Page 1

SERVICE MANUAL

SERVICE MANUAL

MODEL : M5 C/AH

© NAD 2006

NAD ELECTRONICS INTERNATIONAL

TORONTO

CD/SACD PLAYER

M5 C/AH

SERVICE MANUAL

M5 C/AH

M5 C/AH

CD/SACD PLAYER

CD/SACD PLAYER

Page 2

CONTENTS

SECTION 1 SUMMARY

SECTION 3 ELECTRICAL

SECTION 2 CABINET & MAIN CHASSIS

SECTION 4 MECHANISM

SECTION 5 REPLACEMENT PARTS LIST

SECTION 1 . . . .SUMMARY

SECTION 2 . . . .CABINET & MAIN CHASSIS

SECTION 3 . . . .ELECTRICAL

SECTION 4 . . . .MECHANISM

SECTION 5 . . . .REPLACEMENT PARTS LIST

Page 3

SECTION 1 SUMMARY

CONTENTS

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO PRODUCTS

SERVICING PRECAUTIONS ........................................................................... 1-3

• General Servicing Precautions

• Insulation Checking Prodedure

• Electrostatically Sensitive Devices

SPECIFICATIONS

...........................................................................................

............. 1-2

1-4

1-1

Page 4

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO PRODUCTS

CAUTION : DO NOT ATTEMPT TO MODIFY THIS

PRODUCT IN ANY WAY, NEVER PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFACTURER’S

APPROVAL. UNAUTHORIZED MODIFICATIONS WILL

NOT ONLY VOID THE WARRANTY, BUT MAY LEAD TO

YOUR BEING LIABLE FOR ANY RESULTING PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY

AFTER YOU ARE THOROUGHLY FAMILIAR WITH ALL

OF THE FOLLOWING SAFETY CHECKS AND SERVICING GUIDELINES. TO DO OTHERWISE,INCREASES

THE RISK OF POTENTIAL HAZARDS AND INJURY TO

THE USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION FROM A.C. LINESHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS

BEEN CORRCTED. A CHECK SHOULD BE MADE OF

THE FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1.BE SURE THAT ALL COMPONENTS ARE POSI-

TIONED IN SUCH A WAY AS TO AVOID POSSIBILITY

OF ADJACENT COMPONENT SHORTS.THIS IS ESPECIALLY IMPORTANT ON THOSE MODULES WHICH

ARE TRANSPORTED TO AND FROM THE REPAIR

SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES SUCH AS INSULATORS, BARRIERS,

COVERS, SHIELDS, STRAIN RELIEFS, POWER

SUPPLY CORDS, AND OTHER HARDWARE HAVEBEEN REINSTALLED PER ORIGINAL DESIGN. BE

SURE THAT THE SAFETY PURPOSE OF THE POLARIZED LINE PLUG HAS NOT BEEN DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER

POSSIBLE COLD SOLDER JOINTS, SOLDER

SPLASHES OR SHARP SOLDER POINTS. BE CERTAIN TO REMOVE ALL LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE

OR DETERIORATION TO PARTS AND COMPONENTS.

FOR FRAYED LEADS, DAMAGED INSULATION

(INCLUDING A.C. CORD). AND REPLACE IF NECES-

5. NO LEAD OR COMPONENT SHOULD TOUCH A

RECIVING TUBE OR A RESISTOR RATED AT 1 WATT

OR MORE. LEAD TENSION AROUND PROTRUNING

METAL SURFACES MUST BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES,

FLAMEPROOF RESISTORS, CAPACITORS, ETC.

MUST BE REPLACED WITH EXACT FACTORY TYPES,

DO NOT USE REPLACEMENT COMPONENTS OTHER

THAN THOSE SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT MODIFICATIONS.

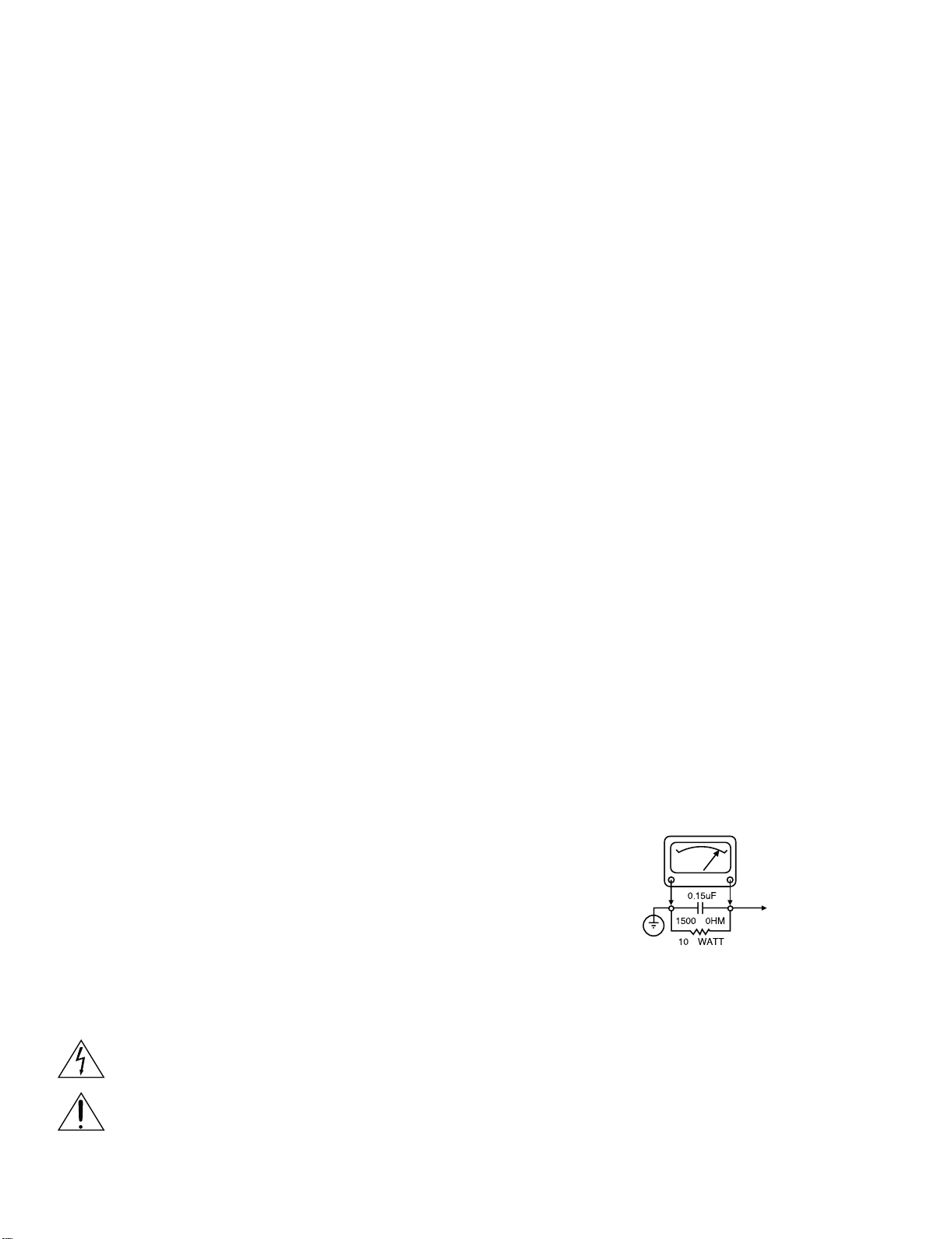

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN A.C. LEAKAGE TEST ON ALL EXPOSED

METALLIC PARTS OF THE CABINET, (THE CHANNEL

SELECTOR KNOB, ANTENNA TERMINALS. HANDLE

AND SCREWS) TO BE SURE THE SET IS SAFE TO

OPERATE WITHOUT DANGER OF ELECTRICAL

SHOCK. DO NOT USE A LINE ISOLATION TRANSFORMER DURING THIS TEST USE AN A.C. VOLTMETER, HAVING 5000 OHMS PER VOLT OR MORE SENSITIVITY, IN THE FOLLOWING MANNER; CONNECT A

1500 OHM 10 WATT RESISTOR, PARALLELED BY A

.15 MFD. 150.V A.C TYPE CAPACITOR BETWEEN A

KNOWN GOOD EARTH GROUND (WATER PIPE,

CONDUIT,ETC.) AND THE EXPOSED METALLIC

PARTS, ONE AT A TIME. MEASURE THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500OHM

RESISTOR AND .15 MFD CAPACITOR. REVERSE THE

A.C. PLUG AND REPEAT A.C. VOLTAGE MEASUREMENTS FOR EACH EXPOSED METALLIC PART. VOLTAGE MEASURED MUST NOT EXCEED 75 VOLTS

R.M.S. THIS CORRESPONDS TO 0.5 MILLIAMP A.C

ANY VALUE EXCEEDING THIS LIMIT CONSTITUTES A

POTENTIAL SHOCK HAZARD AND MUST BE CORRECTED IMMEDIATELY.

A.C. VOLTMETER

GOOD EARTH GROUND

SUCH AS THE WATER

PIPE. CONDUIT. ETC

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

SUBJECT: GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN AN EQUILATERAL TRIANGLE, IS INTENDED

TO ALERT THE SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED “DANGEROUS VOLTAGE”

THAT MAY BE OF SUFFICIENT MAGNITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE SERVICE

PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN SERVICE LITERATURE.

1-2

Page 5

SERVICING PRECAUTIONS

CAUTION

this service data and its supplements and addends, read and

follow the SAFETY PRECAUTIONS. NOTE: if unforeseen

circumstances create conflict between the following servicing

precautions and any of the safety precautions in this publication,

always follow the safety precautions.

Remember Safety First:

General Servicing Precautions

1. Always unplug the Stereo amplifier AC power cord from the

AC power source before:

(1) Removing or reinstalling any component, circuit board,

(2) Disconnecting or reconnecting any internal electrical

(3) Connecting a test substitute in parallel with an electrolytic

Caution: A wrong part substitute or incorrect polarity

2. Do not spray chemicals on or near this Stereo amplifier or

any of its assemblies.

3.Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner,

cottontipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

which instruments covered by this service manual might be

equipped.

5. Do not apply AC power to this Stereo amplifier and/or any

of its electrical assemblies unless all solid-state device heat

sinks are correctly installed.

6. Always connect test instrument ground lead to the

appropriate ground before connecting the test instrument

positive lead. Always remove the test instrument ground lead

last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn the

power on. Connect an insulation resistance meter (500V) to the

blades of the attachment plug. The insulation resistance

between each blade of the attachment plug and accessible

conductive parts (Note 1) should be more than 1 M-ohm.

Note 1: Accessible Conductive Parts including Metal panels,

Input terminals, Earphone jacks, etc.

: Before servicing the Stereo amplifier covered by

module, or any other assembly.

plug or other electrical connection.

capacitor.

installation of electrolytic capacitors may result in an

explosion hazard.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical Es devices are integrated circuits and some field effect

transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handing any semiconductor component

or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known earth

ground. Alternatively, obtain and wear a commercially

available discharging wrist strap device, which should be

removed for potential shock reason prior to applying power to

the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an antistatic solder removal device. Some solder

removal devices not classified a “anti-static” can generate

electrical charges sufficient to damage ES devices.

5. Do not use freonpropelled chemicals. These can generate

electrical charge sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum

foil, or comparable conductive material).

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution: Be sure no power is applied to the chassis or circuit,

and observe all other safety precautions.

8.Minimize bodily motions when handing unpackaged

replacement ES devices. (Normally harmless motion such as

the brushing together of your clothes fabric or the lifting of

your foot from a carpeted floor can generate static electricity

sufficient to damage an ES device.)

1-3

Page 6

SPECIFICATIONS

•GENERAL

Power requirements: AC 100-240 V , 50/60 Hz

Power consumption: 45W

Dimensions (Approx.): 435 x 100 x 300 mm (W xHxD)without foot

Weight (Approx.): 8.6 kg

Operating temperature: 5 °C to 35 °C (41 °F to 95 °F)

Operating humidity: 5 % to 90 %

• OUTPUTS

VIDEO OUT: 1 Vp-p 75 sync negative, RCA jack x 1

AUDIO OUT: 2.0 Vrms (1 KHz, 0 dB),

60 &+8QEDODQFH%DODQFH

PXWL&+

RCA jack (L, R) x 1/ XLR jack (L, R) x 1/ RCA jack(6-ch) x 1

DIGITAL OUT (COAXIAL): 0.5 V (p-p), 75 RCA jack x 2SWLFDO[ 1,AES/EBU x 1

• System

Laser:

6LJQDO system:

Frequency response:

SLJQDO-to-noise ratio(A-W): More than 110 dB (2CH ANALOG OUT )

Harmonic distortion: Less than 0.005%

Dynamic range: More than

• Accessories

Video FDEOe (1), Audio FDEOe (1), Remote controO (1), Batteries (2)

Semiconductor ODVer, ZDYHOHQgth 650 nm

PAL / PAL 6 0 / NTSC

SACD:8Hzto50kHz

CD: 8 Hz to 20 kHz

More than 100 dB (muti-CH ANALOG OUT )

95dB (CD/SACD muti-ch)

More than 105dB (SACD 2-ch)

1-4

Page 7

SECTION 2 CABINET & MAIN CHASSIS

CONTENTS

EXPLODED VIEWS................................................................................................................ 2-2

1. Cabinet and Main Frame Section ................................................................................ 2-2,3

2. Exploded view parts list......

3. Packing accessory section............................................................................................2-5

.................................................................................................. 2-4

