MV Agusta Brutale Oro-S, F4 Brutale 750 ORO, 750 S, 910 S Workshop Manual

Motorcycle Workshop - Manual

MV AGUSTA BRUTALE ORO - S

- 2 -

Statement

This manual, to be used by the MV Agusta authorised workshops has been realised with the

purpose of assisting authorised personnel in maintenance and repairs operations of the

motorcycle. The knowledge of technical data herein noted, determines the complete professional training of the technician.

With purpose of making the reading of this manual immediately comprehensible, the paragraphs have been aligned with detailed illustrations that highlight the argument dealt with.

Useful advice

To prevent any problems and to reach an excellent final result, MV Agusta recommends

keeping to the following guidelines:

- In the case of an eventual repair, evaluate the client’s impressions who states that there

is an abnormal functioning of the motorcycle and to formulate the right questions to

clarify the symptoms of the problem.

- Clearly diagnose the cause of the abnormality. The basic fundamental theories can be

absorbed by reading this manual that must necessarily be integrated to the personal

experience and the participation of training courses that are periodically organised by

MV Agusta.

- Rationally plan the repair to avoid slack periods, e.g. the collection of spare parts, the

preparation of tools and equipment, etc.

- To reach the part to be repaired limiting the work to the essential operations.

With regards to this, a valid help would be to consult this manual with regards to the

sequences of removal demonstrated in this manual.

Informative note

MV Agusta S.p.A. is committed to a policy of continuous improvement of their products. For

this reason, there could be slight differences between that which is written here and the

motorcycle on which repairs and/or maintenance are about to be carried out. MV Agusta

models are exported to many countries where different norms in relation to the highway

code and homologation procedures are valid. Hoping that you will comprehend these problems, MV Agusta S.p.A. reserves the right to make modifications to its products and technical documentation at any moment and without prior announcement.

Respect and defend the environment

Everything that we do has repercussions on the entire planet and its resources.

MV Agusta, wanting to protect the interest of the people, would like to make the client and

the technicians of the technical assistance centres aware and to adopt modalities of use of

the motorcycle and the disposure of its parts in full respect of the norms in force in terms of

environmental pollution, disposal and the recycling of waste.

Freni

- 3 -

General Index

GENERAL DESCRIPTION........................................................................................

MAINTENANCE ........................................................................................................

BODYWORK ............................................................................................................

AIR INTAKE INJECTION SYSTEM ..........................................................................

ELECTRICAL SYSTEM ............................................................................................

SUSPENSION AND WHEELS ..................................................................................

FRAME ......................................................................................................................

BRAKES....................................................................................................................

COOLING SYSTEM AND LUBRICATION SYSTEM ................................................

SPECIAL TOOLS ......................................................................................................

TORQUE PRESSURES ............................................................................................

DIAGNOSTICS..........................................................................................................

ANALYTICAL INDEX ................................................................................................

A

Rev. 0

B

Rev. 1

C

Rev. 0

D

Rev. 0

E

Rev. 0

F

Rev. 1

G

Rev. 0

H

Rev. 0

L

Rev. 0

M

Rev. 0

N

Rev. 0

O

Rev. 0

P

Rev. 0

- 1 -

General description

A

SECTION A

Revision 0

- 2 -

General description

A

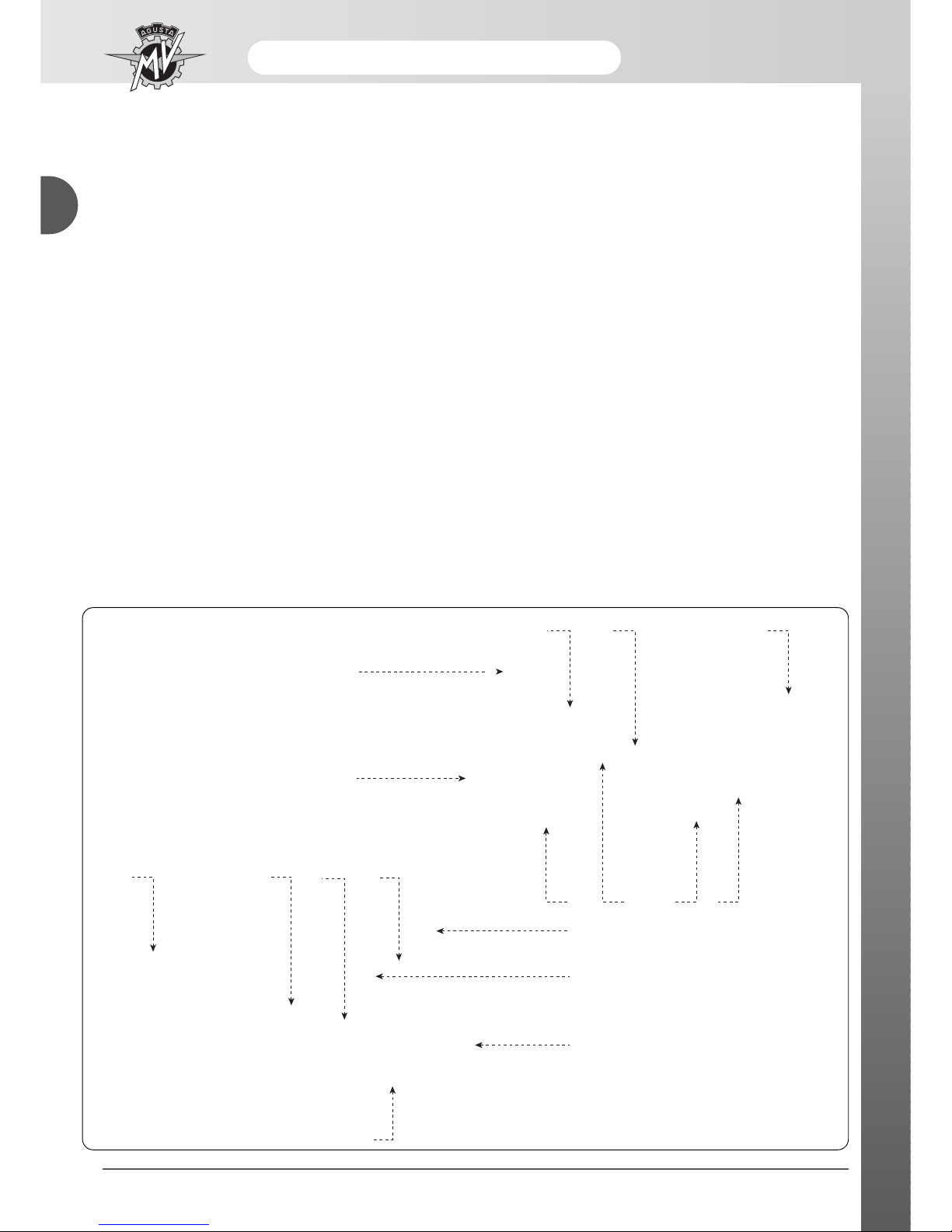

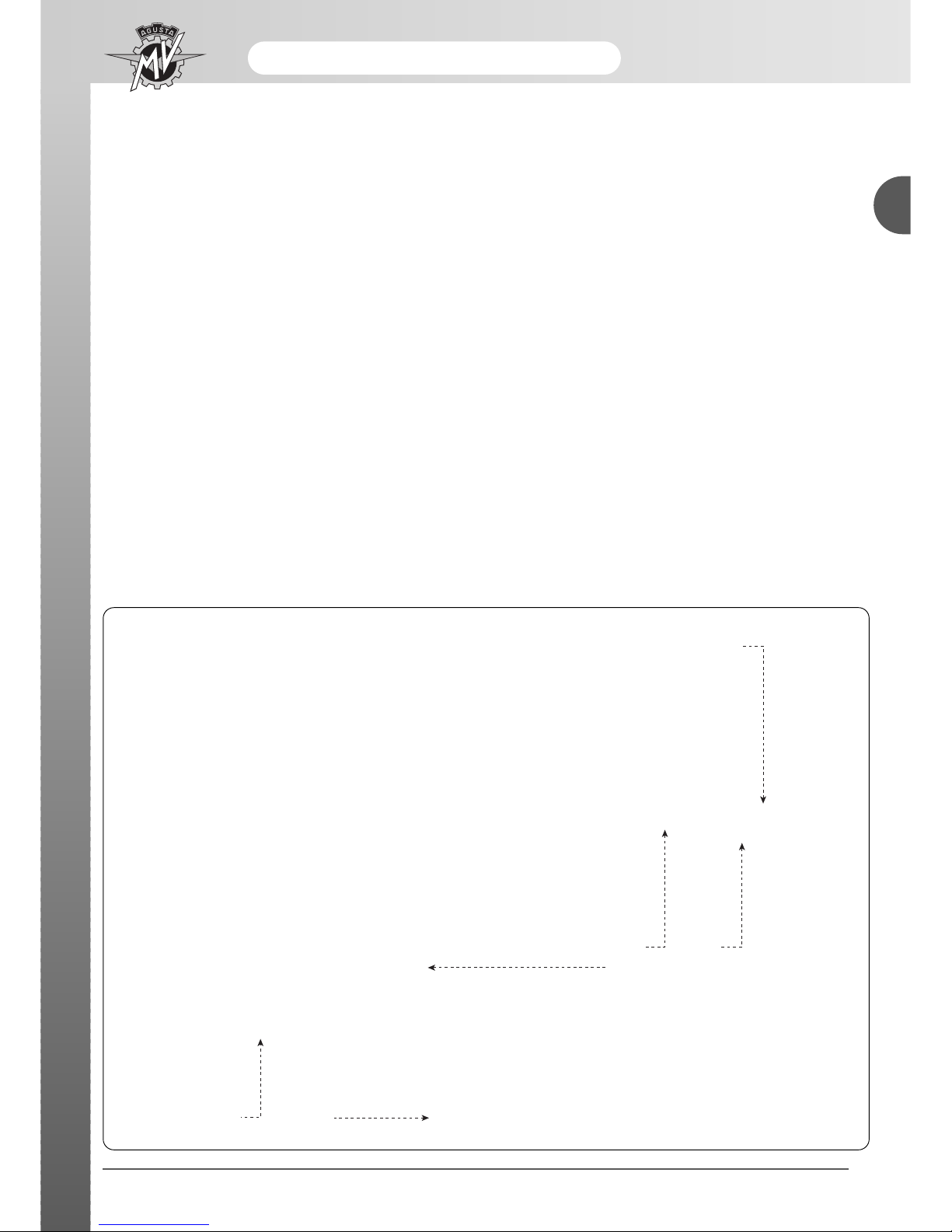

SUMMARY

HOW TO CONSULT THIS MANUAL .........................................................................................................PAGE 3

