Semiconductor Components Industries, LLC, 1999

November, 1999 – Rev. 6

1 Publication Order Number:

LM317M/D

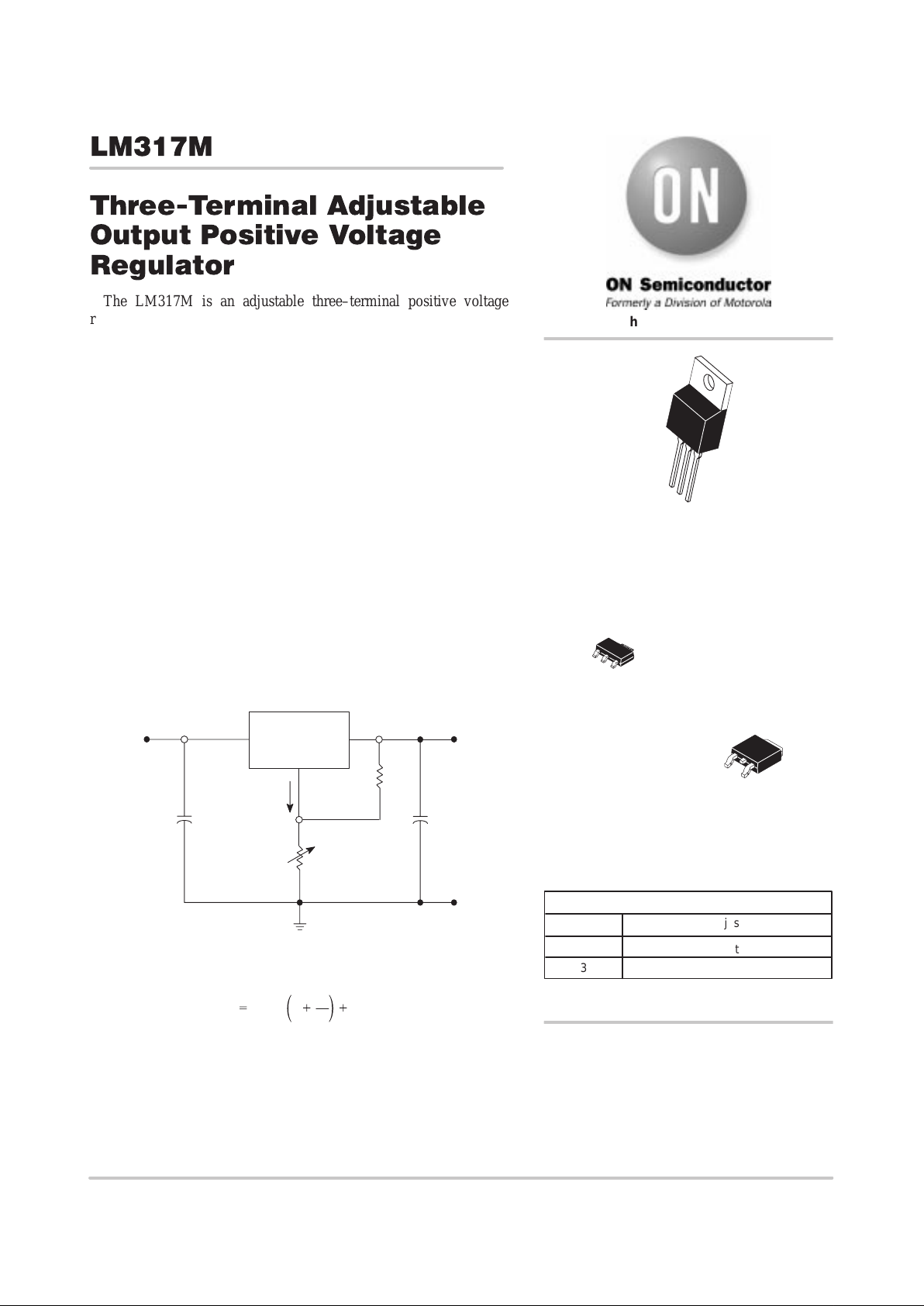

LM317M

Three-Terminal Adjustable

Output Positive V oltage

Regulator

The LM317M is an adjustable three–terminal positive voltage

regulator capable of supplying in excess of 500 mA over an output

voltage range of 1.2 V to 37 V. This voltage regulator is exceptionally

easy to use and requires only two external resistors to set the output

voltage. Further, it employs internal current limiting, thermal

shutdown and safe area compensation, making it essentially blow–out

proof.

The LM317M serves a wide variety of applications including local,

on–card regulation. This device also makes an especially simple

adjustable switching regulator, a programmable output regulator , or by

connecting a fixed resistor between the adjustment and output, the

LM317M can be used as a precision current regulator.

• Output Current in Excess of 500 mA

• Output Adjustable between 1.2 V and 37 V

• Internal Thermal Overload Protection

• Internal Short Circuit Current Limiting

• Output T ransistor Safe–Area Compensation

• Floating Operation for High Voltage Applications

• Eliminates Stocking Many Fixed Voltages

Simplified Application

* = Cin is required if regulator is located an appreciable distance from power supply filter.

