Page 1

XPRESS5800/120Mf

()

■ ■ ■ ■ ■ ■ ■

■ ■ ■ ■ ■ ■ ■

■ ■ ■ ■ ■ ■ ■

■ ■ ■ ■ ■ ■ ■

■ ■ ■ ■ ■ ■ ■

■ ■ ■ ■ ■ ■ ■

E

■ ■ ■ ■ ■ ■ ■

■ ■ ■ ■ ■ ■ ■

■ ■ ■ ■ ■ ■ ■

■ ■ ■ ■ ■ ■ ■

■ ■ ■ ■ ■ ■ ■

■ ■ ■ ■ ■ ■ ■

■ ■ ■ ■ ■ ■ ■

Service Guide

■ ■ ■ ■ ■ ■ ■

Page 2

Page 3

CONTENTS

Preface........................................................................................................................................... v

Safety Indications.......................................................................................................................vi

Notes on Using the Server.............................................................................................. 1-1

About Warning Labels ..................................................................................................................1-1

Safety Notes..................................................................................................................................1-2

General .....................................................................................................................................1-2

Power Supply and Power Code Use.........................................................................................1-3

Installation, Relocation, Storage, and Connection....................................................................1-5

Cleaning and Working with Internal Devices...........................................................................1-6

During Operation......................................................................................................................1-7

For Proper Operation ....................................................................................................................1-8

Transfer To Third Party.................................................................................................................1-9

NEC Express server ............................................................................................................1-9

Provided software ...............................................................................................................1-9

Disposal And Consumables ........................................................................................................1-10

Advice for Health..............................................................................................................1-11

User Support ...............................................................................................................................1-12

iii

Overview........................................................................................................................... 2-1

Appearance ...................................................................................................................................2-1

Specifications................................................................................................................................2-2

Unit Configuration ........................................................................................................... 3-1

Specifications................................................................................................................................3-1

Names and Functions of Components ..........................................................................................3-3

Connector location........................................................................................................................3-3

Block diagram...............................................................................................................................3-3

Cable connection list.....................................................................................................................3-4

Troubleshooting............................................................................................................... 4-1

POST Error Message List.............................................................................................................4-1

Error Beep Codes..........................................................................................................................4-8

POST Codes..................................................................................................................................4-9

Preventive Maintenance.................................................................................................. 5-1

Periodic Maintenance ...................................................................................................................5-1

Maintenance by User ....................................................................................................................5-1

Installing Internal Optional Devices............................................................................... 6-1

Preparing for Installation and Removal ........................................................................................6-1

Power Supply Cage.......................................................................................................................6-2

Removing the Power supply unit (CAGE)..........................................................................6-2

Installing the Power supply unit (CAGE) ...........................................................................6-3

Fan Unit ........................................................................................................................................6-4

Removing the FAN unit ......................................................................................................6-4

Installing the FAN unit........................................................................................................6-4

Motherboard .................................................................................................................................6-5

Removing the Motherboard ................................................................................................6-5

Installing the New Motherboard .........................................................................................6-5

Making Backup Copies of NVRAM Information...............................................................6-6

Restoring NVRAM Information .........................................................................................6-7

If the System is Unable to Make Backup Copies of NVRAM Information........................6-9

Page 4

iv

Updating SDR FW ............................................................................................................6-11

Mounting a Heat Sink on the CPU....................................................................................6-11

Removing the Motherboard ..............................................................................................6-11

How to Attach the Motherboard....................................................................................... 6-14

SCSI Back Panel (SCSI-B.P) & SAF-TE Board........................................................................ 6-16

Removing the SCSI-B.P. .................................................................................................. 6-16

Installing the SCSI Back Panel ........................................................................................ 6-17

CD-ROM Drive ......................................................................................................................... 6-18

Removing the CD-ROM Drive ........................................................................................ 6-18

Floppy Disk Drive ..................................................................................................................... 6-19

Removing the FDD .......................................................................................................... 6-19

FRONT Bezel ............................................................................................................................ 6-20

Removing the Front Bezel................................................................................................ 6-20

Front Sub Bezel ......................................................................................................................... 6-21

Removing the Front Sub Bezel ........................................................................................ 6-21

Front Panel Board ...................................................................................................................... 6-22

Removing the Front Panel Board ..................................................................................... 6-22

Other Option Parts ..................................................................................................................... 6-23

Rack Mount Conversion ............................................................................................................ 6-23

Maintenance Parts ........................................................................................................... 7-1

Maintenance Parts List................................................................................................................. 7-1

Notes ................................................................................................................................. 8-1

About the Use of Screws.............................................................................................................. 8-1

About the Transporting ................................................................................................................ 8-1

Page 5

Preface v

Preface

Welcome to the Express5800/120Mf server Service Guide. This manual describes the

maintenance work necessary for the Express5800/120Mf basic processing unit. Keep this guide

at hand for quick reference at any time it may be required.

Read the section “Safety Indications” first, then proceed to “Notes On Using The Nec Express

Server”.

Page 6

vi Preface

Safety Indications

Follow the instructions given in this service guide for proper operation and safe use

of the NEC Express5800.

This guide describes server components with possible danger, hazards that may be

caused by ignoring warnings, and preventive actions against such hazards.

Server components with possible danger are indicated with a warning label placed

on or around them. They are also described in this guide.

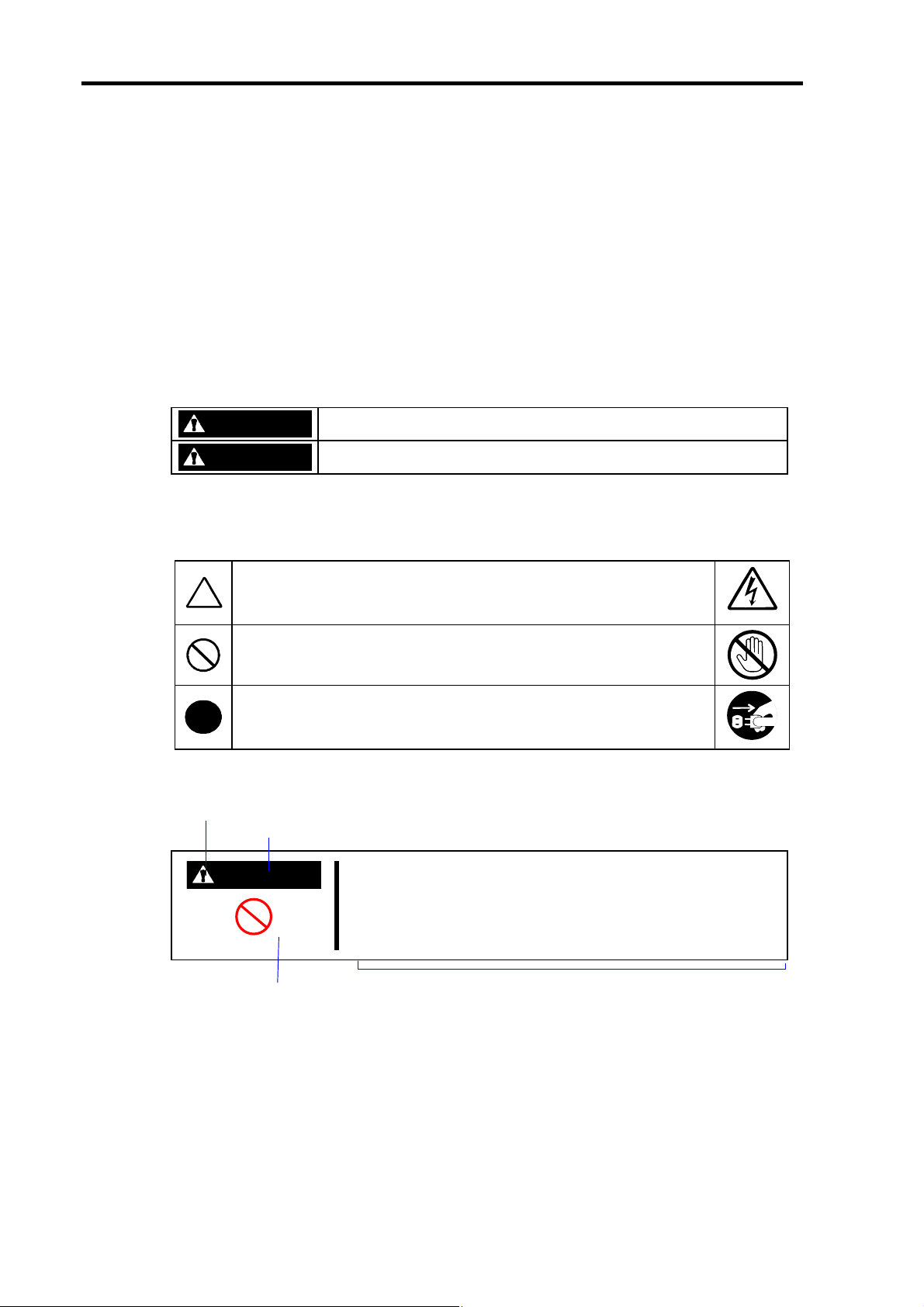

In the user’s guide and on warning labels, “WARNING” or “CAUTION” is used to

indicate a degree of danger. These terms are defined as follows:

WARNING

CAUTION

Precautions and notices against hazards are presented with one of the following 3

symbols. The individual symbols are defined as follows:

This symbol indicates the presence of a hazard if the instruction is

ignored. An image in the symbol illustrates the hazard type.

(Attention)

Indicates the presence of a hazard that may cause loss of life or serious

personal injury if the instruction is ignored.

Indicates the presence of a hazard that may cause minor personal injury,

including burns or property damage, if the instruction is ignored.

This symbol indicates prohibited actions. An image in the symbol

illustrates a particular prohibited action. (Prohibited Action)

This symbol indicates mandatory actions. An image in the symbol

illustrates a mandatory action to avoid a particular hazard.

(Mandatory Action)

( Example)

Symbol to draw attention

Term indicating a degree of danger

CAUTION

Symbol indicating a

prohibited action (may not

always be indicated)

Do not touch components in the NEC Express server while

they are hot.