2-1

Page 8

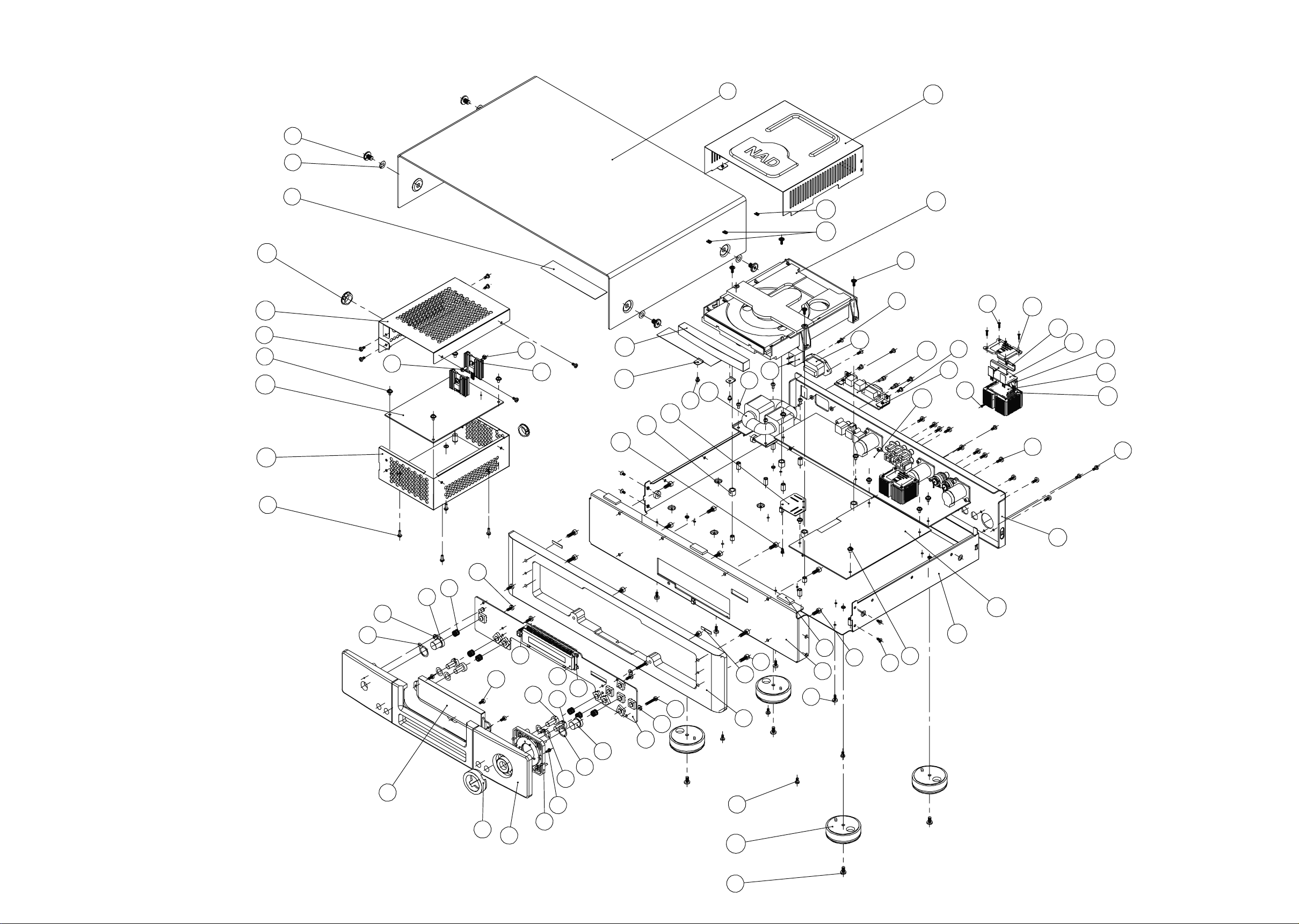

EXPLODED VIEWS

1.Cabinet and main frame section

S021

T003

T002

C009

C008

S013

S010

C007

C006

S012

S014

P001

C014

C013

C010

C011

C012

S015

C005

T001

S011

R003

C017

C016

R002

S019

S016

C004

C003

C016

C015

RS01

S008

S018

S017

A001

S020

A002

A003

A004

A003

A005

S008

S012

F007

F008

F003

F009

F010

S001

F002

S001

F001

FP01

F011

F004

FP02

F012

S002

F005

FP03

F006

F013

F014

S003

S004

S008

C016

F016

F015

S005

S008

F018

F017

S006

S007

R001

C002

C001

S010

2-2

S009

2-3

Page 9

2.EXPLODED VIEW PARTS LIST

REF.NO. PART NO. DESCRIPTION Qty. REF.NO. PART NO. DESCRIPTION Qty.

New PN 67-051002-1

C002 01-50501-00 Decode Board 1 T002 86-018002-1 Expanded Rubber 2

C003 01-50502-00 Audio Board 1 T003 76-046001-0 Screw Washer 4

C004 01-50505-00 RS232 Board 1

C005 18-55017-20 R Type Transformer(C Version) 1

18-55017-10 R Type Transformer(AH Version) 2tekcarB0-010010-6610SR1

C006 68-051002-1 Shielding Box(down) 1

C008 68-051001-1 Shielding Box(up) 1

C009 85-051001-0 Snap Bushing 2 A003 01-50506-01 Module Board 4

C010 85-051002-0 PCB Spacer 3 A004 78-048004-0 Insulated Cushion 8

C017 69-051004-0 Loader Clamp 2 2

C018 68-051003-0 Loader Cover 1

C019 83-043001-0 Foot Assembly 4

F003 76-051001-0

F004 77-051001-1 Cursor Holder 1 S005 61-224512-1 Hex Head Screw (M4X12) 6

F005 87-048002-0 Input Button Pad 4 S006 61-224508-1 Hex Head Screw (M4X8) 7

F006 87-048003-0 Power Button Pad 2 S007 61-063106-0 Self Taping Screw (STF3X6) 4

F007 86-046001-0 Led Lens Gum 1 S008 61-023106-2 Self Taping Screw (STB3X6) 17

F009 70-048013-0 Power Button 1

F010 92-048001-0 Spring for Button 6 S011 61-023506-1 Machine Screw(MB3×6-Ni) 4

F012 70-051006-1 Stop-Menu Button 2

F016 86-046002-0 Fascia Padding 2

F018 86-010004-0 3mm Rubber Pad 3 S019 61-073108-0 Self Taping Screw (STO3X8) 2

R001 67-051003-0 Rear Panel (C Version) 1 S021 61-246508-0 Machine Screw (MB6X8-Cr) 4

67-051005-0 Rear Panel (AH Version) 1

R003 11-01101-03 Rocker Switch 1

VFD window 1 S004 61-023616-0 Self Taping Screw (TBBT3×16) 2

A002 66-048001-0 Module Tr. Braccket 4

1pmalCeniL0-200150-57210C

1rooDDVD1-100150-07410C

FP03 75-051001-0 Display Bracket 1

S001 61-023206-1 Self Taping Screw (BTB3X6) 7

(rehsaW0-503011-36300S1rosruCgniR0-200150-07200F 3× 7×0.5 2

S010 61-373506-0 Machine Screw (MB3X6W.S-Ni) 11

S013 61-023106-1 Self Taping Screw (STB3X6-Ni) 6

S017 61-062206-1 Self Taping Screw (BTF2×6) 8

S020 61-023208-0 Self Taping Screw (BTB3X8) 11

1telnICA20-20070-71200R

1revoCpoT0-200150-76100T1sissahC0-200760-76100C

2revoCeludoM0-100840-07100A1draoBUSP00-30505-10700C

2esaBeludoM1-100760-07500A4recapS2-200150-96110C

2knistaeH0-500150-07100P2pmalCrooDDVD0-200150-66310C

1tekcarBRI0-110150-5610PF1redaoL00-63880-73510C

1DFV00-95555-3220PF41pmalCredaoL0-300150-96610C

2)iN-6X5.2BM(wercSenihcaM6-605220-16200S12aicsaF0-400150-07100F

4)8X4BTS(wercSgnipaTfleS1-801420-16900S1sneLdeL0-100800-67800F

6)8X3BM(wercSenihcaM0-805320-16210S2nottuBtupnI1-210840-07110F

2)3M(tuN2-203010-26410S1nottuBretnE0-700150-07310F

2)iN-4X3BM(wercSenihcaM1-405320-36510S1PPF00-40555-10410F

4)8X3WPTS(wercSgnipaTfleS0-801380-16610S11aicsaF1-300160-07510F

4)8×2FTS(wercSgnipaTfleS1-801260-16810S1aicsafbuS1-100150-76710F

2-4

Page 10

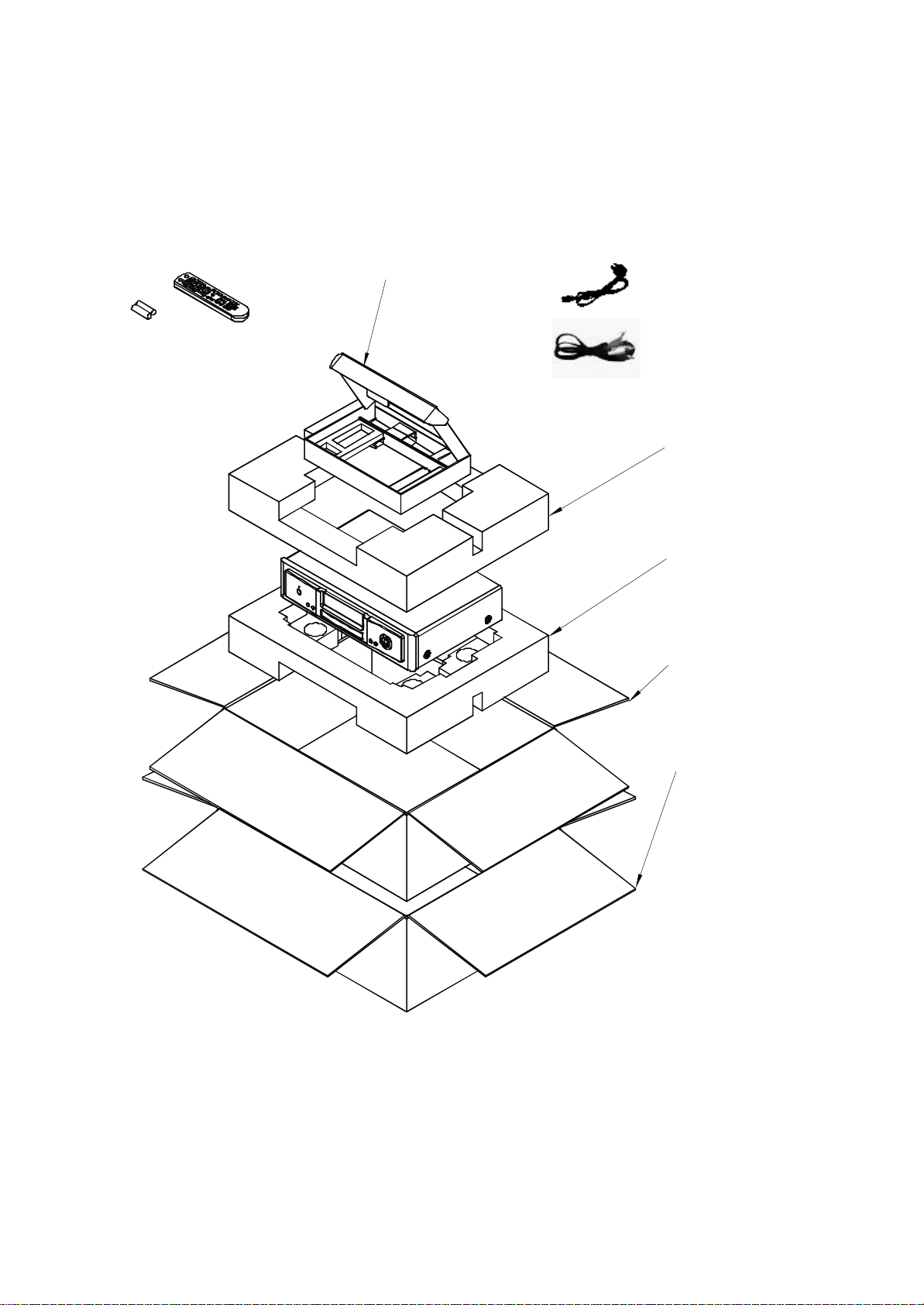

3.PACKING ACCESSORY SECTION

Batteries

REMOCON

Accessory Box

AC Cord

Audio and Video Cord

Polyfoam(up)

Polyfoam(down)

