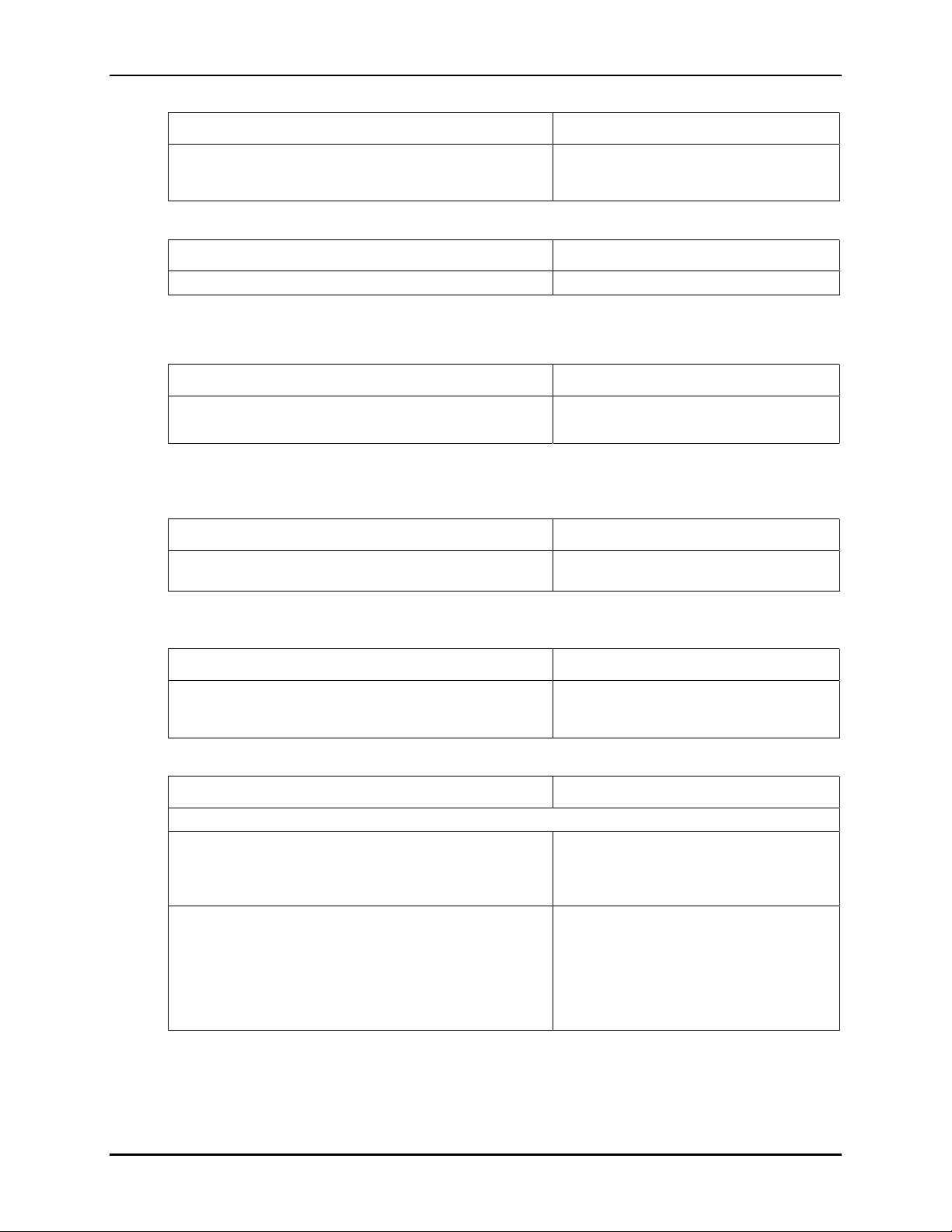

TEST RESULTS

Model: N-20 Serial:_____________________________

Date:___________Customer Name:________________________________

Description Pass Fail

Performance Tests _____ ____

Backlight Test _____ ____

Battery Performance _____ ____

Testing the Low Battery Indicator _____ ____

Power-Up Performance _____ ____

How to Run the Self-Test _____ ____

Printer Test _____ ____

Pulse Oximeter Test _____ ____

Normal Operation _____ ____

I certify that the monitor listed in this form has successfully passed all of these tests.

Technician:_________________________________________________Date:____________

I certify that the above signed technician has performed the tests listed on this form and the monitor performs

satisfactorily.

Support Center Manager:___________________________________________________Date:____________

3-6

Page 17

4 TROUBLESHOOTING

4.1 How to Use This Section

4.2 Who Should Perform Repairs

4.3 Replacement Level Supported

4.4 Obtaining Replacement Parts

4.5 Troubleshooting Guide

4.6 Service Procedures

4.7 Error Codes

WARNING: Disassembly of the instrument exposes hazardous voltages. To avoid

injury or instrument damage, disassembly or maintenance must be attempted only by

qualified service personnel.

4.1 How to Use this Section

This section explains how to identify and correct monitor difficulties and provides procedures for

common service-related activities, such as battery replacement, clearing paper jams, and adjusting

printer darkness.

Use this section in conjunction with Section 3,

To remove and replace a part you suspect is defective, follow the instructions in Section 5,

Disassembly Guide. The functional circuit analysis, located in the Technical Supplement at the end of

this manual, offers information on how the device functions, as well as part locator diagrams and

detailed schematic diagrams.

4.2 Who Should Perform Repairs

Only qualified service personnel should open the device housing, remove and replace components, or

make adjustments. If your medical facility does not have qualified service personnel, contact

Mallinckrodt Technical Services.

4.3 Replacement Level Supported

The replacement level supported for this product is to the printed circuit board (PCB) and major

subassembly level. Once you isolate a suspected PCB, replace the PCB with a known good PCB.

Check to see that the trouble symptom disappears and the device passes all performance tests. If the

trouble symptom persists, swap the replacement PCB and the suspected malfunctioning PCB (the

original PCB that was installed when you started troubleshooting) and continue troubleshooting as

directed.

4.4 Obtaining Replacement Parts

Mallinckrodt Technical Services provides technical assistance information and replacement parts. To

obtain replacement parts, contact Mallinckrodt. Refer to parts by the part names and part numbers

listed in Section 6,

Spare Parts

.

Performance Verification

, and Section 6,

Spare Parts

.

