MOTOROLA LM317MBSTT1, LM317MBDTRK, LM317MBDT, LM317MADTRK, LM317MABT Datasheet

...

Semiconductor Components Industries, LLC, 1999

November, 1999 – Rev. 6

1 Publication Order Number:

LM317M/D

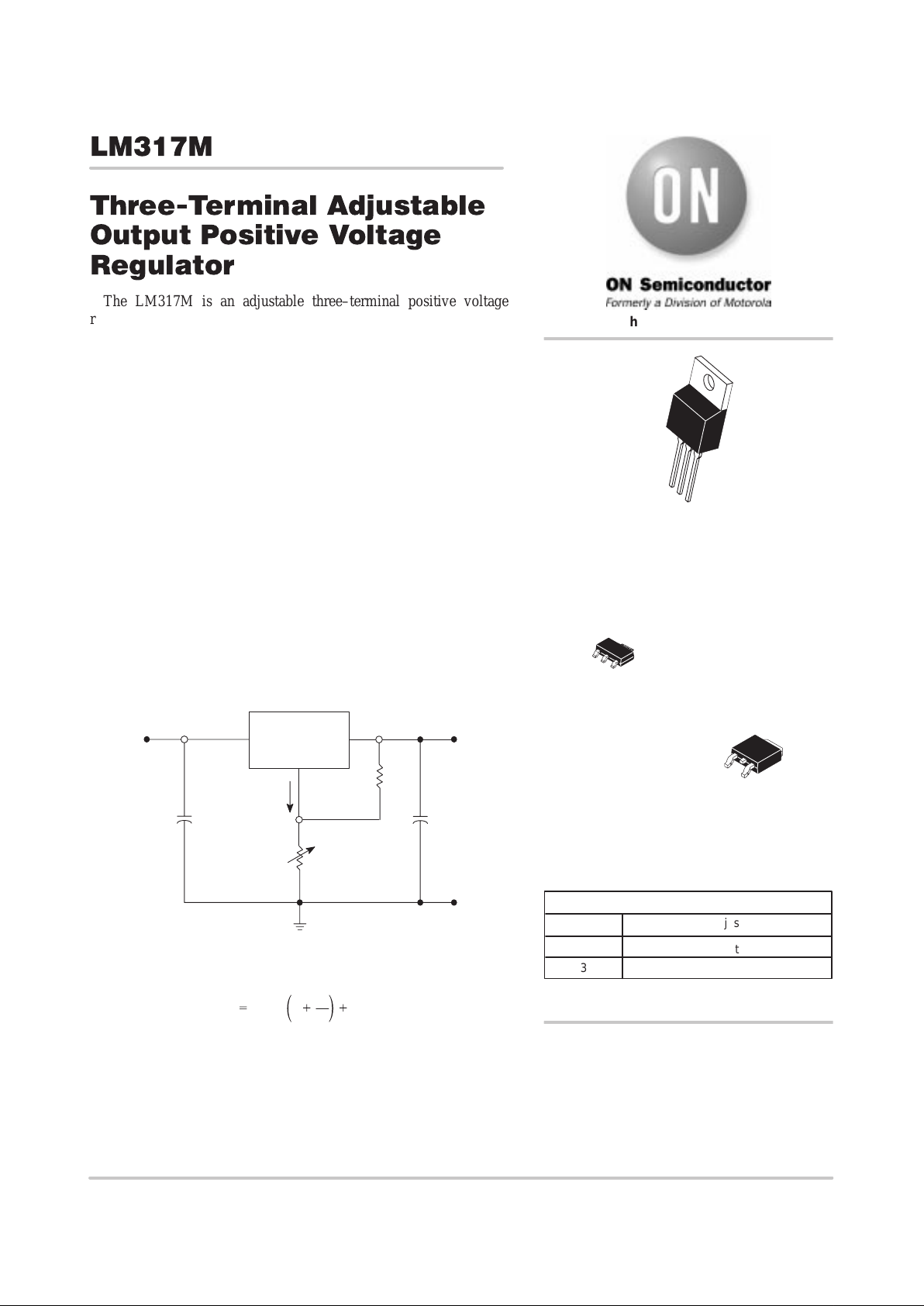

LM317M

Three-Terminal Adjustable

Output Positive V oltage

Regulator

The LM317M is an adjustable three–terminal positive voltage

regulator capable of supplying in excess of 500 mA over an output

voltage range of 1.2 V to 37 V. This voltage regulator is exceptionally

easy to use and requires only two external resistors to set the output

voltage. Further, it employs internal current limiting, thermal

shutdown and safe area compensation, making it essentially blow–out

proof.

The LM317M serves a wide variety of applications including local,

on–card regulation. This device also makes an especially simple

adjustable switching regulator, a programmable output regulator , or by

connecting a fixed resistor between the adjustment and output, the

LM317M can be used as a precision current regulator.

• Output Current in Excess of 500 mA

• Output Adjustable between 1.2 V and 37 V

• Internal Thermal Overload Protection

• Internal Short Circuit Current Limiting

• Output T ransistor Safe–Area Compensation

• Floating Operation for High Voltage Applications

• Eliminates Stocking Many Fixed Voltages

Simplified Application

* = Cin is required if regulator is located an appreciable distance from power supply filter.

** = CO is not needed for stability, however, it does improve transient response.

Since I

Adj

is controlled to less than 100 µA, the error associated with this

term is negligible in most applications.