Components (e.g., especially hard disk drive) in the server are

hot immediately after the power is turned off. Mount/dismount

components only when they are cool.

Contents of a danger

Page 7

Chapter 1

Notes on Using the Server

This chapter includes useful information for proper and safe operation of the NEC Express server.

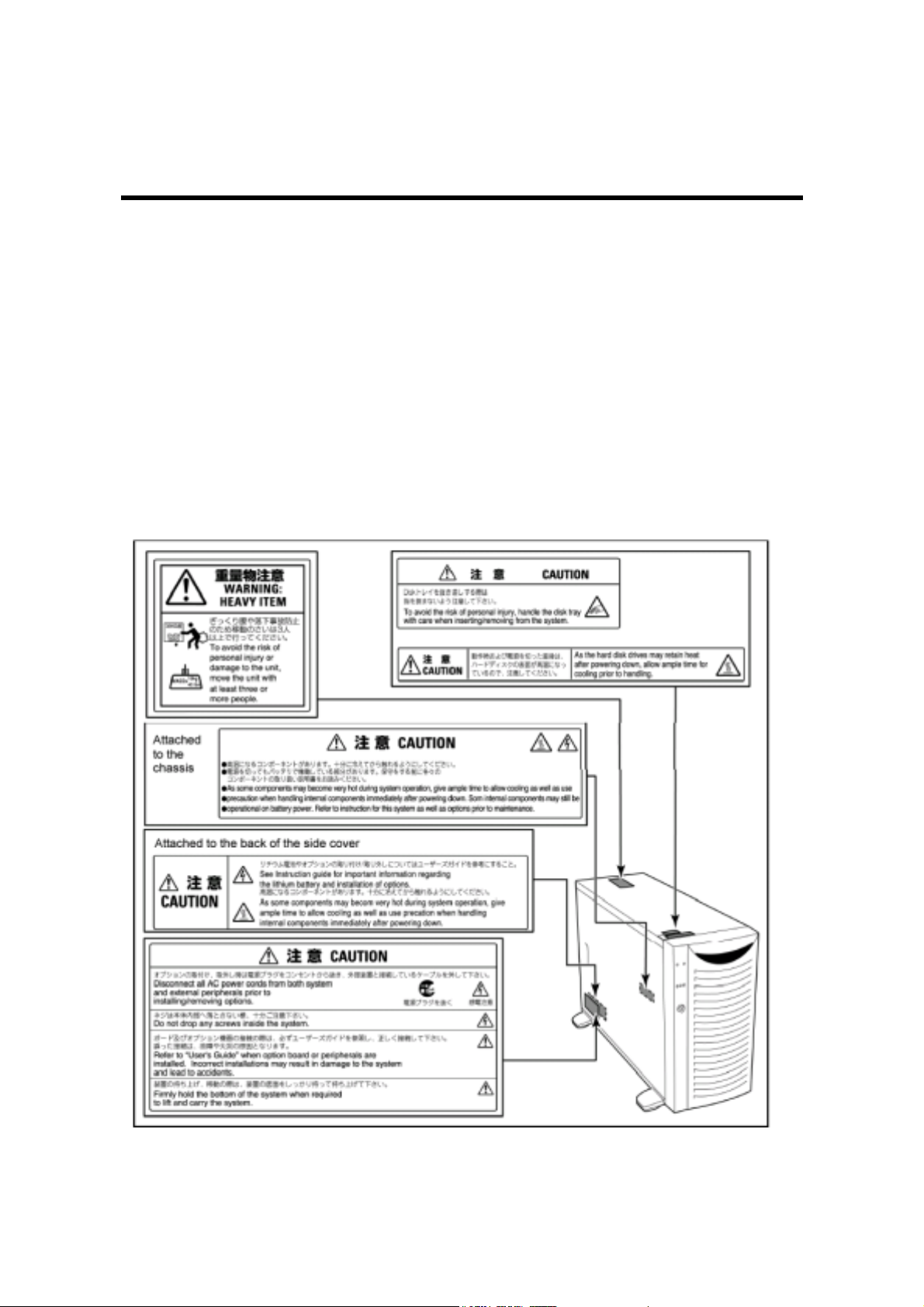

ABOUT WARNING LABELS

The warning label is attached to components with possible danger or their vicinity in the NEC

Express server to inform the user that a hazardous situation may arise when operating the server.

(Do not take off any label or soil it.)

If you find any label unattached, almost peeled off, or soiled, making the warning illegible, contact

your sales agent.

Page 8

1-2 Notes on Using the Server

SAFETY NOTES

This section provides notes on using the NEC Express server safely. Read this section carefully

to ensure proper and safe use of the server. For symbols, see "SAFETY INDICATIONS"

provided earlier.

General

WARNING

Do not use the NEC Express server for services involving human lives or

equiring high reliability. r

The NEC Express server is not intended to be used with or control facilities or

devices concerning human lives, including medical devices, nuclear facilities

and devices, aeronautics and space devices, transportation facilities and

devices; and facilities and devices requiring high reliability. NEC assumes no

liability for any accident resulting in personal injury, death, or property damage

f the NEC Express server has been used in the above conditions. i

Do not use the NEC Express server if any smoke, odor, or noise is present.

If smoke, odor, or noise is present, immediately turn off the POWER switch

and disconnect the power plug from the outlet, then contact your sales agent.

sing the server in such conditions may cause a fire. U

Keep needles or metal objects away from the NEC Express server.

Do not insert needles or metal objects into ventilation holes in the NEC

Express server or openings in the floppy disk or CD-ROM drive. Doing so

ay cause an electric shock. m

CAUTION

Keep water or foreign matter away from the NEC Express server.

Do not let any form of liquid (water etc.) or foreign matter (e.g., pins or paper

clips) enter the NEC Express server. Failure to follow this warning may

cause an electric shock, a fire, or a failure of the server. When such things

accidentally enter the server, immediately turn off the power and disconnect

the power plug from the outlet. Do not disassemble the server. Contact

your sales agent.

Page 9

Power Supply and Power Code Use

1-3 Notes on Using the Server

WARNING

Do not hold the power plug with a wet hand.

Do not disconnect/connect the plug while your hands are wet. Failure to

ollow this warning may cause an electric shock. f

Do not connect the ground wire to a gas pipe.

Never connect the ground wire to a gas pipe. Failure to follow this warning

ay cause a gas explosion. m

CAUTION

Plug in to a proper power source.

Use a proper wall outlet. Use of an improper power source may cause a fire

or a power leak.

Do not install the NEC Express server where you need an extension cord.

Use of a cord that does not meet the power specifications of the NEC Express

erver may heat up the cord and cause a fire. s

Do not connect the power cord to an outlet that has an illegal number of

onnections. c

The electric current exceeding the rated flow overheats the outlet, which may

ause a fire. c

Insert the power plug into the outlet as far as it goes.

Heat generation resulting from a halfway inserted power plug (imperfect

contact) may cause a fire. Heat will also be generated if condensation is

formed on dusty blades of the halfway inserted plug, increasing the possibility

f fire. o

Page 10

1-4 Notes on Using the Server

CAUTION

Use the authorized power cord only.

Use only the power cord that comes with the NEC Express server. Use of an

unauthorized power cord may cause a fire when the electric current exceeds

the rated flow.

Also, observe the following to prevent an electric shock or fire caused by a

damaged cord.

• Do not stretch the cord harness.

• Do not pinch the power cord.

• Do not bend the power cord.

• Keep chemicals away from the power cord.

• Do not twist the power cord.

• Do not place any object on the power cord.

• Do not bundle power cords.

• Do not alter, modify, or repair the power cord.

• Do not secure the power cord with staples or equivalents.

• Do not use any damaged power cord. (Replace a damaged power cord

with a new one of the same specifications. Ask your sales agent for

replacement.)

Page 11

1-5 Notes on Using the Server

Installation, Relocation, Storage, and Connection

CAUTION

Never attempt to lift the NEC Express server only by yourself.

The NEC Express server weighs up to 44 kg (depending on its hardware

configuration). Carrying the server only by yourself may strain your back.

Hold the server firmly by its bottom with another person to carry it. Do not

hold the front door to lift the server. The front door may be disengaged from

he server, causing personal injury. t

Do not install the NEC Express server in any place other than specified.

Do not install the NEC Express server in the following places or any place

other than specified in this User's Guide. Failure to follow this instruction may

cause a fire.

! a dusty place

! a humid place such as near a boiler

! a place exposed to direct sunlight

! an unstable place

Do not connect any interface cable with the power cord of the NEC Express

erver plugged to a power source. s

Make sure to power off the NEC Express server and unplug the power cord

from a power outlet before installing/removing any optional internal device or

connecting/disconnecting any interface cable to/from the server. If the NEC

Express server is off-powered but its power cord is plugged to a power source,

touching an internal device, cable, or connector may cause an electric shock

r a fire resulted from a short circuit. o

Do not use any unauthorized interface cable.

Use only interface cables provided by NEC and locate a proper device and

connector before connecting a cable. Using an authorized cable or

connecting a cable to an improper destination may cause a short circuit,

resulting in a fire.

Also, observe the following notes on using and connecting an interface cable.

! Do not use any damaged cable connector.

! Do not step on the cable.

! Do not place any object on the cable.

! Do not use the NEC Express server with loose cable connections.

Page 12

1-6 Notes on Using the Server

Cleaning and Working with Internal Devices

WARNING

Do not disassemble, repair, or alter the NEC Express server.

Never attempt to disassemble, repair, or alter the NEC Express server on any

occasion other than described in this User's Guide. Failure to follow this

instruction may cause an electric shock or fire as well as malfunctions of the

erver. s

Do not look into the CD-ROM drive

A laser beam is used in the CD-ROM drive. Do not look into or insert a mirror

into the drive while the drive is powered. If a laser beam is caught in your

yes, you may lose your eyesight (the laser beam is invisible). e

Do not remove the lithium battery.

