NAD L73 Service Manual

SERVICE MANUAL

L73

DVD RECEIVER

L73

DVD RECEIVER

1-3

SECTION 1

SUMMARY

CONTENTS

PRODUCT SAFETY SERVICING GUIDELINES.......................................................................................... 1-4

SERVICING PRECAUTIONS ....................................................................................................................... 1-5

* General Servicing Precautions

* Insulation checking prodedure

* Electrostatically Sensitive Devices

SPECIFICATIONS ......................................................................................................................................... 1-6

DISASSEMBLY .............................................................................................................................................. 1-7

PRINCIPAL PART LOCATION ...................................................................................................................... 1-8

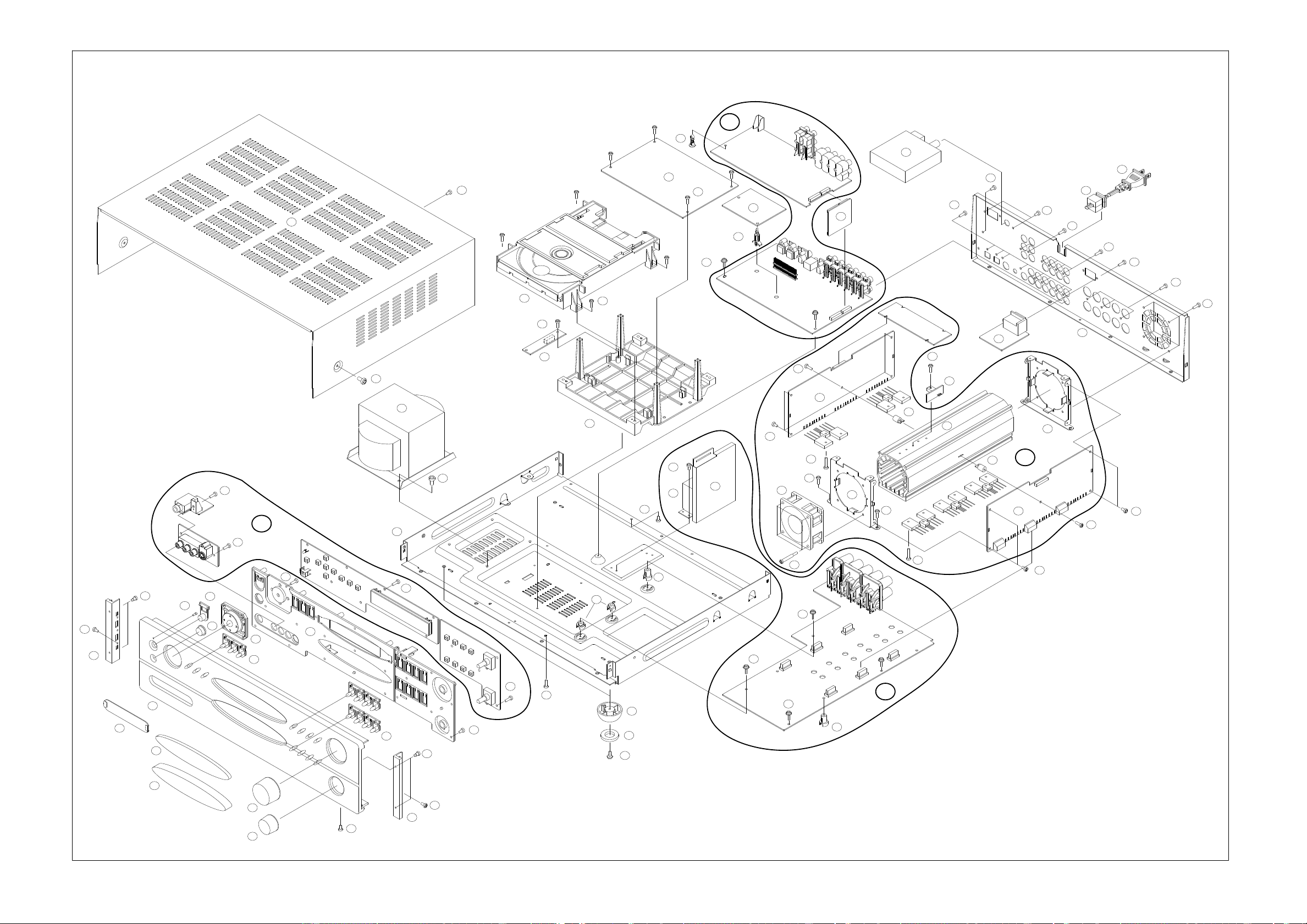

EXPLODED VIEW ............................................................................................................................. 1-9 ~ 1-13

1-4

PRODUCT SAFETY SERVICING GUIDELINES

CAUTION : DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN

ANY WAY. NEVER PERFORM CUSTOMIZED INSTALLATIONS

WITHOUT MANUFACTURER’S APPROVAL. UNAUTHORIZED

MODIFICATIONS WILL NOT ONLY VOID THE WARRANTY, BUT

MAY LEAD TO YOUR BEING LIABLE FOR ANY RESULTING

PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU

ARE THOROUGHLY FAMILIAR WITH ALL OF THE FOLLOWING

SAFETY CHECKS AND SERVICING GUIDELINES. TO DO

OTHERWISE, INCREASES THE RISK OF POTENTIAL HAZARDS

AND INJURY TO THE USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR

PROTECTION FROM AC LINE SHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN

CORRECTED. A CHECK SHOULD BE MADE OF THE

FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN

SUCH A WAY AS TO AVOID POSSIBILITY OF ADJACENT

COMPONENT SHORTS. THIS IS ESPECIALLY IMPORTANT

ON THOSE MODULES WHICH ARE TRANSPORTED TO AND

FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE

DEVICES SUCH AS INSULATORS, BARRIERS, COVERS,

SHIELDS, STRAIN RELIEFS, POWER SUPPLY CORDS, AND

OTHER HARDWARE HAVE BEEN REINSTALLED PER

ORIGINAL DESIGN. BE SURE THAT THE SAFETY PURPOSE

OF THE POLARIZED LINE PLUG HAS NOT BEEN DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE

COLD SOLDER JOINTS, SOLDER SPLASHES OR SHARP

SOLDER POINTS. BE CERTAIN TO REMOVE ALL LOOSE

FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR

DETERIORATION TO PARTS AND COMPONENTS. FOR

FRAYED LEADS, DAMAGED INSULATION (INCLUDING AC

CORD). AND REPLACE IF NECESSARY FOLLOW ORIGINAL

LAYOUT, LEAD LENGTH AND DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECEIVING

TUBE OR A RESISTOR RATED AT 1 WATT OR MORE. LEAD

TENSION AROUND PROTRUDING METAL SURFACES MUST

BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES,

FLAMEPROOF RESISTORS, CAPACITORS, ETC. MUST BE

REPLACED WITH EXACT FACTORY TYPES, DO NOT USE

REPLACEMENT COMPONENTS OTHER THAN THOSE

SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT

MODIFICATIONS.

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN

AC LEAKAGE TEST ON ALL EXPOSED METALLIC PARTS OF

THE CABINET, (THE CHANNEL SELECTOR KNOB, ANTENNA

TERMINALS. HANDLE AND SCREWS) TO BE SURE THE SET

IS SAFET TO OPERATE WITHOUT DANGER OF ELECTRICAL

SHOCK. DO NOT USE A LINE ISOLATION TRANSFORMER

DURING THIS TEST USE AN AC VOLTMETER, HAVING 5000

OHMS PER VOLT OR MORE SENSITIVITY, IN THE

FOLLOWING MANNER; CONNECT A 1500 OHM 10 WATT

RESISTOR, PARALLELED BY A .15 MFD, 150V AC TYPE

CAPACITOR BETWEEN A KNOWN GOOD EARTH GROUND

(WATER PIPE, CONDUIT, ETC.) AND THE EXPOSED

METALLIC PARTS, ONE AT A TIME.

MEASURE THE AC VOLTAGE ACROSS THE COMBINATION

OF 1500 OHM RESISTOR AND .15 MFD CAPACITOR.

REVERSE THE AC PLUG AND REPEAT AC VOLTAGE

MEASUREMENTS FOR EACH EXPOSED METALLIC PART.

VOLTAGE MEASURE MUST NOT EXCEED 75 VOLTS R.M.S.

THIS CORRESPONDS TO 0.5 MILLIAMP AC ANY VALUE

EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED IMMEDIATELY.

SUBJECT : GRAPHIC SYMBOLS

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS,

CUBBYHOLE OR CLOSELY FITTING SHELF SPACE. OVER

OR CLOSE TO HEAT DUCT, OR IN THE PATH OF HEATED

AIR FLOW.

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS:

OUTDOOR PATIO INSTALLATIONS WHERE DEW IS A

FACTOR, NEAR STEAM RADIATORS WHERE STEAM

LEAKAGE IS A FACTOR, ETC.

3. AVOID PLACEMENT WHERE DRAPERIES MAY OBSTRUCT

REAR VENTING. THE CUSTOMER SHOULD ALSO AVOID THE

USE OF DECORATIVE SCARVES OR OTHER COVERINGS

WHICH MIGHT OBSTRUCT VENTILATION.

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A

COMMERCAL MOUNTING KIT MUST FOLLOW THE FACTORY

APPROVED MOUNTING INSTRUCTIONS A PRODUCT

MOUNTED TO A SHELF OR PLATFORM MUST RETAIN ITS

ORIGINAL FEET (OR THE EQUIVALENT THICKNESS IN

SPACERS) TO PROVIDE ADEQUATE AIR FLOW ACROSS

THE BOTTOM, BOLTS OR SCREWS USED FOR FASTENERS

MUST NOT TOUCH ANY PARTS OR WIRING. PERFORM

LEAKAGE TEST ON CUSTOMIZED INSTALLATIONS.

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A

PRODUCT ON SLOPING SHELF OR A TILTED POSITION,

UNLESS THE PRODUCT IS PROPERLY SECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE

ON ITS MOUNTING TO THE CART. CAUTION THE

CUSTOMER ON THE HAZARDS OF TRYING TO ROLL A CART

WITH SMALL CASTERS ACROSS THRESHOLDS OR DEEP

PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR

STAND WHICH HAS NOT BEEN LISTED BY UNDERWRITERS

LABORATORIES, INC. FOR USE WITH THEIR SPECIFIC

MODEL OF TELEVISION RECEIVER OR GENERICALLY

APPROVED FOR USE WITH T.V.’S OF THE SAME OR

LARGER SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION

CORDS, EXPLAIN THAT A FOREST OF EXTENSIONS

SPROUTING FROM A SINGLE OUTLET CAN LEAD TO

DISASTROUS CONSEQUENCES TO HOME AND FAMILY.

THE LIGHTNING FLASH WITH ARROWHEAD SYMBOL, WITHIN AN

EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE USER TO THE

PRESENCE OF UNINSULATED “DANGEROUS VOLTAGE” WITHIN THE

PRODUCT’S ENCLOSURE THAT MAY BE OF SUFFICIENT MAGNITUDE TO

CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS

INTENDED TO ALERT THE USER TO THE PRESENCE OF IMPORTANT

OPERATING AND MAINTENANCE (SERVICING) INSTRUCTIONS IN THE

LITERATURE ACCOMPANYING THE APPLIANCE.

1-5

SERVICING PRECAUTIONS

CAUTION : Before servicing the A/V Receiver covered by this

service data and its supplements and addends, read and follow the

SAFETY PRECAUTIONS. NOTE : if unforeseen circumstances

create conflict between the following servicing precautions and any

of the safety precautions in this publication, always follow the safety

precautions.

Remember Safety First:

General Servicing Precautions

1. Always unplug the A/V Receiver AC power cord from the AC

power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnecting or reconnecting any internal electrical plug or

other electrical connection.

(3) Connecting a test substitute in parallel with an electrolytic

capacitor.

Caution : A wrong part substitution or incorrect polarity installation

of electrolytic capacitors may result in an explosion hazard.

2. Do not spray chemicals on or near this A/V Receiver or any of its

assemblies.

3. Unless specified otherwise in this service data, clean electrical

contacts by applying an appropriate contact cleaning solution to

the contacts with a pipe cleaner, cottontipped swab, or

comparable soft applicator.

Unless specified otherwise in this service data, lubrication of

contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with which

instruments covered by this service manual might be equipped.

5. Do not apply AC power to this A/V Receiver and/or any of its

electrical assemblies unless all solid-state device heat sinks are

correctly installed.

6. Always connect test instrument ground lead to the appropriate

ground before connecting the test instrument positive lead. Always

remove the test instrument ground lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn the

power on. Connect an insulation resistance meter(500V) to the

blades of the attachment plug. The insulation resistance between

each blade of the attachment plug and accessible conductive parts

(Note 1) should be more than 1M-ohm.