** = CO is not needed for stability, however, it does improve transient response.

Since I

Adj

is controlled to less than 100 µA, the error associated with this

term is negligible in most applications.

LM317M

V

in

V

out

R

1

240

R

2

Adjust

I

Adj

*

C

in

0.1µF

**

+

C

O

1.0µF

V

in

V

out

V

out

+

1.25 V

ǒ

1

)

R

2

R

1

Ǔ

)

I

AdjR2

TO–220AB

T SUFFIX

CASE 221A

1

2

3

PIN ASSIGNMENT

1

2

3V

in

Adjust

V

out

http://onsemi.com

ORDERING INFORMATION

See detailed ordering and shipping information in the package

dimensions section on page 10 of this data sheet.

1

2

3

1

3

Heatsink Surface (shown as terminal 4 in

case outline drawing) is connected to Pin 2.

SOT–223

ST SUFFIX

CASE 318E

DPAK

DT SUFFIX

CASE 369A

Heatsink surface

connected to Pin 2

2

LM317M

http://onsemi.com

2

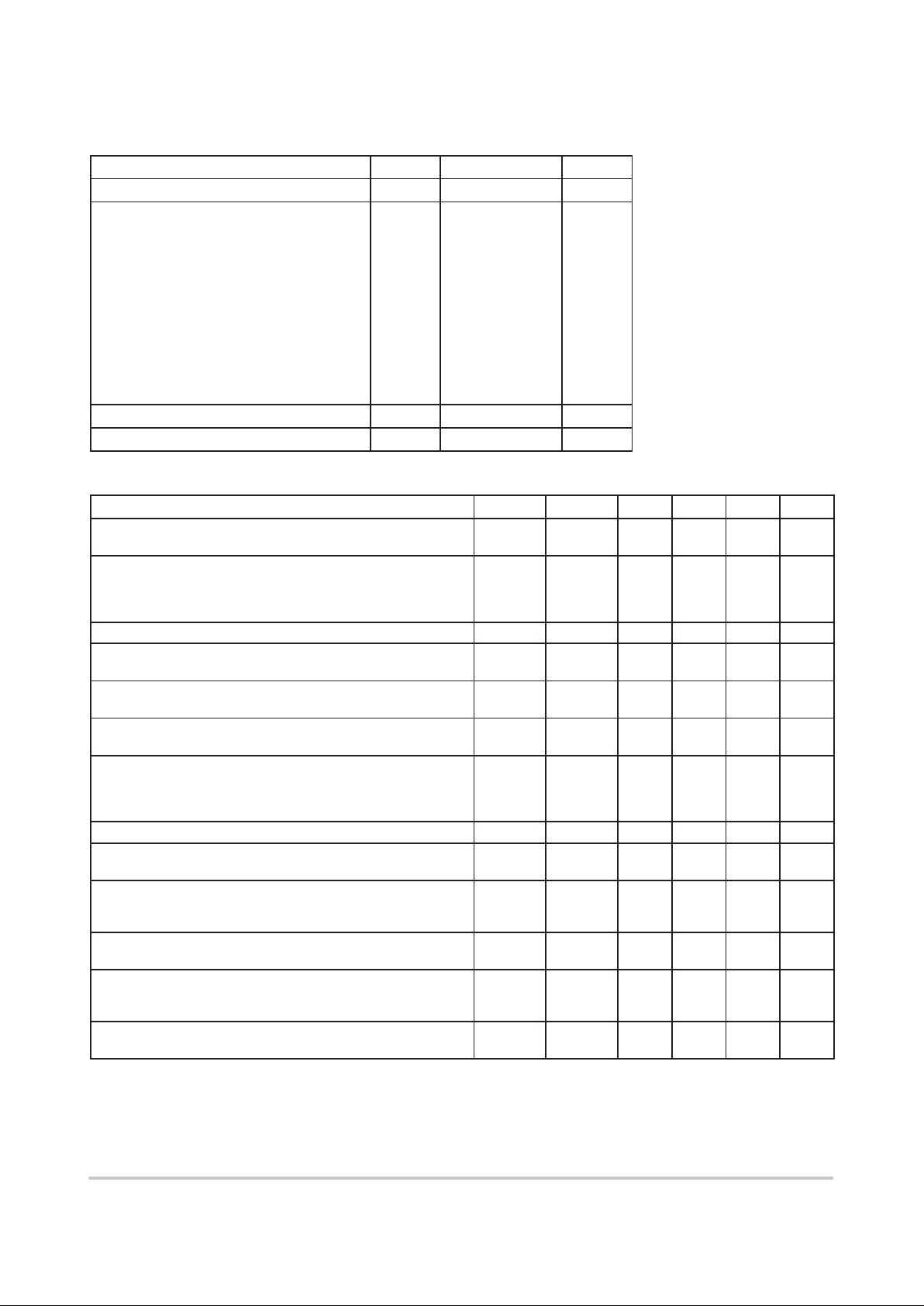

MAXIMUM RATINGS (T

A

= 25°C, unless otherwise noted.)

