Page 1

MSD 6-Mod Controller

for Carbureted and EFI Gen III Engines

PN 6011

Parts Included

1 - Ignition Controller, PN 6011

1 - Pro-Data+ Software CD

1 - Harness

1 - Parts Bag

1 - 2-Bar MAP Sensor

WARNING: During installation, disconnect the battery cables. When Disconnecting, always remove

the Negative cable first and install it last.

Note: Solid core spark plug wires or non-resistor spark plugs cannot be used with an MSD Ignition

Control.

Optional Accessories

Hand Held Monitor, PN 7550

EFI Harness and Tach Adapter Kit, PN 88814

CARBURETOR

The PN 6011 Ignition Controller is designed for Ford Modular engines that have been retro-fit with an

intake manifold and carburetor. The Controller is supplied with a wiring harness that connects to the

factory connectors for a simple installation.

EFI

This Controller can also be used in stock EFI applications, by using accessory Harness PN 88814.

This Harness allows the PN 6011 Controller to tap into the sensor signals without interrupting the OEM

ECU. The ECU and coils operate as normal while the PN 6011 controls the timing and rpm. When

using with an EFI system, a tach adapter harness will be required, PN 88813.

OPERATION

The MSD Controller offers several programmable features that allow rpm and timing adjustments. This

can be achieved through the supplied Pro-Data+ software via a PC or with the optional Hand Held

Programmer, PN 7550. Timing adjustments and selections can also be made with plug-in modules.

Software installation, operation and the programmable features of the Controller are explained in detail

in this document. More information can be found in the Pro-Data+ Software Help section.

MOUNTING

The Controller is designed to be mounted under the hood or on the firewall. Do not mount the unit

near exhaust. Find a suitable location, confirm that all of the wires reach their connections. Mark the

mounting hole locations using the unit or the template shown in Figure 3, page 7. Drill the holes with

a 3/16" bit.