Gift Box

Shipping Box

2-5

Page 11

SECTION 3 ELECTRICAL

CONTENTS

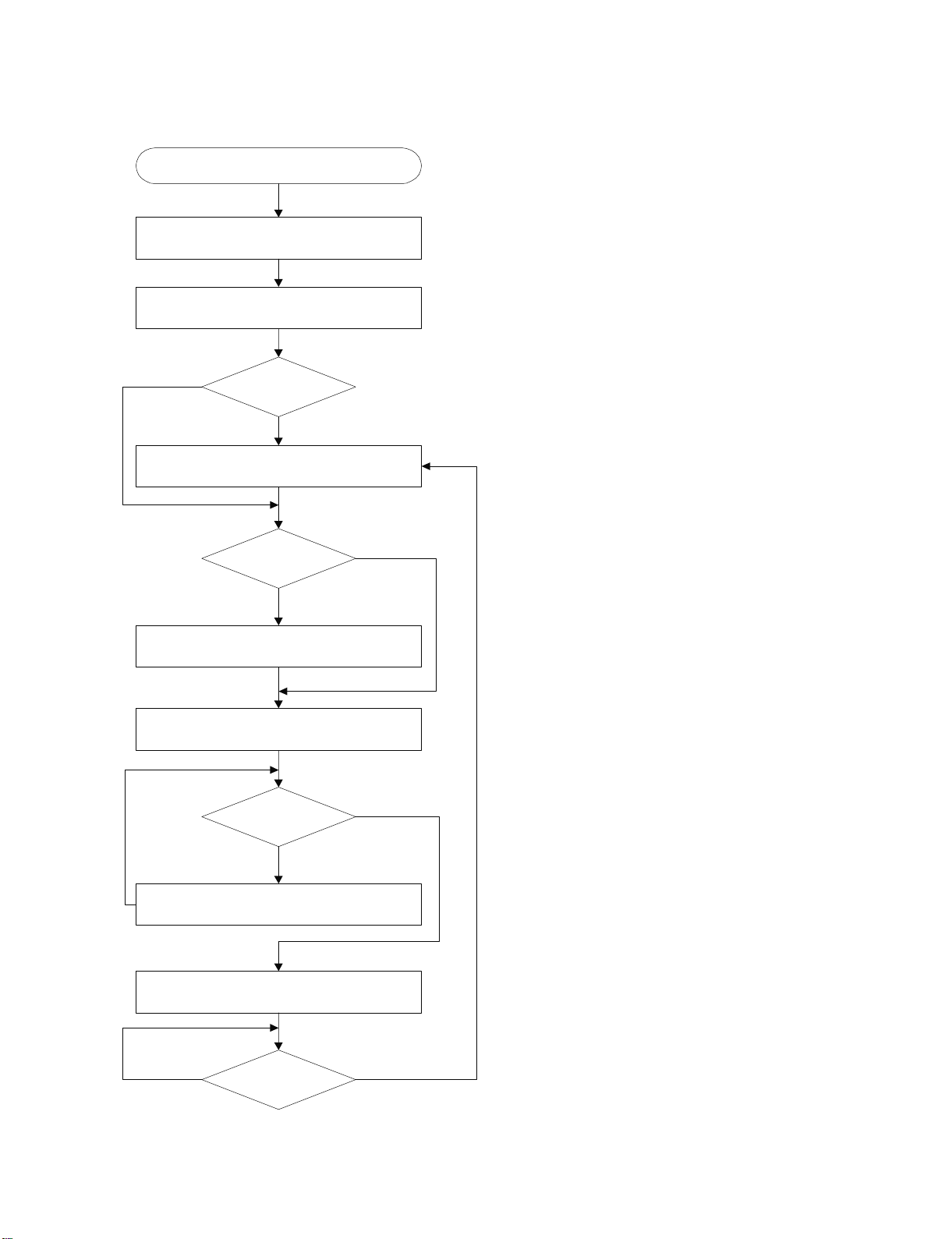

ELECTRICAL TROUBLESHOOTING GUIDE

1. Power check flow………………………………………………………………………3-2

2. System operation flow…………………………………………………………………3-3

3. Test & debug flow……………………………………………………………………... 3-4,9

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGING

1. System 27MHz clock,reset,flash R/W signal………………………………………..3-10

2. SDRAM clock…………………………………………………………………………..3-11

3. TRAY OPEN/CLOSE signal…………………………………………………………..3-11

4. SLED control related signal(NO disc control)……………………………………....3-12

5. LENS control related signal(NO disc control)……………………………………… 3-13

6. FOCUS control related signal(NO disc control)…………………………………… 3-14

7. SPINDLE control WAVEFORM……………………………………………………… 3-15

8. FOCUS ON WAVEFORM……………………………………………………………. 3-16

9. RF WAVEFORM…………………………………………………………….…………3-17

10. ES6168F Audio optical and coaxialoutput(SPDIF)………………………………. 3-17

11. ES6168F Video output to Audio DAC……………………………………….……..3-18

12. Audio output(1KHz odB)……………………………………………………….…… 3-18

BLOCK DIAGRAMS

1. Overall block diagram………………………………………………………………… 3-19

2. Power(SMPS) block diagram…………………………………………………………3-20

3. Servo block diagram………………………………………………………………….. 3-21

CIRCUIT DIAGRAMS

1. Power(SMPS) circuit diagram……………………………………………………….. 3-22

2. Decode board-ES6168 section……………………………………………………....3-23,24

3. Decode board-DSP section………………………………………………………......3-25,26

4. Decode board-H-POWER & DRIVER section……………………………………...

5. Decode board-RF section……………………………………………………………. 3-28

6. Decode board-CONNECT AND 232 section…………………………………........ 3-29

7. Audio board…………………………………………………………………............... 3-30,31

8. 232 AND AMP module board………………………………………………………...3-32

9. Front panel board…………………………………………………………………….....3-33

CIRCUIT VOLTAGE CHARGE

PRINT CIRCUIT BOARD DIAGRAM

1. Decode board………………………………………………………………….............3-42,43

2. Audio board………………………………………………………………………….....3-44,45

3. SMPS board………………………………………………………………………....... 3-46

4. Front panel board……………………………………………………………………...3-47,48

5. RS232 board……………………………………………………………………….......3-47,48

6. AMP module board…………………………………………………………………… 3-47,48

………………………………….…………………........3-34,41

3-27

3-1

Page 12

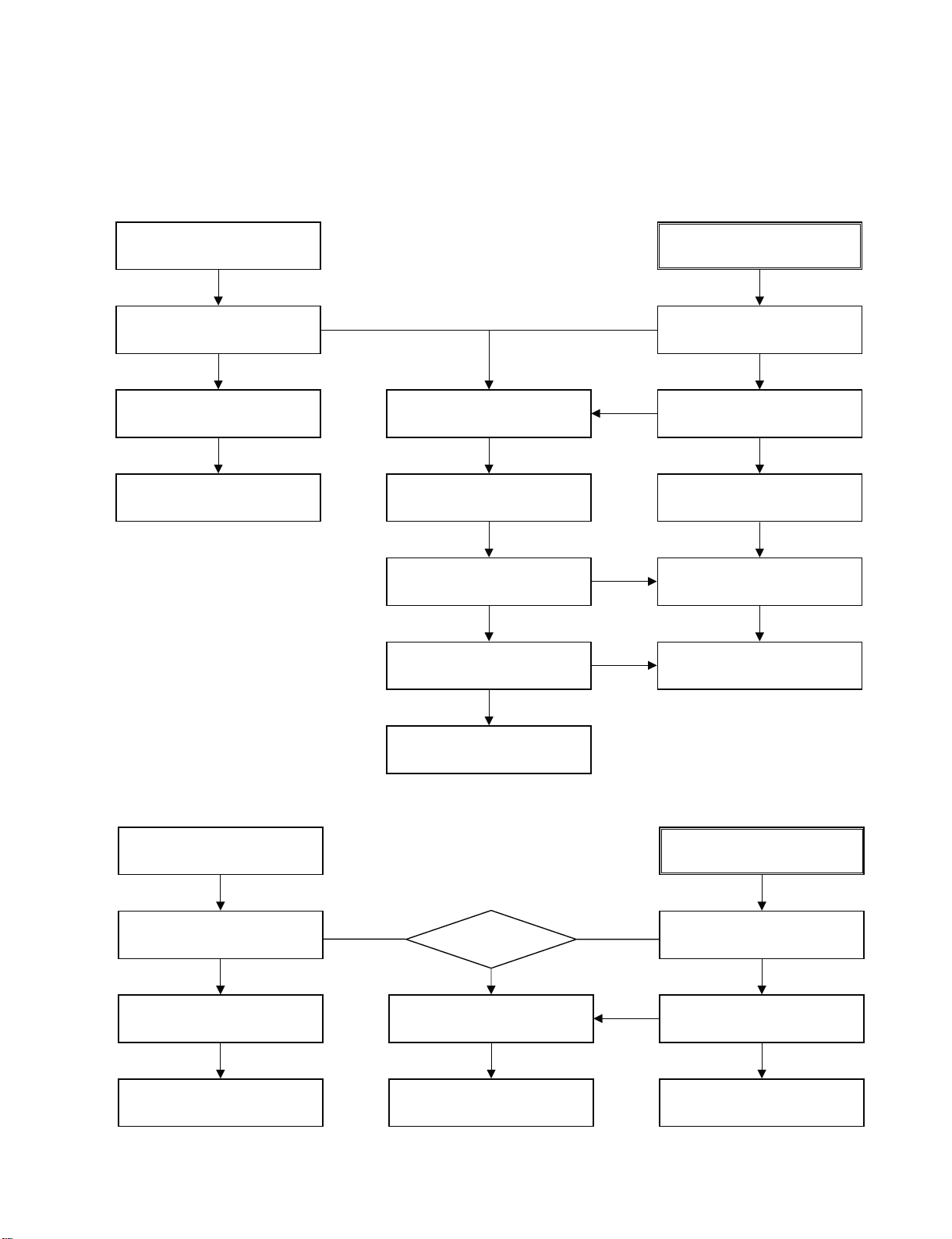

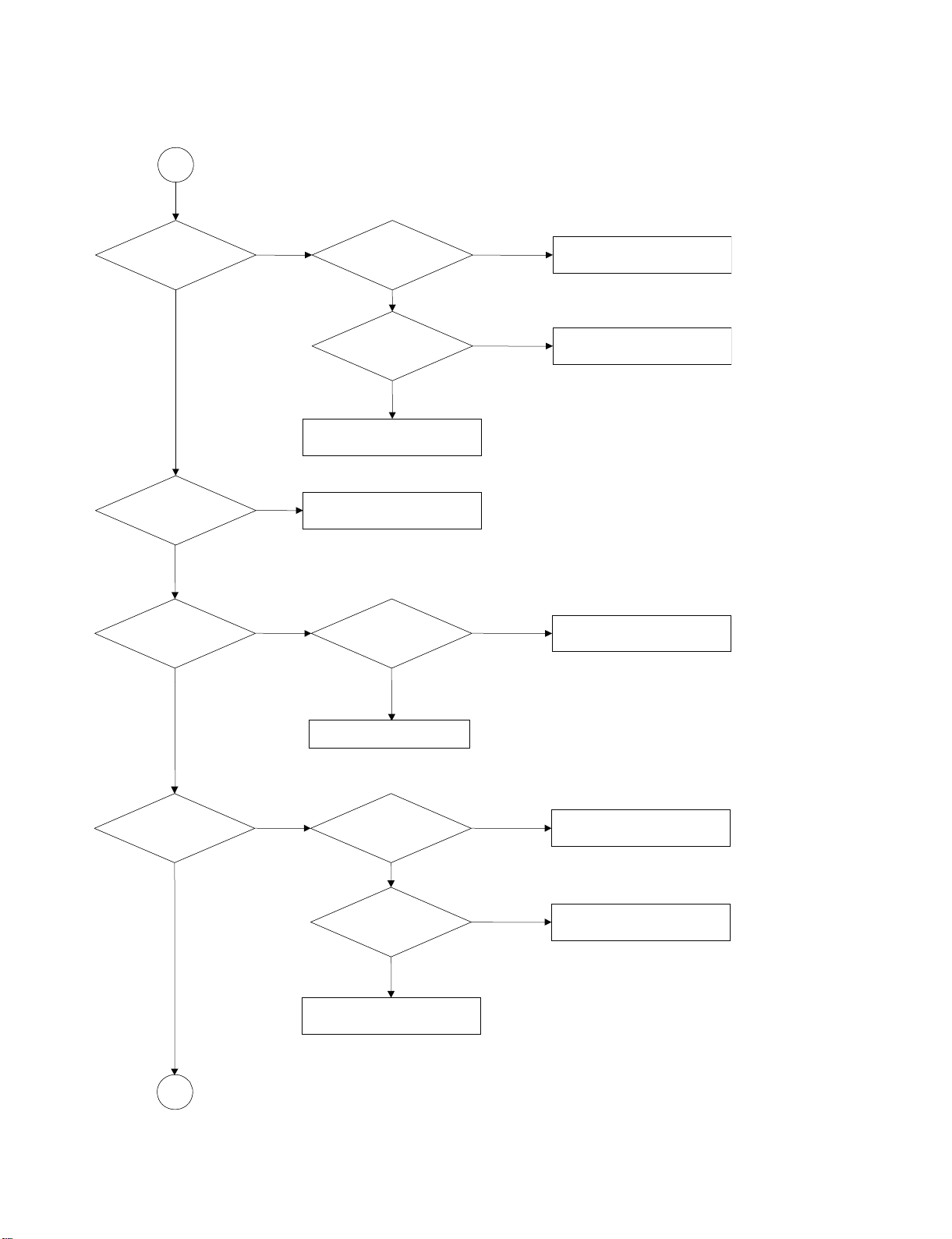

ELECTRICAL TROUBLESHOOTING GUIDE

1.

Power check flow

Digital circuit supply

A.

No VF+

Is 5VD section working?

YES

Check D910

No

Replace D910

NO

No 5VD

Check FH900

Is there a AC voltage at

one terminal of RT900?

YES

Is there a DC voltage At

(+) terminal of B900?

YES

B.

No 5VS

NO

Is 5VD section working?

YES

NO

Is 5VD present at input

of U911?

YES

Replace U911.

YES

NO

NO

Replace RT900.

YES

Replace B900.

Analog circuit supply

A.

No +/-12V

Is +/-VCCA works well?

YES

Check U605 U606

Replace U605/U606

NO

Replace U900.

Is 5VD right

Yes

Check Q619 Q621 Q623

Yes

Check Transformer

3-2

B.

No 5VA

NO

Is VM works well

YES

NO

Check U658

YES

Replace U658.

