Mtd OEM-290-252 owners guide

CHECK YOUR PARTS

Be sure to check the contents of your kit to make sure that everything is

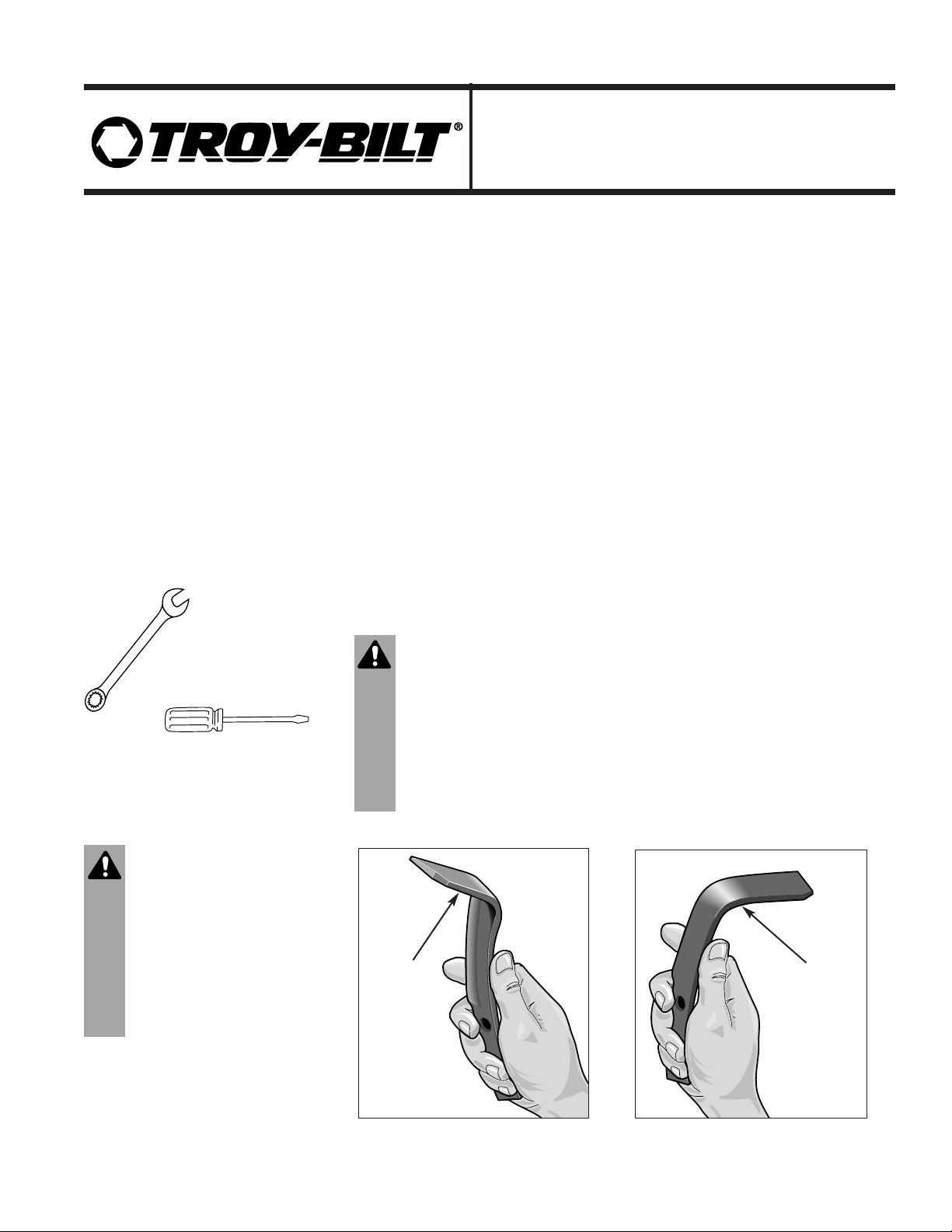

present. Refer to Figure 1 to distinguish a right-hand tine from a left-hand tine.

The Bolo Tine Kit includes the following parts:

Part No. Description Qty.