The NEC Express server contains a lithium battery. Do not remove the

battery. Placing the lithium close to a fire or in the water may cause an

xplosion. e

When the server does not operate appropriately due to the dead lithium

battery, contact your sales agent. Do not disassemble the server to replace

r recharge the battery by yourself. o

Disconnect the power plug before cleaning the NEC Express server.

Make sure to power off the NEC Express server and disconnect the power

plug from a power outlet before cleaning or installing/removing internal

optional devices. Touching any internal device of the NEC Express server

with its power cord connected to a power source may cause an electric shock

ven of the NEC Express server is off-powered. e

Disconnect the power plug from the outlet occasionally and clean the plug with

a dry cloth. Heat will be generated if condensation is formed on a dusty plug,

hich may cause a fire. w

CAUTION

High temperature

Immediately after the NEC Express server is powered off, its internal

components such as hard disks are very hot. Leave the server until its

internal components fully cool down before installing/removing any

omponent. c

Make sure to complete board installation.

Always install a board firmly. An incompletely installed board may cause a

ontact failure, resulting in smoking or fire. c

Page 13

During Operation

1-7 Notes on Using the Server

CAUTION

Stay away from the fan.

Keep your hand or hair away from the cooling fan on the rear of the NEC

Express server. Failure to follow this warning may get your hand or hair

aught in the fan, resulting in injury. c

Do not touch the NEC Express server when it thunders.

Disconnect the power plug from the outlet when a thunderstorm is

approaching. If it starts thundering before you disconnect the power plug, do

not touch any part of the NEC Express server including the cables. Failure to

ollow this warning may cause a fire or an electric shock. f

Keep any animal (pet) away from the NEC Express server.

Pet's discharges or fur may enter the NEC Express server and cause a fire or

lectric shock. e

Do not place any object on top of the NEC Express server.

The NEC Express server may fall and cause property damage to the

urroundings. s

Do not leave the NEC Express server with its CD-ROM tray ejected.

Dust may enter the server through openings and cause malfunctions of the

EC Express server. Any person may also bump it and get injured. N

Take off the headset before connection.

Make sure to take off the headset before plugging it to the headset jack.

Failure to follow this instruction may hurt your ears. Make also sure to turn

own the volume before connection. d

Do not use a cellular phone or pager around the NEC Express server.

Turn off the cellular phone or pager. Radio interference may cause

alfunctions of the NEC Express server. m

Page 14

1-8 Notes on Using the Server

FOR PROPER OPERATION

Observe the following notes for successful operation of the NEC Express server. Use of the NEC

Express server ignoring the notes will cause malfunctions or failures of the server.

! Install the NEC Express server in a place that meets requirements for successful operation.

For details, see Chapter 2, "Setting Up the Server."

! Do not delete the hard disk partition exclusively provided for maintenance of the NEC

Express server although it may appear on the OS.

! Make sure to power off the NEC Express server before connecting or disconnecting

cables between the server and peripheral devices.

! Verify that the access lamp on the NEC Express server is unlit before turning off the

server or ejecting the floppy disk.

! Do not turn on the server after plugging the power cord.

! Do not turn off the server until the "NEC" logo and the some characters appear on the

screen.

! When you have just turned off the NEC Express server, wait at least 30 seconds before

turning it back on.

! Turn off the power and unplug the power cord from the outlet before relocating the NEC

Express server.

! You may use a software command to eject the tray or a media from the CD-ROM drive or

an optional device, for example a DAT, installed in the 5.25-inch device bay, respectively.

Make sure that the front door is open before ejecting the tray or media with a software

command. Running the command when the front door is closed will cause the tray or

media to hit against the front door, which may cause a hardware failure of the NEC

Express server as well as a software error.

! Clean the NEC Express server on a regular basis. (See Chapter 5 for cleaning.)

Regular cleaning proactively prevents various failures of the server.

! Lightning may cause a momentary voltage drop. To prevent this problem, it is

recommended to use an uninterruptible power supply unit.

! Make sure to use optional devices supported by the NEC Express server. Some

non-supported devices may be physically installed/connected but cause failures of the

server as well as a malfunction of the server.

! NEC recommends you use NEC's genuine products. Some third-party products claim

that they support the NEC Express server. However, repair of the server due to a failure

or damage resulted from use of such third-party products will be charged.

Page 15

1-9 Notes on Using the Server

TRANSFER TO THIRD PARTY

The following must be observed when you transfer (or sell) the server or software provided with

the server to a third party:

NEC Express server

Make sure to provide the User’s Guide along with the server to a third party.

Provided software

To transfer or sell any software application that comes with the NEC Express server to a third party,

the following requirements must be satisfied:

! All provided software applications must be transferred and no backup copies must be

retained.

! Transfer requirements listed in "Requirements for Software Use" that comes with each

software application must be satisfied.

! Software applications that are not approved for transfer must be uninstalled before

transferring the NEC Express server.

Page 16

1-10 Notes on Using the Server

DISPOSAL AND CONSUMABLES

! Dispose the server, hard disk drives, floppy disks, CD-ROMs, and optional boards as

required by the local regulations. Ask your local government for details.

IMPORTANT: For disposal (or replacement) of the battery

on the motherboard of the NEC Express server, consult with

your sales agent.

! The NEC Express server contains some components that are only good for a limited

period of time and require replacement, such as fans, internal batteries, the internal

CD-ROM drive, the floppy disk drive, and the mouse. For stable operation of the NEC

Express server, NEC recommends you replace these components on a regular basis.

Consult with your sales agent for replacement or the product lives.

WARNING

Do not remove the lithium battery.

The NEC Express server contains the lithium battery. Do not remove the

battery. Placing the lithium or nickel cadmium battery close to a fire or in the

water may cause an explosion.

When the server does not operate appropriately due to the dead lithium battery,

contact your sales agent. Do not disassemble the server to replace or

recharge the battery by yourself.

Mother board

Page 17

Advice for Health

1-11 Notes on Using the Server

The longer you keep using the computer equipment, the more you become tired,

which may cause disorders of your body. When you use a computer, observe

the following to keep yourself from getting tired:

Good Working Posture

You have good posture if the following are satisfied when you use a computer:

• You sit on a chair with your back straight.

• Your hands are parallel with the floor when you put them on the

keyboard.

• You look at the screen slightly lower than your eye height.

You have "good working posture" as described in the above when no part of

your body is under excess strain, in other words when your muscles are most

relaxed.

You have "bad posture" when you sit with your back hunched up or you operate

a display unit with your face close to the screen. Bad working posture may

cause eye strain or poor eyesight.

Adjustment of Display Unit Angles

Most display units are designed for adjustment of the horizontal and vertical

angles. This adjustment is important to prevent the screen from reflecting

bright lights and to make the display contents easy to see. You will not be able

to keep "good working posture" and you will feel more tired than you should if

you operate a display unit without adjusting horizontal and vertical angles.

Adjustment of Screen Brightness and Contrast

The display unit has brightness and contrast adjustment functions. The most

suitable brightness and contrast depend on the individual and the working

environment (well-lighted room or insufficient light). Adjust brightness and

contrast so that the screen will be easy to see. An extremely bright or dark

screen will give a bad effect to your eyes.

Adjustment of Keyboard Angle

The keyboard provided with the NEC Express server is designed for adjustment

of an angle. Adjust the keyboard angle at which the keyboard is easy to

operate. The adjustment assists in reducing strain on your shoulders, arms,

and fingers.

Cleaning of Equipment

Clean equipment regularly. It is difficult to see the display contents on a dusty

screen. Keeping equipment clean is also important for your sight.

Fatigue and Rest

If you feel tired, you should stop working and do light exercises.

Page 18

1-12 Notes on Using the Server

USER SUPPORT

Before Asking for Repair, do the following when the NEC Express server appears to fail:

1. Check if the power cord and the cables to other devices are properly connected.

2. See Chapter 6 to find if your problem fits the description. If it does, take the

recommended measure for it.

3. Check if the software required for operation of the NEC Express server is properly

installed.

If the NEC Express server still appears to fail after you have taken the above actions, consult with

your sales agent immediately. Take notes on lamp indications of the server and alarm indications

on the display unit before consultation, which may provide a significant help to your sales agent.

