Page 1

DIESEL FUEL

F L O W S E N S O R S

Installation and

Operation Manual

English .................... 3

Español ................. 38

Português ............. 73

www.navman.com

NAV MAN

Page 2

FCC Statement

Note: This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a normal installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an output on a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced technician for help.

A shielded cable must be used when connecting a peripheral to the serial ports.

2

Diesel fuel fl ow sensor kit Installation and Operation Manual

Page 3

Contents

Contents ................................................................................................. 3

Important ................................................................................................ 5

1 Introduction .................................................................................. 6

1-1 Diesel fuel flow sensor features ................................................. 6

1-2 A typical system ........................................................................... 7

A diesel flow sensor .....................................................................................7

1-3 The bypass valve ..........................................................................7

2 Understanding boat performance data ...................................... 8

Boats ............................................................................................................8

Fuel Consumption ........................................................................................8

Engine RPM .................................................................................................8

Boat Speed ..................................................................................................8

3 Plotting a fuel consumption curve ............................................. 9

3-1 Fuel consumption table ............................................................. 12

Notes on filling out this table ......................................................................12

3-2 Understanding the fuel consumption curve ............................ 14

A typical fuel consumption curve ................................................................14

Understanding your fuel consumption curve ..............................................14

Note on fuel usage .....................................................................................14

4 Measuring your propeller’s performance ................................ 15

Propeller size .............................................................................................15

Slip factor ...................................................................................................15

Calculating the slip factor ...........................................................................15

Understanding your slip factor ...................................................................16

5 Measuring engine performance ................................................ 17

5-1 Engine power and propeller curves ......................................... 17

The theoretical propeller load curve ...........................................................18

5-2 Specific fuel consumption curve .............................................. 19

6 Diesel fuel flow sensor hardware ............................................. 20

6-1 What comes with your diesel fuel flow sensor kit .................. 20

6-2 Options and accessories ........................................................... 20

Filtering the fuel ..........................................................................................20

6-3 Sensor fittings ............................................................................ 21

Diesel fuel flow sensor kit Installation and Operation Manual

NAVMAN

3

Page 4

7 Installing the diesel flow sensor kit .......................................... 22

Installation sequence .................................................................................22

7-1 Twin engine installations ........................................................... 22

7-2 Notes on pipes, fittings and installation .................................. 23

7-2-1 Pipe ..........................................................................................................23

7-2-2 Flare Nuts ..................................................................................................23

7-2-3 Flexible Hoses. ..........................................................................................23

7-2-5 Threadseal tape or paste ............................................................................23

7-3 Planning where the parts of the kit will be fitted ..................... 25

7-3-1 Overview ....................................................................................................25

7-3-2 Mounting a sensor ......................................................................................25

7-3-3 Locating the sensors in the fuel lines .........................................................26

Locating the supply sensor ........................................................................26

Locating the return sensor .........................................................................26

Sensor mounting positions .........................................................................26

7-4 Installing the temporary straight through pipes ..................... 28

7-4-1 Installing a through pipe with flare joints into a copper pipe run ................29

7-5 Test running and installing the sensors ................................. 31

7-6 Installing the tachometer pickup .............................................. 33

Locating the tachometer pickup .................................................................33

Installing the tachometer pickup .................................................................34

7-7 Installing the cables ................................................................... 35

7-7-1 Link and tachometer cables .......................................................................35

7-7-2 Connecting to a DIESEL 3200 ...................................................................35

Appendix A Specifications ................................................................. 37

4

NAVMAN

Diesel fuel flow sensor kit Installation and Operation Manual

Page 5

Important

It is the owner’s sole responsibility to install and use the instrument and its sensor(s) in a manner

that will not cause accidents, personal injury or property damage. The user of this product is

solely responsible for observing safe boating practices.

Fuel type: Navman diesel flow sensors (metal) and DIESEL 3200 instruments have been

specifically developed for use in marine applications with diesel engines and are not warranted

for any other type of application. These sensors and instruments must NOT be used with petrol

(gasoline) engines.

Fuel formulation: Every effort has been made by the manufacturer to ensure that the materials

used in the Navman fuel flow sensor(s) will operate reliably with different fuel mixtures. The

manufacturer or its distributors can not be held responsible for fuel formulation or any affect this

may have on the performance and durability of the fuel flow sensor(s).

Back pressure: A diesel fuel flow sensor will create additional back pressure in a fuel system

of an estimated 0.3” of mercury at 25 US gallons /hour (100 litres/hour) and 1.5” of mercury at

80 US gallons per hour (300 litres/hour).

It is the owners responsibility to ensure that fitting the fuel flow sensor(s) does not cause fuel

starvation which may lead to poor engine performance.

Fuel Computer: Fuel economy can alter drastically depending on the boat loading and sea

conditions. The fuel computer should not be the sole source of information concerning available

fuel onboard and the electronic information should be supplemented by visual or other checks

of the fuel load. This is necessary due to possible operator induced errors such as forgetting to

reset the fuel used when filling the tank, running the engine with the fuel computer not switched

on or other operator controlled actions that may render the device inaccurate. Always ensure

that adequate fuel is carried onboard for the intended trip plus a reserve to allow for unforeseen

circumstances.

Specific requirements: Your boat’s fuel installation boat might be subject to specific requirements

(such as USCG, NMMA and ABYC guidelines or local laws), particularly if the boat is licensed,

surveyed, charted or inspected. It is the owner’s sole responsibility to install and use the instrument

and its sensor(s) in compliance with these requirements.

NAVMAN NZ LIMITED DISCLAIMS ALL LIABILITY FOR ANY USE OF THIS PRODUCT IN A

WAY THAT MAY CAUSE ACCIDENTS, DAMAGE OR THAT MAY VIOLATE THE LAW.

Governing Language: This statement, any instruction manuals, user guides and other information

relating to the product (Documentation) may be translated to, or has been translated from,

another language (Translation). In the event of any conflict between any Translation of the

Documentation, the English language version of the Documentation will be the official version

of the Documentation.

This manual represents Navman’s Diesel fuel flow sensor kit as at the time of printing. Navman

NZ Limited reserves the right to make changes to specifications without notice.

Copyright © 2004 Navman NZ Limited, New Zealand. All rights reserved. Navman is a registered

trademark of Navman NZ Limited.

Diesel fuel flow sensor kit Installation and Operation Manual

NAVMAN

5

Page 6

1 Introduction

The Navman diesel fuel flow sensor kit

measures the fuel consumption and RPM of

your diesel engined boat. But that is a gross

understatement of the capabilities of this

powerful diagnostic tool. This manual is written

to help you understand the many functions the

system can perform, and to help you interpret

the numbers it can provide. We also give some

basic information on some of the factors which

can influence boat performance, and what the

various readings from the sensors can reveal

about your boat. Hopefully, by understanding

more, you will no longer think of the engine as

just a noisy and expensive mystery.

In the end we should be able to help you make

your boating experience more relaxing, safer,

more economical and better informed.

This manual describes:

How to install a diesel fuel flow sensor kit

onto a diesel engine (sections 6 and 7).

How to understand and interpret the fuel

sensor readings (sections 2 and 3).

How to use the fuel flow readings to

understand and optimise your propeller

and engine performance (sections 4 and

5).

Note that this fuel flow sensor kit does not

have a display. The kit must be installed with a

Navman marine instrument to display the fuel

readings, such as the DIESEL 3200. A second

sensor kit can be fitted for twin engine boats.

It is vital to read this document and the Navman

display instrument’s installation and operation

manual before installing or using this kit.

1-1 Diesel fuel flow sensor features

A positive displacement flowmeter, with

one moving internal part - there are no

fine pointed shafts and jewelled bearings

to get worn or hammered by diesel

pulsing.

Diecast aluminium housing.

A direct flow bypass valve, to take the

sensor out of the fuel line if required.

Low pressure drop across the sensor.

Simple, in-line installation, much like a

primary fuel filter.

The inlet and outlet ports have a

commonly-available thread: a ¼ NPT

parallel female thread on sensor is used

with a ¼ NPT taper male thread on the

fitting.

No restrictions on pipe geometry on entry

or exit from sensor.

Supplied with temporary straight through

pipes to make installation safer.

Factory tested and calibrated - sensors

do not normally require calibrating again.

Each engine is fitted with two fuel flow sensors.

One sensor, in the the fuel supply line measures

flow from tank to engine. The other sensor, in

the fuel return line measures flow from the

engine back to the tank.

The flow sensor system calculates the engine

consumption from the supply and return flow

rates. It compensates for:

Reverse flow pulsing from diaphragm lift

pumps.

