Page 1

Universal Flying Magnet Crank Trigger Kit

Parts Included:

1 – Trigger Wheel, 7.25” Diameter 1 – Pickup Holder Base

1 – Universal Pickup Holder 1 – Non-Magnetic Pickup, PN 8276

1 – Universal Bracket 2 – Bolts, 5/16 – 24 x 1.25”

2 – Washers, 5/16” 6 – Matched Magnets and Rivets

Note: This Kit requires fabrication for your specific application. It is recommended to use a

professional machine shop.

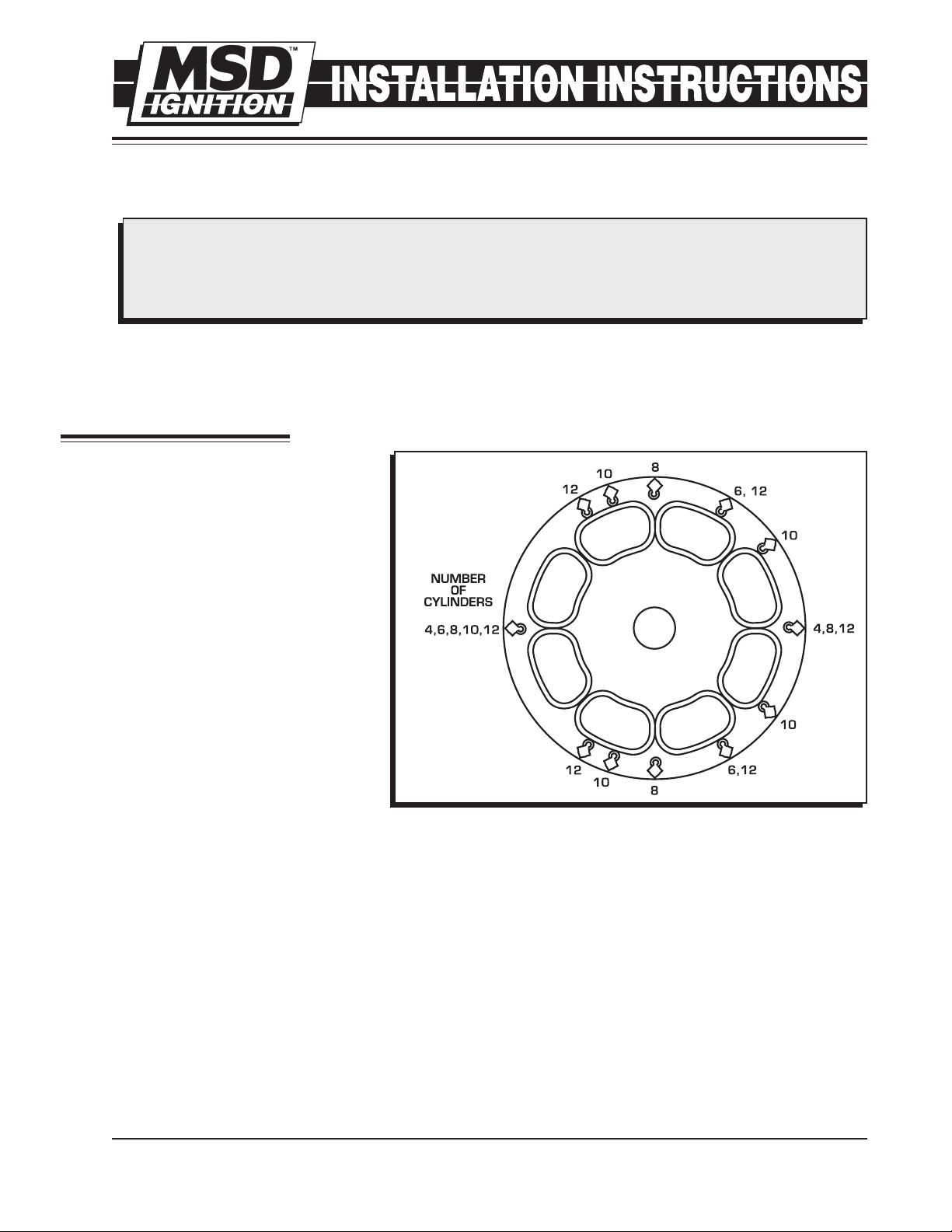

TRIGGER WHEEL

The Trigger Wheel is 3/8” thick

aluminum, has a 7.25” diameter

and a 1” hole in the center. It has

magnet positions machined for

up to 12-cylinder applications (six

magnets). Figure 1 shows where

each magnet needs to be installed

depending on the number of

cylinders.