LM317M

V

in

V

out

R

1

240

R

2

Adjust

I

Adj

*

C

in

0.1µF

**

+

C

O

1.0µF

V

in

V

out

V

out

+

1.25 V

ǒ

1

)

R

2

R

1

Ǔ

)

I

AdjR2

TO–220AB

T SUFFIX

CASE 221A

1

2

3

PIN ASSIGNMENT

1

2

3V

in

Adjust

V

out

http://onsemi.com

ORDERING INFORMATION

See detailed ordering and shipping information in the package

dimensions section on page 10 of this data sheet.

1

2

3

1

3

Heatsink Surface (shown as terminal 4 in

case outline drawing) is connected to Pin 2.

SOT–223

ST SUFFIX

CASE 318E

DPAK

DT SUFFIX

CASE 369A

Heatsink surface

connected to Pin 2

2

LM317M

http://onsemi.com

2

MAXIMUM RATINGS (T

A

= 25°C, unless otherwise noted.)

Rating

Symbol Value Unit

Input–Output Voltage Differential VI–V

O

40 Vdc

Power Dissipation (Package Limitation) (Note 1)

Plastic Package, T Suffix, Case 221A

TA = 25°C

Thermal Resistance, Junction–to–Air

Thermal Resistance, Junction–to–Case

Plastic Package, DT Suffix, Case 369A

TA = 25°C

Thermal Resistance, Junction–to–Air

Thermal Resistance, Junction–to–Case

Plastic Package, ST Suffix, Case 318E

TA = 25°C

Thermal Resistance, Junction–to–Air

Thermal Resistance, Junction–to–Case

P

D

θ

JA

θ

JC

P

D

θ

JA

θ

JC

P

D

θ

JA

θ

JC

Internally Limited

70

5.0

Internally Limited

92

5.0

Internally Limited

245

15

°C/W

°C/W

°C/W

°C/W

°C/W

°C/W

Operating Junction Temperature Range T

J

–40 to +125 °C

Storage Temperature Range T

stg

–65 to +150 °C

NOTE: 1. Figure 23 provides thermal resistance versus pc board pad size.

ELECTRICAL CHARACTERISTICS (V

I–VO

= 5.0 V; IO = 0.1 A, TJ = T

low

to T

high

[Note 1], unless otherwise noted.)