4.5 Troubleshooting Guide

This section discusses potential symptoms, possible causes, and actions for their resolution. Should

this troubleshooting guide fail to address the symptoms evident in a particular N-20/N-20P, please

4-1

Page 18

Troubleshooting

contact Mallinckrodt's Technical Services Department or a local Mallinckrodt representative for

assistance.

If the N-20/N-20P does not perform as expected:

Check for proper sensor placement.

•

• Depending on concentration, indocyanine green, methylene blue, and other intravascular dyes

may affect the accuracy of a measurement.

• These instruments are calibrated to read oxygen saturation of functional arterial hemoglobin

(saturation of hemoglobin functionally capable of transporting oxygen in the arteries), and

significant levels of dysfunctional hemoglobins such as carboxyhemoglobin or methemoglobin

may affect the accuracy of a measurement.

If the electronics and/or display functions require testing, refer to Section 3,

Battery access door may not be properly latched. Check access door and ensure it is properly

Batteries may be discharged. Exchange them for a new set.

Batteries may be incorrectly installed. Ensure that batteries are oriented according

Batteries may not be making proper electrical contact. Inspect contacts for deformity; clean contacts

Fuse F1 on the auxiliary PCB may be open. See paragraph 4.6.5, Fuse Replacement.

Dust may have accumulated under Measure button causing

loss of electrical contact.

Performance Verification

Symptom 1: No response to Measure button.

Cause Action

latched.

to the polarity indicator.

to remove oxidization.

Clean contact points under Measure button

(see Section 5.3,

N-20 Disassembly Guide).

.

4-2

Page 19

Troubleshooting

Symptom 2: Pulse Search indicator appears for more than 5-10

seconds.

Cause Action

Sensor may be improperly positioned. Ensure the sensor is correctly applied (see

sensor directions for use).

Incorrect sensor may be in use. See sensor directions for use to ensure that

the patient's weight and sensor application is

correct. Test the sensor on another person to

verify proper operation.

Perfusion may be too low. Check patient status. Test the instrument on

someone else, or try another type of sensor.

The N-20/N-20P will not make a

measurement if perfusion is inadequate.

Foreign material on the sensor LEDs or photodetector may be

affecting performance.

Patient motion may be interfering with the instrument's ability

to find a pulse pattern.

Environmental motion may be interfering with the

instrument's ability to track a pulse

The sensor may be too tight, there may be excessive

illumination (e.g., a surgical or bilirubin lamp or direct

sunlight), or the sensor may be placed on an extremity with a

blood pressure cuff, arterial catheter, or intravascular line.

The DB-9 sensor connector on the N-20/N-20P may be

broken.

Clean the test area and ensure that nothing

blocks the sensor site.

If possible, ask the patient to remain still.

Verify that the sensor is securely applied and

replace it if necessary, move it to a new site,

or use a sensor that tolerates patient

movement, such as an appropriate adhesive

sensor.

Replace the DB-9 connector (Section 4.6.6).

Symptom 3: Pulse Search indicator appears after successful

measurements have been made.

Cause Action

Patient perfusion may be too low. Check patient status. Test the instrument on

someone else, or try another type of sensor.

The N-20/N-20P will not make a

measurement if perfusion is inadequate.

Patient motion may be interfering with the instrument's ability

to find a pulse pattern.

Environmental motion may be interfering with the

instrument's ability to track a pulse.

The sensor may be too tight, there may be excessive

illumination (e.g., a surgical or bilirubin lamp or direct

sunlight), or the sensor may be placed on an extremity with a

blood pressure cuff, arterial catheter, or intravascular line.

If possible, ask the patient to remain still.

Verify that the sensor is securely applied and

replace it if necessary, move it to a new site,

or use a sensor that tolerates patient

movement, such as an appropriate adhesive

sensor.

Symptom 4: Dashes (– – –) appear in the display.

Cause Action

The sensor is not connected to the instrument. Check all sensor connections; try substituting

another sensor. Check all extension cables. If

an extension cable is in use, remove it and

plug the sensor directly into the instrument.

Symptom 5: Pr Err is displayed during the Power-On Self-Test (N-20P only).

4-3

Page 20

Troubleshooting

Cause Action

The printer is not operational, but the N-20P continues to

obtain patient measurements.

Check to see if the paper is jammed.

Examine the print head and ensure that it has

returned to the home position.

Symptom 6: Err followed by a number appears on the display.

Cause Action

See Section 4.7 for error codes. Record the number that is displayed.

Symptom 7: Time or date is incorrect (N-20P only).

Cause Action

The real-time clock (RTC) battery may be exhausted. Replace the RTC battery (see Section 4.6.4).

Reset the time and date (see Section 4.6.3).

Symptom 8: Printer fails to operate (N-20P only).

Cause Action

Fuse F2 on the auxiliary PCB may be open. See paragraph 4.6.5 for information about

fuses.

Symptom 9: Printer paper advances but instrument does not print (N-20P

only).

The thermal paper may be improperly loaded; characters can

be printed on only one side of the thermal paper roll.

Symptom 10: Paper mechanism jams (N-20P only).

Note: If a printer paper jam is detected during Power-On Self-Test, Pr Err may appear on the display.

4.6 Service Procedures

Cause Action

Ensure that the thermal paper is properly

loaded; if needed, remove the roll of printer

paper and reload the printer paper.

Cause Action

Switch off the N-20P. Then check to see if

the print head is at the home position; if so,

attempt to pull the paper out by pulling

gently—do not force it.

If the print head is not at the home position,

and the paper cannot be easily pulled out

from the printer, then the printer may need to

be disassembled to remove the paper jam

(see Sections 5.3,

Procedure,

Printer Paper).

N-20 Disassembly

and 4.6.2,

Loading/Clearing

4-4

The following service procedures are most likely to be encountered by the service technician. The

PCB designation for a component appears in parentheses, for example, (BT1) or (U15).

Page 21

4.6.1 Installing Batteries

1. Remove the battery cover access door by pressing the battery compartment access door latch.

Install four alkaline "C" cell batteries. Be sure to observe the polarity indicator sticker.

2.

3. Replace the battery cover access door.

4.6.2 Loading/Clearing Printer Paper

The N-20P uses a thermal paper that can show printed characters on one side only. Make sure that the

paper roll is correctly installed; always refer to the graphical instruction label found on the paper roll.