Page 19

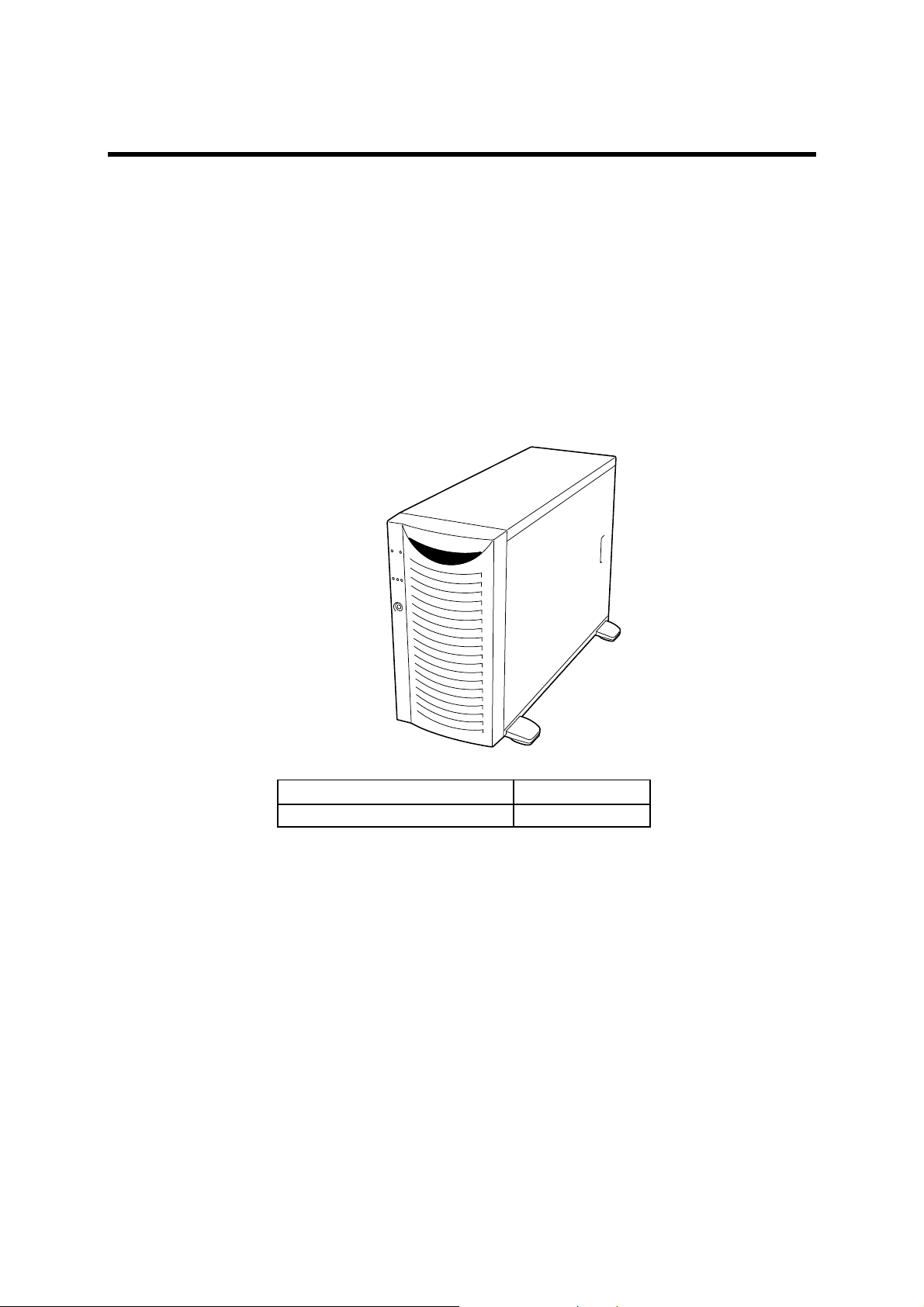

Chapter 2

Overview

This manual describes the maintenance method for NEC Express5800/120Mf basic

processing unit. The explanation is for maintenance personnel who perform site

adjustment, periodic inspection, and repair of NEC Express5800/120Mf basic processing

unit.

APPEARANCE

External dimensions (WDH, mm)

Weight (kg : MAX) 23kg (Max 44kg)

321×675×450

Page 20

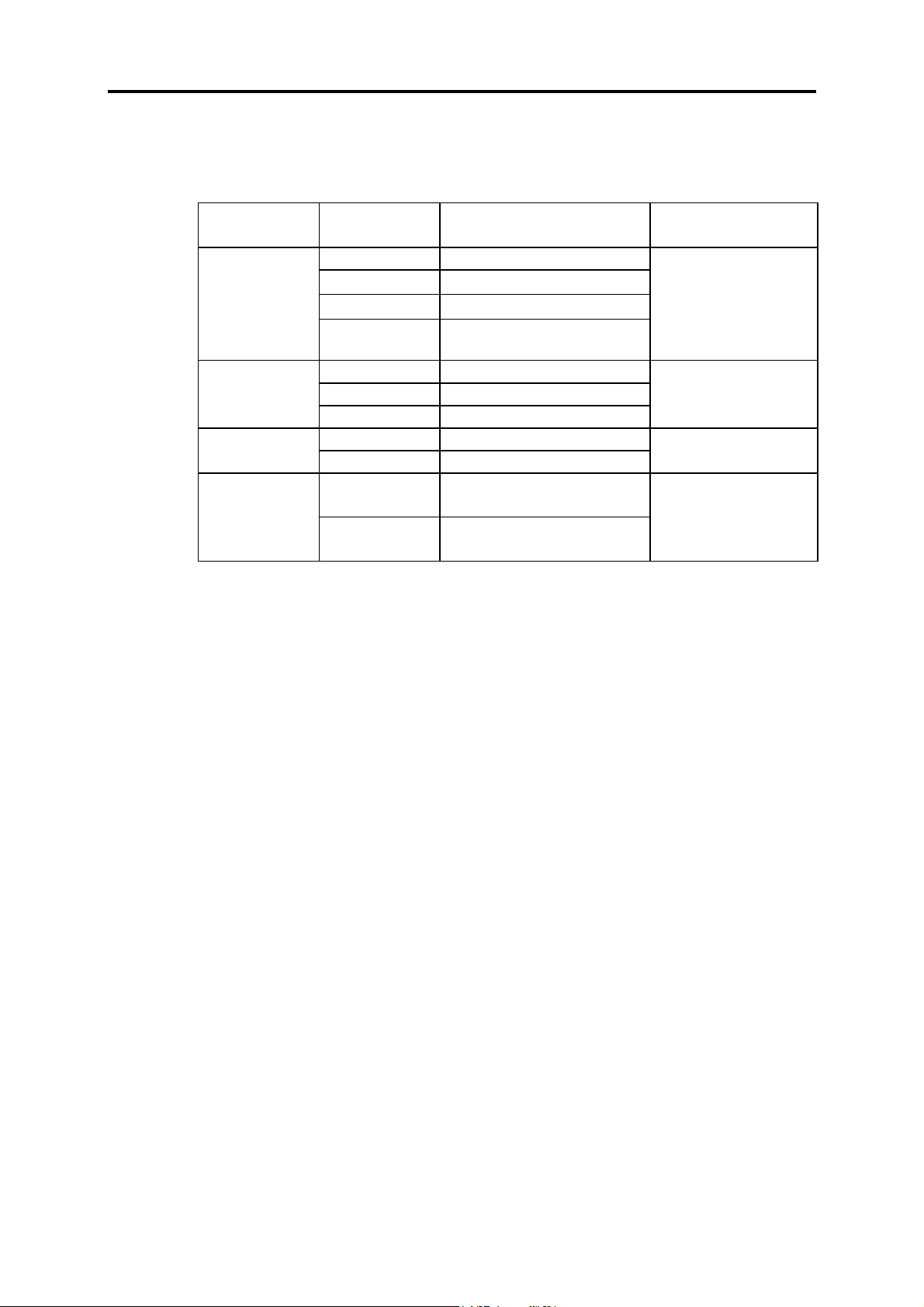

2-2 Overview

SPECIFICATIONS

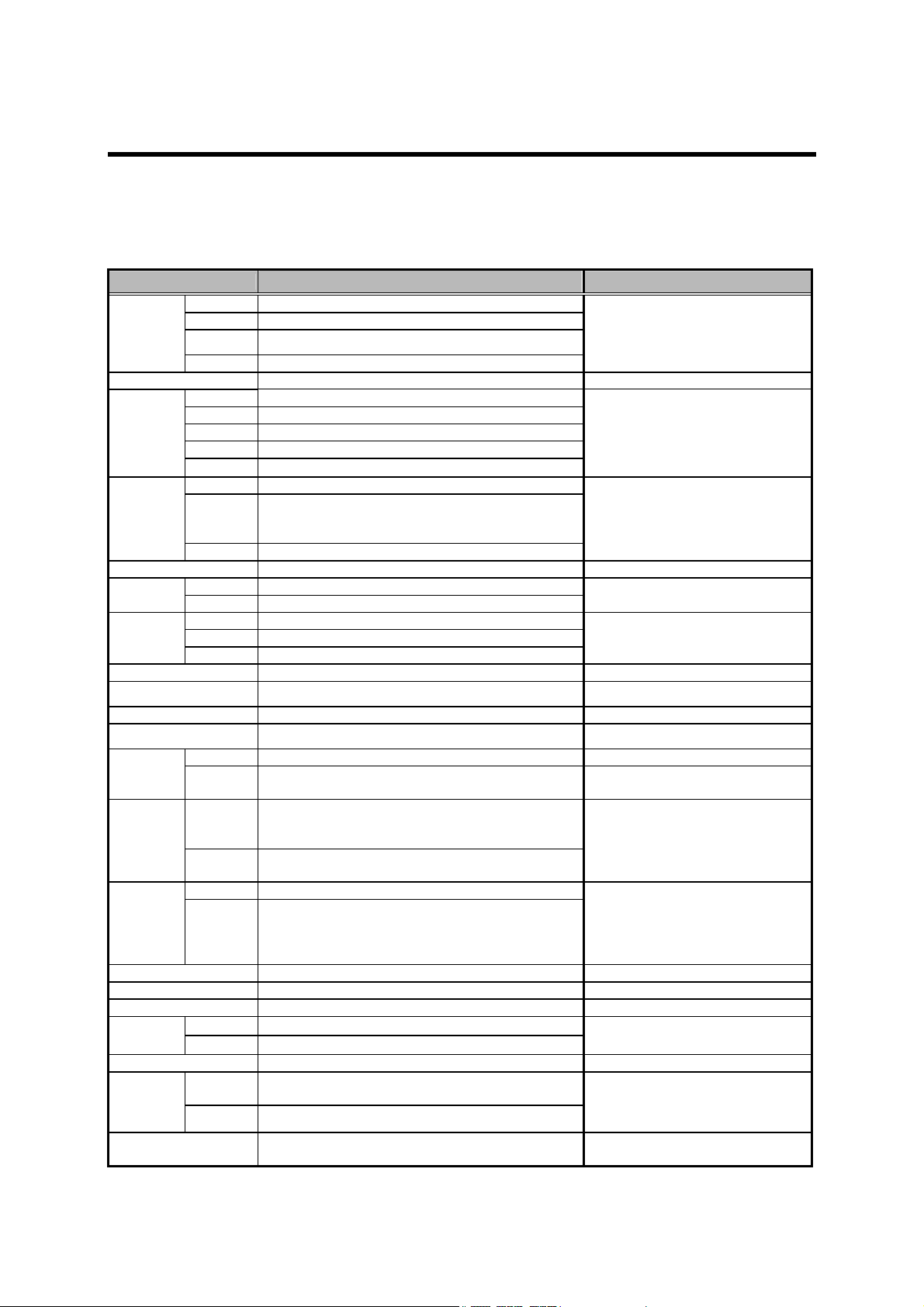

The table below lists the general specifications of the unit.

