Page 1

SERVICE MANUAL

M4 C/AH

STEREO

M4 C/AH

STEREO

FM/AM/DAB/XM TUNER

FM/AM/DAB/XM TUNER

Page 2

CONTENTS

SECTION 1 . . . .SUMMARY

SECTION 2 . . . .CABINET & MAIN CHASSIS

SECTION 3 . . . .ELECTRICAL

SECTION 4 . . . .REPLACEMENT PARTS LIST

Page 3

SECTION 1

SUMMARY

CONTENTS

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO PRODUCTS

SERVICING PRECAUTIONS ...........................................................................1-3

• General Servicing Precautions

• Insulation Checking Prodedure

• Electrostatically Sensitive Devices

SPECIFICATIONS ........................................................................................... 1-4,5

............. 1-2

1-1

Page 4

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO PRODUCTS

CAUTION : DO NOT ATTEMPT TO MODIFY THIS

PRODUCT IN ANY WAY, NEVER PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFACTURER’S

APPROVAL. UNAUTHORIZED MODIFICATIONS WILL

NOT ONLY VOID THE WARRANTY, BUT MAY LEAD TO

YOUR BEING LIABLE FOR ANY RESULTING PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY

AFTER YOU ARE THOROUGHLY FAMILIAR WITH ALL

OF THE FOLLOWING SAFETY CHECKS AND SERVICING GUIDELINES. TO DO OTHERWISE,INCREASES

THE RISK OF POTENTIAL HAZARDS AND INJURY TO

THE USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION FROM A.C. LINESHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS

BEEN CORRCTED. A CHECK SHOULD BE MADE OF

THE FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1.BE SURE THAT ALL COMPONENTS ARE POSI-

TIONED IN SUCH A WAY AS TO AVOID POSSIBILITY

OF ADJACENT COMPONENT SHORTS.THIS IS ESPECIALLY IMPORTANT ON THOSE MODULES WHICH

ARE TRANSPORTED TO AND FROM THE REPAIR

SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES SUCH AS INSULATORS, BARRIERS,

COVERS, SHIELDS, STRAIN RELIEFS, POWER

SUPPLY CORDS, AND OTHER HARDWARE HAVEBEEN REINSTALLED PER ORIGINAL DESIGN. BE

SURE THAT THE SAFETY PURPOSE OF THE POLARIZED LINE PLUG HAS NOT BEEN DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER

POSSIBLE COLD SOLDER JOINTS, SOLDER

SPLASHES OR SHARP SOLDER POINTS. BE CERTAIN TO REMOVE ALL LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE

OR DETERIORATION TO PARTS AND COMPONENTS.

FOR FRAYED LEADS, DAMAGED INSULATION

(INCLUDING A.C. CORD). AND REPLACE IF NECES-

5. NO LEAD OR COMPONENT SHOULD TOUCH A

RECIVING TUBE OR A RESISTOR RATED AT 1 WATT

OR MORE. LEAD TENSION AROUND PROTRUNING

METAL SURFACES MUST BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES,

FLAMEPROOF RESISTORS, CAPACITORS, ETC.

MUST BE REPLACED WITH EXACT FACTORY TYPES,

DO NOT USE REPLACEMENT COMPONENTS OTHER

THAN THOSE SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT MODIFICATIONS.

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN A.C. LEAKAGE TEST ON ALL EXPOSED

METALLIC PARTS OF THE CABINET, (THE CHANNEL

SELECTOR KNOB, ANTENNA TERMINALS. HANDLE

AND SCREWS) TO BE SURE THE SET IS SAFE TO

OPERATE WITHOUT DANGER OF ELECTRICAL

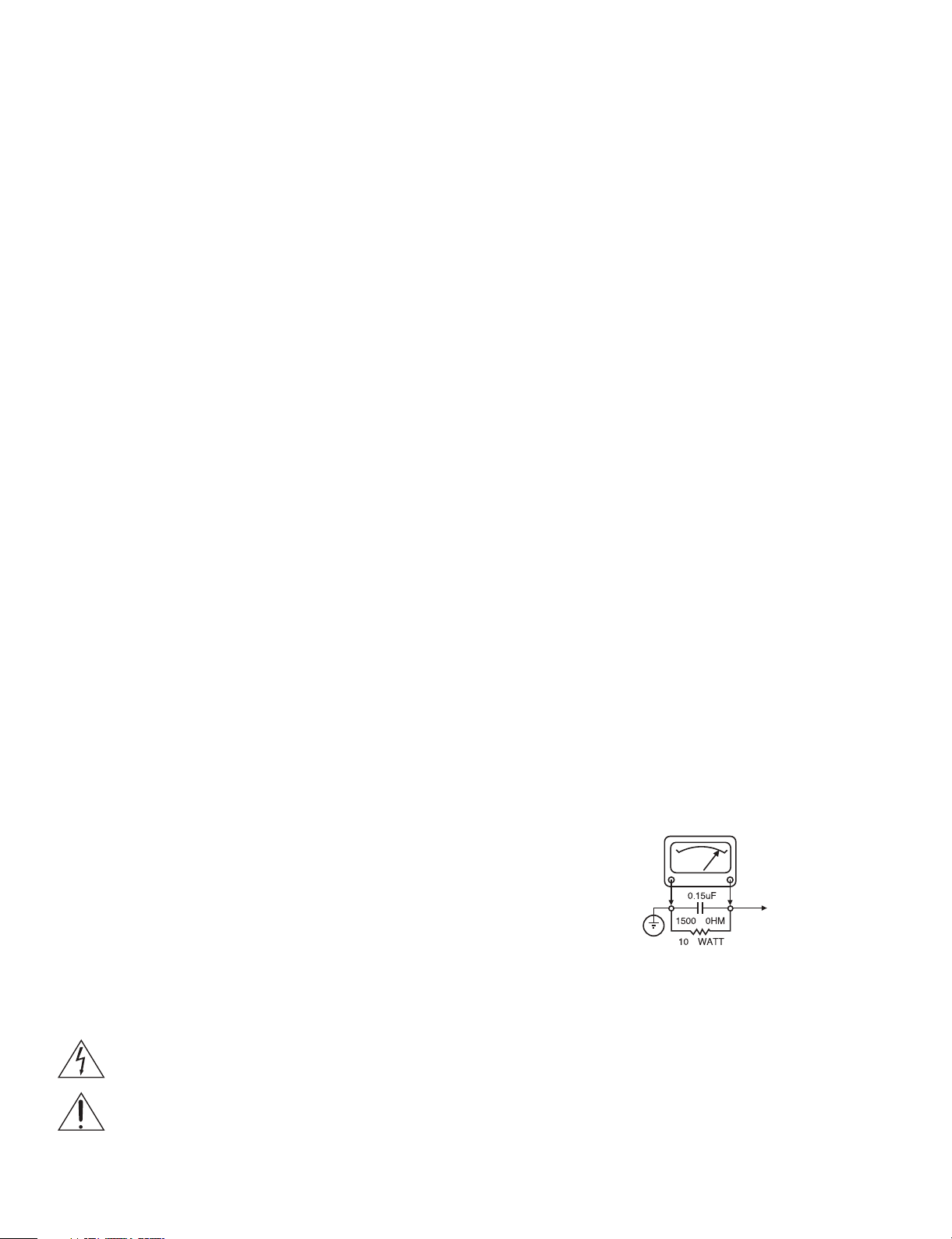

SHOCK. DO NOT USE A LINE ISOLATION TRANSFORMER DURING THIS TEST USE AN A.C. VOLTMETER, HAVING 5000 OHMS PER VOLT OR MORE SENSITIVITY, IN THE FOLLOWING MANNER; CONNECT A

1500 OHM 10 WATT RESISTOR, PARALLELED BY A

.15 MFD. 150.V A.C TYPE CAPACITOR BETWEEN A

KNOWN GOOD EARTH GROUND (WATER PIPE,

CONDUIT,ETC.) AND THE EXPOSED METALLIC

PARTS, ONE AT A TIME. MEASURE THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500OHM

RESISTOR AND .15 MFD CAPACITOR. REVERSE THE

A.C. PLUG AND REPEAT A.C. VOLTAGE MEASUREMENTS FOR EACH EXPOSED METALLIC PART. VOLTAGE MEASURED MUST NOT EXCEED 75 VOLTS

R.M.S. THIS CORRESPONDS TO 0.5 MILLIAMP A.C

ANY VALUE EXCEEDING THIS LIMIT CONSTITUTES A

POTENTIAL SHOCK HAZARD AND MUST BE CORRECTED IMMEDIATELY.

A.C. VOLTMETER

GOOD EARTH GROUND

SUCH AS THE WATER

PIPE. CONDUIT. ETC

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

SUBJECT: GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN AN EQUILATERAL TRIANGLE, IS INTENDED

TO ALERT THE SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED “DANGEROUS VOLTAGE”

THAT MAY BE OF SUFFICIENT MAGNITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE SERVICE

PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN SERVICE LITERATURE.

1-2

Page 5

SERVICING PRECAUTIONS

CAUTION

this service data and its supplements and addends, read and

follow the SAFETY PRECAUTIONS. NOTE: if unforeseen

circumstances create conflict between the following servicing

precautions and any of the safety precautions in this publication,

always follow the safety precautions.

Remember Safety First:

General Servicing Precautions

1. Always unplug the Stereo Tuner AC power cord from the AC

power source before:

(1) Removing or reinstalling any component, circuit board,

(2) Disconnecting or reconnecting any internal electrical

(3) Connecting a test substitute in parallel with an electrolytic

Caution: A wrong part substitute or incorrect polarity

2. Do not spray chemicals on or near this Stereo Tuner or any of its assemblies.

3.Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner,

cottontipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

which instruments covered by this service manual might be

equipped.

5. Do not apply AC power to this Stereo Tuner and/or any of its

electrical assemblies unless all solid-state device heat sinks

are correctly installed.

6. Always connect test instrument ground lead to the

appropriate ground before connecting the test instrument

positive lead. Always remove the test instrument ground lead

last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn the

power on. Connect an insulation resistance meter (500V) to the

blades of the attachment plug. The insulation resistance

between each blade of the attachment plug and accessible

conductive parts (Note 1) should be more than 1 M-ohm.

Note 1: Accessible Conductive Parts including Metal panels,

Input terminals, Earphone jacks, etc.

: Before servicing the Stereo Tuner covered by

module, or any other assembly.

plug or other electrical connection.

capacitor.

installation of electrolytic capacitors may result in an

explosion hazard.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical Es devices are integrated circuits and some field effect

transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handing any semiconductor component

or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known earth

ground. Alternatively, obtain and wear a commercially

available discharging wrist strap device, which should be

removed for potential shock reason prior to applying power to

the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an antistatic solder removal device. Some solder

removal devices not classified a “anti-static” can generate

electrical charges sufficient to damage ES devices.

5. Do not use freonpropelled chemicals. These can generate

electrical charge sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum

foil, or comparable conductive material).

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution: Be sure no power is applied to the chassis or circuit,

and observe all other safety precautions.

8.Minimize bodily motions when handing unpackaged

replacement ES devices. (Normally harmless motion such as

the brushing together of your clothes fabric or the lifting of

your foot from a carpeted floor can generate static electricity

sufficient to damage an ES device.)

