Page 1

NAD ELECTRONICS INTERNATIONAL

TORONTO

© NAD 2007

M15 C/AH

SURROUND

SOUND PREAMPLIFIER

SOUND PREAMPLIFIER

SURROUND

SERVICE MANUAL

M15 C/AH

02'(/ 06(59,&(0$18$/

SERVICE MANUAL

SOUND PREAMPLIFIER

SURROUND

M15 C/AH

Page 2

CONTENTS

SECTION 1 . . . .SUMMARY

SECTION 2 . . . .CABINET & MAIN CHASSIS

SECTION 3 . . . .ELECTRICAL

SECTION 4 . . . .REPLACEMENT PARTS LIST

SECTION 5 . . . .VERSION HISTORY

Page 3

SECTION 1

SUMMARY

CONTENTS

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO PRODUCTS

SERVICING PRECAUTIONS ........................................................................... 1-3

• General Servicing Precautions

• Insulation Checking Prodedure

• Electrostatically Sensitive Devices

ADJUSTMENT PROCEDURE .............................................................................

• OSD VCO Oscillation Frequency (VIDEO BOARD)

SPECIFICATIONS ........................................................................................... 1-5

............. 1-2

1-4

1-1

Page 4

PRODUCT SAFETY SERVICING GUIDELINES FOR AUDIO PRODUCTS

CAUTION : DO NOT ATTEMPT TO MODIFY THIS

PRODUCT IN ANY WAY, NEVER PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFACTURER’S

APPROVAL. UNAUTHORIZED MODIFICATIONS WILL

NOT ONLY VOID THE WARRANTY, BUT MAY LEAD TO

YOUR BEING LIABLE FOR ANY RESULTING PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY

AFTER YOU ARE THOROUGHLY FAMILIAR WITH ALL

OF THE FOLLOWING SAFETY CHECKS AND SERVICING GUIDELINES. TO DO OTHERWISE,INCREASES

THE RISK OF POTENTIAL HAZARDS AND INJURY TO

THE USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION FROM A.C. LINESHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS

BEEN CORRCTED. A CHECK SHOULD BE MADE OF

THE FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1.BE SURE THAT ALL COMPONENTS ARE POSI-

TIONED IN SUCH A WAY AS TO AVOID POSSIBILITY

OF ADJACENT COMPONENT SHORTS.THIS IS ESPECIALLY IMPORTANT ON THOSE MODULES WHICH

ARE TRANSPORTED TO AND FROM THE REPAIR

SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES SUCH AS INSULATORS, BARRIERS,

COVERS, SHIELDS, STRAIN RELIEFS, POWER

SUPPLY CORDS, AND OTHER HARDWARE HAVEBEEN REINSTALLED PER ORIGINAL DESIGN. BE

SURE THAT THE SAFETY PURPOSE OF THE POLARIZED LINE PLUG HAS NOT BEEN DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER

POSSIBLE COLD SOLDER JOINTS, SOLDER

SPLASHES OR SHARP SOLDER POINTS. BE CERTAIN TO REMOVE ALL LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE

OR DETERIORATION TO PARTS AND COMPONENTS.

FOR FRAYED LEADS, DAMAGED INSULATION

(INCLUDING A.C. CORD). AND REPLACE IF NECES-

5. NO LEAD OR COMPONENT SHOULD TOUCH A

RECIVING TUBE OR A RESISTOR RATED AT 1 WATT

OR MORE. LEAD TENSION AROUND PROTRUNING

METAL SURFACES MUST BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES,

FLAMEPROOF RESISTORS, CAPACITORS, ETC.

MUST BE REPLACED WITH EXACT FACTORY TYPES,

DO NOT USE REPLACEMENT COMPONENTS OTHER

THAN THOSE SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT MODIFICATIONS.

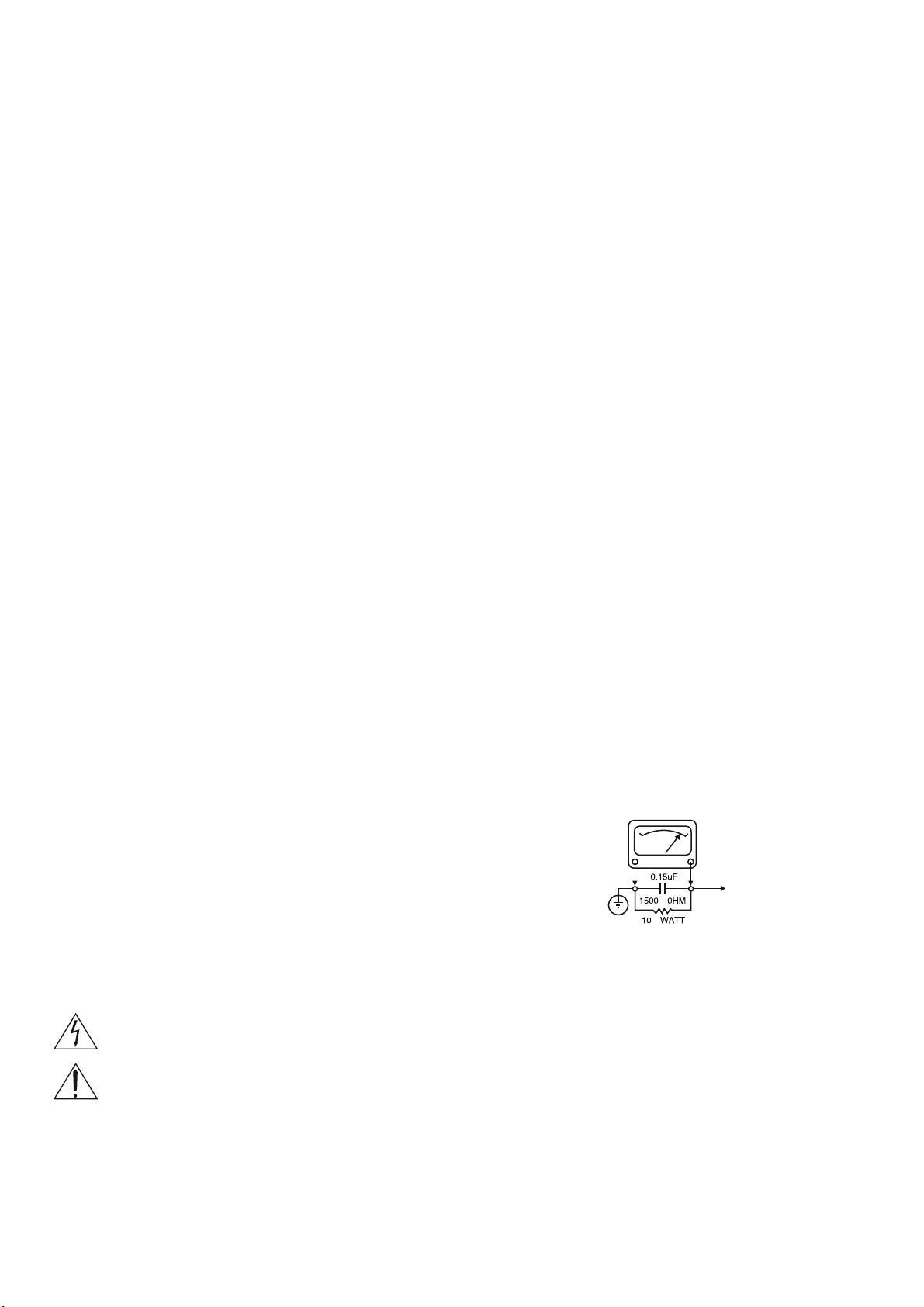

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN A.C. LEAKAGE TEST ON ALL EXPOSED

METALLIC PARTS OF THE CABINET, (THE CHANNEL

SELECTOR KNOB, ANTENNA TERMINALS. HANDLE

AND SCREWS) TO BE SURE THE SET IS SAFE TO

OPERATE WITHOUT DANGER OF ELECTRICAL

SHOCK. DO NOT USE A LINE ISOLATION TRANSFORMER DURING THIS TEST USE AN A.C. VOLTMETER, HAVING 5000 OHMS PER VOLT OR MORE SENSITIVITY, IN THE FOLLOWING MANNER; CONNECT A

1500 OHM 10 WATT RESISTOR, PARALLELED BY A

.15 MFD. 150.V A.C TYPE CAPACITOR BETWEEN A

KNOWN GOOD EARTH GROUND (WATER PIPE,

CONDUIT,ETC.) AND THE EXPOSED METALLIC

PARTS, ONE AT A TIME. MEASURE THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500OHM

RESISTOR AND .15 MFD CAPACITOR. REVERSE THE

A.C. PLUG AND REPEAT A.C. VOLTAGE MEASUREMENTS FOR EACH EXPOSED METALLIC PART. VOLTAGE MEASURED MUST NOT EXCEED 75 VOLTS

R.M.S. THIS CORRESPONDS TO 0.5 MILLIAMP A.C

ANY VALUE EXCEEDING THIS LIMIT CONSTITUTES A

POTENTIAL SHOCK HAZARD AND MUST BE CORRECTED IMMEDIATELY.

A.C. VOLTMETER

GOOD EARTH GROUND

SUCH AS THE WATER

PIPE. CONDUIT. ETC

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

SUBJECT: GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN AN EQUILATERAL TRIANGLE, IS INTENDED

TO ALERT THE SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED “DANGEROUS VOLTAGE”

THAT MAY BE OF SUFFICIENT MAGNITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE SERVICE

PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN SERVICE LITERATURE.

1-2

Page 5

SERVICING PRECAUTIONS

CAUTION: Before servicing the Surround sound preamplifier

covered by this service data and its supplements and addends,

read and follow the SAFETY PRECAUTIONS. NOTE: if

unforeseen circumstances create conflict between the following

servicing precautions and any of the safety precautions in this

publication, always follow the safety precautions. Remember

Safety First:

General Servicing Precautions

1. Always unplug the Surround sound preamplifier AC

power cord from the AC power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnecting or reconnecting any internal electrical plug

or other electrical connection.

(3) Connecting a test substitute in parallel with an electrolytic

capacitor.

Caution: A wrong part substitute or incorrect polarity

installation of electrolytic capacitors may result in an

explosion hazard.

2. Do not spray chemicals on or near this Surround sound

preamplifier or any of its assemblies.

3. Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner, cotton

tipped swab, or comparable soft applicator. Unless

specified otherwise in this service data, lubrication of

contacts is not required.

Electro statically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electro statically Sensitive (ES) Devices. Examples of

typical Es devices are integrated circuits and some field effect

transistors and semiconductor chip components. The

following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handing any semiconductor component

or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a commercially

available discharging wrist strap device, which should be

removed for potential shock reason prior to applying power

to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an antistatic solder removal device. Some solder

removal devices not classified a “anti-static” can generate

electrical charges sufficient to damage ES devices.

5. Do not use Freon propelled chemicals. These can generate

electrical charge sufficient to damage ES devices.

4. Do not defeat any plug/socket B+ voltage interlocks with

which instruments covered by this service manual might be

equipped.

5. Do not apply AC power to this Surround sound preamplifier

and/or any of its electrical assemblies unless all solid-state

device heat sinks are correctly installed.

6. Always connect test instrument ground lead to the

appropriate ground before connecting the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn the

power on. Connect an insulation resistance meter (500V) to the

blades of the attachment plug. The insulation resistances

between each blade of the attachment plug and accessible

conductive parts (Note 1) should be more than 1 M-ohm.

Note 1: Accessible Conductive Parts including Metal panels,

Input terminals, Earphone jacks, etc.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum

foil, or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution: Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handing unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static

electricity sufficient to damage an ES device.)

1-3

Page 6

ADJUSTMENT PROCEDURE

OSD VCO Oscillation Frequency (VIDEO BOARD)

Connect M15 CVBS monitor out to a TV set. Press “Enter” key on remote control to call OSD out.

Then clockwise adjust C1162 and observe the OSD till the characters are just disappear, record

the adjustment slot position A; then anticlockwise C1162 to make the OSD characters disappear

and record the adjustment slot position B again. Adjust the adjustment slot position in the middle

of A and B. Get in “DISPLAY SETUP” OSD Menu and switch the unit in both “NTSC” and PAL”

mode, observe the OSD characters, they should be all stable displaying without any flicker.