PURPOSE OF THE MANUAL....................................................................................................................PAGE 3

GLOSSARY AND SYMBOLS.....................................................................................................................PAGE 4

RIGHT HAND AND LEFT HAND STANDARD ..........................................................................................PAGE 5

SAFETY .....................................................................................................................................................PAGE 6

WARNING ..................................................................................................................................................PAGE 8

INDEX..........................................................................................................................................................PAGE 8

OPERATIVE TECHNICAL SPECIFICATIONS ...........................................................................................PAGE 9

General description

HOW T

O CONSULT THIS MANUAL

Order of the subjects

This manual is divided into chapters that deal with the

sub-groups of the motorcycle.

To quickly find the chapter required, the pages of each

chapter are marked with a reference mark aligned to

the relative item in the general index.

- 3 -

A

EXAMPLE

Steering pin tightening

Screw in the steering pin flange ring, without tightening.

This operation must be done manually.

Check that the steering base is at the end of its travel,

to the right.

Using the special tool tighten the ring (1) by rotating it

10° calculated approximately as one third of the

movement between the two holes of the ring (2) of the

steering head (see the figure).

Specific tool N. 800091645

Display of the operations

The operations of disassembly , assembly, removal and control are presented with the help of illustrations (designs and

photographs).

The illustrations contain symbols that indicate the procedure, special tools and other information. See the symbols lists

for their significance.

The procedures are described step after step.

PURPOSE OF THE MANUAL

Principally, this manual has been written for MV Agusta dealers and qualified mechanics.

It is not possible to document all the knowledge necessary for a mechanic in a manual. Those who utilise it must have a

basic knowledge of mechanical concepts and the inherent procedures in the techniques of repairing motorcycles. Without

this knowledge, The maintenance and repair operations can render the motorcycle unsafe for use.

Updates

MV Agusta S.p.A. is committed to a policy of continuous updating of the models produced. The modifications and

significant changes to the specifications and the procedures will be communicated to the official dealers and will

appear in future editions of this manual.

All information, instructions and technical data included in this manual are based upon information on the product

updated at the moment of going to print. MV Agusta S.p.A. reserves the right to carry out changes at any moment

without prior notice and without incurring any obligation.

- 4 -

General description

A

This signifies that the lack of

or the incomplete observance of this advice can be gravely dangerous for your

safety and for the safety of

other persons.

ATTENTION

This signifies that the lack of

observance of these instructions can bring the risk of

damage to the motorcycle

and the equipment.

Supplies key information for the best fulfilment of the operation.

N.B.

Utilise a specific tool or equipment for

the correct carrying out of the operation

described.

Tighten to the specified torque.

Tolerance or limit of use.

Utilise the tester.

Use the recommended oil.

Use the recommended grease.

Use the recommended brake fluid

Use the recommended suspension fluid.

Use the recommended coolant.

Use the recommended thread-locking

fluid.

Use the recommended sealant.

Use the recommended adhesive.

Carry out accurate cleaning.

Use new components.

Substitute the component.

Do not leave litter about.

The information marked with this symbol

refer to the F4 Brutale model series ORO.

