Page 1

i

LP6

Plus,

LP10

and

LP20

Service

Manual

5.

Install

angle

of

two

brackets.

the

bracket.

new

8-32 x 3/8"

The

ends

of

hex

the

set

screws

screws

should

into

be

flush

each

with

Right

of

the

piston

the

inside

End

Steel

piston

(flat

toward

bracket)

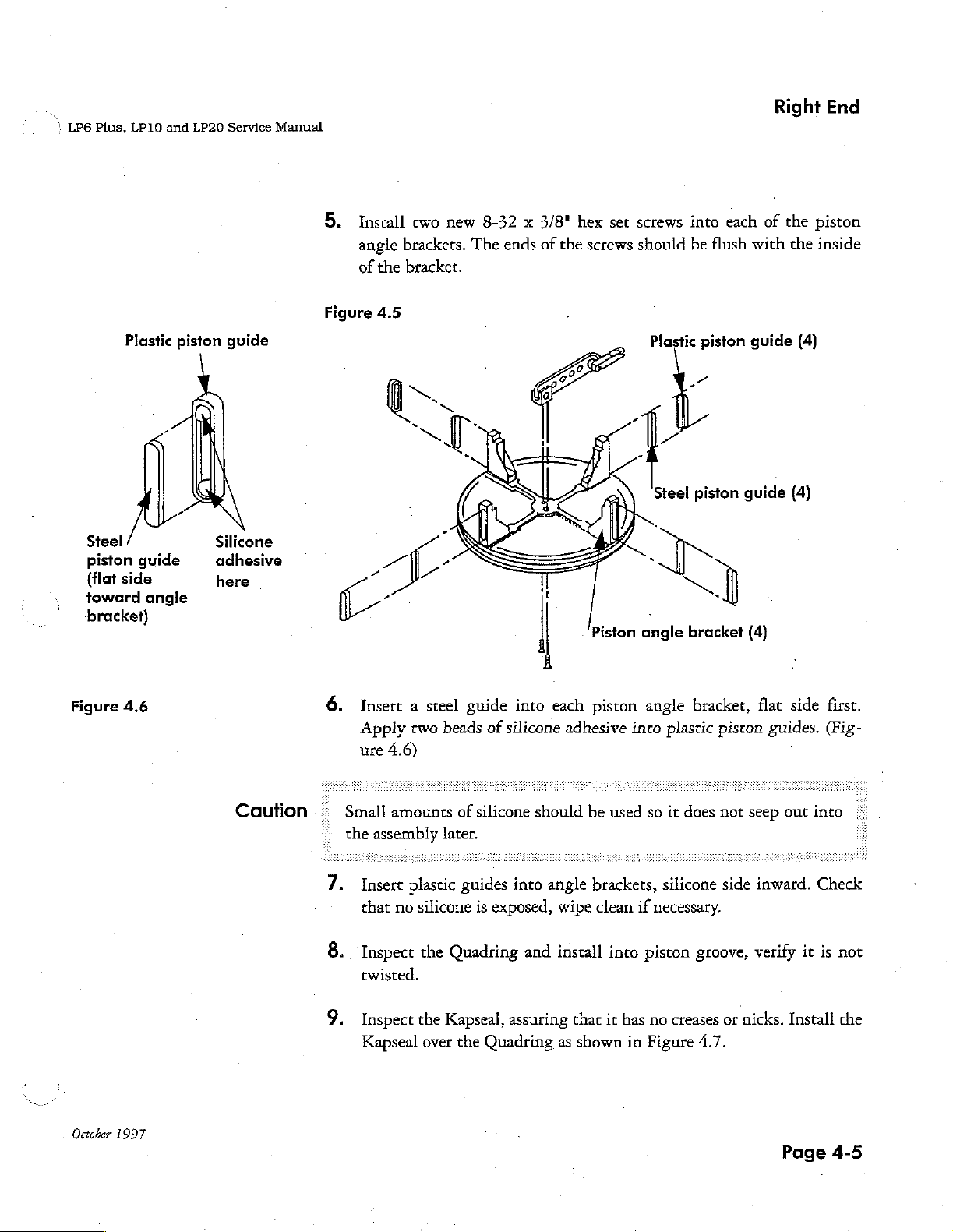

Figure

Plastic

guide

side

angle

4.6

piston

Silicone

adhesive

here

guide

Figure

6.

4.5

Insert a steel

Apply

ure

4.6)

two

guide

beads

into

of

silicone

each

adhesive

Piston

piston

into

Plastic

~

:

angle

angle

plastic

piston

~

=.

bracket

bracket,

piston

guide

(4)

flat

guides.

(4)

side

first.

(Fig-

October

1997

Caution

=

-

7.

8.

9.

Small

the

amounts

assembly

Insert

that

Inspect

plastic

no

silicone

the

twisted.

Inspect

Kapseal

the

over

of

silicone

should

later.

guides

Quadring

into

is

exposed,

and

angle

wipe

install

Kapseal, assuring

the

Quadring

as

be

used

brackets,

clean

into

that

it

has

shown

so

it

silicone

if

necessary.

piston

no

creases

in

Figure

does

not

side

groove,

or

4.7.

seep

out

inward.

verify

nicks.

Install

Page

into

Check

it

is

not

the

4-5

Page 2

Repairs

LP6

Plus,

LP10

and

LP20

Service

Manual

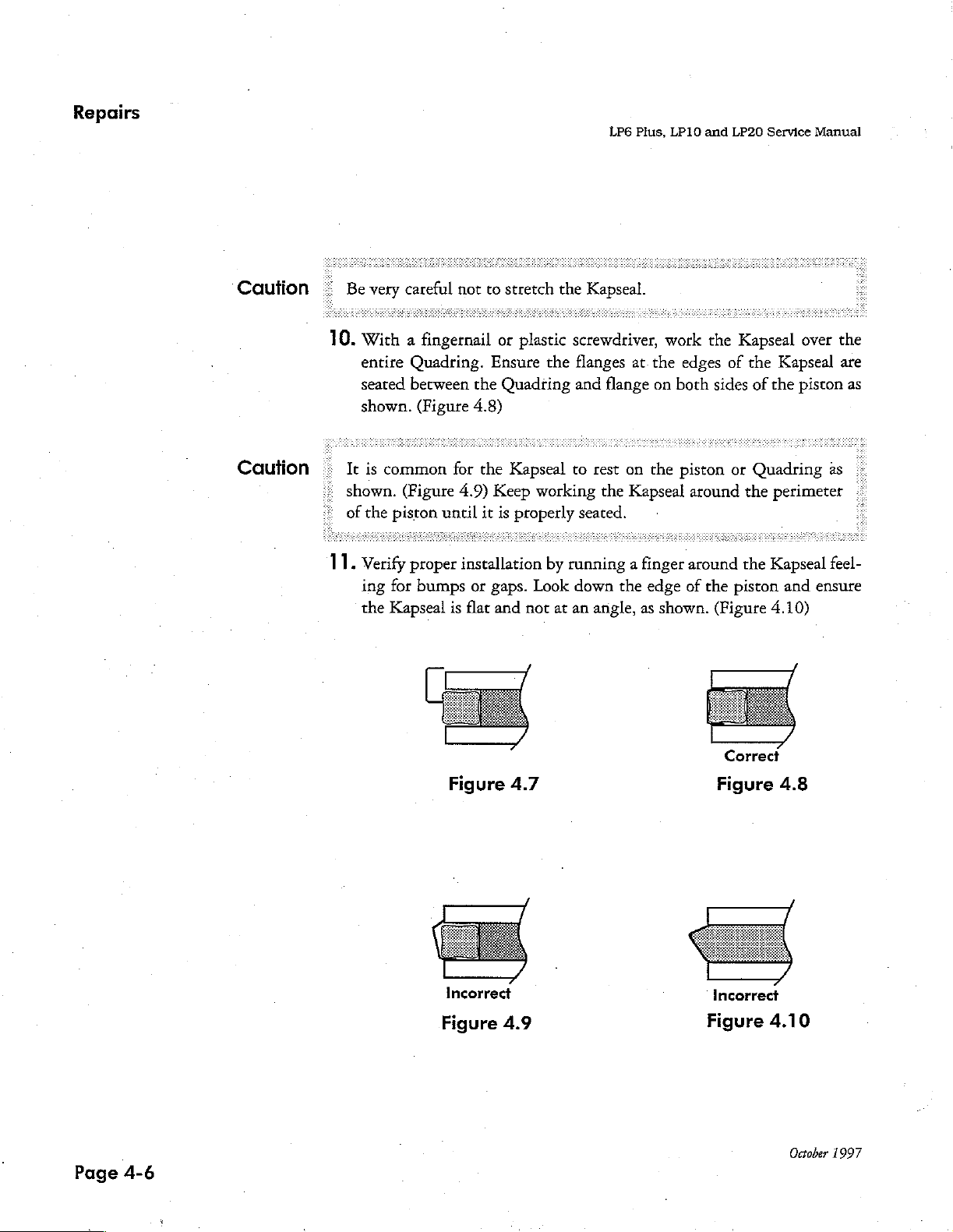

Caution

Caution

©:

Be

very

careful

10.

With a fingernail

|:

It

»

shown.

©

of

entire

seated

shown.

is

common

the

piston

Quadring.

between

(Figure

(Figure

11.

Verify

ing

the

proper

for

bumps

Kapseal

not

to

stretch

or

plastic

Ensure

the

Quadting

4.8)

for

the

Kapseal

4.9)

Keep

until

it

is

properly

installation

or

gaps.

is

flat

and

the

Kapseal.

screwdriver,

the

flanges

and

to

rest

working

the

seated.

by

running a finger

Look

down

not

at

an

angle,

at.the

flange

on

on

the

Kapseal

the

edge

as

work

edges

both

piston

around

around

of

the

shown.

the

Kapseal

of

the

sides

of

or

Quadring

the

the

piston

(Figure

Correct

over

the

Kapseal

the

piston

as

perimeter

Kapseal

4.10)

and

feel-

ensure

are

as

©

..

|

Page

4-6

Figure

Incorrect

Figure

4.7

4.9

Figure

Incorrect

Figure

4.8

4.10

October

1997

Page 3

“\

LP6

Plus,

LP10

and

LP20

Service

Manual

Right

End

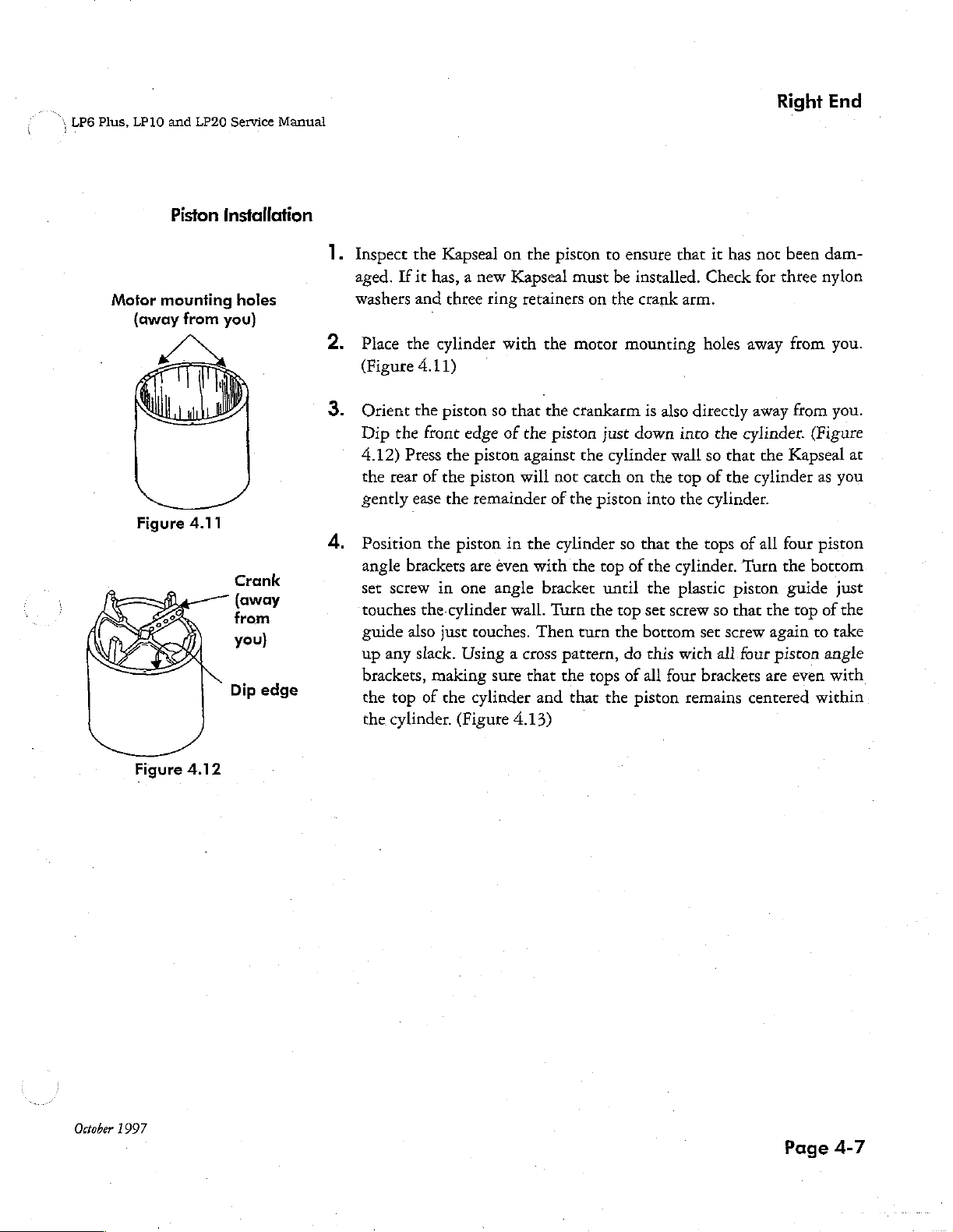

Motor

{away

Figure

Piston

mounting

from

4.11

Installation

holes

you)

Crank

(away

from

you)

Dip

edge

.