Characteristics Figure Symbol Min Typ Max Unit

Line Regulation (Note 2)

TA = 25°C, 3.0 V ≤ VI–VO ≤ 40 V

1 Reg

line

– 0.01 0.04 %/V

Load Regulation (Note 2)

TA = 25°C, 10 mA ≤ IO ≤ 0.5 A

VO ≤ 5.0 V

VO ≥ 5.0 V

2 Reg

load

–

–

5.0

0.1

25

0.5mV% V

O

Adjustment Pin Current 3 I

Adj

– 50 100 µA

Adjustment Pin Current Change

2.5 V ≤ VI–VO ≤ 40 V, 10 mA ≤ IL ≤ 0.5 A, PD ≤ P

max

1,2 ∆I

Adj

– 0.2 5.0 µA

Reference Voltage

3.0 V ≤ VI–VO ≤ 40 V, 10 mA ≤ IO ≤ 0.5 A, PD ≤ P

max

:

3 V

ref

1.200 1.250 1.300

V

Line Regulation (Note 2)

3.0 V ≤ VI–VO ≤ 40 V

1 Reg

line

– 0.02 0.07 %/V

Load Regulation (Note 2)

10 mA ≤ IO ≤ 0.5 A

VO ≤ 5.0 V

VO ≥ 5.0 V

2 Reg

load

–

–

20

0.3

70

1.5mV% V

O

Temperature Stability (T

low

≤ TJ ≤ T

high

) 3 T

S

– 0.7 – % V

O

Minimum Load Current to Maintain Regulation

(VI–VO = 40 V)

3 I

Lmin

– 3.5 10 mA

Maximum Output Current

VI–VO ≤ 15 V, PD ≤ P

max

VI–VO = 40 V, PD ≤ P

max

, TA = 25°C

3 I

max

0.5

0.15

0.9

0.25

–

–

A

RMS Noise, % of V

O

TA= 25°C, 10 Hz ≤ f ≤ 10 kHz

– N – 0.003 – % V

O

Ripple Rejection, VO = 10 V, f = 120 Hz (Note 3)

Without C

Adj

C

Adj

= 10 µF

4 RR

–

66

65

80

–

–

dB

Long–Term Stability, TJ = T

high

(Note 4)

TA= 25°C for Endpoint Measurements

3 S – 0.3 1.0 %/1.0 k

Hrs.

NOTES: 1.T

low

to T

high

= 0° to +125°C for LM317M T

low

to T

high

= –40 ° to +125°C for LM317MB

2. Load and line regulation are specified at constant junction temperature. Changes in VO due to heating effects must be taken into account separately.

Pulse testing with low duty cycle is used.

3.C

Adj

, when used, is connected between the adjustment pin and ground.

4.Since Long–Term Stability cannot be measured on each device before shipment, this specification is an engineering estimate of average stability

from lot to lot.