Note 1 : Accessible Conductive Parts including Metal panels, Input

terminals, Earphone jacks, etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by

static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical Es

devices are integrated circuits and some field effect transistors and

semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any electrostatic

charge on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging wrist strap device, which should be removed for

potential shock reasons prior to applying power to the unit under

test.

2. After removing an electrical assembly equipped with ES devices,

place the assembly on a conductive surface such as aluminum

foil, to prevent electrostatic charge buildup or exposure of the

assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices.

4. Use only an antistatic solder removal device. Some solder

removal devices not classified a “anti-static” can generate

electrical charges sufficient to damage ES devices.

5. Do not use freonpropelled chemicals. These can generate

electrical charge sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically

shorted together by conductive foam, aluminum foil, or

comparable conductive material).

7. lmmediately before removing the protective material from the

leads of a replacement ES device, touch the protective material to

the chassis or circuit assembly into which the device will be

installed.

Caution : Be sure no power is applied to the chassis or circuit, and

observe all other safety precautions.

8. Minimize bodily motions when handing unpackaged replacement

ES devices. (Normally harmless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a

carpeted floor can generate static electricity sufficient to damage

an ES device.)

1-6

SPECIFICATIONS

Amplifier Section

Output Power (Front) :

F.T.C Rating:

60 watts RMS per channel minimum, both channels

driven into 8 ohms from 20 Hz to 20kHz with no

more than 0.09% total harmonic distortion

Surround Output Power (0.5% THD, 1 kHz, 8 ohms) :

50 + 50 Watt (Front)

50 Watt (Center)

50 + 50 Watt (Rear)

Total Harmonic Distortion (Front) :

0.05 % (at 30 watts, 1 kHz)

Delay Time :

DOLBY DIGITAL : REAR : 0 - 15 ms

CENTER : 0 - 5 ms

DOLBY PRO LOGIC : REAR : 15 - 30 ms

Audio Input Sensitivity/Impedance :

*LINE : 320 mV/47 k ohms

Output Level / Impedance :

VCR REC : 300 mV/2.2 k ohms

Frequency Response :

*LINE : 10 Hz - 60 kHz, +1/ -3 dB

Signal-to-Noise Ratio : 1 Watt

*LINE : 70 dB (IHF-A)

Tone Control :

BASS : ±10 dB at 100 Hz

TREBLE : ±10 dB at 10 kHz

Digital Audio Section

Sampling Frequency :

32 kHz, 44.1 kHz, 48 kHz, 96 kHz

DIGITAL Input Level/Impedance

COAXIAL : 0.5 Vp-p/75 ohms

OPTICAL : -15 dBm ~ -21 dBm

Video Section

Input Sensitivity /Impedance : 1.0 Vp-p/75 ohms

Output Level /Impedance : 1.0 Vp-p/75 ohms

*LINE means CABLE/SAT, VCR, VIDEO4

•

Improvements may result in specifications and features

changing without notice.

•

lllustrations may differ slightly from production models.

FM Tuner Section

(Without notes 100.1 MHz, 65 dBf)

Tuning Range :

87.5 MHz - 108.0 MHz C: 50 kHz steps

AH: 100 kHz steps

AM Suppression Ratio: C: 50 dB

AH: 60 dB

Total Harmonic Distortion (1 kHz) :

Mono : 0.4%

Stereo : 0.5%

Frequency Respones : 20 Hz - 15 kHz, +1/ -1. 5 dB

Stereo Separation (1 kHz) : C: 40 dB

AH: 35 dB

Signal-to-Noise Ratio :

Mono : 70 dB

Stereo : 65 dB

AM Tuner Section

Tuning Range:

C : 522 kHz - 1,620 kHz (9 kHz steps)

AH : 520 kHz - 1,710 kHz (10 kHz steps)

Usable Sensitivity : 55 dB/m

Total Harmonic Distortion : 0.1% at 85 dB/m

Signal-to-Noise Ratio : 40 dB at 85 dB/m

General

Power Requirements :

C : 230V AC, 50Hz

AH : 120V AC, 60Hz

Power Consumption : C: 1.3A

AH: 2.5A

AC Outlets : unswitched x 1, Total 100 W max. (1A)