Rating

Symbol Value Unit

Input–Output Voltage Differential VI–V

O

40 Vdc

Power Dissipation (Package Limitation) (Note 1)

Plastic Package, T Suffix, Case 221A

TA = 25°C

Thermal Resistance, Junction–to–Air

Thermal Resistance, Junction–to–Case

Plastic Package, DT Suffix, Case 369A

TA = 25°C

Thermal Resistance, Junction–to–Air

Thermal Resistance, Junction–to–Case

Plastic Package, ST Suffix, Case 318E

TA = 25°C

Thermal Resistance, Junction–to–Air

Thermal Resistance, Junction–to–Case

P

D

θ

JA

θ

JC

P

D

θ

JA

θ

JC

P

D

θ

JA

θ

JC

Internally Limited

70

5.0

Internally Limited

92

5.0

Internally Limited

245

15

°C/W

°C/W

°C/W

°C/W

°C/W

°C/W

Operating Junction Temperature Range T

J

–40 to +125 °C

Storage Temperature Range T

stg

–65 to +150 °C

NOTE: 1. Figure 23 provides thermal resistance versus pc board pad size.

ELECTRICAL CHARACTERISTICS (V

I–VO

= 5.0 V; IO = 0.1 A, TJ = T

low

to T

high

[Note 1], unless otherwise noted.)

Characteristics Figure Symbol Min Typ Max Unit

Line Regulation (Note 2)

TA = 25°C, 3.0 V ≤ VI–VO ≤ 40 V

1 Reg

line

– 0.01 0.04 %/V

Load Regulation (Note 2)

TA = 25°C, 10 mA ≤ IO ≤ 0.5 A

VO ≤ 5.0 V

VO ≥ 5.0 V

2 Reg

load

–

–

5.0

0.1

25

0.5mV% V

O

Adjustment Pin Current 3 I

Adj

– 50 100 µA

Adjustment Pin Current Change

2.5 V ≤ VI–VO ≤ 40 V, 10 mA ≤ IL ≤ 0.5 A, PD ≤ P

max

1,2 ∆I

Adj

– 0.2 5.0 µA

Reference Voltage

3.0 V ≤ VI–VO ≤ 40 V, 10 mA ≤ IO ≤ 0.5 A, PD ≤ P

max

:

3 V

ref

1.200 1.250 1.300

V

Line Regulation (Note 2)

3.0 V ≤ VI–VO ≤ 40 V

1 Reg

line

– 0.02 0.07 %/V

Load Regulation (Note 2)

10 mA ≤ IO ≤ 0.5 A

VO ≤ 5.0 V

VO ≥ 5.0 V

2 Reg

load

–

–

20

0.3

70

1.5mV% V

O

Temperature Stability (T

low

≤ TJ ≤ T

high

) 3 T

S

– 0.7 – % V

O

Minimum Load Current to Maintain Regulation

(VI–VO = 40 V)

3 I

Lmin

– 3.5 10 mA

Maximum Output Current

VI–VO ≤ 15 V, PD ≤ P

max

VI–VO = 40 V, PD ≤ P

max

, TA = 25°C

3 I

max

0.5

0.15

0.9

0.25

–

–

A

RMS Noise, % of V

O

TA= 25°C, 10 Hz ≤ f ≤ 10 kHz

– N – 0.003 – % V

O

Ripple Rejection, VO = 10 V, f = 120 Hz (Note 3)

Without C

Adj

C

Adj

= 10 µF

4 RR

–

66

65

80

–

–

dB

Long–Term Stability, TJ = T

high

(Note 4)

TA= 25°C for Endpoint Measurements

3 S – 0.3 1.0 %/1.0 k

Hrs.

NOTES: 1.T

low

to T

high

= 0° to +125°C for LM317M T

low

to T

high

= –40 ° to +125°C for LM317MB

2. Load and line regulation are specified at constant junction temperature. Changes in VO due to heating effects must be taken into account separately.

Pulse testing with low duty cycle is used.

3.C

Adj

, when used, is connected between the adjustment pin and ground.

4.Since Long–Term Stability cannot be measured on each device before shipment, this specification is an engineering estimate of average stability

from lot to lot.