1. Press down and outward on the top of the paper compartment door to remove it.

2. Feed the paper into the paper compartment slot; refer to the graphic label for orientation.

3. Press and hold the ADV button until the end of the paper appears at the paper exit slot.

4. Replace the paper compartment door.

If the paper jams either during the loading process or during printing, proceed as follows:

1. Remove both the paper door and the printer-head access cover.

2. Firmly grab and pull the paper roll backward—out and away from the print head—observe

the access to the print head to determine whether or not the paper escaped from the jammed

position.

3. If paper remains jammed between the print head and printer, press the ADV button; the

jammed paper may work its way out. If the paper remains jammed, and the printer drive does

not advance the paper, manually advance the drive gear on the side of the printer to free the

paper.

4. If these attempts fail to free the jammed paper, remove the printer from the unit to gain full

access (see paragraph 5.3, N-20 Disassembly Procedure).

Troubleshooting

4.6.3 Setting Date and Time

The following procedure applies to the N-20P only.

The following code letters and numbers appear in both Oxygen Saturation and Pulse Rate display

fields. The symbol "xx" represents information in the Oxygen Saturation display field and "yy"

represents information in the Pulse Rate display field.

Begin this procedure by first removing any sensor from the instrument.

1.

Turn on the monitor without the sensor connected. Switch on the N-20P and allow the

unit to run the Power-On Self-Test.

2. When dashes appear in the Oxygen Saturation and Pulse Rate displays, press the D/D

(day/date) button once. At this point, the Oxygen Saturation display field shows "txx", with

"t" representing time; "xx" representing hours, and "yy" representing minutes. Note that "xx"

(hours) is flashing.

3.

4.

Press the ADV (advance) button repeatedly until the correct hour is displayed.

Press the D/D button once. Note that "yy" (minutes) is now flashing.

5. Press the ADV button repeatedly until the correct minute is displayed.

6. At this point, the Oxygen Saturation display field shows "dxx", with "d" representing date;

"xx" representing the month, and "yy" representing the date. Note that "xx" (month) is

flashing.

7.

Press the ADV button repeatedly until the correct month is displayed.

8. Press the D/D button once. Note that "yy" (date) is flashing.

9. Press the ADV button repeatedly until the correct date is displayed.

10. Press the D/D button. At this point, the Oxygen Saturation display field shows "Yxx", with

"Y" representing "year.” Note that "xx" (year number) is flashing.

11.

12.

Press the ADV button repeatedly until the correct year number is displayed.

Press the D/D button once. The N-20P turns itself off within 5 seconds.

4-5

Page 22

Troubleshooting

13. Date and time are now correct. Check by switching on the N-20P with the printer enabled.

After the N-20P executes its Power-On Self-Test, the printer prints the spot check mode

header with the correct date and time.

4.6.4 Replacing the Real-Time Clock (RTC) Battery

The socket for the RTC battery (BT1) is located on the auxiliary PCB at grid location 5D.

Typical life of the clock battery is 5 years.

1. Disassemble the N-20 (see Section 5.3, N-20, Disassembly Procedure).

2. Using a thin flathead screwdriver, gently pry the RTC battery from its socket.

3.

Insert a new battery into the socket, observing the polarity indication (socket's clip and

battery's flat side are positive).

4. Reassemble the unit.

5. Reset the clock (see paragraph 4.6.3, Setting Date and Time).

4.6.5 Replacing Fuses

Two fuses (F1 and F2) are located on the auxiliary PCB. Fuse F1 may open to protect the CPU and its

associated components from damage if the power supply malfunctions. Fuse F2 may open to protect

the printer from damage due to excessive voltage if the printer head jams or has been physically

damaged. Refer to the auxiliary PCB schematic for the locations of F1 and F2.

4.6.6 Replacing the DB-9 Connector

1. Disassemble the N-20 (see Section 5.2); the connector is on the main PCB at grid location 3A.

2. Using a low-power soldering iron, unsolder the connector from the PCB and remove it. Save all

Teflon tubing, ferrite blocks, and insulating materials for the replacement connector.

3. Install ferrite blocks between plastic lead spacer on the connector and the PCB.

4. Insulate connector pin numbers 2, 3, and 5 with Teflon tubing, and insert inside ferrite block.

5. Add insulating material between each end of ferrite block and PCB, and secure with Loctite glue.

6. Solder new connector to PCB and visually check PCB for stray drops of solder before

reassembling.

7. Switch on the N-20/N-20P and test the connector with a patient sensor.

4.6.7 Adjusting Printer Darkness

Caution: Adjust the printer darkness setting until the lightest legible print is visible.

Setting the print darker than this could reduce the life of the printer-head. Although the N-20P is

designed to automatically compensate for conditions that might influence the quality of the printout,

the user may want to adjust the print darkness. The normal darkness setting is set at the factory; this

setting maximizes both readability and life of the printer-head.

1. Switch on the N-20P in spot check mode. (Depressing the instrument Measure button once starts

Spot-check mode.)

2. Simultaneously press and hold the ADV and ON buttons for 2 seconds. If these buttons are not

pressed at the same time, two audible beeps will sound and the N-20P either advances the paper

or switches off, depending on which button press is first sensed. If the buttons are pressed at the

same time, a single audible beep will sound, Pr SEt is displayed, and the printer prints one of the

following 6 lines:

4-6

PRINTING LIGHTER (10% lighter than normal darkness)

PRINTING LIGHT (5% lighter than normal)

PRINTING NORMAL (normal darkness)

PRINTING DARK (5% darker than normal)

PRINTING DARKER (10% darker than normal)

PRINTING DARKEST (15% darker than normal)

Page 23

Note: The parenthetic line description is not printed, and button presses are

ignored whenever the printer is printing.

1. Press the ADV button to change the darkness setting. The printer prints a line with each button

press, and the setting increments from lighter to darkest and then wraps back to lighter.

2. Allow the N-20P to switch off (about 30 seconds). The last print darkness setting is remembered

when the N-20P is switched back on. Test this by repeating the procedure and skipping step 3.

4.7 Error Codes

If a failure is detected during the Power-On Self-Test or during any performance test, the error

message (Err) appears in the Oxygen Saturation display and a 3-digit error code number appears in the

Pulse Rate display.