1-3

Page 6

SPECIFICATIONS

AM TUNER SECTION

Usable Sensitivity (999/1000kHz) 30dBμ

S/N Ratio (5mV in) 38dB

THD (5mV in) <3%

IF Rejection (450kHz) >36dB

Image Rejection (F+2xIF) 28dB

Selectivity 17dB

Output 130mV ±20mV

Loop Sensitivity (20dB S/N)

999/1000 kHz 66 dB

603/600 kHz 66 dB

1404/1400 kHz 66 dB

Frequency response (100 - 2.3 kHz, 5mV) ±6 dB

FM TUNER SECTION

Usable Sensitivity (98 MHz) 6 dBμ

Signal / Noise Ratio Mono 72 dB

(60 dBμ, IHF wtd) Stereo >66 dB

Frequency Response

(20 Hz - 15 kHz, 60 dBμ) ±1.0 dB

Channel Separation (60 dBμ)

30 Hz >33 dB

1 kHz >42 dB

10 kHz >35 dB

Alternate Channel Sensitivity

(40 dBμ, ±400 kHz) 60 dB

Capture Ratio (40 dBμ) 1.5 dB

AM Suppression

(60 dBμ, 100% Mod.FM, 30% Mod.AM) 65 dB

Image Rejection (119.4 MHz) 85 dB

I.F. Rejection (10.7 MHz) 80 dB

Pilot Suppression (60 dBμ) 60 dB

THD (60 dBμ, L=R 75 kHz for North America version; 40 kHz

deviation for Europe version)

1-4

Page 7

Mono 0.20%

Stereo 0.25%

Auto-Search

Sensitivity On 24dBμ

Sensitivity Off 15 dBμ

RDS Decode Sensitivity 25 dBμ

DAB SECTION

Band lll 174MHz-240MHz

Input 50 Ohm, nominal

Max signal ~ -3dBm

Sensitivity ~ -96dBm

Adjacent Channel Rejection ~ 35dB

Display 2-line by 16-character

DOT Matrix

Audio Output Stereo 2.5Vp-p

48kHz sample rate 16 bit sample Resolution

Optical S/PDIF IEC60958 Compliant

48kHz sample rate 24 bit sample resolution

1-5

Page 8

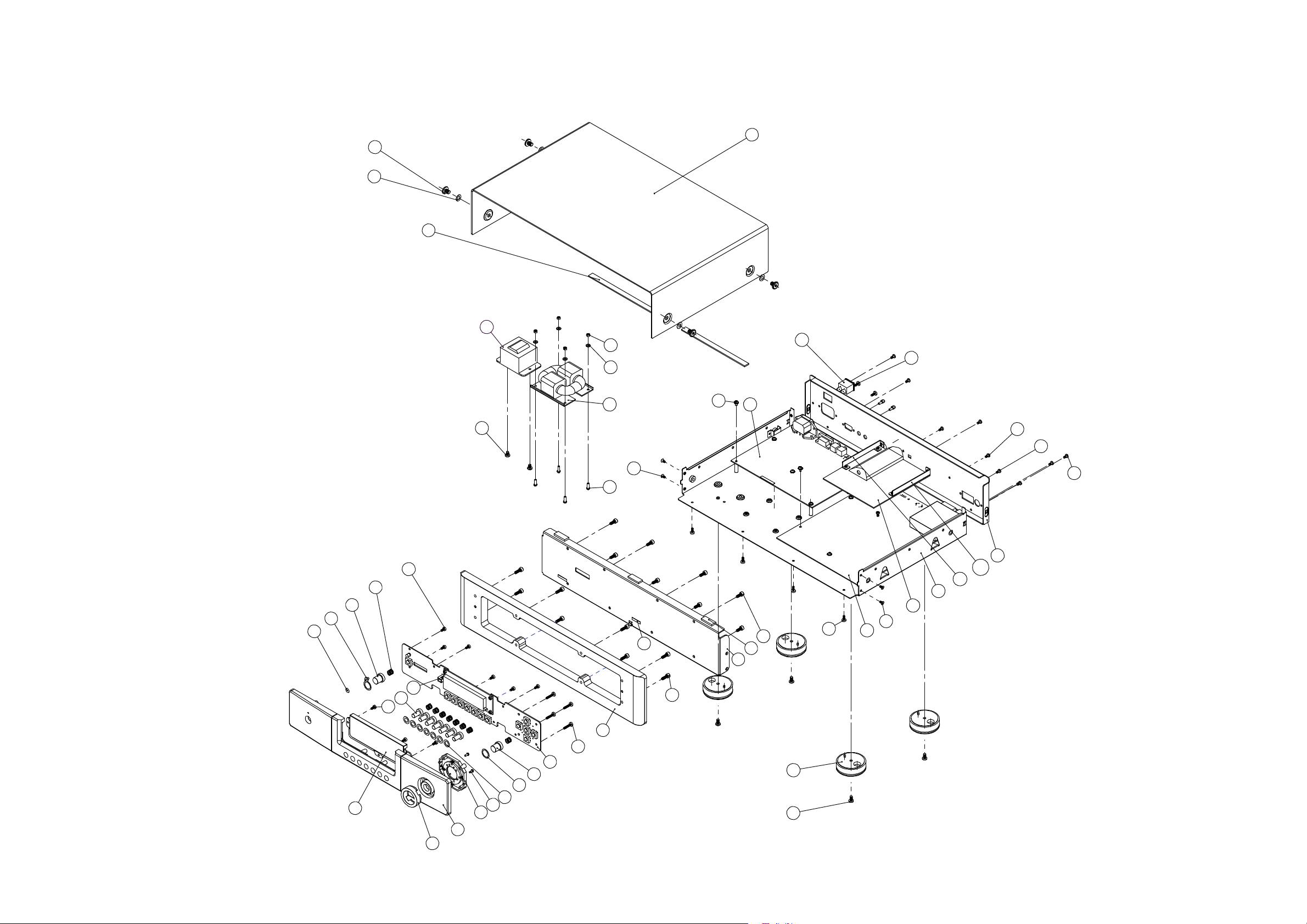

SECTION 2

CABINET & MAIN CHASSIS

CONTENTS

EXPLODED VIEWS.................................................................................. 2-2

1. Cabinet and main frame section...................................................................

2. Packing accessory section . . . .. ........................................................................ 2-3

3. Exploded view parts list.. .. . .. .. ........................................................................ 2-4

2-2

2-1

Page 9

6

7

7

M4 EXPLODED VIEWS

&

6

6

6

7

5

6

&&

)

)

)

)

)

6

)

6

)3

)

)

)

6

6

)

)

)

)

6

)

6

6

)

6

)

)

6

&

6

6

6

6

6

5

;'

;'

&

&

6

&

2-2

Page 10

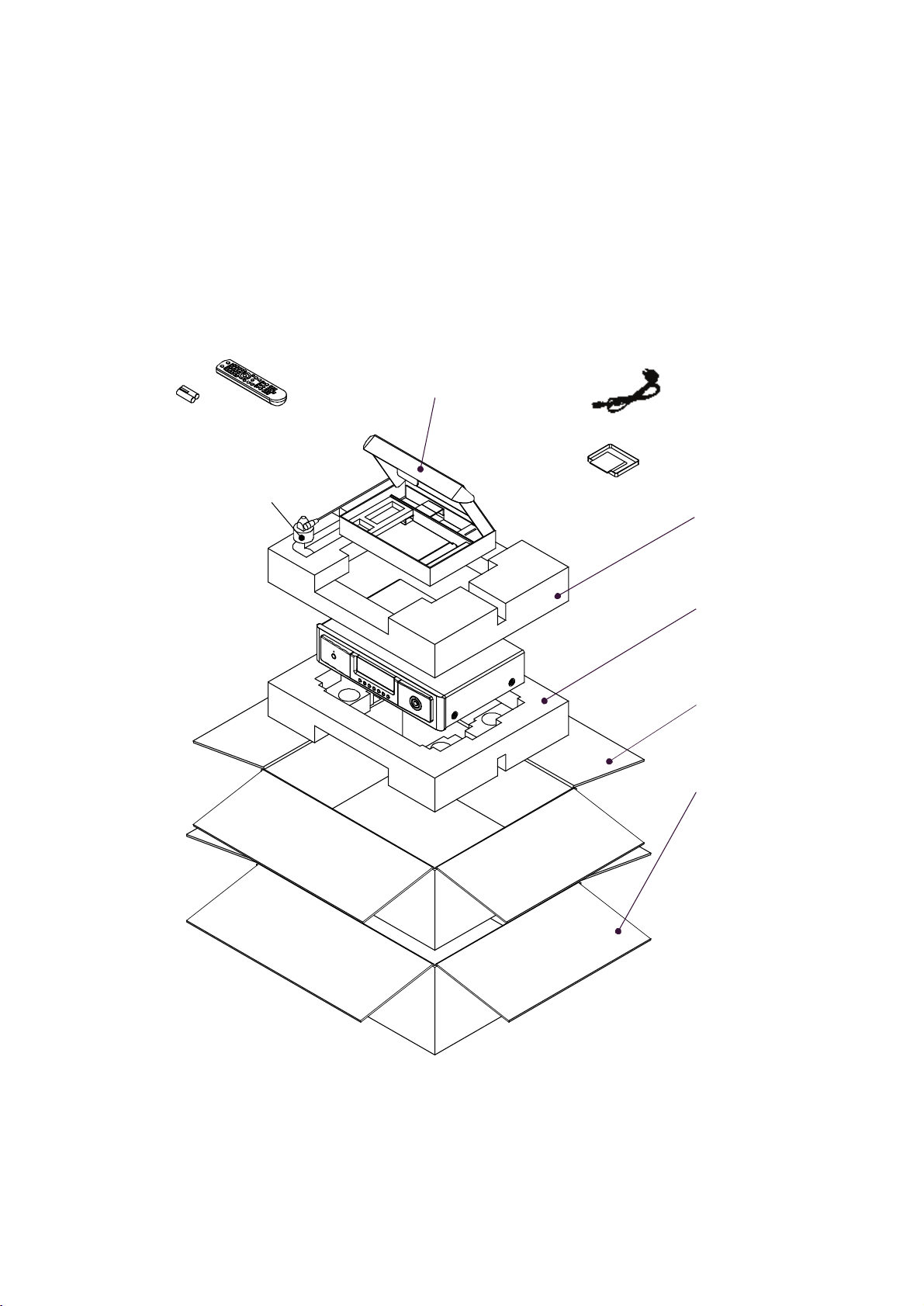

M4 Packing Accessory Section

Batteries

REMOCON

DAB Antenna

Accessory Box

AC Cord

AM Antenna

Polyfoam(up)

polyfoam(down)

