Page 1

Motorola GmbH, Mobile Devices, CSS Center

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 1 / 40

Doc. No: TSG_3G_V6

Version: 1.0

Date: 23.07.2007

Troubleshooting Guide MotoRAZR maxx V6

Level 3

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 2

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 2 / 40

Revision History

Date Version Comment

2007-07-23 1.0 Initial release of document

Contents

Revision History .......................................................................................................................2

Contents...................................................................................................................................2

Introduction...............................................................................................................................3

Audience...............................................................................................................................3

Requirements .......................................................................................................................3

About this Troubleshooting Guide ........................................................................................3

Related Documents..............................................................................................................3

Basic information on troubleshooting Motorola 3G phones..................................................3

Tools.........................................................................................................................................4

Required Tools .....................................................................................................................4

Additional Tools....................................................................................................................4

Troubleshooting Level 2...........................................................................................................5

No speaker audio..................................................................................................................5

No microphone audio............................................................................................................7

No ring tone/alert function.....................................................................................................8

No vibrator function.............................................................................................................10

No display/-backlight/poor picture quality...........................................................................12

Keypad/ side keys – no function.........................................................................................13

Telephone will not turn on or stay on..................................................................................14

Can’t make voice call/no service ........................................................................................15

Troubleshooting Level3..........................................................................................................16

Audio problems...................................................................................................................16

No speaker audio................................................................................................................16

No microphone audio..........................................................................................................17

No ring tone/alert function...................................................................................................18

No vibrator function.............................................................................................................19

No display/-backlight/poor picture quality...........................................................................20

Flip detect problem.............................................................................................................21

Keypad/side keys – no function/hangs...............................................................................22

On/Off switch not working...................................................................................................23

No keypad backlight ...........................................................................................................24

SIM card – check card/insert SIM.......................................................................................25

TransFlash Memory Card – no function .............................................................................26

No turn on...........................................................................................................................27

Turn off – powers down in standby.....................................................................................29

Battery life short/charging problems/no turn on due to excessive current drain.................29

Does not charge .................................................................................................................30

Invalid Battery.....................................................................................................................31

Battery Thermistor problem................................................................................................32

Accessory detection problem..............................................................................................33

Can’t make voice call/no service ........................................................................................34

No or low TX output power in GSM....................................................................................34

No or low TX output power in WCDMA ..............................................................................36

No RX GSM........................................................................................................................37

No RX WCDMA..................................................................................................................38

Flash procedures....................................................................................................................40

Software update..................................................................................................................40

Recovering Flash Memory in Forced Flash Mode..............................................................40

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 3

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 3 / 40

Introduction

Audience

This document aids service personnel in testing and repairing V6 telephones. Service

personnel should be familiar with electronic assembly, testing, and troubleshooting methods,

and with the operation and use of associated test equipment.

Requirements

Follow the current Technical Requirements for servicing Motorola products as described in

Requirement List for Motorola Authorized Service Centers.

the

About this Troubleshooting Guide

This document was created to assist analyzers troubleshooting problems on Motorola 3G

Phones. All information was collected during the repair in the Repair Entitlement Group

Flensburg.

Related Documents

V6 Level 1&2 Service Manual

V6 mechanical Overview

V6 Disassembly Video

V6 Assembly Video

Basic information on troubleshooting Motorola 3G phones

Make sure on any problem, that it is not a software related one by simply doing a 1FF reflash

with a Master Reset/Master Clear afterwards. In many cases a simple Master Reset can

already fix the problem.

Make sure all contacts are clean.

Use newest approved Software.

Do a visual inspection on customer abuse/liquid contamination.

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 4

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 4 / 40

Tools

Required Tools

Main Lens Press Fixture http://md-service.corp.mot.com/Bulletins/PPreview.aspx?Key=1827

Keypad Tab Bent Fixture http://md-service.corp.mot.com/Bulletins/PPreview.aspx?Key=1830