C1162

VIDEO BOARD

SOFTWARE VERSION:

TO DISPLAY SOFTWARE VERSIONS, PRESS FRONT PANEL video & audio SIMULTANEOUSLY

1-4

Page 7

SPECIFICATIONS

DECODING FORMATS

Dolby Digital, Dolby Digital EX, Dolby Pro Logic II, Dolby Pro Logic IIx, DTS, DTS ES,

DTS Neo:6, DTS 96/24, THX Surround EX, THX Ultra 2

SAMPLING RATES 32kHz, 44.1kHz, 48kHz, 88.2k, 96kHz

MODES EARS, Enhanced stereo, Mono

VIDEO (input and output impedance)

75Ω

THD + NOISE 0.002%

PRE-AMP SECTION LINE LEVEL INPUTS

Input impedance(R + C) 56KΩ/180PF

Frequency response(20Hz to 20KHZ) 20Hz to 20kHz @ +/-0.3dB

LINE LEVEL OUTPUTS

Output impedance 470Ω

Tape Source Z + 2kΩ

Signal/noise ratio >102dB

Maximum Output Level 6Vrms

Multiroom Output (Zone 2) 470Ω

TONE CONTROLS

Bass ±10dB@20Hz

Treble ±10dB@20kHz

Center Dialog ±6dB@1kHz

+12VOLT TRIGGER OUT

Output Voltage +12V +/- 20%

Minimum Output Current >40ma

Maximum Short Circuit Current <60mA

PHYSICAL SPECIFICATIONS

Operating temperature: 5 °C to 35 °C (41 °F to 95 °F)

Operating humidity: 5 % to 90 %

Dimensions (W x H x D) NET 17.13 x 5.24 x 13.98"(435 x 133 x 355mm)

Gross* 17.13 x 5.79 x 14.96”(435 x 147 x 380mm)

Net Weight 15 lbs

Shipping Weight 20 lbs

1-5

Page 8

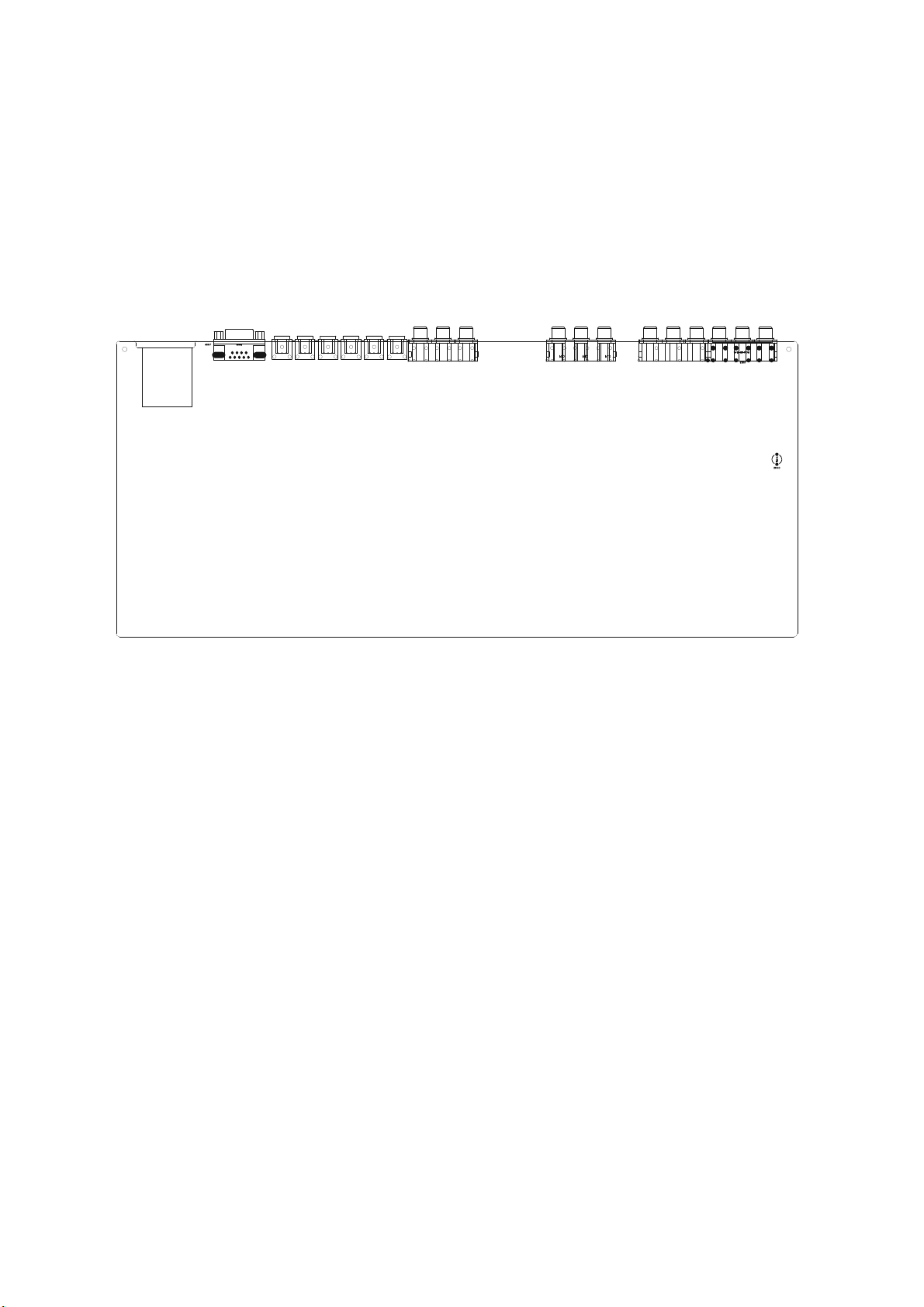

SECTION 2

CABINET & MAIN CHASSIS

CONTENTS

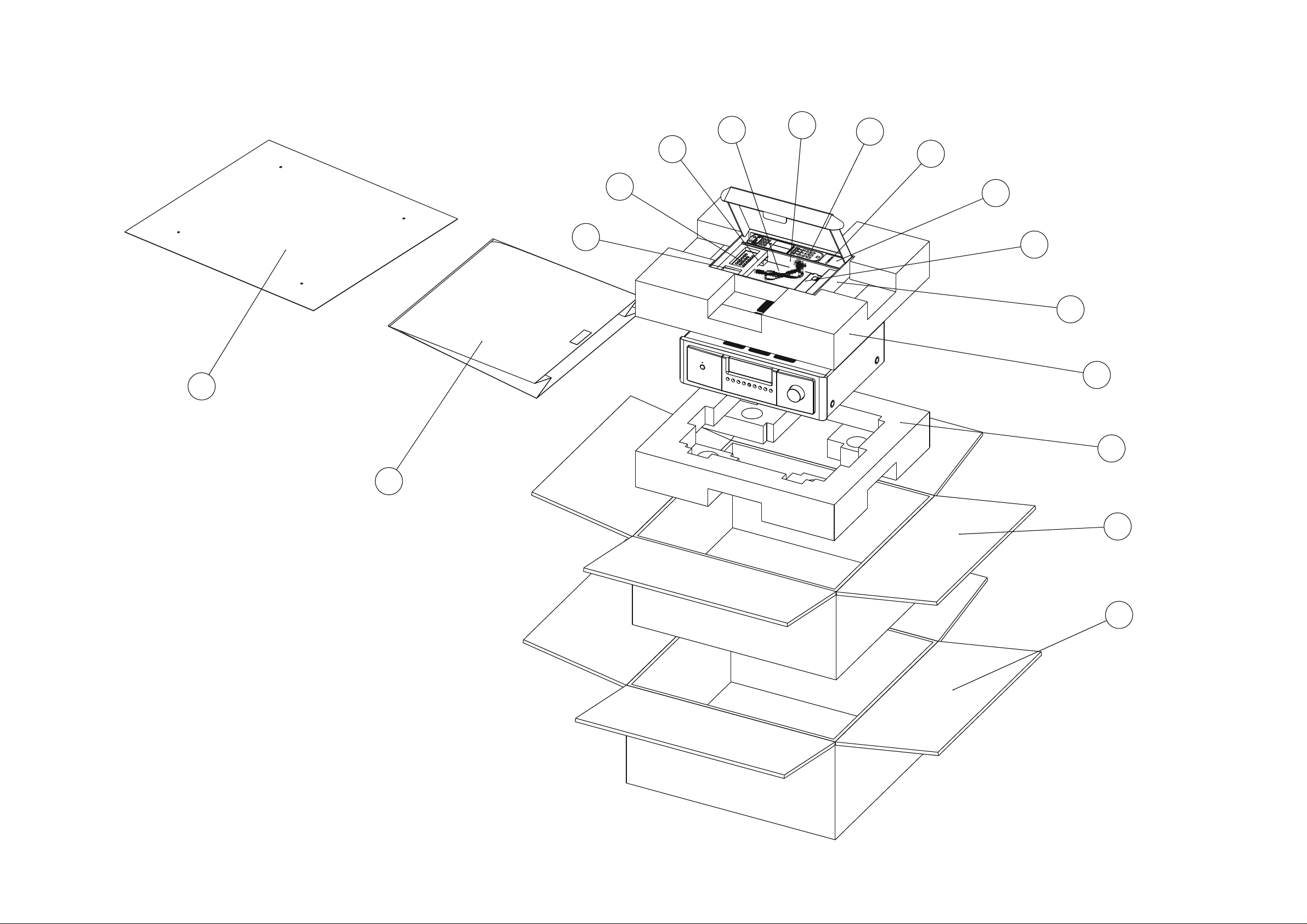

EXPLODED VIEWS.................................................................................. 2-2

1. Cabinet and main frame section...................................................................

2. Packing accessory section.............................................................................

3. Exploded view parts list................................................................................. 2-4

2-2

2-3

2-1

Page 9

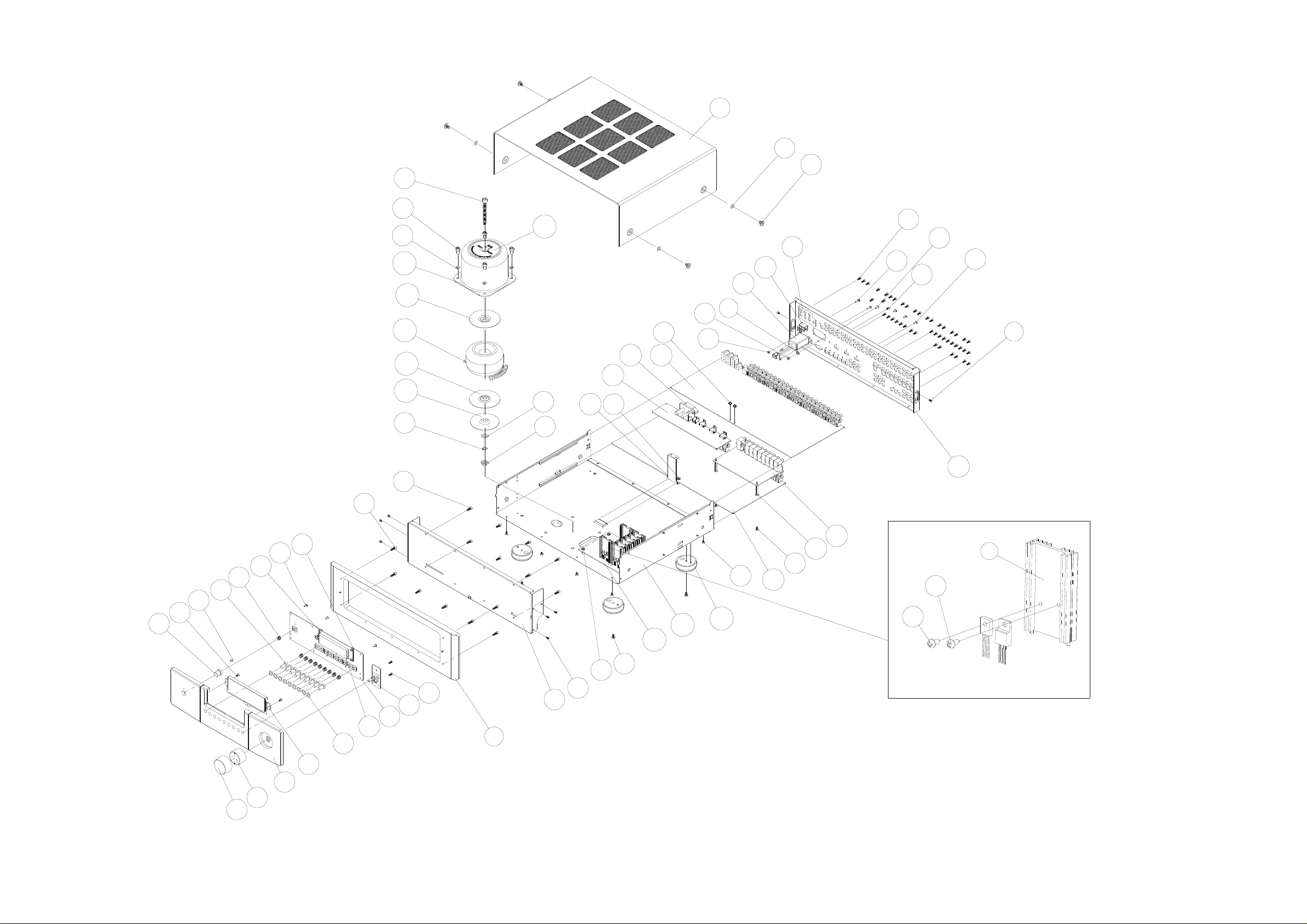

EXPLODED VIEW

1.Cabinet and mainframe section

NOTE: S009, S004, S005, S006, C004, C005, C006,

C007, & C008 are sold as one part number; 18-51512-00

S009

S008

S007

C007

C005

C006

C005

C004

C008

S006

R006

R003

S003

R008

S003

R002

S022

S021

T001

S023

R009

R010

T002

T003

S017

S015

S013

S018

S020

S019

S012

F009

S016

F011

F012

F013

S014

S013

S015

F010

S011

FP01

F004

S005

S010

F005

S013

F003

S004

F002

S012

S003

S001

C003

C001

C002

S002

R005

S013

R007

R001

R004

P01

S019

S002

(1:2)

F007

F006

F001

F008

2-2

Page 10

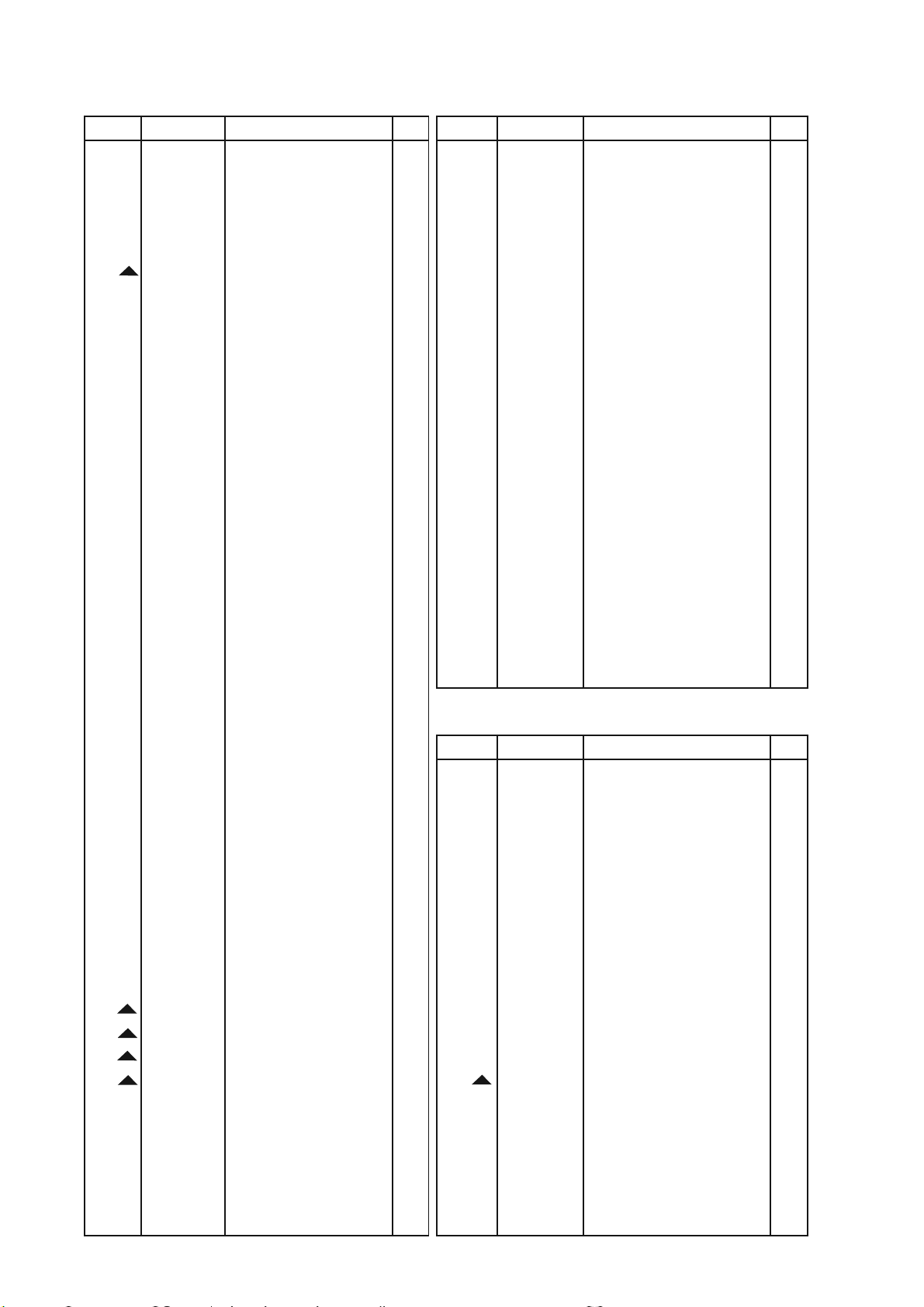

2.Packing accessory section

P016

P014

P013

P012

P011

P010

P009

P008

P007

P006

P005

P004

P015

P003

P002

P001

2-3

Page 11

3. EXPLODED VIEW PARTS LIST

REF.NO PART NO. DESCRIPTION Qty. REF.NO PART NO. DESCRIPTION Qty.