Gift Box

Shipping Box

2-3

Page 11

M4 EXPLODED VIEW PARTS LIST

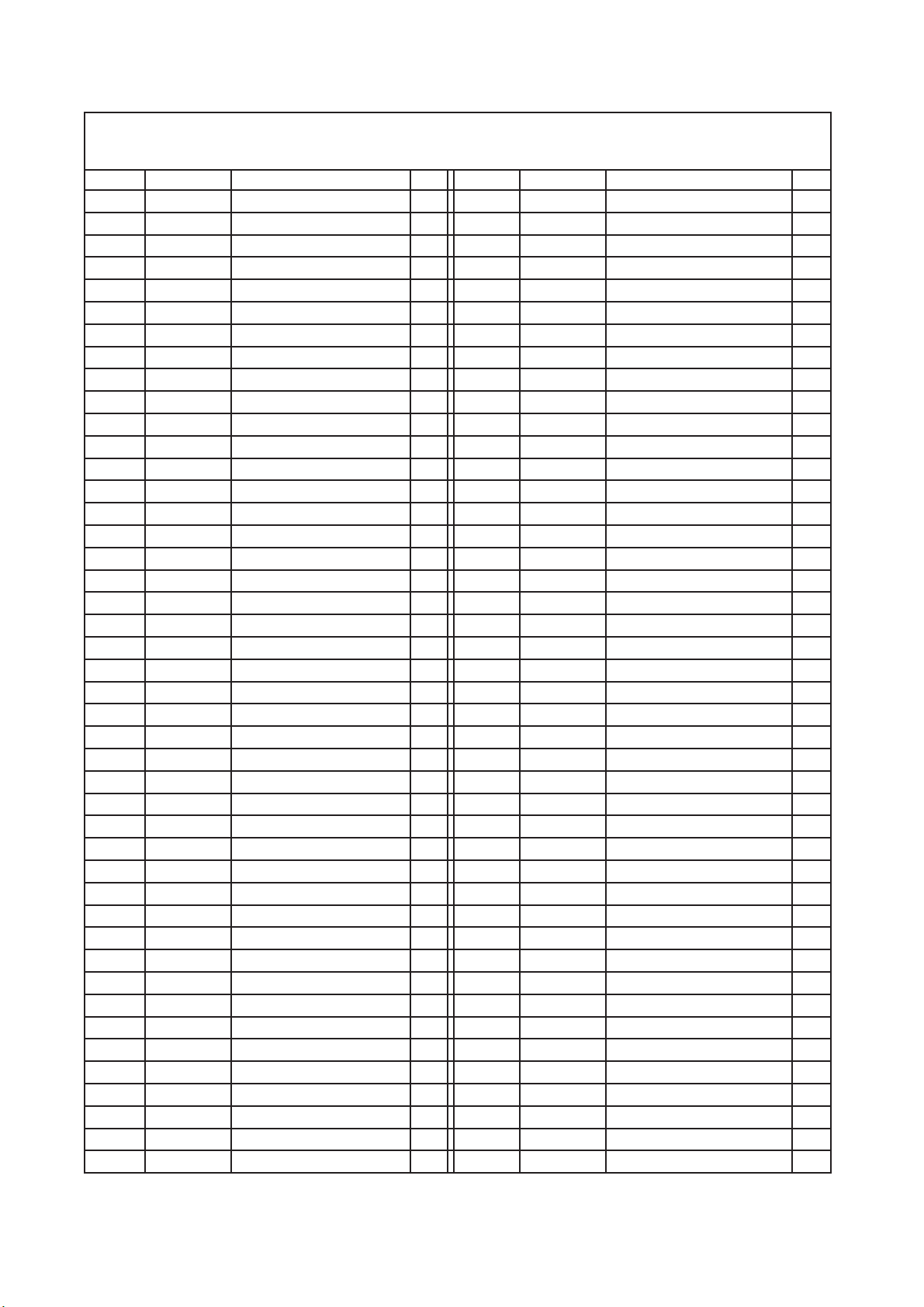

REF.NO. PART NO. DESCRIPTION Qty. REF.NO. PART NO. DESCRIPTION Qty.

C002 01-50404-10 XM BOARD(AH) 1

01-50403-20

C003 01-54245-20 C425 Main Board(AH Version) 1 S001 61-023206-1 Self Taping Screw (BTB3X6) 13

01-54245-10 C425 Main Board(C Version) 1 S002 61-022506-6 Machine Screw (MB2.5X6-Ni) 2

C004 01-50401-10 MAIN BOARD(AH Version) 1 S003 61-023616-0 Self Taping Screw(TBBT3×16) 4

01-50401-20 MAIN BOARD(C Version) 1 S004 61-224512-1 Hex Head Screw (M4X12) 8

C005 A18-50420-00 R Type Transformer 1 S005 61-224508-1 Hex Head Screw (M4X8) 8

C006 A18-50407-00 standby Transformer 1 S006 61-063106-0 Self Taping Screw (STF3X6) 4

C007 83-043001-0 Foot Assembly 4 S007 61-023106-2 Self Taping Screw (STB3X6) 15

F003 76-048010-0

F005 87-048002-0 Input Button Pad 7 S013 61-024106-0 Self Taping Screw (STB4×6) 2

F006 87-048003-0 Power Button Pad 2 S014 61-023508-0 Machine Screw (MB3X8) 4

F007 86-046001-0 Led Lens Gum 1 S015 63-020308-1 Spring Washer 4

F009 70-048013-0 Power Button 1

F010

F012 70-051007-0 Enter Button 1

F015 86-046002-0

F017 86-010004-0 3mm Rubber Pad 3

92-048001-0 Spring for Button 9

DAB BOARD includes DB1 ( C ) 1

S008 61-024108-1 Self Taping Screw (STB4X8) 4

S009 61-373506-0 Machine Screw (MB3X6W.S-Ni) 8

VFD window 1 S012 61-023208-0 Self Taping Screw (BTB3X8) C:9

7nottuB tupnI1-210840-07110F

1draoB PPF00-20405-10310F

11aicsaF0-200470-07J410F

Fascia Padding 2

1aicsafbuS0-300470-76610F

1tekcarB RI0-200840-6610PF1sissahC2-100470-76100C

2)iN-6X3BTS( wercS gnipaT fleS1-601320-16010S12aicsaF0-100470-07100F

4)rC-8X6BM( wercS enihcaM0-805642-16110S1rosruC gniR0-200150-07200F

6:HA1redloH rosruC1-100470-77400F

4)3M(tuN2-203010-26610S1 sneL deL0-100800-67800F

R001 67-074002-1 Rear Panel (C Version) 1

67-074004-1 Rear Panel (AH Version) 1

R002 11-01101-03 Rocker Switch 1

T003 76-046001-0 Screw Washer 4

XD01 66-083003-0 PCB Left Bracket 1

XD02 66-083004-0 PCB Right Bracket 1

1revoC poT0-200150-76100T

2x2/1daP RC0-510910-98200T

Page 12

SECTION 3

ELECTRICAL CONTENTS

ELECTRICALTROUBLESHOOTING GUIDE…………………………………..3-2

1. Power check flow……………………………………………………………………………...3-2

2. Preamp operation flow……………………………………………………..…………………3-3,4

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING

1. SYSTEM 18.432MHz CLOCK…………………………………………………...…..………3-5

2. M30281 reset in low active…………………………………………………………………...3-5

3. I2C control SDA and SCL…………………………………………………………………….3-6

4. DAB/XM control RXD……………………………………………………………………….…3-6

BLOCK DIAGRAMS…………………………………………………...…………..3-7

CIRCUIT DIAGRAMS

1. MAIN BOARD DIG SECTION………………………………………………………….….….3-8

2. MAIN BOARD PSU SECTION…………………………………………………………….….3-9

3. FRONT PANEL BOARD………………………………………………………………………3-10

4. DAB BOARD (C VERSION ONLY)…………………………………………………………..3-11

5. XM BOARD (AH VERSION ONLY)…………………………………………………………..3-11

PRINTED CIRCUIT DIAGRAMS

1. MAIN BOARD……………………………………………………………………………….…3-12

2. FRONT PANEL BOARD……………………………………………………………………...3-13

3. DAB BOARD (C VERSION ONLY)………………………………………………………….3-14

4. XM BOARD (AH VERSION ONLY)………………………………………………………….3-15

5. AM FM TUNER BOARD AH & C ...................................................................................3-16

Page 13

ELECTRICAL TROUBLESHOOTING GUIDE

1.Power Check Flow

Power switch on

Orange LED ON?

NO

5V is Right ?

NO

Check Power Switch and its cable

Check F600

Check the standby Transformer

Check U601 on the PSU board

YES

Press the standby button

Hear the relay’s click?

YES

NO

YES

Check the MCU on the FPP board

Check Q300--Q303,U302,U303

Check the cable from J300 to J105

Check the MCU on the FPP board

Check Q112,Q600 and K600

Check if the main transformers

has been plugged in

+/-13.5V

power supply is correct?

YES

+5.3V

power supply is correct?

YES

+5V power

supply output from U110

is correct?

NO

NO

NO

Check R621 and R622

Check the main transformer

Check D602,Q601,Q603,Q604,

Q605,Q606,Q607

Check PSU PCB

Check R619,R620

Check D601

Check U603

Check the sockets and plugs

Check U110

YES

The End

3-2

Page 14

2. Operation flow

Power on

Orange LED change to

blue?

YES

Wait for 10 second

Hear the relay’s click?

NO

NO

Check FPP board

Check 5.3V relay supply

Check Q101

Check SOURCE SELECT signal

YES

Press band key to change

source FM,AM,DAB/XM

mode

Relay respond properly?

YES

NO

Press band key to select AM

mode, input AM test signal

1K 500mV sinewave at antenna

side,check output

Level=0.5V±0.1V ?

YES

A

NO

THD>3%?

Check C425 board

YES

NO

Check conection between C425 and main

board

Check RL101 RL102 R184 R185

3-3

Page 15

A

Press band key to select DAB(or XM)

mode, input DAB (XM) test signal

1K 500mV(0dBFS) sinewave at antenna

side,check output

DAB:Level=500mV±50mV

THD<0.03%?

XM: Level=2V±0.1V

THD<0.03%?

YES

Press band key to select AM

mode, input AM test signal

1K 500mV sinewave at antenna

side,check output

Level=500mV±50mV

THD<5%?

NO

NO

Check conection between C425 and main

board

Check RL101 RL102 R184 R185

Check U104 input IIs signal

Check U105 U106 U107 U108

check DB1 module

YES

THE END

3-4

Page 16

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING

1. SYSTEM 18.432MHz CLOCK

2. M30281 reset in low active

Page 17

3. I2C control SDA and SCL

4. DAB/XM control RXD

Page 18

FM/AM SECTION

C425 BOARD

M4 BLOCK DIAGRAM

L

R

ANALOG OUTPUT

XM SECTION

(AH VERSION ONLY)

XM BOARD

MAIN MCU

M30281FAHP

UART CONTROL LINE

FPP BOARD

KEY IR AND DISPLAY

DAB SECTION

(C VERSION ONLY)