Additional Tools

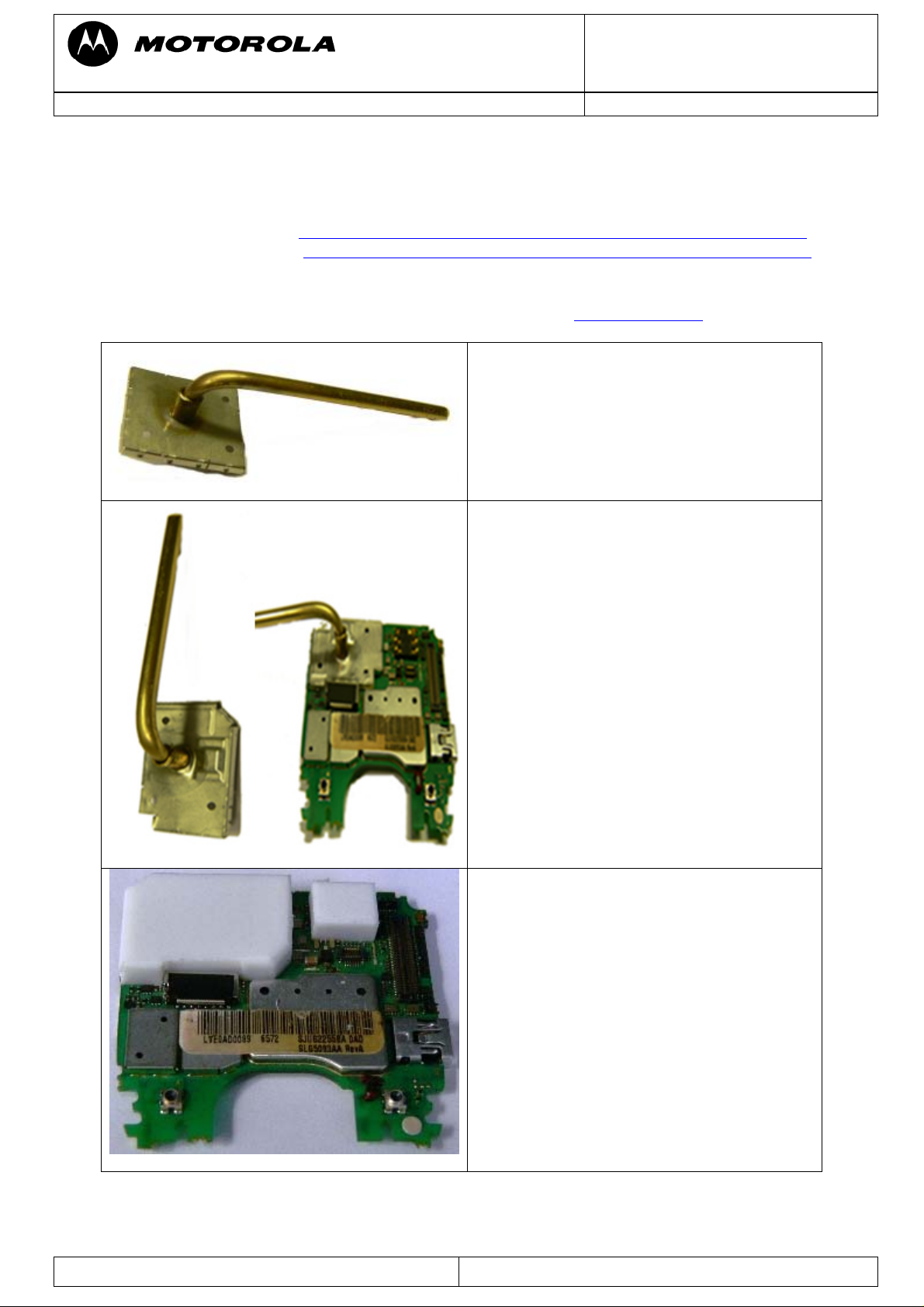

Following passive and active cooling devices are available at

V6 Shield Direktkühlung POP-Processor

Artikelnummer: 946071

www.multitast.de.

Figure 1

Figure 2

V6 Shield Direktkühlung Atlas

Artikelnummer: 946072

V6 Teflon shield-Set (3pcs)

Artikelnummer: 946073

Figure 3

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 5

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 5 / 40

Troubleshooting Level 2

No speaker audio

Probable cause:

a) Transceiver board assembly defective

Verification: Temporarily replace the flip assembly with a known good flip assembly. If the

fault has not been cleared, it is because of a defective transceiver board assembly. Forward

to an authorized Level 3 Service Center or proceed to

b) Speaker bad soldered/defective

Remove flip cover and visually inspect soldered contacts at speaker. If not ok, resolder

speaker. Otherwise replace speaker with a new one.

level 3 troubleshooting.