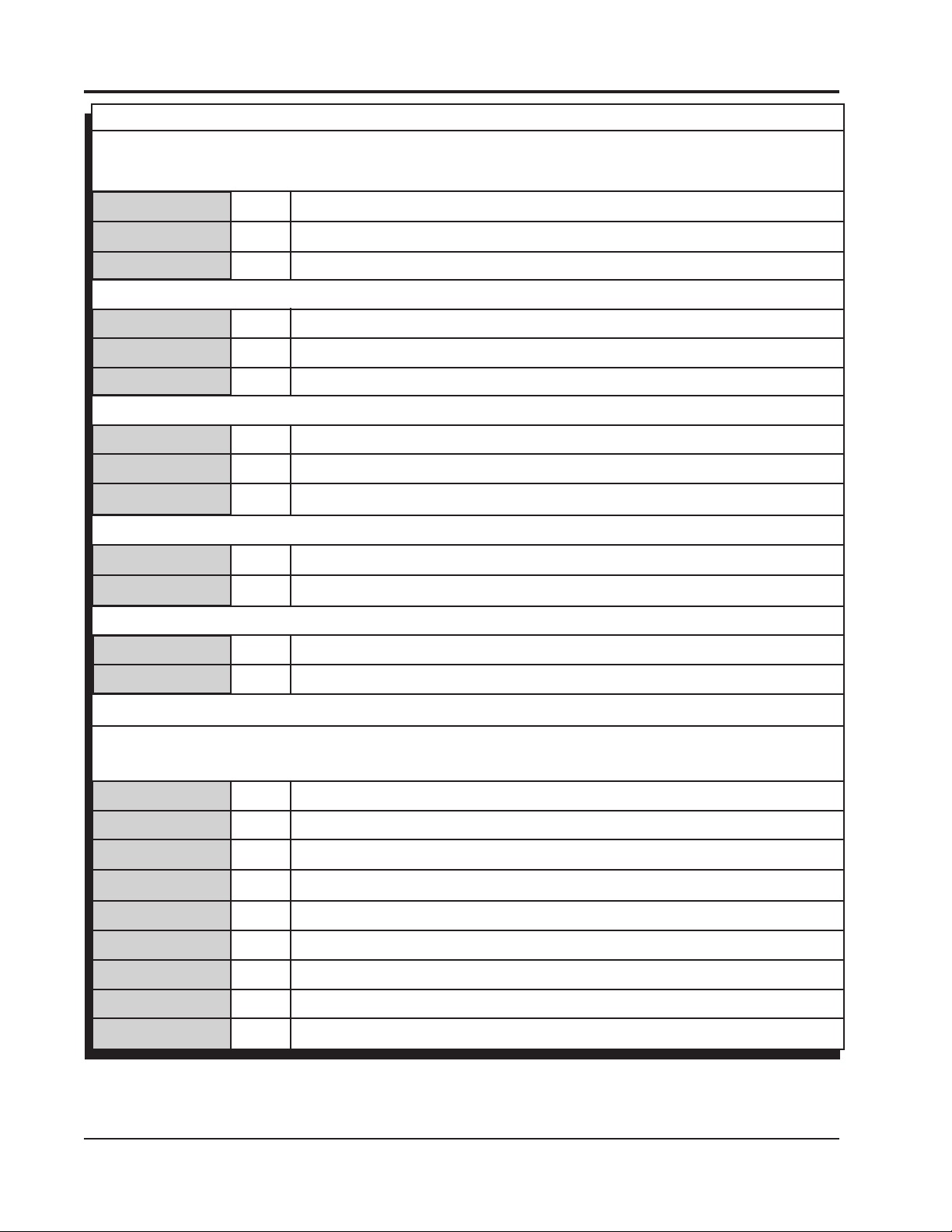

WIRING

All of the wiring, except four wires, are routed into factory style connectors to ensure an easy installation

on a SOHC engine. On DOHC engines the coil polarity is reversed. In these applications, the coil

wiring needs to be relocated. It is recommended to look at the polarity markings on the coil to confirm

the polarity. The wire descriptions follow in the chart on page 2.

MSD IGNITION • 1490 HENRY BRENNAN DR., EL PASO, TEXAS 79936 • (915) 857-5200 • FAX (915) 857-3344

Page 2

2 INSTALLATION INSTRUCTIONS

POWER WIRES

Note: For carburetor applications this connector is cut off and the Brown/Yellow is not used. For EFI applications,

this connects to the number one coil connector.

RED 12-volt input. Connect to switched 12 volts.

BROWN/YELLOW Use only with EFI. Coil input wire.

BLACK Ground. Connect eyelet to ground.

LOOSE WIRES

YELLOW Tach Signal. Provides a 12 volt square wave source.

PINK Step Retard. When 12 volts are applied, the step retard is activated.

BLUE 2-Step. When 12 volts are applied, the RevLaunch rpm value is active.

MAP SENSOR

BROWN

GREEN Pin-B Map Signal

ORANGE Pin-C 5-volt supply

CRANKSHAFT SENSOR

BLACK Pin-A Signal Negative (-)

RED Pin-B Signal Positive (+)

CAMSHAFT SENSOR

BROWN Pin-A Ground

TAN Pin-B Signal Wire

COIL CONNECTORS

RED Pin-A* 12-volt supply

VIOLET

RED/GREEN Pin-B* Coil-2 Trigger

LT. BLUE Pin-B* Coil-3 Trigger

Pin-A Ground

*Note: The harness is set up for use on a SOHC engine. DOHC engines use coils with reversed polarity. In these

applications, the location of two coil wires needs to be swapped in each connector.

Pin-B* Coil-1 Trigger

BROWN/GREEN Pin-B* Coil-4 Trigger

GREEN Pin-B* Coil-5 Trigger

WHITE/BLUE Pin-B* Coil-6 Trigger

PINK Pin-B* Coil-7 Trigger

VIOLET/BLUE Pin-B* Coil-8 Trigger

MSD IGNITION • 1490 HENRY BRENNAN DR., EL PASO, TEXAS 79936 • (915) 857-5200 • FAX (915) 857-3344

Page 3

INSTALLATION INSTRUCTIONS 3

B-RED

A-BLACK

CRANK

COIL 4

A-RED

B-PURPLE/BLUE

COIL 3

A-RED

B-PINK

COIL 2

A-RED

B-WHITE/BLUE

COIL 1

COIL 8

COIL 7

COIL 6

COIL 5

A-RED

B-GREEN

B-BROWN/GREEN

A-RED

B-LT. BLUE

A-RED

B-RED/GREEN

A-RED

B-VIOLET

A-RED, COMMON 12V

12V

COIL INPUT

TO TACH

ADAPTER

GROUND

CAM

2-STEP/RETARD

BLUE

PINK

MAP

YELLOW-TACH

OEM COIL1

CONNECTOR

GREEN

ORANGE

BROWN

EFI APPLICATIONS

REQUIRES HARNESS

PN 88814

FOR CARBURETOR APPLICATIONS,

CUT WIRES. CONNECT RED TO A

SWITCHED 12 VOLT SOURCE.

BROWN/YELLOW IS NOT USED.

applications, the location of two coil wires needs to be swapped in each connector.

Note: The harness is set up for use on a SOHC engine. DOHC engines use coils with reversed polarity. In these

Figure 1 Wiring the MSD Gen III Controller.