If an error message appears, find its category (the first digit of the error code represents the category)

and record the error code number. Match the number to the description in the following table, and

contact Mallinckrodt's Technical Services Department or Mallinckrodt's local representative for

assistance.

Internal tests are performed in the order of the table listing. The first error condition encountered is the

one displayed.

4.7.1 Category 1 — Microprocessor Errors

Troubleshooting

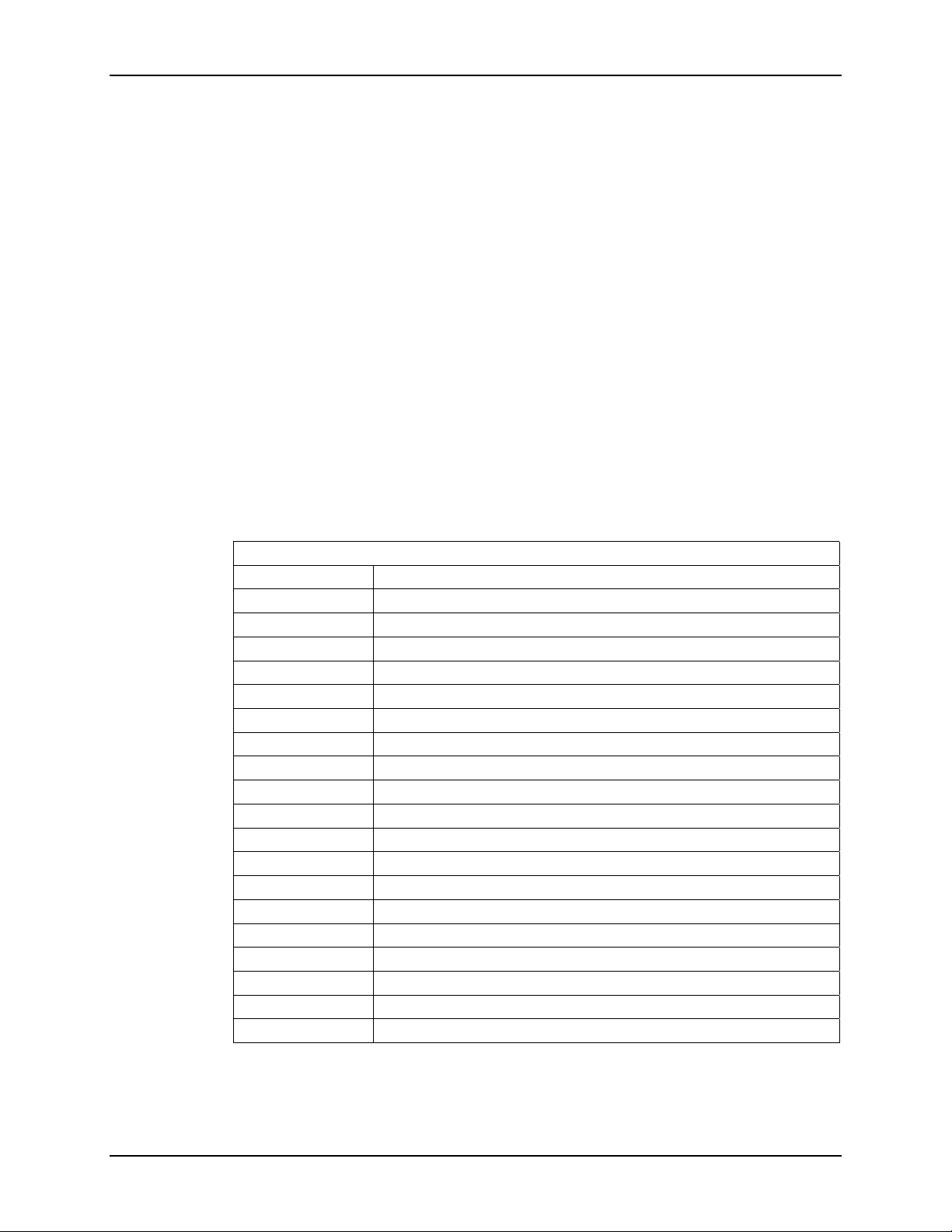

Table 4-1: Microprocessor Error Codes

Errors in the CPU (main PCB). Likely action is replacement of the CPU.

101 Error in internal RAM registers test

102 Error in zero register test

103 Error in register contents clearing test

104 Error in register contents increment test

105 Error in register contents decrement test

106–109 Errors in logical operations test

110 Error in exchange test

111 Error in timer tests

112 Error in window select register test

113, 114 Errors in stack manipulation test

115–117 Errors in CPU flags test

118 Error in interrupt pending register test

119 Error in program counter test

120 Error in CPU serial port test

121 Error in pulse width modulation register test

122 Error in A/D register test

123 Error in addressing modes test

124 Error in high speed input register test

125 Error in content addressable memory test

126–129 Errors in arithmetic operations test

4.7.2 Category 2 — RAM Memory Errors

Errors in RAM memory (main PCB). Likely action is replacement of the main PCB.

4-7

Page 24

Troubleshooting

201–203 Errors in external RAM test

4.7.3 Category 3 — PROM Errors

Errors in PROM memory (main PCB). Likely action is replacement of the PROM.

301 Error in PROM test

4.7.4 Category 4 — I/O Port Errors

Errors in the CPU's internal I/O port (main PCB). Likely action is replacement of either the CPU or

the main PCB.

401–409 Errors in I/O port test

4.7.5 Category 5 — Reserved

4.7.6 Category 6 — Clock Errors

Failure of the real-time clock (auxiliary PCB), or timing differences between the CPU’s clock and the

real-time clock. Likely action is replacement of the main or auxiliary PCB.

601 Failure of real-time clock

602, 603 Errors in real-time clock

4.7.7 Category 7 — Watchdog-Timer Errors

Error in the watchdog-timer circuit of the CPU (main PCB). Likely action is replacement of the CPU.

701, 702 Errors in watchdog-timer

4.7.8 Category 8 — Printer Errors

Error in the printer (see Section 5.1, Troubleshooting).

If a printer error condition occurs, no error code number will display, rather the display reads Pr Err.

4-8

Page 25

5 DISASSEMBLY GUIDE

5.1 Introduction

5.2 Required Equipment/Tools

5.3 N-20 Disassembly Procedure

5.4 N-20P Disassembly Procedure

WARNING: Only qualified service personnel must perform repair and testing. Improper

repair and/or adjustment may compromise patient safety or the accuracy of the instrument.