NAD DB1 MODULE

IIS SIGNAL

IIS SIGNAL

AUDIO DAC

PCM1796

L

R

OUTPUT FILTER

32A

32A

DIGITAL COAX OUT

DIGITAL OPTO OUT

232 TRIG IR INTERFACE

ANALOG OUT L

1

1

ANALOG OUT R

Page 19

CIRCUIT DIAGRAMS

1.MAIN BOARD DIG SECTION

J103

LOUT

J104

ROUT

J102

R185

0R

R170

C128

84

84

84

84

C119

C113

C114

C111

+13.5V

3V3

5V3

5V3

C121

U111

TPS2011

123

FROM C425 BOARD

R184

0R

C139

8N2

300R

C108

220N

U107A

2

C131

2N7

R153

620R

1

R144

820R

4N7

2

U108C

U107C

U106C

OP275

100N

C120

100N

C115

100N

100N

C112

100N

100N

C118

100N

100N

-13.5V

C145

10U/10V

G

1

OUT

2

IN

3

C144

10U/10V

C142

100N

R189

2R7

DGND

5V3_EN

100N

2

3

4

1

IN

IN

EN

GND

OUT

OUT

OUT6OUT

5

8

7

3V3

R100 100R

R114 100R

123

456

J101

5V3

1

4

78

D103

1N4148

RL101B

HFD3

RL101A

HFD3

RL101C

HFD3

6

3K3

10U/10V

C110

U104

DAB/XM_RST

2V4

R143 820R

100N

28

VCC2L

ZEROL1ZEROR2MSEL

R103

C122

DGND

MUTE/UNLOCK

1112131415

10

Q101

5

C153

10N

R182

DGND

D101

2V4

6

5

U107B

OPA2134

C137

22P

7

C132

2N7

330R

R158

R154

620R

R150

360R

7

U105B

4N7

C134

OP275

6

5

C125

C124

22U/6.3V

C151

100N

R142

10K

24

26

22

19

27

23

21

20

25

IREF

VCC1

AGND2

IOUTL-

AGND1

VCOML

IOUTL+

VCOMR

AGND3L

LRCK

BCK

SCK7DGND8VDD9MS10MDI

DATA

4

6

3

5

10K

R119

10U/10V

C106

LRCKO

DATAO

BCLKO

MCLKO

R104 100R

R102 100R

R101 100R

16

18

DGND

1Y2

1Y1

C100

100N

20

3V3

1G1A1

2

DGND

BCLK

DATA

BCLK

LRCLK

MCLK

161718

19

20

3

2

R175

22K

D102

C105

47UF/16V

R162

3K3

1

R161

OPA2134

3

R157

330R

C129

15N

R149

360R

4N7

C127

U105A

OP275

3

OPA2134

C123

OPA2134

OP275

U105C

3V3

O

4

U102

AMS1117-3.3

DGND DGND

DAB/XM_TX

DAB/XM_RX

DT_LNK

IIS_RATE

DT_ANTREV

789

1K

R121

2SC1815

DGND

C116

100P

4K7

R180

4K7

C140

8N2

R171

300R

R176

22K

C109

220N

C107

47UF/16V

R164

3K3

1

C138

R163

3K3

U108A

OPA2134

2

3

C135

2N7

R155

630R

R159

330R

R160

C130

15N

R152

R151

360R

1

R148

820R

4N7

U106A

OP275

C133

R145 820R

2

3

22U/6.3V

C126

C143

10U/10V

10U/10V

5VA

2

C199

100N

Vout

15

17

16

18

IOUTR-

12

11

R120

10K

100N

SCL

12

14

1Y3

VCC

A2

4

6

DATA

LRCLK

Vin

U110

VCC2R

IOUTR+

3

AGND3R

MDO

RST

MC

PCM1796

13

14

R177

10R

R129

10K

3V3

+13.5V

C102

100N

10K

DGND

SDA

3.3VD

3.3VD

3V3

4K7

R118

DGND

U135

74CB3Q3125PW

GND

7

2B

6

2A

5

2QE

4

1B

3

1A

2

1QE

1

3.3VD

C101

DXRST

I2C_CLK

I2C_DATA

R203 100R

IIS_RATEO

DT_LNKO

DT_ANTREVO

BREAK

7

5

3

9

U100

74LCX244

1Y4

2Y2

2Y3

2Y4

2Y1

GND

10

B2

A4

B1

B3

A3

2G

B4

8

19

17

13

11

15

DGND

MCLK

IIS_RATE

DT_LNK

DT_ANTREV

MUTE/UNLOCK

15

DGND

141415

TO DAB/XM_SCH J301

J117

C156

100P

C155

100P

5V3

1

4

HFD3

RL102B

6

5

6

22P

7

C136

2N7

330R

R156

630R

360R

7

U106B

6

5

C146

100N

GND

LM1117MPX-5.0

1

C117

R188

1K

1K

R187

Q105

DTC114

DGND

3B

8

3A

9

3QE

10

4B

11

4A

12

4QE

13

VCC

14

DGND

100N

4R7

R217

DGND

Q106

DGND

10

12

11

13

10

12

11

13

78

D104

1K

RL102A

HFD3

R122

2

3

5

U108B

OPA2134

R137

4K7

3.3VD

R136

4K7

OP275

100N

C147

10U/16V

DGND

DT_LNKO

DAB/XM_RX

DAB/XM_TX

FMP_EN

DAB/XM_RST

5V3

Q115

2SA1015

2SA1015

R218

4K7

R219

4R7

33R

33R

33R

R115

R105

R186

SCKFM

SDAFM

9

3

44556677889

1N4148

RL102C

HFD3

Q102

2SC1815

DGND

C198

100P

R183

4K7

C154

10N

R181

4K7

MAIN MUTE

TRIG_IN

MAIN MUTE

TRIG_ON/OFF

SOURCE SELECT SOURCE SELECT

3.3VD

1

2

3

R146

2R7

5VD

STANDBY

R138

R173 33R

R172 33R

TPG4

TPG3

TPG5

3 4

1 2

0R

0R

CLK1

CNVssCERESET

R106

R112

I2C_CLK

I2C_DATA

CLK2

P73

FMP_EN

Q100

DTC114

R125

4K7

DGND

Q113

DTC114

DGND

Q114

2SC3326

TPG2TPG1

MB

2

112

3

TO FM/AM BOARD

C183

100N

C182

G

OUT

IN

C181

C180

33R

3.3VD

5 6

7 8

R232_RX

FM RST

1mmMA1mm

TPG7

3.3VD

10U/10V

O

4

U118

AMS1117-3.3

10U/10V

DGND DGND

100N

R168

32

30

31

P30

P31

TXD0/P63

33

RXD0/P62

34

P61

35

P60

36

P27

37

P26

38

P25

39

P24

40

P23

41

P22

42

SCL/P21

43

SDA/P20

44

P17

45

P16

46

P15

47

P03

48

P0150P0051P10752P10653P10554P104

P02

49

DGND

9 10

11 12

13 14

J112

HEADER 7X2 2.54 pitch

R232_TX

BUSY

KEYB5

3.3VD

DGND

TPG10

TPG8

TPG9

11

10

J111

J109

J110

+12 TRIG IN

R141

10K

10K

R194

R169

3K3

C191

100N

R178

10R

Q111

R108

4K7

2SC1815

DGND

R190

47K

TRIG_IN

STANDBY

HS4-B007-M4-PSU-VM1_0

HS4-B007-M4-PSU-VM1_0.SCH

1

3

2

a1

a2

gnd

C170

100N

y2

y1

vcc

U114

5

4

6

3V3

DGND

47K

CLK1

BUSY

23

19

25

26

17

22

18

P75

P77

P7420P7321P72

P6527P6428P3329P32

P76

TXD2/P7024TXD1/P67

RXD1/P66

RXD2/P71

P103

P102

P101

P10060VREF

P9363P92

AVSS

AVCC

61

59

62

56

57

55

58

64

TPG6

R206

33R

R202

10R

3.3VD

R216

0R

1

2

C194

22UF/16V

J106

CON2

4

MR

RESET

3

2

5V3_EN

KEYB1

KEYB2

KEYB3

KEYB4

IR_F

KEYB1

KEYB2

KEYB3

R207 33R

R208 33R

R212 33R

14

18

16

9

7

12

DGND

C174

100N

1Y3

1Y1

1Y2

2Y1

2Y2

1Y4

VCC

20

A1

A2

A4

2G

1G

A3

B1

2

4

1

6

8

11

19

DGND

DGND

181920

J105

R111

C150

R110

4K7

R109

4K7

3.3VD

2SC1815

Q109

R191

47K

TRIG_ON/OFF

DGND

3V3

NC7WZ16

R135

47K

R215 100R

R214 100R

FM_TX

FM_RX

DGND

3.3VD

U117

M30281FAHP

P80

16

P81

15

P82/INT0

14

P83/INT1

13

P84/INT2

12

P85/NMI

11

VCC

10

XIN

9

VSS

8

XOUT

7

RESET

6

P86/XCOUT

5

CE

P87/XCIN

4

CNVSS

3

P90

2

P91

1

R220

CNVss

RESET

3.3VD

C168

100N

DGND

100K

3.3VD

R127

2

1

J100

CON2

DGND

5

3.3VD

VDD

RESET1GND

C175 100N

U119

TPS3825

DGND

KEY_CLK

KEYB4

KEYB5

KEY_DATA

KEY_EN

33R

33R

R133

R132

33R

33R

R210

R211

R209 33R

5

3

U109

74HCT244

2Y3

2Y4

GND

10

DGND

B2

B3

B4

13

15

17

789

11

10

1314151617

12

IR IN

C166

4K7

100N

3.3VD

R198 33R

47K

3.3VD

3.3VD

3.3VD

33R

R134

3.3VD 3.3VD 3.3VD

10N

2

R179

10R

R193

330R

C165

10N

R140

10K

DGND

R139

10K

Q110

2SC3326

R107

4K7

R192

2

1

1MEG

R205

R167

R166

R165

5VD

23456

1

DGND

100R

IR IN

IR IN

C179

22N

R147

10R

D110

1SS352

DGND

232GND

D109

1SS352

TO C425 UART

J107

DGND

C173

20P

20P

C172

DGND

Y102

18.432 MHz

C178

C141

C171

3K3

3K3

3K3

DGND

TO FPP_SCH CZ72

3.3VD

10U/10V

DGND

C103

100N

DGND

100N

DGND

100R

100R

100R

R113

R117

R174

IIS_RATEO

DT_ANTREVO

BREAK

IR_F

R131

NC

R130

NC

Q107

DTC114

R123

NC

Q104

DTC114

DGND

Q103

DTC114

123

EMI100p

330R

R195

C162

C161

10R

R213

R126

47K

R124

47K

3V3 DGND

789

3

C195

1

100N

100N

1

2

/EN

16

3.3VD

DXRSTA

1

100N

6

DXRST

D Connector 9

456

3C196

EMI100p

2

1

330R

232GND

R196

C164

100N

232GND

3

4

6

5

8

7

C163

100N

V-

V+

C1-

C2-

C1+

C2+

RIN

ROUT

DIN11FCON12DOUT13GND14VCC15/FCOFF

/INV

U115

MAX3221

9

10

232GND

C160

100N

R200

100R

R201

100R

R232_RX

R232_TX

C177

10U/10V

XM5

HOLE

FM RSTA

2

3

a2

a1

gnd

y1

y2

vcc

4

5

U103

NC7WZ16

FM RST

CLK2

P73

XM4

XM3

XM2

XM1

I2C_CLK

I2C_DATA