GLOSSAR

Y AND SYMBOLS

WARNING

★

General description

- 5 -

Lato DX

Cilindro 4

Lato SX

Lato DX

Lato SX

Cilindro 3

Cilindro 1

Cilindro 2

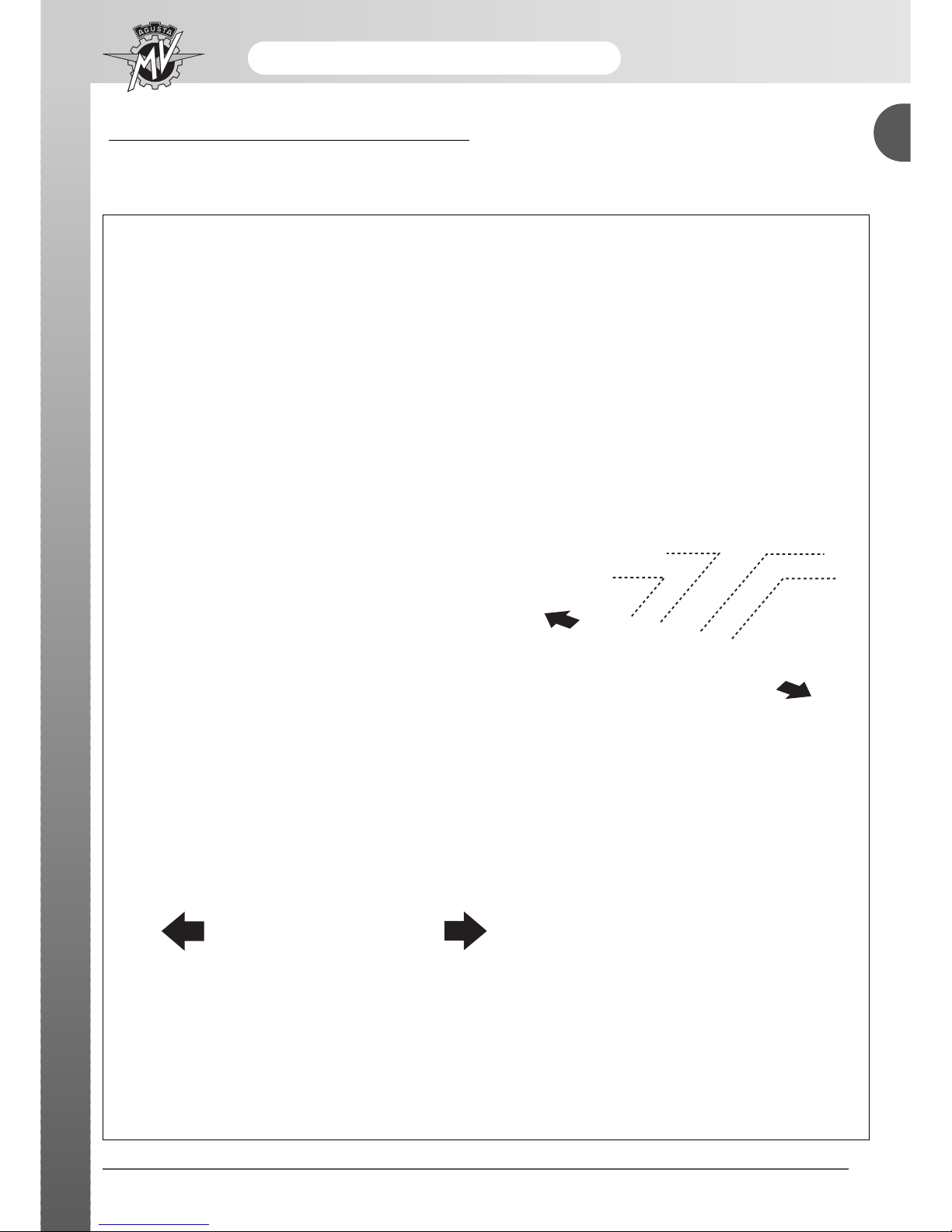

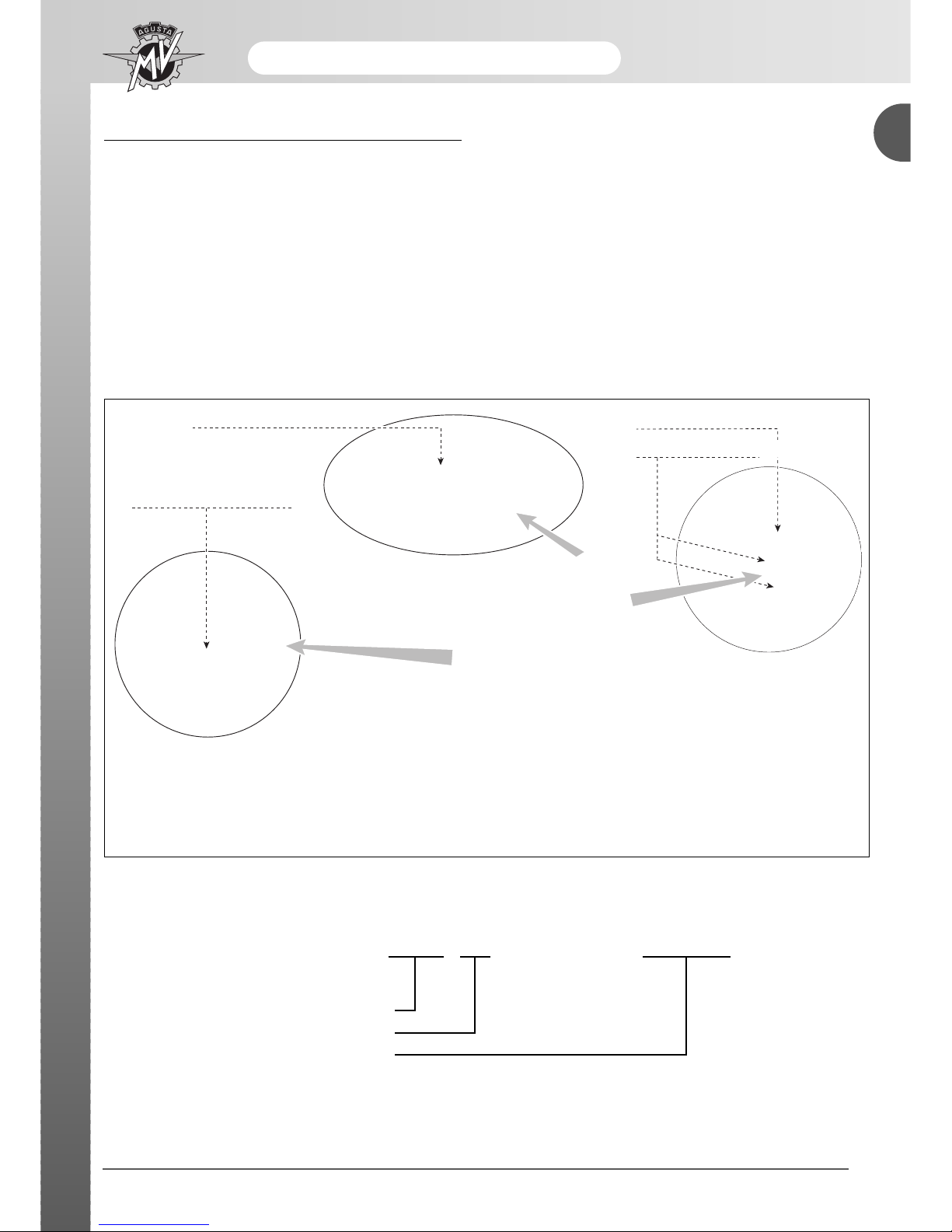

RIGHT HAND

AND LEFT HAND STANDARD

In order to specify the right/left convention used within the chapters of this manual, see the following motorcycle

and engine scheme where all sides which refer to are reported.

A

Cylinder 4

Cylinder 3

Cylinder 1

Cylinder 2

Right side

Left side

Right side

Left side

- 6 -

General description

A

SAFETY

Carbon Monoxide

• Exhaust gases contain carbon monoxide (CO) that is poisonous. Carbon monoxide can cause the loss of consciousness and death.

• If it is necessary to switch on the engine, check that the environment is well ventilated. Never switch on the engine

in an enclosed environment.

• Switching on the engine can only be carried out in an enclosed environment when there are the appropriate devices

for the evacuation of exhaust gases.

Petrol

• Petrol is extremely inflammable and under certain conditions can be explosive.

• Keep sources of heat, sparks and flames away from the work area.

• Always work in a well-ventilated area.

• Never use petrol as a cleaning solvent. Generally, avoid handling it unless it is absolutely necessary.

• Do not use petrol for cleaning components by using compressed air.

• Keep petrol out of reach of children.

Engine oil

• Engine oil can cause skin illnesses if in constant and long contact with the skin.

• If the skin comes into contact with engine oil, wash the parts affected as soon as possible with soap and water.

• If engine oil comes into contact with the eyes, abundantly rinse with water and consult a doctor immediately.

• If engine oil is swallowed, do not provocate vomiting to avoid the aspiration of the product into the lungs. Transport

the injured person immediately to hospital.

• Used oil contains dangerous substances and poisonous for the environment. To substitute oil, it is recommended to

go to an authorised MV Agusta dealer who is equipped to deal with the collection of used oil in respect of the norms

in force.

• Do not dispose of used oil in the environment.

• Keep used oil out of the reach of children.

Engine coolant

• Under certain situations, the ethylene glycol contained in the engine coolant is inflammable and its flame is invisible.

Ethylene glycol would cause serious burns if ignited because it is invisible.

• Avoid bringing the engine coolant into contact with hot parts. Such parts could be sufficiently hot to ignite the coolant.

• The engine coolant (ethylene glycol) can cause irritation of the skin and is poisonous if swallowed.

• If the engine coolant comes into contact with the skin, immediately remove any contaminated clothing and wash with

soap and water. If it comes into contact with the eyes, abundantly rinse with clean water and immediately consult a

doctor. If swallowed, do not provocate vomiting to avoid the aspiration of the product into the lungs. Administer clean

water and transport the injured person immediately to hospital and show the product to the doctor.

• If exposed to high concentrations of vapour, transport the injured person to a non-poisonous atmosphere and if

necessary call a doctor.

• Do not remove the radiator cap when the engine is still hot. Being under pressure, the engine coolant can be violently ejected and therefore provocate burns.

• The engine coolant contains dangerous and poisonous substances and is therefore dangerous for the environment.

To substitute used engine coolant, it is advisable to go to the authorised MV Agusta dealer who is equipped to deal

with the collection of used engine coolant in respect of the norms in force.

• Do not dispose of engine coolant in the environment.

• Keep engine coolant out of reach of children.

ATTENTION

The information contained in this paragraph is fundamental so that the operations carried

out on the motorcycle can be conducted with minimum risk to the mechanic.

General description

- 7 -

A

Brake fluid

• Brake fluid is extremely corrosive.

• Avoid any contacts with the eyes, skin and the mucous membrane.

• If brake liquid comes into contact with the skin, remove all contaminated clothing and wash immediately with soap

and water.

• If brake fluid comes into contact with the eyes, abundantly rinse with water and call a doctor.

• If swallowed, do not provocate vomiting to avoid aspiration of the product into the lungs. Immediately call a doctor.

• Take the injured person immediately to hospital, if he has breathed brake fluid into the lungs.

• In the case of exposure to high concentrations of vapour, move the injured person to a non-poisonous atmosphere

and if necessary call a doctor.

• In the case of accidental contact, rinse abundantly with water and call a doctor.

• Keep brake fluid out of reach of children.

Thread-locking fluid

• As it is not classified as dangerous, the prolonged contact with the skin, particularly with regards to abrasions can

provocate sensitiveness and dermatitis. In the case of contact with the skin, rinse abundantly with running water.

• Move the injured person into the open air and call a doctor if the injured person feels ill after having breathed in the

product.

• In the case of contact with the eyes, rinse abundantly with water for at least 15 minutes.

• If the thread-locking fluid has been swallowed, drink an abundant quantity of water or milk. Do not provocate vomiting to avoid the aspiration of the product into the lungs. Immediately call a doctor.

• Keep out of reach of children.

Nitrogen - rear shock absorber

• The rear shock absorber contains nitrogen under pressure.

• Before disposing of used shock absorbers, discharge the nitrogen via the depressurising valve.

• Utilise only nitrogen to pressurise the shock absorber. The use of unstable gases can cause explosions that could

cause burns.

• Do not place the shock absorber near to flames or sources of heat as this could cause explosions with consequent

burns.

• Keep out of reach of children.

Battery

• The battery produces explosive gases. Keep it away from sparks, flames or cigarettes. During recharging, adequately ventilate the environment.

• The battery contains a solution of sulphuric acid (electrolyte).

• Sulphuric acid is corrosive and it destroys many materials and clothing. On contact with small quantities of water it

generates a violent reaction that manifests itself by creating large quantity of heat and spurts of hot acid. Sulphuric

acid attacks many metals thereby liberating hydrogen: an inflammable gas that forms an explosive mixture when

mixed with air.

• Contact with sulphuric acid can cause burns. In the case of contact, remove immediately all contaminated clothing

and wash the skin with abundant quantities of water. Take the injured person to hospital if necessary.

• In the case of contact with the eyes, rinse immediately with abundant water. Call a doctor and continue with the treatment until the doctor arrives.

• If the electrolyte is swallowed, rinse the mouth with water without swallowing. Take the injured person immediately

to hospital and explain to the doctor there what the injured person has swallowed.

• The battery contains dangerous substances that are poisonous for the environment. It is advisable to substitute it at

an MV Agusta dealer that is equipped to dispose of this product in respect of the norms in force.

• Do not dispose of used batteries in the environment.

• Keep out of reach of children.

Hot parts

• The engine and the exhaust system become very hot and maintain this temperature for some time after the engine

has been switched off. Wait for these parts to cool down before handling them or working on the motorcycle near to

them. Use protective gloves.

- 8 -

General description

A

GENERAL INDEX

SUMMARY OF EACH CHAPTER

INDEX

WARNING

The information contained in this

paragraph is important so that the

operations carried out on the

motorcycle can be conducted without damaging the motorcycle.

• Thoroughly clean the motorcycle before disassembling it.

• During disassembly, clean all parts and place them in containers respecting exactly the order of disassembly.

• Always use the special utensils where necessary and

each time where prescribed.

• Always use adhesives, sealants and lubricants where prescribed. Respect the instructions about their technical

characteristics.