5.1 Introduction

The N-20/N-20P can be disassembled down to all major component parts, including:

• PCBs

battery

•

• cables

• chassis enclosures

WARNING: Before attempting to open or disassemble the N-20/N-20P, disconnect the

power cord.

Caution: Observe ESD (electrostatic discharge) precautions when working within the unit.

Note: Some spare parts have a business reply card attached. When you receive these

spare parts, please fill out and return the card.

5.2 Required Equipment/Tools

Screwdriver, Phillips-head, small

•

Screwdriver, Phillips-head, medium

•

Pliers, long nose

•

• Screwdriver, small flathead

• Soldering iron, low-power

Screwdriver, small blade

•

Needle-nose pliers

•

5.2.1 N-20 Disassembly Procedure

Whenever repair or disassembly is required, always wear a ground strap connected to active ground.

Before any disassembly or service procedure, switch instrument power off.

5-1

Page 26

Disassembly Guide

Figure 5-1: Sensor Lock, and Printer, Paper, and Battery Access Doors

1. Remove the battery door (19) and batteries.

2. Remove the sensor lock (34) by lightly pressing in on its ears and pulling out from the sensor

shroud.

3. Remove the paper door (20) and paper roll, and the printer door (21).

20

21

34

19

5-2

Page 27

5.2.2 Removing the Covers

Disassembly Guide

16

18

27

26

15

31

30

Figure 5-2: N-20 Covers with the PCB and Display Assembly

1. Remove screw cap (30), and loosen the captive screw (31), which secures the rear cover (15).

2. Separate the front cover (16) from the rear cover by wedging a thin flathead screw driver between

the covers at the base of the instrument and slowly prying them apart.

Note: The covers are hinged at the top end in a different way; do not attempt to

separate the covers using this technique at the top of the instrument. Once the covers

are separated at the bottom end, lift away the bottom end of the front cover first,

allowing the tabs at the top end to act as a hinge.

5-3

Page 28

Disassembly Guide

5.2.3 Removing the PCBs and Display Assembly

Tab #1

Flex #1

Flex #3

Tab #3

18

Flex #2

Tab #4

Tab #2

27

11

12

13

26

Detail B

6

Detail A

5

Figure 5-3: Main, Auxiliary, and Display PCB Assembly

1. Remove the Measure button (6) from the main PCB.

2. Remove the entire PCB/Taliq display assembly from the rear cover by tilting opposite the

Battery-Check button (5).

3. Raise the locking tabs on the connectors (11, 12, and 13) to release the cable, on the auxiliary

PCB (26), and remove the three flex display circuits.

4. Separate the auxiliary PCB from the main PCB (27) by pulling the PCB headers apart at the base.

5. Remove the display assembly (18) from the main PCB by unsoldering the four tabs that are

physically bent around the main PCB. These tabs are bent to ensure contact with the ground

plane of the main PCB.

6. Using a long-nose plier, remove the display assembly by untwisting the four tabs (see Detail A

and B).

5.2.4 N-20P Disassembly Procedure

1. Remove the paper door (20) and any printer paper by firmly grasping the paper roll, and pulling

the roll outward from the printer.

2. See paragraphs 5.2.1 and 5.2.2, N-20 Disassembly Procedure, for removal of covers, PCBs, and

the display assembly.

5-4

Page 29

5.2.5 Disassembling the Printer/Flex Circuit Assembly

29

32

4

Disassembly Guide

7

37

28

24

Figure 5-4: Printer and Flex Circuit Installation

1. Remove the printer button retaining plate (37) by sliding it away from the case assembly.

2. Disconnect the two flex-circuit headers of the printer (29) from the connectors on the printer flex

circuit (28) by slowly pulling outward from side to side at alternating ends of the connectors.

3. Remove the printer button strip (7) from the printer flex-circuit.

4. Remove the printer flex-circuit insulator (24).

5. Remove printer hold-down bracket (4) from the back cover by removing the Phillips screw (32).

6. Press the printer hold-down bracket into the back cover and remove the printer.

5-5

Page 30

Page 31

6 SPARE PARTS

6.1 N-20/N-20P Spare Parts

6.1 N-20/N-20P Spare Parts

To order replacement parts, contact Mallinckrodt's Technical Services Department and order by part

number. Item numbers correspond to the callout numbers in the figures.