Page 13

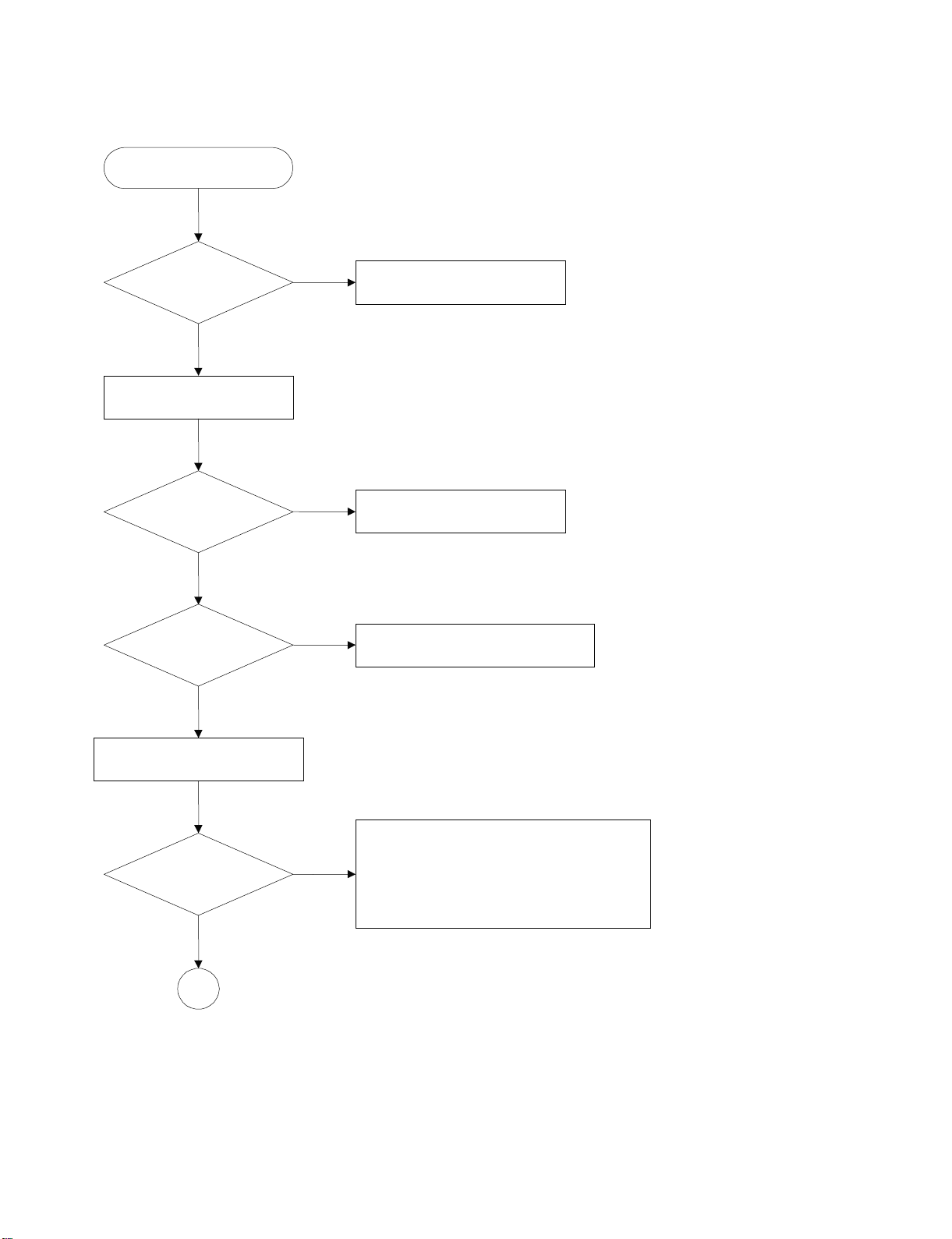

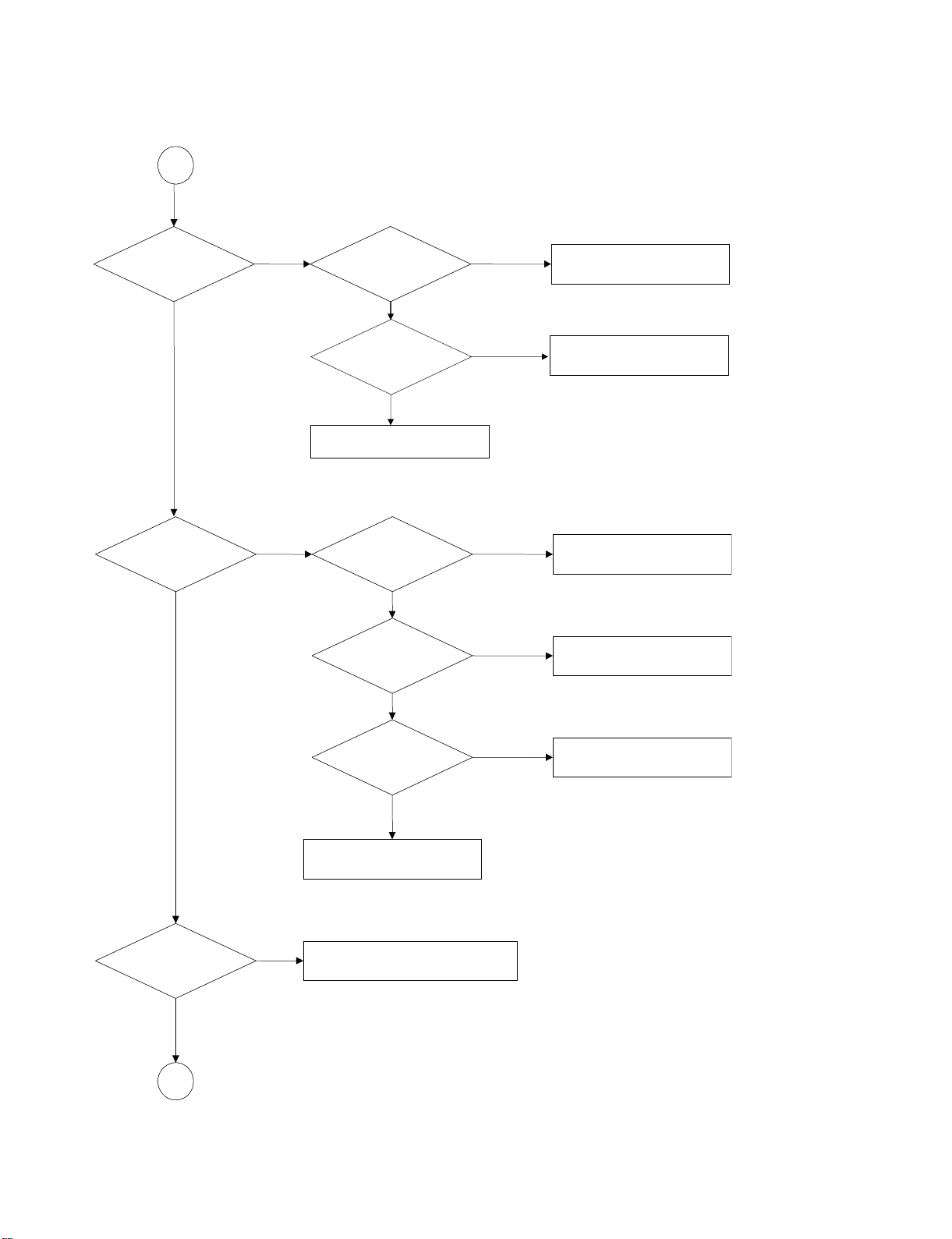

2. System operation flow

Power On

1. ES6168 initializes SERVO & the other DSPs

Show LOGO

YES

Tray Closed?

NO

Tray Close to Closed position

SLED at Inner

Side ?

NO

SLED Moves to Inner Positi on

1. Judge whether have disc and disc type

2. Jump to related disc reading procedure

Reci eve

OPEN/CLOSE

Key?

YES

YES

NO

1. Execute Pressed Key & IR Key

2. System operation Routine Loop

1. Stop Playback & Open Tray

2. Display tray open message & LOGO

NO

Receive

CLOSE Key?

YES

3-3

Page 14

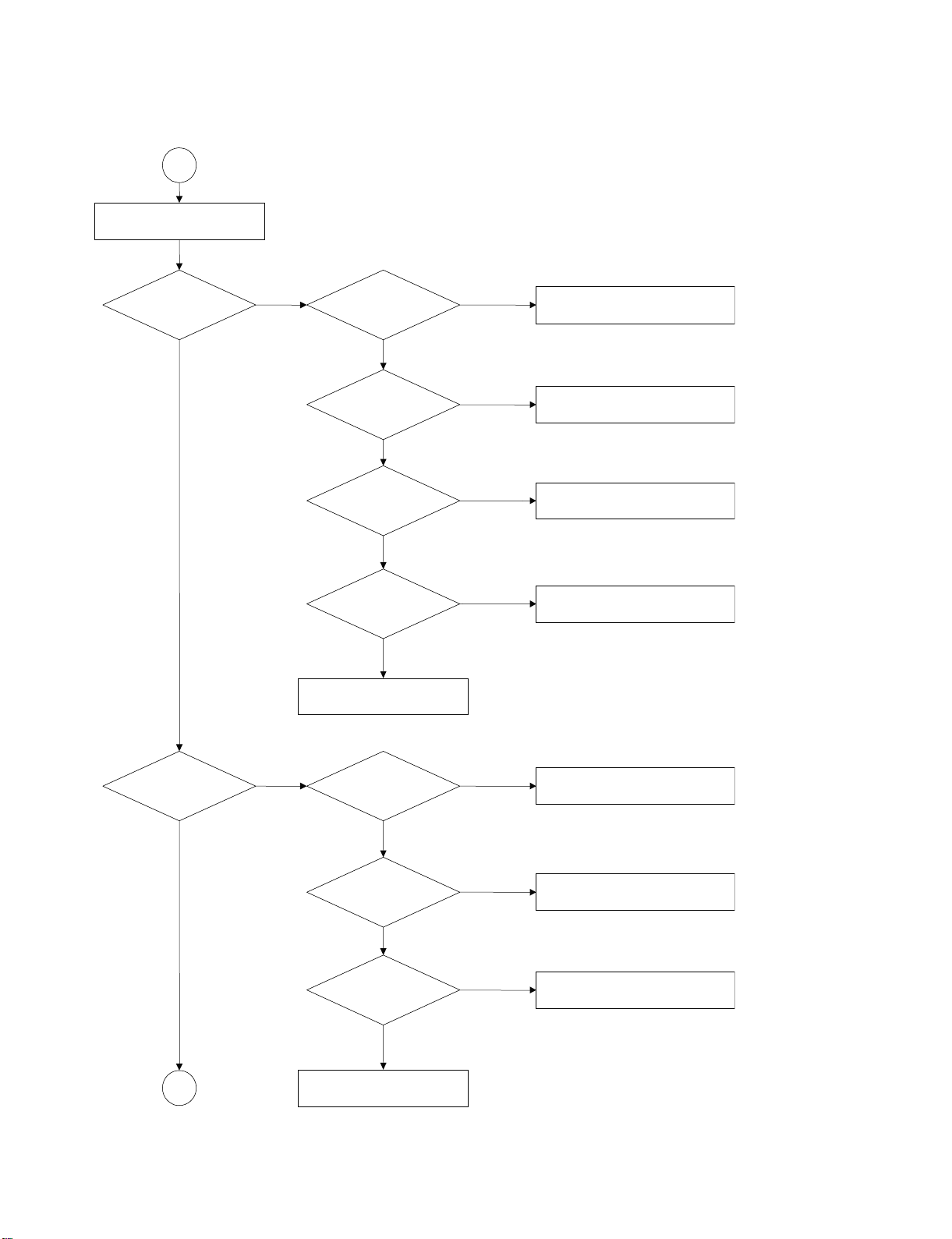

3. Test & debug flow

Switch on the Power switch

Check the AC Voltage on

Power PCB (110V or 220V)

YES

Press the power key on front panel

Is the DC Voltage

outputs OK?

(5V,3.3V,9V,±12V,5VA)

YES

Is 3.3V,1.8V and 2V DC

outputs normal on decode

PCB?

YES

NO

NO

NO

Check Fuse and connections

to AC inlet

Repair or Replace Power PCB

Replace R-core Transformer

Check the regulators or related diodes.

Insert the upgrade disc to update

the FLASH memory code.

Update FLASH

successfully?

YES

A

NO

1. Check 27MHz system clock.

2. Check system reset circuit.

3. Check FLASH R/W enable signal LOE#,WRLL.

4. Check servo related circuit.

5. Check FLASH Memory related circuit.

3-4

Page 15

A

RESET or Power On.

Show LOGO?

NO

Flash Memory operates

properly?

YESYES

SDRAM works properly?

YES

ES6168

Video PINs outputs

properly?

YES

Have TV signal output?

YES

Check AV cable connection

to TV set.

NO

NO

NO

NO

Check connection lines between FLASH

& ES6168 and the FLASH access time

whether is suitable or not.

Check connection lines between

SDRAM & ES6168 and the SDRAM

is damaged.

Check the related ICs

Check the filtering circuit of

TV signal.

Does Tray move

inside when it is not

at closed position?

YES

B

NO NO

Normal OPEN_SW&

CLOSE_SW signals?

YES

Normal LDM1 &

LDM2 signal?

YES

Normal EJ+ & EJ-

signal?

YES

Check the cable connection

between decode PCB and loader.

NO

NO

3-5

Check the load OPEN & CLOSE

switch

Check the Tray control IO pins on

CXD1885 & FAN8042.

Check the Tray control amplifying

circuit on Motor driver.