PN 8655

The Wheel retaining holes must

be machined, as well as a

centering method. It is imperative

that the wheel be centered

accurately.

Figure 1 Magnet Location for Different Engine Applications.

AUTOTRONIC CONTROLS CORPORATION • 1490 HENRY BRENNAN DR., EL PASO, TEXAS 79936 • (915) 857-5200 • FAX (915) 857-3344

Page 2

2 INSTALLATION INSTRUCTIONS

MAGNET INSTALLATION

The magnets that are supplied are a

matched set and must be installed in one

position to produce the correct trigger

signal.

1. Determine which side of the wheel will

face out. Mark this position.

2. Install the magnet in the wheel with the

hole in the plastic overmolding facing

out from the engine (Figure 2). The

chamfer on the magnet must be

positioned next to the aluminum rivet.

3. Install the rivet. It must be set by using a

press or vice with a set of smooth,

parallel jaws (such as the vice on a

milling machine).

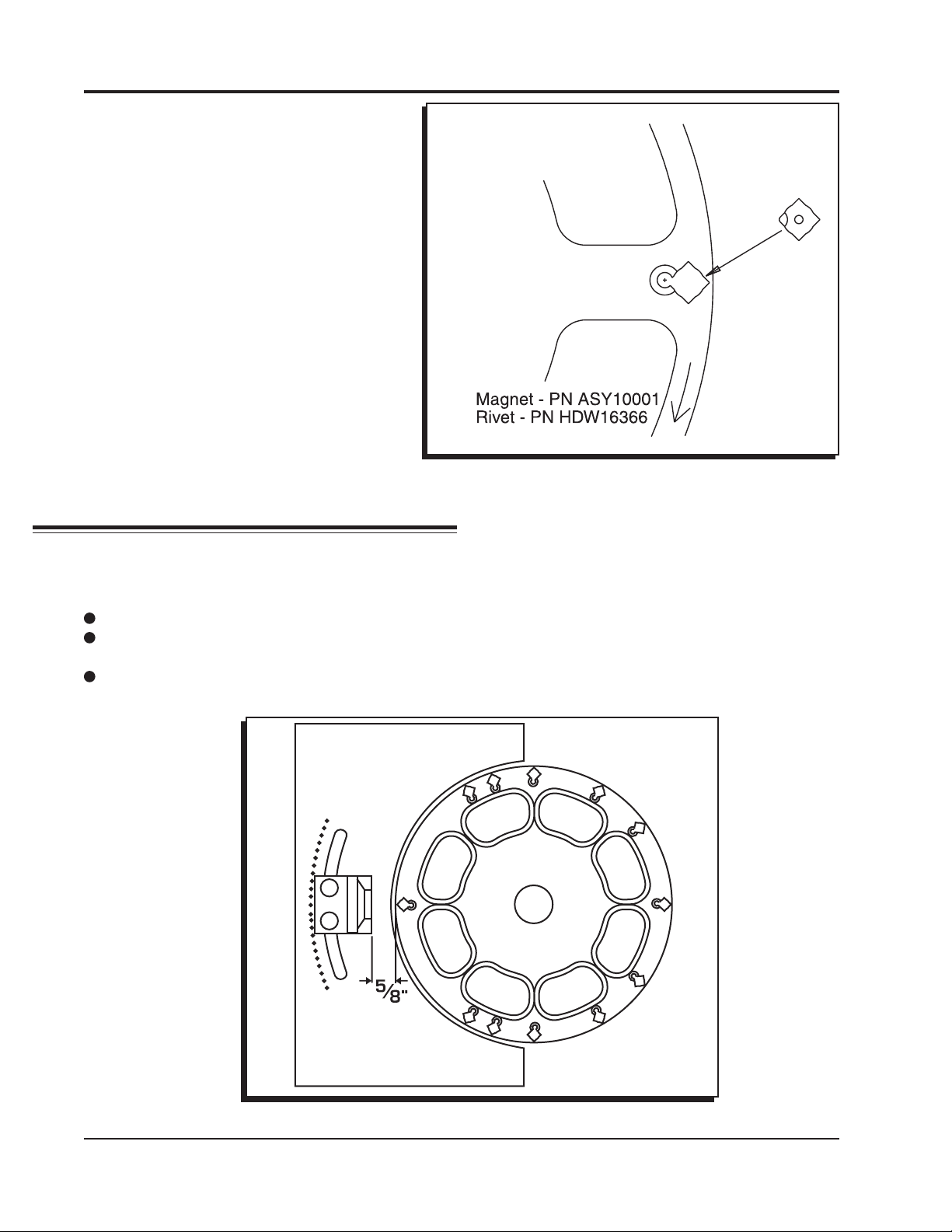

BRACKET AND PICKUP MOUNT

Figure 2 Installing the Magnets.

Once the Trigger Wheel mounting is complete, the brackets need to be created. The mounting

bracket can be cut and machined to meet your requirements. Consider these tips when machining

the bracket:

It is required to have at least two retaining bolts to secure the bracket.

Do not mount the bracket flush to the block. It will be necessary to be able to install the pickup

holder bolt retainer behind the bracket.

The pickup must be spaced 5/8” away from the trigger wheel (Figure 3). This is required so the

air gap between the pickup and trigger wheel will remain constant through its adjustment range.

Figure 3 Pickup Bracket Placement.

AUTOTRONIC CONTROLS CORPORATION • 1490 HENRY BRENNAN DR., EL PASO, TEXAS 79936 • (915) 857-5200 • FAX (915) 857-3344

Page 3

INSTALLATION INSTRUCTIONS 3

PICKUP HOLE

To machine the Pickup Holder, the bracket and trigger wheel must be installed. This is necessary

to center the Non-Magnetic Pickup to the trigger wheel (Figure 4).

1. Bolt the Pickup Holder to the bracket.

2. Locate the center of the trigger wheel and mark this location on the Pickup Holder.

3. Use an 11/16” drill bit, and tap the hole to ¾-16 threads.

4. Install the pickup and lock nut. Set the air-gap to .050”-.080” (Figure 5).