Different fuel temperatures in the supply

and return lines - as fuel heats up it

expands and its viscosity changes

The flow characteristics of the sensors.

The system also has a tachometer to measure

the engine RPM with digital accuracy.

The system reports the fuel flow, total fuel

consumed and engine RPM over a serial digital

information link to the Navman instrument to

display the fuel data.

6

NAVMAN

Diesel fuel flow sensor kit Installation and Operation Manual

Page 7

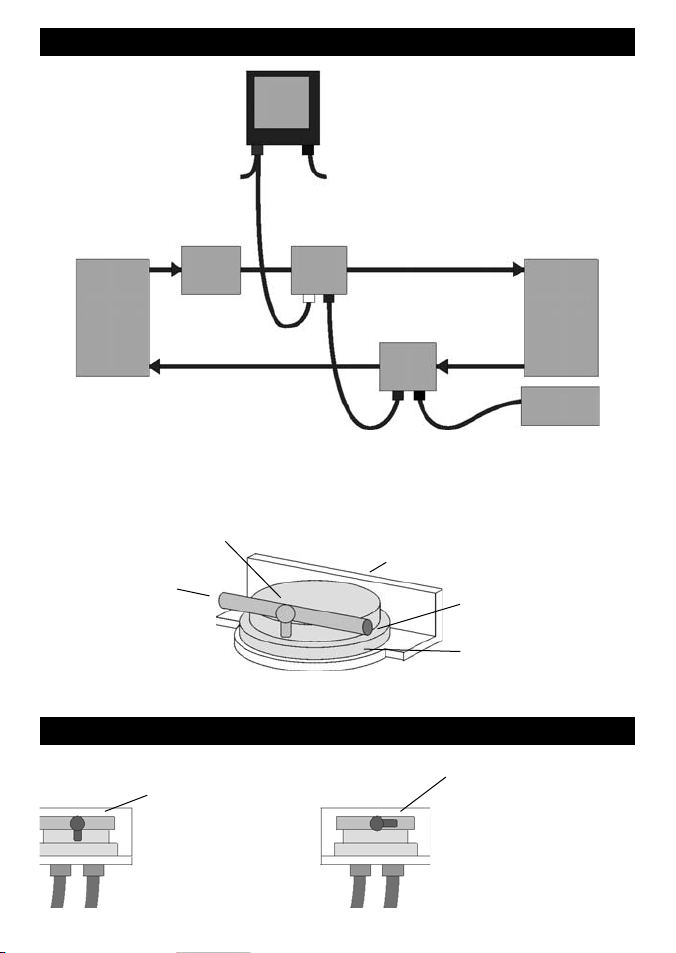

1-2 A typical system

Other wiring and

connection to sensors on

a second engine (optional)

Primary

filter

Diesel

tank

Return fuel line

A diesel flow sensor

Bypass valve (see below)

Fuel inlet / outlet port

Display unit,

such as a

DIESEL 3200

Other connector(s)

Sensor cable

Supply

flow

sensor

Link cable

Supply fuel line

Return

flow

sensor

Tachometer cable

These parts are included

in a diesel flow sensor kit

Mounting bracket

Fuel inlet / outlet port

Diesel

engine

Tachometer

pickup

Two electrical connectors

LED, blinks when fuel is passing

(underneath)

through sensor (underneath)

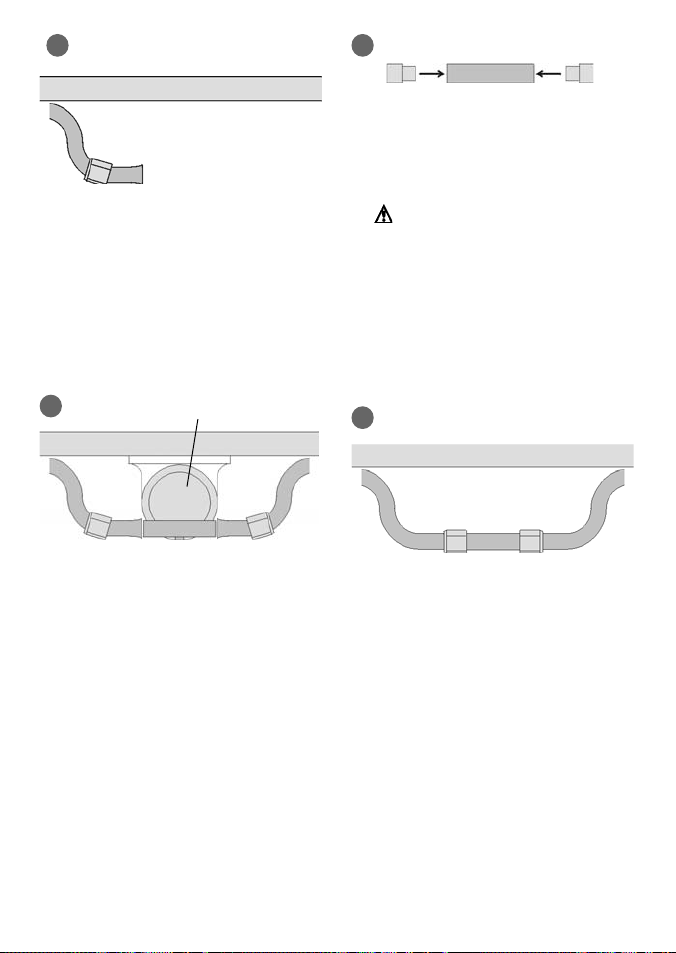

1-3 The bypass valve

Each flow sensor is fitted with a bypass

valve:

Diesel fuel flow sensor kit Installation and Operation Manual

Bypass valve

Normal position, fuel

flows through sensor

NAVMAN

Identification band:

Blue: Supply line sensor

Red: Return line sensor

Bypass valve

Bypass position, fuel flows

directly from the sensor inlet

to the outlet and does not

pass through the sensor

- bypass the sensor if you

suspect the sensor is not

working properly

7

Page 8

2 Understanding boat performance data

As with all measurements, you will get no

meaningful data if you do not have accurate

instruments. Once you have accurate fuel

consumption, boat speed and engine speed

figures, then the true power of the diesel flow

sensors can be used.

Boats

All boats are different - even consecutive boats

off a production line can be quite different

in performance. So there is no real ‘generic’

data that can be applied to your particular

boat/engine/propeller combination.

Fuel Consumption

The simplest set of information you can get

from the diesel flow sensors is fuel consumption

- US Gallons per nautical mile or Litres per

mile. This figure will depend on many factors

- the condition of the hull (clean or fouled), the

loading and trim of the boat, wave and wind

conditions. Over time you will get an idea as to

how different conditions affect the performance

of your boat.

Engine RPM

Engine revolutions per minute (RPM) is the

single most important item in any instrument

package, as it is the base line against which

such things as boat speed, fuel usage, and

propeller efficiency are measured - if your base

line is inaccurate all the readings using it are

inaccurate. Accuracy is all important.

Many rev counters supplied with engines are

not very accurate, and should be recalibrated

after they have been installed in your vessel.

Navman have designed a tachometer as part

of the diesel flow kit. The tachometer measures

engine RPM digitally, with timing derived from

the highly accurate crystal running the whole

system. This digital tachometer never needs

calibrating.

Boat Speed

Check that your boat speed instrument is

reading correctly. If necessary, recalibrate

boat speed as described in the instrument’s

operation manual.

Remember that there are two distinct ways

to describe the movement of a boat - speed

through the water, and speed over the ground.

In still water with no tides or currents then

these two speeds produce the same reading;

otherwise they are quite different, and you need

to be sure you are using the correct one:

Speed through the water is usually read

from a paddle-wheel sensor. Use this

speed to check your boat’s performance

and fuel consumption.

Speed over ground is usually read from

a GPS receiver. Use this speed to work

out maximum range, fuel reserve and

time of arrival.

8

NAVMAN

Diesel fuel flow sensor kit Installation and Operation Manual

Page 9

3 Plotting a fuel consumption curve

A fuel consumption curve gives a picture of how

fuel consumption varies with engine RPM, and

allows you to select an economical cruising

speed for the given conditions. By plotting

fuel consumption curves for different boat and

weather conditions, you can understand how

fuel consumption, economy and range vary with

different conditions.

When you first get your Navman diesel flow

system installed on your boat, perform a test

run and plot a fuel consumption curve. For your

first test run, choose a calm day, with light wind

and little current; have a typical load aboard and

a freshly cleaned hull.