İnspect

aged.

washers

Place

(Figure

Orient

Dip

the

4.12)

the

rear

gently

Position

angle

set

screw

touches

guide

up

any

brackets,

the

top

the

cylinder.

the

Kapseal

If

it

has, a new

and

three

the

cylinder

4.11)

the

piston

front

edge

Press

the

piston

of

the

piston

ease

the

remainder

the

piston

brackets

in

are

one

the-cylinder

also

just

touches.

slack.

Using a cross

making

of

the

cylinder

(Figure

on

the

Kapseal

ring

retainers

with

the

so

that

the

of

the

against

will

in

the

even

with

angle

bracket

wall.

Turn

Then

sure that

and

4.13)

piston

piston

not

of

cylinder

to

must

on

motor

crankarm

just

the

cylinder

catch

the

piston

the

top

until

the

turn

pattern,

the

tops

that

the

ensure

be

installed.

the

crank

mounting

is

also

down

on

the

into

so

that

of

the

the

top

set

the

bottom

do

this

of

all

four

piston

that

it

has

Check

arm.

holes

directly

into

the

wall

so

that

top

of

the

the

cylinder.

the

tops

cylinder.

plastic

screw

with

so

set

all

piston

that

screw

brackets

remains

not

been

for

three

away

from

away

from

cylinder.

the

cylinder

of

all

Turn

four

centered

Kapseal

four

the

guide

the

top

again

piston

are

even

(Figure

bottom

dam-

nylon

you.

you.

ar

as

you

piston

just

of

the

to

take

angle

with

within

October

Figure

1997

4.12

Page

4-7

Page 4

Repairs

LP6

Plus,

LP10

and

LP20

Service

Manual

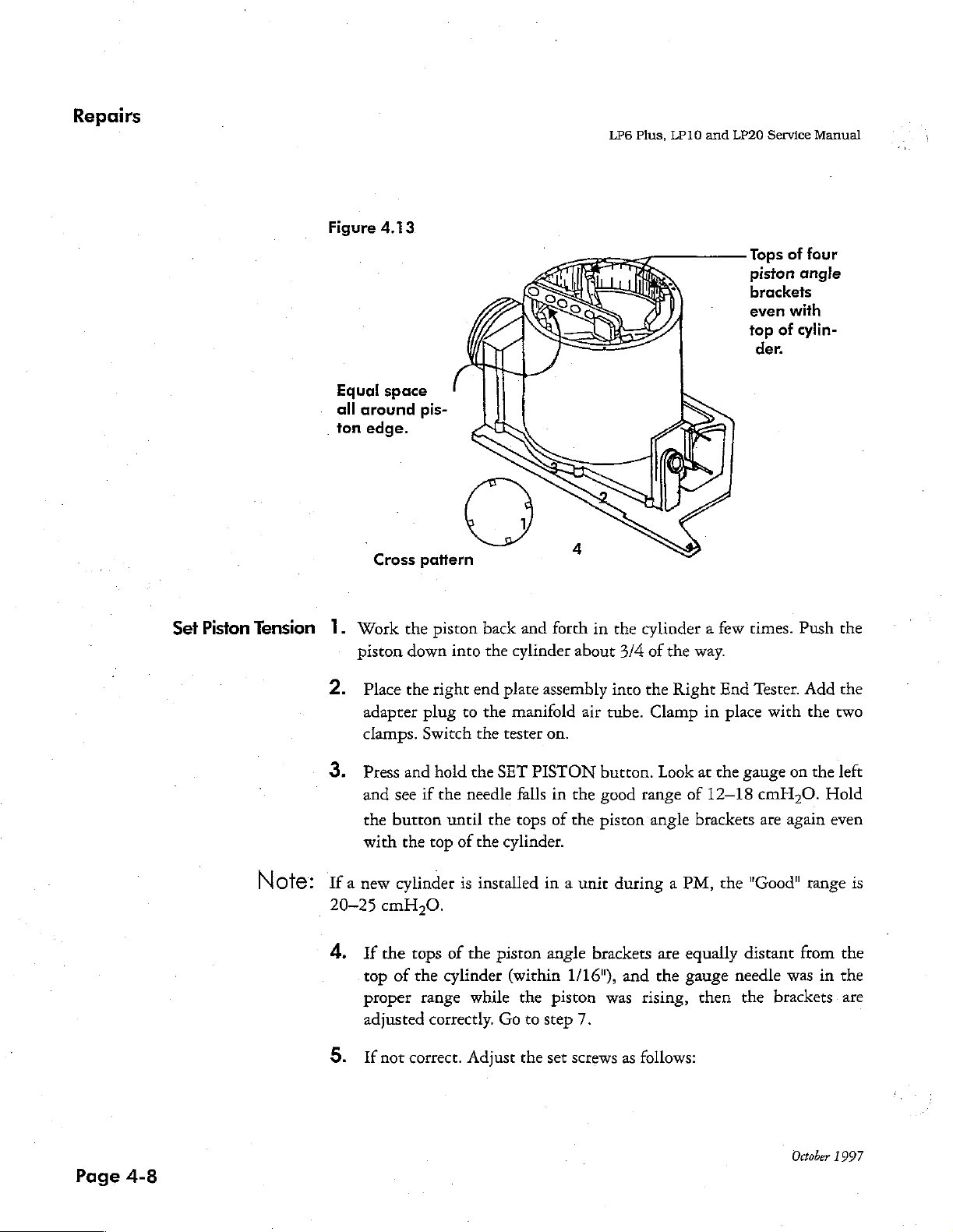

Set

Piston

Tension

Figure

Equal

all

around

ton

edge.

1.

Work

piston

4.13

space

Cross

the

down

Tops

of

four

piston

brackets

even

top

pis-

of

der.

angle

with

cylin-

pattern

piston

into

back

the

cylinder

and

forth

in

about

the

cylinder a few

3/4

of

the

way.

times.

Push

the

Note:

2.

Place

adapter

clamps.

Press

and

the

with

Ifa

new

20-25

4.

If

top

proper

adjusted

If

the

plug

Switch

and

see

if

button

the

top

cylinder

cmH,0.

the

tops

of

the

range while

correctly.

not

correct.

right

end

to

the

the

hold

the

the

needle

until

of

the

is

installed

of

the

cylinder

Adjust

plate

assembly

manifold

tester

on.

SET

PISTON

falls

the

tops

cylinder.

in a unit

piston

Go

angle

(within

the

to

step

the

air

in

the

of

the

1/16"),

piston

7.

set

screws

into

the

tube.

Clamp

button.

good

piston

brackets

was

Look

range

angle

during a PM,

are

and

the

rising,

as

follows:

Right

in

at

of

End

the

12-18

brackets

the

equally

gauge

then

Tester.

place

gauge

cmH,O.

are

"Good"

distant

needle

the

Add

with

the

on

the

Hold

again

range

from

was

in

brackets.

the

two

left

even

is

the

the

are

Page

4-8

October

1997

Page 5

Right

:

LP6

Plus,

LP10

and

LP20

Service

Manual

End

Note:

]

If

the

top

bracket

bracket

a.

b.

e.

set

screw

will

be

forced a little

to

ride a little

For

brackets

Verify

For

Verify

After

to

If

by

an

adjust

proper

After

to

bottom

brackets

bottom

adjustments

re-test

the

tension

the

gauge)

equal

screws

range

adjustments

re-test

is a little

tighter

higher.

lower.

that

are

too

set

screw

that

are

too

set

screw

are

made,

the

piston

amount

of

the

was

tension.

piston

outside

in

all

counter-clockwise

the

adjust

piston

screws

are

made,

tension.

than

The

high,

is

still

low,

is

still

return

against

the

of

the

clockwise

return

the

reverse

loosen

snug

tighten

snug

the

but

the

but

to

the

cylinder

proper

range,

brackets.

to

lower

ro

to

bottom

is

true

top

not

overly

top

not

overly

the

beginning

adjust

If

above

pressure.

raise

pressure.

the

beginning

screw

to

cause

set

screw

set

screw

wall

that

an

slightly.

tight.

slightly.

tight.

of

this test

(as

measured

all

set

proper

If

of

this

angle

angle

screws

range

below

test

6.

7.

Repeat

Check

steps

that

as

necessary

the

piston

to

obtain

is

centered

proper

in

the

leveling

cylinder.

and

tension.

October

1997

Page

4-9

Page 6

Repairs

LP6

Plus,

LP10

and

LP20

Service

Manual

System

Leak

Test

1.

Press

the

right

is

depressed.

is

released.

Press

the

manifold.

Remove

Remove

Apply a drop

bly

such

Push

Inspect

a.

b.

and

hold

side

and

the

the

that

the

piston

the

The

solenoid

All

three

erly,

and

the

must

Pressure

hold

the

assembly

air

tube

of

Loctite

the

about

Manifold

is

pieces

no

kinks

LEAK

stay

in

may

TEST

the

drop

VENT

from

adapter

242

Loctite

1/2

way

Assembly

securely

of

1/4"

are

present.

button.

GOOD

very

button

the

Right

plug.

on

each

flows

around

down

and

mounted.

internal

range

slowly

to

release

End

set

screw

the

into

verify

tubing

The

needle

when

when

the

Tester.

and

threads,

the

cylinder.

that:

are

of

the

the

leak

LEAK

TEST

pressure

tilt

the

wipe

present,

seated

gauge

test

button

button

from

inside

subassem-

off

excess.

prop-

on

Page

4-10

C.

Patient

secure,

Pressure

and

clean.

and

Exhalation

Valve

tubes

appear

straight,

October

1997

Page 7

i:

\LP6

Plus,

LP10

and

LP20

Service

Manual

Right

End

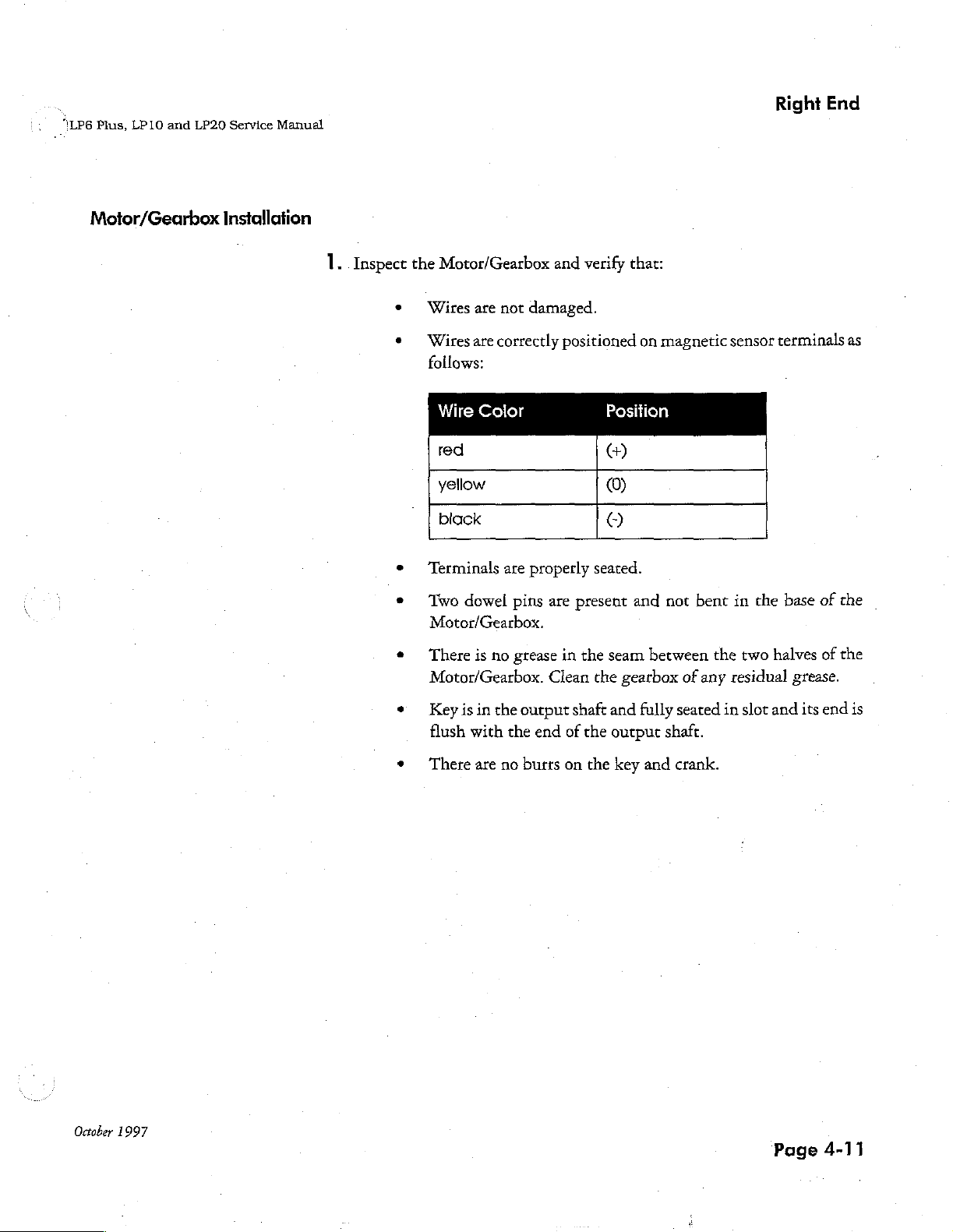

Motor/Gearbox

Installation

1.

Inspect

the

Motor/Gearbox

Wires

Wires

are

not

are

correctly

follows:

Wire

Color

red

yellow

black

Terminals

Two

Motor/Gearbox.