Figure 4 Centering the Pickup Mounting Hole.

Figure 5 Setting the Pickup Air-Gap.

AUTOTRONIC CONTROLS CORPORATION • 1490 HENRY BRENNAN DR., EL PASO, TEXAS 79936 • (915) 857-5200 • FAX (915) 857-3344

Page 4

Service

In case of malfunction, this MSD component will be repaired free of charge according to the terms of

the warranty. When returning MSD components for service, Proof of Purchase must be supplied for warranty

verification. After the warranty period has expired, repair service is charged based on a minimum and

maximum charge.

Send the unit prepaid with proof of purchase to the attention of: Customer Service Department,

Autotronic Controls Corporation, 12120 Esther Lama, Suite 114, El Paso, Texas 79936.

When returning the unit for repair, leave all wires at the length in which you have them installed. Be

sure to include a detailed account of any problems experienced, and what components and accessories

are installed on the vehicle.

The repaired unit will be returned as soon as possible after receipt, COD for any charges. (Ground

shipping is covered by warranty). All units are returned regular UPS unless otherwise noted. For more

information, call the MSD Customer Service Line (915) 855-7123. MSD technicians are available from 8:00

a.m. to 5:00 p.m. Monday - Friday (mountain time).

Limited Warranty

A

utotronic Controls Corporation warrants MSD Ignition products to be free from defects in material

and workmanship under normal use and if properly installed for a period of one year from date of

purchase. If found to be defective as mentioned above, it will be replaced or repaired if returned prepaid

along with proof of date of purchase. This shall constitute the sole remedy of the purchaser and the sole

liability of Autotronic Controls Corporation. To the extent permitted by law, the foregoing is exclusive

and in lieu of all other warranties or representations whether expressed or implied, including any implied

warranty of merchantability or fitness. In no event shall Autotronic Controls Corporation be liable for

special or consequential damages.

AUTOTRONIC CONTROLS CORPORATION • 1490 HENRY BRENNAN DR., EL PASO, TEXAS 79936 • (915) 857-5200 • FAX (915) 857-3344

FRM24324 Created 01/03 Printed In U.S.A.

Loading...

Loading...