KEY_CLK

KEY_DATA

KEY_EN

DGND

C197

100N

5

8

6

7

3.3VD

WP

Vdd

SCL

SDA

A01A1

Vss

A2

U112

24LC16

2

4

3

DGND

D108

HOLE

HOLE

HOLE

HOLE

1SS352

D107

1SS352

DGND DGND

C193

22N

DGND

R116

100R

DGNDAGND

C104

22N

AGND

R199

100R

D106

1SS352

D105

1SS352

AGND AGND

3-8

Page 20

CIRCUIT DIAGRAMS

2.MAIN BOARD PSU SECTION

U601

3

LM7805

1

5V3

5VD

C631

100N

C630

100uF/16V

2

C606

100N

DGND

C605

3300UF/16V

D600

DB104

C601

220N

R618

R617

0.33R 1/4W FR

2

J603

0.33R 1/4W FR

1

2*3.96

S3

IN

C607

100N

C609

100uF/16V

R601

200R/1%

C608

10U/50V

U603

LM317M

R600

649R/1%

C616

100N

C613

3300UF/16V

D601

DB104

R619

0.33R 1/4W FR

H3

HEATSINK

+13.5V

DGND

R615

R612

4K99/1%

Q601

2SC2690

Q605

2SA1015

R608

120

R607

2R2 2W

C602

220N

R620

0.33R 1/4W FR

234

5

J605

AGND

C619

100N

C623

100uF/16V

2K21/1%

C625

10U/50V

R613

1K1/1%

R614

100R

U602

TL431

Q607

Q603

1

2SA1015

2SA1015

R610

8K2

R611

8K2

C617

100N

C614

2200uF/25V

D602

DB104

C603

R621

0.33R 1/4W FR

AGND

5*3.96

220N

-13.5V

C620

100N

C624

100uF/16V

R616

2K/1%

C627

47P

C626

10U/50V

Q602

2SA1220

Q606

2SC1815

120

Q604

2SC1815

R609

C618

100N

C615

2200uF/25V

R606

2R2 2W

C604

220N

+13.5V

-13.5V

1

2

3

4

5

6

7

8

J601

TO 425 POWER

AGND

AGND

R622

0.33R 1/4W FR

H2

1

234

5

J602

CON5

JP600

230V

JP602

120V

F600

500mAT/120V

S1

250mAT/250V

1

2

3

C600

POWER SWITCH

J600

4N7/400V

C612

CON3

10N/275V

L600

C611

10N/275V

J606

10mH UF10.5

PLUG AC MALE2

S4

HEATSINK

H1

HEATSINK

8VAC

13.5VAC13.5VAC

H4

HEATSINK

Main transformer

120VAC

230VAC

C628

4N7/400V

234

5

J604

5VD

C610

10N

3.3VD

DTA114

Q112

STANDBY

K600

Relay-SPST

D604

1N4148

JP603

120V

JP601

Q600

2SC1815

C629

100P

R603

1K

R602

1K

R204

100K

DGND

230V

DGND

S2

1AT/120V

F606

500mAT/250V

S5

120C BREAKER

1

Header 3

3-9

Page 21

CIRCUIT DIAGRAMS

3.FRONT PANEL BOARD

R310

10K

Q301

2SA1015

5VD

Q300

2SA1015

R308

10K

STR

1

KEY_EN

D

2

KEY_DATA

CLK

KEY_CLK

3

OE

15

VCC

16

5VD

C301

100N

DGNDDGND

U303

CD4094

STR

1

KEY_EN

D

2

CLK

3

KEY_CLK

OE

15

VCC

16

5VD

C300

100N

U302

CD4094

KEYA1

KEYA2

KEYA3

KEYB1

KEYB2

KEYB3

KEYB4

KEYB5

S311

SW-PB

S312

SW-PB

SW-PB

SW-PB

S309

SW-PB

SW-PB

S307

SW-PB

U301

20T202DA1J

U300

IR RECEIVER

R301

10K

R300

10K

5VD

C304

100N

C303

100N

C302

10U/10V

GND

1

VCC

2

RST

3

RS

4

R/W

5

E

6

DB0

7

DB1

8

DB2

9

DB3

10

DB4

11

NAD M4

DB5

12

DB6

13

DB7

14

R327

S

1

G

2

V

3

5VD

R328

10R

100R

C309

100N

C307

S304

S302

S300

10U/10V

SW-PB

SW-PB

SW-PB

VD1

VD2

VD3

VD4

VD5

VD6

VD7

VD8

DGND

S305

S303

S301

DGND

LEDA

LEDB

DGND

RST

RS

E

IR

1N4148

D303

D302

1N4148

D301

1N4148

SW-PB

S310

SW-PB

S308

SW-PB

S306

R306

R305

R304

R303

R302

R316

R315

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Q8

GND

QS

QS

Q1

Q2

Q3

Q4

Q5

Q6

Q7

Q8

GND

QS

QS

R311

10K

Q303

470

D300

270

10K

10K

10K

10K

10K

2SC1815

POWER

LED_CON

R309

10K

Q302

2SC1815

4

VD1

5

VD2

VD3

6

VD4

7

VD5

14

VD6

13

VD7

12

VD8

11

8

9

10

DGND

4

5

RS

E

6

LEDA

7

14

LEDB

13

KEYA1

12

KEYA2

11

KEYA3

8

9

10

DGND

R314

10K

5VD5VD5VD

R313

10K

DGND

R323

10K

XM34

DGND

DGND

5VD

KEY_EN

HOLE

XM32

HOLE

XM33

HOLE

XM31

HOLE

RST

C310

100N

R325

10K

R326

10K

Q307

2SC3326

R324

10K

TPG31

KEY_DATA

KEY_CLK

R321

NC

Q306

DTC114

R318

NC

Q305

DTC114

R317

NC

Q304

DTC114

C312

22N

DGND

R330

100R

DGND

D307

1SS352

D306

1SS352

DGND DGND

C311

22N

DGND

R329

100R

DGND

D305

1SS352

DGND

D304

1SS352

DGND

DGND

DGND

TPG32

TPG33

C305

100N

DGND

C306

100uF/10V

20

5VD

0R

0R

DGND

19

18

17

R322 0R

16

15

14

R320

13

12

R319

11

10

9

KEYB5

8

KEYB4

7

KEYB3

6

KEYB2

5

KEYB1

4

3

IR

2

1

J300

TO MAIN_SCH J105

DGND

3-10

Page 22

CIRCUIT DIAGRAMS

4. DAB BOARD (C VERSION ONLY)

J401

1

2

SPDIF

3

4

5

6

7

8

9

10

DGND

TO DAB MODULE

TPG41

XM42

HOLE

XM41

HOLE

R427

100R

R422

5V3

DAB_TX

C404

100N

DAB_RX

0R

TPG2

TPG1

TPG42

TPG43

TPG44

5

1

OE

2

R400

100R

R418

100R

A

3

R436

NC

DGND

R430

22N

R431

22N

DGND

VCC

GND

DGND

C412

1N

Y

C411

10uF/10V

DGND

U404

74AC125

5V3

C415

100N

4

3V3

DGND

3V3

C403

100N

R419

100R

C421

10UF/10V

L400

10UH

C414

22N

C413

1N

DGND

R411

3V3

R417

R428

10K

C429

NC

3V3

R403

DGND

DGND

C417A

100N

C418

10N

C419

10N

47K

NC

D400

4V7

3K

DAB_RST

DIR UNLOCK

5VD

C417B

100N

C417C

U400

100N

CS8416

1

RXP3

2

RXP2

3

RXP1

4

RXP0

5

RXN

6

VA

7

AGND

8

FILT

9

RST

10

RXSEL1

11

RXSEL0

12

TXSEL1

13

TXSEL0

NV/RERR14AUDIO

R432

33R

R433

33R

R435

33R

OLRCK

OSCLK

SDOUT

OMCK

RMCK

DGND

RCBL

96kHz

R405 NC

3V3

DGND

R406 47K

28

27

26

25

24

R404

23

VD

0R

22

21

VL

20

TX

TPG3

19

C

18

U

17

16

15

R412 47K

R413 47K

R414 47K

R415 47K

R416 47K

3V3

R434

10K

Q400

DTC114

DGND

R408 100R

R409 100R

R410 100R

100R

DGND

DAB_LRCLK

DAB_BCLK

DAB_DATA

R407

DAB_MCLK

C416

100N

3V3

DGND

1

1

C422

39P

DGND

RST

DIR UNLOCK

5VD

OE

A2Y

DGND

5VD

OE

A2Y

DAB_BCLK

DAB_DATA

DAB_LRCLK

DAB_MCLK

DGND

DAB_TX

DAB_RXI

5

VCC

GND

3

5

VCC

GND

3

DGND

U402

74AC125

U403

74AC125

4

4

DGND

DGND

DGND

1

2

4

6

8

19

11

13

15

17

C420

10uF/10V

C407

100N

C408

100N

5V3

C406

100N

3V3

C405

100N

20

DGND

1G

1Y1

A1

1Y2

VCC

A2

1Y3

A3

1Y4

A4

2G

2Y1

B1

2Y2

B2

2Y3

2Y4

B3

B4

GND

10

DGND

R420

C409

330R

100N

R402

100R

DGND

DGND

R423 100R

R424 100R

R425 100R

R426 100R

18

16

14

12

9

7

5

3

U401

74LCX244

5VD

C410

100N

DAB_RST

UNLOCK

DAB_TXO

DAB_RX

R421

91R

DGND

2

1

3

3V3

DAB_TXO

DAB_RXI

RST

UNLOCK

BCLK

DATA

LRCLK

MCLK

T103

AES/SPDIF 1:1

1

2

3

4

VCC

DATA

GND

J404A

D401

1SS352

DGND

TO MAIN_SCH J101

DGND

D402

1SS352

i/o gnd

J404B

OP+RCA

8

7

6

5

i/o gnd

R429

100R

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

J403

C423

22N

5. XM BOARD (AH VERSION ONLY)

TPG51

TPG52

TPG53

J500

8

7

6

5

4

3

2

1

CON8

C507

10uF/10V

J502

XM READY

DGND

DGND

DGND

C508

XM_RST

XM_TX

TXEN

XM_RX

DT_LNK

100N

DGND

3V3

5V3

3V3

D501

D502

DGND

R507100K

R50010K

12

7

8

6

9

5

10

11

VSS

VDD

RESET

13

I2S_RATE

14

LINKACTIVE

15

TXEN

COM_P

R530

100R

R532

100R

1K

R533

R531

1K

0

4

3

2

1

0

DGND

4V7

4V7

D503

4V7

4V7

D504

COM_M

DGND

DGND

DGND

3V3

3V3

C51620P

C51720P

D500

6V3

16

17

18

19

20

21

22

23

24

DGND

R536

R537

3V3

DGND

COMM_TX_EN

VSS

VDD

COMM_RX_P

COMM_RX_M

VDD

VSS

COMM_TX_M

COMM_TX_P

VSS

R525

R534

1MEG

DGND DGND

0R

0R

ANT_REV

SLAVE_SEL

RFU(I2C_SDA)

VSS25OSC_OUT26VDD27OSC_IN28SC_RATE29TEST30VSS31HSDP_DATA32VDD33HSDP_CLK34DT4_MODE35HSDP_EN

100R

Y500

R504 10K

DGND

45.1584MHz

C514

C515

20P

20P

C501 100N

C502 100N

5V3

C518 20P

C519 20P

RFU(I2C_SCL)