Dimensions (W x H x D) : 435 x 133 x 375

Weight (net) : 11.8kg

1-7

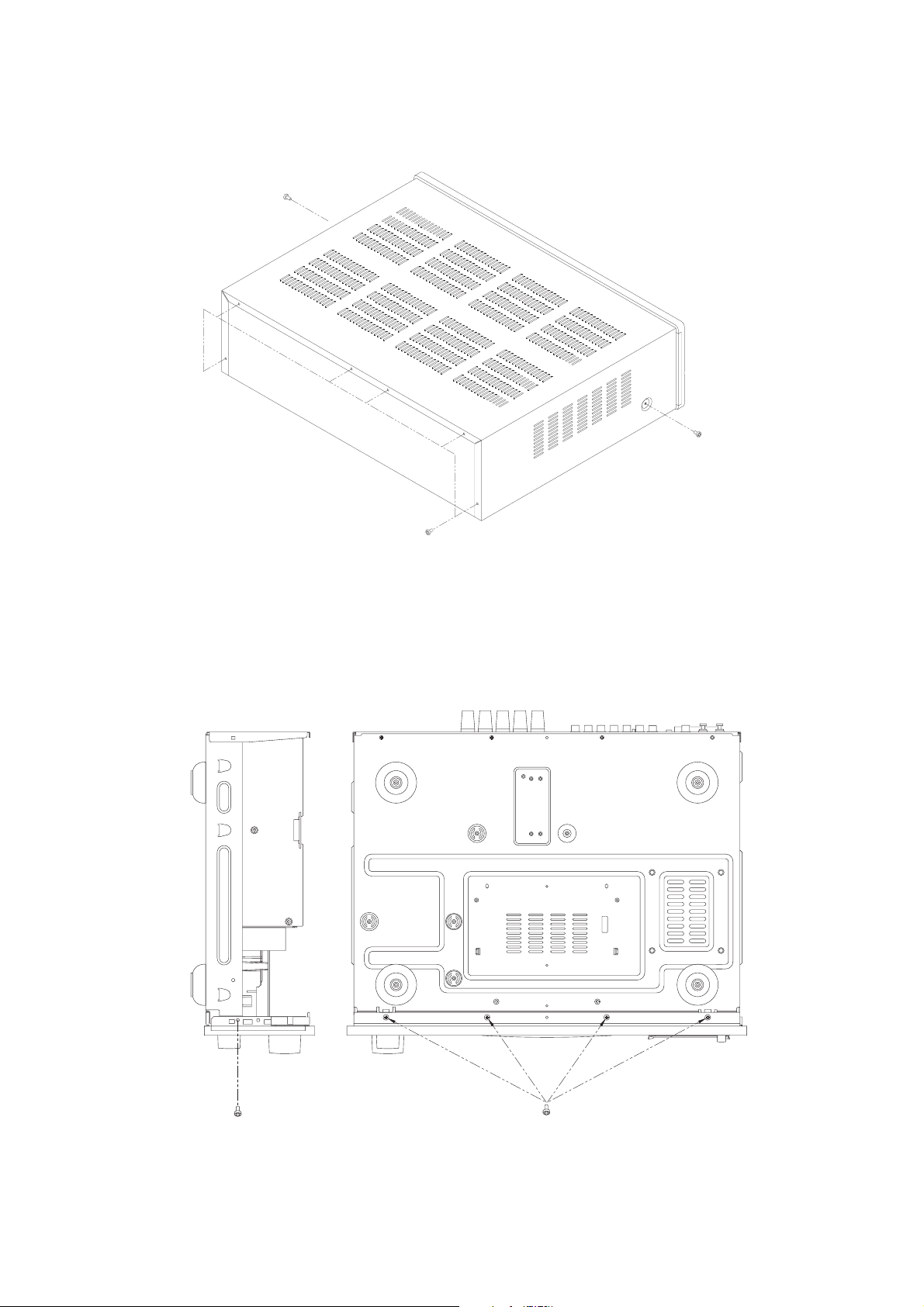

DISASSEMBLY

1> REMOVAL OF TOP COVER

2> REMOVAL OF FRONT PANEL

1-8

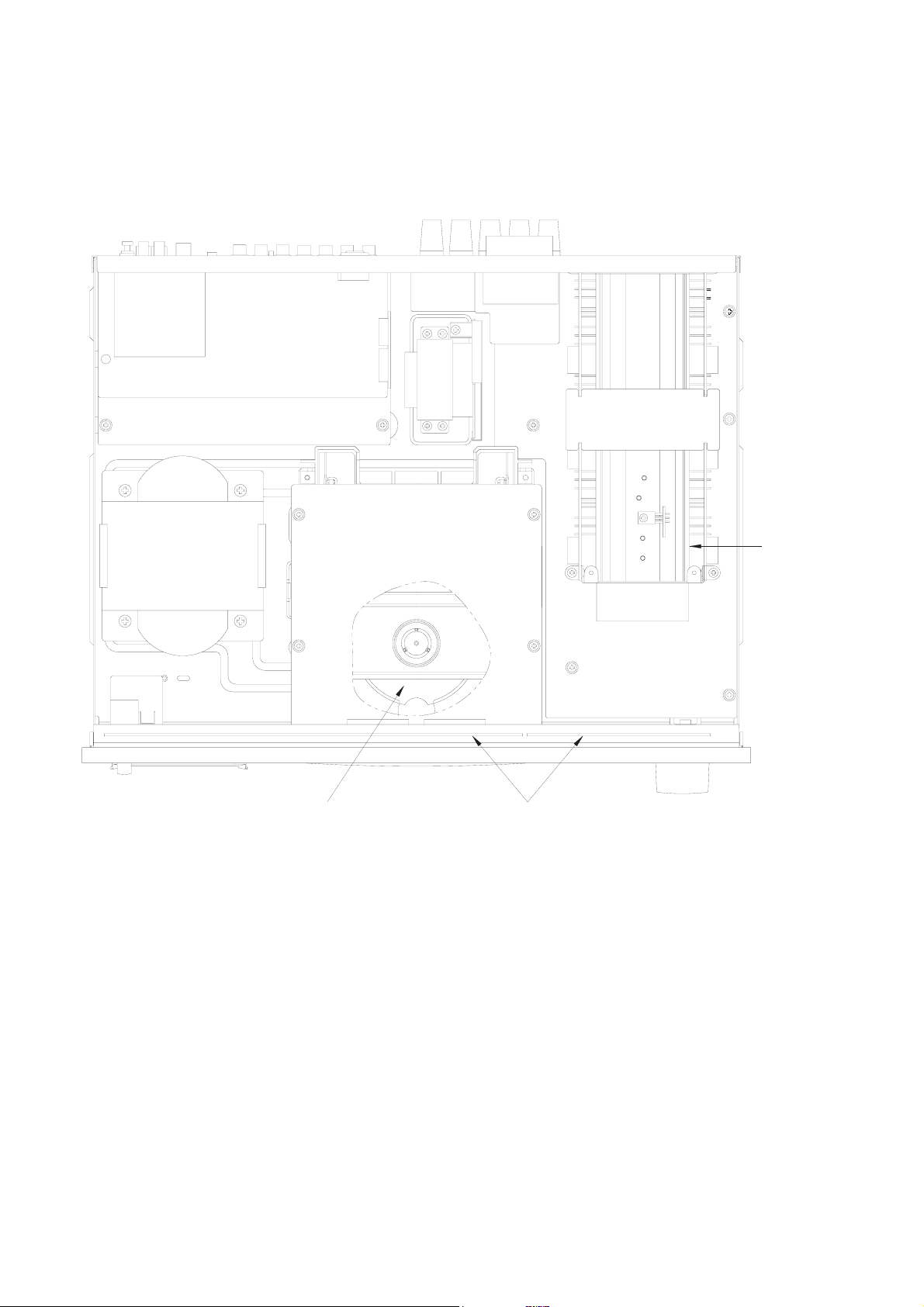

PRINCIPAL PARTS LOCATION

TUNER

PACK

INPUT, DSP, PCB

VIDEO PCB

TRANSFORMER

MICOM PCB

HEATSINK

FAN

POWER PCB

FRONT PCBDVD MECHANISM

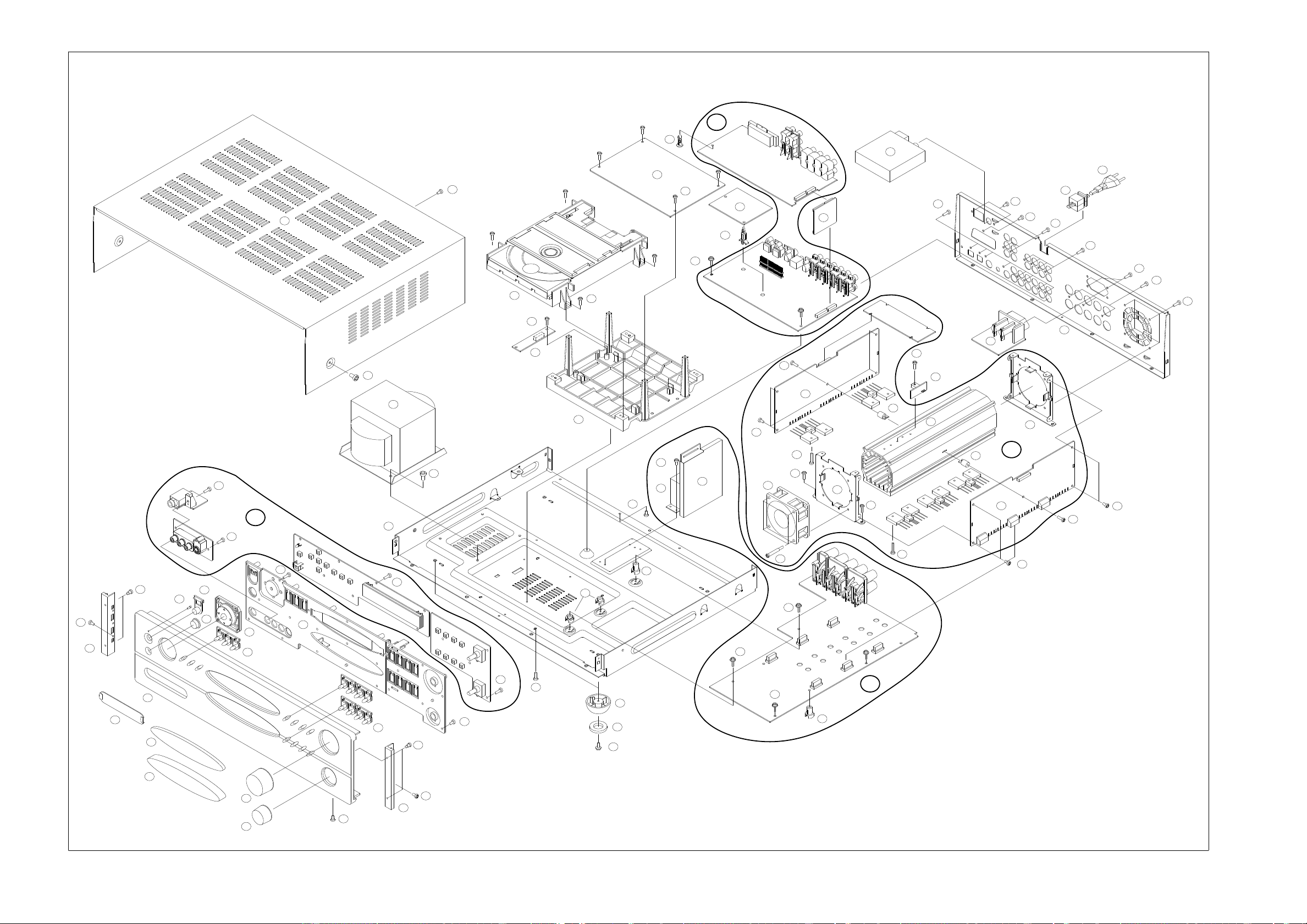

EXPLODED VIEW : L73C

17

34

40

43

33

X6

S4

32

X2

S7

X4

S7

X4

S7

X8

38

S6

13

X2

39

X2

S9

X2

S6

S20

44

X2

S6

36

24

13

X2

S8

S10

S2

13

28

19

30

X4

S1

29

27

26

45

X4

S6

X2

S6

X3

S6

X4

S5

S15

X5

S16

X4

S7

13

18

S2

41

X4

S1

42

25

X6

S12

26

S11

29

31

28

S10

X2

S1

S7

S15

S14

X4

S2

X8

S18

X2

12

11

S1

7

10

9

15

8

S7

23

X4

S7

X4

S7

6

1

2

X4

8

S18

X2

S19

X20

S9

22

S13

S12

S9

X4

20

X4

21

X4

X2

22

24

X9

X2

S1

3

4

S1

7

X4

5

S3

1-9 1-10

EXPLODED VIEW : L73AH

17

34

40

43

33

X6

S4

32

X2

S7

X4

S7

13

X2

S8

X4

S7

38

X2

39

X2

S9

13

S6

S2

S10

13

S5

44

X8

24

S20

X3

X2

S6

36

28

19

30

X4

S1

29

27

26

45

X4

S6

X2

S6

X3

S6

X4

S5

S15

X5

S16

X4

S7

13

18

S2

41

X4

S1

42

25

X6

S12

26

S11

31

29

28

S10

X2

S1

S7

S15

S14

X4

S2

X8

S18

X2

12

11

S1

7

10

9

15

8

S7

23

X4

S7

X4

S7

6

1

2

X4

8

S18

X2

S19

X20

S9

22

S13

S17

24

S9

X4

20

X4

21

X4

X2

22

X9

X2

S1

3

4

S1

7

X4

5

S3

1-11 1-12

Y

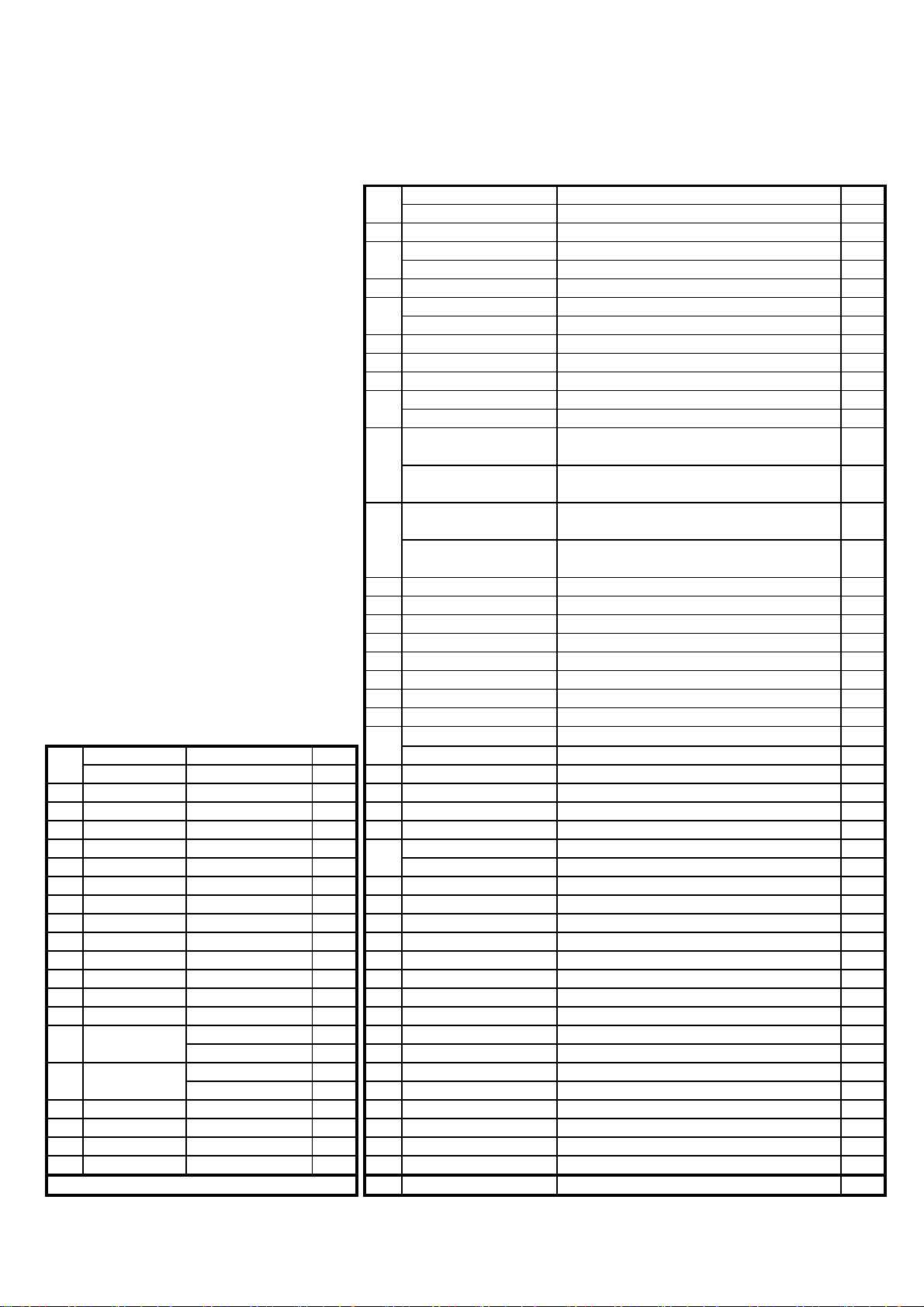

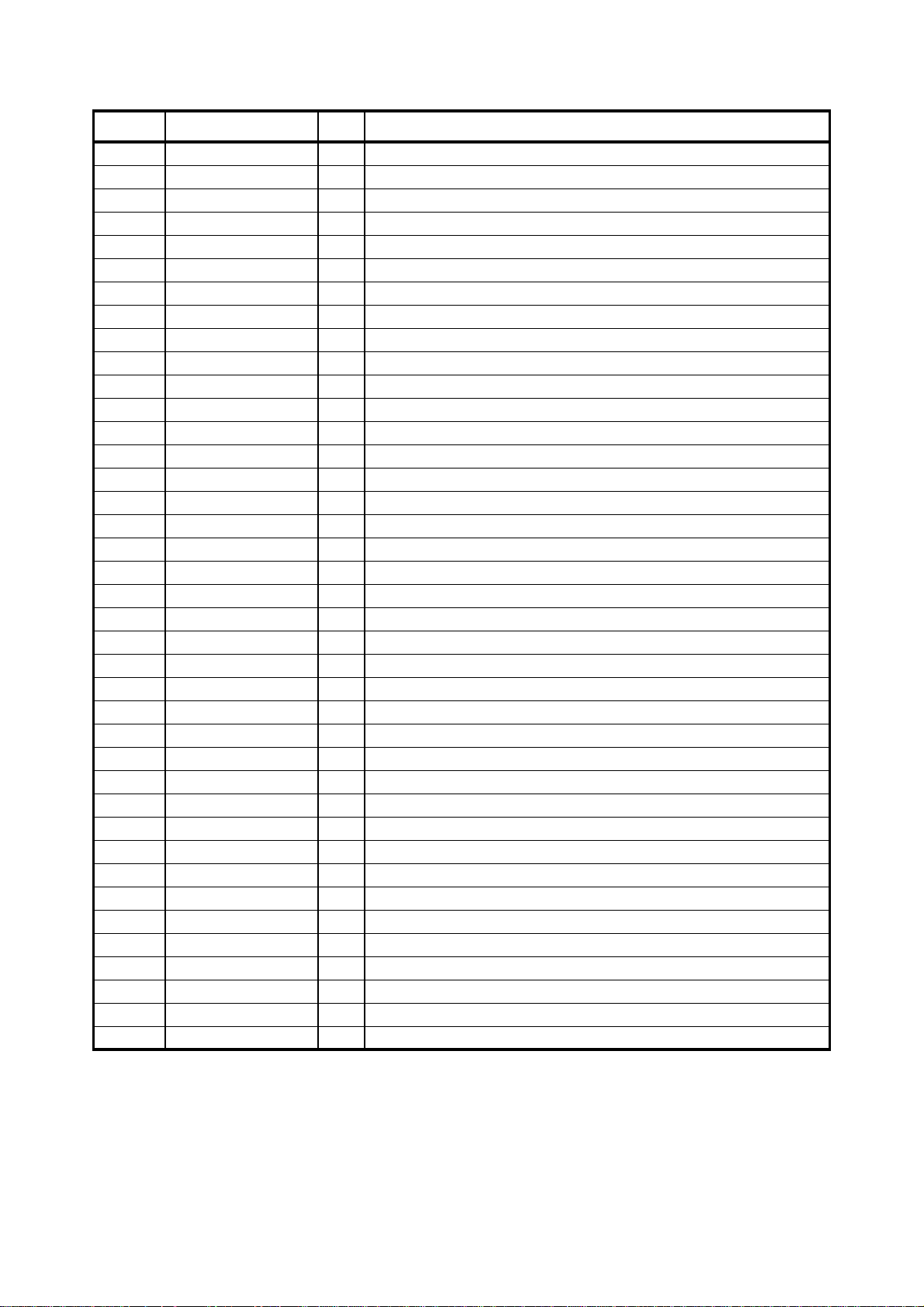

L73AH/C EXPLODED VIEW PARTS LIST

1-13

CJA523FBYA CORD, POWER(AH Ver.) 1

45

CJA2B068ZA CORD, POWER(C Ver.) 1

44 KHR1A028 BUSHING, AC CORD 1

HNVTFCE1U116A TUNER MODULE(AH Ver.) 1

43

CNVKSTMB014MA18 TUNER MODULE(C Ver.) 1

42 CMX1A139 INSULATOR 1

CLT5L055ZU SUB TRANS.ASS'Y(AH Ver.) 1

41

CLT5L055ZE SUB TRANS.ASS'Y(C Ver.) 1

40 KRE1A056 SUPPORT, PCB 1

39 KRE1A058 SUPPORT, PCB 2

38 CIP11755BSMD DSP PCB ASS'Y 1

CKF4A244WK1 PANEL, REAR(AH Ver.) 1

36

CKF3A244VK1 PANEL, REAR(C Ver.) 1

COP11736B

34

COP11736C

COP11737B

33

COP11737C

32 HJDRL-S2004ZA MECHANISM ASS'Y 1

31 CMYL70CCC

30 CMH2A189 SUPPORT, MECHA 1

29 CMH1A119 MOUNT, PCB 2

28 CUP11555Z AMP PCB ASS'Y 1

27 CMY1A197 HEAT SINK 1

26 CMD1A479 BRACKET, HEATSINK 2

25 HDMKD1206PTS3 FAN 1

COP11556D POWER PCB ASS'Y(AH Ver) 1

CTB3+8GFZ SCREW(AH Ver.) 3 COP11556E POWER PCB ASS'Y(C VER)