LM317M

http://onsemi.com

3

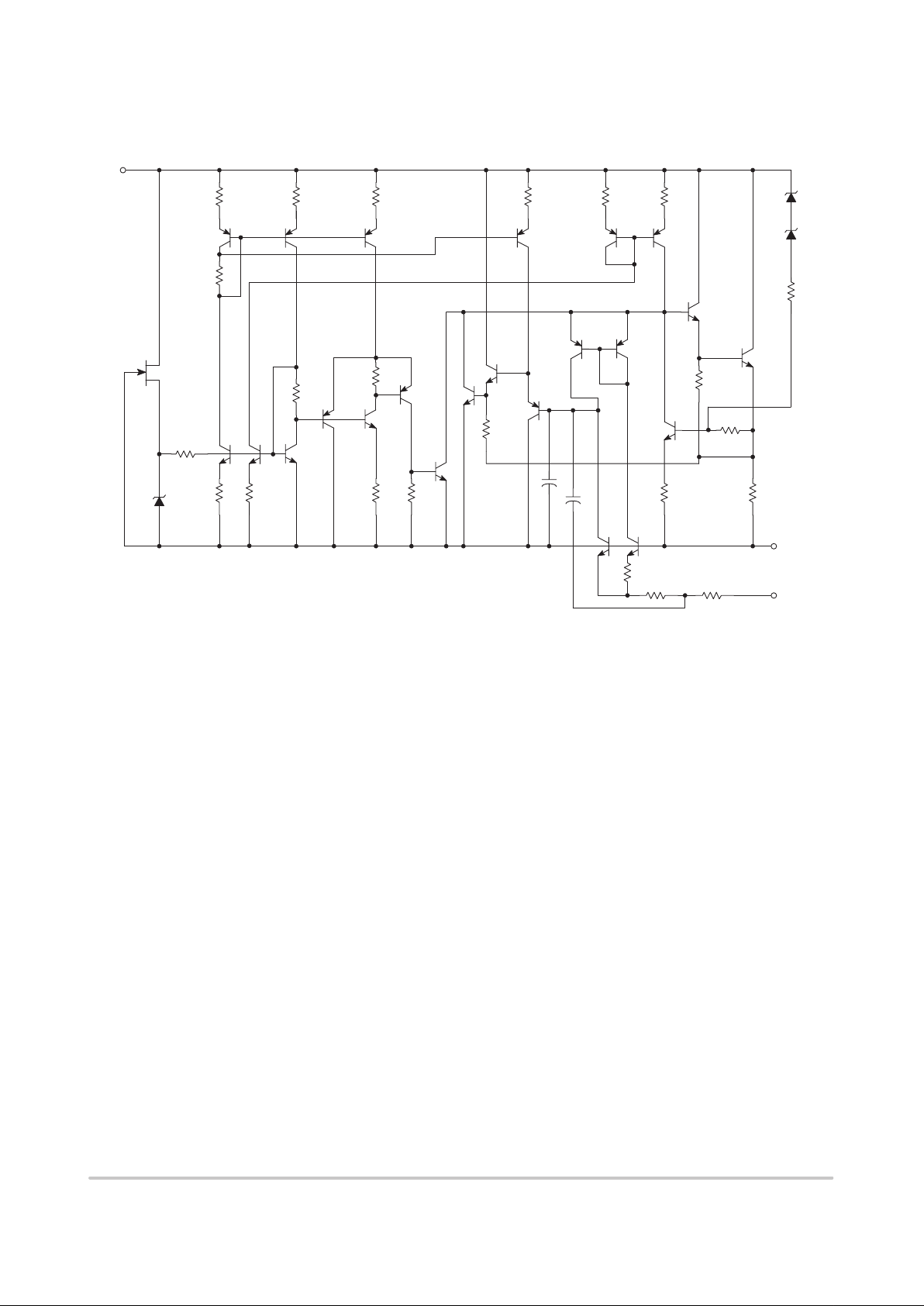

Representative Schematic Diagram

18k

6.8V

6.8V

350

300 300 300 3.0k 300 70

200k

1.2560

50

130

8.67k

500

400

2.4k

12.8k

V

out

5.1k

6.3V

2.0k 6.0k

Adjust

V

in

180 180

10

pF

10

pF

LM317M

http://onsemi.com

4

* Pulse Testing Required:

1% Duty Cycle is suggested.

Line Regulation (%/V) =

VOH – V

OL

x 100

*

V

CC

V

IH

VILV

in

V

out

V

OH

V

OL

R

L

+

1.0µFC

O

240

1%

R

1

Adjust

R2

1%

C

in

0.1µF

LM317M

I

Adj

Figure 1. Line Regulation and ∆I

Adj

/Line Test Circuit

V

OL

* Pulse Testing Required:

1% Duty Cycle is suggested.

Load Regulation (mV) = VO (min Load) –VO (max Load)

Load Regulation (% VO) =

VO (min Load) – VO (max Load)

X 100

VO (min Load)

VO (max Load)

LM317M

C

in

0.1µF

Adjust

R

2

1%

C

O

1.0µF

+

*

R

L

(max Load)

R

L

(min Load)

V

out

R

1

240

1%

V

in

V

in

I

Adj

I

L

Figure 2. Load Regulation and ∆I

Adj

/Load T est Circuit

VO (min Load)

LM317M

http://onsemi.com

5

*Pulse Testing Required:

1% Duty Cycle is suggested.