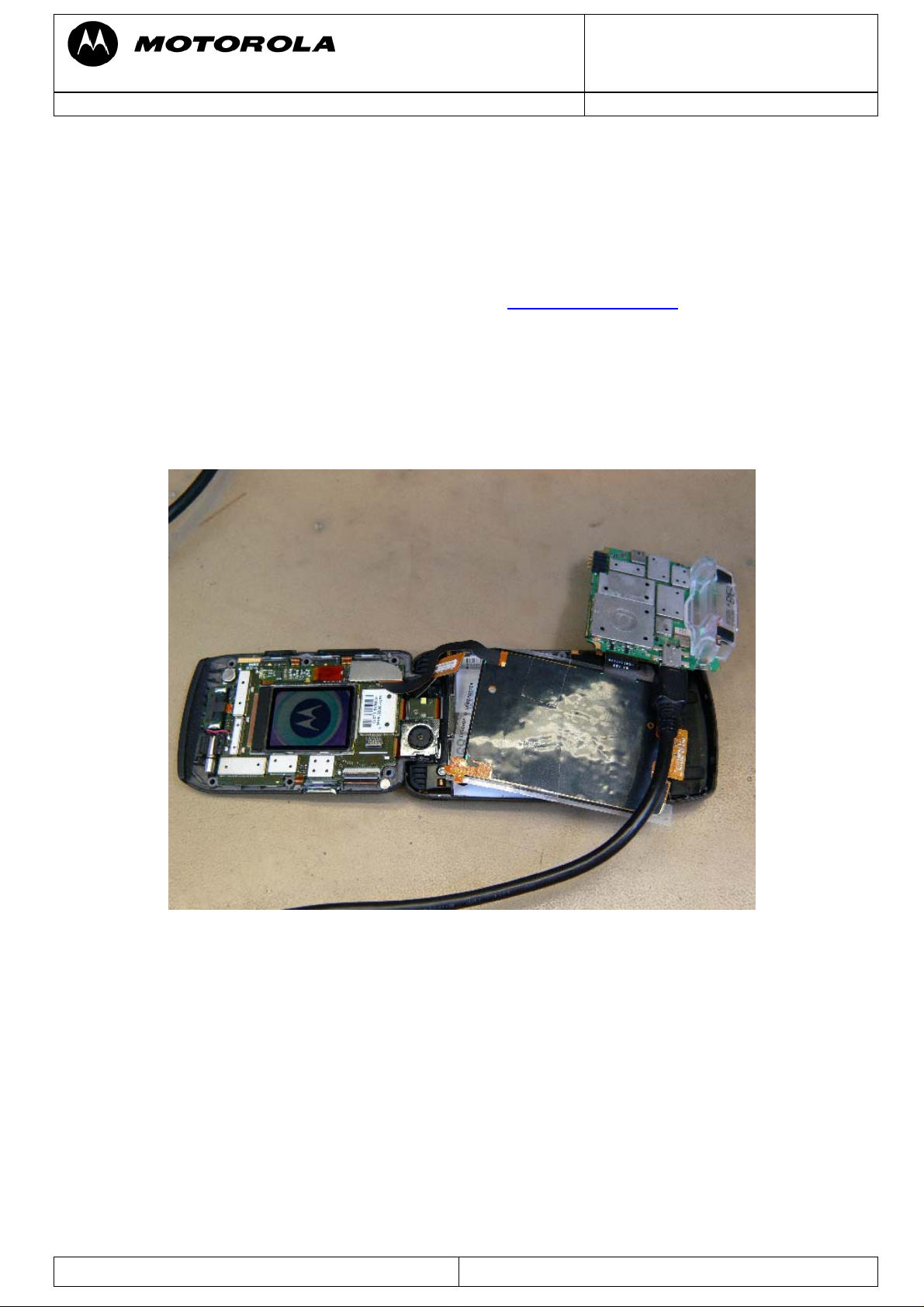

Figure 4

c) Keyboard flex assy defective

Remove flip cover. Unseat the display module assembly flex connector from its socket and

temporarily connect the display module assembly and transceiver board assembly with a

known good keyboard flex assy as shown on Figure 3. Check speaker function by turning on

a 1 kHz test tone via RepairStudio/Radiocomm. If the fault has been cleared, reassemble flip

assy with new keyboard flex assy.

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 6

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 6 / 40

Figure 5

d) Flip PCB defective

If the fault has not been cleared with one of the previous steps a), b) or c), it is most likely a

defective Flip PCB.

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 7

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 7 / 40

No microphone audio

Probable cause:

a) Dust/Foreign particles on microphone

Gain access to the transceiver board assembly and make sure that no dust/foreign particles

are on microphone/speaking hole in flip assembly

Figure 6

b) Transceiver board assembly defective

Forward to an authorized Level 3 Service Center or proceed to

level 3 troubleshooting.

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 8

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 8 / 40

No ring tone/alert function

Probable cause:

a) Faulty alert speaker (part of rear housing assy)

Verification: Remove rear housing assy and temporarily replace the rear housing assy with a

known good one. If the fault has been cleared, reassemble with new rear housing assy.

Figure 7

b) Faulty connection transceiver board assembly to alert speaker

Remove antenna assembly and check contacts. Temporarily replace antenna assy with a

known good one. If the fault has been cleared, reassemble with a new antenna assy.

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 9

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 9 / 40

Figure 8

c) Faulty transceiver board assembly

Verification: temporarily replace the transceiver board assembly with a known good one. f the

fault has been cleared, forward to an authorized Level 3 Service Center or proceed to

level 3

troubleshooting.

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 10

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 10 / 40

No vibrator function

Probable cause:

a) Transceiver board assembly defective

Verification: Temporarily replace the flip assembly with a known good flip assembly. If the

fault has not been cleared, it is because of a defective transceiver board assembly. Forward

to an authorized Level 3 Service Center or proceed to

level 3 troubleshooting.

b) Vibrator bad soldered/defective

Remove flip cover and visually inspect soldered contacts at vibrator. If not ok, resolder

vibrator. Otherwise replace vibrator with a new one.

c) Keyboard flex assy defective

Remove flip cover. Unseat the display module assembly flex connector from its socket and

temporarily connect the display module assembly and transceiver board assembly with a

known good keyboard flex assy as shown on Figure 8. Check vibrator function by turning on

vibrator via RepairStudio/Radiocomm. If the fault has been cleared, reassemble flip assy with

new keyboard flex assy.

Repair Support Information

Figure 9

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 11

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 11 / 40

Figure 10

d) Flip PCB defective

If the fault has not been cleared with one of the previous steps a), b) or c), it is most likely a

defective Flip PCB.

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 12

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 12 / 40

No display/-backlight/poor picture quality

Probable cause:

a) Transceiver board assembly defective

Verification: Temporarily replace the flip assembly with a known good flip assembly. If the

fault has not been cleared, it is because of a defective transceiver board assembly. Forward

to an authorized Level 3 Service Center or proceed to

level 3 troubleshooting.

b) Transceiver board connections faulty

Remove rear housing assy from unit and check general condition of flexible printed cable

(keyboard flex assy). If the flex is good, check that the flex connector is fully pressed down.

c) Keyboard flex assy defective

Remove flip cover. Unseat the display module assembly flex connector from its socket and

temporarily connect the display module assembly and transceiver board assembly with a

known good keyboard flex assy as shown on Figure 9. Check function of both displays. If the

fault has been cleared, reassemble flip assy with new keyboard flex assy.

Figure 11

d) Main display or CLI display faulty

Check function of both displays. If just one of them has no function, most likely that display

itself is defective

e) Flip PCB defective

If the fault has not been cleared with one of the previous steps a), b), c) or d), it is most likely

a defective Flip PCB.