Major

classification

Input power

Power

consumption

humidity

Noise

Minor

classification

Power supply Single phase, 2-pole grounding

Voltage

Frequency

Waveform

distortion

Input current 5.3 A

Apparent power 530 VA

Active power 520 W

Temperature 10 to 35oC Temperature and

Humidity 20 to 80%RH

POWER level

Sound pressure

level

100 to 240 VAC±10%

50±1 Hz or 60±1 Hz

10%

62.8 dB (operating)

60.9 dB (standby)

52.9 dB (operating)

51.7 dB (standby)

Standard Remarks

The power supply itself

is capable between 100

to 240 VAC, however,

the value at the left is

used as a unit

specification.

AC100V

No condensation is

allowed

Page 21

Chapter 3

Unit Configuration

SPECIFICATIONS

Processor Prestonia x 1-2

CPU

Chipset

Memory

HDD

IDE I/F

SCSI I/F

DiskArray

LAN

Video (VRAM) 640x480 ~ 1280x1024 (8MB)

FDD 3.5" (2mode) x1

CD-ROM Standard (x48/Half Height)

Device bay

I/O slot

I/O

interface

Power Supply(PS) Hotswap 2+1 x 350W (PFC) 1 AC cable/1 Power Supply

Redundant PS Yes (option) Hotswapable

Redundant FAN Yes (standard) Hotswapable

Switch

Front door Key Yes

LED

Chassis design

(WxDxH)

FSB

Package

L3 Cache

Grand Champion-LE(REV A3.1)

Max. 6GB (6 DIMMs)

DIMM

ECC Yes

Chipkill Yes

SpareMem Yes

Standard 0GB

Max.

HotPlug Yes

Non RAID

RAID

Internal Option

Max. 4 boards

Ext. Option

5.25” 3* (One for CDROM) *2 slots when rack conversion

3.5”

Slot

Hot Plug

PCI

Front Serial(DB9) x1*,USB x1

Rear

Front Power, Sleep, Reset, Dump

Rear No

Front

Rear LAN Link/Act. X2, LAN Speed x2, UID

DDR266

U320 10Krpm 36GB/73GB/146GB

U320 15Krpm 36GB/73GB

10/100/1000BASE-T x2

Standard: 5(1”) + Option 5(1”)

(64bit/133MHz PCI-X x1, 64bit /100MHz PCI-X x2,

CRT x1, KB(PS/2) x1, Mouse(PS/2) x1,

USB x3,Serial(DB9) x2*,

Parallel x1, 1000BASE-T x2,

Ultra320 SCSI x1, ICMB x2(PCI slot option)

Power/Sleep, System Status, HDD

Middle-Tower (321 x 675 x 450mm) Rack conversion(5U)

120Mf

533MHz

FC-mPGA2

512KB

SDRAM DIMM(Registered)

10 x 146GB+

Ultra ATA100 x1ch For CD-ROM/DVD-ROM/DVD-RAM

Ultra320

32bit/33MHz PCI x3)

LAN Link/Act. x2, UID

SCSI x2ch

iROC

Total 6slots

No

2Way-Interleave

128/256/512MB/1GB DIMM

*Online Spare memory

Intel Alliance Carrier

Ultra320,10K/15Krpm, SCA2

Standard: 5 slots

Optional: 5 slots added HDD cage

On-Board (AIC7899W)

LL MegaRAID

On-Board, RemoteWakeUp

Max. 2HDD cages

Ultra160 SCSI BP

* Alternatively used

Notes

On Board, RageXL

Standard CDROM:

Page 22

3-2 Unit Configuration

NAMES AND FUNCTIONS OF COMPONENTS

Please refer to the User’s Guide.

CONNECTOR LOCATION

Please refer to the User’s Guide.

BLOCK DIAGRAM

See next page.

Page 23

3-3 Unit Configuration

Page 24

3-4 Unit Configuration

CABLE CONNECTION LIST

Page 25

Chapter 4

Troubleshooting

If your NEC Express server does not operate as expected, read this chapter before

assuming a failure.

NOTE: Troubleshooting and POST error messages refer to

User Guides.

POST Error Message List

On-screen error message Description Cause Action

0200 Failure Fixed Disk Hard disk failure

0210 Stuck Key

0211 Keyboard error Keyboard error Keybord failed Check connection

0212

0213

0220

0230

0231

0232

0250

0251

0252

0260 System timer error A system timer error

0270 Real time clock error A real-time clock error RTC failed

Keyboard controller

Failed

Keyboard locked Unlock key switch

Monitor type does not

match CMOS - Run

SETUP

System RAM Failed

at offset

Shadow Ram Failed at

offset

Extended RAM Failed

at address line

System battery is dead

- Replace and run

SETUP

System CMOS

checksum bad Default configuration

used

Password checksum

bad - Passwords

cleared

Keyboard connection

error

Keyboard controller

failure

Keyboard is locked. Keyboard is locked. Release Keyboard lock

The monitor type is not

consistent with the

CMOS data.

System RAM error.

Shadow RAM error.

Extended RAM error.

The system battery is

worn out.

The system CMOS

checksum is incorrect.

The checksum of a

password is inaccurate.

1. Incorrect setting in

Setup

2. HDD failed

3. Motherboard failed

Poor keyboard

connection

Keybord controller

failed

Incorrect monitor type

setting

DIMM failed 1. Replace DIMM

NV-RAM battery Replace Motherboard

NVRAM failed 1. Reset Setup parameters

Password cleared

1. Check parameters

entered in Setup

2. Replace HDD

3. Replace Motherboard

1. Disconnect and reconnect

keyboard.

2. Replace keyboard

3. Replace Motherboard

1. Check connection

2. Re-Start

3. Replace Mother Board

1. Reset default values in

Setup.

2. Clear CMOS

2. Replace Motherboard

2. Replace Motherboard

Reset Setup parameters

Replace Motherboard

Page 26

4-2 Troubleshooting

On-screen error message Description Cause Action

0271

Check data and time

setting

The real-time clock

time setting is incorrect.

Unusual time setup of

RTC

1. Reset Setup parameters

2. Replace Motherboard

0280

02B0 Diskette drive A error A floppy disk A error

02B1 Diskette drive B error A floppy disk B error

02B2

02B3

02D0

02D1

02F4

02F5 DMA Test Failed DMA test error

02F6 Software NMI Failed Software NMI error

02F7

0611

0612

0613

0614

0615

0616

0617

0618

0619

061A

0B00

0B01

Previous boot

incomplete - Default

configuration used

Incorrect Drive A type

- run SETUP

Incorrect Drive B type

– run SETUP

System cache error Cache disabled

System Memory

exceeds the CPU's

caching limit.

EISA CMOS not

write able

Fail-safe Timer NMI

Failed

IDE configuration

changed

IDE configuration

error-device disabled

COM A configuration

changed

COM A config. errordevice disabled

COM B configuration

changed

COM B config. Errordevice disabled

Floppy configuration

changed

Floppy config. error device disabled

Parallel port

configuration changed

Parallel port config.

error - device disabled

Rebooted during

BIOS boot at Post

Code

Rebooted during OS

boot.

The last boot is

imperfect.

Incorrect drive A type

Incorrect drive B type

A system cache error 1. CPU failed

The memory exceeds

the limit of the cache of

CPU.

It cannot write in EISA

CMOS.

Fail-safe Timer error

The composition error

of IDE

The composition device

error of IDE

The composition error

of COM A

The composition device

error of COM A

The composition error

of COM B

The composition device

error of COM B

The composition error

of Floppy

The composition device

error of Floppy

The composition error

of Parallel port

The composition device

error of Parallel port

The system re-started

during BIOS boot

The system re-started

during OS boot

Default value was set. Reset Setup parameters

FDD error Replace FDD

Incorrect settings Reset Setup parameters

1. CPU Exchange

2. Motherboard failed

Motherboard failed Replace Motherboard

2. Replace Motherboard

Page 27

4-3 Troubleshooting

On-screen error message Description Cause Action

0B02

0B1B

0B1C

Rebooted during OS

Runtime.

PCI System Error on

Bus/Device/Function

PCI Parity Error on

Bus/Device/Function

The system re-started

during OS Running

A PCI system error

occurred on the bus,

device, or function.

A PCI parity error

occurred on the bus,

device, or function.

0B22

0B28

0B29

0B30 Fan 1 Alarm occurred.

0B31 Fan 2 Alarm occurred.

0B32 Fan 3 Alarm occurred.

0B33 Fan 4 Alarm occurred.

0B34 Fan 5 Alarm occurred.

0B35 Fan 6 Alarm occurred.

0B50

0B51

0B5F

0B60

0B61

0B62

0B70

0B71

0B74

Processors are

installed out of order.

Unsupported

Processor detected on

Processor 1

Unsupported

Processor detect on

Processor 2

CPU #1 with error

taken off line

CPU #2 with error

taken off line

Forced to use

Processor with error

DIMM group #1 has

been disabled

DIMM group #2 has

been disabled

DIMM group #3 has

been disabled

The error occurred

during temperature

sensor reading.

System Temperature

out of the range.

The error occurred

during voltage sensor

reading.

Failure of a processor

Unsupported processor

mounted as processor 1.

Unsupported processor

mounted as processor 2.

Fan errors 1. Fan is blocked

CPU #1 was degraded

due to an error detected

for CPU #1.

CPU #2 was degraded

due to an error detected

for CPU #1.

A CPU error was

detected.

A memory error was

detected. Memory #1 is

degraded.

A memory error was

detected. Memory #2 is

degraded.

A memory error was

detected. Memory #3 is

degraded.

An error was detected in

the course of thermal

error detection.

A thermal error was

detected.

An error occurred while

detecting the voltage.