C001 67-043002-0 Chassis 1 S006 63-010816-0

C002 83-048010-0 Foot Assy 4 S007 63-020616-0

C003 01-51506-00 PSU Board 1 S008 61-226508-0 Hex Screws 6X8, 4

C004 66-001008-0 Metal Disc 1 S009 64-208060-1 Bolts GB/T70.1 M8X60 1

C005 Transformer rubber pad 2 S010 61-224508-1 Hex Screws GB/T70.1 4X8 8

!

C006 18-51512-00 Transformer 1 S011 61-224512-1 Hex Screws GB/T70.14X12 7

C007 67-043007-0 Shielding Box 1 S012 61-063106-0 Self Taping Screws STF3X6 8

C008 94-043001-0 Transformer label 1 S013 61-023208-0 Self Taping Screws BTB3X8 55

C009 75-043002-0 PCB Guide 4 S014 62-010302-1 M3 Lock-Nut 4

S015 61-023508-0 Machine Screws MB3X8 6

F001 70-043011-0 M15 Fascia 2 1 S016 61-023206-0 Self Taping Screws BTB3X6 3

F002 67-043003-1 Subfascia 1 S017 61-246508-0 Machine Screws M6X8 4

F003 70-043010-1 M15 Fascia 1 1 S018 61-024506-0 Machine Screws MB4X6 1

F004 01-51503-00 FPP Board 1 S019 61-023106-0 Self Taping Screws STB3X6 11

F005 01-51507-00 Encoder Board 1 S020 61-023506-0 Machine Screws MB3X6 3

F006 76-048010-0 Window lens 1 S021 62-010302-2 M3 Nut 2

F007 70-048014-0 Knob Skin 1 S022 62-010402-1 M4 Nut 1

F008 75-048020-0 Knob Core 1

F009 70-048013-0 Power Button 1

F010 87-048002-0 Button pad 9 S024 86-004002-0

F011 76-008001-0 LED Lens 1

F012 70-048012-1 Input Button 9 P01 70-043001-0 HEATSINK 03 8

F013 92-048001-0 Spring for Button 10

S023

40405-063-0404Spring Washer M4 1

Washers GB97-87 8

Spring Washers GB93 6

Washer 3X1

1

4

4

FP01 23-30202-00 VFD 1

PACKING PART LIST

REF.NO PART NO. DESCRIPTION Qty.

T001 67-043001-0 Top Cover 1

T002 76-046001-0 Screw W asher 4

T003 xx-xxxxxx-x Insulation sheet 1

R001 67-043004-1

R002 01-51502-00 AUD Board 1

R003 01-51505-20

R004 01-51504-00 CSS Board 1 30-45150-12 Instruction Manual 2 1

R005 00-51501-20

R006 67-043005-0 VID Bracket 1

R007 75-043003-0 PCB Spacer 2

!

R008 17-07002-12 AC-Output(AH only) 1

!

17-07002-20 AC-Output(C only) 1

!

R009 17-07003-03 AC Inlet 1 15-17251-20 AC cord ( C ) 1

!

R010 11-01101-03 Rocker Switch 1 15-17121-10 AC cord (AH) 1

S001 61-024108-0 Self Taping Screws STB4X8 4

S002 61-023108-0 Self Taping Screws STB3X8 16

S003 61-373506-0 Self Taping Screws M3X6 8

S004 62-010802-0 Nuts GB6170, M8 1

S005 63-020820-1

Rear Pane C

Multifunctional Board C

VID Board C

Spring Washers GB93 8

P001

P002

P003

1

P004

P005

1 30-45150-11 Instruction Manual 1 1

P006

1 30-45150-03 Instruction Manual (Chinese) 1

P007

P008

P009 HTRM

P010

P011

P015

P016

P012

P013

1

P014

88-043001-0 shipping box 1

88-043002-0 Gift box 1

89-043001-1 Polyfoam -Bottom 1

89-043002-1 Polyfoam-Cap 1

87-043003-0 Accessories box 1

89-043004-0 Accessories box polyfoam (A) 1

30-28601-00 Batteries 1

Remote control (HTRM) NSP 1

88-043004-0 Box sheet 1

!