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 13

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 13 / 40

Keypad/ side keys – no function

Probable cause:

a) Transceiver board assembly defective

Verification: Temporarily replace the flip assembly with a known good flip assembly. If the

fault has not been cleared, it is because of a defective transceiver board assembly. Forward

to an authorized level 3 service center or proceed to

level 3 troubleshooting.

b) Keyboard flex assy defective

Remove flip cover. Unseat the display module assembly flex connector from its socket and

temporarily connect the display module assembly and transceiver board assembly with a

known good keyboard flex assy as shown on Figure 10. Check function of keyboard. If the

fault has been cleared, reassemble flip assy with new keyboard flex assy.

c) Flip PCB defective

If the fault has not been cleared with one of the previous steps a) or b), it is most likely a

defective Flip PCB.

Repair Support Information

Figure 12

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 14

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 14 / 40

Telephone will not turn on or stay on

Probable cause:

a) Battery either discharged or defective

Try to switch on telephone with a known good battery. If the telephone turns on, make sure

that the phone is able to charge the battery. If ok, replace battery with a new one. If the

phone does not charge the battery, forward to Level 3 Service Center or proceed to

troubleshooting.

b) Battery contacts open or misaligned

Visually inspect the battery connectors on both the battery and the telephone. Realign and

clean contacts, if necessary. For battery connector replacement forward to an authorized

Level 3 Service Center.

level 3

c) Keyboard flex assy defective

If the telephone turns on via EMU USB cable and is unable to power down after pressing the

ON/OFF button, it could be because of a faulty keyboard flex assy. For verification

reassemble the unit with a known good flip assy. If the fault has been cleared, replace

keyboard flex assy with a new one.

d) Software corrupt

If the telephone shows a bootloader menu as shown in Figure 10 or is able to enter the

bootloader menu by holding “*” + “#” keys while turning on, the phone software possibly can

be recovered by a 1FF software reflash. Proceed to

recovering flash memory in forced flash

mode.

e) Transceiver board assembly defective

If none of the previous issues fixed the problem it is most likely a defect on the transceiver

board assembly – forward to an authorized Level 3 Service Center or proceed to

troubleshooting.

Repair Support Information

Figure 13

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

level 3

Page 15

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 15 / 40

Can’t make voice call/no service

Probable cause:

a) Antenna assembly defective

Check to make sure that the antenna contacts are properly connected to the antenna

contacts on the transceiver board assembly. If connected properly, substitute a known good

antenna. If the fault is still present, proceed to b).

Figure 14

b) Transceiver board assembly defective

Forward to an authorized Level 3 Service Center or proceed to

level 3 troubleshooting.

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 16

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 16 / 40

Troubleshooting Level3

Audio problems

First step on every audio related problem is to identify which audio paths are affected. If

audio signals in loop are ok, there could be an audio problem in a network call. Then it is

most likely a problem with the ARGON – forward to an authorized level 4 service center.

No speaker audio

Check

offset voltage, if audio loop is switched on, and additional up to 3Vpp at 1 kHz, if test tone is

switched on via RepairStudio/Radiocomm.

EAR_SP+ at C2303-1 and EAR_SP- at C2304-1, both should have around 1.5Vdc

- if not: check

J2300/C2303/C2304 and Resistors R4000/R4001 (both 10 Ohm)

- if ok: change ATLAS IC

U3000

Repair Support Information

Figure 15

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 17

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 17 / 40

No microphone audio

Set radio in audio loop via RepairStudio/Radiocomm.

Check

for misplaced part/ low resistance to GND – if they are ok, replace ATLAS IC

If

MIC_BIAS at C4107-1 – should be around 2.1Vdc. If not, check R4105/C4106/C4107

U3000.

MIC_BIAS is ok, check MIC_INPUT at C4102-1 while blowing into the microphone to see

the audio signal caused by the blowing. If there is no audio signal visible, replace

microphone

MK1. If there is an audio signal visible, replace ATLAS IC U3000.

Figure 16

Repair Support Information

Figure 17

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 18

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 18 / 40

No ring tone/alert function

Check LOUD_SPM (M4000) and LOUD_SPP (M4001), both should have around 2.2Vdc.

- If not, check

FL4100, VS4001 and capacitors C4104, C4502, C4501, C4108 for

misplaced/ defective parts.

- If ok, change ATLAS IC

Figure

18

U3000.

The alert signal is amplified by the ATLAS IC and generated by the ARGON IC. If the ATLAS

alert audio path is ok, there could be a problem with the ARGON not generating the alert

signals – forward to authorized level 4 service center.