Processor errors 1. Replace CPU

2. Fan failed

3. Motherboard failed

1. CPU# 1 failed

2. Motherboard failed

1. CPU# 2 failed

2. Motherboard failed

1. Replace CPU

1. Replace Memory #1

1. Replace Memory #2

1. Replace Memory #3

1. SMBus Device

failed

2. SMBus Cable

failed

1. Clean fan

Motherboard failed 1. Turn off AC

2. Replace Motherboard

1. Check fan connection

2. Clean fan

3. Replace fan

4. Replace Motherboard

1. Replace CPU #1

2. Replace Motherboard

1. Replace CPU #2

2. Replace Motherboard

2. Replace Motherboard

2. Replace Motherboard

2. Replace Motherboard

2. Replace Motherboard

1. Turn off AC

2. Check cable

3. Replace Motherboard

2. Replace fan

3. Replace boards

2. Check connection of

internal cables

Page 28

4-4 Troubleshooting

On-screen error message Description Cause Action

0B75

0B78

0B7C

0B7D

0B80

0B81

0B82

0B83

System Voltage out of

the range.

The error occurred

during fan sensor

reading.

The error occurred

during redundant

power module

confirmation.

The normal operation

can't be guaranteed

with use of only one

PSU.

BMC Memory Test

Failed.

BMC Firmware Code

Area CRC check

failed.

BMC core hardware

failure.

BMC IBF or OBF

check failed.

A system voltage error

was detected.

An error was detected

during fan sensor

reading.

The error was detected

while having constituted

the redundant power

supply.

Basic power supply

composition required

for this equipment is not

filled.

A BMC device (chip)

failure

Access to the BMC

address failed.

1. SMBus Device

failed

2. SMBus Cable

failed

1. SMBus Device

failed

2. SMBus Cable

failed

Power supply error Replace a power supply

BMC failed 1. Turn off AC and re-start

internal cables

3. Replace internal cables

4. Replace boards

1. Turn off AC

2. Check cable

3. Replace Motherboard

2. Replace Motherboard

0B8A BMC SEL area full.

0B8B

0B8C

0B8D

0B8E

0B8F

0B90

0B91

0B92

0B93

BMC progress check

timeout.

BMC command

access failed.

Could not redirect the

console - BMC Busy -

Could not redirect the

console - BMC Error -

Could not redirect the

console - BMC

Parameter Error -

BMC Platform

Information Area

corrupted.

BMC update firmware

corrupted.

Internal Use Area of

BMC FRU corrupted

BMC SDR Repository

empty.

An opening is not in the

capacity of SEL.

BMC check was

interrupted temporarily.

BMC command access

failed.

Console redirection

cannot be carried out

(BMC Busy)

Console redirection

cannot be carried out

(BMC error)

Console redirection

cannot be carried out

(BMC Parameter error)

A BMC device (chip)

failure

An error of the SROM

that stores the chassis

information

A BMC device (chip)

failure

BMC failed

1. SROM failed

2. BMC failed

BMC failed

1. Turn off AC and re-start

2. Replace Motherboard

Page 29

4-5 Troubleshooting

On-screen error message Description Cause Action

0B94

0B95

0B96

0B97

0B98 BMC RAM test error. BMC RAM error

0B99

0B9A

0B9B

0B9C

0B9D

0B9E

0B9F SEL corrupt.

0BB0

0BB1

IPMB signal lines do

not respond.

BMC FRU device

failure.

BMC SDR Repository

failure.

BMC SEL device

failure.

BMC Fatal hardware

error.

Management

controller not

responding

Private I2C bus not

responding.

BMC internal

exception

BMC A/D timeout

error.

SDR repository

corrupt.

SMBIOS - SROM

data read error.

SMBIOS - SROM

data checksum bad.

An SMC (Sattelite

Management

Controller) error

An error of the SROM

that stores the chassis

information

The access error to

FMEM sector in which

SDR information was

stored

A BMC device (chip)

failure

BMC error

BMC error

It-less answers from

private I2 C bus

BMC error

BMC error

The error of BMC or

the data of SEL is

destroyed.

The error of BMC or

the data of SEL is

destroyed.

Incorrect SROM data

read

Incorrect SROM data

checksum

BMC failed 1. Turn off AC and re-start

2. Replace Motherboard

Turn off AC and

replace CPU#1

1. Turn off AC and re-start

2. Replace boards

0BC0

0BC1

0BD0

0BD1

0BD2 1st SMBus timeout.

POST detected startup

failure of 1st

Processor.

POST detected startup

failure of 2nd

Processor.

1st SMBus device

address not

acknowledged.

1st SMBus device

Error detected.

Processor 1 error

Processor 2 error

A device-less answers

to 1st SMBus access.

The error was detected

to 1st SMBus access

The timeout occurred to

1st SMBus access.

Turn off AC and replace

CPU#1

Turn off AC and replace

CPU#2

SMBus Access error 1. Turn off AC and re-start

2. Replace boards

3. Replace internal cables

Page 30

4-6 Troubleshooting

On-screen error message Description Cause Action

0BD3

nd

SMBus device

2

address not

A device-less answers

nd

SMBus access.

to 2

acknowledged.

0BD4

0BD5 2nd SMBus timeout.

nd

SMBus device

2

Error detected.

The error was detected

nd

to 2

SMBus access

The timeout occurred to

2nd SMBus access.

0BD6

rd

SMBus device

3

address not

A device-less answers

rd

SMBus access.

to 3

acknowledged.

0BD7

0BD8 3rd SMBus timeout.

0BD9

rd

SMBus device

3

Error detected.

th

SMBus device

4

address not

The error was detected

rd

to 3

SMBus access

The timeout occurred to

rd

SMBus access.

3

A device-less answers

th

SMBus access.

to 4

acknowledged.

0BDA

0BDB 4th SMBus timeout.

0BDC

th

SMBus device

4

Error detected.

th

SMBus device

5

address not

The error was detected

th

to 4

SMBus access

The timeout occurred to

th

4

SMBus access.

A device-less answers

th

to 5

SMBus access.

acknowledged.

0BDD

0BDE 5th SMBus timeout.

0BE8

0BE9

0BEA IPMB timeout.

th

SMBus device

5

Error detected.

IPMB device address

not acknowledged.

IPMB device Error

detected.

The error was detected

th

to 5

SMBus access

The timeout occurred to

th

5

SMBus access.

A device-less answers

to IPMB access

The error was detected

to IPMB access

The timeout occurred to

IPMB Access error

IPMB access.

8100

8101

Memory Error

detected in DIMM

group #1

Memory Error

A memory error was

detected.

DIMM error Replace two DIMMs.

detected in DIMM

group #2

8102

Memory Error

detected in DIMM

group #3

8120

8121

Unsupported DIMM

detected in DIMM

group #1

Unsupported DIMM

Unsupported DIMM

was detected.

detected in DIMM

group #2

Page 31

4-7 Troubleshooting

On-screen error message Description Cause Action

8122

8130

8131

8132

8140

8141

8142

8150

8160

8161

Unsupported DIMM

detected in DIMM

group #3

Mismatch DIMM

Type detected in

DIMM group #1.

Mismatch DIMM

Type detected in

DIMM group #2.

Mismatch DIMM

Type detected in

DIMM group #3.

DIMM group #1 with

error is enabled.

DIMM group #2 with

error is enabled.

DIMM group #3 with

error is enabled.

NVRAM Cleared By

Jumper

Mismatch Processor

Speed detected on

Processor 1

Mismatch Processor

Speed detected on

Processor 2

The type of DIMM is

not in agreement.

Failed DIMM in group

#1 was detected.

Failed DIMM in group

#2 was detected.

Failed DIMM in group

#3 was detected.

NVRAM was cleared

by jumper setup.

The frequency of

processor 1 is not

correct.

The frequency of

processor 2 is not

correct.

1. Check that DIMMs of the

same type are installed in

groups.

2. Replace DIMMs.

Replace both DIMMs.

Incorrect jumper

setting

Processor errors

Turn off power and change

the jumper setting back to

its default position.

Page 32

4-8 Troubleshooting

Error Beep Codes

Beep Error Cause Troubleshooting

1-2-2-3 ROM checksum error FMEM checksum error Replace MotherBoard

1-3-1-1 DRAM refresh test error Memory refresh error Replace DIMM

1-3-1-3 Keyboard controller error Keyboard controller

error

1-3-3-1 DIMM can not be detected Memory not installed or

cannot write.

1-3-3-1 Memory check error ↑ ↑

1-3-4-3 DRAM test low byte error Memory address signal

fault (low side)

2-2-3-1 Unjust exception test error Unjust exception Replace MotherBoard

1-2 Video configuration fails Expansion VGA BIOS

memory Deployment failure

1-2 OPTION ROM Checksum failure Expansion ROM BIOS

memory Deployment failure

Replace MotherBoard

Check DIMM

Mounting or Replace

DIMM

Replace MotherBoard

or DIMM

or CPU

Replace MotherBoard

or Graphic board

Replace MotherBoard

or Option board

Page 33

POST Codes

The code displayed using the postcard is shown below.