R528

R508100K

4

3

VDD

SC_RX_IN

SC_TX_OUT

47K

R529

3V3

10K

R503

NC

R542

1

2

VSS

SAII_DATA

I2S_LRCLK

36

47K

R505

3V3

10K

R501

LSDP

SAII_EN

VDD

SAII_CLK

MUTE

I2S_OCLK

VDD

I2S_SCLK

I2S_DATA

10K

R506

10K

3V3

DGND

D505

1SS352

3V3

R509

22K

DGND

U500

VSS

VSS

XM/DT REV3B/4A

R535

NC

DGNDi/o gnd

D506

1SS352

i/o gnd

R510

R511

22K

22K

C500

100N

48

47

46

3V3

45

44

43

42

DGND

41

40

3V3

39

38

DGND

37

3V3

DGND

R543

100R

3V3

DGND

3V3

DGND

R512 100R

R513 100R

R541 100R

R514 0R

R515 100R XM_TX

R516 100R

10K

R502

47K

R526

47K

R527

R518 100R

R519 100R

R520 100R

R517100R

3V3

C510

C509

100N

100N

DGND

C522

10uF/10V

C523

22N

DGND

DT_LNK

IIS_RATE

XM_RST

DT_ANTREV

XM_RX

XM MUTE

DGND

XM_MCLK

XM_LRCLK

XM_BCLK

XM_DATA

C503

39P

DGND

3V3

3V3

C511

100N

DGND

C512

100N

3V3

DGND

C513

100N

3V3 DGND

R539 100R

XM_RX

XM_TXO

R540 0R

XM_TX

XM_RXI

1

DGND

XM_MCLK

2

XM_LRCLK

4

6

XM_BCLK

8

XM_DATA

19

DGND

11

DT_LNK

IIS_RATE

13

15

DT_ANTREV

17

XM_RST

6

5

4

U502

1G

A1

A2

A3

A4

2G

B1

B2

B3

B4

C521

10uF/10V

C520

100N

y1

vcc

y2

NC7WZ16

5V3

3V3

20

VCC

GND

10

DGND

C504

100N

1Y1

1Y2

1Y3

1Y4

2Y1

2Y2

2Y3

2Y4

gnd

a1

a2

C505

100N

1

2

3

DGND

DGND

U501

18

16

14

12

DT_LNKO

9

IIS_RATEO

7

DT_ANTREVO

5

3

74LCX244

DGND

R524 100R

R522 100R

R523 100R

R521100R

BCLK

DATA

RST

C506

10uF/10V

3V3

XM_TXO

XM_RXI

DT_ANTREVO

IIS_RATEO

DT_LNKO

RST

XM MUTE

MCLK

LRCLK

DGND

TO MAIN_SCH J101

XM52

HOLE

i/o gnd

XM51

HOLE

i/o gnd

J501

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

3-11

Page 23

PRINTED CIRCUIT DIAGRAMS

1. MAIN BOARD

J102

RO

G

R184

R170

R162

C115

U107

R153

R157

R149

C129

C111

R144

R143

C124

C126

C151

U114

R136

R137

U135

C163

U102

C600

U104

C108

C127

C143

C142

R176

R175

C107

C105

13.5V

GND

C104

C119

R164

C109

C114

U108

C120

C137

R161

C132

R158

R150

C199

R103

R138

C145

C135

C136

R154

R159

R155

R151

C130

C146

U106

C125

C118

R142

C106

R120

R119

R106

R187

R112

R188

C197

U112

C101

C144

Q112

R204

R602

C610

R603

C629

C612

R160

C134

C113

C133

R148

R145

C123

C110

C122

C102

C607

C609

R189

C630

C631

Q600

K600

FOR CONTINUED PROTECTION

13.5V

D106

D105

R199

R163

R156

R152

C103

R129

U103

D604

C625

C619

C138

C623

C626

C620

R177

C624

C147

C117

U110

Q114

R105

Q113

Q100

R219

R218

R217

Q115

R125

R124

R126

R601

R600

H1

C616

C606

F606 230V : T500mAL/250V

120V : T1AL/250V

J600

C628

CAUTION:

AGAINST RISK OF FIRE

REPLACE ONLY

WITH SAME

J601

R613

R612

Q601H3R614

R615

R616

Q607

C627

H2

Q602

MCLK

GND

J117

Q106

U100

R186

R115

C608

U603

U601

GND

XM_MUTE

LRCK

DATA

GND

GND

BCK

GND

R203

R104

R102

C100

R101

D107

D108

C613

H4

TYPE FUSE !

U602

R608

Q606

IIS_RAT

DT_LNK

RST

R172

R173

C193

R116

J104

R180

C153

J109

J110

J111

R182

C116

C139

D102

RL101

R121

J103

C155

D101

R183

R181

C198

FMTX

FMRX

C196

C195

C179

LO

D103

Q101

R185

C156

R171

C140

C131

R122

RL102

C128

D104

C154

Q102

J107

R139

C165

R140

R193

R179

C166

R141

R110

R178

R169

C191

R194

R196

R195

R147

2007 C COYPRIGHT NAD ELECTRONICS

M4 MAIN BOARD VM1.0

U105

C112

R215

R135

C170

R214

Q110

R107

R192

R109

R191

Q109

C150

R111

R108

R190

Q111

R213

C177

C160

R200

R201

R118

Q105

U115

C161

C162

C164

D110

D109

J606

C611

L600

Version select: C version

put the jumper on those designator marked as 230V

Version select: AH version

put the jumper on those designator marked as 120V

C617

Q605

Q603

R610

R611

Q604

R609

C618

DT_REV

XMRX

XMTX

5V3

GND

3V3

5V3

J101

R100

R114

C180

U111

R205

Y102

C121

R206

R113

R117

R174

C178

C172

C173

C141

U117

R220

J112

C194

D601

D600

F600 230V : T250mAL/250V

F606

F600

C605

JP601

JP603

JP600

JP602

120V : T500mAL/250V

230V

120V

120V

C614

C615

C604 C603

C181

U118

C182

C183

C175

U119

R198

R202

C168

TPG6

R212

R209

J100

J106

C602

C601

R211

R216

R620

R619

R618

R617

J604

J602

R127

R168

230V

ATTENTION:

UTILISER UN FUSIBLE DE

RECHANGE DE

MEME TYPE

ET CALIBRE !

TOP BOTTOM

R606

R607

D602

J605

R621

R622

R146

R123

Q103

R130

Q104

R131

Q107

C174

J105

J603

5V

5V

GND

KEY_CLK

GND

KEY_DATA

GND

KEY_EN

GND

GND

GND

KEYB5

KEYB4

KEYB3

KEYB2

KEYB1

GND

IR

GND

GND

R207

R208

R210

R132

R165

R133

R166

R134

C171

R167

U109

3-12

Page 24

PRINTED CIRCUIT DIAGRAMS

2. FRONT PANEL BOARD

TOP BOTTOM

TUNE+

S312

S311

PRESET+

S309

S310

D306

C312

D307

R330

S307

ENTER

TUNE-

M4 FPP BOARD VM1.0

2007 C COYPRIGHT NAD ELECTRONICS

PRESET-

S308

MEMORY

INFO

S306

S305

DIMMER

S303

BLEND

S301

MENU/FM MUTE

S304

AUTO TUNE

BAND

U301

U300

R329

C311

D304

D305

C300

R308

R300

R301

Q300

R309

Q302

R316

R315

C303

C302

R327

C309

C307

D303

R328

C301

U303

5V

5V

GND

KEY_CLK

GND

KEY_DATA

GND

KEY_EN

GND

GND

GND

KEYB5

KEYB4

KEYB3

KEYB2

KEYB1

R310

GND

IR

GND

GND

Q301

R311

Q303

D300

POWER

S302

C310

D302

R325

Q307

R326

R324

D301

C304

U302

C305

C306

R321

R322

R314

Q306

R313

R318

Q305

R320

R319

R323

Q304

R317

R306

R305

R304

R303

J300

S300

R302

3-13

Page 25

PRINTED CIRCUIT DIAGRAMS

3. DAB BOARD (C VERSION ONLY)

2007 C COYPRIGHT NAD ELECTRONICS

M4 DAB BOARD VM1.0

TOP BOTTOM

C406

C411

GND

RO

LO

RX

GND

GND

TX

SPD

5V3

5V3

R422

R427

J401

R400

J404

R435

R436

C403

R418

U404

R417

R411

R432

R433

R428

C429

L400

C415

C414

C418

R403

C413

C412

C419

C417

U400

Q400

C416

R414

R416

R412

R408

R407

R413

R415

C422

U401

R434

R404

R409

R410

R406

R405

R426

R425

R424

R423

C405

R419

C404

D400

D401

C409

C421

C407

U402

R421

C408

U403

R420

R402

R430

R429

D402

C423

MS0122C

T103

C410

C420

J403

5V3

GND

UN_LOCK

RST

GND

GND

GND

DAB_RX

DAB_TX

3V3

5V3

GND

GND

MCLK

GND

LRCK

DATA

BCK

GND

GND

R431

3-14

Page 26

PRINTED CIRCUIT DIAGRAMS

3. XM BOARD (AH VERSION ONLY)

TOP BOTTOM

C509

C522

C523

R543

R530

R531

C508

C507

R533

R532

D502

D504

C519

R536

C501

C517

C502

R537

C518

C516

R512

R513

R500

R510

R507

R514

R501

R511

C500

R541

R508

R515

R509

D505

D506

C505

J502

D501

D503

C506

D500

J500

RST

GND

TXEN

XMTX

LINK

XMRX

3V3

5V3

J501

3V3

5V3

RST

5V3

GND

XMTX

C521

R540

R539

BCK

GND

GND

GND

GND

DT_LNK

C520

U502

GND

MCLK

LRCK

DATA

XM_MUTE

Y500

C510

R528

C515

R529

R506

R521

R524

R523

R522

M4 XM BOARD VM1.0

U501

C504

C503

R535

2007 C COYPRIGHT NAD ELECTRONICS

R504

R505

C511

R534

C514

R525

R503

R542

U500

C512

C513

R527

R502

R517

R520

R526

R516

R519

R518

XMRX

DT_REV

IIS_RAT

3-15

Page 27

PRINTED CIRCUIT DIAGRAMS

4. AM FM TUNER BOARD AH & C

3-16

Page 28

SECTION 4 REPLACEMENT PARTS LIST

MODEL: M4 C/AH(NAD)