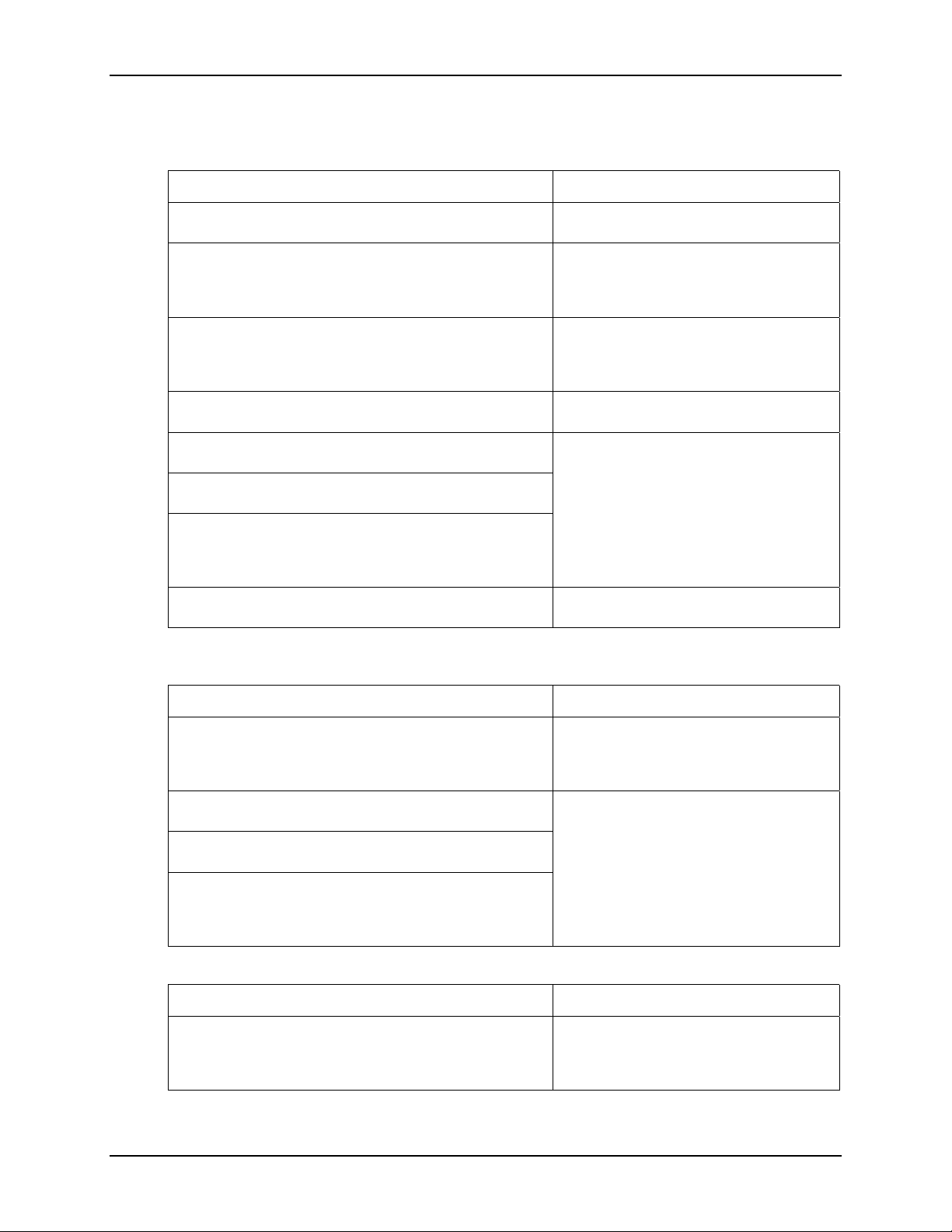

Item Designator Description P/N

1 SW1 Battery switch (auxiliary PCB) 630106

2 BT1 Battery holder (auxiliary PCB) 901582

3 BT1 Battery, lithium (auxiliary PCB) 640112

4 Bracket, printer, hold-down 023133

5 Button, battery-check 023301

6 S2 Button, measure 022948

7 Buttons, printer, strip 022947

9 Connector shield, DB-9 023467

10 P1 Connector, DB-9 463103

11 JP17, JP18 Connector, pin header 10x2, low profile (auxiliary PCB) 491244

12 JP5 Connector, ZIF, flex, 7-pin (auxiliary PCB) 491242

13 JP9 Connector, ZIF, flex, 22-pin (auxiliary PCB) 491250

14 JP2,3 Connector, ZIF, flex, 32-pin (auxiliary PCB) 491243

15 Cover, rear (non-printer model) 022929

16 Cover, front, with gasket assembly 022921

17 D8 Diode, photo, 8440 (main PCB) 591017

18 Display, Taliq, analog shield assembly 024466

19 Door, battery 022924

20 Door, paper. 022938

21 Door, printer 026338

22 F2 Fuse, micro, 1 amp (auxiliary PCB) 691236

23 F1 Fuse, micro, 1.5 amp (auxiliary PCB) 691239

24 Insulator, printer 026139

25 Nut, keps,SS, 4-40 851101

26 PCB, auxiliary 024472

27 PCB, main 024468

28 Printer flex circuit 024464

29 Printer 024462

30 Screw cap 023451

Button, measure (European version) 026386

Buttons, printer, strip (European version) 026387

Cover, rear (printer model) 026339

Display, Taliq, analog shield assembly (European version) 026765

6-1

Page 32

Spare Parts

31 Screw, captive 891324

32

33 Screw, plastite 871031

34 Sensor lock 022943

35 Sensor shroud 022944

36 Spacer 023452

37 Stiffener, printer button 023131

38

39 BZ1 Transducer, audio, piezo ceramic 691230

Item Designator Description P/N

Screw, Phillips, 4-40 × 1/4

Tape, foam (.88" × .38")

801025

023300

6-2

Page 33

7 PACKING FOR SHIPMENT

7.1 General Instructions

7.2 Repacking in Original Carton

7.3 Repacking in a Different Carton

Should you need to ship the N-20/N-20P monitor for any reason, follow the instructions in this

section.

7.1 General Instructions

Pack the monitor or printer carefully. Failure to follow the instructions in this section may result in

loss or damage not covered by the Mallinckrodt warranty. If the original shipping carton is not

available, use another suitable carton or call Mallinckrodt Technical Services to obtain a shipping

carton.

Prior to shipping the device, contact Mallinckrodt Technical Services for a returned goods

authorization (RGA) number. Mark the shipping carton and any shipping forms with the RGA

number.

7.2 Repacking in Original Carton

If available, use the original carton and packing materials. Pack the monitor or printer as follows:

Place the monitor, or printer, and, if necessary, accessory items in original packaging.

Place in shipping carton and seal carton with packing tape.

Label carton with shipping address, return address, and RGA number.

7.3 Repacking in a Different Carton

If the original carton is not available:

1. Place the monitor or printer in plastic bag.

2. Locate a corrugated cardboard shipping carton with at least 200 pounds per square inch (psi)

bursting strength.

3. Fill the bottom of the carton with at least 2 inches of packing material.

4. Place the bagged unit on the layer of packing material and fill the box completely with packing

material.

5. Seal the carton with packing tape.

6. Label carton with shipping address, return address, and RGA number.

7-1

Page 34

Page 35

8 SPECIFICATIONS

8.1 Readout

8.2 Controls

8.3 Operating Modes

8.4 Printer Output

8.5 N-20/N-20P Performance

8.6 Sensor Types

8.7 Electrical Specifications

8.8 Environmental Specifications

8.9 Physical Specifications

8.10 Quality Information

8.1 Readout

Display shows SpO

included are a Pulse Search and Low Battery indicator, and an electroluminescent backlight.

8.2 Controls

8.2.1 N-20

The Measure button switches the instrument on and off, and initiates the measurement cycle.

The Battery-Check button is used to check battery condition and switches beeper on and off.

8.2.2 N-20P

The Measure button switches the instrument on, initiates the measurement cycle, and switches

instrument off.

The Battery-Check button is used to check battery condition and switches beeper on and off.

button switches the printer on and off.