There

Motor/Gearbox.

dowel

is

no

are

and

damaged.

properly

pins

are

grease

Clean

positioned

present and

in

verify

Position

(+)

(0)

O

seated.

the

seam

the

gearbox

that:

on

magnetic

not

between

bent

of

sensor

in

the

any

residual

the

two

terminals

base

of

halves

of

grease.

as

the

the

|

October

1997

Key

is

flush

There

in

the

with

are

output

the

no

burrs

end

shaft

of

the

on

the

and

fully

output

key and

seated

shaft.

crank.

in

slot

and

its

Page

end

4-11

is

Page 8

Repairs

LP6

Plus,

LP10

and

LP20

Service

Manual

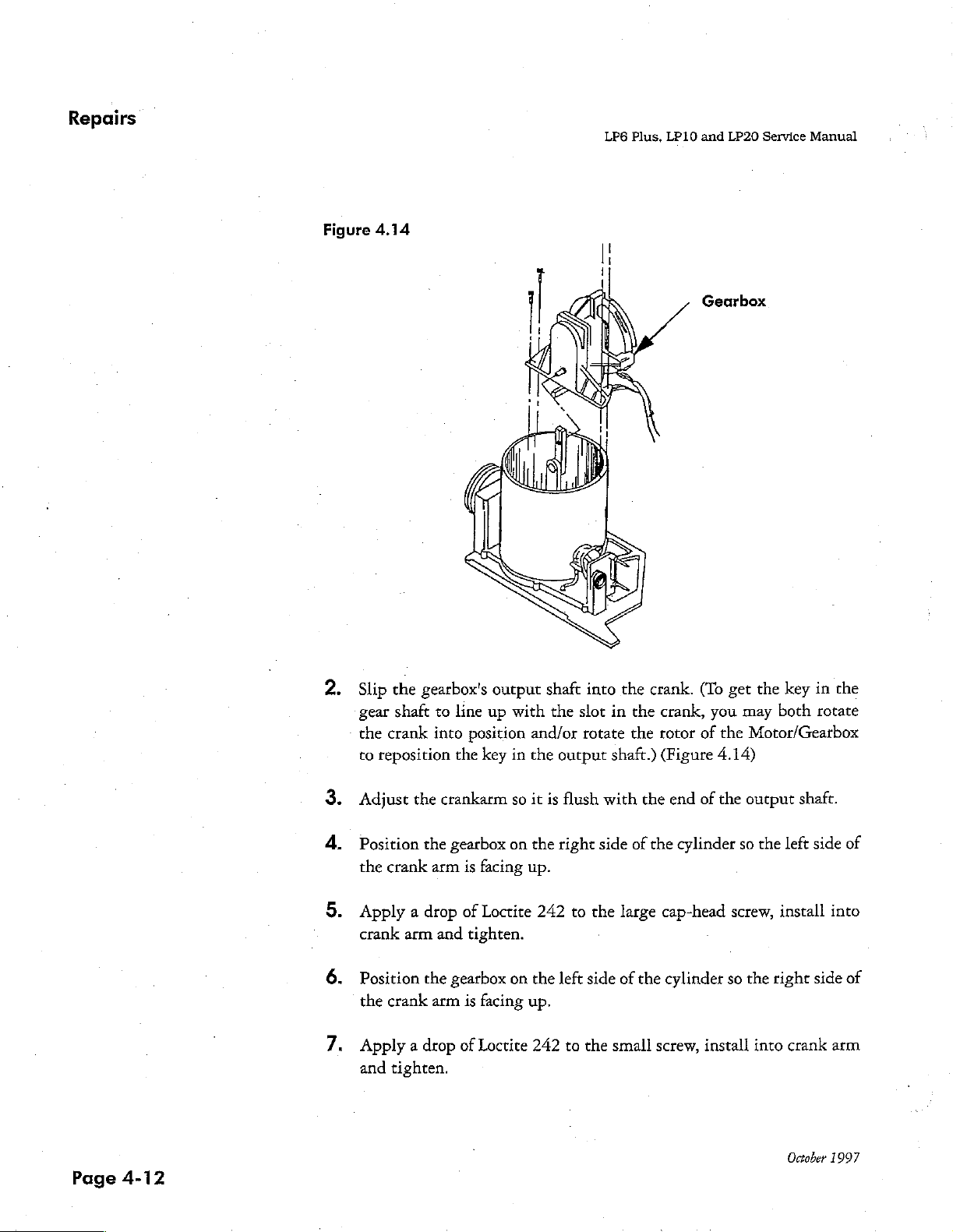

Figure

4.14

Gearbox

Slip

the

gearbox's

gear

shaft

to

the

crank

into

to

reposition

Adjust

Position

the

Apply a drop

crank

Position

the

Apply a drop

and

the

crankarm

the

crank

arm

arm

and

the

crank

arm

tighten.

gearbox

gearbox

output

line

up

position

the

key

is

facing

of

Loctite

tighten.

is

facing

of

Loctite

with

and/or

in

the

so

it

on

the

up.

on

the

up.

242

shaft

the

output

is

flush

right

242

left

to

into the

slot

in

rotate

shaft.)

with

side

to

the

É

side

the

small

crank.

the

the

the

of

the

large

of

the

screw,

(To get

crank,

rotor

(Figure

cap-head

you

of

the

4.14)

end

of

the

cylinder

cylinder

install

the

key

may

both

Motor/Gearbox

output

so

screw,

so

the

the

left

install

right

into

shaft.

side

side

crank

in

the

rotate

of

into

of

arm

Page

4-12

October

1997

Page 9

"i

LP6

Plus,

LP10

and

LP20

Service

Manual

Right

End

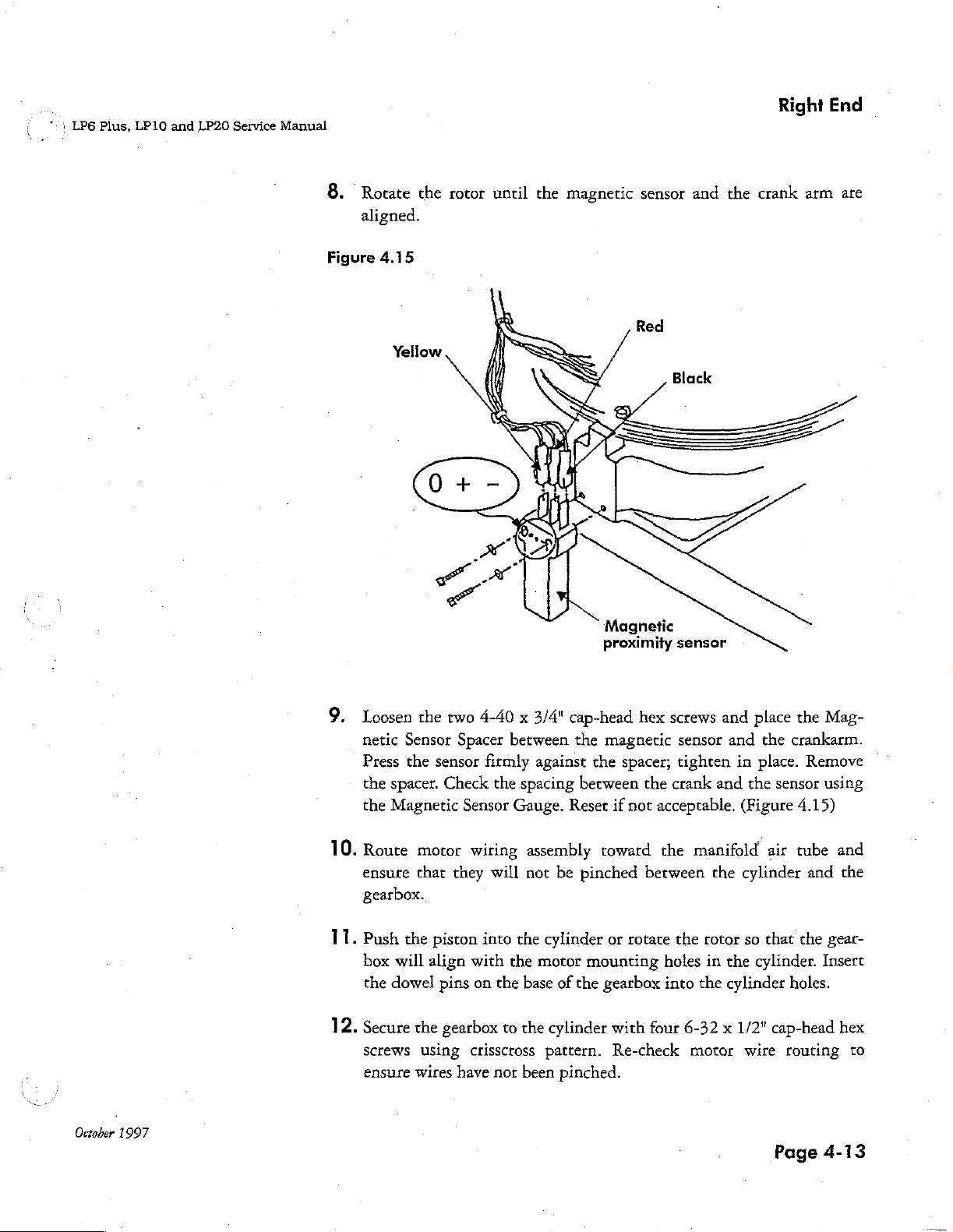

Rotate

8.

aligned.

Figure

the

rotor until

4.15

the

magnetic

sensor

and

the

crank

arm

are

Magnetic

proximity

sensor

October

1997

Loosen

netic

Press

the

spacer.

the

Magnetic

10.

Route motor

ensure

gearbox.

11.

Push

box

the

dowel

12.

Secure

Screws

ensure

the

Sensor

the

that

the

will

align

the

using

wires

two

Spacer

sensor

Check

Sensor

wiring

they

piston

with

pins

on

gearbox

crissctoss

have

4-40 x 3/4"

between

firmly

into

the

spacing

Gauge.

will

the

the

the

base

to

the

nor

been

against

assembly

not

be

cylinder

motor

of

cylinder

pattern.

pinched.

cap-head

the

magnetic

the

spacer;

between

Reset

if

not

toward

pinched

or

rotate

mounting

the

gearbox

with

Re-check

hex

screws

the

crank

acceptable. (Figure

the

between

holes

into the

four

and

sensor

tighten

the

and

in

and

the

manifold

the

cylinder

rotor

so

in

the

cylinder

6-32 x 1/2"

motor

wire

place

place.

cylinder.

the

the

crankarm.

Remove

sensor

4.15)

air

tube

and

that

the

holes.

cap-head

routing

Page

Mag-

using

and

the

gear-

Insert

hex

to

4-13

Page 10

Repairs

LP6

Plus,

LP10

and

LP20

Service

Manual

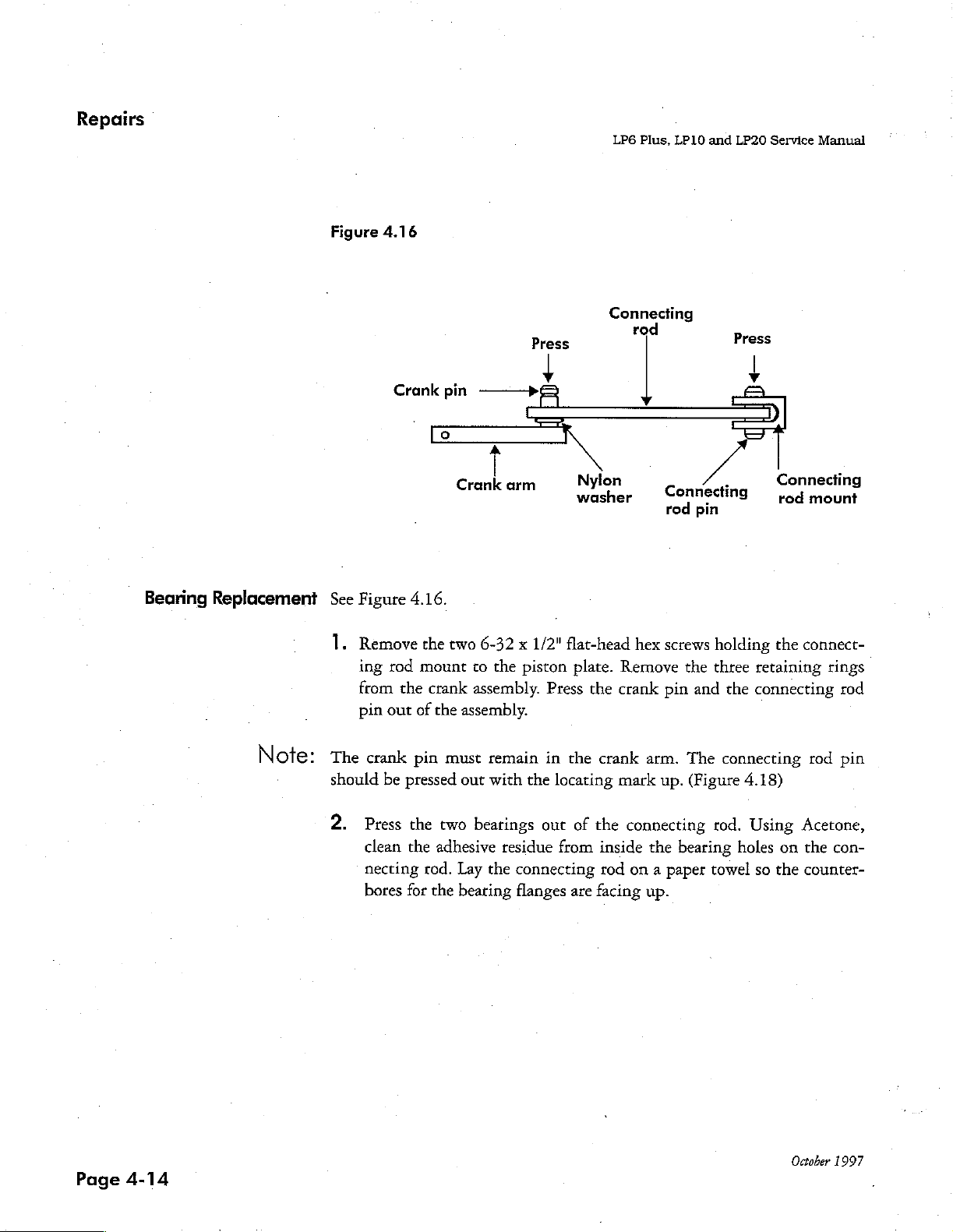

Bearing

Replacement

Figure

See

Figure

1.