S20

CHD1A055 SCREW(C Ver.) 1 23 CHE1A030 HOLDER, PCB 2

S19 CTB3+6F SCREW 20 22 CHE170 HOLDER, PCB 2

S18 CHD1A016 SCREW 4 21 CHG1A297 CUSHION, FOOT 4

S17 CTW3+14J SCREW 1 20 CKL1A086 FOOT 4

S16 CHD1A023 SCREW,TRANS. 4 CLT5V031ZU POWER TRANS. (AH Ver.) 1

S15 CHD1A012 SCREW,TR 15 CLT5V031ZE POWER TRANS. (C Ver.) 1

S14 CHD1A036 SCREW,FAN 4 18 CUA1A223 CHASSIS, BOTTOM 1

S13 CTW3+20J SCREW 1 17 CKC1A141S35 CABINET, TOP 1

S12 CTB3+14J SCREW 1 15 CGW1A351M7K102 PANEL, SUB 1

S11 CTB3+20J SCREW 1 13 COP11738B FRONT PCB ASS'Y 1

S10 CTB3+16J SCREW 2 12 CBT1A746M7K102 KNOB, POWER 1

S9 CTW3+8J SCREW 9 11 CGL1A188 INDICATOR, POWER 0.17

S8 CTB4+6FFC SCREW 2 10 CGU1A245A10 WINDOW, SENSOR 1

S7 CTB3+10G SCREW 28 9 CBT1A853M7K102 KNOB, ENTER 1

S6 CTB3+10GFZ

S5 CTB3+8JFZ

S4 CTB3+8JFC SCREW 6 4 HGK2A063YA VOLUME KNOB ASS'Y 1

S3 CTS3+8J SCREW 4 3 CGR1A287M7YK102 ORNAMENT, DOOR 1

S2 CTB3+8J SCREW 7 2 CGU1A244A8 WINDOW, FIP 1

S1 CTB3+6J SCREW 15 1 CGR1A288M7K102 COVER, JACK 1

NO. PARTS NO. DESCRIPTION Q'TY NO. PARTS NO. DESCRIPTION Q'TY

SCREW(AH Ver.) 19 8 CBT1A745M7K102 KNOB, DISPLAY 5

SCREW(C Ver.) 21 7 CKM2A062C37 BAR, SIDE 2

SCREW(AH Ver.) 5 6 CKM1A130XC37 PANEL, AL 1

SCREW(C Ver.) 4 5 HGK1A081ZA ROTARY KNOB ASS'Y 1

24

19

INPUT,DSP & VIDEO

PCB ASS'Y(AH Ver.)

INPUT,DSP & VIDEO

PCB ASS'Y(C Ver.)

MICOM & POWER SUPPLY PCB

ASS'Y(AH Ver.)

MICOM & POWER SUPPLY PCB

ASS'Y(C Ver.)

AMPLIFIER ASS'

1

1

1

2-1

SECTION 2

ELECTRICAL CONTENTS

CONTENTS

IC BLOCK DIAGRAMS & PIN DESCRIPTION .......................................................................................... 2-2

DIAGRAM .................................................................................................................................................... 2-27

1. BLOCK DIAGRAM ................................................................................................................................ 2-27

2. WIRING DIAGRAM .............................................................................................................................. 2-29

3. SCHEMATIC DIAGRAM ...................................................................................................................... 2-31

•

FRONT PART ............................................................................................................................. 2-31

•

µ-COM & POWER SUPPLY PART............................................................................................ 2-33

•

INPUT & VOLUME PART........................................................................................................... 2-35

•

CODEC & LPF PART ................................................................................................................. 2-37

•

DSP PART................................................................................................................................... 2-39

•

VIDEO PART............................................................................................................................... 2-41

•

AMP PART .................................................................................................................................. 2-43

•

POWER PART ............................................................................................................................ 2-45

4. PRINTED CIRCUIT BOARDS ............................................................................................................. 2-47

•

FRONT PART ............................................................................................................................. 2-47

•

µ-COM & POWER SUPPLY PART............................................................................................ 2-49

•

DSP PART................................................................................................................................... 2-50

•

INPUT, VOLUME, CODEC, LPF & VIDEO PART..................................................................... 2-51

•

AMP PART .................................................................................................................................. 2-55

•

POWER PART ............................................................................................................................ 2-57

5. TROUBLESHOOTING .......................................................................................................................... 2-59

2-2

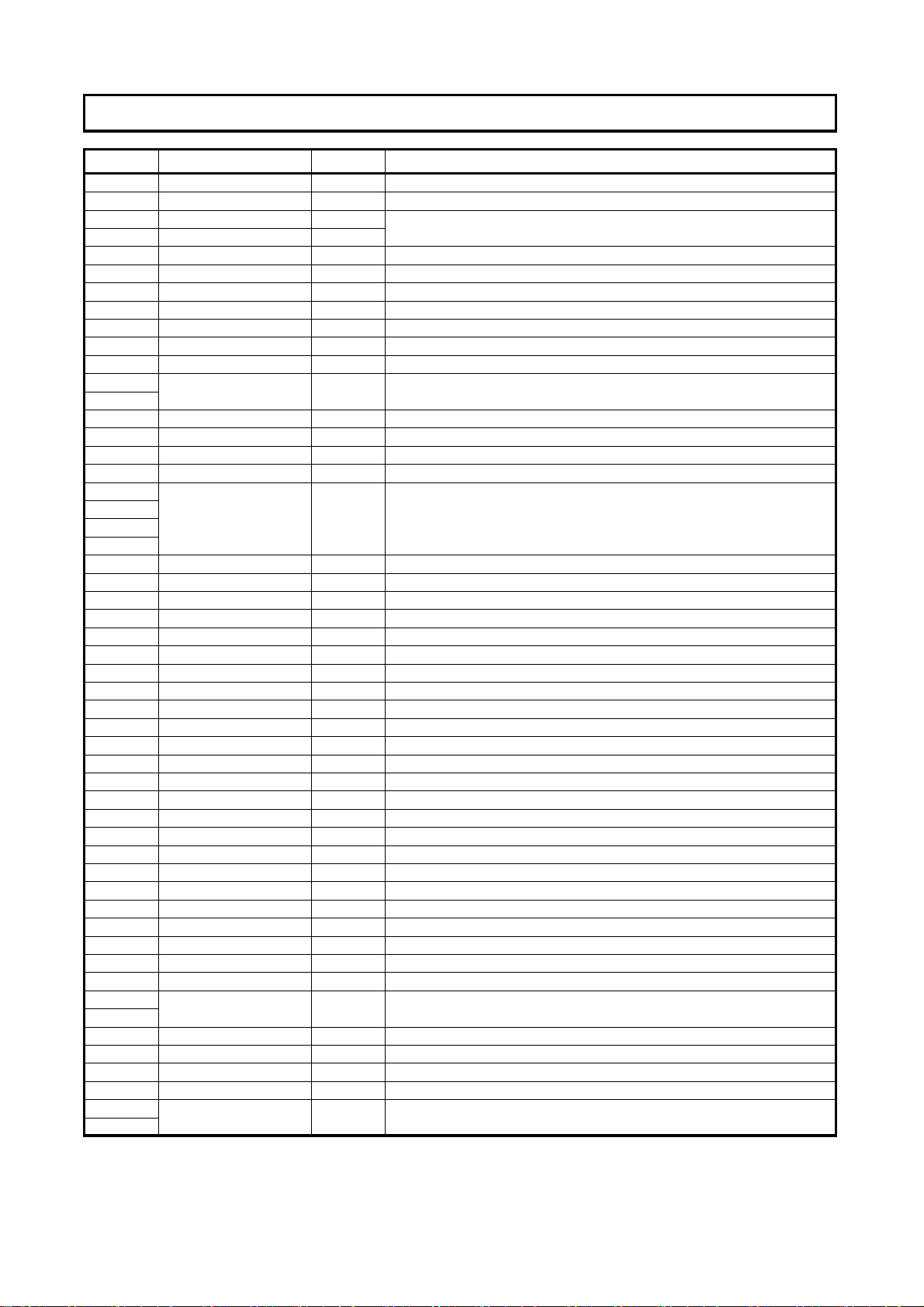

I.C PIN DESCRIPTIONS ( IC81 : FLASH u-COM : ST92F124VIT6 )

PIN No PIN Name I/O

1 T-MUTE O

2 DVD_FAN O

3 N.C

4 N.C

5 SIN I

6 SOUT O

7 TXCLK O

8 RXCLK I

9 VFD_DATA O

10 VFD_CK O

11 VFD_CS O

12

13

14 GND1 15 VDD1 16 V-MUTE O

17 ROM-SEL O

18

19

20

21

22 DVD_RESET O

23 DVD_FREQ O

24 GND 25 DVD_TX O

26 DVD_RX I

27 DVD_CLK I

28 VREG 29 N.C 30 PLL_DOUT I

31 TUNED I

32 N.C 33 PLL_CE O

34 STEREO I

35 PLL/FUNC_DA O

36 PLL/FUNC_CLK O

37 FUNC_CE I

38 GND2 39 VDD2 40 VREG 41 VTEST 42 EVOL_CE O

43 EVOL_DA O

44 EVOL_CK O

45 RDS_DA I

46

47

48 AK_INTERRUPT I

49 AK/CS_CK O

50 AK/CS_DA O

51 DATA_IN I

52

53

N.C

N.C

NC - No Connection

NC No Connection

Function

Tuner mute port

DVD Fan port

No Connection

Micom update port

Micom update port

Micom update TX port

Micom update RX port

VFD Display Data out port

VFD Display Clock port

VFD Display Chip selector port

-

-

-

No Connection

GND Port1

Power Supply Port1

Video mute port

8M Flash Memory (IC46) selector port

No Connection

DVD Reset port

DVD Request port

GND

DVD Data out port (TX)

DVD Data in port (RX)