MSD IGNITION • 1490 HENRY BRENNAN DR., EL PASO, TEXAS 79936 • (915) 857-5200 • FAX (915) 857-3344

Page 4

4 INSTALLATION INSTRUCTIONS

PROGRAMMABLE FEATURES

The following explains the programmable features of the PN 6011 Controller. The features are listed

in the same order shown on the Data Editor list in the software. Note that the Help pull down menu

of the software offers explanations of all the features.

Note: STATS Stat 1 or SCAN are display features only used with the Hand Held Monitors, PN

7550 or PN 7553.

RPM TABLE (RPMtbl)

This setting can only be modified from the RPM Timing Curve edit graph on the lower right of the

screen (It can also be set with the Hand Held Monitor). The chart allows you to map out an entire

timing curve, much like the centrifugal advance of a mechanical distributor.

To create a map, simply position the mouse at a point on the chart and right click to add a dot. Up

to 10 points can be added. By moving the mouse over this point and a left click, the dot changes to

red (active) and you can move it around the map by clicking and dragging.

Note: The timing has minimum and maximum limits that are set in the Data Editor Menu. These

settings include the cumulative value of any vacuum advance or retard as well as the Switch

Retard if used.

MAP TABLE (MAPtbl)

Note: In order to take advantage of a vacuum advance, a MAP sensor is required.

This is a Manifold Absolute Pressure (MAP) chart. It gives you the capability of modifying the timing

curve based on manifold pressure (vacuum or boost). A curve can be created from the MAP Advance

Curve graph on the upper right of the screen (It can also be set with the Hand Held Monitor). The

chart allows you to map out an advance curve based on manifold vacuum (much like the vacuum

advance on a mechanical distributor).

To create a map, simply position the mouse at a point on the chart and right click to add a dot. Up

to 10 points can be added. By moving the mouse over this point and a left click, the dot changes to

red (active) and you can move it around the map by clicking and dragging.

Note: The timing has minimum and maximum limits that are set in the Data Editor Menu. These

settings include the cumulative value of any vacuum advance or retard as well as the Step

Retard if activated.

MAP SENSOR SELECT

Allows the selection of a 1, 2 or 3-bar MAP sensor. This setting should be set to match the MAP Sensor

in use: 1-bar (0-15 psia), 2-bar (0-30 psia), 3-bar (0-45 psia). A 2-bar Sensor is supplied.

TIMING LIMIT

There are two adjustments that set the limits of ignition timing. These settings are meant as safety

targets to keep the timing in check. Both the Minimum and Max values include any timing retards or

advancements.

Min Timing This is the minimum amount of timing advance. It is adjustable from 0°-20° BTDC

with a default of 5°.

Max Timing This is the maximum amount of timing advance. It is adjustable from 25°-65°

BTDC with a default of 45°.

MSD IGNITION • 1490 HENRY BRENNAN DR., EL PASO, TEXAS 79936 • (915) 857-5200 • FAX (915) 857-3344

Page 5

INSTALLATION INSTRUCTIONS 5

PRO-DATA+

Installation of the Pro-Data+ Software

1. Insert the installation CD into your PC.

2. In Windows, click on Start then select Run.

3. In the box type, “D: Setup” and press Enter (or corresponding drive).

4. The screen will walk you through several steps.

5. Once loaded, your monitor will have an MSD Graph View logo. Click on it to open the software.

6. A program will open. Go to the upper left corner of the screen and click on File, then Open.

7. This will open a menu of part numbers. Select “6011”.

8. This will open another menu of versions. Highlight and open the “6011vxx.IGN” (xx determines the

versions, such as 02). This will open the Pro-Data+ software for the Ignition Controller.

Saves and Transfers

Whenever a change is made to a program, it either must be saved to a file in your PC or it needs to be

transferred to the Controller. You will notice that whenever you make a change to a program, the bullet

next to the modified value will turn red. It will remain red until you save it to a file or to the MSD. There

are two ways to save your files.

Save to MSD: This step will save any changes directly into the Controller. If you are only making one

or just a couple modifications this works well.

Save to PC: This will save your changes to only show on the PC screen (indicated by a red bullet

point next to any altered values). These modifications will not be active or saved until

you save the file or transfer the information to the MSD.

You can create numerous files on your PC and download them for testing purposes or save programs

you used at different races or events.

Real Time

Monitor

Notes

Menu

Tree

MAP Advance Chart

Timing Map

Gauges

Figure 2 Pro-Data+ Screen and Programming Windows.

MSD IGNITION • 1490 HENRY BRENNAN DR., EL PASO, TEXAS 79936 • (915) 857-5200 • FAX (915) 857-3344

Page 6

6 INSTALLATION INSTRUCTIONS

REV LIMITS

The Controller allows you to program two rev limits; one for an over-rev safety and another that

provides a low limit for use as a launch, or two step limit.

