Page 1

`

Consumer Solutions & Support

US Competency Center

600 North US Highway 45

Libertyville, Illinois 60048

Website: gs.mot.com

FIELD SERVICE BULLETIN

FSB Number: LVCCFSB2005-15

Author: Tony Bryan

Date: January 27, 2005

Total No. of Pages: 3

Subject: GSM Triplets Refresh (V600R) – Flip Detect Switch

Phone Models: GSM V620, V600i

Level of Repair: 2

Problem

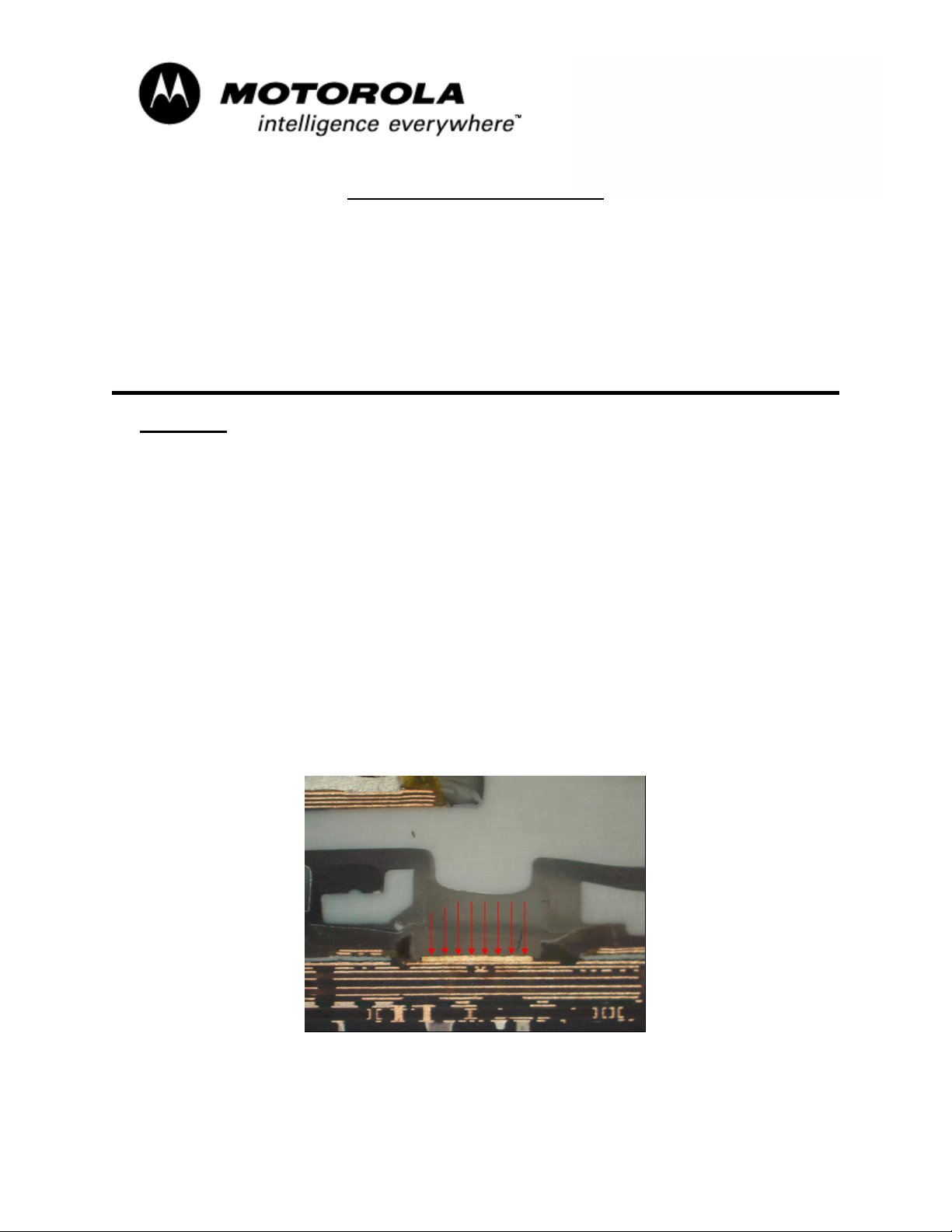

Service is aware of an issue, identified during the NPI Analysis on GSM

V620/V600i. Some units, returned with customer complaints related to improper

operation of the “Secondary/External Display” were found to have an intermittent

problem were the flip detection switch would not activate when the flip was

closed. Analysis revealed the issue to be caused by a poor or uneven

compression force between the keypad gold puck and the flip switch contacts on

the PCB. See Fig. 1.0 below.