DVD Chip enable port

Stabilization capacitor(s) for internal voltage regulator

No Connection

PLL Data OUT port

Tuner module TUNED control port

No Connection

PLL Chip enable port

Tuner module STEREO control port

PLL/FUNCTION data output port

PLL/FUNCTION clock output port

FUNCTION IC chip enable port

GND2

Power Supply port2

Stabilization capacitor(s) for internal voltage regulator

Must be kept low in standard operating mode

Electronic volume IC chip enable port

Electronic volume IC data port

Electronic volume IC clock port

RDS data in port

DIR+CODEC (IC31) interrupt port

DSP(IC45) / DIR+CODEC(IC31) clock port

DSP(IC45 )/ DIR+CODEC(IC31) data out port

DSP(IC45) / DIR+CODEC(IC31) data in port

2-3

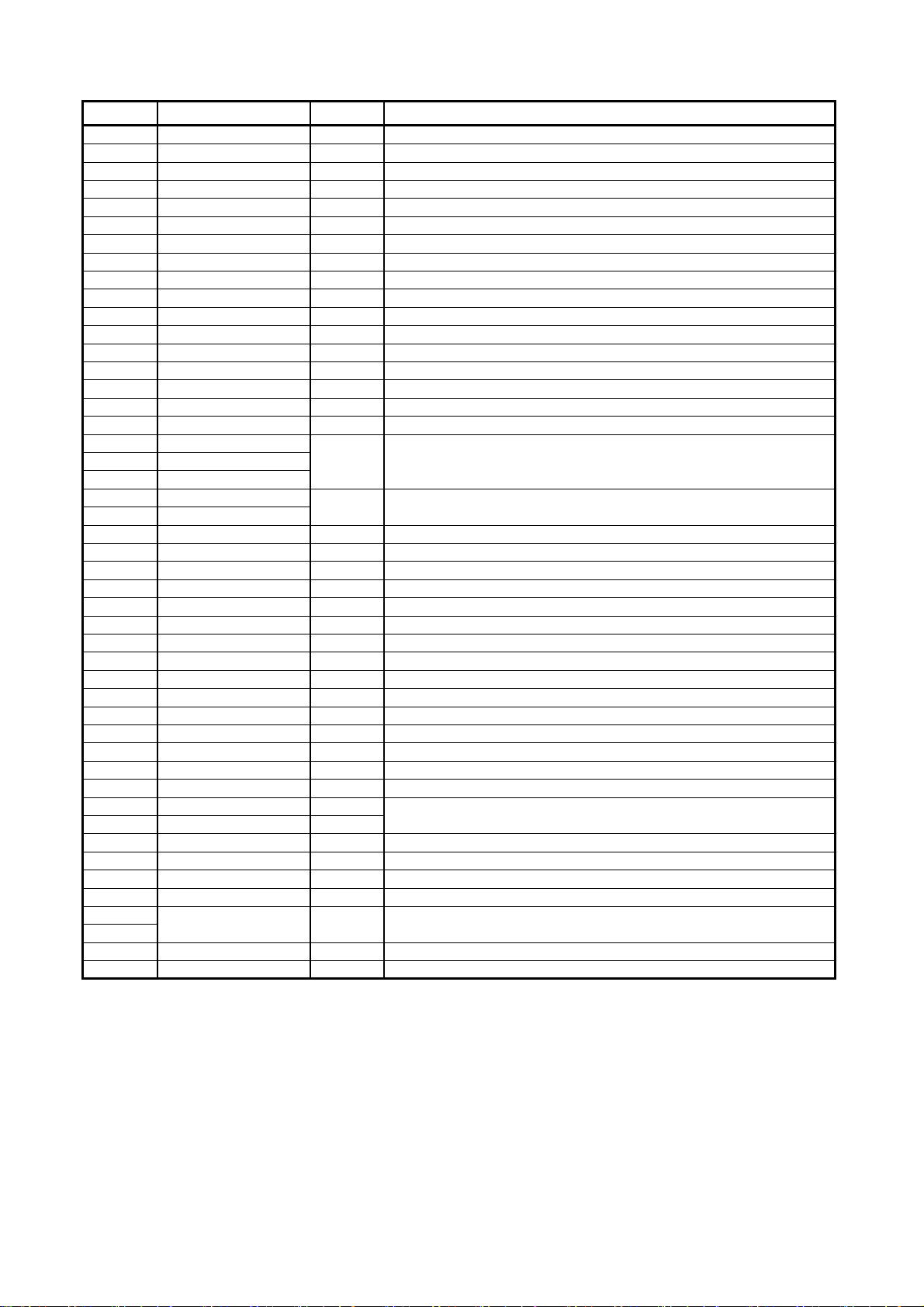

PIN No PIN Name I/O

54 DSP_RESET I

55 AK_RESET I

56 AK_CE I

57 HINBSY I

58 DSP_C_CS O

59 DSP_AB_CS O

60 INT_REQ I

61 GND3 62 VDD3 63 FINTREQ I

64 REMOTE_IN I

65 HOST_CE I

66 RDS_CLK I

67 DVD_MREQ I

68 OPTION1 I

69 OPTION2 I

70 NC 71 KEY_IN1

72 KEY_IN2

73 KEY_IN3

74 VOL_B

75 VOL_A

76 FUNC_A I

77 FUNC_B I

78 FAN_DET I

79 AVDD 80 GND4 81 POWER_H O

82 FUNC_MUTE(H) O

83 H/PHONE_IN(L) I

84 DVDPW_ON O

85 DVDA_SEL O

86 EXP_CLK O

87 EXP_DA O

88 EXP_CE O

89 GND5 90 VDD4 91 OSCIN 92 OSCOUT 93 RESET I

94 HW0SW1 95 N.C 96 PROTECT_IN(L) I

97

98

99 RTC_SDA O

100 RTC_SCL O

N.C -

Function

DSP(IC45) reset port

DIR+CODEC(IC31) reset port

DIR+CODEC(IC31) chip enable port

HOST BUSY

DSP(IC45) C Chip selector port

DSP(IC45) AB Chip selector port

DSP(IC45) interrupt request port

GND3

Power Supply port3

DSP(IC45) interrupt request port

System remote Input port

HOST(IC81) Chip enable port

RDS Clock port

DVD Main request port

* H : FM 50KHz step ,* L : FM 100KHz step

* H : AM 9KHz step ,* L : AM 10KHz step

No Connection

I

I

KEY Data input port

Volume Data Input port(Master Volume)

Function A control port

Function B control port

Fan Detector port

Analog Power Supply port

GND4

Power on control port (Active "H")

Function mute port (Active "H")

Headphone in port (Active "L")

DVD Power ON port

DVD Audio selector port

Expander IC14 Clock port

Expander IC14 Data out port

Expander IC14 Chip enable port

GND5

Power Supply port4

4MHz Crystal Connection port

Reset port

Watchdog option port

No Connection

Protection port (Active"L")

No Connection

Real time control serial data out port

Real time control serial clock port

2-4

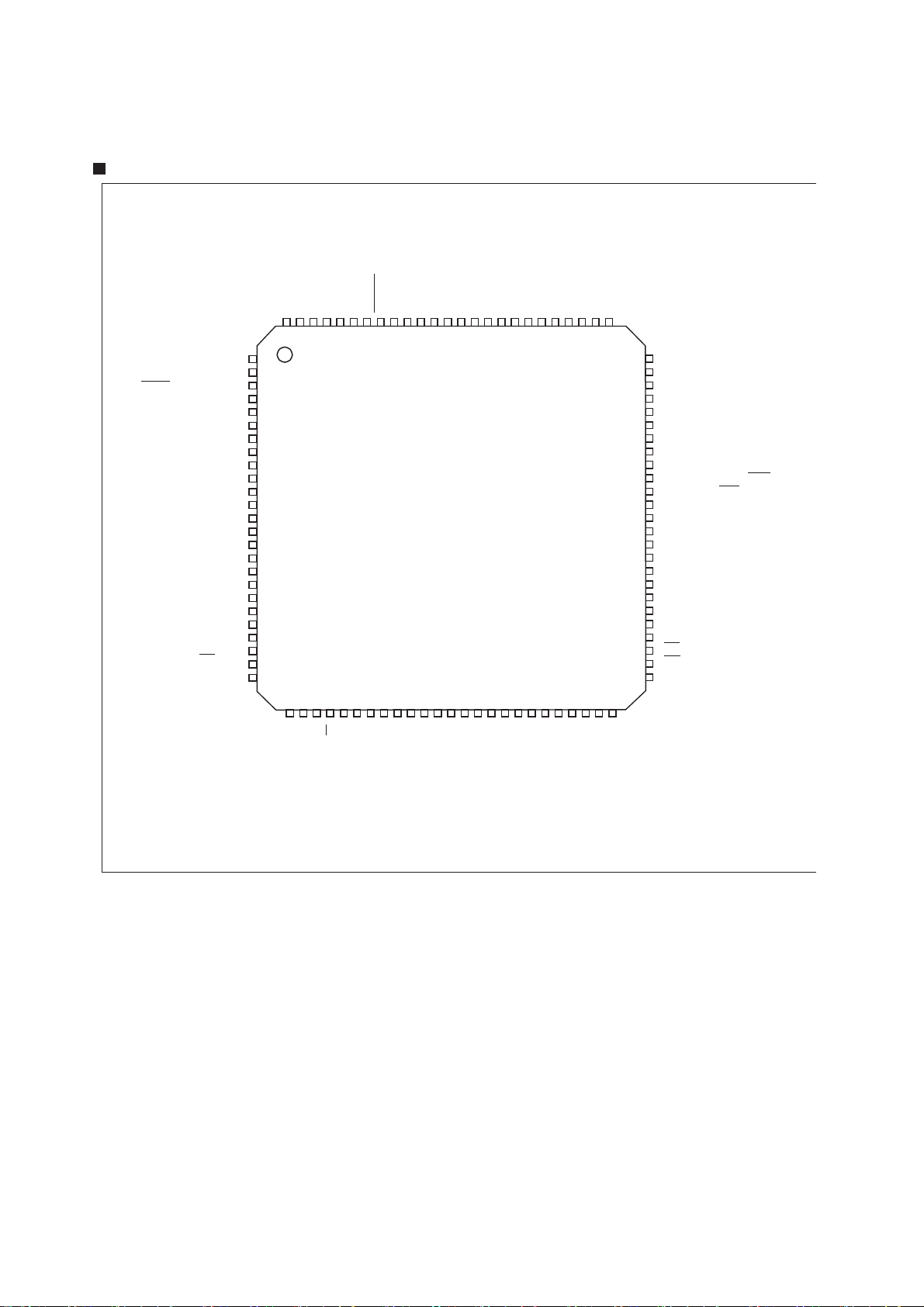

ST92F124V1: Pin Configuration (Top-view TQFP100)

SS

RESET

OSCOUT

DD

P7.7/AIN15/7/ WKUP13

P7.6/AIN14/WKUP12

OSCIN

V

P7.5/AIN13/WKUP11

V

A20/P9.6

A21/P9.7

W

AIT/WKUP5/P5.0

WKUP6/WDOUT/P5.1

SIN/WKUP2/P5.2

WDIN/SOUT/P5.3

TXCLK/CLKOUT/P5.4

RXCLK/WKUP7/P5.5

DCD/WKUP8/P5.6

WKUP9/RTS/P5.7

ICAPA1/P4.0

CLOCK2/P4.1

OCMPA1/P4.2

V

V

ICAPB1/OCMPB1/P4.3

DD

EXTCLK1/WKUP4/P4.4

EXTRG/STOUT/P4.5

SDA/P4.6

WKUP1/SCL/P4.7

ICAPB0/P3.1

ICAPA0/OCMPA0/P3.2

OCMPB0/P3.3

EXTCLK0/SS

/P3.4

MISO/P3.5

P9.5/A19

P9.4/A18

P9.2/A16

P9.3/A17

100999897969594939291908988878685848382818079787776

1

2

3

4

5

6

7

8

9

10

11

12

13

14

SS

15

16

17

18

19

20

21

22

23

24

25

27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 4647 48 49 50

26

HW0SW1

P9.0/RDI

P9.1/TDO

ST92F124V1

P7.4/AIN12/WKUP3

P7.1/AIN9

P7.3/AIN11

P7.0/AIN8/CK_AF

P7.2/AIN10

P8.7/AIN7

AVSSAVDDP8.6/AIN6

P8.5/AIN5

75

P8.4/AIN4

74

P8.3/AIN3

73

P8.2/AIN2

72

P8.1/AIN1/WKUP15

71

P8.0/AIN0/WKUP14

70

NC

69

P6.5/WKUP10/INTCLK

68

P6.4/NMI

67

P6.3/INT3/INT5

66

P6.2/INT2/INT4/DS2

65

P6.1/INT6/RW

64

P6.0/INT0/INT1/CLOCK2/8

63

P0.7/A7/D7

V

62

DD

V

61

SS

P0.6/A6/D6

60

P0.5/A5/D5

59

P0.4/A4/D4

58

P0.3/A3/D3

57

P0.2/A2/D2

56

P0.1/A1/D1

55

P0.0/A0/D0

54

AS

53

DS

52

P1.7/A15

51

RW

REG

V

MOSI/P3.6

SCK/WKUP0/P3.7

* V

must be kept low in standard operating mode.