ON

sets display date and time.

D/D

ADV advances paper and increments time and date.

8.3 Operating Modes

8.3.1 Spot Check Mode

(saturation of arterial hemoglobin oxygen), pulse rate, and pulse amplitude; also

2

Pressing the instrument Measure button once for less than 2 seconds starts the spot check mode. Spot

check mode computes SpO

end of the measurement interval. If the printer is activated, the printout shows the displayed SpO

pulse rate.

8.3.2 Extended Mode

Extended mode is started by holding down the instrument Measure button for approximately 3

seconds, plus any time required to complete the power-on self-test. The N-20/N-20P displays updated

SpO2 and pulse rate with every pulse (after five valid pulses have been detected). The N-20/N-20P

remains active until 3 minutes after the sensor is removed, or until the instrument is turned off.

averaged over five valid pulses and displays SpO2 and pulse rate at the

2

and

2

8-1

Page 36

Specifications

For the N-20, a 2% or greater decrease in SpO2 is indicated by two brief, low-pitched tones.

The N-20P printout shows SpO2 and pulse rate at 30-second intervals. For the N-20P, a 2% or greater

decrease in SpO2 is indicated by two brief, low-pitched tones and an asterisk (*) on the printout. At

the end of the measurement period, a header and statistical summary values (minimum, maximum, and

mean of both pulse rate and oxygen saturation) are printed.

8.4 Printer Output

When activated by the printer

spot check mode), with space provided for writing in patient identification. The thermal paper

printout measures roughly 40 mm (1.6 in.) by 100 mm (4.0 in.) in size.

If the N-20P is in spot check mode and the printer is turned on any time during a measurement or after

a measurement is taken and before the N-20P powers down, the printer will catch up and print a

complete record of the measurements recorded up to the current moment.

8.5 N-20/N-20P Performance

8.5.1 Range

Saturation: 0–100%

Pulse Rate: 20–250 beats per minute (bpm) ± 1 standard deviation

8.5.2 SpO2 Accuracy

1

Adults: 70–100% ± 2 digits

Neonates: 70–100% ± 3 digits

Pulse Rate: 20 –250 bpm ± 3 digits

8.5.3 Response

In spot check mode, the measurement cycle (from button press to display of data) is five valid pulses.

button, the N-20P output shows date, time, SpO2, and pulse rate (in

ON

2

2

2

In extended mode, the instrument measures for a period of up to 30 minutes and continuously displays

updated SpO2 and pulse rate.

70-100%. This variation equals plus or minus one standard deviation (1SD), which encompasses 68% of the population.

All accuracy specifications are based on testing the subject monitor on healthy adult volunteers in induced hypoxia studies

across the specified range. Adult accuracy is determined with Oxisensor II D-25 sensor. Neonatal accuracy is determined

with Oxisensor II N-25 sensor.

8-2

1

Accuracies are expressed as plus or minus “X” digits (saturation percentage points) between saturations of

2

This variation equals one SD.

Page 37

8.6 Sensor Types

Specifications

Table 8-1: Sensors

Sensor Model Patient Size

Oxisensor

Oxibandoxygen transducer (reusable with disposable

nonsterile adhesive)

Durasensoroxygen transducer (reusable, nonsterile)

Nellcor reflectance oxygen transducer (reusable, nonsterile) RS-10 >40 kg

Dura-Ymultisite oxygen transducer (reusable, nonsterile)

For use with the Dura-Y sensor:

Ear clip (Reusable, nonsterile)

Pedi-Check pediatric spot-check clip (reusable,

nonsterile)

OxiCliqoxygen transducers (sterile, single-use only)

II oxygen transducers (sterile, single-use only)

N-25/N-25LF

I-20/I-20LF

D-20

D-25/D-25L

R-15

OXI-A/N

OXI-P/I

DS-100A >40 kg

D-YS

D-YSE

D-YSPD

P

N

I

A

<3 or >40 kg

3 to 20 kg

10 to 50 kg

>30 kg

>50 kg

<3 or >40 kg

3 to 40 kg

>1 kg

>30 kg

3 to 40 kg

10 to 50 kg

<3 or >40 kg

3 to 20 kg

>30 kg

8.7 Electrical Specifications

8.7.1 Battery

Type: four 1.5-V alkaline "C" cell batteries

Battery Capacity: typically 37 hours for N-20

typically 32 hours for N-20P

8.7.2 Instrument

Power Requirements: 4–6 VDC, supplied by battery only

Leakage Current: Meets applicable IEC- 601 and AAMI/ANSI standards;

the N-20/N-20P has no power or ground connections

Patient Isolation:No electrical connection to patient (inherently insulated)

8-3

Page 38

Specifications

8.8 Environmental Specifications

8.8.1 Operating Temperature

Instrument: 0 to 40 °C (32 to 104 °F)

8.8.2 Storage Temperature

-20 to 50 °C (4 to 122 °F)

Humidity: Any humidity/temperature combination without condensation

Altitude: 0 to 6200 meters (0 to 20,000 ft)

8.9 Physical Specifications

Physical specifications are based on product without the protective boot.

8.9.1 Weight (with batteries installed)

N-20: 0.6 kg (1.3 lb)

N-20P: 0.62 kg (1.4 lb)

8.9.2 Dimensions

N-20: 19.0 cm high × 7.6 cm wide × 5.08 cm deep

(7.5 in. × 3.0 in. × 2.0 in.)

N-20P: 19.0 cm high × 7.6 cm wide × 6.35 cm deep

(7.5 in. × 3.0 in. × 2.5 in.)

8.10 Qualifying Information

The Nellcor N-20/N-20P is calibrated to measure arterial hemoglobin oxygen saturation of functional

hemoglobin. The specified accuracy of this measurement is based on statistical analysis of arterial

blood samples as measured on an IL282 CO-Oximeter.

Indocyanine green, methylene blue, and other intravascular dyes, depending on concentration, may

interfere with the accuracy of data obtained from the instrument. Carboxyhemoglobin or other

dyshemoglobins may also interfere with the accuracy of the data if present in significant

concentration.