Remove

ing

from

pin

4.16

Crank

rod

the

out

pin

4.16.

the

mount

crank

of

the

——>&

Crank

two

arm

6-32 x 1/2"

to

the

assembly.

assembly.

Press

+

piston

Press

Connecting

rod

Nylon

washer

flat-head

plate.

the

hex

Remove

crank

Connecting

rod

pin

screws

pin

the

and

holding

three

the

y

Connecting

rod

mount

the

connect-

retaining

connecting

rings

rod

Page

4-14

Note:

The

crank

should

2.

Press

clean

necting

bores

pin

be

pressed

the

the

for

must

out

two

bearings

adhesive

tod.

Lay

the

bearing

remain

with

the

out

residue

the

connecting

flanges

in

the

crank

locating

of

the

from

inside

rod

are

facing

arm.

The

mark

up.

(Figure

connecting

the

bearing

on a paper

up.

connecting

4.18)

rod.

Using

holes

towel

so

rod

Acetone,

on

the

the

counter-

October

pin

con-

1997

Page 11

LP6

Plus,

LP10

and

LP20

Service

Manual

Right

End

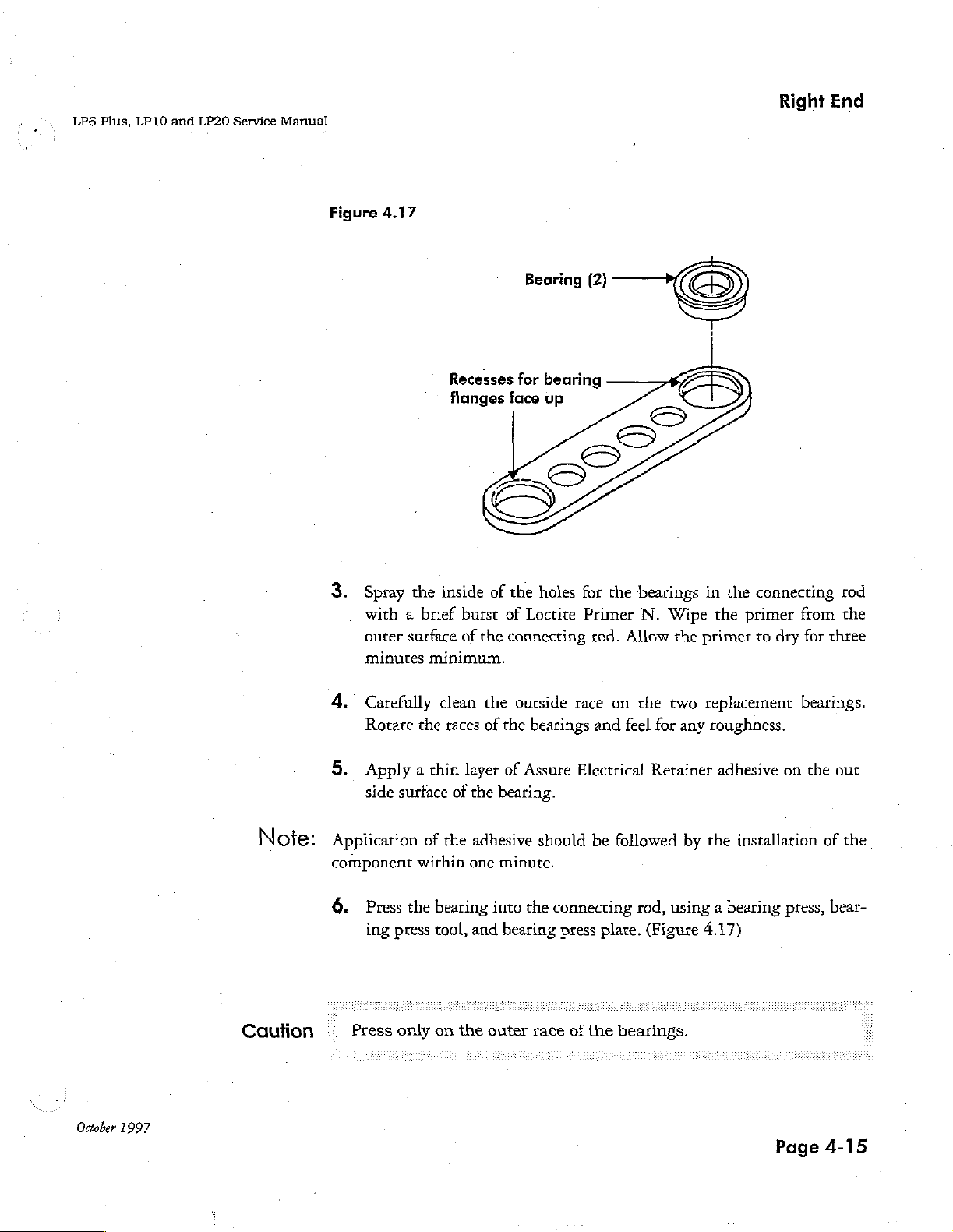

Figure

3.

4.17

Spray

with a brief

outer

minutes

Recesses

flanges

the

inside

burst

surface

of

minimum.

for

face

of

the

of

Loctite

the

connecting

earing

bearing

up

holes

for

the

Primer

rod.

Allow

ο

bearings

N.

Wipe

the

primer

in

the

the

connecting

primer

to

dry

from

for

three

rod

the

October

1997

Note:

Caution

4.

Carefully

Rotate

5.

Apply a chin

side

Application

component

6.

Press

ing

Press

the

surface

within

the

press

only

clean

races

layer

of

the

of

the

adhesive

one

bearing

tool,

and

on

the

the

outside

of

the

bearings

of

Assure

bearing.

minute.

into

the

bearing

outer

race

race

on the

and

Electrical

should

be

connecting

press

plate.

of

the

two

feel

for

any

Retainer

followed

rod,

bearings.

by

using a bearing

(Figure

replacement

roughness.

adhesive

the

on

installation

press,

4.17)

Page

bearings.

the

out-

of

the

bear-

4-15

Page 12

Repairs

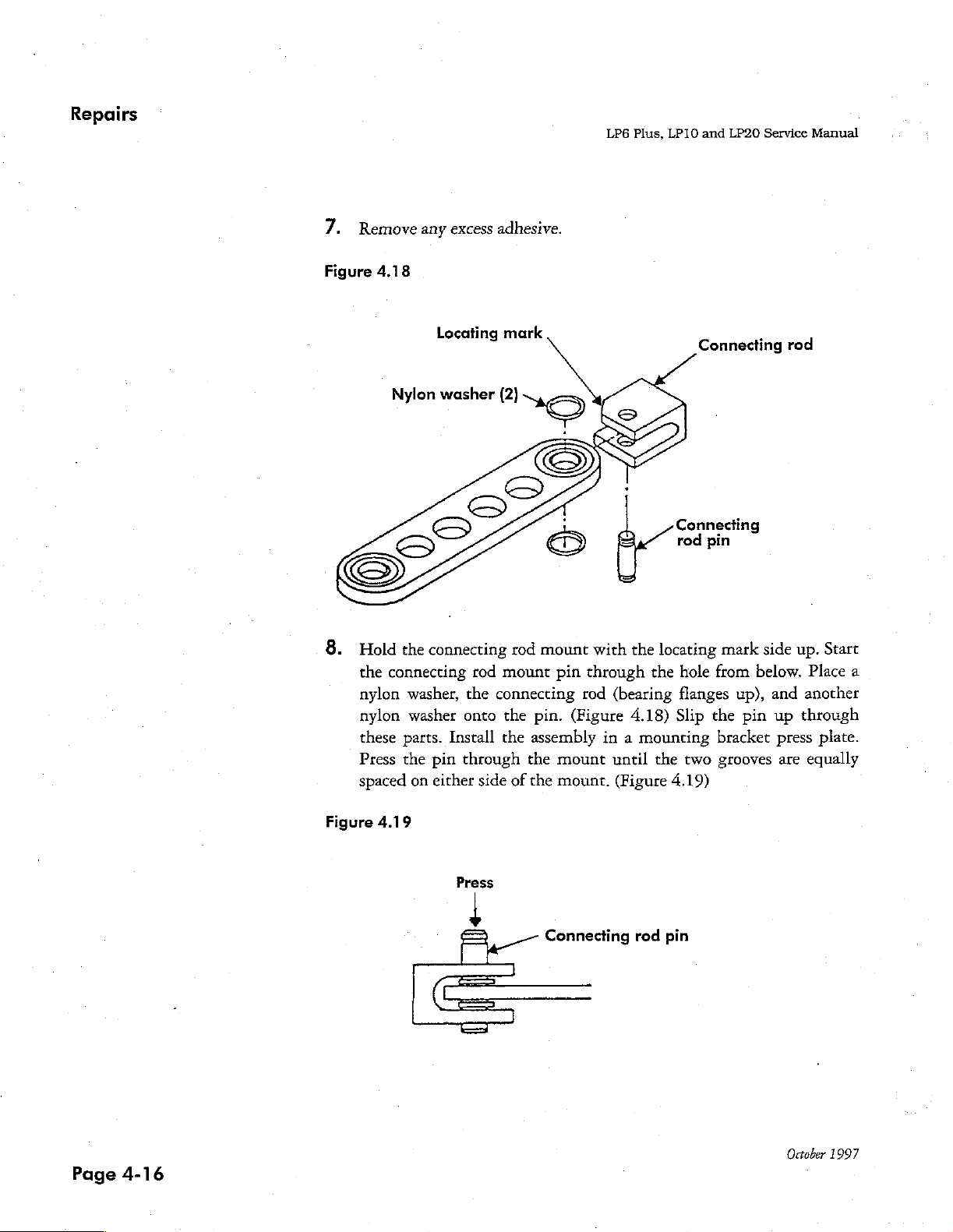

7.

Remove

any

excess

adhesive.

LP6

Plus,

LP10

and

LP20

Service

Manual

Figure

4.18

Nylon

Locating

washer

mark

(2)

8.

Hold

the

connecting

the

connecting

nylon

nylon

these

Press

spaced

washer,

washer

parts.

the

on

rod

the

onto

Install

pin

through

either

mount

connecting

the

the

side

rod

mount

pin.

assembly

the

of

the

with

pin

through

rod

(Figure

mount

mount.

Connecting

Connecting

rod

the

locating

the

hole

(bearing

4.18)

in a mounting

until

(Figure

flanges

Slip

the

two

4.19)

pin

mark

from

up),

the

pin

bracket

grooves

rod

side

up.

below.

and

up

through

press

are

Start

Place

a

another

plate.

equally

Page

4-16

Figure

4.19

Press

Connecting

red

pin

October

1997

Page 13

7

LP6

Plus,

LP10

and

LP20

Service

Manual

Right

End

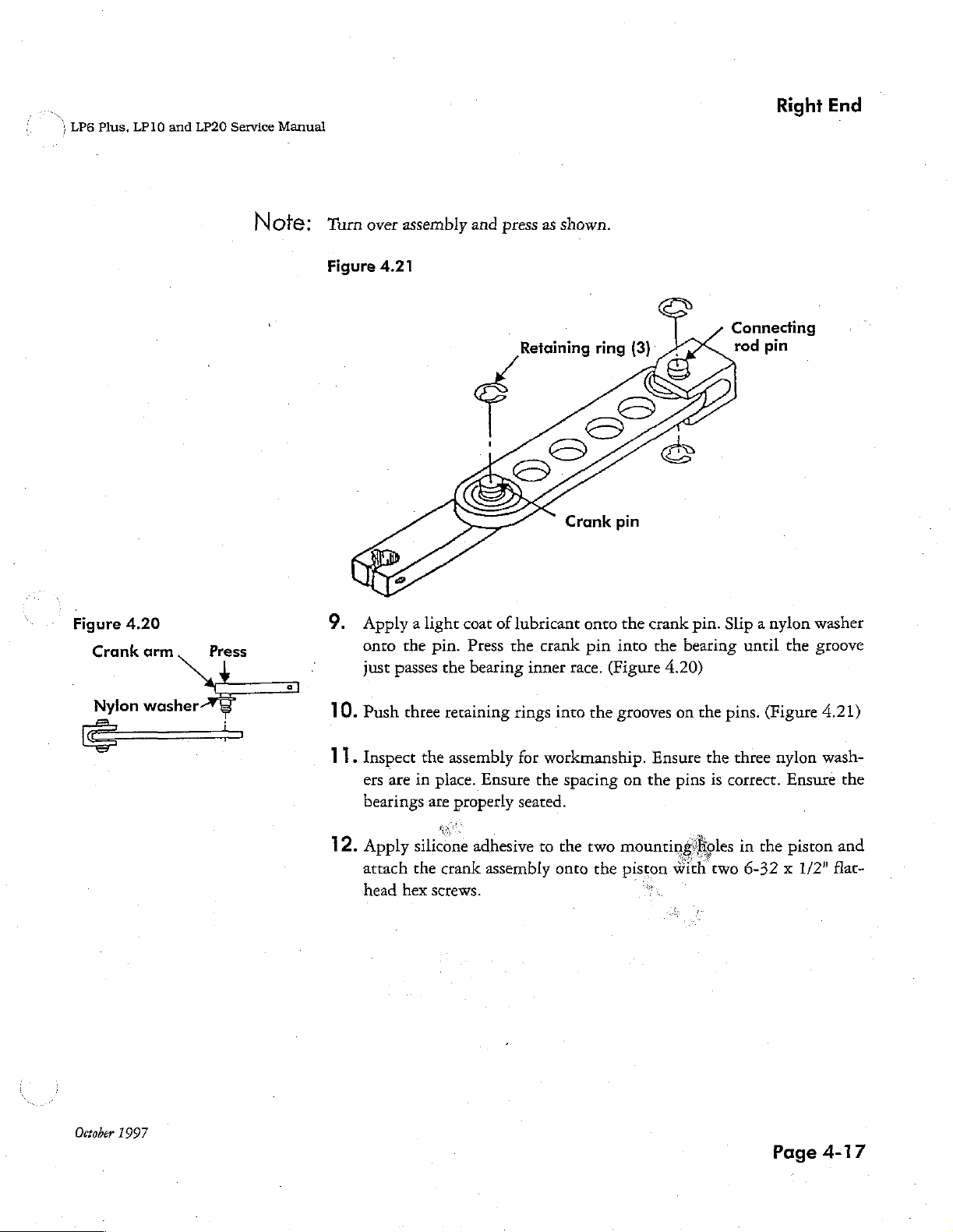

Figure

Crank

4.20

arm

Note:

Turn

over

assembly

Figure

4.21

9.