TEST

SS

DD

V

V

TEST

REG

V

*V

A8/P1.0

A9/P1.1

TINPB0/P2.1

TINPA0/P2.0

TINPB1/P2.5

TINPA1/P2.4

TOUTA0/P2.2

TOUTB0/P2.3

TOUTB1/P2.7

TOUTA1/P2.6

NC

WKUP6

A10/P1.2

A11/P1.3

A12/P1.4

A13/P1.5

A14/P1.6

2-5

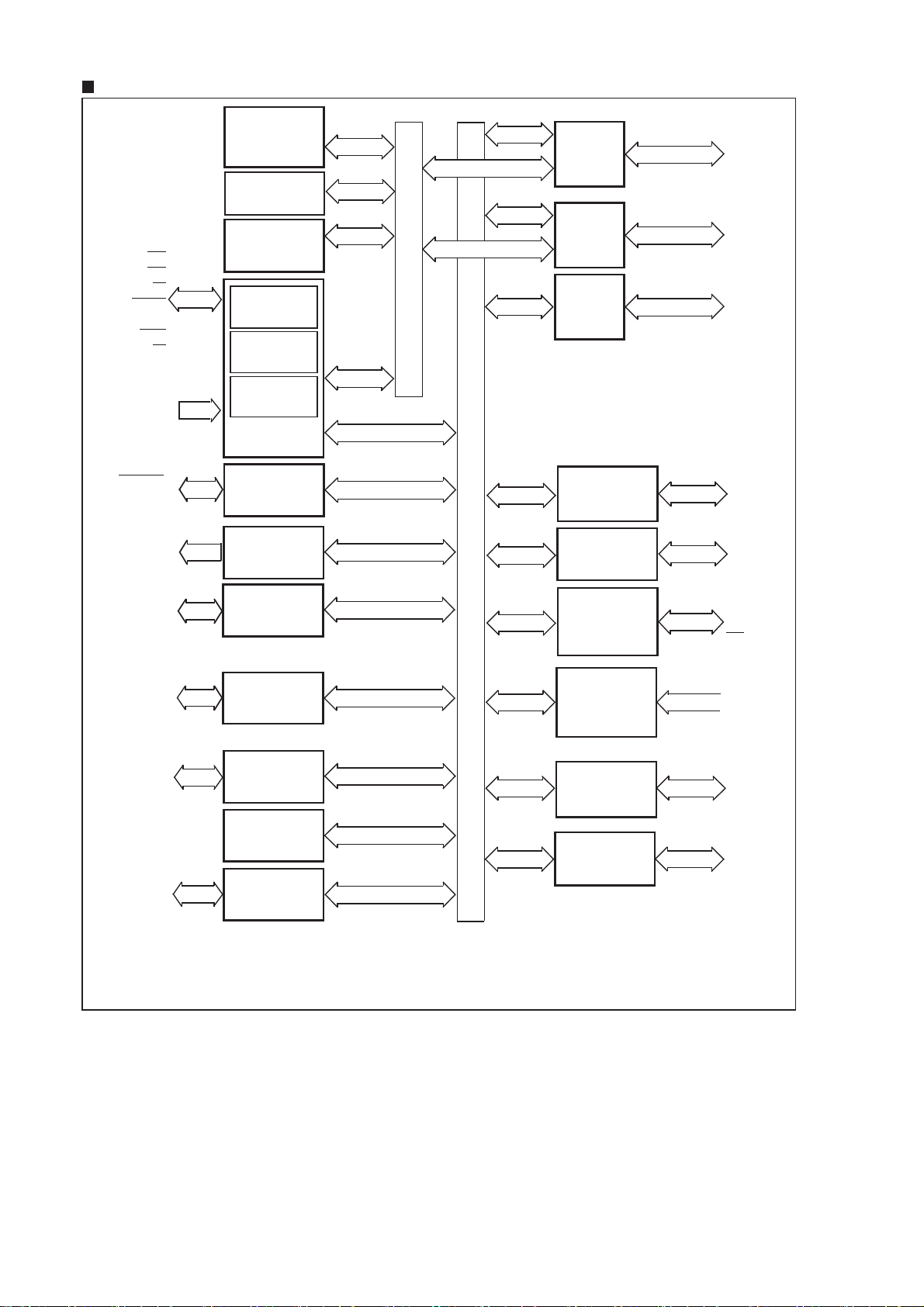

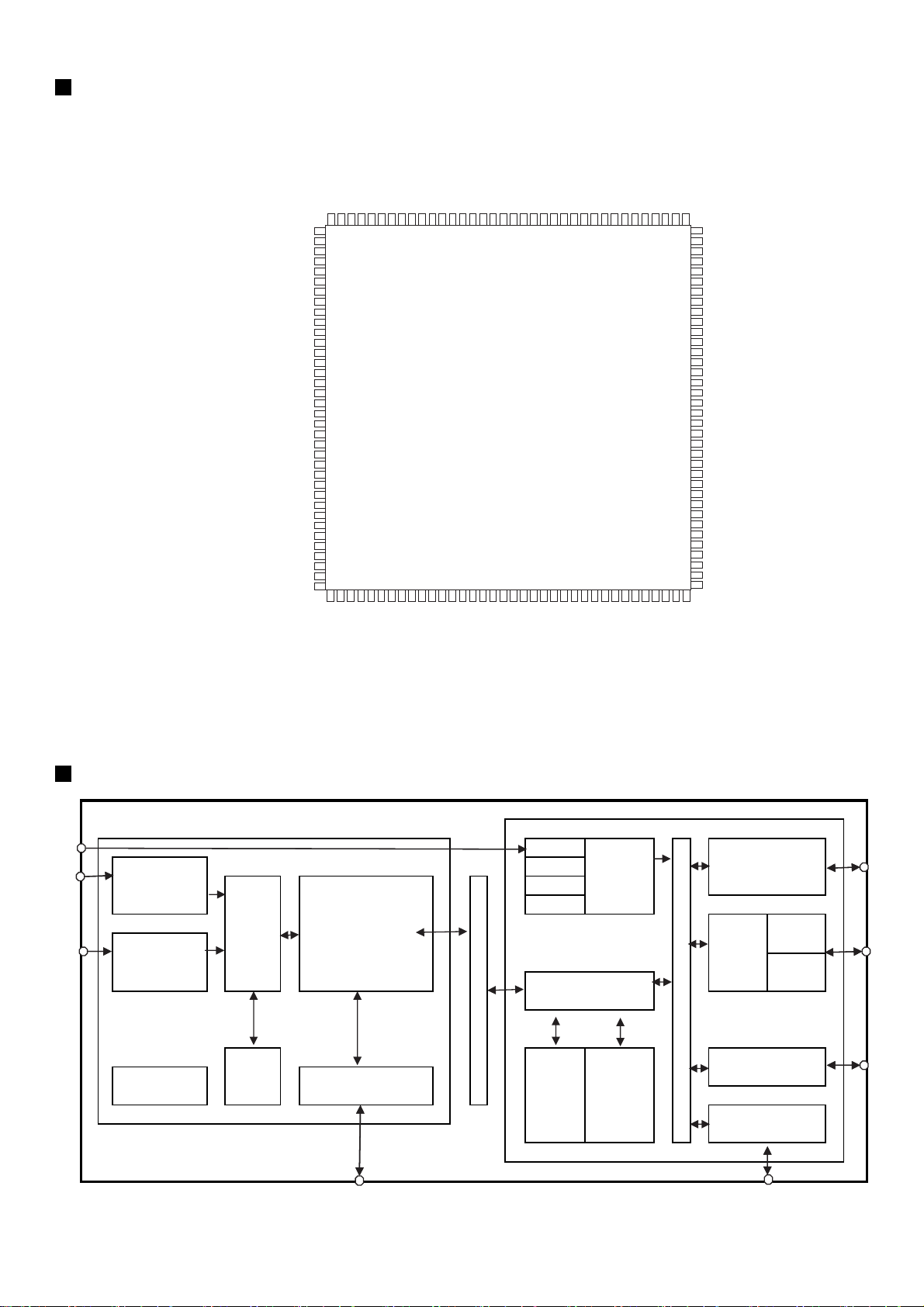

ST92F124V1: Architectural Block Diagram

RW

WAIT

NMI

DS2

RW

INT[6:0]

WKUP[15:0]

OSCIN

OSCOUT

RESET

CLOCK2/8

INTCLK

CK_AF

STOUT

ICAPA0

OCMPA0

ICAPB0

OCMPB0

EXTCLK0

ICAPA1

OCMPA1

ICAPB1

OCMPB1

EXTCLK1

TINPA0

TOUTA0

TINPB0

TOUTB0

TINPA1

TOUTA1

TINPB1

TOUTB1

V

REG

AS

DS

FLASH

128 Kbytes

3 TM

E

1 Kbyte

RAM

4 Kbytes

256 bytes

Register File

8/16 bits

CPU

Interrupt

Management

ST9 CORE

RCCU

ST. TIMER

EF TIMER 0

EF TIMER 1

MF TIMER 0

MF TIMER 1

VOLTAGE

REGULATOR

Ext. MEM.

ADDRESS

DATA

Port0

Ext. MEM.

ADDRESS

Ports

1,9

A[7:0]

D[7:0]

A[10:8]

A[21:11]

P0[7:0]

P1[7:3]

Fully

MEMORY BUS

Prog.

I/Os

P1[2:0]

P2[7:0]

P3[7:4]

P3[3:1]

P4[7:4]

P4[3:0]

P5[7:0]

P6[5:2,0]

P6.1

P7[7:0]

P8[7:0]

P9[7:0]

I2C BUS

WATCHDOG

SDA

SCL

WDOUT

HW0SW1

MISO

SPI

REGISTER BUS

ADC

MOSI

SCK

SS

AV

DD

AV

SS

AIN[15:8]

AIN[7:0]

EXTRG

TXCLK

RXCLK

SIN

SCI M

DCD

SOUT

CLKOUT

RTS

SCI A

RDI

TDO

The alternate functions (

Port8 and Port9.

Italic characters

) are mapped on Port 0, Port 1, Port2, Port3, Port4, Port5, Port6, Port7,

2-6

I.C PIN DESCRIPTIONS (IC45 : AUDIO DSP : CS494003)

PIN No PIN Name I/O

1 UHS0 O

2 HUS1 O

3 INTREQ,ABODY O

4 FA1,FSCDIN I

5 GPIO20 O

6 FA0,FSCCLK I

7 FHS2,FSCDIO O

8 GPIO21 O

9 FDAT7 I

10 VDD6

11 VSS6

12 FWR,FDS I

13 FRD,FR/W O

14 FDAT6 I

15 FCS I

16 FINTREQ O

17 FDBCK I

18 FDAT5 I

19 FDAT4 I

20 VDD7

21 VSS7

22 FDAT3 I

23 FDBDA I

24 FDAT2 I

25 DBDA I

26 DBCK I

27 FDAT1 I

28 TEST I

29 FDAT0 I

30 NV_WE O

31 NV_OE O

32 NV_CS O

33 SD_WE O

34 SD_DATA0 O

35 SD_DATA1 O

36 SD_DATA2 O

37 SD_DATA3 O

38 SD_DATA4 O

39 SD_DQM0 O

40 SD_DATA5 O

41 VSSSD4

42 VDDSD4

43 SD_DATA6 O

44 SD_DATA7 O

45 SD_DQM1 O

46 SD_DATA15 O

Function

DSP C Control Mode Select BIT 0

DSP C Control Mode Select BIT 0

Open-drain interrupt-request output

Host Address Bit One or SPI Serial Control data input

General Purpose output

Host parallel Address Bit Zero or Serial Control Port Clock

DSP AB Control port mode select bit2

General Purpose output

DSP AB Bidirectional data bus

2.5V Supply Voltage

2.5V Ground

Host write Strobe or Host data strobe

Host Parallel Output Enable or

DSP AB Bidirectional data bus

Host Parallel Chip Select , Host Serial SPI Chip Select

Open-drain interrupt-request output

Reserved

DSP AB Bidirectional data bus

DSP AB Bidirectional data bus

2.5V Supply Voltage

2.5V Ground

DSP AB Bidirectional data bus

Reserved

DSP AB Bidirectional data bus

Debug Data

Debug Clock

DSP AB Bidirectional data bus

Reserved

DSP AB Bidirectional data bus

SRAM Write Enable

SRAM Output Enable

SRAM Chip Select

SDRAM Write Enable

SDRAM Data Bus 0

SDRAM Data Bus 1

SDRAM Data Bus 2

SDRAM Data Bus 3

SDRAM Data Bus 4

SDRAM Data Mask 0

SDRAM Data Bus 5

SDRAM Ground

SDRAM Power Supply

SDRAM Data Bus 6

SDRAM Data Bus 7

SDRAM Data Mask 1

SDRAM Data Bus 15

2-7

PIN No PIN Name I/O

47 SD_DATA14 O

48 NC5

49 SD_DATA13 O

50 VSSSD3

51 VDDSD3

52 SD_DATA12 O

53 SD_DATA11 O

54 SD_DATA10 O

55 SD_DATA9 O

56 SD_DATA8 O

57 VSSSD2

58 VDDSD2

59 SD_CLK_OUT O

60 SD_ADR9 O

61 SD_CLK_IN I

62 SD_ADR8 O

63 SD_ADR7 O

64 SD_CLK_EN I

65 SD_ADR6 O

66 SD_ADR5 O

67 SD_ADR4 O

68 SD_CS I

69 VSSSD1

70 VDDSD1

71 SD_BA O

72 SD_ADR10 O

73 SD_ADR0 O

74 SD_ADR1 O

75 SD_ADR2 O

76 SD_ADR3 O

77 SD_RAS O

78 SD_CAS O

79 SDATAN3 I

80 SDATAN2 I

81 SDATAN1 I

82 SDATAN0 I

83 NC4

84 NC3

85 LRCLKN I

86 SCLKN I

87 LRCLK1 O

88 NC2

89 NC1

90 VDD1

91 VSS1

92 XMT958,AUDATA7 O

93 AUDATA6 O

94 AUDATA5 O

95 HDATA7 O

Function

SDRAM Data Bus 14

No Connect (Ground)