• Always substitute parts such as gaskets, O-rings, security

washers with new parts.

• Loosening and tightening nuts or screws, always start

from the bigger ones or the centre. Always comply with the

torque wrench settings.

• Utilise only MV Agusta spare parts.

WARNING

General description

- 9 -

A

OPERA

TIVE TECHNICAL SPECIFICATIONS

MOTORCYCLE IDENTIFICATION

1) Frame registration number

2) Engine registration number

3) Homologation date

4) "Limited series" number

★

The registration number of the motorcycle is stamped on the right side of the steering head.

The engine part number is stamped on the top half casing near the fork.

2) numero di matricola motore

4) numero "serie limitata"

1) numero di matricola telaio

3) dati di omologazione

★ Only for the F4 BRUTALE series ORO: the pre-

sence of the nameplate indicates that the motorcycle has been constructed on a limited series basis.

Each example is identified by a progressive number stamped on a nameplate in 24 carat gold.

ZCG F4 01 AA Y V 000000

Manufacturer identification

Vehicle model

Progressive frame number

Below is an example of the designation of the frame registration number:

1) Frame registration number

2) Engine registration number

4) "Limited series" number ★

3) Homologation date

- 10 -

General description

A

B

- 1 -

Maintenance

SECTION B

Revision 0

- 2 -

Maintenance

B

SUMMAR

Y

TECHNICAL INFORMATION....................................................................................................................PAGE 3

TECHNICAL DATA ..................................................................................................................................PAGE 3

COMPONENTS IN CARBON FIBRE (F4 BRUTALE ORO) ....................................................................PAGE 6

MAGNESIUM COMPONENTS (F4 BRUTALE ORO) ..............................................................................PAGE 7

PERIODICAL MAINTENANCE SCHEDULE ............................................................................................PAGE 9

MAINTENANCE AND TUNING OPERATIONS........................................................................................PAGE 11

ENGINE OIL AND OIL FILTER.................................................................................................................PAGE 11

ENGINE COOLANT..................................................................................................................................PAGE 19

ELECTRIC COOLING FAN.......................................................................................................................PAGE 21

VALVE MECHANISM ADJUSTMENT ......................................................................................................PAGE 22

SPARK PLUGS.........................................................................................................................................PAGE 33

FUEL FILTERS..........................................................................................................................................PAGE 34

FUEL PUMPASSEMBLY.........................................................................................................................PAGE 44

FUEL UNION TUBES...............................................................................................................................PAGE 47

FUEL TUBES ASSEMBLY .......................................................................................................................PAGE 47

THROTTLE BODY ADJUSTMENT AND TUNING ..................................................................................PAGE 50

AIR FILTER...............................................................................................................................................PAGE 57

BRAKES AND CLUTCH...........................................................................................................................PAGE 60

BRAKE/CLUTCH/GEARCHANGE COMMANDS CHECK............................................................................PAGE 63

BRAKE PADS...........................................................................................................................................PAGE 65

ACCELERATOR CONTROL.....................................................................................................................PAGE 65

LOCKS .....................................................................................................................................................PAGE 67

STEERING ................................................................................................................................................PAGE 69

TRANSMISSION CHAIN............................................................................................................................PAGE 69

TYRES ......................................................................................................................................................PAGE 72

FRONT WHEEL BEARINGS....................................................................................................................PAGE 72

WHEELS ...................................................................................................................................................PAGE 73

REAR WHEEL HUB..................................................................................................................................PAGE 74

OSCILLA TING ARM BEARINGS .............................................................................................................PAGE 74

REAR SHOCK ABSORBER .....................................................................................................................PAGE 74

SIDE STAND.............................................................................................................................................PAGE 75

FRONT FORK...........................................................................................................................................PAGE 76

SCREWS AND NUTS ...............................................................................................................................PAGE 76

TUBE BAND FASTENERS.......................................................................................................................PAGE 76

ELECTRICAL SYSTEM .............................................................................................................................PAGE 77

BA TTER Y...................................................................................................................................................PAGE 77

INSTRUMENTS AND WARNING LIGHTS...............................................................................................PAGE 80

LIGHTS......................................................................................................................................................PAGE 85

FRONT HEADLAMP.................................................................................................................................PAGE 92

B

Maintenance

- 3 -

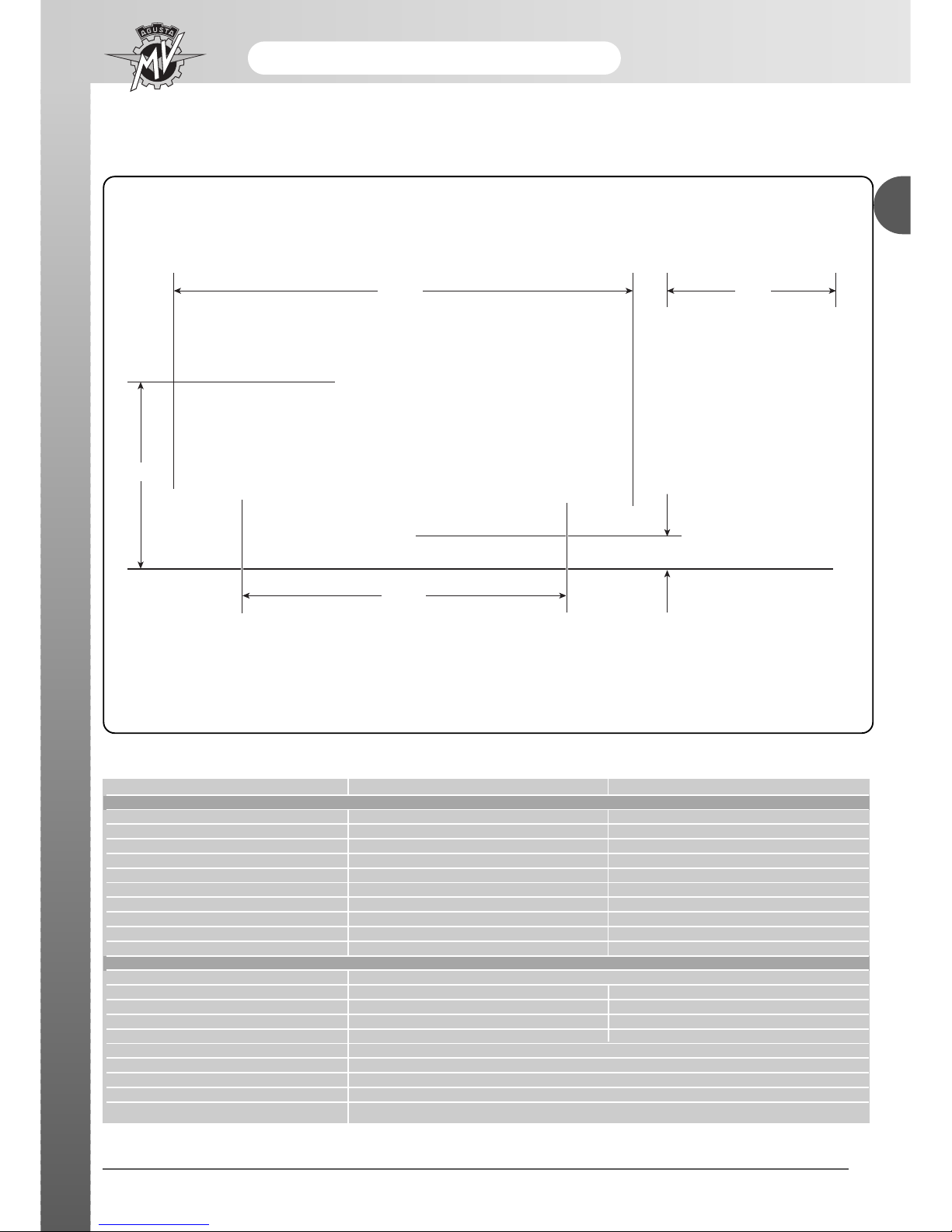

2020

1410

135

805

760

TECHNICAL INFORMATION

TECHNICAL DATA

Description BRUTALE ORO BRUTALE S

CHARACTERISTICS

Wheelbase (mm) (*) 1410 1410

Total length (mm) (*) 2020 2020

Maximum width (mm) 760 760

Seat height (mm) (*) 805 805

Ground clearance (mm) (*) 135 135

Trail (mm) (*) 101.5 101.5

Dry weight (kg) 179 185

Fuel tank capacity (litres) (**) 19 19

Fuel reserve (litres) (**) 4 4

Sump oil quantity (kg) 3.5 3.5

ENGINE

Type 4 Stroke four cylinder, 16 valves

Bore (mm) 73.8 73.8

Stroke (mm) 43.8 43.8

Displacement (cm3) 749.4 749.4

Compression ratio 12 : 1 12 : 1

Starter system Electrical

Cooling Liquid with oil cooler

Engine casing and covers Die-cast

Cylinder head and cylinders Chill-cast

Valves Bi-metal/mono-metal

* : I The data declared are not binding. They are susceptible to variations due to riding conditions.

**: I The data declared are not binding. They are susceptible to variations due to external temperature, engine temperature and the evaporation point of the petrol used.