15-86221-00 AC cord (BC) 1

87-043003-0 Non-woven bag 1

90-005001-0 Polybag 1

89-043003-0 Accessories box polyfoam (B) 1

30-11501-00 Remote control (ZR2) 1

30-25150-00 Batteries AA 4

2-4

Page 12

SECTION 3

ELECTRICAL CONTENTS

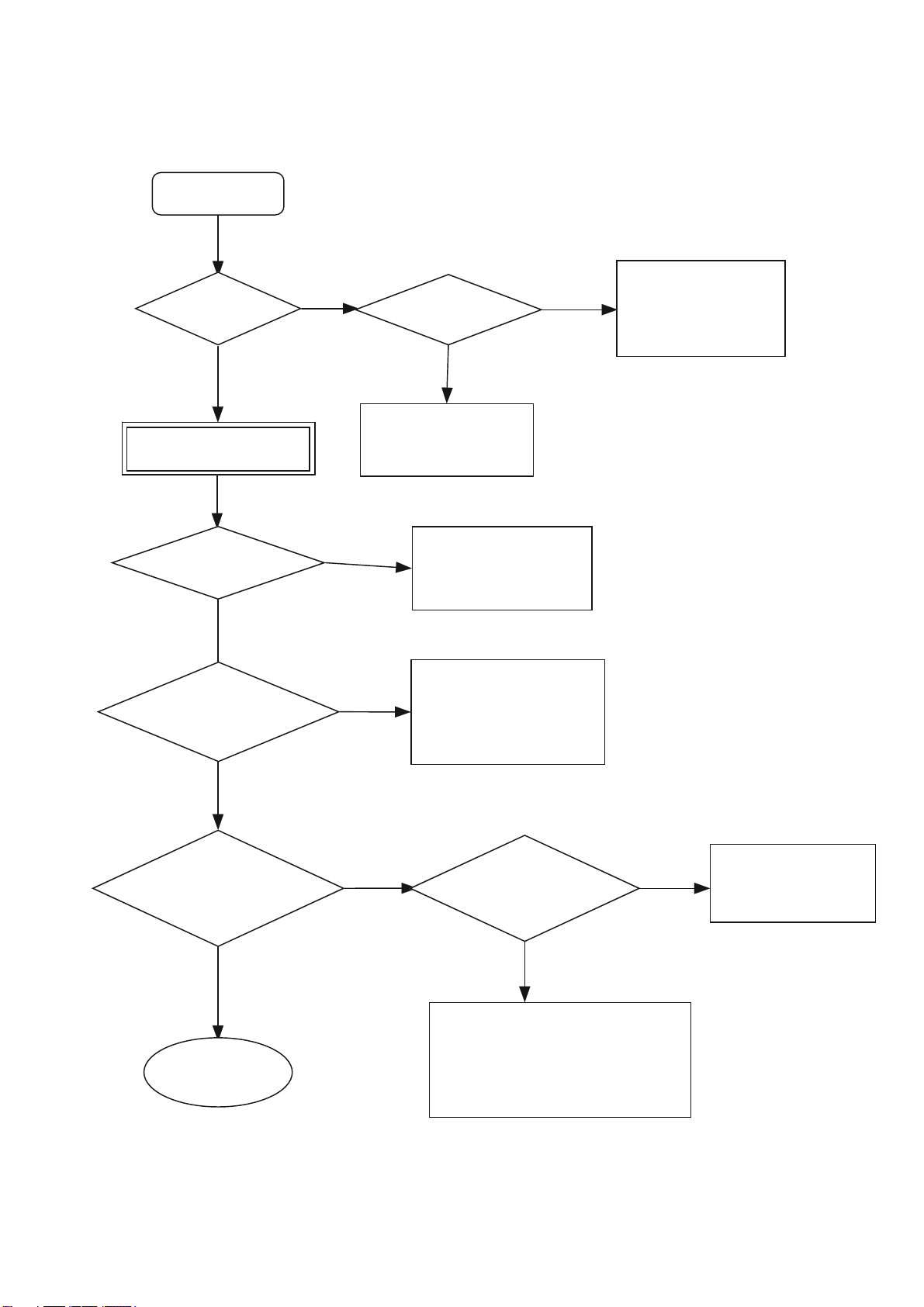

ELECTRICAL TROUBLESHOOTING GUIDE……………………………….3-2

1. Power check flow……………………………………………………………………….3-2,3

DETAILS AND WAVERORMS ON SYSTEM TEST AND DEBUGGING….3-4

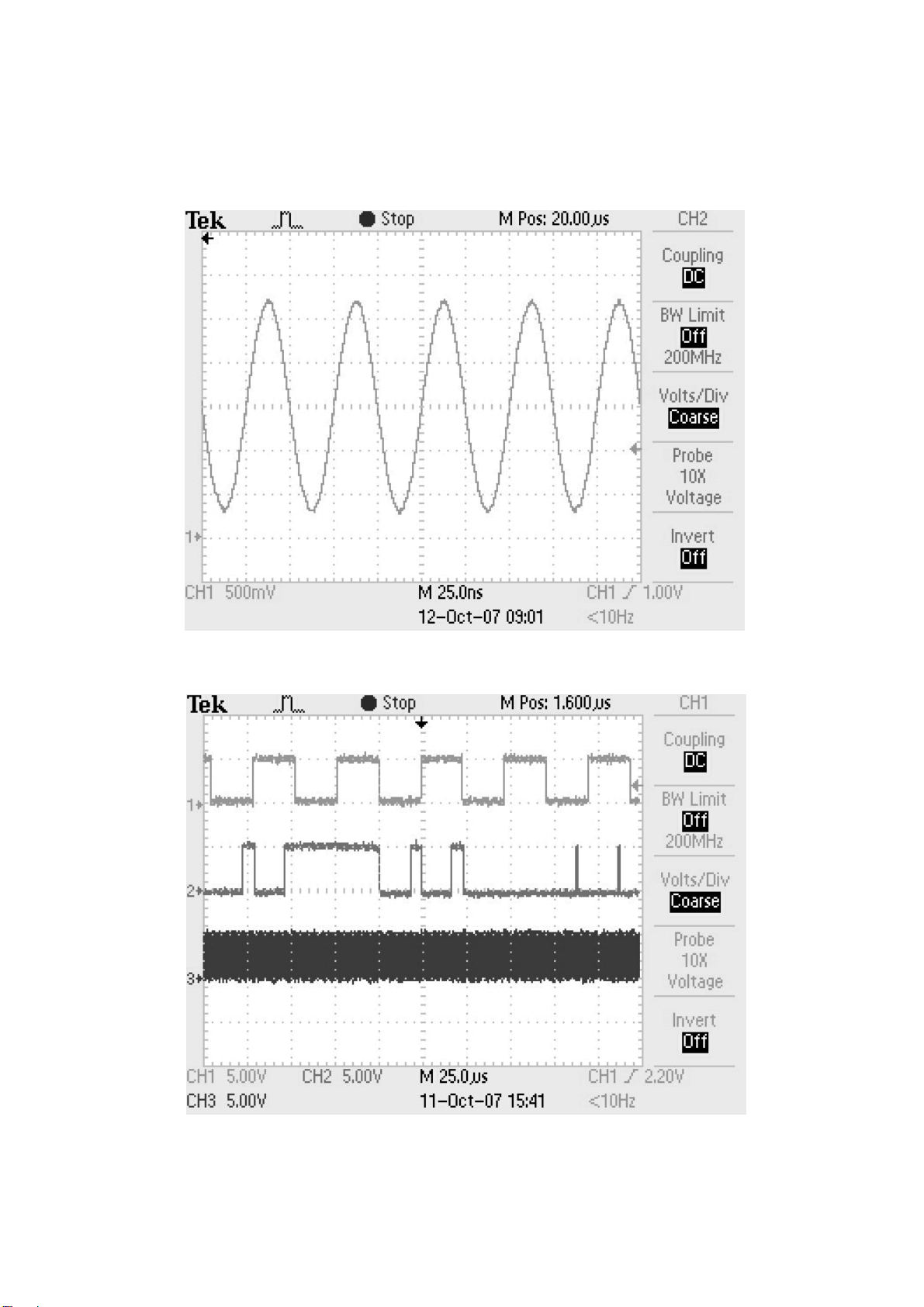

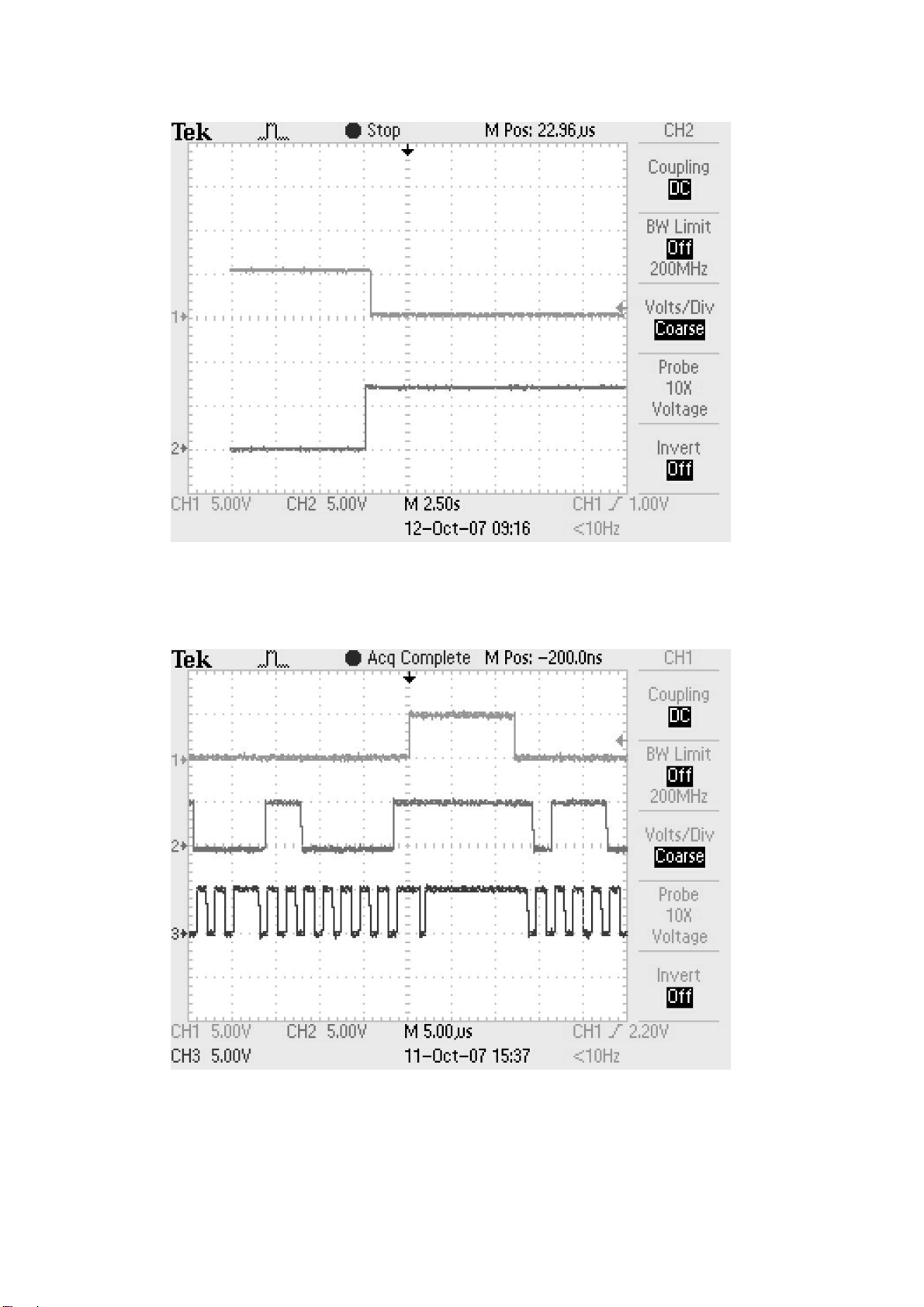

1.DSP clock 20MHz;Volume control STB, DATA and CLOCK…………………………3-4

2.AT89C51 reset is high active;WM8740 DAC STB,DATA and CLOCK……………...3-5

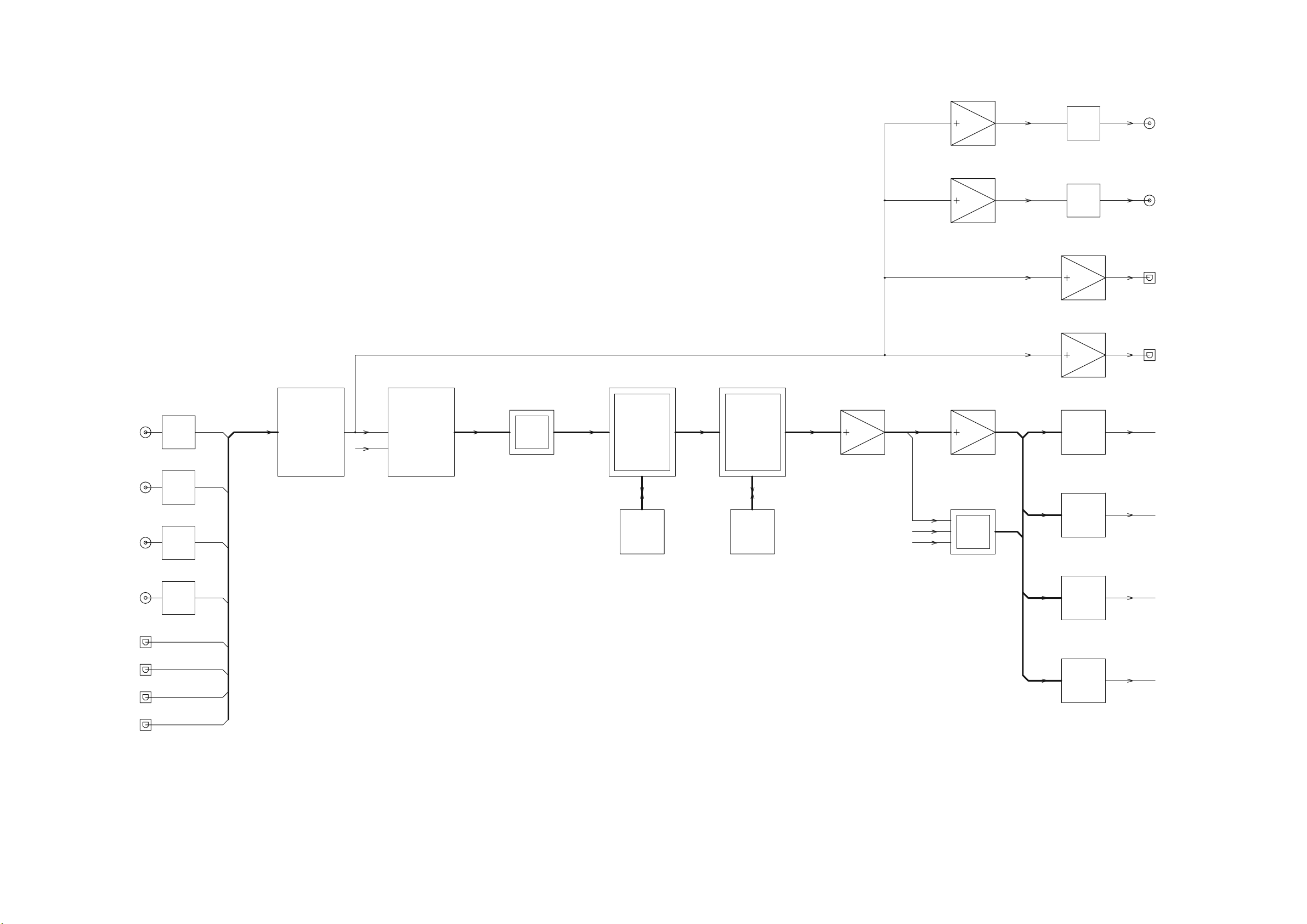

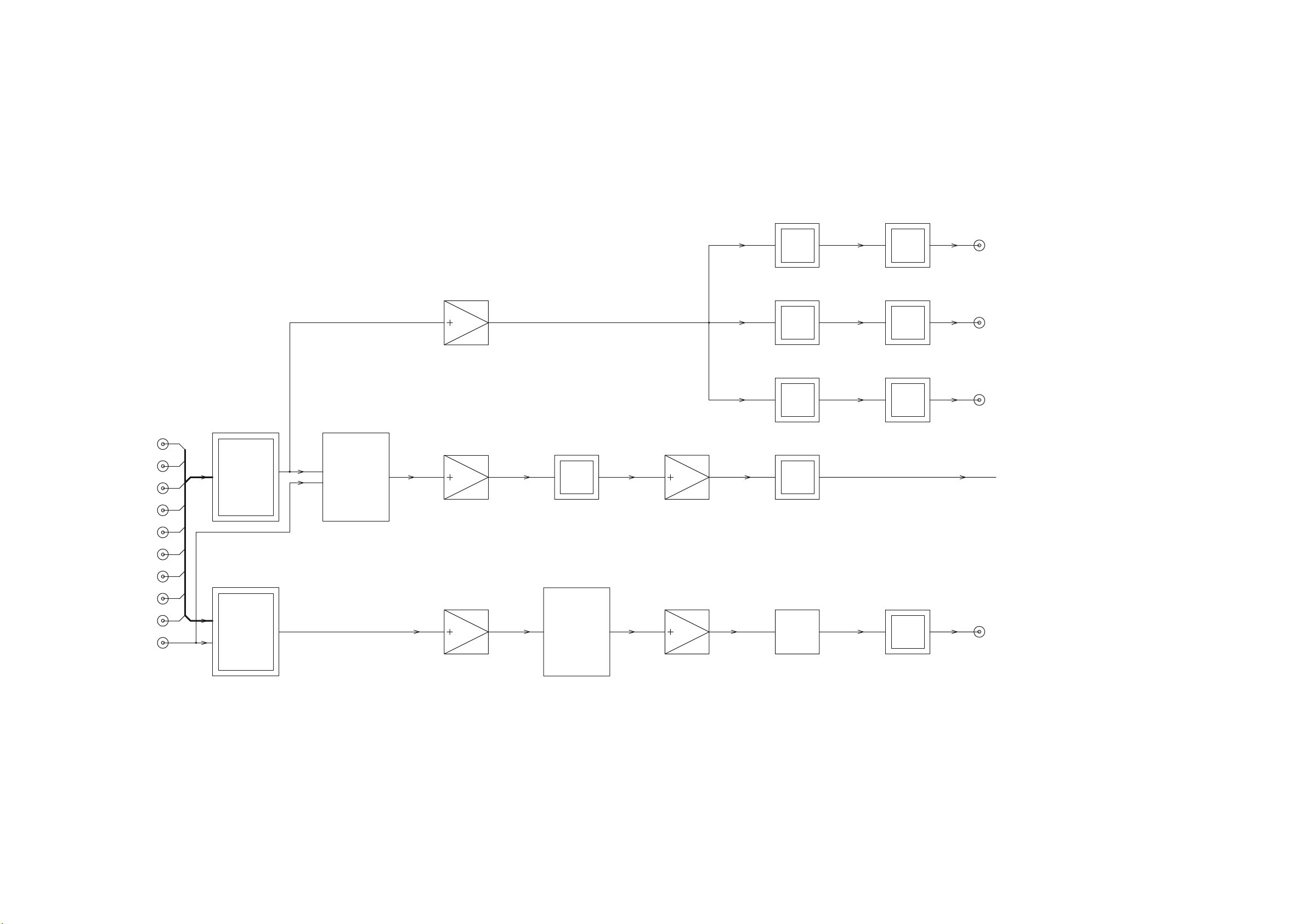

BLOCK DIAGRAMS…………………………………………………………….

1. Digital section…………………………………………………………………………...3-6

2. Analog input section……………………………………………………………………3-7

3. Volume and EXT.section/L/R/C/SW…………………………………………………..3-8

4. Volume and EXT.section/SL/SR/SBL/SBR…………………………………………..3-9

5. Component video………………………………………………………………………3-10

6. S video section…………………………………………………………………………3-11

7. Composite video……………………………………………………………………….3-12

3-6

WIRING DIAGRAM…………………………………………………………….3-13

1.Wiring diagram……………………………………………………………….3-13

CIRCUIT DIAGRAMS…………………………………………………………3-14

1. Power supply circuit diagram………………………………………………………..3-14

2. Front panel circuit diagram…………………………………………………………..3-15

3. HDMI circuit diagram…………………………………………………………………3-16

4. CSS circuit diagram…………………………………………………………………..3-17

5. Audio circuit diagram…………………………………………………………………3-18,19,20

6. Video circuit diagram…………………………………………………………………3-21,22,23

PRINTED CIRCUIT DIAGRAM…………………………………………………….3-24

1. PSU board…………………………………………………………………………….3-24

2. FPP board……………………………………………………………………………..3-25

3. HDMI board……………………………………………………………………………3-26

4. CSS board……………………………………………………………………………..3-27

5. Audio board……………………………………………………………………………3-28

6. Video board……………………………………………………………………………3-29

3-1

Page 13

ELECTRICAL TROUBLESHOOTING GUIDE

Power check flow

Power switch on

Amber LED

ON?

No

5vs is Right?

No

Check CON602

Check U611

Check D605

Check F609

Yes

No

Press the standby button

Blue LED ON?

Yes

12vt power

supply is correct?

Yes

No

Yes

Check Q312 , U302,U301 on

FPP board

Check Q303 , U302,U301 on

FPP board

Check U304

Check D608,F608

Check U304

Check D608,F608

-15Va,15Va power

supply is correct?

Yes

A

No

Q614 Base pole

is oV?

Yes

Check Q614 collector is 0v?