Repair Support Information

Figure 19

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 19

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 19 / 40

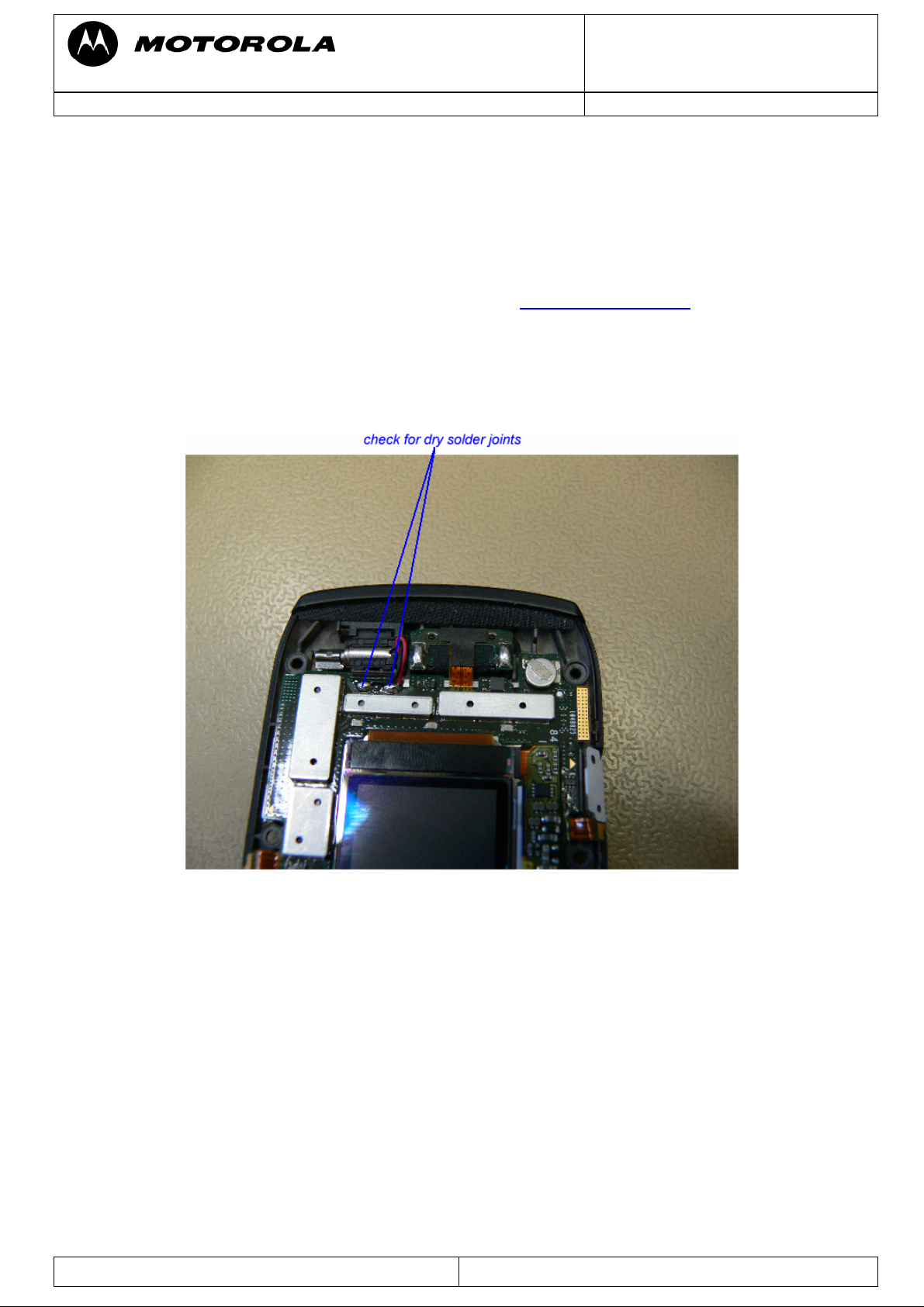

No vibrator function

Turn on vibrator via RepairStudio/Radiocomm. Measure VVIB_1_3V at J2300-19, it should

be 3Vdc.

- If ok check

J2300 for defective part/ dry solder joints

- If not ok, change ATLAS IC

-

U3000.

Figure 20

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 20

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 20 / 40

No display/-backlight/poor picture quality

Make sure that the problem is not located in the flip assembly, by testing PCB with a good

one and do a visual check of

J2300.

The following supply voltages for the flip assembly should be present:

-

B+

-

VCAM

-

VGPU_CORE_1_5V

-

VLVIO_1_8V

-

VHVIO_2_775V

The voltages can be ok without a flip connected, but can break down, if a flip is plugged in,

although the flip is ok! Additionally check the clock signal:

APPS_CLK at E2310 (should be 26Mhz)

-

only present the first seconds after power on!

If ok check:

- Filters

FL2300, FL2301, FL2302, FL2303, FL2304

You can check the function of these parts by using an Ohm Meter to check the resistance to

GND for verification, which line is affected. By using MotoPCB, it can be tracked which filter

the signal passes until it reaches the ARGON.

If all of these are ok, it should most likely be a problem with the ARGON

U1000 – forward to

an authorized level 4 service center.

We have seen some phones with the symptom: After a few seconds after turn on the display

seems to loose synchronization as shown on Figure 19. In most cases this issue was caused

by a skewed

E2310. In some cases the PCB was damaged because of lifted pads. It seems

to be damaged by a poor disassembly process.

Repair Support Information

Figure 21

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 21

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 21 / 40

Flip detect problem

Units with a flip detect problem will show following symptoms:

- no power on via battery

- no main display via EMU connector supply

- CLI display is not switching on open/close flip

- No keypad function

Check

FLIP_DETECT_F at R2316-2 – should be 1.8Vdc (High signal), if it is low check

VIPU_1_8V at R2316-1. If 1.8Vdc are present check J2300/FL2306 for dry solder

joints/solder shorts/defective part – if ok it is most likely a problem with the ARGON

forward to an authorized level 4 service center.

U1000 –

Figure 22

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 22

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 22 / 40

Keypad/side keys – no function/hangs

Due to the keypad matrix architecture with 8 rows in 8 columns it is quite useful to verify

which keys (if not all) are affected. By knowing which keys are not working, it is possible to

find out which row or column is affected. You can use an Ohm Meter to check the resistance

to GND for verification, which line is affected. By using the MotoPCB it can be tracked which

filters the signal passes until it reaches the ARGON.

Figure 23

In practice the defective part can very often be found by doing a visual inspection. Check:

J2300

-

-

FL2305

-

FL2306

-

FL2307 for solder shorts/dry solder joints/defective part.

If the keypad connector/filters are ok, it’s most likely a problem with the ARGON – forward to

an authorized level 4 service center.