Then you can plot other fuel consumption

curves for different boat, weather or sea

conditions. Compare these with your first curve

to see how your boat’s performance changes

with conditions. These curves will be the

reference curves for your boat. As time goes by

you can refer back to this set of reference data

- you can plot another fuel consumption curve

under the same conditions and compare it to

the reference curve to check how your boat’s

performance is changing over time.

To plot a fuel consumption curve for given

conditions:

1 Take a series of readings of the fuel flows

and boat speed at different engine revs

and fill out the fuel consumption table

(see section 3-1)

2 Plot the data from the fuel consumption

table on a graph. Either photocopy the

graph on the next page or download a

copy from www.navman.com. On the one

graph, plot:

a Boat speed (column 5) against engine

RPM (column 1)

b Economy (column 6) against engine

RPM (column 1)

Section 3-2 shows a typical graph.

3 Interpret this curve to understand your

boat performance (see section 3-2).

Diesel fuel flow sensor kit Installation and Operation Manual

NAVMAN

9

Page 10

1.2

Economy - L / nautical mile

1.0

0.8

0.6

0.4

0.2

0

Displacement Craft

18

10

15

12

NAVMAN

9

6

3

Speed - knots

Diesel fuel flow sensor kit Installation and Operation Manual

0 500 1000 1500 2000 2500 3000

0

Page 11

Economy - L / nautical mile

6

5

4

3

2

1

0

Planing Craft

30

Diesel fuel flow sensor kit Installation and Operation Manual

25

20

15

NAVMAN

10

Speed - knots

5

0 500 1000 1500 2000 2500 3000

0

11

Page 12

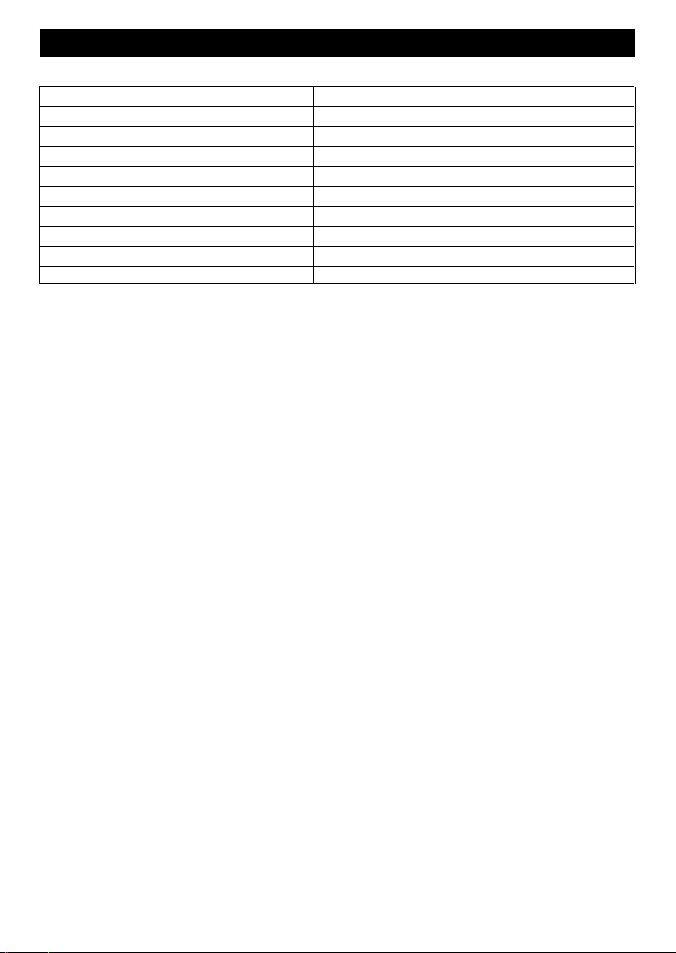

3-1 Fuel consumption table

Photocopy this page or download a copy from www.navman.com

Date Weather Conditions

Vessel Sea State

Displacement

Load aboard

Gearbox ratio Passengers aboard

Engines Water Tanks

Fuel Tanks

Propeller

Max. Fuel Capacity

Working fuel capacity (max x 0.9)

Notes on filling out this table

Start at a slow speed. Allow a minute or two for

the boat to settle to its speed and trim and for

the display readings to stabilise. Then write the

displayed fuel flow(s) and boat speed in a line

of the table on the right, as described below.

Then increase the engine revs by another

100 or 200 rpm, wait a minute or two for the

readings to stabilise and repeat the readings.

Take readings up to the maximum service RPM

of your engine.

Column 1 - Engine RPM

Use the Navman tachometer reading if

possible, to be sure of accurate results. Write

the engine RPM in column 1.

Columns 2 and 3 - Fuel consumption

Units are litres or gallons - we presume you will

want to work in the units you are familiar with,

and that you have set-up the system display to

work in gallons or litres.

For a single engine boat, write the flow rate in

column 2. For a twin engine boat, write the port

engine flow rate in column 2 and the starboard

engine flow rate in column 3. The numbers for

each engine on a twin engine boat should be

very similar.

Column 4 - Total fuel flow rate

This is just the sum of the port and starboard

engine figures. Add together the flow rates

in column 2 and 3 and write the sum in

column 4.

Column 5 - Boat speed

Write the boat speed through the water in

12

NAVMAN

column 5. Remember that speed through the

water is not the same as GPS speed if there

are any tidal or other currents.

Column 6 - Economy

If there is a speed instrument connected to the

display then this number can be read directly

for each rpm setting. Write the economy in

column 6. Otherwise, to calculate gallons

per nautical mile divide the consumption in

gallons/hr (column 4) by the speed in knots

(column 5); or to calculate Litres per nautical

mile divide the consumption in L/hour (column

4) by the speed in knots (column 5). Write the

answer in column 6.

Column 7 - range

This is for future reference. Note - please use

the range calculated as an indication, rather

than as a range that you know you can achieve.

For safety’s sake it is strongly recommended

that the calculation is done using 90% of the full

fuel capacity - that will leave 10% of the tank

as a reserve. Call this 90% value the working

capacity of the fuel tank. Also note that the

range would apply only in calm conditions

- difficult wind or sea conditions will drastically

reduce the distance you can go on a full tank.

A more heavily loaded boat will also have its

range reduced.

To get the maximum range for each engine

rpm setting, take the economy (the number

in column 6) and multiply it by the working

capacity of the fuel tank. Write the range in

column 7.

Diesel fuel flow sensor kit Installation and Operation Manual

Page 13

1 Column 2 Reading 3 Reading 4 Calculate 5 Reading 6 Calculate 7 Calculate

Fuel

Engine

RPM

Flow

L/hr or

Gal./hr

Single or

port

Fuel Flow

L/hr or

Gal./hr

Starboard

Total flow

L/hr or

Gal./hr Both

2 + 3

Speed

Naut. m/hr

(Knots)

Economy

L/Naut.

mile or Gal

per Naut

mile

Range

On full tank

Naut. Miles

400

800

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

3000

Diesel fuel flow sensor kit Installation and Operation Manual

NAVMAN

13

Page 14

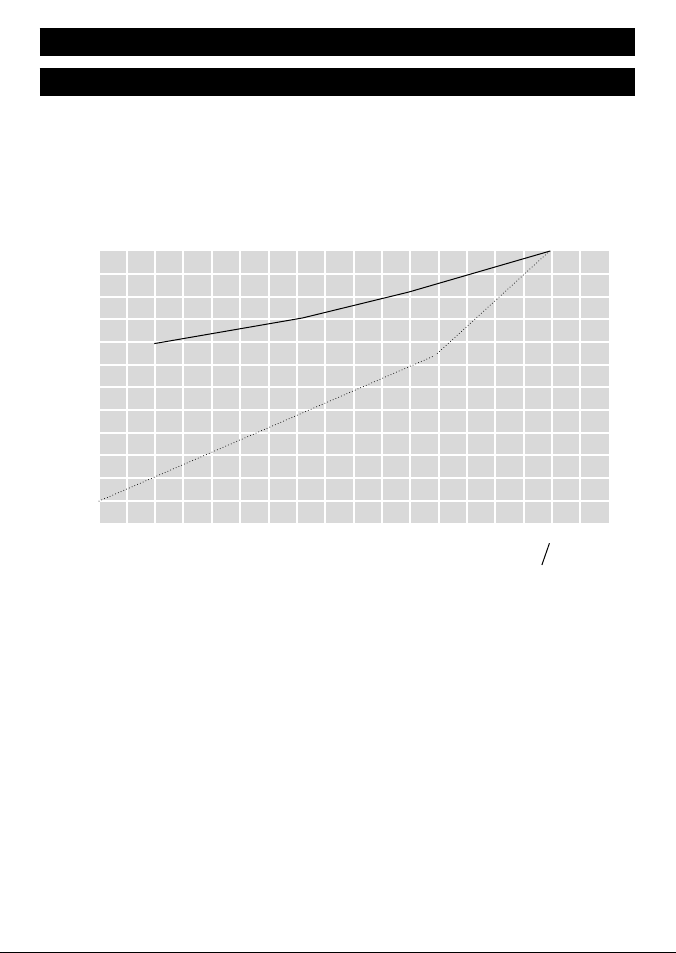

3-2 Understanding the fuel consumption curve

A typical fuel consumption curve

Boats which plane will produce curves similar

to the example below. The curve will change

with boat and sea conditions.