Check U606

Check D603

Check F603,F604

Check Q615,Q611,Q610

Check U607

3-2

No

Check Q311,U301,U302

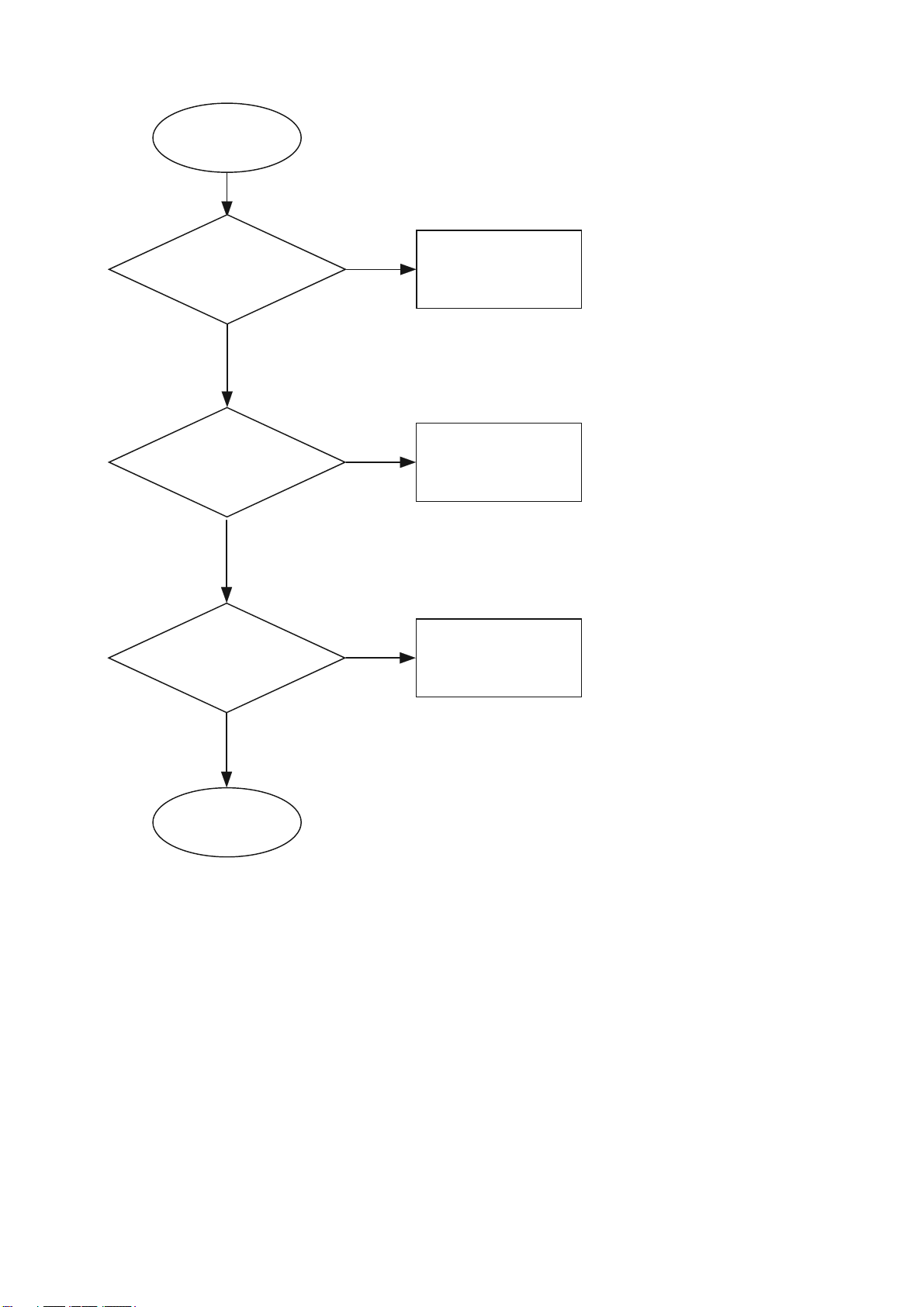

Page 14

A

Yes

5Vd power

supply is correct?

Yes

10vv,-5vv power

supply is correct?

Yes

8vd power supply

is correct?

No

No

No

Check U608 input supply

Check Q616,Q617

Check D604,F606

Check U603 input supply

Check Q686,Q684,Q682

Check D683,F681,F682

Check U604 input supply

Check Q609,Q607

Check D681,F605

Yes

End

3-3

Page 15

DETAILS AND WAVEFORMS ON SYSTEM TEST

AND DEBUGGING

1.DSP clock 20MHz

2.Volume control STB(CH1) , DATA(CH2) and CLOCK(CH3)

3-4

Page 16

3.AT89C51 RESET IS HIGH ACTIVE,STB(CH1),+5V(CH2)

4.WM8740 DAC STB(CH1) , DATA(CH2) AND CLOCK(CH3)

3-5

Page 17

BLOCK DIAGRAM

1.Digital Section

Digital Input

Input Transformer

T1000(12:18)

Coaxial Input1

Input Transformer

T1001(12:18)

Coaxial Input2

Input Transformer

T1002(12:18)

Coaxial Input3

Input Transformer

T1003(12:18)

Coaxial Input4

Input Selector

U1006(AK4114VQ)

From ADC

SPDIF

U1006(AK4114VQ)

SPDIF&HDMI Selector

U1032(74VHC244)

HDMI is not

active d in th is

version

Decoder DSP

U1018(DSPD56367)

Decode:

Dolb y Digit al(D.D )

Dolby PL2 Moive

Dolby PL2X

D.D EX

DTS

DTS-ES Matrix 6.1

DTS-ES Discrete 6.1

DTS NEO:6 Cinema

DTS NEO:6 Music

Other Mode

RAM

U1032(74VHC244)

Process DSP

U1900(DSPB56367)

THX

Bass Management

Delay

RAM

U1032(74VHC244)

Buffer

U1031(74ACT541)

SPDIF MCK

Local MCK

HDMI MCK

Buffer

U1033(74AC04)

Buffer

U1033(74AC04)

Buffer

U2047(74AC541)

MCK Selector

U2042(74AC153)

HDMI is not

active d in th is

version

Output Transformer

T1004(18:4)

Coaxial Output1

Output Transformer

T1005(18:4)

Coaxial Output2

Buffer

U1033(74AC04)

Optical Output1

Buffer

U1033(74AC04)

Optical Output2

DAC

U2055(WM8740)

to L/R DAC LPF

DAC

U2056(WM8740)

to C/SW DAC LPF

DAC

U2057(WM8740)

to SL/SR DAC LPF

Optical Input1

Optical Input2

Optical Input3

Optical Input4

DAC

U2058(WM8740)

to SBL/SBR DAC LPF

3-6

Page 18

2.Analog Input Section

Analog Input

0dB(200mVrms)

DVD

SAT

VCR

Video4

Input Selector

U2030-2031(TC9274F-001)

If select Digital input as

"NONE" on OSD Menu,

this signal will go through

DSP. Butitis noteffect

to VCR, Video4 and Tape

output

Tape Monitor Selector

U2030-2031(TC9274F-001)

Buffer

U2008(OPA2134)

Buffer

U2005(OPA2134)

0dB

0dB

0dB, -3dB, -6dB Attenuation

Q2008-2011(SC3326)

Select by OSD

Menu

ADC Input LPF(85KHz 2rd)

U2006-2007(OPA2134)

Mute

Q2013, Q2016(SC3326)

If select VCR

as Input,

0dB

disable the

output

Mute

Q2014, Q2017(SC3326)

If select

Video4as

Input, disable

the output

Mute

Q2012, Q2015(SC3326)

If select Tape

as Input,

disable the

output

ADC

U2041(AK5394A)

0dBfs=-1.4dB

Bd5.1-Bd0Bd0

Attenuation

R2191, R2194(2K)

0dB

Attenuation

R2192, R2195(2K)

0dB

Attenuation

R2193, R2196(2K)

0dB

If load is

10Kohms,

attenuation is

1.5dB

If load is

10Kohms,

attenuation is

1.5dB

If load is

10Kohms,

attenuation is

1.5dB

V3 Analog Output

-1.5dB

V4 Analog Output

0dB

-1.5dB

Tape Analog Output

Bd0Bd0

-1.5dB

To SPDIF

-20.1dBfs

Video5

Video6

CD

DISC

Tuner

Tape

MS Selector

U2030-2031(TC9274F-001)

Can be selected by MS

remote, use "LOCA L"

buttononMSremotemay

switch Main select and

local select

If use MSoutput, the user

need connect analog audio

to analog audio input

Buffer

U2009(OPA2134)

0dB

Volume

U2036(WM8816)

Output Buffer

U2010(OPA4134)

Bd0Bd0

Mute

Q2018-Q2021(SC3326)

Attenuation

R2226, R2227(220R) etc.

If load is

10Kohms,

0dB0dB

attenuation is

0.5dB

MS Analog Output

-0.5dB

3-7

Page 19

3.Volume and EXT. Section/L/R/C/SW

e

e

r

e

DAC LPF(55KHz 2rd Butterworth with 16.5dB gain)

U2013(OPA2134)

From DAC L

-20dBfs

Muti-Source Selector

U2059(TC9274N-008)

13dBr

)rBd5.2(Bd0)smrVm002(Bd0

Muti-Source Selector

U2059(TC9274N-008)

13dBr

)rBd5.2(Bd0)smrVm002(Bd0

L EXT. Input

R EXT. Input

is -32d Bfs if

without "SW"

From DAC R

-20dBfs

is -32d Bfs if

without"SW"

Buffer

U2011(OPA4134)

DAC LPF(55KHz 2rd Butterworth with 16.5dB gain)

U2014(OPA2134)

Buffer

U2011(OPA4134)

13dBr(DAC)

2.5dBr(EXT)

13dBr(DAC)

2.5dBr(EXT)

Buffer

U2021(OPA2134)

Buffer

U2021(OPA2134)

13dBr(DAC)

2.5dBr(EXT)

13dBr(DAC)

2.5dBr(EXT)

Volume

U2037(WM8816)

Reduce 12.5dB if input

from DAC and Compens at

gain if D AC outp ut is

changed

Reduce 4dB ifDIALNORM

is 27

Reduce 2dB ifinput from

EXT.

Volume

U2037(WM8816)

Reduce 12.5dB if input

from DAC and Compens at

gain if D AC outp ut is

changed

Reduce 4dB ifDIALNORM

is 27

Reduce 2dB ifinput from

EXT.

Output Buffer

U2025(OPA4134)

0.5dBr

Output Buffer

U2025(OPA4134)

0.5dBr

Mute

Q2022, Q2023(SC3326)

0.5dBr

Mute

Q2024, Q2025(SC3326)

0.5dBr

Attenuation

R2230, R2231(220R), R2205(47R)

If load is

10Kohms,

0.5dBr

attenuation is

0.5dB

Attenuation

R2232, R2233(220R), R2206(47R)

If load is

10Kohms,

0.5dBr

attenuation is

0.5dB

Main L Output

0dBr(150mVrms)

Main R Output

0dBr(150mVrms)

CEXT.Input

SW EXT. Input

From DAC C

-20dBfs

is -23d Bfs if

mode is PL2 o

PL2X or

NEO:6

From DAC SW

-20dBfs

is -36 dBfs if

all are "small"

DAC LPF(55KHz 2rd Butterworth with 16.5dB gain)

U2015(OPA2134)

Muti-Source Selector

U2059(TC9274N-008)

Buffer

U2012(OPA4134)

13dBr

)rBd5.2(Bd0)smrVm002(Bd0

DAC LPF(55KHz 2rd Butterworth with 16.5dB gain)

U2016(OPA2134)

Muti-Source Selector

U2059(TC9274N-008)

Buffer

U2012(OPA4134)

13dBr

)rBd5.21(Bd01)smrVm236(Bd01

13dBr(DAC)

2.5dBr(EXT)

13dBr(DAC)

12.5dBr(EXT)

Buffer

U2024(OPA2134)

Buffer

U2024(OPA2134)

13dBr(DAC)

2.5dBr(EXT)

13dBr(DAC)

12.5dBr(EXT)

Volume

U2038(WM8816)

Reduce 12.5dB if input

from DAC and Compens at

gain if D AC outp ut is

changed

Reduce 4dB ifDIALNORM

is 27

Reduce 2dB ifinput from

EXT.

Volume

U2038(WM8816)

Reduce 2.5dB if input from

DAC and Compensate gain

if DAC output is changed

Reduce 4dB ifDIALNORM

is 27

Reduce 2dB ifinput from

EXT.

Output Buffer

U2026(OPA4134)

0.5dBr

LPF(1KHz 1st)

U2026(OPA4134)

10.5dBr

Mute

Q2026, Q2027(SC3326)

0.5dBr

Mute

Q2028, Q2029(SC3326)

Attenuation

R2234, R2235(220R), R2207(47R)

If load is

10Kohms,

0.5dBr

attenuation is

0.5dB

Attenuation

R2236, R2237(220R), R2208(47R)

If load is

10Kohms,

10.5dBr10.5dBr

attenuation is

0.5dB

Main C Output

0dBr(150mVrms)

Main SW Output

10dBr(150mVrms)

3-8

Page 20

4.Volume and EXT. Section/SL/SR/SBL/SBR

e

e

x

e

x

e

DAC LPF(55KHz 2rd Butterworth with 16.5dB gain)

U2017(OPA2134)

From DAC SL

-20dBfs

is -23d Bfs if

Surround is

"single" or

SL EXT. Input

SR EXT. Input

mode is

NEO:6

From DAC SR

is -23d Bfs if

mode is

NEO:6

Buffer

U2011(OPA4134)

DAC LPF(55KHz 2rd Butterworth with 16.5dB gain)

U2018(OPA2134)

-20dBfs

Buffer

U2011(OPA4134)

Muti-Source Selector

U2059(TC9274N-008)

13dBr

)rBd5.2(Bd0)smrVm002(Bd0

Muti-Source Selector

U2059(TC9274N-008)

13dBr

)rBd5.2(Bd0)smrVm002(Bd0

13dBr(DAC)

2.5dBr(EXT)

13dBr(DAC)

2.5dBr(EXT)

Buffer

U2022(OPA2134)

Buffer

U2022(OPA2134)

13dBr(DAC)

2.5dBr(EXT)

13dBr(DAC)

2.5dBr(EXT)

Volume

U2039(WM8816)

Reduce 12.5dB if inp ut

from DAC and Compens at

gain if D AC outp ut is

changed

Reduce 4dB ifDIALNORM

is 27

Reduce 2dB ifinput from

EXT.

Volume

U2039(WM8816)

Reduce 12.5dB if inp ut

from DAC and Compens at

gain if D AC outp ut is

changed

Reduce 4dB ifDIALNORM

is 27

Reduce 2dB ifinput from

EXT.