Repair Support Information

Figure 24

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 23

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 23 / 40

On/Off switch not working

The On/Off button function can easily be checked by attaching a known good flip assembly

to the PCB. By inserting an EMU Bus USB cable the phone should turn on. Check

ON_OFF_END_B at FL2307-8. It should be a HIGH signal of 2.8Vdc and LOW signal if

Button is pressed.

- If signal is at HIGH level and not switching down when On/Off button is pressed,

check

- If signal is always at LOW level or down (below 2.8Vdc), check

are ok, it is most likely a problem with the ATLAS IC

J2300 and FL2307.

R3993/C3955. If they

U3000.

Repair Support Information

Figure 25

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 24

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 24 / 40

No keypad backlight

Keypad lighting is done by EL. The EL driver is located on the keyboard PCB. Turn on

keypad backlight via RepairStudio/Radiocomm. Check

- if

ELEN1 is HIGH, check J2300

- If

ELEN1 is LOW, it is most likely a problem with the ARGON U1000 – forward to an

ELEN1,

authorized level 4 service center.

Figure 26

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 25

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 25 / 40

SIM card – check card/insert SIM

Measurement on the SIM interface is a little bit difficult, as not all signals will be present until

a SIM card and a battery are inserted. As far as we know, there is still no SIM feature

implementation in RepairStudio or Radiocomm. In the most cases it should be possible to

figure out which part is defective by simply using an Ohm Meter to measure the following

signals to GND:

-

VSIM at M5500-3, M5500-5

If far less than 30 kOhm to GND, it could be a defective ATLAS IC

USIM_CLK_1 at M5500-1

-

-

USIM_RST_1 at M5500-2

-

USIM_IO_1 at M5500-6

U3000.

If any of these has far less than 30 kOhm to GND, it could be a defective ARGON IC

– forward to an authorized level 4 service center.

U1000

Before replacing the ATLAS IC

U3000 or the ARGON U1000, make sure that none of the

associated capacitors/diodes have low resistance to GND.

Repair Support Information

Figure 27

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 26

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 26 / 40

TransFlash Memory Card – no function

Insert a known good TransFlash card.

Under Menu – Settings – Phone Status – Storage Devices the Memory Card should

appear next to the internal phone memory.

If not, disassemble the phone and do a visual inspection of the TransFlash Connector

J5801

itself. If there are any visible damages/bent contacts/solder shorts or dry joints, change it.

Check

SD1_DET_B at R5811-1:

- Without TransFlash card inserted there should be a HIGH signal of 1.9Vdc, if not

check

R5811 for dry solder joints/tombstoned part.

- With TransFlash card inserted the signal should change to LOW signal (0V)

If

SD1_DET_B without TransFlash card inserted is ok (HIGH/1.9Vdc), but is not switching

down to 0V with inserted TransFlash card, replace TransFlash connector

Check

ok, it is probably a problem with the ARGON

VMMC_2_9V at R5801-1 (2.9Vdc). If low, check VR5801 for internal short to GND. If

U1000 – forward to an authorized level 4

J5801.

service center.

Repair Support Information

Figure 28

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 27

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 27 / 40

No turn on

Verify if radio doesn’t turn on (assembled with display). If it does, but doesn’t enumerate via

EMU-Connector at RSD/RepairStudio there should be a problem with the USB connection.

In some cases a 1FF SW reflash in

FORCED FLASH MODE (by connecting EMU-Connector

to radio while “*” and “#” are pressed) can fix this issue.

- If not, visually check EMU-Connector

J5000 for mechanical defects or contamination

on contacts, bad soldered pins or solder shorts

- Check

- If ok, change ATLAS IC

D5002/C5001/C5002 for internal short to GND, R3650/R3651 (22 Ohm)

U3000

If the problem remains, it could be a problem with the ARGON IC

authorized level 4 service center.

U1000 – forward to an

Repair Support Information

Figure 29

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 28

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 28 / 40

If radio doesn’t turn on, but draws high current (>500 mA)

- Please follow troubleshooting instructions as described in the Battery life

short/Charging problems/No turn on due to excessive current drain section of this

document.

If radio draws no current it’s most likely a problem with the 32.768 KHz clock generated by

Y3986.

- Change crystal

Y3986. (It might be difficult replacing Y3986 without damaging the

underfilled ATLAS IC U3000. Wherever possible try using a solder iron instead of the

heatgun)

- If unsuccessful change ATLAS IC

U3000.

If the current consumption is in normal range (40mA to 300mA), try doing a 1FF SW reflash

in

FORCED FLASH MODE. If radio enters the forced flash mode or starts in flash mode by

itself the main supply voltages for the logic section should be ok. Most likely the trouble can

be found in the logic section (ARGON/Flash Memory) – forward to an authorized level 4

service center.

If the radio won’t give any sign of life with a current consumption of about 160 to 170mA for

less than a second, dropping to ~ 12mA it is a problem with the ARGON

an authorized level 4 service center.

Repair Support Information

Figure 30

U1000 – forward to

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 29

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 29 / 40

Turn off – powers down in standby

If radio stores panic: DSM_MEASUREMENT_ERROR there is most likely a problem with the

32.768 KHz clock, on which the radio is running while entering the deep sleep mode.

- Change

Y3986 and test radio with a network SIM card and let radio entering the deep

sleep mode

- If radio still powers down, change ATLAS IC

U3000

If radio soft resets/power cycles and turns on again (possibly with a blank/white screen) try

doing a software upgrade with latest operator approved software. If the trouble remains, it

could be a problem with the ATLAS IC

U3000 or with the ARGON U1000 – forward to an

authorized level 4 service center.