8-4

Page 39

9 TECHNICAL SUPPLEMENT

9.1 Overview

9.2 Functional versus Fractional Saturation

9.3 Measured versus Calculated Saturation

9.4 Circuit Analysis

9.5 Functional Overview

9.6 Definition of Terms

9.7 Overall Block Diagram

9.8 SpO

9.9 Digital Circuitry

9.10 Circuit Illustrations

9.1 Overview

Analog Circuit

2

The N-20/N-20P is based on the principles of spectrophotometry and optical plethysmography.

Optical plethysmography uses light absorption technology to reproduce wave forms produced by

pulsatile blood. The changes that occur in the absorption of light due to vascular bed changes are

reproduced by the pulse oximeter as plethysmographic wave form.

Spectrophotometry uses various wavelengths of light to qualitatively measure light absorption through

given substances. Many times each second, the N-20/N-20P passes red and infrared light into the

sensor site and determines absorption. The measurements, which are taken during the arterial pulse,

reflect absorption by arterial blood, nonpulsatile blood, and tissue. The measurements that are

obtained between arterial pulses reflect absorption by nonpulsatile blood and tissue.

By correcting "during pulse" absorption for "between pulse" absorption, the N-20/N-20P determines

red and infrared absorption by pulsatile arterial blood. Because oxyhemoglobin and deoxyhemoglobin

differ in red and infrared absorption, this corrected measurement can be used to determine the percent

of oxyhemoglobin in arterial blood: SpO

is the ratio of corrected absorption at each wavelength.

2

9.2 Functional versus Fractional Saturation

The N-20/N-20P measures functional saturation, that is, oxygenated hemoglobin expressed as a

percentage of the hemoglobin that is capable of transporting oxygen. It does not detect significant

levels of dyshemoglobins. In contrast, some instruments such as the IL282 Co-oximeter measure

fractional saturation, that is, oxygenated hemoglobin expressed as a percentage of all measured

hemoglobin, including dyshemoglobins.

Consequently, before comparing N-20/N-20P measurements with those obtained by an instrument that

measures fractional saturation, measurements must be converted as follows:

functional saturation =

100 - (% carboxyhemoglobin + %methemoglobin)

fractional saturation

9.3 Measured versus Calculated Saturation

When saturation is calculated from a blood gas measurement of the partial pressure of arterial oxygen

(PaO2), the calculated value may differ from the N-20/N-20P SpO2 measurement. This is because the

calculated saturation may not have been corrected for the effects of variables that can shift the

relationship between PaO2 and saturation.

x100

9-1

Page 40

Technical Supplement

Figure 9-1 illustrates the effect that variations in pH, temperature, partial pressure of carbon dioxide

(PCO2), and concentrations of 2,3-DPG and fetal hemoglobin may have on the oxyhemoglobin

dissociation curve.

100

Saturation (%)

50

0

pH

Temperature

PCO

2

2,3-DPG

Fetal Hb

PO2(mmHg)

pH

Temperature

PCO

2

2,3-DPG

10050

Figure 9-1: Oxyhemoglobin Dissociation Curve

9.4 Circuit Analysis

The following paragraphs discuss the circuits of the N-20/N-20P.

9.5 Functional Overview

This section provides a detailed explanation of N-20/N-20P operation using block diagrams and

circuit schematics.

The relationship between these components and their interconnection is illustrated in the overall block

diagram (Figure 9-2). The main component circuitry has been divided into the following subsections:

9-2

Page 41

Technical Supplement

9.6 SpO

Patient

sensor

Batteries

4-6 VDC

Main PCB

2

analog

SpO

Microprocessor

Memory

Display control

Sensors: temperature

ambient light

battery voltage

20-pin headers

Auxiliary PCB

time

Measure

button

Check

battery

button

PROM

Power supply

Printer interface

Display control

Audio beeper

Realclock

Flex

connectors

Figure 9-2: Overall Block Diagram

Analog Circuitry Block Diagram (Figure 9-3)

2

Display

backlight

Printer

flex circuit

Printer

N-20P only

Analog circuitry has high signal sensitivity and reduced susceptibility to noise. Its design allows for a

wide range of input signal levels and a broad range of pulsatile modulation. The SpO

analog circuit

2

(Figure 9-3) consists of four subsections:

1. Sensor output/LED control, where the CPU controls the gain of both LEDs so that signals

received at the input amplifier are in its acceptable dynamic range

2. Input signal conditioning, where sensor output current is converted to voltage

3. Signal gain, where the separated LED signals are amplified so their current levels are within the

A/D converter's acceptable range; and

4. AC ranging, where DC offset is eliminated from each LED signal.

Patient

sensor

LEDs

Input signal

conditioning

photocurrent

to voltage

conversion

demutiplexed

to 2 channels

Main PCB

LED drivers

(red & IR)

Main PCB

Signal gain

variable gain,

filtered for

each LED

channel

Main PCB

Control

AC Ranging

offset

substraction;

additional gain

and filtering

Main PCB

Microprocessor

Main PCB

To digital section

Figure 9-3: SpO2 Analog Circuitry Block Diagram

9-3

Page 42

Technical Supplement

9.6.1 Digital Circuitry Block Diagram (Figure 9-4)

Figure 9-4

shows the N-20/N-20P hardware and circuits, which include the CPU and system memory,

the power supply and power control circuitry, user controls, display and ambient light sensors, audio

output, thermal printer (N-20P only) and ambient temperature sensor, and the real-time clock.

Measure

Check Battery

Power supply

To analog section

& control

CPU

Main PCB

Memory

&

software

N-20/N-20P Control buttons

AUX

PCB

Real-time

clock

AUX

PCB

Ambient

light sensor

Ambient

temp. sensor

Figure 9-4: Digital Circuitry Block Diagram

9.6.2 Power Supply Block Diagram (Figure 9-5)

Main

PCB

Main

PCB

AUX PCB

Display

drivers

Audio beeper

Printer

ON ADV D/D

Display

AUX PCB

(N-20 only)

Printer Control button

Power supply circuitry (Figure 9-5) is located on the auxiliary PCB and consists of four subsections:

1. Four "C" size batteries that provide 4-6 VDC

2. Power control circuitry that senses a press of the Measure button and switches power on

3. Power shutoff circuit that controls power to all circuits except the power control circuit

4. Power supply circuits include a regulated power supply at 5 VDC, unregulated power supplies of

-5 VDC, 10 VDC, and 12 VDC, and a high voltage power supply of 70 VDC.

Measure

Disposable

batteries

4-6 VDC

button