LM317M

V

in

V

out

Adjust

R

1

240

1%

+

1µFC

O

R

L

C

in

R

2

1%

T o Calculate R2:

V

out

= I

SET R2

+ 1.250 V

Assume I

SET

= 5.25 mA

I

L

I

Adj

I

SET

V

ref

V

O

V

I

0.1µF

Figure 3. Standard Test Circuit

LM317M

V

in

V

out

V

out

= 10 V

R

L

C

in

0.1µF

Adjust

R

1

240

1%

D1 *

1N4002

C

O

+

1.0µF

24V

14V

R

2

1.65K

1%

C

Adj

10µF

+

*D1 Discharges C

Adj

if Output is Shorted to Ground.

**C

Adj

provides an AC ground to the adjust pin.

f = 120 Hz

V

O

**

Figure 4. Ripple Rejection Test Circuit

LM317M

http://onsemi.com

6

I

out

, OUTPUT CURRENT (A)

I

B

, QUIESCENT CURRENT (mA)

V

in

–V

out

, INPUT–OUTPUT VOLTAGE

DIFFERENTIAL (V)

Figure 5. Load Regulation Figure 6. Ripple Rejection

Figure 7. Current Limit Figure 8. Dropout Voltage

Figure 9. Minimum Operating Current Figure 10. Ripple Rejection versus Frequency

0.4

0.2

0

–0.2

–0.4

–0.6

–0.8

–1.0

–50 –25 0 25 50 75 100 125 150

∆ V

out

TJ, JUNCTION TEMPERATURE (°C)

, OUTPUT VOLTAGE CHANGE (%)

Vin = 45 V

V

out

= 5.0 V

IL = 5.0 mA to 40 mA

Vin = 10 V

V

out

= 5.0 V

IL = 5.0 mA to 100 mA

80

70

60

50

RR, RIPPLE REJECTION (dB)

–50 –25 0 25 50 75 100 125 150

TJ, JUNCTION TEMPERATURE (°C)

IL = 100 mA

f = 120 Hz

V

out

= 10 V

Vin = 14 V to 24 V

–50 –25 0 25 50 75 100 125 150

TJ, JUNCTION TEMPERATURE (°C)

2.5

2.0

1.5

1.0

0.5

IL = 500 mA

1.0

0.80

0.60

0.40

0.20

0

01020304050

Vin–V

out

, INPUT–OUTPUT VOLTAGE DIFFERENTIAL (V)

TJ = 25°C

TJ = 125°C

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

010203040

V

in–Vout

, INPUT–OUTPUT VOLTAGE DIFFERENTIAL (Vdc)

100

90

80

70

60

50

40

30

20

10

10 100 1.0 k 10 k 100 k 1.0 M

f, FREQUENCY (Hz)

RR, RIPPLE REJECTION (dB)

IL = 40 mA

Vin = 5.0 V ± 1.0 V

PP

V

out

= 1.25 V

90

Without C

Adj

= 10 µF

Without C

Adj

IL = 100 mA

TJ = 25°C

TJ = 125°C

LM317M

http://onsemi.com

7

V

out

, OUTPUT VOLTAGE∆

DEVIATION (V)

V

out

, OUTPUT VOLTAGE∆

DEVIATION (V)

V

in

, INPUT VOLTAGE∆

CHANGE (V)

V

out

, OUTPUT VOLTAGE CHANGE (%)∆

I

Adj

, ADJUSTMENT PIN CURRENT ( A)µ

ref

V , REFERENCE VOLTAGE (V)

CL = 0.3 µF; C

Adj

= 10 µF

Figure 11. Temperature Stability Figure 12. Adjustment Pin Current

Figure 13. Line Regulation Figure 14. Output Noise

Figure 15. Line Transient Response

010203040

t, TIME (µs)

CL = 1.0 µF

CL = 0

V

in

V

out

= 10 V

IL = 50 mA

TJ = 25°C

010203040

t, TIME (µs)

I

CURRENT (A)

L

, LOAD

CL = 1.0 µF; CAdj = 10 µF

Vin = 15 V

V

out

= 10 V

INL = 50 mA

TJ = 25°C

I

L

–50 –25 0 25 50 75 100 125 150

TJ, JUNCTION TEMPERATURE (°C)

Vin = 4.2 V

V

out

= V

ref

IL = 5.0 mA

–50 –25 0 25 50 75 100 125 150

TJ, JUNCTION TEMPERATURE (°C)

Vin = 6.25 V

V

out

= V

ref

IL = 10 mA

IL = 100 mA

–50 –25 0 25 50 75 100 125 150

TJ, JUNCTION TEMPERATURE (°C)

Vin = 4.25 V to 41.25 V

V

out

= V

ref

IL = 5.0 mA

–50 –25 0 25 50 75 100 125 150

TJ, JUNCTION TEMPERATURE (°C)