Battery life short/charging problems/no turn on due to excessive current drain

In probably most cases these problems are caused by an off current. Start with verifying,

whether there is an off current. If there is an off current, it should be checked whether the

radio draws current via battery and/or via external power supply (USB).

In case of an off current via battery there should be a low resistance (less than ~200 Ohm)/

or a short from

BATT+_RAW (J5400-1) to GND.

To localize the defective part causing the short/low resistance a simple but effective way is to

freeze the board with a coolant spray, supply a battery voltage from a power supply using

micro clamp-type test probes, and see which parts are getting warm. This is a very basic

and essential method to troubleshoot off current/ high current consumption failures.

The power supply (for

BATT+_RAW) should be set to 3.8Vdc with current limitation set to 2A.

We recommend using the Power Supply Unit current drain meter to check the current drain

of the PCB.

Shields covering suspected parts should be removed before freezing the PCB.

The PCB should be handled with care. After removing the shields the PCB should be given

some time to cool down slowly before freezing it to far below zero to avoid physical stress to

the multilayer PCB with lead free soldered parts.

In some cases the part, which is getting warm has an internal short itself. After removing this

part, the off current should be fixed. For verification, check off current or measure resistance

BATT+_RAW (J5400-1) to GND. A new part can be placed.

If the short/ low resistance remains after replacing the part which was getting warm, it should

be checked which signals/ voltages this part provides. In most cases this part will provide a

supply voltage to other parts which can also get warm due to an internal short.

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 30

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 30 / 40

Does not charge

If the phone seems to charge, but battery meter stays at low level, check whether there is a

high current consumption or an off current via battery. If so, follow troubleshooting as

described in the

Battery life short/charging problems/no turn on due to excessive current

drain section of this document.

If there is no off current, check the whole path for the charging current. Make a

battery/charger phasing to see, if only the charger current or additionally the battery phasing

is affected. For a charger current problem only:

- Check the whole charger path for misplaced parts/solder shorts/defective parts

- If ok, replace ATLAS IC U3000

Repair Support Information

Figure 31

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 31

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 31 / 40

Invalid Battery

Check

R5400/R5401 for misplaced part.

Verify

2.775V. If it is low, check

BATT_DAT at J5400-2 while PCB is connected via EMU USB cable. It should be

BATT_DAT at R5400-2, if it is 2.775V here, change/resolder J5400.

In any other case it is most likely a problem with the ARGON

authorized level 4 service center.

U1000 – forward to an

Figure 32

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 32

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 32 / 40

Battery Thermistor problem

Because the signals which could be measured are not accessible without removing the

ATLAS shield

the best way to start with replacing the battery connector

replace additionally the ATLAS IC

SH1009 (which would damage the underfilled ATLAS IC U3000), it is probably

J5400. If the trouble remains

U3000.

For replacement of the battery connector J5400 the air cooling device for protecting

the ATLAS IC should be used.

Repair Support Information

Figure 33

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 33

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 33 / 40

Accessory detection problem

Some phones do not detect connected accessories (Charger/Headset). Those phones will

turn on if connected to a charger (instead of entering charging mode). If so

- check

- If less than 1MOhm

USB_ID (J5000-4) to GND with an ohmmeter

D5002 should be removed.

- If still less than 1MOhm it should be because of a defective ATLAS IC, replace

U3000.

A new diode array

D5002 has to be placed after successful repair.

Figure 34

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 34

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 34 / 40

Can’t make voice call/no service

First step in every call related problem should be to figure out whether there is a receiving

problem or a transmitting problems and which bands are affected.

Make sure that the RF connectors

M001/M002 are cleaned (with cleaner or alcohol) before

making a phasing/call processing test or if the test fails.

No or low TX output power in GSM

Check the connection to the antenna to ensure it is properly plugged. Prior to remove any

shields for measurements, visually inspect the antenna circuit for skewed/misplaced parts.

Figure 35

Let radio transmit on GSM900 using RepairStudio/Radiocomm. Make sure to provide a

battery voltage via micro clamp-type test probes to battery contacts

J5400.

Measure the power at the output of the GSM PA

If output power

- Check to see if PA

- Check the input power

EGSM_OUT from PA is low

U800 is soldered down properly

TX_LB_IN to the PA from TransAAM at C841-1

Figure 36

U800 at R804-1.

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 35

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 35 / 40

- If input power to PA is low it is most likely a problem with the TransAAM

- If input power to PA is ok it is most likely a problem with the PA

If output power

EGSM_OUT from PA is good the trouble is most likely related to a bad FEM

U800 itself.

U500.

U001 (do a visual check for misplaced parts around FEM U001).

GSM TX signals:

TX_LB_IN and TX_HB_IN: modulated input TX signal from TransAAM

-

-

IPC_BCM: mode switch between GMSK and EDGE. Currently BCM is associated

with GMSK mode and should be logic 0. In EDGE mode, IPC mode is selected and

should be logic 1:

-

TX_LB_HB_IN: mode switch between LB and HB. LB is logic 0 and HB logic 1

-

VRAMP: voltage that controls PA operation. If probed with an oscilloscope, you will

see signals close to a rectangular pulse of value 1.8V to 2.2V for max power output

-

PAC_DET: power detector with voltage reading corresponds to VRAMP value

-

TX_EN: logic signal that enables the PA

-

GSM_TCXO: 26MHz clock for TransAAM

TX Supply voltages

VRF_TX_2_775V

-

-

BATT+

-

LVDD

-

JVDD

-

QVDD_1_8

-

VDDA_2_7

-

VDDA_CP_2_7

-

VDD_ACE_2_7

-

VDD_TXRX_2_7

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 36

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 36 / 40

No or low TX output power in WCDMA

Let radio transmit on WCDMA using RepairStudio/Radiocomm. Make sure to provide a

battery voltage via micro clamp-type tests probes to battery contacts

J5400.