SDRAM Data Bus 13

SDRAM Ground

SDRAM Power Supply

SDRAM Data Bus 12

SDRAM Data Bus 11

SDRAM Data Bus 10

SDRAM Data Bus 9

SDRAM Data Bus 8

SDRAM Ground

SDRAM Power Supply

SDRAM CLOCK DATA OUT

SDRAM Address Bus

SDRAM CLOCK DATA IN

SDRAM Address Bus 8

SDRAM Address Bus 7

SDRAM Ground

SDRAM Address Bus 6

SDRAM Address Bus 5

SDRAM Address Bus 4

SDRAM Chip Select

SDRAM Ground

SDRAM Power Supply

SDRAM Bank Address Select

SDRAM Address Bus 10

SDRAM Address Bus 0

SDRAM Address Bus 1

SDRAM Address Bus 2

SDRAM Address Bus 3

SDRAM Row Address Strobe

SDRAM Column Address Strobe

PCM Audio input Data 3

PCM Audio input Data 2

PCM Audio input Data 1

PCM Audio input Data 0

No Connect (Ground)

PCM audio input sample rate clock

PCM audio input bit clock

Audio Output Sample Rate Clock

No Connect (Ground)

2.5V Supply Voltage

2.5V Ground

Digital Audio Output 7 , S/PDIF Transmitter

Digital Audio Output 6

Digital Audio Output 5

DSP C Bidirectional data bus 7

2-8

PIN No PIN Name I/O

96 HDATA6 O

97 HDATA5 O

98 SCLK1 O

99 MCLK I

100 VDD2

101 VSS2

102 AUDATA4 O

103 HDATA4 O

104 SCLK0 O

105 HDATA3 O

106 AUDATA3 O

107 AUDATA2 O

108 LRCLK0 O

109 AUDATA1 O

110 AUDATA0 O

111 CMPCLK,SCLKN2 I

112 HDATA2 O

113 VSS3

114 VDD3

115 HDATA1 O

116 HDATA0 O

117 CMPREQ,FLRCLK2 I

118 CMPDAT,FSDATA2 I

119 FLRCLKN1 I

120 WR,DS I

121 RD,R/W I

122 PLLVSS

123 FILT2

124 FILT1

125 PLLVDD

126 XTALO O

127 XTAL,1CLKIN I

128 CLKSEL I

129 CS O

130 A0 O

131 FSDATAN1 I

132 VDD4

133 VSS4

134 FSCLKN1,STCLK2 I

135 SCS I

136 SCDIN I

137 VSS5

138 VDD5

139 A1 O

140 SCDOUT O

141 HNBSY I

142 SCCLK O

143 UHS2,CS_OUT O

144 RESET I

Function

DSP C Bidirectional data bus 6

DSP C Bidirectional data bus 5

Audio output bit clock

Audio Master clock

2.5V Supply Voltage

2.5V Ground

Digital Audio Output 4

DSP C Bidirectional data bus 4

Audio output bit clock

DSP C Bidirectional data bus 3

Digital Audio Output 3

Digital Audio Output 2

Audio Output Sample Rate Clock

Digital Audio Output 1

Digital Audio Output 0

PCM audio input bit clock

DSP C Bidirectional data bus 2

2.5V Ground

2.5V Supply Voltage

DSP C Bidirectional data bus 1

DSP C Bidirectional data bus 0

PCM Audio Data input bit clock

PCM Audio data input Number two

PCM audio data input one

DSP AB Control port mode select bit 0

DSP AB Control port mode select bit 1

PLL Ground voltage

Phase-Locked Loop Filter

Phase-Locked Loop Filter

PLL supply voltage

Crystal OSC Output

External Clock input/Crystal OSC input

DSP Clock select

Host parallel Chip Select

Host Parallel Address bit 0

PCM Audio Data input one

2.5V Supply Voltage

2.5V Ground

PCM audio input bit clock

Host Serial SPI Chip Select (Active "L")

SPI Serial control data input

2.5V Ground

2.5V Supply Voltage

Host Address bit 1

Serial control port data

Input Host Message status

Serial control port clock

DSP C Control Mode Select BIT 2

Master Reset Input

2-9

y

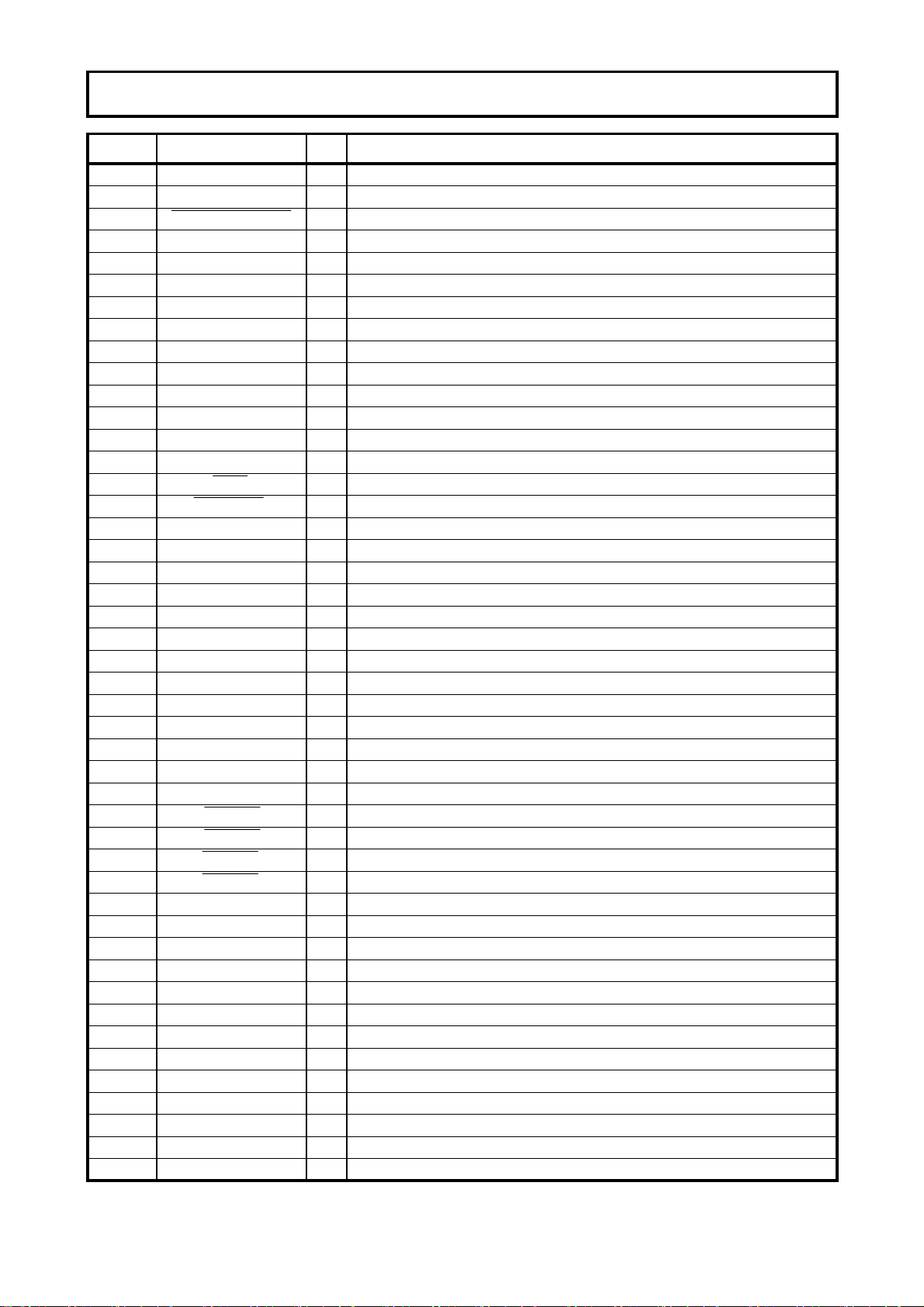

PIN ASSIGNMENT(IC45: CS494003)