Output Buffer

U2027(OPA4134)

0.5dBr

Output Buffer

U2027(OPA4134)

0.5dBr

Mute

Q2030, Q2031(SC3326)

0.5dBr

Mute

Q2032, Q2033(SC3326)

Attenuation

R2238, R2239(220R), R2209(47R)

If load is

10Kohms,

0.5dBr

attenuation is

0.5dB

Attenuation

R2240, R2241(220R), R2210(47R)

If load is

10Kohms,

0.5dBr0.5dBr

attenuation is

0.5dB

Main SL Output

0dBr(150mVrms)

Main SR Output

0dBr(150mVrms)

SBL EXT. Input

SBR EXT. Input

From DAC SBL

-20dBfs

is -23d Bfs if

Back surround

is "s ingle" or

mode is

NEO:6 or

DTS5.1 matri

From DAC SBR

-20dBfs

is -23d Bfs if

mode is

NEO:6 or

DTS5.1 matri

DAC LPF(55KHz 2rd Butterworth with 16.5dB gain)

U2019(OPA2134)

Muti-Source Selector

U2059(TC9274N-008)

Buffer

U2012(OPA4134)

13dBr

)rBd5.2(Bd0)smrVm002(Bd0

DAC LPF(55KHz 2rd Butterworth with 16.5dB gain)

U2020(OPA2134)

Muti-Source Selector

U2059(TC9274N-008)

Buffer

U2012(OPA4134)

13dBr

)rBd5.2(Bd0)smrVm002(Bd0

13dBr(DAC)

2.5dBr(EXT)

13dBr(DAC)

2.5dBr(EXT)

Buffer

U2023(OPA2134)

Buffer

U2023(OPA2134)

13dBr(DAC)

2.5dBr(EXT)

13dBr(DAC)

2.5dBr(EXT)

Volume

U2040(WM8816)

Reduce 12.5dB if inp ut

from DAC and Compens at

gain if D AC outp ut is

changed

Reduce 4dB ifDIALNORM

is 27

Reduce 2dB ifinput from

EXT.

Volume

U2040(WM8816)

Reduce 12.5dB if inp ut

from DAC and Compens at

gain if D AC outp ut is

changed

Reduce 4dB ifDIALNORM

is 27

Reduce 2dB ifinput from

EXT.

Output Buffer

U2028(OPA4134)

0.5dBr

Output Buffer

U2028(OPA4134)

0.5dBr

Mute

Q2034, Q2035(SC3326)

Mute

Q2036, Q2037(SC3326)

0.5dBr

Attenuation

R2242, R2243(220R), R2211(47R)

If load is

10Kohms,

0.5dBr0.5dBr

attenuation is

0.5dB

Attenuation

R2244, R2245(220R), R2212(47R)

If load is

10Kohms,

0.5dBr

attenuation is

0.5dB

Main SBL Output

0dBr(150mVrms)

Main SBR Output

0dBr(150mVrms)

3-9

Page 21

5.Component Video

Component Cy Input

Component Input1

Component Input2

Component Input3

fromComposite Circuit

from S vi deo Circuit -6dB

Component Cb Input

Component Input1

Component Input2

Component Input3

0dB(2Vp-p)

0dB(1.4Vp-p)

Input Selector

U1711(74HC4052)

Video Conversion

U1802(TVP5146)

If Monitor outputis

selected as Component

video and input signal is

not Component video,

convert Composite or S

video to Component

-6dB

video

Input Selector

U1712(74HC4052)

Video conversion Selector

U1712(74HC4053)

-6dB

-6dB

Video DAC

U1809(SAA7127H)

Video conversion Selector

U1712(74HC4053)

-6dB

-6dB

Gain

U1709(MAX4018)

d6-

OSD input Selector

U1014(74HC4053)

Gain

U1709(MAX4018)

Cvbs, S-Y, Cy Selector

If source is selected as

"Normal" on OSD, select

Composite

If sourceis selected as "S

Video" on OSD, select Sy

Bd0B

If source is selected as

Component("CV1 etc")on

OSD, select Cy

OSD Input Buffer

U1706(MAX4016)

S-c, Cb Selector

If sourceis selected as "S

Video" on OSD, select Sc

If source is selected as

Component("CV1 etc") on

OSD, select Cb

Bd0Bd6-

OSD Output Selector

If OSD is not used bypass

OSD circuit

0dB

0dB

OSD

U1005(LC74763)

OSD Output Selector

If source and monitor

output is not component

video, disable the Cb

monitor output

0dB

0dB

)3504CH47(6101U)2504CH47(2101U

Attenuation

R1100

Output Buffer

U1707(MAX4016)

Monitor Component Cy Output

OSD Output Buffer

U1706(MAX4016)

Bd0Bd0

Gain

U1708(MAX4018)

0dB

Clear Component Cy Output

Bd0Bd0Bd0Bd0

)3504CH47(6101U)2504CH47(2101U

Attenuation

R1099

-6dB

Output Buffer

U1704(MAX4016)

0dB

Monitor Component Cb Output

Bd0Bd0

0dB

fromComposite Circuit

from S vi deo Circuit

Component Cr Input

Component Input1

Component Input2

Component Input3

fromComposite Circuit

from S vi deo Circuit

0dB(1.4Vp-p)

Video Conversion

U1802(TVP5146)

If Monitor outputis

selected as Component

video and input signal is

not Component video,

convert Composite or S

video to Component

-6dB

video

-6dB

Input Selector

U1712(74HC4052)

Video Conversion

U1802(TVP5146)

If Monitor outputis

selected as Component

video and input signal is

not Component video,

convert Composite or S

video to Component

-6dB

video

-6dB

Video DAC

U1809(SAA7127H)

Video conversion Selector

U1712(74HC4053)

-6dB

-6dB

Video DAC

U1809(SAA7127H)

Gain

U1709(MAX4018)

OSD color

U1015(74HC4053)

0dB

Bd0Bd6-

OSD color

U1017(74HC4053)

0dB

If source is selected as

Component("CV 1 etc") on

OSD, select Cb offset

while OSD enable

If source is selected as

Component("CV1 etc") on

OSD, select Cr offset

while OSD enable

OSD Output Selector

U1016(74HC4053)

If source and monitor

output is not component

video, disable the C r

monitor output

0dB

0dB

Attenuation

R1097

Gain

U1708(MAX4018)

-6dB

Output Buffer

U1704(MAX4016)

Bd0Bd0

Gain

U1708(MAX4018)

-6dB

Clear Component Cb Output

0dB

Monitor Component Cr Output

0dB

Clear Component Cr Output

0dB

3-10

Page 22

6 . S Video Section

DVD

SAT

VCR

Video4

Video5

Video6

Sy Input

0dB(2Vp-p)

Input Selector

U4002(TEA6415)

Cvbs,S-Y,CySelector

If sourceis selected as

"Normal" on OSD,select

Composite

If source is selected as "S

Video" on OSD, select Sy

If sourceis selected as

Component("CV1 etc")on

OSD, select Cy

OSD Output Selector

Bd5.0Bd5.0

0.5dB

Attenuation

R4045

Output Buffer

U4702(MAX4016)

V3 Sy Output

Bd0Bd5.0

0dB

Attenuation

R4046

Output Buffer

U4702(MAX4016)

Video4 Sy Output

Bd0Bd5.0

0dB

)3504CH47(6101U)2504CH47(2101U

Attenuation

R1100

Output Buffer

U1707(MAX4016)

Attenuation

R1111

Output Buffer

U4705(MAX4016)

Monitor Sy Output

Bd0Bd3.0Bd3.0Bd5.0

0dB

OSD input Selector

U1014(74HC4053)

OSD Input Buffer

U1706(MAX4016)

OSD

U1005(LC74763)

OSD Output Buffer

U1706(MAX4016)

Sc Input

0dB(0.572Vp-p)

-6dB

to Video Convers ion Circuit

Input Selector

U4002(TEA6415)

S-c, Cb Selector

If source is selected as "S

Video" on OSD, select Sc

If sourceis selected as

Component("CV1 etc")on

OSD, select Cb

0.5dB

OSD Output Selector

)3504CH47(6101U)2504CH47(2101U

If sourceis not S video,

disable the Sc m onitor

output. Although select

monitor typeas "S Video"

0.5dB Bd0Bd5.0

Attenuation

R4045

Attenuation

R4046

Attenuation

R1098

Bd5.0Bd5.0Bd5.0Bd5.0

Output Buffer

U4702(MAX4016)

Bd0Bd5.0

Output Buffer

U4702(MAX4016)

Bd0Bd5.0

Output Buffer

U4705(MAX4016)

V3 Sc Output

0dB

V4 Sc Output

0dB

Monitor Sc Output

0dB

-6dB

to VideoConversion Circuit

3-11

Page 23

7.Composite Video

Composite Input

DVD

SAT

VCR

Video4

Video5

Video6

0dB(2Vp-p)

Input Selector

U4000(TEA6415)

If use MS compos ite video

output, the user need

connect compos ite video

to composite video input

Cvbs, S-Y, Cy Selector

If source is sel ected as

"Normal" on OSD , select

Composite

If source is select ed as "S

0.5dB

Video" on OSD, select Sy

If source is select ed as

Component("CV1 etc") on

OSD, select Cy

OSD Output Selector

If OSD is not used bypass

OSD circuit

0.5dB

0.5dB

Attenuation

R4041

If select VCR

as Input,

disable the

output

Attenuation

R4042

If select

Video4 as

Input, disable

the output

)3504CH47(6101U)2504CH47(2101U

Attenuation

R1100

Output Buffer

U1707(MAX4016)

Attenuation

R1111

Output Buffer

U4701(MAX4016)

Output Buffer

U4701(MAX4016)

Output Buffer

U4705(MAX4016)

VCR Composite Output

Bd0Bd0Bd5.0

0dB

Video4 Composite Output

Bd0Bd0Bd5.0

0dB

Monitor Composite Output

.0

Bd3.0Bd3.0Bd5

0dB

0dB

Video Conversion

to Video Conversion Circuit

-6dB 0.5dB

OSD input Selector

U1014(74HC4053)

0.5dB

0.5dB

MS OSD Output Selector

U1014(74HC4053)

0.5dB

0.5dB

OSD Input Buffer

U1706(MAX4016)

OSD

U1005(LC74763)

Attenuation

R1043

OSD Output Buffer

U1706(MAX4016)

Bd5.0Bd5.0

Output Buffer

U1707(MAX4016)

Bd0Bd5.0

MS Composite Output

0dB

3-12

Page 24

WIRING DIAGRAM

3-13

Page 25

CIRCUIT DIAGRAMS

1.POWER SUPPLY CIRCUIT DIAGRAM

18Vrms@1Arms

18Vrms@1Arms

8.9Vrms@0.4Arms

13.4Vrms@1.2Arms

13.4Vrms@1.2Arms

11.6Vrms@1.2Arms

13.9Vrms@0.4Arms

7.6Vrms@1Arms

12.7Vrms@0.1Arms

CON608

5PIN

CON611

5PIN

CON604

5pin

19.8va

Q613

KSC2690A-Y

C631

4700u/25

D603

+-

KBL04

~

C603

47nK

C604

47nK

C693

47nK

C696

47nK

FC603 FUSE CLIP

~18v+

agnd1

~18v-

~0v(~8.9v+)

~8.9v+

5

4

3

2

1

F603

2A

FC613 FUSE CLIP

FC604 FUSE CLIP

F604

2A

FC614 FUSE CLIP

FC606 FUSE CLIP

F606

2A

FC616 FUSE CLIP

~

C632

2200u/25

KSA1220A-Y

-20.7va

10.8vd

D604

+-

KBL04

~

~

C643

2200u/16

KSC2690A-Y

Q610

Q616

Q612

DTA114

Q611

DTC114

Q617

DTA114

R629

4K7J

4K7J

R625

R624

4K7J

17.2vv

Q684

KSC2690A-Y

C682

4700u/25

D683

+-

KBL04

~

C688

47nK

FC681 FUSE CLIP

~13.4v+

5

4

3

2

1

~13.4v-

vgnd1

~0v(~11.6v+)

~11.6v+

F681

2A

FC682 FUSE CLIP

FC683 FUSE CLIP

F682

2A

FC684 FUSE CLIP

FC605 FUSE CLIP

F605

2A

FC615 FUSE CLIP

C689

47nK

C684

47nK

C685

47nK

~

C644

2200u/25

KSA1220A-Y

-17.8vv

13.8vd

C619

4700u/16

KSC2690A-Y

D681

+-

KBL04

~

~

Q682

Q607

Q685

DTA114

Q681

DTC114

Q608

DTA114

R684

4K7J

4K7J

R683

R616

4K7J

18.4vt

D682

+-

KBL04

~

C686

47nK

~13.9v+

~0v(~13.9v+)

5

4

3

2

1

~7.6v+

~0v(12.7v+7.6v+)