CP Reason

01 Initialize BMC

02 Verify Real Mode

03 Test BMC

04 Get Processor type

06 Initialize system hardware

08 Initialize chipset registers with initial POST values

09 Set in POST flag

0A Initialize Processor registers

0B Enable Processor cache

0C Initialize caches to initial POST values

0E Initialize I/O

0F Initialize the local bus IDE

10 Initialize Power Management

11 Load alternate registers with initial POST values

12 Restore Processor control word during warm boot

13 Initialize PCI Bus mastering devices

14 Initialize keyboard controller

16 BIOS ROM checksum

17 Initialize external cache before memory autosize

18 8254 timer initialization

1A 8237 DMA controller initialization

1C Reset Programmable Interrupt Controller

20 Test DRAM refresh

22 Test 8742 Keyboard Controller

24 Set ES segment register to 4GB

28

Autosize DRAM, system BIOS stops execution here if the BIOS does not detect any

usable memory DIMMs

29 Initializes the POST Memory Manager

2A Clear 8 MB base RAM

2C Base RAM failure, BIOS stops execution here if entire memory is bad

2E Test the first 4MB of RAM

2F Initialize external cache before shadowing

32 Test Processor bus-clock frequency

33 Initializes the Phoenix Dispatch Manager

34 Test CMOS

35 RAM Initialize alternate chipset registers

36 Warm start shut down

37 Reinitialize the chipset

38 Shadow system BIOS ROM

39 Reinitialize the cache

3A Autosize cache

3C Configure advanced chipset registers

3D Load alternate registers with CMOS values

41 Check unsupported processor

40 Set Initial Processor speed new

42 Initialize interrupt vectors

4-9 Troubleshooting

Page 34

4-10 Troubleshooting

CP Reason

44 Initialize BIOS interrupts

45 POST device initialization

46 Check ROM copyright notice

47 Initialize manager for PCI Option ROMs

48 Check video configuration against CMOS

49 Initialize PCI bus and devices

4A Initialize all video adapters in system

4B Display QuietBoot screen

4C Shadow video BIOS ROM

4E Display copyright notice

4F Allocate memory for the multiboot data

50 Display Processor type and speed

52 Test keyboard

54 Set key click if enabled

55 USB initialization

56 Enable keyboard

58 Test for unexpected interrupts

59 Initialize the POST display service

5A Display prompt “Press F2 to enter SETUP”

5B Disable L1 cache during POST

5C Test RAM between 512 and 640k

60 Test extended memory

62 Test extended memory address lines

64 Jump to UserPatch1

66 Configure advanced cache registers

67 Quick init of all AP's early in post

68 Enable external and processor caches

69 Initialize the SMM handler

6A Display external cache size

6B Load custom defaults if required

6C Display shadow message

6E Display non-disposable segments

70 Display error messages

72 Check for configuration errors

74 Test real-time clock

76 Check for keyboard errors

7A Test for key lock on

7C Set up hardware interrupt vectors

7D Intelligent system monitoring

7E Test coprocessor if present

81 POST device initialization routine

82 Detect and install external RS232 ports

83 Configure non-MCD IDE controllers

84 Initialize parallel ports

85 Initialize PC-compatible PnP ISA devices

86 Re-initialize on board I/O ports

87 Configure Mother Board Configurable Devices

88 Initialize BIOS Data Area

89 Enable Non-Maskable Interrupts

Page 35

4-11 Troubleshooting

CP Reason

8A Initialize Extended BIOS Data Area

8B Test and initialize PS/S mouse

8C Initialize floppy controller

90 Initialize hard disk controller

91 Initialize local bus hard disk controller

92 Jump to UserPatch2

93 Build MPTABLE for multi-processor boards

94 Disable A20 address line

95 Install CD-ROM for boot

96 Clear huge ES segment register

97 Fixup Multi Processor table

98 Search for option ROMs. One long, two short beeps on checksum failure

99 Check for SMART Drive

9A Shadow option ROMs

9C Set up Power Management

9D Initialize security engine

9E Enable hardware interrupts

A0 Set time of day

A2 Check key lock

A4 Initialize typematic rate

A8 Erase F2 prompt

A9 Prepare boot

AA Scan for F2 key stroke

AC Print bottom message

AE Clear the POST flag

B0 Check POST Error

B2 POST End

B4 Beep once

B5 End the Quiet Boot

B6 Check Password

B7 Configuration ACPI

B9 Prepare boot

BA DMI Configuration

BC Clear parity checkers

BD Display Boot Menu

BE Clear Screen

C0 INT19

C1 Initialize the POST Error Manager

C2 Invoke End of POST Error Logging

C3 Invoke End of POST Error Message Display

C6 Initialize Console Redirection

C7 Control Console Port

CD Initialize Console Redirection

D1 Initialize BIOS stack

D3 Find an A20-agnostic place in memory

Page 36

4-12 Troubleshooting

Page 37

Chapter 5

Preventive Maintenance

PERIODIC MAINTENANCE

The following items are to be periodically maintained every 6 months.

No. Check Item

1 Cleaning of FDD head

2 Check fan operation

3 Check T&D operation

4 Check date and time of

internal clock

5 Check UPS battery

6 Cleaning of CD-ROM head

7 Check switches

* If any option is added, follow the instructions for that option.

MAINTENANCE BY USER

Request the user for maintenance of the following items.

No. Item Frequency Remarks

1 Confirm date and time of the

internal clock

2 Check test programs At site adjustment

3 Execution of test program at

failure, and collection of error

data

4 Cleaning of head and running

section of CD-ROM and DAT

Site Regular Daily

Frequency

○ ○

○ ○

○ ○

○ ○ ○

○ ○ ○

At restart of the system

after holidays.

At error occurrence

At regular check

At error occurrence

Once a day According to the

○

○ ○

Clean it at the same time.

Remarks

Clean options such as

DAT.

Check smoothness.

instruction manual

Page 38

5-2 Preventive Maintenance

Page 39

Chapter 6

Installing Internal Optional Devices

PREPARING FOR INSTALLATION AND REMOVAL

Follow the procedure below to prepare for installing or removing components.

a. Shut down the OS.

b. Press the POWER switch to power off the NEC Express server (the POWER lamp goes

off).

c. Unplug the power cord of the NEC Express server from a power outlet.

The power cord appended to

the server as standard.

d. Remove all cables from the rear of the NEC Express server.

e. A clearance of one to two meters must be provided around and over the NEC Express

server.

The power cord appended to

the extension power unit.

Page 40

6-2 Installing Optional Internal Devices

POWER SUPPLY CAGE

Removing the Power supply unit (CAGE)

a. See the section “Preparing for Installation and Removal” described earlier to prepare.

b. Remove the left side cover

c. Remove all power cables from the motherboard, 5.25-inch devices, floppy drive and

SCSI-BP.

NOTE: Make sure not to hitch the cable when pulling out the Power supply unit.

d. Remove the two screws on the rear side.

screws

e. Remove the two screws on the front side.

f. Pull out the Power cage gently away from the server chassis.

# Be careful not to force the cage out of the server or not to hook a cable.

Page 41

6-3 Installing Optional Internal Devices

Installing the Power supply unit (CAGE)

Follow the removal procedure in reverse order to install the Power supply unit.

Page 42

6-4 Installing Optional Internal Devices

FAN UNIT

Removing the FAN unit

<HDD FAN UNIT>

a. See the section “Preparing for Installation and Removal” described earlier to prepare.

b. Remove the left side cover.

c. Remove the FAN cover (foaming material: gray color).

d. Remove the FAN DC cable from the Motherboard, and pull out the FAN unit.

<REAR FAN UNIT>

a. See the section “Preparing for Installation and Removal” described earlier to prepare.

b. Remove the left side cover.

c. Remove the FAN DC cable from the Motherboard.

d. Remove the lock of the rear fan unit. Pull out the FAN unit.

Installing the FAN unit

Lock

Follow the removal procedure in reverse order to install the FAN unit.

Page 43

6-5 Installing Optional Internal Devices

MOTHERBOARD

Removing the Motherboard

* After replacing the motherboard, you need to re-set the NvRAM information

and SDR FW on the new motherboard.

Make backup copies of the current NvRAM information before replacing the

motherboard, and restore the information onto the new motherboard after the

replacement. For details, see "Management of Setup Information."

If the system is unable to make backup copies, set the NvRAM information.

a. See the section “Preparing for Installation and Removal” described earlier to prepare.

b. Remove the left side cover

c. Take out the DIMM boards, PCI boards and cables.

d. Remove the screws securing the Motherboard.

e. Take out the Motherboard carefully to avoid any damage.

Installing the New Motherboard

Follow the removal procedure in the reverse order to mount the new motherboard.

Note the following points in mounting it:

1) Confirm that all the cables are connected correctly, no wire is caught, and all the

connectors are connected correctly.

2) Do not bend the springs and gaskets for EMI prevention measures.

3) After mounting the new motherboard, connect the cables firmly by using clamps.

4) For mounting of the heat sink, see Section 5.

5) Mount the provided heat-conduction sheet between the CPU and the heat sink.

Be careful not to bend the heat-conduction sheet when mounting it.

Page 44

6-6 Installing Optional Internal Devices

Making Backup Copies of NVRAM Information

a. Set the NEC EXPRESSBUILDER CD-ROM in the CD-ROM drive, and activate the

NEC EXPRESSBUILDER.

b. When the NEC EXPRESSBUILDER becomes active, activate the Offline Maintenance

utility by selecting "Tool" from the menu → "Offline Maintenance Utility" → " Manage

System Information".

c. When the Offline Maintenance utility becomes active, select "Save" from the menu.

After that, a message is displayed "asking if you want to format the floppy disk."

Respond to the message to format the floppy disk if necessary.

The data backup confirmation screen appears after the format confirmation screen.

Press the "Enter" key to perform backup processing.

(Screen image)

Offline Maintenance Utility

Edit/Display HW Logs

Edit/Display SW Logs

Edit/Display HW Event Logs

Display BIOS Setup Information

Display System Information

Manage System Information

Set Remote Maintenance Information

Help

Exit

Manage System Information

Save

Menu for Maintenance Persons

Exit

Page 45

6-7 Installing Optional Internal Devices

Restoring NVRAM Information

a. Set the NEC EXPRESSBUILDER CD-ROM in the CD-ROM drive, and activate the

NEC EXPRESSBUILDER.

b. When the NEC EXPRESSBUILDER becomes active, activate the Offline Maintenance

utility by selecting "Tool" from the menu → "Offline Maintenance Utility" → " Manage

System Information."

c. When the Offline Maintenance utility becomes active, select "Menu for Maintenance

Persons" from the menu.

(Screen image)

Offline Maintenance Utility

Edit/Display HW Logs

Edit/Display SW Logs

Edit/Display HW Event Logs

Display BIOS Setup Information

Display System Information

Manage System Information

Set Remote Maintenance Information

Help

Exit

Manage System Information

Save

Menu for Maintenance Persons

Exit

d. Do not care about a notice displayed, and press the Enter key. The system asks you to

enter the password. Enter the password as shown below.