Maintenance

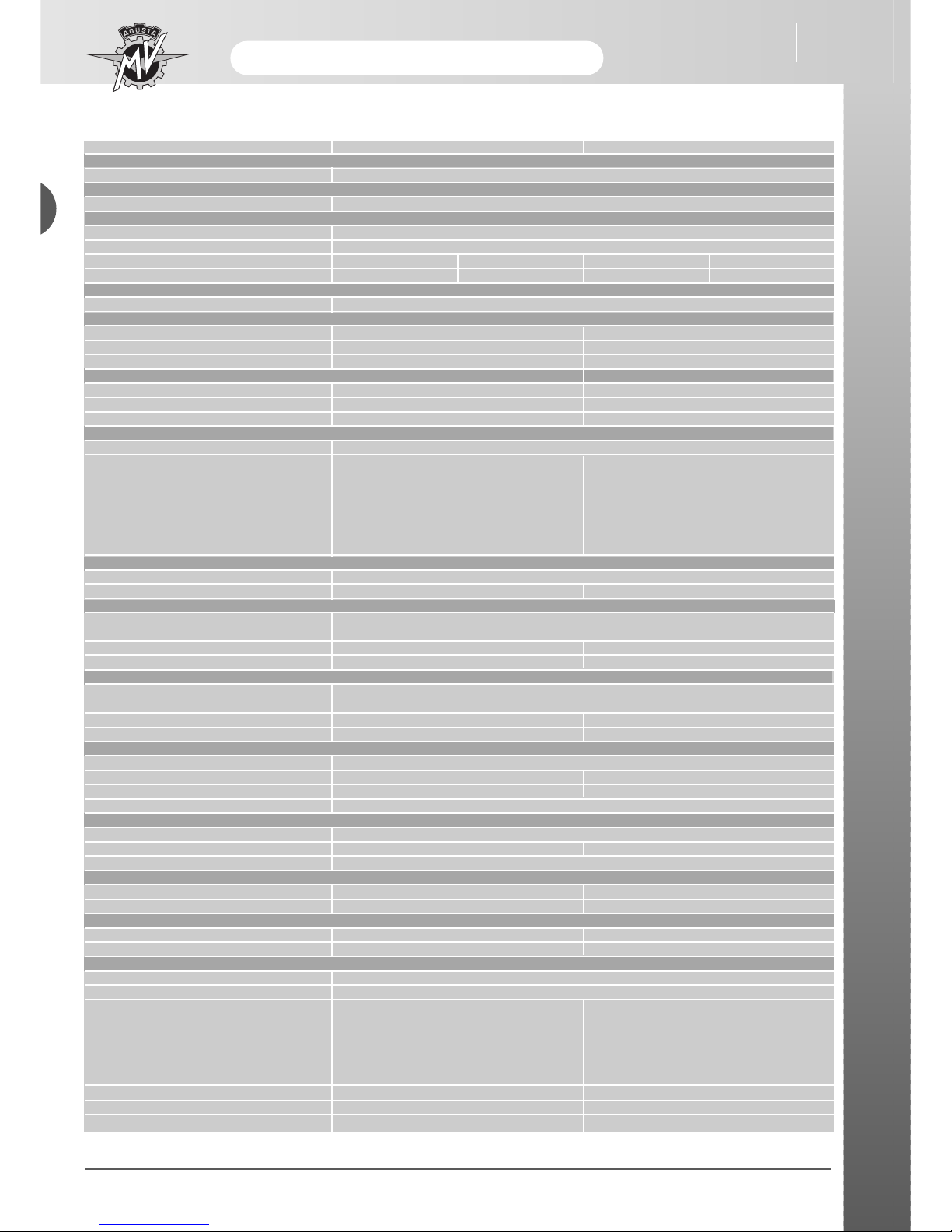

TECHNICAL DATA

- 4 -

Description BRUTALE ORO BRUTALE S

TIMING

Type D.O.H.C. radial valves

LUBRICATION

Type Wet sump

IGNITION – FUEL FEED SYSTEM

Type Weber-Marelli ignition/injection 1.6 M integrated system

Inductive charge electronic ignition, Multipoint electronic injection

Spark plugs (alternatively) NGK CR9 EB Champion G59c NGK CR9 EB Champion G59c

Spark gap (mm) 0.7 ÷ 0.8 0.6 ÷ 0.7 0.7 ÷ 0.8 0.6 ÷ 0.7

CLUTCH

Type Wet multi-plate

PRIMARY TRANSMISSION

N° teeth - engine crankshaft gear Z = 47 Z = 47

N° teeth - clutch gear Z = 81 Z = 81

Transmission ratio 1.72 1.72

SECONDARY TRANSMISSION

N° teeth – pinion wheel Z = 14 Z = 14

N° teeth – crown wheel Z = 41 Z = 41

Transmission ratio 2.93 2.93

GEAR CHANGE

Type Extractable six speed, with gearing always inserted

Gear ratios (total ratios)

1

st

2.92 (14.71) 2.92 (14.71)

2

nd

2.21 (11.14) 2.21 (11.14)

3

rd

1.78 (8.97) 1.78 (8.97)

4

th

1.50 (7.56) 1.50 (7.56)

5

th

1.32 (6.65) 1.32 (6.65)

6

th

1.21 (6.10) 1.21 (6.10)

FRAME

Type Tubular framework in wire-drawn steel tubes 25 CrMo (TIG welding)

Fork fulcrum plates Magnesium alloy Aluminium alloy

FRONT SUSPENSION

Type

Hydraulic telescopic forks with the stems positioned upside down, equipped with

a system of external adjustment for extension, compression and spring preload

Ø stems (mm) 50 with titanium nitride treatment 50

Telescopic movement (mm) 128 128

REAR SUSPENSION

Type

Progressive, single-steering damper adjustable in extension, in compression

(high/low speed), and in spring-preloading

Mono-arm fork Magnesium alloy Aluminium alloy

Wheel travel (mm) 120 120

FRONT BRAKE

Type Floating double disk with the braking area in steel

Ø Discs (mm) 310 310

Disc flanges Aluminium Steel

Pincers (Ø pistons mm) 6 pistons (Ø 22.65; Ø 25.4; Ø 30.23)

REAR BRAKE

Type Disc type in steel

Ø Discs (mm) 210 210

Pincers (Ø pistons mm) 4 pistons (Ø 25.4)

FRONT WHEEL

Material Magnesium alloy Aluminium alloy

Dimensions 3.50” x 17” 3.50” x 17”

REAR WHEEL

Material Magnesium alloy Aluminium alloy

Dimensions 6.00” x 17” 6.00” x 17”

TYRES

Front 120/65-ZR 17 (56 W)

Rear 190/50-ZR 17 (73 W) o 180/55-ZR 17 (73 W)

Brand and type PIRELLI - Dragon Evo MTR 21 Corsa (Ant.)

PIRELLI - Dragon Evo MTR 22 Corsa (Post.)

DUNLOP - Sport Max D 207 PIRELLI - Diablo Corsa

Race Replica MICHELIN - Pilot Sport

MICHELIN - Pilot Power

DUNLOP - Sport Max D 207 Race Replica

Tyre pressures (*)

Front 2.3 bar (33 psi) 2.3 bar (33 psi)

Rear 2.3 bar (33 psi) 2.3 bar (33 psi)

* : In the event of different make tyres being used as opposed to those advised, refer to the pressure values marked on the side of the tyre by the manufacturer.