Page 16

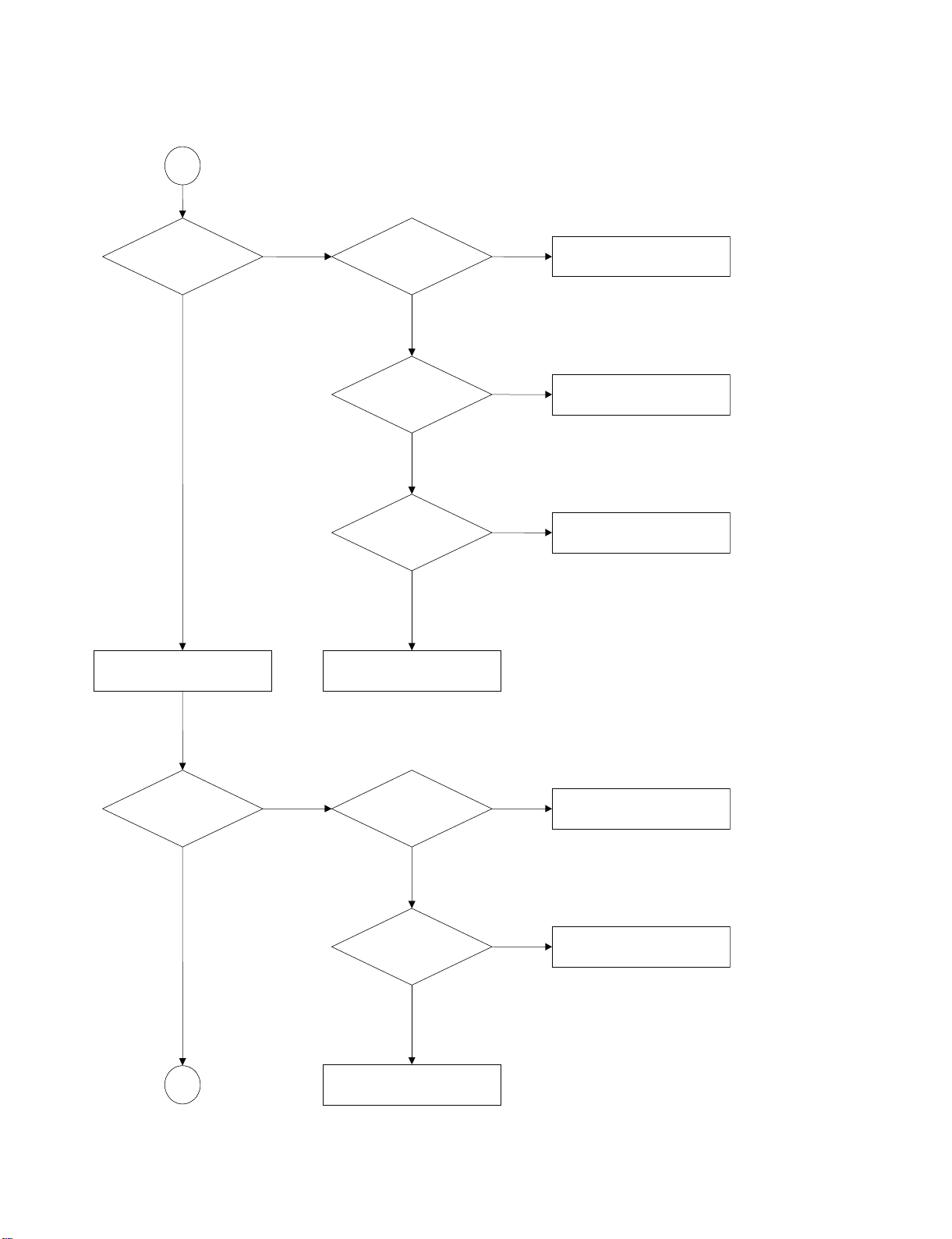

B

Does

the SLED move

to inner side when it is at

outter position?

Do not put in disc and tray

close.

Motor Driver

XFTSMUTE

Pin is High?

SEYSEY

Is SLED DC Level lower

than 1.65V?

YES

SL+ and SL- output

properly?

YES

Check the cable connection with

MECHA.

NO

NO

ONON

Check the connection line of

XFTSMUTE signal.

Check the related circuit of

SLED.

Check the amp circuit on motor

driver.

Optical Lens has

movements for searching

Focus?

C

Proper FSCON outputs

to motor driver?

YESYES

Proper F+ & F- outputs?

YES

Check cable connect on with

pick-up head.

3-6

NO

ONON

Check FSCON connection on

CXD1885Q and motor dirver.

Check the amp circuit on motor

dirver.

Page 17

C

Laser turns on when

reading disc?

YES

YES

Disc ID is correct?

NO

NO

NO

DVDLD or CDLD

output properly?

YES

Collector voltage of

power transistor is OK?

YES

Check cable connection between

transistor ouput and pick-up

head.

fforesaL?nicsidtuP

Proper RFSIN signal

on CXD1881?

YES

NO

NO

NO

Check the laser power circuit

on CXD1881 and connecting to

power transistor.

Check the related circuit on

laser power transistor

Check the related circuit

on CXD1881 RFSIN signal.

YES

Does spindle rotate?

YES

D

NO

Check DVDLD & CDLD signal

Proper SPWM signal on

CXD1885Q

YES

SP+ & SP- output

properly?

YES

Check the cable connection

between spindle and main PCBA.

NO

NO

Check SPWM related

circuit on CXD1885Q.

Check the spindle control

amp circuit of motor

driver.

3-7

Page 18

D

YES

Focus ON OK?

YES

Track On OK?

YES

NO NO

NO

Proper signals on

A,B,C,D of CXD1881

YES

Check FEO signal

on CXD1881

YES

Check FSCON signal

on CXD1885Q

Normal TEO Signal on

CXD1881 ?

YES

Properly TSCON

signal on CXD1885Q?

YES

NO

NO

NO

Check connections between

CXD1881 and pick-up head.

Check the FSCON connection on

CXD1885Q and motor driver.

Check the related

circuit on CXD1881

Check the TSCON

connection on CXD1885Q

and motor dirver.

Disc is play ?

YES

E

NO

T+ & T- output

properly?

YES

Check cable connection on

pick-up head.

Check RF-OP & RFAC signal waveform.

NO

3-8

Check the tracking control

amp circuit on motor

driver.

Page 19

E

Normal Audio output

when disc playback?

YES

Normal IR.VFD & Front

pannel key functions?

YES

TEST END

NO NO

NO

Audio DAC received

correct data stream?

YES

Normal Audio DAC

out?

YES

Check Audio filter,amplify,mute

ES6168 is normally

Check the cable connection on

circuit.

Communications between

IR.VFD Front pane

Front pannel.

YES

lkey &

l

?

NO

NO

Check connection between ES6168

& CXD2753 & Audio DAC.

Check the related

circuit of Audio DAC.

Check communication lines on

ES6168.

3-9

Page 20

DETAILS AND WAVEFORMS ON SYSTEM

TEST AND DEBUGGING

1.SYSTEM 27MHz CLOCK, RESET, FLASH R/W SIGNAL.

1) ES6168F main clock is at 27MHz(pin49)

2) ES6168F( pin24) reset is low active.

FIG 1-1

Ch1 VCC

CH2 RESET

FI1-2

3-10

Page 21

2. SDRAM CLOCK

FIG 2-1

3. TRAY OPEN/CLOSE SIGNAL

CH1 EJ-

CH2 EJ+

FIG 3-1

3-11

Page 22

CH1 EJ-

CH2 EJ+

FIG 3-2

4. SLED CONTROL RELATED SIGNAL(NO DISC CONDITION)

SLED CONTROL

FIG 4-1

FIG 4-2

CH1 SL+

CH2 SL-

3-12

Page 23

5. LENS CONTROL RELATED SIGNAL(NO DISC CONDITION)

LDON

FIG 5-1

FIG 5-2

CH1 DVD_LD

CH2 CD_LD

3-13

Page 24

6. FOCUSE CONTROL RELATED SIGNAL(NO DISC CONDITION)

FSCON

FIG 6-1

CH1 FOCUS-

CH2 FOCUS+

FIG 6-2

3-14

Page 25

7. SPINDLE CONTROL WAVEFORM

CH1 SPWM2

CH2 SPWM1

FIG 7-1(DVD)

FIG 7-2(CD)

CH1 SPWM2

CH2 SPWM1

3-15

Page 26

8. FOCUS ON WAVEFORM(FSCON)

FIG 8-1(CD)

FIG 8-2 (SACD)

3-16

Page 27

9. RF WAVEFORM

),*&'

),*6$&'

10.ES6168F AUDIO OPTICAL AND COAXIAL OUTPUT (SPDIF)

),*

3-17

Page 28

11. ES6168F AUDIO OUTPUT TO AUDIO DAC

FIG 11-1

CHI1 BITCLOCK

CH2 LRCLOCK

12. AUDIO OUTPUT (1KHZ 0DB)

FIG 12-1

3-18

Page 29

RF AMP CXD1881

DVD SERVO CXD1885

DSD DECODER CXD2753

ESS 6168

IC 25 FAN8042

Motor Driver

IC18

IC21

IC25

IC16

Pick Up

M

M

M

DSIC

POWER

BOARD

AC 100V-240V

50Hz/60Hz

VF+

VF-

-22VA

-15V

+15V9V3.3VD

5VS

IC20

4Mbit EDO

X4

33.8688MHz

IC17

CPLD

Y3

27MHz

U13

U14

EEPROM

SCL, SDA

SDRAM

64M

DQM0,DQM1

DQ[0:15]

DCLK,WE,CAS,RAS

CS,DCKE,MA[0:11]

U6

FLASH MEMORY

(16M)

A[0:19]

PWR,PCE,PRD

AD[0:7]

U652

AUDIO DAC

5.1CH

AMP OPA2134UA

U653-U655

ML MR

FLFR

SL SR

CENTERSUB

MLMR

FL FR

SLSR

CENTER SUB

SPINDLE[+,-]

SLED[+,-]

LOAD[+,-]

IC15

M12L1616A-7T

DCKE

DCLK

A[0:11] DSD

T+,T-F+,F-

ABCDEF

LMT SW

OPN SW

CLS SW

LD M1

LD M2

RA[0:9]

RD[0:15]

VDT[0:7]

XSAK

SDEF

XSHD

PLCK

SDCK

DSAR

DSAL

DSALS

DSDASW

DSAC

DSARS

U10

DD[0:7]

RFAC

AMPSEN

AMPSDT

AMPSCK

DFCT

MIRR

RFAC

TEO

FEO

PI

U20

SC16C550IB18

RS232

Y3

1.8432MHz

AUX5

LA2

LA1

LA0

U21

MAX3221

HTXD

HRXD

RS232

JACK

P1

RXD

TXD

PT6311

U801

KEY INPUT

VFD DATA

VFD CLK

VFD CS

FLD DISPLAY

POWER CONTROL

U3

74HC86

IR PHONE

U802

HS0038B

IR IN

IR RECEIVER

COAXIAL

SPDIF

SW503

J501A

OFF

ON

TRIG O/F

+12V O/F

BLOCK DIAGRAM

1.OVERAL BLOCK DIAGRAM

IR

U604

AUDIO DAC

2CH

U601-U602

AND NAD AMP

MODULE

DSD ML MR

PCM ML MR

IICBUSS

IICBUSS

VIDEO OUT

VIDEO OUT

3-19

Page 30

2.POWER(SMPS)BLOCK DIAGRAM

POWER CONTROL

F+F--22VA

5VD

3.3VD

REG(3.3V)

LPF

+9VS

REG(9V)

LPF

5VS

REG(5V)

GND

LPF

RECTIFIER(FLD)

RECTIFIER(3.3V)

RECTIFIER(9.6V)

RECTIFIER(5.7V)

FEED.B

TRANS

SWITCHING IC

LINE FILTERRECTIFIER

AC 100-240V

3-20

Page 31

3.SERVO Block Diagram

DFCT

MIRR

IC21

IC20

RFAC

4MBit EDO

IC18

PI

FBO

TEO

RF AMP CXD1881

DVD SERVO CXD1885

LIMIT,TRIN,TROUT

IC17

CPLD

X4

33.8688MHz

IC16

DSD DECODER CXD2753

ADIN

STBY

FOSO,TRSO

DMSO,TROPEN,TRCLOSE

IC25

Motor Driver

IC 25 FAN8042

V20,PICKSEL

MDL1

F+,F-,T+,T-

LD01,LDO2,IOA

PICK UP

DVD:A,B,C,D,RFO

CD:A,B,C,D,E,F,RFO

3-21

SL+,SL-

SP+,SP-

M/D

LOAD+,LOAD-

Page 32

CIRCUIT DIAGRAMS

1.POWER(SMPS) BOARD

+15V

-15V

SGND

AGND

13

+VCCA

12

DGND

5VD

10

11

DGND

9

3.3VD

8

STB

5VS

7

5

6

+12V

-VCCA

14

15

J906

+9VS

4

-22V

VF+

VF-

1

2

3

CON15*2MM

+VCCA

+5VD

3.3VD

STB

+5VS

VF-

VF+

10K

R957

10K

R954

R956

10K

Q921

C1815

R955

10K

+5VD

10K

R944

Q907

A1015

+5VD

10K

10K

R942

R943

Q906

C1815

Q900

C1815

-22V

C949

47u/50V

5.6V

D911

D910

FR104

D912

FR205

10

12

11

+3.3VV

+3.3VV

2

3

g

Vd

Vo

U910

Vi

KA278R33

1

10k

R958

L906

22uH

C950

100u/50V

D913

SR340/SR360

14

15

16

13

+5VD

3.3VD

C964

0.1u

3.3VD

C956

2

3

100u/16V

g

Vd

Vo

R951

10K

4

Vi

1

R953

10K NA

U909

KA278R33

C955

470u/25V

C954

1000U/16V

D909

SR504

18

17

VF-

STB

VF+

-22V

+5VS

C944

100u/16V

4

R969

C957

+9VS

2

Vo

Vi

10k

1

L907

R933

270R

R934

3

22uH

D915

+5VD

STB

R970

470R

R967

4K7

22K

R968

Q923

C1815

R965

10K

0.1u

+5VS

+5VD

C959

100u/16V

g

Vd

4

U912

KA78R09

C958

470u/25V

FR205

1%

4K3

R935

C942

0.1u/50v

3K9

C945

100u/16V

2

3

+5VD

g

Vd

Vo

4

U911

Vi

KA78R05

1

R971

D916

1N4004

L904

22uH

C966

3K3

R937

6.9K

R936

U908

TL431

10k

C961

470u/25V

1000u/16V

1%

T900

BCK 08A10C

9

C943

3300P/250V

5

R930

56K 1W

C914

103/1KV

47K/1W

R900

C900

100u/400V

D908

B900

3

1

30R

R932

D900

FR104

R911

Ipk

Vstr

5

6

7

8

FR107

DB105

C935

RT900

NTC 5D-11

4

Vfb

Drain

3

Vcc

Drain

2

GND

Drain

1

100P/400V

C939

L900

0.1u/275V

100P/400V

C940

U907

PC817

ൟѸ⌕⬉ᆍ఼

Y1

ˉ14d- 2E4-332M -YA

---X1ˈ

C941

6.2K

U900

FSDM0365RNB

33n/50V

C933

47u/50V

48mH

R912

C934

MYG-05D301K

~AC IN

㉏

YA

CT81-400VAC

TOJ900

CT81-400VACˉ08d-2E4-101K-YA

FH900

0.1u/275V

1

FUSE_HOLDER1

2

2

1

J901

J900

AC SOCKET

SWITCH

3-22

Page 33

2. DECODE BOARD-ES6168 SECTION

R11 OPEN R62 0OHM

R60 0 OHM

R12 OPEN

R14 OPEN

R71 0R

U6

1

A15

2

A14

3

A13

4

A12

5

A11

6

A10

7

A9

8

A8

9

A19

10

NC

11

W

12

RP

13

VPP

14

DU/WP

15

NC

16

NC

17

A17

18

A7

19

A6

20

A5

21

A4

22

A3

23

A2

24

A1

MX29LV160ABTC-70

R15 OPEN

R61 0R

R64 open

R51 0R

4MBIT EPROM/FLASH

U11

8MBIT EPROM

13

LD0

D0

14

LD1

D1

15

LD2

D2

17

LD3

D3

18

LD4

D4

19

LD5

D5

20

LD6

D6

21

LD7

D7

VCC

32

VCC

16

GND

27C040/080-90 NA

LD[0..7]