Bandwidth 100 Hz to 10 kHz

Figure 16. Load Transient Response

1.5

1.0

0.5

0

–0.5

–1.0

–1.5

1.0

0.5

0

3.0

2.0

1.0

0

–1.0

–2.0

–3.0

1.5

1.0

0.5

0

1.260

1.250

1.240

1.230

1.220

80

70

65

60

55

50

45

40

35

0.4

0.2

0

–0.2

–0.4

–0.6

–0.8

–1.0

10

8.0

6.0

4.0

NOISE VOLTAGE ( V)µ

LM317M

http://onsemi.com

8

APPLICATIONS INFORMATION

Basic Circuit Operation

The LM317M is a three–terminal floating regulator. In

operation, the LM317M develops and maintains a nominal

1.25 V reference (V

ref

) between its output and adjustment

terminals. This reference voltage is converted to a

programming current (I

PROG

) by R1 (see Figure 17), and this

constant current flows through R2 to ground. The regulated

output voltage is given by:

V

out

+

V

ref

ǒ

1

)

R

2

R

1

Ǔ

)

I

AdjR2

Since the current from the terminal (I

Adj

) represents an

error term in the equation, the LM317M was designed to

control I

Adj

to less than 100 µA and keep it constant. T o do

this, all quiescent operating current is returned to the output

terminal. This imposes the requirement for a minimum load

current. If the load current is less than this minimum, the

output voltage will rise.

Since the LM317M is a floating regulator, it is only the

voltage differential across the circuit which is important to

performance, and operation at high voltages with respect to

ground is possible.

+

V

ref

Adjust

V

in

V

out

LM317M

R

1

I

PROG

V

out

R

2

I

Adj

V

ref

= 1.25 V Typical

Figure 17. Basic Circuit Configuration

Load Regulation

The LM317M is capable of providing extremely good

load regulation, but a few precautions are needed to obtain

maximum performance. For best performance, the

programming resistor (R1) should be connected as close to

the regulator as possible to minimize line drops which

effectively appear in series with the reference, thereby

degrading regulation. The ground end of R2 can be returned

near the load ground to provide remote ground sensing and

improve load regulation.

External Capacitors

A 0.1 µF disc or 1.0 µF tantalum input bypass capacitor

(Cin) is recommended to reduce the sensitivity to input line

impedance.

The adjustment terminal may be bypassed to ground to

improve ripple rejection. This capacitor (C

Adj

) prevents

ripple from being amplified as the output voltage is

increased. A 10 µF capacitor should improve ripple

rejection about 15 dB at 120 Hz in a 10 V application.

Although the LM317M is stable with no output

capacitance, like any feedback circuit, certain values of

external capacitance can cause excessive ringing. An output

capacitance (CO) in the form of a 1.0 µF tantalum or 25 µF

aluminum electrolytic capacitor on the output swamps this

effect and insures stability.

Protection Diodes

When external capacitors are used with any IC regulator

it is sometimes necessary to add protection diodes to prevent

the capacitors from discharging through low current points

into the regulator.

Figure 18 shows the LM317M with the recommended

protection diodes for output voltages in excess of 25 V or

high capacitance values (CO > 25 µF, C

Adj

> 5.0 µF). Diode

D1 prevents CO from discharging thru the IC during an input

short circuit. Diode D2 protects against capacitor C

Adj

discharging through the IC during an output short circuit.

The combination of diodes D1 and D2 prevents C

Adj

from

discharging through the IC during an input short circuit.