Note: V620/V600i hardware included a fix for an issue where the main display

lens would be scratched by the keypad. This fix combined a thinner main display

lens and added height to the rubber base bumpers. This is a factor which is

contributing to this failure mode.

The failure rate for this issue was much higher on units built with ITT keypads

versus units built with TeeHwa keypads. Analysis of the keypads found, although

no keypads were found to be out of specification, some of the keypads were at

the low end of the tolerance and that was the reason for the higher failure rate.

Fig. 1.0 – Cross-Section showing uneven compression force on flip detect switch, concentrates contact

area on a small portion (right side) of the PCB contact area.

MOTOROLA INTERNAL USE ONLY Page 1

Page 2

`

Consumer Solutions & Support

US Competency Center

600 North US Highway 45

Libertyville, Illinois 60048

Website: gs.mot.com

Solution

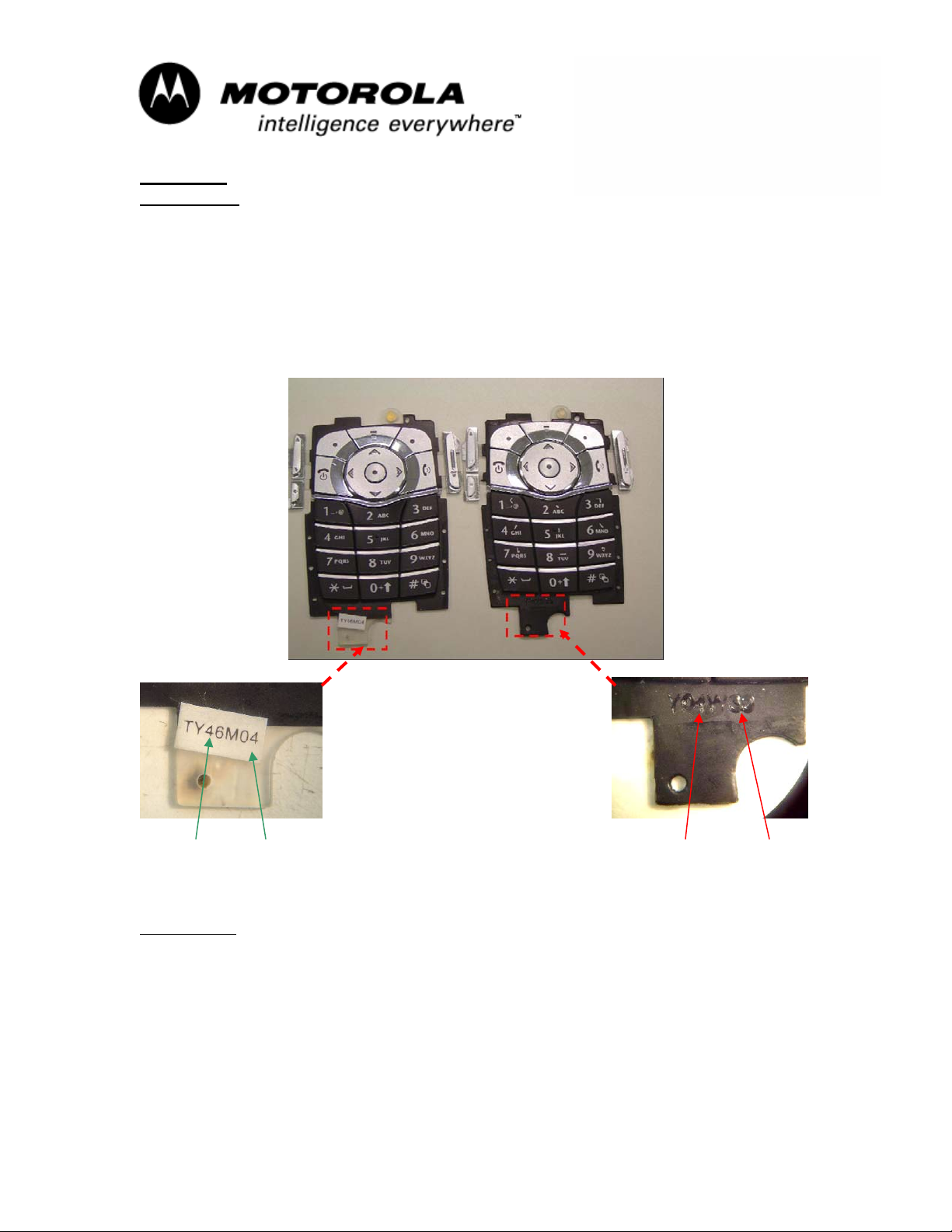

Short-Term: (1) Factory took immediate action. A shim was added to the

functional testing for flip switch operation. The shim holds the flip open an

additional 1mm higher than in normal use to screen out units with potentially

weak compression on the flip switch. – WW43 ‘04.

(2) All ITT keypads were purged from the factory as well as TeeHwa keypads

that were found to be on the low end of the tolerance for gold puck height. Only

TeeHwa keypads, measuring on the high end of the tolerance, are used. –

WW48 ’04.

Clear for TeeHwa Black for ITT

Week Year Year Week

Good after WW48 ‘04

Long-Term: (1) Keypad 3888470Yxx Rev. B - Modify keypad plunger to create

chamfered surface to allow for more uniform compression. - February ‘05

(2) Flip Front Housing 0188382N03 Rev. G - Modify flip inside housing flip detect

protrusion to account for flip bias due to hinge spring. This will better align the flip

detect protrusion with the keypad plunger/gold puck. - April ’05

(3) Side-Key Flex 8489088N04 Rev. D - Modify side-key flex to pull back

adhesive from around flip detect switch opening to reduce opportunity from

foreign material to collect around the PCB contacts. – March ’05

MOTOROLA INTERNAL USE ONLY Page 2

Page 3

`

Consumer Solutions & Support

US Competency Center