Password >CENVRAM

e. Select restoration of the old board information when the following screen appears after

you enter the password:

Menu for Maintenance Persons

Restore (at replacement of the mother board)

Update Product/Cabinet Information

Return to the Previous Menu

Page 46

6-8 Installing Optional Internal Devices

f. When the "Restore (at replacement of the mother board)" screen appears, insert the

floppy disk containing the backup copies of the NVRAM information into the floppy disk

drive, and press the Enter key.

(The following is an image screen, which may be different from the actual one.)

Restore (at replacement of the mother board)

Data Name Device Address Size File Name Setup

BIOS Information 1 -------- -------- -------- -------- O

BIOS Information 2 -------- -------- -------- -------- O

Maintenance Utility Information -------- -------- -------- -------- O

BMC Information 1 -------- -------- -------- -------- O

BMC Information 2 -------- -------- -------- -------- O

BMC Information 3 -------- -------- -------- -------- O

ROM Pilot Information 1 -------- -------- -------- -------- O

ROM Pilot Information 2 -------- -------- -------- -------- O

Product Information -------- -------- -------- -------- O

Cabinet Information -------- -------- -------- -------- O

Internal useara -------- -------- -------- -------- O

Start restoration (Data with a circle shown in the column "Setup" is restored.)

Exit: [ESC]

g. Press the Enter key when the following confirmation screen appears.

After that, the NVRAM information is loaded from the floppy disk.

Restore (at replacement of the mother board)

Execute: [Enter] Cancel: [ESC]

The restore processing is in progress.

Wait until the processing is completed.

h. The screen displays restoration results as shown below.

(The following is an image screen, which may be different from the actual one.)

Restore (at replacement of the mother board): Execution results = normal

Data Name Device Address Size File Name Setup Result

BIOS Information 1 -------- -------- -------- -------- O O

BIOS Information 2 -------- -------- -------- -------- O O

Maintenance Utility Information -------- -------- -------- -------- O O

BMC Information 1 -------- -------- -------- -------- O O

BMC Information 2 -------- -------- -------- -------- O O

BMC Information 3 -------- -------- -------- -------- O O

ROM Pilot Information 1 -------- -------- -------- -------- O O

ROM Pilot Information 2 -------- -------- -------- -------- O O

Product Information -------- -------- -------- -------- O O

Cabinet Information -------- -------- -------- -------- O O

Internal useara -------- -------- -------- -------- O O

Exit: [ESC]

i. Terminate the Offline Maintenance utility when the NVRAM information has been

loaded from the floppy disk.

Page 47

6-9 Installing Optional Internal Devices

If the System is Unable to Make Backup Copies of NVRAM Information

Set the NVRAM information on the new motherboard by taking the following steps.

a. Set the NEC EXPRESSBUILDER CD-ROM in the CD-ROM drive, and activate the

NEC EXPRESSBUILDER.

b. When the NEC EXPRESSBUILDER becomes active, activate the Offline Maintenance

utility by selecting "Tool" from the menu → "Offline Maintenance Utility" → "Manage

System Information."

c. When the Offline Maintenance utility becomes active, select "Menu for Maintenance

Persons" from the menu.

(Screen image)

Offline Maintenance Utility

Offline Maintenance Utility

Manage System Information

Execute the Offline Maintenance Utility

Set Remote Maintenance Information

Return to the Custom Setup Menu

⇓

Manage System Information

Save

Menu for Maintenance Persons

Exit

d. Do not care about a notice displayed, and press the Enter key. The system asks you to

enter the password. Enter the password as shown below.

Password >CENVRAM

e. Select "Update Product/Cabinet Information" when the following screen appears after

you enter the password:

Menu for Maintenance Persons

Restore (at replacement of the mother board)

Update Product/Cabinet Information

Return to the Previous Menu

f. The screen shown below appears. Move the cursor to "Set Default Values" and press the

Enter key.

Page 48

6-10 Installing Optional Internal Devices

Update Product/Cabinet Information

Data Name Set Value

Manufacturer (Manufacturer Name) NEC

Model Name (Product Name) NEC Express5800/1**** (*: Model name)

N Code (Product Part) [N8100-***]

FR Number (Product Version) FR*.*

Serial Number (Product Serial)

Cabinet Information 0000***

Set Default Values

Update

g. The device type list is displayed. Select the target device type.

(If the target device type is not in the list, select an arbitrary device type.)

h. The screen in step 6 is displayed again. Correct the values according to the selected

device.

The following must be changed:

• FR Number

• Serial Number

Cabinet information:

Model

Cabinet

type

120Me 07 856-060230-001-00 05 06

Cabinet model

number

Cabinet

ID

i. Return to the screen in step 6, move the cursor to "Update," and press the Enter key.

When the confirmation screen shown below appears, press the Enter key again.

Cabinet

attribute

Update Product/Cabinet Information

Execute: [Enter] Cancel: [ESC]

Do you want to update the

product/cabinet information?

When the update processing terminates normally, terminate the NEC

EXPRESSBUILDER according to the instructions displayed on the screen, and confirm

that the device starts up normally.

j. When the NEC Logo screen appears during device startup, press the "F2" key to activate

the BIOS SETUP menu, and set the previously set information again.

Page 49

6-11 Installing Optional Internal Devices

d

Updating SDR FW

Refer to the update procedure document of the Motherboard maintenance parts.

Mounting a Heat Sink on the CPU

Refer to the Express Server User’s guide.

Removing the Motherboard

a. Turn off the power, and then pull the AC cable out.

b. Remove a side cover.

c. Extract heat sinks, CPUs, memory boards, PCI boards, etc.

The following procedure explains how to remove a heat sink. (Please DO NOT pull

up straight to draw out a heat sink. If it is removed that way, CPU may be taken out

with heat sink. )

1. When removing retention, use a minus

driver or the tool only for removal of a clip,

hook on a hole and remove.

To remove a CPU, follow the procedure for installing a heat sink in reverse order.

2. Remove the retention.

3. Please turn the heat sink to the right an

left lightly to remove it. Please DO NOT pull

up straight.

Page 50

6-12 Installing Optional Internal Devices

d. Remove the screws fixing the Motherboard.

Remove R / M fixed

screws as well.

e. Take out the Motherboard carefully so as to avoid damaging it.

Be sure to respect the specified order when removing components

When you remove a motherboard, first remove CPUs and heat sinks (a total of eight screws)

before removing retention modules. Refer to the following page.

Page 51

6-13 Installing Optional Internal Devices

d

t

Retention module

CPU socket

Retention module

CPU socket

<Caution>

When attaching a Heat sink to the newly installed motherboard, please use the new cool sheet

appended to mother board set. Moreover, please remove the old cool sheet of the heat sink with a

driver etc.

Please remove the ol

cool sheet of the hea

sink with a driver etc. Heat Sink

Page 52

6-14 Installing Optional Internal Devices

a

p

How to Attach the Motherboard

To attach the motherboard, follow the removal procedure in the reverse order. Be careful of the

following points.

a. Check cables, confirm that wires are not pressed, install all connectors, etc.

b. Do not bend the spring for EMI and a gasket.

c. Use clamps to connect cables after Motherboard is installed.

d. Follow the instructions below to attach a Heat Sink

The Retention module can be removed by using a minus driver or the removing clip tool.

Socket with dust cover (sponge) removed

1. Pull up the lever.

Lever

2. Install a processor.

3. Push the lever back down and fix

rocessor.

Page 53

p

f

4. Position the heat sink on the

rocessor and hook it on one side o

the retention module.

6-15 Installing Optional Internal Devices

5. Fix the other side of retention

module.

* Caution

When removing the retention, hook the hole

(designated by the arrow on the picture left)

using a thin minus driver or a tool.

Page 54

6-16 Installing Optional Internal Devices

SCSI BACK PANEL (SCSI-B.P) & SAF-TE BOARD

Removing the SCSI-B.P.

a. See the section "Preparing for Installation and Removal" described earlier to prepare.

b. Pull out all hard disks.

c. Remove the left side cover.

d. Remove the cable for SCSI-B.P.

e. Remove five screws and pull out the disk cage gently away from the server chassis.

Page 55

6-17 Installing Optional Internal Devices

f. Remove four screws, and remove the SCSI-B.P. (with SAF-TE board) gently away from

the disk cage.

SCSI-B.P

Installing the SCSI Back Panel

Follow the removal procedure in reverse order to install the SCSI Back Panel.

SAF-TE board

Page 56

6-18 Installing Optional Internal Devices

CD-ROM DRIVE

Removing the CD-ROM Drive

a. See the section "Preparing for Installation and Removal" described earlier to prepare.

b. Remove the left side cover.

c. Remove all cables connected to the CD-ROM drive.

d. Remove four screws in front of the case, and pull out the CD-ROM bracket gently away

from the server.

e. Remove all screws on the side of the CD-ROM drive.

Page 57

6-19 Installing Optional Internal Devices

FLOPPY DISK DRIVE

Removing the FDD

a. See the section "Preparing for Installation and Removal" described earlier to prepare.

b. Remove the left side cover.

c. Remove all cables connected to the FDD.

d. Remove two screws in front of the case, and pull out the CD-ROM bracket gently away

from the server.

e. Remove all screws from the FDD bracket.

Page 58

6-20 Installing Optional Internal Devices

FRONT BEZEL

Removing the Front Bezel

a. Open the front bezel.

b. Use pliers to draw out the pins in the upper and lower corners on the right side of the

server.

Page 59

6-21 Installing Optional Internal Devices

FRONT SUB BEZEL

Removing the Front Sub Bezel

a. See the section "Preparing for Installation and Removal" described earlier to prepare.

b. Remove the left side cover.

c. Remove the lock of the front sub bezel.

d. After shifting the front sub bezel up, pull it toward you and remove it.

.

Lock

Page 60

6-22 Installing Optional Internal Devices

FRONT PANEL BOARD

Removing the Front Panel Board

a. See the section "Preparing for Installation and Removal" described earlier to prepare.