Measure the power at the output of the WCDMA PA

If output power

- Check to see if PA

- Check the input power

PA_2100_RF_OUT from WCDMA PA is low

U400 is soldered down properly

TX_WB_2100 to the PA from SYMPHONY at C408-1

U400 at R400-1.

Figure 37

- If input power to PA is low it is most likely a problem with the SYMPHONY U100.

- If input power to PA is ok it is most likely a problem with the PA

If output power

FEM

U001 (do a visual check for misplaced parts around FEM U001).

PA_2100_RF_OUT from PA is good the trouble is most likely related to a bad

U400 itself.

WCDMA TX signals

TX_WB_2100: modulated input TX signal from SYMPHONY

-

-

PA_2100_EN: logic signal that enables the WCDMA PA

-

PA_VBA: controls the gain of the WCDMA PA

-

PA_VDET: power detect signal

-

PASSKEY_VLD: determines two modes of operation: - Hi Power Mode/Low Power

Mode

WCDMA TX supply voltages

VRF_TX_2_775V

-

-

BATT+

-

VRFCP_2_775V

-

VHVIO_2_2_775V

-

VRF_LVIO_1_875V

-

VMELODY_CORE

-

VRF_RX_2_775VV

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 37

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 37 / 40

No RX GSM

Inject a RF from Test Set. The power level should be set to max power. Check ANT_FEM at

antenna switch

M001-1. Check for presence of GSM_RX_IN at C524-2.

- If not ok replace FEM

U001

- If ok there is most likely a problem with the SAW Filter

the ARGON

U1000 – forward to an authorized level 4 service center.

FL500, the TransAAM U500 or

Note: For AFC phasing the receiver is used. So, if there is any RX fail, the AFC phasing on

that frequency band also fails. If the RX phasing is ok, but only AFC phasing fails, a bad

crystal is the most likely cause – replace

In addition the FEM state after FEM logic table can be checked. If one of them is missing, it

is most likely a problem with the ARGON U1000 – forward to an authorized level 4 service

center.

Repair Support Information

Figure 38

Y190.

Figure 39

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 38

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 38 / 40

No RX WCDMA

WCDMA RX is diplexed with Bluetooth TX/RX and uses the secondary antenna

M002.

The diplexer performance is dependent on both the WCDMA RX and Bluetooth sides of the

circuit. Bluetooth components (

FL5600, C5627, C5628 and L5628) must all be properly

placed for the WCDMA RX to function properly. Visually inspect these components when

presented with a WCDMA RX front-end failure.

Figure 40

Visually inspect WCDMA diplexer components (L012, L13 and C10)

Figure 41

If a unit passes performance testing at 12.2k but fails at a higher data rate, the issue is

typically caused by the SYMPHONY

U100 or the ARGON U1000 – forward to an authorized

level 4 service center.

Check RX signal path from connector

If ok, suspect SYMPHONY. Also check

Inject a RF from Test Set. The power level should be set to max power. Check

antenna switch

M002-1.

Repair Support Information

M002 to SYMPHONY inputs, look for misplaced parts.

26MHz TCXO and surrounding components.

BT_RF_IN at

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 39

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 39 / 40

- If bad, replace

- Check for presence of

- Check

RX_WB_2100_NEG/RX_WB_2100_POS at R305, if ok in size and form (if

unsure compare with a known good PCB) suspect the SYMPHONY

- If

RX_WB_2100_NEG/RX_WB_2100_POS are not ok, check VRF_RX_2_775V at

M002

2100_PREFILT_OUT at FL001-1, if bad replace FL001

U100

R304, if ok check/replace U300/FL300

Repair Support Information

Figure 42

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Page 40

Doc. No: TSG_3G_V6

Version: 1.0

Motorola GmbH, Mobile Devices, CSS Center

Date: 23.07.2007

Title: Troubleshooting-Guide MotoRAZR maxx V6 Page: 40 / 40

Flash procedures

Note: It is very important to do a restart after every flash process! Otherwise the phone may

start in flash mode again.

Software update

Following steps are necessary to update the Software to latest approved Software:

- unlock phone (if subsidy locked)

- flash customer specific 1FF superfile (example:

R26117LD_U_98.20.33BR_LP0039_DRM1003_VSTU_207_0C_JPUK_R26117VOLANSVF_

03_USVOLANSVFUKR26117062_1FF.sbf

)

- after restart:

- take out of “In Factory” – if necessary

- do Master Reset/Master Clear

Recovering Flash Memory in Forced Flash Mode

If the phone doesn’t start because of corrupted software it might be possible to recover it:

DC One File Flash:

- connect phone to EMU-cable while pressing “*” and “#”

The phone should start in flash mode now: S Flash Argon.

- flash 1FF superfile (example:

R26117LD_U_98.20.33BR_LP0039_DRM1003_VSTU_207_0C_JPUK_R26117VOLANSVF_

03_USVOLANSVFUKR26117062_1FF.sbf

DC One File Flash:

)

- after restart:

- do Master Reset/Master Clear

If the phone doesn’t start in flash mode, there is a problem –

troubleshooting.

proceed to level 3

Repair Support Information

© Copyright 2003-2007 Motorola Inc. All Rights reserved.

Motorola internal use

Loading...

Loading...