U12

1

RST#

RESET

3

WE

ADDR/CE1

ROM EMULATOR SOCKET

4-PIN EXTENSION FOR ROM EMULATOR INTERFACE

DIRQ

DIRQ

DRST#

DRST#

DWR#

DWR#

DRD#

DRD#

DD[0..15]

DD0

DD1

DD2

DD3

DD4

DD5

DD6

DD7

DD8

DD9

R435

0R

EAUX40

EAUX33

EAUX44

EAUX34

EAUX37

EAUX36

DWRQ#

DWRQ#

DA0

DA1

DD0

DD1

DD2

DD3

DD4

DD5

DD6

DD7

DD8

DD9

DD10

DD11

DD12

DD13

DD14

DD15

DA0

DA1

DD0

DD1

DD2

DD3

DD4

DD5

DD6

DD7

DD8

DD9

DD10

DD11

DD12

DD13

DD14

DD15

21

GND DGND

GND_RF

A16

BYTE

GND

DQ15/A_1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

VCC

DQ11

MBM29LV160D

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

G

GND

E

A0

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

CE

OE

CLK/CE1

1

2

3

4

R104 33R

R145 47R

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

1

2 7

3

4

1

2

3

4

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

12

11

10

9

8

7

6

5

27

26

23

25

4

28

29

3

2

30

31

R67

1

R68

for eprom

for eprom

22

24

R72 0R

R52 OPEN

2

4

RP15 47x4

RP16 47x4

RP7 33x4

RP8 33x4

RP9 33x4

RP10 33x4

RP11 33x4

VCC

C108

0.1U

LA17

LD7

LD14

LD6LA10

LD13

LD5

LD12

LD4

LD11

LD3

LD10

LD2

LD9

LD1

LD8

LD0

LOE#

LA1

FLASH: INSTALL R51 REMOVE R64

EPROM: INSTALL R64 REMOVE R51

LA0

LA1

LA2

LA3

LA4

LA5

LA6

LA7

LA8

LA9

LA10

LA11

LA12

LA13

LA14

LA15

LA16

LA17

LA[0..19]

LA18

LA19

LA20

LCS2#

LA21

8

7

6

5

8

HA2

7

6

5

8

7

6

5

8

HD0

7

HD1

6

HD2

5

HD3

8

HD4

7

HD5

6

HD6

5

HD7

8

HD8

HD9

6

HD10

5

HD11

8

HD12

7

HD13

6

HD14

5

HD15

VCC33

B30

0.1UF

VCC20

B4

0.1UF

VCC

U9

2

RST#

RST

3

Vcc

1

gnd

TCM809M

LCS1#

LCS2#

LCS3#

WRLL#

WRHL#

WRHL#

LOE#

LA0

LA1

LA2

LA3

LA4

LA5

LA6

LA7

LA8

LA9

LA10

LA11

LA12

LA13

LA14

LA15

LA16

LA17

LA18

LA19

LA20

LA21

LD0

LD1

LD2

LD3

LD4

LD5

LD6

LD7

LD8

LD9

LD10

LD11

LD12

LD13

LD14

B34

0.1UF

B27

0.1UF

LD15

SDRAM

HWR#

HRST#

HRD#

HWRQ#

HIORDY

HIOCS16#

HCS1#

HCS3#

HIRQ

HA0

HA1

HA2

B32

0.1UF

ES6168 DECOUPLING CAPACITORS

B26

0.1UF

B35

0.1UF

B28

0.1UF

27M

105

24

173

174

175

176

198

199

170

204

205

206

207

2

3

4

5

6

7

10

11

12

13

14

15

16

19

20

21

22

23

178

179

180

181

182

185

186

187

188

189

190

191

194

195

196

197

145

150

149

143

142

146

151

152

153

144

154

155

158

122

123

124

125

126

127

128

131

132

133

134

135

136

137

140

141

RST#

10UF/16V

VCC

R73

4.7K

R37

OPEN

(4.7K)

31

25

CLK

RESET

LCS0

LCS1

LCS2

LCS3

LWRLL

LWRHL

TDMTSC

TDMDX/RSEL

LOE

LA0

LA1

LA2

LA3

LA4

LA5

LA6

LA7

LA8

LA9

LA10

LA11

LA12

LA13

LA14

LA15

LA16

LA17

LA18

LA19

LA20

LA21

LD0

LD1

LD2

LD3

LD4

LD5

LD6

LD7

LD8

LD9

LD10

LD11

LD12

LD13

LD14

LD15

HRST/EAUX3[5]

HRD/DCI_ACK/EAUX4[6]

HWR/DCI_CLK/EAUX4[5]

HRDQ/EAUX4[0]/CAMYUV3

HWRQ/DCI_REQ/EAUX4[1]

HIORDY/EAUX3[3]

HIOCS16/CAMPCLK/EAUX3[4]

HCS1FX/EAUX3[7]

HCS3FX/EAUX3[6]

HIRQ/DCI_ERR/EAUX4[7]

HA0/EAUX4[2]

HA1/EAUX4[3]

HA2/EAUX4[4]

HD0/DCI[0]/EAUX1[0]

HD1/DCI[1]/EAUX1[1]

HD2/DCI[2]/EAUX1[2]

HD3/DCI[3]/EAUX1[3]

HD4/DCI[4]/EAUX1[4]

HD5/DCI[5]/EAUX1[5]

HD6/DCI[6]/EAUX1[6]

HD7/DCI[7]/EAUX1[7]

HD8/DCI_FDS/EAUX2[0]

HD9/EAUX2[1]

HD10/EAUX2[2]

HD11/EAUX2[3]

HD12/EAUX2[4]

HD13/EAUX2[5]

HD14/EAUX2[6]

HD15/EAUX2[7]

B58

B56

10UF/16V

B53

B29

10UF/16V

0.1UF

10UF/16V

R83 33R

R85 33R

R86 33R

28

30

29

TDMFS

TDMDR

TDMCLK

NC/CAMVS

42

B54

VCC33E

CAMYUV0

202

VCC33P

111

51

AVCC(PLL)

AVCC(VDAC)

CAMYUV1

203

112

VCC33

VCC

VCC33

PGND

LA0

LD15

LA16

LA15

LA14

LA13

LA12

LA11

LA9

LA20

RST#

LA19

LA18

LA8

LA7

LA6

LA5

LA4

LA3

LA2

WRHL#

WRLL#

LCS2#

LCS3#

DD10

DD11

DD12

DD13

DD14

DD15

NC

R19

VCC

R20

R17

TBCK1

0R

TBCK

NC

U13

LM1117MP-ADJ

VCC33

B3

10UF/16V

LD8

LD9

PCM/DSD

MC

LD10

23

A0

24

A1

25

A2

26

A3

29

A4

30

A5

31

A6

32

A7

33

A8

34

A9

22

A10

35

A11

38

CLK

37

CKE

19

CS

18

RAS

17

CAS

16

WE

15

DQML

39

DQMH

20

BA0

21

BA1

36

NC

40

NC

GLT5640L16(9ns)

32/64MBIT SDRAM

VCC33

3

VCC

VIN

R58

OPEN

R59

OPEN

1

2

3

4

5

6

7

8

9

C3

0.1U

(22PF)

U19

VOUT

VOUT

ADJ

U16

74HCT374

VCCQ

VCCQ

VCCQ

VCCQ

OE

Q0

D0

D1

Q1

Q2

D2

D3

Q3

GND10CP

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

VCC

VCC

VCC

VSSQ

VSSQ

VSSQ

VSSQ

VSS

VSS

VSS

VCC20

2

R505

4

121R 1%

1

R506

75R 1%

B1

10UF/16V

VCC

20

VCC

19

DAC_CS

Q7

18

LD15

D7

17

LD14

D6

16

VFD_CS

Q6

15

STANDBY

Q5

14

LD13

D5

13

21DL11DL

D4

12

LED_POWER

Q4

11

CP1#

DAC_CS

VFD_CS

STANDBY

LED_POWE R

VCC

B12

0.1UF

VCC33

2

DB0

4

DB1

5

DB2

7

DB3

8

DB4

10

DB5

11

DB6

13

DB7

42

DB8

44

DB9

45

DB10

47

DB11

48

DB12

50

DB13

51

DB14

53

DB15

1

14

27

3

9

43

49

6

12

46

52

28

41

54

VCC

EPROM

B2

B52

10UF/16V

0.1UF

B55

10UF/16V

VCC33P

B36

0.1UF

B57

10UF/16V

VCC

VCC33E

24C01

B31

0.1UF

B33

0.1UF

VCC33

1

FB2

FERB

FB3

FERB

VC33

TDM-DATA

TDM-FS

TDM-CLK

18

27

VC33

VC33

VCC33

VC3359VC3368VC3375VC3392VC33

VCC33

Q2

NC/8050

R143

0R

VCC20

9

35

83

121

139

172

99

104

130

148

157

159

164

183

193

VC33

VC33

VC33

VC33

VC33

VC33

VC33

44

201

VC25

VC25

VC25

VC25

VC25

VC33

VC25

VC33

VC25

R44

OPEN

R74

4.7K

U10

ES6168

MCLK

TBCK

TWS/SEL_PLL2

TSD0/SEL_PLL0

TSD1/SEL_PLL1

TSD2

TSD3

RSD

SPDIF/SEL_PLL3

PCLK2XSCN/CAMYUV4

PCLKQSCN/CAMYUV5/AUX3[2]

HSSCN/CAMYUV7/EAUX3[0]

VSSCN/CAMYUV6/EAUX3[1]

YUV0/UDAC

YUV1/VREF

YUV2/CDAC

YUV3/COMP

YUV4/RSET

YUV5/YDAC

YUV6/VDAC

YUV7/FDAC

DCS0

DCS1

DRAS0

DBANK0/DRAS1

DBANK1/DRAS2

DCAS

DWE

DSCK/DOE

DQM

ES6168

DSCK

DMA0

DMA1

DMA2

DMA3

DMA4

DMA5

DMA6

DMA7

DMA8

DMA9

DMA10

DMA11

DB10

DB11

DB12

DB13

DB14

DB15

AUX0

AUX1

AUX2

AUX3

AUX4

AUX5

AUX6

AUX7

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

DB8

DB9

XIN

VSS

VSS

VSS

VSS

VSS

VSS

AVSS(PLL)

AVSS(VDAC)

52

VSS

8

17

34

43

60

26

67

R22

68R

R21

2R2

5

GND

OUT

B11

0.1UF

8

Vcc

Y3

27MHz

NC

VSS

VSS

VSS

VSS

VSS

VSS

VSS

VSS

VSS

98

76

84

91

129

103

120

138

VSS

VSS

VSS

VSS

VSS

VSS

VSS

156

147

171

177

200

163

184

208

192

XIN

7

1

XOUT

CAMYUV2

VSS

48

C23

OPEN

(150PF)

VCC33

39

40

32

33

36

37

38

47

46

45

41

116

117

119

118

106

107

108

109

110

113

114

115

100

97

72

73

74

69

71

70

101

102

53

54

55

56

57

58

61

62

63

64

65

66

77

78

79

80

81

82

85

86

87

88

89

90

93

94

95

96

160

161

162

165

166

167

168

169

49

50

R75

OPEN

R48

4.7K

XIN

XOUT

YUV0

YUV1

YUV2

YUV3

YUV4

YUV5

YUV6

YUV7

DMA0

DMA1

DMA2

DMA3

DMA4

DMA5

DMA6

DMA7

DMA8

DMA9

DMA10

DMA11

DB0

DB1

DB2

DB3

DB4

DB5

DB6

DB7

DB8

DB9

DB10

DB11

DB12

DB13

DB14

DB15

AUX5

VCC33

R76

OPEN

(4.7K)

R49

4.7K

R5 390R

R18

0R

R89

R90

VCC VCC

mute

R87

33R

R91 33R

R92 0R

R93 0R

C1 0.1u

33R

33R

R107

R108

1K

1K

P/I SELECT

AUX5

VCC33

R77

OPEN

(4.7K)