LM317M

http://onsemi.com

3

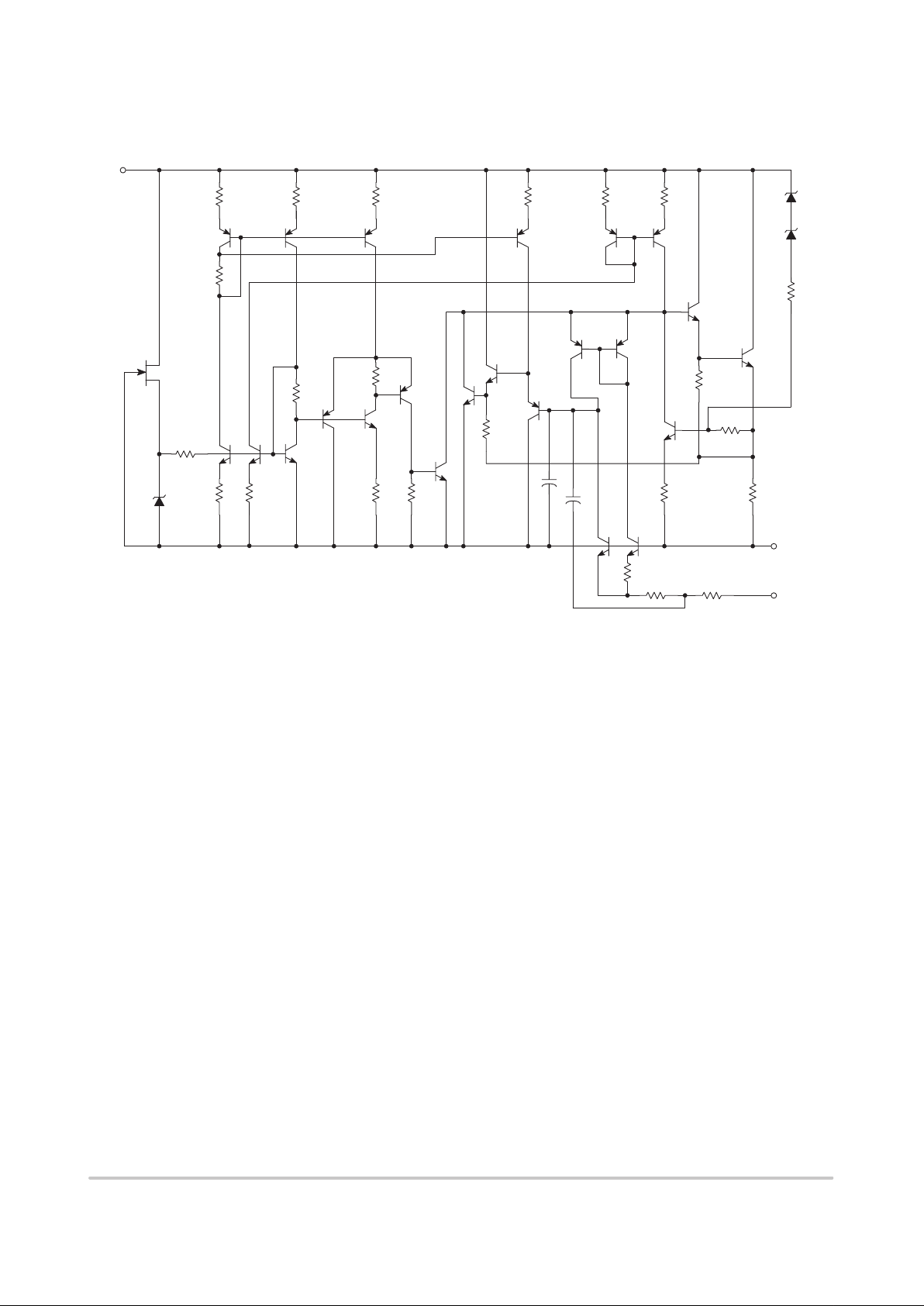

Representative Schematic Diagram

18k

6.8V

6.8V

350

300 300 300 3.0k 300 70

200k

1.2560

50

130

8.67k

500

400

2.4k

12.8k

V

out

5.1k

6.3V

2.0k 6.0k

Adjust

V

in

180 180

10

pF

10

pF

LM317M

http://onsemi.com

4

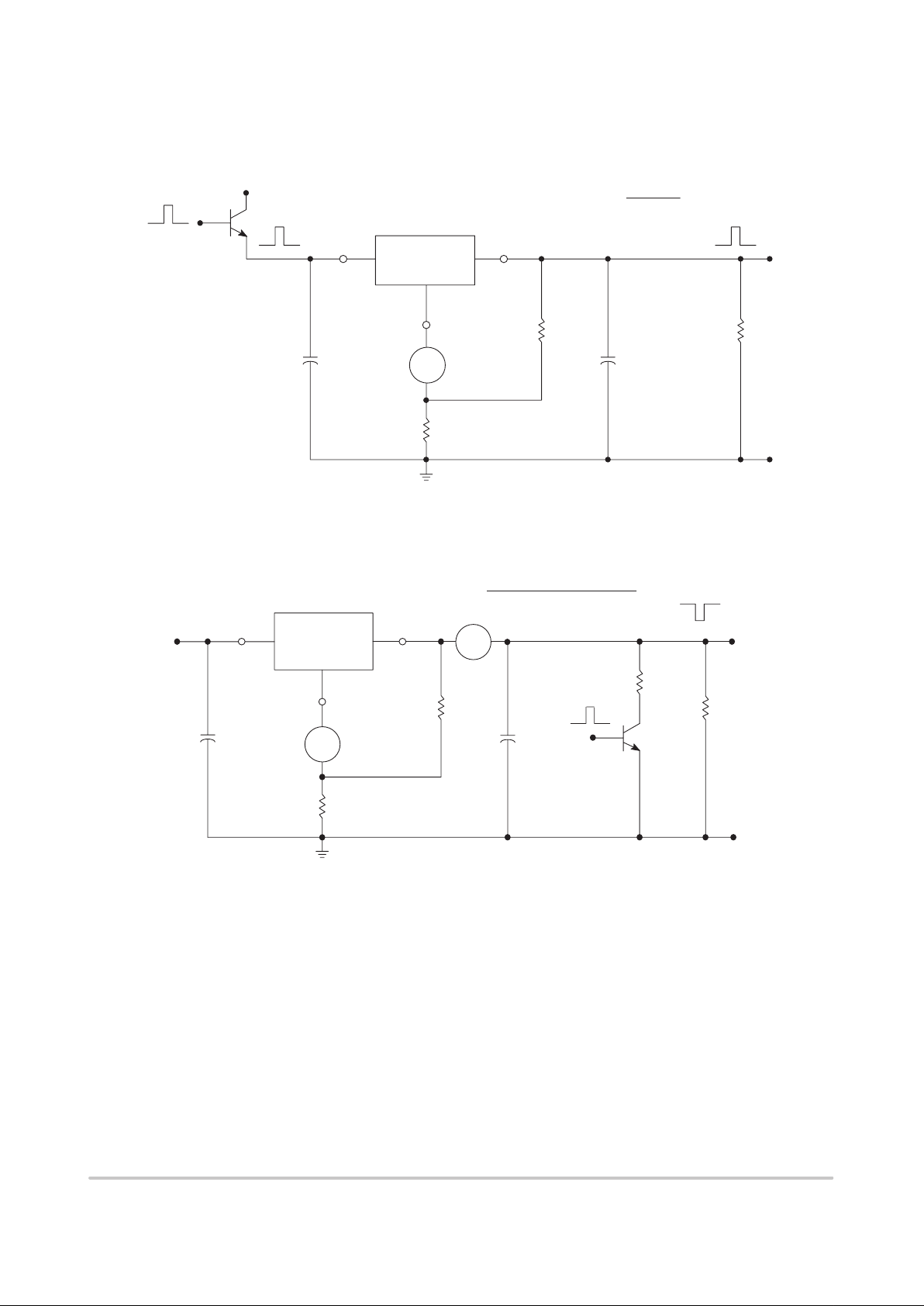

* Pulse Testing Required:

1% Duty Cycle is suggested.

Line Regulation (%/V) =

VOH – V

OL

x 100

*

V

CC

V

IH

VILV

in

V

out

V

OH

V

OL

R

L

+

1.0µFC

O

240

1%

R

1

Adjust

R2

1%

C

in

0.1µF

LM317M

I

Adj

Figure 1. Line Regulation and ∆I

Adj

/Line Test Circuit

V

OL

* Pulse Testing Required:

1% Duty Cycle is suggested.

Load Regulation (mV) = VO (min Load) –VO (max Load)

Load Regulation (% VO) =

VO (min Load) – VO (max Load)

X 100

VO (min Load)

VO (max Load)

LM317M

C

in

0.1µF

Adjust

R

2

1%

C

O

1.0µF

+

*

R

L

(max Load)

R

L

(min Load)

V

out

R

1

240

1%

V

in

V

in

I

Adj

I

L

Figure 2. Load Regulation and ∆I

Adj

/Load T est Circuit

VO (min Load)

Loading...

Loading...