Apply a light coat

onto

the

pin.

just

passes

the

and

press

of

lubricant

Press

the

bearing

as

shown.

Crank

crank

inner

onto

pin

race.

(Figure

pin

the

into

crank

pin. Slip a nylon

the

bearing

4.20)

Connecting

rod

pin

until

the

washer

groove

Nylon

October

1997

washer

10

11.

12.

.

Push

Inspect

Apply

attach

three

the

ers

are

in

bearings

silicone

the

head

hex

retaining

assembly

place.

are

screws.

Ensure

properly

adhesive

crank

assembly

rings

into the

for

workmanship.

the

spacing

seated.

to

the

onto

two

mountin

the

grooves

Ensure

on

the

piston

로

on

the

pins

Holes

with

pins.

the

three

is

correct.

in

two

6-32 x 1/2”

(Figure

nylon

Ensure

the

piston

Page

4.21)

wash-

the

and

flat-

4-17

Page 14

Repairs

:

LP6

Plus,

LP10

and

LP20

Service

Manual

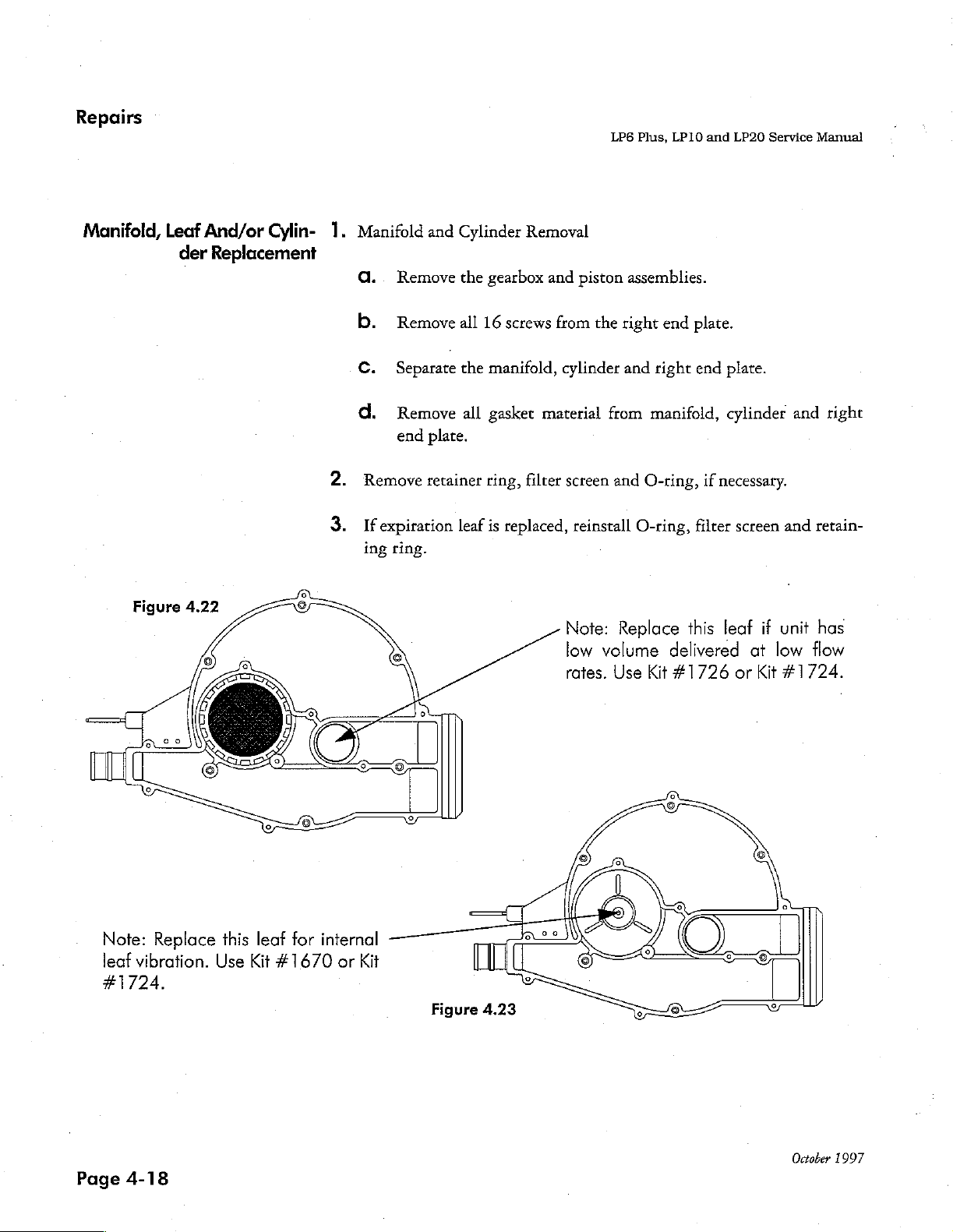

Manifold,

Leaf

And/or

der

Replacement

Cylin-

1.

Manifold

a.

b.

9

a

2.

Remove

3.

If

ing

and

Remove

Remove

Separate

Remove

end

plate.

retainer

expiration

ring.

Cylinder

the

all

the

all

leaf

Removal

gearbox

16

screws

manifold,

gasket

ring,

filter

is

replaced,

and

piston

from

the

cylinder

material

screen

reinstall

Note:

low

volume

rates.

assemblies.

right

end

and

right

from

manifold,

and

O-ring,

O-ring,

Replace

delivered

Use

Kit

#1726

plate.

end

plate.

cylinder

if

necessary.

filter

screen

this

leaf

or

if

at

Kit

and

and

retain-

unit

low

flow

#1724.

right

has

Note:

leaf

#1724,

Page

4-18

Replace

vibration.

this

Use

leaf

Kit

#1670

for

internal

or

Kit

Figure

4.23

October

1997

Page 15

1126

Plus,

LP10

and

LP20

Service

Manual

Right

End

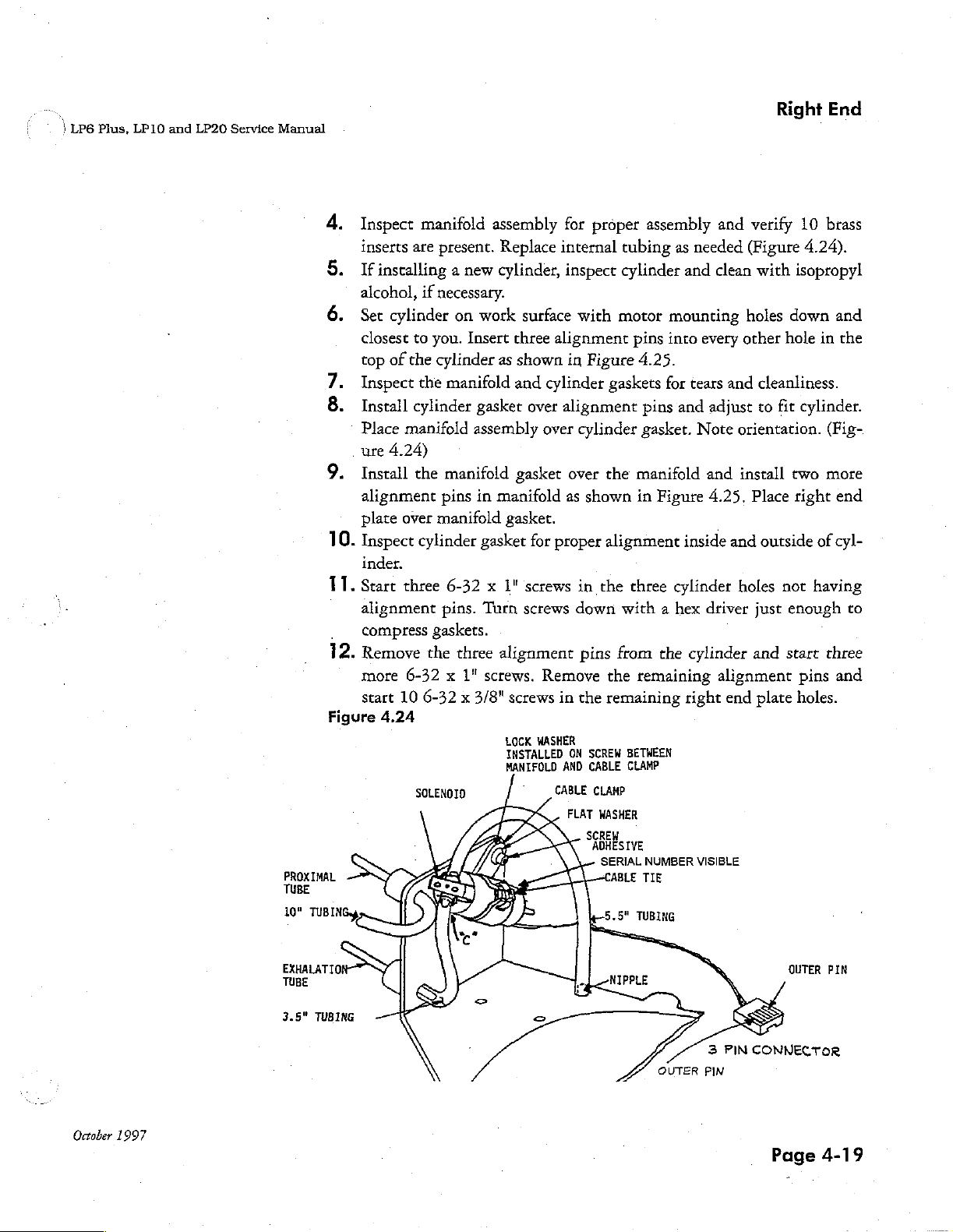

Inspect

inserts

If

installing a new

alcohol,

Set

closest

top

Inspect

æn

Install

Place

.

ure

Install

alignment

plate

10.

Inspect

inder.

11.

Start

alignment

compress

12.

Remove

more

start

Figure

4.24

manifold

are

present.

if

necessary.

cylinder

of

to

you.

the

cylinder

the

on

manifold

cylinder

manifold

4.24)

the

manifold

pins

over

manifold

cylinder

three

6-32 x 1"

pins.

gaskets.

the

three

6-32 x 1"

10

6-32 x 3/8"

SOLENOID

assembly

Replace

cylinder,

work

Insert

three

as

shown

and

gasket

assembly

gasket

in

manifold

gasket.

gasket

Turn

alignment

screws.

screws

LOCK

INSTALLED

MANIFOLD

for

internal

inspect

surface

with

alignment

in

cylinder

over

alignment

over

cylinder

over

as

for

proper

screws

screws

in

down

pins

Remove

in

the

WASHER

ON

AND

CABLE CLAMP

FLAT

proper

tubing

cylinder

motor

pins

Figure

4.25.

gaskets

pins

gasket.

the

manifold

shown

SCREW

CABLE CLAMP

SCREW

in

alignment

the

three

with a hex

from

the

remaining

remaining

BETWEEN

WASHER

ADHESIVE

SERIAL

assembly

as

needed

and

mounting

into

every

for

tears

and

adjust

Note

and

Figure

the

NUMBER

4.25,

inside

cylinder

driver

cylinder

right

VISIBLE

and

verify

(Figure

clean

with isopropyl

holes

down

other

hole

and

cleanliness.

to

fit

orientation.

install

Place

and

outside

holes

not

just

enough

and

start

alignment

end

plate

10

brass

4.24).

and

in

the

cylinder.

(Fig-

two

more

right

end

of

cyl-

having

to

three

pins

and

holes.