Maintenance

- 5 -

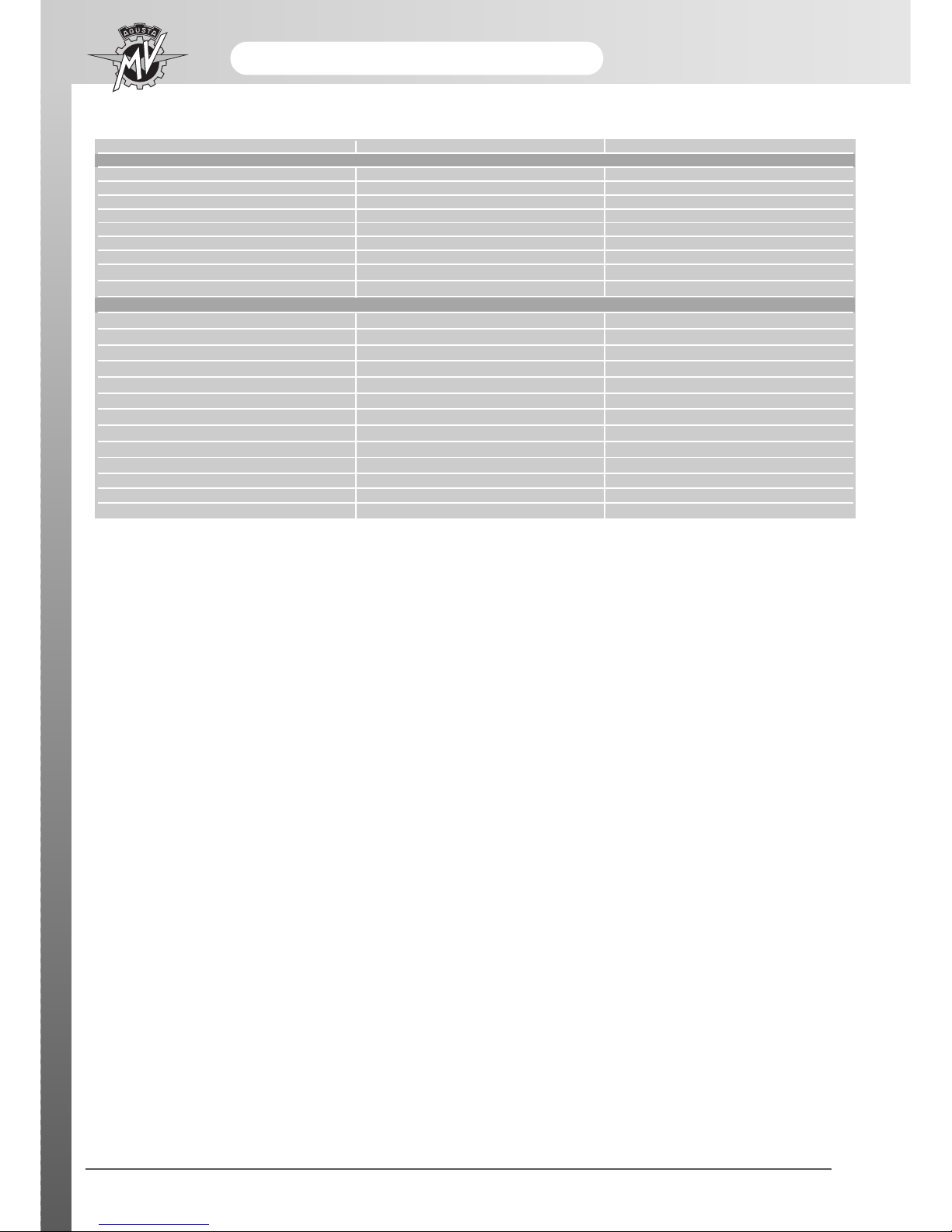

TECHNICAL DATA

Description BRUTALE ORO BRUTALE S

ELECTRICAL SYSTEM

Voltage 12V 12V

Front dipped beam light bulb 12V 55W 12V 55W

Front main beam light bulb 12V 60W 12V 60W

Front sidelight bulb 12V 5W 12V 5W

Rear light bulb 12V 5W 12V 5W

Rear stop light bulb 12V 21W 12V 21W

Direction indicators 12V 10W 12V 10W

Battery 12V - 9Ah 12V - 9Ah

Alternator 650W a 5000 r.p.m. 650W a 5000 r.p.m.

BODYWORK

Tank Thermo-plastic material Thermo-plastic material

Air filter compartment conveyors Carbon fibre Thermo-plastic material

Tank side panel Carbon fibre Thermo-plastic material

Tail unit rear side panel Carbon fibre Thermo-plastic material

Tail unit Carbon fibre Thermo-plastic material

Instrumentation protection Carbon fibre Thermo-plastic material

Ignition switch cover Carbon fibre Thermo-plastic material

Exhaust tube protection Carbon fibre Thermo-plastic material

Chain guard Carbon fibre Thermo-plastic material

Oil cooler protection Carbon fibre Thermo-plastic material

Number plate carrier Thermo-plastic material Thermo-plastic material

Rear-view mirrors Thermo-plastic material Thermo-plastic material

Protezione tubo scarico Aluminium Aluminium

- 6 -

Maintenance

B

★ COMPONENTS IN CARBON FIBRE (F4 BRUTALE ORO)

9

3

2 94

58

7

1

10

13

10

7

1213 6 11

8 - Ignition switch cover

9 - Tail unit

10 - Front mudguard

11 - Top chain protection

12 - Lower chain protection

13 - Oil cooler protection

1 - Right air filter compartment side panel

2 - Left air filter compartment side panel

3 - Right tank side panel

4 - Left tank side panel

5 - Right cylinder cover

6 - Left cylinder cover

7 - Instrument panel protection

Maintenance

- 7 -

B

★ MAGNESIUM COMPONENTS (F4 BRUTALE ORO)