GW-50049-01 Bolo Tine, Right-hand....................................8

GW-50049-02 Bolo Tine, Left-hand......................................8

1901447 Hardware Kit

710-0514 Hex Screw, 3/8-16 x 1.0................................16

712-0798 Hex Nut, 3/8 ..................................................16

736-0169 Lock Washer, 3/8...........................................16

❒ Wrenches (two 9/16 inch)

❒ Screwdriver (medium-sized)

❒ Soft Rubber Mallet

❒ Penetrating Oil

These instructions apply only

to owners of the following

tillers:

❒ BRONCO

TM

Model

❒ SUPER BRONCO

TM

Model

❒ TUFFY

®

Model

Carefully look at the figures

on the opposite side of this

page while following the

instructions.

Thanks for buying new bolo tines. These tines were designed for your model tiller and

will handle all of your tilling needs including sod busting, seedbed preparation,

cultivating, and turning under crop residue.

THANK

YOU!

Bolo Tine Kit

OEM-290-252 / 290-252-081

for BRONCOTM, SUPER BRONCOTM,and TUFFY®Tillers

Installation Instructions

Tine edges can be sharp and

can have slivers that could

cause personal injury. Use

care at all times when

handling tines. The tine hood

edges may also be sharp. To

prevent personal injury, wear

thick gloves when touching

the edges of the hood.

CAUTION

To prevent serious personal injury when removing or installing your bolo

tines:

• Stop the engine, and remove the electric start key (if your tiller features

electric start).

• Let the engine and muffler area cool.

• Disconnect the spark plug wire, and position the wire away from the plug

to prevent accidental starting.

WARNING

Tools Needed

Figure 1: Left-hand tine & Right-hand tine

Blunt

Edge

Blunt

Edge

A. Tine Inspection:

With use, the tines installed at the

factory will become shorter, narrower

and pointed. Badly worn tines will

result in a loss of tilling depth, and

reduced effectiveness when chopping

up and turning under organic matter.

B. Tine Removal and Installation:

1. With the engine shut off and the

spark plug wire disconnected, carefully

tilt the tiller forward until the engine is

resting on the ground. (On some

models it may be necessary to prop up

the rear of the tiller or to add additional

weight to the engine to stabilize the tiller

in this position.)

2. Raise the tiller hood flap and secure

it out of the way with a heavy rubber

band or string.