24

20

16

12

Speed - knots

8

4

0

600 800 1000 1200 1400 1600 1800

Engine RPM

Understanding your fuel

consumption curve

Notice that while the speed is constantly

increasing as the engine RPMs increase, the

economy figure usually has a dip in its curve,

as shown above. The high consumption before

the dip is caused by the boat trying to climb up

over its own bow wave. This is a very inefficient

speed to try to operate the boat at.

The drop in consumption at the dip occurs as

the boat gets up onto the plane. Thereafter, as

you would expect, the faster you go the more

fuel is consumed.

If your graph shows such a dip, then running

the engine at the corresponding RPMs (1300

in the example above) will give the best speed

for the least fuel consumption.

Note on fuel usage

A significant feature of diesel engines is

Note: If the boat does not plane, there will be

no dip in economy as illustrated.

12

10

Speed

Economy

that engine RPM alone does not dictate the

amount of fuel the engine is demanding. A

diesel engine’s governor will hold the engine

at the RPM you set. The amount of fuel it uses

at that RPM is determined by the load on the

engine.

If you are sliding down the surface of a big wave

like a surfer then very little power is required,

so to hold the RPM you have selected requires

very little fuel. Conversely, if the load increases

because you are battering into a head sea,

have a build-up of growth on the hull, or your

propeller is damaged or covered in barnacles

it is going to require a lot more fuel to maintain

that same RPM. SO, an engine’s thirst is

determined by load, not the RPM which it is

being asked for.

Understanding that point will be necessary

when we discuss propeller and load curves

later.

8

6

4

Economy - L / nautical mile

2

0

14

NAVMAN

Diesel fuel flow sensor kit Installation and Operation Manual

Page 15

4 Measuring your propeller’s performance

The propeller is the final link in the chain that

decides if your vessel is a peak performer or just

another boat. The best hull and the strongest

engine will be wasted unless your propeller is

the right size and shape.

From the fuel consumption curve, you can

very simply work out how well your propellers

are working. The performance of a propeller

is measured by its slip factor, and this section

describes how to calculate the slip factor of

your propeller.

Propeller size

First of all, a few basics on propellers. Propellers

are described by a series of numbers - nearly

all propeller people seem to prefer inches to the

metric measurement. For example if a propeller

is described as 24 x 21 then:

The diameter is 24 inches,

The pitch is 21 inches. The pitch is the

theoretical distance the propeller would

move forward through the water for each

full turn.

Slip factor

In reality, because water is a liquid and some

of it will sneak around the edge of the propeller

blades, the boat will not move forward by the

pitch for every turn of the propeller. This is called

the “slippage” or slip factor. The amount of slip

depends on many things - shape of hull, any

rudders, struts, keels etc near the propeller.

Calculating the slip factor

It is very useful to work out the slip factor for

your propeller.

You will need to know:-

A boat speed and RPM setting. Use the

boat speed at maximum rated engine

RPM:

a Either use figures you have taken

from the fuel consumption table (see

section 3).

b Or run the boat at the maximum rated

engine revs and note the revs and

boat speed through the water.

The ratio of the gearbox(es) on your boat

- this will be a number typically between 1

and 3.

The pitch of your propeller in inches.

First calculate theoretical speed:

1 Take the engine RPM and divide by

the gearbox ratio. This will give you the

number of revolutions per minute the

propeller turns.

2 Multiply this number by the pitch of your

propeller in inches. This gives the number

inches forward per minute, if there was no

slip.

3 - Multiply this number by 60. This gives the

number of inches forward per hour.

4 - Divide this number by 72912. (72912 is

the number of inches in a nautical mile)

As an equation it is:-

Theoretical speed =

RPM x pitch x 60 .

Gearbox ratio 72912

The answer is the theoretical speed, for the

chosen RPM, if there was no slippage. The

units are nautical miles per hour (knots).

Because of slippage, the actual speed you

were able to achieve is less than the theoretical

speed.

To find the slip factor (as a percentage):

1 Take the theoretical speed you worked

out above.

2 Subtract the actual speed of the boat to

get the difference in speed.

3 Divide this by the theoretical speed.

4 Multiply by 100 to express it as a

percentage.

As an equation it is:-

Slip factor (percentage) =

Theoretical speed - Actual speed x 100

Theoretical speed

Diesel fuel flow sensor kit Installation and Operation Manual

NAVMAN

15

Page 16

Understanding your slip factor

Now, some slip is always to be expected. This

slip factor varies with different types of hull, and

typical slip factors are -

A propeller encased in an aperture behind

a keel, as in a yacht: 40%.

A hard chine planing hull with a full keel,

or deadwood: 30% to 35%.

· A hard chine planing hull with little or no

keel: 25% to 30%.

Twin engined planing hulls: 18% to 25%.

If your calculations show you have a slip factor

that is much more than the figure above, then

further investigation is warranted. The propeller

may be the wrong size for the present engine,

or it might have got damaged, or there may be

a fitting on the hull that is disturbing the flow

ahead of the propeller. Propellers like to bite into

undisturbed water, and will not work efficiently

if water is aerated or churned up.

If the propeller is undersize, then it drills a hole

in the water, and the engine’s excess power just

makes frothy water.

If the propeller is oversize for the engine, the

engine will not be able to reach its maximum

operating RPM. The engines speed governor

will still try to achieve that RPM, and will open

up the throttle and pour as much fuel into the

engine as it can. If the engine can’t generate

any more power at that RPM, all that extra fuel

just ends up as heat, and that’s when things get

really expensive if the situation persists for any

length of time. Be warned - over propping an

engine will drastically shorten its life.

An excellent book with lots more information and

analysis of propellers is “Propeller Handbook”

by Dave Gerr (ISBN 0 7136 5751 0).

16

NAVMAN

Diesel fuel flow sensor kit Installation and Operation Manual

Page 17

5 Measuring engine performance

5-1 Engine power and propeller curves

Engine curves are published by the manufacturer

of every engine. If you do not have the curve

for your engine, ask your marine dealer for

the curve.

Usually there will be several curves showing

the different characteristics of your

300

250

200

150

100

Power - horsepower

50

0

600 800 1000 1200 1400 1600 1800 2000 2200 2400

engine

Power

- horsepower

plotted against engine revs.

The curve we want to discuss is the power

(horsepower or kW) versus engine RPM. The

curve will look something like this:

Propeller load

Engine RPM

, fuel consumption etc, each

Maximum engine RPM

In the above graph:

a The top line shows the maximum power

that the engine is able to provide at each

engine rpm setting - the amount that

would be available if you were to ask

for it. This curve will be published by your

engine manufacturer.

b The lower line shows the propeller load

curve. This is amount of power required

to propel the boat, with the engine doing

those RPM (Remember that usually there

is a gearbox between the engine and

propeller - for all this discussion we will

refer to the RPM of the engine, not the

RPM of the propeller itself).

Diesel fuel flow sensor kit Installation and Operation Manual

It takes a set amount of power (hp or kW) to

drive a particular hull at a particular speed, and

it doesn’t matter what the engine is, or how

much extra power might be available, or what

rpm and gearbox ratio you use. It is roughly

equivalent to the power required to tow the

boat through the water. So the lower curve

represents the power that the propeller draws

from the engine, or the load that the propeller

puts onto the engine.

This propeller load curve (the lower line in the

above graph) depends on many things, and is

unique to your boat. The propeller load curve

depends obviously on the diameter and pitch of

the propeller, but also on the hull shape around

NAVMAN

17

Page 18

and ahead of the propeller, the degree of fouling

of the hull, and the amount of weight aboard.

You will probably not be able to find the exact

propeller load curve for your boat, but knowing

the general shape of the curve will help you

understand how your boat performs.

The important thing to notice is that, for a

correctly sized propeller, the engine is loaded to

the maximum only at the maximum RPM. (that

is where the two curves meet) At all RPM less

than maximum, the engine, if it were asked to,

could actually generate more power than the

boat requires.