A

859

3

TMX

O

IP

,3ATAD

G

2

,

0

3

A

0

T

K

A

A

L

TADH

K

L

D

CR

CS

UA

UA

L

1

8

9

1

1

OI

O

I

PG

P

G

,

,0

1S

S

H

H

U

U

501

5

02

TO

NID

OIPG

OB

C

S

A

F

,1AF

QE

R

T

NI,

AUDATA1

AUDATA0

CMPCLK, FSCLKN2

HDATA2, GPIO2

VSS3

VDD3

HDATA1, GPIO1

HDATA0, GPIO0

CMPREQ, FLRCLKN2

CMPDAT, FSDATAN2

FLRCLKN1

WR, DS, GPIO10

RD, R/W, GPIO11

PLLVSS

PLLVDD

CS, GPIO9

A0, GPIO13

FSDATAN1

VDD4

FSCLKN1, STCCLK2

UHS2, CS_OUT, GPIO17

VSS4

SCS

SCDIN

VSS5

VDD5

A1, GPIO12

SCDOUT, SCDIO

HINBSY, GPIO8

SCCLK

RESET

110

115

120

125

130

135

140

144

13

OI

P

G

,

B85

0

8

2

4

OI

OI

PG

P

,4

G ,4A

A

T

K

2

AD

2S

T

L

A

D

C

D

SV

D

U

A

M

H

V

00

1

9

3

2

5

OIP

G

,5

1

A

T

K

A

L

DH

CS

9TMX

6OI

7O

O

OI

I

I

P

P

P

P

G

G

,

,

,6

G ,6A

G

5

7

,

7

A

AT

A

T

T

ATAD

T

A

D

H

H

5

9

1

ADUA

A

A

1S

D

D

D

S

D

U

U

A

A

V

V

09

3

2OIP

22

O

IP

G

,

G ,NK

NK

1

K

LC

L

2C

1

L

C

C

C

R

R

N

L

S

N

L

58

CS494003

0

1

7T

1

6

T

KLC

2

DD

U

A

OI

ODC

D

V

CS

P

F

G

F

S

,

F

,OI

OAF

D

C

S

F

,

2

S

HF

6

S

S

V

S

/

D

RF

F

,

,W

R

D

W

R

F

F

,

,1

0SH

SHF

F

51

6

S

TADF

C

F

02

7

7

5

4

KCB

Q

T

TA

E

AD

RT

D

D

F

F

F

NI

F

2T

3

A

T

SS

DDV

D

AD

AD

B

V

D

F

F

F

5

7

6

2

2

2

2

O

O

O

OI

I

I

I

P

P

P

P

G ,0

G ,

G ,3

G ,

1

2

S

N

A

T

3

4C

A

C

D

S4

N

N

5

2

1

A

K

T

D

CBD

AD

BD

F

S

N

N

N

AC

A

AT

ATA

A

R

T

_

_D

A

AD

D

D

DS

S

S

S

S

08

0

3

6

0T

51

4

T

1

1

SE

A

O

O

O

I

I

I

D

T

P

PG ,

PG ,

F

G

,

SC

E

E

O

W

_

_V

_

V

V

N

N

N

1

2

3

0

A

A

A

A

T

T

T

TX

XE,

XE

XE,

E

,

,

2

3R

0

1

RD

R

R

D

DDA

DD

D

DA

A

A

_D

_D

_

_D

D

S

S

S

S

5

7

SD_ADDR10, EXTA10

SD_BA, EXTA19

VDDSD1

70

VSSSD1

SD_CS

SD_ADDR4, EXTA4

SD_ADDR5, EXTA5

65

SD_ADDR6, EXTA6

SD_CLK_EN

SD_ADDR7, EXTA7

SD_ADDR8, EXTA8

SD_CLK_IN

60

SD_ADDR9, EXTA9

SD_CLK_OUT

VDDSD2

VSSSD2

SD_DATA8, EXTA11

SD_DATA9, EXTA12

55

SD_DATA10, EXTA13

SD_DATA11, EXTA14

SD_DATA12, EXTA15

VDDSD3

50

VSSSD3

SD_DATA13, EXTA16

NC5

SD_DATA14, EXTA17

SD_DATA15, EXTA18

45

SD_DQM1

SD_DATA7, EXTD7

SD_DATA6, EXTD6

VDDSD4

VSSSD4

40

SD_DATA5, EXTD5

SD_DQM0

SD_DATA4, EXTD4

SD_DATA3, EXTD3

5

3

2D

0D

1

E

D

W_

T

TX

TX

XE

DS

E ,

E ,

,2

1AT

0

A

AT

T

A

AD

A

D

D

_

_D

_D

D

S

S

S

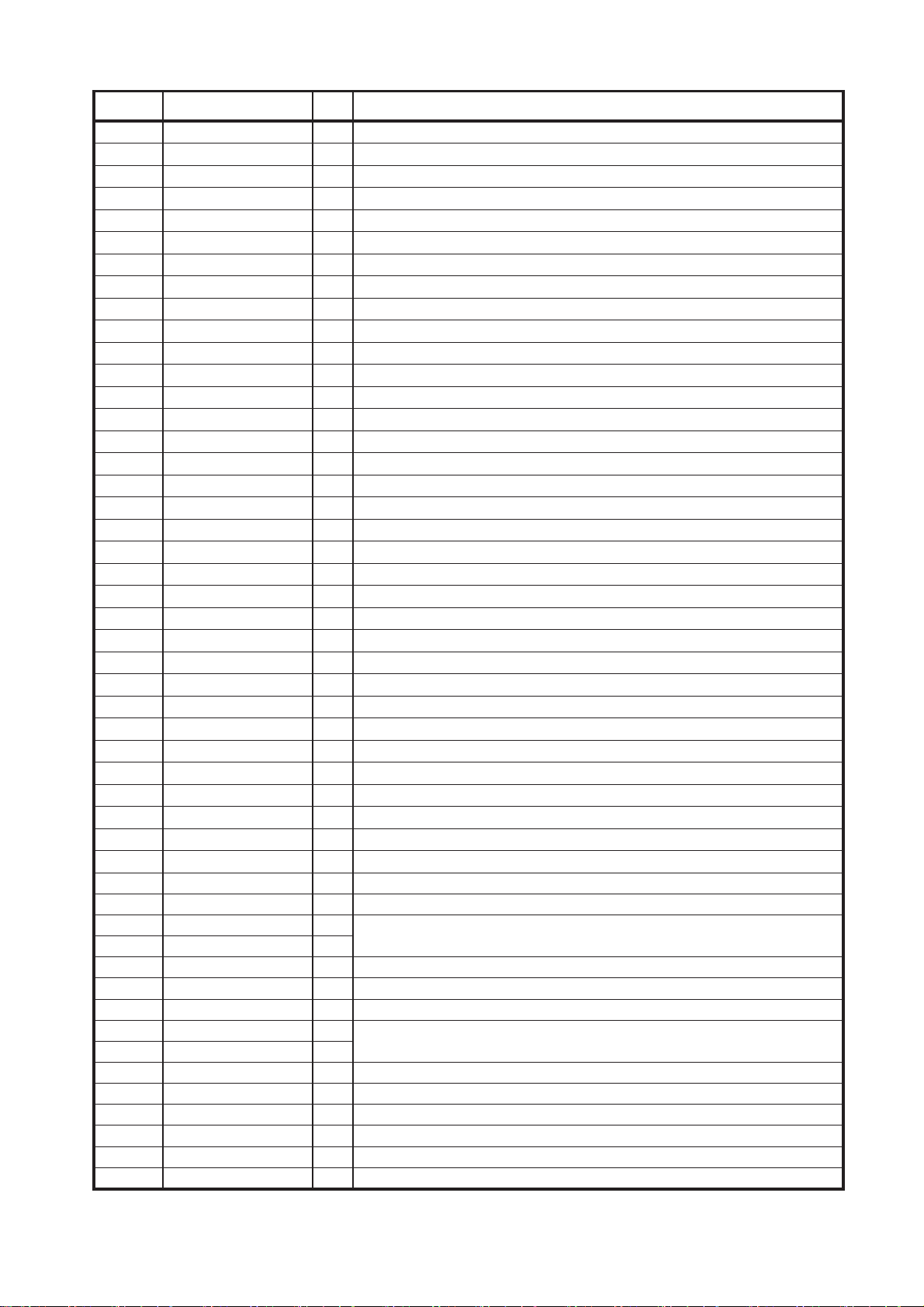

BLOCK DIAGRAM(IC45: CS494003)

SAI 0 Serial

Compressed SAI 1 Audio

Digital

Interface SAI 3

Farme

Digital Shifter

Multi-Standard

Audio Decoder

Audio Audio

Input

DSP AB

Input

PLL Clock Buffer

Manager RAM

Parallel or Serial

Host Interface

S

H

A

R

E

D

M

E

M

O

R

Y

SAI 2 Interface

DSP C

Programmable

32-Bit DSP

DSP DSP

RAM ROM

External Memor

Interface

I

N

T

Digital

E

R

Output

N

A

L

B

GPIO and I/O

U

S

Controller

Parallel or Serial

Host Interface

DAO 0

DAO 1

2-10

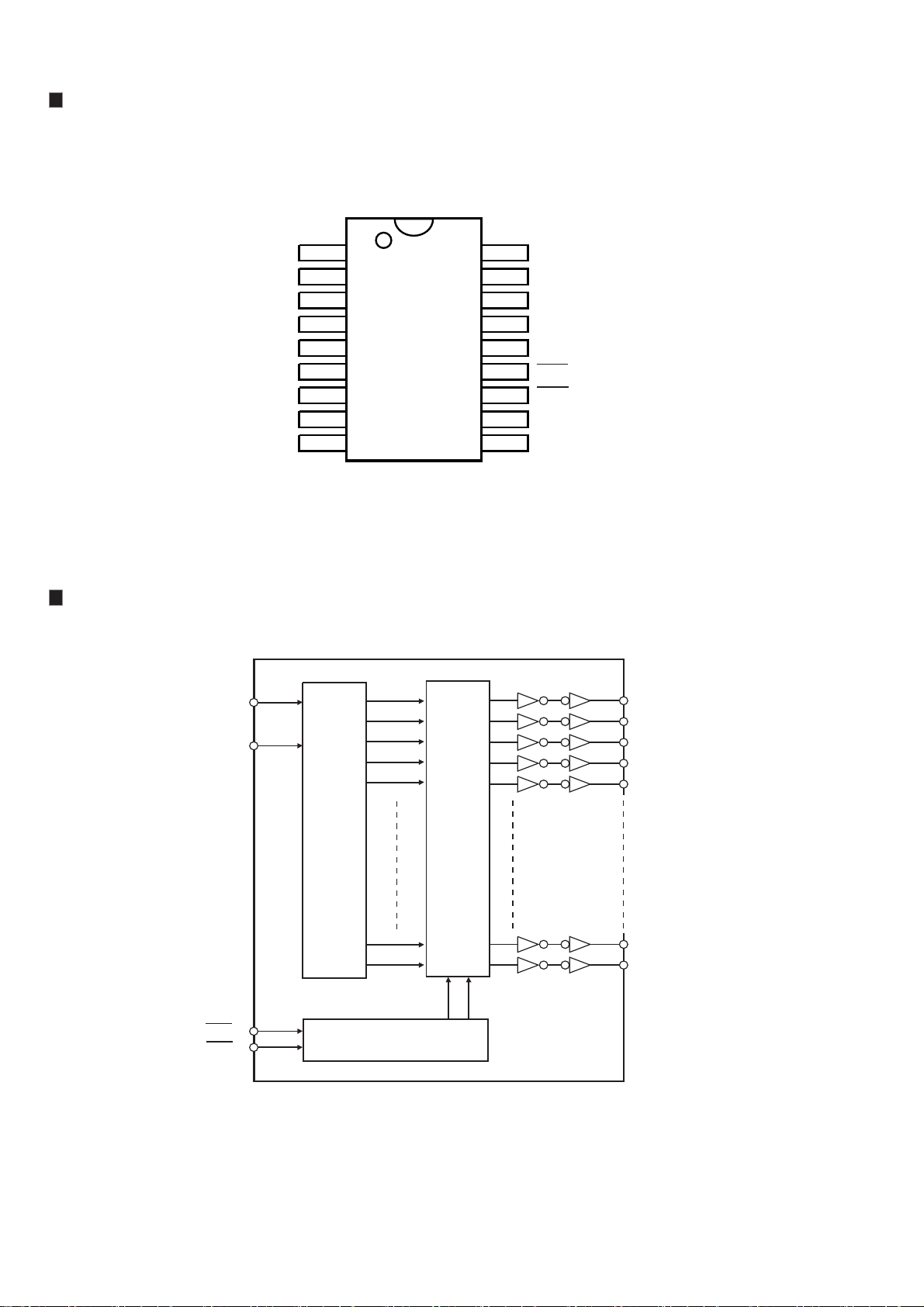

NJU3713

(IC14 : EXPANDER / MAIN)

BLOCK DIAGRAM

DATA

CLK

P5

P6

P7

P8

Vss

P9

P10

P11

P12

10

11

1

2

3

4

5

6

7

8

9

18

17

16

15

14

13

12

11

10

DD

V

P4

P3

P2

P1

CLR

STB

CLK

DATA

14

15

16

17

P1

P2

P3

P4

1

P5

STB

CLR

12

13

Shift Circuit

Controller Circuit

Latch Circuit

8

P11

9

P12

2-11

A

X

I.C PIN DESCRIPTIONS (IC31:AUDIO CODEC WITH DIR : AK4588)

PIN No PIN Name I/O

1 AK_INT O

2NC

3 TVDD

4 DVDD

5 DVSS

6NC

7 XTAL_IN I

8 DVSS

9 MCLK O

10 MCLK O

11 NC

12 NC

13 NC

14 SDATA1 O

15 FSCLK O

16 FLRCLK O

17 SDATA2 O

18 SCLK0 O

19 LRCLK1 O

20 AK/CS_DOUT O

21 AK/CS_CK I

22 AK/CS_DA I

23 AK_CE I

24 GND

25

26 AUDIODATA2 I

27 AUDIODATA1 I

28 AUDIODATA0 I

29 GND

30 +5VD

31 AK_RST

32 DVSS

33 NC

34 NC

35 DMIXL_DSP O

36 NC

37 DMIXR_DSP O

38 NC

39 SR-DSP O

40 NC

41 SW-DSP O

UDIODATA_DMI

I

Function

Interrupt pin

Not connect

3.3V Power Supply

5V Power Supply

Digital ground pin

Not connect

X`tal clock input pin

Digital ground pin

Masster clock

Masster clock

Not connect

Not connect

Not connect

Audio serial data 1

Systm clock

Audio serial data L/R clock

Audio serial data 2

Bit clock

Audio serial data L/R clock

Digital audio out

System clock

Control data

Chip enable

High impeadance ground

Audio data downmix data

AUDIODATA2

AUDIODATA1

AUDIODATA0

High impeadance ground

5V Pull up

Chip reset

Digital ground pin

Not connect

Not connect

Downed L-ch analog output

Not connect

Downed R-ch analog output

Not connect

Surround right-ch analog output

Not connect

Subwoofer-ch analog output

2-12

PIN No PIN Name I/O

42 NC

43 FR-DSP O

44 NC

45 SL-DSP O

46 NC

47 FL-DSP O

48 NC

49 CEN-DSP O

50 NC

51 ADLIN-DSP I

52 ADRIN-DSP I

53 VCOM

54 +5VD

55 +5VD

56 AVSS

57 SPDIF_IN

58 DVSS

59 OPTICAL_IN

60 DVSS

61 COAXIAL_IN

62 DVSS

63 NC

64 DVSS

65 GND

66 +5VD

67 NC

68 DVSS

69 NC

70 +5VD

71 NC

72 DVSS

73 NC

74 DVSS

75 DAUX2

76 +5VD

77 MCLK

78 NC

79 DIGITAL_OUT

80 AK_INT

Function

Not connect

Front right-ch analog output

Not connect

Surround left-ch analog output

No Connection

Front left-ch analog output

Not connect

Center-ch analog output

Not connect

L-ch analog input

R-ch analog input

GND(AC)

5V power supply port

5V power supply port

Analog ground

SPDIF input port

Digital ground pin

Optical input port

Digital ground pin

Coaxial input port

Digital ground pin

Not connect

Digital ground pin

High impeadance ground

5V power supply port

Not connect

Digital ground pin

Not connect

5V Pull up

Not connect

Digital ground pin

Not connect

Digital ground pin

Auxiliary audio data input port

5V Pull up

Master clock

Not connect

Digital output port

Interrupt pin

Loading...

Loading...