~12.7v+

FC621 FUSE CLIP

F611

1A

FC622 FUSE CLIP

FC609 FUSE CLIP

F609

1A

FC619 FUSE CLIP

FC608 FUSE CLIP

F608

1A

FC618 FUSE CLIP

C687

47nK

C605

47nK

C694

47nK

C606

47nK

C695

47nK

~

D605

+-

KBL04

~

~

8.82vs

C651

2200u/25

C655

2200u/16

D608

S1GM4

C652

100nZ

C656

100nZ

19.0va

-19.9va

10.2vd

16.4vv

-17.2vv

13.1vd

C629

47u/25

C636

22u/25

C635

22u/25

C683

47u/25

C681

22u/25

C660

47u/25

U606 LM7815CT

1

Vin

2

C637

100nZ

C638

100nZ

1

2

Vin

U607 LM7915CT

U608 LM7805CT

1

Vin

2

C645

100nZ

U603 7810

1

Vin

2

C622

100nZ

C646

100nZ

1

2

Vin

U609 LM7905CT

U604 LM7808CT

1

Vin

2

C625

100nZ

U610 LM7812CT

1

Vin

2

U611 LM7805CT

1

Vin

2

GND

GND

GND

GND

GND

GND

GND

GND

Vout

Vout

Vout

Vout

Vout

Vout

Vout

Vout

3

C641

22u/25

C639

100nZ

Q614

DTC114

agnd1

Q615

C642

10u/25

C640

100nZ

MMBT2907A

3

3

C647

C649

100nZ

10u/25

Q618

DTC114

dgnd1

3

C624

22u/25

C623

100nZ

Q686

DTC114

vgnd1

Q683

C650

10u/25

C648

100nZ

MMBT2907A

3

3

C626

C627

100nZ

22u/25

Q609

DTC114

15va

TO AUD +15VA

-15va

TO AUD -15VA

5vd

TO AUD +5VD

10vv

TO VID +10VD

-5vv

TO VID -5V

8vd

TO VID +8VD

poweron

15va

640mA

-350mA

-15va

5vd

14mA

10vv

340mA,max360mA

-110mA,max120mA

-5vv

8vd

460mA,max480mA

poweron

agnd1

15va

agnd1

-15va

5vd

dgnd1

vgnd1

-5vv

vgnd1

10vv

8vd

dgnd2

CON605

6pin

1

2

3

4

5

6

CON607

6pin

1

2

3

4

5

6

TO AUD

TO VID

C672

22nK

R672

100RJ

C673

22nK

R673

100RJ

C690

22nK

R690

100RJ

C675

22nK

R675

100RJ

agnd1

dgnd1

vgnd1

dgnd2

agnd1 agnd1

n3 n4

dgnd1 dgnd1

vgnd1 vgnd1

n1 n2

dgnd2dgnd2

HS606

HS36X11X80

For Q613&U606

HS607

HS36X11X80

For Q610&U607

HS608

HS36X11X80

For Q616&U608

HS603

HS36X11X80

For Q684&U603

HS609

HS36X11X80

For Q682&U609

HS604

HS36X11X80

For Q607&U604

P606

HS36X11 JYP

P607

HS36X11 JYP

P608

HS36X11 JYP

P603

HS36X11 JYP

P609

HS36X11 JYP

P604

HS36X11 JYP

dgnd2

3

C654

C653

10u/25

100nZ

12vt

TO TRIG +12VS

12vt

10mA,max160mA

C674

22nK

R674

100RJ

dgnd3

dgnd3 dgnd3

HS611

HS36X11X80

For U610&U611

P611

HS36X11 JYP

tgnd1

3

C657

C658

100nZ

10u/25

dgnd3

C659

R626

2u2/50

10KJ

5vs

5vs

TO FPP +5VS

TO FPP FOR WATCH DOG

200mA, max220mA, standby160mA

16vunreg

16vunreg

12vt

tgnd1

poweron

5vs

dgnd3

16vunreg

CON602

6pin

6

5

4

3

2

1

TO FPP

C691

22nK

R691

100RJ

tgnd1

tgnd1 tgnd1

HS610

HS36X11X80

For U610

P610

HS36X11 JYP

dgnd3

PCB61

HS4-M15_B008V3_1_0-PSU

3-14

Page 26

2.FRONT PANEL CIRCUIT DIAGRAM

C340

dgnd

100nZ

U312

1

pstb0

sh/ld

vcc

2

pclk

clk

clkinh

3

dgnd

d4

d3

4

dgnd

to AUD board

dgnd

CON301

s1

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

s2

1

24pin

U311

IR SHELL

CON321

8pin from CON722

dgnd

smute

dgnd

rst

dgnd

dgnd

ir in

dgnd

ir1 out

dgnd

ir2 out

dgnd

dgnd

trig1 out

dgnd

trig2 out

dgnd

trig3 out

IR receiver

U307

HS0038B4

D

G

V

1

1

2

2

dgnd

1

2

3

4

5

6

7

8

tgnd

12vt

1

2

3

bumte

poweron

VolB

VolA

5vs

ir

IR input/output

dgnd

R321

10RJ

C320

470nZ

dgnd

5vs

tgnd

12vt

5vs

dgnd

16vu

dgnd

5vs

C311

10u/50/5mm

5vs

RemRx

100KJ

dgnd

R325

1

2

3

4

5

6

poweron

girtni girt

U305

74HC132

a1

b1

y1

a2

b2

y2

gnd7y3

5vs

vcc

dgnd

d5

d2

5

blkst

d6

d1

6

trig

d7

d0

7

q

ser

8

gnd

dgnd

74HC165

5vs

14

13

a4

12

b4

11

y4

10

b3

9

a3

8

Q311

DTA114

C308

100nZ

dgnd

/pon

5vs

D301

R317

270RJ

1 2

R318

470RJ

PCB71

5vs

5vs

U303

1

5vs

dgnd

fppdi

fppclk

fppdo

fpprxd

fpptxd

RemRx

VolA

pfail

VolB

dgnd

R306

47RJ

trig1

trig2

/pon

pon

Vfdrst

D371

5V6

q1

2

q2

3

q3

4

q4

5

q5

6

q6

7

q7

gnd8q'h

dgnd

74HC595

U302

1

q1

2

q2

3

q3

4

q4

5

q5

6

q6

7

q7

gnd8q'h

dgnd

74HC595

C306

100nZ

U301

6

P1.5

7

p1.6

8

P1.7

9

RST

10

RxD

11

TxD

12

P3.2

13

P3.3

14

P3.4

15

P3.5

5vs

16

15

dgnd

14

dgnd

13

dgnd

12

dgnd

11

dgnd

10

dgnd

9

mpublkst

q

fpp232/sc232

TP1

T.P.(NI)

dgnd

mreset

47RJ

R372

AT89C51ED2-3CSC

16vu

U304

1

8

rst

RST

7

/rst

RST

6

nc

5

pfi

1.25v at power fail-->

R324

1MF

R316

182KF

C315

1u/50/5mm

MR+

2

Vcc

5vs

3

gnd

PFI4PFO

MAX707CSA

dgnd

pfi

5

16

pstb0

mpublkst

P3.6

pstb1

C316

22pJ

vcc

q0

ser

/g

rck

sck

/sclr

vcc

q0

ser

/g

rck

sck

/sclr

fppmu

fppst

P3.717XTAL2

19

18

16

15

14

13

12

11

10

9

16

15

14

13

12

11

10

9

fppi

XTAL1

20

dgnd

5vs

P1.01P1.12P1.23P1.34P1.4

GND

dgnddgnd

C301 100nZ

pdat

dgnd

pstb0

pclk

5vS

C302 100nZ

pdat

rst

pstb1

pclk

5vs

5vs

40

Vcc

P2.0

21

Vfd0

X301

18.432M

C317

22pJ

k0k1k2

39

P2.122P2.2

23

Vfd1

Vfd2

24

Vfd3

dgnd

dgnd

P2.3

25

Vfd4

K320

Key

K322

Key

K323

K304

Key

K305

Key

K306

Key

pclk

pdat

vfdrw

vfdrs

vfde

/fpppsen

Vfd7

Vfd6

Vfd5

5vs

47KJ

R326

9

vfde

8

vfdrs

7

vfdrw

6

pdat

R371

5

pclk

4

k2

3

k1

2

k0

1

5vS

8X10k

*

P0.336P0.237P0.138P0.0

P0.4

P0.5

P0.6

P0.7

ALE

PSEN

P2.7

P2.6

P2.5

35

34

33

32

31

EA

30

29

28

27

26

k0

k1

K314

Key

K315

Key

k2

k00 search down

k01 preset down

k02 display

k03 FM mute

k04 audio

k05 ext 7.1

k06 tape mon

Key

K324

Key

K325

Key

k10 search up

k11 preset up

k12 memory

k13 AM/FM

k14 video

k15 surround mode

k25 levels

CON722

8

7

6

5

4

bpoweron

3

bVolB

2

bVolA

1

8pin to CON321

k20 spkr A(power)

k21 spkr B

k22 tone controls

k23 tone defeat

k24 digital audio

k25 levels

b12vt

b16vu

btgnd

b5vs

bdgnd

b5vs

P2.4

dgnd

5vs

vfdrst

Vfdrs

Vfdrw

Vfde

Vfd0

Vfd1

Vfd2

Vfd3

Vfd4

Vfd5

Vfd6

Vfd7

*

CON311

14pin

1

2

3

4

5

6

7

8

9

10

11

12

13

14

dgnd

5vs

vfdrst

Vfdrs

Vfdrw

Vfde

Vfd0

Vfd1

Vfd2

Vfd3

Vfd4

Vfd5

Vfd6

Vfd7

1

gnd

2

Vcc

3

rst

4

RS

5

R/W

6

E

7

d0

8

d1

9

d2

10

d3

11

d4

12

d5

13

d6

14

d7

20T202DA1(J)

M301

C709

bVolA

10nK

R713

R711

10KJ

R712

10KJ

R714

bVolB

1K2J

1K2J

C751

C752

C710

Bdgnd

100nZ

100nZ

10nK

Sub board(Encoder Board)

pfail

fppclk

fppdi

fppdo

fppi

fppst

fppmu

blkst

C318

22nK

R328

100RJ

R329

100RJ

dgnd

C314

22nK

dgnd

chassis1

chassis2

V701

A

B

C

volume control

dgnd

U306

1

2

3

4

5

6

7

8

9

dgnd

74HCT244

chassis3

chassis6

HS4-M15_B008V3_0_0-ENC

from psu

encode

C741

22nK

bdgnd

5vs

C307

100nZ

20

1/g

vcc

19

1a1

2/g

18

R307A

2y4

1y1

17

bfppclk

1a2

2a4

16

R307B

2y3

1y2

15

bfppdo

1a3

2a3

14

R307C

2y2

1y3

13

bfppst

1a4

2a2

12

R307D

2y1

1y4

11

bblkst

gnd102a1

C333

22nK

dgnd

C334

22nK

dgndchassis4

C335

22nK

dgndchassis5

C336

22nK

dgnd

CON702

1

2

3

4

5

6

6pin to CON602

C742

22nK

dgnddgnd

47RJ

47RJ

47RJ

47RJ

bpoweron

bdgndchassis12

mpfi

bfppdi

mfppi

smute

C337

C338

C339

22nK

22nK

22nK

bdgnd

btgnd

b16vu

b5vs

b12vt

dgndchassis7

dgndchassis8

dgndchassis9

fpp232/sc232

/fpppsen

mfppi

bfppdi

mpfi

mreset

bfppclk

bfppdo

bfppst

bblkst

fpprxd

fpptxd

CON304

1

s2

24pin

dgnd

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

s1

24

dgnd

dgnd

dgnd

dgnd

dgnd

dgnd

5vs

dgnd

dgnd

dgnd

dgnd

dgnd

dgnd

PADS JP1.1 and JP1.2 of M301 are linked . Pin3=/Reset

need TEST Q312 voltage

Q312

DTA114

dgnd

Amber=standby,

Blue/Amber

LED as

Blue=on

Q303

DTC114

pon

PCB31

HS4-M15_B008V3_0_0-FPP.sch

3-15

Page 27

3.HDMI CIRCUIT DIAGRAM

dgnd dgnd

pbdo

dgnd

C513

100nZ

C518

100nZ

1718192021

bmrst

from VID

16

dgnd

pbs7

dgnd

C514

100nZ

C519

100nZ

mcmck

dgnd

xdaa

dgnd

C515

100nZ

C520

100nZ

xfsa

dgnd

xscka

dgnd

C516

100nZ

C521

100nZ

xmcka

dgnd

pbi7

dgnd

5vd

C531

100nZ

C532

100nZ

dgnd

3v3d

dgnd

3v3d

s1

24

pbst

CON55

24pin

23

dgnd

C512

100nZ

C517

100nZ

22

dgnd

pbclk

dgnd

dgnd

59

60

58

nc

vcc

hpd2

sda2

scl2

gnd

gnd

b21

a21

vcc

b22

a22

gnd

b23

a23

vcc

b24

a24

gnd

vcc

hpd1

gnd

nc

sda1

3

1

2

bsda

bsck

3v3d thpd

61

ahpd

62

asda

63

asck

64

dgnd

65

dgnd

66

aclk-

67

aclk+

68

3v3d

69

adata0-

70

71

adata0+

72

dgnd

adata1-

73

74

adata1+

3v3d

75

adata2-

76

adata2+

77

dgnd

78

3v3d

79

bhpd

80

dgnd

3v3d

56

53

52

54

57

55

a33

a34

vcc

gnd

a32

b33

b34

scl1

b128b13

vcc

gnd

a116a129a1312a14

b11

7

4

5

3v3d

dgnd

bdata0+

bdata0-

bclk+

bclk-

C55

s2

123456789101112131415

3v3d

48

49

51

50

vcc

b31

a31

b32

vcc

gnd

10

13

11

3v3d

dgnd

bdata1-

bdata1+

pbs7

pbdo

pbclk

pbst

dgnd

dgnd

46

47

gnd

b14

15

14

bdata2+

bdata2-

dgnd

U55

1

1/g

vcc

2

1a1

3

2y4

1y1

4

1a2

2a4

5

2y3

1y2

6

1a3

2a3

7

2y2

1y3

8

1a4

2a2

9

2y1

1y4

gnd102a1

dgnd

74LCX244

3v3d

dgnd

45

43

42

44

/oe

vcc

scl3

sda3

hpd3

hpd_sink

vsadj

vcc

gnd

pre

18

17

16

19

3v3d

dgnd

"pre" is output pre-emphasis adjustment, high=3dB

pre

3v3d C56

100nZ

3v3d

20

19

dgnd

2/g

18

dgnd

17

16

dgnd

15

14

dgnd

13

12

dgnd

11

41

U58

do

clk

stb

3v3d

5vd t5vhdmi

R58

10RJ

R52A

10kJ

R52B

10kJ

R52C

10kJ

R52D

10kJ

do

clk

stb

nc

40

tsda

39

sda_sink

38

gnd

gnd

z1

y1

vcc

z2

y2

gnd

z3

y3

vcc

z4

y4

gnd

s3

s2

s1

TMDS341

tsck

dgnd

37

dgnd

36

tclk-

35

34

tclk+

3v3d

33

32

tdata0-

31

tdata0+

dgnd

30

29

tdata1-

28

tdata1+

3v3d

27

tdata2-

26

tdata2+

25

dgnd

24

23

dgnd

22

s2

21

bcab

5vd

C58

100u/16

scl_sink

nc

20

3

C59

100nZ

in

dgnd

1

s2

2

pre

3

4

5

6

7

8

dgnd

U59

LM1117MPX-ADJ

adj

1

100nZ

U56

q1

q2

q3

q4

q5

q6

q7

gnd

74HC595

out

C510

10u/50

vcc

sck

/sclr

2

3v3d

3v3d

16

bcab

15

q0

14

do

ser

13

dgnd

/g

stb

12

rck

clk

11

3v3d

10

9

q'h

3v3d

R54

243RF

392RF

R53

C511

100u/16

dgnd

dgnd

dgnd

bhpd

19

ahpd

19

18

detect

C523

22nK

18

detect

C524

22nK

5v

5v

dgnd

17

dgnd

17

bsda

16

g

asda

16

g

sda

bsck

cec

13

14

nc

sck15sda

J56

HDMI SOCKET

asck

cec

15

13

14

nc

sck

J55

HDMI SOCKET

bclk-

12

clk-

cec(nc)

aclk-

12

clk-

cec(nc)

dgnd

11

dgnd

11

clkg

clkg

bclk+

10

aclk+

10

bdata0-

9

clk+

data0-

adata0-

9

clk+

data0-

dgnd

8

dgnd

8

bdata0+

7

data0g

data0+

adata0+

7

data0g

data0+

bdata1-

dgnd

5

6

data1-

adata1-

dgnd

5

6

data1-

bdata1+

4

data1g

data1+

adata1+

4

data1g

data1+

bdata2-

dgnd

2

3

data2-

adata2-

dgnd

2

3

data2-

bdata2+

1

data2g

data2+

adata2+

1

data2g

data2+

2

J51

L

N

1

AC-OUTPUT(C only)

from AC inlet

AC-OUTPUT(AH only)

dgnd

2

1

CON52

2pin

R55

4k64F

L

N

ni

li

1

J52

3

To VID

FC51 FUSE CLIP

FC52 FUSE CLIP

CS51

CON53

2pin

3

F51

2A

2n2/400vac

1

from AC Switch

li1

CON51

2pin

t5vhdmi

5v

dgnd

17

g

tsda

16

tsck

cec

tclk-

12

13

14

nc

sck15sda

clk-

cec(nc)