For example, at 1200 rpm this engine is capable

of generating 250 horsepower, but at those

engine revs the boat only needs about 125

horsepower transmitted through the propeller.

This is where the governor on the marine

engine comes into play. The throttle on a boat

behaves quite differently from the accelerator

pedal in a car. It does not directly control the

amount of fuel the engine burns. The boat

throttle levers just set the rpms at which you

want the engine to turn - that is all. The injector

and governor system of the diesel engine then

works out how much fuel it needs to feed into

the engine to keep the engine turning at that

speed. If you ask for 1500 rpm with your boat

heavily loaded and with a lot of fouling on the

hull, the engine will do 1500 rpm, but use a lot

more fuel compared to how much it would use

if lightly laden and clean.

The theoretical propeller load

curve

For those interested, the theoretical propeller

load curve for a correctly chosen propeller

follows the form of:

Propeller load = K x RPM

Where:

y is a number that is determined by the

type of boat. The value of y can range

from around 2.2 for ducted propellers

to around 3 for slow, heavy commercial

boats. The most common value of y is

around 2.7, and for medium to high speed

pleasure boats, y is usually around 2.7.

y

K is deliberately chosen to make the curve

pass through the point on the engine

power curve that is max revs/max power.

To work out K for a pleasure craft use:

Some engine manufacturers will plot an ideal

propeller load curve on their engine data

sheets, using an exponent of 2.7.

Maximum engine power

K =

Maximum engine RPM

2.7

18

NAVMAN

Diesel fuel flow sensor kit Installation and Operation Manual

Page 19

5-2 Specific fuel consumption curve

Most engine manufacturers publish graphs

of the specific fuel consumption for their

engines.

Specific fuel consumption is a graph showing

how much fuel the engine burns to produce

one horsepower (or kW) for one hour. Each

engine has a particular RPM range where it

burns the least amount of fuel to produce one

unit of power. Some engines are designed to

work most efficiently at high RPM, others at low

RPM. Modern lightweight diesels commonly

have a most economical and efficient speed

of operation at around 70 to 80% of maximum

rated RPM.

The specific fuel consumption curve is worked

out for the engine working at its rated load,

at the RPM settings along the bottom of the

graph.

As you can see from the discussion on engine

and propeller curves (see section 5-1), the only

point where the engine is working at its rated

load should be at maximum RPM. At any speed

less than the maximum RPM, the engine is not

working to its maximum, and often well below

its maximum. So the specific fuel consumption

curve is of limited use to get overall boat fuel

consumption. It will give you an indication of

whether your engine has been designed for

high or low speed efficiency.

Sometimes a manufacturer will also give a

curve of fuel consumption for that engine when

matched to the theoretical ideal propeller. This

will give you a reasonable estimate of the fuel

consumption of your engine, provided you have

a well chosen propeller. It will not, of course,

take into account different loads carried or sea

state, or any other factor that affects the actual

fuel consumption.

One rule of thumb you can use to estimate fuel

is that a modern, large, high efficiency diesel,

when averaged out over most of its operating

range, will produce 23hp for one hour from one

US gallon of fuel (3.33 kW for one hour out of 1

litre of fuel). That is quite a good engine.

Smaller, older, less efficient engines might sink

as low as only 19 horsepower for one hour from

one US gallon of fuel (3.11 kW for one hour

from 1 litre of fuel)

Over all the engines available in the pleasure

craft market there is very little difference in

the fuel burning rate, when averaged out over

their normal working range. Some engines

will have an optimum at lower revs, others at

higher revs.

The important thing to remember is that the

quantity of fuel you actually use is determined

by your propeller and hull much more than by

your particular choice of engine.

Diesel fuel flow sensor kit Installation and Operation Manual

NAVMAN

19

Page 20

6 Diesel fuel flow sensor hardware

6-1 What comes with your diesel fuel flow sensor kit

Diesel flow sensor

for

supply line

The two sensors are distinguished by a different

coloured band around the body. The supply

line sensor has a blue band (think cooler fuel)

and the return line sensor has a red band

(think warmer fuel, after it has been through

the engine).

Also supplied: Self adhesive reflective tape

for tachometer, alcohol wipe for cleaning

where this tape will be placed, warranty card,

this manual

Diesel flow

sensor for

return line

Tachometer pickup

with cable

4 m (13 ft) long

Yellow connector

Sensor cable for

DIESEL 3200.

20 m (65 ft) long

White connector

Two straight through

pipes for installation

or to replace the

sensors if they are

removed

Link cable.

2 m (6 ft) long

Brown connectors

6-2 Options and accessories

From your Navman dealer:

Extension cables for the sensor, link and

tachometer cables.

Each diesel flow sensor kit measures

data from one engine. A second kit can be

fitted if the boat has twin engines and twin

tanks.

From a marine, hydraulic or diesel dealer:

Fittings to connect the two sensors to the

fuel lines (see section 6-3).

Filtering the fuel

The primary fuel filter will filter all particles larger

than typically 25 to 50 microns.

The clearances within the sensor are more than

100 micron, so provided there is an adequate

primary filter there will be no problems with

particles in the fuel interfering with the sensor.

If there isn’t an adequate primary filter, then

20

NAVMAN

the secondary filter will be quickly blocked,

and any effects on the sensor will be the

least of the problems on the boat!. But just in

case your primary filter fails, the sensors are

equipped with a by-pass valve - one quick turn

and the entire mechanism is bypassed (see

section 1-3).

Diesel fuel flow sensor kit Installation and Operation Manual

Page 21

6-3 Sensor fittings

Each sensor inlet or outlet requires one or

more fittings to connect it to the fuel line. The

fuel sensor connections are all ¼ NPT taper

thread, fixed female.

The fittings required will vary with where in

the fuel lines the sensors are installed. For a

discussion of the issues involved, see section

7-3-3.

You will need threaded barrel adaptors to suit

the piping on your boat. Because there are so

many different threads and piping sizes around

the world there is no possibility of having all

the adaptors required supplied from Navman.

The Navman fuel sensors are supplied with a

standard ¼ NPT female thread for the inlets

and outlets. Any reasonable marine store,

hydraulic or diesel fitting supply house will have

a selection of threaded barrel adaptors that will

have ¼ NPT male thread on one end, and the

appropriate thread for your particular boat on the

other. It is preferable to use ¼ NPT thread, but

if necessary a ¼ BSP male threaded fitting will

fit in a ¼ NPT female thread.

There are many types of pipe and pipe fittings,

and it can get very confusing. If you are wanting

adaptors to fit a particular fitting on your boat, if

at all possible remove that fitting from the boat

and take it into the fitting store. It will save a lot

of time and doubt. Be sure to cover the exposed

ends of the pipes and fittings on your boat to

prevent dirt entering, and make allowances

for some fuel that may well drip from the pipes

while you are away at the store.

Frequently the supply line to the engine is larger

in diameter than the fuel return line. Measure

both before you go to get the fittings.

Fuel sensors are often connected to solid

copper pipe with flare joints. Each connection

requires a flare nut to fit the pipe and a barrel

union to connect the flare nut to the sensor.

For example, to connect a 3/8 inch OD pipe to

a sensor requires:

A 3/8 inch flare nut

A 3/8 inch flare to ¼ NPT taper thread

barrel union fitting

You will need to know the diameter of the fuel

pipe (see section 7-2-1). Fitting a flare joint is

described in section 7-4-1. This requires the

use of a pipe cutting tool, a flaring tool, possibly

pipe bending tools, and flare nuts.

Diesel fuel flow sensor kit Installation and Operation Manual

NAVMAN

21

Page 22

7 Installing the diesel flow sensor kit

Installation sequence

The fuel lines are modified and temporary

straight through pipes fitted where the sensors

will be fitted. The engine is run, then the real

sensors are fitted. This procedure ensures

that debris from the installation does not enter

the sensors.

The recommended installation sequence is:

1 Read this manual and the documentation

that comes with the other parts. Read

section 7-1 for background information on

fuel pipes and fittings.

2 Plan the installation and choose where

the fuel flow sensors and cables will

be located (see section 7-3). Choose

suitable fittings for connecting the sensors

to the fuel lines (see section 6-3)

3 Install temporary straight through pipes in

the fuel line where the sensors will later

be fitted (see section 7-4).

4 Bleed the fuel lines and test run the

engine. Then remove the two straight

through pipes and fit the two fuel flow

sensors (see section 7-5).

6 Install the tachometer (see section 7-6).

7 Install the cables to link the parts of the

system together and to the Navman

display instrument (see section 7-7).

Warnings

Correct installation is critical to the

performance of the unit. Before starting

installation, it is vital to read this manual

and the documentation that comes with

the other parts.