October

1997

3.5"

TUBING

OUTER

3

PIN

PIN

CONNECTOR

OUTER

Page

PIN

4-19

Page 16

Repairs

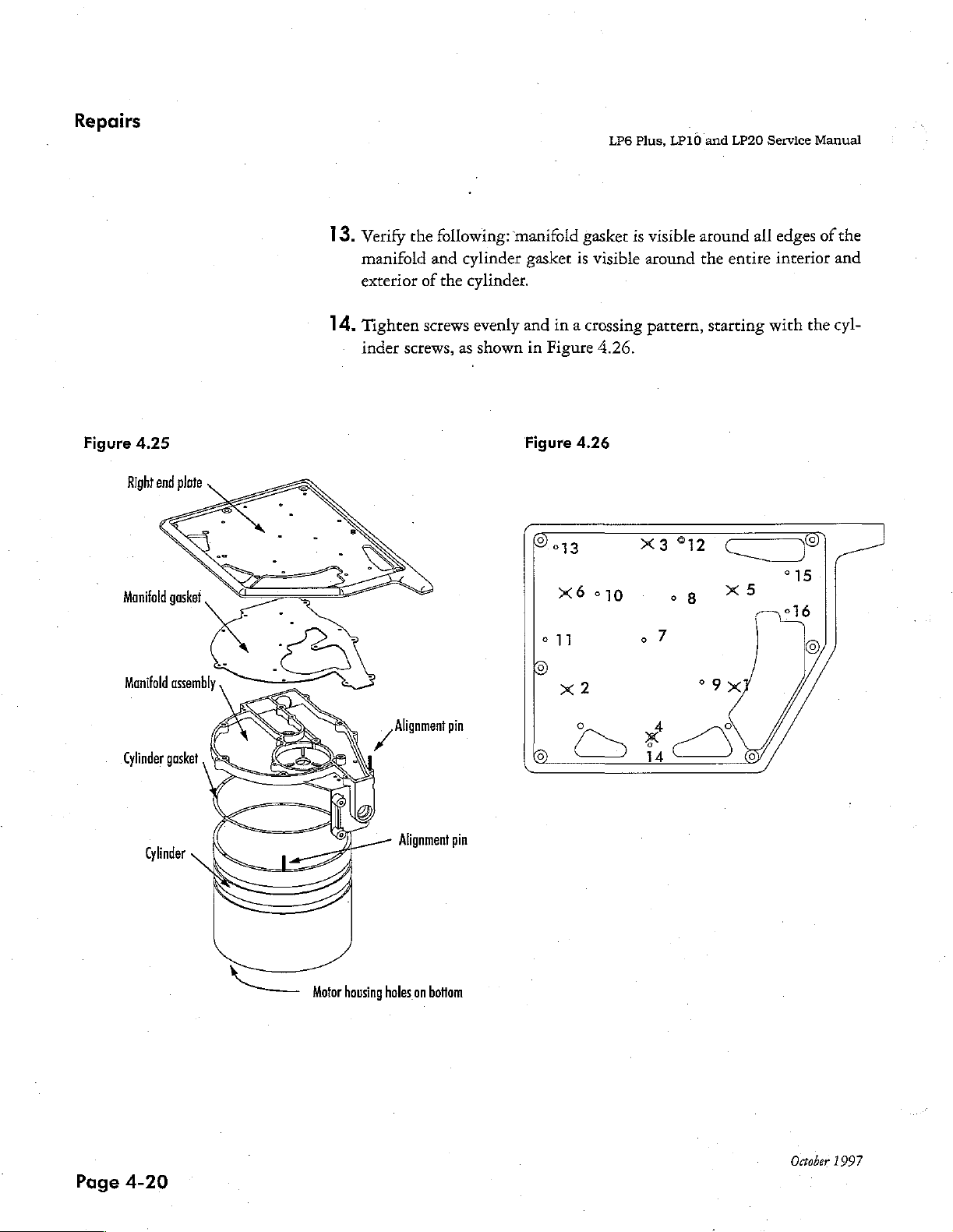

13.

Verify

manifold

exterior

14,

Tighten

inder screws,

the

following:

and

cylinder

of

the

screws

as

manifold

gasket

cylinder.

evenly

shown

and

in

LP6

gasket

is

visible

in a crossing

Figure

4.26.

Plus,

LP10

is

visible

around

pattern,

」

and

LP20

around

the

entire

starting

Service

all

edges

interior

with

Manual

of

the

the

and

cyl-

Figure

Manifold

Manifold

Cylinder

4.25

Right

end

gasket

assembly

gasket , a

Cylinder

plate

gs

SV

p

N

^

σ

の

LS

EN

(Te

È

Alignment

/

Alignment

9

pin

pin

P

Figure

4.26

Page

4-20

Motor

housing

holes

on

bottom

October

1997

Page 17

LP6

Plus,

LP10

and

LP20

Service

Manual

Back

Panel

Back

Panel

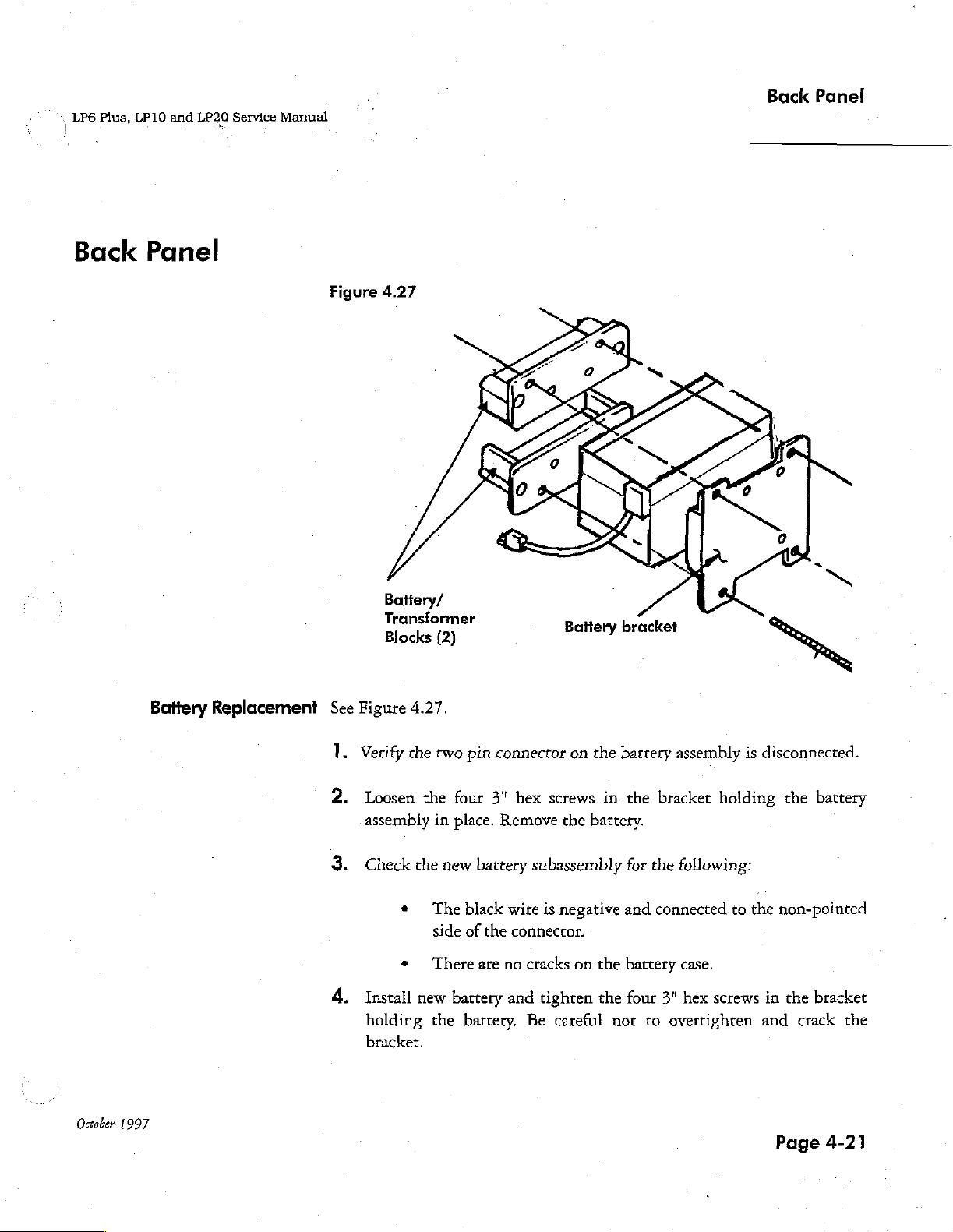

Figure

4.27

Battery/

Transformer

Blocks

(2)

Battery

bracket

x

October

1997

Battery

Replacement

See

1.

2.

3.

4.

Figure

Verify

4.27.

the

Loosen

assembly

Check

Install

holding

bracket.

the

che

e

e

new

two

pin

four

in

place.

new

The

black

side

of

There

battery

the

battery.

connector

3"

hex

Remove

battery

the

are

subassembly

wire

connector.

no

cracks

and

Be

on

the

screws

the

battery.

is

negative

on

tighten

careful

battery

in

the

for

and

the

battery

the

four

not

assembly

bracket

the

following:

connected

case.

3"

hex

to

overtighten

is

disconnected.

holding

to

the

screws

and

the

battery

non-pointed

in

the

bracket

crack

Page

4-21

the

Page 18

Repairs

LP6

Plus,

LP10

and

LP20

Service

Manual

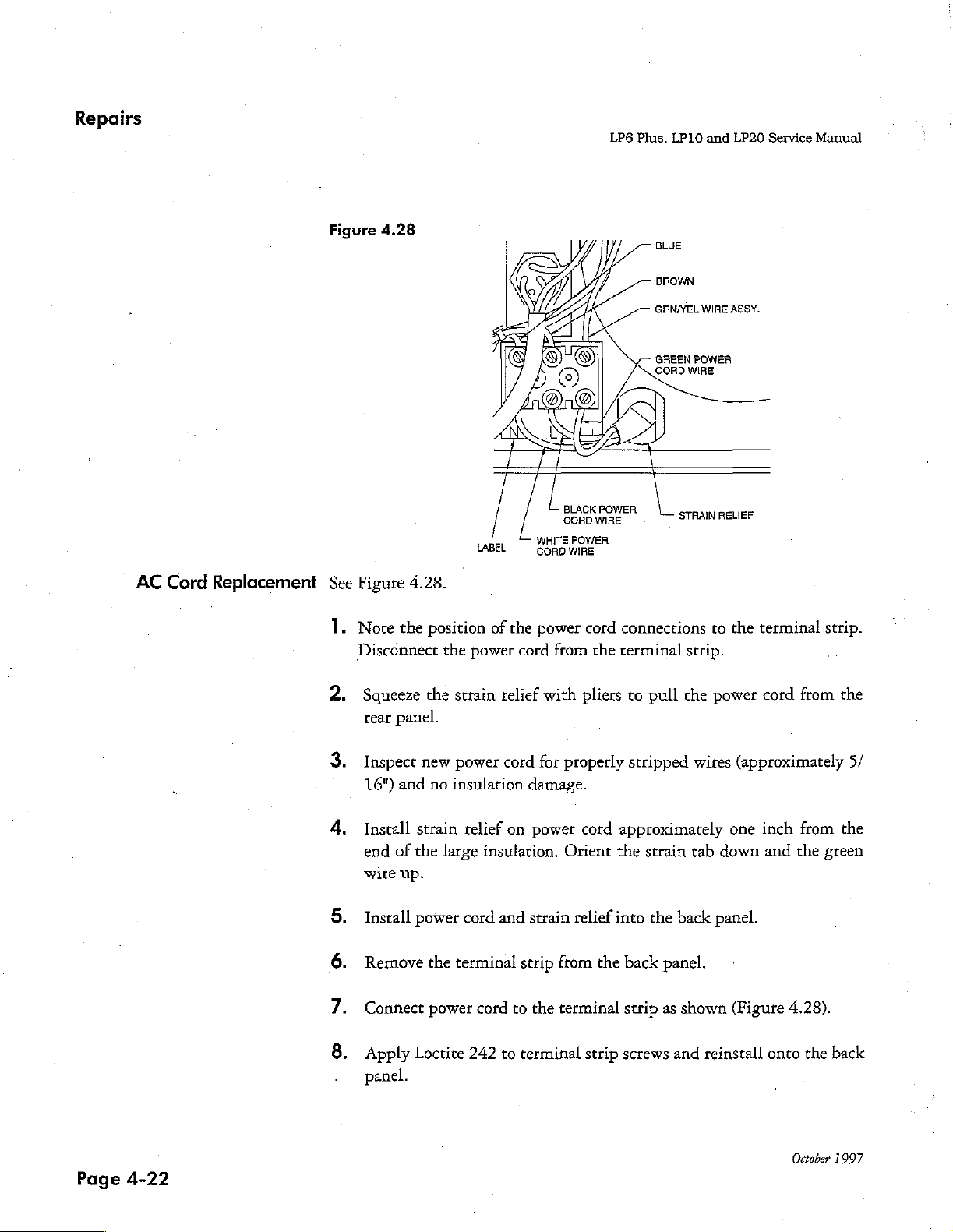

AC

Cord

Replacement

Figure

See

1

4.28

Figure

Note

Disconnect

4.28.

the

position

the

LABEL

of

the

power

cord

BLACK

CORD

WHITE

POWEA

CORDWIRE

power

from

cord

the

BLUE

BROWN

GRN/YEL

GREEN

CORD

POWER

WIRE

connections

terminal

WIRE

POWER

WIRE

STRAIN

to

strip.

ASSY.

RELIEF

the

terminal

strip.

Squeeze

rear

Inspect

16")

Install

end

wire

Install

a

Remove

の

N

Connect

Apply

©

panel.

the

panel.

new

and

no

strain

of

the

up.

power

the

power

Loctite

strain

relief

power

insulation

large

cord

relief

on

insulation.

cord

and

terminal

cord

242

to

with

for

properly

damage.

power

Orient

strain

strip

from

to

the

terminal

terminal

pliers

to

stripped

cord

approximately

the

relief

into

the

back

strip

strip

screws

pull

the

wires

strain

tab

the

back

panel.

as

shown

and

power

cord

(approximately

one

inch

down

and

panel.

(Figure

reinstall

4.28).

onto

from

from

the

the

the

5/

the

green

back

Page

4-22

October

1997

Page 19

Back

*

LP6

Plus,

LP10

and

LP20

Service

Manual

Panel

Replacement

of

AC

ON/OFF

Switch

Figure

See

1.

4.29

Figure

Disconnect

their

BROWN

RFI

WIRE

RFI

WIRE

FILTER

FROM

FILTER

FROM

BLUE

BLUE

WIRE

ASSY.