RUN DATE:HS40-M4_B17VM1.8

0 00-50400-10 AH VERSION 1

0 00-50400-20 C VERSION 1

.1 01-50401-10 MAIN BOARD AH 1

.1 01-50401-20 MAIN BOARD C 1

..2

PCB

...3 1mm051×mm391 ,mm6.1 ,4-RFBCP NIAM12-10405-61A

DIODE

...3 33-40352-01 DIODE 1SS352 D105, D106, D107, D108, D109, D110 SOD-323 6

...3 343LL406D,401D ,301D8414LLedoiD hctiwS11-84144-33

...3 243LL201D ,101DW2/1 ,V4.2DMS edoiD reneZ10-90421-33

TRANSISTOR

...3 432-TOS111Q ,901Q ,201Q ,101Q5181CS2rotsisnarT10-51810-13

...3 132-TOS511Q5101AS2rotsisnarT10-51010-13

...3 31-00114-05 Transistor DTC114EKA Q100, Q105,Q113,Q103, Q104, Q107 SOT-23 6

...3 132-TOS211QAKE411ATDrotsisnarT10-41100-13

...3 295CS411Q,011Q A6233CS2SNART NPN10-62330-13J

ICS

...3 18OS211UA61CL42MORPEE20-61420-30

...3 146POSS711UPHAF18203MUCM01-18203-30

....4 146POSSPHAF18203MUCM10-18203-30J

...3 15-32TOS911UTVBD33-5283SPTTESER33-52830-30

...3 28OS801U ,701UAU4312APOpmapO00-43120-30J

...3 28OS601U ,501UZSG572POpmapO10-57200-30J

...3 03-01117-33 Regulator LM1117MPX-3.3/AMS1117-3.3 U102, U118 SOT223 2

...3 1322-TOS011U0.5-XPM7111MLrotalugeR11-71110-30

...3 03-02011-01

...3 207CS411U ,301UX6P61ZW7CNreffuB latcO10-61700-30

...3 03-00244-05

...3 03-00244-01 Octal Buffer

...3 J03-01796-01

...3 161POSST531U WP5213Q3BC47NSHCTIWS SUB10-52130-30

...3 161POSS511UEAC1223XAM/RBDC1223XAMREVIECER 232SR20-12230-30J

Capacitor

...3 26-20051-00

...3 26-10151-00

...3 26-10351-00

...3 26-22351-00

...3 26-10451-00

...3 26-22051-01

...3 26-10151-11

...3 06-10011-11

...3 27-10011-00

...3 06-22060-02

RESISTOR

...3 07-90000-00 Chip Resistor 0603,0Ω 33

...3 07-90479-00 Chip Resistor 0603,4.7Ω 23060912R,712R%5± ,

...3 07-90100-00 Chip Resistor 0603,10Ω, ±5% R178, R179 , R202, R147 0603 4

...3 07-90330-00 Chip Resistor 0603,33Ω, ±5%

...3 07-90101-00 Chip Resistor 0603,100Ω, ±5%

...3 07-90331-00 Chip Resistor 0603,330Ω 33

...3 07-90102-00 Chip Resistor 0603,1KΩ, ±5% R187, R188, R602, R603, 0603 4

02-50401-00 MAIN BOARD SMT 1

POWER-

DISTRIBUTION

Octal Buffer

Digital to analog

convertor

Ceramic Chip

Capacitor

Ceramic Chip

Capacitor

Ceramic Chip

Capacitor

Ceramic Chip

Capacitor

Ceramic Chip

Capacitor

Ceramic Chip

Capacitor

Low ESL Feed

Through

Chip Tantalum

Electrolytic Capacitor

Chip Tantalum

Electrolytic Capacitor

Chip Tantalum

Electrolytic Capacitor

MM74HCT244WM/MC74HCT24

4ADW/M74HCT244M/SN74HCT

74LCX244WM/MC74LCX244DW

Through,0805,X5R,100p,50V,Ta

244DWR

/SN74LVC244ADW

100pF, 50V, ±5%, NPO C116, C198, C629,C155, C156

10nF, 50V, ±10%, X7R C153, C154, C165, C610,C166 0603-CAP 5

22nF, 50V, ±10%, X7R C104, C193, C179 0603-CAP 3

C100, C101, C102, C103, C106,C110, C111,

C112, C113, C114,C115, C117, C118, C119,

100nF, 50V, ±20%, Y5V

EMI100p Low ESL Feed

pe

10uF/10V, ±20%

C120,C121, C141, C142,C146 C150,

C151,C160, C161, C162, C163, C164,C168,

C171, C175, C180, C183,C191, C197, C199,

C170,C174

C195, C196 CKD510

C123, C126,C143 C144, C145, C177, C178,

C181, C182, C122

R132, R133,R134, R207, R208, R209, R210,

R211, R105, R172, R173, R115, R186, R206,

R212, R138,R198

R100, R101, R102, R104,R203,R200, R201,

R113, R192, R114, R116, R117, R174, R199,

R214,R215

0603-CAP

0603-CAP

3216A 10

0603 17

0603 16

060211R ,601R ,612R %5± ,

060691R ,591R ,391R%5± ,

ytQtnirptooFrotangiseDepyT traPnoitpircseDN/P PCL

18CIOS111UD1102SPT

102CIOS901U

102CIOS001U

1 82POSS401UBD6971MCP

2PAC-3060371C ,271COPN ,%5± ,V05 ,Fp02

5

36

2PAC-5080831C ,731COPN ,%5± ,V05 ,Fp22

2

1B8253741C%02± ,V61/Fu01

2A6123521C ,421C%02± ,V3.6/Fu22

Page 29

...3 07-90332-00 Chip Resistor 0603,3.3KΩ, ±5% R165, R166, R167, R169 0603 4

...3 07-90472-00 Chip Resistor 0603,4.7KΩ, ±5%

...3 07-90103-00 Chip Resistor 0603,10KΩ, ±5%

...3 07-90473-00 Chip Resistor 0603,47KΩ, ±5% R190, R191, R124, R126, R135, R168, R220 0603 7

...3 07-90104-00 Chip Resistor 0603,100KΩ 23060402R ,721R%5± ,

...3 13060502R%5± ,GEM1,3060rotsiseR pihC00-50109-70

...3 07-90000-01 Chip Resistor 0805,0Ω 25080581R ,481R%5± ,

...3 07-90100-01

...3 07-92000-01 Chip Resistor 0805,200Ω 15

...3 07-90101-01 Chip Resistor 0805,100Ω 25080171R ,071R%5± ,

...3 07-93300-01 Chip Resistor 0805,330Ω, ±1% R157, R158, R159, R160 0805 4

...3 07-93600-01 Chip Resistor 0805,360Ω, ±1% R149, R150, R151, R152 0805 4

...3 07-96200-01 Chip Resistor 0805,620Ω, ±1% R153, R154, R155, R156 0805 4

...3 07-96490-01

...3 07-98200-01 Chip Resistor 0805,820Ω, ±1% R143, R144, R145, R148 0805 4

...3 07-90102-01 Chip Resistor 0805,1KΩ 25080221R ,121R%5± ,

...3 07-93301-01 Chip Resistor 0805,3.3KΩ, ±1% R161, R162, R163, R164 0805 4

...3 07-90223-01 Chip Resistor 0805,22KΩ 25080671R ,571R%5± ,

...3 07-90279-02 Chip Resistor 2.7Ω 26021981R ,641R%5± ,

...3 07-90100-02 Chip Resistor 10Ω 16021771R %5± ,

CONNECTOR

...3 2mm0.1*02DMS501J ,101JBP02-9-0.1DMS rotcennoC CPF10-02012-31

...3 711JBP51-9-0.1DMS rotcennoC CPF00-51012-31

Chip Resistor 0805,10Ω 15080312R%5± ,

Chip Resistor

0805,649Ω 15080006R%1± ,

R107, R108, R109, R110, R111, R118, R125,

R180, R181, R182, R183, R136, R137,R218

R139, R140,R141, R142, R194,R103, R119,

R120, R129

0603 14

0603 9

080106R%1± ,

SMD15*1.0mm

W

ytQtnirptooFrotangiseDepyT traPnoitpircseDN/P PCL

1

CRYSTAL

...3 1)2.3*5(DMS201YzHM234.81LATSYRC10-24811-40

RECTIFIER BRIDGE

..2 34PID206D ,106D ,006D401BDegdirB reifitceR00-24103-33

TRANSISTOR

..2 31-01015-00

..2 329-OT606Q ,406Q ,006QRG-5181CS2rotsisnarT00-51810-13

..2 1DOM621-OT206QUTSYA0221ASKrotsisnarT00-02210-13

..2 1DOM621-OT106QUTSYA0962CSKrotsisnarT00-09620-13

ICS

..2 129-OT206U134AK/134EA/134LTrotalugeRCI00-13400-30

..2 1022-OT306UT713MLrotalugeR00-71300-30

..2 1022-OT106UTC5087MLrotalugeR00-50870-30

RESISTOR

..2 07-20101-50 Metal Film Resistor 100Ω 1

..2 07-20121-50 Metal Film Resistor 120Ω 2

..2 07-21101-50 Metal Film Resistor

..2 07-22001-50 Metal Film Resistor 2kΩ 1mm5.7=hctiP616R%1± ,W6/1 ,

..2 07-22211-50 Metal Film Resistor 2.21kΩ 1

..2 07-24991-50 Metal Film Resistor 4.99kΩ 1mm5.7=hctiP216R%1± ,W6/1 ,

..2 07-20822-50 Metal Film Resistor 8.2kΩ 2mm5.7=hctiP116R ,016R%5± ,W6/1 ,

..2 07-30229-03 Oxidized Film Resistor

..2 07-50338-00 Fusible Resistor 0.33Ω, 1/4W, ±10% R617, R618, R619, R620, R621, R622 Pitch=12.5mm 6

..2 21-06000-00

Capacitor

..2 A25-10322-04 Polyester Capacitors MKP64,X1,Y2 ,10nF,275V, ±20% C611, C612 Pitch=10mm 2