Ensure that any holes that you cut will not

weaken the boat’s structure. If in doubt,

consult a qualified boat builder.

One important thing to stress is the need

for cleanliness in the installation process.

Diesel engines, and the Navman sensors

are built to fine tolerances - do not allow

any dust, dirt, water or particles to enter

the fuel system.

DAMAGE WILL RESULT if you ignore

this warning.

8 Setup the Navman instrument to use the

fuel flow sensors and tachometer, as

described in the instrument’s installation

and operation manual. Take the boat on

a test run and check that the sensors are

performing correctly.

If you are unsure where a part should be

installed, mount and wire the part temporarily,

without cutting holes in the boat. After the sea

trials have been completed, install and wire the

part permanently.

7-1 Twin engine installations

If the boat has twin engines then a second diesel flow sensor kit can be fitted and connected to

the same Navman instrument. To install the kits, fit a kit to each engine, following the instructions

above for each engine and tank. At the display unit, connect the sensor cables from the two kits

in parallel (see section 7-7-2).

The sensors need to be identified as port and starboard in the display unit. You may find more

instructions included in the display head manual.

22

NAVMAN

Diesel fuel flow sensor kit Installation and Operation Manual

Page 23

7-2 Notes on pipes, fittings and installation

This section discusses fuel pipes terminology

and the fittings and tape used to join the pipes.

7-2-1 Pipe

Diesel fuel lines are often solid copper pipe.

Copper pipes are rated by their diameter:

Usually fuel lines will be called by their

outside diameter (OD) - this is also typical

of refrigeration pipe fittings.

However, domestic copper water pipe

is commonly measured by its inside

diameter (ID).

So ½ inch refrigeration pipe is a different size

from ½ inch water pipe - make sure you know

what size your boat fuel piping is before you

purchase fittings to install the sensors.

7-2-2 Flare Nuts

Flare nuts are often used to connect a sensor to

a solid copper fuel line. There are two different

systems of flare fittings:

45 degree flare: 45 degree fittings are

more common, and are in standard use

for refrigeration pipe work.

37½ degree flare: 37½ degree fittings

are more common for hydraulic systems.

JIC fittings are 37½ degree flare.

Fitting flare nuts

Warnings for flare nuts

Only use fittings with the same flare in

your system. Do not mix fittings with

different flares.

If you don’t know how to use a flare

tool, then don’t fit a fuel flow sensor at

your first attempt. Ask to be shown how

to use the tool, then practice on some

scrap pipe before working on the pipes

on your boat!.

Here are some comments and reminders:

Mark the pipe where you wish to cut it,

then cut it using a pipe cutter.

Do not cut the pipe with a hack saw - it

will leave small metal particles in the

pipes that will harm the sensor and other

items in the fuel line.

Diesel fuel flow sensor kit Installation and Operation Manual

Push the flare nut along the pipe before

flaring the pipe!! Then flare the end of

the pipe using the flaring tool. Inspect the

inside face of the flared pipe - it must be

smooth and scratch-free. If it is not, cut it

off and try again.

7-2-3 Flexible Hoses.

Flexible hoses can make installation a lot

easier, but modern recommendations are that

only one short length of flexible hose should be

used - on the final link from the pipework fixed

to the boat to the engine, to allow for flexing

and vibration.

In many countries a boat licensed to carry

paying passengers has stringent codes of

installation practice to comply with - frequently

these require fixed, rigid fuel piping until the

last section. If your boat has to meet such

inspections, then check carefully before

attempting to use flexible hoses. At the very

least you may have to use metal braided flexible

hose to meet fire regulations.

There are also recommendations that the

fittings on the end of the flexible hose should

be professionally hydraulically crimped on.

Failing that, there are recommendations on

specific forms of field fitted hose fittings. Check

the use of flexible hoses against Coast Guard

recommendations, ABYC guidelines or with a

marine surveyor before deciding to use flexible

hose on your boat.

7-2-5 Threadseal tape or paste

Threadseal tape or paste is needed for all joints

where thread to thread sealing is required, for

example the adaptor fitting threads that are

screwed to the diesel fuel flow sensor.

Some manufacturers say to never use tape,

only use paste, while others say tape is OK.

Follow any requirements given by the engine

or boat manufacturer. The one thing you must

guard against with either type of threadseal is

bits of the thread sealer breaking off and getting

into the fuel.

Warning: Make sure pieces of the

threadseal tape or paste can not break off

and enter the fuel pipe.

NAVMAN

23

Page 24

If you do use tape, then to prevent pieces of

tape from breaking off:

Make sure you wind the tape on to the

male thread so that the first couple of

threads remain uncovered; do not cover

all of the threads.

Be careful when snapping off the tape

that threads of tape do not fall back over

the end of the fitting.

If removing fittings from previous installs make

sure the male threads are cleaned of any

remnants of the thread sealer used. If re-using

any fittings with female threads be particularly

careful about removing remnants of thread seal

- it is hard to see on an internal thread.

24

NAVMAN

Diesel fuel flow sensor kit Installation and Operation Manual

Page 25

7-3 Planning where the parts of the kit will be fitted

Plan where all the parts will be located before starting to install the parts.

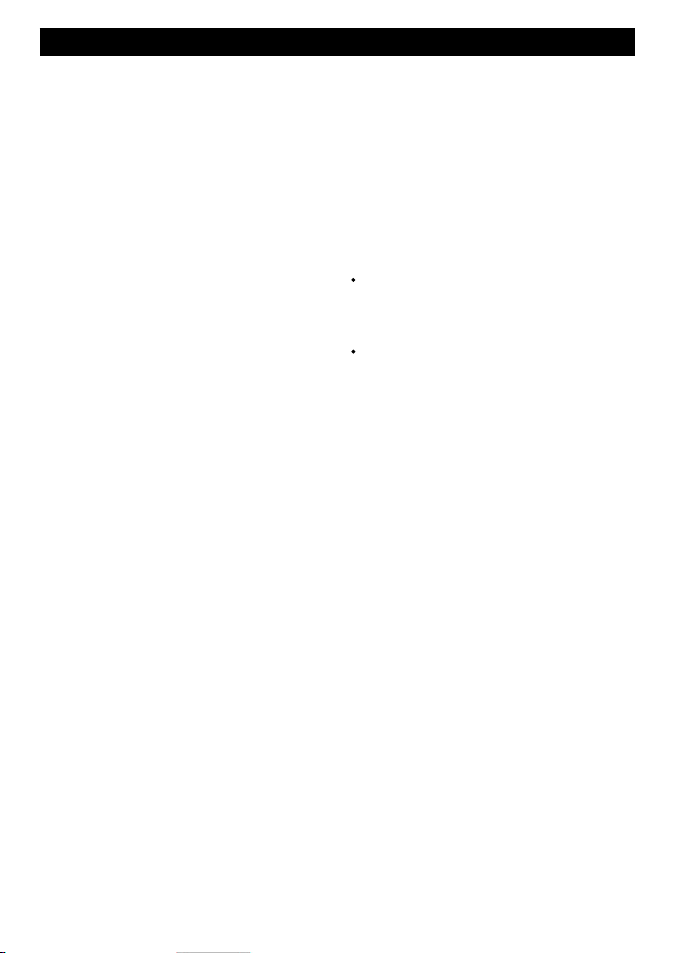

7-3-1 Overview

Other wiring and

connection to sensors

on a second engine

(optional)

Primary

filter

Diesel

tank

White connector

Return fuel line

Two flow sensors are fitted. The

supply flow sensor has a blue band,

the return flow sensor a red band.

Sensor cable

Link cable

Display unit,

such as a

DIESEL 3200

Other connector(s)

Supply

flow

sensor

Supply fuel line

Brown connector

Locate the two sensors and the

tachometer reasonably close together

to allow for neat and tidy cable

routing. Supplied with the sensors

are the sensor cable (20 m (65 ft));

the link cable (2 m (6 ft)) and the

tachometer cable (4 m (13 ft)).

Extension cables are available for all

of these cables.

Diesel

engine

Return

flow

sensor

Yellow connector

Brown connector

Tachometer

pickup

Tachometer cable

7-3-2 Mounting a sensor

Mount the fuel

flow sensor

horizontally

Have the

electrical

connectors

facing down

Allow for easy

access to plug

and unplug the

cables.

Diesel fuel flow sensor kit Installation and Operation Manual

Do not install the sensor

where it will get wet from

water in the bilges.

Bypass valve.

Allow for easy access to the bypass valve

Attach the sensors firmly to

a vertical panel or mounting

block on the boat. While

the sensors are not heavy,

they should not be left

hanging from the pipework.