RevLaunch This is the low rpm limit that is designed to be used while staged at the starting

line. It is activated when the Blue wire is connected to 12 volts. When there is

no 12 volts on this wire, the High Rev Limit is active. It is adjustable in 100 rpm

increments from 2,000 - 12,500 rpm.

RevMax This is the high, or over-rev rpm limit. It is active whenever the Blue wire (RevLO)

is not connected to 12 volts. It is adjustable in 100 rpm increments from 2,000 12,500 rpm.

STEP RETARD

A step retard will provide an adjustable amount of retard at a specific moment. This is ideal when

using nitrous oxide. The amount of retard is adjustable from 0° - 15° in 1° increments. The retard is

activated when the Pink wire is switched to 12 volts. Default is 10°.

TIMING SOURCE

This adjustment allows you to select a timing curve. The 6-Mod lets you run a Built-In default curve

that can easily be modified by using the RPM Table chart. On engines using the factory EFI you can

select OEM Advance or OEM Retard to use the factory ECU’s timing map.

Built-In: This is a general timing curve that is designed to work well with most stock

type engines. This chart is shown in the RPM Table and MAP Table charts.

These can easily be modified by clicking and dragging on the dots, or by

adding a dot (right click) and saving to the ignition.

OEM Advance: This selection is used with a factory EFI equipped engine. The 6-Mod will use

the factory ECU’s timing curve. By using the OEM Timing Mod option below,

the entire timing curve will be advanced the amount you set.

OEM Retard: This selection is used with a factory EFI equipped engine. The 6-Mod will use

the factory ECU’s timing curve. By using the OEM Timing Mod option below,

the entire timing curve will be retarded the amount you set.

OEM TIMING MOD

This option is available only when running the factory ECU’s timing curve on EFI equipped engines

(Selected as OEM Advance or Retard). Here you set the total amount of advance or retard for the

factory timing curve. The default is 0°.

OEMtimingmod: Adjustable from 0° - 10°.

MSD IGNITION • 1490 HENRY BRENNAN DR., EL PASO, TEXAS 79936 • (915) 857-5200 • FAX (915) 857-3344

Page 7

INSTALLATION INSTRUCTIONS 7

3.93”

4.40”

5.77”

Figure 3 Mounting Template.

MSD IGNITION • 1490 HENRY BRENNAN DR., EL PASO, TEXAS 79936 • (915) 857-5200 • FAX (915) 857-3344

Page 8

TECH NOTES

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

_________________________________________________________________________________________________________________________

Service

In case of malfunction, this MSD component will be repaired free of charge according to the terms

of the warranty. When returning MSD components for service, Proof of Purchase must be supplied for

warranty verification. After the warranty period has expired, repair service is charged based on a minimum

and maximum charge.

All returns must have a Return Material Authorization (RMA) number issued to them before being

returned. To obtain an RMA number please contact MSD Customer Service at (915) 855-7123 or fax a

request to (915) 857-3344. Send the unit prepaid with proof of purchase to the attention of: MSD Ignition,

Customer Service - RMA #,

12120 Esther Lama, Dock 5, El Paso, Texas 79936

.

When returning the unit for repair, leave all wires at the length in which you have them installed. Be

sure to include a detailed account of any problems experienced, and what components and accessories

are installed on the vehicle.

The repaired unit will be returned as soon as possible after receipt, COD for any charges. (Ground

shipping is covered by warranty). All units are returned regular UPS unless otherwise noted. For more

information, call the MSD Customer Service Line (915) 855-7123. MSD technicians are available from

7:00 a.m. to 6:00 p.m. Monday - Friday (mountain time).

Limited Warranty

M

SD IGNITION warrants MSD Ignition products to be free from defects in material and workmanship

under normal use and if properly installed for a period of one year from date of purchase. If found to be

defective as mentioned above, it will be replaced or repaired if returned prepaid along with proof of date of

purchase. This shall constitute the sole remedy of the purchaser and the sole liability of MSD Ignition. To

the extent permitted by law, the foregoing is exclusive and in lieu of all other warranties or representations

whether expressed or implied, including any implied warranty of merchantability or fitness. In no event

shall MSD Ignition be liable for special or consequential damages.

MSD IGNITION • 1490 HENRY BRENNAN DR., EL PASO, TEXAS 79936 • (915) 857-5200 • FAX (915) 857-3344

© 2006 Aut otro nic Controls C orpor ation

FRM27776 Created 08/06 Printed in U.S.A.

Loading...

Loading...