600 North US Highway 45

Libertyville, Illinois 60048

Website: gs.mot.com

Field Service Action

Customer Returns:

When servicing affected GSM V620/V600i customer returns, with customer

complaints related to improper operation of the “Secondary/External Display”,

then:

1. Test and evaluate the unit for proper performance of the Flip Switch.

a. If the Flip Switch operates normally, then follow normal

troubleshooting procedures to determine the fault per the customer

complaint.

2. Disassemble the unit and inspect the PCB contact and keypad gold puck

to ensure no foreign material is present, which may be interfering with the

connection.

3. Remove any foreign material found on PCB or keypad gold puck.

Isopropyl Alcohol (IPA) can be used to clean the contacts.

4. Replace the keypad with a TeeHwa keypad date coded after WW48 ’04.

See information above.

5. Reassemble and completely retest to confirm unit is properly repaired.

When available, additional parts (Keypad, Flip Front Housing, Side-Key Flex)

should also be replaced with the latest revisions. See above.

Service Inventory:

Please stock inventory of only the TeeHwa keypad for field replacement on the

GSM V620/V600i product. 3888470Y08 (English), 3888470Y14 (Cyrillic)

Please deplete current inventory of the Flip Front Housing 0188382N03 and

Side-Key Flex 8489088N04 and restock with latest revisions. See above.

Call Center Action:

When responding to problem product inquiries, on the GSM V620/V600i product,

where the complaint relates to improper operation of the “Secondary/External

Display”, please direct them to their local Service Center to have there phone

repaired per this FSB.

Service Entry Code

Please ensure that repairs of this type are logged on the Service Link database

as follows:

Global M-Claims Codes:

Customer Complaint Code: DIS03 (Display Secondary - Corrupt/Error Display)

Problem Found Code: DIS03 (Display Secondary - Corrupt/Error Display )

REF Designator Code: S (Switch)

Repair Code: RMP10 (Replace Mechanical Part – CSB/FSB)

PRC E-service Entry Codes:

Fault Code: 3103 (Display Secondary- Corrupt/Error Display)

Repair Code: 1310 (Replace Mechanical Part – CSB/FSB)

MOTOROLA INTERNAL USE ONLY Page 3

Loading...

Loading...