Page 1

1

Ovator S-600: Design, engineering and technology

Southampton Road, Salisbury SP1 2LN, ENGLAND

Introduction

High-end hi-fi speaker design is a multidisciplinary

endeavour embracing elements of acoustics,

mechanics, materials, vibration, electronics and musical

psychology. And thanks both to the extraordinary

discrimination of our ears, and our hard-wired sensitivity

to ideas and emotions expressed through music,

success in speaker design requires that the elements of

each discipline be thoroughly optimised. A successful

high-end speaker is truly more than the sum of its parts.

So the story of the Ovator S-600 is not simply that of a

new drive unit technology, it is one of the optimisation of

a multitude of interdependent elements where even the

apparently mundane can have an influential role to play.

The Ovator S-600 builds on proven Naim speaker

design techniques while simultaneously introducing new

technologies, new ideas and new refinements; all

incorporated in a scheme that offers a striking yet subtle

aesthetic and provides great ease of installation.

Paul Neville

Naim Audio

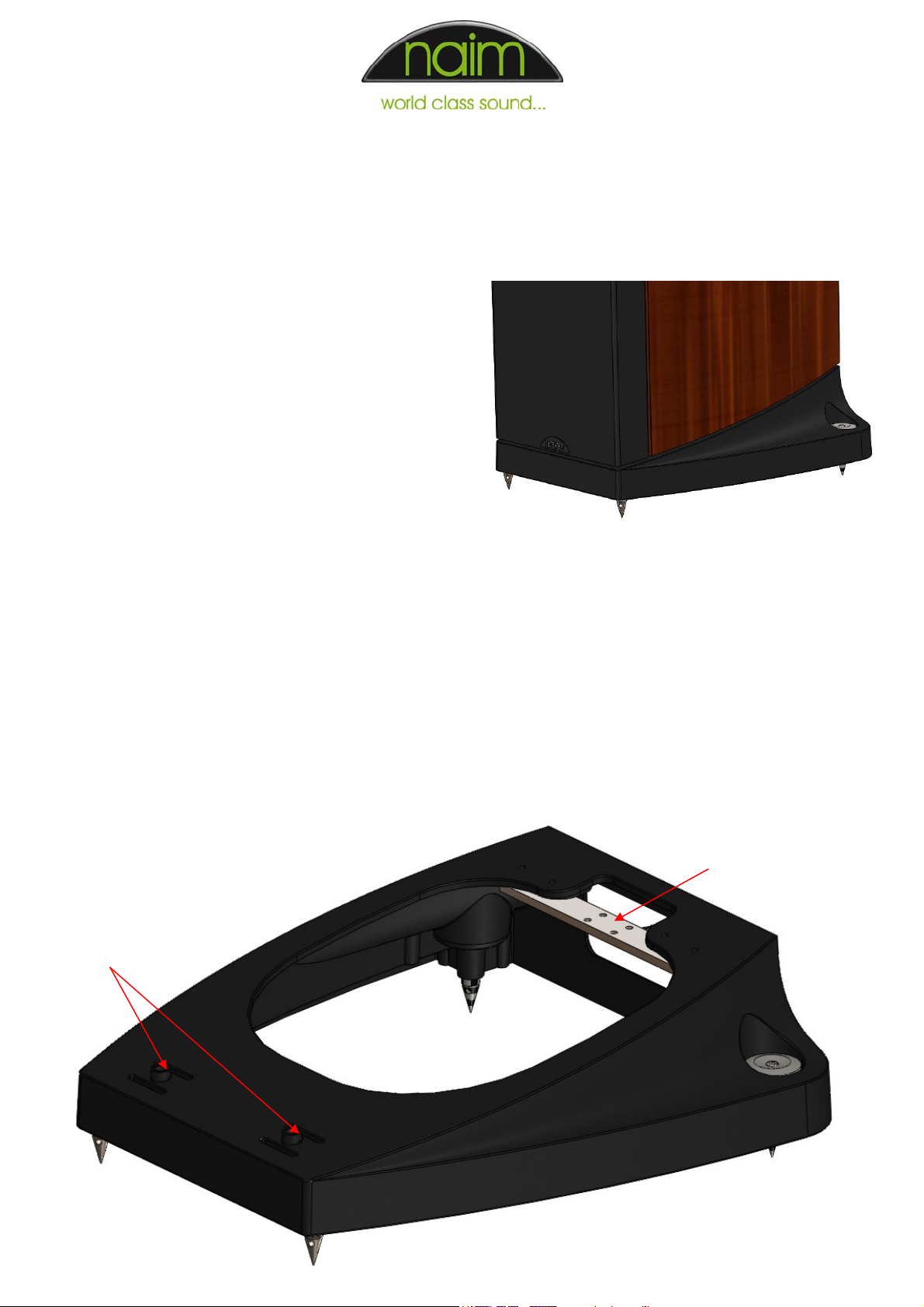

Fig. 1 Plinth and Floor Spikes

The Ovator S-600 Plinth, Cabinet and Driver Chassis

The foundation of the Ovator S-600 is its plinth. An

extremely rigid high pressure aluminium die-casting, the

plinth provides location for the cabinet, floor spike

fittings, and mounting points for the passive crossover

module (or active loom interface) and terminal panel.

The floor spike fittings comprise conventional M8

tapped holes at the front, but at the rear the form of the

plinth and the detail design of the spikes enables them

to be conveniently adjusted and locked from above. The

spikes themselves are manufactured from hardened

stainless steel.

Connection Bosses

Fig. 2

Plinth Leaf Spring

Leaf Spring

Page 2

2

The Ovator S-600 cabinet is attached to the plinth at

two locations towards the front and via a leaf-spring at

the rear. The leaf spring is a 200mm stainless steel

bar that runs laterally underneath the cabinet and

attaches centrally to its underside. At each end the

leaf-spring is bolted, via tapped bosses, to the plinth.

The front locations comprise stand-off bosses through

which a bolt is inserted and screwed into the cabinet.

A slot feature either side of each boss introduces

some controlled compliance to the front cabinet

locations that in combination with the leaf-spring

results in the cabinet rotationally (forward and

