Page 1

Hard Disk Player Thermal Analysis

Paul Neville

Naim Audio

Southampton Road, Salisbury, SP1 2LN, England

Abstract

When designing hi-fi components attention has to be

paid to the thermal performance. Excessive heat would

cause longer term reliability problems and short term

problems in adhering to the various safety standards

around the world. Naim products are sold and used

worldwide in many climates.

1. Target Performance

The specification required the unit to run happily at

ambient temperatures at or below 25 degrees C without

the use of a fan to cool the components. At higher

ambient temperatures the fan would be required to run

to keep components inside the box cool.

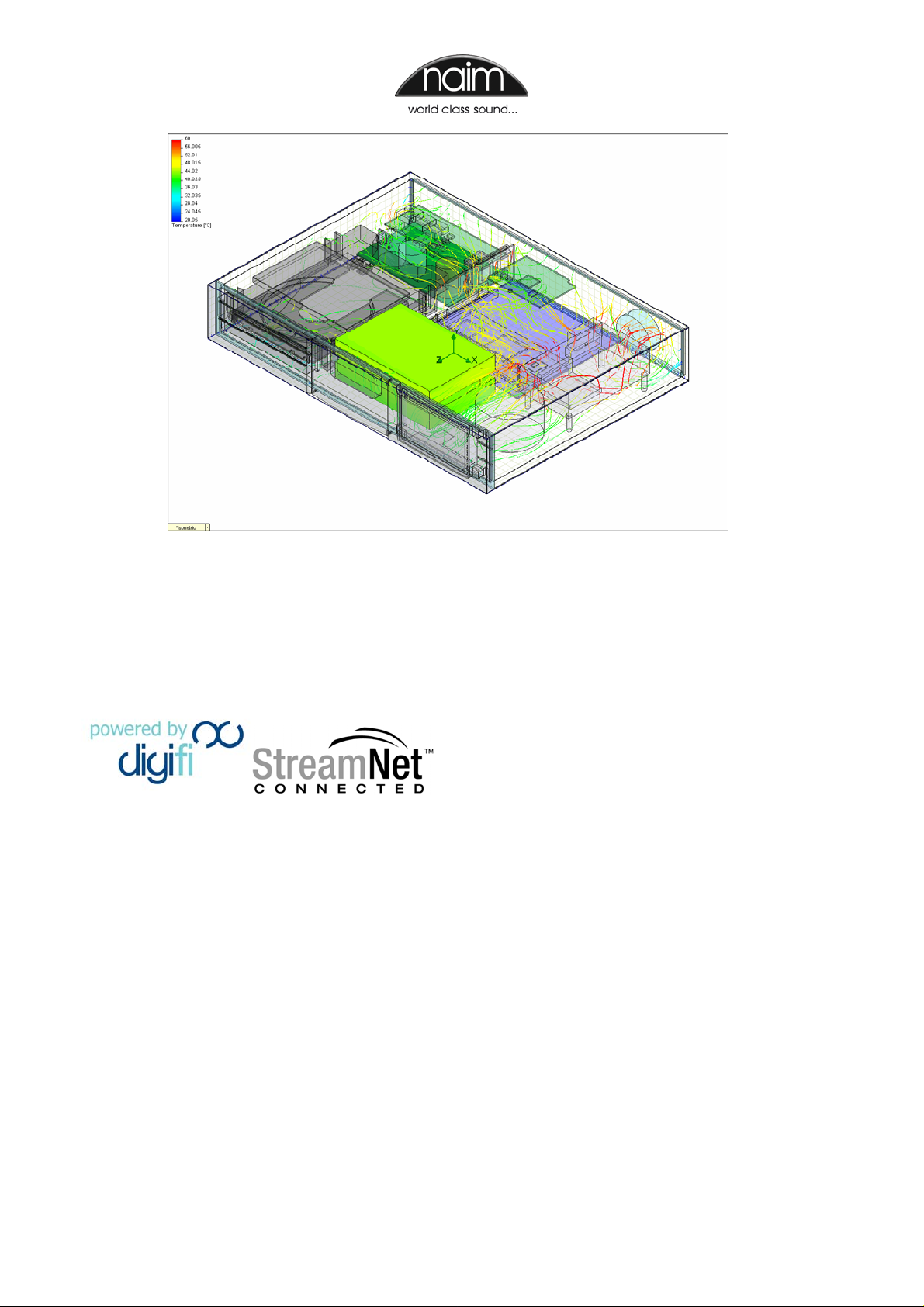

2. Modelling

To optimise the thermal performance of the Naim Hard

Disk player and server products a combination of

computer analysis and verification testing was used.

Using the mechanical CAD model of the product as a

start point, a thermal model was created and analysed

using FEA (Finite Element Analysis) and CFD

(Computational Fluid Dynamics) to predict airflow

patterns within the product and the temperatures of key

components. This involved calculating heat output

values for all the heat generating components such as

processors, power supplies and both hard drives.

The software uses these values and the thermal

properties of the materials to predict the flow patterns

and maximum temperatures reached from a meshed

model. The software model predicted temperatures at

different ambient temperatures and with the fan turned

on or off. It was also possible to use the model to

optimise the position of the fan and to confirm that the

planned airflow was ideal.

The Thermal model allowed predictions of what would

happen when materials or the design changed and to

fine tune the design for thermal performance.

The product case is constructed from 5mm thick

aluminium, which provides an in-built heat sink for the

components and a path to remove heat from the

product. Key components have been coupled to the

case to provide a direct conductive heat path to the

cover and hence, the outside world. For instance the

hard drives are connected directly to the cover via thick

machined aluminium blocks.

The back-up drive is sent to sleep when not in use to

limit the heat that is generated and the primary drive is

located closest to the cover to shorten the distance of

the heat path to the outside world.

The best grades of material were selected to minimise

thermal resistance to provide a product with optimum

passive cooling. The final product was sent to the design

and verification test centre of Seagate (the hard drive

manufacturer) who confirmed our analysis and testing.

The results indicated that “the drive will remain within

specification limits up to ambient conditions over 40°C

even with the fan off.”

We have chosen to use the fan at ambient temperatures

above 25 Degrees C to maintain the best reliability of the

hard drives (the fan is controlled by monitoring the on

board temperature sensor on the hard drives). The

product also monitors the motherboard processor

temperatures.

www.naimaudio.com - 1 - 24

th

April 2008

Page 2

3. Conclusion

Thermal modeling using CAD, FEA and CFD has saved

a huge amount of time in the development process.

The verification by Seagate’s labs further increased

confidence in the use and analysis of these powerful

software tools thus potentially shortening product

development times.

Naim’s HDX is powered by the DigiFi™

platform; leading edge software

technology licensed from

DigiFi Ltd of London

www.naimaudio.com

- 2 - 24

th

April 2008

Loading...

Loading...