1 - Steering base

2 - Frame side plate

3 - Front wheel rim

4 - Rear wheel rim

5 - Mono-arm fork

4

1

23

2 5

- 8 -

Maintenance

B

Manutenzione

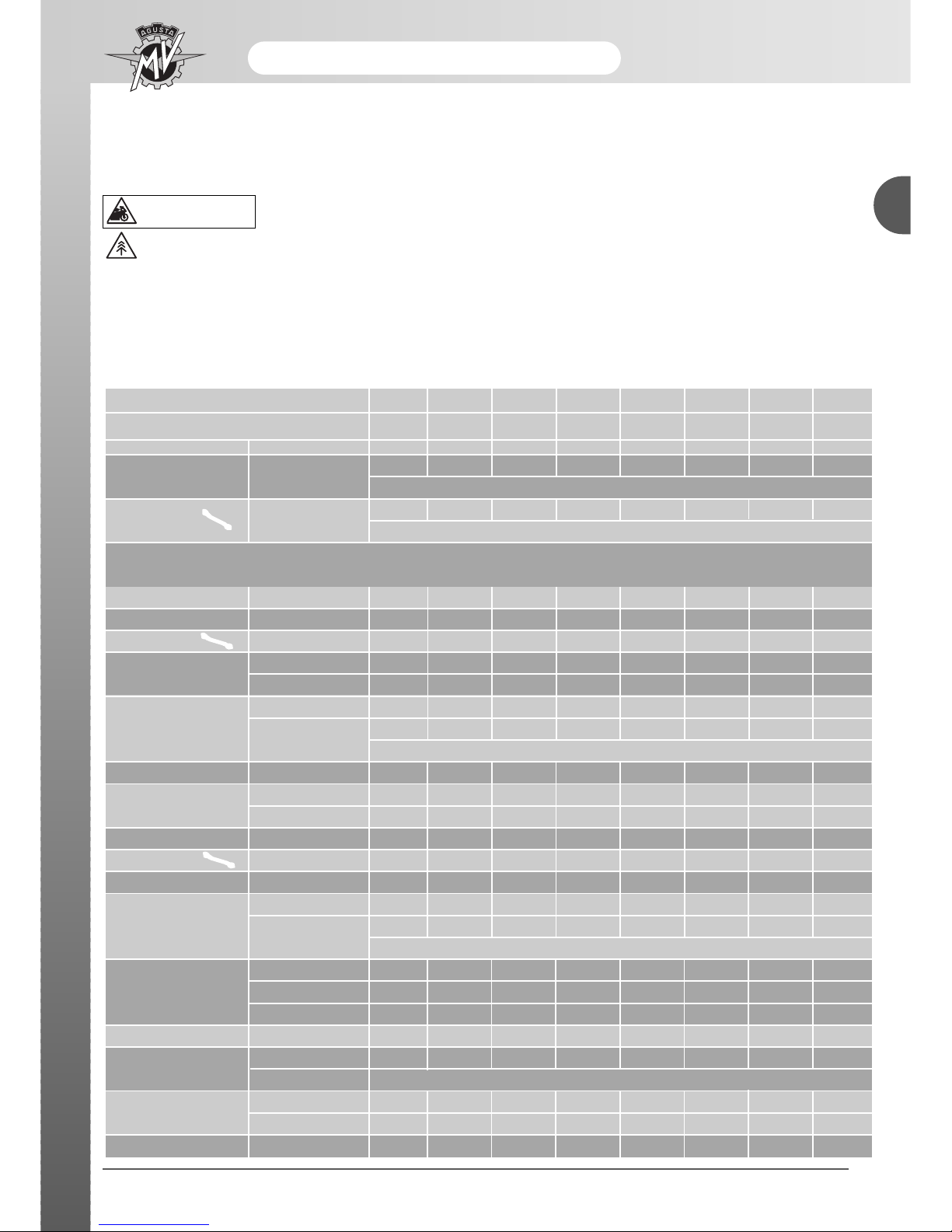

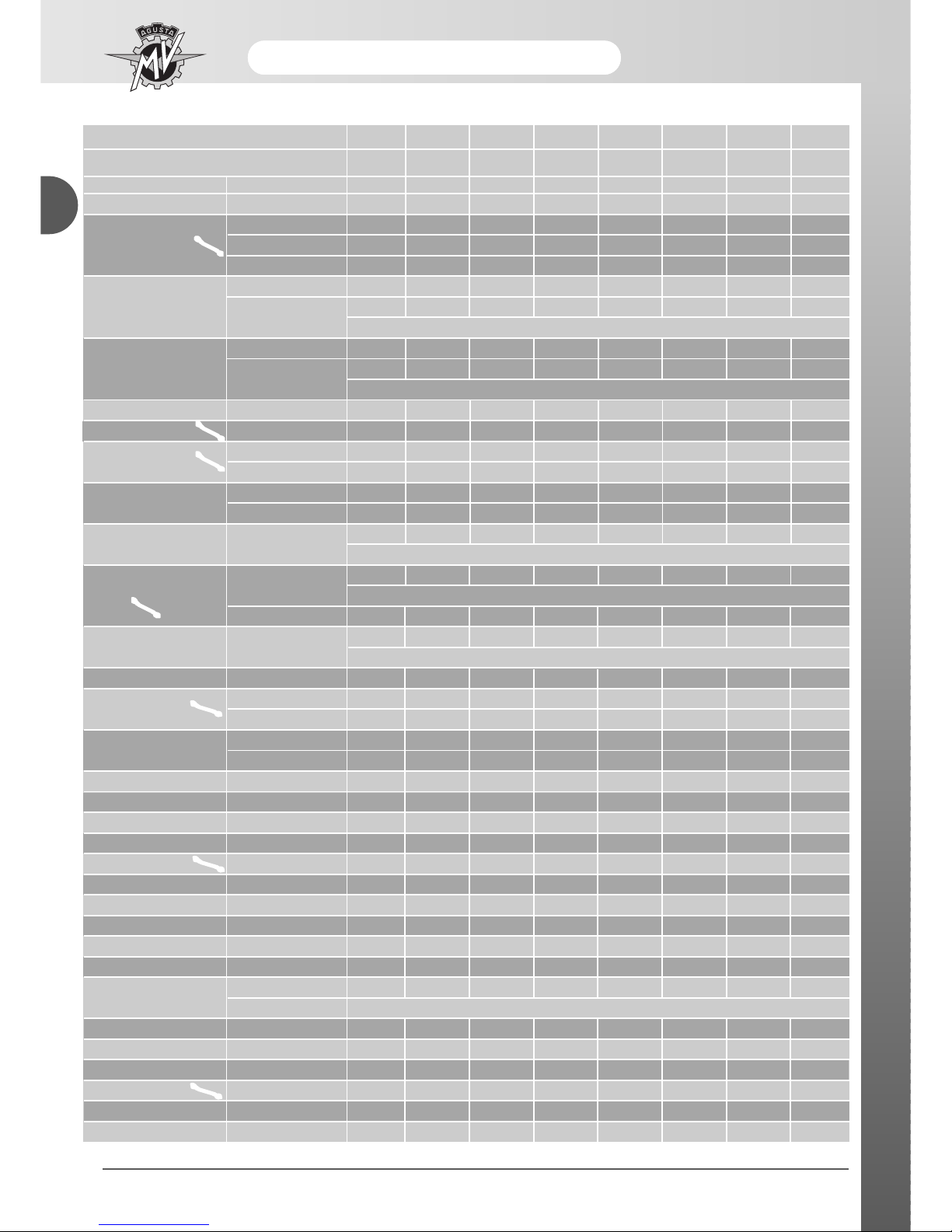

PERIODICAL MAINTENANCE SCHEDULE

The following table shows the recommended intervals for the interventions of periodical maintenance. Periodical

maintenance is necessary to keep the motorcycle in an optimum condition. The intervals are expressed in kilometres.

For motorcycles used in particularly severe conditions, maintenance operations must be

carried out more frequently.

We respect and defend the environment.

Everything that we do has repercussions on the whole planet and on its resources.

MV Agusta, to protect the interests of the everyone, ask clients and technical assistance operators to use

the motorcycle and dispose of its used parts with respect to the norms in force in terms of environmental

pollution, disposal and recycling of refuse.

★ The information marked with this symbol refers only to the F4 BRUTALE model

series ORO.

WARNING

Maintenance

- 9 -

B

0 1000 6000 12000 18000 24000 30000 36000

(600) (3800) (7500) (11200) (14900) (18600) (22400)

Pre-

delivery

Description Operation

Km (mi) covered

Service

AB C DE F G

Programmed maintenance schedule

Substitution

(Utilise only originali MV

Agusta oil filters)

Cleaning of contact lever /

pump piston area

( front and rear )

Engine oil Substitution

●●●●●●●

At least once a year

Engine oil filter

●●●●●●●

At every substitution of engine oil

Engine coolant

Check level and top-up

●●●●●●●●

Substitution At least every two years

Cooling system Check for leakages ●●●●●●●●

Electric fan Check functioning ●●●●●●●●

Valves Check / adjustment ●●●●

Timing chain

Check ●●●

Substitution ●

Pattino mobile distribuzione

Check / Substitution ●●●

Substitution

●

At least every substitution of the timing chain

Timing chain tensioner Check / Substitution ●●●

Spark plugs

Check / Substitution ●●●●

Substitution ●●●

Fuel filter Check / Substitution ●●●

Throttle body Check and adjust ●●●●●●●

Air filter Check / Substitution ●●●●●●

Fluido freni e frizione

Check level ●●●●● ●●

Substitution

●

At least every two years

Check functioning ●●●●●●●●

Brakes and clutch Check circuit ●●●●●●●●

●●●●●●●●

Brake pads

Check / Substitution ●●●●●●●

Fuel tubes

●●●●●●●

Substitution At least every three years

Accelerator control

Check functioning ●●●●●●●●

Check/adjust play ●●●●●●●●

Starter control Check functioning ●●●●●●●●

Mobile timing chain guide

Brake and clutch fluid

Check for defects and

leakages

- 10 -

Maintenance

B

Manutenzione

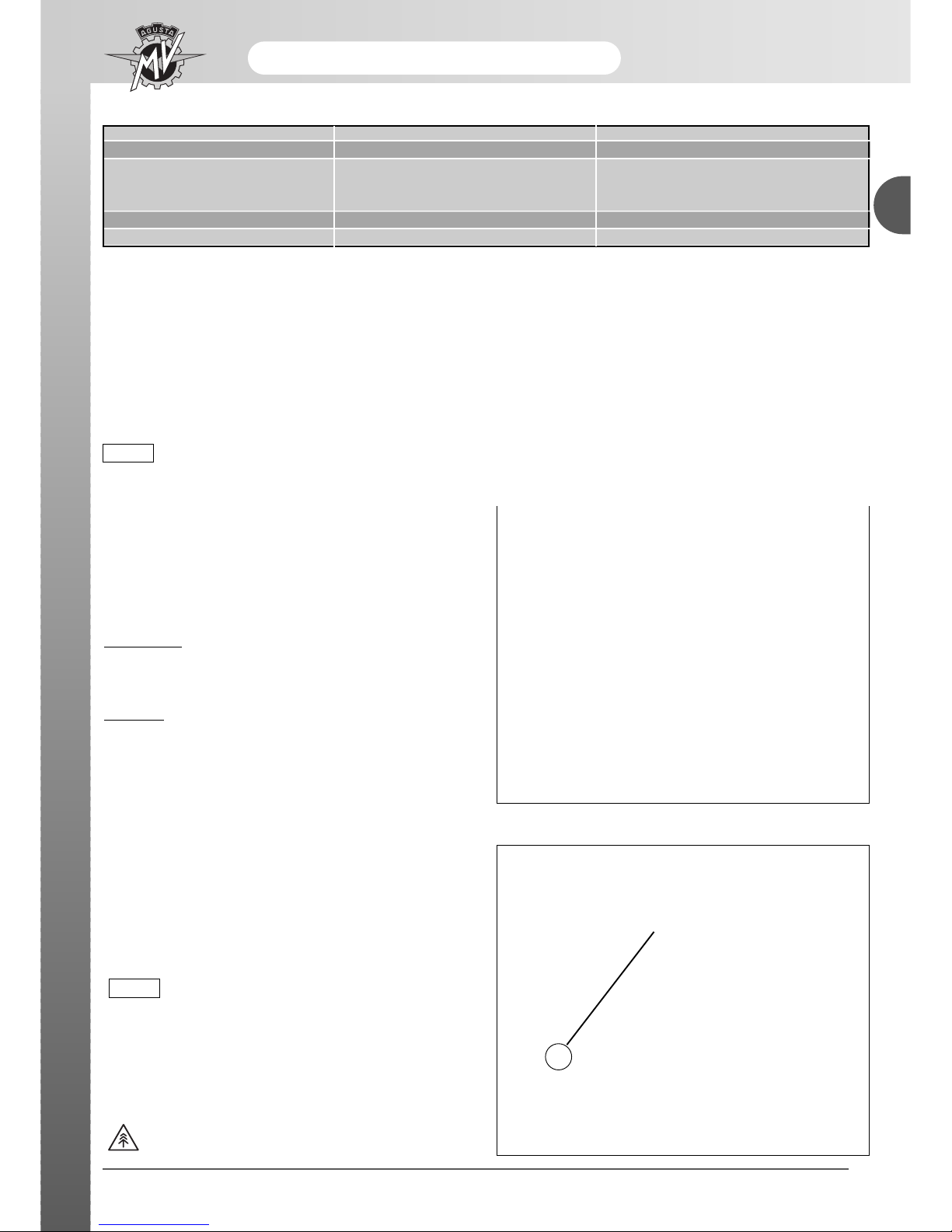

Programmed maintenance schedule

Frequenza Km (mi)

Tagliando

AB C DE F G

lubricate roller

bearings and

guides

lubricate roller

bearings and

guide

0 1000 6000 12000 18000 24000 30000 36000

(600) (3800) (7500) (11200) (14900) (18600) (22400)

Pre-

delivery

Description Operation

Cleaning of contact lever

area with side stand

Transmission and flexible controls Check / Adjust ●●●●●●●●

Check / Adjust ●●●●●●●●

Transmission chain Lubricate ●●●●

Substitution

★★

● ★★● ★★●

Check ●●●●

Pinion wheel/stop washer

Substitution

★★● ★★

● ★★●

At least at each substitution of the transmission chain

Check ●●●●

Crown wheel

Substitution

★★● ★★● ★★●

At least at each substitution of the transmission chain

Crown wheel tension regulator Check

★★● ★★● ★★●

Steering head flange ring Check / Adjust ●●●●

Steering bearings

Check / Adjust ●●●●

Lubricate ●

Tyres

Check for pressure ●●●●●●●●

Check for wear ●●●●●●●

Wheel rims Visual check

●●●●●●●

Every tyre substitution

Check

●●●●●

Front wheel bearings

Every tyre substitution

Substitution ●

Parts in magnesium

Visual check for knocks

★ ★ ★ ★ ★ ★ ★

and scratches

★ At least every six months

Side stand Check functioning ●●●●●●●●

Side

Check functioning ●●●●●●●●

stand switch

●●●●●●●●

Rear wheel hub

Check / ●●

Substitution /

●

Rear fork bearings Check / lubricate ●

Rear fork chain guide Check / substitution ●●●●●●●

Chain guide frame plate Check / substitution ●●●●●●●

Rear shock absorber Check / Adjust ●●●●

Front fork oil Substitution ●

Battery connections Check and clean ●●●●●●●

Electrical system Check functioning ●●●●●●●●

Instrument Check functioning ●●●●●●●●

Lights/visual signals Check functioning ●●●●●●●●

Horn Check functioning ●●●●●●●●

Front headlight

Check functioning ●●●●●●●●

Adjust At every variation of the riding set-up of the motorcycle

IIgnition switch Check functioning ●●●●●●●●

Locks Check functioning ●●●●●●●●

Torque settings – nuts and bolt Check / tightness ●●●●●●●●

Tube band fasteners Check / tightness ●●●●●●●●

General lubrication ●●●●●●●●

General check ●●●●●●●●

Km (mi) covered

Service

Maintenance

MAINTENANCE AND TUNING OPERATIONS

Each operation of periodical maintenance is described

in this chapter.