backward) decoupling from the plinth above 12Hz.

The entire plinth and cabinet system was the subject

of Finite Element Analysis modelling to analyze,

predict and fine-tune its vibration characteristics with

the aim of ensuring that any resonant behaviour within

the audible band is minimised. Limited decoupling of

the system outside the audible band is inherent in

achieving this aim. The cabinet/plinth leaf-spring was

first introduced on the Naim Allae loudspeaker

although the leaf-sprung cabinet concept goes back to

the Intro and Credo.

Fig. 3 8” Drive Unit Basket

Contact Points

Fig. 4

BMR Sub-assembly

The Ovator S-600 BMR Drive Unit

The Ovator S-600 BMR (Balanced Mode Radiator) has

its own separate enclosure formed by a 12.7mm thick

aluminium alloy cylinder nested within the cabinet. A

unique suspension system comprising two, four

element, duralumin circumferential leaf-springs

decouples the BMR module from the rest of the cabinet.

The suspension system prevents low frequency

mechanical energy from the bass drivers interacting

with the BMR and stops mid/high frequency mechanical

energy being transmitted to the cabinet. The cylinder is

held by one leaf-spring at the front of the cabinet and

one at the back. The system was Finite Element

Analysis modelled and the design optimised to provide

a decoupling from 4Hz – more than six octaves below

the beginning of the BMR pass-band. The BMR

enclosure is gradient filled with a mix of wool felt and

reticulated foam and has a vent at the back so that

changes in temperature or atmospheric pressure do not

impact upon performance. A simple transit system

locks-up and protects the suspension system during

shipping.

Page 3

3

The Ovator S-600 cabinet is of composite construction

with 25mm thick curved sides created from the

lamination of nine MDF sheets bonded under heat and

pressure. This construction effectively incorporates

constrained layer damping within the structure of the

material to create an immensely rigid and non-resonant

panel. The 50mm thick front baffle is created from the

lamination of four layers of 12.5mm MDF to create a

significantly more rigid and better damped panel than

would be achieved through the use of a single sheet.

The outside edges of the front baffle are radiused to

minimise diffracted radiation and internal bracing and

strategic mass damping contribute further to a cabinet

that, in acoustic terms, is fundamentally benign. The

cabinet is internally lined with 20mm wool felt.