BROWN

4.29.

the

four

wires

location.

WIRE

on

ASSY.

the old

ON/OFF

switch,

taking

note

of

2.

Depress

remove

3.

Bend

the

4.

Install

toward

5.

Reconnect

OFF

to

two

old

ON/OFF

the

the

switch.

the

bottom

che

the

lugs

two

locking

switch

on

switch.

new

ON/OFF

bottom

the

four

The

wires

edge

from

the

new

edge

wires

of

the

tabs

the

ON/OFF

switch

of

the

to

from

back

on

each

back

back

their

the

panel

end

panel.

switch

in

the

panel.

previous

terminal

(Figure

of

the

ON/OFF

to

match

back

panel

locations

strip

go

4.29).

the

on

to

bent

with

the

the

switch

Ings

the

new

lugs

closest

and

on

zero

ON/

October

1997

Page

4-23

Page 20

Repairs

LP6

Plus,

LP10

and

LP20

Service

Manual

Front

Panel

Meter

Replacement

1.

Disconnect

two

#10

2.

Remove

3.

While

can

no

markings

exactly

meter

meter

4.

Check

dow

panel.

5.

Install

Install

flat

stud.

is

straight

Tighten

Kep

and

holding

be

adjusted

on

window.

window.

the

with

anti-static

one

meter

washer,

Mount

the

meter

nuts

discard

the

at

to

the

-10

when

Install

meter

flat

washer

bracket

one

lock

meter

by

looking

brass

wires

from

from

the

meter

the

old

meter.

replacement

least.

two

divisions

left

of

-10,

done.

Install

long

piece

window

to

for

spray

and

on

each

over

the

washer,

the

front

through

nuts

with a nut

J12

on

the

and

remove

meter

each

use

your

short piece

of

foam

scratches

wipe

of

the

four

round

and

portion

one

panel

meter

driver.

Logic

Board

the

wires.

vertically,

own

and

clean.

verify

side

of

judgment.

of

foam

around

the

debris.

Install

-10.

threaded

of

the

brass

nut

(finger

with

three

screws.

window

of

and

that

Since

Set

directly

sides

Spray

meter

studs

meter.

tight)

the

remove

the

there

the

and

meter

into

on

the

Install

on

Verify

top

overlay.

the

needle

are

needle

below

top

of

win-

front

meter.

one

each

meter

Figure

Page

Stud

Red

4-24

4.30

wire

6.

Check

no

damaged

meter

wire

insulation.

Meter

10-32

Kep

(2)

Black

assembly

nut

wire

for

proper

7.

Attach

the red

with a plus

to

4.30).

Kep

tighten

8.

Plug

Board

cuit

crimps,

meter

wire

(+)

the

other

To

secure

nut

on

with

connector

and

tuck

boards.

no

wire

over

and

stud

wires,

each

3/8"

to

wires

exposed

assembly

the

stud

the

black

as

shown

place a #10

stud

nut

driver.

J12

on

between

wire,

marked

(Figure

and

the

October

and

with

wire

hand

Logic

cir-

1997

Page 21

*,

LP6

Plus,

LP10

and

LP20

Service

Manual

Front

Panel

Circuit

Board

Removal

Caution

Figure

Use

panel

4.31

Tİ

of

and

E

an

anti-static

circuit

boards

Power/motor

|

|

|

M

Front

panel

workstation

safely.

is

board

5

|

Logic

pe

~

necessary

to

board

handle

the

=

front

Power/Motor

October

1997

Board

Removal

1.

Check

Board;

five

Board

2.

Remove

dampener.

3.

Raise

two

for

the

presence

install

6-32 x 3/16"

to

the

sets

resistor

the

stand-offs.

the 6 -

Power

of

pin

connectors.

32 x 3/4"

Motor

of

the

resistor

plug

for a minimum

button-head

(Figure

button-head

Board

carefully

hex

screws

4.31)

plug

of

hex

from

in

J3

on

one

minute.

securing

screw

from

the

front

the

Power/Motor

Remove

the

Power/Motor

the

heat

panel.

There

Page

the

sink

are

4-25

Page 22

Repairs

LP6

Plus,

LP10

and

LP20

Service

Manual

Logic

Display

Circuit

Board

Display

Board

Board

Replacement

Board

Installation

Removal

Note:

Removal

Do

not

1.

Turn

screws

rings

Remove

head

ing

Disconnect

Disconnect

Board.

.

Remove

the

the

.

Check

remove

all

seven

securing

(behind

the

hex

screw

the

Logic

(Raise

the

display

Display

the

Display

the

pressure

knobs

the

BREATHING

five

6-32 x 5/8"

and

Board

the

meter

the

Display

the

Logic

two

6-32 x 3/16"

board,

Board.

limit

completely

knobs

the

one

to

the

wire

Board

and

the

Remove

Board

for

knob

(LP1O

counter-clockwise.

to

the shafts.

EFFORT

and

stand-offs,

4-40 x 3/16"

front

panel.

assembly

Board

ribbon

from

the

button-head.hex

three

flat

head

the

Display

damaged

components

only).

Remove

the

the

VOLUME).

one

6-32 x 3/16"

button-head

from

J12

cable

from

front

panel.)

screws

screws

Board.

knobs

on

from

and

Loosen

hex

screw

the

Logic

J9 on

from

the

traces.

the:

and

the

button-

secur-

Board.

the

Logic

the

top

bottom

set

O-

of

of

Page

4-26

Note:

Check

that

Mount

head

head

The

Logic

tricity.

boards.

Take

the

ribbon

the:

*

Connectors

*

Wires

‧

Colored

connector.

the

the

Display

hex

screws

screws

on

Board

precautions

cable

are

are

not

broken.

line

on

(This

connector.)

Board

on

the

the

bottom

and

the

Power/Motor

to

on

the

replacement

fully

pressed

the

cable

is

the

pin

by

installing

top

of

the

of

the

eliminate

together.

is

connected

indicated

the

Display

Display

Board

static

before

Display

to

the

Board

#1

by a polarizing

two

6-32 x 3/16"

Board.

Board

are

Install

using

sensitive

handling

ensuring

pin

in

the

mark

button-

the

three

Loctite

to

static

242.

the

October

gray

on

flat

elec-

circuit

1997

Page 23

.

¡

LPG

Plus,

LP10

and

LP20

Service

Manual

Front

Panel

Logic

Board

Installation

1.

2.

3.

Check

*

*

©

*

*

*

*.

Mount

tighten

head

hex

Connect

nect

meter

the

Logic

Board

Theproperorientation

locking

No

component

No

trace

Nuts

on

Polarity

notch

indicators

All

leads

Presence

(U25

and

the

Logic

stand-offs

screw

and

Display

wiring

for

the

nuts

should

damage.

or

pad

damage.

switches

of

ROMs

are

of

U26).

Board

using a nut

one

Board

assembly

and

on

seated

"stick-on"

with

6-32 x 3/16"

ribbon

following:

ofthe

transducer

be

on

the

pots

are

by

matching

the

board.

correctly

labels

driver.

to

J12

and

on

five

6-32 x 5/8"

Install

button-head

cable

to

on

the

mounting

transducer

tight.

the

notches

not

bent.

the

two

large

one

4-40 x 3/16"

J9

on

the

Logic

Board.

screws.

side.)

on

ROMs

EPROM

stand-offs.

button-

hex

screw.

Logic

Board.

(The

to

the

chips

Hand-

Con-

:

October

1997

Figure

4.32

STM

al

E

i

i

Power/motor

|

Front

panel

$

|

|

я

board

Logic

board

기

Page

Y

|

|

|

YA

4-27

Page 24

Repairs

LP6

Plus,

LP10

and

LP20

Service

Manual

Power/Motor

Installation

Board

1.

2.

3.

A.

Check

the

Power/Motor

No

The

of

Polarity

on

EPROM

EPROM

Carefully

pins

onto

Check

bent

Secure

in

the

the

all

and

the

mount

pins.

the

all

hex screws.

Board

component

resistor

the

the

Logic

(Figure

pins

pins

plug

board

away

of

EPROM

ROM

to

leads

are

has a label.

the

Power/Motor

Board.

4.32)

connecting

are

fully

Power/Motor

to

damage

is

inserted

from

(U10)

the

notch

seated

Press

the

seated

Board

ensure

exists.

into

the

heat

is

correct

indicator

correctly

Board

the

Power/Motor

boards

into

the

using

five

that:

the

J3

connector

sink).

by

matching

on

the

and

not

by

positioning

Board

to

make

sure

connectors.

6-32 x 3/16"

(at

the

board.

bent.

it

evenly

that

no

button-head

the

corner

notches

over

down

pins

the

are

Page

4-28

5.

Install a 6-32 x 3/4"

dampener

to

the

button-head

front

panel.

hex

screw

to

secure

the

heat

sink

October

1997

Page 25

|

LP6

Plus,

LP10

and

LP20

Service

Manual

Front

Panel

Knob

Installation

1.

2.

3.

Note:

The

ting

4.

Verify

all

shafts

on

the

Place

O-rings

brass

nuts

with

respect

ing

with a .025

Tighten

Take

five.5/8"

feeler

gauge

counter-clockwise)

indicators

marks

Check

that

on

that

there

(VOLUME

the

set

on

the

all

is

some

into

locking

to

the

minimum

feeler

screws

regular

and

orient

setting

the

knobs

overlay.

knobs

tension

front

and

gauge

in

each

knobs.

indicator

must

are

in

on

panel

are

knobs

BREATHING

and

overlay

between

knob.

Obtain

marks

on

align

fact

turned

the

locking

fully

counter-clockwise.

install

markings.

lines

the

precisely

onto

the

EFFORT).

Position

Obtain

the

knob

and

correct

overlay.

fully

knobs

spacing

at

the

minimum

Tighten

with

the

counter-clockwise.

during

two

shafts

the

correct

the

front

panel.

with a .025

(furthest

knobs.

minimum

Check

rotation.

with

knobs

spac-

set-

October

1997

Page

4-29

Page 26

Repairs

LP6

Plus,

LP10

and

LP20

Service

Manual

Overlay

Replacement

Figure

See

1.

4.33

Striker

Figure

4.33.

Remove

pletely

overlay

2.

Check

silk-screening

3.

Remove

both

front

anti-static

plate

the

overlay

from

the

is

adhered

overlays

adhesive

and

spray

front

will

for

or

holes)

backing

back

and

to

be

replaced.

panel.

Residue

cause a bubble

flaws

(scratches,

before

installing.

from

of

meter

wipe

to

prevent

window

Scrape

left

on

or

bump.

discoloration,

top

overlay

area

spotting.

Top

the

adhesive

the

front

window,

of

the

overlay

residue

panel

bubbles,

if

present.

top

overlay

com-

where

the

illegible

Spray

with

Page

4-30

4.

The

G.

D.

5.

Check

following

for

Peel

Position

adhesive

backing

removed

Peel

overlay

Smooth

Check

the

all

overlays

continuous

are

suggestions

adhesive

back a small

the

overlay

portion

while

to

back

on

overlay

overlays

as

needed.

pressing

avoid

the

entire

panel

from

to

of

air

lightly

ensure

on

for

installing

portion

of

accurately

the

overlay.

down

bubbles

overlay,

and

center

to

edges

the

back

the

the

overlay

and

then

Now

the

overlay

from

being

carefully

press

up

outside

are

even

of

the

overlay.

overlays:

backing

press

down

peel

the

as

trapped.

holding

the

center

edges.

with

panel

on

one

the

exposed

remainder

the

backing

the

edges.

of

the

overlay.

edges.

Smooth

October

end.

of

1997

the

is

Lay

Page 27

Front

\

LP6

Plus,

LP10

and

LP20

Service

PLC

Replacement

(LP10/LP20

PLC

Manual

only)

Removal

1.

2.

Remove

Remove

Valve"

the

PLC

the

bezel

printed

on

knob

and

overlay

it.

knob

with

spring,

using a 1/16" hex

"Patient

Pressure"

and

Panel

driver.

"Exhalation

PLC

Installation

Remove

Remove

driver.

Remove

Remove

Remove

64"

Remove

1.

Fasten

hex

Rotate

pointing

Install

hex

the

head

the

the

two

the

two

the

bezel.

the

gasket

the

four

driver.

the

PLC

PLC

screws,

the

PLC

to

the

patient

Phillips

hex

head

from

hex

head

Manifold.

manifold

and

tighten

knob

shaft

right

of

the

pressure

head

screws

screws

around

screws

to

the

from

from

the

patient

from

the

ventilator's

using a crisscross

clockwise

until

assembly.

port

gasket.

the bezel.

the

bezel,

pressure

PLC

front

pattern.

the

using a 7/64"

port.

manifold,

panel

two

using a 5/

with

set

screws

the

hex

four

are

October

1997

Set

the

bezel

Install

using

Install

using

two

only

two

only

Phillips

light

hex

light

Install a new

onto

the

head

pressure.

head

pressure.

bezel

overlay

PLC

manifold.

screws

Do

screws

Do

over

in

in

not

the

not

the

the

top

over

tighten.

bottom

over

tighten.

two

of

the

bezel.

of

the

bezel.

Phillips

head

Hand

Hand

screws.

Page

tighten,

tighten,

4-31

Page 28

Repairs

PLC

Knob

Installation:

1.