R50

4.7K

MCLK

C20

OPEN

(15PF)

VCC33E

RP6 33x4

1 8

2

3 6

4 5

RP12 10x4

4 5

3 6

2 7

1 8

RP14 10x4

4 5

3

2 7

1 8

4 5

3 6

2 7

1

RP13 10x4

DB[0..15]

VCC

SCL

SDA

R95 33R

C2

0.1u

VCO

SERIAL EEPROM

U14

8

VCC

7

WC

6

SCL

5

SDA

24LC16A/MICCHIP

27M

TWS1

TSD31

R78

4.7K

TRIG_O/F

+12V_O/F

7

R103

MA0

MA1

MA2

MA3

MA4

6

MA5

MA6

MA7

MA8

MA9

MA10

8

MA11

S0

S1

S2

GND

-22V

VF+

VF-

FROM PSU BOARD

R88 33 OHM

C21

OPEN

(22PF)

TRIG_O/F

+12V_O/F

R94 33R

R69 0R

R55 OPEN

R70

10R

MA[0..11]

1

2

3

4

IR IN

R82 4.7K

R105 33R

VFD_CS

LED_POWER

-22V

VF+

VF-

TBCK1

SPDIF

C22

OPEN

(15PF)

TWS

TSD31

TSD3

0R

VCC

U21

1

PCM/DSD

S

2

TWS1

mute

J3

S12B-PH-SM3-TB

VFD+REMOTE INTERFACE

I0a

3

I1a

4

Za

5

I0b

6

I1b

7

Zb

GND8Zd

74AC257/NA

SC16C550 RESET

AUDIO DAC MODE CONTROL

VCC33

MUTE

R27

4.3K

R16

+5V

1

IR

2

GND

3

VFD-CS

4

VFD-CLK

5

VFD-DATA

6

LED_POW

7

GND

8

-22V

9

VF+

10

VF-

11

NC

12

16

Vcc

15

OE

14

I0c

13

I1c

12

Zc

11

I0d

10

I1d

9

0R

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

MA9

MA10

MA11

CLK

CKE

CS0#

RAS0#

CAS#

WE#

DQMX

BANK0

BANK1

VCC

R56

OPEN

R57

OPEN

3-23

3-24

Page 34

3.DECODE BOARD-DSP SECTION

To RF Block

AMPSEN AMPSEN

AMPSEN

AMPSDT AMPSDT

AMPSDT

AMPSCK AMPSCK

AMPSCK

DFCT DFCT

DFCT

MIRR

RFAC RFAC

RFAC

TEO

FEO

PI PI

PI

AMPMNT

CD/XDVD

CD/XDVD

LDON

LDON

A1.8V

A1.8V

L32

PCB Coil

D1.8V

D1.8V

D1.8V

D3.3V

D3.3V

D3.3V

DGND

DGND

VC16

VC16

AGND

DGND

TSCON

TSCON

SLED

SLED

FSCON

FSCON

SPWM1

SPWM1

SPWM2

SPWM2

LDRSPD

LDRSPD

SPEED_SP

SPEED_SP

XFTSMUTE

XSPMUTE

TSD-M

LDM1

LDM2

CLS_SW

OPN_SW

LMT_SW

To Power & Drivers Block

TE1

R426 10K

1

FE1

R427 10K

SPEED_SP SPEED_SP

A3.3V

A1.8V

A3.3V

A1.8V

12

12

C464

C465

22uF/6.3V

22uF/6.3V

DGND

1

R441 33K

C233

0.01uF

XLCAS

XUCAS

XMOE

0.1uF

G-LINK

RA[0..9]

XMOE

XUCAS

XLCAS

CD/XDVD

LDON

MIRR

XFTSMUTE

XSPMUTE

TSD-M

LDM1

LDM2

CLS_SW

OPN_SW

LMT_SW

2

R449

1.5K

2 1

VC16

RA3

RA2

RA1RA6

D3.3V

21

22

Vcc

Vss23A424A525A626A727A828A929OE

RA4

RA5

RA0

17

16

A018A119A220A3

NC

RA9

RA7

RA8

TSCON

SLED

FSCON

SPWM1

SPWM2

XLCAS

XUCAS

XMOE

RA9

RA8

RA7

RA6

RA5

RA4

RA3

RA2

RA1

RA0

XRAS

XMWR

D3.3V

14

15

13

NC

WE

RAS

IC20

M11L16161SA-45T

UCAS

LCAS32NC

30

33

31

DGND

XLCAS

XUCAS

XMOE

DGND

2

R440 33K

C471

0.047uF

A3.3V

RD7

RD6

RD5

RD4

RD3

RD2

RD1

RD0

RD15

RD14

RD13

RD12

RD11

RD10

RD9

RD8

21

C335 0.1uF

DGND

C336 0.1uF

C337 0.1uF

TSCON

SLED

FSCON

AGND

SPWM1

SPWM2

XLCAS

XUCAS

XMOE

DGND

RA9

RA8

RA7

RA6

RA5

D3.3V

RA4

RA3

RA2

RA1

D1.8V

RA0

XRAS

XMWR

RD7

RD6

DGND

RD5

RD4

RD3

RD2

RD1

RD0

RD15

RD14

RD13

RD12

RD11

RD10

RD9

D1.8V

DGND

DGND

RD[0..15]

D3.3V

C475

RD5

RD7

RD4

RD6

RD0

RD1

RD2

RD3

100uF/16V

1

C414 0.1uFC412

1

6

5

10

NC11NC12NC

34

Vcc

Vcc

DQ02DQ13DQ24DQ3

DQ47DQ58DQ69DQ7

Vss44DQ1543DQ1442DQ1341DQ1240Vss39DQ1138DQ1037DQ936DQ835NC

RD13

RD14

RD15

RD12

RD8

RD10

RD9

RD11

C405 0.1uF

C338 0.1uF

C339 0.1uF

C340 0.1uF

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

C407 0.1uF

C406 0.1uF

C415 0.1uF

C416 0.1uF

SE

A1.8V

VC16

A3.3V

A1.8V

A3.3V

AVDD33

TSCON(DA0)

SLED(DA1)

FSCON(DA2)

SLED2_TILT (DA3)

AVSS

FG

SPWM1

SPWM2

GPWM<0>

GPWM<1>

GPWM<2>

GPWM<3>

GPWM<4>

GPWM<5>

XLCAS

XUCAS

XMOE

RA<11>

RA<10>

DVSS

RA<9>

RA<8>

RA<7>

RA<6>

RA<5>

DVDD33

RA<4>

RA<3>

RA<2>

RA<1>

DVDD18

RA<0>

XRAS

XMWR

RD<7>

RD<6>

DVSS

RD<5>

RD<4>

RD<3>

RD<2>

RD<1>

RD<0>

RD<15>

RD<14>

RD<13>

RD<12>

RD<11>

RD<10>

RD<9>

DVDD18

D3.3V

D1.8V

DGND

VREFL

104

103

VREFL

AVDD18

RD<8>

DVDD33

157

158

21

2

AMPMNTAMPMNT

VC16

VREFH

102

VREFH

TEST<0>

159

C452 330pF

C453 330pF

JMOUT

101

99

100

RSV_AD1 (AD9)

RSV_AD0 (AD8)

TEST<1>

TEST<2>

160

161

162

PLCK

CDDAT

CDCLK

CDFRM

CDERR

DRVRDY

DGND

D1.8V

DRVRST

DRVIRQ

DCK0

XSHD0

VEFG0

XHAC0

HDRQ0

VDT0

VDT1

VDT2

VDT3

VDT4

VDT5

DGND

VDT6

VDT7

DGND

XTAL_O

XTAL_I

D1.8V

MCK0

XINT

XRDY

XRD

D3.3V

XWR

XCS1

DGND

D7

D6

DGND

D5

D4

D3

D2

D1

D0

A9

A8

A7

A6

A5

A4

A3

A2

A1

A0

D3.3V

C408 0.1uF

DRVCLK

DRVRX

DRVTX

DRVRST

DRVIRQ

R420 NM

1

2

I/O 26

I/O 25

NRST

TDO

GND

TMS

SEL

C466

22uF/6.3V

1

33

32

31

30

29

28

27

26

25

24

23

DGND

XSHD

XRST_PLD

TDO_PLD

DGND

XSRQ

TMS_PLD

HDRQ

DVD/SACD

SD7

XINT

XRDY

XRD

XWR

XCS1

D[0..7]

A[0..9]

XRST

R365

10K

D3.3V

SD7

DGND

2

XRST_PLD

D3.3V

2

R428 10K

4

1

2

D24

1SS355

XRST

1

1

D25

1SS355

5

DRVRST

2

IN_2

VCC

OUT

1

IN_1

GND

IC19

NM

3

DGND

RM14 10Kx4

567

8

RM13

10Kx4

123

4

4

21

R430 10K

5

C334 0.1uF

SDEF

XSAK

SDCK

DGND

XHAC0

XSHD0

DCK0

VEFG0

HDRQ0

42

43

44

36

38

40

41

34

35

37

39

Vcc

I/O 0

GND

DCK_COR

DCK_DEC

VEFG_DEC

VEFG_COR

XSHD_COR

XHAC_DEC

HDRQ_COR

VDT_COR_0

VDT_COR_1

VDT_COR_2

TDI

MCLKI

GND

TCK

VDT_COR_3

VDT_COR_4

VDT_COR_5

VDT_COR_6

2 1

R457 220R

21

5

8

D1.8V

FB5

2

IC17

PLD M4A3-64/32

VDT_DEC_0

VDT_COR_7

12

13

SD0

FERB

OUT

X4

33.8688MHz

R453

NM

XHAC_COR

VDT_DEC_1

14

SD1

SD2

DGND

GND

1

VDT_DEC_215VDT_DEC_3

Vcc16GND17VDT_DEC_4

C404

0.1uF

NC1Vcc

18

I/O 16

19

SD3

7

VDT_DEC_7

VDT_DEC_521VDT_DEC_6

22

20

SD4

SD5

SD6

R456 68R

2 1

2

R458

220R

XSHD_DEC

HDRQ_DEC

HDRQ_DVD

1

VDT0

2

VDT1

3

VDT2

4

TDI_PLD

5

MCK_PLD

6

DGND

7

TCK_PLD

8

VDT3

9

VDT4

10

VDT5

11

VDT6

VDT7

C402 0.1uF/NA

C403 0.1uF

VDT0

1

1

VDT1

VDT2

VDT3

VDT4

VDT5

2

VDT6

VDT7

R25

33R/NC

C410

0.1uF

C409 0.1uF

DGND

D1.8V

12

C467

22uF/6.3V

CN17

8

NC

7

TRST

6

GND

5

TMS

4

TCI

3

TCK

2

TDO

1

GND

8 pin 1mm pitchFFC Header/NA

DGND

2

R450 0R

Q1

A1015

DGND

12

DGND

R451 NM

R26

4K7

D3.3V

C468

22uF/6.3V

5V

2

R455 68R

R454

2.2R

1

C411

0.1uF

DGND

XINT

XRDY

XRD

XWR

XCS1

D[0..7]

A[0..9]

XRST

D3.3V

D3.3V

Vcc 5V

MIRRMIRR

TE1

DGND

C455 0.15uF

21

DGND

R431 1.8K

2

1

AMPMNT

SPEED_SP

AGND

SE

AGND

A3.3V

VC16

PI

95

92

97

90

91

96

94

98

93

88

89

AVSS

AVSS

AVDD33

SE (AD3)

TE (AD1)

FE (AD0)

JITT (AD7)

FSUM (AD2)

TILTIN (AD4)

VREFC (AD6)

AMPMNT (AD5)

TEST<3>

TEST<4>

TEST<5>

TEST<6>

TEST<7>

TEST<8>

TEST<9>

TEST<10>

TEST<11>

TEST<12>

TEST<13>

163

164

165

166

167

168

169

170

171

172

173

EDCNG

CLVLOCK

C456 100pF

R442

LPF2

RC

LPF287LPF1

TEST<14>

TEST<15>

174

SYNCLOCK

CD/XDVD

LDON

MIRR

XFTSMUTE

XSPMUTE

TSD-M

LDM1

LDM2

CLS_SW

OPN_SW

LMT_SW

2

1

22K

LPF1

86

85

IC18

CXD1885Q

MODSEL<0>

175

176

VCOI

MODSEL<1>

C459 0.022uF

R432 1.8K

JMOUT

A1.8V

84

AVDD18

DVSS

177

DGND

C332

0.1uF

2

HF

C457 100pF

R433 68K

1

C473 150pF

21

21

R445 47K

R446 47K

21

83

178

C461 0.022uF

RM12

1

JMOUT

C460 0.022uF

R443 100K

21

21

21

T

RFOKGH

LDM2 (GIO11/TC11)

A

CDD

CDERR

DGND

DGND

AMPSCK

AMPSEN

AMPSDT

CDCLK

68

67

SO

SCLKH

CLOSESW (GIO12/INT)

DVSS

194

193

CLS_SWCLS_SW

DRVRDYCDFRM

61

62

59

58

63

66

57

65

64

SI

CSL

BCK

C2OP

LRCK

DOTX60DADT

EXVCO

EXPLDT

DRVRDY

TSD-M (GIO15/INT)

TRST

OPENSW(GIO13/INT)

INNERSW( GIO14/INT)

RSV0(GIO17)

RSV1 (GIO18)

BUFEMP (GIO19)

TMS

TDI

FOK (GIO16)

196

204

198

195

199

203

197

202

200

201

TRST

BUFEMP

FOK

TDI

TMS

RSV1

OPN_SWOPN_SW

LMT_SWLMT_SW

RSV0

SV1

BUFEMP

FOK

R

RSV0

TMS

TRST

R447 470R

R448 150K

DGND

DGND

MIRR

DFCT

AGND

R444 47K

75

72

70

69

78

81

79

76

73

82

74

71

80

HF

ATC

DTC

CHG

VFBC

JMREF

JMOUT

MODSEL<2>

CD/XDVD (GIO0)