..2 25-10461-07

..2 25-22461-02

..2 25-27261-01

..2 25-47261-01

..2 25-82261-00

..2 25-15312-01

..2 1mm5=hctiP726C%01± ,VK1 ,Fp74roticapaC cimareC 00-31074-50

..2 A05-47242-00

Transistor 2SA1015-GR Q106, Q603, Q605, Q607 TO-92

1.1k¡, 1/6W, ±1%

R606, R607 Pitch=12.5mm

C:JP600, JP601

AH:JP602, JP603

C620

C600, C628 Pitch=10mm 2

Jumper L=5mm

Metallized Polyester

Film Capacitor

Metallized Polyester

Film Capacitor

Metallized polystyrene

Film Capacitor

Metallized polystyrene

Film Capacitor

Metallized polystyrene

Film Capacitor

Metallized polystyrene

Film Capacitor

High Voltage Ceramic

Capacitor

4.7nF, 400V(X1),250V(Y1), ±20%

RY21S 2.2¡, 2W, ±5%

CL23B,100nF, 63V, ±5%

CL23B,220nF, 63V, ±5% C108, C109, C601, C602, C603, C604 Pitch=5mm 6

ASS21A,2.7nF, 63V, ±5% C131, C132, C135, C136 Pitch=3.2mm 4

ASS21A,4.7nF, 63V, ±5% C127, C128, C133, C134 Pitch=3.2mm 4

ASS21A,8.2nF, 63V, ±5% C139, C140 Pitch=3.2mm 2

CBB11,15nF, 100V, ±5% C129, C130 Pitch=4.5mm 2

C631, C606, C607, C616, C617,C618, C619,

mm5.7=hctiP416R%5± ,W6/1 ,

mm5.7=hctiP906R ,806R%5± ,W6/1 ,

mm5.7=hctiP516R%1± ,W6/1 ,

L=5mm 2

Pitch=5mm 8

4

1mm5.7=hctiP316R

2

Page 30

..2 06-10051-03

..2 06-22051-01

..2 06-47011-08

..2 06-10111-00

..2 06-22221-01

..2 06-33211-01

RELAY

..2 23DFH201LR ,101LRV5 3DFHYALER LANGIS01-20220-21

..2 1006KV5 V052/A51 U1HDYALER REWOP10-10120-21A

Inductor

..2 1006LA2,5.01-FU,Hm01ROTCUDNI RETLIF20-52000-22

CONNECTOR

..2 2mm5.2=S601J ,001J45.2 ,NIP2rotcennoC00-20521-31

..2 1mm5.2=S701JNIP2rotcennoC00-20522-31

..2 1mm5.2=S106JNIP8rotcennoC00-80522-31

..2 1mm5.2=S201JNIP3rotcennoC00-30522-31

..2 1mm9.3=S506JHV-P5BrotcennoC03-50932-31

..2 1mm9.3=S306JHV-P2BrotcennoC03-20932-31

..2 1mm29.7=S006JHV A2-A29.7rotcennoC10-30932-31JG

..2 2mm29.7=S406J ,206JHV A3-A29.7rotcennoC10-50932-31JG

..2 1606JNIP2 09103-R/1.0059.1PSGTELNI CA00-20170-71A

..2 1F/9BD111JSF/232SR 232SRtekcoS232SR00-90080-71

..2 2011J ,901JP3-20-5.3-XKC / 40-B323-TSkcaj enohp mm5.340-10020-71

..2 2011J ,901J10B0SX00P943JCSkcaj enohp mm5.330-10020-71ro

..2 1MACR401JDER,ACR GNOSNAHACR31-10010-71

..2 1MACR301JETIHW,ACR GNOSNAHACR21-10010-71

FUSE

..2 2DLOHESUF606F ,006F1-300-FHREDLOH ESUF10-00002-02A

..2 1:C006FV052/TAm052ESUF10-15221-02A

..2 1HA006FV052/TAm005ESUF00-10521-02A

..2 1:C606FV052/TAm005ESUF00-10521-02A

..2 1HA606FV052/TA1ESUF00-20121-02A

Alu Electrolytic

Capacitor

Alu Electrolytic

Capacitor

Alu Electrolytic

Capacitor

Alu Electrolytic

Capacitor

Alu Electrolytic

Capacitor

Alu Electrolytic

Capacitor

CD110,10uF, 50V, ±20% C608, C625, C626 Pitch=2.5mm 3

CD110,100uF, 16V, ±20% C609, C630, C623, C624 Pitch=5mm 4

CD263,2200UF/25V,±20% C614, C615 PITCH=7.5MM 2

CD263,3300UF/16V,±20%

16*25mm

C605, C613 PITCH=7.5MM

ytQtnirptooFrotangiseDepyT traPnoitpircseDN/P PCL

1mm5.2=hctiP491C%02± ,V05 ,Fu22,011DC

2MM5.2=HCTIP701C ,501CV61/FU74,A11DC

2

MECHANICAL PARTS

..2 2)2(TELNI CA6×3BTBswercS gnipaT fleS0-602320-16

..2 20962CSK ,0221ASK52Fknis taeH0-100400-07

..2 25087ML ,713MLD knistaeHknis taeH0-510840-07

..2 78-001001-0 Sleeve Boot 811810-23 2

..2 25

..2 20962CSK ,0221ASK8×3BTBWERCS0-802320-16

.1 01-50402-00

..2 02-50402-00 FPP BOARD SMT

PCB

...3 1mm85×mm033 ,mm6.1 ,4-RFBCP PPF12-20405-61A

DIODE

...3 45080D703D ,603D ,503D ,403D253SS1EDOID10-25304-33

...3 3FLEMINIM303D ,203D ,103D8414LLedoiD hctiwS11-84144-33

TRANSISTORS

...3 2A32-TOS103Q ,003Q5101AS2SNART PNP10-51010-13

...3 2A32-TOS303Q ,203Q5181CS2SNART NPN10-51810-13

...3 332-TOS603Q ,503Q ,403QAKE411CTDrotsisnarT50-41100-13

...3 195CS703QA6233CS2SNART NPN10-62330-13J

ICS

...3 261POSD303U ,203U4904DCRETSIGER20-49040-30

CAPACITORS

...3 26-10451-00

...3 26-22351-00

...3 06-10011-11

...3 06-10121-05

FPP BOARD

Ceramic Chip

Capacitor

Ceramic Chip

Capacitor

Chip Tantalum

Capacitor

Chip Alu Electrolytic

Capacitor

100nF, 50V, +80-20%, Y5V

C300, C301, C303, C304, C305, C309, C310 0603-CAP 7

087ML ,713ML6×3BTBswercS gnipaT fleS0-602320-16

2PAC-3060213C,113CV05,Kn22

2A6123703C ,203C%02± ,V01/Fu01

17.7×3.6603C%02± ,V52 ,Fu001

RESISTORS

Page 31

...3 07-90101-00 Chip Resistor 100Ω 33060033R ,923R ,723R%5± ,

...3 07-90000-00 Chip Resistor 0Ω 33060223R,023R ,913R%5± ,

...3 07-90103-00 Chip Resistor 10KΩ, ±5%

...3 07-91009-01 Chip Resistor 10Ω 15080823R%1± ,

...3 07-90271-01 Chip Resistor 270Ω 15080513R%5± ,

...3 07-90471-01 Chip Resistor 470Ω 15080613R%5± ,

R300, R301, R302, R303, R304, R305, R306,

R308, R309, R310, R311, R313, R314, R323,

R324, R325, R326

ytQtnirptooFrotangiseDepyT traPnoitpircseDN/P PCL

0603 17

CONNECTORS

...3 003JBWP02-9-0.1DMS rotcennoC CPF50-02012-31

DIODE

..2 33-50565-01

ICS

..2 J23-30202-00 VFD MODULE

..2 1003U4B8300SHREVIECER RI04-83000-30

SWITCH

..2 11-04101-08 Tact Switch IT-1103AA-1160

CONNECTORS

..2 1

MECHANICAL PARTS

..2 66-048002-0 IR Bracket

..2 61-023508-0 Machine Screw VFD(4) 4

..2 )4(DFVtuN-kcoL 3M1-203010-26 4

..2 )4(DFVrehsaW0-200400-68 4

.1 01-50403-20 C:1

PCB

...3 1mm021×mm031 ,mm6.1 ,4-RF BCP BAD12-30405-61A

Inductor

...3 1BF-5080004LHu01DMS rotcudnI20-00140-80

LED φ 10

20T202DA1˄J˅ REVE

S300, S301, S302, S303, S304, S305, S306,

S307, S308, S309, S310, S311, S312

WLQ

TMS00-30405-202.. C:1

03D5

SMD20*1.0mm

W

13

mm5.2=S103Umm8=L ,45.2 ,NIP41rotcennoC30-41521-31

1

1103U

1

DIODE

...3 25080D204D ,104D253SS1EDOID10-25304-33

...3 1FLEMINIM004DW2/1 ,V7.4DMS edoiD reneZ01-90741-33

TRANSISTOR

...3 132-TOS004QAKE411CTDrotsisnarT50-41100-13

...3 03-00125-06 Buffer SN74AHC1G125DCK U402, U403, U404 SSOT23DCK

...3 03-00244-01 Octal Buffer

...3 182POSST004UZZC-6148SCreviecer oidua latigiD20-61480-30J

Capacitor

...3 26-39051-00

...3 26-10251-10

...3 26-22351-00

…3 26-22351-01

...3 26-10451-00

...3 26-10351-01

...3 26-10451-01

...3 26-10451-30

...3 06-10011-11

Ceramic Chip

Capacitor

Ceramic Chip

Capacitor

Ceramic Chip

Capacitor

Ceramic Chip

Capacitor

Ceramic Chip

Capacitor

Ceramic Chip

Capacitor

Ceramic Chip

Capacitor

Ceramic Chip

Capacitor

Chip Tantalum

Electrolytic Capacitor

74LCX244, SOIC0.3inch,

Tube/Tape

100nF, 50V, +80-20%, Y5V

U401

C403, C404, C405, C406, C407, C408,C410,

C415, C416

SOIC/20P/P1.2

7/12.8X10.3/12

.8X7.5/2X.55

0603-CAP 9

3

1

1PAC-3060224COPN ,%5± ,V05 ,Fp93

2PAC-3060314C ,214COPN ,%5± ,V05 ,Fn1

2PAC-3060324C ,414CR7X ,%01± ,V05 ,Fn22

25080134R,034RR7X ,%01± ,V05 ,Fn22

25080914C ,814CR7X ,%01± V05 ,Fn01

15080904C%02-%08+,V05 ,Fn001

14X3060714CV5Y ,%5± ,V05 ,Fn001

3A6123024C ,114C ,124C%02± ,V01/Fu01

RESISTOR

...3 07-90000-00

...3 07-90330-00 Chip Resistor 33Ω 33060534R,334R,234R%5± ,

Chip Resistor 0Ω 23

060,724R ,404R%5± ,

Page 32

ytQtnirptooFrotangiseDepyT traPnoitpircseDN/P PCL

...3 07-90101-00 Chip Resistor 100Ω, ±5%

...3 07-90910-00 Chip Resistor 91Ω 13060124R%5± ,

...3 07-90331-00 Chip Resistor 330Ω 13060024R%5± ,

...3 07-93001-00 Chip Resistor 3KΩ 13060304R%1± ,

...3 07-90103-00 Chip Resistor 10KΩ 23060434R,824R%5± ,

...3 07-90473-00 Chip Resistor 47KΩ, ±5% R406, R411, R412, R413, R414, R415, R416 0603 7

...3 07-90101-02 Chip Resistor 100Ω 16021914R%5± ,

CONNECTOR

...3 304JBWP02-9-0.1DMS rotcennoC CPF50-02012-31

TRANSFORMER

...3 22-12204-01

ICS

..2 1004UELUDOM 1BAD DAN00-10405-73J

CONNECTOR

..2 1PID104JROTCENNOCmm2*01NOC00-01022-31

..2 1404JACR ,50-QG+VALACITPO+ACR30-10060-71

7UDQVIRUPHU

R407, R408, R409, R410, R423,R424, R425,

R426, R400, R418, R422, R402, R429

0603 13

SMD20*1.0mm

W

Mechanical Parts

..2 2)2(eludoM BAD21X4TMwercS enihcaM0-215440-16

..2 2)2(eludoM BAD4MtuN0-204010-26

..2 1)1(BCP BADtekcarB tfeL BCP0-300380-66

..2 1)1(BCP BADtekcarB thgiR BCP0-400380-66

..2 4)2(thgir BCP,)2(tfel BCP6×3BTSwercS gnipaT fleS0-601320-16

.1

PCB

...3 1mm021×mm031,mm6.1 ,4-RFBCP MX12-40405-61A

DIODE

...3 25080D605D ,505D253SS1EDOID10-25304-33

...3 4FLEMINIM405D ,305D ,205D ,105DW2/1 ,V7.4DMS edoiD reneZ01-90741-33

...3 1FLEMINIM005DW2/1 ,V3.6DMS edoiD reneZ01-90361-33

01-50404-10 AH:1

TMS00-40405-202.. AH:1

1

1RT GID301TLN1218SM

ICS

...3 107cs205UX6P61ZW7CNreffuB latcO10-61700-30

...3 03-00244-01 Octal Buffer

...3 1005U10-E8262F A4/B3 veR CITDMXCITDMX10-82620-30J

Capacitor

...3 26-20051-00

...3 26-39051-00

...3 26-22351-00

...3 26-10451-00

...3 26-10451-11

...3 06-10011-11

RESISTOR

...3 07-90000-00 Chip Resistor 0Ω 43060045R ,735R ,635R ,415R%5± ,

...3 07-90101-00 Chip Resistor 100Ω, ±5%

...3 07-90102-00 Chip Resistor 1KΩ 23060135R ,035R%5± ,

...3 07-90103-00 Chip Resistor 10KΩ, ±5% R500, R501, R502, R503, R504, R505, R506, 0603 7

...3 07-90223-00 Chip Resistor 22KΩ 33060115R ,015R ,905R%5± ,

...3 07-90473-00 Chip Resistor 47KΩ 43060925R ,825R ,725R ,625R%5± ,

...3 07-90104-00 Chip Resistor 100KΩ 23060805R ,705R%5± ,

...3 13060435R%5± ,GEM1rotsiseR pihC00-50109-70

Ceramic Chip

Capacitor

Ceramic Chip

Capacitor

Ceramic Chip

Capacitor

Ceramic Chip

Capacitor

Ceramic Chip

Capacitor

Chip Tantalum

Electrolytic Capacitor

74LCX244, SOIC0.3inch,

Tube/Tape

20pF, 50V, ±5%, NPO

100nF, 50V, +80-20%, Y5V

10uF/10V, ±20% C506, C507, C521, C522 3216A

C514, C515, C516, C517, C518, C519 0603-CAP 6

C500, C504, C505, C508, C509, C510, C511,

R512, R513, R515, R516, R517, R518, R519,

R520, R521, R522, R523, R524, R525, R532,

U501

C512, C513, C520

R533, R539, R541, R543

SOIC/20P/P1.2

7/12.8X10.3/12

.8X7.5/2X.55

PAC-3060305COPN ,%5± ,V05 ,Fp93

0603-CAP 10

0603

1

1

1PAC-3060325CR7X ,%01± ,V05 ,Fn22

25080205C ,105CR7X ,%01± V05 ,Fn001

4

18

CRYSTAL

...3 1DMS94005YzHM4851.54 LATSYRC00-21541-40

Page 33

ytQtnirptooFrotangiseDepyT traPnoitpircseDN/P PCL

CONNECTOR

...3 105JBWP02-9-0.1DMS rotcennoC CPF50-02012-31

SMD20*1.0mm

W

1

CONNECTOR

..2 1BSU INIM205J6451-130UMBSU INIM80-10080-71

Metal Parts

..2 1)1(BCP MXtekcarB tfeL BCP0-300380-66

..2 1)1(BCP MXtekcarB thgiR BCP0-400380-66