D

1

V

in

C

in

1N4002

LM317M

V

out

R

1

+

C

O

D

2

R

2

C

Adj

1N4002

Adjust

V

out

Figure 18. Voltage Regulator with

Protection Diodes

LM317M

http://onsemi.com

9

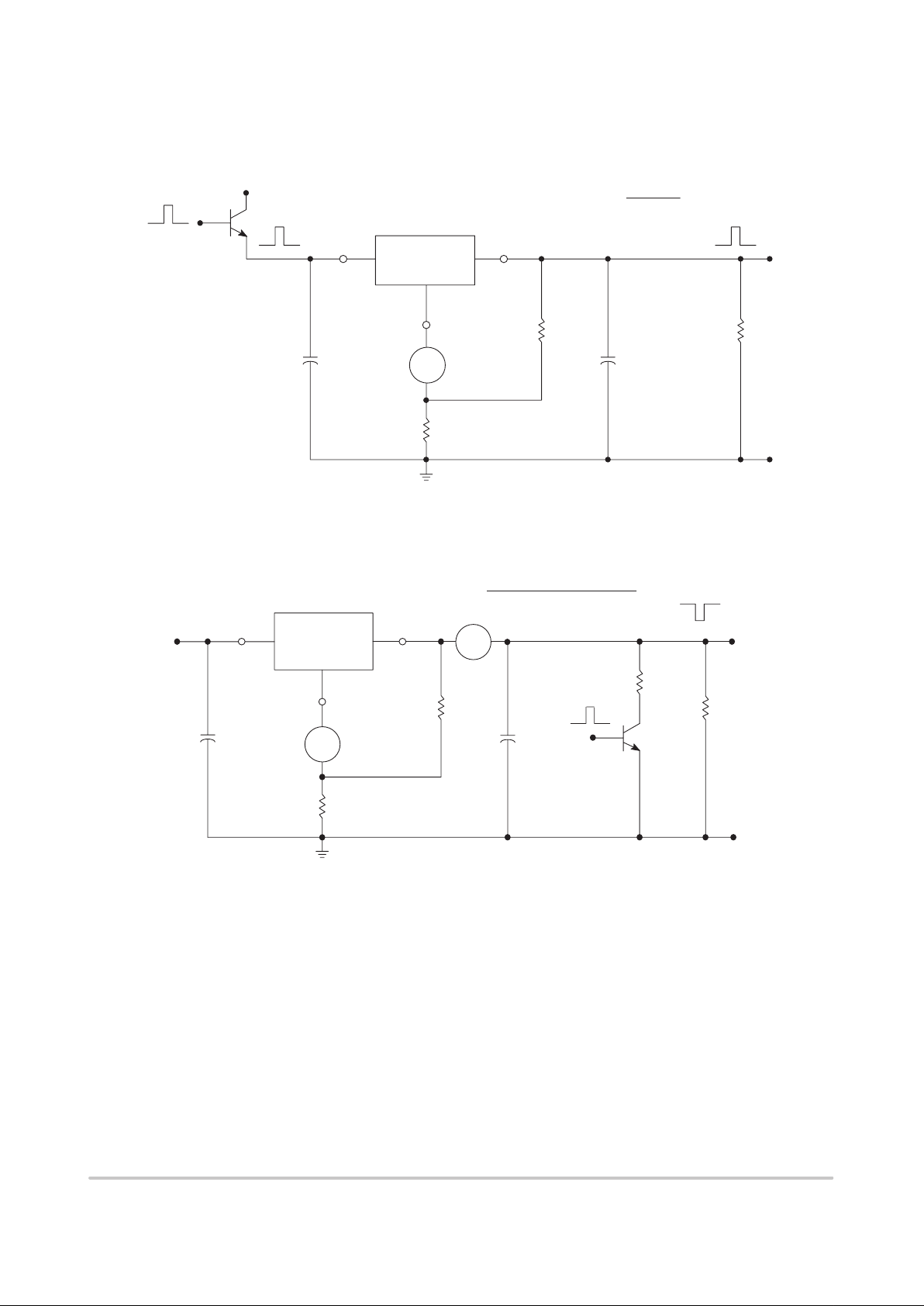

Figure 19. Adjustable Current Limiter Figure 20. 5 V Electronic Shutdown Regulator

Figure 21. Slow Turn–On Regulator Figure 22. Current Regulator

V

ref

+25V

V

in

LM317M

V

out

R

1

V

O

1.25k

Adjust

I

O

D2

1N914

1N5314

R

2

500

* To provide current limiting of I

O

to the system ground, the source of

the current limiting diode must be tied to

a negative voltage below – 7.25 V.

R2 ≥

V

ref

R1 =

VSS*

D1

1N914

VO < POV + 1.25 V + V

SS

I

Lmin

– IP < IO < 500 mA – I

P

As shown O < IO < 495 mA

+

10µF

V

in

V

out

240

1N4001

LM317M

Adjust

MPS2907

R

2

50k

V

in

D

1

1N4002

V

out

120

Adjust

720

+

1.0µF

MPS2222

1.0k

TTL

Control

LM317M

Minimum V

out

= 1.25 V

D1 protects the device during an input short circuit.

LM317M

V

in

R

1

R

2

Adjust

I

Adj

I

out

5.0 mA < I

out

< 100 mA

V

out

I

outmax

=

V

ref

+ I

Adj

^

1.25 V

R1 + R

2

V

out

V

out

V

in

I

DSS

I

Omax

+ I

DSS

R1 + R

2

40

50

60

70

80

90

100

0

0.4

0.8

1.2

1.6

2.0

2.4

010203025155.0

L, LENGTH OF COPPER (mm)

P

D(max)

for TA = 50°C

Minimum

Size Pad

L

L

ÎÎÎ

ÎÎÎ

ÎÎÎ

Free Air

Mounted

Vertically

R

θJA

2.0 oz. Copper

Figure 23. DPAK Thermal Resistance and Maximum

Power Dissipation versus P.C.B. Copper Length

Figure 24. SOT–223 Thermal Resistance and Maximum

Power Dissipation versus P.C.B. Copper Length

40

80

120

160

200

240

280

0.35

0.42

0.50

0.63

0.83

1.25

2.50

010203025155.0

L, LENGTH OF COPPER (mm)