Over time vibration and

heavy pounding from rough

seas could lead to the fuel

lines fracturing, with tragic

consequences.

It does not matter which

sensor pipe is the inlet and

which is the outlet

NAVMAN

25

Page 26

7-3-3 Locating the sensors in the

fuel lines

The supply sensor will be installed in the fuel

supply line between the the primary fuel filter

and the engine fuel intake. The return sensor

will be installed in the fuel return line between

the engine fuel return and the fuel tank. There

are several options where to locate each

sensor, discussed below, and the best option

will depend on the layout of your engine’s fuel

system and what fittings are used. Because

there is so much variation in fuel systems, this

can only be a guide to where the sensor should

be located. If in doubt, consult a qualified diesel

engineer.

Locating the supply sensor

Before planning where to install the sensor,

identify the supply line of the fuel system:

Find the primary filter - this will be in the

fuel line coming from the fuel tank, before

the lines reach the engine. To meet

modern recommendations these lines will

probably be of metal tubing, not flexible

hose. The primary filter is typically large

and has a clear sightglass and water and

sediment separation bowl. It should be

fixed firmly to the structure of the boat.

Find the outlet of the primary filter

- this should be labelled on the filter.

Sometimes there is a one-way or

non-return valve fitting on the outlet also.

Identify the fuel supply line from the

primary filter to the engine. A solid fuel

line usually has a flexible portion joining it

to the engine.

There are four options of locating the supply

sensor in the supply line:

1 On the outlet of the primary filter (see a

below).

2 In the solid fuel line between the primary

filter and the engine (see b below).

3 At the junction of the solid pipe and the

flexible hose leading to the engine (see c

below).

4 After the lift pump (see d below).

Locating the return sensor

Before planning where to install the sensor,

identify the return line of the fuel system. This

return line will most probably start from the

injector body on the engine, have a flexible

section to take account of engine movement,

then return to the tank in solid wall pipe.

There are three options of locating the return

sensor in the return line:

1 At the junction of the solid pipe and the

flexible hose leading from the engine (see

c below).

2 In the solid fuel line between the engine

and the tank (see b below).

3 On the return inlet of the fuel tank (see e

below).

Sensor mounting positions

This section discusses issues relating to the

different mounting positions for supply or

return sensors.

a On the outlet of the primary filter

(supply sensor only)

Install the sensor after any one-way or nonreturn valve fitting on the outlet of the filter.

This might be the best option if the fuel line

is all flexible.

Note:

You have to recognise and obtain the

correct fitting to match the fitting on the

outlet of the filter.

The diesel flow sensor has a female

thread. Connection to a filter with a

female thread outlet, will require two

fittings, a male to free rotating female and

a male to male.

Ensure there is little strain on the sensor

or the filter. When using solid fittings, the

sensor mounting block must be made

accurately and the sensor positioned

accurately. If the installation requirements

allow, use a short length of flexible fuel

hose between the filter outlet and the

sensor.

26

NAVMAN

Diesel fuel flow sensor kit Installation and Operation Manual

Page 27

The fuel line to the engine needs to be

connected to the outlet of the sensor. If

the fuel line is solid copper, a flare joint

is probably easiest to install (see section

6-3). Note that if the flaring fails you will

need to cut the flare off the copper pipe

- this can be a problem if the fuel line is

straight or the line can not be shuffled

along in its retaining clamps.

b In a solid fuel line (supply or return

sensor)

See section 7-4-1. This is usually the easiest

option to find fittings for.

The sensor can be located anywhere along the

pipe, which might make mounting easier.

You will need to cut the pipe and will usually fit

flare joints. This method does require using a

flaring tool, and possibly a pipe bender.

c At the junction of the solid pipe and

the flexible hose leading to the engine

(supply or return sensor)

This can be the best option because there is

less potential to strain the sensor fittings.

If possible, fit the sensor inlet to the existing

fitting on the solid fuel line and fit the sensor

outlet to the flexible fuel line. This requires

space for the sensor. You must obtain the exact

fittings to match those on the end of the pipe.

Another option is to cut the solid fuel line line

and connect the sensor using a flare joint.

In all cases, the sensor must be mounted solidly

to the boat. Get a fitting to adapt the sensor

outlet to flexible fuel line.

d After the lift pump (supply sensor

only)

If the engine is very sensitive to pressure drop in

the fuel line, then it may be necessary to install

the supply line flow sensor after the lift pump.

The Navman diesel flow sensor has a very low

pressure drop across it at moderate flow rates

(see appendix A). If your engine has particularly

high flow rates in the fuel lines, and if it can not

tolerate any pressure drop in the line before the

lift pump (on the suction side of the lift pump),

then it might be necessary to install the flow

sensor in the fuel line after the lift pump.

This is often more difficult than the other

options, because the lift pump is usually

mounted on the engine and the fuel line from

the lift pump to the injector body is steel tube.

However, being after the lift pump does get rid

of any of the problems of pressure drop across

the sensor.

If the sensor is mounted on the engine, then

the high temperature and vibration can affect

the accuracy of the sensor. It is better to

mount the sensor on the boat and connect it

with two flexible fuel lines if your requirements

allow this.

e On the return inlet of the fuel tank (return

sensor only)

Install the sensor before any existing fittings on

the fuel tank. This might be the best option if

the fuel line is all flexible. Note:

You have to recognise and obtain the

correct fitting to match the fitting on the

inlet of the tank.

The diesel flow sensor has a female

thread. Connection to a tank with a

female thread inlet, will require two

fittings, a male to free rotating female and

a male to male.

Ensure there is little strain on the sensor

or the tank. When using solid fittings, the

sensor mounting block must be made

accurately and the sensor positioned

accurately. If the installation requirements

allow, use a short length of flexible fuel

hose between the sensor outlet and the

tank.

The return fuel line needs to be

connected to the inlet of the sensor. If

the fuel line is solid copper, a flare joint

is probably easiest to install (see section

6-3). Note that if the flaring fails you will

need to cut the flare off the copper pipe

- this can be a problem if the fuel line is

straight or the line can not be shuffled

along in its retaining clamps.

Diesel fuel flow sensor kit Installation and Operation Manual

NAVMAN

27

Page 28

7-4 Installing the temporary straight through pipes

Before fitting the straight through pipes, plan

where the sensors will be fitted (see section

7-3). This section describes how to fit the

temporary through pipes where the flow

sensors will be fitted. The actual sensors are

not fitted until later, after the engine has been

checked (see section 7-5).

1 Wear gloves to protect your hands from

the diesel fuel.

2 Turn OFF the fuel tap at the outlet of the

boat’s fuel tank.

3 Put a tray of rags under the pipe where

you will cut it to absorb the fuel that will

spill.

4 Disconnect or cut the fuel line where the

supply and return sensors will be fitted.

To cut solid pipe, use a pipe cutter. Do not

use a hack saw - it will leave small metal

particles in the pipes that will harm the

sensor and other items in the fuel line.

5 Fit the temporary through pipes in the

supply and return pipes where the

sensors will be fitted. Note:

The two flow sensors will be mounted

horizontally, with the wire connectors

underneath. It does not matter which

fuel connection is the inlet and which

is the outlet (see 7-3).

The exact details of how you fit the

through pipes will depend on where

you are installing the through pipes

and the configuration of your engine

installation. Instructions for the

common case of installing the pipe in

the middle of a solid copper pipe run

are given in section 7-4-1. If in doubt,

consult a qualified diesel engineer.

Apply thread sealer to the all fittings

(see section 7-2-5)

Warning: Make sure pieces of

the threadseal tape or paste can

not break off and enter the fuel pipe

Do up the fittings tightly with the

correct tool. The through pipe has

flats for attaching a spanner or

wrench.

However, when fitting the through

pipe in the supply line, tighten the

inlet connection but leave the outflow

connection loose temporarily.

Keep a real sensor on hand and use it

to check for available space, that the

fuel line aligns with the sensor ports,

and that the cables and connectors

will not be difficult to get to later.

When the sensors are fitted later they

must be firmly attached to a panel

in the boat or a mounting block. If

necessary, fit the mounting block

now. Check that the sensor can be

attached to the boat without straining

the pipe joint.

6 Carefully open the fuel tap at the fuel tank

until fuel drips from the joint at the outlet

of the through pipe in the supply line. This

should have filled the pipe and first joint

with fuel - meaning there will be less air in

the system that has to be bled out to start

the engine. Turn the tap off.

Note that there is no need to expel air

from the return pipe - it will happen

automatically when the engine starts and

fuel starts flowing.

7 Tighten the connection on the outflow

side of the supply through pipe with the

correct tools.