ENGINE OIL AND OIL FILTER

Engine oil

Substitute:→ at the first 1000 kilometres and then

every 6000 kilometres

Oil filter

Substitute:→ at the first 1000 kilometres and then

every 6000 kilometres (or at least

every oil change)

To accede to the oil filter and the discharge and filling

holes of the engine oil, it is necessary to carry out certain operations beforehand:

n Place the motorcycle on the rear stand.

The substitution of the engine oil must

be done with a hot engine as opposed to

the oil-check that is done with a cold

engine.

Place a container underneath the engine to collect the

used oil.

Remove the oil discharge plug (1).

Recover the oil in an appropriate container.

Do not scatter the drainage oil into the environment.

- 11 -

B

N.B.

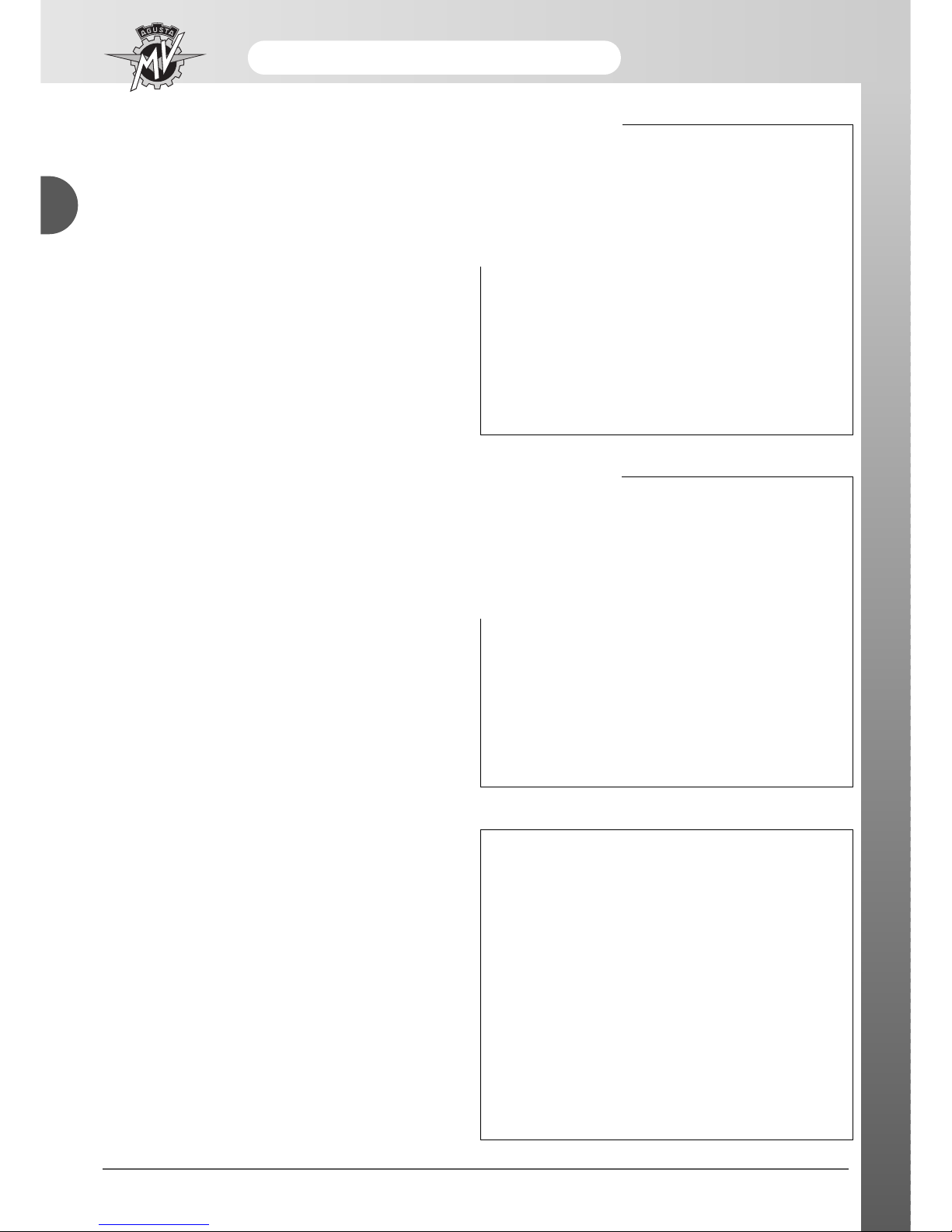

Description Recommended product Specification

Engine oil AGIP RACING 4T 10W/60 (*) SAE 10W/60 - API SJ

Ethylene-glycol

Engine coolant AGIP ECO - PERMANENT diluited with 40%

distilled water

Brake and clutch fluid AGIP BRAKE FLUID DOT4 DOT4

Chain lubrication oil MOTUL CHAIN LUBE PLUS –

Table of lubricants and fluids

*

: To find the recommended product, MV Agusta suggests going directly to the authorised MV Agusta dealers.

AGIP Racing 4T 10W/60 has been manufactured for the F4 engine. If the described oil is not available, MV

Agusta suggests using completely synthetic oils with characteristics that

conform or exceed the following norms:

– Conforming to API SJ

– Conforming to ACEAA3

– Conforming to JASO MA

– Grade SAE 20 W-50 o 10 W-60

The above specifications indicated are marked either on their

own or together with others on the container of the lubricating

oil.

Engine oil

SAE 10 W-60

API SJ

ACEA A3

JASO MA

N.B.

1

- 12 -

Maintenance

B

1

Remove the oil filler plug (1) on the right side of the

motorcycle so that it facilitates the discharge of the

used oil.

Wait until the lubrication system is completely empty of

used engine oil.

Substitution of the oil filter

In order to proceed to replace the oil filter you should

remove the exhaust manifolds of the cylinders 3 and 4.

Release the two side clamps of the oil cooler.

Unscrew the lower fixing screws of the oil cooler protection on the lower basis of the water radiator.

Remove the oil cooler protection.

Maintenance

Slightly move the coolers towards the front area of the

motorcycle, then unscrew the nut on the fixing flange of

the exhaust manifilds of the cylinder group.

During this operation pay attention to the

exhaust pipes in order to avoid from scorching.

Release the union spring between compensator and

manifolds of cylinders 3 and 4.

- 13 -

B

20÷22 N•m

Remove the manifold of cylinders 3 and 4.

In order to facilitate the reassembly of the

manifolds you should place the fixing flange on the manifolds before these

manifolds are pleced on the engine.

Insert the flange in the manifolds and then

turn it.

Place the flange-manifolds assembly on

the fixing stud, then tighten the check nut

to the torque wrench shown.

Torque wrench of exhaust manifold check

nut: 20÷22 Nm

N.B.

- 14 -

Maintenance

B

Loosen the safety clamp and remove it.

Unscrew the oil filter by an appropriate wrench.

In the event of a filter branded TOYO ROKI use the

wrench for oil filter:

TOYO ROKI

FACOM D. 139 tool

Part code 8000A4317

In the event of a filter branded Champion use the wrench for oil filter:

Champion

Part code N° 800099010

Clean accurately any oily parts.

Using a clean cloth to clean accurately the area and

the filter face.

Take out the oil filter from the new engine oil filter kit.

- Toyo Roki oil filter kit: Part code 8000A3702

- Champion oil filter kit: Part code 8000A1428

Only use original components of MV Agusta.

If you use an oil filter Toyo Roki (Part code

8000A3702), you should the following preliminary operation.

Take out the gasket from the engine oil filter kit of new

equipment and insert on the filter as shown in the figure on the left.

Only use a new gasket.

Slide the gasket up to bring in contact with the oil filter

back ring (see figure on the right).

Lubricate the gasket on the filter with engine oil.

Maintenance

- 15 -

B

- 16 -

Maintenance

B

Insert the filter in its seat.

Turn the filter manually until the gasket is into slight

contact with the machined surface.

Tighten the filter using the appropriate tool and a torque wrench.

- TOYO ROKI oil filter:

FACOM D. 139 tool

Part code 8000A4317

Oil filter torque wrench:

24 N·m

- Champion oil filter:

Tool code 800099010

Oil filter torque wrench:

15 N·m

After having tightened the filter, take out the clamp for

engine oil filter and its screw from the new oil filter kit.

Only use a new clamp.

Insert the clamp and slide it until it brings in contact

with the oil filter back ring.

TOYO ROKI:

24 N•m

Champion:

15 N•m

Loading...

Loading...