LDON (GIO1)

FTSMUTE (GIO2)

180

179

181

XFTSMUTE

CD/XDVD

LDON

HFD

IREF

TLC177TLC0

AVSS

AVDD33

MIRRORH

DVDD33

SPMUTE (GIO3)

MIRR(GIO4)

ST1 (GIO5)

ST2 (GIO6)

ST3(GIO7)

DVDD18

ST4 (GIO8/TC8)

XTSD-M (GIO9/TC9)

LDM1 (GIO10/TC10)

192

183

182

184

185

186

187

188

191

189

190

LDM1

TSD-M

XSPMUTE

LDM2

ST1

ST2

ST3

ST4

MIRR

TSD-M

8

2

7

3

6

4 5

10Kx4

D3.3V

DRVCLK

DRVTX

DRVRX

C401 0.1uF

56

55

53

54

DGND

DRVRX

DRVTX

DVDD33

DRVCLK

52

DVDD18

51

DRVRST

50

DRVIRQ

49

DCK

48

XSHD

47

VEFG

46

XHAC

45

HDRQ

44

VDT<0>

43

VDT<1>

42

VDT<2>

41

VDT<3>

40

VDT<4>

39

VDT<5>

38

DVSS

37

VDT<6>

36

VDT<7>

35

DVSS

34

XO

33

XI

32

DVDD18

31

SYSCK

30

MINT

29

MRDY

28

MRD

27

DVDD33

26

MWR

25

MCS

24

MALE

23

MD<7>

22

MD<6>

21

DVSS

20

MD<5>

19

MD<4>

18

MD<3>

17

MD<2>

16

MD<1>

15

MD<0>

14

TESTSEL

13

MA<8>

12

MA<7>

11

MA<6>

10

MA<5>

9

MA<4>

8

MA<3>

7

MA<2>

6

MA<1>

5

MA<0>

4

MSEL<1>

3

MSEL<0>

2

ALCR

1

DVDD33

TDO

TCK

VMCHG

DVDD18

206

205

207

208

C417 0.1uF

C418 0.1uF

VMCHG

TDO

TCK

VMCHG

D3.3V

R429

10K

2 1

TDO

TCKTDI

CDDAT

H_CDDAT

CDCLK

H_CDCLK

CDFRM

H_CDFRM

CDERR

H_CDERR

DRVRDY

H_DRVRDY

DRVCLK

H_DRVCLK

DRVRX

H_DRVRX

DRVTX

H_DRVTX

DRVRST

H_DRVRST

DRVIRQ

H_DRVIRQ

MUTE_DAC

H_MUTE

DVD/SACD

H_DVD/SACD

SMUTE

H_SMUTE

XRST

RST#

MSREADY

H_MSREADY

MSDATAO

H_MSDATAO

MSDATAI

H_MSDATAI

MSCK

H_MSCK

XMSLAT

H_XMSLAT

CDDAT

CDCLK

CDFRM

CDERR

XMSLAT

MSCK

MSDATAI

MSDATAO

MSREADY

XRST

SMUTE

MUTE_DAC

MCK

PLCK

XSRQ

SDCK

XSHD

SDEF

XSAK

SD[0..7]

SDCK

H_DSTB

XSHD

H_XSHD

SDEF

H_VERR

XSAK

H_XHAC

HDRQ

H_HDRQ

SD0

H_VDT0

SD1

H_VDT1

SD2

H_VDT2

SD3

H_VDT3

SD4

H_VDT4

SD5

H_VDT5

SD6

H_VDT6

SD7

H_VDT7

D3.3V

5

678

567

8

123

4

123

4

123

123

4

RM16

10Kx4

678

567

8

CN15

1

D3.3V

2

TDO_PLD

3

TDI_PLD

4

5

6

TMS_PLD

7

DGND

8

TCK_PLD

RM15

10Kx4

XINT

XRDY

XRD

XWR

XCS1

DGND

D7

D6

D5

D4

DGND

D3

D2

D1

D0

DGND

A9

A8

A7

A6

A5

DGND

A4

A3

A2

A1

A0

DGND

XRST

VMCHG

RM17

DGND

10Kx4

D3.3V

Falseta DSP BLOCK

VCC

TDO

TDI

XENABLE

NC

TMS

GND

TCK

CDDAT

CDCLK

CDFRM

CDERR

XMSLAT

MSCK

MSDATAI

MSDATAO

MSREADY

XRST

SMUTE

MUTE_DAC

MCK

PLCK

XSRQ

SDCK

XSHD

SDEF

XSAK

SD[0..7]

To DSD Block

CON8*2.54

3-25 3-26

Page 35

4.DECODE BOARD-H-POWER & DRIVER SECTION

C446

0.1uF

GND

C439

C441

P8V

P5V

0.1uF

3

IN

1

OUT

IC24

LM1117-MPX1.8

4

2

0.1uF

PGND

PGND

C445

0.1uF

C442

0.1uF

GND

1

TAB

IC26

LM1117-MPX2.5

C440

0.1uF

DGND

C448

0.1uF

3

IN

GND

1

OUT

TAB

2

4

C447

0.1uF

D3.3V

D2.5V

D2.5V

D3.3V

DGND

D1.8V

D1.8V

LDRSPD

DGND

D3.3V

A3.3V

FSCON

TSCON

SPWM2

SPWM1

SLED

VC16

To DSD Block

SLED

A3.3V

D3.3V

LDRSPD

SPWM2

TSCON

FSCON

SPWM1

VC16

A5V

A3.3V

D3.3V

A5V

D3.3V

A3.3V

PCB Coil

P5V

L34

3

IN

OUT

TAB

IC23

LM1117-MPX3.3

4

2

L33

PCB Coil

R498

VC16

SPWM1

SPWM2

VC16

R486 33K

R485 33K

LDRSPD

SPDL0

C462 0.022uF

R491 7.5K

C235

LDM2

LDM1

XSPMUTE

LDM2

LDM1

TSD-M

XFTSMUTE

P8V

0.01uF

R494 56K

R492 7.5K

SLD

C463 0.022uF

C479 0.001uF

R487 22K

11

10

9

12

PGND

13

14

15

16

17

18

19

20

21

22

23

24

AGND

IN3-

IN4+

OUT3

IN4-

OUT4

CTL

FWD

REV

GND

GND

SGND

MUTE123

MUTE4

TSD-M

PVCC2

DO5+

DO5-

DO4-

26

27

28

25

AGND

VC16

R495 56K

C458 100pF

R488 33K

2

5

4

3

8

IN3+

OUT2

FAIRCHILD

DO4+

DO3-

29

1

7

IN1-

IN2-

GND6GND

IN2+

OUT1

IC25

FAN8042

GND

DO1-

DO3+

DO2-33DO2+

GND

31

35

32

34

30

36

PGND

T-

F+

T+

VC16

R496 56K

C501 100pF

R493 39K

R466 100K

C243 0.01uF

22uF/6.3V

A5V

IN1+

OPIN+

48

OPIN-

47

OPOUT

46

SVCC

45

VREF

44

GND

43

GND

42

OPIN2+

41

OPIN2-

40

OPOUT2

39

PS

38

PVCC1

37

DO1+

P5V

F-

0.01uF

VC16

C239 0.01uF

C238

C237 0.01uF

C236 0.01uF

AGND

PGND

PGND

C470

12

0.01uF

R465100K

C240

2

R37110K

1

C503

1 2

C502

R370 10K

A3.3V

56K

R497 56K

SPEED_SP1

To DSP Block

SPEED_SP

LDM1

AGND

VC16 VC16

10uF/16V

10uF/16V

R368

SPEED_SP

R369

10K

10K

LDM2

CLS_SW

OPN_SW

TSD-M

XFTSMUTE

LMT_SW

XSPMUTE

OPN_SW

LMT_SW

CLS_SW

To RF Block

R346 10K

R366 10K

22K

R476

22K

R475

NC

R311

R478

R474

0R

R477

0R

NC

A:R311 R474

B:R477 R478

5

3

2

4

4

5

CN20

DGND

3

112

CON5

SP-

SP+

5

6

6

CN19

DGND

SL-

SL+

DGND

LMT_SW

4

2

3

112

5

3

4

CON6

R4

NC

R2

0R

R3

NC

R1

0R

A: R1R2

B:R3 R4

OPN_SW

CLS_SW

AGND

DGND

3-27

Page 36

5.DECODE BOARD-RF SECTION

A3.3V

AMPMNT

PI

VC16

FEO

AMPSEN

AMPSDT

AMPSCK

RFAC

CD/XDVD

TEO

D3.3V

To DSP Block

MIRR

DFCT

LDON

VC25

RFAC

A5V

Q43

31

R459

2SK3019

CD/XDVD

47K

To SACD Block

Q45

3

2

31

31

2

DTC144EUA

Q44

2SK3019

31

CD/XDVD

AMPMNT

D3.3V

AMPSCK

AMPSEN

AMPSDT

2

Q47

NM

2

Q46

NM

C228 NM

C229NM

C423 0.1uF

C422 0.1uF

47K

R460

1

2

A5V

GND_RF

C476 0.001uF

R468 12K +/- 1%

RX

49

GND_RF

RFAC

C420 0.1uF

C419 0.1uF

GND_RF

MEV

50

VNA

51

FNN

52

FNP

53

DIP

54

DIN

55

BYP

56

C421 0.1uF

57

VPA

58

AIP

59

AIN

60

61

62

63

64

C424 0.1uF

C234 0.01uF

C425 0.1uF

R462 820R

AMPSDT

AMPSCK

AMPSEN

46

48

47

SCLK

SDEN

SDATA

RFAC

ATON

ATOP

RFSIN

RFDC

DVDRFP1DVDRFN2A23B24C25D26CP7CN8D

DVDRFN

A_2

DVDRFP

C480 2200pF

C481 2200pF

B

A

R463

220R

D3.3V

LCP

44

45

V33

B_2

C_2

C482 2200pF

D

C472 0.047uF

LCN

43

LCP

D_2CPCN

C483 2200pF

C

AMPMNT

42

LCN

IC21

A5V

C488

D3.3V

R490

C494

33uF/6.3V

47R

32

47R

33uF/6.3V

C493

47R

32

47R

100uF/16V

C430

0.1uF

DGND

470R

C478

0.001uF

GND_RF

1

C500

10uF/16V

L36

47uH

10uF/16V

C499

1 2

Q48

2SB1132

R484

33k

D40

1SS355

12

R489

470R

1Q49

L35

2SB1132

1 2

GND_RF

To Power Supply & Driver Block

0.001uF

C477

C498

10uF/16V

47uH

C497

10uF/16V

R483

33k

F-

T-

F+

T+

T+

T-

F-

F+

C492

C4290.1uF

100uF/16V

C428 0.1uF

OETOET

VC16

A3.3V

PI

FEO

A3.3V

VC16

FEO

PI

CE

37

41

36

40

39

38

PI

FE

CE

TE

V25

MNTR

SONY

CXD1881AR

B

A

C

9

12

10

11

13

D

C

A

C454 330pF

100uF/16V

C486

C427

0.1uF

100uF/16V

0.1uF

MEVO

MIN

MLPF

MB

MP

MIRR

LDON

VNB

CDPD

DVDPD

CDLD

DVDLD

VC

VPB

CD_E

CD_F

MIRR

GND_RF

LINK

MIRR

C474 150p

C495 0.033uF

C484 1uF/10v

32

31

30

29

28

27

26

LDON

25

24

23

22

21

20

19

18

17

R4703.9K

R471 100R

R469 100K

GND_RF

VC25

0.1uF

C434

GND_RF

B101

NA

B100

NA

100R

R472

C485

C426

DFCT

TPH

DFCT

GND_RF

35

33

34

TPH

DFT

V125

LINK

CD_D

CD_C14CD_B15CD_A

16

C

B

A

LDON

A5V

0.1uF

C438

GND_RF

C496 0.033uF

VC25

CDLD

A5V

GND_RF GND_RF

LD-CD

R482

A5V

R481

DVDLD

R480

A5V

R479

GND_RF

D26

1SS355

12

GND_RF

R461 100R

R473 100R

T+T-F-

F+

1

2

3

FCS -

FCS +

CN18

B

VC25

F B

D

C

CD/XDVD

RF-OP

5

7

8

6

4

C / c

D /d

MSW

TRK -

TRK +

E

GND_RF

A D

A5V

13

11

12

15

14

9

10

16

F

RF

E

Vc

Vcc

A /a

B/b

GND

LD-DVD

VR-CD

LD-CD

GND_RF

VR-DVD

PD

23

17

18

19

21

20

24

22

PD

N/C

N / C

N / C

CD VR

CDLD

DVD LD

DVD VR

LD GND

C431 0.1uF

KHM-313

C490 100uF/16V

C432 0.1uF

C489 100uF/16V

A5V

3-28

Page 37

6.DECODE BOARD-CONNECT AND 232 SECTION

TO DSP BLOCK

VCCVCC33

P5VP8V

TO DSP BLOCK

H_VDT6

H_VDT4

H_VDT5

H_VDT4

H_VDT0

H_VDT1

H_VDT3

H_VDT2

H_VDT6

H_VDT5

H_VDT7

DD4

DD5

DD6

DD7

PGND

STB

-22V

VF+

5VD

GND

3.3VD

GND

J6

234

1

VF-

P5V

P8V

7

8

5

6

91011

VF-

VF+

-22V

STANDBY

B86

B85

B70

B84

B83

DD3

DD2

DD1

S11B-PH-SM3-TB

PGND

220UF/6.3V

220UF/6.3V

0.1UF

100UF/16V

PGND

100UF/16V

PGND

DD0