8 Do not leave diesel soaked rags in the

boat when you have finished - they are a

fire hazard. Take them out and dispose of

them properly.

9 Test run the engines (see section 7-5).

28

NAVMAN

Diesel fuel flow sensor kit Installation and Operation Manual

Page 29

7-4-1 Installing a through pipe with flare joints into a copper pipe run

This describes how to install a through pipe

with a flare joint. For the full procedure, follow

the steps of section 7-4.

Fitting a flare joint requires the use of a pipe

cutting tool, a flaring tool, possibly pipe bending

tools and flare nuts. To take the example of a

3/8 OD inch pipe, you will need to find from a

fitting supplier, for each flare joint:

a 3/8 inch flare nut

a 3/8 inch flare to ¼ NPT taper thread

barrel union

some Teflon® tape or Teflon® threadseal

paste.

1

Fit barrel unions to a sensor temporarily. Do not

apply threadseal. Do up the unions loosely.

Top view

2

Hold pipe away from panel

Remove clamps to release pipe

Panel

Cut pipe with pipe cutter

Top view

3

If necessary, bend the pipe in an ‘S’ curve to

align it with the sensor port, 65mm (2.5”) out from

the surface where the sensor will be mounted.

Hold the sensor in place by hand to check that

the pipe lines up with the sensor port.

Gentle, large radius bends can be made by

bending the pipe around a curved former by

hand, but take care not to kink or crush the

tube. If room is restricted and you must form

tight radius bends then you will have to use a

pipe bending tool.

Do not bend the pipe too close to the end - you

must have at least 50mm (2”) or more of straight

pipe to allow the flare nut on and still have room

for the flaring tool to work.

If necessary, use the pipe cutter to cut the pipe

to the exact length to match the sensor port.

Do not make the curves too tight and do not

cut the pipe short. It is also wise to allow for

the possibility that you might make a mistake

on the flaring process, and have to cut your

first attempt off and start again. It is better to

allow for the possibility, than to cut the pipe to

absolutely the shortest possible.

Hold sensor in place

At least

50 mm

(2 in)

straight

65 mm

(2.5 in)

Cut pipe to exact length

with pipe cutter

If the pipe is fixed to a panel, such as a beam or

bulkhead, you will have to release it and bend

the pipe out to be able to cut it. Mark the pipe

where you wish to put the sensor and cut it

using a pipe cutter. Do not use a hack saw.

Diesel fuel flow sensor kit Installation and Operation Manual

NAVMAN

29

Page 30

4

6

Put flare nut on first

Flare end of tube

Put the flare nut on the pipe first!! Then flare

the end of the pipe using the flaring tool. Inspect

the inside face of the flared pipe - it must be

smooth and scratch-free. If it is not, cut the end

of the tube off and try again.

5

To attach a flare joint at the other end of the

sensor, repeat steps 3 and 4 above to bend

and cut the pipe, fit a flare nut and flare the

end of the pipe. Cut the pipe to length so the

flared end will meet the fittings on the sensor

port exactly. The exact amount you cut out will

depend on how much pipe length was used

up in the bends.

Otherwise, attach a different type of fitting

following the manufacturer’s instructions.

Hold the sensor in place and hand tighten the

fittings to check that the pipe lines up with the

sensor port and there is little strain on the joints.

Adjust the pipe bends so that the sensor will sit

flat against your chosen mounting surface.

Hold sensor in place

Install the required fittings to the straight

through pipe (for flare joints use a barrel union

fitting):

1 Apply thread sealer to the fitting’s ¼ NPT

threads.

Warning: Make sure pieces of the

threadseal tape or paste can not break

off and enter the fuel pipe (see section

7-2-5).

2 Screw each fitting in to the through pipe.

Use a spanner or wrench on the fitting and

another on the flats of the through pipe.

It does not matter which way round the through

pipe goes in the fuel line.

7

Fit the straight through pipe. Tighten each fitting

with the correct tools (for a flare joint, use a

spanner or wrench on the flare nut and on the

barrel union). The fitting needs to be tight to

prevent leakage. Replace any pipe clamps that

you removed earlier.

Note: Leave the flare nut on the outlet side

of the install pipe loose now (see section 7-4,

step 5).

30

NAVMAN

Diesel fuel flow sensor kit Installation and Operation Manual

Page 31

7-5 Test running and installing the sensors

This section describes how to test run the

engine and then install the flow sensors in place

of the straight through installation pipes:

1 When you have both supply and return

lines connected up and all fittings

tightened, bleed the fuel lines. This is the

same procedure you use after changing a

fuel filter - consult your engine manual.

2 Turn on the fuel tap at the tank. Run the

engine for 5 minutes. This will flush any

particles that you have introduced in the

installation process into the supply line

down to the secondary filter. Any particles

in the return line will be flushed back to

the tank. Check for pipe leaks.

3 Once you are happy with the pipework

changes, turn off the fuel tap at the tank.

4 Wear gloves to protect your hands from

the diesel fuel.

5 Put a tray of rags under the pipe where

you will disconnect it to absorb the fuel

that will spill.

6 Undo the fittings on the straight through

pipes and remove the straight through

pipes. Remove the ¼ NPT adaptors

from the ends of the install pipe. Clean

the thread sealer from the threads in the

install pipes and fittings.

the gap where the sensor came from, and

no re-work of the pipework is necessary.

7 Apply new threadseal to the ¼ NPT

adaptor threads (see section 7-5-2).

Warning: Make sure pieces of the

threadseal tape or paste can not break

off and enter the fuel pipe (see section

7-2-5).

8 Screw the adaptors into the real sensor.

Do not overtighten the adaptors - the

sensor body is diecast aluminium and

applying too much force when tightening

the adaptors will strip the threads.

9 Put the sensor in position:

Fit the sensor with the blue band in

the supply line.

Fit the sensor with the red band in the

return line.

Tip: Keep the straight through pipes in a

safe place near to the sensors - you may

want them if you ever have to remove

the sensors, for service or to move the

system to another boat. If you have the

straight through pipe you can just put it in

Diesel fuel flow sensor kit Installation and Operation Manual

Hand tighten the connections.

10 Screw the sensor to the mounting block

or support panel with the screws supplied.

11 Do up the fittings tightly with the correct

tool, except for the fitting on the outflow

side of the sensor in the supply line.

Leave this loose temporarily.

On flare nuts, use a spanner or wrench

on the flare nut, and another on the flats

of the barrel union. Flare nuts need to be

NAVMAN

31

Page 32

tight to prevent leakage.

12 Carefully open the fuel tap at the fuel tank

until fuel drips from the joint at the outlet

of the sensor in the supply line. This

should have filled the pipe and first joint

with fuel - meaning there will be less air in

the system that has to be bled out to start

the engine. Turn the tap off.

13 Tighten the fitting on the outflow side of

the supply sensor with the correct tool.

On a flare nut, use a spanner or wrench

on the flare nut, and another on the flats

of the barrel union. Flare nuts need to be

tight to prevent leakage.

14 On both sensors, turn the bypass valve to

vertical (normal operation).

15 When you have both supply and return

lines connected up and all fittings

tightened, bleed the fuel lines. This is the

same procedure you use after changing a

fuel filter - consult your engine manual.

16 Turn on the fuel tap at the tank. Run the

engine for 5 minutes. Check for pipe

leaks.

17 Do not leave diesel soaked rags in the

boat when you have finished - they are a

fire hazard. Take them out and dispose of

them properly.

18 Continue with installation (see section

7-6).

32

NAVMAN

Diesel fuel flow sensor kit Installation and Operation Manual

Page 33

7-6 Installing the tachometer pickup

This section describes how to install the

tachometer pickup. The tachometer is optional

and need not be installed, however the

tachometer gives a precise measurement of

engine RPM, essential for measuring engine

fuel consumption at different speeds.

The pickup operates by sending a beam of

pulses of infrared light towards the crankshaft

pulley. A piece of reflective tape applied to the

crankshaft pulley reflects the beam back to the

pickup, where an infra-red receiver detects the

light pulses. A light on the sensor will light up

when its detector is receiving enough reflected

light to operate properly.

Locating the tachometer pickup

It is important that the reflective tape is attached

to part of the crankshaft, such as the flywheel or

a pulley. Do not attach the tape to any part that is

not rotating at the same RPM as the crankshaft,

such as a pulley driven accessory.

The optimum distance from the pickup to the

reflective tape is about 50 mm (2 in) away from

the reflective tape. If it is positioned closer than

25 mm (1 in) to most flywheels or pulleys then

enough infra red will be reflected back from

the surface of the wheel to trigger the pickup.