P

D(max)

for TA = 50°C

Minimum

Size Pad

P

L

L

APOERPAON

Free Air

Mounted

Vertically

R

θJA

2.0 oz. Copper

R

, T

HER

M

A

L

RE

SIST

AN

C

E

,

JAθ

J

U

N

CTI

ON

–T

O

–

A

I

R

( C/W)°

LM317M

http://onsemi.com

10

ORDERING INFORMATION

Device Operating Temperature Range Package Shipping

LM317MT TJ = 0°C to 125°C TO–220 50 units/rail

LM317MDT TJ = 0°C to 125°C DPAK 75 units/rail

LM317MDTRK TJ = 0°C to 125°C DPAK 2500 units/Tape & Reel

LM317MSTT3 TJ = 0°C to 125°C SOT–223 4000 units/Tape & Reel

LM317MBT TJ = –40°C to 125°C TO–220 50 units/rail

LM317MBDT TJ = –40°C to 125°C DPAK 75 units/rail

LM317MBDTRK TJ = –40°C to 125°C DPAK 2500 units/Tape & Reel

LM317MBSTT3 TJ = –40°C to 125°C SOT–223 4000 units/Tape & Reel

P ACKAGE DIMENSIONS

T SUFFIX

PLASTIC PACKAGE

CASE 221A–09

ISSUE Z

(SOT–223)

ST SUFFIX

PLASTIC PACKAGE

CASE 318E–04

ISSUE J

H

S

F

A

B

D

G

L

4

123

0.08 (0003)

C

M

K

J

DIMAMIN MAX MIN MAX

MILLIMETERS

0.249 0.263 6.30 6.70

INCHES

B 0.130 0.145 3.30 3.70

C 0.060 0.068 1.50 1.75

D 0.024 0.035 0.60 0.89

F 0.115 0.126 2.90 3.20

G 0.087 0.094 2.20 2.40

H 0.0008 0.0040 0.020 0.100

J 0.009 0.014 0.24 0.35

K 0.060 0.078 1.50 2.00

L 0.033 0.041 0.85 1.05

M 0 10 0 10

S 0.264 0.287 6.70 7.30

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

____

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION Z DEFINES A ZONE WHERE ALL

BODY AND LEAD IRREGULARITIES ARE

ALLOWED.

DIM MIN MAX MIN MAX

MILLIMETERSINCHES

A 0.570 0.620 14.48 15.75

B 0.380 0.405 9.66 10.28

C 0.160 0.190 4.07 4.82

D 0.025 0.035 0.64 0.88

F 0.142 0.147 3.61 3.73

G 0.095 0.105 2.42 2.66

H 0.110 0.155 2.80 3.93

J 0.018 0.025 0.46 0.64

K 0.500 0.562 12.70 14.27

L 0.045 0.060 1.15 1.52

N 0.190 0.210 4.83 5.33

Q 0.100 0.120 2.54 3.04

R 0.080 0.110 2.04 2.79

S 0.045 0.055 1.15 1.39

T 0.235 0.255 5.97 6.47

U 0.000 0.050 0.00 1.27

V 0.045 ––– 1.15 –––

Z ––– 0.080 ––– 2.04

Q

H

Z

L

V

G

N

A

K

123

4

D

SEATING

PLANE

–T–

C

S

T

U

R

J

LM317M

http://onsemi.com

11

P ACKAGE DIMENSIONS

(DPAK)

DT SUFFIX

PLASTIC PACKAGE

CASE 369A–13

ISSUE Z

D

A

K

B

R

V

S

F

L

G

2 PL

M

0.13 (0.005) T

E

C

U

J

H

–T–

SEATING

PLANE

Z

DIM MIN MAX MIN MAX

MILLIMETERSINCHES

A 0.235 0.250 5.97 6.35

B 0.250 0.265 6.35 6.73

C 0.086 0.094 2.19 2.38

D 0.027 0.035 0.69 0.88

E 0.033 0.040 0.84 1.01

F 0.037 0.047 0.94 1.19

G 0.180 BSC 4.58 BSC

H 0.034 0.040 0.87 1.01

J 0.018 0.023 0.46 0.58

K 0.102 0.114 2.60 2.89

L 0.090 BSC 2.29 BSC

R 0.175 0.215 4.45 5.46

S 0.020 0.050 0.51 1.27

U 0.020 ––– 0.51 –––

V 0.030 0.050 0.77 1.27

Z 0.138 ––– 3.51 –––

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

123

4

LM317M

http://onsemi.com

12

USA/EUROPE Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303–675–2175 or 800–344–3860 T oll Free USA/Canada

Fax: 303–675–2176 or 800–344–3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

Fax Response Line*: 303–675–2167

800–344–3810 Toll Free USA/Canada

*To receive a Fax of our publications

N. America Technical Support: 800–282–9855 Toll Free USA/Canada

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes

without further notice to any products herein. SCILLC makes no warranty , representation or guarantee regarding the suitability of its products for any particular

purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability ,

including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or

death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold

SCILLC and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable

attorney fees arising out of, directly or indirectly , any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim

alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer .

PUBLICATION ORDERING INFORMATION

ASIA/PACIFIC: LDC for ON Semiconductor – Asia Support

Phone: 303–675–2121 (Tue–Fri 9:00am to 1:00pm, Hong Kong T ime)

Email: ONlit–asia@hibbertco.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

4–32–1 Nishi–Gotanda, Shinagawa–ku, T okyo, Japan 141–8549

Phone: 81–3–5487–8345

Email: r14153@onsemi.com

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local Sales Representative.

LM317M/D

Loading...

Loading...