The lower portion of the cabinet is divided into two

separate 30 Litre closed box enclosures – one for each

bass driver. Closed box loading was chosen thanks to

the distinct advantages it offers over other loading

techniques in terms of time domain performance and

dynamic compression. The Ovator S-600 low frequency

system resonance is at 38Hz with a Q of 0.6. The free

field -3dB point is 50Hz.

Both the Ovator S-600 bass driver and BMR chassis are

custom designed high-pressure die-castings modelled

using Finite Element Analysis to optimise their

performance by managing the vibration energy that is

an unavoidable consequence of their operation. The

bass driver chassis for example is characterised by a

triangulated structure that not only provides great rigidity

but also maximises the open area behind the cone.

Additionally, it features minimal interface mating

surfaces so that mechanical energy transfer to the

cabinet is controlled and predictable.

Fig. 5

Speaker Cross-section

Page 4

4

The Ovator S-600 Crossover

A significant benefit of the of using a BMR to cover the

entire mid and high frequency band is that the typical

2kHz – 3kHz crossover, with its unavoidable phase and

dispersion discontinuities, is not required. The Ovator S600 crossover between bass drivers and BMR operates

at 380Hz with fourth order acoustic slopes and minimal

phase discontinuity. Thanks to the similarly wide

dispersion of the bass drivers and BMR at crossover

there is no dispersion discontinuity,

The crossover module itself is attached to the underside

of the plinth and comprises a MDF panel carrying a

glass-fibre printed circuit board. It is suspended from the

plinth via an elastomeric mounting system and selected

crossover components also benefit from discrete

mechanical decoupling. The topology of the printed

circuit board borrows many of the layout and earthing

principles of Naim power amplifiers. Components are all

of extremely high quality, each selected following

extensive technical analysis and listening. Four different

types of metalised polypropylene ClarityCap capacitors

are used including the new and outstanding ESA type

employed as the main BMR feed capacitor. The

inductors are a combination of air core and laminate

steel core. The LF feed inductor is a huge laminated

steel core item of 2.8mH with only 0.08Ω series

resistance. The crossover filter and equalisation curves

were extensively computer modelled and correlated with

measurement and listening. The crossover presents a

benign load to driving amplifiers with a minimum

impedance of 3.2Ω at 100Hz and a maximum phase

shift throughout the entire audible band of ±30°.

For bi-amp or tri-amp active operation the entire

crossover can be simply removed and replaced with an

active wiring loom adaptor. The terminal panel is also

exchanged for one carrying three sets of terminals.

The Ovator S-600 Connectors

The Ovator S-600 features custom designed input

terminals that offer a significant advance on

conventional items. The conception and design of the

terminals was informed by the experience gained from

the Naim Hi-Line and Power-Line projects to generate

an innovative and high performance speaker connection

solution.

The terminal is designed to work optimally with the new

Naim high conductivity copper alloy speaker pins but

can also accept standard banana plugs. The sprung

contacts optimise contact pressure and minimise

contact resistance. They are manufactured from a

unique grade of copper alloy with an IACS (International

Annealed Copper Standard) of over 90% and enhanced

spring properties. The terminal housing is designed to

eliminate eddy currents and allow the contacts to float in

order to minimise microphonic effects. The complete

housing is also designed to float within the aluminium

back plate of the speaker.

Silver plate on both the contacts and the pins were

chosen from listening tests, which confirmed the

findings from previous projects. The use of the same

plating of both pin and contact minimises the potential

for galvanic corrosion.

Fig. 6 Speaker Connectors

The Ovator S-600 In Use

Installing and setting-up the Ovator S-600 is simple. It is

fitted when packed with a pair of castor trolleys and,

with its carton upright and opened at the front, it can

simply be wheeled into position. Once in position the

caster trolleys can be removed and the Ovator S-600

placed on its pre-fitted floor spikes. Spike adjustment

and levelling is simplified significantly by the rear spikes’

top adjustment and locking access.

The Ovator S-600 is a wide bandwidth, neutrally

balanced and uncoloured speaker capable of very high

volume levels without significant compression or

distortion. Its exceptional time domain behaviour and

extremely low noise-floor mean that fine musical detail

is reproduced naturally with coherence and clarity. It is

designed primarily for “free-space” positioning within

the listening room. However, thanks to its consistent

and wide dispersion it is relatively insensitive to

positioning. Its listening sweet-spot is also considerably

wider than typical conventional speakers.

Loading...

Loading...