J57

HDMI SOCKET

dgnd

11

clkg

tclk+

10

tdata0-

9

clk+

dgnd

8

data0-

data0g

tdata1-

tdata0+

7

6

data0+

dgnd

5

data1-

tdata1+

4

data1g

data1+

tdata2-

dgnd

2

3

data2-

tdata2+

1

data2g

data2+

thpd

3

1

D52

5V6

19

18

detect

dgnd

100RJ

C522

22nK

R56

dgnd

PCB51

HS4-M15_B008V3_1_0-HDMI

3-16

Page 28

4.CSS CIRCUIT DIAGRAM

CV1

i/o gnd

CV2

i/o gnd

CV3

i/o gnd

CV4

chassis6 chassis7

i/o gnd

CV5

i/o gnd

CV6

chassis5

i/o gnd

i/o gnd

J4011A S+RCA

SV1

J4012A S+RCA

SV2

J4013A S+RCA

SV3

J4015A S+RCA

SV4

J4017A S+RCA

SV5

J4018A S+RCA

SV6

S+RCA

S+RCA

S+RCA

S+RCA

S+RCA

S+RCA

chassis5

C4405

22nK

J4011B

J4012B

J4013B

J4015B

J4017B

J4018B

i/o gnd

i/o gnd

i/o gnd

i/o gnd

i/o gnd

i/o gnd

R4405

100RJ

dgndi/o gnd

R4000

75RF

R4001

75RF

R4002

75RF

R4003

75RF

R4004

75RF

R4005

75RF

R4014

75RF

R4015

75RF

R4016

75RF

R4017

75RF

R4023

75RF

R4024

75RF

dgnd

i/o gnd

dgnd

dgnd

dgnd

dgnd

dgnd

dgnd

dgnd

chassis6

C4406

22nK

dgnd

dgnd

dgnd

dgnd

dgnd

dgnd

C4000

220nZ

C4001

220nZ

C4002

220nZ

C4003

220nZ

C4004

220nZ

C4005

220nZ

C4007

220nZ

C4014

220nZ

C4015

220nZ

C4016

220nZ

C4017

220nZ

C4018

220nZ

C4023

220nZ

C4027

220nZ

R4406

100RJ

i/o gnd

chassis7

C4407

22nK

dgnd

100RJ

dgnd

min. 20mA

typ. 30mA

max. 40mA

R4407

min. 20mA

typ. 30mA

max. 40mA

dgnd

cvbs zone2

dgnd

cvbs

dcvbs

U4701A

3

MAX4016ESA

1

2

R4721

10KF

24RJ

U4701B

5

MAX4016ESA

7

6

10KF

24RJ

R4722

C4711

100nZ

dgnd

C4712

100nZ

R4063

75RF

R4064

75RF

5vv

8

U4701C

MAX4016ESA

4

-5vv

C4041

470u/10

C4042

470u/10

R4111

75RF

C4167

470u/10

C4006

220nZ

47KJ

R4267

D4000

1SS352

1

in3

2

SD

3

in2

4

SCK

5

in0

6

in1

7

p

8

in4

9

Vcc

in510in7

TEA6415CD

dgnd

GND

GND

R4034

10RJ

C4034

100u/16

U4000

out0

out1

out2

out3

out4

out5

C4701

5vv

vsca

vsda

20

in6

19

dgnd

18

17

16

15

14

13

12

dgnd

11

10vv

C4008

220nZ

dgnd

R4041

150RF

R4801

100RF

R4042

150RF

R4802

100RF

R4811

100RF

R4051

R4701

R4052

R4702

R4814

dgnd

dgnd

dgnd

dgnd

3K92F

10KF

3K92F

10KF

10KF

22u/25

C4602

22u/25

C4702

22u/25

C4604

22u/25

C4811

47u/16

R4711

R4712

dgnd

10vv

5vv -5vv

C4741

C4742

10u/25

U4705B

MAX4016ESA

7

5vv

U4705C

MAX4016ESA

-5vv

C4743

10u/25

dgnddgnd

100u/16

dgnd

dgnd

dgnd

U4702A

3

MAX4016ESA

1

2

R4723

10KF

24RJ

U4702B

5

MAX4016ESA

7

6

10KF

24RJ

R4724

svY

csv&sy ma

R4602

100KF

dsvY

dgnd

5vv

C4713

84

100nZ

U4702C

dgnd

MAX4016ESA

C4714

100nZ

-5vv

C4053

22u/25

R4103

R4066

75RF

R4067

75RF

C4048

470u/10

C4049

470u/10

5

6

10KF

24RJ

R4727

C4087

84

100nZ

dgnd

C4085

100nZ

R4266

5vv

47KJ

vscb

D4003

vsdb

db

U4002

1SS352

1

20

in3

in6

2

19

SD

GND

GND

R4037

10RJ

C4038

100u/16

dgnd

18

out0

17

out1

16

out2

15

out3

14

out4

13

out5

12

dgnd

11

10vv

C4020

220nZ

dgnd

C4019

220nZ

3

in2

4

SCK

5

in0

6

in1

7

p

8

in4

9

Vcc

in510in7

TEA6415CD

dgnd

R4045

150RF

R4046

150RF

R4803

100RF

R4812

100RF

R4118

R4119

R4703

R4815

dgnd

dgnd

dgnd

dgnd

3K92F

3K92F

10KF

10KF

C4703

22u/25

R4713

C4704

22u/25

R4714

C4603

22u/25

C4812

47u/16

csv m

dgnd

10vv

dgnd

5vv

dgnd

-5vv

cvbs zone2

sc ma

csv&sy ma

z2out

svc

dcvbs

svy

dsvy

cvbs

dsvc

vsda

vsca

vsdb

vscb

J4014B

S+RCA

CV3 out

i/o gnd

J4019B

S+RCA

Composite Monitor

i/o gnd

J4016B

S+RCA

CV4 out

i/o gnd

CON401

dgnd

dgnd

16pin

CON402

dgnd

dgnd

dgnd

dgnd

dgnd

dgnd

dgnd

dgnd

dgnd

dgnd

dgnd

dgnd

24pin

J4020

RCA2-Y-U-NOS

16s2s1

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

s1

s2

dgnd

From VID

dgnd

dgnd

From VID

dgnd

dgnd

R4025

75RF

R4026

75RF

R4027

75RF

R4030

75RF

R4031

75RF

R4032

75RF

dgnd

dgnd

dgnd

dgnd

dgnd

dgnd

dgnd

C4024

220nZ

C4025

220nZ

C4026

220nZ

C4028

220nZ

C4029

220nZ

C4030

220nZ

C4031

220nZ

dgnd

dgnd

U4703A

3

MAX4016ESA

1

2

R4725

10KF

24RJ

U4703B

5

MAX4016ESA

7

6

10KF

24RJ

R4726

svC

sc ma

R4795

100KF

dsvC

dgnd

5vv

C4715

84

100nZ

U4703C

dgnd

MAX4016ESA

C4716

100nZ

-5vv

C4202

100nZ

R4089

R4072

75RF

R4071

75RF

C4050

470u/10

C4047

470u/10

U4705A

3

MAX4016ESA

2

10KF

24RJ

R4728

C4170

R4112

1

75RF

470u/10

C4168

R4116

75RF

470u/10

J4014A S+RCA

i/o gnd

J4016A S+RCA

i/o gnd

J4019A S+RCA

sc m

i/o gnd

sy m

PCB41

HS4-M15_B008V3_0_0-CSS

SV3 out

SV4 out

SV Monitor

C4705

R4049

5vv

R4221

47KJ

5vv

R4222

47KJ

5vv

R4220

47KJ

5vv

R4223

47KJ

5vv

R4225

47KJ

5vv

R4224

47KJ

10vv

db

min. 20mA

typ. 30mA

max. 40mA

C4032

220nZ

U4004

1

in3

2

SD

3

in2

4

SCK

5

in0

6

in1

7

p

8

in4

9

Vcc

in510in7

TEA6415CD

dgnd

GND

GND

R4038

10RJ

C4040

100u/16

vscb

20

in6

19

dgnd

18

out0

17

out1

16

out2

15

out3

14

out4

13

out5

12

dgnd

11

10vv

C4033

220nZ

dgnd

150RF

R4050

150RF

R4804

100RF

R4813

100RF

R4124

R4125

R4705

R4816

dgnd

dgnd

dgnd

dgnd

3K92F

3K92F

10KF

10KF

22u/25

R4715

C4706

22u/25

R4716

C4201

22u/25

C4813

47u/16

3-17

Page 29

5.AUDIO CIRCUIT DIAGRAM-1

DVD

SAT

VCR

V4

V5

ir in

ir o1

ir o2

trig o1

trig in

trig o3

trig o2

L

R

L

R

L

R

L

R

L

R

tgnd

dgnd

J2001A

RCA6-W-R

R2412

chassis1

J2001B

RCA6-W-R

R2414

J2001C

RCA6-W-R

R2038

J2001D

RCA6-W-R

R2039

J2001E

RCA6-W-R

R2040

J2001F

RCA6-W-R

R2041

J2002C

RCA6-W-R

R2042

J2002D

RCA6-W-R

R2043

J2003A

RCA6-W-R

R2027

chassis3

J2003B

RCA6-W-R

R2029

J2904

SCJ349-SD

J2903B

SCJ351-DS SW

J2903A

SCJ351-DS SW

J2902B

SCJ351-DS SW

J2902A

SCJ351-DS SW

J2901B

SCJ351-DS SW

J2901A

SCJ351-DS SW

C2913

N.I.

DVDLi

DVDRi

SATLi

SATRi

VCRLi

VCRRi

V4Li

V4Ri

V5Li

V5Ri

56K2F

56K2F

56K2F

56K2F

56K2F

56K2F

56K2F

56K2F

56K2F

56K2F

5

2

1

25

21

5

4

1

25

21

5

4

1

25

21

5

4

1

R2913

0RJ

ir gnd

ir gnd

ir gnd

tgnd

tgnd

tgnd

tgnd

R2411

332RF

C2411

180pJ

R2413

332RF

C2412

180pJ

R2012

332RF

C2012

180pJ

R2013

332RF

C2013

180pJ

R2014

332RF

C2014

180pJ

R2015

332RF

C2015

180pJ

R2016

332RF

C2016

180pJ

R2017

332RF

C2017

180pJ

R2001

332RF

C2001

180pJ

R2003

332RF

C2003

180pJ

ir i

R2912

ir1 o

ir2 o

trig1 o

trig i

10KJ

R2910

trig3 o

trig2 o

agnd

agnd

agnd

agnd

agnd

agnd

agnd

agnd

agnd

agnd

N.I.

ir gnd

D2933

N.I.

10

9

U2001D

OPA4134UA

12

13

U2001C

OPA4134UA

3

2

U2001A

OPA4134UA

5

6

U2001B

OPA4134UA

10

9

U2002D

OPA4134UA

12

13

U2002C

OPA4134UA

3

2

U2002A

OPA4134UA

5

6

U2002B

OPA4134UA

10

9

U2003D

OPA4134UA

12

13

U2003C

OPA4134UA

D2951 1SS352

R2909

2K2J

5vs

R2907

560rJ

R2908

560rJ

R2905

3R9J

R2906

33KJ

12vt

R2903

3R9J

R2904

3R9J

D2934

N.I.

C2909

47nK

C2907

47pJ

C2908

47pJ

8

14

1

7

8

14

1

7

8

14

ir gnd

ir gnd

ir gnd

ir i

tgnd

tgnd

tgnd

tgnd

R2951

1KJ

ir gnd

C2511

C2541

100nZ

C2542

100nZ

C2543

100nZ

C2544

100nZ

C2545

100nZ

C2546

100nZ

C2547

100nZ

C2548

100nZ

C2549

100nZ

C2550

100nZ

BI22u

10KF

agndC2512

BI22u

10KF

agndC2513

BI22u

10KF

agndC2514

BI22u

10KF

agndC2515

BI22u

10KF

agndC2516

BI22u

10KF

agndC2517

BI22u

10KF

agndC2518

BI22u

10KF

agndC2519

BI22u

10KF

agndC2520

BI22u

10KF

agnd

i/o gnd agnd

C2905

100nZ

C2906

100nZ

C2903

100nZ

C2904

100nZ

DVDL

R2511

DVDR

R2512

SATL

R2513

SATR

R2514

VCRL

R2515

VCRR

R2516

V4L

R2517

V4R

R2518

V5L

R2519

V5R

R2520

Q2922

KSA1220A-Y

1SS352

R2922

10KJ

tgnd

12vt

5vs

100KJ

dgnd

D2922

Tuner

Tape

5vs

10KJ

dgnd

R2928

trig in

Q2930

DTC114

R2925

3R9J

D2924

1SS352

trig2 out

Q2927

DTC114

L

V6

R

L

CD

R

L

Disc

R

L

R

L

R

R2927

ir in a