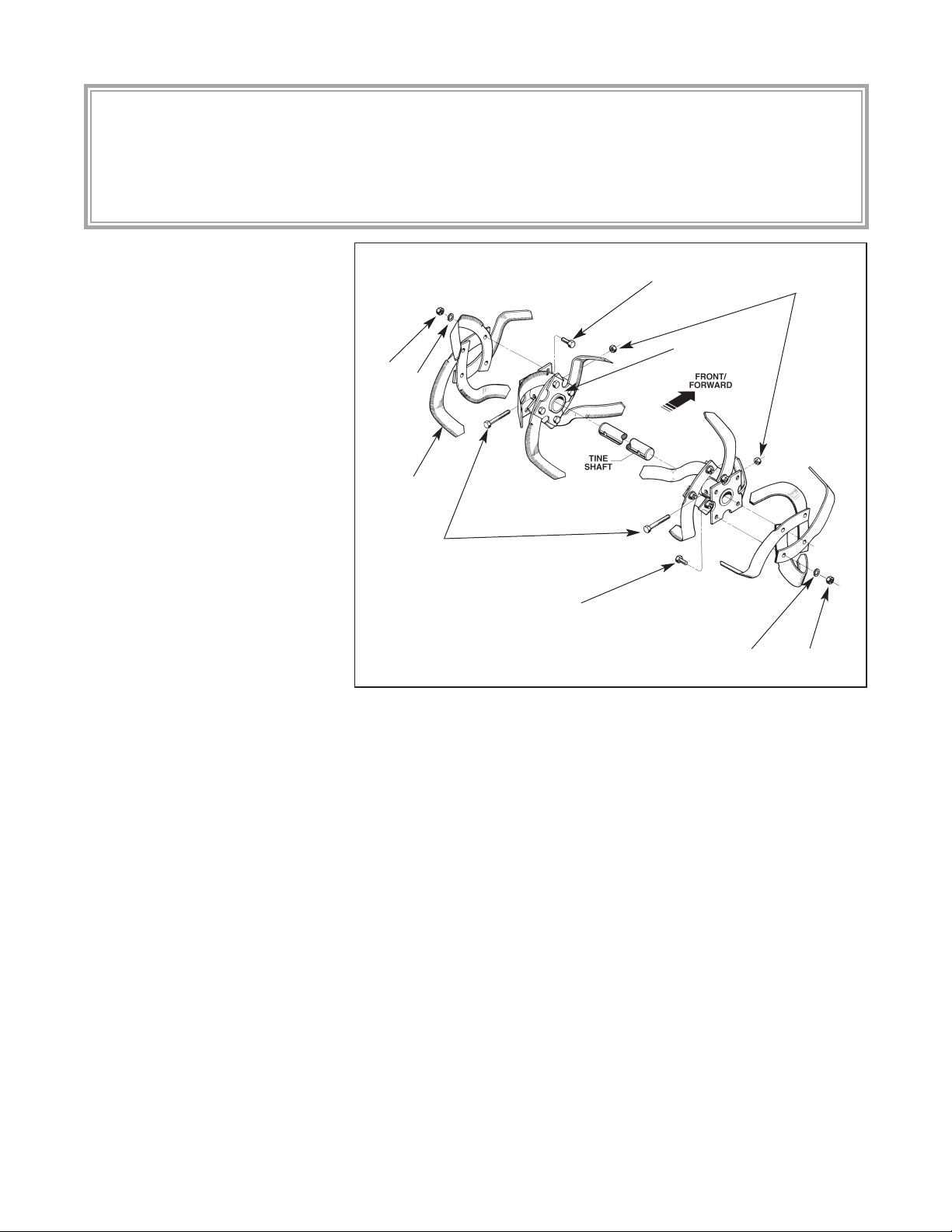

NOTE: Removing the tine holders from

the tine shaft may ease the installation

of your new bolo tines, but is not

necessarty. To do so, remove the screw

and nut which secure the tine holder to

the tine shaft, refer to Figure 2.

NOTE: Replace the inner tines (both

left-hand & right-hand) before

proceeding to the outer tines.

3. Use two 9/16-inch wrenches to

remove the two screws (A, Figure 2),

lockwashers (B) and nuts (C) that attach

a single tine to a tine holder. If needed,

use penetrating oil on the nuts.

4. Always discard old hardware and

tines. Use only the hardware which

came with your new tines.

5. When installing a replacement tine,

be sure to position it so that its cutting

edge (sharp) will enter the soil first as

the tiller moves forward.

6. Loosely fasten the new tine with the

screws, lockwashers and lock nuts

included in this kit. Refer to Figure 2.

7. In a clockwise fashion, replace the

remaining three tines in the gang-offour. Use two 9/16-inch wrenches to

securely tighten all four tines in place.

8. Proceed to the next four tines and

repeat the previous steps until all

sixteen bolo tines are replaced.

For customer assistance, visit www.troybilt.com, contact your nearest authorized dealer or:

TROY-BILT LLC, P.O. BOX 361131, CLEVELAND, OHIO 44136-0019, 1-866-840-6483

Printed in U.S.A. Form 769-00138 (03/2002)

Figure 2: Install tines so that cutting edge of tines enter soil first when tiller moves

forward.

A

Tine Holder

Nuts

B

C

Screws

Cutting

Edge

B

A

C

Bolt Removal Tips

❑

Loosen all four nuts on a holder plate or tine gang before trying to remove any of the nuts and bolts.

❑

If necessary, use penetrating oil to loosen stubborn nuts.

❑

If necessary, place the closed (boxed) end of a wrench on the nut and sharply tap the wrench with the

rubber mallet until the nut is loose.

Loading...

Loading...