Install

shaft

the

busing.

coil

spring

over

LP6

the

adjustment

Plus,

LP10

shaft

and

LP20

to

Service

rest

around

Manual

the

2

3

4,

5

6

Install

Align

Apply

Compress

Install

the

Check

knob

notches

adhesive,

the

flat

side

the

base,

grooved

in

knob

LOCTITE

the

spring

top

knob

of

the

shaft.

function

of

base

with

on

the

Tighten

the

side

connecting

to

the

corners

425,

to

the

knob

adjustment

the

locking

knob.

the

base

set

with

of

top

knob

and

shaft,

screw.

the

the

shaft

hold

with

spring.

set

screw

down.

the

busing.

threads.

set

screw

on

Page

4-32

October

1997

Page 29

Forms

On

the

the

LP6

*

Ventilator

e

Ventilator

following

Plus,

LP10,

Run-In

Service

pages

and

Log

Record

are

LP20

blank

Volume

copies

of

Ventilators.

the

forms

These

used

forms

when

are

servicing

the:

Photocopy

your

ventilator.

ensure

You

Nellcor

Volume

accurate

must

Puritan

Ventilator.

these

forms

and

use

Use

these

forms

records

complete a Service

Bennett

ate

each

kept

them

for

about

Record

time

to

document

your

necessary

and

Run-In

you

repair

maintenance

internal

documentation

maintenance

Log

an

LP6

and

and

return a copy

Plus,

LP10,

and

repair

repairs.

or

and

LP20

of

to

to

October

1997

Page

5-1

Page 30

Forms

LP6

Plus,

LP10

and

LP20

Service

Manual

Page

5-2

October

1997

Page 31

NELLCOR

PURITAN

Ventilator

Dealer:

Address:

Reason

for

return:

Inspection

LEDSs/Alarms

Part/Procedure

results:

Service

Pass/Fail

Serial

number

Record

Tech | Date

Technician:

Software

Work

Check-In

level

performed

Serial

Number:

Model:

Start

Date:

BENNETT.

Hours

in:

Visual

Controls

Alarm

check/output

Volume

Assembly

Stability

Relief

Valve

Power

Switch

High

alarm

FINAL

INSPECTION

test

(<4)

(<35)

Calibration

Reassembly

Calibration

Reassembly

Begin

Run-In

End

Run-tn

Begin

Run-In

End

Run-In

Final

Final

P=poss

F=fail

Visual

Controls

Alarm

check/output

Volume

Relief

Valve

Power

Switch

High

alarm

Assembly

FINAL

INSPECTION

test

Stability

(<4)

(<35)

P=poss

F=fail

Date:

Signature:

Hours

out:

Page 32

Forms

LP6

Plus,

LP10

and

LP20

Service

Manual

Page

5-4

October

1997

Page 33

NELLCOR

PURITAN

BENNETT.

Ventilator

Serial

Number:

DATE

1-day

run

complete

1-day

run

complete

1-day

run

complete

TIME

Run-In

“Name

Log

OCCURANCE

Begin 1 day

Begin

End

End 1 day

Name

Begin 1 day

Begin

End

End 1 doy

Begin 1 day

Begin

End

End 1 day

Name

run-in.

battery

run-down

battery

run-down.

run-in,

run-in.

battery

run-down

battery

run-down.

run-in.

run-in.

battery

run-down

battery

run-down.

run-in.

Begin

16

Begin

16

Begin

16

minutes

hour

run.

minutes

hour

run.

minutes

hour

run.

to

low

to

low

to

low

power.

power.

power.

Notes:

Page 34

Forms

LP6

Plus,

LP10

and

LP20

Service

Manual

Page

5-6

October

1997

Page 35

NOU-@3-1999

69:58

Mallinckrodt

Tech

SUpport

6126943883

F.02/03

Initial

Ventilator

Nelleor

The

purpose

may

also

ating

Check-Out

Modeli

0.

Puritan

properly.

be

Bennett,

of

this

used

for a brief

procedure

Inc.,

inspection

Procedure

1

General

Exterior

Appearance:

Any

broken

orloose

Imobs,

Any

dants

or

scratches

Condition

-

Eneure

Is

İs

2.

Enguré

Ensure

=

4

Set

AG

Mode

Low

High

Volume

Breath

Inspiratory

Breathing

Pressure

Note:

These

tings.

5.

Funcional

Plug

BREATHING

BREATHING

‘Connect a patient

EXHALATION

Set

All

An alarm

Only

‘The

PATIENT

Disconnect

EXHALATION

should

of

the

that

no

the

exterior

af

setting

information

that

a new

that

the

contro!

Power

Switch

Alarm

Alarm

Rate

Time

Effort

Limit

are

test

Testing:

tha

unit

EFFORT

tha

MODE

front

panel

sounds

the

AC

ventilator

PRESSUHE

the

indicate

surface

the

into

EFFORT

VALVE

PWH/SATT.

VALVE

which

AC

power

cord?

Squid

spills

have

tres

of any

on

the

alr

inlet

PATIENT

knobs

as

follows:

(LP20,

LP10,

.

(LP20,

LP1Q

settings

and

an

AC

power

famp

just

knob

back

circuit

and

port,

switch

lo

ABSIST/CONTROL

lamps

light

momentarily

momentarily

CHARGE

cydes

with

no

registers

patient

cireult.

port.

Measure

10604100

må.

PRESSURE

α

and

has

conducted

is

to

provide

ewitches,

may

indicate

leaked

foreign

front

panel

filter

[x

installed.

LP6

Plus

・

oriy)

not

typical

sourne.

comes

to

5.

test

lung

lamp

alarm

conditions

with

each

Attach a respiromatey

tha

Performance

several

instructions

of a ventilator

rubber

feat,

filter

dropping

or

into

the

ventilator.

material?

behind

the

neadle

Is

within

only)

-

'

palient

set.

Tum

the

BREATHING

an.

it

should

Eght

to

the

PATIENT

remains

lit

machine

cycle”

to

volume

delivered

quality

for the

which

.

housings,

other

abuse?

|

door

legible?

one

division

On

Standby

a

90

10

8

89

-5

Fuly

EFFORT

close

to

AIR

tube,

the

PATIENT

at

the

PATIENT

PURITAN

BENNETT.

‘Ventilator

tests

on

completion

has

not

had

ete?

of

-10.

(LP20/LP10/.P6

(approx.)

clockwisa

knob

foward

the

“0”

marking.

PATIENT

PRESSURE

AIR

tube

AIR

Inspection

Serial

Number:

this

ventilator

of

any

zero

Setihe

por,

and

black

tube; the

before

an

initial

inspection

internal

respirameter

Plug)

Battery

until

the

and

the

repairs

Charge

shipment.

upon

performed

Pass

σος

σισιος

(LPS)

-

a

ojooooan

receipt.

to

This

ensure

Fail

procedure

that

it

is

'

0000698

a

0000800

oper-

09-095200-000

Е

Page 36

Page 37

MV

-BS-1333

89:59

Mallinckrodt

Tech

Support

6126943883

P.Ø3/Ø3

Procedure

Connect

EXHALATION

When

Disconnect

Press

Piug

‘The

Set

Sat

Note

tre

patient

VALVE

fhe

pressure

exhalation

LIMIT

should

alarm

LP20

‘The

An alarm

The

Press

Press

The

The

LOWC

Unplug

‘The

An

‘Tha

The

Press

«Press

‘The

The

10\

Plug

To

butions

plied

or

(LPG

The

any

manifold

to

$0

and

presging

the

tast

sound

(dual-tone

by

pressing

only:

Press

the

ALARM

an

external

POWER

SWITCHOVER

sounds

EXTERNAL

patent

lho

and

EXTERNAL

battery

BATTERY

pressure

ALARM

hold the

BATTERY

condifion

MEDIUM

tha

external

POWER

SWITCHOVER

alarm

sounds

INTERNAL

patient

and hold

INTERNAL

battery

BATTERY

pressure

the

ALARM

the

BATTERY

condition

MEDIUMDI © HIGHO — (ow

he

AC

power

chack

the

number

at

the

same

by

200

(100

LPS

Plus,

10 = 2000

only)

of

legs

number

of

hours

the

MODE

switch

the

AC

POWER

comments

circuit

and

test

port.

Sat the

exceeds

60, a high

on

the

patient

the

ALARM

lung

from

the

on

the

LPS,

the

ALARM

SHLENCE/RESET

the

ALARA

SILENCE/RESET

SILENCE/RESET

battery

into

the

back

lamp

lamp

fights

continues

SILENCERESET

BATTERY

on

the

to

TEST

lamp

blinks

PATIENT

HIGHT

battery

lamp

lamp

lights

continues

SILENCEMESET

BATTERY

on

cord

of

time,

for

tha

than

to

switch

on

to

TEST

lamp

continues

the

PATIENT

back

into

hours

on

The

value

LPG)

will

hours,

for

380

(LPG

currently

on

STANDBY

10

OFF

inspection

Jung

to

the

PATIENT

HIGH

ALARMILIMIT

pressure

circuit

shotri

SILENCEMESET

patient

circuit.

double-pulsed

switch.

bution. The

bution

again.

of

the

ventflater.

blinks

cycle

with

each

button

to

reset

button

PRESSURE

Δον

battery

blinks

cycle

with

each

bution

to

reset

button

to

blink

PRESSURE

battery

an

AC

power

the

ventilatar,

pointed

to

correspond

LPS

Plus,

the

(OFF

(LP20,

unit,

to

10 « 1000

LP10,

LP2D),

ventilator:

on

the

LPS)

LP10,

comective

AIR

to

60

alarn

should

open.

Reset

svdich.

After

two

on

the

Tha

SETTING

Unplug

machine

the

alarm

meter

charge

machine

the

alarm

meter

charge

source

press

the

by

the

needle

the

numbar

hours).

*

and

LPG

action

tube,

PATIENT

and

compres

sound

the

cycles,

LP20},

SETTING

ERROAPRESLENCE

the AC

cycle

indicates

is

not

cycle

indicates:

ls

nol

ALARM

on

of

Note:

hours

Plus

only)

the

and

tha

alarm

by

retuming

the

LOW

PRESSURTIAPHEA

Reconnect

ERROR/PRESILENCE

power

acceptable)

accentable)

SILENGEMESET

the

PATIENT

operating

hours,

will

not

taken, or

PRESSURE

recommendations

port,

and

test

lung

in

your

mushroom

the

cord

PRESSURE

register И less

valve

the

HIGH

test

lung.

LED

and

BATTERY

(8.0.

for

LED

will

mater

LP20,

than

hand.

in

ALARM

alarm

Reset

will

turn

mulfi-

250

Pass

he

the

fight.

off.

TEST

LPIO,

.

for

further

Fail

o

a a

а a

0

Q q

a a

a

n

Q

а

G

a

a

Q

a

a

a

a a

a

action.

a

.а

a

с’

„A

」

'

Dat

e

O...

*<<ÂÂ

.

Inspection

performed

by:

TOTAL

P.

Page 38

Page 39

Equipment

Calibration

Calibration

of

Model

Note:

6960

Perform

1.

Remove

ventilator

from

2.

Connect

MUNICATION

3.

Plug

Standby.

4.

Monitor

connector

5.

Remove

screwdriver,

tored

this

procedure

the

the

harness.

the

the

the

the

voltage

Calibrator

at

least

left

side

cover

that

is

ready

for

Calibrator

PORT

of

the

ventilator

Set

the

DC

on

the

bottom

adjust

is

into

back

panel

voltage

Calibrator.

cover

R60

13.80+0.01

every

three

months.

from a functional

calibration.

to

the

Internal

ventilator.

AC

power

ON/OFF

across

of

on

the

VDC.

the

Power/Motor

switch

the red

ventilator.

LPG

Plus,

Disconnect

Battery

and

and

harness

set

the

to

ON.

black

wires

Using a non-conductive

board

the

internal

MODE

such

LP10,

and

the

of

the

that

or

LP20

battery

COM-

switch

two-pin

the

moni-

to

October

1997

Note:

6.

Adjust

until

Do

not

readjustment

7.

Press

pot

8.

Pull

calibrated

the

the

press

and

on

the

the

CHARGE

VOLTAGE

the

CHARGE

is

necessary,

hold

the

Calibrator

syringe

on

pressure

VOLTAGE

LED

button

wait

CHARGE

until

the

Calibrator

meter

lights

three

button;

the

voltmeter

to

the

pot

on

solidly.

for

longer

minutes

adjust

to

the

open

brass

the

than

and

then

the

shows

end

port.

bottom

10

of

of

seconds

repeat

CHARGE

10.50+0.01

its

stroke

Page

the

Calibrator

at a time.

the

step.

CURRENT

VDC.

and

attach

6-1

If

a

Page 40

Equipment

Calibration

9.

Apply

50+0.1cmH;0.

10.

Adjust

50

CM

11.

The

play

pressure

the

PRESSURE

LED

lights

contrast

contrast

of

pot

with

solidly.

the

display

on the

the

syringe

pot

on the

can

be

Calibrator.

LP6

Plus,

LP10

until

the

Calibrator

set

as

desired

and

LP20

pressure

until

the

by

adjusting

Service

meter

PRESSURE

Manual

indicates

the

dis-

Page

6-2

October

1997

Page 41

Calibration

.

| ;

LP6

Plus,

LP10

and

LP20

Service

Manual

of

Model

6951

Right-end

Tester

Calibration

of

Model

Note:

6951

Perform

1.

this

Disconnect

the

face

Connect a large

on

the

Apply

sure

meter.

Using

reads

12.

Apply

sure

meter.

Repeat

Right-end

procedure

the

plates.

left.

12+0.2

the

zero

18+0.2

The

this

step

at

tubing

syringe

cmH,0

screw,

cmH)O

left

for

pressure

Tester

least

every

six

from

the

two

and a calibrared

of

pressure

adjust

pressure

the

needle

pressure,

as

gauge

readings

months.

pressure

pressure

as

indicated

of

the

indicated

should

of

20

cmH,0

gauges.

indicate

meter

by

the

left

pressure

by

the

Carefully

1842.0

and

remove

to

the

gauge

calibrated

-

calibrated

25

gauge

cmH,0.

cmH0.

pres-

so

pres-

it

8.

9.

10.

11.

Connect

gauge

Apply

sure

Using

Remove

Install

Check

on

100+0.2

meter.

the

the

the

the

syringe and

the

right.

zero

screw,

the